Page 1

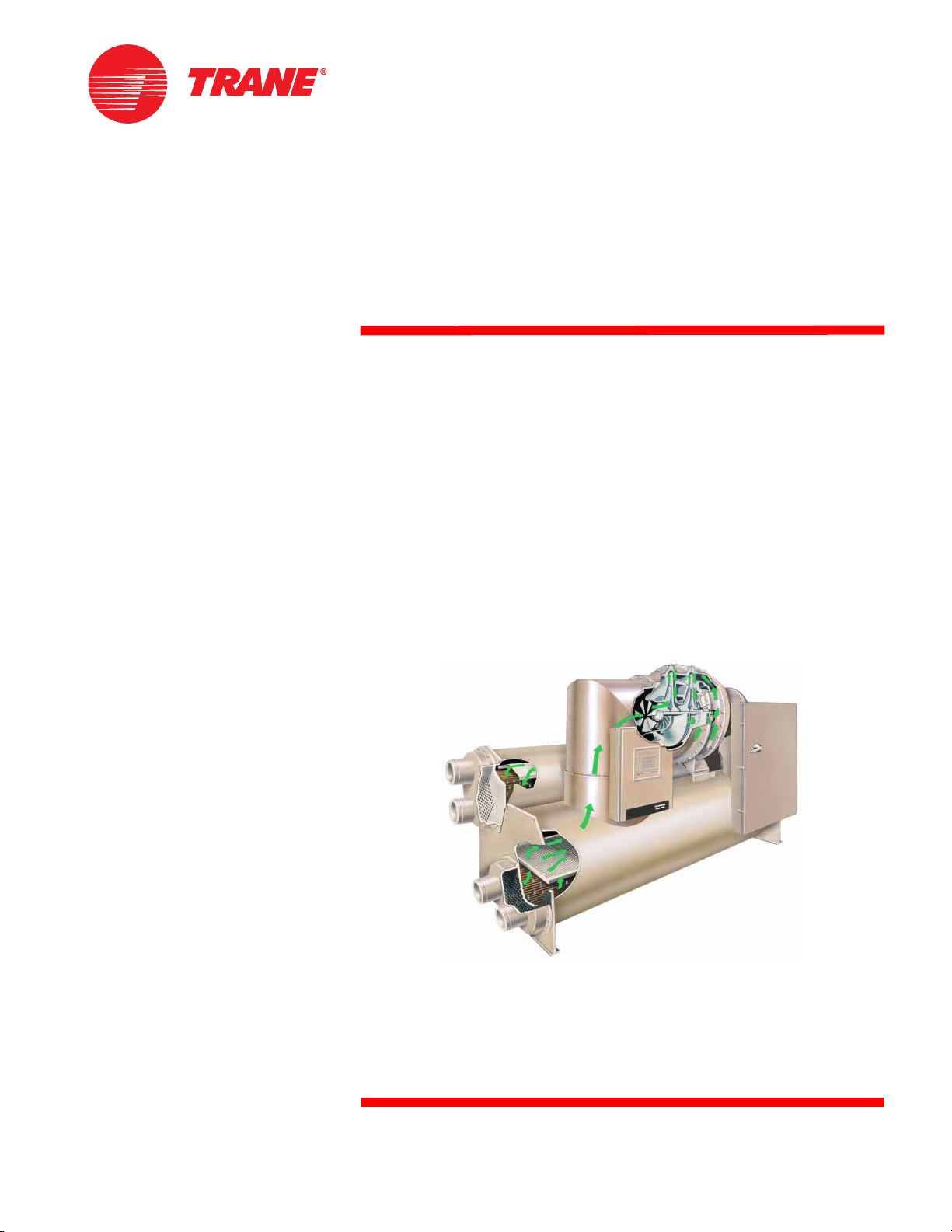

Air Conditioning

Clinic

Centrifugal

Water Chillers

One of the Equipment Series

TRG-TRC010-EN

Page 2

BUSINESS REPLY MAIL

FIRST-CLASS MAIL LA CROSSE, WIPERMIT NO. 11

POSTAGE WILL BE PAID BY ADDRESSEE

THE TRANE COMPANY

Attn: Applications Engineering

3600 Pammel Creek Road

La Crosse WI 54601-9985

123267$*(

1(&(66$5<

,)0$,/('

,17+(

81,7('67$7(6

BUSINESS REPLY MAIL

FIRST-CLASS MAIL LA CROSSE, WIPERMIT NO. 11

POSTAGE WILL BE PAID BY ADDRESSEE

THE TRANE COMPANY

Attn: Applications Engineering

3600 Pammel Creek Road

La Crosse WI 54601-9985

&URSWRZLGWKRIµ

123267$*(

1(&(66$5<

,)0$,/('

,17+(

81,7('67$7(6

Page 3

3HUIRUDWLRQµIURPHGJH 3HUIRUDWLRQµIURPERWWRPWRS

'SQQIRX'EVH

;I[ERXXSIRWYVIXLEXSYVIHYGEXMSREPQEXIVMEPWQIIX]SYVIZIVGLERKMRKVIWSYVGIHIZIPSTQIRXRIIHW

4PIEWIXEOIEQSQIRXXSGSQQIRXSRXLIIJJIGXMZIRIWWSJXLMW%MV'SRHMXMSRMRK'PMRMG

'IRXVMJYKEP;EXIV'LMPPIVW

3RISJXLI)UYMTQIRX7IVMIW

86+86')2

%FSYXQI|

+MZIXLIGSQTPIXIHGEVHXSXLI

TVIWIRXIVSVHVSTMXMRXLIQEMP

8LERO]SY

0IZIPSJHIXEMPGMVGPISRI 8SSFEWMG .YWXVMKLX 8SSHMJJMGYPX

6EXIXLMWGPMRMGJVSQr2IIHW-QTVSZIQIRXXSr)\GIPPIRX|

'SRXIRX

&SSOPIXYWIJYPRIWW

7PMHIWMPPYWXVEXMSRW

4VIWIRXIVWEFMPMX]

8VEMRMRKIRZMVSRQIRX

3XLIVGSQQIRXW# CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

8]TISJFYWMRIWW CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

.SFJYRGXMSR CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

3TXMSREP REQI CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

TLSRI CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

EHHVIWW CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

8LI8VERI'SQTER]w;SVPH[MHI%TTPMIH7]WXIQW+VSYT

4EQQIP'VIIO6SEHw0E'VSWWI;-

[[[XVERIGSQ

%R%QIVMGER7XERHEVH'SQTER]

6IWTSRWI'EVH

;ISJJIVEZEVMIX]SJ,:%'VIPEXIHIHYGEXMSREPQEXIVMEPWERHXIGLRMGEPVIJIVIRGIWEW[IPPEWWSJX[EVIXSSPW

XLEXWMQTPMJ]W]WXIQHIWMKREREP]WMWERHIUYMTQIRXWIPIGXMSR8SVIGIMZIMRJSVQEXMSREFSYXER]SJXLIWI

MXIQWNYWXGSQTPIXIXLMWTSWXEKITEMHGEVHERHHVSTMXMRXLIQEMP

)HYGEXMSRQEXIVMEPW

7SJX[EVIXSSPW

4IVMSHMGEPW

3XLIV#

8LERO]SYJSV]SYVMRXIVIWX

%MV'SRHMXMSRMRK'PMRMGWIVMIW

)RKMRIIVIH7]WXIQW'PMRMGWIVMIW 2EQI CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

8VERI%MV'SRHMXMSRMRK1ERYEP 8MXPI CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

8VERI7]WXIQW1ERYEP &YWMRIWWX]TI CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

)UYMTQIRXWIPIGXMSR 4LSRIJE\ CCCCCCCCCCCCCCCCCCCCC CCCCCCCCCCCCCCCCCCCCC

7]WXIQHIWMKREREP]WMW )QEMPEHHVIWW CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

)RKMRIIVW2I[WPIXXIV 'SQTER] CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

CCCCCCCCCCCCCCCCCCCCCCCCCCCCC %HHVIWW CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

%FSYXQI|

CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

8LI8VERI'SQTER]w;SVPH[MHI%TTPMIH7]WXIQW+VSYT

4EQQIP'VIIO6SEHw0E'VSWWI;-

[[[XVERIGSQ

%R%QIVMGER7XERHEVH'SQTER]

Page 4

Centrifugal

Water Chillers

One of the Equipment Series

A publication of

The Trane Company—

Worldwide Applied Systems Group

Page 5

Preface

Centrifugal Water Chillers

A Trane Air Conditioning Clinic

Figure 1

The Trane Company believes that it is incumbent on manufacturers to serve the

industry by regularly disseminating information gathered through laboratory

research, testing programs, and field experience.

The Trane Air Conditioning Clinic series is one means of knowledge sharing.

It’s intended to acquaint a nontechnical audience with various fundamental

aspects of heating, ventilating, and air conditioning.

We’ve taken special care to make the clinic as uncommercial and

straightforward as possible. Illustrations of Trane products only appear in

cases where they help convey the message contained in the accompanying

text.

This particular clinic introduces the concept of centrifugal water chillers.

© 1999 American Standard Inc. All rights reserved

ii

TRG-TRC010-EN

Page 6

Contents

Introduction ........................................................... 1

period one Components .......................................................... 3

Compressor ............................................................ 4

Condenser .............................................................. 7

Expansion Device .................................................... 8

Economizer ............................................................. 9

Evaporator ............................................................ 11

Motor ................................................................... 12

Controls and Starter .............................................. 13

period two Refrigeration Cycle ............................................ 15

Refrigerants .......................................................... 19

Purge System ....................................................... 20

period three Compressor Capacity Control ........................ 22

period four Maintenance Considerations .......................... 30

period five Application Considerations ............................. 36

Condensing Temperature Control .......................... 37

Constant or Variable Evaporator Water Flow .......... 39

Short Evaporator-Water Loops ............................... 40

Heat Recovery ...................................................... 42

Free Cooling .......................................................... 44

Equipment Certification Standards ......................... 46

period six Review ................................................................... 48

Quiz ......................................................................... 52

Answers ................................................................ 54

Glossary ................................................................ 55

TRG-TRC010-EN iii

Page 7

iv TRG-TRC010-EN

Page 8

notes

Introduction

Chilled

Water

System

Figure 2

Water chillers are used in a variety of air conditioning and process cooling

applications. They are used to make cold water that can be transported

throughout a facility using pumps and pipes. This cold water can be passed

through the tubes of coils to cool the air in an air conditioning application, or it

can provide cooling for a manufacturing or industrial process.

Systems that employ water chillers are commonly called chilled water

systems.

absorption

helical-rotary

There are several types of water chillers. They differ from each other based on

the refrigeration cycle or the type of compressor they use.

Absorption water chillers make use of the absorption refrigeration cycle and do

not have a mechanical compressor involved in the refrigeration cycle.

centrifugal

Figure 3

TRG-TRC010-EN 1

Page 9

Introduction

notes

Water chillers using the vapor-compression refrigeration cycle vary by the type

of compressor used. Reciprocating and scroll compressors are typically used in

small chillers. Helical-rotary (or screw) compressors are typically used in

medium-sized chillers. Centrifugal compressors are typically used in large

chillers.

As mentioned earlier, this particular clinic discusses centrifugal water

chillers.

