Page 1

Packaged Cooling with

Electric Heat Rooftop Units

Precedent

TSC060-120

50 Hz

™

November 2003

RT-PRC0 16-EN

Page 2

Introduction

© 2003 American Standard Inc. All rights reserved.

Precedent

with added flexibility. Precedent is a

flexible line of packaged units that covers

a wide variety of applications.

ReliaTel™ microprocessor controls

provide superior flexibility for the

simplest to the most sophisticated

applications. In addition to controls,

Precedent offers many other outstanding

features and option choices.

™

. . . The same Trane quality ...

With its sleek compact cabinet, rounded

corners and beveled top, it may just be

the most aesthetically pleasing packaged

unit on the planet. And, of course,

Precedent carries the Trane reputation

for excellence, quality and reliability.

hard to stop a Trane

From simple applications, to the most

complex, Precedent has the solution.

.

It’ s

RT-PRC016-EN

Page 3

Contents

Introduction

Features and Benefits

Application Considerations

Selection Procedure

Model Number Description

General Data

Performance Data

Zone Controls

Electrical Data

Jobsite Connections

Dimensional Data

W eights

2

4

9

10

12

13

14

33

34

35

36

44

RT-PRC016-EN

Mechanical Specifications

45

3

Page 4

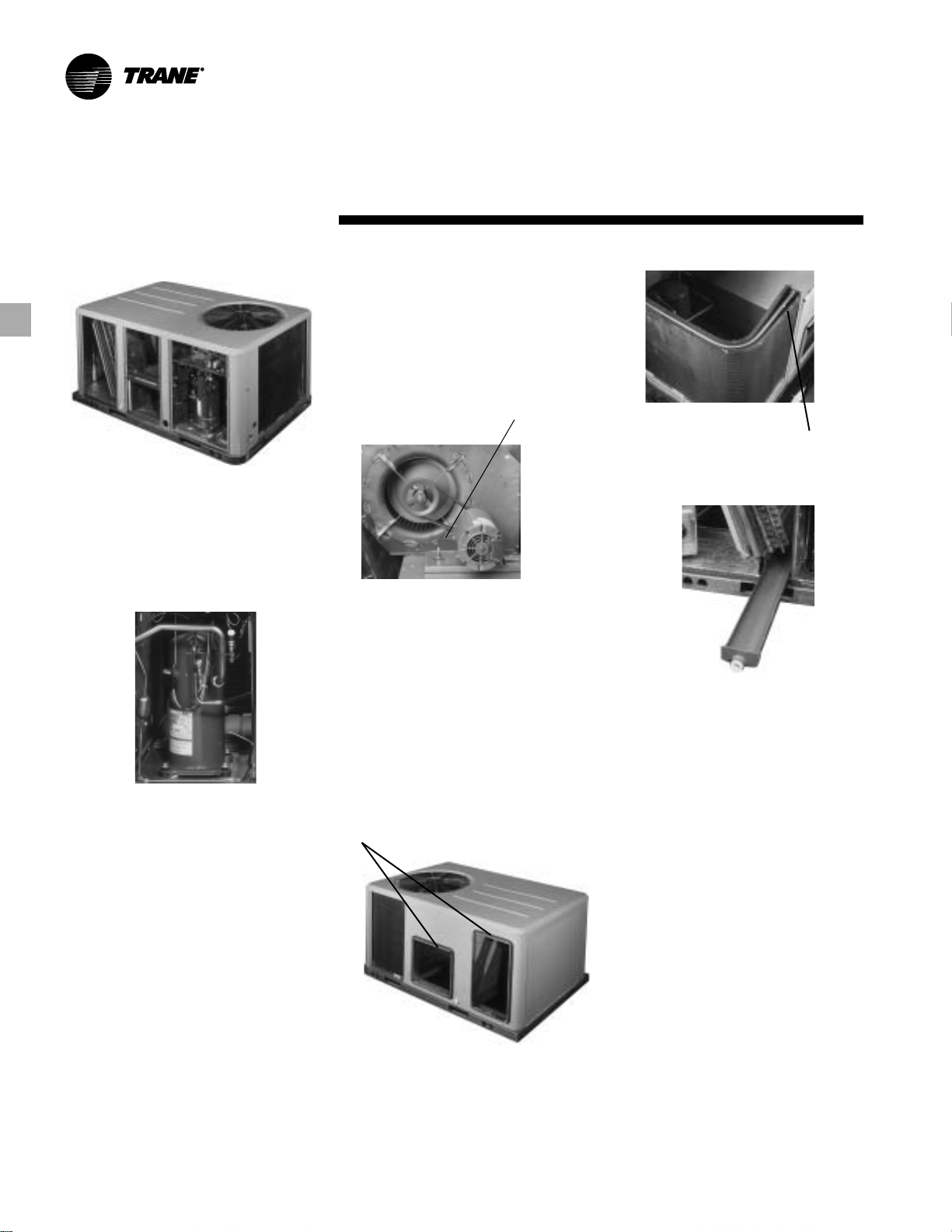

Unit Cabinet

The compact cabinet with rounded

corners takes up less room and is less

costly to ship. The beveled and ribbed

top is not only aesthetically pleasing, it is

designed to prevent water from pooling.

Single Point Power

A single electrical connection powers the

unit.

Features and Benefits

Easy Access Panels

Remove two screws for access to the

standardized internal components and

wiring.

Easy-Adjust Idler Arm

With the Easy-Adjust Idler Arm, the belt

and sheaves can be quickly adjusted

without moving the mounted fan motor.

The result is a major savings in time and

money.

Colored And Numbered Wiring

You save time and money tracing wires

and diagnosing the unit.

Patented Condenser Coil

Precedent boasts a patented 1+1+1

Hybrid coil, permanently gapped for

easy of cleaning.

Compressors

Precedent

compressor technology available to

achieve the highest possible

performance. Our compressor line

includes Trane built reciprocating and

scrolls.

Easy Access Panels

Easy access panels reduce the number of

possible water entry points.

Low Ambient Cooling

All Precedent units have cooling

capabilities down to 0°F as standard.

™

contains the best

Convertible Units

• The units ship in a downflow

configuration. They can be easily

converted to horizontal by simply

moving two panels.

• Units come complete with horizontal

duct flanges so the contractor doesn’t

have to field fabricate them. These

duct flanges are a time and cost saver.

Unit Base

For added water integrity, Precedent has

a raised 29 mm (1

unit’s downflow supply and return to

prevent water from blowing into the

ductwork.

1

/8") lip around the

Sloped Drain Pans

Every Precedent unit has a noncorrosive, removable, double-sloped

drain pan that’s easy to clean and

reversible to allow installation of drain

trap on either side of the unit.

Through the Base Condensate

Every unit includes provisions for

through the base condensate drain

connections. This allows the drain to be

connected through the roof curb instead

of a roof penetration.

Foil-Faced Insulation

All panels in the Evaporator section of

the unit have cleanable foil-faced

insulation. All edges are either captured

or sealed to ensure no fibers get into the

airstream.

4

RT-PRC016-EN

Page 5

Features and

Benefits

Standardized Components

• Components are placed in the same

location on all Precedent™ units.

Familiarize yourself with one Precedent

and you are familiar with every

Precedent.

Easy Access Low Voltage Terminal

Board

Precedent’s Low Voltage Terminal Board

is external to the electrical control

cabinet. It is extremely easy to locate and

attach the thermostat wire. This is

another cost and time saving installation

feature.

Flexible Applications

• Only two roof curbs for the 5-10 ton

Precedent line. . .simplifies curb

selection.

• ReliaTel microprocessor controls to

meet either the simple or the more

complex application.

• Airflow is outstanding. The Precedent

can replace an older machine with old

ductwork and, in many cases, improve

comfort through better air distribution.

• Belt drive — standard or oversized

supply fan motors meet a wide airflow

range.

• Precedent offers ultimate flexibility.

Options and components are not prepackaged at the factory. Units are built

to order in our standard “shortest in

the industry” ship cycle time.

RT-PRC016-EN

Low Voltage Connections

The wiring of the low voltage

connections to the unit and the zone

sensors is as simple as 1-1, 2-2, and 3-3.

This simplified system makes it easy for

the installer to wire

Single-Side Service

Single-side service is standard on all

Precedent units.

5

Page 6

Features and

Benefits

Micro Controls

Several years ago, Trane was the first to

introduce microprocessor controls into

the Light Commercial Market. That

design, along with immeasurable

experience, has provided the

technology for Trane’s secondgeneration ReliaTel

controls.

™

ReliaTel

• Provides unit control for heating,

• Improves quality and reliability

•Prevents the unit from short cycling,

• Ensures that the compressor will run

• Reduces the number of components

Micro:

cooling, and ventilating by utilizing

input from sensors that measure

outdoor and indoor temperature.

through the use of time-tested

microprocessor controls and logic.

considerably improving compressor

life.

for a specific amount of time, which

allows oil to return for better

lubrication, enhancing the reliability of

the compressor.

required to operate the unit, thereby

reducing possibilities for component

failure.

™

microprocessor

• Eliminates the need for field-installed

components with its built-in antishort-cycle timer, time delay relay

and minimum ‘’on’’ time controls.

These controls are factory tested to

assure proper operation.

• Requires no special tools to run the

Precedent unit through its paces

during testing. Simply place a

jumper between Test 1 and Test 2

terminals on the Low Voltage

Terminal Board and the unit will walk

through its operational steps. The

unit automatically returns control to

the zone sensor after stepping

through the test mode a single time,

even if the jumper is left on the unit.

• As long as the unit has power and

the LED is lit, the Micro is

operational. The light indicates that

the Micro is functioning properly.

• Features expanded diagnostic

capabilities when used with Trane’s

Integrated Comfort

• As an energy benefit, softens

electrical ‘’spikes’’ by staging on fans,

compressors and heaters.

• The Intelligent Fallback or Adaptive

Control is a benefit to the building

occupant. If a component goes

astray, the unit will continue to

operate at predetermined

temperature set points.

• Intelligent Anticipation is a standard

feature of the Micro. Functioning

constantly, the Micro and zone

sensors work together in harmony,

to provide tight comfort control.

™

Systems.

6

RT-PRC016-EN

Page 7

Features and

Benefits

Factory-installed Options

Hinged Access Doors

These doors permit easy access to the

filter, fan/heat, and compressor/control

sections. They reduce the potential roof

damage from screws or sharp access

door corners.

Economizer

Equipped with either dry bulb, reference

or comparative enthalpy sensing, this

feature provides free cooling as the

outdoor temperature and/or humidity

decreases. Economizers, correctly

installed, offer a valuable energy

savings. Factory-installed economizers

save time and ensure proper installation.

Clogged Filter/Fan Fail Switches

These sensors allow a zone sensor

service light or Integrated Comfort

System to indicate a dirty filter or a fan

that’s not working. The field installation

charges for these valuable feedback

devices often eliminate them from

consideration. Factory installation can

make such features a good investment.

Comm-3/4 Trane Communication

Interface

Available factory or field-installed. This

module when applied with ReliaTel

easily interfaces with Trane’s Integrated

Comfort™ System.

™

The following options round-out the

complete line of Precedent™ options:

— 0 - 50% Manual or Motorized

Outside Air

— Hail Protection Quality Coil Guards

— Electric Heaters (available as field

installed accessories)

— Discharge Air Sensor

— Wide array of Zone Sensors and

Thermostats

— Factory built Roof Curb

One of Our Finest Assets:

Trane Sales Representatives are a

Support group that can assist you with:

— Product

— Application

— Service

— Training

— Special Applications

— Specifications

— Computer Programs and much more

Precedent has the features and benefits

that make it first class in the light

commercial rooftop market. Designed

with input from field contractors and

engineers, its airflow performance is

outstanding.

Precedent…The same Trane

quality…with added flexibility.

RT-PRC016-EN

7

Page 8

Features and

Benefits

Quality And Reliability Testing

• All Precedent

rain tested at the factory to ensure

water integrity.

• Actual shipping tests were performed

to determine packaging requirements.

Units were test shipped around the

country to determine the best

packaging.

• Factory shake and drop tests were

used as part of the package design

process to help assure that the unit

arrives at the job site in top condition.

• Rigging tests include lifting a unit into

the air and letting it drop one foot,

assuring that the lifting lugs and rails

hold up under stress.

