Page 1

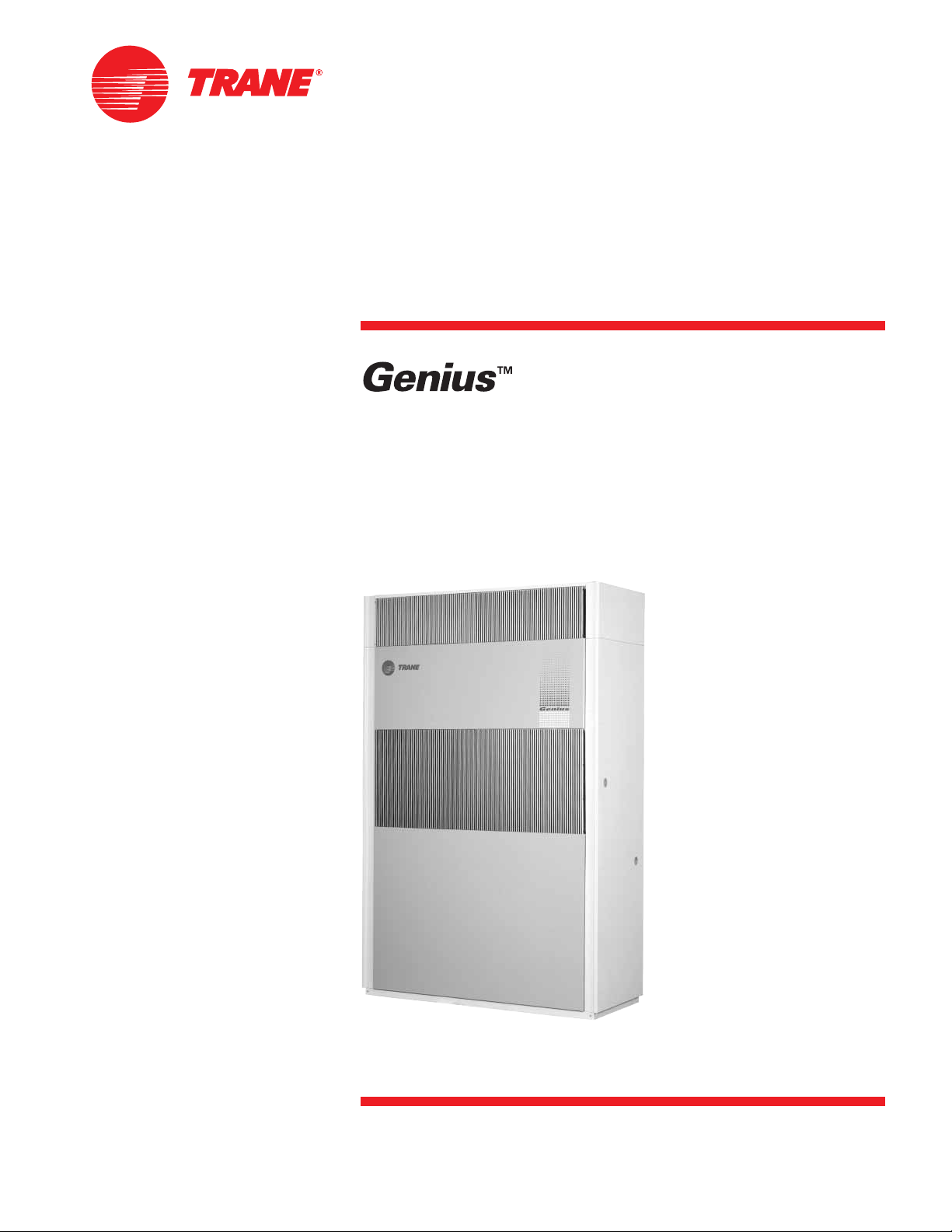

Ver tic al

Self-Contained

Air Conditioning

Air and Water Cooled

5 - 15 Tons

60 Hz

PKG-PRC007-EN

Page 2

Introduction

The TRANE Company, a world leader in

the HVAC industry, has developed

another option to meet the needs of our

customers . . . the Genius! Built to

provide not only the indoor comfort but

also the confidence that the unit is

reliable, durable, easy to install and

maintain.

The Genius line has been designed to

satisfy the demands of the international

markets.

IAQ standards, microcontrols and

simplified maintenance were all

considered during its design.

©American Standard Inc. 2000

Water Cooled Unit

PKG-PRC007-EN

Page 3

Contents

I

ntroduction 2

Features and Benefits 4

Model Number Description 8

General Data 9

Selection Procedure 10

Performance Data 11

Controls 36

Electrical Data 37

Dimensions 47

Mechanical Specification 51

PKG-PRC007-EN

3

Page 4

Features and Benefits

The Genius line was built to provide not

only ultimate indoor comfort but also

the comfort of knowing that our selfcontained units are reliable as well as

easy to install and maintain.

Genius is the most flexible vertical selfcontained of the market. Suitable to use

in offices, residences or restaurants.

Available as water cooled, integrated air

cooled (or package unit) or with remote

air coded condenser; the modern design

of the Genius line allows you, for the first

time, to select the color of the unit.

Why Consider Self-Contained

Floor-by-Floor Systems?

Improved Cash Management

Factory installed options and testing:

•

Reduces field labor and installation risk

and improves system reliability

Requires less sophisticated maintenance

•

than built-up systems

Tenant Satisfaction

Complete HVAC system on each floor or

•

area minimizes tenant inconvenience

during routine maintenance.

Tenants can control system after hours

•

to increase productivity and minimize

expense

Low First Cost

Factory packaged controls and piping

•

reduce field labor, installation time and

cost

Flexible arrangement to match most

•

building configurations

Lower Installed Cost

Single point power connection

•

Single point water connection

•

Factory commissioned and tested

•

controls

Factory installed options

•

SRVE

(with discharge plenum)

Economical Operation

Floor-by-floor system results in energy

•

savings since only air conditioners on

floors requiring cooling need to operate

Annual system energy consumption

•

comparable to central chilled water

system but with significant energy

consumption reduction during partial

occupancy and after-hours

Assured Acoustical Performance

Horizontal discharge plenum provides

•

smooth airflow, reducing static pressure

losses for optimum acoustical

performance.

Scroll compressor design smooths gas

•

flow for quieter operation

Micro Controls

Trane was the first to introduce

Microelectronics to commercial unitary

products and has continued to expand

its application to other products.

The new self-contained with Micro

provides the highest performance,

reliability and best serviceability in the

industry. Trane, a world class

manufacturer can provide this winning

combination for your facility.

The Trane Micro, provided as a factory

installed option, was designed with two

thoughts in mind: reliability and comfort.

The Micro accurately orchestrates all

other system operations whether it is

heating or cooling.

Since it is factory mounted it will provide

smooth, trouble-free start-up.

The microprocessor provides powerful

operation and diagnostic information.

The micro eliminates the need for a field

installed anti short-cycle timer and time

delay relays, which are an integral part

of the micro controller.

The IAQ standard, the microelectronics

and the simplified maintenance

capability were all considered a priority

during the design phase of this selfcontained unit.

PKG-PRC007-EN4

Page 5

Features and

Benefits

Air Handling Section

In accordance to the ASHRAE Standard

62-89 for Indoor Air Quality, Trane has

developed an exclusive and innovative

design for the drain pan. This design

insures proper drainage, preventing

conditions of water stagnation that could

result in microbial growth.

All the air handlers feature a factory

installed belt drive and ball bearing

evaporator fan with adjustable shelves.

The unit can be installed indoors; the

condenser air can be ducted to the

outside or installed in a remote location.

For free horizontal application, the

optional discharge plenum with

aluminum grills insures a quiet

operation and maintains the aesthetics

of the units.

In the return section an optional

aluminum grill grants an easy and

elegant installation.

How the Scroll Compressor Works

General

The compressor has two scrolls. The top

scroll is fixed and the bottom scroll

orbits. Each scroll has walls in a spiral

shape that intermesh.

3 Filter Types

To meet Commercial and Industrial

needs you can select the filter media for

the application.

Nylon Electrostatic Filters

Wire Mesh Permanent Filters

Throwaway Filters

Many other options available as special

(Contact your local Trane

Representative).

Scroll Compressor

offers significant efficiency and reliable

benefits. With fewer moving parts than

comparable reciprocating compressors,

there is less internal friction and

therefore greater efficiency. A smooth

compressor cycle, due to the low torque

variation, creates less stress on the

motor for greater reliability and

efficiency.

Inlet — First Orbit

As the bottom scroll orbits, two

refrigerant gas pockets are formed and

enclosed.

Compression — Second orbit

The refrigerant gas is compressed as the

volume is reduced closer to the center of

the scroll.

Discharge — Third Orbit

The gas is compressed further and

discharged through a small port in the

center of the fixed scroll.

5PKG-PRC007-EN

Page 6

Features and

Benefits

Integrated Self-Contained Systems:

Profitable, Simple

Integrated Comfort

Trane’s Integrated Comfort

improves job profit and increases job

control by combining Trane selfcontained units and a Tracker

management system. This integrated

system provides total building comfort

and control. The primary motivation for

building owners/managers in making the

purchasing decision of an HVAC controls

system is no longer just saving energy; it

is having the ability to automate their

facilities and the convenience of interface

to control systems.

™

System (ICS)

™

system

®

building

Genius is three times ingenious in many

ways.

Available in 3 models

SRVE - Self-contained unit with

INTEGRATED air cooled condenser

SIVE - Self contained unit with REMOTE

air-cooled condenser

SAVE - Self-contained WATER-cooled

unit with shell and tube condenser

Available 3 Colors

The attractive highly functional design of

the Genius line offers the customers the

selection of three equipment colors to

blend with any architectural style:

Gray

Black

Red

3 Motor Sizes

The units have the capability to meet any

static pressure application up to 1.5”

with their 3 options:

- Low Static Motor Option

- Medium Static Option

- High Static Option

3 Control Options

Standard Thermostat

All units are furnished with a standard

thermostat that can be installed

remotely or directly on the equipment.

Programmable Thermostat (PT)

PT programming is very simple! PT has

a display that shows the hour, the day of

the week, the selected program and the

ambient temperature. PT can be

programmed for up to four setpoints for

each day of the week. Using the button

“timed-override” the customer can

prolong the machine operation beyond

the programmed schedule, according to

customer needs.

As an additional benefit the Micro

allows the Genius to be integrated to

the Tracker. This ability allows the

multiple units to be controlled and

diagnosed from a central location, from

across town or even across the country.

Just imagine the HVAC installed in your

facility capable of being scheduled,

monitored and let you know when it is

having problems.

Microcontrol

This state of the art control offers a

complete family of sensors and wall

mounted devices to compliment the

capabilities of the Trane Micro.

3 Filter Options

Three filter options exist which may be

installed in Genius units.

1. Permanent washable filters of

electrostatic fabric (standard).

2. Disposable 2” filters.

3. The combination of the two placed in

series.

PKG-PRC007-EN6

Page 7

Features Summary

Quality and Reliability

Galvanized steel casing

•

Synthetic enamel paint

•

Innovative Drain Pan

•

Scroll Compressors

•

Flexibility

Air or Water Cooled

•

Free discharge plenum or ducted

•

discharge

Voltages available:

•

220/3/60, 440/3/60, 380/3/60 and 380/50/3

Controls

Thermostat unit mounted or remote

•

Optional Programmable thermostat

•

Optional Microprocessor

•

ICS compatible, Tracker is your ideal

•

partner for small buildings applications.

Filters

Throwaway

•

Washable - Nylon type

•

Washable - Aluminum Mesh

•

Wide range of Models available:

SRVE: Self Contained with Integral Air Cooled Condenser

SIVE: Self Contained with Remote Air Condenser

SAVE: Self Contained with Water cooled

Nominal Capacity: From 5 to 15 Tons

You can reach up to 1.5” esp with our Double Inlet Forward curved

Supply fan. It also has variable V-belt drives.

The case has been insulated with BIDIM insulation.

Other options:

Aluminum decorative grill

Plenum discharge box for free air discharge

Service Valves

Sight Glass

Solenoid Valve

7PKG-PRC007-EN

Page 8

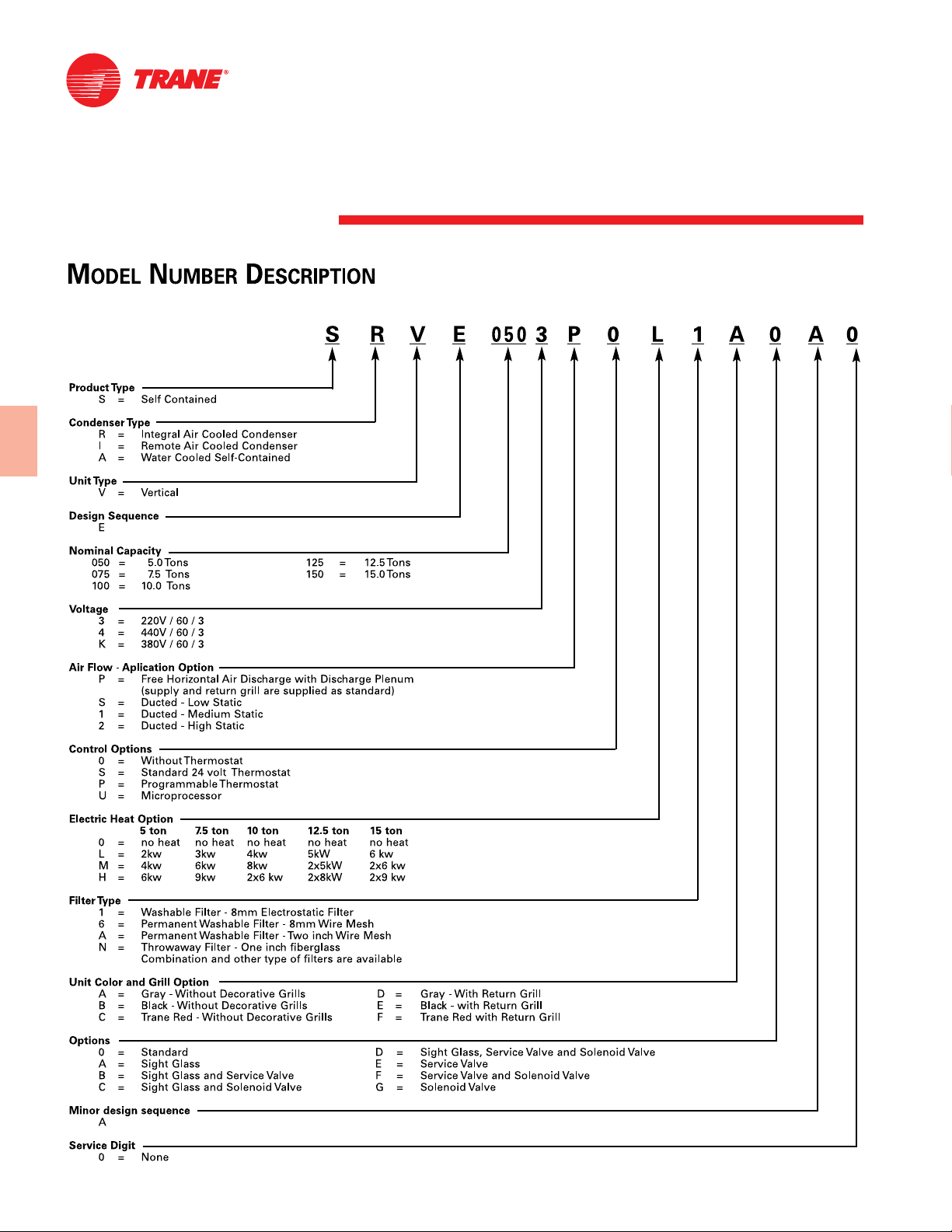

Model Number Description

PKG-PRC007-EN8

Page 9

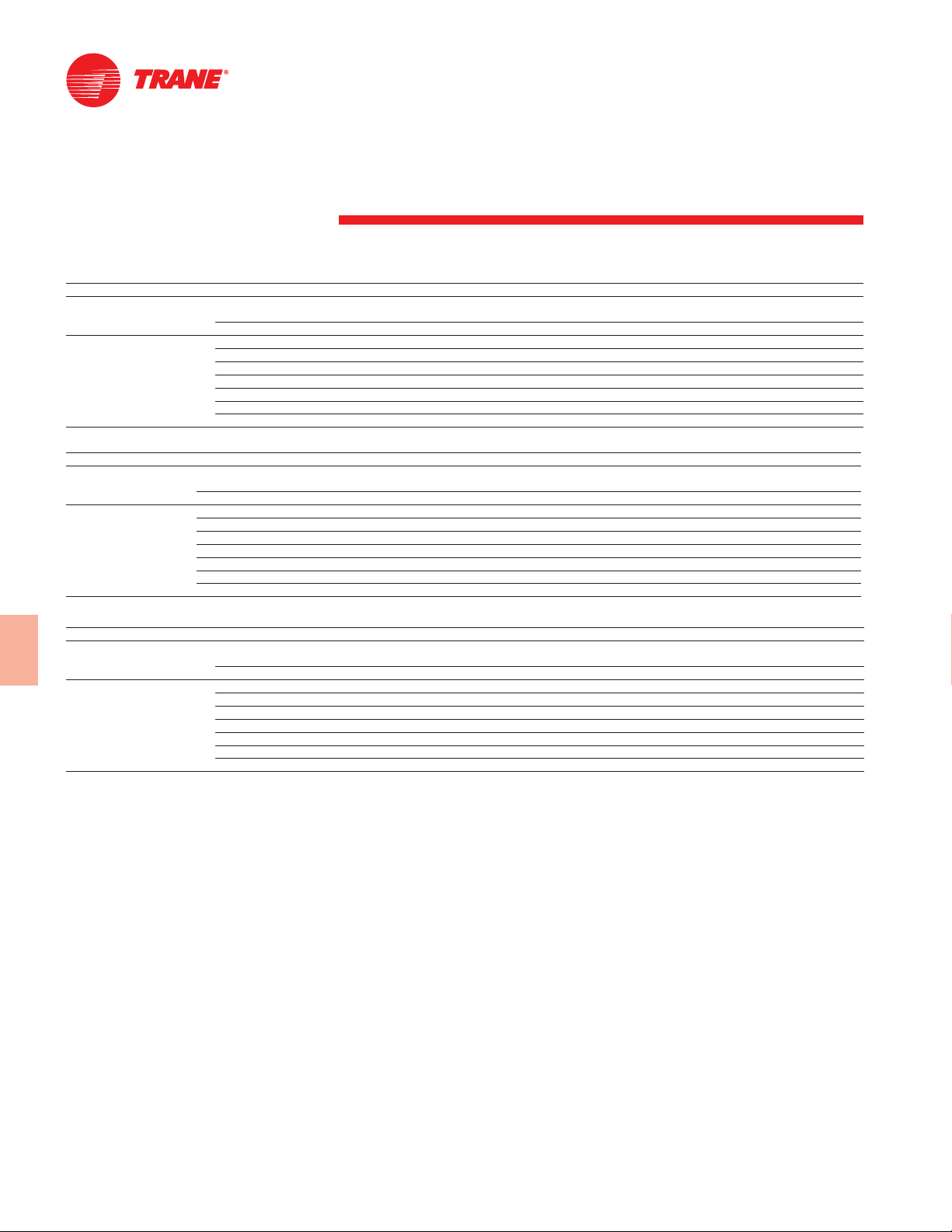

General Data

Table GD-1 — Genius – General Data

SAVE Model 050 T 075 T 100 2T 125 2T 150 2T

Nominal TR Capacity 5 7.5 10 12.5 15

Length (mm) 960 1190 1500 1700 1700

Depth (mm) 600 600 600 600 600

Height (mm) 2000 2000 2000 2000 2000

Height w/ Plenum Box (mm) 2295 2295 2295 2295 2295

Net Weight (kg) 247 288 376 440 461

SRVE Model 050 T 075 T 100 2T 125 2T 150 2T

Nominal TR Capacity 5 7.5 10 12.5 15

Length (mm) 960 1190 1500 1700 1700

Depth (mm) 720 720 830 1000 1000

Height (mm) 2000 2000 2000 2000 2000

Height w/ Plenum Box (mm) 2295 2295 2295 2295 2295

Net Weight (kg) 268 310 416 459 490

SIVE Model 050 T 075 T 100 2T 125 2T 150 2T

Nominal TR Capacity 5 7.5 10 12.5 15

Evaporator Units

Quantity/Model 1/SIVE050 1/SIVE075 1/SIVE100 1/SIVE125 1/SIVE 150

Length (mm) 960 1190 1500 1700 1700

Depth (mm) 600 600 600 600 600

Height (mm) 2000 2000 2000 2000 2000

Height w/ Plenum Box (mm) 2295 2295 2295 2295 2295

Net Weight (kg) 190 225 235 347 392

Condensing Units

Quantity/Model 1/CRCB050 1/CRCB075 1/CRCB100 1/CRCB125 1/CRCB150

Length (mm) 987 1241 1341 1646 1646

Depth (mm) 631 631 631 714 714

Height (mm) 890 890 941 1018 1247

Net Weight (kg) 93 124 139 180 212

Compressor

Quantity TR 1 / 5 1 / 7.5 2 / 5 5 + 7.5 2 / 7.5

Evaporator Coil

Rows 3 3 3 3 4

Finned Height (mm) 536 508 612 663 714

Finned Length (mm) 711 965 1143 1328 1321

Finned Clearance (m) 0.38 0.49 0.70 0.88 0.94

FPF ( Fins Per Foot) 132 132 132 132 132

Evaporator Fan

Quantity 1 1 2 2 2

Diameter x Length 270 x 270 321 x 321 270 x 270 321 x 321 321 x 321

Plenum Box Option (CV) 0.5 0.5 0.5 0.5 1.0

Standard Motor Option (CV) 1.0 1.5 1.5 2.0 3.0

Motor Option 1 (CV) 1.0 2.0 2.0 3.0 4.0

Motor Option 2 (CV) 1.5 3.0 3.0 4.0 5.0

Minimum Air Flow (m

Maximum Air Flow (m3/h) 3825 5740 7650 9560 11475

Condenser Fan

(SRVE and CRCB)

Quantity 1 1 2 2 2

Diameter x Length 321 x 321 321 x 321 270 x 270 321 x 321 321 x 321

Motor (CV) 1.0 3.0 3.0 4.0 5.0

Air Flow (CFM) 5450 8315 9935 13930 17320

Water Condenser

(SAVE)

Minimum Water Flow GPM 1.4 2.0 2.7 3.4 4.1

Maximum Water Flow GPM 4.0 6.0 8.0 9.9 11.9

Maximum Pressure Drop (ca feet) 1.9 4.6 1.8 3.0 3.1

Condenser Coil

(SRVE, CRCB)

Rows 4 4 4 4 4

Finned Height (mm) 711 813 864 940 1168

Finned Length (mm) 762 1016 1143 1473 1473

FPF (Fins per Foot) 168 168 168 168 168

3

/h) 3060 4590 6120 7650 9180

9PKG-PRC007-EN

Page 10

Selection Procedure

The selection of a Genius self-contained

unit can be accomplished in three easy

steps.

1

LOAD: Determine the load requirements

for heating and cooling (include outside

air) using Trane’s load estimate forms,

®

TRACE

method.

2

UNIT TYPE: Self-contained air

conditioners are available in either

water-cooled or remote air-cooled

models to match individual needs.

3

SELECT THE UNIT: The conditions under

which the unit must operate and the

design load will give the final selection.

SELECTION EXAMPLE

Design Conditions

Water-cooled unit

Entering air temperature — 80/67 F

Total gross capacity required —

55,000 BTUH

Entering water temperature — 85 F

Leaving water temperature — 92 F

Airflow — 1,950 CFM at 0.5” duct static

pressure.

Voltage

Unit Selection

Tentatively select a 5-ton unit — Model

SAVE050. Refer to Table PD-6 to obtain

gross total and sensible unit capabilities,

gpm, and leaving water temperature at

nominal conditions:

Total MBh — 60.6

Sensible MBh — 43.5

GPM — 14.5

LWT — 95

The SAVE-050 meets the total and

sensible design requirements.

Easy/600 or any standard

Since the difference between entering

and leaving water is 7°F multiply the

capacities and water flow by correction

factors on Capacity Correction Factor

Table.

Cooling capacity multiplier 1.01

Sensible capacity multiplier 1.05

Water flow multiplier 1.39

60.6 x 1.01 = 61.21 MBh

43.5 x 1.01 = 43.94 MBh

14.5 x 1.39 = 20.16 GPM

Refer to Table PD-1 to determine

approximate brake horsepower and fan

rpm:

1035 rpm and 0.66 bhp.

Determine net capacities by subtracting

fan motor heat from gross capacities:

2.8 x 0.66 bph = 1.85 MBh

Net total capacity =

61.21 - 1.85 = 59.36 MBh

Net sensible capacity =

43.94 - 1.85 = 42.09 MBh

Supply air temperature DB

Q

= 1.085 x CFM x (Tr-TS)

s

42,090 = 1.085 x 1950 x (80-T

= 80 - 42,090

T

S

T

S

Air-Cooled

Design Conditions

— 80 F/67 F DB/WB return air

— 95 F Ambient

— 0.380 External Static Pressure

— 4200 CFM

— 0.25 External static pressure

Required

1. Select unit

2. Fan speed and BHP for

a) Evaporator fan

b) Condenser fan

3. Supply air temperature DB

(1.085) (1950)

= 60.1°F

temperature

— 109300 BTUH Total Net

— 76500 BTUH Sensible Net

(evaporator fan)

(condenser fan)

)

S

Solution

1. Select Unit

Initially Select a 10-Ton Unit

From Table PD-13

80/67 EAT

95 F AMB = 118.7 MBh Total Gross

4200 CFM 86.6 MBh Sensible

2. Fan speed and BHP determination

Total Static Pressure

Evaporator

0.380 esp

From Table PD-3

Evaporator

10-ton unit

4200 CFM = 1107 RPM

0.5 ESP = 1.63 BHP

Note: If values fall between cfm’s or

esp’s it is proper to interpolate between

values. Do not extrapolate beyond

values in catalog. Contact Trane

marketing department for assistance.

Fan Motor Heat Equation

Fan motor heat = 2.8 x 1.63 = 4.56 MBh

Net total capacity = 118.7 - 4.50

= 114.14 MBh

Net sensible capacity = 86.6 - 4.56

= 82.04 MBh

Conclusion:

Required — 109300 BTUH Total Net

76500 BTUH Total

Sensible Net

Provided — 114140 BTUH Total Net

82040 BTUH Total Net

The 10-ton unit is the proper choice for

this application.

PKG-PRC007-EN10

Page 11

Performance

Fan

Data

Data

Three transmission options exist for the

evaporator fan motor: Std. option,

option 1, option 2. In addition, there is an

option for those cases in which the unit

is operated with a plenum box. The

motors for each transmission option can

be found in the general facts tables.

Table PD-1 — Fan Performance SRVE/SIVE/SAVE 5 Tons

External static pressure with permanent air filter inches of water (Pa)

Option 5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

STD FS: 184 (8") 2028 3443 897 0.56 931 0.59 964 0.62 996 0.65

Option 5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP1 FS: 133 (6") 2028 3443 1027 0.68 1058 0.72 1117 0.79 1175 0.86 1230 0.94

Model Airflow (19.9) (39.8) (59.8) (77.2) (97.1) (124.5)

MT 1.0 CV 1877 3188 843 0.45 879 0.48 914 0.51 948 0.53 981 0.57

MS: 78,5 A 106,5 1952 3315 869 0.50 904 0.53 938 0.56 971 0.59 1003 0.62

B: 1X A36 2102 3570 925 0.62 957 0.65 989 0.68

Model Airflow (39.8) (59.8) (77.2) (97.1) (124.5) (156.9) (196.7) (234.1) (273.9)

MT 1.0 CV 1877 3188 1013 0.60 1076 0.67 1136 0.74 1195 0.81 1251 0.89

MS: 78,5 A 106,5 1952 3315 1035 0.66 1096 0.73 1155 0.80 1212 0.88

B: 1X A32 2102 3570 1020 0.71 1051 0.75 1081 0.78 1139 0.85 1195 0.93 1249 1.01

1802 3060 815 0.40 852 0.43 888 0.45 923 0.48 957 0.51 990 0.54

2178 3698 952 0.68 984 0.71

2253 3825 981 0.75

External static pressure with permanent air filter inches of water (Pa)

1802 3060 1055 0.61 1117 0.68 1176 0.75 1234 0.83

2178 3698 1015 0.74 1045 0.78 1075 0.81 1104 0.85 1160 0.92 1215 1.00

2253 3825 1012 0.78 1042 0.81 1071 0.85 1100 0.88 1128 0.92 1183 0.99 1237 1.07

.16 .24 .31 .39 .50 .63 .79 .94 1.10

.08 .16 .24 .31 .39 .50

External static pressure with permanent air filter inches of water (Pa)

Option 5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP2 BS: 108 (5") 2028 3443 1284 1.02 1337 1.10 1387 1.18 1437 1.25

MT = Motor (CV).

