Page 1

P ackaged Roof top

Air Conditioners

27 ½ to 50 Ton - 60 Hz

Voy ager™ Commer cial

October 2001

RT-PRC007 -EN

Page 2

Introduction

P ackaged Roof top

Air Conditioners

Through the years, Trane has designed

and developed the most complete line of

Pac kaged Rooftop products available in

the market today. T rane was the first to

introduce the Micro —microelectronic

unit controls— and again moved ahead

with the introduction of the Voyager

Commercial products.

The Voyager Commercial line offers 27½

to 50 ton models; five sizes to meet the

changing demands of the commercial

rooftop market.

Our customers demand that Trane

products provide exceptional reliability,

meet stringent performance

requirements, and to be competitively

priced. T rane delivers with Voyager

Commercial.

V oyager Commercial features cutting

edge technologies like the reliable 3-D

Scroll compressors, Trane engineered

microprocessor controls, computer aided run testing, and Integrated

Comfort™ Systems. S o, whether you’re

the contractor, the engineer , or the

owner you can be certain Voyager

Commercial Products are built to meet

your needs.

®

It’s Hard To Stop A Trane

.

®

©American Standard Inc. 2001

RT-PRC007-EN

Page 3

Contents

Introduction

Featur es and Benefits

Application Considerations

Selection Procedur e

Model Number Description

General Data

P erformance Data

Performance Adjustment Factors

Controls

Electric P o wer

Dimension and W eights

Mechanical Specifications

2

4

10

12

14

15

19

18

28

32

34

41

RT-PRC007-EN

3

Page 4

Features and Benefits

Standard Featur es

• Factory installed and commissioned

microelectronic controls

• T rane 3-D™ Scroll Compressors

• Dedicated downflow or horizontal

configuration

• CV or V AV control

• FROST AT™ coil frost protection on all

units

• Supply air overpressurization

protection on VA V units

• Supply airflow proving

• Emergency stop input

• Compressor lead-lag

• Occupied-Unoccupied switching

• Timed override activation

• FC supply fans

• UL and CSA listing on standard options

• T wo inc h standard ef ficiency filters

• Finish exceeds salt spray requirements

of ASTM B1 1 7

• Sloped condensate drain pan

Optional Features

• Electric heat

• Natural gas heat

• LP gas heat (kit only)

• Power Exhaust

• Barometric Relief

• High Efficiency 2” Throwaway Filters

• High Efficiency 4” Throwaway Filters

• High Efficiency supply fan motors

• Manual fresh air damper

• Economizer with dry bulb control

• Economizer with reference enthalpy

control

• Economizer with differential

(comparative) enthalpy control

• Inlet guide vanes on VAV units

• V ariable frequency drives on V A V

units (with or without bypass)

• Service V alves

• Through-the-base electrical provision

• Factory mounted disconnect with

external handle (non-fused)

• Factory powered 15A GFI

convenience outlet

• Field powered 15A GFI convenience

outlet

• Integrated Comfort™ System Control

Option

• V entilation Override

• Hinged Service Access

• Factory installed condenser coil

guards

• Black epoxy coated condenser coil

• Sloped stainless steel evaporator coil

drain pans

RT-PRC007-EN4

Page 5

Features and

Benefits

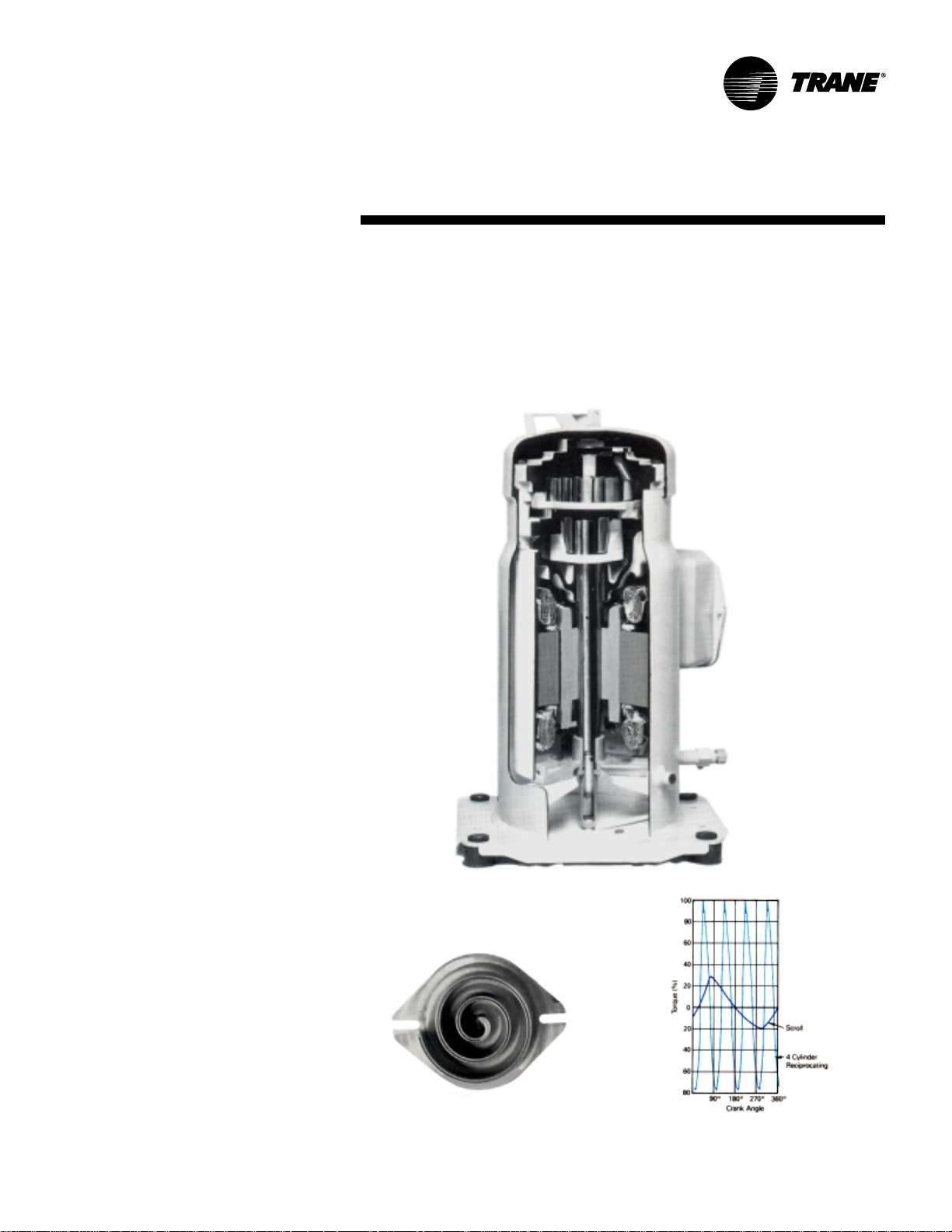

Trane 3-D® Scroll Compressor

Simple Design with 70% Fewer P arts

Fewer parts than an equal capacity

reciprocating compressor means

significant reliability and efficiency

benefits. The single orbiting scroll

eliminates the need for pistons,

connecting rods, wrist pins and valves.

Fewer parts lead to increased reliability .

Fewer moving parts, less rotating mass

and less internal friction means greater

efficiency than reciprocating

compressors.

The T rane 3-D Scroll pro vides important

reliability and efficiency benefits. The 3-D

Scroll allows the orbiting scrolls to touch

in all three dimensions, forming a

completely enclosed compression

chamber whic h leads to increased

efficiency . In addition, the orbiting scrolls

only touch with enough force to create a

seal; there is no wear between the scroll

plates. The fixed and orbiting scrolls are

made of high strength cast iron which

results in less thermal distortion, less

leakage, and higher efficiencies. The

most outstanding feature of the 3-D

Scroll compressor is that slugging will

not cause failure. In a reciprocating

compressor, however , the liquid or dir t

can cause serious damage.

Low T orque Variation

The 3-D Scroll compressor has a very

smooth compression cycle; torque

variations are only 30 percent of that

produced by a reciprocating compressor.

This means that the scroll compressor

imposes very little stress on the motor

resulting in greater reliability. Low torque

variation reduces noise and vibration.

Suction Gas Cooled Motor

Compressor motor efficiency and

reliability is further optimized with the

latest scroll design. Cool suction gas

keeps the motor cooler for longer life and

better efficiency.

Proven Design Through Testing and

Research

With over twenty years of development

and testing, T rane 3-D Scroll

compressors have undergone more

than 400,000 hours of laboratory testing

and field operation. This work combined

with over 25 patents makes T rane the

worldwide leader in air conditioning

scroll compressor technology .

One of two matched scroll plates —

the distinguishing feature of the scroll

compressor.

Chart illustrates low torque variation of

3-D Scroll compressor vs

reciprocating compressor.

5RT-PRC007-EN

Page 6

Quality and Reliability

Features and

Benefits

Forced Combustion Blowe r

Negative Pressur e Gas Valve

Hot Surface Ignitor

Drum and Tube Heat Exchanger

Micro Controls

The Micro provides unit control for

heating, cooling and ventilating utilizing

input from sensors that measure outdoor

and indoor temperature.

Quality and Reliability are enhanced

through the use of time-tested microprocessor controls and logic.

The Micro:

• prevents the unit from short cycling,

considerably improving

compressor life.

• ensures that the compressor will run

for a specific amount of time which

allows oil to return for better

lubrication, enhancing the reliability

of the commercial compressor.

The Voyager with the Micro reduces the

number of components required to

operate the unit, thereby reducing

possibilities for component failure.

Drum and Tube Heat Exchanger

The drum and tube heat exchanger is

designed for increased efficiency and

reliability and has utilized improved

technology incorporated in the large roof

top commercial units for almost

20 years.

The heat exchanger is manufactured

using aluminized steel with stainless

steel components for maximum

durability. The requirement for cycle

testing of heat exchangers is 1 0,000

cycles by ANSI Z21.47. This is the

standard required by both UL and AGA

for cycle test requirements. Trane

requires the design to be tested to 2

times this current standard. The drum

and tube design has been tested and

passed over 150,000 cycles which is over

15 times the current ANSI cycling

requirements.

1

/

2

The negative pressure gas valve will not

allow gas flow unless the combustion

blower is operating. This is one of our

unique safety features.

