Page 1

Installation, Operation,

and Maintenance

Programmable Zone Sensor

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

June 2010 BAS-SVX17B-EN

Page 2

2 BAS-SVX17B-EN

Copyright

© 2010 Trane All rights reserved

This document and the information in it are the property of Trane and may not be used

or reproduced in whole or in part, without the written permission of Trane. Tranereserves

the right to revise this publication at any time and to make changes to its content without

obligation to notify any person of such revision or change.

Trademarks

Trane and its logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

Warnings, Cautions, and Notices

Warnings, cautions, and notices are provided in appropriate places throughout this

document:

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

NOTICE: Indicates a situation that may result in equipment or property-damage-

only accidents.

Page 3

BAS-SVX17B-EN 3

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Height Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wire Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the Back Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replacing the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Applying Power to the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Set-up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Changing the System Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Changing the Fan Setting (CV/HP Configuration only) . . . . . . . . . . . . . . 19

Setting the Time Clock and the Day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Scheduling for VAV Occupied Periods . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Temporary Override Set-up (CV/HP only) . . . . . . . . . . . . . . . . . . . . . . . . . 22

Locking or Unlocking the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Status Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Default Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setpoint Only Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Weekly Operating Schedule Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Conducting a Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Check Filter Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Declaration of CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 4

4 BAS-SVX17B-EN

General Information

This section provides a description of the sensors, as well as part numbers and dimensions.

Product Description

The Trane®programmable zone sensor (p/n X1379088401) can be used with UCP, Reliatel, and

IntelliPak control units. It has the following features:

• A liquid crystal display (LCD) with symbols for zone temperature, temperature setpoints,

system operating modes, day of the week, time of day, and occupancy settings

• Configurable to operate with constant-volume (CV) units, heat pump (HP) units, and variableair-volume (VAV) units

• System modes:

– CV: Heat, Cool, Auto, Off

– HP: Emergency Heat, Heat, Cool, Auto, Off

– VAV: Auto, Off

• A cooling setpoint range (occupied) of 45ºF to 98ºF (7.2ºC to 36.7ºC)

• A heating setpoint range (occupied) of 43ºF to 96ºF (6.1ºC to 35.6ºC)

• Two fan modes (CV and HP only): On, Auto

• A table of configurable functional options (see Tab l e 3 , p . 1 4 and Ta b l e 4 , p . 1 6 )

• Scheduling function: 7 days per week and up to 4 periods per day, occupied/unoccupied mode

• Temporary override function

• During occupied periods, an auxiliary relay rated for 1.25 A @ 30 Vac with one set of single-pole

double-throw contacts is activated.

Page 5

BAS-SVX17B-EN 5

General Information

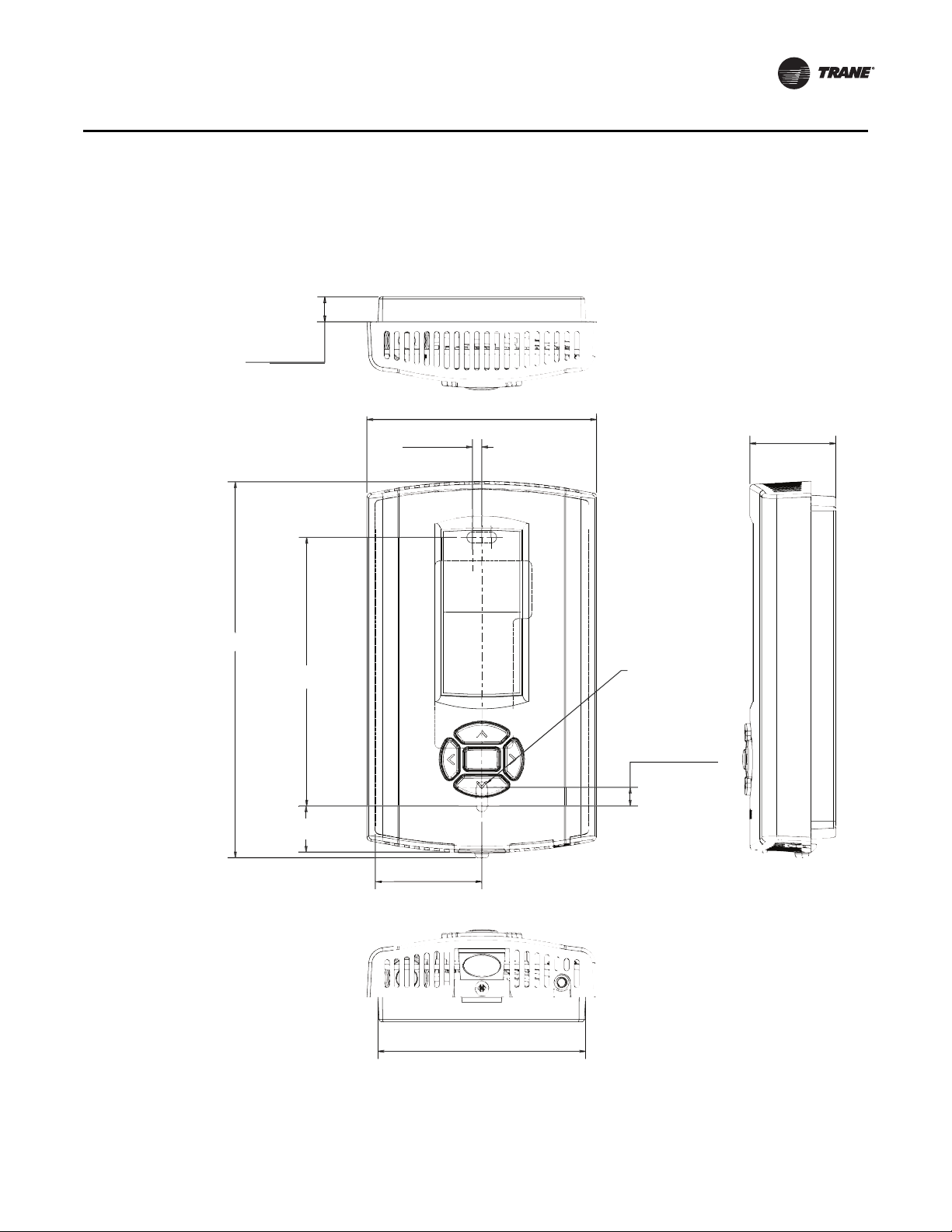

Dimensions

The following illustration provides specific dimension details. The dimensions are the same for all

models.

2.9 in (73.5 cm)

1.08 in (27.5 mm)

4.68 in (118.9 mm)

1.34 in (34.14 mm)

0.58 in (14.76 mm)

0.31 in (8 mm)

0.12 in (3 mm)

TYP R.07 in

(R1.80 mm)

3.39 in (86 mm)

0.24 in (6.00 mm)

2.62 in (66.5 mm)

Page 6

6 BAS-SVX17B-EN

Pre-Installation

This section provides the following pre-installation information:

• Location considerations

• Height requirements

• Mounting surfaces

• Recommended wire lengths

Location Considerations

Placement of the sensor is critical to proper operation. When selecting a location, avoid the

following:

• Areas of direct sunlight

• Areas in the direct airstream of air diffusers

• Exterior walls and other walls that have a temperature differential between the two sides

• Areas that are close to heat sources such as sunlight, appliances, concealed pipes, chimneys,

or other heat-generating equipment

• Drafty areas

• Dead spots behind doors, projection screens, or corners

• Walls that are subject to high vibration

• Areas with high humidity

• High traffic areas (to reduce accidental damage or tampering)

Height Requirements

It is recommended that you mount the back plate a maximum distance of 54 inches above the floor.

If a parallel approach by a person in a wheelchair is required, reduce the maximum height to 48

inches.

Note: Consult section 4.27.3 of the 2002 ADA (Americans with Disability Act) guideline, and local

building codes, for further details regarding wheelchair requirements.

Mounting Surfaces

Using the hardware provided, mount the back plate to a flat surface such as sheetrock or plaster,

or an electrical junction box. The sensor must be mounted plumb for accurate temperature control

and to ensure proper air movement through the sensor.

