Page 1

Installation,

Operation, and

Maintenance

Packaged Terminal Air Conditioner

PTEE070/PTHE070 (7,000 Btuh)

PTEE090/PTHE 090 (9,000 Btuh)

PTEE120/PTHE120 (12,000 Btuh)

PTEE150/PTHE150 (15,000 Btuh)

September 2006 PTAC-SVX01C-EN

Page 2

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ta b le 1 . Minimum interior and exterior projections . . . . . . . . 6

Table 2. Minimum clearances and projections . . . . . . . . . . .7

Receiving and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Energy Management System . . . . . . . . . . . . . . . . . . . . . . 19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Refrigeration System Service . . . . . . . . . . . . . . . . . . . . . . 31

Brazing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cooling Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ground Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 27. Thermistor indoor coil resistance . . . . . . . . . . . . 38

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 28. Diagnostic codes . . . . . . . . . . . . . . . . . . . . . . . 41

Table 29. Latching diagnostics, reset required . . . . . . . . . 41

Table 30. Automatically resetting diagnostics . . . . . . . . . . 41

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Full 1st Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Full 2nd - 5th Sealed System Warranty . . . . . . . . . . . . . . . 50

Limited 2nd through 5th Year Functional Parts Warranty 50

2 PTAC-SVX01C-EN

Page 3

Model Number Description

Each Packaged Terminal Air

Conditioner/Heat Pump is assigned a

multiple-character alphanumeric

model number that precisely

identifies each unit.

An explanation of the identification

code that appears on the unit

nameplate is shown below.

The model number helps owner/

operator, installing contractors, and

service technicians to define the

operation, components and options

for a specific unit.

P T E E 0 9 0 1 * A A

1 2 3 4 5 6 7 8 9 10 11

Digits 1, 2—Packaged Terminal Air Conditioner

Digit 3—Product Type

E = Air Conditioner with auxiliary heat

H= Heat Pump

Digit 4—Development Sequence

E = Fifth Development Series

Digit 5, 6, 7—Unit Cooling Capacity

070 = 7,000 Btu

090 = 9,000 Btu

120 = 12,000 Btu

150 = 15,000 Btu

Refer to the model number printed

on the equipment nameplate when

ordering replacement parts or

requesting service.

Digit 8—Main Power Supply

1 = 230-208V/60Hz/1phase

2 = 265V/60Hz/1phase

4 = 115V/60Hz/1phase (Hydronic Only)

Digit 9 —Electric Heat Capacity*

U = Universal Heater (Heater kW determined by

power cord, see Accessories Section)

W = Hydronic (ships with no front cover & no

electric heater)

Digit 10 — Unit Features

A = Standard

C = Corrosion Resistant

D = Internal Condensate Pump

Digit 11—Minor Design Sequence

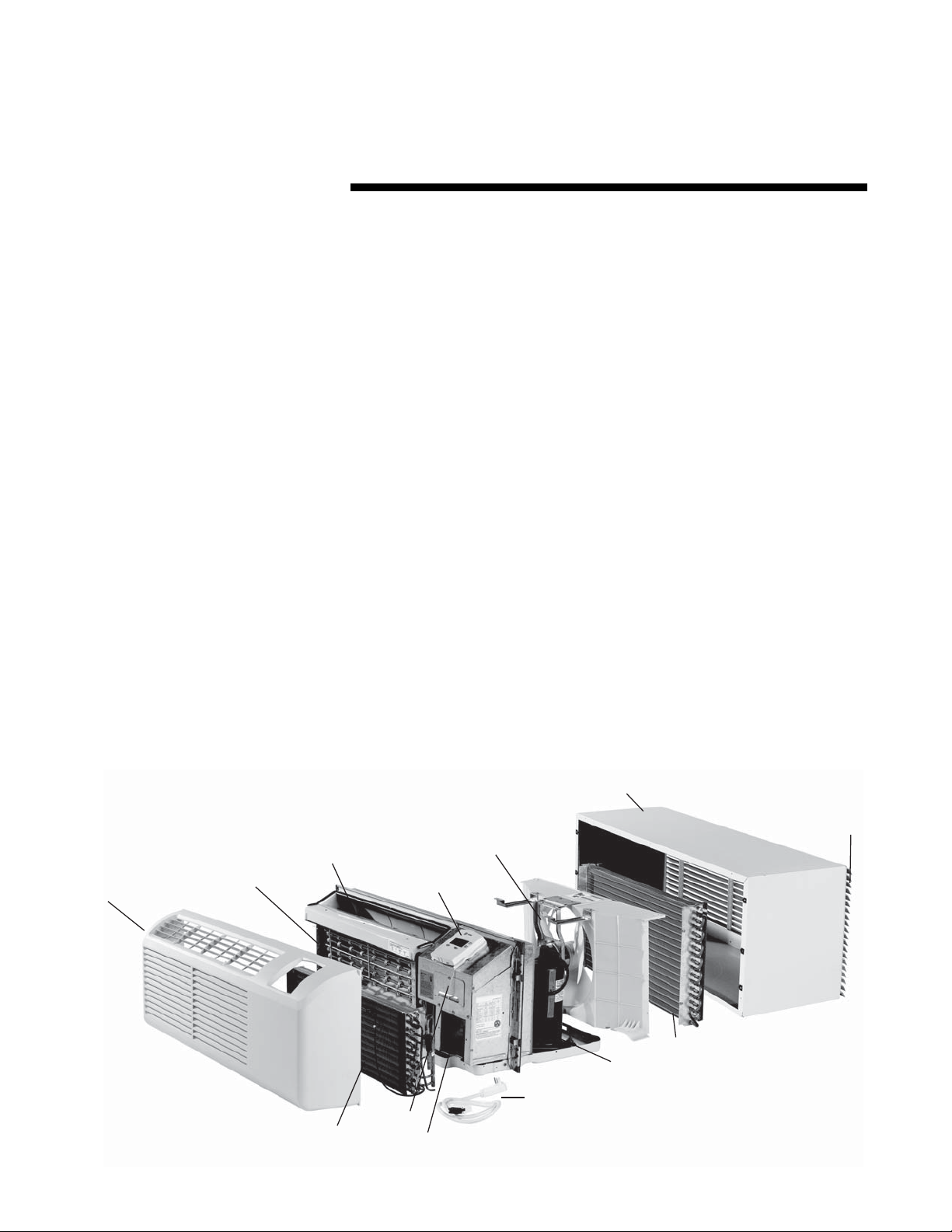

Front and discharge grille

Electric heater

Indoor coil

*All heat pump units must have electric heat.

Wall sleeve

Outdoor grille

Outdoor fan

Indoor Fan

Display Module

Outdoor coil

Rotary compressor

Power cord

Control box

Power cord coverplate (not shown)

PTAC-SVX01C-EN 3

Page 4

General Information

General Information

NOTICE:

Warnings and Cautions appear in

appropriate sections throughout this

manual. Read these carefully.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

CAUTION

Indicates a situation that may result

in equipment or property-damageonly accidents.

Overview of Manual

Note: One copy of this document

ships with each unit and is

customer property. It must be

retained by the customer.

This booklet describes proper

installation, operation, and

maintenance procedures for PTACs.

By carefully reviewing the

information within this manual and

following the instructions, the risk of

improper operation and/or

component damage will be

minimized.

It is important that periodic

maintenance be performed to help

assure trouble free operation. A

maintenance schedule is provided at

the end of this manual. Should

equipment failure occur, contact a

service organization with qualified,

experienced HVAC technicians to

properly diagnose and repair this

equipment.

Important

Environmental Concerns!

Scientific research has shown that

certain man-made chemicals can

affect the earth’s naturally occurring

stratospheric ozone layer when

released to the atmosphere.

In particular, several of the identified

chemicals that may affect the ozone

layer are refrigerants that contain

Chlorine, Fluorine and Carbon (CFCs)

and those containing Hydrogen,

Chlorine, Fluorine and Carbon

(HCFCs).

Not all refrigerants containing these

compounds have the same potential

impact to the environment.

The manufacturer advocates the

responsible handling of all

refrigerants—including industry

replacements for CFCs such as

HCFCs and HFCs.

Responsible Refrigerant

Practices!

The manufacturer believes that

responsible refrigerant practices are

important to the environment, our

customers, and the air conditioning

industry.

All technicians who handle

refrigerants must be certified. The

Federal Clean Air Act (Section 608)

sets forth the requirements for

handling, recovering, recycling and

reclaiming of certain refrigerants and

the equipment that is used in these

service procedures.

In addition, some states or

municipalities may have additional

requirements that must also be

adhered to for responsible

management of refrigerants. Know

the applicable laws and follow them.

WARNIN G

Hazardous Voltage with

Capacitators!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure the

power can not be inadvertently

energized. Failure to disconnect

power before servicing could result

in death or serious injury.

Disconnect all electric power,

including remote disconnects and

discharge all motor start/run

capacitors before servicing. Follow

proper lockout/tagout procedures to

ensure the power cannot be

inadvertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Failure

to disconnect power and discharge

capacitors before servicing could

result in death or serious injury.

CAUTION

Use Copper Conductors Only!

Unit terminals are not designed to

accept other types of conductors.

Failure to use copper conductors

may result in equipment damage.

© 2005 American Standard Inc. All rights reserved PTAC-SVX01C-EN

Page 5

General Information

Refrigerant Handling Procedures

WARNING

Contains Refrigerant!

System contains oil and refrigerant

under high pressure. Recover

refrigerant to relieve pressure before

opening the system. See unit

nameplate for refrigerant type. Do

not use non-approved refrigerants,

refrigerant substitutes, or refrigerant

additives.

Failure to follow proper procedures

or the use of non-approved

refrigerants, refrigerant substitutes,

or refrigerant additives could result

in death or serious injury or

equipment damage.

Environmental Accountability Policy

The manufacturer urges that all

HVAC servicers make every effort to

eliminate, if possible, or vigorously

reduce the emission of CFC, HCFC,

and HFC refrigerants to the

atmosphere. Always act in a

responsible manner to conserve

refrigerants for continued usage

even when acceptable alternatives

are available.

Recover and Recycle Refrigerants

Never release refrigerant to the

atmosphere!

Always recover and/or recycle

refrigerant for reuse, reprocessing

(reclaimed), or properly dispose if

removing from equipment.

Always determine the recycle or

reclaim requirements of the

refrigerant before beginning the

recovery procedure.

Obtain a chemical analysis of the

refrigerant if necessary.

Questions about recovered

refrigerant and acceptable refrigerant

quality standards are addressed in

ARI Standard 700.

Refrigerant Handling and Safety

Consult the manufacturer’s material

safety data sheet (MSDS) for

information on refrigerant handling

to fully understand health, safety,

storage, handling, and disposal

requirements.

Use only approved containment

vessels and refer to appropriate

safety standards. Comply with all

applicable transportation standards

when shipping refrigerant

containers.

Service Equipment and Procedures

To minimize refrigerant emissions

while recovering refrigerant, use the

manufacturer’s recommended

recycling equipment per the MSDS.

Use equipment and methods which

will pull the lowest possible system

vacuum while recovering and

condensing refrigerant. Equipment

capable of pulling a vacuum of less

than 1,000 microns (1.0 mm) of

mercury is recommended.

Do not open the unit to the

atmosphere for service work until

refrigerant is fully removed/

recovered.

When leak-testing with trace

refrigerant and nitrogen, use HCFC22 (R-22) rather than CFC-12 (R-12) or

any other fully-halogenated

refrigerant.

Be aware of any new leak test

methods which may eliminate

refrigerants as a trace gas.

Perform evacuation prior to charging

with a vacuum pump capable of

pulling a vacuum of 1,000 microns

(1.0 mm) of mercury or less. Let the

unit stand for 12 hours and with the

vacuum not rising above 2,500

microns (2.6 mm) of mercury.

A rise above 2,500 microns (2.5 mm)

of mercury indicates a leak test is

required to locate and repair any

leaks. A leak test is required on any

repaired area.

Charge refrigerant into the

equipment only after equipment

does not leak or contain moisture.

Refer to proper refrigerant charge

requirements in the maintenance

section of this manual to ensure

efficient machine operation.

When charging is complete, purge or

drain charging lines into an approved

refrigerant container.

Seal all used refrigerant containers

with approved closure devices to

prevent unused refrigerant from

escaping to the atmosphere.

Take extra care to properly maintain

all service equipment directly

supporting refrigerant service work

such as gauges, hoses, vacuum

pumps, and recycling equipment.

When cleaning system components

or parts, avoid using CFC-11 (R-11) or

CFC-113 (R-113). Use only cleaningsolvents that do not have ozone

depletion factors.

Properly dispose of used materials.

Refrigeration system cleanup

methods using filters and driers are

preferred.

Check for leaks when excessive

purge operation is observed.

Keep abreast of unit enhancements,

conversion refrigerants, compatible

parts, and manufacturer’s

recommendations that will reduce

refrigerant emissions and increase

equipment operating efficiencies.

