Page 1

Operator's Manual

Trimble®GCS900 Grade Control System for

Excavators

Version 12.10

Revision A

Part Number 65129-03-ENG

July 2011

11

Page 2

Contact Information

Trimble Engineering and Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

USA

800-538-7800 (toll free in USA)

+1-937-245-5600 Phone

+1-937-233-9004 Fax

www.trimble.com

Copyright and Trademark s

© 2000–2011, Caterpillar Trimble Control Technologies LLC. All

rights reserved.

Trimble, the Globe & Triangle logo, GCSFlex, CC SFlex, and

SiteVision are trademarks of Trimble Navigation Limited, registered in

the United States and other countries. PROTECTED UNDER U.S.

PATENTS: 5,107,932; 5,375,663; 6,691,437; 7,307,710; 7,246,456;

7,139,662; 5,987,379; 6,324,455; 6,253,160; 4,888,890; 5,235,511;

4,924,374.

SiteNet, CMR and CMR+ are trademarks of Trimble Navigation

Limited.

For STL support, the software uses the STLPort adaptation of the

Moscow Center for SPARC Technology S tandard Template Library.

Copyright © 1994 Hewlett-Packard Company, C opyright © 1996, 97

Silicon Graphics Computer Systems, Inc., Copyright © 1997 Moscow

Center for SPARC Technology, Copyright © 1999, 2000 Boris

Fomitchev.

Microsoft, Windows, and Windows NT are trademarks or registered

trademarks of Microsoft Corporation in the United States and/or other

countries. Wi-Fi is a trademark of the Wi-Fi Alliance, registered in the

United States and other countries. WPA and WPA2 are trademarks of

the Wi-Fi Alliance. Developed under a License of the European Union

and the European Space Agency. Portions of the software are copyright

© 2003 Open Design Alliance. All rights reserved.

All other trademarks are the property of their respective owners.

Release Notice

This is the July2011 release (Revision A) of the GCS900 Grade

Control System for ExcavatorsOperator's Manual, part number 6512903-ENG. It applies to version 12.10 of the GCS900 Grade Control

System software.

The following limited warranties give you specific legal rights. You

may have others, which vary from state/jurisdiction to

state/jurisdiction.

Trimble Navigation Limited

END-USER LICENSE AGREE MENT

IMPORTANT, READ CAREFULLY. THIS END USER LICENSE

AGREEMENT ("AGREEMENT") IS A LEGAL AGREEMENT

BETWEEN YOU AND CATERPILLAR TRIMBLE CONTROL

TECHNOLOGIES LLC ("CTCT") and applies to the computer

software provided by CTCT with the GCS900 or AccuGrade system

(the "Product") purchased by you (whether built into hardware circuitry

as firmware, embedded in flash memory or a PCMCIA card, or stored

on magnetic or other media), or provided as a stand-alone computer

software product, and includes any accompanying printed materials and

any "online" or electronic documentation ("Software"). The Software

also includes any CTCT software (including, without limitation,

upgrades and updates) relating to the Product that is furnished by

Trimble Navigation Limited (“Trimble”) or its dealers (including,

without limitation, CTCT software downloaded from Trimble's or its

dealers' website(s)) unless accompanied by different license terms and

conditions that will govern its use.

BY CLICKING ''YES" OR "I ACCEPT" IN THE ACCEP TANCE

BOX, OR BY INSTALLING, COPYING OR OTHERWISE USING

THE S OFTWARE, YOU AGREE TO BE BOUND BY THE TERMS

OF THIS AGREEMENT. IF YOU DO NOT AGREE TO THE

TERMS OF THIS AGREEMENT, DO NOT USE THE PRODUCT

OR COPY THE SOFTWARE.INSTEAD PROMPTLY RETURN

THE UNUSED SOFTWARE AND ACCOMPANYING P RODUCT

TO THE PLACE FROM WHICH YOU OBTAINED THEM FOR A

FULL REFUND.

1 SOFTWAREP RODUCT LICENSE

1.1 License Grant. Subject to this Agreement, CTCT grants you a

limited, non-exclusive, non-sublicensable right to use one (1) copy of

the Software in a machine-readable form on the Product. Such use is

limited to use with the Product for which it was intended and into

which it was embedded. You may use the installation S oftware from a

computer solely to download the S oftware to one Product. In no event

shall the installation Software be used to download the S oftware onto

more than one Product without securing a separate license. A license

for the Software may not be shared or used concurrently on different

computers or Products.

1.2 Other Rights and Limitations.

(1) You may not copy, modify, make derivative works of, rent, lease,

sell, distribute or transfer the S oftware, in whole or in part, except as

otherwise expressly authorized under this Agreement, and you agree to

use all commercially reasonable efforts to prevent its unauthorized use

and disclosure.

(2) The Software contains valuable trade secrets proprietary to CTCT

and its licensors. You shall not, nor allow any third party to copy,

decompile, disassemble or otherwise reverse engineer the Software, or

attempt to do so, provided, however, that to the extent any applicable

mandatory laws (such as, for example, national laws implementing EC

Directive 91/250 on the Legal Protection of Computer Programs) give

you the right to perform any of the aforementioned activities without

CTCT's consent in order to gain certain information about the

Software for purposes specified in the respective statutes (i.e.,

interoperability), you hereby agree that, before exercising any such

rights, you shall first request such information from C TCT in writing

detailing the purpose for which you need the information. Only if and

after CTCT, at its sole discretion, partly or completely denies your

request, may you exercise such statutory rights.

(3) This S oftware is licensed as a single product. You may not separate

its component parts for use on more than one Product.

(4) You may not rent, lease, or lend, the Software separate from the

Product for which it was intended.

(5) No service bureau work, multiple-user license or time-sharing

arrangement is permitted. For purposes of this Agreement "service

bureau work” shall be deemed to include, without limitation, use of

the Software to process or to generate output data for the benefit of, or

for purposes of rendering services to any third party over the Internet

or other communications network.

(6) You may permanently transfer all of your rights under this

Agreement only as part of a permanent sale or transfer of the Product

for which it was intended, provided you retain no copies, you transfer

all of the Software (including all component parts, the media and

printed materials, any upgrades, and this Agreement) and the recipient

agrees to the terms of this Agreement. If the Software portion is an

upgrade, any transfer must include all prior versions of the Software.

(7) You acknowledge that the Software and underlying technology

may be subject to the export administration regulations of the United

States Government relating to the export of technical data and

products. This Agreement is subject to, and you agree to comply with,

any laws, regulations, orders or other restrictions on the export of the

Software from the United S tates which may be imposed by the United

States Government or agencies thereof.

(8) At the request of CTCT, you agree to cooperate with CTCT to

track the number of Products using Software at your site(s) to ensure

compliance with the license grant and installation restrictions in this

Agreement.

1.3 Termination. You may terminate this Agreement by ceasing all use

of the Software. Without prejudice as to any other rights, CTCT may

terminate this Agreement without notice if you fail to comply with the

2 GCS900GradeControlSystem for Excavators Operator's Manual

Page 3

terms and conditions of this Agreement. In either event, you must

destroy all copies of the Software and all of its component parts, and

provide an affidavit to C TCT stating that you have done the same.

1.4 Copyright. All title and copyrights in and to the Software

(including but not limited to any images, photographs, animations,

video, audio, music, and text incorporated into the Software), the

accompanying printed materials, and any copies of the S oftware are

owned by CTCT and its licensors. You shall not remove, cover or alter

any of CTCTs patent, copyright or trademark notices placed upon,

embedded in or displayed by the Software or on its packaging and

related materials.

1.5 U.S. Government Restricted Rights. The Software is provided with

“RESTRICTED RIGHTS”. Use, duplication, or disclosure by the

United States Government is subject to restrictions as set forth in this

Agreement, and as provided in DFARS 227.7202-1(a) and 227.72023(a)(1995), DFARS 252.227-7013(c)(1)(ii) (OCT 1988), FAR

12.212(a) (1995), FAR 52.227-19, or FAR 52.227-14(ALT III), as

applicable.

2 LIMITED WARRANTY

2.1 Limited Warranty. CTCT warrants that the Software will perform

substantially in accordance with the accompanying written materials

for a period of one (1) year from the date of receipt. This limited

warranty gives you specific legal rights, you may have others, which

vary from state/jurisdiction to state/jurisdiction.

2.2 Customer Remedies. CTCT's and its licensors' entire liability, and

your sole remedy, with respect to the Software shall be either, at

CTCT's option, (a) repair or replacement of the S oftware, or (b) return

of the license fee paid for any Software that does not meet CTCT's

limited warranty. This limited warranty is void if failure of the

Software has resulted from (1) accident, abuse, or misapplication; (2)

alteration or modification of the Software without CTCT’s prior

written authorization; (3) interaction with software or hardware not

supplied by CTCT or Trimble; (4) improper, inadequate or

unauthorized installation, maintenance, or storage of the Software or

Product; or (5) if you violate the terms of this Agreement. Any

replacement Software will be warranted for the remainder of the

original warranty period or thirty (30) days, whichever is longer.

2.3 NO OTHER WARRANTIES. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, C TCT AND ITS

LICENSORS DISCLAIM ALL OTHER WARRANTIES AND

CONDITIONS, EITHER EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO, IMPLIED WARRANTIES AND

CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, TITLE, AND NON INFRINGEMENT

WITH REGARD TO THE SOFTWARE AND THE PROVISION OF

OR FAILURE TO PROVIDE S UPPORT SERVICES. THE ABOVE

LIMITED WARRANTY DOES NOT APPLY TO ERROR

CORRECTIONS, UPDATES OR UPGRADES OF THE

SOFTWARE AFTER EXPIRATION OF THE LIMITED

WARRANTY PERIOD, WHICH ARE PROVIDED "AS IS" AND

WITHOUT WARRANTY. BECAUSE THE S OFTWARE IS

INHERENTLY C OMPLEX AND MAY NOT BE COMPLETELY

FREE OF NONCONFORMITIES, DEFECTS OR ERRORS , YOU

ARE ADVISED TO VERIFY YOUR WORK. CTCT DOES NOT

WARRANT THE RESULTS OBTAINED THROUGH USE OF THE

SOFTWARE, OR THAT THE SOFTWARE WILL OPERATE

ERROR F REE OR UNINTERRUPTED, WILL MEET YOUR

NEEDS OR EXPECTATIONS, OR THAT ALL

NONCONFORMITIES CAN OR WILL BE CORRECTED. TO THE

EXTENT ALLOWED BY APPLICABLE LAW, IMPLIED

WARRANTIES AND CONDITIONS ON THE SOFTWARE ARE

LIMITED TO ONE (1) YEAR. YOU MAY HAVE OTHER LEGAL

RIGHTS WHICH VARY FROM S TATE/JURISDICTION TO

STATE/JURISDICTION.

