Page 1

Installation/

Operation

Maintenance

VariTrane

™

Pneumatic Controls

March 2002

VAV-SVX02B-EN

Page 2

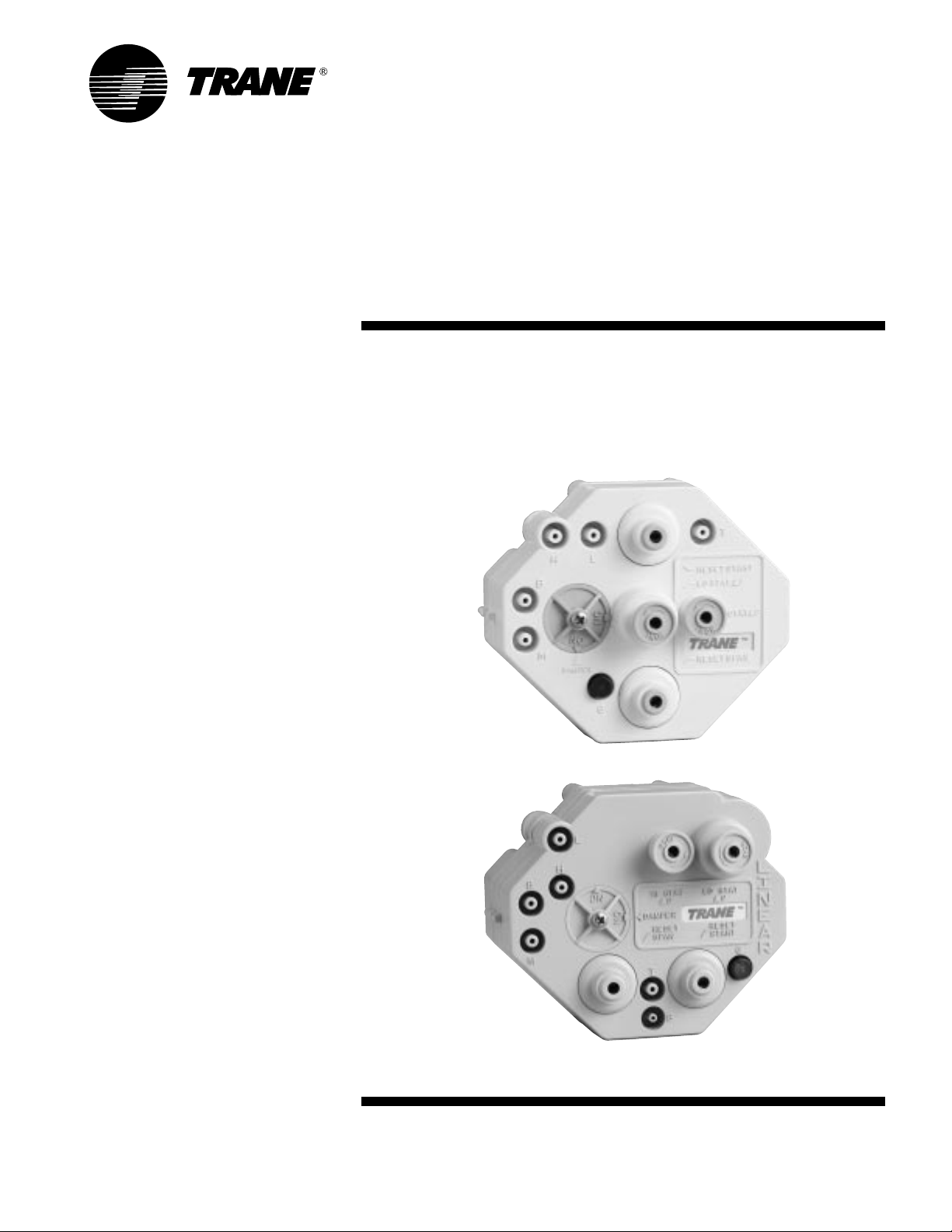

Thermostat

20

(137.9)

(103.4)

Thermostat Selection

and Location

In general, both one- and two-pipe

thermostats have a gain of 2.5 psi per

degree Fahrenheit, unless special

thermostats are used that provide a

different gain. The major difference

between them is that a one-pipe

thermostat is considered a lowcapacity thermostat and a two-pipe

thermostat is considered a highcapacity thermostat.

When selecting between one-pipe and

two-pipe thermostats consider the

following:

Use one-pipe thermostat when:

tubing runs are less than 50 feet from

thermostat to controller.

a single thermostat will control no

more than three controllers.

slower response is desired from the

thermostat.

Use two-pipe thermostat when:

tubing runs exceed 50 feet from

thermostat to controller.

a single thermostat will control four or

more controllers.

high capacity air is required due to

restrictions in the air line.

Thermostat Piping

The two-pipe thermostat (Figure 1)

includes a restrictor (internally). Attach

supply air line and output pressure

(branch) line to the thermostat.

The one-pipe thermostat (Figure 2)

requires an external restrictor tee.

Connect main air supply to restricted

leg of restrictor tee. Connect branch line

from restrictor tee to the thermostat.

Figure 1–Two-Pipe Remote Thermostat (Reverse-Acting)

Tee

S

Figure 2–Typical One-Pipe Thermostat (Reverse-Acting)

Restrictor

Tee

Tee

Restricted Leg

S

20

Fan

(137.9)

P.E.

