Page 1

Product Catalog

Water Source Heat Pump

Axiom™ High Efficiency Vertical Stack — GET

¾–3Tons—60 Hz

November 2013

WSHP-PRC020D-EN

Page 2

Introduction

Water-Source Vertical High-Rise

The 3/4-ton through 3-ton vertical high-rise water-source heat pump is a floor mounted, “furred-

in” unit, designed to be hidden from view behind drywall to blend with the room’s natural decor.

In multi-story buildings, the units may be stacked one on top of the other to minimize piping and

electrical costs.Supply, return and condensate riser piping may be factory mounted to simplify job

site installation of the equipment.

The high-rise configuration is often used in hotels, dorms and assisted living facilities where a

single unit could provide comfort to a single or multiple room dwelling. Because the units are

mounted directly in the space, ductwork is optional.

All water-source heat pumps are commissioned, tested and quality certified prior to leaving the

factory.This assures global quality standards from controls, water, refrigeration, and aesthetics to

the building owner and installing contractor.

Key features of the water-source, vertical stack heat pump include:

1. Removable/replaceable chassis 8.

2. Ducted and free discharge cabinet selections available

3.

Factory mounted flow control with strainer and

isolation valve option

4. Plug-in chassis and plug-in thermostat design 12. Auxiliary drain pan

5. Factory supplied riser options 13. Rust resistant chassis drain pan

6. Maintenance accessibility for coil fin cleaning 14. Intelligent controls

Extra quiet design includes enhanced and deluxe sound

7.

proofing choice

Through the front high and low pressure service ports

accessible

9. Tamper proof hinged acoustical door option

10. Unit mounted switch and fuse option

11. Lower height cabinet for ducted applications

Refrigeration Control

TXV

Water-Out Connection

Water-In Connection

Auxiliary

Drain Pan

Refrigeration Section

Completely Enclosed

Chassis Rails

Trademarks

Axiom, ReliaTel,TOPSS,Tracer,Trane, and theTrane logo are trademarks or registered trademarks

ofTrane in the United States and other countries.Trane is a business of Ingersoll Rand. All

trademarks referenced in this document are the trademarks of their respective owners.

LonTalk is a registered trademark of Echelon Corporation.

BACnet is a registered trademarks. All trademarks referenced in this document are the trademarks

of their respective owners.

Revision Summary

WSHP-PRC020D-EN (09 November 2013): Performance Data (Efficiency Upgrades);WPRD Chassis

© 2013Trane All rights reserved WSHP-PRC020D-EN

Page 3

Table of Contents

Introduction ......................................................2

Features and Benefits ..............................................4

Application Considerations ..........................................7

Selection Procedures ..............................................13

Model Number Descriptions ........................................14

General Data .....................................................16

Performance Data ................................................ 17

Unit Fan Performance .............................................38

Electrical Data ....................................................42

Dimensional Data .................................................43

Controls ........................................................51

Water-Source Vertical High-Rise ................................. 2

Deluxe 24V Electronic Controls ................................. 51

Deluxe 24V features include: ................................... 51

Tracer ZN510 functions include: ................................ 53

Thermostats and Zone Sensors .....................................55

Accessories ......................................................56

Mechanical Specifications ..........................................57

WSHP-PRC020D-EN 3

Page 4

Features and Benefits

Unit Description

The vertical high-risewater-source heat pumpis a floor mounted configuration available in a ¾ ton,

1 ton, 1¼ ton, 1½ ton, 2 ton and 3 ton sizes.

The unit cabinet may be ordered for early shipment to aid in early installation of drywall, plumbing

and electrical. See “Model Number Descriptions,” p. 14.The cabinet design is available in either an

88-inch height (free discharge) or 80-inch height (ducted) configuration. As many as 3 supply-air

discharges are available for the 1¼ ton-3 ton, free discharge cabinets to provide multiple supplyair through one unit.

Air distribution is made through a rigid bar type extruded aluminum grille mounted to the

sheetrock. It is both durable and attractive in design.

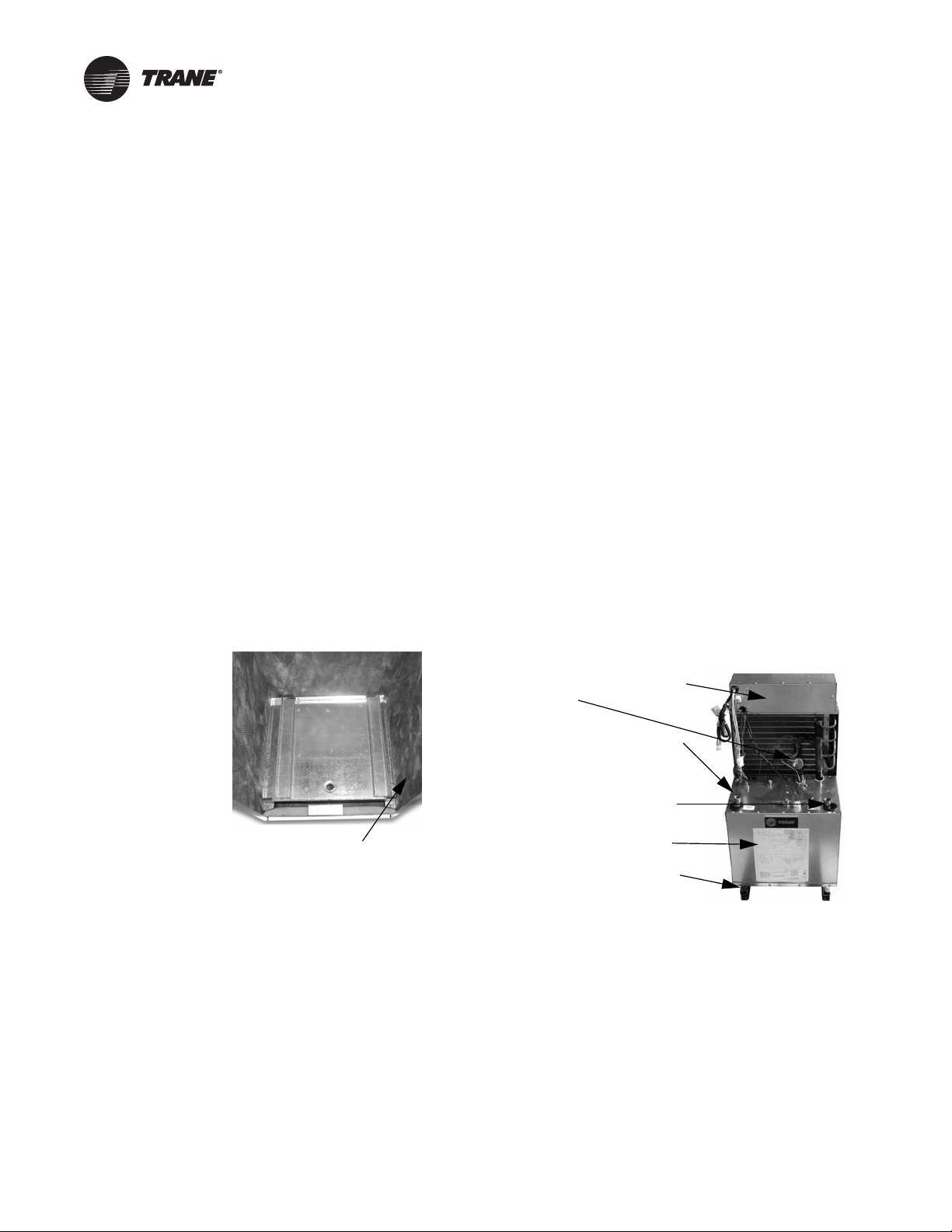

The return-air panel is a hinged acoustical door, see Figure 1, p. 4.The door allows for easy access

to the unit’s filter and for maintenance of the equipment.

The hinged acoustical panel provides greater sound attenuation, and is mounted flush to the wall.

This panel is easily removed for filter maintenance or chassis removal through the magnetic catch

door. An optional tamper proof latch is available on the hinged door design to impede access if

required.

Figure 1. Return-air flush mounted hinged door

Blower/Motor Assembly

The unit’s blower/motor assembly includes double width, double inlet (DWDI) blower with direct

drive PSC motor or optional ECM motor for improved efficiency and power factor. It may be easily

removed for cleaning or service after removal of the unit chassis.The PSC motor is a multi-speed

design, factory wired to high speed or low speed (order specific).The tap will be wired and capped

inside the unit control box for easy field convertibility.The ECM motor is programmed to provide

four constant CFM profiles and is shipped on Profile B – the rated CFM of the unit.To change the

PSC speed tap or the ECM CFM profile, see installation manualWSHP-SVX03*-EN for instructions.

Controls

Standard controls include a 24V, micro-processor Deluxe controller for a wall-mounted thermostat

option.The thermostat is typically placed above the return-air door. Even though the thermostat

is considered to be unit mounted, the thermostat is mounted to the dry-wall that covers the front

of the unit.

4 WSHP-PRC020D-EN

Page 5

Features and Benefits

Thermostat selections are provided in the “Thermostats and Zone Sensors,” p. 55 section of the

catalog.They are available in manual or automatic changeover options.

The deluxe controller includes relays for: anti-short cycle compressor protection, random start

delay, brown-out protection low pressure time delay, compressor delay on start and night setback

control.These extended control features offer greater system performance to extend the

equipment’s life.

Figure 2. Deluxe control box

TheTracer™ ZN510 controller (option) is provided on the vertical stack design for direct digital

control (DDC) systems.This controller offers the building owner innovative ways to optimize

heating and cooling energy for the building. Faults and sensors include: random start delay,

heating/cooling status, occupied/unoccupied mode, and fan/filter status.

Figure 3. ZN510 control box

TheTracer™ Loop Controller (TLC) may be added to either the Deluxe controls or the ZN510

controls to maintain system loop operation. See WMCA-IOP-1 for more information on the TLC.

The ZN510 controller may also be applied with theTracker and Summit building management

systems to further enhance system operation.

Non-fused switch and fused entrance block may be factory added to the equipment to save

installation time of these components in the field where local building codes allow.

Deluxe 24V Electronic Controls

General alarm is accomplished through the lockout relay and is usedto drive light emitting diodes.

This feature will drive dry contacts only, and may not be used to drive field installed control inputs.

Factory Installed Flow Control

Optional factory mounting of the isolation valve and flow control valves is available to speed field

equipment installation, and help provide optimum water flow balancing support.

Refrigeration Section

The unit’s compressor is a highly efficient, hermetically sealed with internal vibration isolation.

External isolation is provided between the compressor and mounting plate tohelp reduce radiated

noise that is typically associated with compressor start.

The air-to-refrigerant coil is easily accessible for cleaning purposes behind the unit’s removable

return-air door/panel.

The water-to-refrigerantcoil is acopper or cupro-nickel (option)co-axial tube-within-a-tube design.

The inner-water tube is deeply fluted to enhance heat transfer and minimize fouling and scaling.

The outer refrigerant gas tube is made from steel material.The coil is leak tested to assure there

WSHP-PRC020D-EN 5

Page 6

Features and Benefits

is no cross leakage between the water tube and the refrigerant gas (steel tube) coil.The ½” (009/

012/015/018) and ¾”(024/036) threaded water connections to the water-coil are available on the

exterior chassis top.A flexible hose connectionwith shut-off istypically used between the riser and

water-coil in/out connections on the chassis to reduce water vibration.

The refrigerant flow metering is made through a thermal expansion valve (TXV).TheTXV allows

the unit to operate with an entering fluid temperature from 25°F to 120°F, and an entering air

temperature from 40°F to 90°F.The valve precisely meters refrigerant flow through the circuitry to

achieve desired heating or cooling.

Unlike cap-tube assemblies, theTXV allows the exact amount of refrigerant required to meet the

coil load demands.This precise metering increases the over-all efficiency of the unit.

The unit’s reversing valve is piped to be energized in the cooling mode. All vertical high-rise units

ship in a heat pump configuration with a system reversing valve.

Supply/Return/Condensate Risers

Supply, return and condensate risers are available as a factory mounted and shipped option.The

risers are constructed from type L or M copper.The top of each riser is swaged to accept the same

size diameter riser from above.This helps facilitate installation of the water supply, return and

condensate to and from the unit. Insulation may be factory installed or field installed per order

selection.The insulation helps keep moisture from forming on the pipes and damaging building

construction.

The riser length may be ordered as standard in 96” to 120” lengths. See “Equipment Risers,” p. 9

for riser application information.

Unit Safety

All unit safety devices are provided to help prevent compressor damage. Low pressure switch and

high pressure switch are added to help protect the compressor operation under a low charge (40

psig) or during high discharge (650 psig) pressures. In cases where a low charge, or excessive loss

of charge occurs, each compressorcomes equipped withan overload device tohalt the compressor

operation.

A safety lockout provides the mechanical communication of the low and high pressure switches to

prevent compressor operation if the unit is under low or high refrigerant pressures, or during a

condensate overflow condition.The lockout relay may be reset at the thermostat, by cycling power

to the unit or through a LonTalk™ front end device (ZN510 control option).

6 WSHP-PRC020D-EN

Page 7

Application Considerations

Advantages of Geothermal

The advantages of a geothermal heat pump system can literally decrease heating and cooling

operating costs by 30%-40%.The units are durable, and typically last longer than conventional

systems.They are protected from harsh outdoor weather conditions, because the unit is installed

indoors and the loop underground. According to ASHRAE, the estimated service life for a

commercial water-to-air heat pump is 19 years.

Geothermal heat pumps have fewer mechanical components, making them more reliable and less

prone to failure.

Geothermal heat pumps work toward the preservation of the environment by reducing the

environmental impacts of electric power generation.