PTAC-SVX01C-EN 5

Page 6

Pre-Installation

Pre-Installation

Pre-Installation Considerations

Before beginning installation, make

the following considerations:

1. Verify the wall opening is in the

correct location and the

correct size.

2. Drill mounting holes on both

sides of the wall sleeve, if

equipment requires any of the

following options: subbase,

leveling legs, or hydronic heat

kit.

If dimension A in Figure 2 is at or

near the minimum specified in

Ta b l e 2, p . 7 , accessory options

should be mounted to the sleeve

prior to installing the sleeve in

the wall. Otherwise, there may

not be enough access room for

the tools used to mount the

accessories to the wall sleeve.

3. If additional wall sleeve support

is required, the leveling leg

accessory kit or a subbase kit

that includes leveling legs can be

used to provide extra support.

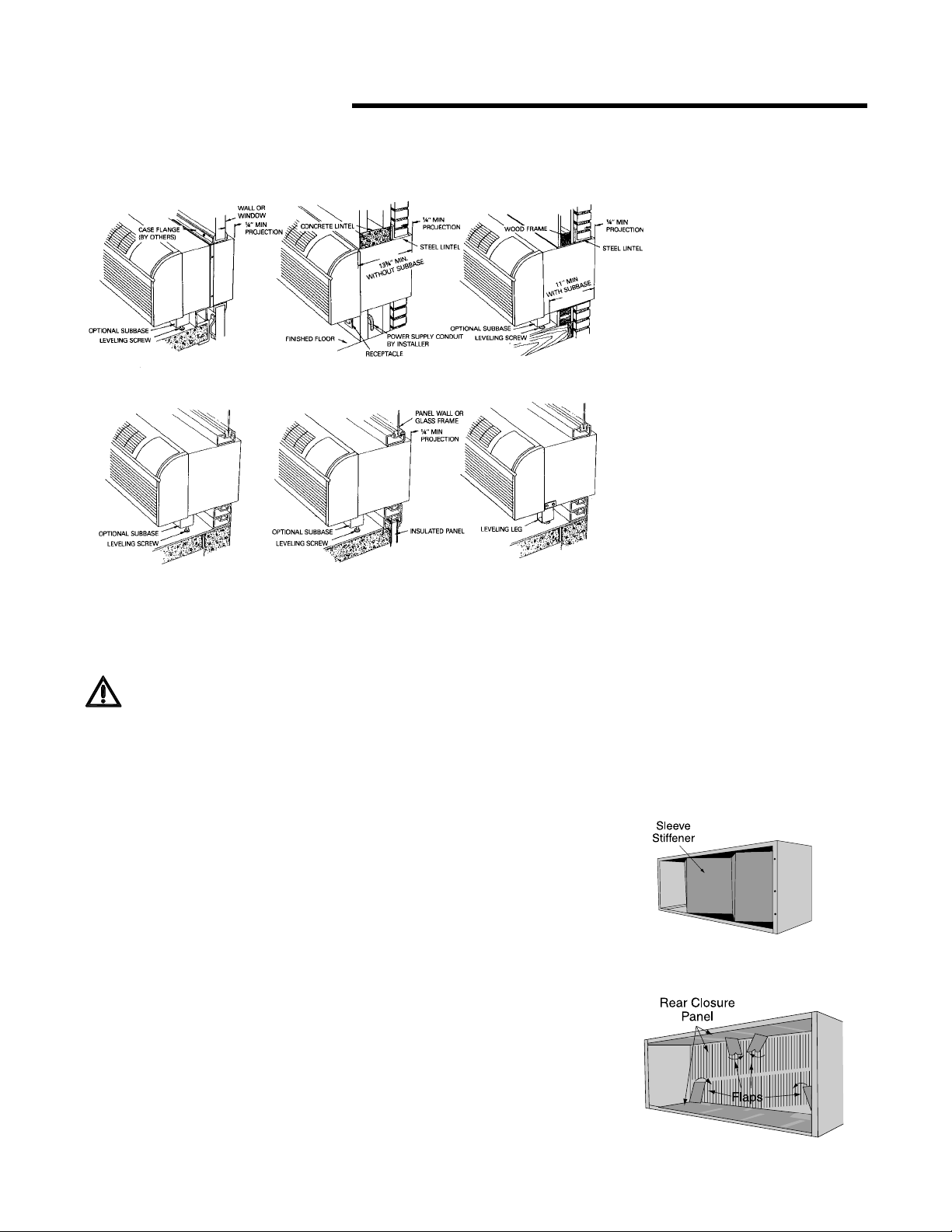

4. If installing in a concrete or

masonry wall, you must provide

a lintel in the wall opening for

support. Do not use the wall

sleeve as a lintel.

See Figure 1 for a typical lintel

construction.

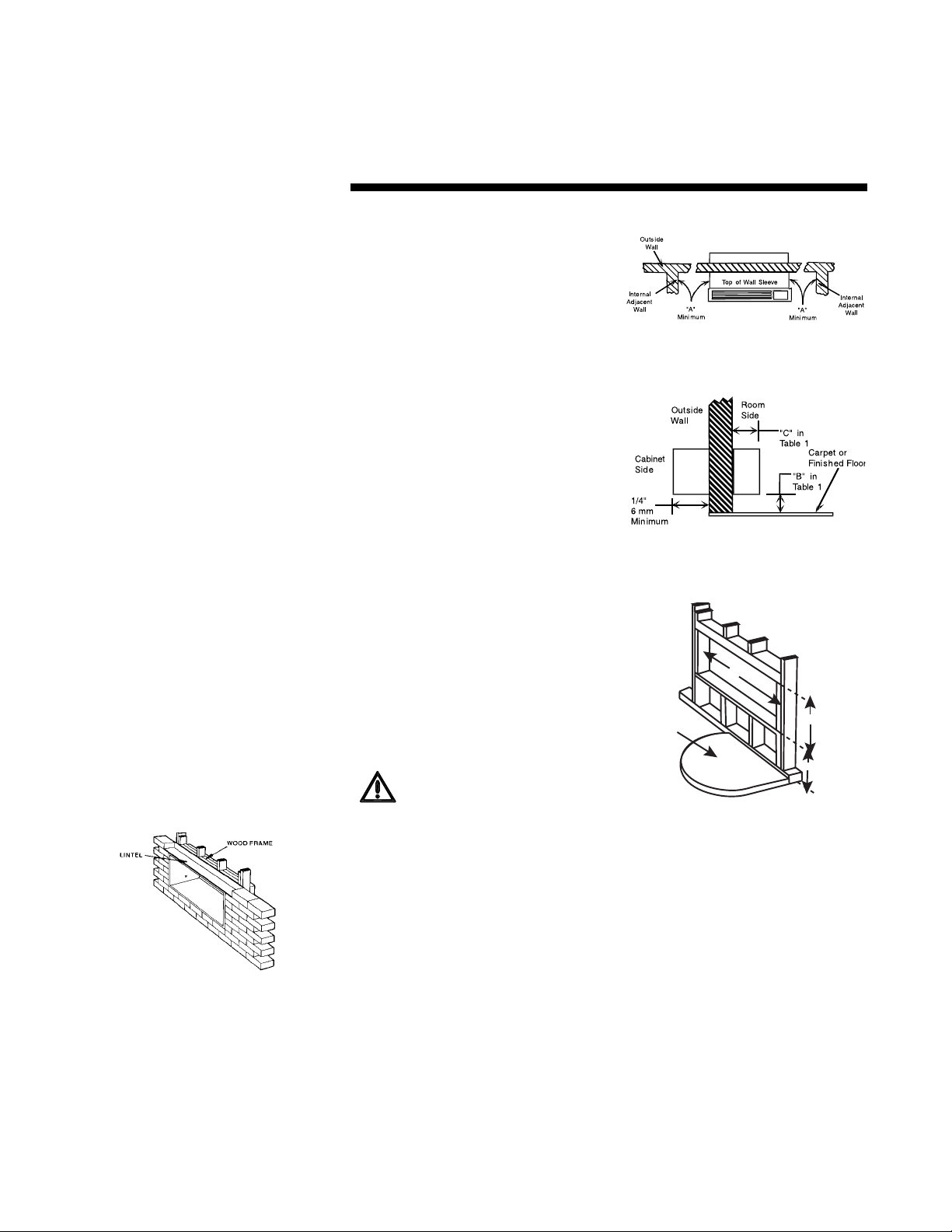

Figure 1. Typical Installation

framing with lintel

5. When installing in walls that are

deeper than 13 1/2 inches, use an

extended wall sleeve. A sleeve

without the proper depth will

require special care to prevent

problems with rain water,

condensate drainage, and intake/

discharge air.

Under these circumstances,

careful jobsite analysis and

cautions are required. Consult

your local HVAC representative

before attempting such

installations.

Checklist

The following checklist provides an

overview of the factoryrecommended pre-installation

considerations. Follow the

procedures in this section to ensure

the installation is complete and

adequate for proper unit operation.

Verify this checklist is complete

before beginning unit installation.

• If unit arrives shipped on its side,

do not accept.

• Verify the unit size and tagging

with the unit nameplate to

ensure the correct unit is

received.

• Inspect the unit for possible

shipping damage and make any

necessary claims with the freight

delivery company immediately.

• Verify the installation location is

free of airflow obstructions, such

as curtains, furniture, trees, or

other objects that may block

airflow to and from the unit.

WARNIN G

Fire Hazard!

Do not use extension cords. Using

extension cords could cause a fire.

• Make provisions for correct

supply power and that the

electrical receptacle is within 52

inches of the lower right corner

of the equipment.

• Ensure the unit wall opening is

level.

• Ensure adequate sealing and

insulation is around the wall

sleeve.

Figure 2. Minimum unit clearance

Table 1. Minimum interior and exterior

projections

42 1/2” min.

Finished

Floor

Figure 3. Minimum wall opening

dimensions

16 1/4” min.

Dimension B

6 PTAC-SVX01C-EN

Page 7

Pre-Installation

Table 2. Minimum clearances and

projections

Option In. Mm In. Mm In. Mm

Minimum clearances Minimum projection

AB C

Wall sleeve only 3 75 0 0 0 0

Subbase kit 3 75 3 1/4 85 2 3/4 70

Leveling legs kit 3 75 3 75 2 50

Hydronic heat kit

Drain kit 3 75 0

Hardwire kit 3 75 3 75 0 0

(1)

Max height is based on skirt options available.

(2)

This dimension can be from 2-6", but if this dimension exceeds 6" an extended standard kick plate is

necessary.

(3)

This dimension can be from 50-150mm, but if this dimension exceeds 150mm an extended standard kick

plate is necessary.

(4)

To achieve a flush fit between the hydronic front and the finished wall, dimension "C" must be between

3" and 3-1/8". If this dimension is more than 3-1/8" there will be a gap between the front and the wall.

This gap could permit occupant access to hydronic lines or other dangerous parts.

(5)

To achieve a flush fit between the hydronic front and the finished wall, dimension "C" must be between

76-80mm. If this dimension is more than 80mm there will be a gap between the front and the wall. This

gap could permit occupant access to hydronic lines or other dangerous parts.

(6)

If inside mounted then B = 1-1/2 inches

(7)

If inside mounted then B = 40 mm

(1)

9 230 2-6”

(6)

(2)

50 -150

(7)

1

(3)

(4)

3-3 1/

76-80

8

00

(5)

Receiving and Handling

Shipping Package

The chassis and the cabinet front

ship in one carton. Accessories ship

separate.

Receiving Checklist

Complete the following checklist

immediately after receiving unit

shipment to detect possible shipping

damage.

• Verify that the unit nameplate

data corresponds to the sales

order and bill of lading (including

electrical data).

• Visually inspect the unit exterior

for physical signs of shipping

damage or material shortages.

• If a unit appears damaged,

inspect it immediately before

accepting the shipment. Remove

access panels and check for

interior component damage.

Make specific notations

concerning the damage on the

freight bill. Do not accept

delivery.

• Report concealed damage to the

freight line within the allotted

time after delivery. Verify with

the carrier what their allotted

time is to submit a claim.

Note: Failure to follow these

procedures may result in no

reimbursement for damages

from the freight company.

• Do not move damaged material

from the receiving location. It is

the receiver’s responsibility to

provide reasonable evidence that

concealed damage did not occur

after delivery.

• Do not continue unpacking the

shipment if it appears damaged.

Retain all packaging. Take photos

of damaged material if possible.

• Notify the carrier’s terminal of the

damage immediately by phone

and mail. Request an immediate

joint inspection of the damage by

the carrier and consignee.

• Notify your HVAC representative

of the damage and arrange for

repair. Have the carrier inspect

the damage before making any

repairs to the unit.

