Page 1

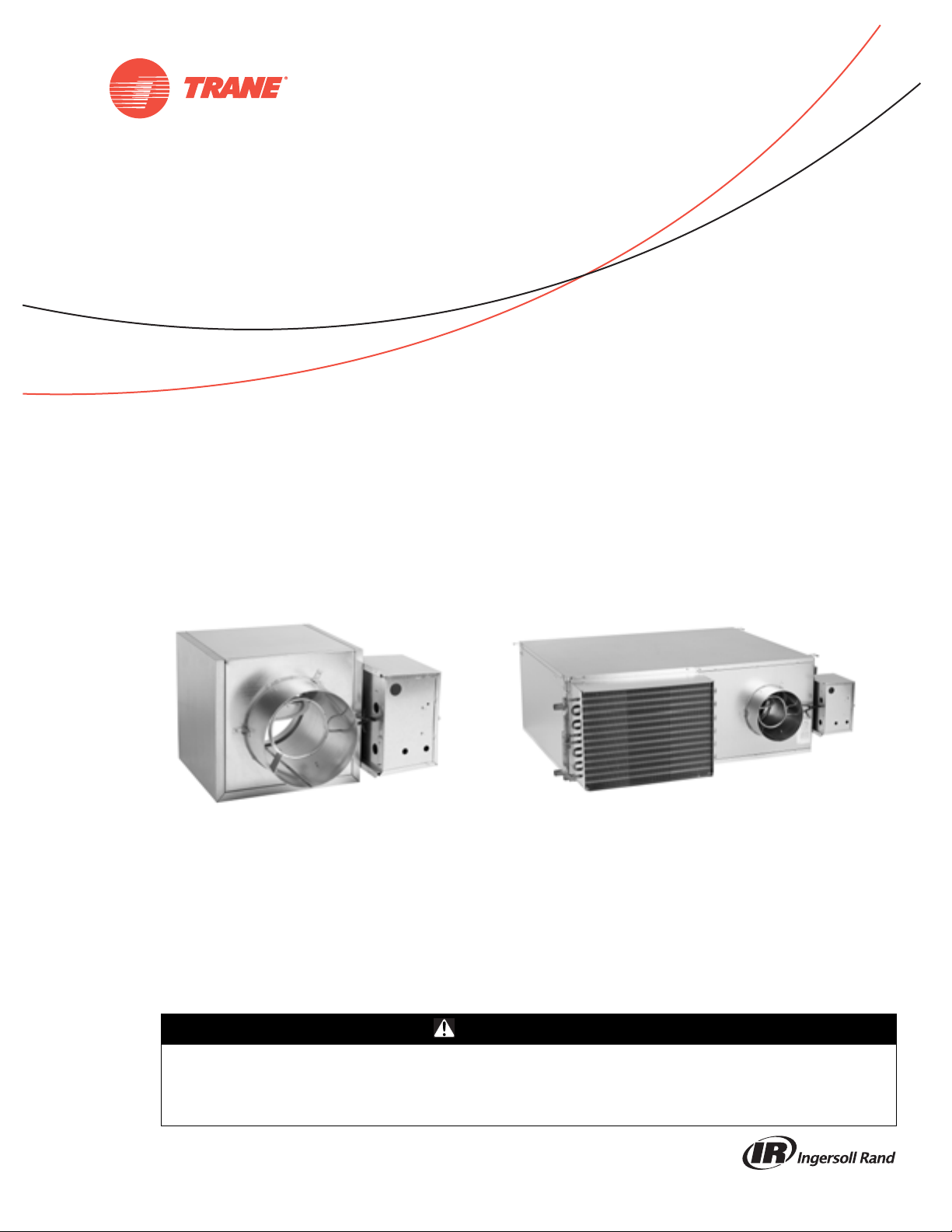

Installation, Operation,

and Maintenance

VariTrane™

Single-Duct and Fan-Powered Units

All VariTrane VAV models with pneumatic, electronic, DDC controls, and diffusers.

VCCF04 - 24

VCEF04 - 24

VCWF04 - 24

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

September 2014

VAV-SVX08E-EN

Page 2

Introduction

Read this manual thoroughly before operating or servici ng

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

© 2014 Trane All rights reserved VAV-SVX08E-EN

Page 3

WARNING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or repair will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. Glass wool fibers could result in respiratory,

skin or eye irritation.

Introduction

This manual describes the installation of VariTrane™ VAV

units with recommended wiring, piping, and mounting of

single-duct, dual-duct, fan-powered, low-height terminal

units, and diffusers.

See also the following reference documents:

• BAS-SVX40A-EN —Wireless Comm IOM

• BAS-SVX55A-EN — Wireless Comm Network Design

Best Practices Guide

Receiving and Handling

VariTrane units are shipped completely assembled with

the exceptions of optional attenuators for fan-powered

units and accessories.

Upon receiving the equipment, complete the following:

• Locate the nameplate and refer to the model and sales

order number and check that the correct units have

been delivered.

• Inspect the control enclosures and air valve casing for

dents or punctures.

• Verify that all options have been included, such as

filters, controls, heating coils, water valves, etc. Also

check that the unit voltages agree with the building

parameters.

• Manually rotate fan (if applicable) to assure that there

are no obstructions within the housing.

• Claims for in-transit damage must be filed

immediately with the delivery carrier.

• For hot water re-heat units, check the coil fins and make

sure that coils are not damaged.

• Locate and verify that the correct zone sensors are with

the order. These will be marked with an orange

“Accessories Enclosed” label. Store in a secure

location until needed. Accessories lost at the job site

are NOT covered by Trane’s warranty.

• If a discrepancy occurs between what was ordered and

what is received, contact you local Trane

representative immediately.

• Read appropriate section in this manual for installation

procedures prior to starting equipment.

Introduction

Upon receiving the equipment, please inspect each unit

and components for external or internal damage. Refer to

the bill of lading to insure all equipment and accessories

have been received. Contact your local Trane sales

representative and notify the trucking company

immediately of any short ship or damaged equipment.

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

Trane, VariTrane and the Trane logo are trademarks or

registered trademarks of Trane in the United States and

other countries. Trane is a business of Ingersoll Rand. All

trademarks referenced in this document are the

trademarks of their respective owners.

LonTalk is a registered trademarks of Echelon Corporation.

Revision History

VAV-SVX08E-EN (16 Sep 2014)

Updated for universal mount project.

VAV-SVX08D-EN (11 Jul 2013)

Updated model number for Sinro valve.

VAV-SVX08D-EN (27 Jun 2013)

Added Bottom Access with Cam Lock configuration and

stand alone control information for UCM 4.2, VV550

LonTalk, UC400, UC210 and WCI.

VAV-SVX08E-EN 3

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings, Cautions, and Notices . . . . . . . . 2

Important Environmental Concerns . . . . . 2

Important Responsible Refrigerant

Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Receiving and Handling . . . . . . . . . . . . . . . 3

Model Number Descriptions . . . . . . . . . . . . . . 5

Single-Duct Units . . . . . . . . . . . . . . . . . . . . . . 5

Dual-Duct Units . . . . . . . . . . . . . . . . . . . . . . . 8

Fan-Powered Units . . . . . . . . . . . . . . . . . . . . 9

Unit Information . . . . . . . . . . . . . . . . . . . . . . . . 11

Single-Duct Units . . . . . . . . . . . . . . . . . . . 11

Dual-Duct Units . . . . . . . . . . . . . . . . . . . . 11

Fan-Powered and Fan-Powered

Low-Height Units . . . . . . . . . . . . . . . . . . . 12

Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . 13

Unit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

(SCR) Motor Speed Control Adjustment

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electrically Commutated Motor (ECM) . . 28

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . 42

Heaters with Contactors . . . . . . . . . . . . . . . 42

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Installation of Diffusers . . . . . . . . . . . . . . . . . . 53

General . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

T-Bar Ceiling . . . . . . . . . . . . . . . . . . . . . . . 53

Concealed Spline Ceiling . . . . . . . . . . . . . 53

Drywall/Plaster Ceiling . . . . . . . . . . . . . . . 54

4 VAV-SVX08E-EN

Page 5

Model Number Descriptions

Single-Duct Units

Digit 1, 2 — Unit Type

VC = VariTrane Single Duct

Digit 3—Reheat

C = Cooling Only

E = Electric Heat

W = Hot Water Heat

Digit 4—Development Sequence

F= Sixth

Digit 5, 6—Primary Air Valve

04 = 4" inlet (225 cfm)

05 = 5" inlet (350 cfm)

06 = 6" inlet (500 cfm)

08 = 8" inlet (900 cfm)

10 = 10" in le t (140 0 cfm )

12 = 12" inlet (20 00 cfm)

14 = 14" inlet (300 0 cfm)

16 = 16" inlet (40 00 cfm)

24 = 24" x 16" inlet (8000 cfm)

Digit 7, 8, 9—Not Used

000= N/A

Digit 10, 11—Design Sequence

** = Factory Assigned

Digit 12, 13, 14, 15—Controls

DD00 Trane Actuator Only and

Enclosure

DD01= UCM4 Cooling Only Control

DD02= UCM4 N.C. On/Off Hot Water

DD03= UCM4 Prop. Hot Water

DD04= UCM4 Staged On/Off E-Heat

DD05= UCM4 Pulse Width MOD E-Heat

DD07= UCM4 N.O. On/Off Hot Water

DD11= VV550 DDC Controller - Cooling

Only

DD12= VV550 DDC Ctrl to operate N.C.

On/Off water valve

DD13= VV550 DDC Ctrl to operate Prop

water valve

DD14= VV550 DDC Ctrl - On/Off Electric

Heat

DD15= VV550 DDC Ctrl w/Pulse Width

Modulation

DD16= VV550 DDC Controller -

Ventilation Flow

DD17= VV550 DDC Ctrl to operate N.O.

