Page 1

Installation

Owner

Diagnostics

Split System Cooling Condensers

Model CTA 7 1/2 to 15 Tons

Models

CTA

090A***A

120A***A

120B***A

180B***A

September 2007

– 60 HZ

– 60 HZ

– 60 HZ

– 60 HZ

“A” and later Design Sequence

PKG-SVX17A-EN

Page 2

Notice

Overview of Manual

Note: One copy of this document

ships inside each unit and is customer

property. It must be retained by the

unit’s maintenance personnel.

This booklet describes proper installation, operation, and maintenance procedures for air cooled systems. By

carefully reviewing the information

within this manual and following the

instructions, the risk of improper

operation and/or component damage

will be minimized.

It is important that periodic maintenance be performed to help assure

trouble free operation. A maintenance

schedule is provided at the end of this

manual. Should equipment failure

occur, contact a qualified service

organization with qualified, experienced HVAC technicians to properly

diagnose and repair this equipment.

NOTICE:

Warnings and Cautions appear at

appropriate sections throughout this

manual. Read these carefully.

WARNING– Indicates a

potentially hazardous situation

which, if not avoided, could

result in death or serious injury.

CAUTION – Indicates a

potentially hazardous situation

which, if not avoided, may result

in minor or moderate injury. It

may also be used to alert against

unsafe practices.

CAUTION – Indicates a situa-

tion that may result in equipment

or property-damage-only accidents.

IMPORTANT NOTE: All phases of this

installation must comply with the

NATIONAL, STATE & LOCAL CODES.

In addition to local codes, the installation must conform with National Electric Code -ANSI/NFPA NO. 70 LATEST

REVISION.

Note: Do Not release refrigerant

to the atmosphere! If adding or

removing refrigerant is required, the

service technician must comply with

all federal, state, and local laws.

© 2007 American Standard All rights reserved PKG-SVX17A-EN

Page 3

Contents

Installation/Startup/Commissioning

Model Number Description 4

Unit Dimensions

Electrical Data

Unit Inspection 9

Initial Leak Test

Lifting Recommendations

Clearances 10

Unit Mounting 10

Refrigerant Piping 10

Leak Check 12

System Evacuation 12

Refrigeration Charging 12

Electrical Wiring 13

Low Voltage Wiring 14

4

5

8

9

9

Refrigeration Schematic

Installation Checklist 21

Sequence of Operation

Maintenance 23

Warranty

PKG-SVX17A-EN 3

20

22

25

Page 4

Model Number Description

Model Number Description

All products are identified by a multiple-character model number that precisely identifies a particular type of

unit. An explanation of the alphanumeric identification code is provided

below. Its use will enable the owner/

operator, installing contractors, and

service engineers to define the opera

tion, specific components, and other

options for any specific unit.

When ordering replacement parts or

requesting service, be sure to refer to

the specific model number, serial

number, and DL number (if applica

ble) stamped on the unit nameplate.

-

Split System Condensing Model Nomenclature

C T A 0 9 0 A 1 0 0 A A

1 2 3 4 5 6 7 8 9 10 11 12

Digits 1,2,3 - Product Type

CTA = Remote Air-Cooled Condenser

Digits 4,5,6 - Nominal Gross

-

Cooling Capacity (MBh)

090 = 090 MBh-used with

3 & 5T SCRH

120 = 120 MBh - used with

7.5 & 10T SCRH

180 = 180 MBh - used with

12 & 15T SCRH

Digits 7 - Major Development

Sequence

A = 1 Refrig Cir.(3, 5, 7.5T SCRH)

B = 2 Refrig Cir. (10, 12, 15T SCRH)

