Page 1

769-08425 / 00 09/12

NEED HELP? CALL 1-800-828-5500 IN U.S. OR 1–800–668–1238 IN CANADA

TB22 EC

2-Cycle Trimmer

Operator’s Manual

English — Page 1Español — Page 7

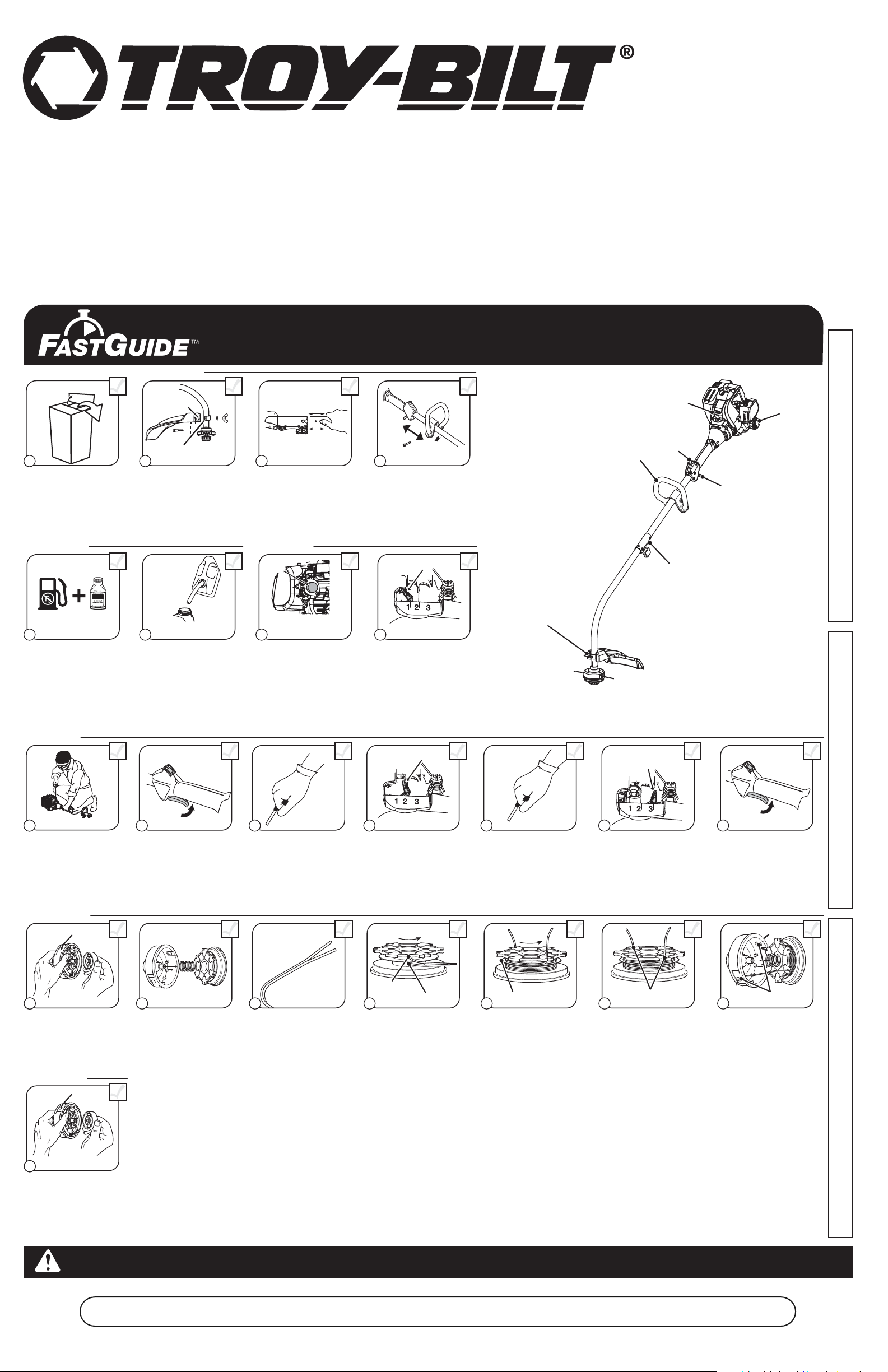

Removing Unit From Carton

11 2

Remove all contents from

carton.

Assemble The Unit

40:1

1 Gallon 3.2 oz

5

Mix thoroughly in separate

fuel can:

– 3.2 fl. oz. of 2-cycle

engine oil

– 1 gallon of unleaded

gasoline (less than 30

days old)

NOTE: Do not mix directly in

fuel tank.

Assemble The Unit

Slot

Bracket

Slide shield’s slot onto

mounting bracket. Rotate

shield onto shaft. Push

square bolt through shield

and bracket. Tighten

washer and wing nut

onto bolt.

6 7

Place unit on a level surface.

Fill fuel tank.

3

Remove cap from lower

boom. Push cutting

attachment into coupler.

Turn coupler knob clockwise

to tighten.

Starting The Unit

Primer

Bulb

10 X

Press primer bulb 10 times,

or until fuel is visible

Min. 6”

4

Push the handle onto the shaft

housing. The bolt hole should be

to the right. Insert the bolt into the

bolt hole. Tighten the bolt, but not

completely. Move the handle to

the location that provides the best

grip. Move the handle a minimum

of 6 inches away from the shaft

grip. Tighten the bolt until the

handle is secure.

Choke Lever

8

Move choke lever to

Position 1.

Electric Starter or

Power Start Bit Optional!

THESE OPTIONAL ACCESSORIES

ARE SOLD SEPARATELY!

This unit has an alternate starting method

that many find easier to use than pulling a

rope. Please contact a local retailer or call

1-800-828-5500 for more information.

Information may also be found at

www.troybilt.com

ASSEMBLY TOOLS

REQUIRED:

• 3/8” Socket

Cutting Head Shield

Starter Rope

D-Handle

On/ Off Switch

Throttle Control

Coupler

Need Help?

Call 1-800-828-5500

DIDN’T START?

Repeat these instructions.

IF engine fails to start after 2 attempts,

move choke lever to position 3 and pull

the starter rope until engine starts

IF unit still fails to start, refer to the

operator’s manual for additional starting

and troubleshooting information

Fuel Cap

Starting The Unit

19 10

Crouch in starting position. SQUEEZE and HOLD

Reloading the Line*

Bump

Knob

11 2

Unscrew the bump knob

counterclockwise.

Reloading the Line

18

Hold the inner reel and outer

spool together. Firmly pull the

two line ends to release them

from the holding slots. Screw

the bump knob on clockwise.

Tighten the bump knob

securely.

throttle for ALL further

steps.

Outer

Spool

Spring

Remove the inner reel and

spring.

For replacement line, call 1–800-800-7310 or go to

an authorized service dealer.

For single line installation or replacement spool

installation instructions, refer to the Replacing the

Trimming Line section of this manual.

*This is to assist in the reloading of Splitline® only. These instructions

are NOT part of the fast assembly instructions. Line does not need to

be installed on the initial assembly and start-up.

Inner

Reel

Choke Lever

5 X

11

Pull rope 5 times. Move choke lever to

3

Cut one 6-foot (1.8 m) length

of new 0.095” split line

trimming line. Split each end

about 6 inches (150 mm).

12

Position 2 and squeeze

throttle.

Top Hole

4

Insert the end of one line into

the top hole and the end of

the other line into the bottom

hole.

Bottom Hole

13

Pull rope 3-5 times to start

engine. Run unit for 30-60

seconds to warm up.

5

Wind the line tightly in the

direction shown on the inner

reel. The split wall will divide

the line. Wind the line until it

is completely divided and

about 6 inches (150 mm) of

line remains.

3-5 X

Split Wall

Choke Lever

14

Continue to squeeze

throttle. Move choke lever

to Position 3.

Holding Slots

6

Insert the two 6-inch sections

into the two .095 holding

slots.

15

Continue to squeeze

throttle. Run unit for an

additional 60 seconds to

complete warm-up. Unit

may be used during this

time.

7

Pass the two line ends

through the eyelets. Place the

spring inside the inner reel.

Insert the inner reel into the

outer spool. Push the inner

reel and outer spool together.

Eyelets

IMPORTANT: READ THE OPERATOR’S MANUAL THOROUGHLY AND FOLLOW THE SAFE OPERATION PRACTICES WHILE OPERATING THE UNIT.

Page 2

2

• SAFETY AND INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating, maintenance, and repair information.

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract attention to possible dangers. The safety symbols,

and their explanations, deserve careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper

accident prevention measures.

NOTE:

Advises of information or instructions vital to the operation or maintenance of the equipment.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal combustion engines operated on forest brush and/or grass-

covered areas be equipped with a spark arrestor, maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention of fire. Check with your state or local authorities for

regulations pertaining to these requirements. Failure to follow these requirements could subject you to liability

or a fine. This unit is factory equipped with a spark arrestor. If it requir

es replacement, ask your LOCAL

SERVICE DEALER to install the Accessory Part #753-05997 Muffler Assembly.

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls and proper use of the unit.

• Do not operate this unit when tired, ill, or under the influence of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use the unit, except for teens guided by an adult.

• All guards and safety attachments must be installed properly before operating the unit.

•Inspect the unit before use. Replace damaged parts. Check for fuel leaks. Make sure all fasteners are in

place and secure. Replace parts that are cracked, chipped, or damaged in any way. Do not operate the

unit with loose or damaged parts.

• Carefully inspect the area before starting the unit. Remove all debris and hard or sharp objects such as

glass, wir

e, etc.

