Page 1

769-09031 / 00 05/13

Operator’s Manual

4-Cycle Electric Start Capable

Handheld Blower / Vacuum

TB4BV EC

TABLE OF CONTENTS

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

All information, illustrations, and specifications in this manual are based

on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

Copyright© 2013 MTD SOUTHWEST INC, All Rights Reserved.

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

For assistance regarding the assembly, controls, operation or

maintenance of the unit, please call the Customer Support Department

at 1-800-828-5500 in the United States or 1-800-668-1238 in Canada.

Additional information about the unit can be found on our website:

www.troybilt.com (U.S.) or www.troybilt.ca (Canada).

For service, please call the Customer Support Department to obtain

a list of authorized service dealers near you. Service on this unit,

both within and after the warranty period, should only be performed

by an authorized and approved service dealer. When servicing, use

only identical replacement parts.

SAVE THESE INSTRUCTIONS

SERVICE

IMPORTANT: Read this manual thoroughly before using this product. Follow all instructions.

Page 2

• IMPORTANT SAFETY INSTRUCTIONS •

SAFETY

2

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor. If it requires

replacement, ask your LOCAL SERVICE DEALER to install the

Accessory Part #753-05900 Muffler Assembly.

Read the operator’s manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

SYMBOL MEANING

WARNING:

Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in

serious injury to yourself or to others.

CAUTION:

Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in

property damage or injury to yourself or to others.

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

DANGER:

Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in

serious injury or death to yourself or to others.

CALIFORNIA PROPOSITION 65

WARNING:

Engine exhaust, some of its constituents and

certain finished components contain or emit chemicals known

to the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

• Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

• Children must not operate the unit. Teens must be accompanied

and guided by an adult.

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Be aware of risk of injury to the head, hands and feet.

• Carefully inspect the area before starting the unit. Remove

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments or

repairs before using the unit.

WARNING:

When using the unit, all safety rules must be

followed. Please read these instructions before operating

the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

• Always add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. DO NOT smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

WARNING:

Gasoline is highly flammable and its vapors

can explode if ignited. Take the following precautions:

Page 3

3

WHILE OPERATING

• Wear safety glasses or goggles that meet current ANSI Z87.1

standards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face mask or dust mask if the

operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting and Stopping.

• Use the right tool. Only use this tool for its intended purpose.

• Always hold the unit with a firm grip when operating.

• Do not overreach. Always keep proper footing and balance. Take

extra care when working on steep slopes or inclines.

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop moving parts.

• Do not touch the engine or muffler. These parts get extremely hot

from operation, even after the unit is turned off.

• Do not operate the unit faster than the speed needed to do the job.

Do not run the unit at high speed when not in use.

• Do not force the unit. It will do a better, safer job when used at

the intended rate.

• Always stop the unit when operation is delayed or when walking

from one location to another.

• If you strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate the unit

before repairing damage. Do not operate the unit with loose or

damaged parts.

• Turn the engine to off and disconnect the spark plug for

maintenance or repair.

• Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit. These are available from your

authorized service dealer. Use of any other parts or accessories

could lead to serious injury to the user, or damage to the unit,

and void the warranty.

• Keep the unit clean. Carefully remove vegetation and other

debris that could block moving parts.

• To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

• If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

generally an indicator of trouble.

OTHER SAFETY WARNINGS

• All service, other than the maintenance procedures described in

this manual, should be performed by an authorized service dealer.

• Before inspecting, servicing, cleaning, storing, transporting or

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving parts have stopped.

3. Allow the unit to cool.

4. Disconnect the spark plug wire.

• Secure the unit while transporting.

• Never store the unit with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep the unit out of the reach of

children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean and free from debris. Clean the unit

after each use. Refer to Cleaning and Storage.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

SAVE THESE INSTRUCTIONS

BLOWER / VACUUM SAFETY

• Do not insert anything into the air openings, blower tubes or

nozzle. Do not operate the unit if any of the air openings or

tubes are blocked. Keep the air openings free from dust, lint,

hair and anything else that may reduce airflow.

• Do not operate the unit without the blower tubes, or vacuum

tubes and vacuum bag, securely attached. Make sure the

vacuum bag is completely zipped closed.

• Do not use the unit to spray liquids, especially flammable or

combustible liquids, such as gasoline. Do not use the unit in

areas where such liquids are present.

• Do not use the unit for spreading chemicals, fertilizer or any

other substance that may contain toxic materials.

• Do not set the unit down on any surface while the unit is

running. Debris can be picked up by the air intake and thrown

out the discharge opening, resulting in damage to the unit or

property or causing serious injury to bystanders or the operator.

• During operation, never point the unit in the direction of people,

animals, windows or automobiles. Always direct blowing debris

away from people, animals, windows or automobiles.

• Use extra caution when blowing debris near solid objects, such

as trees, walls, fences, etc. When possible, blow away from

such objects, not toward them.

• Take care when working near valuable plants. The force of the

blown air could damage tender plants.

• The unit is designed to pick up dry materials, such as leaves,

grass, small twigs or bits of paper. To avoid serious injury to the

operator and severe damage to the unit, do not vacuum wet

debris or water. To avoid severe damage to the unit, do not

vacuum hard materials, such as metal, glass, etc.

• Avoid situations that could cause the vacuum bag to catch fire.

Do not operate the unit near an open flame. Do not vacuum warm

ash from fire places, fire pits, etc. Do not vacuum discarded

cigars or cigarettes unless the cinders are completely cool.

Page 4

4

• SAFETY & INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

WARNING: Read the operator’s manual(s) and

follow all warnings and safety instructions. Failure to

do so can result in serious injury to the operator

and/or bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting current ANSI Z87.1 standards and

ear protection when operating this unit. Use a full face

shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator’s manual for the proper type of oil.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing

greater than 10% ethanol will likely damage this

engine and void the warranty.

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

• THROWN OBJECTS CAN CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high

speed, causing injury.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children

and pets, at least 50 feet (15 m) from the operating area.

• HOT SURFACE

WARNING: Do not touch a hot muffler or cylinder.

You may get burned. These parts get extremely hot

from operation. When turned off they remain hot for a

short time.

• BLOWERS – ROTATING IMPELLER BLADES CAN

CAUSE SEVERE INJURY

WARNING: Stop the engine and allow the impeller

to stop before changing tubes, cleaning or performing

any maintenance.

