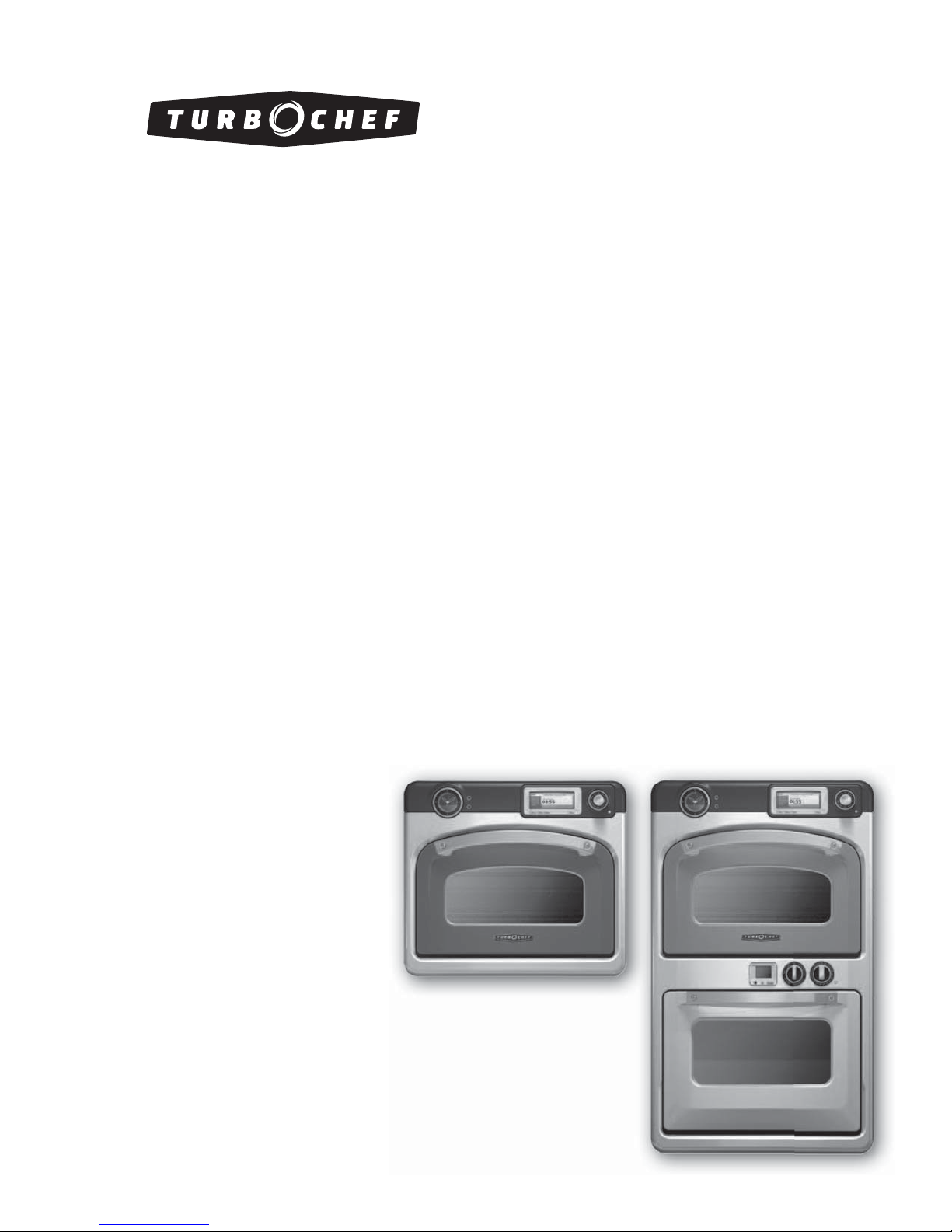

TurboChef Residential Single and Double Wall Oven, TDO30, DWO Gen 1, DWO, SWO Service Manual

...Page 1

TM

Accelerating the World of Cooking

TM

Service Manual

®

©2008 TurboChef Technologies, Inc.

Page 2

Page 3

For further information, call

866.447.3783

or

+1 214.379.6000

Page 4

e information contained in this manual is important for the proper installation, use, maintenance, and repair of this oven. Follow these procedures and instructions to help ensure satisfactory baking results and years

of trouble-free service.

Errors – descriptive, typographic, or pictorial – are subject to correction. Specifi cations are subject to change

without notice.

PLEASE CAREFULLY READ THIS MANUAL AND RETAIN IT FOR FUTURE REFERENCE.

©2008 TurboChef Technologies, Inc.

Page 5

Table Of Contents

Safety Instructions

Safety Precautions i

To Reduce the Risk of Fire in the Cook Cavity ii

Precautions to be Observed Before and During Servicing to Avoid Possible

Exposure to Excessive Microwave Energy ii

Grounding Instructions ii

Do Not Touch Heating Elements or Interior Surfaces of Oven ii

Power Connections ii

Self-Cleaning Oven Guidelines ii

RF Interference Considerations iii

Section 1 - Speci cations and Installation

eory of Operation 1.1

Catalytic Converter 1.1

Certifi cations 1.1

Electrical Specifi cations 1.1

Dimensions - Double Wall Oven 1.2

Dimensions - Single Wall Oven 1.2

Installation 1.3

Installation Safety Instructions 1.3

Double Wall Oven Cabinet Dimensions 1.5

Single Wall Oven Cabinet Dimensions 1.5

Installing the Oven 1.5

Section 2 - Oven Controls and Cooking - The Speedcook Oven

Speedcook Oven Controls 2.1

Cook Modes 2.2

Air-Crisp 2.2

Bake 2.2

Broil 2.2

Dehydrate 2.2

Favorites 2.2

Roast 2.3

Toast 2.3

Favorites Cooking 2.3

Cooking a Recently Prepared Dish 2.3

Cooking a ”Favorite” Dish 2.3

Using the Convection Bake Function 2.4

Using the Defrost Function 2.4

Using the Microwave Function 2.4

Basic Cooking 2.5

Mode 1: Oven Off 2.5

Mode 2: Select a Food Item 2.5

Page 6

Mode 3: Confi rm Settings 2.6

Mode 4: Preheat 2.6

Mode 5: Ready to Cook 2.6

Mode 6: Cooking 2.6

Mode 7: 80% Complete 2.6

Mode 8: 100% Complete 2.7

Mode 9: Remove Food from Oven 2.7

Adjusting a Recipe’s Cook Time 2.8

Adjusting a Cook Temperature 2.8

e Advanced Cook Mode 2.8

Saving to Favorites 2.9

Renaming a Dish (in Favorites) 2.10

Deleting a Dish (from Favorites) 2.10

Reheat Setting 2.10

Self-Clean Mode - Speedcook Oven 2.10

Section 3 - Oven Controls and Cooking - Lower Oven

(Double-Wall Oven Only)

Lower Oven Controls 3.1

Cook Modes 3.2

Bake 3.2

Broil 3.2

Convection Bake 3.2

Convection Roast 3.2

Roast 3.2

Warm Setting 3.2

Proof Setting 3.2

Basic Cooking 3.3

e Sabbath Mode 3.3

Self Clean Mode 3.4

Section 4 - Info Mode

Overview of the Info Mode 4.1

Adjusting Oven Sounds 4.1

Adjusting Display Settings 4.2

Adjusting the Oven’s Units & Measurements 4.2

Accessing Help Topics and General Cooking Information 4.2

Updating the Oven Software 4.3

Backing Up/Restoring Favorites 4.3

Accessing the Version Information 4.4

Installer Setup 4.4

Top (or Single Wall) Oven Component Tests 4.4

Bottom Oven Component Tests 4.4

Oven Confi guration 4.4

AC Voltage Confi guration 4.4

Simulation/Demo State, and printf Mask 4.4

Page 7

Section 5 - Oven Systems

Convection System - Speedcook Oven 5.1

Blower Motor (Bottom) 5.1

Blower Motor (Top) 5.1

Blower Motor Controller (BMSC) 5.1

Heater Assembly 5.1

Jetplate (Bottom) 5.1

Jetplate (Top) 5.1

Stirrer Motor and Assembly 5.1

Convection System - Lower Oven (Double Wall Oven Only) 5.2

Broil Element 5.2

Bake Element 5.2

Convection Element 5.2

Convection Fan 5.2

Speedcook Oven Door 5.2

Removing/Reinstalling the Speedcook Oven Door 5.2

Door Skin Replacement 5.3

Left Lock Motor Assembly 5.3

Right Lock Motor Assembly 5.3

Measuring RF Leakage for Microwave Safety 5.4

Halogen Light Assembly 5.5

Lower Oven Door (Double Wall Oven Only) 5.5

Removing/Reinstalling the Lower Oven Door 5.5

Halogen Bulb Replacement 5.6

Microwave System 5.6

Doubler Circuit, Voltage 5.6

High-Voltage Capacitors 5.6

High-Voltage Diode 5.6

High-Voltage Transformers 5.7

Wiring a High-Voltage Transformer 5.7

Magnetrons 5.7

Stirrer Motor and Assembly 5.7

Waveguides 5.7

Control System 5.8

Air Switch (Single Wall Oven) 5.8

Clock 5.8

Control Board 5.8

CookWheel Control 5.8

Display, Lower Oven 5.8

Attaching the Lower Display Cable 5.8

Display, Speedcook Oven 5.9

Electrical Compartment Cooling Fans 5.9

EMI Filter 5.9

Fuses 5.9

High Limit ermostats 5.9

Latch Mechanism (Lower Oven) 5.9

Light Switch, Control Panel 5.9

Page 8

M.O.V. Filter 5.9

Magnetron Cooling Fan 5.10

Magnetron ermostats 5.10

Power Supply, 12 VDC 5.10

Power Supply, 24 VDC 5.10

Relay Board (Gen 2 Oven) 5.10

Relay - K2 Monitor (Gen 1 Oven) 5.10

Relay - K3 T1 HV Transformer (Gen 1 Oven) 5.10

Relay - K4 T2 HV Transformer (Gen 1 Oven) 5.10

Relay - K5 Mag Cooling Fan (Gen 1 Oven) 5.10

Relay - K6 Right Side Door Lock (Gen 1 Oven) 5.10

Relay - K7 Left Side Door Lock (Gen 1 Oven) 5.10

Relay - K8 Preheat (Gen 1 Oven) 5.10

Relay - K9 L2 Speedcook Heating Elements 5.11

Relay - K10 Lower Door Lock (Gen 1 Oven) 5.11

Relay - K13 L2 Lower Heating Elements (Double Wall Oven Only) 5.11

RJ Cables 5.11

RTD 5.11

SD Card 5.11

Selector Switches 5.11

Solid State Relay - K1 L1 Speedcook Heating Elements 5.12

Solid State Relay - K11 Bake and Convection Elements (Double Wall Oven Only) 5.12

Solid State Relay - K12 Broil Elements: Inner and Outer (Double Wall Oven Only) 5.12