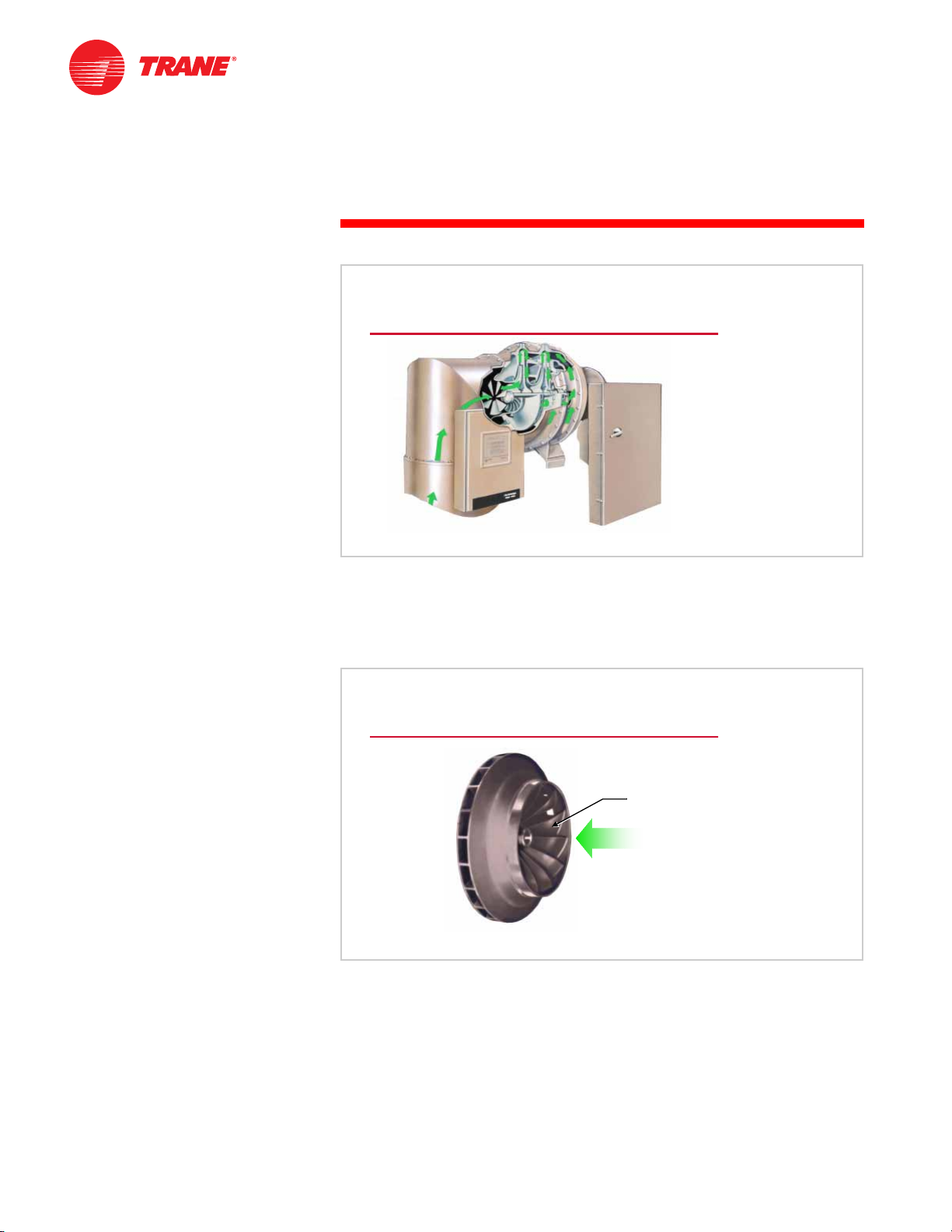

Centrifugal Water Chillers

Figure 4

Centrifugal water chillers can also be divided into two types based on the

method used to reject heat to the atmosphere: water-cooled or air-cooled. Since

most centrifugal chillers are water-cooled, they are the primary focus of this

clinic. Water-cooled centrifugal chillers are generally available from 100 to 3,000

tons [350 to 10,500 kW] as prefabricated machines, and up to 8,500 tons

[30,000 kW] as built-up machines.

2 TRG-TRC010-EN

Page 10

notes

period one

Components

Centrifugal Water Chillers

period one

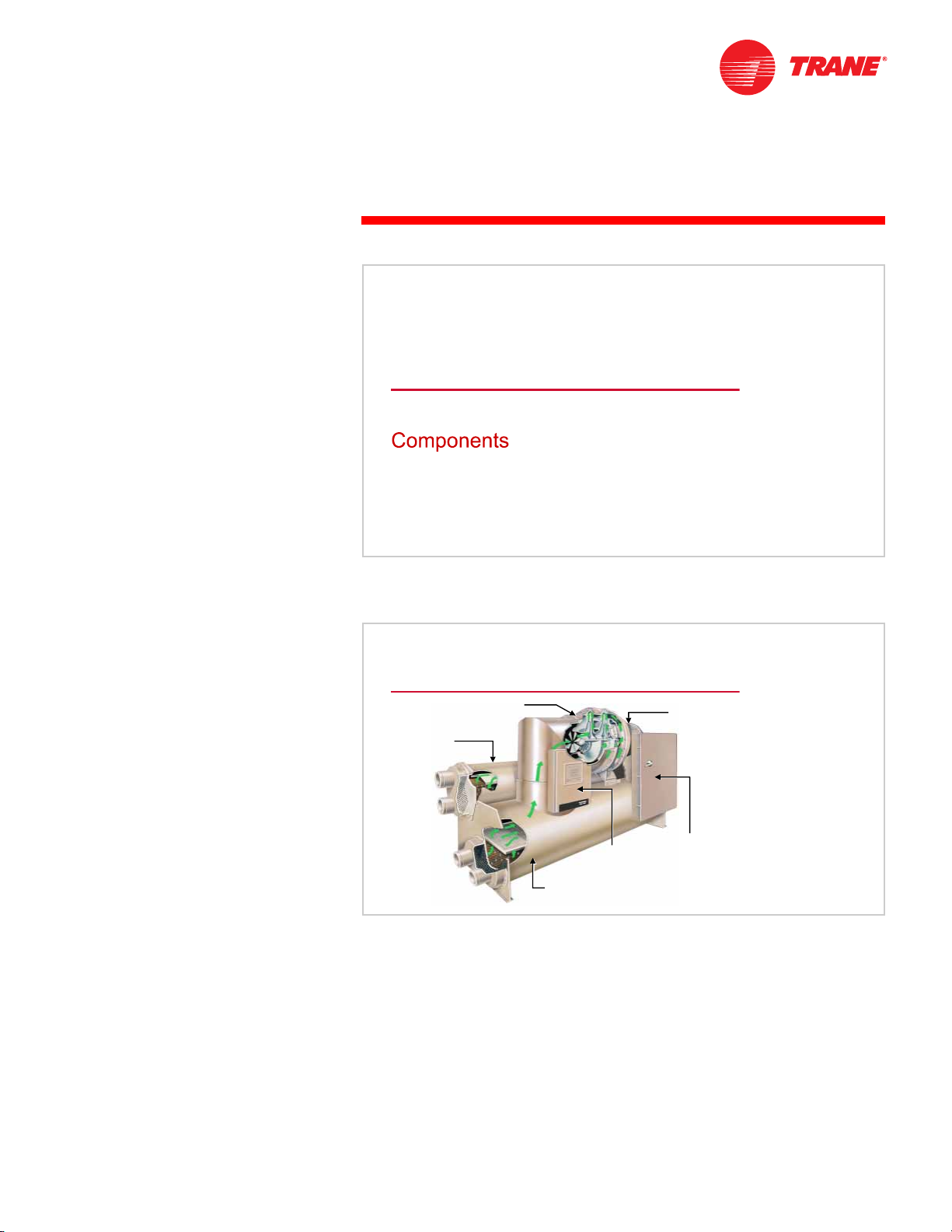

Figure 5

Many of the components of the centrifugal water chiller are similar to those of

other chiller types.

components of a

Centrifugal Water Chiller

compressor

compressor

condenser

condenser

control

control

panel

panel

evaporator

evaporator

This particular centrifugal water chiller makes use of a shell-and-tube

evaporator where refrigerant absorbs heat from the water flowing through the

tubes. The compressor is made up of 1 or more centrifugal impellers. A second

shell-and-tube heat exchanger serves as the water-cooled condenser, where

refrigerant is condensed inside the shell and water flows inside tubes.

Refrigerant is metered through the system using an expansion device such as a

fixed orifice plate. An economizer can be used to enhance the efficiency of a

chiller with multiple compressor impellers. A control panel is also provided on

the chiller and a starter is either mounted on the chiller or located remotely.

motor

motor

starter

starter

Figure 6

TRG-TRC010-EN 3

Page 11

notes

period one

Components

Compressor

Figure 7

Compressor

The centrifugal compressor uses the principle of dynamic compression,

which involves converting energy from one form to another, to increase the

pressure and temperature of the refrigerant. It converts kinetic energy to static

energy.

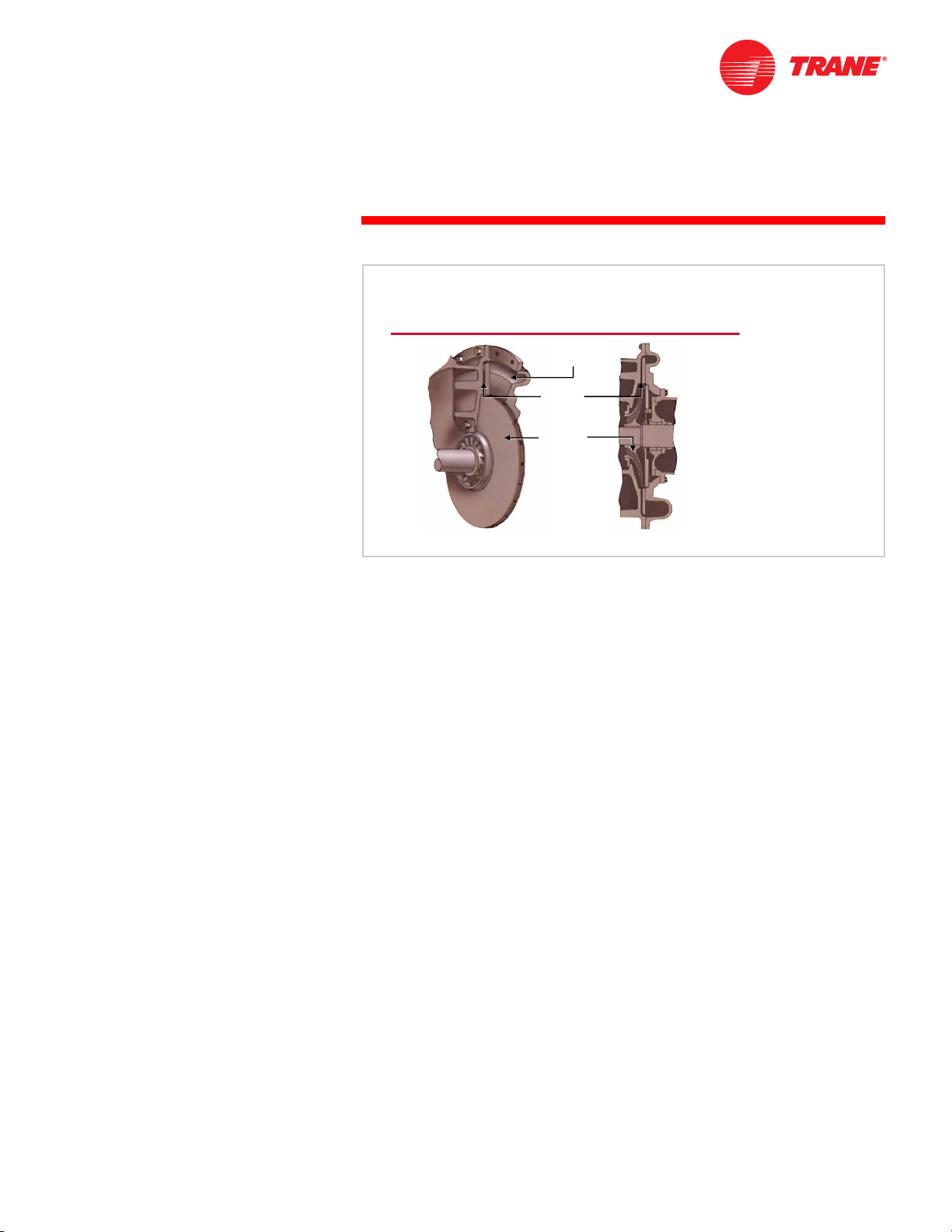

Impeller

blades

blades

Figure 8

The core component of a centrifugal compressor is the rotating impeller. The

center, or eye, of the impeller is fitted with blades that draw refrigerant vapor

into radial passages that are internal to the impeller body.