• Be aware of the risk of injury to the head, hands and feet.

• Clear the area of children, bystanders, and pets. At a minimum, keep all children, bystanders, and pets

outside a 50 feet (15 m) radius; there still may be a risk to bystanders from thrown objects. Bystanders

should be encouraged to wear eye protection. If approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns automatically to the idle position. Make all

adjustments or repairs before using unit.

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and approved for the storage of such materials.

• Always stop the engine and allow it to cool before filling the fuel tank. Never remove the fuel tank

cap or add fuel when the engine is hot. Always loosen the fuel tank cap slowly to r

elieve any

pressure in the tank before fueling. Do not smoke.

• Always add fuel in a clean, well-ventilated outdoor area where there are no sparks or flames. Do

not smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any spilled fuel from the unit

immediately before starting the engine. Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not smoke.

• Never start or run the unit inside a closed room or building. Breathing exhaust fumes can kill. Only

operate this unit in a well-ventilated outdoor area.

WHILE OPERATING

• Wear safety glasses or goggles that are marked as meeting ANSI Z87.1 standards. Also wear ear/hearing

protection when operating this unit. Wear a face or dust mask if the operation is dusty

. Long sleeve shirts

are recommended.

• Wear heavy, long pants, boots and gloves. Do not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

•This unit has a clutch. The tines remain stationary when the engine is idling. If they do not, have the unit

adjusted by an authorized service technician.

•Be sure the tines are not in contact with anything before starting the unit.

•Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator and

unit must be in a stable position while starting. See Starting and Stopping Instructions.

•Use the right tool. Only use this tool for the purpose intended.

•Use extreme caution when reversing or pulling the unit backwards.

• Do not overreach. Always keep pr

oper footing and balance. Take extra care when working with on steep

slopes or inclines.

• Always hold the unit with both hands when operating. Keep a firm grip on the handle.

• Keep hands, face, and feet at a distance from all moving parts. Do not touch or try to stop the tines while

they are rotating.

• Do not touch the engine or muffler. These parts get extremely hot from operation. They remain hot for a

short time after turning off the unit.

• Do not operate the engine faster than the speed needed for the job. Do not run the engine at high speed

when the unit is not in use.

• Always stop the engine when work is delayed or when walking from one location to another.

• If striking or becomes entangled with a foreign object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do not operate the unit with loose or damaged parts.

• Stop and switch the engine to off for maintenance or repair.

•Use only original equipment manufacturer replacement parts and accessories for this unit. These

are available from an authorized service dealer. The use of any unauthorized parts or accessories

could lead to serious injury to the user

, or damage to the unit, and void the warranty.

• Keep unit clean of vegetation and other materials that may become lodged or entangled in the unit.

• To reduce fire hazard, keep the engine and muffler free from grass, leaves, excessive grease or carbon

build up.

After use

• Clean the unit with household cleaner to remove any gum buildup. Oil the tines with machine oil to

prevent rust.

OTHER SAFETY WARNINGS

• Never store a fueled unit inside a building where fumes may reach an open flame or spark.

• Allow the engine to cool before storing or transporting. Be sure to secure the unit while transporting.

• Store the unit in a dry area, locked up or up high to prevent unauthorized use or damage. Keep out of the

reach of children.

• Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean and free from

debris. Clean after each use. See the Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to instruct other users. If loaning someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

• IMPORTANT SAFETY INSTRUCTIONS •

SERVICE INFORMATION

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Oil and Fuel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Starting and Stopping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Optional Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

All information, illustrations, and specifications in this manual are based on the latest product information

available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2012 MTD SOUTHWEST INC, All Rights Reserved.

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED

FOR WARRANTY SERVICE.

For assistance r

egarding the assembly, controls, operation or maintenance of the unit, please call the

Customer Support Department at 1-800-828-5500 in the United States or 1-800-668-1238 in Canada.

Additional information about the unit can be found on our website at www.troybilt.com or

www.troybilt.ca.

For service, please call the Customer Support Department to obtain a list of authorized service dealers

near you. Service on this unit, both within and after the warranty period, should only be performed by an

authorized and approved service dealer. When servicing, use only identical replacement parts.

WARNING:

When using the unit, all safety rules must be followed. Please read these

instructions before operating the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

WARNING:

Gasoline is highly flammable, and its vapors can explode if ignited. Take the

following precautions:

RULES FOR SAFE OPERATION

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other symbols

or pictographs.

• READ OPERATOR'S MANUAL

WARNING: Read the operator’s manual(s) and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can cause severe eye injury and hearing

loss. Wear eye protection meeting ANSI Z87.1 standards and ear protection when

operating this unit. Use a full face shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel

• OIL

Refer to operator’s manual for the proper type of oil.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing greater than 10% ethanol will

likely damage this engine and void the warranty.

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 50 feet (15

m) from the operating area.

• THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high speed, causing injury. Keep

away from the rotating rotor.

• HOT SURFACE

WARNING: Do not touch a hot engine. These parts get extremely hot from

operation and may cause severe burns. When the unit is turned off the engine will

remain hot for a short time.

• SHARP BLADE

WARNING: Sharp blade on cutting attachment shield. To prevent serious injury, do

not touch the line cutting blade.

READ THE OPERATOR’S MANUAL AND FOLLOW ALL WARNINGS AND SAFETY

INSTRUCTIONS. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY TO THE OPERATOR

AND/OR BYSTANDERS.

SYMBOL MEANING

SAFETY ALERT:

Indicates danger, warning or caution. Attention is required in order to

avoid serious personal injury. May be used in conjunction with other symbols or pictographs.

DANGER:

Failure to obey a safety warning will result in serious injury to yourself or to

others. Always follow the safety precautions to reduce the risk of fire, electric shock and

personal injury.

WARNING:

Failure to obey a safety warning can result in injury to yourself and others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION:

Failure to obey a safety warning may result in property damage or personal

injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire,

electric shock and personal injury.

CALIFORNIA PROPOSITION 65

WARNING: Engine exhaust, som e of its constituents and certain finished components

contain or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

Page 3

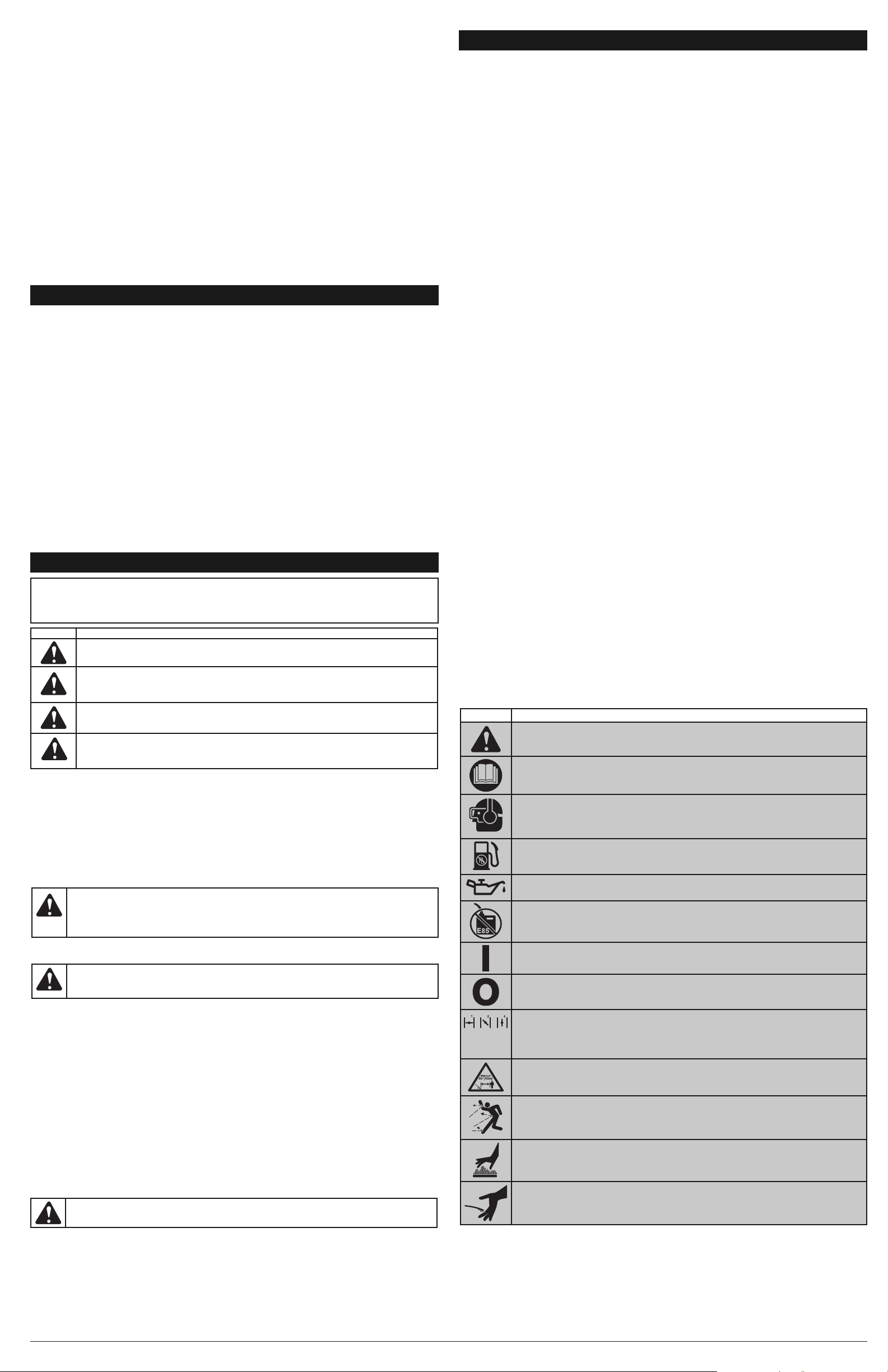

INSTALLING THE CUTTING HEAD SHIELD

Use the following instructions if the cutting head shield is not installed. Use only the instructions that

apply to the type of shaft and shield equipped with this unit.

