Page 1

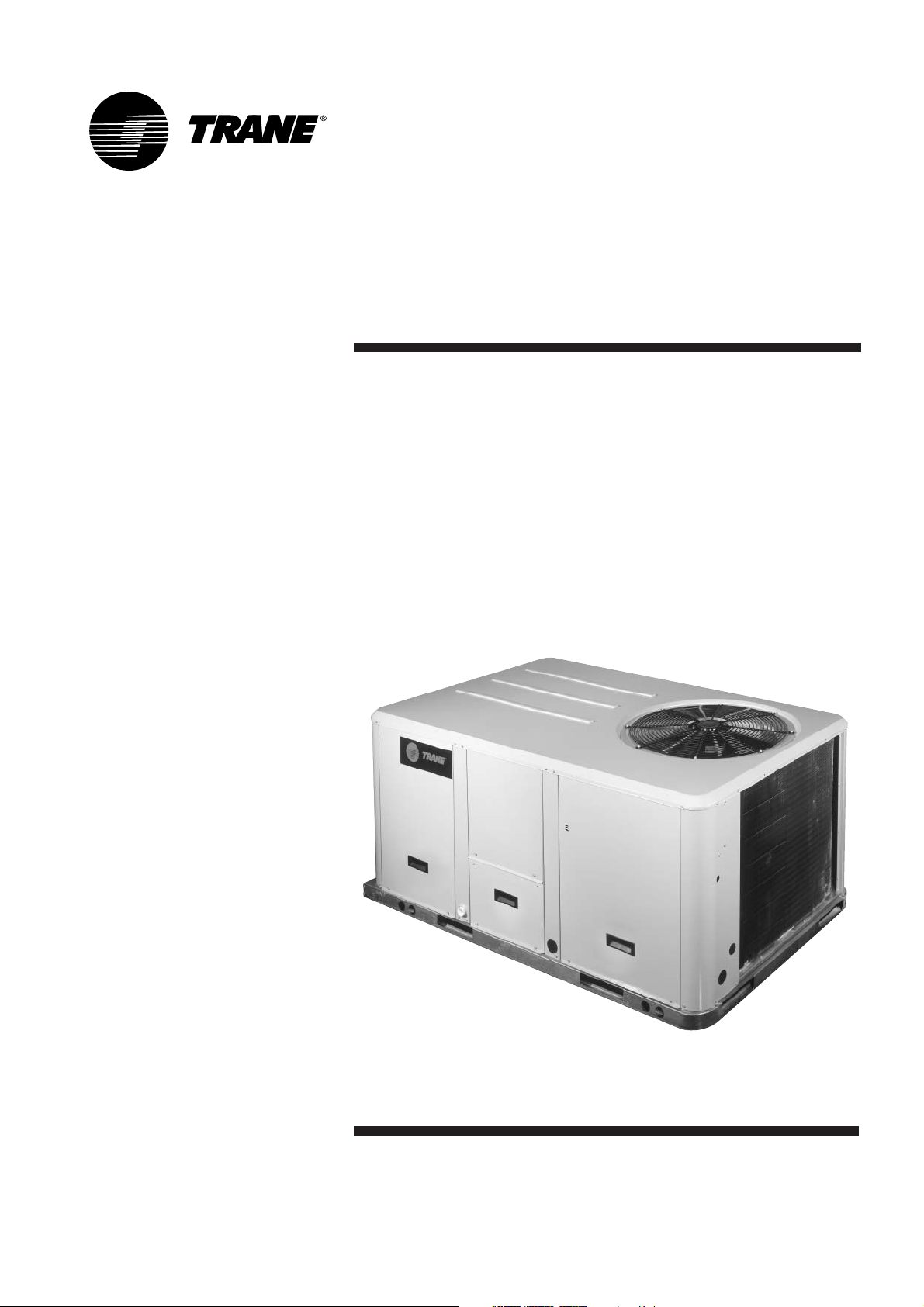

Voyager™ I Rooftop Units

Cooling-only TSD/TSH 060 072 102 120

Reversible WSD/WSH 060 072 090

Gas-fired YSD/YSH 060 072 090 102 120

Installation

Operation

Maintenance

RT-SVX20A-E4

Page 2

General information

RT-SVX20A-E42

Foreword

These instructions are given as a

guide to good practice in the

installation, start-up, operation, and

maintenance by the user, of Trane

TSD/TSH, WSKD/WSH and YSD/YSH

units. They do not contain full

service procedures necessary for

the continued successful operation

of this equipment. The services of a

qualified technician should be

employed through the medium of a

maintenance contract with a

reputable service company. Read

this manual thoroughly before unit

start-up.

TSD/TSH units are designed to

operate in cooling mode only, with

optional auxiliary heat (electric

heater or hot water coil).

WSD/WSH can operate in cooling

mode or heating mode by reversing

the refrigeration cycle with or

without auxiliary heat.

YSD/YSH units are designed to

operate In cooling mode and

equipped with a gas fired heating

module.

TSD/TSH, WSD/WSH and YSD/YSH

units are assembled, pressure

tested, dehydrated, charged and run

tested before shipment.

Warnings and cautions

Warnings and Cautions appear at

appropriate sections throughout

this manual. Your personal safety

and the proper operation of this

machine require that you follow

them carefully. The constructor

assumes no liability for installations

or servicing performed by

unqualified personnel.

WARNING! : Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION! : Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury. It may also be

used to alert against unsafe

practices or for equipment or

property-damage-only accidents.

Page 3

General information

3RT-SVX20A-E4

Reception

On arrival, inspect the unit before

signing the delivery note. In case of

visible damage: The consignee (or

the site representative) must specify

any damage on the delivery note,

legibly sign and date the delivery

note, and the truck driver must

countersign it. The consignee (or the

site representative) must notify

Trane Epinal Operations - Claims

team and send a copy of the

delivery note. The customer (or the

site representative) should send a

registered letter to the last carrier

within 3 days of delivery.

Reception in France only:

Concealed damage must be looked

for at delivery and immediately

treated as visible damage.

Reception in all countries except

France:

In case of concealed damage: The

consignee (or the site

representative) must send a

registered letter to the last carrier

within 7 days of delivery, claiming

for the described damage. A copy of

this letter must be sent to Trane

Epinal Operations - Claims team.

Warranty

Warranty is based on the general

terms and conditions of the

manufacturer. The warranty is void

if the equipment is repaired or

modified without the written

approval of the manufacturer, if the

operating limits are exceeded or if

the control system or the electrical

wiring is modified. Damage due to

misuse, lack of maintenance or

failure to comply with the

manufacturer's instructions or

recommendations is not covered by

the warranty obligation. If the user

does not conform to the rules of

this manual, it may entail

cancellation of warranty and

liabilities by the manufacturer.

Refrigerant

The refrigerant provided by the

manufacturer meets all the

requirements of our units. When

using recycled or reprocessed

refrigerant, it is advisable to ensure

its quality is equivalent to that of a

new refrigerant. For this, it is

necessary to have a precise analysis

made by a specialized laboratory. If

this condition is not respected, the

manufacturer warranty could be

cancelled.

Storage

Take precautions to prevent

condensate formation inside the

unit's electrical components and

motors when:

1. The unit is stored before it is

installed; or,

2. The unit is set on the roof curb

and temporary auxiliary heat is

provided in the building.

Isolate all side panel service

entrances and base pan openings

(e.g., conduit holes, S/A and R/A

openings, and flue openings) to

minimize ambient air from entering

the unit until it is ready for start-up.

Do not use the unit's heater as

temporary heat without completing

the start-up procedures detailed

under "Unit Start-Up".

The Trane Company will not assume

responsibility for equipment

damage resulting from

accumulation of condensate on the

unit electrical components.

Maintenance contract

It is strongly recommended that you

sign a maintenance contract with

your local Service Agency. This

contract provides regular

maintenance of your installation by

a specialist in our equipment.

Regular maintenance ensures that

any malfunction is detected and

corrected in good time and

minimizes the possibility that

serious damage will occur. Finally,

regular maintenance ensures the

maximum operating life of your

equipment. We would remind you

that failure to respect these

installation and maintenance

instructions may result in

immediate cancellation of the

warranty.

Training

To assist you in obtaining the best

use of it and maintaining it in

perfect operating condition over a

long period of time, the

manufacturer has at your disposal a

refrigeration and air conditioning

service school. The principal aim of

this is to give operators and

technicians a better knowledge of

the equipment they are using, or

that is under their charge. Emphasis

is particularly given to the

importance of periodic checks on

the unit operating parameters as

well as on preventive maintenance,

which reduces the cost of owning

the unit by avoiding serious and

costly breakdown.

Page 4

Contents

RT-SVX20A-E44

General information 2

Foreword 2

Warnings and Cautions 2

Reception 3

Warranty 3

Refrigerant 3

Maintenance contract 3

Storage 3

Training 3

Installation 6

Reception of units 6

Roof curb installation 6

Dimensions/Weights/Clearances 7

Installing the unit 9

Connection of duct network 10

Condensate drain piping 12

Gas pipework installation 13

Filter installation 14

Supply fan adjustment 14

Component air pressure drops 16

Supply fan performances 17

Electrical connection 30

Controls 33

Control wiring 33

CO2sensors 35

Remote potentiometer 39

Fire thermostat 40

Clogged filter detector 41

Smoke detector 41

High temperature safety thermostat 41

Remote fault relay 41

Thermostats 42

Communication Interfaces 43

Page 5

Contents

5RT-SVX20A-E4

Unit Options 44

Hot water coil 44

Electric Heater 45

Soft Starter 45

0 - 25% fresh air hood 46

Barometric relief 47

Operation 48

Operation with a conventional thermostat 48

Setting the economizer 50

Test procedures 52

Test modes 53

Unit Start-up 54

Cooling without an Economizer 56

Low Ambient Operation 57

Cooling with an Economizer 57

Economizer Set-Up 58

ReliaTel™ Control Heating Operation 58

Ignition Module 58

Final installation checklist 59

Maintenance 60

End user routine maintenance 60

Service technician maintenance 61

Troubleshooting 62

Page 6

Installation

RT-SVX20A-E46

General information:The

installation must conform to all

local standards and regulations.

Reception of units

Rooftop unit

There are two ways to handle the

unit:

1. Use the openings in the base to

handle the machine using a

forklift, in accordance with

applicable safety regulations.

2. Use a lifting beam correctly

adjusted to fit the unit (Figure 1).

Unit handling

The units are supplied on the truck

but are not unloaded. An opening is

provided on each corner of the unit

base to facilitate handling. Four

shackles and four slings are

required. Use a lifting beam to

prevent the cables pressing too hard

on top of the unit during lifting. The

structure accommodating the unit(s)

must be designed to support the

equipment in operation, as a

minimum. (Refer to Figures 1 and

2 and Tables 2 and 3.)

Important: For unit to fit on the roof

curb the fork lift pockets must be

removed.