PTAC-SVX01C-EN 7

Page 8

Unit Dimensions

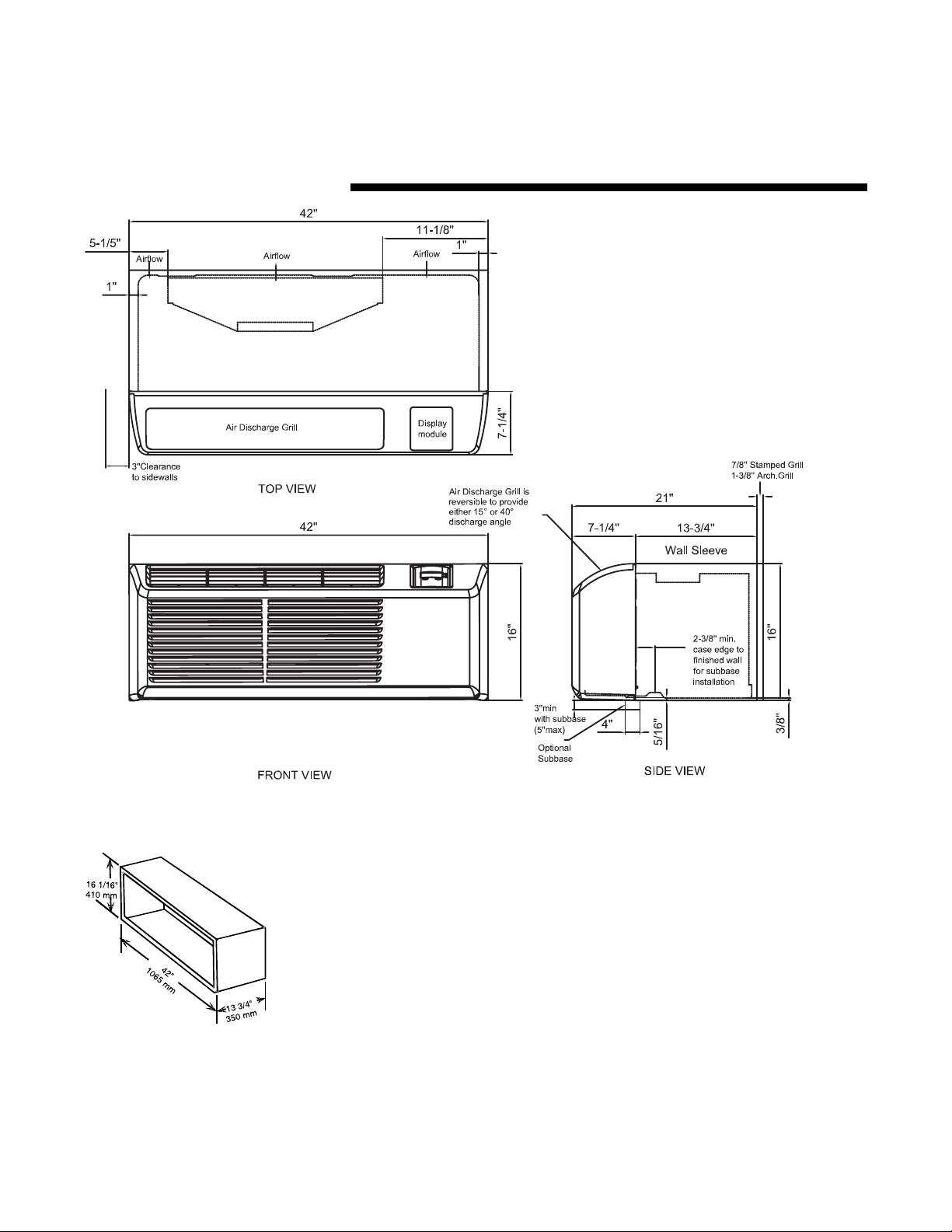

Unit Dimensions

Figure 4. Unit with wall sleeve and subbase accessory

Figure 5. Wall Sleeve

8 PTAC-SVX01C-EN

Page 9

Unit Dimensions

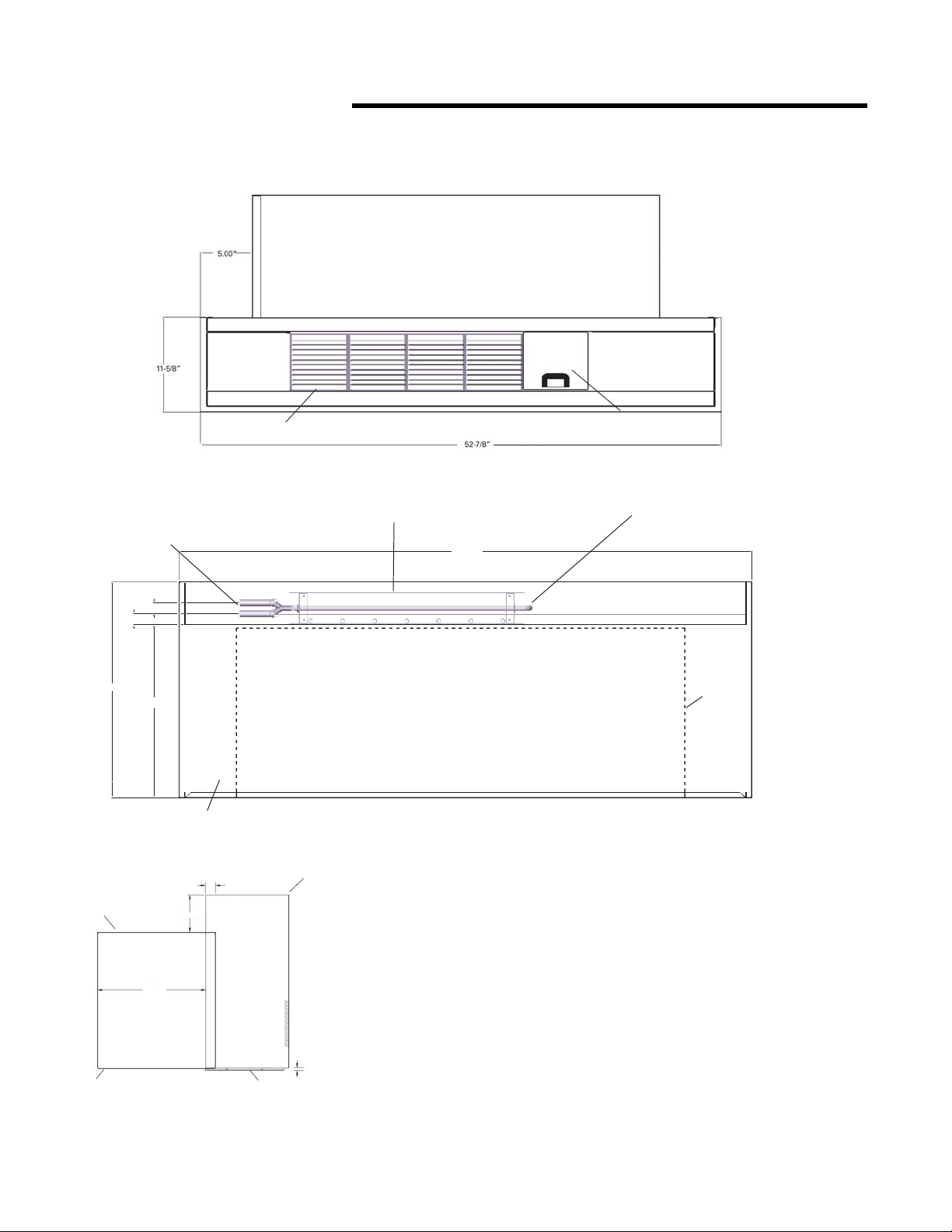

PTAC Wall Sleeve

Air discharge

Figure 6. Top view of the hydronic kit

Hotwater or steam inlet and outlet

connection (left hand coil connection)

1“

1-1/20”

20-1/4”

16-1/5”

Air inlet

Figure 7. Hydronic kit front view

Steam/water

coil position

Front View

Unit controls

compartment

Steam inlet and outlet connection

(right hand coil connection)

53-2/3”

PTAC

Hydronic front

Toe plate 0 to 3.0” long

Top of wall sleeve

Bottom of wall sleeve

1-3/8” - 1-1/2”

5.00”

12.62

Figure 8. Hydronic kit side view

PTAC-SVX01C-EN 9

Page 10

WARNIN G

Live Electrical Components!

During installation, testing, servicing

and troubleshooting of this product,

it may be necessary to work with live

electrical components. Have a

qualified licensed electrician or other

individual who has been properly

trained in handling live electrical

components perform these tasks.

Failure to follow all electrical safety

precautions when exposed to live

electrical components could result in

death or serious injury.

WARNING

Fire Hazard!

Do not use an extension cord with

this unit. Doing so may cause a fire.

Installation

Installation

CAUTION

Use Copper Conductors Only!

Unit terminals are not designed to

accept other types of conductors.

Failure to use copper conductors

may result in equipment damage.

Electrical Requirements

The PTAC can be powered by a

power cord connected to a receptacle

in the wall or in a subbase. It can also

be connected directly to the building

supply wires with a hard wire kit.

For U.S. approval, 265V units must

have a permanent wiring connection.

This requirement can be met either

by supplying a subbase for

concealed cord connection or by

direct wiring with the hard wire kit.

The power cord measures 60 inches,

with 56 inches usable from the point

where the cord exits the unit cabinet

and the attached plug.