2.4 LIMITATION OF LIABILITY. CTCT'S ENTIRE LIABILITY

UNDER ANY PROVISION OF THIS AGREEMENT SHALL B E

LIMITED TO THE GREATER OF THE AMOUNT PAID B Y YOU

FOR THE SOFTWARE LICENSE OR U.S. $25.00. TO THE

MAXIMUM EXTENT P ERMITTED BY APPLICABLE LAW, IN

NO EVENT SHALL CTCT OR ITS LICENSORS BE LIABLE F OR

ANY SPECIAL, INCIDENTAL, INDIRECT OR CONSEQUENTIAL

DAMAGES WHATSOEVER (INCLUDING, WITHOUT

LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS,

BUSINESS INTERRUPTION, LOSS OF BUSINESS

INFORMATION, OR ANY OTHER PECUNIARY LOSS) ARISING

OUT OF THE USE OR INABILITY TO USE THE S OFTWARE, OR

THE P ROVISION OF OR FAILURE TO PROVIDE S UPPORT

SERVICES, EVEN IF CTCT HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES

AND JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT

APPLY TO YOU.

3 GENERAL

3.1 This Agreement shall be governed by the laws of the State of Ohio

and applicable United S tates Federal law without reference to “conflict

of laws" principles or provisions. The United Nations Convention on

Contracts for the International Sale of Goods will not apply to this

Agreement. Jurisdiction and venue of any dispute or court action

arising from or related to this Agreement or the Software shall lie

exclusively in or be transferred to the courts of the Montgomery

County, Ohio, and/or the United States District Court for Ohio. You

hereby consent and agree not to contest, such jurisdiction, venue and

governing law.

3.2 Notwithstanding Section 3.1, if you acquired the Product in

Canada, this Agreement is governed by the laws of the Province of

Ontario, Canada. In such case each of the parties to this Agreement

irrevocably attorns to the jurisdiction of the courts of the P rovince of

Ontario and further agrees to commence any litigation that may arise

under this Agreement in the courts located in the Judicial District of

York, Province of Ontario.

3.3 Official Language. The official language of this Agreement and of

any documents relating thereto is English. For purposes of

interpretation, or in the event of a conflict between English and

versions of this Agreement or related documents in any other language,

the English language version shall be controlling.

3.4 CTCT reserves all rights not expressly granted by this Agreement.

2011©, Caterpillar Trimble Control Technologies LLC. All Rights

Reserved.

Product Warranty Information

For applicable product warranty information, please refer to the

Warranty Card included with this product, or consult your dealer.

Notices

Class B Statement – Notice to Users. This equipment has been tested

and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communication. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

GCS900GradeControlSystem for Excavators Operator's Manual 3

Page 4

Changes and modifications not expressly approved by the

manufacturer or registrant of this equipment can void your authority to

operate this equipment under F ederal Communications Commission

rules.

Canada

This digital apparatus does not exceed the Class B limits for radio

noise emissions from digital apparatus as set out in the radio

interference regulations of the C anadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de Classe B

prescrites dans le règlement sur le brouillage radioélectrique édicté par

le Ministère des Communications du Canada.

Europe

This product has been tested and found to comply with the

requirements for a Class B device pursuant to European

Council Directive 89/336/EEC on EMC, thereby satisfying

the requirements for CE Marking and sale within the European

Economic Area (EEA). Contains Infineon radio module ROK 104001.

These requirements are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

residential or commercial environment.

Australia and New Zealand

This product conforms with the regulatory requirements of

the Australian Communications Authority (ACA) EMC

framework, thus satisfying the requirements for C-Tick

Marking and sale within Australia and New Zealand.

Taiwa n – Battery Rec yc ling Requirements

The product contains a removable Lithium-ion battery.

Taiwanese regulations require that waste batteries are recycled.

Notice to Our European Union Customers

For product recycling instructions and more information, please go to

www.trimble.com/environment/summary.html.

Recycling in Europe: To recycle Trimble WEEE (Waste

Electrical and Electronic Equipment, products that run on

electrical power.), Call + 31 497 53 24 30, and ask for the

"WEEE Associate". Or, mail a request for recycling instructions

to:

Trimble Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

4 GCS900GradeControlSystem for Excavators Operator's Manual

Page 5

Safety Information

Most accidents that involve product operation, maintenance and repair are caused

by failure to observe basic safety rules or precautions. An accident can often be

avoided by recognizing potentially hazardous situations before an accident occurs.

A person must be alert to potential hazards. This person should also have the

necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be

dangerous and could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product,

until you have read and understood the operation, lubrication, maintenance and

repair information.

Safety precautions and warnings are provided in this manual and on the product. If

these hazard warnings are not heeded, bodily injury or death could occur to you or

to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal

Word” such as “DANGER”, “WARNING” or “CAUTION”. The Safety Alert

“WARNING” label is shown below.

WARNING — This alert warns of a potential hazard which, if not avoided, can cause severe

injury.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either

written or pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on

the product and in this publication.

Trimble® cannot anticipate every possible circumstance that might involve a

potential hazard. The warnings in this publication and on the product are, therefore,

not all inclusive. If a tool, procedure, work method or operating technique that is not

specifically recommended by Trimble is used, you must satisfy yourself that it is

safe for you and for others. You should also ensure that the product will not be

damaged or be made unsafe by the operation, lubrication, maintenance or repair

procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis

of information that was available at the time that the publication was written. The

specifications, torques, pressures, measurements, adjustments, illustrations, and

other items can change at any time. These changes can affect the service that is

GCS900GradeControlSystem for Excavators Operator's Manual 5

Page 6

Safety Information

Safety (Laser)

given to the product. Obtain the complete and most current information before you

start any job. Dealers have the most current information available.

The IEC and the United States Government Center of Devices for Radiology Health

(CDRH) has classified this laser as a Class II laser product. The maximum radiant

power output of this laser is less than 5 milliwatts.

Refer to the operator's manual of the laser transmitter for installation and operating

instructions.

The laser that is supplied with the GCS900 - Laser System complies with all

applicable portions of “Title 21” of the “Code of Federal Regulations, Department

of Health and Human Services, Food and Drug Administration, Federal Register,

Volume 50, Number 161, 20 August 1985”.

This laser complies with “OSHA Standards Act, Section 1518.54” for use without

eye protection. Eye protection is not required or recommended. The following

safetyrules should be observed:

l Never look into a laser beam or point the beam into the eyes of other people.

Set the laser at a height that prevents the beam from flashing directly into

people's eyes.

l Do not remove any warning signs from the laser.

l Use of this product by personnel that are not trained on this product may result

in exposure to hazardous laser light.

l If initial service requires the removal of the outer protective cover, removal of

the cover must be performed by trained personnel.

Crushing Prevention and Cutting Prevention

Support the equipment properly when you work beneath the equipment. Do not

depend on the hydraulic cylinders to hold up the equipment. An attachment can fall

if a control is moved, or if a hydraulic line breaks.

Unless you are instructed otherwise, never attempt adjustments while the machine

is moving. Also, never attempt adjustments while the engine is running.

Whenever there are attachment control linkages, the clearance in the linkage area

will increase or the clearance in the linkage area will decrease with movement of

the attachment. Stay clear of all rotating and moving parts.

Keep objects away from moving fan blades. The fan blade will throw objects or cut

objects. Do not use a kinked wire cable or a frayed wire cable.

Wear gloves when you handle wire cable. When you strike a retainer pin with

force, the retainer pin can fly out. The loose retainer pin can injure personnel. Make

sure that the area is clear of people when you strike a retainer pin.

6 GCS900GradeControlSystem for Excavators Operator's Manual

Page 7

In order to avoid injury to your eyes, wear protective glasses when you strike a

retainer pin.

Chips or other debris can fly off objects when you strike the objects. Make sure that

no one can be injured by flying debris before striking any object.

Operation

Clear all personnel from the machine and from the area.

Clear all obstacles from the machine's path. Beware of hazards (wires, ditches,

etc).

Be sure that all windows are clean.

Secure the doors and the windows in the open position or in the shut position.

Adjust the rear mirrors (if equipped) for the best visibility close to the machine.

Make sure that the horn, the travel alarm (if equipped), and all other warning

devices are working properly.

Fasten the seat belt securely.

Safety Information

Warm up the engine and the hydraulic oil before operating the machine.

Only operate the machine while you are in a seat.

The seat belt must be fastened while you operate the machine. Only operate the

controls while the engine is running.

While you operate the machine slowly in an open area, check for proper operation

of all controls and all protective devices. Before you move the machine, you must

make sure that no one will be endangered.

Do not allow riders on the machine unless the machine has the following equipment:

l Additional seat

l Additional seat belt

l Rollover Protective Structure (ROPS)

Note any needed repairs during machine operation. Report any needed repairs.

Avoid any conditions that can lead to tipping the machine. The machine can tip

when you work on hills, on banks and on slopes. Also, the machine can tip when

you cross ditches, ridges or other unexpected obstructions.

Avoid operating the machine across the slope. When possible, operate the machine

up the slopes and down the slopes.

Maintain control of the machine.

Do not overload the machine beyond the machine capacity.

Be sure that the hitches and the towing devices are adequate.

Never straddle a wire cable. Never allow other personnel to straddle a wire cable.

GCS900GradeControlSystem for Excavators Operator's Manual 7

Page 8

Safety Information

Warnings

Before you maneuver the machine, make sure that no personnel are between the

machine and the trailing equipment.

Always keep the Rollover Protective Structure (ROPS) installed during machine

operation.

Monitor the location of components that are mounted to the blade. Ensure that the

components do not come into contact with other parts of the machine during

operation.

WARNING — When replacement parts are required for this product Trimble recommends

using Trimble replacement parts or parts with equivalent specifications including, but not

limited to, physical dimensions, type, strength and material. Failure to heed this warning can

lead to premature failures, product damage, personal injury or death.

WARNING — If you create a ramp or other work platform that is too steep, machines and

vehicles using the ramp or platform could become difficult to control. This could result in

harm to the operator, to others, or damage to the machine. To ensure your safety and the

safety of others, find out what the maximum slope for your site is and make sure you do not

exceed it.

WARNING — Do not operate or work on this machine unless you have read and understand

the instructions and warnings in the system manual. Failure to follow the instructions or heed

warnings could result in injury or death. Contact your dealer for replacement manuals.

