Page 1

Trimble DiNi® 12, 12T, 22

Short Form User Guide

PN 571 703 081

www.trimble.com

Page 2

Page 3

Introduction

Welcome to DiNi

By purchasing a Digital Level from Trimble

have opted for a leading-edge product in the field

of surveying instruments.

We congratulate you on your choice and would

like to thank you for the trust placed in our company.

These abridged instructions are intended to serve

as start-up aid for you. Please find more detailed

descriptions in the full Operating Instructions.

Good luck.

®

you

3

Page 4

Safety Notes

Do not point the telescope directly at the sun.

Do not use the instrument and accessories in

rooms with danger of explosion.

Operate the instrument only in the compliance

with the operating conditions specified.

Protect operator and instrument sufficiently at the

site of measurement (e.g. construction site, roads,

etc.). Observe any relevant national regulations and

the Road Traffic Act.

Tread tripod legs firmly into the ground to prevent

sinking in and falling over of the instrument by wind

pressure.

Mount the instrument to the tripod using the

tripod screw immediately after you take the instrument from its case. Never leave the instrument

placed loosely only on the tripod head. After loosening the tripod screw, immediately store the instrument in its case.

Don’t make any changes or repairs on the instru-

ment and accessories. This must be done only by a

service team or by authorised technical staff.

4

Page 5

Safety Notes

When you work with staves in the vicinity of elec-

tric plants (e.g. electric railways, aerial lines, transmitting stations, etc.) your life is acutely endangered.

This risk exists independent of the staff material (e.g.

aluminium or wood). In such cases it is necessary to

inform the competent and authorised safety authorities and observe their instructions.

Don't use the instrument too long when it is rain-

ing. During breaks, cover the instrument with the

protective hood. Wipe the instrument and case dry in

the field and let it dry completely indoors, with the

case open.

In a thunderstorm, don't carry out surveying work

to avoid being struck by a lightning.

Remove the batteries in case of unloading or a

longer time without using the instrument. Recharge

the batteries with Single Battery Charger.

Properly dispose of the batteries and equipment

taking into account the applicable national regulations. Prevent improper use of the disposed instrument by proper disposal.

5

Page 6

Safety Notes

Before every use of the instrument, verify that it is

in perfect condition, particularly after longer transportation, fall or any other improper use. Systematic

check measurements particularly before and after

extensive surveying projects will help to avoid erroneous measurements.

Do not operate the battery charger and PC Card

reader in humid conditions (risk of electrical shock).

Make sure the voltage setting is identical on the

battery charger and voltage source. Do not use instruments while they are wet.

The magnetic PC Card cover should always be in

place to stop environment damage (water, dust).

Do not use destroyed plugs and cables for accesso-

ries with the instrument.

6

Page 7

Environmental information

NOTICE FOR TRIMBLE'S EUROPEAN UNION CUSTOMERS

Trimble is pleased to announce a new recycling

program for our European Union customers. At

Trimble, we recognize the importance of

minimizing the environmental impacts of our

products. We endeavor to meet your needs, not

only when you purchase and use our products,

but also when you are ready to dispose of them.

That is why Trimble is actively pursuing, and will

continue to pursue, the expanded use of

environmentally friendly materials in all its

products, and why we have established a

convenient and environmentally friendly recycling

program.

As Trimble makes additional recycling facilities

available for your use, we will post their locations

and contact information to our Recycling

Instructions web page.

For product recycling instructions and more information, please go to

http://www.trimble.com/environmentT

Recycling in Europe:

To recycle Trimble WEEE,

Call +31 497 53 2430, and ask for the “WEEE

Associate” Or Mail a request for recycling

instructions to:

7

Page 8

Environmental information

Trimble Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

8

Page 9

Contents

Introduction................................................... 3

Safety Notes................................................... 4

Environmental Information............................. 7

Contents ........................................................ 9

Hardware overview....................................... 10

Software overview DiNi

Software overview DiNi

12,22..................... 12

12T........................ 13

Setting up and switching on......................... 14

The control panel ......................................... 15

Preparing for measurement .......................... 16

Projects and inputs....................................... 20

Line levelling ................................................ 22

Line interruption........................................... 24

Line adjustment............................................ 26

Reference Heights in the Memory ................. 28

Data Transfer ............................................... 29

Data Memory PCMCIA Card.......................... 31

Adjustment .................................................. 32

Accessories for DiNi

.................................... 35

Updates ....................................................... 36

Maintenance and Care ................................. 37

9

Page 10

Hardware overview

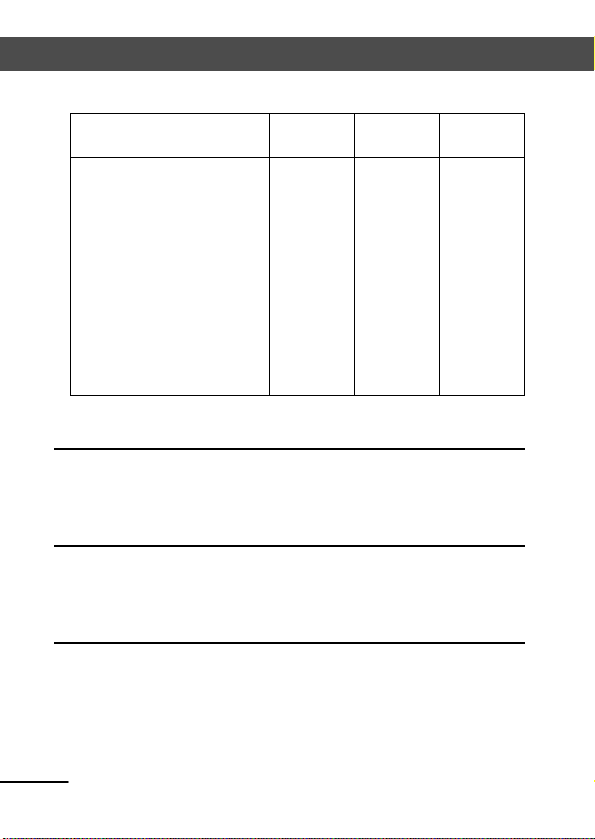

Standard deviation as

per DIN 18723

Standard deviation on

1 km of double

levelling

Electronic measurement:

- invar precision

barcode staff

- foldable bar code staff

Visual measurement:

- foldable staff,

metric scale

DiNi

12

- Graduated circle, external

- Exchangeable PCMCIA Card

DiNi

12 T

- Elektronic circle

- Exchangeable PCMCIA Card

DiNi

22

12 DiNi 22 DiNi12T

DiNi

0.3 mm

1.0 mm

1,5 mm

0.7 mm

1.3 mm

2.0 mm

0.3 mm

1.0 mm

1,5 mm

- Graduated circle, external

- Internal data memory

10

Page 11

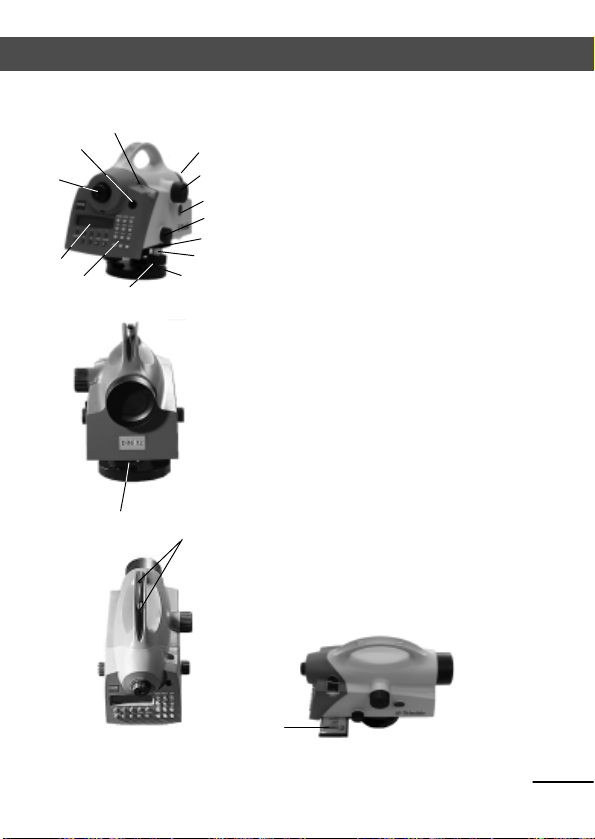

15 16 14

3

6

10 7 5

Hardware overview

13

12

11

9

8

1 Telescope objective with integrated

sunshield

2 Telescope focusing control

1

3 Trigger key for measurement

2

4 Horizontal tangent screw

4

(endless slow motion drive)

5 Graduated circle, external

6 PCMCIA Card plug-in module

(DiNi

(DiNi

®

12, 22)

®

12, 12 T)