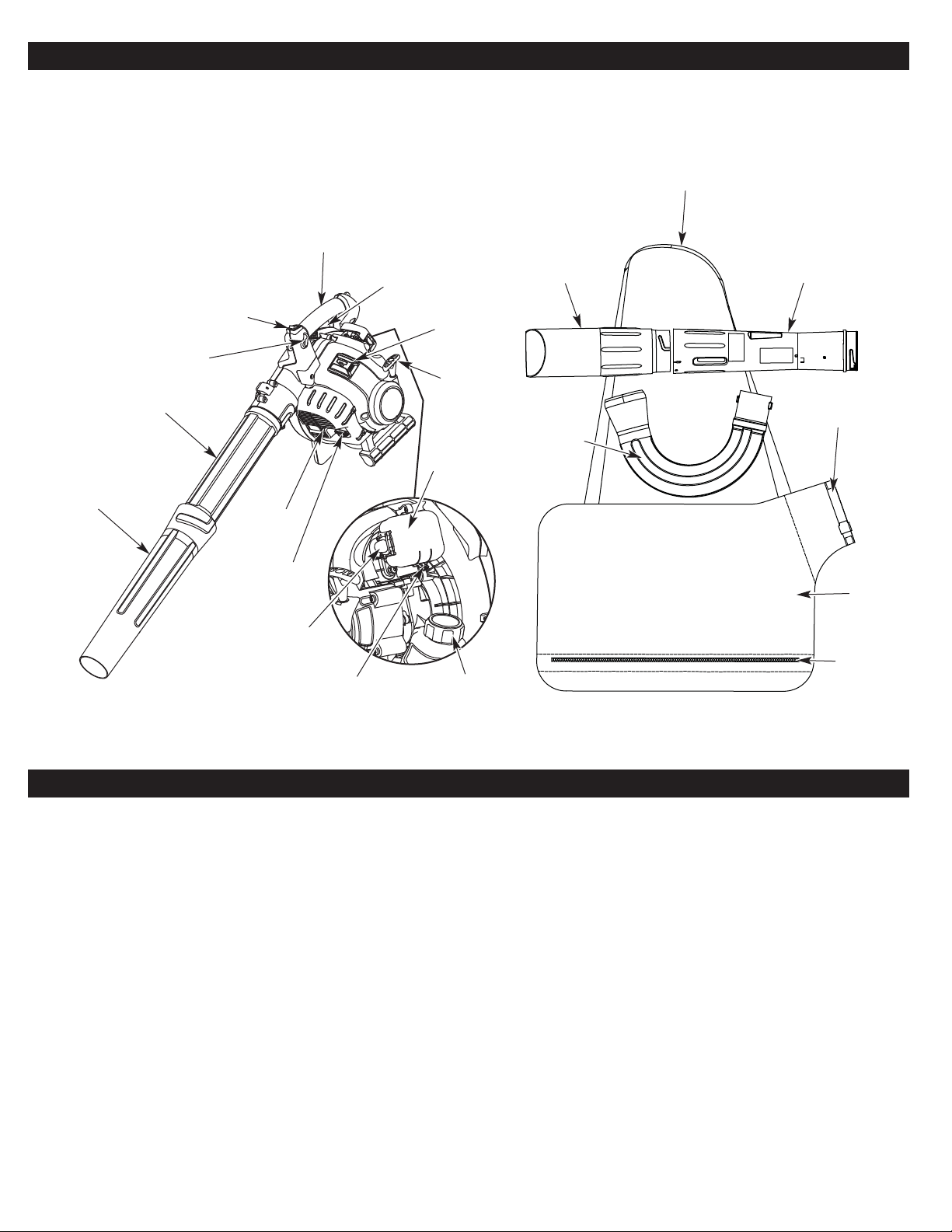

Page 5

Fuel Cap

Starter

Rope Grip

Throttle

Control

Spark Plug

Cover

Muffler

On/Off Switch

Primer Bulb

Choke Lever

Air Filter

Cover

Handle

Cruise Control

Lower Blower

Tube

Upper Blower

Tube

Oil Fill Plug

Lower

Vacuum Tube

Upper

Vacuum Tube

Vacuum

Elbow Tube

Shoulder Strap

Cinch Strap

Vacuum

Bag

Zipper

5

KNOW YOUR UNIT

APPLICATIONS

• Cleaning yards, garages, driveways, porches, patios, around

walls, fences and more

SPECIFICATIONS*

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

Engine Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 4-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 cc (1.52 cu. in.)

Blower Air Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 450 cfm (12.7 cmm)

Blower Air Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 150 mph (240 kmh)

Mulching Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 10:1

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RDZ4H or equivalent plug

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SAE 30 Oil

Crankcase Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.03 oz. (60 mL)

Fuel Tank Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 oz. (414 mL)

Vacuum Bag Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 bushel (35 L)

Approximate Unit Weight (No fuel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 12 lbs. (5 - 5.4 kg)

ASSEMBLY TOOLS REQUIRED:

• Flat-head Screwdriver

Page 6

ASSEMBLY

6

Fig. 1

Blower

Outlet

Upper Blower Tube

Handle

Fig. 2

Upper

Blower Tube

Slots

Bumps

Lower

Blower Tube

Bumps

Slots

Fig. 3

Tube Lock

ASSEMBLING THE UNIT AS A BLOWER

Installing the Upper Blower Tube

1. Align the bumps on the upper end of the upper blower tube with

the slots on the blower outlet (Fig. 1).

2. Insert the upper blower tube into the blower outlet (Fig. 1).

3. While holding the handle, twist the upper blower tube clockwise

until it locks into place (Fig. 1).

Installing the Lower Blower Tube

1. Align the bumps on the lower end of the upper blower tube with

the slots on the lower blower tube (Fig. 2).

2. Slide the lower blower tube onto the upper blower tube (Fig. 2).

3. While holding the upper blower tube, twist the lower blower tube

clockwise until it locks into place (Fig. 2).

WARNING:

To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing blower tubes, vacuum tubes or the vacuum bag.

ASSEMBLING THE UNIT AS A VACUUM

Removing the Upper Blower Tube

1. Insert a flat-head screwdriver into the tube lock. Turn the

screwdriver counterclockwise 1/4 turn and hold it in place (Fig. 3).

2. Twist the upper blower tube counterclockwise until it unlocks

from the blower outlet (Fig. 3).

3. Remove the upper blower tube from the blower outlet.

Removing the Lower Blower Tube

1. While holding the upper blower tube, twist the lower blower tube

counterclockwise until it unlocks from the upper blower tube.

2. Remove the lower blower tube from the upper blower tube.

Installing the Upper Vacuum Tube

1. Insert a flat-head screwdriver into the hole in the impeller door

and press the impeller door lock tab inward (Fig. 4). Open the

impeller door.

2. While holding the impeller door open, align the slots on the

upper vacuum tube with the tabs in the impeller intake (Fig. 5).

3. Insert the upper vacuum tube into the impeller intake (Fig. 6).

4. Twist the upper vacuum tube clockwise with both hands until it

locks into place (Fig. 6).

Installing the Lower Vacuum Tube

1. Align the arrow on the lower vacuum tube with the arrow on the

upper vacuum tube (Fig. 7).

2. Insert the lower vacuum tube into the upper vacuum tube (Fig. 7).

3. Twist the lower vacuum tube clockwise with both hands until it

locks into place (Fig. 7).

NOTE: When properly assembled, the dot on the lower vacuum

tube should align with the dot on the upper vacuum tube (Fig. 7).

Fig. 4

Impeller

Door

Impeller Door

Lock Tab

Page 7

7

Fig. 5

Ta bs

Fig. 6

Impeller Intake

Impeller Intake

Upper

Vacuum Tube

Fig. 7

Upper

Vacuum Tube

Fig. 8

Bumps

Blower Outlet

Slots

Lower

Vacuum Tube

Arrows

Dots

Vacuum

Elbow Tube

Installing the Vacuum Bag

1. Align the bumps on the vacuum elbow tube with the slots on the

blower outlet (Fig. 8). The flared end of the vacuum elbow tube

should point to the right.

2. Insert the vacuum elbow tube into the blower outlet (Fig. 8).

3. Twist the vacuum elbow tube clockwise until it locks into place

(Fig. 8).

4. Insert the flared end of the vacuum elbow tube approximately 4

inches (10 cm) into the vacuum bag (Fig. 9).

5. Pull the cinch strap to tighten the vacuum bag around the

vacuum elbow tube.

NOTE: The cinch strap should be tight enough to prevent the

vacuum elbow tube from slipping out of the vacuum bag, but

loose enough for the vacuum bag to have limited movement

along the vacuum elbow tube.

Fig. 9

Vacuum Bag

4 inches

(10 cm)

Vacuum

Elbow Tube

Cinch Strap

Cinch Buckle

Page 8

8

OIL AND FUEL

USING THE RIGHT OIL

Use a high-quality SAE 30 weight oil. DO NOT use dirty oil. Failure

to use clean oil of the correct type can cause premature engine

wear and failure.

ADDING OIL: INITIAL USE

NOTE: This unit was shipped without oil in the crankcase. Oil must

be added before starting the unit.

NOTE: This unit comes with a 2.03 fluid oz. (60 mL) bottle of oil.

1. Unscrew the top of the oil bottle. Remove the paper seal.

Reinstall the top of the oil bottle.

2. Remove the cap from the oil bottle. Cut the tip off the funnel

spout (Fig. 10).

3. Set the unit on a flat, level surface.

4. Unscrew the oil fill plug (Fig. 11).

5. Pour the entire bottle into the oil fill hole (Fig. 11). DO NOT

overfill. Refer to Checking the Oil Level.

NOTE: Never add oil directly to the fuel tank. This unit has a four-

cycle engine. DO NOT mix oil with gasoline.