4 TRG-TRC010-EN

Page 12

notes

period one

Components

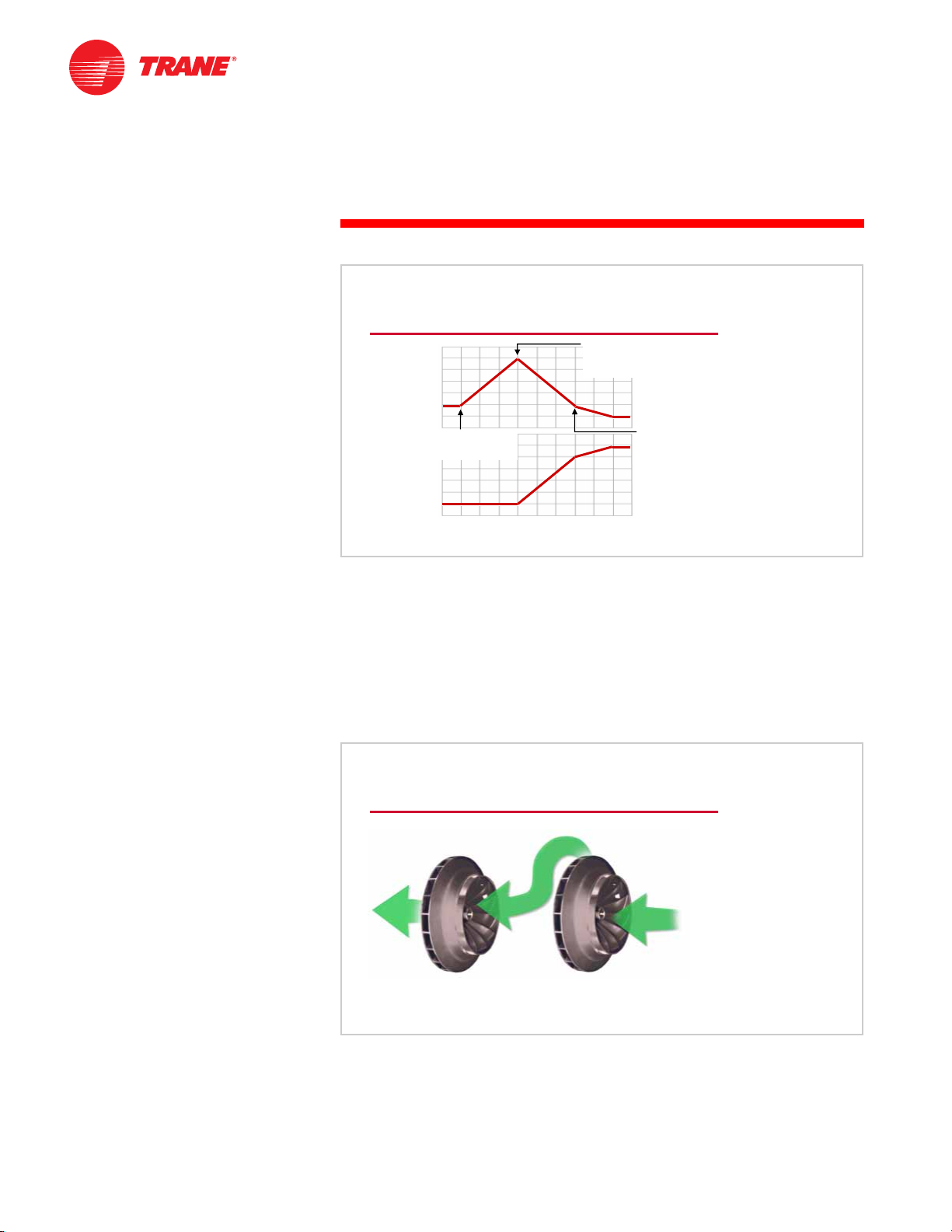

Centrifugal Compressor

volute

volute

diffuser

diffuser

passage

passage

impeller

impeller

passages

passages

Figure 9

The rotation of the impeller causes the refrigerant vapor to accelerate within the

impeller passages, increasing its velocity and kinetic energy.

The accelerated refrigerant vapor leaves the impeller and enters the diffuser

passages. These passages start out small and become larger as the refrigerant

travels through them. As the size of the diffuser passages increases, the

velocity, and therefore the kinetic energy, of the refrigerant decreases.

The first law of thermodynamics states that energy is not destroyed—only

converted from one form to another. Thus, the refrigerant’s kinetic energy is

converted to static energy or static pressure.

Refrigerant, now at a higher pressure, collects in a larger space around the

perimeter of the compressor called the volute. The volute also becomes larger

as the refrigerant travels through it. Again, as the size of the volute increases,

the kinetic energy is converted to static pressure.

Due to its pressure and temperature, the refrigerant leaving the compressor is

in a condition that allows its heat to be rejected from the chiller.

TRG-TRC010-EN 5

Page 13

notes

period one

Components

centrifugal compressor

Energy Conversion

refrigerant

refrigerant

enters

enters

diffuser

diffuser

velocity

velocity

refrigerant

refrigerant

refrigerant

enters impeller

enters impeller

static pressure

static pressure

path through compressor

path through compressor

Again, in the passages of the rotating impeller, the refrigerant vapor

accelerates, increasing its velocity and kinetic energy. As the area increases in

the diffuser passages, the velocity, and therefore the kinetic energy, of the

refrigerant decreases. This reduction in kinetic energy is offset by an increase in

the refrigerant’s static energy or static pressure. Finally, the high pressure

refrigerant collects in the volute around the perimeter of the compressor, where

further energy conversion takes place.

refrigerant

enters volute

enters volute

Figure 10

The resulting pressure and temperature of the refrigerant is now high enough

that its heat can be rejected from the chiller.

Multistage Compressor

Figure 11

Centrifugal compressors use 1 or more impellers to compress the refrigerant. A

multistage compressor uses 2 or 3 impellers to increase the pressure of the

refrigerant in steps instead of performing the task within a single impeller.

Compressed refrigerant vapor travels from the outlet of the first-stage

compressor impeller to the inlet of the second-stage compressor impeller. After

6 TRG-TRC010-EN

Page 14

period one

Components

notes

the accelerated refrigerant vapor leaves the last impeller, it collects in the

compressor volute and travels on to the condenser.

Condenser

refrigerant vapor

refrigerant vapor

baffle

baffle

cooling

cooling

tower

tower

water

water

liquid

tube

tube

bundle

bundle

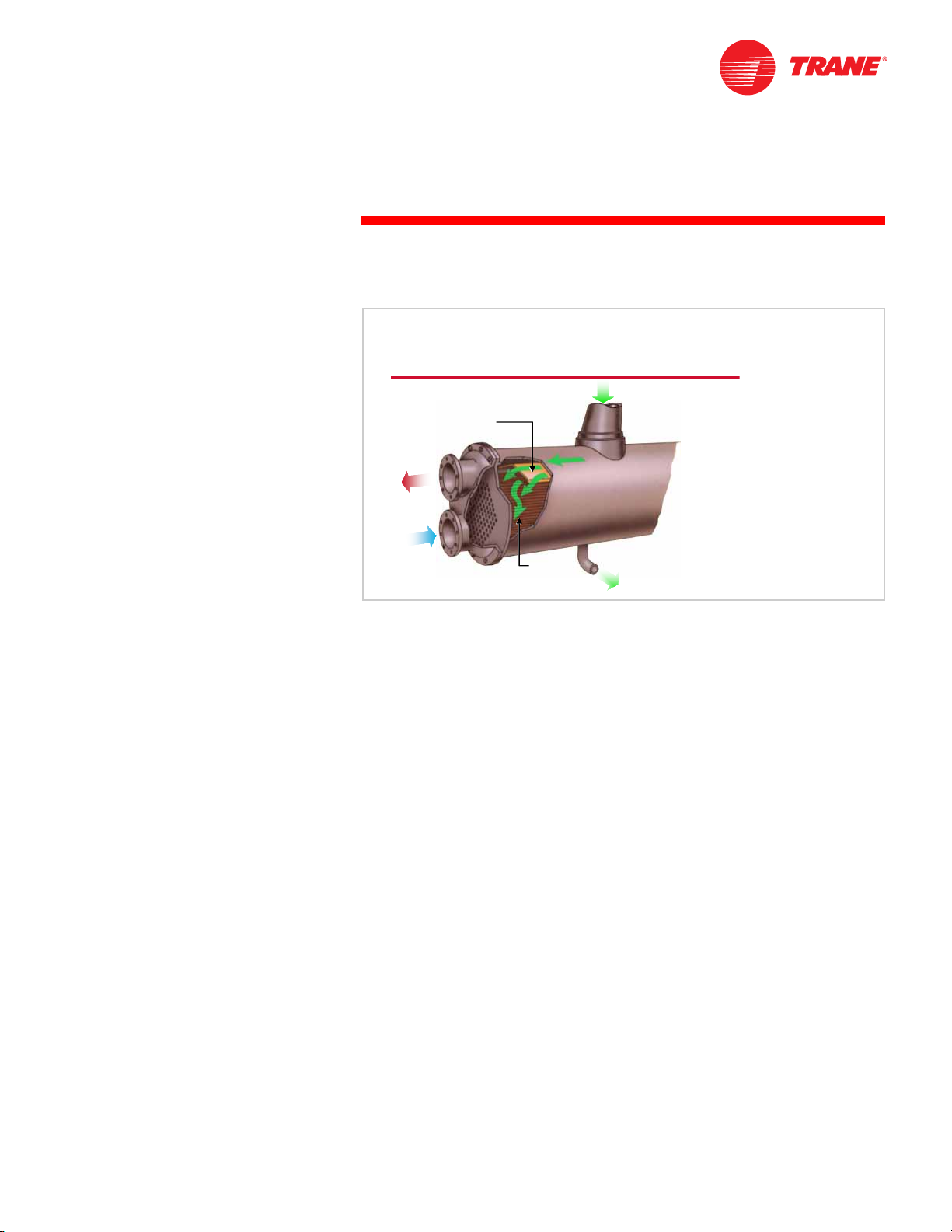

Condenser

The high-pressure refrigerant vapor is discharged from the compressor into a

heat exchanger that acts as a condenser.

In a water-cooled condenser, water is pumped through the tubes of the shell-

and-tube heat exchanger while refrigerant vapor fills the shell space

surrounding the tube bundle. A baffle inside the condenser helps distribute the

refrigerant evenly. As heat transfers from the hot, high-pressure refrigerant

vapor to the water, refrigerant condenses on the tube surfaces.

liquid

refrigerant

refrigerant

Figure 12

Cooling water flows first through the lower tubes and then through the upper

tubes. This produces a nearly constant temperature difference between the

downward-moving refrigerant and the tube surfaces, resulting in a uniform

heat transfer rate within the tube bundle.

Condensed liquid refrigerant collects in the bottom of the shell and flows

through the liquid line to the expansion devices and economizer.