Switch–1

(N.O.)

9 PSI

(62.06 kPa)

Two-Pipe

Remote-Mounted

T-Stat

(Reverse-Acting)

One-Pipe

Remote-Mounted

T-Stat

(Reverse-Acting)

2

VAV-SVX02B-EN

Page 3

Thermostat

Specifications

TP970 Series Pneumatic T-stats

Maximum Safe Air Pressure:

25psi (172 kPa)

Maximum Safe Air Temperature:

150°F (66°C)

Throttling Range:

2–10°F (1–5°C)

Gain:

2.5 psi/°F Adjustable

Operation

Pneumatic thermostats modulate

output air pressure in response to room

air temperature. Pneumatic thermostats fall into two categories: directacting or reverse-acting. This section

describes how thermostat output

pressure responds to changes in room

temperature.

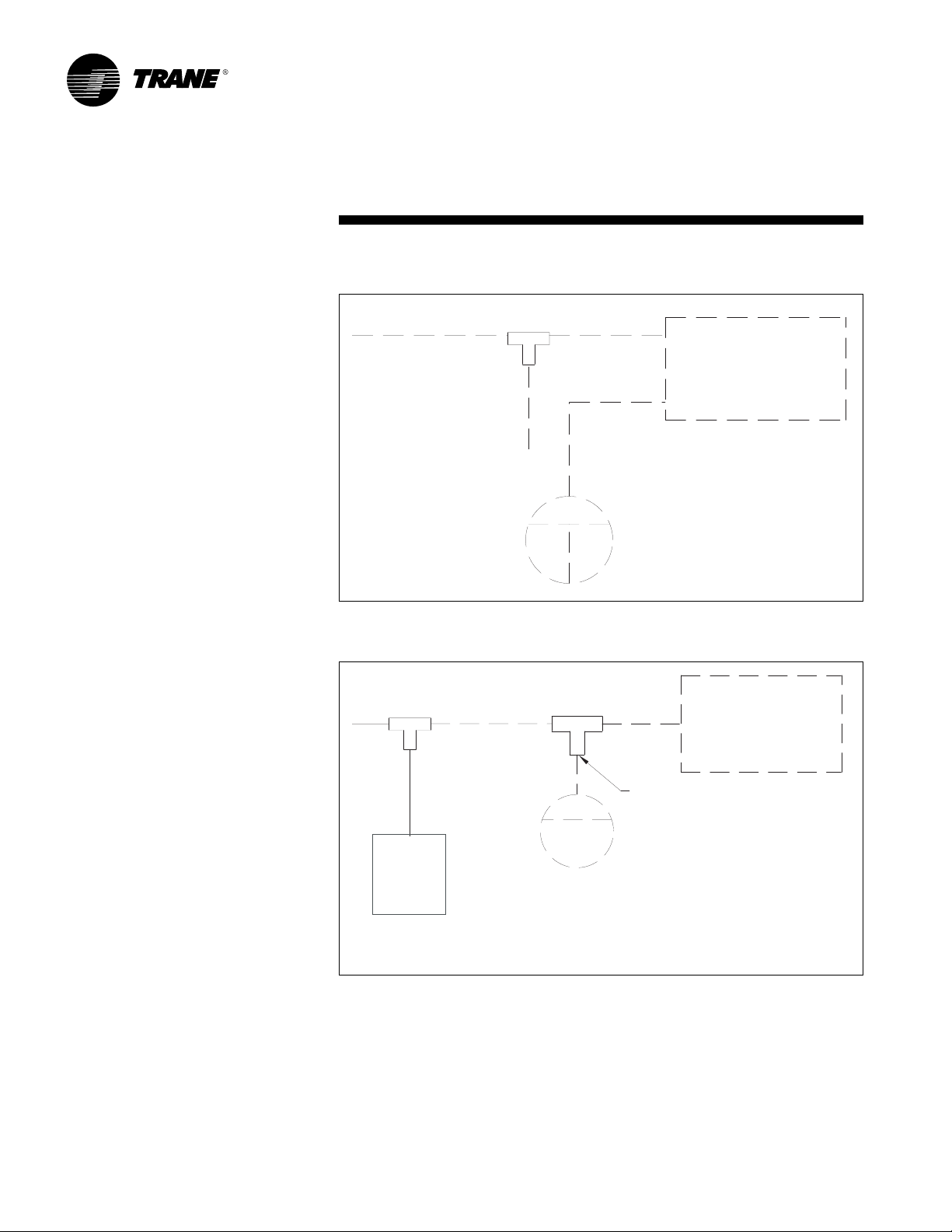

Figure 3 graphically illustrates the

relationship between room

temperature and output pressure of a

direct-acting thermostat. The graph in

Figure 3 shows that as the room

temperature increases, so does the

output pressure of the thermostat.

Figure 3–Direct-Acting

Thermostat Response

Output Pressure

Figure 4 illustrates the pressure/

temperature characteristics for a

reverse-acting thermostat. As room

temperature increases, the thermostat

output pressure decreases.

Figure 4 –Reverse-Acting

Thermostat Response

Output Pressure

Input Temperature

A thermostat in proper working order

will be able to output a pressure

ranging from approximately .5 psi to

supply air pressure depending on

distance from indicated setpoint.

