Page 1

Installation

Operation

Programming

VAV VV550 LonTalk

Controller

May 2010

VAV-SVP01A-E N

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. Warnings are provided to alert installing contractors

to potential hazards that could result in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout

this literature. Read these carefully.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury. It could also be used to alert against unsafe practices.

NOTICE: Indicates a situation that could result in equipment or property-damage-only

accidents.

WARN ING

This equipment is to be serviced/installed by qualified personnel ONLY. Under NO

circumstances should an unqualified person service/install it. Servicing/installing this

equipment is a job requiring specific knowledge and MUST be left to a professional. It involves

working with hazardous components that are potentially life threatening if not handled

properly. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury.

WARN ING

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS

sheets and OSHA guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put on all necessary Personal Protective

Equipment (PPE) in accordance with NFPA70E for arc/flash protection PRIOR to servicing the

unit.

Failure to follow recommendations could result in death or serious injury.

© 2010 Trane All rights reserved VAV-SVP01A-EN

Page 3

Warnings, Cautions and Notices

WARN ING

Electrocution and Fire Hazards with Improperly Installed and Grounded

Field Wiring!

Improperly installed and grounded field wiring poses FIRE & ELECTROCUTION hazards. To avoid

these hazards, you MUST follow requirements for field wiring installation and grounding as

described in NEC and your local/state electrical codes. All field wiring MUST be performed by

qualified personnel. Failure to follow these requirements could result in death or serious injury.

Overview of Manual

Note: One copy of this document ships inside the control panel of each unit and is customer

property. It must be retained by the unit's maintenance personnel.

This booklet describes proper installation, operation, and maintenance procedures for delivered

air systems. By carefully reviewing the information within this manual and following the

instructions, the risk of improper operation and/or component damage will be minimized. It is

important that periodic maintenance be performed to help assure trouble free operation. A

maintenance schedule is provided at the end of this manual. Should equipment failure occur,

contact a qualified service organization with qualified, experienced HVAC technicians to properly

diagnose and repair this equipment.

VAV-SV P01A-E N 3

Page 4

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unit Control Module VAV VV550 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

VV550 Enhancements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VV550 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shipping & Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Data Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

VAV Start Up/Check Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

VV550 Pre-Power Check-Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

VV550 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Light Emitting Diode (LED) Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Communication Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wireless Zone Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

VAV VV550 Controller Programming and Operation . . . . . . . . . . . . . . . . . . . . . . 42

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Accessing Rover/Comm5 LonTalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

VV550 Controller Device Home Tabs: At a Glance . . . . . . . . . . . . . . . . . . . . . 44

Entering and Exiting the Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overriding VAVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

VAV VV550 Controller Device Home Tabs: Instructions . . . . . . . . . . . . . . . . . . . . 54

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setpoints Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Unit Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Setup Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Inputs Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Outputs Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Test Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Other Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Overrides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Sequence of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4 VAV-SVP01A-EN

Page 5

Occupancy Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Space Temperature Control: Single Duct Units . . . . . . . . . . . . . . . . . . . . . . . . 69

Space Temperature Control: Fan-Powered Units . . . . . . . . . . . . . . . . . . . . . . 72

Ventilation Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Flow Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Air and Water Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Air Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Rover Air and Water Balancing Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Diagnosing the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Trane/Honeywell Proportional Valve Check Out Procedures . . . . . . . . . . . 105

VAV-SV P01A-E N 5

Page 6

General Information

Chapter Overview

This chapter contains information about the following:

• Unit Control Module VAV VV550 Controller

• Specifications

• VAV VV550 Controller Enhancements

• VAV VV550 Controller Features

• Shipping & Storage

• Data Lists

Unit Control Module VAV VV550 Controller

The VV550 is a microprocessor-based, Direct Digital Controller (DDC) for the (Variable Air Volume)

VAV terminal unit. Units have been made with either pneumatic, analog electronic, or

microprocessor controls (DDC VAV). This manual discusses only terminal units with Comm 5 VAV

VV550 DDC Controller. Factory installed DDC/VAV controls are available with all single duct

terminal units, dual duct units, as well as parallel fan-powered and series fan-powered units. Two

VAV VV550 Controllers are required for dual duct units (one for the heating duct and one for the

cooling duct) and another application requiring to controllers is Flow tracking (one unit controller

is programmed from the factory with the Space temperature program and the other is downloaded

with the Flow tracking program.

The VAV VV550 Controller can be configured from the factory with three different application

programs. The VAV VV550 Controller programmed for space temperature control modulates a

VAV's damper blade based on a zone temperature, measured airflow, and set points to

continuously control conditioned air delivery to the space. The volume of incoming air is

monitored and the damper adjusts to provide accurate control independent of the duct pressure.

The damper modulates between operator set points depending on space conditions. Additionally,

fan and heat outputs may be energized depending on the application.

The VAV VV550 Controller programmed for ventilation flow control is applied to a VAV terminal and

used to temper cold outdoor air (OA) that is brought into a building for ventilation purposes. The

tempered air is intended to supply an air-handling unit (AHU), which provides comfort control to

the zones it is serving. The VAV terminal supplies the correct amount of ventilation air and, when

reheat is added, tempers the ventilation air to reduce the load on the air handler by sensing the

discharge air temperature of VAV unit.

The VAV VV550 Controller programmed for Flow Tracking Control (FTC) has two VAV VV550

Controllers working together to provide flow tracking control. One VAV VV550 controller is

programmed from the factory with the Space temperature program and the other is downloaded

with the Flow tracking program. The space temperature controller airflow output is bound to the

flow tracking controller airflow setpoint input. The flow tracking controller adds the configured

airflow tracking offset (positive or negative) to the airflow setpoint (communicated airflow setpoint)

and controls the airflow to this setpoint.

The VAV VV550 Controller utilizes an FTT-10A Free Topology transceiver, which supports nonpolarity sensitive, free topology wiring, which allows the system installer to utilize star, bus, and

loop architectures. Available inputs include a twisted/shielded communication link, zone sensor,

auxiliary temperature sensor (optional), and Occupy/Unoccupied Sensor (optional), and 24VAC

power.

6 VAV-SVP01A-EN

Page 7

Specifications

General Information

Power Requirements

The UCM VV550 requires 18-32 Vac (24VAC nominal), 50/60 Hz, and up to 50 VA, depending on the

number of heat outputs (stages), which consume 10 VA each.

Operating Environments - VAV VV550 Controller

32° to 140°F (0° to 60°C), 5% to 90% relative humidity, non-condensing

Storage Environments - VAV VV550 Controller

-40° to 185°F (-40° to 85°C), 5% to 90% relative humidity, non-condensing

From 5 to 95% non-condensing

Relative humidity:

From 5 to 95% non-condensing

Analog Inputs

Space temperature; thermistor: 10 kΩ@ 77°F (25°C) From 14 to 122°F (-10 to 50°C)

Space setpoint; potentiometer: 1 kΩ From 50 to 90°F (-10 to 32.2°C)

Primary/discharge air temperature; thermistor: 10 kΩ@ 77°F (25°C) From -40 to 212°F (-40 to 100°C)

Primary air flow; pressure transducer: From 0 to 2 in. water (0 to 498 Pa)

Binary Input

Occupancy or generic (dry contact)

Binary Outputs

Air valve close: maximum output rating: 12 VA

Air valve open: maximum output rating: 12 VA

Heat stage 1: maximum output rating: 12 VA

Heat stage 2: maximum output rating: 12 VA

Heat stage 3/Fan on/off: maximum output rating: 12 VA

Agency Listings/Compliance

VAV VV550 Controller:

UL 873 and CSA C22.2 No. 24-93:

Temperature Indicating and Regulating

Equipment

VAV VV551 Controller:

UL-916-PAZX-energy management

CUL-C22.2-signal devices-Canada

UL 94-5V (UL flammability rating for plenum use)

FCC Part 15, Class A

CE marked

Mounting

Typically, the VAV VV550 Controller is factory installed. However, the VAV VV550 Controller is

available with retrofit kits, in which case it must be field installed, and it’s named VV551.

Tracer Summit and VV550 Communications Link Wiring

Use 22 AWG Level 4 unshielded communication wire for most Comm5 installations. Limit Comm5

links to 4,500 ft and 60 devices maximum (without a repeater). Use one repeater for an additional

4,500 ft, 60 devices, and 8 communication stubs. Refer to Chapters 2 and 3 for further information

about wire selection.

VAV-SV P01A-E N 7

Page 8

General Information

VV550 Enhancements

Controller Interface Flexibility

VV550 controller allows VAV units to communicate on a Trane Comm5 or LonTalk. This controller

works in standalone mode, peer-to-peer with one or more other units, or when connected to a Trane

Tracer Summit or a 3rd party building automation system that supports LonTalk.

Manual Test Function

The VV550 controller includes a manual test button that allows the field technician to manually

exercise the outputs of the controller. This feature is simple enough for the electrician to use to

check valve operation. Though this feature is standard on other Comm5 controllers, the feature is

not available on the VAV VV550 Controller.

Flow Tracking

The VV550 controller has been designed with the ability to be applied in flow tracking applications.

This allows the controller to pair with one of its peers to mirror the flow if that lead box, with or

without an offset (positive or negative static pressure as desired).

Ventilation Flow Control w/ Tempering

The VV550 controller has been designed with the ability to be applied in ventilation flow control

applications. These applications pair a fresh air unit with ventilation boxes to provide fresh

(tempered) air to a floor/area. This feature also includes a freeze protection sequence to protect the

hot water reheat coil from low supply air temperatures.

Auto-commissioning Sequence

The VV550 controller has been designed with an auto-commissioning sequence. With a discharge

air temperature sensor, this feature exercises the air valve, fan, and heat in the box and records the

temperature before and after the action. This allows the installer to more easily checkout the

operation of the box and commission by exception.

Automatic Calibration

The VV550 controller has been designed to automatically calibrate the flow transducer each time

the box transitions to unoccupied. This eliminates the need to initiate/schedule calibration for most

installations. The exception is 24/7 sites, in which case Tracer Summit can be used to initiate/

schedule calibration.

Temporary Heat (Construction Mode)

Upon reset (and power-up) if the controller does not detect a valid space temperature the controller

will provide temporary heat by driving the air valve to the heating maximum position. Of course,

the box will only provide heat if hot air is being provided by the air-handling unit.

Local versus Remote Reheat Flexibility

The controller can be configured to have local and/or remote heat. Plus, configuration flexibility is

offered that allows the installer to select whether local or remote heat has priority.

Zone Sensor Air Balancing

When applied with a Trane zone sensor module that includes a setpoint thumbwheel and ON and

CANCEL buttons, the controller offers a zone sensor air-balancing feature. This feature allows the

balancing contractor to drive the box to either its minimum or maximum flow setting by turning

the setpoint thumbwheel on the zone sensor module. Then, the balancing contractor can calibrate

the flow reading by pressing the ON (adjusts the reading upwards) or CANCEL (adjusts the reading

downwards) buttons on the zone sensor module.

8 VAV-SVP01A-EN

Page 9

General Information

Flash Download

The VAV controller has been designed with flash memory. This allows us the option of upgrading

the controller in the field (features, corrections to defects) without changing out the controller.

Air/Water Balancing Application

An air/water balancing application is available in Rover that simplifies the startup, checkout and

balancing of VAV systems. This application is specifically designed for the balancing contractor.

Service Pin from the Trane Zone Sensor

Several Comm5 installation and commissioning scenarios have the technician pressing the

"service" button on the controller. By doing so, a service pin message is broadcast and received by

either the Rover service tool or by Tracer Summit (depending on the scenario). Because access to

the service button on the controller is often difficult, functionality has been included in the

controller that allows the technician to press and hold the ON button on the zone sensor to replicate

a service button press.

Trane Controller Compatibility

The VV550 is a Comm5 controller. As such, the controller is compatible with the latest generation

of Trane controls. This allows the VV550 controller to exist on the same communication wire as the

rest of our Comm5 controllers and share data with them as required. Additional inputs and outputs

can easily be added to the same communication link (Tracer MP503) for any required auxiliary

functions. In the past the cost of adding additional inputs and outputs (Comm4 link by way of a

UPCM) was much less cost-effective.

Drive Min and Max from Zone Sensor

When applied with a Trane zone sensor module that includes a thumbwheel setpoint, the VV550

controller can easily be overridden to minimum and maximum flow. By simply turning the

thumbwheel to "*" (end of range in one direction) the controller drives the air valve to the minimum

cooling flow setpoint. Similarly, turning the thumbwheel to the and "**" (end of range in the other

direction) the controller drives the air valve to the maximum cooling flow setpoint.

VV550 Features

Auto-commissioning Report (Tracer Summit)

Tracer Summit v15 and greater includes an auto-commissioning report that extracts and formats

the commissioning data for each VAV controller. This commissioning report is valuable both for the

installer and for the owner. The feature enables the system to be commissioned by exception -- a

benefit for the installer. The feature also can be used as validation -- valuable to the owner.

Simpler VAS

Tracer Summit v15 includes a new VAV Air System (VAS) specifically designed for Comm5

controllers. This new VAS was designed to be much simpler to understand and setup compared

to the existing (Comm3/4) VAS.

Static Pressure Optimization

As a part of the standard application, VAS calculates the duct static pressure setpoint based on the

most open VAV box. Until Tracer Summit v15, this feature was provided by way of field custom

programming.

Ventilation Optimization

As a part of the standard application, the VAV system has the ability to calculate the ventilation

setpoint for the air-handling unit. In addition, the VV550 controller has a ventilation ratio limit

feature that automatically increases airflow to maintain the required ventilation while operating

VAV-SV P01A-E N 9

Page 10

General Information

within system limits for outside air percent concentrations in the supply air stream. Until Tracer

Summit v15, this feature was provided by way of field custom programming.