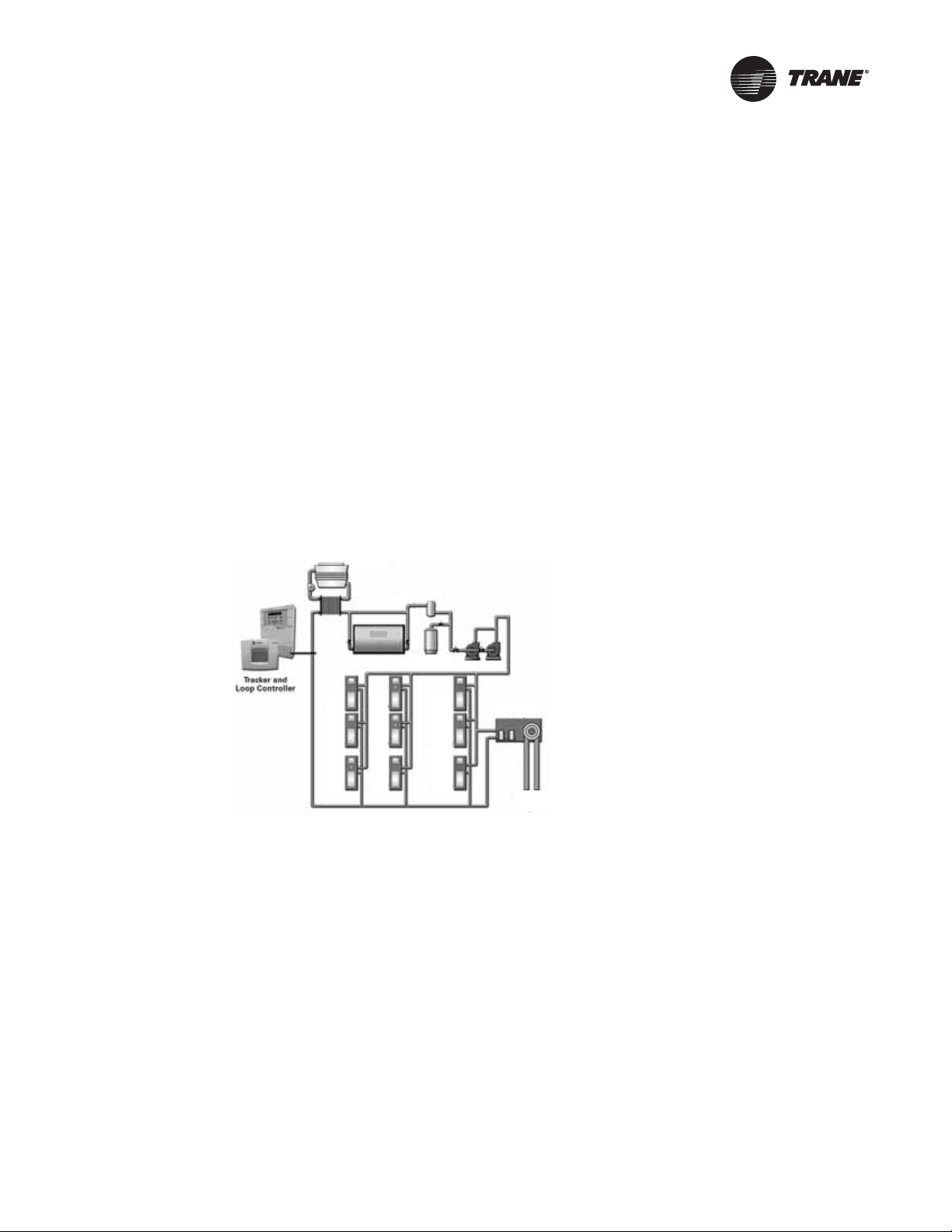

Flexibility

The vertical, high-rise water-source heat pump system is versatile for installation in boiler/cooling

tower applications, as well as ground-source (geothermal) applications.The system typically

employs a central pumping design.The central pumping design involves a single pump design,

usually located within a basement or mechanical room to fulfill pumping requirements for the

entire building system. An auxiliary pump is typically applied to lessen the likelihood of system

downtime if the main pump malfunctions.

Furring-In the Unit

The vertical high-rise water-source heat

pump is designed to be a furred-in

application. Dry-wall (sheetrock) is attached

to furring studs (not unit cabinet) until the

entire cabinet, exceptthe front access panel,

is enclosed. Access to the unit is made

entirely through thefront panel which spans

approximately one-half of the unit height.

The dry-wall enclosure allows the unit to

blend in with the decor of the room. If

renovations are needed, the drywall portion

of the unit can simply be re-papered or

repainted with the remainder of the room.

With careful design, the high-riseWSHP can

be incorporated into a room design, while

occupying minimum floor space.

WSHP

WSHP

WSHP

Cooling Tower

Boiler

WSHP

WSHP

WSHP

Expansion Tank

Water Storage

Tank

WSHP

WSHP

WSHP

Central Pumps

Water t o Water

Heat Pump

To Fresh Air

Ventilation

System

Installation Tips

When installing a high-rise water-source heat pump, there are specific installation requirements

that should be taken into consideration.These include:

• Noise control

• Riser location

• Furring-in the unit

Sound Attenuation

The high-rise heat pump is better suited for acoustically sensitive water-source heat pump

applications than other water-source products. Compressor and water noise are attenuated by the

filter panel, sheet rock and the acoustically lined door. Air noise is silenced through the extended

and insulated duct portion at the top of the vertical cabinet.

WSHP-PRC020D-EN 7

Page 8

Application Considerations

Figure 4. Installation illustration

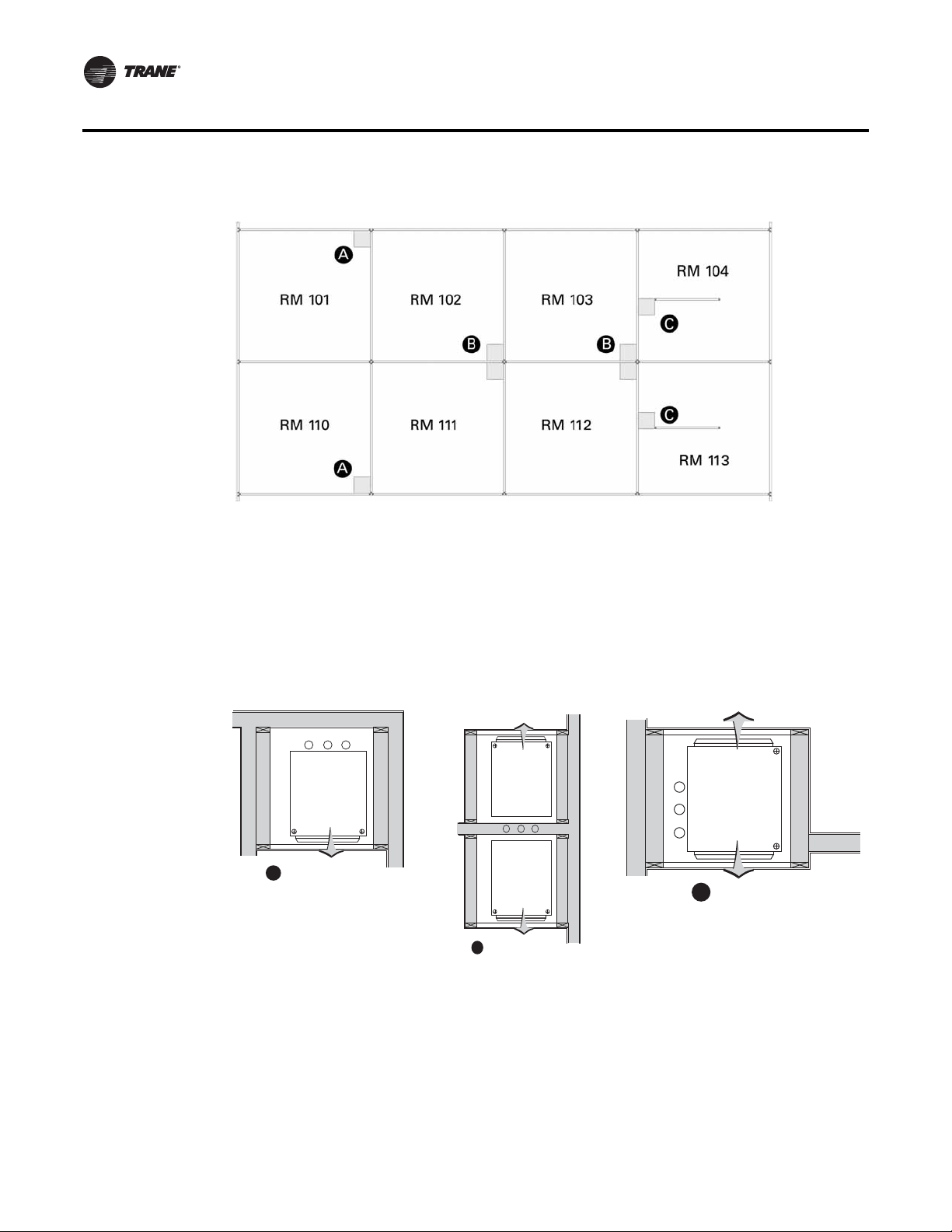

Equipment Installation

The vertical high-rise unit is versatile in design to fit numerous applications. It is typically applied

to dorm rooms, hotels and motels where multiple supply air configurations may be required for

individual tenantheating and cooling.The equipment requires little space, and is tucked away from

sight, and rough handling.The vertical stack design is economical to install, requiring no ductwork

for air supply.The riser design may be stacked one on top of another for multi-story applications,

or shared between two units (see example B) when architectural design permits. Because the

chassis is removable, serviceability to the equipment is enhanced. If service does become a

requirement, the chassis is simple to remove from the cabinet, replaced with a back-up chassis,

then repaired off-site at a convenient time.

RSD

R

A

SINGLE SUPPLY

CORNER SET-UP

SD

B

SINGLE SUPPLY

PRIMARY/SECONDARY SET-UP

RSD

C

DUAL SUPPLY

DIVIDING WALL SET-UP

8 WSHP-PRC020D-EN

Page 9

Application Considerations

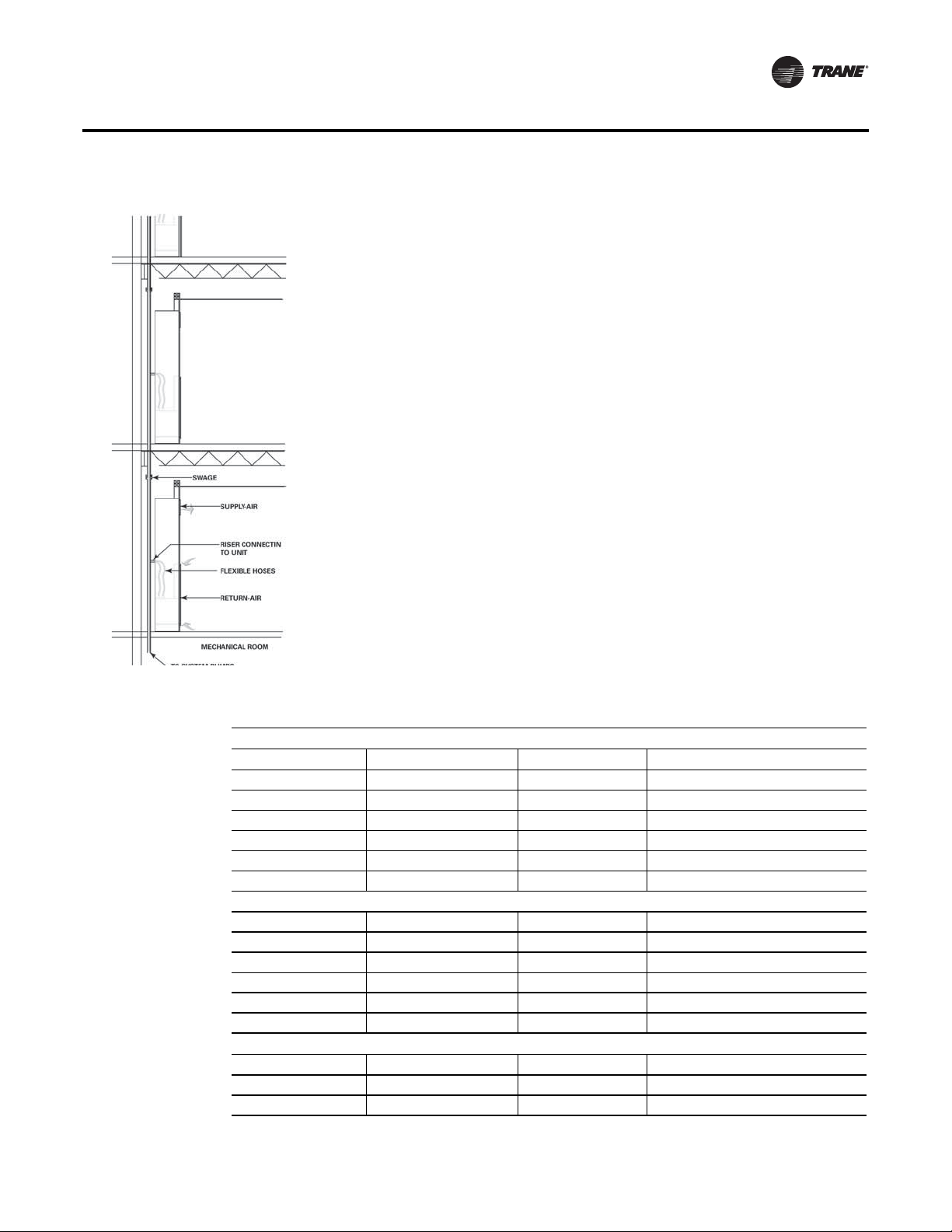

Equipment Risers

The riser provides an easy way to facilitate the water flow

through a multi-story building and the high-rise heat pump.The

high-rise heat pump is best applied to a building with identical

zones on each floor, and zones that are typically small. An

example building might include a hotel, dorm, condominium or

assisted living facility. With these types of buildings, the riser

column (external to the unit cabinet) can be stacked one on top

of the other.The piping installation for the entire HVAC system

becomes very simple to install because it is pre-measured, and

pre-fabricated at the factory.

Factory risers are available asType K (design special), L

(standard design), and M (standard design).The differences

between these types of materials is the wall thickness of the

copper. Table 1, p. 9 shows the wall thickness for the most

common diameters ofrisers. Itis recommended formost jobs to

use type L or Mcopper.Type Krisers are generally notnecessary

for most high-rise heat pump applications.

The riser design contains threaded stubouts to facilitate

connection of the supply and return risers to the hose kits.The

hose kits are then connected to the water-in/out of the unit’s

chassis.

Note: Supply/return/drain risers that are ordered and supplied

through the factory may be ordered as insulated.

Drain risers aregenerallymade of typeM copper.If copper, drain

risers are used, the risers should be insulated since the typical

temperatures of condensate may cause the riser to sweat.

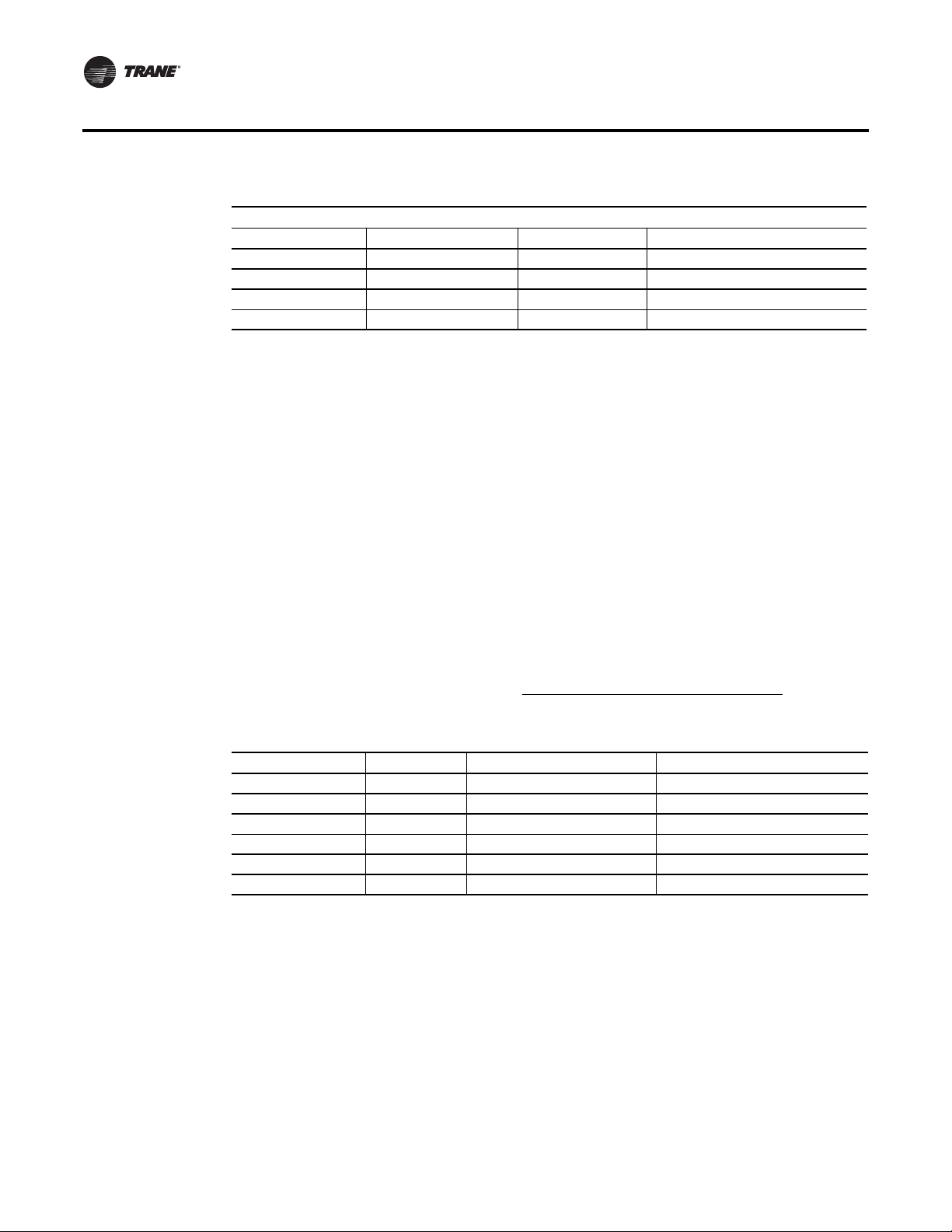

Table 1. Riser characteristics

Type K (special design)

Riser Size (in.) I.D. (in.) O.D. (in.) Copper Wall Thickness (in.)

