Page 1

Packaged Terminal Air

Conditioners & Heat Pumps

PTAC-PR C001 -ENOctober 2000

Page 2

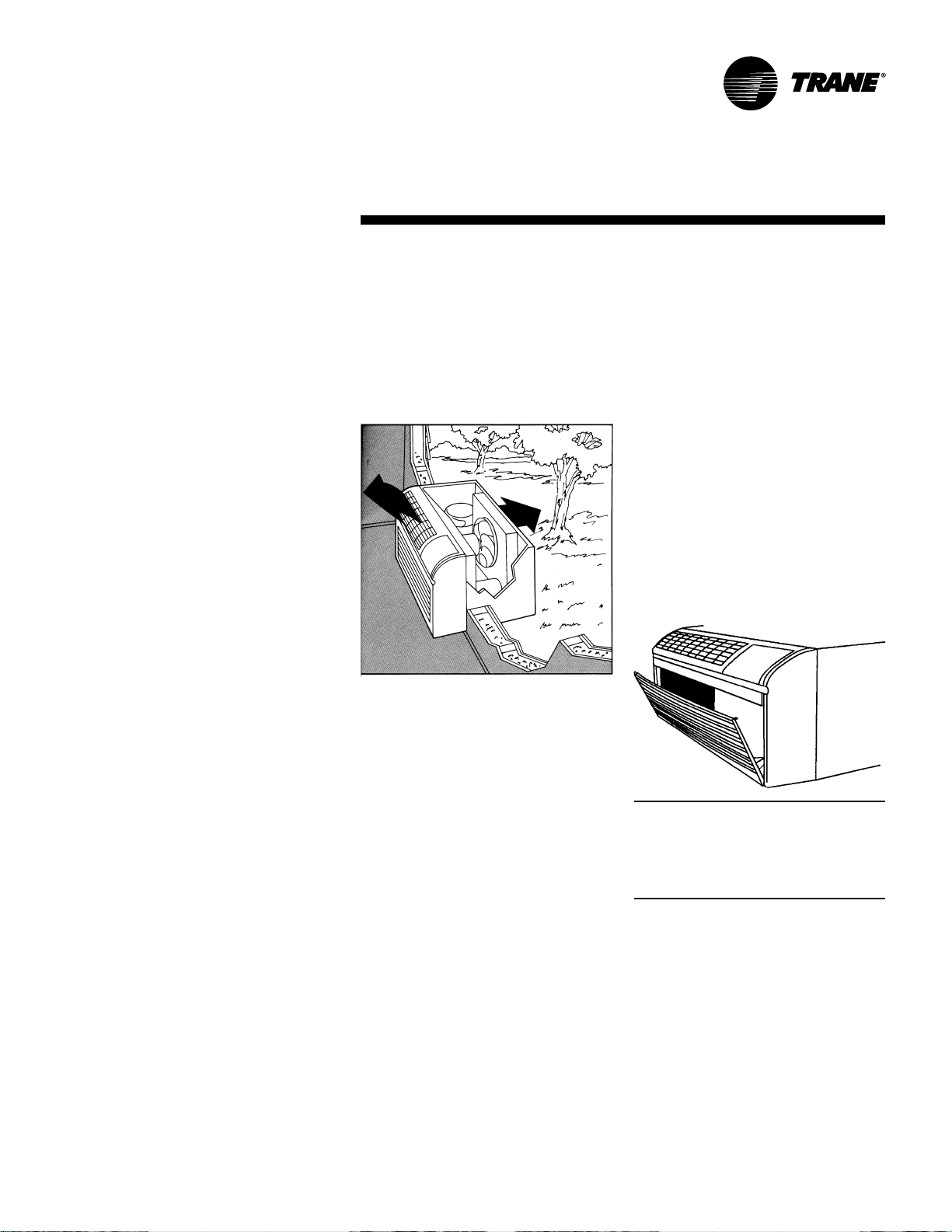

Introduction

The new T r ane pack ag ed ter minal air conditioners (PTACs) and heat pumps are ideally suited for of fices, apar tments, hotels,

motels and institutional homes. K ey benefits whic h mak e the units a wise choice ar e:

• Energy efficiency

• Reliability

• Quiet operation

• Comfort

• Easy-to-use controls

• Attractive and compact design

• Ease of installation and servicing

©American Standard Inc. 2000

PTAC-PRC00 1 -EN

Page 3

Contents

Introduction

Featur es and Benefits

Application Considerations

Selection Procedur e

Model Number Description

P erformance Data

Cool and Heat Performance

Electric P o wer

Power Connection Wiring

Dimension and W eights

Mechanical Specifications

Options

War ranty

2

4

6

7

7

8

8

15

15

16

20

22

24

PTA C-PRC001 -EN

3

Page 4

Features and Benefits

Energy Efficiency

T rane PTAC units and heat pumps are

among the most efficient in the industry,

with EERs of up to 11 .6 and COPs of up

to 3.3. The efficient design of the PSC

motor and airflow pattern help to reduce

the energy consumption of the fan.

Packaged terminal heat pumps tend to

be more efficient than electric heat only.

In fact, operating savings may result in a

payback of less than one year . During

heating operation, refrigerant in the heat

pump runs in the reverse direction of the

cooling operation. The outside air is

cooled, thereby giving up heat to the

refrigerant in the heat pump.

This heat is then pumped back inside,

resulting in up to three Btu’s of heat for

every Btu of energy consumed.

During cooling operation, heat is

removed from the building as the air is

cooled. This heat proceeds through the

compression cycle and is ultimately

rejected to the outside air.

Energy-saving options available with

PT AC units include:

Front Desk Contact P oint

Each unit has low voltage interface

capability with a field-supplied ON/OFF

switch. Turn off heating or cooling to

unoccupied rooms.

Fan Mode Switc h

Select continuous fan operation or cycle

the fan ON and OFF with the compressor

or heat operation. The switch is

concealed to help prevent tampering by

unauthorized personnel.

Temperature Limiter

This unit-mounted mechanical control

allows guests to adjust in-room

temperature settings within a preprogrammed range.

Reliability

These features help assure reliable

operation:

Freeze Pr ot ection

When the unit senses temperatures of

40°F or below, the unit activates the fan

motor and either the electric resistance

heater or the hydronic heater to help

prevent pipes or fixtures from freezing.

This also overrides front desk control of

the unit mounted or wall sensor.

Automatic Emer gency Heat

Each unit automatically switc hes over to

electric resistance heat if for any reason

the heat pump compressor system fails

or if the heating load is greater than the

unit capacity.

Random Restart

Avoid troublesome power surges that

can damage electrical circuits. Each unit

has a random restart circuit to prevent all

units from restarting at one time after

power disruption.

Compressor Restart Delay

Extend compressor life. The unit

automatically delays any restart at tempt

by three minutes to allow the refrigerant

pressures time to equalize.

Quiet Operation

State-of-the-art design and construction

provide a quiet environment for guests

to relax. Contributing to the quiet

operation of the unit are:

•An acoustically insulated bulkhead.

•Acoustical rubber -in-shear isolators

under the compressor.

•An isolated fan motor.

Operating sound levels are further

dampened when the unit is in the LO W

FAN mode of operation.

Comfort

Dehumidification and air filtration are

both factors affecting comfort. When the

air is dehumidified, occupants feel more

comfortable at higher temperatures.

T rane PTACs help maintain lower

humidity levels in rooms, without the

need for expensive add-on’s. Another

benefit is that dehumidification can help

extend the life of furniture, wall

coverings and fixtures.

When ventilation air is filtered, rooms

stay cleaner, longer. The hidden

ventilation air intake filters outside air to

reduce dust and pollen.

User -F r iendly Contr ols

Controls are easy to read, understand

and activate.

PTAC-PRC00 1 -EN4

Page 5

Features and

Benefits

Remote Thermostat Control

Each unit is built to be operated from a

remote-mounted thermostat, if desired.

Even if it is started without a remote, a

built-in low voltage power source can

accommodate a large variety of

thermostat choices — manual, auto

changeover or programmable — at a

later date.