Input Temperature

VAV-SVX02B-EN

3

Page 4

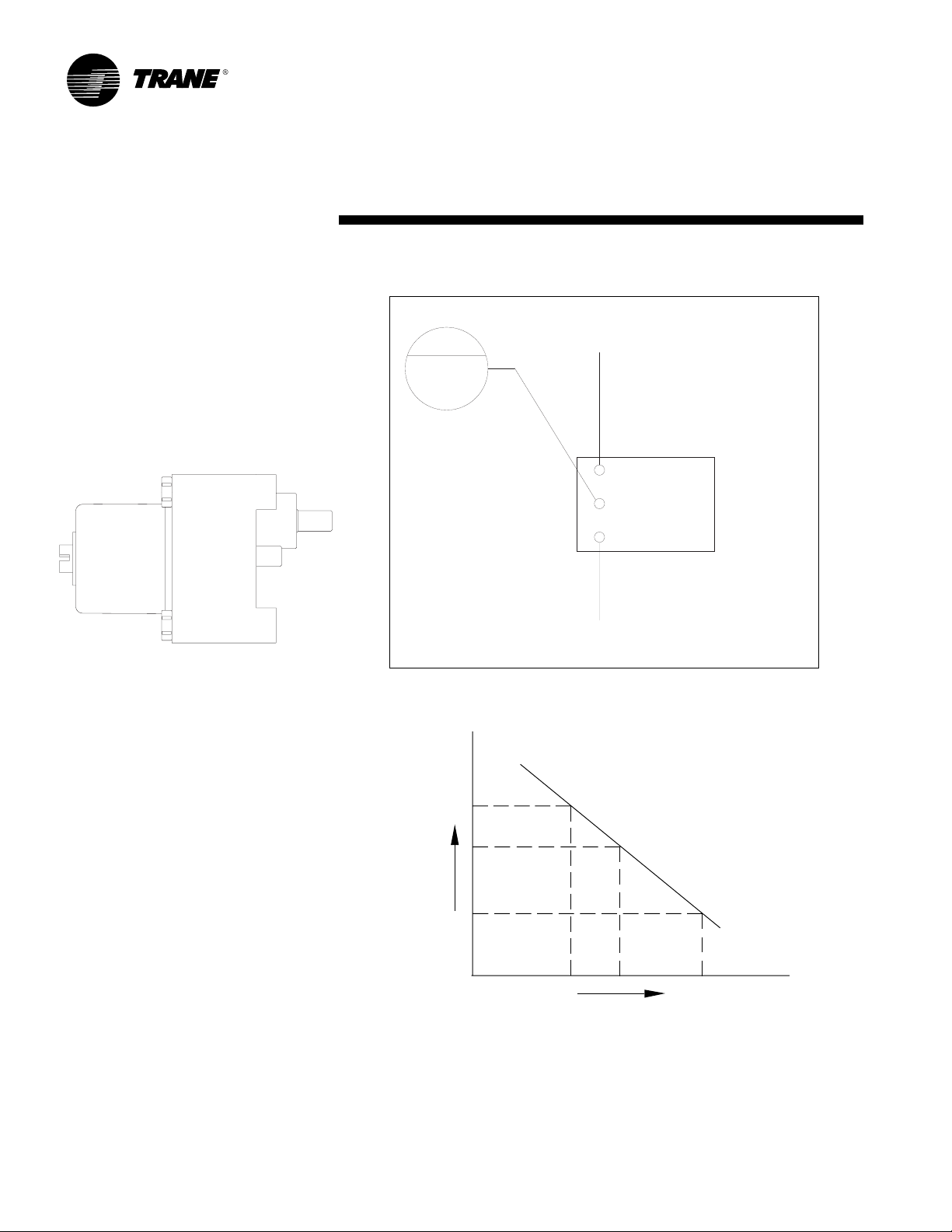

Reversing Relay

Installation and Operation

The reversing relay is a proportional,

non-bleeding device for use in pneumatic control systems where a proportional signal from a controlling device

must be reversed (see Figure 5). The

most common use of the reversing

relay is to change the action of a

pneumatic thermostat.

Figure 5 –Pneumatic Reversing Relay

Trane Part No. RLY-755

The reversing relay requires three

piping connections: main/supply air,

input signal air, and output branch air

(see Figure 6). The branch line pressure

decreases in direct proportion to an

increase in the input signal pressure

and vice-versa. The input signal is also

amplified, thereby minimizing any

pneumatic line transmission lag

(see Figure 7).

Input pressure to the relay and output

pressure to the PR should always add

up to a constant, which is usually set

between 16 and 25 psi. For example,

with a constant of 18, six-pound input

signal will result in a 12 pound branch

signal. A bias adjustment screw is

provided to retard or advance the out

signal.

Figure 6 –Reversing Relay Connections

Output

S

Branch

20

(137.9)

Input

Branch

Figure 7 – Reversing Relay Characteristics

15

Inc.

12

3

Output Branch Pressure

3

Input Pressure Signal

B

Reversing

M

S

6

Relay

9 PSI In

(62.06 kPa)

9 PSI Out

(62.06 kPa)

15

Inc.