1 0.995 1.125 0.065

1¼ 1.245 1.375 0.065

1½ 1.481 1.625 0.072

2 1.959 2.125 0.083

2½ 2.435 2.625 0.095

3 2.907 3.125 0.109

Type L (standard)

1 1.025 1.125 0.05

1¼ 1.265 1.375 0.055

1½ 1.505 1.625 0.06

2 1.985 2.125 0.07

2½ 2.465 2.625 0.08

3 2.945 3.125 0.09

Type M (standard)

Riser Size (in.) I.D. (in.) O.D. (in.) Copper Wall Thickness (in.)

1 1.055 1.125 0.035

1¼ 1.291 1.375 0.042

WSHP-PRC020D-EN 9

Page 10

Application Considerations

Table 1. Riser characteristics (continued)

Riser Size (in.) I.D. (in.) O.D. (in.) Copper Wall Thickness (in.)

1½ 1.527 1.625 0.049

2½ 2.495 2.625 0.065

Note: Pressure ratings for risers are typically greater than the maximum pressure rating of the

coaxial water-to-refrigerant heat exchangers.This is true with exception ofType M copper

in a 3" diameter.The maximum pressure rating forType M, 3" diameter copper is 380 psig.

All other diameters forType M copper, and all 1" through 3"Type L copper are greater than

the 400 psig rating on the coaxial water-to-refrigerant heat exchanger.

Riser Sizing

The proper selection of riser diameter is critical when designing a cost effective job. If the riser

diameter is too small, the flow of water to the heat pump may be restricted, making the pumping

power requirement excessive. On the other hand, if the riser diameter is too large, the cost of the

equipment may become unnecessarily high.

To determine the riser size, calculate the flow at a particular riser. Riser columns will begin with

large diameters at the bottom of the column and decrease diameter as the water travels up toward

the top floor.The GPM at the first floor is determined by totaling the GPM of all the units on the

riser column.The GPM for the second floor is then determined by taking the total GPM and

subtracting the flow from the first floor.

The proper size of the riser is determined by calculating the velocity of the water in the riser.The

maximum water velocity that a riser should experience is about 6 or 7 feet/second. Table 2, p. 10

can be used as a quick reference chart fordetermining the maximum GPMallowed for a given riser

size. Riser flow diagram can be found in the

used to calculate the precise water velocity for a given riser diameter and flow.

Type M (standard)

2 2.009 2.125 0.058

3 2.981 3.125 0.072

2009 ASHRAE Fundamentals Handbook and may be

Table 2. Maximum riser flow rate

Riser Size (in.) Max. GPM Water Velocity (ft./sec.) Head Loss (ft.100 ft.)

1 16 6.2 15.6

1¼ 24 6.1 11.8

1½ 34 6.1 9.38

2 58 6.0 6.6

2½ 90 6.0 5.1

3 130 6.1 4.2

Note: Table 2, p. 10 is for general design calculation reference. It is not intended to take the place

of an engineered piping design.

10 WSHP-PRC020D-EN

Page 11

Application Considerations

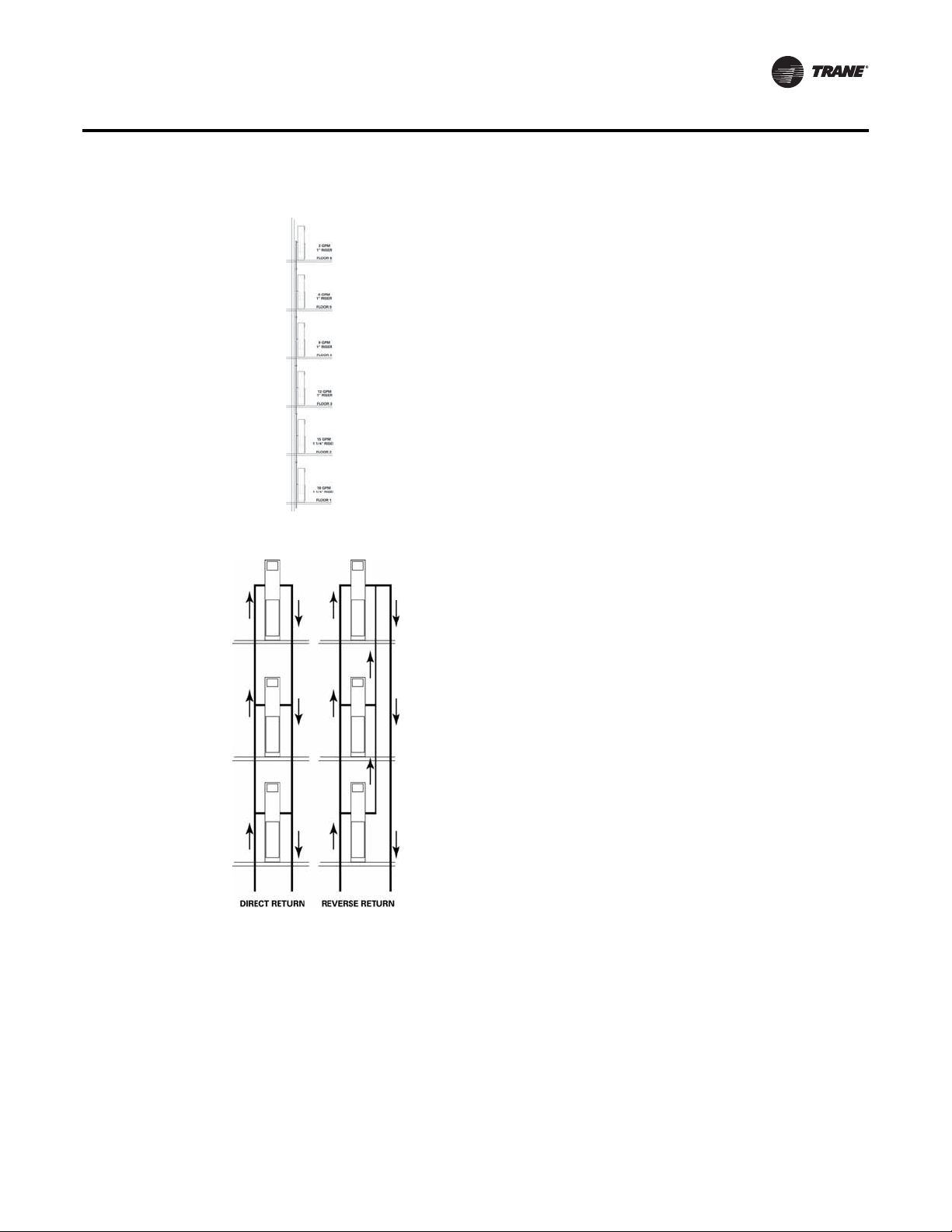

Riser Size Example

Assume a sixstory building is servedby a high-rise water-source

heat pump.When referencing the catalog, determine each highrise heat pump uses 3 gallons per minute to meet the required

capacity of the 1-ton unit. What is the minimum riser diameter

that can be used on each floor?

With this arrangement, determine the volume of water used at

each floor is 3 GPM.The top floor riser therefore only needs to

be sized for 3 GPM. Referring to Table 2, p. 10, we know that a 1inch type M riser can handle up to 16 GPM, therefore the riser

size is determined to be 1-inch.

The first floor will see 18 GPM through the riser. Since 18 GPM

will result in more than 6 ft./second in a 1” riser, it would be

advisable to move to a 1¼” riser.

Piping Layout of the Riser

Two methods may be used when piping a riser column.These

include direct return or reverse return.

Advantages may be seen in both types of piping methods. For

a direct return installation, the riser system is straightforward

leaving little confusionabout properly sized risers.Thisprovides

a more cost effective advantage during the installation process.

The disadvantages of this system is the pressure drop.The total

pressure drop on the unit forthe sixth floor ismuch greater than

the total pressure drop on the unit for the first floor.This means

that the riser column will require balancing from floor-to-floor

during installation.

Piping advantages for the reverse return system include the

ability to design the riser column so that the total system

pressure drop through each unit is equalized.The overall

pressure drop is also lower, allowing some energy savings

potential.This piping method however does not eliminate the

need for proper balancing at each unit.

The disadvantage of this system relates to cost and complexity.

The reverse return method typically costs more because of the

additional pipe required for each riser column.

Central Plant Control

Proper central plant control is critical to the operation of a water-source heat pump system. Loss

of waterflow or loop temperatures outside of the recommended range will severely impact the

operation of the equipment.The following should be followed as minimum operational

recommendation for the central plant:

• Heat rejector control (i.e. closed circuit cooling tower, or geothermal loop)

• Heat adder (i.e. boiler or geothermal loop)

• Circulating pumps

• Sensing elements

WSHP-PRC020D-EN 11

Page 12

Application Considerations

Heat Rejection through a Closed Circuit CoolingTower

Cooling towers serve to reject heat from the condenser water loop to the atmosphere.Two types

of cooling towers are used with water-source heat pump systems: open or closed-circuit.The

towers themselves are different, but when an open tower is used in conjunction with a water-towater heat exchanger, the control of the two tower types is essentially the same.

Control for the closed-circuit cooling towers may be made with aTrane®Tracer™ Loop Controller

(TLC). With the TLC, up to four stages of cooling tower control are possible.

When the loop supply temperature is 4°F below the loop supply high setpoint, the first stage of

cooling is initiated by opening the closure dampers on the cooling tower.

At 2° F below the setpoint the next stage of cooling is initiated which is the starting of the tower’s

circulating pump. If the amount of heat rejected by the first two stages is not enough, the loop

temperature will continue to rise.When the temperature reaches the loop supply high setpoint,the

next stage of cooling is initiated.This is the first stage of cooling tower fans.

The differential between the stages now become 3°F and the temperature must remain above the

differential for three minutes. Up to three individual fan stages may be sequenced or the second

stage of fan can be the high speed of a multi-speed motor.

There are five different fan arrangements that theTLC supports: A single fan with a single motor,

a single fan with dual motors (pony motors), a maximum of three fans with a maximum of three

motors, a variable speed fan with a field supplied variable frequency drive, and a single multispeed motor.

Multiple cooling towers can be supported only if the cooling towerstages are controlled in parallel.

Boiler Operation

TheTLC will operate a boiler and the mixing valve respectively. Boiler control is traditionally

controlled by a separate boiler controller, provided by the boiler manufacturer.The boiler mixing

valve will control the mixture of the boiler water into the main loop to achieve the desired loop

supply water.

When the loop temperature falls below the low loop-supply setpoint, theTLC enables the boiler.

The ideal arrangementis for the boiler tohave its own bypass loopso the boiler pump can circulate

water through the heat exchanger. The boiler will maintain the temperature of the water to the

desired setting in the packaged boiler control.

The three-way mixing valve is controlled by theTLC to add heat to themain loopby mixingin water

from the boiler loop. A proportional-integral-derivative algorithm controls the valve. The boiler is

not disable until the main loop temperature is 5°F greater than the low loop supply setpoint for

more than 5 minutes.

TheTLC will also monitor the boiler loop temperature and provide an alarm if the temperature is

below the boiler loop low limit after 30 minutes of run time.The TLC will provide an alarm if the

boiler loop temperature exceeds the boiler loop high limit after 30 minutes continually.

Facilities Management

Water-source heat pump systems are naturally decentralized; thus they inherently provide

individual zone control.Typical installations use mechanical thermostats to provide localized

control. Central plant control is typically handledby a control panel located in the main mechanical

room. Minimal coordination is usually required between the central plant and the individual watersource heat pumps for successful operation of the system. A direct digital control system is

recommended to help support coordination efforts between the central plant and the individual

water-source heat pumps.This enhanced coordination can result in reductions in operating cost

of the entire system.The following items are typical of the additional coordination: Night setback

and setup; After hourusage for tracking and billing;Pump cycling foroccupied/unoccupied control;

Zone scheduling; Maintenance reporting for monitoring unit fault conditions;Trend logging of the

system water temperatures;Monitoring of systemlevels for items such as waterflow, temperature,

faults, heat rejector status, heat adder status and circulating pump status.

12 WSHP-PRC020D-EN

Page 13

Selection Procedures

Model Number

Two model number designators have been defined for the cabinet configuration, and the chassis

configuration. Both model numbers require input for the order to be complete and built to

specification.

Typically the vertical stack equipment ships in two sections. (1)The cabinet and riser section ship

first to allow the contractor to furr-in the equipment during sheetrock installation, and (2) the

chassis (refrigeration/water) section ship approximately two to four weeks later eliminating

storage requirements of the chassis and possible damage at the job site while waiting for

installation. For this reason, there are two model number designators specific to the unit chassis,

and the cabinet for the equipment.