TRG-TRC010-EN 7

Page 15

notes

period one

Components

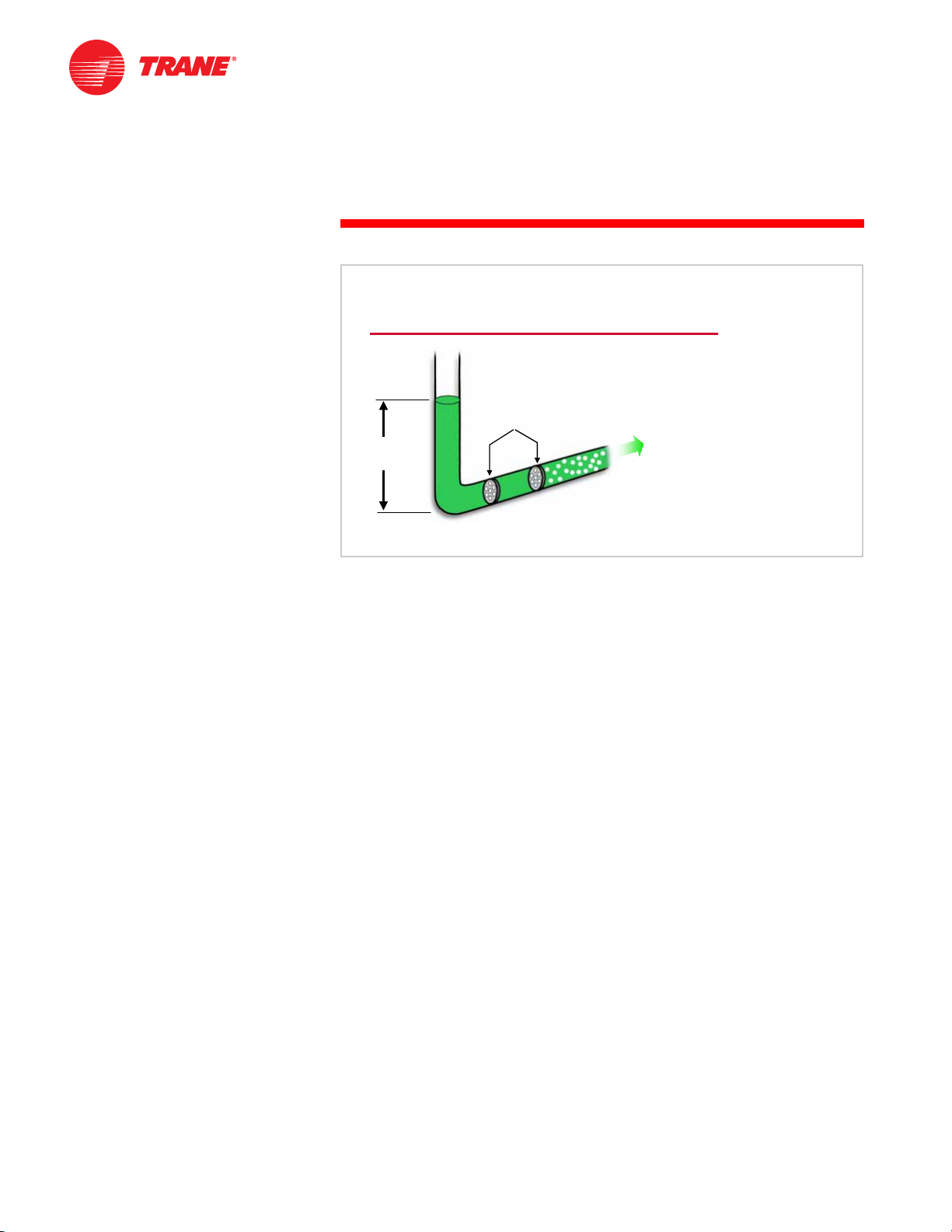

expansion device

Orifice Plates

orifice plates

orifice plates

H

H

1

1

Expansion Device

An expansion device is used to maintain the pressure difference between the

high-pressure (condenser) and low-pressure (evaporator) sides of the

refrigeration system, as established by the compressor. This pressure

difference allows the evaporator temperature to be low enough for the

refrigerant to absorb heat from the water being cooled, and the condenser

temperature to be high enough for the refrigerant to reject heat to water at

normally available temperatures. High-pressure liquid refrigerant flows through

the expansion device, causing a pressure drop that reduces the refrigerant

pressure to that of the evaporator. This pressure reduction causes a small

portion of the liquid to boil off, or “flash,” cooling the remaining refrigerant to

the evaporator temperature.

to

to

evaporator

evaporator

Figure 13

The expansion device is also used as a liquid refrigerant metering system,

balancing the refrigerant flow rate with the evaporator load condition. In our

example centrifugal chiller, the expansion device used is a set of 2 orifice

plates. At full load, a large amount of refrigerant is moving through the chiller.

The column of liquid refrigerant in the liquid line pressurizes the liquid at its

base. During passage through the orifice plates, the liquid refrigerant

undergoes a pressure drop equal to the head (H

vapor.

8 TRG-TRC010-EN

) before some of it flashes to

1

Page 16

notes

period one

Components

expansion device

Orifice Plates

orifice plates

orifice plates

H

H

2

2

As the load decreases, less refrigerant moves through the chiller and the level

of the liquid column drops. Now, as the liquid refrigerant passes through the

orifice plates, it only undergoes a pressure drop equal to the lower head (H

before some of it flashes to vapor. This causes additional flashing at the orifice

plate which, in turn, feeds less liquid to the evaporator.

to

to

evaporator

evaporator

Figure 14

)

2

Other types of expansion devices found in centrifugal chillers include: float

valves, expansion valves (thermostatic or electronic), and variable orifices.

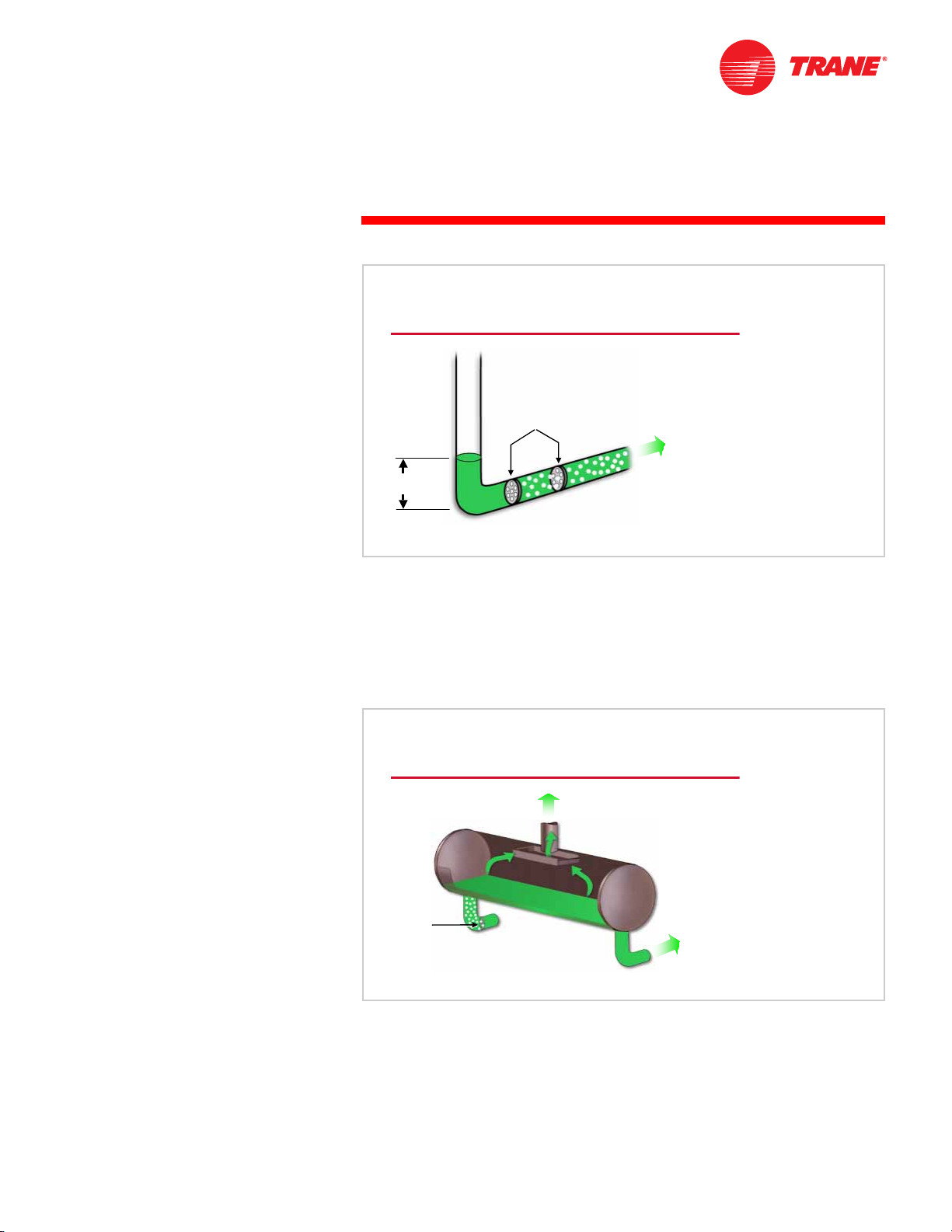

2-stage chiller

Economizer

refrigerant vapor

refrigerant vapor

to second stage

to second stage

of compression

of compression

liquid refrigerant

orifice

orifice

liquid refrigerant

liquid refrigerant

from condenser

from condenser

Economizer

An economizer can be used in conjunction with multiple expansion devices to

improve the efficiency of a multistage chiller. In a chiller with a 2-stage

compressor, the expansion process can be separated into 2 steps with an

economizer chamber between.

liquid refrigerant

to evaporator

to evaporator

Figure 15

TRG-TRC010-EN 9

Page 17

period one

Components

notes

Liquid refrigerant from the condenser enters the first expansion device, which

reduces the pressure of the refrigerant to that of the second-stage impeller

inlet. This pressure drop causes a portion of the liquid refrigerant to evaporate,

or flash, and the resulting mixture of liquid and vapor enters the economizer

chamber. Here, the vapor is separated from the mixture and is routed directly to

the inlet of the second stage impeller. The remaining liquid travels on to the

second expansion device and evaporator.

Just before entering the evaporator, the liquid refrigerant flows through a

second expansion device that reduces its pressure and temperature to

evaporator conditions.

Flashing a portion of the refrigerant prior to the economizer reduces the

amount of compressor power required, since the refrigerant vapor generated in

the economizer only needs to be compressed by the second-stage impeller.

The benefit of the economizer will be discussed in greater detail in Period 2.

