Page 1

TB4HB EC

4-Cycle Electric Start Capable Handheld Blower

Operator’s Manual

Removing Unit From Carton

11 2

Remove all contents from

the carton.

Assemble The Unit

5

Place unit on a level surface.

Fill fuel tank.

Assemble The Unit

Insert the upper blower

tube into the blower outlet

and turn it clockwise until it

locks into place.

Starting The Unit

Primer

Bulb

10 X

6

Press primer bulb 10 times,

or until fuel is visible

3

Install the lower blower tube

onto the upper blower tube

and turn it clockwise until it

locks into place.

7

Move choke lever to

Position 1.

4

Place the unit on a level

surface, remove the oil plug

from the crankcase, and pour

the entire bottle of oil into the

fill hole.

8

Crouch in starting position.

Tools Required:

• Flathead Screwdriver

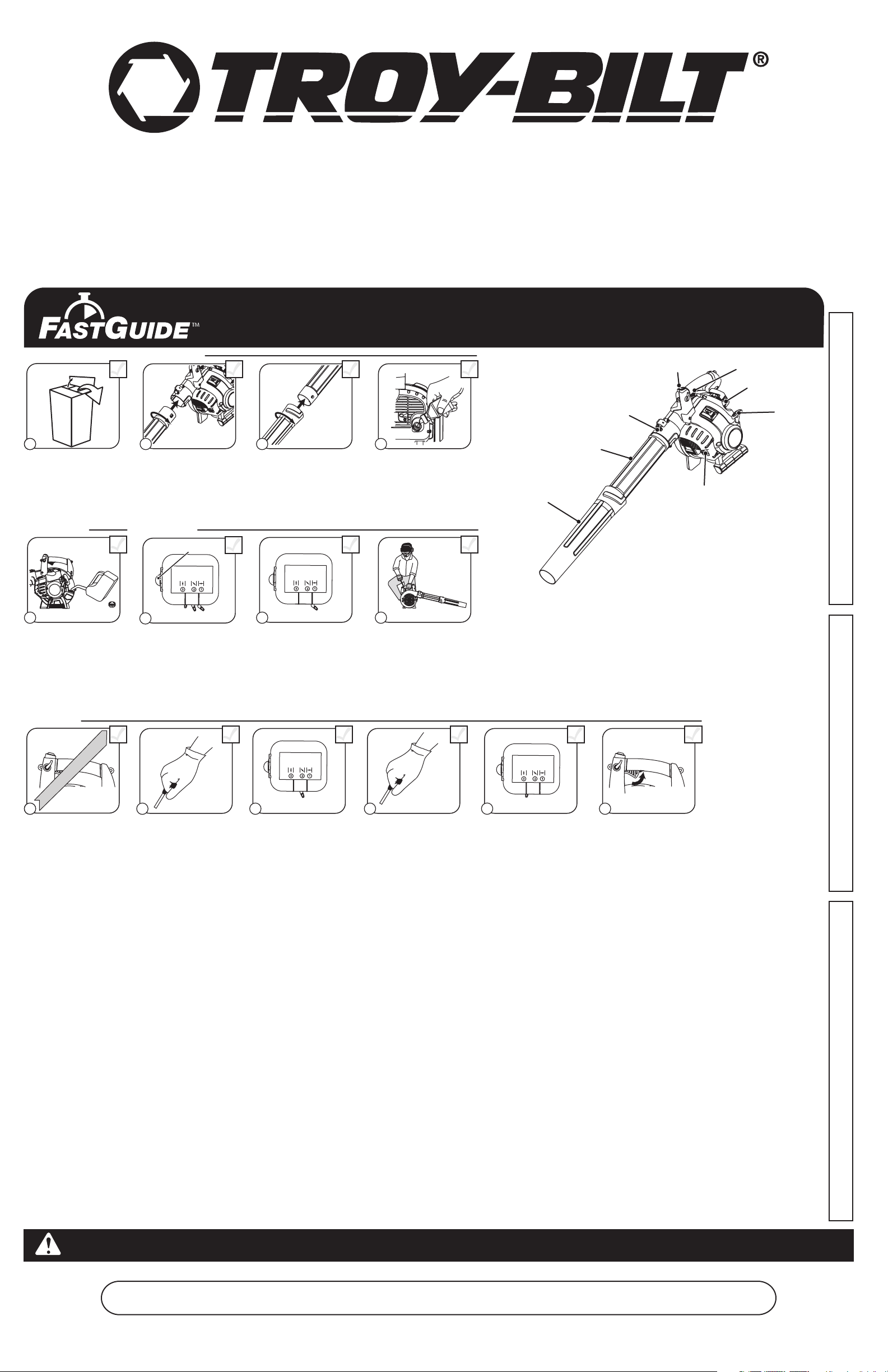

Upper Blower Tube

Lower Blower Tube

Blower Outlet

On/Off Switch

Oil Plug

Throttle Control

Primer Bulb

Starter Rope

DIDN’T START?

Repeat the starting instructions.

IF engine fails to start after 2 attempts,

move choke lever to position 3 and pull

the starter rope until engine starts

IF unit still fails to start, refer to operator’s

manual for additional starting and

troubleshooting information

ENGLISH — PAGE 1

Starting The Unit

19 10

DO NOT squeeze throttle

control.

5 X

11

Pull rope 5 times. Move choke lever to

Position 2 .

12

Pull rope 3-5 times to start

engine. Squeeze throttle

control and allow unit to

warm up for 30-60 seconds.

3-5 X

13

Continue to squeeze

throttle. Move choke lever

to Position 3.

14

Continue to squeeze

throttle. Warm unit for an

additional 60 seconds to

complete warm-up. Unit

may be used during this

time.

ESPAÑOL — PAGE 9

IMPORTANT: READ OPERATOR’S MANUAL THOROUGHLY AND FOLLOW THE SAFE OPERATION PRACTICES WHILE OPERATING THE UNIT.

NEED HELP? Call 1-800-828-5500 in U.S. or 1–800–668–1238 in Canada

769-07792 P00 05/12

Page 2

SERVICE INFORMATION

TABLE OF CONTENTS

Service Information

Rules for Safe Operation

Know Your Unit

Assembly Instructions

Oil and Fuel Information

Starting/Stopping Instructions

Operating Instructions

Maintenance and Repair Instructions

Cleaning and Storage

Optional Accessory

Troubleshooting Chart

Specifications

Warranty Information

................................................................................................................................ 2

........................................................................................................................2

...................................................................................................................................... 3

............................................................................................................................3

.........................................................................................................................3

............................................................................................................... 4

...........................................................................................................................4

.................................................................................................... 5

............................................................................................................................ 6

................................................................................................................................ 6

............................................................................................................................6

........................................................................................................................................6

...........................................................................................................................16

All information, illustrations, and specifications in this manual are based on the latest product information

available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2012 MTD SOUTHWEST INC, All Rights Reserved.

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED

FOR WARRANTY SERVICE.

For assistance regarding the assembly, controls, operation or maintenance of the unit, please call the

Customer Support Department at 1-800-828-5500 in the United States or 1-800-668-1238 in Canada.

Additional information about the unit can be found on our website at www.troybilt.com or www.troybilt.ca.

Service on this unit, both within and after the warranty period, should only be performed by an

authorized and approved service dealer.

RULES FOR SAFE OPERATION

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal combustion engines operated on forest brush and/or grasscovered areas be equipped with a spark arrestor, maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention of fire. Check with your state or local authorities

for regulations pertaining to these requirements. Failure to follow these requirements could subject you to

liability or a fine. This unit is factory equipped with a spark arrestor. If it requires replacement, ask your

LOCAL SERVICE DEALER to install the Accessory Part #753-05900 Muffler Assembly

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention and understanding. The safety warnings do not

by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

Symbol meaning

WARNING: Failure to obey a safety warning can result in injury to yourself and others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal

injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal

injury to yourself or to others. Always follow the safety precautions to reduce the risk of

fire, electric shock and personal injury.

SAFETY ALERT: Indicates danger, warning or caution. Attention is required in

order to avoid serious personal injury. May be used in conjunction with other symbols or

pictographs.

RULES FOR SAFE OPERATION

• Use the right tool. Only use this tool for its intended purpose.

• Do not force unit. It will do the job better and with less likelihood of injury at a rate for which it was

designed.

• Do not overreach or use from unstable surfaces such as ladders, trees, steep slopes, rooftops, etc.

Always keep proper footing and balance.

• Always hold the unit with a firm grip when operating.

•

Keep hands, face, and feet away from all moving parts. Do not touch or try to stop the impeller when it

is rotating. Do not operate without guards in place.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dirt, debris,

and anything that may reduce the air flow.

• Do not touch the engine or muffler. These parts get extremely hot from operation, even after the unit

is turned off.

• Do not operate the engine faster than the speed needed to do the job. Do not run the engine at high

speed when not in use.

• Always stop the engine when operation is delayed or when walking from one location to another.

• Use only genuine factory replacement parts and accessories for this unit. These are available from

your authorized service dealer. Use of any unauthorized parts or accessories could lead to serious

injury to the user or damage to the unit, and void your warranty.

•

If you strike or come into contact with a foreign object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do not operate the unit with loose or damaged parts.

• To reduce fire hazard, replace faulty muffler and spark arrestor. Keep the engine and muffler free from

grass, leaves, excessive grease or carbon build up.

SAFETY WARNINGS FOR GAS UNITS

WARNING: Gasoline is highly flammable and its vapors can explode if ignited. Take the

following precautions:

• Store fuel only in containers specifically designed and approved for the storage of such materials.

• Always stop the engine and allow it to cool before filling the tank. Never remove the fuel tank cap or

add fuel when the engine is hot. Always loosen the fuel tank cap slowly to relieve any pressure in the

tank before fueling. DO NOT smoke.

• Always add fuel in a clean, well-ventilated outdoor area where there are no sparks or flames. DO

NOT smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any spilled fuel from the unit, immediately

before starting the unit. Move the unit at least 30 ft. (9.1 m) from the fueling source and site before

starting the engine. DO NOT smoke.

•

Never start or run the unit inside a closed room or building. Breathing exhaust fumes can kill. Operate

this unit only in a well ventilated outdoor area.

