Page 1

Commercial Self-Contained

Deluxe Self-Contained Units

3 –15 Ton Water-Cooled and

Air-Cooled Air Conditioners

Remote Air-Cooled Condensers

December 2001

PKG-PRC010-EN

Page 2

Introduction

Deluxe Self-Contained Units —

Commercial and Industrial Quality Built into Each Unit

Deluxe self-contained units are single packaged units designed for lowcost installation in the conditioned space or equipment room.

Features include:

• Water-cooled or air-cooled

• Vertical or horizontal fan discharge options, ducted or free return

• Return air options include front or rear

• Easy-to-connect piping and power from either side of unit

• Fully assembled and factory-tested

• Optional accessories:

• plenums

• cupronickel water-cooled condensers

• hot water or steam coils

Industrial options with protective coatings are available to help increase

resistance to acids, mild alkalides, solvents, inorganic salts, and water:

PKG-PRC010-EN©2001American Standard Inc.

Page 3

Contents

Introduction

Features and Benefits

Application Considerations

Selection Procedure

Model Number Description

General Data

Performance Data

Airside Pressure Drop

Fan Data

Waterside Pressure Drop

Correction Factors/Heat of Rejection

Water-Cooled Unit Performance

Air-Cooled Unit Performance

Heating Coil Performance

Electrical Data

2

4

6

7

8

11

13

13

14

18

19

20

25

30

33

Dimensions and Weights

Mechanical Specifications

34

46

3PKG-PRC010-EN

Page 4

Features and Benefits

Deluxe Self-Contained air conditioners,

available in 3–15 tons, are single package

units designed for low cost installation in

the conditioned space or equipment

room. Durable construction, strict quality

control, and demanding factory testing

ensure reliability from start-up through

years of operation.

All units are shipped fully factory assembled and tested, thereby reducing

field labor, installation time, and costs.

They can also be easily converted from

vertical to horizontal discharge arrangements to match most building configurations. Discharge can be either free or

ducted. Power and water connections can

be made from either side of the unit

adding to the unit flexibility.

Available Unit Configurations

3, 5, and 7.5-Ton Units

Standard Features

• 3 through 15-ton industrial/commerical

self-contained units

• Water-cooled or air-cooled condensing

applications

• Single point power connection

• Single point water connection on watercooled units

• Both water and power connections can

be made from either side of the unit

• Front or rear return air openings

• Vertical and horizontal discharge

arrangements

• UL listing on standard unit

• All compressors are protected with

internal motor winding temperature

cutouts

• All compressors have crankcase

heaters as standard

• Variable pitch sheaves allow for field

adjustment of airflow

• High pressure cutout switches on all

units

• Low pressure cutout switches on all

units

• High pressure relief device on watercooled units

Optional Features

• Hydronic heating coils

• Horizontal discharge plenums

• Water regulating valves for condensing

pressure control on water-cooled units

• Protective coating for unit and evaporator coil

• CuproNickel condensers

• Permanent filters

• Unit or remote mounted thermostats

• Low ambient control operation on aircooled condenser

• Oversized fan motor and drive kits

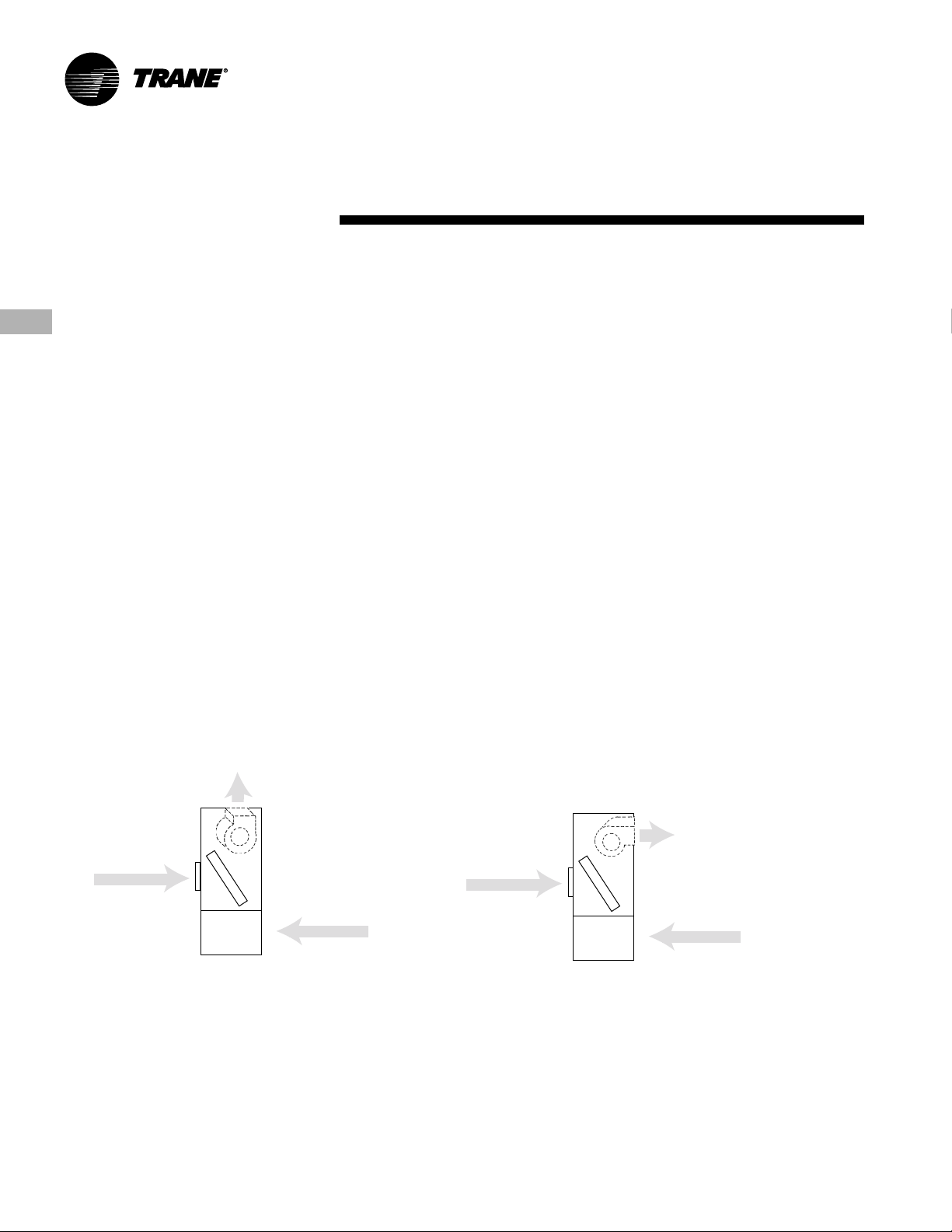

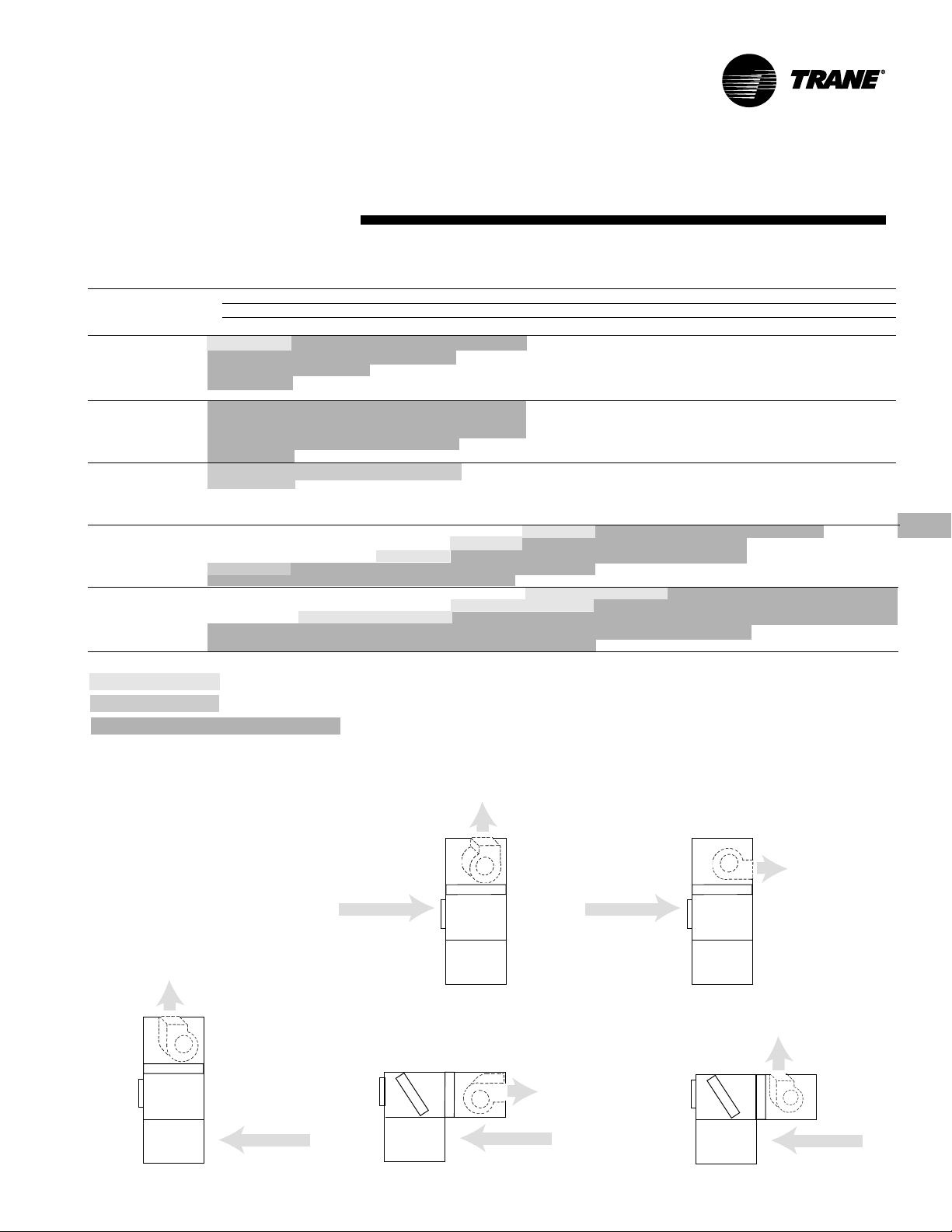

Front Return

standard

Rear Return

field convertible

Figure FB-1. Deluxe Self-Contained 3, 5, & 7.5-Ton Unit

With Vertical Discharge, As Shipped

4

field convertible

fan discharge

Front Return

standard

Figure FB-2. Deluxe Self-Contained 3, 5, & 7.5-Ton Unit

With Horizontal Discharge, Field Converted

Rear Return

field convertible

PKG-PRC010-EN

Page 5

Available Unit Configurations

10 and 15-Ton Units

Features and

Benefits

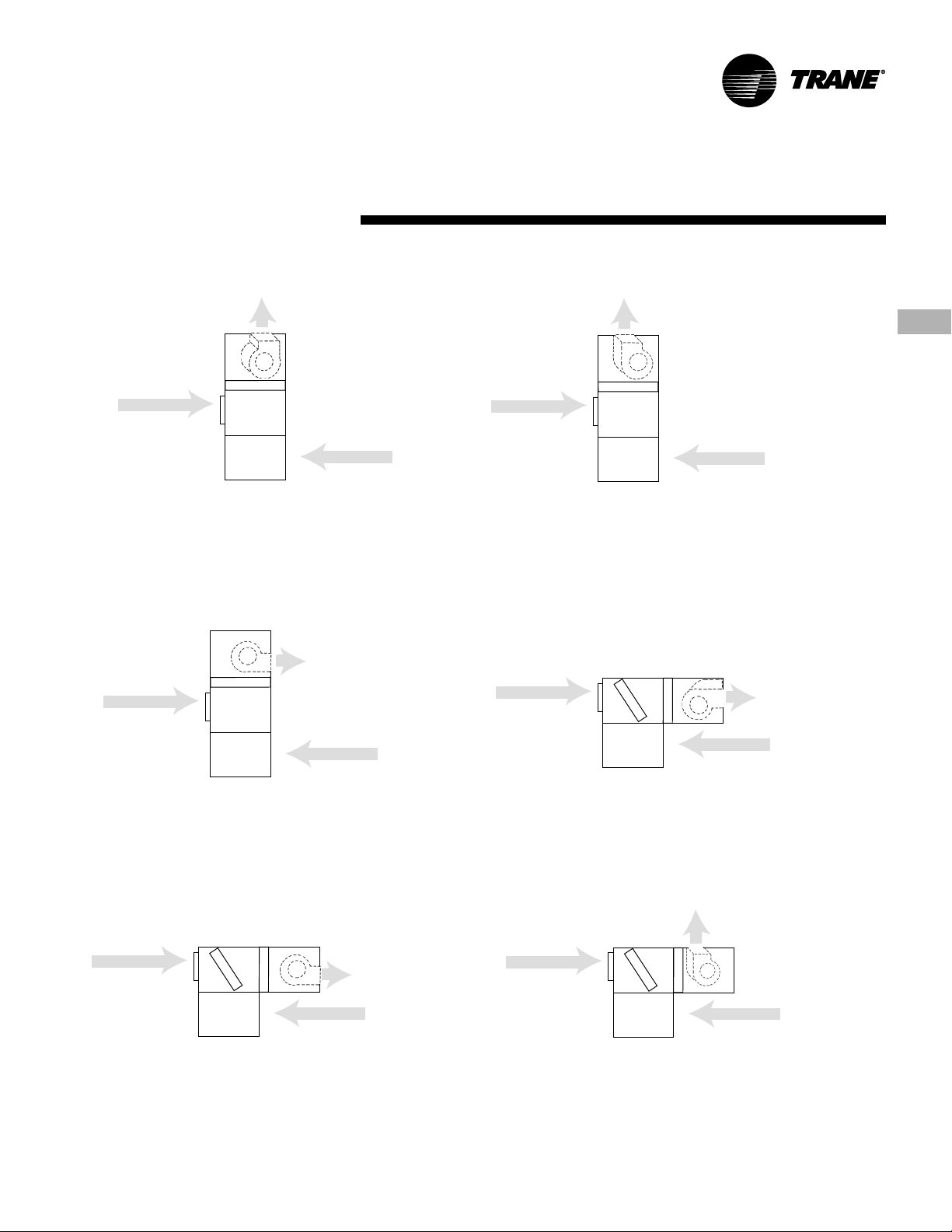

field convertible

clockwise vertical discharge

Front Return

field convertible

Rear Return

standard

Figure FB-3. Deluxe Self-Contained 10 & 15-Ton Unit With

Counter-Clockwise Vertical Discharge, As Shipped

field convertible

counter-clockwise

Front Return

field convertible

horizontal discharge

Rear Return

standard

Figure FB-5. Deluxe Self-Contained 10 & 15-Ton Unit With

Counter-Clockwise Horizontal Discharge, Field Converted

Front Return

field convertible

Rear Return

standard

Figure FB-4. Deluxe Self-Contained 10 & 15-Ton Unit With

Clockwise Vertical Discharge, Field Converted

Front Return

field convertible

Rear Return

standard

field convertible

clockwise horizontal

discharge

Figure FB-6. Deluxe Self-Contained 10 & 15-Ton Unit With

Clockwise Horizontal Discharge, Field Converted

Front Return

field convertible

Rear Return

standard

field convertible

counter-clockwise

horizontal discharge

Figure FB-7. Deluxe Self-Contained 10 & 15-Ton Unit With

Counter-Clockwise Horizontal Discharge, Field Converted

field convertible

clockwise vertical

Front Return

field convertible

discharge

Rear Return

standard

Figure FB-8. Deluxe Self-Contained 10 & 15-Ton Unit With

Clockwise Vertical Discharge, Field Converted

5PKG-PRC010-EN

Page 6

Application

CCRA Air-Cooled

CCRA Unit Location

Unobstructed condenser airflow is

essential to maintain capacity and

operating efficiency. When determining

unit placement, give careful consideration to assure sufficient airflow across

the condenser coils. Avoid these two

detrimental conditions: warm air recirculation and coil starvation.