The forced combustion blower supplies

pre-mixed fuel through a single stainless

steel burner screen into a sealed drum

where ignition takes place. It is more

reliable to operate and maintain than a

multiple burner system.

The hot surface ignitor is a gas ignition

device which doubles as a safety device

utilizing a continuous test to prove the

flame. The design is cycle tested at the

factory for quality and reliability.

All the gas/electric rooftops exceed all

California seasonal efficiency

requirements. They also perform better

than required to meet the California NOx

emission requirements.

RT-PRC007-EN6

Page 7

Features and

Benefits

FC Fans with Inlet Guide V anes

T rane’s forw ard-curved fans with inlet

guide vanes pre-rotate the air in the

direction of the fan wheel, decreasing

static pressure and horsepower,

essentially unloading the fan wheel. The

unloading characteristics of a Trane FC

fan with inlet guide vanes result in

superior part load performance.

Excellent P art-Load Ef ficiency

The Scroll compressor’s unique design

allows it to be applied in a passive

parallel manifolded piping scheme,

something that a “recip” just doesn’t do

very well.

When the unit begins stage back at part

load it still has the full area and circuitry

of its evaporator and condenser coils

available to transfer heat. In simple

terms this means superior part-load

efficiencies (IPLV) and lower unit

operating costs.

Rigorous T esting

All of Voyager’s designs were rigorously

rain tested at the factory to ensure water

integrity.

Actual shipping tests are performed to

determine packaging requirements.

Units are test shipped around the

country. Factory shake and drop tested

as part of the pac kage design process to

help assure that the unit will arrive at

your job site in top condition.

Rigging tests include lifting a unit into

the air and letting it drop one foot,

assuring that the lifting lugs and rails

hold up under stress.

We perform a 100% coil leak test at the

factory. The evaporator and condenser

coils are leak tested at 200 psig and

pressure tested to 450 psig.

All parts are inspected at the point of

final assembly. Sub-standard par ts are

identified and rejected immediately.

Every unit receives a 100% unit run test

before leaving the production line to

make sure it lives up to rigorous Trane

requirements.

Ease of Installation

Contractors look for lower installation

(jobsite) costs. Voyager’s conversionless

units provide many time and money

saving features.

Conversionless Units

The dedicated design units (either

downflow or horizontal) require no panel

removal or alteration time to convert in

the field — a major cost savings during

installation.

Improv ed Airflow

U-shaped airflow allows for improved

static capabilities. The need for high static

motor conversion is minimized and time

isn’t spent changing to high static

oversized motors.

Single Point P ow er

A single electrical connection powers the

unit.

Micro™

The function of the Micro replaces the

need for field installed anti-shortcycle

timer and time delay relays. The Micro

ensures that these controls are integral

to the unit. The contractor no longer has

to purchase these controls as options

and pay to install them.

The wiring of the low voltage

connections to the unit and the zone

sensors is as easy as 1-1, 2-2, and 3-3.

This simplified system makes it easier

for the installer to wire.

7RT-PRC007-EN

Page 8

Features and

Benefits

Easy to Service

Because today’s owners are very costconscious when it comes to service and

maintenance, the Trane Voyager was

designed with direct input from service

contractors. This valuable information

helped to design a product that would

get the serviceman off the job quic ker

and save the owner money. Voyager

does this by offering:

A Simpler Design

The Voyager design uses fewer parts

than previous units. Since it is simpler in

design, it is easier to diagnose.

Micro

The Micro requires no special tools to

run the Voyager unit through its paces.

Simply place a jumper between T est 1

and T est 2 terminals on the Low Voltage

Terminal Board and the unit will walk

through its operational steps

automatically.

— The unit automatically returns

control to the zone sensor after

stepping through the test mode a

single time, even if the jumper is

left on the unit.

As long as the unit has power and the

“system on” LED is lit, the Micro is

operational. The light indicates that the

Micro is functioning properly.

The Micro features expanded diagnostic

capabilities when utilized with T rane’s

Integrated Comfort™ Systems.

Some Zone Sensor options have central

control panel lights which indicate the

mode the unit is in and possible

diagnostic information (dirty filters for

example).

Easy Access Low V oltage T erminal Board

V oyager’s Low Voltage Terminal Board is

external to the electrical control cabinet.

It is extremely easy to locate and attach

the thermostat wire. This is another cost

and time-saving installation feature.

V alue

Low Ambient Cooling

All Voyager Commercial units have

cooling capabilities down to 0 F as

standard.

Pow er Exhaust Option

Provides exhaust of the return air when

using an economizer to maintain proper

building pressurization. Great for

relieving most building

overpressurization problems.

Micro Benefits

The Micro in the Voyager units has builtin anti-short-cycle timer , time delay relay

and minimum “on” time controls. These

controls are functions of the Micro and

are factory tested to assure proper

operation.

The Micro softens electrical “spikes” by

staging on fans, compressors and

heaters.

Intelligent Fallback is a benefit to the

building occupant. If a component goes

astray, the unit will continue to operate

at predetermined temperature setpoint.

Intelligent Anticipation is a standard

feature of the Micro. It functions

constantly as the Micro and zone sensor

work together in harmony to provide

tighter comfort control than conventional

electro-mechanical thermostats.

Horizontal Dischar ge with

Power Exhaust Option

RT-PRC007-EN8

Page 9

Features and

Benefits

VariTrac

VariTrac

T rane’s c hangeo ver VAV S ystem for light

commercial applications is also

available. Coupled with Voyager

Commercial, it provides the latest in

technological advances for comfort

Downflow and Hor izontal Economiz ers

The economizers come with three

control options dry bulb, enthalpy and

differential enthalpy . (Photo above

shows the three fresh air hoods on the

Horizontal Discharge Configuration).

management systems and can allow

thermostat control in every zone served

by V ariTrac™.

®

Central

Control Panel

Trane Communication Interface (TCI)

Available factory or field installed. This

module when applied with the Micro

easily interfaces with Trane’s Integrated

Comfort™ System.

V ar iable F requency Dr iv es (VFD)

TIME

CLOCK

INPUT/

STATUS

PANEL

EDIT

TERMINAL

V ariable Frequency Drives are factory

installed and tested to provide supply fan

motor speed modulation. VFD’s, as

compared to inlet guide vanes or

discharge dampers, are quieter , more

efficient, and are eligible for utility

rebates. The VFD’s are available with or

without a bypass option. Bypass control

will simply provide full nominal airflow

in the event of drive failure.

Trane factory built roof curbs

Available for all units.

One of Our Finest Assets

T rane Commercial S ales Engineers are a

support group that can assist you with:

— Product

— Application

— Service

— Training

— Special Applications

— Specifications

— Computer Programs and more

9RT-PRC007-EN

Page 10

Application Considerations

Exhaust Air Options

When is it necessary to provide building

exhaust?

Whenever an outdoor air economizer is

used, a building generally requires an

exhaust system. The purpose of the

exhaust system is to exhaust the proper

amount of air to prevent over or under pressurization of the building.

A building may have all or part of its

exhaust system in the rooftop unit. Often,

a building provides exhaust external to

the air conditioning equipment. This

external exhaust must be considered

when selecting the rooftop exhaust

system.

Voyager Commercial roof top units of fer

two types of exhaust systems:

1

Power exhaust fan.

2

Barometric relief dampers.

Application Recommendations

Pow er Exhaust Fan

The exhaust fan option is a dual,

nonmodulating exhaust fan with

approximately half the air -mo ving

capabilities of the supply fan system. The

experience of The Trane Company is that

a non-modulating exhaust fan selected

for 40 to 50 percent of nominal supply

cfm can be applied successfully.

The power exhaust fan generally should

not be selected for more than 40 to 50

percent of design supply airflow. Since it

is an on/off nonmodulating fan, it does

not vary exhaust cfm with the amount of

outside air entering the building.

Therefore, if selected for more than 40 to

50 percent of supply airflow, the building

may become underpressurized when

economizer operation is allowing lesser

amounts of outdoor air into the building.

If, however , building pressure is not of a

critical nature, the non-modulating

exhaust fan may be sized for more than

50 percent of design supply airflow.

Consult T able PD-1 6 for specific exhaust

fan capabilities with Voyager Commercial

units.

Barometric Relief D ampers

Barometric relief dampers consist of

gravity dampers which open with

increased building pressure. As the

building pressure increases, the pressure

in the unit return section also increases,

opening the dampers and relieving air.

Barometric relief may be used to provide

relief for single story buildings with no

return ductwork and exhaust

requirements less than 25 percent.

Altitude Corr ections

The rooftop performance tables and

curves of this catalog are based on

standard air (.075 lbs/ft). If the rooftop

airflow requirements are at other than

standard conditions (sea level), an air

density correction is needed to project

accurate unit performance.

