Trane Roof Curbs Installation and Maintenance Manual

Installation Instructions

Roof Curbs

for Performance Climate Changer™ Air Handlers

Sizes 3-120

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improper ly installed, adjusted or alter ed equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

X-396412040 10

October 2011

CLCH-SVN05A-EN

Warnings, Cautions and Notices

Warnings, Cautions and Notices.

appropriate intervals throughout this manual. Warnings are provided to alert installing contractors

to potential hazards that could result in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Y our personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

ATTENTION:

this literature. Read these carefully.

WARNING:

result in death or serious injury.

CAUTION:

result in minor or moderate injury . It could also be used to aler t against unsafe practices.

NOTICE:

accidents.

WARNING

Warnings, Cauti ons and Notice s appe ar a t app rop riat e s ection s th roug hout

Indicates a potentially hazardous situation which, if not avoided, could

Indicates a potentially hazardous situation which, if not avoided, could

Indicates a situation that could result in equipment or property-damage-only

Note that warnings, cautions and notices appear at

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) r ecomm ended f or the work being under taken. ALWAYS ref e r t o a ppr o priate

MSDS and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to appropriate MSDS and

OSHA guidelines for information on allowable personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a r isk of arc or flash, technicians MUS T put on all Personal Protective Equipment (PPE)

in accordance with NFPA70E or other country-specific requirements for arc/flash protection

PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

Introduction

Overview of Manual

Performance Climate Changer™ air handlers may be mounted on the roof with a roof curb or pier

mount. This manual includes the assembly instructions for Performance air handler roof curb s.

Before proceeding with the installation, refer to the unit submittal drawings and unit tagging for

correct placement of air handler sections. Failure to review the submittal drawings could result in

performance or assembly problems. If there are any discrepancies, contact your local Trane sales

engineer before proceeding. Carefully review the procedures discussed in this manual to minimize

installation and startup difficulties.