MS = Motor Sheave, variable pitch (mm).

FS = Fan Sheave (mm).

B = Belt.

Model Airflow (234.1) (273.9) (313.7) (353.6) (390.9)

MT 1.5 CV 1877 3188 1305 0.97 1358 1.05 1409 1.12

MS: 78.5 A 106.5 1952 3315 1267 0.95 1320 1.03 1372 1.11 1422 1.19

B: 1X A31 2102 3570 1302 1.09 1353 1.16 1403 1.24 1452 1.32

1802 3060 1289 0.91 1343 0.98 1395 1.05

2178 3698 1269 1.08 1320 1.15 1371 1.23 1420 1.31 1467 1.39

2253 3825 1289 1.14 1340 1.22 1389 1.30 1437 1.39

.94 1.10 1.26 1.42 1.57

11PKG-PRC007-EN

Page 12

Performance

Fan

Data

Data

Table PD-2 — Fan Performance SRVE/SIVE/SAVE 7.5 Tons

External static pressure with permanent air filter inches of water (Pa)

Option 7.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

STD BS: 209 (9") 3041 5163 760 0.90 788 0.95 816 1.00 844 1.05 871 1.10

Option 7.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP1 BS: 159 (7") 3041 5163 897 1.15 949 1.25 999 1.36 1047 1.47 1094 1.59 1140 1.72

Model Airflow (19.9) (39.8) (59.8) (77.2) (97.1) (124.5)

MT 1.5 CV 2815 4780 712 0.72 743 0.76 773 0.81 802 0.86 831 0.91 859 0.96

MS: 78,5 A 106,5 2927 4970 735 0.81 765 0.85 794 0.90 822 0.95 850 0.99 877 1.05

B: 1X A35 3154 5355 784 1.01 811 1.06 838 1.10 865 1.15

Model Airflow (59.8) (77.2) (97.1) (124.5) (156.9) (196.7) (234.1) (273.9) (313.7) (353.6)

MT 2.0 CV 2815 4780 913 1.06 966 1.17 1017 1.28 1066 1.39 1113 1.50

MS: 78,5 A 106,5 2927 4970 931 1.16 982 1.26 1031 1.37 1079 1.49 1126 1.60

B: 1X A32 3154 5355 891 1.21 917 1.26 968 1.36 1016 1.47 1064 1.59 1110 1.71 1154 1.83

2703 4590 688 0.64 720 0.68 751 0.72 781 0.77 811 0.82 840 0.87

3267 5548 808 1.12 834 1.17 861 1.22

3380 5740 834 1.24 859 1.29

External static pressure with permanent air filter inches of water (Pa)

2703 4590 896 0.97 950 1.08 1002 1.19 1052 1.30 1100 1.41 1147 1.51

3267 5548 886 1.27 912 1.32 937 1.37 986 1.47 1034 1.58 1080 1.70 1125 1.83

3380 5740 885 1.34 910 1.39 935 1.44 959 1.49 1007 1.59 1053 1.70 1098 1.83 1142 1.96

.24 .31 .39 .50 .63 .79 .94 1.10 1.26 1.42

.08 .16 .24 .31 .39 .50

External static pressure with permanent air filter inches of water (Pa)

Option 7.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP

OP2 BS: 118 (5") 3041 5163 1184 1.86 1227 2.03

MT = Motor (CV).

MS = Motor Sheave, variable pitch (mm).

FS = Fan Sheave (mm).

B = Belt.

Model Airflow (313.7) (353.6) (390.9)

MT 3.0 CV 2815 4780 1159 1.61 1204 1.75

MS: 80 A 110 2927 4970 1171 1.74 1215 1.88

B: 1X B27 3154 5355 1198 2.01 1240 2.17

2703 4590 1193 1.60

3267 5548 1169 1.97 1211 2.16 1253 2.34

3380 5740 1185 2.15 1227 2.32 1268 2.50

1.26 1.42 1.57

PKG-PRC007-EN12

Page 13

Performance

Fan

Data

Data

Table PD-3 — Fan Performance SRVE/SIVE/SAVE 10 Tons

External static pressure with permanent air filter inches of water (Pa)

Option 10 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

STD BS: 184 (8") 4055 6885 924 1.16 957 1.22 989 1.28

Option 10 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP1 BS: 133 (6") 4055 6885 1021 1.35 1051 1.42 1082 1.49 1140 1.64 1197 1.79

Model Airflow (19.9) (39.8) (59.8) (77.2) (97.1)

MT 1.5 CV 3754 6375 866 0.94 902 0.99 936 1.05 969 1.11 1002 1.17

MS: 78,5 A 106,5 3905 6630 895 1.04 929 1.10 963 1.16 995 1.23

B: 1X A35 4205 7140 954 1.29 986 1.35

Model Airflow (19.9) (39.8) (59.8) (77.2) (97.1) (124.5) (156.9) (196.7) (234.1) (273.9) (313.7)

MT 2.0 CV 3754 6375 1034 1.24 7096 1.38 1156 1.53 1213 1.68 1269 1.83

MS: 78,5 A 106,5 3905 6630 1027 1.29 1058 1.36 1118 1.51 1176 1.66 1232 1.81

B: 1X A31 4205 7140 1017 1.42 1048 1.49 1078 1.56 1107 1.63 1164 1.78

3604 6120 839 0.84 875 0.89 911 0.94 945 1.00 979 1.07

4355 7395 984 1.42

4505 7650

External static pressure with permanent air filter inches of water (Pa)

.08 .16 .24 .31 .39 .50 .63 .79 .94 1.10 1.26

3604 6120 1012 1.13 1075 1.26 1136 1.41 1195 1.55 1252 1.71 1307 1.87

4355 7395 1015 1.49 1045 1.55 1075 1.63 1104 1.70 1132 1.77

4505 7650 1013 1.56 1043 1.63 1072 1.70 1101 1.77 1130 1.84 1157 1.92

.08 .16 .24 .31 .39

External static pressure with permanent air filter inches of water (Pa)

Option 10 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP2 BS: 118 (5") 4055 6885 1252 1.94 1305 2.10 1357 2.26 1407 2.42 1456 2.57

MT = Motor (CV).

MS = Motor Sheave, variable pitch (mm).

FS = Fan Sheave (mm).

B = Belt.

Model Airflow (156.9) (96.7) (234.1) (273.9) (313.7) (353.6) (390.9)

MT 3.0 CV 3754 6375 1322 1.98 1375 2.14 1425 2.29

MS: 80 A 110 3905 6630 1287 1.97 1340 2.12 1391 2.28 1441 2.43

B: 1X B31 4205 7140 1220 1.93 1273 2.08 1325 2.24 1376 2.40 1425 2.56 1473 2.71

3604 6120 1360 2.01 1412 2.16

4355 7395 1188 1.92 1242 2.07 1295 2.23 1346 2.39 1395 2.54 1444 2.71

4505 7650 1212 2.06 1265 2.22 1316 2.37 1366 2.53 1414 2.69

.63 .79 .94 1.10 1.26 1.42 1.57

13PKG-PRC007-EN

Page 14

Performance

Fan

Data

Data

Table PD-4 — Fan Performance SRVE/SIVE/SAVE 12.5 Tons

External static pressure with permanent air filter inches of water (Pa)

Model Airflow (19.9) (39.8) (59.8) (77.2) (97.1) (124.5) (156.9)

Option 12.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

MT 2.0 CV 4694 7970 649 0.93 684 1.01 718 1.09 751 1.18 783 1.27 814 1.37

MS: 78,5 A 106,5 4882 8290 670 1.04 703 1.12 736 1.20 768 1.29 799 1.39 830 1.49

STD BS: 184 (8") 5069 8608 690 1.15 723 1.24 754 1.32 785 1.41 816 1.51 845 1.61

B: 1X A33 5256 8925 711 1.28 743 1.37 774 1.46 804 1.55 833 1.65 862 1.75

Option 12.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP1 FS: 169 (7") 5069 8608 902 1.82 957 2.04 1010 2.26 1060 2.48

Option 12.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP2 FS: 143 (6") 5069 8608 1109 2.69 1156 2.89 1203 3.13

MT = Motor (CV).

MS = Motor Sheave, variable pitch (mm).

FS = Fan Sheave (mm).

B = Belt.

Model Airflow (97.1) (124.5) (156.9) (195.7) (234.1) (273.9)

MT 3.0 CV 4694 7970 874 1.57 931 1.79 985 2.00 1038 2.23

MS: 79 A 105 4882 8290 888 1.69 944 1.91 997 2.13 1049 2.35

B: 1X B32 5256 8925 918 1.97 971 2.18 1023 2.40

Model Airflow (234.1) (273.9) (313.7) (353.6) (390.9)

MT 4.0 CV 4694 7970 1089 2.44 1139 2.65 1187 2.81

MS: 79 A 105 4882 8290 1099 2.56 1148 2.77 1195 2.92

B: 1X B29 5256 8925 1073 2.62 1121 2.84 1167 2.95 1213 3.20

4505 7650 630 0.81 666 0.89 701 0.98 735 1.08 768 1.18 800 1.29 8.61 1.50

5445 9243 731 1.41 762 1.50 792 1.60 821 1.69 850 1.79

5630 9560 753 1.56 783 1.65 812 1.75 841 1.85

External static pressure with permanent air filter inches of water (Pa)

4505 7650 919 1.62 975 1.88 1029 2.06

5445 9243 878 1.90 932 2.11 985 2.33 1035 2.55

5630 9560 868 1.95 896 2.06 949 2.27 1000 2.49

External static pressure with permanent air filter inches of water (Pa)

4505 7650 1081 2.26 1131 2.52 1179 2.73

5445 9243 1084 2.77 1131 2.98 1177 3.10

5630 9560 1050 2.71 1098 2.93 1144 3.15 1189 3.30

.08 .16 .24 .31 .39 .50 .63

.39 .50 .63 .79 .94 1.10

.94 1.10 1.26 1.42 1.57

PKG-PRC007-EN14

Page 15

Performance

Fan

Data

Data

Table PD-5 — Fan Performance SRVE/SIVE/SAVE 15 Tons

External static pressure with permanent air filter inches of water (Pa)

Option 15 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

STD FS: 219 (9") 6080 10323 728 1.69 757 1.79 785 1.89 813 1.99

Option 7.5 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

OP1 FS: 169 (7") 6080 10323 841 2.09 868 2.19 921 2.40 972 2.61 1021 2.83 1069 3.06

Model Airflow (19.9) (39.8) (59.8) (77.2) (97.1) (124.5)

MT 3.0 CV 5632 9563 686 1.36 717 1.45 747 1.54 777 1.64 806 1.73

MS: 79 A 105 5857 9945 707 1.52 737 1.61 766 1.71 795 1.81

B: 1X B35 6302 10700 749 1.88 777 1.98 804 2.08

Model Airflow (39.8) (59.8) (77.2) (97.1) (124.5) (156.9) (196.7) (234.1) (273.9) (313.7)

MT 4.0 CV 5632 9563 835 1.83 890 2.03 944 2.25 995 2.47 1045 2.69

MS: 79 A 105 5857 9945 824 1.91 852 2.01 906 2.21 958 2.43 1008 2.65 1057 2.87

B: 1X B31 6302 10700 832 2.19 858 2.28 885 2.39 936 2.59 986 2.80 1034 3.02

5406 9180 664 1.22 696 1.30 728 1.38 759 1.48 789 1.57 818 1.66

6530 11088 771 2.08 798 2.19

6758 11475 793 2.30

External static pressure with permanent air filter inches of water (Pa)

5406 9180 875 1.87 930 2.08 983 2.30 1033 2.52 1082 2.74

6530 11088 825 2.29 851 2.40 877 2.50 903 2.60 953 2.81 1002 3.02 1049 3.24

6758 11475 819 2.41 845 2.52 871 2.62 896 2.72 921 2.85 970 3.03 1017 3.23 1064 3.46

.16 .24 .31 .39 .50 .63 .79 .94 1.10 1.26

.08 .16 .24 .31 .39 .50

External static pressure with permanent air filter inches of water (Pa)

Option 15 TR CFM (m3/h) RPM BHP RPM BHP RPM BHP RPM BHP

OP2 FS: 143 (6") 6080 10323 1115 3.29 1160 3.53 1204 3.80

MT = Motor (CV).

MS = Motor Sheave, variable pitch (mm).

FS = Fan Sheave (mm).

B = Belt.

