Page 1

Commercial Self-Contained

IntelliPak® Signature Series

20-80 Ton Water-Cooled Air Conditioners

20-60 Ton Air-Cooled Air Conditioners

Remote Air-Cooled Condensers

December 2001 PKG-PRC002-EN

Page 2

Introduction

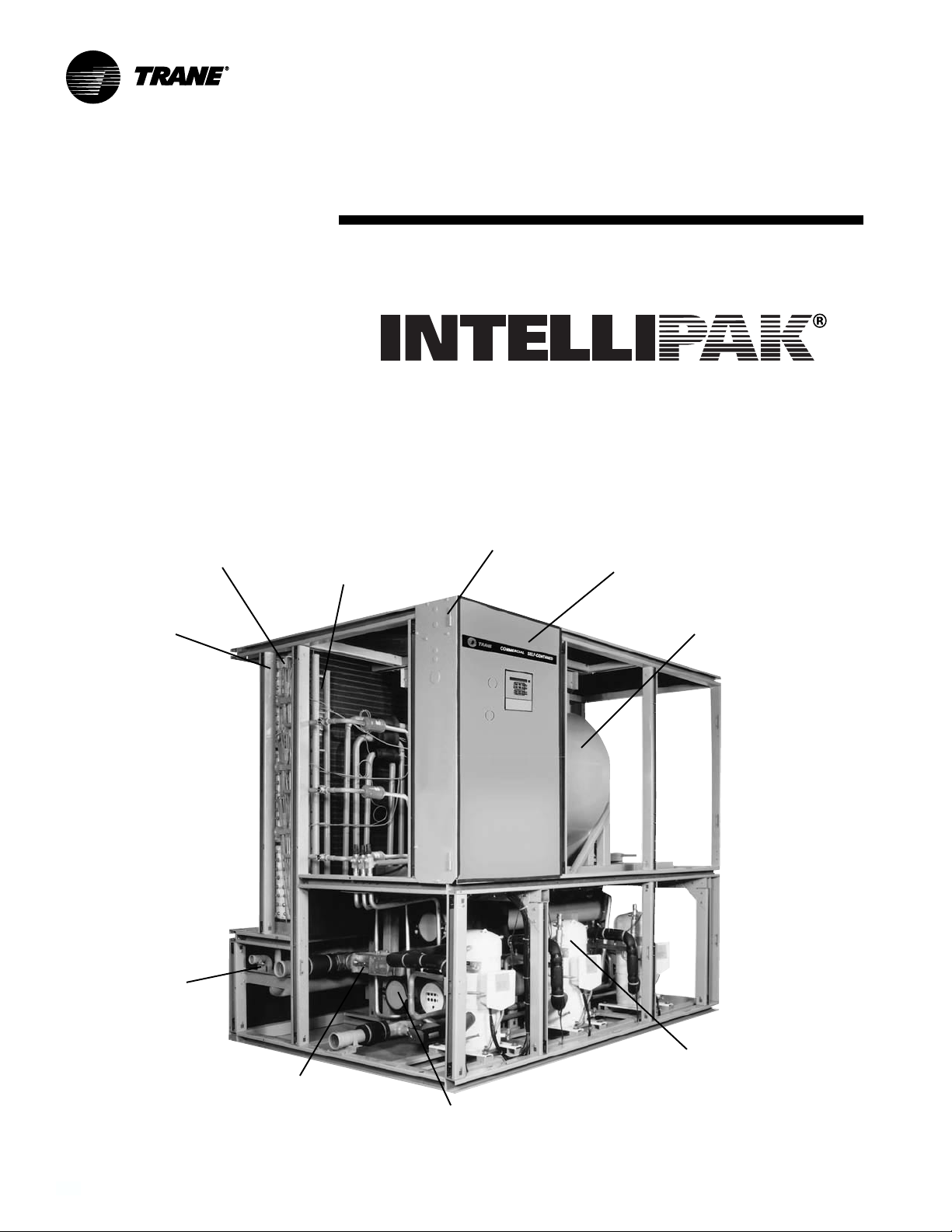

Affordable Self-Contained Value from Trane…

Signature Series Self-Contained Units

Trane’s advanced technology brings unmatched reliability, high performance, and affordable cost!

Hinged and removable control

Waterside economizer

(cleanable option shown)

2-inch flat filter

box inside unit

casing

Sight glasses with

ports for viewing

while unit is running

panel door for easy access

Unit mounted microprocessor

control with easy-to-read human

interface panel

Energy saving single fan

with inlet guide vanes or

variable frequency drive

Internally trapped

drain for low cost

installation

©2001 American Standard Inc.

Waterside valve

package option to

enhance system

efficiency

Two-bolt connection on cleanable

condenser for quick, easy

maintenance

®

Trane 3-D

for reliability, efficiency and

quiet operation

Scroll Compressor

PKG-PRC002-EN2

Page 3

Contents

Introduction 2

Features and Benefits 4

Application Considerations 8

Selection Procedure 12

Model Number Description 14

General Data 17

Performance Data 22

Airside Pressure Drops 22

Waterside Pressure Drops 29

Water-Cooled Units 31

Air-Cooled Units 60

Heating Coils 68

Controls 69

Electrical Data 79

Dimensions and Weights 81

Mechanical Specifications 95

Options 97

PKG-PRC002-EN 3

Page 4

Features and Benefits

Why consider the

Signature Series

self-contained floor-by-floor

systems?

Improved Cash Management

• Factory-installed and tested options

reduce field labor and installation risk,

while improving system reliability

• Requires less sophisticated

maintenance than built-up systems

Tenant Satisfaction

• Complete HVAC system on each floor

minimizes tenant inconvenience during

routine maintenance

• Tenants can control system after hours

to increase productivity and minimize

expense

Low First Cost

• Reduce field labor, installation time, and

cost with factory packaged controls and

piping

• Reduce installed tonnage up to 20

percent by taking advantage of building

diversity and VAV flexibility

• Flexible air discharge arrangement

matches most building configurations

Lower Installed Cost

• Single point power connection

• Single point water connection

• Factory commissioned and tested

controls

• Factory installed options

• Internally trapped drain connection

Economical Operation

• Free cooling with waterside or airside

economizer

• Energy savings with floor-by-floor

system since only units on floors

requiring cooling need to operate

• Significant annual energy consumption

reduction due to partial occupancy

after-hours, when compared to a

central chilled water system

• Simple heating alternatives include

perimeter radiation and fan-powered

VAV

• Energy savings from the integrated

water valve control using pump

unloading

Assured Acoustical Performance

• Flexible, horizontal discharge plenum

provides smooth airflow, reducing static

pressure losses for optimum acoustical

performance

• Multiple compressor design reduces

acoustical levels. Scroll compressor

design smooths gas flow for quieter

operation

Indoor Air Quality (IAQ) Features

• Sloped drain pan

• Stainless steel sloped drain pan option

• Internally trapped drain connection

• Double wall construction option

• Matt-faced fiberglass insulation

• High efficiency throwaway filter option

• Easily cleanable evaporator,

condensers, and waterside

economizers

• Filter access door allows easy removal

to encourage frequent filter changing

• Airside economizer with Traq™ damper

allows direct measurement and control

of outdoor air

Enhanced Serviceability

• Self-supporting removable panels

• Quick access service panel fasteners

• Eye level control/service center

• Refrigerant line sight glasses in view

during operation

PKG-PRC002-EN4

Page 5

Features and

Benefits

Standard Features

• 20 through 80 ton industrial/commercial

water-cooled self-contained units

• 20 through 60 ton industrial/commercial

remote air-cooled self-contained units

• Fully integrated, factory-installed, and

commissioned microelectronic controls

• Unit mounted human interface panel

with a two line x 40 character clear

language (English, Spanish, or French)

display and a 16-function keypad that

includes custom, diagnostics, and

service test mode menu keys

• Improved Trane 3-D

• Compressor lead/lag

• CV or VAV system control

• Low ambient compressor lockout

adjustable control input

• FROSTAT

units

• Daytime warmup (occupied mode) on

units with heat and morning warmup

operation on all units

• Supply air static overpressurization

protection on units with inlet guide

vanes or variable frequency drives

(VFD’s)

• Supply airflow proving

• Supply air tempering control with

heating option

• Supply air heating control on VAV with

hydronic heating option

• Emergency stop input

• Mappable sensors and setpoint sources

• Occupied/unoccupied switching

• Timed override activation

• Refrigeration circuits are completely

factory piped and tested on watercooled units

• Factory piped and tested, mechanically

cleanable water-cooled condensers

• Two-bolt removable condenser

waterboxes for quick and easy cleaning

• Sloped drain pans to ensure complete

condensate removal for IAQ

• Internally trapped drain connection with

cleanout

• Internally isolated centrifugal supply fan

• 14-gauge galvanized steel framework

with easily removable painted exterior

panels of 18-gauge galvanized steel

• UL listing on standard options

• Fan belts and grease lines are easily

accessible

• Access panels and clearance provided

to clean both evaporator and waterside

economizer coil fins

™

coil frost protection on all

®

scroll compressor

• Condensing pressure control on all

variable water flow systems with valves

• Programmable water purge during

unoccupied mode

• High entering air temperature limit

• Low entering air temperature limit with

waterside economizer or hydronic heat

Optional Features

• Trane communication interface module:

ICS interface control module

• Generic BAS interface

• Comparative enthalpy control

• Ventilation override from up to five

external inputs

• Remote human interface controls up to

four units

• Fully integrated, factory-installed/

commissioned variable frequency drive

control with or without optional

integrated bypass

• Fully integrated, factory-installed and

commissioned inlet guide vanes on FC

supply fan

• Waterside economizer with factory

installed piping and controls

• Waterside modulating condensing

temperature control valves include

factory installed piping and control

wiring

• Removable cast iron headers on

cleanable waterside economizer

• Flexible horizontal discharge plenum

with or without factory cut holes

• Heating options include hot water,

steam, and electric

• Refrigerant suction discharge line

service (shut-off) valves

• Protective coatings for the unit and/or

evaporator coils

• Double wall construction

• Stainless steel sloped drain pan

• Medium efficiency throwaway filters

• Through-the-door non-fused disconnect

switch

• Trane’s air quality Traq

airside economizer mixing box

• High duct temperature thermostat

• Dual electrical power connection

reset input

•CO

2

™

damper in

FC Fans With Inlet Guide Vanes

Trane’s forward-curved fans with inlet

guide vanes pre-rotate the air in the

direction of the fan wheel. This decreases

static pressure and horsepower. The

unloading characteristics of a Trane FC

fan with inlet guide vanes results in

superior part load performance.

Variable Frequency Drives (VFD)

Variable frequency drives are factory

installed, wired, and tested to provide

supply fan motor speed modulation.

VFD’s are quieter and more efficient than

inlet quide vanes and may even be

eligible for utility rebates. The VFD’s are

available with and without a manual

integrated bypass option, controlled

through the human interface (HI) panel.

Bypass control provides full nominal

airflow control to CV zone setpoints in the

unlikely event of a drive failure by

manually placing the drive in the bypass

mode.

Field Installed Accessories

• Airside economizer control with or

without mixing box

• Programmable sensors with or without

night set back for CV and VAV systems

• ICS zone sensors used with Tracer

system for zone control

• Field installed module kits available for

field upgrade of controls

• Ultra low leak dampers for 0-100

percent modulating fresh air

economizer

®

PKG-PRC002-EN 5

Page 6

Features and

Benefits

Integrated Self-Contained

Systems

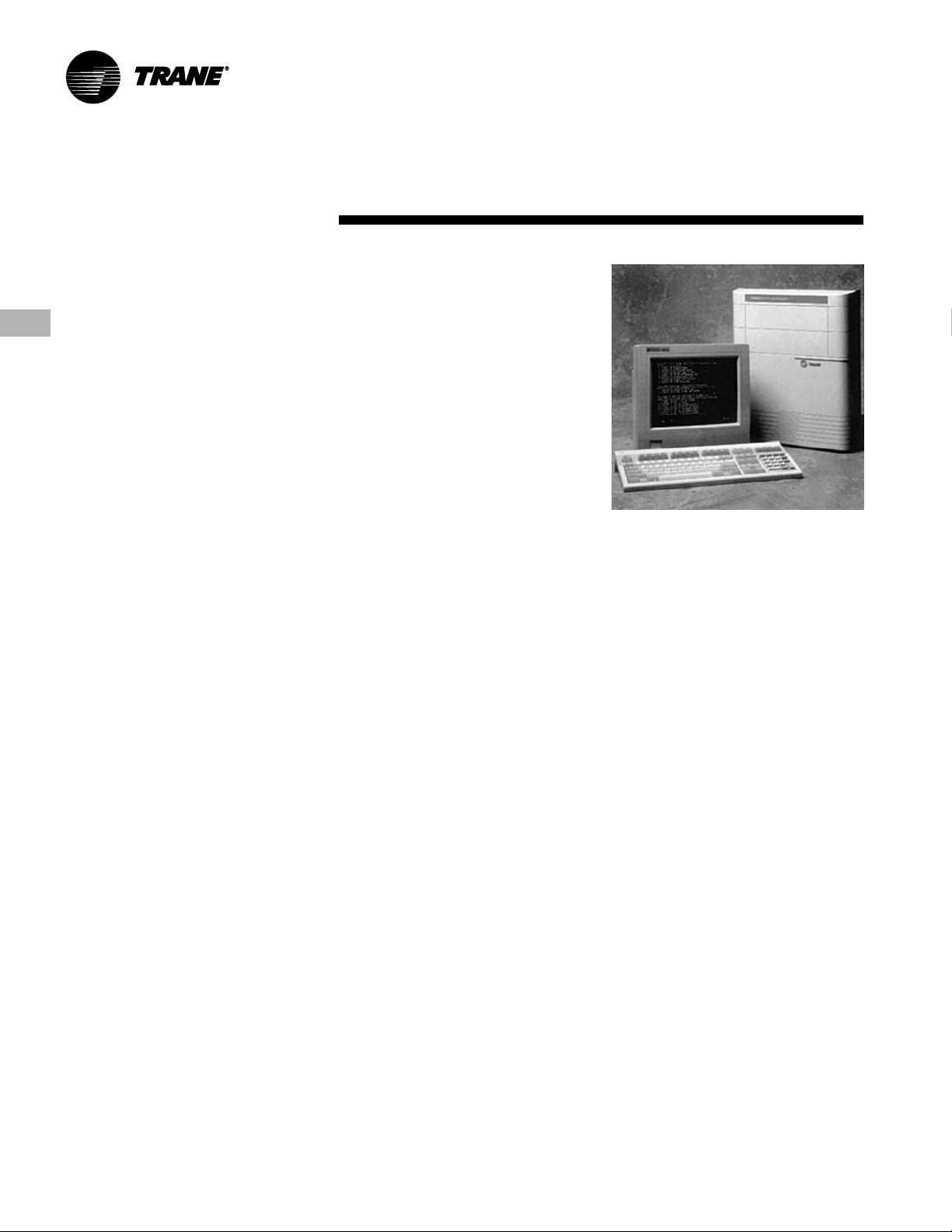

Integrated Comfort™ System (ICS)

Trane’s Integrated Comfort

(ICS) increases job control by combining

IntelliPak

®

Signature Series selfcontained units and a Tracer

management system. This integrated

system provides total building comfort

and control. Building owners and

managers not only save energy when

using ICS—they have the ability to

automate their facilities and the

convenience of a control system

interface.