WSHP-PRC020D-EN 13

Page 14

Model Number Descriptions

Vertical High-Rise Cabinet

WSHP

Digits 1-3: Unit Configuration

GET = High Efficiency Vertical High Rise

Heat Pump

Digit 4: Development Sequence

E = R-410A

Digits 5-7: Nominal Size (Tons)

009=¾Tons

012=1Tons

015=1¼Tons

018=1½Tons

024 = 2Tons

036 = 3Tons

Digit 8: Voltage (Volts/Hz/Phase)

1 = 208/60/1

2 = 230/60/1

7 = 265/60/1

Digit 9: Heat Exchanger

1 = Copper Water Coil

2 = Cupro-Nickel Water Coil

3 = Copper Water Coil with Isolation

Valve and Low Flow Control

4 = Cupro- Nickel Water Coil with

Isolation Valve and Low Flow Control

5 = Copper Water Coil with Isolation

Valve and High Flow Control

6 = Cupro-Nickel Water Coil with Isolation

Valve and High Flow Control

Digit 10: Current Design

Sequence

Digit 11: Refrigeration Circuit

0 = Heating and Cooling Circuit

Digit 12: Blower Configuration

1 = Free Discharge - PSC motor

2 = Ducted Discharge - PSC motor

3 = Free Discharge w/1" Flange -

PSC motor

4 = Free Discharge w/3" Flange -

PSC motor

5 = ECM motor w/o flange

6 = ECM motor w/1" flange

7 = ECM motor w/3" flange

8 = Chassis only/No motor (ECM Control)

9 = Chassis only/No motor (PSC Control)

Digit 13: Freeze Protection

A = 20° freezestat

B = 35° freezestat

Digit 14: Open Digit

0 = Open

S = Special

Digit 15: Supply Air

Arrangement

0 = No Supply Air Arrangement

1 = Back and Front Supply Air

2 = Back and Left Supply Air

3 = Back and Right Supply Air

4 = Front and Left Supply Air

5 = Front and Right Supply Air

6 = Left and Right Supply Air

7 = Back, Front and Right Supply Air

8 = Back, Front and Left Supply Air

9 = Front, Right and Left Supply Air

B = Back Supply Air

L = Left Supply Air

R = Right Supply Air

T =Top Supply Air

F = Front Supply Air

Digit 16: Return Air

Arrangement

0 = No Return Air Door (Field Provided)

1 = Flush with Wall, Acoustic Hinged

Return Air Door with Keyless Entry

2 = Flush with Wall, Acoustic Hinged

Return Air Door with Keylock Entry

Digit 17: Control Types

D = Deluxe 24V Controls

C =Tracer™ ZN510 Controls

Digit 18:Thermostat Sensor

Location

0 = Wall Mounted Location

Digit 19: Fault Sensors

0 = No Fault Sensors

1 = Condensate Overflow Sensor

2 = Filter MaintenanceTimer

3 = Condensate Overflow and Filter

MaintenanceTimer

Digit 20-22: Open Digits

Digit 23: Unit Mounted

Disconnect

0 = No Unit Mounted Switch

C =Toggle Switch Only

D =Toggle Switch with Fuses

Digit 24: Filter Type

1 = 1-inch Throwaway Filter

Digit 25: Acoustic Arrangement

0 = Enhanced Sound Attenuation

1 = Deluxe Sound Attenuation

Digit 26: Factory Configuration

3 = R-410A Cabinet

Digit 27: Paint Color

8 = Polar White

Digit 28: Outside Air Option

0 = No Outside Air

Digit 29: Piping Arrangement

B = Back Riser Location

L = Left Hand Riser Location

R = Right Hand Riser Location

Digit 30: Riser Type

0 = No Riser

L =Type L Riser

M=Type M Riser

Digit 31: Supply Riser

0 = No Riser

B = 1" Dia. Riser with Insulation

C = 1¼" Dia. Riser with Insulation

D = 1½" Dia. Riser with Insulation

E = 2 Dia. Riser with Insulation

F = 2½" Dia. Riser with Insulation

G = 3" Dia. Riser with Insulation

2 = 1" Dia. Riser

3 = 1¼" Dia. Riser

4 = 1½" Dia. Riser

5 = 2" Dia. Riser

6 = 2½" Dia. Riser

7 = 3" Dia. Riser

Digit 32: Return Riser

0 = No Riser

B = 1" Dia. Riser with Insulation

C = 1¼" Dia. Riser with Insulation

D = 1½" Dia. Riser with Insulation

E = 2" Dia. Riser with Insulation

F = 2½" Dia. Riser with Insulation

G = 3" Dia. Riser with Insulation

2 = 1" Dia. Riser

3 = 1¼" Dia. Riser

4 = 1½" Dia. Riser

5 = 2" Dia. Riser

6 = 2½" Dia. Riser

7 = 3" Dia. Riser

Digit 33: Condensate Riser

0 = No Riser

B = 1" Dia. Riser with Insulation

C = 1¼" Dia. Riser with Insulation

D = 1½" Dia. Riser with Insulation

E = 2" Dia. Riser with Insulation

F = 2½" Dia. Riser with Insulation

G = 3" Dia. Riser with Insulation

2 = 1" Dia. Riser

3 = 1¼" Dia. Riser

4 = 1½" Dia. Riser

5 = 2" Dia. Riser

6 = 2½" Dia. Riser

7 = 3" Dia. Riser

14 WSHP-PRC020D-EN

Page 15

Model Number Descriptions

Digit 34, 35, 36: Riser Length

000 = No Riser

096 = 96" Riser Length

097 = 97" Riser Length

098 = 98" Riser Length

099 = 99" Riser Length

100 = 100" Riser Length

101 = 101" Riser Length

102 = 102" Riser Length

103 = 103" Riser Length

104 = 104" Riser Length

105 = 105" Riser Length

106 = 106" Riser Length

107 = 107" Riser Length

108 = 108" Riser Length

109 = 109" Riser Length

110 = 110" Riser Length

111 = 111" Riser Length

112 = 112" Riser Length

113 = 113" Riser Length

114 = 114" Riser Length

115 = 115" Riser Length

116 = 116" Riser Length

117 = 117" Riser Length

118 = 118" Riser Length

119 = 119" Riser Length

120 = 120" Riser Length

Vertical High-Rise Chassis

WSHP

Digits 1-3: Unit Configuration

GET = High Efficiency Vertical High Rise

Heat Pump (cabinet with blower/motor)

Digit 4: Development Sequence

E = R-410A

Digits 5-7: Nominal Size (Tons)

009=¾Tons

012=1Tons

015=1¼Tons

018=1½Tons

024 = 2Tons

036 = 3Tons

Digit 8: Voltage (Volts/Hz/Phase)

1 = 208/60/1

2 = 230/60/1

7 = 265/60/1

Digit 9: Heat Exchanger

1 = Copper Water Coil

2 = Cupro-Nickel Water Coil

3 = Copper Water Coil with Isolation

Valve and Low Flow Control

4 = Cupro- Nickel Water Coil with Isolation

Valve and Low Flow Control

5 = Copper Water Coil with Isolation

Valve and High Flow Control

6 = Cupro-Nickel Water Coil with Isolation

Valve and High Flow Control

Digit 10: Current Design

Sequence

Digit 11: Refrigeration Circuit

0 = Heating and Cooling Circuit

Digit 12: Blower Configuration

1 = Free Discharge - PSC motor

2 = Ducted Discharge - PSC motor

3 = Free Discharge w/1" Flange -

PSC motor

4 = Free Discharge w/3" Flange -

PSC motor

5 = ECM motor w/o flange

6 = ECM motor w/1" flange

7 = ECM motor w/3" flange

8 = Chassis only/No motor (ECM Control)

9 = Chassis only/No motor (PSC Control)

Digit 13: Freeze Protection

0 = None or Standard

A = 20° Freezestat

B = 35° Freezestat

Digit 14: Open Digit

0 = Open

Digit 15: Supply Air

Arrangement

0 = No Supply Air Arrangement

1 = Back and Front Supply Air

2 = Back and Left Supply Air

3 = Back and Right Supply Air

4 = Front and Left Supply Air

5 = Front and Right Supply Air

6 = Left and Right Supply Air

7 = Back, Front and Right Supply Air

8 = Back, Front and Left Supply Air

9 = Front, Right and Left Supply Air

B = Back Supply Air

L = Left Supply Air

R = Right Supply Air

T =Top Supply Air

F = Front Supply Air

Digit 16: Return Air

Arrangement

0 = No Door (Chassis Only)

1 = Flush with Wall, Acoustic Hinged

Return Air Door with Keyless Entry

2 = Flush with Wall, Acoustic Hinged

Return Air Door with Keylock Entry

Digit 17: Control Types

0 = Basic Controls for WPRD Retrofit

Chassis

D = Deluxe 24V Controls

C =Tracer™ ZN510 Controls

Digit 18:Thermostat Sensor

Location

0 = Wall Mounted Location

Digit 19: Fault Sensors

0= No Fault Sensors

1 = Condensate Overflow Sensor

2 = Filter Maintenance Timer

3 = Condensate Overflow and Filter

MaintenanceTimer

Digit 20-22: Open Digits

Digit 23: Unit Mounted

Disconnect

0 = No Unit Mounted Switch

C = Switch Only

D = Switch with Fuses

Digit 24: Filter Type

1 = 1-inch Throwaway Filter

Digit 25: Acoustic Arrangement

0 = Enhanced Sound Attenuation

1 = Deluxe Sound Attenuation

Digit 26: Factory Configuration

2 = R-410A Chassis

R = WPRD Retrofit Chassis

Digit 27: Paint Color

8 = Polar White

Digit 28: Outside Air Option

0 = No Outside Air

Digit 29: Piping Arrangement

B = Back Riser Location

L = Left Hand Riser Location

R = Right Hand Riser Location

Digit 30: Riser Type

0 = No Riser (Chassis Only)

Digit 31: Supply Riser

0 = No Riser (Chassis Only)

Digit 32: Return Riser

0 = No Riser (Chassis Only)

Digit 33: Condensate Riser

0 = No Riser (Chassis Only)

Digit 34, 35, 36: Riser Length

000 = No Riser (Chassis Only)

WSHP-PRC020D-EN 15

Page 16

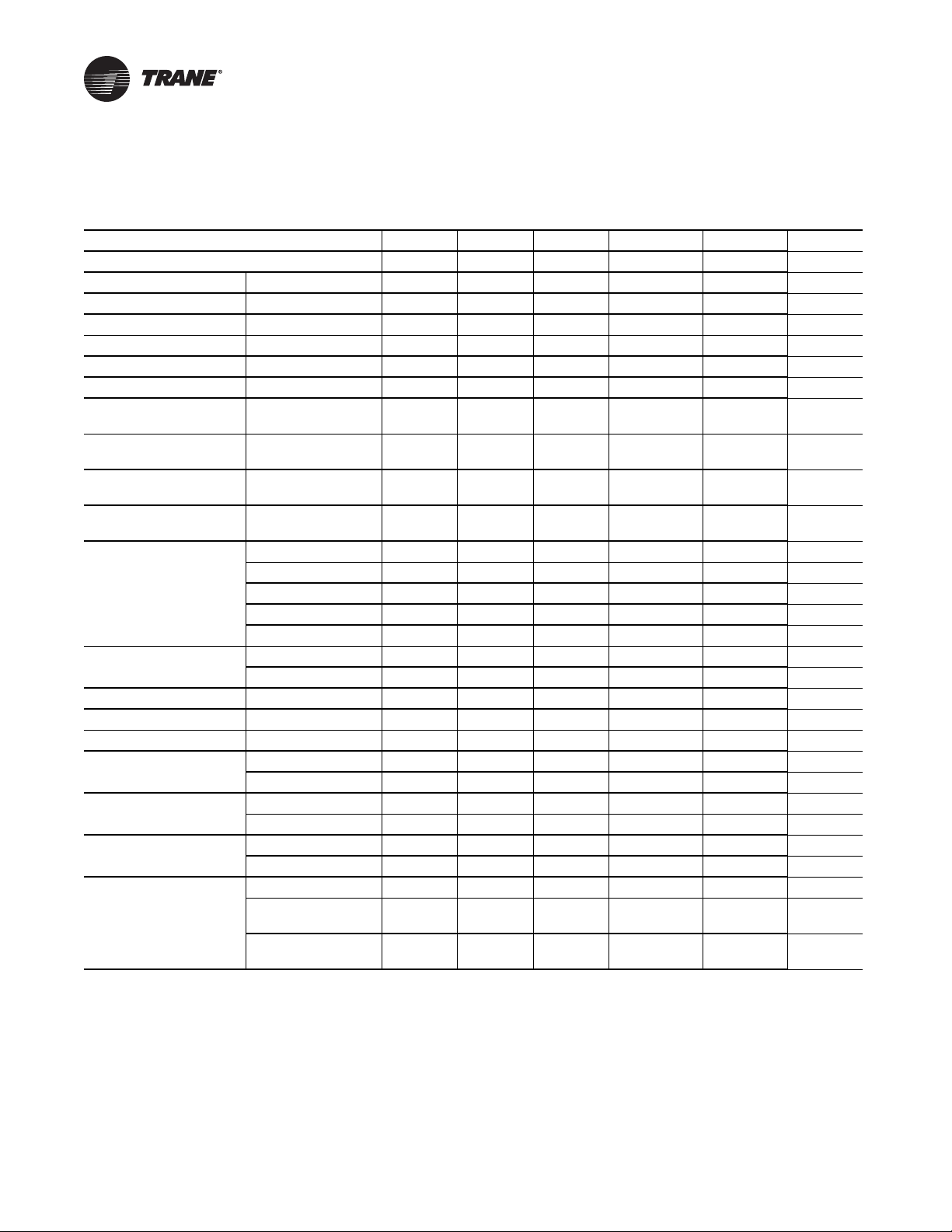

General Data

Table 3. General Data

Model Number 009 012 015 018 024 036

Compressor Type Rotary Rotary Rotary Rotary Scroll Scroll

Cabinet Size Depth (in.)

Height (in.)

Depth (mm)

Height (mm)

Width (mm)

Approximate weight

cabinet with Pallet (lb.)

Approximate weight

cabinet without Pallet (lb.)

Approximate weight

chassis with Pallet (lb.)

Approximate weight

chassis without Pallet (lb.)

Face Area (ft.2)

Face Area (cm2)

Air-to-Refrigerant Coil

Fins Per Inch

Fins Per cm.

Nominal 1”

Filter Size

Water In/Out size NPTI

Condensate Plastic Hose ID (in)

Riser Connection NPTE

PSC Ducted Discharge

PSC Free Discharge

ECM Motor

Refrig. Side (PSIG)

Water-to-Refrigerant

Coil Water Side (PSIG)

Internal Volume

Width (in.)

Rows

Inches

mm

Blower

Motor HP

Blower

Motor HP

Blower

Motor HP

(gal)

16.0 16.0 18.0 18.0 24.0 24.0

88.0 88.0 88.0 88.0 88.0 88.0

16.0 16.0 20.0 20.0 24.0 24.0

406.4 406.4 457.2 457.2 609.6 609.6

2235.2 2235.2 2235.2 2235.2 2235.2 2235.2

406.4 406.4 508.0 508.0 609.6 609.6

135 135 175 175 225 225

115 115 150 150 195 195

88 107 112 117 174 190

78 97 102 107 164 180

1.35 1.35 2.11 2.11 2.88 2.88

1254 1254 1959 1959 2676 2676

244 4 3 4

14 14 14 14 14 14

5.5 5.5 5.5 5.5 5.5 5.5

14 x 20 14 x 20 18 x 25 18 x 25 20 x 30 20 x 30

356 x 508 356 x 508 457 x 635 457 x 635 508 x 762 508 x 762

½" ½" ½" ½" ¾" ¾"

¾" ¾" ¾" ¾" ¾" ¾"

½" ½" ½" ½" ¾" ¾"

