Page 1

RELEASE NOTES

EZ-Guide® 500 Lightbar Guidance System

Firmware Version 5.10

Introduction

Changes

Field-IQ crop input control

system

Expanded third party variable

rate controller compatibility

GPS position quality indicator

Krohne Liquid manure flow

meter support

Version 5.10

Revision A

March 2010

Part Number 66022-85-ENG

*66022-85-ENG*

EZ-Boom granular fertilizer

spreading

Upgrade procedure

Page 2

Contact information

trimble_support@trimble.com

www.EZ-Guide.com

Legal Notices

Copyright and Trademarks

© 2007–2010, Trimble Navigation Limited. All rights reserved.

Trimble, the Globe & Triangle logo, AgGPS, EZ-Boom,

EZ-Guide, EZ-Office, EZ-Steer, and Tru Count Air Clutch are

trademarks of Trimble Navigation Limited, registered in the

United States and in other countries. Autopilot, FmX,

Rawson, and Tru Count LiquiBlock are trademarks of Trimble

Navigation Limited.

All other trademarks are the property of their respective

owners.

Release Notice

This is the March 2010 release (Revision A) of the

EZ-Guide 500 Lightbar Guidance System Release Notes, part

number 66022-85-ENG. It applies to version 5.10 of the

EZ-Guide firmware.

LIMITED WARRANTY TERMS AND CONDITIONS

Product Software

Product software, whether built into hardware circuitry as

firmware, provided as a standalone computer software

product, embedded in flash memory, or stored on magnetic

or other media, is licensed solely for use with or as an integral

part of the Product and is not sold. If accompanied by a

separate end user license agreement (“EULA”), use of any

such software will be subject to the terms of such end user

license agreement (including any differing limited warranty

terms, exclusions, and limitations), which shall control over

the terms and conditions set forth in this limited warranty.

Software Fixes

During the limited warranty period, if any, you will be entitled

to receive such Fixes to the Product software that Trimble

releases and makes commercially available and for which it

does not charge separately, subject to the procedures for

delivery to purchasers of Trimble products generally. If you

have purchased the Product from an authorized Trimble

dealer rather than from Trimble directly, Trimble may, at its

option, forward the software Fix to the Trimble dealer for final

distribution to you. Minor Updates, Major Upgrades, new

products, or substantially new software releases, as identified

by Trimble, are expressly excluded from this update process

and limited warranty. Receipt of software Fixes or other

enhancements shall not serve to extend the limited warranty

period.

For purposes of this warranty the following definitions shall

apply: (1) “Fix(es)” means an error correction or other update

created to fix a previous software version that does not

substantially conform to its Trimble specifications; (2) “Minor

Update” occurs when enhancements are made to current

features in a software program; and (3) “Major Upgrade”

occurs when significant new features are added to software,

or when a new product containing new features replaces the

further development of a current product line. Trimble

reserves the right to determine, in its sole discretion, what

constitutes a Fix, Minor Update, or Major Upgrade.

Warranty Remedies

If the Trimble Product fails during the warranty period for

reasons covered by this limited warranty and you notify

Trimble of such failure during the warranty period, Trimble

will repair OR replace the nonconforming Product with new,

equivalent to new, or reconditioned parts or Product, OR

refund the Product purchase price paid by you, at Trimble’s

option, upon your return of the Product in accordance with

Trimble's product return procedures then in effect.

How to Obtain Warranty Service

To obtain warranty service for the Product, please contact

your local Trimble authorized dealer. Alternatively, you may

contact Trimble to request warranty service at +1-408-4816940 (24 hours a day) or e-mail your request to

trimble_support@trimble.com. Please be prepared to

provide:

– your name, address, and telephone numbers

– proof of purchase

– a copy of this Trimble warranty

– a description of the nonconforming Product including the

model number

– an explanation of the problem

The customer service representative may need additional

information from you depending on the nature of the

problem.

Warranty Exclusions and Disclaimer

This Product limited warranty shall only apply in the event

and to the extent that (a) the Product is properly and

correctly installed, configured, interfaced, maintained , stored,

and operated in accordance with Trimble's applicable

operator's manual and specifications, and; (b) the Product is

not modified or misused. This Product limited warranty shall

not apply to, and Trimble shall not be responsible for, defects

or performance problems resulting from (i) the combination

or utilization of the Product with hardware or software

products, information, data, systems, interfaces, or devices

not made, supplied, or specified by Trimble; (ii) the operation

of the Product under any specification other than, or in

addition to, Trimble's standard specifications for its products;

(iii) the unauthorized installation, modification, or use of the

Product; (iv) damage caused by: accident, lightning or other

electrical discharge, fresh or salt water immersion or spray

(outside of Product specifications); or exposure to

environmental conditions for which the Product is not

intended; (v) normal wear and tear on consumable parts (e.g.,

batteries); or (vi) cosmetic damage. Trimble does not warrant

or guarantee the results obtained through the use of the

Product, or that software components will operate error free.

NOTICE REGARDING PRODUCTS EQUIPPED WITH

TECHNOLOGY CAPABLE OF TRACKING SATELLITE SIGNAL S

FROM SATELLITE BASED AUGMENTATION SYST EMS (SBAS)

(WAAS/EGNOS, AND MSAS), OMNISTAR, GPS, MODERNIZED

GPS OR GLONASS SATELLITES, OR FROM IALA BEACON

SOURCES: TRIMBLE IS NOT RESPONSIBLE FOR THE

OPERATION OR FAILURE OF OPERATION OF ANY SATELLITE

BASED POSITIONING SYSTEM OR THE AVAILABILI TY OF ANY

SATELLITE BASED POSITIONING SIGNAL S.

THE FOREGOING LIMITED WARRANTY TERMS STATE

TRIMBLE’S ENTIRE LIABILITY, AND YOUR EXCLUSIVE

REMEDI ES, RELATING TO THE TRIMBLE PRODUCT. EXCEPT AS

OTHERWISE EXPRESSLY PROVIDED HEREIN, THE PRODUCT,

AND ACCOMPANYING DOCUMENTATION AND MATERIALS

ARE PROVIDED “AS-IS” AND WITHOUT EXPRESS OR IMPLIED

WARRANTY OF ANY KIND, BY EITHER TRIMBLE OR ANYONE

2 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 3

WHO HAS BEEN INVOLVED IN ITS CREATION, PRODUCTION,

INSTALLATION, OR DISTRI BUTION, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, TITLE, AND NONINFRINGEMENT. THE STATED

EXPRESS WARRANTIES ARE IN LIEU OF ALL OBLIGATIONS OR

LIABILITIES ON THE PART OF TRIMBLE ARISING OUT OF, OR IN

CONNECTION WITH, ANY PRODUCT. BECAUSE SOME STATES

AND JURISDICTIONS DO NOT ALLOW LIMITATIONS ON

DURATION OR THE EXCLUSION OF AN IMPLIED WARRANTY,

THE ABOVE LIMITATION MAY NOT APPLY OR FULLY APPLY TO

YOU.