4

VAV-SVX02B-EN

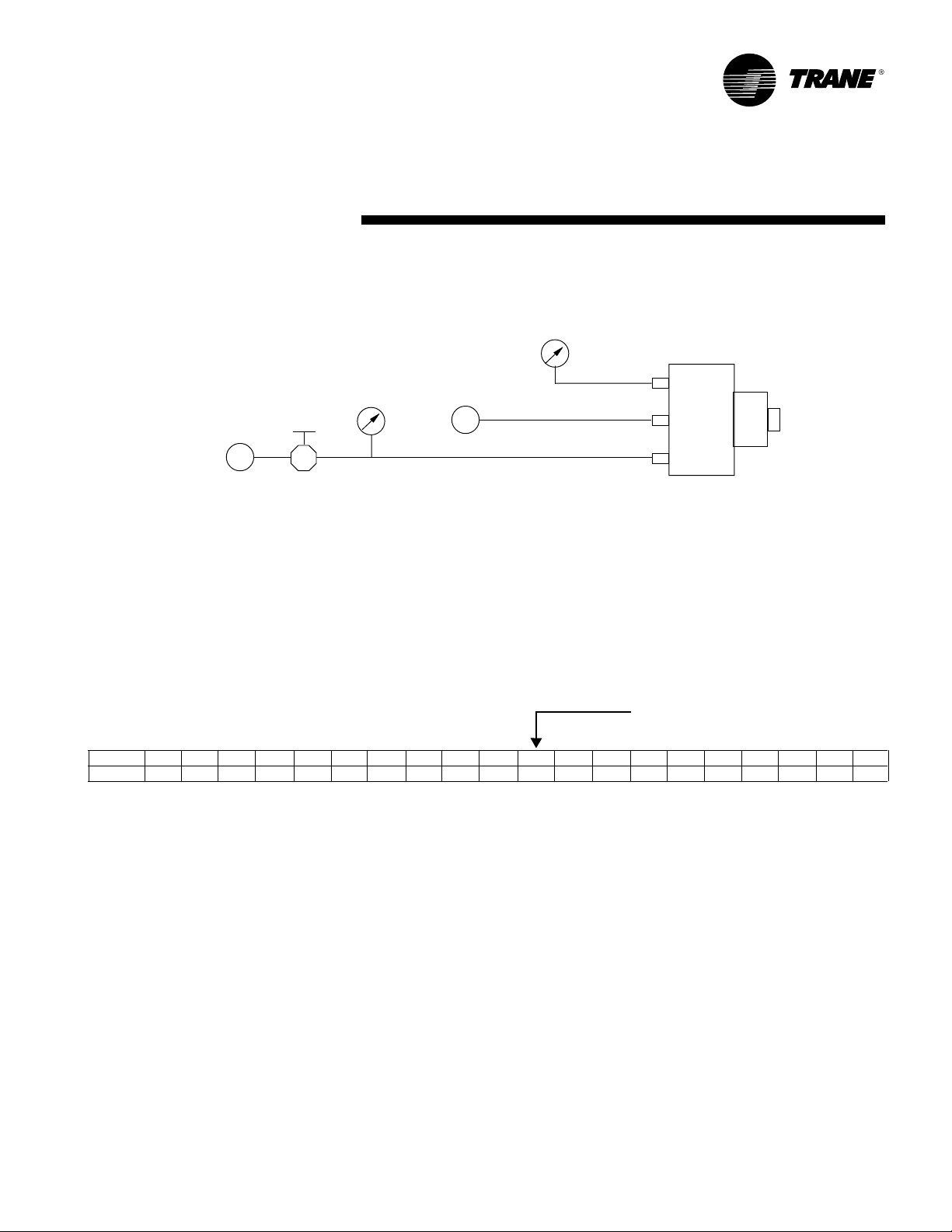

Page 5

Reversing Relay

Calibration

By using the “bias” adjustment on the

relay, the factory-set 8.0–9.0 “crossover” can be changed. To recalibrate,

the relay should be connected as

illustrated in Figure 8.

Pressure

Regulator

M

If the new desired “cross-over”

pressure is 11.0 psi, this must be applied

to port #3 by adjusting the pressure

regulator. The “bias” adjustment is then

turned until 11.0 psi is obtained on the

output gage. Turning the “bias” adjustment “CW” increases the out put;

“CCW” decreases it.

This 11.0 psi “cross-over” would yield

the following operational chart:

Chart

Figure 8 – Recalibrating Reversing Relay

Gage

M

1

C

3

New Cross-over pressure

Bias

Adjustment

Screw

Input: 1234567891011121314151617181920

Output: 2019181716151413121110987654321

Specifications

Maximum Pressure:

30 psig

Connections:

3/16" (4.& mm) nipples for ¼" (6.4 mm) OD

polyethylene tubing

Air Consumption:

0.5 SCFH (.236 L/M) @ 20 psig

Material:

ABS

Ambient Limits:

+40°F/+120°F operating (+4°C/+49°C)

Mounting:

In-line via air connections

Factory Settings:

9 psig in./9 psig out and 8 psig in./8 psig

out

Bias Adjustment:

+/-15 psi

Weight:

3 ½ oz

VAV-SVX02B-EN

5

Page 6

Model 3011—Pneumatic

C

N

I

N

I

C

Volume Regulator

Model 3011

The model 3011 Pneumatic Volume

Regulator (PVR) is capable of operating

with normally-open or normally-closed

air valves and can operate with either

direct-acting (DA) or reverse-acting

(RA) thermostats.

