Page 1

Catalog

Vertical Stack Fan Coil Units

Model RSG

3/4 through 4 ton capacity

July 2013

UNT-PRC019-EN

Page 2

Vertical Stack Fan Coil Units

6

2

4

5

8

1

7

3

T rane vertical stack fan coil units are used in high-rise hotels, condominiums, dormitories, military

barracks, and residential buildings. Trane specializes in flexible response to customers’ needs.

We work closely with engineers at the design stage to ensure optimum use of the units within the

HVAC system.

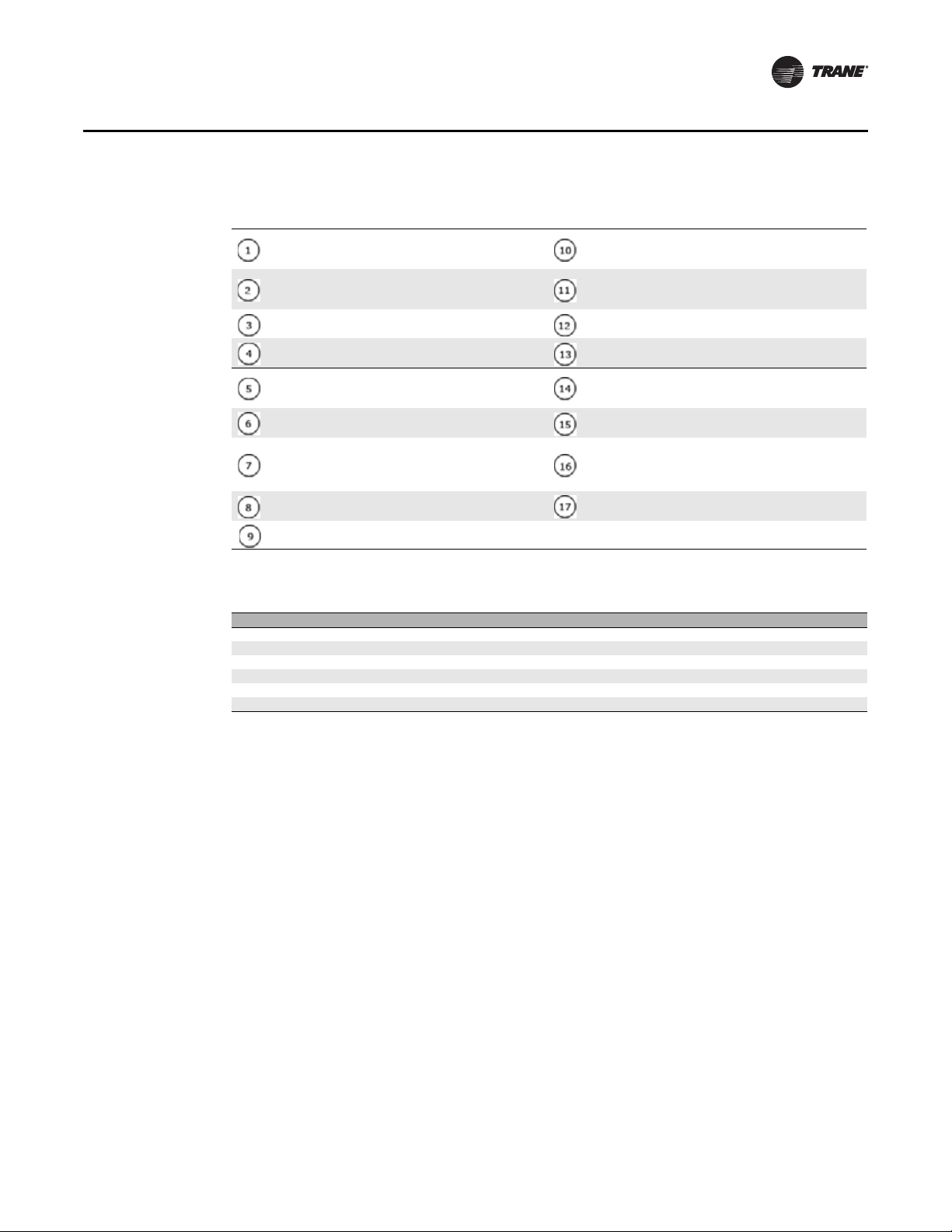

Figure 1. Fan coil - Model RSG Figure 2. Furred-in f a n coil

18 ga. galvanized cabinet with acoustical liner

Direct-drive centrifugal fan - PSC fan motor

with sealed bearings standard

Piping package factory installed (HW pre-

heat)

CW/HW coils - 2-pipe or 4-pipe

Drain pan - galvanized, positively sloped to

outlet - standard

Optional electric heater (behind panel)

Optional electrical box for unit-mounted

thermostat

Supply air opening (multiple openings

available)

Also available but not shown:

•Risers

• Double deflection supply air grille/

registers

• Return air panel

•Filter

• Fan shield/motor cover

standard color is white.

Grille and return air panel

2 UNT-PRC019-EN

Page 3

Table of Contents

Vertical Stack Fan Coil Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Riser Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Raised Base Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Supply Air Grille/Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Heating Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sound Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Components and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fans Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Motor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tracer ZN521 Zone Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Tracer UC400 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Vertical Fan Coil Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-Pipe Chilled Water Cooling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-Pipe Chilled Water Cooling Unit with Electric Heat . . . . . . . . . . . . . . . . 24

4-Pipe Chilled Water Cooling and Hot Water Heating Unit . . . . . . . . . . . 26

Fan Coil Units Without Risers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Riser Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Raised Base Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Raised Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Raised Base with Condensate Pump and Front Access Panel . . . . . . . . . 32

Return Air Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Return Air Panel with Flush Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Return Air Panel with Framed Out Drywall with Hinged Filter Acce ss . . 34

Fan Coil Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Piping Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

UNT-PRC019-EN 3

Page 4

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Riser Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Return Air Access Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Supply Air Grilles and Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Raised Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4 UNT-PRC019-EN

Page 5

Model Number Description

The following is a complete description of

the vertical stack fan coil model number.

Each digit in the model number has a

corresponding code that identifies

specific unit options. Example of model

number:

RS-GF05-86MKX-WWX-R1PDABCDEFGA

Digits 1, 2 – Finished Goods

Identifier

Must always be “RS”

Digit 3 – Spacer

Digits 4, 5 – Unique Part

Identifier - Reserved

Must always be “GF”

Digits 6, 7 – Cabinet Footprint

05 = 17-in. x 17-in. Cabinet footprint (350

and 450 CFM models)

08 = 20-in. x 20-in. Cabinet footprint (600

and 800 CFM models)

12 = 20-in. x 24-in. Cabinet footprint (1000

and 1200 CFM models)

Digit 8 – Spacer

Digits 9, 10 – Unique Part

Identifier - Reserved

Must always be digits “86”

Digits 11, 12, 13 – Unique Part

Identifier – Reserved

Must always be entered as “MKX”

Digit 14 – Spacer

Digit 15 – Pr imary Cooling Means

C = Chilled Water (Single Purpose Coil)

W = Chilled Water (2-pipe Changeover

Coil - requires a change-over sensor)

X = No Cooling Coil

Digit 16 – P rimar y Heating Means

H = Hot Water (Single Purpose Coil)

W = Hot Water (2-pipe Changeover Coil)

E = Electric Resistance

X = No Heating Coil

Digit 17 – Auxiliary Heating

Means

E = Electric Resistance (requires

additional change-over sensor)

X = No Heating Coil

Digit 18 – Spacer

Digit 19 – Cabinet Nominal CFM

E = 350

G = 450

K = 600

M = 800

P = 1000

R = 1200

Digit 20 – Unit Connection

Voltage

1 = 120/1/60

2 = 208/1/60

3 = 240/1/60

4 = 277/1/60

Digit 21 – Motor Type

P = PSC

D = ECM (Discrete speed)

V = ECM (Variable Speed)

Digit 22 – Water Coil and Fins

Per Inch (FPI)

Note: X/Y format, where X = Number of

Cooling rows and Y = Number of

Heating rows. Function (cooling

only, changeover, etc) is handled

in positions 15 and 16 of the model

number.

3 row coils

K = 3/0 (2-pipe), 12 FPI

L = 3/1 (4-pipe), 12 FPI

M = 3/2 (4-pipe), 12 FPI

N = 3/0 (2-pipe), 14 FPI

P = 3/1 (4-pipe), 14 FPI

Q = 3/2 (4-pipe), 14 FPI

4-row coils

U = 4/0 (2-pipe), 12 FPI

V = 4/1 (4-pipe), 12 FPI

W = 4/2 (2-pipe), 12 FPI

X = 4/0 (2-pipe), 14 FPI

Y = 4/1 (4-pipe), 14 FPI

Z = 4/2 (4-pipe), 14 FPI

Digit 23 – Chilled Water Piping

Packages

Note: Manual air vent, drain cock,

flexible braided hoses and unions

on supply and return are standard

features. Control valves are

mounted on coil return.

A = 2-way control valve, shutoff valves on

supply and return

B = 3-way control valve, shutoff valves on

supply and return

C = 2-way control valve, shutoff valve on

supply, manual balancing valve with

shutoff on return.

D = 3-way control valve, shutoff valve on

supply, manual balancing valve with

shutoff on return.

E = 2-way control valve, combo strainer/

shutoff valve on supply, manual

balancing valve with shutoff on return

F = 3-way control valve, combo strainer/

shutoff valve on supply, manual

balancing valve with shutoff on return

G = 2-way control valve, combo strainer/

shutoff valve on supply, automatic

balancing valve with shutoff on return

H = 3-way control valve, combo strainer/

shutoff valve on supply, automatic

balancing valve with shutoff on return

Digit 24 – Hot Water Piping

Packages

Note: Manual air vent, drain cock,

flexible braided hoses and unions

on supply and return are standard

features. Control valves are

mounted on coil return.

A = 2-way control valve, shutoff valves on

supply and return

B = 3-way control valve, shutoff valves on

supply and return

C = 2-way control valve, shutoff valve on

supply, manual balancing valve with

shutoff on return.

D = 3-way control valve, shutoff valve on

supply, manual balancing valve with

shutoff on return.

E = 2-way control valve, combo strainer/

shutoff valve on supply, manual

balancing valve with shutoff on return

F = 3-way control valve, combo strainer/

shutoff valve on supply, manual

balancing valve with shutoff on return

G = 2-way control valve, combo strainer/

shutoff valve on supply, automatic

balancing valve with shutoff on return

H = 3-way control valve, combo strainer/

shutoff valve on supply, automatic

balancing valve with shutoff on return

Digit 25 – Electric Heat

Note: Must operate at supply voltage,

subject to cabinet size and airflow.