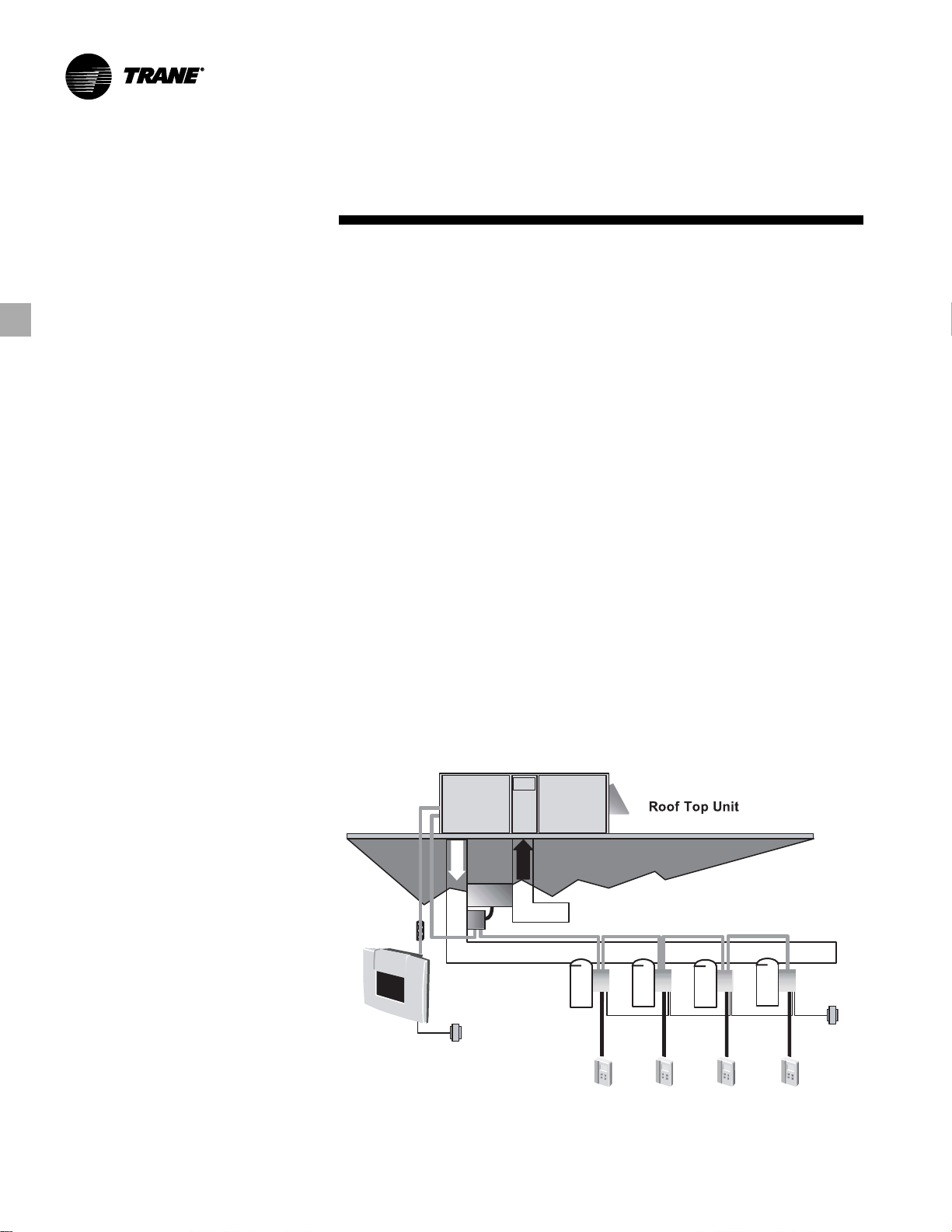

VariTrac

™

designs were rigorously

™

• We perform a 100% coil leak test at the

factory. The evaporator and condenser

coils are leak tested at 1375 kPa (200

psig) and pressure tested to 3100 kPa

(450 psig).

• All parts are inspected at the point of

final assembly. Sub-standard parts are

identified and rejected immediately.

• Every unit receives a 100% unit run test

before leaving the production line to

make sure it lives up to rigorous Trane

requirements.

We test designs at our factory not on

our customers!

VariTrac

When T rane’ s changeover VAV System

for light commercial applications is

coupled with Precedent, it provides the

latest in technological advances for

comfort management systems and can

allow thermostat control in every zone

served by VariTrac.

8

RT-PRC016-EN

Page 9

Application Considerations

Application of this product should be

within the cataloged airflow and cooling

considerations.

Low Ambient Cooling

The Precedent™ line features, with

ReliaTel™ microprocessor controls, low

ambient cooling down to 18°C (0°F).

Contact your local Trane Representative

for more assistance with low ambient

cooling applications.

Barometric Relief

This product line offers an optional

barometric relief damper. for use in

conjunction with economizer option.

This accessory consists of gravity

dampers which open with increased

pressure. As the building air pressure

increases, the pressure in the unit return

air section also increases, opening the

dampers and relieving the conditioned

space.

NOTE: THE EFFECTIVENESS OF

BAROMETRIC RELIEF DAMPER

DURING ECONOMIZING OPERATION

IS SYSTEM RELATED.

PRESSURE DROP OF THE RETURN AIR

SYSTEM SHOULD BE CONSIDERED TO

CONTROL BUILDING PRESSURIZATION.

Condensate Trap

The evaporator is a draw-thru

configuration. A trap must be field

provided prior to start-up on the cooling

cycle.

Clearance Requirements

The recommended clearances identified

with unit dimensions should be

maintained to assure adequate service

maximum capacity and peak operating

efficiency. Actual clearances which

appear inadequate should be reviewed

with the local Trane sales personnel.

Unit Pitch

These units have reversible sloped

condensate drain pans. Units must be

installed level, any unit slope must be

toward the side of unit where

condensate drain is connected.

RT-PRC016-EN

9

Page 10

Selection

Procedure - SI Units

Cooling Capacity

Step 1

Calculate the building’s total and sensible

cooling loads at design conditions. Use

the Trane calculation methods or any

other standard accepted method.

Factors used in unit selection:

A

Total Cooling Load: 16.7 kW

B

Sensible Cooling Load: 11.7 kW

C

Airflow: 3400 m

D

Electrical Characteristics: 380-415/50/3

E

Summer Design Conditions: Entering

Evaporator Coil: 27 DB, 19 WB Outdoor

Ambient: 35

F

External Static Pressure: 110 Pa

Step 2

Table PD-1 shows that a TSC060AD has a

gross cooling capacity of 17.8 kW and

14.4 kW sensible capacity at 3400 m

and 35 DB outdoor ambient with 27 DB,

19 WB air entering the evaporator.

To Find Capacity at Intermediate

Conditions Not in the Table

When the design conditions are between

two numbers that are in the capacity

table, interpolation is required to

approximate the capacity. Note:

Extrapolation outside of the table

conditions is not recommended.

3

/h

3

/h

Step 3

In order to select the correct unit which

meets the building’s requirements, the

fan motor heat must be deducted from

the gross cooling capacity. The amount

of heat that the fan motor generates is

dependent on the effort by the motor cfm and static pressure. To determine

the total unit static pressure:

External Static (duct system)

Standard Filter 1 in. 37 Pa

from T able PD-21

Economizer 5 Pa

(100% Return Air) from

Table PD-21

Electric Heater Size 7.5 kW 17 Pa

from T able PD-21

Total Static Pressure 169 Pa

Note: The Evaporator Fan Performance

Table PD-6 has deducted the pressure

drop for a 25 mm filter already in the

unit (see note below Table PD-6).

Therefore, the actual total static pressure

is 169-17 (from Table PD-21) = 152 Pa.

With 3400 m

Table PD-6 shows .67 kW for this unit.

Note below the table gives a formula to

calculate Fan Motor Heat,

Fan Motor Heat (kw) =

1.144 x (Fan kW) + 0.132

= 1.144 x 0.67 + 0.132 = 0.90 kW

Now subtract the fan motor heat from

the gross cooling capacity of the unit:

Net Total Cooling Capacity

= 17.8 kW - 0.9 = 16.9 kW.

Net Sensible Cooling Capacity

= 14.4 kW - 0.9 = 13.5 kW.

Step 4

If the performance will not meet the

required load of the building’s total or

sensible cooling load, try a selection at

the next higher size unit.

3

/h and 152 Pa

110 Pa

Heating Capacity

Step 1

Calculate the building heating load using

the Trane calculation form or other

standard accepted method.

Step 2

Size the system heating capacity to

match the calculated building heating

load. The following are building heating

requirements:

A

Total heating load of 5 kW

B

2000 cfm

C

380 volt/3 phase Power Supply

The electric heat accessory capacities are

listed in Table PD-23. From the table, the

smallest heater will deliver 7.5 kW at

380 V. Referring to Table ED-2, the

electric heater selection is

BAYHTRR412A.

Air Delivery Selection

External static pressure drop through the

air distribution system has been

calculated to be 110 Pa. From Table PD21 static pressure drop through the

economizer is 5 Pa and the 7.5 kW heater

is 17 Pa (110 + 5 + 17). Enter Table PD-6

for a TSC060AD at 3400 m3/h and 132 Pa

static pressure. The standard motor will

give the desired airflow at a rated kW of

0.64.

Accessory Selection

Select accessories needed to

accommodate the application.

10

RT-PRC016-EN

Page 11

Selection

Procedure - IP Units

Cooling Capacity

Step 1

Calculate the building’s total and sensible

cooling loads at design conditions. Use

the Trane calculation methods or any

other standard accepted method.

Factors used in unit selection:

A

Total Cooling Load: 59 MBh

B

Sensible Cooling Load: 40 MBh

C

Airflow: 2000 cfm

D

Electrical Characteristics: 380-415/50/3

E

Summer Design Conditions: Entering

Evaporator Coil: 80 DB, 67 WB Outdoor

Ambient: 95

F

External Static Pressure: 0.45 in. wg

Step 2

Table PD-1a shows that a TSC060AD has

a gross cooling capacity of 62.0 MBh and

46.4 MBh sensible capacity at 2000 cfm

and 95 DB outdoor ambient with 80 DB,

67 WB air entering the evaporator.

To Find Capacity at Intermediate

Conditions Not in the Table

When the design conditions are between

two numbers that are in the capacity

table, interpolation is required to

approximate the capacity. Note:

Extrapolation outside of the table

conditions is not recommended.

Step 3

In order to select the correct unit which

meets the building’s requirements, the

fan motor heat must be deducted from

the gross cooling capacity. The amount

of heat that the fan motor generates is

dependent on the effort by the motor cfm and static pressure. To determine

the total unit static pressure:

External Static (duct system)

0.45 wg

Standard Filter 1 in. 0.15 wg

from T able PD-21a

Economizer 0.02 wg

(100% Return Air) from

Table PD-21a

Electric Heater Size 26 MBh 0.07 wg

from T able PD-21a

Total Static Pressure 0.69 wg

Note: The Evaporator Fan Performance

Table PD-6a has deducted the pressure

drop for a 1 in. filter already in the unit

(see note below Table PD-6a). Therefore,

the actual total static pressure is 0.69 -

0.15 (from Table PD-21a) = 0.50 wg.

With 2000 cfm and 0.50 wg.

Table PD-6a shows .83 bhp for this unit.

Note below the table gives a formula to

calculate Fan Motor Heat,

Fan Motor Heat (MBh) =

2.915 x (Fan BHP) + 0.451

= 2.915 x 0.83 + 0.451 = 2.87 MBh

Now subtract the fan motor heat from

the gross cooling capacity of the unit:

Net Total Cooling Capacity

= 62 MBh - 2.87 = 59.1 MBh.

Net Sensible Cooling Capacity

= 46.4 MBh - 2.87 = 43.5 MBh.

Step 5

If the performance will not meet the

required load of the building’s total or

sensible cooling load, try a selection at

the next higher size unit.

Heating Capacity

Step 1

Calculate the building heating load using

the Trane calculation form or other

standard accepted method.

Step 2

Size the system heating capacity to

match the calculated building heating

load. The following are building heating

requirements:

A

Total heating load of 15 MBH

B

2000 cfm

C

380 volt/3 phase Power Supply

The electric heat accessory capacities are

listed in Table PD-23a. From the table,

the smallest heater will deliver 26 MBh at

380 volts. Referring to Table ED-2, the

electric heater accessory selection is

BAYHTRR412A.

Air Delivery Selection

External static pressure drop through the

air distribution system has been

calculated to be 0.45 inches of water.

From Table PD-21a static pressure drop

through the economizer is 0.02 and the

26 kW heater is 0.07 inches of water (0.45

+ 0.02 + 0.07). Enter Table PD-6a for a

TSC060AD at 2000 cfm and 0.54 static

pressure. The standard motor will give

the desired airflow at a rated bhp of

about 1.01.

Accessory Selection

Select accessories needed to

accommodate the application.