On/Off Water Valve

DD19= VV550 DDC Controller with Flow

Trac ki ng

DD20= VV550 DDC Vent Flow cntrl to

operate N.C. water valve

DD21= VV550 DDC - Vent Flow w/ On/Off

Elec Heat

DD22= VV550 DDC Vent Flow cntrl to

operate prop water valve

DD23= VV550 DDC- Basic plus- Local

(Electric heat- PWM) Remote

(Staged EH)

DD24= VV550 DDC-Basic plus- Local

(Water heat- Modulating)

Remote (Water- N.C. 2 position)

DD25= VV550 DDC-Basic plus- Local

(Water heat- Modulating)

Remote (Water- N.O. 2 position)

DD26= VV550 DDC-Basic plus- Local

VAV-SVX08E-EN 5

DD27= VV550 DDC-Basic plus- Local

DD28= VV550 DDC-Basic plus- Local

DD29= VV550 DDC-Basic plus- Local

DD30= VV550 DDC-Basic plus- Local

DD31= VV550 DDC-Basic plus- Local

DD32= VV550 DDC-Basic plus- Local

DD33= VV550 DDC Vent Flow cntrl to

DD41= UC400 DDC-Basic (No water or

DD42= UC400 DDC-Basic (Water heat-

DD43= UC400 DDC-Basic (Water heat-

DD44= UC400 DDC-Basic (Electric heat-

DD45= UC400 DDC-Basic (Electric heat-

DD46= UC400 DDC Ventilation flow-

DD47= UC400 DDC-Basic (Water heat-

DD49= UC400 DDC-Flow Tracking

DD50= UC400 DDC-Ventilation Flow

DD51= UC400 DDC-Ventilation Flow

DD52= UC400 DDC-Ventilation Flow

DD53= UC400 DDC-Basic plus- Local

DD54= UC400 DDC-Basic plus- Local

DD55= UC400 DDC-Basic plus- Local

DD56= UC400 DDC-Basic plus- Local

DD57= UC400 DDC-Basic plus- Local

DD58= UC400 DDC-Basic plus- Local

DD59= UC400 DDC-Basic plus- Local

DD60= UC400 DDC-Basic plus- Local

DD61= UC400 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- Modulating)

(Water heat- N.C. 2-position)

Remote (Water- Modulating)

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

(Water heat- N.C. 2-position)

Remote (Water- NC 2-position)

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

(Water heat- N.C. 2-position)

Remote (Water- N.O. 2-position)

(Electric heat- Staged) Remote

(Staged EH)

operate N.O. On/Off water valve

electric heat)

N.C.- 2 position)

Modulating)

staged)

PWM)

cooling only

N.O.- 2 position)

(Cooling only)

(Water heat- N. C.- 2 position)

(Electric heat- staged)

(Water heat- Modulating)

(Electric heat- PWM) Remote

(Staged EH)

(Water heat- Modulating)

Remote (Water- N.C. 2 position)

(Water heat- Modulating)

Remote (Water- N.O. 2 position)

(Water heat- N.O. 2-position)

Remote (Water- Modulating)

(Water heat- N.C. 2-position)

Remote (Water- Modulating)

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

(Water heat- N.C. 2-position)

Remote (Water- N.C. 2-position)

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

(Water heat- N.C. 2-position)

DD62= UC400 DDC-Basic plus- Local

DD63= UC400 DDC-Ventilation Flow

DD65= UC400 Basic

DD66= UC400 Basic plus-Local

DD67= UC400 Ventilation Flow

DD71= UC210 DDC-Basic (No water or

DD72= UC210 DDC-Basic (Water heat-

DD73= UC400 DDC-Basic (Water heat-

DD74= UC210 DDC-Basic (Electric heat-

DD75= UC210 DDC-Basic (Electric heat-

DD76= UC210 DDC Ventilation flow-

DD77= UC210 DDC-Basic (Water heat-

DD79= UC210 DDC-Flow Tracking

DD80= UC210 DDC-Ventilation Flow

DD81= UC210 DDC-Ventilation Flow

DD82= UC210 DDC-Ventilation Flow

DD83= UC210 DDC-Basic plus- Local

DD84= UC210 DDC-Basic plus- Local

DD85= UC210 DDC-Basic plus- Local

DD86= UC210 DDC-Basic plus- Local

DD87= UC210 DDC-Basic plus- Local

DD88= UC210 DDC-Basic plus- Local

DD89= UC210 DDC-Basic plus- Local

DD90= UC210 DDC-Basic plus- Local

DD91= UC210 DDC-Basic plus- Local

DD92= UC210 DDC-Basic plus- Local

DD93= UC210 Ventilation Flow

DD95= UC210 Basic

DD96= UC210 Basic plus-Local

Remote (Water- N.O. 2-position)

(Electric heat- Staged) Remote

(Staged EH)

(Water heat- N.O. 2-position)

(Electric HeatModulating SCR)

(Electric heat-Modulating SCR)

Remote (Staged EH)

(Electric heat-Modulating SCR)

electric heat)

N.C.- 2 position)

Modulating)

staged)

PWM)

cooling only

N.O.- 2 position)

(Cooling only)

(Water heat- N. C.- 2 position)

(Electric heat- staged)

(Water heat- Modulating)

(Electric heat- PWM) Remote

(Staged EH)

(Water heat- Modulating)

Remote (Water- N.C. 2 position)

(Water heat- Modulating)

Remote (Water- N.O. 2 position)

(Water heat- N.O. 2-position)

Remote (Water- Modulating)

(Water heat- N.C. 2-position)

Remote (Water- Modulating)

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

(Water heat- N.C. 2-position)

Remote (Water- N.C. 2-position)

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

(Water heat- N.C. 2-position)

Remote (Water- N.O. 2-position)

(Electric heat- Staged) Remote

(Staged EH)

(Water heat- N.O. 2-position)

(Electric HeatModulating SCR)

Page 6

Model Number Descriptions

(Electric heat-Modulating SCR)

DD97= UC210 Ventilation Flow

ENCL= Shaft Only in Enclosure

ENON= Shaft Out Side for Electric Units

FM00= Other Actuator and Control

FM01= Trane Supplied Actuator, Other

PC00= N.C. Actuator and Linkage Only

PC04= N.C. with DA Stat, 3000 Series

PC05= N.C. with RA STAT, 3000 Series

PCSS= Normally Closed Special

PN00= N.O. Actuator and Linkage Only

PN04= N.O. 3000 Series, DA STAT

PN05= N.O. 3000 Series, RA STAT

PN11= Auto Dual Min.

PN32= N.O. PNEU Constant Vol.

PN34= N.O. 3000 Series Constant

PNON= Shaft Out Side for Pneumatic

PNSS= Normally Open Special

N.C .= Normally-closed

N.O. = Normally-opened

DA Stat = Direct-acting pneumatic t-stat

RA Stat = Reverse-acting pneumatic

PN = Pneumatic

FM = Factory installation of customer-

PVR = Pneumatic Volume Regulator

Remote (Staged EH)

(Electric heat-Modulating SCR)

Ctrl

Vol.,RA STAT

Units

(by others)

t-stat (by others)

supplied controller

Digit 16—Insulation

A = 1/2" Matte-faced

B = 1" Matte-faced

D = 1" Foil-faced

F = 1" Double-wall

G = 3/8" Closed-cell

Digit 17 & 18—Not Used

00 = N/A

Digit 19—Outlet Plenum

(Connection is Slip & Drive)

0= None

A= 1 Outlet RH

B= 1 Outlet END

C = 1 Outlet LH

D = 2 Outlets, 1 RH, 1 END

E = 2 Outlets, 1 LH, 1 END

F = 2 Outlets, 1 RH, 1 LH

H = 3 Outlets, 1 LH, 1 RH, 1 END

J = 4 Outlets, 1 LH, 1 RH, 2 END

Note: See unit drawings for outlet sizes/

damper information.

Digit 20—Not Used

0= N/A

Digit 21—Water Coil

0= None

1= 1-Row

2= 2-Row

3= 3-Row

4= 4-Row

A= 1-Row Premium

B = 2-Row Premium

C = 3-Row Premium

D = 4-Row Premium

Digit 22—Electrical Connections

F = Flippable (can be flipped in the

field for LH or RH connections

- VCEF only)

L = Left (Airflow hitting you in the

face)

R = Right (Airflow hitting you in the

face)

0 = Opposite side connection – coil

and control (VCWF only)

Note: VCCF, VCWF can be flipped in field

for opposite-hand connection

Digit 23—Transformer

0= None

1 = 120/24 volt (50 VA)

2 = 208/24 volt (50 VA)

3 = 240/24 volt (50 VA)

4 = 277/24 volt (50 VA)

5 = 480/24 volt (50 VA)

6 = 347/24 Volt (50 VA)

7 = 380/24 Volt (50 VA)

8 = 575/24 Volt (50 VA)

Note: For VCEF units with transformers

the VA depends on the staging,

control, and contactor type

(ranges are 50 VA to 75 VA, for 1

and 3 phase)

Digit 24—Disconnect Switch

0= None

W= With

Note: VCCF, VCWF – Toggle Disconnect;

VCEF – Door Interlocking Power

Disconnect

Digit 25—Power Fuse

0= None

W= With

Digit 26—Electric Heat Voltage

0= None

A = 208/60/1

B = 208/60/3

C = 240/60/1

D = 277/60/1

E = 480/60/1

F = 480/60/3

G = 347/60/1

H = 575/60/3

J = 380/50/3

K = 120/60/1

Digit 27 - 29—Electric Heat kW

000= None

010 = 1.0 kW

015 = 1.5 kW

460 = 46.0 kW

Note: 0.5 to 8.0 kW – ½ kW increments

8.0 to 18.0 kW – 1 kW increments

18.0 to 46.0 kW – 2 kW increments

Digit 30—Electric Heat Stages

0= None

1 = 1 Stage

2 = 2 Stages Equal

3 = 3 Stages Equal

Digit 31—Electrical Heat

Contactors

0= None

1 = 24-volt magnetic

2 = 24-volt mercury

3 = PE with magnetic

4 = PE with mercury

5 = SCR heat UC400/UC210

6 = SCR heat FMTD/ENCL/DD00

A = 24-volt mercury (left hand)

B = 24-volt mercury (right hand)

C = PE with mercury (left hand)

D = PE with mercury (right hand)

Digit 32 & 33—Not Used

00 = N/A

Digit 34—Actuator

0= Standard

A = Spring Return (Normally Open)

B = Spring Return (Normally Closed)

C = Belimo Actuator

Digit 35—Sensor Options

0 = Standard (Wired)

1 = Factory Mounted Wireless

Receiver (Sensor Accessory)

2 = Wireless Comm Interface

Modular FM

Digit 36—Pre-Wired Factory

Solutions

0= None

1 = Factory Mounted DTS

2 = HW Valve Harness

3 = Both DTS & HW Valve Harness

4 = Averaging DTS factory installed

in unit (Required for

UC210/UC400 with SCR heat)

Digit 37—Bottom Access with

Cam Locks

0= None

1 = Access Left Side Terminal Unit

2 = Access Right Side Terminal Unit

3 = Access Left Side Terminal Unit

with Water Connection on Right

4 = Access Right Side Terminal Unit

with Water Coil Connection on

Left

6 VAV-SVX08E-EN

Page 7

Model Number Descriptions

Digit 38—Piping Package

0= None

A = 2-way Automatic Balancing)

B = 3-way Automatic Balancing

Digit 39—Water Valve

0= None

1 = Proportional, HW Valve, 0.7 Cv

2 = Proportional, HW Valve, 2.7 Cv

3 = Proportional, HW Valve, 6.6 Cv

4 = Proportional, HW Valve, 8.0Cv

Digit 40—Flow Rate

00 = None

A = 0.5 gpm (0.03 l/s)

B = 1.0 gpm (0.06 l/s)

C = 1.5 gpm (0.09 l/s)

D = 2.0 gpm (0.13 l/s)

E = 2.5 gpm (0.16 l/s)

F = 3.0 gpm (0.19 l/s)