Remote T emperature Sensing

Occupants enjoy ultimate comfort with

consistent climate control. Attach an

optional, inexpensive remote thermistor

temperature sensing device and

temperatures are held more closely to

the chosen room set ting.

Attractive and Compact Design

The unit front has a sleek seven-inch

depth, one of the shallowest silhouettes

in the industry today. To inhibit

tampering, the front can be secured to

the chassis with hidden screws.

Our unit’s new stylish design and neutral

color make it compatible with virtually

any room decor or arc hitectural design. It

blends into the room’s color scheme.

Special Paint Prot ection

The electrodeposition paint system on

the exterior panels assure the unit and

wall sleeve will withstand years of

moisture and atmospheric pollutants

without giving up its looks to rust and

corrosion.

Ease of Installation and Servicing

After the sleeve is in place, plug in or

directly hard-wire the unit and it is ready

to run. This unit has been designed to

replace most competitors’ units. In fact

this unit can fit into most existing

sleeves, making replacement of old or

inefficient units easy and economical.

And of course, the units may be installed

flush with the outside wall.

The main components are easily

serviced; the unit is easy to diagnose or

troubleshoot to spot potential problems.

When the filter needs to be cleaned or

replaced, the filt er access door tilts

forwar d for easy access. F or more

extensive service, the unit slides out of

the sleeve easily for full access t o all

working components.

5PTAC-PRC001-EN

Page 6

Application Considerations

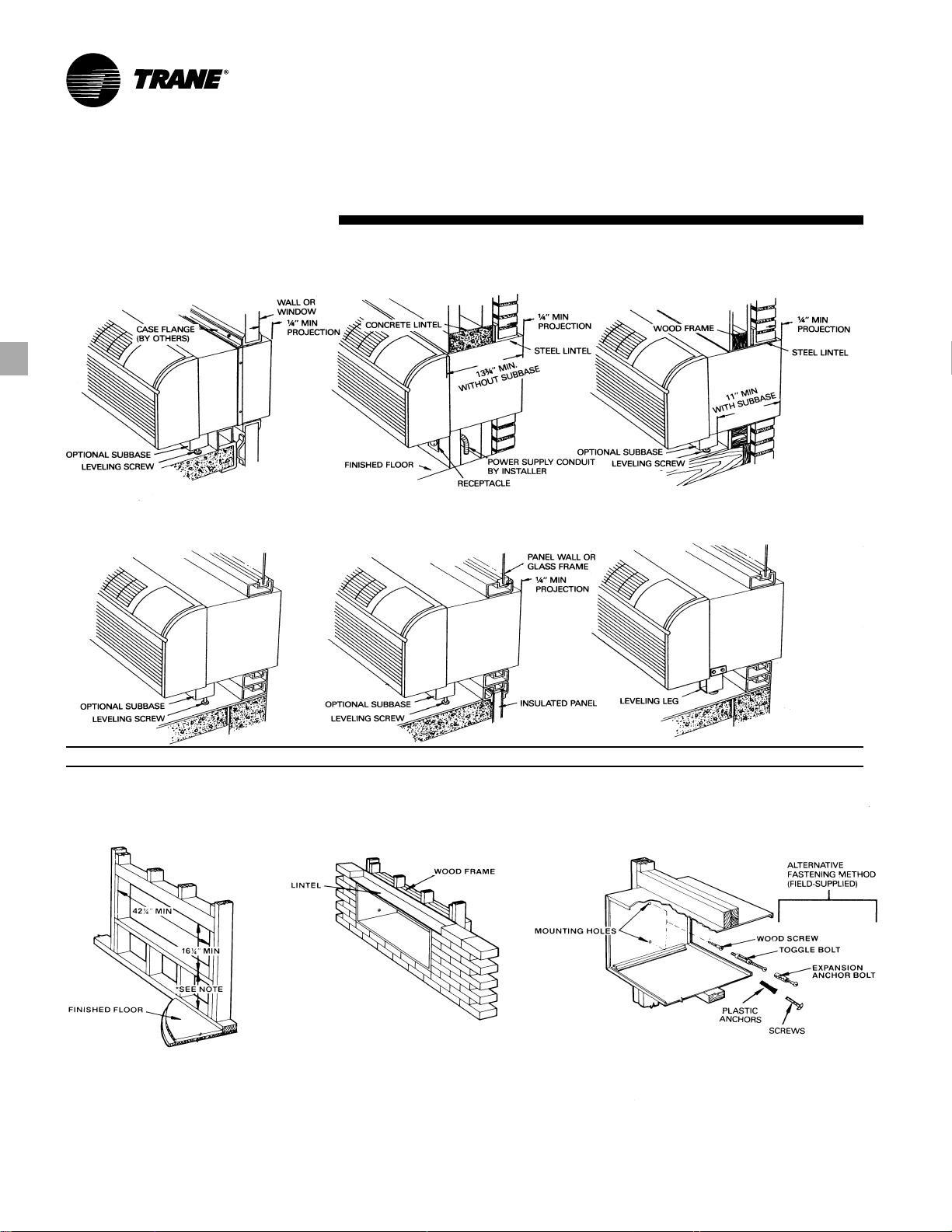

Curtain Wall Installation Block and Brick Veneer Installation Frame and Bric k Veneer Installation

Optional Leveling LegPanel Wall Installation Panel Wall and Block V eneer Installation

On applications not requiring subbase or lev eling legs, unit may be flush mount ed t o floor.

Sleeve Installation Da ta

Framing for Wall Case Framing With Lintel Attaching W all Sleeve to Opening

1. 3¼” minimum with subbase.

2. On applications not requiring subbase or

leveling legs, unit may be flush mounted to floor.

PTAC-PRC00 1 -EN6

Page 7

Model Number Description

MODEL NOMENCLATURE

PT E C 090 1 G * A

Digits 1,2 — Packag ed T e r minal

Air Conditioner

Digit 3 — Product T ype

E = Air Conditioner

H = Heat Pump

Digit 4 — Development Sequence

C = Third Development

Digits 5,6,7 — Unit Cooling Capacity

070 = 7,000 Btu

090 = 9,000 Btu

120 = 12,000 Btu

150 = 15,000 Btu

Notes:

1. Corrosion resistant, condensate pump, power vent units and all special units require extended ship cycles.

2. Only the following units are available from stock and can normally ship within 3 days after release.

3. Contact your local Trane representative for current stock availability and information on minimum quantity

requirements and shipping schedule for special production units.

Digit 8 — Main Pow er Supply

1 = 208-230/60/1

2 = 265/60/1

Digit 9 — Electric Heating Capacity**

0 = No Electric Heat – Air Conditioners Only

E = 2.5 kW

G = 3.5 kW (208-230V)

G = 3.7 kW (265V)

J = 5.0 kW*

Digit 10 — Design Sequence

Digit 1 1— Miscellaneous

A = Standard

B = Power Vent

C = Corrosion Resistant

D = Condensate Pump

H = Hydronic Chassis

F = Hydronic with Power Vent and Door

G = Hydronic with Power Door

J = Power Door

K = Condensate Pump with Power Vent

L = Condensate Pump with Power Door

Stock Style Models

PTEC0701GCA

PTEC0901GCA

PTEC120 1GCA

PTEC150 1GCA

PTEC150 1JCA

PTHC0701GCA

PTHC0901GCA

PTHC120 1GCA

PTHC150 1GCA

PTHC150 1JCA

PTEC0902GCA

PTHC0902GCA

PTEC1202GCA

PTHC1202GCA

PTEC1502GCA

PTHC1502GCA

*Sizes 09, 12 and 15 only.