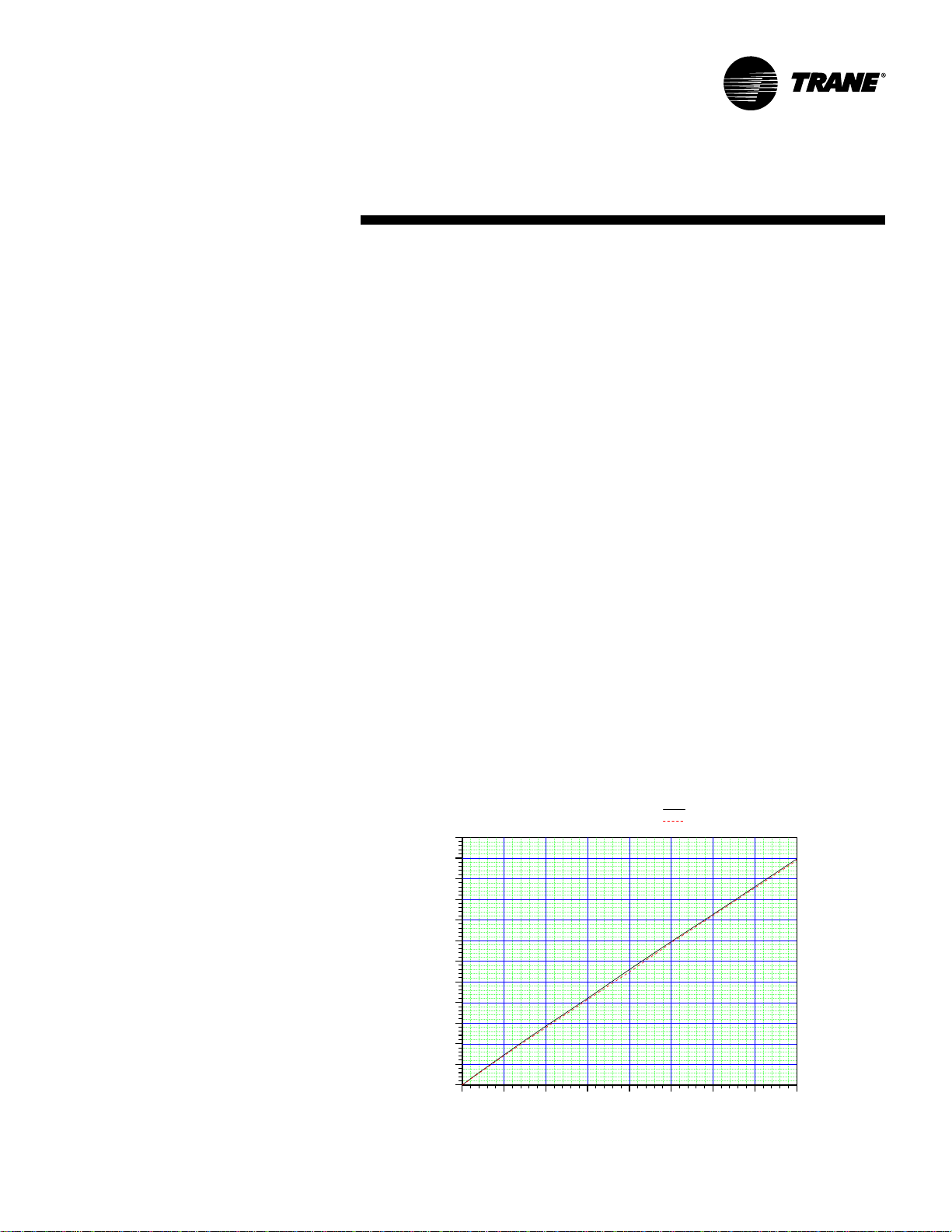

Figure PD-1 shows the air density ratio at

various temperatures and elevations.

T rane roof tops are designed to operate

between 40 and 90 degrees Fahrenheit

leaving air temperature.

The procedure to use when selecting a

supply or exhaust fan on a rooftop for

elevations and temperatures other than

standard is as follows:

1

First, determine the air density ratio

using Figure PD-1 .

2

Divide the static pressure at the

nonstandard condition by the air density

ratio to obtain the corrected static

pressure.

3

Use the actual cfm and the corrected

static pressure to determine the fan rpm

and bhp from the rooftop performance

tables or curves.

4

The fan rpm is correct as selected.

5

Bhp must be multiplied by the air density

ratio to obtain the actual operating bhp.

In order to better illustrate this procedure,

the following example is used:

Consider a 30-ton rooftop unit that is to

deliver 1 1,000 actual cfm at 1.50 inches

total static pressure (tsp), 55 F leaving air

temperature, at an elevation of 5,000 ft.

1

From Figure PD-1, the air density ratio is

0.86.

2

Tsp=1 .50 inc hes/0.86=1.74 inches tsp.

3

From the performance tables: a 30-ton

rooftop will deliver 11,000 cfm at 1 .74

inches tsp at 668 rpm and 6.93 bhp.

4

The rpm is correct as selected — 668

rpm.

5

Bhp = 6.93 x 0.86 = 5.96 .

Compressor MBh, SHR, and kw should

be calculated at standard and then

converted to actual using the correction

factors in T able PD-2. Apply these factors

to the capacities selected at standard cfm

so as to correct for the reduced mass

flow rate across the condenser.

RT-PRC007-EN10

Page 11

Application

Considerations

Heat selections other than gas heat will

not be affected by altitude. Nominal gas

capacity (output) should be multiplied by

the factors given in Table PD-3 before

calculating the heating supply air

temperature.

Acoustical Considerations

Proper placement of rooftops is critical to

reducing transmitted sound levels to the

building. The ideal time to make

provisions to reduce sound

transmissions is during the design

phase. And the most economical means

of avoiding an acoustical problem is to

place the rooftop(s) away from

acoustically critical areas. If possible,

rooftops should not be located directly

above areas such as: of fices, conference

rooms, executive office areas and

classrooms. Instead, ideal locations

might be over corridors, utility rooms,

toilets or other areas where higher

sound levels directly below the unit(s)

are acceptable.

Several basic guidelines for unit

placement should be followed to

minimize sound transmission through

the building structure:

1

Never cantilever the compressor end of

the unit. A structural cross member must

support this end of the unit.

2

Locate the unit’s center of gravity which

is close to, or over, a column or main

support beam.

3

If the roof structure is very light, roof

joists must be replaced by a structural

shape in the critical areas described

above.

4

If several units are to be placed on one

span, they should be staggered to

reduce deflection over that span.

It is impossible to totally quantify the

effect of building structure on sound

transmission, since this depends on the

response of the roof and building

members to the sound and vibration of

the unit components. However, the

guidelines listed above are experienceproven guidelines which will help reduce

sound transmissions.

Clearance Requirements

The recommended clearances identified

with unit dimensions should be

maintained to assure adequate

serviceability, maximum capacity and

peak operating efficiency . A reduction in

unit clearance could result in condenser

coil starvation or warm condenser air

recirculation. If the clearances shown are

not possible on a particular job, consider

the following:

Do the clearances available allow for

major service work such as c hanging

compressors or coils?

Do the clearances available allow for

proper outside air intake, exhaust air

removal and condenser airflow?

If screening around the unit is being

used, is there a possibility of air

recirculation from the exhaust to the

outside air intake or from condenser

exhaust to condenser intake?

Actual clearances which appear

inadequate should be reviewed with a

local T rane sales engineer .

When two or more units are to be placed

side by side, the distance between the

units should be increased to 150 percent

of the recommended single unit

clearance. The units should also be

staggered for two reasons:

1

To reduce span deflection if more than

one unit is placed on a single span.

Reducing deflection discourages sound

transmission.

2

To assure proper dif fusion of exhaust air

before contact with the outside air intake

of adjacent unit.

Duct Design

It is important to note that the rated

capacities of the rooftop can be met only

if the rooftop is properly installed in the

field. A well designed duct system is

essential in meeting these capacities.

The satisfactory distribution of air

throughout the system requires that

there be an unrestricted and uniform

airflow from the rooftop discharge duct.

This discharge section should be straight

for at least several duct diameters to

allow the conversion of fan energy from

velocity pressure to static pressure.

However, when job conditions dictate

elbows be installed near the rooftop

outlet, the loss of capacity and static

pressure may be reduced through the

use of guide vanes and proper direction

of the bend in the elbow. The high

velocity side of the rooftop outlet should

be directed at the outside radius of the

elbow rather than the inside.

11RT -PRC007 -EN

Page 12

Selection Pr ocedure

Selection of T rane commercial air

conditioners is divided into five basic

areas:

1

Cooling capacity

2

Heating capacity

3

Air delivery

4

Unit electrical requirements

5

Unit designation

Factors Used In Unit Cooling Selection:

1

Summer design conditions — 95 DB/

76 WB, 95 F entering air to condenser.

2

Summer room design conditions —

76DB/66 WB.

3

Total peak cooling load — 321 MBh (27.75

tons).

4

Total peak supply cfm — 12,000 cfm.

5

External static pressure — 1 .0 inc hes.

6

Return air temperatures — 80 DB/66 WB.

7

Return air cfm — 4250 cfm.

8

Outside air ventilation cfm and load —

1200 cfm and 18.23 MBh (1 .52 tons).

9

Unit accessories include:

a

Aluminized heat exchanger — high heat

module.

b

2” Hi-efficiency throwaway filters.

c

Exhaust fan.

d

Economizer cycle.

Step 1 — A summation of the peak

cooling load and the outside air

ventilation load shows: 27.75 tons + 1 .52

tons = 29.27 required unit capacity. F rom

Table 18-2, 30-ton unit capacity at 80 DB/

67 WB, 95 F entering the condenser and

12,000 total peak supply cfm, is 30.0 tons.

Thus, a nominal 30-ton unit is selected.

Step 2 — Having selected a nominal 30ton unit, the supply fan and exhaust fan

motor bhp must be determined.

Supply Air Fan:

Determine unit static pressure at design

supply cfm:

External static pressure 1 .20 inc hes

Heat exchanger .14 inc hes

(Table PD-1 4)

High efficiency filter 2” .09 inches

(Table PD-14)

Economizer .076 inches

(Table PD-14)

Unit total static pressure 1 .50 inc hes

Using total cfm of 12,000 and total

static pressure of 1.50 inc hes, enter Table

PD-12. T able PD-1 2 shows 7.27 bhp with

652 rpm.

Step 3 — Determine evaporator coil

entering air conditions. Mixed air dry

bulb temperature determination.

Using the minimum percent of OA (1,200

cfm ÷ 12,000 cfm = 10 percent),

determine the mixture dry bulb to the

evaporator. RADB + %O A (OADB - RADB)

= 80 + (0.10) (95 - 80) = 80 + 1.5 = 81.5F

Approximate wet bulb mixture

temperature:

RAWB + O A (O A WB - RAWB) = 66 + (0.1 0)

(76-66) = 68 + 1 = 67 F.

A psychrometric c har t can be used to

more accurately determine the mixture

temperature to the evaporator coil.

Step 4 — Determine total required unit

cooling capacity:

Required capacity = total peak load +

O.A. load + supply air fan motor heat.

From Figure SP-1, the supply air fan

motor heat for 7.27 bhp = 20.6 MBh.

Capacity = 321 + 18.23 + 20.6 =

359.8 MBh (30 tons)

Step 5 — Determine unit capacity:

From Table PD-4 unit capacity at 81.5 DB.

67 WB entering the evaporator, 12000

supply air cfm, 95 F entering the

condenser is 361 MBh (30.1 tons) 279

sensible MBh.

Step 6 — Determine leaving air

temperature:

Unit sensible heat capacity, corrected for

supply air fan motor heat 279 - 20.6 =

258.4 MBh.

Supply air dry bulb temperature

difference = 258.4 MBh ÷ (1.085 x 12,000

cfm) = 19.8 F.