6. Wipe up any oil that may have spilled.

7. Reinstall the oil fill plug.

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 11).

NOTE: Save the empty oil bottle. Use the bottle to measure the

correct amount of oil during future oil changes.

Fig. 11

Fig. 10

Oil Fill Plug

Oil Fill Hole

Funnel Spout

WARNING:

OVERFILLING THE CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY. Check the oil level

before each use. The importance of maintaining the proper

oil level cannot be overemphasized. Change the oil

according to the Maintenance Schedule.

O-Ring

Page 9

9

FUELING THE UNIT

1. Position the unit with the fuel cap facing up.

2. Remove the fuel cap.

3. Place the fuel container spout into the fill hole on the fuel tank

and fill the tank.

NOTE: Do not overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and

the fueling site before starting the engine.

USING THE RIGHT FUEL

The use of old fuel is the most common cause of performance

problems. Use only fresh, clean unleaded gasoline.

NOTE: This unit has a four-cycle engine. DO NOT mix oil with gasoline.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as 1% water in the fuel can make fuel and oil

separate, forming acids when stored. ALWAYS use fresh fuel (less

than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local

regulations.

Using Blended Fuels

If using a blended fuel:

• Always use fresh unleaded gasoline

• Use the fuel additive STA-BIL

®

or an equivalent

• Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

Use a fuel additive, such as STA-BIL Fuel Stabilizer or an

equivalent, to inhibit corrosion and minimize gum deposits. Add 0.8

oz. (23 mL) of fuel additive per gallon of fuel, according to the

instructions on the container. NEVER add fuel additives directly to

the unit's fuel tank.

WARNING:

Gasoline is extremely flammable. Ignited

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a distance

from the area.

WARNING:

Remove the fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING: Add fuel in a clean, well ventilated outdoor

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilled fuel. Do not start the engine

until fuel vapors dissipate.

WARNING:

DO NOT USE E85 FUEL IN THIS UNIT.

It has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the warranty.

Page 10

10

STARTING AND STOPPING

WARNING:

Operate this unit only in a well-ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING:

Avoid accidentally starting the unit. To avoid

serious injury, the operator and the unit must be in a stable

position when pulling the starter rope (Fig. 14).

STARTING INSTRUCTIONS

1. Check the oil level. Refer to Checking the Oil Level.

2. Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in

the ON ( I ) position at all times (Fig. 12).

3. Slowly press and release the primer bulb 10 times (Fig. 13). If

fuel cannot be seen in the primer bulb, press and release the

primer bulb until fuel is visible.

4. Move the choke lever to Position 1 (Fig. 13).

NOTE: DO NOT squeeze the throttle control until step 9 (Fig. 12).

5. DO NOT squeeze the throttle control. Crouch in the starting

position (Fig. 14).

6. DO NOT squeeze the throttle control. Pull the starter rope with a

controlled and steady motion 5 times (Fig. 14).

7. DO NOT squeeze the throttle control. Move the choke lever to

Position 2 (Fig. 13).

8. DO NOT squeeze the throttle control. Pull the starter rope with a

controlled and steady motion 3 to 5 times to start the engine.

9. Squeeze and hold the throttle control or move the cruise control

to the FAST position (Fig. 12). Allow the engine to warm up for

30 to 60 seconds.

10. Continue to squeeze the throttle control or keep the cruise

control in the FAST position (Fig. 12). Move the choke lever to

Position 3 (Fig. 13) and continue warming the engine for an

additional 60 seconds. The unit may be used during this time.

NOTE: The engine is properly warmed up when it accelerates

without hesitation.

NOTE: Once the engine is properly warmed, the cruise control may

be adjusted and the throttle control can be used normally.

IF... the engine does not start, begin the starting procedure with step 3.

IF... the engine fails to start after a few attempts, move the choke

lever to Position 3. Squeeze and hold the throttle control or

move the cruise control to the FAST position. Pull the starter

rope with a controlled and steady motion 3 to 8 times. The

engine should start. If it does not, repeat this instruction.

IF... the engine is already warm, begin the starting procedure with

step 7.

STOPPING INSTRUCTIONS

1. Release the throttle control, or move the cruise control to the

SLOW position, and allow the engine to idle.

2. Press and hold the On/Off switch in the OFF (O) position until

the engine comes to a complete stop (Fig. 12).

Fig. 12

Fig. 14

On ( I ) / Start

Off (O) / Stop

Throttle Control

Starting

Position

Starter Rope Grip

Fig. 13

Primer Bulb

Position 1Position 2

Position 3

Choke Lever

Cruise Control

SLOW

FAST

WARNING: When starting the unit, make sure it is not

directed toward people, animals, windows, automobiles or

loose debris.

Page 11

11

STARTING INSTRUCTIONS

1. Check the oil level. Refer to Checking the Oil Level.

2. Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in

the ON ( I ) position at all times (Fig. 12).

3. Slowly press and release the primer bulb 10 times (Fig. 13). If

fuel cannot be seen in the primer bulb, press and release the

primer bulb until fuel is visible.

4. Move the choke lever to Position 1 (Fig. 13).

NOTE: DO NOT squeeze the throttle control until step 11 (Fig. 12).

5. DO NOT squeeze the throttle control. Crouch in the starting

position (Fig. 14).

6. DO NOT squeeze the throttle control. Insert the electric start

accessory into the electric start port (Fig. 15). Refer to the

Operation section of the electric start accessory operator’s manual.

7. DO NOT squeeze the throttle control. Run the electric start

accessory for 2 seconds.

8. DO NOT squeeze the throttle control. Move the choke lever to

Position 2 (Fig. 13).

9. DO NOT squeeze the throttle control. Run the electric start

accessory in intervals no longer than 2 seconds each until the

unit starts.

10. DO NOT squeeze the throttle control. Remove the electric start

accessory from the unit.

11. Squeeze and hold the throttle control or move the cruise control

to the FAST position (Fig. 12). Allow the engine to warm up for

30 to 60 seconds.

12. Continue to squeeze the throttle control or keep the cruise

control in the FAST position (Fig. 12). Move the choke lever to

Position 3 (Fig. 13) and continue warming the engine for an

additional 60 seconds. The unit may be used during this time.

NOTE: The engine is properly warmed up when it accelerates

without hesitation.

NOTE: Once the engine is properly warmed, the cruise control may

be adjusted and the throttle control can be used normally.

IF... the engine does not start, begin the starting procedure with step 3.

IF... the engine fails to start after a few attempts, move the choke lever

to Position 3. Squeeze and hold the throttle control or move the

cruise control to the FAST position. Run the electric start accessory

in intervals no longer than 2 seconds each until the unit starts.

The engine should start. If it does not, repeat this instruction.

IF... the engine is already warm, begin the starting procedure with

step 8.

STOPPING INSTRUCTIONS

1. Release the throttle control, or move the cruise control to the

SLOW position, and allow the engine to idle.

2. Press and hold the On/Off switch in the OFF (O) position until

the engine comes to a complete stop (Fig. 12).

USING THE ELECTRIC START ACCESSORY

This unit can be started with an optional electric start accessory

(items sold separately). Refer to the electric start accessory

operator’s manual for the proper use of this feature.

Please contact your local retailer, call the Customer Support

Department or visit our website for more information.