CO2 Based Demand Control Ventilation

As a part of the standard application, the VAV system has the ability to calculate the ventilation

setpoint for the air-handling unit based on the CO2 in one or more spaces. Until Tracer Summit v15,

this feature was provided by way of field custom programming. Plus, functionality was added to

the VV550 controller to support this feature (as standard). Providing the equivalent functionality

with the current VAV controller would require lots of custom programming.

Ventilation Flexibility

Ventilation can be managed in the following ways:

• Fixed occupancy ventilation setpoint

• Scheduled (or otherwise calculated) ventilation setpoint

• Occupancy sensor to switch between normal and reduced ventilation

•CO

Temperature Statistics

As a part of the standard application, VAS calculates the minimum space temperature (and source),

maximum space temperature (and source), and the average space temperature. Until Tracer

Summit v15, this feature was provided by way of field custom programming.

sensor for demand-controlled ventilation

2

2

Note: CO

sensor input not available on VV550.

VAV VV550 Controller Compatibility

The VAV VV550 Controller is designed with LonWorks technology and will be LonMark certified.

VV550 controller allows VAV units to communicate on a Trane Comm5 or LonTalk link. This

controller works in standalone mode, peer-to-peer with one or more other units, or when

connected to a Trane Tracer Summit or a 3rd party building automation system that supports

LonTalk. The Space Comfort Controller (SCC) is the profile assigned to the VV550 controller.

VAV VV550 Controller Outputs

VAV VV550 Controller Triac outputs for controlling a fan or reheat are rated at 12 VA each.

Wiring Diagram

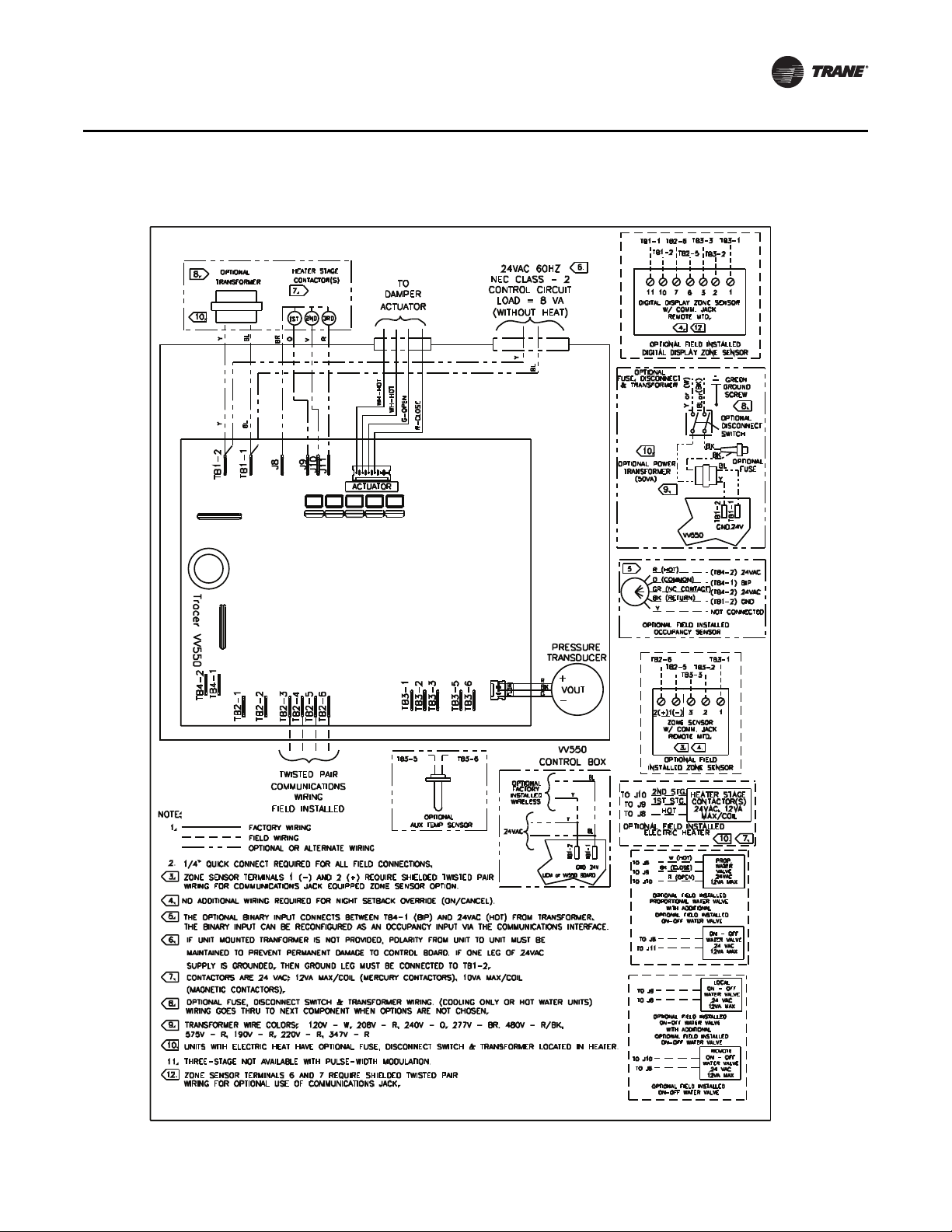

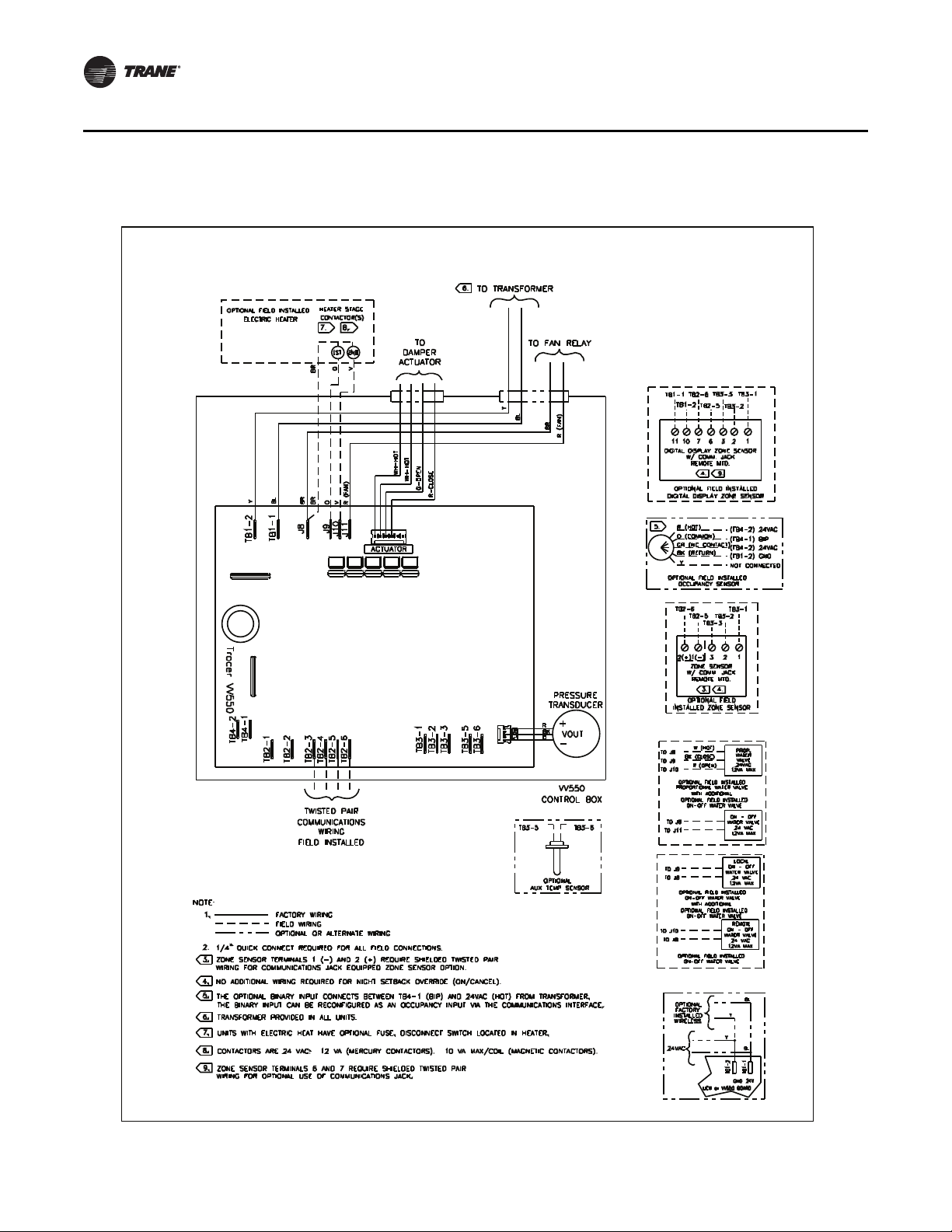

Figure 2, p. 17 shows a typical wiring diagram for the redesigned VAV VV550 hardware. The new

service part number is BRD2960.