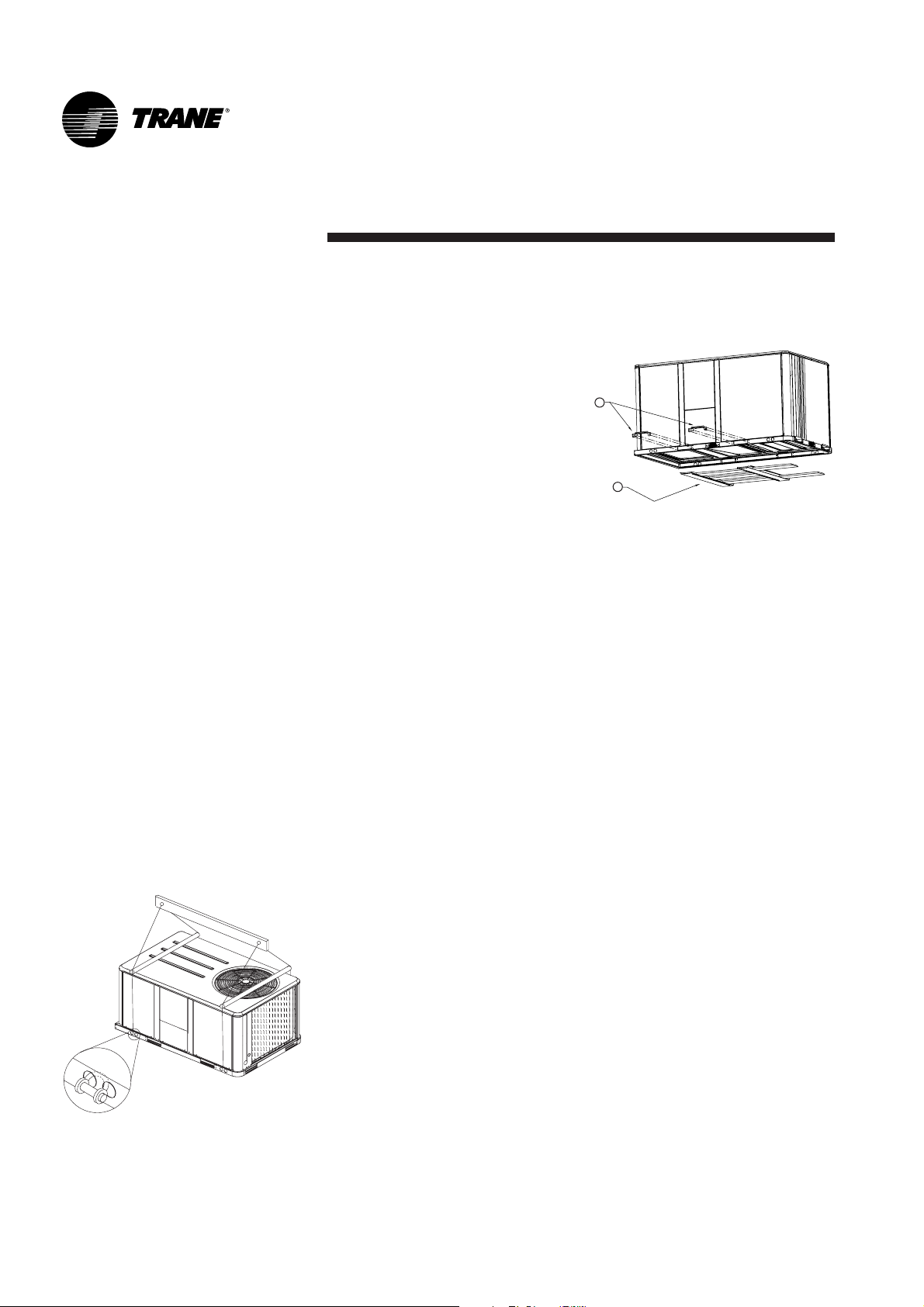

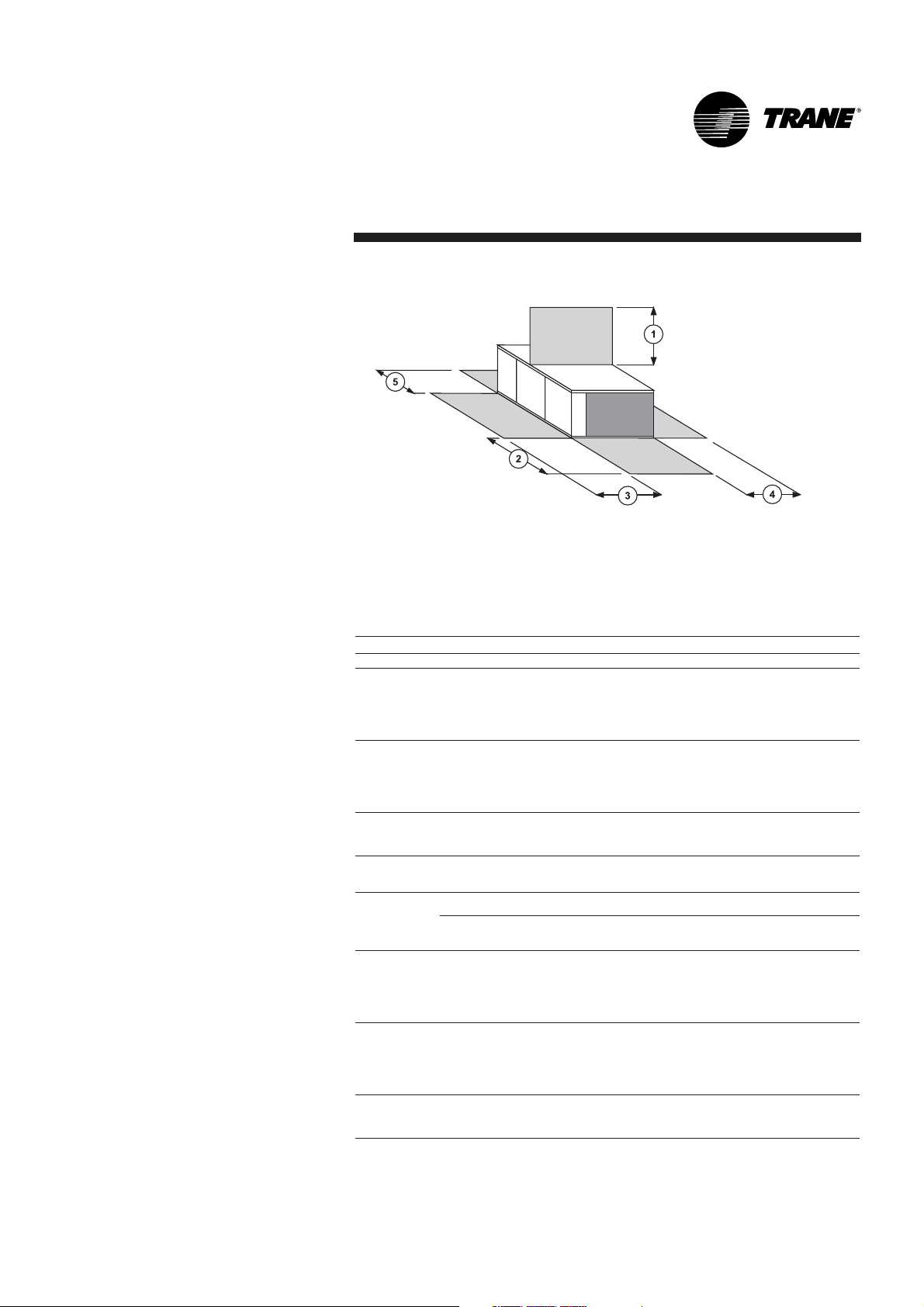

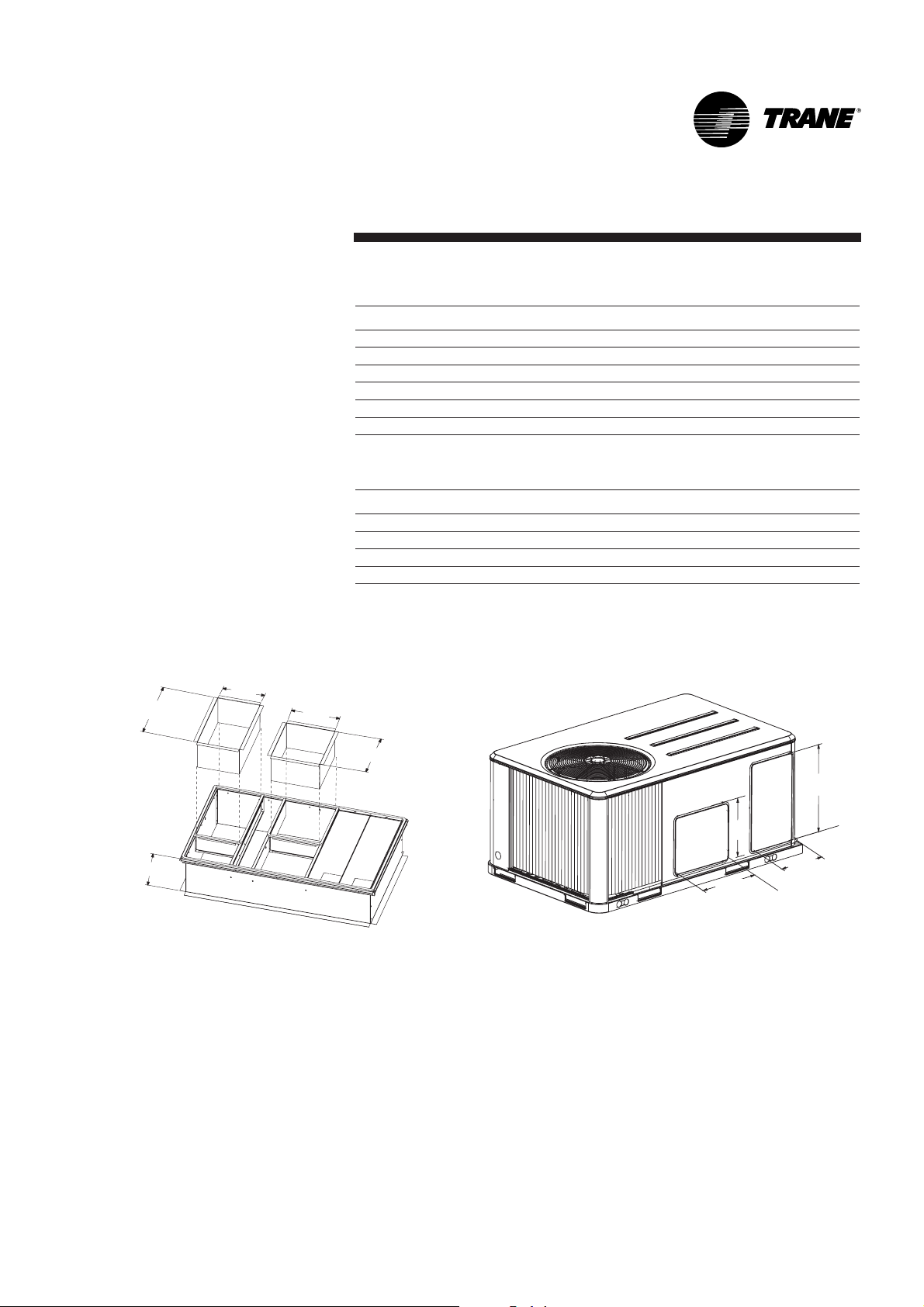

Figure 1 - Unit handing

Roof curb (accessory)

Roof curbs are available as an

accessory for downflow units. The

curbs can be adjustable and

supplied pre-assembled on wooden

pallets, packed under plastic film.

Two types of self-adhesive seals are

provided to ensure the roof curb

seal is leak-tight (40 mm wide for

the perimeter, 20 mm wide for the

crosspieces).

Roof curb Installation

(TSD-WSD-YSD

accessories)

Roof curbs are available as an

accessory for "downflow" units to

support the unit and ensure the

water tightness between the rooftop

and the roof.

The curbs can be adjustable and

supplied pre-assembled on wooden

pallets, packed under plastic film.

Two types of self-adhesive seals are

provided separate. (40 mm wide for

the perimeter, 20 mm wide for the

cross pieces). Make sure they are

properly installed where indicated

to assure an adequate curb to unit

seal.

Instructions for the roof curb

assembly and installation with curb

dimensions are provided with each

roof curb kit.

Figure 2 - Rigging

1 = Remove 2 fork lift brackets

2 = Remove 2 metal runners and 3

wooden boards

Lift the unit enough to allow the

removal of two Fork Lift brackets

and hardware. Remove the two Fork

Lift brackets, two metal runners and

three wooden boards as shown in

Figure 2.

1

2

Page 7

Installation

7RT-SVX20A-E4

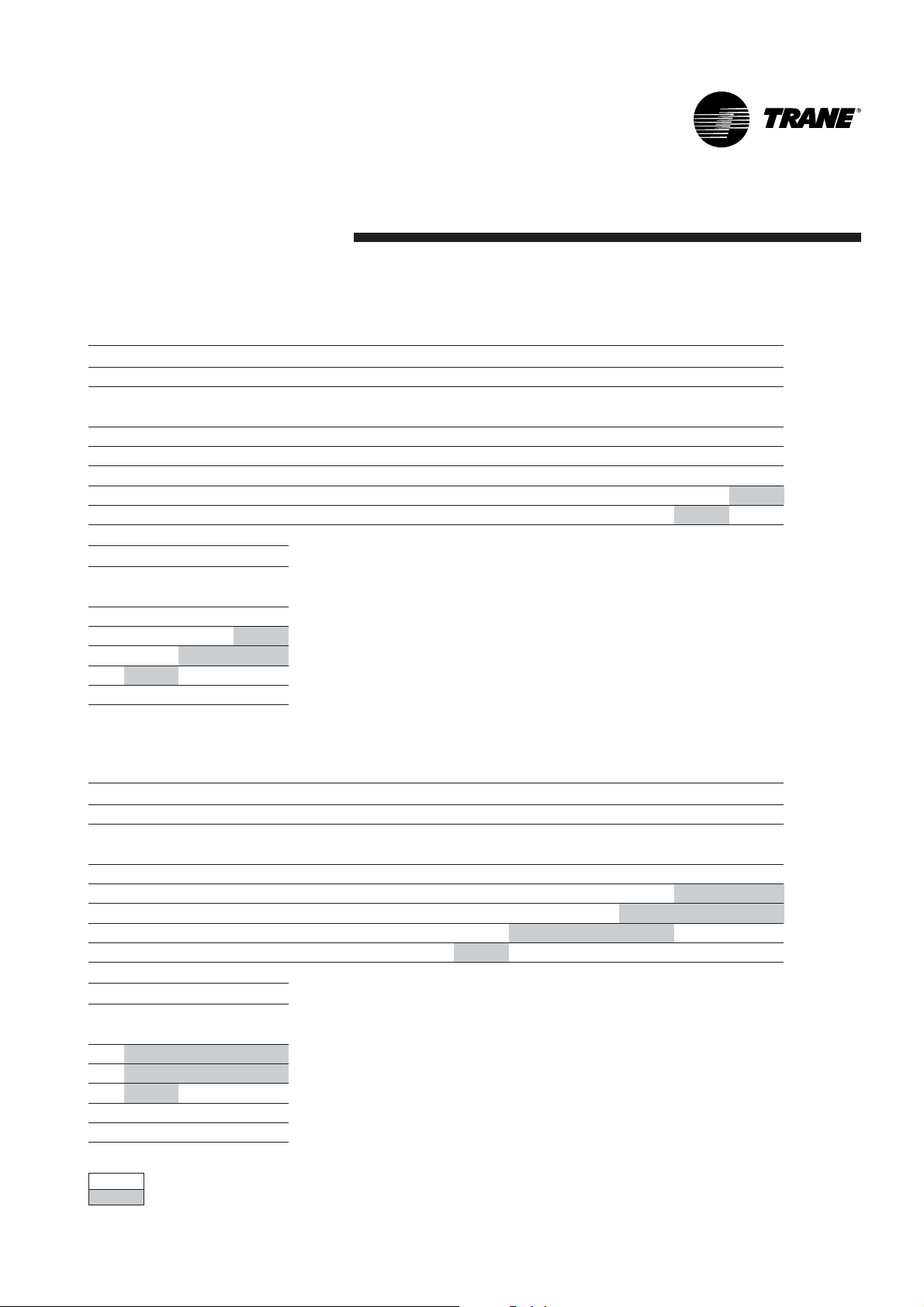

Dimensions/Weights/

Clearances

The structure accommodating the

unit(s) must be designed to support

the equipment in operation, as a

minimum. Refer to Table 2 and the

space requirement plan.

Figure 3 - Minimum clearances

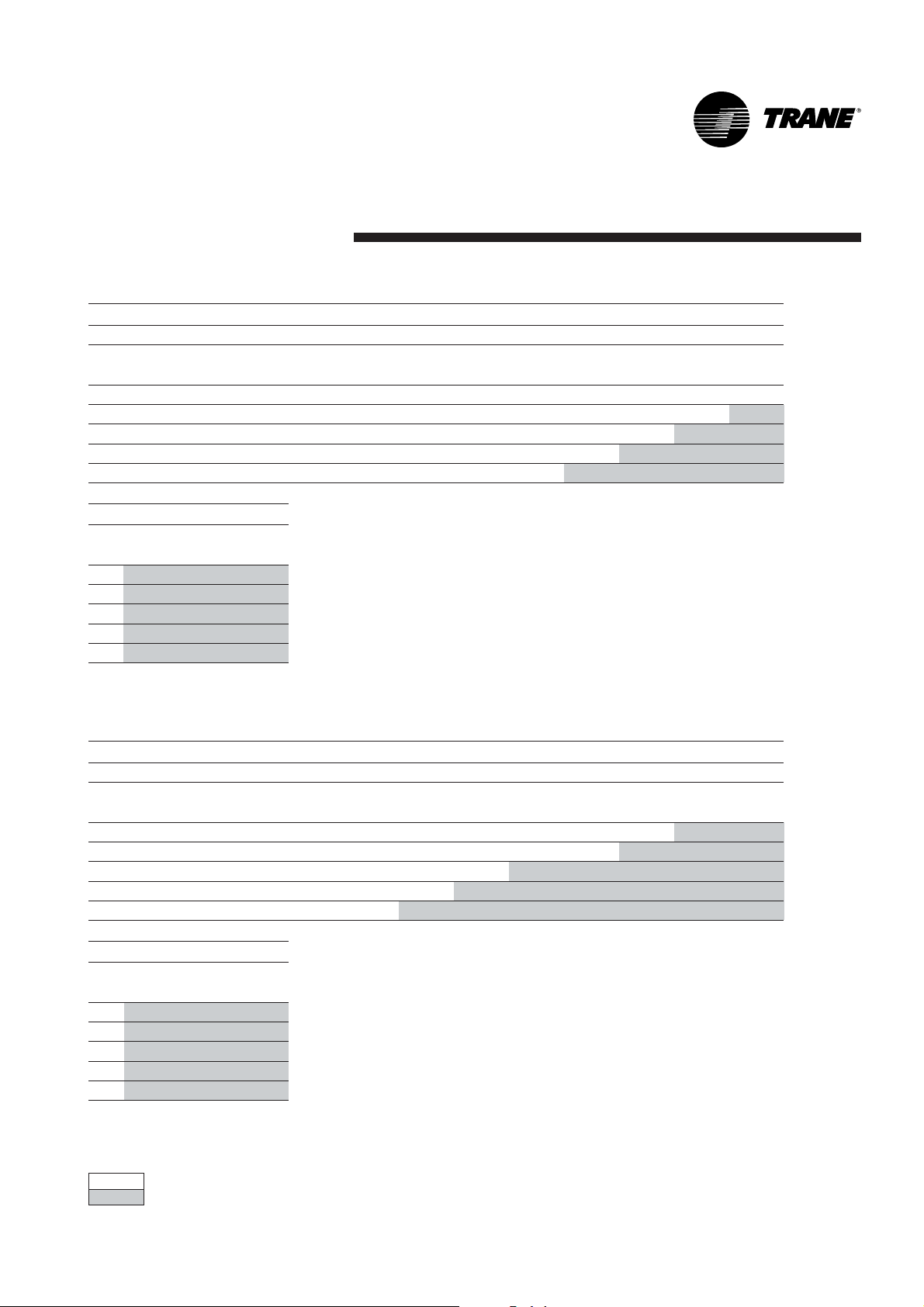

Table 1 - Minimum recommended clearances

Table 2 - Unit weights and center of gravity

Notes:

(1) Corner weights are given for information only. All models must be supported continuously by a curb or

equivalent frame support.