90-6TDD 90-6TDD 90-6RDD 100-6TDD 100-6TDD 120-8TDD11

0.05 0.125 0.125 0.2 0.33 0.5

90-6TDD 90-6TDD 90-6RDD 100-6TDD 100-6TDD 120-8TDD11

0.05 0.125 0.125 0.125 0.33 0.5

90-6TDD 90-6TDD 100-6TDD 100-6TDD 120-8TDD11 120-8TDD11

0.33 0.33 0.5 0.5 0.5 0.75

650 650 650 650 650 650

400 400 400 400 400 400

0.081 0.081 0.228 0.228 0.271 0.368

16 WSHP-PRC020D-EN

Page 17

Performance Data

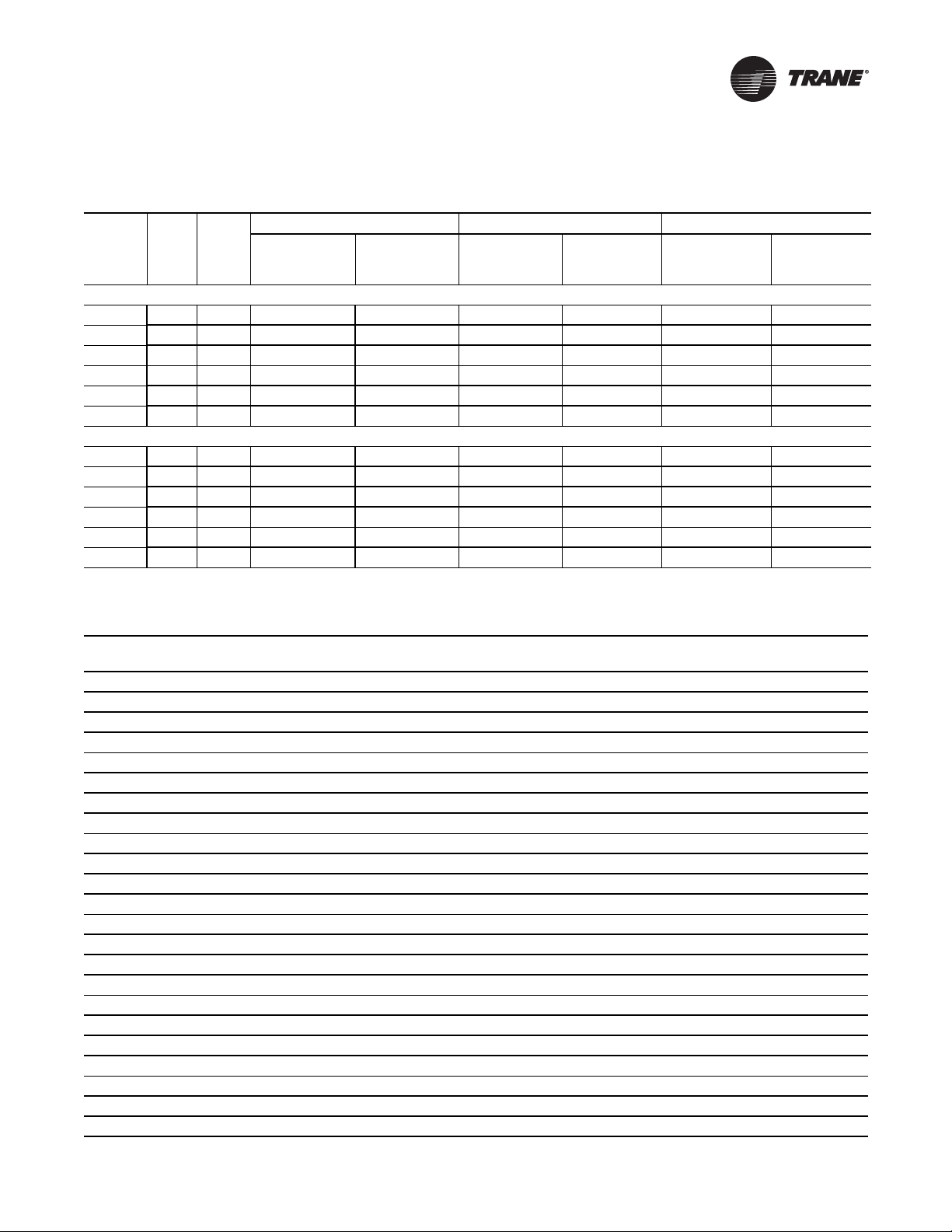

Table 4. AHRI-ISO performance

Rated

Flow

Rate

Unit Size

GET 009 2.1 340 8200 12.8 10800 4.6 9700 18.4 8700 3.8 8800 14.9 6600 3.2

GET 012 2.8 440 11900 13.5 14100 4.6 13100 18.9 11800 4.0 12300 15.1 9000 3.2

GET 015 3.5 540 14700 13.1 17700 4.6 16600 20.1 13700 3.7 15400 14.8 11800 3.3

GET 018 4.2 650 18100 13.0 22900 4.5 19500 18.0 17900 3.7 18700 14.3 14800 3.3

GET 024 5.6 820 23300 13.1 26600 4.3 25600 18.6 23600 3.9 24300 14.9 18700 3.2

GET 036 8.4 1170 33700 13.0 41300 4.3 37900 18.7 34400 3.7 35100 14.6 27300 3.2

GET 009 2.1 340 8300 13.9 10500 4.6 9600 21.1 8500 3.9 8700 16.2 6500 3.2

GET 012 2.8 440 12000 14.2 14300 4.8 14100 23.2 11600 4.0 12600 16.5 8700 3.2

GET 015 3.5 540 14900 15.0 18000 5 17000 23.9 14800 4.3 15600 17.5 11300 3.5

GET 018 4.2 650 18500 14.6 22300 4.6 21100 22.6 18400 4.2 19500 17 14200 3.4

GET 024 5.6 820 24200 16.0 26300 4.8 26800 24 23100 4.4 25200 18.4 17800 3.5

GET 036 8.4 1170 34200 15.2 40200 4.6 38200 24 33500 4.1 35600 17.8 26300 3.3

Note: Certified in accordance with AHRI Water to Air and Brine to Air Heat Pump Certification Program which is based on ISO Standard 13256-1: 1998.

(GPM)

Certified conditions are 80.6°F DB/66.2°F WB EAT in cooling and 68°F DB/59°F WB EAT in heating.

Rated

Air

Flow

(CFM)

Cooling

Capacity

(Mbtuh) EER

Water Loop Ground Water Ground Loop

Heating

Capacity

(Mbtuh) COP

Cooling

Capacity

(Mbtuh) EER

PSC Motor

ECM Motor

Heating

Capacity

(Mbtuh) COP

Cooling

Capacity

(Mbtuh) EER

Heating

Capacity

(Mbtuh) COP

Table 5. GET 009 cooling performance

EWT GPM

45 1.1 10.3 8.0 0.77 11.7 0.41 65.7 2.1

45 1.5 10.4 8.0 0.77 11.8 0.40 60.7 3.4

45 1.8 10.5 8.0 0.76 11.9 0.39 58.2 4.7

45 2.1 10.6 8.1 0.76 12.0 0.39 56.4 6.2

45 2.3 10.8 8.1 0.75 12.1 0.39 55.7 6.9

45 2.4 10.8 8.1 0.75 12.1 0.39 55.1 7.8

45 2.6 10.8 8.1 0.75 12.2 0.39 54.3 9.1

55 1.1 9.8 7.8 0.79 11.3 0.44 75.1 2.0

55 1.5 10.0 7.9 0.79 11.4 0.42 70.2 3.3

55 1.8 10.1 7.9 0.78 11.5 0.42 67.8 4.5

55 2.1 10.2 7.9 0.78 11.6 0.41 66.0 5.9

55 2.3 10.2 7.9 0.78 11.6 0.41 65.3 6.7

55 2.4 10.2 7.9 0.78 11.6 0.41 64.7 7.5

55 2.6 10.3 8.0 0.77 11.7 0.41 63.9 8.7

68 1.1 9.4 7.7 0.82 11.1 0.49 87.7 1.9

68 1.5 9.5 7.7 0.81 11.1 0.47 82.8 3.1

68 1.8 9.6 7.7 0.81 11.1 0.46 80.4 4.3

68 2.1 9.6 7.7 0.80 11.2 0.46 78.6 5.6

68 2.3 9.6 7.8 0.80 11.2 0.45 77.9 6.4

68 2.4 9.7 7.8 0.80 11.2 0.45 77.3 7.1

68 2.6 9.7 7.8 0.80 11.2 0.45 76.5 8.3

75 1.1 9.2 7.6 0.83 11.0 0.53 94.5 1.8

75 1.5 9.3 7.6 0.82 11.0 0.51 89.7 3.1

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

WSHP-PRC020D-EN 17

Page 18

Performance Data

Table 5. GET 009 cooling performance (continued)

EWT GPM

75 1.8 9.3 7.7 0.82 11.0 0.49 87.2 4.2

75 2.1 9.4 7.7 0.82 11.0 0.49 85.5 5.5

75 2.3 9.4 7.7 0.82 11.0 0.48 84.8 6.2

75 2.4 9.4 7.7 0.82 11.1 0.48 84.2 7.0

75 2.6 9.4 7.7 0.82 11.1 0.48 83.4 8.2

77 1.1 9.1 7.6 0.83 11.0 0.54 96.5 1.8

77 1.5 9.2 7.6 0.83 11.0 0.52 91.6 3.0

77 1.8 9.3 7.6 0.82 11.0 0.51 89.2 4.2

77 2.1 9.3 7.7 0.82 11.0 0.50 87.5 5.5

77 2.3 9.3 7.7 0.82 11.0 0.49 86.8 6.2

77 2.4 9.3 7.7 0.82 11.0 0.49 86.2 6.9

77 2.6 9.3 7.7 0.82 11.0 0.49 85.4 8.1

86 1.1 8.9 7.5 0.85 10.9 0.60 105.4 1.8

86 1.5 8.9 7.5 0.84 10.9 0.57 100.5 3.0

86 1.8 9.0 7.5 0.84 10.9 0.56 98.1 4.1

86 2.1 9.0 7.6 0.84 10.9 0.55 96.4 5.3

86 2.3 9.0 7.6 0.84 10.9 0.55 95.7 6.0

86 2.4 9.0 7.6 0.84 10.9 0.54 95.0 6.7

86 2.6 9.0 7.6 0.84 10.9 0.54 94.3 7.9

95 1.1 8.6 7.4 0.86 10.9 0.67 114.4 1.7

95 1.5 8.7 7.5 0.86 10.8 0.64 109.5 2.8

95 1.8 8.7 7.5 0.86 10.8 0.62 107.0 3.8

95 2.1 8.7 7.5 0.86 10.8 0.61 105.3 5.1

95 2.3 8.7 7.5 0.86 10.8 0.61 104.6 5.7

95 2.4 8.7 7.5 0.86 10.8 0.61 104.0 6.4

95 2.6 8.7 7.5 0.86 10.8 0.60 103.2 7.5

105 1.1 8.4 7.4 0.88 10.9 0.76 124.4 1.6

105 1.5 8.4 7.4 0.88 10.8 0.72 119.5 2.7

105 1.8 8.4 7.4 0.88 10.8 0.71 117.0 3.7

105 2.1 8.4 7.4 0.88 10.8 0.70 115.2 4.9

105 2.3 8.4 7.4 0.88 10.8 0.69 114.6 5.5

105 2.4 8.4 7.4 0.88 10.7 0.69 113.9 6.2

105 2.6 8.4 7.4 0.88 10.7 0.69 113.2 7.3

115 1.1 8.1 7.3 0.90 11.0 0.86 134.6 1.6

115 1.5 8.1 7.3 0.90 10.9 0.83 129.6 2.6

115 1.8 8.1 7.3 0.90 10.9 0.81 127.1 3.6

115 2.1 8.1 7.3 0.90 10.8 0.80 125.3 4.8

115 2.3 8.1 7.3 0.90 10.8 0.80 124.6 5.4

115 2.4 8.1 7.3 0.90 10.8 0.79 124.0 6.1

115 2.6 8.1 7.3 0.90 10.8 0.79 123.2 7.1

120 1.1 8.0 7.3 0.91 11.2 0.94 139.9 1.6

120 1.5 8.0 7.2 0.91 11.0 0.90 134.7 2.6

120 1.8 8.0 7.2 0.91 11.0 0.88 132.2 3.6

120 2.1 8.0 7.2 0.91 10.9 0.87 130.4 4.7

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

18 WSHP-PRC020D-EN

Page 19

Table 5. GET 009 cooling performance (continued)

Performance Data

EWT GPM

120 2.3 8.0 7.2 0.91 10.9 0.86 129.7 5.3

120 2.4 7.9 7.2 0.91 10.9 0.86 129.0 6.0

120 2.6 7.9 7.2 0.91 10.8 0.85 128.3 7.0

Notes: Cooling performance data is tabulated at 80.6°F DB/66.2°F WB entering air at AHRI/ISO 13256-1 rated cfm.For AHRI/ISO 13256-1 certified

ratings, see Table 4, p. 17. See Performance correction tables to correct performance at conditions other than those tabulated. Interpolation of

data is permissible, extrapolation is not. Rated GPM 2.1; Minimum cfm 292; Rated cfm 340; Maximum cfm 408.