Simplifying The Comfort System

Trane’s designers combined new

technology and innovation to bring you

more system capabilities and flexibility.

Our Integrated Comfort

with HVAC equipment is easy to use,

install, commission, and service.

Everything you need to know about your

self-contained VAV system is available

using Tracer

®

, Trane’s family of building

automation products. Tracer

software package that minimizes custom

programming requirements and allows

easy system setup and control using

your personal computer. Operating data

from all system components is readily

available for evaluation. You can control,

monitor, and service your facility—all

from your personal computer.

®

The IntelliPak

self-contained unit, as

part of Trane ICS, provides powerful

maintenance monitoring, control, and

reporting capabilities. Tracer

self-contained unit in the appropriate

operating mode for: system on/off, night

setback, demand limiting, setpoint

adjustment based on outside

parameters and much more. You can

monitor unit diagnostic conditions

through Tracer such as: sensor failures,

loss of supply airflow, and an inoperative

refrigerant circuit.

™

system

®

building

™

system (ICS)

®

is a

®

places the

®

IntelliPak

contained monitoring points available

using Tracer

Signature Series self-

®

• Compressor on/off status

• Ventilation status

• Condenser water flow status

• Heat status

• Supply air pressure

• Supply air temperature

• Suction temperature of each circuit

• Entering economizer water

temperature

• Zone temperature

• Entering condenser water temperature

• Supply air temperature reset signal

• Morning warmup sensor temperature

• Entering air temperature

Tracer control points for IntelliPak

®

Signature Series Self-Contained Units

• Cooling and heating setpoints

• VAV discharge air temperature

setpoints

• Supply air pressure setpoint

• Cooling and heating enable/disable

• Air economizer enable/disable

• Airside economizer minimum position

• Unit priority shutdown

Commissioning, control, efficiency, and

information…it simply all adds up to one

reliable source…Trane.

PKG-PRC002-EN6

Page 7

Trane 3-D® Scroll Compressor

Simple Design with 70% Fewer Parts

Fewer parts than an equal capacity

reciprocating compressor means

significant reliability and efficiency

benefits. The single orbiting scroll

eliminates the need for pistons,

connecting rods, wrist pins, and valves.

Fewer parts lead to increased reliability.

Fewer moving parts, less rotating mass,

and less internal friction means greater

efficiency than reciprocating compressors.

Patented 3-D Scroll Compliance

Trane 3-D scroll compliance provides

important reliability and efficiency

benefits. 3-D compliance allows the

orbiting scrolls to touch in all three

dimensions, forming a completely

enclosed compression chamber that leads

to increased efficiency. In addition, 3-D

compliance means the orbiting scrolls only

touch with enough force to create a seal—

so there is no wear between the scroll

plates. The fixed and orbiting scrolls are

made of high strength cast iron—resulting

in less thermal distortion, less leakage,

and higher efficiencies. The most

outstanding feature of the scroll

compressor 3-D compliance is that

slugging will not cause failure. In a

reciprocating compressor, however, liquid

or dirt can cause serious damage.

Low Torque Variation

The 3-D scroll compressor has a very

smooth compression cycle with torque

variations that are only 30 percent of that

produced by a reciprocating compressor.

This means the scroll compressor

imposes very little stress on the motor for

greater reliability. Low torque variation

means reduced noise and vibration.

Suction Gas Cooled Motor

Compressor motor efficiency and

reliability are further optimized with this

design. Cool suction gas keeps the motor

cooler for longer life and better efficiency.

Proven Design Through Testing and

Research

With over twenty years of development

and testing, Trane 3-D scroll compressors

have undergone more than 400,000 hours

of laboratory testing and field operation.

This work combined with over 25 patents

makes Trane the worldwide leader in air

conditioning scroll compressor technology.

Features and

Benefits

One of two matched scroll plates — the

distinguishing feature of the scroll

compressor.

The Chart above illustrates low torque

variation of 3-D Scroll compressors as

compared to a reciprocating compressor.

PKG-PRC002-EN 7

Page 8

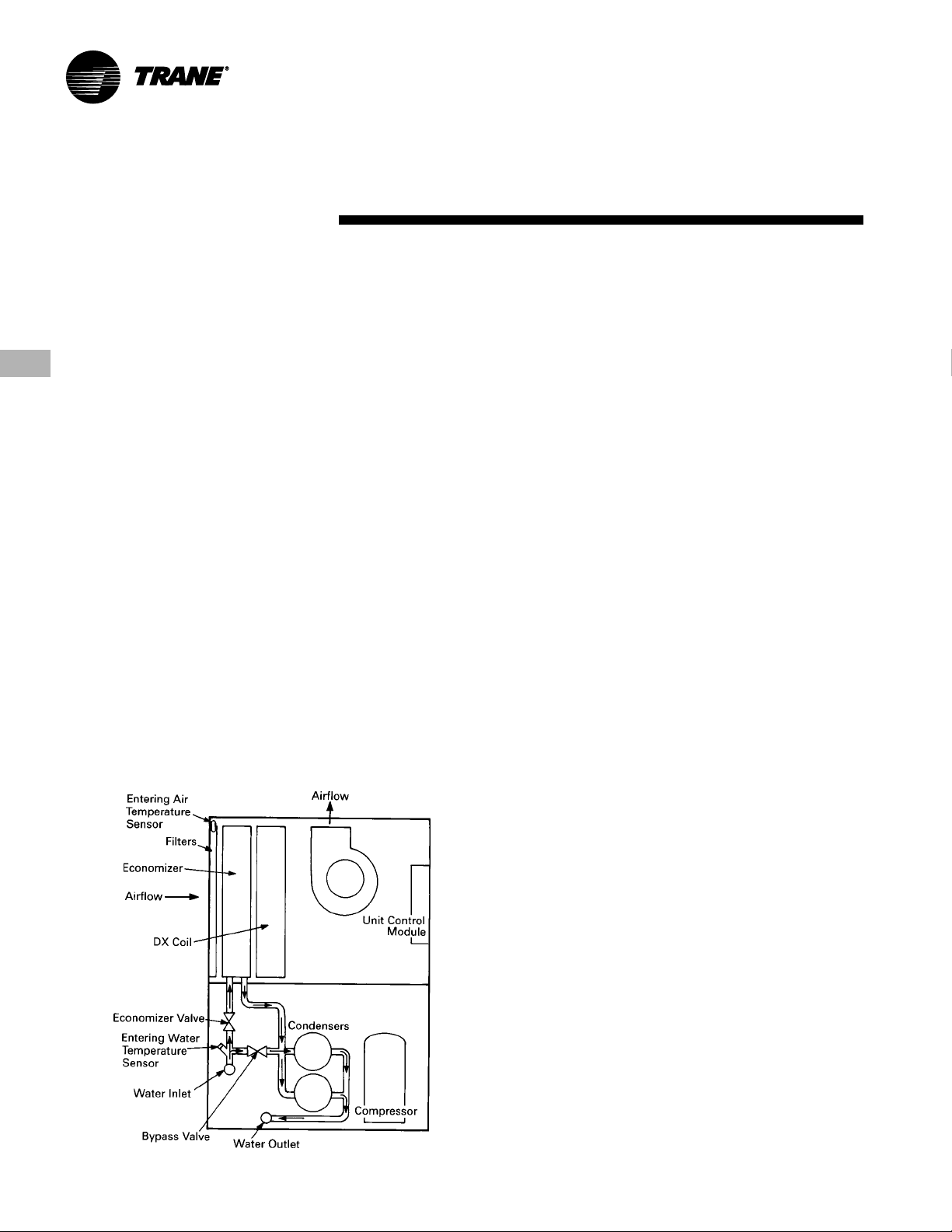

Application

Self-Contained Acoustical

Recommendations

Successful acoustical results are

dependent on many system design

factors.

Following are general acoustical

recommendations. For more information,

or if there is concern about a particular

installation, contact a professional

acoustical consultant.

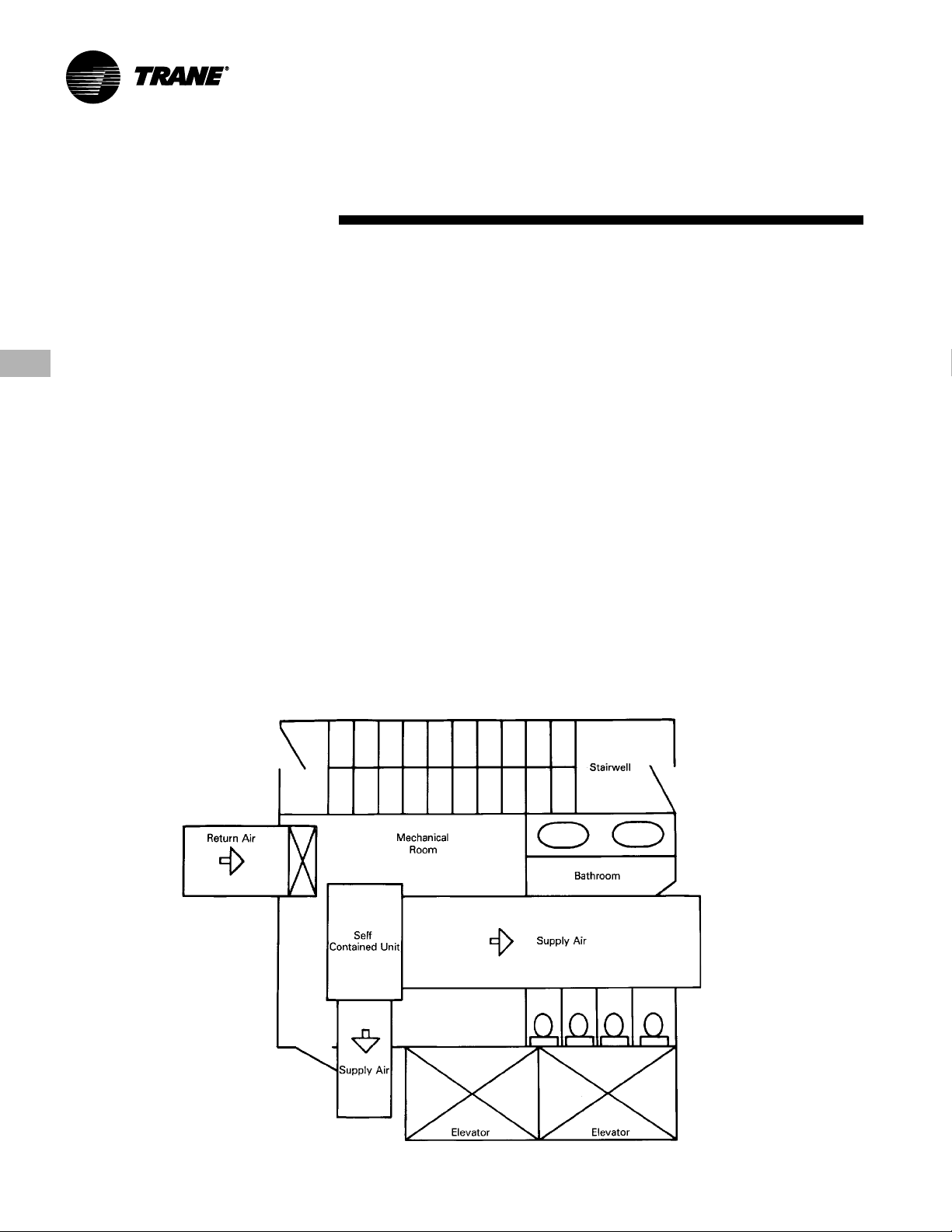

Location and Orientation of the

Mechanical Equipment Room

Locate the equipment room adjacent to

stairwells, utility rooms, electrical closets,

and rest rooms if possible (See figure

below). This minimizes the acoustic

effects and risk of workmanship or

installation errors. Place the discharge

and return air ductwork over these less

acoustically sensitive areas, using vertical

or horizontal fresh air shafts. Consult code

requirements for fresh air and smoke

purge constraints.