10 VAV-SVP01A-EN

Page 11

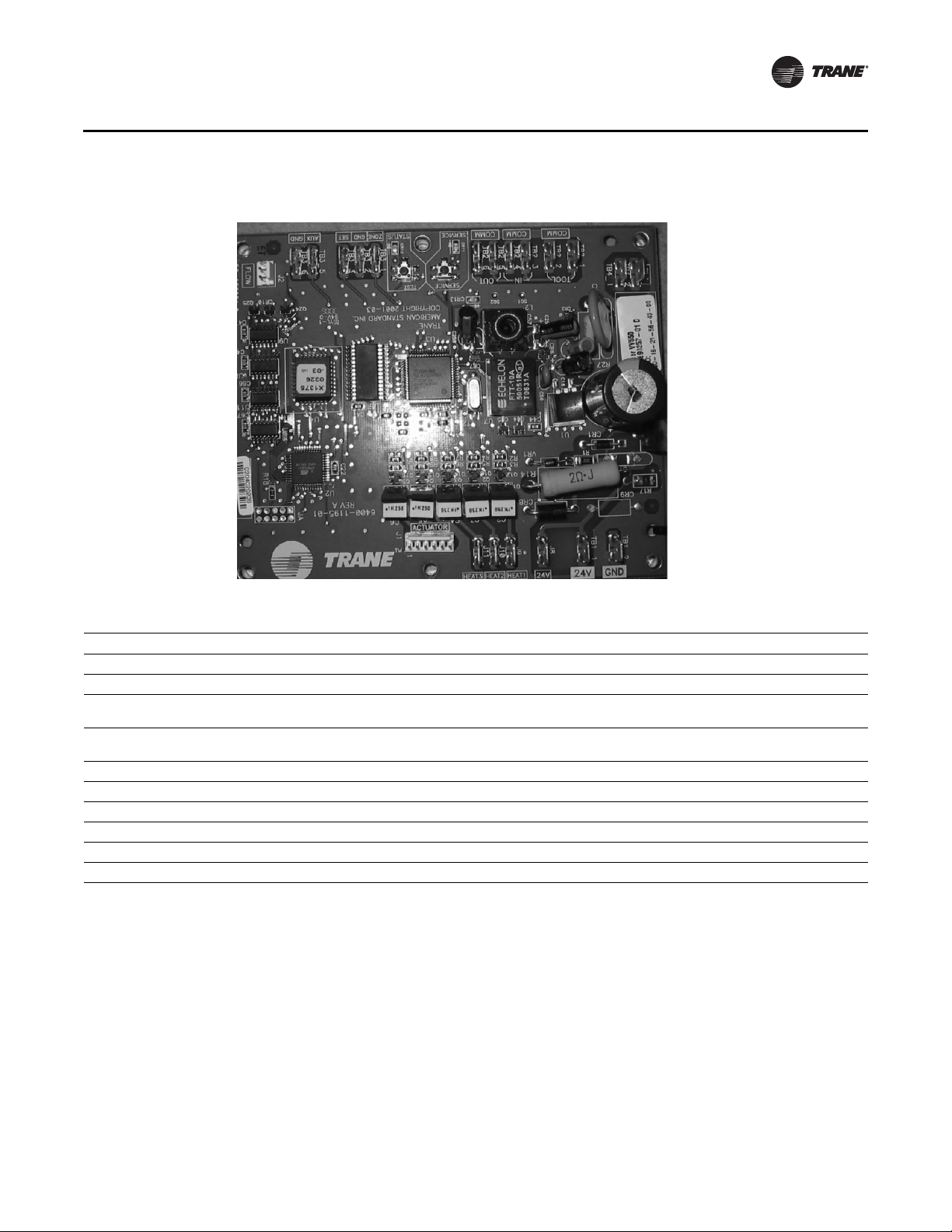

Figure 1. VV550 board layout

General Information

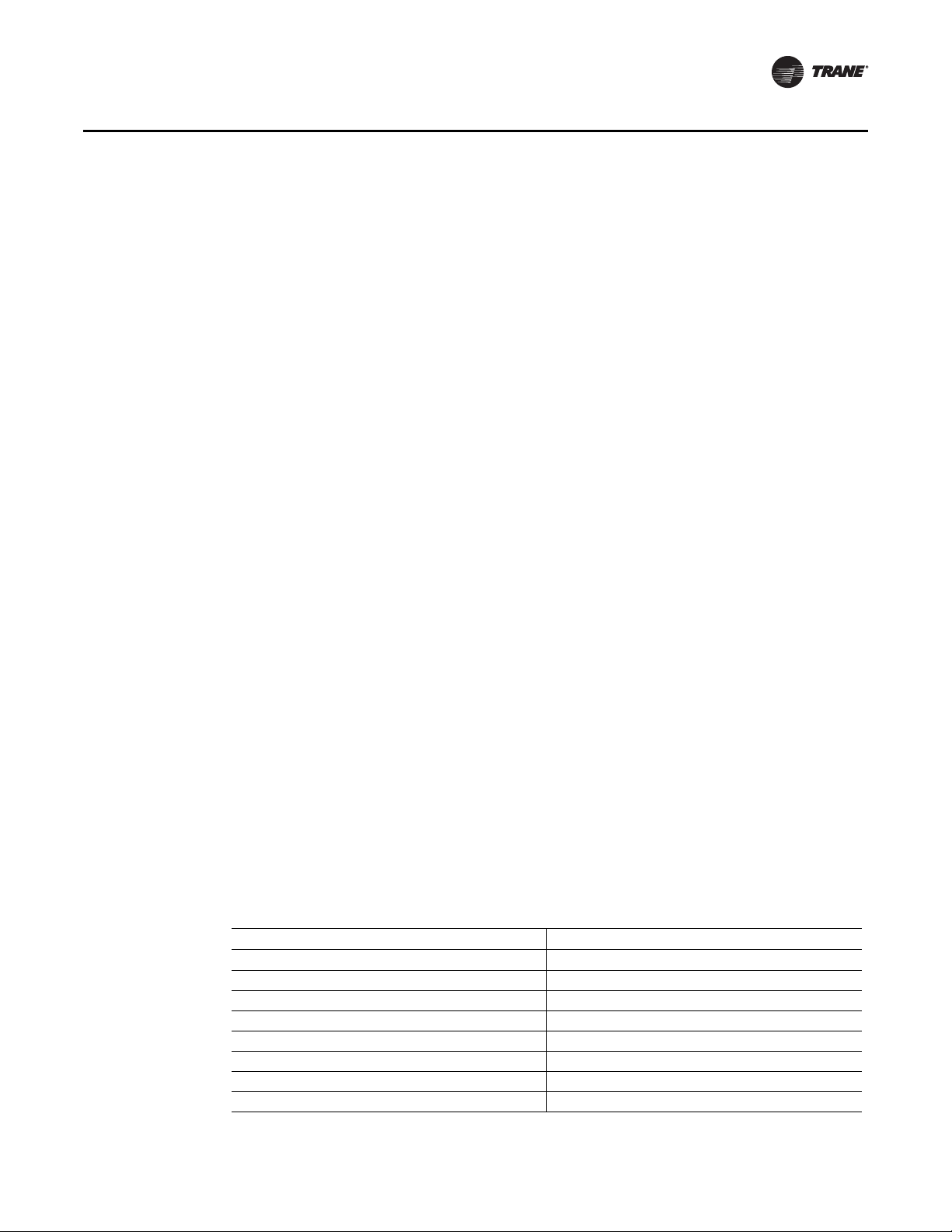

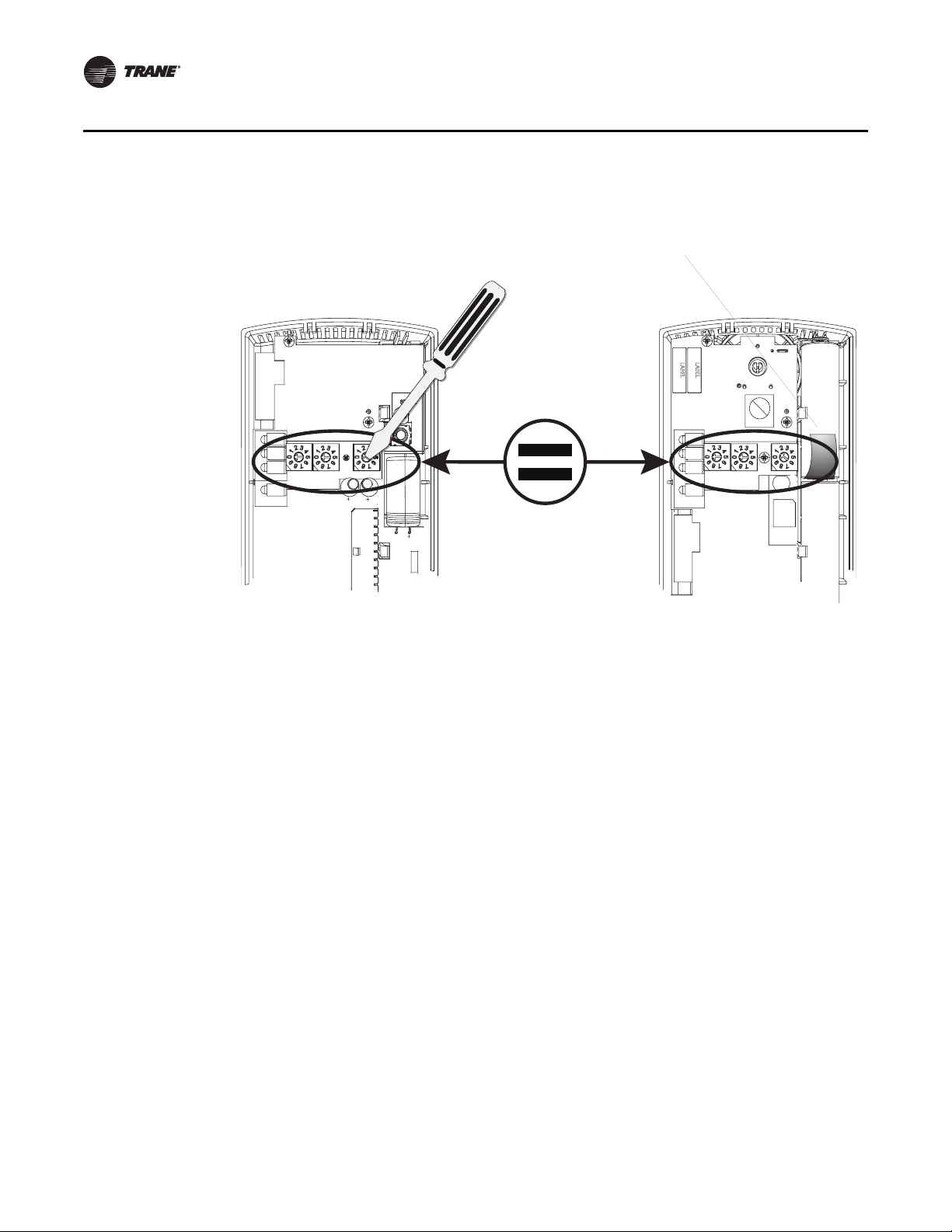

VAV VV550 controller and VAV 4.2 controller comparisons

VAV VV550 VAV 4.2

Supports Comm5 Supports only Comm4 or Comm3 (VariTrac or VariTrane)

No local CO2 sensor input. Uses only a communicated value Local CO2 sensor input is available.

Single star (*) initiates cool minimum airflow override.

Double star (**) initiates cool maximum airflow override.

Does not support VariTrac central control panel (CCP2 and CCP3). Does not support VariTrac CCP2 and CCP3.

Supports ventilation flow control Does not support ventilation flow control.

Supports flow tracking control. Does not support flow tracking control.

Supports enhanced ventilation control sequences. Does not support enhanced ventilation control sequence.

Supports auto-commissioning sequence. Does not support auto-commissioning sequence.

Supports zone sensor air balance sequences. Does not support zone sensor air balance sequence.

Single star (*) initiates maximum flow override after pressing the ON

button. Override is held until you move the thumbwheel.

Double star (**) initiates unoccupied override after pressing the ON

button. Override is held until you move the thumbwheel.

Shipping & Storage

Each VAV product and its service literature are shipped in the same package. When unpacking,

make sure that the literature is not lost or discarded with the packing material. Visually inspect the

individual components for obvious defects or damage. All components are thoroughly inspected

before leaving the factory. Any claims for damage incurred during shipment must be filed with the

carrier.

When any component of the VAV system and/or field installed accessories must be stored for a

period of time prior to being installed, they must be protected from the elements. The storage

location temperature should be between -40° to 150°F (-40° to 65.6°C) and the relative humidity

should be 10% to 90%, non-condensing. The warranty will not cover damage to the VAV system or

controls due to negligence during storage. A controlled indoor environment must be used for

storage.

VAV-SV P01A-E N 11

Page 12

General Information

Data Lists

If you’re going to connect to a generic building automation system, use Table 1, p. 12 and Ta bl e 2 ,

p. 13 for your points list.

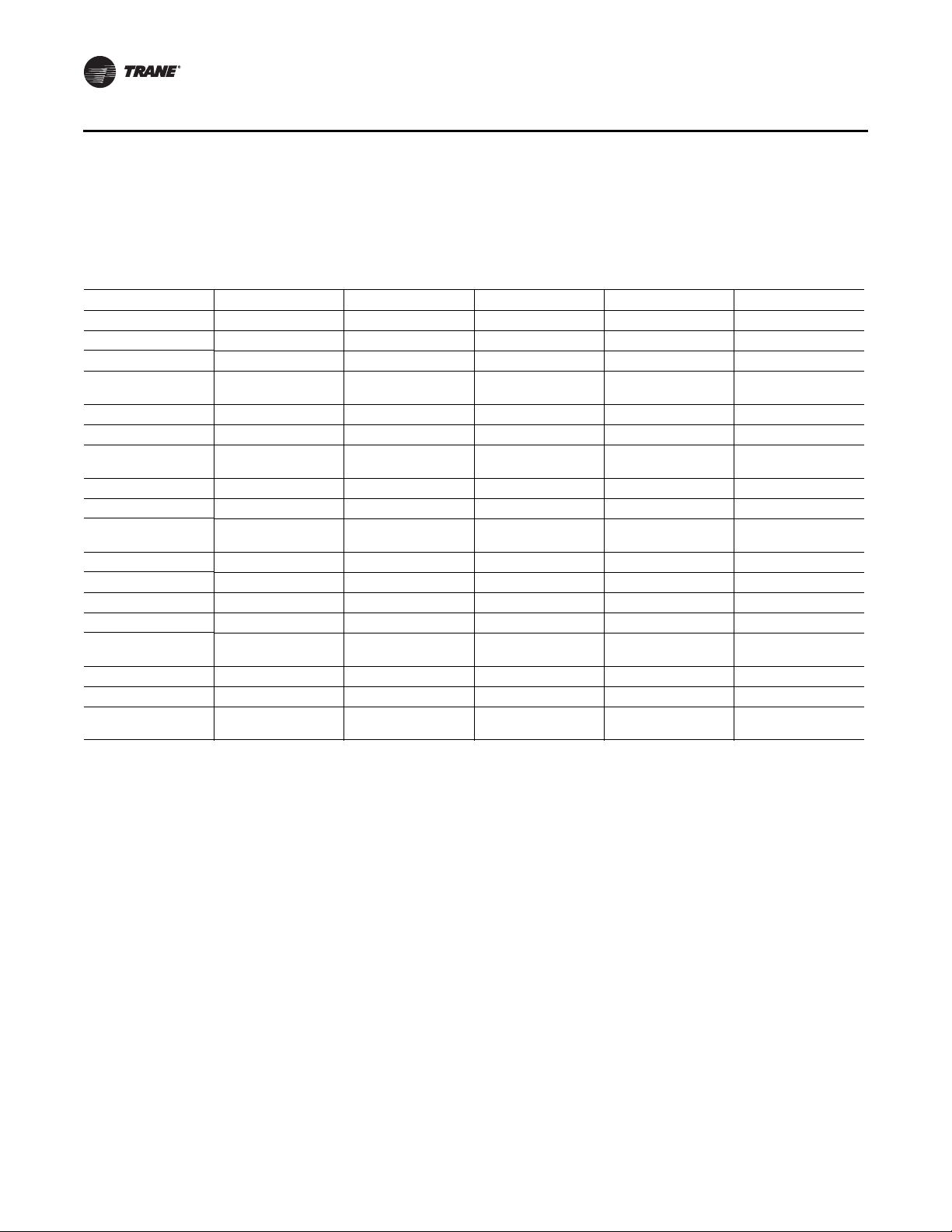

Table 1. Input/output listing

Input Description Input SNVT type Output description Output SNVT type

Space temperature nviSpaceTemp SNVT_temp_p Space temperature nvoSpaceTemp SNVT_temp_p

Setpoint nviSetpoint SNVT_temp_p Unit status, mode nvoUnitStatus SNVT_hvac_status

Occupancy, schedule nviOccSchedule SNVT_tod_event Effective setpoint nvoEffectSetpt SNVT_temp_p

Occupancy, manual

command

Occupancy sensor nviOccSensor SNVT_occupancy Heat cool mode nvoHeatCool SNVT_hvac_mode

Application mode nviApplicMode SNVT_hvac_mode Setpoint nvoSetpoint SNVT_temp_p

Heat/cool mode input nviHeatCool SNVT_hvac_mode

Fan speed command nviFanSpeedCmd SNVT_switch Terminal load nvoTerminalLoad SNVT_lev_percent

Auxiliary heat enable nviAuxHeatEnable SNVT_switch Space CO

Valve override nviValveOverride SNVT_hvac_overid

Flow override nviFlowOverride SNVT_hvac_overid Air flow nvoAirFlow SNVT_flow

Emergency override nviEmergOverride SNVT_hvac_emerg File table address nvoFileDirectory

Source temperature nviSourceTemp SNVT_temp_p Object status nvoStatus

Space CO

Clear alarms/

diagnostics

Air flow setpoint input nviAirFlowSetpt SNVT_flow

Ventilation ratio limit nviVentRatioLim SNVT_lev_percent

Ventilation for the zone

input

(a) Part of the node object.