• If mounting onto sheetrock or plaster, use the plastic threaded anchors (pre-drilling holes is not

usually necessary) and the two M3.5 x 20 mm mounting screws.

• For mounting onto an electrical junction box, use the two 6-32 x 3/4 in. screws.

• If you are replacing a horizontally mounted sensor and need to cover an opening in the wall,

use the adapter kit (p/n BAYMTPL103A).

Page 7

BAS-SVX17B-EN 7

Pre-Installation

Wire Length

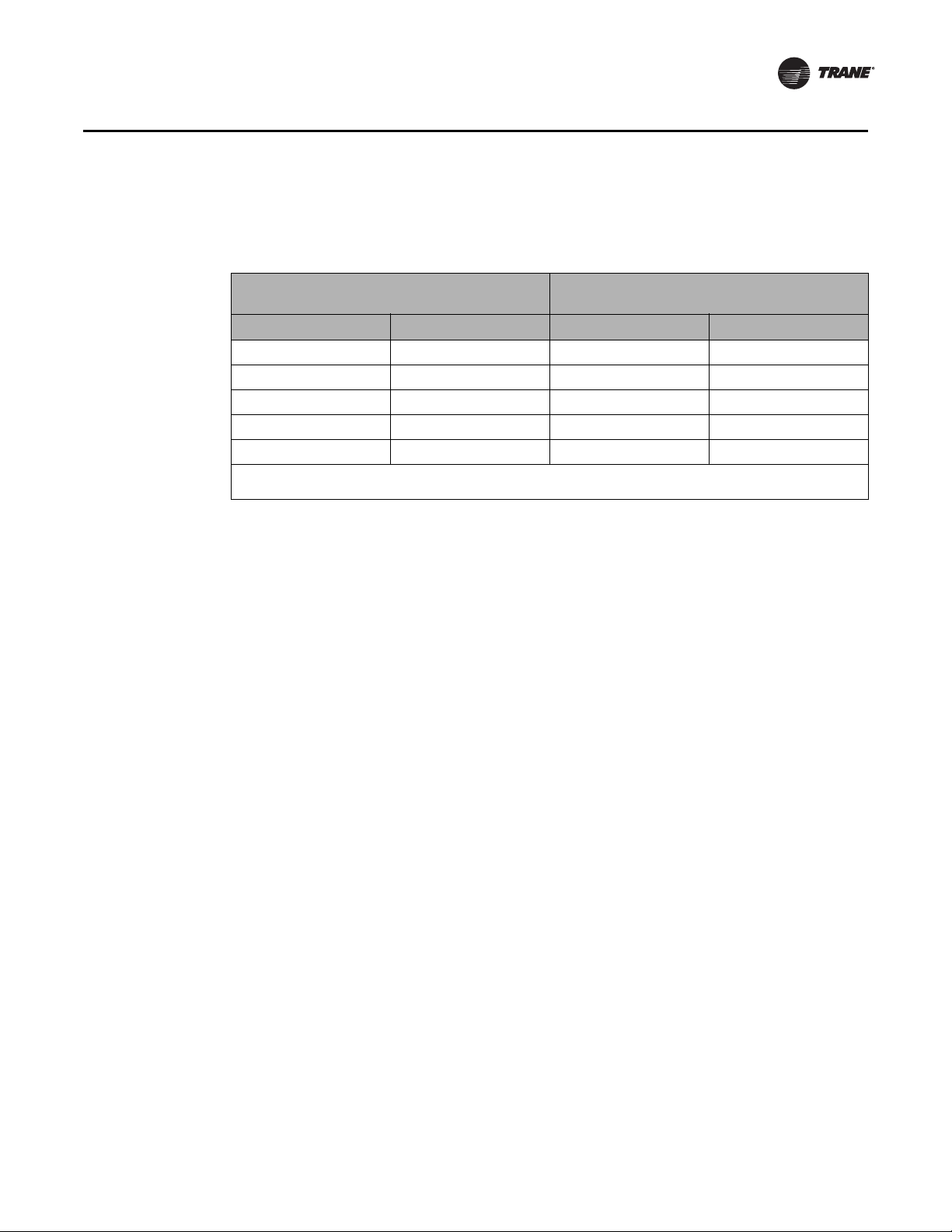

Maximum recommended wire lengths for the sensor are given in Ta b l e 1 :

Table 1. Recommended wire lengths

Wire size

Maximum recommended wire length from unit

controller to sensor

AWG mm

2

Meters Feet

22 0.33 0–46 0–150

20 0.50 47–73 151–240

18 0.75 74–117 241–385

16 1.30 118–185 386–610

14 2.00 186–296 611–970

Note: The total resistance of these low voltage wires must not exceed 2.5 Ω/conductor. Any resistance greater than 2.5 Ω

may cause the control to malfunction due to an excessive voltage drop.

Page 8

8 BAS-SVX17B-EN

Installation

This section provides step-by-step installation instructions. Read through the pre-installation

information before proceeding with the installation.

Note: Before installing the sensor, ensure that:

• A wire access hole is available at the sensor location

• The wires are accessible through the hole

• The wires are attached to the appropriate unit controller

• There is continuity between the sensor location and the unit controller

• The wires are accurately labeled or identified by color

Mounting the Back Plate

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

NOTICE

Equipment damage!

Applying excessive voltage to the sensor will permanently damage it.

Note: Refer to the illustration below when installing the sensor.

1. Shut off power to the unit controller.

2. Remove the cover by firmly pressing the thumb tab at the bottom of the cover and pulling the

cover away from the back plate.

Note: If present, remove the security screw before removing the cover.

3. Determine the number of wires required by referring to Tab l e 2, p . 10 .

4. Feed the wires through the opening in the back plate.

5. Hold the back plate against the mounting surface and mark the screw locations.

6. Secure the back plate to the mounting surface using the included hardware.

Security screw

Page 9

BAS-SVX17B-EN 9

Installation

Wiring the Sensor

WARNI NG

Hazardous voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power cannot be inadvertently energized. Failure to

disconnect power before servicing could result in death or serious injury.

NOTICE

Equipment damage!

Applying excessive voltage to the sensor will permanently damage it.

To wire the sensor to the unit controller (see guidelines for wire sizes and lengths in Table 1, p. 7.):

1. Ensure that the wires are connected to the appropriate

terminals at the unit controller.

2. Connect the wires to the terminal block (included in the hardware package with the sensor). See

Ta b l e 2 , p . 10 to determine where to terminate wires in the terminal block.

Note: The numbers on the terminal block correspond to the numbers on the terminals of the

unit controllers most frequently used with the sensor.