Supply air dry bulb: 81 .5 - 1 9.8 = 61.7.

Unit enthalpy difference = 361 ÷ (4.5 x

12,000) = 6.7

Btu/lb leaving enthalpy = h (ent WB) =

31 .62

Leaving enthalpy = 31 .62 Btu/lb -

6.7 Btu/lb = 24.9 Btu/lb.

From Table PD-1, the leaving air wet bulb

temperature corresponding to an

enthalpy of 24.9 Btu/lb = 57.5.

Leaving air temperatures =

61 .7 DB/57.5 WB

RT-PRC007-EN12

Page 13

Selection

Pr ocedure

Heating capacity selection:

1

Winter outdoor design conditions—5 F.

2

Total return air temperature — 72 F.

3

Winter outside air minimum ventilation

load and cfm — 1,200 cfm and 87.2 MBh.

4

Peak heating load 225 MBh.

Utilizing unit selection in the cooling

capacity procedure.

Mixed air temperature = RADB + %O.A.

(OADB - RADB) = 72

+ (0.10) (0-72) = 64.8 F.

Supply air fan motor heat temperature

rise = 20,600 BTU ÷ (1.085 x 1 2,000) cfm

= 1 .6 F.

Mixed air temperature entering heat

module = 64.8 + 1 .6 = 66.4 F.

Total winter heating load = peak heating

+ ventilation load - total fan motor heat =

225 + 87.2 - 20.6 = 291 .6MBh.

Electric Heating Syst em

Unit operating on 480/60/3 power supply.

From Table PD-9, kw may be selected for

a nominal 30-ton unit operating on 480volt power . The high heat module — 90

KW or 307 MBh will satisfy the winter

heating load of 291 . 6 MBh.

Table PD-9 also shows an air

temperature rise of 23.6 F for 12,000 cfm

through the 90 kw heat module.

Unit supply temperature at design

heating conditions = mixed air

temperature + air temperature rise = 66.4

+ 23.6 = 90 F.

Natural Gas Heating Syst em

Assume natural gas supply — 1 000 Btu/

3

. From T able PD-11, select the high heat

ft

module (486 MBh output) to satisfy 291 .6

at unit cfm.

Table PD-11 also shows air temperature

rise of 37.3 F for 12,000 cfm through

heating module.

Unit supply temperature design heating

conditions = mixed air temperature + air

temperature rise = 66.4 + 37.3 = 103.7 F.

Air Delivery Procedur e

Supply air fan bhp and rpm selection.

Unit supply air fan performance shown

in T able PD-1 2 includes pressure drops

for dampers and casing losses. Static

pressure drops of accessory

components such as heating systems,

and filters if used, must be added to

external unit static pressure for total

static pressure determination.

Figure SP -1 — Fan Motor Heat

120

110

100

90

80

70

60

50

40

FAN MOTOR HEAT - MBH

30

20

10

0

0 5 10 15 20 25 30 35 40

MOTOR BRAKE HORSE POWER

The supply air fan motor selected in the

previous cooling capacity determination

example was 7.27 bhp with 652 rpm.

Thus, the supply fan motor selected is 7.5

hp.

To select the drive, enter Table PD-15 for

a 30-ton unit. Select the appropriate

drive for the applicable rpm range. Drive

selection letter C with a range of 650

rpm, is required for 652 rpm. Where

altitude is significantly above sea level,

use T able PD-2 and PD-3, and Figure PD-1

for applicable correction factors.

Unit Electrical Requirements

Selection procedures for electrical

requirements for wire sizing amps,

maximum fuse sizing and dual element

fuses are given in the electrical service

selection of this catalog.

Unit Designation

After determining specific unit

characteristics utilizing the selection

procedure and additional job

information, the complete unit model

number can be developed. Use the

model number nomenclature on page

14.

STANDARD MOTOR

HIGH EFFICIENCY MOTOR

13RT -PRC007 -EN

Page 14

Model Number Description

YCD480 A4 HA1 A4 F D1A0000000 00 000

12 3 456 7 8 9 1011 1213 14 151617 18192021222324 2526 272829

Digit 1, 2 — Unit F unction

TC = DX Cooling, No Heat

TE = DX Cooling, Electric Heat

YC = DX Cooling, Natural Gas Heat

Digit 3 — Unit Airflo w Design

D = Downflow Configuration

H = Horizontal Configuration

Digit 4, 5, 6 — Nominal Cooling Capacity

330 = 27½ Tons

360 = 30 Tons

420 = 35 Tons

480 = 40 Tons

600 = 50 Tons

Digit 7 — Major Development Sequence

A = First

Digit 8 — Po w er Supply (See Note 1)

E = 208/60/3

F = 230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 9 — Heating Capacity (See Note 4)

0 = No Heat (TC only)

L = Low Heat (YC only)

H = High Heat (YC only)

Note: When second digit is “E” for Electric

Heat, the following values apply in the ninth

digit.

A = 36 KW

B = 54 KW

C = 72 KW

D = 90 KW

E = 108 KW

Digit 13 — Supply F an Motor, HP

1 = 7.5 Hp Std. Eff.

2 = 10 Hp Std. Eff.

3 = 15 Hp Std. Eff.

4 = 20 Hp Std. Eff.

5 = 7.5 Hp Hi. Eff.

6 = 10 Hp Hi. Eff.

7 = 15 Hp Hi. Eff.

8 = 20 Hp Hi. Eff.

Digit 14 — Supply Air Fan Dr iv e

Selections (See Note 3)

A = 550 RPM H = 500 RPM

B = 600 RPM J = 525 RPM

C = 650 RPM K = 575 RPM

D = 700 RPM L = 625 RPM

E = 750 RPM M = 675 RPM

F = 790 RPM N = 725 RPM

G = 800 RPM

Digit 15 — Fr esh Air Selection

A = No Fresh Air

B = 0-25% Manual Damper

C = 0-100% Economizer, Dry Bulb Control

D = 0-100% Economizer, Reference

Enthalpy Control

E = 0-100% Economizer, Diff erential

Enthalpy Control

F = “C” Option and Low Leak Fresh

Air Damper

G = “D” Option and Low Leak Fresh

Air Damper

H = “E” Option and Low Leak Fresh

Air Damper

Digit 16 — Sys tem Contr ol

1 = Constant Volume

2 = VAV Supply Air Temperature Control

w/o Inlet Guide Vanes

3 = VAV Supply Air Temperature Control

w/Inlet Guide Vanes

4 = VAV Supply Air Temperature Control

w/Variable Frequency Drive w/o Bypass

5 = VAV Supply Air Temperature Control

w/Variable Frequency Drive and Bypass

Note: Zone sensors are not included with

option and must be ordered as a separate

accessory.

Digit 17 - 29 — Miscellaneous

A = Service Valves (See Note 2)

B = Through the Base Electrical Provision

C = Non-Fused Disconnect Switch with

External Handle

D = Factory-Powered 15A GFI

Convenience Outlet and Non-Fused

Disconnect Switch with

External Handle

E = Field-Powered 15A GFI

Convenience Outlet

F = ICS Control Option — Trane

Communication Interface, Supply Air

Sensing and Clogged Filter Switch

G = Ventilation Override

H = Hinged Service Access

J = Condenser Coil Guards

K = LonTalk Communication Interface

L = Special

M = Stainless Steel Drain Pans

N = Black Epoxy Coated Condenser Coil

Digit 10 Design Sequence

A = First

Digit 1 1 — Exhaust

0 = None

1 = Barometric Relief

(Available w/Economizer only)

2 = Power Exhaust Fan

(Available w/Economizer only)

Digit 12 — Filter

A = Standard 2” Throwaway Filters

B = High Efficiency 2” Throwaway Filters

C = High Efficiency 4” Throwaway Filters

Note:

1. All voltages are across the line starting only.

2. Option includes Liquid, Discharge, Suction Valves.

3. Supply air fan drives A thru G are used with 27½-35 ton units only and drives H thru N are used with 40 & 50

ton units only.

4. Electric Heat KW ratings are based upon voltage ratings of 240/480/600 V. Voltage offerings are as follows (see

table PD-9 for additional information):

Tons Voltage 36 54 72 90 108

27½ to 35 240 x x

480 xxxx

600 x x x

40 and 50 240 x

480 x x x x

600 x x x x

5. The service digit for each model number contains 29 digits; all 29 digits must be referenced.

KW

5

RT-PRC007-EN14

Page 15

General Data

Table GD-1 — General Data — 27 1/2 - 30 Tons

Cooling Performance

Nominal Gross Capacity 329,000 363,000

Natural Gas Heat

1

2

Low High Low High

Heating Input (BTUH) 350,000 600,000 350,000 600,000

First Stage 250,000 425,000 250,000 425,000

Heating Output (BTUH) 283,500 486,000 283,500 486,000

First Stage 202,500 344,500 202,500 344,500

Steady State Efficiency (%)

3

81 .00 81.00 81.00 81.00

No. Burners 1 2 1 2

No. Stages 2 2 2 2

Gas Connection Pipe Size (in.)

Electric Heat

KW Range

5

3

/

4

Capacity Steps: 2 2

Compressor

Number/T ype 2/Scroll 2/Scroll

Size (Nominal) 10/15 15

Unit Capacity Steps (%) 100/40 100/50

Motor RPM 3450 3450

Outdoor Coil — Type Lanced Lanced

T ube Siz e (in.) OD

Face Area (sq. f t.) 51.33 51.33

Rows/Fins Per Inch 2/16 2/16

Indoor Coil — Type Hi-Performance Hi-Performance

T ube Siz e (in.) OD

Face Area (sq. f t.) 31.67 31.67

Rows/Fins Per Foot 2/180 2/180

Refrigerant Control TXV TXV

No. of Circuits 1 1

Drain Connection No./Size (in) 1/1.25 1/1.25

T ype PVC PVC

Outdoor Fan Type Propeller Propeller

No. Used/Diameter 3/28.00 3/28.00

Drive T ype/No. Speeds Direct/1 Direct/1

CFM 24,800 24,800

No. Motors/HP/RPM 3/1.1 0/1125 3/1 .10/1125

Indoor Fan Type FC FC

No. Used 1 1

Diameter/Width (in) 22.38/22.00 22.38/22.00

Drive Type/No. Speeds Belt/1 Belt/1

No. Motors/HP 1/7.50/10.00 1/7.50/10.00

Motor RPM 1760 1760

Motor Frame Size 213/215T 213/215T

Exhaust Fan Type Propeller Propeller

No. Used/Diameter (in) 2/26.00 2/26.00

Drive Type/No. Speeds/Motors Direct/2/2 Direct/2/2

Motor HP/RPM 1 .0/1 075 1.0/1 075

Motor Frame Size 48 48

Filters — Type Furnished Throwaway Throwaway

No./ Recommended Size (in)

Refrigerant Charge (Lbs of R-22)

Minimum Outside Air Temperature

For Mechanical Cooling 0 F 0 F

Notes:

1. Cooling Performance is rated at 95 F ambient, 80 F entering dry bulb, 67 F entering wet bulb. Gross capacity does not include the effect of fan motor heat. Rated and tested in

accordance with the Unitary Large Equipment certification program, which is based on ARI Standard 340/360-93.

