Page 1

™

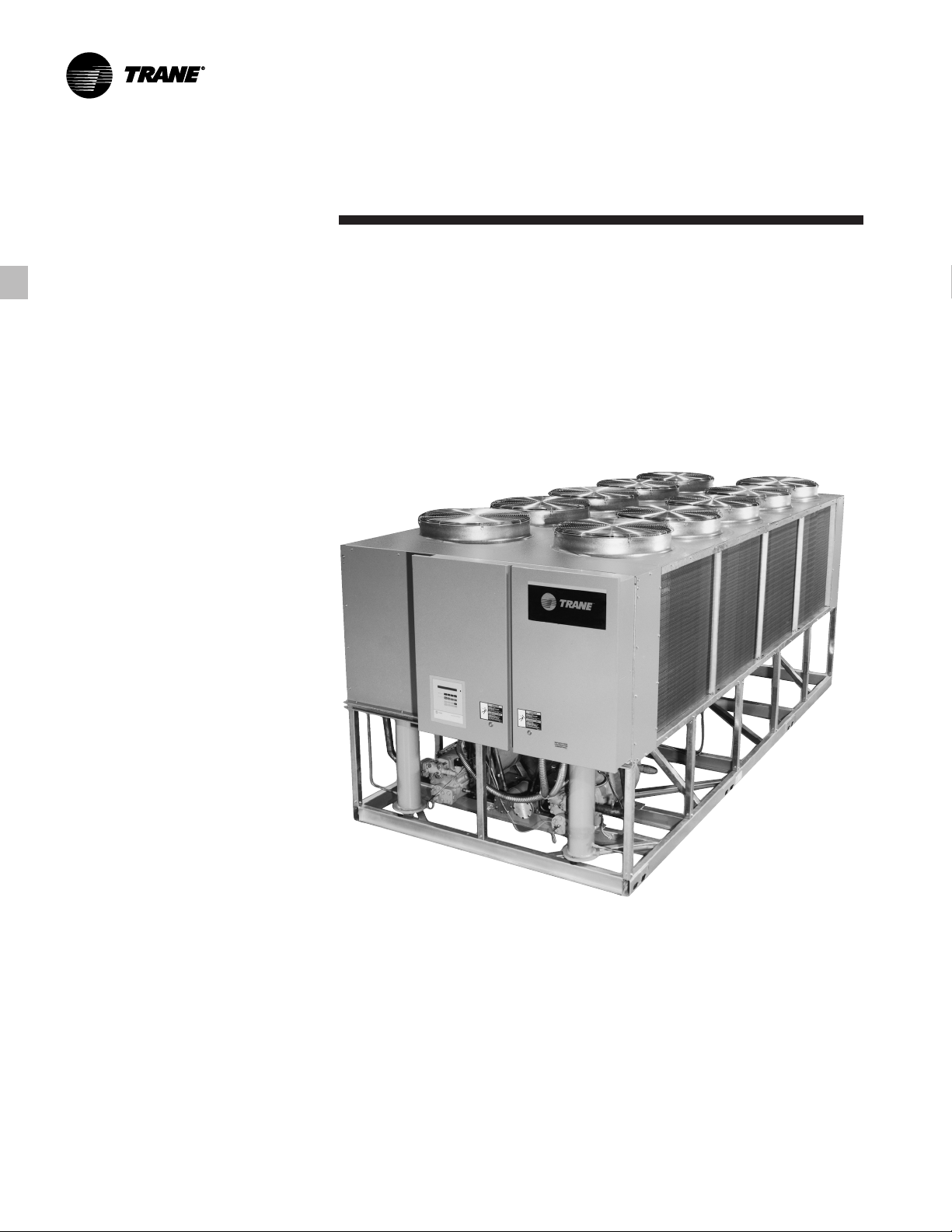

Air-Cooled Series R

Rotary Liquid Chiller

Model RTAA

70 to 125 Tons

Built for the Industrial and Commercial Markets

RLC-PRC016-ENAugust 2002

Page 2

Features and

Benefits

Yo u…

Like its chillers, Trane wants its

relationships with customers to last.

Trane is interested in maintaining long

term, loyal relationships. This

perspective means the point in time that

a customer purchases a chiller is the

beginning of a relationship, not the end.

Your business is important, but your

satisfaction is paramount.

Designed by Customers….

Trane’s RTAA 70-125 was designed with

the end user’s requirements in mind.

Reliability, efficiency, sound, and

physical size were primary design

concerns in expanding the RTAA product

line down to 70 tons. The result is a

reliable chiller that will help you achieve

your bottom line goals.

© 2002 American Standard Inc. All rights reserved.

RLC-PRC016-EN2

Page 3

Contents

Features and Benefits

Model Number Description

General Data

Selection Procedure

Application Considerations

Performance Adjustment Factors

Performance Data

Electrical Data

Jobsite Connections

Controls

Dimensional Data

Weights

2

13

14

15

16

20

22

29

30

32

40

41

The standard ARI rating condition

(54/44°F and 95°F) and IPLV are ARI

certified. All other ratings, including the

following, are outside the scope of the

certification program and are excluded:

• Glycol.

• 50 Hz.

• Remote evaporator models.

RLC-PRC016-EN

Options

Typical Wiring Diagrams

Features Summary

Mechanical Specifications

Water Chiller

42

43

45

46

Systems Business Unit

3

Page 4

Features and

Benefits

Improvements

The RTAA 70-125 offers the same high

reliability of its larger predecessor

coupled with lowered sound levels,

increased energy efficiency, and reduced

physical footprint, all due to its advanced

design, low speed/direct drive

compressor and proven Series R

performance.

Some of the major advantages of the

Model RTAA 70-125 vs its larger

predecessor are:

• Higher energy efficiency

• Lower sound levels

• Smaller physical footprint

The Series R

industrial grade design built for both the

industrial and commercial markets. It is

ideal for schools, hospitals, retailers,

office buildings, Internet service

providers and industrials.

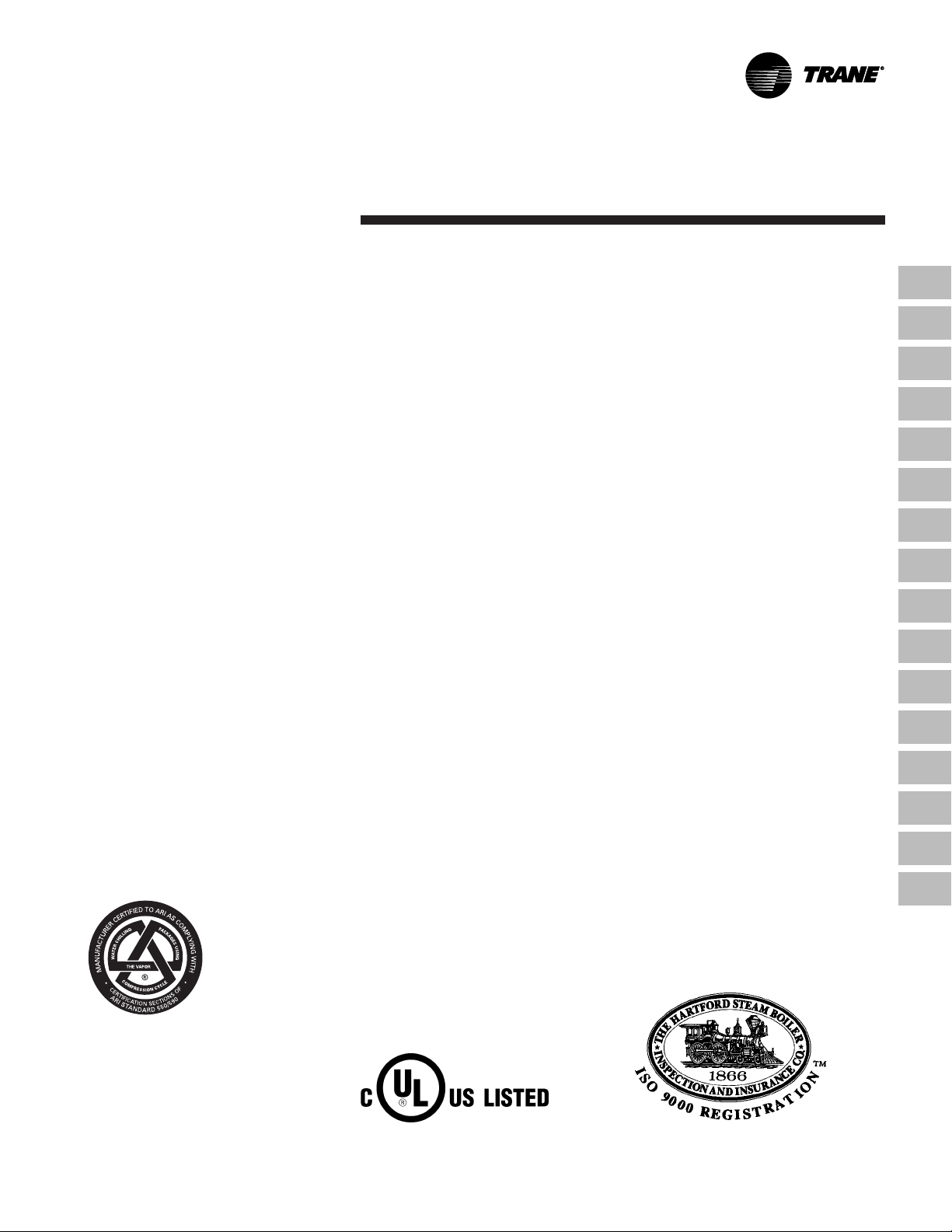

ASHRAE Standard 90.1 and RTAA 70125 World Class Energy Efficiency…

The importance of energy efficiency

cannot be understated. Fortunately,

ASHRAE has created a guideline

emphasizing its importance.

Nonetheless, energy is often dismissed

as an operational cost over which the

owner has little control. That perception

results in missed opportunities for

energy efficiency, reduced utility bills,

and higher profits. Lower utility bills

directly affect profitability. Every dollar

saved in energy goes directly to the

bottom line. Trane’s RTAA 70-125 is one

way to maximize your profits.

™

Model RTAA 70-125 is an

™

ASHRAE Standard 90.1 & Executive

Order

- New technology applied to the

design, controls, and manufacturing

have created superior efficiency levels in

the RTAA 70-125 that are unmatched in

the industry. All Trane air-cooled chillers

meet the new efficiency levels mandated

by ASHRAE Standard 90.1. This new

standard requires higher efficiencies

than past technologies can deliver. The

US Federal Government has adopted

standard 90.1 and, in some cases,

requires even higher efficiencies.

Federal Executive Order mandates

energy consuming devices procured

must be in the top 25% of their class or

be at least 10% better than any product

standard for that product. In the case of

chillers, that product standard is

ASHRAE 90.1. Trane’s RTAA 70-125

meets and exceeds the efficiency

requirements of 90.1, with some units

meeting the “stretch goals” of Executive

Order.

Risk.

The US Federal Government has

adopted ASHRAE 90.1, and it’s expected

to be adopted domestically, if not

globally, in the future. Domestic

acceptance has already begun. Make

sure that your chillers as well as your

entire HVAC system complies, or you

may be caught retrofitting your project

with new equipment and paying extra

design dollars if the code is adopted

during construction.

Precise Capacity Control.

patented unloading system allows the

compressor to modulate infinitely and

exactly match building loads. At the

same time chilled water temperatures

will be maintained within +/- 1/2ºF of

Trane’s

setpoint, potentially eliminating the need

for external considerations to maintain

temperatures. Reciprocating and screw

chillers with stepped capacity control do

well to maintain chilled water

temperatures within 2ºF of setpoint.

Stepped control also results in

overcooling or undercooling your space

because rarely does the capacity of the

machine match the building load. The

result can be 10% higher energy bills.

Trane’s RTAA optimizes the part load

performance of your machine for energy

efficiency, precise temperature control

for all modes of operation, and your

personal comfort regardless of changing

conditions.

RLC-PRC016-EN4

Page 5

Excellent Reliability

A building environment is expected to

be comfortable. When it is, no one says

a word. If it’s not… that’s a different

story. The same is true with chillers. No

one ever talks about chillers, yet alone

compressors, until they fail, and tenets

are uncomfortable and productivity is

lost. Trane’s helical rotary compressors

have a first year reliability rate of over

99%, which means our chillers stay

running when you need them.