RT-PRC016-EN

11

Page 12

Model Number Description

T S C 060 A D R O A ** C 0 0 0 0 0 0 0 0 0 0 1

1 2 3 4,5,6 7 8 9 10 11 12,13 14 15 16 17 18 19 20 21 22 23 24 25

Digit 1 - Unit Function

T = DX Cooling

Digit 2 - Efficiency

S = Standard Efficiency

Digit 3 - Airflow

C = Convertible

Digits 4,5,6 - Nominal Gross Cooling

Capacity (MBh)

kW Tons

060 = 17.6 5

072 = 21.1 6

090 = 26.4 7.5

102 = 29.9 8.5

120 = 35.1 10

Digit 7 - Major Design Sequence

A = First

Digit 8 - Unit Voltage

D = 380-415/50/3

Digit 9 - Unit Controls

R = ReliaTel™ Microprocessor

Digit 10 - Heating Capacity

0 = No Electric Heat

Digit 11 - Minor Design Sequence

A = First Sequence

Digits 12, 13 - Service Sequence

**= Factory Assigned

Digit 14 - Fresh Air Selection

0 = No Fresh Air

A = Manual Outside Air Damper 0-50%

B = Motorized Outside Air Damper 0-50%

C = Economizer, Dry Bulb 0-100%

without Barometric Relief

D = Economizer, Dry Bulb 0-100%

with Barometric Relief

E = Economizer, Reference Enthalpy

0-100% without Barometric Relief

F = Economizer, Reference Enthalpy

0-100% with Barometric Relief

G = Economizer, Comparative Enthalpy

0-100% without Barometric Relief

H = Economizer, Comparative Enthalpy

0-100% with Barometric Relief

Digit 15 - Supply Fan/Drive Type/Motor

0 = Standard Drive

1 = Oversized Motor

Digit 16 - Hinged Service Access/Filters

0 = Standard Panels/Standard Filters

A = Hinged Access Panels/Standard Filters

B = Standard Panels/

50 mm (2”) Pleated Filters

C = Hinged Access Panels/

50 mm (2”) Pleated Filters

Digit 17 - Condenser Coil Protection

0 = Standard Coil

1 = Standard Coil with Hail Guard

2 = Epoxy Coated Condenser Coil

3 = Epoxy Coated Condenser Coil with

Hail Guard

Digit 18 - Through the Base Provisions

0 = No Through the Base Provisions

Digit 19 - Disconnect/Circuit Breaker

0 = No Disconnect or Circuit Breaker

Digit 20 - Convenience Outlet

0 = No Convenience Outlet

Digit 21 - Communications Options

0 = No Communications Interface

1 = Comm-3/4 Communications Interface

2 = Comm-5 Communications Interface

Digit 22 - Refrigeration System Option

0 = Standard Refrigeration System

Digit 23 - Refrigeration Controls

0 = No Refrigeration Control

Digit 24 - Smoke Detector

0 = No Smoke Detector

Digit 25 - Monitoring Controls

0 = No Monitoring Control

1 = Clogged Filter Switch

2 = Fan Failure Switch

3 = Discharge Air Sensing Tube

4 = Clogged Filter Switch and Fan Fail

Switch

5 = Clogged Filter Switch and Discharge

Air Sensing Tube

6 = Fan Fail Switch and Discharge Air

Sensing Tube

7 = Clogged Filter and Fan Fail Switches

and Discharge Air Sensing Tube

12

RT-PRC016-EN

Page 13

General Data

Table GD - 1 — General Data

Convertible Units Convertible Units Convertible Units Convertible Units Convertible Units

Cooling Performance

Gross Capacity - kW (MBh) 18.2 (62.0) 23.2 (79.0) 26.7 (91.0) 31 .1 (106.0) 34.9 (1 19.0)

COP (EER)

Nominal Airflow - m

Rated Airflow - m

1

2

3

/h (cfm) 3400 (2000) 4080 (2400) 5100 (3000) 5780 (3400) 6800 (4000)

3

/h (cfm) 3400 (2000) 3570 (2100) 4460 (2625) 5100 (3000) 5950 (3500)

Net Capacity - kW (MBh) 17.3 (59.0) 22.0 (75.0) 25.2 (86.0) 29.9 (102.0) 33.1 (113.0)

System Power - kW 5.78 7.14 8.35 9.90 1 1.08

Compressor

Number - Type 1-Climatuff Scroll 1-Trane 3-D Scroll 1-Trane 3-D Scroll 2-Climatuff Scroll 2-Climatuff Scroll

Outdoor Sound Rating - dB

3

Outdoor Coil - Type Lanced Lanced Lanced Lanced Lanced

T ube Size - in. OD 0.3125 0.3125 0.3125 0.3125 0.3125

Face Area - m

2

(sq ft) 1.02 (10.96) 1.29 (13.88) 1.29 (13.88) 1.75 (18.89) 2.41 (25.92)

Rows / FPI 3 / 17 2 / 17 2 / 17 2 / 17 2 / 17

Indoor Coil - T ype Lanced Lanced Lanced Lanced Lanced

T ube Size OD - in. 0.3125 0.3125 0.3125 0.3125 0.3125

Face Area - m

2

(sq ft) 0.62 (6.68) 0.92 (9.89) 0.92 (9.89) 1.15 (12.36) 1.15 (12.36)

Rows / FPI 3 / 16 2 / 16 3 / 16 3 / 16 4 / 16

Refrigerant Control Short Orifice Short Orifice Short Orifice Short Orifice Short Orifice

Drain Connection No. / Size - in. 1 / 0.75 NPT 1 / 0.75 NPT 1 / 0.75 NPT 1 / 0.75 NPT 1 / 0.75 NPT

Outdoor Fan - T ype Propeller Propeller Propeller Propeller Propeller

No. Used / Diameter - in. 1 / 22 1 / 26 1 / 26 1 / 26 1 / 26

Drive Type / No. Speeds Direct / 1 Direct / 1 Direct / 1 Direct / 1 Direct / 1

CF M 2900 5100 5200 5500 5800

No. Motors / kW (HP) 1 / 0.30 (0.40) 1 / .56 (0.75) 1 / .56 (0.75) 1 / .56 (0.75) 1 / .56 (0.75)

Motor RPM 950 950 950 950 950

Belt Drive Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used 1 1 1 1 1

Fan Diameter x Width - mm (in.) 280 X 280 (11 x 1 1) 305 X 305 (12 x 12) 305 X 305 (12 x 12) 381 X 381 (15 x 15) 381 X 381 (15 x 15)

Drvie Type / No. Speeds Belt / V ariable Speed Belt / Variable Speed Belt / Variable Speed Belt / Variable Speed Belt / Variable Spee d

No. Motors 1 1 1 1 1

Standard Motor Power - kW (HP) 1.1 (1.5) 1.1 (1.5) 1.5 (2.0) 1.5 (2.0) 2.2 (3.0)

Oversized Motor Power - kW (HP) - 1.5 (2.0) 2.2 (3.0) 2.2 (3.0) Motor RPM - Standard / Oversized 1450 / - 1450 / 1450 1450 / 2850 1450 / 2850 2850 / Motor Frame Size 56 56 56 56 56

Filters - Type Furnished Throwaway Throwaway Throwaway Throwaway Throwaway

(No.) Size Reccommended - mm (2) 508 X 762 X 25 (4) 406 X 635 X 50 (4) 406 X 635 X 50 (4) 508 X 635 X 50 (4) 508 X 635 X 50

(No.) Size Reccommended - in. (2) 20 X 30 X 1 (4) 16 X 25 X 2 (4) 16 X 25 X 2 (4) 20 X 25 X 2 (4) 20 X 25 X 2

Refrigerant Charge - kg (lbs) of R-22

Notes:

1. Cooling Performance is rated at 35.0 C (95 F) ambient, 26.7 C (80 F) entering dry bulb, 19.4 C (67 F) entering wet bulb. Gross capacity does not include the effect of fan motor

heat. Net capacity includes the effect of fan motor heat. Units are suitable for operation to ± 20 % of nominal airflow.

2. EER are rated at ARI conditions.

3. Outdoor Sound rating shown is tested in accordance with ARI Standard 270. For more information refer to Performance Data Table "Sound Power Level".

4. Refrigerant charge is an approcimate value. For a more precise value, see unit nameplate and service literature.

4

TSC060AD TSC072AD TSC090AD TSC102AD TSC120AD

2.99 (10.2) 3.08 (10.5) 3.02 (10.3) 3.02 (10.3) 2.99 (10.2)

80 85 85 83 79

3.7 (8.2) 3.7 (8.2) 4.5 (10.0) Circuit 1 - 3.8 (8.3) Circuit 1 - 3.4 (7.5)

Circuit 2 - 2.0 (4.4) Circuit 2 - 3.3 (7.3)

RT-PRC016-EN

13

Page 14

Performance Data

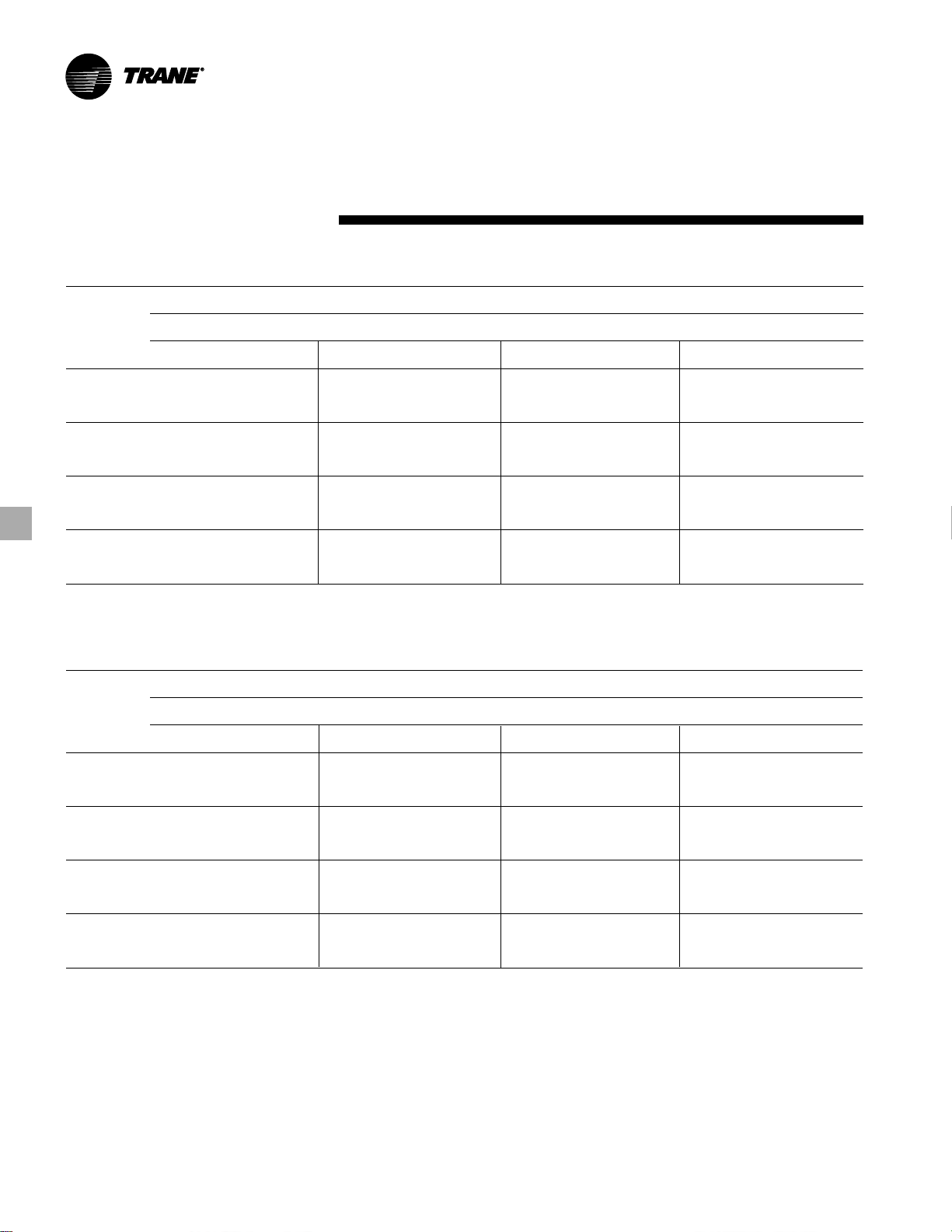

Table PD-1 — Gross Cooling Capacities (kW) - TSC060AD - (SI)

Enter. 30 35 40 45

Dry

m3/h T emp 16 19 22 16 19 22 16 19 22 16 19 22

Airflow (C) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

3060

3400

3740

4080

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

24 16.2 13.9 18.5 11.3 19.9 8.3 15.0 13.3 17.4 11.3 19.3 8.0 13.9 12.7 16.1 10.7 18.4 7.5 12.7 12.1 14.7 9.5 17.3 7.0

27 16.7 16.7 18.6 14.1 20.0 11.1 15.8 15.8 17.4 13.6 19.4 10.8 14.8 14.8 16.1 13.0 18.5 10.3 13.8 13.8 14.7 12.3 17.3 9.8

30 18.1 18.1 18.7 16.9 20.2 13.6 17.2 17.2 17.7 16.5 19.5 13.5 16.2 16.2 16.5 15.9 18.5 13.1 15.1 15.1 15.1 15.1 17.3 12.6

33 19.3 19.3 19.2 19.2 20.3 16.2 18.5 18.5 18.5 18.5 19.6 16.1 17.6 17.6 17.6 17.6 18.7 15.9 16.6 16.6 16.6 16.6 17.5 15.4

24 16.7 14.8 18.8 11.8 20.1 8.6 15.5 14.2 17.8 11.3 19.5 8.3 14.2 13.5 16.5 11.4 18.7 7.7 13.1 12.9 15.0 10.8 17.6 7.2

27 17.5 17.5 18.9 14.9 20.2 11.4 16.5 16.5 17.8 14.4 19.6 11.2 15.4 15.4 16.5 13.8 18.8 10.8 14.4 14.4 15.1 13.1 17.6 10.3

30 18.8 18.8 19.1 17.9 20.4 14.1 17.9 17.9 18.2 17.6 19.7 14.1 16.9 16.9 17.0 17.0 18.8 13.8 15.8 15.8 15.8 15.8 17.7 13.4

33 19.8 19.8 19.8 19.8 20.6 16.8 19.2 19.2 19.2 19.2 19.9 16.9 18.3 18.3 18.3 18.3 19.0 16.8 17.4 17.4 17.4 17.4 17.9 16.4