Unit Size

Maximum weight Corner weight (1) Center of gravity

Shipping

(kg)

Net

(kg)

A

(kg)B(kg)C(kg)D(kg)

Length

(mm)

Width

(mm)

TSD/TSH 060 259 235 75 56 48 56 790 480

TSD/TSH 072 365 326 107 83 58 78 970 560

TSD/TSH 090 428 389 131 101 67 89 970 530

TSD/TSH 102 445 405 133 106 72 94 990 560

TSD/TSH 120 485 445 147 115 81 104 990 560

YSD/YSH 060 285 260 81 64 54 62 810 510

YSD/YSH 072 390 350 113 90 64 83 990 560

YSD/YSH 090 458 419 139 110 75 95 970 530

YSD/YSH 102 474 434 141 114 79 100 1020 560

YSD/YSH 120 520 481 155 126 89 111 1020 560

WSD/WSH 060 266 241 77 58 49 58 790 480

WSD/WSH 072 408 368 122 93 66 87 970 560

WSD/WSH 090 418 378 128 95 67 88 970 530

Unit size Mimum clearances (mm)

12345

TSD/TSH 060 1829 1219 914 914 914

TSD/TSH 072 1829 1219 914 914 914

TSD/TSH 090 1829 1219 914 914 914

TSD/TSH 102 1829 1219 914 914 914

TSD/TSH 120 1829 1219 914 914 914

YSD/YSH 060 18 29 1219 914 914 914

YSD/YSH 072 18 29 1219 914 914 914

YSD/YSH 090 18 29 1219 914 914 914

YSD/YSH 102 18 29 1219 914 914 914

YSD/YSH 120 18 29 1219 914 914 914

WSD/WSH 060 1829 1219 914 914 914

WSD/WSH 072 1829 1219 914 914 914

WSD/WSH 090 1829 1219 914 914 914

Page 8

Installation

RT-SVX20A-E48

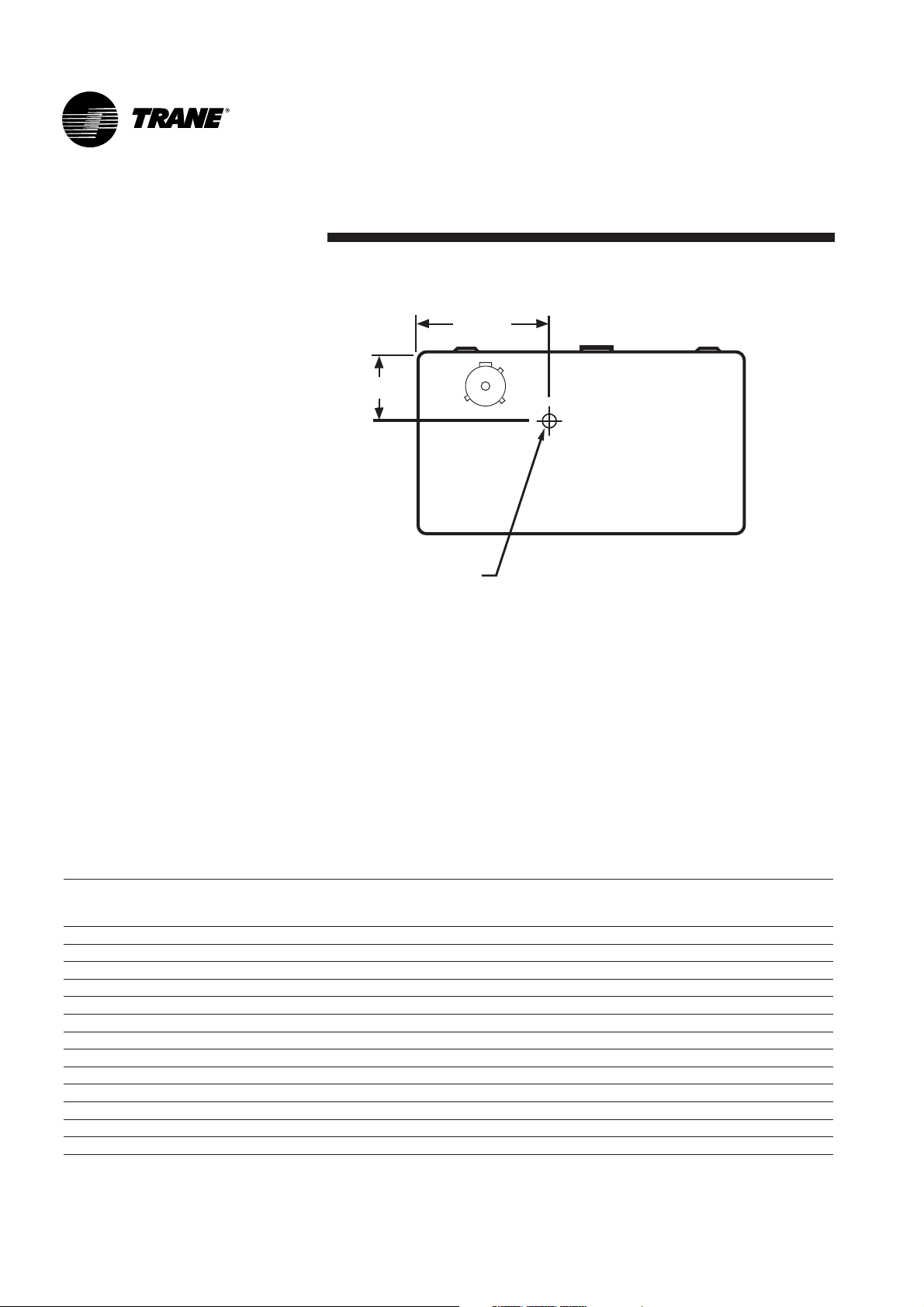

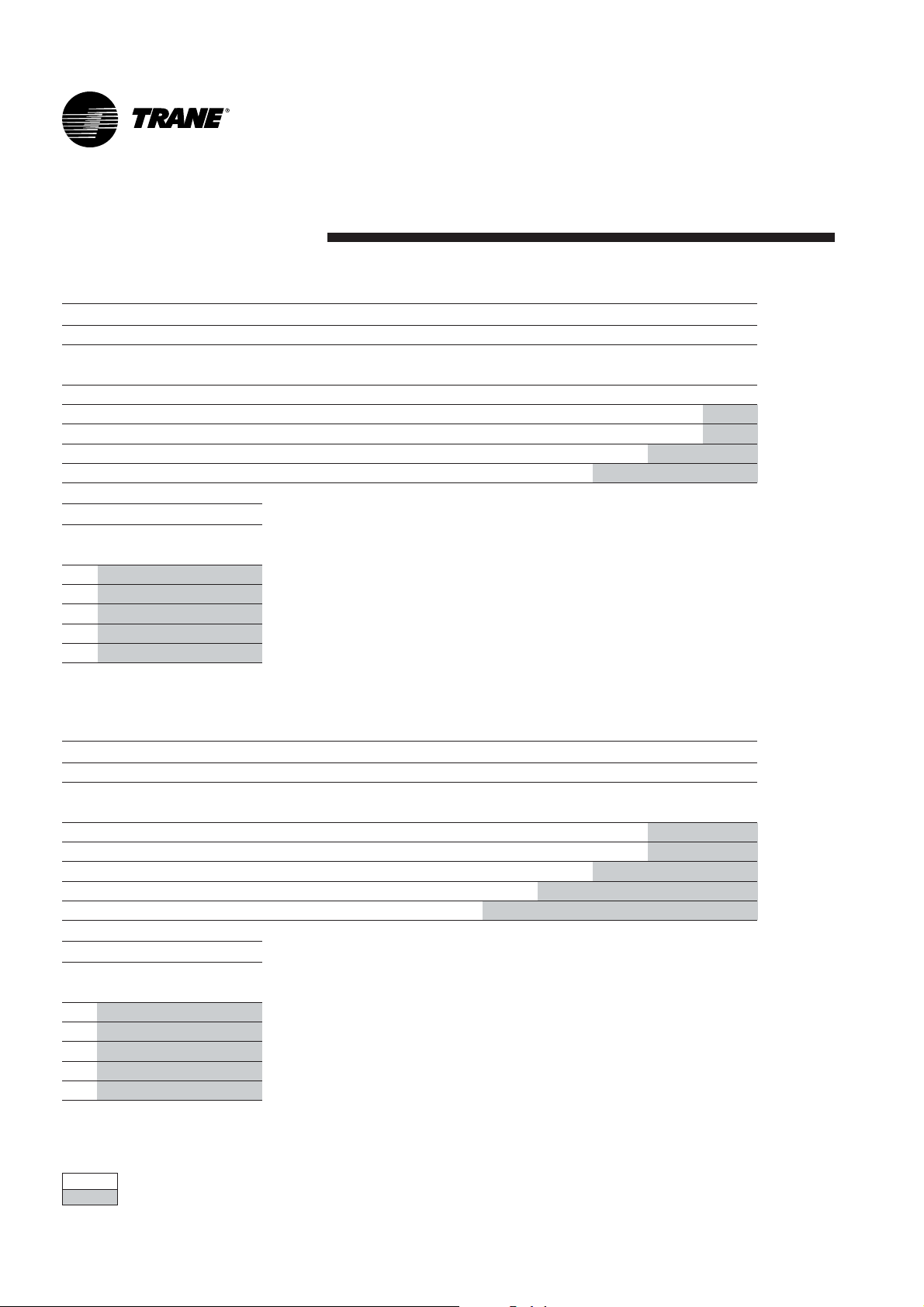

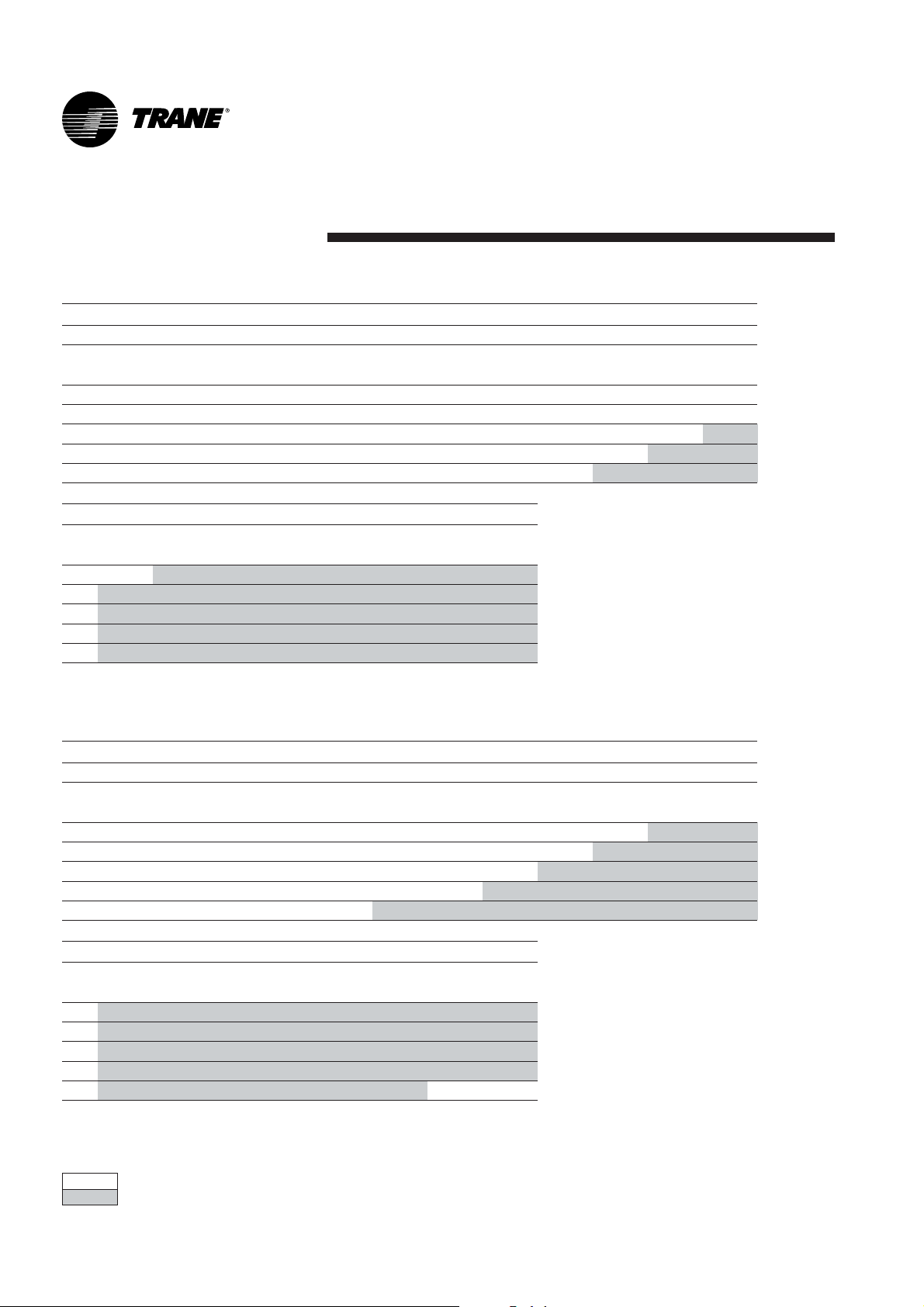

Figure 4

Table 3 - Factory-installed options and accessories net weights (kg)

Notes:

(1) Weights for options not listed are < 3 kg.

(2) Net weight should be added to unit weight when ordering factory-installed accessories.

(3) Some accessories are not available on all units.

Unit size Economizer

Barometric

Relief

Motorized

Outside Air

Damper

Manual

Outside Air

Damper

Roof Curb

Oversized

Motor

Electric

Heaters

Hot water

coil

TSD/TSH 060 11,8 3,2 9,1 7,3 31,8 - 6,8 14,0

TSD/TSH 072 16,3 4,5 13,6 11,8 52,2 3,6 13,6 17,0

TSD/TSH 090 16,3 4,5 13,6 11,8 52,2 3,6 13,6 17,0

TSD/TSH 1020 16,3 4,5 13,6 11,8 52,2 3,6 13,6 19,0

TSD/TSH 120 16,3 4,5 13,6 11,8 52,2 3,6 13,6 19,0

YSD/YSH 060 11,8 3,2 9,1 7,3 31,8 - 6,8

YSD/YSH 072 16,3 4,5 13,6 11,8 52,2 3,6 13,6

YSD/YSH 090 16,3 4,5 13,6 11,8 52,2 3,6 13,6

YSD/YSH 102 16,3 4,5 13,6 11,8 52,2 3,6 13,6

YSD/YSH 120 16,3 4,5 13,6 11,8 52,2 3,6 13,6

WSD/WSH 060 11,8 3,2 9,1 7,3 31,8 - 6,8 14,0

WSD/WSH 072 16,3 4,5 13,6 11,8 52,2 3,6 13,6 17,0

WSD/WSH 090 16,3 4,5 13,6 11,8 52,2 3,6 13,6 17,0

Center of

A

Center of

gravity width

gravity length

B

D

Center of

gravity

C

Page 9

Installation

9RT-SVX20A-E4

Installing the unit

Discharge Conversion

If a unit is to be converted to

Vertical discharge, a panel must be

acquired from Trane.

If a unit is to be converted to

Horizontal discharge, the following

conversion must be performed:

1. Remove the return and supply

duct covers.

2. Apply gasket to the return duct

cover.

3. Position duct covers as shown in

Figure 4. The supply duct cover is

installed (insulation side down)

over the downflow return

opening by engaging one side of

the panel under a retaining angle

and securing the other side with

3 screws.

4. Slide return duct cover

(insulation side up) into supply

openings until outer edge of the

duct cover engages with the two

retaining clips on the duct

flanges. Secure the outer edge of

the each duct cover with two

screws.

