Page 1

Installation

Operation

Maintenance

Series R Air-Cooled Helical Rotary

Liquid Chillers

Preliminary

© American Standard Inc. 2006

Models

RTAC 140-500 ton units (60 Hz)

RTAC 140-400 ton units (50 Hz)

January 2006 RTAC-SVX01F-EN

Page 2

NOTICE: Warnings and Cautions appear at appropriate sections throughout this literature. Read these carefully.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

CAUTION: Indicates a situation that may result in equipment or propertydamage only accidents.

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can

affect the earth’s naturally occurring stratospheric ozone layer when

released to the atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants that contain

Chlorine, Fluorine and Carbon (CFCs) and those containing Hydrogen,

Chlorine, Fluorine and Carbon (HCFCs). Not all refrigerants containing

these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants—including

industry replacements for CFCs such as and HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the

environment, our customers, and the air conditioning industry. All

technicians who handle refrigerants must be certified. The Federal Clean

Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the

equipment that is used in these service procedures. In addition, some

states or municipalities may have additional requirements that must

also be adhered to for responsible management of refrigerants. Know

the applicable laws and follow them.

WARNING

Contains Refrigerant!

System contains oil and refrigerant under high pressure. Recover

refrigerant to relieve pressure before opening the system. See unit

nameplate for refrigerant type. Do not use non-approved refrigerants,

refrigerant substitutes, or refrigerant additives.

Failure to follow proper procedures or the use of non-approved

refrigerants, refrigerant substitutes, or refrigerant additives could result

in death or serious injury or equipment damage.

2 RTAC-SVX01F-EN

Page 3

Table of Contents

General Information ............................................................................................. 7

Literature History.................................................................................................... 7

Unit Identification - Nameplates ............................................................................. 7

Unit Inspection ....................................................................................................... 8

Inspection Checklist ............................................................................................... 8

Loose Parts Inventory ............................................................................................ 8

Unit Description...................................................................................................... 8

Installation - Mechanical..................................................................................... 28

Installation Responsibilities ................................................................................... 28

Nameplates ........................................................................................................... 28

Outdoor Unit Nameplate ....................................................................................... 28

Compressor Nameplate ........................................................................................ 28

Storage .................................................................................................................. 29

General .................................................................................................................. 29

Location Requirements ......................................................................................... 29

Setting the Unit ..................................................................................................... 29

Isolation and Sound Emission ............................................................................... 36

Noise Considerations ............................................................................................ 37

Foundation............................................................................................................. 38

Clearances ............................................................................................................. 38

Unit Isolation and Leveling .................................................................................... 41

Neoprene Isolator Installation................................................................................ 41

Drainage ................................................................................................................ 41

Evaporator Water Piping........................................................................................ 41

Evaporator Piping .................................................................................................. 41

Entering Chilled Water Piping................................................................................ 42

Leaving Chilled Water Piping................................................................................. 42

Evaporator Drain .................................................................................................... 42

Evaporator Flow Switch......................................................................................... 42

Evaporator Water Pressure Drop RTAC 140 - 250 Ton ......................................... 43

Evaporator Water Pressure Drop RTAC 250 - 500 Ton ......................................... 44

Water Pressure Gauges ........................................................................................ 45

Water Pressure Relief Valves ................................................................................ 46

Freeze Protection .................................................................................................. 46

Low Evaporator Refrigerant Cutout and % Glycol Recommendations ................. 46

Procedure .............................................................................................................. 46

Important ............................................................................................................... 47

Specials ................................................................................................................. 47

Installation - Mechanical

Remote Evaporator Option ................................................................................ 49

Line Sizing ............................................................................................................. 53

Liquid Line Sizing Steps ........................................................................................ 54

Example Liquid Line Sizing .................................................................................... 55

Suction Line Sizing Steps ...................................................................................... 56

Example Suction Line Sizing.................................................................................. 56

Suction Accumulator Sizing ................................................................................... 57

Example of Suction Accumulator Line Sizing ........................................................ 57

Piping Installation Procedures ............................................................................... 57

Refrigerant Sensors............................................................................................... 58

Refrigerant Pressure Relief Valve Venting............................................................. 58

RTAC-SVX01F-EN 3

Page 4

Table of Contents

Leak Test and Evacuation ..................................................................................... 58

Refrigerant and Additional Oil Charge .................................................................. 60

Refrigerant Charge Determination........................................................................ 60

Oil Charge Determination ..................................................................................... 61

Installation - Electrical........................................................................................ 62

General Recommendations .................................................................................. 62

Installer-Supplied Components............................................................................. 75

Power Supply Wiring ............................................................................................ 75

Control Power Supply ........................................................................................... 76

Heater Power Supply and Convenience Outlet (Packaged Units Only) ................ 76

Water Pump Power Supply .................................................................................. 77

Interconnecting Wiring ......................................................................................... 77

Chilled Water Flow (Pump) Interlock .................................................................... 77

Chilled Water Pump Control ................................................................................. 77

Alarm and Status Relay Outputs (Programmable Relays)..................................... 78

Relay Assignments Using TechView.................................................................... 79

Low Voltage Wiring .............................................................................................. 79

Emergency Stop ................................................................................................... 79

External Auto/Stop................................................................................................ 80

External Circuit Lockout – Circuit #1 and Circuit #2.............................................. 80

Ice Building Option ............................................................................................... 80

External Chilled Water Setpoint (ECWS) Option................................................... 81

External Current Limit Setpoint (ECLS) Option..................................................... 81

Chilled Water Reset (CWR) .................................................................................. 82

Communications Interface options....................................................................... 84

Optional Tracer Communications Interface .......................................................... 84

LonTalk Communications Interface for Chillers (LCI-C) ........................................ 84

Operating Principles ........................................................................................... 86

Refrigeration Cycle ............................................................................................... 86

Refrigerant R134a................................................................................................. 88

Compressor .......................................................................................................... 88

Condenser and Subcooler .................................................................................... 88

Expansion Valve.................................................................................................... 89

Evaporator ............................................................................................................ 89

Oil System ............................................................................................................ 89

Controls Interface ............................................................................................... 91

CH530 Communications Overview ...................................................................... 91

Controls Interface ................................................................................................. 91

DynaView Interface .............................................................................................. 91

Key Functions ....................................................................................................... 92

Radio Buttons ....................................................................................................... 92

Spin Value Buttons ............................................................................................... 92

Action Buttons ...................................................................................................... 92

Hot Links .............................................................................................................. 92

File Folder Tabs .................................................................................................... 92

Display Screens .................................................................................................... 93

Basic Screen Format ............................................................................................ 93

Front Panel Lockout Feature ................................................................................ 94

Front Panel Display During Cold Ambients........................................................... 94

4 RTAC-SVX01F-EN

Page 5

Table of Contents

Modes Screen ....................................................................................................... 95

Chiller Screen ....................................................................................................... 101

Compressor Screen.............................................................................................. 101

Refrigerant Screen ............................................................................................... 102

Setpoint Screen .................................................................................................... 103

Diagnostic Screen ................................................................................................ 104

Power-Up ............................................................................................................. 105

Display Formats.................................................................................................... 105

Units ..................................................................................................................... 105

Languages ............................................................................................................ 105

TechView ............................................................................................................ 106

Minimum PC requirements to install and operate TechView ............................... 107

Unit View .............................................................................................................. 107

Compressor Service View .................................................................................... 109

Status View .......................................................................................................... 110

Setpoint View ....................................................................................................... 113

Diagnostics View .................................................................................................. 117

Software View ...................................................................................................... 122

Binding View ........................................................................................................ 123

Replacing or Adding Devices................................................................................ 124

Software Download.............................................................................................. 124

Instructions for First Time TechView Users ......................................................... 124

Diagnostics ......................................................................................................... 126

Legend to Diagnostics Table ................................................................................ 126

Pre-Start Checkout ............................................................................................. 137

Installation Checklist............................................................................................. 137

Receiving .............................................................................................................. 137

Unit Location and Mounting ................................................................................. 137

Unit Piping ............................................................................................................ 137

Electrical Wiring.................................................................................................... 138

General ................................................................................................................. 139

Unit Voltage Power Supply................................................................................... 140

Unit Voltage Imbalance ........................................................................................ 141

Unit Voltage Phasing ............................................................................................ 141

Water System Flow Rates.................................................................................... 142

Water System Pressure Drop............................................................................... 142

CH530 Set-Up ...................................................................................................... 143

Unit Start-Up Procedures .................................................................................. 144

Daily Unit Start-Up ................................................................................................ 144

General ................................................................................................................. 144

Seasonal Unit Start-Up Procedure ........................................................................ 145

System Restart After Extended Shutdown .......................................................... 146

Unit Shutdown Procedures ............................................................................... 147

Temporary Shutdown And Restart ....................................................................... 147

Extended Shutdown Procedure ........................................................................... 147

RTAC-SVX01F-EN 5

Page 6

Table of Contents

Periodic Maintenance........................................................................................ 149

Weekly Maintenance ........................................................................................... 149

Maintenance Procedures .................................................................................. 155

Refrigerant and Oil Charge Management ............................................................ 155

R134a Field Charging Procedure ......................................................................... 156

Factory (initial) Refrigerant Charging Procedure .................................................. 156

Field Refrigerant Charging Procedure .................................................................. 156

Adding charge:..................................................................................................... 157

Charge Isolation in the high or low side of system.............................................. 157

High side charge isolation procedure: ................................................................. 157

Returning unit to running condition: .................................................................... 158

Low side charge isolation procedure: .................................................................. 158

Refrigerant Filter Replacement Procedure .......................................................... 159

Lubrication System .............................................................................................. 159

Oil Charging Procedure........................................................................................ 159

Factory (initial) Oil Charging Procedure................................................................ 161

Evaporator tube replacement .............................................................................. 163

Compressor Replacement ................................................................................... 163

Unit Wiring ......................................................................................................... 165

6 RTAC-SVX01F-EN

Page 7

General Information

Literature History

RTAC-SVX001-EN (December 2000)

New manual.

RTAC-SVX01B-EN (September 2001)

New manual describes installation, operation, and maintenance of RTAC units and the

remote evaporator option.

RTAC-SVX01C-EN (February 2002)

Revised manual includes additional RTAC units to size 500 tons, new installation and

maintenance material, and expanded CH530 diagnostics.

RTAC-SVX01D-EN (July 2003)

Revised manual for new evaporator design for 2 compressor units. Design Sequence

H0 and later.

RTAC-SVX01E-EN (July 2004)

Revised manual for new evaporator design for 3 and 4 compressor units. Design

Sequence J0 and later.

RTAC-SVX01F-EN (January 2006)

Revised manual for new control panel design.

Unit Identification - Nameplates

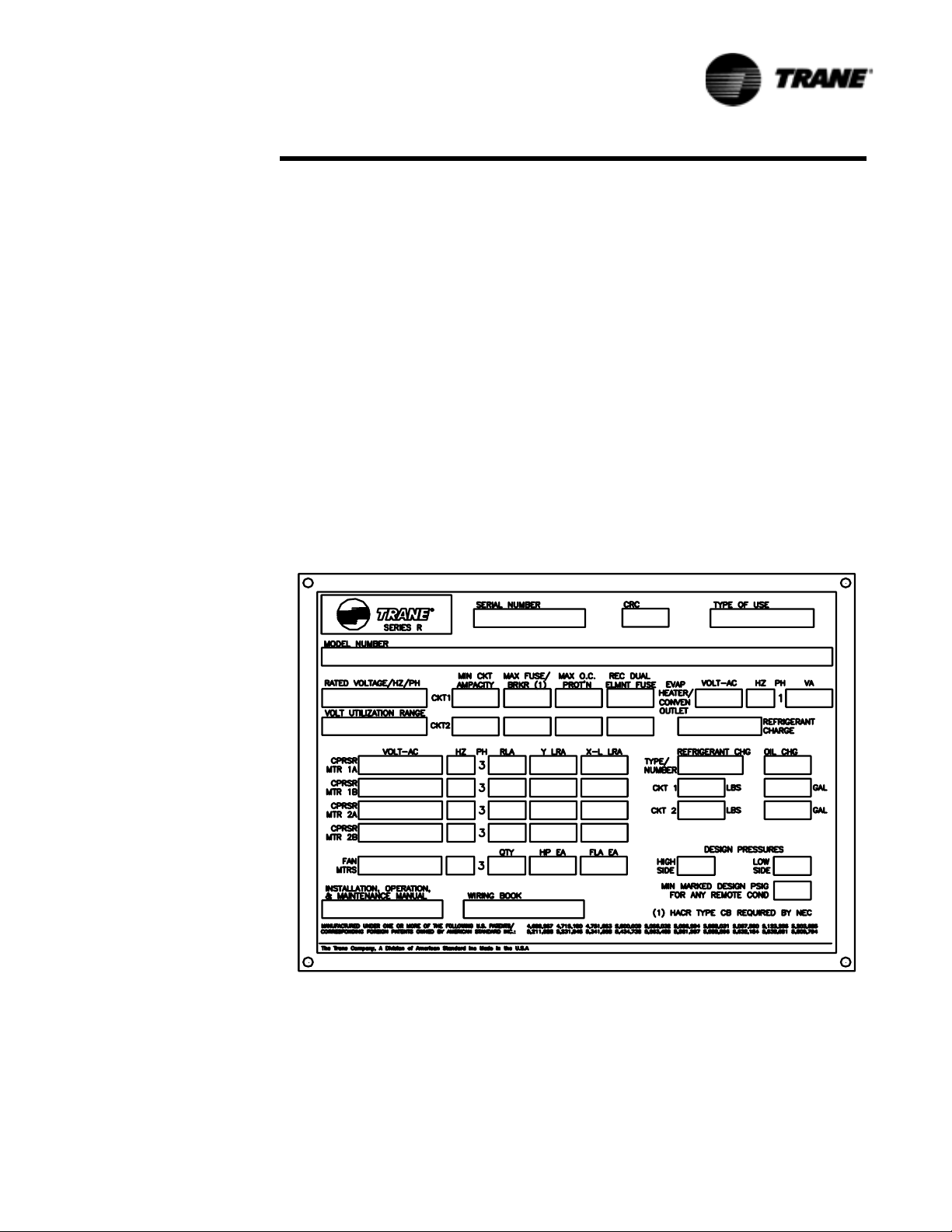

When the unit arrives, compare all nameplate data with ordering, submittal, and shipping information. A typical unit nameplate is shown in Figure 1.