Both warm air recirculation and coil

starvation cause reductions in unit

efficiency and capacity because of the

higher head pressure associated with

them. In more severe cases, nuisance

unit shutdowns will result from excessive

head pressures.

Considerations

Clearance

Ensure vertical condenser air discharge is

unobstructed. While it is difficult to

predict the degree of warm air recirculation, a unit installed with a ceiling or

other obstruction above it will experience

a capacity reduction that will reduce the

maximum ambient operation. Nuisance

high head pressure tripouts may also

occur.

The coil inlet must also be unobstructed.

A unit installed closer than the minimum

recommended distance to a wall or other

vertical riser will experience a combination of coil starvation and warm air

recirculation. This may result in unit

capacity and efficiency reductions, as

well as possible excessive head pressures. Reference the service clearance

section on page 45 for recommended

lateral distances.

Condenser

Ambient Limitations

Standard ambient control allows operation down to 45°F (7.2°C) with cycling of

condenser fans. Units with the low

ambient option are capable of starting

and operating in ambient temperatures

down to 0°F (-17.8°C). Optional low

ambient units use a condenser fan

damper arrangement that controls

condenser capacity by modulating

damper airflow in response to saturated

condenser temperature.

Maximum cataloged ambient temperature operation of a standard condenser is

115°F (46.1°C). Operation at design

ambient above 115°F can result in

excessive head pressures. For operation

above 115°F, contact the local Trane sales

office.

6

PKG-PRC010-EN

Page 7

Selection Procedure

Selection Procedure

The selection of a deluxe self-contained

unit can be accomplished in three easy

steps.

Step 1 - Load

Determine the load requirements for

heating and cooling (include outside air)

using Trane’s load estimate program or

any standard method.

Step 2 - Unit Type

Self-contained air conditioners are

available in either water-cooled or

remote air-cooled models to match

individual needs.

Step 3 - Select the Unit

The conditions under which the unit must

operate and the design load will give the

final selection.

Selection Example

Design conditions for a water-cooled unit:

Entering air temperature = 80/67°F

Total gross capacity required = 64,400

Btu/h

Entering water temperature = 85°F

Leaving water temperature = 95°F

Airflow = 2,400 cfm at 0.5-inch duct static

pressure

Unit Selection

Tentatively select a 5-ton unit: Model

SCWB-B50. Refer to Table PD-10 on

page 21 to obtain gross total and sensible

unit capacities, gpm, and leaving water

temperature at nominal conditions:

Total capacity = 66 MBh

Sensible capacity = 45 MBh

Water flow rate = 20 gpm

Leaving water temperature = 93.1°F

Since the design cfm is greater than the

nominal cfm, the capacities and condenser water delta T must be adjusted to

reflect the higher cfm.

Self-Contained

Design cfm = 2,400

Nominal cfm = 2,000 + 20% of nominal

cfm

Refer to Table PD-6 on page19 to obtain

the capacity correction factors for +20%

of nominal cfm:

Cooling capacity multiplier = 1.03

Sensible capacity multiplier = 1.05

Multiply the capacities by the correction

factors:

66 MBh x 1.03 = 68.0 MBh

45 MBh x 1.05 = 47.3 MBh

The SCWB-B50 meets the total and

sensible design requirements.

Subtract the entering water temperature

from the leaving water temperature to

determine condenser water delta T of

8.1°F. Multiply the delta T by the cooling

capacity correction factor of 1.03 to

obtain the new delta T of 8.3°F and add

this to the entering water temperature to

obtain the actual leaving water temperature of 93.3°F. The leaving condenser

water temperature is within the design

delta T of 10°F.

Refer the fan data Table PD-1 on page 14

to determine approximate brake horsepower and fan rpm:

Fan brake horsepower = 1.09 bhp

Fan rpm = 934 rpm

Determine net capacities by subtracting

fan motor heat from gross capacities:

2.8 X 1.09 bhp = 3.1 MBh

Net total capacity = 67.8 MBh - 3.1 MBh

= 64.7 MBh

Net sensible capacity = 48.7MBh - 3.1

MBh = 45.6 MBh

Refer to the Trane psychrometric chart to

determine leaving air temperatures.

7PKG-PRC010-EN

Page 8

Selection

Model Number

Procedure

Description

Deluxe Self-Contained Model Number Description

Following is a complete description of the deluxe self-contained model number. Each digit in the model number has a corresponding code that identifies specific unit options.

S C W B B30 4 4 * * 1 0 1 1 A 0 1 2 A A 0 0 F A 0 1 0 0 U

1 2 3 4 567 8 9 1011 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Digit 1 - Unit Model

S = Self Contained

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

W = Water-Cooled

R = Remote Air-Cooled

Digit 4 - Development Sequence

B = Development Series

Digit 5, 6, 7 - Unit Nominal Capacity

B30 = 3 Tons

B50 = 5 Tons

B75 = 7.5 Tons

C10 = 10 Tons

C15 = 15 Tons

Digit 8 - Unit Voltage

4 = 460 Volt/60 Hz/3 ph

5 = 575 Volt/60 Hz/3 ph

6 = 208-230 Volt/60 Hz/3 ph

Digit 9 - Air Volume/Temp Control

4 = CV - Zone Temp Cool Only

5 = CV - Zone Temp Heat/Cool

0 = CV - With No Temp Control

Digit 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Construction

1 = Vertical Discharge with Front Return

3 = Vertical Discharge with Rear Return

Digit 13 - Plenum Type

0 = Without Plenum

Digit 14 - Motor Type

1 = Standard Motor

Digit 15 - Fan Drive Kits

1 = Standard Drive Kit

Digit 16 - Filter Type

A = 1” Construction Throwaway

Digit 17 - Heating Type

0 = Without Factory Installed Heat

Digit 18 - Unit Finish

1 = Paint - Deluxe Beige

2 = Protective Coating

3 = Protective Coating with Finish Coat

Digit 19 - Unit Connection

2 = Terminal Block

Digit 20 - Coil Option

A = Non-coated Aluminum Evaporator

C = Corrosion Protective Coated

Aluminum Evaporator

Digit 21 - Drain Pan Type

A = Galvanized Standard

Digit 22 - Economizer Type

0 = Without Unit Economizer

Digit 23 - Waterside Valves

0 = Without Water Valve(s)

Digit 24 - Unit Insulation

F = Matte-Faced Fiberglass Insulation

Digit 25 - Condenser Type

A = Standard Condenser

E = 90/10 CuNi Condenser

0 = Without Condenser

Digit 26 - Compressor Service Valves

0 = Without Service Valves

Digit 27 - Temperature Control

0 = Remote Thermostat Interface

1 = Standard Unit Mounted

Thermostat

3 = Remote Thermostat, 0H/2C

4 = Remote T’stat, 2H/2C (Manual)

5 = Remote T’stat, 2H/2C (Auto)

6 = Remote Prog. T’stat, 1H/2C

7 = Remote Prog. T’stat. 2H/2C

Digit 28 - System Control

0 = Without System Control

Digit 29 - Control Options

0 = No System Control Options

Digit 30 - Agency Listing

B = UL and CSA Agency Approval

T = CSA Agency Approval

U = UL Agency Approval

0 = No Agency Approval

8

PKG-PRC010-EN

Page 9

Selection

Model Number

Procedure

Description

Self-Contained Accessory Model Number Description

A 1 0 1 0 0 A 0 B 0 0 2 0 2 A 1 0 0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Digit 1 - Discharge Plenum

A = 3 Ton Standard Plenum

B = 3 Ton Protective Coated Plenum

C = 5 Ton Standard Plenum

D = 5 Ton Protective Coated Plenum

E = 7.5 Ton Standard Plenum

F = 7.5 Ton Protective Coated Plenum

G = 10 Ton Standard Plenum

H = 10 Ton Protective Coated Plenum

I = 15 Ton Standard Plenum

J = 15 Ton Protective Coated Plenum

0 = None

Digit 2 - Permanent Filters

1 = 3 Ton (1) 20 x 25 x 1

2 = 5 Ton (2) 16 x 25 x 1

3 = 7.5 Ton (4) 15 x 20 x 1

4 = 10 Ton (3) 20 x 25 x 2

5 = 15 Ton (8) 15 x 20 x 2

0 = None

Digit 3 - Front Return Air Grille

A = 10 Ton Front Return Air Grille

B = 10 Ton Protective Coated Front Rtn

Air Grille

C = 15 Ton Front Return Air Grille

D = 15 Ton Protective Coated Front Rtn

Air Grille

0 = None

Digit 4 - Rubber-In-Shear Isolators

1 = 3 Ton Isolators

2 = 5 Ton Isolators

3 = 7.5 Ton Isolators

4 = 10 Ton Standard Configuration

Isolators

5 = 10 Ton Horz. Inverted “L” Isolators

(Air-Cooled Units Only)

6 = 10 Ton Horz. Inverted “L” Isolators

(Water-Cooled Units Only)

7 = 15 Ton Standard Configuration

Isolators

8 = 15 Ton Horz. Inverted “L” Isolators

(Air and Water-Cooled Units)

0 = None

Digit 5 - Steel Spring Isolators

A = 3 Ton Isolators

B = 5 Ton Isolators

C = 7.5 Ton Isolators

D = 10 Ton Standard Configuration

Isolators (Air-Cooled Units Only)

E = 10 Ton Standard Configuration

Isolators (Water-Cooled Units Only)

F = 10 Ton Horz. Inverted “L” Isolators

(Air and Water-Cooled Units)

G = 15 Ton Standard Configuration

Isolators

H = 15 Ton Horz. Inverted “L” Isolators

(Air and Water Cooled Units)

0 = None

Digit 6 - Unit Mounted Thermostat

1 = 10 & 15 Ton 2 Cool Thermostat

2 = 3, 5, & 7.5 Ton 2 Cool Thermostat

0 = None

Digit 7 - Remote Mounted Thermostat

A = 3, 5, & 7.5 Ton 0H/2C (Auto)

B = 10 & 15 Ton 2H/2C (Manual)

C = 10 & 15 Ton 2H/2C (Auto)

0 = None

Digit 8 - Programmable Night Setback

Thermostat

1 = 3, 5, & 7.5 Ton 1H/2C

2 = 10 & 15 Ton 2H/2C

0 = None

Digit 9 - Fan Motor Kits (Includes Drives)

A = 3 Ton,

B = 3 Ton,

C = 5 Ton, 1 HP, 208-230 Volt

D = 5 Ton, 1 HP, 460 Volt

E = 5 Ton, 1F = 5 Ton, 1-1/2 HP, 460 Volt

G = 7.5 Ton, 10 = None

Digit 10 - Oversize Fan Motor Kits

1 = 10 Ton, 3 HP, 208-230 & 460 Volt

2 = 15 Ton, 5 HP, 208-230 & 460 Volt

0 = None

Digit 11 - Accessory Drive Kits

A = 10 Ton, Underspeed Drive Kit

B = 15 Ton, Underspeed Drive Kit

C = 10 & 15 Ton, Overspeed Drive Kit

D = 15 Ton, Extra Overspeed Drive Kit

0 = None

Digit 12 - Hot Water Heating Coil

1=3 Ton

2 = 3 Ton with Corrosion Protection

3=5 Ton

4 = 5 Ton with Corrosion Protection

5 = 7.5 Ton

3

/4 HP, 208-230 Volt

3

/4 HP, 460 Volt

1

/2 HP, 208-230 Volt

1

/2 HP, 208-230 & 460 Volt

6 = 7.5 Ton with Corrosion Protection

7 = 10 Ton

8 = 10 Ton with Corrosion Protection

9 = 15 Ton

A = 15 Ton with Corrosion Protection

0 = None

Digit 13 - Steam Heating Coil

A=3 Ton

B = 3 Ton with Corrosion Protection

C=5 Ton

D = 5 Ton with Corrosion Protection

E = 7.5 Ton

F = 7.5 Ton with Corrosion Protection

G = 10 Ton

H = 10 Ton with Corrosion Protecton

I = 15 Ton

J = 15 Ton with Corrosion Protection

0 = None

Digit 14 - 90/10 Cupronickel Condensers

1 = 3 Ton CuNi Condenser

2 = 3 Ton CuNi Protective Coated

Condenser

3 = 5 Ton CuNi Condenser

4 = 5 Ton CuNi Protective Coated

Condenser

5 = 7.5 Ton CuNi Condenser

6 = 7.5 Ton CuNi Protective Coated

Condenser

7 = 10 Ton CuNi Condenser

8 = 10 Ton CuNi Protective Coated

Condenser

9 = 15 Ton CuNi Condenser

A = 15 Ton CuNi Protective Coated

Condenser

Digit 15 - Water Regulating Valve Kit

A = 3 Ton Water Reg. Valve Kit

B = 5 & 7.5 Ton Water Reg. Valve Kit

C = 10 & 15 Ton Water Reg. Valve Kit

Digit 16 - Anti-Recycle Timer

1 = Anti-Recycle Timer

0 = None

Digit 17 - Time Delay Relay

1 = 10 & 15 Ton Time Delay Relay

0 = None

Digit 18 - Low Ambient Damper

A = 3 & 5 Ton Low Ambient Damper

B = 7.5 Ton Low Ambient Damper

C = 10 Ton Low Ambient Damper

D = 15 Ton Low Ambient Damper

0 = None

9PKG-PRC010-EN

Page 10

Selection

Model Number

Procedure

Description

Remote Air-Cooled Condenser

C C R A B50 2 0 * * 4 A U

1 2 3 4 567 8 9 10 11 12 13 14

Digit 1 - Unit Model

C = Condenser

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

R = Remote Air-cooled

Digit 4 - Development Sequence

A=A

Digit 5, 6, 7 - Nominal Capacity

B30 = 3 Tons

B50 = 5 Tons

B75 = 7.5 Tons

C10 = 10 Tons

C15 = 15 Tons

Digit 8 - Unit Voltage

1 = 208-230 Volt/60 Hz/1 ph

2 = 460 Volt/60 Hz/1 ph

8 = 575 Volt/60 Hz/1 ph

Digit 9 - Low Ambient

C = Low Ambient Damper(s)