Model Airflow (273.9) (313.7) (353.6) (390.9)

5406 9180 1130 2.95 1176 3.17

MT 5.0 CV 5632 9563 1093 2.91 1140 3.13 1185 3.37

MS: 79 A 105 5857 9945 1104 3.10 1150 3.33 1194 3.58

B: 1X B29 6302 10700 1081 3.26 1126 3.50 1171 3.77 1214 4.02

6530 11088 1095 3.48 1139 3.74 1183 4.00 1225 4.27

6758 11475 1108 3.71 1152 4.00 1195 4.20 1236 4.45

1.10 1.26 1.42 1.57

15PKG-PRC007-EN

Page 16

Performance

Water Cooled

Data

60 Hz

Table PD-6 — Gross Cooling Capacities SAVE-050 English

75 85

Ent. 61 67 73 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 55.0 45.2 12.8 61.6 35.2 14.5 68.6 24.9 15.9 53.5 44.4 12.8 59.9 34.4 14.5 67.0 24.4 15.9

1800 80 55.2 53.1 12.8 61.5 43.4 14.5 68.6 33.1 15.9 53.7 52.3 12.8 59.9 42.6 14.5 66.8 32.4 15.9

85 56.7 57.8 13.2 61.5 50.1 14.5 68.5 39.8 15.9 55.4 56.5 13.2 59.8 49.4 14.1 66.8 39.2 15.9

90 59.2 60.4 14.1 61.5 56.7 14.5 68.5 46.5 15.9 58.0 59.1 14.1 59.9 56.0 14.5 66.7 45.9 15.9

75 55.7 46.6 13.2 62.3 36.0 14.5 69.4 25.2 15.9 54.1 45.9 13.2 60.7 35.3 14.5 67.7 24.6 15.9

1950 80 56.0 54.9 13.2 62.3 44.7 14.5 69.3 33.8 15.9 54.6 54.1 13.2 60.6 43.5 14.5 67.7 33.2 15.9

85 58.0 59.1 13.7 62.2 51.9 14.5 69.3 41.0 15.9 56.7 57.8 13.7 60.6 51.1 14.5 67.6 40.3 15.9

90 60.7 61.8 14.1 63.4 58.8 14.5 69.2 48.1 15.9 59.4 60.6 14.1 60.8 58.1 14.5 67.6 47.5 15.9

75 56.3 48.1 13.2 62.9 36.9 14.5 70.1 25.4 16.3 54.7 47.4 13.2 61.3 36.1 14.5 68.4 24.8 16.3

2100 80 56.9 56.6 13.7 62.9 46.0 14.5 70.0 34.5 16.3 55.4 55.7 13.2 61.3 45.3 14.5 68.3 33.9 15.9

85 59.1 60.3 14.1 62.8 53.6 14.5 70.0 42.1 16.3 57.9 59.0 14.1 61.2 52.8 14.5 68.3 41.5 15.9

90 61.9 63.1 14.5 63.1 60.8 14.5 69.9 49.7 16.3 60.7 61.8 14.5 61.6 60.0 14.5 68.2 49.0 15.9

75 56.9 49.5 13.7 63.5 37.6 15.0 70.8 25.6 16.3 55.2 48.7 13.2 61.9 37.0 14.5 69.0 25.0 16.3

2250 80 57.7 58.1 13.7 63.5 47.3 15.0 70.7 35.3 16.3 56.2 57.0 13.7 61.8 46.5 14.5 68.9 34.5 16.3

85 60.3 61.4 14.1 63.4 55.2 15.0 70.7 43.2 16.3 58.9 60.1 14.1 61.8 54.5 14.5 68.9 42.5 16.3

90 63.1 64.4 14.5 64.0 62.6 15.0 70.6 51.1 16.3 61.8 63.0 14.5 62.3 61.7 15.0 68.8 50.5 16.3

ENT Water Temp (°F)

Entering Wet Bulb Temperature (°F)

Table PD-6 — Gross Cooling Capacities SAVE-050 (Cont.)

ENT Water Temp (°F)

Ent. 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 51.9 43.7 12.8 58.3 33.7 14.1 65.2 23.6 15.9

1800 80 52.2 51.5 12.8 58.2 41.9 14.1 65.1 31.8 15.9

85 54.2 55.2 13.7 58.2 48.6 14.1 65.1 38.5 15.9

90 56.8 57.9 14.1 58.3 55.2 14.1 65.0 45.3 15.9

75 52.5 45.2 13.2 59.0 34.5 14.5 65.9 23.8 15.9

1950 80 53.0 53.1 13.2 58.9 43.3 14.5 65.8 32.6 15.9

85 55.4 56.5 13.7 58.9 50.4 14.5 65.8 39.7 15.9

90 58.1 59.2 14.1 59.1 57.2 14.5 65.7 46.8 15.9

75 53.1 46.6 13.2 59.6 35.4 14.5 66.5 24.2 15.9

2100 80 54.0 54.6 13.7 59.5 44.5 14.5 66.5 33.3 15.9

85 56.5 57.6 14.1 59.5 52.2 14.5 66.4 40.8 15.9

90 59.3 60.5 14.5 59.9 59.1 14.5 66.4 48.3 15.9

75 53.7 48.0 13.2 60.2 36.2 14.5 67.2 24.4 16.3

2250 80 54.8 55.9 13.7 60.1 45.8 14.5 67.1 33.9 16.3

85 57.6 58.7 14.1 60.1 53.8 14.5 67.1 41.9 16.3

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 60.4 61.5 15.0 60.8 60.8 15.0 67.0 49.8 16.3

Entering Wet Bulb Temperature (°F)

95

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°F) GPM MBh MBh

4.5 2.21 1.01 1.01

7.2 1.39 1.01 1.01

10.0 1.00 1.00 1.00

12.6 0.79 0.99 1.00

15.3 0.66 0.99 1.00

18.0 0.56 0.98 0.99

PKG-PRC007-EN16

Page 17

Performance

Water Cooled

Data

60 Hz

Table PD-6 — Gross Cooling Capacities SAVE-050 Metric

24.0 29.5

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 16.1 13.2 0.81 18.0 10.3 0.92 20.1 7.3 1.00 15.7 13.0 0.81 17.6 10.1 0.92 19.6 7.1 1.00

3060 27 16.2 15.6 0.81 18.0 12.7 0.92 20.1 9.7 1.00 15.7 15.3 0.81 17.6 12.5 0.92 19.6 9.5 1.00

29 16.6 16.9 0.83 18.0 14.7 0.92 20.1 11.7 1.00 16.2 16.6 0.83 17.5 14.5 0.89 19.6 11.5 1.00

32 17.4 17.7 0.89 18.0 16.6 0.92 20.1 13.6 1.00 17.0 17.3 0.89 17.6 16.4 0.92 19.6 13.4 1.00

24 16.3 13.7 0.83 18.3 10.6 0.92 20.3 7.4 1.00 15.8 13.4 0.83 17.8 10.3 0.92 19.8 7.2 1.00

3315 27 16.4 16.1 0.83 18.3 13.1 0.92 20.3 9.9 1.00 16.0 15.8 0.83 17.7 12.8 0.92 19.8 9.7 1.00

29 17.0 17.3 0.86 18.2 15.2 0.92 20.3 12.0 1.00 16.6 16.9 0.86 17.7 15.0 0.92 19.8 11.8 1.00

32 17.8 18.1 0.89 18.6 17.2 0.92 20.3 14.1 1.00 17.4 17.8 0.89 17.8 17.0 0.92 19.8 13.9 1.00

24 16.5 14.1 0.83 18.4 10.8 0.92 20.6 7.4 1.03 16.0 13.9 0.83 18.0 10.6 0.92 20.0 7.3 1.03

3570 27 16.7 16.6 0.86 18.4 13.5 0.92 20.5 10.1 1.03 16.2 16.3 0.83 18.0 13.3 0.92 20.0 9.9 1.00

29 17.3 17.7 0.89 18.4 15.7 0.92 20.5 12.3 1.03 17.0 17.3 0.89 17.9 15.5 0.92 20.0 12.2 1.00

32 18.1 18.5 0.92 18.5 17.8 0.92 20.5 14.6 1.03 17.8 18.1 0.92 18.0 17.6 0.92 20.0 14.4 1.00

24 16.7 14.5 0.86 18.6 11.0 0.94 20.7 7.5 1.03 16.2 14.3 0.83 18.1 10.8 0.92 20.2 7.3 1.03

3825 27 16.9 17.0 0.86 18.6 13.8 0.94 20.7 10.3 1.03 16.5 16.7 0.86 18.1 13.6 0.92 20.2 10.1 1.03

29 17.7 18.0 0.89 18.6 16.2 0.94 20.7 12.6 1.03 17.3 17.6 0.89 18.1 16.0 0.92 20.2 12.5 1.03

32 18.5 18.9 0.92 18.7 18.3 0.94 20.7 15.0 1.03 18.1 18.5 0.92 18.3 18.1 0.94 20.2 14.8 1.03

ENT Water Temp (°C)

Entering Wet Bulb Temperature (°C)

Table PD-6 — Gross Cooling Capacities SAVE-050 (Cont.)

ENT Water Temp (°C)

Ent. 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 15.2 12.8 0.81 17.1 9.9 0.89 19.1 6.9 1.00

3060 27 15.3 15.1 0.81 17.1 12.3 0.89 19.1 9.3 1.00

29 15.9 16.2 0.86 17.1 14.2 0.89 19.1 11.3 1.00

32 16.6 17.0 0.89 17.1 16.2 0.89 19.0 13.3 1.00

24 15.4 13.2 0.83 17.3 10.1 0.92 19.3 7.0 1.00

3315 27 15.5 15.6 0.83 17.3 12.7 0.92 19.3 9.5 1.00

29 16.2 16.6 0.86 17.3 14.8 0.92 19.3 11.6 1.00

32 17.0 17.4 0.89 17.3 16.8 0.92 19.3 13.7 1.00

24 15.6 13.7 0.83 17.5 10.4 0.92 19.5 7.1 1.00

3570 27 15.8 16.0 0.86 17.4 13.0 0.92 19.5 9.8 1.00

29 16.6 16.9 0.89 17.4 15.3 0.92 19.5 12.0 1.00

32 17.4 17.7 0.92 17.6 17.3 0.92 19.5 14.2 1.00

24 15.7 14.1 0.83 17.6 10.6 0.92 19.7 7.1 1.03

3825 27 16.1 16.4 0.86 17.6 13.4 0.92 19.6 9.9 1.03

29 16.9 17.2 0.89 17.6 15.8 0.92 19.6 12.3 1.03

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 17.7 18.0 0.94 17.8 17.8 0.94 19.6 14.6 1.03

Entering Wet Bulb Temperature (°C)

35.0

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°C) l/s kW kW

2.5 2.21 1.01 1.01

4.0 1.39 1.01 1.01

5.5 1.00 1.00 1.00

7.0 0.79 0.99 1.00

8.5 0.66 0.99 1.00

10.0 0.56 0.98 0.99

17PKG-PRC007-EN

Page 18

Performance

Water Cooled

Data

60 Hz

Table PD-7 — Gross Cooling Capacities SAVE-075 English

75 85

Ent. 61 67 73 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 79.4 64.2 18.1 89.4 49.9 19.8 100.1 35.3 22.0 77.2 63.1 18.1 86.8 48.8 19.8 97.1 34.2 22.0

2700 80 79.8 75.6 18.1 89.3 61.6 19.8 100.0 47.0 22.0 77.7 74.3 18.1 86.7 60.6 19.8 97.0 46.0 22.0

85 82.5 81.7 18.5 89.1 71.5 19.8 99.9 56.8 22.0 80.6 79.8 18.5 86.6 70.4 19.8 97.0 55.8 22.0

90 86.5 85.7 19.4 89.4 81.1 19.8 99.7 66.6 22.0 84.5 83.7 19.4 86.8 79.9 19.8 96.9 65.5 21.6

75 80.5 66.3 18.1 90.4 51.1 20.3 101.2 35.7 22.5 78.1 65.2 18.1 87.9 50.0 20.3 98.3 34.5 22.0

2925 80 81.1 78.1 18.5 90.3 63.6 20.3 101.1 48.2 22.5 79.0 76.8 18.5 87.6 63.0 20.3 98.2 47.0 22.0

85 84.4 83.6 18.9 90.3 74.0 20.3 101.0 58.5 22.0 82.5 81.7 18.9 87.6 72.9 20.3 98.1 57.4 22.0

90 88.5 87.7 19.8 90.6 84.0 20.3 100.9 68.8 22.0 86.5 85.7 19.8 88.1 82.7 20.3 97.9 67.7 22.0

75 81.3 68.4 18.5 91.5 52.3 20.3 102.3 36.0 22.5 79.0 67.2 18.5 88.7 51.2 20.3 99.2 34.9 22.5

3150 80 124.4 80.3 18.5 91.4 65.5 20.3 102.2 49.1 22.5 80.2 78.9 18.5 88.6 64.4 20.3 99.1 48.1 22.5

85 86.1 85.3 19.4 91.3 76.4 20.3 102.1 60.1 22.5 84.1 83.3 19.4 88.6 75.4 20.3 99.0 59.0 22.5

90 90.3 89.5 20.3 91.8 86.7 20.3 102.0 71.0 22.5 88.3 87.5 20.3 89.3 85.4 20.3 98.9 69.8 22.0

75 82.2 70.2 18.5 92.3 53.4 20.7 103.1 36.3 22.5 79.7 69.2 18.5 89.6 52.3 20.3 100.1 35.2 22.5

3375 80 83.5 82.3 18.9 92.2 67.3 20.3 103.0 50.2 22.5 81.4 80.6 18.9 89.5 66.2 20.3 100.0 49.0 22.5

85 87.7 86.8 19.8 92.1 78.9 20.7 103.0 61.6 22.5 85.6 84.8 19.8 89.4 77.7 20.3 99.9 60.5 22.5

90 92.1 91.2 20.3 93.0 89.3 20.7 102.9 73.1 22.5 89.9 89.0 20.3 90.4 87.8 20.7 99.7 71.9 22.5

ENT Water Temp (°F)

Entering Wet Bulb Temperature (°F)

Table PD-7 — Gross Cooling Capacities SAVE-075 (Cont.)