BLOWER SAFETY INSTRUCTIONS

• Stop the engine for maintenance, repair, to install or remove the blower tubes. The unit must be

stopped and the impeller no longer turning to avoid contact with the rotating blades.

• Never use this unit for spreading chemicals, fertilizers or other substances which may contain toxic

materials.

• Never point the blower in the direction of bystanders, animals, windows or automobiles.

SPECIAL NOTE:

POWERED HAND TOOLS COULD CAUSE BLOOD VESSEL OR NERVE DAMAGE IN THE FINGERS,

HANDS, AND JOINTS OF PEOPLE PRONE TO CIRCULATION DISORDERS OR ABNORMAL

SWELLING. Prolonged use in cold weather has been linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as numbness, pain, loss of strength, change in skin color

or texture, or loss of feeling in the fingers, hands or joints, discontinue use of this tool and seek

medical attention. An anti-vibration system does not guarantee avoidance of these problems.

Users who operate power tools on a regular basis must closely monitor their physical condition and

the condition of this tool.

EXPOSURE TO VIBRATIONS THROUGH PROLONGED USE OF GASOLINE

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to

others. Always follow the safety precautions to reduce the risk of fire, electric shock and

personal injury.

NOTE: Advises of information or instructions vital to the operation or maintenance of the equipment.

Read the Operator’s Manual and follow all warnings and safety instructions. Failure to do so

can result in serious injury to the operator and/or bystanders.

FOR QUESTIONS, CALL

1-800-828-5500 IN THE U.S. OR 1-800-668-1238 IN CANADA

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

GENERAL SAFETY INSTRUCTIONS

WARNING: When using the unit, all safety rules must be followed. Please read these

instructions before operating the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

CALIFORNIA PROPOSITION 65

WARNING: Engine exhaust, some of its constituents and certain finished components

contain or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

• Read the instructions carefully. Be familiar with the controls and proper use of the unit.

• Do not operate this unit when tired, ill, or under the influence of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use the unit, except for teens guided by an adult.

• All guards and safety attachments must be installed properly before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for fuel leaks. Make sure all fasteners

are in place and secure. Replace parts that are cracked, chipped, or damaged in any way. Do not

operate the unit with loose or damaged parts.

• Carefully inspect the area before starting the unit. Remove all debris and hard or sharp objects such

as glass, wire, etc.

•

Clear the area of children, bystanders, and pets. At a minimum, keep all children, bystanders, and pets

outside a 50 feet (15 m) radius; there still may be a risk to bystanders from thrown objects. Bystanders

should be encouraged to wear eye protection. If you are approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns automatically to the idle position. Make all

adjustments or repairs before using unit.

• Never store the unit, with fuel in the tank, inside a building where fumes may reach an open flame

(pilot lights, etc.) or sparks (switches, electrical motors, etc.).

• Allow the engine to cool before storing or transporting. Be sure to secure the unit while transporting.

• Store the unit in a dry place, either locked up or up high to prevent unauthorized use or damage.

Keep out of the reach of children.

• Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean, and free from

debris. Clean after each use. See Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to instruct other users. If you loan this

unit to others, also loan these instructions to them.

• Wear safety glasses or goggles that are marked as meeting ANSI Z87.1–1989 standards and are

marked as such.

• Never run the unit without the proper equipment attached. Do not operate the unit without the

blower tubes attached.

• To reduce the risk of hearing loss associated with sound level(s), always wear ear/hearing protection

when operating this unit.

• Wear heavy long pants, boots, gloves, and a long sleeve shirt. Do not wear loose clothing, jewelry,

short pants, sandals or go barefoot. Secure hair above shoulder level.

• Use the unit only in daylight or good artificial light.

• Keep outside surfaces free from oil and fuel.

• Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator

and unit must be in a stable position while starting. Refer to Starting/Stopping Instructions.

• Do not set unit on any surface except a clean, hard area while engine is running. Debris such as

gravel, sand, dust, grass, etc. could be picked up by the air intake and thrown out by the discharge

opening, damaging unit, property, or causing serious injury to bystanders or operator.

SAVE THESE INSTRUCTIONS

2

Page 3

• SAFETY & INTERNATIONAL SYMBOLS •

vacuum door, installing or changing tubes or bag, or before cleaning or performing

This operator’s manual describes safety and international symbols and pictographs that may

appear on this product. Read the operator’s manual for complete safety, assembly, operating and

maintenance and repair information.

Symbol meaning

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other

symbols or pictographs.

• READ OPERATOR’S MANUAL

WARNING: Read the operator’s manual(s) and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the operator and/or

bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING:

Thrown objects and loud noise can cause severe eye injury and hearing

loss. Wear eye protection meeting ANSI Z87.1-1989 standards and ear protection when

operating this unit. Use a full face shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing greater than 10% ethanol

will likely damage this engine and void the warranty.

• OIL

Refer to operator’s manual for the proper type of oil.

• ON/OFF CONTROL

ON / START / RUN

• ON/OFF CONTROL

OFF or STOP

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• CHOKE CONTROL

1.•FULL choke position

2.•PARTIAL choke position

3.•RUN choke position

• THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high speed, causing injury. Keep

away from the rotating rotor.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 50 feet

(15 m.) from the operating area.

• HOT SURFACE

WARNING: Do not touch any metal engine components. The engine gets

extremely hot from operation and may cause severe burns. Allow the unit to

completely cool prior to any maintence or servicing.

• BLOWERS – ROTATING IMPELLER BLADES CAN CAUSE SEVERE INJURY

WARNING: Stop the engine and allow the impeller to stop before opening the

any maintenance.

ASSEMBLY INSTRUCTIONS

ASSEMBLING UNIT

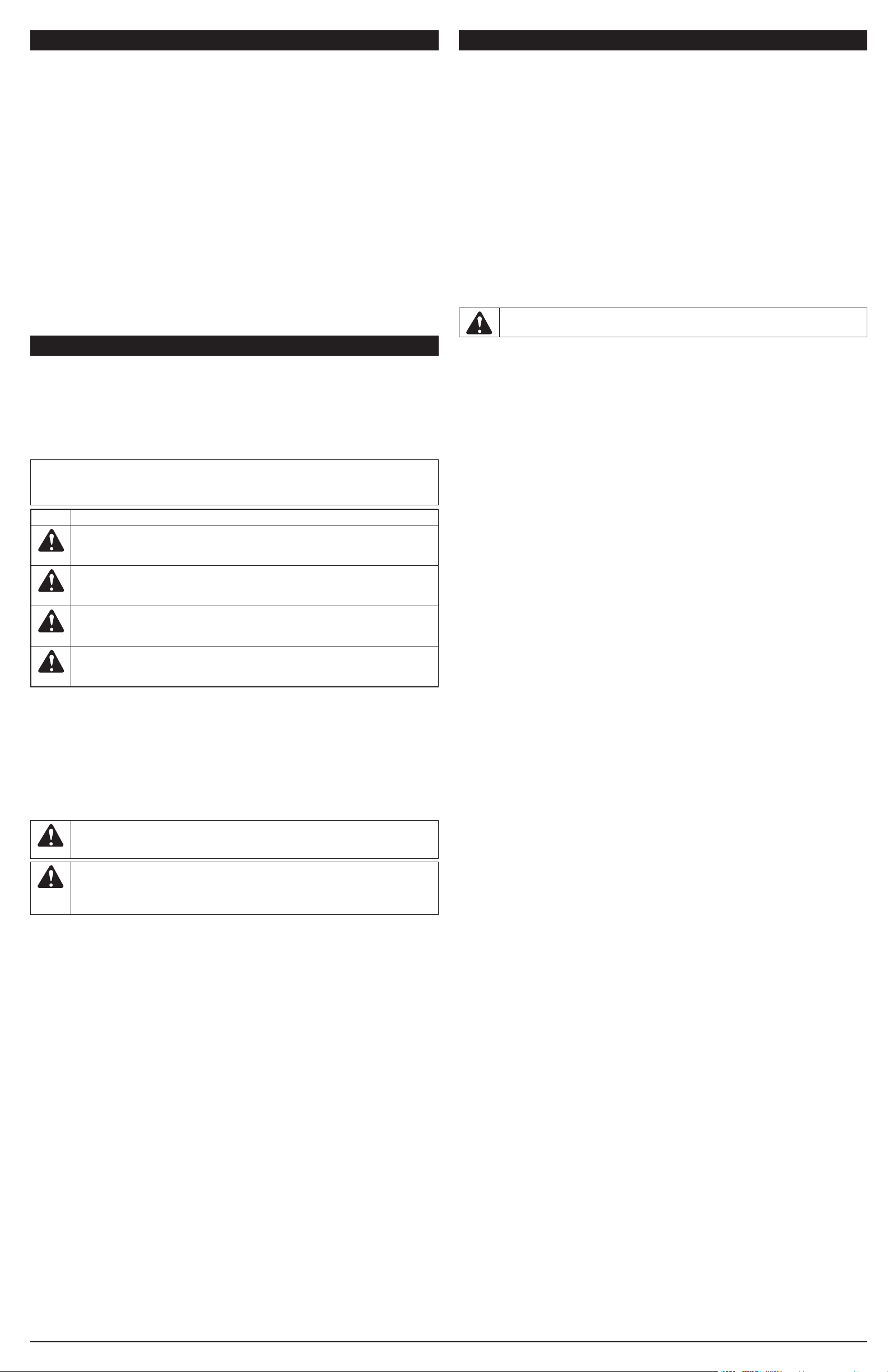

Installing the Upper Blower Tube

1. Align the bump on the end of the upper blower tube with the

bump slot on the bottom end of the blower outlet (Fig. 1).

2. Insert the upper blower tube into the blower outlet (Fig. 1).

3. Twist the upper blower tube clockwise until it locks into place

(Fig. 1).

Installing the Lower Blower Tube

1. Align the bump slot on the top end of the lower blower tube

with the bump on the end of the upper blower tube (Fig. 2).

2. Place the lower blower tube onto the upper blower tube (Fig. 2).

3. Twist the lower blower tube clockwise until tight (Fig. 2).

Removing the Upper Blower Tube

1. Hold the unit firmly.

2. Insert a flathead screwdriver into the tube lock. Twist the

screwdriver counterclockwise 1/4 turn and hold (Fig. 3).