1. Remove the wing nut

and washer from the

cutting head shield.

2. Insert the short tab

(the one without a

hole) on the mount

bracket into the slot

on the cutting head

shield (Fig. 1).

3. Rotate the cutting

head shield

counterclockwise to

align the hole on the

cutting head shield

with the hole on the

mount bracket (Fig. 1).

4. Insert the square bolt into the hole underneath the cutting head shield (Fig. 2). Push the square bolt

through the cutting

head shield and

mount bracket.

5. Put the washer onto

the square bolt (Fig. 2).

6. Screw the wing nut

onto the square bolt

until the cutting head

shield is firmly in

place (Fig. 2).

OPERA

TING THE COUPLER

The coupler enables the use of various optional attachments.

NOTE: To make installing or removing the attachment

easier, place the unit on the ground or on a work bench.

Installing the Attachment

NOTE: Remove the protective cap and gray spacer from

the upper and lower shafts prior to assembling the

attachment.

1. Turn the knob counterclockwise to loosen (Fig. 4).

2. While firmly holding the attachment, push it straight

into the coupler until the release button snaps firmly

into the primary hole (Fig. 6).

NOTE: Aligning the release button with the guide recess

will help installation (Fig. 5).

3. Turn the knob clockwise to tighten (Fig. 4).

For decorative edging with a string trimmer attachment,

lock the release button into the 90° edging hole (Fig. 4).

Removing the Attachment

1. Turn the knob counterclockwise to loosen (Fig. 4).

2. Press and hold the release button (Fig. 5).

3.

While firmly holding the upper shaft housing, pull the

attachment straight out of the coupler (Fig. 6).

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons for the unit not running properly. Be sure to use

fresh, clean unleaded fuel. Follow the instructions carefully for the proper fuel/oil mixture.

DEFINITION OF BLENDED FUELS

Today's fuels are often a blend of gasoline and oxygenates such as ethanol, methanol, or MTBE (ether).

Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can make fuel and oil separate. It

forms acids when stored. When using alcohol-blended fuel, use fresh fuel (less than 30 days old).

USING BLENDED FUELS

If choosing to use a blended fuel, or its use is unavoidable, follow recommended precautions:

• Always use the fresh fuel mix explained in the operator's manual

•Use the fuel additive STA-BIL® or an equivalent

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

USING FUEL ADDITIVES

The bottle of 2-cycle oil contains a fuel additive which will help inhibit

corrosion and minimize the formation of gum deposits. It is

recommended to use our 2-cycle oil with this unit.

If unavailable, use a good 2-cycle oil designed for air-cooled engines

along with a fuel additive, such as STA-BIL Gas Stabilizer or an

equivalent. Add 0.8 oz. (23 ml) of fuel additive per gallon of fuel

according to the instructions on the container. NEVER add fuel additives directly to the unit’s fuel tank.

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded fuel in a separate fuel can. Use a

40:1 fuel/oil ratio. Do not mix them directly in the engine fuel tank. See the table for specific gas and oil

mixing ratios.

NOTE:

One gallon (3.8 liters) of unleaded fuel mixed with one 3.2 oz. (95 ml) bottle of 2-cycle oil makes a 40:1

fuel/oil ratio.

NOTE: Dispose of the old fuel/oil mix in accordance to federal, state and local regulations.

FUELING THE UNIT

1. Turn unit on its side, with the fuel cap facing up, and remove the fuel cap.

2. Place the gas container’s spout into the fill hole on the fuel tank and fill the tank.

NOTE: Do not overfill the tank.

3. Wipe up any gasoline that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source and site before starting the engine.

MIXING RATIO - 40:1

3

KNOW YOUR UNIT

APPLICATIONS

As a trimmer:

• Cutting grass and light weeds.

• Edging

• Decorative trimming around trees,

fences, etc.

Throttle Control

D-Handle

Shaft Grip

Air Filter

Cover

Spark Plug

Shaft Housing

Starter Rope Grip

Line Cutting

Blade

Muffler

On/Off Control

Cutting Head

Cutting Head Shield

Fuel Cap

OIL AND FUEL INFORMATION

ASSEMBLY INSTRUCTIONS

WARNING:

To prevent serious personal injury, never operate the trimmer without the

cutting attachment shield in place.

Choke Lever

Primer Bulb

UNLEADED GAS 2 CYCLE OIL

1 GALLON US

(3.8 LITERS)

3.2 FL. OZ.

(95 ml)

1 LITER 25 ml

CAUTION:

For proper engine operation and maximum

reliability, pay strict attention to the oil and fuel mixing

instructions on the 2-cycle oil container. Using improperly

mixed fuel can severely damage the engine.

WARNING:

Gasoline is extremely flammable. Ignited vapors may explode. Always stop

the engine and allow it to cool before filling the fuel tank. Do not smoke while filling the

tank. Keep sparks and open flames at a distance from the area.

WARNING:

Remove fuel cap slowly to avoid injury from fuel spray. Never operate the

unit without the fuel cap securely in place.

WARNING:

Add fuel in a clean, level and well ventilated outdoor area. Wipe up any spilled fuel

immediately. Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel

vapors dissipate.

WARNING:

It has been proven that fuel containing greater than 10% ethanol will likely

damage this engine and void the warranty.

Coupler

ASSEMBLY TOOLS REQUIRED:

• 3/8” Socket

INSTALLING AND ADJUSTING THE HANDLE

Installing the Handle

1. Push the handle down onto the shaft housing (Fig. 3). The bolt hole in the handle should be to the right.

2. Insert the bolt into

the bolt hole and

push it through (Fig.

3). Tighten the bolt

with a 3/ 8” socket,

but do not tighten the

bolt completely .

3. While holding the unit

in the operating

position (Fig. 10),

move the handle to

the location that

provides the best

grip. Place it a

minimum of 6 inches

(15.24 cm) from the

end of the shaft grip

(Fig. 3).

4. Tighten the bolt with a 3/ 8” socket until the handle is secure.

Adjusting the Handle

If the handle requires adjustment:

1. Loosen the bolt with a 3/ 8” socket (Fig. 3).

2. While holding the unit in the operating position (Fig. 10), move the handle to the location that

provides the best grip. Place it a minimum of 6 inches (15.24 cm) from the end of the shaft grip

(Fig. 3).

3. Tighten the bolt with a 3/ 8” socket until the handle is secur

e.

Fig. 3

Bolt

Shaft Grip

Minimum 6 in.

(15.24 cm)

Handle

Shaft

Housing

Fig. 5

Fig. 6

Fig. 4

Release Button

Guide Recess

90˚ Edging Hole

(Trimmer Only)

Knob

Primary Hole

Lower Shaft

Housing

Upper Shaft

Housing

WARNING:

Before using any attachment, read and understand the manual that came

with the attachment. Follow all safety information contained within.

CAUTION:

Before operating the unit, make sure the release button is fully snapped

into the primary hole (Fig. 6) and the knob (Fig. 4) is securely tightened.

WARNING:

To avoid serious personal injury and damage to the unit, shut the unit off

before removing or installing an attachment.

CAUTION:

The release button should be snapped into the primary hole only. Using the

wrong hole could lead to personal injury or damage to the unit.

Coupler

ASSEMBLY INSTRUCTIONS

Fig. 1

Mount Bracket

Cutting Head

Shield

Fig. 2

Washer

Square Bolt

Slot

Wing Nut

Cutting Head

Shield

Mount Bracket

Page 4

HOLDING THE UNIT

Before operating the unit, stand in the operating position (Fig. 10). Check

for the following:

• The operator is wearing eye protection and proper clothing

• With a slightly-bent right arm, the operator’s hand is holding the shaft

grip

• The operator’s left arm is straight, the left hand holding the D-handle

• The unit is at waist level

• The cutting head is parallel to the ground and easily contacts the grass without the need to bend

over

ADJUSTING TRIMMING LINE LENGTH

The Bump Head™ cutting head allows the release of trimming line without stopping the engine. To release more

line, lightly tap the cutting head on the ground (Fig. 11) while operating the unit at high speed.

NOTE:

Always keep the trimming line fully extended. Line release becomes more

difficult when the cutting line gets shorter.

Each time the head is bumped, about 1 inch (25.4 mm) of trimming line releases. A

blade in the cutting head shield will cut the line to the proper length if any excess

line is released.

For best results, tap the bump knob on bare ground or hard soil. If attempting a line

release in tall grass, the engine may stall. Always keep the trimming line fully

extended. Line release becomes more difficult when the cutting line gets shorter.

NOTE: Do not rest the Bump Head™ on the ground while the unit is running.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence posts

TIPS FOR BEST TRIMMING RESULTS

• Keep the cutting head parallel to the ground.

• Do not force the cutting head. Allow the tip of the line to do the cutting, especially along walls. Cutting with more

than the tip will reduce cutting efficiency and may overload the engine.

• Cut grass over 8 inches (200 mm) by working from top to bottom in small increments to avoid premature line

wear or engine drag.

• Cut from right to left whenever possible. Cutting to the left improves the unit's cutting efficiency. Clippings are

thrown away from the operator.