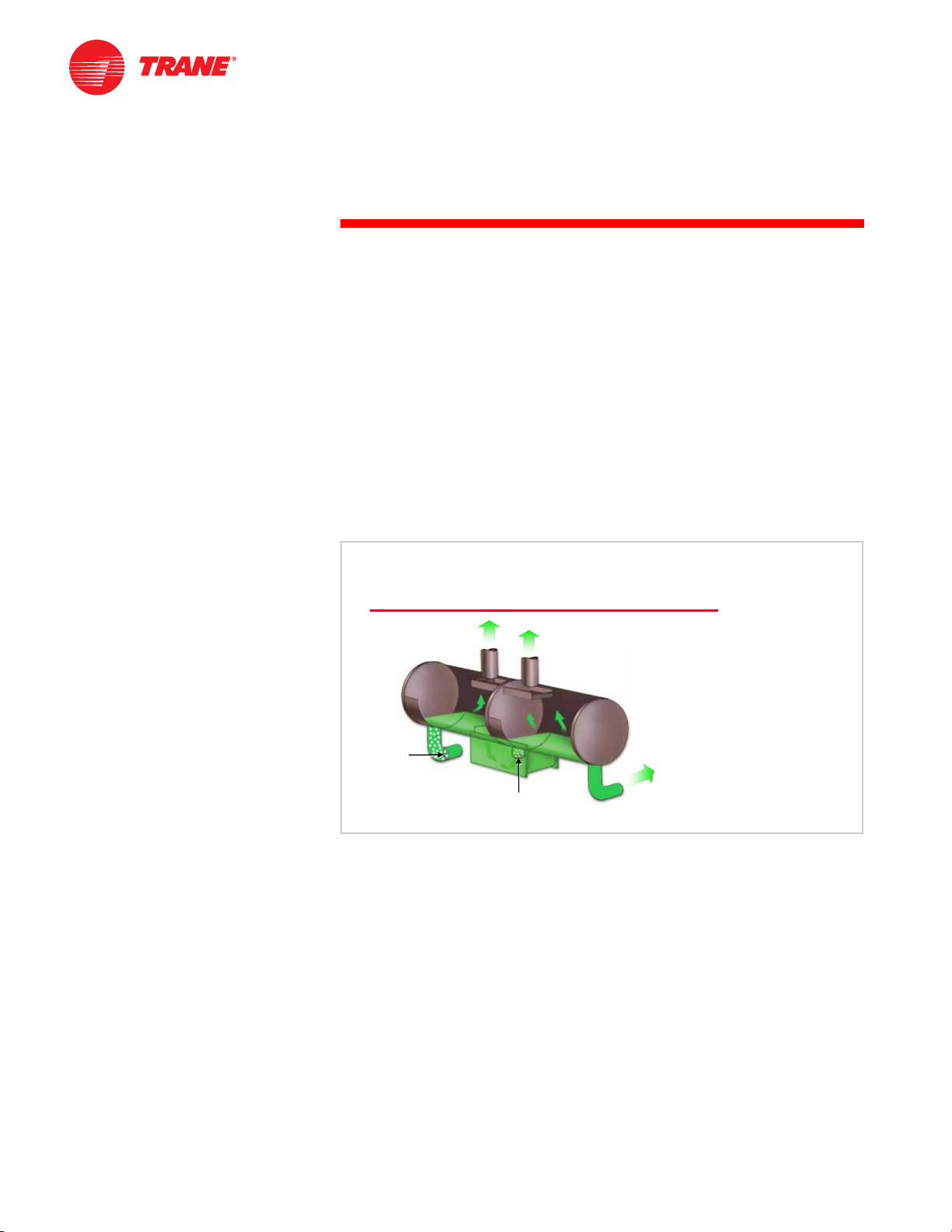

3-stage chiller

Economizer

refrigerant vapor

refrigerant vapor

to third stage

to third stage

of compression

of compression

refrigerant vapor

refrigerant vapor

to second stage

to second stage

of compression

of compression

liquid refrigerant

orifice

orifice

liquid refrigerant

liquid refrigerant

from condenser

from condenser

In a chiller with a 3-stage compressor, the expansion process can be separated

into 3 steps with separate economizer chambers between the steps.

Liquid refrigerant from the condenser enters the first orifice (expansion device),

which reduces the pressure of the refrigerant to that of the third-stage impeller

inlet. This pressure drop causes a portion of the liquid refrigerant to flash, and

the resulting mixture of liquid and vapor enters the high-pressure chamber of

the economizer. Here, the vapor is separated from the mixture and is then

routed directly to the inlet of the third-stage impeller. The remaining liquid

travels on to the second expansion device.

The second expansion device further reduces the pressure of the refrigerant to

that of the second-stage impeller inlet. This pressure drop causes a portion of

the liquid refrigerant to flash, and the resulting mixture of liquid and vapor

enters the low-pressure chamber of the economizer. Here, the vapor is

separated from the mixture and routed directly to the inlet of the second-stage

impeller. The remaining liquid travels on to the third expansion device and

evaporator.

10 TRG-TRC010-EN

orifice

orifice

liquid refrigerant

to evaporator

to evaporator

Figure 16

Page 18

period one

Components

notes

Again, the final expansion device reduces the pressure and temperature of the

refrigerant to evaporator conditions.

Evaporator

tube bundle

tube bundle

liquid

liquid

refrigerant

refrigerant

chilled

chilled

water

water

return

return

liquid

liquid

distributor

distributor

eliminator

eliminator

Evaporator

In the flooded shell-and-tube evaporator shown, the low-pressure mixture

of liquid refrigerant and refrigerant vapor enters the distribution system that

runs the entire length of the shell. Small openings and baffles in the passage of

the liquid distributor provide an even spray of refrigerant over the surfaces of

the tubes inside the evaporator shell, where the refrigerant absorbs heat from

relatively warm water flowing through the tube bundle. This transfer of heat

boils the liquid refrigerant on the tube surfaces. The resulting vapor passes

through an eliminator that prevents liquid from being drawn upward. The vapor

collects in a large chamber at the top of the shell and is drawn back to the

compressor. The now-cool water can be used in a variety of comfort or process

applications.

orifice system

orifice system

Figure 17

Some chiller designs may make use of a direct expansion (DX) shell-andtube evaporator. In this type of evaporator, liquid refrigerant flows through

the tubes and water fills the surrounding shell. As heat is transferred from the

water to the refrigerant, the refrigerant boils inside the tubes and the resulting

vapor is drawn to the compressor.

TRG-TRC010-EN 11

Page 19

notes

period one

Components

Motor

motor

motor

gear-drive

impeller

impeller

motor

motor

impellers

impellers

direct-drive

gears

gears

Figure 18

Motor

A motor is used to rotate the impeller(s). A direct-drive motor is connected

directly to the impeller shaft and the impeller rotates at the same speed as the

motor. A gear-drive motor transfers its energy to the impeller shaft using a set

of gears. This allows the impeller to rotate at a higher speed than the motor.

The direct-drive motor requires fewer bearings and does not incur gear losses.

Additionally, since the compressor rotates at a lower speed, it can be much

quieter.

Direct-drive compressors are, however, only practical in centrifugal chillers that

use low-pressure refrigerants.

Hermetic Motor Cooling

stator

stator

rotor

rotor

liquid

liquid

refrigerant

refrigerant

Another important difference in compressor motors is the issue of hermetic

versus open. A hermetic motor is totally enclosed within the chiller’s

refrigeration system. An open motor is mounted externally—outside of the

drain

drain

Figure 19

12 TRG-TRC010-EN

Page 20

period one

Components

notes

chiller’s refrigeration system—and uses a coupling to connect the motor and

compressor shafts.

The heat generated by the hermetic motor is absorbed by liquid refrigerant that

flows around, through, and over the motor. The heat must be rejected by the

chiller’s condenser.

The heat generated by the open motor is rejected to the air drawn in from the

equipment room. This heat must still be rejected from the equipment room,

either by mechanical ventilation or, if the room is conditioned, the building’s

cooling system. In some designs, this air is simply drawn into the motor

housing by the rotating motor shaft. The vent passages tend to get dirty and

clog, resulting in higher operating temperatures and hot spots that adversely

affect motor efficiency and reliability. Other designs, such as totally-enclosed

fan-cooled (TEFC) and totally-enclosed air-over (TEAO), use a separate fan with

a protective housing to cool the motor.

Hermetic compressor motors eliminate the need for the shaft couplings and

external shaft seals that are associated with open motors. The coupling needs

precise alignment, and these seals are a prime source of oil and refrigerant

leaks. On the other hand, if a motor burns out, a hermetic chiller will require

thorough cleaning, while a chiller with an open motor will not.

Controls and Starter

starter

control

control

panel

panel

starter

Figure 20

Controls and Starter

A microprocessor-based control panel is provided on the chiller to provide

accurate chilled-water control as well as monitoring, protection, and adaptive

limit functions. These controls monitor chiller operation and prevent the chiller

from operating outside its limits. They can compensate for unusual operating

conditions, keeping the chiller running by modulating system components

rather than simply shutting it down when a safety setting is violated. When

serious problems occur, diagnostic messages aid troubleshooting.

Modern control systems not only provide accurate, optimized control and

protection for the chiller, but can also interface with a building automation

system for integrated system control. In a chilled water system, optimal

TRG-TRC010-EN 13

Page 21

period one

Components

notes

performance is a system-wide issue, not just a matter of chiller design and

control.

A starter links the chiller motor and the electrical distribution system. Its

primary function is to connect (start) and disconnect (stop) the chiller from line

power—similar to what a switch does for a light bulb. The starter, however,

handles much more current and must have the appropriate interlocks to work

with the chiller control panel and oil pump.

Every electrically driven chiller requires a starter. It must be compatible with the

characteristics of both the compressor motor and the electrical circuitry of the

chiller. There are many types of starters, including star-delta, across-the-line,

auto-transformer, primary reactor, and solid state. A variable-speed drive,

which is used to modulate the speed of the motor during normal operation,

also serves as a starter. Important characteristics to consider when selecting a

starter include first cost, reliability, line voltage, and available current.

Starters

line power

line power

control power

control power

wiring

wiring

starter

starter

line power

line power

unit-mounted

control power

control power

wiring

wiring

remote-mounted

Figure 21

The starter may be mounted on, or remotely from, the chiller. Use of a unitmounted starter reduces electrical installation costs. It may also improve

reliability and save system design time, since all of the components are preengineered and factory mounted.

Depending on the type of starter selected, there are several options that can

simplify installation. Disconnects allow the starter to be isolated from the

electrical distribution system, and short-circuit protection can be provided

using fuses or a circuit breaker.

14 TRG-TRC010-EN

Page 22

notes

period two

Refrigeration Cycle

Centrifugal Water Chillers

period two

Figure 22

A pressure–enthalpy (p-h) chart illustrates the refrigeration cycle of the

centrifugal water chiller.

2-stage centrifugal chiller

Refrigeration Cycle

2-stage

2-stage

compressor

compressor

economizer

economizer

condenser

evaporator

evaporator

expansion devices

expansion devices

First, let’s review the components of a 2-stage centrifugal chiller in the context

of the refrigeration cycle.

Refrigerant vapor leaves the evaporator and flows to the compressor, where it

is compressed to a higher pressure and temperature. High-pressure refrigerant

vapor then travels to the condenser where it rejects heat to water, and then

leaves as a saturated liquid. The pressure drop created by the first expansion

device causes part of the liquid refrigerant to evaporate and the resulting

mixture of liquid and vapor enters the economizer. Here, the vapor is separated

from the mixture and routed directly to the inlet of the second-stage impeller.

The remaining saturated liquid refrigerant enters the second expansion device.

condenser

Figure 23

TRG-TRC010-EN 15

Page 23

period two

Refrigeration Cycle

notes

The pressure drop created by the second expansion device lowers the pressure

and temperature of the refrigerant to evaporator conditions, causing a portion

of the liquid refrigerant to evaporate. The resulting mixture of liquid and vapor

enters the evaporator. In the evaporator, the liquid refrigerant boils as it absorbs

heat from water and the resulting vapor is drawn back to the compressor to

repeat the cycle.

Pressure-Enthalpy (

subcooled

subcooled

liquid

liquid

pressure

pressure

$

15.5 Btu/lblb

15.5 Btu/

[201.0 kJ/kg]

[201.0 kJ/kg]

[0.034

[0.034

psia

5 5 psia

MPa]]

MPa

mixture of

mixture of

liquid and

liquid and

vapor

vapor

enthalpy

enthalpy

p-h)

%

92.4 Btu/lblb

92.4 Btu/

[380.4 kJ/kg]

[380.4 kJ/kg]

Chart

superheated

superheated

vapor

vapor

Figure 24

The pressure-enthalpy chart plots the properties of a refrigerant—refrigerant

pressure (vertical axis) versus enthalpy (horizontal axis). Enthalpy is a

measure of the heat content, both sensible and latent, per pound [kg] of

refrigerant.

liquid

For example, A represents the heat content of saturated

HCFC-123

refrigerant at 5 psia [0.034 MPa] and 34°F [1.1°C]. B represents the heat content

vapor

of saturated

HCFC-123 refrigerant at the same pressure and temperature.