G = 3.5 gpm (0.22 l/s)

H = 4.0 gpm (0.25 l/s)

J = 4.5 gpm (0.28 l/s)

K = 5.0 gpm (0.31 l/s)

L = 5.5 gpm (0.35 l/s)

M = 6.0 gpm (0.38 l/s)

N = 6.5 gpm (0.41 l/s)

P = 7.0 gpm (0.44 l/s)

Q = 7.5 gpm (0.47 l/s)

R = 8.0 gpm (0.50 l/s)

S = 9.0 gpm (0.57 l/s)

T = 10.0 gpm (0.63 l/s)

U = 11.0 gpm (0.69 l/s)

V = 12.0 gpm (0.76 l/s)

W = 13.0 gpm (0.82 l/s)

X = 14.0 gpm (0.88 l/s)

Y = 15.0 gpm (0.95 l/s)

Z = 16.0 gpm (1.01 l/s)

1 = 17.0 gpm (1.07 l/s)

2 = 18.0 gpm (1.14 l/s)

3 = 19.0 gpm (1.20 l/s)

4 = 20.0 gpm (1.26 l/s)

5 = 21.0 gpm (1.32 l/s)

6 = 22.0 gpm (1.39 l/s)

7 = 23.0 gpm (1.45 l/s)

VAV-SVX08E-EN 7

Page 8

Model Number Descriptions

Dual-Duct Units

Digit 1, 2, 3—Unit Type

VDD= VariTrane dual-duct

Digit 4—Development Sequence

F= Sixth

Digit 5, 6—Primary Air Valve

05 = 5" inlet (350 cfm)

06 = 6" inlet (500 cfm)

08 = 6" inlet (900 cfm)

10 = 10" in le t (140 0 cfm )

12 = 12" inlet (20 00 cfm)

14 = 14" inlet (300 0 cfm)

16 = 16" inlet (40 00 cfm)

Digit 7, 8—Secondary Air Valve

05 = 5" inlet (350 cfm)

06 = 6" inlet (500 cfm)

08 = 8" inlet (900 cfm)

10 = 10" in le t (140 0 cfm )

12 = 12" inlet (20 00 cfm)

14 = 14" inlet (300 0 cfm)

16 = 16" inlet (40 00 cfm)

Digit 9—Not Used

0= N/A

Digit 10, 11—Design Sequence

** = Factory Assigned

Digit 12, 13, 14, 15—Controls

DD00= Trane Actuator Only

DD01= UCM4 Cooling Only Control

DD08= UCM4 Dual Duct

Constant Volume

DD11= VV550 DDC Controller -

Cooling Only

DD18= VV550 DDC Controller w

Constant Volume

DD41= UC400 DDC-Basic (No water or

electric heat)

DD48= UC400 DDC-Basic (Constant

Vol ume)

DDSS= Digital Special

ENON= Shaft Out Side for Electric

Units

FM00= Other Actuator and Control

FM01= Trane Supplied Actuator, Other

Ctrl

PC03= NC Heating Valve, N.O. Cooling

Val ve

PCSS= Normally Closed Special

PN08= N.O. Heat/Cool Actuators &

Linkage Only

PN09= N.O. Heating, N.O. Cooling,

w/PVR’s

PN10= N.O. Heating, N.O. Cooling,

w/PVR’s (CV DISCH)

PNON= Shaft Out Side for Pneumatic

Units

PNSS= Normally Open Special

Notes:

N.C. = Normally-closed

N.O. = Normally-opened

DA Stat = Direct-acting pneumatic t-stat

(by others)

RA Stat = Reverse-acting pneumatic tstat (by others)

PN = Pneumatic

FM = Factory installation of customer-

supplied controller

PVR = Pneumatic Volume Regulator

Digit 16—Insulation

A = 1/2" Matte-faced

B = 1" Matte-faced

D = 1" Foil-faced

F = 1" Double-wall

G = 3/8" Closed-cell

Digit 17—Not Used

0= N/A

Digit 18—Not Used

0= N/A

Digit 19—Outlet Plenum

(Connection is slip & drive)

0 = none

A = 1 outlet–RH

B = 1 outlet–END

C = 1 outlet–LH

D = 2 outlets–1 RH, 1 END

E = 2 outlets–1 LH, 1 END

F = 2 outlets–1 RH, 1 LH

G = 2 outlets - END

H = 3 outlets–1 LH, 1 RH, 1 END

J = 4 outlets–1 LH, 1 RH, 2 END

Note: See unit drawings for outlet sizes/

damper information.

Digit 20—Not Used

0= N/A

Digit 21—Not Used

0= N/A

Digit 22—Not Used

0= N/A

Digit 23—Transformer

0= None

1 = 120/24 volt (50 VA)

2 = 208/24 volt (50 VA)

3 = 240/24 volt (50 VA)

4 = 277/24 volt (50VA)

5 = 480/24 volt (50 VA)

6 = 347/24 volt (50 VA)

7 = 575/24 volt (50 VA)

Digit 24—Disconnect Switch

0= None

W = With Toggle

Digit 25—Power Fuse

0= None

W= With

Digit 26—Not Used

0= N/A

Digit 27—Not Used

0= N/A

Digit 28—Not Used

0= N/A

Digit 29—Not Used

0= N/A

Digit 30—Not Used

0= N/A

Digit 31—Not Used

0= N/A

Digit 32—Not Used

0= N/A

Digit 33—Special Options

0= None

X = Varies - Factory Assigned

Digit 34—Actuator

A = Belimo Actuator

Digit 35—Wireless Sensor

0 = Sensor/Receiver Standard

1 = Wireless Sensor/Receiver

Mounted

Note: All sensors selected in

accessories

Digit 36—Duct Temp Sensor

0= None

1 = With Duct Temp Sensor

8 VAV-SVX08E-EN

Page 9

Model Number Descriptions

Fan-Powered Units

Digit 1, 2—Unit Type

VP = VariTrane Fan-Powered Parallel

VS = VariTrane Fan-Powered Series

LP = VariTrane Fan-Powered

Low-Height Parallel

LS = VariTrane Fan-Powered

Low-Height Series

Digit 3—Reheat

C = Cooling Only

E = Electric Heat

W = Hot Water Heat

Digit 4—Development Sequence

F= Sixth

Digit 5, 6—Primary Air Valve

05 = 5" inlet (350 max cfm)

06 = 6" inlet (500 max cfm)

08 = 8" inlet (900 max cfm)

10 = 10" in le t (140 0 max cf m)

12 = 12" inlet (2000 max cfm)

14 = 14" inlet (3000 max cfm)

16 = 16" inlet (4000 max cfm)

RT = 8" x 14" inlet (1800 max CFM)

Note: 10, 12, 14, 16 Not Available on

Low-Height

Digit 7, 8—Secondary Air Valve

00 = N/A

Digit 9—Fan

P = 02SQ fan (500 nominal cfm)

Q = 03SQ fan (1100 nominal cfm)

R = 04SQ fan (1350 nominal cfm)

S = 05SQ fan (1550 nominal cfm)

T = 06SQ fan (1850 nominal cfm)

U = 07SQ fan (2000 nominal cfm)

V = 08SQ Fan (500 nominal cfm)

W = 09SQ Fan (900 nominal cfm)

X = 10SQ Fan (1800 nominal cfm)

Digit 10, 11—Design Sequence

** = Factory assigned

Digit 12, 13, 14, 15—Controls

DD01= Cooling Only Control

DD02= N.C. On/Off Hot Water

DD03= Prop. Hot Water

DD04= Staged On/Off E-Heat

DD05= Pulse Width Mod of E-Heat

DD07= N.O. On/Off Hot Water

DD11= VV550 DDC Controller - Cooling

Only

DD12= VV550 DDC Ctrl w/N.C. On/Off

HW Valve

DD13= VV550 DDC Ctrl w/Prop. HW

Valve

DD14= VV550 DDC Ctrl - On/Off

Electric Heat

DD15= VV550 DDC Ctrl w/Pulse Width

Modulation

DD17= VV550 DDC Ctrl w/N.O. On/Off

HW Valve

DD23= VV550 DDC- Basic plus- Local

(Electric heat- PWM) Remote

(Staged EH)

DD28= VV550 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

DD29= VV550 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.C. 2-position)

DD30= VV550 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

DD31= VV550 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.O. 2-position)

DD32= VV550 DDC-Basic plus- Local

(Electric heat- Staged) Remote

(Staged EH)

DD41= UC400 DDC-Basic (No water or

electric heat)

DD42= UC400 DDC-Basic (Water heat-

Normally Closed- 2 position)

DD43= UC400 DDC-Basic (Water heat-

Modulating)

DD44= UC400 DDC-Basic (Electric heat-

staged)

DD45= UC400 DDC-Basic (Electric heat-

PWM)

DD47= UC400 DDC-Basic (Water heat-

Normally Opened- 2 position)

DD53= UC400 DDC-Basic plus- Local

(Electric heat- PWM) Remote

(Staged EH)

DD58= UC400 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

DD59= UC400 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.C. 2-position)

DD60= UC400 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

DD61= UC400 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.O. 2-position)

DD62= UC400 DDC-Basic plus- Local

(Electric heat- Staged) Remote

(Staged EH)

DD65= Basic (Electric Heat- Modulating

SCR)

DD66= Basic plus – Local (Electric heat –

Modulating SCR) Remote

(Staged EH)

DD71= UC210 DDC-Basic

(Cooling only)

DD72= UC210 DDC-Basic

(Water heat-nc 2pos)

DD73= UC210 DDC-Basic

(Water heat-Modulating)

DD74= UC210 DDC-Basic

(Electric heat-staged)

DD75= UC210 DDC-Basic

(Electric heat-pwm)

DD77= UC210 DDC-Basic

(Water heat-NO 2pos)

DD83= UC210 DDC-Basic+ Local

(Electric heat-pwm)

Remote (Staged)

DD84= UC210 DDC-Basic+ Local

(Water heat Modulating)

Remote (Water-NC 2pos)

DD85= UC210 DDC-Basic+ Local

(Water heat Modulating)

Remote (Water-NO 2pos)

DD86= UC210 DDC-Basic+ Local

(Water heat NO 2pos)

Remote (Water-Modulating)

DD87= UC210 DDC-Basic+ Local

(Water heat NC 2pos)

Remote (Water-Modulating)

DD88= UC210 DDC-Basic+ Local

(Water heat NO 2pos)

Remote (Water-NO 2pos)

DD89= UC210 DDC-Basic+ Local

(Water heat NC 2pos)

Remote (Water-NC 2pos)

DD90= UC210 DDC-Basic+ Local

(Water heat NO 2pos)

Remote (Water-NC 2pos)

DD91= UC210 DDC-Basic+ Local

(Water heat NC 2pos)

Remote (Water-NO 2pos)

DD92= UC210 DDC-Basic+ Local

(Electric heat-staged)

Remote (Staged)