ENT Water Temp (°F)

Ent. 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 74.7 62.0 18.1 84.1 47.7 19.8 94.0 33.2 21.6

2700 80 75.4 73.0 18.1 84.0 59.4 19.8 94.0 44.9 21.6

85 78.5 77.8 18.5 84.0 69.2 19.8 93.9 54.6 21.6

90 82.5 81.7 19.4 84.3 78.6 19.8 93.8 64.4 21.6

75 75.6 63.0 18.1 85.0 48.9 19.8 95.1 33.5 22.0

2925 80 76.7 75.2 18.5 84.9 61.4 19.8 95.0 46.0 22.0

85 80.3 79.6 18.9 84.9 71.7 19.8 95.0 56.3 22.0

90 84.4 83.6 19.8 85.5 81.4 20.3 94.9 66.6 22.0

75 76.4 66.0 18.1 85.9 50.1 20.3 96.0 33.8 22.0

3150 80 78.0 77.1 18.5 85.8 63.2 20.3 95.9 46.9 22.0

85 81.9 81.2 19.4 85.8 74.1 20.3 95.8 57.9 22.0

90 86.1 85.3 20.3 86.7 83.9 20.3 95.7 68.8 22.0

75 77.2 68.0 18.5 86.6 51.1 20.3 96.8 34.1 22.5

3375 80 79.3 78.5 18.9 86.5 65.0 20.3 96.7 47.9 22.5

85 83.4 82.6 19.8 86.5 76.4 20.3 96.7 59.4 22.0

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 87.6 86.7 20.3 87.9 86.1 20.3 96.6 70.8 22.0

Entering Wet Bulb Temperature (°F)

95

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°F) GPM MBh MBh

4.5 2.21 1.01 1.01

7.2 1.39 1.01 1.01

10.0 1.00 1.00 1.00

12.6 0.79 0.99 1.00

15.3 0.66 0.99 1.00

18.0 0.56 0.98 0.99

PKG-PRC007-EN18

Page 19

Performance

Water Cooled

Data

60 Hz

Table PD-7 — Gross Cooling Capacities SAVE-075 Metric

24.0 29.5

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 23.3 18.8 1.14 26.2 14.6 1.25 29.3 10.3 1.39 22.6 18.5 1.14 25.4 14.3 1.25 28.4 10.0 1.39

4590 27 23.4 22.2 1.14 26.2 18.1 1.25 29.3 13.8 1.39 22.8 21.8 1.14 25.4 17.8 1.25 28.4 13.5 1.39

29 24.2 23.9 1.17 26.1 21.0 1.25 29.3 16.6 1.39 23.6 23.4 1.17 25.4 20.6 1.25 28.4 16.3 1.39

32 25.3 25.1 1.22 26.2 23.8 1.25 29.2 19.5 1.39 24.8 24.5 1.22 25.4 23.4 1.25 28.4 19.2 1.36

24 23.6 19.4 1.14 26.5 15.0 1.28 29.7 10.5 1.42 22.9 19.1 1.14 25.7 14.6 1.28 28.8 10.1 1.39

4970 27 23.8 22.9 1.17 26.5 18.6 1.28 29.6 14.1 1.42 23.1 22.5 1.17 25.7 18.5 1.28 28.8 13.8 1.39

29 24.7 24.5 1.19 26.5 21.7 1.28 29.6 17.1 1.39 24.2 23.9 1.19 25.7 21.4 1.28 28.7 16.8 1.39

32 25.9 25.7 1.25 26.6 24.6 1.28 29.6 20.2 1.39 25.3 25.1 1.25 25.8 24.2 1.28 28.7 19.8 1.39

24 23.8 20.0 1.17 26.8 15.3 1.28 30.0 10.6 1.42 23.1 19.7 1.17 26.0 15.0 1.28 29.1 10.2 1.42

5355 27 36.5 23.5 1.17 26.8 19.2 1.28 29.9 14.4 1.42 23.5 23.1 1.17 26.0 18.9 1.28 29.0 14.1 1.42

29 25.2 25.0 1.22 26.7 22.4 1.28 29.9 17.6 1.42 24.6 24.4 1.22 26.0 22.1 1.28 29.0 17.3 1.42

32 26.5 26.2 1.28 26.9 25.4 1.28 29.9 20.8 1.42 25.9 25.6 1.28 26.2 25.0 1.28 29.0 20.5 1.39

24 24.1 20.6 1.17 27.1 15.7 1.31 30.2 10.6 1.42 23.4 20.3 1.17 26.2 15.3 1.28 29.3 10.3 1.42

5740 27 24.5 24.1 1.19 27.0 19.7 1.28 30.2 14.7 1.42 23.9 23.6 1.19 26.2 19.4 1.28 29.3 14.4 1.42

29 25.7 25.4 1.25 27.0 23.1 1.31 30.2 18.1 1.42 25.1 24.9 1.25 26.2 22.8 1.28 29.3 17.7 1.42

32 27.0 26.7 1.28 27.2 26.2 1.31 30.2 21.4 1.42 26.3 26.1 1.28 26.5 25.7 1.31 29.2 21.1 1.42

ENT Water Temp (°C)

Entering Wet Bulb Temperature (°C)

Table PD-7 — Gross Cooling Capacities SAVE-075 (Cont.)

ENT Water Temp (°C)

Ent. 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 21.9 18.2 1.14 24.6 14.0 1.25 27.5 9.7 1.36

4590 27 22.1 21.4 1.14 24.6 17.4 1.25 27.5 13.2 1.36

29 23.0 22.8 1.17 24.6 20.3 1.25 27.5 16.0 1.36

32 24.2 23.9 1.22 24.7 23.0 1.25 27.5 18.9 1.36

24 22.1 18.5 1.14 24.9 14.3 1.25 27.9 9.8 1.39

4970 27 22.5 22.0 1.17 24.9 18.0 1.25 27.8 13.5 1.39

29 23.5 23.3 1.19 24.9 21.0 1.25 27.8 16.5 1.39

32 24.7 24.5 1.25 25.1 23.8 1.28 27.8 19.5 1.39

24 22.4 19.4 1.14 25.2 14.7 1.28 28.1 9.9 1.39

5355 27 22.9 22.6 1.17 25.1 18.5 1.28 28.1 13.8 1.39

29 24.0 23.8 1.22 25.1 21.7 1.28 28.1 17.0 1.39

32 25.2 25.0 1.28 25.4 24.6 1.28 28.0 20.2 1.39

24 22.6 19.9 1.17 25.4 15.0 1.28 28.4 10.0 1.42

5740 27 23.2 23.0 1.19 25.3 19.0 1.28 28.3 14.0 1.42

29 24.4 24.2 1.25 25.3 22.4 1.28 28.3 17.4 1.39

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 25.7 25.4 1.28 25.7 25.2 1.28 28.3 20.7 1.39

Entering Wet Bulb Temperature (°C)

35.0

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°C) l/s kW kW

2.5 2.21 1.01 1.01

4.0 1.39 1.01 1.01

5.5 1.00 1.00 1.00

7.0 0.79 0.99 1.00

8.5 0.66 0.99 1.00

10.0 0.56 0.98 0.99

19PKG-PRC007-EN

Page 20

Performance

Water Cooled

Data

60 Hz

Table PD-8 — Gross Cooling Capacities SAVE-100 English

75 85

Ent. 61 67 73 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 109.9 87.9 26.0 122.7 68.5 28.6 136.6 48.7 31.7 106.7 86.3 26.0 119.5 67.1 28.6 133.2 47.5 31.3

3600 80 110.1 103.3 26.0 122.6 84.1 28.6 136.5 64.4 31.7 107.1 101.7 26.0 119.4 82.7 28.6 133.1 63.1 31.3

85 112.7 112.7 26.9 122.5 97.1 28.6 136.4 77.4 31.7 110.1 110.1 26.9 119.3 95.8 28.6 133.0 76.1 31.3

90 117.7 117.7 27.8 122.5 110.0 28.6 136.3 90.3 31.7 115.3 115.3 27.8 119.3 108.6 28.6 132.9 89.0 31.3

75 111.2 90.7 26.4 124.2 70.1 29.1 138.2 49.2 31.7 108.0 89.2 26.4 120.9 68.7 29.1 134.7 47.9 31.7

3900 80 111.8 106.8 26.4 124.1 86.7 29.1 138.0 65.8 31.7 108.8 105.1 26.4 120.7 85.3 29.1 134.6 64.6 31.7

85 115.3 115.3 27.3 124.0 100.5 29.1 137.9 79.6 31.7 112.7 112.7 27.3 120.7 99.1 29.1 134.5 78.3 31.7

90 120.5 120.5 28.2 124.1 114.0 29.1 137.8 93.3 31.7 117.9 117.9 28.2 120.9 112.5 29.1 134.4 92.0 31.7

75 112.5 93.4 26.9 125.6 71.7 29.5 139.6 49.6 32.2 109.3 91.9 26.4 122.2 70.2 29.1 136.1 48.4 32.2

4200 80 113.3 110.1 26.9 125.5 89.2 29.5 139.5 67.2 32.2 110.3 108.2 26.9 122.1 87.9 29.1 136.0 65.9 32.2

85 117.6 117.6 27.8 125.3 103.8 29.5 139.4 81.7 32.2 114.9 114.9 27.8 122.0 102.4 29.1 135.9 80.4 31.7

90 123.0 123.0 28.6 125.7 117.8 29.5 139.3 96.2 32.2 120.4 120.4 28.6 122.5 116.3 29.5 135.8 94.9 31.7

75 113.6 96.0 26.9 126.7 73.1 29.5 140.8 50.1 32.6 110.3 94.6 26.9 123.3 71.8 29.5 137.3 48.7 32.2

4500 80 114.8 113.0 27.3 126.6 91.7 29.5 140.7 68.5 32.6 111.9 110.9 27.3 123.2 90.2 29.5 137.2 67.3 32.2

85 119.7 119.7 28.2 126.5 106.9 29.5 140.6 83.7 32.2 117.0 117.0 28.2 123.1 105.6 29.5 137.1 82.5 32.2

90 125.2 125.2 29.5 127.2 121.3 29.5 140.5 99.0 32.2 122.6 122.6 29.5 124.0 119.7 29.5 137.0 97.7 32.2

ENT Water Temp (°F)

Entering Wet Bulb Temperature (°F)

Table PD-8 — Gross Cooling Capacities SAVE-100 (Cont.)

ENT Water Temp (°F)

Ent. 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 103.6 84.9 26.0 116.1 65.6 28.6 129.7 46.1 31.3

3600 80 104.1 100.0 26.0 116.0 81.4 28.6 129.6 61.8 31.3

85 107.6 107.6 26.9 115.9 94.3 28.6 129.5 74.8 31.3

90 112.7 112.7 27.8 116.1 107.0 28.6 129.4 87.7 31.3

75 105.0 87.7 26.4 117.5 67.3 29.1 131.1 46.7 31.7

3900 80 105.8 103.3 26.4 117.4 83.9 28.6 131.0 63.2 31.7

85 110.1 110.1 27.3 117.3 97.6 28.6 130.9 76.9 31.7

90 115.3 115.3 28.2 117.7 110.9 29.1 130.8 90.6 31.7

75 106.1 90.3 26.4 118.8 68.8 29.1 132.5 47.1 31.7

4200 80 107.3 106.2 26.9 118.6 86.4 29.1 132.4 64.6 31.7

85 112.3 112.3 27.8 118.6 100.9 29.1 132.3 79.1 31.7

90 117.6 117.6 29.1 119.3 114.5 29.1 132.2 93.5 31.7

75 107.0 93.0 26.9 119.8 70.4 29.5 133.6 47.5 32.2

4500 80 109.0 108.7 27.3 119.7 88.8 29.5 133.5 65.9 32.2

85 114.3 114.3 28.2 119.6 104.1 29.5 133.4 81.2 32.2

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 119.9 119.9 29.5 120.7 117.8 29.5 133.3 96.4 32.2

Entering Wet Bulb Temperature (°F)

95

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°F) GPM MBh MBh

4.5 2.21 1.01 1.01

7.2 1.39 1.01 1.01

10.0 1.00 1.00 1.00

12.6 0.79 0.99 1.00

15.3 0.66 0.99 1.00

18.0 0.56 0.98 0.99

PKG-PRC007-EN20

Page 21

Performance

Water Cooled

Data

60 Hz

Table PD-8 — Gross Cooling Capacities SAVE-100 Metric

24.0 29.5

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 32.2 25.7 1.64 35.9 20.1 1.81 40.0 14.3 2.00 31.3 25.3 1.64 35.0 19.6 1.81 39.0 13.9 1.97

6120 27 32.3 30.3 1.64 35.9 24.7 1.81 40.0 18.9 2.00 31.4 29.8 1.64 35.0 24.2 1.81 39.0 18.5 1.97

29 33.0 33.0 1.70 35.9 28.5 1.81 40.0 22.7 2.00 32.3 32.3 1.70 34.9 28.1 1.81 39.0 22.3 1.97

32 34.5 34.5 1.75 35.9 32.2 1.81 39.9 26.5 2.00 33.8 33.8 1.75 34.9 31.8 1.81 38.9 26.1 1.97

24 32.6 26.6 1.67 36.4 20.6 1.83 40.5 14.4 2.00 31.7 26.1 1.67 35.4 20.1 1.83 39.5 14.0 2.00

6630 27 32.7 31.3 1.67 36.4 25.4 1.83 40.4 19.3 2.00 31.9 30.8 1.67 35.4 25.0 1.83 39.4 18.9 2.00

29 33.8 33.8 1.72 36.3 29.5 1.83 40.4 23.3 2.00 33.0 33.0 1.72 35.4 29.0 1.83 39.4 22.9 2.00

32 35.3 35.3 1.78 36.4 33.4 1.83 40.4 27.3 2.00 34.6 34.6 1.78 35.4 33.0 1.83 39.4 27.0 2.00

24 33.0 27.4 1.70 36.8 21.0 1.86 40.9 14.5 2.03 32.0 26.9 1.67 35.8 20.6 1.83 39.9 14.2 2.03

7140 27 33.2 32.3 1.70 36.8 26.1 1.86 40.9 19.7 2.03 32.3 31.7 1.70 35.8 25.7 1.83 39.8 19.3 2.03

29 34.5 34.5 1.75 36.7 30.4 1.86 40.8 23.9 2.03 33.7 33.7 1.75 35.7 30.0 1.83 39.8 23.6 2.00

32 36.0 36.0 1.81 36.8 34.5 1.86 40.8 28.2 2.03 35.3 35.3 1.81 35.9 34.1 1.86 39.8 27.8 2.00

24 33.3 28.1 1.70 37.1 21.4 1.86 41.3 14.7 2.06 32.3 27.7 1.70 36.1 21.0 1.86 40.2 14.3 2.03

7650 27 33.6 33.1 1.72 37.1 26.9 1.86 41.2 20.1 2.06 32.8 32.5 1.72 36.1 26.4 1.86 40.2 19.7 2.03

29 35.1 35.1 1.78 37.1 31.3 1.86 41.2 24.5 2.03 34.3 34.3 1.78 36.1 30.9 1.86 40.2 24.2 2.03

32 36.7 36.7 1.86 37.3 35.6 1.86 41.2 29.0 2.03 35.9 35.9 1.86 36.3 35.1 1.86 40.1 28.6 2.03

ENT Water Temp (°C)

Entering Wet Bulb Temperature (°C)

Table PD-8 — Gross Cooling Capacities SAVE-100 (Cont.)