Proper care is your responsibility.

WARNING — If the machine’s direction is locked, for example if it is locked in the forward

direction, the distance to avoidance zones will be calculated incorrectly when you are driving

in the opposite direction, resulting in unreliable avoidance zone warnings. Entering an

avoidance zone could cause personal injury or damage to the machine. Always be aware of

nearby avoidance zones when operating a machine with direction lock on.

WARNING — In order to prevent personal injury during installation and removal of a GPS

receiver or a UTS target, use an approved access system in order to reach the mounting

locations of the GPS receiver or UTS target at the top of the mast.

WARNING — Do not stare into the laser beam when the laser transmitter is operating. For

more information, refer to the documentation that came with your laser.

WARNING — Falling Hazard. Do not climb onto the machine in order to access the GPS

receiver or UTS target. Climbing on the machine could result in a fall which could cause

serious injury or death. Use the raise and lower mechanism to access the GPS receiver or

UTS target for all required maintenance and service.

8 GCS900GradeControlSystem for Excavators Operator's Manual

Page 9

Contents

Safety Information 5

1 About This Manual 13

1.1 Scope and audience 14

1.2 Trimble training classes and technical assistance 14

1.3 To learn more about Trimble 14

1.4 Your comments 14

2 Using the Control Box and Lightbars 15

2.1 Introduction 16

2.2 Control box basics 16

2.2.1 Power key 17

2.2.2 System memory and the USB flash drive 17

2.2.3 Transferring data to and from the control box 18

2.3 Working with control box information 21

2.3.1 Working with menus and dialogs 22

2.3.2 Working with guidance screens 27

2.3.3 Guidance views 32

2.4 Understanding lightbar information 34

2.4.1 External lightbars 34

2.4.2 Internal lightbars 35

2.4.3 3D excavator lightbar behaviour 35

2.4.4 2D excavator lightbar behavior 38

2.5 3D remote switch 39

2.6 System beeper 39

3 Preparing to Work 41

3.1 Introduction 42

3.2 Power up checks 42

3.2.1 Lightbar power up 42

3.2.2 Control box power up 43

3.3 Software option keys 44

3.3.1 Option key structure 44

3.3.2 Software support 44

3.3.3 Troubleshooting option keys 44

3.4 Work preparation checks 45

3.4.1 Machine settings 46

3.4.2 Switching guidance modes 47

3.4.3 Main screen views 47

3.4.4 Display brightness 49

GCS900GradeControlSystem for Excavators Operator's Manual 9

Page 10

Contents

3.4.5 Keypad backlight brightness 49

3.4.6 Lightbar brightness 50

3.4.7 Display settings 50

3.4.8 Lightbar tolerances 51

3.4.9 Set depth and slope increment values 53

3.4.10 Checking bucket wear 53

3.5 Configuring the machine radio 54

3.6 Wi-Fi networking 57

3.6.1 About cellular modems 57

3.6.2 About Wi-Fi networking 57

3.6.3 SNRx20 radio modem status indicators 57

3.6.4 Managing Wi-Fi networks 58

3.6.5 Connecting to a Wi-Fi network 58

3.7 Exchanging files with a Connected Community filespace 59

3.7.1 Initiating Connected Community file exchange from the machine 59

3.7.2 Connected Community file synchronization 60

3.7.3 Troubleshooting Connected Community file exchange 60

3.8 Selecting an excavator bucket 61

3.9 Selecting a 3D vertical guidance method 62

3.10 Selecting a Depth and Slope vertical guidance method 63

4 Using 2D Depth And Slope Guidance in the Field 65

4.1 Introduction 66

4.2 Setting the focus point 66

4.3 Selecting or creating a guidance model 66

4.3.1 Selecting a vertical guidance method 67

4.3.2 Depth and Slope system softkeys 68

4.3.3 Depth and slope models 68

4.3.4 Depth dual slope models 71

4.3.5 Profile models 75

4.4 Establishing an elevation reference 77

4.4.1 Using the bucket focus as the reference elevation 78

4.4.2 Using a laser plane as the reference elevation 78

4.5 Working with Depth and Slope guidance 79

4.5.1 Transferring a benchmark reference elevation 80

4.5.2 Using the bucket position to measure site features 82

5 Using 3D Guidance in the Field 85

5.1 Introduction 86

5.2 Preparing 3D sensors 86

5.2.1 Starting the UTS system 87

5.2.2 Benching a UTS target 89

5.2.3 Setting the UTS accuracy level 90

5.2.4 Initializing single-3D excavator orientation 91

5.2.5 Setting GPS accuracy mode 92

10 GCS900GradeControlSystem for Excavators Operator's Manual

Page 11

Conttents

5.2.6 GPS geoid grid support 92

5.3 Checking 3D cutting edge guidance 93

5.4 Loading or creating a design 94

5.4.1 Loading a design 94

5.4.2 Creating a design 97

5.5 Working with 3D guidance 103

5.5.1 Setting the working surface lift and/or vertical offset 104

5.5.2 Selecting horizontal alignment 105

5.5.3 Selecting focus for horizontal guidance 107

5.5.4 Setting horizontal offset 108

5.5.5 3D remote switch support 108

5.5.6 Reacquiring UTS lock 109

5.5.7 Re-initializing orientation after moving the machine 109

5.5.8 Clearing the UTS benched elevation 109

5.5.9 Turning off UTS guidance 110

6 Using Mapping/Recording in the Field 111

6.1 Introduction 112

6.2 Automatic mapping 112

6.2.1 Fixed mapping rules 112

6.2.2 Machine mapping rules 112

6.3 Loading or creating a map 113

6.3.1 Creating a map file 113

6.3.2 Loading a map file 114

6.4 Configuring Mapping/Recording 114

6.5 Using Mapping/Recording 115

6.5.1 Mapping/Recording states 115

6.5.2 Plan view mapping types 116

6.6 Minimum height mapping 117

6.7 Point recording 117

7 Troubleshooting in the Field 119

7.1 Introduction 120

7.2 General troubleshooting 120

7.3 Running system diagnostics 120

7.3.1 UTS diagnostics 122

7.3.2 GPS diagnostics and satellite monitoring 126

7.4 Troubleshooting flashing warning messages 130

7.4.1 General warning messages 131

7.4.2 UTS warning messages 132

7.4.3 GPS warning messages 134

7.4.4 Excavator warning messages 137

7.5 Troubleshooting error messages 138

7.5.1 Software support option errors 138

7.5.2 Avoidance zone warnings 139

GCS900GradeControlSystem for Excavators Operator's Manual 11

Page 12

Contents

7.5.3 Other selected error messages 139

7.6 Troubleshooting system components 145

7.6.1 External lightbar system status indicators 145

7.6.2 GPS receiver status indicators 146

7.6.3 SNRx10 data radio status indicators 147

7.6.4 SNR900, SNR450, and SiteNet 450 data radio indicators 148

7.6.5 MT900 machine target status indicators 148

7.6.6 Excavator arm sensor error indication 149

7.7 Troubleshooting UTS systems 149

7.8 Troubleshooting GPS systems 151

7.9 Before you contact your dealer 152

Index 155

12 GCS900GradeControlSystem for Excavators Operator's Manual

Page 13

C H A P T E R

1

1About This Manual

In this chapter:

n Scope and audience

n Trimble training classes and

technical assistance

n To learn more about Trimble

n Your comments

Welcome to the GCS900 Grade Control System

for Excavators Operator's Manual. This manual

provides procedural information for the day to

day operation of the system. The system is

designed specifically for earthmoving

equipment in the construction industry.

GCS900GradeControlSystem for Excavators Operator's Manual 13

Page 14

1 About This Manual

1.1 Scope and audience

This manual is intended for personnel who operate the system, including:

l Machine operators

l Dealers

l Installation technicians

l Site supervisors

This manual describes how to use the standard features of the system. To learn

about the underlying concepts of the system, refer to the Trimble GCS900 Grade

Control System Reference Manual.

For information on how to use features not described in this manual, refer to the

Trimble GCS900 Grade Control System Site Supervisor’s Manual.

Even if you have used other machine guidance systems before, Trimble

recommends that you spend some time reading this manual to learn about the

special features of this product.

Trimble manuals that are related to this product are available in PDF format on the

GCS900 Grade Control System release media. To view or print the manuals, use

Adobe Reader (provided on the media). Utilities that do not have an accompanying

manual have integrated Help.

1.2 Trimble training classes and technical assistance

Contact your dealer for:

l Technical support, information notes, and other technical notes

l Information about:

the support agreement contracts for software and firmware

extended warranty programs for hardware

training classes

1.3 To learn more about Trimble

For an interactive look at Trimble, go to www.trimble.com.

1.4 Your comments

Your feedback about the supporting documentation helps us to improve it with each

revision. Email your comments to ReaderFeedback@trimble.com.

14 GCS900GradeControlSystem for Excavators Operator's Manual

Page 15

C H A P T E R

2

2Using the Control Box and Lightbars

In this chapter:

n Control box basics

n Working with control box

information

n Understanding lightbar

information

n 3D remote switch

n System beeper

As you work with the GCS900 Grade Control

System, you need to set up and control the

guidance system and understand the guidance

information the system provides.

GCS900GradeControlSystem for Excavators Operator's Manual 15

Page 16

2 Usingthe ControlBox andLightbars

2.1 Introduction

The control box is a computer that runs the system software. You control the

guidance system with, and are given guidance information by, the following system

components:

l the control box and lightbars

l the remote switches, if installed

l the audible alarm, or beeper

This chapter describes, in general terms, how these components are used.

For more information on these components, refer to the GCS900 Grade Control

System Reference Manual.

2.2 Control box basics

The control box has a color LCD screen to display guidance and other information,

and push button controls to operate the system. In addition, the control box has

internal lightbars, and a USB flash drive port for loading and saving machine and

display configuration data, and for loading and saving data. See Figure 2.1 and the

following table that describes the items in the figure.

Power button

1

Next key

4

Zoom-out key

7

OK key

a

Figure 2.1 The control box

16 GCS900GradeControlSystem for Excavators Operator's Manual

2

5

8

b

Softkey label area

Zoom-in key

Escape key

USB flash drive port

Softkeys

3

Beeper

6

Arrow keys

9

Menu key

c

Page 17

Description Function

LCD screen Displays guidance information

UsingtheControl Box andLightbars 2

Softkey labels See

Softkeys See

Zoom-in key

Zoom-out key

Next key

Menu key

USB flash drive port See

Arrow keys

+

-

N

M

( )

Zoom in on the machine

Zoom out from the machine

View the next guidance screen or select the next field in a dialog

View the

Pan a guidance view, select an item in a list, or enter data in a field

[ ]

OK key

Escape key

Power key

Beeper

\

=

P

Save changes made in a dialog, and exit the dialog

Exit from a dialog without saving changes, or exit from a menu

See

See 2.6 System beeper

2.3.1 Working with menus and dialogs

2.3.1 Working with menus and dialogs

Setup Menu – Configuration

2.2.2 System memory and the USB flash drive

2.2.1 Power key

dialog

2.2.1 Power key

The P key turns the control box on and off.