3. Grasp the upper blower tube and twist it counterclockwise

(Fig. 3).

4. Pull the upper blower tube from the blower outlet.

Removing the Lower Blower Tube

1. Hold the upper blower tube firmly.

2. Grasp the lower blower tube and twist it counterclockwise until

the lower blower tube unlocks from the upper blower tube.

3. Remove the lower blower tube from the upper blower tube.

Blower

Outlet

Upper

Blower Tube

Upper Blower

Tube

Lower

Blower

Tube

Tube Lock

Bump

Fig. 1

Bump

Fig. 2

Fig. 3

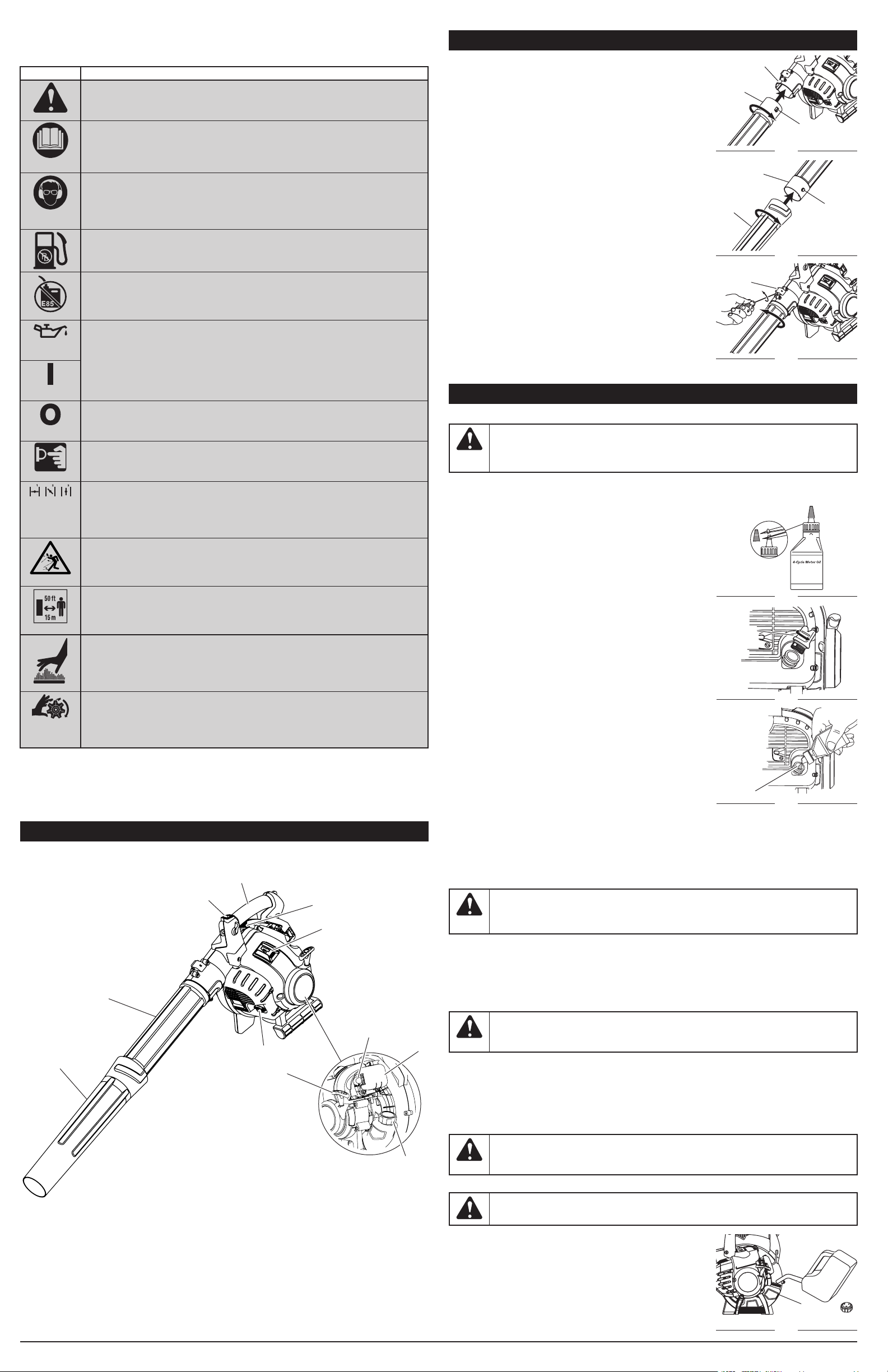

OIL AND FUEL INFORMATION

RECOMMENDED OIL TYPE

WARNING: OVERFILLING OIL CRANKCASE MAY CAUSE SERIOUS PERSONAL

INJURY. Check and maintain the proper oil level in the crankcase; it is important and

cannot be overemphasized. Check the oil before each use and change it as needed. See

Changing the Oil.

Using the proper type and weight of oil in the crankcase is extremely important. Check the oil before

each use and change the oil regularly. Failure to use the correct oil, or using dirty oil, can cause

premature engine wear and failure.

Use a high-quality SAE 30 weight oil of API (American Petroleum

Institute) service class SF, SG, SH.

ADDING OIL TO CRANKCASE: INITIAL USE

This unit is shipped without oil in the engine. To avoid

NOTE:

damage to the unit, put oil in the crankcase prior to starting

the unit.

This unit is supplied with one 2.03 fl.oz.

(60 ml) bottle of SAE 30 SF, SG, SH oil (Fig. 4).

Save the empty oil bottle. It can be used to measure the

NOTE:

correct amount during future oil changes. See Changing the Oil.

1. Unscrew the top of the bottle of oil and remove the paper seal

covering the opening. Replace the top and cut the tip off the

funnel spout (Fig. 4).

2. With the unit on a flat level surface, remove the oil plug (Fig. 5).

3. Pour the entire bottle of oil into the oil fill hole (Fig. 6).

NOTE: Never add oil to the fuel or fuel tank.

4. Wipe up any oil that may have spilled and reinstall the oil fill

plug.

Check oil before each use and change as needed. Refer to

Checking the Oil Level.

Oil Plug

Fig. 4

Fig. 5

APPLICATIONS

• Cleaning yards, garages, driveways,

porches, patios, around walls,

fences and more

TOOLS REQUIRED:

• Flathead Screwdriver

Upper Blower Tube

Lower Blower Tube

KNOW YOUR UNIT

Grip

On/ Off Switch

Oil Plug

Starter Rope Grip

Throttle Control

Spark Plug Cover

Primer Bulb

Air Filter

Cover

RECOMMENDED FUEL TYPE

Old fuel is the primary reason for poor unit performance. Be sure

to use fresh, clean, unleaded gasoline.

This is a four cycle engine. In order to avoid damage to the

NOTE:

unit, do not mix oil with gasoline.

Oil Fill Hole

Fig. 6

Definition of Blended Fuels

Today’s fuels are often a blend of gasoline and oxygenates such as ethanol, methanol or MTBE (ether).

Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can form acids when stored. Use

fresh fuel (less than 30 days old), when using alcohol-blended fuel.

Using Blended Fuels

WARNING: DO NOT USE E85 FUEL IN THIS UNIT.

It has been proven that fuel containing greater than 10% ethanol will likely damage this

engine and void the warranty.

If choosing to use a blended fuel, or its use is unavoidable, follow recommended precautions:

• Always use fresh unleaded gasoline

• Use the fuel additive STA-BIL® or an equivalent

• Drain tank and run the engine dry before storing unit

Using Fuel Additives

WARNING: Gasoline is extremely flammable. Ignited vapors may explode. Always stop

the engine and allow it to cool before filling the fuel tank. Do not smoke while filling the

tank. Keep sparks and open flames at a distance from the area.

The use of fuel additives, such as STA-BIL Gas Stabilizer or an equivalent, will inhibit corrosion and

minimize the formation of gum deposits. Using a fuel additive can keep fuel from forming harmful

deposits in the carburetor for up to six (6) months. Add 0.8 oz. (23 ml) of fuel additive per gallon of fuel

according to the instructions on the fuel additive container. NEVER add fuel additives directly to the

unit’s gas tank.

Fuel Cap

FUELING THE UNIT

WARNING: Add fuel in a clean, level and well ventilated outdoor area. Wipe up any

spilled fuel immediately. Avoid creating a source of ignition for spilled fuel. Do not start the

engine until fuel vapors dissipate.

1. Remove the fuel cap (Fig. 7).

WARNING:

without the fuel cap securely in place.

2. Place the gas container’s spout into the fill hole on the fuel

tank and fill.

NOTE: Do not overfill the tank.

3. Wipe up any gasoline that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine.

Dispose of any old gasoline in accordance with federal,

NOTE:

state and local regulations.