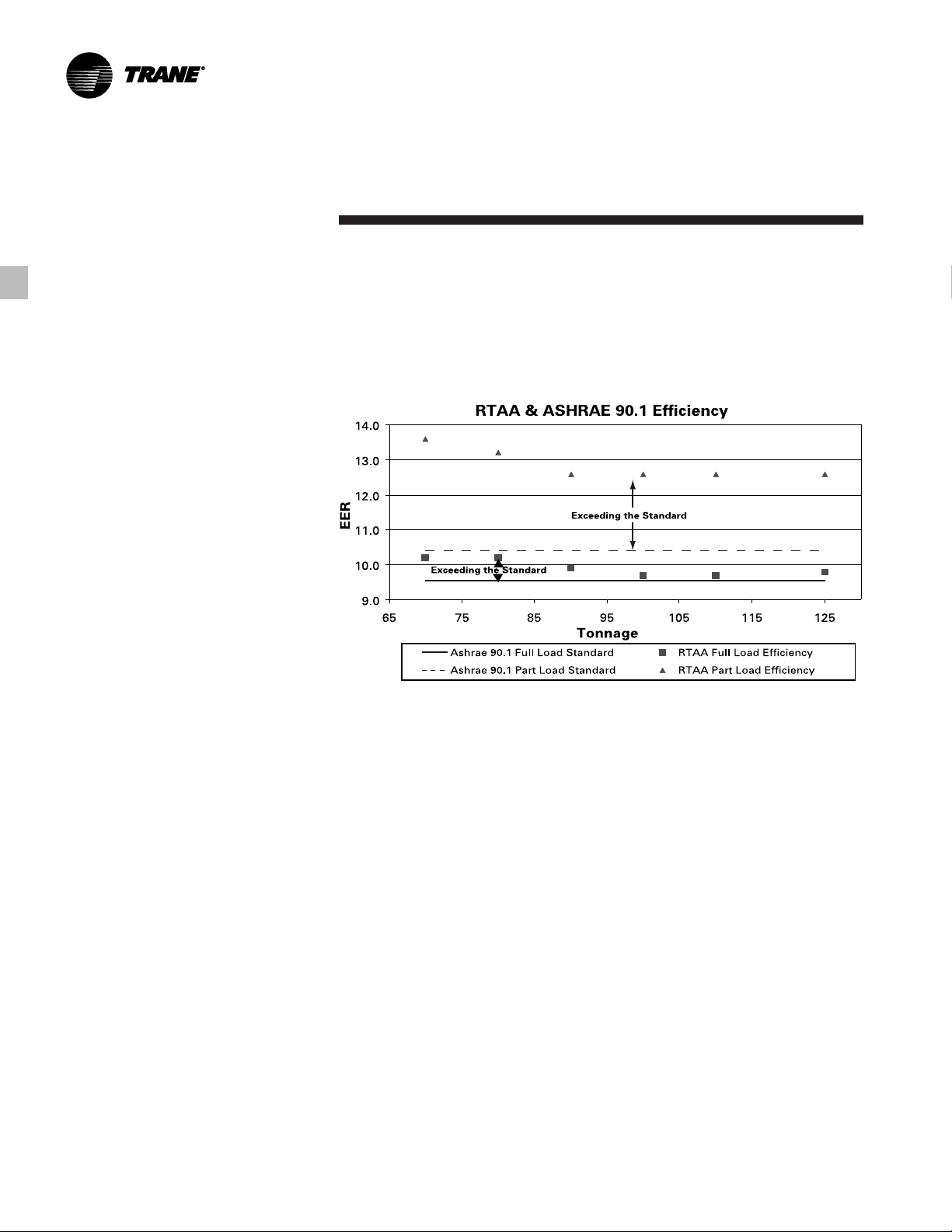

Screw compressors were designed to

replace the inherent design flaws of a

reciprocating compressor. Trane’s helical

rotary compressor has successfully

achieved this goal, proven by the over

99% reliability rating of our compressor

in the first year of operation. A good

design like Trane’s should maintain this

level of reliability for several years of

chiller operation. Not all screw

compressors maintain a high reliability

and Trane is the only manufacturer that

will publish a reliability number. The

point is to make sure that you are getting

a reliable screw chiller design so that you

don’t end up with the downtime and lost

earnings that the industry is trying to

Features and

Benefits

avoid by getting away from

reciprocating technology.

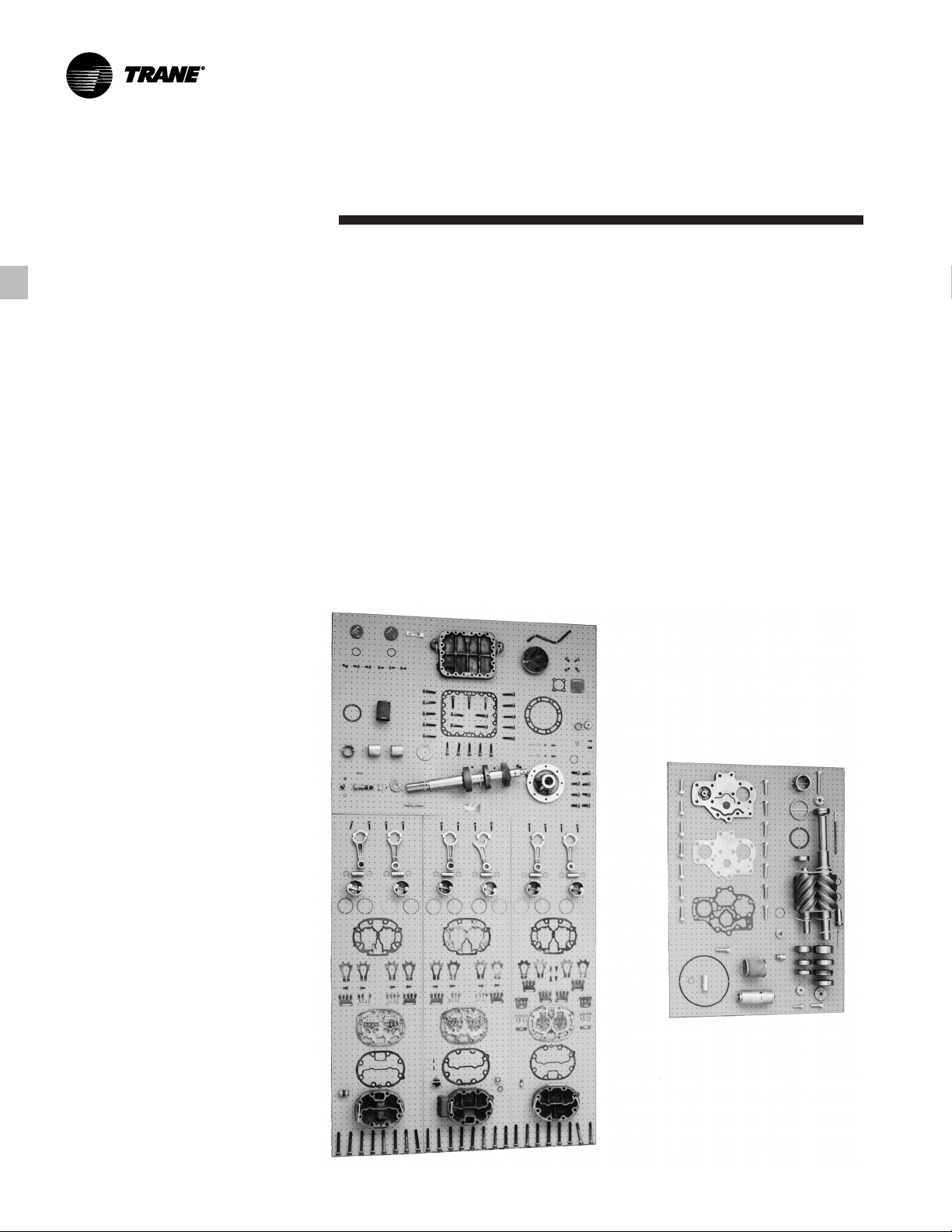

Fewer moving parts.

rotary compressors have only two major

rotating parts: the male and female rotor.

A reciprocating compressor can have

more than 15 times that number of

critical parts. Multiples of pistons,

valves, crankshafts, and connecting rods

in a reciprocating unit all represent

different failure paths for the

compressor. In fact, reciprocating

compressors can easily have a failure

rate four times that of a helical rotor.

Combine this with two to three

reciprocating compressors for each

helical rotary compressor on chillers of

equal tonnage, and statistics tell you it’s

Trane’s helical

a matter of time before you lose a

reciprocating compressor.

Robust parts.

compressors are precisely machined

using state of the art processes from

solid metal bar stock. Tolerances are

maintained within a micron or less than

a tenth of the diameter of a human hair.

The resulting compressor is a robust yet

highly sophisticated assembly capable of

ingesting liquid refrigerant without risk

of damage. Contrast this to a

reciprocating compressor, which can be

destroyed by a single slug of liquid.

Series R

• Direct-drive, low speed for high

efficiency and reliability.

• Simple design with only four moving

parts, resulting in high reliability and

low maintenance.

• Field serviceable compressor for easy

maintenance.

• Precise rotor tip clearance for optimal

efficiency.

• Suction gas-cooled motor, resulting in

lower operating temperatures for

increased motor life, and giving the

capability for:

• Five-minute start-to-start/two minute

stop-to-start capability, which allows

for closer water loop temperature

control.

Helical rotary

™

Compressor Highlights

RLC-PRC016-EN

5

Page 6

Features and

Benefits

RTAA 70-125 Chiller Highlights

• High Reliability, with over 99%

compressor reliability rate in the first

year of operation, and Adaptive

Controls to keep the chiller on line

producing cold water during adverse

conditions.

• High Efficiency (all units exceed

ASHRAE 90.1 efficiency standard).

• Low sound levels.

• Small footprint, with smallest required

application space (operating footprint)

in the industry.

• Years of research, testing, and

successful applications. The Trane

helical rotary compressor has amassed

thousands of hours of testing, much of

it at severe operating conditions. Not

to mention the successful application

of RTAA chillers for over 11 years, with

a developed reputation as the industry

standard.

• Trouble free startup through factory

testing of compressor and completed

chiller and factory installation of chiller

accessories.

• +/- ½°F leaving water temperature

control, resulting from PID feedforward controls, and linear load

matching, also allowing for 10% flow

rate change per minute while

maintaining ± ½°F leaving water

temperature control.

Trane helical rotary screw compressor

component parts versus reciprocating

compressor components.

RLC-PRC016-EN6

Page 7

Features and

Optimum

Benefits

Superior Full Load Efficiency

Precise Rotor Tip Clearances

Higher energy efficiency in a helical

rotary compressor is obtained by

reducing the rotor tip clearances. This

reduces the leakage between high and

low pressure cavities during

compression. Precise rotor tip clearance

is achieved with the latest manufacturing

and machining technology. Trane is the

first helical rotary compressor

manufacturer to electronically check

compressor parts machining accuracy as

part of the standard production process.

Optimized Compressor Parts Profiles

Rotor and slide valves are unique

designs, optimized for the air

conditioning application. The rotors are

designed for the pressure ranges in the

air conditioning application. The unloader

valve has a unique profile that resulted

from computer performance modeling in

typical part-load situations.

Advanced Heat Transfer Surfaces

Condenser and evaporator tubes use the

latest heat transfer technology for

increased efficiency.