Fig. 15

Electric Start

Port

Item No. Description

49M2027P966 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electric Starter

49MESCBP953 . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engine Starter Bit

Page 12

12

OPERATION

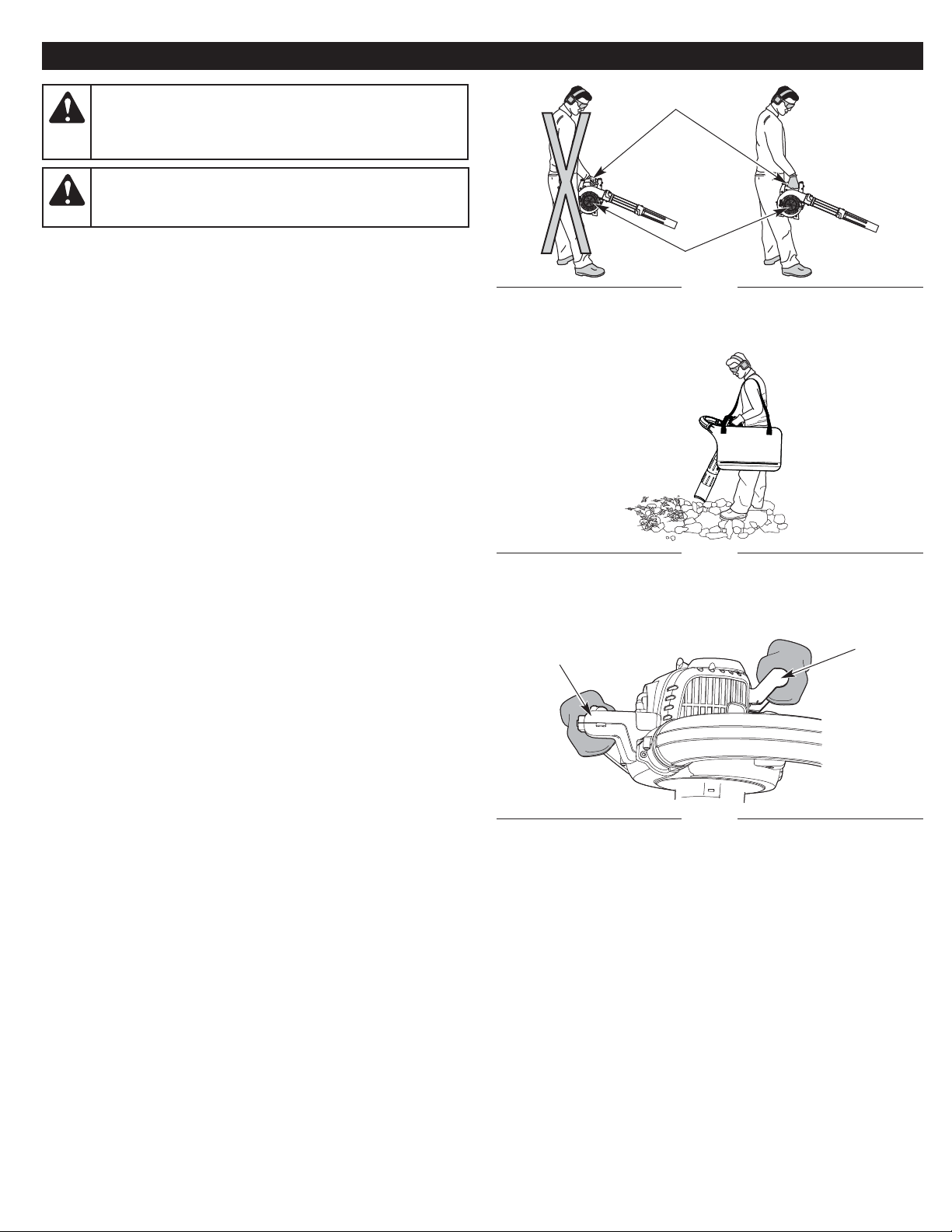

HOLDING THE UNIT

As a Blower

• Stand in the operating position (Fig. 16).

• Hold the handle firmly with the right hand (Fig. 16). Holding the

handle with the left hand could cause the air intake to be

blocked by the left side of the body (Fig. 16). DO NOT block the

air intake.

As a Vacuum

• Stand in the operating position (Fig. 17).

• Place the shoulder strap over the left shoulder (Fig. 17).

• Hold the handle firmly with the right hand (Fig. 18). Hold the

secondary handle firmly with the left hand (Fig. 18).

WARNING:

Always wear eye, hearing, hand, foot and body

protection to reduce the risk of injury when operating this unit.

Wear a face mask or dust mask if the operation is dusty.

Fig. 16

Fig. 17

Fig. 18

TIPS FOR BEST RESULTS

• Operate the unit only at reasonable hours, not early in the morning

or late at night when people might be disturbed. Comply with

times listed in local ordinances. Usual recommendations are 9:00

a.m. to 5:00 p.m., Monday through Saturday.

• To reduce noise levels, operate the unit at the lowest speed

needed to do the job. Limit the number of pieces of power

equipment used at any one time.

• Use rakes or brooms to loosen debris before operation.

• Use the cruise control to make continuous operation easier (Fig. 12).

• Clean up after operation. Dispose of debris appropriately.

As a Blower

• Conserve water by using the blower instead of a hose to

perform many outdoor cleaning actions.

• In dusty conditions, slightly dampen surfaces.

• Watch out for children, pets, open windows and freshly washed

cars. Blow debris safely away. Never direct the unit toward

anyone while the unit is in operation.

• Sweep the unit from side to side with the blower tube several

inches above the ground. Slowly advance, keeping the

accumulated debris in front of the operator.

WARNING:

To prevent serious personal injury, never

operate the unit without the blower tubes, or vacuum tubes

and vacuum bag, securely attached. Make sure the

vacuum bag is completely zipped closed.

Handle

Air Intake

Handle

Secondary

Handle

Page 13

13

As a Vacuum

• Tilt the vacuum tube slightly.

• Sweep the unit from side to side with the vacuum tube a few

inches above the ground.

WARNING:

The unit is designed to pick up dry

materials, such as leaves, grass, small twigs or bits of

paper. To avoid serious injury to the operator and severe

damage to the unit, do not vacuum wet debris or water. To

avoid severe damage to the unit, do not vacuum hard

materials, such as metal, glass, etc.

WARNING:

Avoid situations that could cause the

vacuum bag to catch fire. Do not operate the unit near an

open flame. Do not vacuum warm ash from fire places, fire

pits, etc. Do not vacuum discarded cigars or cigarettes

unless the cinders are completely cool.

EMPTYING THE VACUUM BAG

Vacuumed debris is mulched as it passes through the impeller. This

allows the vacuum bag to hold more debris.

Empty the vacuum bag whenever it becomes full. When the vacuum

bag is full, suction will decrease noticeably. Also empty the vacuum

bag after each operation to prevent the deterioration of the vacuum

bag and the obstruction of air flow.

1. Wear eye protection and a dust mask.

2. Lift the buckle to loosen the cinch strap (Fig. 9).

3. Remove the vacuum elbow tube from the vacuum bag (Fig. 9).

4. Unzip the vacuum bag and empty the contents into a garbage

bag or an appropriate container.

5. Turn the vacuum bag inside-out and vigorously shake out any

remaining dust and debris. Turn the vacuum bag right-side-out.

6. Re-install the vacuum bag. Refer to Installing the Vacuum Bag in

the Assembly section.

WARNING:

To avoid serious personal injury, always stop

the engine and allow the impeller to come to a complete stop

before opening the vacuum bag.

Page 14

14

WARNING:

To prevent serious injury, never perform

maintenance or repairs while the unit is running. Always

allow the unit to cool before servicing or repairing the unit.

Disconnect the spark plug wire to prevent the unit from

starting accidentally.

MAINTENANCE

FREQUENCY MAINTENANCE REQUIRED

Every 10 hours • Clean and re-oil the air filter. Refer to

Maintaining the Air Filter.

After the first

10 hours and

at 38 hours

• Change the oil. Refer to Changing the Oil.

• Have the rocker arm clearance checked by

an authorized service dealer.

• Check the spark plug condition and gap.

Refer to Maintaining the Spark Plug.

CHECKING THE OIL LEVEL

1. Stop the engine and allow it to cool.

2. Set the unit on a flat, level surface, such as a workbench or

table.

NOTE: Failure to keep the engine level may cause the oil to overfill.

3. Clean the area around the oil fill plug (Fig. 19) to prevent debris

from entering the oil fill hole.

4. Unscrew the oil fill plug.

5. Look into the oil fill hole; use a flashlight if necessary. The oil

level should just touch the bottom thread of the oil fill hole

(Fig. 20). If the oil level is too low, add oil to the oil fill hole until

the oil level touches the bottom thread of the oil fill hole.

NOTE: DO NOT overfill the crankcase.

6. Wipe up any oil that may have spilled.

7. Reinstall the oil fill plug.

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 19).