**All heat pump units must have electric coils.

7PTAC-PRC001-EN

Page 8

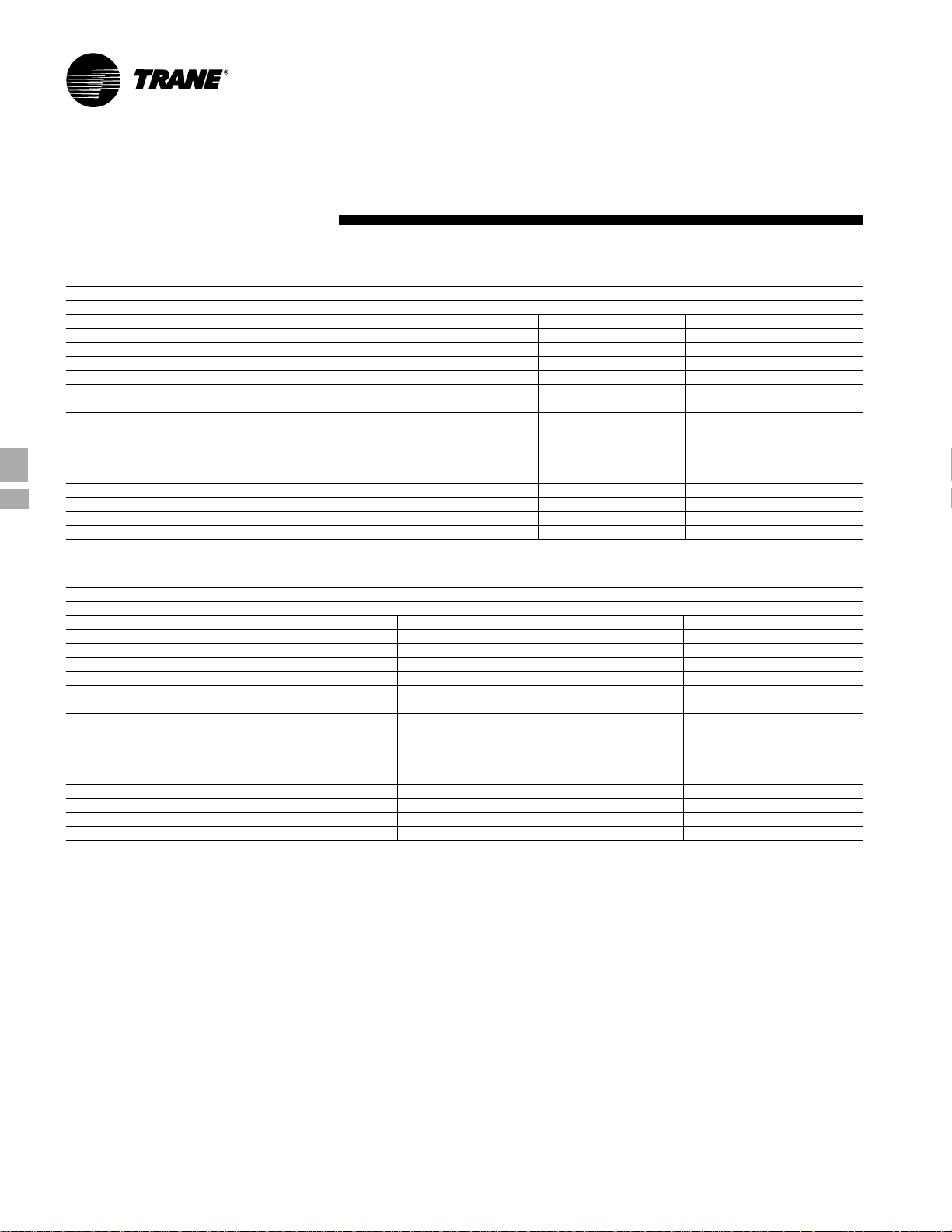

P erformance Data

Table PD-1 — Cooling Performance — Air Conditioner with Electr ic Heat Models

Model Type Air Conditioner

Model No.

Voltage

Capacity (Btu)

Amps 3.0 2.8 2.3 3.8 3.7 3.0 5.0 5.0 4.3 6.9 6.9 5.9

Watts 600 610 610 785 805 805 1 110 11 10 1130 1520 1545 1525

EER 1 1.6 11.6 1 1.6 11.3 1 1.3 11.3 10.7 10.7 1 0.7 9.2 9.2 9.3

Unit without Electric Heater

Min. Circuit/Ampacity

cfm (cool, wet coil)

cfm (dry coil)

Ventilated Air, cfm (fan only) 65* 65* 65* 65* 65* 65* 70* 70* 70* 70* 70* 70*

Dehumidification (pints/hr.) 1.6 1.6 1.6 2.6 2.6 2.6 3.5 3.5 3.5 4.4 4.4 4.4

Net wt. (approximate lbs.) 90 90 90 95 95 95 105 105 105 11 0 1 10 110

Shipping wt. (approximate lbs.) 105 105 105 110 11 0 110 120 120 120 125 125 125

* 95 cfm with optional power vent kit. Actual vent cfm performance will vary due to application and installation conditions.

Table PD-2 — Cooling Performance —Heat Pump with Electric Heat Models

Model Type Heat Pumps

Model No.

Voltage

Capacity(Btu)

Amps 3.0 2.8 2.3 3.8 3.5 3.0 5.0 4.6 4.3 6.9 6.3 5.9

Watts 610 615 615 785 805 805 1 110 1 120 1120 1485 1505 1505

EER 1 1.5 11.5 1 1.5 11.2 1 1.2 11.2 10.7 10.7 10.7 9.3 9.3 9.3

Unit without Electric Heater

Min Circuit/Ampacity

cfm (cool, wet coil)

cfm (dry coil)

Ventilated Air, cfm (fan only) 65* 65* 65* 65* 65* 65* 70* 70* 70* 70* 70* 70*

Dehumidification (pints/hr.) 1.6 1.6 1.6 2.6 2.6 2.6 3.5 3.5 3.5 4.4 4.4 4.4

Net wt. (approximate lbs.) 95 95 95 100 100 100 11 0 110 11 0 115 115 115

Shipping wt. (approximate lbs.) 11 0 110 110 115 115 115 125 125 125 130 130 130

*95 cfm with optional power vent kit. Actual vent cfm performance will vary due to application and installation conditions.

Notes:

1. All 265 volt models must use Trane’s subbase or Trane’s hard-wire junction box kit.

2. Minimum branch circuit ampacity ratings conform to the National Electric Code. However, local codes should apply.

3. Minimum voltage on 208/230 volt models is 197 volts; maximum is 253 volts. Minimum voltage on 265 volt models is 238.5 volts; maximum is 291.5 volts.

4. Overcurrent protection for all units without electric heaters is 15 amps. Overcurrent protection on 265 volt models must be cartridge-style time delay fuses (included and

5. Minimum operating ambient = 45°F.

6. Certified in accordance with the Unitary Air-Conditioner Equipment certification program, which is based on ARI standard 310/380.

EER — Energy Efficiency Ratio per American Refrigeration Institute (ARI) Test Procedures.

COP — Coefficient of Performance per ARI Test Procedures.

1 & 5

3

6

2 & 4

High 240 245 245 240 245 245 325 315 325 315 325 325

Low 205 220 220 205 220 220 250 220 250 220 250 250

High 260 265 265 260 265 265 345 335 345 335 345 345

Low 215 230 230 215 230 230 265 235 265 235 265 265

1 & 5

3

6

2 & 4

High 240 245 245 240 245 245 315 325 325 315 325 325

Low 205 220 220 205 220 220 220 250 250 220 250 250

High 260 265 265 260 265 265 335 345 345 335 345 345

Low 215 230 230 215 230 230 235 265 265 235 265 265

factory installed on Trane chassis). Note: All heat pump units must have electric coils.

PTEC 07 PTEC 09 PTEC 12 PTEC 15

208 230 265 208 230 265 208 230 265 208 230 265

7000 71 00 7100 8900 9100 9100 11900 12000 12000 1 4000 14200 14200

4.0 4.0 3.6 5.1 5.1 4.4 6.4 6.4 6.4 8.4 8.4 7.4

PTHC 07 PTHC 09 PTHC 12 PTHC 15

208 230 265 208 230 265 208 230 265 208 230 265

7000 7100 7100 8800 9000 9000 11 800 12000 12000 13800 14000 14000

4.0 4.0 3.6 5.1 5.1 4.4 7.3 7.3 5.7 8.4 8.4 7.4

PTAC-PRC00 1 -EN8

Page 9

P erformance

Data

Table PD-3 — Heat Pump Reverse Cycle Heating Capacity (Btu)

Model No.