2. Heating Performance limit settings and rating data were established and approved under laboratory test conditions using American National Standards Institute standards.

Ratings shown are for elevations up to 4,500 feet.

3. Steady State Efficiency is rated in accordance with DOE test procedures.

4. Refrigerant charge is an approximate value. For a more precise value, see unit nameplate and service instructions.

5. Maximum KW @ 208V = 41, @ 240V = 54.

6. Filter dimensions listed are nominal. For actual filter and rack sizes see the Unit Installation, Operation, Maintenance Guide.

6

4

27 1/2 Ton 30 Ton

1

3

/

4

27-90 27-90

3

/

8

1

/

2

16/16 x 20 x 2 16/16 x 20 x 2

46.00 46.60

1

3

8

/

1

/

2

15RT -PRC007 -EN

Page 16

General Data

Table GD-2— General Data — 35-40 T on

Cooling Performance

Nominal Gross Capacity 417,000 513,000

Natural Gas Heat

1

2

Low High Low High

Heating Input (BTUH) 350,000 600,000 400,000 800,000

First Stage 250,000 425,000 300,000 600,000

Heating Output (BTUH) 283,500 486,000 324,000 648,000

First Stage 202,500 344,500 243,000 486,000

Steady State Efficiency (%)

3

81 .00 81.00 81.00 81.00

No. Burners 1212

No. Stages 2222

Gas Connection Pipe Size (in.)

Electric Heat

KW Range

5

3

/

4

Capacity Steps: 2 2

Compressor

Number/T ype 2/Scroll 3/Scroll

Size (nominal) 15 15/15/10

Unit Capacity Steps (%) 100/50 100/60/40

Motor RPM 3450 3450

Outdoor Coil — Type Lanced Lanced

T ube Siz e (in.) OD

Face Area 51.33 69.79

Rows/Fins Per Inch 2/16 2/16

Indoor Coil — Type Hi-Performance Hi-Performance

T ube Siz e (in.) OD

Face Area (sq. f t.) 31.67 37.50

Rows/Fins Per Foot 3/180 3/180

Refrigerant Control TXV TXV

No. of Circuits 1 2

Drain Connection No./Size (in) 1/1.25 1/1.25

T ype PVC PVC

Outdoor Fan Type Propeller Propeller

No. Used/Diameter 3/28.00 4/28.00

Drive T ype/No. Speeds Direct/1 Direct/1

CFM 24,800 31,700

No. Motors/HP/RPM 3/1.1 0/1125 4/1.10/1125

Indoor Fan Type FC FC

No. Used 1 1

Diameter/Width (in) 22.38/22.00 25.00/25.00

Drive Type/No. Speeds Belt/1 Belt/1

No. Motors/HP 1/7.50/10.00/15.00 1/10.00/15.00

Motor RPM 1760 1760

Motor Frame Size 213/215/254T 215/254T

Exhaust Fan Type Propeller Propeller

No. Used/Diameter (in) 2/26.00 2/26.00

Drive Type/No. Speeds/Motors Direct/2/2 Direct/2/2

Motor HP/RPM 1 .0/1 075 1.0/1 075

Motor Frame Size 48 48

Filters — Type Furnished Throwaway Throwaway

No./Recommended Size (in)

Refrigerant Charge (Lbs of R-22)

6

4

Minimum Outside Air Temperature

For Mechanical Cooling 0 F 0 F

Notes:

1. Cooling Performance is rated at 95 F ambient, 80 F entering dry bulb, 67 F entering wet bulb. Gross capacity does not include the effect of fan motor heat. Rated and tested

in accordance with the Unitary Large Equipment certification program, which is based on ARI Standard 340/360-93.

2. Heating Performance limit settings and rating data were established and approved under laboratory test conditions using American National Standards Institute standards.

Ratings shown are for elevations up to 4,500 feet.

3. Steady State Efficiency is rated in accordance with DOE test procedures.

4. Refrigerant charge is an approximate value. For a more precise value, see unit nameplate and service instructions.

5. Maximum KW @ 208V = 41, @ 240V = 54.

6. Filter dimensions listed are nominal. For actual filter and rack sizes see the Unit Installation, Operation, Maintenance Guide.

35 T on 40 Ton

1

3

/

4

27-90 41-108

3

/

8

1

/

2

16/16 x 20 x 2 17/16 x 20 x 2

51.50 26.00/47 .10 per circuit

1

3

/

8

1

/

2

RT-PRC007-EN16

Page 17

General Data

Table GD-3— General Data — 50 T on

Cooling Performance

Nominal Gross Capacity 616,000

Natural Gas Heat

1

2

Low High

Heating Input (BTUH) 400,000 800,000

First Stage 300,000 600,000

Heating Output (BTUH) 324,000 648,000

First Stage 243,000 486,000

Steady State Efficiency (%)

3

81.00 81.00

No. Burners 1 2

No. Stages 2 2

Gas Connection Pipe Size (in.)

Electric Heat

KW Range

5

3

/

4

Capacity Steps: 2

Compressor

Number/Type 3/Scroll

Size (nominal) 14

Unit Capacity Steps (%) 100/67/33

Motor RPM 3450

Outdoor Coil — Type Lanced

T ube Siz e (in.) OD

Face Area (sq. f t.) 69.79

Rows/Fins Per Inch 2/16

Indoor Coil — Type Hi-Performance

T ube Siz e (in.) OD

Face Area (sq. f t.) 37.50

Rows/Fins Per Foot 4/164

Refrigerant Control TXV

No. of Circuits 2

Drain Connection No./Size (in) 1/1 .25

T ype PVC

Outdoor Fan Type Propeller

No. Used/Diameter 4/28.00

Drive Type/No. Speeds Direct/1

CFM 31,700

No. Motors/HP/RPM 4/1.10/1125

Indoor Fan Type FC

No. Used 1

Diameter/Width (in) 25.00/25.00

Drive Type/No. Speeds Belt/1

No. Motors/HP 1/10.00/15.00/20.00

Motor RPM 1760

Motor Frame Size 215/254/256T

Exhaust Fan Type Propeller

No. Used/Diameter (in) 2/26.00

Drive Type/No. Speeds/Motors Direct/2/2

Motor HP/RPM 1 .0/1 075

Motor Frame Size 48

Filters — Type Furnished Throwaway

No./Recommended Size (in)

Refrigerant Charge (Lbs of R-22)

6

4

Minimum Outside Air Temperature

For Mechanical Cooling 0 F

Notes:

1. Cooling Performance is rated at 95 F ambient, 80 F entering dry bulb, 67 F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. Rated and tested in accordance with the Unitary Large Equipment

certification program, which is based on ARI Standard 340/360-93.

2. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standards Institute standards. Ratings shown are for elevations up to 4,500 feet.

3. Steady State Efficiency is rated in accordance with DOE test procedures.

4. Refrigerant charge is an approximate value. For a more precise value, see unit nameplate and service instructions.

5. Maximum KW @ 208V = 41, @ 240V = 54.

6. Filter dimensions listed are nominal. For actual filter and rack sizes see the Unit Installation, Operation,

Maintenance Guide.

50 Ton

41-108

3

/

8

1

/

2

17/16 x 20 x 2

25.70/54.30 per circuit

1

Table GD-4 — Economizer Outdoor Air

Damper Leakage (Of Rat ed Airflow)

∆P Across Dampers (In. WC)

Standard 1 .5 % 2.5 %

Optional “Low Leak” 0.5 % 1.0 %

Note: Above data based on tests completed in

accordance with AMCA Standard 575.

0.5 (In.) 1 .0 (In.)

17RT -PRC007 -EN

Page 18

P erformance Adjustment Factors

Table PD-1— Enthalpy of Saturated AIR

Wet Bulb Temperature Btu Per Lb.

40 15.23

41 15.70

42 16.17

43 16.66

44 17.15

45 17.65

46 18.16

47 18.68

48 19.21

49 19.75

50 20.30

51 20.86

52 21.44

53 22.02

54 22.62

55 23.22

56 23.84

57 24.48

58 25.12

59 25.78

60 26.46

61 27.15

62 27.85

63 28.57

64 29.31

65 30.06

66 30.83

67 31.62

68 32.42

69 33.25

70 34.09

71 34.95

72 35.83

73 36.74

74 37 .66

75 38.61

Figure PD-1 — Air Density Ratios

Altitude/Temperature Correction

Air Density

Ratio (Density

at New

Air Density)

Condition/Std.

Rooftop Leaving Air Temperature (degrees F)

Table PD-2 — Cooling Capacity Altitude Cor r ection F act ors

Cooling Capacity

Multiplier 1 .00 0.99 0.99 0.98 0.97 0.96 0.95 0.94

KW Correction

Multiplier

(Compressors) 1.00 1.01 1 .02 1.03 1.04 1 .05 1.06 1 .07

SHR Correction

Multiplier 1.00 .98 .95 .93 .91 .89 .87 .85

Maximum

Condenser

Ambient 115 F 114 F 113 F 112 F 111 F 110 F 109 F 108 F

Note:

SHR = Sensible Heat Ratio

Sea Level 1000 2000 3000 4000 5000 6000 7000

Altitude (Ft.)

Table PD-3 — Gas Heating Capacity Altitude Cor r ection F act ors

Sea Level 2001 2501 3501 4501 5501 650 1

Capacity

Multiplier 1.00 .92 .88 .84 .80 .76 .72

Note:

Correction factors are per AGA Std 221.30 — 1964, Part VI, 6.12. Local codes may supersede.