• Slowly move the unit into and out of the cutting area at the desired height. Move either in a forward-backward or

side-to-side motion. Cutting shorter lengths produces the best results.

• Trim only when grass and weeds are dry.

• The life of the cutting line is dependent upon:

• Following the trimming techniques

• What vegetation is being cut

• Where vegetation is cut

For example, the line will wear faster when trimming against a foundation wall

as opposed to trimming around a tree.

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all vegetation around trees,

posts, fences, etc..

Rotate the whole unit so that the cutting head is at a 30° angle to the ground (Fig. 12).

4

Fig. 12

Fig. 11

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures

should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these

procedures, take your unit to any non-road engine repair establishment, individual or authorized

service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be

performed by any non-road engine repair establishment, individual or authorized service dealer.

NOTE: Please read the California/EPA statement that came with the unit for a complete listing of terms

and coverage for the emissions control devices, such as the spark arrestor, muffler, carburetor, etc.

MAINTENANCE AND REPAIR INSTRUCTIONS

FREQUENCY MAINTENANCE REQUIRED SEE

Every 10 hours Clean and re-oil air filter p. 5

Every 25 hours Check spark plug condition and gap p. 5

WARNING:

To prevent serious injury, never perform maintenance or repairs with unit

running. Always service and repair a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start.

OPERATING INSTRUCTIONS

WARNING:

Always wear eye, hearing, foot and body

protection to reduce the risk of injury when operating this unit.

Fig. 10

WARNING:

Do not remove or alter the line cutting blade assembly. Excessive line length

will cause premature engine failure and / or unit damage.

STARTING INSTRUCTIONS

1. Mix fuel with oil. Fill fuel tank with fuel/oil mixture. See Oil and Fuel

Mixing Instructions.

2. Fill the fuel tank with fresh, clean fuel mix. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off Control is in the

ON ( I ) position at all times (Fig. 7).

3. Fully press and release the primer bulb 10 times, slowly. Some amount

of fuel should be visible in the primer bulb and fuel lines (Fig. 8). If fuel

can not be seen in the bulb, press and release the bulb until fuel is

visible.

4. Place the choke lever in Position 1 (Fig. 8).

5. Crouch in the starting position (Fig. 9). Squeeze

the throttle control lever. Pull the starter rope 5

times.

6. Place the choke lever in Position 2 (Fig. 8)

7. Squeeze the throttle control, pull the starter rope

in a controlled motion 3 to 5 times to start

engine.

8. Keep the throttle squeezed and allow the engine

to warm up for 30 to 60 seconds.

9

. Continue squeezing the throttle control, move the

choke lever to Position 3 (Fig. 8) and continue

warming the engine for an additional 60 seconds.

The unit may be used during this time.

NOTE: Unit is properly warmed up when engine

accelerates without hesitation.

IF... the engine hesitates, return the choke lever to

Position 2 (Fig. 8) and continue warm-up.

IF... the engine does not start, go back to step 3.

IF...the engine fails to start after 2 attempts, place

the choke lever in Position 3 and squeeze the

throttle control. Pull

the starter rope out with a controlled and steady

motion 3 to 8 times. The engine should start. If

not, repeat.

IF WARM... If the engine is already warm, go back

to step 6.

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine

to cool down by idling.

2. Press and hold the On/Off Control switch in the

OFF (O) position until the unit comes to a

complete stop (Fig. 7).

STARTING AND STOPPING INSTRUCTIONS

WARNING:

Avoid accidental starting. Make sure you are in the starting position when

pulling the starter rope (Fig. 9). To avoid serious injury, the operator and unit must be in a stable

position while starting.

WARNING:

Operate this unit in a well-ventilated outdoor area. Carbon monoxide

exhaust fumes can be lethal in a confined area.

HOW TO START THE UNIT USING THE ELECTRIC STARTER OR POWER START BIT

ACCESSORY.

NOTE: This Unit Can Use an Electric Start or Power Start Bit™ Optional Accessory!

Please refer to the Electric Starter or Power Start Bit operator’s manual for proper use of this feature.

(Items Sold Separately! Please refer to Fig. 23 of this manual about purchasing these accessories.)

STARTING INSTRUCTIONS

1. Mix fuel with oil. Fill fuel tank with fuel/oil mixture. See Oil and Fuel Mixing Instructions.

2. Fill the fuel tank with fresh, clean fuel mix. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off Control is in the ON ( I ) position at all times (Fig.

7).

3. Fully press and release the primer bulb 10 times, slowly. Some amount of fuel should be visible in the

primer bulb (Fig. 8). If fuel cannot be seen in the bulb, press and release the bulb until fuel is visible.

4. Move the choke lever to Position 1 (Fig. 8).

5. Crouch in the starting position (Fig. 9). Place the electric starter or power start bit into the back of the

unit. Refer to the Operation section of the Electric Starter or Power Start Bit operator’s manual.

6. Squeeze the throttle control lever. Press and hold the electric starter or drill ON (I) button for 2

seconds.

7. Move the choke lever to Position 2 (Fig. 8).

8. Squeeze the throttle control lever, press and hold the electric starter or drill ON (I) button for 2second intervals until the unit starts.

9.

Continue to squeeze the throttle control, remove the electric starter or drill from the unit and allow the

engine to warm up for 30 to 60 seconds.

10. Continue squeezing the throttle control, move the choke lever to Position 3 (Fig. 8) and run

the unit for an additional 60 seconds. The unit may be used during this time

NOTE: Unit is properly warmed up when engine accelerates without hesitation.

IF... the engine hesitates, return the choke lever to Position 2 (Fig. 8) and continue warm-up.

IF... the engine does not start, go back to step 3.

IF... the engine fails to start after 2 attempts, place the choke lever in Position 3 and squeeze the

throttle control. Press and hold the electric starter or drill ON (I) button for 2-second intervals until the

unit starts.

IF WARM... If the engine is alr

eady warm, start the unit with the blue choker lever in Position 2. After

the unit starts, move the blue choker lever to Position 3.

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to cool down by idling.

2. Press and hold the On/Off Control switch in the OFF (O) position until the unit comes to a complete

stop (Fig. 7).

IF USING THE OPTIONAL ELECTRIC STARTER OR POWER START BIT™ ACCESSORY

Fig. 8

Choke Lever

Primer Bulb

Fig. 9

Starting

Position

Starter Rope

Fig. 7

OFF (O)

ON (I)

Throttle

Control

30°

Page 5

MAINTAINING THE SPARK PLUG

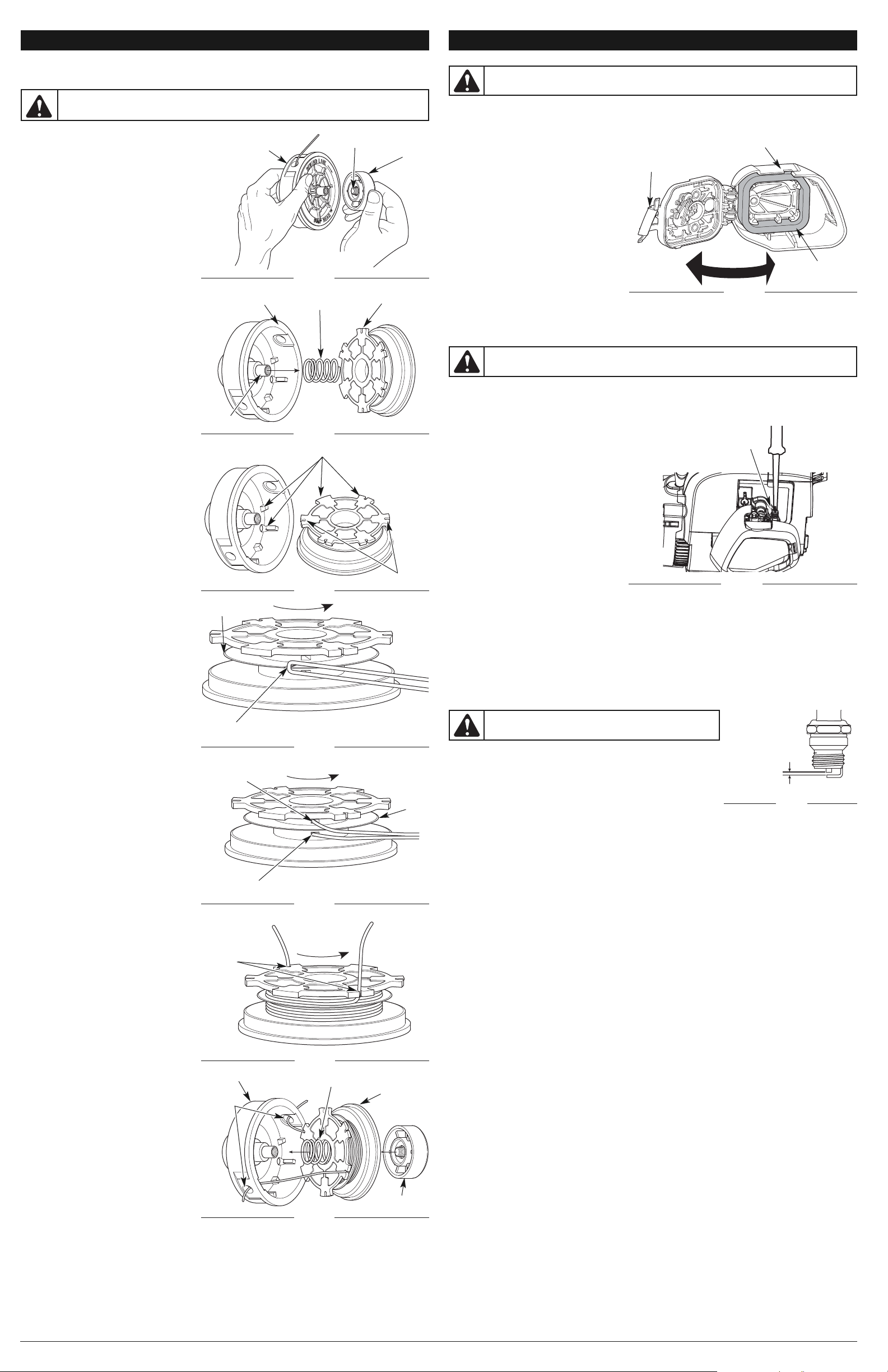

1. Stop the engine and allow it to cool. Grasp the spark plug boot firmly and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug from the cylinder head with a 5/8-inch

socket, turning counterclockwise.