24 17.1 15.6 19.1 12.3 20.2 8.8 15.9 15.0 18.1 11.8 19.7 8.5 14.6 14.3 16.8 11.2 18.9 7.9 13.4 13.4 15.3 11.4 17.8 7.5

27 18.1 18.1 19.2 15.5 20.4 11.6 17.1 17.1 18.2 15.1 19.8 11.5 16.0 16.0 16.9 14.6 19.0 11.3 14.9 14.9 15.4 13.9 17.9 10.8

30 19.3 19.3 19.5 18.7 20.6 14.5 18.5 18.5 18.6 18.6 20.0 14.6 17.6 17.6 17.6 17.6 19.1 14.4 16.5 16.5 16.5 16.5 17.9 14.1

33 20.2 20.2 20.2 20.2 20.8 17.4 19.6 19.6 19.6 19.6 20.2 17.6 18.9 18.9 18.9 18.9 19.3 17.6 18.0 18.0 18.0 18.0 18.3 17.4

24 17.4 16.4 19.3 12.6 20.3 9.1 16.2 15.8 18.4 12.2 19.8 8.8 14.9 14.9 17.1 11.7 19.0 8.1 13.9 13.9 15.5 12.1 18.0 7.7

27 18.6 18.6 19.4 16.1 20.5 12.3 17.7 17.7 18.4 15.8 19.9 11.8 16.6 16.6 17.2 15.3 19.1 11.6 15.4 15.4 15.8 14.6 18.1 11.2

30 19.7 19.7 19.7 19.4 20.7 14.9 19.0 19.0 19.0 19.0 20.1 15.0 18.1 18.1 18.1 18.1 19.3 15.0 17.1 17.1 17.1 17.1 18.2 14.7

33 20.5 20.5 20.5 20.5 20.9 17.9 20.0 20.0 20.0 20.0 20.4 18.2 19.3 19.3 19.3 19.3 19.5 18.3 18.4 18.4 18.4 18.4 18.6 18.2

Ambient T emperature (C)

Entering Wet Bulb Temperature (C)

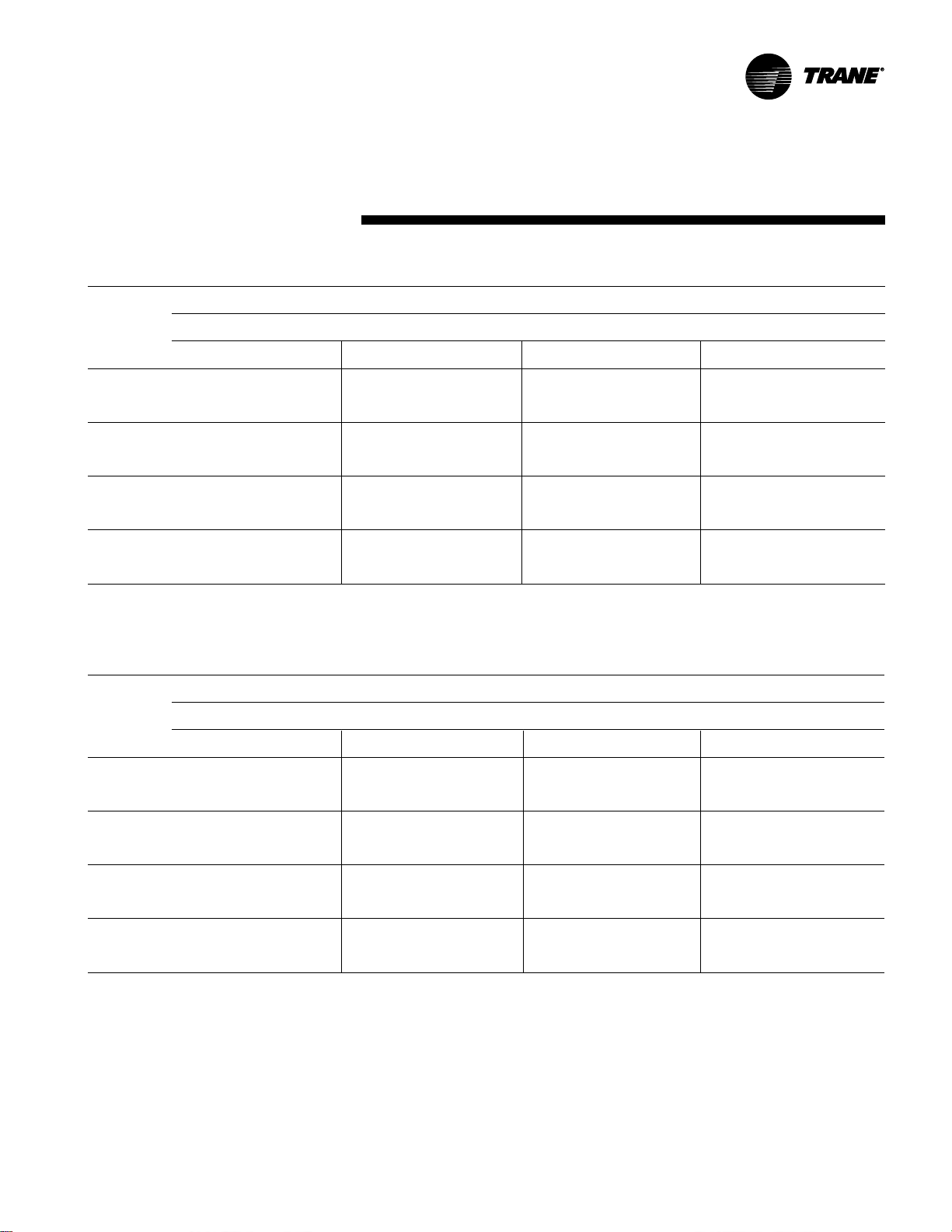

Table PD-1a — Gross Cooling Capacities (MBH) _ TSC060AD _ (IP)

Enter. 85 95 105 115

Dry

CFM Temp 61 67 73 61 67 73 61 67 73 61 67 73

Airflow (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

1800

2000

2200

2400

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

75 56.1 47.1 64.4 37.0 68.8 25.1 51.6 44.7 60.6 36.7 66.9 23.9 47.0 42.4 55.6 34.5 64.0 22.6 42.4 40.1 50.2 30.3 60.0 20.8

80 57.3 56.5 64.6 45.8 69.3 34.2 53.3 53.3 60.7 43.9 67.3 32.9 49.5 49.5 55.7 41.6 64.2 31.4 45.7 45.7 50.4 39.2 60.1 29.6

85 61.3 61.3 64.9 54.5 69.7 42.0 57.7 57.7 61.0 52.9 67.6 41.4 53.9 53.9 56.3 50.7 64.4 40.3 50.0 50.0 51.2 48.3 60.2 38.4

90 65.0 65.0 65.8 63.3 70.4 49.7 62.1 62.1 62.4 62.2 68.0 49.7 58.5 58.5 58.5 58.5 64.6 48.8 54.4 54.4 54.4 54.4 60.3 47.2

75 57.5 49.8 65.4 38.5 69.3 25.5 53.0 47.5 61.8 38.7 67.5 24.4 48.3 45.1 56.9 36.6 64.7 23.0 43.7 42.8 51.3 34.2 60.9 21.4

80 59.3 59.3 65.6 47.9 69.8 35.4 55.7 55.7 62.0 46.4 68.0 34.2 51.6 51.6 57.1 44.1 65.0 32.7 47.7 47.7 51.5 41.6 61.0 30.9

85 63.6 63.6 66.0 57.3 70.5 43.1 60.3 60.3 62.5 56.2 68.3 43.0 56.4 56.4 58.0 54.1 65.2 42.1 52.2 52.2 52.8 51.7 61.2 40.6

90 66.9 66.9 67.2 66.5 71.1 51.4 64.4 64.4 64.4 64.4 68.9 51.8 61.0 61.0 61.0 61.0 65.6 51.3 57.1 57.1 57.1 57.1 61.5 50.1

75 58.8 52.5 66.1 39.8 69.6 25.9 54.3 50.2 62.8 38.1 67.9 24.9 49.4 47.8 58.0 38.6 65.3 23.4 44.8 44.8 52.2 36.2 61.6 21.7

80 61.5 61.5 66.4 49.8 70.3 36.8 57.8 57.8 63.0 48.6 68.3 35.0 53.6 53.6 58.2 46.5 65.6 33.9 49.4 49.4 52.6 44.0 61.8 32.2

85 65.4 65.4 67.0 59.8 71.0 44.6 62.4 62.4 63.7 59.2 69.0 44.3 58.7 58.7 59.4 57.4 66.0 43.8 54.3 54.3 54.3 54.3 62.0 42.5

90 68.4 68.4 68.4 68.4 71.7 52.8 66.1 66.1 66.1 66.1 69.6 53.6 63.1 63.1 63.0 63.0 66.4 53.6 59.3 59.3 59.3 59.3 62.4 52.7

75 60.0 55.1 66.6 40.8 70.0 26.4 55.5 52.8 63.6 39.6 68.3 25.3 50.6 50.4 59.0 37.4 65.7 24.0 46.2 46.2 53.1 38.2 62.2 22.1

80 63.2 63.2 67.1 51.4 70.7 37.7 59.6 59.6 63.8 50.7 68.8 35.8 55.4 55.4 59.2 48.8 66.2 35.0 51.1 51.1 53.5 46.3 62.4 33.4

85 66.7 66.7 67.8 62.0 71.5 45.3 64.1 64.1 64.8 61.9 69.5 45.5 60.5 60.5 60.8 60.6 66.6 45.2 56.3 56.3 56.2 56.2 62.7 44.3

90 69.5 69.5 69.5 69.5 72.1 54.1 67.4 67.4 67.4 67.4 70.2 55.3 64.6 64.6 64.5 64.5 67.1 55.7 61.1 61.1 61.0 61.0 63.2 55.1

Ambient T emperature (F)

Entering Wet Bulb Temperature (F)

14

RT-PRC016-EN

Page 15

Performance

Data

Table PD-2 — Gross Cooling Capacities (kW) - TSC072AD - (SI)

Enter. 30 35 40 45

Dry

m3/h T emp 16 19 22 16 19 22 16 19 22 16 19 22

Airflow (C) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

3670

4080

4490

4900

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

24 20.9 17.5 23.3 14.6 24.6 10.3 19.7 16.8 22.4 13.6 24.0 9.9 18.4 16.1 21.2 12.9 23.2 9.4 17.1 15.4 19.7 12.9 22.0 9.0

27 21.6 21.2 23.4 17.4 24.8 13.5 20.4 20.4 22.5 17.0 24.1 13.3 19.4 19.4 21.2 16.4 23.3 12.8 18.2 18.2 19.8 15.7 22.1 12.3

30 22.9 22.9 23.6 20.6 25.0 16.5 22.1 22.1 22.7 20.4 24.3 16.3 21.0 21.0 21.5 19.9 23.5 16.1 19.9 19.9 20.2 19.2 22.2 15.6

33 24.0 24.0 24.1 23.8 25.2 19.4 23.4 23.4 23.3 23.3 24.5 19.3 22.5 22.5 22.4 22.4 23.6 19.3 21.4 21.4 21.4 21.4 22.3 18.8

24 21.5 18.5 23.6 15.2 24.8 10.6 20.3 17.9 22.8 14.2 24.2 10.1 19.0 17.2 21.6 13.6 23.4 9.8 17.6 16.4 20.1 12.9 22.3 9.3

27 22.3 22.3 23.8 18.1 25.1 14.5 21.3 21.3 22.9 17.9 24.3 13.6 20.2 20.2 21.6 17.3 23.6 13.4 19.0 19.0 20.2 16.6 22.4 12.8

30 23.6 23.6 24.0 21.6 25.3 17.6 22.9 22.9 23.2 21.5 24.6 16.8 21.8 21.8 22.0 21.1 23.7 16.7 20.7 20.7 20.8 20.5 22.5 16.3

33 24.6 24.6 24.6 24.6 25.5 20.0 23.9 23.9 23.9 23.9 24.8 20.1 23.1 23.1 23.1 23.1 23.9 20.1 22.1 22.1 22.1 22.1 22.7 19.8

24 22.0 19.5 23.9 15.8 25.0 10.7 20.8 18.9 23.1 14.7 24.4 10.4 19.5 18.2 21.9 14.2 23.5 10.1 18.1 17.4 20.5 13.5 22.5 9.6

27 22.9 22.9 24.0 18.7 25.3 13.9 22.1 22.1 23.2 18.6 24.5 13.9 20.9 20.9 22.0 18.2 23.7 13.6 19.7 19.7 20.6 17.6 22.6 13.3

30 24.1 24.1 24.3 22.4 25.5 17.4 23.4 23.4 23.5 22.4 24.8 17.3 22.5 22.5 22.5 22.2 23.9 17.2 21.3 21.3 21.3 21.3 22.8 17.0

33 25.0 25.0 25.0 25.0 25.7 20.7 24.4 24.4 24.4 24.4 25.1 20.8 23.7 23.7 23.7 23.7 24.2 20.8 22.6 22.6 22.6 22.6 23.1 20.7

24 22.4 20.3 24.1 16.3 25.2 10.9 21.2 19.8 23.2 15.1 24.5 10.7 19.9 19.1 22.2 14.7 23.6 10.3 18.5 18.4 20.8 14.0 22.7 9.9