0 = Without Low Ambient Control

Digit 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Finish

2 = Protective Coating

3 = Protective Coating with

Finish Coat

4 = Unpainted Unit

Digit 13 - Coil Options

A = Non-Coated Aluminum

C = Protective Coated Aluminum

Digit 14 - Agency Listing

B = UL and CSA Agency Approval

T = CSA Agency Approval

U = UL Agency Approval

0 = No Agency Approval

10

PKG-PRC010-EN

Page 11

General Data

Self-Contained

Table GD-1. SCRB/SIRB/SCWB/SIWB Deluxe Self-Contained General Data

Unit Size 357.51015

Compressor Data

Quantity 11122

Nominal Ton/Comp 3 5 7.5 5 7.5

Circuits 11122

Evaporator Coil Data

Rows 33333

Sq. Ft. 2.68 5.08 7.08 9.82 16.04

Sq. m (.25) (.47) (.66) (.91) (1.49)

FPF 144 144 144 144 144

Condenser Data (Water-Cooled Only)

Quantity 12222

Minimum gpm 5 8 11 15 23

Minimum liters / sec. (.32) (.50) (.69) (.95) (1.45)

Maximum gpm 12 2 0 30 40 50

Maximum liters / sec. (.76) (1.26) (1.89) (2.52) (3.15)

Minimum EWT w/out valve, °F 65 65 65 65 65

Minimum EWT with valve, °F 35 35 35 35 35

Evaporator Fan Data

Quantity 11122

Size Dia. x width - inches 10 x 10 12 x 12 15 x 15 12 x 9 12 x 9

Size Dia. x width - mm (254x254) (305x305) (381x381) (305x229) (305x229)

Standard HP

Oversized HP Available

Minimum Design cfm 960 1600 2400 3200 4800

Minimum Design liter / sec. (453) (755) (1133) (1510) (2265)

1

/

2

3

/

4

Maximum Design cfm 1440 2400 3600 4800 7200

Maximum Design liter / sec. (680) (1133) (1699) (2265) (3398)

General Data

EER (SXRB) 10.0 10.0 10.3 10.3 9.7

EER (SXWB) 12.1 12.1 11.5 11.5 12.0

Refrigerant Charge - lbs. R-22 per Circuit

Total Charge (SXWB) 6.0 11.0 10.0 8.0/8.0 7.5/7.5

Refrigerant Charge - kg R-22

Total Charge (SXWB) (2.18) (3.63) (3.99) (5.35) (7.26)

Capacity Steps - % 100/0 100/0 100/0 100/50/0 100/50/0

Filter Data

Quantity 12438

Size (inches) 20x25x1 16x25x1 15x20x1 20x25x1 15x20x1

Size (mm) (508x635x25) (406x635x25) (381x508x25) (508x635x25) (381x508x25)

Heating Coil Data

Steam Coil

Coil Type SDS SDS SDS NS NS

Rows 11111

Size (inches) 12 x 23

Size (mm) (305 x 591) (381 x 711) (457 x 811) (305 x 1346) (305 x 1854)

1

/

FPF 180 180 180 144 144

Hot Water Coil

Coil Type WC WC WC WC WC

Rows 22222

Size (inches) 15 x 20

Size (mm) (381 x 519) (381 x 635) (381 x 737) (742 x 1388) (508 x 1921

7

/

FPF 108 108 108 108 108

Notes:

1. All units operate with R-22. Water-cooled units ship with full operating charge. Air-cooled units ship with a dry nitrogen

holding charge.

2. Hot water coils do not have turbulators. See Capacity DataTables PD-19 and PD-20 for coil capacities.

3. Steam Coil capacities are shown in Table PD-21.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

6. SCWB/SIWB/SCRB/SIRB 3, 5, 7.5, and 10 ton units are rated at ARI Standard 210/240-1994. SCWB/SIWB/SCRB/SIRB 15-ton

units are rated at ARI Standard 340/360-2000.

7. SCRB/SIRB 3 and 5-ton units are rated as SEER.

3

/

4

1, 1-1/

2

15 x 28 18 x 31 15/

4

15 x 25 15 x 29 5/820 x 54 5/820 x 75 5/

16

123

1-1/

2

35

12 x 53 12 x 73

16

8

11PKG-PRC010-EN

Page 12

Air-Cooled

General Data

Condenser

Table GD-2. CCRA/CIRA Remote Air-Cooled Condenser General Data

Unit Size 357.51015

Gross Heat Rejection (MBh) 59 102 116 207 232

Gross Heat Rejection (kW) (17.3) (29.9) (34.0) (60.7) (68.0)

Condenser Fan Data

Number/Type 1/Prop 1/Prop 2/Prop 2/Prop 4/Prop

Size (inches) 18” 22” 22” 22” 20”

Size (mm) (457) (559) (559) (559) (508)

Fan Drive Direct Direct Direct Direct Direct

No. of Motors/HP ea. 1/0.33 1/0.75 2/0.75 2/0.75 4/0.75

Nominal cfm

Nominal (liters / sec)

Condenser Coil Data

Circuit 1 Size (in.) 36 x 48 36 x 48 72 x 96 36 x 48 36 x 48

Circuit 1 Size (mm) (914 x 1219) (914 x 1219) (1828x 2438) (914 x 1219) (914 x 1219)

Circuit 2 No./Size (in.) n/a n/a n/a 36 x 48 36 x 48

Circuit 2 No./Size (mm) (914 x 1219) (914 x 1219)

Face Area (sq. Ft.) 12.0 12.0 24.0 24.0 24.0

Face Area (sq.m) (1.1) (1.1) (2.2) (2.2) (2.2)

Rows/fpf 2/144 3/144 3/144 3/144 3/144

Ambient Temp. Operating Range

Standard Ambient (°F) 40 - 115 40 - 115 40 - 115 40 - 115 40 - 115

Standard Ambient (°C) (4.4 - 46.1) (4.4 - 46.1) (4.4 - 46.1) (4.4 - 46.1) (4.4 - 46.1)

Low Ambient Option (°F) 0 - 115 0 - 115 0 - 115 0 - 115 0 - 115

Low Ambient Option (°C) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1)

Notes:

1. Gross heat rejection is at a 30°F (-1.1°C) ITD (initial temperature difference) between condensing temperature and

ambient air entering condenser (includes the effect of subcooling).

12

PKG-PRC010-EN

Page 13

Performance

Heating

Data

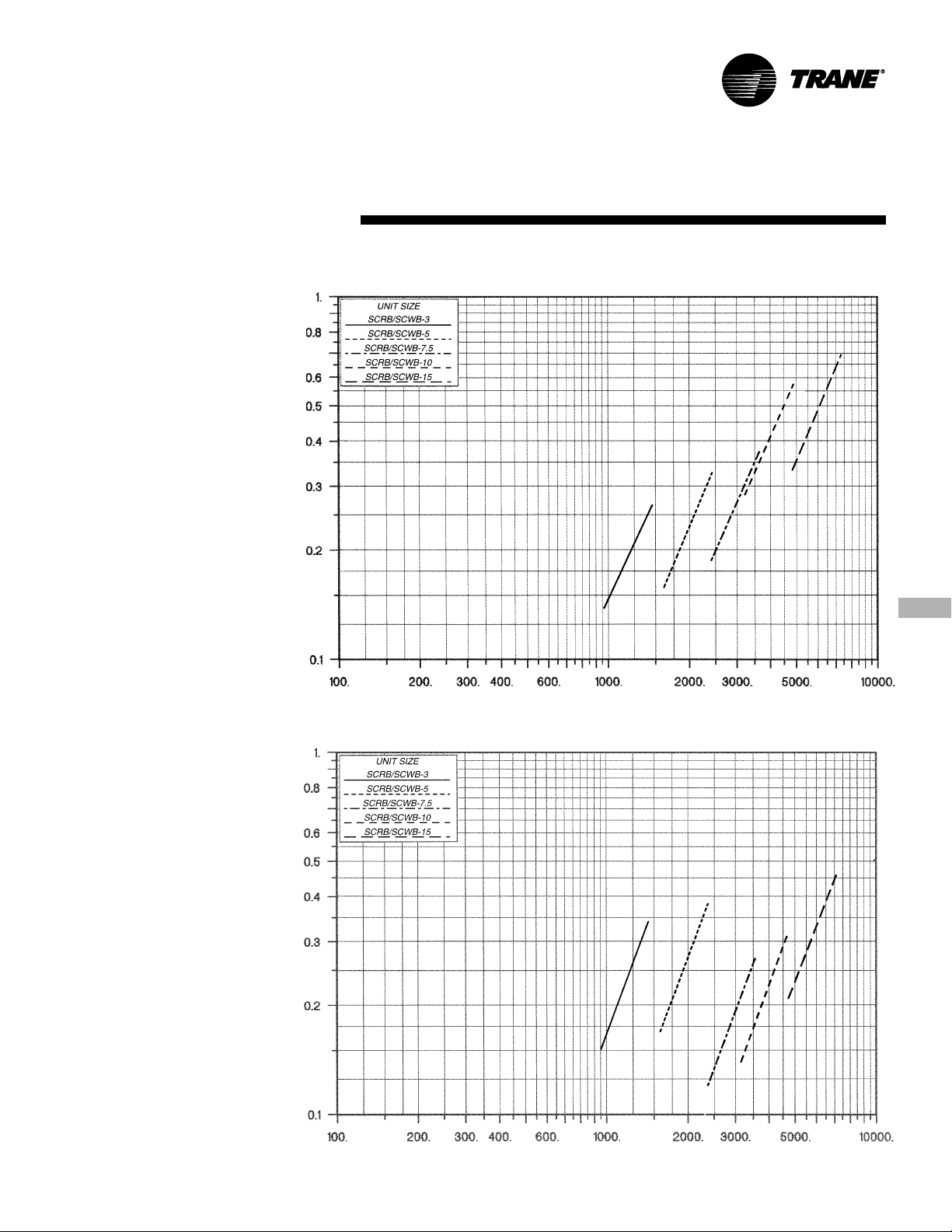

Chart PD-1. Heating Coil Airside Pressure Drop

Pressure Drop, in. wc.

Coils

Chart PD-2. Plenum Airside Pressure Drop

Pressure Drop, in. wc.

Unit Airflow, cfm

Unit Airflow, cfm

13PKG-PRC010-EN

Page 14

Performance

Data

Fan Data

Table PD-1. Fan Performance Data, 0.10 to 0.80 esp

External Static Pressure

Unit 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

Size cfm rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp

3-Ton 960 616 0.14 682 0.17 750 0.21 816 0.25 880 0.30 940 0.35 993 0.40 1044 0.45

5-Ton 1600 557 0.29 611 0.32 660 0.37 708 0.42 760 0.49 817 0.57 869 0.66 919 0.75

7.5-Ton 2400 517 0.42 556 0.50 598 0.59 638 0.68 677 0.78 710 0.87 745 0.98 782 1.09

10-Ton 3200 589 0.53 641 0.60 684 0.66 730 0.74 775 0.82 813 0.88 853 0.96 891 1.05

15-Ton 4800 521 0.92 554 0.97 589 1.08 624 1.17 656 1.28 689 1.39 721 1.50 752 1.60

Note:

Non-standard drive selection

Oversize motor required

Oversize motor required and non-standard drive selection

1080 677 0.19 735 0.22 796 0.26 856 0.36 915 0.35 972 0.40 1027 0.46 1077 0.52

1200 739 0.25 792 0.28 845 0.33 901 0.37 955 0.42 1007 0.47 1059 0.53 1110 0.59

1320 802 0.32 852 0.35 898 0.40 949 0.45 999 0.50 1048 0.55 1196 0.61 1143 0.67

1440 866 0.41 913 0.44 955 0.49 1000 0.54 1046 0.60 1092 0.65 1137 0.71

1800 612 0.40 664 0.43 709 0.47 751 0.54 793 0.67 839 0.67 888 0.75 937 0.85

2000 668 0.55 717 0.57 759 0.61 799 0.67 837 0.74 875 0.84 915 0.88 958 0.97

2200 724 0.72 771 0.75 812 0.77 849 0.83 884 0.90 919 0.98 953 1.05 989 1.13

2400 781 0.93 826 0.96 865 0.99 900 1.02 934 1.09 966 1.17 998 1.26 1029 1.34

2700 570 0.57 607 0.66 643 0.75 680 0.86 715 0.96 751 1.08 781 1.18 811 1.28

3000 625 0.76 661 0.87 691 0.96 725 1.07 758 1.18 789 1.29 822 1.42

3300 681 1.00 715 1.11 742 1.21 771 1.31 803 1.44

3600 739 1.28 767 1.39 796 1.50

3600 649 0.72 698 0.81 739 0.88 777 0.95 819 1.04 860 1.14 894 1.21 929 1.29

4000 709 0.97 755 1.06 796 1.15 832 1.23 865 1.31 903 1.41 942 1.52 974 1.60

4400 771 1.26 814 1.37 853 1.47 888 1.56 920 1.64 950 1.73 984 1.84 1020 1.97

4800 833 1.61 874 1.74 911 1.85 945 1.95 976 2.05 1005 2.14 1033 2.24 1062 2.35

5400 578 1.29 608 1.34 637 1.43 669 1.56 700 1.66 729 1.77 758 1.90 787 2.02

6000 636 1.76 663 1.80 689 1.87 717 2.00 745 2.14 773 2.26 799 2.38 825 2.51

6600 694 2.34 719 2.38 743 2.43 767 2.53 792 2.68 819 2.84 844 2.98 868 3.10

7200 752 3.03 776 3.07 798 3.12 820 3.20 842 3.32 866 3.49 890 3.67 913 3.82

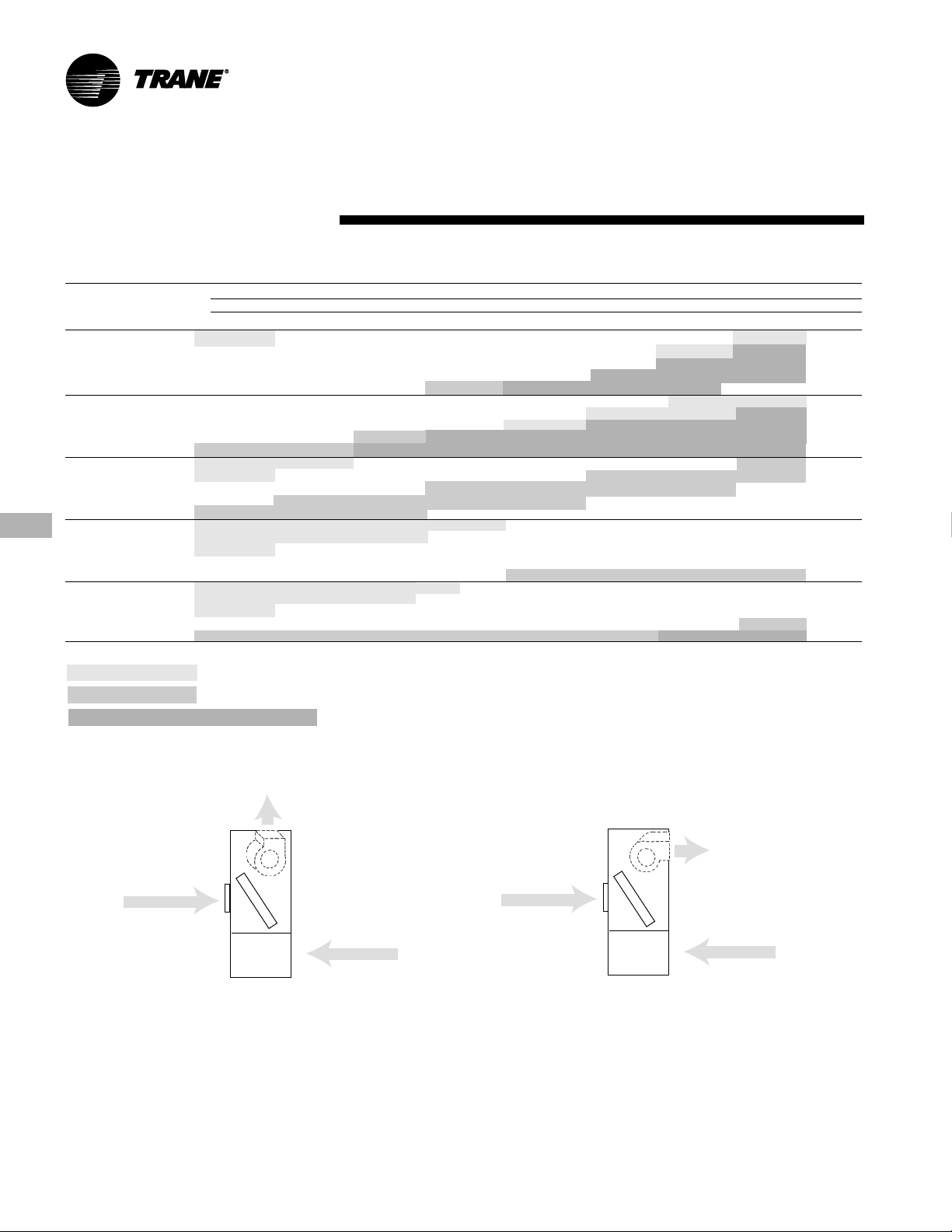

Use Tables PD-1 and PD-2 with these unit configurations:

3, 5, & 7.5-Ton Units

Front Return

standard

Rear Return

field convertible

14

Front Return

standard

field convertible

fan discharge

Rear Return

field convertible

PKG-PRC010-EN

Page 15

Performance

Data

Fan Data

Table PD-2. Fan Performance Data, 0.90 to 2.50 esp

External Static Pressure

Unit 0.90 1.00 1.10 1.25 1.50 1.75 2.00 2.25 2.50

Size cfm rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp

3-Ton 960 1092 0.50 1138 0.55 1183 0.60 1248 0.69

5-Ton 1600 968 0.84 1017 0.94 1064 1.04 1134 1.19

7.5-Ton 2400 817 1.21 850 1.33 880 1.44

10-Ton 3200 928 1.14 967 1.23 1007 1.33 1063 1.48 1150 1.76 1234 2.11 1314 2.47 1391 2.86

15-Ton 4800 782 1.71 810 1.82 836 1.92 873 2.08 935 2.36 997 2.70 1062 3.09 1125 3.52 1186 3.98

Note:

Non-standard drive selection

Oversize motor required

Oversize motor required and non-standard drive selection

1080 1124 0.57 1169 0.63 1212 0.68

1200 1158 0.66 1202 0.72

1320 1190 0.74

1440

1800 984 0.95 1029 1.05 1072 1.16 1137 1.31

2000 1003 1.07 1046 1.18 1088 1.29 1149 1.46

2200 1027 1.21 1067 1.32 1108 1.44

2400 1062 1.42

2700 843 1.41

3000

3300

3600

3600 965 1.38 998 1.48 1031 1.58 1082 1.74 1170 2.01 1248 2.30 1324 2.66

4000 1005 1.68 1037 1.78 1069 1.89 1114 2.05 1189 2.33 1269 2.64 1342 2.94

4400 1052 2.07 1080 2.16 1108 2.25 1152 2.41 1222 2.71

4800 1096 2.48 1128 2.61 1156 2.72 1194 2.86

5400 815 2.14 843 2.26 869 2.39 907 2.57 964 2.86 1019 3.17 1074 3.51 1130 3.89 1187 4.34

6000 851 2.66 877 2.78 903 2.92 940 3.12 998 3.46 1051 3.79 1101 4.13 1150 4.47 1199 4.86

6600 892 3.24 916 3.39 939 3.55 974 3.77 1032 4.14 1085 4.51 1134 4.88

7200 936 3.95 945 4.10 979 4.25 1012 4.51 1065 4.92

Use Tables PD-1 and PD-2 with these unit configurations:

10 & 15-Ton Units

Front Return

field convertible

field convertible

clockwise vertical discharge

Rear Return

standard

Rear Return

standard

Front Return

field convertible

field convertible

clockwise horizontal

discharge

field convertible

counter-clockwise

horizontal discharge

field convertible

clockwise vertical

discharge

Rear Return

standard

15PKG-PRC010-EN

Page 16

Performance

Data

Fan Data

Table PD-3. Fan Performance Data, 0.10 to 0.80 esp

Unit 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

Size cfm rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp

10-Ton 3200 460 0.45 520 0.49 572 0.56 623 0.63 670 0.70 716 0.78 762 0.86 805 0.95

15-Ton 4800 478 0.77 516 0.85 555 0.95 597 1.05 634 1.17 668 1.26 700 1.34 733 1.45

Note:

Non-standard drive selection

Oversize motor required

Oversize motor required and non-standard drive selection

3600 501 0.62 558 0.67 608 0.73 653 0.80 698 0.89 741 0.97 782 1.05 823 1.14

4000 544 0.84 597 0.89 644 0.95 698 1.03 728 1.11 768 1.20 808 1.29 845 1.38

4400 586 1.10 637 1.16 682 1.22 724 1.29 763 1.38 799 1.47 836 1.57 872 1.67

4800 632 1.41 679 1.48 721 1.54 761 1.61 799 1.70 834 1.79 867 1.89 900 2.00

5400 529 1.08 562 1.15 596 1.25 632 1.37 670 1.48 703 1.62 734 1.74 763 1.82

6000 582 1.47 611 1.53 641 1.64 672 1.76 705 1.88 739 2.01 770 2.16 798 2.31

6600 634 1.94 660 2.00 688 2.10 716 2.22 744 2.36 773 2.50 804 2.63 834 2.79

7200 688 2.51 711 2.57 736 2.66 761 2.78 787 2.92 813 3.07 840 3.22 868 3.37

External Static Pressure

Use Tables PD-3 and PD-4 with these unit configurations:

10 & 15-Ton Units

Front Return

field convertible

Front Return

field convertible

field convertible

clockwise vertical

discharge

field convertible

clockwise horizontal

discharge

field convertible

counter-clockwise

horizontal discharge

Rear Return

Front Return

field convertible

Rear Return

standard

Front Return

field convertible

Rear Return

standard

field convertible

counter-clockwise

horizontal discharge

field convertible

clockwise vertical discharge

standard

16

PKG-PRC010-EN

Page 17

Performance

Data

Table PD-4. Fan Performance Data, 0.90 to 2.50 esp

Unit 0.90 1.00 1.10 1.25 1.50 1.75 2.00 2.25 2.50

Size cfm rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp rpm bhp

10-Ton 3200 846 1.03 887 1.13 925 1.24 980 1.40 1064 1.67 1141 1.95 1215 2.28 1287 2.59 1356 2.94

15-Ton 4800 765 1.58 796 1.70 825 1.81 869 1.98 939 2.31 1007 2.70 1071 3.14 1132 3.60 1189 4.07

Note:

Non-standard drive selection

Oversize motor required

Oversize motor required and non-standard drive selection

3600 863 1.24 900 1.33 937 1.43 992 1.59 1077 1.89 1154 2.19 1225 2.50 1293 2.83

4000 882 1.48 918 1.58 955 1.69 1006 1.84 1088 2.13 1166 2.45 1238 2.78

4400 907 1.77 940 1.87 973 1.97 1024 2.15 1102 2.44 1178 2.74

4800 934 2.11 967 2.21 998 2.33 1044 2.50 1121 2.80

5400 792 1.92 821 2.05 849 2.19 891 2.39 956 2.71 1020 3.05 1081 3.45 1141 3.91 1198 4.44

6000 825 2.42 851 2.51 877 2.62 916 2.84 979 3.22 1039 3.57 1097 3.93 1153 4.84 1208 4.80

6600 861 2.96 886 3.11 910 3.23 945 3.39 1008 3.75 1063 4.18 1118 4.57 1171 4.96

7200 896 3.53 922 3.72 946 3.90 980 4.12 1034 4.41 1088 4.80

External Static Pressure

Fan Data

17PKG-PRC010-EN

Page 18

Performance

Waterside

Data

Chart PD-3. Waterside Pressure Drop

Pressure Drop, ft water

Pressure Drop

Note: Chart PD-3 includes factory piping and condenser. If adding a water regulating valve, add valve WPD to the

value in Chart PD-3. 10 and 15 ton units use two water regulating valves. Therefore, divide the gpm and WPD by 2 to

determine values through each valve.

Table PD-5. Water Regulating Valve Pressure Drop, ft of water

9 101112131415161718192021222324252627282930

4.6 6.0 6.9 8.1 9.9 12.0 16.6 18.4 21.0 23.1 28.9 34.6 36.9 40.4 43.4 46.2 53.1 56.6 61.9 64.0 69.3 76.2

Note: Table PD-5 is based on wide open water valve.

gpm

Condenser Flowrate, gpm

18

PKG-PRC010-EN

Page 19

Performance

Data

Table PD-6. Cfm Capacity Correction Table – Cooling

Cfm Compared Cooling Sensible

To Rated Capacity Capacity

Quanitity Multiplier Multiplier

-20% 0.96 0.95

DX Cooling Std 1.00 1.00

* If, after applying these multipliers, the SHR is greater than 1.0, use 1.0

Table PD-7. Cfm Capacity Correction Table – Heating

Hydronic Heating Std 1.00

-10% 0.98 0.98

+10% 1.02 1.02*

+20% 1.03 1.05*

Cfm Compared Heating

To Rated Capacity

Quanitity Multiplier

-20% 0.89

-10% 0.94

+10% 1.06

+20% 1.12

Table PD-8. Altitude Correction Factors

Altitude 2000 4000 6000 8000 10,000

Cooling Capacity Multiplier 0.98 0.95 0.92 0.89 0.86

Chart PD-4. CCRA/CIRA Gross Heat of Rejection

Heat of Rejection, MBh

Initial Temperature Difference (ITD)

19PKG-PRC010-EN

Page 20

Performance

Water-Cooled

Data

3 Ton

Table PD-9. SCWB/SIWB 3 Gross Cooling Capacity - 1200 cfm

65°F 75°F 85°F 95°F 100°F

EDB EWB Flow Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT

F F gpm MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W

70 62 5 34 21 83.5 2.1 33 20 93.1 2.3 31 19 102.6 2.4 30 19 112.1 2.5 29 18 116.7 2.6

75 62 5 34 25 83.5 2.1 33 24 93.1 2.2 31 23 102.6 2.4 30 23 112.0 2.5 29 22 116.7 2.6

80 62 5 34 29 83.5 2.1 33 28 93.1 2.2 31 28 102.6 2.4 29 27 112.0 2.5 29 26 116.6 2.6

85 62 5 34 33 83.5 2.1 33 32 93.1 2.3 31 31 102.7 2.4 30 30 112.3 2.5 29 29 117.0 2.6

Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. TOT = total gross cooling capacity. 3. SEN = sensible heat capacity.

6 35 21 79.0 2.0 33 20 88.7 2.2 32 20 98.3 2.3 30 19 107.9 2.5 29 18 112.6 2.5

9 36 21 74.4 1.9 34 21 84.2 2.1 32 20 93.9 2.2 31 19 103.7 2.4 30 19 108.5 2.5

12 36 22 72.0 1.8 34 21 81.9 2.0 33 20 91.7 2.2 31 19 101.5 2.4 30 19 106.4 2.4

67 5 38 17 85.1 2.2 36 16 94.7 2.3 34 15 104.2 2.5 33 14 113.6 2.7 32 14 118.2 2.7

6 38 17 80.2 2.0 37 16 89.9 2.2 35 15 99.5 2.4 33 15 109.1 2.6 32 14 113.8 2.7

9 39 17 75.2 1.9 38 16 85.0 2.1 36 16 94.8 2.3 34 15 104.5 2.5 33 15 109.3 2.6

12 39 17 72.7 1.9 38 17 82.5 2.1 36 16 92.3 2.3 34 15 102.2 2.4 33 15 106.9 2.5

6 35 25 79.0 2.0 33 24 88.7 2.2 32 24 98.3 2.3 30 23 107.9 2.5 29 23 112.6 2.5

9 36 26 74.3 1.9 34 25 84.2 2.1 32 24 93.9 2.2 31 23 103.7 2.4 30 23 108.5 2.5

12 36 26 72.0 1.8 34 25 81.9 2.0 33 24 91.7 2.2 31 23 101.5 2.4 30 23 106.3 2.4

67 5 38 21 85.1 2.2 36 20 94.7 2.3 34 19 104.2 2.5 33 18 113.6 2.7 32 18 118.2 2.7

6 38 21 80.2 2.0 37 20 89.9 2.2 35 20 99.5 2.4 33 19 109.1 2.6 32 18 113.8 2.7

9 39 21 75.2 1.9 37 21 85.0 2.1 36 20 94.8 2.3 34 19 104.5 2.5 33 19 109.2 2.6

12 39 21 72.7 1.9 38 21 82.5 2.1 36 20 92.3 2.3 34 19 102.1 2.4 33 19 106.9 2.5

72 5 41 16 86.8 2.3 40 16 96.4 2.4 38 15 105.8 2.6 36 14 115.2 2.8 35 14 119.8 2.9