0 = No Electric Heating Coil

A = 0.75 kW

B = 1.0 kW

C = 1.5 kW

D = 2.0 kW

E = 2.5 kW

F = 3.0 kW

G = 3.5 kW

H = 4.0 kW

J = 4.5 kW

K = 5.0 kW

M = 6.0 KW

P = 7.0 KW

R = 8.0 KW

Digit 26 – Control Type

(Provided and installed by factory unless

otherwise noted)

0 = Low-voltage control by Others,

Installed by Others, Terminal Strip

provided.

A = Auto Changeover, NonProgrammable, Fan Speed Switch

B = Auto Changeover, Programmable, Fan

Speed Switch

C = Auto Changeover, NonProgrammable, No Fan Speed Switch

D = Auto Changeover, Programmable, No

Fan Speed Switch

E = Manual Changeover, NonProgrammable, Fan Speed Switch

F = Manual Changeover, Programmable,

Fan Speed Switch

UNT-PRC019-EN 5

Page 6

Model Number Description

G = Manual Changeover, NonProgrammable, No Fan Speed Switch

H = Manual Changeover, Programmable,

No Fan Speed Switch

1 = Tracer™ ZN521 (zone sensor ordered

separately)

2 = Tracer™ UC400 (zone sensor ordered

separately)

Digit 27 – Actuator Operation

(Provided and installed by factory unless

otherwise noted)

0 = None, Low Voltage, installed by

others, outside of unit

C = Control Contractor Supplied, Low

Voltage, installed by factory

L = Line Voltage, 2-position

B = 24 V 2-position (normally closed

spring return)

F = 3-Wire Floating Point

M = 0-10 or 2-10 V Modulating

Digit 28 – Cabinet Type/

Thermostat Location/Insulation

1 = Flush Mounted RA panel, remote

mounted thermostat (Fiberglass

insulation)

2 = Flush Mounted RA panel unit

mounted thermostat (Fiberglass

insulation)

3 = Hinge Mounted RA panel, remote

mounted thermostat (Fiberglass

insulation)

4 = Hinge Mounted RA panel unit

mounted thermostat (Fiberglass

insulation)

5 = Flush Mounted RA panel, remote

mounted thermostat (Closed Cell

Insulation)

6 = Flush Mounted RA panel unit

mounted thermostat (Closed Cell

Insulation)

7 = Hinge Mounted RA panel, remote

mounted thermostat (Closed Cell

Insulation)

8 = Hinge Mounted RA panel unit

mounted thermostat (Closed Cell

Insulation)

Digit 29 – Drain Pan

0 = None (Heating Only Unit)

1 = Acrylic coated galvanized steel double

sloped drain pan

2 = Acrylic coated galvanized steel double

sloped drain pan CW float switch

3 = Stainless Steel double sloped drain

pan

4 = Stainless Steel double sloped drain

pan CW float switch

Digit 30 – Design Sequence

Current design sequence is “A”

Riser Package

Digit 1, 2, 3 – Riser Package

Must always be “YRP”

Digit 4 – Configuration

A = 2-pipe system

S = 4-pipe system

Digit 5 – Spacer

Digit 6 – Riser Type

1 = Single

2 = Master

Digit 7 – Copper Pipe Type

1 = All risers - type “M”

2 = All risers - type “L”

3 = Supply, Return - type “L”, Condensate type “M”

4 = Supply, Return - type “M”, No

Condensate

Digit 8, 9, 10 – Riser Insulation

Type*

0 = None

1 = Closed cell polyolefin

2 = Closed cell elastomeric

4 = Fiberglass

X = n/a

Digit 11 – Spacer

Digit 12, 13, 1 4 – Riser Insulation

Thickness*

0 = None

2 = 1/2 inch

4 = 1 inch

X = n/a

Note:

Note: *For a 4-pipe system:

*

For a 2-pipe system:

First character: Use to describe the

cooling supply and return (or

heating supply and return)

Second character: Enter “X”

Third character: use to describe

condensate

First character: Use to describe

cooling supply and return.

Second character: Use to describe

heating supply and return.

Third character: Use to describe

condensate.

Raised Base Package

Digit 1, 2, 3, 4 – Raised Base

Package

Must always be “YRBP”

Digit 5 – Spacer

Digit 6 – Unit Foot Print

1 = 350/450 (17 in. x 17 in.)

2 = 600/800 (20 in. x 20 in.)

3 = 1000/1200 (24 in. x 20 in.)

Digit 7, 8 – Raised Base Height

04 = 4 inches

08 = 8 inches

12 = 12 inches

Digit 9 – Access Panel**

0 = None

1 = Yes, front

Digit 10 – Condensate Pump*

(Voltages are connection

voltages)

0 = No pump

1 = 120V

2 = 208V

3 = 240V

4 = 277V (c/w Transformer)

Note: Raised base is not insulated.

Optional access panel only

available on the front side.

Note: *If condensate pump is required,

raised base with condensate

pump must be factory installed.

Electrical connections to the pump

are by Trane.

Note: **Access panel is only available

with a 12-inch raised base.

6 UNT-PRC019-EN

Page 7

Model Number Description

Supply Air Grille/

Registers

Digit 1, 2, 3 – Grille Supply

GSS = Grille Supply Steel

GSR = Grille Supply Steel with Register

GSA = Grille Supply Aluminum

GSB = Grille Supply Aluminum with

Register

Digit 4 – Spacer

Digit 5, 6 – Width**

XX = Round inches

Digit 7 – Type

0= Double deflection, horizontal front

blades with mounting clips

1 = Double deflection, horizontal front

blades with mounting holes

Digit 8, 9 – Height**

XX = round inches

Digit 10 – Color/Finish

W = Nailorhart White

C = Custom color

Note: * Mounting holes are on front

flange of supply grille.

Note: ** Dimensions given for nominal

frame size. These correspond to

the nominal unit opening.

Table 1. Return Air Gr ille Part

Numbers

Return Air Panel Type

Flush Mounted FSM 0145XA FSM 0145XB

Hinge Mounted GRS 14152W GRS 16154W

Flush Mounted FSM 0145XAC FSM 0145XBC

Hinge Mounted GRS 14152C GRS 16154C

Size 350/450/600/800 Size 1000/1200

Standard White

Custom Color

Table 2. Register/Grille Quick

Reference

Nominal

Size

14 x 5 GSS 14005W GSR 14005W GSS 14105W GSR 14105W

14 x 8 GSS 14008W GSR 14008W GSS 14108W GSR 14108W

14 x 10 GSS 14010W GSR 14010W GSS 14110W GSR 14110W

14 x 12 GSS 14012W GSR 14012W GSS 14112W GSR 14112W

14 x 14 GSS 14014W GSR 14014W GSS 14114W GSR 14114W

16 x 12 GSS 16012W GSR 16012W GSS 16112W GSR 16112W

16 x 14 GSS 16014W GSR 16014W GSS 16114W GSR 16114W

Note: For custom color grille, replace “W” with “C” at the end of the part number.

Registers and grilles are only available in the sizes list ed in this table.

Grilles Registers Grilles Registers

Clips Screw Holes

Filters

Table 3. Filter Part Numbers

Filter Part Numbers

Size 1000/1200

16 x 25 nominal size

FRX 14125 FRX 16125

Filter Type

Pleated - MERV 13 FPH 14125 FPH 16125

Throwaway Wire Frame - for Units with

Throwaway Cardboard Frame - for Units

Note: All filters are 1-inch thick.

Pleated - MERV 10 FPY 14125 FPY 16125

Hinged Access Panel

with Flush Mounted Access Panel

Size 350/450/600/800

14 x 25 nominal size

FWX 14125A FWX 16125

UNT-PRC019-EN 7

Page 8

Performance Data

Cooling Capacities

AHRI-certified cooling performance is based on ANSI/AHRI Standard 440-2008: Performance

Rating of Room Fan-Coils: 80/67°F entering air temperature, 45°F entering chilled water

temperature with a 10°F delta T. All performance measured on high speed tap using a 120 V AC

motor, 0.05 inches ESP without filters or grilles.

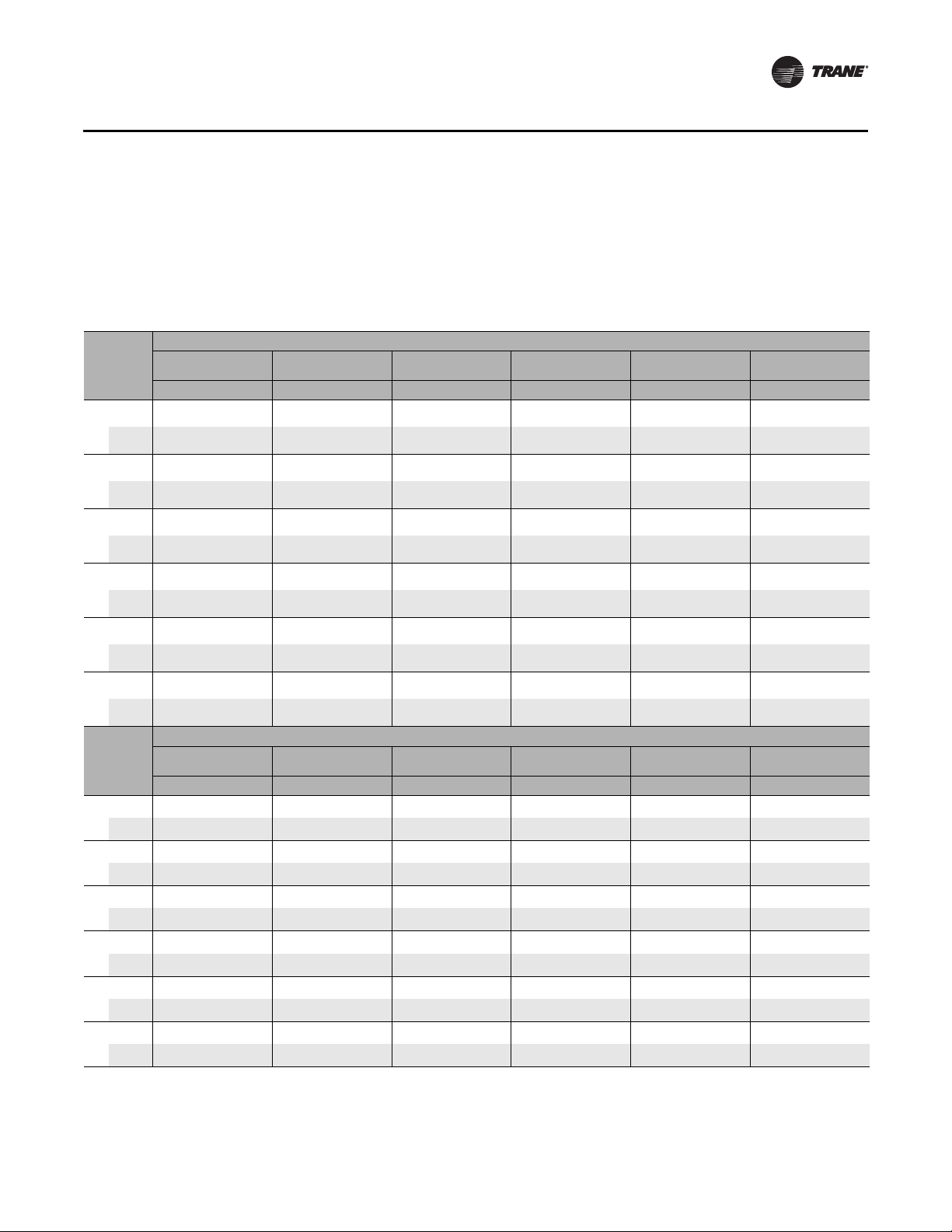

Table 4. AHRI-certified rating s for cooling capacities

Size Coil

350

450

600

800

1000

1200

Note: EC motor also available.