3. Inspect the spark plug. If the spark plug is cracked, fouled or

dirty, replace it with a replacement part #753-06193, a

Champion RDJ7J or an equivalent spark plug.

4. Use a feeler gauge to set the air gap at 0.025 in. (0.635 mm)

(Fig. 22).

5. Install the spark plug in the cylinder head. Tighten the spark

plug with a 5/8-inch socket, turning it clockwise until snug.

NOTE: If using a torque wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m). Do not over tighten.

6. Reattach the spark plug boot.

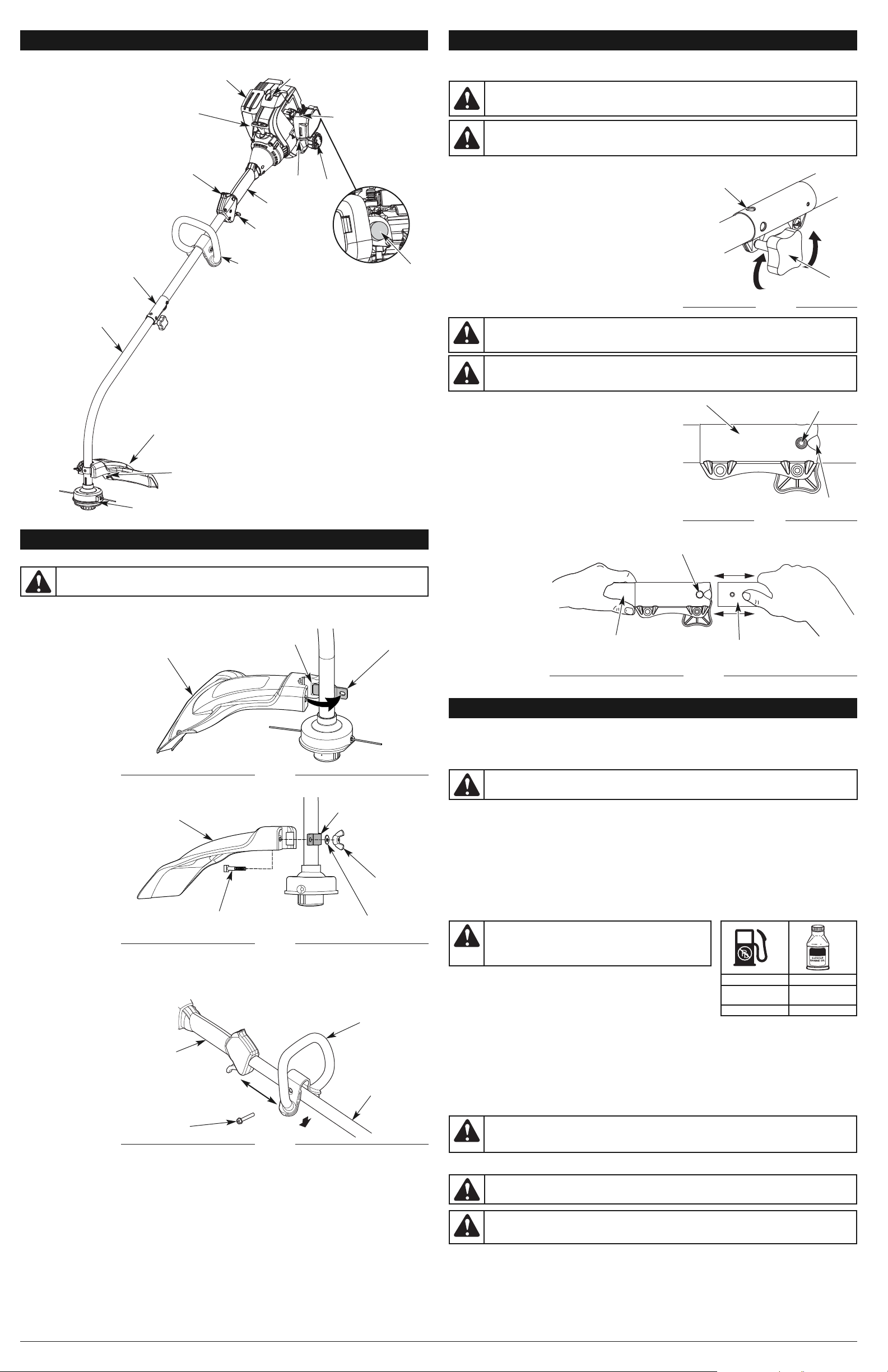

REPLACING THE TRIMMING LINE

Only use the trimming line described in the Specifications section. Other types of trimming line may

cause the engine to overheat or fail.

NOTE: Always use the corr

ect line length

when installing trimming line. The line

may not release properly if the line is too

long.

Part 1 - Removing the Inner Reel

1. Hold the outer spool with one hand and

unscrew the bump knob

counterclockwise (Fig. 13).

NOTE: The outer spool will remain attached

to the unit.

2. Inspect the bolt inside the bump knob to

make sure it moves freely. Replace the

bump knob if it is damaged.

3. Remove the inner reel from the outer

spool (Fig. 14).

4. Remove the spring from the inner reel

(Fig. 14).

5. Use a clean cloth to clean the inner reel,

spring, shaft and inner surface of the

outer spool.

6. Check the indexing teeth and holding slots

for wear (Fig. 15). If necessary

, remove

burrs or replace the inner reel and outer

spool.

Proceed to Part 2 - Winding New Trimming

Line onto the Inner Reel.

Part 2 - Winding New Trimming Line onto

the Inner Reel

• If using single line, refer to Winding

Single Line.

• If using split line, refer to Winding Split

Line.

• If using a prewound inner reel, proceed to

Part 3 - Installing the Inner Reel.

Winding Single Line

1. Cut one 12-foot (3.7 m) length of new

single trimming line. Fold the line in half

to create a loop in the middle.

2. Insert the loop into the slot in the split

wall (Fig. 16). Wind the line tightly in the

direction shown on the bottom of the

inner reel until about 6 inches (150 mm)

of line remains. Keep the top half of the

line above the split wall and the bottom

half of the line below the split wall.

3. Insert the two 6-inch sections into the

two .095 holding slots (Fig. 18).

NOTE: Failure to wind the line in the

direction indicated will cause the cutting

head to operate incorrectly.

Proceed to Part 3 - Installing the Inner Reel.

Winding Split Line

1. Cut one 6-foot (1.8 m) length of new split

line trimming line. Split each end about 6

inches (150 mm).

2. Using one split end, insert one line into

the top hole and the other line into the

bottom hole in the inner r

eel (Fig. 17).

3. Wind the line tightly in the direction

shown on the bottom of the inner reel.

The split wall will automatically divide the

line. Wind the line until it is completely

divided and about 6 inches (150 mm) of

line remains.

NOTE: Failure to wind the line in the

direction indicated will cause the cutting

head to operate incorrectly.

4. Insert the two 6-inch sections into the

two .095 holding slots (Fig. 18).

Proceed to Part 3 - Installing the Inner Reel.

Part 3 - Installing the Inner Reel

1. Pass the two line ends through the

eyelets in the outer spool. Place the

spring inside the inner reel. Insert the

inner reel into the outer spool. Push the

inner reel and outer spool together (Fig.

19).

NOTE: The spring must be assembled on

the inner reel before reassembling the

cutting head.

2. While holding the inner reel and outer

spool together, firmly pull the two line

ends to release them from the holding

slots.

3. While holding the inner reel and outer

spool together, screw the bump knob on

clockwise. Tighten the bump knob

secur

ely.

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Failure to maintain the air filter properly can result in poor performance or can cause permanent damage

to the engine.

1. Open the air filter cover by pressing the

lock tab in and pulling out on the air filter

cover (Fig. 20).

2. Remove the air filter (Fig. 20).

3. Wash the filter in detergent and water.

Rinse the filter thoroughly and allow it to

dry.

4. Apply enough clean SAE 30 motor oil to

lightly coat the filter.

5. Squeeze the filter to spread and remove

excess oil.

6. Replace the air filter into the air filter cover

(Fig. 20).

NOTE: Operating the unit without the air filter

WILL VOID the warranty.

7. Close the air filter cover by swinging it to the left and then pressing it down until the lock tab snaps into

place (Fig. 20).

5

WARNING:

To avoid serious personal injury, always turn the unit off and allow it to cool

before you clean or service it.

Fig. 20

Air Filter Cover

Air Filter

Lock Tab

MAINTENANCE AND REPAIR INSTRUCTIONSMAINTENANCE AND REPAIR INSTRUCTIONS

WARNING:

Never use metal-reinforced line, wire, chain or rope. These can break off and

become dangerous projectiles.