Digits 8 - Electrical

Characteristics

1 = 208-230/60/1

2 = 460/60/1

8 = 575/60/1

Digits 9,10 - Factory Installed

Options

00 = Packed Stock

0A = Coated Coil

Digits 11 - Minor Design Sequence

A = First

Digits 12 - Service Digit

A = First

4 PKG-SVX17A-EN

Page 5

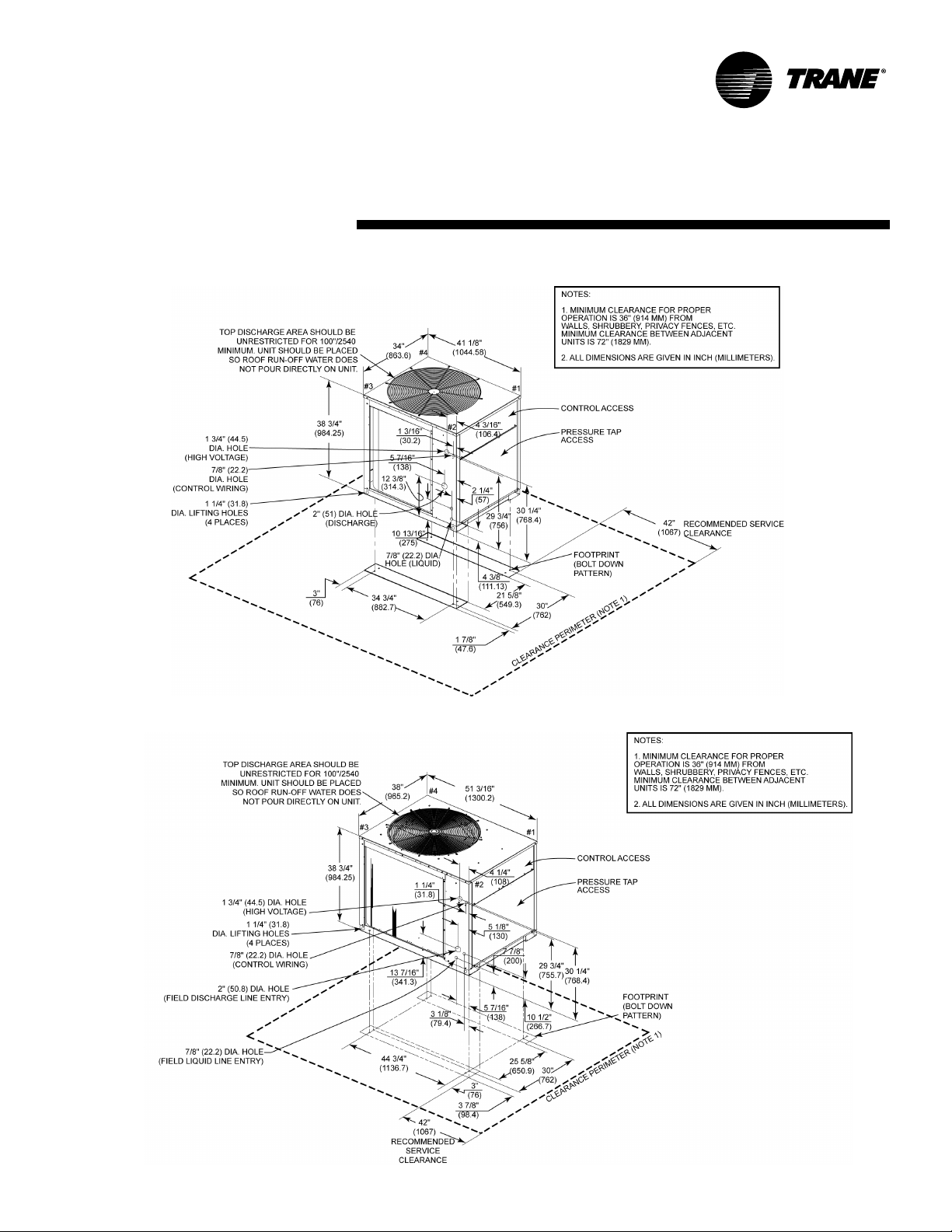

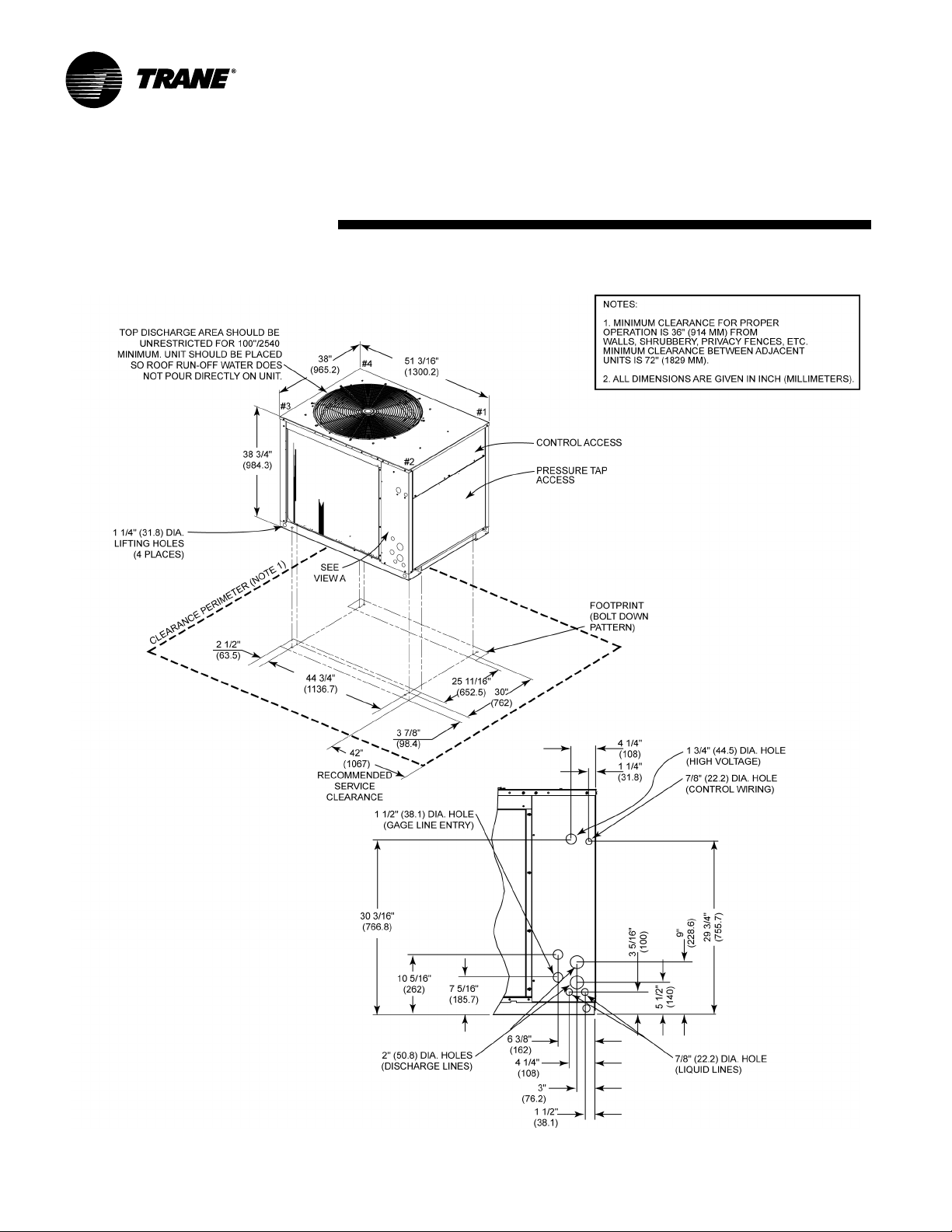

Figure 1 — CTA090A

Unit Dimensions

Figure 2 — CTA120A

PKG-SVX17A-EN 5

Page 6

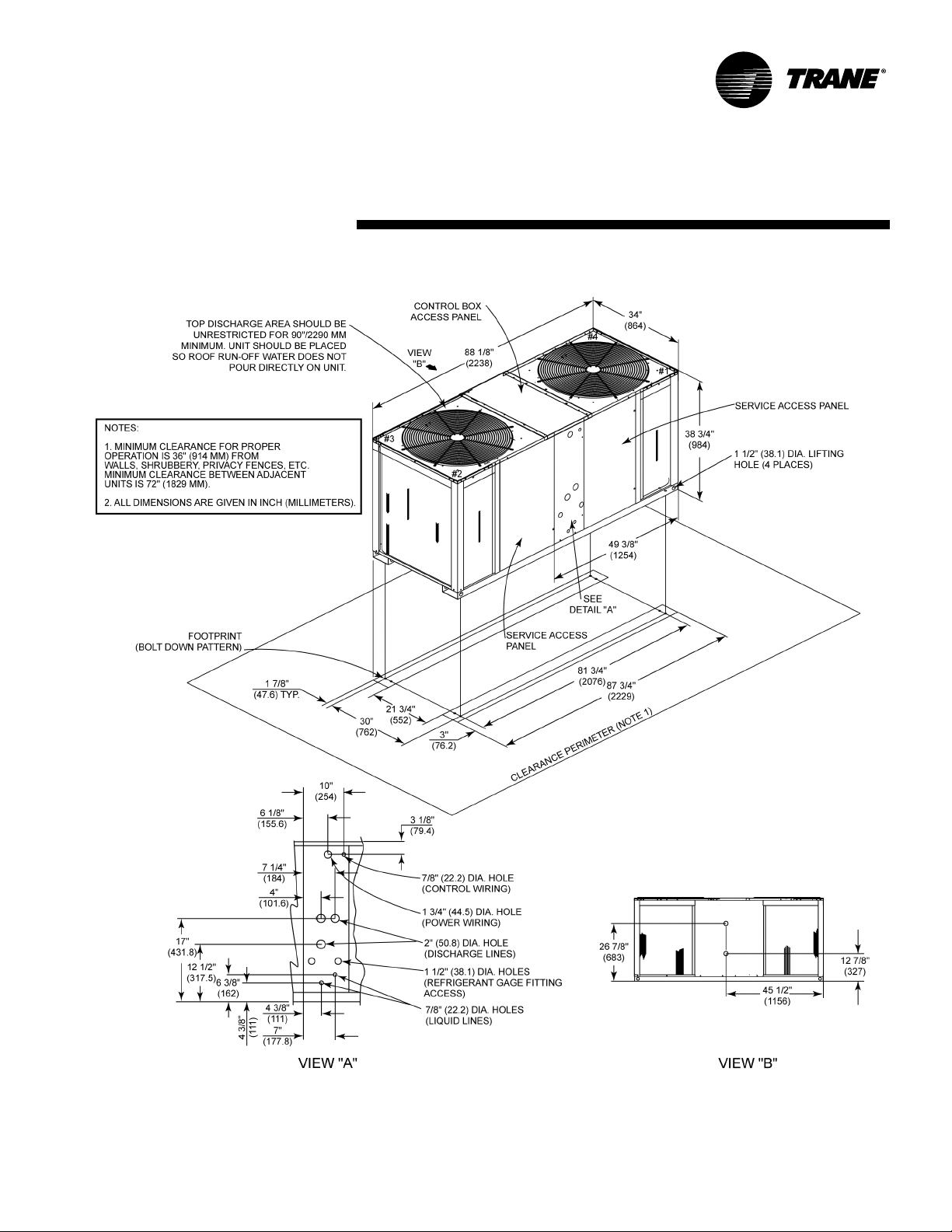

Figure 3 — CTA120B

Unit

Dimensions

6 PKG-SVX17A-EN

Page 7

Figure 4 — CTA180B

Unit

Dimensions

PKG-SVX17A-EN 7

Page 8

Electrical Data

Table 1: CTA Unit Electrical Data

Basic Unit Characteristics Outdoor Fan Motor

Model

Number

CTA090A1 208-230/60/1 187-254 15 15 1 1/2 3.1 8.1

CTA090A2 460/60/1 414-506 15 15 1 1/2 1. 6 3.7

CTA090A8 575/60/1 518-632 15 15 1 1/2 1. 2 3.0

CTA120A1 208-230/60/1 187-254 15 15 1 1 6.0 17.0

CTA120A2 460/60/1 414-506 15 15 1 1 2.7 7. 0

CTA120A8 575/60/1 518-632 15 15 1 1 2.0 5.7

CTA120B1 208-230/60/1 187-254 15 15 1 1 6.0 17.0

CTA120B2 460/60/1 414-506 15 15 1 1 2.7 7. 0

CTA120B8 575/60/1 518-632 15 15 1 1 2.0 5.7

CTA180B1 208-230/60/1 187-254 15 15 2 1/2 3.1 8.1

CTA180B2 460/60/1 414-506 15 15 2 1/2 1. 6 3.7

CTA180B8 575/60/1 518-632 15 15 2 1/2 1.2 3.0

Electrical

Characteristics

Allowable

Voltage

Range

Minimum

Circuit

Ampacity

Maximum

Fuse

Size

Qty. HP

Amps

FLA

Amps

LRA

8 PKG-SVX17A-EN

Page 9

Installation

Installation procedures should be performed in the sequence that they

appear in this manual. Do not destroy

or remove the manual from the unit.