10 PTAC-SVX01C-EN

Page 11

Installation

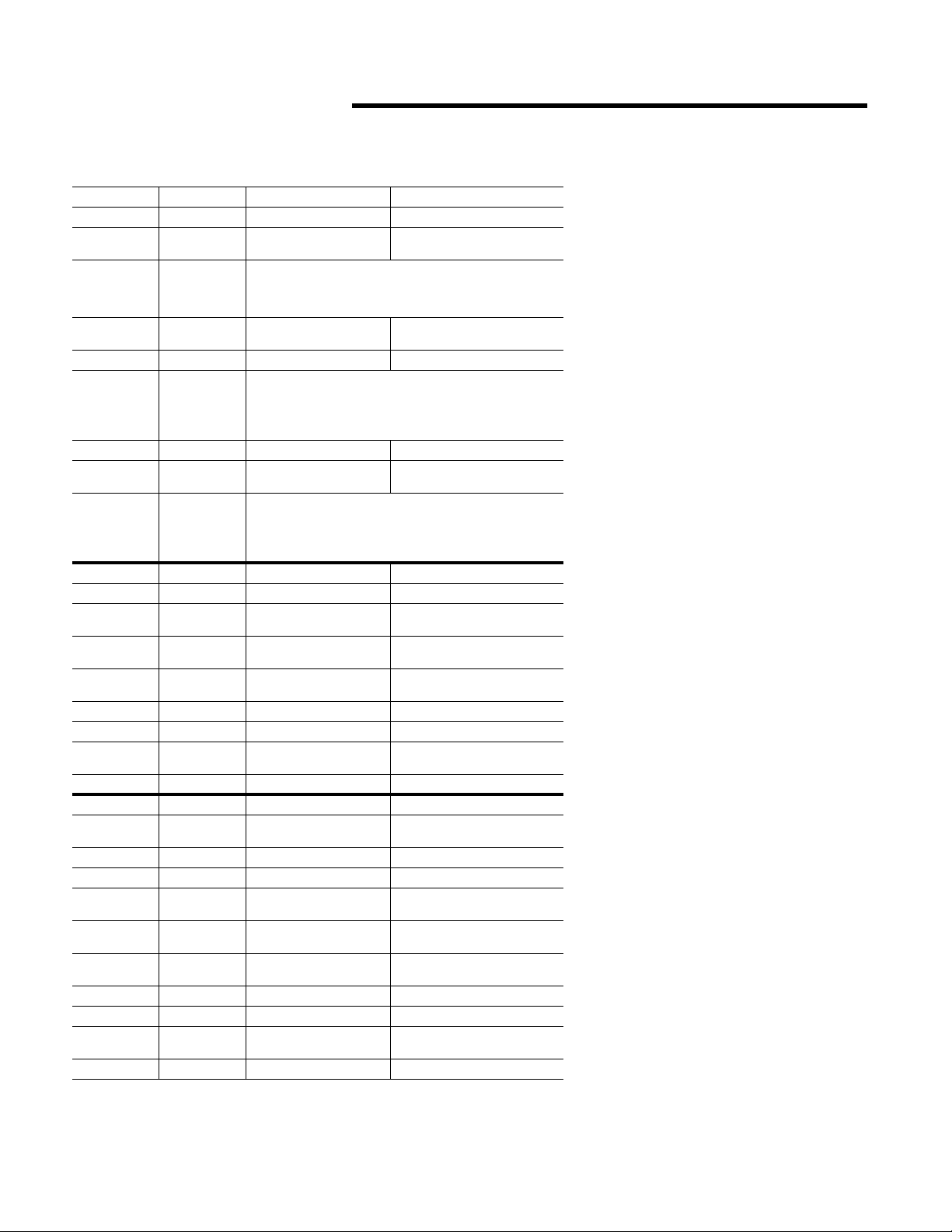

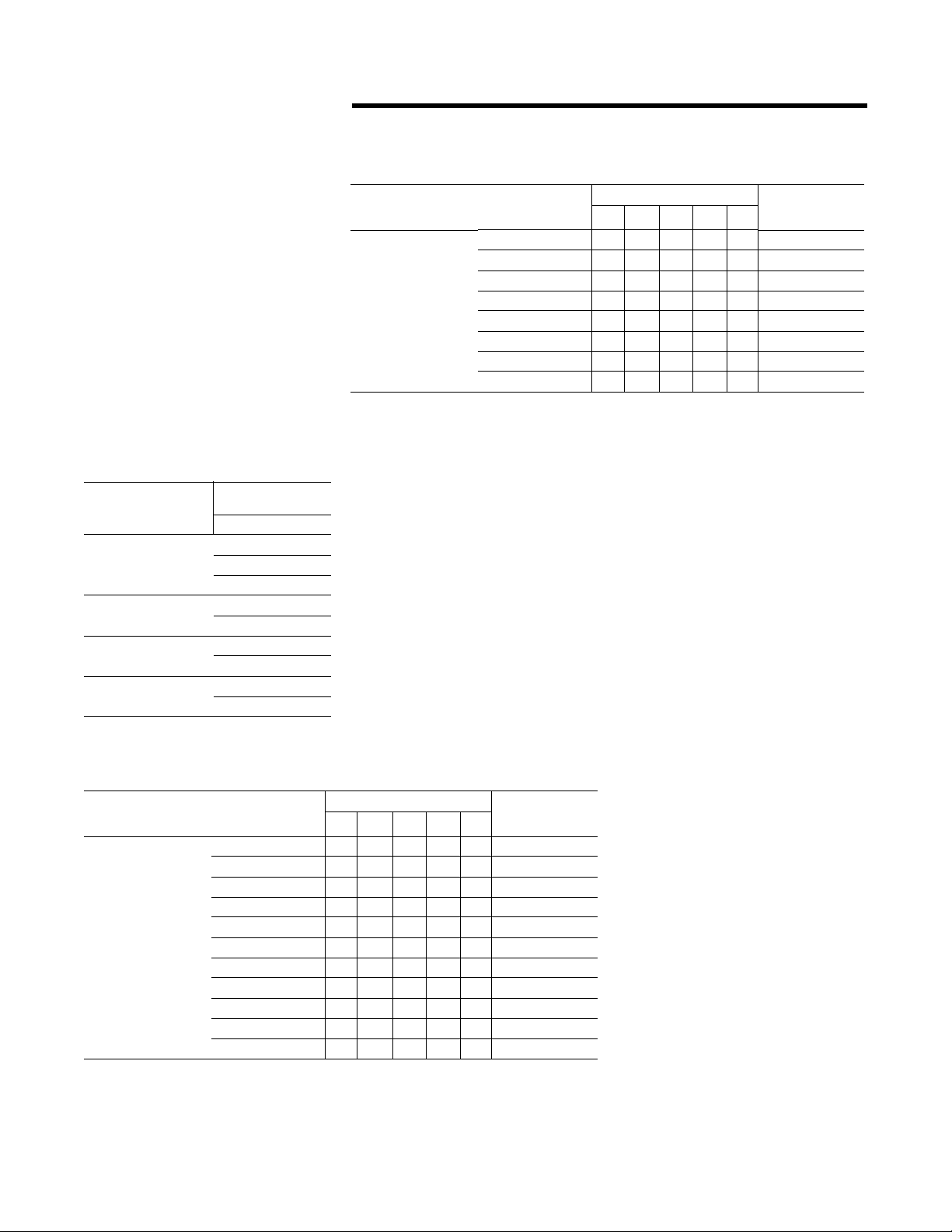

Table 3. Electric heat capacity and electrical data, models PTEE and PTHE

(i)

Nominal heating Building circuit requirement

Electric

Voltage

Size (kW)

heater

(ii)

230/208 2.0/1.6 1 6,800/

230/208 3.0/2.4 1 10,200/

230/208 5.0/4.0 1 17,100/

# of

stages

Btu/h at

230/208V

5,500

8,200

13,700

Btu/h at

265V

- 2000/

- 3000/

- 5000/

Total

watts

1600

2400

4000

Unit

(iii)

total

amps

Minimum

ampacity

(iv)

Maximum

protection

(v)

8.9/7.9 11.4 15 6 - 15 P

13.4/11.8 17 20 6 - 20 P

22.2/19.7 28 30 6 - 30 P

Plug

265 2.0 1 - 6,800 2000 7.7 9.8 15 7 - 20 P

265 3.0 1 - 10,200 3000 11.6 14.7 15 7 - 20 P

265 5.0 1 - 17,100 5000 19.3 24.4 25 7 - 30 P

(i)

All heat pumps have electric heat.

(ii)

Minimum voltage on 230/208 volt models is 187 volts; maximum is 253 volts. Minimum voltage on 265 volt models is 239 volts; maximum is 292 volts.

(iii)

Total watts for 7,000 and 9,000 Btu models; add 70 watts for 12,000 and 15,000 Btu models.

(iv)

Minimum branch circuit ampacity ratings conform to the National Electric Code. However, local codes should apply.

(v)

Overcurrent protection for all units without electric heaters is 15 amps. Overcurrent protection on 265 volt models must be cartridgestyle time delay fuses.

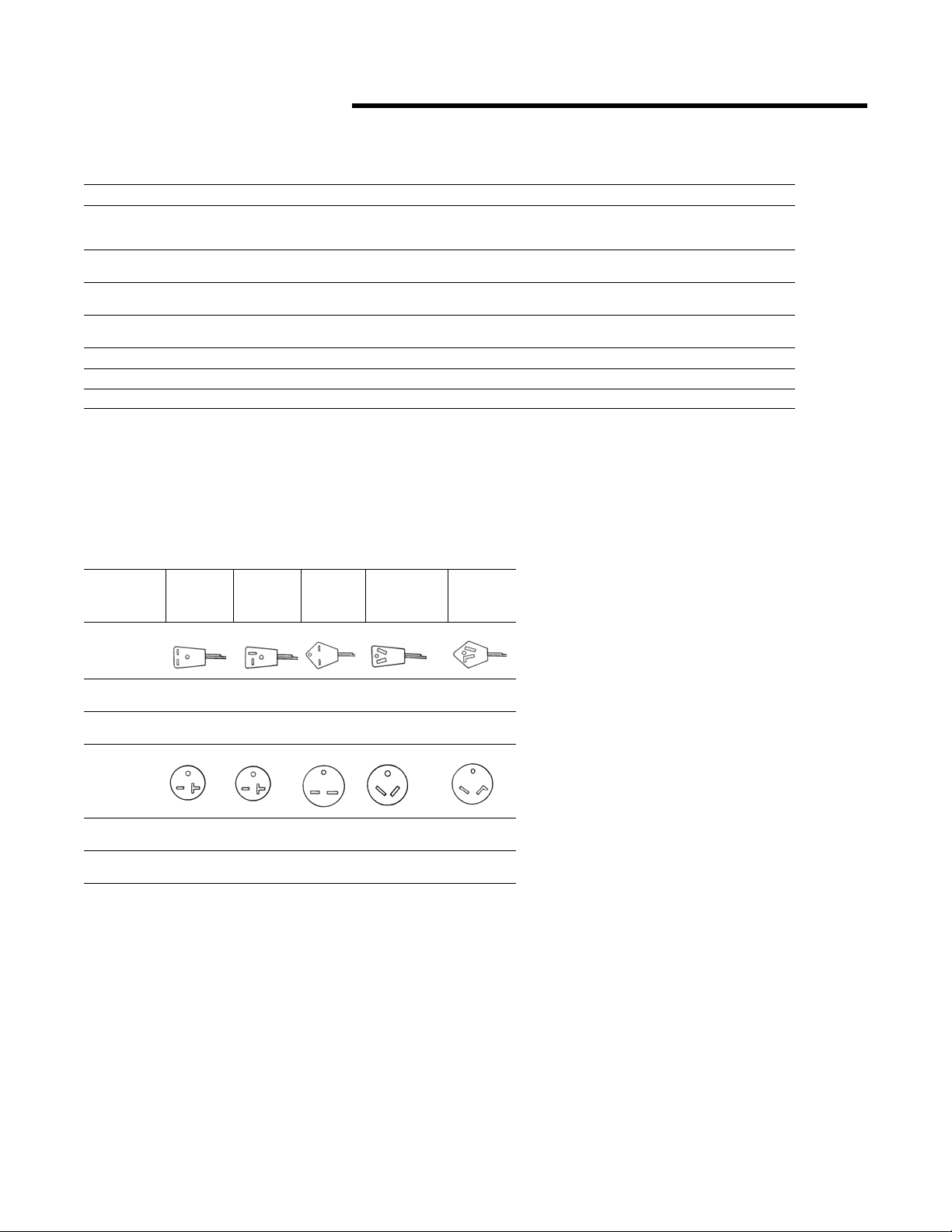

Table 4. Power receptacle configurations

Unit

Voltage

Rating

Unit plug

230/

208

230/

208

230/

208 265 265

Plug amp

rating

NEMA

designation

Receptacle

Receptacle

amp rating

NEMA

designation

15 20 30 15/20 30

6-15P 6-20P 6-30P 7-15P/7-20P 7-30P

20 20 30 20 30

6-20R 6-20R 6-30R 7-20R 7-30R

PTAC-SVX01C-EN 11

Page 12

Installation

Figure 9. Panel wall installation

Installation Procedure

WARNIN G

Hazardous Voltage w/

Capacitors!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure the

power cannot be inadvertently

energized. For variable frequency

drives or other energy storing

components provided by Trane or

others, refer to the appropriate

manufacturer’s literature for

allowable waiting periods for

discharge of capacitors. Verify with

an appropriate voltmeter that all

capacitors have discharged. Failure

to disconnect power and discharge

capacitors before servicing could

result in death or serious

injury.Install components in this

order.

1. Remove rear closure panel from

wall sleeve.

2. Install drain kit (optional).

3. Install outdoor air grille in wall

sleeve.

12 PTAC-SVX01C-EN

4. Install wall sleeve in wall

opening.

5. Install unit chassis in wall sleeve.

6. Install unit power supply.

•Power cord

•Hard wire kit

• Subbase kit

• Electrical receptacle

• Power switch

• Cicuit breaker

7. Install unit controls.

• Display module

• Remote wall thermostat

8. Configure display module

settings.

9. Progammable settings.

Step 1. Remove rear closure panel from wall sleeve.

1. Remove the zigzag folded

cardboard sleeve stiffener. See

Figure 10. Remove the rear

closure panel by folding the four

flaps as indicated in Figure 11

Figure 10. Wall sleeve stiffener

Figure 11. Sleeve rear closure

panel

Page 13

Installation

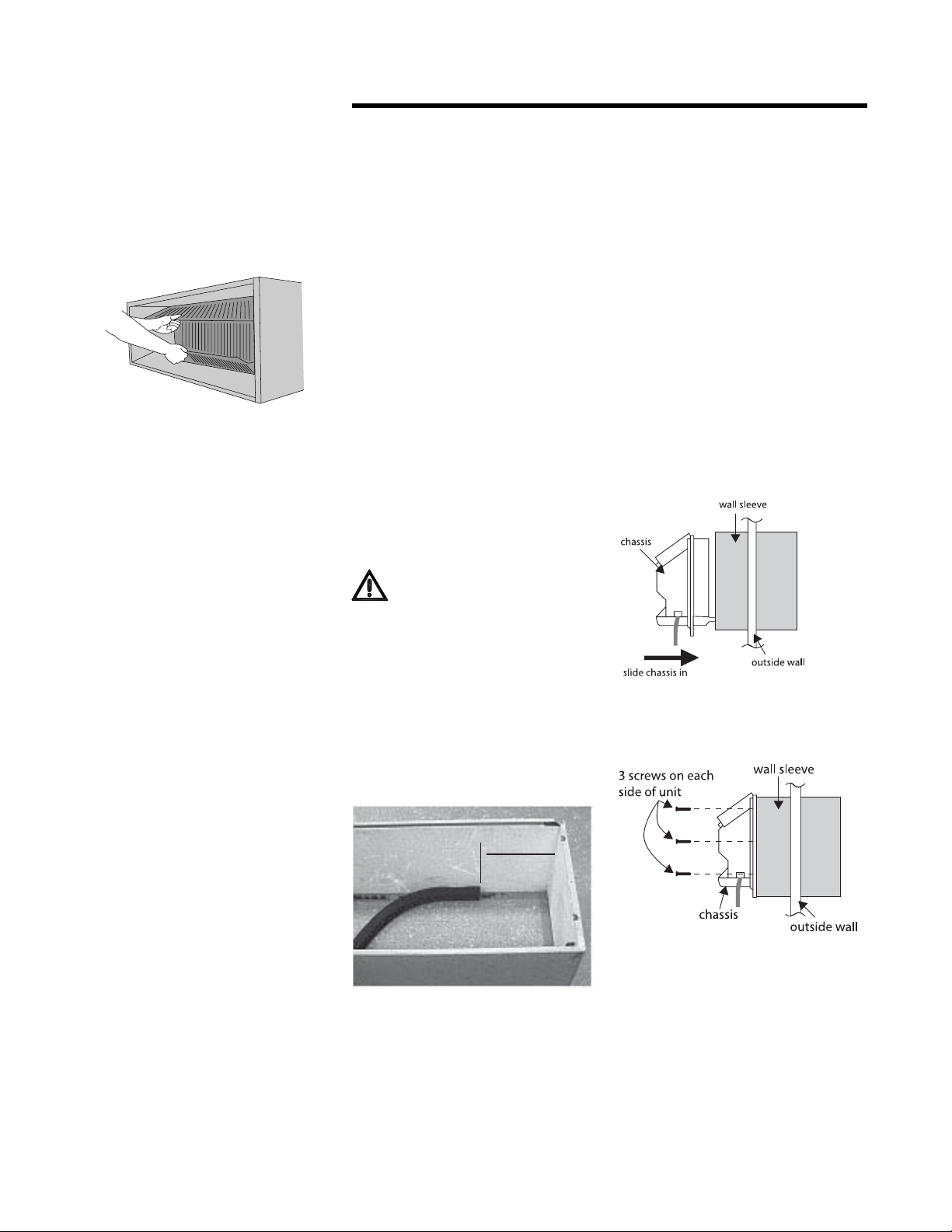

2. Grasping the top and bottom

flanges of the rear closure panel

as shown in Figure 12, the entire

panel is pulled out diagonally

from one side.