2

nviOccManCmd SNVT_occupancy Effective occupancy nvoEffectOccup SNVT_occupancy

nviSpaceCO

nviRequest

nviVentSetpt SNVT_flow

2

(a)

SNVT_ppm Alarm message nvoAlarmMessage SNVT_str_asc

SNVT_obj_request

Discharge air

temperature

2

Effective air flow

setpoint

nvoDischAirTemp SNVT_temp_p

nvoSpaceCO2 SNVT_ppm

nvoEffectFlowSP SNVT_flow

(a)

SNVT_address

(a)

SNVT_obj_status

12 VAV-SV P01A -EN

Page 13

General Information

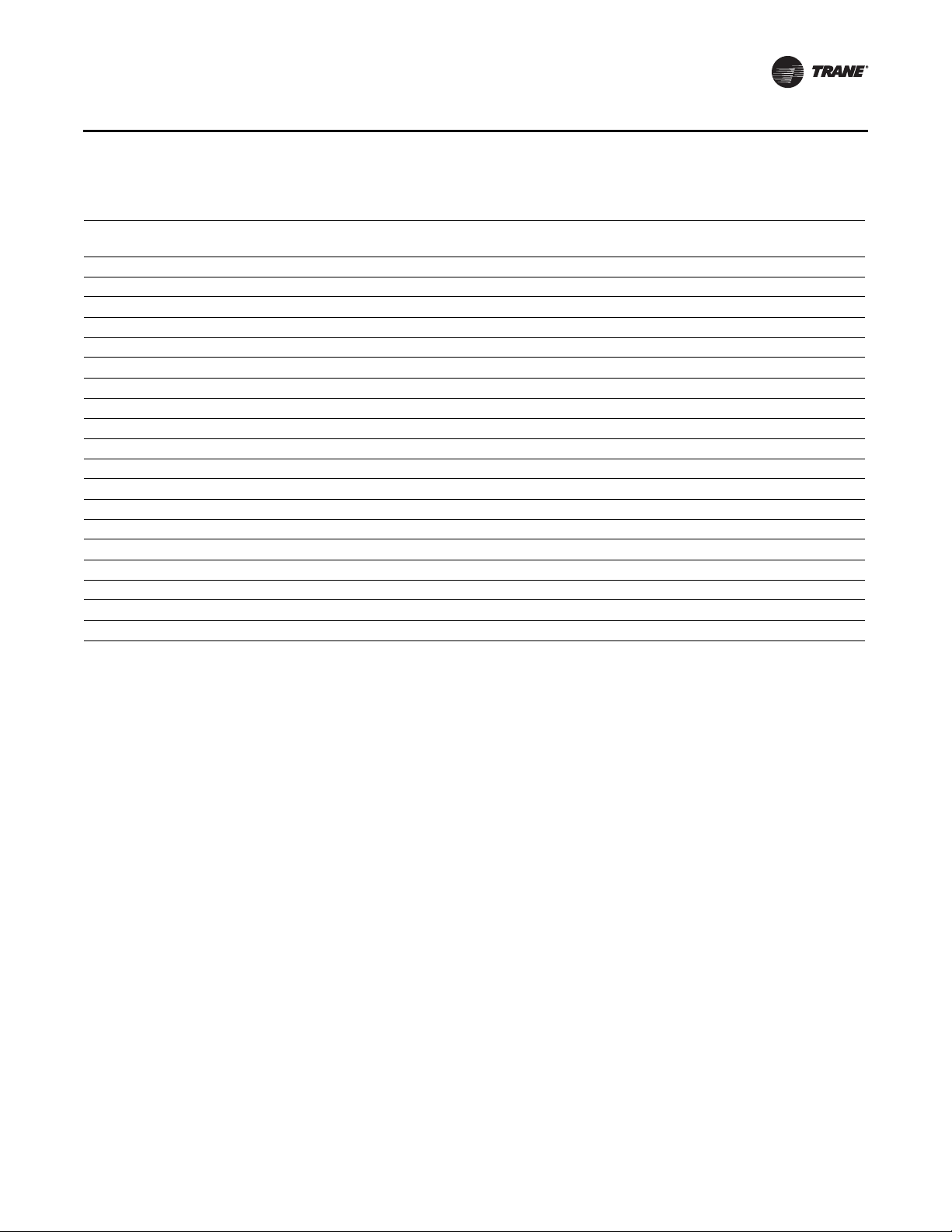

Table 2. Configuration properties

Configuration property

description Configuration property SNVT type SCPT reference

Send heartbeat nciSndHrtBt SNVT_time_sec SCPTmaxSendTime (49)

Occ temperature setpoints nciSetpoints SNVT_temp_setpt SCPTsetPnts (60)

Minimum send time nciMinOutTm SNVT_time_sec SCPTminSendTime (52)

Receive heartbeat nciRecHrtBt SNVT_time_sec SCPTmaxRcvTime (48)

Location label nciLocation SNVT_str_asc SCPTlocation (17)

Local bypass time nciBypassTime SNVT_time_min SCPTbypassTime (34)

Manual override time nciManualTime SNVT_time_min SCPTmanOverTime (35)

Space CO

Nominal air flow nciNomFlow SNVT_flow SCPTnomAirFlow (57)

Air flow measurement gain nciFlowGain SNVT_multiplier SCPTsensConstVAV (67)

Minimum air flow nciMinFlow SNVT_flow SCPTminFlow (54)

Maximum air flow nciMaxFlow SNVT_flow SCPTmaxFlow (51)

Minimum air flow for heat nciMinFlowHeat SNVT_flow SCPTminFlowHeat (55)

Maximum air flow for heat nciMaxFlowHeat SNVT_flow SCPTmaxFlowHeat (37)

Minimum flow for standby nciMinFlowStdby SNVT_flow SCPTminFlowStby (56)

Firmware major version nciDevMajVer

Firmware minor version nciDevMinVer

Flow offset for tracking applications nciFlowOffset SNVT_flow_f SCPToffsetFlow (265)

Local heating minimum air flow nciMinFlowUnitHt SNVT_flow SCPTminFlowUnitHeat (270)

(a) Part of the node object

limit nciSpaceCO2Lim SNVT_ppm SCPTlimitCO2 (42)

2

(a)

(a)

n/a SCPTdevMajVer (165)

n/a SCPTdevMinVer (166)

VAV-SV P01A-E N 13

Page 14

VAV Start Up/Check Out Procedure

Chapter Overview

This chapter contains information about the following:

• VV550 Pre-Power Check-Out

• Power Wiring Requirements

• Light Emitting Diode (LED) Operations

• Communication Wiring

• Space Temperature Controller Analog Inputs

• Zone Sensor Wiring

• Auxiliary Sensor Wiring

• Binary Input Wiring

• Binary Output Wiring

• Ventilation Flow Control

• Auxiliary Sensor Wiring

• Flow Tracking Control

• Wireless Zone Sensor

VV550 Pre-Power Check-Out

WARN ING

Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it may be necessary to

work with live electrical components. Have a qualified licensed electrician or other individual who

has been properly trained in handling live electrical components perform these tasks. Failure to

follow all electrical safety precautions when exposed to live electrical components could result in

death or serious injury.

• Check the supply voltage at TB1. Proper polarity must be maintained. TB1-1 is the hot side (+)

and TB1-2 is the ground side (-) of the 24VAC input. Refer to Figure 2, p. 17 and Figure 3, p. 18

for the VAV VV550 Controller terminal locations. The VAV VV550 Controller cannot be powered

from a common 24VAC transformer that is supplying power to a device containing a full-wave

rectifier bridge in its power supply. The acceptable voltage is 18 to 32 VAC (24VAC cataloged).

However, voltages at either extreme may result in increased system instability.

• Verify that communications wiring has properly been terminated at TB2-1 (+) and TB2-2 (-).

Polarity is not important on the communications link.

• Verify that the zone sensor connections are correct as detailed in this IOP.

• If heat has been added to unit, verify that the proper output connections have been made as

detailed in this IOP.

• Verify that the tubing is properly connected to the transducer.

14 VAV-SVP01A-EN

Page 15

VV550 Power Wiring

Power Requirements

WARN ING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

WARN ING

Electrocution and Fire Hazards with Improperly Installed and Grounded

Field Wiring!

Improperly installed and grounded field wiring poses FIRE & ELECTROCUTION hazards. To avoid

these hazards, you MUST follow requirements for field wiring installation and grounding as

described in the National Electrical Codes (NEC) and your local/state electrical codes. All field

wiring MUST be performed by qualified personnel. Failure to follow these requirements could

result in death or serious injury.

Notice:

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of conductors. Failure to use copper

conductors could result in equipment damage.

VAV Start Up/Check Out Procedure

Use at least 16 AWG for power wiring and connect to terminal TB1-1 (+) and TB1-2 (-). 24VAC is

required to power the VAV VV550 Controller and has an acceptable voltage tolerance of 18 to 32

VAC. Refer to Figure 2, p. 17 and Figure 3, p. 18 for the VAV VV550 Controller terminal locations.

Replace the VAV VV550 Controller control box cover after field wiring to prevent any

electromagnetic interference.

Note: A dedicated 24VAC, 50VA NEC class 2 transformer is recommended to power the VAV VV550

Controller. When powering multiple VAV VV550 Controllers from one transformer, polarity

must be maintained. Terminal TB1-1 is designated positive (+) and terminal TB1-2 is

negative (-) to the unit casing ground

The power consumption for cooling only Series F Models (VariTrac and VariTrane) is 12 VA (4 VA

for the air valve/actuator and 8 VA for the VV550 control board). To determine the total VAV VV550

Controller power requirement, add the power consumption per stage to the circuit board power

requirement. For example, a Series F unit containing magnetic contactors with three stages of

reheat would consume 42 VA.

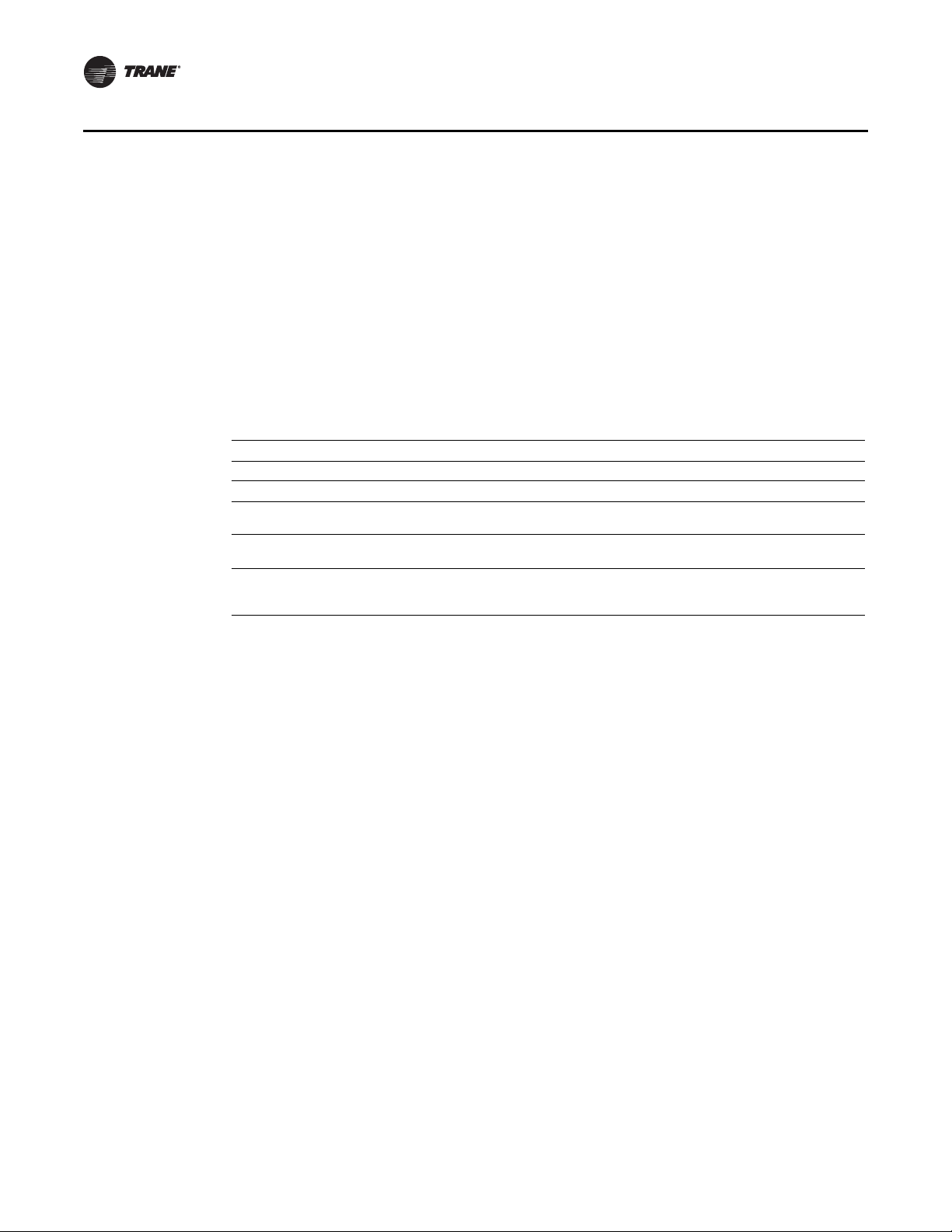

Table 3. VA for factory-installed components

Style Volt Amps

F - Style Actuator 4 VA

Air Valve Actuator C through E Style 12 VA

Varitrac Actuator 3 VA

Fan Power Fan Output 6 VA

Hot Water Proportional 4 VA

Hot Water 2 Position 6.5 VA

Electric Heater Magnetic Contactor 10 VA

Electric Heater Mercury Contactor 12 VA

VAV-SV P01A-E N 15

Page 16

VAV Start Up/Check Out Procedure

Note: VariTrane and VariTrac cooling only Series D and E models consume 20 VA (12 VA for the

actuator and 8 VA for the board). The heating output ratings remain the same.