27 23.4 23.4 24.3 19.3 25.5 14.5 22.6 22.6 23.4 19.2 24.7 14.7 21.5 21.5 22.3 19.0 23.8 14.0 20.3 20.3 20.9 18.4 22.8 13.7

30 24.5 24.5 24.6 23.2 25.6 17.8 23.8 23.8 23.9 23.2 25.0 17.8 23.0 23.0 23.0 23.0 24.1 17.7 21.8 21.8 21.8 21.8 23.0 17.7

33 25.4 25.4 25.4 25.4 25.9 21.2 24.8 24.8 24.8 24.8 25.3 21.4 24.1 24.1 24.1 24.1 24.4 21.4 23.1 23.1 23.1 23.1 23.4 21.6

Ambient T emperature (C)

Entering Wet Bulb Temperature (C)

Table PD-2a — Gross Cooling Capacities (MBH) - TSC072AD - (IP)

Enter. 85 95 105 115

Dry

CFM Temp 61 67 73 61 67 73 61 67 73 61 67 73

Airflow (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

2160

2400

2640

2880

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

75 72.2 59.1 80.6 47.1 85.1 31.0 67.5 56.5 77.7 44.1 82.7 29.6 62.6 53.9 73.0 41.8 79.9 28.0 57.4 51.2 67.5 39.2 75.5 26.0

80 73.8 70.7 81.0 56.1 85.8 42.2 69.4 68.2 77.9 55.0 83.4 40.7 65.0 65.0 73.1 52.6 80.4 39.0 60.6 60.6 67.6 50.0 75.8 36.8

85 77.7 77.7 81.4 66.3 86.3 51.7 74.3 74.3 78.2 65.6 83.8 50.1 70.3 70.3 73.6 63.5 80.7 49.2 66.0 66.0 68.3 61.0 76.1 47.4

90 81.3 81.3 82.4 76.3 87.1 59.8 78.8 78.8 79.4 76.0 84.6 59.4 75.1 75.1 75.3 74.6 81.3 59.0 70.8 70.8 70.7 70.7 76.6 57.4

75 74.2 62.5 81.6 49.2 85.7 31.5 69.3 59.9 78.7 46.0 83.4 30.1 64.4 57.3 74.2 43.7 80.2 28.5 59.1 54.6 68.9 41.1 76.3 26.6

80 76.1 75.0 82.1 58.2 86.5 43.7 72.1 72.1 79.0 57.4 84.2 42.1 67.9 67.9 74.4 55.4 80.9 40.4 63.3 63.3 69.0 53.0 76.8 38.4

85 80.0 80.0 82.6 69.1 86.8 52.8 77.1 77.1 79.5 68.7 84.7 51.6 73.1 73.1 75.3 67.3 81.4 50.7 68.7 68.7 70.1 65.0 77.2 49.4

90 83.3 83.3 83.8 79.7 87.1 61.5 80.7 80.7 80.9 79.4 85.5 61.5 77.5 77.5 77.5 77.5 82.1 61.1 73.3 73.3 73.3 73.3 77.8 60.2

75 75.8 65.6 82.3 50.7 86.2 32.0 71.0 63.2 79.4 49.8 84.0 30.7 66.0 60.6 75.4 45.6 80.7 29.0 60.6 57.8 70.0 42.9 77.0 27.2

80 78.1 78.1 82.9 60.1 87.2 44.1 74.6 74.6 79.8 59.4 84.7 44.3 70.3 70.3 75.6 58.1 81.2 41.3 65.7 65.7 70.1 55.7 77.6 39.8

85 81.7 81.7 83.6 71.6 88.2 54.0 79.1 79.1 80.5 71.3 85.4 53.6 75.4 75.4 76.6 70.7 82.0 52.1 70.9 70.9 71.6 68.7 78.1 51.3

90 84.8 84.8 85.0 82.5 89.1 62.3 82.3 82.3 82.3 82.3 86.1 61.2 79.4 79.4 79.4 79.4 82.8 63.0 75.2 75.2 75.2 75.2 78.7 62.8

75 77.0 68.3 82.9 52.2 86.6 32.5 72.5 66.4 80.0 51.4 84.5 31.2 67.5 63.7 76.2 47.1 81.2 29.5 62.1 61.0 70.8 44.7 77.6 27.8

80 79.6 79.6 83.7 61.8 87.6 44.7 76.6 76.6 80.6 61.3 85.4 44.0 72.4 72.4 76.5 60.5 81.8 42.1 67.7 67.7 71.1 58.2 78.1 40.9

85 83.0 83.0 84.4 73.9 88.7 54.9 80.4 80.4 81.5 73.9 86.2 54.1 77.1 77.1 77.8 73.8 82.7 53.5 72.7 72.7 72.9 71.9 78.8 53.0

90 85.9 85.9 86.0 85.0 89.6 65.2 83.6 83.6 83.6 83.6 87.0 63.2 81.0 81.0 81.0 81.0 83.5 65.0 76.8 76.8 76.8 76.8 79.5 65.3

Ambient T emperature (F)

Entering Wet Bulb Temperature (F)

RT-PRC016-EN

15

Page 16

Performance

Data

Table PD-3 — Gross Cooling Capacities (kW) - TSC090AD - (SI)

Enter. 30 35 40 45

Dry

m3/h T emp 16 19 22 16 19 22 16 19 22 16 19 22

Airflow (C) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

4590

5100

5610

6120

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

24 24.5 21.6 26.9 17.1 28.1 12.0 22.7 20.6 25.8 16.3 27.7 11.5 20.8 19.6 24.1 15.4 26.8 11.0 19.0 18.7 22.0 14.8 25.6 10.3

27 25.4 25.4 27.1 21.1 28.5 15.9 24.1 24.1 25.9 20.8 27.8 15.9 22.5 22.5 24.3 20.0 27.0 15.5 20.9 20.9 22.2 19.0 25.7 14.8

30 27.0 27.0 27.4 25.3 28.7 19.5 26.0 26.0 26.4 25.3 28.1 19.7 24.8 24.8 25.0 24.8 27.1 19.6 23.2 23.2 23.1 23.1 25.8 19.2

33 28.1 28.1 28.1 28.1 29.0 23.3 27.5 27.5 27.5 27.5 28.4 23.6 26.5 26.5 26.5 26.5 27.4 23.9 25.3 25.3 25.3 25.3 26.1 23.6

24 25.1 23.0 27.2 18.1 28.4 12.4 23.4 22.1 26.2 17.1 27.8 11.9 21.4 21.1 24.6 16.8 27.1 11.3 19.7 19.7 22.5 15.3 25.9 10.7

27 26.3 26.3 27.4 22.0 28.6 16.3 25.1 25.1 26.4 22.0 28.0 16.2 23.6 23.6 24.9 21.4 27.2 16.0 21.9 21.9 22.8 20.4 26.0 15.6

30 27.6 27.6 27.8 26.4 29.0 20.2 26.8 26.8 27.0 26.8 28.3 20.4 25.7 25.7 25.7 25.7 27.4 20.6 24.3 24.3 24.3 24.3 26.2 20.4

33 28.6 28.6 28.6 28.6 29.3 24.1 28.1 28.1 28.1 28.1 28.7 24.6 27.3 27.3 27.3 27.3 27.8 25.0 26.2 26.2 26.2 26.2 26.6 25.1

24 25.6 24.2 27.4 18.4 28.4 12.5 24.0 23.5 26.5 18.3 28.0 12.2 22.0 22.0 25.1 17.1 27.3 11.7 20.4 20.4 22.9 16.2 26.2 11.1

27 26.9 26.9 27.7 22.8 28.8 16.5 25.9 25.9 26.8 23.0 28.3 16.7 24.5 24.5 25.4 22.7 27.4 16.5 22.8 22.8 23.5 21.8 26.3 16.3

30 28.0 28.0 28.1 27.3 29.1 20.6 27.4 27.4 27.4 27.4 28.7 21.2 26.5 26.5 26.4 26.4 27.7 21.4 25.2 25.2 25.2 25.2 26.5 21.4

33 28.9 28.9 28.9 28.9 29.5 24.7 28.5 28.5 28.5 28.5 29.1 25.6 27.8 27.8 27.8 27.8 28.1 26.0 26.8 26.8 26.8 26.8 27.0 26.3

24 26.1 25.4 27.6 18.5 28.5 12.7 24.5 24.5 26.7 19.1 28.1 12.5 22.8 22.8 25.4 18.0 27.4 12.0 21.1 21.1 23.4 17.0 26.3 11.4

27 27.3 27.3 27.9 23.4 28.9 16.8 26.5 26.5 27.1 23.9 28.5 17.1 25.3 25.3 25.8 23.8 27.7 17.0 23.6 23.6 24.1 23.1 26.5 16.9

30 28.3 28.3 28.4 28.1 29.2 21.0 27.8 27.8 27.8 27.8 28.8 21.8 27.0 27.0 27.0 27.0 27.9 22.1 25.8 25.8 25.8 25.8 26.8 22.3

33 29.1 29.1 29.1 29.1 29.6 25.2 28.8 28.8 28.8 28.8 29.3 26.4 28.2 28.2 28.2 28.2 28.4 26.9 27.3 27.3 27.3 27.3 27.4 27.4

Ambient T emperature (C)

Entering Wet Bulb Temperature (C)

Table PD-3a — Gross Cooling Capacities (MBH) - TSC090AD - (IP)

Enter. 85 95 105 115

Dry

CFM Temp 61 67 73 61 67 73 61 67 73 61 67 73

Airflow (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

2700

3000

3300

3600

NOTES:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

75 84.4 72.7 92.7 55.2 96.6 35.6 77.7 69.1 89.4 52.6 95.2 34.0 70.4 65.4 83.4 50.6 92.5 32.0 63.7 61.9 75.3 46.9 88.2 29.8

80 86.5 86.5 93.3 67.5 97.8 48.9 81.2 81.2 89.6 66.8 96.2 48.4 75.1 75.1 83.8 64.0 93.1 46.6 69.4 69.4 75.8 60.3 88.5 44.1

85 91.5 91.5 94.2 80.6 98.9 59.9 87.7 87.7 90.6 80.8 97.2 60.5 82.5 82.5 85.1 78.8 93.5 59.5 76.4 76.4 77.7 75.2 88.8 58.1

90 95.1 95.1 95.7 93.2 100.0 71.0 92.6 92.6 92.5 92.5 97.5 71.8 88.7 88.7 88.7 88.7 94.3 72.6 83.7 83.7 83.6 83.6 89.5 71.8

75 86.5 77.3 93.5 56.9 97.1 36.1 80.0 73.9 90.6 56.4 95.8 34.6 72.6 70.1 85.2 52.3 93.2 32.7 65.6 65.6 76.9 49.9 89.1 30.5

80 89.4 89.4 94.3 70.0 98.3 52.8 84.9 84.9 91.0 70.2 96.9 49.4 78.8 78.8 85.6 68.2 93.9 48.9 72.7 72.7 77.8 64.5 89.6 46.3

85 93.6 93.6 95.4 83.8 99.4 61.1 90.6 90.6 92.2 85.2 98.0 62.3 86.1 86.1 87.3 84.2 94.5 61.9 80.1 80.1 80.1 80.1 90.0 61.2

90 96.8 96.8 97.0 96.7 100.5 72.8 94.8 94.8 94.8 94.8 99.0 75.4 91.5 91.5 91.4 91.4 95.4 75.8 87.0 87.0 87.0 87.0 90.9 75.9

75 88.1 81.3 94.3 59.1 97.5 36.7 82.1 78.5 91.4 58.6 96.2 35.2 74.1 74.1 86.4 54.8 93.7 33.4 68.1 68.1 78.5 51.2 89.8 31.2

80 91.4 91.4 95.1 72.1 98.7 50.2 87.6 87.6 92.1 73.3 97.4 50.3 82.2 82.2 87.1 72.0 94.5 49.7 75.6 75.6 79.7 68.7 90.4 48.3

85 95.1 95.1 96.2 86.6 99.8 62.1 92.7 92.7 93.6 89.0 98.5 63.8 88.8 88.8 89.2 89.1 95.2 64.0 83.5 83.5 83.5 83.5 90.9 63.9

90 97.9 97.9 97.9 97.9 101.0 74.3 96.4 96.4 96.3 96.3 99.7 77.5 93.5 93.5 93.5 93.5 96.3 78.6 89.4 89.4 89.4 89.4 92.1 79.5

75 89.5 85.0 95.1 60.6 97.8 37.2 84.0 83.1 92.2 60.7 96.6 35.7 76.7 76.7 87.5 57.3 94.1 34.0 70.4 70.4 80.0 53.8 90.4 31.9

80 92.9 92.9 95.6 74.0 99.0 50.8 89.7 89.7 93.0 76.0 97.8 51.0 84.8 84.8 88.3 75.6 95.2 50.9 78.1 78.1 81.6 72.8 90.9 49.5

85 96.2 96.2 96.9 88.9 100.2 63.1 94.2 94.2 94.7 92.3 99.0 65.1 90.7 90.7 90.7 90.7 95.8 65.8 86.0 86.0 86.0 86.0 91.7 66.3

90 98.7 98.7 98.7 98.7 101.3 75.7 97.5 97.5 97.5 97.5 100.1 79.4 94.9 94.9 94.9 94.9 97.0 81.1 91.2 91.2 91.2 91.2 93.0 82.7