Figure 1 Typical Unit Nameplate

RTAC-SVX01F-EN 7

Page 8

General information

Unit Inspection

When the unit is delivered, verify that it is the correct unit and that it is properly

equipped. Compare the information which appears on the unit nameplate with the

ordering and submittal information.

Inspect all exterior components for visible damage. Report any apparent damage or

material shortage to the carrier and make a “unit damage” notation on the carrier’s

delivery receipt. Specify the extent and type of damage found and notify the appropri

ate Trane Sales Office. Do not proceed with installation of a damaged unit without

sales office approval.

Inspection Checklist

To protect against loss due to damage incurred in transit, complete the following

checklist upon receipt of the unit.

• Inspect the individual pieces of the shipment before accepting the unit. Check for

obvious damage to the unit or packing material.

• Inspect the unit for concealed damage as soon as possible after delivery and

before it is stored. Concealed damage must be reported within 15 days.

• If concealed damage is discovered, stop unpacking the shipment. Do not remove

damaged material from the receiving location. Take photos of the damage, if pos

sible. The owner must provide reasonable evidence that the damage did not

occur after delivery.

• Notify the carrier’s terminal of the damage immediately, by phone and by mail.

Request an immediate, joint inspection of the damage with the carrier and the

consignee.

• Notify the Trane sales representative and arrange for repair. Do not repair the unit,

however, until damage is inspected by the carrier’s representative.

-

-

Loose Parts Inventory

Check all the accessories and loose parts which are shipped with the unit against the

shipping list. Included in these items will be water vessel drain plugs, rigging and

electrical diagrams, and service literature, which are placed inside the control panel

and/or starter panel for shipment.

Unit Description

The 140 - 500 ton Model RTAC units are helical-rotary type, air-cooled liquid chillers

designed for installation outdoors. The compressor circuits are completely assem

bled, hermetic packages that are factory-piped, wired, leak-tested, dehydrated, and

tested for proper control operation before shipment.

NOTE: Packaged units are factory charged with refrigerant and oil.

Figure 2 shows a typical RTAC packaged unit and its components.

Table 1 through Table 5 contain general RTAC mechanical specifications for all unit

sizes.

-

8 RTAC-SVX01F-EN

Page 9

General Information

.

Figure 2 Typical RTAC Unit

Chilled water inlet and outlet openings are covered for shipment. Each compressor

has a separate compressor motor starter. The RTAC series features Trane’s exclusive

Adaptive Control ™ logic, which monitors the control variables that govern the opera

tion of the chiller unit. Adaptive Control logic can adjust capacity variables to avoid

chiller shutdown when necessary, and keep producing chilled water. The units feature

two independent refrigerant circuits. Compressor unloaders are solenoid actuated

and oil pressure operated. Each refrigerant circuit is provided with filter, sight glass,

electronic expansion valve, and charging valves. The shell-and-tube type evaporator is

manufactured in accordance with ASME standards or other international codes. Each

evaporator is fully insulated and is equipped with water drain and vent connections.

Packaged units have heat tape protection to - 20°F (-28.9°C) as standard. As an

option, a convenience outlet can be supplied.

RTAC-SVX01F-EN 9

-

Page 10

General information

Table 1 General Data — 140-250 Ton 60 Hz Units - Standard Efficiency

Size 140 155 170 185 200 225 250

Type STD STD STD STD STD STD STD

Compressor

Quantity 2 2 2 2 2 2 2

Nominal

Size

Water Storage (gallons) 29 32 33 35 39 38 42

Min. Flow (gpm) 193 214 202 217 241 217 241

Max. Flow (gpm) 709 785 741 796 883 796 883

Quantity of Coils 4 4 4 4 4 4 4

Coil Length (inches) 156/156 180/156 180/180 216/180 216/216 252/216 252/252

Coil Height (inches) 42 42 42 42 42 42 42

Fins/Ft 192 192 192 192 192 192 192

Number of Rows 3 3 3 3 3 3 3

Quantity 4/4 5/4 5/5 6/5 6/6 7/6 7/7

Diameter (inches) 30 30 30 30 30 30 30

Total Airflow (cfm) 77000 84542 92087 101296 110506 119725 128946

Nominal Fan

Speed

Tip Speed (ft/min) 8954 8954 8954 8954 8954 8954 8954

Std Unit (Deg F) 25 25 25 25 25 25 25

Low Ambient (Deg F) 0.0 0.0 0.0 0.0 0,0 0.0 0.0

Refrigerant HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a

No. of Independent

Refrigerant Circuits

% Min . lo ad 15 15 15 15 15 15 15

Refrigerant

Charge

Oil Charge (gallons) 1.5/1.5 1.5/1.5 1.5/1.5 2.1/1.5 2.1/2.1 2.1/2.1 2.1/2.1

Base Length (feet) 15 15 15 18 18 21 21

1. Data containing information on two circuits shown as follows: CKT1/CKT 2.

2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser.

(tons) 70/70 85/70 85/85 100/85 100/100 120/100 120/120

Evaporator

(liters) 111 121 127 134 146 145 158

(l/sec) 12 14 13 14 15 14 15

(l/sec) 45 50 47 50 56 50 56

Condenser

(mm) 3962/3962 4572/3962 4572/4572 5486/4572 5486/5486 6401/5486 6401/6401

(mm) 1067 1067 1067 1067 1067 1067 1067

Condenser Fans

(m m) 762 762 762 762 76 2 76 2 762

3

(m

/hr) 130811 143623 156441 172086 187732 203394 219059

(rpm ) 1140 1140 1140 1140 1140 1140 1140

(rps) 19 19 19 19 19 19 19

(m/s) 45 45 45 45 45 45 45

Min Starting/Operating Ambient

(Deg C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

(Deg C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

General Unit

22 22222

(lb) 165/165 175/165 175/175 215/210 215/215 225/215 225/225

(kg) 75/75 79/75 79/79 98/95 98/98 102/98 102/102

(liters) 6/6 6/6 6/6 8/6 8/8 8/8 8/8

10 RTAC-SVX01F-EN

Page 11

General Information

Table 2 General Data — 275- 500 Ton 60 Hz Units - Standard Efficiency

Size 275 300 350 400 450 500

Type STD STD STD STD STD STD

Compressor

Quantity 3 3 3 4 4 4

Nominal

Size

Water Storage (gallons) 60 65 70 81 84 89

Min. Flow (gpm) 309 339 375 404 422 461

Max. Flow (gpm) 1134 1243 1374 1483 1548 1690

Quantity of Coils 8 8 8 8 8 8

Coil Length (inches) 180/108 216/108 252/108 216/216 252/216 252/252

Coil Height (inches) 42 42 42 42 42 42

Fins/Ft 192 192 192 192 192 192

Number of Rows 3 3 3 3 3 3

Quantity 10/6 12/6 14/6 12/12 14/12 14/14

Diameter (inches) 30 30 30 30 30 30

Total Airflow (cfm) 147340 165766 184151 221016 239456 257991

Nominal Fan Speed (rpm) 1140 1140 1140 1140 1140 1140

Tip Speed (ft/min) 8954 8954 8954 8954 8954 8954

Std Unit (Deg F) 25 25 25 25 25 25

Low Ambient (Deg F) 0.0 0.0 0.0 0.0 0.0 0.0

Refrigerant HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a

No. of Independent

Refrigerant Circuits

% Min. load 15 15 15 15 15 15

Refrigerant Charge (lb) 365/200 415/200 460/200 415/415 460/415 460/460

Oil Charge (gallons) 4.6/2.1 5.0/2.1 5.0/2.1 5.0/5.0 5.0/5.0 5.0/5.0

Base Length (feet) 30 36 36 39 45 45

1. Data containing information on two circuits shown as follows: CKT1/CKT 2.

2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser.

(tons) 85/85

100

100 /100

100

120/12 0

100

100/10 0

100/10 0

120/120

100 /100

120/120

120/120

Evaporator

(liters) 229 245 264 306 316 337

(l/sec) 20 21 24 26 27 29

(l/sec) 72 78 87 94 98 107

Condenser

(mm) 4572/2743 5486/2743 6401/4572 5486/5486 6401/5486 6401/6401

(mm) 1067 1067 1067 1067 1067 1067

Condenser Fans

(mm) 762 762 762 762 762 762

3

(m

/hr) 250307 281610 312843 375471 406797 438285

(rps) 19 19 19 19 19 19

(m/s) 45 45 45 45 45 45

Min Starting/Oper Ambient

(Deg C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

(Deg C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

General Unit

222222

(kg) 166/91 188/91 209/91 188/188 209/188 209/209

(liters) 17.4/8 19/8 19/8 19/19 19/19 19/19

RTAC-SVX01F-EN 11

Page 12

General information

Table 3 General Data — 140-400 Ton 60 Hz Units - High Efficiency

Size 140 155 170 185 200 225 250 275 300 350 400

Type HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH

Compressor

Quantity 22222223344

Nominal

Size

Water

Storage

Min. Flow (gpm) 202 217 241 217 241 241 241 375 375 404 461

Max. Flow (gpm) 741 796 883 796 883 883 883 1374 1374 1483 1690

Quantity of

Coils

Coil Length (inches) 180/180 216/180 216/216 252/216 252//252 144/144 180/108 216/144 252/144 216/216 252/252

Coil Height (inches)4242424242424242424242

Fins/Ft 192 192 192 192 192 192 192 192 192 192 192

Number of Rows33333333333

Quantity 5/5 6/5 6/6 7/6 7/7 8/6 8/8 12/6 14/6 12/12 14/14

Diameter (inches)3030303030303030303030

To ta l

Airflow

Nominal

Fan Speed

Tip Speed (ft/min) 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954 8954

Std Unit (Deg F) 25 25 25 25 25 25 25 25 25 25 25

Low

Ambient

Refrigerant HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a

No. of Independent

Refrigerant Circuits

% Min . lo ad 15 15 15 15 15 15 15 15 15 15 15

Refrigerant

Charge

Oil Charge (gallons) 1.5/1.5 1.5/1.5 1.5/1.5 2.1/1.5 2.1/2.1 2.1/2.1 2.1/2.1 4.6/2.2 5.0/2.2 4.6/4.6 5.0/5.0

Base

Length

1. Data containing information on two circuits shown as follows: CKT 1/CKT 2

2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser

(tons) 70/70 85/70 85/85 100/85 100/100 120/100 120/120 85/85

100

100/10 0

100

85/85

85/85

100/10 0

100/10 0

Evaporator

(gallons)3335393842424270708189

(liters) 127 134 146 145 158 158 158 264 264 306 337

(l/sec)1314151415151524242629

(l/sec) 47 50 56 50 56 56 56 87 87 94 107

Condenser

44444888888

(mm) 4572/

4572

(mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

5486/

4572

5486/

5486

6401/

5486

6401/

6401

3658/

3658

4572/

2743

5486/

3658

6401/

3658

5486/

5486

6401/

6401

Condenser Fans

(m m) 762 76 2 762 762 762 762 762 762 762 76 2 762

(cfm) 91993 101190 110387 119598 128812 136958 147242 173733 192098 220778 257626

3

(m

/hr) 156281 171906 187530 203178 218831 232670 250141 295145 326344 375066 437665

(rpm ) 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140 1140

(rps)1919191919191919191919

(m/s)4545454545454545454545

Min Starting/Oper Ambient

(Deg C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

(Deg F) 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

(Deg C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

General Unit

22222222222

(lb) 175/175 215/205 215/215 225/215 225/225 235/235 235/235 415/200 460/200 415/415 460/460

(kg) 79/79 98/93 98/98 102/98 102/102 107/107 107/107 188/91 209/91 188/188 209/209

(liters) 6/6 6/6 6/6 8/6 8/8 8/8 8/8 17/8 19/8 17/17 19/19

(feet) 15 18 18 21 21 30 30 36 39 39 45

12 RTAC-SVX01F-EN

Page 13

General Information

Table 4 General Data - 120-400 Ton 50 Hz Units-Standard Efficiency

Size 140 155 170 185 200 250 275 300 350 375 400

Type STD STD STD STD STD STD STD STD STD STD STD

Compressor

Quantity 22222333444

Nominal

Size

(tons) 70/70 85/70 85/85 100/85 100/100 70-70/100 85-85/100 100-100/

100

85-85/85-85100-10 0/

85-85

100-10 0/

100-10 0

Evaporator

Water

Storage

Min. Flow (gpm) 192 221 200 215 239 262 307 336 384 377 401

Max. Flow (gpm) 702 778 735 789 875 962 1124 1232 1275 1383 1470

(gallons)29 32 33 35 38 546064737780

(liters) 110 120 126 133 145 203 227 243 275 291 304

(l/sec)1213131415171921222425

(l/sec) 44 49 46 50 55 61 72 78 80 87 93

Condenser

Quantity of

Coils

Coil Length (inches) 156/156 180/156 180/180 216/180 216/216 156/108 180/108 216/108 180/180 216/180 252/216

(mm) 3962/

Coil Height (inches) 42 42 42 42 42 42 42 42 42 42 42

(mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

Fins/Ft 192 192 192 192 192 192 192 192 192 192 192

Number of Rows33333333333

44444888888

3962

4512/

3962

4572/

4512

5486/

4572

5486/

5486

3962/

4512

4572/

2743

5486/

2743

4572/

4572

5486/

4572

6401/

5486

Condenser Fans

Quantity 4/4 5/4 5/5 6/5 6/6 8/6 10/6 12/6 10/10 12/10 12/12

Diameter (inches) 30 30 30 30 30 30 30 30 30 30 30

(m m) 76 2 762 762 76 2 762 76 2 762 762 76 2 762 76 2

To t al

Airflow

Nominal

Fan Speed

Tip Speed (ft/min) 7461 7461 7461 7461 7461 7461 7461 7451 7461 7461 7461

(cfm) 63346 69507 75671 83236 90803 108698 121056 136210 151332 166467 181611

3

/hr) 107615 118081 128553 141405 154260 184661 205655 231399 257089 282801 308528