3HC 300 8.5 5.3 2.3 5.2 132

4HC 300 9.2 5.6 2.4 5.3 132

3HC 470 11.8 7.7 3.1 10.0 175

4HC 470 12.9 8.3 3.4 7.5 175

3HC 620 19.8 12.6 4.7 18.6 259

4HC 620 22.4 13.7 5.3 19.1 259

3HC 700 21.6 13.8 5.1 19.7 290

4HC 700 24.6 15.1 5.8 17.9 290

3HC 1010 31.6 20.0 7.4 18.9 446

4HC 1010 36.3 22.1 8.5 16.5 446

3HC 1140 34.3 22.1 8.0 20.4 621

4HC 1140 39.7 24.4 9.3 18.9 621

Airflow

(cfm)

Total Capacity

(MBh)

Cooling Power Input (W)

Sensible Capacity

(MBh)

Water Flow

(GPM)

WPD

(ft H2O)

PSC

8 UNT-PRC019-EN

Page 9

Heating Capacities

Heating performance is based on 70°F entering air temperature, and listed entering water

temperatures. All performance data measured on high speed tap using a 120 V AC motor, 0.05

inches ESP without filters and grilles. 1-row and 2-row coils are in the preheat configuration as part

of a 4-pipe system. 3-row and 4-row coils are only available as part of a 2-pipe system.

Table 5. Heating capacities

Performance Data

Size

350

450

600

800

1000

1200

Size

350

450

600

800

1000

1200

Total

Rows

Heating

1-row

Preheat

2-row

Preheat

1-row

Preheat

2-row

Preheat

1-row

Preheat

2-row

Preheat

1-row

Preheat

2-row

Preheat

1-row

Preheat

2-row

Preheat

1-row

Preheat

2-row

Preheat

Rows

Heating

3-row

Heating

4-row

Heating

3-row

Heating

4-row

Heating

3-row

Heating

4-row

Heating

3-row

Heating

4-row

Heating

3-row

Heating

4-row

Heating

3-row

Heating

4-row

Heating

Capacity

Capacity

WPD

(MBh)

(ft H

0)

2

0.5 GPM 1.0 GPM 2.0 GPM 3.0 GPM 4.0 GPM 5.0 GPM

10.2 0.5 118 13.1 1.8 133 15.3 6.7 144 16.2 14.5 149 - - - - - -

12.5 0.2 109 17.2 0.7 125 20.8 2.6 139 22.3 5.7 145 - - - - - -

11.5 0.5 113 15.6 1.8 128 19.0 6.7 141 20.4 14.5 146 - - - - - -

14.1 0.2 102 20.6 0.7 118 26.6 2.6 133 29.3 5.7 140 - - - - - -

- - - 19.5 0.6 120 25.2 2.3 134 27.9 5.1 141 29.5 8.8 145 - - -

- - - 26.6 0.9 106 35.9 3.3 123 40.3 7.1 133 42.8 12.2 138 - - -

- - - 20.2 0.6 119 26.4 2.3 133 29.4 5.1 140 31.2 8.8 144 32.4 13.6 147

- - - 27.5 0.9 104 38.0 3.3 121 43.0 7.1 131 45.9 12.2 137 - - -

- - - 24.5 0.4 110 33.6 1.6 126 38.3 3.4 134 41.1 5.8 139 43.0 8.8 142

- - - 32.0 0.8 95 47.2 2.7 112 55.3 5.7 122 60.2 9.7 129 63.5 14.7 134

- - - 25.3 0.4 108 35.3 1.6 124 40.5 3.4 132 43.7 5.8 138 45.8 8.8 141

- - - 33.0 0.8 93 49.6 2.7 109 58.9 5.7 120 64.6 9.7 127 68.5 14.7 132

Total

WPD

(MBh)

(ft H

0)

2

0.5 GPM 1.0 GPM 2.0 GPM 3.0 GPM 4.0 GPM 5.0 GPM

10.5 0.2 97 14.7 0.9 110 18.0 3.3 122 19.3 7.2 127 - - - - - -

11.9 0.1 92 16.1 0.5 107 19.7 2.0 120 20.9 4.5 126 - - - - - -

11.7 0.2 93 17.6 0.9 104 23.3 3.3 116 25.9 7.2 122 - - - - - -

13.2 0.1 86 19.2 0.5 101 25.7 2.0 114 28.6 4.5 121 - - - - - -

- - - 22.9 0.6 93 31.8 2.2 108 36.0 4.7 116 38.2 8.2 121 - - -

- - - 24.5 0.4 90 34.7 1.7 105 39.3 3.8 113 41.6 6.6 119 - - -

- - - 23.7 0.6 92 33.7 2.2 106 38.5 4.7 114 41.3 8.2 119 43.0 12.6 123

- - - 25.3 0.4 89 36.7 1.7 103 42.2 3.8 111 45.1 6.6 117 46.9 10.2 121

- - - 27.0 0.4 85 41.5 1.4 98 49.4 3.0 107 54.3 5.1 112 57.4 7.7 117

- - - 28.4 0.2 82 44.9 0.9 94 54.2 1.9 103 59.7 3.3 110 63.1 5.1 114

- - - 27.7 0.4 84 43.6 1.4 96 52.7 3.0 104 58.4 5.1 110 62.3 7.8 115

- - - 29.0 0.2 81 47.2 0.9 92 57.7 2.0 101 64.4 3.3 107 68.7 5.1 112

LWT

(°F)

LWT

(°F)

Total

Capacity

(MBh)

Total

Capacity

(MBh)

WPD

(ft H

WPD

(ft H

LWT

(°F)

0)

2

LWT

(°F)

0)

2

Entering Water Temp. 160°F

Total

Capacity

Capacity

WPD

WPD

LWT

(°F)

0)

2

LWT

(°F)

0)

2

(MBh)

(ft H

Entering Water Temp. 140°F

Total

(MBh)

(ft H

Total

Capacity

(MBh)

Total

Capacity

(MBh)

WPD

(ft H

WPD

(ft H

Total

Capacity

LWT

(°F)

0)

2

Capacity

LWT

(°F)

0)

2

(MBh)

Total

(MBh)

WPD

(ft H

WPD

(ft H

0)

2

0)

2

LWT

(°F)

LWT

(°F)

Total

Capacity

(MBh)

Total

Capacity

(MBh)

WPD

(ft H

WPD

(ft H

LWT

(°F)

0)

2

LWT

(°F)

0)

2

UNT-PRC019-EN 9

Page 10

Performance Data

Sound Data

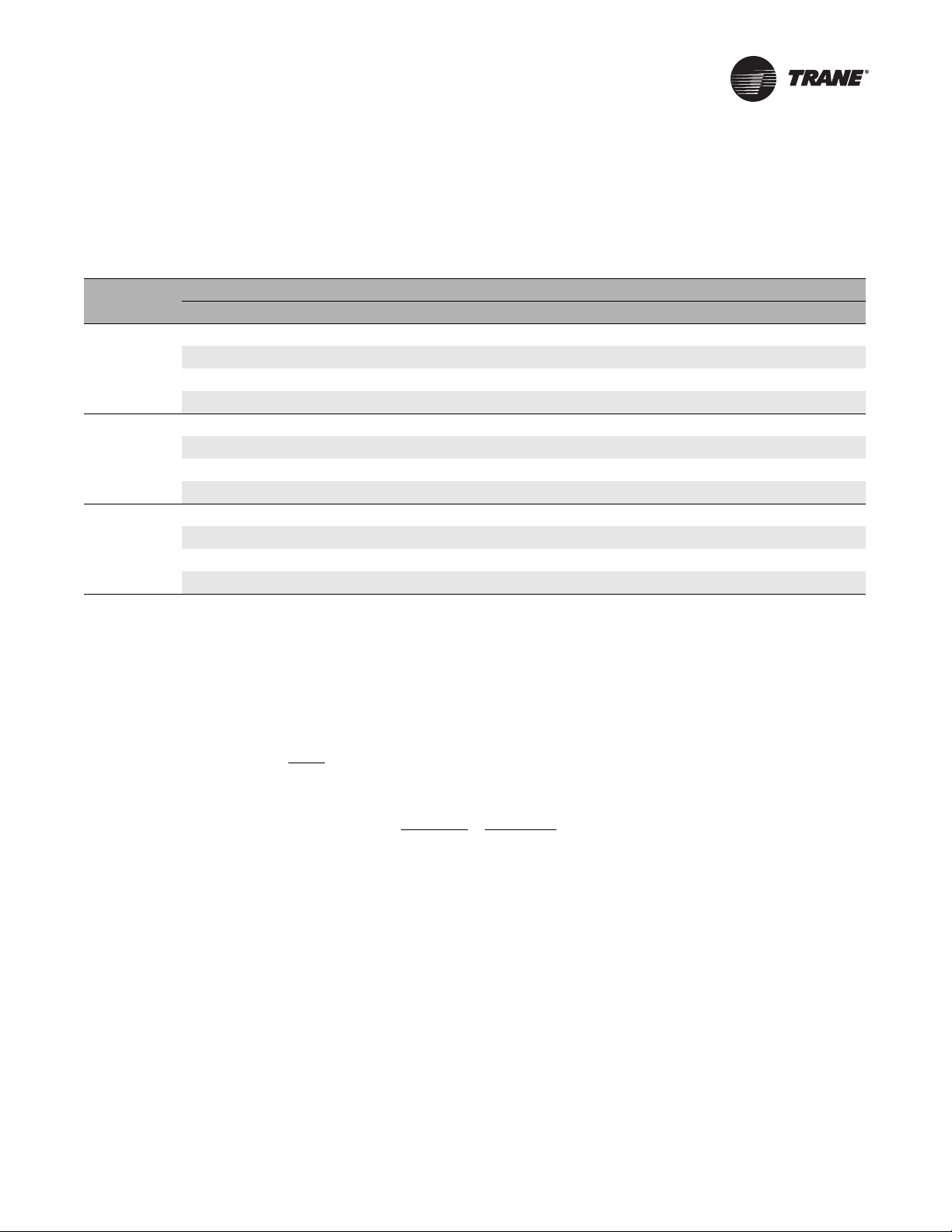

Table 6. Sound data for vertical stack fan coils

Unit Size CFM Fan Speed

325 High 31

350

450

600

800

1000

1200

Note: Sound level is measured at a distance of 8 ft. from the return air grille. Measurements are for a typical furnished and

carpeted hotel suite. CFM in the above chart is approximate. Airflow is dependent on the number of coil rows, coil fins

per inch, the amount of condensate on the fins, supply voltage, motor manufacturer, supply air configuration, filter

cleanliness and altitude.