WARNING:

OVERFILLING THE CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY. Check the oil level

before each use. The importance of maintaining the proper

oil level cannot be overemphasized.

Fig. 19

Oil Fill Plug

Oil Fill Hole

O-Ring

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures, take the unit to

an MTD authorized service dealer.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by an MTD authorized

service dealer.

NOTE: Please read the California/EPA statement that came with the

unit for a complete listing of terms and coverage for the emissions

control devices, such as the spark arrestor, muffler, carburetor, etc.

Fig. 20

Oil Fill Line

Page 15

15

MAINTAINING THE AIR FILTER

Failure to maintain the air filter can result in poor performance or can

cause permanent damage to the engine. Engine failure due to

improper air filter maintenance is not covered by the product warranty.

Cleaning the Air Filter

1. Open the air filter cover: press in the lock tab and swing the air

filter cover to the right (Fig. 23).

2. Remove the air filter (Fig. 23).

3. Wash the air filter in detergent and water. Rinse the air filter

thoroughly and allow it to dry.

4. Lightly coat the air filter with clean SAE 30 oil.

5. Squeeze the air filter to spread and remove excess oil.

6. Reinstall the air filter (Fig. 23).

NOTE: Operating the unit without the air filter and air filter cover will

VOID the warranty.

7. Close the air filter cover: insert the tabs on the air filter cover into

the slots on the backplate. Swing the air filter cover to the left

and press it closed until the lock tab snaps into place (Fig. 23).

WARNING:

To avoid serious personal injury, always stop

the engine and allow it to cool before cleaning or maintaining

the unit.

Fig. 23

Air Filter

Air Filter Cover

Lock Tab

Backplate

Ta bs

Slots

CHANGING THE OIL

Change the oil while the engine is still warm. The oil will flow freely

and carry away more impurities.

1. Clean the area around the oil fill plug (Fig. 19) to prevent debris

from entering the oil fill hole.

2. Unscrew the oil fill plug.

3. Tip the unit vertically to pour the oil out of the oil fill hole and into

a container (Fig. 21). Allow ample time for complete drainage.

NOTE: Dispose of the old oil according to federal, state and local

regulations.

4. Wipe up any oil that may have spilled.

5. Pour 2.03 fl.oz. (60 mL) of SAE 30 oil into the oil fill hole.

NOTE: DO NOT overfill. Refer to Checking the Oil Level.

NOTE: Use the empty oil bottle saved from the initial use to

measure the correct amount of oil. Fill the oil bottle to the 2.03 fl.

oz (60 mL) fill line indicated on the back of the bottle (Fig. 22).

6. Wipe up any oil that may have spilled.

7. Reinstall the oil fill plug.

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 19).

Fig. 21

Fig. 22

Fill Line

Page 16

16

Fig. 25

Spark Plug Cover

MAINTAINING THE SPARK PLUG

1. Stop the engine and allow it to cool.

2. Open the spark plug cover (Fig. 25). Grasp the spark plug boot

firmly and pull it from the spark plug.

3. Clean around the spark plug. Remove the spark plug from the

cylinder head with a 5/8-inch socket, turning counterclockwise.

4. Inspect the spark plug. If the spark plug is cracked, fouled or

dirty, replace it with a replacement part #753-05784, a

Champion RDZ4H or an equivalent spark plug.

5. Use a feeler gauge to set the air gap at 0.025 in. (0.635 mm)

(Fig. 26).

6. Install the spark plug in the cylinder head. Tighten the spark plug

with a 5/8-inch socket, turning it clockwise until snug.

NOTE: If using a torque wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m). Do not over tighten.

7. Reattach the spark plug boot. Close the spark plug cover.

WARNING:

Do not sand blast, scrape or clean spark plug

electrodes. Grit in the engine could damage the cylinder.

ADJUSTING THE IDLE SPEED

NOTE: Careless adjustments can seriously damage the unit. An

authorized service dealer should make carburetor adjustments.

If, after checking the fuel and cleaning the air filter, the engine still

will not idle, adjust the idle speed screw as follows:

1. Start the engine. Refer to Starting and Stopping.

2. Move the cruise control to the SLOW position and let the engine

idle. If the engine stops, use a small Phillips screwdriver to turn the

idle speed screw clockwise, 1/8 of a turn at a time (as needed)

until the engine idles smoothly (Fig. 24).

3. If the engine is idling too quickly, turn the idle speed screw

counterclockwise, 1/8 of a turn at a time (as needed) to reduce the

idle speed (Fig. 24).

Checking the fuel, cleaning the air filter, and adjusting the idle speed

should solve most engine problems. If not, and any of the following

conditions are true, take the unit to an authorized service dealer:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

WARNING:

Wear protective clothing and observe all

safety instructions to prevent serious personal injury.

Fig. 24

Idle Speed Screw

Fig. 26

0.025 in.

(0.635 mm)

Page 17

17

CLEANING AND STORAGE

CLEANING

Use a small brush to clean the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as

pine and lemon, and solvents such as kerosene, can damage plastic.

Wipe off any moisture with a soft cloth.

WARNING:

To avoid serious personal injury, always stop

the engine and allow it to cool before cleaning or maintaining

the unit.

The fuel tank is empty Fill the fuel tank with fresh fuel

The primer bulb was not pressed enough Press the primer bulb 10 times or until fuel is visible

The fuel is old (over 30 days) Drain the fuel tank and add fresh fuel

The spark plug is fouled Replace the spark plug

TROUBLESHOOTING

The fuel is old (over 30 days) Drain the fuel tank and add fresh fuel

The air filter is dirty Clean or replace the air filter

PROBLEM SOLUTION

The air filter is dirty Clean or replace the air filter

The fuel is old (over 30 days) Drain the fuel tank and add fresh fuel

The idle speed is incorrect Adjust the idle speed

The fuel is old (over 30 days) Drain the fuel tank and add fresh fuel

The air filter is dirty Clean or replace the air filter

The spark plug is fouled Replace the spark plug

THE ENGINE WILL NOT START

THE ENGINE WILL NOT IDLE

THE ENGINE WILL NOT ACCELERATE

THE ENGINE LACKS POWER OR STALLS

If further assistance is required, contact an authorized service dealer.

STORAGE

• Never store a fueled unit where fumes may reach an open flame

or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

Long-term Storage

1. Remove the fuel cap, tip the unit and drain the fuel into an

approved container. Reinstall the fuel cap.

2. Start the engine and allow it to run until it stalls. This ensures

that all fuel has been drained from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5 drops

of any high quality motor oil into the cylinder. Pull the starter rope

slowly to distribute the oil. Reinstall the spark plug.

4. Thoroughly clean the unit and inspect it for any loose or

damaged parts. Repair or replace damaged parts and tighten

loose screws, nuts or bolts.

Preparing the Unit for Use after Long-term Storage

1. Remove the spark plug and drain all of the oil from the cylinder.

2. Change the oil. Refer to Changing the Oil.

NOTE: Do not use fuel that has been stored for more than 30 days.

Dispose of old fuel according to federal, state and local regulations.

Page 18

The limited warranty set forth below is given by Troy-Bilt LLC (Troy-Bilt) with respect to new merchandise purchased and used in the United

States, its possessions and territories.

Troy-Bilt warrants this product against defects in material and workmanship for a period of two (2) years commencing on the date of original

purchase and will, at its option, repair or replace, free of charge, any part found to be defective in material or workmanship. This limited

warranty shall only apply if this product has been operated and maintained in accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse, commercial use, neglect, accident, improper maintenance, alteration, vandalism, theft,

fire, water or damage because of other peril or natural disaster. Damage resulting from the installation or use of any accessory or attachment

not approved by Troy-Bilt for use with the product(s) covered by this manual will void your warranty as to any resulting damage. This

warranty is limited to ninety (90) days from the date of original retail purchase for any Troy-Bilt product that is used for rental or commercial

purposes, or any other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH PROOF OF PURCHASE THROUGH YOUR LOCAL AUTHORIZED SERVICE

DEALER. To locate the dealer in your area, visit our website at www.troybilt.com or www.troybilt.ca, check for a listing in the Yellow Pages,

call 1-800-828-5500 or 1-800-668-1238 in Canada, or write to P.O. Box 361131, Cleveland, OH 44136-0019. No product returned directly to

the factory will be accepted unless prior written permission has been extended by the Customer Service Department of Troy-Bilt.