2 CLCH-SVN05A-EN

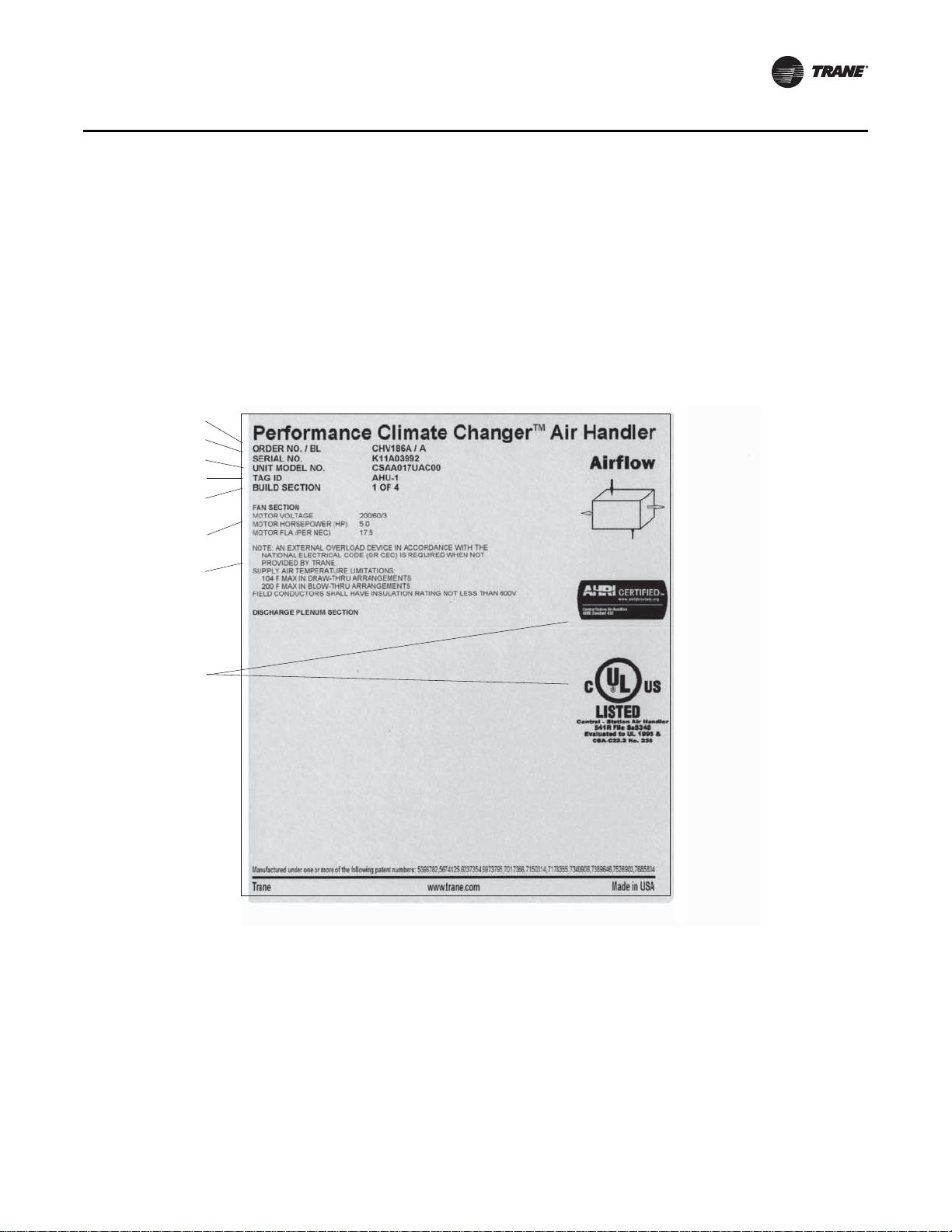

Nameplate

Agency listings and/or

agency certifications

Trane order number

Unit level serial number

Service model number

Unit tagging

Section location

Functional section type

Notes and additional

section information

Each P erformance air handler section shipped includes at least one nameplate/label (see Figure 1),

which identifies the type of section and functional components, cust omer tagging information, the

unit serial number, the unit order number, the bu ild se ction po siti on for in stalla tion , and th e uni t

model number. Refer to this information when ordering replacement parts or requesting service.

Note: The unit serial number and order number is required when ordering parts or requesting

service for a Trane air handler.

Figure 1. Performance air handler section nameplate

General Information

General Information

CLCH-SVN05A-EN 3

As-built submittals show the intended layout of the various air handler sections to meet job site

requirements. Installation information (unit dimensions, clearances, weights, curb location and

roof opening dimensions and locations) may vary with special equipment and applications. For

exact information, always refer to the specific unit submittals, which can be obtained from your

local Trane sales office.

Roof curbs for Performance air handlers are shipped “knocked down” for assembly at the job site.

General Information

Preparing the Unit Site

Ensure the installation site can support the total weight of the air-handling unit, includi ng

accessories and the roof curb. For approximate air handler section weights, refer to Performance

Climate Changer™Air Handler IOM, CLCH-SVX07C-EN. Units with special options or arrangements

will differ in dimensions, clear ances, weights and roof opening dimension s and locations. Always

refer to unit submittals before marking off the dimensions of the unit roof curb, pipe cabinet curb

(if pipe cabinet is ordered), and roof openings. For roof curbs supplied by T rane, approximate roof

curb weights are in Table 1.

Note: To calculate the total curb weight, find the unit length, multiply by the factor supplied in

Table 1 for the applicable roof curb height, and add the curb end weight for the applicable

roof curb height.

Table 1. Curb weights

Curb

height Unit Size 3 4 6 8 10 12 14 17 21 25

14-inch

18-inch

22-inch

26-inch

30-inch

36-inch

Curb

height

14-inch

18-inch

22-inch

26-inch

30-inch

36-inch

Note: Example: Size 21 Performance air handler with airfoil damper mixing section, small coil section, medium access section, medium coil section, small

blank section, VFD control section, and fan section (down discharge) total unit length is 156.75 inches. Total roof curb weight for the 18-inch curb

would be 502.80 lbs (156.75 x 1.05 = 164.5875 lbs + 338.21 = 502.7975 lbs.)