The manual should remain weatherprotected with the unit until all instal

lation procedures are complete.

Note: It is not the intention of this

manual to cover all possible varia

tions in systems that may occur or to

provide comprehensive information

concerning every possible contin

gency that may be encountered during an installation. If additional

information is required or if specific

problems arise that are not fully dis

cussed in this manual, contact your

local Sales office.

Note: “Warnings” and “Cautions”

appear at appropriate

places in this manual. Your personal

safety and the proper

operation of this machine require that

you follow them carefully. The Company assumes no liability for installations or servicing performed by

unqualified personnel.

Installation Checklist

An “Installation Checklist” is provided

at the end of the installation section of

this manual. Use the checklist to verify

that all necessary installation proce

dures have been completed. Do not

use the checklist as a substitute for

reading the information contained in

the manual. Read the entire manual

before beginning installation proce

dures.

Unit Inspection

Inspect material carefully for any shipping damage. If damaged, it must be

reported to, and claims made against

the transportation company. Compare

the information that

appears on the unit nameplate with

ordering and submittal

data to insure the proper unit was

shipped. Available power supply must

-

-

-

-

-

be compatible with electrical characteristics specified on component

nameplates. Replace damaged parts

with authorized parts only.

-

Inspection Checklist

To protect against loss due to damage

incurred in transit, complete the following checklist upon receipt of the

unit.

[ ] Inspect individual pieces of the

shipment before accepting the unit.

Check for obvious damage to the

unit or packing material.

[ ] Inspect the unit for concealed dam-

age before it is stored and as soon

as possible after delivery. Con

cealed damage must be reported

within 15 days. If concealed damage is discovered, stop unpacking

the shipment. Do not remove damaged material from the receiving

location. Take photos of the dam

age if possible. The owner must

provide reasonable evidence that

the damage did not occur after

delivery.

[ ] Notify the carrier’s terminal of dam-

age immediately by phone and by

mail. Request an immediate joint

inspection of the damage by the

carrier and the consignee.

[ ] Notify the sales representative and

arrange for repair. Do not repair the

unit until the damage is inspected

by the carrier’s representative.

Initial Leak Test

All CTA units are shipped with a hold-

ing charge of nitrogen in each circuit.

Remove the service access panel(s)

shown in Figures 1 to 4. Locate the

discharge or liquid line gauge ports

for each circuit. Install gauges to

determine if the circuits are still pressurized. If not, the charge has

escaped. Repair as required to obtain

a leak-free circuit.

Lifting Recommendations

Before preparing the unit for lifting,

estimate the approximate center of

gravity for lifting safety. Because of

placement of internal components,

the unit weight may be unevenly dis

tributed. Approximate unit weights

are given in Table 2.

Table 2: Unit and corner weights (lbs)

Model

CTA090A 254 210 59 63 39 49

CTA120A

CTA120B

CTA180B 532 447 100 105 124 118

-

Heavy Objects!

Do not use cables (chains or

slings) except as shown. Each of

the cables (chains or slings) used

to lift the unit must be capable of

-

supporting the entire weight of

the unit. Lifting cables (chains or

slings) may not be of the same

length. Adjust as necessary for

even unit lift. Other lifting

arrangements may cause equip

ment or property-only damage.

Failure to properly lift unit could

result in death or serious injury.

See details below.

The crated unit can be moved using a

forklift of suitable capacity. For lifting

the unit, attach lifting straps or slings

securely to the lifting holes at each

corner. Use spreader bars to protect

the unit casing from damage. Test lift

the unit to determine proper balance

and stability.

Ship

Max.

Max.

325 281 62 85 57 77

WARNING

Corner Weights

Net

#1 #2 #3 #4

-

-

CAUTION

Equipment Damage!

Use spreader bars to prevent lifting straps from damaging the

unit. Install bars between lifting

straps. Failure to properly lift unit

may result in crushing unit cabi

net or damaging unit finish.

-

PKG-SVX17A-EN 9

Page 10

Installation

Clearances

Provide enough space around the unit

to allow unrestricted access to all service points. Refer to Figure 1 through

Figure 4 for unit dimensions and minimum required service and free air

clearances. Observe the following

points to insure proper unit operation.

A. Do not install the unit under a low

overhang. Condenser discharge must

not be restricted. See Notes in Figure

1 through Figure 4.

NOTICE: Do not obstruct condenser

discharge air. This can result in warm

air recirculation through the coil.

B. Do not locate the unit in a position

where runoff water can fall into the

fan discharge openings.

C. Condenser intake air is supplied

from three or four sides of the unit.

Adhere to the minimum required

clearances given in Figure 1 through

Figure 4.

Unit Mounting

Rooftop Mounting: If the unit will be

roof mounted, determine for certain

that the structure is strong enough to

support the unit and any required

accessories. Unit weights are given in

Table 2. The unit should be elevated

on a level, field fabricated four-inch

steel or wood 4" x 4" mounting frame.

Complete the frame and secure it into

position before lifting the unit to the

roof. The mounting frame must sup

port a minimum of three of the unit’s

four sides and should span roof supports to distribute the load on the

roof.