T o 2000 T o 2500 To 3500 To 4500 T o 5500 T o 6500 To 7500

Altitude (Ft.)

RT-PRC007-EN18

Page 19

P erformance Data

Table PD-4 — 27 1/2 Ton Gross Cooling Capacities (MBh)

Ent Entering Wet Bulb Temperature — Deg F

DB 61 67 73 61 67 73 61 67 73 61 67 73

CFM (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 291 228 323 185 358 130 278 221 309 174 343 123 265 213 295 167 327 116 251 206 279 159 310 109

8000 80 294 268 324 220 359 171 281 261 310 212 343 164 268 253 296 205 327 157 255 246 280 197 311 149

85 301 301 325 258 360 210 290 290 31 1 251 344 203 278 278 297 243 329 196 266 266 282 236 312 188

90 317 317 328 297 361 248 306 306 315 290 345 241 294 294 301 283 330 234 282 282 286 275 313 226

75 299 242 331 189 367 133 285 235 316 182 351 126 272 227 301 175 334 119 257 219 286 168 316 112

9000 80 302 286 332 232 367 178 290 279 318 225 351 171 276 272 303 217 335 164 261 261 287 209 317 157

85 314 314 334 275 368 221 302 302 319 268 352 215 290 290 305 260 336 208 277 277 289 252 319 201

90 331 331 338 319 369 264 319 319 324 312 354 256 306 306 310 304 337 249 293 293 293 293 320 241

75 305 255 337 197 373 136 292 248 322 190 357 129 277 240 307 183 339 122 263 232 291 176 322 11 5

10000 80 310 304 339 244 374 185 297 297 324 237 358 178 283 283 308 229 341 171 270 270 292 221 323 164

85 325 325 341 291 375 233 313 313 326 284 359 226 300 300 311 276 342 219 287 287 295 268 324 212

90 343 343 346 340 376 279 330 330 332 332 360 271 317 317 317 317 343 264 304 304 303 303 326 256

75 311 268 343 205 379 139 297 260 327 198 362 132 282 253 311 191 344 125 268 245 295 183 326 1 17

11 000 80 316 316 344 255 380 192 304 304 329 248 363 185 291 291 313 240 345 178 278 278 297 232 327 170

85 335 335 347 307 381 245 322 322 332 300 364 237 309 309 317 292 347 230 295 295 301 284 329 220

90 353 353 353 353 383 293 340 340 340 340 366 286 327 327 327 327 349 278 313 313 312 312 331 270

75 316 281 348 223 384 142 302 274 332 216 366 135 287 266 316 208 348 128 272 258 299 200 330 121

12100 80 325 325 349 268 385 199 312 312 334 260 368 192 299 299 318 252 350 185 285 285 301 244 331 176

85 344 344 353 324 387 254 331 331 338 317 369 246 317 317 322 309 352 239 303 303 306 301 333 231

90 364 364 363 363 388 309 350 350 350 350 372 301 336 336 336 336 354 294 321 321 321 321 336 286

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total gross capacity.

3. SHC = Sensible heat capacity.

85 95 105 115

Ambient Temperature — Deg F

Table PD-5— 30 Ton Gross Cooling Capacities (Mbh)

Ent Entering Wet Bulb Temperature — Deg F

DB 61 67 73 61 67 73 61 67 73 61 67 73

CFM (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 323 255 358 207 397 1 44 309 247 343 194 380 1 37 295 239 327 186 362 129 279 230 310 178 344 122

9000 80 326 299 359 245 398 190 313 291 344 237 381 182 298 283 328 229 363 175 284 275 311 221 345 167

85 335 335 361 288 399 234 323 323 346 280 382 227 310 310 330 272 364 219 297 297 313 264 345 210

90 352 352 364 332 400 276 340 340 349 324 383 269 327 327 334 316 365 261 313 313 318 308 347 252

75 331 268 366 210 405 147 316 260 350 202 387 140 301 252 333 194 369 132 286 243 316 186 350 125

10000 80 335 317 367 257 406 197 321 309 351 249 388 189 306 301 335 241 370 182 290 290 318 232 351 174

85 347 347 369 304 407 246 334 334 353 296 389 238 321 321 337 288 371 230 307 307 320 280 352 222

90 366 366 374 353 408 292 353 353 358 345 391 284 339 339 342 337 372 276 325 325 324 324 353 267

75 337 281 372 218 411 150 322 273 356 210 393 143 307 265 339 202 374 135 291 256 321 194 355 127

11 000 80 343 335 374 269 412 204 328 327 357 261 394 196 312 312 340 252 375 188 298 298 323 244 356 180

85 358 358 376 321 413 257 345 345 360 312 395 249 331 331 343 304 377 241 316 316 326 296 357 233

90 378 378 382 374 415 306 364 364 367 366 397 298 350 350 349 349 378 290 335 335 334 334 359 282

75 343 294 378 225 417 153 328 285 361 218 398 145 312 277 343 210 379 138 295 268 325 201 359 129

12000 80 348 348 379 280 418 210 334 334 362 272 399 203 321 321 345 263 380 195 306 306 327 255 360 187

85 368 368 382 336 419 268 354 354 366 328 401 260 340 340 349 320 382 252 325 325 331 311 362 244

90 388 388 388 388 421 321 374 374 374 374 402 313 359 359 359 359 383 304 343 343 343 343 364 296

75 349 308 383 246 422 156 333 300 366 238 403 149 317 291 348 229 383 141 300 283 329 221 363 133

13200 80 357 357 385 293 423 218 343 343 368 285 405 210 329 329 350 276 385 202 314 314 332 268 365 194

85 378 378 389 354 425 278 364 364 372 346 406 270 349 349 355 338 387 261 333 333 337 329 366 253

90 399 399 399 399 427 337 384 384 384 384 408 329 369 369 369 369 389 321 353 353 352 352 369 312

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total gross capacity.

3. SHC = Sensible heat capacity.

85 95 105 115

Ambient Temperature — Deg F

19RT -PRC007 -EN

Page 20

P erformance

Data

Table PD-6 — 35 Ton Gross Cooling Capacities (Mbh)

Ent Entering Wet Bulb Temperature — Deg F

DB 61 67 73 61 67 73 61 67 73 61 67 73

CFM (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 377 310 416 240 459 166 361 301 398 231 438 158 343 291 379 223 417 150 325 282 359 214 396 141

10500 80 383 367 417 296 460 224 366 359 399 287 439 216 350 349 380 278 418 207 332 332 360 268 397 198

85 398 398 420 351 461 281 383 383 402 343 440 272 368 368 383 333 419 263 352 352 364 324 397 254

90 419 419 426 409 462 336 404 404 408 400 442 327 388 388 388 388 421 317 371 371 371 371 399 308

75 387 332 425 258 468 171 370 322 406 249 447 162 352 313 387 240 425 154 334 303 366 231 403 145

12000 80 393 393 427 315 469 236 378 378 408 306 448 227 362 362 388 297 426 218 346 346 368 288 404 209

85 415 415 431 379 470 300 399 399 412 370 449 290 383 383 393 361 427 281 366 366 373 351 405 271

90 437 437 437 437 472 361 421 421 421 421 451 352 404 404 404 404 430 342 386 386 386 386 408 333

75 393 346 430 261 473 173 375 337 411 253 452 165 357 327 391 244 429 156 339 317 370 234 406 147

13000 80 402 402 432 328 475 243 387 387 413 319 453 234 370 370 393 310 430 225 353 353 372 300 408 216

85 425 425 437 397 476 312 409 409 418 388 454 303 392 392 399 378 432 294 374 374 379 369 409 285

90 448 448 448 448 478 377 431 431 431 431 457 368 413 413 413 413 435 359 395 395 395 395 412 349

75 398 360 435 270 478 176 380 351 415 261 456 167 362 341 395 252 433 159 343 331 373 243 410 150

14000 80 410 410 437 341 479 250 394 394 417 332 457 241 378 378 397 322 434 232 360 360 376 312 411 223

85 434 434 443 414 480 324 417 417 423 405 458 315 400 400 404 396 436 306 381 381 381 381 413 297

90 458 458 457 457 484 393 440 440 440 440 462 384 422 422 422 422 440 375 403 403 403 403 417 365

75 400 365 436 272 479 177 382 356 416 263 457 168 364 346 396 254 434 160 345 337 375 244 411 151

14400 80 413 413 439 346 481 253 397 397 419 336 459 244 380 380 399 327 436 235 363 363 378 317 412 226

85 437 437 445 421 482 326 420 420 426 412 460 317 402 402 406 402 437 308 384 384 384 384 414 298

90 461 461 461 461 486 400 443 443 443 443 464 390 425 425 425 425 442 381 406 406 406 406 419 371

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total gross capacity.

3. SHC = Sensible heat capacity.

85 95 105 115

Ambient Temperature — Deg F

Table PD-7 — 40 Ton Gross Cooling Capacities (Mbh)

Ent Entering Wet Bulb Temperature — Deg F

DB 61 67 73 61 67 73 61 67 73 61 67 73

CFM (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 460 365 510 288 565 202 439 353 486 276 539 190 416 340 462 263 512 178 393 327 436 250 484 166

12000 80 466 432 51 1 351 566 269 445 419 487 338 540 257 423 406 463 325 513 244 401 393 438 312 486 232

85 480 480 515 415 567 333 461 461 491 402 541 322 441 441 467 390 515 309 421 421 442 376 487 297

90 506 506 521 480 568 398 487 487 498 468 543 385 467 467 475 455 517 373 445 445 450 442 489 360

75 476 396 525 304 580 208 453 383 500 291 553 196 430 370 474 279 525 184 406 357 448 266 496 172

14000 80 484 473 526 378 581 284 463 461 502 365 554 272 438 438 477 352 526 260 417 417 450 339 497 248

85 506 506 532 453 582 359 486 486 508 440 556 347 465 465 482 427 528 335 443 443 457 414 499 321

90 535 535 541 529 585 432 514 514 518 517 559 420 492 492 492 492 531 407 470 470 469 469

75 482 411 530 317 586 211 459 398 505 305 558 199 436 385 479 292 530 187 411 371 452 279

15000 80 489 489 533 391 587 292 469 469 508 379 560 280 448 448 482 366 531 268 426 426 456 352

85 518 518 539 471 588 372 497 497 514 458 561 360 475 475 489 445 533 346 453 453 463 432

90 547 547 546 546 591 449 525 525 525 525 565 437 503 503 503 503 537 424 480 480 480 480

75 488 425 536 321 591 213 465 412 510 309 563 202 441 399 484 296 534 189 416 385 456 282

16000 80 499 499 539 405 592 299 478 478 513 392 565 287 457 457 487 379 536 275 434 434 460 365

85 528 528 546 489 593 383 507 507 521 477 566 371 485 485 495 463 538 358 461 461 469 450

90 558 558 558 558 597 466 536 536 536 536 571 453 513 513 513 513 543 440 489 489 489 489

75 497 448 543 335 598 217 473 435 517 322 570 206 449 422 490 308 541 193 424 408 462 295

17600 80 513 513 547 425 599 311 491 491 521 412 572 299 469 469 495 399 543 286 446 446 467 385

85 543 543 555 518 601 401 521 521 530 505 574 389 498 498 504 492 545 376 474 474 474 474

90 574 574 574 574 606 492 551 551 551 551 579 479 527 527 527 527 551 466

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total gross capacity.