Considerations

Return Air Ductwork

Duct the return air into the mechanical

equipment room. Connect ductwork to

the unit if local code dictates. The return

air ductwork must have an elbow inside

the equipment room. This elbow will

reduce sound transmissions through the

return duct. Extend the ductwork from

the elbow far enough to block the “line of

sight” to the exterior of the equipment

room. Use a minimum ductwork length

of 15 feet to the equipment room

exterior. Line the duct with two-inch,

three-pound density insulation. Use

multiple, small return ducts for better

acoustical performance to the occupied

space.

Supply Air Ductwork

Insulate the supply air duct with two-inch,

three-pound density insulation. Extend

this lining at least 15 feet out from the

equipment room wall, keeping the duct

aspect ratio as small as possible.

Minimize large flat panels since they

Self-Contained

transmit sound. In addition, small aspect

ratios will minimize potential “oil canning”

of the duct due to flow turbulence.

The flexible horizontal discharge plenum

option helps avoid complicated ductwork

transitions. Ductwork turning vanes

typically improve pressure drop but

degrade acoustical performance.

Recommended Maximum Air Velocities

The maximum recommended velocity

for the discharge air duct is 2,000 fpm.

The maximum recommended velocity

for the return air duct is 1,000 fpm. Limit

air velocities below these operating

points to minimize the risk of flow

turbulence that causes regenerated

noise. Using round supply duct and static

regain allows maximum discharge air

velocities up to 3,000 fpm. Lining round

supply duct also substantially lowers

frequency noise attenuation. However,

flow regenerated noise potential

increases dramatically at air velocities

over 3000 fpm.

Equipment Room Location and Orientation

PKG-PRC002-EN8

Page 9

Application

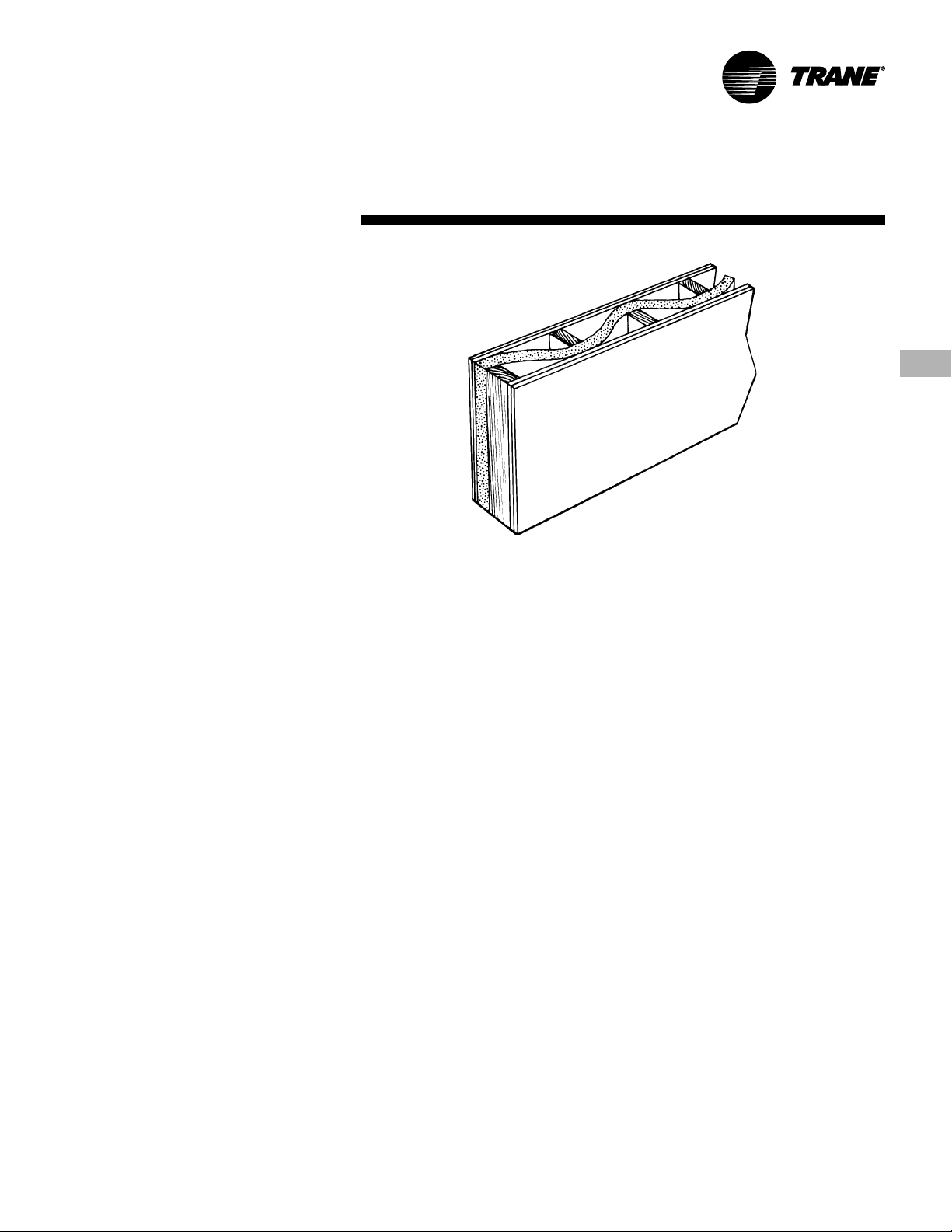

Equipment Room Construction Options

The preferred equipment room wall

construction is concrete block. If this is not

feasible then a double stud offset wall is

suggested (See figure). This removes

physical contact that would transmit

sound through the equipment room wall

to the occupied space. Interweave

fiberglass insulation between the wall

studs. Use two layers of sheetrock on

each side of the wall.

Workmanship details are critical to

acoustical performance. Seal all wall and

floor penetrations by the ductwork, water

piping, and equipment room access

doors with a flexible material such as

caulk and/or gasketing to stop noise and

air leaks.

Locate the equipment room door away

from acoustically sensitive areas like

conference rooms. The door should

swing out of the equipment room, if

possible, so that the low pressure in the

equipment room pulls the door in to help

maintain a tight seal.

Equipment Options

The flexible horizontal discharge plenum

allows multiple tested outlet options. This

minimizes the risk of acoustic and/or

pressure drop problems by avoiding

complex transitions close to the fan

discharge.

Static Pressure Versus Acoustics

Design the system to minimize the total

static pressure required from the selfcontained unit fan. Typically a change in

static pressure of only 0.5 inches can

reduce NC level by approximately 2 or 3

in the occupied space.

Isolation Recommendations

Unit

The Signature Series unit fan and

compressors are internally isolated.

Therefore, external isolation is not

required. Consult a vibration specialist

before considering external or double

vibration isolation.

Ductwork

Design duct connections to the unit using

a flexible material. Consult local codes for

approved flexible duct material to

prevent fire hazard potential.

Considerations

Double Stud Offset Wall with Interwoven Insulation

Piping Connections

Rubber isolator connectors are

recommended for condenser piping to

prevent vibration transmission to or from

the building plumbing. The Signature

Series self-contained unit is internally

isolated and does not require additional

isolation. However, ensure proper

system vibration isolation design

prevents vibration transmission from the

building plumbing to the unit. Also be sure

to properly isolate the drain line.

Condenser Water Piping

Piping Location and Arrangement

Provide at least 24 inches of clearance

between the piping and the unit for

service. Place the risers away from the

side of the unit if possible. Be sure to

allow sufficient space for valves and

unions between the piping and the selfcontained unit. Lay out condenser piping

in reverse returns to help balance the

system. This is accomplished by

equalizing the supply and return pipe

length. Multi-story buildings may use a

direct return system with balancing

valves at each floor. Install all heat

exchangers and most cooling tower

piping below the sump operating water

level to prevent overflow during unit and/

or system shut down.

Self-Contained

Free Cooling Opportunities

and Alternatives

Free cooling is available with either the

airside or waterside economizer options.

Waterside Economizer

The waterside economizer substantially

reduces the compressor energy

requirements because it uses the cooling

water before it enters the condensers.

Additional equipment room space is not

required since the coils are contained

within the overall unit dimensions.

Disadvantages include higher airside

pressure drop and a higher head on

condenser water pumps.

The coils may be mechanically cleanable

(optional) for ease in maintenance versus

expensive and difficult chemical cleaning

methods.

Airside Economizer

The airside economizer substantially

reduces compressor, cooling tower, and

condenser water pump energy

requirements using outside air for free

cooling. It also reduces tower make up

water needs and related water

treatment.

Disadvantages include building

requirements that locate the mechanical

room and self-contained unit toward an

exterior wall to minimize ductwork ,

building barometric control, or additional

air shafts. Also, airside economizers

require additional mechanical room

space.

PKG-PRC002-EN 9

Page 10

Application

Recommended Pump Location

Locate pump downstream of the cooling

tower and upstream of the self-contained

unit. This provides smoother and more

stable unit operation.

When the tower and pump are both roof

mounted, be sure to provide the

necessary net positive suction head

pressure to prevent cavitation. Raise the

tower or submerge the pump in a sump

to provide positive suction. To prevent an

on-line pump failure, use a standby pump

to avoid a complete system shutdown.

Several partial capacity pumps or

variable speed pumps may be used.

Review the economics of these alternate

pumping options.

Strainers and Water Treatment

Water strainers are required at the unit

inlet to eliminate potential unit damage

from dirty water. Specify a water baskettype strainer to avoid an incorrect

stream strainer application. Untreated or

poorly treated water may result in

equipment damage. Consult a water

treatment specialist for treatment

recommendations.

Isolation Valves

Install isolation valves at each unit before

the strainer and after the condenser. This

allows periodic servicing of the unit or

Waterside Economizer Piping

Considerations

strainer while allowing other units in the

system to remain in operation.

Pressure Gauges

Install pressure gauges on the inlet and

outlet of the self-contained unit. Select

the gauge’s scale so that the unit design

operating point is approximately midscale.

Thermometers

Install thermometers on the condenser

water inlet and outlet lines to each unit for

system analysis. Trane Company

recommends using a thermometer

temperature range of 40 to 140 F, using

a 2 F temperature increment.

Drains

The unit condensate drain is internally

trapped to offset the pressure differential

that exists during fan operation. Install a

trapped drain in the low point of the

mechanical equipment room floor to

collect water from cleaning operations.

Condensing Pressure Control

(Water-Cooled condensers)

Often cold condensing water applications

between 35 F (1.7 C) and 54 F (12.2 C)

require a condensing pressure control

valve. Any unit with variable-flow

waterside valves can modulate water

flow to maintain a user defined

condensing temperature. However, to

Self-Contained

utilize this feature, the building water

system must be capable of operating at

reduced water flow rates through the

self-contained units. It is imperative to

install variable volume pumps or an

external bypass in the water distribution

system.

Waterside Economizer Flow Control

Units equipped with waterside

economizer control valves can be set up

for variable or constant water flow.

Use constant water flow

systems that are not capable of

unloading water supply to the unit. The

economizer and condenser valves will

operate in complement to one another to

provide continuous water flow.

Use variable water flow

flow systems that can take advantage of

pump unloading for energy savings.

Since non-cooling operation restricts

water flow during part load economizing

or condensing temperature control, it is

imperative to install variable volume

pumps or an external bypass in the water

distribution system.

Unit Operating Limits

Airflow

The minimum recommended airflow for

proper VAV system staging and

temperature control is 35 percent of

nominal design airflow. Adjusting VAV

boxes with the appropriate minimum

settings will prevent the self-contained

unit from operating in a surge condition at

airflows below this point. Continuous

operation in a surge condition can cause

fan failure. Reference General Data

Tables on pages 17-20 for minimum

airflow conditions.

Signature Series self-contained units use

fixed pitch sheaves. Adjust air balancing

by obtaining alternate fixed pitch sheave

selections from the local Trane sales

office.

Waterflow

Use 3 gpm/ton for optimum unit capacity

and efficiency. Use 2.5 or 2 gpm/ton to

reduce pump energy, cooling tower and

piping costs. However, these reduced

waterflows may impact unit capacity and

efficiency by one or two percent. Consult

General Data Tables on pages 17-20 for

unit specific waterflow ranges.

setup on water

setup with water

PKG-PRC002-EN10

Page 11

Application

Air Cooled

Remote Air-Cooled Condenser

Unit Location

Unobstructed condenser airflow is

essential to maintaining capacity and

operating efficiency. When determining

unit placement, give careful

consideration to assure sufficient airflow

across the condenser coils. Avoid these

two detrimental conditions: warm air

recirculation and coil starvation.

Both warm air recirculation and coil

starvation cause reductions in unit

efficiency and capacity because of the

higher head pressure associated with

them. In more severe cases, nuisance

unit shutdowns will result from excessive

head pressures.

Considerations

Clearance

Ensure vertical condenser air discharge

is unobstructed. While it is difficult to

predict the degree of warm air

recirculation, a unit installed with a ceiling

or other obstruction above it will

experience a capacity reduction that will

reduce the maximum ambient operation

limit. Nuisance high head pressure

tripouts may also occur.

The coil inlet must also be unobstructed.

A unit installed closer than the minimum

recommended distance to a wall or other

vertical riser will experience a

combination of coil starvation and warm

air recirculation. This may result in unit

capacity and efficiency reductions, as

well as possible excessive head

pressures. Reference the service

clearance section on page 93 for

recommended lateral distances.

Condenser

Ambient Limitations

Standard ambient control allows

operation down to 45 F (7.2 C) with

cycling of condenser fans. Units with the

low ambient option are capable of

starting and operating in ambient

temperatures down to 0 F (-17.8 C).

Optional low ambient units use a

condenser fan damper arrangement that

controls condenser capacity by

modulating damper airflow in response

to saturated condenser temperature.

Maximum ambient temperature

operation of a standard condenser is 115

F (46.1 C). Operation at design ambient

above 115 F can result in excessive head

pressures. For applications above 115 F,

contact the local Trane sales office.