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

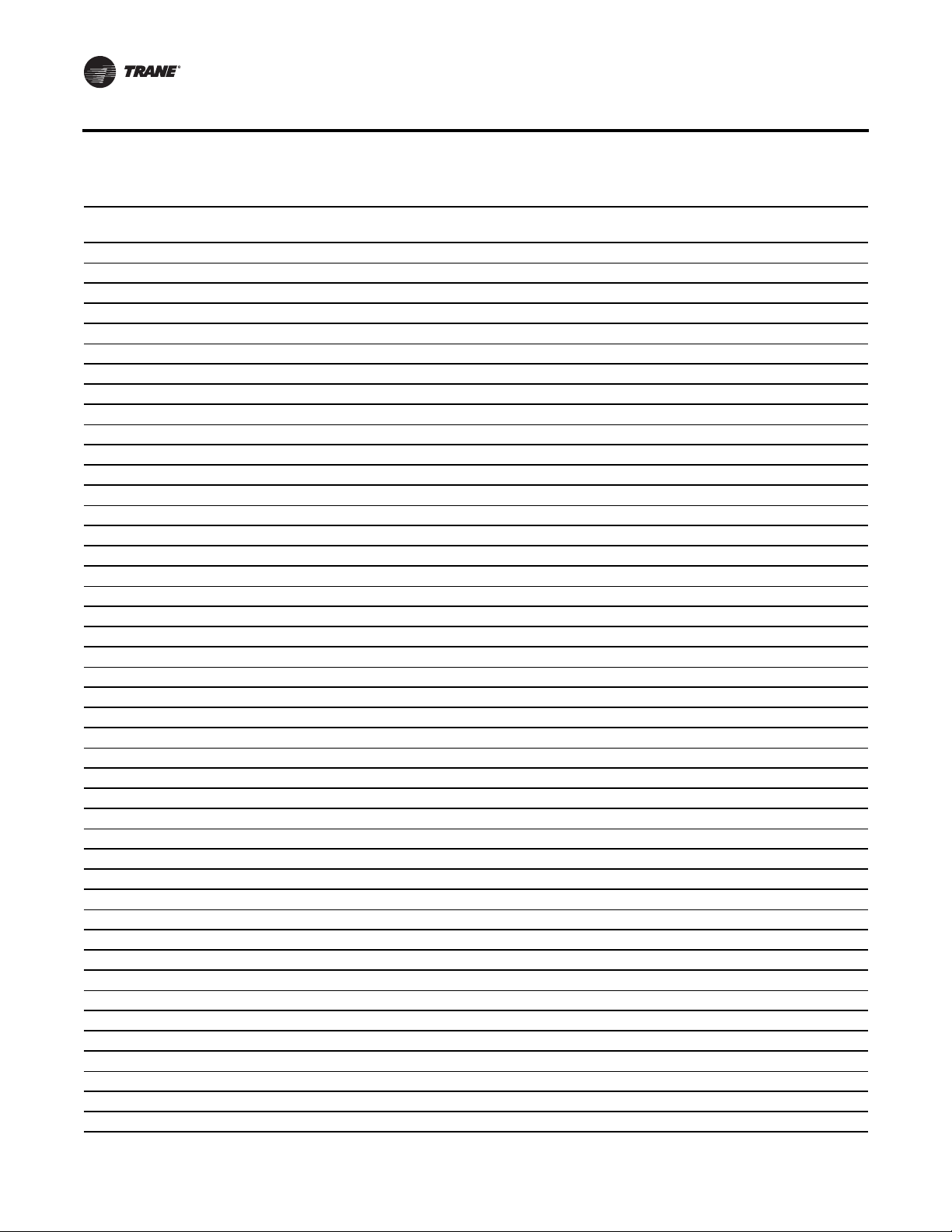

Table 6. GET 009 heating performance

EWT GPM

25 1.1 6.0 4.2 0.52 17.5 2.7

25 1.5 6.2 4.4 0.52 19.1 4.5

25 1.8 6.3 4.5 0.53 20.0 6.2

25 2.1 6.4 4.6 0.53 20.6 8.1

25 2.3 6.4 4.6 0.53 20.9 9.1

25 2.4 6.5 4.7 0.53 21.1 10.2

25 2.6 6.5 4.7 0.53 21.4 11.9

32 1.1 6.7 4.8 0.53 23.4 2.7

32 1.5 6.9 5.1 0.54 25.3 4.4

32 1.8 7.0 5.2 0.54 26.2 6.0

32 2.1 7.1 5.3 0.54 27.0 7.9

32 2.3 7.2 5.3 0.54 27.3 8.9

32 2.4 7.2 5.3 0.54 27.6 9.9

32 2.6 7.3 5.4 0.54 27.9 11.6

45 1.1 8.1 6.2 0.56 34.0 2.1

45 1.5 8.4 6.5 0.57 36.4 3.4

45 1.8 8.6 6.6 0.57 37.6 4.7

45 2.1 8.7 6.7 0.57 38.6 6.2

45 2.3 8.7 6.8 0.57 39.0 6.9

45 2.4 8.8 6.8 0.57 39.3 7.8

45 2.6 8.8 6.9 0.57 39.8 9.1

55 1.1 9.2 7.2 0.58 42.2 2.0

55 1.5 9.5 7.5 0.58 45.0 3.3

55 1.8 9.7 7.7 0.59 46.4 4.5

55 2.1 9.9 7.9 0.59 47.5 5.9

55 2.3 9.9 7.9 0.59 48.0 6.7

55 2.4 10.0 8.0 0.59 48.4 7.5

55 2.6 10.1 8.0 0.59 48.9 8.7

68 1.1 10.6 8.6 0.60 52.8 1.9

68 1.5 11.1 9.0 0.61 56.0 3.1

68 1.8 11.3 9.2 0.61 57.8 4.3

68 2.1 11.5 9.4 0.61 59.1 5.6

68 2.3 11.5 9.4 0.61 59.6 6.4

68 2.4 11.6 9.5 0.61 60.1 7.1

68 2.6 11.7 9.6 0.61 60.7 8.3

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

WSHP-PRC020D-EN 19

Page 20

Performance Data

Table 6. GET 009 heating performance (continued)

EWT GPM

75 1.1 11.4 9.3 0.61 58.5 1.8

75 1.5 11.9 9.8 0.62 62.0 3.1

75 1.8 12.2 10.0 0.62 63.9 4.2

75 2.1 12.4 10.2 0.63 65.3 5.5

75 2.3 12.5 10.3 0.63 65.8 6.2

75 2.4 12.5 10.4 0.63 66.4 7.0

75 2.6 12.6 10.5 0.63 67.0 8.2

77 1.1 11.6 9.5 0.62 60.1 1.8

77 1.5 12.1 10.0 0.62 63.7 3.0

77 1.8 12.4 10.3 0.63 65.6 4.2

77 2.1 12.6 10.5 0.63 67.0 5.5

77 2.3 12.7 10.5 0.63 67.6 6.2

77 2.4 12.8 10.6 0.63 68.2 6.9

77 2.6 12.9 10.7 0.63 68.9 8.1

86 1.1 12.7 10.5 0.63 67.3 1.8

86 1.5 13.3 11.1 0.64 71.3 3.0

86 1.8 13.5 11.3 0.65 73.4 4.1

86 2.1 13.8 11.6 0.65 75.0 5.3

86 2.3 13.8 11.6 0.65 75.7 6.0

86 2.4 14.0 11.7 0.66 76.2 6.7

86 2.6 14.0 11.8 0.65 77.0 7.9

Notes: Heating performance data is tabulated at 68°F DB entering air at AHRI/ISO 13256-1 rated cfm. See Performance correction tables to correct

performance at conditions other than those tabulated. Interpolation of data is permissible, extrapolation is not. Rated GPM 2.1; Minimum cfm

272; Rated cfm 340; Maximum cfm 408.

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

Table 7. GET 012 cooling performance

EWT GPM

45 1.5 13.1 10.3 0.78 14.7 0.45 64.6 4.9

45 2.0 13.2 10.3 0.78 14.7 0.43 59.7 8.1

45 2.4 13.2 10.3 0.78 14.7 0.42 57.2 11.2

45 2.8 13.3 10.3 0.78 14.7 0.41 55.5 14.6

45 3.0 13.3 10.3 0.78 14.7 0.41 54.8 16.5

45 3.2 13.3 10.3 0.78 14.7 0.41 54.2 18.4

45 3.5 13.3 10.3 0.78 14.7 0.41 53.4 21.5

55 1.5 13.0 10.2 0.79 14.8 0.52 74.7 4.7

55 2.0 13.1 10.2 0.78 14.7 0.49 69.7 7.8

55 2.4 13.1 10.2 0.78 14.7 0.48 67.3 10.7

55 2.8 13.1 10.2 0.78 14.7 0.47 65.5 14.1

55 3.0 13.1 10.2 0.78 14.7 0.46 64.8 15.9

55 3.2 13.1 10.3 0.78 14.7 0.46 64.2 17.8

55 3.5 13.1 10.3 0.78 14.7 0.46 63.4 20.7

68 1.5 12.7 10.1 0.79 14.8 0.62 87.7 4.5

68 2.0 12.8 10.1 0.79 14.8 0.59 82.8 7.4

68 2.4 12.8 10.1 0.79 14.7 0.57 80.3 10.2

(Mbtuh)

20 WSHP-PRC020D-EN

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Page 21

Table 7. GET 012 cooling performance (continued)

Performance Data

EWT GPM

68 2.8 12.8 10.1 0.79 14.7 0.56 78.5 13.4

68 3.0 12.8 10.1 0.79 14.7 0.56 77.8 15.1

68 3.2 12.8 10.1 0.79 14.7 0.55 77.2 16.9

68 3.5 12.8 10.1 0.79 14.7 0.55 76.4 19.8

75 1.5 12.5 10.0 0.80 14.8 0.68 94.8 4.4

75 2.0 12.6 10.0 0.80 14.8 0.64 89.8 7.3

75 2.4 12.6 10.0 0.80 14.7 0.63 87.3 10.0

75 2.8 12.6 10.1 0.80 14.7 0.62 85.5 13.1

75 3.0 12.6 10.1 0.80 14.7 0.61 84.8 14.8

75 3.2 12.6 10.1 0.80 14.7 0.61 84.2 16.5

75 3.5 12.6 10.1 0.80 14.7 0.60 83.4 19.4

77 1.5 12.5 10.0 0.80 14.8 0.69 96.8 4.4

77 2.0 12.5 10.0 0.80 14.8 0.66 91.8 7.2

77 2.4 12.5 10.0 0.80 14.7 0.64 89.3 9.9

77 2.8 12.5 10.0 0.80 14.7 0.63 87.5 13.0

77 3.0 12.6 10.0 0.80 14.7 0.63 86.8 14.7

77 3.2 12.6 10.0 0.80 14.7 0.62 86.2 16.4

77 3.5 12.6 10.0 0.80 14.7 0.62 85.4 19.2

86 1.5 12.2 9.9 0.81 14.9 0.78 105.8 4.2

86 2.0 12.2 9.9 0.81 14.8 0.75 100.8 7.0

86 2.4 12.2 9.9 0.81 14.7 0.73 98.3 9.7

86 2.8 12.2 9.9 0.81 14.7 0.71 96.5 12.6

86 3.0 12.2 9.9 0.81 14.7 0.71 95.8 14.3

86 3.2 12.2 9.9 0.81 14.7 0.71 95.2 16.0

86 3.5 12.2 9.9 0.81 14.6 0.70 94.4 18.7

95 1.5 11.8 9.8 0.82 14.9 0.89 114.8 3.7

95 2.0 11.9 9.7 0.82 14.8 0.85 109.8 6.2

95 2.4 11.9 9.8 0.82 14.7 0.83 107.2 8.6

95 2.8 11.9 9.8 0.82 14.6 0.81 105.5 11.3

95 3.0 11.9 9.8 0.82 14.6 0.81 104.8 12.7

95 3.2 11.9 9.8 0.82 14.6 0.80 104.1 14.2

95 3.5 11.9 9.8 0.82 14.6 0.80 103.3 16.7

105 1.5 11.4 9.5 0.84 14.9 1.01 124.8 3.8

105 2.0 11.4 9.6 0.84 14.7 0.97 119.7 6.1

105 2.4 11.4 9.6 0.84 14.7 0.95 117.2 8.3

105 2.8 11.4 9.6 0.84 14.6 0.93 115.4 10.9

105 3.0 11.4 9.6 0.84 14.6 0.93 114.7 12.3

105 3.2 11.4 9.6 0.84 14.6 0.94 114.1 13.8

105 3.5 11.4 9.6 0.84 14.6 0.93 113.3 16.2

115 1.5 10.9 9.3 0.86 14.8 1.15 134.8 3.8

115 2.0 10.9 9.3 0.86 14.7 1.11 129.7 6.0

115 2.4 10.9 9.3 0.86 14.6 1.09 127.2 8.1

115 2.8 10.9 9.3 0.86 14.6 1.07 125.4 10.6

115 3.0 10.9 9.3 0.86 14.5 1.06 124.7 12.0

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

WSHP-PRC020D-EN 21

Page 22

Performance Data

Table 7. GET 012 cooling performance (continued)

EWT GPM

115 3.2 10.9 9.3 0.86 14.5 1.06 124.1 13.4

115 3.5 10.9 9.3 0.86 14.5 1.05 123.3 15.8

120 1.5 10.6 9.2 0.87 14.8 1.23 139.8 3.8

120 2.0 10.6 9.2 0.87 14.7 1.19 134.7 5.9

120 2.4 10.6 9.2 0.87 14.6 1.16 132.2 8.0

120 2.8 10.6 9.2 0.87 14.5 1.14 130.4 10.5

120 3.0 10.6 9.2 0.87 14.5 1.13 129.7 11.8

120 3.2 10.6 9.2 0.87 14.5 1.13 129.0 13.3

120 3.5 10.6 9.2 0.87 14.4 1.12 128.2 15.6

Notes: Cooling performance data is tabulated at 80.6°F DB/66.2°F WB entering air at AHRI/ISO 13256-1 rated cfm.For AHRI/ISO 13256-1 certified

ratings, see Table 4, p. 17. See Performance correction tables to correct performance at conditions other than those tabulated. Interpolation of

data is permissible, extrapolation is not. Rated GPM 2.8; Minimum cfm 303; Rated cfm 380; Maximum cfm 456.

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Table 8. GET 012 heating performance

EWT GPM

25 1.5 7.7 5.4 0.67 17.8 6.9

25 2.0 7.9 5.6 0.68 19.4 11.4

25 2.4 8.1 5.7 0.68 20.2 16.5

25 2.8 8.1 5.8 0.68 20.9 21.2

25 3.0 8.2 5.8 0.68 21.1 23.8

25 3.2 8.2 5.9 0.68 21.3 25.7

25 3.5 8.2 5.8 0.68 21.7 30.6

32 1.5 8.5 6.1 0.69 23.8 6.7

32 2.0 8.7 6.4 0.69 25.6 11.0

32 2.4 8.9 6.5 0.69 26.6 15.1

32 2.8 9.0 6.6 0.69 27.3 19.8

32 3.0 9.0 6.7 0.69 27.6 22.3

32 3.2 9.1 6.7 0.69 27.8 24.9

32 3.5 9.1 6.8 0.70 28.1 29.1

45 1.5 10.1 7.7 0.71 34.8 4.9

45 2.0 10.4 8.0 0.71 37.0 8.1

45 2.4 10.6 8.2 0.71 38.2 11.2

45 2.8 10.7 8.3 0.71 39.1 14.6

45 3.0 10.8 8.3 0.71 39.5 16.5

45 3.2 10.8 8.4 0.71 39.8 18.4

45 3.5 10.9 8.4 0.72 40.2 21.5

55 1.5 11.3 8.9 0.72 43.2 4.7

55 2.0 11.7 9.2 0.73 45.8 7.8

55 2.4 11.9 9.4 0.73 47.1 10.7

55 2.8 12.1 9.6 0.73 48.2 14.1

55 3.0 12.2 9.7 0.73 48.6 15.9

55 3.2 12.2 9.7 0.73 49.0 17.8

55 3.5 12.3 9.7 0.73 49.4 20.7

68 1.5 13.0 10.5 0.74 54.1 4.5

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

22 WSHP-PRC020D-EN

Page 23

Table 8. GET 012 heating performance (continued)

Performance Data

EWT GPM

68 2.0 13.4 10.9 0.75 57.1 7.4

68 2.4 13.7 11.1 0.75 58.7 10.2

68 2.8 13.9 11.3 0.75 59.9 13.4

68 3.0 14.0 11.4 0.75 60.4 15.1

68 3.2 14.0 11.5 0.76 60.8 16.9

68 3.5 14.1 11.6 0.76 61.4 19.8

75 1.5 13.9 11.3 0.75 59.9 4.4

75 2.0 14.4 11.8 0.76 63.2 7.3

75 2.4 14.7 12.1 0.76 65.0 10.0

75 2.8 14.9 12.3 0.77 66.2 13.1

75 3.0 15.0 12.3 0.77 66.8 14.8

75 3.2 15.0 12.4 0.77 67.3 16.5

75 3.5 15.2 12.5 0.77 67.9 19.4

77 1.5 14.1 11.6 0.76 61.6 4.4

77 2.0 14.7 12.1 0.77 64.9 7.2

77 2.4 14.9 12.3 0.77 66.7 9.9

77 2.8 15.2 12.5 0.77 68.1 13.0

77 3.0 15.2 12.6 0.77 68.6 14.7

77 3.2 15.3 12.7 0.77 69.1 16.4

77 3.5 15.4 12.8 0.78 69.7 19.2

86 1.5 15.4 12.7 0.78 69.1 4.2

86 2.0 15.9 13.3 0.79 72.8 7.0

86 2.4 16.3 13.6 0.79 74.7 9.7

86 2.8 16.5 13.7 0.80 76.2 12.6

86 3.0 16.6 13.8 0.80 76.8 14.3

86 3.2 16.7 13.9 0.80 77.3 16.0

86 3.5 16.8 14.0 0.80 78.0 18.7

Notes: Heating performance data is tabulated at 68°F DB entering air at AHRI/ISO 13256-1 rated cfm. See Performance correction tables to correct

performance at conditions other than those tabulated. Interpolation of data is permissible, extrapolation is not. Rated GPM 2.8; Minimum cfm

303; Rated cfm 380; Maximum cfm 456.