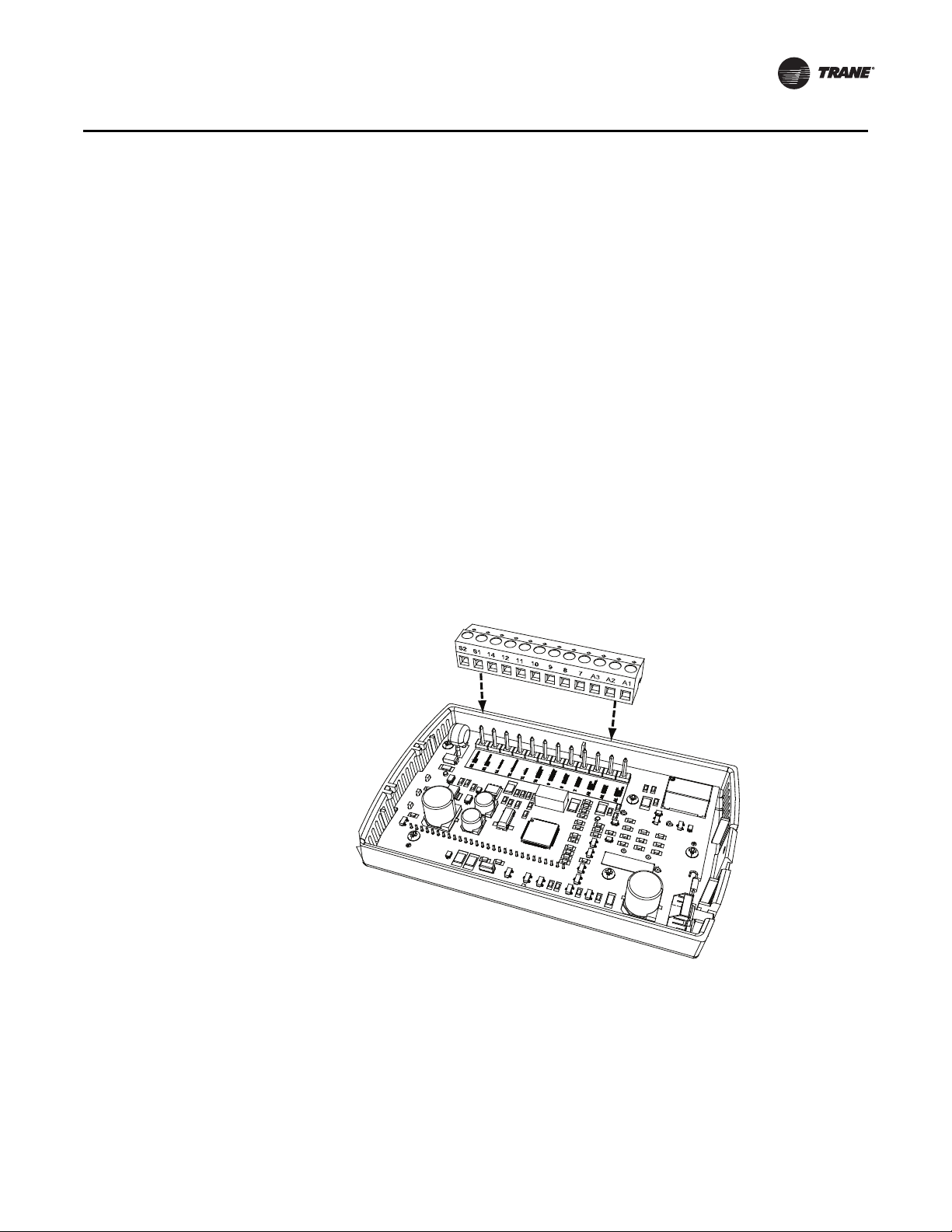

3. Attach the terminal block to the pins on the circuit board inside the sensor cover (Figure 1).

4. Push the excess wire into the wall cavity and plug it with nonflammable insulation to prevent

drafts from affecting the sensor.

Important: Do not coil excess wire inside the back plate.

Figure 1. Attaching the terminal block to the pins on the circuit board

Page 10

10 BAS-SVX17B-EN

Installation

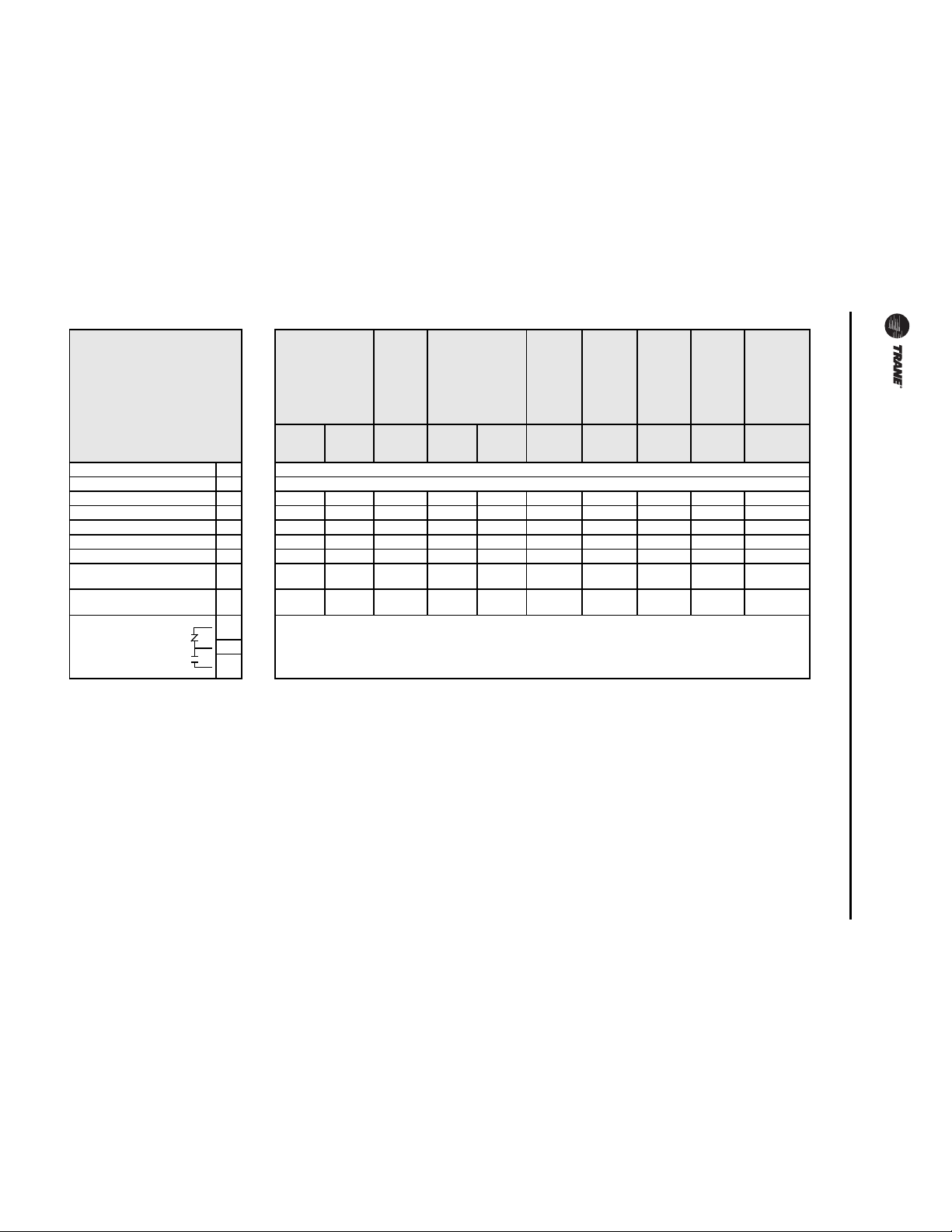

Table 2. Programmable zone sensor wiring diagram

Sensor

3–25 ton

packaged rooftops

*CD/*CH/*SC/

*HC

3–20

split

system

units

TTA/TWA

27.5–50 ton

packaged rooftops

YC*/TC*/TE*

20–130

ton

packaged

rooftops

S*HF/

W*HB

90–162

ton

packaged

rooftops

S*HJ

YC* TE*

TC

330–600

model

number

10th digit

= A+ L

LTB1

YC* TE*

TC

330–600

model

number

10th digit

= M+

RTRM J6

Commercial

self-

contained

(CSC)

S**F, S**G

UCP

control

LTB

(1)

ReliaTel

Control

J6

ReliaTel

Control

J6

UCP

control

LTB1

(1)

ReliaTel

Control J6IntelliPak

1TB4

IntelliPak

1TB4

UCP

control

LTB1

(1)

ReliaTel

Control

J6 IntelliPak

REMOTE SENSOR INPUT

(2)

S2 Optional remote sensor

REMOTE SENSOR INPUT

(2)

S1 Optional remote sensor

24 VAC INPUT

(3)

14 ------- 14

(4)

14 14 14 14 14 1 14 14 1TB11-4

COMMUNICATIONS

(5)

12 ------- 12 12 12 12 12 12 12 12 12 1TB8-12

COMMON

(3)

11 ------- 11 11 11 11 11 6 7 11 11 1TB8-11

SERVICE STATUS (UCM INPUT) 10 ------- 10 10 10 10 10 10 11 10 10 1TB8-10

SYSTEM STATUS (ON/OFF INPUT) 9 ------- 9 9 9 9 9 9 10 9 9 1TB8-9

COOL STATUS

(UCM INPUT)

8 ------- 8 8 8 8 8 8 9 8 8 1TB8-8

HEAT STAT US

(UCM INPUT)

7 ------- 7 7 7 7 7 7 8 7 7 1TB8-7

AUX RELAY (CLOSED—

UNOCCUPIED)

A3

The auxiliary relay on the sensor is form C, rated for 1.25 A at 30 Vac. It is energized during occupied periods.AUX RELAY (COMMON) A2

AUX RELAY (CLOSED—

OCCUPIED)

A1

(1)LTB and LTB1 refer to low-voltage terminal boards with numbers 1–20 and two test terminals.