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 0.56 pounds, and add to the ab ove curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 1.05 pounds, and ad d to the abov e curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 1.22 pounds, and add to the ab ove curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.00 pounds, and ad d to the abov e curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.25 pounds, and add to the ab ove curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.63 pounds, and ad d to the abov e curb end & duct support weight.

117.23 155.82 155.82 175.88 209.84 225.27 242.25 242.25 266.94 266.94

148.76 197.59 197.59 222.98 265.95 285.48 306.96 306.96 338.21 338.21

171.54 227.14 227.14 256.05 304.98 327.22 351.68 351.68 387.26 387.26

215.31 286.02 286.02 322.78 385.00 413.28 444.39 444.39 489.64 489.64

240.72 319.23 319.23 360.06 429.15 460.56 495.11 495.11 545.36 545.36

278.82 369.05 369.05 415.98 495.38 531.48 571.18 571.18 628.93 628.93

Unit Size 30 35 40 50 57 66 80 100 120

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 0.56 pounds, and add to the abo ve curb e nd & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 1.05 pounds, and ad d to the abov e curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 1.22 pounds, and add to the abo ve curb e nd & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.00 pounds, and ad d to the abov e curb end & duct support weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.25 pounds, and add to the abo ve curb e nd & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.63 pounds, and ad d to the abov e curb end & duct support weight.