PKG-PRC002-EN 11

Page 12

Selection Procedure

Following is a sample selection for a

standard applied water-cooled selfcontained at particular operating

conditions. Use Trane Official Product

Selection System, TOPSS

all final selections or contact your local

Trane representative.

Unit Capacities

1

Determine entering air temperature dry

bulb and wet bulb and entering water

temperature.

2

Refer to the Performance Data section

beginning on page 32 to find gross total

and sensible capacity that best meets

capacity requirements.

3

Apply the cfm correction factors from the

capacity correction factor Table

PD-1 on page 31 to determine gross total

and gross sensible capacities at desired

cfm.

4

Multiply condenser water delta T by

the total capacity cfm correction factor to

determine new condenser water delta T.

5

Using design cfm, determine static air

pressure drops for accessories from the

air pressure drop Charts PD-1 through

PD-18. Add accessory static pressure

drops to external supply and return static

air pressure drops. Use the total air

pressure drop to determine rpm and

brake horsepower requirements from the

appropriate fan curve. Note: The fan

curves include refrigerant coil and internal

cabinet static loses.

6

Calculate supply fan motor heat by using

the following equation:

Fan motor heat (MBh) = 2.8 x fan motor

brake horsepower

7

Determine net total capacity and net

sensible capacity by subtracting fan

motor heat from gross total capacity and

gross sensible capacity.

™

, for making

Self-Contained

8

Refer to Trane psychometric chart to

determine leaving air temperatures.

Waterside Economizer Capacity

1

After determining that the unit will meet

the required mechanical cooling capacity,

determine the waterside economizer

capacity by referring to the appropriate

two-row (low capacity) or four-row (high

capacity) waterside economizer capacity

tables on pages 32-58.

2

Determine entering air temperature dry

bulb and wet bulb, condenser water flow

(gpm), and economizer entering water

temperature.

3

Refer to the appropriate waterside

economizer table to find gross total and

sensible capacity and the leaving water

temperature.

4

Apply the cfm correction factor for the

waterside economizer from the

appropriate table to determine the gross

total and sensible capacities at the desired

cfm.

5

Multiply the condenser water delta T by

the total capacity cfm correction factor to

determine the new delta T.

6

Calculate supply fan motor heat by using

the following equation:

Fan motor heat (MBh) = 2.8 x fan motor

brake horsepower

7

Determine net total and sensible capacity

by subtracting fan motor heat from gross

total and sensible capacity.

8

Refer to the Trane psychometric chart to

determine leaving air temperatures.

PKG-PRC002-EN12

Page 13

Selection

Selection Example

Design Conditions

Total gross capacity required =

420 MBh = 35.2 Tons

Total sensible capacity required =

315 MBh

Entering air temperature = 80/67

Entering water temperature = 85

Water flowrate = 105 gpm

Airflow = 14840 cfm at 2.5-inch

duct static pressure

Unit includes:

Inlet guide vanes

Waterside economizer

Medium velocity throwaway filters

Unit Selection

Tentatively select a 35 ton unit

Model SCWF 35.

Refer to Table PD-19 on page 43 to obtain

gross total and sensible unit capacities,

and gpm at the design conditions:

Total capacity = 419.0 MBh

Sensible capacity = 309.0 MBh

Leaving water temperature = 94.7 F

Since the design cfm is greater than the

nominal cfm, adjust the capacities and

condenser water delta T to reflect the

higher cfm:

design cfm 14840 = +6% of nom. cfm

nominal 14000

cfm

Procedure

Refer to Table PD-1 on page 31 to obtain

the capacity correction factors for +6% of

nominal cfm:

Cooling capacity multiplier = 1.009

Sensible capacity multiplier = 1.027

Multiply the capacities by the correction

factors:

419 MBh x 1.009 = 422.8 MBh

309 MBh x 1.027 = 317.3 MBh

The SCWF 35 meets the total and

sensible design requirements.

Multiply the delta T of 9.7 F, by the cooling

capacity correction factor of 1.009 to

obtain new delta T of 9.79 and add this to

the entering water temperature to obtain

the actual leaving water temperature of

94.79 F.

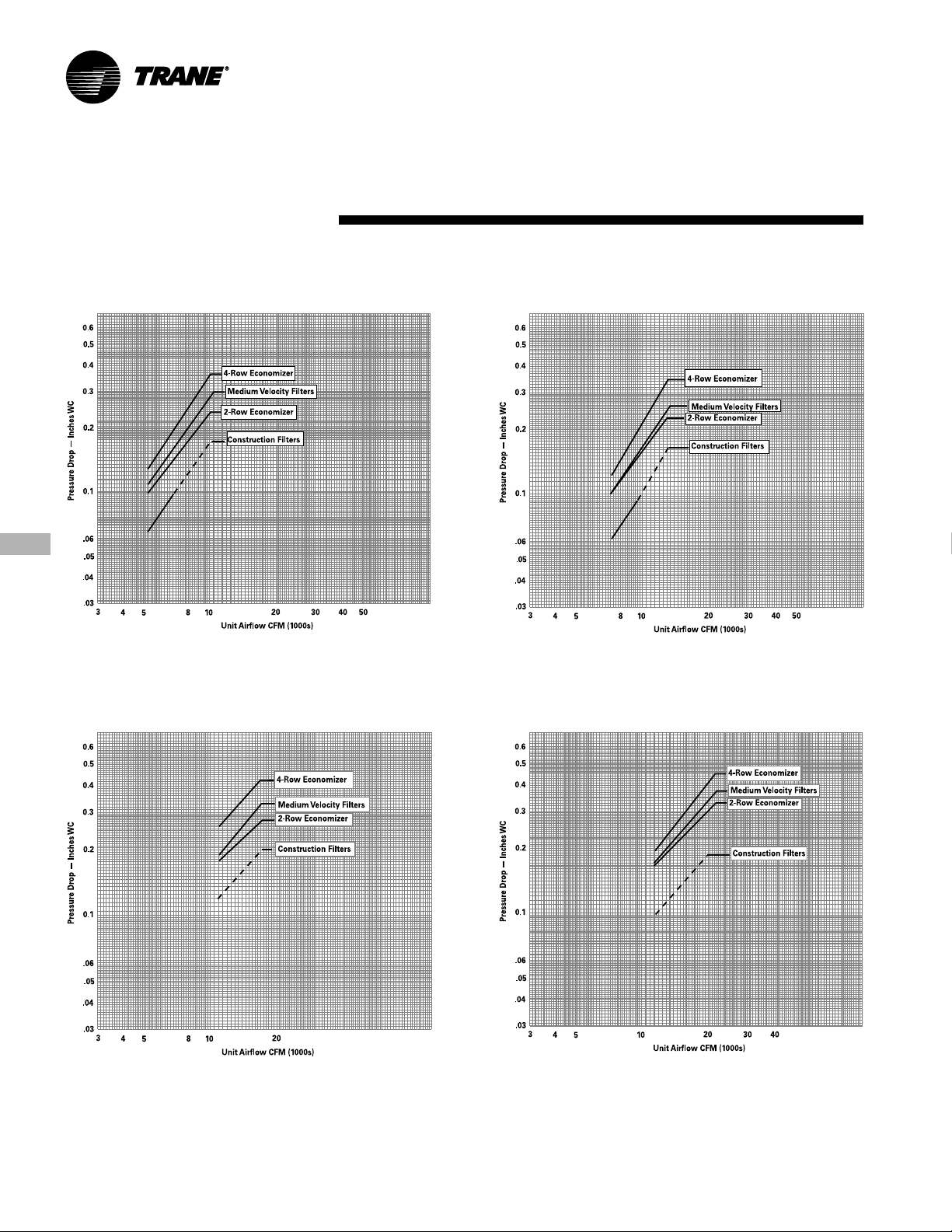

Determine static air pressure drops

through the accessories at the design cfm

from Chart PD-3 on page 22:

4-row waterside economizer = 0.37 in.

Medium velocity filters = 0.28 in.

add this to the 2.5 inch duct static

pressure for a total external static

pressure of 3.15 inches.

Refer to the fan curve with inlet guide

vanes, Chart PD-38 on page 43, to

determine approximate brake

horsepower and fan rpm:

Fan brake horsepower = 16 bhp

Fan rpm = 1020 rpm

Self-Contained

Determine net capacities by subtracting

fan motor heat from gross capacities:

2.8 x 16 bhp = 44.8 MBh

Net total capacity = 422.8 MBh -

44.8 MBh = 378.0 MBh

Net sensible capacity = 317.3 MBh -

44.8 MBh = 272.5 MBh

Determine waterside economizer

capacity by referring to Table PD-17 on

page 42. Use entering air of 80/67 and

entering water temperature of 55 deg F

at 105 gpm. The table provides a gross

total capacity of 282.1 MBh and gross

sensible capacity of 277.2 MBh and

60.4 deg F leaving water temperature at

nominal cfm.

Determine gross capacities at design cfm

by applying the cfm correction factors

from waterside economizer from Table

PD-1 on page 31. Use the following

correction factors:

282.1 MBh x 1.009 = 284.6 MBh

277.2 MBh x 1.027 = 284.7 MBh

Apply the cooling correction factor to

water delta T to determine new delta T of

5.45 F.

Determine net capacities by subtracting

fan motor heat for net total capacity of

239.8 MBh and net sensible capacities of

239.9 MBh.

PKG-PRC002-EN 13

Page 14

Selection

Model Number

Procedure

Description

Self-Contained Model Number Description

S C W F N 20 4 2 BO A B 2 10 065 B A 1 0 1 0 A A C F A 1 1 0 T 2 0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Digit 1 - Unit Model

S = Self Contained

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

W = Water-Cooled

R = Air-Cooled

Digit 4 - Development Sequence

F = Signature Series

Digit 5 - Refrigerant Circuit Configuration

N = Independent (Water-Cooled)

M = Manifolded (30, 35, 40, 50, 60-Ton AirCooled Only)

Digit 6, 7 - Unit Nominal Capacity

20 = 20 Tons (Water or Air)

22 = 22 Tons (Water Only)

25 = 25 Tons (Water or Air)

29 = 29 Tons (Water or Air)

30 = 30 Tons (Air Only)

32 = 32 Tons (Water Only)

35 = 35 Tons (Water or Air)

38 = 38 Tons (Water Only)

40 = 40 Tons (Air Only)

42 = 42 Tons (Water Only)

46 = 46 Tons (Water Only)

50 = 50 Tons (Air Only)

52 = 52 Tons (Water Only)

58 = 58 Tons (Water Only)

60 = 60 Tons (Air Only)

65 = 65 Tons (Water Only)

72 = 72 Tons (Water Only)

80 = 80 Tons (Water Only)

Digit 8 - Unit Voltage

6 = 200 Volt/60 Hz/3 ph

4 = 460 Volt/60 Hz/3 ph

5 = 575 Volt/60 Hz/3 ph

Digit 9 - Air Volume/Temp Control

1 = IGV and Supply Air Temp Ctrl

2 = VFD and Supply Air Temp Ctrl

3 = VFD w/ Bypass and Supply

Air Temp Ctrl

4 = w/o Vol. CTRL, w/ Zone Temp Cool

5 = w/o Vol. CTRL, w/ Zone Temp

Heat/Cool

6 = w/o Vol. CTRL and Supply Air

Temp Ctrl

Digit 10, 11 - Design Sequence

BO = “B” Design

Digit 12 - Unit Construction

A = Vertical Discharge

B = Vertical Discharge with Double Wall

Digit 13 - Flexible Horizontal Discharge

Plenum Type

B = Std Plenum w/ Factory Cut Holes

C = Low Plenum w/ Factory Cut Holes

E = Std Plenum w/ Field Cut Holes

F = Low Plenum w/ Field Cut Holes

H = Std Plenum Double wall

w/ Field Cut Holes

J = Low Plenum Double wall

w/ Field Cut Holes

K = 45” Plenum w/Factory Cut Holes,

Ship Separate

L = Std Plenum w/Factory Cut Holes,

Ship Separate

M = Low Plenum w/Factory Cut Holes,

Ship Separate

N = 45” Plenum w/Field ut Holes, Ship

Separate

P = Std Plenum w/Field Cut Holes, Ship

Separate

R = Low Plenum w/Field Cut Holes, Ship

Separate

T = 45” Double Wall Plenum w/Field Cut

Holes, Ship Separate

U = Std Double Wall Plenum w/Field Cut

Holes, Ship Separate

V = Low Double Wall Plenum w/Field

Cut Holes, Ship Separate

0 = None

Digit 14 - Motor Type

1 = Std Eff. ODP Motor

2 = Premium Eff. ODP Motor

3 = Totally Enclosed Motor

Digit 15, 16 - Motor HP

05 = 5 HP Motor

07 = 7.5 HP Motor

10 = 10 HP Motor

15 = 15 HP Motor

20 = 20 HP Motor

25 = 25 HP Motor

30 = 30 HP Motor

40 = 40 HP Motor

50 = 50 HP Motor (460V & 575V Only)

Digit 17, 18, 19 - Fan RPM

040 = 400 rpm

045 = 450 rpm

050 = 500 rpm

055 = 550 rpm

060 = 600 rpm

065 = 650 rpm

070 = 700 rpm

075 = 750 rpm

080 = 800 rpm

085 = 850 rpm

090 = 900 rpm

095 = 950 rpm

100 = 1000 rpm

105 = 1050 rpm

110 = 1100 rpm

115 = 1150 rpm

120 = 1200 rpm

125 = 1250 rpm

130 = 1300 rpm

135 = 1350 rpm

140 = 1400 rpm

145 = 1450 rpm

150 = 1500 rpm

Digit 20 - Heating Type

A = Steam Coil

B = Hot Water Coil

C = Electric Heat (1 Stage)

F = Hydronic Heat Ctrl Interface

G = Elec. Heat Ctrl Interface (1 stage)