Speaker 5.12

Temperature Switch 5.12

Transformer, Clock, 12 VAC 5.12

ermostat, Cook Cavity 5.12

ermostat, Cooling Fan Control 5.12

USB Port 5.12

Connecting the USB Board (Gen 1 Oven) 5.12

Wiring Harness 5.13

Exhaust System 5.13

Catalytic Converter 5.13

Exhaust Blower 5.13

Vent Catalyst 5.13

Section 6 - Troubleshooting

Overview of Troubleshooting 6.1

Error Screens 6.1

Oven Door Open (Gen 1) 6.1

Oven Door Open (Gen 2) 6.2

Cooling Fan Failure (Gen 1) 6.2

Cooling Fan Failure (Gen 2) 6.2

Temperature Control Failure 6.2

Magnetron Failure 6.3

Magnetron Failure Troubleshooting 6.3

Blower Failure 6.3

Blower Failure Troubleshooting 6.4

Page 9

Oven Over Temperature 6.4

Component Testing and Troubleshooting 6.4

Control System 6.4

Clock Assembly 6.4

Control Board 6.4

CookWheel Control (Speedcook Oven) 6.4

EMI Filter 6.5

Oven Mode Switch (Lower Oven) 6.5

Power Supply, 12 VDC 6.5

Power Supply, 24 VDC 6.5

RTD 6.6

Transformer, 12 VAC (Gen 1) 6.6

Transformer, 12 VAC (Gen 2) 6.6

Halogen Light System 6.7

Light Switch, Control Panel (Manual) 6.7

Light Switch, Speedcook Oven (Door Actuated) 6.7

One Speedcook Oven Light is Out 6.7

Both Speedcook Oven Lights are Out 6.7

Both Speedcook Oven and Both Lower Oven Lights are Out (Double Wall Oven) 6.7

Cooling System 6.7

Cooling Fan Overview (Gen 1) 6.7

Cooling Fan Overview (Gen 2) 6.8

Troubleshooting Cooling Fans (Gen 1) 6.8

Troubleshooting Cooling Fans (Gen 2) 6.9

Air Impingement Systems 6.9

Blower Motors, Speedcook Oven 6.9

Convection Fan, Lower Oven 6.10

Microwave System 6.10

Testing a Capacitor 6.10

Testing a High-Voltage Diode 6.10

Testing a High-Voltage Transformer 6.11

Testing a Magnetron for an Open/Shorted Filament 6.11

Heating System, Speedcook Oven 6.11

Heater Element, Speedcook Oven 6.12

No Heat 6.12

Oven is Heating up Very Slowly 6.12

Testing for Control Voltage to the K1 SSR 6.12

Testing for Control Voltage to the K8 Relay (Gen 1) 6.13

Testing Relay 14 (Pre-Heat) Operation (Gen 2) 6.13

Testing for a K9 Relay that is Stuck Open 6.13

Testing for a K1 SSR that is Stuck Open 6.13

Heating System, Lower Oven 6.13

Lower Oven Heating Element Specifi cations 6.14

No Heat/Slow to Heat 6.14

Testing for Voltage to the K11 SSR 6.14

Testing for Voltage to the K12 SSR 6.14

Testing for a K11 SSR that is Stuck Open 6.15

Testing for a K12 SSR that is Stuck Open 6.15

Testing for a K13 Relay that is Stuck Open 6.15

Page 10

Section 7 - Schematics

Gen 1 Speedcook Oven Schematic 7.1

Gen 1 Bottom Oven Schematic 7.2

Gen 2 Speedcook Oven Schematic 7.3

Gen 2 Bottom Oven Schematic 7.4

Single Wall Oven Schematic 7.5

RWD/RWS Gen 2 Control Board 7.6

RWD/RWS Gen 2 Relay Board 7.7

Appendix - Replacing Oven Components

Comprehensive Table of Oven Components A.1

Component and Assembly Location, DWO Gen 1 and Gen 2 A.6

Removing the Oven A.6

Component and Assembly Location, SWO A.8

Removing the Oven A.8

Front Trim Assembly Detail A.10

Front Trim Assembly Removal A.10

Control Housing Detail A.12

Upper Electrical Compartment, DWO Gen 1 A.13

Diff erentiating Between DWO Gen 1 and DWO Gen 2 A.13

Upper Electrical Compartment, DWO Gen 2 and SWO A.16

Diff erentiating Between DWO Gen 1 and DWO Gen 2 A.16

Controls Assembly Detail, DWO Gen 1, DWO Gen 2, and SWO A.18

Mag Air Diverter Assembly Detail, DWO Gen 1, DWO Gen 2, and SWO A.20

Relay and Relay/Power Assembly Detail, DWO Gen 1, DWO Gen 2, and SWO A.21

Lower Electrical Compartment Detail, DWO Gen 1 and DWO Gen 2 A.22

Diff erentiating Between DWO Gen 1 and DWO Gen 2 A.22

Speedcook Oven Cavity Component Detail, DWO Gen 1, DWO Gen 2, and SWO A.24

Lower Oven Cavity Component Detail, DWO Gen 1 and DWO Gen 2 A.28

Page 11

READ ALL INSTRUCTIONS BEFORE USING

i

WARNING: For your safety, the information in

this manual must be followed to minimize the risk of

fi re or explosion, electric shock, or to prevent property

damage, personal injury, loss of life, or excessive

exposure to microwave energy.

Safety Precautions

When using electrical appliances, basic safety precautions should be followed, including the following:

WARNING: To reduce the risk of burns, electric

shock, fi re, injury to persons or exposure to microwave

energy:

• Read all instructions before using this appliance.

• Read and follow “Precautions to Avoid Possible

Exposure to Excessive Microwave Energy” outlined

later on page ii.

• is appliance must be grounded. See Grounding

Instructions on page ii for further details.

• Install or locate this appliance only in accordance

with the provided installation instructions. Be sure

the appliance is properly installed and grounded by a

qualifi ed technician.

• Always place oven racks in desired location while the

oven is cool. If rack must be moved while oven is

hot, DO NOT let potholder contact hot heating

element in the oven. Oversized foods or oversized

metal utensils should not be inserted in a microwave/toaster oven as they may create a fi re or risk of

electric shock.

• Some products, such as whole eggs and sealed or

unopened food containers – for example, sealed glass

jars – may explode due to a build up of pressure and

SHOULD NOT be heated in this oven.

• Use care when opening oven door – let hot air or

steam escape before removing or replacing food.

• Use only microwaveable heat-resistant cookware –

for example: Pyrex

oven cooking utensils – in the Speedcook section of

this appliance.

• is appliance should be serviced only by qualifi ed

service personnel. Contact TurboChef

Service (866-447-3783) for examination, repair, or

adjustment.

Glassware, Stoneware, standard

®

Customer

®

• Use this appliance only for its intended purpose as

described in this manual. DO NOT use corrosive

chemicals or vapors in this appliance. is oven is

specifi cally designed to heat or cook food and is not

intended for laboratory or industrial use. DO NOT

use the oven to warm or heat a room.

• DO NOT store fl ammable materials in this oven or

near surface units. DO NOT store any materials,

other than manufacturer’s recommended accessories,

in this oven when not in use.

• DO NOT attempt to repair or replace any part of

this oven unless it is specifi cally recommended in

this manual or the Use and Care Guide.

• DO NOT use aluminum foil to cover contents,

racks, or any part of the Speedcook oven. Prolonged

use can cause overheating and damage the microwave components. Use in the bottom oven of a

Double Wall oven is permissible; however, do not

lay foil on the bottom of the oven.

• DO NOT use moist or damp potholders. Moist or

damp potholders on hot surfaces may result in burns

from steam. DO NOT let potholder touch hot

heating elements. DO NOT use a towel or other

bulky cloth.

• DO NOT allow children to operate without adult

supervision. Children should not be left alone or

unattended in the area where this appliance is in use.

ey should never be allowed to sit or stand on any

part of the oven.

• DO NOT operate this appliance wearing loosefi tting or hanging garments.

• DO NOT operate this appliance if it has a damaged

cord or plug, is not working properly, or has been

damaged or dropped.

• DO NOT cover or block any openings on this

appliance. Keep oven vent ducts unobstructed.

• DO NOT store this appliance outdoors.

• DO NOT use this appliance near water – e.g., in a

wet basement or near a swimming pool.

• DO NOT use water on grease fi res. Smother fi re or

fl ame or use dry chemicals or foam extinguisher.

SAFETY INSTRUCTIONS

Page 12

SAFETY INSTRUCTIONSii

To Reduce the Risk of Fire in the Cook Cavity:

• Use only oven-suitable containers in the oven. DO

NOT use paper products in either oven.

• Remove wire twist-ties from paper or plastic bags

being placed in the oven. For oven cooking bags –

DO NOT use wire twist-ties to close the bag.

• If materials inside the oven should ignite, keep the

oven door closed, turn the oven off and shut off

power at the fuse or circuit breaker panel. If the door

is opened, the fi re may spread.

• DO NOT cook items wrapped in cling wrap or

plastic fi lm.

• DO NOT overcook food. Carefully attend to the

oven if paper, plastic, or other combustible materials

are placed inside the oven to facilitate cooking.

Precautions to be Observed Before and During

Servicing to Avoid Possible Exposure to Excessive Microwave Energy

a) DO NOT operate or allow the oven to be operated

with the door open.

b) Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

(1) interlock operation, (2) proper door closing,

(3) seal and sealing surfaces (arcing, wear, and other

damage), (4) damage to or loosening of hinges and

latches, (5) evidence of dropping or abuse.

c) Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, wave guide or

transmission line, and cavity for proper alignment,

integrity, and connections.

d) Any defective or misadjusted components in the

interlock, monitor, door seal, and microwave

generation and transmission systems shall be

repaired, replaced, or adjusted by procedures

described in this manual before the oven is released

to the owner.

e) A microwave leakage check to verify compliance with

the Federal performance standard should be per formed on each oven prior to release to the owner.

Do Not Touch Heating Elements or Interior

Surfaces of Oven

Heating elements may be hot even though they are

dark in color. Interior surfaces of an oven become hot

enough to cause burns. During and after use, do not

touch, or let clothing or other fl ammable materials

contact heating elements or interior surfaces of oven

until they have had suffi cient time to cool.

Power Connections

To avoid potential hazards, only the manufacturer, its

service agent, or a similarly-qualifi ed person should

replace a damaged power cable. Flexible conduit,

conductors and connectors are supplied by the manufacturer. e oven must be connected using the fl exible

conduit and conductors provided.

Self-Cleaning Oven Guidelines

Clean the oven only in accordance with the guidelines

provided on this page, page 2.10, and page 3.4.

• Before self-cleaning the oven, remove broiler pan,

grid, racks, and other cookware. Clean only parts

listed in manual.

• Listen for fan – a fan noise should be heard sometime during the cleaning cycle. If not, call Customer

Service (866.447.3783) before self-cleaning again.

• DO NOT clean the door gasket. e door gasket is

essential for a good seal. Care should be taken not to

rub, damage or move the gasket.

• DO NOT use oven cleaners. No commercial cleaner

or oven liner protective coating of any kind should

be used in or around any part of the oven. Residue

from oven cleaners will damage the inside of the

oven when the self-clean mode is used.

• If the oven is malfunctioning in the self-clean mode,

turn off or disconnect the appliance from the power

supply and have it serviced by a qualifi ed technician.

• Complete instructions on the operation of the

self-clean mode can be found on pages 2.10 and 3.4.

Grounding Instructions

is appliance must be connected to a grounded,

metallic, permanent wiring system, or an equipment

grounding conductor should be run with the circuit

conductors and connected to the equipment grounding

terminal or lead on the appliance.

Page 13

iii

RF Interference Considerations

e appliance has been tested and was determined to

be in compliance with applicable portions of FCC part

18 requirements and with the protection requirements

of Council Directive 89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility at the time of manufacture. However, some equipment with sensitivity to

signals below these limits may experience interference.