To turn on the control box and the system, press P. After a brief pause, an

opening screen appears.

Note – If the system reports that there are upgrade files or other system files on the

control box, or that the operating system is out of date, contact your site supervisor

immediately.

To turn off the control box and the system, press and hold P for two to three

seconds until the control box shuts down. (This delay reduces the risk of you turning

off the power accidentally.) You can turn off the system from any screen or dialog.

2.2.2 System memory and the USB flash drive

Files and data are stored on the control box in an area known as system memory.

The files and data in system memory are used by the system and there is only

limited Site Supervisor access via the control box.

GCS900GradeControlSystem for Excavators Operator's Manual 17

Page 18

2 Usingthe ControlBox andLightbars

To access the files and data in system memory, they need to be transferred from the

control box onto a USB flash drive. The files and data on the USB flash drive can

then be directly accessed from a laptop, an office computer, or SiteVision Office

software.

Note – When you insert a USB flash drive into the control box, system operation is

temporarily disabled. System operation resumes when the USB flash drive is

removed.

The USB flash drive folder structure is:

l At the root directory level is a “Machine Control Data” folder.

l Within the “Machine Control Data” folder are machine specific folders based

on machine names, which contain machine specific data. For example, a

“HEX” folder for Hydraulic Excavator.

Note – If folders do not exist when files are transferred to the USB flash drive, the

system will create them.

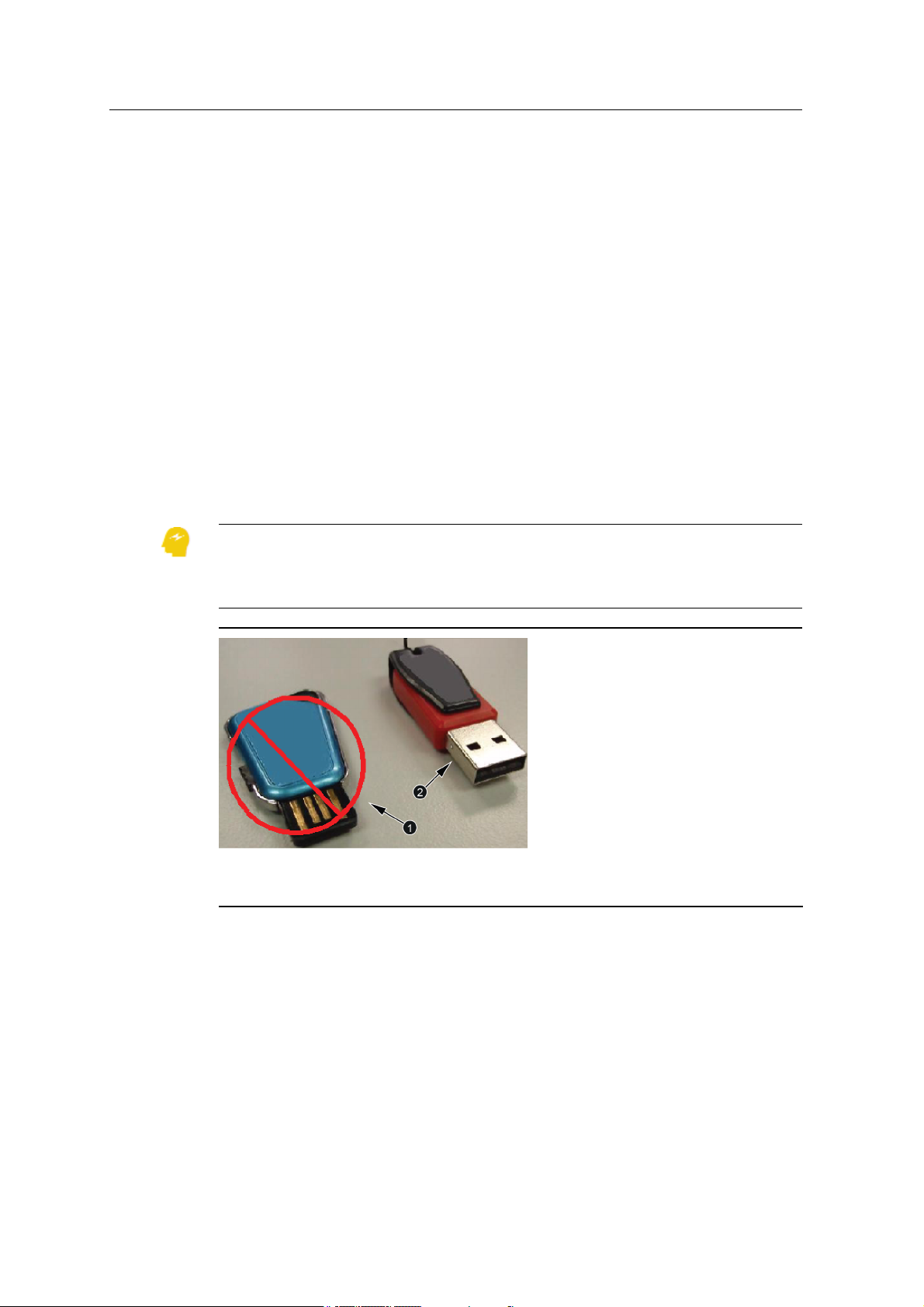

ATTENTION — It is recommended to always use a USB flash drive with a metal surround on

the connector. When using a USB flash drive with no metal surround on the connector, the

drive can be inserted upside down, and due to the lack of the metal part of the connector,

contact can be broken and the file transfer process can be interrupted. See Figure 2.2.

No metal surround on the connector (NOT

1

recommended)

Figure 2.2 USB flash drive connector examples

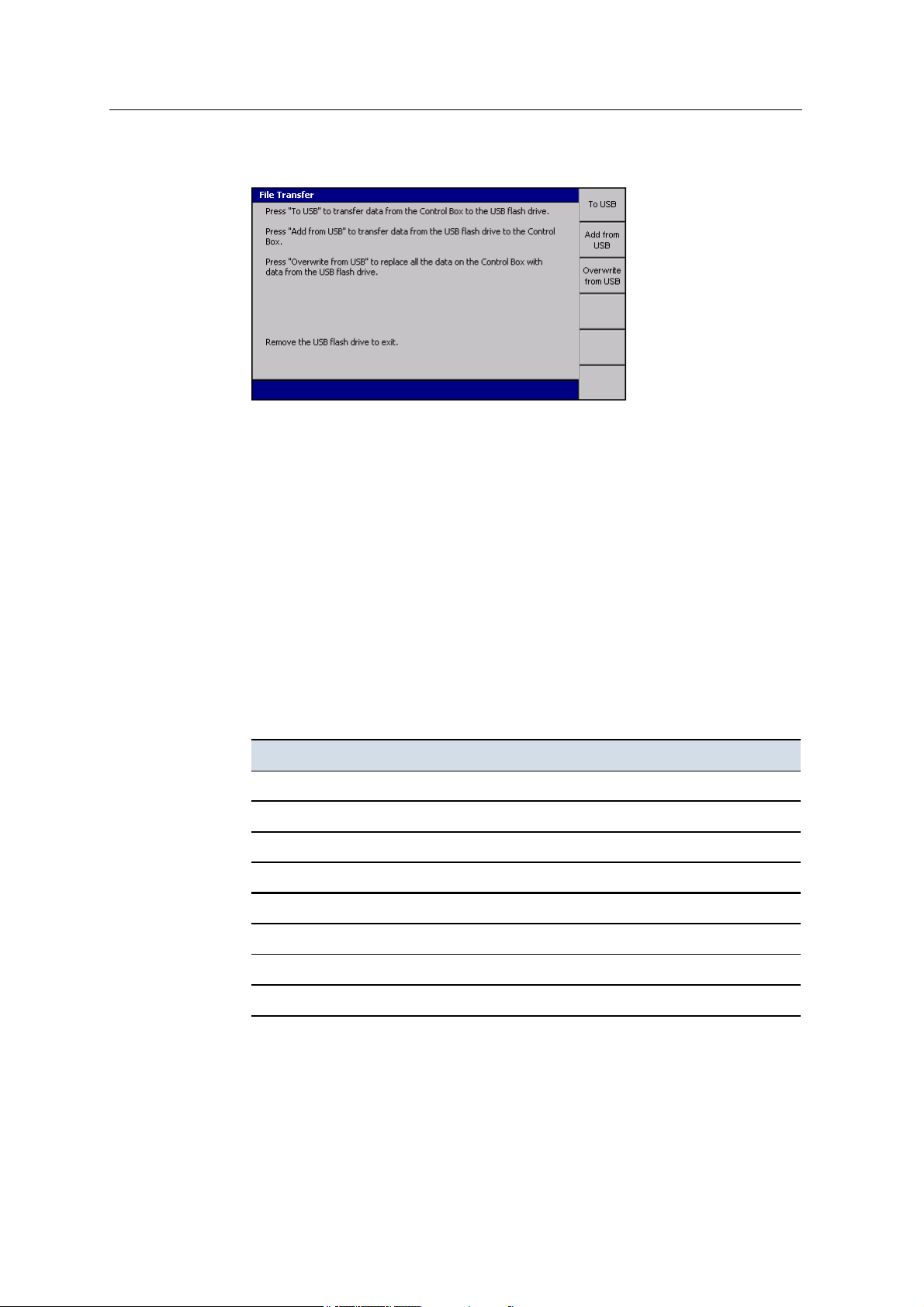

2.2.3 Transferring data to and from the control box

1. Start the control box.

2. Insert the USB flash drive into to the control box USB port. The File Transfer

18 GCS900GradeControlSystem for Excavators Operator's Manual

Metal surround on the connector

2

(recommended)

Page 19

UsingtheControl Box andLightbars 2

dialog appears.

Transferring files to the USB flash drive

Note – If a file or folder to be transferred already has an item with a matching file

name, but different contents on the USB flash drive, the destination item will be

renamed to a backup name generated by appending the item’s last-modified date to

its file name.