Ambient T emperature (F)

Entering Wet Bulb Temperature (F)

16

RT-PRC016-EN

Page 17

Performance

Data

Table PD-4 — Gross Cooling Capacities (kW) - TSC102AD - (SI)

Enter. 30 35 40 45

Dry

m3/h T emp 16 19 22 16 19 22 16 19 22 16 19 22

Airflow (C) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

5200

5780

6360

6940

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

24 28.0 24.3 31.5 19.5 33.4 14.1 26.0 23.3 30.0 18.7 32.5 13.5 23.9 22.2 27.8 17.7 31.3 12.9 21.6 21.6 25.4 17.3 29.7 12.2

27 29.0 28.4 31.6 24.3 33.6 18.7 27.4 27.1 30.1 23.6 32.7 18.5 25.6 25.6 28.0 22.7 31.4 17.8 23.9 23.9 25.6 21.6 29.8 17.1

30 31.0 31.0 31.9 29.0 33.9 23.0 29.7 29.7 30.5 28.6 32.9 22.8 28.1 28.1 28.1 28.1 31.5 22.5 26.3 26.3 26.5 25.7 29.9 22.0

33 32.6 32.6 32.7 32.1 34.1 27.3 31.6 31.6 31.6 31.4 33.2 27.3 30.4 30.4 30.3 30.3 31.8 27.2 28.9 28.9 28.8 28.8 30.2 26.8

24 28.8 25.8 31.9 20.4 33.6 14.4 26.8 24.8 30.5 19.6 32.8 13.9 24.2 24.2 28.5 18.7 31.6 13.4 22.5 22.5 26.0 17.6 30.1 12.6

27 30.1 29.8 32.1 25.4 34.0 19.2 28.6 28.6 30.7 25.0 32.9 19.1 26.8 26.8 28.8 24.2 31.7 18.6 25.0 25.0 26.3 23.1 30.2 17.9

30 32.0 32.0 32.5 30.5 34.2 23.7 30.9 30.9 30.9 30.9 33.2 23.7 29.4 29.4 29.4 29.4 31.9 23.6 27.6 27.6 27.7 27.2 30.3 23.2

33 33.4 33.4 33.4 33.2 34.5 28.1 32.6 32.6 32.5 32.5 33.6 28.5 31.4 31.4 31.4 31.4 32.3 28.5 30.0 30.0 30.0 30.0 30.8 28.3

24 29.5 27.3 32.2 21.1 33.8 14.7 27.6 26.3 31.0 20.5 33.0 14.4 25.1 25.1 29.1 19.6 31.8 13.8 23.5 22.9 26.5 18.5 30.4 12.9

27 31.0 31.0 32.5 26.5 34.2 19.7 29.7 29.7 31.2 26.3 33.3 19.5 27.9 27.9 29.4 25.6 32.0 19.2 26.0 26.0 27.0 24.5 30.5 18.7

30 32.7 32.7 33.0 31.7 34.6 24.5 31.7 31.7 31.7 31.7 33.6 24.6 30.4 30.4 30.5 29.9 32.3 24.5 28.8 28.8 28.8 28.6 30.7 24.3

33 34.0 34.0 34.0 34.0 34.8 28.9 33.2 33.2 33.2 33.2 33.9 29.5 32.1 32.1 32.1 32.1 32.7 29.7 30.9 30.9 30.9 30.9 31.3 29.7

24 30.1 28.7 32.5 21.7 33.9 15.1 27.9 27.9 31.3 21.4 33.1 14.7 26.0 26.0 29.3 20.4 32.2 14.2 24.2 23.9 27.0 19.4 30.6 13.3

27 31.7 31.7 32.8 27.4 34.4 20.0 30.5 30.5 31.6 27.4 33.4 20.0 28.8 28.8 29.8 26.9 32.3 19.7 26.9 26.9 27.6 25.9 30.7 19.4

30 33.2 33.2 33.2 33.2 34.8 25.0 32.3 32.3 32.4 31.7 33.7 25.2 31.2 31.2 31.2 30.9 32.6 25.4 29.7 29.7 29.7 29.7 31.0 25.3

33 34.4 34.4 34.4 34.4 35.2 30.0 33.7 33.7 33.7 33.7 34.2 30.4 32.9 32.9 32.9 32.9 33.1 30.8 31.5 31.5 31.5 31.5 31.4 31.4

Ambient T emperature (C)

Entering Wet Bulb Temperature (C)

Table PD-4a — Gross Cooling Capacities (MBH) - TSC102AD - (IP)

Enter. 85 95 105 115

Dry

CFM Temp 61 67 73 61 67 73 61 67 73 61 67 73

Airflow (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

3060

3400

3740

4080

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

75 96.7 81.9 109.1 63.4 115.0 42.2 89.1 78.1 104.0 60.7 112.1 40.4 81.2 74.1 96.3 59.2 107.9 38.3 73.7 70.3 87.0 55.2 102.4 35.8

80 98.2 98.2 109.4 78.3 116.1 58.1 92.7 90.8 104.2 76.3 113.0 56.2 85.7 85.2 96.6 72.9 108.5 53.9 79.3 79.3 87.4 68.8 102.7 51.3

85 105.0 105.0 110.2 93.1 117.3 70.8 100.0 100.0 105.0 91.8 113.6 70.4 93.6 93.6 98.0 88.8 108.9 68.7 86.8 86.8 89.2 84.7 103.1 66.7

90 110.4 110.4 111.6 107.4 118.0 84.0 106.5 106.5 106.4 106.4 114.4 83.5 101.4 101.4 101.7 99.6 109.6 83.1 94.8 94.8 94.9 94.6 103.5 81.6

75 99.3 87.0 110.2 65.9 115.6 42.9 91.8 83.2 105.8 63.7 112.9 41.1 83.6 79.1 98.7 60.6 108.8 39.0 75.2 75.2 89.0 58.6 103.4 36.5

80 102.5 100.4 110.9 81.6 116.9 59.2 96.7 95.9 106.0 80.4 113.8 58.8 89.7 89.7 99.0 77.4 109.6 56.1 82.9 82.9 89.7 73.3 103.9 53.5

85 108.4 108.4 111.9 97.4 118.2 72.7 104.1 104.1 107.2 97.0 114.6 72.7 98.2 98.2 100.8 94.9 110.1 71.5 91.0 91.0 91.0 91.0 104.2 70.0

90 113.2 113.2 113.1 113.1 119.5 86.5 109.7 109.7 109.9107.6 115.6 86.6 105.1 105.1 105.1 104.4 111.0 86.9 99.4 99.4 99.2 99.2 105.1 86.0

75 101.6 91.8 111.3 67.8 116.2 43.6 94.3 88.2 107.1 66.5 113.5 41.8 84.7 84.7 100.4 63.0 109.5 39.6 78.4 76.4 90.9 59.0 104.2 37.1

80 105.4 104.4 112.1 84.5 117.6 60.0 100.3 100.3 107.4 84.0 114.7 59.4 93.4 93.4 100.9 81.6 110.0 57.9 86.1 86.1 91.7 77.7 104.8 55.6

85 111.0 111.0 113.3 101.2 118.9 74.2 107.0 107.0 108.9101.7 116.0 74.8 101.8 101.8 101.8 101.8 111.2 73.8 94.9 94.9 94.9 94.9 105.3 72.9

90 115.2 115.2 115.2 115.2 120.3 88.6 112.1 112.1 112.1111.1 116.5 89.3 107.8 107.8 107.7 107.7 112.1 90.2 102.6 102.6 102.6102.6 106.4 90.0

75 103.5 96.3 112.1 69.5 116.6 43.8 94.9 94.9 107.9 68.7 114.0 42.5 87.5 87.5 101.8 65.6 110.0 40.3 80.7 79.5 92.4 61.7 104.8 37.8

80 107.9 107.9 113.0 87.1 118.1 60.8 103.1 103.1 108.6 87.3 115.3 60.3 96.8 96.8 102.5 85.6 110.7 59.5 89.1 89.1 93.7 82.0 105.4 57.5

85 112.9 112.9 114.4 104.5 119.5 75.5 109.3 109.3 110.4105.7 116.7 76.5 104.5 104.5 104.5 104.5 111.9 76.7 98.2 98.2 98.6 96.7 106.2 75.5

90 116.7 116.7 116.7 116.7 120.9 90.6 113.9 113.9 113.8113.8 117.9 92.9 109.9 109.9 109.8 109.8 113.0 93.2 104.9 104.9 104.9104.9 107.5 93.5

Ambient T emperature (F)

Entering Wet Bulb Temperature (F)

RT-PRC016-EN

17

Page 18

Performance

Data

Table PD-5 — Gross Cooling Capacities (kW) - TSC120AD - (SI)

Enter. 30 35 40 45

Dry

m3/h T emp 16 19 22 16 19 22 16 19 22 16 19 22

Airflow (C) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

6120

6800

7480

8160

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

24 31.9 28.6 35.3 22.8 37.2 15.9 29.6 27.4 33.6 21.7 36.5 15.4 27.1 26.2 31.0 20.5 35.2 14.8 24.6 24.6 28.4 19.9 33.2 14.0

27 33.4 33.4 35.5 28.2 37.7 21.4 31.6 31.6 33.9 27.8 36.7 21.4 29.5 29.5 31.3 26.6 35.3 20.7 27.5 27.5 28.9 25.5 33.3 19.9

30 35.5 35.5 36.0 33.8 38.1 26.5 34.2 34.2 34.5 33.8 37.0 26.7 32.3 32.3 32.2 32.2 35.5 26.6 30.4 30.4 30.4 30.4 33.4 25.9

33 37.1 37.1 37.1 37.1 38.5 31.6 36.2 36.2 36.2 36.2 37.3 31.9 34.8 34.8 34.8 34.8 35.9 32.3 33.2 33.2 33.2 33.2 34.0 31.8

24 32.7 30.4 35.7 23.8 37.5 16.3 30.5 29.3 34.2 22.8 36.8 15.9 27.8 27.8 31.9 21.8 35.5 15.3 25.7 25.7 29.0 21.2 33.7 14.5

27 34.5 34.5 36.0 29.5 38.0 21.9 32.9 32.9 34.5 29.4 37.0 22.0 30.9 30.9 32.3 28.5 35.7 21.7 28.7 28.7 29.7 27.4 33.8 21.0

30 36.3 36.3 36.6 35.4 38.4 27.4 35.3 35.3 35.3 35.3 37.3 27.6 33.7 33.7 33.7 33.7 35.9 27.8 31.8 31.8 31.7 31.7 34.0 27.5

33 37.9 37.9 37.8 37.8 38.9 32.8 37.0 37.0 37.0 37.0 37.8 33.3 35.9 35.9 35.9 35.9 36.5 33.9 34.4 34.4 34.4 34.4 34.7 33.8

24 33.5 32.2 36.0 24.7 37.8 16.9 31.1 31.1 34.7 23.9 37.0 16.3 28.9 28.9 32.4 22.9 35.8 15.7 26.6 26.6 29.6 22.5 34.1 14.9

27 35.3 35.3 36.4 30.6 38.2 22.4 34.0 34.0 35.0 30.8 37.4 22.7 32.0 32.0 33.0 30.2 36.0 22.5 29.9 29.9 30.5 29.1 34.2 22.0

30 37.0 37.0 37.0 37.0 38.7 28.1 36.1 36.1 36.1 36.1 37.9 28.9 34.7 34.7 34.7 34.7 36.4 29.1 32.9 32.9 32.9 32.9 34.5 29.0

33 38.4 38.4 38.3 38.3 39.2 33.7 37.7 37.7 37.7 37.7 38.4 34.9 36.7 36.7 36.7 36.7 37.0 35.4 35.3 35.3 35.3 35.3 35.3 35.3

24 33.9 33.9 36.3 24.9 37.9 17.3 32.0 32.0 35.0 25.6 37.5 16.1 29.8 29.8 32.8 23.9 36.1 16.2 27.5 27.5 29.8 23.6 34.4 15.3

27 35.9 35.9 36.7 31.7 38.5 22.8 34.8 34.8 35.5 32.2 37.7 23.2 32.9 32.9 33.6 31.9 36.3 23.2 30.6 30.6 30.6 30.6 34.5 23.0

30 37.5 37.5 37.5 37.5 38.9 28.8 36.7 36.7 36.7 36.7 38.1 29.8 35.5 35.5 35.5 35.5 36.7 30.2 33.7 33.7 33.7 33.7 34.9 30.5

33 38.8 38.8 38.7 38.7 39.5 34.6 38.4 38.4 38.2 38.2 38.7 36.1 37.3 37.3 37.3 37.3 37.4 36.7 36.0 36.0 36.0 36.0 36.0 36.0

Ambient T emperature (C)

Entering Wet Bulb Temperature (C)

Table PD-5a — Gross Cooling Capacities (MBH) - TSC120AD - (IP)

Enter. 85 95 105 115

Dry

CFM Temp 61 67 73 61 67 73 61 67 73 61 67 73

Airflow (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

3600

4000

4400

4800

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total Gross Capacity

3. SHC = Sensible Heat Capacity

Bulb

75 109.9 96.4 122.1 73.8 128.5 47.6 101.2 92.1 116.7 70.3 125.9 45.7 91.8 87.5 107.7 67.7 121.6 43.4 82.1 82.1 97.2 63.2 115.0 40.9