Refer to Figure 2, p. 17 and Figure 3, p. 18 for VAV VV550 Controller terminal locations and

Figure 59, p. 107 through Figure 66, p. 114 for wiring of output devices.

Light Emitting Diode (LED) Operations

Green Status LED

The green status LED is typically used to indicate whether or not the controller is powered On

(24VAC). This is the only LED under direct software control. The green status LED is Off when you

press the Test button. The green status LED blinks during manual output testing. Table 4, p. 16

shows and describes the green status LED activity.

Table 4. Green status LED activity

Green status LED activity Description

On Power On, normal operation

Off One of the following: Power Off Controller failure Test button pressed

Blinking for 10 seconds,

0.25 seconds Off; 0.25 seconds On

One blink continuously,

0.25 seconds Off; 2.25 seconds On

Two blinks continuously,

0.25 seconds Off; 0.25 seconds On

0.25 seconds Off; 1.75 seconds On

(a) The wink feature enables you to identify a controller. By sending a request from the Rover service tool, you can request

the controller to wink.

(b) See the diagnostic topic in this guide for a complete list of output override diagnostics.

Wink mode

The controller is in the manual output test mode and no output-override unit

diagnostic2 conditions

The controller is in the manual output test mode and one or more outputoverride unit diagnostic

(a)

(b)

conditions exist

16 VAV-SV P01A -EN

Page 17

Figure 2. VV550 single duct control diagram

VAV Start Up/Check Out Procedure

VAV-SV P01A-E N 17

Page 18

VAV Start Up/Check Out Procedure

Figure 3. VV550 fan-powered control diagram

18 VAV-SV P01A -EN

Page 19

Communication Wiring

WARN ING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

WARN ING

Electrocution and Fire Hazards with Improperly Installed and Grounded

Field Wiring!

Improperly installed and grounded field wiring poses FIRE & ELECTROCUTION hazards. To avoid

these hazards, you MUST follow requirements for field wiring installation and grounding as

described in the National Electrical Codes (NEC) and your local/state electrical codes. All field

wiring MUST be performed by qualified personnel.

Failure to follow these requirements could result in death or serious injury.

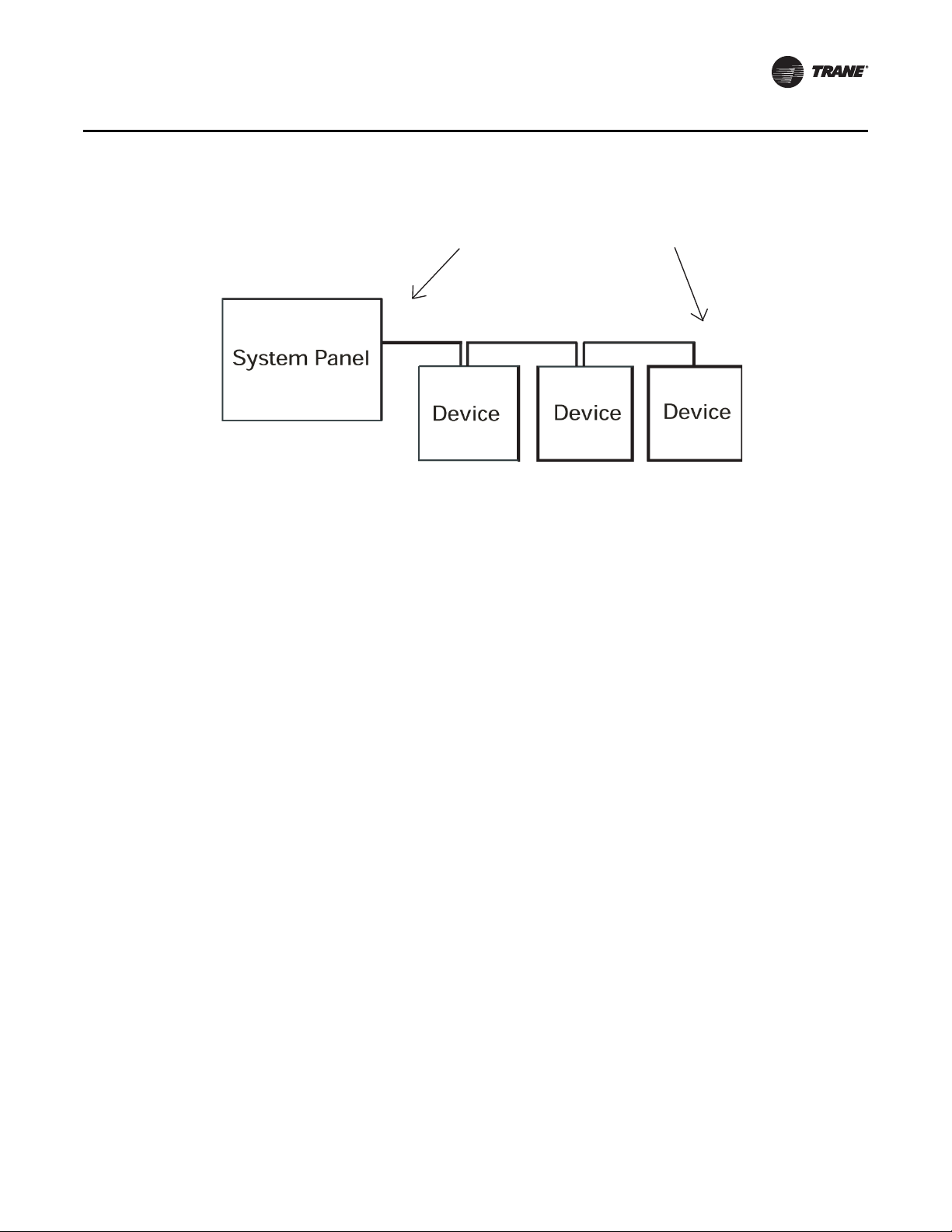

Communication Link Wiring

• Use 22 AWG Level 4 unshielded communication wire for most Comm5 installations.

• Limit Comm5 links to 4,500 ft and 60 devices maximum (without a repeater).

• Use the following termination resistors on all links:

•105

• Use daisy chain topology.

• Limit zone sensor communication stubs to 8 per link, 50 ft each maximum.

• Use one repeater for an additional 4,500 ft, 60 devices, and 8 communication stubs.

Ω at each end for Level 4 wire

VAV Start Up/Check Out Procedure

Recommended Wiring Practices

To ensure proper network communication, follow these recommended wiring and planning

guidelines when installing communication wire:

• All wiring must comply with the National Electrical Code (NEC) and local codes.

• Although Comm5 does not require polarity sensitivity, Trane recommends keeping polarity

consistent throughout the site.

• Make sure that 24VAC power supplies are consistent in how they are grounded. Avoid sharing

24VAC between Comm5 controllers.

• Avoid over tightening cable ties and other forms of cable wraps. This can damage the wires

inside the cable.

• Do not run Comm5 cable alongside or in the same conduit as 24VAC power. This includes the

conductors running from triac-type inputs.

• In open plenums, avoid running wire near lighting ballasts, especially those using 277 Vac.

• Use a daisy chain configuration.

• Use termination resistors as described in "Termination resistance placement for Comm5 links"

• Insulate termination-resistor leads.

• Use only one type of communication wire; do not mix different types

VAV-SV P01A-E N 19

Page 20

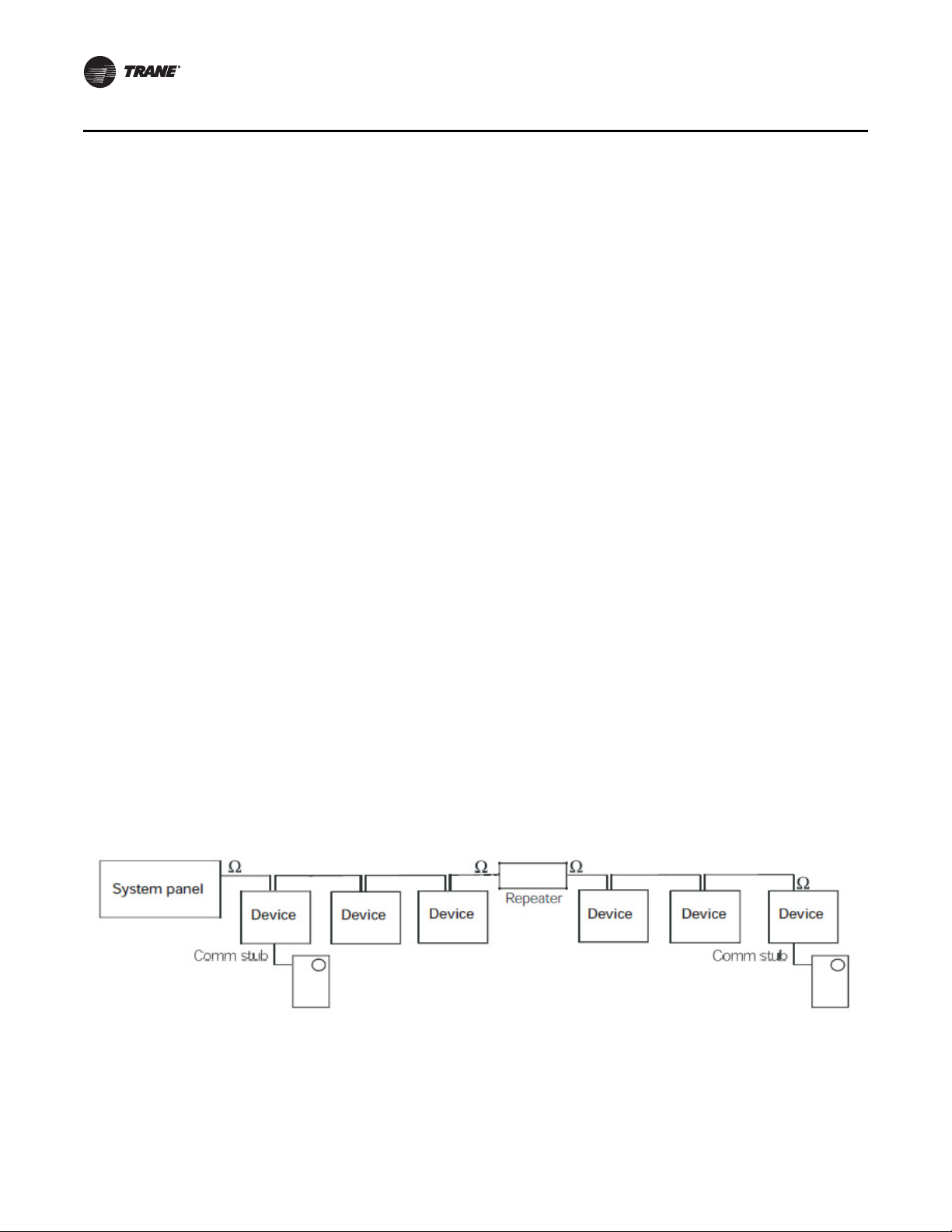

VAV Start Up/Check Out Procedure

Wiring requirements

The recommended Comm5 communication-link wiring is 22 AWG, Level 4, twisted-pair wire. See

Ta ble 5 , p. 2 0 "Specifications for Level 4-compliant cables". The wire can be either shielded or

unshielded. However, unshielded wire is recommended for most installations.

The maximum wire length for Comm5 communication links is 4,500 ft (1,400 m). Comm5

communication-link wiring must be installed in a daisy-chain configuration (Figure 4, p. 21 and

Figure 5, p. 22).