K = Steam Coil Ship Separate

L = Hot Water Coil Ship Separate

0 = Without Heat

Digit 21 - Unit Isolators

A = Isopads

B = Spring Isolators

0 = None

Digit 22 - Unit Finish

1 = Paint - Executive Beige

2 = Protective Coating

3 = Protective Coating w/ Finish Coat

Digit 23 - Future Use

0 = None

Digit 24 - Unit Connection

1 = Disconnect Switch

2 = Terminal Block

3 = Dual Point Power (2 Blocks)

PKG-PRC002-EN14

Page 15

Selection

Model Number

Self-Contained Model Number Continued —

Digit 25 - Industrial Options

A = Protective Coating Evaporator Coil

B = Silver Solder

C = Stainless Steel Screws

D = A and B

E = A and C

F = B and C

G = A, B, and C

0 = None

Digit 26 - Drain Pan Type

A = Galvanized Sloped

B = Stainless Steel Sloped

Digit 27 - Waterside Economizer

A = Mechanical Clean Full Capacity (4-row)

B = Mechanical Clean Low Capacity (2-row)

C = Chemical Clean Full Capacity (4-row)

D = Chemical Clean Low Capacity (2-row)

0 = None

Digit 28 - Ventilation Control

B = Airside Econ w/ Traq

(Top O/A)

C = Airside Econ w/ Standard

Damper (Top O/A)

E = Airside Econ w/ Traq

Comparative Enthalpy

(Top O/A)

F = Airside Econ w/ Standard Damper and

Comparative Enthalpy (Top O/A)

H = None, 2-Position Damper Ventilation

Interface

J = Airside Economizer Interface

K = Airside Economizer Interface w/

Comparative Enthalpy

™

Damper

™

Damper and

Procedure

Digit 29 - Water Piping

D = Left Hand Basic Piping

F = Left Hand Intermediate Piping

K = Left Hand Basic w/ Flow Switch

M = Left Hand Intermediate

w/ Flow Switch

0 = None

Digit 30 - Condenser Tube Type

A = Standard Condenser Tubes

B = 90/10 CuNi Condenser Tubes

0 = None (Air-cooled Only)

Digit 31 - Compressor Service Valves

1 = With Service Valves

0 = None

Digit 32 - Miscellaneous System Control

1 = Timeclock

2 = Interface for Remote HI (IPCB)

3 = Dirty Filter Switch

4 = 1 and 2

5 = 1 and 3

6 = 2 and 3

7 = 1, 2 and 3

0 = None

Digit 33 - Control Interface Options

A = Generic BAS Module (GBAS)

B = Ventilation Override Module

(VOM)

C = Tracer Comm. Interface Module

(TCI)

D = Remote Human Interface (RHI)

E = GBAS and TCI

F = VOM and TCI

G = GBAS and VOM

Description

H = GBAS and RHI

J = VOM and RHI

K = TCI and RHI

L = GBAS, VOM, and TCI

M = GBAS, VOM, and RHI

N = GBAS, TCI, and RHI

P = VOM, TCI, and RHI

R = GBAS, VOM, TCI, and RHI

0 = None

Digit 34 - Agency

T = UL Agency Listing

0 = None

Digit 35 - Filter Type

1 = Construction Throwaway

2 = Med Eff. Throwaway

Digit 36 - Miscellaneous Control Option

A = Low Entering Air Temp. Protect

Device (LEATPD)

B = High Duct Temp T-Stat

(Ship Separate)

C = Plenum High Static Switch

(Ship Separate)

E = A and B

F = A and C

H = B and C

L = A, B, and C

0 = None

Self-Contained Accessory Model Number Description

P S W F S A 1 1 0 AO

1 2 3 4 5 6 7 8 9 10 11

Digit 1 - Parts/Accessories

P = Parts/Accessories

Digit 2 - Unit Model

S= Self-Contained

Digit 3 - Shipment

W = With Unit

Digit 4 - Development Sequence

F = Signature Series

G = Modular Series

Digit 5 - Sensors and Other Accessories

S = Sensors

Digit 6 - Sensors (Field Installed)

A = BAYSENS017 - Zone Temp Only (CV

and VAV)

B = BAYSENS013 - Zone Temp with

Timed Override Button (CV and VAV)

PKG-PRC002-EN 15

C = BAYSENS014 - Zone Temp with

Timed Override Button, Setpoint Dial

(CV and VAV)

E = BAYSENS008 - CV Zone Sensor

F = BAYSENS010 - CV Zone Sensor with

Indicator Lights

G = BAYSENS019 - CV Programmable

Night Setback Sensor

H = BAYSENS021 - VAV Zone Sensor

with Indicator Lights

J = BAYSENS020 - VAV Programmable

Night Setback Sensor

K = Remote Sensor Kit

L = Outside Air Temperature Sensor Kit

M = Outside Air Humidity Sensor Kit

0 = None

Digit 7 - Low Entering Air Temperature

Protection Device (Field Installed)

1 = Low Entering Air Tempeature

Protection Device

0 = None

Digit 8 - Carbon Dioxide Sensor (field

installed)

1 = Carbon Dioxide Sensor Kit

0 = None

Digit 9 - Not Used

0 = None

Digit 10, 11 - Design Sequence

A0 = A Design

Page 16

Selection

Model Number

Procedure

Description

Remote Air-Cooled Condenser Model Number Description

C C R C 020 4 A AO 1 A 0 0 T

1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 5 16

Digit 1 - Unit Model

C = Condenser

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

R = Remote

Digit 4 - Development Sequence

C = C

Digit 5, 6, 7 - Nominal Capacity

020 = 20 Tons

029 = 29 Tons

035 = 35 Tons

040 = 40 Tons

050 = 50 Tons

060 = 60 Tons

Digit 8 - Unit Voltage

4 = 460 Volt/60 Hz/3 ph

5 = 575 Volt/60 Hz/3 ph

6 = 200 Volt/60 Hz/3 ph

Digit 9 - Control Option

0 = No Low Ambient Damper, I-Pak.

A = No Low Ambient Damper, T-Stat.

B = Low Ambient, I-Pak.

C = Low Ambient, T-Stat.

Digit 10, 11 - Design Sequence

AO = “A” Design Sequence

Digit 12 - Unit Finish

1 = Paint (Executive Beige)

2 = Protective Coating

3 = Protective Coating with

Finish Coat

Digit 13 - Coil Options

A = Non-Coated Aluminum

C = Protective Coating Aluminum

Digit 14 - Unit Isolators

0 = None

A = Spring Isolators

B = Isopads

Digit 15 - Panels

0 = None

1 = Louvered Panels

Digit 16 - Agency Listing

0 = None

U = With UL Listing

PKG-PRC002-EN16

Page 17

SCWF/SIWF

General Data

20-38 Tons

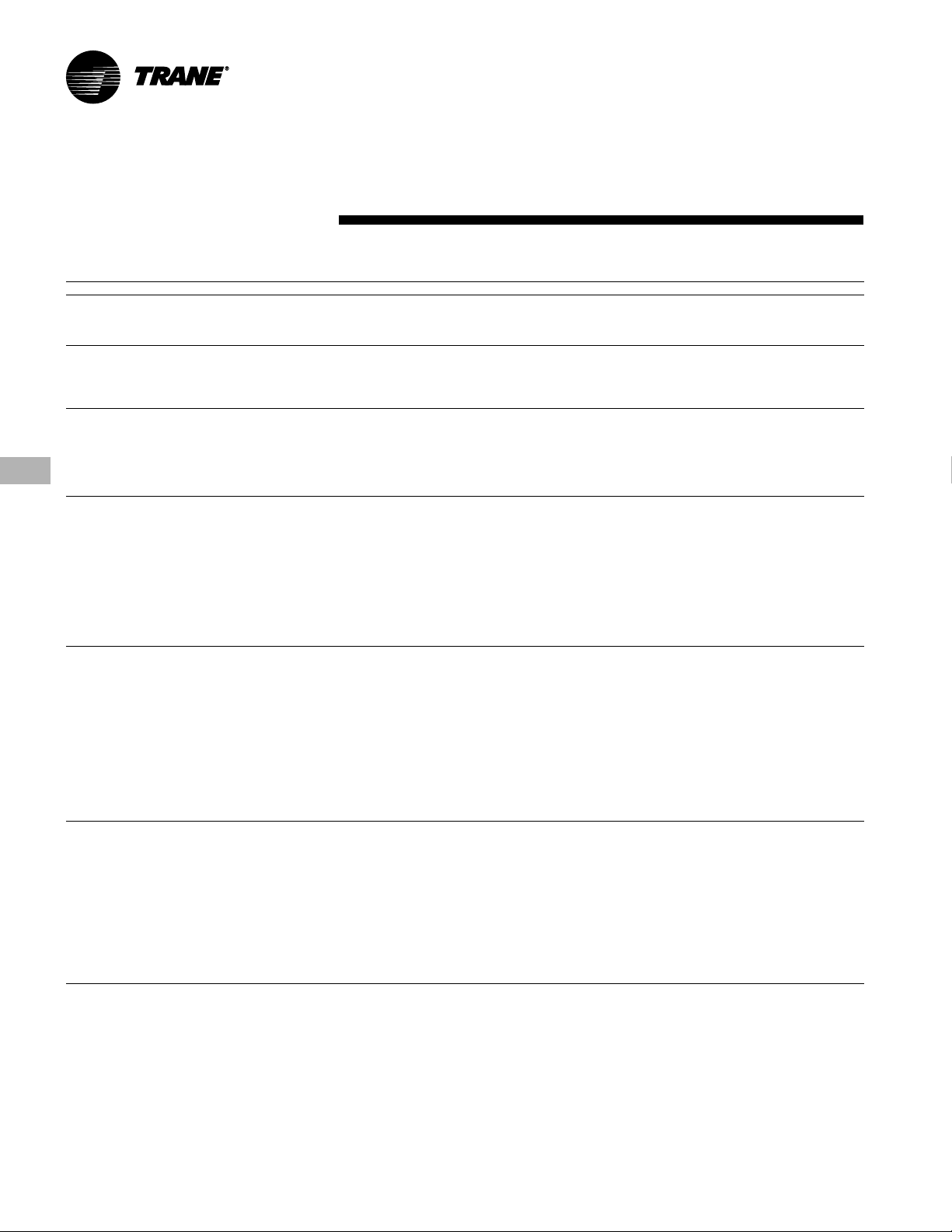

Table GD-1. SCWF/SIWF Water-Cooled Self-Contained, 20-38 Tons

Unit Size 2 0 2 2 2 5 2 9 3 2 3 5 3 8

Compressor Data

Quantity 2 2 2 1/1 1/1 3 3

NominalTon/Comp 10 10 10 15/10 15/10 10 10

Circuits 2 222233

Evaporator Coil Data

Rows 2 232434

Sq. Ft. 21.81 21.81 21.81 29.98 29.98 31.35 31.35

Sq. m (2.03) (2.03) (2.03) (2.79) (2.79) (2.91) (2.91)

FPF 144 144 144 144 144 120 144

Condenser Data

Minimum GPM w/o Econ 3 6 36 36 46 46 54 54

Minimum liters / sec. w/o Econ (2.27) (2.27) (2.27) (2.9) (2.9) (3.41) (3.41)

Minimum GPM w/ Econ 41 41 41 60 60 65 65

Minimum liters / sec. w/ Econ (2.59) (2.59) (2.59) (3.79) (3.79) (4.1) (4.1)

Maximum GPM 80 8 0 80 102 102 119 119

Maximum liters / sec. (5.05) (5.05) (5.05) (6.44) (6.44) (7.51) (7.51)

Evaporator Fan Data

Quantity 1 111111

Size (Dia. - inches) 16.5" 16.5" 16.5" 18.25" 18.25" 20" 20"

Size (Dia. - mm) (419.1) (419.1) (419.1) (463.6) (463.6) (508) (508)

Minimum HP 5 555555

Minimum kW (3.73) (3.73) (3.73) (3.73) (3.73) (3.73) (3.73)

Maximum HP 20 20 20 25 25 2 5 25

Maximum kW (14.91) (14.91) (14.91) (18.64) (18.64) (18.64) (18.64)

Minimum Design CFM 6325 6325 6500 8700 8700 9100 9880

Minimum Design liter / sec. (2985) (2985) (3068) (4106) (4106) (4295) (4663)

Maximum Design CFM 8500 9350 10625 12325 13600 14875 16150

Maximum Design liter / sec. (4012) (4413) (5014) (5817) (6418) (7020) (7622)

General Data

EER 12.9 12.6 13.4 14.1 13.6 13.3 13.4

IPLV 13.6 12.9 13.6 14.5 13.0 12.8 12.4

Refrigerant Charge - lbs. R-22

Circuit A 24 24 24 28 30 24 25

Circuit B 24 24 24 24 25 24 25

Circuit C - ----2425

Refrigerant Charge - kg R-22

Circuit A (10.9) (10.9) (10.9) (12.7) (13.6) (10.9) (11.3)

Circuit B (10.9) (10.9) (10.9) (10.9) (11.3) (10.9) (11.3)

Circuit C - ----(10.9) (11.3)

Capacity Steps - % 100/53/0 100/53/0 100/53/0 100/62/39/0 100/59/39/0 100/65/31/0 100/65/30/0

Filter Data

Quantity 8 888888

Size (inches ) 20x18x2 20x18x2 20x18x2 20x18x2 20x18x2 20x18x2 20x18x2

Size (mm) (508 X 457 X 51) (508 X 457 X 51) (508 X 457 X 51) (508 X 457 X 51) (508 X 457 X 51) (508 X 457 X 51) (508 X 457 X 51)

Quantity 4 444444

Size (inches ) 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2

Size (mm) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51)

Notes:

1. Compressors are Trane 3D® scroll.

2. EER and IPV are rated in accordance to the ARI Standard 340/360-93. Based on 80/67 F (26.7/19.4 C) to the evaporator coil,

nominal airflow and 85-95 F (29.4/35 C) condenser water.