Installation

1. Attach bracket either vertically or horizontally to the illustration surface. Horizontal

is preferred, vertical is acceptable, any other position is not acceptable (see Figure 9).

2. Insert controller into its bracket. Controller may be face up, face down, face left, or

face right. The controller LO and HI stat delta P must be calibrated in the same

position that it is mounted.

Figure 9–Acceptable Installation Positions

Connections

Figure 10 illustrates a typical piping diagram of a normally-open or normallyclosed unit.

Figure 10–Typical Piping Diagram of Normally-Open or Normally-Closed Unit

Normally-Open Unit or

Normally-Closed Unit

One-Pipe

Remote-Installed

T-Stat

Restricted Leg

H

DAMPER

NC

Volume

Regulator

N

C

T

LO STAT

HI STAT

C

RESET SPAN

Restrictor

Tee

∆P

∆P

LO

HI

Actuator

B

M

Airflow Sensor

G

S

20

S

20

Selecting Direct- or Reverse-Acting Thermostat (3011)

The model 3011 PVR must be calibrated to operate with either a direct-acting or

reverse-acting thermostat. The control must also be changed when used with a

normally-open or normally-closed air valve.

6

VAV-SVX02B-EN

Page 7

Model 3011—Pneumatic

C

I

N

RESET SPAN

C

I

N

Volume Regulator

Use the following procedure to set-up the PVR:

1. Select damper action (NO or NC). Loosen damper selection switch screw and align to either the NO or NC pointer with damper

pointer and tighten screw.

2. Now determine the type of thermostat that will be used. If a direct-acting thermostat is used, the reset start pressure is ty pically

8 psi. If a reverse-acting thermostat is used, the reset start pressure is typically 3 psi (see Figure 11).

3. With an accurate gage (0-10 psi) connected to port “G”, regulate the thermostat pressure to port “T” to desired start point pressure.

4. Adjust reset start to indicate 0 psi on port “G” and continuing adjusting to indicate a pressure slightly higher than 0 psi, (i.e., 0.1 psi).

Figure 11–Adjusting Reset Star t

Adjust to obtain 0–0.1 psi at port G

psi

10

0

Connect 0–10 psi Gage

Connect Hand Pump

B

NC

NO

M

DAMPER

G

RESET START

LO STAT ∆P

I

N

HI STAT ∆P

I

N

R

R

C

C

RESET SPAN

0–20 psi

Handpump

Input desired LO stat

pressure at t-stat port

Factory-set at 5 psi

Adjustable (0–10 psi)

NOTE: The arrows on the damper selector must be aligned

exactly or the range of the controller will be limited .0 psi

Adjusting the Reset Span (3011)

The reset span is factory-set at 5 psi. This is the thermostat pressure difference from which the PVR delivers flow from minimum

to maximum setpoints. This range is not normally changed unless a special control scheme is used where control operation

must be changed.

To field adjust a different reset span, follow these steps:

1. Connect an accurate gage to port “G”.

2. Apply 20 psi to port “T”.

3. Adjust reset span to indicate the desired span on port “G” (see Figure 12).

4. LO-stat and HI-stat delta P must now be readjusted (see following calibration procedure)

Figure 12– Adjusting Reset Span

Apply 20 psi

H

B

NC

N

NO

M

DAMPER

T

RESET START

P

LO STAT

HI STAT

R

P

N

C

VAV-SVX02B-EN

PSI

G

100

Adjust to obtain desired reset span

7

Page 8

Calibration

C

I

N

C

I

N

P

Procedures

Calibration Procedure (Steps 1–4 apply to all thermostat models)

1. Be sure the PVR is installed correctly and that all connections are hooked up to the proper ports. See Figure 9 for unit application.

2. Remove the caps on the tees which are connected to the lines to the flow sensor. Connect a 0–2" magnehelic gage to monitor

flow sensor delta P. The higher-pressure port is further upstream on the air valve inlet.

3. Remove the thermostat line and connect a hand pump with a 0–20 psi gage to port “T”.

4. Tee a 0–20 psi gage in the line from port “B” on the volume regulator to the air valve actuator.

Normally-Open Valve

Direct-Acting Thermostat

(See Figure 13 for proper

connections)

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat minimum) adjustment to

desired minimum.

7. Set port “T” input at 16

psi or greater with the

hand pump.

8. Monitor the delta P and

adjust the HI-stat (maximum) adjustment to

desired maximum flow. If

the actuator pressure is

less than 3 psi, the air

valve is wide open and

duct pressure must

increase to increase flow.

9. Set port “T” at 0 psi.

10. Monitor the minimum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Reverse-Acting Thermostat

(See Figure 13 for proper

connections):

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat delta P

(maximum) adjustment to

desired maximum. If the

actuator pressure is less

than 3 psi, the air valve is

wide open and duct

pressure must increase to

increase flow.

7. Set prot “T” to 16 psi

or greater with the

hand pump.

8. Monitor the delta P and

adjust the HI-stat (minimum) adjustment to

desired minimum flow.

9. Set port “T” at 0 psi.

10.Monitor the maximum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Normally-Open Valve

Direct-Acting Thermostat

(See Figure 14 for proper

connections):

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat (minimum) adjustment to

desired minimum.