7 Tribrach

8 Footscrews

9 Keyboard

10 Display

11 Eyepiece

12 Window for circular bubble

13 Cap, to be removed for adjustment of

circular bubble

14 Battery compartment

15 15 Sight vane (notch and bead sights)

16 PCIMCIA Card in the plug-in module

(DiNi

®

12, 12 T)

11

Page 12

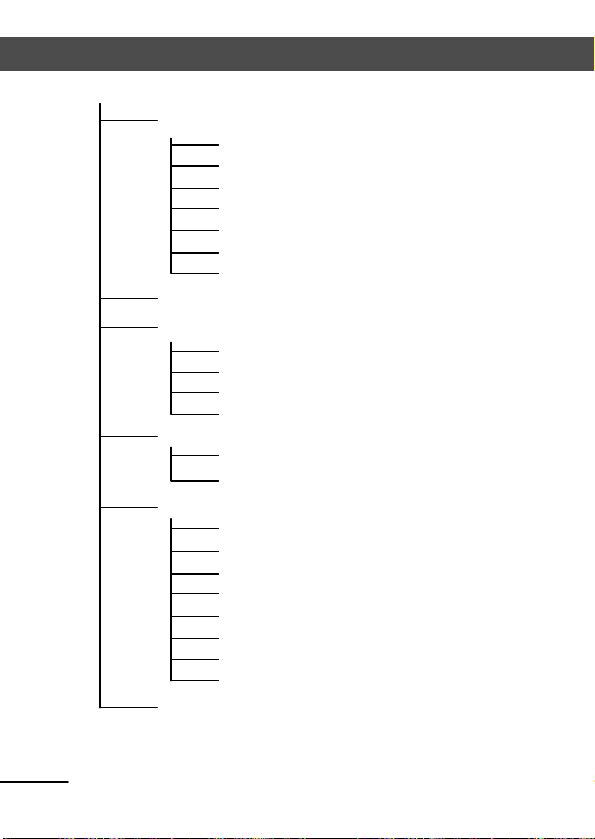

Software overview DiNi 12,22

1 Input

1 max. sighting distance

2 min. sighting height

3 max. station difference

4 Refraction coefficient

5 Addition constant (offset)

6 Date (DiNi

7 Time (DiNi

2 Adjustment

3 Data transfer

1 Interface 1

2 Interface

3 PC-Demo

4 Update/Service

4 Setting of recording

1 Recording data

2 Parameter setting

5 Instrument settings

1 Height

2 INP function

3 Display L

4 Shut off

5 Acoustic signal

6 Language

7 Date (DiNi

8 Time (DiNi

6 Line adjustment (DiNi

12)

12)

12)

12)

12)

12

Page 13

Software overview DiNi 12T

1 Input

.......

2 Adjustment

.......

3 Data transfer

.......

4 Setting of recording

.......

5 Instrument settings

1 Display L

2 Display E

3 Shut off

4 Acoustic signal

5 Language

6 Contrast

6 Set instrument units

1 Height in

2 INP function

3 Direction in

4 Coordinate System

5 Coordinate Display

6 Data

7 Time

7 Line adjustment

........ DiNi

12 and 22

13

Page 14

2

2 2

Setting up and switching on

Set-Up

Set up the tripod securely

Remove instrument from container

Place instrument on tripod and screw down

tightly (tripod retaining screw)

Move bubble into the centre of the circular level

(tripod foot screws)

Switching on

1

1

ON/OFF

Press button

Requirements: Battery charged

Memory Card inserted

14

Page 15

The control panel

DiNi 12 and DiNi 22

Switching

on/off

DiNi

12T

Main menu

Messen

Measurment

Editor

Main menu

Switching

on/off

Measurement

Editor

Measure mode

15

Page 16

Preparing for measurement

Setting recording

Start Screen

7 MENU

Call up Main Menu:

Select from menus in this way

Yes

ESC

MOD

Scroll through menu

Select marked entry

Return to previous menu

or

Change entry

or

Change softkeys

Yes

4 SET REC. PARAM.

16

Page 17

Preparing for measurement

The following settings are requirements for subsequent line adjustment!