Remove fuel cap slowly to avoid injury from fuel spray. Never operate the unit

Fuel Tank

Fig. 7

3

Page 4

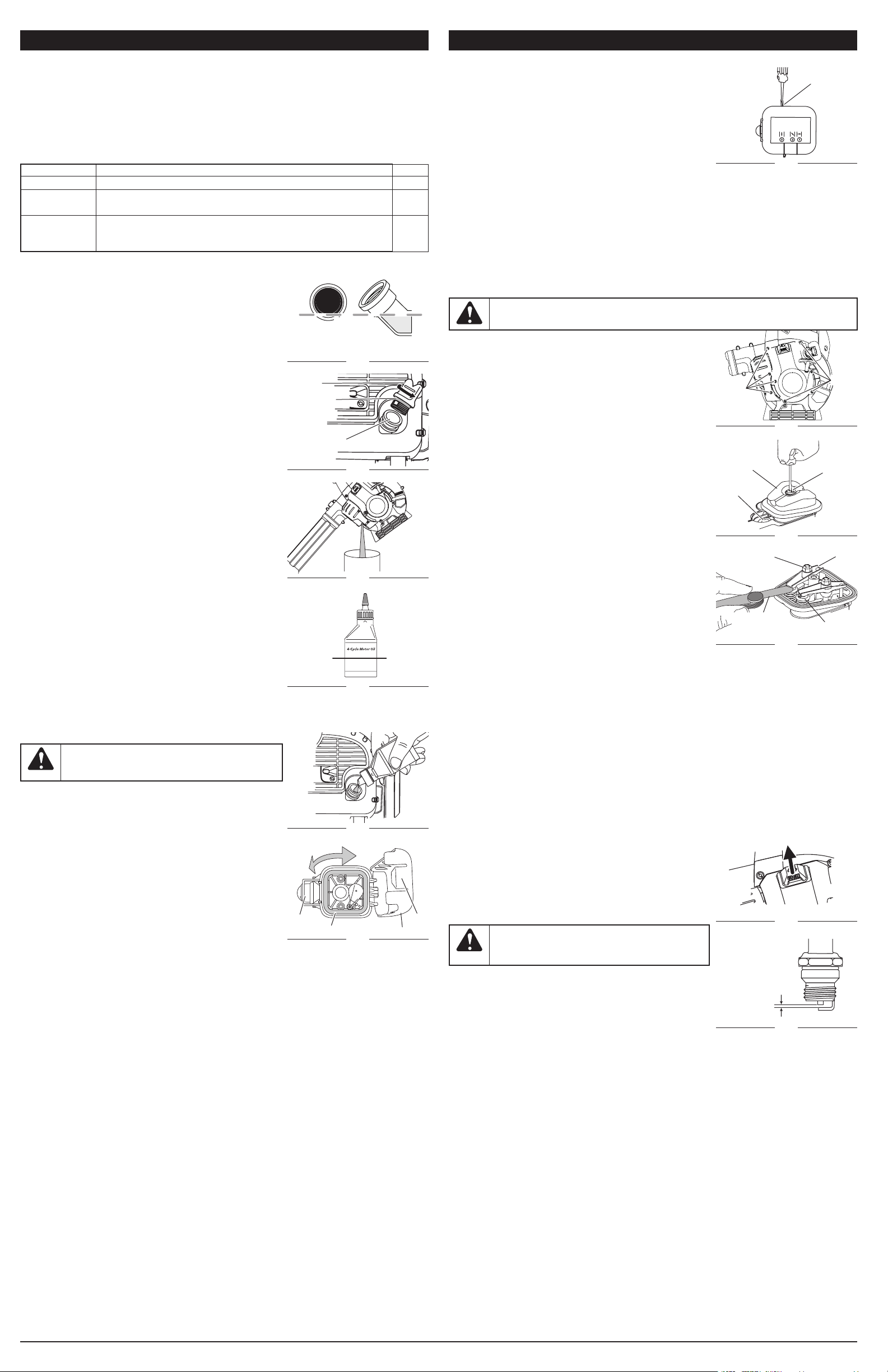

STARTING/STOPPING INSTRUCTIONS

WARNING: Operate this unit only in a well-ventilated outdoor area. Carbon monoxide

exhaust fumes can be lethal in a confined area.

WARNING: Avoid accidental starting. Make sure to be in the starting position when

pulling the starter rope (Fig. 10). To avoid serious injury, the operator and unit must be in a

stable position while starting.

STARTING INSTRUCTIONS

When starting the unit, make sure it is not directed at

NOTE:

bystanders or loose debris.

1. Check the oil level in the crankcase. Refer to Checking the Oil

Level.

2. Fill the fuel tank with fresh, clean unleaded gasoline. Refer to

Fueling the Unit.

NOTE:

There is no need to turn the unit on. The On/Off Control is

in the ON ( I ) position at all times.

3. Fully press and release the primer bulb 10 times, slowly. Some

amount of fuel should be visible in the primer bulb (Fig. 9). If

fuel cannot be seen in the bulb, press and release the bulb

until fuel is visible.

4. Move the choke lever to Position 1 (Fig. 9).

The unit should be started in idle. Do not squeeze the

NOTE:

trigger until step 8 (Fig. 8).

5. Do not squeeze the trigger. Crouch in the starting position

(Fig. 10). Pull the starter rope 5 times in a controlled motion.

6. Move the choke lever to Position 2 (Fig. 9).

7. Do not squeeze the trigger. Pull the starter rope 3-5 times in

a controlled motion to start the engine.

8. Squeeze and hold the trigger, or press down the cruise

control, and allow the engine to warm up for 30 to 60 seconds.

9. Continue to squeeze the trigger. Move the choke lever to

Position 3 (Fig. 9) and continue warming the engine for an

additional 60 seconds. The unit may be used during this time.

IF... the engine does not start, go back to step 3.

IF... the engine fails to start after a few attempts, move the

choke lever to Position 3 and pull the starter rope 3-8 times in

a controlled motion. The engine should start. If not, repeat.

IF WARM... If the engine is already warm, go back to step 6.

On/ Off Control

Primer Bulb

Throttle Control

Fig. 8

Fig. 9

Fig. 10

Choke

Lever

Starting

Position

OPERATING INSTRUCTIONS

HOLDING THE BLOWER

Before operating the unit, stand in the operating position and

check for the following:

• The unit in the right hand and on the right side of the body.

Do not block the air intake which will affect the unit’s

performance (Fig. 11).

• If the conditions are dusty, the operator is wearing a dust

mask or face mask

• The unit is in good working condition

• The tubes are in place and secure

OPERATING TIPS

Using the Variable Speed Cruise Control

Cruise

Control

For longer periods of operation and to eliminate possible finger

fatigue.

1. Move the variable speed cruise control toward the

FAST position to incrementally increase or maintain the unit’s

engine speed (Fig. 12). When the variable speed cruise

control is pressed, the trigger will recede into the handle.

2. To decrease engine speed, move the variable speed cruise

control to the SLOW position and the trigger will return to idle

(Fig. 12).

Other Tips

• Always use a firm grip when holding the unit.

• To reduce the risk of hearing loss, hearing protection is required.

• Operate power equipment only at reasonable hours when people might not be disturbed. Comply

with times listed in local ordinances. Usual recommendations are 9:00 am to 5:00 pm, Monday

through Saturday.

• To reduce noise levels, operate the unit at the lowest possible speed to do the job.

• Use rakes and brooms to loosen debris before blowing.

• Watch for bystanders, open windows or cars; blow debris safely away.

• Use the curved tube extension so the unit can work closer to the ground.

• Clean up after using blowers and other equipment. Dispose of debris appropriately.

Fig. 11

SLOW

FAST

Fig. 12

STOPPING INSTRUCTIONS

1. Release your hand from the trigger. Allow the engine to cool down by idling.

2. Press and hold the On/Off switch in the OFF (O) position until the unit comes to a complete stop

(Fig. 8).

IF USING THE OPTIONAL ELECTRIC STARTER OR POWER START BIT™ ACCESSORY

NOTE: This Unit Can Use an Electric Start or Power Start Bit™ Optional Accessory!

Please refer to the Electric Starter or Power Start Bit™ operator’s manual for proper use of this

feature. (Items Sold Separately! Please refer to page 6 of this manual about purchasing these

accessories.)

STARTING INSTRUCTIONS

NOTE: When starting the unit, make sure it is not directed at bystanders or loose debris.

1. Check the oil level in the crankcase. Refer to Checking the Oil Level.

2. Fill the fuel tank with fresh, clean unleaded gasoline. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off Control is in the ON ( I ) position at all times.

3. Fully press and release the primer bulb 10 times, slowly. Some amount of fuel should be visible in the

primer bulb (Fig. 9). If fuel cannot be seen in the bulb, press and release the bulb until fuel is visible.

4. Move the choke lever to Position 1 (Fig. 9).

NOTE: The unit should be started in idle. Do not squeeze the trigger until step 8 (Fig. 8).

5.

Crouch in the starting position (Fig. 10). Place the electric starter or Power Start Bit™ into the side of

the unit. Refer to the Operation section of the electric starter or Power Start Bit™ operator’s manual.

6. Do not squeeze the trigger. Press and hold the electric starter or drill’s ON (I) button for 2 seconds.

7. Move the choke lever to Position 2 (Fig. 9).

8. Do not squeeze the trigger. Press and hold the electric starter or drill’s ON (I) button for 2-second

intervals until the unit starts.

9. Remove the electric starter or drill from the unit.

10. Squeeze and hold the trigger, or press down the cruise control, and allow the engine to warm up

for 30 to 60 seconds.

11. Continue to squeeze the trigger. Move the choke lever to Position 3 (Fig. 9) and continue warming

the engine for an additional 60 seconds. The unit may be used during this time.

IF...the engine does not start, go back to step 3.

IF...the engine fails to start after a few attempts, move the choke lever to Position 3

and squeeze the

throttle control. Press and hold the electric starter or drill ON (I) button for 2-second intervals until

the unit starts.

IF WARM... If the engine is already warm, go back to step 7.

STOPPING INSTRUCTIONS

1. Release your hand from the trigger. Allow the engine to cool down by idling.

2. Press and hold the On/Off switch in the OFF (O) position until the unit comes to a complete stop

(Fig. 8).

4

Page 5

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These

procedures should also be a part of any seasonal tune-up.

Some maintenance procedures may require special tools or skills. If you are unsure about

NOTE:

these procedures, take your unit to a Troy-Bilt or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be

performed by a Troy-Bilt or other qualified service dealer.

NOTE: Please read the California/EPA statement that came with the unit for a complete listing of

terms and coverage for the emissions control devices, such as the spark arrestor, muffler,

carburetor, etc.

FREQUENCY MAINTENANCE REQUIRED SEE

Every 10 hours Clean and oil air filter p. 5

After 1st 10

hours

Every 40 hours Change oil

Change oil

Check rocker arm to valve clearance and adjust

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 5

p. 5

p. 5

p. 5

p. 5

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil level in

the crankcase cannot be overemphasized. Check oil before each

use:

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the engine on a level surface.

Oil Fill Line

3. Clean the area around the oil plug before removing it. Keep

dirt, grass clippings, and other debris out of the engine.

4. Remove the oil plug (Fig. 14).

Fig. 13

5. Look into the oil fill hole (use a flashlight if needed). The oil

should be just touching the innermost thread (Fig. 13).

6. If the oil level is not touching the innermost thread on the oil fill

hole, add a small amount of oil to the oil fill hole and recheck

Oil Plug

O-Ring

(Fig. 13). Repeat this procedure until the oil level reaches the

innermost thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE:

Make sure the O-ring is in place on the oil plug when

Oil Fill Hole

checking and changing the oil (Fig. 14).