3. All units operate with R-22. Units ships with full operating charge.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

6. Filter sizes are for units without hot water or steam heating coils.

PKG-PRC002-EN 17

Table GD-2. SCWF/SIWF Refrigerant Circuits,

Number of Compressors by Circuit

Unit Size

20/22/25 Ton 1- 10T 1- 10T

29/32 Ton 1- 15T 1- 10T

35/38 Ton 1- 10T 1- 10T 1- 10T

42/46 Ton 1- 15T 1- 10T 1- 10T

52/58 Ton 1- 15T 1- 15T 1- 15T

60/72 Ton 1- 15T 1- 15T 1- 15T 1- 10T

80 Ton 1- 15T 1- 15T 1- 15T 1- 15T

Note: This table depicts compressor location in unit, plan

view from left corner.

Circuit 1 2 3 4

Page 18

SCWF/SIWF

General Data

42-80 Tons

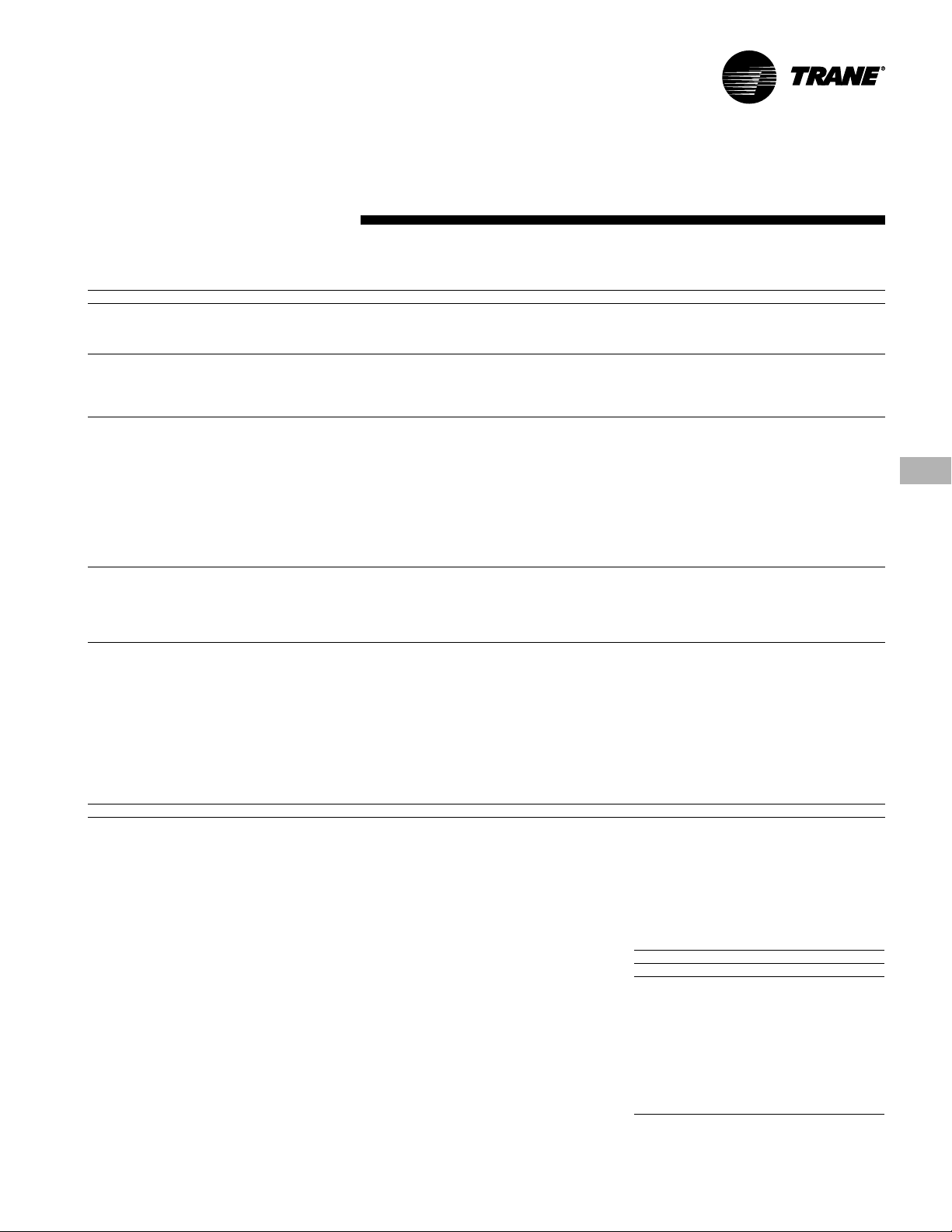

Table GD-3. SCWF/SIWF Water-Cooled Self-Contained, 42-80 Tons

Unit Size 4 2 4 6 5 2 5 8 6 5 7 2 8 0

Compressor Data

Quantity 2/1 2/1 3 3 3/1 3/1 4

NominalTon/Comp 10/15 10/15 15 15 15/10 15/10 15

Circuits 3 333444

Evaporator Coil Data

Rows 3 424346

Sq. Ft. 38.57 38.57 49.09 49.09 49.09 49.09 49.09

Sq. m (3.58) (3.58) (4.56) (4.56) (4.56) (4.56) (4.56)

FPF 144 144 144 144 144 144 144

Condenser Data

Minium GPM w/o Econ 64 64 84 84 102 102 112

Minium liters / sec. w/o Econ (4.04) (4.04) (5.3) (5.3) (6.43) (6.43) (7.07)

Minimum GPM w/ Econ 64 64 84 84 102 102 112

Minium liters / sec. w/ Econ (4.04) (4.04) (5.3) (5.3) (6.43) (6.43) (7.07)

Maximum GPM 142 142 186 186 226 226 248

Maximum liters / sec. (8.96) (8.96) (11.73) (11.73) (14.26) (14.26) (15.65)

Evaporator Fan Data

Quantity 1 111111

Size (Dia. - inches) 25" 25" 25" 25" 27.5" 27.5" 27.5"

Size (Dia. - mm) (635) (635) (635) (635) (698.5) (698.5) (698.5)

Minimum HP 7.5 7. 5 1 0 10 10 10 1 0

Minimum kW (5.59) (5.59) (7.46) (7.46) (7.46) (7.46) (7.46)

Maximum HP 30 30 50 50 50 5 0 50

Maximum kW (22.37) (22.37) (37.29) (37.29) (37.29) (37.29) (37.29)

Minimum Design CFM 11200 11960 14250 15080 16900 18700 20800

Minimum Design liter / sec. (5286) (5645) (6725) (7117) (7976) (8825) (9817)

Maximum Design CFM 17850 19550 22100 24650 27625 29800 29800

Maximum Design liter / sec. (8424) (9227) (10430) (11634) (13038) (14064) (14064)

General Data

EER 14.1 14.2 13.1 13.5 13.1 13.0 13.0

IPLV 13.9 13.6 12.9 12.5 12.4 11.8 11.4

Refrigerant Charge - lbs. R-22

Circuit A 28 30 28 30 28 30 32

Circuit B 24 25 28 30 28 30 32

Circuit C 24 25 28 30 28 30 32

Circuit D - - - - 24 25 32

Refrigerant Charge - kg R-22

Circuit A (12.7) (13.6) (12.7) (13.6) (12.7) (13.6) (14.5)

Circuit B (10.9) (11.3) (12.7) (13.6) (12.7) (13.6) (14.5)

Circuit C (10.9) (11.3) (12.7) (13.6) (12.7) (13.6) (14.5)

Circuit D - - - - (10.9) (11.3) (14.5)

Capacity Steps - % 100/71/43/26/0 100/70/41/30/0 100/65/32/0 100/65/30/0 100/71/44/24/0 100/71/43/23/0 100/73/46/20/0

Filter Data

Quantity 4 444444

Size (inches ) 16x20x2 16x20x2 16x20x2 16x20x2 16x20x2 16x20x2 16x20x2

Size (mm) (406 X 508 X 51) (406 X 508 X 51) (406 X 508 X 51) (406 X 508 X 51) (406 X 508 X 51) (406 X 508 X 51) (406 X 508 X 51)

Quantity 8 888888

Size (inches ) 16x25x2 16x25x2 16x25x2 16x25x2 16x25x2 16x25x2 16x25x2

Size (mm) (406 X 635 X 51) (406 X 635 X 51) (406 X 635 X 51) (406 X 635 X 51) (406 X 635 X 51) (406 X 635 X 51) (406 X 635 X 51)

Quantity 2 222222

Size 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2

Size (mm) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51) (508 X 508 X 51)

Quantity 4 444444

Size 20x25x2 20x25x2 20x25x2 20x25x2 20x25x2 20x25x2 20x25x2

Size (mm) (508 X 635 X 51) (508 X 635 X 51) (508 X 635 X 51) (508 X 635 X 51) (508 X 635 X 51) (508 X 635 X 51) (508 X 635 X 51)

Notes:

1. Compressors are Trane 3D® scroll.

2. EER and IPV are rated in accordance to the ARI Standard 340/360-93. Based on 80/67 F (26.7/19.4 C) to the evaporator coil, nominal airflow and 85-95 F (29.4/35 C) condenser

water.

3. All units operate with R-22. Units ships with full operating charge.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

6. Filter sizes are for units without hot water or steam heating coils

PKG-PRC002-EN18

Page 19

SCRF/SIRF

General Data

20-60 Tons

Table GD-4. SCRF/SIRF Air-Cooled Self-Contained

Unit Size 2 0 2 5 2 9 30 35 40 50 60

Compressor Data

Quantity 2 1/1 1/1 3 3 2/1 3 4

NominalTon/Comp 10 15/10 15/10 10 10 10/15 15 15

Circuits 2 2 2 2 2 2 2 2

Evaporator Coil Data

Rows 3 2 4 3 4 4 4 6

Sq. Ft. 21.81 29.98 29.98 31.35 31.35 38.57 49.09 49.09

Sq. m (2.03) (2.79) (2.79) (2.91) (2.91) (3.58) (4.56) (4.56)

FPF 144 144 144 120 144 144 144 144

Evaporator Fan Data

Quantity 1 1 1 1 1 1 1 1

Size (Dia. - inches) 16.5" 18.25" 18.25" 20" 20" 25" 25" 27.5"

Size (Dia. - mm) (419.1) (463.6) (463.6) (508) (508) (635) (635) (698.5)

Minimum HP 5 5 5 5 5 7 .5 10 10

Minimum kW (3.73) (3.73) (3.73) (3.73) (3.73) (5.59) (7.46) (7.46)

Maximum HP 20 25 25 25 25 40 40 50

Maximum kW (14.91) (18.64) (18.64) (18.64) (18.64) (22.37) (37.29) (37.29)

Minimum Design CFM 6500 8700 8700 9100 9880 11960 15080 20800

Minimum Design liters / sec. (3068) (4106) (4106) (4295) (4663) (5645) (7117) (9817)

Maximum Design CFM 10625 12325 13600 14875 16150 19550 24650 29800

Maximum Design liters / sec. (5014) (5817) (6418) (7020) (7622) (9227) (11634) (14064)

General Data

EER 10.8 10.8 10.8 11.0 11.2 11.3 10.8 9.9

IPLV 11.8 12.1 11.4 12.8 12.6 12.5 12.0 10.0

Refrigerant Charge - lbs. R-22 57.2 66.7 72 57 57.2 66.7 7 2 72

Refrigerant Charge - kg R-22 (25.9) (30.3) (32.7) (25.9) (25.9) (30.3) (32.7) (32.7)

Capacity Steps - % 100/53/0 100/62/39/0 100/59/39/0 100/65/31/0 100/65/30/0 100/70/41/30/0 100/65/30/0 100/73/46/20/0

Filter Data

Quantity 8 8 8 8 8 4 4 4

Size (inches ) 20x18x2 20x18x2 20x18x2 20x18x2 20x18x2 16x20x2 16x20x2 16x20x2

Size (mm) (508x457x51) (508x457x51) (508x457x51) (508x457x51) (508x457x51) (406x508x51) (406x508x51) (406x508x51)

Quantity 4 4 4 4 4 8 8 8

Size (inches ) 20x20x2 20x20x2 20x20x2 20x20x2 20x20x2 16x25x2 16x25x2 16x25x2

Size (mm) (508x508x51) (508x508x51) (508x508x51) (508x508x51) (508x508x51) (406x635x51) (406x635x51) (406x635x51)

Quantity 222

Size (inches) 20x20x2 20x20x2 20x20x2

Size (mm) (508x508x51) (508x508x51) (508x508x51)

Quantity 444

Size 20x25x2 20x25x2 20x25x2

Size (mm) (508x635x51) (508x635x51) (508x635x51)

CCRC/CIRC Unit Match 20 29 29 35 35 40 50 60

Notes:

1. Compressors are Trane 3D® scroll.

2. EER and IPLV are rated in accordance to the ARI Standard 340/360-93. Based on 80/67 F (26.7/19.4 C) to the evaporator coil, nominal airflow and 95 F (35 C) ambient.