-

Figure 5 Roof Mounted Unit

WARNING

Structural Failure!

Ensure that the roof structure

supports are strong enough to

support the weight of the unit

and any accessories. Failure to do

this could result in death or seri

ous injury due to structural failure and could seriously damage

the unit and the building.

Ground Level Mounting

“For ground level installation, the unit

base should be adequately supported

and hold the unit near level. The

installation must meet the guidelines

set forth in local codes.” The support

should extend two inches beyond the

unit base channels at all points. The

unit and support must be isolated

from any adjacent structure to prevent

possible noise or vibration problems.

Any ground level location must com

ply with required clearances given in

Figure 1 through Figure 4.

-

-

Holes must be made in the structure

to run refrigerant lines. For the major

ity of ground-level installations, the

holes can be made in the header that

rests on top of the foundation. Alter

natively, these holes may also be

made in the foundation itself. On roofmounted units, refrigerant lines

should enter the building as close to

the unit as possible; preferably within

three to four inches of the refrigerant

connection on the unit, plus a six-inch

(long radius) 90 degree "L" entering

the building (See Figure 5).

Refrigerant Piping Guidelines

A. Maximum recommended line

lengths: (per circuit)

Maximum linear length..............200 Ft.

(w/o accumulator)

Maximum discharge line lift......200 Ft.

Maximum liquid line lift..............60 Ft.

B. Maximum allowable pressure

drops (R-410A):

Discharge line...............................10 psi

Liquid line (without subcooler)...50 psi

Route refrigerant piping for minimum

linear length, minimum number of

bends and fittings (no reducers) and

minimum amount of line exposed to

outdoor ambients.

C. Recommended line sizes:

CTA090, 120A (single circuit)

CTA120B, 180B (dual circuit)

Discharge line - 7/8 inch sealed type L

refrigerant tubing.

Liquid line - 1/2 inch sealed type L

refrigerant tubing.

-

-

10 PKG-SVX17A-EN

Page 11

Installation

Note: Insulate all refrigerant piping

and connections.

Refrigerant Piping Procedures

(Outdoor Units)

Each CTA unit ships with a holding

charge of dry nitrogen. The nitrogen

should be removed and the entire sys

tem evacuated (at the proper time) to

avoid possible contamination.

1. Remove the service access panel.

2. Locate the liquid and discharge

lines. Check that the piping connection stubs on the valves (Figure 6)

line up properly with the holes in

the unit cabinet.

Figure 6

4. Unbraze the tube seal caps to reveal

the line braze connections.

WARNING:

Hazardous Pressures!

Coil has a nitrogen holding

-

charge. Do not remove seal caps

by heating the caps while coil is

under pressure. Depress the

gauge port valve cores to gradu

ally relieve nitrogen holding

charge. Remove valve cores

before removing the tubing seal

caps. Failure to properly relieve

pressure could result in death or

serious injury.

CAUTION:

Equipment Damage!

Do not remove the seal caps from

refrigerant connections until pre

pared to braze refrigerant lines to

the connections. Excessive exposure to atmosphere may allow

moisture or dirt to contaminate

the system, damaging valve seals

and causing ice formation in sys

tem components.

above the maximum recom

mended unit test pressure as

specified in applicable unit literature. Failure to properly regulate

pressure could result in a violent

explosion, which could result in

death or serious injury or equip

ment or property-only-damage.

CAUTION:

-

Equipment Damage!

Wet-wrap all valves and protect

painted surfaces from excessive

heat. Heat can damage system

components and the unit finish.

6. Shut off nitrogen supply.

7. Shut off the manifold valve for the

line that is connected to the dis

charge line gauge port.

Figure 7

-

-

-

-

-

5. Cut, fit and braze tubing, starting at

the outdoor unit and work toward

the indoor unit.

Note: Use long radius bells for all 90

degree bends.

All brazing should be done using a 2

to 3 psig dry nitrogen purge flowing

3. Locate the gauge ports on the discharge and liquid lines. Depress the

valve core to release the nitrogen

from the unit.

through the pipe being brazed (Figure

6).

WARNING:

Note: If nitrogen is not released from

the unit, there is a leak in the system.

Locate the leak and repair before pro

ceeding with the installation.

PKG-SVX17A-EN 11

Hazardous Pressures!

When using dry nitrogen cylin-

-

ders for pressurizing units for

leak testing, always provide a

pressure regulator on the cylinder

to prevent excessively high unit

pressures. Never pressurize unit

Refrigerant Piping Procedure

(Indoor Unit)

Once liquid and discharge lines are

complete to the refrigerant connec

tions on the indoor unit, depress the

gauge port valve cores on the suction

and discharge lines to gradually

relieve nitrogen holding charge.

-

Page 12

Installation

WARNING:

Hazardous Pressures!

Coil has a nitrogen holding

charge. Do not remove seal caps

by heating the caps while coil is

under pressure. Depress the

gauge port valve cores to gradually relieve nitrogen holding

charge. Remove valve cores

before removing the tubing seal

caps. Failure to properly relieve

pressure could result in death or

serious injury.

1. Remove both seal caps from the

indoor unit connection stubs.

CAUTION:

Equipment Damage!

Do not remove the seal caps from

refrigerant connections until pre

pared to braze refrigerant lines to

the connections. Excessive exposure to atmosphere may allow

moisture or dirt to contaminate

the system, damaging valve seals

and causing ice formation in sys

tem components.

2. Turn nitrogen supply on. Nitrogen

enters through liquid line gauge

port.

WARNING:

Hazard of Explosion and Deadly

Gases!