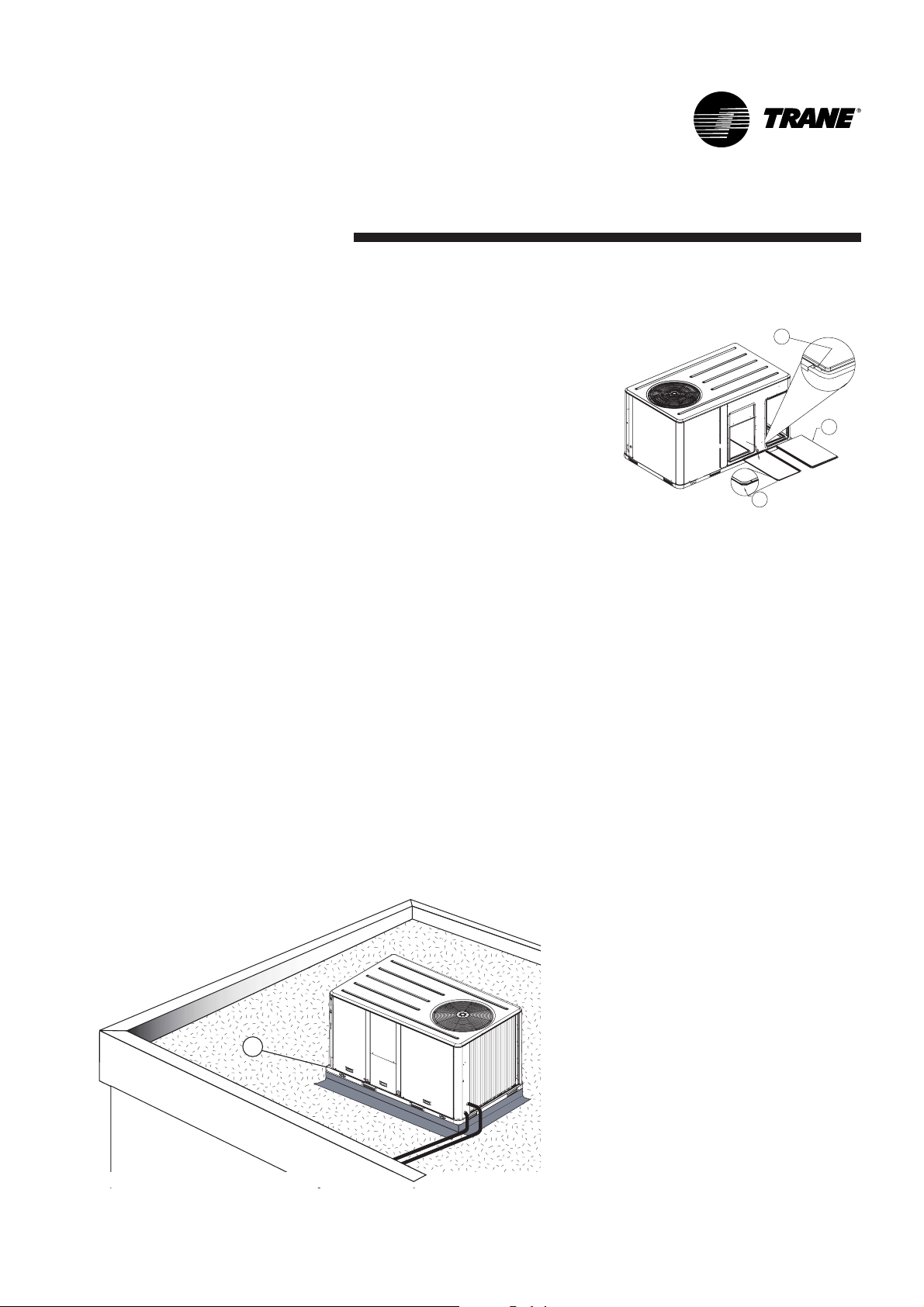

Figure 5 - Conversion to horizontal

discharge

1 = Supply duct cover, insulation side

down

2 = Return duct cover with gasket

installed, insulation side up

3 = Edge of duct cover goes under

retaining angle

Unit mounting on roof

Fix the rooftop curb on the joint

beam of the building's structure.

Make the rooftop curb's sealing

surface level using angle brackets

adjusted by screw bolts, located

around its perimeter. Place the

adhesive seals on the curb's sealing

surface (perimeter and cross

pieces). Make the rooftop leak-tight

around the curbs before installing

the unit, in compliance with current

construction standards.

Note:The unit must be installed

perfectly level to ensure

condensates flow from the

condensate tray.

The rooftop unit nests into the curb

and is supported by it. Position the

unit, taking care to comply with the

indicated directions: the unit's

discharge and intake openings must

match those of the curb.

Figure 6 - Unit mounting on roof

1 = Frame

1

3

1

2

Page 10

Installation

RT-SVX20A-E410

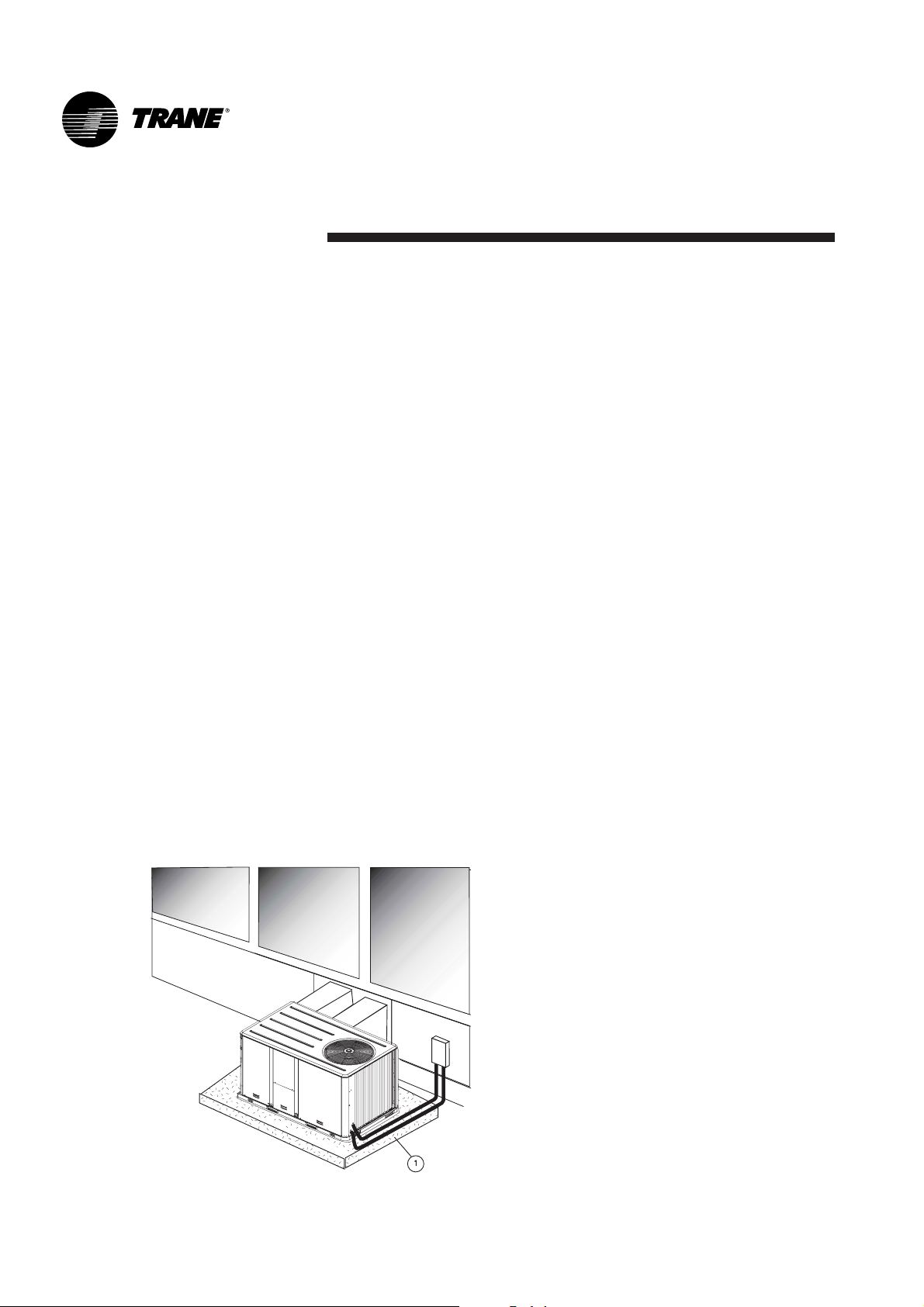

Installing the unit on the ground

To install the unit on the ground, its

base must be level and supported

securely. For horizontal discharge

units, a support is required such as

a metal or concrete slab whose

height must be determined

according to the amount of snow

cover, to prevent problems with

condensation drainage and

obstruction of the external coil. If

necessary use an anti-vibration

material between the rooftop unit's

base and the support.

Note: Unit installation must comply

to local codes

Connection of duct

network

1) Downflow discharge units

(TSD,WSD,YSD)

Using the rooftop curb

• The rooftop curb must be

insulated on the outside walls at

the discharge and intake

openings to prevent

condensation in the ducts.

• The rims around the discharge

and intake openings make it

possible to attach the flanges on

the ends of the ducts. If you are

using rigid duct ends

recommended on the rooftop

curb plan, it is essential to fix

these components before

installing the unit.

• For the design of the duct

network, comply with

recommendations currently

applicable on the market, in

particular:

. Installation of a section of

flexible ducts to limit

transmission of the unit's

vibrations

. Use of movable vanes or

deflectors to reduce the sound

level.

2) Horizontal discharge units

(TSH,WSH,YSH)

• The intake and discharge ducts

must be insulated (thermal

insulation).

• The duct section located outside

must be leak-tight.

• Provide a flexible connector to

prevent transmission of the unit

vibrations. This flexible duct

must be installed inside the

building.

Note: In case of use of units with

economizer option, temperature

and humidity sensors must be

installed in return duct.

Economizer linkage is factory

mounted but the damper position

must be adjusted on site.

Figure 7 - Unit installation on the ground

1 = Concrete slab

Page 11

Installation

11RT-SVX20A-E4

Table 4 - Duct dimensions for downflow units (mm)

Table 5 - Duct dimensions for downflow units (mm)

Unit size ABCD

TSH/WSH 060

591 337 375 438

YSH 060

591 337 375 438

TSH/WSH/YSH 072/090

832 425 606 489

TSH/YSH 102/120

832 425 606 489

Unit size ABCDEFlanges

TSD 060 619 357 411 459 356 32

YSD 060 610 356 394 457 356 32

WSD 060 819 357 411 459 356 32

TSD/WSD 072/090 875 451 451 875 356 31

TSD 102/120 875 451 451 875 356 31

YSD 072/090/102/120 816 444 444 838 356 31

Figure 8 - Duct dimensions for downflow units

S = Supply

R = Return

Figure 9 - Duct dimensions for horizontal units

S = Supply

R = Return

B

A

S

E

C

R

D

A

R

C

S

B

D

Page 12

Installation

RT-SVX20A-E412

Condensate drain piping

A 3/4" condensate drain connection

with P-trap is provided. Follow local

codes and standard piping practices

when running the drain line. Install

a trap and be sure to fill with water

before starting the unit. Pitch the

line downward, away from the unit

to avoid long, level, horizontal runs.

Refer to Figure 11.

The condensate drain is reversible

to allow installation of a drain tap

on either side of the unit.

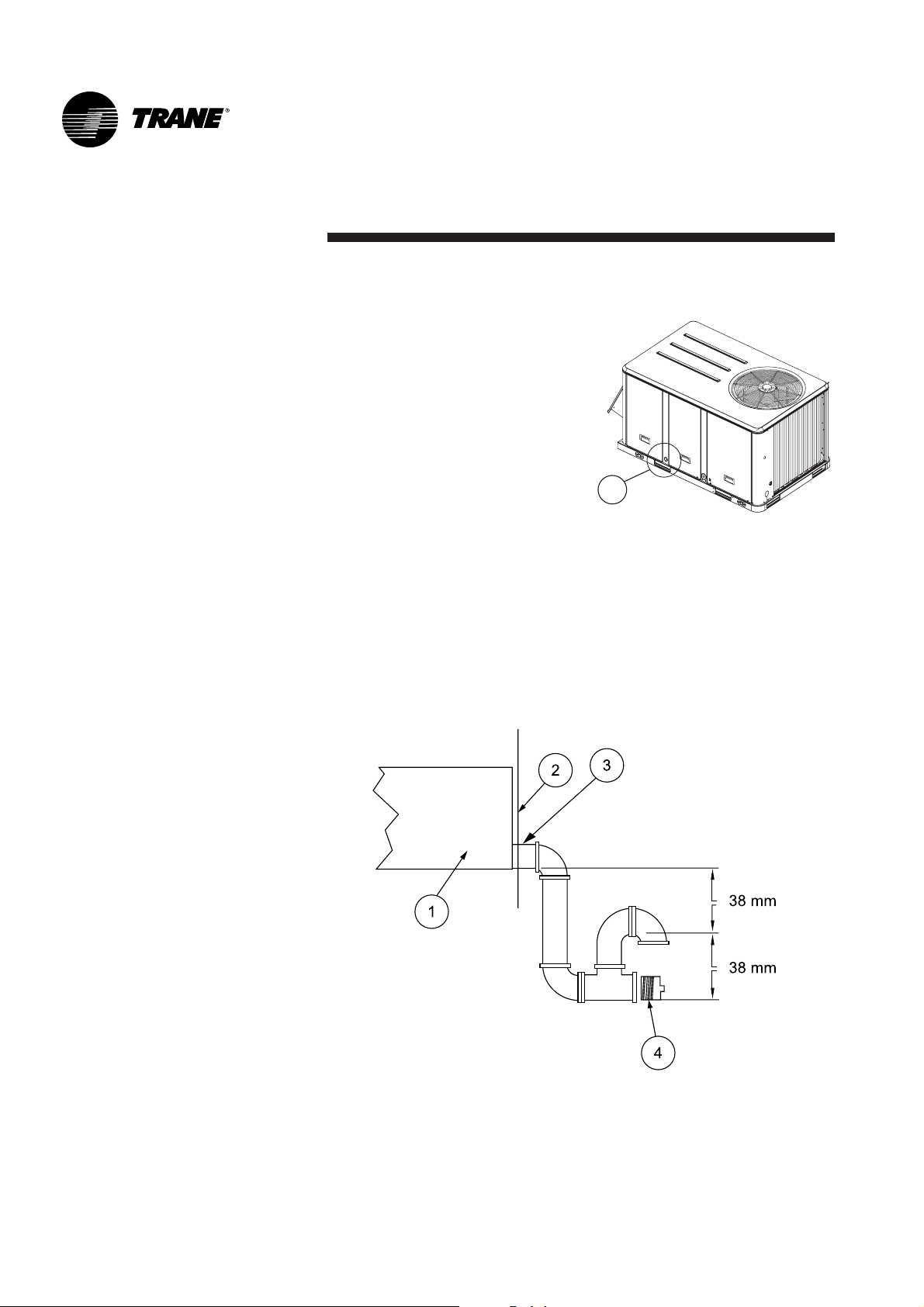

Figure 10 - Condensate drain location

1 = Main condensate drain location

Figure 11 - Condensate drain line location

1 = Static pressure drain pan

2 = Panel enclosure

3 = ¾ " drain

4 = Cleanout plug

1

Page 13

Installation

13RT-SVX20A-E4

Gas pipework installation

The installation must conform to all

standards and regulations.

The gas supply pipework and gas

stop valve to be installed near the

unit must be sized so as to ensure

the gas pressure is sufficient at the

unit inlet when operating at full

load.

CAUTION! Should the pressure at

the unit valve gas inlet be higher

than 0.035 bar, an expansion valve

must be installed.

The pipework must be selfsupporting and the final connection

to the burner must be made by a

flexible pipe. Provide a dust

protection (filter) upstream the unit

connection.

CAUTION!The gas pipework must

not exert any stress on the burner

gas connection.