This limited warranty does not provide coverage in the following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter Pulley, Starter Ropes, Drive Belts, Saw Chains, Guide Bars,

Cultivator Tines, Blades.

C. Troy-Bilt does not extend any warranty for products sold or exported outside of the United States of America, its possessions and

territories, except those sold through Troy-Bilt’s authorized channels of export distribution.

Troy-Bilt reserves the right to change or improve the design of any Troy-Bilt Product without assuming any obligation to modify any product

previously manufactured.

No implied warranty, including any implied warranty of merchantability or fitness for a particular purpose, applies after the

applicable period of express written warranty above as to the parts as identified. No other express warranty or guaranty, whether

written or oral, except as mentioned above, given by any person or entity, including a dealer or retailer, with respect to any product

shall bind Troy-Bilt. During the period of the Warranty, the exclusive remedy is repair or replacement of the product as set forth

above. (Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the sole and exclusive remedy arising from the sales. Troy-Bilt shall not be liable

for incidental or consequential loss or damages including, without limitation, expenses incurred for substitute or replacement lawn

care services, for transportation or for related expenses, or for rental expenses to temporarily replace a warranted product. (Some

states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the amount of the purchase price of the product sold. Alteration of the safety features

of the product shall void this Warranty. You assume the risk and liability for loss, damage, or injury to you and your property and/or to others

and their property arising out of the use or misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the original purchaser, original lessee or the person for whom it was purchased

as a gift.

How State Law Relates to this Warranty: This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

To locate your nearest service dealer, dial 1-800-828-5500 in the United States or 1-800-668-1238 in Canada.

TROY-BILT LLC

P.O. Box 361131

Cleveland, OH 44136-0019

MANUFACTURER’S LIMITED WARRANTY FOR:

Page 19

769-09031 / 00 05/13

Manuel de l’opérateur

Souffleuse / Aspirateur portatif à

démarrage électrique à 4 temps

TB4BV EC

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Apprenez à connaître votre appareil . . . . . . . . . . . . . . . . . . . . . . .23

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Huile et carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Mise en marche et arrêt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Nettoyage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

CONSERVEZ CES INSTRUCTIONS

SERVICE TECHNIQUE

IMPORTANT: Lisez attentivement ce manuel avant d'utiliser ce produit. Respectez toutes les instructions.

Toutes les informations, illustrations et caractéristiques contenues

dans ce manuel reposent sur les dernières informations disponibles

sur ce produit à la date d’impression. Nous nous réservons le droit

d’apporter à tout instant des modifications, sans préavis.

Copyright© 2013 MTD SOUTHWEST INC, Tous droits réservés.

NE RAMENEZ PAS CET APPAREIL CHEZ LE

REVENDEUR. UNE PREUVE D’ACHAT SERA EXIGÉE

POUR AVOIR RECOURS À LA GARANTIE.

Pour obtenir de l’aide concernant l’assemblage, les commandes,

l’utilisation ou l’entretien de cet appareil, veuillez contacter le service

à la clientèle au 1-800-828-5500 (États-Unis) ou au 1-800-668-1238

(Canada). Pour obtenir des informations supplémentaires sur cet

appareil, visitez le site Internet : www.troybilt.com (É.-U.) ou

www.troybilt.ca (Canada).

Pour profiter du service technique, veuillez appeler le service à la

clientèle pour obtenir une liste des centres de réparation agréés les

plus proches. Les réparations de cet appareil doivent être confiées

uniquement à un centre de réparation agréé, à la fois pendant et

après la période de garantie. Lors d’une réparation, utilisez

uniquement des pièces de rechange identiques.

Page 20

20

SÉCURITÉ

NOTE SUR LE PARE-ÉTINCELLES

REMARQUE : à l’intention des utilisateurs sur les terrains

forestiers américains et dans les États de Californie, du Maine,

de l’Oregon et de Washington. Tous les services des forêts

américains et les États de Californie (codes des ressources

publiques 4442 et 4443), de l’Oregon et de Washington exigent, au

titre de la loi, que certains moteurs à combustion interne utilisés

dans les broussailles de forêt et/ou les zones recouvertes d’herbe

soient équipés d’un pare-étincelles, soient maintenus en bon état

de marche, ou soient construits, équipés et entretenus en vue

d’éviter tout risque d’incendie. Veuillez contacter les autorités

nationales ou locales pour connaître les réglementations à cet

égard. Le non-respect de ces exigences pourrait impliquer votre

responsabilité ou entraîner une amende. Cet appareil est équipé

en usine d’un pare-étincelles. Si ce dernier doit être remplacé,

veuillez consulter votre CENTRE DE RÉPARATION LOCAL pour

installer le pot d’échappement réf. 753-05900.

Veuillez lire le manuel de l’opérateur et respecter tous

les avertissements et consignes de sécurité. Dans le cas

contraire, l’opérateur et/ou les passants peuvent subir des

blessures graves.

SYMBOLE SIGNIFICATION

AVERTISSEMENT :

indique un danger GRAVE.

Le non-respect d’un symbole d’AVERTISSEMENT PEUT

provoquer des blessures graves de l’opérateur ou d’autres

personnes.

ATTENTION :

indique un danger MODÉRÉ.

Le non-respect d’un symbole ATTENTION POURRAIT

provoquer des blessures ou des dommages des biens

de l’opérateur ou d’autres personnes.

Les symboles de sécurité visent à attirer votre attention sur les

dangers éventuels. Vous devez accorder une attention particulière

aux symboles de sécurité afin de bien les comprendre. Les

avertissements de sécurité n’éliminent pas les dangers en euxmêmes. Les instructions ou mises en garde ne remplacent en rien

les mesures de prévention appropriées contre les accidents.

REMARQUE : vous donne des informations ou des consignes

essentielles pour l’utilisation ou l’entretien de l’équipement.

DANGER :

indique un danger EXTRÊME.

Le non-respect d’un symbole de DANGER ENTRAÎNERA

des blessures graves, voire un décès, de l’opérateur ou

d’autres personnes.

PROPOSITION 65 DE L’ÉTAT DE CALIFORNIE

AVERTISSEMENT :

les gaz d’échappement, certains

de leurs constituants et certains composants finis

contiennent ou émettent des produits chimiques reconnus

par l’État de Californie comme étant à l’origine de cancers

ou de malformations congénitales ou autres dangers pour

la reproduction. Lavez-vous les mains après avoir

manipulé l’appareil.

• CONSIGNES DE SÉCURITÉ IMPORTANTES •

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS AVANT

• Veuillez lire soigneusement ces instructions. Familiarisez-vous

avec les commandes et l’utilisation correcte de l’appareil.

• N’utilisez pas cet appareil quand vous êtes fatigué, malade ou sous

l’influence de boissons alcoolisées, de drogues ou de médicaments.

• Les enfants ne doivent pas utiliser cet appareil. Les adolescents

doivent être supervisés par des adultes.

• Tous les carters et dispositifs de sécurité doivent être

correctement installés avant l’utilisation de cet appareil.

• Inspectez l’appareil avant l’utilisation. Remplacez les pièces

endommagées. Détectez les fuites de carburant éventuelles.

Assurez-vous que toutes les fixations sont en place et bien

serrées. Remplacez les pièces fissurées, ébréchées ou

endommagées d’une manière ou d’une autre. N’utilisez pas

l’appareil quand des pièces sont desserrées ou endommagées.

• Vous devez être conscient des risques de blessures à la tête,

aux mains et aux pieds.

• Inspectez attentivement la zone de travail avant de démarrer

l’appareil. Retirez les pierres, le verre cassé, les clous, les fils, les

ficelles et autres objets qui peuvent être projetés ou s’enrouler

dans l’appareil.