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

Table 9. GET 015 cooling performance

EWT GPM

45 1.9 16.9 14.0 0.83 18.5 0.49 64.8 4.6

45 2.3 16.9 14.0 0.83 18.4 0.45 61.0 6.6

45 2.8 17.0 14.1 0.83 18.4 0.42 58.2 9.3

45 3.5 17.1 14.1 0.83 18.4 0.39 55.5 13.8

45 3.8 17.1 14.1 0.82 18.5 0.38 54.7 15.9

45 4.1 17.1 14.1 0.82 18.4 0.38 54.0 18.2

45 4.4 17.1 14.1 0.83 18.3 0.37 53.4 20.4

55 1.9 16.7 14.0 0.84 18.8 0.61 75.0 4.4

55 2.3 16.7 13.9 0.83 18.7 0.57 71.2 6.4

55 2.8 16.8 14.0 0.83 18.6 0.54 68.3 9.0

55 3.5 16.8 14.0 0.83 18.6 0.51 65.6 13.3

(Mbtuh)

WSHP-PRC020D-EN 23

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Page 24

Performance Data

Table 9. GET 015 cooling performance (continued)

EWT GPM

55 3.8 16.8 14.0 0.83 18.5 0.50 64.8 15.3

55 4.1 16.8 14.0 0.83 18.5 0.50 64.0 17.5

55 4.4 16.8 14.0 0.83 18.5 0.49 63.5 19.6

68 1.9 16.3 13.8 0.85 18.9 0.76 88.2 4.2

68 2.3 16.4 13.8 0.85 18.8 0.72 84.4 6.1

68 2.8 16.4 13.8 0.84 18.8 0.69 81.4 8.6

68 3.5 16.4 13.9 0.84 18.7 0.67 78.7 12.7

68 3.8 16.5 13.9 0.84 18.7 0.66 77.8 14.6

68 4.1 16.5 13.9 0.84 18.7 0.65 77.1 16.7

68 4.4 16.5 13.9 0.84 18.7 0.65 76.5 18.7

75 1.9 16.1 13.7 0.85 18.9 0.84 95.2 4.1

75 2.3 16.1 13.7 0.85 18.9 0.81 91.4 5.9

75 2.8 16.1 13.8 0.85 18.8 0.78 88.4 8.4

75 3.5 16.2 13.8 0.85 18.7 0.75 85.7 12.4

75 3.8 16.2 13.8 0.85 18.7 0.74 84.8 14.3

75 4.1 16.2 13.8 0.85 18.7 0.74 84.1 16.3

75 4.4 16.2 13.8 0.85 18.7 0.73 83.5 18.3

77 1.9 16.0 13.7 0.86 19.0 0.87 97.2 4.1

77 2.3 16.0 13.7 0.86 18.9 0.83 93.4 5.9

77 2.8 16.1 13.7 0.85 18.8 0.80 90.4 8.3

77 3.5 16.1 13.7 0.85 18.7 0.78 87.7 12.3

77 3.8 16.1 13.7 0.85 18.7 0.77 86.8 14.2

77 4.1 16.1 13.8 0.86 18.7 0.76 86.1 16.2

77 4.4 16.1 13.7 0.85 18.7 0.75 85.5 18.1

86 1.9 15.6 13.6 0.87 19.0 0.99 106.2 4.0

86 2.3 15.6 13.6 0.87 18.9 0.95 102.4 5.7

86 2.8 15.6 13.6 0.87 18.8 0.92 99.4 8.1

86 3.5 15.7 13.6 0.87 18.7 0.89 96.7 11.9

86 3.8 15.7 13.6 0.87 18.7 0.88 95.8 13.8

86 4.1 15.7 13.6 0.87 18.6 0.87 95.1 15.7

86 4.4 15.7 13.6 0.87 18.6 0.87 94.5 17.6

95 1.9 15.2 13.4 0.89 19.0 1.13 115.3 3.7

95 2.3 15.2 13.4 0.88 18.9 1.08 111.4 5.3

95 2.8 15.2 13.4 0.88 18.8 1.05 108.4 7.5

95 3.5 15.2 13.4 0.88 18.7 1.02 105.7 11.2

95 3.8 15.2 13.4 0.88 18.6 1.01 104.8 12.9

95 4.1 15.2 13.4 0.88 18.6 1.00 104.1 14.8

95 4.4 15.2 13.4 0.88 18.6 1.00 103.5 16.6

105 1.9 14.6 13.2 0.90 19.1 1.30 125.3 3.6

105 2.3 14.6 13.2 0.91 18.9 1.25 121.4 5.2

105 2.8 14.6 13.2 0.91 18.8 1.22 118.4 7.3

105 3.5 14.6 13.2 0.91 18.6 1.19 115.7 10.9

105 3.8 14.6 13.2 0.91 18.6 1.18 114.8 12.6

105 4.1 14.6 13.2 0.91 18.6 1.17 114.1 14.4

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

24 WSHP-PRC020D-EN

Page 25

Table 9. GET 015 cooling performance (continued)

Performance Data

EWT GPM

105 4.4 14.6 13.2 0.91 18.5 1.16 113.5 16.1

115 1.9 14.1 13.1 0.93 19.4 1.54 135.7 3.5

115 2.3 14.1 13.0 0.93 19.1 1.48 131.6 5.0

115 2.8 14.0 13.0 0.93 19.0 1.44 128.5 7.1

115 3.5 14.0 13.0 0.93 18.8 1.40 125.7 10.6

115 3.8 14.0 13.0 0.93 18.8 1.39 124.9 12.2

115 4.1 14.0 13.0 0.93 18.7 1.38 124.1 14.0

115 4.4 14.0 13.0 0.93 18.7 1.37 123.5 15.7

120 1.9 13.7 13.0 0.94 19.2 1.60 140.4 3.7

120 2.3 13.7 13.0 0.94 19.0 1.56 136.6 5.1

120 2.8 13.7 12.9 0.94 18.9 1.52 133.5 7.0

120 3.5 13.7 12.9 0.95 18.7 1.48 130.7 10.4

120 3.8 13.7 12.9 0.95 18.7 1.47 129.8 12.0

120 4.1 13.6 12.9 0.95 18.6 1.46 129.1 13.7

120 4.4 13.6 12.9 0.95 18.6 1.45 128.5 15.4

Notes: Cooling performance data is tabulated at 80.6°F DB/66.2°F WB entering air at AHRI/ISO 13256-1 rated cfm.For AHRI/ISO 13256-1 certified

ratings, see Table 4, p. 17. See Performance correction tables to correct performance at conditions other than those tabulated. Interpolation of

data is permissible, extrapolation is not. Rated GPM 3.5; Minimum cfm 432; Rated cfm 540; Maximum cfm 648.

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Table 10. GET 015 heating performance

EWT GPM

25 1.9 9.7 6.9 0.82 17.7 6.2

25 2.3 9.9 7.0 0.83 18.9 8.9

25 2.8 10.0 7.2 0.83 19.9 12.5

25 3.5 10.2 7.4 0.83 20.8 18.4

25 3.8 10.3 7.4 0.83 21.1 21.2

25 4.1 10.3 7.5 0.83 21.4 24.2

25 4.4 10.3 7.5 0.83 21.6 27.1

32 1.9 10.6 7.7 0.84 23.8 6.0

32 2.3 10.8 8.0 0.84 25.1 8.6

32 2.8 11.0 8.1 0.85 26.2 12.1

32 3.5 11.2 8.3 0.85 27.3 17.8

32 3.8 11.3 8.4 0.85 27.6 20.6

32 4.1 11.3 8.4 0.85 27.9 23.5

32 4.4 11.4 8.5 0.85 28.1 26.3

45 1.9 12.6 9.6 0.87 34.7 4.6

45 2.3 12.9 9.9 0.87 36.4 6.6

45 2.8 13.2 10.2 0.88 37.7 9.3

45 3.5 13.4 10.4 0.88 39.1 13.8

45 3.8 13.5 10.5 0.88 39.5 15.9

45 4.1 13.6 10.5 0.88 39.9 18.2

45 4.4 13.6 10.6 0.88 40.2 20.4

55 1.9 14.1 11.1 0.89 43.2 4.4

55 2.3 14.5 11.5 0.89 45.0 6.4

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

WSHP-PRC020D-EN 25

Page 26

Performance Data

Table 10. GET 015 heating performance (continued)

EWT GPM

55 2.8 14.8 11.8 0.90 46.6 9.0

55 3.5 15.1 12.1 0.90 48.1 13.3

55 3.8 15.2 12.2 0.90 48.6 15.3

55 4.1 15.3 12.2 0.90 49.0 17.5

55 4.4 15.4 12.3 0.90 49.4 19.6

68 1.9 16.3 13.2 0.91 54.0 4.2

68 2.3 16.7 13.6 0.90 56.2 6.1

68 2.8 17.1 14.0 0.91 58.0 8.6

68 3.5 17.4 14.4 0.91 59.8 12.7

68 3.8 17.6 14.5 0.91 60.4 14.6

68 4.1 17.7 14.6 0.91 60.9 16.7

68 4.4 17.8 14.7 0.91 61.3 18.7

75 1.9 17.4 14.3 0.91 59.7 4.1

75 2.3 17.9 14.8 0.91 62.1 5.9

75 2.8 18.3 15.2 0.91 64.1 8.4

75 3.5 18.7 15.6 0.91 66.1 12.4

75 3.8 18.9 15.8 0.91 66.7 14.3

75 4.1 19.0 15.9 0.91 67.3 16.3

75 4.4 19.1 16.0 0.91 67.7 18.3

77 1.9 17.7 14.6 0.91 61.4 4.1

77 2.3 18.3 15.2 0.91 63.8 5.9

77 2.8 18.7 15.6 0.91 65.9 8.3

77 3.5 19.1 16.0 0.91 67.9 12.3

77 3.8 19.2 16.1 0.91 68.5 14.2

77 4.1 19.4 16.3 0.91 69.1 16.2

77 4.4 19.5 16.4 0.91 69.5 18.1

86 1.9 19.3 16.2 0.91 68.8 4.0

86 2.3 19.8 16.7 0.91 71.4 5.7

86 2.8 20.3 17.2 0.91 73.7 8.1

86 3.5 20.8 17.7 0.90 75.9 11.9

86 3.8 20.9 17.9 0.90 76.6 13.8

86 4.1 21.1 18.1 0.90 77.2 15.7

86 4.4 21.2 18.1 0.90 77.7 17.6

Notes: Heating performance data is tabulated at 68°F DB entering air at AHRI/ISO 13256-1 rated cfm. See Performance correction tables to correct

performance at conditions other than those tabulated. Interpolation of data is permissible, extrapolation is not. Rated GPM 3.5; Minimum cfm

432; Rated cfm 540; Maximum cfm 648.

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

Table 11. GET 018 cooling performance

EWT GPM

45 2.3 20.1 15.9 0.79 22.5 0.72 65.0 3.8

45 2.9 19.9 15.8 0.79 22.2 0.67 60.3 6.0

45 3.6 19.8 15.8 0.80 22.0 0.64 57.2 8.7

45 4.2 19.7 15.8 0.80 21.8 0.62 55.4 11.4

45 4.6 19.7 15.7 0.80 21.8 0.61 54.5 13.4

(Mbtuh)

26 WSHP-PRC020D-EN

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Page 27

Table 11. GET 018 cooling performance (continued)

Performance Data

EWT GPM

45 5.0 19.6 15.6 0.80 21.6 0.60 53.6 15.5

45 5.3 19.6 15.7 0.80 21.6 0.60 53.2 16.9

55 2.3 20.0 15.9 0.79 22.9 0.84 75.3 3.7

55 2.9 20.0 15.8 0.79 22.7 0.79 70.6 5.7

55 3.6 19.9 15.8 0.79 22.5 0.76 67.5 8.4

55 4.2 19.9 15.8 0.79 22.4 0.74 65.7 11.0

55 4.6 19.9 15.8 0.79 22.4 0.73 64.7 12.9

55 5.0 19.9 15.8 0.80 22.4 0.73 63.9 14.9

55 5.3 19.9 15.8 0.80 22.3 0.72 63.5 16.2

68 2.3 19.6 15.7 0.80 23.0 1.01 88.4 3.5

68 2.9 19.6 15.7 0.80 22.9 0.96 83.8 5.5

68 3.6 19.6 15.7 0.80 22.8 0.92 80.6 8.0

68 4.2 19.6 15.7 0.80 22.7 0.90 78.8 10.5

68 4.6 19.6 15.7 0.80 22.7 0.90 77.9 12.3

68 5.0 19.6 15.7 0.80 22.6 0.89 77.1 14.2

68 5.3 19.6 15.7 0.80 22.6 0.88 76.6 15.5

75 2.3 19.2 15.6 0.81 23.0 1.10 95.4 3.4

75 2.9 19.3 15.6 0.81 22.8 1.05 90.8 5.4

75 3.6 19.3 15.6 0.81 22.8 1.02 87.6 7.8

75 4.2 19.3 15.6 0.81 22.7 1.00 85.8 10.2

75 4.6 19.3 15.6 0.81 22.7 0.99 84.9 12.0

75 5.0 19.3 15.6 0.81 22.7 0.98 84.1 13.9

75 5.3 19.3 15.6 0.81 22.6 0.98 83.6 15.1

77 2.3 19.1 15.5 0.81 23.0 1.13 97.4 3.4

77 2.9 19.2 15.6 0.81 22.8 1.08 92.7 5.3

77 3.6 19.2 15.6 0.81 22.8 1.04 89.6 7.8

77 4.2 19.2 15.6 0.81 22.7 1.03 87.8 10.2

77 4.6 19.2 15.6 0.81 22.7 1.02 86.9 11.9

77 5.0 19.2 15.6 0.81 22.6 1.01 86.1 13.8

77 5.3 19.2 15.6 0.81 22.6 1.00 85.6 15.0

86 2.3 18.6 15.3 0.83 22.9 1.26 106.3 3.3

86 2.9 18.6 15.4 0.83 22.7 1.21 101.7 5.2

86 3.6 18.6 15.4 0.82 22.6 1.17 98.6 7.5

86 4.2 18.6 15.4 0.82 22.6 1.15 96.7 9.9

86 4.6 18.7 15.4 0.82 22.6 1.14 95.8 11.6

86 5.0 18.7 15.4 0.82 22.5 1.13 95.0 13.4

86 5.3 18.7 15.4 0.82 22.5 1.13 94.6 14.6

95 2.3 17.9 15.1 0.84 22.7 1.41 115.2 3.0

95 2.9 18.0 15.1 0.84 22.6 1.35 110.6 4.8

95 3.6 18.0 15.1 0.84 22.5 1.32 107.5 7.0

95 4.2 18.0 15.2 0.84 22.4 1.30 105.7 9.1

95 4.6 18.0 15.2 0.84 22.4 1.28 104.7 10.7

95 5.0 18.0 15.2 0.84 22.4 1.28 104.0 12.4

95 5.3 18.0 15.2 0.84 22.4 1.27 103.5 13.6

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

WSHP-PRC020D-EN 27

Page 28

Performance Data

Table 11. GET 018 cooling performance (continued)

EWT GPM

105 2.3 17.2 14.9 0.86 22.7 1.60 125.2 2.9

105 2.9 17.2 14.9 0.86 22.5 1.54 120.5 4.6

105 3.6 17.3 14.9 0.86 22.4 1.50 117.4 6.8

105 4.2 17.3 14.9 0.86 22.3 1.47 115.6 8.9

105 4.6 17.3 14.9 0.86 22.3 1.46 114.7 10.4

105 5.0 17.3 14.9 0.86 22.2 1.45 113.9 12.1

105 5.3 17.3 14.9 0.86 22.2 1.45 113.5 13.2

115 2.3 16.5 14.6 0.89 22.7 1.83 135.2 2.9

115 2.9 16.5 14.6 0.88 22.5 1.76 130.5 4.5

115 3.6 16.5 14.6 0.89 22.3 1.72 127.4 6.6

115 4.2 16.5 14.6 0.89 22.2 1.69 125.6 8.7

115 4.6 16.5 14.6 0.89 22.2 1.68 124.6 10.2

115 5.0 16.5 14.6 0.89 22.2 1.67 123.9 11.8

115 5.3 16.5 14.6 0.89 22.1 1.66 123.4 12.8

120 2.3 15.7 14.2 0.90 22.2 1.90 139.8 3.0

120 2.9 15.8 14.3 0.90 22.1 1.85 135.2 4.5

120 3.6 15.8 14.3 0.90 22.0 1.81 132.2 6.5

120 4.2 15.9 14.3 0.90 21.9 1.78 130.4 8.5

120 4.6 15.9 14.3 0.90 21.9 1.76 129.5 10.0

120 5.0 15.9 14.3 0.90 21.9 1.75 128.8 11.6

120 5.3 15.9 14.4 0.90 21.9 1.75 128.3 12.7

Notes: Cooling performance data is tabulated at 80.6°F DB/66.2°F WB entering air at AHRI/ISO 13256-1 rated cfm.For AHRI/ISO 13256-1 certified

ratings, see Table 4, p. 17. See Performance correction tables to correct performance at conditions other than those tabulated. Interpolation of

data is permissible, extrapolation is not. Rated GPM 4.2; Minimum cfm 501; Rated cfm 650; Maximum cfm 780.