3. SHC = Sensible heat capacity.

85 95 105 115

Ambient Temperature — Deg F

RT-PRC007-EN20

Page 21

P erformance

Data

Table PD-8 — 50 Ton Gross Cooling Capacities (MBh)

Ent Entering Wet Bulb Temperature — Deg F

DB 61 67 73 61 67 73 61 67 73 61 67 73

CFM (F) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 556 459 614 356 679 244 529 444 585 342 647 230 502 429 555 327 614 216 475 414 524 312

15000 80 565 547 616 439 680 331 539 533 588 424 649 318 51 1 51 1 558 409 616 303 487 487 527 394

85 590 590 622 524 682 417 567 567 593 509 651 403 542 542 564 494 618 389 517 517 534 479

90 623 623 631 61 1 684 500 599 599 604 597 654 486 574 574 574 574 622 471 547 547 547 547

75 570 491 627 373 691 250 543 476 597 359 659 236 515 460 566 344 625 222 486 445 533 328

17000 80 581 581 630 468 693 348 557 557 601 453 661 334 532 532 570 437 627 320 506 506 538 422

85 615 615 637 564 694 443 590 590 608 549 662 429 565 565 578 534 629 414 538 538 547 518

90 650 650 649 649 698 536 624 624 624 624 667 522 597 597 597 597 634 507

75 576 506 633 386 696 252 548 491 602 371 663 239 520 476 570 356 629 224 491 460 538 340

18000 80 591 591 636 482 698 355 566 566 606 467 666 342 541 541 575 451 632 327 514 514 543 436

85 626 626 644 583 699 455 601 601 615 568 668 441 574 574 584 553 634 426 547 547 553 537

90 661 661 661 661 703 554 635 635 635 635 673 540 608 608 607 607 640 525

75 581 522 638 391 701 255 554 507 607 377 668 241 525 491 575 362 633 227 496 475 542 345

19000 80 600 600 642 495 702 363 575 575 611 480 670 350 549 549 580 465 636 335 522 522 547 449

85 636 636 651 602 704 467 610 610 621 587 673 453 583 583 590 572 639 438 555 555 559 556

90 671 671 671 671 709 571 645 645 645 645 678 557 617 617 617 617 645 543

75 587 537 642 400 705 257 559 522 61 1 386 672 244 530 506 579 371 637 230 501 490 545 353

20000 80 609 609 647 509 707 371 583 583 616 494 674 357 557 557 584 478 640 343 529 529 551 463

85 645 645 657 621 708 479 619 619 627 606 677 465 591 591 596 591 643 450 563 563 562 562

90 681 681 681 681 714 589 654 654 654 654 683 575 626 626 626 626 650 560

Notes:

1. All capacities shown are gross and have not considered indoor fan heat. To obtain net cooling, subtract indoor fan heat.

2. TGC = Total gross capacity.

3. SHC = Sensible heat capacity.

85 95 105 115

Ambient Temperature — Deg F

21RT -PRC007 -EN

Page 22

P erformance

Data

Table PD-9 — Electric Heat Air Temperatur e Rise

KW T otal Cfm

Input MBH 8000 9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000

3612314.212.611.310.39.48.78.17.6—————

54 184 21.2 18.9 17.0 15.4 14.2 13.1 12.1 1 1.3 10.6 10.0 9.4 8.9 8.5

72 246 28.3 25.2 22.6 20.6 18.9 17.4 16.2 15.1 14.2 13.3 12.6 11.9 1 1.3

90 307 35.4 31.5 28.3 25.7 23.6 21.8 20.2 18.9 17.7 16.7 15.7 14.9 14.2

108369————28.3 26.1 24.3 22.6 21.2 20.0 18.9 17.9 17.0

Notes:

1. Air temperature rise = (KW x 3413)/(scfm x 1.085).

2. All heaters on constant volume units provide 2 increments of capacity. All VAV units provide 1 step of heating capacity.

3. Air temperature rise in this table are based on heater operating at 240, 480 or 600 volts.

Table PD-10 — A v ailable Electr ic Heat KW Ranges

Nominal Nominal Voltage

Unit Size

T ons 208 240 480 600

27½ 27-41 36-54 36-90 54-90

30.0 27-41 36-54 36-90 54-90

35.0 27-41 36-54 36-90 54-90

40.0 41 54 54-108 54-108

50.0 41 54 54-108 54-108

Notes:

1. KW ranges in this table are based on heater operating at 208, 240, 480, and 600 volts.

2. For other than rated voltage, KW =

3. Electric heaters up to 54 KW are single element heaters, those above 54 KW are dual element heaters.

Applied Voltage

(

Rated Voltage

2

x Rated KW.

)

Table PD-11 — Nat ural Gas Heating Capacities

T ons Unit Model No. (See Note 1) (See Note 1) Air Temp. Rise, F

27½-35 YCD/YCH360**L 350,000/250,000 283,500/202,500 10-40

27½-35 YCD/YCH360**H 600,000/425,000 486,000/344,500 25-55

40-50 YCD/YCH600**L 400,000/300,000 324,000/243,000 5-35

40-50 YCD/YCH600**H 800,000/600,000 648,000/486,000 20-50

Note:

1. Second stage is total heating capacity. Second Stage/First Stage.

YCD/YCH330**L

YCD/YCH420**L

YCD/YCH330**H

YCD/YCH420**H

YCD/YCH480**L

YCD/YCH480**H

Heat Input MBH Heating Output MBH

RT-PRC007-EN22

Page 23

P erformance

Data

Table PD-12 — Supply Fan Perfor mance — 27½ - 35 T on

SCFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

8000 341 1.39 401 1.85 451 2.30 501 2.84 552 3.45 599 4.11 644 4.80 686 5.51 726 6.24

8500 355 1.60 412 2.08 462 2.58 508 3.09 556 3.71 602 4.38 646 5.09 688 5.83 728 6.59

9000 368 1.84 423 2.35 473 2.88 516 3.39 561 4.00 606 4.68 649 5.41 691 6.16 730 6.94

9500 382 2.10 435 2.64 484 3.20 526 3.73 568 4.32 611 5.00 653 5.74 694 6.51 732 7.31

10000 396 2.39 448 2.96 495 3.53 537 4.12 576 4.69 616 5.36 657 6.11 697 6.89 735 7.71

10500 41 0 2.71 461 3.31 506 3.89 549 4.53 585 5.10 623 5.76 662 6.50 701 7.30 738 8.13

11000 425 3.07 474 3.68 518 4.29 560 4.95 597 5.57 631 6.20 668 6.93 705 7.73 74 2 8.58

11500 440 3.46 488 4.08 530 4.72 571 5.39 608 6.08 641 6.71 676 7.41 711 8.20 747 9.06

12000 455 3.89 501 4.52 542 5.19 582 5.86 619 6.60 652 7.27 684 7.95 718 8.73 752 9.57

12500 470 4.34 515 4.98 555 5.69 593 6.38 630 7.13 664 7 .87 694 8.55 726 9.30 758 10.14

13000 485 4.84 528 5.47 569 6.23 605 6.94 641 7 .69 675 8.49 706 9.21 734 9.93 765 10.76

13500 501 5.36 542 6.00 582 6.79 617 7.54 652 8.29 686 9.12 717 9.91 745 10.65 77 4 11 .43

14000 516 5.91 555 6.58 595 7.40 630 8.18 664 8.95 697 9.78 729 10.64 757 1 1.42 784 12.19

14500 532 6.51 570 7.20 609 8.04 643 8.85 676 9.65 708 10.48 740 1 1.38 768 12.22 795 13.02

Notes:

1. Fan performance table includes internal resistances of cabinet, and 2” standard filters. For other components refer to component static pressure drop table. Add the

pressure drops from any additional components to the duct (external) static pressure, enter the table, and select motor bhp.