308.62 328.68 367.27 407.39 407.39 453.70 453.70 496.91 581.80

390.95 416.34 465.17 515.95 515.95 574.54 574.54 629.23 736.65

447.31 476.22 531.82 589.64 589.64 656.36 656.36 718.63 840.95

566.00 602.77 673.47 747.00 747.00 831.85 831.85 911.03 1066.58

630.15 670.98 749.50 831.15 831.15 925.37 925.37 1013.31 1186.04

726.38 773.30 863.54 957.38 957.38 1065.66 1065.66 1166.73 1365.24

4 CLCH-SVN05A-EN

Installation Considerations

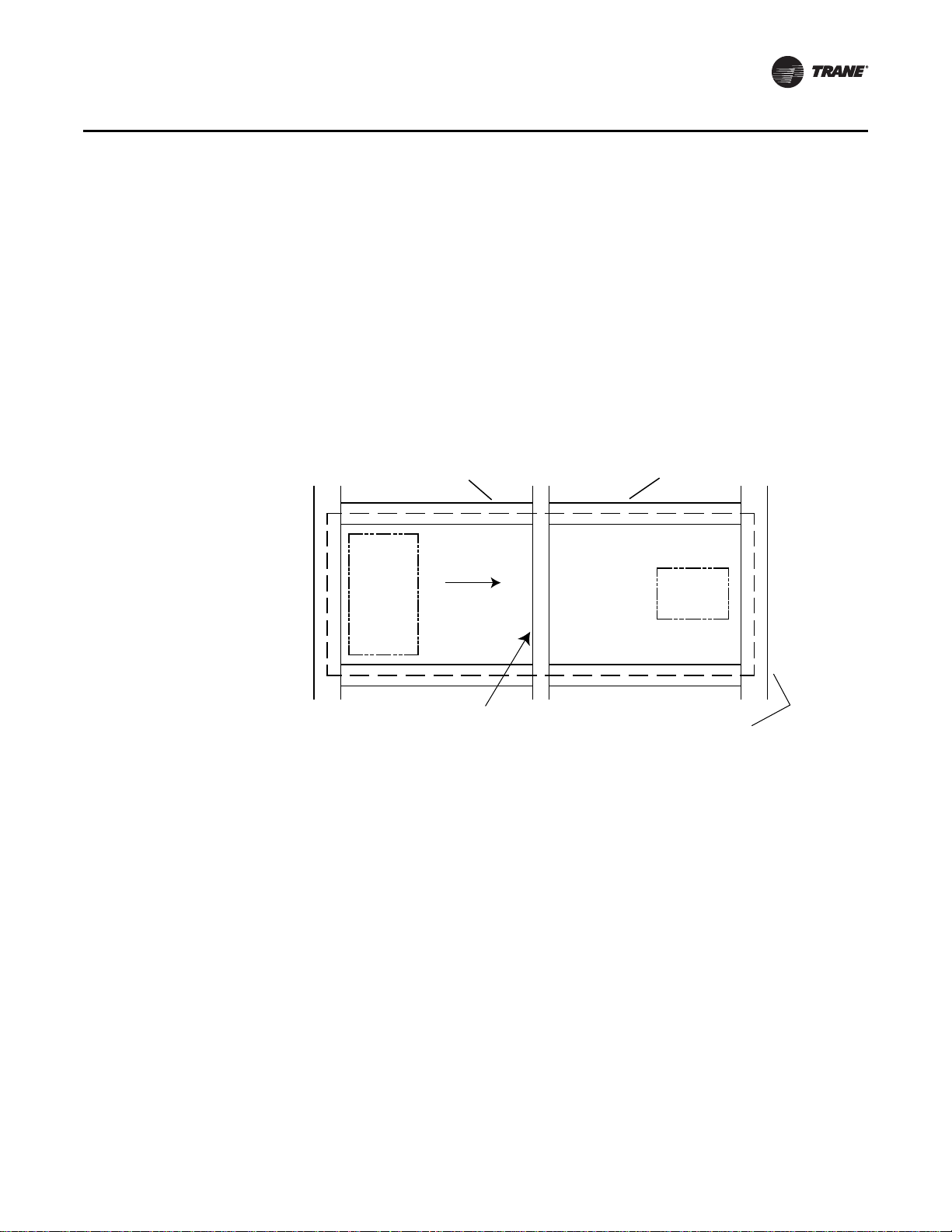

Discharge

Intake

Airflow

Auxillary support

loaded under curbs

Roof mounting curb

inside edge

Main roof support member

capable of supporting unit

weight

Main roof support member

or auxillary support located

under center of unit or under

section joints

• Isolation rails should not be installed on top of Trane roof curbs. If isolation rails or isolation

curbs are required, the entire curb system should be supplied by a specialty curb company.

Note: For proper operation, the unit must be supported around the entire unit base perimeter.

The roof curb must be supported al ong its entire perimeter . The curb may be set paralle l or at right

angles to roof support members. If at right angles to the supp ort members, there must be adequate

supporting roof cross members between the ends (in the direction of airflow). Be sure the cross

members do not interfere with the connection of supply and return ducts to the uni t. See Figure 2

for details.

Figure 2. Unit set perpendicular to roof curb members

Installation Considerations

• When mounting the unit on its roof curb, make sure that the gasketing between the roof curb

and unit base provides an airtight seal.

Note: When pulling shipping split sections together , the field-supplied gasket material may bunch

up between bases. Make certain this does not prevent tight contact between shipping

CLCH-SVN05A-EN 5

sections.