Efficiencies

Great Part Load Efficiency

With Trane Helical Rotary

Screw Compressors and

Electronic Expansion Valve

Trane Helical Rotary Screw Compressor

Means Superior Part Load Performance

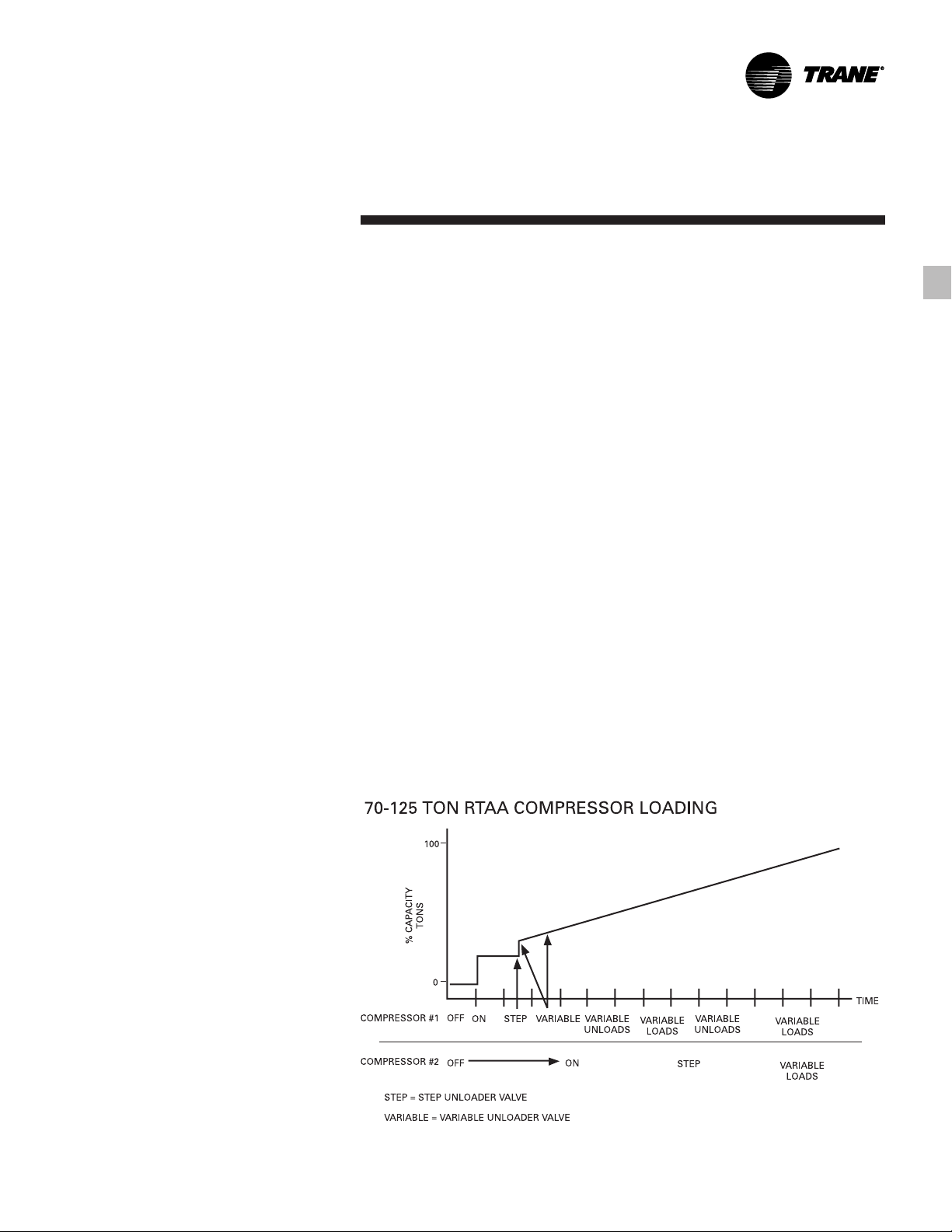

The air-cooled Series R

part-load performance. The combination

patented unloading system on the

“general purpose” compressor utilizes

the variable unloading valve for the

majority of the unloading function

similar to that of the slide valve. The

“general purpose” compressor also

uses a step unloader valve which is a

single unloading step to achieve the

minimum unloading point of the

compressor. The result of both of these

designs is optimized part-load

performance far superior to single

reciprocating compressors.

™

chiller has great

RLC-PRC016-EN

7

Page 8

Features and

Benefits

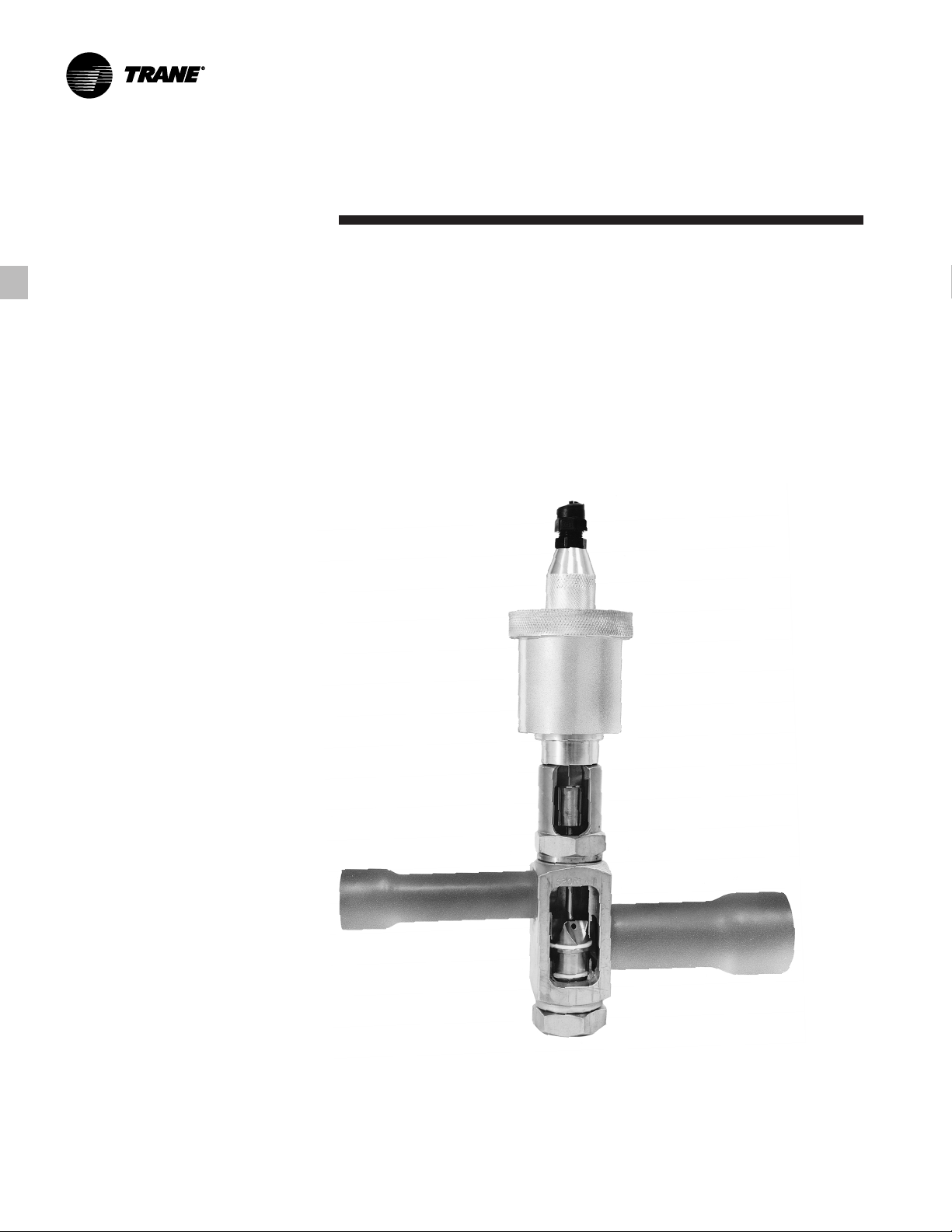

Electronic Expansion Valve

When coupled with Trane’s Adaptive

™

Control

expansion valve significantly improves

part-load performance of the Series R

chiller by minimizing superheat in the

evaporator and allowing the chiller to

run at reduced condensing

temperatures. Chillers which use

conventional TXV’s must run at higher

head pressures and consume more

power than necessary at part-loads.

Additionally, the electronic expansion

valve and its controls allow much better

stability and control over dynamic load

and head changes. Under these

conditions a conventional TXV may

never achieve control stability and

extended periods of TXV “hunting” and

liquid slugging are common.

Capacity Control and Load Matching

Infinitely variable compressor

modulation allows the compressor

capacity to exactly match the building

cooling load. Reciprocating and screw

chillers that rely on stepped capacity

control must run at a capacity equal to or

greater than the load. Much of this

excess capacity is lost because

overcooling goes toward building latent

heat removal, causing the building to be

dried beyond normal comfort

requirements. The result is an increase in

chiller energy costs, particularly at the

part-load conditions at which the chiller

operates most of the time.

microprocessor, our electronic

™

PID Chilled Water Setpoint

Control Through Slide Valve

Modulation

Maintain Chilled Water Supply Within

1

±

/2°F of Setpoint

Chillers that have step capacity control

typically can only maintain water

temperature to around ± 2°F. With the

air-cooled Series R™ chiller, maintaining

temperature control has never been so

accurate.

Reduce Compressor Cycling

Modulating capacity control offers better

compressor reliability. Compressor

cycling, typical of reciprocating

compressors, will decrease compressor

component life. Parts like motors and

valves do not stand up well to excessive

compressor cycling.

Cutaway view of Trane’s electronic expansion valve.

RLC-PRC016-EN8

Page 9

Features and

Benefits

Trouble-Free Installation,

Start-Up and Operation

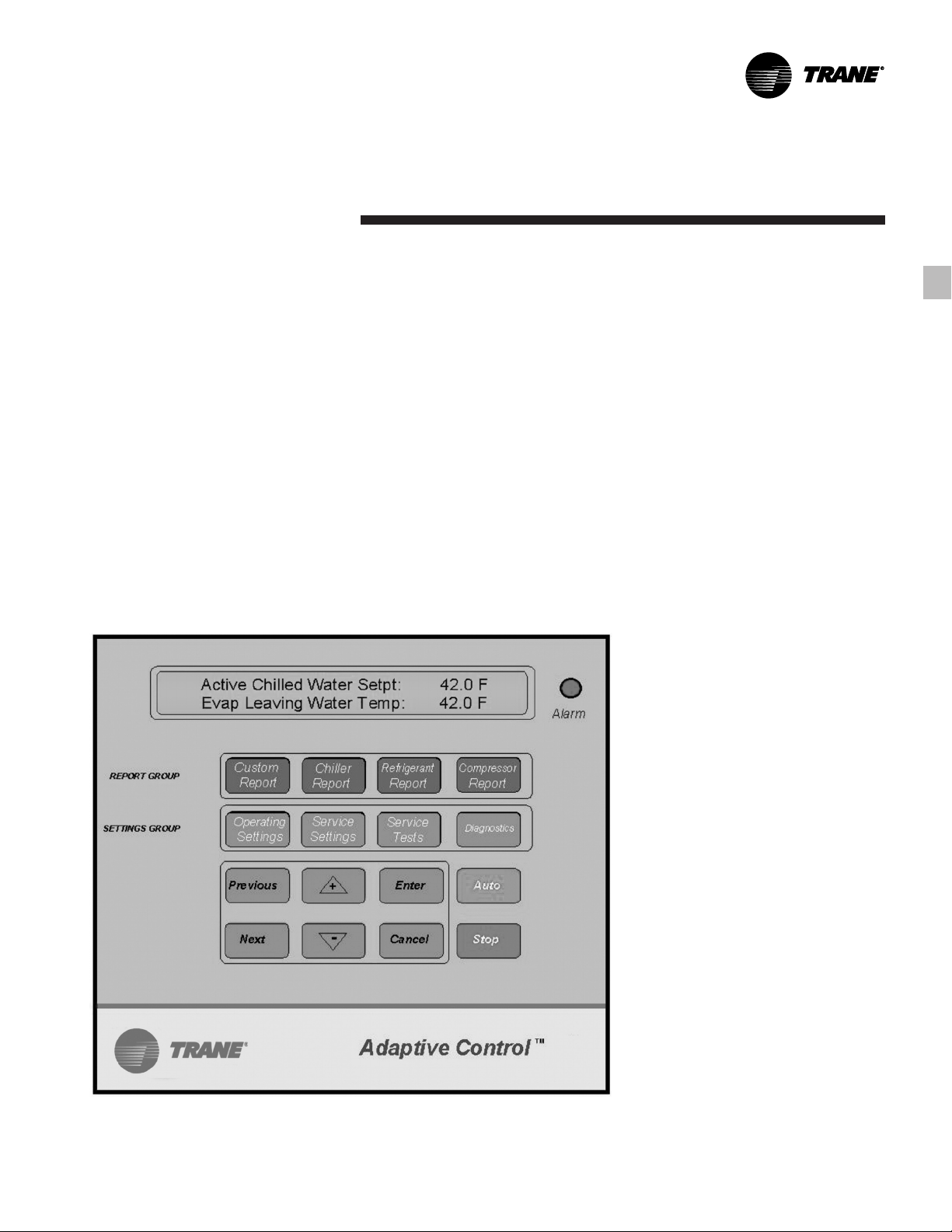

Adaptive Control™ Microprocessor

The RTAA 70-125 chiller offers advanced

microprocessor control and features the

Adaptive Control microprocessor. So

what is the Adaptive Control

microprocessor? Adaptive Control

means the Unit Control Module (UCM)

directly senses the control variables that

govern operation of the chiller: motor

current draw, evaporator temperature,

condenser temperature, etc.