(m

(rpm) 950 950 950 950 950 950 950 950 950 950 950

(rps) 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8

(m/s)38 38 38 38 38 383838383838

Min Starting/Oper Ambient

Std Unit (Deg F) 25 25 25 25 25 25 25 25 25 25 25

(Deg C) -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9 -3.9

Low

Ambient

(Deg F)00000000000

(Deg C) -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8 -17.8

General Unit

Refrigerant HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a

No. of Independent

Refrigerant Circuits

% Min. load 15 15 15 15 15 15 15 15 15 15 15

Refrigerant

Charge

Oil

Charge

Base

Length

1. Data containing information on two circuits shown as follows: CKT 1/CKT 2

2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser

(lb) 165/165 175/165 175/175 215/210 215/215 335/200 365/200 415/200 365/365 415/365 415/415

(kg) 75/75 79/75 79/79 98/95 98/98 152/91 166/91 188/91 166/166 188/166 188/188

(gallons) 1.5/1.5 1.5/1.5 1.5/1.5 2.1/1.5 2.1/2.1 4.6/2.1 4.6/2.1 5.0/2.1 4.6/4.6 5.0/4.6 5.0/5.0

(liters) 6/6 6/6 6/6 8/6 8/8 17.4/8 17.4/8 19.0/8 17.4/17.4 19.0/17.4 19.0/19.0

(feet)15 15 15 18 18 303036393939

22222222222

RTAC-SVX01F-EN 13

Page 14

General information

Table 5 General Data - 120-400 Ton 50 Hz Units-High Efficiency

Size 140 155 170 185 200 250 275 300 350 375 400

Type HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH HIGH

Compressor

Quantity 2 2 2 2 2 3 3 3 4 4 4

Nominal Size (tons) 7 0/70 85/70 85/8 5 100/85 100/100 70-70/

100

Evaporator

Water

Storage

Min. Flow (gpm) 200 215 239 215 239 336 371 371 401 419 457

Max. Flow (gpm) 735 789 875 789 875 1232 1362 1362 1470 1535 1675

(gallons)33 353838416469 6980 83 89

(liters) 126 133 145 145 157 243 262 262 304 314 335

(l/sec) 13 14 15 14 15 21 23 23 25 26 29

(l/sec) 46 50 55 50 55 78 86 86 93 97 106

Condenser

Qty of Coils 4 444488 88 8 8

Coil Length (inches) 180/180 216/180 216/216 252/216 252/252 180/108 216/144 252/144 216/216 252/216 252/252

(mm) 4572/

Coil Height (inches) 42 42 42 42 42 42 42 42 42 42 42

(mm) 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067 1067

Fins/Ft 192 192 192 192 192 192 192 192 192 192 192

Number of Rows 3 3 3 3 3 3 3 3 3 3 3

4572

5486/

4572

5486/

5486

6401/

5486

6401/

6401

4572/

2743

Condenser Fans

Quantity 5/5 6/5 6/6 7/6 7/7 10/6 12/6 14/6 12/12 14/12 14/14

Diameter in. (mm) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762) 30 (762)

Total Airflow (cfm) 75575 83130 90687 98256 105826 120971 142969 158112 181371 194731 211648

Nominal Fan

Speed

Tip Speed (ft/min) 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461 7461

3

/hr) 128390 141225 154063 166921 179781 205510 242881 268607 308120 330817 359556

(m

(rpm) 950 950 950 950 950 950 950 950 950 950 950

(rps) 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8

(m/s) 38 38 38 38 38 38 38 38 38 38 38

Min Starting/Oper Ambient

Std Unit Deg F

Low

Ambient

(C)

Deg F

(C)

25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9) 25 (-3.9)

0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8) 0 (-17.8)

General Unit

Refrigerant HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a HFC-134a

No. of Independent

Refrigerant Circuits

% Min. load 15 15 15 15 15 15 15 15 15 15 15

Refrigerant

Charge

Oil Charge (gallons) 1.5/1.5 1.5/1.5 1.5/1.5 2.1/1.5 2.1/2.1 4.6/2.1 4.6/2.1 5.0/2.1 4.6/4.6 5.0/5.0 5.0/5.0

Base Length (feet) 15 18 18 21 21 30 36 39 39 45 45

1. Data containing information on two circuits shown as follows CKT 1/CKT 2

2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser

(lb) 175/175 215/205 215/215 225/215 225/225 365/200 415/200 460/200 415/415 460/415 460/460

(kg) 79/79 98/93 98/98 102/98 102/102 166/91 188/91 209/91 188/188 209/188 209/209

(liters) 6/6 6/6 6/6 8/6 8/8 17.4/8 17.4/8 19.0/8 17.4/17.4 19.0/19.0 19.0/19.0

22222222222

85-85/

100

5486/3658 6401/

100-10 0/

100

3658

85-85/

85-85

5486/5486 6401/5486 6401/

100-10 0/

85-85

100-10 0/

100-10 0

6401

14 RTAC-SVX01F-EN

Page 15

General Information

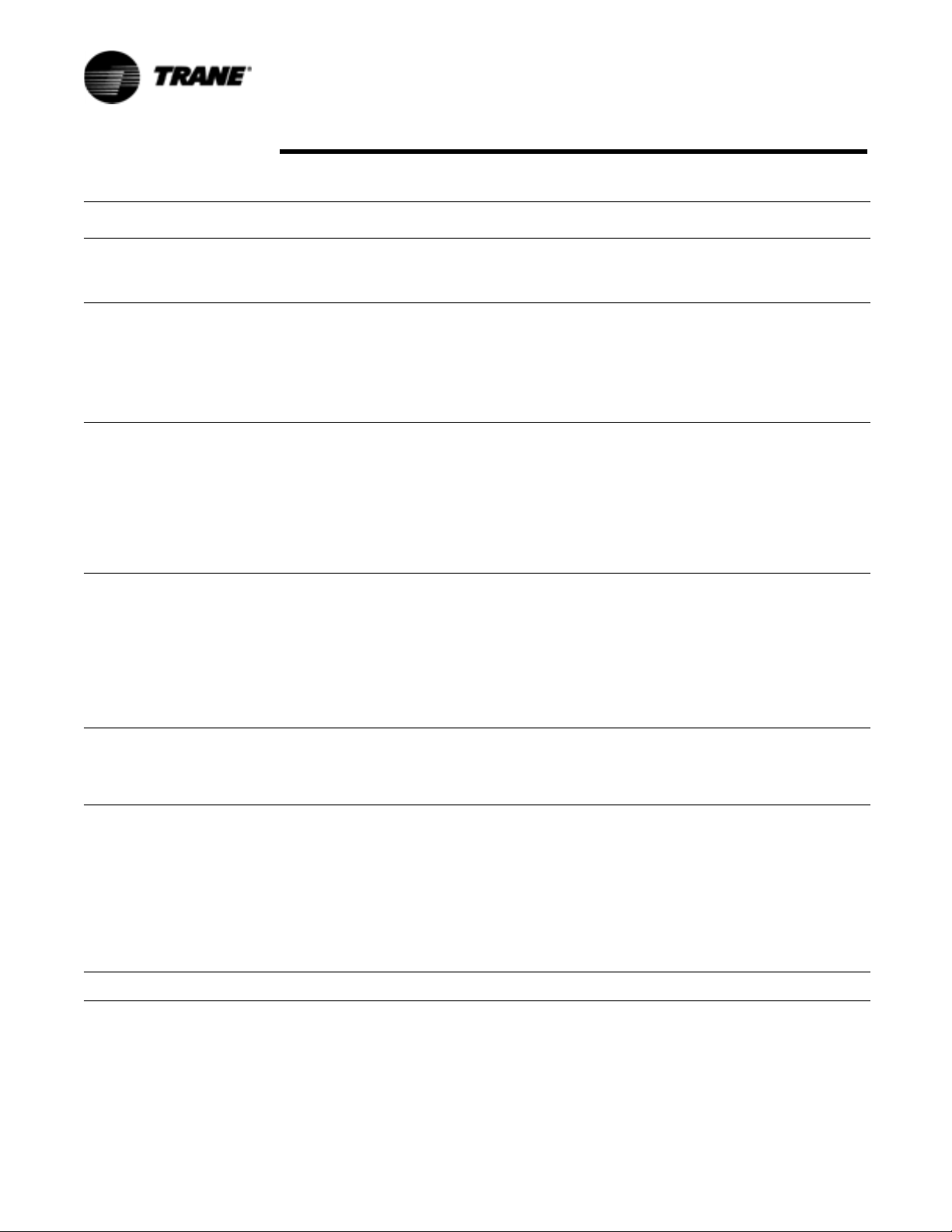

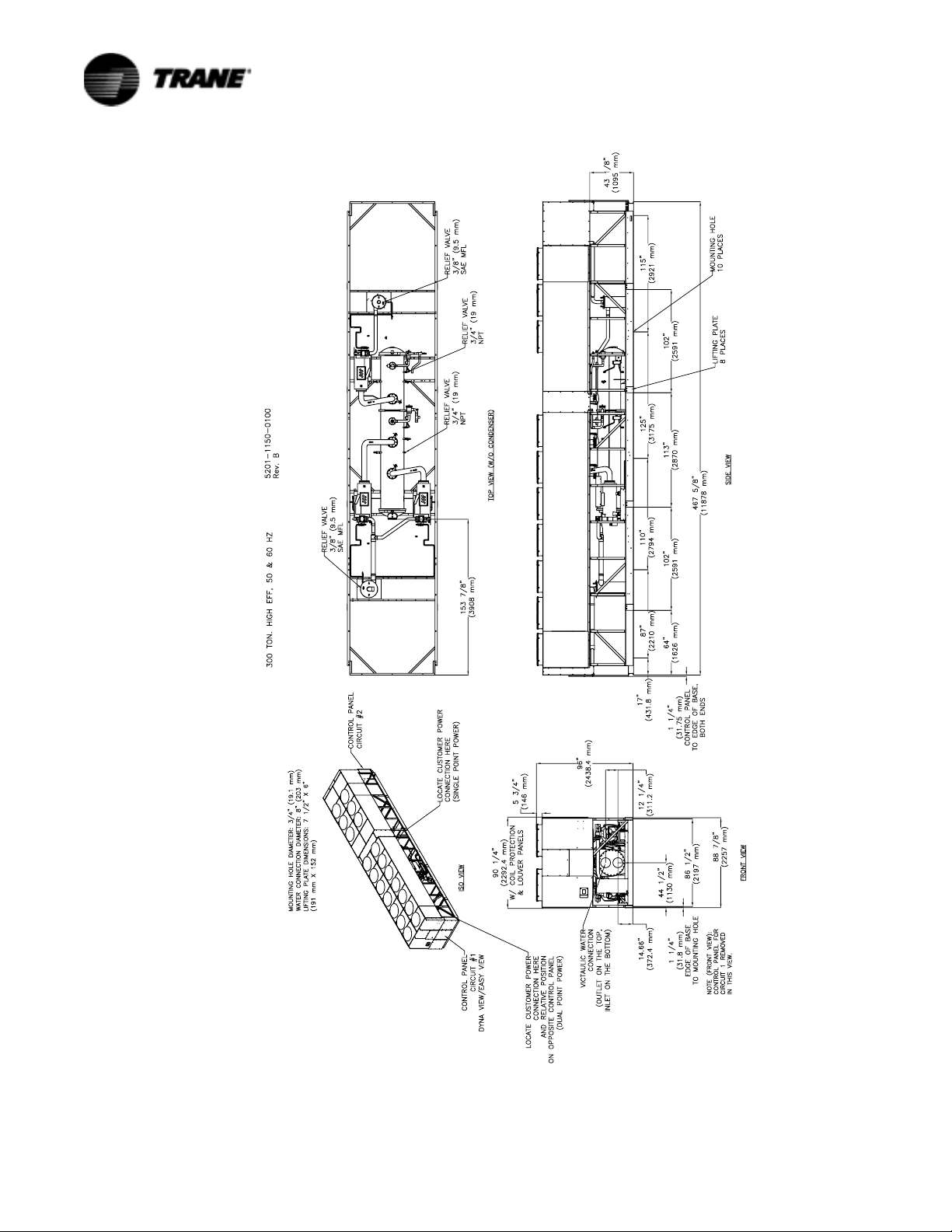

Figure 3 Unit Dimensions 185-200 Ton Standard Efficiency, 60 Hz and 155, 170 Ton, High Efficiency, 50 and 60 Hz