Limitation of Liability

TRIMBLE'S ENTIRE LIABILITY UNDER ANY PROVISION HEREIN

SHALL BE LIMITED TO THE AMOUNT PAID BY YOU FOR THE

PRODUCT. TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, IN NO EVENT SHALL TRIMBLE OR ITS

SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL ,

INCIDENTAL, OR CONSEQUENTIAL DAMAGE WHATSOEVER

UNDER ANY CIRCUMSTANCE OR LEGAL THEOR Y RELATING IN

ANYWAY TO THE PRODUCTS, SOFTWARE AND

ACCOMPANYING DOCUMENTATION AND MATERIALS,

(INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF

BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF DATA,

OR ANY OTHER PECUNIARY LOSS), REGARDLESS OF WHETHER

TRIMBLE HAS BEEN ADVISED OF THE POSSIBI LITY OF ANY

SUCH LOSS AND REGARDL ESS OF THE COURSE OF DEALING

WHICH DEVELOPS OR HAS DEVELOPED BETWEEN YOU AND

TRIMBLE. BECAUSE SOME STATES AND JURISDICTIONS DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY

FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE

LIMITATION MAY NOT APPLY OR FULLY APPLY TO YOU.

PLEASE NOTE: THE ABOVE TRIMBLE LIMITED WARRANTY

PROVISIONS WILL NOT APPLY TO PRODUCTS PURCHASED

IN THOSE JURISDICTIONS (E.G., MEMBER STATES OF THE

EUROPEAN ECONOMIC AREA) IN WHICH PRODUCT

WARRANTIES ARE THE RESPONSI BILITY OF THE LOCAL

TRIMBLE AUTHORIZED DEALER FROM WHOM THE

PRODUCTS ARE ACQUIRED. IN SUCH A CASE, PLEASE

CONTACT YOUR LOCAL TRIMBLE AUTHORIZED DEALER

FOR APPLICABLE WARRANTY INFORMATION.

Official Language

THE OFFICIAL LANGUAGE OF THESE TERMS AND CONDITIONS

IS ENGLISH. IN THE EVENT OF A CONFLICT BETWEEN

ENGLISH AND OTHER LANGUAGE VERSIONS, THE ENGLISH

LANGUAGE SHALL CONTROL.

Registration

To receive information regarding updates and new products,

please contact your local Trimble authorized dealer or visit

the Trimble website at www.trimble.com/register. Upon

registration you may select the newsletter, upgrade, or new

product information you desire.

Notices

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own

expense.

Properly shielded and grounded cables and connectors must

be used in order to meet FCC emission limits. TRIMBLE is

not responsible for any radio or t elevision interference caused

by using other than recommended cables and connectors or

by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user's

authority to operate the equipment.

This device complies with Part 15 of the FCC rules. Operation

is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including

interference that may cause undesired operation.

Responsible Party:

Trimble Navigation Limited

935 Stewart Drive

Sunnyvale CA 94085

Telephone: 1-408 481 8000

Industry Canada Compliance Statement

This Class A digital apparatus meets the requirements of the

Canadian Interference-Causing Equipment Regulations.

Avis de conformité à la réglementation d'Industrie Canada.

Cet appareil numérique de la classe A respecte toutes les

exigences du Règlement sur le matériel brouilleur du Canada.

European Community Compliance Statement

This product is in conformity with the protection

requirements of EU Council Directive 89/336/EEC on the

approximation of the laws of the Member States relating to

electromagnetic compatibility. TRIMBLE cannot accept

responsibility for any failure to satisfy the protection

requirements resulting from a non-recommended

modification of the product, including the fitting of nonTRIMBLE option cards.

Australia and New Zealand Class A Statement

Attention: This is a Class A product. In a domestic

environment this product may cause radio interference in

which case the user may be required to take adequate

measures.

Australia and New Zealand

This product conforms with the regulatory

requirements of the Australian Communications

Authority (ACA) EMC framework, thus satisfying the

requirements for C-Tick Marking and sale within Australia

and New Zealand.

Notice to Our European Union Customers

For product recycling instructions and more information,

please go to www.trimble.com/ev.shtml.

Recycling in Europe: To recycle Trimble WEEE (Waste

Electrical and Electronic Equipment, products that

run on electrical power.), Call +31 497 53 24 30, and

ask for the "WEEE Associate". Or, mail a request for

recycling instructions to:

Trimble Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

EZ-Guide 500 Lightbar Guidance System Release Notes 3

Page 4

Restriction of Use of Certain Hazardous

Declaration of Conformity

We, Trimble Navigation Limited,

935 Stewart Drive

PO Box 3642

Sunnyvale, CA 94088-3642

United States

+1-408-481-8000

declare under sole responsibility that the product:

EZ-Guide 500 lightbar guidance system

complies with Part 15 of FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Substances in Electrical and Electronic

Equipment (RoHS)

This Trimble product complies in all material respects with

DIRECTIVE 2002/95/EC OF THE EUROPEAN PARLIAMENT

AND OF THE COUNCIL of 27 January 2003 on the restriction

of the use of certain hazardous substances in electrical and

electronic equipment (RoHS Directive) and Amendment

2005/618/EC filed under C(2005) 3143, with exemptions for

lead in solder pursuant to Paragraph 7 of the Annex to the

RoHS Directive applied.

4 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 5

Introduction

These Release Notes describe changes and updates for the EZ-Guide® 500

lightbar guidance system. They apply to the EZ-Guide 500 lightbar guidance

system firmware version 5.10.

Note – For on-screen instructions and term definitions, select .

Changes

The following changes are provided in the EZ-Guide 500 lightbar guidance

system firmware version 5.10:

• Field-IQ crop input control system support, see page 5

• Expanded variable rate controller support, see page 30

• Updated GPS status icon with bars, see page 31

• Liquid manure feature, see page 32

• EZ-Boom granular spreading, see page 38

Field-IQ crop input control system

With the Field-IQ™ crop input control system, the EZ-Guide 500 lightbar

guidance system can control planters, liquid strip-till tool-bars, and spinner

spreaders. It can perform automatic section control using a Tru Count Air

®

Clutch

prescription with Rawson

system and/or control seed or liquid fertilizer rates using a

™

drives.

Different functions of the solutions can be configured and controlled by the

Field-IQ system.

EZ-Guide 500 Lightbar Guidance System Release Notes 5

Page 6

Application main functions

Planter • Seed Section Control of up to 48 individual rows (Field-IQ section

control module(s) needed) using Tru Count air clutches.

• Seed Rate Control using up to four Rawson drives to change seed

population (Field-IQ Rawson Control Module(s) needed).

• Liquid Fertilizer Control of up to 48 individual liquid nozzles (FieldIQ section control module(s) needed) using Tru Count LiquiBlock™

valves.

Strip-till

(liquid)

Spreading • Spreading Rate Control using a Rawson Drive (Field-IQ Rawson

• Liquid Section Control of up to 48 individual spray nozzles (FieldIQ Section Control Module(s) needed) using Tru Count LiquiBlock

valves.