DiNi® 12 and 22 only:

Ja Yes

MOD

ESC

1 RECORDING OF DATA

2 RECORD PC Card or iMEM

3 ROD READINGS RMC

Return

DiNi® 12T only:

Ja Yes

MOD

ESC

1 RECORDING OF DATA

2 RECORD PC Card

Return

and

+- TS-M

MOD

MOD

ESC

Set Measure Mode

1 MODE Level

2 REG:- DATA R,HD,Z

Return

17

Page 18

Preparing for measurement

Intermediate sight Stake out

Without reference height

MEAS

Initiate measurement – Repeatable as often as desired

Staff reading Horizantal distance

With reference height

Intm

Start intermediate sight

Input benchmark height:

o.k.

Enter counter values in this way

0,1,....9

o.k.

MEAS

o.k.

Use number keys

Correct input

Confirm input

Measure backsight point

Confirm measured value

18

Page 19

Preparing for measurement

Height difference

to the Backsight

point

Height of the particular point

9 DISP

Browse values

A: Further measurements

B: Return

Stake out the height of a point

SOut

o.k.

MEAS

o.k.

Start staking out

Input benchmark height

Carry out backsight measurement

Confirm nominal value

Input nominal elevation

o.k.

MEAS

Actual height of point to be staked out

Nominalactual

deviation

9 DISP

o.k.

Initiate measurement

Browse values

Repeat until dz is sufficiently small

A: Further nominal elevations

B: Return

Visual rodreading

19

Page 20

Projects and inputs

Generating a new project (DiNi 12 and 12T only)

Call up edit mode

6 EDIT

Select project management

PRJ

Yes

Input name

o.k.

Switch to

Project name

ESC

Present

character set

20

Page 21

Projects and inputs

Input alphanumeric characters in this way

abc, ABC

NUM

DIST.

MEAS

0,1,....9

o.k.

Switch to small, large,

,

numeric

Browse character set

Browse character set

Number keys for characters

Correct input

Confirm input

21

Page 22

Line levelling

Start a new line

Line

n ew line

o.k.

o.k.

o.k.

o.k.

o.k.

Input line number

Select sequence of measurem.

Input benchmark height

Input point number and point code

New line

Procedure:B/F etc.

Alternate:yes/no

22

Page 23

Line levelling

Measuring back and foresights

Height of line of sight

MEAS

backsight

Staff reading

backsight

MEAS

Foresight

Wdhl

Ending line

LEnd

Yes

etc.

Repeat measurement

Specify end of line as a benchmark height

Next sight

Repeat

DISP

Browse values

Overall height

difference

Nominal-actual

deviation

Total

back/foresight

distances

23

Page 24

Line interruption

Intermediate sight on the line

Intermediate sight Stake out

IntM

MEAS

ESC

Start intermediate sight

Initiate measurement

Return

Staking out a height on the line

SOut

o.k.

MEAS

o.k.

ESC

Start staking out

Input nominal elevation

Initiate measurement

Confirm result

Continue with next height to be staked out

Return

Continue with last line

Line

Select option

Continue

with line

levelling

24

Page 25

Line interruption

Continuing with a line from another project

6 EDIT

Call up

project,

confirm

project

Cont. Line

of Project

Select

Option

?PNo

?Cod

?Adr

?LNo

o.k.

Continue

with line

levelling

Search for start line

Confirm end of line

25

Page 26

Line adjustment

DiNi 12 and 12T only

Line adjustments can only be performed if the

levelling line has been completed and saved on

the memory along with the intermediate heights.

In line levelling, a line is linked to points with

known heights at the beginning and at the end

so that the measured height difference can be

compared with the nominal height difference.

The "line adjustment" program allows to spread

the occurring difference over the individual staff

stations proportionally to the sighting distances,

obtaining adjusted heights as result.

7 MENU

Yes

Search for start of line

i.e.

?ZNr

o.k.

26

Page 27

Line adjustment

End of line is automatically found

o.k.

Yes

Input

benchmark

heights

o.k.

Start

Mark changed

data

End line adjustment

ESC

27

Page 28

Reference Heights in the Memory

Besides entering of data it is possible to call up

the stored data from the memory for line levelling

and Staking out.

Call up the data in this way.

Select project

PRJ

?

?PNr

?Code

?Adr

o.k.

To search in memory using specified criteria

Search for:

Point number, point code or address

Confirm the height

28

Page 29

Data Transfer

Cable for Data transfer with Xon/Xoff

protocol:

DiNi

Order number

7081779470000

®

PC cable:

PC Car d Drive

Cable

PMCIA

29

Page 30

Data Transfer

Data transfer via cable

7 MENU

YES

YES

YES

i.e.

all

YES

Select interface

Select transfer direction

Attention !

A requirement for transfer are identical parameters on the instrument and the peripheral

device: format, protocol, baud rate, parity and

stop bits.