RTAC-SVX01F-EN 15

Page 16

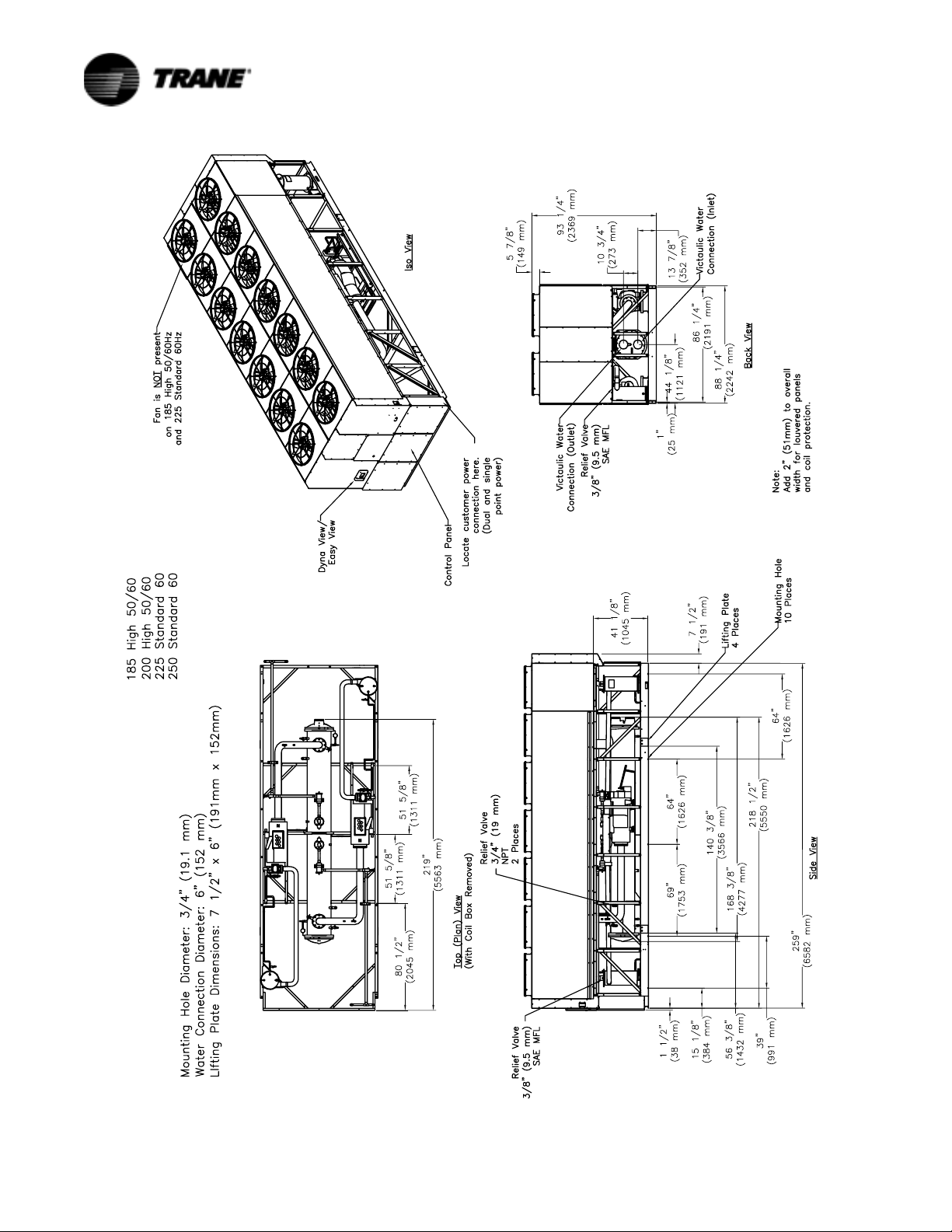

Figure 4 Unit Dimensions 225-250 Ton Standard Efficiency, 60 Hz and 185-200 Ton, High Efficiency, 50 and 60 Hz

16 RTAC-SVX01F-EN

Page 17

Figure 5 Unit Dimensions 225-250 Ton High Efficiency, 60 Hz

RTAC-SVX01F-EN 17

Page 18

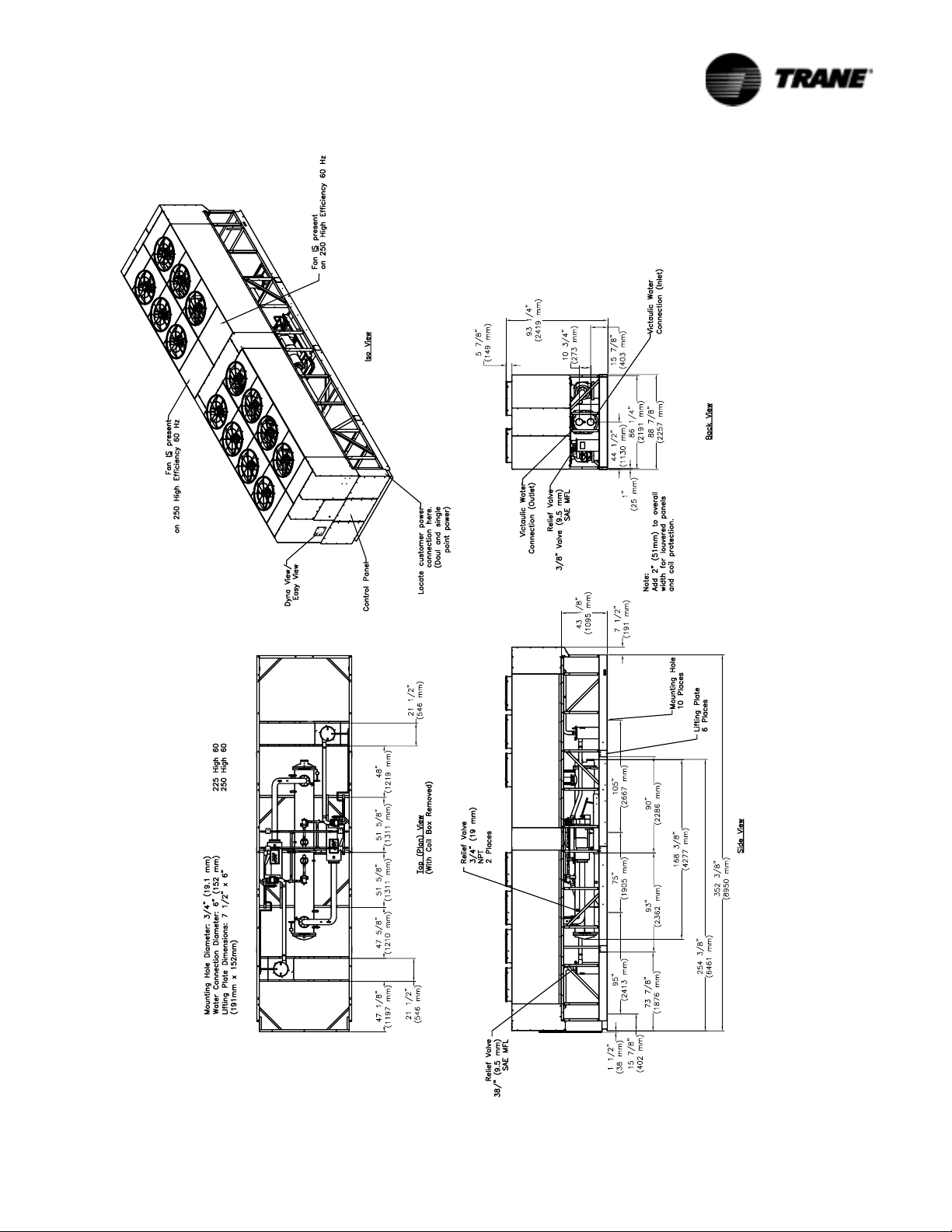

Figure 6 Unit Dimensions 250-275 Ton Standard Efficiency, 50 Hz and 250 Ton High Efficiency, 50 Hz and 275 Ton

Standard Efficiency, 60 Hz

18 RTAC-SVX01F-EN

Page 19

Figure 7 Unit Dimensions 275 Ton High Efficiency, 50 and 60 Hz; 300 Ton, Standard Efficiency, 50 and 60 Hz and 350

Ton, Standard Efficiency 60 Hz

RTAC-SVX01F-EN 19

Page 20

Figure 8 Unit Dimensions 300 Ton High Efficiency, 50 and 60 Hz

20 RTAC-SVX01F-EN

Page 21

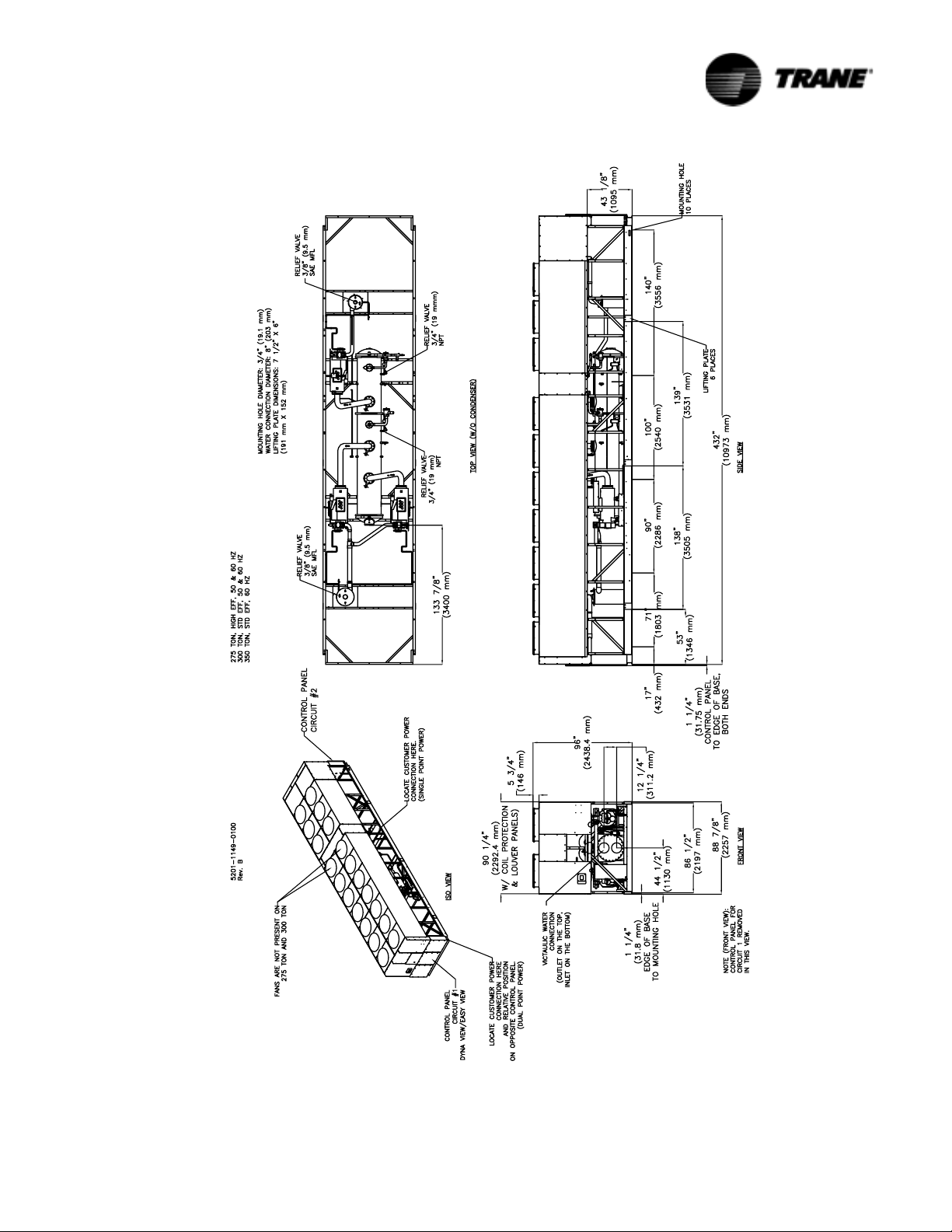

Figure 9 Unit Dimensions 350-400 Ton Standard Efficiency, Hz and 400 Ton, Standard Efficiency, 60 Hz and 350 Ton

High Efficiency, 50 and 60Hz

RTAC-SVX01F-EN 21

Page 22

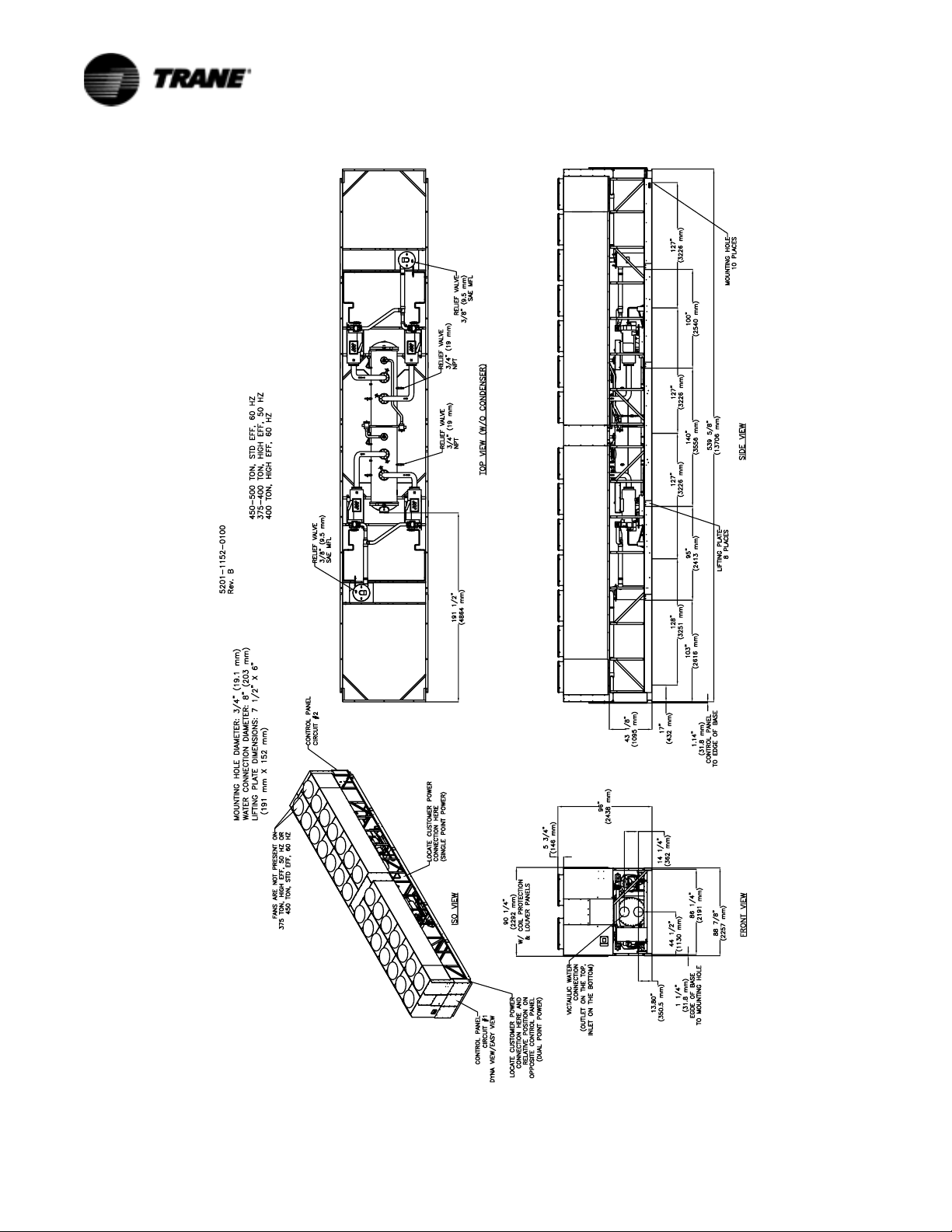

Figure 10 Unit Dimensions 450-500 Ton Standard Efficiency, 60 Hz and 375-400 Ton, High Efficiency, 50 Hz and 400 Ton