If any equipment experiences interference, the following steps should be considered:

• Increase the physical distance between the sensitive

equipment and this oven.

• If the sensitive device can be grounded, do so

following accepted grounding practices.

• If battery-powered microphones are being aff ected,

ensure that the batteries are fully charged.

• Keep sensitive equipment on separate electrical

circuits if possible.

• DO NOT route intercom wires, microphone wires,

or speaker cables near the oven.

SAFETY INSTRUCTIONS

Page 14

iv SAFTEY INSTRUCTIONS

This page intentionally

left blank.

Page 15

Section 1

Speci cations and Installation

Page 16

Page 17

1.1

Theory of Operation

e TurboChef® Residential Speedcook oven

combines high-speed forced air impingement and

microwave energy to cook food up to 15 times faster

than a conventional oven. e re-circulating air

transfers heat to the food and then passes through

a catalytic converter where excess grease and odors

are removed and combusted. Simultaneously, precise

bursts of microwave energy cook the food from the

inside out. is combination of heating technologies

quickly cooks food and seals moisture to help ensure

chef-quality results in a fraction of the time.

is manual includes instructions for servicing,

troubleshooting, installing, cleaning, and operating

the TurboChef Residential double and single wall

ovens. If you have questions not addressed in this

manual, contact Technical Service (866.447.3783,

+1 214-379-6000) or your Authorized Distributor.

Catalytic Converter

e catalytic converter removes odors and grease

from the air inside the cook cavity. It is also

responsible for limiting and removing any smoke

from the cavity in case of a spill. Do not use oven

cleaner when cleaning the Speedcook oven, as the

catalyst can become damaged by the use of caustic

cleaners, resulting in a non-warranty service call.

See pages 2.10, and 3.4 for approved self-cleaning

instructions.

Certi cations

cETLus

Electrical Speci cations

Phase: Single

Frequency: 60 Hz

Current: 50 amp (DWO) / 30 amp (SWO)

Cord: 4-wire (inc. ground)

Voltage: 208 or 240 (depending on model)

Connection: 5½ ft fl ex conduit

Total Connected Power: 50 amp (DWO) / 30 amp

(SWO)

NOTE: Unit includes a 5½-ft fl ex conduit to be

used between the oven and conduit box. Connectors

are supplied by the installation electrician.

NOTE: Branch circuit MUST be protected with a

50-amp (Double Wall Oven) or 30-amp (Single Wall

Oven) over-current protector.

CAUTION: If there is a high leg in supply

voltage, ensure it is not on L2. Having it present on

L2 will damage critical 120V oven components.

SPECIFICATIONS AND INSTALLATION

Page 18

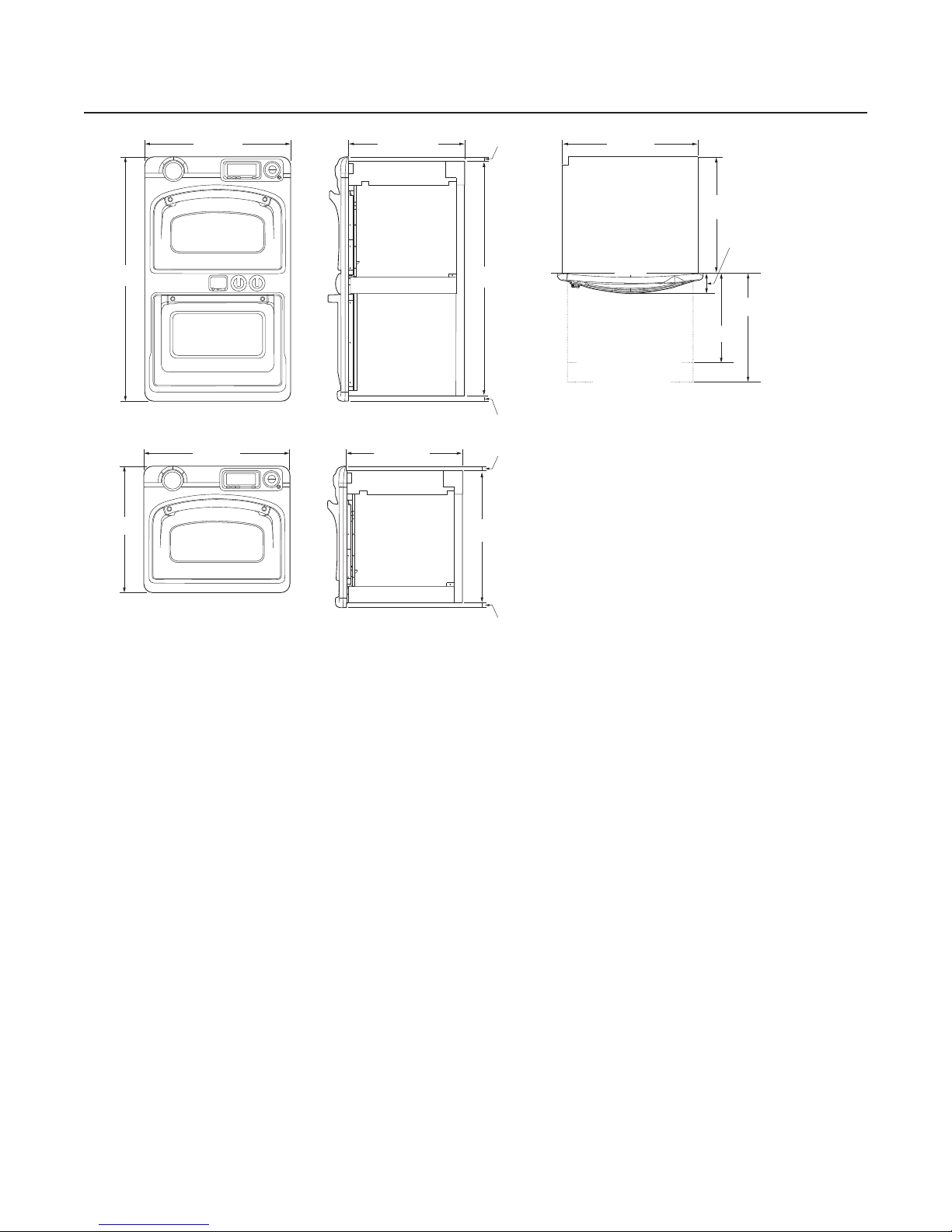

1.2 SPECIFICATIONS AND INSTALLATION

50.25˝

(1276 mm)

26.5”

(673 mm)

30” (762 mm)

30” (762 mm)

23.875” (606 mm )

23.875” (606 mm)

48.75”

(1238 mm)

25”

(635 mm)

.75” (19 mm)

.75” (19 mm)

.75” (19 mm)

28˝ (711 mm)

the wall

Single Wall / Double Wall Top Oven

Double Wall Bottom Oven

23-7/8

(606 mm)

17 -1/ 2˝

(445 mm)

˝

4 -1/4˝ (108 mm)

19 -1/ 2˝

(495 mm)

Figure 1.1: Oven Dimensions

Dimensions - Double Wall Oven

Oven Dimensions

Height: 50.25” (1276 mm)

Width: 30” (762 mm)

Depth: 23.875” (606 mm)

Depth from wall (Doors Closed): 4.25” (108 mm)

With Upper Door Open: 17.5” (445 mm)

With Lower Door Open: 19.5” (495 mm)

Weight: 410 lbs (186 kg)

Upper Cook Cavity Dimensions

Height: 12” (305 mm)

Width: 24” (610 mm)

Depth: 15” (381 mm)

Cooking Space: 2.5 ft

Lower Cook Cavity Dimensions

Height: 15.5” (394 mm)

Width: 24” (610 mm)

Depth: 17.5” (445 mm)

Cooking Space: 3.75 ft

3

(.07 m3)

3

(.106 m3)

.75” (19 mm)

Dimensions - Single Wall Oven

Oven Dimensions

Height: 26.5” (673 mm)

Width: 30” (762 mm)

Depth: 23.875” (606 mm)

Depth from wall (Door Closed): 4.25” (108 mm)

Depth from wall (Door Open): 17.5” (445 mm)

Weight: 230 lbs (105 kg)

Cook Cavity Dimensions

Height: 12” (305 mm)

Width: 24” (610 mm)

Depth: 15” (381 mm)

Cooking Space: 2.5 ft3 (.07 m3)

Page 19

1.3

Installation

Cabinets should be cut according to dimensions on

pages 1.4 and 1.5. Failure to adhere to the Rough

Wall Opening specifi cations may cause corners of

the cabinet opening to be exposed. If the oven is

being installed near a wall or door, there should be at

least .25 in (6.35 mm) space between the wall/door

and the sides of the oven trim.

TurboChef recommends using standard 2x4 wood

support posts with a minimum of .5 in (12.7 mm)

solid base to support the oven. Support posts should

be level with the fl oor line and well secured to the

base of the cabinet. Base cabinet support must be

able to support the oven’s weight – 410 lbs (186

kg) DWO and 230 lbs (105 kg) SWO. TurboChef

strongly recommends a solid base as shown in the

illustrations on the following page.

Due to the oven frame’s overall depth, adhere to the

power supply line location shown in Figures 1.2 and

1.3 on page 1.4 to obtain a proper fi t in the cabinet.

If necessary due to a low or high conduit box, a 2”

diameter hole should be drilled where indicated to

allow the power cord to reach the power source.

NOTE: DO NOT shorten conduit. Correct conduit

before installing oven into cabinet.

e oven utilizes ambient air from the kitchen to

assist in keeping the operational components cool.

is air is drawn in through the top control panel

area through openings in the top access panel and

exhausted through an opening at the base of the

oven. Please allow a 1-inch minimum clearance

above and below these areas.

Should you have any questions or concerns about

how the cabinets are built, please contact TurboChef

Customer Service 866.447.3783 before installing the

oven.

Installation Safety Instructions

Read all installation instructions thoroughly before

installing.

CAUTION: DO NOT lift the oven by the

door handle(s). Doing so will require a door-leakage

test to be performed (see page 5.4), and could cause

the door(s) to come off or misalign, requiring repair

and/or replacement.

CAUTION: e Double Wall Oven weighs 410

lbs (186 kg), and the Single Wall Oven weighs 230

lbs (105 kg). Two or more individuals are required to

lift either oven.

CAUTION: DO NOT remove bottom wood

support rails until the oven is lifted into the cabinet.

Due to the oven’s weight, it is sometimes

necessary for installers to utilize special handling

equipment, such as hand trucks, dollies, etc. Use

of such equipment can damage the kitchen fl oor

surfaces. TurboChef recommends that all exposed

fl oor surfaces be protected by applying laminate

or plywood sheets, along with protective moving

blankets before using such equipment. Failure to

do so may result in scarring and damaging the

homeowner’s fl oors.

Installation, electrical connections, circuit

breakers, and grounding must comply with local

codes.

Ensure power is disconnected at the breaker

throughout the installation process.

is oven contains breakable components – use

extreme caution when lifting and placing it.

A minimum 1-inch clearance, to allow for proper

airfl ow, is required above the top control panel

area and below the base. Failure to maintain this

clearance may cause the oven to function

improperly.

DO NOT push on the outer frame. Doing so

could cause the door(s) to misalign, requiring

repair and/or replacement.

During installation, TurboChef recommends

removing the lower door prior to lifting the oven

from the front (Double Wall Model only.) DO

NOT remove the top door of the oven during

installation or at any other time. is door should

only be removed by an authorized service agent.