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Table 12. GET 018 heating performance

EWT GPM

25 2.3 12.3 8.8 1.03 17.2 5.2

25 2.9 12.6 9.1 1.03 18.7 8.1

25 3.6 12.8 9.3 1.04 19.8 11.7

25 4.2 12.9 9.3 1.04 20.6 15.8

25 4.6 12.9 9.4 1.04 20.9 18.3

25 5.0 12.9 9.4 1.04 21.3 21.0

25 5.3 12.9 9.3 1.04 21.5 22.7

32 2.3 13.5 9.9 1.05 23.2 5.0

32 2.9 13.9 10.3 1.06 24.9 7.8

32 3.6 14.1 10.5 1.06 26.2 11.4

32 4.2 14.4 10.7 1.07 26.9 14.9

32 4.6 14.4 10.8 1.07 27.3 17.5

32 5.0 14.5 10.9 1.07 27.7 20.2

32 5.3 14.6 10.9 1.07 27.9 22.0

45 2.3 16.3 12.5 1.11 33.9 3.8

45 2.9 16.8 13.0 1.12 36.1 6.0

(Mbtuh)

28 WSHP-PRC020D-EN

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

Page 29

Table 12. GET 018 heating performance (continued)

Performance Data

EWT GPM

45 3.6 17.2 13.3 1.13 37.6 8.7

45 4.2 17.4 13.6 1.13 38.5 11.4

45 4.6 17.6 13.7 1.14 39.1 13.4

45 5.0 17.7 13.8 1.14 39.5 15.5

45 5.3 17.7 13.9 1.14 39.7 16.9

55 2.3 18.5 14.5 1.16 42.1 3.7

55 2.9 19.1 15.1 1.17 44.6 5.7

55 3.6 19.6 15.6 1.18 46.4 8.4

55 4.2 19.9 15.8 1.18 47.5 11.0

55 4.6 20.0 15.9 1.18 48.1 12.9

55 5.0 20.1 16.1 1.19 48.6 14.9

55 5.3 20.2 16.1 1.19 48.9 16.2

68 2.3 21.3 17.2 1.21 52.7 3.5

68 2.9 22.2 18.0 1.22 55.6 5.5

68 3.6 22.6 18.5 1.22 57.7 8.0

68 4.2 22.9 18.7 1.23 59.1 10.5

68 4.6 23.0 18.8 1.22 59.8 12.3

68 5.0 23.2 19.0 1.23 60.4 14.2

68 5.3 23.3 19.1 1.23 60.7 15.5

75 2.3 22.9 18.7 1.23 58.4 3.4

75 2.9 23.7 19.5 1.24 61.6 5.4

75 3.6 24.2 20.0 1.24 63.9 7.8

75 4.2 24.5 20.3 1.24 65.4 10.2

75 4.6 24.6 20.4 1.24 66.1 12.0

75 5.0 24.8 20.6 1.24 66.8 13.9

75 5.3 24.9 20.7 1.24 67.1 15.1

77 2.3 23.4 19.1 1.24 60.0 3.4

77 2.9 24.2 19.9 1.25 63.3 5.3

77 3.6 24.6 20.4 1.24 65.7 7.8

77 4.2 25.0 20.7 1.25 67.1 10.2

77 4.6 25.1 20.9 1.24 67.9 11.9

77 5.0 25.2 21.0 1.24 68.6 13.8

77 5.3 25.3 21.0 1.24 69.0 15.0

86 2.3 25.2 20.9 1.26 67.4 3.3

86 2.9 26.0 21.7 1.25 71.0 5.2

86 3.6 26.4 22.2 1.25 73.7 7.5

86 4.2 26.7 22.5 1.24 75.3 9.9

86 4.6 26.8 22.6 1.24 76.2 11.6

86 5.0 26.9 22.7 1.24 76.9 13.4

86 5.3 27.0 22.8 1.23 77.3 14.6

Notes: Heating performance data is tabulated at 68°F DB entering air at AHRI/ISO 13256-1 rated cfm. See Performance correction tables to correct

performance at conditions other than those tabulated. Interpolation of data is permissible, extrapolation is not. Rated GPM 4.2; Minimum cfm

501; Rated cfm 650; Maximum cfm 780.

(Mbtuh)

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

WSHP-PRC020D-EN 29

Page 30

Performance Data

Table 13. GET 024 cooling performance

EWT GPM

45 3.0 27.4 20.9 0.76 30.3 0.84 65.2 3.4

45 3.9 27.8 21.0 0.76 30.4 0.77 60.6 5.5

45 4.7 28.0 21.1 0.75 30.5 0.73 58.0 7.6

45 5.6 28.2 21.1 0.75 30.6 0.70 55.9 10.3

45 6.1 28.3 21.2 0.75 30.6 0.69 55.0 12.0

45 6.5 28.4 21.2 0.75 30.7 0.68 54.4 13.4

45 7.0 28.3 21.2 0.75 30.6 0.67 53.7 15.2

55 3.0 26.6 20.5 0.77 30.0 1.01 75.0 3.3

55 3.9 26.9 20.7 0.77 30.1 0.94 70.4 5.2

55 4.7 27.1 20.7 0.76 30.2 0.91 67.8 7.3

55 5.6 27.2 20.7 0.76 30.2 0.87 65.8 9.9

55 6.1 27.3 20.8 0.76 30.3 0.86 64.9 11.5

55 6.5 27.4 20.8 0.76 30.3 0.85 64.3 12.9

55 7.0 27.4 20.8 0.76 30.3 0.84 63.7 14.6

68 3.0 25.6 20.2 0.79 29.8 1.23 87.9 3.2

68 3.9 25.9 20.3 0.78 29.9 1.17 83.3 5.0

68 4.7 26.0 20.3 0.78 29.9 1.13 80.7 6.9

68 5.6 26.1 20.4 0.78 29.9 1.10 78.7 9.4

68 6.1 26.2 20.4 0.78 29.9 1.09 77.8 11.0

68 6.5 26.2 20.4 0.78 29.9 1.08 77.2 12.3

68 7.0 26.3 20.4 0.78 29.9 1.07 76.6 14.0

75 3.0 25.0 19.9 0.80 29.6 1.36 94.8 3.1

75 3.9 25.3 20.0 0.79 29.7 1.30 90.2 4.9

75 4.7 25.4 20.1 0.79 29.7 1.26 87.6 6.8

75 5.6 25.5 20.1 0.79 29.7 1.23 85.6 9.2

75 6.1 25.6 20.1 0.79 29.7 1.22 84.7 10.7

75 6.5 25.6 20.2 0.79 29.7 1.21 84.1 12.0

75 7.0 25.6 20.2 0.79 29.7 1.20 83.5 13.6

77 3.0 24.8 19.9 0.80 29.6 1.40 96.7 3.1

77 3.9 25.1 19.9 0.80 29.6 1.33 92.2 4.9

77 4.7 25.2 20.0 0.79 29.6 1.30 89.6 6.7

77 5.6 25.3 20.1 0.79 29.7 1.27 87.6 9.2

77 6.1 25.4 20.1 0.79 29.7 1.25 86.7 10.6

77 6.5 25.4 20.1 0.79 29.7 1.25 86.1 11.9

77 7.0 25.5 20.1 0.79 29.7 1.24 85.5 13.5

86 3.0 24.0 19.5 0.81 29.3 1.57 105.6 3.0

86 3.9 24.2 19.6 0.81 29.3 1.50 101.0 4.7

86 4.7 24.3 19.7 0.81 29.4 1.47 98.5 6.6

86 5.6 24.5 19.7 0.81 29.4 1.44 96.5 8.9

86 6.1 24.5 19.7 0.81 29.4 1.43 95.6 10.3

86 6.5 24.6 19.8 0.80 29.4 1.42 95.0 11.6

86 7.0 24.6 19.8 0.80 29.4 1.41 94.4 13.2

95 3.0 23.0 19.2 0.83 29.1 1.77 114.4 2.7

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

30 WSHP-PRC020D-EN

Page 31

Table 13. GET 024 cooling performance (continued)

Performance Data

EWT GPM

95 3.9 23.3 19.3 0.83 29.1 1.70 109.9 4.3

95 4.7 23.4 19.3 0.82 29.1 1.66 107.4 6.0

95 5.6 23.5 19.3 0.82 29.1 1.63 105.4 8.2

95 6.1 23.6 19.3 0.82 29.1 1.61 104.5 9.5

95 6.5 23.6 19.4 0.82 29.1 1.60 103.9 10.6

95 7.0 23.6 19.4 0.82 29.1 1.59 103.3 12.1

105 3.0 21.9 18.7 0.86 28.8 2.01 124.2 2.6

105 3.9 22.2 18.8 0.85 28.8 1.93 119.7 4.2

105 4.7 22.3 18.9 0.85 28.7 1.89 117.2 5.8

105 5.6 22.4 18.9 0.85 28.7 1.86 115.3 7.9

105 6.1 22.4 18.9 0.84 28.7 1.84 114.4 9.2

105 6.5 22.4 19.0 0.84 28.7 1.84 113.8 10.3

105 7.0 22.5 19.0 0.84 28.7 1.83 113.2 11.8

115 3.0 20.7 18.3 0.88 28.4 2.28 134.0 2.6

115 3.9 20.9 18.4 0.88 28.4 2.20 129.6 4.1

115 4.7 21.0 18.4 0.88 28.4 2.15 127.1 5.7

115 5.6 21.1 18.4 0.87 28.3 2.12 125.1 7.7

115 6.1 21.1 18.5 0.87 28.3 2.11 124.3 9.0

115 6.5 21.2 18.5 0.87 28.3 2.09 123.7 10.1

115 7.0 21.2 18.5 0.87 28.3 2.08 123.1 11.5

120 3.0 20.1 18.0 0.89 28.3 2.39 138.8 2.7

120 3.9 20.3 18.1 0.89 28.2 2.32 134.5 4.1

120 4.7 20.4 18.1 0.89 28.2 2.27 132.0 5.6

120 5.6 20.5 18.2 0.89 28.2 2.24 130.1 7.6

120 6.1 20.6 18.2 0.88 28.1 2.22 129.2 8.9

120 6.5 20.6 18.2 0.88 28.1 2.21 128.6 9.9

120 7.0 20.6 18.2 0.88 28.1 2.20 128.0 11.3

Notes: Cooling performance data is tabulated at 80.6°F DB/66.2°F WB entering air at AHRI/ISO 13256-1 rated cfm.For AHRI/ISO 13256-1 certified

ratings, see Table 4, p. 17. See Performance correction tables to correct performance at conditions other than those tabulated. Interpolation of

data is permissible, extrapolation is not. Rated GPM 5.6; Minimum cfm 656; Rated cfm 820; Maximum cfm 984.

(Mbtuh)

Total Gross

Gross Sen

(Mbtuh) SHR

Heat of Rej

(Mbtuh)

Comp Pwr

(kW) LWT

WPD

(feet head)

Table 14. GET 024 heating performance

EWT GPM

25 3.0 14.8 10.4 1.30 18.1 4.7

25 3.9 15.3 10.8 1.30 19.5 7.4

25 4.7 15.5 11.1 1.31 20.3 10.3

25 5.6 15.8 11.3 1.30 21.0 14.0

25 6.1 15.9 11.4 1.31 21.3 16.2

25 6.5 15.9 11.5 1.31 21.5 18.1

25 7.0 16.0 11.6 1.31 21.7 20.6

32 3.0 16.4 12.0 1.31 24.0 4.6

32 3.9 17.0 12.5 1.32 25.6 7.2

32 4.7 17.3 12.8 1.32 26.6 10.0

32 5.6 17.6 13.1 1.32 27.3 13.5

(Mbtuh)

WSHP-PRC020D-EN 31

Total Gross

Heat of Absorb

(Mbtuh)

Compr Power

(kW) LWT

WPD

(feet head)

Page 32

Performance Data

Table 14. GET 024 heating performance (continued)

EWT GPM

32 6.1 17.7 13.2 1.33 27.7 15.7

32 6.5 17.8 13.3 1.33 27.9 17.5

32 7.0 17.9 13.3 1.33 28.2 20.0

45 3.0 19.9 15.3 1.35 34.8 3.4

45 3.9 20.6 15.9 1.36 36.8 5.5

45 4.7 20.9 16.3 1.36 38.1 7.6

45 5.6 21.3 16.6 1.37 39.1 10.3

45 6.1 21.4 16.8 1.37 39.5 12.0

45 6.5 21.5 16.8 1.37 39.8 13.4

45 7.0 21.6 17.0 1.37 40.2 15.2

55 3.0 22.5 17.8 1.38 43.1 3.3

55 3.9 23.3 18.5 1.39 45.5 5.2

55 4.7 23.7 19.0 1.40 46.9 7.3

55 5.6 24.1 19.3 1.40 48.1 9.9

55 6.1 24.3 19.5 1.40 48.6 11.5

55 6.5 24.4 19.6 1.40 49.0 12.9

55 7.0 24.5 19.7 1.41 49.4 14.6

68 3.0 26.0 21.1 1.43 53.9 3.2

68 3.9 26.8 21.9 1.44 56.8 5.0

68 4.7 27.4 22.4 1.45 58.5 6.9

68 5.6 27.8 22.9 1.46 59.8 9.4

68 6.1 28.0 23.0 1.46 60.5 11.0

68 6.5 28.1 23.1 1.46 60.9 12.3

68 7.0 28.3 23.3 1.46 61.4 14.0

75 3.0 27.8 22.9 1.46 59.8 3.1

75 3.9 28.8 23.8 1.48 62.8 4.9

75 4.7 29.4 24.3 1.49 64.7 6.8

75 5.6 29.8 24.7 1.49 66.2 9.2

75 6.1 30.0 24.9 1.49 66.8 10.7

75 6.5 30.1 25.0 1.49 67.3 12.0

75 7.0 30.3 25.1 1.50 67.8 13.6

77 3.0 28.4 23.4 1.47 61.4 3.1

77 3.9 29.3 24.3 1.49 64.6 4.9

77 4.7 29.9 24.8 1.49 66.4 6.7

77 5.6 30.3 25.2 1.50 68.0 9.2

77 6.1 30.5 25.4 1.50 68.7 10.6

77 6.5 30.7 25.6 1.51 69.1 11.9

77 7.0 30.9 25.7 1.51 69.7 13.5

86 3.0 30.7 25.6 1.51 69.0 3.0

86 3.9 31.8 26.6 1.53 72.4 4.7