ENT Water Temp (°C)

Ent. 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 30.4 24.9 1.64 34.0 19.2 1.81 38.0 13.5 1.97

6210 27 30.5 29.3 1.64 34.0 23.8 1.81 38.0 18.1 1.97

29 31.5 31.5 1.70 34.0 27.6 1.81 37.9 21.9 1.97

32 33.0 33.0 1.75 34.0 31.4 1.81 37.9 25.7 1.97

24 30.8 25.7 1.67 34.4 19.7 1.83 38.4 13.7 2.00

6630 27 31.0 30.3 1.67 34.4 24.6 1.81 38.4 18.5 2.00

29 32.3 32.3 1.72 34.4 28.6 1.81 38.4 22.5 2.00

32 33.8 33.8 1.78 34.5 32.5 1.83 38.3 26.6 2.00

24 31.1 26.5 1.67 34.8 20.2 1.83 38.8 13.8 2.00

7140 27 31.4 31.1 1.70 34.7 25.3 1.83 38.8 18.9 2.00

29 32.9 32.9 1.75 34.7 29.6 1.83 38.8 23.2 2.00

32 34.5 34.5 1.83 34.9 33.6 1.83 38.7 27.4 2.00

24 31.4 27.3 1.70 35.1 20.6 1.86 39.1 13.9 2.03

7650 27 31.9 31.8 1.72 35.1 26.0 1.86 39.1 19.3 2.03

29 33.5 33.5 1.78 35.0 30.5 1.86 39.1 23.8 2.03

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 35.1 35.1 1.86 35.4 34.5 1.86 39.1 28.2 2.03

Entering Wet Bulb Temperature (°C)

35.0

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°C) l/s kW kW

2.5 2.21 1.01 1.01

4.0 1.39 1.01 1.01

5.5 1.00 1.00 1.00

7.0 0.79 0.99 1.00

8.5 0.66 0.99 1.00

10.0 0.56 0.98 0.99

21PKG-PRC007-EN

Page 22

Performance

Water Cooled

Data

60 Hz

Table PD-9 — Gross Cooling Capacities SAVE-125 English

75 85

Ent. 61 67 73 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 135.8 109.8 31.3 151.7 85.3 34.4 169.3 60.3 37.9 131.7 107.9 31.3 147.4 83.5 34.4 164.4 58.5 37.4

4500 80 136.1 129.4 31.7 151.6 105.3 34.4 169.1 80.3 37.9 132.3 127.2 31.3 147.3 103.4 34.4 164.3 78.4 37.4

85 140.1 140.1 32.2 151.5 121.8 34.4 168.9 96.8 37.9 136.8 136.8 32.2 147.1 119.9 34.4 164.1 95.0 37.4

90 146.6 146.6 33.5 151.6 138.1 34.4 168.7 113.2 37.9 143.2 143.2 33.5 147.5 136.1 34.4 164.0 111.5 37.4

75 137.3 113.5 31.7 153.6 87.4 34.8 171.3 60.9 38.3 133.2 111.5 31.7 149.1 85.5 34.8 166.3 59.1 37.9

4875 80 138.2 133.7 31.7 153.5 108.6 34.8 171.0 82.0 38.3 134.3 131.4 31.7 149.3 107.0 34.8 166.1 80.2 37.9

85 143.2 143.2 32.6 153.3 126.2 34.8 170.8 99.6 38.3 139.9 139.9 32.6 148.9 124.3 34.8 165.9 97.8 37.9

90 149.9 149.9 33.9 153.7 143.2 34.8 170.7 117.0 38.3 146.5 146.5 33.9 149.4 141.0 34.8 165.9 115.3 37.9

75 138.9 117.0 32.2 155.3 89.4 35.2 172.8 61.5 38.8 134.7 115.0 31.7 150.7 87.5 34.8 167.9 59.6 38.3

5250 80 140.3 137.7 32.2 155.1 111.7 35.2 172.7 83.8 38.8 136.4 134.9 32.2 150.5 109.8 34.8 167.7 82.0 38.3

85 146.2 146.2 33.5 154.9 130.3 35.2 172.6 102.4 38.8 142.7 142.7 33.5 150.4 128.4 34.8 167.7 100.5 38.3

90 153.1 153.1 34.8 155.7 147.9 35.2 172.4 120.8 38.3 149.5 149.5 34.8 151.4 145.6 35.2 167.5 119.0 38.3

75 140.2 120.2 32.2 156.7 91.2 35.2 174.4 62.0 38.8 136.0 119.4 32.2 151.9 89.4 35.2 169.4 60.2 38.8

5625 80 140.7 140.0 32.6 156.5 114.9 35.2 174.2 85.5 38.8 138.5 138.0 32.6 151.9 113.0 35.2 169.2 83.7 38.8

85 148.8 148.8 33.9 156.3 134.3 35.2 174.1 104.9 38.8 145.2 145.2 33.9 151.7 132.4 35.2 169.1 103.1 38.8

90 155.9 155.9 35.2 157.6 152.1 35.7 174.0 124.3 38.8 152.1 152.1 35.2 153.4 149.7 35.7 168.9 122.4 38.8

ENT Water Temp (°F)

Entering Wet Bulb Temperature (°F)

Table PD-9 — Gross Cooling Capacities SAVE-125 (Cont.)

ENT Water Temp (°F)

Ent. 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 127.6 105.9 31.3 142.9 81.6 33.9 159.5 56.7 37.4

4500 80 128.4 124.8 31.3 142.7 101.4 33.9 159.4 76.7 37.4

85 133.4 133.4 32.2 142.6 118.0 33.9 159.2 93.1 37.4

90 139.7 139.7 33.5 143.0 134.0 34.4 159.1 109.5 37.4

75 129.0 109.6 31.3 144.5 83.5 34.4 161.2 57.3 37.9

4875 80 132.6 128.7 31.7 144.4 104.7 34.4 161.0 78.4 37.9

85 136.4 136.4 33.0 144.2 122.3 34.4 161.0 96.0 37.9

90 142.9 142.9 34.4 145.0 138.7 34.8 160.8 113.4 37.9

75 130.3 113.0 31.7 146.0 85.6 34.8 162.8 57.9 37.9

5250 80 132.6 132.0 32.2 145.8 107.9 34.8 162.5 80.1 37.9

85 139.0 139.0 33.5 145.6 126.4 34.8 162.4 98.7 37.9

90 145.8 145.8 34.8 147.0 143.1 34.8 162.2 117.0 37.9

75 131.6 116.2 32.2 147.2 87.5 34.8 164.1 58.3 38.3

5625 80 134.7 134.6 32.6 147.1 111.0 34.8 163.9 81.8 38.3

85 141.5 141.5 33.9 147.0 130.4 34.8 163.8 101.3 38.3

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 148.4 148.4 35.2 161.5 147.0 35.2 163.7 120.6 38.3

Entering Wet Bulb Temperature (°F)

95

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°F) GPM MBh MBh

4.5 2.21 1.01 1.01

7.2 1.39 1.01 1.01

10.0 1.00 1.00 1.00

12.6 0.79 0.99 1.00

15.3 0.66 0.99 1.00

18.0 0.56 0.98 0.99

PKG-PRC007-EN22

Page 23

Performance

Water Cooled

Data

60 Hz

Table PD-9 — Gross Cooling Capacities SAVE-125 Metric

24.0 29.5

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 39.8 32.2 1.97 44.5 25.0 2.17 49.6 17.7 2.39 38.6 31.6 1.97 43.2 24.5 2.17 48.2 17.1 2.36

7650 27 39.9 37.9 2.00 44.4 30.9 2.17 49.5 23.5 2.39 38.8 37.3 1.97 43.2 30.3 2.17 48.1 23.0 2.36

29 41.0 41.0 2.03 44.4 35.7 2.17 49.5 28.4 2.39 40.1 40.1 2.03 43.1 35.1 2.17 48.1 27.8 2.36

32 42.9 42.9 2.11 44.4 40.5 2.17 49.4 33.2 2.39 42.0 42.0 2.11 43.2 39.9 2.17 48.1 32.7 2.36

24 40.2 33.3 2.00 45.0 25.6 2.20 50.2 17.8 2.42 39.0 32.7 2.00 43.7 25.0 2.20 48.7 17.3 2.39

8285 27 40.5 39.2 2.00 45.0 31.8 2.20 50.1 24.0 2.42 39.3 38.5 2.00 43.7 31.4 2.20 48.7 23.5 2.39

29 42.0 42.0 2.06 44.9 37.0 2.20 50.1 29.2 2.42 41.0 41.0 2.06 43.6 36.4 2.20 48.6 28.6 2.39

32 43.9 43.9 2.14 45.0 42.0 2.20 50.0 34.3 2.42 42.9 42.9 2.14 43.8 41.3 2.20 48.6 33.8 2.39

24 40.7 34.3 2.03 45.5 26.2 2.22 50.6 18.0 2.45 39.5 33.7 2.00 44.1 25.6 2.20 49.2 17.5 2.42

8920 27 41.1 40.3 2.03 45.4 32.7 2.22 50.6 24.6 2.45 40.0 39.5 2.03 44.1 32.2 2.20 49.1 24.0 2.42

29 42.8 42.8 2.11 45.4 38.2 2.22 50.6 30.0 2.45 41.8 41.8 2.11 44.1 37.6 2.20 49.1 29.4 2.42

32 44.9 44.9 2.20 45.6 43.3 2.22 50.5 35.4 2.42 43.8 43.8 2.20 44.4 42.7 2.22 49.1 34.9 2.42

24 41.1 35.2 2.03 45.9 26.7 2.22 51.1 18.2 2.45 39.8 35.0 2.03 44.5 26.2 2.22 49.6 17.6 2.45

9560 27 41.2 41.0 2.06 45.8 33.7 2.22 51.0 25.0 2.45 40.6 40.4 2.06 44.5 33.1 2.22 49.6 24.5 2.45

29 43.6 43.6 2.14 45.8 39.3 2.22 51.0 30.7 2.45 42.5 42.5 2.14 44.5 38.8 2.22 49.5 30.2 2.45

32 45.7 45.7 2.22 46.2 44.6 2.25 51.0 36.4 2.45 44.6 44.6 2.22 44.9 43.9 2.25 49.5 35.9 2.45

ENT Water Temp (°C)

Entering Wet Bulb Temperature (°C)

Table PD-9 — Gross Cooling Capacities SAVE-125 (Cont.)

ENT Water Temp (°C)

Ent. 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 37.4 31.0 1.97 41.9 23.9 2.14 46.7 16.6 2.36

7650 27 37.6 36.6 1.97 41.8 29.7 2.14 46.7 22.5 2.36

29 39.1 39.1 2.03 41.8 34.6 2.14 46.6 27.3 2.36

32 40.9 40.9 2.11 41.9 39.3 2.17 46.6 32.1 2.36

24 37.8 32.1 1.97 42.3 24.5 2.17 47.2 16.8 2.39

8285 27 38.9 37.7 2.00 42.3 30.7 2.17 47.2 23.0 2.39

29 40.0 40.0 2.08 42.2 35.8 2.17 47.2 28.1 2.39

32 41.9 41.9 2.17 42.5 40.6 2.20 47.1 33.2 2.39

24 38.2 33.1 2.00 42.8 25.1 2.20 47.7 17.0 2.39

8920 27 38.9 38.7 2.03 42.7 31.6 2.20 47.6 23.5 2.39

29 40.7 40.7 2.11 42.7 37.0 2.20 47.6 28.9 2.39

32 42.7 42.7 2.20 43.1 41.9 2.20 47.5 34.3 2.39

24 38.5 34.1 2.03 43.1 25.6 2.20 48.1 17.1 2.42

9560 27 39.5 39.4 2.06 43.1 32.5 2.20 48.0 24.0 2.42

29 41.5 41.5 2.14 43.1 38.2 2.20 48.0 29.7 2.42

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 43.5 43.5 2.22 47.3 43.1 2.22 48.0 35.3 2.42

Entering Wet Bulb Temperature (°C)

35.0

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°C) l/s kW kW

2.5 2.21 1.01 1.01

4.0 1.39 1.01 1.01

5.5 1.00 1.00 1.00

7.0 0.79 0.99 1.00

8.5 0.66 0.99 1.00

10.0 0.56 0.98 0.99

23PKG-PRC007-EN

Page 24

Performance

Water Cooled

Data

60 Hz

Table PD-10 — Gross Cooling Capacities SAVE-150 English

75 85

Ent. 61 67 73 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 165.6 138.7 37.9 185.4 106.0 41.4 206.9 72.8 45.8 160.4 136.3 37.4 179.6 103.6 41.4 200.2 70.4 45.4

5400 80 167.7 163.2 38.3 185.2 132.7 41.4 206.6 99.4 45.8 163.0 160.0 37.9 179.3 130.3 41.4 200.0 97.1 45.4

85 175.0 173.4 39.6 185.1 154.9 41.4 206.4 121.6 45.8 170.6 169.0 39.6 179.3 152.4 41.4 199.9 119.2 45.4

90 183.4 181.7 41.0 186.5 175.6 41.9 206.3 143.5 45.8 178.8 177.1 41.0 181.0 172.6 41.4 199.7 141.2 45.4

75 167.6 143.7 38.3 187.5 108.8 41.9 209.1 73.5 46.3 162.3 141.2 37.9 181.3 106.4 41.4 202.3 71.1 45.8

5850 80 170.7 168.2 38.8 187.3 137.3 41.9 208.8 101.9 46.3 166.0 164.3 38.8 181.2 135.1 41.4 202.1 99.5 45.8

85 179.0 177.3 40.5 187.3 160.8 41.9 208.6 125.4 46.3 174.4 172.7 40.1 181.4 158.2 41.4 202.0 123.0 45.8

90 187.6 185.8 41.9 189.4 182.0 42.3 208.5 148.8 46.3 182.9 181.2 41.9 183.9 178.8 42.3 201.8 146.4 45.8

75 169.5 148.4 38.3 189.3 111.5 42.3 210.9 74.3 46.7 164.1 145.8 38.3 183.2 109.1 41.9 204.1 71.9 46.3

6300 80 173.8 172.1 39.2 189.2 141.6 42.3 210.8 104.3 46.7 169.2 167.5 39.2 183.0 139.2 41.9 203.9 101.9 45.8

85 182.6 180.9 41.0 189.4 166.4 42.3 210.6 129.2 46.7 177.8 176.1 41.0 183.4 163.7 41.9 203.8 126.8 45.8

90 191.4 189.6 42.7 192.3 187.6 42.7 210.5 154.0 46.7 186.5 184.7 42.7 186.8 184.0 42.7 203.7 151.6 45.8

75 171.2 152.9 38.8 191.0 114.2 42.7 212.7 74.9 46.7 164.1 150.2 38.8 184.8 111.7 42.3 205.8 72.6 46.3

6750 80 176.8 175.1 40.1 190.8 145.9 42.7 212.5 106.6 46.7 172.1 170.5 39.6 184.6 143.4 42.3 205.6 104.2 46.3

85 185.9 184.1 41.9 191.3 171.7 42.7 212.4 132.8 46.7 180.9 179.2 41.4 185.3 169.0 42.3 205.4 130.4 46.3

90 194.9 193.0 43.6 195.1 192.5 43.6 212.2 158.9 46.7 189.8 188.0 43.2 189.7 187.9 43.2 205.3 156.5 46.3

ENT Water Temp (°F)

Entering Wet Bulb Temperature (°F)

Table PD-10 — Gross Cooling Capacities SAVE-150 (Cont.)