When any of the variables approaches a

limit condition where the unit may be

damaged or shut down on a safety, the

UCM takes corrective action to avoid

shutdown and keep the chiller operating.

It does this through combined actions of

compressor slide valve modulation,

electronic expansion valve modulation

and fan staging. Additionally, the UCM

optimizes total unit power consumption

during normal operating conditions. No

other chiller control system in the

marketplace duplicates this

performance.

The End Of Most Nuisance Trip-Outs

And Unnecessary Service Calls?

Unnecessary service calls and unhappy

tenants are reduced. Only when the

UCM has exhausted the corrective

actions it can take and the unit is still

violating an operating limit will the unit

shut down. CONTROLS ON OTHER

CHILLERS TYPICALLY SHUT DOWN THE

CHILLER, QUITE PROBABLY JUST

WHEN IT IS NEEDED THE MOST.

For example:

A typical five-year-old chiller with dirty

coils might trip-out on high pressure

cutout on a 100°F day in August. A hot

day is just when comfort cooling is

needed the most. In contrast, the aircooled Series R™ chiller with an Adaptive

Control microprocessor will stage fans

on, modulate electronic expansion valve,

and modulate slide valve as it

approaches a high pressure cutout.

Thereby KEEPING THE CHILLER ONLINE JUST WHEN YOU NEED IT THE

MOST.

RLC-PRC016-EN

9

Page 10

Features and

Benefits

Close Spacing Of Chiller

The air-cooled Series R

tightest recommended side clearance in

the industry, four feet, but that is not all.

In situations where equipment must be

installed with less clearance than

recommended, such as frequently

occurs in retrofit and rooftop

applications, restricted air flow is

common. Conventional chillers may not

work at all. However, the air-cooled

Series R

microprocessor will simply make as

much chilled water as it can given the

actual installed conditions, stay on line

during any unforeseen abnormal

conditions, and optimize its

performance. Consult your Trane sales

engineer for more details.

Lower Service Expense

Nuisance service calls are avoided.

When there is a real problem that must

be corrected, the UCM’s extensive

diagnostics help assure that the problem

is quickly identified. Down time and

service expense are minimized. And with

the ability to communicate with the

Trane Integrated Comfort™ system or a

remote display panel, service problems

can be identified and diagnosed remote

to the installation.

™

chiller with Adaptive Control

™

chiller has the

™

Factory Testing Means Trouble-Free

Start-Up

All air-cooled Series R

a complete functional test at the factory.

This computer-based test program

completely checks the sensors, wiring,

electrical components, microprocessor

function, communication capability,

expansion valve performance and fans.

In addition, each compressor is run

tested to verify capacity and power

consumption. The end result of this test

program is that the chiller arrives at the

jobsite fully tested and ready to go to

work.

™

chillers are given

Factory Installed And Tested Controls/

Options Speed Installation

All Series R™ chiller options, including

control power transformer, starter

disconnect, low ambient control,

ambient temperature sensor, low

ambient lockout, communication

interface and ice making controls are

factory installed and tested. Some

manufacturers send options in pieces to

be field installed. With Trane, the

customer saves on installation expense

and has assurance that ALL chiller

controls/options have been tested and

will function as expected.

RLC-PRC016-EN10

Page 11

Features and

Benefits

Superior Control

Unit Control Module

Trane’s Adaptive Control

microprocessor control system enhances

the air-cooled Series R™ chiller by

providing the very latest chiller control

technology.

State-of-the-Art Equipment

The 70 to 125 ton air-cooled chillers offer

the exclusive Trane Adaptive Control

logic with the Clear Language Display

(UCM). The Clear Language Display has

various functions that allow the operator

to read unit information and adjust

setpoints. The Clear Language Display

panel has 16 keys, the readout screen is a

two-line, 40 character liquid crystal with a

backlight. The backlight allows the

operator to read the display in low-light

conditions.

™

Unit Control Module Features

Equal Compressor Sequencing

Trane maximizes both compressor and

motor life by equalizing both the number

of starts and the operating hours. The

UCM will start the compressor with the

least number of starts and turn off the

compressor with the most operating

hours. Conventional “auto” lead-lag

control will equalize starts, but running

hours will typically be unequal.

Equalizing both starts and running hours

will provide equal compressor wear.

Internal “Built-In” Chiller Flow

Protection

The UCM automatically detects a no

waterflow condition. An external flow

switch is not required, which lowers

costs versus typical chillers. Built-in flow

protection also eliminates nuisance flow

switch problems.

RLC-PRC016-EN

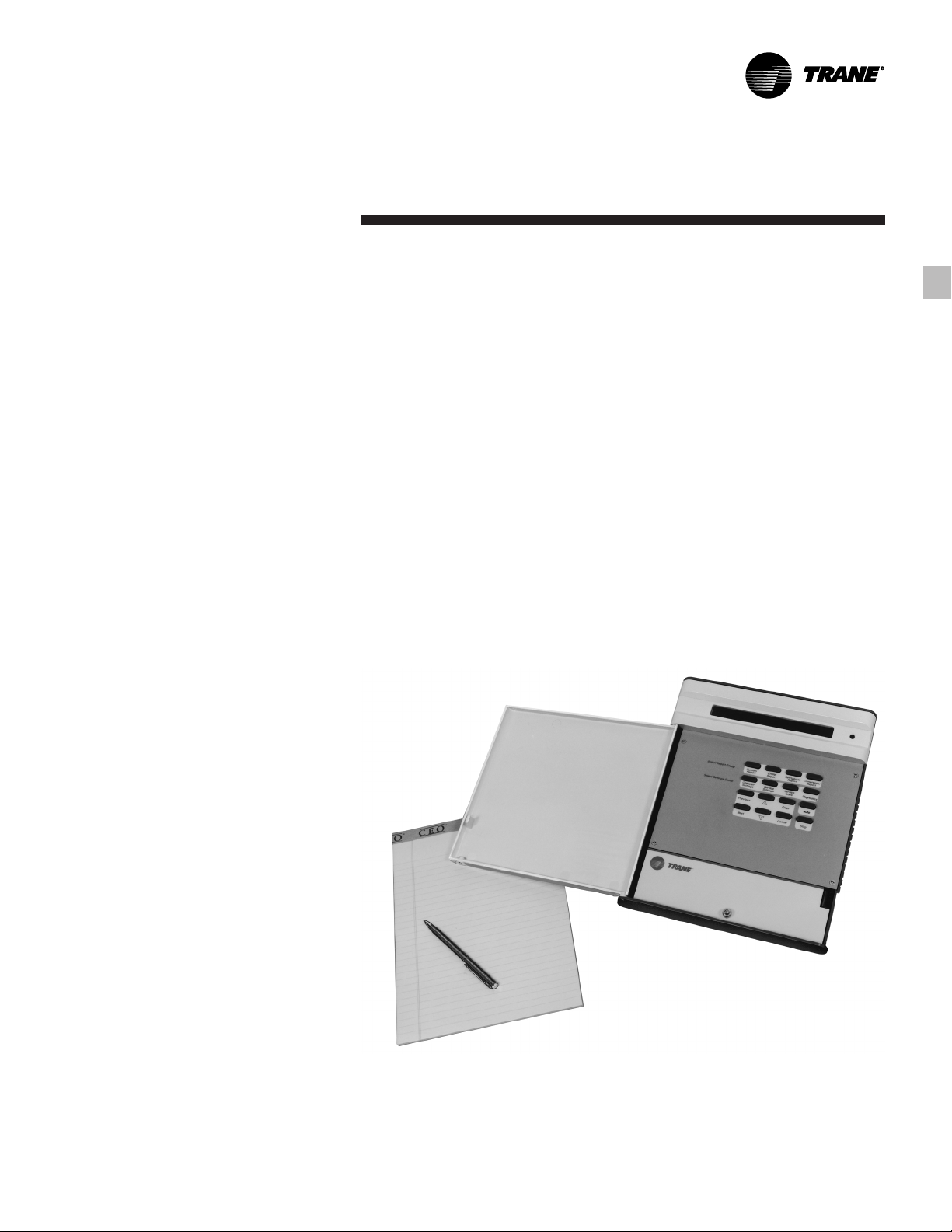

Remote Clear Language Display Panel

for 70 to 125-ton air-cooled chillers.

11

Page 12

Features and

Benefits

Easy Chiller System Logging

The UCM displays data required to log

the chiller system. The following

information is available either as

standard or as an option with the AirCooled Series R

• Entering and leaving chilled water

temperatures

• Ambient air temperature

• Evaporator and condenser refrigerant

temperatures and pressures

• Compressor suction temperature

• Percent RLA for each compressor

• Percent line voltage

• Compressor starts and running hours

• Active setpoints:

chilled water setpoint

current limit setpoint

ice termination setpoint

low ambient lockout setpoint

• Over 90 diagnostic and operating

conditions

• Part failure diagnostics:

water temperature sensors

refrigerant temperature sensors

compressor contactors

Remote Display Panel

Trane air-cooled Series R

chillers are available with a twisted pair

connection to an optional remote display

panel. Chiller operation can be controlled

similarly to the control interface on the

chiller itself. Through a twisted pair of

wires the unit can be turned on or off,

change the chilled water setpoint, and

display over 90 operating and diagnostic

conditions. The remote display panel can

be mounted indoors so access to chiller

information is just steps away,

eliminating any need to go outdoors or

on the roof.

The clear language display for chiller

sizes of 70-125 tons has the ability to

control multiple units. In a multiple unit

configuration, the Remote Clear

Language Display Panel has the

capability to communicate with up to

four units. Each unit requires a separate

communication link with the Remote

Display Panel.

™

Chiller microprocessor:

™

70-125 ton

Easy Interface To The Building

Management System

Controlling the air-cooled Series R

chiller with building management

systems is state-of-the-art yet simple.

Chiller inputs include:

• Chiller enable/disable

• Circuit enable/disable

• Chilled water setpoint

• Current limit setpoint

• Ice making enable

Chiller outputs include:

• Compressor running indication

• Alarm indication (CKt 1/CKt2)