6 42 17 81.5 2.1 40 16 91.2 2.3 39 15 100.8 2.5 37 14 110.3 2.7 36 14 115.0 2.8

9 43 17 76.1 2.0 41 16 85.9 2.2 39 16 95.6 2.4 37 15 105.3 2.6 37 14 110.1 2.7

12 43 17 73.3 1.9 42 16 83.2 2.1 40 16 93.0 2.3 38 15 102.8 2.5 37 15 107.6 2.6

6 35 29 78.9 2.0 33 29 88.6 2.2 32 28 98.3 2.3 30 27 107.9 2.5 29 27 112.6 2.5

9 35 30 74.3 1.9 34 29 84.2 2.1 32 28 93.9 2.2 31 27 103.7 2.4 30 27 108.4 2.5

12 36 30 72.0 1.8 34 29 81.9 2.0 33 28 91.7 2.2 31 27 101.5 2.3 30 27 106.3 2.4

67 5 38 25 85.1 2.2 36 24 94.6 2.3 34 23 104.1 2.5 33 23 113.6 2.7 32 22 118.2 2.7

6 38 25 80.2 2.0 37 24 89.8 2.2 35 24 99.5 2.4 33 23 109.1 2.6 32 22 113.8 2.7

9 39 25 75.2 1.9 37 25 85.0 2.1 36 24 94.7 2.3 34 23 104.5 2.5 33 23 109.2 2.6

12 39 26 72.7 1.9 38 25 82.5 2.1 36 24 92.3 2.3 34 23 102.1 2.4 33 23 106.9 2.5

72 5 41 20 86.8 2.3 39 20 96.3 2.4 38 19 105.8 2.6 36 18 115.2 2.8 35 18 119.8 2.9

6 42 21 81.5 2.1 40 20 91.2 2.3 39 19 100.8 2.5 37 19 110.3 2.7 36 18 115.0 2.8

9 43 21 76.1 2.0 41 20 85.8 2.2 39 20 95.6 2.4 37 19 105.3 2.6 36 19 110.1 2.7

12 43 21 73.3 1.9 42 21 83.2 2.1 40 20 93.0 2.3 38 19 102.8 2.5 37 19 107.6 2.6

6 35 33 78.9 2.0 33 33 88.7 2.2 32 32 98.3 2.3 30 30 108.0 2.5 30 30 112.8 2.6

9 35 34 74.3 1.9 34 33 84.2 2.1 32 32 93.9 2.2 31 31 103.7 2.4 30 30 108.6 2.5

12 36 34 72.0 1.8 34 33 81.9 2.0 33 32 91.7 2.2 31 31 101.6 2.4 31 31 106.4 2.4

67 5 38 29 85.1 2.2 36 28 94.9 2.3 34 27 104.1 2.5 32 27 113.6 2.7 32 26 118.2 2.7

6 38 29 80.2 2.0 37 28 89.8 2.2 35 28 99.5 2.4 33 27 109.1 2.6 32 27 113.7 2.7

9 39 29 75.2 1.9 37 29 85.0 2.1 36 28 94.7 2.3 34 27 104.5 2.5 33 27 109.2 2.6

12 39 30 72.6 1.9 38 29 82.5 2.1 36 28 92.3 2.3 34 27 102.1 2.4 33 27 106.9 2.5

72 5 41 24 86.8 2.3 39 24 96.3 2.4 38 23 105.8 2.6 36 22 115.2 2.8 35 22 119.8 2.9

6 42 25 81.5 2.1 40 24 91.1 2.3 38 23 100.7 2.5 37 23 110.3 2.7 36 22 115.0 2.8

9 43 25 76.1 2.0 41 24 85.8 2.2 39 24 95.6 2.4 37 23 105.3 2.6 36 23 110.1 2.7

12 43 25 73.3 1.9 41 25 83.2 2.1 40 24 93.0 2.3 38 23 102.8 2.5 37 23 107.6 2.6

Entering Water Temperature

20

PKG-PRC010-EN

Page 21

Performance

Water-Cooled

Data

5 Ton

Table PD-10. SCWB/SIWB 5 Gross Cooling Capacity - 2000 cfm

65°F 75°F 85°F 95°F 105°F

EDB EWB Flow Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT

F F gpm MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W

70 62 8 63 38 85.3 3.8 60 37 95.0 4.2 58 36 104.6 4.5 55 35 114.2 4.9 52 33 123.7 5.2

75 62 8 63 46 85.3 3.8 60 45 95.0 4.2 58 44 104.6 4.5 55 43 114.2 4.9 52 42 123.7 5.2

80 62 8 63 55 85.3 3.8 60 53 95.0 4.2 58 52 104.6 4.5 55 51 114.2 4.8 52 50 123.7 5.2

85 62 8 63 62 85.4 3.9 61 61 95.1 4.2 58 58 104.8 4.6 56 56 114.6 4.9 54 54 124.3 5.3

Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. TOT = total gross cooling capacity. 3. SEN = sensible heat capacity.

10 64 39 80.3 3.6 61 38 90.1 4.0 59 37 99.8 4.3 56 35 109.5 4.7 53 34 119.2 5.0

15 65 40 75.3 3.4 63 38 85.1 3.8 60 37 94.9 4.1 57 36 104.8 4.5 55 35 114.5 4.8

20 65 40 72.7 3.3 63 39 82.6 3.7 61 37 92.5 4.0 58 36 102.3 4.4 55 35 112.2 4.7

67 8 68 30 86.9 4.0 66 29 96.6 4.3 63 28 106.2 4.7 60 26 115.7 5.1 57 25 125.2 5.4

10 70 30 81.6 3.7 67 29 91.3 4.1 64 28 101.0 4.5 61 27 110.7 4.8 58 26 120.3 5.2

15 71 31 76.1 3.5 68 30 85.9 3.9 66 29 95.8 4.3 63 28 105.5 4.6 60 26 115.3 5.0

20 - - - - 69 30 83.2 3.7 66 29 93.1 4.1 64 28 102.9 4.5 60 27 112.8 4.9

10 64 47 80.3 3.6 61 46 90.1 4.0 59 45 99.8 4.3 56 43 109.5 4.7 53 42 119.2 5.0

15 65 48 75.3 3.4 63 46 85.1 3.8 60 45 94.9 4.1 57 44 104.7 4.5 55 43 114.5 4.8

20 65 48 72.7 3.3 63 47 82.6 3.7 61 46 92.5 4.0 58 44 102.3 4.4 55 43 112.2 4.7

67 8 68 38 86.9 4.0 66 37 96.6 4.3 63 36 106.2 4.7 60 34 115.7 5.1 57 33 125.2 5.4

10 70 38 81.5 3.7 67 37 91.3 4.1 64 36 101.0 4.5 61 35 110.7 4.8 58 34 120.3 5.2

15 71 39 76.1 3.5 68 38 85.9 3.9 66 37 95.7 4.3 63 36 105.5 4.6 60 34 115.3 5.0

20 - - - - 69 38 83.2 3.7 66 37 93.1 4.1 63 36 102.9 4.5 60 35 112.8 4.9

72 8 74 29 88.6 4.1 71 28 98.2 4.5 68 27 107.8 4.9 65 26 117.3 5.3 - - - -

10 76 30 82.8 3.8 73 29 92.6 4.2 70 28 102.2 4.6 67 26 111.9 5.0 63 25 121.5 5.4

15 - - - - 74 29 86.8 4.0 72 28 96.6 4.4 68 27 106.4 4.8 65 26 116.1 5.2

20 - - - - 75 30 83.9 3.8 72 29 93.7 4.2 69 27 103.6 4.6 66 26 113.4 5.1

10 64 55 80.3 3.6 61 54 90.1 4.0 59 53 99.8 4.3 56 51 109.5 4.7 53 50 119.2 5.0

15 65 56 75.2 3.4 62 54 85.1 3.8 60 53 94.9 4.1 57 52 104.7 4.5 55 51 114.5 4.8

20 65 56 72.7 3.3 63 55 82.6 3.7 61 54 92.5 4.0 58 52 102.3 4.4 55 51 112.2 4.7

67 8 68 46 86.9 4.0 66 45 96.6 4.3 63 44 106.1 4.7 60 42 115.7 5.1 57 41 125.1 5.4

10 69 46 81.5 3.7 67 45 91.3 4.1 64 44 101.0 4.5 61 43 110.7 4.8 58 42 120.3 5.2

15 71 47 76.1 3.5 68 46 85.9 3.9 66 45 95.7 4.3 63 44 105.5 4.6 60 42 115.3 5.0

20 - - - - 69 46 83.2 3.7 66 45 93.1 4.1 63 44 102.9 4.5 60 43 112.7 4.9

72 8 74 37 88.6 4.1 71 36 98.2 4.5 68 35 107.7 4.9 65 34 117.2 5.3 - - - -

10 76 38 82.8 3.8 73 37 92.5 4.2 70 36 102.2 4.6 67 34 111.9 5.0 63 33 121.5 5.4

15 - - - - 74 37 86.8 4.0 71 36 96.6 4.4 68 35 106.3 4.8 65 34 116.1 5.2

20 - - - - 75 38 83.9 3.8 72 37 93.7 4.2 69 35 103.5 4.6 66 34 113.4 5.1

10 64 63 80.3 3.6 62 61 90.1 4.0 59 59 99.9 4.3 57 57 109.7 4.7 55 55 119.5 5.1

15 65 63 75.3 3.4 63 62 85.1 3.8 60 60 95.0 4.1 58 58 104.9 4.5 56 56 114.7 4.9

20 65 64 72.7 3.3 63 62 82.6 3.7 61 61 92.5 4.0 59 59 102.4 4.4 56 56 112.3 4.8

67 8 68 54 86.9 4.0 65 53 96.5 4.3 63 52 106.1 4.7 60 50 115.7 5.1 57 49 125.1 5.4

10 69 54 81.5 3.7 67 53 91.3 4.1 64 52 101.0 4.5 61 51 110.6 4.8 58 50 120.3 5.2

15 71 55 76.1 3.5 68 54 85.9 3.9 66 53 95.7 4.3 63 52 105.5 4.6 60 50 115.3 5.0

20 - - - - 69 54 83.2 3.7 66 53 93.1 4.1 63 52 102.9 4.5 60 51 112.7 4.9

72 8 74 45 88.6 4.1 71 44 98.2 4.5 68 43 107.7 4.9 65 42 117.2 5.3 - - -

10 75 46 82.8 3.8 73 45 92.5 4.2 70 44 102.2 4.6 67 42 111.8 5.0 63 41 121.4 5.4

15 - - - - 74 45 86.8 4.0 71 44 96.6 4.4 68 43 106.3 4.8 65 42 116.1 5.2

20 - - - - 75 46 83.8 3.8 72 44 93.7 4.2 69 43 103.5 4.6 66 42 113.4 5.0

Entering Water Temperature

21PKG-PRC010-EN

Page 22

Performance

Water-Cooled

Data

7.5 Ton

Table PD-11. SCWB/SIWB 7.5 Gross Cooling Capacity - 3000 cfm

65°F 75°F 85°F 95°F 105°F

EDB EWB Flow Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT

F F gpm MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W

70 62 11 97 59 86.8 6.6 92 57 96.3 7.0 88 54 105.7 7.5 83 52 115.1 7.9 78 50 124.4 8.3

75 62 11 97 71 86.8 6.5 92 68 96.2 7.0 88 66 105.7 7.5 83 64 115.0 7.9 78 62 124.4 8.3

80 62 11 97 83 86.8 6.5 92 80 96.2 7.0 87 78 105.6 7.5 83 76 115.0 7.9 78 73 124.4 8.3

85 62 11 97 94 86.8 6.5 93 92 96.3 7.0 88 88 105.8 7.5 84 84 115.4 8.0 80 80 125.0 8.5

Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. TOT = total gross cooling capacity. 3. SEN = sensible heat capacity.

15 99 60 81.1 6.2 94 58 90.7 6.7 90 55 100.3 7.2 85 53 109.9 7.7 80 51 119.4 8.1

23 101 61 75.8 5.9 96 59 85.6 6.4 92 56 95.3 7.0 87 54 105.0 7.4 82 52 114.7 7.9

30 102 61 73.1 5.7 97 59 82.9 6.3 92 57 92.8 6.8 88 54 102.5 7.3 82 52 112.3 7.8

67 11 106 46 88.6 6.9 101 44 98.0 7.4 96 42 107.4 7.9 91 40 116.8 8.3 85 38 126.1 8.8

15 108 47 82.5 6.5 103 45 92.1 7.0 98 43 101.6 7.6 93 41 111.2 8.1 88 39 120.7 8.5

23 - - - - 106 46 86.5 6.7 100 44 96.2 7.3 95 42 105.9 7.8 90 39 115.6 8.3

30 - - - - 107 47 83.6 6.5 102 44 93.4 7.1 96 42 103.2 7.6 91 40 113.0 8.2

15 99 72 81.1 6.2 94 69 90.7 6.7 90 67 100.3 7.2 85 65 109.9 7.7 80 63 119.4 8.1

23 101 73 75.8 5.9 96 70 85.6 6.4 91 68 95.3 7.0 87 66 105.0 7.4 81 63 114.7 7.9

30 102 73 73.1 5.7 97 71 82.9 6.3 92 69 92.8 6.8 87 66 102.5 7.3 82 64 112.3 7.8

67 11 106 58 88.6 6.9 101 56 98.0 7.4 96 54 107.4 7.9 91 52 116.8 8.3 85 49 126.1 8.8

15 108 59 82.4 6.5 103 57 92.1 7.0 98 55 101.6 7.6 93 53 111.2 8.1 88 50 120.6 8.5

23 - - - - 105 58 86.5 6.7 100 56 96.2 7.3 95 54 105.9 7.8 90 51 115.5 8.3

30 - - - - 106 58 83.6 6.5 101 56 93.4 7.1 96 54 103.2 7.6 91 52 113.0 8.2

72 11 115 45 90.5 7.2 110 43 99.9 7.7 104 41 109.3 8.3 99 39 118.6 8.8 - - - -

15 118 46 83.9 6.7 113 44 93.5 7.3 107 42 103.0 7.9 102 40 112.5 8.4 96 38 112.0 9.0

23 - - - - 115 45 87.4 6.9 110 43 97.1 7.5 104 41 106.8 8.1 98 39 116.5 8.7

30 - -- - ---- 1114494.1 7.3 105 42 103.9 7.9 100 39 113.6 8.5

15 99 84 81.1 6.2 94 81 90.7 6.7 90 79 100.3 7.2 85 77 109.9 7.7 80 74 119.4 8.1

23 101 84 75.8 5.9 96 82 85.6 6.4 91 80 95.3 7.0 86 78 105.0 7.4 81 75 114.7 7.9

30 102 85 73.1 5.7 97 83 82.9 6.3 92 80 92.7 6.8 87 78 102.5 7.3 82 76 112.3 7.8

67 11 106 70 88.6 6.8 101 68 98.0 7.4 96 66 107.4 7.9 91 63 116.7 8.3 85 61 126.0 8.8

15 108 71 82.4 6.5 103 69 92.0 7.0 98 67 101.6 7.6 93 64 111.1 8.1 88 62 120.6 8.5