1. Press To USB.

Only files that have been generated or modified on the control box transfer to

the “Machine Control Data” folder on the USB flash drive and are written to

the machine’s sub-folder. The machine’s sub-folder name is the same as the

machine name set on the control box.

The following table describes the action that is applied to each file type during

a file transfer to the USB flash drive.

File type Copy Move

Design files

Map design files

Program log files

ZSnap and .gif files

Production .tag files (when 2-way data communication IS NOT enabled)

Production .tag files (when 2-way data communication IS enabled)

Points .csv files

RemoteBase.txt file

P

P

P

P

P

P

P

P

GCS900GradeControlSystem for Excavators Operator's Manual 19

Page 20

2 Usingthe ControlBox andLightbars

Note – A copy action copies the file and leaves the original file on the control

box. A move action copies the file and deletes the original file from the control

box.

A progress bar appears, showing the progress of the data transfer.

2.

To exit, press \ or remove the USB flash drive.

Transferring files from the USB flash drive

Two types of file transfer from the USBflash drive are available:

l Add from USB

l Overwrite from USB

Add from USB

Note – If a file or folder to be transferred already has an item with a matching file

name, but different contents on the display, the destination item will be renamed to a

backup name generated by appending the item’s last-modified date to its file name.

Files and folders matching this backup naming convention, generated by a previous

“to USB” operation, will NOT be transferred from the USB flash drive to the

display.

1. Press Add from USB.

Data in the “\Machine Control Data\MachineName” folder and sub-folders,

and the “\Machine Control Data\All” folder of the USB flash drive transfers to

the control box.

A progress bar appears, showing the progress of the data transfer.

2.

To exit, press \ or remove the USB flash drive.

Overwrite from USB

Note – Use with caution, as this transfer deletes all existing files from the control

box.

1. Press Overwrite from USB. The following actions occur:

a. A warning is displayed. Read the warning message carefully and only

press \ if you are sure you want to continue.

b. The control box is backed up. All current files on the control box are saved

to a backup folder on the USB flash drive. Your site supervisor can restore

from backup.

c. The entire data content is deleted from the control box.

20 GCS900GradeControlSystem for Excavators Operator's Manual

Page 21

UsingtheControl Box andLightbars 2

d. Data in the “\Machine Control Data\MachineName” folder and sub-

folders, and the “\Machine Control Data\All” folder is transferred from

the USB flash drive to the control box.

A progress bar appears, showing the progress of the data transfer.

2.

To exit, press \ or remove the USB flash drive.

Data transfer error messages

When transferring data, a warning message appears when there is insufficient

space on either the control box or the USB flash drive.

Control box storage capacities

Available control box file storage capacities are:

l CB450 - 450 MB

l CB460 - 3.5 GB

Data transfer suspend and resume

If the USB flash drive is removed from the control box, or if the = key is pressed

during a file transfer operation, the file transfer is suspended and will resume when:

l the USB flash drive is re-inserted into the control box, and/or

l the relevant softkey is pressed to resume the last file transfer operation

2.3 Working with control box information

When you work with the control box, you use a mix of keys, softkeys, menus,

dialogs, and guidance screens. The availability of many of these items is determined

by the following factors:

l The sensors installed on the machine. For example, some configuration screens

are only available when particular sensors are installed.

l The guidance configuration of the system. Your selection of guidance method

affects the guidance information available on the display and the guidance

configuration options you get.

l The operator configuration of the system. The menus and screens selected for

you by your site supervisor affect the setup information you can view and

modify.

Note – This manual only covers the menu options that are available to

operators by default.

GCS900GradeControlSystem for Excavators Operator's Manual 21

Page 22

2 Usingthe ControlBox andLightbars

Any configuration and guidance options not covered in this manual are described in

the GCS900 Grade Control System Site Supervisor’s Manual.

2.3.1 Working with menus and dialogs

Before you can begin work, you must enter configuration and set-up information into

the system, and view the current system state, by using screens called menus and

dialogs. Menus let you select a dialog. Dialogs let you specify set-up and

configuration information, or view information about the state of system

components.

Softkeys and softkey labels

Softkeys are the six physical keys immediately to the right of the screen. The

function of these physical keys depends on the information displayed and is

identified by the softkey label beside the key. See Figure 2.3 for an example.

Softkey labels are graphical “keys” that appear down the side of the screen.

The following tables list the softkey labels that display on the guidance screens of

the control box with a brief description of each softkey's functionality.

Generic softkey icons

CB4x0 icon Functionality

Direction: Unknown

Direction

Direction: Forward

open the

Direction: Reverse

open the

GPS

UTS

dialog.

Direction

Direction

- Press to open the

- Press to open the

dialog.

dialog.

- Direction of motion is unknown. Press to open the

- Direction of motion is calculated to be forwards. Press to

- Direction of motion is calculated to be in reverse. Press to

dialog.

GPS

dialog.

UTS

22 GCS900GradeControlSystem for Excavators Operator's Manual

Page 23

Excavator softkey icons

CB4x0 icon Functionality

UsingtheControl Box andLightbars 2

Bucket Tip: Center

focus to the right side of the bucket.

Bucket Tip: Left

focus to the center of the bucket.

Bucket Tip: Right

focus to the left side of the bucket.

H. Offset

V. Offset

Map recording softkey icons

CB4x0 icon Functionality

Reset Map

displayed in Manager Mode.

- Focus is on the center of the bucket. Press to change the

- Focus is on the left side of the bucket. Press to change the

- Focus is on the right side of the bucket. Press to change the

- Press to open the

- Press to open the

- Press to open the

Horizontal Offset

Vertical Offset

Reset Map

dialog. (3D only)

dialog. By default, this softkey is only

dialog. (3D only)

Mapping: Auto

working. Press to change map recording to theOnmode.

Mapping: On

data.

Mapping: Off

mode.

Auto

- Map data is recorded when the machine is considered to be

- Map data is recording continuously. Press to stop recording map

- Map data is not recording. Press to change map recording to the

Record Point - Record a point, when point recording is active.

GCS900GradeControlSystem for Excavators Operator's Manual 23

Page 24

2 Usingthe ControlBox andLightbars

2D Depth and Slope excavator softkey icons

Table 2.1 — Softkey icons

Icon Description

Touch point

Accept laser strike

Depth memory

Slope memory

Depth dual slope memory

Select profile

Flip profile

Select profile origin

Bench

Bench rotation

The text on a softkey label can show the following details:

l A description of the operation that is performed when you press the softkey

once.

l The setting that is currently selected. The text on the softkey label changes

when you press the softkey to switch between options. The top line of the

softkey label ends with a colon (:) and the bottom line shows the current option

or setting.

The icon on a softkey label can show the following details:

24 GCS900GradeControlSystem for Excavators Operator's Manual

Page 25

UsingtheControl Box andLightbars 2

l A graphical representation of the operation that is performed when you press

the softkey once.

l The setting that is currently selected. The icon on the softkey label changes

when you press the softkey to switch between options.

l Softkeys that have a fold on the bottom right corner support press and hold

functionality to directly access the associated operation.

For example, the softkey labels Bucket Tip: Center, Bucket Tip: Left and Bucket Tip:

Right (1) show the side of the bucket that is selected for horizontal guidance on 3D

systems.

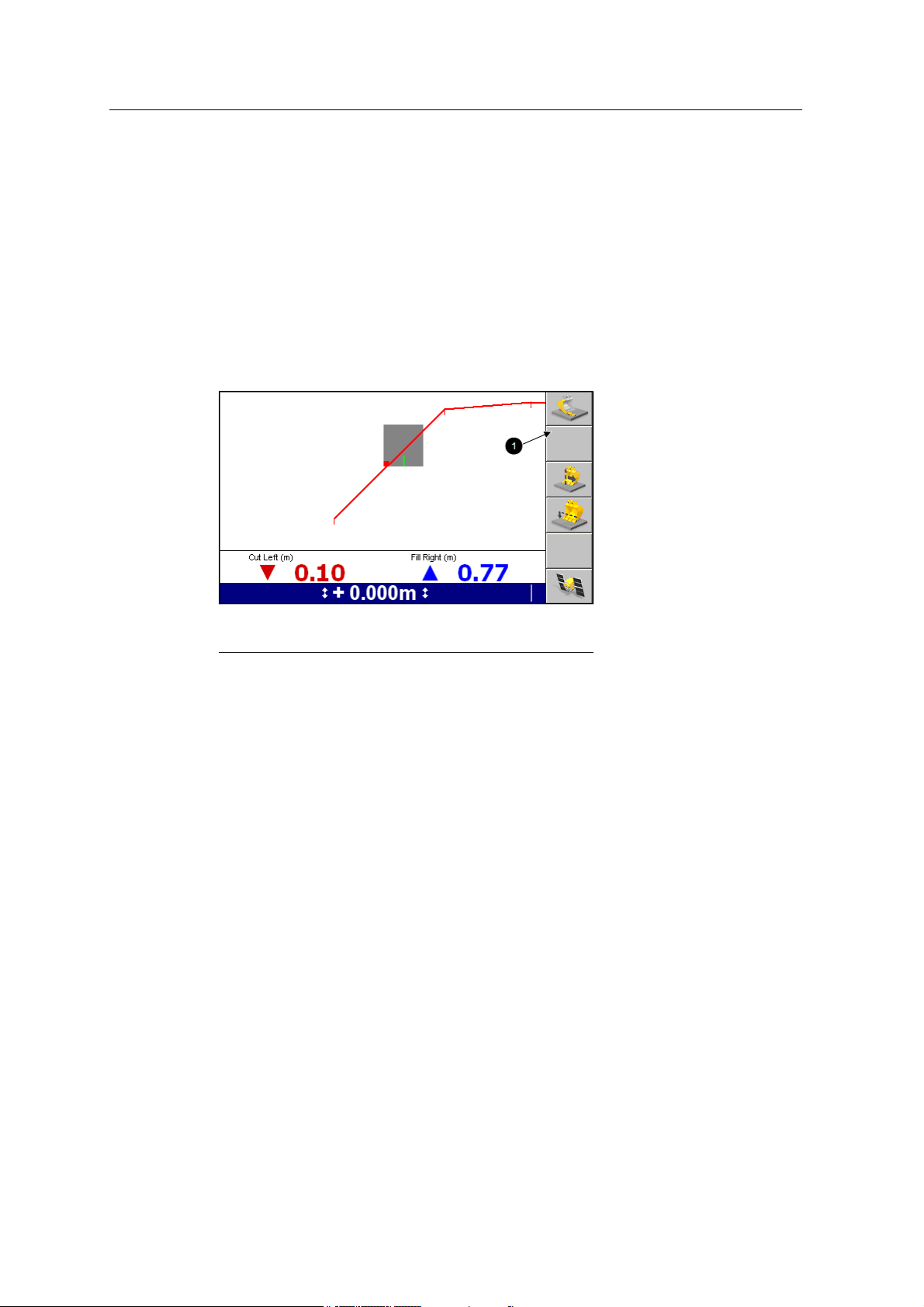

Softkey labels

1

Figure 2.3 Example softkey labels on a guidance

screen

Some softkey labels appear in more than one screen, in which case the function of

the softkey they identify is always the same.