DD95= UC210 DDC-Ctrl w/Modulating

SCR

DD96= UC210 DDC-Space Temp Ctrl w/

Local SCR & Remote Stge Elec

Heat

DD00= Trane Actuator Only

ENCL= Shaft Only in Enclosure

ENON= Shaft Out Side for Electric Units

FM00= Other Actuator and Control

FM01= Trane supplied actuator,

other control

PN00= N.O. Actuator and Linkage Only

PN05= N.O. 3000 Series, RA Stat

PN51= Pneumatic normally open

w/3011,DPS fan

PN52= Pneumatic normally open

w/3011, DPM fan

PNON= Shaft Out Side for Pneumatic

Units

Notes:

N.C. = Normally-closed

N.O. = Normally-opened

DA Stat = Direct-acting pneumatic t-stat

(by others)

RA Stat = Reverse-acting pneumatic

t-stat (by others)

PN = Pneumatic

FM = Factory installation of customer-

supplied controller

PVR = Pneumatic Volume Regulator

Digit 16—Insulation

A = 1/2” Matte-faced

B = 1" Matte-faced

D = 1" Foil-faced

F = 1" Double-wall

G = 3/8” Closed-cell

Digit 17—Motor Type

D = PSC Motor

E = High-efficiency motor (ECM)

Digit 18—Motor Voltage

1 = 115/60/1

2 = 277/60/1

3 = 347/60/1

4 = 208/60/1

5 = 230/50/1

VAV-SVX08E-EN 9

Page 10

Model Number Descriptions

Digit 19—Outlet Connection

1 = Flanged

2 = Slip & Drive

Digit 20—Attenuator

0 = No Attenuator

W = With Attenuator

Digit 21—Water Coil

0= None

1 = 1-Row–Plenum inlet installed RH

2 = 2-Row–Plenum inlet installed RH

3 = 1-Row–Discharge installed, LH

4 = 1-Row–Discharge installed, RH

5 = 2-Row–Discharge installed, LH

6 = 2-Row–Discharge installed, RH1

A = 1-Row–Premium water coil inlet

B = 2-Row–Premium water coil inlet

C = 1-Row–Premium hot coil

on discharge, LH

D = 1-Row–Premium hot coil

on discharge, RH

E = 2-Row–Premium hot coil

on discharge, LH

F = 2-Row–Premium hot coil

on discharge, RH

Note: 1- and 2-row not available with

Low-Height

Digit 22—Electrical Connections

L = Left (Airflow hitting you in the

face)

R = Right (Airflow hitting you in the

face)

W = Narrow Corridor LH, Hi-Volt Inlet

Facing

X = Narrow Corridor RH, Hi-Volt Inlet

Facing

Note: (W & X) Fan Powered Series Only

Digit 23—Transformer

0 = N/A (provided as standard)

Digit 24—Disconnect Switch

0= None

W= With

Electric Reheat w/ door interlocking

power disconnect, Cooling Only and

Water Reheat w/ toggle disconnect

Digit 25—Power Fuse

0= None

W= With

Digit 26—Electric Heat Voltage

0= None

A = 208/60/1

B = 208/60/3

C = 240/60/1

D = 277/60/1

E = 480/60/1

F = 480/60/3

G = 347/60/1

H = 575/60/3

J = 380/50/3

K = 120/60/1

Note: K not available with Low Height

Digit 27, 28, 29—Electric Heat

kW

000= None

050 = 0.5 kW

010 = 1.0 kW

015 = 1.5 kW

260 = 26.0 kW

Note: Electric Heat Voltage -

0.5 to 8.0 kW–½ kW increments

8.0 to 18.0 kW –1 kW increments

18.0 to 46.0 kW–2 kW increments

Digit 30—Electric Heat Stages

0= None

1 = 1 Stage

2 = 2 Stages Equal

3 = 3 Stages Equal

Note: 3 not available with Low Height

Digit 31—Contactors

0= None

1 = 24-volt magnetic

2 = 24-volt mercury

3 = PE with magnetic

4 = PE with mercury

5 = SCR heat UC400

6 = SCR heat FMTD/ENCL/DD00

Note: SCR cannot be selected with the

following configuration:

• KW > 10, 208 volt 3 phase, Low

Height

• KW > 22, 480 volt 3 phase, Low

Height

• Voltage = 575 volt

Digit 32—Airflow Switch

0= None

W= With

Digit 33—Not Used

0= N/A

Digit 34—Actuator

0 = Standard

A = Belimo actuator

Digit 35—Wireless Sensors

0= None

1 = Factory Mounted Wireless

Receiver (Sensor Assembly)

2 = Wireless Comm Interface

Modular FM

Note: All sensors selected in

accessories

Digit 36—Pre-Wired Factory

Solutions

0= None

1 = Factory Mounted DTS

2 = HW Valve Harness

3 = Both DTS & HW Valve Harness

Digit 37—Bottom Access

0= None

W = Access Left Side of Terminal Unit

Digit 38—Piping Package

0= None

A = 2-way Automatic Balancing)

B = 3-way Automatic Balancing

Digit 39—Water Valve

0= None

1 = Proportional, HW Valve, 0.7 Cv

2 = Proportional, HW Valve, 2.7 Cv

3 = Proportional, HW Valve, 6.6 Cv

4 = Proportional, HW Valve, 8.0Cv

Digit 40—Flow Rate

0= None

A = 0.5 gpm (0.03 l/s)

B = 1.0 gpm (0.06 l/s)

C = 1.5 gpm (0.09 l/s)

D = 2.0 gpm (0.13 l/s)

E = 2.5 gpm (0.16 l/s)

F = 3.0 gpm (0.19 l/s)

G = 3.5 gpm (0.22 l/s)

H = 4.0 gpm (0.25 l/s)

J = 4.5 gpm (0.28 l/s)

K = 5.0 gpm (0.31 l/s)

L = 5.5 gpm (0.35 l/s)

M = 6.0 gpm (0.38 l/s)

N = 6.5 gpm (0.41 l/s)

P = 7.0 gpm (0.44 l/s)

Q = 7.5 gpm (0.47 l/s)

R = 8.0 gpm (0.50 l/s)

S = 9.0 gpm (0.57 l/s)

T = 10.0 gpm (0.63 l/s)

U = 11.0 gpm (0.69 l/s)

V = 12.0 gpm (0.76 l/s)

W = 13.0 gpm (0.82 l/s)

10 VAV-SVX08E-EN

Page 11

Unit Information

Single-Duct Units

The basic unit consists of a sheet metal casing with an air

valve, which is used to modulate the air being delivered

into the occupied zone. The unit is designed to modulate

either cooling or heating air between the temperatures of

40°F and 140°F. Air enters the air valve through the round

or rectangular inlet and exits into the sheet metal casing to

be distributed to the zone either through integral round

outlets in the casing or through rectangular duct attached

to the discharge of the unit.

The basic unit can also be ordered with factory-mounted

electric or hot water heating coils attached to the

discharge. See Figure 2, p. 11.

These re-heat units are used primarily to reheat air-to-zone

temperature when the load in the occupied space is low.

Primary air is modulated through the VariTrane air valve by

rotating the damper blade. All air valves have a round/

rectangular inlet for easy fit-up with incoming duct work.

Typical Single-Duct Units

Figure 1. Typical single duct unit — VCCF

Figure 2. Typical single duct unit — VCWF

Figure 3. Typical single duct unit — VCEF

Dual-Duct Units

Dual-duct units provide two air valves: one as heating

primary air and the other as cooling primary air. Both

discharge into the common outlet, which leads to the zone

being controlled. See Figure 4, p. 11.

Units are provided with a slip and drive rectangular duct

connection or can be ordered with integral outlet plenum.

Sequencing of hot and cold air valve is dependent on job

requirements. One typical control is valves working in

conjunction to respond to zone temperature.

When the cooling valve becomes fully closed or reaches a

specified minimum, the heating valve will begin to

modulate or vice versa. The typical result is that air flowing

to the zone varies from maximum down to a minimum and

back up to maximum as load varies and controls would

cause one air valve to close and the other to open.

Another typical application is when the unit provides a

constant volume to the zone. When the zone sensor is tied

directly to the heating valve, it will modulate the heating

valve according to the zone temperature.

When the heating valve is fully closed or there is a call for

cooling in the zone, the cooling valve will be at constant

supply. As the space becomes too cool, the heating valve

will modulate open, decreasing the cooling valve flow. The

typical result is that the air flowing into the zone stays at a

constant flow whether the unit is heating or cooling.

Figure 4. Typical dual-duct unit: VDDF

VAV-SVX08E-EN 11

Page 12

Unit Information

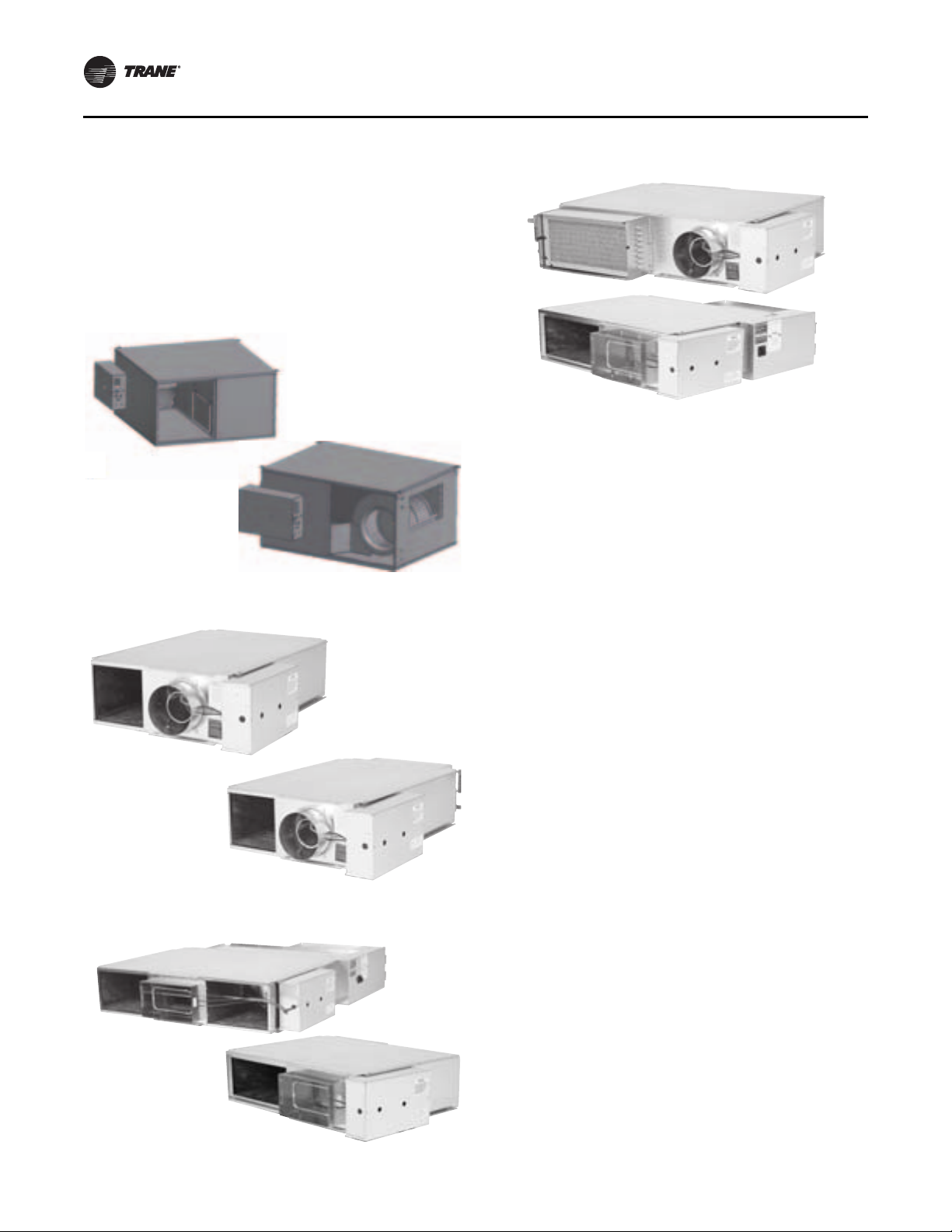

Fan-Powered and Fan-Powered LowHeight Units

VariTrane fan-powered and low-height fan-powered units

can be either parallel or series, with or without re-heat.