Figure 12. Pull rear closure panel

out of wall sleeve

Step 2. Install drain kit in wall sleeve.

Drain kits are available for indoor or

outdoor installation to help

condensate drain from either the

right or left side of the wall sleeve

externally, or from the bottom of the

sleeve internally.

Note: For installation procedures,

please refer to the Installation

Guide that accompanied the

accessory.

If you do not use the drain kit,

condensate will drain out of the rear

of the wall sleeve. The drain kit must

be installed before the outdoor grille

is installed.

Step 3. Install outdoor air

Step 4. Install wall sleeve in wall opening.

For condensate to drain properly

inside the unit, the sleeve must be

installed properly:

• level from right to left

• with a slight downward pitch

from the indoor side to the

outdoor side

Note: If equipment is 230/208 volt,

verify the electrical receptacle

is located within 52 inches of

the sleeve’s right hand corner.

Do not use an extension cord.

Note: For installation procedures,

please refer to the Installation

Guide that accompanied the

accessory.

5. Install unit chassis in wall

sleeve.

WARNING

Fire Hazard!

Do not use an extension cord with

this unit. Doing so may cause a fire.

1. Attach the insulation strip to the

upper rear of the wall sleeve. See

Ta bl e 1 3 . If using an extended

wall sleeve, attach the insulation

strip between the two baffles,

touching the baffle surface facing

towards the front.

4. Slide the chassis into the wall

sleeve until the chassis flanges

contact the front edge of the wall

sleeve. See Figure 14.

5. Secure the chassis to the wall

sleeve using three screws on

each side of the chassis to ensure

a proper seal between the

chassis and the wall sleeve . The

screws are supplied in a plastic

bag which is attached to the

power cord. See Figure 15.

6. Verify the indoor and outdoor

grilles are free of airflow

obstructions.

7. Make the power supply

connections as detailed in the

next step.

Figure 14. Slide unit chassis into

the wall sleeve

grille in wall sleeve.

An outdoor air grille directs airflow

for proper unit operation and to

protect the outdoor coil. Install the

grille before installing the chassis.

Outdoor air grille options are either a

stamped grille or an architectural

grille. When replacing an old chassis

with an existing grille, please check

with your HVAC representative to

determine if the new chassis can be

used with the old outdoor grille.

Using the wrong type outdoor grille

can decrease cooling or heating

capacity, increase energy usage, or

shorten compressor life.

Note: For installation procedures,

please refer to the Installation

Guide that accompanied the

accessory.

PTAC-SVX01C-EN 13

Front

Bottom

Figure 13. Insulation strip location

2. Remove the cabinet front from

the chassis by pulling the bottom

of the cabinet front away from

the chassis until the retaining

clips disengage.

3. If using a subbase, be sure the

right-hand subbase cover is

removed before installing the

chassis in the wall sleeve.

11”

Rear

Figure 15. Secure chassis to wall

sleeve

Step 6. Install unit power supply.

Note: For installation procedures,

please refer to the Installation

Guide that accompanied the

accessory.

Page 14

Installation

Table 5. Unit power supply

Voltage Options Accessory Accessory part number

115V

Option 1.

Option 2.

Option 3. Required: Hard Wire Kit BAYHWRK001

265 V

Option 1. Required: Universal Subbase BAYSUB001

Option 2. Required: Hard Wire Kit BAYHWRK001

230/ 208 V

Option 1. Required: Universal Power Cord

Option 2. Required: Universal Subbase BAYSUB001

Option 3. Required: Hard Wire Kit BAYHWRK001

1. All units required either a power cord or hard wire kit to power the unit

2. The Hydronic chassis "W" ships with no electric heat

3. All Hydronic Chassis "W" units required a power cord

4. All 265volt Hydronic chassis "W" required subbase, fuses and socket.

Required: Universal Power Cord 15

Required: Universal Power Cord 15

Optional Power Switch BAYPSW002

Optional Power Switch if 30 Amp BAYPSW002

Optional Power Switch BAYPSW002

Optional Circuit Breaker 15, 20 or

Optional Power Switch BAYPSW002

Amp

A field supplied 115 volt 15 amp receptacle is mounted

in the building floor or wall. A Trane 115 volt 15 amp

power cord BAYPCRD007 is connected to the PTAC and

plugged into the receptacle.

Amp

Universal Subbase BAYSUB001

A Trane subbase BAYSUB001 is attached to the wall

sleeve. A field supplied 115 volt 15 amp receptacle is

mounted into the subbase. A Trane 115 volt 15 amp

power cord BAYPCRD007 is connected to the PTAC and

plugged into the receptacle

Connector for Hardwire

Kit for 15 Amp

A Trane hardwire kit BAYHRK001 is direct wired to the

building power supply and attached to the PTAC. A

Trane connector kit BAYCNHK031 is connected to the

PTAC and connected to the hard wire kit in the unit

mounted junction box

Socket for subbase 20 or

30 Amp

Universal Power Cord

15,20 or 30 Amp

Fuses 15, 20 or 30 Amp BAYFUSE001, BAYFUSE002,

Connector for Hardwire

Kit for 15, 20 or 30 Amp

15,20 or 30 Amp

Socket for subbase 20

or 30 Amp

Universal Power Cord

15,20 or 30 Amp

30 Amp

Power Switch BAYPSW002

Connector for Hardwire

Kit for 15, 20 or 30 Amp

BAYPCRD007

BAYPCRD007

BAYCNHK031

BAYSCKT003, BAYSCKT004

BAYPCRD004, BAYPCRD005,

BAYPCRD006

BAYFUSE003

BAYCNHK021, BAYCNHK022 ,

BAYCNHK023

BAYPCRD001, BAYPCRD002,

BAYPCRD003

BAYSCKT001, BAYSCKT002

BAYPCRD001, BAYPCRD002,

BAYPCRD003

BAYCBKR001, BAYCBKR002,

BAYCBKR003

BAYCNHK011, BAYCNHK012,

BAYCNHK013

Step 7. Install the unit controls.

The PTAC controller’s normal

operation can be operated by using

either

• Display module - can be wallmounted or unit mounted.

• Remote Class 2 thermostat -

For Remote Class 2 Thermostat

Installation, read installation,

operation, and maintenance booklet

carefully.

Look in Wiring Diagram section for

information on wiring.

If a remote thermostat is connected,

the unit's display will not be present

and the controller's normal space

temperature control functionality is

overridden by the remote device.

When the controller is being directed

by a remote thermostat, the

following inputs/functions are

disabled or not present:

1. User display inputs (setpoint/

mode/fan)

2. Dehumidification

3. Configuration setup (indoor fan,

setpoint limits, EMS offset,

display units)

4. Energy management system

5. Manual Test

Unit functions that remain under

direct supervision of the controller

are:

1. Random Restart

2. Heat Pump OAT switchover

3. Tubing burst protection

4. Room freeze protection

5. Indoor coil freeze protection

6. Defrost control

When connected to a remote

thermostat, the controller interprets

the combination of thermostat inputs

as its operating mode and behaves

accordingly.

It is recommended to use a small

screwdriver to gently pryt the

removable treminal block "TB2" up

and off for easy connection.

14 PTAC-SVX01C-EN

Page 15

Installation

Note: If using a third party

thermostat to control the

unit, the thermostat must

have a clearly marked OFF

state or position.

Note: It is important to make sure

that the control board’s fuse

is functioning. The specs for

the control board fuse are:

5x20mm, 250V, 315mA, fast

acting. For more inormation

on a blown fuse on the

control board, check the

Troubleshooting section of

this document.

Table 6. Maximum wire length for front

External Interface

Thermostat

Energy mgmt system #20 900 ft.

Remote fan #20 60 ft.

Display module #20 100 ft.

desk switch and remote

control connections

Wire

Specification

Size Length

#22 100 ft.

#20 200 ft

#18 300 ft.

#18 1500 ft.

#18 66 ft.

#18 120 ft.

Table 7. Wiring Voltage

Unit Mode

High Heat Pump 24 0 0 24 0 Heat

High Auxiliary Heat 24 0 24 0 X Heat

Low Auxiliary Heat 0 24 24 0 X Heat

PTEE Air Conditioner

(Auxiliary is Electric,

Hot Water, or Steam

Notes: In the event that none of the

combinations listed in the table above is

present, the input will be deemed invalid and all

heating, cooling, and fan operation will be

disabled.

High Cooling 24 0 0 24 X Cool

Low Cooling 0 24 0 24 X Cool

High Fan 24 0 0 0 X Fan Only

Low Fan 0 24 0 0 X Fan Only

Off 0 0 0 0 X Off – no capacity

Voltage at terminal Corresponding

Normal

OperationGH GL W Y O

Table 7. Wiring Voltage

Unit Mode

PTHE Heat Pump

Auxiliary is Electric

only

Voltage at terminal Corresponding

High Heat Pump 24 0 0 24 0 Heat

Low Heat Pump 0 24 0 24 0 Heat

High Emgcy Heat 24 0 24 0 0 Heat

24 0 24 24 0 Electric Heat Only

Low Emgcy Heat 0 24 24 0 0 Heat

0 24 24 24 0 Electric Heat Only

High Cooling 24 0 0 24 24 Cool

Low Cooling 0 24 0 24 24 Cool

High Fan 24 0 0 0 0 Fan Only

Low Fan 0 24 0 0 0 Fan Only

Off 0 0 0 0 0 Off – no capacity

Normal

OperationGH GL W Y O

PTAC-SVX01C-EN 15

Page 16

Installation

Table 8. Output settings

ID

User Mode / Model

High Heat Pump

(PTHE only)

Low Heat Pump

(PTHE only)

High Emergency/

Auxiliary Heat

Low Emergency/

Auxiliary Heat

High Cooling ON OFF OFF ON ON ON EN EN EN

Low Cooling OFF ON OFF ON ON ON EN EN EN

High Fan ON OFF OFF OFF N/C OFF EN EN EN

Low Fan OFF ON OFF OFF N/C OFF EN EN EN

Off OFF OFF OFF OFF N/C OFF OFF EN OFF

Notes: EN = Enabled - operations based on

other logic

Notes: N/C = No change from prior state

Fan

High

ON OFF OFF ON OF ON EN EN EN

OFF ON OFF ON OFF ON EN EN EN

ON OFF ON OFF N/C OFF EN EN EN

OFF ON ON OFF N/C OFF EN EN EN

ID

Fan

Low

Aux

Heat Comp

Rev

Valve

(PTHE)

OD

Fan

Rmt

Fan

Cond

Pump

(PTHE)

Vent

Door

/Fan

Step 8. Configure the display module settings

Indoor Temperature setpoint

The indoor temperature setpoint

buttons tell the unit how warm or

cool the occupant wants the room.

The setpoint is set by pressinging the

up/down buttons on the interface

module. These buttons do not scroll

(i.e. holding the button will not

continue to adjust the setpoint value)

because each adjustment of the

setpoint value requires its own

unique button press.

Default setpoint on first power up:

72°F (22.0°C – closest approximation)

Setpoint resolution: ± 1°F (± 0.5°C)

User Mode Selection

Pressing the MODE button on the

unit tells the unit which mode the

occupant prefers. There are four

modes to choose from.

1. C OO L

2. HEAT

3. FAN (fan only)

4. OFF (default for first power up)

Figure 16. Digital display module

Fan Speed Selection

Pressing the FAN button on the

interface module determines fan

speed. There are two fan speeds to

choose from.

1. LOW (default for first power up)

2. HIGH

Field commissioning support

Manual Test Mode

A manual test mode is provided to

allow a field technician to verify

proper output and end device

operation through a predetermined,

timed sequence.

Fan

Mode

The sequence will automatically

advance through all outputs and exit

when the sequence has completed; it

is left to the technician to monitor the

status of the end devices during the

test to verify that each operates

properly.