Note: Expansion valve must be

adapted to the type of gas used:

• G 20: 20 mb

• G 25: 25 mb

• G 31 (Propane): 37 or 50 mb

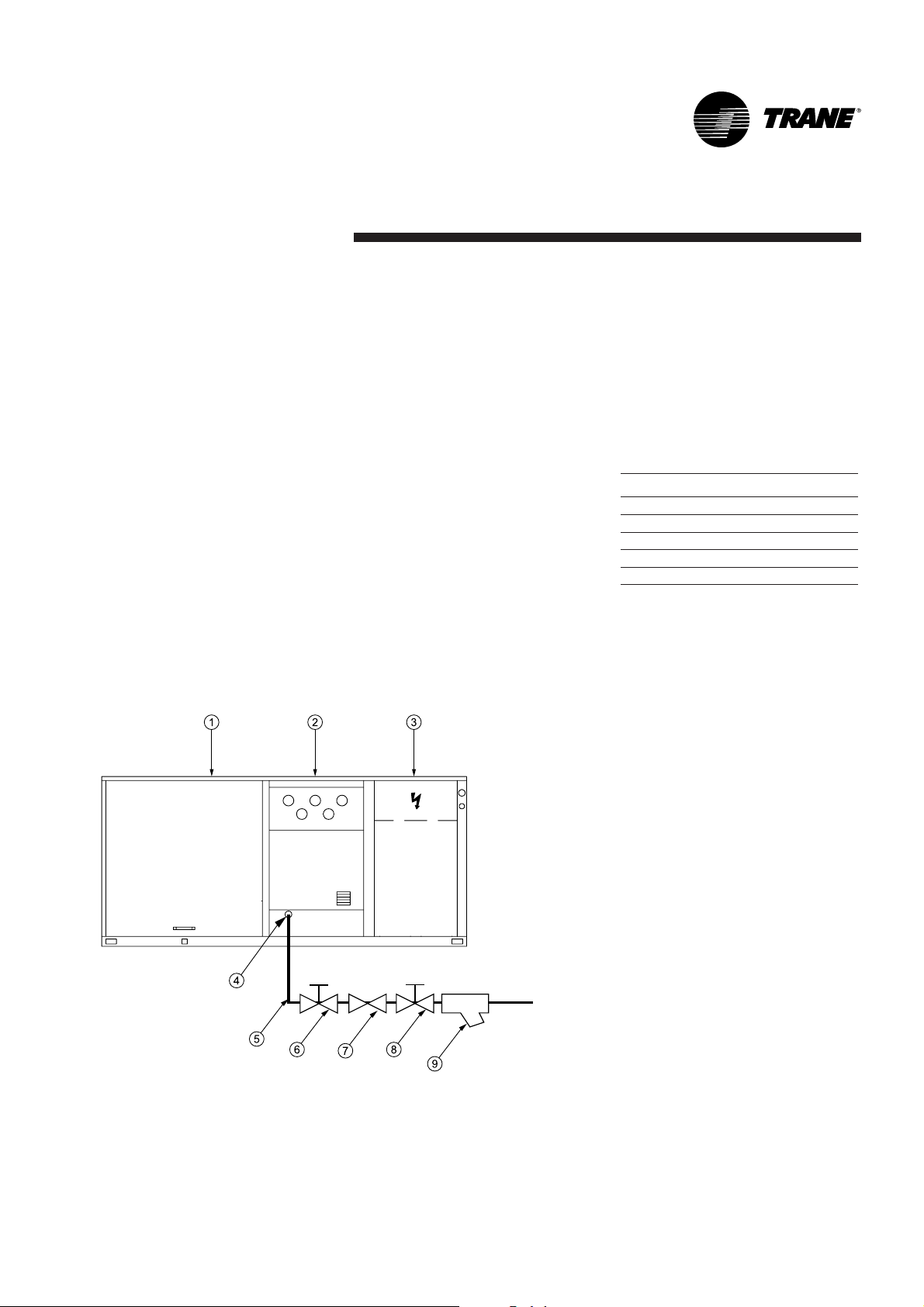

Table 6 - Gas burner models

See Table 51 for burner

performance.

Gas leak check procedure

1. Vent the gas line

2. Gas supply line pressure test:

close valve 4 and open valve 2

3. Leak-check the gas pipe.

Look for gas pipe leaks using

"Typol", "1000 bulles" or a similar

product. Do not use soapy water.

WARNING! Never use an open

flame to check for gas leaks.

Required gas pressure at the unit

inlet connection are given in

Table 50.

Note:To operate with propane gas,

the burner is fitted with a pressure

limiter (supplied by Trane)

Unit Burner size

YSD/YSH 060 G120

YSD/YSH 072 G200

YSD/YSH 090 G200

YSD/YSH 102 G250

YSD/YSH 120 G250

Figure 12 - Typical gas supply pipework

1 = Evaporator section

2 = Gas burner section

3 = Condenser section

4 = Gas supply connection

5 = Gas supply line

6, 8 = Gas stop valve (Field supplied)

7 = Expansion valve (Field supplied)

9 = Filter (Field supplied)

Page 14

Installation

RT-SVX20A-E414

Filter installation

To gain access to filters, remove the

supply fan access panel on

downflow units and the filter access

panel on the end for horizontal

units.

Number and size of filters is

determined by size and

configuration of the unit. If

disposable filters were chosen as an

option, they are shipped in the

supply fan section.

CAUTION! Do not operate unit

without filters in place.

The maximum pressure drops

allowable on filters are:

EU2/G2: 120 Pa

EU4/G4: 150 Pa

Table 7 - Filter arrangement

Unit

EU2/G2 EU4/G4

Quantity Size Quantity Size

TSD/TSH/YSD/YSH/WSD/WSH 060 2 (508x762x25) 2 (500x750x25)

TSD/TSH/YSD/YSH/WSD/WSH 072 4 (406x635x50) 4 (395x625x50)

TSD/TSH/YSD/YSH/WSD/WSH 090 4 (406x635x50) 4 (395x625x50)

TSD/TSH/YSD/YSH 102 4 (508x635x50) 4 (500x625x50)

TSD/TSH/YSD/YSH 120 4 (508x635x50) 4 (500x625x50)

Supply fan adjustment

Use the following procedure to

determine the proper adjustment of

the supply fan for a specific

application.

1. Determine total external static

pressure about system and

accessories.

• Obtain the design airflow rate

and the design external static

pressure drop through the

distribution system.

• Add static pressure drop of the

accessories installed on the unit.

(Table 9)

• Add the total accessory static

pressure drop (from step 1b) to

the design external static

pressure (from step 1a). The sum

of these two values is the total

system external static pressure.

2. Using the Tables 10 through 35 to

find the external static pressure

that most closely approximates

total system external static

pressure. Then locate the

appropriate airflow rate for your

unit. The value obtained

represents the brake horsepower

for the supply fan motor and the

fan RPM.

3. Adjust motor sheave according

to Table 8.

Page 15

Installation

15RT-SVX20A-E4

To adjust belt

The fan belts must be inspected

periodically to assure proper unit

operation. Replacement is

necessary if the belts appear frayed

or worn.

Units with dual belts require a

matched set of belts to ensure equal

belt length.

When removing or installing the

new belts, do not stretch them over

the sheaves. Loosen the belts using

the belt tension adjustment bolts on

the motor mounting base.

Once the new belts are installed,

adjust the belt tension.

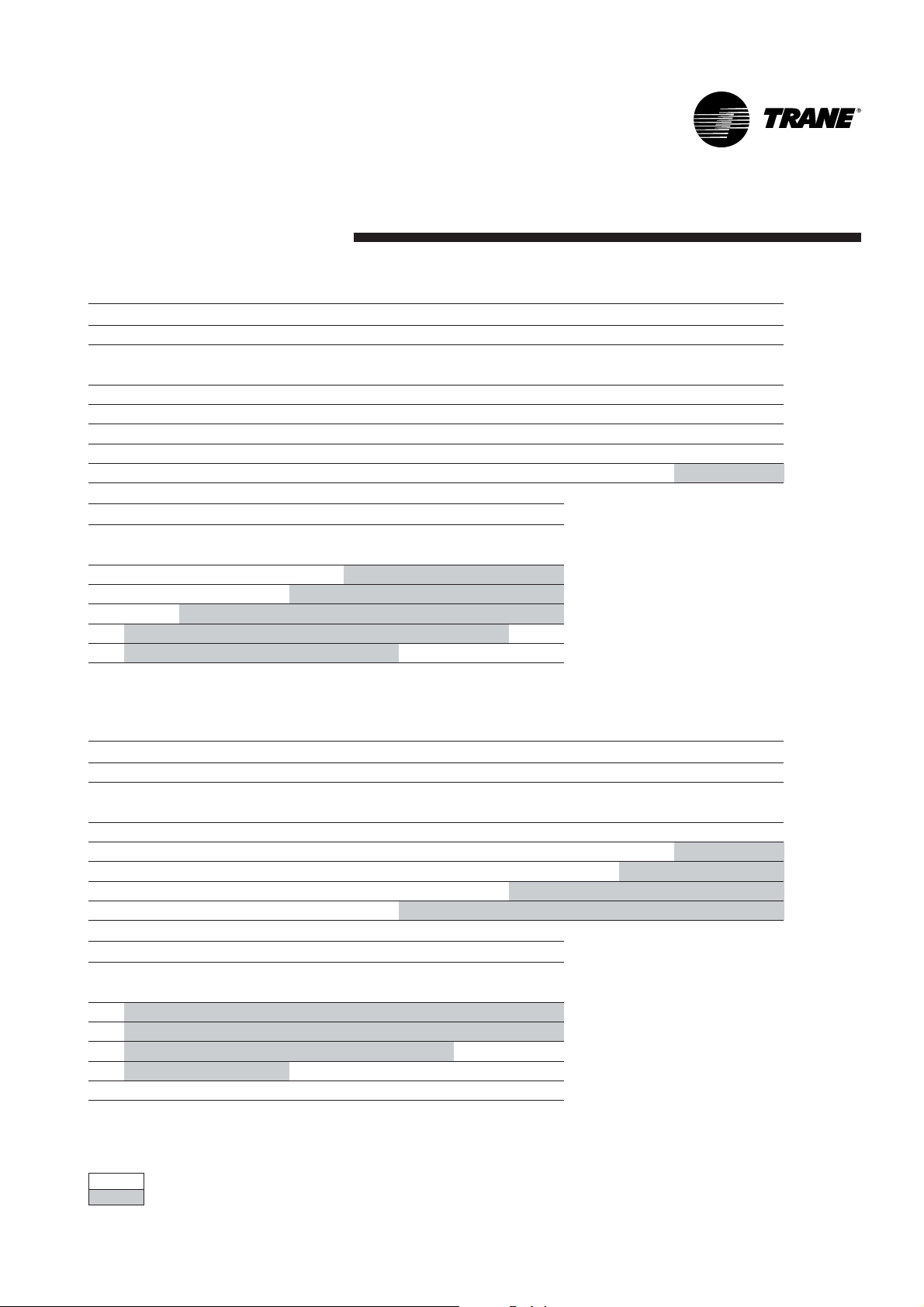

Table 8 - Motor sheave / Fan speed

Fan speed (RPM)

Standard drive & motor

Unit

6 turns

Open

5 turns

Open

4 turns

Open

3 turns

Open

2 turns

Open

1 turns

Open

Closed

TSD/TSH 060 N/A 898 967 1036 1105 1174 1243

TSD/TSH 072 N/A 698 751 806 859 913 967

TSD/TSH 090 N/A 752 806 860 914 968 1020

TSD/TSH 102 N/A 688 737 786 835 885 934

TSD/TSH 120 N/A 782 838 894 950 1006 1062

YSD/YSH 060 N/A 1036 1105 1174 1243 1312 1381

YSD/YSH 072 N/A 806 860 913 968 1022 1074

YSD/YSH 090 859 913 967 1021 1075 1129 N/A

YSD/YSH 102 786 836 885 934 982 1032 N/A

YSD/YSH 120 894 950 1006 1062 1118 1174 N/A

WSD/WSH 060 N/A 898 967 1036 1105 1174 1243

WSD/WSH 072 N/A 698 751 806 859 913 967

WSD/WSH 090 N/A 752 806 860 914 968 1020

Fan speed (RPM)

Oversized drive & motor

Unit

6 turns

Open

5 turns

Open

4 turns

Open

3 turns

Open

2 turns

Open

1 turns

Open

Closed

TSD/TSH 060 N/A 1243 1311 1379 1450 1515 1588

TSD/TSH 072 N/A 967 1021 1075 1128 1183 1235

TSD/TSH 090 1112 1182 1252 1322 1392 1460 N/A

TSD/ T S H 10 2 N/A 97 1 1041 1111 118 1 1251 13 2 1

TSD/TSH 120 1062 1118 1174 1229 1285 1341 N/A

YSD/YSH 060 ------YSD/YSH 072 N/A 967 1021 1075 1128 1183 1235

YSD/YSH 090 1112 1182 1252 1322 1392 1460 N/A

YS D / YS H 102 N/A 971 1041 1111 118 1 1251 1321

YSD/YSH 120 1062 1118 1174 1229 1285 1341 N/A

WSD/WSH 060 N/A 1243 1311 1379 1450 1515 1588

WSD/WSH 072 N/A 967 1021 1075 1128 1183 1235

WSD/WSH 090 1112 1182 1252 1322 1392 1460 N/A

To increase airflow

Loosen variable sheave set screw

and turn sheave clockwise.

To decrease airflow

Loosen variable sheave set screw

and turn sheave counter-clockwise.

Page 16

Component air pressure drops

Table 9 - Pressure drop through accessories

Unit

size

Airflow

(m3/h)

Filter

EU2/G2

Filter

EU4/G4

Economizer

100 %

outside air

Electric

heater

Hot water

coil

060

3060 31 50 38 17 49

34003855462155

3740 46 61 55 25 62

4080 55 66 64 30 68

072

3670 13 37 27 7 46

4080 16 42 29 9 52

4490 19 46 31 11 58

49002350331364

090

4590 19 47 33 12 66

5100 24 52 39 15 74

56102957452083

6120 35 62 52 25 92

102

5200 16 42 40 8 64

5780 20 47 50 10 72

6360 25 52 62 12 81

6940 30 57 75 15 90

120

6120 22 50 52 11 84

68002755621495

7480 33 61 73 17 106

8160 40 66 85 20 117

Installation

RT-SVX20A-E416

Page 17

Installation

17RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 10 - TSD 060 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

2720 - - - - - - ----8990.439440.499850.5410230.5910600.6410930.6911260.74

3060 - - - - - - - - 904 0.49 947 0.54 988 0.58 1028 0.64 1067 0.70 1104 0.76 1138 0.82 1171 0.87

34 0 0 - - - - - - 91 8 0 . 57 95 8 0 . 6 2 99 8 0 . 67 10 3 6 0. 7 1 10 7 3 0. 76 1111 0 .8 2 114 7 0 .8 9 118 2 0. 96 1 2 15 1.0 2

3740 - - - - 930 0.65 977 0.71 1016 0.77 1053 0.82 1089 0.88 1124 0.93 1158 0.98 1191 1.03 1226 1.10 1258 1.17

4080 909 0.71 950 0.76 990 0.80 1034 0.87 1074 0.93 1110 1.00 1143 1.06 1177 1.12 1209 1.17 1241 1.23 1272 1.29 - -

325 350 375

m

3

/h kW kW kW

2720 1160 0.79 1190 0.84 1222 0.90

3060 1203 0.93 1232 0.98 1262 1.04

3400 1246 1.09 1276 1.15 1306 1.21

3740 1290 1.25 - - - -

4080 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 11 - TSH 060 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

2720 - - - - - - 898 0.43 953 0.48 1001 0.54 1045 0.59 1087 0.65 1129 0.71 1168 0.77 1206 0.83 1241 0.89

3060 - - - - 897 0.48 953 0.54 1008 0.60 1058 0.67 1102 0.73 1143 0.79 1181 0.85 1219 0.92 1256 0.99 1291 1.05

34 0 0 - - 9 0 8 0 . 54 9 6 1 0 . 60 1 012 0 .6 7 10 62 0 . 74 1111 0 .8 1 115 7 0 .8 8 119 8 0 .9 5 1 2 37 1. 0 2 12 74 1. 0 9 13 09 1. 16 1 34 3 1.2 4

3740 923 0.63 978 0.69 1028 0.76 1075 0.83 1120 0.91 1166 0.99 1211 1.06 1254 1.14 1294 1.22 1330 1.29 - - - -

4080 997 0.80 1049 0.87 1096 0.94 1140 1.02 1183 1.10 1223 1.18 1266 1.27 - - - - - - - - - -

325 350 375

m

3

/h kW kW kW

2720 1275 0.96 1306 1.02 1338 1.09

3060 1326 1.12 1359 1.19 1390 1.26

3400 1376 1.31 - - - -

3740 - - - - - -

4080 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Supply fan performances

Page 18

Installation

RT-SVX20A-E418

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 12 - TSD 072 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

3260 - - - - - - ----7260.417690.478110.528510.588890.659250.719600.77

3670 - - - - - - - - 706 0.43 751 0.49 792 0.55 832 0.61 871 0.67 908 0.74 944 0.81 978 0.87

4080 - - - - - - - - 732 0.51 777 0.58 818 0.64 856 0.71 893 0.77 930 0.84 964 0.91 998 0.99

4490 - - - - - - 715 0.54 758 0.60 802 0.68 845 0.75 883 0.82 919 0.89 953 0.96 986 1.04 1019 1.11