(2)Connect an optional remote sensor (p/n BAYSENS017) to terminals S1 and S2. Connect the shield wire (drain wire) from the shielded cable to terminal 11.

(3)Connect the 24 Vac power supply from the unit controller to terminals 11 and 14. (IntelliPak power supply voltage is 12–15 Vac.)

(4)Use terminal 15 on older 3–25 ton Voyager units with low-voltage terminal boards numbered 1–18 with two test terminals.

(5)Data communication between the unit controller and the sensor is accomplished by a serial link connected at terminal 12.

Page 11

BAS-SVX17B-EN 11

Installation

Replacing the Cover

To replace the cover:

1. Hook the cover over the top of the back plate. Apply light pressure to the bottom of the cover

until it snaps in place.

2. Secure the cover by installing the security screw into the bottom of the cover.

Security screw

Page 12

12 BAS-SVX17B-EN

Installation

Applying Power to the Sensor

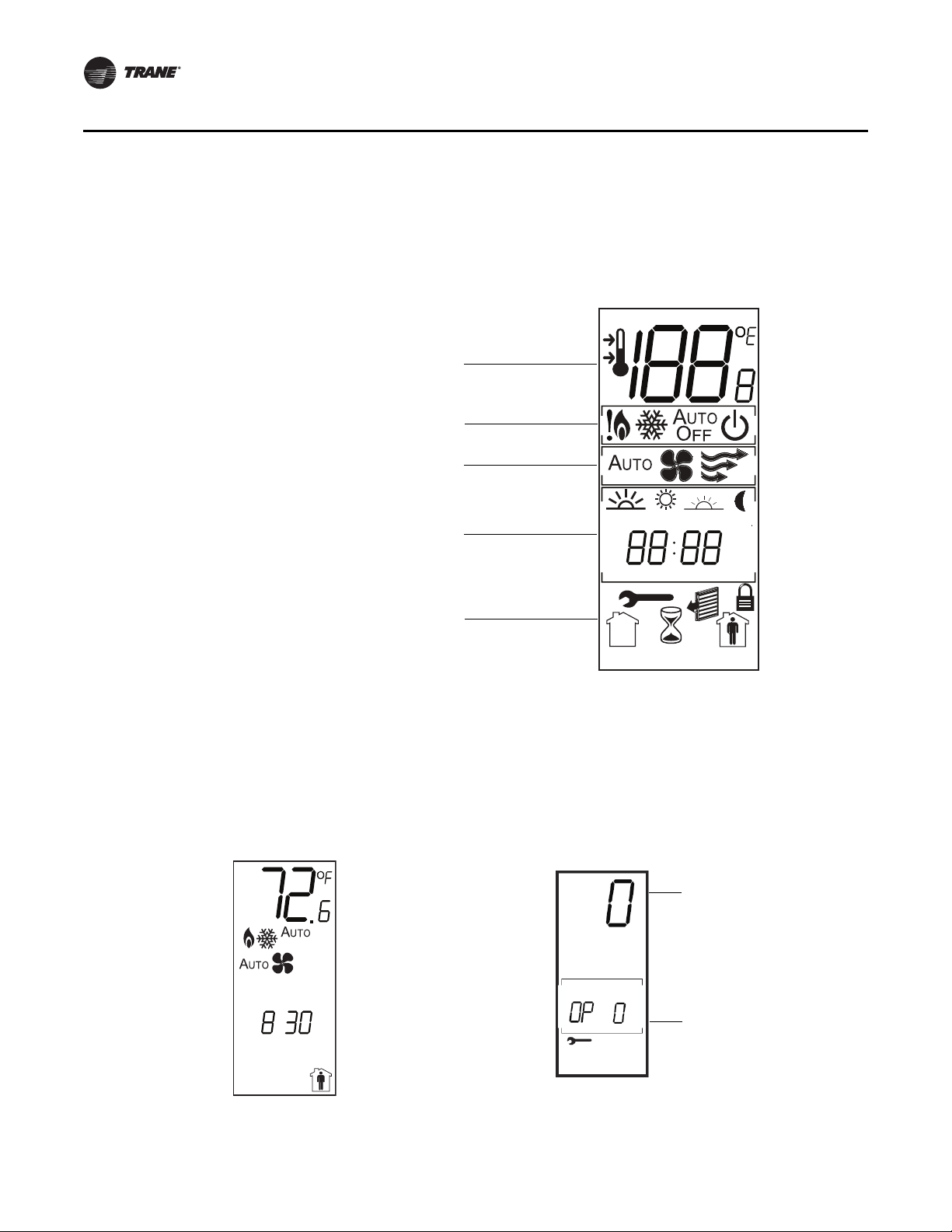

Restore power to the unit controller. The following sequence appears on the display:

• The display lights up and all of the symbols appear for 2 seconds (see Figure 2).

• The software version appears for 2 seconds.

• If the sensor has been in service for any length of time, the home screen appears (see Figure 3A

example). If the sensor is new, the configuration screen appears (see Figure 3B). If no buttons

are pressed for 90 seconds, the display returns to the home screen in constant-volume (CV)

configuration.

• The light dims.

Figure 2. Display with all the symbols appearing

AM

PM

DAYS

HOURS

Mo Tu We Th Fr SatSu

.

Service indicator, filter timer,

keypad lockout, occupancy

indicator, temporary override

Zone temperature and

setpoint temperature

System settings

Fan sett ings

Scheduling area/day and clock

Figure 3. Display at power-up

.

.

Mo

AM

A. Home screen

B. Configuration screen

Option value

Option number

Page 13

BAS-SVX17B-EN 13

Configuration

The programmable zone sensor is configured by selecting options to determine system and

functional operations.

The sensor can be configured to operate with one of the following units:

• A constant-volume (CV) unit

• A heat pump (HP) unit

• A variable-air-volume (VAV) unit

The functional options that are available depend on whether the sensor is configured for a CV, an

HP, or a VAV unit.

To configure the sensor:

1. Press and hold the Test/Configuration button for 2 seconds (Figure 4). The configuration screen

appears (see Figure 3, p. 12).

2. Use the keypad on the sensor cover to select the system and functional options. See Ta b le 3 ,

p. 14 for sensors used with CV or HP units; see Table 4, p. 16, for sensors used with VAV units.

• Press , , or to change the option number.

• Press or to change the option value.

3. To confirm the selection and return the display to the home screen, either:

• Press the Test/Configuration button, or

• Press and hold for 2 seconds

Note: The sensor will revert to the home screen if no buttons are pressed for 90 seconds.

Figure 4. Pressing the Test/Configuration button

Test/Configuration button

Keypad

Page 14

14 BAS-SVX17B-EN

Configuration

Table 3. Configuration options for sensors used with constant-volume (CV) or heat pump (HP) units

Option

number

Function Option value Default Description

0

(See Note)

Operation mode

0 = Constant-volume (CV)

1 = Heat pump (HP)

2 = Variable-air-volume (VAV)

0

Configures the operation mode of the sensor.

Note: To access option number 0, with the configuration

screen showing, press the up and down arrows

simultaneously for 2 seconds. Option number 0 will

appear on the display.

1 Morning warm-up

0 = Disabled

1 = Enabled

0

If enabled, the heat turns on when the program switches

from unoccupied to occupied and the zone temperature is

2ºF (1.1ºC) below the heating setpoint temperature. The

heat terminates after 60 minutes regardless of whether

the setpoint has been reached.