As a softkey’s function relates to particular screens or dialogs, that functionality is

only available when the appropriate screen or dialog appears. For example the New

Level function is available only when the Select Design File screen appears, as that

function relates only to that screen.

If a softkey has no function in a screen or dialog, the softkey label is blank.

By convention, this manual refers to a softkey/function combination by softkey

label.

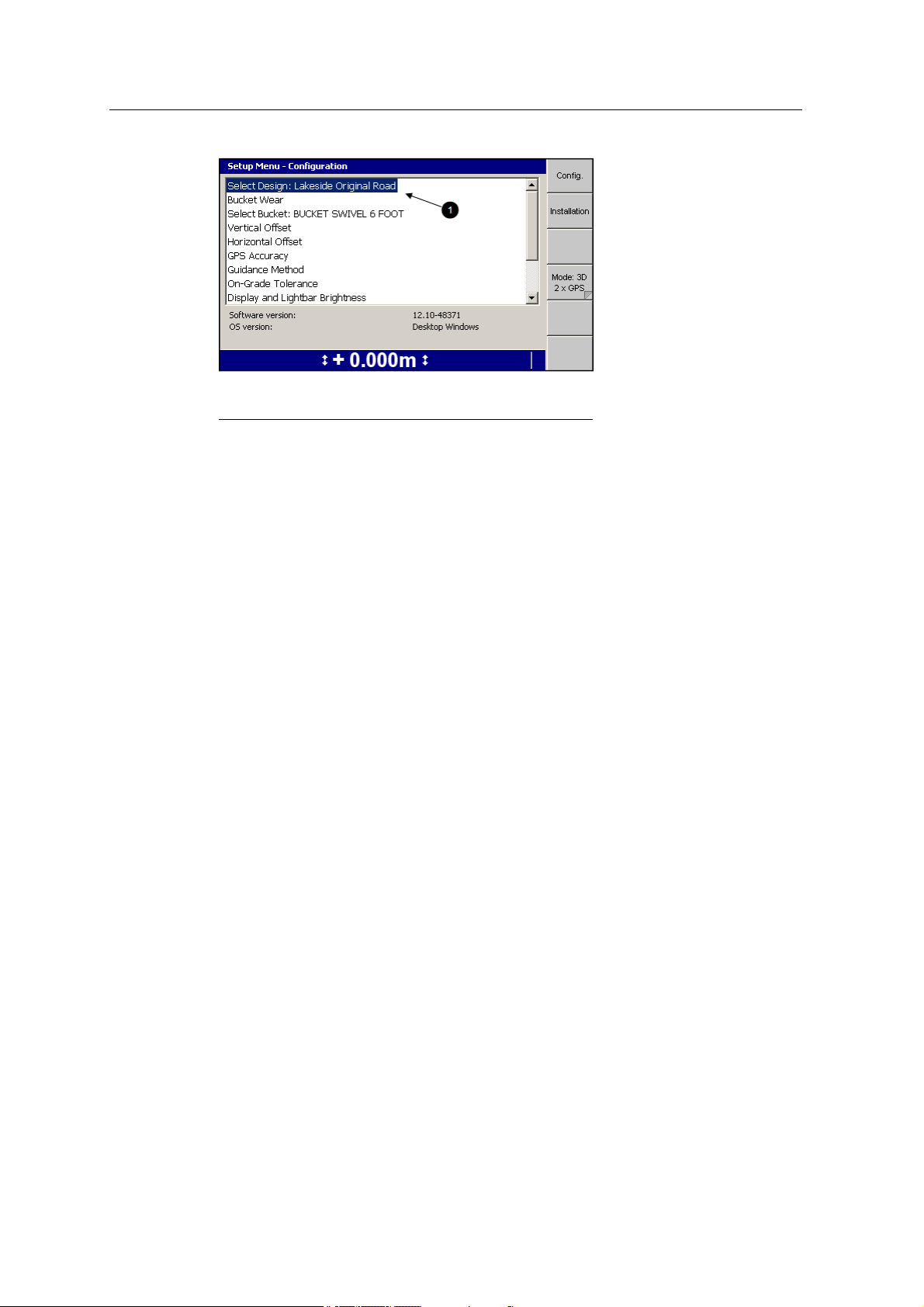

Menus

Menus let you choose another menu or dialog from a list. To move up or down the

list of menu items use the ] or [ keys. Once you highlight the item you want

to view, press \ to select it. See Figure 2.4 for an example.

To leave a menu without making a selection, press =.

GCS900GradeControlSystem for Excavators Operator's Manual 25

Page 26

2 Usingthe ControlBox andLightbars

Highlighted menu item

1

Figure 2.4 Example menu

Dialogs

Dialogs let you enter data into the system. Dialogs can contain any of the following

items:

l Text fields. Text fields let you enter text information, such as the name of a

machine. Once you select a field, you can enter data into it. A selected field

appears as white text on a blue background.

l Number fields. Number fields let you enter numerical values, such as the

height of a benchmark. Once you select a field, you can enter data into it. A

selected field appears as white text on a blue background.

l Lists. Lists let you select a single item from a list of items, such as a list of

machine settings files.

l Check lists. Check lists let you select one or more items, or no items, from a

list of items, such as a list of sensors.

l Yes/No fields. Yes/No fields let you enable and disable particular features.

l Information to help you make your selection.

To move between fields in a dialog, press N.

To enter data into a text or number field, use the arrow keys as follows:

l

Press ] or [ to scroll through the upper case alphabet (A through Z),

numbers (0 through 9), the decimal point (.), the negative sign (–), the positive

sign (+), a space ( ), and back to A.

Note – Available values depend on the type of field that is selected. For

example, the only values available for number fields are 0 through 9, the

decimal point (.), –, and +.

26 GCS900GradeControlSystem for Excavators Operator's Manual

Page 27

UsingtheControl Box andLightbars 2

When you change a character in a field, the keys start stepping from the

existing character.

l

) steps to the next character to the right.

In fields that allow spaces, press) twice to insert a space.

l

( steps back one character to the left. This deletes the character in the space

to the left.

To select an item from a list, press ] or [ to highlight the item you want to

select, and press \.

To leave the dialog without saving the new data or selection, press =. If you have

made changes to a dialog setting, and you choose to exit without saving those

changes, the following warning appears:

To confirm that you want to abandon the changes you have made to the dialog, press

\.

2.3.2 Working with guidance screens

While you work, you read guidance information from the system using guidance

screens.

Guidance screens display a mix of text and graphics that give you information such

as the slope or elevation of the cutting edge or the position of the machine.

Depending on the configuration of the system, as setup by your site supervisor, you

can view varying numbers of guidance screens:

l Plan view

l Terrain

l Pass count

l Cut/Fill pass count

l Radio coverage

GCS900GradeControlSystem for Excavators Operator's Manual 27

Page 28

2 Usingthe ControlBox andLightbars

l Cross-section view

l Profile view

l Split screen (profile and cross-section) view

l Level (bubble) view

l Text view 1

l Text view 2

To move between guidance screens, press N.

The availability of each screen, and the information the screen contains, changes

with the following configuration items:

l The sensors installed on the machine

l The guidance configuration of the system

l The operator configuration of the system

l The type of design currently loaded

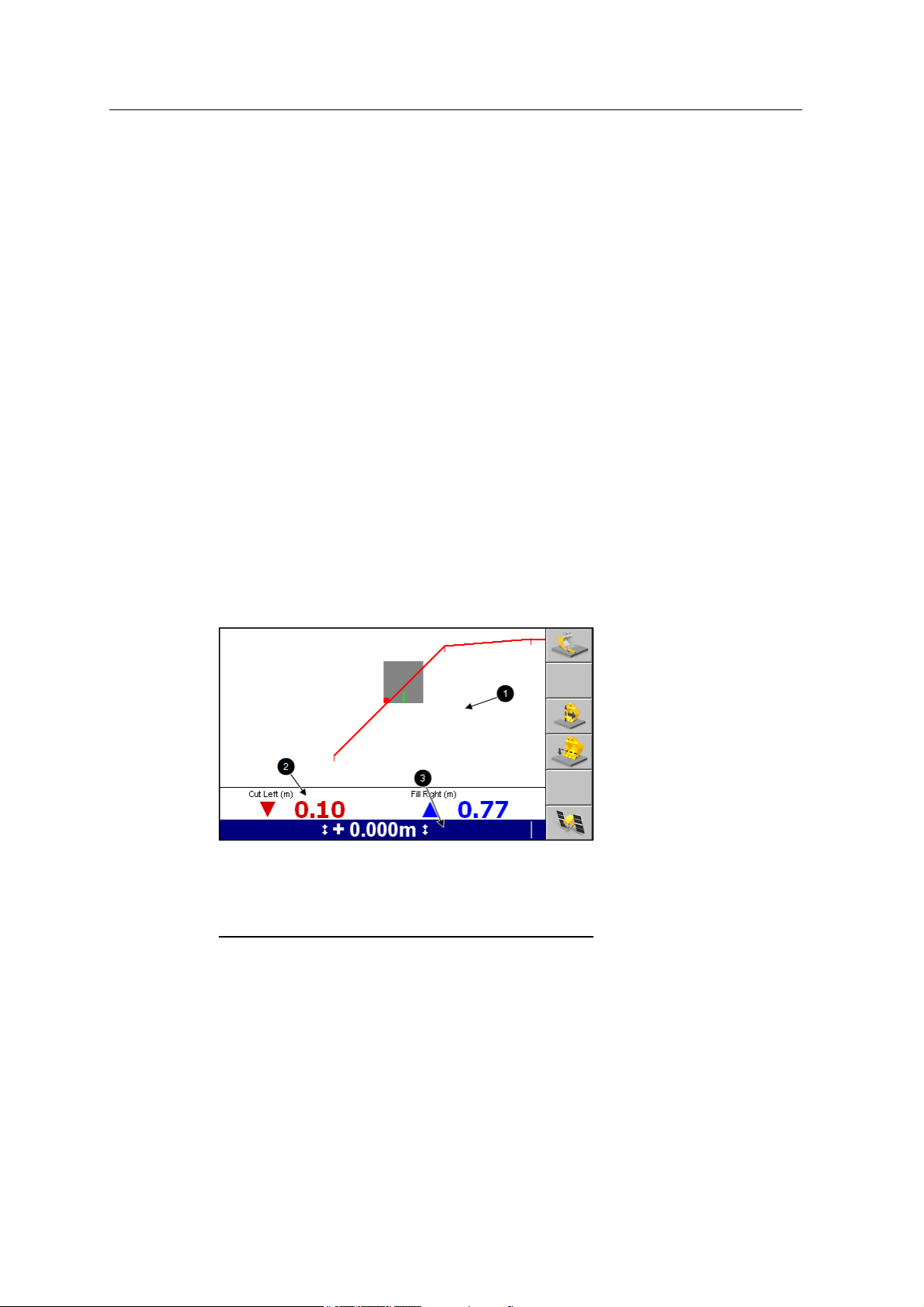

Guidance screen components

Figure 2.5 shows the main components of the guidance screens:

Guidance view area

1

Guidance settings status

3

bar

Figure 2.5 Guidance screen components

Optional text i nformation

2

area

The three main areas of a guidance screen are:

l The guidance view area. The guidance view area displays the machine

relative to the surface being worked. There is no guidance view area in the text

screens.