CHANGING THE OIL

Fig. 14

Change the oil while the engine is still warm. The oil will flow freely

and carry away more impurities.

1. Remove the oil fill plug.

2. Pour the oil out of the oil fill hole and into a container by

tipping the unit to a vertical position (Fig. 15). Allow ample

time for complete drainage.

3. Wipe up any oil residue on the unit and clean up any oil that

may have spilled. Dispose of the oil according to federal, state

and local regulations.

4. Refill the crankcase with 2.03 fl.oz. (60 ml) of SAE 30 SF, SG,

Fig. 15

SH oil (Fig. 17).

NOTE:

Use the bottle and spout saved from initial use to

measure the correct amount of oil. The fill line on the bottle’s

label measures approximately 2.03 fl.oz. (60 ml) (Fig. 16).

5. Check the level. See Checking the Oil Level.

6. Once full, replace the oil plug.

Fill Level

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Fig. 16

Failure to maintain the air filter will VOID the warranty.

1. To open the air filter cover, push the tab on the left side of the cover inward and pull the air filter

cover slightly out and to the right (Fig. 18).

2. Remove the air filter (Fig. 18).

WARNING: To avoid serious personal injury,

always turn the unit off and allow it to cool before

cleaning or maintaining it.

3. Wash the filter in detergent and water. Making sure to rinse the

filter thoroughly and allow it to dry.

4. Lightly coat the filter with clean SAE 30 motor oil.

5. Squeeze the filter to spread and remove excess oil.

6. Replace the filter.

NOTE: Operating the unit without the air filter will VOID the

warranty.

7. To reinstall the air filter cover, position the hooks on the right

side of the air filter cover into the slots at the right side of the

back plate (Fig. 18).

8. Swing the cover to the left and press closed so the air filter

cover tab snaps into the slot on the back plate (Fig. 18).

Slot

Air Filter

Fig. 17

Tab

Air Filter Cover

Fig. 18

MAINTENANCE AND REPAIR INSTRUCTIONS

IDLE SPEED ADJUSTMENT

The idle speed of the engine is adjustable. An idle adjustment

screw is between the air filter cover and the engine starter housing

(Fig. 19).

Careless adjustments can seriously damage to the unit. A

NOTE:

Idle Adjustment

Screw

qualified service dealer should make carburetor adjustments.

If, after checking the fuel and cleaning the air filter, the engine still

will not idle, adjust the idle speed screw as follows:

1. Start the engine and warm up according to the Starting/

Stopping Instructions.

2. Release the trigger and let the engine idle. If the engine stops,

Fig. 19

insert a small Phillips screwdriver in between the air filter cover

and the engine cover (Fig. 19). Turn the idle speed screw 1/8 of a turn clockwise at a time until the

engine idles smoothly.

Checking the fuel, cleaning the air filter, and adjusting the idle speed should solve most engine

problems. If not and all of the following are true:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

take the unit to a qualified service dealer.

ROCKER ARM CLEARANCE

WARNING: To avoid serious personal injury, always turn the unit off and allow it to cool

before cleaning or maintaining it.

This requires disassembly of the engine. If you feel unsure or

unqualified to perform this, take the unit to a qualified service

dealer.

• The engine must be cold when checking or adjusting the

rocker arm clearance.

• This task should be performed inside, in a clean, dust free

Screws

area.

1. Remove the 8 engine cover screws with the appropriate tool

(Fig. 20), then remove the cover.

NOTE:

Make sure to store the screws so that they can be

reinstalled into their original holes.

2. Disconnect the spark plug wire.

3. Clean dirt from around the spark plug and rocker arm cover.

Remove the spark plug from the cylinder by turning a 5/8 in.

socket counterclockwise.

4. Remove the screw holding the rocker arm cover with the

appropriate tool (Fig. 21). Remove the rocker arm cover and

Spark

Plug

Hole

Rocker

Cover

Fig. 20

Arm

Screw

gasket.

5. Turn the flywheel slowly to bring the piston to the top of its

travel (known as top dead center). Check that:

• The piston is at the top of its travel by looking in the spark

plug hole (Fig. 21)

• Both rocker arms move freely, and both valves are closed.

Fig. 21

Adjustment Nut

Rocker Arm

If these statements are not true, repeat this step.

6. Slide the feeler gauge between the rocker arm and the valve

return spring. Measure the clearance between the valve stem

and rocker arm (Fig. 22). Measure both the intake and exhaust

valves.

The recommended clearance for both intake and exhaust is .003

– .006 in. (.076 – 0.152 mm). Use a standard automotive .005 in.

0.003–0.006 in.

(0.076–0.152 mm)

Feeler Gauge

Fig. 22

Valve

Stem

(0.127 mm) feeler gauge. The feeler gauge should slide between

the rocker arm and valve stem with a slight amount of resistance, without binding (Fig. 22.)

7. If the clearance is not within specification:

a.

Turn the adjusting nut using a 5/16 inch (8 mm) wrench or nut driver (Fig. 22).

• To increase clearance, turn the adjusting nut counterclockwise.

• To decrease clearance, turn the adjusting nut clockwise.

b. Recheck both clearances, and adjust as necessary.

8. Reinstalltherockerarmcoverusinganewgasket(Fig.21).Torquethescrewto:20–30in•lb

(2.2–3.4N•m).

9. Check the spark plug and reinstall. See Replacing the Spark Plug.

10. Reinstall the spark plug wire.

11. Reinstall the engine cover. Check alignment of the cover before tightening the screws. Tighten

screws.

NOTE: Make sure that the screws are reinstalled into their original holes (Fig. 20).

REPLACING THE SPARK PLUG

Use a replacement part number 753-05784 or Champion® spark

plug #RDZ4H. The correct spark gap is 0.025 in. (0.635 mm).

1. Stop the engine and allow it to cool.

2. Open the spark plug cover (Fig. 23).

3. Grasp the plug wire firmly and pull the cap from the spark plug.

4. Clean dirt from around the spark plug. Remove the spark

plug from the cylinder head by turning a 5/8 in. socket

counterclockwise.

Fig. 23

WARNING: Do not sand blast, scrape or clean

spark plug electrodes. Grit in the engine could

damage the cylinder.

Screws

5. Replace cracked, fouled or dirty spark plug. Set the spark gap

at 0.025 in. (0.635 mm) using a feeler gauge (Fig. 24).

6. Install a correctly-gapped spark plug in the cylinder head. Turn

the 5/8 in. socket clockwise until snug.

7. Reinstall the spark plug cover.

If using a torque wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m) Do not over tighten.

0.025 in.

(0.635 mm)

Fig. 24

5

Page 6

CLEANING AND STORAGE

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household

cleaners that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can

damage plastic housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes may reach an open flame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated are a.

• Store the unit out of the reach of children.

LONG TERM STORAGE

1. Drain all gasoline from the gas tank into a container. Do not use gas that has been stored for more

than 30 days. Dispose of the old gasoline in accordance with federal, state and local regulations.

2. Start the engine and allow it to run until it stalls. This ensures that all gasoline has been drained

from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5 drops of high quality motor oil into the

cylinder. Pull the starter rope slowly to distribute the oil. Reinstall the spark plug.

NOTE:

Remove the spark plug and drain all of the oil from the cylinder before attempting to start the

blower after storage.

4. Change the oil, referring to Changing the Oil. Dispose of the old oil in accordance with federal,

state and local regulations.

5. Thoroughly clean the unit and inspect for any loose or damaged parts. Repair or replace damaged

parts and tighten loose screws, nuts or bolts. The unit is ready for storage.

OPTIONAL ACCESSORY

ELECTRIC STARTER AND POWER START BIT™ FEATURES

This unit is designed to be started with an optional electric starter or Power Start Bit™, which are sold

separately. If choosing to start the unit using one of these features or have questions, please contact

your local retailer or call 1-800-828-5500 in the U.S (1-800-668-1238 in Canada) for more information

and purchasing. You may also go to www.troybilt.com or www.troybilt.ca

TROUBLESHOOTING

PROBLEM SOLUTION

ENGINE WILL NOT START, IDLE OR ACCELERATE

Empty fuel tank Fill fuel tank with fuel

Primer bulb wasn't pressed enough Slowly press primer bulb 10 times

Old fuel (over 30 days) Drain fuel tank and add fresh fuel

Fouled spark plug Replace or clean the spark plug

Air filter is plugged Replace or clean the air filter

Improper idle speed

Adjust according to the Idle Speed

Adjustments section.

ENGINE LACKS POWER OR STALLS

Old fuel (over 30 days) Drain fuel tank and add fresh fuel

Fouled spark plug Replace or clean the spark plug

SPECIFICATIONS*

Engine Type .............................................................................................................. Air-Cooled, 4-Cycle

Displacement

Operating RPM

Idle Speed RPM

Blower Velocity

Blower Air Output

Valve clearance

Spark Plug Gap

Lubrication

Crankcase Oil Capacity

Fuel

...........................................................................................................................................Unleaded

Fuel Tank Capacity

Approximate Unit Weight (No fuel)

.................................................................................................................................. 25 cc

........................................................................................................................7,000 rpm

..........................................................................................................3,600 – 4,600 rpm

................................................................................................up to 150 mph (240 kmh)

...........................................................................................up to 450 cfm (12.7 cmm)

..................................................................................0.003–0.006 in. (0.076–0.152 mm)

.................................................................................................... 0.025 inch (0.635 mm)

............................................................................................................................. SAE 30 Oil

................................................................................................2.03 fl.oz. (60 ml)

.............................................................................................................14 oz (414 ml)

..................................................................................... 11 lbs. (5 kg)

Electric Start

Feature

* All specifications are based on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

Fig. 19

6

Page 7

NOTES

7

Page 8

NOTES

8

Page 9

TB4HB EC

Sopladora manual de motor de 4 tiempos con posibilidad de arranque eléctrico

Manual del Operador

Sacar la unidad de la caja

11 2

Saque todo el contenido

de la caja.

Ensamblado de la unidad

5

Coloque la unidad en una

superficie plana. Llene el

tanque de combustible.