80 113.5 113.5 122.6 90.4 129.9 65.7 106.6 106.6 117.1 89.2 127.2 65.0 99.0 99.0 108.4 85.4 122.2 62.4 91.0 91.0 98.2 81.0 115.2 59.7

85 120.2 120.2 123.8 108.0 131.3 80.9 115.2 115.2 118.5107.9 127.8 81.5 108.1 108.1 110.5 104.9 122.6 80.6 100.3 100.3 100.3100.3 115.4 78.4

90 125.4 125.4 125.4 125.4 132.7 96.3 121.8 121.8 121.8121.8 128.7 97.3 116.4 116.4 116.4 116.4 123.6 98.2 109.2 109.2 109.2109.2 116.4 97.0

75 112.7 102.4 123.1 75.6 129.3 48.4 104.2 98.3 118.5 73.6 126.9 46.6 93.7 93.7 109.9 70.9 122.7 44.3 85.6 85.6 99.3 67.2 116.5 41.9

80 117.3 117.3 124.1 94.1 130.8 66.9 111.1 111.1 119.0 94.0 128.2 66.8 103.5 103.5 110.8 90.8 123.5 65.3 95.2 95.2 100.8 86.6 116.8 62.5

85 123.2 123.2 125.6 112.8 132.3 82.9 119.0 119.0 120.8114.1 129.5 84.5 112.5 112.5 112.5 112.5 124.1 84.2 104.9 104.9 104.8104.8 117.1 83.0

90 127.9 127.9 127.9 127.9 133.8 99.2 124.9 124.9 124.9124.9 130.8 102.4 120.2120.2 120.2 120.2 125.3103.1 113.9 113.9 113.8 113.8 118.4102.9

75 115.1 108.2 124.5 77.5 130.0 49.2 107.0 104.4 119.8 77.6 127.6 47.4 97.3 97.3 111.7 73.2 123.6 45.2 88.7 88.7 101.1 71.1 117.6 42.7

80 120.1 120.1 125.3 97.3 131.6 67.9 114.9 114.9 120.6 98.4 129.0 68.2 107.3 107.3 112.9 96.1 124.5 68.1 98.9 98.9 103.1 92.0 118.0 65.1

85 125.5 125.5 127.0 116.9 133.1 84.7 121.9 121.9 122.8119.6 130.5 87.0 116.4 116.4 116.3 116.3 125.3 88.0 108.7 108.7 108.7108.7 118.4 87.0

90 130.0 130.0 129.7 129.7 134.7 101.8 127.3 127.3 127.2127.2 131.9 105.9 123.0123.0 123.0 123.0 126.7107.5 117.2 117.2 117.2 117.2 120.2 108.4

75 117.1 113.2 125.5 81.7 130.6 50.0 108.8 108.8 120.8 80.6 128.3 48.2 100.5 100.5 113.2 76.3 124.3 46.1 91.6 91.6 102.7 72.1 118.5 43.6

80 122.3 122.3 126.5 100.7 132.2 68.9 117.8 117.8 122.0102.4 129.8 69.5 110.5 110.5 114.9 101.3 125.7 69.3 102.2 102.2 105.2 97.3 119.0 67.7

85 127.2 127.2 128.4 121.1 133.8 86.3 124.1 124.1 124.1124.1 131.2 89.2 119.0 119.0 119.0 119.0 126.5 90.9 112.0 112.0 112.0112.0 119.7 90.9

90 131.3 131.3 131.5 131.5 135.4 104.2 129.3 129.3 129.0129.0 132.8 108.9 125.2125.2 125.2 125.2 127.8111.4 119.8 119.8 119.8 119.8 121.7 113.3

Ambient T emperature (F)

Entering Wet Bulb Temperature (F)

18

RT-PRC016-EN

Page 19

Performance

Data

Table PD-6 — Belt Drive Evaporator Fan Performance - TSC060AD - Downflow Configuration (SI)

m3/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

25 50 75 100 125 150 175 200 225 250

1.12 Nom kW Standard Motor & Low Static Drive 1.12 Nom kW Standard Motor & Drive

2720 - - 703 0.27 757 0.31 806 0.35 854 0.39 899 0.43 944 0.49 985 0.54 1023 0.59 1060 0.64

3060 706 0.32 760 0.35 815 0.40 861 0.45 904 0.49 947 0.54 988 0.58 1028 0.64 1067 0.70 1104 0.76

3400 773 0.43 821 0.46 873 0.51 918 0.57 958 0.62 998 0.67 1036 0.71 1073 0.76 1111 0.82 1147 0.89

3740 840 0.56 885 0.60 930 0.65 977 0.71 1016 0.77 1053 0.82 1089 0.88 1124 0.93 1158 0.98 1191 1.03

4080 909 0.71 950 0.76 990 0.80 1034 0.87 1074 0.93 1110 1.00 1143 1.06 1177 1.12 1209 1.17 1241 1.23

External Static Pressure (Pascals)

CFM RPM kW RPM kW RPM kW RPM kW RPM kW

2720 1093 0.69 1126 0.74 1160 0.79 1190 0.84 1222 0.90

3060 1138 0.82 1171 0.87 1203 0.93 1232 0.98 1262 1.04

3400 1182 0.96 1215 1.02 1246 1.09 1276 1.15 1306 1.21

3740 1226 1.10 1258 1.17 1290 1.25 - - - 4080 1272 1.29 - - - - - - - -

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1.12 kW - Fan Motor Heat (kW) = 1.144 x Fan kW + 0.132

275 300 325 350 375

1.12 Nom kW Standard Motor & Drive

External Static Pressure (Pascals)

1.12 Nom kW Standard Motor &

←←

←

←←

Hi Static Drive

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

Table PD-6a — Belt Drive Evaporator Fan Performance -TSC060AD - Downflow Configuration (IP)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1600 - - 703 0.36 757 0.41 806 0.47 854 0.52 899 0.58 944 0.65 985 0.73 1023 0.79 1060 0.86

1800 706 0.42 760 0.47 815 0.54 861 0.60 904 0.66 947 0.72 988 0.78 1028 0.86 1067 0.94 1104 1.02

2000 773 0.57 821 0.62 873 0.69 918 0.76 958 0.83 998 0.90 1036 0.96 1073 1.02 1111 1.10 1147 1.19

2200 840 0.75 885 0.80 930 0.87 977 0.95 1016 1.03 1053 1.10 1089 1.17 1124 1.24 1158 1.31 1191 1.39

2400 909 0.96 950 1.02 990 1.08 1034 1.16 1074 1.25 1110 1.34 1143 1.419 1177 1.50 1209 1.57 1241 1.65

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1600 1093 0.92 1126 0.99 1160 1.06 1190 1.13 1222 1.20

1800 1138 1.10 1171 1.17 1203 1.25 1232 1.32 1262 1.39

2000 1182 1.28 1215 1.37 1246 1.46 1276 1.54 1306 1.62

2200 1226 1.48 1258 1.57 1290 1.67 - - - 2400 1272 1.73 - - - - - - - -

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1 1/2 HP - Fan Motor Heat (MBH) = 2.915 x Fan BHP + 0.451

.10 .20 .30 .40 .50 .60 .70 .80 .90 1.00

1-1/2 HP Standard Motor & Low Static Drive 1-1/2 HP Standard Motor & Drive

External Static Pressure (Inches of Water)

1.10 1.20 1.30 1.40 1.50

1-1/2 HP Standard Motor & Drive

External Static Pressure (Inches of Water)

1-1/2 HP Standard Motor &

←←

←

←←

Hi Static Drive

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

RT-PRC016-EN

19

Page 20

Performance

Data

Table PD-7 - Belt Drive Evaporator Fan Performance- TSC060AD - Horizontal Configuration - (SI)

3

m

/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

2720 707 0.26 774 0.31 837 0.37 898 0.43 953 0.48 1001 0.54 1045 0.59 1087 0.65 1129 0.71 1168 0.77

3060 778 0.36 840 0.41 897 0.48 953 0.54 1008 0.60 1058 0.67 1102 0.73 1143 0.79 1181 0.85 1219 0.92

3400 850 0.48 908 0.54 961 0.60 1012 0.67 1062 0.74 1111 0.81 1157 0.88 1198 0.95 1237 1.02 1274 1.09

3740 923 0.63 978 0.69 1028 0.76 1075 0.83 1120 0.91 1166 0.99 1211 1.06 1254 1.14 1294 1.22 1330 1.29

4080 997 0.80 1049 0.87 1096 0.94 1140 1.02 1183 1.10 1223 1.18 1266 1.27 - - - - - -

25 50 75 100 125 150 175 200 225 250

1.12 Nom kW Std Motor & Low Static Drive 1.12 Nom kW Standard Motor & Drive

External Static Pressure (Pascals)

←

←←

←←

1.12 Nom kW Standard Motor & Hi Static Drive

CFM RPM kW RPM kW RPM kW RPM kW RPM kW

1.12 Nom kW Standard Motor & Drive

2720 1206 0.83 1241 0.89 1275 0.96 1306 1.02 1338 1.09

3060 1256 0.99 1291 1.05 1326 1.12 1359 1.19 1390 1.26

3400 1309 1.16 1343 1.24 1376 1.31 - - - 3740 - - - - - - - - - 4080 - - - - - - - - - -

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1.12 kW - Fan Motor Heat (kW) = 1.144 x Fan kW + 0.132

275 300 325 350 375

External Static Pressure (Pascals)

1.12 Nom kW Standard Motor &

←←

←

←←

Hi Static Drive

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

Table PD-7a - Belt Drive Evaporator Fan Performance- TSC060AD - Horizontal Configuration - (IP)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1600 707 0.35 774 0.42 837 0.50 898 0.57 953 0.65 1001 0.72 1045 0.80 1087 0.87 1129 0.95 1168 1.03

1800 778 0.48 840 0.56 897 0.64 953 0.72 1008 0.81 1058 0.89 1102 0.98 1143 1.06 1181 1.15 1219 1.23

2000 850 0.65 908 0.73 961 0.81 1012 0.90 1062 1.00 1111 1.09 1157 1.19 1198 1.28 1237 1.37 1274 1.47

2200 923 0.84 978 0.93 1028 1.02 1075 1.12 1120 1.22 1166 1.32 1211 1.43 1254 1.53 1294 1.63 1330 1.74

2400 997 1.07 1049 1.17 1096 1.27 1140 1.37 1183 1.48 1223 1.59 1266 1.70 - - - - - -

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1600 1206 1.12 1241 1.20 1275 1.28 1306 1.37 1338 1.46

1800 1256 1.32 1291 1.41 1326 1.50 1359 1.60 1390 1.69

2000 1309 1.56 1343 1.66 1376 1.76 - - - 2200 - - - - - - - - - 2400 - - - - - - - - - -

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1 1/2 HP - Fan Motor Heat (MBH) = 2.915 x Fan BHP + 0.451

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

1-1/2 HP Standard Motor &

Low Static Drive 1-1/2 HP Standard Motor & Drive

1.10 1.20 1.30 1.40 1.50

1/2 HP Standard Motor & Drive 1-1/2 HP Standard Motor & Hi Static Drive

External Static Pressure (Inches of Water)

External Static Pressure (Inches of Water)

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

←

←←

←←

1-1/2 HP Standard Motor & Hi Static Drive

20

RT-PRC016-EN

Page 21

Performance

Data

Table PD-8 — Belt Drive Evaporator Fan Performance -TSC072AD - Downflow Configuration (SI)

External Static Pressure (Pascals)

m3/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

3260 - - - - 573 0.25 630 0.30 680 0.36 726 0.41 769 0.47 811 0.52 851 0.58 889 0.65

3670 - - 548 0.26 602 0.31 656 0.37 706 0.43 751 0.49 792 0.55 832 0.61 871 0.67 908 0.74

4080 - - 584 0.33 635 0.38 682 0.45 732 0.51 777 0.58 818 0.64 856 0.71 893 0.77 930 0.84

4490 569 0.35 621 0.42 670 0.47 715 0.54 758 0.60 802 0.68 845 0.75 883 0.82 919 0.89 953 0.96

4890 612 0.45 660 0.51 706 0.58 749 0.64 789 0.71 830 0.79 870 0.87 909 0.95 945 1.02 979 1.10

CFM RPM kW RPM kW RPM kW RPM kW RPM kW

3260 925 0.71 960 0.77 994 0.83 1026 0.89 1057 0.95

3670 944 0.81 978 0.87 1010 0.94 1043 1.01 1073 1.08

4080 964 0.91 998 0.99 1030 1.06 1063 1.14 1092 1.21

4490 986 1.04 1019 1.11 1051 1.19 1082 1.27 1112 1.35

4890 1011 1.18 1043 1.26 1073 1.34 1103 1.42 1133 1.51

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1.12 kW - Fan Motor Heat (kW) = 1.144 x Fan kW + 0.132

1.50 kW - Fan Motor Heat (kW) = 1.178 x Fan kW + 0.464

25 50 75 100 125 150 175 200 225 250

1.12 Nom kW Standard Motor & Low Static Drive 1.12 Nom kW Standard Motor & Drive

1.12 Nom kW Standard Motor

275 300 325 350 375

External Static Pressure (Pascals)