ENT Water Temp (°F)

Ent. 61 67 73

DB

CFM (°F) TGC SHC GPM TGC SHC GPM TGC SHC GPM

75 155.0 133.7 37.4 173.4 101.1 41.0 193.4 68.0 44.9

5400 80 158.0 156.2 37.9 173.3 127.8 41.0 193.2 94.6 44.9

85 165.9 164.3 39.6 173.4 149.8 41.0 193.1 116.8 44.9

90 174.0 172.3 41.0 175.4 169.5 41.4 192.9 138.7 44.9

75 156.8 138.5 37.9 175.2 103.9 41.4 195.3 68.7 45.4

5850 80 161.3 159.7 38.8 175.0 132.3 41.4 195.2 97.1 45.4

85 169.6 168.0 40.1 175.4 155.6 41.4 195.0 120.6 45.4

90 177.9 176.2 41.9 178.3 175.0 41.9 194.9 144.0 45.4

75 158.4 143.1 37.9 176.8 106.6 41.4 197.0 69.5 45.8

6300 80 164.3 162.8 39.2 176.7 136.7 41.4 196.9 99.4 45.8

85 172.8 171.2 41.0 177.2 161.0 41.9 196.7 124.4 45.4

90 181.3 179.6 42.3 181.3 179.5 42.3 196.6 149.1 45.4

75 160.0 147.4 38.3 178.3 109.2 41.9 198.6 70.1 45.8

6750 80 167.2 165.6 39.6 178.1 140.9 41.9 198.3 101.7 45.8

85 175.8 174.1 41.4 179.0 166.1 42.3 198.2 127.9 45.8

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 184.5 182.7 43.2 184.5 182.7 43.2 198.0 154.0 45.8

Entering Wet Bulb Temperature (°F)

95

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°F) GPM MBh MBh

4.5 2.21 1.01 1.01

7.2 1.39 1.01 1.01

10.0 1.00 1.00 1.00

12.6 0.79 0.99 1.00

15.3 0.66 0.99 1.00

18.0 0.56 0.98 0.99

PKG-PRC007-EN24

Page 25

Performance

Water Cooled

Data

60 Hz

Table PD-10 — Gross Cooling Capacities SAVE-150 Metric

24.0 29.5

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 48.5 40.6 2.39 54.3 31.1 2.61 60.6 21.3 2.89 47.0 39.9 2.36 52.6 30.3 2.61 58.7 20.6 2.86

9180 27 49.1 47.8 2.42 54.3 38.9 2.61 60.5 29.1 2.89 47.7 46.9 2.39 52.5 38.2 2.61 58.6 28.5 2.86

29 51.3 50.8 2.50 54.2 45.4 2.61 60.5 35.6 2.89 50.0 49.5 2.50 52.5 44.6 2.61 58.6 34.9 2.86

32 53.7 53.2 2.58 54.6 51.4 2.64 60.5 42.1 2.89 52.4 51.9 2.58 53.0 50.6 2.61 58.5 41.4 2.86

24 49.1 42.1 2.42 54.9 31.9 2.64 61.3 21.5 2.92 47.6 41.4 2.39 53.2 31.2 2.61 59.3 20.8 2.89

9945 27 50.0 49.3 2.45 54.9 40.2 2.64 61.2 29.9 2.92 48.6 48.1 2.45 53.1 39.6 2.61 59.2 29.2 2.89

29 52.5 52.0 2.56 54.9 47.1 2.64 61.1 36.7 2.92 51.1 50.6 2.53 53.2 46.3 2.61 59.2 36.0 2.89

32 55.0 54.5 2.64 55.5 53.3 2.67 61.1 43.6 2.92 53.6 53.1 2.64 53.9 52.4 2.67 59.1 42.9 2.89

24 49.7 43.5 2.42 55.5 32.7 2.67 61.8 21.8 2.95 48.1 42.7 2.42 53.7 32.0 2.64 59.8 21.1 2.92

10710 27 50.9 50.4 2.47 55.4 41.5 2.67 61.8 30.6 2.95 49.6 49.1 2.47 53.6 40.8 2.64 59.7 29.9 2.89

29 53.5 53.0 2.58 55.5 48.8 2.67 61.7 37.8 2.95 52.1 51.6 2.58 53.7 48.0 2.64 59.7 37.1 2.89

32 56.1 55.6 2.70 56.3 55.0 2.70 61.7 45.1 2.95 54.6 54.1 2.70 54.7 53.9 2.70 59.7 44.4 2.89

24 50.1 44.8 2.45 56.0 33.5 2.70 62.3 21.9 2.95 48.1 44.0 2.45 54.1 32.7 2.67 60.3 21.3 2.92

11475 27 51.8 51.3 2.53 55.9 42.8 2.70 62.3 31.2 2.95 50.4 49.9 2.50 54.1 42.0 2.67 60.2 30.5 2.92

29 54.5 53.9 2.64 56.1 50.3 2.70 62.2 38.9 2.95 53.0 52.5 2.61 54.3 49.5 2.67 60.2 38.2 2.92

32 57.1 56.6 2.75 57.2 56.4 2.75 62.2 46.6 2.95 55.6 55.1 2.72 55.6 55.1 2.72 60.1 45.9 2.92

ENT Water Temp (°C)

Entering Wet Bulb Temperature (°C)

Table PD-10 — Gross Cooling Capacities SAVE-150 (Cont.)

ENT Water Temp (°C)

Ent. 16.0 19.5 23.0

DB

m3/h (°C) TGC SHC l/s TGC SHC l/s TGC SHC l/s

24 45.4 39.2 2.36 50.8 29.6 2.58 56.7 19.9 2.83

9180 27 46.3 45.8 2.39 50.8 37.5 2.58 56.6 27.7 2.83

29 48.6 48.1 2.50 50.8 43.9 2.58 56.6 34.2 2.83

32 51.0 50.5 2.58 51.4 49.7 2.61 56.5 40.6 2.83

24 45.9 40.6 2.39 51.3 30.4 2.61 57.2 20.1 2.86

9945 27 47.3 46.8 2.45 51.3 38.8 2.61 57.2 28.5 2.86

29 49.7 49.2 2.53 51.4 45.6 2.61 57.1 35.3 2.86

32 52.1 51.6 2.64 52.2 51.3 2.64 57.1 42.2 2.86

24 46.4 41.9 2.39 51.8 31.2 2.61 57.7 20.4 2.89

10710 27 48.1 47.7 2.47 51.8 40.0 2.61 57.7 29.1 2.89

29 50.6 50.2 2.58 51.9 47.2 2.64 57.6 36.4 2.86

32 53.1 52.6 2.67 53.1 52.6 2.67 57.6 43.7 2.86

24 46.9 43.2 2.42 52.2 32.0 2.64 58.2 20.5 2.89

11475 27 49.0 48.5 2.50 52.2 41.3 2.64 58.1 29.8 2.89

29 51.5 51.0 2.61 52.5 48.7 2.67 58.1 37.5 2.89

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 54.1 53.5 2.72 54.1 53.5 2.72 58.0 45.1 2.89

Entering Wet Bulb Temperature (°C)

35.0

Capacity Correction Factor Table

Delta T

Water Total Cap. Sens. Cap.

(°C) l/s kW kW

2.5 2.21 1.01 1.01

4.0 1.39 1.01 1.01

5.5 1.00 1.00 1.00

7.0 0.79 0.99 1.00

8.5 0.66 0.99 1.00

10.0 0.56 0.98 0.99

25PKG-PRC007-EN

Page 26

Performance

Air Cooled

Data

60 Hz

Table PD-11 — Gross Cooling Capacities SRVE-050 English

85 95

Ent. 61 67 73 61 67 73

DB

CFM (ºF) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 53.7 44.2 60.2 34.1 67.1 23.9 52.2 43.5 58.4 33.4 65.1 23.1

1800 80 54.1 52.0 60.1 42.4 67.0 32.1 52.6 51.2 58.4 41.7 65.1 31.4

85 56.0 56.0 60.1 49.2 67.0 38.9 54.6 54.6 58.3 48.4 65.0 38.2

90 58.6 58.6 60.2 55.8 66.9 45.7 57.2 57.2 58.5 54.9 65.0 44.9

75 54.4 45.7 61.0 35.0 67.8 24.1 52.8 44.9 59.0 34.2 64.6 23.4

1950 80 54.9 53.7 60.8 43.8 67.7 32.9 53.4 52.8 59.0 42.9 65.7 32.1

85 57.2 57.2 60.8 51.0 67.7 40.1 55.9 55.9 58.9 50.2 65.7 39.3

90 60.0 60.0 61.2 57.9 67.6 47.3 58.5 58.5 59.4 56.9 65.6 46.5

75 55.0 47.2 61.5 35.8 68.5 24.3 53.3 46.4 59.7 35.1 66.5 23.6

2100 80 55.8 55.3 61.5 45.1 68.4 33.5 54.3 54.2 59.6 44.3 66.4 32.8

85 58.4 58.4 61.4 52.7 68.4 41.1 57.0 57.0 59.6 51.9 66.3 40.4

90 61.2 61.2 61.9 59.7 68.3 48.8 59.7 59.7 60.2 58.7 66.3 48.0

75 55.5 48.5 62.0 36.6 69.1 24.5 53.8 47.8 60.2 35.8 67.0 23.7

2250 80 56.6 56.6 62.0 46.3 69.0 34.2 55.2 55.2 60.1 45.6 66.9 33.5

85 59.5 59.5 62.0 54.4 68.9 42.3 58.0 58.0 60.1 53.5 66.9 41.6

90 62.3 62.3 62.6 61.4 71.3 50.2 60.8 60.8 61.0 60.3 66.8 49.5

Ambient Temperature (°F)

Entering Wet Bulb Temperature (°F)

Table PD-11 — Gross Cooling Capacities SRVE-050 (Cont.) English

105 115

Ent. 61 67 73 61 67 73

DB

CFM (ºF) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 50.6 42.7 56.6 32.6 63.0 22.4 48.9 42.0 54.6 31.8 60.6 21.5

1800 80 51.1 50.2 56.5 40.8 63.0 30.5 49.5 49.2 54.5 40.1 60.6 29.8

85 53.3 53.3 56.5 47.7 62.9 37.4 51.8 51.8 54.5 46.9 60.5 36.6

90 55.8 55.8 56.7 54.1 62.9 44.1 54.3 54.3 54.9 53.0 60.5 43.2

75 51.1 44.2 57.1 33.5 63.6 22.6 49.4 43.4 55.1 32.6 61.3 21.7

1950 80 51.9 51.7 57.1 42.2 63.6 31.3 50.5 50.5 55.1 41.3 61.2 30.4

85 54.5 54.5 57.1 49.4 63.5 38.5 52.9 52.9 55.1 48.5 61.2 37.6

90 57.0 57.0 57.6 56.0 63.5 45.7 55.4 55.4 55.8 54.8 61.1 44.8

75 51.6 45.6 57.7 34.2 64.1 22.8 49.9 44.9 55.7 33.5 61.7 21.9

2100 80 52.9 52.9 57.7 43.5 64.1 32.0 51.4 51.4 55.5 42.7 61.7 31.2

85 55.5 55.5 57.7 51.1 64.0 39.6 54.0 54.0 55.7 50.2 61.6 38.8

90 58.2 58.2 58.4 57.6 64.0 47.3 56.5 56.5 56.5 56.3 61.6 46.3

75 52.2 47.0 58.2 35.1 64.7 23.0 50.4 46.1 56.1 34.2 62.2 22.2

2250 80 53.7 53.7 58.1 44.7 64.7 32.6 52.3 52.3 56.1 43.9 62.1 31.8

85 56.5 56.5 58.2 52.7 64.6 40.7 54.8 54.8 56.2 51.8 62.1 39.9

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 59.1 59.1 59.3 59.0 64.6 48.7 57.5 57.5 57.5 57.5 62.0 47.8

Ambient Temperature (°F)

Entering Wet Bulb Temperature (°F)

PKG-PRC007-EN26

Page 27

Performance

Air Cooled

Data

60 Hz

Table PD-11 — Gross Cooling Capacities SRVE-050 Metric

29.5 35.0

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (ºC) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

24 22.5 18.6 25.2 14.3 28.1 10.0 21.7 18.2 24.3 14.0 27.1 9.6

4590 27 22.6 21.9 25.2 17.8 28.0 13.5 21.9 21.5 24.3 17.5 27.1 13.1

29 23.4 23.4 25.1 20.7 28.0 16.3 22.8 22.8 24.3 20.3 27.1 16.0

32 24.6 24.6 25.2 23.5 28.0 19.2 23.9 23.9 24.4 23.1 27.1 18.9

24 22.7 19.2 25.5 14.7 28.4 10.1 22.0 18.9 24.6 14.3 27.4 9.7

4970 27 23.0 22.6 25.4 18.4 28.4 13.8 22.3 22.1 24.6 18.0 27.4 13.4

29 24.0 24.0 25.4 21.5 28.3 16.8 23.3 23.3 24.6 21.1 27.3 16.5

32 25.1 25.1 25.6 24.3 28.3 19.9 24.5 24.5 24.8 23.9 27.3 19.5

24 23.0 19.8 25.7 15.0 28.6 10.2 22.2 19.4 24.8 14.7 27.6 9.8

5355 27 23.3 23.2 25.7 18.9 28.6 14.1 22.6 22.6 24.8 18.6 27.6 13.7

29 24.5 24.5 25.7 22.2 28.6 17.3 23.8 23.8 24.8 21.8 27.6 16.9

32 25.7 25.7 25.9 25.1 28.6 20.5 24.9 24.9 25.1 24.6 27.6 20.2

24 23.2 20.4 25.9 15.3 28.9 10.2 22.4 20.0 25.0 15.0 27.9 9.9

5740 27 23.7 23.7 25.9 19.5 28.9 14.3 23.0 23.0 25.0 19.1 27.8 14.0

29 24.9 24.9 25.9 22.9 28.8 17.7 24.2 24.2 25.0 22.5 27.8 17.4

32 26.1 26.1 26.2 25.8 28.8 21.1 25.4 25.4 25.4 25.3 27.8 20.8

Ambient Temperature (°C)

Entering Wet Bulb Temperature (°C)