• Liquid Rate Control using up to 2 Rawson drives connected to

fixed displacement pumps, such as CDS-John Blue piston

pumps, to change liquid rate (Field-IQ Rawson Control Module(s)

needed).

Control Module(s) needed).

Definition of terms

Calibration

constant

Jump start Use this function if you lose a GPS signal or you want to start applying

Prime the

system

This represents the output of a granular applicator per revolution of

the drive. Use this number to fine tune the Field-IQ system to match

the actual output of the spreader.

before your implement is up to speed.

This fills the system with product in preparation for calibration.

6 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 7

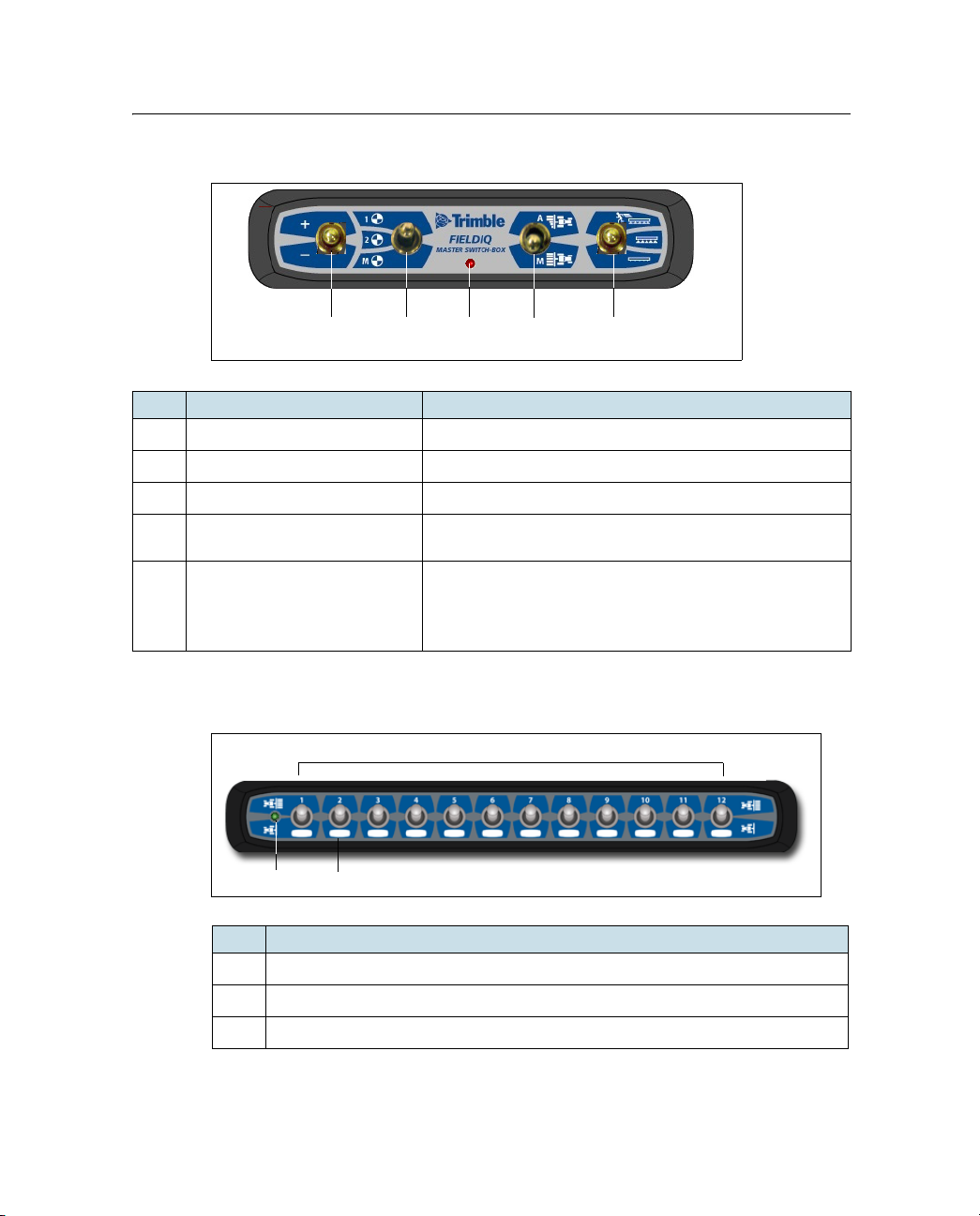

Field-IQ master switch box

c

de

f

g

d

e

c

Item Position

Increment/decrement switch

c

Rate switch Rate 1, Rate 2, Manual Rate

d

LED indicator

e

Automatic/Manual section

f

switch

Master switch Off, On, Jump Start position.

g

You can switch from Automatic to Manual mode while

traveling.

Use the jump start function if you lose a GPS signal or

you want to start applying before your implement is up

to speed.

Field-IQ 12-section switch box (optional)

Item

LED indicator

c

Section switches

d

Space to write which row the switch controls.