SPECIFICATIONS AND INSTALLATION

Page 20

1.4 SPECIFICATIONS AND INSTALLATION

724

(186 kg).

279

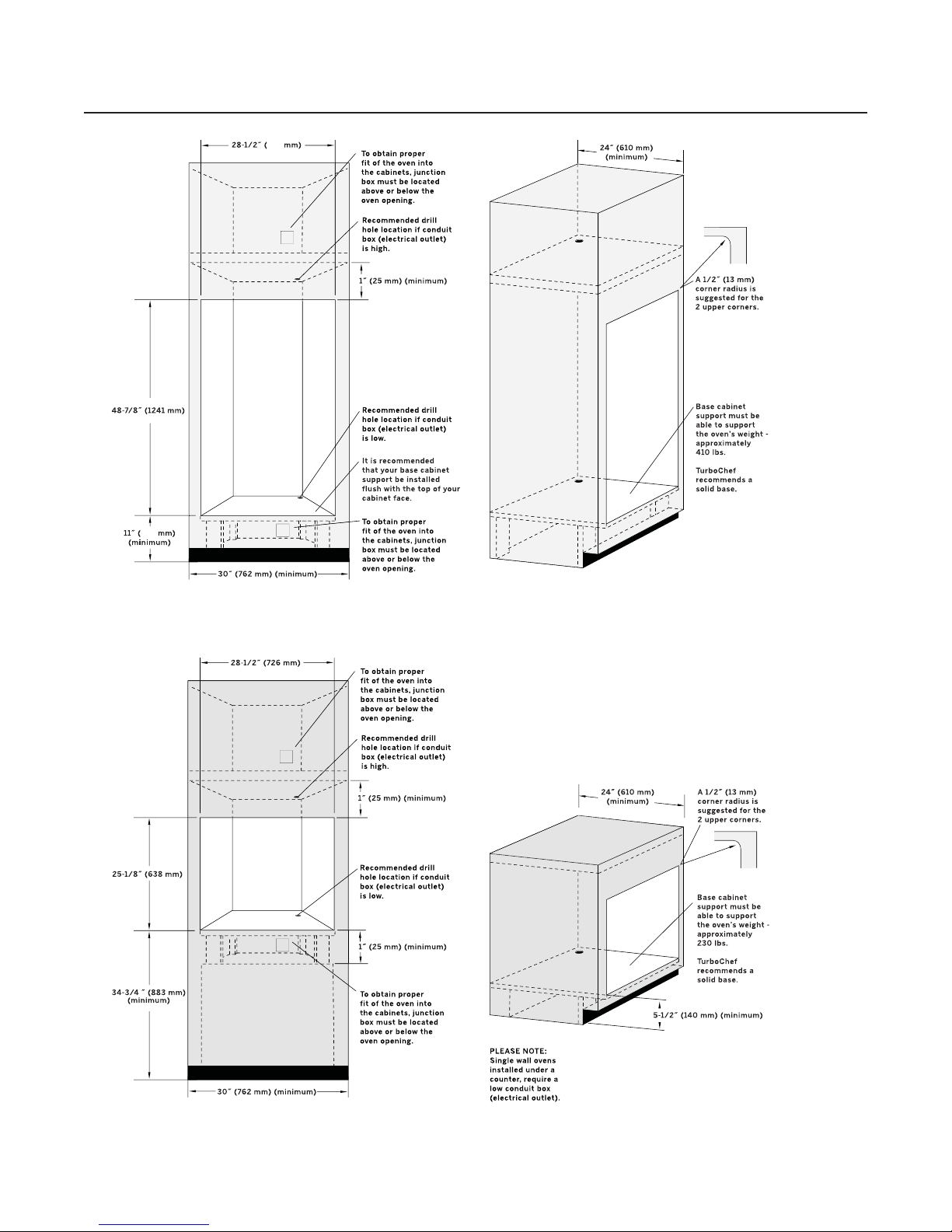

Figure 1.2: Cabinet Dimensions and Speci cations, Double Wall Oven

(105 kg).

Figure 1.3: Cabinet Dimensions and Speci cations, Single Wall Oven

(Wall Installation)

Figure 1.4: Cabinet Dimensions and Speci cations,

Single Wall Oven (Under Counter)

Page 21

1.5

Double Wall Oven Cabinet Dimensions

Cabinet

Width (min): 30” (762 mm)

Wood Fascia ickness (min): ⅜” (10 mm)

Rough Wall Opening

Height (min/max): 48⅞” (1241 mm)

Width (min/max): 28½” (726 mm)

Upper Corner Radius (preferred): ½” (13 mm)

Depth (min): 24” (610 mm)

Cabinet Base Height

Wall Installations (min): 11” (279 mm)

Wall Installations (max): 15” (381 mm)

NOTE: Failure to adhere to the rough wall opening

specs may cause corners of the cabinet opening to be

exposed.

Single Wall Oven Cabinet Dimensions

Cabinet

Width (min): 30” (762 mm)

Wood Fascia ickness (min): ⅜” (10 mm)

Installing the Oven

CAUTION: Before installing the oven, verify

voltage at the wall receptacle matches the voltage

specifi ed on the oven’s rating plate (located behind

the Speedcook oven door). Each oven is voltage

specifi c and will not function properly if supply

voltage is diff erent than intended voltage.

1. Ensure power is disconnected at the breaker.

2. Remove oven from box/crate and place on a

level surface.

NOTE: e oven is shipped with two support rails

attached to the bottom. ese rails allow the oven

to sit level and keep the bottom of the frame from

being damaged during installation. To properly place

the oven into the cabinets, these support rails must

be removed.

3. Remove all packing materials.

4. Verify the cabinet is built to the proper

specifi cations.

Rough Wall Opening

Height (min/max): 25⅛” (638 mm)

Width (min/max): 28½” (726 mm)

Upper Corner Radius (preferred): ½” (13 mm)

Depth (min): 24” (610 mm)

Cabinet Base Height

Wall Installations (min): 34¾” (883 mm)

Wall Installations (max): 38¾” (984 mm)

Under Counter Installations (min): 5½” (139 mm)

NOTE: Failure to adhere to the rough wall opening

specifi cations may cause corners of the cabinet opening to be exposed.

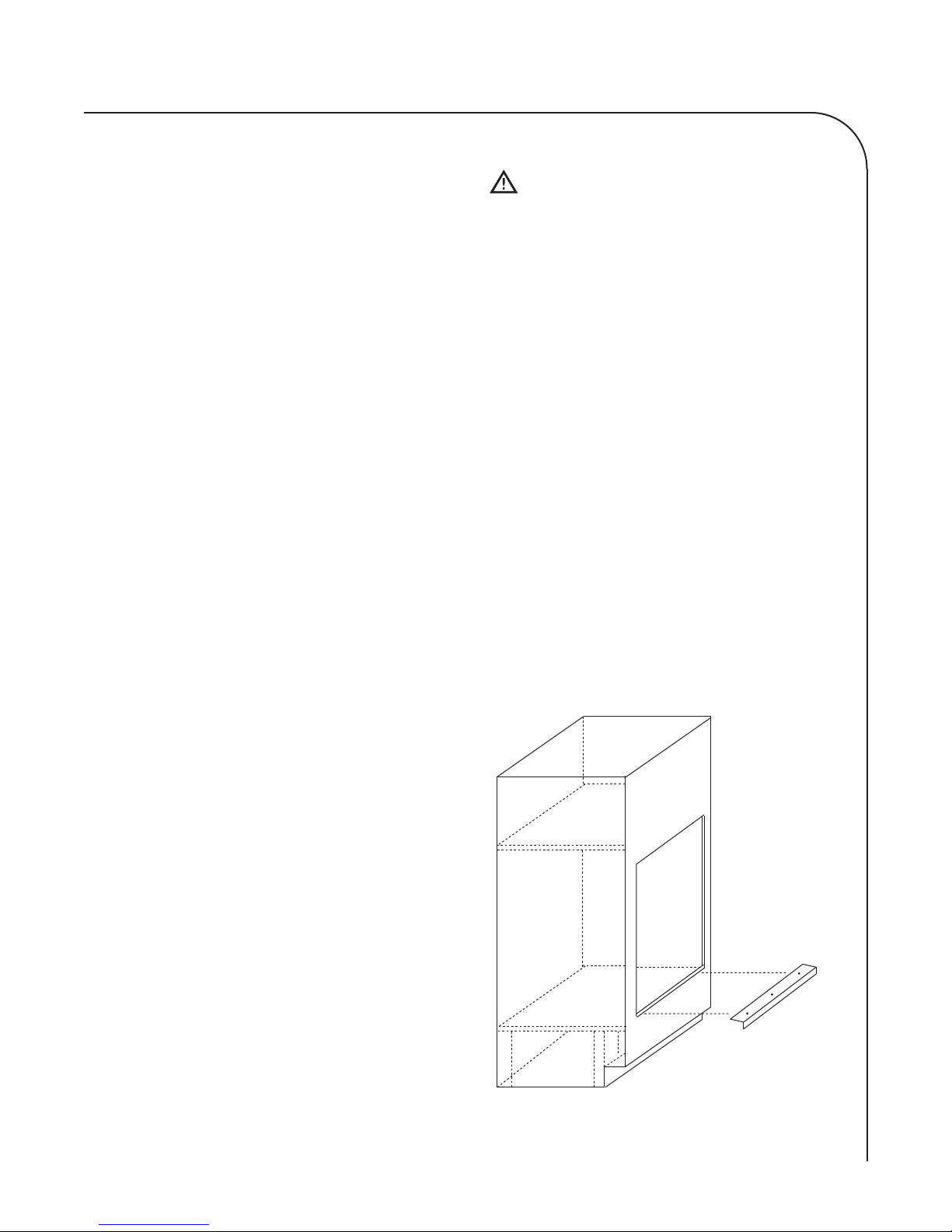

5. If provided, install the base slide plate (Figure

1.5, below). is plate will make installation

and future servicing of the oven easier.

SPECIFICATIONS AND INSTALLATION

.

.

.

Figure 1.5: Base Slide Plate Installation

Page 22

1.6 SPECIFICATIONS AND INSTALLATION

NOTE: You may screw or nail the base slide plate in

place if required.

NOTE: If the cabinet is not built to the proper

specifi cations, please consult with the contractor,

builder, or end user.

6. Place the oven in front of the cabinet, allowing

room to access wires.

7. Make the electrical connection. e electrical

supply should be a 4-wire single-phase AC.

Connect the red, black, white, and green

(ground) oven wires to the corresponding

colors of the electrical supply wires. Route fl ex

conduit to allow for oven removal for servicing.

NOTE: For branch circuits installed before 1996, a

3-wire hook up may be allowed. See NEC, or

qualifi ed electrician for details.

8. Place the oven into the cabinet.

WARNING: e Double Wall Oven weighs

approximately 410 lbs (186 kg), e Single Wall

Oven weighs approximately 230 lbs. (105 kg.). Each

oven requires two or more individuals to lift it.

WARNING: DO NOT push on the outer

frame. Doing so could cause door(s) to misalign,

requiring repair and/or replacement.

When the unit is lifted into the cabinet opening, the

installer must remove the support rails one at a time

to allow the oven to slide into the opening properly.

Remove each support rail by unscrewing the support

screw on either side of the rail. Supports should then

slide off the oven base.