High Efficiency, 60 Hz

22 RTAC-SVX01F-EN

Page 23

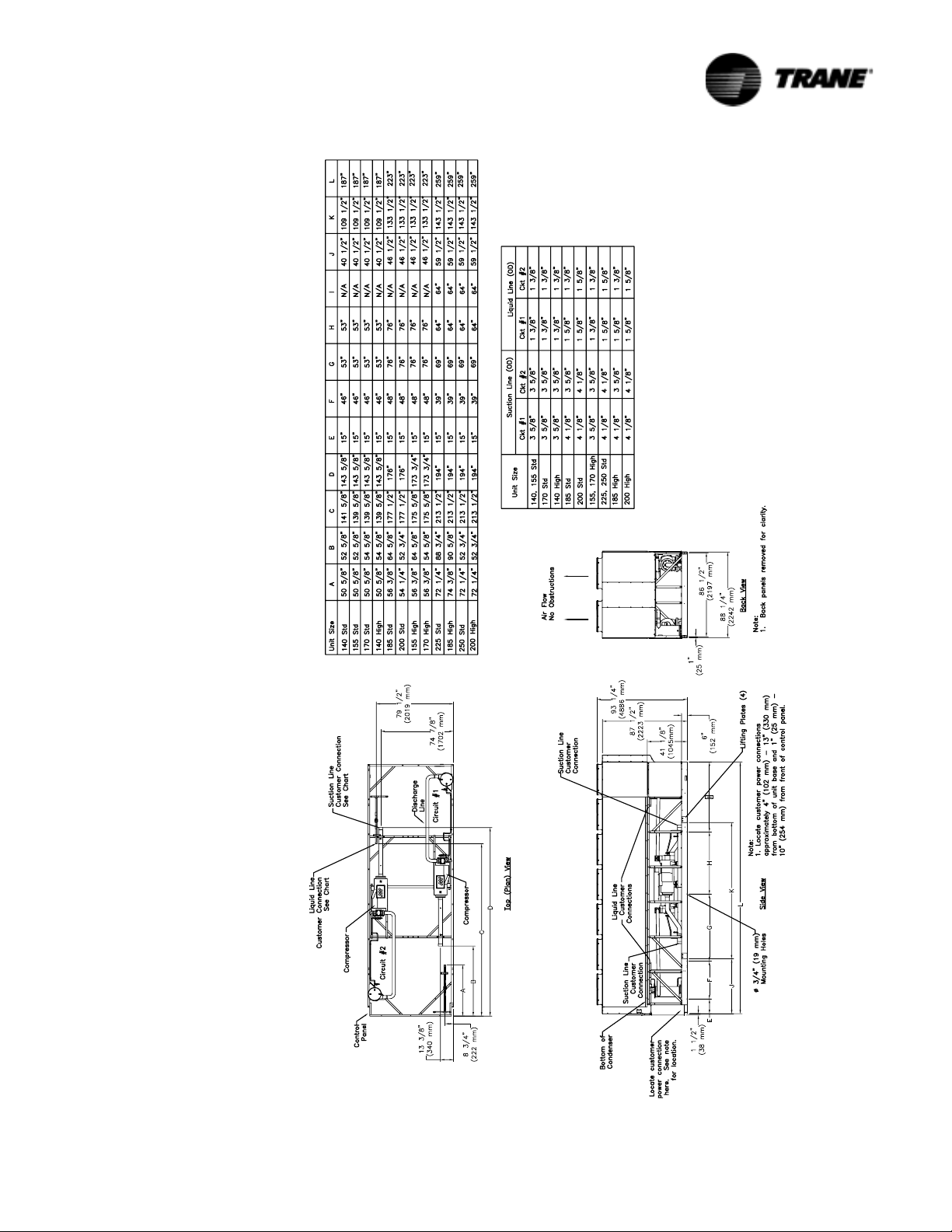

Figure 11 Unit Dimensions of Condenser/Compressor Unit for Remote Evaporator Option

RTAC-SVX01F-EN 23

Page 24

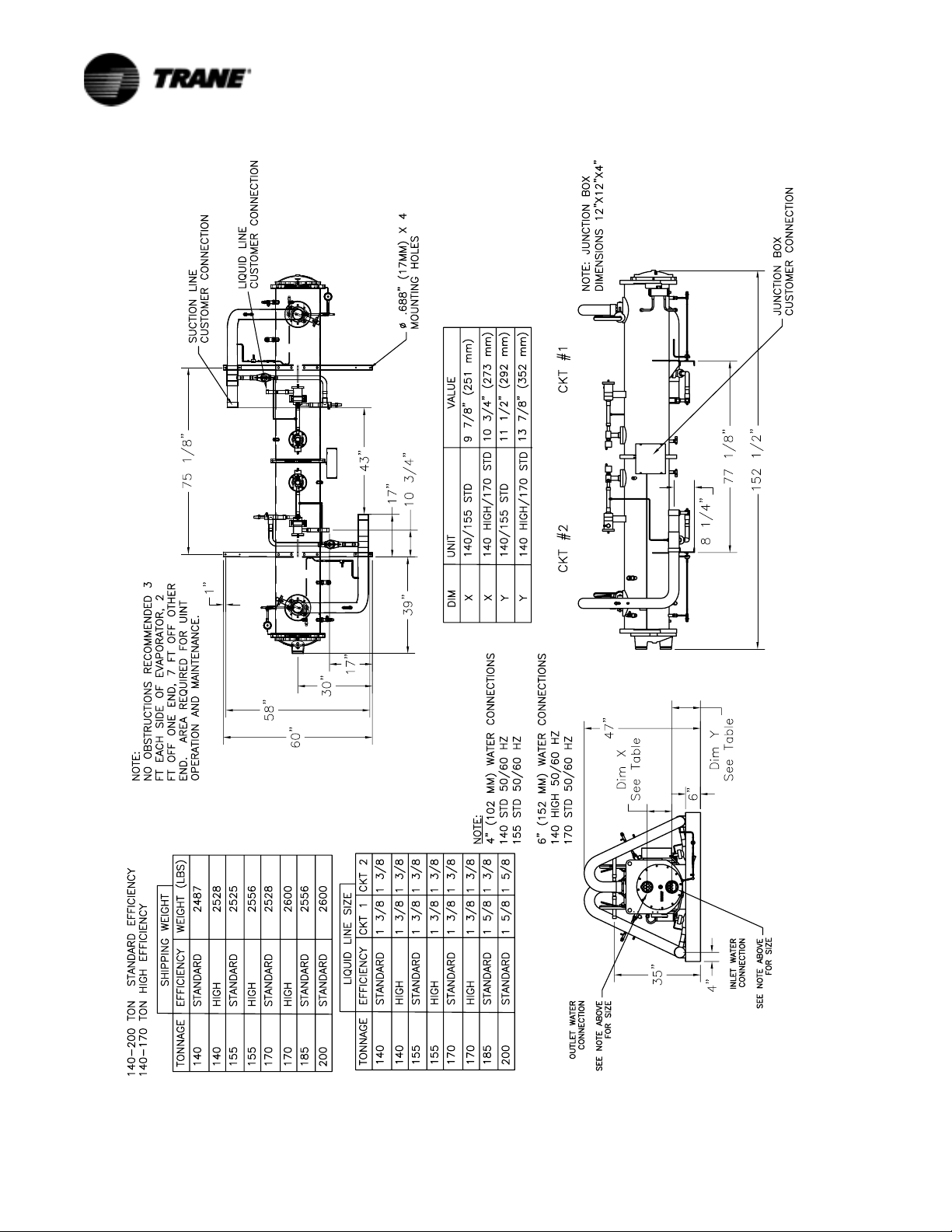

Figure 12 Unit Dimensions for Remote Evaporator 140-170 Ton Standard Efficiency and 140 Ton High Efficiency

24 RTAC-SVX01F-EN

Page 25

Figure 13 Unit Dimensions for Remote Evaporator185-250 Ton Standard Efficiency and 155-200 Ton High Efficiency

RTAC-SVX01F-EN 25

Page 26

Model Number Coding System

The model numbers for the unit and the starter are composed of numbers and letters

that represent features of the equipment. Shown in the following table is a sample of

typical unit model number and the coding system for each.

Each position, or group of positions, in the model number is used to represent a feature. For example, in the first table, position 08 of the unit model number, Unit Voltage, contains the number “4”. A 4 in this position means that the unit voltage is 460/

60/3.

Unit Model Number

An example of a typical unit model number (M/N) is:

RTAC 350A UA0N NAFN N1NX 1TEN NN0N N01N

Model number digits are selected and assigned in accordance with the following defi-

nitions using the model number example shown above.

26 RTAC-SVX01F-EN

Page 27

Digit 1-4

Unit Model

RTAC Air Cooled Series R® chiller

Digit 5-7

Unit Nominal Capacity

140 140 Nominal Tons

155 155 Nominal Tons

170 170 Nominal Tons

185185 Nominal Tons

200 200 Nominal Tons

225 225 Nom inal Tons

250 250 Nom inal Tons

275 275 Nom inal Tons

300 300 Nominal Tons

350 350 Nom inal Tons

375 375 Nom inal Tons

400 400 Nominal Tons

450 450 Nom inal Tons

500 500 Nominal Tons

Digit 8

Unit Voltage

A 200V/60Hz/3Ph power

K 220V/50Hz/3 Ph power

C 230V/60Hz/3Ph power

J380V/60Hz/3Ph power

D 400V/50Hz/3Ph power

4 460V/60Hz/3Ph power

5 575V/60Hz/3Ph power

Digit 9

Manufacturing Location

U Pueblo

ECharmes

Digit 10-11

Design Sequence

XX Factory/ABU Assigned

Digit 12

Unit Type

N Std. Efficiency/Performance

H High Efficiency/Performance

Digit 13

Agency Listing

N No agency listing

U C/UL listing

Digit 14

Pressure Vessel Code

A ASME pressure vessel code

C Canadian code

D Australian code

L Chinese code

R Vietanamese code

S Special

Digit 15

Evaporator Temperature Range &

Application Type

F Standard Temp. with Frz Prot

RRem Evap, Std. Temp, No Frz

Prot

G Low Temp, with Frz Prot

Digit 16

Evaporator Configuration

N Standard pass arrangement,

insulated

Digit 17

Condenser Temperature Range

N Standard ambient range

25-115 deg F

H High ambient capability

25-125 deg F

LLow ambient capability

0-115 deg F

WWide ambient capability

0-125 deg F

Digit 18

Condenser Fin Material

1 Standard aluminum slit fins

2 Copper fins, non-slit fins

4Complete Coat aluminum fins

Digit 19

Condenser Fan/Motor Configuration

N Condenser fans with ODP

motors

W Low Noise fans

T Condenser fans with TEAO

motors

Digit 20

Compressor Motor Starter Type

X Across-the-line starters

Y Wye-delta closed transition

starters

Digit 21

Incoming Power Line Connection

1 Single point power connection

2 Dual point power connection (1/

ckt)

Digit 22

Power Line Connection Type

TTerminals only

D Non-fused disconnect

switch(es)

C Circuit Breaker(s), HACR-rated

Digit 23

Unit Operator Interface

E Easy-View operator interface

D Dyna-View operator interface

Digit 24

Remote Interface

N No remote interface

C Tracer Comm 3 interface

LLon Talk Communication interface

(LCI)

Digit 25

Control Input Accessories/Options

N No remote input

RRemote leaving water temp stpt

CRemote current limit setpoint

BRemote lvg. temp.setpoint and

remote current limit setpoint

Digit 26

COOP 26

Control Output Accessories/Options

N No output options

AAlarm relay

CIcemaking

DIcemaking and alarm relay

Digit 27

Short Circuit Rating

0 No short circuit withstand rating

5 10000A SCR

4 35000A SCR

6 65000A SCR

Digit 28

Electrical Accessories and Export

Packing

N No flow switches

F NEMA-1 flow switch - 150 psi

E Vapor Proof FS - 150 psi

Digit 29

Control Panel Accessories

N No convenience outlet

A 15A 115V convenience outlet

(60HZ)

Digit 30

Refrigerant Service Valves

1 Suction service valves

Digit 31

Compressor Sound Attenuator

Option

0 No sound attenuator

1 Factory installed sound attenuator

Digit 32

Appearance Options

N No appearance options

A Architectural louvered panels

CHalf Louvers

G Access guards

B Access guards and half louvers

P Painted unit

L Painted unit with full louvered

panels

H Painted unit with half louvered

panels

K Painted unit with access guards

W Painted w/access guards and half

louvers

Digit33

Installation Accessories

N No installation accessories

R Neoprene isolators

F Flanged water connection kit

G Neoprene isolators and flange

wtr conn kit

Digit 34

Factory Test

0 No factory run test

P Performance test

WWitness test

Digit 35

Label, and Literature Language

EEnglish

G Chinese

Digit 36

Special Order

X Standard catalog configuration

S Unit has special order feature

Digit 37

Safety Devices

N None

X Standard

RTAC-SVX01F-EN 27

Page 28

Installation - Mechanical

Installation Responsibilities

Generally, the contractor must do the following when installing an RTAC unit:

• Install unit on a flat foundation, level (within 1/4” [6 mm] across the length and

width of the unit), and strong enough to support unit loading.