4890 - - - - 706 0.58 749 0.64 789 0.71 830 0.79 870 0.87 909 0.95 945 1.02 979 1.10 1011 1.18 1043 1.26

325 350 375

m

3

/h kW kW kW

3260 994 0.83 1026 0.89 1057 0.95

3670 1010 0.94 1043 1.01 1073 1.08

4080 1030 1.06 1063 1.14 1092 1.21

4490 1051 1.19 1082 1.27 1112 1.35

4890 1073 1.34 1103 1.42 1133 1.51

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 13 - TSH 072 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

3260 - - - - - - - - 726 0.39 771 0.45 814 0.51 857 0.57 899 0.63 939 0.70 978 0.76 1015 0.83

3670 - - - - - - 716 0.42 762 0.48 804 0.54 843 0.60 883 0.67 922 0.74 960 0.81 996 0.87 1034 0.95

4080 - - - - 701 0.45 751 0.51 798 0.59 839 0.65 877 0.71 914 0.78 950 0.85 984 0.93 1020 1.00 1055 1.08

4490 - - 710 0.51 745 0.56 788 0.62 833 0.69 875 0.77 914 0.85 949 0.91 984 0.98 1016 1.06 1049 1.14 1081 1.23

4890 726 0.58 762 0.64 795 0.70 828 0.76 869 0.82 911 0.91 950 0.99 986 1.07 1019 1.14 1051 1.22 1081 1.30 1112 1.38

325 350 375

m

3

/h kW kW kW

3260 1051 0.90 1086 0.97 1118 1.04

3670 1069 1.02 1103 1.09 1136 1.17

4080 1089 1.16 1122 1.23 1154 1.31

4490 1113 1.31 1144 1.40 1176 1.48

4890 1141 1.47 1170 1.57 1199 1.66

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 19

Installation

19RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 14 - TSD 090 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4080 - - - - - - - - 750 0.54 794 0.60 834 0.67 873 0.73 909 0.80 945 0.87 980 0.95 1013 1.02

4590 - - - - - - - - 787 0.66 830 0.74 871 0.82 908 0.89 943 0.96 977 1.04 1010 1.11 1043 1.19

5100 - - - - 747 0.68 789 0.74 827 0.82 867 0.90 906 0.98 944 1.06 980 1.15 1013 1.23 1045 1.31 1076 1.39

56 10 - - 7 55 0 .7 7 7 9 7 0 .8 5 8 3 6 0 .9 2 8 7 3 1. 0 0 9 0 8 1. 0 8 94 4 1. 17 98 0 1. 26 101 6 1. 35 1 05 0 1. 45 1 08 1 1.5 4 1111 1. 63

6120 771 0.88 809 0.96 848 1.06 885 1.14 921 1.22 954 1.30 986 1.39 1019 1.49 1052 1.58 1085 1.69 1116 1.79 1148 1.89

325 350 375

m

3

/h kW kW kW

4080 1046 1.10 1076 1.17 1106 1.25

4590 1074 1.27 1105 1.36 1134 1.44

5100 1105 1.47 1134 1.56 1163 1.65

5610 1141 1.72 1168 1.80 1197 1.90

6120 1177 1.99 1204 2.08 1232 2.18

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 15 - TSH 090 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4080 - - - - - - 769 0.54 814 0.61 855 0.67 893 0.73 929 0.81 965 0.88 999 0.96 1035 1.04 1070 1.12

4590 - - - - 773 0.62 817 0.68 862 0.76 904 0.85 941 0.92 975 0.98 1009 1.06 1041 1.14 1073 1.22 1104 1.31

5100 771 0.68 805 0.74 837 0.81 870 0.87 912 0.94 951 1.03 989 1.12 1025 1.21 1056 1.28 1088 1.36 1117 1.44 1146 1.53

5610 842 0.89 873 0.96 903 1.03 930 1.10 963 1.17 1000 1.25 1037 1.34 1073 1.45 1106 1.55 1136 1.63 1165 1.72 1194 1.80

6120 913 1.14 942 1.22 970 1.30 996 1.37 1021 1.45 1052 1.52 1086 1.61 1121 1.71 1153 1.82 1184 1.93 1215 2.04 1242 2.13

325 350 375

m

3

/h kW kW kW

4080 1104 1.19 1137 1.27 1168 1.35

4590 1136 1.40 1167 1.48 1198 1.57

5100 1176 1.62 1205 1.72 1233 1.82

5610 1220 1.88 1248 1.98 1275 2.08

6120 1269 2.22 1295 2.31 1319 2.40

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 20

Installation

RT-SVX20A-E420

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 16 - TSD 102 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4620 - - - - - - ----6950.627330.717690.818020.908331.008631.118921.21

5200 - - - - - - - - 688 0.64 725 0.73 761 0.83 796 0.93 828 1.03 861 1.13 891 1.24 919 1.35

5780 - - - - - - 689 0.68 724 0.76 759 0.86 792 0.96 825 1.07 856 1.18 887 1.28 917 1.40 946 1.51

6350 - - - - 693 0.72 729 0.82 764 0.92 795 1.01 826 1.11 857 1.22 887 1.34 916 1.46 945 1.58 974 1.70

6930 - - 706 0.80 738 0.89 770 0.98 804 1.09 834 1.19 864 1.30 892 1.40 920 1.52 948 1.64 976 1.78 1002 1.91

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

4620 920 1.33 946 1.44 973 1.55 999 1.67 1025 1.79 1050 1.90 1073 2.02 1098 2.14

5200 946 1.46 973 1.58 999 1.71 1024 1.83 1048 1.96 1072 2.09 1096 2.22 1119 2.34

5780 974 1.63 1001 1.75 1026 1.88 1051 2.01 1074 2.14 1099 2.27 1121 2.41 1143 2.55

6350 1001 1.82 1028 1.95 1054 2.08 1079 2.20 1103 2.34 1126 2.48 1148 2.62 1170 2.76

6930 1029 2.04 1055 2.17 1081 2.30 1105 2.43 1130 2.58 1154 2.72 1176 2.85 1199 3.01

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 17 - TSH 102 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4620 - - - - - - 689 0.58 734 0.67 781 0.77 826 0.88 865 0.98 898 1.07 928 1.16 956 1.25 982 1.33

5200 - - - - 693 0.64 735 0.73 773 0.82 812 0.92 855 1.03 897 1.15 934 1.27 969 1.38 999 1.49 1026 1.58

5780 - - 711 0.75 743 0.82 781 0.91 819 1.01 853 1.11 886 1.21 925 1.34 964 1.47 1000 1.60 1034 1.73 1067 1.86

6350 735 0.89 770 0.97 799 1.04 830 1.12 865 1.23 899 1.34 930 1.45 960 1.56 994 1.68 1028 1.82 1063 1.96 1098 2.11

6930 796 1.14 828 1.23 857 1.31 883 1.39 913 1.48 945 1.60 977 1.72 1006 1.84 1034 1.96 1061 2.08 1093 2.23 1125 2.38

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

4620 1008 1.42 1033 1.51 1056 1.60 1079 1.69 1102 1.78 1125 1.87 1146 1.95 1168 2.04

5200 1052 1.68 1078 1.78 1101 1.88 1124 1.98 1146 2.08 1168 2.18 1188 2.27 1209 2.37

5780 1094 1.97 1120 2.08 1145 2.20 1168 2.31 1191 2.42 1213 2.53 1234 2.63 1254 2.74

6350 1129 2.26 1158 2.40 1185 2.53 1210 2.66 1234 2.78 1256 2.90 1278 3.03 1299 3.15

6930 1157 2.53 1188 2.70 1218 2.86 1245 3.01 1273 3.16 1297 3.31 - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 21

Installation

21RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 18 - TSD 120 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

5440 - - - - - - ------7890.938221.038561.148871.259171.369451.47

6120 ----------7970.998291.108601.228921.349221.469511.579791.69

6800 - - - - - - 782 1.01 814 1.11 844 1.21 874 1.32 903 1.44 932 1.56 960 1.69 988 1.82 1015 1.95

7480 - - - - 803 1.14 834 1.24 864 1.36 894 1.48 922 1.59 948 1.70 975 1.82 1001 1.95 1028 2.09 1053 2.23

8160 803 1.21 833 1.31 861 1.42 887 1.52 916 1.64 945 1.77 972 1.90 997 2.02 1022 2.14 1046 2.27 1071 2.41 1095 2.55

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

5440 973 1.60 999 1.72 1024 1.84 1048 1.97 1072 2.10 1095 2.23 1117 2.37 1140 2.51

6120 1007 1.82 1033 1.94 1059 2.07 1082 2.20 1107 2.34 1130 2.49 1152 2.63 1173 2.77

6800 1042 2.08 1068 2.21 1093 2.35 1117 2.48 1142 2.63 1164 2.76 1187 2.91 1209 3.06

7480 1078 2.38 1103 2.52 1128 2.66 1152 2.81 1176 2.95 1198 3.10 1221 3.25 - -

8160 1119 2.70 1142 2.86 1166 3.02 1189 3.17 1212 3.33 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 19 - TSH 120 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

5440 - - - - - - - - 807 0.94 844 1.04 886 1.16 926 1.28 965 1.41 1000 1.53 1029 1.64 1057 1.75

6120 - - - - 792 0.99 829 1.08 865 1.19 898 1.30 930 1.41 965 1.53 1002 1.67 1038 1.81 1072 1.95 1106 2.10

68 0 0 8 02 1. 13 8 3 3 1. 2 2 8 6 0 1.2 9 89 0 1.3 8 9 23 1. 50 9 5 6 1. 62 9 8 6 1.7 3 10 15 1. 8 5 104 4 1. 9 8 107 7 2 .1 2 1111 2 . 28 114 3 2. 4 3

7480 876 1.49 905 1.58 931 1.67 955 1.75 983 1.86 1014 1.99 1045 2.12 1072 2.25 1098 2.37 1125 2.51 1152 2.65 1182 2.81

8160 950 1.91 977 2.02 1002 2.11 1025 2.20 1048 2.30 1074 2.42 1102 2.56 1131 2.71 1156 2.84 1181 2.98 1205 3.12 1229 3.27

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

5440 1084 1.86 1108 1.96 1132 2.06 1155 2.17 1177 2.27 1198 2.37 1219 2.48 1239 2.58

6120 1134 2.22 1160 2.35 1185 2.47 1209 2.59 1231 2.70 1252 2.82 1274 2.94 1295 3.06

6800 1174 2.58 1204 2.74 1232 2.90 1260 3.05 1283 3.18 1306 3.32 - - - -

748012112.9712413.1412703.31----------

8160 ----------------

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 22

Installation

RT-SVX20A-E422

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 20 - YSD 060 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

2720 - - - - - - --------10430.6210780.6711130.7211450.7711770.82

3060 - - - - - - ------10660.7011030.7611370.8211690.8712020.9312320.98

3400 - - - - - - - - 1052 0.73 1089 0.79 1126 0.85 1162 0.92 1196 0.98 1229 1.05 1260 1.11 1289 1.17

3740 - - - - 1051 0.82 1087 0.87 1122 0.92 1156 0.98 1190 1.03 1224 1.10 1257 1.17 1288 1.24 1320 1.32 - -

4080 1055 0.90 1093 0.97 1127 1.03 1160 1.09 1193 1.15 1225 1.20 1256 1.26 1288 1.32 - - - - - - - -

325 350 375

m

3

/h kW kW kW

2720 1208 0.87 1238 0.93 1268 0.98

3060 1262 1.04 1290 1.09 1319 1.15

3400 1319 1.24 1347 1.30 - -

3740 - - - - - -

4080 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 21 - YSH 060 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

2720 - - - - - - ----10690.631111 0 . 6 8 1151 0 .74 11 8 9 0. 8 0 1 22 5 0. 8 7 1 2 60 0. 93 1 29 3 0. 9 9

3060 - - - - - - 1056 0.66 1100 0.73 1141 0.79 1180 0.85 1218 0.92 1255 0.98 1290 1.05 1324 1.12 1357 1.19

3400 - - 1033 0.70 1083 0.77 1131 0.84 1176 0.91 1216 0.98 1253 1.05 1289 1.13 1323 1.20 1357 1.27 - - - -

3740 1072 0.83 1117 0.90 1163 0.98 1209 1.06 1251 1.14 1292 1.21 1329 1.29 - - - - - - - - - -

4080 1161 1.06 1203 1.14 1245 1.23 1287 1.31 - - - - - - - - - - - - - - - -

325 350 375

m

3

/h kW kW kW

2720 1324 1.06 1355 1.13 1383 1.20

3060 1390 1.26 - - - -

3400------

3740 - - - - - -

4080 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 23

Installation

23RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 22 - YSD 072 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

3260 - - - - - - ------8200.548590.608960.669320.729680.7810000.84

3670 - - - - - - ----8140.588540.648910.719280.789630.849960.9110280.98

4080 - - - - - - - - 814 0.64 853 0.70 890 0.77 926 0.84 961 0.91 994 0.98 1027 1.05 1058 1.13

4490 - - - - - - 815 0.70 857 0.77 894 0.84 929 0.91 963 0.98 996 1.06 1028 1.14 1060 1.22 1090 1.29

4890 - - - - 818 0.77 860 0.85 899 0.93 936 1.01 970 1.08 1003 1.16 1035 1.24 1066 1.32 1096 1.40 1125 1.48

325 350 375

m

3

/h kW kW kW

3260 1033 0.90 1063 0.96 1094 1.03

3670 1061 1.05 1091 1.12 1121 1.18

4080 1090 1.21 1118 1.28 1149 1.36

4490 1120 1.38 1150 1.46 1178 1.54

4890 1155 1.57 1181 1.66 1210 1.75

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 23 - YSH 072 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

3260 - - - - - - ----8240.528660.599070.659470.719860.7810230.8410590.92

3670 - - - - - - - - 826 0.57 865 0.64 903 0.71 943 0.78 979 0.84 1017 0.91 1053 0.98 1087 1.06

4080 - - - - - - 836 0.64 874 0.70 911 0.77 947 0.84 982 0.92 1017 1.00 1051 1.07 1085 1.15 1119 1.23

4490 - - - - 847 0.72 888 0.80 924 0.86 959 0.93 993 1.00 1026 1.08 1058 1.17 1089 1.25 1122 1.34 1153 1.42

4890 818 0.74 858 0.81 900 0.88 940 0.97 977 1.05 1010 1.13 1042 1.20 1073 1.27 1104 1.36 1133 1.45 1163 1.54 1192 1.64

325 350 375

m

3

/h kW kW kW

3260 1093 0.98 1126 1.06 1156 1.12

3670 1121 1.13 1153 1.21 1185 1.29

4080 1151 1.30 1182 1.38 1214 1.47

4490 1184 1.50 1215 1.59 - -

4890 1221 1.72 - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 24

Installation

RT-SVX20A-E424

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 24 - YSD 090 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4080 - - - - - - ----8690.739060.809410.879760.9410091.0110421.0910731.17

4590 - - - - - - - - 887 0.85 922 0.92 958 0.99 991 1.07 1024 1.14 1055 1.22 1086 1.30 1117 1.39

5100 - - - - 865 0.89 905 0.98 943 1.06 979 1.15 1012 1.23 1044 1.31 1075 1.39 1105 1.47 1134 1.56 1163 1.65

5610 858 0.97 894 1.05 929 1.13 965 1.22 1001 1.32 1036 1.41 1068 1.50 1099 1.59 1129 1.68 1157 1.77 1185 1.86 1212 1.95

6120 930 1.24 963 1.33 995 1.42 1028 1.51 1061 1.61 1093 1.71 1126 1.82 1157 1.92 1185 2.02 1212 2.11 1239 2.21 1265 2.31

325 350 375

m

3

/h kW kW kW

4080 1104 1.24 1134 1.32 1163 1.40

4590 1146 1.47 1174 1.56 1203 1.65

5 10 0 11 9 1 1. 74 1 2 1 8 1. 8 3 1 2 4 5 1. 9 2

5610 1238 2.04 1265 2.14 1292 2.24

6120 1290 2.40 1316 2.51 1340 2.61

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 25 - YSH 090 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4080 - - - - - - 851 0.67 889 0.73 926 0.80 962 0.88 997 0.95 1031 1.03 1067 1.11 1101 1.19 1134 1.26