The difference in heat content, or enthalpy, between A and B—that is, 76.9 Btu/

pound [179.4 kJ/kg]—is the amount of heat required to transform 1 pound of

saturated liquid refrigerant to saturated refrigerant vapor at the same pressure

and temperature.

If the heat content of the refrigerant at any pressure falls to the right of the

curve, the vapor is superheated. Similarly, if the heat content of the refrigerant

falls to the left of the curve, the liquid is subcooled. Finally, when the heat

content of the refrigerant falls inside the curve, the refrigerant exists as a

mixture of liquid and vapor.

Let’s plot the theoretical vapor-compression refrigeration cycle for a 2-stage

centrifugal water chiller on a pressure-enthalpy chart.

16 TRG-TRC010-EN

Page 24

notes

period two

Refrigeration Cycle

2-stage centrifugal chiller

Refrigeration Cycle

condenser

6

condenser

P

P

c

c

pressure

pressure

P

P

1

1

P

P

e

e

expansion

expansion

devices

devices

6

5

economizer

economizer

8

8

7

7

9

9

evaporator

evaporator

5

3

3

1

1

4

4

2-stage

2-stage

2

2

compressor

compressor

enthalpy

enthalpy

Figure 25

Refrigerant leaves the evaporator as saturated vapor ➀ and flows to the first-

stage impeller of the compressor. There, the refrigerant vapor is compressed to

a higher pressure (P

) and temperature ➁. Cooler refrigerant vapor that flashed

1

within the economizer is mixed with the refrigerant discharged from the first-

stage impeller, reducing the heat content of the mixture ➂. The second stage of

compression further elevates the pressure (P

) and temperature of the

c

refrigerant ➃.

Energy provided to the compressor is imparted to the refrigerant as an increase

in pressure and superheat. Superheated refrigerant vapor leaves the

compressor and enters the condenser.

Water flowing through the condenser absorbs heat from the hot, high-pressure

refrigerant vapor, causing it to desuperheat ➄ and condense into saturated

liquid ➅ before leaving the condenser to travel to the first expansion device.

The first expansion device reduces the pressure (➅ to ➆) of the refrigerant to

the second-stage impeller inlet pressure (P

). This pressure drop causes a

1

portion of the liquid refrigerant to evaporate, or flash. The evaporating

refrigerant absorbs heat from the remaining liquid refrigerant, reducing its

enthalpy from ➆ to ➇. The resulting mixture of liquid and vapor enters the

economizer ➆. Here, the vapor is separated from the mixture and routed

directly to the second-stage impeller inlet ➂ and the remaining liquid travels on

to the second expansion device ➇.

Just before it enters the evaporator, the liquid refrigerant flows through a

second expansion device that reduces its pressure (P

) and temperature to

e

evaporator conditions ➈. The cool, low-pressure mixture of liquid and vapor

enters the distribution system in the evaporator shell and absorbs heat from

water that flows through the tubes. This transfer of heat boils the liquid

refrigerant, and the resulting saturated refrigerant vapor is drawn back to the

compressor ➀ to repeat the cycle.

TRG-TRC010-EN 17

Page 25

notes

period two

Refrigeration Cycle

2-stage centrifugal chiller

Refrigeration Cycle

condenser

6

condenser

P

P

c

c

pressure

pressure

P

P

1

1

P

P

e

e

expansion

expansion

devices

devices

6

5

economizer

economizer

8

8

7

7

10

10

9

9

evaporator

evaporator

5

3

3

1

1

4

4

2-stage

2-stage

2

2

compressor

compressor

&%

enthalpy

enthalpy

$

Figure 26

The change in enthalpy from C to A that occurs during the refrigeration cycle is

called the refrigeration effect. This is the amount of heat that each pound

[kg] of liquid refrigerant will absorb when it evaporates.

The benefit of the economizer can be demonstrated by comparing the

refrigeration cycles with and without an economizer.

Without an economizer, refrigerant from the condenser ➅ expands directly to

evaporator conditions ➉, producing a smaller refrigeration effect (B to A).

Some chiller designs may subcool the liquid refrigerant in the condenser (➅

moves to the left) to increase this refrigeration effect.

Also, in a chiller without an economizer, all of the refrigerant vapor must go

through both stages of compression to return to condensing conditions. In a

chiller with an economizer, refrigerant vapor that flashes in the economizer

bypasses the first stage of compression, resulting in an overall energy savings

of 3 to 4 percent.

18 TRG-TRC010-EN

Page 26

notes

period two

Refrigeration Cycle

Refrigerant Operating Pressures

HCFC-22

HCFC-22

HFC-134a

HFC-134a

pressure

pressure

HCFC-123

HCFC-123

atmospheric

atmospheric

pressure

pressure

temperature

temperature

Refrigerants

When selecting which refrigerant to use in a centrifugal water chiller, the

manufacturer considers efficiency, operating pressures, compatibility with

materials, heat transfer properties, stability, toxicity, flammability, cost,

availability, and environmental impact.

Figure 27

Refrigerants commonly used in centrifugal chillers can be classified as low,

medium, or high pressure based on the normal operating pressures in the

refrigeration cycle.

Chillers using a high-pressure refrigerant like HCFC-22, or a medium-pressure

refrigerant like HFC-134a, operate at pressures that are well above atmospheric

pressure. As we are about to see, some sections of chillers that use a lowpressure refrigerant such as HCFC-123 operate at below-atmospheric pressure.

TRG-TRC010-EN 19

Page 27

notes

period two

Refrigeration Cycle

20 TRG-TRC010-EN

Page 28

notes

period three

Compressor Capacity Control

Multistage Compressor

impellers

impellers

inlet vanes

inlet vanes

In a multistage centrifugal compressor, the operating characteristics of

each impeller are modulated by the impeller’s own set of inlet vanes.

Figure 33

This example shows 2 impellers in series. These impellers share the task of

compressing the refrigerant. Centrifugal water chillers are generally available

with 1, 2, or 3 impellers.

Impeller

V

V

r

r

R

R

V

V

t

t

Figure 34

The forces that act on the refrigerant vapor within the centrifugal compressor

impeller can be broken down into 2 components. One component acts to move

the refrigerant away from the impeller in a radial direction. This component is

called radial velocity (V

The second component acts to move the refrigerant in the direction of impeller

rotation. This component is called tangential velocity (V

Together, these components generate the resultant velocity vector (R), the

length of which is proportional to the amount of kinetic energy in the

).

r

).

t

TRG-TRC010-EN 23

Page 29

period three

Compressor Capacity Control

notes

refrigerant. Recall that kinetic energy is converted to static energy, or static

pressure.

Impeller Dynamics

V

refrigerant flow rate

∝

refrigerant flow rate

V

r

r

V

V

r

r

R

R

V

V

t

t

rotational

rotational

speed

speed

The radial velocity (V

) for a given compressor is directly proportional (∝) to the

r

flow rate of refrigerant vapor through the compressor.

The tangential velocity (V

) is proportional to the product of impeller rotational

t

speed and impeller diameter.

Therefore, the static-pressure-producing capacity of a compressor can be

adjusted by changing the flow rate of refrigerant, the impeller speed, or the

diameter of the impeller.

rotational speed × diameter

∝

V

rotational speed × diameter

V

t

t

diameter

diameter

refrigerant

refrigerant

flow rate

flow rate

Figure 35

24 TRG-TRC010-EN

Page 30

notes

period three

Compressor Capacity Control

Compressor Unloading

V

V

r

R

R

V

V

t

t

r

R

R

V

V

t

t

V

V

r

r

full load

part load

Figure 36

Consider a given-diameter compressor impeller that rotates at a constant

speed. As the load on the chiller decreases, the inlet vanes partially close and

the flow rate of refrigerant through the compressor drops. Radial velocity (V

),

r

which is proportional to refrigerant flow, decreases as well.

Even though the speed of rotation and diameter of the impeller are constant,

the tangential velocity (V

) (which is proportional to the product of impeller

t

rotational speed and impeller diameter) drops because of the pre-swirling of

the refrigerant caused by the inlet vanes.

The result is a shorter resultant velocity vector (R), which means that less static

pressure is generated.

TRG-TRC010-EN 25

Page 31

notes

period three

Compressor Capacity Control

Surge

V

V

r

r

R

R

V

V

t

t

As the load and the corresponding refrigerant flow rate continue to fall, the

radial velocity (force) drops, too. At some point, the radial force becomes

smaller than the generated static pressure, letting the pressurized refrigerant

vapor flow backward from the diffuser passages into the impeller. This

instantaneously reduces the pressure within the passages below the radial

force and the compressor is able to re-establish the proper direction of

refrigerant flow.

V

< static pressure

V

< static pressure

rr

Figure 37

This condition is known as surge. So long as this unstable load condition

exists, the refrigerant alternately flows backward and forward through the

compressor impeller, generating noise and vibration.

Compressor Map

e

e

g

g

r

r

u

u

s

s

51

51

36

10

10

14

pressure difference

pressure difference

14

25

25

refrigerant flow rate

refrigerant flow rate

36

vane position

vane position

(degrees)

(degrees)

These curves represent the performance of a typical 2-stage compressor over a

range of inlet vane positions. The pressure difference between the compressor

inlet (evaporator) and outlet (condenser) is on the vertical axis and the

refrigerant flow rate is on the horizontal axis. The dashed line represents the

90

90

75

75

63

63

Figure 38

26 TRG-TRC010-EN

Page 32

period three

Compressor Capacity Control

notes

conditions that cause the compressor to surge. Any operating point that falls to

the right of this line is satisfactory for stable operation.

Operating Point

operating

operating

point

point

pressure difference

pressure difference

refrigerant flow rate

refrigerant flow rate

To balance the load on the chiller, the compressor must pump a certain quantity

of refrigerant vapor at evaporator pressure and elevate it to the pressure

dictated by the condensing conditions.

The intersection of the refrigerant flow rate and the pressure difference

between the inlet and outlet of the compressor identifies the compressor

operating point.

Figure 39

compressor map for a

2-Stage Compressor

operating

operating

point

point

e

e

g

g

r

r

u

u

s

s

51

51

36

10

10

14

pressure difference

pressure difference

14

25

25

refrigerant flow rate

refrigerant flow rate

36

vane position

vane position

(degrees)

(degrees)

Superimposing the operating point on the previous compressor performance

curves establishes the point at which the compressor will balance the load. In

this example, the compressor will balance the load with its inlet vanes open

90°.

TRG-TRC010-EN 27

90

90

75

75

63

63

Figure 40

Page 33

notes

period three

Compressor Capacity Control

compressor map for a

2-Stage Compressor

$

e

e

g

g

r

r

u

u

s

s

&

10

10

14

pressure difference

pressure difference

14

25

25

unloading line

unloading line

%

51

51

36

36

90

90

75

75

63

63

refrigerant flow rate

refrigerant flow rate

Figure 41

The starting point (A) is the full-load operating point. As the load on the chiller

decreases, the inlet vanes partially close, reducing the flow rate of refrigerant

vapor through the compressor and balancing the chiller capacity with the new

load (B).

Less refrigerant, and therefore less heat, is transferred to the condenser. Since

the heat rejection capacity of the condenser is now greater than required, the

refrigerant condenses at a lower temperature and pressure. This reduces the

pressure difference between the evaporator and the condenser.

Continuing along the unloading line, the compressor remains within its stable

operating range until it reaches the surge region at C.