28 GCS900GradeControlSystem for Excavators Operator's Manual

Page 29

UsingtheControl Box andLightbars 2

l The optional text information area. The text information area lets you view

user-selectable information. In the text screen guidance views, the text

information area uses the guidance view area.

If there are more than three text items selected for display, then the text

information area appears down the right side of the screen.

If there is no text information configured for that view, the text information

area does not appear.

l The guidance settings status bar. The guidance settings status bar displays

the current sensors and guidance settings being used to generate guidance

information. For more information, see Guidance settings, page 30.

Machine icons

The system uses a variety of icons to identify the machine in the guidance views:

l The bucket icon provides information on the bucket slope in cross-section view.

l The cutting edge tip in an icon corresponds exactly to the cutting edge tip of the

machine.

l The bucket edge in an icon corresponds exactly to the bucket cutting edge of

the machine.

l As you move the machine and bucket, the icon mimics the movements on the

screen.

l The red square on the bucket indicates the horizontal guidance point (the

bucket focus), if applicable. The green line on the bucket indicates the vertical

guidance point(s).

Note – The position of symbols for other parts, in particular the tracks/wheels or

rear corners, are approximate and for indication only.

Table 2.2 — 3D guidance machine type and icon

Machine type Plan View icon Profile View Icon

Excavator

GCS900GradeControlSystem for Excavators Operator's Manual 29

Page 30

2 Usingthe ControlBox andLightbars

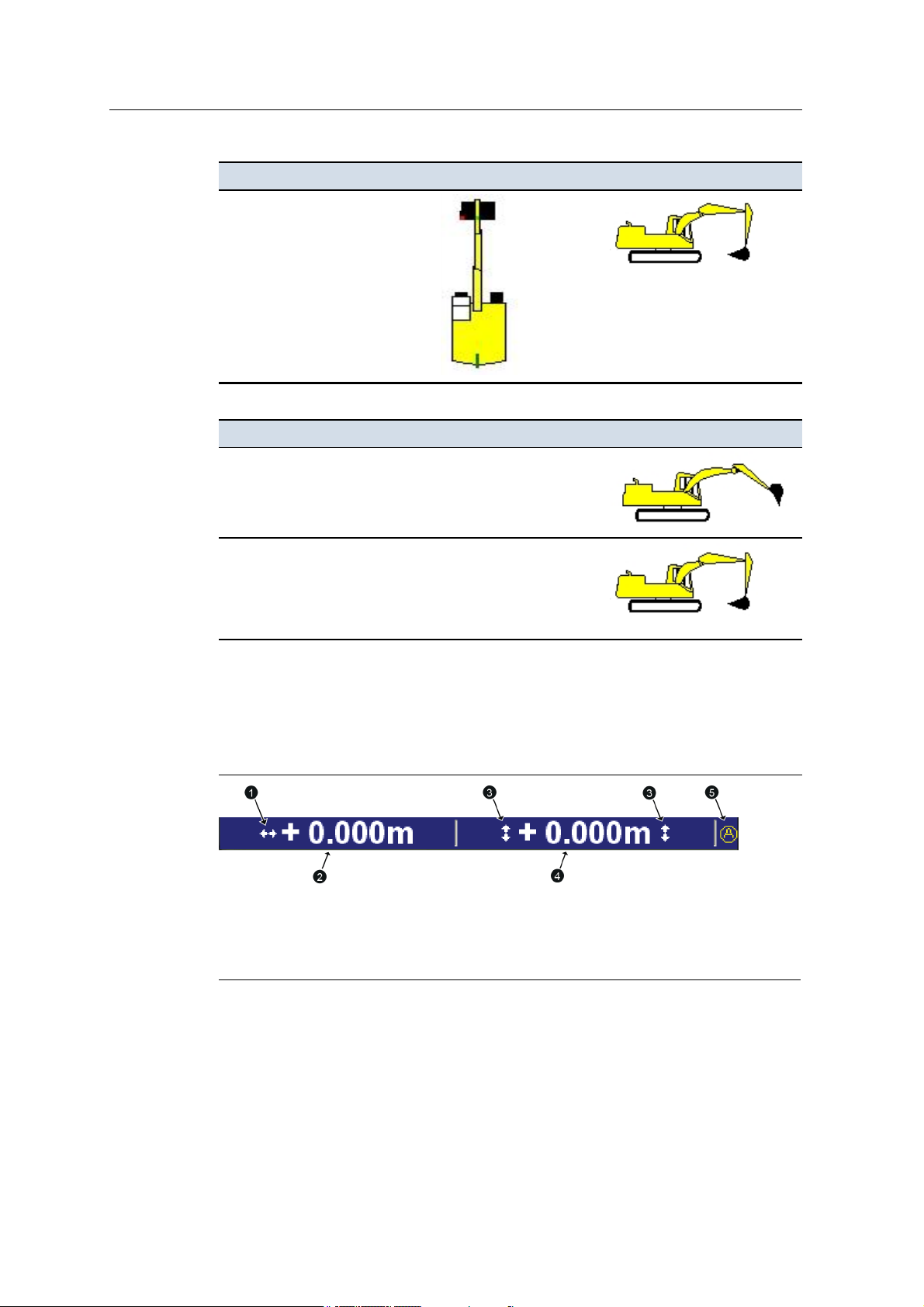

Machine type Plan View icon Profile View Icon

Excavator with variable angle boom

Table 2.3 — 2D Depth and Slope guidance machine type and icon

Machine type Profile View Icon

Excavator

Excavator with variable angle boom

Guidance settings

To display guidance settings, the system uses a variety of icons to identify the

sensors being used to generate guidance information, and text to display numerical

values.

3D horizontal guidance

1

icon

Vertical offset

4

Figure 2.6 Example guidance setting area for a 3D excavator system

Horizontal offset

2

Mapping/Recording icon -

5

set to Auto

Elevation guidance icons

3

30 GCS900GradeControlSystem for Excavators Operator's Manual

Page 31

UsingtheControl Box andLightbars 2

Slope memory icon

1

Elevation offset

4

Figure 2.7 Example guidance setting area for a 2D Depth and Slope excavator

system

Table 2.4 — Guidance setting icons used by the system

Guidance setting icon Meaning

Elevation guidance is available.

For Depth and Slope systems, the system has been benched, but the

benchmark elevation has not been referenced to a laser plane.

3D horizontal guidance information is being generated.

Use of a laser catcher is enabled i n the installation menu.

Elevation guidance is available. The system has been benched and

the benchmark elevation has been referenced to a laser plane.

The system has no bench. The bench data has been cleared. The

Bench Required

Elevation guidance is available. The system is using a laser plane

as the elevation reference.

Current slope memory

2

Laser catcher enabled

4

3D vertical guidance information is being generated.

flashing message is displayed.

2D elevation guidance

3

icon

Auto

On

Off

Slope guidance is available.

Note – The icon illustrated indicates positive slope.

Reliable bucket tilt data i s temporarily unavailable, typically due to

radial movement of the arm or curling of the bucket.

No avoidance zone guidance is available. (3D only)

Mapping/Recording status.

GCS900GradeControlSystem for Excavators Operator's Manual 31

Page 32

2 Usingthe ControlBox andLightbars

Zooming the view

There are four possible ways of zooming a view:

l

Press + to zoom in on the current view.

l

Press - to zoom out of the current view.

l

Press and hold + to zoom the machine.

l

Press and hold - to zoom out as much as possible.

Tip – The system saves the sizes of the views when you turn off the control box. The views

automatically load at their previous size when you next use the system.

2.3.3 Guidance views

Guidance views enable the operator to view the machine guidance in a variety of

ways.

Split screen view

The split screen view displays both the profile view and cross-section view in a

single screen. Split screen view is useful for monitoring the position of the bucket

cutting edge, relative to the guidance surface.

Note – The split screen view replaces both the cross-section and profile views;

when the split screen view is available, you cannot view the cross-section and

profile views as full screen views.

Level (bubble) view

Level view displays the current pitch and roll of an excavator, and is useful for

helping you to level the machine.

Level view displays a level bubble, horizontal and vertical level bars, and an angle

measurement. The level bubble provides a visual representation of the current pitch

32 GCS900GradeControlSystem for Excavators Operator's Manual

Page 33

UsingtheControl Box andLightbars 2

and roll information coming from the pitch and roll sensor(s). The Pitch and Roll

text items appear in level view by default, and are the only text items available.

The outer ring represents 45°; the inner ring represents 22.5°.

The bubble, the horizontal and vertical level bars, and the text items all update as

the machine moves and the pitch and roll readings change.

Figure 2.8 shows the level view for the Depth and Slope excavator system.

Inner ring

1

Outer ring

3

Machine roll

5

Figure 2.8 An example of a level view

Level bubble

2

Machine pitch

4

The level bubble units are the same as the cross slope units set in the Units dialog.

When the pitch and/or roll sensor(s) are not connected, or when a value is not

available, N/A appears for that value and the bubble does not appear.

Text view 1 and text view 2

The site supervisor configures the text items that display in text view 1 and text

view2. The following figure shows an example text view guidance screen.

GCS900GradeControlSystem for Excavators Operator's Manual 33

Page 34

2 Usingthe ControlBox andLightbars

Note – Up to 10 text view items can be displayed in full screen view and the text

size scales automatically to fit the available screen space.