e

EZ-Guide 500 Lightbar Guidance System Release Notes 7

Page 8

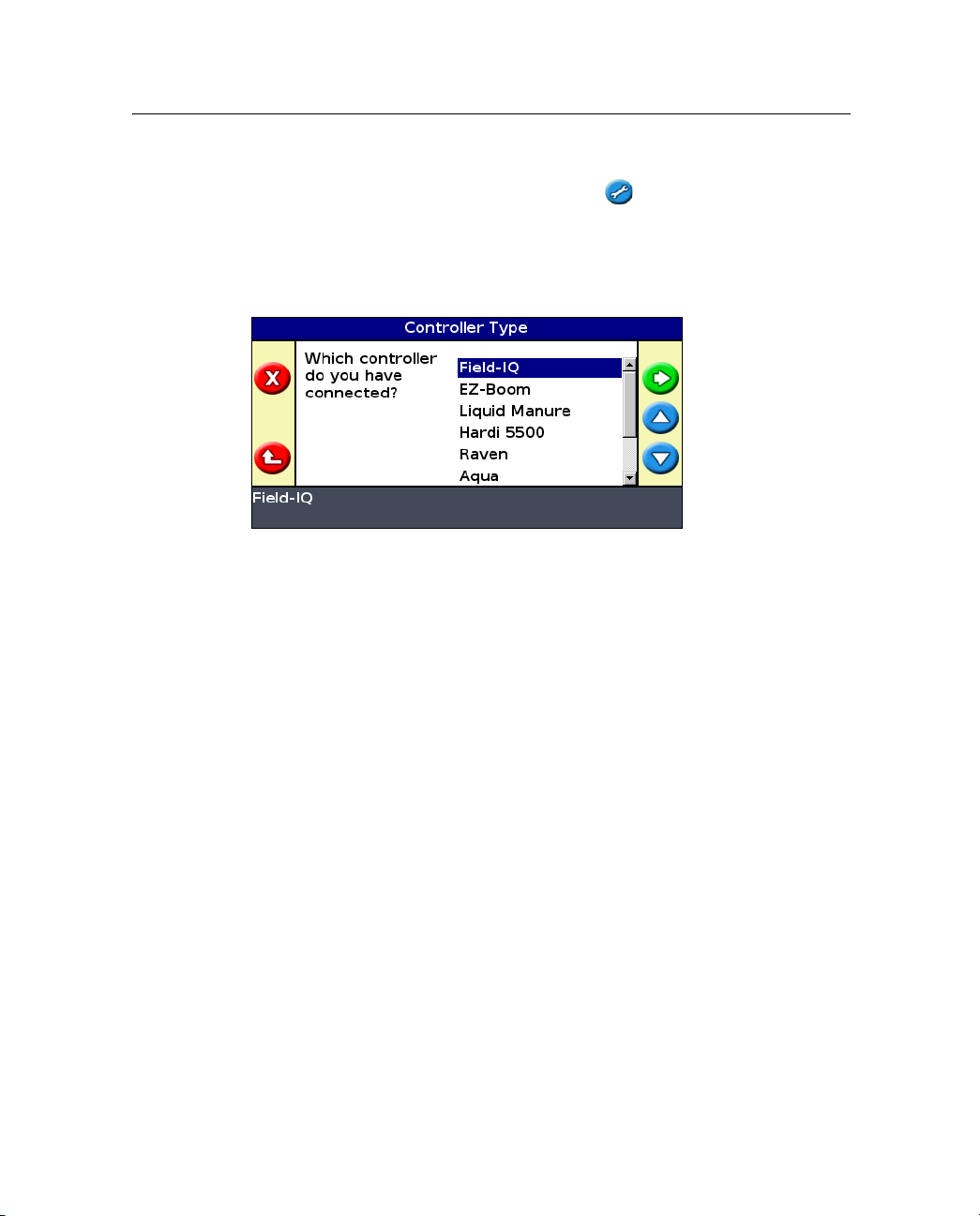

Enabling the Field-IQ system

1. From the main guidance screen, select the icon and then press .

The Configuration screen appears.

2. Make sure that the user mode is set to Advanced.

3. Select Application Control / Controller Settings / Field-IQ:

4. Select an application controller mode. The options are:

– Row Crop Planting, see Setting up Field-IQ planting, page 8

– Liquid, see Setting up Field-IQ liquid application, page 13

– Granular, see Setting up Field-IQ granular application, page 19

– Spreading, see Setting up Field-IQ spreading, page 24

Setting up Field-IQ planting

Entering implement measurements

1. In the Controller Type screen, select Field-IQ and then select Row Crop

Planting.

2. Complete the Setup wizard to enter the implement measurement values:

– Number of Rows

– Row Spacing

– Implement Mount Type

8 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 9

– Hitched / 3pt

– Drawbar

– Forward/Back Offset

– Capacity

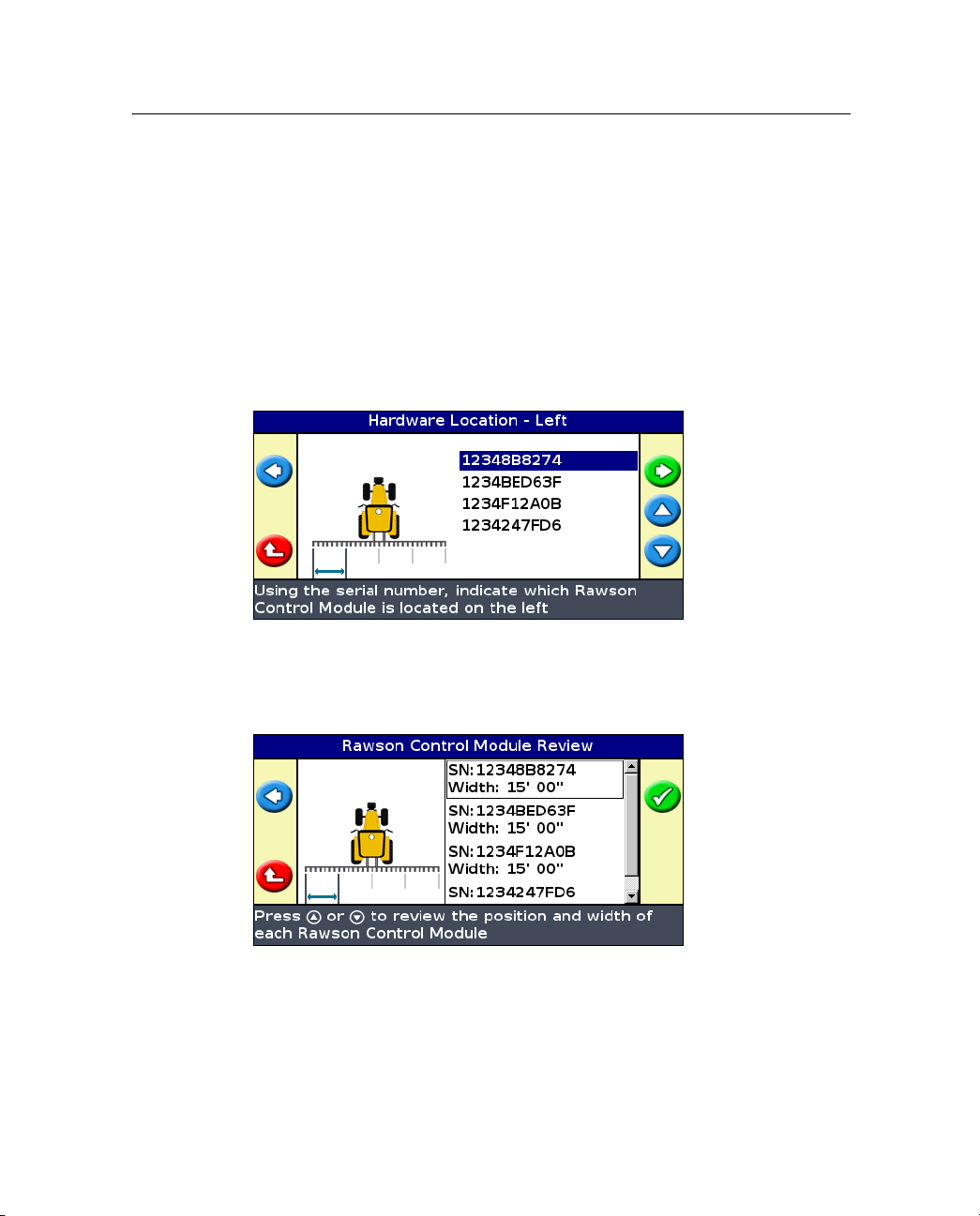

Setting up the Rawson control modules

1. Use the module serial numbers to indicate where each module can be

found on the planter:

2. Enter the width of each section.

The Rawson Control Module Review screen is informational and shows the

serial number and width of each module:

EZ-Guide 500 Lightbar Guidance System Release Notes 9

Page 10

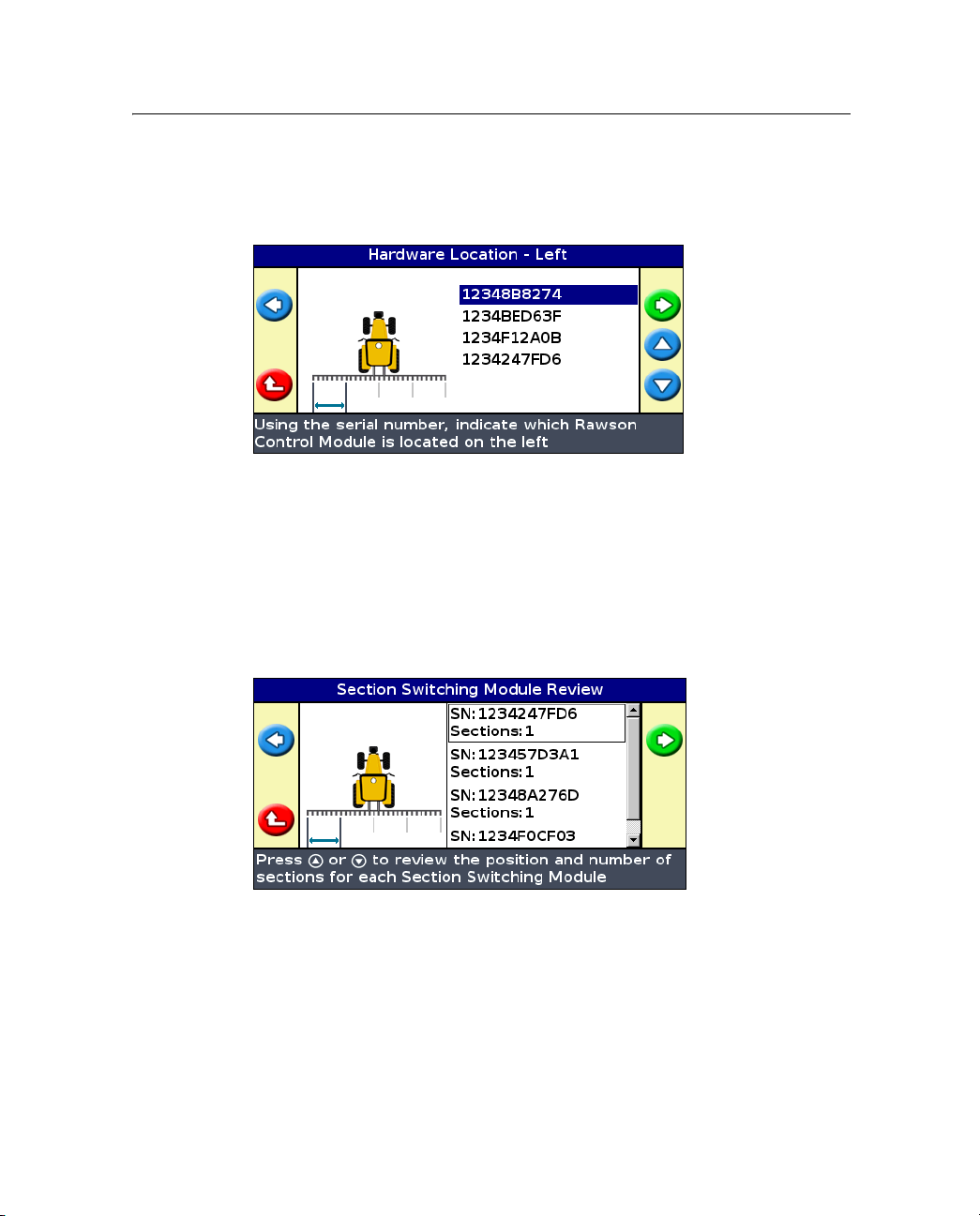

Setting up the Field-IQ section control modules

1. Using the module serial numbers, indicate where each Field-IQ module

can be found on the planter:

2. Enter the number of sections each controller module will control.

3. Select the boom switching mode:

– Liquid Boom

– Tru Count

The Section Switching Module Review screen is informational and shows

the serial number and width of each module:

4. Enter the width of each section.

10 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 11

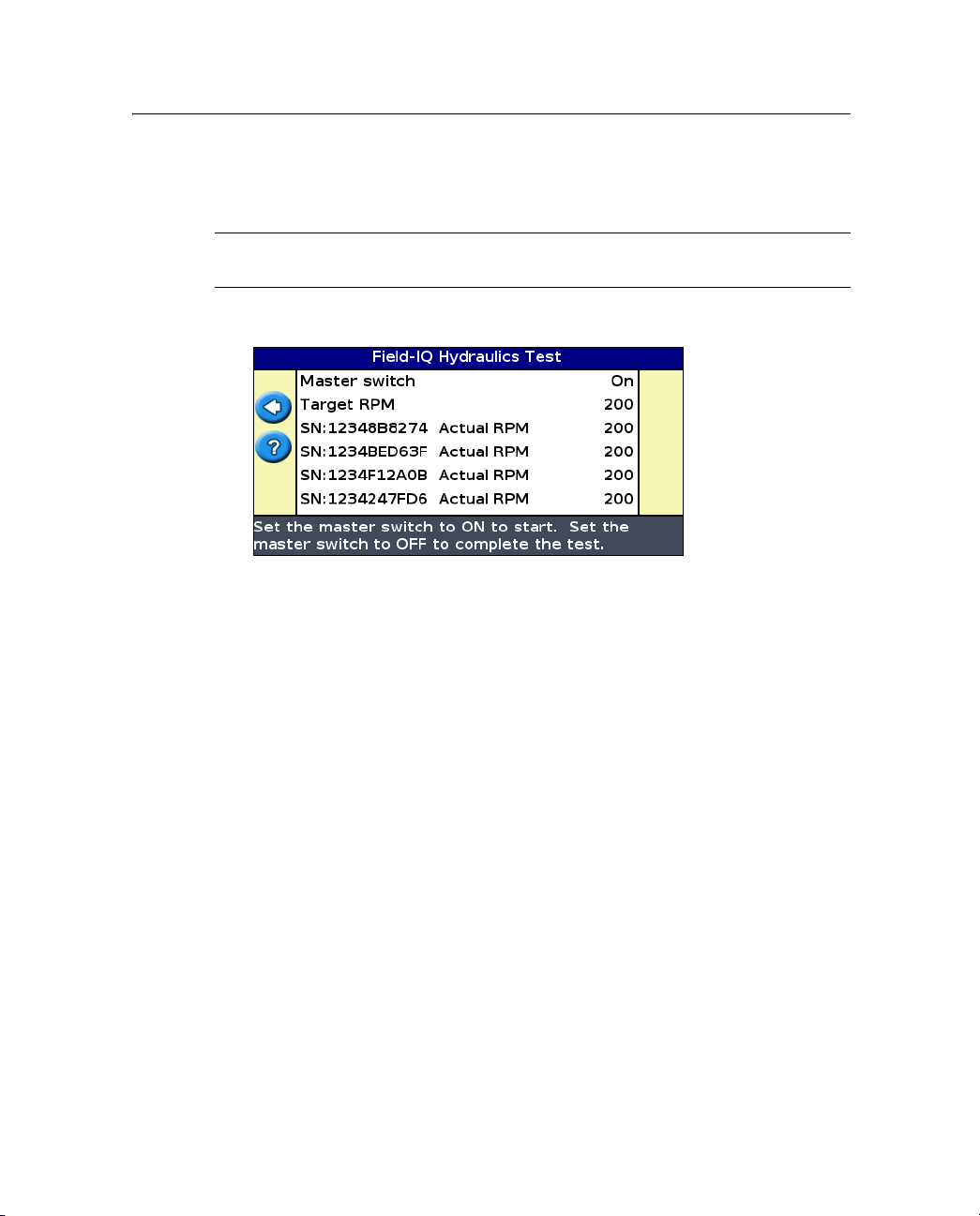

Performing the Field-IQ hydraulics test

1. Enter the target RPM.

CAUTION – When you turn the master switch on, parts of the implement will

C

move.

2. Turn the master switch on. The hydraulics test begins:

3. Turn the master switch off once the test is complete.

Note – If the motors did not achieve the desired RPM, you must alter the hydraulic

setup. Refer to the Field-IQ Installation Instructions or Rawson Installation

Instructions.

Calibrating the Rawson control modules and rate controller

1. Enter the jump start speed. This setting controls the speed to be used

when the Field-IQ master switch is put in the jump start position.

2. Enter the number of seeds per disk for your planter.

3. Do one of the following:

– If you know the gear ratio for your implement, enter it into the

Calibrate Rate Controller screen.

– If you do not know the gear ratio for your implement, use the gear

ratio calculator.

EZ-Guide 500 Lightbar Guidance System Release Notes 11

Page 12

4. Enter the calibration constant. In the planting application, the calibration

constant defaults to 1. When you have completed the seed drop test

(Step 7 through Step 9), you may need to adjust this value.

5. Enter the target rate, target speed, and number of revolutions.

Note – The higher the number of revolutions the more accurate the calibration;

Trimble recommends 5 to 10 revolutions.

6. To prime the system, select

Yes.

7. To begin calibration, turn the master switch on.

The Calibration Progress screen is informational and indicates the status

of the calibration:

8. Turn the master switch off.

9. Count the number of seeds dropped from one row unit and then enter the

number.

10. If required, adjust the Verify Rate and Speed Range. The system

automatically calculates the fastest and slowest speed that will allow you

to successfully achieve these numbers.

11. The next two screens are informational and show the operating speed

ranges for your target rates.

Note – If speed limits are not within the required range, alter the gear ratio.

12 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 13

12. In the Apply Calibration screen, do one of the following:

– Select Yes to apply the calibration data from the current rate

controller to the remaining rate controllers.

– Select No to calibrate each controller separately.

Setting up Field-IQ liquid application

Entering implement measurements

1. In the Controller Type screen, select Field-IQ and then select Liquid.

2. Complete the Setup wizard to enter the implement measurement values:

– Number of rows

– Row spacing

– Implement Mount Type

Hitched / 3pt

Drawbar

– Forward/Back Offset

– Capacity

EZ-Guide 500 Lightbar Guidance System Release Notes 13

Page 14

Setting up the Rawson control modules

1. Use the module serial numbers to indicate where each module can be

found on the planter:

2. Enter the width of each section.

The Rawson Control Module Review screen is informational and shows the

serial number and width of each module:

14 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 15

Setting up the Field-IQ section control modules

1. Using the module serial numbers, indicate where each Field-IQ module

can be found on the planter:

2. Enter the number of sections each controller module will control.

3. Select the boom switching mode:

– Liquid Boom

– Tru Count

The Section Switching Module Review screen is informational and shows

the serial number and width of each module:

4. Enter the width of each section.

EZ-Guide 500 Lightbar Guidance System Release Notes 15

Page 16

Performing the Field-IQ hydraulics test

1. Enter the target RPM.

CAUTION – When you turn on the master switch, parts of the implement will

C

move.

2. Turn on the master switch. The hydraulics test begins:

3. Turn off the master switch once the test is complete.

Note – If the motors did not achieve the desired RPM, you must alter the hydraulic

setup. Refer to the Field-IQ Installation Instructions or Rawson Installation

Instructions.

Calibrating the Rawson control modules and rate controller

1. Enter the jump start speed. This setting controls the speed to be used

when the Field-IQ master switch is put in the jump start position.

2. Do on of the following:

– If you know the gear ratio for your implement, enter it into the

Calibrate Rate Controller screen.

– If you do not know the gear ratio for your implement, use the gear

ratio calculator.

16 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 17

3. Enter the pump constant. This is the amount of liquid pumped in one

revolution. See the pump manufacturer's instructions for this value:

Note – Leaving the value at 0 prompts the system to auto calibrate.

4. Enter the target rate, target speed, and number of revolutions.

Note – The higher the number of revolutions the more accurate the calibration;

Trimble recommends 5 to 10 revolutions.

5. To prime the system, select

Yes.

6. To begin calibration, turn the master switch on.

The Calibration Progress screen is informational and indicates the status

of the calibration:

7. Turn the master switch off.

EZ-Guide 500 Lightbar Guidance System Release Notes 17

Page 18

8. Perform the calibration three (3) times. Enter the average amount of

liquid dispensed for the three calibration tests:

9. In the Calibration OK? screen, do one of the following:

– Select Yes to end the calibration.

– Select No to return to the Pump Constant screen.

10. If required, adjust the Verify Rate and Speed Range. The system

automatically calculates the fastest and slowest speed that will allow you

to successfully achieve these numbers.

11. The next two screens are informational and show the operating speed

ranges for your target rates.

Note – If speed limits are not within the required range, alter the gear ratio.

12. In the Apply Calibration screen, do one of the following:

– Select Yes to apply the calibration data from the current rate

controller to the remaining rate controllers.

– Select No to calibrate each controller separately.

18 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 19

Setting up Field-IQ granular application

Entering implement measurements

1. In the Controller Type screen, select Field-IQ and then select Granular.

2. Complete the Setup wizard to enter the implement measurement values:

– Implement Width

– Implement Mount Type

Hitched / 3pt

Drawbar

– Forward/Back Offset

– Capacity

EZ-Guide 500 Lightbar Guidance System Release Notes 19

Page 20

Setting up the Rawson control modules

1. Use the module serial numbers to indicate where each module can be

found on the planter:

2. Enter the width of each section.

The Rawson Control Module Review screen is informational and shows the

serial number and width of each module:

20 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 21

Setting up the Field-IQ section control modules

1. Using the module serial numbers, indicate where each Field-IQ module

can be found on the planter:

2. Enter the number of sections each controller module will control.

The Section Switching Module Review screen is informational and shows

the serial number and width of each module:

3. Enter the width of each section.

EZ-Guide 500 Lightbar Guidance System Release Notes 21

Page 22

Performing the Field-IQ hydraulics test

1. Enter the target RPM.

CAUTION – When you turn on the master switch parts of the implement will

C

move.