2

Economizer minimum

position override during

unoccupied period

0 = Disabled

1 = Enabled

1

If enabled, the minimum position of the economizer

damper is overridden during the unoccupied period.

3Temperature scale

0 = ºF

1 = ºF + 0.5

2 = ºF + 0.1

3 = ºC

4 = ºC + 0.5

5 = ºC + 0.1

0 Displays the temperature in the selected format.

4Supply air tempering

0 = Disabled

1 = Enabled

0

If enabled, this setting sends the tempering signal to the

UCP.

5Time clock

0 = 12 hour

1 = 24 hour

0

• 0 sets clock to 12-hour format with AM and PM.

• 1 sets clock to 24-hour military time.

6 Smart fan

0 = Disabled

1 = Enabled

1

If enabled, the supply fan operates in the Auto mode

during unoccupied periods, regardless of the fan setting.

7 Computed recovery

0 = Disabled

1 = Enabled

0

If enabled, this option offsets the setpoint temperature

and starts the system before the scheduled occupied

period to efficiently reach the occupied temperature

setpoint. The time is calculated based on a recovery rate

of 6ºF (3.3ºC) per hour. If configured for an HP unit, option

7 is disabled for emergency heat operation.

8

Programmable days per

week

0 = 7 days (M, T, W, Th, F, S, S)

1 = 5 +1 days (M–F, S, S)

2 = 5 + 2 days (M–F, S–S)

3 = 1 day

0

• If 0 is selected, all 7 days to be programmed differently.

• If 1 is selected, week days, Sat, and Sun can be

programmed differently from one another.

• If 2 is selected, week days can be programmed one way

and Sat-Sun can be programmed another way.

• If 3 is selected, all seven days are limited to being

programmed the same way.

9

Programmable periods

per day

2 = Day and Night

3 = Morning, Day, Night

4 = Morning, Day, Evening,

Night

4

• If 2 is selected, only Day and Night periods can be

programmed.

• If 3 is selected, only Morning, Day, and Night periods can

be programmed.

• If 4 is selected, Morning, Day, Evening, and Night

periods can be programmed.

10

Programmable fan

operation

0 = Disabled

1 = Enabled

0

If enabled, the supply fan operation can be programmed

for On or Auto operation for each programmed period.

11 Remote sensor installed

0 = No

1 = Yes

0

If Yes is selected, the space temperature of the remote

sensor will appear on the display and will be communicated

to the unit controller.

12 Check filter interval

0 = Disabled

1–1

99 = Number of 1-day

increments

30

Adjustable in 1-day increments. The check filter symbol

flashes when the accumulated run time is greater than the

programmed setting.

Page 15

BAS-SVX17B-EN 15

Configuration

13

Display zone

temperature

0 = No

1 = Yes

1

If the sensor is in a normal running state or in temporary

occupancy (timed override), the zone temperature

appears.

14 Keypad lockout

0 = Disabled

1 = Enabled

1 If enabled, the keypad can be locked out.

15

Default temporary

override timer setting

1, 2, 3, 4, 5 (hours) 3 Sets the default temporary override time in hours.

16

Zone temperature

calibration

Displays current temperature

reading with any offsets:

• 1 = –9.9ºF (–5.5ºC)

• 100 = 0.0ºF (0.0ºC)

• 199 = 9.9ºF (9.9ºC)

100

(0

offset)

Allows for field calibration in 0.1ºF (0.6ºC) increments of

either the internal sensor on the sensor, or the remote

sensor if used.

Important: Apply power to the sensor for 60 minutes before

calibrating.

17 Baud rate

0 = 1024 baud

1=1200 baud

1

Set to 0 for 3–25 ton Voyager units built before January 1,

1996, that have the original UCP.

18 Default cooling setpoint 45–98ºF (7.2–36.7ºC) 74

If no setpoint has been programmed or the program is lost,

the value that is set becomes the operation setpoint.

19 Default heating setpoint 43–96ºF (6.1–35.6ºC) 68

If no setpoint has been programmed or the program is lost,

the value that is set becomes the operation setpoint.

20

Minimum cooling

setpoint

45–98ºF (7.2–36.7ºC) 45

Sets the minimum programmable cooling temperature

setpoint.

21

Maximum heating

setpoint

43–96ºF (6.1–35.6ºC)) 96

Sets the maximum programmable heating temperature

setpoint.

22

Minimum setpoint

deadband

0 = 2ºF (1ºC)

1 = 4ºF (2ºC)

2 = 5ºF (3ºC)

3 = 7ºF (4ºC)

4 = 8ºF (5ºC)

5 = 10ºF (6ºC)

0

Sets the minimum difference between the heating and

cooling setpoints.

Table 3. Configuration options for sensors used with constant-volume (CV) or heat pump (HP) units (continued)

Option

number

Function Option value Default Description

Page 16

16 BAS-SVX17B-EN

Configuration

Table 4. Configuration options for sensors used with variable-air-volume (VAV) units

Option

number

Function Option Value Default Description

0

(See Note)

Operation mode

0 = Constant-volume (CV)

1 = Heat pump (HP)

2 = Variable-air-volume (VAV)

0

Configures the operation mode of the sensor.

Note: To access option number 0, with the configuration

screen showing, press the up and down arrows

simultaneously for 2 seconds. Option number 0 will

appear on the display.

1 Morning warm-up

0 = Disabled

1 = Enabled

0

If enabled, the heat turns on when the program switches

from unoccupied to occupied and the zone temperature is

1.5ºF (0.8ºC) below the warm-up setpoint temperature.

2

Economizer minimum

position override during

unoccupied period

0 = Disabled

1 = Enabled

1

If enabled, the minimum position of the economizer

damper is overridden during the unoccupied period.

3Temperature scale

0 = ºF

1 = ºF + 0.5

2 = ºF + 0.1

3 = ºC

4 = ºC + 0.5

5 = ºC + 0.1

0 Displays the temperature in the selected format.

4 Heat installed

0 = No

1 = Yes

0

Allows the warm-up setpoint to be programmed during

occupied periods.

5 Time Clock

0 = 12 hour

1 = 24 hour

0

• 0 sets clock to 12-hour format with AM and PM.

• 1 sets clock to 24-hour military time.

6 Modulated heat

0 = No

1 = Yes

0

The modulated heat is controlled to the supply air heating

setpoint.

7Daytime warm-up

0 = Disabled

1 = Enabled

0

If enabled, this setting allows the system to automatically

switch between supply air cooling and constant-volume

heating operation during an occupied period.

8

Programmable days per

week

0 = 7 days (M, T, W, Th, F, S, S)

1 = 5 +1 days (M–F, S, S)

2 = 5 + 2 days (M–F, S–S)

3 = 1 day

0

• If 0 is selected, all 7 days to be programmed differently.

• If 1 is selected, week days, Sat, and Sun can be

programmed differently from one another.

• If 2 is selected, week days can be programmed one way

and Sat-Sun can be programmed another way.

• If 3 is selected, all seven days are limited to being

programmed the same way.

9

Programmable periods

per day

2 = Day and Night

3 = Morning, Day, Night

4 = Morning, Day, Evening,

Night

4

• If 2 is selected, only Day and Night periods can be

programmed.

• If 3 is selected, only Morning, Day, and Night periods can

be programmed.

• If 4 is selected, Morning, Day, Evening, and Night

periods can be programmed.

10 Remote sensor installed

0 = No

1 = Yes

0

If yes is selected, the space temperature of the remote

sensor will appear on the display and will be

communicated to the unit controller.

11 Check filter interval

0 = Disabled

1–199 = Number of 1-day

increments

30

Adjustable in 1-day increments. The check filter symbol

flashes when the accumulated run time is greater than the

programmed setting.

12

Display zone

temperature

0 = No

1 = Yes

1

If

sensor is in a normal running state or in temporary

occupancy (timed override), the zone temperature

appears.