AVERTISSEMENT :

quand vous utilisez l’appareil,

vous devez respecter toutes les règles de sécurité. Veuillez

lire ces consignes avant d’utiliser l’appareil pour assurer la

sécurité de l’opérateur et de tous les passants. Veuillez

conserver ces instructions pour référence ultérieure.

• Éloignez les enfants, les passants et les animaux domestiques ;

ils doivent rester dans un rayon d’au moins 15 mètres (50 pieds).

Même à cette distance, il existe néanmoins un risque de

projectiles pour les personnes à proximité. Encouragez-les à

porter des lunettes de sécurité. Si quelqu’un s’approche de

vous, arrêtez immédiatement l’appareil.

• Appuyez sur la manette des gaz et vérifiez qu’elle revient

automatiquement à la position de ralenti. Effectuez tous les

réglages ou réparations avant d’utiliser l’appareil.

AVERTISSEMENTS DE SÉCURITÉ POUR LES APPAREILS

À GAZ

• Stockez le carburant uniquement dans des récipients

spécifiquement conçus à cet usage et approuvés pour le

stockage de telles substances.

AVERTISSEMENT :

l’essence est extrêmement

inflammable et ses vapeurs peuvent exploser en présence

d’une source d’inflammation. Prenez les précautions

suivantes :

Page 21

21

SÉCURITÉ RELATIVE À LA SOUFFLEUSE/L'ASPIRATEUR

• N'insérez pas d'objet dans les ouvertures d'aération, les tubes

ou les buses du ventilateur. N'utilisez pas l'appareil si l'une des

ouvertures d'aération ou l'un des tubes sont bloqués. Gardez les

ouvertures d'aération exemptes de poussière, de peluches, de

cheveux et de tout ce qui peut réduire la circulation de l'air.

• N'utilisez pas l'appareil sans que les tubes de souffleuse ou de

l'aspirateur et qu'un sac d'aspirateur y soient solidement fixés.

Assurez-vous que la fermeture à glissière du sac de l'aspirateur

est entièrement fermée.

• N'utilisez pas l'appareil pour pulvériser des liquides,

particulièrement des liquides inflammables ou combustibles,

comme l'essence. N'utilisez pas l'appareil dans des zones où

ces liquides sont présents.

• N'utilisez pas l'appareil pour épandre des produits chimiques,

de l'engrais ou toute autre substance pouvant contenir des

matières toxiques.

• Ne déposez pas l'appareil pendant qu'il fonctionne. Les débris

peuvent être captés par l'entrée d'air et être rejetés par l'ouverture

de décharge, entraînant des dégâts matériels ou causant de

graves blessures aux personnes présentes ou à l'opérateur.

• Pendant le fonctionnement, ne pointez jamais l'appareil vers des

personnes, des animaux, des fenêtres ou des automobiles.

Dirigez toujours les débris soufflés à l'écart des gens, des

animaux, des fenêtres ou des automobiles.

• Redoublez de prudence lors du nettoyage des débris se

trouvant à proximité d'objets solides, tels des arbres, des murs,

des clôtures, etc. Lorsque cela est possible, soufflez dans la

direction opposée à ces objets, et non vers eux.

• Faites attention lorsque vous travaillez à proximité de précieuses

plantes. La force de l'air soufflé peut endommager les plantes

délicates.

• L'appareil est conçu pour ramasser des matériaux secs, comme

des feuilles, de l'herbe, des brindilles ou des morceaux de papier.

Pour éviter les blessures graves de l'opérateur et de graves

dommages à l'appareil, n'aspirez pas des débris humides ou de

l'eau. Afin d'éviter de graves dommages à l'appareil, n'aspirez

pas de matériaux durs tels que le métal, le verre, etc.

• Évitez les situations qui pourraient provoquer l'incendie du sac de

l'aspirateur. N'utilisez pas cet appareil à proximité d'une flamme.

N'aspirez pas les cendres chaudes des cheminées, des foyers,

etc. N'aspirez pas de cigares ou cigarettes ayant été jetés à

moins que les cendres soient complètement refroidies.

PENDANT L’UTILISATION

• Portez des lunettes de sécurité conformes aux normes ANSI Z87.1

en vigueur et marquées comme telles. Portez une protection

auditive pendant l’utilisation de cet appareil. Portez un écran facial

ou un masque antipoussières si la tâche est poussiéreuse.

• Portez un pantalon long et épais, des bottes, des gants et une

chemise à manches longues. Ne portez pas des vêtements

amples, des bijoux, un pantalon court, des sandales et ne travaillez

pas pieds nus. Attachez vos cheveux au-dessus des épaules.

• Utilisez l’appareil uniquement en plein jour ou avec un bon

éclairage artificiel.

• Évitez tout démarrage accidentel. Placez-vous dans la position de

démarrage dès que vous tirez sur le câble de démarreur. L’opérateur

et l’appareil doivent être dans une position stable pendant le

démarrage. Consultez les sections Mise en marche et Arrêt.

• Utilisez le bon outil. Utilisez uniquement cet outil pour l’usage prévu.

• Tenez toujours fermement l'appareil lors de l'utilisation.

• Ne vous penchez pas trop en avant. Conservez toujours une

position stable et un bon équilibre. Montrez-vous très prudent

quand vous travaillez sur des pentes raides.

• Éloignez vos mains, votre visage et vos pieds des pièces

mobiles. Ne touchez pas ou n’essayez pas d’arrêter des pièces

en mouvement.

• Ne touchez pas le moteur ni le silencieux. Ces composants

deviennent extrêmement chauds pendant l’utilisation, même

après l’arrêt de l’appareil.

• N’utilisez pas l’appareil à une vitesse supérieure à celle

nécessaire pour réaliser le travail. Ne faites pas fonctionner

l’appareil à haute vitesse quand vous ne l’utilisez pas.

• Ne forcez pas l’appareil. Il sera plus efficace et plus sûr si vous

l’utilisez à la vitesse pour laquelle il a été conçu.

• Arrêtez toujours l’appareil quand le travail est interrompu ou

quand vous vous déplacez d'un endroit à un autre.

• Si vous heurtez ou enroulez un objet étranger dans l’appareil,

arrêtez immédiatement l’appareil et vérifiez les dommages

éventuels. Ne redémarrez pas l’appareil avant de l’avoir réparé.

N’utilisez pas l’appareil quand des pièces sont desserrées ou

endommagées.

• Arrêtez le moteur et débranchez la bougie pour les tâches

d’entretien ou les réparations.

• Utilisez uniquement des pièces et des accessoires de rechange

du fabricant d’origine pour cet appareil. Ils sont disponibles

auprès de votre centre de réparation agréé. L’utilisation d’autres

pièces ou accessoires pourrait entraîner de graves blessures de

l’utilisateur ou endommager l’appareil, et annuler la garantie.

• L’appareil doit rester propre. Retirez avec précaution la végétation

et autres débris qui pourraient bloquer les pièces mobiles.

• Pour réduire les risques d’incendie, remplacez un pot

d’échappement et un pare-étincelles défectueux. Nettoyez l’herbe,

les feuilles, les couches de graisse excessives ou les dépôts de

carbone présents sur le moteur et le pot d’échappement.

• Si l’appareil commence à vibrer de façon anormale, arrêtez-le

immédiatement. Inspectez l’appareil pour découvrir l’origine des

vibrations. Les vibrations indiquent en général un problème.

• Arrêtez toujours le moteur et laissez-le refroidir avant de remplir

le réservoir d’essence. N’enlevez jamais le bouchon du réservoir

de carburant ou ne remplissez jamais ce dernier quand le

moteur est chaud. Dévissez toujours lentement le bouchon du

réservoir de carburant afin de relâcher toute pression présente

avant de le remplir.

• Ajoutez toujours du carburant dans un endroit propre et bien

aéré en plein air, où il n'y a pas d'étincelles ou de flammes. NE

FUMEZ PAS.

• N’utilisez jamais l’appareil quand le bouchon du réservoir de

carburant n’est pas correctement vissé.

• Évitez de créer une source d’inflammation en présence d’un

déversement de carburant. Essuyez immédiatement tout

carburant échappé du réservoir avant de démarrer l’appareil.