23 - - - - 105 70 86.4 6.7 100 68 96.2 7.3 95 65 105.9 7.8 90 63 115.5 8.3

30 - - - - 106 70 83.6 6.5 101 68 93.4 7.1 96 66 103.2 7.6 91 64 112.9 8.2

72 11 115 57 90.5 7.2 110 55 99.9 7.7 104 53 109.2 8.3 99 51 118.6 8.8 - - - -

15 118 58 83.9 6.7 113 56 93.4 7.3 107 54 103.0 7.9 102 52 112.5 8.4 96 50 112.0 9.0

23 - - - - 115 57 87.4 6.9 110 55 97.1 7.5 104 53 106.8 8.1 98 51 116.4 8.7

30 - -- - ---- 1115694.1 7.3 105 53 103.9 7.9 100 51 113.6 8.5

15 99 95 81.1 6.2 95 93 90.8 6.7 90 90 100.4 7.2 86 86 110.1 7.7 82 82 119.8 8.2

23 101 96 75.8 5.9 96 94 85.6 6.4 92 91 95.3 7.0 87 87 105.1 7.5 83 83 114.9 8.0

30 102 97 73.1 5.7 97 94 82.9 6.3 93 92 92.8 6.8 88 88 102.6 7.3 84 84 112.4 7.9

67 11 105 82 88.5 6.8 101 80 98.0 7.4 96 77 107.4 7.9 90 75 116.7 8.3 85 73 126.0 8.8

15 108 83 82.4 6.5 103 81 92.0 7.0 98 78 101.6 7.6 93 76 111.1 8.1 87 74 120.6 8.5

23 - - - - 105 82 86.4 6.7 100 79 96.2 7.2 95 77 105.9 7.8 90 75 115.5 8.3

30 - - - - 106 82 83.6 6.5 101 80 93.4 7.1 96 78 103.2 7.6 91 75 112.9 8.1

72 11 115 69 90.4 7.2 110 67 99.9 7.7 104 65 109.2 8.3 99 63 118.5 8.8 - - - -

15 118 70 83.8 6.7 112 68 93.4 7.3 107 66 103.0 7.9 102 64 112.5 8.4 96 62 121.9 9.0

23 - - - - 115 69 87.4 6.9 110 67 97.1 7.5 104 65 106.8 8.1 98 62 116.4 8.7

30 - -- - ---- 1116794.1 7.3 105 65 103.9 7.9 99 63 113.6 8.5

Entering Water Temperature

22

PKG-PRC010-EN

Page 23

Performance

Water-Cooled

Data

10 Ton

Table PD-12. SCWB/SIWB 10 Gross Cooling Capacity - 4000 cfm

65°F 75°F 85°F 95°F 105°F

EDB EWB Flow Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT

F F gpm MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W

70 62 15 121 75 84.8 7.8 116 72 94.5 8.5 111 70 104.1 9.2 106 68 113.7 9.8 100 65 123.2 10.5

75 62 15 121 91 84.8 7.8 116 88 94.5 8.5 111 86 104.1 9.2 106 84 113.7 9.8 100 81 123.2 10.5

80 62 15 121 107 84.8 7.8 116 104 94.4 8.5 111 102 104.1 9.2 106 99 113.7 9.8 100 97 123.2 10.5

85 62 15 121 121 84.9 7.8 117 117 94.6 8.5 113 113 104.4 9.2 109 109 114.1 9.9 104 104 123.8 10.7

Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. TOT = total gross cooling capacity. 3. SEN = sensible heat capacity.

20 124 76 80.0 7.4 119 74 89.7 8.1 114 71 99.5 8.8 109 69 109.2 9.4 103 66 118.8 10.1

30 126 77 75.1 6.9 122 75 84.9 7.6 117 73 94.8 8.4 112 70 104.6 9.1 106 68 114.3 9.8

40 128 78 72.6 6.6 123 76 82.5 7.4 118 73 92.3 8.1 113 71 102.2 8.9 107 68 112.0 9.6

67 15 132 58 86.3 8.1 126 55 96.0 8.8 121 53 105.6 9.5 115 51 115.1 10.2 109 48 124.6 11.0

20 135 59 81.1 7.6 130 57 90.9 8.3 124 54 100.6 9.1 118 52 110.3 9.8 112 50 119.9 10.5

30 138 60 75.8 7.0 133 58 85.7 7.8 128 56 95.5 8.6 122 53 105.3 9.3 116 51 115.1 10.1

40 139 61 73.2 6.7 135 59 83.1 7.5 129 57 92.9 8.3 124 54 102.8 9.1 118 52 112.6 9.9

20 124 92 80.0 7.4 119 90 89.7 8.1 114 87 99.5 8.8 109 85 109.2 9.4 103 82 118.8 10.1

30 126 93 75.0 6.9 122 91 84.9 7.6 117 89 94.7 8.3 111 86 104.5 9.1 106 84 114.3 9.8

40 128 94 72.6 6.6 123 92 82.5 7.4 118 89 92.3 8.1 113 87 102.2 8.9 107 84 112.0 9.6

67 15 131 74 86.3 8.1 126 71 96.0 8.8 121 69 105.6 9.5 115 67 115.1 10.2 109 64 124.6 10.9

20 135 75 81.1 7.6 130 73 90.9 8.3 124 70 100.6 9.1 118 68 110.3 9.8 112 65 119.9 10.5

30 138 76 75.8 7.0 133 74 85.7 7.8 127 72 95.5 8.6 122 69 105.3 9.3 116 67 115.1 10.1

40 139 77 73.2 6.7 134 75 83.1 7.5 129 73 92.9 8.3 123 70 102.8 9.1 117 68 112.6 9.9

72 15 142 56 87.9 8.4 137 54 97.5 9.1 131 52 107.1 9.9 125 49 116.6 10.7 - - - -

20 146 58 82.4 7.8 141 56 92.1 8.6 135 53 101.8 9.4 129 51 111.4 10.1 122 48 121.0 11.0

30 150 59 76.7 7.2 144 57 86.5 8.0 139 55 96.3 8.8 133 52 106.1 9.6 126 50 115.8 10.4

40 152 60 73.8 6.8 146 58 83.7 7.7 141 56 93.5 8.5 135 53 103.4 9.3 128 51 113.2 10.2

20 124 108 79.9 7.4 119 106 89.7 8.1 114 103 99.5 8.8 108 101 109.2 9.4 103 98 118.8 10.1

30 126 109 75.0 6.9 122 107 84.9 7.6 117 105 94.7 8.3 111 102 104.5 9.1 106 99 114.3 9.8

40 128 110 72.6 6.6 123 108 82.4 7.4 118 105 92.3 8.1 113 103 102.2 8.8 107 100 112.0 9.6

67 15 131 89 86.3 8.1 126 87 95.9 8.8 121 85 105.5 9.5 115 82 115.1 10.2 109 80 124.6 10.9

20 134 91 81.1 7.6 129 89 90.9 8.3 124 86 100.6 9.1 118 84 110.3 9.8 112 81 119.9 10.5

30 138 92 75.8 7.0 133 90 85.7 7.8 127 88 95.5 8.6 122 85 105.3 9.3 116 83 115.1 10.1

40 139 93 73.2 6.7 134 91 83.0 7.5 129 88 92.9 8.3 123 86 102.8 9.1 117 83 112.6 9.9

72 15 142 72 87.9 8.3 137 70 97.5 9.1 131 68 107.1 9.9 125 65 116.6 10.6 - - - -

20 146 73 82.3 7.8 141 71 92.1 8.6 135 69 101.8 9.4 129 67 111.4 10.1 122 64 121.0 10.9

30 150 75 76.7 7.2 144 73 86.5 8.0 139 71 96.3 8.8 132 68 106.1 9.6 126 66 115.8 10.4

40 151 76 73.8 6.8 146 74 83.7 7.7 141 71 93.5 8.5 134 69 103.4 9.3 128 67 113.2 10.2

20 124 123 80.0 7.4 120 120 89.8 8.1 116 116 99.6 8.8 111 111 109.5 9.5 106 106 119.2 10.3

30 127 125 75.1 6.9 122 122 84.9 7.6 118 118 94.8 8.4 114 114 104.7 9.1 109 109 114.6 9.9

40 128 125 72.6 6.6 124 123 82.5 7.4 119 119 92.4 8.1 115 115 102.3 8.9 110 110 112.2 9.6

67 15 131 105 86.3 8.1 126 103 95.9 8.8 121 101 105.5 9.5 115 98 115.1 10.2 108 96 124.6 10.9

20 134 107 81.7 7.6 129 104 90.9 8.3 124 102 100.6 9.1 118 100 110.2 9.8 112 97 119.9 10.5

30 137 108 75.8 7.0 133 106 85.7 7.8 127 103 95.5 8.6 122 101 105.3 9.3 115 98 115.1 10.1

40 139 109 73.1 6.7 134 106 83.0 7.5 129 104 92.9 8.3 123 102 102.8 9.1 117 99 112.6 9.9

72 15 142 88 87.9 8.3 137 86 97.5 9.1 131 83 107.1 9.9 124 81 116.6 10.6 - - - -

20 146 89 82.3 7.8 140 87 92.1 8.6 135 85 101.8 9.4 128 83 111.4 10.1 122 80 121.0 10.9

30 149 91 76.7 7.2 144 89 86.5 8.0 138 86 96.3 8.8 132 84 106.1 9.6 126 82 115.8 10.4

40 151 91 73.8 6.8 146 89 83.7 7.7 140 87 93.5 8.5 134 85 103.4 9.3 128 82 113.2 10.2

Entering Water Temperature

23PKG-PRC010-EN

Page 24

Performance

Water-Cooled

Data

15 Ton

Table PD-13. SCWB/SIWB 15 Gross Cooling Capacity - 6000 cfm

65°F 75°F 85°F 95°F 105°F

EDB EWB Flow Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT Tot Sen LWT

F F gpm MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W MBh MBh F k W

70 62 23 202 126 87.0 13.1 192 122 96.5 14.1 182 117 105.9 15.0 172 113 115.2 15.9 161 108 124.5 16.7

75 62 23 202 154 87.0 13.1 192 150 96.5 14.1 182 145 105.9 15.0 172 141 115.2 15.8 161 136 124.5 16.7

80 62 23 202 182 87.0 13.1 192 178 96.5 14.1 183 173 105.9 15.0 173 169 115.3 15.9 162 162 124.6 16.7

85 62 23 205 205 87.3 13.2 197 197 96.9 14.2 189 189 106.5 15.3 180 180 116.1 16.3 171 171 125.6 17.3

Notes: 1. All capacities shown are gross and have not considered indoor fan heat. 2. TOT = total gross cooling capacity. 3. SEN = sensible heat capacity.

30 206 128 81.7 12.4 196 124 91.3 13.5 186 119 100.8 14.5 176 114 110.3 15.4 165 110 119.8 16.3

45 210 130 76.2 11.7 200 125 85.9 12.9 190 121 95.6 13.9 180 116 105.3 14.9 169 111 115.0 15.8

50 211 130 75.1 11.6 201 126 84.8 12.7 191 121 94.6 13.8 181 116 104.3 14.8 170 112 114.0 15.8

67 23 220 96 88.9 13.7 210 92 98.3 14.7 199 88 107.6 15.8 188 83 116.9 16.7 177 79 126.2 17.6

30 225 99 83.1 12.9 215 94 92.6 14.1 204 90 102.1 15.1 193 85 111.6 16.2 182 81 121.1 17.1

45 230 101 77.1 12.1 219 96 86.8 13.3 209 92 96.5 14.5 197 87 106.2 15.6 186 82 115.8 16.6

50 231 101 75.9 12.0 220 96 85.7 13.2 210 92 95.4 14.3 198 87 105.1 15.4 187 83 114.8 16.5

30 206 156 81.7 12.4 196 152 91.2 13.5 186 147 100.8 14.5 176 142 110.3 15.4 165 138 119.8 16.3

45 210 158 76.2 11.7 200 154 85.9 12.9 190 149 95.6 13.9 180 144 105.3 14.9 169 139 115.0 15.8

50 211 159 75.1 11.6 201 154 84.8 12.7 191 149 94.6 13.8 180 144 104.3 14.8 170 140 114.0 15.8

67 23 220 125 88.8 13.7 210 120 98.2 14.7 199 116 107.6 15.7 188 111 116.9 16.7 177 107 126.2 17.6

30 225 127 83.0 12.9 215 122 92.6 14.1 204 118 102.1 15.1 193 113 111.6 16.1 181 109 121.1 17.1

45 230 129 77.1 12.1 219 124 86.8 13.3 208 120 96.5 14.5 197 115 106.2 15.6 186 110 115.8 16.6

50 231 129 75.9 12.0 220 125 85.7 13.2 209 120 95.4 14.3 198 115 105.1 15.4 187 111 114.8 16.5

72 23 239 94 90.8 14.3 228 90 100.1 15.4 217 86 109.4 16.5 205 82 118.7 17.5 – – – –

30 245 97 84.5 13.5 234 92 94.0 14.7 222 88 103.5 15.8 211 84 113.0 16.9 199 79 122.4 18.0

45 250 99 78.1 12.5 239 94 87.8 13.8 228 90 97.5 15.0 216 86 107.1 16.2 204 81 116.8 17.3

50 252 99 76.8 12.3 240 95 86.5 13.6 229 91 96.3 14.9 217 86 105.9 16.1 205 82 115.6 17.2

30 206 184 81.6 12.4 196 180 91.2 13.5 186 175 100.8 14.5 176 170 110.4 15.4 166 165 119.9 16.3

45 210 186 76.2 11.7 200 182 85.9 12.9 190 177 95.6 13.9 180 172 105.3 14.9 170 167 115.0 15.9

50 211 187 75.1 11.6 201 182 84.8 12.7 191 177 94.6 13.8 181 173 104.3 14.8 171 168 114.0 15.8

67 23 220 153 88.8 13.7 210 148 98.2 14.7 199 144 107.6 15.7 188 139 116.9 16.7 177 135 126.2 17.6

30 225 155 83.0 12.9 214 150 92.6 14.1 204 146 102.1 15.1 193 141 111.6 16.1 181 136 121.1 17.1

45 229 157 77.1 12.1 219 152 86.8 13.3 208 148 96.5 14.5 197 143 106.2 15.6 186 138 115.8 16.6

50 230 157 75.9 11.9 220 153 85.7 13.2 209 148 95.4 14.3 198 143 105.1 15.4 187 139 114.8 16.5

72 23 239 122 90.7 14.3 228 118 100.1 15.4 217 114 109.4 16.5 205 110 118.7 17.5 – – – –

30 245 125 84.5 13.5 234 120 94.0 14.7 222 116 103.5 15.8 210 112 113.0 16.9 198 107 122.4 17.9

45 250 127 78.1 12.5 239 122 87.8 13.8 228 118 97.5 15.0 216 114 107.1 16.2 204 109 116.7 17.3

50 251 127 76.8 12.3 240 123 86.5 13.6 229 118 96.2 14.9 217 114 105.9 16.1 205 109 115.6 17.2