• Maximum capacity

™

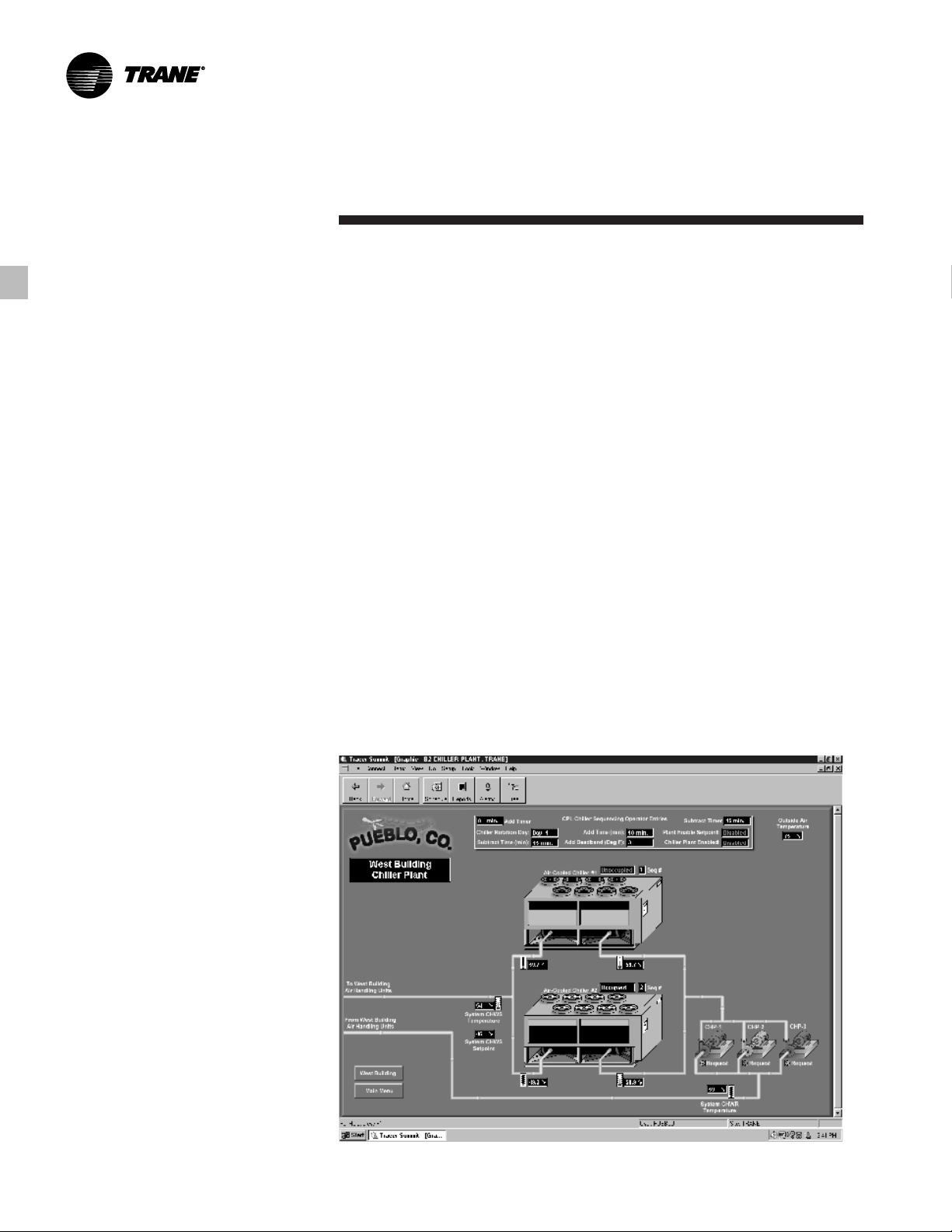

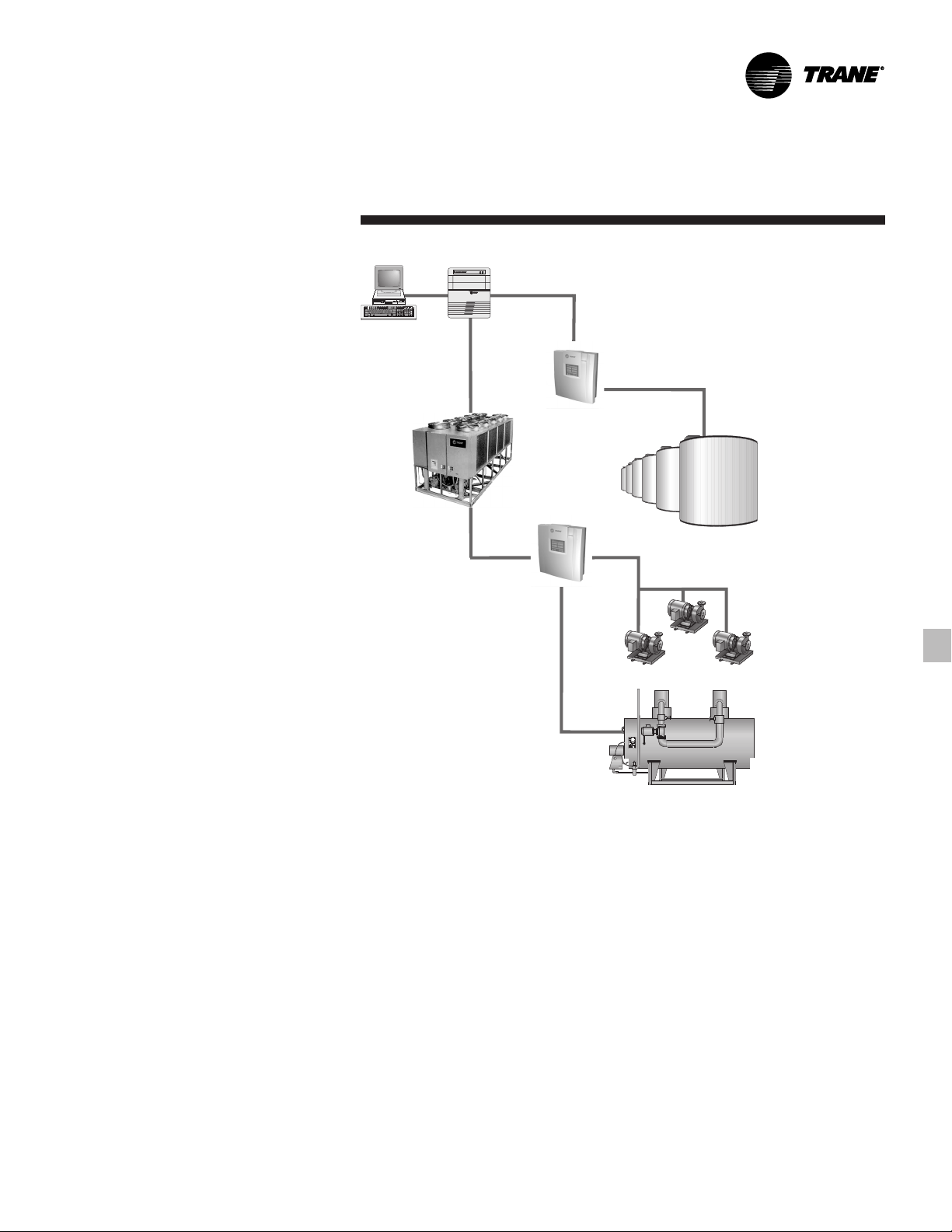

Trane Chiller Plant Manager/ICS

The Tracer

Building Management System

provides building automation and

energy management functions

through stand- alone control. The

Chiller Plant Manager is capable of

monitoring and controlling your entire

chiller plant system.

Application software available:

• Time-of-day scheduling

• Duty cycle

• Demand limiting

• Chiller sequencing

• Process control language

• Boolean processing

• Zone control

• Reports and logs

• Custom messages

• Run time and maintenance

• Trend log

• Totalizing

• PID control loops

And of course, Trane’s Chiller Plant

Manager Panel can be used on a

stand- alone basis or tied into a

complete building automation

system.

™

Chiller Plant Manager

RLC-PRC016-EN12

Page 13

Model Number

Description

Model Nomenclature Digit Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

70-125 Tons

Digits 1,2 — Unit Model

RT = Rotary Chiller

Digit 3 — Unit Type

A = Air Cooled

Digit 4 — Development Sequence

A = First Sequence

Digit 5, 6 & 7 — Nominal Capacity

070 = 70 tons

080 = 80 tons

090 = 90 tons

100 = 100 tons

110 = 110 tons

125 = 125 tons

Digit 8 — Unit Voltage

A = 200/60/3

C = 230/60/3

D = 380/60/3

4 = 460/60/3

5 = 575/60/3

S = Special

Digit 9 — Compressor Starter Type

Y = Y-Delta Closed Transition

X = X-Line (Across the Line)

S = Special

Digit 10, 11 — Design Sequence

** = Factory Input

Digit 12 — Evaporator Leaving Temperature

1 = Standard 40 to 65°F

2 = Low 0 to 39°F

3 = Ice-Making 20 to 65°F

S = Special

Digit 13 — Condenser Coil Fin Material

A = Aluminum

S = Special

2 = Copper Fins

4 = CompleteCoat

Digit 14 — Agency Listing

0 = No Agency Listing

3 = C/UL Listing

Digit 15 — Control Interface

C = Deluxe without Communication

D = Deluxe with Communication

Digit 16 — Chilled Water Reset

0 = No Chilled Water Reset

1 = Based on Return Water Temperature

2 = Based on Outside Air Temperature

Digit 17 — Miscellaneous Factory Installed

Options

A = Architectural Louvered Panels

B = Control Power Transformer

C = Convenience Outlet

D = Low Ambient Lockout Sensor

F = Mech. Disconnect Switch

G = Low Ambient Operation

K = Coil Protection

M = Access Guard

P = Circuit Breaker (Single Point Power)

Z = Circuit Breaker (Dual Point Power)

Field Installed Options

Q = Spring Isolators

N = Neoprene Isolators

R = Remote Display Panel

3 = 5 Year Compressor Warranty

8 = Architectural Louvered Panels

9 = Coil Protection

0 = Access Guard

J = Remote Evaporator

H = Sound Attenuator

RLC-PRC016-EN

13

Page 14

General Data

Table G-1 — General Data RTAA — 70-125 Ton

Size 70 80 90 100 110 125

Compressor

Quantity 2 2 2 2 2 2

Nominal Size (1) (Tons) 35/35 40/40 50/40 50/50 60/50 60/60

Evaporator

Water Storage (Gallons) 39.8 37.3 34.4 32.1 53.4 45.8

Min. Flow (GPM) 84 96 108 120 132 150

Max. Flow (GPM) 252 288 324 360 396 450

Condenser

Qty of Coils 4 4 4 4 4 4

Coil Length (In) 156/156 156/156 168/156 168/168 204/168 204/204

Coil Height (In) 42 42 42 42 42 42

Fins/Ft. 192 192 192 192 192 192

Number of Rows 2 2 2 2 2 2

Condenser Fans

Quantity (1) 4/4 4/4 5/4 5/5 5/5 5/5

Diameter (In) 30 30 30 30 30 30

Total Airflow (CFM) 71750 71750 77640 83530 87505 91480

Nominal RPM 850 850 850 850 850 850

Tip Speed (Ft/Min) 6675 6675 6675 6675 6675 6675

Motor HP (Ea) 1.0 1.0 1.0 1.0 1.0 1.0

Min Starting/Oper Ambient (2)

Std Unit (Deg F) 25 25 25 25 25 25

Low Ambient (Deg F) -10 -10 -10 -10 -10 -10

General Unit

Refrigerant HCFC-22 HCFC-22 HCFC-22 HCFC-22 HCFC-22 HCFC-22

No. of Independent

Refrigerant Circuits 2 2 2 2 2 2

% Min. Load (3) 15 15 15 15 15 15

Refrigerant Charge (1) (Lb) 58/58 61/61 73/61 73/73 98/73 98/98

Oil Charge (1) (Gallons) 2.5/2.5 2.5/2.5 3/2.5 3/3 3/3 3/3

1. Data containing information on two circuits shown as follows: ckt 1/ckt2.

2. Minimum start-up/operating ambient based on a 5 mph wind across the condenser.

3. Percent minimum load is for total machine at 50°F ambient and 44°F LWT, not each individual circuit.

(Liters) 150.6 143.1 130.2 121.5 202.11 173.4

(L/Sec) 5.3 6.1 6.8 7.6 8.3 9.5

(L/Sec) 15.9 18.2 20.4 22.7 25.0 28.4

(Kg) 26/26 28/28 34/28 34/34 44/34 44/44

(Liters) 10.6/10.6 10.6/10.6 12.7/10.6 12.7/12.7 12.7/12.7 12.7/12.7

RLC-PRC016-EN14

Page 15

Selection

Procedure

The chiller capacity tables, P-1 through

P-12, cover the most frequently

encountered leaving water

temperatures. The tables reflect a 10°F

(6°C) temperature drop through the

evaporator. For temperature drops other

than 10°F (6°C), refer to Table F-1, and

apply the appropriate Performance Data

Adjustment Factors. For chilled brine

selections, refer to Figures F-2 and 3 for

Ethylene and Propylene Glycol

Adjustment Factors.

To select a Trane air-cooled Series R

chiller, the following information is

required:

1. Design load in tons of refrigeration

2. Design chilled water temperature drop

3. Design leaving chilled water

temperature

4. Design ambient temperature

Evaporator flow rates can be determined

by using the following formulas:

GPM =

OR L/S =

NOTE: Flow rates must fall within the

limits specified in Table G-1 (for GPM or

for l/s).

Tons x 24

Temperature Drop (Degrees F)

kW (Capacity) x .239

Temperature Drop (Degrees C)

™

Selection Example

Given:

Required System Load = 115 Tons

Leaving Chilled Water Temperature

(LCWT) = 44°F Chilled Water

Temperature Drop = 10°F Design

Ambient Temperature = 95°F

Evaporator Fouling Factor = 0.0001

1. To calculate the required chilled water

flow rate we use the formula given

below:

GPM =

2. From Table P-6 (RTAA Performance

Data), an RTAA 125 at the given

conditions will produce 120.1 tons

with a compressor power input of

136.3 kW and a unit EER of 9.8.