(SeeFigure 5, p. 12 thru Figure 8, p. 12.)

Typical Fan-Powered Units

Figure 5. Parallel fan-powered terminal unit (top) &

series fan-powered terminal units (bottom)

Figure 6. Low height series: LSCF (top) & low height

series: LSWF (bottom)

Figure 7. Low height series: LSEF (top) & low height

parallel: LPCF (bottom)

Figure 8. Low height parallel: LPWF (top) & low height

parallel: LPEF (bottom)

The fan on a series unit runs continuously whenever the

main air handler unit is in operation. There are various

options for starting the fan. The fan can be started three

ways: 1) remotely, 2) by a duct pressure switch, or 3) by a

combination of both. The particular fan control method

may vary from unit to unit, depending upon job needs.

Typically, heater is off while air valve modulates primary

air and responds to zone temperature. If zone temperature

decreases to the point where a decrease in primary air will

not maintain the desired temperature, the re-heat will be

activated to increase the temperature of the discharge air.

On a parallel unit, the VariTrane air valve delivers primary

cooling air to the unit outlet. When the space temperature

decreases beyond air valve control, the fan is turned on as

the first stage of heat. The fan delivers plenum air from

above the occupied space to the unit outlet, which is mixed

with primary air and delivered to the occupied space.

Note: Either the fan, the air valve, or both can deliver

airflow into the occupied space. In order to prevent

primary airflow from exiting through the fan when

the fan is not running on a parallel unit, a back draft

damper is provided. When the fan is not running,

the efficiency of this system is the same as a

standard single-duct VAV unit.

Typically, the control systems applied to parallel units

cause the air valve to close to zero or a minimum flow

before the fan is activated. After the fan is activated, the

optional heat will be activated upon further reduction in

zone temperature. Therefore, minimal primary air is mixed

with the heated air.

VariTrane fan-powered unit fan sizes 02SQ–05SQ and

08SQ–10SQ were performance tested at .12 in. w.g. and

sizes 06SQ and 07SQ were tested at .15 in. w.g. Units are

not designed to operate unducted and below these tested

static pressures.

Note: Fan-powered units are available with rectangular

discharge connection only. The optional heater is

mounted on the discharge of the unit. Hot water

coils are connected to either the plenum inlet or on

the discharge on parallel units, and to the discharge

of series units.

12 VAV-SVX08E-EN

Page 13

Unit Installation

Inlet Size

B C A

1.376" (35 mm)

25.154" (639 mm) 1.376" (35 mm)

37.25" (946 mm)

25.25" (641 mm) 23.154" (588 mm)

12" thru 16"

5" thru 10"

AIR

VALVE

AIR

VALVE

COOLING

HEATING

C

A

B

TOP VIEW

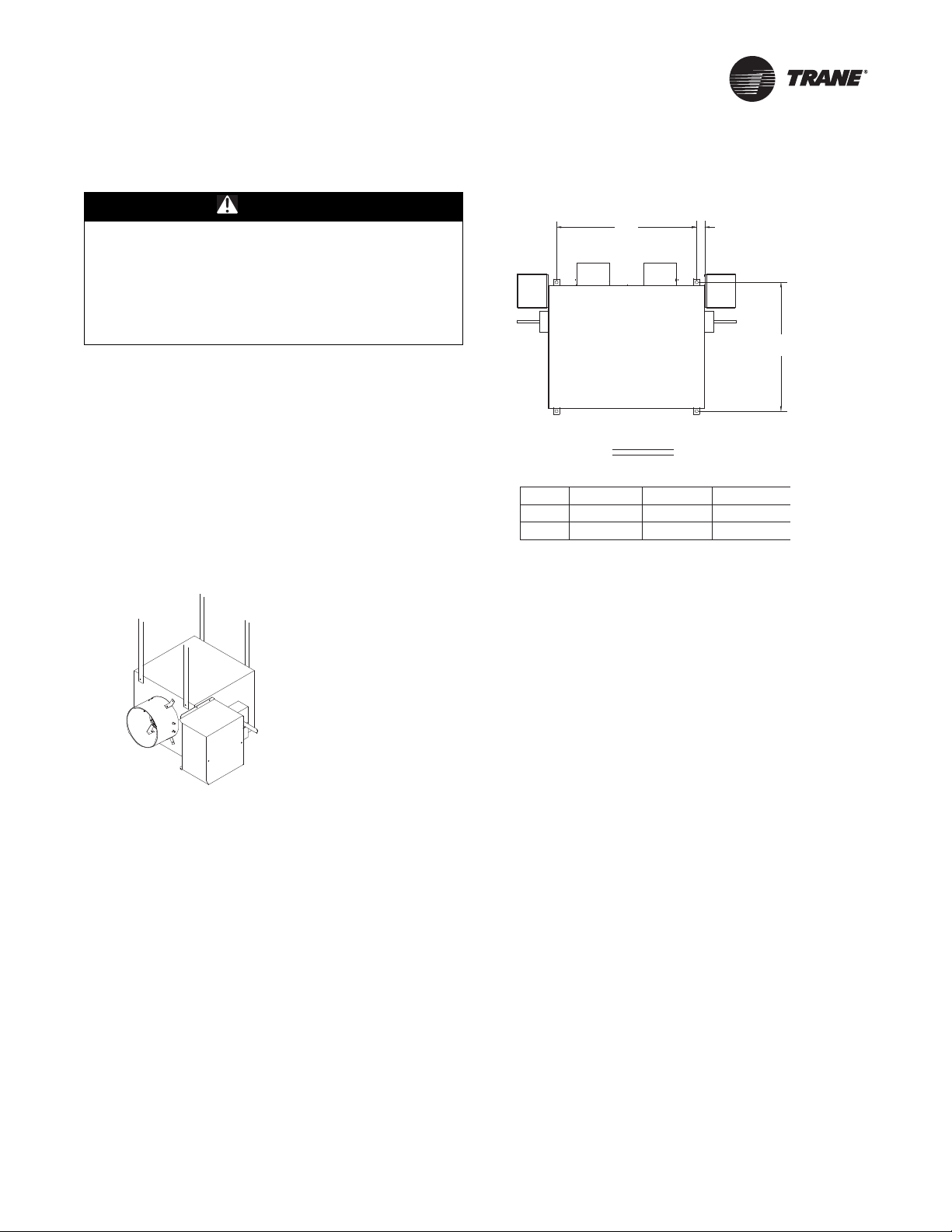

WARNING

Proper Structural Support Required!

Ceiling structure must be strong enough to support the

weight of the unit. If unsure, check with a structural

engineer. Refer toTable 1, p. 24 thruTable 6, p. 26 for unit

weights. Failure to ensure proper structural ceiling

support could result in unit failing from its location

which could result in death or serious injury.

Due to their weight, the VAV terminal units should be

suspended from the uppermost ceiling, independent of

the false ceiling grid. Suspension devices are to be

supplied by the installer. Units must be installed level and

upright. Failure to level the unit properly may prevent

proper operation of the controls and/or terminal unit.

Units are not designed to be installed vertically.

Consequently, this will also void the UL ratings and any

warranty on the unit.

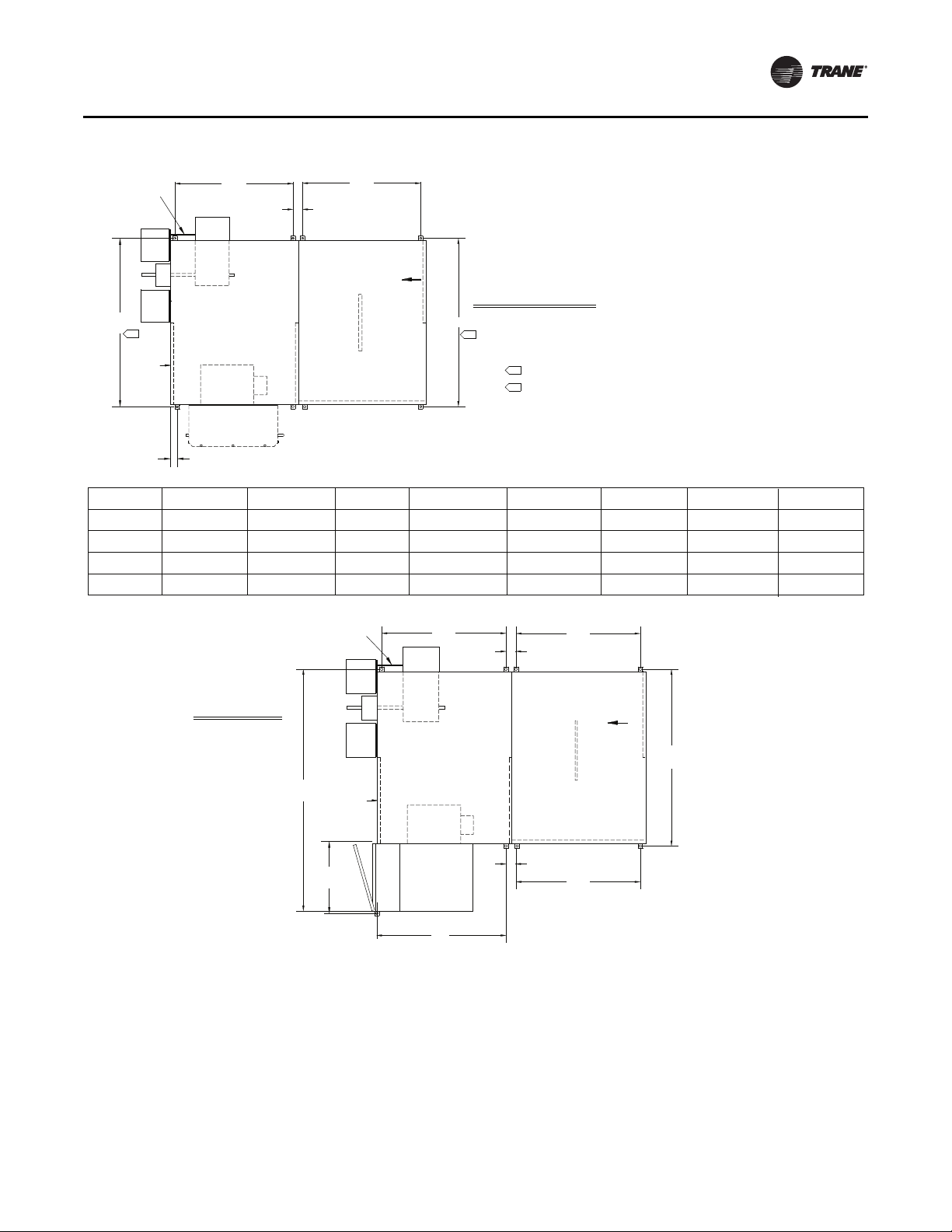

Single-Duct

Figure 9. Single-duct hanging recommendations

.