• Install unit per the instructions contained in the Installation-Mechanical and

Installation-Electrical sections of this manual.

• Install any optional sensors and make electrical connections at the CH530.

• Where specified, provide and install valves in water piping upstream and

downstream of evaporator water connections to isolate the evaporator for

maintenance, and to balance/trim system.

• Furnish and install flow switch to prove chilled water flow.

• Furnish and install pressure gauges in inlet and outlet piping of the evaporator.

• Furnish and install a drain valve to the bottom of the evaporator waterbox.

• Supply and install a vent cock to the top of the evaporator waterbox.

• Furnish and install strainers ahead of all pumps and automatic modulating valves,

and at inlet of evaporator.

• Provide and install field wiring.

• Install heat tape and insulate the chilled water lines and any other portions of the

system, as required, to prevent sweating under normal operating conditions or

freezing during low ambient temperature conditions.

• Install evaporator drain plug. The plug ships in unit control panel.

• Start unit under supervision of a qualified service technician.

Nameplates

The RTAC outdoor unit nameplates (Figure 1) are applied to the exterior of the Control

Panel. A compressor nameplate is located on each compressor.

Outdoor Unit Nameplate

The outdoor unit nameplate provides the following information:

– Unit model and size description.

– Unit serial number.

– Identifies unit electrical requirements.

– Lists correct operating charges of R-134a and refrigerant oil (Trane OIL00048).

– Lists unit test pressures.

– Identifies installation, operation and maintenance and service data literature

(Pueblo).

– Lists drawing numbers for unit wiring diagrams (Pueblo).

Compressor Nameplate

The compressor nameplate provides following information:

– Compressor model number.

– Compressor serial number.

– Compressor electrical characteristics.

– Utilization range.

– Recommended refrigerant.

28 RTAC-SVX01F-EN

Page 29

Installation - Mechanical

Storage

Extended storage of the outdoor unit prior to installation requires the following precautionary measures:

1. Store the outdoor unit in a secure area.

2. At least every three months (quarterly), check the pressure in the refrigerant circuits to verify that the refrigerant charge is intact. If it is not, contact a qualified

service organization and the appropriate Trane sales office.

3. Close the discharge and liquid line isolation valves.

General

Report any damage incurred during handling or installation to the Trane sales office

immediately.

Location Requirements

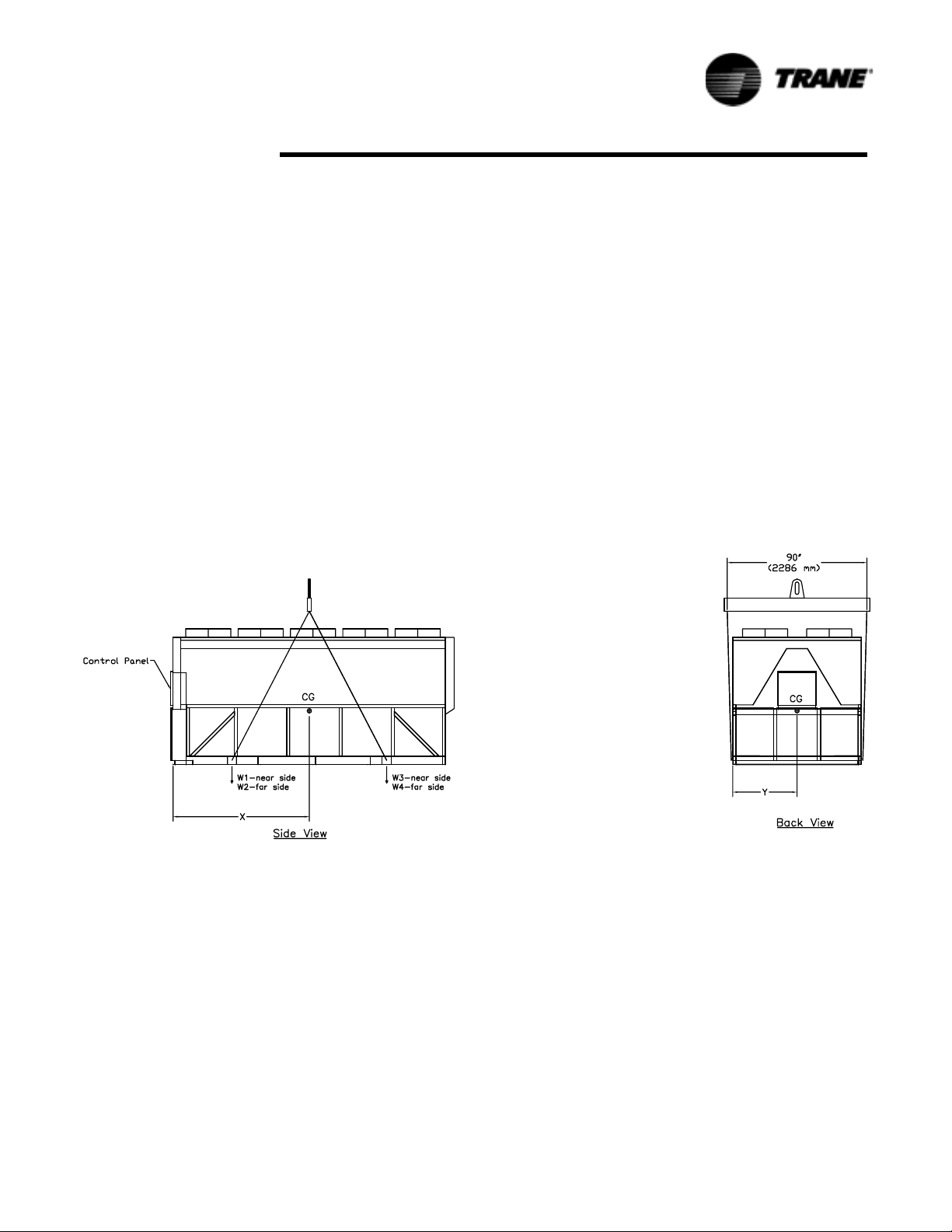

Setting the Unit

A base or foundation is not required if the selected unit location is level and strong

enough to support the unit’s operating weight as listed in

the General Information section.

See Table 6 for lifting weights and center of gravity (CG) dimensions.

Tab l e 1 through Tab l e 5 in

1. Lifting chains/cables will not

be the same length. Adjust to keep unit level while lifting.

2. Do not fork lift unit.

3. Weights are typical for units with R-134a charge.

Figure 14 Lifting the Unit (Package and Remote) 15-21-foot Base

RTAC-SVX01F-EN 29

Page 30

Installation - Mechanical

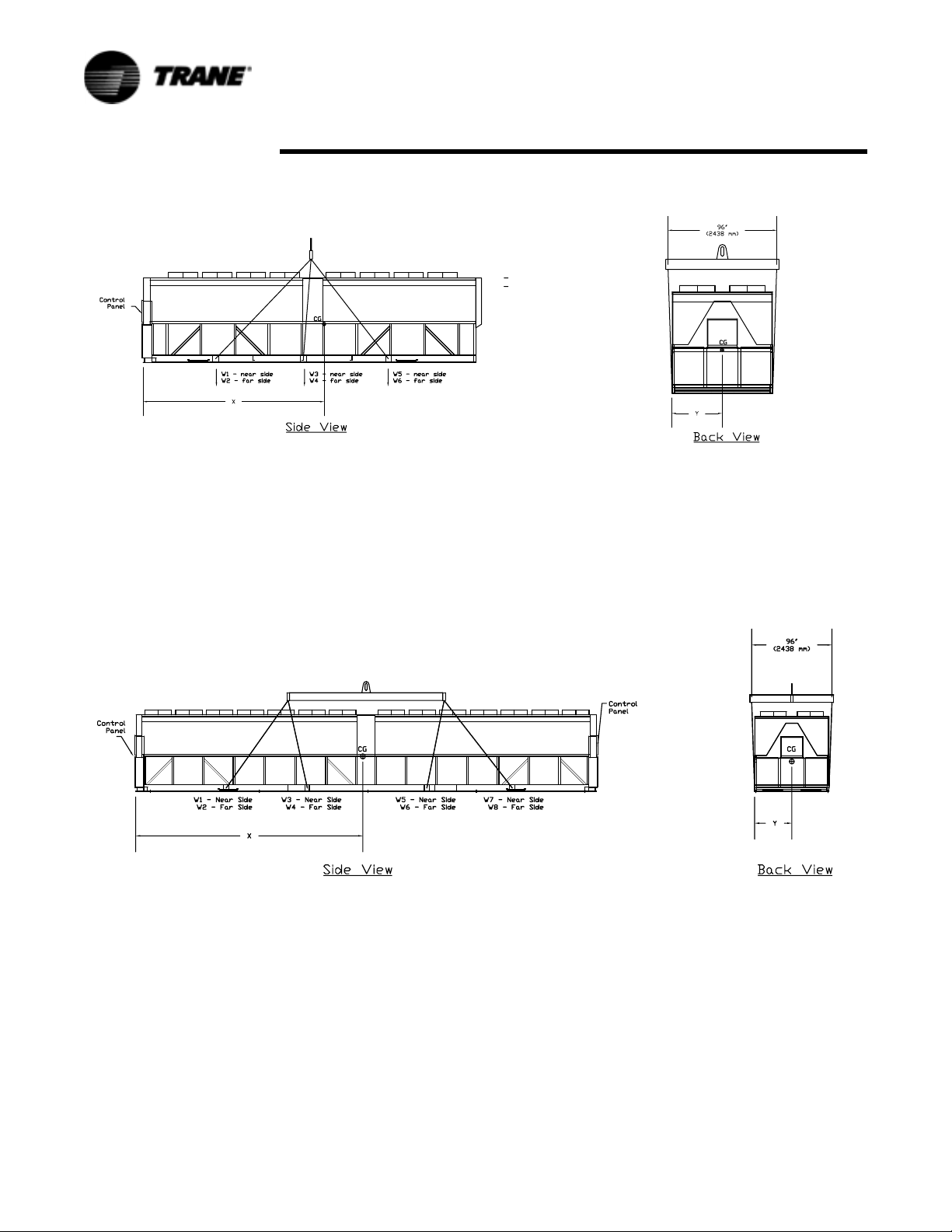

1. Lifting chains/cables will not be the same length. Adjust to

keep unit level while lifting.

2. Do not fork lift unit.

3. Weights are typical for units with R-134a charge.

Figure 15 Lifting the Unit (Package and Remote) 30-36-foot Base

1. Lifting chains/cables will not be the same length. Adjust to

keep unit level while lifting.

2. Do not fork lift unit.

3. Weights are typical for units with R-134a charge.

Figure 16 Lifting the Unit 39-45-foot Base

30 RTAC-SVX01F-EN

Page 31

Installation - Mechanical

Table 6 Lifting Weights and CG Dimensions (Refer to Figure 14 - Figure 15)

:

W1 W2 W3 W4 W5 W6 W7 W8 Shipping

Xcg Ycg

Weight

Unit

140 Ton 50 Hz High Eff 2499 2874 2686 3019 NA NA NA NA 11077 88 45

140 Ton 50 Hz Std Eff 2488 2859 2668 3000 NA NA NA NA 11015 88 45

140 Ton 60 Hz High Eff 2495 2869 2680 3013 NA NA NA NA 11057 88 45

140 Ton 60 Hz Std Eff 2484 2855 2662 2994 NA NA NA NA 10995 88 45

155 Ton 50 Hz High Eff 3281 3588 2747 3055 NA NA NA NA 12671 106 44

155 Ton 50 Hz Std Eff 2601 2882 2794 3033 NA NA NA NA 11309 88 44

155 Ton 60 Hz High Eff 3168 3562 2604 2998 NA NA NA NA 12332 106 45

155 Ton 60 Hz Std Eff 2493 2862 2675 3004 NA NA NA NA 11034 88 45

170 Ton 50 Hz High Eff 3308 3721 2760 3173 NA NA NA NA 12962 106 45

170 Ton 50 Hz Std Eff 2598 2990 2838 3177 NA NA NA NA 11603 89 45

170Ton 60 Hz High Eff 3186 3586 2623 3024 NA NA NA NA 12418 106 45

170 Ton 60 Hz Std Eff 2498 2873 2684 3018 NA NA NA NA 11073 88 45

185 Ton 50 Hz High Eff 3650 4199 3113 3662 NA NA NA NA 14624 124 45

185 Ton 50 Hz Std Eff 3342 3763 2745 3166 NA NA NA NA 13015 106 45

185 Ton 60 Hz High Eff 3526 4117 2990 3581 NA NA NA NA 14214 124 46

185 Ton 60 Hz Std Eff 3296 3635 2707 3047 NA NA NA NA 12685 106 44

200 Ton 50 Hz High Eff 3778 4252 3175 3649 NA NA NA NA 14853 124 45

200 Ton 50 Hz Std Eff 3370 3789 2828 3247 NA NA NA NA 13234 106 45

200 Ton 60 Hz High Eff 3719 4187 3110 3578 NA NA NA NA 14593 124 45

200 Ton 60 Hz Std Eff 3340 3756 2796 3212 NA NA NA NA 13104 106 45

225 Ton 60 Hz Std Eff 3711 4229 3114 3632 NA NA NA NA 14687 124 45

250 Ton 60 Hz Std Eff 3778 4252 3175 3649 NA NA NA NA 14853 124 45

250 Ton 50 Hz High Eff 3360 2930 3390 2959 3430 3000 NA NA 19069 177 41

250 Ton 50 Hz Std Eff 2951 2522 3238 2809 3430 3000 NA NA 17949 182 41

275 Ton 50 Hz High Eff 3403 2997 3689 3283 3977 3571 NA NA 20920 202 42

kg

1134 1303 1218 1369 5025 2245 1140

1128 1297 1210 1361 4996 2245 1140

1132 1301 12 16 13 67 5015 22 45 1140

1127 1295 1208 1358 4987 2243 1140

1488 1628 1246 1386 5748 2695 1123

1180 1307 1267 1376 5130 2243 1120

1437 1616 1181 1360 5594 2682 1140

1131 1298 1213 1362 5005 2245 1138

1501 1688 1252 1439 5880 2695 1140

1179 1356 1287 1441 5263 2256 1138

1445 1627 1190 1371 5633 2685 1140

1133 1303 1218 1369 5023 2245 1140

1655 1905 1412 1661 6633 3160 1153

1516 1707 1245 1436 5904 2682 1140

1600 1867 1356 1624 6447 3157 1161

1495 1649 1228 1382 5754 2680 1128

1714 1928 1440 1655 6737 3147 1140

1529 1719 1283 1473 6003 2697 1138

1687 1899 1411 1623 6619 3142 1140

1515 1704 1268 1457 5944 2697 1138

1683 1918 1413 1648 6662 3147 1148

1714 1928 1440 1655 6737 3147 1140

1526 1330 1539 1344 1557 1362 8657 4483 1052

1340 1145 1470 1275 1557 1362 8149 4623 1046

1545 1361 1675 1491 1805 1621 9498 5128 1064

lbs

lbs

kg

lbs

kg

lbs

kg

lbs

kg

Aluminum Fins

lbs

kg

lbs

kg

lbs kglbs

kg

in

mm

in

mm

RTAC-SVX01F-EN 31

Page 32

Installation - Mechanical

Table 6 Lifting Weights and CG Dimensions (Refer to Figure 14 - Figure 15)