13 Keypad lockout

0 = Disabled

1 = Enabled

1 If enabled, the keypad can be locked out.

Page 17

BAS-SVX17B-EN 17

Configuration

14

Default temporary

override timer setting

1, 2, 3, 4, 5 (hours) 3 Sets the default temporary override time in hours.

15

Zone temperature

calibration

Displays current temperature

reading with any offsets:

• 1 = –9.9ºF (–5.5ºC)

• 100 = 0.0ºF (0.0ºC)

• 199 = 9.9ºF (9.9ºC)

100

(0

offset)

Allows for field calibration in 0.1ºF (0.6ºC) increments of

either the internal sensor on the sensor, or the remote

sensor if used.

Important: Apply power to the sensor for 60 minutes before

calibrating.

16 Default cooling setpoint 45–98ºF (7.2–36.7ºC) 74

If no setpoint has been programmed or the program is

lost, the value that is set becomes the operation setpoint.

17 Default heating setpoint 43–96ºF (6.1–35.6ºC) 68

If no setpoint has been programmed or the program is

lost, the value that is set becomes the operation setpoint.

18 Default supply air cool 40–80ºF (4.4–26.7ºC) 55

If no setpoint has been programmed or the program is

lost, the value that is set becomes the operation setpoint.

19 Default supply air heat 60–100ºF (15.6–37.8ºC) 100

If no setpoint has been programmed or the program is

lost, the value that is set becomes the operation setpoint.

20 Default warm-up 50–90ºF (10–32.2º) 68

If no setpoint has been programmed or the program is

lost, the value that is set becomes the operation setpoint.

21

Minimum cooling

setpoint

45–98ºF (7.2–36.7ºC) 45

Sets the minimum programmable cooling temperature

setpoint.

22

Maximum heating

setpoint

43–96ºF (6.1–35.6ºC) 96

Sets the maximum programmable heating temperature

setpoint.

23 Minimum supply air cool 40–80ºF (4.4–26.7ºC) 40

Sets the minimum programmable cooling temperature

setpoint.

24

Maximum supply air

heat

60–160ºF (15.6–71.1ºC) 160

Sets the maximum programmable heating temperature

setpoint.

25

Maximum warm-up

time

50–90ºF (10–32.2º) 90

Sets the maximum programmable heating temperature

setpoint.

26

Minimum setpoint

deadband

0 = 2ºF (1ºC)

1 = 4ºF (2ºC)

2 = 5ºF (3ºC)

3 = 7ºF (4ºC)

4 = 8ºF (5ºC)

5 = 10ºF (6ºC)

0

Sets the minimum difference between the heating and

cooling setpoints.

Table 4. Configuration options for sensors used with variable-air-volume (VAV) units (continued)

Option

number

Function Option Value Default Description

Page 18

18 BAS-SVX17B-EN

Operation

This section describes sensor operations, explains sensor symbols, and provides the default

settings.

Set-up Procedures

The following procedures show how to set up the programmable zone sensor for operation using

the keypad and display. Procedures begin at the home screen (see Figure 5).

Changing the System Setting

Figure 5. Programmable zone sensor showing an example of the home screen on the display

System in cooling mode

1. From the home screen, select the system setting by

pressing twice.

2. Press or to select the desired system setting.

3. To confirm your setting, press or wait 10 seconds.

The home screen will apprear.

System in heating mode

Emergency heat (HP only). Used by facility

operators or service technicians only.

System Auto. The system automatically switches

between heating and cooling as needed.

System Off.

.

.

Mo

AM

Keypad

Occupancy indicator

Tem p e rat u re

System setting

Fan sett ing

Day and clock

Page 19

BAS-SVX17B-EN 19

Operation

Changing the Fan Setting (CV/HP Configuration only)

Setting the Time Clock and the Day

Fan Auto: The fan automatically

powers On and Off as needed to reach

the selected temperature.

1. From the home screen, select the fan setting by pressing

twice and then .

2. Press or to select the desired fan setting.

Note: The sensor can be configured for programmable fan

operation (see Table 3, p. 14). If this feature is enabled,

fan operation is controlled by the schedule. If you

attempt to change the fan setting, the sensor display will

change to temporary override set-up. Follow the

procedure in “Temporary Override Set-up (CV/HP only),”

p. 22 to override the fan setting.

3. To confirm your setting, press or wait 10 seconds. The

home screen will appear.

Fan On: Fa n is po wered On.

Day of week and time clock

1. From the home screen, select the time clock and day

setting by pressing twice and then three times.

2. Press or to select the hour. The hour flashes.

3. Press or to change the hour.

4. Press to select the minutes. The minutes flash.

5. Press or to change the minutes.

6. Press to select the days of the week. All days of the

week appear, and the currently selected day flashes.

7. Press or to change the day.

8. To confirm your settings, press for 2 seconds, or wait

10 seconds. The home screen will appear.

.

.

Mo

AM

Page 20

20 BAS-SVX17B-EN

Operation

Scheduling

1

The programmable zone sensor has a feature that “copies” the schedule for one of the five

weekdays to the other four weekdays, and one of the two weekend days to the other weekend day.

To use this feature, the sensor must be configured for 7 programmable days per week and

scheduling must be completely blank. If you set a complete schedule for any one weekday, that

schedule will be copied to the other four weekdays. If you set a complete schedule either Saturday

or Sunday, the schedule will be copied to the other weekend day. You can modify each day

individually, as necessary.

Notes:

• To erase all scheduling, select scheduling and press the Test/Configuration button for 2 seconds.

1

For VAV occupied periods, refer to “Scheduling for VAV Occupied Periods,” p. 21

Scheduling

setting selected

1. From the home screen, select the scheduling setting by pressing

twice and then two times.

Days of week

selected

2. Press or to select the days of the week. All days of the week

appear and Monday flashes.

3. Press or to select the day you want to schedule.

Morning, Day, Evening, Night

Period of day

selected

4. Press to select the period of the day. All periods appear, and

the first period (morning) flashes.

5. Press or to select the period of the day you want to schedule.

Period start time

selected

6. Press or to select the period start time. The selected period

start time flashes (or dashes flash if nothing has been set).

7. Press or to change the period start time.

Occupancy

setting selected

8. Press to select occupancy. Both occupancy symbols appear

and the selected symbol flashes.

9. Press or to select the occupancy setting you want for the

period you are scheduling.

Heating setpoint

selected

10.Press to select the heating setpoint. The bottom arrow of the

setpoint symbol and the heating symbol flash. The current

heating setpoint appears (or dashes if nothing has been set).

11. Press or to change the heating setpoint for the period

you are scheduling.

Mo Tu We Th Fr SatSu

Mo Tu We Th Fr SatSu

Page 21

BAS-SVX17B-EN 21

Operation

Scheduling for VAV Occupied Periods

Cooling setpoint

selected

12.Press to select the cooling setpoint. The top arrow of the

setpoint symbol and the cooling symbol flash. The current

cooling setpoint appears (or dashes if nothing has been set).

13.Press or to change the cooling setpoint for the period

you are scheduling.

Fan Auto

Fan On

14.Press to select the fan setting. The fan setting appears and

the currently selected fan setting flashes.

Note: CV/HP only, and only if the programmable fan option is enabled.

15.Press or to select the fan setting for the period you are

scheduling.

16. To confirm your schedule settings, press and hold for 2

seconds, or wait 30 seconds. The home screen will appear.

Occupancy setting

selected

1. Follow steps 1—8 of the procedure described in “Scheduling,”

p. 20.

2. Press or to select the occupied setting.

Warm-up setpoint

selected

3. Press to select the warm-up setpoint. The bottom current

period will flash.

Note: Only if the heat installed option is enabled.

4. Press or to change the setpoint.

Supply air heating

setpoint selected

5. Press to select the supply air heating setpoint. The bottom

arrow of the setpoint symbol, the heating symbol, and the fan

and arrow outlines all flash.

Note: Only if the modulated heat option is enabled.

6. Press or to change the setpoint.

Supply air cooling

setpoint selected

7. Press to select the supply air cooling setpoint.The top

arrow of the setpoint symbol, the cooling symbol, and the fan

and arrow outlines all flash.