Figure 10. Dual-duct hanger bracket locations

Fan-Powered (Standard and Low-Height)

Fan-powered units should be supported by either hanger

straps or by using a threaded rod in conjunction with the

hanger brackets that are provided on the unit. Care should

be exercised to insure that the hanging straps do not block

the side access panel. See Figure 11, p. 16 thru Figure 18,

p. 22.

Depending upon the size and weight of the single-duct

unit, it may be capable of being supported by the ductwork

that is connected to it. No hanger brackets are provided on

these units since the unit should be supported by means

of a hanger strap. The hanger strap should be secured

directly to the unit casing as shown in Figure 9, p. 13.

For cooling only single-duct units or single-duct units with

hot water coil, the unit may be rotated 180° for opposite

side connections.

For units with electric heat, the unit can be flipped to either

RH or LH connection orientation if model number digit 22

Electrical Connections = F.

Dual-Duct

Dual-duct units should be supported by either hanger

straps or by using a threaded rod in conjunction with the

hanger brackets that are provided on the unit. See

Figure 10, p. 13.

Duct Connections

All VariTrane units should be provided with a minimum of

1.5-duct diameters of straight duct prior to the inlet of the

unit. It is recommended that at least 48 inches of straight

duct be provided from the discharge of the units prior to

any take-offs or transitions.

Important: This is a requirement for electric heat fan-

powered units used in applications with

100% downward discharge.

Note: In order to maintain good air distribution over the

elements and not create turbulence which could

cause a limit cutout there should be four feet of

ductwork, consistent of the discharge dimensions

of the heater. downstream of the reheat coil prior to

any diffuser takeoffs for VariTrane™ electric coils.

1. After all connections are made, check that the entire

ductwork system is airtight. In some high-pressure

systems, duct sealer may be necessary.

Note: All inlet duct on the VAV boxes are sized

approximately 1/8" smaller in diameter than the

nominal size in order to allow the incoming duct

to slide over the inlet of the VAV box.

2. Provide insulation around the entire inlet collar (all the

way to the unit casing).

VAV-SVX08E-EN 13

Page 14

Unit Installation

Note: Use caution not to damage the flow tubes when

making ductwork connections or insulating.

3. Cut “slits” in the insulation for the flow tubes and

secure with duct tape.

4. If the unit is to be installed in a location with high

humidity, external insulation around the heating coil

should be installed as required.

Water Coil Connections

Note: The following coils have 3/8” OD water coil piping

connections.

• Single Duct 1-row coils (inlet sizes 05, 05, 06, 08

or 10 only)

• Low Height Parallel Inlet 1-row

• Low Height Parallel Discharge 1-row

All others require a 7/8” OD water coil piping connections.

Note:

1. If necessary, you can change the coil connection from

left-handed to right-handed (and vice-versa) by

disconnecting the coil from the unit and rotating the

coil “like a steering wheel” 180°.

Note: Exception - Coil connection cannot be changed

on parallel fan powered unit with hot water coil

on plenum inlet.

2. Use port at the bottom for inlet and top for outlet on

single row coils. For multirow coils, always plumb in

counter flow orientation.

• Water inlet is always on the airflow downstream

side of the hot water coil.

• Water outlet is always on the upstream side of the

hot water coil.

3. Care should be taken to properly support the water coil

piping connections while connecting the adjoining

pipe.

4. It is recommended that piping to the water coil should

be done after field-mounted controls, external

insulation, and ductwork connections have been

completed.

Important: Do not connect water valve or pipe

extensions to the water coil connections

unless supported.

Unit Accessibility

• Single-duct and dual-duct units provided with hot

water reheat have an access panel located on the side

of the water coil. All other single-duct and dual-duct

units are provided without access, as all functioning

components are external to the unit.

• Fan-powered terminals are provided with a sliding side

access.

• Low-height terminal units have a removable bottom

panel.

Clearances

For proper service, it is recommended that at least 36” of

side clearance be provided to service and access singleduct and dual-duct terminals units.

• Fan-powered VAV units have a plenum inlet that must

be clear of obstructions. Allow at least 36” of clearance

in front of the side access and plenum opening.

• Low-height fan-powered terminals require the same

plenum clearance requirement that applies to the

standard fan-powered units. However the access to the

internal components is located on the bottom of the

unit.

It is also recommended that 6” of clearance be provided to

the top and bottom of all the units.

Note: The minimum clearance for controls and heater

controls should be 36” for all models except units

with 575-volt electric heaters, which require 48” of

clearance. NEC and/or local codes override all

clearance requirements.

Actuator Mounting

Important: When installing or replacing the actuator

tighten the actuator set screw per the

manufacturer’s instructions. Failure to

follow the manufacturer’s specifications

may result in unit malfunction.

Trane offers a factory-mounted actuator with a 90-second

drive time. The actuator drives 1 degree per second. A

field-installed actuator may be used if desired. The

actuator shaft has a ½-inch diameter and is designed to

travel clockwise to close the damper and counterclockwise to open the damper. There is an indicator on the

end of the actuator shaft that can be used to determine the

position of the damper.

Stand Alone UCM 4.2

When there is no communication to the UCM control and

the unit is in the stand alone mode the control action is

determined by the auxiliary temperature sensor located

on TB3-5 and TB3-6 terminals on the UCM board. In order

for the auxiliary sensor to determine the control action

(heat, cool) it must be located in the supply duct. The

auxiliary temperature is then compared to the zone

temperature. If the supply air temperature is 10 degrees

above the zone temperature, then the control action will be

heat. If the supply air temperature is less than or equal to

the zone temperature, then the control action will be cool.

If the supply air temperature is between the zone

temperature and the zone temperature + 10ºF (5.5°C)(zone

temperature < supply air temperature < zone temperature

+ 10ºF) (5.5°C), the control action remains the same and the

UCM controls to the minimum flow set point. If an

auxiliary sensor is not installed the UCM will retain the last

control action in effect

.

14 VAV-SVX08E-EN

Page 15

Stand Alone VV550 LonTalk™ Control

When there is no communication to the VV550 control and

the unit is in the stand alone mode the control action is

determined by the auxiliary temperature sensor located

on TB3-5 and TB3-6 terminals on the VV550 board. The

control must also be configured through the “Inputs Tab”

of Analog Input 4 as “Primary Supply Air Sensor”. In order

for the auxiliary sensor to determine the control action

(heat, cool) it must be located in the supply inlet of the

duct. The auxiliary temperature is then compared to the

zone temperature. If the supply air temperature is 10

degrees above the zone temperature, then the control

action will be heat. If the supply air temperature is less

than or equal to the zone temperature, then the control

action will be cool. If the supply air temperature is between

the zone temperature and the zone temperature + 10ºF

(5.5°C)(zone temperature < supply air temperature < zone

temperature + 10ºF) (5.5°C), the control action remains the

same and the UCM controls to the minimum flow set

point. If an auxiliary sensor is not installed the UCM will

retain the last control action in effect.

Stand Alone UC400

When there is no communication to the UC400 control and

the unit is in the stand alone mode the control action is

determined by the auxiliary temperature sensor located

on AI5 terminals on the UC400 control. This input may

have to be changed from AI4 (Discharge Air Input) as wired

from the factory. In order for the auxiliary sensor to

determine the control action (heat, cool) it must be located

in the supply inlet of the duct. The auxiliary temperature is

then compared to the zone temperature. If the supply air

temperature is 10 degrees above the zone temperature,

then the control action will be heat. If the supply air

temperature is less than or equal to the zone temperature,

then the control action will be cool. If the supply air

temperature is between the zone temperature and the

zone temperature + 10ºF (5.5°C)(zone temperature <

supply air temperature < zone temperature + 10ºF) (5.5°C),

the control action remains the same and the UCM controls

to the minimum flow set point. If an auxiliary sensor is not

installed the UCM will retain the last control action in

effect.