4590 - - - - 880 0.80 919 0.88 955 0.94 989 1.01 1022 1.09 1054 1.17 1086 1.26 1117 1.35 1148 1.43 1180 1.52

5100 869 0.87 910 0.94 950 1.03 989 1.12 1023 1.21 1056 1.28 1086 1.36 1116 1.43 1146 1.52 1175 1.62 1204 1.72 1232 1.81

5610 949 1.14 985 1.22 1023 1.30 1058 1.40 1092 1.51 1124 1.60 1154 1.68 1182 1.77 1210 1.85 1237 1.94 1264 2.04 1290 2.14

6120 1029 1.47 1061 1.55 1096 1.64 1130 1.74 1162 1.85 1193 1.96 1222 2.06 1250 2.16 1276 2.25 1302 2.34 1327 2.43 1352 2.53

325 350 375

m

3

/h kW kW kW

4080 1166 1.34 1197 1.42 1229 1.50

4590 1210 1.60 1241 1.69 1269 1.78

5100 1260 1.91 1287 2.00 1316 2.10

5610 1316 2.25 1342 2.36 1367 2.46

6120 1376 2.64 1401 2.75 1425 2.87

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 25

Installation

25RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 26 - YSD 102 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4620 - - - - - - ------7870.858190.968501.068791.179071.279341.39

5200----------7940.928271.028591.138901.239181.349461.469711.58

5780 - - - - - - - - 805 1.00 837 1.11 869 1.22 900 1.33 929 1.44 959 1.56 986 1.68 1011 1.80

6350 - - - - 792 1.00 823 1.10 854 1.21 884 1.33 914 1.45 943 1.57 971 1.69 999 1.81 1025 1.94 1051 2.06

6930 786 1.03 818 1.14 848 1.24 877 1.34 905 1.46 933 1.58 961 1.71 988 1.84 1015 1.97 1041 2.10 1067 2.23 1092 2.36

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

4620 960 1.50 987 1.62 1013 1.73 1038 1.85 1064 1.97 1087 2.09 1111 2 .2 1 113 4 2. 3 4

5200 997 1.70 1023 1.83 1047 1.95 1070 2.08 1094 2.21 1117 2.34 1140 2.47 1163 2.60

5780 1037 1.93 1061 2.06 1085 2.19 1107 2.33 1130 2.46 1151 2.60 1174 2.75 1194 2.88

6350 1077 2.19 1100 2.32 1123 2.46 1147 2.61 1168 2.75 1189 2.89 1211 3.04 1231 3.19

6930 1117 2.50 1140 2.64 1164 2.78 1187 2.92 1208 3.07 1229 3.22 - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 27 - YSH 102 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4620 - - - - - - 787 0.79 831 0.89 869 0.99 901 1.08 931 1.17 959 1.26 986 1.35 1011 1.43 1036 1.52

5200 - - - - 798 0.88 841 1.00 883 1.11 923 1.23 958 1.35 989 1.45 1017 1.55 1045 1.65 1070 1.75 1094 1.85

5780 793 0.94 830 1.04 863 1.14 898 1.25 937 1.37 975 1.51 1011 1.64 1045 1.77 1075 1.89 1103 2.01 1128 2.12 1152 2.23

6350 865 1.23 899 1.34 930 1.45 961 1.56 994 1.68 1028 1.82 1063 1.96 1097 2.11 1129 2.26 1159 2.40 1186 2.53 1210 2.65

6930 937 1.57 970 1.70 999 1.81 1027 1.93 1055 2.05 1085 2.19 1118 2.34 1150 2.50 1181 2.66 1211 2.82 1239 2.97 1267 3.13

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

4620 1059 1.61 1082 1.69 1104 1.78 1127 1.87 1149 1.96 1170 2.05 1191 2.14 1212 2.24

5200 1117 1.95 1139 2.05 1161 2.15 1182 2.24 1203 2.35 1222 2.44 1243 2.54 1262 2.64

5780 1176 2.34 1198 2.45 1219 2.56 1241 2.67 1261 2.78 1280 2.88 1299 2.99 1319 3.11

6350 1233 2.78 1256 2.90 1278 3.03 1298 3.15 1319 3.27 - - - - - -

6930 1291 3.27 - - - - ----------

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 26

Installation

RT-SVX20A-E426

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 28 - YSD 120 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

5440 - - - - - - --------8911.269211.379491.499761.6110011.73

6120 ------------9131.429421.549711.669991.7810251.9010522.03

6800 - - - - - - - - 913 1.48 941 1.60 969 1.73 997 1.86 1024 1.99 1050 2.12 1076 2.26 1101 2.39

7480 - - 895 1.48 923 1.59 949 1.70 976 1.83 1003 1.96 1029 2.10 1054 2.24 1079 2.38 1104 2.53 1129 2.67 1153 2.81

8160 939 1.75 967 1.87 992 1.99 1017 2.12 1042 2.24 1066 2.38 1090 2.52 1114 2.67 1138 2.83 1161 2.98 1184 3.14 1207 3.30

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

5440 1027 1.86 1051 1.99 1075 2.12 1098 2.25 1120 2.38 1143 2.52 1166 2.66 1189 2.80

6120 1076 2.17 1100 2.30 1122 2.44 1145 2.58 1167 2.73 1188 2.87 1210 3.02 1230 3.17

6800 1126 2.53 1149 2.67 1172 2.81 1194 2.96 1216 3.12 1236 3.26 - - - -

748011762.9612003.1112223.26----------

8160 ----------------

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 29 - YSH 120 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

5440 - - - - - - - - 924 1.28 962 1.40 998 1.52 1028 1.64 1055 1.74 1082 1.85 1107 1.95 1131 2.06

6120 - - - - 921 1.37 955 1.49 992 1.63 1028 1.77 1063 1.91 1096 2.05 1126 2.19 1153 2.31 1178 2.43 1202 2.55

6800 943 1.57 973 1.68 1002 1.80 1031 1.92 1062 2.06 1096 2.21 1129 2.36 1161 2.52 1192 2.68 1222 2.84 1249 2.99 1273 3.13

7480 1031 2.06 1060 2.19 1086 2.32 1113 2.45 1139 2.57 1167 2.73 1198 2.90 1228 3.07 1257 3.24 - - - - - -

8160 1119 2.58 1146 2.79 1171 2.93 1195 3.07 1219 3.21 1243 3.36 - - - - - - - - - - - -

325 350 375 400 425 450 475 500

m

3

/h kW kW kW kW kW kW kW kW

5440 1154 2.16 1176 2.27 1197 2.37 1218 2.47 1238 2.58 1257 2.68 1276 2.78 1296 2.89

6120 1224 2.67 1247 2.79 1268 2.91 1288 3.02 1308 3.14 1328 3.26 - - - -

680012963.26--------------

7480 ----------------

8160 ----------------

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 27

Installation

27RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 30 - WSD 060 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

2720 - - - - - - ------9330.479750.5310140.5810500.6310850.6811180.72

3060 - - - - - - - - 892 0.48 935 0.52 976 0.57 1016 0.62 1056 0.68 1093 0.74 1128 0.80 1160 0.86

3400 - - - - - - 904 0.55 945 0.60 985 0.65 1023 0.70 1061 0.75 1098 0.80 1135 0.86 1170 0.93 1203 1.00

3740 - - - - 913 0.63 959 0.68 1001 0.74 1038 0.80 1074 0.85 1109 0.90 1143 0.96 1177 1.01 1212 1.07 1244 1.14

4080 - - 933 0.74 972 0.78 1014 0.84 1056 0.90 1094 0.97 1128 1.03 1160 1.09 1193 1.15 1225 1.20 1256 1.26 1287 1.32

325 350 375

m

3

/h kW kW kW

2720 1151 0.78 1183 0.83 1214 0.88

3060 1192 0.91 1223 0.97 1252 1.02

3400 1235 1.06 1265 1.12 1295 1.19

3740 1276 1.21 1308 1.29 - -

4080 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 31 - WSH 060 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

2720 - - - - - - - - 941 0.47 990 0.52 1034 0.58 1077 0.64 1119 0.70 1158 0.75 1196 0.82 1231 0.88

3060 - - - - - - 937 0.52 992 0.58 1043 0.65 1088 0.71 1130 0.77 1169 0.83 1207 0.90 1244 0.96 1280 1.03

3400 - - - - 945 0.58 995 0.65 1045 0.72 1094 0.79 1141 0.86 1185 0.93 1224 1.00 1260 1.07 1295 1.14 1330 1.21

3740 901 0.60 958 0.67 1009 0.73 1057 0.80 1101 0.88 1146 0.95 1192 1.03 1235 1.11 1277 1.18 1314 1.26 - - - -

4080 973 0.76 1026 0.84 1075 0.91 1120 0.98 1163 1.06 1204 1.14 1245 1.23 - - - - - - - - - -

325 350 375

m

3

/h kW kW kW

2720 1265 0.94 1298 1.00 1330 1.07

3060 1314 1.10 1346 1.16 1380 1.24

3400 1363 1.28 - - - -

3740 - - - - - -

4080 - - - - - -

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 28

Installation

RT-SVX20A-E428

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 32 - WSD 072 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

3260 - - - - - - - - 705 0.38 751 0.44 794 0.50 835 0.56 874 0.62 912 0.68 948 0.75 982 0.81

3670 - - - - - - - - 736 0.47 779 0.53 821 0.59 860 0.65 898 0.72 936 0.79 971 0.86 1004 0.93

4080 - - - - - - 720 0.50 768 0.56 810 0.63 850 0.70 888 0.76 925 0.83 961 0.91 995 0.98 1027 1.06

4490 - - - - 709 0.53 753 0.60 799 0.67 843 0.75 882 0.82 919 0.89 954 0.97 987 1.04 1021 1.12 1053 1.20

4890 - - 705 0.58 749 0.64 791 0.72 832 0.79 874 0.88 914 0.96 950 1.04 985 1.12 1018 1.20 1050 1.28 1081 1.36

325 350 375

m

3

/h kW kW kW

3260 1015 0.87 1047 0.93 1079 0.99

3670 1037 1.00 1069 1.07 1099 1.14

4080 1060 1.13 1091 1.21 1121 1.29

4490 1085 1.28 1115 1.36 1145 1.45

4890 1112 1.44 1140 1.53 1170 1.62

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 33 - WSH 072 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

3260 - - - - - - - - 750 0.42 794 0.48 838 0.55 882 0.61 923 0.67 963 0.73 1002 0.80 1038 0.87

3670 - - - - 695 0.40 745 0.46 789 0.51 830 0.58 871 0.65 910 0.72 950 0.79 987 0.86 1025 0.93 1060 1.00

4080 - - - - 737 0.49 787 0.57 831 0.64 870 0.70 908 0.76 944 0.84 980 0.92 1015 0.99 1051 1.07 1085 1.15

4490 - - 740 0.55 781 0.61 828 0.68 872 0.77 911 0.84 948 0.91 983 0.98 1016 1.06 1049 1.14 1081 1.23 1113 1.31

4890 761 0.64 795 0.70 828 0.76 871 0.83 913 0.91 953 1.00 990 1.08 1023 1.15 1055 1.23 1086 1.31 1117 1.40 1147 1.49

325 350 375

m

3

/h kW kW kW

3260 1073 0.94 1107 1.01 1140 1.09

3670 1096 1.07 1129 1.15 1162 1.23

4080 1118 1.23 1152 1.31 1185 1.39

4490 1146 1.40 1178 1.49 1208 1.57

4890 1178 1.59 1206 1.68 1236 1.77

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 29

Installation

29RT-SVX20A-E4

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Standard drive

Oversize drive

Note : Data includes pressure drops for standard filters and wet coils

Table 34 - WSD 090 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4080 - - - - - - - - 768 0.56 810 0.63 850 0.70 888 0.76 925 0.83 961 0.91 995 0.98 1027 1.06

4590 - - - - - - 763 0.63 807 0.70 850 0.78 889 0.85 926 0.93 961 1.00 995 1.08 1027 1.15 1059 1.23

5100 - - - - 770 0.71 810 0.78 849 0.86 890 0.95 929 1.03 967 1.12 1000 1.20 1034 1.28 1065 1.36 1095 1.45

5610 - - 782 0.83 823 0.90 861 0.97 897 1.05 933 1.12 969 1.23 1006 1.33 1041 1.42 1074 1.52 1104 1.60 1134 1.70

6120 798 0.94 838 1.04 876 1.12 913 1.20 947 1.28 980 1.37 1013 1.47 1047 1.57 1080 1.67 1113 1.77 1144 1.88 1173 1.98

325 350 375

m

3

/h kW kW kW

4080 1060 1.13 1091 1.21 1121 1.29

4590 1091 1.32 1121 1.40 1151 1.49

5100 1125 1.53 1154 1.62 1183 1.71

5610 1163 1.79 1191 1.88 1217 1.97

6120 1202 2.08 1229 2.17 1256 2.27

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Table 35 - WSH 090 Available static pressure

External Static Pressure (Pa)

25 50 75 100 125 150 175 200 225 250 275 300

m

3

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW kW kW

4080 - - - - - - 787 0.57 831 0.64 870 0.70 908 0.76 944 0.84 980 0.92 1015 0.99 1051 1.07 1085 1.15

4590 - - 753 0.59 792 0.65 839 0.72 882 0.80 922 0.88 958 0.95 992 1.02 1026 1.10 1058 1.18 1090 1.27 1122 1.36

5100 789 0.71 822 0.78 853 0.84 892 0.91 935 0.99 974 1.08 1011 1.18 1044 1.25 1076 1.33 1106 1.41 1136 1.49 1165 1.59

5610 862 0.93 892 1.01 921 1.08 951 1.15 988 1.22 1026 1.31 1062 1.42 1096 1.52 1129 1.61 1158 1.69 1187 1.78 1214 1.86

6120 934 1.20 963 1.28 990 1.35 1016 1.43 1045 1.51 1079 1.59 1115 1.69 1148 1.80 1180 1.91 1210 2.02 1239 2.12 1266 2.21

325 350 375

m

3

/h kW kW kW

4080 1118 1.23 1152 1.31 1185 1.39

4590 1153 1.45 1185 1.53 1216 1.62

5100 1194 1.68 1223 1.78 1251 1.88

5610 1242 1.96 1269 2.06 1296 2.17

6120 1291 2.30 1317 2.39 1343 2.49

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Fan

RPM

Page 30

Installation

RT-SVX20A-E430

Electrical connection

The electric panel is located in the

unit compressor section. Remove

the compressor access panel. The

unit is designed to run with 400 V

+/- 5%/50 Hz/ 3 ph.

Factory supplied disconnect switch

(option)

The disconnect switch is factory

mounted. It is located in the

compressor section. Mount the

disconnect switch onto the exterior

of the unit, between the condenser

coil and the electrical panel (near

the unit top corner). Wire the

disconnect switch from the power

terminal block in the panel to the

disconnect switch with the wire

bundle provided by following the

electrical diagram found in the unit.

Figure 13 - Power supply

1 = Power supply

Over current protection

The branch circuit feeding the unit

must be protected in accordance

with national or local codes and

maximum unit amps indicated in

Table 36.

Power wiring

The unit's power supply must be

provided by 4-wire cable with crosssectional areas complying with

legislation.

The power supply cables must be

laid in leak-tight pipes and pass

through the bottom of the electric

panel for units without electric

heaters and through the heat

section when electric heater option

is selected. The cables must not be

taut.

Appropriate connectors must be

provided. Flexible pipe supports are

required to prevent noise

transmission in the building's

structure. Ensure all the connections

are tightened.

Note:

1. Earthing must be executed in

compliance to national and local

legislation.

2. The machines are designed for a

short-circuit current of 10 kA. In

the event of a higher application,

contact your local sales office.

Compressor electrical phasing

Proper phasing of the electrical

power wiring is critical for proper

operation and reliability of the scroll

compressor and fans.

Proper rotation of the scroll

compressor must be established

before the unit is started. This is

accomplished by confirming that

the electrical phase sequence of the

power supply is correct. The motor

is internally connected for clockwise

rotation with the inlet power supply

phased A,B,C.

The direction of rotation may be

reversed by interchanging any two

of the line wires. It is this possible

interchange of wiring that makes a

phase sequence indicator necessary

if the operator is to quickly

determine the phase rotation of the

compressor motor.