30 208 208 81.8 12.5 200 200 91.5 13.6 192 192 101.2 14.7 183 183 110.9 15.7 175 175 120.6 16.8

45 211 211 76.2 11.8 203 203 86.1 12.9 195 195 95.9 14.1 187 187 105.7 15.2 178 178 115.4 16.2

50 212 212 75.1 11.6 204 204 85.0 12.8 196 196 94.8 13.9 187 187 104.6 15.1 179 179 114.4 16.1

67 23 220 180 88.8 13.7 209 176 98.2 14.7 199 172 107.6 15.7 188 167 116.9 16.7 – – – –

30 224 182 83.0 12.9 214 178 92.6 14.1 203 173 102.1 15.1 192 169 111.6 16.1 210 210 123.3 18.5

45 229 185 77.1 12.1 219 180 86.8 13.3 208 175 96.5 14.5 197 171 106.2 15.6 215 215 117.3 17.8

50 230 185 75.9 11.9 220 180 85.6 13.2 209 176 95.4 14.3 198 171 105.1 15.4 216 216 116.1 17.6

72 23 239 150 90.7 14.3 228 146 100.1 15.4 217 142 109.4 16.5 205 137 118.7 17.5 – – – –

30 244 152 84.5 13.4 233 148 94.0 14.6 222 144 103.5 15.8 210 139 113.0 16.9 198 135 122.4 17.9

45 250 154 78.1 12.5 239 150 87.8 13.8 227 146 97.5 15.0 216 141 107.1 16.2 203 137 116.7 17.3

50 251 155 76.8 12.3 240 151 86.5 13.6 228 146 96.2 14.9 217 142 105.9 16.1 204 137 115.6 17.2

Entering Water Temperature

24

PKG-PRC010-EN

Page 25

Performance

Air-Cooled

Data

3 Ton

Table PD-14. SCRB/SIRB 3 Gross Cooling Capacity

75°F 85°F 95°F 105°F 115°F

Airflow EDB EWB Total Sensible Total Sensible Total Sensible Total Sensible Total Sensible

cf m F F MBh MBh MBh MBh MBh MBh MBh MBh MBh MBh

9607067 371630183114----

75 67 37 20 35 19 33 18 31 17 29 16

80 67 36 23 35 22 33 22 31 21 29 20

85 67 36 27 35 26 33 25 31 24 29 24

1200 70 67 38 17 31 19 32 14 ----

75 67 38 21 36 20 34 19 32 18 30 18

80 67 38 25 36 24 34 24 32 23 30 22

85 67 38 29 36 29 34 28 32 27 30 26

1440 70 67 39 17 32 21 33 15 ----

75 67 39 22 37 21 35 20 33 20 31 19

80 67 39 27 37 26 35 25 33 24 31 23

85 67 39 32 37 31 35 30 33 29 31 28

Notes: 1. Performance based on matched air-cooled unit and remote condenser. 2. All capacities are gross and have not considered indoor fan heat. 3. CAP = total gross cooling capacity. 4. SHC =

sensible heat capacity.

62 332035152817----

72 32193314------

62 33 23 32 23 30 22 28 21 26 20

72 40 16 38 15 36 14 34 14 32 13

62 33 27 31 26 30 25 28 24 26 23

72 40 20 38 19 36 18 34 17 32 16

62 33 30 31 30 30 29 28 28 26 26

72 40 23 38 22 36 22 34 21 32 20

62 352136162919----

72 33203415------

62 35 25 33 24 31 24 29 23 27 22

72 42 17 40 16 38 15 36 14 33 13

62 35 30 33 29 31 28 29 27 27 26

72 42 21 40 20 38 19 36 18 33 18

62 35 34 33 33 31 31 30 30 28 28

72 42 25 40 24 38 23 36 23 33 22

62 362237163020----

72 34213516------

62 36 27 34 26 32 25 30 24 28 24

72 43 17 41 16 39 15 37 15 34 14

62 36 32 34 31 32 30 30 29 28 28

72 43 22 41 21 39 20 37 19 34 19

62 36 36 35 35 33 33 32 32 30 30

72 43 27 41 26 39 25 37 24 34 23

Entering Ambient Air Temperature

25PKG-PRC010-EN

Page 26

Performance

Air-Cooled

Data

5 Ton

Table PD-15. SCRB/SIRB 5 Gross Cooling Capacity

75°F 85°F 95°F 105°F 115°F

Airflow EDB EWB Total Sensible Total Sensible Total Sensible Total Sensible Total Sensible

cf m F F MBh MBh MBh MBh MBh MBh MBh MBh MBh MBh

1600 70 67 65 28 54 33 56 25 ----

75 67 65 35 62 34 59 33 56 31 53 30

80 67 65 42 62 41 59 39 56 38 53 37

85 67 65 49 62 47 59 46 56 45 53 43

2000 70 67 67 29 56 35 58 26 ----

75 67 67 38 65 36 62 35 58 34 55 32

80 67 67 46 64 44 62 43 58 42 55 40

85 67 67 53 64 52 61 51 58 50 55 48

2400 70 67 69 30 58 38 60 27 ----

75 67 69 40 66 38 63 37 60 36 56 34

80 67 69 49 66 48 63 46 60 45 56 44

85 67 69 58 66 57 63 56 60 54 56 53

Notes: 1. Performance based on matched air-cooled unit and remote condenser. 2. All capacities are gross and have not considered indoor fan heat. 3. CAP = total gross cooling capacity. 4. SHC =

sensible heat capacity.

62 593562275132----

72 57345926------

62 59 42 57 41 54 40 51 38 48 37

72 71 28 68 27 65 26 62 24 58 23

62 59 49 57 48 54 46 51 45 48 44

72 71 35 68 33 65 32 62 31 58 30

62 59 56 57 54 54 53 52 51 49 49

72 70 41 68 40 65 39 61 38 58 36

62 623865285334----

72 59376227------

62 62 46 59 45 56 43 53 42 50 41

72 73 29 70 28 67 27 64 25 60 24

62 61 54 59 53 56 51 53 50 50 49

72 73 37 70 36 67 35 64 33 60 32

62 62 61 60 60 57 57 55 55 52 52

72 73 45 70 44 67 42 64 41 60 40

62 634066295536----

72 61396328-----

62 63 49 61 48 58 47 55 45 51 44

72 75 30 72 29 69 27 65 26 61 25

62 63 59 61 57 58 56 55 54 52 52

72 75 39 72 38 69 37 65 35 61 34

62 65 65 63 63 60 60 58 58 55 55

72 75 48 72 47 69 46 65 44 61 43

Entering Ambient Air Temperature

26

PKG-PRC010-EN

Page 27

Performance

Air-Cooled

Data

7.5 Ton

Table PD-16. SCRB/SIRB 7.5 Gross Cooling Capacity

75°F 85°F 95°F 105°F 115°F

Airflow EDB EWB Total Sensible Total Sensible Total Sensible Total Sensible Total Sensible

cf m F F MBh MBh MBh MBh MBh MBh MBh MBh MBh MBh

2400 70 67 99 44 81 50 84 37 ----

75 67 99 54 94 52 89 49 84 47 78 45

80 67 99 64 94 62 89 60 84 57 78 55

85 67 99 74 94 72 89 70 84 67 78 65

3000 70 67 104 45 85 53 87 38 ----

75 67 103 57 98 55 93 53 87 51 - -

80 67 103 70 98 67 93 65 87 63 - -

85 67 103 82 98 79 92 77 87 75 - -

3600 70 67 107 47 87 57 89 40 ----

75 67 106 61 101 58 95 56 89 54 - -

80 67 106 75 101 72 95 70 89 68 - -

85 67 106 89 101 86 95 84 89 82 - -

Notes: 1. Performance based on matched air-cooled unit and remote condenser. 2. All capacities are gross and have not considered indoor fan heat. 3. CAP = total gross cooling capacity. 4. SHC =

sensible heat capacity.

62 915494417647----

72 86528939------

62 91 65 86 62 81 60 76 58 71 55

72 109 43 103 41 98 39 92 36 - -

62 90 75 86 72 81 70 76 68 71 65

72 108 53 03 51 98 49 92 47 - -

62 90 85 86 83 81 80 77 77 73 73

72 108 63 103 61 98 59 92 57 - -

62 955898437951----

72 90569341------

62 94 70 90 68 84 66 79 63 74 61

72 113 4 4 107 42 101 40 9 5 38 - -

62 94 82 89 80 84 78 79 75 74 73

72 113 5 7 107 54 101 52 9 5 50 - -

62 95 94 90 90 86 86 82 82 78 78

72 113 6 9 107 67 101 64 9 5 62 - -

62 9761101448154----

72 92599542------

62 97 75 92 73 87 71 81 68 76 66

72 116 4 6 110 44 104 41 9 8 39 - -

62 97 89 92 87 87 85 82 82 77 77

72 116 6 0 110 58 104 55 9 8 53 - 62 99 99 95 95 91 91 86 86 82 82

72 116 7 4 110 71 104 69 9 8 67 - -

Entering Ambient Air Temperature

27PKG-PRC010-EN

Page 28

Performance

Air-Cooled

Data

10 Ton

Table PD-17. SCRB/SIRB 10 Gross Cooling Capacity

75°F 85°F 95°F 105°F 115°F

Airflow EDB EWB Total Sensible Total Sensible Total Sensible Total Sensible Total Sensible

cf m F F MBh MBh MBh MBh MBh MBh MBh MBh MBh MBh

3200 70 67 135 59 113 68 117 51 ----

75 6 7 135 7 3 129 70 123 68 117 65 - -

80 6 7 134 8 7 129 84 123 82 117 79 - -

85 6 7 134 100 129 9 8 123 95 117 92 110 90

4000 70 67 140 61 117 73 122 53 ----

75 6 7 140 7 8 134 75 128 73 122 70 - -

80 6 7 140 9 4 134 92 128 89 121 86 - -

85 6 7 140 110 134 108 128 105 121 102 114 99

4800 70 67 144 63 121 78 125 55 ----

75 6 7 144 8 2 138 80 132 77 125 74 - -

80 6 7 144 101 138 9 8 131 96 124 93 - -

85 6 7 144 120 138 117 131 114 124 112 117 109

Notes: 1. Performance based on matched air-cooled unit and remote condenser. 2. All capacities are gross and have not considered indoor fan heat. 3. CAP = total gross cooling capacity.

4. SHC = sensible heat capacity.

62 123741295710766----

72 1187112454------

62 123 8 7 118 85 113 82 107 7 9 - -

72 147 5 8 141 56 135 53 128 5 1 - -

62 123 101 118 9 9 113 96 107 93 - -

72 147 7 2 141 69 135 67 128 6 4 - -

62 123 115 118 112 113 110 107 106 102 102

72 147 8 5 141 83 135 81 128 7 8 121 75

62 128791355911171----

72 1237612856------

62 128 9 5 123 93 117 90 111 8 7 - -

72 153 6 0 146 58 140 55 133 5 2 - -

62 128 112 123 109 117 106 111 103 - -

72 153 7 7 146 74 140 72 132 6 9 - -

62 129 127 124 124 119 119 114 114 109 109

72 152 9 3 146 90 139 88 132 8 5 125 82

62 132831386111475----

72 1278113258------

62 132 102 127 100 120 9 7 114 94 - -

72 157 6 2 150 60 143 57 136 5 4 - -

62 132 121 126 118 121 116 114 112 - -

72 157 8 1 150 78 143 76 136 7 3 - 62 135 135 130 130 125 125 120 120 114 114

72 157 9 9 150 97 143 94 135 9 2 127 89

Entering Ambient Air Temperature

28

PKG-PRC010-EN

Page 29

Performance

Air-Cooled

Data

15 Ton

Table PD-18. SCRB/SIRB 15 Gross Cooling Capacity

75°F 85°F 95°F 105°F 115°F

Airflow EDB EWB Total Sensible Total Sensible Total Sensible Total Sensible Total Sensible

cf m F F MBh Mbh Mbh MBh MBh MBh MBh MBh MBh MBh

4800 70 67 207 91 169 106 174 77 ----

75 6 7 207 115 197 110 186 105 174 101 - -

80 6 7 207 138 196 134 185 129 174 124 - -

85 6 7 207 162 196 158 185 153 174 148 - -

6000 70 67 216 95 176 115 180 80 ----

75 6 7 215 124 204 119 192 114 180 109 - -

80 6 7 215 152 204 148 192 143 180 138 - -

85 6 7 215 181 204 176 192 171 180 167 - -

7200 70 67 222 98 180 124 185 84 ----

75 6 7 221 132 209 127 197 122 185 117 - -

80 6 7 221 165 209 160 197 156 184 151 - -

85 6 7 221 199 209 194 198 189 186 183 - -

Notes: 1. Performance based on matched air-cooled unit and remote condenser. 2. All capacities are gross and have not considered indoor fan heat. 3. CAP = total gross cooling capacity. 4. SHC =

sensible heat capacity.