Ensamblado de la unidad

Inserte el tubo superior de

la sopladora dentro de la

salida de la sopladora y

gire en sentido de las

agujas del reloj hasta que

caiga en su lugar y cierre.

Cómo arrancar la unidad

Palanca del

obturador

10 X

6

Oprima 10 veces la pera

del cebador, o bien hasta

que se vea el combustible.

3

Inserte el tubo inferior de la

sopladora dentro del tubo

superior de la sopladora y

gire en el sentido de las

agujas del reloj hasta que

caiga en su lugar y cierre.

7

Coloque la palanca del

obturador en la Posición 1.

4

Ponga la unidad en una

superficie llana, quite el

enchufe de aceite del cárter

del motor, y vierta la botella

entera de aceite en el agujero

del terraplén.

8

Colóquese en la posición

de arranque.

Se necesitan herramientas:

• Destornillador plano

Tubo superior

de la sopladora

Tubo inferior

de la sopladora

la Sopladora

el manual del operador para obtener información adicional

Control de encendido

Salida de

Repita las instrucciones de arranque.

SI el motor no arranca después de 2 intentos, mueva la

la posición 3 y tire de la cuerda de arranque hasta que

SI el motor todavía no arranca, consulte

sobre cómo solucionar problemas en el arranque.

y apagado

Enchufe de aceite

Gatillo del

regulador

¿NO ARRANCÓ?

palanca del obturador hasta

arranque el motor.

Palanca del

obturador

Cuerda de

arranque

ENGLISH — PAGE 1

Cómo arrancar la unidad

19 10

No exprima el control de

válvula reguladora.

5 X

Tire de la cuerda

de arranque 5 veces.

11

Coloque la palanca del

obturador en la Posición 2.

12

Tire de la cuerda

de arranque fuertemente

de 3 a 5 veces para arrancar

el motor. Haga funcionar

la unidad entre 30 y 60

segundos para calentar

el motor.

3-5 X

13

Mantenga apretado

el control del regulador.

Coloque la palanca

del obturador

en la Posición 3.

14

Mantenga apretado

el control del regulador. Haga

funcionar la unidad durante 60

segundos más para completar

el calentamiento.

Se puede usar la unidad

durante este tiempo.

ESPAÑOL — PAGE 9

IMPORTANTE: LEA BIEN EL MANUAL DEL OPERADOR Y, AL OPERAR LA UNIDAD, SIGA LAS INSTRUCCIONES PARA EL FUNCIONAMIENTO SEGURO.

¿NECESITA AYUDA? LLAME AL 1-800-828-5500 en EE.UU. o al

1-800-668-1238 en Canada

769-07792 P00 05/12

Page 10

LLAMADAS A APOYO AL CLIENTE

TABLA DE CONTENIDO

Información sobre servicio

Normas para operarlo de manera segura

Conozca su unidad

Instrucciones de ensamblaje

Información sobre el aceite y el combustible

Instrucciones de arranque y parada

...................................................................................................................10

............................................................................................ 10

.............................................................................................................................. 11

............................................................................................................... 11

...................................................................................... 11

.................................................................................................... 12

Instrucciones de operación..................................................................................................................12

Instrucciones de mantenimiento y reparación

Limpieza y almacenamiento

Accesorio opcional

..............................................................................................................................14

................................................................................................................14

Localizacíon y solución de problemas

Especificaciones

Garantía

.................................................................................................................................. 14

...............................................................................................................................................16

..................................................................................... 13

................................................................................................. 14

Toda la información, las ilustraciones y las especificaciones contenidas en este manual se basan en

la información más reciente disponible en el momento de impresión del manual. Nos reservamos el

derecho de hacer cambios en cualquier momento sin aviso previo.

Copyright© 2012 MTD SOUTHWEST INC. Todos los derechos reservados.

Llame 1-800-828-5500 en EE.UU. o al 1-800-668-1238 en Canada para obtener una lista de distribuidores

de servicio localizados cerca de usted. Para obtener más detalles sobre su unidad, visite nuestro sitio en

www.troybilt.com o www.troybilt.ca

NO REGRESE SU UNIDAD AL VENDEDOR. PARA SOLICITAR SERVICIO POR LA GARANTIA,

DEBERA PRESENTAR PRUEBA DE SU COMPRA.

El servicio de esta unidad, ya sea durante o después del período cubierto por la garantía, debe ser

realizado solamente por un proveedor de servicios autorizado y aprobado.

NORMAS PARA UNA OPERACIÓN SEGURA

NOTA SOBRE EL PARACHISPAS

NOTA: Para usuarios de la Zona Forestal de EE. UU., y los estados de California, Maine, Oregón y

Washington. Todas las Zonas Forestales de los EE.UU. y el estado de California (Códigos de Recursos

Públicos 4442 y 4443), Oregon y Washington requieren, según la ley, que ciertos motores de combustión

interna que operen en el bosque y/o en zonas cubiertas de hierba, se encuentren equipados con un

parachispas, sean mantenidos en buen estado de funcionamiento, o que el motor sea construido,

equipado y mantenido, para prevenir incendios. Compruebe con sus autoridades estatales o locales las

regulaciones relacionadas con estos requisitos. Si no cumple con estos requisitos podría estar sujeto

a responsabilidad civil o a una multa Esta unidad viene equipada de fábrica con un parachispas. Si

necesita reemplazarlo, pídale a su DISTRIBUIDOR DE SERVICIO LOCAL instalarle la Pieza Accesorio

#753-05900 del ensamblaje del silenciador.

Los símbolos de seguridad se utilizan para llamar su atención sobre posibles peligros. Los símbolos

de seguridad y sus explicaciones merecen toda su atención y comprensión. Los símbolos de

seguridad no eliminan ningún peligro por sí mismos. Las instrucciones o advertencias que ofrecen

no substituyen las medidas adecuadas de prevención de accidentes.

Símbolo Significado

ADVERTENCIA: El no seguir una advertencia de seguridad puede conducir a que

usted u otras personas sufran lesiones. Siga siempre las precauciones de seguridad para

reducir el riesgo de incendio, descarga eléctrica y lesiones personales.

PRECAUCIÓN: El no seguir una advertencia de seguridad puede conducir a daño

patrimonial o a que usted u otras personas sufran lesiones personales. Siga siempre

las precauciones de seguridad para reducir el riesgo de incendio, descarga eléctrica y

lesiones personales.

ALERTA DE SEGURIDAD: Indica peligro, advertencia o precaución. Debe prestar

atención para evitar sufrir graves lesiones personales. Puede ser utilizado junto con otros

símbolos o figuras.

PELIGRO: El no obedecer una advertencia de seguridad puede conducir a que usted u

otras personas sufran graves lesiones. Siga siempre las precauciones de seguridad para

reducir el riesgo de incendio, descarga eléctrica o lesiones personales.

Indica información o instrucciones de vital importancia para la operación o el mantenimiento

NOTA:

del equipo.

Lea el manual del operador y siga todas las advertencias e instrucciones de seguridad.

De no hacerlo, el operador y/o los espectadores pueden sufrir graves lesiones.

SI TIENE PREGUNTAS, LLAME AL

1-800-828-5500

en EE.UU.

o al 1-800-668-1238 en Canada

• IMPORTANTE INFORMACION DE SEGURIDAD •

LEA TODAS LAS INSTRUCCIONES ANTES DE OPERAR LA UNIDAD

ADVERTENCIA: Se deben seguir las siguientes reglas de seguridad cuando

use la unidad. Por favor lea estas instrucciones para su propia seguridad y las de los

espectadores, antes de hacer funcionar la unidad. Por favor mantenga estas instrucciones

en un lugar seguro para uso futuro.

PROPOSICIÓN 65 DEL ESTADO DE CALIFORNIA

ADVERTENCIA: Los gases de escape, algunos de sus componentes y determinados

productos terminados contienen o emiten productos químicos de los que el estado de

California tiene conocimiento provocan cáncer, malformaciones congénitas u otros daños

al sistema reproductor. Lávese las manos después de manipularlo.

INSTRUCCIONES DE SEGURIDAD GENERALES

•

Lea las instrucciones cuidadosamente. Familiarícese con los controles y el uso adecuado de la unidad.

•

No opere esta unidad si está cansado, enfermo, o bajo los efectos del alcohol, drogas o medicamentos.

• Los niños y los adolescentes menores de 15 años de edad no deben usar la unidad. Los

adolescentes pueden hacerlo bajo la supervisión de un adulto.

• Todos los dispositivos de protección y los accesorios de seguridad deben estar instalados

adecuadamente antes de operar la unidad.

• Inspeccione la unidad antes de usarla. Cambie las piezas dañadas. Verifique que no haya fugas de

combustible. Asegúrese de que todos los sujetadores estén colocados y asegurados. Cambie las

piezas rajadas, melladas o dañadas de cualquier forma. No opere la unidad si tiene piezas flojas o

dañadas.

• Inspeccione cuidadosamente el área antes de encender la unidad. Elimine todos los escombros y

los objetos duros o filosos tales como cristales, alambres, etc.

• Aleje a los niños, personas presentes y animales domésticos. Mantenga todos los niños, personas

presentes y animales domésticos a un radio de por lo menos 50 pies (15 m); aun así puede existir

riesgo de que vuelen objetos contra las personas presentes. Debe sugerir a los presentes que usen

protección para los ojos. Si alguien se le acerca, pare la unidad de inmediato.

• Oprima el control del regulador y compruebe que regresa automáticamente a la posición de mancha

en vacío. Haga todos los ajustes o reparaciones antes de usar la unidad.

• No guarde nunca la unidad con combustible en el tanque, ni dentro de un edificio donde las

emanaciones puedan alcanzar una llama viva (luces pilotos, etc.) o chispas (interruptores, motores

eléctricos, etc.).

• Espere a que el motor se enfríe antes de guardar o transportar la unidad. Cerciórese de que la

unidad esté segura al transportarla.

• Guarde la unidad en un lugar seco, ya sea bajo llave o en un sitio alto, a fin de evitar que sea

utilizado por personas no autorizadas o que se dañe. Manténgala fuera del alcance de los niños.