Never solder, braze or weld on

refrigerant lines or any unit com

ponents that are above atmospheric pressure or where

refrigerant may be present.

Always remove refrigerant by fol

lowing the guidelines established by the EPA Federal Clean

Air Act or other state or local

codes as appropriate. After refrig

erant removal, use dry nitrogen to

bring system back to atmospheric

pressure before opening system

for repairs. Mixtures of refrigerants and air under pressure may

become combustible in the presence of an ignition source leading

to an explosion. Excessive heat

from soldering, brazing or welding with refrigerant vapors

present can form highly toxic

gases and extremely corrosive

acids. Failure to follow all proper

safe refrigerant handling prac

tices could result in death or serious injury.

3. Braze the liquid line connections.

4. Open the gauge port on the discharge line and then braze the discharge line to the connection stub.

Nitrogen will bleed out the open

gauge port on the discharge line.

5. Shut off nitrogen supply.

-

Leak Check

After the brazing operation of the outdoor and indoor refrigerant lines is

complete, check the field brazed con

nections for leaks. Pressurize the system through the gauge port with dry

-

nitrogen to 200 psi. Use soap bubbles

or other leak-checking methods to

ensure that all field joints are leak

free. If not, release pressure, repair

and repeat the leak test.

System Evacuation

1. After completion of leak check,

replace suction, liquid and dis

charge valve cores, and evacuate

the system.

2. Attach appropriate hoses from the

-

manifold gauge to suction and discharge line gauge ports.

Note: Unnecessary switching of hoses

can be avoided and complete evacua

-

tion of lines leading to a sealed system can be accomplished with

manifold center hose and connecting

branch hose to cylinder of R-410A and

-

vacuum pump.

3. Attach center hose of manifold

gauges to the vacuum pump.

4. Evacuate the system to hold a 350

micron vacuum.

5. Close off the valve to the vacuum

pump and observe the micron

gauge. If gauge pressure rises

above 500 microns in one (1)

minute, evacuation is incomplete or

the system has a leak.

6. If vacuum gauge does not rise

-

-

-

above 500 microns in one (1)

minute, the evacuation should be

complete.

7. With vacuum pump and micron

gauge blanked off, open the valve

on R-410A cylinder and allow refrigerant pressure to build up to 100

psig.

8. Close valve on the R-410A supply

cylinder. Close valves on the manifold gauge. Set and remove the

refrigerant charging hoses from the

discharge and suction gauge ports.

9. Leak test the entire system. Using

proper procedures and caution,

repair any leaks found and repeat

the leak test.

Refrigerant Charging Procedure

If charging by weight, refer to refrigerant charges that are provided in Table

3. If additional refrigerant is needed

because of length of line, calculate the

requirements using Table 4. Charge

by weight through the gauge port on

the suction line in the indoor unit.

When charging is complete, replace

the cap on the gauge port.

Insulating and Isolating

Refrigerant Lines

Insulate the entire discharge line with

refrigerant piping insulation. Also

-

insulate any portion of the liquid line

exposed to temperature extremes.

Insulate and isolate liquid and dis

charge lines from each other. Isolate

refrigerant lines from the structure

and any ductwork.

Note: To prevent possible noise or

vibration, be certain to isolate refrigerant lines from the building.

-

12 PKG-SVX17A-EN

Page 13

Installation

Table 3: CTA Refrigerant Charge

Model

CTA090A

w/SCRH030

CTA090A

w/SCRH050

CTA120A

w/SCRH075

CTA120B

w/SCRH100

CTA180B

w/SCRH120

CTA180B

w/SCRH150

* Sufficient operating charge for listed unit

and 33 feet of nominally sized refrigerant

piping.

Refrigerant Charge

(R-410A)*

18.1 lbs

19.9 lbs

20.8 lbs

11.9 lbs

(Ckt. #1 & #2)

16.8 lbs. (Ckt. #1)

16.0 lbs. (Ckt. #2)

17.5 lbs. (Ckt. #1)

16.9 lbs. (Ckt. #2)

Table 4: Additional Refrigerant

Tubing Sizes Additional

Discharge Liquid

7/8" 1/2" 15 ft. 1.3 l b s

7/8" 1/2" 25 ft. 2.2 lbs

7/8" 1/2" 32 ft. 2.8 lbs

7/8" 1/2" 40 ft. 3.5 lbs

Note: Amounts shown are based on 0.087

lbs of refrigerant per foot of 7/8" and 1/2"

lines.

Tubing

Length

Additional

Refrig.

Note: For tubing over 40 feet, calculate

the additional refrigerant needed,

based on notes above.

Gaseous Charging

This procedure is accomplished with

the unit operating. Electrical connec

tions must be complete. Do not proceed until the system is ready to

operate.

Procedure

1. Connect R-410A drum with gauge

manifold to the gauge ports (pres

sure taps) on the compressor discharge and suction lines (Figure 7).

Note: On the CTA units, the service

access panel must be installed when

the unit is running and being charged.

WARNING:

Hazardous Energy Sources!

Use extreme caution while servicing the unit when the control box

access panel is removed and

power is applied to the unit. Fail

ure to observe all safety precautions could result in death or

serious injury.

2. Turn on power to the unit. Allow the

system to run for five to ten minutes

to stabilize operating conditions.

3. Measure airflow across the indoor

coil. Compare the measurements

with the fan performance data in the

Data/Submittal.

4. Check suction line superheat and

condenser sub-cooling to ensure

the unit is operating properly.

5. Disconnect all power to the unit.

WARNING:

Hazardous Voltage

w/Capacitors!