62 19011619786159101----

72 18011118681------

62 189 140 179 135 169 130 158 125 - -

72 226 8 9 215 85 203 80 191 7 6 - -

62 189 164 179 159 169 154 159 149 - -

72 226 113 215 108 203 104 191 9 9 - -

62 190 187 180 180 172 172 163 163 - -

72 226 137 214 132 203 128 191 123 - -

62 19712520490164110----

72 18712019385------

62 197 154 187 149 176 144 164 139 - -

72 235 9 3 223 88 210 84 197 7 9 - -

62 197 183 187 178 177 173 165 165 - -

72 235 122 222 117 210 113 197 108 - -

62 202 202 193 193 184 184 175 175 - -

72 234 150 222 146 210 141 197 136 - -

62 20313321093168118----

72 19212919789------

62 203 167 192 162 180 157 168 152 - -

72 241 9 6 228 92 215 87 202 8 2 - -

62 204 200 193 193 183 183 174 174 - -

72 241 130 228 125 215 120 202 116 - 62 213 213 204 204 194 194 184 184 - -

72 240 163 228 158 215 154 201 149 - -

Entering Ambient Air Temperature

29PKG-PRC010-EN

Page 30

Performance

Heating

Data

Coils

Table PD-19. Hot Water Coil Heating Capacity, 180°F Entering Water Temperature

20°F 30°F 40°F

Unit Airflow EAT Flow Capacity LAT Flow Capacity LAT Flow Capac ity LAT

Size cfm F gpm MBh F gpm MBh F gpm MBh F

960 60 3.5 35.2 93.8 1.8 27.1 86.1 0.7 13.4 72.9

3 Ton 1200 60 3.9 38.9 89.9 2.0 30.2 83.2 0.7 14.0 70.8

1440 60 4.2 41.9 86.8 2.2 32.7 80.9 0.7 14.3 69.2

1600 60 5.2 52.4 89.6 2.9 43.3 84.5 1.5 30.8 77.4

5 Ton 2000 60 5.7 57.0 85.8 3.1 47.1 81.3 1.7 34.2 75.5

2400 60 6.1 60.7 82.9 3.3 50.1 78.9 1.8 36.8 73.9

2400 60 7.0 70.2 86.4 4.0 59.6 82.4 2.4 47.7 78.0

7.5 Ton 3000 60 7.5 75.7 82.8 4.3 64.1 79.3 2.6 51.6 75.5

3600 60 8.0 80.0 80.1 4.5 67.6 77.0 2.7 54.5 73.7

3200 60 15.7 157.0 105.1 9.4 141.2 100.7 6.3 125.5 96.2

10 Ton 4000 60 17.5 176.0 100.5 10.5 157.9 96.4 7.0 140.1 92.3

4800 60 19.1 191.0 96.7 11.4 171.5 92.9 7.6 152.0 89.2

4800 60 21.4 214.1 100.3 13.0 195.8 96.9 8.9 177.4 93.4

15 Ton 6000 60 23.7 237.1 95.7 14.4 216.5 92.6 9.8 195.9 89.5

7200 60 25.5 255.6 92.1 15.5 233.2 89.3 10.5 210.7 86.5

40 4.3 43.3 81.6 2.3 35.7 74.3 1.2 24.5 63.5

80 2.7 27.1 106.0 1.2 17.2 96.5 0.5 10.2 89.8

40 4.8 47.9 76.8 2.6 39.6 70.4 1.4 28.0 61.5

80 3.0 30.0 103.0 1.3 19.7 95.1 0.5 10.6 88.1

40 5.1 51.5 73.0 2.8 42.7 67.3 1.5 30.7 60.0

80 3.2 32.3 100.7 1.4 21.6 93.8 0.5 10.8 86.9

40 6.5 64.9 75.3 3.7 55.6 70.2 2.3 45.1 64.5

80 4.0 40.2 103.6 2.0 30.7 98.0 0.7 13.1 87.7

40 7.1 70.6 70.7 4.0 60.4 66.2 2.5 49.2 61.4

80 4.4 43.8 100.6 2.2 33.6 95.8 0.7 13.4 86.3

40 7.5 75.1 67.2 4.3 64.1 63.2 2.6 52.4 59.0

80 4.7 46.7 98.3 2.4 36.0 94.1 0.7 13.7 85.4

40 8.6 86.5 71.3 5.0 75.4 67.3 3.2 64.2 63.2

80 5.4 54.4 101.3 3.0 44.0 97.2 1.4 28.6 91.2

40 9.3 93.2 67.0 5.4 81.1 63.5 3.5 69.0 60.0

80 5.9 58.7 98.4 3.1 47.5 94.8 1.6 31.9 90.0

40 9.8 98.3 63.7 5.7 85.5 60.6 3.6 72.6 57.5

80 6.2 62.1 96.2 3.3 50.1 93.1 1.7 34.3 89.0

40 18.8 188.0 94.1 11.5 172.1 89.6 7.8 156.2 85.0

80 - - - 7.4 110.2 111.8 4.7 94.7 107.3

40 21.0 211.0 88.5 12.8 192.6 84.4 8.7 174.5 80.2

80 14.1 141.0 112.4 8.2 123.2 108.4 5.3 105.5 104.3

40 22.9 229.1 84.0 14.0 209.4 80.2 9.5 189.6 76.4

80 15.3 153.0 109.4 8.9 133.8 105.7 5.7 114.3 102.0

40 26.0 260.5 87.2 16.1 241.8 83.8 11.1 222.7 80.3

80 16.9 169.5 113.1 10.1 151.6 109.7 6.7 133.7 106.1

40 28.8 288.0 81.7 17.8 266.9 78.7 12.3 245.7 75.6

80 18.8 187.9 109.4 11.2 167.9 106.3 7.4 147.6 103.1

40 31.0 310.2 77.5 19.1 287.2 74.7 13.2 264.1 71.9

80 20.2 202.7 106.4 12.2 181.0 103.6 8.0 158.8 100.7

Water Temperature Drop

30

PKG-PRC010-EN

Page 31

Performance

Heating

Data

Coils

Table PD-20. Hot Water Coil Heating Capacity, 200°F Entering Water Temperature

20°F 30°F 40°F

Unit Airflow EAT Flow Capacity LAT Flow Capacity LAT Flow Capacity LAT

Size cfm F gpm MBh F gpm MBh F gpm MBh F

960 60 4.4 44.2 102.4 2.5 37.4 96.0 1.4 28.9 87.7

3 Ton 1200 60 4.9 48.9 97.6 2.7 41.3 91.8 1.6 32.3 84.8

1440 60 5.2 52.6 93.7 3.0 44.5 88.5 1.7 35.0 82.4

1600 60 6.5 65.0 96.7 3.8 56.4 91.9 2.4 47.5 86.9

5 Ton 2000 60 7.1 70.8 92.0 4.1 61.4 87.8 2.6 51.8 83.4

2400 60 7.5 75.4 88.4 4.3 65.3 84.6 2.7 55.0 80.7

2400 60 8.6 86.5 92.6 5.1 76.3 88.7 3.3 66.1 84.9

7.5 Ton 3000 60 9.3 93.4 88.2 5.5 82.2 84.8 3.5 71.1 81.4

3600 60 9.8 98.7 84.8 5.8 86.8 81.8 3.7 74.8 78.8

3200 60 18.8 189.1 114.5 11.6 174.2 110.2 7.9 159.1 105.9

10 Ton 4000 60 21.1 212.1 108.9 13.0 195.1 105.0 8.9 177.8 101.0

4800 60 23.0 230.9 104.4 14.1 212.1 100.7 9.6 193.2 97.1

4800 60 25.6 257.1 108.4 15.9 239.5 105.1 11.1 221.5 101.7

15 Ton 6000 60 28.4 284.8 102.9 17.6 264.9 99.9 12.2 244.9 96.9

7200 60 30.6 307.2 98.6 19.0 285.5 95.8 13.2 263.7 93.1

40 5.2 52.3 90.2 3.0 45.6 83.8 1.9 37.8 76.3

80 3.6 36.1 114.7 1.9 29.1 108.0 0.9 17.9 97.2

40 5.8 57.9 84.5 3.3 50.3 78.6 2.1 42.0 72.3

80 4.0 39.9 110.7 2.1 32.3 104.8 1.0 30.0 96.1

40 6.2 62.4 80.0 3.6 54.1 74.6 2.2 45.3 69.0

80 4.3 42.9 107.5 2.3 34.8 102.3 1.1 23.2 94.9

40 7.8 77.8 82.3 4.6 69.0 77.5 3.0 60.1 72.7

80 5.2 52.6 110.9 2.9 44.4 106.0 1.7 34.6 100.3

40 8.4 84.7 76.8 5.0 75.0 72.6 3.3 65.2 68.3

80 5.7 57.3 107.0 3.2 48.3 102.7 1.9 38.0 97.8

40 9.0 90.2 72.6 5.2 79.6 68.8 3.4 69.2 65.0

80 6.9 61.2 103.9 3.4 51.4 100.1 2.0 40.6 95.9

40 10.3 103.2 77.4 6.1 92.6 73.5 4.0 82.1 69.7

80 7.0 70.4 107.6 4.0 60.5 103.7 2.5 50.4 99.7

40 11.1 111.2 77.2 6.6 99.6 68.9 4.4 88.1 65.5

80 7.6 76.1 103.8 4.3 65.3 100.4 2.7 54.3 97.0

40 11.7 117.4 68.3 7.0 105.1 65.4 4.6 92.8 62.4

80 8.0 80.5 101.0 4.6 68.9 98.0 2.8 57.3 94.9

40 21.9 200.2 103.4 13.6 205.2 99.1 9.5 190.1 94.8

80 --- --- - --

40 24.6 247.1 97.0 15.3 230.0 93.0 10.6 212.6 89.0

80 - - - -- - - 7.2 143.2 113.0

40 26.8 269.1 91.7 16.6 250.1 88.1 11.5 231.0 84.4

80 - - - 11.6 174.1 113.4 7.8 155.5 109.9

40 30.3 304.4 95.1 19.0 286.3 91.8 13.4 267.9 88.5

80 - - - - - 8.8 177.0 144.6

40 33.5 336.7 88.8 21.0 316.3 85.8 14.7 295.7 82.8

80 - - - 14.3 215.3 113.7 9.8 195.8 110.6

40 - - - 22.6 340.4 81.1 15.9 318.0 78.4

80 25.3 253.5 113.0 15.4 232.2 110.3 10.5 211.0 107.5

Water Temperature Drop

31PKG-PRC010-EN

Page 32

Performance

Heating

Data

Coils

Table PD-21. Steam Coil Heating Capacity

2525

Unit Airflow EAT Capacity LAT Capacity LAT Capacity LAT

Size cfm F MBh F MBh F MBh F

960 60 78.0 134.9 82.2 139.0 101.7 157.7

3 Ton 1200 60 87 .7 127.4 92.5 131.1 114.4 148.0

1440 60 96.8 122.1 102.1 125.4 126.4 141.0

1600 60 122.7 130.7 129.3 134.6 160.0 152.3

5 Ton 2000 60 137.9 123.6 145.4 127.1 179.9 143.0

2400 60 152.4 118.6 160.7 121.8 198.8 136.4

2400 60 178.6 128.7 188.4 132.4 233.1 149.6

7.5 Ton 3000 60 201.0 121.8 212.0 125.2 262.4 140.7

3600 60 222.5 117.0 234.6 120.1 290.3 134.4

3200 60 209.4 120.4 221.6 123.9 277.2 139.9

10 Ton 4000 60 234.2 114.0 248.1 117.2 311.3 131.8

4800 60 254.1 108.9 269.4 111.8 388.9 125.1

4800 60 229.5 117.6 317.4 121.0 398.4 136.6

15 Ton 6000 60 335.1 111.5 355.5 114.7 447.9 128.9

7200 60 - - 389.6 109.6 490.3 122.8

40 87.8 124.4 92.0 128.4 115.0 147.2

80 68.1 145.5 72.4 149.6 91.7 168.3

40 98.8 115.9 103.5 119.6 125.5 136.5

80 76.6 138.9 81.4 142.6 103.3 159.5

40 109.1 109.9 114.0 113.3 138.6 128.8

80 84.6 134.2 89.9 137.6 114.1 153.1

40 138.1 119.6 144.8 123.5 175.5 141.2

80 107.2 141.8 113.9 145.7 144.6 163.4

40 155.3 111.6 162.8 115.1 197.3 131.0

80 120.5 135.6 128.0 139.1 162.5 155.0

40 171.6 106.0 179.9 109.2 218.0 123.8

80 133.1 131.2 141.5 134.4 179.6 149.0

40 201.2 117.3 210.9 121.1 255.6 138.3

80 156.1 140.0 165.8 143.8 210.5 160.9

40 226.4 109.6 237.4 113.0 287.7 128.5

80 175.7 134.0 186.7 137.4 237.0 152.9

40 250.5 104.2 262.7 107.3 318.4 121.6

80 194.4 129.8 206.6 133.0 262.3 147.2

40 235.3 107.9 247.7 111.4 303.9 127.6

80 183.3 132.9 195.4 136.3 250.5 152.2

40 263.1 100.7 277.3 104.0 341.3 118.7

80 205.2 127.4 218.8 130.5 281.2 144.9

40 - - 301.0 97.9 371.5 111.4

80 222.8 122.8 237.8 125.7 306.2 138.9

40 336.4 104.7 354.6 108.2 436.8 124.0

80 262.5 130.5 280.0 133.8 360.0 149.2

40 - - 396.9 101.1 491.1 115.5

80 293.8 125.2 313.7 128.3 404.8 142.3

40 - - 434.8 95.7 537.3 108.9

80 321.8 121.3 344.0 124.1 445.3 137.1

Steam PSIG

32

PKG-PRC010-EN

Page 33

Electrical Data

Electrical Data Calculations

RLA = Rated Load Amps

Compressor LRA = Locked Rotor Amps

Fan Motor LRA = Locked Rotor Amps,

N.E.C. Table 430 - 151

FLA = Full Load Amps, N.E.C.

Table 430 - 150

Voltage utilization range is ±10 percent

Determination of Minimum Circuit

Ampacity (MCA)

MCA = 1.25 x largest motor amps (FLA

or RLA) + the sum of the remaining motor

amps.

Determination of Maximum Fuse Size

(MFS) and Maximum Circuit Breaker Size

(MCB)

MFS and MCB = 2.25 x largest motor

amps (FLA or RLA) + the sum of the

remaining motor amps.

If the rating value determined does not

equal a standard current rating of over

current protective device, use the next

lower standard rating for the marked

maximum rating.

Note: MFS for CXRA units is for non-time

delay fuses.

Table ED-1. SCWB/SIWB/SCRB/SIRB Electrical Data

SCWB/SIWB SCRB/SIRB

Compressor Motor Data Compressor Motor Data Fan Motor Data SCWB/SIWB SCRB/SIRB

3 Ton 460V 1 4.2 51 3.0 4.2 5 1 3.0 1/0.5 1.0 6 0.44 6 15 6 15

5 Ton 460V 1 10.0 71 5.2 10.0 71 5.2 1/0.75 1.4 8 0.73 14 20 14 20

7.5 Ton 460V 1 11.2 79 7.5 10.7 79 7.5 1/1.0 1.8 11 1.1 16 25 15 25

10 Ton 460V 2 10.0 71 5.3 10.0 71 5.3 1/2.0 3.4 23 1.3 26 35 26 35

15 Ton 460V 2 11.2 79 7.5 10.7 79 7.5 1/3.0 4.8 38 1.9 30 40 29 35

Note: Fan motor kW base on three phase motors. Compressor kW based on 80/67°F to evaporator, nominal airflow, and 105ºF condensing temperature, 3 phase/60hz.

208-230V 1 10.5 101 3.0 10.5 101 3.0 1/0.5 4.0 21 0.44 17 25 17 25

575V - - - - - - - - - - - - - - -

208-230V 1 15.4 118 5.2 15.4 118 5.2 1/0.75 4.5 31 0.73 24 35 24 35

575V 1 5.8 43 5.2 5.8 43 5.2 1/0.75 1.4 11 0.73 9 15 9 15

208-230V 1 25.9 164 7.5 24.7 164 7.5 1/1.0 3.7 22 1.1 36 60 35 50

575V 1 8.4 63 7.5 8.4 63 7.5 1/1.5 1.8 16 1.1 12 20 12 20

208-230V 2 15.4 118 5.3 15.4 118 5.3 1/2.0 7.5 46 1.3 42 50 42 50

575V 2 5.8 43 5.3 5.8 43 5.3 1/2.0 2.3 18 1.3 15 20 15 20

208-230V 2 25.9 164 7.5 24.7 164 7.5 1/3.0 10.6 72 1.9 69 90 66 90

575V 2 8.4 63 7.5 8.4 63 7.5 1/3.0 3.3 23 1.9 22 30 22 30

Qty. RLA LRA kW RLA LRA kW Qty/hp FLA LRA kW MCA MFS MCA MFS

Table ED-2. CCRA/CIRA Condenser Electrical Data