Fig. 13

Bolt

Bump Knob

Outer Spool

Fig. 14

Outer Spool

Spring

Inner Reel

Shaft

Fig. 15

Indexing Teeth

Holding Slots

Fig. 16

Slot

Split Wall

Fig. 17

Top Hole

Bottom Hole

Split

Wall

Fig. 18

Holding

Slots

Fig. 19

Outer Spool

Bump Knob

Inner Reel

Spring

Eyelets

IDLE SPEED ADJUSTMENT

NOTE: Careless adjustments can seriously damage the unit. An authorized service dealer should make

carburetor adjustments.

If, after checking the fuel mixture and cleaning the air filter, the engine still will not idle, adjust the idle

speed screw as follows:

1. Start the engine and run for one minute to

warm up. Refer to Starting and Stopping

Instructions.

2. Release the throttle trigger and let the

engine idle. If the engine stops, insert a

small Phillips screwdriver into the idle

adjustment screw (Fig. 21). Turn the idle

speed screw clockwise 1/8 of a turn at a

time (as needed) until the engine idles

smoothly.

3. If the engine appears to be idling too fast,

turn the idle speed screw

counterclockwise 1/8 of a turn at a time

(as needed), to r

educe idle speed.

Checking the fuel mixture, cleaning the air

filter and adjusting the idle speed should

solve most engine problems. If not and all of

the following are true:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

Have the carburetor adjusted by an authorized service dealer.

Fig. 21

Idle Adjustment Screw

WARNING:

Do not sand blast, scrape or clean

electrodes. Grit in the engine could damage the cylinder.

WARNING:

The cutting attachment will spin during idle speed adjustments. Wear

protective clothing and observe all safety instructions to prevent serious personal injury.

Fig. 22

0.025 in.

(0.635 mm.)

Page 6

6

SPECIFICATIONS

CLEANING AND STORAGE

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household cleaners

that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can damage plastic

housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store a fueled unit where fumes may reach an open flame or spark.

• Allow the engine to cool before storing.

• Store the unit locked up to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

Short Term Storage (1-2 weeks)

1. Store the unit in a horizontal position. If this is not possible, store the unit vertically with the engine at

the top.

Long-term Storage

1. Remove the fuel cap, tip the unit and drain the fuel into an approved container.

NOTE: Do not use gasoline that has been stored for more than 30 days. Dispose of old gasoline in

accordance with federal, state and local regulations.

2. Start the engine and allow it to run until it stalls. This ensures that all fuel has been drained from the

carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5 drops of any high quality motor oil or 2-

cycle oil into the cylinder. Pull the starter rope slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the cylinder before attempting to start the

unit after storage.

4. Thoroughly clean the unit and inspect it for any loose or damaged parts. Repair or replace damaged

parts and tighten loose screws, nuts or bolts. The unit is ready for storage.

WARNING:

To avoid serious personal injury, always turn the unit off and allow it to cool

before you clean or service it.

CAUSE ACTION

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

Fouled spark plug Replace or clean the spark plug

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

Cutting head bound with grass Stop the engine and clean the cutting head

Dirty air filter Clean or replace the air filter

Empty fuel tank Fill fuel tank with properly mixed fuel

The primer bulb wasn't pressed enough Press the primer bulb 10 times or until fuel is visible

Engine is flooded

With the choke lever in position 3, squeeze the trigger

and pull the starter rope

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

Fouled spark plug Replace or clean the spark plug

Cutting head bound with grass Stop the engine and clean cutting head

Cutting head out of line Refill with new line

Inner reel bound up Rewind the inner reel

Cutting head dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section and rewind

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed

Push the bump knob and pull out line until 4 inches (102 mm)

of line is outside of the cutting head

Oil, cleaner or lubricant in cutting head Clean and thoroughly dry the cutting head

Air filter is plugged Replace or clean the air filter

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

Improper idle speed Adjust the idle speed

TROUBLESHOOTING

ENGINE WILL NOT STAR T

ENGINE WILL NOT IDLE

ENGINE WILL NOT ACCELERATE

IF FURTHER ASSISTANCE IS REQUIRED, CONTACT AN AUTHORIZED SERVICE DEALER.

ENGINE LACKS POWER OR STAL LS

CUTTING LINE ADVANCES UNCONTROLLABLY

CUTTING HEAD WILL NOT ADVANCE LINE

Engine Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 2-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 cc

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel/Oil Mixture

Fuel/Oil Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 fl. oz. (296 ml)

Approximate Unit Weight (No fuel, with cutting attachment, shield and D-handle)10 - 11 lbs. (4.5 - 5 kg)

Cutting Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bump Head™

Trimming Line Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.095 in. (2.41 mm)

Cutting Path Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 in. (43.18 cm)

* All specifications are based on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

ELECTRIC STARTER AND POWER START BIT™ FEATURES

This unit is designed to be started with an optional

electric starter or Power Start Bit™, which are sold

separately. If choosing to start the unit using one of

these features or have questions, please contact

your local retailer or call 1-800-828-5500 in the U.S.

(1-800-668-1238 in Canada) for more information

and purchasing. You may also go to

www.troybilt.com or www.troybilt.ca

OPTIONAL ACCESSORY

Fig. 23

Electric Start

Feature

Page 7

TB22 EC

Recortador de

2 Ciclos

769-08425 / 00 09/12

¿NECESITA AYUDA? LLAME AL 1-800-828-5500 EN EE.UU.

O AL 1-800-668-1238 EN CANADA

English — Page 1Español — Page 7

Manual del Operador

Sacar la unidad de la caja

11 2

Saque todo el contenido

de la caja.

Ensamblado de la unidad

40:1

1 galón 3.2 onzas

5 6 7

Mezcle bien en un recipiente de

combustible aparte:

– 3.2 onzas fluidas de aceite

para motor de 2 tiempos

– 1 galón de gasolina sin

plomo (con menos de

30 días de antigüedad)

NOTA: No lo mezcle directamente en

el tanque de combustible.

Cómo arrancar la unidad

Ensamblado de la unidad

Ranura

Soporte

Resbale la ranura del

protector sobre consola de

montaje. Gire el protector

sobre el eje. Empuje el

perno cuadrado a través

del protector y del soporte.

Apriete la tuerca de la

arandela y de ala sobre el

perno.

Coloque la unidad en una

superficie plana. Llene el

tanque de combustible.

Quite la tapa del brazo.

Empuje el accesorio de corte

dentro del acoplador. Para

apretar, haga girar la perilla en

sentido de las agujas del reloj.

3

Cómo arrancar la unidad

Pera del

cebador

10 X

Oprima 10 veces la pera

del cebador, o bien hasta

que se vea el combustible.

Min. 6”

4

Oprima la manija hacia abajo sobre el

alojamiento del eje. El orificio del perno

de la manija debe quedar a la derecha.

Inserte el perno en el orificio del perno.

Apriete el perno pero no apriete por

completo. Mientras sujeta la unidad en

la posición de funcionamiento. Ubíquela

como mínimo a 6 pulgadas (15.24 cm)

del extreme de la empuñadura del eje.

Apriete el perno hasta que la manija

esté segura.

Palanca del obturador

8

Coloque la palanca del

obturador en la Posición 1.

Palanca del obturador

¡Arranque eléctrico

o accesorio de arranque

eléctrico opcional!

¡ESTOS ACCESORIOS OPCIONALES

SE VENDEN POR SEPARADO!

Esta unidad posee un método de arranque

alternativo que, para muchas personas, resulta

más sencillo de usar que tirar la cuerda de

arranque. Comuníquese con el distribuidor

local o llame al 1-800-828-5500

para obtener mayor información.

También puede encontrar información

en www.troybilt.com

HERRAMIENTAS

NECESARIAS PARA

EL ENSAMBLAJE:

• Llave tubular de 3/8”

Protector del cabezal de corte

Palanca del obturador

Cuerda de arranque

Interruptor de

Encendido/Apagado

Manija en D

Control del regulador

Acoplador

Tapa de

combustible

¿Necesita ayuda?

Llame al

1-800-828-5500

¿NO ARRANCÓ?

Repita estas instrucciones.

SI el motor no arranca después de 2 intentos,

mueva la palanca del obturador hasta

la posición 3 y tire de la cuerda de arranque

hasta que arranque el motor.

SI el motor todavía no arranca, consulte

el manual del operador para obtener

información adicional sobre cómo solucionar

problemas en el arranque.

19 10

Colóquese en la posición

de arranque.

Recarga de la línea*

Perilla

percusiva

11 2

Desatornille la perilla del

topetón a la izquierda.

Recarga de la línea

18

Sostenga a la vez el carrete

interior y la bobina exterior. Hale

firmemente los dos extremos de

línea para sacarlos de las ranuras

de sujeción. Atornille la perilla

percusiva hacia la derecha.

Apriete bien la perilla percusiva.

5 X

11

APRIETE y MANTENGA

APRETADO el control

del regulador en TODOS

los pasos que se describen

a continuación.

Bobina

exterior

Resorte

Quite el carrete interno y

suelte.

Carrete

interior

Para obtener una línea de repuesto, llame al 1–800-800-7310

o vaya a un distribuidor de servicio autorizado.

Para ver las instrucciones de instalación de una sola línea o

de un carrete de repuesto, vea la sección Cambiar la línea de

corte de este manual.

*Éste es asistir a la recarga de Splitline® solamente. Estas instrucciones no son

parte de las instrucciones de asamblea rápidas. La línea no necesita ser

instalada en la asamblea inicial y el arranque.

Tire de la cuerda

de arranque 5 veces.

3

Corte aproximadamente 6

pies (1.8 m) de largo de una

nueva línea de corte dividida

de 0.095” (2.41 mm). Separe

cada uno de los extremos

aproximadamente 6 pulgadas

(152 mm).