When sliding the oven into its fi nal position, the

installer should continually pull the conduit through

the electrical drill hole for it to remain taut and not

become twisted or lodged behind the oven.

NOTE: Ovens are built voltage specifi c. A 208volt oven will not operate properly if connected to

a 240-volt source, and vice versa. Improper voltage

supplied to the oven will void the manufacturer’s

warranty and cause damage to oven components.

9. Reconnect power to the breaker.

10. Secure the oven to the cabinets:

a. Open the oven door(s).

b. Making sure the oven is fully installed

against the front of the cabinet, install two

of the supplied screws in the upper cavity,

and two in the lower cavity (lower cavity

screws only applicable to the Double Wall

Oven), through the side trim holes on either

side. e screws should engage the inner

cabinet and secure the oven in place.

11. Remove all plastic wire ties and packing

material from the top and bottom oven

cavities/racks (bottom oven cavity only

applicable to the DWO oven).

12. Verify the oven is functional and set the clock.

a. “Re-Boot” the oven after the initial

installation.

i. Advance the CookWheel on the top oven

to “Bake.”

ii. Press and hold all four buttons on the

display at the same time for two seconds.

b. e display should illuminate, the

TurboChef logo should appear, and the

oven should chime. Once this is verifi ed,

return CookWheel to the “Off ” position.

NOTE: DO NOT attempt to program any cook

programs in the top oven during installation.

c. Confi rm that the oven is set to the proper

confi guration: Double Wall Oven or Single

Wall Oven (see Oven Confi guration page 4.4).

d. Set the clock by pressing the Set Clock

Knob (top knob next to the clock). e

knob will pop out. Turn the knob left or

right to set the correct time. When the time

is set, press the knob back in to its original

position.

13. Leave all warning decals and instructional labels

on the oven for the consumer to view.

14. Ensure all paper and plastic is removed from

the cook cavity. Ensure the consumer is aware

of and has access to the provided oven literature

and operating instructions.

Page 23

Section 2

Oven Controls and Cooking The Speedcook Oven

Page 24

Page 25

2.1

123

Figure 2.1: Oven Controls

Speedcook Oven Controls

1. Analog Clock and Timer

e clock and timer run with advanced electronic

control knobs. To operate, see 2. Set Clock Knob and

3. Set Timer Knob.

2. Set Clock Knob

To set the time,

1. Press knob to extend.

2. Turn knob to set time.

3. Press knob back in to original position.

7

125411610

98

7. CookWheel™ (outer knob)

Turn to select a Speedcook mode, Self-Clean, or to

turn the oven off . Modes include: Air-Crisp, Bake,

Broil, Favorites, Dehydrate, Roast, and Toast.

8. Oven Light Switch

Press to illuminate the top cook cavity.

9. Start Key

Press to select an option, begin a preheat cycle, or

initiate a cook cycle.

3. Set Timer Knob

To set the timer,

1. Press knob to extend.

2. Turn knob to set timer – up to 60 minutes.

3. Press knob back into original position.

NOTE: e timer does not begin counting down

until the knob is pressed back in. e oven will

chime four times at the end of the timer cycle.

4. Cook Navigator™

Consists of the Display (5), Start Key (9), Back Key

(10), Cancel Key (11), and Info Key (12).

5. Display

e display shows information relevant to the

current oven operation and/or user options.

6. CookWheel™ (inner knob)

Turn to navigate through the options on the display.

Press knob to select an option, begin a preheat cycle,

or initiate a cook cycle.

NOTE: Pressing the “Start” key performs the same

function as pressing in the inner CookWheel knob.

10. Back Key

Press to return to the previous screen.

11. Cancel Key

Press to terminate a cook cycle or to return to the

main screen.

12. Info Key

Press to display information on the Oven Setup

(sound, units & measurements, display, and software

updates), Help Topics, and Oven Tips.

NOTE: When the oven is in the middle of a cook

cycle, you will not be able to access the Info screen.

OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

Page 26

2.2 OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

Cook Modes

e Speedcook oven features seven modes that

enable the user to cook a wide variety of foods.

- Air-Crisp

- Bake

- Broil

- Dehydrate

- Favorites

- Roast

- Toast

To access Air-Crisp, Bake, Broil, Dehydrate,

Favorites, Roast, or Toast cook modes, turn the

CookWheel to the desired cook mode.

NOTE: Unlike traditional ovens or the lower double

wall oven, Speedcook oven cooking parameters will

vary signifi cantly on a cook-by-cook basis. For

troubleshooting cooking problems, see section 6 in

this manual. For information on component

measurements and testing, see section 5.

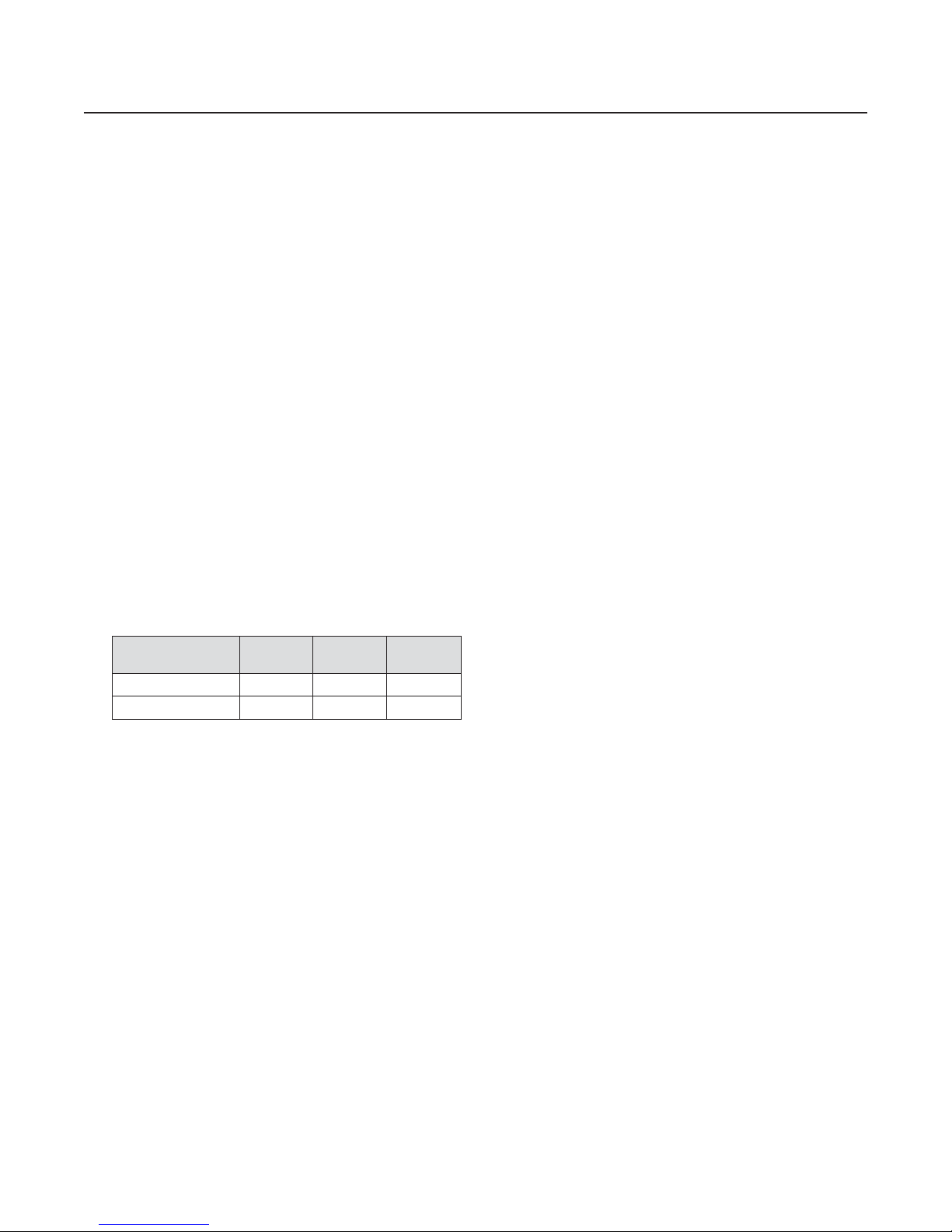

e table below details heater element activity.

Mode Convection

Fan

Preheat Off 30.8 ± 3.0 28.8 ± 3.0

All Modes Off 20.5 ± 2.0 19.2 ± 2.0

208 VAC

Value

240 VAC

Value

In the TurboChef® Speedcook Oven, the traditional

explanation of baking remains the same. However,

the hot air is moved through the cook cavity at

higher speeds than in a traditional oven. is rapid

movement of air decreases cook times while ensuring

foods bake evenly and retain more moisture.

When in the Bake mode, keep in mind that metal

cookware will provide more bottom browning while

items in glass cookware will cook a little faster. Bake

pizzas on a pizza pan or place them directly on the

oven rack. Some casseroles may need to be covered

with parchment paper to prevent over-browning.

Broil

Broiling directly exposes food to radiant heat (as

over a fi re or on top of a grill). e heat is direct and

intense, and it diff ers from baking or roasting in

that only one side of the food is exposed to the heat

source. Generally, broiled foods are quick cooking,

inherently tender, relatively lean, and not too thick.

e Broil mode on the TurboChef Speedcook Oven

will yield the same or superior results as broiling in

any traditional oven. e only real diff erence is that

your food cooks faster due to the hot air moving

through the cook cavity at increased speeds.

Cast iron grill pans, metal sheet pans, and metal

broiling pans all work well in this mode.

Air-Crisp

ink of Air-Crisp as air-frying. is mode is great

for foods that traditionally taste best when fried –

like french fries – as well as items containing any sort

of breading or stuffi ng that should toast and brown

in the cooking process – like stuff ed mushrooms.

In this mode, high temperature air moves through

the cook cavity at varying speeds to brown and crisp

the food product. Food comes out with a nice

caramelization and is lower in fat content than if it

had been deep fried. Metal sheet pans work well in

this mode.

Bake

Traditionally, baking is cooking with dry heat. Hot

air from the top and bottom of the oven envelopes

the food in a radiant dry heat, perhaps with a little

moisture from the food, which circulates as a vapor

in the oven.

Dehydrate

Considered the original form of preservation, dehydrating food removes the product’s natural moisture

by slowly drying it with a low heat. Manually, food

can be dehydrated by placing thin slices on racks

and allowing them to dry assisted only by sun or air.

To shorten the dehydrating process, the TurboChef

oven utilizes low temperature air moving at higher

speeds.

is mode is ideal for products like banana chips

and other dried fruits, as well as dried meats, like

beef jerky. Sheet pans, TurboChef tefl on screens, and

pizza pans (with or without holes) are all recommended for use with this mode.

Favorites

e Favorites mode is a tool that allows the user to

store and easily recall up to 9,999 cook settings for

the user’s favorite recipes. is mode truly allows you

Page 27

2.3

to cook any recipe quickly and easily – regardless of

whether it is a perfect match to one of the preprogrammed settings or not. In addition to any settings that the user saves, the settings for the last ten

cooks are always saved in this mode. e Favorites

mode gives the user access to Convection Bake, Defrost, and Microwave functions. To learn more about

the Favorites mode, see below.

Roast

Traditionally, roasting implies cooking food with an

open fl ame, as on a spit in front of a fi re.