2. Turn on the master switch. The hydraulics test begins:

3. Turn off the master switch once the test is complete.

Note – If the motors did not achieve the desired RPM, you must alter the hydraulic

setup. Refer to the Field-IQ Installation Instructions or Rawson Installation

Instructions.

Calibrating the Rawson control modules and rate controller

1. Enter the jump start speed. This setting controls the speed to be used

when the Field-IQ master switch is put in the jump start position.

2. Enter the density of the material to apply.

3. Do one of the following:

– If you know the gear ratio for your implement, enter it into the

Calibrate Rate Controller screen.

– If you do not know the gear ratio for your implement, use the gear

ratio calculator.

4. Enter the calibration constant.

5. Enter the target rate, target speed, and number of revolutions.

22 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 23

Note – The higher the number of revolutions the more accurate the calibration;

Trimble recommends 5 to 10 revolutions.

6. To prime the system, select

Yes.

7. To begin calibration, turn the master switch on.

The Calibration Progress screen is informational and indicates the status

of the calibration:

8. Turn the master switch off.

9. Enter the weight of the material that was dropped by the spreader.

10. If required, adjust the Verify Rate and Speed Range. The system

automatically calculates the fastest and slowest speed that will allow you

to successfully achieve these numbers.

11. The next two screens are informational and show the operating speed

ranges for your target rates.

Note – If speed limits are not within the required range, alter the gear ratio.

12. In the Apply Calibration screen, do one of the following:

– Select Yes to apply the calibration data from the current rate

controller to the remaining rate controllers.

– Select No to calibrate each controller separately.

EZ-Guide 500 Lightbar Guidance System Release Notes 23

Page 24

Setting up Field-IQ spreading

Entering implement measurements

1. In the Controller Type screen, select Field-IQ and then select Spreading.

2. Complete the Setup wizard to enter the implement measurement values:

– Implement Width

– Implement Mount Type

Hitched / 3pt

Drawbar

– Forward/Back Offset

– Capacity

24 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 25

Setting up the Rawson control modules

1. Use the module serial numbers to indicate where each module can be

found on the planter:

2. Enter the width of each section.

The Rawson Control Module Review screen is informational and shows the

serial number and width of each module:

EZ-Guide 500 Lightbar Guidance System Release Notes 25

Page 26

Setting up the Field-IQ section control modules

1. Using the module serial numbers, indicate where each Field-IQ module

can be found on the planter:

2. Enter the number of sections each controller module will control.

The Section Switching Module Review screen is informational and shows

the serial number and width of each module:

3. Enter the width of each section.

26 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 27

Performing the Field-IQ hydraulics test

1. Enter the target RPM.

CAUTION – When you turn on the master switch, parts of the implement will

C

move.

2. Turn on the master switch. The hydraulics test begins:

3. Turn the master switch off once the test is complete.

Note – If the motors did not achieve the desired RPM, you must alter the hydraulic

setup. Refer to the Field-IQ Installation Instructions or Rawson Installation

Instructions.

Calibrating the Rawson control modules and rate controller

1. Enter the jump start speed. This setting controls the speed to be used

when the Field-IQ master switch is put in the jump start position.

2. Enter the gate height, gate width and spreader belt length per revolution.

3. Enter the density of the material to apply.

4. Do on of the following:

– If you know the gear ratio for your implement, enter it into the

Calibrate Rate Controller screen.

– If you do not know the gear ratio for your implement, use the gear

ratio calculator.

EZ-Guide 500 Lightbar Guidance System Release Notes 27

Page 28

The spreader constant calculates automatically. You can adjust the value

if required—follow the on-screen instructions:

5. Enter the target rate, target speed, and number of revolutions.

Note – The higher the number of revolutions the more accurate the calibration;

Trimble recommends 5 to 10 revolutions.

6. To prime the system, select

Yes.

7. To begin calibration, turn the master switch on.

The Calibration Progress screen is informational and indicates the status

of the calibration:

8. Turn the master switch off.

9. Enter the weight of the material that was dropped by the spreader.

10. If required, adjust the Verify Rate and Speed Range. The system

automatically calculates the fastest and slowest speed that will allow you

to successfully achieve these numbers.

28 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 29

11. The next two screens are informational and show the operating speed

ranges for your target rates.

Note – If speed limits are not within the required range, alter the gear ratio.

12. In the Apply Calibration screen, do one of the following:

– Select Yes to apply the calibration data from the current rate

controller to the remaining rate controllers.

– Select No to calibrate each controller separately.

Using the Field-IQ system

1. From the main guidance screen, select and then create a new field or

select an existing field.

2. Select the Refill icon to:

– adjust the current bin volume

– select the refill method

– refill bin now

3. Select the Refill icon to adjust:

– Swath Control Setup

Select Liquid Boom when using Liquiblock valves, or select Tru Count

no Inverter when using Tru Count clutches. (Use the following screens

to configure the Boom Switching Mode.)

– Boom Switching Mode

Select Liquid Boom when using Liquiblock valves, or select Tru Count

no inverter when using Tru Count clutches.

– Boundary Switching Overlap

4. Select Application Setup to:

– Turn rate control on or off.

– Adjust target rate 1.

– Adjust target rate 2.

EZ-Guide 500 Lightbar Guidance System Release Notes 29

Page 30

– Adjust the rate increment.

– Turn rate snapping on or off.

– Adjust the jump start speed.

5. Select Boundaries to select:

– Enabled

– Disabled for This Field

– Disabled for All Fields

Expanded third party variable rate controller compatibility

The EZ-Guide 500 system now supports the following variable rate controllers:

• Amazone Amatron+

• LH Agro LH5000

Variable rate functionality can only be accessed when the user mode is set to

Advanced. When a compatible rate controller is connected, the EZ-Guide 500

system uses a prescription map to send application rate commands to the

controller. Once this happens, the controller changes to the appropriate rate,

as instructed by the lightbar.

These variable rate controllers connect through the COM connection on the

EZ-Guide 500 lightbar guidance system.

This function requires the variable rate unlock.

30 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 31

GPS position quality indicator

You can now select the level of GPS quality that you want the system to use.

This gives you the option of extending your operating hours by running the

system when GPS satellites are less available and possibly providing lower

position quality. Alternatively, you can select the best level of quality in order to

achieve the maximum accuracy for each correction type.

The bars on the GPS position quality indicator represent the overall quality of

the position. The quality is determined by factoring satellite availability,

health, and a calculated accuracy estimate. The more green bars shown, the

higher the level of GPS position quality.

A black bracket under the GPS signal bars indicates the quality level you

selected:

Bars Option Select ...

Favor Accuracy For operations that require the highest accuracy, such

as row crop planting or strip-till applications.