Table 5. Cable specifications

Specification Value

dc resistance

(Maximum resistance of a single copper conductor regardless of whether or not it is solid or stranded and regardless

of whether or not it is metal coated.)

dc resistance unbalance (maximum) 5%

Mutual capacitance of a pair (maximum) 17 pF/foot

Pair-to-ground unbalance (maximum) 1,000 pF/foot/1,000 ft

Characteristic impedence

Attenuation (maximum dB/1,000 ft at 20°C)

Worst-pair near-end crosstalk (minimum)

(Values shown are for information only. The minimum NEXT coupling loss for any pair combination at

room temperature is to be greater than the value determined using the formula NEXT (F

(0.772)-15

ft.)

dc resistance unbalance (maximum) 5%

log10

(F

/0.72) for all frequencies in the range of 0.772 MHz-20 MHz for a length of 1,000

MHz

MHz

)>NEXT

772 kHz 102 Ω

1.0 MHz 100 Ω

4.0 MHz 100 Ω

8.0 MHz 100 Ω

10.0 MHz 100 Ω

16.0 MHz 100 Ω

20.0 MHz 100 Ω

772 kHz 4.5 dB/1,000 ft at 20°C

1.0 MHz 5.5 dB/1,000 ft at 20°C

4.0 MHz 11.0 dB/1,000 ft at 20°C

8.0 MHz 15.0 dB/1,000 ft at 20°C

10.0 MHz 17.0 dB/1,000 ft at 20°C

772 kHz 58 dB

1.0 MHz 56 dB

4.0 MHz 47 dB

8.0 MHz 42 dB

10.0 MHz 41 dB

16.0 MHz 38 dB

20.0 MHz 36 dB

18.0 Ω/1,000 ft 20°C

± 15%

± 15%

± 15%

± 15%

± 15%

± 15%

± 15%

20 VAV-SVP01A-EN

Page 21

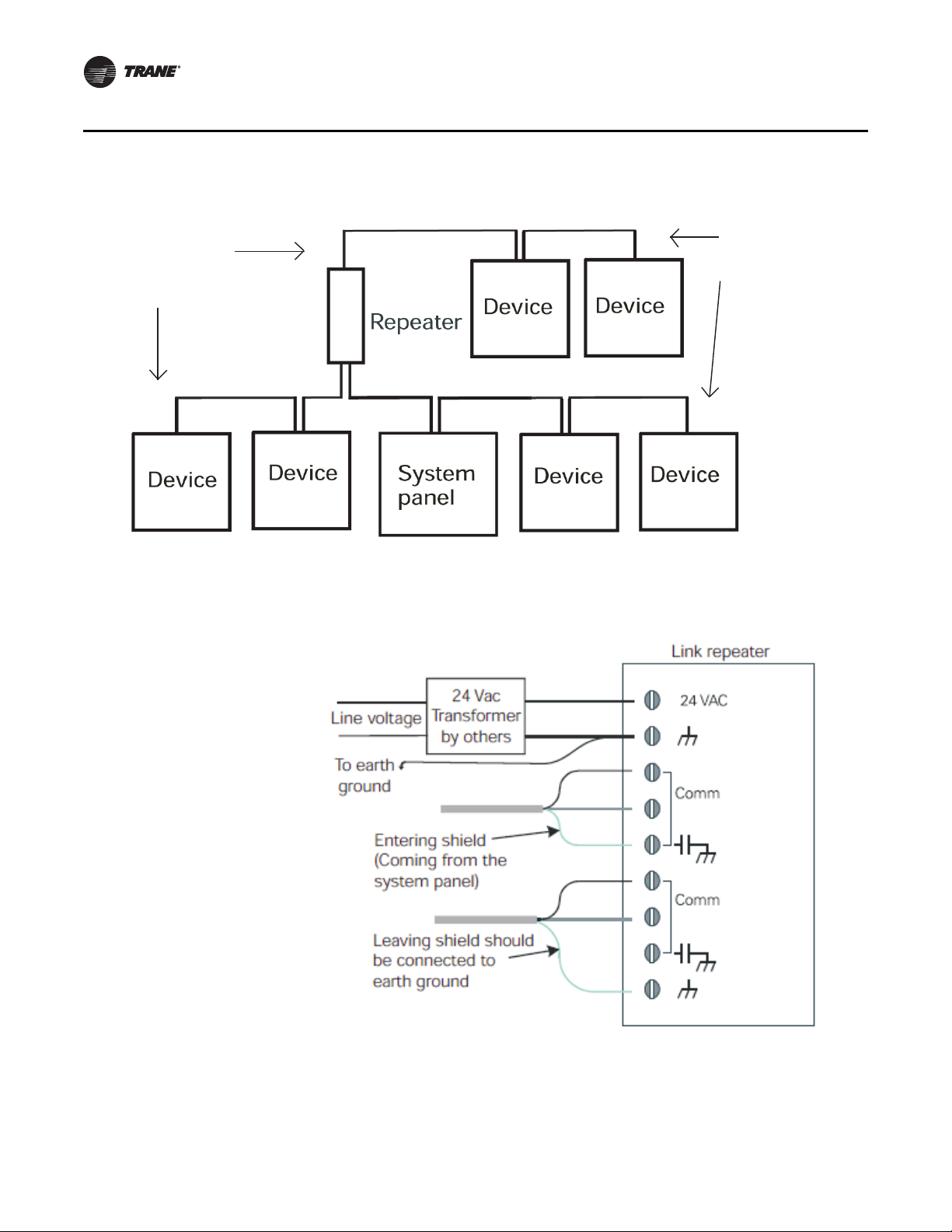

Figure 4. Daisy chain configuration

Note: Use 105 Ω, 1%, 1/4 W for 22 AWG, Level 4.

Comm5 Link Repeater

A Comm5 link repeater regenerates the signal on a Comm5 link. The configurations on either side

of the repeater should be daisy chain. Both link segments require proper termination (Figure 5,

p. 22).

VAV Start Up/Check Out Procedure

Termination Resistor

Ω

Ω

Link repeater requirements.

A link repeater is required when:

• The total wire length is greater than the maximum wire run length of 4,500 ft (1,400 m).

• More than 60 devices are connected to a link-This total does not include the BCU, the link

repeater, and the temporary use of a service tool on the same link.

• More than eight zone sensor communication stubs (maximum 50 ft) are required on a Comm5

link

Link repeater connections.

The recommended shield connections are shown in Figure 6, p. 22. Use these connections for

instances where shielded communication wire is used. For an example of using a repeater to create

an extended daisy chain configuration, see Figure 5, p. 22.

Follow these guidelines when using a repeater:

• Read the Comm5 repeater installation (3270 3285) information that comes with the link

repeater.

• For information about terminating daisy chain configurations, see "Termination resistance

placement for Comm5 links" onFigure 4, p. 21.

• Connect shield-drain wires entering the repeater to a terminal marked with a capacitor symbol.

The entering shield-drain wire must be connected to earth ground at the system panel.

• Connect shield-drain wires leaving the repeater to the repeater terminal marked with an earth

ground symbol.

VAV-SV P01A-E N 21

Page 22

VAV Start Up/Check Out Procedure

Ω

Ω

Ω

Ω

Termination

Resistors

Termination

Resistors

Figure 5. Alternate daisy chain configuration

Notes:

1. Maximum wire length for the entire configuration is 4,500 ft (1,400 m).

2. Comm5 wire length limitations can be extended through the use of a link repeater, see “Comm5 physical link repeater.”

Figure 6. Comm5 shield repeater connection

22 VAV-SVP01A-EN

Page 23

VAV Start Up/Check Out Procedure

Yellow Comm LED

The yellow Comm5 LED blinks whenever another controller is transmitting. However, the yellow

Comm5 LED does not blink when the controller is transmitting data. The yellow Comm5 LED cannot

distinguish between messages meant for the controller and messages that the controller ignores.

Ta ble 6 , p. 2 3 shows and describes the yellow Comm LED activity.

Table 6. Yellow comm LED activity

Yellow Comm LED activity Description

LED Off continuously The controller is not detecting communication. (Normal for stand-alone applications.)

LED blinks or flickers The controller detects communication. (Normal for communicating applications, including data sharing.)

LED On continuously Abnormal condition or extremely high traffic on the link.

Table 7. Red service LED activity

Red service LED activity Description

LED is Off continuously after power is applied to the controller. Normal operation

LED is On continuously, even when power is first applied to the

controller.

LED flashes about once every two seconds. Uninstalled (normal controller mode). Use the Rover service tool to restore

Someone is pressing the Service push button or the controller failed.

the unit to normal operation. Refer to the Rover product literature for more

information.

Service Push Button

Important: If the Service button is held down for more than 15 seconds, the controller will

uninstall itself from the Comm5 network. The red service LED flashing

approximately once two every seconds indicates this mode (see Red service LED

above). Use the Rover service tool to restore the unit to normal operation. Refer the

Rover product literature for more information.

The Service push button can be used, as one of several methods, to install the controller in a

communication network. Refer to the Rover service tool product literature EMTX-SVX01*-EN for

more information.

Space temperature controller Analog Inputs

Zone Sensor Hardwired Option. Depending on the zone sensor options used, a maximum of

five wires may be required to run from the VAV VV550 Controller to the zone sensor. The zone

sensor options are:

• Zone sensor only (2 wires) - Part Number X13511528010.

• Sensor with night set back- Part Number X13511530010.

• Zone sensor with external adjustable - Part Number X13511529010.

• Zone sensor with external adjustable night set back, timed override (TOV) on/cancel button Part Number X13511527010.

• Digital zone sensor - Part Number X13511530010

• Communications jack - Part Number X13651467020 (for one box of 12)

Note: All wiring from the zone sensor to the Com link must be twisted shielded pair wiring.

VAV-SV P01A-E N 23

Page 24

VAV Start Up/Check Out Procedure

Zone Sensor Wireless Option (Wireless Zone Sensor). Receiver is used to receive a signal

from the wireless zone sensor and can be factory installed- Part Number X13790855010. The wiring

harness connects the receiver to the VAV VV550 Controller - Part Number X19051672010.

Zone Sensor Wireless Option (Zone Sensor). The wireless zone sensor with night setback

timed override (TOV) on/cancel button. Also can be ordered for Celsius and Fahrenheit setpoint

adjustment - Part Number X13790492010 (F), Digital Display wireless zone sensor- Part Number

X13790822010

Zone Sensor Wiring

Location and Mounting. A zone sensor in each control zone should be located in the most

critical area of the zone. Sensors should not be mounted in direct sunlight or in the area's supply

air stream. Subdivision of the zone may be necessary for adequate control and comfort. Avoid

mounting zone sensors in areas subject to the following:

• Drafts or "dead spots" behind doors or corners.

• Hot or cold air ducts.

• Radiant heat from the sun or appliances.

• Concealed pipes or chimneys.

• Unheated or uncooled surfaces behind the sensor such as outside walls.

• Air flows from adjacent zones or other units.

Wiring. Each unit must be controlled by a zone sensor that is designated specifically for use with

the VAV VV550 Controller. Field wiring for the zone sensors must meet the following requirements:

• Must be 14 to 18 AWG.

•Refer to Figure 2, p. 17 and Figure 3, p. 18 and the sensor instructions for terminal connections.

• If local codes require enclosed conductors, the zone sensor wires should be installed in conduit.

Do not route zone sensor wires in conduit with 24VAC or other high power conducting wires.

Zone sensor comm stubs. For the most reliable communications, limit the number of zone

sensor communication stubs to 8 per Comm5 link unless using a repeater then it is 16 stubs. Each

stub should not exceed 50 feet. Exceeding these limits increases the likelihood of communication

problems. Connect Communication wire to terminals TB2-5 and TB2-6 on VV550 controller and to

comm. Jack in zone sensor

Figure 7. Communication stubs used with a repeater

Notes:

1. Maximum wire length on either side of the repeater is 4,500 ft (1,400 m).

2. The link repeater is limited to 60 devices on either side of the link.

3. Place termination resistors at the end of the link. Use a 105 X resistor at each end of the link for Level 4 wire

24 VAV-SVP01A-EN

Page 25

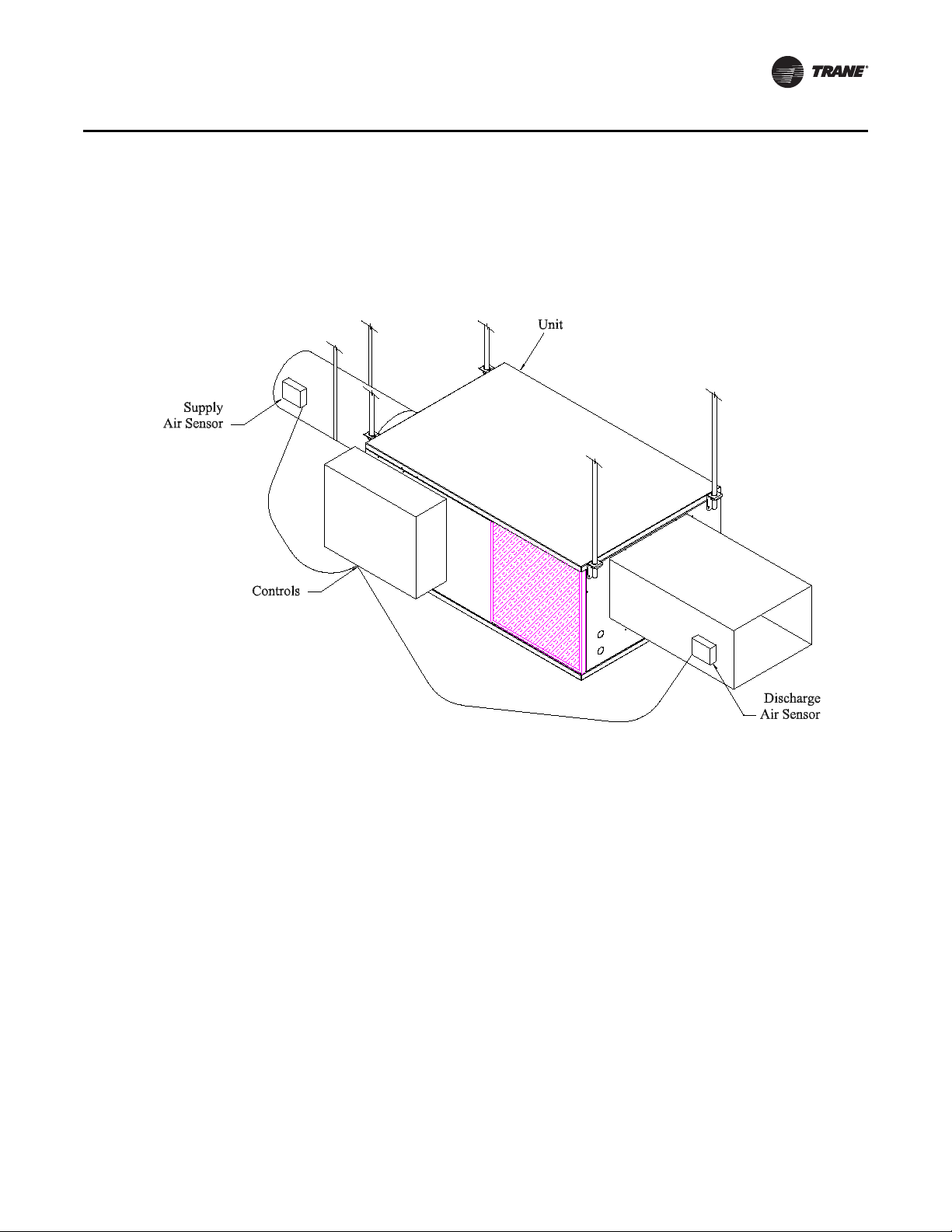

Auxiliary Duct Temperature Sensor

The typical mounting position of the auxiliary sensor is upstream of the VAV unit and connected

into the DDC controller at TB3-5 and TB3-6. Comm5 could be mounted downstream of the reheat

for improved diagnostics (Figure 8, p. 25). Refer to Controller Diagrams Figure 2, p. 17 and

Figure 3, p. 18 for the VAV VV550 Controller terminal locations.