275 Medium 29

225 Low 28

500 High 37

425 Medium 34

325 Low 31

650 High 39

500 Medium 37

425 Low 35

725 High 41

600 Medium 39

500 Low 37

1050 High 45

950 Medium 43

800 Low 41

1175 High 50

1100 Medium 47

1000 Low 44

dBA

Sound Pressure Level -

10 UNT-PRC019-EN

Page 11

Components and Options

Electric Heat

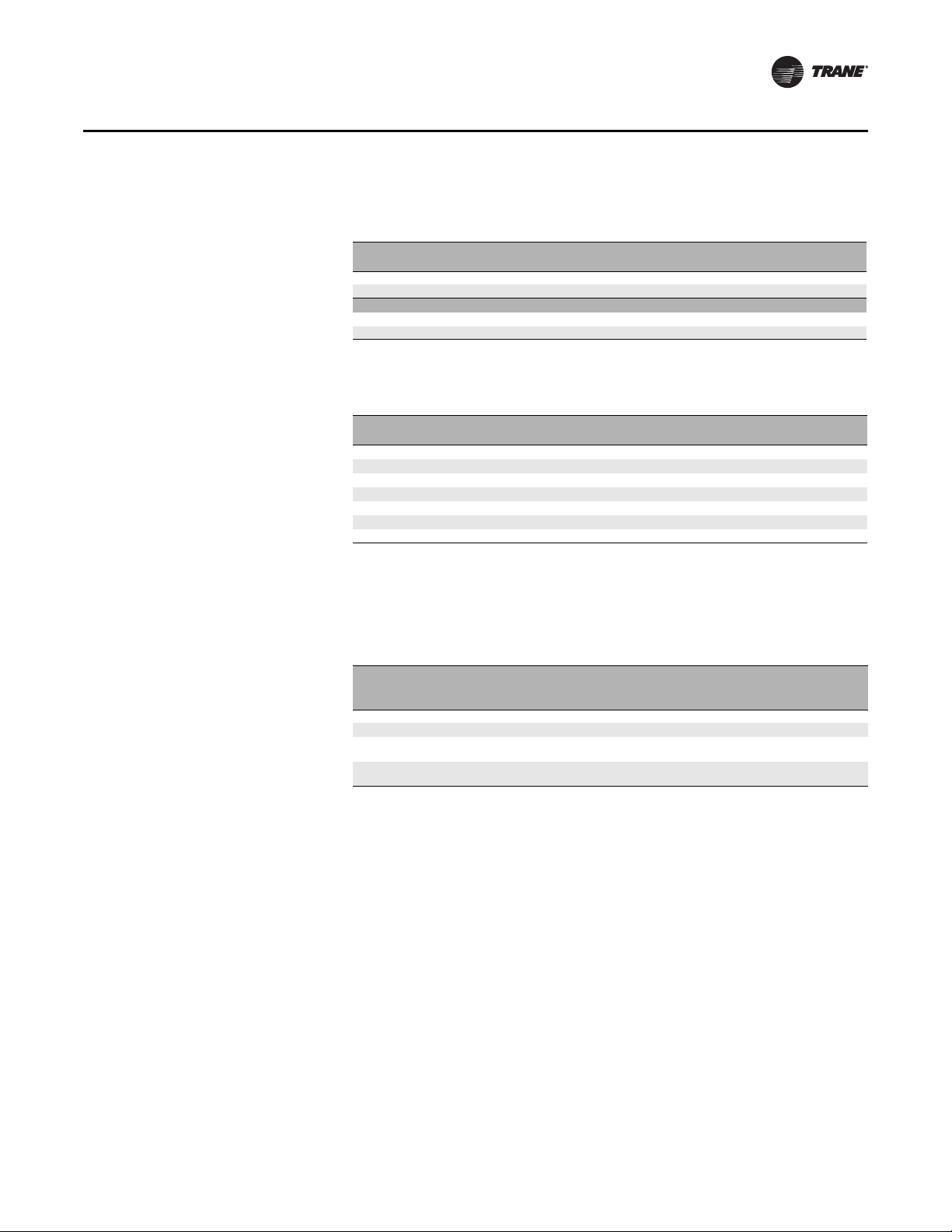

Table 7. Kilowatts (kW) per model

kW 0.75 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0 7.0 8.0

Model

350/450

600/800

1000/1200

Volts/ph/Hz Heater Amps

120V/1/60 6.3 8.3 12.5 16.7

208V/1/60 4.8 7.2 9.6 12.0 14.4 16.8

240V/1/60 4.2 6.3 8.3 10.4 12.5 14.6

277V/1/60 3.6 5.4 7.2 9.0 10.8 12.6

120V/1/60 6.3 8.3 12.5 16.7

208V/1/60 4.8 7.2 9.6 12.0 14.4 16.8 19.2 21.6 24.0 28.8

240V/1/60 4.2 6.3 8.3 10.4 12.5 14.6 16.7 18.8 20.8 25.0

277V/1/60 3.6 5.4 7.2 9.0 10.8 12.6 14.4 16.2 18.1 21.7

120V/1/60 6.3 8.3 12.5 16.7

208V/1/60 4.8 7.2 9.6 12.0 14.4 16.8 19.2 21.6 24.0 28.8 33.7 38.5

240V/1/60 4.2 6.3 8.3 10.4 12.5 14.6 16.7 18.8 20.8 25.0 29.2 33.3

277V/1/60 3.6 5.4 7.2 9.0 10.8 12.6 14.4 16.2 18.1 21.7 25.3 28.9

• Heaters are wired for single stage operation.

• An auto-reset high limit device is included.

• Power connection is single point.

• The heater is located in the reheat position relative to the cooling coil.

• The fan coil unit does not include a fuse or fusible type disconnect. Motor sub-fusing as per

electrical code.

Amps = Watts

Volts

Air temp. rise (Delta T) = kW x 3160

= MBH x 925

CFM CFM

S.A. = Supply Air

FLA = Full Load Amps

= S.A. fan motor Amps + Electric Heater Amps

MCA = Minimum Circuit Ampacity

= FLA x 1.25

MOP = Rating of maximum overcurrent protection device

= (2.25 x S.A. fan motor Amps) + Electric Heater Amps

UNT-PRC019-EN 11

Page 12

Components and Options

Requirements of Standards: UL 1995 and CSA C22.2 No.236

• If the value of the calculated rating does not equal a standard current rating of overcurrent

protective device, the mark ed maximum rating shall be the next lower standard rating.

• Exception No. 1: The marked maximum rating of the overcurrent protective device shall be the

standard rating next higher than the computed value if the next lower standard ratings is less

than 125 percent of the current rating of an electric heater load, when the unit includes an

electric heater.

• Exception No. 2: if the computed value of the overcurrent protective device is less than the

minimum ampacity of the supply circuit, the marked rating of the device shall be increased to

the largest standard overcurrent protective device rating appropriate for the marked minimum

circuit ampacity.

• Exception No. 3: If the marked minimum circuit ampacity does not correspond to a standard

protective device rating, the next higher standard rating of the protective device may be

marked.