12

Mueva la palanca

del obturador hasta

la Posición 2 y oprima

el control del regulador.

Agujero

superior

4

Inserte un extremo de la línea

en el agujero exterior; y el

otro, en el inferior.

Agujero

inferior

13

Tire de la cuerda

de arranque fuertemente

de 3 a 5 veces para arrancar

el motor. Haga funcionar

la unidad entre 30 y 60

segundos para calentar

el motor.

Pared separadora

5

Enrolle firmemente la línea en

el sentido indicado en el

carrete interior. La pared

separadora dividirá la línea.

Enrolle la línea hasta que esté

completamente dividida y

queden aproximadamente 6

pulgadas (150 mm) de línea.

3-5 X

14

Mantenga apretado

el control del regulador.

Coloque la palanca

del obturador

en la Posición 3.

Ranuras de sujeción

6

Inserte las dos secciones de

6 pulgadas en las dos

ranuras de sujeción de 0.095

(2.41 mm).

15

Mantenga apretado

el control del regulador.

Haga funcionar la unidad

durante 60 segundos más

para completar

el calentamiento.

Se puede usar la unidad

durante este tiempo.

7

Pase los dos extremos de la

línea por los ojetes. Ponga el

resorte dentro del carrete

interior. Inserte el carrete

interior en la bobina exterior.

Empuje a la vez el carrete

interior y la bobina exterior.

Ojetes

IMPORTANTE: LEA BIEN EL MANUAL DEL OPERADOR Y, AL OPERAR LA UNIDAD, SIGA LAS INSTRUCCIONES PARA EL FUNCIONAMIENTO SEGURO.

Page 8

8

• SIMBOLOS DE SEGURIDAD E INTERNACIONALES •

Este manual del operador describe los símbolos y figuras de seguridad e internacionales que pueden

aparecer en este producto. Lea el manual del operador para obtener información completa acerca de

la seguridad, ensamble, operación y mantenimiento y reparación.

• Evite el peligro de incendio debido a combustible derramado. Limpie de inmediato todo combustible

derramado de la unidad antes de encenderla. Antes de arrancar el motor, aleje la unidad a una distancia de

30 pies (9.1 m) como mínimo del lugar de abasto de combustible. No fume.

• No arranque ni use nunca la unidad dentro de una habitación o edificio cerrados. Respirar los vapores de

escape puede ocasionarle la muerte. Opere esta unidad solamente en un área exterior bien ventilada.

CUANDO ESTÉ OPERANDO

•Use gafas protectoras que cumplan con la norma Z87.1 de ANSI y tengan la marca que lo indica. Use

protección para la oreja/audición cuando opere esta unidad. Use máscara facial o para polvo si la

operación produce mucho polvo.

•Use pantalones largos fuertes, botas, guantes y camisa de mangas largas. No use ropa holgada, joyas,

pantalones cortos, sandalias, ni esté descalzo. Asegúrese el cabello por encima del nivel de los hombros.

• El protector del accesorio de corte debe estar siempre colocado cuando se utilice la unidad como

recortador. No opere la unidad sin ambas líneas de corte extendidas y con la línea adecuada instalada. No

extienda la línea de corte más allá de la longitud del protector.

•Asegúrese de que el accesorio de corte no está en contacto con ningún objeto antes de arrancar la

unidad.

•A

juste la manija a su tamaño para proporcionar un mejor agarre.

• El accesorio de corte puede estar girando durante los ajustes del carburador. Use ropa que lo proteja y

cumpla con todas las instrucciones de seguridad para prevenir graves lesiones personales.

•Use la unidad solamente de día o con buena luz artificial.

• Evite arranques accidentales. Esté en la posición de arranque cada vez que hale la cuerda de arranque. El

operador y la unidad deben estar en una posición estable al arrancar. Consulte las Instrucciones de

Arranque/Parada.

•Use la herramienta correcta. Use esta herramienta solamente para el propósito para el cual fue diseñada.

• No se estir

e demasiado. Mantenga siempre la base de apoyo y equilibrio adecuados.

• Sostenga siempre la unidad con ambas manos cuando la opere. Mantenga un agarre firme sobre ambas

manijas.

• Mantenga las manos, la cara y los pies alejados de todas las partes en movimiento. No toque ni trate de

parar el accesorio de corte cuando esté girando.

• No toque el motor, la caja de engranajes ni el silenciador. Estas piezas están muy calientes durante la

operación, incluso después de que se apaga la unidad.

• No opere el motor a más velocidad de la necesaria para cortar, recortar o recortar bordes. No haga

funcionar el motor a alta velocidad cuando no esté cortando.

• Pare siempre el motor cuando deje de cortar o cuando esté caminando de un lugar de corte hacia otro.

• Si golpea o se enreda con un objeto extraño, pare el motor inmediatamente y verifique si ha habido algún

daño. No lo oper

e antes de reparar el daño. No opere la unidad con piezas sueltas o dañadas.

• Pare la unidad, apague el motor y desconecte la bujía para mantenimiento o reparación.

•Use solamente piezas y accesorios de reemplazo del fabricante del equipo original para esta unidad. Éstos

están disponibles en su proveedor de servicio autorizado. El uso de cualquier pieza o accesorio no

autorizado podría causar lesiones graves al usuario, o daños a la unidad, y anular su garantía.

• Mantenga la unidad limpia de vegetación y otros materiales. Pudieran quedar obstruidas entre el accesorio

de corte y el protector.

• Para reducir el peligro de incendio, mantenga el motor y el silenciador libre de hierba, hojas, exceso de

grasa o acumulación de carbón.

OTROS AVISOS DE SEGURIDAD

• Nunca almacene una unidad con combustible dentro de un edificio en el cual los vapores puedan llegar a

una llama expuesta o una chispa.

• Deje que el motor se enfríe antes de almacenarlo o transportarlo. Asegúrese de fijar bien la unidad mientras

la transporta.

• Almacene la unidad en un área seca y cerrada, o en un lugar alto para evitar uso no autorizado o daños.

Manténgala alejada del alcance de los niños.

• Nunca rocíe ni chorree la unidad con agua ni ningún otro líquido. Mantenga las manijas secas, limpias y

libres de escombros. Límpiela después de usarla, vea las instrucciones de Limpieza y Almacenamiento.

• Conserve estas instrucciones. Consúltelas con frecuencia y úselas para instruir a otros usuarios. Si le

pr

esta esta unidad a alguien, préstele también estas instrucciones.

CONSERVE ESTAS INSTRUCCIONES

• SIMBOLO DE ALERTA DE SEGURIDAD

IIndica peligro, advertencia o precaución. Puede ser utilizado junto con otros símbolos

o figuras.

• ADVERTENCIA DE SUPERFICIE CALIENTE

No toque un silenciador ni un cilindro caliente. Puede quemarse. Estas partes se

calientan mucho con el uso. Luego de apagarse permanecen calientes durante un

corto tiempo.

• LEA EL MANUAL DEL OPERADOR

ADVERTENCIA: Lea el manual del operador y siga todas las advertencias e

instrucciones de seguridad. De no hacerlo, el operador y/o los espectadores pueden

sufrir graves lesiones.

•USE PROTECCION OCULAR Y AUDITIVA

ADVERTENCIA: Los objetos arrojados por la unidad y el ruido fuerte pueden

causar graves lesiones oculares y pérdida auditiva. Utilice protección ocular que

cumpla con las normas ANSI Z87.1 y protección auditiva cuando opere esta unidad.

Use una careta completa cuando la necesite.

• MANTENGA ALEJADOS A LOS ESPECTADORES

ADVERTENCIA: Mantenga a todos los espectadores, en especial a niños y

animales domésticos a por lo menos 50 pies (15 m.) del área de corte.

•LOS OBJETOS DESPEDIDOS Y LA CUCHILLA ROTATIVA PUEDEN CAUSAR

GRAVES LESIONES

ADVERTENCIA: No opere esta unidad si la protección plástica de línea no está

colocada en su lugar. Manténgase alejado de la cabeza de corte giratorio.

SIMBOLO SIGNIFICADO

• CONTROL DEL OBTURADOR

1 • Posición de OBTURACIÓN COMPLETA

2 • Posición de OBTURACIÓN PARCIAL

3 • Posición de MARCHA

• COMBUSTIBLE SIN PLOMO

Use siempre combustible limpio, nuevo y sin plomo.

• INDICADOR DE ACEITE

Consulte el manual del operador para obtener información acerca del tipo correcto de aceite.

• CUCHILLA AFILADA

ADVERTENCIA: La protección del accesorio de corte contiene una cuchilla

afilada. Para prevenir graves lesiones, no toque la cuchilla.

• NO UTILICE COMBUSTIBLE E85 EN ESTA UNIDAD

ADVERTENCIA: Se ha demostrado que el combustible que contiene más del

10% de etanol probablemente ocasionará daños al motor y anulará la garantía.

LEA TODAS LAS INSTRUCCIONES ANTES DE OPERAR LA UNIDAD

• Lea las instrucciones cuidadosamente. Familiarícese con los controles y el uso adecuado de la unidad.

• No opere esta unidad cuando esté cansado, enfermo o bajo la influencia de alcohol, drogas o

medicamentos.

•Los niños y los adolescentes menores de 15 años de edad no deben usar la unidad. Los adolescentes

pueden hacerlo bajo la supervisión de un adulto.

• Todos los dispositivos de protección y los accesorios de seguridad deben estar instalados

adecuadamente antes de operar la unidad.