Table PD-11 — Gross Cooling Capacities SRVE-050 (Cont.) Metric

40.5 46

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (ºC) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

24 20.9 17.9 23.4 13.6 26.1 9.3 20.1 17.5 22.5 13.2 25.1 8.9

4590 27 21.2 21.0 23.4 17.1 26.1 12.8 20.5 20.4 22.5 16.7 25.1 12.4

29 22.2 22.2 23.4 20.0 26.1 15.6 21.5 21.5 22.5 19.6 25.0 15.2

32 23.3 23.3 23.6 22.7 26.1 18.5 22.5 22.5 22.7 22.2 25.0 18.1

24 21.2 18.5 23.7 14.0 26.4 9.4 20.3 18.1 22.7 13.6 25.3 9.0

4970 27 21.6 21.6 23.7 17.7 26.3 13.0 20.9 20.9 22.7 17.3 25.3 12.7

29 22.6 22.6 23.7 20.7 26.3 16.1 21.9 21.9 22.7 20.3 25.3 15.7

32 23.8 23.8 23.9 23.4 26.3 19.2 23.0 23.0 23.0 22.9 25.3 18.8

24 21.4 19.1 23.9 14.3 26.6 9.4 20.5 18.7 23.0 13.9 25.5 9.1

5355 27 22.0 22.0 23.9 18.2 26.6 13.4 21.2 21.2 22.9 17.8 25.5 13.0

29 23.1 23.1 23.9 21.4 26.6 16.6 22.3 22.3 23.0 21.0 25.5 16.2

32 24.2 24.2 24.3 24.1 26.5 19.8 23.4 23.4 23.4 23.4 25.5 19.4

24 21.6 19.6 24.1 14.6 26.8 9.5 20.7 19.2 23.1 14.2 25.7 9.2

5740 27 22.3 22.3 24.1 18.7 26.8 13.6 21.6 21.6 23.1 18.3 25.7 13.3

29 23.5 23.5 24.1 22.1 26.8 17.0 22.7 22.7 23.2 21.6 25.7 16.6

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 24.6 24.6 24.6 24.6 26.7 20.4 23.8 23.8 23.8 23.8 25.7 20.0

Ambient Temperature (°C)

Entering Wet Bulb Temperature (°C)

27PKG-PRC007-EN

Page 28

Performance

Air Cooled

Data

60 Hz

Table PD-12 — Gross Cooling Capacities SRVE-075 English

85 95

Ent. 61 67 73 61 67 73

DB

CFM (ºF) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 76.6 63.5 85.9 48.9 95.8 34.0 74.1 62.2 83.0 47.7 92.5 32.9

2700 80 77.2 74.7 85.9 60.8 95.7 46.0 74.7 73.2 83.0 59.6 92.4 44.7

85 80.0 80.0 85.8 70.7 95.6 55.8 77.9 77.9 82.9 69.4 92.3 54.6

90 84.0 84.0 86.0 80.2 95.5 65.6 81.7 81.7 83.3 78.9 92.3 64.4

75 77.5 65.6 86.9 50.1 96.8 34.5 74.9 64.3 84.0 48.9 93.5 33.2

2925 80 78.4 77.1 86.8 62.8 96.8 47.0 76.0 75.5 83.8 61.5 93.4 45.8

85 81.8 81.8 86.7 73.2 96.7 57.5 79.6 79.6 83.8 72.0 93.3 56.3

90 85.8 85.8 87.2 83.1 96.6 67.8 83.5 83.5 84.5 81.6 93.3 66.7

75 78.3 67.6 87.8 51.3 97.7 34.7 75.7 66.4 84.8 50.0 94.3 33.5

3150 80 79.6 79.2 87.7 64.7 97.6 48.0 77.3 77.3 84.7 63.4 94.2 46.9

85 83.5 83.5 87.7 75.7 97.5 59.0 81.2 81.2 84.7 74.4 94.1 57.8

90 87.6 87.6 88.4 85.6 97.5 70.0 85.1 85.1 85.6 84.1 94.1 68.8

75 79.1 69.5 88.5 52.4 98.5 35.0 76.4 68.3 85.4 51.2 95.1 33.8

3375 80 80.9 80.9 88.5 66.5 98.5 49.0 78.7 78.7 85.3 65.2 95.0 47.8

85 85.0 85.0 88.4 78.0 98.4 60.5 82.6 82.6 85.4 76.6 94.9 59.4

90 89.0 89.0 89.5 88.0 98.3 72.1 86.6 86.6 86.8 86.2 94.9 70.9

Ambient Temperature (°F)

Entering Wet Bulb Temperature (°F)

Table PD-12 — Gross Cooling Capacities SRVE-075 (Cont.) English

105 115

Ent. 61 67 73 61 67 73

DB

CFM (ºF) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 71.3 61.0 80.0 46.4 89.1 31.7 68.5 59.7 76.9 45.2 85.6 30.4

2700 80 72.3 71.6 79.9 58.3 89.0 43.6 69.9 69.6 76.7 57.0 85.5 42.3

85 75.7 75.7 79.8 68.2 88.9 53.3 73.4 73.4 76.7 66.9 85.4 52.0

90 79.4 79.4 80.5 77.4 88.9 63.2 76.9 76.9 77.5 75.7 85.4 61.9

75 72.2 63.1 80.9 47.7 90.0 32.0 69.3 61.7 77.6 46.3 86.4 30.7

2925 80 73.7 73.6 80.8 60.3 89.9 44.5 71.2 71.2 77.5 58.9 86.3 43.2

85 77.3 77.3 80.8 70.7 89.9 55.0 74.8 74.8 77.6 69.3 86.3 53.7

90 81.1 81.1 81.6 79.9 89.8 65.4 78.5 78.5 78.7 78.0 86.2 64.1

75 72.9 65.1 81.6 48.8 90.8 32.2 70.0 63.7 78.3 47.5 87.1 31.0

3150 80 74.9 74.9 81.5 62.1 90.7 45.6 72.5 72.5 78.2 60.7 87.0 44.3

85 78.8 78.8 81.5 73.0 90.6 56.6 76.2 76.2 78.3 71.7 87.0 55.3

90 82.6 82.6 82.8 82.2 90.5 67.5 79.9 79.9 79.9 79.9 86.9 66.3

75 73.6 67.0 82.3 49.9 91.5 32.5 70.7 65.5 78.9 48.5 87.8 31.3

3375 80 76.2 76.2 82.2 63.9 91.4 46.5 73.7 73.7 78.9 62.5 87.7 45.3

85 80.1 80.1 82.3 75.3 91.4 58.1 77.5 77.5 79.1 73.8 87.6 56.8

Notes:

TGC = Total Gross Capacity (MBh)

SHC = Sensible Heat Capacity (MBh)

90 84.1 84.1 84.0 84.0 91.3 69.6 81.3 81.3 81.3 81.3 87.6 68.3

Ambient Temperature (°F)

Entering Wet Bulb Temperature (°F)

PKG-PRC007-EN28

Page 29

Performance

Air Cooled

Data

60 Hz

Table PD-12 — Gross Cooling Capacities SRVE-075 Metric

29.5 35.0

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (ºC) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

24 22.5 18.6 25.2 14.3 28.1 10.0 21.7 18.2 24.3 14.0 27.1 9.6

4590 27 22.6 21.9 25.2 17.8 28.0 13.5 21.9 21.5 24.3 17.5 27.1 13.1

29 23.4 23.4 25.1 20.7 28.0 16.3 22.8 22.8 24.3 20.3 27.1 16.0

32 24.6 24.6 25.2 23.5 28.0 19.2 23.9 23.9 24.4 23.1 27.1 18.9

24 22.7 19.2 25.5 14.7 28.4 10.1 22.0 18.9 24.6 14.3 27.4 9.7

4970 27 23.0 22.6 25.4 18.4 28.4 13.8 22.3 22.1 24.6 18.0 27.4 13.4

29 24.0 24.0 25.4 21.5 28.3 16.8 23.3 23.3 24.6 21.1 27.3 16.5

32 25.1 25.1 25.6 24.3 28.3 19.9 24.5 24.5 24.8 23.9 27.3 19.5

24 23.0 19.8 25.7 15.0 28.6 10.2 22.2 19.4 24.8 14.7 27.6 9.8

5355 27 23.3 23.2 25.7 18.9 28.6 14.1 22.6 22.6 24.8 18.6 27.6 13.7

29 24.5 24.5 25.7 22.2 28.6 17.3 23.8 23.8 24.8 21.8 27.6 16.9

32 25.7 25.7 25.9 25.1 28.6 20.5 24.9 24.9 25.1 24.6 27.6 20.2

24 23.2 20.4 25.9 15.3 28.9 10.2 22.4 20.0 25.0 15.0 27.9 9.9

5740 27 23.7 23.7 25.9 19.5 28.9 14.3 23.0 23.0 25.0 19.1 27.8 14.0

29 24.9 24.9 25.9 22.9 28.8 17.7 24.2 24.2 25.0 22.5 27.8 17.4

32 26.1 26.1 26.2 25.8 28.8 21.1 25.4 25.4 25.4 25.3 27.8 20.8

Ambient Temperature (°C)

Entering Wet Bulb Temperature (°C)

Table PD-12 — Gross Cooling Capacities SRVE-075 (Cont.) Metric

40.5 46

Ent. 16.0 19.5 23.0 16.0 19.5 23.0

DB

m3/h (ºC) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

24 20.9 17.9 23.4 13.6 26.1 9.3 20.1 17.5 22.5 13.2 25.1 8.9

4590 27 21.2 21.0 23.4 17.1 26.1 12.8 20.5 20.4 22.5 16.7 25.1 12.4

29 22.2 22.2 23.4 20.0 26.1 15.6 21.5 21.5 22.5 19.6 25.0 15.2

32 23.3 23.3 23.6 22.7 26.1 18.5 22.5 22.5 22.7 22.2 25.0 18.1

24 21.2 18.5 23.7 14.0 26.4 9.4 20.3 18.1 22.7 13.6 25.3 9.0

4970 27 21.6 21.6 23.7 17.7 26.3 13.0 20.9 20.9 22.7 17.3 25.3 12.7

29 22.6 22.6 23.7 20.7 26.3 16.1 21.9 21.9 22.7 20.3 25.3 15.7

32 23.8 23.8 23.9 23.4 26.3 19.2 23.0 23.0 23.0 22.9 25.3 18.8

24 21.4 19.1 23.9 14.3 26.6 9.4 20.5 18.7 23.0 13.9 25.5 9.1

5355 27 22.0 22.0 23.9 18.2 26.6 13.4 21.2 21.2 22.9 17.8 25.5 13.0

29 23.1 23.1 23.9 21.4 26.6 16.6 22.3 22.3 23.0 21.0 25.5 16.2

32 24.2 24.2 24.3 24.1 26.5 19.8 23.4 23.4 23.4 23.4 25.5 19.4

24 21.6 19.6 24.1 14.6 26.8 9.5 20.7 19.2 23.1 14.2 25.7 9.2

5740 27 22.3 22.3 24.1 18.7 26.8 13.6 21.6 21.6 23.1 18.3 25.7 13.3

29 23.5 23.5 24.1 22.1 26.8 17.0 22.7 22.7 23.2 21.6 25.7 16.6

Notes:

TGC = Total Gross Capacity (kW)

SHC = Sensible Heat Capacity (kW)

32 24.6 24.6 24.6 24.6 26.7 20.4 23.8 23.8 23.8 23.8 25.7 20.0

Ambient Temperature (°C)

Entering Wet Bulb Temperature (°C)

29PKG-PRC007-EN

Page 30

Performance

Air Cooled

Data

60 Hz

Table PD-13 — Gross Cooling Capacities SRVE-100 English

85 95

Ent. 61 67 73 61 67 73

DB

CFM (ºF) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 107.1 86.8 120.1 66.3 134.0 45.5 103.8 85.1 116.3 64.6 129.7 43.8

3600 80 107.7 102.8 119.9 82.8 133.9 62.0 104.4 100.9 116.2 81.2 129.6 60.4

85 111.1 111.1 119.9 96.6 133.7 75.6 108.3 108.3 116.1 94.9 129.5 74.1

90 116.4 116.4 120.0 110.1 133.6 89.4 113.5 113.5 116.4 108.3 129.4 87.7

75 108.6 89.7 121.5 67.9 135.5 45.9 105.1 88.1 117.6 66.4 131.1 44.4

3900 80 109.3 106.4 121.4 85.6 135.4 63.4 106.1 104.3 117.5 85.5 131.0 61.9

85 113.7 113.7 121.3 100.2 135.3 78.0 110.7 110.7 117.4 98.5 130.9 76.4

90 119.0 119.0 121.6 114.1 135.2 92.5 116.1 116.1 118.0 112.3 130.8 90.9

75 109.8 92.5 122.7 69.5 136.8 46.3 106.2 90.9 118.8 68.0 132.3 44.7

4200 80 110.9 109.4 122.6 88.2 136.7 64.9 107.8 107.1 118.7 86.5 132.2 63.3

85 116.0 116.0 122.5 103.6 136.6 80.2 113.0 113.0 118.6 101.9 132.1 79.1

90 121.5 121.5 123.3 117.9 136.5 95.5 118.5 118.5 119.6 116.0 132.0 94.0

75 110.7 95.4 123.8 71.2 138.0 46.8 107.1 93.6 119.9 69.5 133.4 45.1

4500 80 112.6 112.2 123.7 90.7 137.8 66.3 109.4 109.4 119.8 89.1 133.3 64.6

85 118.0 118.0 123.7 106.9 137.7 82.4 115.0 115.0 119.7 105.2 133.2 80.8

90 123.8 123.8 124.8 121.4 137.6 98.4 120.7 120.7 121.2 119.4 133.1 96.9

Ambient Temperature (°F)

Entering Wet Bulb Temperature (°F)

Table PD-13 — Gross Cooling Capacities SRVE-100 (Cont.) English

105 115

Ent. 61 67 73 61 67 73

DB

CFM (ºF) TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC TGC SHC

75 100.4 83.5 112.4 63.0 125.2 42.2 96.9 81.9 108.2 61.3 120.2 40.4

3600 80 101.2 99.0 112.3 79.6 125.1 58.8 97.9 96.8 108.1 77.8 120.1 57.0

85 105.4 105.4 112.2 93.3 125.0 72.5 102.4 102.4 108.0 91.6 120.0 70.6

90 110.5 110.5 112.6 106.4 124.9 86.1 107.3 107.3 108.7 104.3 119.9 84.3