Manual test is initiated by combining

the following conditions:

• User Mode = OFF

• Press and hold MODE &

SETPOINT DOWN for 5 seconds

During the test process, the word

"STEP" and the corresponding step

number will be lighted on the

display. After the final step has been

executed, the controller will exit

Manual test and force the controller

to into a reset.

Manual test mode may be cancelled

by pressing any button on the

display.

Manual test is not available if there is

no interface module, as is in Class 2

control applications.

The test sequence attempts to clear

unit diagnostics and restore normal

unit operation prior to testing the

outputs. If the diagnostics remain

after an attempt to clear them,

manual test may be affected or

disallowed.

Dehumidification

The PTAC controller does not directly

measure room humidity.

The PTAC provides dehumidfication

by combining the following actions

in a predefined sequence.

1. The PTAC subcools the room to a

preset state, a dehumidification

offset below the cooling setpoint.

2. The unit will automatically adjust

the fan speed.

3. When incorporating the vent

door option, the controller will

automatically adjust its position.

16 PTAC-SVX01C-EN

Page 17

Installation

Step 9. Programmable Settings

The controller has a total of six (7)

parameters that are userconfigurable:

1. Vent Door Configuration

2. Indoor Fan Cycle configuration

3. Temperature Setpoint Limiting

configuration

4. Energy Management Setpoint

Offset configuration

5. Display Units configuration

6. Indoor Temperature Calibration

7. DH Offset

The interface module texts

“SETTING” and “STEP” provide user

feedback when the unit is in the

configuration mode. The number

directly above the word “STEP”

indicates the configuration step that

is being adjusted. The numbers

above the word “SETTING” (XX.x)

indicate the value of the parameter.

In order for the user to access the

configurable parameters, a digital

display module must be present.

The configuration set-up mode is

entered by pressing and holding the

"MODE" and "FAN" buttons

simultaneously for 5 seconds.

Table 9. Set point configuration

Configuration

step Step description

1 Ventilation Enable 0

2 Indoor fan cycle

3

4Energy

5

6Indoor

7 DH offset

Tempera tu r e

Setpoint Limits

Management

Display units 0 (default) IP (English)

Tempera tu r e

Calibration

Configuration

setting Setting description

1 (default)

0 (default) Cycle with compressor

1

2

0 (default) cool 50 - 90°F, heat 50 - 90°F

1 cool 55 - 90°F, heat 50 - 85°F

2 cool 60 - 90°F, heat 50 - 80°F

3 cool 65 - 90°F, heat 50 - 75°F

Default: 10°F (5.5°C)

Range: 0 to 20°F

(0.0 to 10.0°C)

Resolution: 1.0°F

(0.5°C)

1SI (Metric)

Default: 0°F (0.0°C)

Range: -9 to 9°F

(-5.0 to 5.0°C)

Resolution: 1.0°F

(0.5°C)

Default: 1°F (0.5°C)

Range: 0 to 2°F

(0.0 to 1.0°C)

Resolution 1.0°F Value of zero disables DH.

(0.5°C)

Ventilation is disabled

Ventilation is enabled

continuously, OFF in OFF mode

ON continuously, HIGH in OFF

mode

PTAC-SVX01C-EN 17

Page 18

Installation

1. Ventilation Door Function

The power door works based upon

control logic functions. When the unit

is on, the vent door will open to allow

fresh air to be conditioned before

entering the room. When the unit is

off, the door closes to prevent

unconditioned air from entering the

room.

For more information on vent door

function with dehumidificaiton, refer

to the dehumidification chart.

2. Indoor Fan Cycle set up

The indoor fan can be configured to

provide different types of operation

between its OFF and ON (high/low)

states. This setting is adjustable and

does not force the unit to reset.

3. Temperature Setpoint Limiting

set up

The range of temperature control

setpoints can be limited using this

configuration parameter. After the

controller has determined the

desired user setpoint from the

display, the resulting value is

validated against the setpoint limits.

There are four valid combinations of

heating and cooling setpoint limits:

These set point limits apply to both

the occupied and unoccupied

standby, heating and cooling

setpoints. This setting is adjustable

“on-the-fly” and will not force the

unit into a restart condition.

4. Energy Management Setpoint

Offset set up

The range of the Energy

Management System's effect on

setpoints can be adjusted using this

configuration parameter. This

parameter is adjustable "on-the-fly"

and will not force the controller into a

restart condition. The range and

resolution of available selections is

Range: 0°F to 20°F( 0.0°C to 11.0°C)

Resolution: 1.0°F( 0.5°C)

5. Display Unit set up

The user can change the way the

interface module displays

temperature. The symbols °F and °C

will not be present on the display;

however, the range and precision of

the room temperature and setpoint

values will make the selection

obvious.

6. Indoor temperature calibration

The indoor temperature can be

calibrated to match an independent

reading. The adjustment range is +/-

10.0°F (6°C) with a resolution of 1°F

(0.5°C).

7. Dehumidification Offset

The offset defines the point below

the setpoint where the unit will stop

running the compressor. A DH

display module is required to use this

feature.

The PTAC allows the options of 0°F

(disable), 1°F (default) and 2°F

(optional) for the dehumidification

offset. The dehumidification feature

will be disabled when the

configuration of 0°F is selected.

Last User Setpoint, Mode, and

Fan Selections

The controller saves the last inputs

that the user has chosen 5 seconds

after the user has ceased changing

them. These settings will be used

after the next power cycle or

controller reset.

Operation without configuration

The controller tests the configuration

for validity. If the data is corrupted

the controller will revert to default

values for every parameter. A

diagnostic code will be displayed

when using the default values.

Table 10. Display units

Selection #Unit of

0 IP (English) 77 (DEFAULT)

1SI (Metric)24.5

Table 11. Setpoint limiting

Selection

#Low Limit

0 50°F 90°F 50°F 90°F (DEFAULT)

1 55°F 90°F 50°F 85°F

2 60°F 90°F 50°F 80°F

3 65°F 90°F 50°F 75°F

Measure

Cooling Setpoint Heating Setpoint

Display

Example

High

Limit

Low

Limit High Limit

18 PTAC-SVX01C-EN

Page 19

Table 12. Indoor fan cycle configuration

Config # Indoor Fan Cycle Mode

Indoor fan will not run when the user mode is OFF. (DEFAULT)

Indoor fan will cycle to the user selected speed in conjunction with

0

1

2

the compressor or electric heat during HEAT or COOL

Indoor fan will run continuously at the user selected fan speed

during FAN

EMS has no affect.

Indoor fan will normally run continuously at the user selected fan

speed.

Indoor fan will not run when the user mode is OFF.

Indoor fan will cycle in conjunction with the compressor or electric

heat when the EMS is enabled.

Indoor fan will normally run continuously at the selected fan

speed.

Indoor fan will run at HIGH speed when the user mode is OFF.

Indoor fan will cycle in conjunction with the compressor or electric

heat when the EMS is enabled.

Installation

Energy Management System

Occupancy States

The controller is designed to handle

two possible occupancy states:

• occupied

• occupied standby

When the Energy Management

System input is present, it is possible

for the controller to switch between

the two occupancy states.

If the EMS input is not connected, the

controller will always assume the

occupied state.

Table 13. Occupancy arbitration for

energy management

EMS Input State

Open or Not Present Occupied

Closed Occupied Standby

Occupied state

When the controller is in the

occupied state, the unit runs space

comfort control using the occupied

setpoints. All heating/cooling/

ventilation features are enabled.

Controller

Occupancy State

Occupied Standby state

When the controller is in occupied

standby state, the unit runs space

comfort control using the occupied

standby setpoints. All heating/

cooling/ventilation features are

enabled. Because the occupied

standby setpoints cover a wider

range than the occupied setpoints

the demand for heating and cooling

the space is reduced.

PTAC-SVX01C-EN 19

Page 20

Installation

Table 14. PTEE manual test sequence

Step

1 All off Off Off Off Off N/A (Off) Off N/A (Off) Off Off 10 sec

2 Fan high On Off Off Off N/A (Off) Off N/A (Off) Off Off 20 sec

3 Fan Low Off On Off Off N/A (Off) Off N/A (Off) Off Off 20 sec

4 Remote

5 Outdoor

6 Compres

7 Aux Heat Off On Off OnOff N/A (Off) Off N/A (Off) On Off 60 sec

8Vent

Exit

Fan

Fan

sor

Door

Indoor

Fan High

Off On On Off N/A (Off) Off N/A (Off ) Off Off 20 sec

Off On Off On N/A (Off) Off N/A (Off) Off Off 20 sec

Off On Off On N/A (Off) On N/A (Off) Off Off 60 sec

Off On Off OnOff N/A (Off) Off N/A (Off) Off On 20 sec

Table 15. PTHE manual test sequence

Step

1 All off Off Off Off Off Off Off Off Off Off 10 sec

2 Fan High On Off Off Off Off Off Off Off Off 20 sec

3 Fan Low Off On Off Off Off Off Off Off Off 20 sec

4 Remote Fan Off On On Off Off Off Off Off Off 20 sec

5 Outdoor Fan Off On Off On Off Off Off Off Off 20 sec

6 Condensate

7 Compressor

8 Compressor

9 Compressor

10 Aux Heat Off On Off OnOff Off Off OnOff On Off 60 sec

11 Vent Door Off On Off OnOff Off Off Off Off On 20 sec

Exit

Pump

on Cooling

Off

on Heating

Indoor

Fan High

Off On Off On On1 Off Off Off Off 20 sec

Off On Off On Off On OffOn Off Off 60 sec

Off Off On Off On Off Off OffOn Off 60 sec

Off On Off On Off On OnOff Off Off 60 sec

Indoor

Fan Low

Indoor

Fan Low

Remote

Fan

Remote

Fan

Outdoor

Fan

Outdoor

Fan

Condensate

Pump Comp

Condensate

Pump Comp

Reversing

Valve Aux. Heat

Reversing

Valve

Aux

Heat

Ventilation

Door/Fan

Ventilation

Door/Fan

Time in

Step

Time in

Step

20 PTAC-SVX01C-EN

Page 21

Operation

Sequence of Operation

Automatic 3-minute Compressor Lockout

After the compressor cycles off, it

will not restart for three minutes.

This feature prevents the

compressor from short cycling and

extends the overall life.

Automatic 2nd Stage Electric Heat (PTHE only)

If the room temperature falls to 2.5°F

below the setpoint temperature or

the unit compressor fails, the reverse

cycle heat is shut off and the electric

heat is turned on.

Indoor Room Freeze Protection

When the unit senses room

temperatures of 40°F or below, the

unit activates the indoor fan motor

and either the electric resistance

heater or the hydronic heater to help

prevent pipes or fixtures from

freezing.

This also overrides the Energy

Management System input for unit

mounted or wall mounted display

modules

Random Restart Function

This function allows random restart

of the PTAC units in the event of a

power outage. The restart delay

reduces the initial inrush current

from the building to help prevent a

second power outage caused by too

much current draw.

The random restart function will

occur after every power up cycle by

delaying the operation of the unit for

0 to 90 seconds. Compressor

minimum off time is enforced after

the random restart function has

completed.

Door Switch Occupancy Sensor

The PTAC can accommodate a fieldinstalled door switch and occupancy

sensor to operate the energy

management feature.

Remote Thermostat Control

Each unit can be operated from any

standard 4 or 5-wire, remotemounted thermostat. Also, the unit

has a built-in low voltage power

source that can accommodate either

a manual, auto changeover, or

programmable thermostat.

Setpoint Limiting

The setpoint limiting feature reduces

energy costs by controlling the

maximum setpoint in heating and

the minimum setpoint in cooling.

Active Defrost (PTHEs only)

PTACs have an active defrost system

that removes ice build-up on the

outdoor coil, which may occur

during the heat pump cycle.

Remote Thermostat Operation

The GL, GH, O, W, Y, R, and C

terminals provide control inputs for a

remote wall-mounted thermostat.

The terminals listed control the

operation of the unit when no

display module is used. A display

module will take precedence over

any of these inputs.

Mode Button Operation

OFF - cooling and heating functions

stop.

HEAT - room temperature is

maintained by cycling in heat pump

mode or electric heat. The model

PTHE switches from heat pump

mode to electric heat when the

outdoor air temperature is below

20°F (approximately), or when the

heat pump cannot keep up with the

heating load when using a two-stage

thermostat.

COOL - room temperature is

maintained by cycling the air

conditioner.

FAN - the fan runs at the user

selected speed or runs as otherwise

configured.

Fan

Figure 17. Digital display module

Mode

Fan Operation

The fan speed may be user selected

as either high or low. Fan cycling

versus continuous is operation

configurable. See section on

configuration for details.

Front Desk Control (FD1, FD2 Inputs)

The energy management input is

used to move the setpoint up in the

case of cooling and down in the case

of heating. This conserves energy

by reducing the demand in the

space.

The energy management input is a

dry contact closure; typically this is

driven from either a occupancy

sensor or a front desk control

system.