12 UNT-PRC019-EN

Page 13

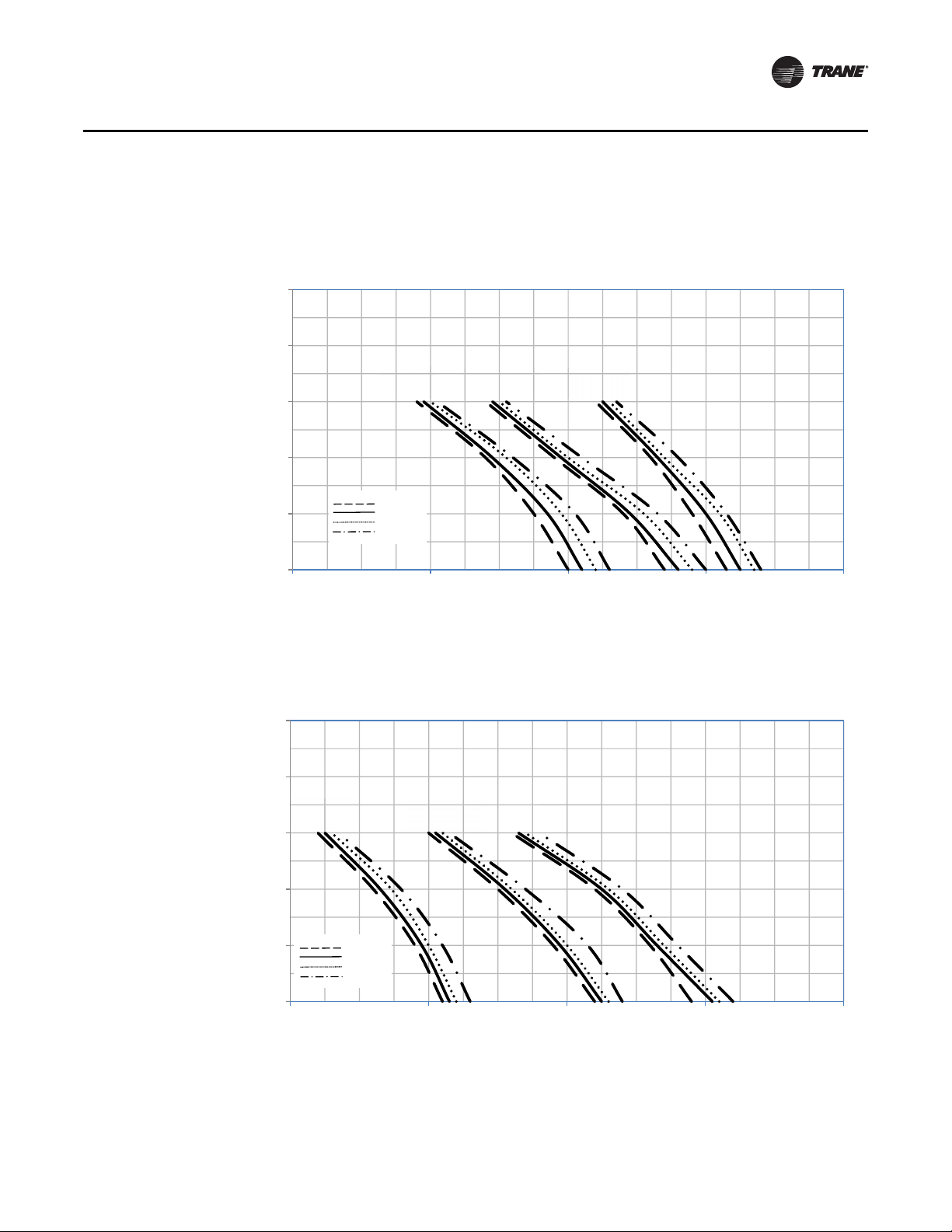

Fans Curves

0

0.1

0.2

0.3

0.4

0.5

0 100 200 300 400

External Static Pressure (in. wg.)

Supply Air Volume (SCFM)

Medium

Low

6 Row

5 Row

4 Row

3 Row

0

0.1

0.2

0.3

0.4

0.5

200 300 400 500 600

External Static Pressure (in. wg.)

Supply Air Volume (SCFM)

High

Medium

Low

6 Row

5 Row

4 Row

3 Row

Components and Options

Figure 3. Unit size 350

High

Figure 4. Unit size 450

UNT-PRC019-EN 13

Page 14

Components and Options

0

0.1

0.2

0.3

0.4

0.5

300 400 500 600 700

External Static Pressure (in. wg.)

Supply Air Volume (SCFM)

High

Medium

Low

6 Row

5 Row

4 Row

3 Row

0

0.1

0.2

0.3

0.4

0.5

300400500600700800

External Static Pressure (in. wg.)

Supply Air Volume (SCFM)

High

Medium

Low

6 Row

5 Row

4 Row

3 Row

Figure 5. Unit size 600

Figure 6. Unit size 800

14 UNT-PRC019-EN

Page 15

Figure 7. Unit size 1000

0.5

0.4

Components and Options

Low

0.3

0.2

0.1

External Static Pressure (in. wg.)

6 Row

5 Row

4 Row

3 Row

0

600 700 800 900 1000 1100 1200

Figure 8. Unit size 1200

0.5

0.4

Low

0.3

Medium

Medium

High

Supply Air Volume (SCFM)

High

0.2

External Static Pressure (in. wg.)

5 Row

4 Row

3 Row

6 Row

0.1

0

800 900 1000 1100 1200 1300

Supply Air Volume (SCFM)

Fan curves are based on 120V AC PSC motor at high, medium and low fan speed settings. The

following test conditions apply:

• Centrifugal direct drive fan with double inlet and forward curved impeller.

• Cooling coil is dry.

• One-inch throwaway filter is clean.

UNT-PRC019-EN 15

Page 16

Components and Options

Motor Data

Table 8. Motor data

Size

350

450

600

800

1000

1200

Note: EC motors have been programmed for three (3) discrete speed operation. Variable speed also available (not shown.) Motor nameplate data is show n

in table. Fan motors are single phase and have a minimum of three speeds. Trane has several fan motor suppliers in order to ensure availability . Amp

draws may differ between motors from different manufacturers. Trane reserves the right to change motor HP and therefore amp draws without notice

Connection Voltage

Volts/ph/Hz

120V/1/60 1/20 1.2 1/3 4.8

208-240V/1/60 1/14 0.6 1/3 2.8

277V/1/60 1/12 0.6 1/3 2.6

120V/1/60 1/6 1.7 1/3 4.8

208-240V/1/60 1/12 0.8 1/3 2.8

277V/1/60 1/12 0.6 1/3 2.6

120V/1/60 1/6 2.6 1/3 4.8

208-240V/1/60 1/12 0.8 1/3 2.8

277V/1/60 1/12 0.6 1/3 2.6

120V/1/60 1/6 2.6 1/3 4.8

208-240V/1/60 1/6 1.4 1/3 2.8

277V/1/60 1/6 0.9 1/3 2.6

120V/1/60 1/4 4.6 1/3 4.8

208-240V/1/60 1/4 2.2 1/3 2.8

277V/1/60 1/4 1.6 1/3 2.6

120V/1/60 1/3 6.4 1/2 6.8

208-240V/1/60 1/3 3.1 1/2 4.1

277V/1/60 1/3 2.1 1/2 3.6

Max. Plate Ratings Max. Plate Ratings

HP Amps HP Amps

PSC ECM

Control Packages

T rane offers a range of standard thermostats and controllers for the vertical stack fan coil units. For

applications where a larger BAS is to be installed, T rane can provide factory mounting of the ZN521

or UC400 controllers.

Thermostats

Table 9. Thermostat information

Thermostat

Voltage Manufacturer Model

24 Honeywell TB8575A1000 Automatic or Manual User Selectable 3

24 Honeywell TB7100A10001Automatic or Manual User Selectable 3 Residential

120/208/240 Honeywell TB6575A1000 Automatic or Manual User Selectable 3

24 HotelTech LT24A Automatic see Note 2 2 Hotel

24 HotelTech LT24A3 Automatic see Note 2 3 Hotel

120 HotelTech LT120A Automatic see Note 2 2 Hotel

208-230 HotelTech LT220A Automatic see Note 2 2 Hotel

277 HotelTech LT277A Automatic see Note 2 2 Hotel

1. The Honeywell TB7100A1000 is a 7-day programmable thermostat.

2. The HotelTech thermostats feature automatic fan speed switching between the available speeds and off. The thermostat selects speed based on

deviation of the room temperature from set point. The occupant can also manually select between the available speeds.

Heat/Cool

Changeover Fan Operation

Available Fan

Speeds Application

Residential or

Hospitality

Residential or

Hospitality

16 UNT-PRC019-EN

Page 17

Residential applications include: Condominiums, apartments, student residences/dormitories,

assisted living/retirement facilities, and military barracks.

T rane recommends the remote mounting of low voltage (24V) thermostats to achieve optimal zone

control. When thermostats are remote mounted, a terminal strip is provided inside the unit for field

connection to the remote thermostat. Unit mounting of thermostat is also available, however all

thermostats are shipped loose for field installation after the unit is installed, drywall is applied and

the walls are painted.

The standard standalone thermostats listed above cycle a two position (on/off) valve and feature

discrete speed fan speed operation. If modulating (0-10V DC or 3-wire floating point) valve

actuators or modulating or 0-10V DC EC motors are a requirement, a thermostat or controller with

the necessary analog outputs must be used.

Tracer ZN521 Zone Controller

The T racer ZN521 is a factory-installed LonTalk® control board designed to provi de control of th e

fan-coil products (see Figure 9).

Figure 9. Tracer ZN521 controller

Components and Options

Features include:

• Automatic fan-speed reset

• Automatic ventilation reset

• Manual output test

• Filter maintenance

• Master slave

• Water valve override

• Freeze avoidance

• Interoperability

• Three generic I/O ports

The Tracer ZN521 controller is designed to be used in the following applications:

• As part of the T rane T racer Summit building automation system, the T racer ZN521 becomes an

important part of the Trane Integrated Comfort system (ICS).

• The Tracer ZN521 can function as a completely standalone controller in situations where a

building automation system (BAS) is not present.

• For situations when a non-T rane BAS is present, the T racer ZN521 can be where ever a LonT alk

front-end system is present.

Through building management of the HVAC system, optimizing energy consumption becomes

possible at a zone level. Each unit is capable of functioning independently of one another during

occupied and unoccupied hours of the day. This allows the temperature setpoint and ventilation

setting to be changed automatically based on zone usage (see Figure 10).

UNT-PRC019-EN 17

Page 18

Components and Options

Fan

coil

Fan

coil

To other

building products

To other

Trane products

Security

system

Rover™

(optional)

Tracer

Summit®

System

Lighting

system

Fire safety

system

Figure 10. Tracer ZN521 System

Two Systems in One

In an ICS environment, the Tracer ZN521 is pre-designed to install quickly and easily into the

system. Since the controller is mounted on the unit, the start-up time for the entire system is

minimized. T rane becomes the single source of responsibility for the equipment, unit controls, and

building automation system.

Once power is applied to the controller, it will automatically start up and run based upon the

setpoint on the local zone sensor. The Tracer ZN521 is certified to the interoperable L

Space Comfort Controller profile. This allows the controller to be used with another vendor’ s BAS

and thereby still provide the high quality of factory installation. In addition, the Tracer ZN521

provides one of the most extensive interoperable data lists of any controller of its type in the

industry.

Automatic Fan and Ventilation Reset

With the Tracer ZN521 controller, a multi-speed fan control for the fan coil delivers the airflow

output customized to support the cfm space needs. When less cfm is necessary to meet the load

of the zone (typically 75 to 80 percent of the time), the equipment operates on low speed. However,

if the room temperature rises, the controller will switch to high speed.

18 UNT-PRC019-EN

Manual Output Test

The T racer ZN521 controller includes a manual output test function. This function may be initiated

from the blue test push button on the controller or through the Rover™ service tool. This feature

is used to manually exercise the outputs in a defined sequence.

The purpose of this test sequence is to verify output and end device operation. The manual output

test function may also be used in the following situations:

• Reset latching diagnostics

• Verify output wiring and operation

• Force the water valve(s) open to balance the hydronic system during installation set-up or

service.

ONMARK

®

Page 19

Components and Options

Filter Maintenance

Filter status for the controller is based on the cumulative run hours of the unit fan. The controller

compares the amount of fan run time against an adjustable fan run hour (stored in the controller)

to determine when maintenance is recommended for the unit. The run-hours value may be user

edited as required (through Rover). The valid range for the fan run hours limit is 0 to 5000 hours

with a default of 600 hours. Once the run hours limit has been exceeded, the controller generates

a maintenance required diagnostic (unit will not shut-down). The user will be notified of th is

diagnostic through the building automa tion system or when a T rane Service T ool is communicating

with the controller.