Voltage

Amps 3.0 2.6 2.2 3.6 3.2 2.6 5.1 4.5 3.9 6.3 5.7 5.4

Wat ts 550 570 570 730 740 740 1000 1020 1020 1380 1390 1390

Btu

COP

cfm (dry) 230 235 235 230 235 235 290 310 310 335 345 345

Heating2 Btu °F

Outdoor Ambient 62 8200 8400 8400 1 0200 10300 10300 13000 13200 13200 16300 16400 16400

Rating Point (COP) 3.3 3.3 3.3 3.2 3.2 3.2 3.1 3.1 3.1 2.8 2.8 2.8

2

Watts 62 730 745 745 935 940 940 1230 1245 1245 1705 1715 1715

Outdoor Ambient 57 675 690 690 880 890 890 1150 1 170 1 170 1600 1610 1610

Notes:

1. All 265 volt models must use Trane’s subbase or Trane’s hard-wire junction box kit.

2. Heating capacity and efficiency is based on unit operation without condensate pump. Unit automatically switches to electric heat at 25°F outdoor coil temperature.

1

3

2

2

57 7600 7800 7800 9600 9700 9700 12200 12400 12400 15300 15400 15400

52 6900 7100 7100 8900 9000 9000 11400 11600 11600 14200 14300 14300

47 6200 6400 6400 8000 8100 8100 10600 10800 10800 13200 13300 13300

42 5500 5700 5700 7200 7300 7300 9800 10000 10000 12200 12300 12300

37 4900 5100 5100 6400 6500 6500 9000 9200 9200 11200 11300 11300

32 4300 4500 4500 5600 5700 5700 8200 8400 8400 10100 10200 10200

52 610 630 630 815 825 825 1075 1095 1095 1485 1495 1495

47 550 570 570 730 740 740 1000 1020 1020 1380 1390 1390

42 490 505 505 660 670 670 925 945 945 1275 1285 1285

37 435 450 450 585 595 595 850 870 870 1170 1180 1180

32 380 400 400 510 520 520 775 795 795 1055 1065 1065

Depending upon relative humidity conditions, this will occur at approximately 35 degrees outdoor ambient temperature.

PTHC 07 PTHC 09 PTHC 12 PTHC 15

208 230 265 208 230 265 208 230 265 208 230 265

6200 6400 6400 8000 8100 8100 1 0600 10800 10800 13500 13300 13300

3.3 3.3 3.3 3.2 3.2 3.2 3.1 3.1 3.1 2.8 2.8 2.8

9PTAC-PRC001-EN

Page 10

P erformance

Data

Table PD-4 — PTEC Air Conditioner — 208V

WBT Ent DBT Ent Outdoor T emperature (°F)

Nominal Indoor Indoor 85 95 105 1 15

Unit Coil Coil Total Sen % T otal Sen % T otal Sen % Total Sen %

Size (°F) (°F) Btu Btu SH Btu Btu SH Btu Btu SH Btu Btu SH

61 80 6930 6930 100 6665 6665 100 6270 6270 100 5980 5980 1 00

07 67 80 7345 5385 73 *7000 5250 75 6660 5295 80 6270 5175 83

73 80 8245 3980 48 7875 3850 49 7415 3845 52 7010 3710 53

61 80 8335 7390 89 7905 7165 91 7435 6930 93 7050 7050 1 00

09 67 80 9410 6240 66 *8900 5820 65 8355 5610 67 7795 5335 68

73 80 10585 4790 45 10020 4580 46 9420 4365 46 8795 4145 47

61 80 11220 10210 91 10575 9890 94 9815 9525 97 9110 9110 100

12 67 80 12630 8330 66 *11 900 8025 67 111 15 7705 69 10200 7370 72

73 80 14260 6520 46 13460 6230 46 12640 5930 47 11630 5575 48

61 80 13140 11930 91 12345 11515 93 11 395 11045 97 107 60 10760 100

15 67 80 14845 9745 66 *14000 9375 67 13020 8975 69 11990 8575 72

73 80 16780 7655 46 15870 7315 46 14835 6905 47 13635 6445 47

*These capacities are based on ARI rating point 80/67 entering air temperature, 95°F outdoor ambient.

75 6680 5695 85 6380 5545 87 6030 5665 94 571 0 5530 97

85 7205 7205 100 7030 7030 100 6745 6745 100 6320 6320 1 00

75 7440 4005 54 7155 4140 58 6680 4150 62 6290 4000 64

85 7390 6570 89 7105 6445 91 6690 6270 94 6330 6330 100

75 8335 2835 34 7885 2800 36 7485 2665 36 7070 2520 36

85 8150 5285 65 7750 4995 64 7345 4845 66 6940 4705 68

75 8385 6285 75 7940 6065 76 7460 5830 78 6960 5600 80

85 8480 8480 100 8130 8130 100 7765 7765 100 7345 7345 1 00

75 9510 501 0 53 9075 4810 53 8465 4610 54 7900 4510 57

85 9255 7295 79 8825 7165 81 8210 6890 84 7680 6470 84

75 1 071 0 3705 35 10135 3490 34 9555 3280 34 8935 3060 34

85 10450 5875 56 9880 5665 57 9270 5445 59 8640 5230 61

75 11265 8715 77 10610 8410 79 9875 8070 82 9000 7675 85

85 11505 11505 1 00 10965 10965 100 10300 10300 100 9605 9605 100

75 12770 6910 54 12205 6670 55 11320 6305 56 10440 5950 57

85 12425 9815 79 11805 9560 81 10905 9215 85 9980 8875 89

75 14435 5060 35 13645 4765 35 12840 4470 35 11 925 4145 35

85 14070 7985 57 13290 7700 58 12370 7400 60 11350 7020 62

75 13245 10205 77 12490 9830 79 11570 9405 81 10610 8940 84

85 13465 13465 1 00 12775 12775 100 11 965 1 1965 100 11 325 11325 100

75 15035 8120 54 14365 7835 55 13280 7345 55 12200 6875 56

85 14575 1 1 455 79 13785 111 25 81 12670 10680 84 11790 10370 88

75 16875 5915 35 16120 5625 35 15130 5260 35 14010 4790 34

85 16535 9330 56 15595 8970 58 14530 8610 59 13385 8225 61

PTAC-PRC00 1 -EN10

Page 11

Table PD-5 — PTEC Air Conditioner — 230/265V

P erformance

Data

Nominal Indoor Indoor 85 95 105 1 15

*These capacities are based on ARI rating point 80/67 entering air temperature, 95°F outdoor ambient.