• No moje nunca ni rocíe la unidad con agua ni con ningún otro líquido. Mantenga las manijas secas,

limpias y sin residuos. Limpie la unidad después de cada uso, lea las Instrucciones de Limpieza y

Almacenamiento.

• Guarde estas instrucciones. Consúltelas con frecuencia y utilícelas para enseñar a otros usuarios. Si

le presta esta unidad a alguien, préstele también estas instrucciones.

•

Nunca arranque ni opere la unidad dentro de una habitación o edificio cerrado. Respirar los vapores de

escape puede ocasionarle la muerte. Opere esta unidad solamente en un área exterior bien ventilada.

• Use espejuelos o gafas de seguridad que indiquen que cumplen con las normas ANSI Z87.1– 1989 y

10

NORMAS PARA UNA OPERACIÓN SEGURA

que estén marcados como tal. Use protección para las orejas u oidos cuando opere esta unidad.

• Nunca opere la unidad sin haber conectado el equipo adecuado.

• Para reducir el peligro de pérdida de audición relacionada con nivel(es) de ruido, use siempre

protección para las orejas u oídos al operar esta unidad.

• Use pantalones largos y gruesos, botas, guantes y camisa de mangas largas. No use ropa holgada,

alhajas, pantalones cortos, sandalias, ni permanezca descalzo. Asegure su cabello sobre el nivel de

los hombros.

• Use la unidad únicamente con la luz del día o con buena luz artificial.

• Mantenga las superficies exteriores libres de aceite y combustible.

• Evite los arranques accidentales. Debe estar en la posición de arranque siempre que tire de la

cuerda. El operador y la unidad deben estar en una posición estable durante el arranque. Consulte

las Instrucciones de Arranque y Apagado.

• Mientras el motor esté funcionando, no coloque el equipo sobre ninguna superficie, excepto sobre

un área limpia y sólida. La toma de aire pudiera recoger residuos tales como gravilla, arena, polvo,

hierba, etc., los que luego serían lanzados por la abertura de descarga, dañando de esta forma la

unidad, la propiedad, u ocasionar lesiones graves a las personas presentes o al operador.

• Use la herramienta correcta. Use esta herramienta solamente para el propósito previsto.

• No fuerce el equipo. El equipo funcionará mejor y con menos probabilidad de accidentes a la

velocidad para la que fue diseñado.

• No intente alcanzar demasiado lejos ni lo use desde superficies inestables como escaleras, árboles,

pendientes pronunciadas, techos, etc. Mantenga siempre la posición y el equilibrio adecuados.

• Sostenga siempre la unidad con firmeza cuando la esté operando.

• Mantenga las manos, la cara y los pies lejos de todas las partes móviles. No toque ni trate de

detener el impelente cuando esté girando. No opere la unidad sin tener los protectores en su lugar.

•

No ponga ningún objeto en las aberturas. No opere la unidad si alguna de las aberturas está obstruida;

manténgala libre de mugre, residuos y cualquier otra cosa que pueda reducir el flujo de aire.

• No toque el motor ni el silenciador. Estas partes se calientan mucho durante el funcionamiento y se

mantienen así aun después de apagarse la unidad.

• No opere el motor a una velocidad mayor que la necesaria para realizar el trabajo.

No ponga a funcionar el motor a alta velocidad si no lo está usando.

• Apague siempre el motor cuando demore el corte o cuando camine de un lugar a otro.

• Si golpea o se enreda con un objeto extraño, pare el motor de inmediato y compruebe si ha habido

algún daño. No ponga a funcionar el equipo antes de reparar el daño. No opere la unidad si tiene

piezas flojas o dañadas.

• Use únicamente piezas de repuesto y accesorios del fabricante original para esta unidad. Se

encuentran disponibles en el distribuidor autorizado. El uso de piezas o accesorios que no sean

genuinos puede ocasionarle lesiones graves al usuario o dañar la unidad y anular la garantía.

• Para evitar el peligro de incendio, reemplace el silenciador y parachispas defectuosos. Mantenga el

motor y el silenciador sin hierbas, hojas, grasa excesiva, e incrustaciones de carbón.

SEGURIDAD SOBRE EL ACEITE Y COMBUSTIBLE

ADVERTENCIA: La gasolina es altamente inflamable y sus gases pueden explotar si

se encienden. Tome las siguientes precauciones.

• Almacene el combustible solamente en los recipientes diseñados y aprobados específicamente

para estos materiales.

• Pare siempre el motor y deje que se enfríe antes de llenar el tanque de combustible. No quite

nunca la tapa del tanque de combustible ni eche combustible cuando el motor esté caliente. No

opere nunca la unidad si la tapa del combustible no está bien asegurada en su lugar.

• Mezcle o eche siempre el combustible en un área exterior bien ventilada y limpia, donde no haya

chispas ni llamas. No fume.

• No opere nunca la unidad si la tapa del combustible no está bien asegurada en su lugar.

• Evite el peligro de incendio debido a combustible derramado. Limpie de inmediato todo

combustible derramado de la unidad antes de encenderla. Antes de arrancar la unidad, aleje la

unidad a una distancia de 30 pies (9.1 m) como mínimo del lugar de abasto de combustible. No

fume.

• Nunca arranque ni opere la unidad dentro de una habitación o edificio cerrados. Respirar los

gases de escape puede ser fatal. Opere esta unidad solamente en un área exterior bien ventilada.

• Verifique que la unidad no tenga fugas de combustible.

• Afloje la tapa del tanque de combustible lentamente para disipar la presión del mismo.

• No guarde nunca la unidad con combustible en el tanque ni dentro de una edificación en la que

los gases puedan ponerse en contacto con una llama expuesta (luces pilotos, etc.) o chispas

(interruptores, motores eléctricos, etc.).

• Para evitar el peligro de incendio, reemplace el silenciador y parachispas defectuosos. Mantenga

el motor y el silenciador sin hierbas, hojas, grasa excesiva e incrustaciones de carbón.

• Evite los arranques accidentales. Debe estar en la posición de arranque siempre que tire de la

cuerda. El operador y la unidad deben estar en una posición estable durante el arranque.

• No toque el motor, el bastidor del engranaje ni el silenciador. Estas partes se ponen

extremadamente calientes durante el funcionamiento y aun después de apagada la unidad.

• Apague el motor y desconecte la bujía para darle mantenimiento o hacer una reparación.

INSTRUCCIONES DE SEGURIDAD DEL SOPLADOR

• Apague el motor para realizar el mantenimiento, reparaciones o para instalar o quitar los tubos del

soplador. Para evitar el contacto con las aspas giratorias, se debe parar la unidad y esperar a que el

impelente no dé más vueltas.

• Nunca apunte la sopladora ni los residuos hacia las personas, animales o contra las ventanas. Dirija

siempre los residuos lejos de las personas, animales y ventanas. Tenga mucho cuidado al soplar los

residuos cerca de objetos masivos como árboles, automóviles, paredes, etc.

NOTA ESPECIAL:

LA EXPOSICIÓN A LAS VIBRACIONES POR EL USO PROLONGADO DE

HERRAMIENTAS MANUALES CON MOTORES DE GASOLINA PODRÍA OCASIONAR

DAÑOS A LOS VASOS SANGUÍNEOS O NERVIOS DE LOS DEDOS, MANOS Y ARTICULACIONES

DE PERSONAS PROPENSAS A PROBLEMAS CIRCULATORIOS O INFLAMACIONES ATÍPICAS.

Su uso prolongado en climas fríos se ha relacionado con daños a las venas de otras personas

por el contrario, sanas. Si se presentan síntomas como entumecimiento, dolor, pérdida de fuerza

cambios en el color o textura de la piel o pérdida de sensibilidad en los dedos, las manos o

las articulaciones, suspenda el uso de la herramienta y busque atención médica. Un sistema

anti vibratorio no garantizaría evitar estos problemas. Los usuarios que operan habitualmente

herramientas motorizadas deben monitorear de cerca su estado de salud y las condiciones de la

herramienta.

GUARDE ESTAS INSTRUCCIONES

Page 11

Los objetos pequeños pueden ser lanzados a gran velocidad

NORMAS PARA UNA OPERACIÓN SEGURA

• SÍMBOLOS INTERNACIONALES Y DE SEGURIDAD •

Este manual del operador describe símbolos y pictografías internacionales y de seguridad que

posiblemente aparezcan en este producto. Lea el manual del operador para obtener información

completa acerca de la seguridad, el ensamblaje, la operación, el mantenimiento y la reparación.

Símbolo Significado

• SÍMBOLO DE ALERTA DE SEGURIDAD

Indica peligro, advertencia o precaución. Puede utilizarse junto a otros símbolos o

pictografías.

• LEA EL MANUAL DEL OPERADOR

ADVERTENCIA: Lea el manual o los manuales del operador y siga todas las

advertencias e instrucciones de seguridad. No hacerlo puede ocasionar lesiones

graves al operador y/o a las personas presentes.

• USE PROTECCIÓN PARA LOS OJOS Y OÍDOS

ADVERTENCIA:

Los objetos que salen volando y el ruido fuerte pueden ocasionar

lesiones oculares severas y pérdida de la audición. Póngase gafas o lentes de protección

que cumplan con las normas ANSI Z87.1-1989 y protección para los oídos cuando opere

esta unidad. De ser necesario, use un protector de cara entera

• COMBUSTIBLE SIN PLOMO

Use siempre combustible limpio, fresco y sin plomo

• NO USE COMBUSTIBLE E85 EN ESTA UNIDAD

ADVERTENCIA: Se ha comprobado que es probable que el combustible con

más de un 10% de etanol dañe este motor, lo que anulará la garantía.

• CONTROL DE ENCENDIDO Y APAGADO

ENCENDIDO / ARRANQUE / EN MARCHA

• CONTROL DE ENCENDIDO Y APAGADO

APAGADO o PARADA

INSTRUCCIONES DE ENSAMBLAJE

ENSAMBLAJE DE LA UNIDAD

Instalación del tubo superior de la sopladora

1. Alinee el saliente del extremo del tubo superior de la

sopladora con la ranura de tope del extremo inferior de la

salida de la sopladora (Fig. 1).

2. Inserte el tubo superior de la sopladora en la salida de la

sopladora (Fig. 1).