Unit Installation

VAV-SVX08E-EN 15

Page 16

Unit Installation

Water

Coil

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

Primary

Airflow

TOP VIEW

Parallel Cooling & Hot Water

Flow Ring

Tubing

Air

Valve

Airflow

Discharge Outlet

A

B

C

D

EF

ADE

F

B

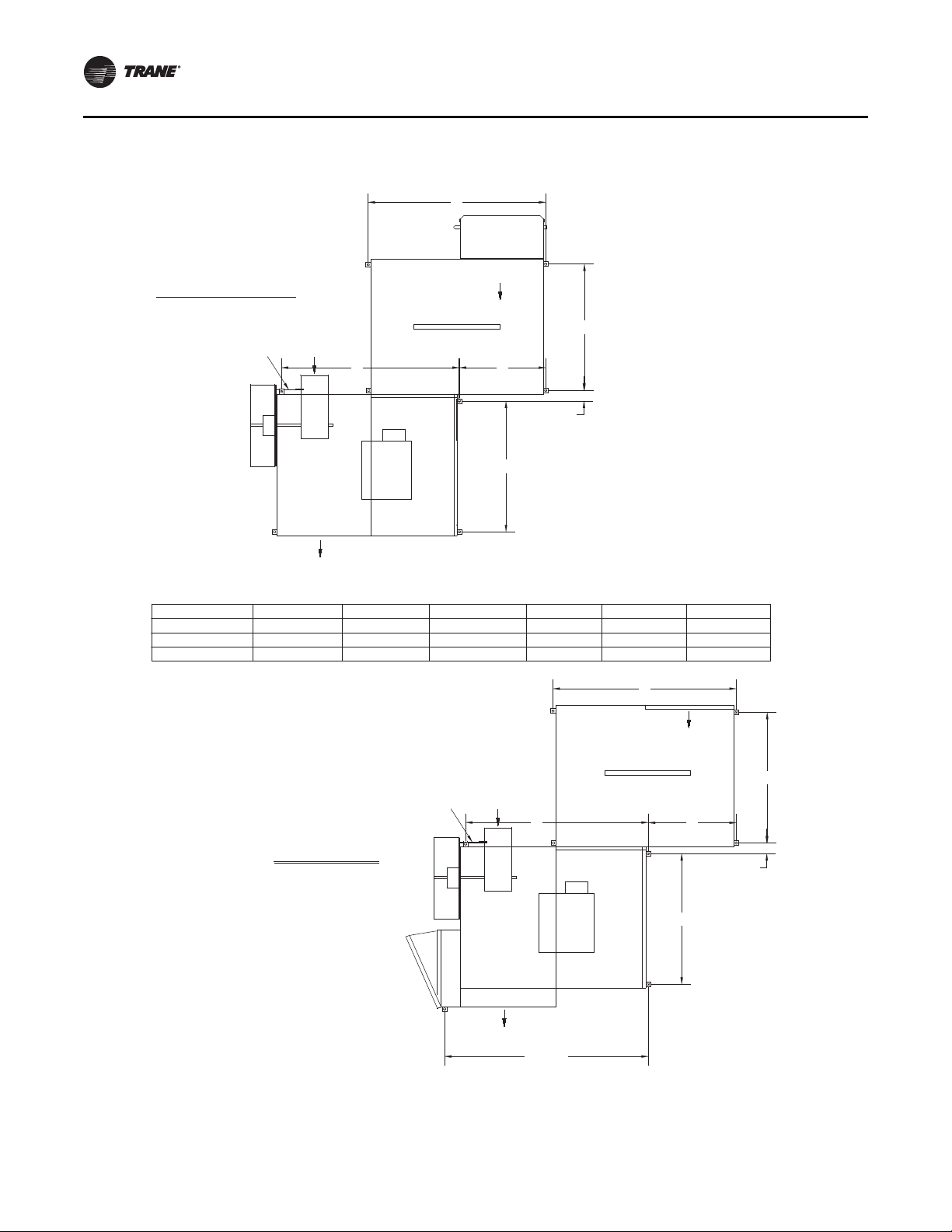

C

FAN SIZE

02SQ

03SQ, 04SQ, 05SQ

06SQ, 07SQ

26.75" (679 mm)

26.75" (679 mm)

26.75" (679 mm)

26.75" (679 mm)

29.75" (756 mm)

36.75" (933 mm)

41.154" (1041 mm)

41.154" (1041 mm)

41.154" (1041 mm)

3.25" (83 mm)

3.25" (83 mm)

3.25" (83 mm)

20.00" (508 mm)

20.00" (508 mm)

20.00" (508 mm)

38.95" (989 mm)

38.95" (989 mm)

38.95" (989 mm)

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

Primary

Airflow

TOP VIEW

Parallel Electric Heat

Flow Ring

Tubing

Air

Val ve

Airflow

Discharge Outlet

A

D

EF

B

C

Heater

Terminal Box

43.546

(1106 mm)

Figure 11. Parallel hanger bracket locations sizes

16 VAV-SVX08E-EN

Page 17

Figure 12. Series hanger bracket locations

Water

Coil

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

TOP VIEW

Series Cooling & Hot Water

Flow Ring

Tubing

Air

Valve

A

D

B

C

TOP VIEW

Series Electric Heat

1.

1.

2.

1.625"

(41 mm)

All attenuators are the same length and width.

Sizes 01 and 02 units are smaller than attenuators.

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

Flow Ring

Tubing

Air

Valve

A B

Electric

Heater

D

G

F

C

B

B

C

A D E

FAN SIZE

(Elec. Heat Only)

3.25" (83 mm)

3.25" (83 mm)

3.25" (83 mm)

3.25" (83 mm)

41.154" (1041 mm)

41.154" (1041 mm)

41.154" (1041 mm)

41.154" (1041 mm)

41.154" (1041 mm)

41.154" (1041 mm)

41.154" (1041 mm)

26.75" (679 mm)

26.75" (679 mm)

26.75" (679 mm)

26.75" (679 mm) 02SQ

06SQ, 07SQ

03SQ, 04SQ

05SQ 26.75" (679 mm)

20.75" (527 mm)

18.75" (476 mm)

27.25" (692 mm)

35.154 (740 mm)

23.875 (606 mm)

29.875" (759 mm)

28.966" (736 mm)

20.132" (511 mm)

Fan Inlet w/o

Attenuator

Fan Inlet w/o

Attenuator

F

C

E

2.

J

(Elec. Heat Only)

59.750” (1517 mm)

58.250" (1479 mm)

59.750" (1517 mm)

53.750" (1365 mm)

G

(Elec. Heat Only)

19.00" (483 mm)

17.50" (445 mm)

19.00" (483 mm)

19.00" (483 mm)

J

Unit Installation

VAV-SVX08E-EN 17

Page 18

Unit Installation

31.65"

(804 mm)

23.90"

(607 mm)

13.00"

(330 mm)

19.86"

(504 mm)

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

24.30"

(617 mm)

Primary

Airflow

Airflow

Discharge Outlet

13.80"

(350 mm)

4.00"

(102 mm)

23.10"

(587 mm)

3.35"

(85 mm)

TOP VIEW

TOP VIEW

3.35"

(85 mm)

Airflow

Discharge Outlet

31.65"

(804 mm)

23.90"

(607 mm)

13.00"

(330 mm)

19.86"

(504 mm)

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

24.30"

(617 mm)

Primary

Airflow

13.80"

(350 mm)

4.00"

(102 mm)

23.10"

(587 mm)

3.00"

(76 mm)

Heater

Terminal Box

Figure 13. Low-height parallel 08SQ/09SQ w/hot water or electric heat

18 VAV-SVX08E-EN

Page 19

Figure 14. Low-height parallel 10SQ

Primary

Airflow

Air

Valve

38.95"

(989 mm)

1.625"

(41 mm)

Flow Ring

Tubing

5.625"

(143 mm)

41.137"

(1045 mm)

Airflow

Discharge Outlet

Optional Heater

Terminal Box

5.625"

(143 mm)

TOP VIEW

38.75"

(984 mm)

Plenum

Inlet

Unit Installation

VAV-SVX08E-EN 19

Page 20

Unit Installation

g

19.86"

(504 mm)

3.35"

(85 mm)

31.65"

(804 mm)

12.85"

(326 mm)

10.13"

(257 mm)

4.00"

(102 mm)

34.30"

(871 mm)

10.13"

(257 mm)

3.35"

(85 mm)

4.00"

(102 mm)

27.00"

(686 mm)

20.00"

(508 mm)

Primary

Airflow

Air

Valv e

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

Wate r

Coil

Primary

Airflow

Airflow

TOP VIEW

19.86"

(504 mm)

3.35"

(85 mm)

31.65"

(804 mm)

12.85"

(326 mm)

34.30"

(871 mm)

3.35"

(85 mm)

27.00"

(686 mm)

20.00"

(508 mm)

Air

Val ve

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

Optional

Electric Heater

Airflow

TOP VIEW

Figure 15. Low-height series 08SQ/09SQ w/hot water or electric heat

20 VAV-SVX08E-EN

Page 21

Figure 16. Low-height series 10SQ w/hot water or electric heat

31.65"

(804 mm)

19.86"

(504 mm)

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

31.65"

(804 mm)

Primary

Airflow

Airflow

Discharge Outlet

10.12"

(257 mm)

42.00"

(1067 mm)

30.30"

(770 mm)

3.35"

(85 mm)

TOP VIEW

Optional Attenuator

Field Installed

Airflow

Plenum Inlet

19.45"

(494 mm)

19.45"

(494 mm)

19.86"

(504 mm)

3.35"

(85 mm)

3.50"

(89 mm)

3.50"

(89 mm)

31.65"

(804 mm)

19.86"

(504 mm)

Airflow

Plenum Inlet

Optional Attenuator

Field Installed

31.65"

(804 mm)

Primary

Airflow

Airflow

Discharge Outlet

10.12"

(257 mm)

42.00"

(1067 mm)

30.30"

(770 mm)

3.35"

(85 mm)

TOP VIEW

Optional Attenuator

Field Installed

Airflow

Plenum Inlet

19.45"

(494 mm)

19.45"

(494 mm)

19.86"

(504 mm)

3.35"

(85 mm)

3.50"

(89 mm)

3.50"

(89 mm)

1.92"

(49 mm)

Terminal Box

Plenum Area

Optional

Heater

Unit Installation

VAV-SVX08E-EN 21

Page 22

Unit Installation

Mounting Bracket

Optional Attenuator

Field Installed

1. Attach attenuator as shown with provided mounting brackets.

Optional Attenuator

Field Installed

Mounting Bracket

1. Attach attenuator as shown with provided mounting brackets.

Figure 17. Attenuator installation - parallel units

Note: Bottom bracket not shown. Bottom bracket to be installed in same orientation on bottom of unit.

Figure 18. Attenuator installation - series units

Note: Bottom bracket not shown. Bottom bracket to be installed in same orientation on bottom of unit.

22 VAV-SVX08E-EN

Page 23

Figure 19. Attenuator installation - low-height parallel units

1. Attach attenuator to unit as shown with provided mounting brackets.

MOUNTING BRACKET

OPTIONAL ATTENUATOR

FIELD INSTALLED

1. Attach attenuator to unit as shown with provided mounting brackets.

MOUNTING BRACKET

OPTIONAL ATTENUATOR

FIELD INSTALLED

MOUNTING BRACKET

OPTIONAL ATTENUATOR

FIELD INSTALLED

MOUNTING BRACKET

OPTIONAL ATTENUATOR

FIELD INSTALLED

Notes: Bottom bracket not shown. Bottom bracket to be installed in same orientation on bottom of unit.

Figure 20. Attenuator installation - low-height series units

Unit Installation

Note: Bottom bracket not shown. Bottom bracket to be installed in same orientation on bottom of unit.

Bottom Access

An optional bottom access can be provided in the casing

of fan powered series or parallel terminal unit. See

Figure 21.

The 22 ga. door is lined with 1” 26 ga. dual wall insulation

and thermally lined with 1” – 1 lb. density fiberglass

insulation with a 3.85 R-value.

Each door includes 4 to 6 cam locs that are used to secure

the door to the casing.

The cam loc engages a metal encapsulated frame on the

unit that encloses the unit insulation to prevent air erosion.

The cam loc engagements are interlocked using a flat head

screwdriver. Once unlocked the entire door assembly can

be removed for access.