WBT Ent DBT Ent Outdoor Temperature (°F)

Unit Coil Coil Total Sen % T otal Sen % T otal Sen % Total Sen %

Size (°F) (°F) Btu Btu SH Btu Btu SH Btu Btu SH Btu Btu SH

61 80 7030 7030 100 6765 6765 100 6370 6370 100 6080 6080 100

07 67 80 7445 5485 74 *7100 5350 75 6760 5395 80 6370 5275 83

73 80 8345 4080 49 7975 3950 50 7515 3945 52 7110 3810 54

61 80 8535 7590 89 8105 7365 91 7635 7130 93 7250 7250 1 00

09 67 80 9610 6440 67 *9100 6020 66 8555 5810 68 7995 5535 69

73 80 10785 4990 46 10220 4780 47 9620 4565 47 8995 4345 48

61 80 11320 10310 91 10675 9990 94 9915 9625 97 9210 9210 100

12 67 80 12730 8430 66 *12000 8125 68 11 215 7805 70 10300 7470 73

73 80 14360 6620 46 13560 6330 47 127 40 6030 47 11730 5675 48

61 80 13340 12130 91 12545 1 171 5 93 11 595 11245 97 10960 10960 100

15 67 80 15045 9945 66 *14200 9575 67 13220 9175 69 12190 8775 72

73 80 16980 7855 46 16070 7515 47 15035 7105 47 13835 6645 48

75 6780 5795 85 6480 5645 87 6130 5765 94 5810 5630 97

85 7305 7305 100 7130 7130 100 6845 6845 100 6420 6420 100

75 7540 4105 54 7255 4240 58 6780 4250 63 6390 4100 64

85 7490 6670 89 7205 6545 91 6790 6370 94 6430 6430 100

75 8435 2935 35 7985 2900 36 7585 2765 36 7170 2620 37

85 8250 5385 65 7850 5095 65 7445 4945 66 7040 4805 68

75 8585 6485 76 8140 6265 77 7660 6030 79 7160 5800 81

85 8680 8680 100 8330 8330 100 7965 7965 100 7545 7545 100

75 9710 5210 54 9275 50 10 54 8665 4810 56 8100 4710 58

85 9455 7495 79 9025 7365 82 841 0 7090 84 7880 6670 85

75 10910 3905 36 10335 3690 36 9755 3480 36 9135 3260 36

85 10650 6075 57 10080 5865 58 9470 5645 60 8840 5430 61

75 11365 8815 78 1071 0 8510 79 9975 8170 82 9100 7775 85

85 11605 11605 100 11 065 11065 100 10400 10400 100 9705 9705 100

75 12870 7010 54 12305 6770 55 11 420 6405 56 10540 6050 57

85 12525 9915 79 11905 9660 81 11 005 9315 85 10080 8975 89

75 14535 5160 36 13745 4865 35 12940 4570 35 12025 4245 35

85 14170 8085 57 13390 7800 58 12470 7500 60 11 450 7120 62

75 13445 10405 77 12690 10030 79 11770 9605 82 10810 9140 85

85 13665 13665 100 12975 12975 100 12165 12165 100 11525 11525 100

75 15235 8320 55 14565 8035 55 13480 7545 56 12400 7075 57

85 14775 11655 79 13985 11325 81 12870 10880 85 11990 10570 88

75 17075 6115 36 16320 5825 36 15330 5460 36 14210 4990 35

85 16735 9530 57 15795 9170 58 14730 8810 60 13585 8425 62

11PTA C-PRC001 -EN

Page 12

Table PD-6 — PTHC Heat Pump — 208V

P erformance

Data

Nominal Indoor Indoor 85 95 105 1 15

*These capacities are based on ARI rating point 80/67 entering air temperature, 95°F outdoor ambient.

WBT Ent DBT Ent Outdoor Temperature (°F)

Unit Coil Coil Total Sen % T otal Sen % T otal Sen % Total Sen %

Size (°F) (°F) Btu Btu SH Btu Btu SH Btu Btu SH Btu Btu SH

61 80 6930 6930 100 6665 6665 100 6270 6270 100 5980 5980 100

07 67 80 7345 5385 73 *7000 5250 75 6660 5295 80 6270 5175 83

73 80 8245 3980 48 7875 3850 49 7415 3845 52 7010 3710 53

61 80 8225 7175 87 7785 6945 89 7315 6705 92 6810 6790 100

09 67 80 9305 5890 63 *8800 5660 64 8250 5485 66 7675 5170 67

73 80 10480 4705 45 9920 4495 45 9315 4275 46 8690 4050 47

61 80 1 1120 10 110 91 1 0475 9790 93 9715 9425 97 9010 9010 100

12 67 80 12530 8230 66 *1 1800 7925 67 1 1 015 7605 69 10100 7270 72

73 80 14160 6420 45 13360 6130 46 12540 5830 46 11530 5475 47

61 80 12955 11755 91 12170 11350 93 1 1 230 10885 97 10605 10605 100

15 67 80 14635 9605 66 *13800 9240 67 12830 8845 69 11820 8450 71

73 80 16540 7545 46 15645 7210 46 14625 6805 47 13440 6355 47

75 6680 5695 85 6380 5545 87 6030 5665 94 5710 5530 97

85 7205 7205 100 7030 7030 100 6745 6745 100 6320 6320 1 00

75 7440 4005 54 7155 4140 58 6680 4150 62 6290 4000 64

85 7390 6570 89 7105 6445 91 6690 6270 94 6330 6330 100

75 8335 2835 34 7885 2800 36 7485 2665 36 7070 2520 36

85 8150 5285 65 7750 4995 64 7345 4845 66 6940 4705 68

75 8290 6120 74 7840 5900 75 7350 5660 77 6855 5420 79

85 8285 8285 100 7920 7920 100 7525 7525 100 7105 7105 100

75 9420 4905 52 8960 4775 53 8360 4500 54 7785 4400 57

85 9145 7085 77 8710 6945 80 8095 6670 82 7520 6400 85

75 1 061 0 3675 35 10050 3465 34 9450 3245 34 8835 3020 34

85 10345 5730 55 9775 5520 56 9165 5300 58 8535 5075 59

75 1 1165 8615 77 10510 8310 79 9775 7970 82 8900 7575 85

85 1 1 405 11405 100 10865 10865 100 10200 10200 100 9505 9505 1 00

75 12670 6810 54 12105 6570 54 1 1 220 6205 55 10340 5850 57

85 12325 9715 79 11705 9460 81 10805 91 15 84 9880 8775 89

75 14335 4960 35 13545 4665 34 12740 4370 34 11825 4045 34

85 13970 7885 56 13190 7600 58 12270 7300 59 1 1250 6920 62

75 13055 10055 77 12310 9690 79 1 1 405 9270 81 10460 8815 84

85 13275 13275 1 00 12590 12590 100 1 1795 11795 100 11 165 1 1165 100

75 14820 8000 54 14160 7720 55 13090 7240 55 12025 6775 56

85 14370 11290 79 13585 10970 81 12485 10530 84 1 1620 10220 88

75 16635 5825 35 15890 5540 35 14915 5185 35 13810 4720 34

85 16300 9195 56 15370 8845 58 14320 8490 59 13195 8105 61

PTAC-PRC00 1 -EN12

Page 13

Table PD-7 — PTHC Heat Pump — 230/265V

P erformance

Data

Nominal Indoor Indoor 85 95 105 1 15

*These capacities are based on ARI rating point 80/67 entering air temperature, 95°F outdoor ambient.

WBT Ent DBT Ent Outdoor Temperature (°F)