Disconnect all electrical power,

including remote disconnects and

discharge all motor start/run ca

pacitors before servicing. Follow

proper lockout/tagout procedures

to ensure the power cannot be in

advertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Fail

ure to diconnect power and discharge capacitors before

servicing could result in death or

serious injury.

Note: For additional information

regarding the safe discharge of

capacitors, see PROD-SVB06A-EN

or PROD-SVB06A-FR.

6. Remove the charging system from

the unit and replace all access pan

els.

-

-

Electrical Wiring

CTA field wiring consists of providing

power supply to the unit, installing the

system indoor thermostat and provid

ing low voltage system interconnecting wiring. Access to electrical

connection locations is shown in Fig

ures 1 through 4.

Unit Power Supply

The installer must provide line voltage

circuit(s) to the unit main power termi

nals as shown by the unit wiring diagrams in Figures 9 and 10 on page 15.

Power supply must include a discon

nect switch in a location convenient to

the unit. Ground the unit according to

local codes and provide flexible conduit if codes require and/or if vibration

transmission may cause noise prob

lems.

CAUTION:

Use Copper Conductors Only!

Unit terminals are not designed to

accept other types of conductors.

Failure to use copper conductors

may result in equipment damage.

CAUTION:

All wiring must comply with applicable local and national NEC

codes. Type and location of dis

connect switches must comply

with all applicable codes.

WARNING:

Ground Wire!

All field-installed wiring must be

completed by qualified personnel.

All field-installed wiring must

comply with NEC and applicable

local codes. Failure to follow this

instruction could result in death

or serious injuries.

WARNING:

Grounding Required!

Follow proper local and state electrical code on requirements for

grounding. Failure to follow code

-

could result in death or serious in

jury

-

-

-

-

-

-

-

PKG-SVX17A-EN 13

Page 14

Figure 8: Typical Field Wiring

Note:

1. Wiring shown with dashed lines is to

be furnished and installed by the cus

tomer. All customer supplied wiring

must be copper only and must conform to NEC and local electrical codes.

Codes may require line of sight between disconnect switch and unit.

CTA090A/S(C,I)RH030

CTA090A/S(C,I)RH050

CTA120A/S(C,I)RH075

CTA120B/S(C,I)RH100

Field Wiring:

A — 2 power wires. Line voltage for

single phase

B — 3 power wires. Line voltage for

3 phase; 2 wires for single phase

C — Cooling only thermostat: 3 wires,

24 volts.

— Digital thermostat: add 1 addi-

tional wire, 24 volts.

D — 2 control wires, 24 volts.

Wiring Low Voltage

CTA180B/S(C,I)RH120

CTA180B/S(C,I)RH150

-

Field Wiring:

A — 2 power wires. Line voltage for

single phase

B — 3 power wires. Line voltage for

3 phase

C — Cooling only thermostat: 4 wires,

24 volts.

D — 3 control wires, 24 volts.

WARNING:

Hazardous Voltage w/Capacitors!

Disconnect all electrical power,

including remote disconnects and

discharge all motor start/run ca

pacitors before servicing. Follow

proper lockout/tagout procedures

to ensure the power cannot be in

advertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Fail

ure to diconnect power and discharge capacitors before

servicing could result in death or

serious injury.

Note: For additional information

regarding the safe discharge of

capacitors, see PROD-SVB06A-EN

or PROD-SVB06A-FR.

Determine proper wire sizes and unit

protective fusing requirements by

referring to the unit nameplate. Field

wiring diagrams for accessories

are shipped with the accessory.

-

-

-

14 PKG-SVX17A-EN

Page 15

Field Wiring

PKG-SVX17A-EN 15

Page 16

Wiring

16 PKG-SVX17A-EN

Page 17

Wiring

PKG-SVX17A-EN 17

Page 18

Wiring

18 PKG-SVX17A-EN

Page 19

Wiring

PKG-SVX17A-EN 19

Page 20

Refrigeration Diagram

Figure 11: Typical Split System Cooling Diagram

20 PKG-SVX17A-EN

Page 21

System Pre-Start Procedure

Installation Checklist

Complete this checklist once the unit

is installed to verify that all recommended procedures have been

accomplished before starting the system. Do not operate the system until

all items covered by this checklist are

complete.

[ ] Inspect unit location for proper

required service clearances.

[ ] Inspect unit location for proper free

air clearances.

[ ] Inspect unit location for secure,

level mounting position.

Refrigerant Piping

[ ] Performed initial leak test?

[ ] Connected properly sized and con-

structed liquid and discharge lines

to the connection stubs at both the

indoor and outdoor units?

[ ] Insulated the entire discharge line?

[ ] Insulated portions of liquid line

exposed to extremes in tempera

ture?

-

Electrical Wiring

WARNING:

Hazardous Voltage

w/Capacitors!

Disconnect all electrical power,

including remote disconnects and

discharge all motor start/run capacitors before servicing. Follow

proper lockout/tagout procedures

to ensure the power cannot be inadvertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Failure to diconnect power and discharge capacitors before

servicing could result in death or

serious injury.

Note: For additional information

regarding the safe discharge of

capacitors, see PROD-SVB06AEN or PROD-SVB06A-FR.

[ ] Provided unit power wiring (with

disconnect) to proper terminals in

the unit control section?

[ ] Installed system indoor thermo-

stat?

[ ] Evacuated each refrigerant circuit

to 350 microns?

[ ] Charged each circuit with proper

amount of R-410A?

PKG-SVX17A-EN 21

[ ] Installed system low voltage inter-

connecting wiring to proper terminals of outdoor unit, indoor unit

and system thermostat?