VAV-SVX08E-EN 23

Figure 21. Bottom access

Page 24

Unit Installation

Table 1. Single-duct units

Unit

Size

4

5

6

8

10

12

14

16

24

VCCF

(lbs/kg)

22/10

27/12

32/15

35/16

52/24

16/7

16/7

16/7

16/7

Dual Wall

(lbs/kg)

19/9

19/9

19/9

20/9

27/12

34/15

41/19

46/21

63/29

Table 2. Dual-duct units

Unit Size VDDF (lbs/kg) VDDF w/Dual Wall (lbs/kg)

0505

0506

0606

0508

0608

0510

0808

0610

0810

1010

0612

0812

1012

1212

0814

1014

1214

1414

0816

1016

1216

1416

1616

VCCF w/

VCEF

(lbs/kg)

38/17

38/17

38/17

38/17

46/21

52/24

60/27

69/31

84/38

VCEF w/

Dual

Wall

(lbs/kg)

48/22

48/22

48/22

49/22

60/27

68/31

80/36

91/41

106/48

VCWF

1-Row

(lbs/kg)

21/10

21/10

21/10

21/10

29/13

37/17

44/20

49/22

70/32

VCWF

2-Row

(lbs/kg)

22/10

22/10

22/10

24/11

32/15

40/18

48/22

54/24

77/35

54/24

54/24

54/24

55/25

55/25

56/25

56/25

56/25

57/26

61/28

57/26

58/26

59/27

60/27

78/35

79/36

80/36

81/37

79/36

80/36

81/37

82/37

83/38

VCWF

3-Row

(lbs/kg)

23/11

23/11

22/10

24/11

32/15

41/19

51/23

56/25

76/35

VCWF

4-Row

(lbs/kg)

24/11

24/11

24/11

26/12

36/16

45/20

55/25

61/28

82/37

VCWF

1-Row w/

Dual Wall

(lbs/kg)

24/11

24/11

24/11

25/11

34/15

43/20

53/24

60/27

81/37

VCWF

2-Row w/

Dual Wall

(lbs/kg)

25/11

25/11

25/11

28/13

37/17

47/21

57/26

65/29

88/40

68/31

68/31

68/31

68/31

69/31

69/31

70/32

70/32

70/32

74/34

70/32

71/32

72/33

84/38

102/46

103/47

104/47

105/48

103/47

104/47

105/48

105/48

106/48

VCWF

3-Row w/

Dual Wall

(lbs/kg)

26/12

26/12

25/11

28/13

37/17

48/22

60/27

67/30

87/40

VCWF

4-Row w/

Dual Wall

(lbs/kg)

27/12

27/12

27/12

30/14

41/19

52/24

64/29

72/33

93/42

24 VAV-SVX08E-EN

Page 25

Table 3. Parallel fan-powered units

Unit Installation

Unit

Size

0502SQ

0602SQ

0603SQ

0802SQ

0803SQ

0804SQ

1002SQ

1003SQ

1004SQ

1005SQ

1006SQ

1007SQ

1203SQ

1204SQ

1205SQ

1206SQ

1207SQ

1404SQ

1405SQ

1406SQ

1407SQ

1606SQ

1607SQ

VPCF

(lbs/kg)

81/37

80/36

83/38

81/37

83/38

84/38

82/37

84/38

85/39

98/44

114/52

122/55

85/39

86/39

99/45

115/52

123/56

87/39

100/45

116/53

124/56

117/53

125/57

VPCF w/Dual

Wall (lbs/kg)

115/52

114/52

117/53

115/52

117/53

118/54

116/53

118/54

119/54

132/60

148/67

156/71

119/54

120/54

133/60

149/68

157/71

121/55

134/61

150/68

158/72

151/68

159/72

VPEF

(lbs/kg)

110/550

109/49

112/51

110/50

112/51

113/51

111/50

113/51

114/52

128/58

144/65

152/69

114/52

115/52

129/59

145/66

153/69

116/53

130/59

146/66

154/70

147/67

155/70

VPEF w/Dual

Wall (lbs/kg)

144/65

143/65

146/66

144/65

146/66

147/67

145/66

147/67

148/67

162/73

178/81

186/84

148/67

149/68

163/74

179/81

187/85

150/68

164/74

180/82

188/85

181/82

189/86

VPWF 1-Row

(lbs/kg)

92/42

91/41

105/48

92/42

105/48

106/48

93/42

106/48

107/49

120/54

127/58

135/61

107/49

108/49

121/55

128/58

136/62

109/49

122/55

129/59

137/62

130/59

138/63

VPWF 2-Row

(lbs/kg)

95/43

94/43

108/49

95/43

108/49

109/49

96/44

109/49

110/50

123/56

130/59

138/63

110/50

111/50

124/56

131/59

139/63

112/51

125/57

132/60

140/64

133/60

141/64

VPWF 1-Row

w/Dual Wall

(lbs/kg)

126/57

125/57

139/63

126/57

139/63

140/64

127/58

140/64

141/64

154/70

161/73

169/77

141/64

142/64

155/70

162/73

170/77

143/65

156/71

163/74

171/78

164/74

172/78

VPWF 2-Row

w/Dual Wall

(lbs/kg)

129/59

128/58

142/64

129/59

142/64

143/65

130/59

143/65

144/65

157/71

164/74

172/78

144/65

145/66

158/72

165/75

173/78

146/66

159/72

166/75

174/79

167/76

175/79

VPxF

Attenuator

(lbs/kg)

46/21

46/21

48/22

46/21

48/22

48/22

46/21

48/22

48/22

48/22

54/24

54/24

48/22

48/22

48/22

54/24

54/24

48/22

48/22

54/24

54/24

54/24

54/24

Table 4. Series fan-powered

VSCF w/

Dual Wall

(lbs/kg)

93/42

93/42

92/42

100/45

111/50

94/43

101/46

112/51

96/44

104/47

115/52

116/53

133/60

146/66

106/48

116/53

118/54

134/61

147/67

117/53

120/54

135/61

148/67

136/62

149/68

Unit Size

0402SQ

0502SQ

0602SQ

0603SQ

0604SQ

0802SQ

0803SQ

0804SQ

1002SQ

1003SQ

1004SQ

1005SQ

1006SQ

1007SQ

1203SQ

1204SQ

1205SQ

1206SQ

1207SQ

1404SQ

1405SQ

1406SQ

1407SQ

1606SQ

1607SQ

VSCF

(lbs/kg)

78/35

78/35

77/35

76/34

87/39

79/36

77/35

88/40

81/37

80/36

91/41

92/42

104/47

117/53

82/37

92/42

94/43

105/48

118/54

93/42

96/44

106/48

119/54

107/49

120/54

VSEF

(lbs/kg)

104/47

104/47

103/47

105/48

116/53

105/48

106/48

117/53

107/49

109/49

120/54

121/55

135/61

148/67

111/50

121/55

123/56

136/62

149/68

122/55

125/57

137/62

150/68

138/63

151/68

VSEF w/

Dual Wall

(lbs/kg)

119/54

119/54

118/54

129/59

140/64

120/54

130/59

141/64

122/55

133/60

144/65

145/66

164/74

177/80

135/61

145/66

147/67

165/75

178/81

146/66

149/68

166/75

179/81

167/76

180/82

VSWF

1-Row

(lbs/kg)

85/39

85/39

84/38

88/40

99/45

86/39

89/40

100/45

88/40

92/42

103/47

104/47

119/54

132/60

94/43

104/47

106/48

120/54

133/60

105/48

108/49

121/55

134/61

122/55

135/61

VSWF

2-Row

(lbs/kg)

87/39

87/39

86/39

92/42

103/47

88/40

93/42

104/47

90/41

96/44

107/49

108/49

124/56

137/62

98/44

108/49

110/50

125/57

138/63

109/49

112/51

126/57

139/63

127/58

140/64

VSWF

1-Row

w/Dual Wall

(lbs/kg)

100/45

100/45

99/45

112/51

123/56

101/46

113/51

124/56

103/47

116/53

127/58

128/58

148/67

161/73

118/54

128/58

130/59

149/68

162/73

129/59

132/60

150/68

163/74

151/68

164/74

VSWF

2-Row

w/Dual Wall

(lbs/kg)

102/46

102/46

101/46

116/53

127/58

103/47

117/53

128/58

105/48

120/54

131/59

132/60

153/69

166/75

122/55

132/60

134/61

154/70

167/76

133/60

136/62

155/70

168/76

156/71

169/77

VSxF

Attenuator

(lbs/kg)

46/21

46/21

46/21

48/22

48/22

46/21

48/22

48/22

46/21

48/22

48/22

48/22

54/24

54/24

48/22

48/22

48/22

54/24

54/24

48/22

48/22

54/24

54/24

54/24

54/24

VAV-SVX08E-EN 25

Page 26

Unit Installation

Table 5. Low-height parallel units

LPCF w/

Unit Size

0508SQ

0608SQ

0609SQ

0808SQ

0809SQ

0810SQ

14RT09SQ

14RT10SQ

LPCF

(lbs/kg)

69/31

68/31

73/33

69/31

74/34

90/41

83/38

97/44

Dual Wall

(lbs/kg)

89/40

88/40

93/42

89/40

94/43

110/50

103/47

117/53

Table 6. Low-height series units

LSCF w/

Dual Wall

(lbs/kg)

86/39

85/39

95/43

86/39

96/44

120/54

105/48

130/59

Unit Size

0508SQ

0608SQ

0609SQ

0808SQ

0809SQ

0810SQ

14RT09SQ

14RT10SQ

LSCF

(lbs/kg)

71/32

70/32

80/36

71/32

81/37

95/43

90/41

105/48

LPEF

(lbs/kg)

84/38

83/38

88/40

84/38

89/40

105/48

98/44

112/51

LSEF

(lbs/kg)

86/39

85/39

95/43

86/39

96/44

120/54

105/48

130/59

LPEF w/

Dual Wall

(lbs/kg)

104/47

103/47

108/49

104/47

109/49

125/57

118/54

132/60

LSEF w/

Dual Wall

(lbs/kg)

101/45

100/45

110/50

101/46

111/50

145/66

120/54

155/70

LPWF

1-Row

(lbs/kg)

78/35

77/35

82/37

78/35

83/38

99/45

92/42

106/48

LSWF

1-Row

(lbs/kg)

80/36

79/36

89/40

80/36

90/41

111/50

99/45

121/55

LPWF

2-Row

(lbs/kg)

81/37

80/36

85/39

81/37

86/39

102/46

95/43

109/49

LSWF

2-Row

(lbs/kg)

82/37

81/37

91/41

82/37

92/42

115/52

101/46

125/57

LPWF 1-Row

w/Dual Wall

(lbs/kg)

98/44

97/44

102/46

98/44

103/47

119/54

112/51

126/57

LSWF 1-Row

w/Dual Wall

(lbs/kg)

95/43

94/43

104/47

95/43

105/48

136/62

114/52

146/66

LPWF 2-Row

w/DualWall

(lbs/kg)

101/46

100/45

105/48

101/46

106/48

122/55

115/52

129/59

LSWF 2-Row

w/Dual Wall

(lbs/kg)

97/44

96/44

106/48

97/44

107/49

140/64

116/53

150/68

LPxF

Attenuator

(lbs/kg)

10/5

10/5

10/5

10/5

10/5

10/5

10/5

10/5