Unit Coil Coil Total Sen % T otal Sen % T otal Sen % Total Sen %

Size (°F) (°F) Btu Btu SH Btu Btu SH Btu Btu SH Btu Btu SH

61 80 7030 7030 100 6765 6765 100 6370 6370 100 6080 6080 1 00

07 67 80 7445 5485 74 *7100 5350 75 6760 5395 80 6370 5275 83

73 80 8345 4080 49 7975 3950 50 7515 3945 52 711 0 3810 54

61 80 8425 7375 88 7985 7145 89 7515 6905 92 701 0 6990 100

09 67 80 9505 6090 64 *9000 5860 65 8450 5685 67 7875 5370 68

73 80 10680 4905 46 101 20 4695 46 951 5 4475 47 8890 4250 48

61 80 11320 1 0310 91 10675 9990 94 9915 9625 97 9210 9210 100

12 67 80 12730 8430 66 *12000 8125 68 1121 5 7805 70 10300 7470 73

73 80 14360 6620 46 13560 6330 47 12740 6030 47 11730 5675 48

61 80 13155 1 1955 91 12370 11550 93 11430 11 085 97 10805 10805 100

15 67 80 14835 9805 66 *14000 9440 67 13030 9045 69 12020 8650 72

73 80 167 40 7745 46 15845 7410 47 14825 7005 47 13640 6555 48

75 6780 5795 85 6480 5645 87 6130 5765 94 5810 5630 97

85 7305 7305 100 7130 7130 100 6845 6845 100 6420 6420 1 00

75 7540 4105 54 7255 4240 58 6780 4250 63 6390 4100 64

85 7490 6670 89 7205 6545 91 6790 6370 94 6430 6430 100

75 8435 2935 35 7985 2900 36 7585 2765 36 7170 2620 37

85 8250 5385 65 7850 5095 65 7445 4945 66 7040 4805 68

75 8490 6320 7 4 8040 6100 76 7550 5860 78 7055 5620 80

85 8485 8485 100 8120 8120 100 7725 7725 100 7305 7305 1 00

75 9620 5105 53 9160 4975 54 8560 4700 55 7985 4600 58

85 9345 7285 78 8910 7145 80 8295 6870 83 7720 6600 85

75 10810 3875 36 10250 3665 36 9650 3445 36 9035 3220 36

85 10545 5930 56 9975 5720 57 9365 5500 59 8735 5275 60

75 11365 8815 78 10710 8510 79 9975 8170 82 9100 7775 85

85 11605 11605 100 1 1065 11065 100 10400 10400 100 9705 9705 100

75 12870 7010 54 12305 6770 55 11420 6405 56 10540 6050 57

85 12525 9915 79 11905 9660 81 11005 9315 85 10080 8975 89

75 14535 5160 36 13745 4865 35 12940 4570 35 12025 4245 35

85 14170 8085 57 13390 7800 58 12470 7500 60 11450 7120 62

75 13255 10255 77 12510 9890 79 11605 9470 82 10660 9015 85

85 13475 13475 100 12790 12790 100 11995 11995 100 1 1 365 11365 100

75 15020 8200 55 14360 7920 55 13290 7440 56 12225 6975 57

85 14570 11490 79 13785 11170 81 1 2685 10730 85 1 1820 10420 88

75 16835 6025 36 16090 5740 36 15115 5385 36 1401 0 4920 35

85 16500 9395 57 15570 9045 58 14520 8690 60 13395 8305 62

13PTA C-PRC001 -EN

Page 14

P erformance

Data

Table PD-8 — Heating Capacity — W ater

Pressure 7000 & 9000 Btu Units 12000 Btu Units 15000 Btu Units

Drop

(psig) 200°F EWT 180°F EWT 200°F EWT 180°F EWT 200°F EWT 180°F EWT

gpm Coil Valve Hi Lo Hi Lo Hi Lo Hi Lo Hi Lo Hi Lo

1 .00 0.93 0.19 14910 13388 12639 11186 16945 14387 14257 12152 17858 15534 15049 1 3312

1 .1 3 1 .03 0.24 15216 13706 12898 11452 17360 14689 14607 12407 18276 15955 1540 1 13672

1 .25 1.1 4 0.30 15500 13997 13139 1 1696 17745 14968 14930 12642 18666 16338 15729 14001

1 .38 1 . 26 0.36 15762 14262 13361 11917 18099 15222 15228 12858 1 9025 16684 16032 14297

1 .50 1 .40 0.43 16003 14501 13565 12117 18423 15454 15501 13053 19356 16991 16311 14561

1.63 1 .55 0.50 *16222 1471 4 13751 12295 18717 15661 15748 13228 19658 17261 16565 14792

1 .75 1 . 71 0.58 16420 14900 13919 12450 18980 15845 15969 13384 1 9930 17494 16794 14991

1 .88 1 .89 0.66 16596 15061 14068 12584 19212 16006 16165 13519 201 73 17689 16999 15158

2.00 2.10 0.76 16751 15195 141 99 12696 *19268 16142 16212 13635 20387 17846 17179 15293

2.13 2.32 0.85 16884 15302 1 4312 12786 19586 16255 16479 13730 *20445 17965 17229 15395

2.25 2.57 0.96 16995 15384 14407 12854 19727 16345 16598 13806 20727 18047 1 7466 15465

2.38 2.84 1.07 17085 15439 14483 12900 19838 16410 16691 13861 20853 18091 17572 15503

2.50 3.14 1.18 17154 15467 14541 12924 19919 16452 16759 13897 20950 18097 17654 15508

2.63 3.48 1.30 17201 15470 14581 12926 19968 16471 16801 13912 210 18 18065 1771 1 15481

2.75 3.85 1.43 17226 15505 14603 12956 19988 16580 1681 7 14004 21056 18140 17744 15545

*Based on ARI Rating Conditions of 70°F Entering Air Temp., 200°F Entering Water Temp and 180°F Leaving Water Temp.

Max Water Temperature 200°F Max. Water Pressure - 200 psig.

2-Way Fan Speed F an Speed Fan Speed Fan Speed Fan Speed F an Speed

Heating Capacity (Btu) Hot Water

Table PD-9 — Heating Capacity — Steam

7,000 & 9,000 Btu Units 12,000 Btu Units 15,000 Btu Units

Steam Fan Speed Fan Speed Fan Speed

PSIG High Low High Low High Low

2 20,236 17,816 21,694 18,306 23,709 —

3 20,686 18,253 22,100 19,003 25,676 21,099

4 20,821 18,544 22,822 19,313 26,325 23,678

PTAC-PRC00 1 -EN14

Page 15

Electric Power

Table EP-1 — Electric Heat Capacity and Electrical D ata (F or PTEC and PTHC Models)***

Electric Nominal Heating Minimum Circuit Overcurrent

2

Voltage

208/230 2.0/2.5 1 6,800 8,500 — 2,140/2,650 10.2/11.5 14.2 15 6-15 P

208/230 2.9/3.5 1 9,900 12,000 — 3,040/3,650 14.5/15.8 19.6 20 6-20 P

208/230 4.1/5.0 ** 14,000 17,100 — 4,240/5,150 20.3/22.3 27.7 30 6-30 P

265 2.5 1 — — 8,500 2,650 1 0 12.4 15 7-20 P

265 3.7 1 — — 12,600 3,850 14.6 18.1 20 7-20 P

265 5.0 ** — — 17,100 5,150 19.5 24.2 25 7-30 P

Notes:

1. Minimum branch circuit ampacity ratings conform to the National Electric Code. However, local codes should apply.

2. Minimum voltage on 208/230 volt models is 197 volts; maximum is 253 volts. Minimum voltage on 265 volt models is 238.5 volts; maximum is 291.5 volts.

3. Overcurrent protection for all units without electric heaters is 15 amps. Overcurrent protection on 265 volt models must be cartridge-style time delay fuses (included and

factory installed on Trane chassis).

4. Total watts for 7,000 and 9,000 Btu models; add 40 watts for size 12 and 70 watts for size 15.

**PTHC07, 09 and 12 are two-stage; PTHC15 is one-stage.

*** Note: All heat pumps must have electric coils.

Table EP-2 — Pow er Receptacle Configurations

Voltage 208/230 265

Unit Supplied Plug

Heater No. Of T otal T otal Power

Size (kW) Stages Btu 208 Btu 230 Btu 265 Watts

4

Amps Ampacity1Protection

3

Cord

Amps 1 5 20 30 20 30

NEMA Rating 6-15P 6-20P 6-30P 7-20P 7-30P

Receptacle

Amps 20 20 30 20 30

NEMA Rating 6-20R 6-20R 6-30R 7-20R 7-30R

Notes:

1. All wiring, including receptacles, must be made in accordance with local electrical codes and regulations.

2. NEMA 6-15 and 6-20 plugs fit in NEMA 6-20 receptacles.

3. Receptacles shown for 208/230 applications are factory supplied with subbase, per local codes for wall mounted receptacles use or the corresponding NEMA receptacles.

4. Receptacles shown for 265 volt applications are factory supplied with subbase. Codes do not allow 265 volt units to mate with wall mounted receptacles. They may however be

hard-wired per Local Codes.

15PTA C-PRC001 -EN

Page 16

Unit with Wall Sleeve and Subbase Accessory

Dimension and Weights

T op View

Front View

Notes:

1. Allow a minimum of 31/4” clearance between cabinet and floor to permit installation of options subbase.

2. Allow minimum of 3” clearance between cabinet and side walls to permit front panel removal.

3. Drain tube can be mounted either right side, left side or bottom of sleeve. Bottom drain to be located by customer. Drain kit shipped separate.