Master Slave (Data Sharing)

Because the Tracer ZN521 controller utilizes LONW

receive data (setpoint, heat/cool mode, fan request, space temperature, etc.) to and from other

controllers on the communication link with or without the existence of a building automation

system. This applies to applications where multiple units might share one zone sensor for both

stand-alone (with communication wiring between units) and a building automation system.

®

ORKS

technology, the controller can send or

Water Valve Override

The Tracer ZN521 can be commanded via the Rover service tool to open all hydronic valves

100 percent. This allows for the faster water balancing of each unit and the entire system when the

command is sent globally to all controllers. A properly balanced system is essential for proper and

efficient operation.

Hydronic Coil Freeze Protection (Freeze Avoidance)

Fan coil systems in cold climates need to take precautions to avoid hydronic coil freeze-up. The

T racer ZN521 does this from three different aspects. Any of these methods of protections will result

in the unit fan being disabled, the outside air damper being shut , and the hydronic valves being

opened 100 percent.

The three methods of freeze avoidance include:

1 . A binary freeze protection thermostat is mounted on the coil and will cause a latching diagnostic

if the coil temperature falls below 35°F.

2. An analog discharge air sensor monitors the temperature of the air coming off of the coil and

if the temperature falls below 40°F the outside air damper is closed, the fan is turned off and

the valves are fully opened.

3. When in the unoccupied mode the Tracer ZN521 has an adjustable freeze avoidance setpoint.

If the outside air temperature is below the setpoint the unit will open the valves to allow water

to flow through the coils.

Interoperability

Interoperability allows the owner freedom to select multiple vendors, and multiple products. With

this advantage, the owner can choose the best products, the best application, and the best service

from a variety of suppliers to meet their evolving building control needs in a cost effective manner.

Generic Binary Input/Output

The three generic binary inputs/outputs are not part of the normal control, but are actually

controlled through the Tracer Summit system (when present) to issue commands to the Tracer

ZN521 control to turn the generic inpu ts/outputs of add-on equipment (suc h as baseboard heating,

exhaust fans, occupancy sensor, lighting, etc.) on and off. This binary port is not affected when

other binary diagnostics interrupt unit operation.

UNT-PRC019-EN 19

Page 20

Components and Options

Tracer UC400 Controller

The T racer UC400 is a factory-installed BACnet® MS/TP control designed to pro vide control o f the

fan coil (see Figure 11). The Tracer UC400 controller is designed to be used in the following

applications: as stand-alone operation, part of the T rane T racer SC building automation system, or

part of another BACnet MS/TP Building Automation System. The Tracer UC400 can function as a

completely standalone controller in situations where a building automation system (BAS) is not

present.

Figure 11. Tracer UC400 Controller

Features include:

• Single Zone VAV

• Automatic ventilation reset

• Filter maintenance

• Wa t er valve overri de

• Freeze avoidance

• Interoperability

• Unused I/O can be used as generic I/O

The T racer UC400 is designed to install quickly and easily into the system. T rane becomes the single

source of responsibility for the equipment, unit controls, and building automation system. As a

standalone controller, the T racer UC400 is ideally suited for fix-on-fail replacement of units with old

pneumatic controllers, or in situations where a BAS will be added at a later date. Once power is

applied to the controller , it will automatically start up and run based upon the setpoint on the local

zone sensor. An individual time clock can be added to the unit for local scheduling. The Tracer

UC400 is BTL listed as B-ASC profile. This ensures the controller to be use d with other BACnet

building automation systems.

The Tracer UC400 controller delivers single zone VAV control and can be used in a stand-alone

application or as part of a Trane Integrated Comfort™ System (ICS).

In the stand-alone configuration, Tracer UC400 receives operation commands from the zone sensor

and/or the auto changeover sensor (on auto changeover units). The entering water temperature is

read from the auto changeover sensor and determines if the unit is capable of cooling or heating.

The zone sensor module is capable of transmitting the following information to the controller:

• Timed override on/cancel request

• Zone setpoint

• Current zone temperature

• Fan mode selection (off-auto-high-med-low)

For optimal system performance, fan coils can operate as part of an ICS building automation

system controlled by T racer Summit. The controller is linked directly to the Summit control panel

via a twisted pair communication wire, requiring no additional interface device (i.e., a command

unit). The T rane ICS system can monitor or over ride T racer UC400 control points. This includes such

points as temperature and output positions.

®

20 UNT-PRC019-EN

Page 21

Components and Options

Discharge temp setpoint (°F)

Fan speed command (%)

Single Zone VAV with Fully Modulating Fan Speed

With a single zone VAV with fully modulating fan speed, and EDM with modulating signal is

required. The Tracer UC400 will minimize fan speed, and in turn energy usage, by only delivering

the air flow needed. See Figure 12.

Figure 12. Cool mode nominal hydronic cooling control

Filter Maintenance

Filter status for the controller is based on the cumulative run hours of the unit fan. The controller

compares the amount of fan run time against an adjustable fan run hour (stored in the controller)

to determine when maintenance is recommended for the unit. The run-hours value may be user

edited as required. The valid range for the fan run hours limit is 0 to 5000 hours with a default of

600 hours. Once the run hours limit has been exceeded, the con t roller generates a maintenance

required diagnostic (unit will not shut-down). The user will be no tified of this di agnosti c through

the building automation system or when a Trane

controller.

®

service tool is communicating with the

Hydronic Coil Freeze Protection (Freeze Avoidance)

Fan coil systems in cold climates need to take precautions to avoid hydronic coil freeze-up. The

controller does this from three different aspects. Any of these methods of protections will result

in the unit fan being disabled, the outside air damper being shut , and the hydronic valves being

opened 100 percent.

The three methods of freeze avoidance include:

1 . A binary freeze protection thermostat is mounted on the coil and will cause a latching diagnostic

if the coil temperature falls below 35°F.

2. An analog discharge air sensor monitors the temperature of the air coming off of the coil and

if the temperature falls below 40°F the outside air damper is closed, the fan is turned off and

the valves are fully opened.

3. When in the unoccupied mode, the controller has an adjustable freeze avoidance setpoint. If the

outside air temperature is below the setpoint, the unit will open the valves to allow water to flow

through the coils.

UNT-PRC019-EN 21

Interoperability

Interoperability allows the owner freedom to select multiple vendors, and multiple products. With

this advantage, the owner can choose the best products, the best application, and the best service

from a variety of suppliers to meet their evolving building control needs in a cost effective manner.

Page 22

Dimensions and Weights

FRONT VIEW

SIDE SECTION

(Flush Mounted Panel Option)

TOP VIEW

F. F.L .

SIDE VIEW

(Hinged Panel Option)

E

86 in.

C

36 in.

2 1/8 in.

A

B

8

16

2

3

4

5

6

14

15

7

13

9

6

10

12

11

1

9

6 in.

1/2 in.

1 1/2 in.

D

47 in.

4 in.

Vertical Fan Coil Units

2-Pipe Chilled Water Cooling Unit

Figure 13. 2-pipe chilled water cooling unit - hot water c hangeover coil optional

22 UNT-PRC019-EN

Page 23

Dimensions and Weights

Table 10. 2-pipe chilled water cooling unit callouts

18 ga. steel cabinet, lined with 1/2-inch fiberglass

insulation coated on air side; 3/8-inch closed-cell

foam optional.

Direct-drive centrifugal fan and PSC moto r; EC motor

optional.

Chilled water coil; hot water changeover optional. Hinged return air grille/access panel (optional).

Acrylic coated galvanized steel drain pan, pitched in

two directions, insulated on the underside; stainless

steel optional.

Drain hose from drain pan to condensate riser. The

flexible hose forms a running trap.

Double deflection steel supply air grille at front, left,

right or back or any combination when there are

multiple openings. Dimension “D” varies with CFM:

5, 8, 10, 12, or 14 inches.

Flush mounted return air grille/access panel

attached by quarter turn fasteners.

One inch disposable filter.

1/2-inch flange on front of unit. Allows direct

application of drywall to the unit.

7/8-inch hole on each side of cabinet for power and

control cable entry points on all units. See CLCHSVX021A-EN installation manual for details.

2 1/8-inch flange on front of unit. Drywall to be

framed out in front of unit.

Unit mounting location for thermostat/controller.

Fan shield, acoustically lined. Identification and

safety caution labels are affixed to this panel.

Vertical centerline of coil connection run outs.

Connections are at the back, left or right sides of the

unit.

T op supply air opening (knock out) for attachment of

ductwork.

Table 11. 2-pipe chilled water cooling unit dimensions (inches)

Size A B C E

350 17 17 14 52

450 17 17 14 52

600 20 20 14 52

800 20 20 14 52

1000 20 24 16 54

1200 20 24 16 54

UNT-PRC019-EN 23

Page 24

Dimensions and Weights

FRONT VIEW

SIDE SECTION

(Flush Mounted Panel Option)

TOP VIEW

F. F.L .

SIDE SECTION

(Hinged Panel Option)

A

E

86 in.

36 in.

1/2 in.

D

C

B

9

17

3

4

5

6

7

15

16

8

2

14

1

9

7

12

13

10

47 in.

1 1/2 in.

2 1/8 in.

6 in.

11

4 in.

2-Pipe Chilled Water Cooling Unit with Electric Heat

Figure 14. 2-pipe chilled water cooling unit with electric heat

24 UNT-PRC019-EN

Page 25

Dimensions and Weights

Table 12. 2-pipe chilled water cooling unit with electric heat callouts

18 ga. steel cabinet, lined with 1/2-inch fiberglass

insulation coated on air side; 3/8-inch closed-cell

foam optional.

Electric heater (primary or auxiliary).

Direct-drive centrifugal fan and PSC moto r; EC motor

optional.

Chilled water coil; hot water changeover optional.

Acrylic coated galvanized steel drain pan, pitched in

two directions, insulated on the underside; stainless

steel optional.

Drain hose from drain pan to condensate riser. The

flexible hose forms a running trap.

Double deflection steel supply air grille at front, left,

right or back or any combination when there are

multiple openings. Dimension “D” varies with CFM:

5, 8, 10, 12, or 14 inches.

Flush mounted return air grille/access panel

attached by quarter turn fasteners.

One inch disposable filter.

1/2-inch flange on front of unit. Allows direct

application of drywall to the unit.

7/8-inch hole on each side of cabinet for power and

control cable entry points on all units. See CLCHSVX021A-EN installation manual for details.

Hinged return air grille/access panel (optional).

2 1/8-inch flange on front of unit. Drywall to be

framed out in front of unit.

Unit mounting location for thermostat/controller.