3. Gire el tubo superior de la sopladora en el sentido de las

agujas del reloj hasta que trabe en su sitio (Fig. 1).

Tubo superior de la sopladora

1. Alinee la ranura del saliente del extremo superior del tubo

inferior de la sopladora con el saliente en el extremo del tubo

superior de la sopladora (Fig. 2).

2. Coloque el tubo inferior de la sopladora en el tubo superior de

la sopladora (Fig. 2).

3. Gire el tubo inferior de la sopladora en el sentido de las agujas

del reloj hasta que quede apretado (Fig. 2).

Quitar el tubo superior de la sopladora

1. Sujete la unidad firmemente.

2. Inserte un destornillador de cabeza plana en el cierre del tubo.

Gire el destornillador en sentido contrario a las agujas del reloj

1/4 de vuelta y déjelo así (Fig. 3).

3. Sujete el tubo superior de la sopladora y gírelo en sentido

contrario a las agujas del reloj (Fig. 3).

4. Hale el tubo superior de la sopladora por la salida de la

sopladora.

Quitar el tubo inferior de la sopladora

1. Sujete firmemente el tubo superior de la sopladora.

2. Sujete el tubo inferior de la sopladora y gírelo en sentido contrario a las agujas del reloj hasta que el

tubo inferior de la sopladora se destrabe del tubo superior de la sopladora.

3. Saque el tubo inferior de la sopladora del tubo superior de la sopladora.

Salida de la

sopladora

Tubo superior

de la sopladora

Tubo superior de

la sopladora

Tubo inferior de

la sopladora

Traba del

Tubo

Saliente

Fig. 1

Saliente

Fig. 2

Fig. 3

• ACEITE

Consulte el tipo de aceite adecuado en el manual del operador.

• PERA DEL CEBADOR

Oprima lentamente y por completo la pera del cebador, 10 veces

• CONTROL DEL OBTURADOR

1.•PosicióndeOBTURACIÓN COMPLETA

2.•PosicióndeOBTURACIÓN PARCIAL

3.•PosicióndeMARCHA

• LOS OBJETOS QUE SALEN VOLANDO Y LA CUCHILLA GIRATORIA PUEDEN

OCASIONAR LESIONES GRAVES

ADVERTENCIA:

y ocasionar lesiones. Manténgase alejado del rotor cuando esté girando.

• MANTENGA ALEJADOS A LOS ESPECTADORES

ADVERTENCIA: Manténgase alejado a una distancia mínima de 50 pies (15

m) de todas las personas, especialmente niños y animales domésticos que se

encuentren a su alrededor.

• SUPERFICIE CALIENTE

ADVERTENCIA: No toque ninguno de los componentes metálicos del motor.

El motor se pone extremadamente caliente durante el funcionamiento y puede

ocasionar graves quemaduras. Deje que la unidad se enfríe completamente antes

de hacerle cualquier mantenimiento o servicio.

• LAS SOPLADORAS– CUCHILLAS GIRATORIAS DEL ROTOR PUEDEN

CAUSAR LESIONES GRAVES

ADVERTENCIA: Pare el motor y permita que el rotor se detenga antes

de instalar o cambiar tubos o la bolsa, o antes de limpiar o hacerle cualquier

mantenimiento.

CONOZCA SU UNIDAD

APLICACIONES

• Limpieza de patios, garajes, entrada

de autos, pórticos, terrazas, aceras,

derredores de muros, cercas y otros

SE NECESITAN HERRAMIENTAS:

• Destornillador plano

Interruptor de

Encendido y

Apagado

Agarre

Control del

acelerador

Tapa de la bujía

INFORMACIÓN SOBRE EL ACEITE Y EL COMBUSTIBLE

TIPO DE ACEITE RECOMENDADO

ADVERTENCIA: EL LLENAR DEMASIADO EL CÁRTER DE ACEITE PUEDE CAUSAR

LESIONES PERSONALES GRAVES. Revise y mantenga el nivel de aceite adecuado en el

cárter; es importante y no se puede exagerar la importancia. Verifique el aceite antes de

cada uso y cámbielo según sea necesario. Vea la sección Cambio de aceite.

El uso de un aceite del tipo y peso correctos en el cárter es extremadamente importante. Verifique el

aceite antes de cada uso y cambie el aceite con frecuencia. Si no usa el aceite correcto, o utiliza aceite

sucio, puede ocasionar desgaste y fallas prematuras del motor.

Use un aceite de alta calidad SAE 30 de API (American Petroleum

Institute) de la categoría de servicio SF, SG, SH.

CÓMO ECHAR ACEITE EN EL CÁRTER: USO INICIAL

Esta unidad se envía sin aceite en el motor. Para evitar que

NOTA:

se dañe la unidad, eche aceite en el cárter antes de arrancar

la unidad.

Esta unidad se suministra con una botella de 2.03 onzas fluidas

(60 ml) de aceite SAE 30 SF, SG, SH (Fig. 4).

NOTA:

Guarde la botella de aceite vacía. Puede utilizarse para

medir la cantidad correcta durante futuros cambios de aceite.

Vea la sección Cambio de aceite.

Tapón de

aceite

1. Desenrosque la tapa de la botella de aceite y quite el sello de

papel que cubre la abertura. Vuelva a colocar la tapa y corte la

punta de la boquilla del embudo (Fig. 4).

2. Con la unidad colocada en una superficie plana nivelada,

quite el tapón del recipiente de aceite (Fig. 5).

3. Vierta la botella de aceite completa en el agujero de llenado

de aceite (Fig. 6).

Nunca eche aceite al combustible ni al tanque de

NOTA:

combustible.

4. Limpie todo el aceite que pueda haberse derramado y vuelva

a instalar el tapón del aceite.

Revise el aceite antes de cada uso y cada cambio, según sea

necesario. Consulte el tema Cómo comprobar el nivel de aceite.

TIPO DE COMBUSTIBLE RECOMENDADO

Agujero

de llenado

de aceite

La principal causa de un funcionamiento inadecuado de la unidad

es un combustible viejo. Asegúrese de usar gasolina fresca, limpia

y sin plomo.

NOTA:

Este es un motor de cuatro tiempos. Para evitar dañar la unidad, no mezcle el aceite con la

gasolina.

Definición de combustibles mezclados

Los combustibles actuales con frecuencia son una mezcla de gasolina y oxigenados como el etanol,

el metanol o el MTBE (éter). El combustible mezclado con alcohol absorbe agua. Un porcentaje

de agua tan pequeño como un 1% en el combustible puede formar ácidos cuando está guardado.

Cuando use combustible con mezcla de alcohol, utilice combustible fresco (almacenado durante

menos de 30 días).

Fig. 4

Fig. 5

Fig. 6

Tubo superior de la

sopladora

Tubo inferior de la

sopladora

Tapón de aceite

Agarre de la cuerda

de arranque

Pera del

cebador

Tapa del tanque

de combustible

Tapa del

filtro de aire

Uso de combustibles mezclados

ADVERTENCIA: NO USE COMBUSTIBLE E85 EN ESTA UNIDAD.

Se ha comprobado que es probable que el combustible con más de un 10% de etanol

dañe este motor, lo que anulará la garantía.

Si decide usar un combustible mezclado, o no puede utilizar otro, le recomendamos que tome las

siguientes precauciones:

• Use siempre gasolina fresca sin plomo

• Use el aditivo especial de combustible STA-BIL® o uno similar

• Drene el tanque y eche a andar el motor en seco antes de guardar la unidad

Uso de aditivos para el combustible

ADVERTENCIA: La gasolina es sumamente inflamable. Los gases pueden explotar si

se encienden. Detenga siempre el motor y deje que se enfríe antes de llenar el tanque de

combustible. No fume mientras llena el tanque. Mantenga alejadas del área las chispas y

llamas expuestas.

El uso de aditivos, como el estabilizador de gasolina STA-BIL® o un equivalente, inhibirá la corrosión

y minimizará la formación de depósitos de goma. El uso de aditivos puede evitar que se formen

depósitos dañinos en el carburador por hasta sais (6) meses. Agregue 23 ml (0,8 de onza) de aditivo

por galón de combustible de acuerdo a las instrucciones del envase. No agregue NUNCA los aditivos

directamente al tanque de combustible de la unidad.

11

Page 12

INFORMACIÓN SOBRE EL ACEITE Y EL COMBUSTIBLE

CÓMO ABASTECER DE COMBUSTIBLE A LA UNIDAD

ADVERTENCIA: Eche el combustible en un área exterior nivelada y bien ventilada.

Limpie de inmediato todo el combustible derramado. Evite el peligro de incendio debido

a combustible derramado. No arranque el motor hasta que no se hayan disipado los

vapores de combustible.

1. Quite la tapa del tanque de combustible (Fig. 7).

ADVERTENCIA: Quite lentamente la tapa de combustible a fin de evitar lesiones por

salpicaduras. No opere nunca la unidad sin la tapa del combustible colocada firmemente

en su lugar.

2. Coloque la boquilla del depósito de gasolina en el orificio de

llenado en el tanque de combustible, y llénelo.

NOTA: No rebose el tanque.

3. Limpie toda la gasolina que pueda haberse derramado.

4. Vuelva a colocar la tapa de la gasolina.

5. Aleje siempre la unidad a por lo menos 30 pies (9.1 m) de la

fuente y sitio de combustible antes de arrancar el motor.

NOTA: Deseche la gasolina vieja conforme a las regulaciones

federales, estatales y locales.

Tanque de

gasolina

Fig. 7

INSTRUCCIONES DE ARRANQUE Y PARADA

INSTRUCCIONES DE ARRANQUE

Al arrancar la unidad, asegúrese de que no esté dirigida hacia personas presentes o residuos

NOTA:

sueltos.

1. Compruebe el nivel de aceite en el cárter. Consulte el tema Cómo comprobar el nivel de aceite.

2. Llene el tanque de combustible con gasolina nueva, limpia y sin plomo. Consulte Cómo llenar la

unidad de combustible.

No hay necesidad de arrancar la unidad. El control de Encendido/Apagado está en la posición

NOTA:

ENCENDIDO ( I ) en todo momento.

3. Oprima y suelte completamente la pera del cebador 10 veces,

lentamente. Deberá verse alguna cantidad de combustible