4. Unit provides 20 percent outside air.

5. Detachable cord ships attached to unit. Cord can be removed for direct attachment of building wiring or wiring from junction box kit.

6. For U.S. approval — 265 volt units and units with duct packages must have permanent wiring connection. Permanent wiring requirement can be met either by supplying

afull length subbase for concealed cord connection or by direct wiring with junction box kit.

7. Control door provided on standard unit for access to controls.

Right Side View

PTAC-PRC00 1 -EN16

Page 17

Dimension and

Weights

Field Supplied Extension

17PTA C-PRC001 -EN

Page 18

Hydronic Heat Kit

NOTE: W all sleeve must

extend exactly 3 inches

from finished interior

wall

Dimension and

Weights

Notes:

1. This kit completely encloses all plumbing and coils, but still allows easy access to controls.

2. The chassis can slide out for easy service without removing hydronic plumbing.

3. The kits feature left or right-hand piping.

4. Unit retains complete service access with kit installed.

PTAC-PRC00 1 -EN18

Page 19

Dimension and

Weights

Duct Pack age

When two adjacent rooms need to be conditioned, a main duct kit and a duct extension kit are possible options. These kits transfer

air from one room to another, yet allow different air flows for the rooms (airflow distribution can be adjusted from

65/45 to 80/20.)

Front View

Duct T ermination Kit

The Duct Termination Kit

includes a grille and a

sleeve for fit ting duct or

duct extension through

the wall.

19PTA C-PRC001 -EN

Page 20

Mec hanical Specifications

Unit Chassis

Each unit will be slide-out design shipped

with room cabinet front installed. Unit

chassis will have the ability to be installed

with zero reversing clearance from

finished floor. An electrical power cord

will be included with chassis and

installed by the manufacturer to assure

proper NEMA 6 or 7 configuration and

UL approved length. Unit will be tested

for conformance to AS TME w ater

infiltration specification AS TME 331 -86

which assures no water infiltration when

tested at eight inches of rain per hour at

63 mph wind for 15 minutes.

Room Cabinet/Front P anel

The room cabinet/front panel will have

sloped discharge so that obstructions are

not placed on unit. The discharge

conditioned air can be directed into the

room at an angle of 15 to 40 degrees

from the vertical position. The discharge

grille will be a polycarbonate material to

resist bending, cracking, rusting and

corrosion. The front panel will be able to

be field secured to chassis to inhibit

tampering. Cabinet depth will be seveninch to minimize unit’s impact on room

space.

Filter

The filter will be accessible without

removing room front. Filter material will

be nylon mesh, permanent cleanable.

Condenser/Evaporat or F ans

One direct drive with a permanent split

capacitor two-speed motor. The

condenser fan will be propeller type and

the indoor evaporator fan will be a

centrifugal blower type.

Cooling Condensate Remov al

High humidity conditions may call for

condensate removal system. The

outdoor fan diffuses water directly on to

the outdoor condenser coil for rapid

evaporation and increased cooling

efficiency .

Compressor

The compressor will be hermetically

sealed, internally isolated, rotary-type

and permanently mounted on rubber

isolators. No removal or adjustment of

compressor hold down bolts will be

required during installation.

Coils

Coils will have rifled copper tubing

expanded into rippled-edge louvered

aluminum fins.

Heat Pumps

Heat pumps will include a changeover

thermostat that senses an outside coil

switch-over temperature of 25°F,

lock-open refrigerant valve during heat

pump operation, temperature-activated

defrost drain and automatic emergency

heat operation to override the heat

pump’s changeover thermostat and

bring on electric resistance heaters in the

event of a sealed system failure. Unit will

not operate compressor and electric

heaters simultaneously.

Outside Air Damper/V ent Control

The vent control will allow 65 to 70 cfm

of fresh air to be drawn into the room.

This fresh air can provide ventilation

when the blower is operating. T o obtain

access to the vent control, remove the

cabinet front. The vent control lever is on

the left side of the c hassis. The control

lever must be rotated to either open or

close the damper. Actual vent cfm

performance will vary due to application

and installation conditions.

Filtered Outdoor Air Intake

The outdoor air intake will be filtered

with a talc-filled polypropylene filter that

will reduce dust from coming into the

room.

Paint System Cor r osion Pr otection

All units are built with hot-dipped

galvanized steel. Metal parts are then run

through a six-stage zinc phosphate

cleaner/pretreatment, painted with a

cathodic electroplating of an epoxy resin

paint and baked for 20 minutes at 350°F.

All exterior parts that are exposed to

sunlight get an additional coating of

polyester and are baked for 20 minutes

at 350°F for additional protection from

the fading effects of ultraviolet rays. This

paint process makes the unit highly

resistant to normal rust, corrosion and

fading. It is the best paint process in the

industry today.

Corrosion-Resistant Chassis (Standar d Option)

The condenser coil is painted using

cathodic electrocoat. The bottom ¼ of the

compressor is coated with a water borne

resin. The outdoor side of interior parts

are top coated, in addition, the base pan

is cathodic electrocoated.

PTAC-PRC00 1 -EN20

Page 21

Mec hanical

Specifications

Unit Controls

The unit controls will be full solid-state

and accessible from the top. The

standard unit mounted controls will

include two rotary (switch) knobs

controlling unit operational and

temperature mode. The unit operational

switch includes:

• Off position.

• Fan only — unit operates on low fan

speed.

• Low cool — unit operates on low fan

speed to circulate air for cooling.

• High cool — unit operates on high fan

speed to circulate air for cooling.

• Low heat — unit operates on low fan

speed to circulate air for heating.

• High heat — unit operates on high fan

speed to circulate air for heating.

Temperature Switc h

The temperature switch is controlled by

turning the knob clockwise for a cooler

room temperature; turning it

counterclockwise will provide a w armer

room temperature. Adjusting the

thermostat to the mid setting (vertical)

will set the room temperature at

approximately 75°F.

Remote Control Operation

To operate units with remote

thermostats, the Standard/Remote unit

mounted switch must be set to the

remote position. When in the remote

position, the unit will only respond to the

wall-mounted thermostat inputs. Unit

will operate on low or high fan.

Remote Thermostat/Sensor T erminals

These terminals provide control inputs

for a remote thermostat or sensor.

Front Desk Contr ol Terminals

These terminals provide control inputs

for a front desk switch.

Load Shedding Terminals

The LS/IN terminals will provide a

connection for a switch that can be

added to close the circuit and lockout the

compressor and electric heat when the

power company or energy management

system is trying to reduce its load for a

specific time.

On Board Diagnostics

An LED light will flash a code displaying

8 conditions: Control OK, 24 Vac Fuse

Blown, ICT (Indoor Coil T emperature)

Probe Failure, Mode Switc h F ailure,

Potentiometer Failure, Bad Thermostat

Input Failure, Bad Communications in

Slave Mode, and IAT (Indoor Air

Temperature) Failure. A spare 500 MA

fuse has been provided on the board.

Temperature Limiter

The temperature limiting feature can

reduce energy costs by controlling the

maximum temperature in heating and

the minimum temperature in cooling.

Room Freez e Prot ection

Freeze protection is built into all units

and will activate the electric resistance

heater (when it senses a temperature of

40°F room temperature) to maintain an

above freezing temperature at the

sensor.

Fan Cycle S witch

The fan cycle switch sets the operational

mode of the fan. In the ON position, the

fan will run continuously whenever the

unit is in the heat or cool position. In the

AUTO position, the fan will cycle on and

off with the compressor or electric heater

when the unit is in the cool or heat

mode.

Aut omatic Emerg ency Heat Staged Thermostat

On every unit mounted control heat

pump, electric heat engages

automatically if the sealed system or

compressor fails.

Compressor Time Delay

The compressor will not try to restart

once running or until approximately

three minutes have elapsed after

shutdown.