3. To determine the evaporator pressure

drop we use the flow rate (GPM) and

the evaporator water pressure drop

curves, Figure F-1. Entering the curve

at 276 GPM, the pressure drop for a

nominal 125 ton evaporator is 18 feet.

4. For selection of chilled brine units or

applications where the altitude is

significantly greater than sea level or

the temperature drop is different than

10°F, the performance adjustment

factors from Tables F-1, F-2, and/or F-3

should be applied at this point.

115 Tons x 24 = 276 GPM

10°F

For example:

Corrected Capacity = Capacity

(unadjusted) x Glycol Flow Rate

Adjustment Factor

5. The final unit selection is:

• QTY (1) RTAA 125

• Cooling Capacity = 120.1 tons

• Entering/Leaving Chilled Water

Temperatures = 54/44°F

• Chilled Water Flow Rate = 276 GPM

• Evaporator Water Pressure Drop = 18

feet

• Compressor Power Input = 136.3 kW

• Unit EER = 9.8

Minimum Leaving Chilled Water

Temperature Setpoint

The minimum leaving chilled water

temperature setpoint for water is 40°F.

For those applications requiring lower

setpoints, a glycol solution must be used.

Contact the local Trane sales engineer for

additional information.

RLC-PRC016-EN

15

Page 16

Application

Considerations

Application Considerations

Certain application constraints should be

considered when sizing, selecting and

installing Trane air-cooled Series R

™

chillers. Unit and system reliability is

often dependent upon properly and

completely complying with these

considerations. Where the application

varies from the guidelines presented, it

should be reviewed with your local

Trane sales engineer.

Unit Sizing

Unit capacities are listed in the

performance data section. Intentionally

oversizing a unit to assure adequate

capacity is not recommended. Erratic

system operation and excessive

compressor cycling are often a direct

result of an oversized chiller. In addition,

an oversized unit is usually more

expensive to purchase, install, and

operate. If oversizing is desired, consider

using two units.

Unit Placement

1. Setting The Unit

A base or foundation is not required if

the selected unit location is level and the

base is strong enough to support the

unit’s operating weight as listed in Tables

W-1 and W-2.

2. Isolation and Sound Emission

The most effective form of isolation is to

locate the unit away from any soundsensitive area. Structurally transmitted

sound can be reduced by

ELASTOMERIC vibration eliminators.

Spring isolators have proven to be of

little benefit on air-cooled Series R

™

chiller installations and are not

recommended. An acoustical engineer

should always be consulted in critical

sound applications.

For maximum isolation effect, water

lines and electrical conduit should also

be isolated. Wall sleeves and rubber

isolated piping hangers can be used to

reduce the sound transmitted through

water piping. To reduce the sound

transmitted through electrical conduit,

use flexible electrical conduit.

State and local codes on sound

emissions should always be considered.

Since the environment in which a sound

source is located affects sound pressure,

unit placement must be carefully

evaluated. Sound power levels for Trane

air-cooled Series R

™

chillers are available

on request.

3. Servicing

Adequate clearance for evaporator and

compressor servicing should be

provided. Recommended minimum

space envelopes for servicing are

located in the dimensional data section

and can serve as a guideline for

providing adequate clearance. The

minimum space envelopes also allow

for control panel swing and routine

maintenance requirements. Local code

requirements may take precedence.

4. Unit Location

a. General

Unobstructed flow of condenser air is

essential to maintain chiller capacity and

operating efficiency. When determining

unit placement, careful consideration

must be given to assuring a sufficient

flow of air across the condenser heat

transfer surface. Two detrimental

conditions are possible and must be

avoided if optimum performance is to be

achieved: warm air recirculation and coil

starvation.

Warm air recirculation occurs when

discharge air from the condenser fans is

recycled back to the condenser coil inlet.

Coil starvation occurs when free airflow

to (or from) the condenser is restricted.

Both warm air recirculation and coil

starvation cause reductions in unit

efficiency and capacity because of the

higher head pressures associated with

them. The air-cooled Series R

™

chiller

offers an advantage over competitive

equipment in these situations.

Performance is minimally affected in

many restricted air flow situations due to

its unique condensing coil geometry.

Also, through its advanced Adaptive

™

Control

microprocessor logic, the

chiller will attempt to stay on-line where

competitive chillers would usually shut

down.

Trane’s unique Adaptive Control

microprocessor has the ability to

understand the operating environment

of the chiller and adapt to it by first

optimizing its performance and second,

staying on line through abnormal

conditions. For example, high ambient

temperatures combined with a restricted

air flow situation will generally not cause

the air-cooled Series R

™

chiller to shut

down. Competitive chillers would

typically shut down on a high pressure

nuisance cut-out in these conditions.

Debris, trash, supplies, etc. should not be

allowed to accumulate in the vicinity of

the air-cooled Series R

™

chiller. Supply

air movement may draw debris into the

condenser coil, blocking spaces between

coil fins and causing coil starvation.

Special consideration should be given to

low ambient units. Condenser coils and

fan discharge must be kept free of

obstructions to permit adequate airflow

for satisfactory unit operation.

RLC-PRC016-EN16

Page 17

b. Provide Vertical Clearance

Vertical condenser air discharge must be

unobstructed. While it is difficult to

predict the degree of warm air

circulation, a unit installed as shown on

the left would have its capacity and

efficiency significantly reduced.

Performance data is based on free air

discharge.

c. Provide Lateral Clearance

The condenser coil inlet must not be

obstructed. A unit installed closer than

the minimum recommended distance to

a wall or other vertical riser may

experience a combination coil starvation

and warm air recirculation, resulting in

unit capacity and efficiency reductions.

Once again, the Adaptive Control

microprocessor will allow the chiller to

stay on line, producing the maximum

available capacity, even at less than

recommended lateral clearances.

The recommended lateral clearances are

depicted in the dimensional data section.

These are estimates and should be

reviewed with the local Trane sales

engineer at the jobsite.

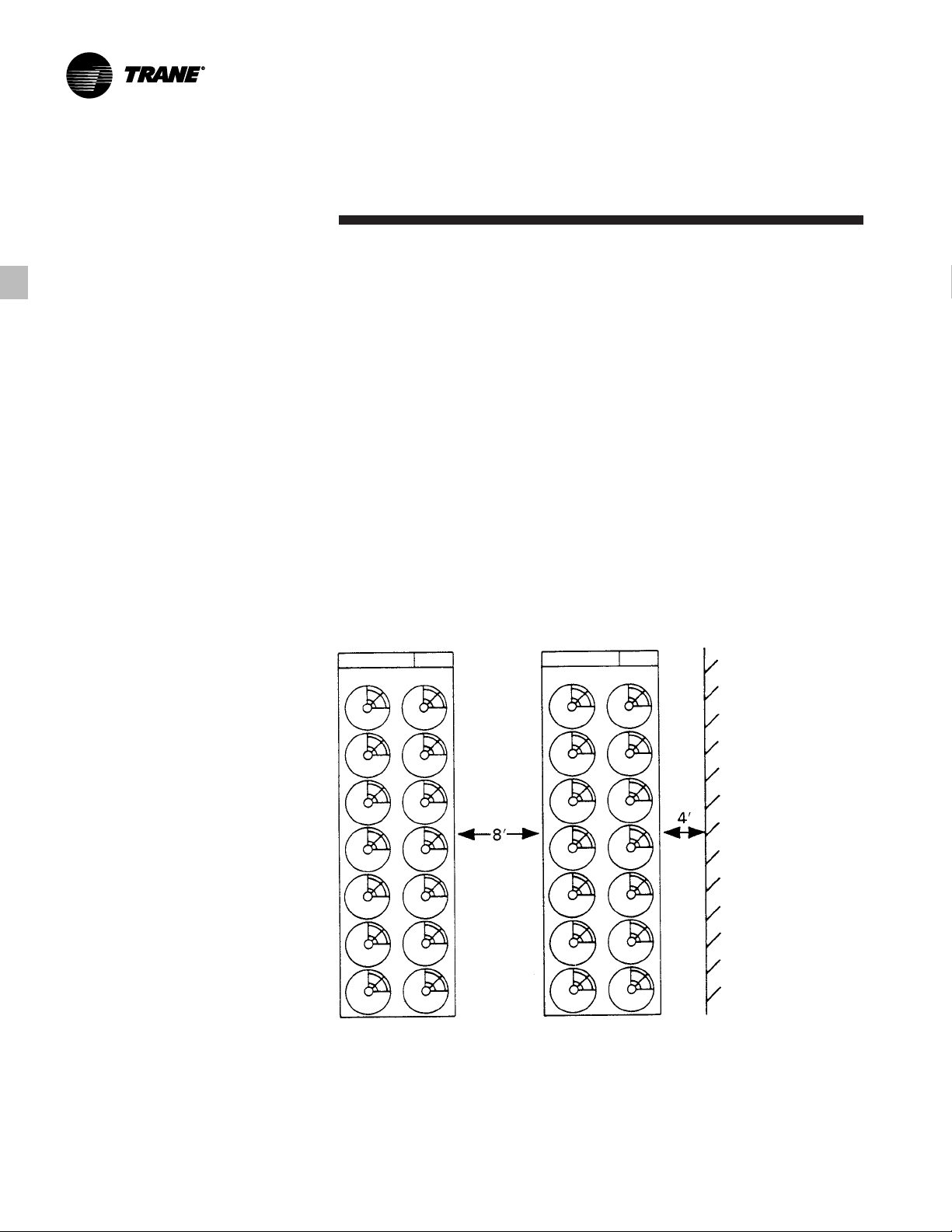

d. Provide Sufficient Unit-to-Unit

Clearance

Units should be separated from each

other by a sufficient distance to prevent

warm air recirculation or coil starvation.

The air-cooled Series R

lowest recommended unit-to-unit

clearance in the industry, eight feet.

Consult the local Trane sales engineer for

applications concerning close spacing

and restricted airflows.

e. Walled Enclosure Installations

When the unit is placed in an enclosure

or small depression, the top of the fans

should be no lower than the top of the

enclosure or depression. If they are,

consideration should be given to ducting

the top of the unit. Ducting individual

fans, however, is not recommended.

Such applications should always be

reviewed with the local Trane sales

engineer.

™

chiller has the

™

Application

Considerations

RLC-PRC016-EN

17

Page 18

Application

Considerations

Water Treatment

Dirt, scale, products of corrosion and

other foreign material will adversely

affect heat transfer between the water

and system components. Foreign matter

in the chilled water system can also

increase pressure drop and,

consequently, reduce waterflow. Proper

water treatment must be determined

locally, depending on the type of system

and local water characteristics.

Neither salt nor brackish water is

recommended for use in Trane aircooled Series R

™

chillers. Use of either

will lead to a shortened life to an

indeterminable degree. The Trane

Company encourages the employment

of a reputable water treatment specialist,

familiar with local water conditions, to

assist in this determination and in the

establishment of a proper water

treatment program.

The capacities given in the performance

data section of this catalog are based on

water with a fouling factor of .00010. For

capacities at other fouling factors, see

adjustment factors in Table F-1.

Effect Of Altitude On Capacity

Air-cooled Series R™ chiller capacities

given in the performance data tables, P-1

through P-12, are for use at sea level. At

elevations substantially above sea level,

the decreased air density will decrease

condenser capacity and, therefore, unit

capacity and efficiency. The adjustment

factors in Table F-1 can be applied

directly to the catalog performance data

to determine the unit’s adjusted

performance.

Ambient Limitations

Trane air-cooled Series R

™

chillers are

designed for year-round applications

over a range of ambients. Chillers from

70-125 tons offer operation for ambients

from 25 to 115°F as standard, and will

operate down to -10°F with the low

ambient option.

The minimum ambient temperatures are

based on still conditions (winds not

exceeding five mph). Greater wind

velocities will result in a drop in head

pressure, therefore increasing the

minimum starting and operating

ambient temperature. Once again, the

Adaptive Control

™

microprocessor will

attempt to keep the chiller on-line when

high or low ambient conditions exist,

making every effort to avoid nuisance

trip-outs and provide the maximum

allowable tonnage.

Waterflow Limits

The minimum waterflow rates are given

in Table G-1. Evaporator flow rates

below the tabulated values will result in

laminar flow causing freeze-up

problems, scaling, stratification and poor

control.