Figure 8. Duct temperature sensors: upstream/downstream

VAV Start Up/Check Out Procedure

Binary Input Wiring

Each VAV VV550 Controller provides one binary input. On the VV550 factory-installed controller, the

binary input configuration is set up at the factory. The binary input can be configured with Rover

service tool as occupancy or generic or not used. The input associates 0 Vac with open contacts and

24VAC with closed contacts. It is activated by a dry contact switch closure.

• Must be 14 to 18 AWG.

•Refer to Figure 2, p. 17 and Figure 3, p. 18 and the sensor instructions for terminal connections.

Occupancy Binary Input. The occupancy binary input can be configured as NO or NC. Occupied

is the normal state. It is also the initial state at power-up and after a reset. Unoccupied is the other

state. If the binary input is configured as generic, the default occupancy mode is occupied.

Generic Binary Input. The generic binary input can be configured as NO or NC. Normal state is

inactive and is also the initial state at power-up and after a reset. Active is the other state.

Not Used Input. When no device is connected to the input, configure the controller input as not

used.

Binary Outputs Wiring

Binary outputs that are required for unit operation are factory wired and commissioned.

VAV-SV P01A-E N 25

Page 26

VAV Start Up/Check Out Procedure

Ventilation Flow control

See Auxiliary Duct Temperature Sensor wiring on Space temperature controller Analog Inputs

Note: If heat is installed Auxilary sensor will be located at the discharge of the VAV unit.

Flow Tracking Control

Two controls are used in Flow tracking controller. One is configured with the Space temperature

control program and the other controller will be set up as flow tracking controller and it will not

need any input or output device connected to the controller. See Operation section for details.

26 VAV-SVP01A-EN

Page 27

Wireless Zone Sensor

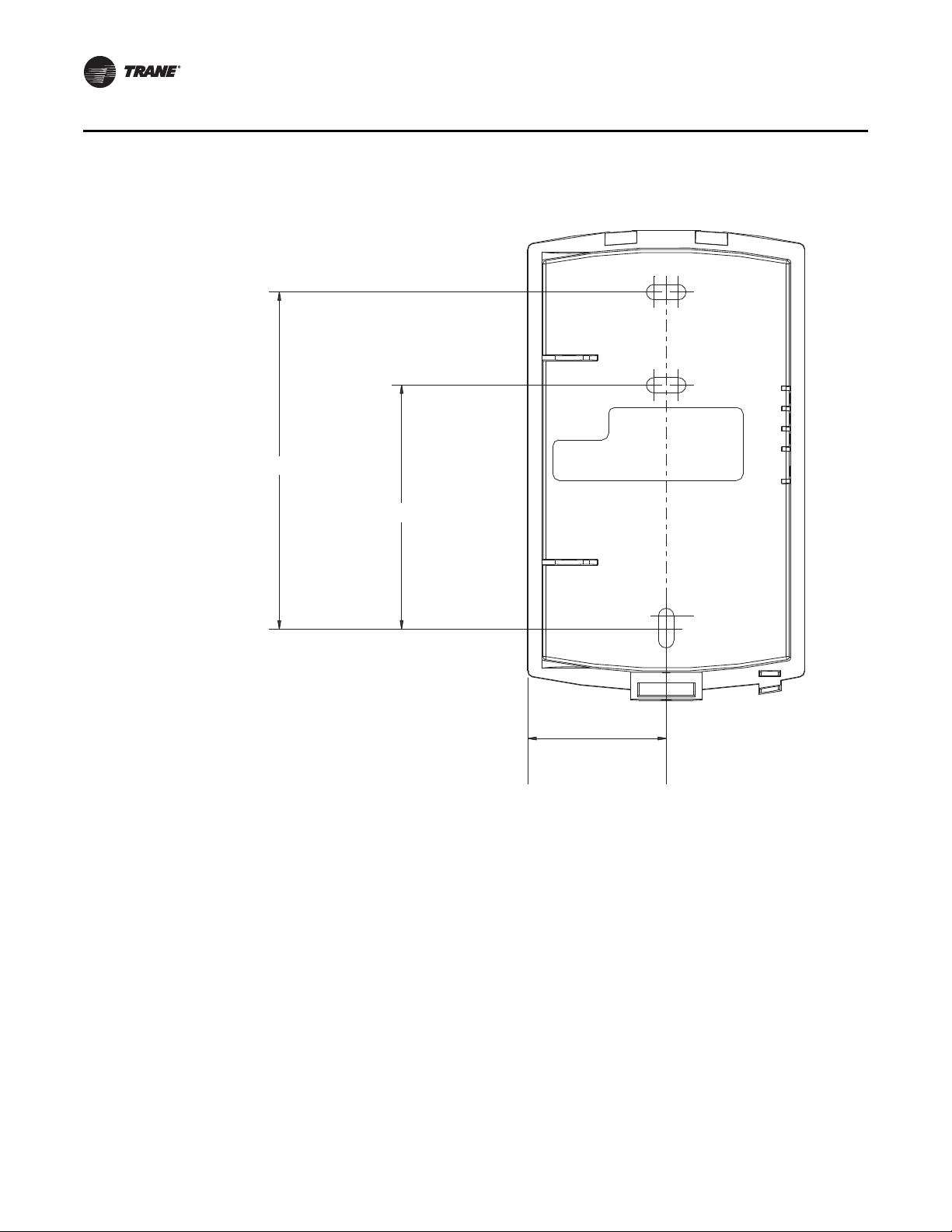

2.90 in (7.35 cm)

1.08 in (2.75 cm)

4.78 in (12.14 cm)

2.62 in (6.65 cm)

Note: The dimensions are the

same for both the sensor

and the receiver.

Overview

The Trane Wireless Zone Sensor set includes a sensor and a receiver that work together to provide

the same functions as the equivalent Trane wired sensor, such as the standard 10 k temperature

input (with the exception of the communication jack). No further software or hardware is necessary

for site evaluation, installation, or maintenance.

The sensor transmits the zone temperature, all zone temperature setpoint functions, timed override

Occupied (On) and timed override Unoccupied (Cancel) information to the receiver. The receiver

electrically reproduces the zone temperature resistance, all zone temperature setpoint function

resistances, and timed override On and timed override Cancel information as sent by the sensor.

Dimensional Diagrams

See Figure 9, p. 27 and Figure 10, p. 28 for dimensions of the Wireless Zone Sensor set. The

dimensions are the same for both the sensor and the receiver.

Figure 9. Outside dimensions for sensor

VAV Start Up/Check Out Procedure

VAV-SV P01A-E N 27

Page 28

VAV Start Up/Check Out Procedure

3.27 in (8.30 cm)

2.36 in (6.00 cm)

1.34 in (3.41 cm)

Note: The dimensions are the

same for both the sensor

and the receiver.

Figure 10. Mounting hole dimensions for sensor

Setting the Address, Mounting, Wiring, and Associating the Receiver and Sensor

28 VAV-SVP01A-EN

The following procedure list shows the recommended order for installation:

• Choosing a Location for Mounting the Sensor.

• Setting the Rotary Address Switches on the Receiver and on the Sensor.

• Replacing and Securing the Receiver Cover.

• Powering the Sensor and Associating the Sensor to the Receiver.

• Applying Power to the Receiver.

• Testing Signal and Battery Strength.

• Disassociation.

Page 29

Choosing a Location for Mounting the Sensor

Placement of the receiver and the sensor set is critical to proper operation. In most installations,

distance is not the limiting factor for proper radio signal quality. It is more greatly affected by walls,

barriers, and general clutter. For best radio transmission range and reliability, wherever possible,

mount the receiver and sensor in line of sight. Try to minimize the number of barriers between the

pair of devices. In general, sheetrock walls and ceiling tiles offer little restriction to the propagation

of the radio signal throughout the building; concrete or metal barriers offer the most restriction.

The transmission range for the sensor is as follows:

• Open range: 2,500 ft (762 m) (packet error rate = 2%)

• Usable range: 200 ft (61 m)

• Typical range: 75 ft (23 m)

Ambient considerations

Avoid locations that are outside the operating temperature and humidity range.

Location Considerations for the Sensor

When selecting a location for the sensor, consider both thermal and radio transmission

characteristics of the location.

Thermal considerations

• Avoid areas of direct sunlight.

• Avoid areas in the direct air stream of air diffusers.

• Avoid exterior walls and other walls that have a temperature differential between their two

sides.

• Avoid areas close to sources of heat such as sunlight, appliances, or other equipment.

• Avoid drafty areas.

• Avoid dead spots behind doors, projection screens, or corners.

Radio transmission considerations

• Avoid metal barriers between the sensor and receiver, such as plastered walls with metal lathe.

They will decrease radio signal quality.

• Avoid placing the sensor inside metal enclosures.

• Avoid radio transmissions through thick, solid concrete walls.

VAV Start Up/Check Out Procedure

Setting the Rotary Address Switches on the Receiver and the Sensor

Note: To expedite the installation and association process, set the addresses before applying

power to the receiver.

The process of establishing communication between the receiver and sensor is referred to as

association. The receiver and the sensor must have their rotary switches set to the same address

in order to enable communication between the two devices (see Figure 11, p. 30). Important

limitations are as follows:

• Only one associated receiver/sensor set can communicate within the reception range of the

wireless system.

• It is not possible to associate more than one sensor to a receiver, nor is it possible to associate

more than one receiver to a sensor.

VAV-SV P01A-E N 29

Page 30

VAV Start Up/Check Out Procedure

DRESS

IN

LED3

L

ED2

T

A

S

S

Figure 11. Setting the rotary address switches on the receiver and the sensor

Do not remove the

insulation strip yet.

B1 +

!

LED1

SIGNAL

LED5

BATTERY

STATUS

S1

ADDRESS

Pb

Pb-FREE

S3

STATUS

S4

WIRELESS

INSTALL

LED4

S2

LED1

LED2

LED3

LED5

SIGNAL

POWER

S5

S1

ADD

HEATING SET

FAN/SYSTEM

5

S

SETPOINT

ZONE

GND

24VAC/DC

GND

COMM +

COMM -

WIRELESS

L

STAL

LED4

S4

S3

S2

C33

C34

J1

C35

R77

Setting the Receiver Address

1. Using a small screwdriver, set the three rotary address switches (locations S1, S2, S3) on the

receiver (Figure 11, p. 30) to an address between 001 and 999.

Note: Do not use 000 as an address for installation. If you set the receiver address to 000, it will:

– Return the receiver outputs to their factory defaults indefinitely (zone temperature and

setpoint outputs: 72.5°F [22.5°C]).

– Remove all association knowledge.

– Make the receiver unable to associate with a sensor.

• Read the switches from left to right in the order in which they are numbered (S1, S2, S3).

• Zero is at the nine o'clock position.

2. Make a notation of the address and location of the receiver.

Setting the Sensor Address

1. Using a small screwdriver, set the three rotary address switches (locations S1, S2, S3) on the

sensor (Figure 11, p. 30) to the same address used for the receiver it is to be associated with.

2. Make a notation of the address and location where this sensor is to be mounted.

Note: Do not use 000 as an address for installation. If you set the address to 000, it will:

– Remove all association knowledge.

30 VAV-SVP01A-EN

– Revert to a low-power hibernation mode.

– Send a disassociation request to the receiver. If the sensor and receiver are associated and

communicating at the time the sensor is set to 000 and the Test button is pressed, the

receiver will also become unassociated and will be available for re-association.

• Read the switches from left to right in the order in which they are numbered (S1, S2, S3).

• Zero is at the 9 o'clock position.

Page 31

3. Make a notation of the address and location of the sensor.

Factory Wiring of the Receiver to the VAV Unit Controller

The required power for the receiver is 24VAC or 24 Vdc and is less than 1 VA. The receiver is

designed to be powered by the VAV VV550 Controller. See Figure 12, p. 31.

Note: A dedicated transformer is not necessary or advised.

Figure 12. Factory wiring of the receiver to the VAV VV550 controller

VAV Start Up/Check Out Procedure

VAV-SV P01A-E N 31

Page 32

VAV Start Up/Check Out Procedure

Table 8. Wiring harness: wire identification

Wire Label Color Function

HEATING SET Brown

FAN SYSTEM Green Fan and system control (WDS only)

SETPOINT Red

ZONE White Zone temperature

GND-SIGNAL Black Ground for setpoint and zone signal

24VAC/DC Blue 24VAC/vdc power

GND-POWER Yellow Ground for 24VAC/dc

Replacing and Securing the Receiver Cover

1. To replace the receiver cover on the base plate, hook the cover over the top of the base plate.

Apply light pressure to the bottom of the cover until it snaps in place.

2. If necessary to keep the cover securely attached, install the security screw into the bottom of

the receiver (Figure 13, p. 32).