21PTA C-PRC001 -EN

Page 22

Options

Options

Wall Sleeves

Wall sleeves shall be industry standard

size of 13¾”D x 42”W x 16

Extended Wall Sleeves

Extended wall sleeves shall be industry

standard size of 18”D x 42”W x 16

or 24” D x 42”W x 16

Drain Kit

Drain kit attaches to the bot tom of the

wall sleeve for directional controlled

internal or external disposal of

condensate and defrost water.

Outdoor Grilles

Outdoor grilles are available as

architectural extruded, anodized

aluminum and four standard colors.

Special colors are also available or

standard stamped aluminum.

Condenser Baffle Kit

The condenser baffle kit is required

when replacing an existing packaged

terminal unit and/or the original outdoor

grille is not made by Trane. These baffles

are required to deflect discharge air

away from the inlet, preventing

recirculation of hot condenser air.

Leveling Legs Kit

Attaches easily to the w all sleeve for

support and accurate unit leveling on

units without subbases. Adjustable from

5/8

” to 5 ¼”.

2

Subbases

Subbases are prewired to facilitate field

electrical connections and include a

NEMA 6 or 7 configuration electrical

receptacle. The subbases include two

leveling screws for sleeve support and

accurate unit leveling during installation.

Subbases include locations for field

installation of physical disconnect

switches, cartridge-style fuse holders

and circuit breakers. Side skirts will be

included with subbases.

1/16

”H.

1/16

”H.

1/16

”H

Pow er Disconnect S witch Kit

A power disconnect switch must be

installed in hard-wire junction or

subbase for use as a physical disconnect

where required by local codes.

Circuit Breaker Kit

A circuit breaker kit is installed in the

subbase to provide overcurrent

protection for proper 208/230 volt

amperage. Can also be used as a

physical disconnect where local codes

permit 208/230 volts.

Fuse Holder Kit

Fuses are included in 265 volt units. For

208/230 volts, these kits allow fusing in

15, 20 and 30 amps. Fuses are not

included. Fuse holders must be installed

in the unit or subbase.

Hard-Wire Junction Box Kit

Provides for easy electrical connection

when permanent wiring is required.

Hard-wire kit must be used on 265 volt

units if subbases are not used.

Duct T r ansition and Ext ended Kit

A main duct transition piece will attac h to

the discharge of the unit and a duct

extension will be attached to the

transition piece to carry up to 40 percent

of the conditioned air to the adjoining

room.

Pow ered Outside V ent and Damper Kit

An optional power vent kit can be

installed to increase cfm to 95. The

power damper will automatically open

when the unit is operating and close

when not powered. Actual vent cfm

performance will vary due to application

and installation conditions.

Hydronic Heat Kit

The hydronic heat kit is a field-installed

package that can attac h to air

conditioners to provide central system

hot water or steam heat capability on top

of units. The kit includes left or right-hand

piping. The units retain complete service

access with kit installed.

Control V alves

24 volt water valves are available in

either two-way or three-way for 208/230

volt units and 265 volt units. 24 volt

steam valves are also available for

208/230 and 265 volt units.

Remote/Wall Ther mostats

Manual changeover thermostat

One-stage heat, One-stage cool and Off

Switch.

Automatic changeover thermostat with

T wo-stage Heat and One-stage Cool and

Off Switc h.

T wo-stage Heat (heat pump only) First

stage brings on electric coil when room

temperature is more than 3.8°F cooler

than thermostat setting; then electric

heat will turn off and heat pump cycles

on. Also one-stage Cool with Manual

Changeover.

T wo-stage Heat and One-stage Cool with

Manual Changeover and Programmable.

Remote T emperature Sensor

This temperature sensor overrides

standard unit mounted sensor to allow

temperature sensing on internal wall for

more accurate temperature control.

Condensate Remov al Pump —Heat Pump Only

The internal condensate pump serves as

an effective means for disposing of

condensate generated during heat pump

operation by transferring it to the indoor

coil. The warm coil surface and the warm

room air help in evaporation of the

condensate while adding humidity to the

room. As with any equipment of this

type, the addition of this kit will decrease

the sensible heating capacity of the unit.

This kit is not intended for use in

seacoast or corrosive environments.

Note: Under extreme high humidity conditions, the

internal condensate pump may not be able to dispose of

all the condensate produced, and condensate would

then drip from the outside of the wall sleeve. If this

condensation is unacceptable, then a drain system

(including factory approved drain kit for the wall sleeve)

should be installed.

Control Cov er Key Loc k Kit

Allows the owner to lock the control

panel access to prevent unauthorized

operation.

PTAC-PRC00 1 -EN22

Page 23

Options

Subbase Kit

The fully skirted subbase conceals wiring

while providing strong support. A plug-in

receptacle and field wiring access

expedites installation. Electrical

accessories such as fuse holders, circuit

breakers and disconnect switches meet

N.E.C. requirements.

Fuse Holder Kit

Cartridge-style fuses can be installed in

the fuse holder for use in the subbase or

chassis. It is available in 1 5, 20 and 30

amp and included on the 265 volt unit.

Condensate Drain Kit

This kit attaches to the w all sleeve base

pan for controlled internal or external

disposal of condensate and defrost

water .

Outdoor Grilles

Outdoor grilles are available in stamped

aluminum and an attractive extruded

aluminum architectural grille.

Security Ke y Locks

The installation of T rane’s security key

locks helps prevent tampering of the

controls used to set temperature,

heating and cooling functions. Locks are

available for all PT AC models.

Deflector Baffle Kit

The kit includes two air deflection baffles.

These deflectors direct the air in toward

the center and away from the inlet to

prevent recirculation of the hot

condenser air. This kit is

when the outdoor grille is provided by

T rane.

Hard-Wire Kit

This kit is used to permanently wire to

chassis when standard subbase and

power cord are not utilized.

Circuit Breaker Kit

The circuit breaker kit, available in 15, 20,

25 or 30 amp, can be used with T rane’s

subbases. It gives overcurrent protection

and its location allows turning unit on or

off without tools.

not

to be used

Pow er Disconnect Switc h

The power disconnect switch can be

used for 265 or 208/230 volt physical

disconnect where required by local

codes. The switch is rated at 30 amp

capacity. The switch is for use with

T rane’s standard subbases or hard

wire kit.

Pow er Vent and D amper Kit

Installation of the power vent can

increase the cfm to 70. The damper will

automatically close when unit is not

powered.

Pow er Door Kit

Door will power open to allow fresh air

when the unit fan is on and spring

closed when the unit fan is off.

Remote T emperature Sensor

This sensor allows for inexpensive

temperature sensing on an internal wall

for more accurate temperature control.

23PTA C-PRC001 -EN

Page 24

Warranty

W ar ranty Info r mation

Standard War ranty

•Full First-Year W arranty

T rane will repair or replace, free of

charge including labor , an y part whic h

proves to be defective due to

workmanship or materials.

•Full Fiv e-Year Sealed System

Warranty

T rane will repair or replace, free of

charge including labor , the evaporator,

condenser, compressor or connecting

tubing which proves to be defective due

to workmanship or materials.

•Limited Second thr ough Fif th Year

Warranty

During the 2nd through 5th year, Trane

will provide, free of charge, functional

parts whic h prove to be defective due to

workmanship or materials. Components

covered are switc hes, solenoids, fan

motors, thermostats, circuit boards,

factory installed heaters, blower wheel,

fan propeller and capacitor.

This limited warranty does not include

diagnostic time, labor or any

transportation and reinstallation c harges

that may be required.

PTAC-PRC00 1 -EN24

Page 25

The T rane Company

An American Standard Company

www.trane.com

For more information contact your local

distributor (dealer), local district office, or

e-mail us at comfort@trane.com

Literature Order Number

File Number

Supersedes

Stocking Location

PTA C-PRC001 -EN

PL-UN-PTAC-PRC001-EN-10-00

PTA C-DS-1 6/98

Inland - La Crosse

Since The Trane Company has a policy of continuous product and product data improvement, it reserves the

right to change design and specifications without notice.

Loading...

Loading...