Note – Trimble recommends this option for the best

pass-to-pass and year-to-year repeatability. This option

is equivalent to the quality level of previous versions of

the EZ-Guide firmware.

EZ-Guide 500 Lightbar Guidance System Release Notes 31

Page 32

Bars Option Select ...

Balanced Quality To trade potential accuracy for a slight increase in

production time.

Favor Availability To extend production time further, with more

potential for reduced accuracy.

Note – This option sometimes trades some accuracy

for more availability or runtime. This option may still

achieve the highest level of accuracy that is applicable

for your correction source. If you select this option

when using RTK corrections, the system may use

positions that are greater than 1'' pass-to-pass

accuracy.

To adjust the GPS position quality indicator, go to Configuration / SBAS,

OmniStar, or RTK.

Krohne Liquid manure flow meter support

The EZ-Guide 500 Lightbar Guidance System now supports the Krohne

liquid/slurry electromagnetic flow meter for as-applied mapping of manure

applications.

You need an EZ-Guide 500 to Krohne interface cable (P/N 78369) to connect

the two devices.

Liquid manure application, tracking, and reporting

The EZ-Guide 500 lightbar guidance system now allows you to generate liquid

manure handling records to satisfy regulatory requirements. Use this option to

easily track the location of the area covered, along with the volume per area

and other important data points.

When this feature is enable and connected to a flow meter, the EZ-Guide

system records the actual rate from the flow meter that is being applied for

each field. These values will then appear as an as-applied coverage map in the

32 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 33

Summary Report for that field. When you are finished, you can transfer the

Summary Report to a computer through a USB connection or import the field

data into the EZ-Office

®

software.

Setting up Krohne support

Before setup, the guidance screen appears as follows. Note that there is no

application bar:

1. Make sure that User Mode is set to Advanced.

2. Go to the Application Control option and from the Application Control

menu, select Controller Settings.

3. Select Liquid Manure:

EZ-Guide 500 Lightbar Guidance System Release Notes 33

Page 34

4. Enter the pulses per gallon that the flow meter outputs—for more

information, refer to the flow meter's configuration display or the user

documentation. A common measurement is one pulse per gallon:

The system is now configured to read information from the flow meter.

Read the information on this screen before continuing:

5. Select Ta rg et Rat e. The target rate is the rate you want to achieve through

varying the speed of the vehicle or through altering the pump pressure or

volume:

34 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 35

6. Scroll up or down to achieve the required rate and then select OK:

7. Confirm that the screen shows the correct rate. Press the

return to the guidance screen:

I button twice to

EZ-Guide 500 Lightbar Guidance System Release Notes 35

Page 36

The guidance screen now shows the application bar at the bottom:

T = target rate

A = actual rate. Reported

in gallons per acre when

vehicle is moving

F = flow rate. Reported

in gallons per minute when

vehicle is stationary.

36 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 37

Application bar

c

d

e

Item Description

Flow/application indicator The wheel spins when flow meter pulses are detected.

c

Boom section status indicator Change color to show the current state of each boom

d

Auto/manual switching

e

indicator

section:

• Green: The boom section is enabled and applying

product.

• Orange: The boom section is enabled but not

currently applying.

• Red: The section is off (no flowmeter pulses

detected).

Shows which switching mode the controller is in.

• When the system is in manual switching mode, the

indicator is gray.

• When the system is in automatic switching mode,

the indicator is in color.

EZ-Guide 500 Lightbar Guidance System Release Notes 37

Page 38

EZ-Boom granular fertilizer spreading

The EZ-Guide 500 lightbar guidance system now supports granular fertilizer

application with the EZ-Boom system. Using a rate sensor and a Servo or

PWM control valve, you can control a single product on a pull-type or

self-propelled spreader.

The granular spreading feature allows you to select a jump start speed to

compensate when operating under a low GPS signal.

This feature is available from Controller Settings / EZ-Boom.

Upgrade procedure

Installing additional language packs

CAUTION – Do not add language packs to the lightbar when the internal

C

memory is nearly full (less than 15 hours remaining). To free up internal memory,

save all of the data to a USB drive and then copy the data on the drive to an

office computer. Delete the field data from the internal memory. Install the

language packs and then, if necessary, use the drive to replace the field data in

the lightbar’s internal memory.

A number of language packs are available as a web release. Language packs are

loaded onto the lightbar from a USB drive:

1. Transfer the required language pack (.lpf file) from

www.ez-guide.com to an office computer.

2. Copy the language pack to a USB drive and then insert the USB drive into

the USB port on the lightbar. Make sure the files are copied to the root of

the USB drive, not to any folders on the USB drive.

3. Turn on the lightbar.

38 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 39

4. Select the main guidance screen and then wait for up to 1 minute. The

language pack is automatically detected:

5. Press to load the language pack(s).

Once the language pack is installed, the language selection screen

appears.

6. Select the language you require:

EZ-Guide 500 Lightbar Guidance System Release Notes 39

Page 40

Upgrading the firmware

CAUTION – Do not upgrade the lightbar’s firmware when the internal memory is

C

nearly full (less than 15 hours remaining). If you do, the lightbar may lose your

current settings. Before upgrading the firmware, save the lightbar’s settings and

the data to a USB drive and then transfer all of the data on the drive to an office

computer. If necessary, use the drive to replace the field data in the lightbar’s

internal memory after the upgrade is complete.

Note – Before upgrading to version 5.10 of the EZ-Guide 500 system, make sure

™

that you are using the AgGPS Autopilot

or later.

Before you begin to update the firmware in the lightbar, check which firmware

version is currently installed:

1. Select Configuration / About the EZ-Guide.

2. Check the Vers ion number:

automated steering system version 4.52

This is the firmware version. If the number is 4.05.xxx.x, you have firmware

version 4.05. If the number is 5.10.xxx.x, you already have firmware version 5.10.

To upgrade the lightbar to version 5.10:

1. Download the firmware version 5.10 upgrade file from www.EZ-

Guide.com to your office computer.

2. Extract the contents to the USB drive. Make sure the files are copied to

the root of the USB drive, not to any folders on the USB drive.

3. Insert the USB drive in the lightbar.

40 EZ-Guide 500 Lightbar Guidance System Release Notes

Page 41

4. Turn on the lightbar.

When the USB drive is detected, the lightbar runs the upgrade wizard

automatically.

If you currently have firmware version 4.05 or earlier, the firmware version

5.10 upgrade file appears:

CAUTION – Do not turn the lightbar off while the firmware is being updated.

C

This could render the lightbar inoperable.

5. Select the EZ-Guide firmware .img file and then press . The wizard

installs the monitor file and the firmware version 5.10. When the

firmware is installed, the lightbar restarts.

The lightbar firmware is upgraded to version 5.10.

Note – When upgrading to this new firmware, the previously set SNR and

Elevation Mask GPS settings remain active until you next turn off and then turn

on the lightbar.

EZ-Guide 500 Lightbar Guidance System Release Notes 41

Page 42

42 EZ-Guide 500 Lightbar Guidance System Release Notes

Loading...

Loading...