Figure 13. Snap receiver cover on base plate and attach security screw

Space temperature heating setpoint

(WDS only)

Space temperature setpoint (WDS and

W2S only)

Security screw

32 VAV-SVP01A-EN

Page 33

Applying Power to the Receiver

LED5 stays constantly On

RECEIVER

LED3

LED3 will begin

to blink after

10 seconds

Restore power to the VAV VV550 Controller. Observe LED5 on the receiver (Figure 14, p. 33). It will

light and stay constantly On when 24 V power is normal.

Figure 14. LED5 stays on after applying power to the receiver

VAV Start Up/Check Out Procedure

Receiver Indicates Readiness to Associate

After initial power up, the receiver conducts a channel scan for 10 seconds. During this time, the

receiver selects from 16 available channels the clearest channel on which to operate. LED1, LED2,

and LED3 flash rapidly in succession (round-robin style) while the channel scan is in progress.

Note: Do not attempt association until the channel scan is finished. After the channel scan is

finished, LED3 will begin blinking (one-blink pattern) to show that the receiver is ready to

be associated with a sensor. LED3 will stop blinking when association has been established

(Figure 15, p. 33).

Figure 15. LED3 blinks when the receiver is ready to be associated with a sensor

VAV-SV P01A-E N 33

Page 34

VAV Start Up/Check Out Procedure

B1 +

B2 -

IINSTALL

WIRELESS

S4

S3

S2

S1

ADDRESS

STATUS

BATTERY

LED5

SIGNAL

J1

Pb

Pb-FREE

STATUS

LED4

LED5

LED1

LED2

LED3

S5

SENSOR

+

–

+

–

Powering the Sensor and Associating the Sensor to the Receiver

1. Verify that the sensor is set to the same address as the receiver it is to be associated with.

2. Remove the insulation barrier, which is a plastic strip located between the two batteries

(Figure 16, p. 34).

3. Association will automatically occur between the sensor and the receiver. If the first association

attempt is unsuccessful, the sensor will automatically reattempt association with the receiver

every 10 minutes.

Note: A disassociated sensor will transmit an association request every 10 minutes. An associated

sensor that has lost communication with the receiver will transmit an association request

every 50 minutes.

Note: LED3 on the receiver stops blinking to indicate that association has been established.

Figure 16. Removing the insulation barrier on the sensor

34 VAV-SVP01A-EN

Page 35

Testing Signal and Battery Strength

LED1

LED2

LED3

LED5

srosnes SDW ledoMsrosnes SZW dna STW ledoM

Tes t bu tt on

Push firmly,

then release

Push firmly,

then release

Tes t bu tt on

The following recommended test indicates signal and battery strength. It verifies that the

association process was successful and that the batteries have adequate charge. (For more

information on LEDs, see "Troubleshooting" chapter.)

1. Firmly press and release the Test button (S5) on the bottom of the sensor (Figure 17, p. 35).

2. View LED1, LED2, and LED3 to determine the strength of the signal. View LED5 to determine

the strength of the battery.

Note: The LEDs will turn Off after 5 seconds to conserve battery strength.

3. Record the results in your commissioning statement.

Figure 17. Wireless sensors

VAV Start Up/Check Out Procedure

Disassociation

The receiver removes all stored association information, conducts a channel scan, and restarts

itself, if any of the following are true:

• The receiver address is changed from its current setting (001-999).

• The receiver receives a disassociation notification from its associated sensor.

• The receiver does not receive a communication from its associated sensor within 35 minutes.

Configuring the Wireless Sensor (Model Digital Display WDS only)

The configuration of the sensor determines which system features can be accessed and changes

can be made by the tenant (for example, changes to cooling/heating mode, setpoint, or fan speed.

VAV-SV P01A-E N 35

Verify system and associated unit features before configuring the sensor.

Page 36

VAV Start Up/Check Out Procedure

Configuration button

The building owner or operator may choose to limit tenant access to certain features. This can be

done through configuration. Or, if a sensor is configured to match all control capabilities of the

building automation system, the locking feature can be used to restrict the tenant from making

changes.

Configuration Procedure

To configure settings on the model WDS sensor, follow this procedure in the order presented.

1. Press the configuration button for 3 seconds.

Figure 18. Configurations

The display will change to configuration mode. When the sensor is in configuration mode, a

wrench symbol appears on the display and the menus are separated by lines, as illustrated

below.

Figure 19. Configuration mode

2. Press the center button on the keypad to begin the configuration process.

36 VAV-SVP01A-EN

Page 37

Figure 20. Center button

Setting Configuration options

Temperature

• Choose Fahrenheit or

Celsius

• Choose the degree

resolution (whole degrees,

half degrees, or tenths of

degrees).

Setpoint

Deadband (available for dual

setpoint system only)

Note: Deadband refers to the

minimum difference

between the heating and

cooling setpoints.

System

a) Single setpoint

. .

.

.

.

.

dual setpoint

no

setpoint

single

setpoint

.

heat/cool setpoint offset

(1.8˚F – 10.8˚F, 1˚C – 6˚C)

3. Configure the sensor options in the order shown in the table.

• Press or to scroll to the next selection.

• Press or to move to the next menu.

Figure 21. Wireless configuration

VAV Start Up/Check Out Procedure

Center button

VAV-SV P01A-E N 37

Page 38

VAV Start Up/Check Out Procedure

System (continued)

b) Dual setpoint

c) No setpoint

Fan

Note: Fan control not available

on VAV units.

Occupancy (timed

override)

Setting Configuration options

emergency heat/

heat/cool/off

heat/cool/

auto/off

emergency heat/

heat/cool/auto/off

no system

options enabled

auto/off/low

med/high

auto/off/

low/high

auto/off

off/high (on)

off/low/high off/low/

med/high

no fan options

enabled

auto/high (on)

38 VAV-SVP01A-EN

Page 39

4. Review the display to ensure that you have selected the correct configuration options.

Figure 22. Configuration options

To return the display to operating mode, press the configuration button (See Step 1).

Note: The sensor will revert to operating mode if no buttons are pressed for 10 minutes.

The following example shows a configured display in operating mode.

Figure 23. Display

VAV Start Up/Check Out Procedure

The example shows a display that has been configured for:

• Dual setpoint

• Temperature units (Fahrenheit)

• Temperature resolution to tenths of a degree

• System settings: Heat, Cool, Off

• Fan Settings: Auto and On

• Occupied/unoccupied option enabled

Display shows the following:

• Temperature units (Fahrenheit)

• Temperature resolution to tenths of a degree

• System setting: Cooling

• Fan Setting: Auto

• Occupied/Unoccupied option enabled

If an error exists, it appears at the bottom of the display between the occupancy symbols, as shown

in below. SeeTable 20, p. 92 for error code definitions.

Figure 24. Error message

VAV-SV P01A-E N 39

Page 40

VAV Start Up/Check Out Procedure

Arrow

indicates

setpoint is

shown on

display

Setpoint

System menu

Optional Features

Displaying Setpoint or Temperature

You can configure the sensor to display either the temperature (default) or setpoint. To select either

option:

1. Verify that the sensor is in operating mode and at the home screen.

2. Press the up and down arrows for 3 seconds. The arrow indicates setpoint display, as shown

in the illustration.

Figure 25. Setpoint or temperature display

Locking and Unlocking Settings

You can lock or unlock the setpoint, system, or fan setting to prevent changes.

To lock or unlock the settings:

1. Verify that the sensor is in operating mode and at the home screen.

2. Choose a setting to lock or unlock.

• Select the setpoint by pressing the up or down arrow.

Figure 26. Setpoint

• Select the system menu by pressing the center button. Use the left or right arrow to choose

the setting.

Figure 27. System menu

• From the system menu, press the down arrow to select the fan menu. use the left or right

arrow to choose the setting.

40 VAV-SVP01A-EN

Page 41

VAV Start Up/Check Out Procedure

Fan menu

Note: Fan on VAV units cannot be controlled from the zone sensor.

Figure 28. Fan menu

3. Press the left and right arrows for 4 seconds.

Figure 29. Arrows

If you try to access a feature that is locked, the lock symbol wi ll app ear on the displays. If you press

a keypad button to try and change a locked setting, the locked symbol will flash.

VAV-SV P01A-E N 41

Page 42

VAV VV550 Controller Programming and Operation

Chapter Overview

This chapter contains information about the following:

• Accessing Rover/Comm5 LonTalk

• VV550 Controller Device Home Tabs: At a Glance

• Entering and Exiting the Service Mode

• Overriding VAVs

• Saving VAV Program

• VV550 Controller Device Home Tabs: Instructions

Accessing Rover/Comm5 LonTalk

Rover Overview

Rover is a service tool that allows parameters to be viewed or adjusted in the VAV VV550 Controller.

The operating and programming guide for Rover is EMTX-SVX01*-EN. Rover Comm5 is a software

application for monitoring, configuring, balancing, binding and testing VAV VV550 Controllers on

Comm 5 links.

Note: For Instructions on how to use Rover Comm5, refer to the Rover Comm5 online Help by

clicking Contents and Index on the Help menu.

Laptop Requirements and Complete Connection Instructions

For instructions on connecting a PC laptop to a Comm5 link, refer to the Installing Rover Service

Tool Version 5.0, 3270 3275.

Note: A hard copy of this document is in the Rover package and an electronic copy

(Installation.pdf) can be found on the Rover installation CD-ROM.

To connect to a Comm5 Link

1. Insert the Comm5 card in the PC laptop.

2. Connect the cables as shown in the appropriate figure. Refer toFigure 30, p. 42 for connecting

to a Comm5 controller through a zone sensor and Figure 31, p. 43 for Connecting to a Comm5

controller using alligator clips.

Note: Make sure to maintain polarity.

Figure 30. Connecting to a Comm5 controller through a zone sensor.

Comm5

Adapter cable

RJ11

plug

42 VAV-SVP01A-EN

PCMCIA card

Page 43

VAV VV550 Controller Programming and Operation

Figure 31. Connecting to a Comm5 controller using alligator clips

Comm5

PCMCIA card

Red

Black

RJ11 plug

Adapter

cable

3. Double-click the Rover icon on the laptop PC desktop. The Rover Service Tool screen will

appear.

4. Double-click on the Comm5 Configuration Only Service Tool icon to access a Comm5

VV550. This tool allows the user to monitor, configure, and test Comm5 VV550 controller.

Note: The configuration-only Rover Comm5 software runs only in the Passive mode. This means

that you can configure setpoints and other controller parameters but cannot create bindings

or set up peer-to-peer Comm5 networks. All other Rover Comm5 features are available.

Figure 32. Rover service tool

5. Rover Comm5 will launch and the Rover service tool will automatically Scan for Neron ID of

Devices.

6. Once the scan is complete, the results will populate the device tree on the left-hand side of the

Rover Comm5 screen.

7. Access the desired VAV VV550 Controller from the device tree.

VAV-SV P01A-E N 43

Page 44

VAV VV550 Controller Programming and Operation

VV550 Controller Device Home Tabs: At a Glance

Unit Information Tab

Figure 33. Unit tab

Space Temp: The temperature, as reported by the zone sensor.

Active Setpoint: The active (or actual) setpoint currently used by the VAV VV550 Controller. Can

be either Heating or Cooling depending on operating mode.

Primary Air / Discharge Air Temperature: Shows the auxiliary temperature input.

Note: This will be defined in configuration as either Primary Air or Discharge air temperature

depending on unit control strategies. See Configuration section for more details.

Airflow: Measured in CFM. When a valid flow value is present, the controller operates under

pressure independent control. If after an airflow sensor failure, the airflow returns to the valid range

(airflow value greater than 10% of configured nominal airflow), the controller automatically

resumes pressure independent control. When the communicated airflow setpoint is invalid, the

flow sensor has failed, or calibration has failed, the controller closes the air valve if the configured

44 VAV-SVP01A-EN

Page 45

VAV VV550 Controller Programming and Operation

airflow tracking offset is negative. If the configured airflow tracking offset is positive, the controller

opens the air valve to the configured maximum airflow space.Once a valid differential pressure is

established through the local hardwired input and then is no longer present, the controller

generates a flow sensor failure diagnostic.

Airflow Setpoint: The VV550 controllers support one modulating air valve for heating and

cooling operation. The controller positions the modulating air valve to deliver the desired airflow

(cooling or heating capacity). The desired airflow is called the active flow setpoint. The airflow

control algorithm compares the active airflow setpoint with the measured airflow and calculates

the necessary air valve movement to minimize error. The airflow setpoint is limited by applicable

minimum and maximum flow setpoints.

Space CO2: Communicated Value only. CO2-based demand control ventilation uses the

communicated space CO2 value. The controller cannot monitor CO2 from a local CO2 sensor. The

controller compares the space CO2 concentration to the configured band of CO2 values and

determines the demand ventilation rate of the zone. The resulting ventilation rate is called the

effective ventilation setpoint. The effective ventilation setpoint is the outdoor airflow required to

provide ventilation. It is used to calculate the ventilation ratio of the zone.

Diagnostic

This is a log that records each diagnostic independently of other diagnostics.

Note: A list of diagnostics will be located in troubleshooting section of this manual.

Use the ‘Reset Diagnostic’ button to reset the diagnostic from this point. A reset clears latching

diagnostics and enables the controller to try to run normally. If the latching condition is still present

after the reset, the controller shuts down. A reset resets a unit that is running normally. There are

five ways to reset unit diagnostics:

• Manual output test at the controller

• Cycling power to the controller

• BAS (communicated status request, clear alarm)

• Rover service tool (communicated status request, clear alarm)

• A communicating device able to access the controller diagnostic reset input (communicated

status request, clear alarm)

Operating Status

Occupancy Modes: There are four valid occupancy modes of the VAV VV550 Controller, and they