PTAC-SVX01C-EN 21

Page 22

Operation

Table 16. User inputs

Input Function

TB1

+Remote display

-Remote display

TB2

EN Energy management

VT Ventilation input

O Reversing valve (class 2

GL Low fan speed (class 2

GH High speed fan (class 2

Y Cool (class 2 thermostat)

W Heat (class 2 thermostat)

R 24VAC common1

C Ground2

RF Remote fan relay output

Notes:

1. Connection to R enables input functions W, Y,

2. Connect 24VAC, 3VA maximum Remote Fan

communications link (+)

communications link (-)

system input

thermostat)

thermostat)

thermostat)

GL, GH, O,VT, and/or EN.

Control Relay to RF and C

Remote Fan Operation

PTACs can operate a remote fan to

provide conditioned air to additional

rooms or areas that are not well

ventilated. The remote fan operates

any time the PTAC indoor fan is

operating.

The remote fan requires a 24 VAC, 3

VA maximum relay that connects to

the control board RF and C terminal

user inputs. The relay and remote fan

are field supplied. Refer to the wiring

diagrams section for wiring details.

CAUTION

Freezing Temperatures!

Do not allow liquid refrigerant to

contact skin. If it does, treat the

injury similar to frostbite. Slowly

warm the affected area with

lukewarm water and seek immediate

medical attention. Direct contact

with liquid refrigerant may cause

minor or moderate injury.

Air Discharge Grille

The discharge grille can be adjusted

to expel air at either a 15° or 40° (40°

default) angle. Figure 18.

To change the discharge air airflow

angle:

1. Remove the front cabinet.

2. Position the front cabinet so that

the backside is accessible.

3. Remove the four screws which

secure the discharge air grille to

the cabinet front with a phillipshead screwdriver. See Figure 31.

4. Rotate the grille 180° end-forend.

5. Reinstall the screws securing the

discharge air grille to the cabinet

front. Reinstall the cabinet front

on the unit.

Screws

Vent Control

Vent control draws fresh air into the

conditioned area to provide

ventilation when the indoor fan is

operating. However, this may

increase heating cooling loads and

operating costs.

To obtain access to the vent control,

remove the cabinet front and locate

the vent control lever on the left side

of the chassis. Push the vent control

lever up to open the vent or down to

close.

The unit ships with the vent door

closed and secured by a screw.

22 PTAC-SVX01C-EN

Figure 18. Discharge air grille

Page 23

Operation

Table 17. Air conditioner performance data

PTEE 07 PTEE 09 PTEE 12 PTEE 15

Voltage (V)

Cooling data

Cooling

capacity

(Btu/H)

Cooling amps

(A)

EER (Btu/H/

watt)

Moisture

removal

(Pts/h)

Heat pump

heating data

Heating

capacity

(Btu/H) * * * ** * * * * * * *** *

Heating amps

(A)

Heating power

(W)

COP (W/W)

Airflow

Indoor cfm

(wet)

@0.3 esp (hi) 280 225 256 256 325 225 256 256 350 295 325 325 320 350 350

Indoor cfm

(wet)

@0.3 esp (lo) 250 191 225 225 294 191 225 225 320 266 294 294 290 320 320

Indoor cfm

(dry)

@0.3 esp (hi) 312 260 290 290 350 260 290 290 400 320 350 350 365 400 400

Indoor cfm

(dry)

@0.3 esp (lo) 280 235 266 266 323 235 266 266 360 293 323 323 330 360 360

Electric heat

data

Heater size

(kW)

208V * 1.6 2.4 * * 1.6 2.4 4.0 * 1.6 2.4 4.0 1.6 2.4 4.0

230V

265V

Btu/H

208V * 5,500 8,200 * * 5,500 8,200 13,700 * 5,500 8,200 13,700 5,500 8,200 13,700

230V

265V

Heating watt

208V * 1,600 2,400 * * 1,600 2,400 4,000 * 1,600 2,400 4,000 1,600 2,400 4,000

230V

265V

Heating amps

208V * 7.9 11.8 * * 7.9 11.8 19.7 * 7.9 11.8 19.7 7.9 11.8 19.7

230V

265V

115 208 230 265 115 208 230 265 115 208 230 265 208 230 265

7,200 6,800 7,000 7,300 9,300 8,800 9,000 8,700 12,000 11,600 11,800 11,800 13,700 13,900 14,400

5.3 2.9 2.7 2.4 7.3 3.9 3.6 3.1 9.7 5.1 4.8 4.1 6.9 6.4 5.7

12.2 12.0 12.0 12.0 11.5 11.4 11.4 11.3 11.2 11.2 11.2 11.3 10.0 10.0 9.8

1.8 2.1 2.1 2.1 2.2 2.5 2.6 2.6 3.0 3.1 3.1 3.1 4.1 4.1 4.1

* * * ** * * * * * * ****

* * * ** * * * * * * ****

* * * ** * * * * * * ****

* 2.0 3.0 * * 2.0 3.0 5.0 * 2.0 3.0 5.0 2.0 3.0 5.0

* 2.0 3.0 * * 2.0 3.0 5.0 * 2.0 3.0 5.0 2.0 3.0 5.0

* 6,800 10,200 * * 6,800 10,200 17,100 * 6,800 10,200 17,100 6,800 10,200 17,100

* 6,800 10,200 * * 6,800 10,200 17,100 * 6,800 10,200 17,100 6,800 10,200 17,100

* 2,000 3,000 * * 2,000 3,000 5,000 * 2,000 3,000 5,000 2,000 3,000 5,000

* 2,000 3,000 * * 2,000 3,000 5,000 * 2,000 3,000 5,000 2,000 3,000 5,000

* 8.9 13.4 * * 8.9 13.4 22.2 * 8.9 13.4 22.2 8.9 13.4 22.2

* 7.7 11.6 * * 7.7 11.6 19.3 * 7.7 11.6 19.3 7.7 11.6 19.3

Notes: Certified in accordance with the Unitary Air-Conditioner Equipment Certification Program, which is based on ARI Standard 310/380.

PTAC-SVX01C-EN 23

Page 24

Operation

Table 18. Heat pump performance

PTHE 07 PTHE 09 PTHE 12 PTHE 15

Voltage (V)

Cooling data

Cooling

capacity(Btu/H)

Cooling amps

(A)

EER(Btu/H watt)

Moisture

removal (Pts/h)

Heat pump

heating data

Heating capacity

(Btu/H)

Heating amps

(A)

Heating power

(W)

COP (W/W)

Airflow

Indoor cfm (wet)

@0.3 esp (hi)

Indoor cfm (wet)

@0.3 esp (lo)

Indoor cfm (dry)

@0.3 esp (hi)

Indoor cfm (dry)

@0.3 esp (lo)

Electric heat

data

Heater size

(kW)

208V 1.6 2.4 *1.62.44.0 1.6 2.4 4.0 1.6 2.4 4.0

230V

265V

Btu/H

208V 5,500 8,200 * 5,500 8,200 13,700 5,500 8,200 13,700 5,500 8,200 13,700

230V

265V

Heating watt

208V 1,600 2,400 * 1,600 2,400 4,000 1,600 2,400 4,000 1,600 2,400 4,000

230V

265V

Heating amps

208V 7.9 11.8 * 7.9 11.8 19.7 7.9 11.8 19.7 7.9 11.8 19.7

230V

265V

208 230 265 208 230 265 208 230 265 208 230 265

7,200 7,400 7,200 8,900 9,100 8,700 11,700 12,000 11,700 13,300 13,600 13,600

2.9 2.7 2.3 3.9 3.7 3.1 5.1 4.8 4.2 6.8 6.3 5.5

12.0 12.0 12.0 11.4 11.4 10.8 11.2 11.2 11.0 9.9 9.9 9.9

2.1 2.1 2.1 2.5 2.6 2.6 3.0 3.1 3.1 4.1 4.1 4.1

5,900 6,100 6,100 7,600 7,800 7,300 9,900 10,100 10,100 12,200 12,500 12,500

2.6 2.5 2.1 3.4 3.2 2.6 4.3 4.0 3.5 5.8 5.4 4.7

540 560 560 695 715 715 935 955 925 1230 1260 1260

3.2 3.2 3.2 3.2 3.2 3.0 3.1 3.1 3.2 2.9 2.9 2.9

225 256 256 225 256 256 295 325 325 320 350 350

191 225 225 191 225 225 266 294 294 290 320 320

260 290 290 260 290 290 320 350 350 365 400 400

235 266 266 235 266 266 293 323 323 330 360 360

2.0 3.0 *2.03.05.0 2.0 3.0 5.0 2.0 3.0 5.0

2.0 3.0 *2.03.05.0 2.0 3.0 5.0 2.0 3.0 5.0

6,800 10,200 * 6,800 10,200 17,100 6,800 10,200 17,100 6,800 10,200 17,100

6,800 10,200 * 6,800 10,200 17,100 6,800 10,200 17,100 6,800 10,200 17,100

2,000 3,000 * 2,000 3,000 5,000 2,000 3,000 5,000 2,000 3,000 5,000

2,000 3,000 * 2,000 3,000 5,000 2,000 3,000 5,000 2,000 3,000 5,000

8.9 13.4 * 8.9 13.4 22.2 8.9 13.4 22.2 8.9 13.4 22.2

7.7 11.6 * 7.7 11.6 19.3 7.7 11.6 19.3 7.7 11.6 19.3

Notes: Certified in accordance with the Unitary Air-Conditioner Equipment Certification Program, which is based on ARI Standard 310/380.

Notes: Shaded area is rating ampere

24 PTAC-SVX01C-EN

Page 25

Operation

Table 19. Cooling temperature change - air conditioners

PTEE0701 PTEE0702 PTEE0901 PTEE0902 PTEE1201 PTEE1202 PTEE1501 PTEE1502

Room

air dry

bulb

90

85

80

75

70

Temperature across

Room air wet

bulb

Rating Btu/H 7200 7600 8800 9000 11700 12000 14100 14300

Rating cfm 230 260 240 270 300 330 315 355

85 13261514

80 8 1311149 138 12

75 19 22 19 22 18 22 16 20

70 30 33 28 30 26 30 25 27

80 4 9 7 11 5 10 5 8

75 14 19 15 18 13 18 12 16

70 23 27 23 25 21 25 20 23

65 34 36 31 33 29 33 28 30

75 9 1411149 138 12

70 18 21 18 20 15 20 15 18

65 26 29 24 27 23 26 21 24

60 35 36 32 33 29 33 29 30

70 12 16 13 16 10 15 10 14

65 18 22 18 21 15 20 15 19

60 25 28 23 26 21 25 20 24

55 31 34 28 31 26 30 26 28

65 12 15 12 14 9 13 9 13

60 17 20 16 18 13 17 13 17

55 22 24 20 22 18 21 17 21

indoor coil (∆ T)

MinMaxMinMaxMinMaxMinMax

Temperature across

indoor coil (∆ T)

Temperature across

indoor coil (∆ T)

Temperature across

indoor coil (∆ T)

Table 20. Cooling temperature change - heat pumps

PTHE0701 PTHE0702 PTHE0901 PTHE0902 PTHE1201 PTHE1202 PTHE1501 PTHE1502

Room

airdry

bulb

90

85

80

Temperature across

Room air wet

bulb

rating Btu/H 7300 7600 9000 9300 11800 12000 14000 14600

rating cfm 195 225 240 270 315 355 315 355

85 1 3 2 6 1 5 1 4

80 8 13 11 1510138 12

75 19 22 19 22 18 22 17 20

70 30 33 29 30 26 30 25 28

80 4 9 7 11 5 10 5 9

75 14 19 15 18 14 18 12 16

70 23 27 23 25 21 25 21 23

65 33 36 31 33 30 33 28 31

75 9 14 11 1510138 12

70 18 21 18 20 16 20 16 18

65 26 29 24 27 23 26 22 25

60 35 36 32 33 30 33 29 31

indoor coil (∆ T)

Min Max Min Max Min Max Min Max

Temperature

acrossndoor coil (∆ T)

Temperature across

indoor coil (∆ T)

Temperature across

indoor coil (∆ T)

PTAC-SVX01C-EN 25

Page 26

Operation

Table 20. Cooling temperature change - heat pumps (continued)

PTHE0701 PTHE0702 PTHE0901 PTHE0902 PTHE1201 PTHE1202 PTHE1501 PTHE1502

Room

airdry

bulb

75

70

Room air wet

bulb

70 12 16 13 16 11 15 10 14

65 18 22 18 21 16 20 16 19

60 24 28 23 26 21 25 21 24

55 31 34 29 31 26 30 26 29

65 12 15 12 15 10 13 9 13

60 17 20 16 18 14 17 13 17

55 22 24 20 22 18 21 18 21

Temperature across

indoor coil (∆ T)

Min Max Min Max Min Max Min Max

Table 21. Cooling amperage — air conditioners

Condenser

inlet air

temp.