W1 W2 W3 W4 W5 W6 W7 W8 Shipping

Xcg Ycg

Weight

Unit

275 Ton 50 Hz Std Eff 3668 3194 3478 3004 3356 2877 NA NA 19577 172 41

1665 1450 1579 1364 1524 1306 NA NA 8888 4376 1046

275 Ton 60 Hz High Eff 3251 2863 3571 3183 3894 3505 NA NA 20266 203 42

1476 1300 1621 1445 1768 1591 9201 515 9 1064

275 Ton 60 Hz Std Eff 3345 2936 3351 2942 3356 2947 NA NA 18876 176 42

1518 1333 1521 1336 1523 1338 8570 4473 1057

300 Ton 50 Hz High Eff 2955 2628 2892 2565 2822 2495 2759 2432 21548 222 42

1342 1193 1313 1164 1281 1133 1253 1104 9783 5644 1059

300 Ton 50 Hz Std Eff 3328 2917 3564 3153 3802 3393 NA NA 20314 201 42

1511 1394 1618 1431 1726 1540 9222 5100 1059

300 Ton 60 Hz High Eff 2955 2628 2892 2565 2782 2495 2759 2432 21508 222 42

1342 1193 1313 1165 1263 1133 1253 1104 9765 5641 1062

300 Ton 60 Hz Std Eff 3456 3074 3615 3233 3774 3393 NA NA 19572 199 42

1569 1396 1641 1468 1713 1540 8886 5044 1067

350 Ton 50 Hz High Eff 3278 3258 3179 3159 3075 3055 2977 2957 24936 234 44

1488 1479 1443 1434 1396 1387 1352 1342 11321 5951 1125

350 Ton 50 Hz Std Eff 3018 2998 2933 2914 2844 2824 2760 2740 23031 235 44

1370 1361 1332 1323 1291 1282 1253 1244 10456 5956 1125

350 Ton 60 Hz High Eff 3140 3123 3038 3020 2930 2912 2828 2811 23803 234 44

1426 1418 1379 1371 1330 1322 1284 1276 10806 5941 1125

350 Ton 60 Hz Std Eff 3374 2998 3772 3367 4172 3767 NA NA 21450 205 42

1532 1361 1712 1529 1894 1710 9738 5197 1064

375 Ton 50 Hz High Eff 3393 3372 3278 3257 3108 3086 2986 2965 25444 266 44

1541 1531 1488 1478 1411 1401 1356 1346 11552 6754 1125

375 Ton 50 Hz Std Eff 3328 3296 3116 3083 2892 2859 2681 2649 23903 229 44

1511 1496 1414 1400 1313 1298 1217 1202 10852 5827 1123

400 Ton 50 Hz High Eff 3345 3271 3377 3303 3425 3350 3458 3384 26912 274 44

1519 1485 1533 1499 1555 1521 1570 1536 12218 6957 1115

400 Ton 50 Hz Std Eff 3299 3279 3201 3180 3098 3077 3001 2939 25073 234 44

1498 1488 1453 1444 1406 1397 1362 1334 11383 5951 1125

400 Ton 60 Hz High Eff 3345 3271 3377 3303 3425 3350 3458 3384 26913 274 44

1519 1485 1533 1500 1555 1521 1570 1536 12219 6955 1118

400 Ton 60 Hz Std Eff 3299 3279 3201 3180 3098 3077 3001 2939 25074 234 44

1498 1489 1453 1444 1406 1397 1362 1334 11383 5951 1125

450 Ton 60 Hz Std Eff 3423 3402 3307 3286 3137 3116 3015 2994 25678 266 44

1554 1544 1501 1492 1424 1414 1369 1359 11658 6754 1125

500 Ton 60 Hz Std Eff 3363 3289 3395 3321 3442 3368 3476 3402 27056 274 44

1527 1493 1541 1508 1563 1529 1578 1544 12283 6955 1115

140 Ton 50 Hz High Eff 2972 3464 3410 3805 NA NA NA NA 13651 90 45

1348 1571 1547 1726 6192 2289 1140

140 Ton 50 Hz Std Eff 2961 3450 3392 3786 NA NA NA NA 13589 90 45

1343 1565 1539 1717 6164 2286 1140

140 Ton 60 Hz High Eff 2969 3460 3404 3799 NA NA NA NA 13631 90 45

1347 1569 1544 1723 6183 2289 1140

140 Ton 60 Hz Std Eff 2957 3445 3386 3780 NA NA NA NA 13569 90 45

1341 1563 1536 1715 6155 2286 1140

155 Ton 50 Hz High Eff 4027 4454 3591 4018 NA NA NA NA 16091 108 44

1827 2020 1629 1823 7299 2743 1128

155 Ton 50 Hz Std Eff 3074 3472 3518 3819 NA NA NA NA 13883 90 44

1394 1575 1596 1732 6297 2286 1125

155 Ton 60 Hz High Eff 3915 4428 3448 3961 NA NA NA NA 15752 108 45

1776 2009 1564 1797 7145 2736 1140

kg

lbs kglbs

lbs

kg

lbs

kg

Copper Fins

lbs

kg

lbs

kg

lbs kglbs

kg

lbs

kg

in

mm

in

mm

32 RTAC-SVX01F-EN

Page 33

Installation - Mechanical

Table 6 Lifting Weights and CG Dimensions (Refer to Figure 14 - Figure 15)

W1 W2 W3 W4 W5 W6 W7 W8 Shipping

Xcg Ycg

Weight

Unit

155 Ton 60 Hz Std Eff 2967 3453 3399 3790 NA NA NA NA 13608 90 45

170 Ton 50 Hz High Eff 4055 4587 3604 4136 NA NA NA NA 16382 108 45

170 Ton 50 Hz Std Eff 3071 3581 3562 3963 NA NA NA NA 14177 90 45

170Ton 60 Hz High Eff 3932 4452 3467 3987 NA NA NA NA 15838 108 45

170 Ton 60 Hz Std Eff 2972 3463 3409 3804 NA NA NA NA 13647 90 45

185 Ton 50 Hz High Eff 4585 5283 4161 4860 NA NA NA NA 18889 126 45

185 Ton 50 Hz Std Eff 4088 4629 3589 4129 NA NA NA NA 16435 108 45

185 Ton 60 Hz High Eff 4462 5201 4039 4778 NA NA NA NA 18479 126 46

185 Ton 60 Hz Std Eff 4042 4501 3551 4010 NA NA NA NA 16105 108 45

200 Ton 50 Hz High Eff 4713 5336 4223 4846 NA NA NA NA 19118 126 45

200 Ton 50 Hz Std Eff 4116 4654 3672 4211 NA NA NA NA 16654 108 45

200 Ton 60 Hz High Eff 4654 5271 4158 4775 NA NA NA NA 18858 126 45

200 Ton 60 Hz Std Eff 4087 4622 3640 4175 NA NA NA NA 16524 108 45

225 Ton 60 Hz Std Eff 4646 5313 4163 4830 NA NA NA NA 18952 126 45

250 Ton 60 Hz Std Eff 4713 5336 4223 4846 NA NA NA NA 19118 126 45

250 Ton 50 Hz High Eff 4303 3872 4188 3756 4111 3679 NA NA 23909 174 42

250 Ton 50 Hz Std Eff 3534 3104 3918 3488 4174 3744 NA NA 21962 183 42

275 Ton 50 Hz High Eff 4366 3959 4618 4211 4872 4465 NA NA 26492 200 42

275 Ton 50 Hz Std Eff 4611 4136 4276 3801 4057 3577 NA NA 24458 171 42

275 Ton 60 Hz High Eff 4214 3877 4501 4111 4789 4399 NA NA 25891 201 42

275 Ton 60 Hz Std Eff 4287 3877 4149 3739 4057 3647 NA NA 23758 174 42

300 Ton 50 Hz High Eff 3836 3508 3689 3360 3526 3197 3379 3050 27544 220 42

300 Ton 50 Hz Std Eff 4360 3948 4476 4064 4593 4182 NA NA 25623 197 42

300 Ton 60 Hz High Eff 3799 3508 3689 3360 3526 3197 3379 3050 27508 219 42

300 Ton 60 Hz Std Eff 4488 4105 4527 4144 4593 4182 NA NA 26039 195 43

350 Ton 50 Hz High Eff 4173 4152 4053 4032 3927 3905 3808 3787 31836 235 44

kg

1346 1566 1542 1719 6173 2286 1140

1839 2081 1635 1876 7431 2743 1140

1393 1624 1616 1798 6431 2296 1140

1784 2019 1573 1808 7184 2738 1140

1348 1571 1546 1725 6190 2289 1140

2080 2396 1888 2204 8568 3211 1151

1854 2100 1628 1873 7455 2733 1140

2024 2359 1832 2167 8382 3211 1158

1834 2042 1611 1819 7305 2733 1133

2138 2420 1916 2198 8672 3200 1140

1867 2111 1666 1910 7554 2746 1140

2111 2391 1886 2166 8554 3198 1140

1854 2097 1651 1894 7495 2746 1140

2108 2410 1888 2191 8597 3200 1146

2138 2420 1916 2198 8672 3200 1140

1954 1758 1901 1705 1866 1670 10855 4422 1067

1605 1409 1779 1583 1895 1700 9971 4638 1062

1982 1797 2097 1912 2212 2027 12027 5070 1077

2093 1878 1941 1725 1842 1624 11104 4338 1062

1913 1760 2043 1866 2174 1997 11754 5093 1077

1946 1760 1884 1698 1842 1656 10786 4415 1069

1742 1592 1675 1526 1601 1451 1534 1385 12505 5575 1074

1980 1792 2032 1845 2085 1899 11633 4999 1074

1725 1593 1675 1525 1601 1451 1534 1385 12489 5573 1074

2038 1864 2055 1881 2085 1899 11822 4956 1080

1895 1885 1840 1830 1783 1773 1729 1719 14453 5956 1125

lbs

lbs

kg

lbs

kg

lbs

kg

lbs

kg

lbs

kg

lbs kglbs

kg

lbs

kg

in

mm

in

mm

RTAC-SVX01F-EN 33

Page 34

Installation - Mechanical

Table 6 Lifting Weights and CG Dimensions (Refer to Figure 14 - Figure 15)