Fan shield, acoustically lined. Identification and

safety caution labels are affixed to this panel.

Vertical centerline of coil connection run outs.

Connections are at the back, left or right sides of the

unit.

T op supply air opening (knock out) for attachment of

ductwork.

Table 13. 2-pipe chilled water cooling unit with electric heat dimensions (inches)

Size A B C E

350 17 17 14 52

450 17 17 14 52

600 20 20 14 52

800 20 20 14 52

1000 20 24 16 54

1200 20 24 16 54

UNT-PRC019-EN 25

Page 26

Dimensions and Weights

9

17

2

5

6

7

15

16

8

3

4

14

9

7

12

1

1310

FRONT VIEW

SIDE SECTION

(Flush Mounted Panel Option)

TOP VIEW

F. F.L .

SIDE SECTION

(Hinged Panel Option)

6 in.

E

86 in.

36 in.

1 1/2 in.

D

C

B

A

1/2 in.

4 in.

47 in.

2 1/8 in.

11

4-Pipe Chilled Water Cooling and Hot Water Heating Unit

Figure 15. 4-pipe chilled water cooling and hot water heating unit

26 UNT-PRC019-EN

Page 27

Dimensions and Weights

Table 14. 4-pipe chilled water cooling hot water heating unit callouts

18 ga. steel cabinet, lined with 1/2-inch fiberglass

insulation coated on air side; 3/8-inch closed-cell

foam optional.

Direct-drive centrifugal fan and PSC moto r; EC motor

optional.

Chilled water coil. Hinged return air grille/access panel (optional).

Hot water coil.

Acrylic coated galvanized steel drain pan, pitched in

two directions, insulated on the underside; stainless

steel optional.

Drain hose from drain pan to condensate riser. The

flexible hose forms a running trap.

Double deflection steel supply air grille at front, left,

right or back or any combination when there are

multiple openings. Dimension “D” varies with CFM:

5, 8, 10, 12, or 14 inches.

Flush mounted return air grille/access panel

attached by quarter turn fasteners.

One inch disposable filter.

1/2-inch flange on front of unit. Allows direct

application of drywall to the unit.

7/8-inch hole on each side of cabinet for power and

control cable entry points on all units. See CLCHSVX021A-EN installation manual for details.

2 1/8-inch flange on front of unit. Drywall to be

framed out in front of unit.

Unit mounting location for thermostat/controller.

Fan shield, acoustically lined. Identification and

safety caution labels are affixed to this panel.

Vertical centerline of coil connection run outs.

Connections are at the back, left or right sides of the

unit.

T op supply air opening (knock out) for attachment of

ductwork.

Table 15. 4-pipe chilled water cooling and hot water heating unit dimensions (inches)

Size A B C E

350 17 17 14 52

450 17 17 14 52

600 20 20 14 52

800 20 20 14 52

1000 20 24 16 54

1200 20 24 16 54

UNT-PRC019-EN 27

Page 28

Dimensions and Weights

B K

C

CWS

HWS

HWR

CWR

B K

C

SR

12 3

4

6

5

2-pipe slave unit

with BK connection

4-pipe slave unit

with BK connection

Stub-out detail - typical

Inside

unit

Outside

unit

36 in.

2 5/8 in.

Condensate

connection

5/8 in. I.D. hose

Supply and return

connections

1/2 in. or 3/4 in. nom.

Copper pipe

3 3/4 in.

5 1/4 in.

3 3/4 in.

86 in.

7"

1 1/2 in.

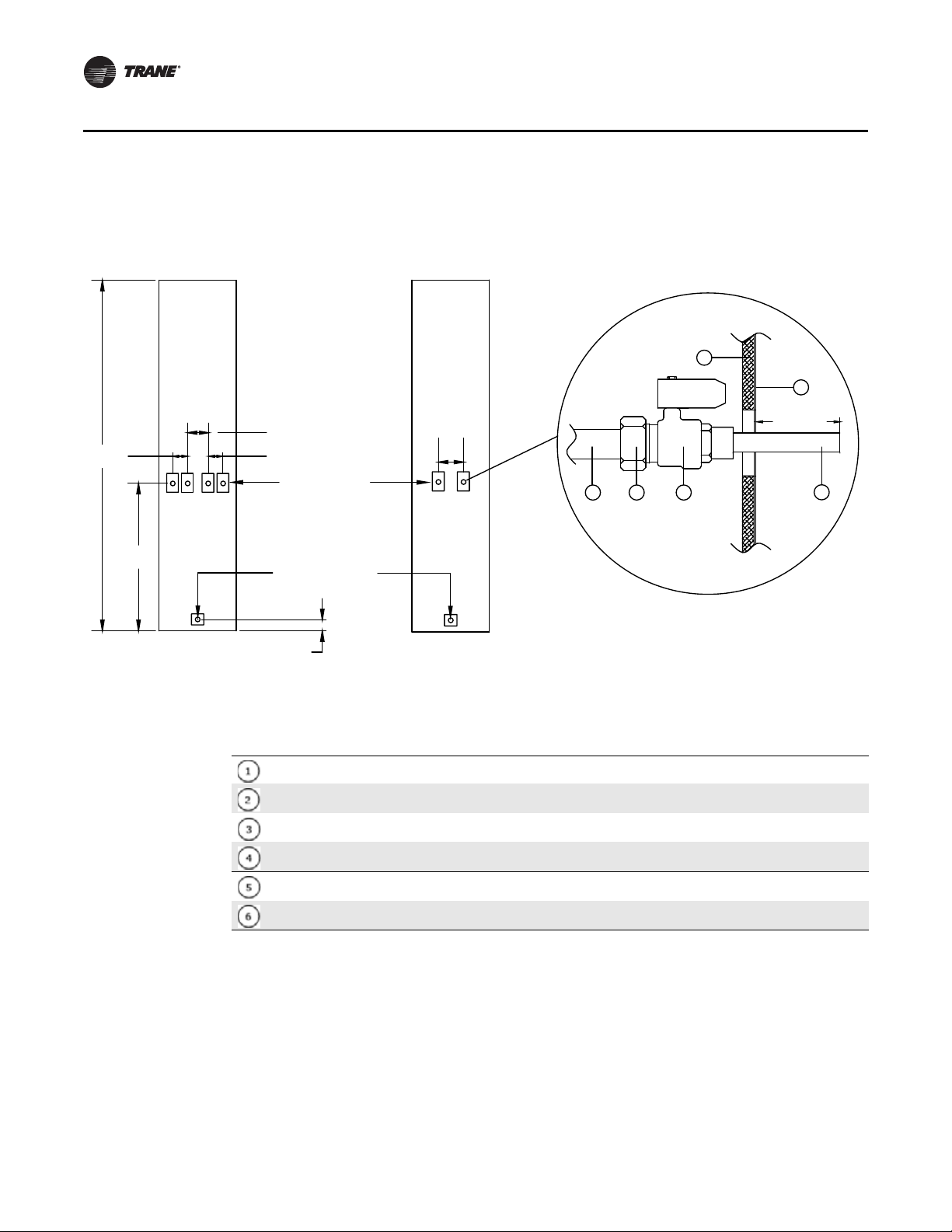

Fan Coil Units Without Risers

Figure 16. Fan Coil Units Without Risers

Table 16. Fan coil units without risers - 2-pipe and 4-pipe slave units callouts

1/2-inch or 3/4-inch supply and return coil branch copper pipe

Union fitting

Ball valve (shut-off valve)

1/2-inch or 3/4-inch copper tail piece soldered into valve body at factory

28 UNT-PRC019-EN

Insulation lining on interior surface of fan coil cabinet

Fan coil cabinet

Page 29

Riser Packages

RA

RA

RA

RA

RA

RA

3 1/2 in.

3 1/2 in.

Right risers (RT)

R

CS

Reverse right risers (RR)

R

CS

R

C

S

Back risers (BK)

R

C

S

Reverse back risers (RB)

R

Left risers (LT)

TOP VIEW

CS

R

Reverse left risers (RL)

TOP VIEW

CS

S = Supply riser

R = Return riser

C = Condensate riser

C

L

RARARA

RARARA

3 3/4 in.

2 5/8 in.

3 3/4 in.

2 5/8 in.

HWS

HWR

Cond.

CWR

CWS

HWS

HWR

Cond.

CWR

CWS

HWS

HWR

Cond.

CWR

CWS

Left risers (LT)

Back risers (BK) Right risers (RT)

HWS = Hot Water Supply Riser

HWR = Hot Water Return Riser

CWS = Chilled Water Supply Riser

CWR = Chilled Water Return Riser

Cond. = Condensate Riser

TOP VIEW

C

L

HWS

HWR

Cond.

CWR

CWS

HWS

HWR

Cond.

CWR

CWS

HWS

HWR

Cond.

CWR

CWS

Reverse left risers (RL)

Reverse back risers (RB)

Reverse right risers (RR)

TOP VIEW

Reverse Riser orientations are used to aid in eliminating cross over piping when units on a riser

stack change position from floor to floor or when two units share a common riser (Master/Slave).

R

Reverse right risers (RR)Right risers (RT)

TOP VIEW

C

S

R

C

S

R

C

S

Back risers (BK)

Reverse back risers (RB)

R

C

S

TOP VIEW

Figure 17. Riser 2-Pipe Package

Dimensions and Weights

Figure 18. Riser 4-Pipe Package

UNT-PRC019-EN 29

Page 30

Dimensions and Weights

L = F + 2 inches

Spool Piece Length = F - L + 4 inches

L = F - Spool Length + 4 inches

Standard Installation

Standard Installation Using

Spool Pieces

92 in.

92 in.

F

F

L

L

92 in.

92 in.

F

F

L

L

F - L + 4 in.

Figure 19. Riser Installation Dimensions (inches)

30 UNT-PRC019-EN

Page 31

Raised Base Options

Available in 4-inch, 8-inch and 12-inch heights (shown)

Side View

12 in.

B

Front View

12 in.

A

Raised Base

Figure 20. Raised base - no access panel

Dimensions and Weights

Table 17. Raised base dimensions (inches)

Size A B

350 17 17

450 17 17

600 20 20

800 20 20

1000 24 20

1200 24 20

UNT-PRC019-EN 31

Page 32

Dimensions and Weights

Front View Left Side View

Side ViewFront View

1

12 in.

8

6

7

Drywall

F. F.L .

2

3

4

5

3

Available only with 12 inch raised base.