8. Press or to change the setpoint.

9. To confirm your schedule settings, press and hold for 2

seconds, or wait 30 seconds. The home screen will appear.

Page 22

22 BAS-SVX17B-EN

Operation

Temporary Override Set-up (CV/HP only)

To override a setting for a specified period of time, start at the home screen and proceed

as follows:

The heating setpoint symbol

flashes when selected.

The cooling setpoint symbol

flashes when selected.

The override symbol flashes

throughout the temporary

override set-up operation.

1. Press or . The current temperature setpoint

appears.

2. Within 5 seconds of Step 1, press to raise the

setpoint or to lower the setpoint. The thermostat

enters timed override mode, giving you the

opportunity to specify the other parameters of the

override.

• The override symbol flashes, and continues

flashing throughout the procedure.

• Either the heating or cooling setpoint symbol

flashes.

Note: The current zone temperature determines whether

the heating or cooling setpoint symbol appears first.

3. Press or to toggle between the heating and

cooling setpoints.

4. Press or to increase or decrease the heating

or cooling setpoint.

The fan setting flashes when

selected.

5. To override the fan setting, press (if starting from

the heating setpoint, press twice). Press or to

change between Auto and On.

Note: Only if the programmable fan option is enabled.

The time setting for override

set-up.

6. Press to specify the amount of time the override

las ts. Pres s or t o s ele ct t he n umb er o f h o ur s.

If your override time is over 23 hours, press or to

select days. Press or to select the number of

days.

The occupancy setting flashes

when selected.

7. To override occupancy, press (if starting from

days, press twice). The occupancy symbol flashes.

Press or to change between occupied and

unoccupied.

The temporary override

symbol appears on the display

and stays on while an override

is present.

8. To confirm your override settings, press and hold

2 seconds, or wait 15 seconds. The home screen

appears with the override symbol on it.

Note: To delete override settings, select temporary override

set-up and press the Test/Configuration button. The

home screen appears without the override symbol.

DAYS

HOURS

Page 23

BAS-SVX17B-EN 23

Operation

Locking or Unlocking the Keypad

You can lock or unlock the keypad to prevent changes as follows:

Status Inputs

Default Operation

If the sensor has not been scheduled, it operates with the following default settings:

• For sensors configured to operate with CV or HP units:

– Occupied

– Heating setpoint: 68ºF (20ºC)

– Cooling setpoint: 74ºF (23.3ºC)

• For sensors configured to operate with VAV units:

– Occupied

– Warm-up setpoint: 68ºF (20ºC)

– Supply-air heating setpoint: 100ºF (37.8ºC)

– Supply-air cooling setpoint: 55ºF (12.8ºC)

Locked symbol

1. Begin at the home screen.

2. Press and simultaneously for 4 seconds.

The locked symbol appears on the display if the keypad is locked.

If you press a keypad button, the locked symbol flashes three

times.

If the service symbol appears, the system requires service.

If the colon on the time clock is flashing, the system is powered up.

If the cooling symbol is flashing, the system is in cooling mode.

If the heating symbol is flashing, the system is in heating mode.

.

.

AM

Page 24

24 BAS-SVX17B-EN

Operation

Setpoint Only Display

You can configure the zone sensor to present setpoints instead of the space temperature on the

main display. To display setpoints instead of space temperatures, follow these steps:

1. Begin at the home screen

2. Press the and simultaneously for four seconds. The active setpoint now appears

instead of the space temperature. Setpoint presentation is indicated by an arrow in the upper

left corner of the display (see Figure 6).

3. Press

or to toggle between the heating and cooling setpoints.

4. To return to showing space temperature on the display, press the and

simultaneously for four seconds.

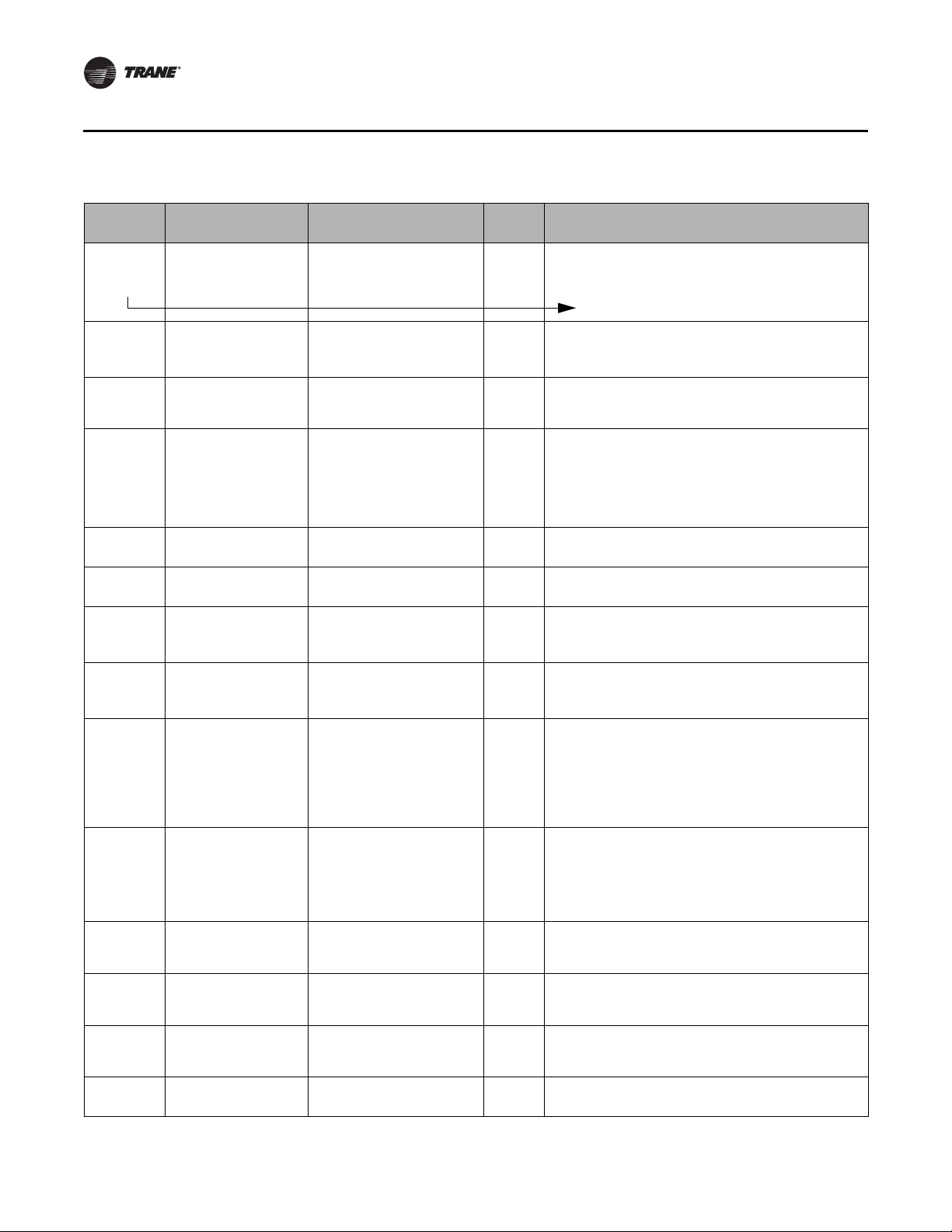

Weekly Operating Schedule Forms

The easiest scheduling procedure is sequential. You should complete the schedule setup for each

period of the day, in order, before you move on to the next day. For instance (refer to Figure 7

below), once the schedule is opened, you will start with Monday and the Morning period (1). Set

the start time, occupancy, heating and cooling setpoints, and fan operation if applicable. Once you

finish with the morning period, you will complete the Day period (2)(same settings as for

Morning...start time, occupancy, etc.). You should complete all available periods for Monday before

moving on to Tuesday (5). The same rules apply for Tuesday. Each period should be set in order

before moving on to Wednesday. This applies to all days in the schedule.