The maximum evaporator waterflow

rate is also given in the general data

section. Flow rates exceeding those

listed may result in excessive tube and

baffle erosion.

The evaporator can withstand up to 50

percent water flow reduction as long as

this flow is equal or above the minimum

gpm requirements.

Variable Evaporator Flow

Air-cooled Series R

™

chillers have the

capability to handle variable evaporator

flow without losing leaving water

temperature control. Flow rates can be

varied up to 10% of design without

decreasing the leaving water

temperature control capabilities.

Temperature Limits

1. Leaving Water Temperature Range

Trane air-cooled Series R

™

chillers have

three distinct leaving water categories:

standard, low temperature, and ice

making.

The standard leaving water temperature

range is 40 to 65°F. Low temperature

machines produce leaving water

temperatures between 0°F and 39°F.

Since water supply temperature

setpoints from 0 to 39°F result in suction

temperatures at or below the freezing

point of water, a glycol solution is

required for all low temperature

machines. Ice making machines have a

leaving water temperature range of 20 to

65°F. Ice making controls include dual

setpoint controls and safeties for ice

making and standard cooling

capabilities. Consult your local Trane

sales engineer for applications or

selections involving low temperature or

ice making machines.

The maximum water temperature that

can be circulated through an evaporator

when the unit is not operating is 108°F.

The evaporator becomes thermal stress

limited at this temperature.

2. Supply Water Temperature Drop

The performance data for the Trane aircooled Series R

™

chiller is based on a

chilled water temperature drop of 10°F.

Temperature drops outside this range

will result in unit performance that

differs from that cataloged. For

performance data outside the 10°F

range, see Table F-1 for adjustment

factors. Chilled water temperature drops

from 6 to 18°F may be used as long as

minimum and maximum water

temperature and minimum and

maximum flow rates are not violated.

Temperature drops outside 6 to 18°F are

beyond the optimum range for control

and may adversely affect the

microcomputer’s ability to maintain an

acceptable supply water temperature

range.

Further, temperature drops of less than

6°F may result in inadequate refrigerant

superheat. Sufficient superheat is always

a primary concern in any direct

expansion refrigerant system and is

especially important in a package chiller

where the evaporator is closely coupled

to the compressor. When temperature

drops are less than 6°F, an evaporator

runaround loop may be required.

RLC-PRC016-EN18

Page 19

Application

Considerations

Typical Water Piping

All building water piping must be

flushed prior to making final connections

to the chiller. To reduce heat loss and

prevent condensation, insulation should

be installed. Expansion tanks are also

usually required so that chilled water

volume changes can be accommodated.

A typical piping arrangement is shown in

Figure A-1.

Short Water Loops

The proper location of the temperature

control sensor is in the supply (outlet)

water. This location allows the building

to act as a buffer and assures a slowly

changing return water temperature. If

there is not a sufficient volume of water

in the system to provide an adequate

buffer, temperature control can be lost,

resulting in erratic system operation and

excessive compressor cycling. A short

water loop has the same effect as

attempting to control from the building

return water.

The Air-Cooled Series R™ 70-125 ton

chiller has excellent leaving chilled water

control capabilities because of

exceptional controls, EXV and linear

unloading. However, it is still a good idea

to make sure the evaporator water loop

is sized sufficiently to help maintain

temperature control.

As a guideline, ensure the volume of

water in the evaporator loop equals or

exceeds two times the evaporator flow

rate. For a rapidly changing load profile,

the amount of volume should be

increased.

To prevent the effect of a short water

loop, the following items should be

given careful consideration:

A storage tank or larger header pipe to

increase the volume of water in the

system and, therefore, reduce the rate of

change of the return water temperature.

Multiple Unit Operation

Whenever two or more units are used

on one chilled water loop, Trane

recommends that their operation be

controlled from a single control device,

such as a Trane Tracer

™

system.

1. Series Operation

Some systems require large chilled

water temperature drops (16 to 24°F).

For those installations, two units with

their evaporators in series are usually

required. Control of the units should be

from a common temperature controller

to prevent the separate thermostats

fighting one another and continually

hunting. It is possible to control from the

two individual unit controls, but a

common temperature controller

provides a positive method for

preventing control overlap, more closely

matches system load, and simplifies

compressor lead-lag capability.

2. Parallel Operation

Some systems require more capacity or

standby capability than a single machine

can provide. For those installations, two

units with their evaporators in a parallel

configuration are typical. The only

effective way of controlling two units in

parallel is with a single temperature

controller. Two individual temperature

controllers are not capable of providing

reliable system control and will often

result in unsatisfactory operation.

Figure A-1 — Recommended Piping Components For Typical Evaporator Installation

Valved

Pressure

Gauge

Flow

Switch

(Optional)

Union

Gate Valve

Balancing Valve

Vibration

Eliminator

Drain

RLC-PRC016-EN

Vents

Union

Vibration

Eliminator

Water

Strainer

Gate Valve

19

Page 20

Performance

Adjustment

Factors

Table F-1 — Performance Data Adjustment Factors

Fouling Water Sea Level 2000 Feet 4000 Feet 6000 Feet

Factor Temp. Drop CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW

0.00010 10 1.000 1.000 1.000 0.997 0.996 1.004 0.993 0.992 1.007 0.988 0.988 1.015

0.00025 10 0.988 0.989 0.998 0.986 0.985 1.000 0.981 0.981 1.004 0.977 0.976 1.011

Chilled Altitude

8 1.000 1.249 1.000 0.996 1.245 1.004 0.991 1.240 1.007 0.987 1.234 1.014

12 1.001 0.835 1.001 0.997 0.832 1.004 0.993 0.828 1.009 0.988 0.824 1.015

14 1.003 0.716 1.001 0.999 0.714 1.004 0.994 0.711 1.009 0.990 0.708 1.015

16 1.004 0.628 1.001 1.000 0.626 1.005 0.997 0.623 1.009 0.991 0.620 1.016

8 0.988 1.235 0.996 0.984 1.230 1.000 0.980 1.225 1.004 0.975 1.220 1.010

12 0.990 0.825 0.998 0.987 0.822 1.000 0.983 0.819 1.005 0.978 0.815 1.011

14 0.991 0.708 0.998 0.988 0.706 1.001 0.984 0.703 1.005 0.980 0.700 1.011

16 0.993 0.621 0.999 0.990 0.619 1.001 0.986 0.617 1.006 0.981 0.614 1.012

Figure F-1 — Evaporator Water Pressure Drops, 70-125 Ton Units

FLOW (L/s)

RLC-PRC016-EN20

Page 21

Performance

Adjustment

Factors

Figure F-2 — Ethylene Glycol Performance Factors Figure F-3 — Propylene Glycol Performance Factors

RLC-PRC016-EN

Figure F-4 — Ethylene Glycol and Propylene Glycol Freeze Point

21

Page 22

Performance Data

Table P-1 — 60 Hz RTAA 70 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 72.6 58.6 12.9 68.7 64.3 11.2 64.6 70.8 9.7 60.4 77.9 8.4 55.5 84.8 7.1

42 75.0 59.4 13.1 71.1 65.1 11.5 66.9 71.6 10.0 62.6 78.7 8.6 57.1 84.8 7.3

44 77.6 60.2 13.4 73.5 65.9 11.8 69.3 72.4 10.2 64.9 79.6 8.8 58.6 84.8 7.5

46 80.2 61.1 13.7 76.0 66.8 12.0 71.7 73.2 10.5 67.2 80.5 9.0 60.2 84.8 7.7

48 82.8 61.9 14.0 78.5 67.6 12.3 74.1 74.1 10.7 69.5 81.4 9.3 61.8 84.8 7.9

50 85.4 62.8 14.3 81.1 68.5 12.6 76.5 75.0 11.0 71.8 82.3 9.5 63.4 84.8 8.1

55 92.2 64.9 14.9 87.6 70.6 13.2 82.8 77.2 11.6 77.8 84.7 10.0 67.3 84.6 8.7

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 251.7 66.1 3.4 238.7 71.9 3.0 225.0 78.3 2.6 209.6 84.8 2.2

8 267.6 67.6 3.5 253.5 73.4 3.1 239.4 79.9 2.7 219.8 84.9 2.4

10 283.4 69.1 3.6 269.0 75.0 3.2 254.2 81.5 2.8 229.6 84.8 2.5

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0000176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

Table P-2 — 60 Hz RTAA 80 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 83.0 68.9 12.8 78.8 75.6 11.2 74.4 83.1 9.7 69.8 91.3 8.4 65.0 100.4 7.2

42 86.0 70.1 13.0 81.6 76.8 11.4 77.1 84.2 9.9 72.3 92.5 8.6 67.4 101.6 7.3

44 89.0 71.3 13.3 84.5 78.0 11.7 79.8 85.4 10.2 74.9 93.7 8.8 69.9 102.8 7.5

46 92.0 72.5 13.5 87.4 79.2 11.9 82.6 86.6 10.4 77.6 94.9 9.0 72.4 104.1 7.7

48 95.2 73.8 13.8 90.4 80.4 12.1 85.4 87.9 10.6 80.3 96.2 9.2 74.4 104.7 7.9

50 98.3 75.1 14.0 93.4 81.7 12.4 88.3 89.1 10.8 83.0 97.4 9.4 75.9 104.8 8.0

55 106.5 78.3 14.6 101.3 84.9 13.0 95.8 92.4 11.4 90.1 100.7 9.9 80.0 105.0 8.5

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 289.4 77.9 3.3 275.0 84.7 2.9 259.8 92.1 2.6 244.0 100.2 2.2

8 307.7 80.1 3.5 292.5 86.9 3.1 276.4 94.3 2.7 259.8 102.4 2.3

10 326.6 82.4 3.6 310.5 89.1 3.2 293.9 96.6 2.8 276.4 104.7 2.4

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0000176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

RLC-PRC016-EN22

Page 23

Performance Data

Table P-3 — 60 Hz RTAA 90 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 94.7 81.9 12.3 89.9 88.9 10.9 84.8 97.0 9.5 79.5 106.2 8.2 73.9 116.4 7.0

42 97.9 83.3 12.6 93.0 90.3 11.1 87.8 98.4 9.7 82.3 107.5 8.4 76.5 117.8 7.2

44 101.2 84.7 12.8 96.2 91.7 11.3 90.8 99.8 9.9 85.1 108.9 8.6 79.2 119.2 7.4

46 104.6 86.2 13.0 99.4 93.2 11.6 93.8 101.2 10.1 88.0 110.4 8.8 81.7 120.4 7.5

48 108.1 87.7 13.3 102.6 94.6 11.8 96.9 102.7 10.3 91.0 111.8 9.0 82.9 120.1 7.7

50 111.5 89.2 13.5 106.0 96.2 12.0 100.1 104.2 10.5 93.9 113.3 9.2 84.3 120.0 7.8

55 120.5 93.2 14.0 114.5 100.1 12.5 108.2 108.1 11.0 101.6 117.2 9.6 88.4 119.6 8.2

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 329.4 91.6 3.2 312.9 98.9 2.9 295.3 107.1 2.5 277.1 116.2 2.2

8 349.8 94.2 3.4 332.3 101.5 3.0 313.6 109.7 2.6 294.3 118.8 2.3

10 370.6 96.9 3.5 352.0 104.2 3.1 332.6 112.4 2.7 307.7 120.0 2.4

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0000176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

Table P-4 — 60 Hz RTAA 100 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 105.1 94.3 12.0 99.9 101.7 10.6 94.2 110.5 9.3 88.2 120.5 8.1 81.9 131.9 6.9

42 108.6 95.9 12.2 103.2 103.3 10.8 97.4 112.0 9.5 91.2 122.1 8.2 84.7 133.5 7.1

44 112.2 97.5 12.4 106.6 104.9 11.0 100.6 113.6 9.7 94.3 123.7 8.4 87.6 135.1 7.2

46 115.9 99.2 12.6 110.1 106.6 11.2 103.9 115.3 9.9 97.4 125.3 8.6 90.6 136.7 7.4

48 119.6 101.0 12.8 113.6 108.3 11.4 107.3 117.0 10.1 100.6 127.0 8.8 92.0 136.7 7.5

50 123.4 102.8 13.0 117.2 110.1 11.6 110.7 118.7 10.3 103.8 128.7 8.9 93.4 136.6 7.6

55 133.1 107.5 13.5 126.5 114.7 12.1 119.4 123.2 10.7 112.0 133.1 9.3 98.1 136.6 8.0