Start data transfer

30

Page 31

Data Memory PCMCIA Card

Formatting a PC Card

With the DiNi 12 and 12T it is possible to format

a SRAM - PC Card.

7 MENU

YES

YES

YES

Attention !

Make sure to transfer the data stored in the PC

Card to another storage medium beforehand, as

all data in the memory is lost during formatting.

31

Page 32

Adjustment

7 MENU

YES

Different

Methods

with identical result

The instrument adjustment defines the necessary

corrections and correction values for the line sight

of DiNi®, which are required to ensure optimum

measuring accuracy.

Before starting any adjustment, allow the instrument to adapt to the ambient temperature.

Situation

A 1 2 B

Förstner

I

1/3 I 1/3 I 1/3 I

1 A B 2

Nähbauer

I

1/3 I 1/3 I 1/3 I

2 A 1 B

Kukkamäki

I

app. 20m I app. 20m I

32

Page 33

Adjustment

MEAS

o.k.

After the selection of the adjustment method, you

can change the settings of earth curvature and

refraction. This is not possible at another point of

the DiNi® menu system. Changes of earth curvature and refraction settings become effective only

if you adjust the system afterwards. The line of

sight will then be corrected accordingly.

with graphic help

.....

Result

If the new line of sight correction is adopted, the

program requests the checking of the reticule

alignment (for visual reading).

screw below the eyepiece - 1

1

33

Page 34

Adjustment

Adjustment of circular bubble

Check the function of circular bubble:

By turning the instrument 180° round the vertical

axis the circular bubble has to remain within the

circle.

Adjustment of circular bubble:

Remove the screw (2) of the protection cap with

the adjusting tool and detach the protection-cap.

2

Turn the instrument 180°.

J3

J2

Eliminate half the residual deviation of the circular

bubble by means of the tribrach screw and half

by adjusting the circular bubble (J1..3).

J1

Repeat this procedure and check the residual

deviation.

Fix the protection cap again. Make sure that the

rubber joint is placed in the groove.

34

Page 35

Accessories for DiNi

Foldable staff made of wood

length: 3 m or 4 m

Telescopic staff made of aluminium

length: 4 m or 5 m

Special parts and invar tape

made of aluminium, invar and foil

length: 30 cm, 50 cm and 1 m

Invar staff

- small and wide base

- length: 1 m, 2 m and 3 m

- Transport case

- Telescopic support

Battery pack and charger

Memory Card and data transmission cable

35

Page 36

Updates

DiNi PC

Cable:

Ordernumber

708177-

9470.000

Software updates are offered by the manufacturer on Internet sites with reservation as to extensions of the functional range. Surf to our Web

sites. The dealer will be pleased to communicate

the Internet site names, when required.

The updates offered contain the following

functions:

- Update of the instrument computer

- Update of the interface computer (DiNi

®

12 and

DiNi® 12 T only )

- Loading of an additional language (four lan guages can be loaded)

The files loaded from the Internet sites have to be

unpacked and copied on a floppy disk.

For the update processes , the operating system

DOS has to be used in any case.

Additionally to the files required for the update

process, the

update instructions have to be

loaded from the Internet in any case and have to

be observed

strictly. No liability will be assumed

for claims resulting from the non-compliance with

the specification.

In these instructions, all steps are described in

detail. They may contain and explain commands

that differ from the description given here.

36

Page 37

Maintenance and Care

Instructions for Maintenance and Care

Allow sufficient time for the instrument to adjust

to the ambient temperature.

Use a soft cloth to remove dirt and dust from the

instrument.

When working in wet weather or rain, cover the

instrument during longer breaks with the protective hood.

Clean the optics with special care using a clean

and soft cloth, cotton wool or a soft brush, do

not use any liquid except pure alcohol.

Do not touch the optical surface with the fingers.

For transportation over long distances, the instrument should be stored in its case.

When working in wet weather, wipe the instrument and case dry in the field and let it dry completely indoors, with the case open.

Let wet instruments and accessories dry before

packing them up.

After a long storage, check the adjustment of the

instrument prior to use.

Observe the boundary values for the temperature

of storing, especially in the summer (interior of

the vehicle).

37

Page 38

38

Page 39

Page 40

Trimble Engineering and Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424

U.S.A.

800-538-7800 (Toll Free in U.S.A.)

+1-937-233-8921 Phone

+1-937-233-9004 Fax

www.trimble.com

Loading...

Loading...