28 TRG-TRC010-EN

Page 34

notes

period three

Compressor Capacity Control

Adjustable-Frequency Drives

inlet vanes only

inlet vanes only

AFD + inlet vanes

AFD + inlet vanes

power consumption

power consumption

load

load

An adjustable-frequency drive (AFD), or variable-speed drive, is another

device used to vary the capacity of a centrifugal compressor. AFDs are widely

used with fans and pumps, and with the advancement of microprocessor-based

controls for chillers, they are now being applied to centrifugal water chillers.

Figure 42

Using an AFD with a centrifugal chiller can degrade the chiller’s full-load

efficiency. It will, however, offer energy savings by reducing motor speed at

low-load conditions when cooler condenser water is available. An AFD also

controls the inrush current at start-up, reducing stress on the compressor

motor.

Certain system characteristics favor the application of an adjustable frequency

drive, including:

■ A substantial number of part-load operating hours

■ The availability of cooler condenser water

■ Chilled-water reset control

■ High electrical charges

Performing a comprehensive energy analysis is the best method of determining

if an adjustable-frequency drive is desirable. Depending on the application, it

may make sense to take the additional money needed to purchase an AFD and

use it to purchase a more efficient chiller instead.

TRG-TRC010-EN 29

Page 35

notes

period four

Maintenance Considerations

Centrifugal Water Chillers

period four

Figure 43

This period discusses general maintenance requirements of centrifugal water

chillers. Although some of the information applies specifically to the design

presented in this clinic, requirements for other centrifugal chiller designs are

also included.

Maintenance Considerations

▲ Operating log

▲ Mechanical components

▲ Heat-transfer surfaces

▲ Fluid analysis

Figure 44

Once a centrifugal chiller is installed and put into operation, it usually continues

to function without a full-time attendant. In many cases, the machine starts and

stops on a schedule controlled by a building automation system or a simple

time clock. The only daily maintenance requirement is to complete and review

the operating log.

Water chillers are designed for maximum reliability with a minimum amount of

maintenance. Like all large mechanical systems, however, certain routine

maintenance procedures are either required or recommended.

30 TRG-TRC010-EN

Page 36

notes

period four

Maintenance Considerations

operating log

ASHRAE Guideline 3

▲ Chilled water inlet and outlet

temperatures and pressures

▲ Chilled water flow

▲ Evaporator refrigerant

temperature and pressures

▲ Evaporator approach

temperature

▲ Condenser water inlet and

outlet temperatures and

pressures

▲ Condenser water flow

▲ Condenser refrigerant

temperature and pressures

▲ Condenser approach

temperature

▲ Oil pressures, temperature, and

levels

▲ Addition of refrigerant

▲ Addition of oil

▲ Vibration levels

Figure 45

Guideline 3, “

and Air Conditioning Equipment and Systems

Reducing Emission of Halogenated Refrigerants in Refrigeration

,” is one of several advisory

documents published by the American Society of Heating, Refrigerating and

Air-Conditioning Engineers (ASHRAE). This guideline includes a list of

recommended data points to be logged daily for each chiller. Much of this data

may be available from the display on the chiller control panel.

Special attention should be given to:

■ Reviewing the operating log and trends

■ Observing the oil pressure drop to determine if the oil filter needs to be

replaced

■ Monitoring evaporator and condenser approach temperatures

■ Observing and recording the oil level

■ Monitoring purge pump-out operation

TRG-TRC010-EN 31

Page 37

notes

period four

Maintenance Considerations

maintenance considerations

Mechanical Components

▲ Required maintenance

◆ Compressor and motor: no maintenance required

◆ Controls: no maintenance or calibration required

▲ Recommended maintenance

◆ Visually inspect overall unit

◆ Inspect safety controls and electrical components

◆ Tighten electrical connections

◆ Check for leaks

Figure 46

The compressor/motor assembly in direct-drive, hermetic compressor designs

requires little periodic maintenance. The hermetic motor eliminates the need

for external shaft seals associated with open motors. (These seals are a prime

source of oil and refrigerant leaks and should be inspected on a regular basis.)

Hermetic motor designs also eliminate the annual coupling and seal

inspections, alignment, and shaft seal replacement associated with open

motors.

With the advent of microprocessor-based controls, the control panel and

auxiliary controllers require no recalibration or maintenance. Remotelymounted electronic sensors send information to the unit controller, which can

be connected to a building automation system to communicate information

and allow system-level optimization. These systems can notify the operator

with an alarm or diagnostic message when a problem occurs.

As for any mechanical equipment, a daily visual inspection of the chiller is

recommended to look for oil leaks, condensation, loosened electrical or control

wiring, or signs of corrosion. Special attention should be given to safety

controls and electrical components.

A qualified service technician should check the chiller annually for leaks. The

United States Environmental Protection Agency (EPA) mandates refrigerant

recovery whenever a refrigeration circuit is opened during the normal service of

any air conditioning system.

32 TRG-TRC010-EN

Page 38

notes

period four

Maintenance Considerations

maintenance considerations

Mechanical Components

▲ Other design-specific requirements

◆ Change oil when oil analysis dictates

◆ Replace oil filter periodically

◆ Replace filter drier periodically

◆ Clean oil strainers annually

◆ Check shaft alignment annually

◆ Check coupling annually

◆ Replace shaft seal every 2 to 4 years

◆ Compressor teardown inspection every 5 to 10 years

Figure 47

Some centrifugal compressor designs do require periodic maintenance of

mechanical system components. This includes oil and refrigerant filter changes,

oil strainer changes, and a compressor inspection.

Open-motor compressor designs require shaft alignment, coupling inspection,

bearing lubrication, and cleaning of the motor windings on a quarterly or

annual basis.

In all cases, strictly follow the maintenance requirements and

recommendations published by the manufacturer.

maintenance considerations

Heat Transfer Surfaces

▲ Recommended maintenance

◆ Use a qualified water treatment

specialist

◆ Clean condenser tubes as

needed

◆ Clean water-side strainers

◆ Test tubes every 3 years

Figure 48

To ensure optimum heat transfer performance, the heat transfer surfaces must

be kept free of scale and sludge. Even a thin deposit of scale can substantially

reduce heat transfer capacity. Engage the services of a qualified water

treatment specialist to determine the level of water treatment required to

remove contaminants from the cooling tower water.

TRG-TRC010-EN 33

Page 39

period four

Maintenance Considerations

notes

Scale deposits are best removed by chemical means. During this process, the

water-cooled condenser is commonly isolated from the rest of the coolingtower-water circuit by valves, while a pump circulates cleaning solution

through the condenser tubes.

Sludge is removed mechanically. This typically involves removing the water

boxes from the condenser and loosening the deposits with a stiff-bristled

brush. The loosened material is then flushed from the tubes with clear water. As

part of this procedure, the strainers in both the chilled-water and cooling-towerwater circuits should be cleaned every year.

Every 3 years (more frequently in process or critical applications), a qualified

service organization should perform nondestructive inspections of the

evaporator and condenser tubes. The eddy-current tube test is a common

method.

Rarely, problems may arise that cause refrigerant or water leaks. These must be

repaired immediately.

Fluid Analysis

▲ Oil analysis

◆ Conduct annual analysis to verify

system integrity

◆ Measure oil pressure drop to

determine if filter needs changing

◆ Measure charge

▲ Refrigerant charge

◆ Conduct analysis of refrigerant

◆ Inspect purge system

Figure 49

Oil analysis is an important annual maintenance task required for centrifugal

water chillers. It may be conducted more frequently for chillers that run

continuously or more often than normal. This test, performed by a qualified

laboratory, verifies the integrity of the refrigeration system by testing the

concentrations of moisture, acidity, and metal. This analysis can determine

where problems exist or could potentially develop. By taking oil samples on a

regular basis, normal operating trends for the compressor and bearing metals

can be analyzed. Instead of adopting a “change the oil once a year whether it

needs it or not” approach, regular oil analyses can be used to determine proper

oil change intervals and predict major problems before they occur.

Refrigerant analysis measures contamination levels and determines suitability

for continued use. It can also determine if recycled refrigerant is suitable for

reuse. Refrigerant analysis helps extend the life of the existing charge and

ensures that the chiller is operating at peak efficiency.

34 TRG-TRC010-EN

Page 40

period four

Maintenance Considerations

notes

Regularly logging oil and refrigerant charges, and examining the trends of this

data, can help identify potential problems before they occur.

Oil Analysis

▲ Why perform regular oil analysis?

◆ Helps reduce maintenance costs

◆ Detects problems without

compressor disassembly

◆ Extends service life of oil charge

◆ Reduces environmental problems

related to oil disposal

◆ Helps maintain compressor

efficiency and reliability

◆ Helps lower refrigerant emissions

Figure 50

An oil analysis is a key preventive maintenance measure and should be

conducted at least annually. It will help the compressor last longer while

maintaining chiller efficiency and reducing refrigerant emissions.

A certified chemical laboratory can be contracted to perform the analysis for all

types of compressors. Often the chiller manufacturer can provide this service.

TRG-TRC010-EN 35

Page 41

notes

period five

Application Considerations

Centrifugal Water Chillers

period five

Figure 51

Several considerations must be addressed when applying centrifugal water

chillers, including:

■ Condensing temperature control

■ Constant or variable evaporator-water flow

■ Short evaporator-water loops

■ Heat recovery

■ Free cooling

■ Equipment certification standards

While not all-inclusive, this list of considerations does represent some of the

key issues.

36 TRG-TRC010-EN

Page 42

notes

period five

Application Considerations

Condensing Temperature Control

51

51

(degrees)

(degrees)

$

90

90

75

75

63

63

Figure 52

e

e

g

g

r

r

u

u

s

s

%

10

10

14

pressure difference

pressure difference

14

25

25

unloading line

unloading line

refrigerant flow rate

refrigerant flow rate

&

36

36

vane position

vane position

Condensing Temperature Control

To achieve stable compressor unloading over a wide range of conditions, a

reduction in condensing pressure (condenser relief) must accompany a

reduction in load.

The starting point (A) is the full-load operating point. As the chiller load

decreases, the flow rate of refrigerant vapor through the compressor also

decreases. In turn, the pressure difference between the evaporator and the

condenser moves the operating point downward toward B.

If the condenser pressure had been controlled to a constant value instead, the

compressor would have unloaded along a nearly constant pressure line toward

C. This would result in a greatly reduced range of operation.

Condenser relief is, however, only beneficial to a certain point. ALL chillers

require a minimum pressure difference between the evaporator and condenser

to ensure proper management of oil and refrigerant. This minimum pressure

difference depends on the chiller’s design and controls. The most common

method of maintaining this pressure difference at various load conditions is to

control the condensing temperature by varying the temperature or flow rate of

water through the condenser. By controlling condensing temperature, most

centrifugal water chillers can start and operate over a wide range of conditions.

Controlling condensing temperature: (1) maintains chiller efficiency, (2)

maintains the required pressure differential between the evaporator and

condenser for controlled flow through the refrigerant metering system, and

(3) prevents the pressure imbalance that could cause oil loss problems.

TRG-TRC010-EN 37

Page 43

notes

period five

Application Considerations

condensing temperature control

Cooling Tower Bypass

40°F

40°F

[4°C]

[4°C]

55°F

55°F

[13°C]

[13°C]

Controlling the refrigerant pressure difference between the evaporator and

condenser of a water-cooled chiller is accomplished by varying the temperature

or flow rate of the water flowing through the condenser. The following are 5

common methods used to control condensing temperature:

cooling tower

cooling tower

bypass

bypass

condenser

condenser

diverting

diverting

valve

valve

65°F

65°F

[18°C]

[18°C]

Figure 53

1) Cycling or varying the speed of the cooling tower fans to control the

temperature of the water leaving the cooling tower

2) Using a cooling tower bypass pipe to mix warmer leaving-condenser water

with the colder tower water and control the temperature entering the condenser

as illustrated here

3) Modulating a throttling valve to restrict the flow of water through the

condenser

4) Using a chiller bypass pipe to vary the flow rate of water through the

condenser

5) Using a variable-speed drive on the condenser water pump to vary the water

flow rate through the condenser

Each of these strategies has its advantages and disadvantages. Selecting the

appropriate condensing temperature control scheme will depend on the

specific requirements of the application.