Roasting and baking in an oven are essentially the

same thing, but roasting is mostly used for meats

and vegetables. In the top oven, a combination of

low and high speed air is used to brown the outside

of food while retaining moisture inside.

Roasting pans (without lids), glass casserole dishes

(with or without lids), and sheet pans all work well

with this mode. Shallow pans will allow food to

brown more. An uncovered pan without liquids will

help keep the heat dry and allow foods to brown and

crisp. Setting meats and poultry directly on a rack in

a pan keeps them from steaming in their own juices.

Toast

Toasting browns and crisps foods like bread, bagels,

and tortillas. Using high heat and high speed air, the

Toast Mode can enhance fl avor and melt cheese.

For best results, place food directly on the oven rack.

For products that may run over, like fi lled pastries,

use a metal sheet pan.

NOTE: Convection bake, defrost, and microwave

cook cycles cannot be saved to Favorites and will not

appear in “View Last Cooked (10).”

is section contains information about the

following:

- Cooking a Recently Prepared Dish

- Cooking a “Favorite” Dish

- Using the Convection Bake Mode

- Using the Defrost Mode

- Using the Microwave Mode

NOTE: If the oven does not contain some of these

options, verify it has received the most recent software upgrade. See page 4.3 for details.

NOTE: If for some reason the SD card must be

replaced, you must back up your Favorites to retain

them. See page 4.3 for more details.

Cooking a Recently Prepared Dish

e Speedcook oven automatically saves a record of

the user’s last 10 cooks, including any adjustments

made to the selected preprogrammed setting, giving

the user quick access to their most recently-used

cook settings.

OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

To cook a recently-prepared dish,

1. Turn the CookWheel to “Favorites.”

2. Select “View Last Cooked (10).”

3. Select the dish to be cooked.

4. Select “Cook” and press start or the inner

CookWheel knob.

5. Follow the Basic Cooking steps (page 2.5),

beginning with 3.

Favorites Cooking

e Favorites mode allows the user to store and

quickly access the cook settings for their favorite

recipes and food items and gives them access to the

convection bake, defrost, and microwave modes

(for information on how to access convection bake,

defrost, and microwave functions, see page 2.4).

Cooking in the Favorites mode generally follows the

Basic Cooking process on page 2.5; however, users

must choose between cooking a recently prepared

dish, cooking a “Favorites” dish, or using the

convection bake, defrost, or microwave functions.

Cooking a ”Favorite” Dish

e Favorites mode allows the user to store and

quickly access the cook settings for your favorite

recipes and food items. To save a dish to Favorites,

see page 2.9.

To cook a “Favorite” dish,

1. Turn the CookWheel to “Favorites.”

2. Select the dish to be cooked.

3. Select “Cook” and press start or the inner

CookWheel knob.

4. Follow the Basic Cooking steps from 3.

Page 28

2.4 OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

Using the Convection Bake Function

e Favorites mode gives the user access to the

convection bake function. When set to convection

bake, the Speedcook oven operates as a standard

convection oven with the fans running at a low

speed. e Speedcook oven’s convection bake

function creates the same cooking environment as

setting the bottom oven in the Double Wall Model

to the convection bake mode.

To use the convection bake function,

1. Turn the CookWheel to “Favorites.”

2. Select “Convection Bake” and press start or the

inner CookWheel knob.

3. Set the desired time.

4. Set the desired temperature.

5. Press start to begin preheating.

6. When preheating is complete (the oven will

chime), place food in the oven and press start.

WARNING: Inside of oven and oven door are

hot! Use extreme caution.

NOTE: Food placed in the oven will begin cooking

regardless of whether start is pressed or not.

However, when start is pressed, the timer begins

counting down.

3. Set the desired time.

4. Set the desired power level.

NOTE: For defrost applications, the power level

automatically defaults to 10% (recommended for

most foods).

5. Place food item in the oven and press start.

6. When defrosting is complete (the oven will

chime), remove the food from the oven.

WARNING: Dish and inside of oven/oven

door are hot! Use extreme caution.

NOTE: If additional time is needed, the user can

add time to the timer by pressing start.

7. When done defrosting, turn the oven off by

turning the CookWheel to Off .

Using the Microwave Function

e Favorites mode gives the user access to the

microwave function. When the microwave function

is selected, the Speedcook oven operates as a

standard microwave oven. is function should

be used primarily for applications such as popping

popcorn or boiling water.

7. When cooking is complete (the oven will

chime), remove the food from the oven.

WARNING: Dish and inside of oven/oven

door are hot! Use extreme caution.

NOTE: If additional time is needed, the user can

add time to the timer by pressing start.

8. When done cooking, turn the oven off by

turning the CookWheel to Off .

Using the Defrost Function

e Favorites mode gives the user access to the

defrost function. e defrost function should be

used to aid in the thawing of foods, especially frozen

meats and casseroles.

To use the defrost function,

1. Turn the CookWheel to “Favorites.”

2. Select “Defrost” and press start or the inner

CookWheel knob.

To use the microwave function,

1. Turn the CookWheel to “Favorites.”

2. Select “Microwave” and press start or the inner

CookWheel knob.

3. Set the desired time.

4. Set the desired power level.

5. Place food item in the oven and press start.

6. When cooking is complete (the oven will

chime), remove the food from the oven.

WARNING: Dish and inside of oven/oven

door are hot! Use extreme caution.

NOTE: If additional time is needed, the user can

add time to the timer by pressing start.

7. When done cooking, turn the oven off by

turning the CookWheel to Off .

Page 29

2.5

Roast

Please select

an option

Roast

To start cook

cycle, select

Begin Preheat

Meat Lamb Rack of Lamb 14 to 16 oz

1 Rack

2 Racks

... Rack of Lamb 14 to 16 oz 1 Rack

SUGGESTED SETTINGS

Cook Time Oven Temp

04:00 500

mins : secs

Adjust Settings

Begin Preheat

1

2

3

Roast

! Do not put

the dish into

the oven until

preheat is

complete.

Roast

Carefully place

dish into oven. To

begin cooking

press the

Start

button.

Roast

The oven will

remind you to

check the dish

and tone when

cooking is 80%

complete.

Lamb Rack of Lamb 14 to 16 oz 1 Rack

COOK TIME: 04:00 COOK TEMP: 500

Preheat Time Oven Temp

PREHEAT - get screenshot

03:18 347

mins : secs

Preheating, please wait to insert dish

Lamb Rack of Lamb 14 to 16 oz 1 Rack

COOK TIME: 04:00 COOK TEMP: 500

Cook Time Oven Temp

Ready to cook - get screenshot

04:00 500

mins : secs

Preheat complete, oven ready

... Rack of Lamb 14 to 16 oz 1 Rack

COOK TIME: 04:00 COOK TEMP: 500

Time Remaining

03:55

Cooking has started

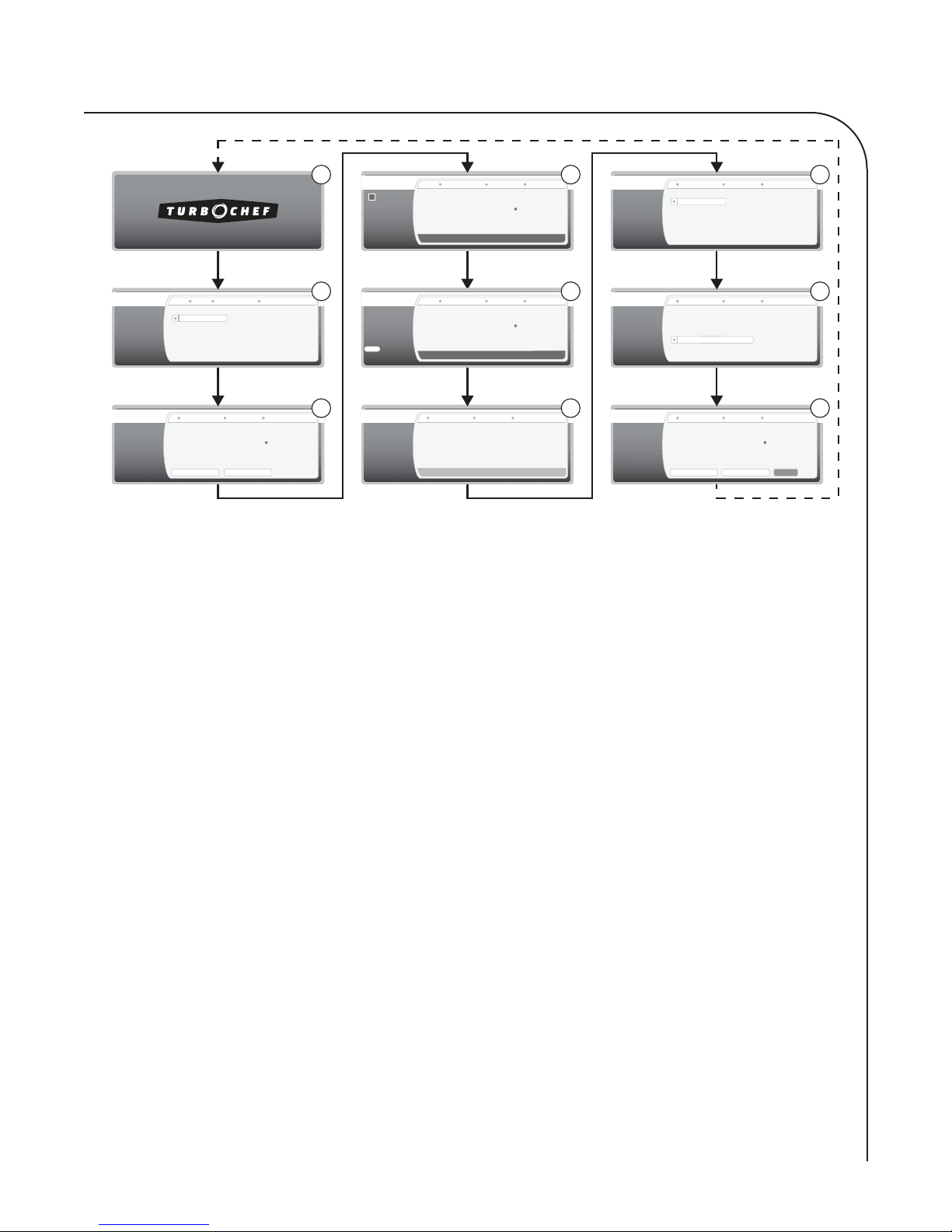

Figure 2.2: Standard Operation Modes

Basic Cooking

Figure 2.2

is section explains how to cook a food item by

describing the “standard operation” modes through

which the Speedcook oven progresses.

4

5

6

Roast

Roast

Roast

Please check

your dish. Be

careful when

removing from

Oven.

... Rack of Lamb 14 to 16 oz 1 Rack

COOK TIME: 04:00 COOK TEMP: 500 TIME LEFT: 00:48

No Change

Cook Less

Brown Less

Cook and Brown Less

... Rack of Lamb 14 to 16 oz 1 Rack

COOK TIME: 04:00 COOK TEMP: 500 TIME LEFT: 00:00

Cook More

Brown More

Cook and Brown More

Done Cooking this Dish

... Rack of Lamb 14 to 16 oz 1 Rack

SUGGESTED SETTINGS

Cook Time Oven Temp

04:00 500

mins : secs

Save to Favorites Cook Another

7

8

9

Done

Mode 1: Oven O

Mode during which the oven is turned off . To begin

cooking, the user must fi rst select, using the CookWheel, one of the seven speedcook modes (AirCrisp, Bake, Broil, Dehydrate, Favorites, Roast, or

Toast).

OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

e oven is preprogrammed with recipe settings at

the time of manufacture and is ready to operate after

installation.

NOTE: Modes are not always sequential, as shown

in Figure 2.2, above.

- 1: Oven Off

- 2: Select a Food Item

- 3: Confi rm Settings

- 4: Preheat

- 5: Ready to Cook

- 6: Cooking

- 7: 80% Complete

- 8: 100% Complete

- 9: Remove Food from Oven

Happens When...

- e user turns the CookWheel to the “Off ”

position at any time.

Goes To...

- 2 when the user turns the CookWheel to

Air-Crisp, Bake, Broil, Dehydrate, Roast, or

Toast.

- Favorites when the user turns the CookWheel

to Favorites (for more information on Favorites,

see page 2.3).

Mode 2: Select a Food Item

Mode during which the user specifi es which dish to

cook. Use the inner CookWheel knob to select the

item and item specifi cations. To make a selection,

scroll to the desired option and press the inner

CookWheel knob or start key.

Page 30

2.6 OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

Happens When...

- e user turns the CookWheel to Air-Crisp,

Bake, Broil, Dehydrate, Roast, or Toast from

1.

- e user presses cancel from 7.

- e user selects “Done” from 9.

Goes To...

- 3 when the user selects the desired food

item and item specifi cations.

Mode 3: Con rm Settings

Mode during which the user either confi rms the

suggested cook settings, or chooses to adjust the

cook settings (for more information on adjusting

cook settings, see page 2.8).

Happens When...

- When the user selects the desired food item and

item specifi cations from 2.

Goes To...

- 4 when the user selects the “Begin

Preheat” option.

- Adjust Settings when the user selects the

“Adjust Settings” option (for more information

on adjusting cook settings, see page 2.8).

Mode 4: Preheat

Mode during which the oven preheats to the set

temperature. e oven automatically begins

counting down the remaining preheat time and

displays the current temperature. Preheating will

take approximately 8-14 minutes.

Happens When...

- e user selects the “Begin Preheat” option

from 3.

Mode 5: Ready to Cook

Mode during which the oven is ready to cook a food

item. Place the food into the oven at this time. Press

start to begin the cook cycle.

WARNING: Inside of oven and oven door are

hot! Use extreme caution.

Happens When...

- e oven has reached the set temperature. e

oven will chime, indicating it is ready to cook.

- e user selects “Cook Another“ from 9.

Goes To...

- 6 when the user presses start.

Mode 6: Cooking

Mode during which the oven cooks a food item.

NOTE: To immediately terminate cooking, turn the

CookWheel to off .

NOTE: e oven door must be completely closed

before the oven will initiate a cook cycle. If the door

is opened while the oven is cooking, the oven

displays the message “ e oven door is open. You

must close the oven door before continuing.” If

applicable, the microwave system shuts off and the

air will power down to 30%.

Happens When...

- e user presses start from 5.

Goes To...

- 7 when the cook cycle is 80% complete

(if the cook cycle exceeds 2:30).

- 8 if the cook cycle is less than 2:30.

Mode 7: 80% Complete

Goes To...

- 5 when the oven chimes, indicating that

the preheat cycle is complete.

NOTE: If the door is opened while the oven is

preheating, the oven displays the message “ e oven

door is open. You must close the oven door before

continuing.” If applicable, the air will power down

to 30%.

Mode during which the cook cycle is 80% complete.

When the cook cycle is 80% complete, a chime

sounds, the cook cycle pauses, and the user has the

option to check the food and, if desired, adjust the

cook settings. At this point in the cook cycle, the

user can choose one of the following four options:

- No Change: Select if dish is cooking to

expectations.

- Cook Less: Select if product is overcooking or

internal temperature is too high.

Page 31

2.7

- Brown Less: Select if the outside of the dish is

browning faster than desired.

- Cook and Brown Less: Select if dish is cooking

and browning more than expected, but requires

additional cooking time.

If after 30 seconds the oven has not been addressed

(door opened or inner CookWheel knob pressed),

the oven will complete the cook cycle according to

the original settings.

NOTE: For food items with a cook time of 2:30

or less, the cook cycle does not pause at the 80%

complete mark.

NOTE: If the food item is done at this time,

remove it from the oven and press cancel to end the

cook cycle. If you end the cook cycle at this point,

the cook cycle will not be recorded in “View Last

Cooked (10)” (for more information on “View Last

Cooked (10), see page 2.3).

Happens When...

- e cook cycle is 80% complete.

Goes To...

- 2 if the user presses cancel.

- 8 after 30 seconds of inactivity, or if the

user selects “No Change,” “Cook Less,” “Brown

Less,” or “Cook and Brown Less.”

Mode 8: 100% Complete

Mode during which the cook cycle is 100%

complete. At the end of a cook cycle, a chime sounds

notifying the user that the food item is done. e

user has the option to add additional cook time, if

desired. At this point in the cook cycle, the user can

choose one of the following four options:

- Cook More: Select if the outside meets expecta tions, but the inside needs to cook longer.

- Brown More: Select if the inside meets

expectations, but outside needs to cook longer.

- Cook and Brown More: Select if both the

inside and outside need to cook longer.

- Done Cooking this Dish: Select if no

adjustments are needed.

NOTE: If the user selects “Cook More,” “Brown

More,” or “Cook and Brown More,” the user can

add up to 30% of the original cook time in 5-second

increments. is can be repeated as many times as

necessary.

is option is available for 3 minutes. After 3

minutes of inactivity, the oven assumes the item is

done.

Happens When...

- e cook cycle is 100% complete.

Goes To...

- 9 if the user selects “Done Cooking this

Dish.”

- 6 if the user selects one of the “cook/

brown more” options.

Mode 9: Remove Food from Oven

Mode during which cooking is complete, and the

food item is ready to be removed from the oven. e

user has the option to “Save to Favorites,” “Cook

Another,” or “Done.”

WARNING: Dish and inside of oven/oven

door are hot! Use extreme caution.

OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

NOTE: e display will not change until “Save to

Favorites,” “Cook Another,” or “Done” is selected or

until the oven is turned off .

Happens When...

- e user selects “Done Cooking this Dish”

from 8.

Goes To...

- 1 if the user turns the CookWheel to off .

- 2 if the user selects “Done.”

- 5 if the user selects “Cook Another.”

- Save to Favorites (see page 2.9), if the user

selects “Save to Favorites.”

NOTE: If the user selects “Cook Another,” the next

cook cycle will use the same settings as the previous

cook cycle. is includes any adjustments made at

any point during the previous cook cycle.

Page 32

2.8 OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

Adjusting a Recipe’s Cook Time

Cook times may be altered up to 25% in either

direction of the preprogrammed time. Be aware that

preprogrammed cook times can vary signifi cantly

from traditional settings.

To adjust the cook time,

1. From 3, select “Adjust Settings”

(Figure 2.3).

2. Use the inner CookWheel knob to scroll to the

cook time and press the knob to select it

(Figure 2.4).

3. Turn the inner CookWheel knob to adjust the

cook time in 5-second increments. e

original cook time cannot be altered more

than 25% in either direction (Figure 2.5).

4. Press the inner CookWheel knob to confi rm

the new cook time.

5. Scroll to and select “Begin Preheat.”

Adjusting a Cook Temperature

Temperatures may be altered up to 25°F (14°C) in

either direction. Note that preprogrammed temperatures can vary signifi cantly from traditional settings.

To adjust a cook temperature,

1. From 3, select “Adjust Settings”

(Figure 2.3).

2. Use the inner CookWheel knob to scroll to

“Oven Temp,” press knob to select (Figure 2.6).

3. Turn the inner CookWheel knob to adjust the

temperature in 5°F (2°C) increments. e

temperature cannot be altered more than 25°F

(14°C) in either direction (Figure 2.7).

4. Press the inner CookWheel knob to confi rm

the new temperature.

5. Scroll to and select “Begin Preheat.”

The Advanced Cook Mode

In the advanced cook mode (Figures 2.8 and 2.9),

the user can adjust the airfl ow and microwave power

levels of a preprogrammed setting. In addition to

customizing an existing setting, making adjustments

in the advanced cook mode enables the user to

develop new settings from pre-existing ones. A high

level of familiarity with the oven is suggested before

attempting to make changes in this mode.

Each programmed setting is divided across four

intervals, each of which has four associated settings:

- Time: e length (run time) of an interval.

Time settings are not adjustable - only the total

cook time can be adjusted (see adjacent).

- Upper Air: Controls speed of the air coming

from the top of the oven. Adjust in 10%

increments from 0-100%.

- Lower Air: Controls speed of the air coming

from the bottom of the oven. Adjust in 10%

increments from 0-100%.

- Microwave: Controls the amount of microwave

power being used. Adjust in 10% increments

from 0-100%.

Use the inner CookWheel knob to scroll to and

select the desired setting(s).

To use the Advanced Cook Mode,

1. From 3, select “Adjust Settings”

(Figure 2.3).

Roast

To start cook

cycle, select

Begin Preheat

Figure 2.3: Adjusting Recipe Settings

Roast

! Time has

been

calculated for

best results.

Adjusting

time is not

advised.

Figure 2.4: Selecting Cook Time

... Rack of Lamb 14 to 16 oz 1 Rack

SUGGESTED SETTINGS

Cook Time Oven Temp

04:00 500

mins : secs

Adjust Settings

... Rack of Lamb 14 to 16 oz 1 Rack

Cook Time Oven Temp

0:04:00 500

hours:mins:secs

Advanced...

Begin Preheat

Begin Preheat

Roast

To adjust

time, turn

knob to the

desired time

and press to

set.

Figure 2.5: Adjusting Cook Time

Roast

! Temp has

been

calculated for

best results.

Adjusting

temp is not

advised.

Figure 2.6: Selecting Oven Temp

... Rack of Lamb 14 to 16 oz 1 Rack

Cook Time Oven Temp

03:55 500

mins:secs

Advanced...

... Rack of Lamb 14 to 16 oz 1 Rack

Cook Time Oven Temp

04:00 500

mins:secs

Advanced...

Begin Preheat

Begin Preheat

Page 33

2.9

2. Use the inner CookWheel knob to scroll to

“Advanced...” and press the knob to select it

(Figure 2.8).

3. Select the setting to be adjusted and make the

desired changes (Figure 2.9).

4. Press the inner CookWheel knob to confi rm

the new settings.

5. Select “Done” to confi rm changes or “Original

Settings” to cancel changes (Figure 2.9).

Saving to Favorites

By allowing the user to store up to 9,999 cook

settings, the Favorites mode allows the user to cook

anything quickly and easily. e user can create the

perfect cook cycle for any product by using a preprogrammed setting and making adjustments at the

80% and 100% complete points. Once the settings

are perfected, saving to favorites enables the user to

store and easily recall the perfect setting for the next

time they cook that recipe.

e user can save to favorites when:

- Cooking is paused via oven door being open

- A cook cycle is 80% or 100% complete

- Selecting a recently-cooked dish from View

Last Cooked (10).

To save a dish to favorites,

1. From any of the above listed conditions, choose

Save to Favorites.

- Turn the inner CookWheel knob to advance

the cursor to the word you wish to edit or

delete, or to select the space between words

where you want to add text.

- Press the knob to select the word or space

between words.