2. The pressure drop from the supply fan to the space cannot exceed 2.25”.

3. Maximum air flow for 27½ ton — 12,100 cfm, 30 ton — 13,200 cfm, 35 ton — 14,400 cfm.

4. Maximum motor horsepower for 27½ ton — 10 hp, 30 ton — 10 hp, 35 ton — 15 hp.

0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25

Static Pressure (in. wg)

1

Figure PD-2

4.2

800 rpm

0% wocfm

3.8

3.4

3.0

750 rpm

700 rpm

650 rpm

10 HP

15 HP

50% wocfm

60% wocfm

2.6

600 rpm

2.2

550 rpm

7.5 HP

70% wocfm

1.8

500 rpm

1.4

STATIC PRESSURE, in. H2O

450 rpm

3 HP

5 HP

80% wocfm

1.0

400 rpm

0.6

90% wocfm

0.2

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000 22000 24000

CFM

23RT -PRC007 -EN

Page 24

P erformance

Data

Table PD-13 — Supply Fan Perfor mance — 40 and 50 T on

0.25 0.50 0.75 1 .00 1.25 1 .50 1.75 2.00 2.25 2.50

Static Pressure (in. wg)

SCFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

12000 365 3.02 408 3.66 448 4.32 485 4.99 522 5.70 556 6.44 588 7 .20 620 7.96 652 8.75 682 9.56

13000 388 3.73 427 4.40 468 5.13 501 5.84 536 6.57 569 7.34 601 8.15 631 8.96 660 9.80 690 10.66

14000 412 4.54 448 5.26 486 6.03 520 6.80 551 7.57 584 8.36 615 9.21 643 10.06 672 10.96 699 11.86

15000 436 5.46 471 6.25 505 7.04 540 7.89 569 8.70 599 9.54 629 10.40 658 11 .31 685 12.21 711 13.15

16000 460 6.53 493 7.36 525 8.17 559 9.08 588 9.96 615 10.83 643 11.73 672 12.66 699 13.60 724 14.58

17000 485 7.72 516 8.59 546 9.46 577 10.39 608 1 1.36 634 12.28 659 13.20 687 14.17 713 15.15 739 16.16

18000 509 9.06 540 9.97 568 10.91 596 11.84 627 12.88 654 13.86 678 14.84 702 15.83 728 16.85 753 17.88

19000 534 10.54 563 11.50 590 12.49 617 13.45 645 14.51 674 15.60 697 16.64 719 17.64 743 18.71 768 19.79

20000 560 12.18 587 13.18 613 14.24 638 15.25 664 16.31 692 17.45 717 18.57 739 19.66 760 20.74 783 21.85

Notes:

1. Fan performance table includes internal resistances of cabinet, and 2” standard filters. For other components refer to component static pressure drop table. Add the

pressure drops from any additional components to the duct (external) static pressure, enter the table, and select motor bhp.

2. The pressure drop from the supply fan to the space cannot exceed 2.50”.

3. Maximum air flow for 40 ton — 17,600 cfm, 50 ton — 20,000 cfm.

4. Maximum motor horsepower for 40 ton — 15 hp, 50 ton — 20 hp.

1

Figure PD-3

4.0

3.5

3.0

2.5

7

6

5

600 RPM

8

0

7

0

0

0

R

0 R

5

0

R

P

M

P

M

PM

R

P

M

M

F

C

O

W

%

0

4

M

F

C

O

W

%

0

5

M

F

C

O

W

%

0

6

M

F

C

O

W

%

0

7

5

5

0

2.0

Static Presure in. H2O

1.5

1.0

0.5

0.0

R

P

M

5

0

0

R

P

M

4

5

0

R

P

M

4

0

0

R

P

M

0 2000 4000 6000 8000 10000 1200 0 14000 16000 18 000 20000 22000 24 000 26000 28000

7

CFM

1

0

H

.

5

H

P

1

5

P

2

0

H

H

P

P

M

F

C

O

W

%

0

8

M

F

C

O

W

%

0

9

RT-PRC007-EN24

Page 25

P erformance

Data

Table PD-14 — Component Static Pressure Drops (in. W.G.)

Nominal CFM Gas Heat Electric Heat

T ons Std Air Low High 1 Element 2 Element Adder 2” 4” Vanes Economizer

27½ 10000 0.13 0.10 0.08 0.09 0.00 0.06 0.05 0.08 0.05

30 11 000 0.15 0.12 0.10 0.11 0.00 0.08 0.05 0.10 0.06

35 12500 0.20 0.15 0.13 0.14 0.14 0.10 0.07 0.13 0.08

40 15000 0.02 0.05 0.13 0.20 0.00 0.14 0.10 0.06 0.10

50 17000 0.02 0.07 0.17 0.26 0.15 0.18 0.13 0.08 0.12

Notes:

1. Static pressure drops of accessory components must be added to external static pressure to enter fan selection tables.

2. Throwaway filter option limited to 300 ft/min face velocity.

3. Electric Heaters 36-54 KW contain 1 element; 72-108 KW 2 elements.

8000 0.08 0.06 0.05 0.06 0.00 0.04 0.03 0.05 0.04

9000 0.10 0.08 0.07 0.07 0.00 0.05 0.04 0.07 0.04

11000 0.15 0.12 0.10 0.11 0.00 0.08 0.05 0.10 0.06

12000 0.18 0.14 0.12 0.13 0.00 0.09 0.07 0.12 0.07

9000 0.10 0.08 0.07 0.07 0.00 0.05 0.04 0.07 0.04

10000 0.13 0.10 0.08 0.09 0.00 0.06 0.05 0.08 0.05

12000 0.18 0.14 0.12 0.13 0.00 0.09 0.07 0.12 0.07

13000 0.21 0.16 0.14 0.15 0.00 0.1 1 0.08 0.14 0.09

10500 0.14 0.11 0.09 0.10 0.1 1 0.07 0.05 0.09 0.06

11500 0.17 0.13 0.11 0.12 0.12 0.08 0.06 0.11 0.07

13500 0.23 0.18 0.15 0.16 0.16 0.11 0.08 0.15 0.10

14500 0.26 0.20 0.18 0.19 0.18 0.13 0.10 0.18 0.11

12000 0.01 0.03 0.08 0.13 0.00 0.09 0.07 0.04 0.07

13000 0.01 0.04 0.10 0.15 0.00 0.11 0.08 0.05 0.08

14000 0.02 0.05 0.11 0.18 0.00 0.12 0.09 0.05 0.09

16000 0.02 0.06 0.15 0.23 0.00 0.16 0.12 0.07 0.11

17000 0.02 0.07 0.17 0.26 0.00 0.18 0.13 0.08 0.12

15000 0.02 0.05 0.13 0.20 0.12 0.14 0.10 0.06 0.10

16000 0.02 0.06 0.15 0.23 0.13 0.16 0.12 0.07 0.11

18000 0.03 0.08 0.19 0.29 0.16 0.20 0.15 0.09 0.14

19000 0.03 0.08 0.21 0.32 0.18 0.23 0.16 0.10 0.16

20000 0.03 0.09 0.23 0.36 0.19 0.25 0.18 0.11 0.18

Heating System Filters

1

3

ID Coil High Eff. Filters Inlet Guide

2

25RT -PRC007 -EN

Page 26

P erformance

Data

Table PD-15 — Supply Air Fan Dr iv e Selections

Nominal Drive Drive Drive Drive

T ons RPM No RPM No RPM No RPM No

27½T 650 C

30T 650 C

35T 700 700 D

40T 625 625 L

50T 625 625 L

Note:

*For YC gas/electrics only.

**For TC and TE Cooling only and with electric heat units only.

7.5 HP 10 HP 15 HP 20 HP

550 A

600 B

700 700 D

750 750* E

550 A

600 B

700 700 D

750 750 E

600 B

650 650 C

790 790** F

800 800* G

500 500 H

525 525 J

575 575 K

675 675 M

725 725 N

525 525 J

575 575 K

675 675 M

725 725 N

RT-PRC007-EN26

Page 27

P erformance

Data

Table PD-16— Power Exhaust F an P erfor mance

Exhaust External Static Pressure — Inches of Water

Airflow High Speed Med Speed Low Speed

(Cfm) ESP ESP ESP

3500 0.900 — —

4000 0.860 — —

4500 0.820 — —

5000 0.780 — 0.400

5500 0.745 — 0.380

6000 0.700 — 0.360

6500 0.660 — 0.330

7000 0.610 0.400 0.300

7500 0.560 0.365 0.260

8000 0.505 0.330 0.215

8500 0.445 0.300 0.170

9000 0.385 0.255 0.120

9500 0.320 0.210 0.070

10000 0.255 0.165 0.020

10500 0.190 0.125 —

11000 0.125 0.060 —

11500 0.065 0.000 —

Notes:

1. Performance in table is with both motors operating.

2. High speed = both motors on high speed. Medium speed is one motor on high speed and one on low speed.

3. Power Exhaust option is not to be applied on systems that have more return air static pressure drop than the

12000 0.005 — —

Low speed is both motors on low speed.

maximum shown in the table for each motor speed tap.

27RT -PRC007 -EN

Page 28

Controls

V AV Units Only

Sequence of Operation

1

Supply Air Pressure Control

Inlet Guide Vane Control

Inlet guide vanes are driven by a

modulating 2-10 vdc signal from the VAV

Module. A pressure transducer

measures duct static pressure, and the

inlet guide vanes are modulated to

maintain the supply air static pressure

within an adjustable user -defined range.

The range is determined by the supply

air pressure setpoint and supply air

pressure deadband, which are set

through a unit mounted potentiometer.

Inlet guide vane assemblies installed on

the supply fan inlets regulate fan

capacity and limit horsepower at lower

system air requirements. When in an y

position other than full open, the vanes

pre-spin intake air in the same direction

as supply fan rotation. As the vanes

approach the full-closed position, the

amount of “spin” induced by the vanes

increases at the same time that intake

airflow and fan horsepower diminish.

The inlet guide vanes will close when the

supply fan is shut down.

Supply Air Static Pressur e Limit

The opening of the inlet guide vanes and

VAV boxes are coordinated, with respect

to time, during unit start up and

transition to/from Occupied/Unoccupied

modes to prevent overpressurization of

the supply air ductwork. However, if for

any reason the supply air pressure

exceeds the fixed supply air static

pressure limit of 3.5” W .C., the supply

fan is shut down and the inlet guide

vanes are closed. The unit is then

allowed to restart four times. If the

overpressurization condition occurs on

the fifth time, the unit is shut down and a

manual reset diagnostic is set and

displayed at any of the remote panels

with LED status lights or communicated

to the Integrated Comfort system.

V ar iable F requency Dr iv es (VFD) Contr ol

V ariable frequency drives are driven by a

modulating 0-10 vdc signal from the VAV

module. A pressure transducer

measures duct static pressure, and the

VFD is modulated to maintain the supply

air static pressure within an adjustable

user -defined range. The range is

determined by the supply air pressure

setpoint and supply air pressure

deadband, which are set through a unit

mounted potentiometer. Variable

frequency drives provide supply fan

motor speed modulation. The drive will

accelerate or decelerate as required to

maintain the supply static pressure

setpoint. When subjected to high

ambient return conditions the VFD shall

reduce its output frequency to maintain

operation. Bypass control is offered to

provide full nominal airflow in the event

of drive failure.

2

Supply Air Temperatur e Controls

Cooling/Economizer

During occupied cooling mode of

operation, the economizer (if available)

and primary cooling are used to control

the supply air temperature. The supply

air temperature setpoint is user -defined

at the unit mounted VAV Setpoint Panel

or at the remote panel. If the enthalpy of