2.4 Understanding lightbar information

The system uses LED arrays, called lightbars, to provide the operator with guidance

information.

Lightbars let you simultaneously view guidance information, the cutting edge, and

the surface being worked.

The CB460 control box supports either internal or external lightbars. The

characteristics of internal and external lightbars differ as follows.

2.4.1 External lightbars

External lightbars can be installed in the cab, as required to replace the internal

lightbars.

Note – External lightbars are only supported on CB430 and CB460 control boxes.

In each external lightbar there are seven sets of LEDs in two colors, as shown

below.

Amber LEDs

1

Figure 2.9 LB400 external lightbar LEDs

Green LEDs

2

When the cutting edge is within half of the on-grade or on-line tolerance, only the

central green LED is lit. When the cutting edge is within the on-grade or on-line

tolerance, the central green LED and one other green LED are lit. If any LED,

other than a green LED is lit, then the cutting edge is off grade or off line.

When the cutting edge is within half of the on-grade or on-line tolerance, only the

central green LED is lit. When the cutting edge is within the on-grade or on-line

tolerance, the central green LED and one other green LED are lit. If any LED,

other than a green LED is lit, then the cutting edge is off grade or off line.

When the drum is within half of the on-grade or on-line tolerance, only the central

green LED is lit. When the drum is within the on-grade or on-line tolerance, the

central green LED and one other green LED are lit. If any LED, other than a green

LED is lit, then the drum is off grade or off line.

34 GCS900GradeControlSystem for Excavators Operator's Manual

Page 35

2.4.2 Internal lightbars

Internal lightbars are built into the control box and can be disabled if not required.

In each internal lightbar there are seven LEDs in two colors, as shown below.

UsingtheControl Box andLightbars 2

Amber LEDs

1

Figure 2.10 Control box internal lightbar LEDs

When the cutting edge is within the on-grade or on-line tolerance, only the central

green LED is lit. If any LED, other than a green LED is lit, then the cutting edge is

off grade or off line.

Excavator lightbar behavior depends on the system installed. The following sections

describe how Depth and Slope and 3D guidance information is displayed using

lightbars.

2.4.3 3D excavator lightbar behaviour

Up to three lightbars can be used with a 3D excavator system. Each lightbar shows

different information about the bucket position:

l The left vertical cut/fill lightbar provides corrections for cut and for fill. This

lightbar displays information for the lowest bucket tip relative to the design.

l The horizontal left/right lightbar indicates left and right corrections to the arm

position relative to the horizontal alignment, for the bucket tip that has focus.

l The right vertical reach lightbar indicates extension and retraction corrections

to the arm position relative to the horizontal alignment line, for the bucket tip

that has focus.

2

Green LED

Only one of either the horizontal lightbar or the right vertical lightbar is active at

any one time. The system automatically selects which lightbar is activated, based

on the excavator’s orientation relative to the selected horizontal alignment.

The left vertical cut/fill lightbar gives guidance to only one bucket tip at a time and

indicates guidance to the following points:

l The bucket tip with the smallest Cut value, when both bucket tips are above the

temporary working surface.

GCS900GradeControlSystem for Excavators Operator's Manual 35

Page 36

2 Usingthe ControlBox andLightbars

l The bucket tip with the largest Fill value, when both bucket tips are below the

temporary working surface.

l The Fill bucket tip, when one bucket tip is below and one bucket tip is above

the temporary working surface.

Note – For machines fitted with a tilting bucket, the lightbar gives guidance to one

bucket tip at a time in the same way as described above.

Tip – Use text items to see the cut/fill values for both bucket tips at the same time.

Left vertical cut/fill lightbar guidance

The cut/fill lightbar on an excavator gives on-grade guidance to the working

surface, as shown in Figure 2.11.

Cut/fill lightbar

1

Figure 2.11 Excavator vertical cut / fill 3D guidance

Horizontal left/right lightbar guidance

Excavators can operate parallel to a horizontal alignment. Horizontal guidance is

given by the left/right lightbar once the excavator has turned so that it is parallel to

the selected alignment. See Figure 2.12

36 GCS900GradeControlSystem for Excavators Operator's Manual

Lowest tip guidance. One amber LED lit. Cut

2

down.

Page 37

UsingtheControl Box andLightbars 2

Left/right lightbar

1

Figure 2.12 Excavator horizontal left/right 3D guidance

Left/right guidance. One amber LED lit. Steer

2

left.

Right vertical extend/retract lightbar guidance

An excavator can also work square to (toward) an alignment. The right vertical

extend/retract lightbar guidance gives extension guidance to the selected alignment.

This is shown in Figure 2.13.

GCS900GradeControlSystem for Excavators Operator's Manual 37

Page 38

2 Usingthe ControlBox andLightbars

Extend/retract lightbar

1

Figure 2.13 Excavator reach 3D guidance

2.4.4 2D excavator lightbar behavior

Note – The horizontal lightbar is not currently used in 2D excavator systems.

Extension guidance. Three amber LEDs lit and

2

flashing. Retract arm to move bucket in.

Bucket guidance. Green and three amber

1

LED lit. Lower bucket.

Figure 2.14 Using a 2D excavator’s lightbars

38 GCS900GradeControlSystem for Excavators Operator's Manual

Laser strike guidance. No LEDs lit. No

2

laser strike.

Page 39

The left lightbar displays cut/fill information. The cut/fill information is relative to

the guidance surface under the bucket.

The right lightbar behaves in the following way when the laser catcher receives

laser strikes:

l Green LED lit – laser strike detected in the center of the laser catcher window.

l Green and two amber LEDs lit – laser strike detected close to the center of the

laser catcher window.

l Green and three amber LEDs lit – laser strike detected far from the center of

the laser catcher window.

l No LEDs lit. No laser strike detected.

To set lightbar brightness, see 3.4.6 Lightbar brightness.

2.5 3D remote switch

The 3D excavator system supports the use of a remote switch for:

UsingtheControl Box andLightbars 2

l turning map recording events on and off:

Pass count coverage – On/Off/Auto.

Radio Map – On/Off/Auto.

Terrain – On/Off/Auto.

Cut/Fill Map – On/Off/Auto.

l recording a point.

Configuration of which of these events (if any) is available is managed by your Site

Supervisor.

Note – 3D remote switch support is not available when using a 2D Depth and Slope

system.

2.6 System beeper

In addition to the display and lightbars, the system also uses an audible alarm, or

beeper, to alert you to status changes and other events.

The following table lists the pattern of sounds generated by the beeper, and the

events that cause them. By default, the beeper will sound for all the events listed in

the table, but alerts for some events may be turned off by your site supervisor.

GCS900GradeControlSystem for Excavators Operator's Manual 39

Page 40

2 Usingthe ControlBox andLightbars

Table 2.5 — Beeper patterns

Event Sounds when... Pattern

Inside Avoidance Zone the machine is inside an avoidance zone. Repeated:

150 msec on,

175 msec off,

300 msec on,

175 msec off

Above Grade the bucket is more than the vertical tolerance and less

than four times the vertical tolerance above grade.

On-Grade the bucket is within the vertical tolerance of grade. Continuous:

Below Grade the bucket is more than the vertical tolerance and less

than four times the vertical tolerance below grade.

Approach Avoidance Zone the machine is within the warning distance of an

avoidance zone.

No Avoid the No Avoid message appears. Once only:

Warning Message Appears a warning message appears. Once only:

Warning Message Disappears a warning message automatically disappears. Once only:

GPS Accuracy the GPS accuracy level changes. Once only:

Continuous:

50 msec on,

50 msec off

On

Continuous:

100 msec on,

100 msec off

Once only:

200 msec on,

200 msec off,

400 msec on

200 msec on

200 msec on,

200 msec off,

200 msec on

200 msec on

200 msec on

UTS Tracking the UTS loses lock on the machine target. Once only:

200 msec on

Laser Alerts a l aser strike is detected in the laser catcher window. Once only:

200 msec on

Key/Switch Beeps a key or a switch is pressed. Once only:

200 msec on

40 GCS900GradeControlSystem for Excavators Operator's Manual

Page 41

C H A P T E R

3

3Preparing to Work

In this chapter:

n Power up checks

n Software option keys

n Work preparation checks

n Configuring the machine radio

n Wi-Fi networking

n Exchanging files with a

Connected Community filespace

n Selecting an excavator bucket

n Selecting a 3D vertical guidance

method

n Selecting a Depth and Slope

vertical guidance method

Before you begin work with the GCS900 Grade

Control System, you need to check the state of

the machine and its system components to

ensure the system provides accurate guidance.

GCS900GradeControlSystem for Excavators Operator's Manual 41

Page 42

3 Preparingto Work

3.1 Introduction

This chapter describes how to check the machine before you turn on the system,

what to look for as the system powers up, and how to check the general system

setup once the system is running.

3.2 Power up checks

ATTENTION — In cold environments, when you start the machine to warm it up turn on the

control box as well.

When you power up the system to begin work, observe the system’s start-up

sequence to make sure that all components function correctly. See the following list

of basic checks.

Check For more information, see ...

Lightbar power up

Control box power up

3.2.1 Lightbar power up

Observe the lightbars during start-up and make sure that the lightbars work

correctly.

To perform the lightbar start-up check:

1.

To turn on the system power, press P on the control box.

2. Immediately observe the pattern of the lightbar LEDs.

The LEDs flash in the following sequence:

LEDs on this lightbar Flash

Cut / fil l Bottom to top

Left / right Left to right

In / out (extend / retract) Top to bottom

All Twice, simultaneously

3.2.1 Lightbar power up

3.2.2 Control box power up

The following problems may occur with internal lightbars:

Problem Action

Lightbars do not

illuminate

42 GCS900GradeControlSystem for Excavators Operator's Manual

Use the methods described in 3.2.2 Control box power up to check that

the control box has started successfully.

Page 43

Preparingto Work 3

Problem Action

Use the procedure descri bed in 3.4.6 Lightbar brightness to check that

the lightbar brightness is not set too low.

The following problems may occur when you power up the external lightbars:

Problem Action

Lightbars do not

illuminate

Lightbars flash in the

wrong sequence

3.2.2 Control box power up

Observe the control box after the system has powered up.

You should see a guidance screen, softkeys, and optional text items (if configured).

If the machine has one or more 3D sensors installed and configured, the following

items appear:

l A plan view guidance screen.

l The correct machine icon for your machine type.

l A site plan, if the system has a site plan file.

l A design or map, if one was loaded when the system was last powered down.