1

Page 31

Installation

31RT-SVX20A-E4

The "ABC" indicator on the face of

the phase indicator will glow if

phase is ABC for terminals L1, L2,

L3.

IMPORTANT! After completion of

wiring, check all electrical

connections, and ensure all

connections are tight. Replace and

secure all electrical box covers and

access doors before leaving unit or

connecting power to circuit

supplying the unit.

CAUTION! Units with scroll

compressors are not equipped with

crankcase heaters.

WARNING! Disconnect all power,

including remote disconnects, and

discharge all capacitors before

servicing.

Follow proper lockout/tagout

procedures to ensure the power

cannot be inadvertently energized.

After power is removed, allow

4 minutes for capacitors to

discharge. Verify with an

appropriate voltmeter that all

capacitors have discharged. Failure

to disconnect power and/or

discharge capacitors before

servicing could result in death or

serious injury. For additional

information regarding the safe

discharge of capacitors, see Trane

Service Bulletin PROD-SVB06A.

Table 36 - Unit wiring

Standard Supply Fan Motor Oversized Supply Fan Motor

Unit Model

and size

Main power

supply

(V/Ph/Hz)

Minimum Circuit

Ampacity

(A)

Maximum Overcurrent

Protective Device (Fuse

or Circuit Breaker)

(A)

Minimum circuit

ampacity

(A)

Maximum Overcurrent

Protective Device (Fuse

or Circuit Breaker)

(A)

Without Electric heat option

TSD/TSH 060 400/3/50 18,2 32 19,3 32

TSD/TSH 072 400/3/50 24,4 32 25,5 32

TSD/TSH 090 400/3/50 26,2 40 27,2 40

TSD/TSH 102 400/3/50 28,3 40 29,3 40

TSD/TSH 120 400/3/50 32,6 40 32,6 40

YSD/YSH 060 400/3/50 18,2 32 - YSD/YSH 072 400/3/50 24,4 32 25,5 32

YSD/YSH 090 400/3/50 26,2 40 27,2 40

YSD/YSH 102 400/3/50 28,3 40 29,3 40

YSD/YSH 120 400/3/50 32,6 40 32,6 40

WSD/WSH 060 400/3/50 20,1 32 21,2 32

WSD/WSH 072 400/3/50 23,1 32 24,2 32

WSD/WSH 090 400/3/50 26,2 40 27,2 40

With Electric heat

TSD/TSH 060 400/3/50 26,4 50 27,5 50

TSD/TSH 072 400/3/50 37,8 50 38,9 50

TSD/TSH 090 400/3/50 39,2 50 40,2 50

TSD/TSH 102 400/3/50 50,1 63 51,1 63

TSD/TSH 120 400/3/50 51,8 63 51,8 63

WSD/WSH 060 400/3/50 40,8 50 41,9 50

WSD/WSH 072 400/3/50 55,2 63 56,3 63

WSD/WSH 090 400/3/50 58,3 63 59,3 63

Page 32

Installation

RT-SVX20A-E432

Table 37 - Compressor and condenser motors

Table 38 - Supply fan motor

Standard supply fan motor Oversized supply fan motor

Unit Model

and size

Number

of

motors

Main

power

supply

(V)

Number

of

phases

Motor

HP

(kW)

Rated

amps

(A)

Locked

rotor

amps

(A)

Number

of

motors

Main

power

supply

(V)

Number

of

phases

Motor

HP

(kW)

Rated

amps

(A)

Locked

rotor

amps

(A)

TSD/TSH 060 1 400 3 1,1 3,2 25,3 -----TSD/TSH 072 1 400 3 1,1 3,2 25,3 1 400 3 1,5 4,3 36,4

TSD/TSH 090 1 400 3 1,5 4,3 36,4 1 400 3 2,2 5,3 57.0

TSD/TSH 102 1 400 3 1,5 4,3 36,4 1 400 3 2,2 5,3 57.0

TSD/TSH 120140032,25,357.0 -----YSD/YSH 060140031,13,225,3 -----YSD/YSH 072 1 400 3 1,1 3,2 25,3 1 400 3 1,5 4,3 36,4

YSD/YSH 090 1 400 3 1,5 4,3 36,4 1 400 3 2,2 5,3 57.0

YSD/YSH 102 1 400 3 1,5 4,3 36,4 1 400 3 2,2 5,3 57.0

YSD/YSH 120140032,25,357.0 -----WSD/WSH 060140031,13,225,3 -----WSD/WSH 072 1 400 3 1,1 3,2 25,3 1 400 3 1,5 4,3 36.4

WSD/WSH 090 1 400 3 1,5 4,3 36,4 1 400 3 2,2 5,3 57.0

Compressor motor Condensor fan motor

Unit Model

and size

Number

of

motors

Main

power

supply

(V)

Number

of

phases

Motor

HP

(kW)

Rated

amps

(A)

Locked

rotor

amps

(A)

Number

of

motors

Main

power

supply

(V)

Number

of

phases

Motor

HP

(kW)

Rated

amps

(A)

Locked

rotor

amps

(A)

TSD/TSH 060 1 400 3 4,2 10,3 74 1 400 1 0,3 1.0 2,8

TSD/TSH 072 1 400 3 5,6 13,7 95 1 400 1 0,56 3.0 7,1

TSD/TSH 090 1 400 3 6,2 14,3 100 1 400 1 0,56 3.0 7,1

TSD/TSH 102 2 400 3 4.5 / 2.8 10 / 7.5 74 / 48 2 400 1 0,56 3.0 7,1

TSD/TSH 120 2 400 3 4.5 / 3.5 10.7 / 9.2 74 / 62 2 400 1 0,56 3.0 7,1

YSD/YSH 060 1 400 3 4,2 10,3 74 1 400 1 0,3 1.0 2,8

YSD/YSH 072 1 400 3 5,6 13,7 95 1 400 1 0,56 3.0 7,1

YSD/YSH 090 1 400 3 6,2 14,3 100 1 400 1 0,56 3.0 7,1

YSD/YSH 102 2 400 3 4.5 / 2.8 10 / 7.5 74 / 48 2 400 1 0,56 3.0 7,1

YSD/YSH 120 2 400 3 4.5 / 3.5 10.7 / 9.2 74 / 62 2 400 1 0,56 3.0 7,1

WSD/WSH 060 1 400 3 4,5 11,8 74 1 400 1 0,3 1 2,8

WSD/WSH 072 1 400 3 5 12,6 101 1 400 1 0,56 3 7,1

WSD/WSH 090 1 400 3 6,2 14,3 100 1 400 1 0,56 3 7,1

Page 33

Controls

33RT-SVX20A-E4

Control wiring

The control circuit is 24 V AC. Unit

includes a 400/24 V transformer.

WARNING!The unit disconnect

switch must be opened and locked

open. Risk of injury and

electrocution.

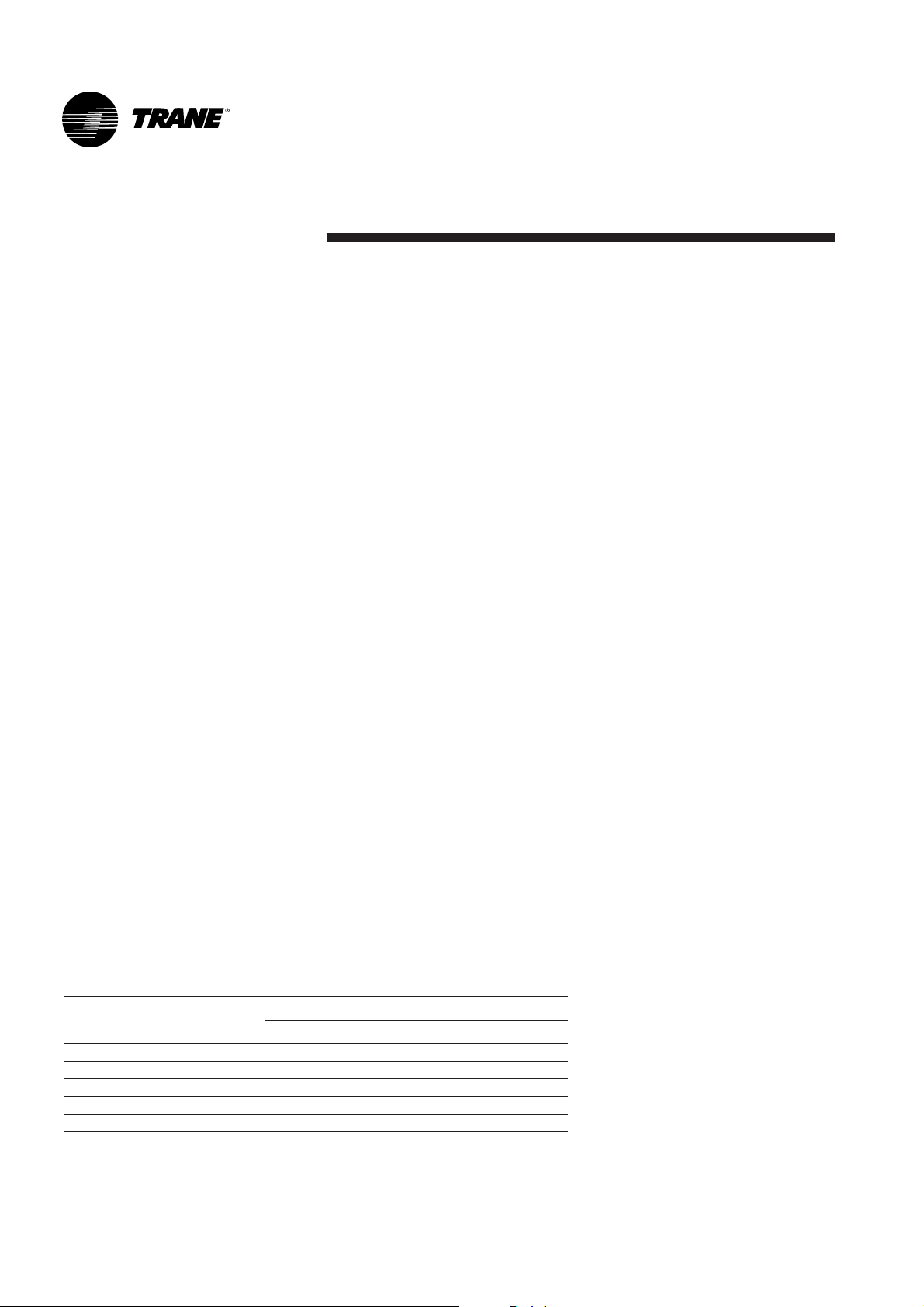

Figure 14 - Thermostat wiring

CAUTION!The unit 24 V transformer

must not be used to power

accessories mounted on site, other

than those proposed by Trane.

Unit controlled by thermostat

J7

J6

Page 34

Controls

RT-SVX20A-E434

Trane THS01,THS02, THP01 and

THP02 Thermostats are directly

connected to RTRM board

(J7 connector).

Trane THS03 and THP03 thermostats

are directly connected to RTRM

board (J6 connector).

Install the electrical link between the

thermostat (thermostat terminal

strip) and the unit (J6 or

J7 connector) in compliance with

the interconnection diagram. The

low voltage wiring must not be laid

in the same pipes as the power

cables.

The sizes and lengths of the

thermostat connection wires are

given in Table 39. The total

resistance of these control cables

must not exceed 5 ohms. If the

resistance exceeds this value the

thermostat may not operate with

the same precision.

Table 39 - Zone sensor wire and

maximum length

Wire size

(mm²)

Maximum

wire lengh

(m)

0,33 45

0,5 76

0,75 115

1,3 185

2300

Unit controlled by BAS

Each unit must be equipped with a

TCI-R board. A communication bus

(twisted shielded pair) must link

each TCI-R to the Trane Roof Top

Manager (RTM) or to the

communication gateway (in the

case of an external BAS). Connect

one temperature sensor to each

unit. LonTalk

®

communication

interface LTCl-R board allows ICS

communication between a

ReliaTel™ unit and LonTalk

®

communication applications.

Unit controlled by Tracker™

supervisor

The units must also be equipped

with the TCI-R communication

board. One remote sensor is

required on each unit for a constant

flow volume. In the case of a

variable flow installation

(VariTrac™) these sensors must not

be installed. A twisted shielded pair

must be used for the

communication link. The main

functions of the Tracker™ supervisor

are control of setpoints, timetable

management (Programming) and

display of faults. For more details

refer to the supervisor

documentation.

Page 35

Controls

35RT-SVX20A-E4

The CO2 sensor is designed to

operate with a nominal 24 Vac

supply. The power supply should

maintain the voltage between 20 to

26 Vac.

Table 41 - CO2sensor wire size

Wire size

(mm²)

Maximum

wire lengh

(m)

0,25 50

0,5 100

1200

Table 40 - Specifications

Wall-mounted Duct-mounted

Measuring range CO

2 0-2000 ppm

Accuracy at 25°C

< +/- [40 ppm CO

2 + 3% of

reading]

(included repeatability and

calibration uncertainty)

< +/- [30 ppm CO2 + 2% of

reading]

(included repeatability and

calibration uncertainty)

Non-linearity < 1.0% full scale

Temperature dependence of output 0.3% full scale/°C

Long-term stability < 5.0% full scale/ 5 years

Recommended calibration interval 5 years

Response time 1 minute (0-63%)

Operating temperature 15-35°C -5-45°C

Storage temperature -20-70°C

Humidity range 0-85% relative humidity

Airflow range 0-10 m/s)

Output signals (jumper selectable) 0-10 Vdc

Resolution of analog outputs 10 ppm CO

2

Recommended external load

Current output: max 500

Voltage output: min. 1000

Power supply Nominal 24 Vac

Power consumption < 5 VA

Warm-up time < 15 minutes

Dimensions (mm) 108 x 80 x 36 80 x 80 x 200

CO2 sensors

Wall-mounted and duct-mounted

CO

2 sensors

Power supply requirements

CAUTION! Make sure that you

connect the power wire only to the

24V terminal. Connecting the power

wire to the output terminal may

result in equipment damage.

Page 36

Controls

RT-SVX20A-E436

Wiring the wall-mounted CO2

sensor

DVC setpoint potentiometer on

economizer module can be adjusted

as follows:

0% - 500ppm, 50% - 1000 ppm,

100% - 1500ppm

The outside air damper will

modulate from minimum position

setting to up to 100% while

attempting to maintain the CO

2

setpoint.

Wiring the duct-mounted CO

2

sensor

1. Connect the common wire from

the controller to the ground

terminal (terminal 0) (Figure 16).

2. For voltage output, connect the

signal wire to terminal V.

3. Connect the power according to

the guidelines in Power supply

requirements.

Figure 15 - Wall-mounted CO2sensor wiring

Figure 16 - Terminal connections and LED locations

1 = Outer jumper

2 = Power terminal

3 = Ground terminal

4 = Output terminals

1

2

3

4

Page 37

Controls

37RT-SVX20A-E4

Mounting the wall-mounted sensor

1. Select a proper location in the

room to mount the CO

2 sensor.

Look for an interior wall with

good air circulation,

approximately 1.4 m from the

floor.

2. Remove the back plate from the

sensor and thread the power

wires and output signal wire

through the hole in the back

plate (Figure 17).

For surface wiring, make cutouts with pliers to the thinner

section of the upper or lower

edge of the back plate and to

thread the wires through.

3. Mount the back plate to the wall

with screws. Note that the arrow

on the back plate shows the

mounting direction.

4. On the circuit board, use the two

jumpers next to the terminal

block to set up the type of output

(0-10 Vdc) (Figure 18).

5. Insert the circuit board in the

back plate. (Figure 18.) Do not

press the metal tube while

inserting the circuit board.

6. Connect the power and signal

wires to the screw terminals of

the circuit board. Figure 16

shows the terminal locations.

Figure 17 - Wall-mounted CO2sensor

1 = Thinner section for cut-out

Figure 18 - Jumper settings

1

Page 38

Controls

RT-SVX20A-E438

Mounting the duct-mounted CO2

sensor

1. Select a proper location on the

duct to mount the CO

2 sensor.

2. Drill a 22-25 mm hole in the

mounting surface for sensor