1.12 Nom kW Std Motor 1.12 Nom kW Standard Motor

& Drive & Hi Static Drive

1.50 Nom kW Over-Sized Motor

& Hi Static Drive

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

& Hi Static Drive

←

←←

←←

Table PD-8a — Belt Drive Evaporator Fan Performance -TSC072AD - Downflow Configuration (IP)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1920 - - - - 573 0.34 630 0.41 680 0.48 726 0.55 769 0.62 811 0.70 851 0.78 889 0.87

2160 - - 548 0.35 602 0.42 656 0.50 706 0.58 751 0.65 792 0.73 832 0.81 871 0.90 908 0.99

2400 - - 584 0.45 635 0.52 682 0.60 732 0.69 777 0.77 818 0.86 856 0.95 893 1.04 930 1.13

2640 569 0.47 621 0.56 670 0.64 715 0.72 758 0.81 802 0.91 845 1.01 883 1.10 919 1.20 953 1.29

2880 612 0.60 660 0.69 706 0.78 749 0.86 789 0.96 830 1.06 870 1.16 909 1.27 945 1.37 979 1.48

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1920 925 0.95 960 1.03 994 1.11 1026 1.19 1057 1.27

2160 944 1.08 978 1.17 1010 1.26 1043 1.36 1073 1.44

2400 964 1.22 998 1.32 1030 1.42 1063 1.53 1092 1.63

2640 986 1.39 1019 1.49 1051 1.60 1082 1.71 1112 1.81

2880 1011 1.58 1043 1.69 1073 1.79 1103 1.90 1133 2.02

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1 1/2 HP - Fan Motor Heat (MBH) = 2.915 x Fan BHP + 0.451

2 HP - Fan Motor Heat (MBH) = 3.000 x Fan BHP + 0.500

.10 .20 .30 .40 .50 .60 .70 .80 .90 1.00

&

1-1/2 HP Standard Motor

External Static Pressure (Inches of Water)

1.10 1.20 1.30 1.40 1.50

1-1/2 HP Standard Mtr

& Drive

Low Static Drive 1-1/2 HP Standard Motor & Drive

2 HP Over-Sized Mtr & Hi Static Drive

External Static Pressure (Inches of Water)

1-1/2 HP Standard Motor

←←

←

←←

Hi Static Drive

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

1-1/2 HP Standard Motor

& Hi Static Drive

&

←

←←

←←

RT-PRC016-EN

21

Page 22

Performance

Data

Table PD-9 — Belt Drive Evaporator Fan Performance -TSC072AD - Horizontal Configuration (SI)

m3/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

3260 - - 565 0.23 627 0.29 679 0.34 726 0.39 771 0.45 814 0.51 857 0.57 899 0.63 939 0.70

3670 566 0.26 609 0.31 663 0.36 716 0.42 762 0.48 804 0.54 843 0.60 883 0.67 922 0.74 960 0.81

4080 619 0.35 660 0.40 701 0.45 751 0.51 798 0.59 839 0.65 877 0.71 914 0.78 950 0.85 984 0.93

4490 672 0.45 710 0.51 745 0.56 788 0.62 833 0.69 875 0.77 914 0.85 949 0.91 984 0.98 1016 1.06

4890 726 0.58 762 0.64 795 0.70 828 0.76 869 0.82 911 0.91 950 0.99 986 1.07 1019 1.14 1051 1.22

25 50 75 100 125 150 175 200 225 250

&

1.12 Nom kW Standard Motor

1.12 Nom kW Standard Motor

Low Static Drive 1.12 Nom kW Standard Motor & Drive

&

Drive 1.12 Nom kW Standard Motor

External Static Pressure (Pascals)

& Hi Static Drive

CFM RPM kW RPM kW RPM kW RPM kW RPM kW

3260 978 0.76 1015 0.83 1051 0.90 1086 0.97 1118 1.04

3670 996 0.87 1034 0.95 1069 1.02 1103 1.09 1136 1.17

4080 1020 1.00 1055 1.08 1089 1.16 1122 1.23 1154 1.31

4490 1049 1.14 1081 1.23 1113 1.31 1144 1.40 1176 1.48

4890 1081 1.30 1112 1.38 1141 1.47 1170 1.57 1199 1.66

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1.12 kW - Fan Motor Heat (kW) = 1.144 x Fan kW + 0.132

1.50 kW - Fan Motor Heat (kW) = 1.178 x Fan kW + 0.464

275 300 325 350 375

External Static Pressure (Pascals)

1.12 Nom kW Standard Motor & Hi Static Drive

1.50 Nom kW Over-Sized Motor & Hi Static Drive

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

Table PD-9a — Belt Drive Evaporator Fan Performance -TSC072AD - Horizontal Configuration (IP)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1920 - - 565 0.31 627 0.39 679 0.45 726 0.52 771 0.60 814 0.69 857 0.77 899 0.85 939 0.93

2160 566 0.35 609 0.41 663 0.48 716 0.57 762 0.64 804 0.72 843 0.80 883 0.90 922 0.99 960 1.08

2400 619 0.47 660 0.54 701 0.60 751 0.69 798 0.78 839 0.87 877 0.95 914 1.04 950 1.14 984 1.24

2640 672 0.61 710 0.68 745 0.76 788 0.83 833 0.93 875 1.04 914 1.13 949 1.22 984 1.31 1016 1.42

2880 726 0.77 762 0.86 795 0.94 828 1.02 869 1.11 911 1.21 950 1.33 986 1.44 1019 1.53 1051 1.63

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1920 978 1.02 1015 1.11 1051 1.20 1086 1.30 1118 1.39

2160 996 1.17 1034 1.27 1069 1.36 1103 1.46 1136 1.56

2400 1020 1.35 1055 1.45 1089 1.55 1122 1.66 1154 1.76

2640 1049 1.53 1081 1.65 1113 1.76 1144 1.87 1176 1.98

2880 1081 1.74 1112 1.86 1141 1.97 1170 2.10 1199 2.22

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1 1/2 HP - Fan Motor Heat (MBH) = 2.915 x Fan BHP + 0.451

2 HP - Fan Motor Heat (MBH) = 3.000 x Fan BHP + 0.500

.10 .20 .30 .40 .50 .60 .70 .80 .90 1.00

1-1/2 HP Standard Motor & Low Static Drive 1-1/2 HP Standard Motor

1-1/2 HP Standard Motor & Drive 1-1/2 HP Std Motor & Hi Static Drive

1.10 1.20 1.30 1.40 1.50

External Static Pressure (Inches of Water)

&

1-1/2 HP Standard Motor

2 HP Over-Sized Motor & High Static Drive

Hi Static Drive

External Static Pressure (Inches of Water)

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

&

Drive

22

RT-PRC016-EN

Page 23

Performance

Data

Table PD-10 — Belt Drive Evaporator Fan Performance -TSC090AD - Downflow Configuration (SI)

m3/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

4080 - - - - - - 701 0.47 750 0.54 794 0.60 834 0.67 873 0.73 909 0.80 945 0.87

4590 - - - - 699 0.53 743 0.59 787 0.66 830 0.74 871 0.82 908 0.89 943 0.96 977 1.04

5100 - - 703 0.61 747 0.68 789 0.74 827 0.82 867 0.90 906 0.98 944 1.06 980 1.15 1013 1.23

5610 713 0.69 755 0.77 797 0.85 836 0.92 873 1.00 908 1.08 944 1.17 980 1.26 1016 1.35 1050 1.45

6120 771 0.88 809 0.96 848 1.06 885 1.14 921 1.22 954 1.30 986 1.39 1019 1.49 1052 1.58 1085 1.69

CFM RPM kW RPM kW RPM kW RPM kW RPM kW

4080 980 0.95 1013 1.02 1046 1.10 1076 1.17 1106 1.25

4590 1010 1.11 1043 1.19 1074 1.27 1105 1.36 1134 1.44

5100 1045 1.31 1076 1.39 1105 1.47 1134 1.56 1163 1.65

5610 1081 1.54 1111 1.63 1141 1.72 1168 1.80 1197 1.90

6120 1116 1.79 1148 1.89 1177 1.99 1204 2.08 1232 2.18

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1.50 kW - Fan Motor Heat (kW) = 1.178 x Fan kW + 0.464

2.24 kW - Fan Motor Heat (kW) = 1.138 x Fan kW + 0.139

25 50 75 100 125 150 175 200 225 250

1.50 Nom kW Standard Motor & Low Static Drive 1.50 Nom kW Standard Motor

275 300 325 350 375

1.50 Nom kW Std Motor 1.50 Nom kW Standard Motor

& Drive & Hi Static Drive

External Static Pressure (Pascals)

2.24 Nom kW Over-Sized Motor

& Hi Static Drive

External Static Pressure (Pascals)

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

&

Drive

1.50 Nom kW Standard Motor

& Hi Static Drive

←

←←

←←

Table PD-10a — Belt Drive Evaporator Fan Performance -TSC090AD - Downflow Configuration (IP)

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2400 - - - - - - 701 0.63 750 0.72 794 0.81 834 0.90 873 0.98 909 1.08 945 1.17

2700 - - - - 699 0.70 743 0.79 787 0.89 830 0.99 871 1.09 908 1.19 943 1.29 977 1.39

3000 - - 703 0.81 747 0.91 789 0.99 827 1.10 867 1.20 906 1.31 944 1.43 980 1.54 1013 1.65

3300 713 0.93 755 1.03 797 1.15 836 1.24 873 1.34 908 1.45 944 1.57 980 1.69 1016 1.82 1050 1.94

3600 771 1.19 809 1.29 848 1.42 885 1.53 921 1.63 954 1.74 986 1.87 1019 1.99 1052 2.13 1085 2.26

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2400 980 1.27 1013 1.37 1046 1.47 1076 1.57 1106 1.68

2700 1010 1.49 1043 1.60 1074 1.71 1105 1.82 1134 1.93

3000 1045 1.76 1076 1.87 1105 1.98 1134 2.09 1163 2.21

3300 1081 2.06 1111 2.18 1141 2.30 1168 2.42 1197 2.55

3600 1116 2.39 1148 2.53 1177 2.66 1204 2.79 1232 2.93

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

2 HP - Fan Motor Heat (MBH) = 3.000 x Fan BHP + 0.500

3 HP - Fan Motor Heat (MBH) = 2.900 x Fan BHP + 0.475

.10 .20 .30 .40 .50 .60 .70 .80 .90 1.00

&

2 HP Standard Motor

1.10 1.20 1.30 1.40 1.50

2 HP Standard Mtr 2 HP Standard Motor &

& Drive Hi Static Drive

Low Static Drive 2 HP Standard Motor & Drive

External Static Pressure (Inches of Water)

3 HP Over-Sized Mtr & Hi Static Drive

External Static Pressure (Inches of Water)

Factory Supplied Motors, In Commercial Equipment, Are

Definite Purpose Motors, Specifically Designed And

Tested To Operate Reliably And Continuously At All

Cataloged Conditions. Using The Full Horsepower Range

Of Our Fan Motors As Shown In Our Tabular Data Will

Not Result In Nuisance Tripping Or Premature Motor

Failure. Our Product’s Warranty Will Not Be Affected.

2 HP Standard Motor

& Hi Static Drive

←

←←

←←

RT-PRC016-EN

23

Page 24

Performance

Data

Table PD-11 — Belt Drive Evaporator Fan Performance -TSC090AD - Horizontal Configuration (SI)

m3/h RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW RPM kW

1.50 Nom kW Std Motor & Low Static Drive 1.50 Nom kW Standard Motor

4080 - - 673 0.42 718 0.47 769 0.54 814 0.61 855 0.67 893 0.73 929 0.81 965 0.88 999 0.96

4590 702 0.51 738 0.56 773 0.62 817 0.68 862 0.76 904 0.85 941 0.92 975 0.98 1009 1.06 1041 1.14

5100 771 0.68 805 0.74 837 0.81 870 0.87 912 0.94 951 1.03 989 1.12 1025 1.21 1056 1.28 1088 1.36

5610 842 0.89 873 0.96 903 1.03 930 1.10 963 1.17 1000 1.25 1037 1.34 1073 1.45 1106 1.55 1136 1.63

6120 913 1.14 942 1.22 970 1.30 996 1.37 1021 1.45 1052 1.52 1086 1.61 1121 1.71 1153 1.82 1184 1.93

CFM RPM kW RPM kW RPM kW RPM kW RPM kW

4080 1035 1.04 1070 1.12 1104 1.19 1137 1.27 1168 1.35

4590 1073 1.22 1104 1.31 1136 1.40 1167 1.48 1198 1.57

5100 1117 1.44 1146 1.53 1176 1.62 1205 1.72 1233 1.82

5610 1165 1.72 1194 1.80 1220 1.88 1248 1.98 1275 2.08

6120 1215 2.04 1242 2.13 1269 2.22 1295 2.31 1319 2.40

Notes:

Data Includes Pressure Drop Due To Wet Coils And Filters.

1.50 kW - Fan Motor Heat (kW) = 1.178 x Fan kW + 0.464

2.24 kW - Fan Motor Heat (kW) = 1.138 x Fan kW + 0.139

25 50 75 100 125 150 175 200 225 250

&

1.50 Nom kW Standard Motor

External Static Pressure (Pascals)

275 300 325 350 375