W1 W2 W3 W4 W5 W6 W7 W8 Shipping

Xcg Ycg

Weight

Unit

350 Ton 50 Hz Std Eff 3778 3757 3675 3654 3566 3545 3465 3444 28882 235 44

1715 1705 1668 1659 1619 1610 1573 1563 13113 5961 1125

350 Ton 60 Hz High Eff 4036 4017 3912 3893 3782 3763 3660 3641 30703 234 44

1832 1824 1776 1767 1717 1708 1661 1653 13939 5949 1125

350 Ton 60 Hz Std Eff 4283 3877 4754 4348 5229 4823 NA NA 27315 204 43

1944 1760 2158 1974 2374 2190 12401 5179 1080

375 Ton 50 Hz High Eff 4502 4479 4244 4221 3863 3841 3592 3569 32311 261 44

2044 2034 1927 1916 1754 1744 1631 1620 14669 6632 1125

375 Ton 50 Hz Std Eff 4332 4298 3984 3950 3618 3584 3274 3240 30279 227 44

1967 1951 1809 1793 1643 1627 1486 1471 13747 5761 1123

400 Ton 50 Hz High Eff 4341 4265 4367 4291 4406 4330 4433 4357 34791 273 44

1971 1936 1983 1948 2000 1966 2013 1978 15795 6939 1118

400 Ton 50 Hz Std Eff 4195 4173 4075 4053 3950 3928 3832 3810 32014 235 44

1904 1894 1850 1840 1793 1783 1740 1730 14534 5956 1125

400 Ton 60 Hz High Eff 4341 4265 4367 4291 4406 4330 4433 4357 34790 273 44

1971 1936 1983 1948 2000 1966 2013 1978 15795 6939 1120

400 Ton 60 Hz Std Eff 4195 4173 4075 4053 3950 3928 3832 3810 32016 234 44

1905 1895 1850 1840 1793 1783 1740 1730 14535 5954 1125

450 Ton 60 Hz Std Eff 4532 4509 4273 4251 3892 3870 3621 3598 32545 261 44

2057 2047 1940 1930 1767 1757 1644 1633 14775 6634 1125

500 Ton 60 Hz Std Eff 4359 4283 4385 4309 4424 4348 4451 4375 34935 273 44

1979 1945 1991 1956 2008 1974 2021 1986 15860 6939 1118

140 Ton 50 Hz High Eff 2033 2292 1972 2244 NA NA NA NA 8542 86 45

922 1040 895 1018 3875 2179 1138

140 Ton 50 Hz Std Eff 2030 2287 1967 2238 NA NA NA NA 8522 86 45

921 1038 892 1015 3866 2177 1138

140 Ton 60 Hz High Eff 2030 2288 1967 2238 NA NA NA NA 8522 86 45

921 1038 892 1015 3866 2177 1138

140 Ton 60 Hz Std Eff 2026 2283 1961 2232 NA NA NA NA 8502 86 45

919 1036 889 1013 3857 2177 1138

155 Ton 50 Hz High Eff 2725 2944 2119 2337 NA NA NA NA 10125 104 44

1236 1335 961 1060 4593 2637 1115

155 Ton 50 Hz Std Eff 2139 2305 2087 2265 NA NA NA NA 8795 86 44

970 1046 947 1027 3989 2177 1113

155 Ton 60 Hz High Eff 2612 2918 1975 2281 NA NA NA NA 9786 103 45

1185 1323 896 1034 4439 2619 1138

155 Ton 60 Hz Std Eff 2031 2285 1968 2236 NA NA NA NA 8520 86 45

921 1037 893 1014 3865 2177 1135

170 Ton 50 Hz High Eff 2749 3073 2128 2451 NA NA NA NA 10400 104 45

1247 1394 965 1112 4717 2637 1138

170 Ton 50 Hz Std Eff 2138 2415 2133 2411 NA NA NA NA 9097 87 45

970 1096 967 1094 4126 2197 1135

170Ton 60 Hz High Eff 2626 2938 1990 2302 NA NA NA NA 9856 103 45

1191 1332 903 1044 4471 2621 1138

170 Ton 60 Hz Std Eff 2033 2291 1971 2243 NA NA NA NA 8538 86 45

922 1039 894 1018 3873 2179 1138

185 Ton 50 Hz High Eff 3034 3485 2423 2875 NA NA NA NA 11817 122 45

1376 1581 1099 1304 5360 3106 1153

185 Ton 50 Hz Std Eff 2786 3118 2116 2449 NA NA NA NA 10469 103 45

12 6 4 14 1 4 9 6 0 1111 4 749 2621 1138

185 Ton 60 Hz High Eff 2911 3403 2300 2793 NA NA NA NA 11407 122 46

1320 1544 1043 1267 5174 3101 1166

kg

lbs kglbs

lbs

kg

lbs

kg

Remote Evaporator Aluminum Fins

lbs

kg

lbs

kg

lbs kglbs

kg

lbs

kg

in

mm

in

mm

34 RTAC-SVX01F-EN

Page 35

Installation - Mechanical

Table 6 Lifting Weights and CG Dimensions (Refer to Figure 14 - Figure 15)

W1 W2 W3 W4 W5 W6 W7 W8 Shipping

Xcg Ycg

Weight

Unit

185 Ton 60 Hz Std Eff 2740 2991 2079 2329 NA NA NA NA 10139 103 44

200 Ton 50 Hz High Eff 3156 3531 2478 2853 NA NA NA NA 12019 122 45

200 Ton 50 Hz Std Eff 2811 3140 2196 2525 NA NA NA NA 10672 104 45

200 Ton 60 Hz High Eff 3097 3466 2413 2782 NA NA NA NA 11759 121 45

200 Ton 60 Hz Std Eff 2781 3108 2163 2490 NA NA NA NA 10542 104 45

225 Ton 60 Hz Std Eff 3096 3516 2425 2845 NA NA NA NA 11880 122 45

250 Ton 60 Hz Std Eff 3156 3531 2478 2853 NA NA NA NA 12019 122 45

140 Ton 50 Hz High Eff 2506 2883 2697 3031 NA NA NA NA 11116 88 45

140 Ton 50 Hz Std Eff 2503 2878 2691 3025 NA NA NA NA 11096 88 45

140 Ton 60 Hz High Eff 2503 2878 2691 3025 NA NA NA NA 11096 88 45

140 Ton 60 Hz Std Eff 2499 2874 2685 3019 NA NA NA NA 11076 88 45

155 Ton 50 Hz High Eff 3472 3810 2963 3301 NA NA NA NA 13545 107 44

155 Ton 50 Hz Std Eff 2612 2896 2811 3051 NA NA NA NA 11369 88 44

155 Ton 60 Hz High Eff 3359 3783 2819 3244 NA NA NA NA 13206 106 45

155 Ton 60 Hz Std Eff 2505 2876 2692 3022 NA NA NA NA 11094 88 45

170 Ton 50 Hz High Eff 3496 3938 2972 3414 NA NA NA NA 13820 107 45

170 Ton 50 Hz Std Eff 2611 3006 2857 3198 NA NA NA NA 11671 89 45

170Ton 60 Hz High Eff 3373 3803 2834 3265 NA NA NA NA 13276 106 45

170 Ton 60 Hz Std Eff 2506 2882 2695 3030 NA NA NA NA 11112 88 45

185 Ton 50 Hz High Eff 3969 4570 3471 4072 NA NA NA NA 16082 125 45

185 Ton 50 Hz Std Eff 3532 3984 2960 3412 NA NA NA NA 13889 106 45

185 Ton 60 Hz High Eff 3846 4487 3349 3990 NA NA NA NA 15672 125 46

185 Ton 60 Hz Std Eff 3487 3857 2923 3293 NA NA NA NA 13559 106 45

200 Ton 50 Hz High Eff 4092 4615 3527 4050 NA NA NA NA 16284 125 45

200 Ton 50 Hz Std Eff 3557 4006 3040 3489 NA NA NA NA 14092 107 45

200 Ton 60 Hz High Eff 4033 4551 3462 3979 NA NA NA NA 16024 125 45

kg

1243 1357 943 1057 4599 2619 1123

1432 1602 1124 1294 5452 3091 1138

1275 1424 996 1146 4841 2644 1138

1405 1572 1095 1262 5334 3084 1138

1262 1410 981 1129 4782 2639 1138

1404 1595 1100 1290 5389 3091 1148

1432 1602 1124 1294 5452 3091 1138

1137 1308 1223 1375 5042 2245 1140

1135 1305 1221 1372 5033 2245 1140

1135 1306 1221 1372 5033 2245 1140

1134 1303 1218 1369 5024 2245 1140

1575 1728 1344 1497 6144 2710 1123

1185 1313 1275 1384 5157 2243 1120

1524 1716 1279 1471 5990 2700 1140

1136 1305 1221 1371 5032 2245 1138

1586 1786 1348 1549 6269 2708 1140

1184 1363 1296 1450 5294 2258 1138

1530 1725 1286 1481 6022 2700 1140

1137 1307 1223 1374 5040 2245 1140

1800 2073 1575 1847 7295 3180 1151

1602 1807 1343 1548 6300 2697 1140

1745 2035 1519 1810 7109 3178 1161

1581 1749 1326 1494 6150 2697 1130

1856 2094 1600 1837 7386 3167 1140

1613 1817 1379 1583 6392 2713 1140

1829 2064 1570 1805 7269 3165 1140

lbs

lbs

kg

lbs

kg

lbs

kg

Remote Evaporator Copper Fins

lbs

kg

lbs

kg

lbs kglbs

kg

lbs

kg

in

mm

in

mm

RTAC-SVX01F-EN 35

Page 36

Installation - Mechanical

Table 6 Lifting Weights and CG Dimensions (Refer to Figure 14 - Figure 15)

W1 W2 W3 W4 W5 W6 W7 W8 Shipping

Xcg Ycg

Weight

Unit

200 Ton 60 Hz Std Eff 3528 3974 3007 3453 NA NA NA NA 13962 107 45

1600 1802 1364 1566 6333 2710 1140

225 Ton 60 Hz Std Eff 4031 4600 3473 4042 NA NA NA NA 16145 125 45

1828 2086 1575 1833 7323 3167 1148

250 Ton 60 Hz Std Eff 4092 4615 3527 4050 NA NA NA NA 16284 125 45

1856 2094 1600 1837 7386 3167 1140

kg

lbs kglbs

lbs

kg

lbs

kg

lbs

kg

lbs

kg

lbs kglbs

kg

lbs

kg

in

mm

Table 7 Remote Evaporator Lifting Weights

Standard Eff Premium Eff

To n n a g e

lbs

Kg

140 155 170 185 200 225 250 140 155 170 185 200

2487

2525

2528

2556

112 8

114 5

114 6

115 9

2600

117 9

2797

1268

2846

1291

2528

114 6

2556

115 9

2600

117 9

2797

1268

Isolation and Sound Emission

The most effective form of isolation is to locate the unit away from any sound sensitive area. Structurally transmitted sound can be reduced by elastomeric vibration eliminators. Spring isolators are not recommended. Consult an acoustical engineer in

critical sound applications.

For maximum isolation effect, isolate water lines and electrical conduit. Wall sleeves

and rubber isolated piping hangers can be used to reduce the sound transmitted

through water piping. To reduce the sound transmitted through electrical conduit, use

flexible electrical conduit.

State and local codes on sound emissions should always be considered. Since the

environment in which a sound source is located affects sound pressure, unit place

ment must be carefully evaluated. Sound power levels for Trane air-cooled Series R®

chillers are available on request.

in

mm

2846

1291

-

5NITSWITH#OMPRESSORS

5NITSWITHORMORE#OMPRESSORS

Figure 17 Unit Isolator Locations

36 RTAC-SVX01F-EN

Page 37

Table 8 Unit Isolators

Installation - Mechanical

Tonnage Efficiency Frequency Unit Type Condenser

Fin Material

140 Std/High 50/60 Packaged AL X10140305620 8

140 Std/High 50/60 Remote AL X10140305610 8

140 Std/High 50/60 Packaged/Remote Cu X10140305620 8

155 Std/High 50/60 Packaged AL X10140305620 8

155 Std/High 50/60 Remote AL X10140305610 8

155 Std/High 50/60 Packaged/Remote Cu X10140305620 8

170 Std/High 50/60 Packaged AL X10140305620 8

170 Std/High 50/60 Remote AL X10140305610 8

170 Std/High 50/60 Packaged/Remote Cu X10140305620 8

185 Std 50/60 Packaged AL X10140305620 8

185 High 50/60 Packaged AL X10140305620 10

185 Std 50/60 Remote AL X10140305610 8

185 High 50/60 Remote AL X10140305610 10

185 Std 50/60 Packaged Cu X10140305620 8

185 High 50/60 Packaged Cu X10140305620 10

185 Std 50/60 Remote Cu X10140305620 8

185 High 50/60 Remote Cu X10140305620 10

200 Std 50/60 Packaged AL X10140305620 8

200 High 50/60 Packaged AL X10140305620 10

200 Std 50/60 Remote AL X10140305610 8

200 High 50/60 Remote AL X10140305610 10

200 Std 50/60 Packaged Cu X10140305620 8

200 High 50/60 Packaged Cu X10140305620 10

200 Std 50/60 Remote Cu X10140305620 8

200 High 50/60 Remote Cu X10140305620 10

225 Std 50/60 Packaged AL X10140305620 10

225 Std 50/60 Remote AL X10140305610 10

225 Std 50/60 Packaged/Remote Cu X10140305620 10

225 High 60 Packaged Al/Cu X10140305620 10

250 Std 50/60 Packaged AL X10140305620 10

250 Std 50/60 Remote AL X10140305610 10

250 Std 50/60 Packaged/Remote Cu X10140305620 10

250 High 60 Packaged Al/Cu X10140305620 10

250 Std 50 Packaged Al/Cu X10140305630 10

250 High 50 Packaged Al/Cu X10140305640 10

275 Std/High 50/60 Packaged Al/Cu X10140305640 10

300 Std/High 50/60 Packaged Al/Cu X10140305640 10

350 Std 60 Packaged Al/Cu X10140305640 10

350 Std 50 Packaged Al/Cu X10140305640 10

350 High 50/60 Packaged Al/Cu X10140305640 10

375 Std/High 50 Packaged Al/Cu X10140305640 10

400 Std/High 50/60 Packaged Al/Cu X10140305640 10

450 Std/High 60 Packaged Al/Cu X10140305640 10

500 Std 60 Packaged Al/Cu X10140305640 10

Isolator Part

Number

Quantity

Noise Considerations

Locate the outdoor unit away from sound sensitive areas. If required, install rubber

vibration isolators in all water piping and use flexible electrical conduit. Consult an

acoustical engineer for critical applications. Also refer to Trane Engineering Bulletins

for application information on RTAC chillers.

RTAC-SVX01F-EN 37

Page 38

Installation - Mechanical

Foundation

Provide rigid, non-warping mounting pads or a concrete foundation of sufficient

strength and mass to support the outdoor unit operating weight (i.e., including com

pleted piping, and full operating charges of refrigerant, oil and water). Refer to Tabl e 1

though Tabl e 5 in the General Information section for unit operating weights. Once in

place, the outdoor unit must be level within 1/ 4" (6 mm) over its length and width.

The Trane Company is not responsible for equipment problems resulting from an

improperly designed or constructed foundation.

NOTE: To allow for cleaning under the condensing coil, it is recommended that an

opening be left between the unit base and the concrete pad.

Clearances

Provide enough space around the outdoor unit to allow the installation and maintenance personnel unrestricted access to all service points. Refer to submittal drawings

for the unit dimensions. A minimum of 4 feet (1.2 m) is recommended for compressor

service. Provide sufficient clearance for the opening of control panel doors. Refer to

Figure 18 through Figure 19 for minimum clearances. In all cases, local codes which

require additional clearances will take precedence over these recommendations.

-

Figure 18 Recommended Unit Clearances 15-foot bases

38 RTAC-SVX01F-EN

Page 39

Installation - Mechanical

Figure 19 Recommended Unit Clearances 18-21 foot bases

Figure 20 Recommended Unit Clearances 30-45 foot bases

RTAC-SVX01F-EN 39

Page 40

Installation - Mechanical

Figure 21 Recommended Remote Evaporator Unit Clearances 15-30 foot bases

Figure 22 Recommended Evaporator Clearance