You can use Table 5, p. 25 to create a weekly operating schedule for sensors configured for CV or

HP units. For sensors configured as VAV, see Tab l e 6 , p . 2 6 .

Figure 6. Setpoint only display

Indicates that setpoints

are on display and not

space temperature

Figure 7. Sequential completion of a weely operating schedule.

Page 25

BAS-SVX17B-EN 25

Operation

Table 5. Weekly operating schedule for sensors configured for CV or HP units

Day Period Start time Occupancy

Heating

setpoint

Cooling

setpoint Fan

(1)

Monday

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

Tuesd ay

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

Wedn esday

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

Thursday

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

Friday

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

Saturday

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

Sunday

Morning : ° ° Auto On

Day : ° ° Auto On

Evening : ° ° Auto On

Night : ° ° Auto On

(1)Applies to CV/HP only and only if the programmable fan is enabled.

Page 26

26 BAS-SVX17B-EN

Operation

Ta bl e 6 can be used to create a weekly operating schedule for sensors configured for VAV units.

Table 6. Weekly operating schedule for sensors configured for VAV units

Day Period Start time Occupancy

Warm-up

or unoccupied

heating

setpoint

Supply air or

unoccupied

cooling

setpoint

Supply air heat

setpoint

(modulating

heat only)

Monday

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Tuesd ay

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Wednesday

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Thursday

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Friday

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Saturday

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Sunday

Morning : ° ° °

Day : ° ° °

Evening : ° ° °

Night : ° ° °

Page 27

BAS-SVX17B-EN 27

Maintenance and Troubleshooting

This section describes maintenance and troubleshooting for the programmable zone sensor.

Error Codes

An error code indicates that technical assistance may be required.

Note: On the display, error codes toggle with the clock.

Conducting a Self-Test

Starting from the home screen, press the Test/Configuration button. The following sequence

appears on the display:

• The display lights up.

• All of the symbols appear for 2 seconds.

• The software version appears for 2 seconds.

• The number of years in service appears for 2 seconds.

• The home screen appears and the light dims.

Check Filter Timer

Check filter interval is a configuration option that allows you to set a timer that is adjustable in 1day increments. After the number of selected days passes, the check filter time symbol will flash

on the display: . The symbol is a reminder to check the condition of the filter.

To reset the timer, press both and for 2 seconds. The check filter symbol will disappear.

Heat failure

Indicates that there is an error in the heating system.

Cool failure

Indicates that there is an error in the cooling system.

Tes t m od e

Indicates that the system is operating in test mode.

Fan fail ure

Indicates that a fan failure has occurred and service is required.

Page 28

28 BAS-SVX17B-EN

Maintenance and Troubleshooting

Troubleshooting Table

Problem Solution

Display does not come on.

Check the 24 Vac power supply at terminals 11 and 14 at the sensor. Verify that

the terminal block is properly positioned on its pins.

No communication to the unit controller.

Check for 22–32 Vdc between terminals 11 and 12 at the sensor. Check wiring if

no voltage is present.

SH appears in the temperature location on the display and

“Off” flashes.

Verify that Option 11 is set correctly for CV/HP configurations (option 10 for VAV

configurations):

• If set to 1, check the wiring from the remote sensor at terminals S1 and S2 for

a shorted condition.

• If set to 0, the on-board thermistor has shorted and the sensor must be

replaced.

OP appears in the temperature location on the display and

“Off” flashes.

Verify that option 11 is set correctly for CV/HP configurations (option 10 for VAV

configurations):

• If set to 1, check the wiring from the remote sensor at terminals S1 and S2 for

an open circuit condition.

• If set to 0, the on-board thermistor is open and the sensor must be replaced.

Zone temperature does not appear.

Verify that option value 1 has been selected for option 13 (CV/HP configurations).

Verify that option value 1 has been selected for option 12 (VAV configurations).

Keypad does not respond.

Check to see if the lock symbol is on. To unlock the keypad, press and hold the

left and right arrow keys for 4 seconds.

The fan is set to the On position, but the fan is not running

(CV/HP configurations only).

Verify that the value for option 10 is set correctly (CV/HP configurations only).

• If set to 1, check that the fan is set to On for the current period of day.

• If set to 0, check the value for Option 6. If it is set to 1, the fan will always

operate in Auto mode for unoccupied periods.

The system is operating before the scheduled period begins

(CV/HP configurations only).

If option 7 is set to 1, the computed recovery option is enabled. This allows system

operation to begin before the scheduled occupied period, so that the occupied

temperature setpoint is reached efficiently.

The check filter symbol flashes.

To reset the timer, press the up and down arrows for 2 seconds. The check filter

symbol will disappear. If this function is not desired, or a different interval is

desired, set option 11 (VAV configurations) or option 12 (CV/HP configurations)

to a different value.

The number “99” flashes. Space temperature is above the measurable range.

The number “32” flashes. Space temperature is below the measurable range.

Page 29

BAS-SVX17B-EN 29

Specifications

Sensor operating temperature 32 to 122ºF (0 to 50ºC)

Storage temperature –67 to 176ºF (–55 to 80°C)

Storage and operating humidity range 5% to 95%, non-condensing

Accuracy ±2.0°F (±1.1°C) over a range of 50 to 90°F (10 to 32°C)

±4.0°F (±2.2°C) when outside this range

Resolution 0.225ºF (0.2°C) over a range of 50 to 90ºF (10 to 32°C)

0.40ºF (0.125°C) when outside this range

Setpoint functional range 43 to 98ºF (6.1 to 36.6ºC)

Input voltage (from unit controller) Nominal 24 Vac (18–32 Vac)

Power consumption <3 VA

Housing Polycarbonate/ABS blend, UV protected, UL 94-5VA

flammability rating, suitable for application in a plenum

Mounting 3.24 in (8.26 cm) for 2 mounting screws (supplied)

Page 30

30 BAS-SVX17B-EN

Declaration of CE Conformity

The manufacturer hereby declares that the product:

Conforms to the following standards or other normative documents:

Manufacturer name:

Tra ne

Manufacturer address:

4833 White Bear Parkway

Saint Paul, MN 55110

USA

Product name:

Programmable Zone Sensor module

Model numbers:

X1379088401

Electromagnetic Emission:

EN61326-1:2006

(by Council Directive 89/336/EEC) Radiated EN55011:2006 2006 Class B limit

Conducted EN55011:2006 2006 Class B limit

Harmonic EN61000-3-2 2006 Class A limit

Flicker EN61000-3-3 EN61000-3-3:1995+A1:2001+A2:2006

Electromagnetic Immunity for Industrial:

EN61326-1:2006

(by Council Directive 89/336/EEC) EN61000-4-2:2006 ±4.0 kV by contact

EN61000-4-2:2006 ±8.0 kV by air

EN61000-4-3:2006 10.0 V/m

EN61000-4-4:2006

±1.0 kV signal lines

±2.0 kV ac power lines

EN61000-4-5:2006

±1.0 kV signal lines

±2.0 kV ac power lines

EN61000-4-6:2006 3 V

EN61000-4-11:2006

Where and When Issued:

Elecromagentic Emmission 07/18/2008

Elecromagentic Immunity 07/18/2008

Mark of Compliance:

European Contact

Societ

E Trane (Epinal, France)

1, rue des Ameriques, B.P. 6

F-88191 Golbey Cedex, France

Phone: (33) 329.31.73.00

Fax: (33) 329.81.24.98

This document valides CE conformity of the Programmable Zone Sensor module.

Page 31

BAS-SVX17B-EN 31

Declaration of CE Conformity

Notes:

Page 32

Trane optimizes the performance of homes and buildings around the world. A business of Ingersoll Rand, the

leader in creating and sustaining safe, comfortable and energy efficient environments, Trane offers a broad

portfolio of advanced controls and HVAC systems, comprehensive building services, and parts. For more

information, visit www.Trane.com.

Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.

© 2010 Trane All rights reserved

BAS-SVX17B-EN 30 Jun 2010

Supersedes BAS-SVX17A-EN (01 Aug 2008)

Loading...

Loading...