- To add text:

a. Use the inner CookWheel knob to scroll

left and right to select letters (A-Z),

numbers (0-9), or punctuation marks.

b. Press the inner CookWheel knob to

confi rm a character. e cursor will

move to the next space.

c. Press the back key to return to a previous

character.

d. Predictive matches appear beneath the

text being added. Use the inner cook wheel knob to scroll to and select a

match (if applicable).

e. When a word is complete, press the inner

CookWheel knob after the fi nal

character is confi rmed.

- To change or delete text:

a. Use the inner CookWheel knob to high light the word to be changed or deleted,

and press the knob to select the word.

b. A drop-down menu will appear with

“change” and “delete” as selectable

options (Figure 2.10).

c. If “change” is selected, follow the above

instructions for adding text.

OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

NOTE: If you do not wish to rename the item being

saved, skip to step 3.

2. To rename a dish:

Roast

To adjust

temp, turn

knob to the

desired temp

and press to

set.

Figure 2.7: Adjusting Oven Temp

Roast

! This mode is

recommended

for advanced

users only.

Figure 2.8: Selecting Advanced

... Rack of Lamb 14 to 16 oz 1 Rack

Cook Time Oven Temp

03:55 495

mins:secs

Advanced...

... Rack of Lamb 14 to 16 oz 1 Rack

Cook Time Oven Temp

04:00 500

mins:secs

Advanced...

Begin Preheat

Begin Preheat

NOTE: When re-saving an existing Favorites recipe,

previous settings will be replaced with those from

the current cook cycle, including any name change.

3. Scroll to and select “Done.”

COOK TIME: 04:00 COOK TEMP: 500

Time Intervals 01:00 min 01:00 min 01:00 min 01:00 min

100%

100%

change

delete

90%

80%

100%

50%

Upper Air

Lower Air

Power

Figure 2.9: Advanced Cook Mode

Favorites

Turn inner

knob to

change the

current letter.

Push inner

knob to

select.

Figure 2.10: Changing or Deleting a Name

Last Cooked 1 Rack Save as Favorite

COOK TIME: 05:00 TEMP: 500

Mary’s 1 Rack

70%

100%

60%

50%

100%

30%

DoneOriginal Settings

Done

Page 34

2.10 OVEN CONTROLS AND COOKING THE SPEEDCOOK OVEN

Renaming a Dish (in Favorites)

At any time - and as often as the user likes - the

user may rename any of the cook settings saved in

Favorites.

To change the name of a setting stored in Favorites,

1. Turn the CookWheel to Favorites.

2. Select the dish/cook setting to be renamed.

3. Use the inner CookWheel knob to select

“Rename” (Figure 2.11).

4. Rename the selected item (see step 2 of “Saving

to Favorites, page 2.9).

5. Select Done.

Deleting a Dish (from Favorites)

Favorite settings that are no longer used or that

the user wishes to delete may be removed from the

Favorites mode.

To delete a dish from favorites,

1. Turn the CookWheel to Favorites.

2. Select the dish/cook setting to be deleted.

3. Use the inner CookWheel knob to select Delete

(Figure 2.11).

NOTE: When Delete is selected, the item/setting

is automatically deleted and the oven returns to the

initial Favorites screen, which lists all stored Favorite

settings in alphabetical order.

Self-Clean Mode - Speedcook

Oven

e Speedcook oven is self-cleaning. Using heat up

to 900°F (482°C), the oven will self-clean the inside

of the cook cavity in approximately 4.5 hours.

NOTE: For the Double Wall Oven, while one oven

is in self-clean mode the other will not be functional.

Additionally, the top and bottom ovens cannot be

self-cleaned at the same time.

NOTE: e oven door will not unlock until the

oven cavity temperature recedes below 500°F

(260°C).

To initiate a self-clean (Figure 2.12),

1. Ensure the cook cavity is empty and remove the

oven rack.

NOTE: Failure to remove the oven rack will cause

the rack to discolor.

2. Turn the CookWheel to Self-Clean.

3. Press the Start button.

4. If terminating a self-clean is required, turn the

outer CookWheel knob to Off .

During the self-clean cycle, the oven door is locked

and oven surfaces can become very hot. When the

cleaning cycle is complete and the oven has returned

to a safe temperature, the screen displays a message

and the oven sounds a tone and powers down.

Reheat Setting

Use the reheat setting to reheat leftovers. e

intended serving size is food for one individual,

or a “plate” of food.

1. Turn the CookWheel to Bake.

2. Scroll to Refrigerated Foods, Reheat.

3. Press the Start button to begin reheating.

Favorites

Please select

an option.

Figure 2.11: Rename a Dish (in Favorites) Figure 2.12: Self Clean

Rack of Lamb

Cook

Rename

Delete

WARNING: e oven is extremely hot during

self-clean. DO NOT touch or attempt to use until

self-clean is complete.

Self-clean

During self-cleaning,

the oven door will be locked.

CAUTION: HOT SURFACES

Self-cleaning is starting.

Page 35

Section 3

Oven Controls and Cooking Lower Oven (Double Wall Oven Only)

Page 36

Page 37

3.1

Figure 3.1: Lower Oven Controls (Double Wall Oven models only)

Lower Oven Controls

ese controls are only applicable to Double Wall

Oven models.

1. Display Screen

Displays the oven and meat probe temperature, as

well as the timer information.

2. Oven Mode Dial

Turn to choose the cook mode. For a list of cook

modes, see page 3.2.

3. Temperature Dial

1

456 7

2

3

5. Lock Key

When the door is locked, a graphical lock appears on

the screen. Hold for 3 seconds to engage/disengage

the door lock. Allow 5-10 seconds for lock/unlock to

engage.

NOTE: To engage the Sabbath Mode, simultaneously

press the “Lock” and “View” keys for 3 seconds. See

page 3.3 for details.

6. View Key

Press to toggle between the oven temperature, meat

probe temperature, and timer information being

displayed in the primary screen position.

Turn the dial to set the oven temperature or to select

Broil Low, Broil High, Proof, or Warm.

4. Set Timer Knob

Use to set the timer:

1. Press knob to extend.

2. Turn knob to set timer.

3. Press knob back in to original position.

e timer does not begin counting down until the

knob is pressed back in. e oven will chime four

times at the end of the timer cycle.

7. Oven Light Switch

Press to illuminate the bottom cook cavity.

OVEN CONTROLS AND COOKING THE BOTTOM OVEN

Page 38

3.2 OVEN CONTROLS AND COOKING THE BOTTOM OVEN

Cook Modes

e bottom oven (double wall only) is both a

conventional and convection oven that provides

uniform cooking throughout. e bottom oven

features fi ve cook modes.

- Bake

- Broil

- Convection Bake

- Convection Roast

- Roast

e table below details heater element activity

within each mode.

Mode Convection

Fan

Bake Off 22.3 ± 2.0 19.8 ± 2.0

Broil (High) Off 14.7 ± 2.0 13.3 ± 2.0

Broil (Low) Off 14.7 ± 2.0 13.3 ± 2.0

Convection Bake On 20.3 ± 2.0 17.5 ± 2.0

Convection Roast On 12.7 ± 2.0 11.0 ± 2.0

Roast Off 18.0 ± 2.0 15.5 ± 2.0

Bake

208 VAC

Value

240 VAC

Value

Convection Bake

Convection Bake uses the same heating elements

as Bake with the addition of a convection fan and

heater in the back of the cook cavity. is fan and

heater help heat and circulate the air evenly

throughout the chamber to produce superior

browning and crisping.

Any food cooked under the Bake mode can also

be prepared using Convection Bake and vice versa.

Items cooked under Convection Bake will cook

about 33% faster than when cooked under Bake.

Convection Roast

Convection Roast uses the same heating elements

as Roast. However, unlike Roast, Convection Roast

utilizes the convection fan and heater in the back of

the oven to help heat and circulate the air throughout the cook cavity.

Any item cooked under Roast can be prepared using

Convection Roast and vice versa. e one diff erence

is that Convection Roast uses additional heating

elements, causing it to cook about 33% faster.

Traditionally, baking is to cook with dry heat. Hot

air from the top and bottom of the oven envelopes

the food in a radiant dry heat, perhaps with a little

moisture from the food, which circulates as a vapor

in the oven.

In the bottom oven of the double wall oven, unlike

most traditional ovens, the bottom heating element

is concealed beneath the cook cavity. is feature

allows for a bigger cook cavity, easier cleaning, and

more uniform heating.

Broil

Broiling directly exposes food to radiant heat (as

over a fi re or on top of a grill). e heat is direct and

intense, and it diff ers from baking or roasting in that

only the top side of the food is exposed to the heat

source.

Generally, you broil foods that are quick cooking,

inherently tender, relatively lean, and not too thick.

Roast

Roasting in an oven is essentially the same as baking,

but roasting is used mostly for meats and vegetables.

Hot air from the top and bottom of the oven is used

to brown the outside of food while retaining

moisture inside.

In the bottom oven of the Double Wall model, the

two top heating elements provide better control and

optimized broiling and roasting.

Warm Setting

e warm setting uses heat from the top and bottom

of the oven to keep the cook cavity at 145°F (63°C),

the perfect holding temperature for food.

Proof Setting

e Proof setting uses heat from the top and bottom of the oven to keep the cook cavity at 90-105°F

(32-41°C), the perfect temperature for yeast dough

to rise. Some doughs may require moisture to proof

correctly. If moisture is needed, place a sheet pan of

water under the lower rack.

Page 39

3.3

Basic Cooking

e bottom oven, when used in combination with

the top oven, off ers the user an expanded capacity.

WARNING: Due to the concealed heating

element in the bottom oven, make sure to not cover

or line the bottom of the oven with foil.

To operate the lower oven,

1. Set the oven mode dial to one of the following:

Convection Bake, Convection Roast, Broil,

Roast, or Bake.

2. Set the oven temperature dial.

- Along with the various temperature settings,

the user could also choose Warm or Proof.

- e oven’s current temperature is displayed

as the primary information on the screen.

3. When the oven fi nishes preheating (Figure 3.2),

insert the dish.

WARNING: Inside of oven and oven door are

hot! Use extreme caution.

4. Set the timer (if desired). See page 3.1 for

instructions on how to set the timer.

NOTE: When the timer is set, the remaining cook

time is displayed as the primary information and the

oven temperature as the secondary (Figure 3.3). Press

the View key to toggle which information is

displayed as primary and secondary (Figure 3.4).

NOTE: When the meat probe is in use, the probe

temperature is displayed while the dish is cooking.

To toggle between the information displayed in the

primary, secondary, and tertiary positions on the

screen (Figure 3.5), press the View key.

5. When food has fi nished cooking, warming, or

proofi ng, carefully remove it from the oven.

The Sabbath Mode

e Sabbath Mode, available for religious faiths with

“no work” requirements on the sabbath, cooks food

over a 72 hour period. e Sabbath Mode is Star-K

certifi ed.

To use the Sabbath Mode,

1. Press the oven light switch to turn the oven

light on.

- By turning the oven light on via the switch,

the light stays on for the duration of the

time the oven is in the Sabbath Mode. If the

oven light is not turned on, the oven light

will turn on and off when the door is

opened and closed.

2. Set the oven mode dial and temperature dial

as if cooking normally.

3. Simultaneously press the Lock and View keys

for 3 seconds. e display will say “Oven

display is off when Sabbath Mode is engaged.”

is message is displayed for 10 seconds. e

display then goes black and remains black as