7. Set port “T” input at

16 psi or greater with the

hand pump.

8. Monitor the delta P and

adjust the HI-stat

(maximum) adjustment

to desired maximum flow.

If the actuator pressure is

greater than 13 psi, the air

valve is wide open and duct

pressure must increase to

increase flow.

9. Set port “T” at 0 psi.

10.Monitor the minimum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Reverse-Acting Thermostat

(See Figure 14 for proper

connections):

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat delta P

(maximum) adjustment to

desired maximum flow. If

the actuator pressure is

greater than 13 psi, the air

valve is wide open and

duct pressure must

increase to increase flow.

7. Set prot “T” to 16 psi

or greater with the

hand pump.

8. Monitor the delta P and

adjust the HI-stat (minimum) adjustment to

desired minimum flow.

9. Set port “T” at 0 psi.

10.Monitor the maximum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Figure 13–Connections of Direct/Reverse-Acting

Thermostat with Normally-Open Valve

0–2' Magnahelic Gage

LO

HI

Normally-Open Unit

LO

HI

Actuator

Airflow Sensor

Volume

Regulator

H

B

NC

R

N

NO

M

DAMPER

G

S

20

8

RESET START

LO STAT

Apply 20 psi

T

P

HI STAT

PSI

0 10

Connect 0–20 psi Gage

Connect Hand Pump

0–2 psi

Handpump

Figure 14–Connections of Direct/Reverse-Acting

Thermostat with Normally-Closed Valve

0–2' Magnahelic Gage

LO

HI

Normally-Closed Unit

Airflow Sensor

LO

HI

Actuator

Volume

Regulator

H

B

NO

R

N

NC

M

DAMPER

G

S

20

RESET START

LO STAT

C

Apply 20 psi

T

P

HI STAT

PSI

0 10

Connect 0–20 psi Gage

Connect Hand Pump

VAV-SVX02B-EN

0–2 psi

Handpump

Page 9

Specifications (3011)

Specifications (3011)

Differential Pressure Range:

0 to 1.0 in. wg

Minimum Setpoint Range:

0 to 1.0" H2O

Maximum Setpoint Range:

minimum to 1.0 in. wg

Operating Static Range:

0.25–6.0 in. wg

Normal Supply Air Pressure:

20.0 psi

Minimum Supply air Pressure:

15.0 psi

Maximum Supply Air Pressure:

30.0 psi

Average Supply Air Consumption:

28.8 scim at 20 psi

Thermostat Pressure Input Range:

Adjustable 0–10 psi band from 0–20 psi

Reset Start Point Range:

0–10 psi

Reset Span Range:

0–10 psi

Maximum Safe Thermostat Input:

30 psi (closed chamber)

Operating Temperature:

+40/+120°F

Storage Temperature:

-40/+140°F

Main, Thermostat, Actuator and Static

Pick-up Connections:

.250 O.D.

VAV-SVX02B-EN 9

Page 10

Model 3501—Pneumatic

Volume Regulator

Model 3501

The model 3501 Pneumatic Volume

Regulator (PVR) is capable of operating

with normally-open or normally-closed

air valves and can operate with either

direct-acting (DA) or reverse-acting

(RA) thermostats.

Installation

1. Attach bracket either vertically or

horizontally to the installation surface.

Horizontal is preferred, vertical is

acceptable, any other position is

not acceptable.

2. Insert controller into its bracket.

Controller may be face up, face down,

face left, or face right. The controller

LO and HI stat delta P must be

calibrated in the same position that it

is installed.

Selecting Direct- or Reverse-Acting

Thermostat (3501)

The model 3501 PVR must be calibrated

to operate with either a direct-acting or

reverse-acting thermostat. The control

must also be changed when used with

a normally-open or normally-closed

air valve.

Use the following procedure to set-up

the PVR:

1. Select damper action (NO or NC).

Loosen damper selection switch

screw and align to either the NO or

NC pointer with damper pointer and

tighten screw.

2. Now determine the type of thermostat

that will be used. If a direct-acting

thermostat is used, the reset start

pressure is typically 8 psi. If a reverseacting thermostat is used, the reset

start pressure is typically 3 psi.

3. With an accurate gage (0–30 psi)

connected to port “G”, regulate the

thermostat pressure to port “T” to

10.5 psi.

4. Adjust reset start to indicate 2.5 psi on

port “G”

Adjusting the Reset Span (3501)

The reset span is factory-set at 5 psi.

This is the thermostat pressure difference from which the PVR delivers

flow from minimum to maximum

setpoints. This range is not normally

changed unless a special control

scheme is used where control

operation must be changed.

To field adjust a different reset span,

follow these steps:

1. Connect an accurate gage to port “G”.

2. Apply 20 psi to port “T”.

3. Adjust reset span to indicate the

desired span on port “G”.

4. LO-stat and HI-stat delta P must now

be readjusted (see following

calibration procedure).

VAV-SVX02B-EN10

Page 11

Calibration

Procedures

Calibration Procedure (Steps 1–4 apply to all thermostat models)

1. Be sure the PVR is installed correctly and that all connections are hooked up to the proper ports.

2. Remove the caps on the tees, which are connected to the lines to the flow sensor. Connect a 0–2" magnehelic gage to monitor

flow sensor delta P. The higher-pressure port is further upstream on the air valve inlet.