Éloignez l’appareil à 9,1 mètres (30 pieds) au moins de la source

de ravitaillement et du site avant de démarrer le moteur. NE

fumez PAS.

• Ne démarrez jamais ou n’utilisez jamais l’appareil à l’intérieur

d’un espace ou d’un bâtiment clos. L’inhalation des fumées

d’échappement peut tuer. Utilisez cet appareil uniquement dans

une zone extérieure bien aérée.

Page 22

22

AUTRES AVERTISSEMENTS DE SÉCURITÉ

• Toutes les réparations, autres que les procédures de

maintenance décrites dans ce manuel, doivent être effectuées

par un centre de réparations agréé.

• Avant une inspection, un entretien, un nettoyage, un entreposage,

un transport ou le remplacement d’une pièce de l’appareil :

1. Arrêtez l’appareil.

2. Assurez-vous que toutes les pièces mobiles se sont arrêtées.

3. Laissez l’appareil refroidir.

4. Débranchez le fil de la bougie.

• Assurez-vous que l’appareil est sécurisé pour les transports.

• Quand le réservoir contient du carburant, ne rangez jamais

l’appareil à l’intérieur d’un bâtiment où des vapeurs d’essence

pourraient atteindre une flamme nue (veilleuses, etc.) ou des

étincelles (interrupteurs, moteurs électriques, etc.).

• Rangez l’appareil dans un endroit sec et sûr ou en hauteur pour

éviter une utilisation non autorisée ou des dommages. Gardez

toujours l’appareil hors de portée des enfants.

• Ne mouillez pas ou n’éclaboussez pas l’appareil avec de l’eau ou

tout autre liquide. Les poignées doivent rester sèches, propres et

dépourvues de tout dépôt. Nettoyez l’appareil après chaque

utilisation. Consultez la section Nettoyage et entreposage.

• Conservez ces instructions. Consultez-les souvent et utilisez-les

pour former d’autres utilisateurs. Si vous prêtez cet appareil à

d’autres personnes, remettez-leur également ces instructions.

CONSERVEZ CES INSTRUCTIONS

• SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX •

Le présent manuel de l’opérateur décrit les symboles et pictogrammes de sécurité et internationaux, susceptibles d’apparaître sur ce

produit. Veuillez lire le manuel de l’opérateur pour connaître les informations complètes sur la sécurité, l’assemblage, l’utilisation, l’entretien

et la réparation.

SYMBOLE SIGNIFICATION SYMBOLE SIGNIFICATION

• SYMBOLE D’ALERTE DE SÉCURITÉ

Indique un danger, un avertissement ou une mise en

garde. Peut être utilisé conjointement avec d’autres

symboles ou pictogrammes.

• LISEZ LE MANUEL DE L’OPÉRATEUR

AVERTISSEMENT : veuillez lire le(s) manuel(s) de

l’opérateur et respecter tous les avertissements et

consignes de sécurité. Dans le cas contraire,

l’opérateur et/ou les passants peuvent subir des

blessures graves.

• PORTEZ DES PROTECTIONS AUDITIVES ET

OCULAIRES

AVERTISSEMENT : la projection d’objets et les

bruits forts peuvent provoquer des blessures oculaires

graves et une perte auditive. Portez une protection

oculaire conforme aux normes ANSI Z87.1 en vigueur,

ainsi qu’une protection auditive pendant l’utilisation

de cet appareil. Utilisez un écran facial complet dès

que nécessaire.

• ESSENCE SANS PLOMB

Utilisez toujours de l’essence sans plomb, propre et

neuve.

• HUILE

Consultez le manuel de l’opérateur pour connaître le

type d’huile à utiliser.

• N’UTILISEZ PAS UN CARBURANT E85 DANS CET

APPAREIL

AVERTISSEMENT : il a été prouvé qu’un carburant

contenant plus de 10 % d’éthanol est susceptible

d’endommager ce moteur et d’annuler la garantie.

• COMMANDE DE MARCHE/ARRÊT

ALLUMAGE / DÉMARRAGE / MARCHE

• COMMANDE DE MARCHE/ARRÊT

ARRÊT

• POIRE D’AMORÇAGE

Poussez complètement et lentement la poire

d’amorçage à 10 reprises.

• COMMANDE DE L’ÉTRANGLEUR

1. • Position d’étranglement MAXIMUM

2. • Position d’étranglement PARTIELLE

3. • Position d’étranglement MARCHE

• LES OBJETS PROJETÉS PEUVENT CAUSER DES

BLESSURES GRAVES

AVERTISSEMENT : Les petits objets peuvent être

propulsés à grande vitesse, provoquant des blessures.

• ÉLOIGNEZ LES PASSANTS

AVERTISSEMENT : éloignez tous les passants,

en particulier les enfants et les animaux domestiques,

à 15 m (50 pieds) au moins de la zone de coupe.

• SURFACE CHAUDE

AVERTISSEMENT : ne touchez pas un pot

d’échappement ou un cylindre chaud. Vous pourriez

vous brûler. Ces éléments chauffent énormément

lorsque l’appareil est en marche. Ils restent chauds

pendant un court instant après l’arrêt.

• SOUFFLEUSES – LES PALES EN ROTATION

PEUVENT CAUSER DES BLESSURES GRAVES

AVERTISSEMENT : Arrêtez le moteur et laissez la

pale s'arrêter avant de changer de tubes, de nettoyer

ou d'effectuer un entretien quelconque.

Page 23

23

Bouchon du

réservoir de carburant

Poignée du

câble de

démarreur

Manette

des gaz

Couvercle de

la bougie

Pot

d’échappement

Interrupteur Marche/Arrêt

Poire d’amorçage

Levier d’étrangleur

Couvercle

du filtre à air

Poignée

Régulateur de vitesse

Tube souffleur

inférieur

Tube souffleur

supérieur

Bouchon de

remplissage

de l'huile

Tube inférieur

de l'aspirateur

Tube supérieur

de l'aspirateur

Tube

coudé de

l'aspirateur

Baudrier

Sangle

Sac de

l'aspirateur

Fermeture

à glissière

APPRENEZ À CONNAÎTRE VOTRE APPAREIL

APPLICATIONS

• Nettoyez les cours, les garages, les entrées, les porches, les

terrasses, autour des murs, des clôtures, etc.

CARACTÉRISTIQUES*

* Toutes les caractéristiques reposent sur les dernières informations disponibles sur le produit au moment de l’impression de ce manuel.

Nous nous réservons le droit d’apporter à tout instant des modifications, sans préavis.

Type de moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refroidi par air, 4 temps

Cylindrée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 cc (1,52 po. cube)

Volume d'air de la souffleuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . jusqu'à 12,7 m³/min (450 pi³/min)

Vitesse d'air de la souffleuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . jusqu'à 240 km/h (150 mi/h)

Ratio de déchiquetage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . jusqu'à 10:1

Écartement des électrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,635 mm (0,025 po.)

Bougie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RDZ4H ou équivalent

Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Huile SAE 30

Capacité d'huile du carter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 mL (2,03 oz.)

Capacité du réservoir de carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414 mL (14 oz.)

Capacité du sac de l'aspirateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 L (1 boisseau)

Poids approximatif de l’appareil (sans carburant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5,4 kg (11 - 12 livres)

OUTILS NÉCESSAIRE POUR

L'ASSEMBLAGE

• Tournevis à tête plate

Page 24

24

ASSEMBLAGE

Fig. 1

Sortie de la

souffleuse

Tube souffleur supérieur

Poignée

Fig. 2

Tube souffleur

supérieur

Fentes

Bosses

Tube souffleur

inférieur

Bosses

Fentes

Fig. 3

Verrou du tube

ASSEMBLAGE DE L'UNITÉ EN SOUFFLEUSE

Installation du tube supérieur de la souffleuse

1. Alignez les bosses de l'extrémité supérieure sur le tube supérieur

de la souffleuse avec les fentes de la sortie de la souffleuse (Fig. 1).

2. Insérez le tube supérieur de la souffleuse dans la sortie de la

souffleuse (Fig. 1).

3. Tout en maintenant la poignée, tournez le tube supérieur de la