Page 22

System

Pre-Start Procedure

Unit Start-Up

Once the unit is properly installed and

pre-start procedures

are complete, start the unit by turning

the System Switch on the indoor thermostat to either HEAT, COOL or AUTO.

The system should operate normally.

Sequence of Operation

General

Operation of the system cooling (and

optional heating) cycles is controlled

by the position of the system switch

on the room thermostat. Once the

system switch is placed in either the

HEAT or COOL position, unit opera

tion is automatic. The optional automatic changeover thermostat, when

in the AUTO position, automatically

changes to heat or cool with sufficient

room temperature change.

Evaporator Fan (Indoor Supply

Air)

The evaporator fan is controlled by an

ON/AUTO switch on the room thermostat. With the switch positioned at

AUTO and the system operating in

the cooling mode, fan operation coin

cides with the cooling run cycles. If

the system is equipped with heat and

is operating in the heating mode

while the fan switch is at AUTO, fan

operation coincides with the heating

run cycles. When the fan switch is

positioned at ON, fan operation is

continuous.

-

Cooling Mode

When the room thermostat system

switch is positioned at COOL and the

fan switch is at AUTO, the condenser

fan relay energizes on a call for cool

ing. When the contacts of the condenser fan relay close, operation of

the condenser fan begins. The evaporator fan contactor also energizes on a

call for cooling and initiates evapora

tor fan operation.

On units with dual circuits, the second

stage of cooling is initiated as a result

of the 2-stage thermostat calling for

additional cooling.

-

-

-

22 PKG-SVX17A-EN

Page 23

Maintenance

WARNING:

Hazardous Service Procedures!

The maintenance and troubleshooting procedures recommended in this section of the manual

could result in exposure to electri

cal, mechanical or other potential

safety hazards. Always refer to

the safety warnings provided

throughout this manual concern

ing these procedures. When possible, disconnect all electrical

power including remote disconnects before servicing. Follow

proper lockout/tagout procedures

to ensure the power can not be in

advertently energized. When necessary to work with live electrical

components, have a qualified licensed electrician or other individual who has been trained in

handling live electrical components perform these tasks. Failure

to follow all of the recommended

safety warnings provided, could

result in death or serious injury.

-

Maintenance

Perform all of the indicated maintenance procedures at the

intervals scheduled. This will prolong

the life of the unit and reduce the possibility of costly equipment failure.

Monthly

Conduct the following maintenance

inspections once per month.

WARNING:

Hazardous Voltage w/Capacitors!

Disconnect all electrical power,

including remote disconnects and

discharge all motor start/run ca-

pacitors before servicing. Follow

proper lockout/tagout procedures

to ensure the power cannot be inadvertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Failure to diconnect power and discharge capacitors before

servicing could result in death or

serious injury.

Note: For additional information

regarding the safe discharge of

capacitors, see PROD-SVB06A-EN

or PROD-SVB06A-FR.

1. Inspect air filters and clean if neces-

sary.

2. Check unit wiring to ensure all con-

nections are tight and that the wiring insulation is intact.

3. Check drain pans and condensate

piping to insure they are free of ob

stacles.

ing mode, check the suction and discharge pressures. Record these

readings on the “Maintenance

Log.”

7. Observe indoor fan operation and

correct any unusual or excessive vi

bration. Clean blower wheels as

needed.

Annually (Cooling Season)

The following maintenance procedures must be performed at the beginning of each cooling season to insure

efficient unit operation.

1. Perform all of the monthly maintenance inspections.

2. With the unit operating, check unit

superheat and record the reading in

the Maintenance Log.

3. Remove any accumulation of dust

and/or dirt from the unit casing.

4. Remove corrosion from any surface

and repaint. Check the gasket

around the control panel door to in

sure it fits correctly and is in good

condition to prevent water leakage.

5. Inspect the evaporator fan belt. If it

is worn or frayed, replace it.

6. Inspect the control panel wiring to

insure that all connections are tight

and that the insulation is intact.

7. Check refrigerant piping and fittings

for leaks.

-

-

-

4. Manually rotate the indoor fan to insure proper operation.

5. Inspect the evaporator and condenser coils for dirt and debris. If the

coils appear dirty, clean them.

6. With the unit operating in the cool-

PKG-SVX17A-EN 23

Page 24

Maintenance Log

Date

Ambient

Te mp .

F

Maintenance

Evaporator Entering Air Compressor Superheat Subcooling

Dry Bulb Wet Bulb

Suction

Pressure

Discharge

Pressure

Circuit #1 (F) Circuit #1 (F)

Note: Perform each inspection once per month (during cooling season) while unit is operating.

24 PKG-SVX17A-EN

Page 25

Warranty

CTA

Warranty Information

Standard Warranty

The standard split system cooling condenser warranty is Trane’s partsonly warranty, running 12-months from startup, not to exceed 18-

months from shipment.

Extended Warranty

The optional extended warranty is a second through fifth year warranty.

The time starts at the end of standard 1-year coverage through the fifth

year.

These extended warranties apply only to new equipment installed in domestic Trane Commercial Systems Group sales territories and must be

ordered prior to start-up.

PKG-SVX17A-EN 25

Page 26

Page 27

Page 28

Trane

A business of American Standard Companies

www.trane.com

For more information, contact your local Trane

office or e-mail us at comfort@trane.com

Literature Order Number PKG-SVX17A-EN

Date September 2007

Supersedes SS-SVN11A-EN October 2004

Trane has a policy of continuous product and product data improvement and reserves the right to

change design and specifications without notice.

Loading...

Loading...