3. Remove the thermostat line and connect a hand pump with a 0–20 psi gage to port “T“.

4. Tee a 0–20 psi gage in the line from port “B” on the volume regulator to the air valve actuator.

Normally-Open Valve

Direct-Acting Thermostat

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat

(minimum) adjustment to

desired minimum.

7. Set port “T” input at

16 psi or greater with

the hand pump.

8. Monitor the delta P and

adjust the HI-stat

(maximum) adjustment to

desired maximum flow. If

the actuator pressure is

less than 3 psi, the air

valve is wide open and

duct pressure must

increase to increase flow.

9. Set port “T” at 0 psi.

10. Monitor the minimum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Reverse-Acting Thermostat

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat delta P

(maximum) adjustment to

desired maximum. If the

actuator pressure is less

than 3 psi, the air valve is

wide open and duct

pressure must increase

to increase flow.

7. Set prot “T” to 16 psi

or greater with the

hand pump.

8. Monitor the delta P and

adjust the HI-stat

(minimum) adjustment

to desired minimum flow.

9. Set port “T” at 0 psi.

10. Monitor the maximum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Direct-Acting Thermostat

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat

(minimum) adjustment

to desired minimum.

7. Set port “T” input at

16 psi or greater with

the hand pump.

8. Monitor the delta P and

adjust the HI-stat

(maximum) adjustment to

desired maximum flow. If

the actuator pressure is

greater than 13 psi, the air

valve is wide open and duct

pressure must increase to

increase flow.

9. Set port “T” at 0 psi.

10. Monitor the minimum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

Normally-Closed

Reverse-Acting Thermostat

5. Set port “T” at 0 psi.

6. Monitor the delta P and

adjust the LO-stat delta P

(maximum) adjustment to

desired maximum. If the

actuator pressure is

greater than 13 psi, the air

valve is wide open and

duct pressure must

increase to increase flow.

7. Set prot “T” to 16 psi

or greater with the

hand pump.

8. Monitor the delta P and

adjust the HI-stat

(minimum) adjustment to

desired minimum flow.

9. Set port “T” at 0 psi.

10.Monitor the maximum

flow delta P. If it is not

correct, adjust the LO-stat

adjustment knob.

VAV-SVX02B-EN 11

Page 12

Specifications (3501)

Specifications (3501)

Differential Pressure Range:

0 to 1.0 in. wg

Minimum Setpoint Range:

0 to 1.0" H2O

Maximum Setpoint Range:

minimum to 1.0 in. wg

Maximum Setpoint Range:

6.0 in. wg

Normal Supply Air Pressure:

20.0 psi

Minimum Supply air Pressure:

15.0 psi

Maximum Supply Air Pressure:

30.0 psi

Output Sensitivity:

5 psi/.02

Average Supply Air Consumption:

43.2 scim at 20 psi

Reset Start Point Range:

0–10 psi

Reset Span Range:

0–7 psi

Operating Temperature:

+40/+120°F

Storage Temperature:

-40/+140°F

VAV-SVX02B-EN12

Page 13

MCP-3631—Rotary

Pneumatic Damper Actuator

MCP-3631—Rotary

Pneumatic Damper Actuator

Description:

Rotary actuators mounts to a standard

½" diameter shaft by a locking collar

and bushing.

Models:

MCP-3631-5000 8–13 psi range

(55–90 kPa) Normally-Closed operation

MCP-3631-8000 3–8 psi range

(21–55 kPa) Normally-Open operation

Installation Method:

Slide collar onto shaft. Slide actuator

onto shaft noting directional rotation.

Slide bushing onto shaft into actuator,

aligns actuator with damper, lock

collar and bushing set screws, and

install bracket.

Maintenance:

No routine maintenance is required.

Specif ications:

Effective Area:

8 sq in. (52 sq cm)

Normal Rotation:

100 deg

Supply Pressure:

0 to 20 psig (138 kPa) operating

30 psig (207 kPa) max

Spring Ranges:

Retracted/extended Torque

(Based on 0 & 20 psi applied)

8–13 psi (55–90 kPa);

68/59 in. lbs (8/7 Nm) @ 90 deg

3– 8 psi (21–55 kPa);

25/102 in. lbs (3/12 Nm) @ 90 deg

Supply Connection:

3/16" (5 mm) nipple for ¼" (6 mm)

OD polyethylene tubing

Material:

Body Glass-filled nylon

Diaphragm Neoprene

Weight:

1.5 lbs (0.68 kg)

Ambient Limits:

Operating -20°F –120°F (-29°C–49°C)

Shipping -40°F –140°F (-40°C –60°C)

VAV-SVX02B-EN 13

Page 14

Constant-Volume Dual-Duct

Val

Calibration (3011)

Constant Volume Dual-Duct

Calibration (3011)

This calibration procedure is used when

a constant volume of air must be

maintained through a unit. On a dualduct unit, a constant-volume discharge

sensor is used to measure the air

leaving the unit. The PVR controlling to a

constant-volume of air leaving the unit

uses the discharge sensor to maintain

the specified cfm.

Figure 15 –Typical Constant-Volume

Dual-Duct Piping Diagram

Outlet

vegV l

Normally-

Open

LO

HI

LO

HI

Cooling

Valve

Normally-

Open

This PVR does not require a thermostat

connected to the PVR.