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 365.7 104.8 3.2 347.0 112.7 2.8 327.3 121.6 2.5 306.6 131.7 2.2

8 387.5 107.7 3.3 367.8 115.6 2.9 347.0 124.6 2.6 325.6 134.7 2.2

10 410.0 110.9 3.4 389.2 118.7 3.0 367.4 127.7 2.7 341.1 136.5 2.3

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0000176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

RLC-PRC016-EN

Entering Condenser Air Temperature (Degrees C)

23

Page 24

Performance Data

Table P-5 — 60 Hz RTAA 110 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 113.3 102.5 11.9 107.7 110.7 10.6 101.7 120.3 9.3 95.2 131.2 8.1 88.4 143.6 6.9

42 117.1 104.3 12.2 111.3 112.4 10.8 105.1 122.0 9.5 98.4 132.9 8.2 91.5 145.3 7.0

44 120.9 106.1 12.4 114.9 114.2 11.0 108.5 123.7 9.7 101.7 134.7 8.4 94.6 147.1 7.2

46 124.8 107.9 12.6 118.6 116.0 11.2 112.0 125.5 9.9 105.1 136.4 8.6 97.7 148.9 7.4

48 128.8 109.8 12.8 122.4 117.8 11.4 115.6 127.3 10.0 108.5 138.3 8.7 99.4 148.9 7.5

50 132.8 111.7 13.0 126.2 119.7 11.6 119.3 129.2 10.2 111.9 140.1 8.9 101.0 148.7 7.6

55 143.1 116.7 13.4 136.1 124.7 12.0 128.6 134.1 10.7 120.6 144.9 9.3 103.6 145.4 8.0

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 394.1 114.0 3.2 374.1 122.6 2.8 353.0 132.4 2.5 331.2 143.4 2.2

8 417.3 117.2 3.3 396.6 125.8 2.9 374.5 135.6 2.6 351.2 146.7 2.2

10 441.6 120.6 3.4 419.5 129.2 3.0 395.9 139.0 2.7 369.5 149.2 2.3

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0000176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

Table P-6 — 60 Hz RTAA 125 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 125.7 113.2 12.1 119.3 122.0 10.8 112.4 132.3 9.4 105.2 144.1 8.2 97.6 157.5 7.0

42 129.9 115.2 12.3 123.3 124.0 11.0 116.2 134.3 9.6 108.8 146.1 8.3 100.9 159.5 7.1

44 134.1 117.2 12.5 127.3 126.0 11.2 120.1 136.3 9.8 112.4 148.1 8.5 104.3 161.5 7.3

46 138.5 119.4 12.7 131.4 128.1 11.3 124.0 138.3 10.0 116.1 150.1 8.7 106.7 162.2 7.4

48 142.9 121.5 12.9 135.6 130.2 11.5 127.9 140.4 10.2 119.8 152.2 8.8 107.2 160.2 7.5

50 147.4 123.7 13.1 139.9 132.4 11.7 132.0 142.6 10.3 123.6 154.4 9.0 107.6 158.0 7.7

55 159.0 129.5 13.6 150.9 138.0 12.2 142.3 148.1 10.7 133.2 159.8 9.4 109.5 152.1 8.1

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 436.7 125.7 3.2 414.2 135.1 2.8 390.3 145.6 2.5 365.3 157.5 2.2

8 462.7 129.4 3.3 438.8 138.7 2.9 413.5 149.3 2.6 387.5 161.2 2.3

10 489.1 133.3 3.4 464.1 142.6 3.0 437.7 153.1 2.7 410.0 165.0 2.3

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0000176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

RLC-PRC016-EN24

Page 25

Performance Data

Table P-7 — 50 Hz RTAA 70 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 62.9 48.7 14.0 59.5 53.4 12.2 56.0 58.7 10.5 52.3 64.7 9.0 48.6 71.2 7.6

42 65.1 49.4 14.3 61.6 54.1 12.4 58.0 59.4 10.8 54.3 65.4 9.2 50.4 71.9 7.9

44 67.3 50.1 14.6 63.7 54.8 12.7 60.1 60.1 11.0 56.2 66.1 9.5 52.3 72.7 8.1

46 69.5 50.8 14.9 65.9 55.5 13.0 62.1 60.8 11.3 58.2 66.8 9.7 54.2 73.5 8.3

48 71.8 51.5 15.2 68.1 56.2 13.3 64.2 61.5 11.5 60.3 67.6 9.9 56.1 74.3 8.5

50 74.2 52.2 15.5 70.4 56.9 13.6 66.4 62.3 11.8 62.3 68.4 10.2 58.1 75.2 8.7

55 80.1 54.0 16.2 76.1 58.7 14.3 71.9 64.1 12.4 67.5 70.4 10.7 63.0 77.5 9.2

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 218.3 54.9 3.6 206.7 59.7 3.2 194.8 65.0 2.8 182.8 70.9 2.4

8 232.1 56.1 3.8 220.1 61.0 3.3 207.4 66.3 2.9 194.8 72.3 2.5

10 246.1 57.4 3.9 233.5 62.3 3.5 220.5 67.7 3.0 207.1 73.8 2.6

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

Table P-8 — 50 Hz RTAA 80 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 72.1 57.4 13.8 68.4 62.9 12.0 64.6 69.0 10.4 60.5 75.9 9.0 56.4 83.4 7.7

42 74.7 58.4 14.1 70.9 63.9 12.3 66.9 70.0 10.7 62.8 76.9 9.2 58.5 84.4 7.8

44 77.4 59.4 14.3 73.4 64.9 12.6 69.3 71.0 10.9 65.1 77.9 9.4 60.7 85.4 8.0

46 80.1 60.4 14.6 76.0 65.9 12.8 71.8 72.1 11.2 67.4 78.9 9.6 62.8 86.5 8.2

48 82.8 61.5 14.9 78.7 66.9 13.1 74.3 73.1 11.4 69.8 80.0 9.8 65.1 87.5 8.4

50 85.7 62.6 15.1 81.4 68.0 13.3 76.9 74.2 11.6 72.2 81.0 10.1 67.4 88.6 8.6

55 92.9 65.3 15.8 88.3 70.8 13.9 83.4 77.0 12.2 78.4 83.8 10.6 73.2 91.5 9.1

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 251.4 64.8 3.6 238.7 70.4 3.2 225.4 76.5 2.8 206.4 81.6 2.4

8 267.6 66.7 3.7 254.2 72.3 3.3 240.1 78.4 2.9 225.0 84.9 2.5

10 284.4 68.6 3.9 270.4 74.2 3.4 255.6 80.3 3.0 240.1 87.1 2.6

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

RLC-PRC016-EN

Entering Condenser Air Temperature (Degrees C)

25

Page 26

Performance Data

Table P-9 — 50 Hz RTAA 90 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 82.1 68.1 13.3 78.0 73.9 11.7 73.5 80.6 10.2 68.9 88.1 8.8 64.0 96.6 7.5

42 85.0 69.3 13.5 80.7 75.1 12.0 76.1 81.7 10.4 71.3 89.3 9.0 66.3 97.7 7.7

44 87.9 70.5 13.8 83.5 76.3 12.2 78.8 82.9 10.7 73.8 90.5 9.2 68.7 98.9 7.9

46 90.9 71.8 14.0 86.3 77.5 12.4 81.5 84.1 10.9 76.4 91.7 9.4 71.1 100.2 8.1

48 93.9 73.1 14.3 89.2 78.8 12.6 84.2 85.4 11.1 79.0 92.9 9.6 73.5 101.4 8.2

50 97.0 74.4 14.5 92.1 80.1 12.9 87.0 86.7 11.3 81.6 94.2 9.8 76.0 102.7 8.4

55 105.0 77.8 15.0 99.7 83.4 13.4 94.2 90.0 11.8 88.3 97.5 10.3 79.9 103.0 8.8

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 286.2 76.2 3.5 271.4 82.2 3.1 256.0 89.0 2.7 240.1 96.5 2.4

8 303.8 78.4 3.6 288.3 84.4 3.2 272.1 91.1 2.8 255.6 98.6 2.5

10 322.1 80.7 3.7 305.9 86.7 3.3 289.0 93.4 2.9 271.1 100.9 2.5

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

Table P-10 — 50 Hz RTAA 100 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 91.1 78.4 12.9 86.6 84.6 11.4 81.7 91.7 10.0 76.5 100.0 8.6 71.0 109.4 7.4

42 94.2 79.8 13.1 89.5 85.9 11.6 84.5 93.1 10.2 79.1 101.3 8.8 73.5 110.7 7.5

44 97.4 81.2 13.3 92.5 87.3 11.8 87.3 94.4 10.4 81.8 102.7 9.0 76.0 112.1 7.7

46 100.6 82.7 13.5 95.6 88.7 12.0 90.2 95.8 10.6 84.5 104.1 9.2 78.6 113.5 7.9

48 103.9 84.2 13.7 98.7 90.2 12.3 93.2 97.3 10.8 87.3 105.5 9.4 81.2 114.9 8.0

50 107.3 85.7 13.9 101.9 91.7 12.5 96.2 98.7 11.0 90.1 106.9 9.6 83.8 116.3 8.2

55 115.9 89.7 14.4 110.1 95.6 12.9 103.9 102.6 11.4 97.4 110.7 10.0 88.6 117.6 8.6

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 317.1 87.1 3.4 301.0 100.0 3.0 283.7 101.0 2.6 265.8 109.3 2.3

8 336.5 89.7 3.5 319.3 102.5 3.1 301.3 103.5 2.7 282.3 111.8 2.4

10 356.2 92.3 3.6 338.2 105.1 3.2 319.3 106.1 2.8 299.2 114.4 2.5

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees F)

Metric

RLC-PRC016-EN26

Page 27

Performance Data

Table P-11 — 50 Hz RTAA 110 Performance Data English

LWT 75 85 95 105 115

(Deg. F) Tons kW EER Tons kW EER Tons kW EER Tons kW EER Tons kW EER

40 98.4 85.3 12.8 93.5 92.0 11.4 88.2 99.9 10.0 82.6 108.9 8.6 76.7 119.1 7.3

42 101.7 86.8 13.1 96.7 93.5 11.6 91.2 101.3 10.2 85.5 110.3 8.8 79.4 120.6 7.5

44 105.1 88.3 13.3 99.9 95.0 11.8 94.3 102.8 10.4 88.3 111.8 9.0 82.1 122.1 7.7

46 108.5 89.9 13.5 103.1 96.5 12.0 97.4 104.3 10.6 91.3 113.3 9.2 84.9 123.6 7.8

48 112.1 91.5 13.7 106.5 98.1 12.2 100.5 105.9 10.7 94.3 114.9 9.3 87.7 125.2 8.0

50 115.6 93.2 13.9 109.9 99.7 12.4 103.8 107.5 10.9 97.3 116.5 9.5 90.5 126.7 8.2

55 124.8 97.5 14.4 118.6 103.9 12.9 112.0 111.6 11.4 105.0 120.5 9.9 92.3 123.5 8.5

Notes:

1. Ratings based on sea level altitude and evaporator fouling factor of 0.00010.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kW input is for compressors only.

4. EER = Energy Efficiency Ratio (Btu/watt-hour). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 10°F.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.

7. Interpolation between points is permissible. Extrapolation is not permitted.

8. Rated in accordance with ARI Standard 550/590-98.

Entering Condenser Air Temperature (Degrees C)

LWT 30 35 40 45

(Deg. C) kWo kWi COP kWo kWi COP kWo kWi COP kWo kWi COP

6 342.5 94.8 3.4 324.9 101.9 3.0 306.6 110.0 2.6 287.3 119.0 2.3

8 362.9 97.5 3.5 344.6 104.6 3.1 325.2 112.7 2.7 304.8 121.8 2.4

10 384.3 100.4 3.6 365.0 107.5 3.2 344.6 115.5 2.8 323.1 124.6 2.5

1. Ratings based on sea level altitude and evaporator fouling factor of 0.0176.

2. Consult Trane representative for performance at temperatures outside of the ranges shown.

3. kWi input is for compressors only.

4. COP = Coefficient of Performance (kWo/kWi). Power inputs include compressors, condenser fans and control power.

5. Ratings are based on an evaporator temperature drop of 5.6°C.

6. 115°F performance data reflects Adaptive Control Microprocessor control algorithms.