Installation Considerations

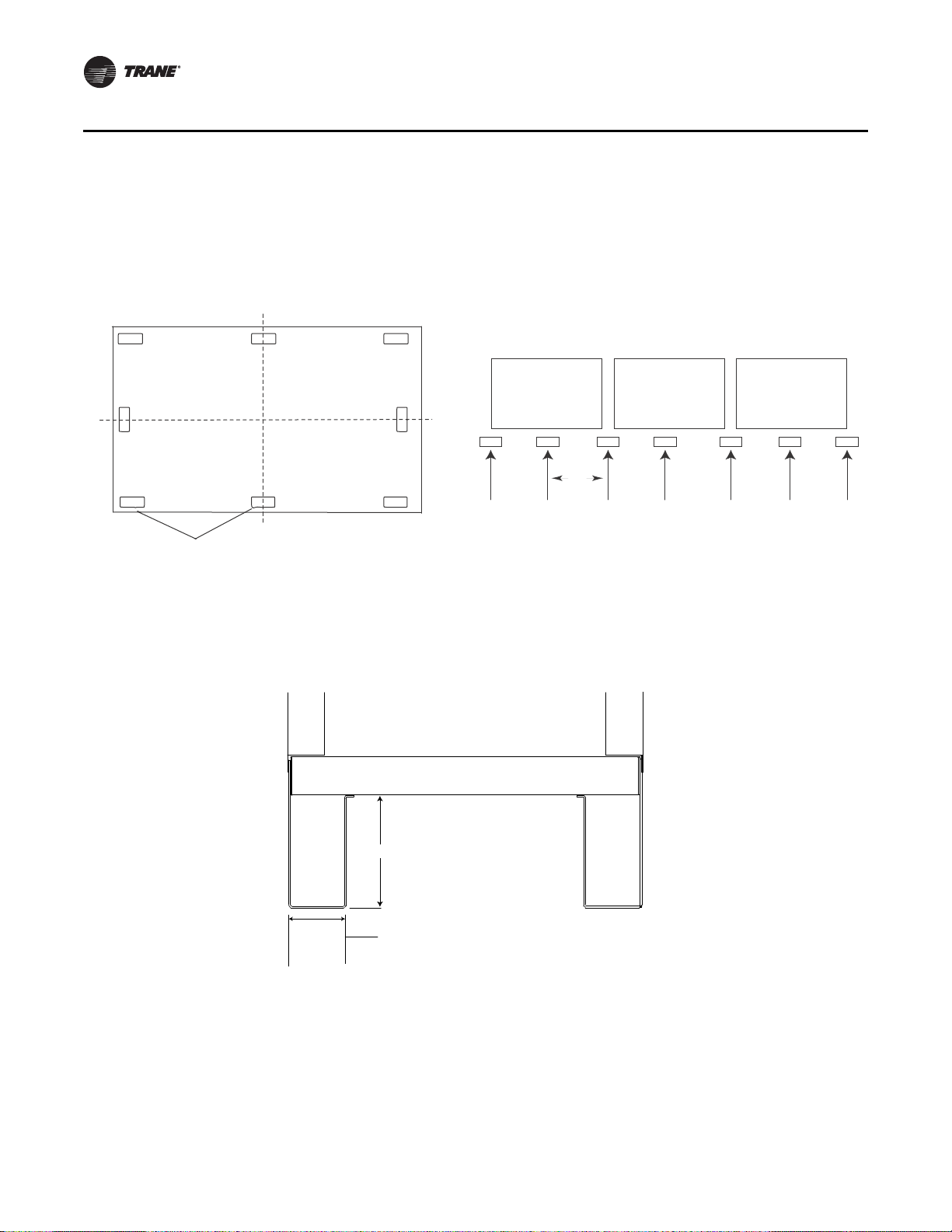

Piers

4 ft

3.0 in. - sizes 3-50

4.0 in. - sizes 57-120

6.0 in. - sizes 3-120

• If a unit is pier-mounted, at a minimum, locate one pier at each corner directly underneath any

shipping split (ensure full support under eac h side), and then every four feet at equally spaced

intervals around the perimeter of the unit. Both the unit and the pipe cabinet should be

supported by their base channel around the entire perimeter (see Figure 3 and Figure 4).

Figure 3. Pier locations (typical) Figure 4. Side view with shipping splits

Note: Piers beneath shipping splits must be structurally sound to support the weight of the unit.

See Figure 5 for typical cross section for pier- or slab-mounted base.

Figure 5. Typical cross section for pier-mounted or slab-mounted base.

• For new building construction, the roof curb may be installed as soon as the roof support

members are in place. Trane recommends that the roof curb be placed directly on the roof

support members and welded into place. If the curb is mounted on the roof deck, additional

support is necessary directly below the curb flanges to minimize vibration.

6 CLCH-SVN05A-EN

Loading...

Loading...