3. All units operate with R-22. Units ships with a dry nitrogen holding charge.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

6. Filter sizes are for units without hot water or steam heating coils

Table GD-5. SCRF/SIRF Refrigerant Circuits,

Number of Compressors by Circuit

Unit Size

20 Ton 1-10T 1- 10T

25/29 Ton 1-15T 1-10T

30/35 Ton 2-10T 1-10T

40 Ton 1- 10T, 1- 15T 1-15T

50 Ton 2-15T 1-15T

60 Ton 2-15T 2-15T

Note: This table depicts compressor location in unit, plan

view from left corner

PKG-PRC002-EN 19

Circuit 1 2

Page 20

General Data

CCRC/CIRC

Table GD-6. CCRC/CIRC Remote Air-Cooled Condenser

Unit Size 2 0 2 9 3 5 4 0 5 0 6 0

Gross Heat Rejection (MBH) 493 53 8 640 725 1040 1122

Gross Heat Rejection (kW) (144.5) (157.7) (187.6) (212.5) (304.8) (328.8)

Condenser Fan Data

Number/Type 4/Prop 4/Prop 6/Prop 6/Prop 8/Prop 8/Prop

Size (inches) 26 26 26 26 26 26

Size (mm) (660.4) (660.4) (660.4) (660.4) (660.4) (660.4)

Fan Drive Direct Direct Direct Direct Direct Direct

No. of Motors/HP ea. 4/1 4/1 6/1 6/1 8/1 8/1

Nominal CFM 18,800 21,200 35,600 39,800 46,200 56,400

Nominal (liters / sec) (8873) (10005) (16801) (18784) (21804) (26618)

Condenser Coil Data

Circuit 1 Size (in.) 1/46x71 1/64x71 2/46x71 2/46x71 2/64x71 2/64x71

Circuit 1 Size (mm) (1/1168x1803) (1/1626x1803) (2/1168x1803) (2/1168x1803) (2/1626x1803) (2/1626x1803)

Circuit 2 No./Size (in.) 1/46x71 1/46x71 1/46x71 1/64x71 1/64x71 2/64x71

Circuit 2 No./Size (mm) (1/1168x1803) (1/1168x1803) (1/1168x1803) (1/1626x1803) (1/1626x1803) (2/1626x1803)

Face Area (sq. ft.) 45.4 54.2 68 76.9 94.7 126.2

Face Area (sq.m) (4.2) (5) (6.3) (7.1) (8.8) (11.7)

Rows/fpf 4/144 4/144 4/144 4/144 4/144 4/144

Ambient Temperature Operating Range

Standard Ambient (F) 50-115 50-115 50-115 50-115 50-115 50-115

Standard Ambient (C) (10 - 46.1) (10 - 46.1) (10 - 46.1) (10 - 46.1) (10 - 46.1) (10 - 46.1)

Low Ambient Option (F) 0-115 0-115 0-115 0-115 0-115 0-115

Low Ambient Option (C) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1) (-17.8 - 46.1)

Notes:

1. Gross Heat Rejection is at a 20 F (-6.7 C) ITD (Initial Temperature Difference) between condensing temperature and ambient air entering condenser (includes the effect of

subcooling).

2. Operating charge is for entire unit, including 100 feet of interconnecting piping.

3. At conditions of 95 F (35 C), condenser is 95 percent full.

Table GD-7. SCRF/SIRF Air–Cooled Self–Contained and CCRC/CIRC Remote Air-Cooled Condenser

Unit Size 2 0 2 9 3 5 4 0 5 0 6 0

Refrigerant Circuit General Data

No. of Refrigerant Circuits 2 2 2 2 2 2

Operating Charge - lbs. R-22 36/36 58/36 72/36 94/36 115/58 115/115

Operating Charge - kg R-22 (16.3/16.3) (26.3/16.3) (32.7/16.3) (42.6/16.3) (52.2/26.3) (52.2/56.7)

Cond. Storage Cap. - lbs. R-22 44/44 61/44 88/44 105/44 122/122 122/122

Cond. Storage Cap. - kg R-22 (20/20) (27.7/20) (39.9/20) (47.6/20) (55.3/55.3) (55.3/55.3)

Notes:

1. Gross heat rejection is at a 20 F (-6.7 C) ITD (initial temperature difference) between condensing temperature and ambient air entering condenser (includes the effect of

subcooling).

2. Operating charge is for entire system, which includes the air–cooled self–contained, remote air–cooled condenser, and 25 feet of interconnecting refrigerant piping.

3. At conditions of 95 F (35 C), condenser storage capacity is 95% full.

4. To determine the correct amount of refrigerant needed for a particuliar application, reference the

Trane Reciprocating Refrigeration Manual

.

PKG-PRC002-EN20

Page 21

General Data

Heating Coil

Table GD-7. Self-Contained Heating Coil

Unit Size SCWF 20 - 38 SCWF 42 - 80 SCRF 20 - 35 SCRF 40 - 60

Steam Coil

Coil Type NS NS NS NS

Rows Rows 1 1 1 1

No./Size (inches) ((2) 24x58) ((2) 30x81) ((2) 24x58) ((2) 30x81)

No./Size (mm) ((2) 609.6x1473.2) ((2) 762x2057.4) ((2) 609.6x1473.2) ((2) 762x2057.4)

FPF 42 42 42 42

Hot Water Coil

Coil Type WC WC WC WC

Rows 1 1 1 1

No./Size (inches) (2) 24x58 (2) 30x81 (2) 24x58 (2) 30x81

No./Size (mm) ((2) 609.6x1473.2) ((2) 762x2057.4) ((2) 609.6x1473.2) ((2) 762x2057.4)

FPF 80 80 80 80

Filter Data

Quantity 4 4 4 4

Size (inches) 20x18x2 16x20x2 20x18x2 16x20x2

Size (mm) (508x457x51) (406x508x51) (508x457x51) (406x508x51)

Quantity 8 8 8 8

Size (inches) 20x20x2 16x25x2 20x20x2 16x25x2

Size (mm) (508x508x51) (406x635x51) (508x508x51) (406x635x51)

Quantity 2 2

Size (inches) 20x20x2 20x20x2

Size (mm) (508x508x51) (508x508x51)

Quantity 4 4

Size (inches) 20x25x2 20x25x2

Size (mm) (508x635x51) (508x635x51)

Notes:

1. Hot water and steam heating coils have Prima-Flo® fins without turbulators.

2. For coil capacites, use TOPSS™ (Trane Official Product Selection Program).

3. Full capacity coils consist of two coils stacked and piped in parallel.

PKG-PRC002-EN 21

Page 22

Performance Airside Pressure

Data Drops

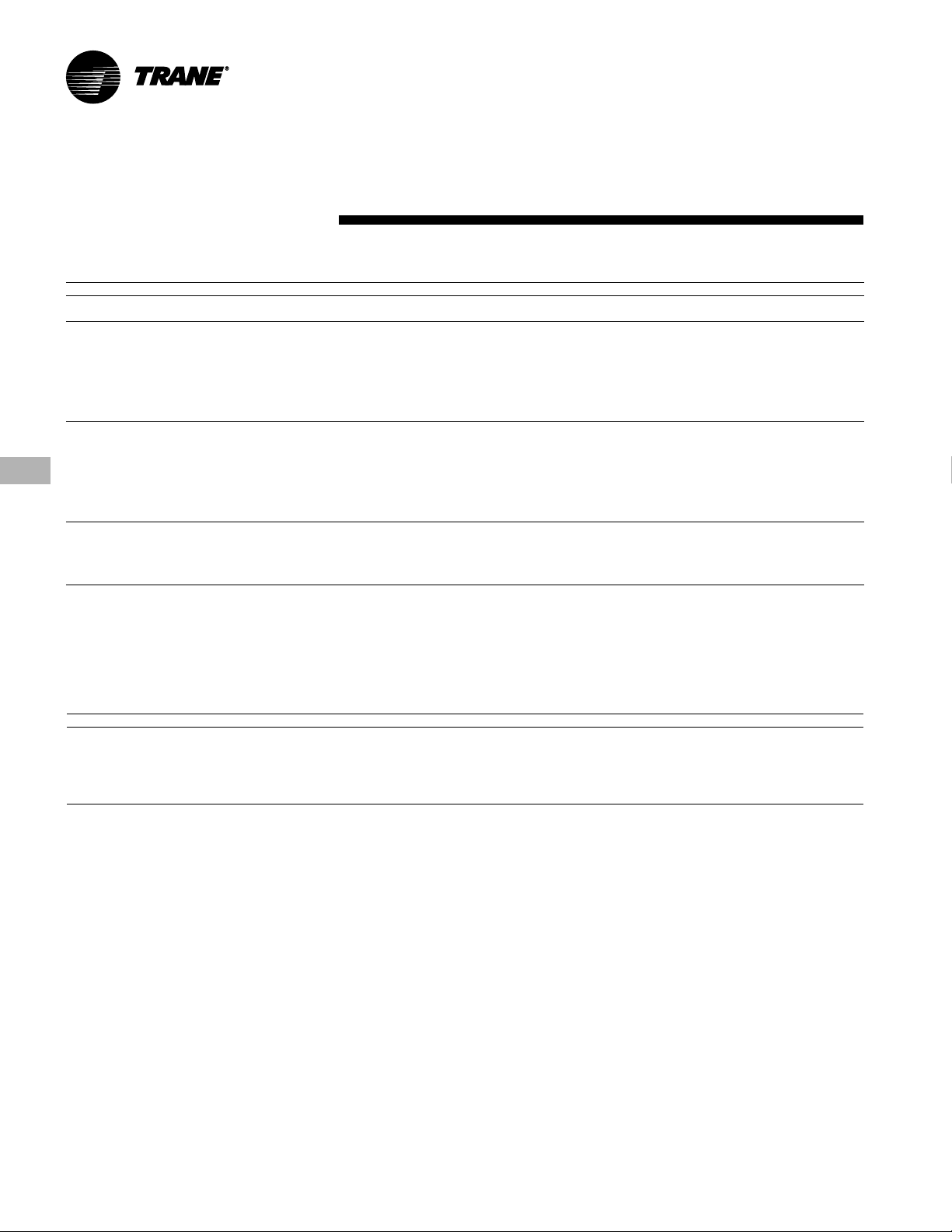

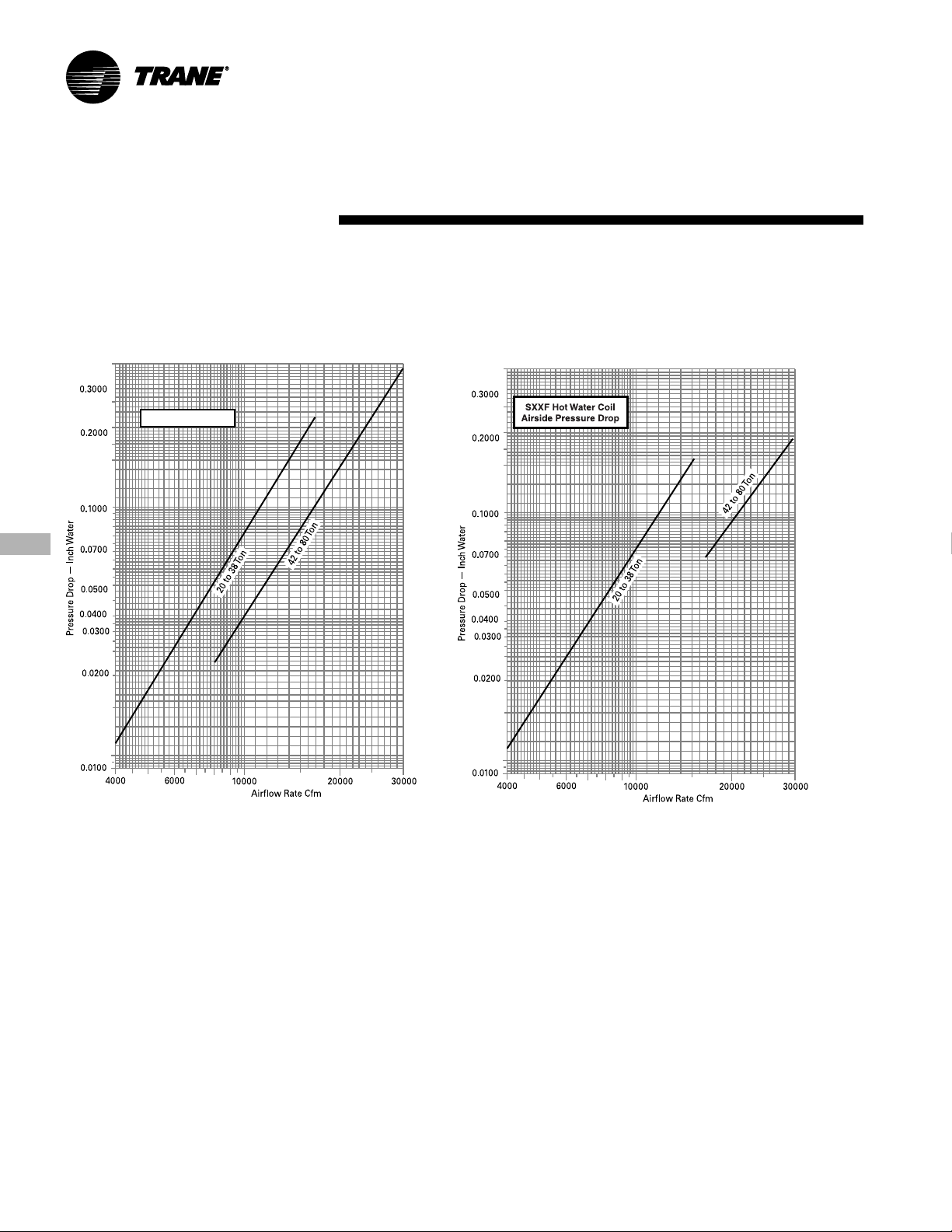

Chart PD-1. Airside Pressure Drop

SCWF/SIWF 20, 22, 25 and SCRF/SIRF 20

Chart PD-3. Airside Pressure Drop

SCWF/SIWF 35, 38 and SCRF/SIRF 30, 35

Chart PD-2. Airside Pressure Drop

SCWF/SIWF 29, 32 and SCRF/SIRF 25, 29

Chart PD-4. Airside Pressure Drop

SCWF/SIWF 42, 46 and SCRF/SIRF 40

Notes:

1. Dotted line on construction filters indicates cfm where face velocity exceeds manufacturer’s recommended maximum of 300 fpm. After startup, construction filters must be

replaced with medium velocity or high velocity filters.