The water flow rate through the chiller condenser must stay between the

minimum and maximum condenser bundle flow rates specified by the chiller

manufacturer.

38 TRG-TRC010-EN

Page 44

notes

period five

Application Considerations

evaporator water flow

Constant or Variable Flow

chilled

chilled

water

water

pump

pump

variable-

variable-

speed

speed

drive

drive

Constant or Variable Evaporator Water Flow

Previous chiller designs required that a constant flow rate of water be

maintained through the evaporator. This requirement has changed due to

advances in chiller controls. Increased sensing and control capabilities now

allow chiller manufacturers to design controls that monitor, and respond faster

to, fluctuating conditions.

evaporator

evaporator

Figure 54

While the chiller may be able to handle variable water flow through the

evaporator, the specific application of the chilled water system may not warrant

variable flow. As always, each application should be analyzed to determine if

variable evaporator water flow is warranted.

variable evaporator water flow

Limitations

▲ Maintain minimum and maximum water flow

rates through the chiller evaporator

▲ Rate at which the evaporator water flow

changes must be kept below the

corresponding limit to:

◆ Maintain the chilled water set point control

◆ Keep the chiller on line

◆ Protect the chiller from damage

Figure 55

The controls on many current chiller designs can properly control the chiller in

response to varying evaporator flow rates, with the following limitations:

TRG-TRC010-EN 39

Page 45

period five

Application Considerations

notes

1) The water flow rate through the chiller evaporator must stay between the

minimum and maximum flow rates for the evaporator bundle, as specified by

the chiller manufacturer. These limits depend on the specific design variables of

the actual evaporator bundle such as the number of tubes, number of passes,

and geometry. Implementation of a method for sensing evaporator water flow

through each chiller is the only way to make sure that the water flow rate stays

within these limits.

2) The rate of change for the evaporator water flow rate must not exceed a

specified level, depending on the level of protection desired. For example, the

maximum rate of change to maintain the chilled water set point is more

stringent than the maximum rate of change to keep the chiller on line. There are

3 common levels of protection desired: maintaining chilled water set point

control, keeping the chiller on line, and protecting the chiller from damage.

The limits for these different levels of protection should be obtained from the

chiller manufacturer.

Short Evaporator-Water Loops

load

load

chilled

chilled

water

water

pump

pump

evaporator

evaporator

Figure 56

Short Evaporator-Water Loops

Proper chilled water temperature control requires that the temperature of the

chilled water returning to the evaporator not change any faster than the chiller

controls can respond. The volume of water in the evaporator loop acts as a

buffer, ensuring that the return water temperature changes slowly and,

therefore, providing stable temperature control. If there is not a sufficient

volume of water in the loop to provide an adequate buffer, temperature control

can be lost, resulting in erratic system operation.

The chiller manufacturer should be consulted for volume requirements of the

evaporator-water loop.

40 TRG-TRC010-EN

Page 46

notes

period five

Application Considerations

Short Evaporator-Water Loops

load

load

tank

tank

chilled

chilled

water

water

pump

pump

Short water loops may be unavoidable in close-coupled or very small

applications, particularly in systems where the load consists of only a few air

handlers or processes.

evaporator

evaporator

Figure 57

To prevent the effect of a short water loop, a storage tank or large header pipe

can be added to the system to increase the volume of water in the loop and

ensure a slowly changing return water temperature.

A second solution is to reduce the water flow rate in the chilled water loop

while using the same size pipes. This also increases the loop time—the time it

takes a particle of water to travel through the chilled water loop—and ensures

that the return water temperature changes slowly. This solution has the added

benefit of reduced pumping energy requirements.

TRG-TRC010-EN 41

Page 47

notes

period five

Application Considerations

Heat Recovery

heat-recovery

heat-recovery

condenser

condenser

cooling

cooling

tower

tower

water

water

standard

standard

condenser

condenser

Figure 58

Heat Recovery

Salvaging usable heat from the refrigeration cycle—heat that would normally

be rejected to the atmosphere—can significantly reduce the operating costs of

many buildings.

Heat recovery is most commonly accomplished using 2 condensers and the fact

that hot refrigerant vapor migrates to the area with the lowest temperature.

Raising the refrigerant condensing temperature in the standard condenser

prompts the refrigerant to flow instead to the second condenser, where it

rejects its heat to the water flowing through the tubes. The condensing

temperature in the standard condenser is controlled by varying the temperature

or the flow rate of the cooling tower water.

Typical uses for the hot water from the second condenser include: heat for

spaces around the perimeter of the building, reheat coils in air conditioning

systems, and bathroom, laundry, or kitchen requirements. Any building with a

simultaneous heating and cooling load is a potential candidate for heat

recovery.

42 TRG-TRC010-EN

Page 48

notes

period five

Application Considerations

Heat-Recovery Chiller Options

heat-recovery

(dual) condenser

◆ Second, full-

size condenser

◆ Large heating

loads

◆ High hot water

temperatures

◆ Controlled

◆ Degrades

chiller efficiency

auxiliary

condenser

◆ Second, smaller

size condenser

◆ Preheating loads

◆ Moderate

hot water

temperatures

◆ Uncontrolled

◆ Improves chiller

efficiency

heat pump

◆ No extra

condenser

◆ Large base heating

loads or continuous

operation

◆ High hot water

temperatures

◆ Controlled

◆ Chiller efficiency

preserved

Figure 59

Three types of heat-recovery chillers are commonly available:

The dual-condenser, or double-bundle, heat-recovery chiller contains a

second, full-size condenser that serves a separate hot water loop. It is capable

of more heat rejection and higher leaving-water temperatures. This type of

chiller allows the amount of heat being rejected to be controlled, although

chiller efficiency is sacrificed for higher hot water temperatures.

Similarly, an auxiliary-condenser heat-recovery chiller makes use of a

second, smaller condenser bundle. It is not capable of rejecting as much heat as

the dual-condenser chiller. Since its leaving-water temperatures are also lower,

it is typically used to preheat returning hot water before it goes to the primary

heating equipment or to preheat incoming water prior to entering a traditional

water heater. It requires no additional controls and actually improves chiller

efficiency.

A heat-pump chiller is a standard chiller (no extra shells are required) applied

where the useful heat transfer occurs in the condenser, not the evaporator. The

evaporator is connected to the chilled water loop, typically upstream of other

chillers, but it only removes enough heat from the chilled water loop to handle

the heating load served by the condenser water loop. This application is useful

in a multiple-chiller installation, where there is a base or year-round comfort or

process load, or where the quantity of heat required is significantly less than

the cooling load. Chiller efficiency is not compromised.

TRG-TRC010-EN 43

Page 49

notes

period five

Application Considerations

Free Cooling

air-side

economizer

◆ Most efficient

◆ Requires larger

outdoor air,

return, and

exhaust duct

systems

strainer

cycle

◆ Coldest water

temperatures

◆ Potential fouling

in chilled water

loop

◆ Requires

additional piping,

valves, and

controls

plate-and-frame

heat exchanger

◆ Potential fouling

limited to heat

exchanger

◆ Requires additional

heat exchanger,

piping, valves, and

controls

◆ Can operate

simultaneously with

chiller

Figure 60

Free Cooling

Many buildings require some form of year-round cooling to handle interior

spaces or other loads. When the outdoor air temperature falls below the indoor

dew point temperature, it is possible to use an air-side economizer to satisfy

these cooling requirements. This method of “free cooling” involves using

outdoor air for cooling instead of recirculating warmer indoor air. It is the most

efficient method of free cooling because it allows all of the chilled water and/or

refrigeration system components to be turned off. This method, however,

requires larger duct systems to deliver the outdoor air to the air handler and to

return and exhaust this larger amount of air.

A second method of applying free cooling is to pump water from the cooling

tower loop directly into the chilled water loop when its temperature is low

enough to satisfy the cooling load. This is commonly called the strainer cycle

because a strainer or filter is needed to prevent debris and contaminants

carried by the cooling tower water from entering the chilled water loop.

Although this method is very efficient, the contamination common in open

cooling tower systems causes concern about “fouling” (deposits of scale or

sludge) inside the chilled water coils. Ongoing treatment of the chilled water

loop is required.

Another method of providing free cooling is similar to the strainer cycle but

involves the use of a plate-and-frame heat exchanger, or water-side

economizer, to isolate the chilled water loop from the cooling tower loop. This

is a popular method of free cooling because it is efficient and eliminates

potential contamination of the chilled water loop. In addition, the heat

exchanger can be operated simultaneously with the chiller.

44 TRG-TRC010-EN

Page 50

notes

period five

Application Considerations

free cooling

Refrigerant Migration

from

from

compressor

compressor

condenser

condenser

to

to

compressor

compressor

evaporator

evaporator

Figure 61

This leads to the discussion of a free cooling principle called refrigerant

migration. It involves adapting a water chiller so that it functions as a simple

heat exchanger.

When the available condenser water is cooler than the desired chilled water

temperature, the compressor is turned off and bypass valves in the chiller

refrigerant circuit are opened to let the refrigerant circulate without help from

the compressor. Because refrigerant migrates to the area with the lowest

temperature, refrigerant boils in the evaporator and the vapor flows to the

cooler condenser bundle. After the refrigerant condenses, it flows (by gravity)

back to the evaporator.

The advantages of refrigerant migration are these: no extra components are

required in the system, control is performed by the chiller itself, and there are

no additional fouling concerns. It is possible for the free cooling chiller to satisfy

many cooling load requirements without operating the compressor, especially

when the system can accommodate warmer chilled water temperatures at partload conditions.

TRG-TRC010-EN 45

Page 51

notes

period five

Application Considerations

equipment certification standards

ARI Standard 550/590

▲ Purpose

◆ Establish definitions, testing,

and rating requirements

▲ Scope

◆ Factory designed and

prefabricated water chillers

◆ Vapor-compression

refrigeration

◆ Air-cooled and water-cooled

condensing

Figure 62

Equipment Certification Standards

The Air Conditioning & Refrigeration Institute (ARI) establishes rating standards

for packaged HVAC equipment. ARI also certifies and labels equipment through

programs that involve random testing of a manufacturer’s equipment to verify

published performance.

The overall objective of ARI Standard 550/590–1998 is to promote consistent

rating and testing methods for all types and sizes of water chillers, with an

accurate representation of actual performance. It covers factory-designed,

prefabricated water chillers, both air-cooled and water-cooled, using vaporcompression refrigeration. This generally includes chillers with centrifugal,

helical-rotary (screw), reciprocating, or scroll compressors.

equipment certification standards

ARI Standard 550/590

▲ Standard rating conditions

◆ Common system conditions for published ratings

◆ Fouling factor

▲ Integrated Part Load Value (IPLV)

◆ Part-load efficiency rating

◆ Based on an “average” single-chiller installation

◆ Standard operating conditions

Figure 63

The standard rating conditions used for ARI certification represent typical

design temperatures and flow rates for which water-cooled and air-cooled

systems are designed. They are not suggestions for good design practice for a

46 TRG-TRC010-EN

Page 52

period five

Application Considerations

notes

given system—they simply define a common rating point to aid comparisons.

Trends toward improved humidity control and energy efficiency have changed

some of the actual conditions selected for specific applications.

Impurities in the chilled- and condenser-water systems eventually deposit on

evaporator and condenser tube surfaces, impeding heat transfer. Catalogued