Raised Base with Condensate Pump and Front Access Panel

Figure 21. Raised base with condensate pump and front access panel

32 UNT-PRC019-EN

Table 18. Raised base with condensate pump and front access panel callouts

Condensate riser (if applicable) 120V - 208V condensate pump

Drain tube factory installed

3/8-inch I.D. outlet tube by contractor Screws for front access panel

12 inch raised base Opening for condensate hose running in and out

Note: If the supply is 277V, an appropriately sized step-down transformer is included for condensate pump.

Front access panel (350 - 800 - 16 in. x 10 in.,

1000, 1200 - 18 in. x 10 in.

Page 33

Return Air Panels

1

9

2

4

5

6

7

8

3

10

10

3

2

Bottom side section

Top side section

Up arrow indicates

locked position

Return Air Panel with Flush Mount

Figure 22. Return air panel - flush mount with quarter turn fasteners

Dimensions and Weights

Table 19. Return air panel - flush mount with quarter turn fasteners callouts

Return air grille/access panel with quarter turn

Features

• Drywall attached directly to front of the unit

fasteners

Throwaway 1-inch filter. Plastic washer

1/2-inch deep collar around return air opening on fan

coil unit

1/4 turn fastener with slotted head and square shaft Bottom hook of access panel

Pawl of the 1/4 turn fastener 1/2-inch drywall

Pawl lock screw

Spring retainer

• Industry standard

• Fast access with quarter turn fasteners

• Easily removable for filter changing

UNT-PRC019-EN 33

Page 34

Dimensions and Weights

1

2

3

4

5

6

6

6

2-in. collar on

front of fan coil unit

Return air panel

Fan coil unit

Front of

fan coil

unit

Drywall stud

by others

Drywall

by others

Return Air Panel with Framed Out Drywall with Hinged Filter Access

Figure 23. Return air panel - framed out drywall with hinged filter access

Table 20. Return air panel with framed out drywall with hinged access filter access callouts

Hinged filter access door

Access panel retaining clip

Throwaway 1-inch filter

Grille frame

Filter channel

Sheet metal screw by contractor

Features

No exposed fasteners

34 UNT-PRC019-EN

Improved aesthetics

Easy filter changing - no tools required

Drywall is framed out around two-inch collar/flange

Page 35

Fan Coil Weights

Table 21. Weights for fan coil units

The weights are approximate. Risers, external sheet metal accessories and supply air grilles are not

included in the weight.

Dimensions and Weights

Size Weight

350 140 lbs (63 kg)

450 150 lbs (68 kg)

600 170 lbs (77 kg)

800 180 lbs (82 kg)

1000 210 lbs (95 kg)

1200 220 lbs (100 kg)

UNT-PRC019-EN 35

Page 36

Mechanical Specifications

Certifications

Performance: Unit per formance is certified by AHRI in accordance with ANSI/AHRI 440-2008:

Performance Rating of Room Fan-Coils.

Safety: All standard units are agency listed in the United States and Canada and comply with the

requirements of the current editions of UL 1995/CSA C22.2 No. 236.

Construction

The cabinets shall be fabricated from 18 g age steel lined with ½-inc h fiberglass insulation bonded

with a thermosetting resin and coated on the airstream side with an acrylic facing. In addition, there

is an option available for 3/8-inch closed cell cabinet insulation.

The drain pan shall be an acrylic (black polyester powder) coated 20 gauge galvanized steel

positively sloped in two directions towards the outlet. The drain pan shall be insulated on the

underside with ½-inch fiberg lass insulation (same as cabinet). The drain hose from the outlet to the

condensate riser shall form a running trap. An optional Stainless Steel drain pan is also available.

A drain pan float switc h is also available. The float switc h will close CW control valve upon detection

of high water level in condensate drain pan.

Fan

The galvanized metal fan wh eels are centrifugal forward-curv ed and double-width. Fan wheels and

housings are corrosion resistant.

Motors

The fan motor shall be a three speed P.S.C. type with internal thermal protection and sealed

bearings. All motors have a maximum ambient operating temperature of 104°F and are

permanently lubricated.

An optional ECM type brushless fan motor is ava ilable. The motor is available, programmed at the

factory for three (3) discrete speed operation. A variable speed EC motor is also available for use

with a 2-10V DC signal.

An unfused service disconnect switch shall be included, mounted inside the unit behind the motor

cover.

Coils

The coil shall have aluminum fins mechanic al ly b onded to ½-in ch copper tube. The coil shall be

factory pressure tested at not less than 300 psig. A manual air vent shall be incorporated at the high

point, and a drain cock at the low point of the connecting pipework to the coil.

Piping Packages

The piping package shall include: Ball type shut-off valves on the coil supply and returns (combined

with balancing valves or strainers when used), and a two- or three-way control valve with twoposition actuator. Chilled water and hot water valves are normally closed.

Control valves are also available in 3 wire floating point or 2-10V DC modulating valves.

Additionally balancing valves (manual or automatic) and strainers supplied as riser system

dictates. These devices are provided as combo-valves with the shut-off on supply and ret urn and

can be equipped with PT ports.

Electric Heat

Units with electric heat shall be wired for single-stage operation with an open wire nickel-c hrome

element. An auto-reset high limit device shall be included.

36 UNT-PRC019-EN

Page 37

Filters

Controls

Mechanical Specifications

A one-inch disposable filter shall be shipped loose with the return air access panel.

Units equipped with one inc h MER V 10 filters have a rating based on ASHRAE Standard 52.2. The

average dust spot efficiency is no less than 35 to 40 percent when tested in accordance with

ASHRAE 52.1 atmospheric dust spot method.

Units equipped with one inch MERV 13 filters have a rating based on A SHRAE Standard 52.2. The

average dust spot efficiency is no less than 90 percent efficiency on 1–3 micron particles and greater

than 90 percent efficiency on 3–10 micron particles when tested in accordance with ASHRAE Test

Standard 52.2.

Thermostat (option)

The fan coil manufacturer shall supply a low voltage (24V) thermostat for remote mounting, or

optionally unit mounted. Remote mounted thermostats are connected to a terminal strip that is

mounted inside the unit. The thermostat is ship ped loose for installation af ter the unit is installed,

dry-wall is applied and the walls are painted.

Line voltage controls for unit mounting is also available. Thermostat quick-connect plug provided;

thermostat ships loose for installation after drywall is applied and walls are painted.

Tracer ZN521 (option)

The T racer ZN521 discrete speed controller can be used in a stand-alone application or used as part

of a T rane Integrated Comfort S ystem (ICS) with LonT alk® communication. The T racer ZN521 offers

the combined advantages of simple and dependable operation. Standard control features include

options normally available on more elaborate control systems. All control options are available

factory-mounted and can be field-configured using a service tool.

Riser Package

Tracer UC400 (option)

The T racer UC400 controller delivers single zone VA V control in a stand-alone application or as part

of a Trane Integrated Comfort system with BACnet® communication. Standard control features

include options normally available on more elaborate control systems.

Risers are available in both type “L” and type “M” copper for supply, return and condensate pipes.

Riser insulation is available in ½-inch and one-inch wall thic kness for closed cell foam (polyolefin),

closed cell elastomeric (similar to Armaflex®) and fiberglass (wrapped with vapor barrier).

Riser diameter and insulation thickness are subject to physical limitations. Contact Trane when

risers are larger than 2 1/2 inches in diameter. The risers shall have an approximately 2 1/2 inch

swaged expansion at the top end to allow a 2 inch insertion of the riser from above without the use

of couplings. Risers may be provided plain ended in lieu of swaged for field supplied/installed

fittings (similar to Pro-Press®).

The riser insulation shall have a flame spread rating of 25 or less and a smoke dev eloped rating

of 50 or less in compliance with AST M E 84. The insulation shall be continuous over the riser length

within the height of the cabinet. Provision for insulation beyond the ends of the cabinet shall be

the responsibility of the installing contractor.

The specification of riser anchoring, expansion loops and fire stopping requirements are not

detailed in this specification and are not part of the Trane fan coils scope. Trane can provide

expansion loops installed on the risers at the factory as per the engineers specification.

Hot water risers which are continuous over twelve or more floors may incorporate expansion

compensation loops within the fan coil cabinet, location and spacing of expansion joints are the

responsibility of the design engineer.

UNT-PRC019-EN 37

Page 38

Mechanical Specifications

Return Air Access Panel

The return air access panel shall have a fixed blade return air grille in the lower portion with filter

access achieved by removal of the panel. The panel installs flush on to the drywall which has been

applied directly to the front of the unit. The panel is of stamped steel construction and shall be

finished in standard white baked enamel. The panel secures to the unit by a hook on the bottom

edge and two quarter -turn fasteners in the upper corners. The panel is shipped loose for installation

after the unit is installed, dry-wall is applied and the walls are painted.

There is also a return air access panel with hinged filter access as an option. Stamped steel

construction with return air grille in lower portion of grille and hinged filter access in the top

portion. Secured to the two-inch flange on the front of the unit with sheet metal screws. Drywall

is framed out in front of the unit and is not applied directly to the unit face.

Supply Air Grilles and Registers

Supply air grilles and registers shall be provided for unit mounting locations. The grilles shall be

steel, have double deflection ai rfoil blade s and shall be finished in standard white baked enamel.

The grilles shall attach to the collar of the fan coil uni t by spring clips. When a unit has more than

one supply air opening a balancing dam p er (horizontal in the front) is included with the grille

(register) to balance the air flow (screw holes optional). Any supply air grilles which are part of

supply air ductwork shall be provided by the sheet metal contractor. Grilles are shipped loose for

installation after the unit is installed, dry-wall applied and the walls are painted.

A line of sight baffle with acoustical wrap shall be included in units which have left and right or front

and back supply air openings.

There is also an option to upgrade the supply air grille material to aluminum as well as the option

to provide custom colors for return air panels and supply air grilles/registers.

Raised Bases

Raised bases are available in heights of 4 inches, 8 inches or 12 inc hes. An access panel is available

only in the 12-inc h hei ght option. If a co ndensate pump is required, 12-inch high raised base with

access panel is required.

38 UNT-PRC019-EN

Page 39

Notes

Notes

UNT-PRC019-EN 39

Page 40

4008161

ETL LISTED

CONFORMS TO

UL STD 1995

CERTIFIED TO

CSA STD C22.2 NO. 236

Trane optimizes the performance of homes and buildings around the world. A business of Ingersoll Rand, the leader in

creating and sustaining safe, comfortable and energy efficient environments, Trane offers a broad portfolio of advanced

controls and HVAC systems, comprehensive building services, and parts. For more information, visit www.Trane.com.

Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.

© 2013 Trane All rights reserved

UNT-PRC019-EN 15 July 201 3

(NEW)

We are committed to using environmentally

conscious print practices that reduce waste.

Loading...

Loading...