•Inspeccione la unidad antes de usarla. Reemplace las piezas dañadas. Verifique si hay fugas de

combustible. Asegúr

ese de que todos los fijadores estén en su lugar y asegurados. Reemplace las piezas

que estén agrietadas, astilladas o dañadas en cualquier forma. No opere la unidad con piezas sueltas o

dañadas.

•Inspeccione cuidadosamente el área antes de operar la unidad. Elimine todos los escombros y los objetos

duros o filosos tales como cristal, alambre, etc.

•Esté consciente del riesgo de lesión en la cabeza, las manos y los pies.

• No permita niños, espectadores ni mascotas en el ár

ea. Los niños, los espectadores y las mascotas deben

estar fuera de un radio de 50 pies (15 m) como mínimo; de todas formas los espectadores correrán el

riesgo de ser golpeados por objetos lanzados por la unidad. Se debe exhortar a los espectadores a que

usen protección para los ojos. Si se le acerca alguien apague la unidad de inmediato.

•Use sólo línea de reemplazo del fabricante original del equipo con un diámetro de 0.095 de pulgada (2.41

mm). Nunca use línea reforzada con metal, alambre o soga. Se pueden romper y convertirse en proyectiles

peligrosos.

• Oprima el control del estrangulador y compruebe que regresa automáticamente a la posición de marcha

en vacío. Haga todos los ajustes o r

eparaciones antes de usar la unidad.

ADVERTENCIAS DE SEGURIDAD PARA LAS UNIDADES A GASOLINA

• Almacene el combustible solamente en los recipientes diseñados y aprobados específicamente para estos

materiales.

• Pare siempre el motor y deje que se enfríe antes de llenar el tanque de combustible. No quite nunca la tapa

del tanque de combustible ni eche combustible cuando el motor esté caliente. Antes de llenar el tanque,

afloje siempre la tapa lentamente para disipar la presión del mismo. No fume.

• Siempre mezcle y agregue el combustible en un área exterior bien ventilada, donde no haya chispas ni

llamas. No fume.

• No opere nunca la unidad si la tapa del combustible no está bien asegurada en su lugar.

• IMPORTANTE INFORMACION DE SEGURIDAD •

LLAMADAS A APOYO AL CLIENTE

INDICE DE CONTENIDOS

Llamadas a apoyo al cliente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Normas para una operación segura . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Conozca su unidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Instrucciones de ensamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Información del aceite y del combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Instrucciones de arranque y apagado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Instrucciones de operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Instrucciones de mantenimiento y reparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Limpieza y almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Accesorio opcional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cuadro de solución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Toda la información, las ilustraciones y las especificaciones contenidas en este manual se basan en la

información más reciente disponible en el momento de impresión del manual. Nos reservamos el

derecho de hacer cambios en cualquier momento sin aviso pr

evio.

Copyright © 2012 MTD SOUTHWEST INC. Todos los derechos reservados.

NO DEVUELVA ESTA UNIDAD AL VENDEDOR. PARA SOLICITAR SERVICIO POR GARANTÍA,

DEBERÁ PRESENTAR EL COMPROBANTE DE COMPRA.

Para solicitar asistencia en relación con el ensamblaje, los controles, la operación o el mantenimiento

de la unidad, llame al Departamento de Atención al Cliente al 1-800-828-5500 en Estados Unidos o el

1-800-668-1238 en Canadá. Puede encontrar más información sobre la unidad en nuestro sitio Web

en www.troybilt.com o www.troybilt.ca.

Con vista a recibir servicios, llame al Departamento de Atención al Cliente para que le faciliten una

lista de los distribuidores de servicio autorizados cercanos a usted. El servicio a esta unidad, tanto

durante como después del período cubierto por la garantía, debe ser llevado a cabo solamente por

un distribuidor de servicio autorizado y apr

obado. Cuando vaya a dar mantenimiento al equipo, utilice

solo piezas de repuesto idénticas.

Lea el manual del operador y siga todas las advertencias e instrucciones de seguridad. De no

hacerlo, el operador y/o los espectadores pueden sufrir graves lesiones.

ADVERTENCIA:

Se deben seguir las siguientes reglas de seguridad cuando use la unidad.

Por favor lea estas instrucciones para su propia seguridad y las de los espectadores, antes de hacer

funcionar la unidad. Por favor mantenga estas instrucciones en un lugar seguro para uso futuro.

ADVERTENCIA:

La gasolina es muy inflamable y sus gases pueden explotar si se

encienden. Tome las siguientes precauciones:

NORMAS PARA UNA OPERACION SEGURA

Los símbolos de seguridad se utilizan para llamar su atención sobre posibles peligros. Los símbolos

de seguridad y sus explicaciones merecen toda su atención y comprensión. Los símbolos de

seguridad no eliminan ningún peligro por sí mismos. Las instrucciones o advertencias que ofrecen

no substituyen las medidas adecuadas de prevención de accidentes.

NOTA: Le ofrece información o instrucciones que son esenciales para la operación o

mantenimiento del equipo.

SIMBOLO SIGNIFICADO

PARACHISPAS

NOTA: Para los usuarios en tierras forestales de los EE.UU. y en los estados de California, Maine, Oregon

y Washington. Todos los terrenos forestales de los EE.UU. y el estado de California (Códigos de Recursos

Públicos 4442 y 4443), Oregon y Washington, requieren por decreto, que ciertos motores de combustión interna

que se hagan funcionar en zonas boscosas y/o zonas cubiertas por pastizales, estén equipados con un

parachispas, que sean mantenidos en buen estado de funcionamiento o que el motor sea construido, esté

equipado y sea mantenido para evitar incendios. Consulte los r

eglamentos pertinentes a esos requisitos con las

autoridades estatales o locales. El incumplimiento de esos requisitos puede responsabilizarle o someterle a la

imposición de una multa. Esta unidad fue equipada en la fábrica con un parachispas. Si requiere sustitución,

hay una Pantalla Parachispas disponible, Pieza #753-06418 al contactar el departamento de servicio.

ALERTA DE SEGURIDAD:

Indica peligro, advertencia o precaución. Debe prestar

atención para evitar sufrir graves lesiones personales. Puede ser utilizado junto con otros

símbolos o figuras.

PELIGRO:

El no obedecer una advertencia de seguridad puede conducir a que usted u

otras personas sufran graves lesiones. Siga siempre las precauciones de seguridad para

reducir el riesgo de incendio, descarga eléctrica y lesiones personales.

ADVERTENCIA:

El no seguir una advertencia de seguridad puede conducir a que

usted u otras personas sufran lesiones. Siga siempre las precauciones de seguridad para

reducir el riesgo de incendio, descarga eléctrica y lesiones personales.

PRECAUCIÓN:

El no seguir una advertencia de seguridad puede conducir a daño patrimonial

o a que usted u otras personas sufran lesiones personales. Siga siempre las precauciones de

seguridad para reducir el riesgo de incendio, descarga eléctrica y lesiones personales.

PROPOSICIÓN 65 DEL ESTADO DE CALIFORNIA

ADVERTENCIA: Los gases de escape, algunos de sus componentes y determinados

productos terminados contienen o emiten productos químicos de los que el estado de

California tiene conocimiento provocan cáncer, malformaciones congénitas u otros daños

al sistema reproductor. Lávese las manos después de manipularlo.

• CONTROL DE ENCENDIDO Y APAGADO

ENCENDIDO /ARRANQUE /MARCHA

• CONTROL DE ENCENDIDO Y APAGADO

APAGADO o PARADO

NORMAS PARA UNA OPERACION SEGURA

Page 9

CONOZCA SU UNIDAD

APLICACIONES

Como recortadora;

• Corte de césped y hierbas delgadas

• Recorte de bordes

• Recorte decorativo alrededor de

árboles, cercos, etc.

Gatillo del

regulador

Manija en D

Manjo

del eje

Cubierta del

filtro de aire

Bujía de encendido

Bastidor del eje

Mango de la

cuerda de

arranque

Cuchilla de

corte de línea

Silenciador

Control de encendido

y apagado

Accesorio de corte

Protección accesoria de corte

Tapa del

combustible

Palanca del

obturador

Bombilla del

cebador

INSTRUCCIONES DE ENSAMBLE

Acoplador

INSTRUCCIONES PARA MEZCLAR EL ACEITE Y EL COMBUSTIBLE

El combustible viejo o mal mezclado son los motivos principales del mal funcionamiento de la unidad.

Asegúrese de usar combustible nuevo, limpio y sin plomo. Siga las instrucciones en detalle para mezclar

correctamente el aceite y el combustible.

Definición de los combustibles de mezcla

Los combustibles actuales con frecuencia son una mezcla de gasolina y oxigenantes como por ejemplo

etanol, metanol o MTBE (éter). El combustible mezclado con alcohol absorbe agua. Una cantidad tan

pequeña como el 1% de agua en el combustible puede causar la separación del combustible y el

aceite. Forma ácidos cuando está almacenado. Cuando use combustible mezclado con alcohol, use

combustible nuevo (de menos de 30 días).

Uso de combustibles de mezcla

Si usted opta por usar un combustible de mezcla o si su uso es inevitable, tome las precauciones

recomendadas.

•Use siempre una mezcla fresca de combustible según lo indica su manual del operador.

•Use el aditivo especial de combustible STA-BIL® o uno similar

• Agite siempre la mezcla de combustible antes de cargarlo en la unidad.

• Drene el tanque y haga funcionar el motor en seco antes de guardar la unidad.

Uso de aditivos en el combustible

La botella de aceite de 2 ciclos que vino con su unidad contiene un aditivo en el combustible que