100 2.6 2.9 2.4 2.6 3.4 4.0 2.9 3.1 5.6 5.6 3.9 4.3 6.6 8.0 5.6 6.2

95 2.4 2.8 2.3 2.5 3.2 3.8 2.7 3.0 5.4 5.3 3.7 4.1 6.2 7.6 5.3 5.9

90 2.3 2.7 2.2 2.4 3.1 3.6 2.6 2.9 5.2 5.1 3.6 3.9 5.9 7.2 5.1 5.6

85 2.2 2.6 2.1 2.3 2.9 3.4 2.5 2.7 4.9 4.8 3.4 3.8 5.6 6.8 4.8 5.3

80 2.1 2.4 2.0 2.2 2.8 3.3 2.3 2.6 4.7 4.6 3.2 3.6 5.3 6.4 4.6 5.1

PTEE0701 PTEE0702 PTEE0901 PTEE0902 PTEE1201 PTEE1202 PTEE1501 PTEE1502

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max

2.6 2.9 2.4 2.4 3.6 3.9 3.2 3.2 4.8 5.2 4.2 4.2 6.5 7.1 5.7 5.7

Temperature

acrossndoor coil (∆ T)

Temperature across

indoor coil (∆ T)

Temperature across

indoor coil (∆ T)

Table 22. Cooling amperage — heat pumps

Condenser

inlet air

temp.

100 2.6 2.9 2.5 2.7 3.4 4.0 3.0 3.2 5.6 5.5 4.1 4.5 6.6 8.0 5.5 6.8

95 2.4 2.8 2.4 2.6 3.2 3.8 2.8 3.1 5.3 5.2 3.9 4.3 6.2 7.6 5.2 5.8

90 2.3 2.6 2.2 2.5 3.1 3.6 2.7 3.0 5.0 5.0 3.7 4.1 5.9 7.2 5.0 5.5

85 2.1 2.5 2.1 2.3 3.1 3.4 2.6 2.9 4.8 4.7 3.5 3.9 5.6 6.8 4.7 5.2

80 2.1 2.3 2.1 2.2 2.9 3.3 2.5 2.7 4.6 4.5 3.3 3.7 5.3 6.4 4.5 4.9

Notes: Shaded area is rating ampere

PTHE0701 PTHE0702 PTHE0901 PTHE0902 PTHE1201 PTHE1202 PTHE1501 PTHE1502

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max

2.6 2.9 2.4 2.4 3.6 3.9 3.2 3.2 4.8 5.2 4.2 4.2 6.5 7.1 6.3 6.3

26 PTAC-SVX01C-EN

Page 27

Operation

Table 23. Heating total wattage input — heat pumps

PTHE

Outside air

dry-bulb

50

45

40

35

PTHE

0701

Room air

dry-bulb

85 580 620 745 790 1030 1115 1295 1435

80 565 600 725 775 1010 1095 1275 1410

75 550 590 710 760 990 1075 1245 1385

70 535 575 695 740 970 1050 1225 1360

65 520 560 675 720 945 1025 1200 1335

85 565 600 710 760 1000 1080 1240 1375

80 550 590 695 740 975 1060 1214 1355

75 630 570 680 730 955 1040 1190 1330

70 515 555 660 710 930 1010 1160 1305

65 500 540 640 690 910 995 1145 1280

85 545 580 680 725 950 1040 1185 1320

80 530 570 660 710 940 1020 1160 1300

75 515 555 640 690 920 1000 1135 1270

70 500 535 630 675 895 980 1110 1250

65 480 520 610 675 875 955 1090 1220

85 525 565 650 695 925 1010 1130 1270

80 510 550 630 675 900 985 1110 1240

75 500 535 610 655 880 965 1080 1220

70 480 520 600 645 855 940 1060 1190

65 465 500 580 625 940 922 1030 1265

0702

Min Max Min Max Min Max Min Max

520 535 670 685 940 965 1210 1235

PTHE

0901

PTHE

0902

PTHE

1201

PTHE

1202

PTHE

1501

PTHE

1502

Notes: Shaded area is rating wattage

Table 24. Heat pump reverse cycle heating capacity

PTEE07 PTEE09 PTEE12 PTEE15

Voltage 208 230 265 208 230 265 208 230 265 208 230 265

Amps 2.5 2.4 2.4 3.4 3.2 2.6 4.3 4.0 3.5 5.7 5.3 4.6

Btu/H 6400 6600 6600 7600 7800 8000 10100 10300 10300 12800 13100 13100

COP 3.6 3.6 3.6 3.2 3.2 3.4 3.3 3.3 3.3 3.0 3.0 3.0

Cfm (dry) 220 230 250 240 270 270 330 360 350 350 390 380

Heating

Btu/H

Outdoor

Ambient

Rating

Point

62 7200 7400 7400 9600 9700 9700 12800 13000 13000 15700 15800 15800

57 6900 7100 7100 9300 9600 9600 12500 12800 12800 15000 15200 15200

52 6500 6700 6700 8700 9000 9000 11700 12000 12000 14200 14400 14400

47 6200 6400 6400 8200 8400 8400 10900 11200 11200 13300 13500 13500

42 5900 6100 6100 7700 7900 7900 10200 10500 10500 12500 12700 12700

37 5600 5800 5800 7200 7400 7400 9500 9700 9700 11700 11900 11900

32 5300 5500 5500 6700 6900 6900 9600 8900 8900 10800 11000 11000

27 5000 5200 5200 6200 6300 6300 7900 8200 8200 10000 10200 10200

24 4800 5000 5000 5800 6000 6000 7500 7800 7800 9500 9700 9700

PTAC-SVX01C-EN 27

Page 28

Operation

Table 25. Unit accessory model numbers

Description Part Number

Architectural Grilles

ARCHITECTURAL ALUMINUM GRILLE BAYAAGL001

ARCHITECTURAL ALUMINUM GRILLE -DARK

BRONZE

ARCHITECTURAL ALUMINUM GRILLE - SOFT

DOVE

ARCHITECTURAL ALUMINUM GRILLE - SPECIAL

COLOR

Circuit breakers

CIRCUIT BREAKER - 208/230 15AMP BAYCBKR001

CIRCUIT BREAKER 208/230 20AMP BAYCBKR002

CIRCUIT BREAKER - 208/230 30AMP BAYCBKR003

Condensate pump

CONDENSATE PUMP 208/230 BAYCPMP001

CONDENSATE PUMP 265 BAYCPMP002

Drain Kit

DRAIN KIT BAYDRAN001

Filters

SPARE FILTERS 10 PACK BAYFLTR009

Hard Wire Kit

HARD WIRE KIT BAYHWRK001

Leveling Legs

LEVELING LEG BAYLVLG001

Power Switch

(1)

POWER SWITCH -115V, 208/230V 265V 30 AMP BAYPSW002

Stamped grille

STAMPED ALUMINUM GRILLE - SINGLE PACK BAYSAG001

STAMPED ALUMINUM GRILLE - TEN PACK BAYSAG002

Wall Sleeve

13 INCH WALL SLEEVE BAYWSLV001

18 INCH WALL SLEEVE BAYWSLV002

24 INCH WALL SLEEVE BAYWSLV003

Power Cord

UNIVERSAL POWER CORD 115 VOLT

- 15 Amp BAYPCRD007

UNIVERSAL POWER CORD 230 VOLT - 15 AMP BAYPCRD001

UNIVERSAL POWER CORD 230 VOLT - 20 AMP BAYPCRD002

UNIVERSAL POWER CORD 230 VOLT - 30 AMP BAYPCRD003

UNIVERSAL POWER CORD 265 VOLT - 15 AMP BAYPCRD004

UNIVERSAL POWER CORD 265 VOLT - 20 AMP BAYPCRD005

UNIVERSAL POWER CORD 265 VOLT - 30 AMP BAYPCRD006

Display Module

DISPLAY MODULE (AMERICAN STANDARD LOGO

STANDARD)

DISPLAY MODULE (AMERICAN STANDARD LOGO

& DEHUMIDIFICATION)

DISPLAY MODULE (TRANE LOGO STANDARD) BAYTRDM001

DISPLAY MODULE (TRANE LOGO &

DEHUMIDIFICATION)

Escutcheon Cover

(2)

ESCUTCHEON COVER FOR FRONT PANEL

(AMSTD LOGO)

ESCUTCHEON COVER FOR FRONT PANEL

(TRANE LOGO)

Plastic Front Cover

(3)

BAYAAGL002

BAYAAGL003

BAYAAGL004

BAYAMDM001

BAYAMDM002

BAYTRDM002

BAYACVR001

BAYTCVR001

Table 25. Unit accessory model numbers

Description Part Number

PLASTIC FRONT COVER FOR PTAC BAYPCVR001

Connector for Hardwire

CONNECTOR FOR HARDWIRE KIT 208/230V 15 AMP

CONNECTOR FOR HARDWIRE KIT 208/230V 20 AMP

CONNECTOR FOR HARDWIRE KIT 208/230V 30 AMP

CONNECTOR FOR HARDWIRE KIT 265V - 15

AMP

CONNECTOR FOR HARDWIRE KIT 265V - 20

AMP

CONNECTOR FOR HARDWIRE KIT 265V - 30

AMP

CONNECTOR FOR HARDWIRE KIT 115V - 15

AMP

Subbase

(5) (6)

UNIVERSAL SUBBASE BAYSUB001

SOCKET FOR SUBBASE 208/230 20 AMP BAYSCKT001

SOCKET FOR SUBBASE 208/230 30 AMP BAYSCKT002

SOCKET FOR SUBBASE 265 20 AMP BAYSCKT003

SOCKET FOR SUBBASE 265 30AMP BAYSCKT004

(1)

The power switch can be installed on the hard wire junction box and

provides a way to shut on and off the PTAC unit. It is an optional accessory when using the power cord to power the PTAC unit. Check local

codes for approval

(2)

This escutcheon cover should be ordered whenever the display module

is wall mounted or a thermostat or third party provider unit controls are

ordered. This escutcheon includes a control cover plate that covers the

normal unit mounted nomenclature. It comes 5 pieces per pack.

(3)

All hydronic PTAC chassis come standard without a plastic front cover.

If a unit is required to work without heat and without a hydronic kit the

plastic front cover should be ordered.

(4)

Not required when using a Hard Wire Kit.

(5)

Provides a space to tie into a building’s wiring with a receptacle to plug

the unit into. It gives additional leveling and support capabilities and

provides a place for fuses, a circuit breaker or a mechanical disconnect

to be mounted. (30A is for units with 5kW electric heat, 20A for 3kW or

less electric heat.)

(6)

All subbases require a socket. For 15 and 20 amp, the 20amp socket

can be used on either the 208/230V or the 265V.

(4)

BAYCNHK011

BAYCNHK012

BAYCNHK013

BAYCNHK021

BAYCNHK021

BAYCNHK023

BAYCNHK031

28 PTAC-SVX01C-EN

Page 29

Table 26. Hydronic heat options

Kit Description

HHydronic

Coil Type

WWater Coil

SSteam Coil

Accessory Type

KKit

Power Voltage

01 208-230 VAC

02 265 VAC

04 115 VAC

Coil Positioning

L Left hand hot water coil

R Right hand hot water coil

Kick Plate

S Standard 2" to 6" adjustable

E Extended standard base kick

M Upgraded kick plate standard

U Upgraded kick plate extended

Color

S Standard Soft Dove II

C Special Color

connection (Standard/

Stocked)

connection (Not Stocked)

kick plate

plate 7" to 13"

height 2" to 6" (Like the unit

ventilator design)

height 7" to 13" (Like the unit

ventilator design)

Operation

PTAC-SVX01C-EN 29

Page 30

Maintenance

Maintenance Procedures

Perform the following maintenance

procedures to ensure proper unit

operation.

WARNING

Live Electrical Components!

During installation, testing, servicing

and troubleshooting of this product,

it may be necessary to work with

live electrical components. Have a

qualified licensed electrician or other

individual who has been properly

trained in handling live electrical

components perform these tasks.

Failure to follow all electrical safety

precautions when exposed to live

electrical components could result in

death or serious injury.

WARNING

Hazardous Voltage!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure the

power can not be inadvertently

energized. Failure to disconnect

power before servicing could result

in death or serious injury.

Chassis

Clean the chassis every four months

or more often as the atmospheric

conditions require. Use water and

detergent to clean the basepan,

center partition and coils.

Using harsh cleaning materials may

cause a deterioration of the coil fins

or end plates.

Do not use a high pressure cleaner

as it could cause severe damage to

the PTAC fins and coils.

Note: It is very important to not get

any of the electronic parts

wet.

A hose is okay to use to clean the

coils, but make sure to cover the

control with a blanket or plastic bag

to prevent it from getting wet.

Wall Sleeve

Clean the wall sleeve every four

months or more often as the

atmospheric conditions require.

Remove any debris from the bottom

of the panel, and from around any

internal or external drain kit

accessory item prior to using water

or detergent. This will ensure that no

debris clogs up the drain holes.

The use of harsh cleaning materials

may cause a deterioration of the

bottom panel over time. Do not use

a high pressure cleaner because it

could spray the side or top panel

insulation material and cause future