The following procedure must be used

when calibrating a constant-volume

dual-duct unit. See Figure 15 for a

typical piping diagram.

1. Set t-stat to full heat.

2. Set LO thermostat (maximum) to the

desired maximum flow on the

heating deck.

Constant-Volume

Flow Ring

3. Set t-stat to full cool.

4. Set HI thermostat (minimum) to

the desired minimum flow on the

heating deck.

5. Set LO thermostat adjustment knob

on cooling deck (CV deck) to desired

constant-volume.

6. Exercise the system to check flows

for proper operation.

Actuator

S

20

(137.9)

H

L

B

Volume

Regulator

T

Actuator

S

20

(137.9)

Two-Pipe

Remote-Mounted

T-Stat

(Direct-Acting)

VAV-SVX02B-EN14

Volume

Regulator

T

Restrictor

Tee

S

20

(137.9)

H

L

B

Page 15

Variable Air Volume Dual-Duct

Heating

Val

Normally-

O

Normally-

O

Cooling

Val

Calibration (3011)

Var iable-Air-Volume DualDuct Calibration (3011)

Figure 16 is a typical piping diagram of

a VAV dual-duct unit. The unit has a

thermostat piped to both pneumatic

volume regulators (PVR) which will

operate the heating deck from a

thermostat signal of 3–8 psi. The cooling

deck will operate from a thermostat

signal of 8–13 psi. With normal

calibration of the PVR, the unit will have

both the heating and cooling deck at

minimum with a thermostat signal of

8 psi.

In order to have a unit minimum cfm

and still have 0 cfm minimums on both

the heating and cooling deck, special

calibration is required. The PVR has a

“reset start” adjustment knob, which

allows the unit to be calibrated to a

minimum cfm. This is achieved by

crossing over the thermostat ranges.

Figure 17 illustrates this concept.

Figure 17– Example

N.O. Heating Valve

Min 0 cfm

Max 1000 cfm

Max

Unit Min

Valve Min

47912

Figure 16–Typical VAV Dual-Duct Piping Diagram

Outlet

LO

HI

Actuator

vegV l

penO

(137.9)

vegV l

penO

LO

HI

G

Volume

Regulator

T

Restrictor

Tee

H

L

B

20

Thermostat Range: 3– 8 psi

Heating Valve = 5 psi range

Thermostat Range: 8–13 psi

Unit Minimum 400 cfm

Cooling Valve = 5 psi range

Approximately 1000 cfm divided by 5 psi =

200 cfm/1b*

N.O. Cooling Valve

Min 0 cfm

Max 1000 cfm

*Due to the relationship between velocity

pressure and cfm; for both the cooling and

heating PVR, a linear relationship between

cfm and psi does not exist.

To obtain a unit minimum cfm of 400 cfm, the

heating deck volume regulator must have its

thermostat range changed from 3–8 psi to

4–9 psi. This is adjusted by changing the “reset

start” point from 3 psi to approximately 4 psi.

The cooling deck volume regulator must have its

8

thermostat range changed from 8–13 psi to

7–12 psi. This is adjusted by changing the “reset

start” point from 8 psi to approximately 7 psi.

By overlapping the thermostat spring ranges, we

were able to have 0 cfm minimum settings on

both the heat and cool deck and still maintain the

required unit minimum cfm of 400 cfm.

The calibration of the PVR is the same as the

normal calibration procedures previously

described in this manual.

S

20

(137.9)

Actuator

S

20

(137.9)

Two-Pipe

Remote-Mounted

T-Stat

(Direct-Acting)

Volume

Regulator

T

H

L

B

VAV-SVX02B-EN 15

Page 16

Constant-Volume

Single-Duct VAV (VCV 3011)

Constant-Volume SingleDuct VAV ( VCV 3011)

This is used when a constant volume of

air is required to supply a zone. A

thermostat is still often required to

modulate a reheat coil to maintain

temperature control. The thermostat is

1. Be sure there is 0 psi at the “T” port.

2. Set LO thermostat adjustment knob to

desired unit cfm.

The unit will now modulate to the

calibrated cfm setting. See Figure 18 for

typical constant volume single-duct

piping diagram.

never connected to the “T” port on the

volume regulator. The following

procedure is used to calibrate this type

of unit with a PVR.

Figure 18 –Typical Constant-Volume Single-Duct Piping Diagram

HI

B

M

S

20

(137.9)

H L

Volume

Regulator

Flow Ring

LO

Actuator

T

S

20

(137.9)

Tee

Trane

An American Standard Company

www.trane.com

For more information contact

your local district office or

e-mail us at comfort@trane.com

Two-Pipe

Remote-Mounted

T-Stat

(Reverse-Acting)

Literature Order Number VAV- SVX02B- EN

File Number SV-TD-VAV000- SVX02B-EN- 0302

Super sedes VAV-SVX02A-EN & VAV-IOM-6

Stoc king Location La Crosse

Trane has a policy of continuous product and product data improvement and reserves the right to change design

and specifications without notice. Only qualified technicians should perform installation and servicing of

equipment referred to in this publication.

11

(75.8)

Stage 1

12.5

(86.2)

Stage 2

14

(96.5)

Stage 3

Electric Heater Terminal Box

Airflow

Safety Switch

P.E. Stage Switch(es)

(Normally-Open)

Loading...

Loading...