2. Air pressure drop through electric heat is 0.5 inches WC.

3. Refer to Page 25-26 for pressure drop through flexible horizontal discharge plenum.

4. Refer to Page 24 for pressure drop through heating coils.

PKG-PRC002-EN22

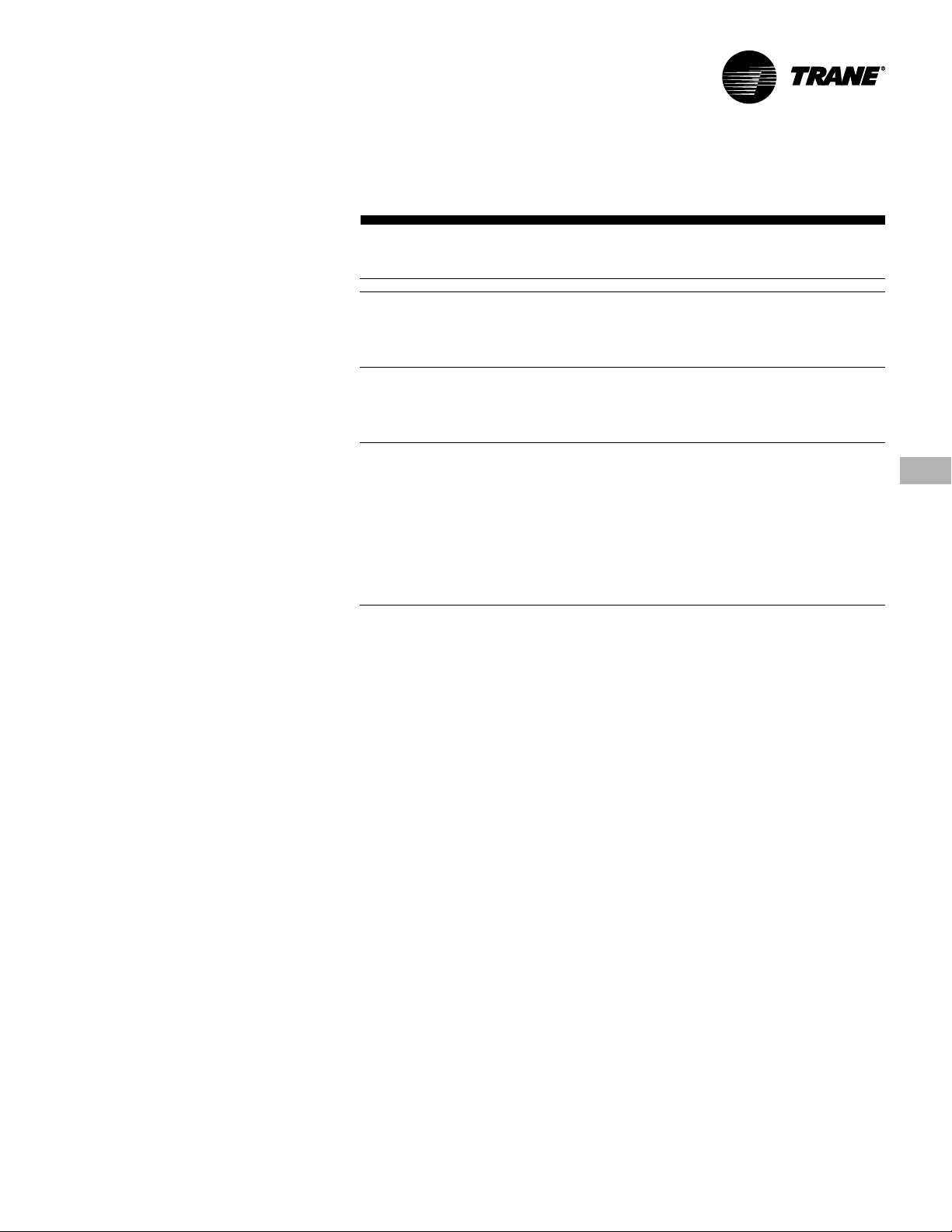

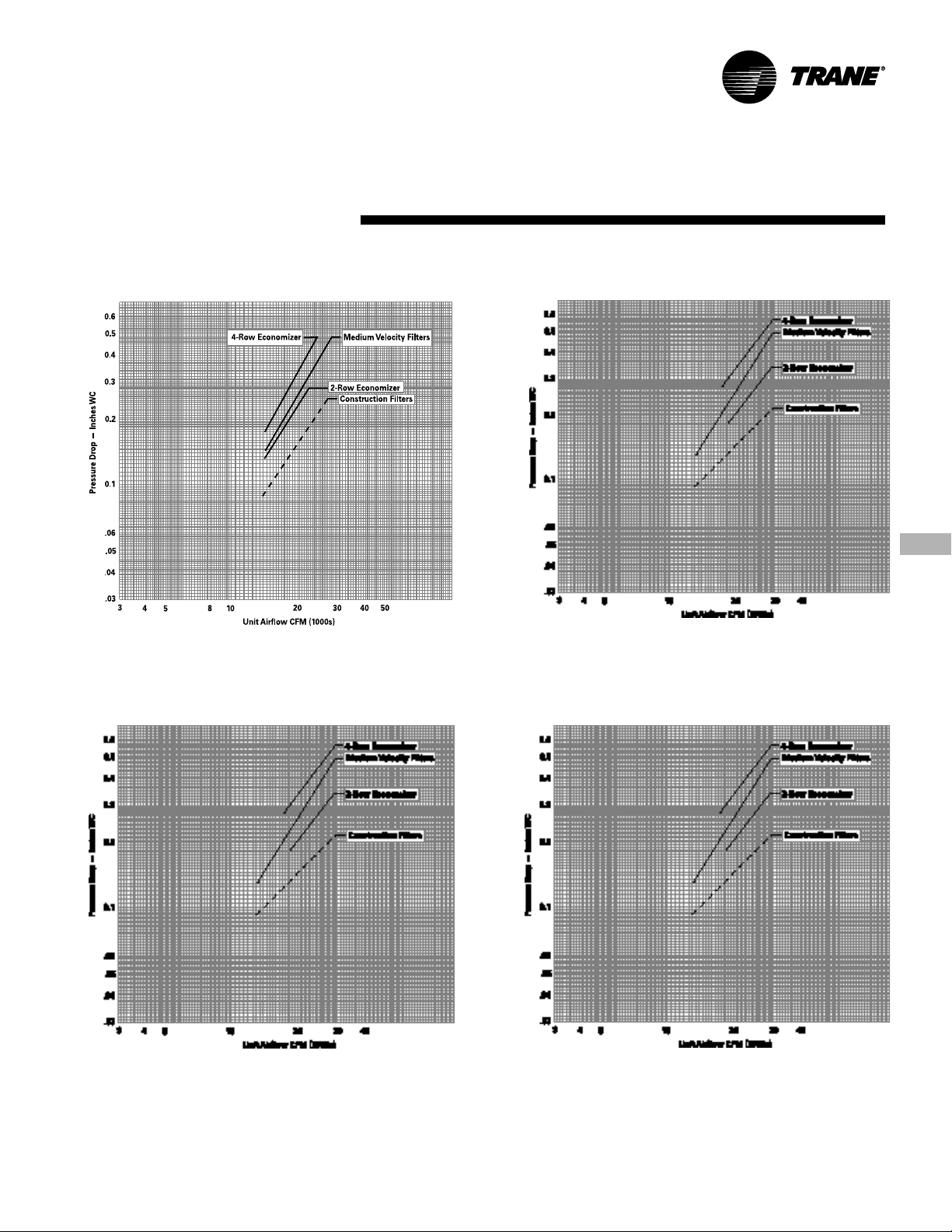

Page 23

Performance Airside Pressure

Data Drops

Chart PD-5. Airside Pressure Drop

SCWF/SIWF 52, 58 and SCRF/SIRF 50

Chart PD-7. Airside Pressure Drop

SCWF/SIWF 72

Chart PD-6. Airside Pressure Drop

SCWF/SIWF 65

Chart PD-8. Airside Pressure Drop

SCWF/SIWF 80 and SCRF/SIRF 60

Notes:

1. Dotted line on construction filters indicates cfm where face velocity exceeds manufacturer’s recommended maximum of 300 fpm. After startup, construction filters must be

replaced with medium velocity or high velocity filters.

2. Air pressure drop through electric heat is 0.5 inches WC.

3. Refer to Page 25-26 for pressure drop through flexible horizontal discharge plenum.

4. Refer to Page 24 for pressure drop through heating coils.

PKG-PRC002-EN 23

Page 24

Heating Coils

Chart PD-9. Airside Pressure Drop

Steam Coil

20 to 80-Ton Units

For NS Coils

Performance Airside Pressure

Data Drops

Chart PD-10. Airside Pressure Drop

Hot Water Coil

20 to 80-Ton Units

PKG-PRC002-EN24

Page 25

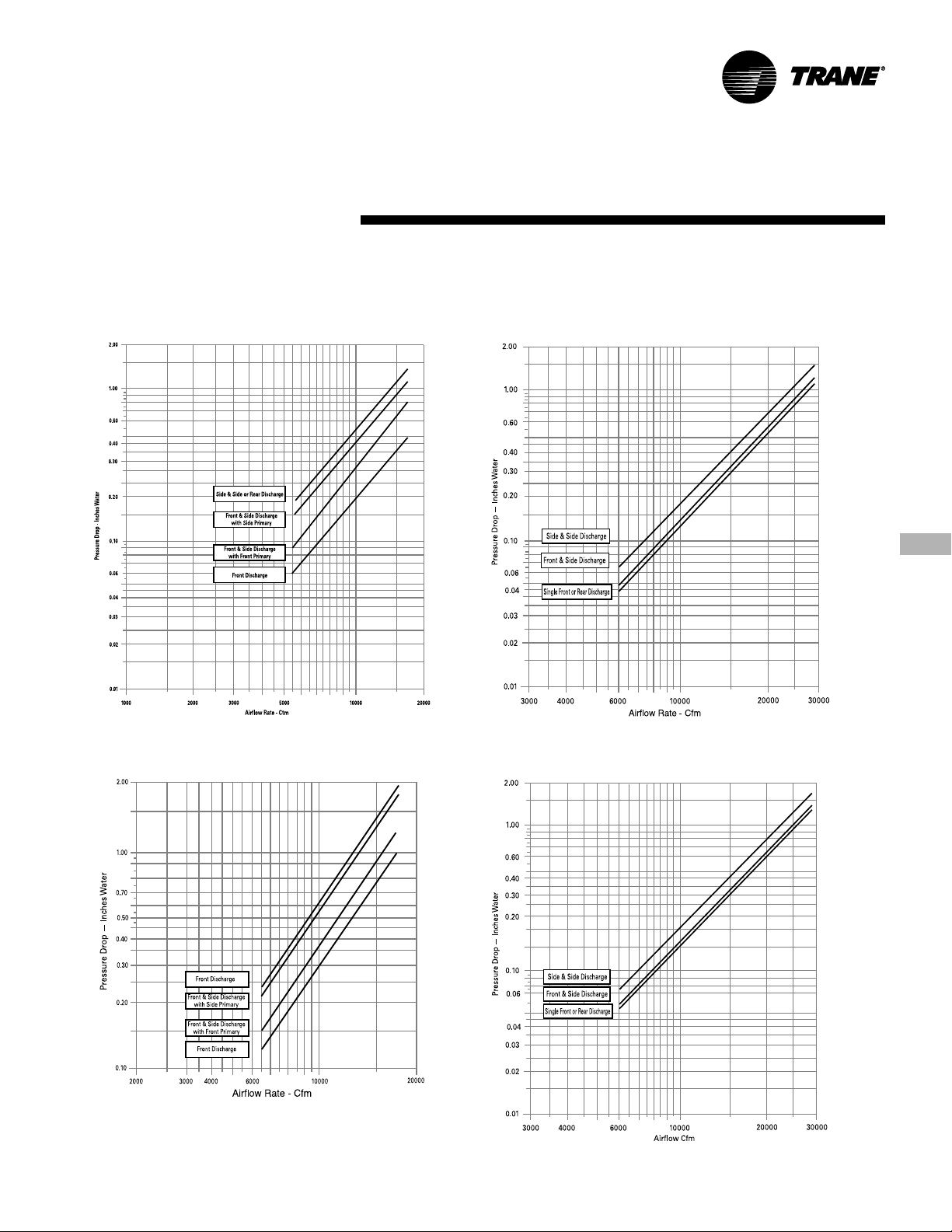

Discharge Plenum

Chart PD-10. Airside Pressure Drop,

Standard Height Discharge Plenum

20 to 38 Ton Unit

Performance Airside Pressure

Data Drops

Chart PD-11. Airside Pressure Drop

Standard Height Discharge Plenum

42 to 80 Ton Unit

Chart PD-12. Airside Pressure Drop

Low Height Discharge Plenum

20 to 38 Ton Unit

Note:

“Primary” refers to the side where the static pressure drop was measured. This value

must be added to the unit external static pressure for proper fan horsepower

determination.

Chart PD-13. Airside Pressure Drop

Low Height Discharge Plenum

42 to 80 Ton Unit

PKG-PRC002-EN 25

Page 26

Performance Airside Pressure

Data Drops

Discharge Plenum

Chart PD-14. Airside Pressure Drop

Extended Height Discharge Plenum

20 to 38-Ton Unit

Chart PD-15. Airside Pressure Drop

Extended Height Discharge Plenum

42 to 80-Ton Unit

PKG-PRC002-EN26

Page 27

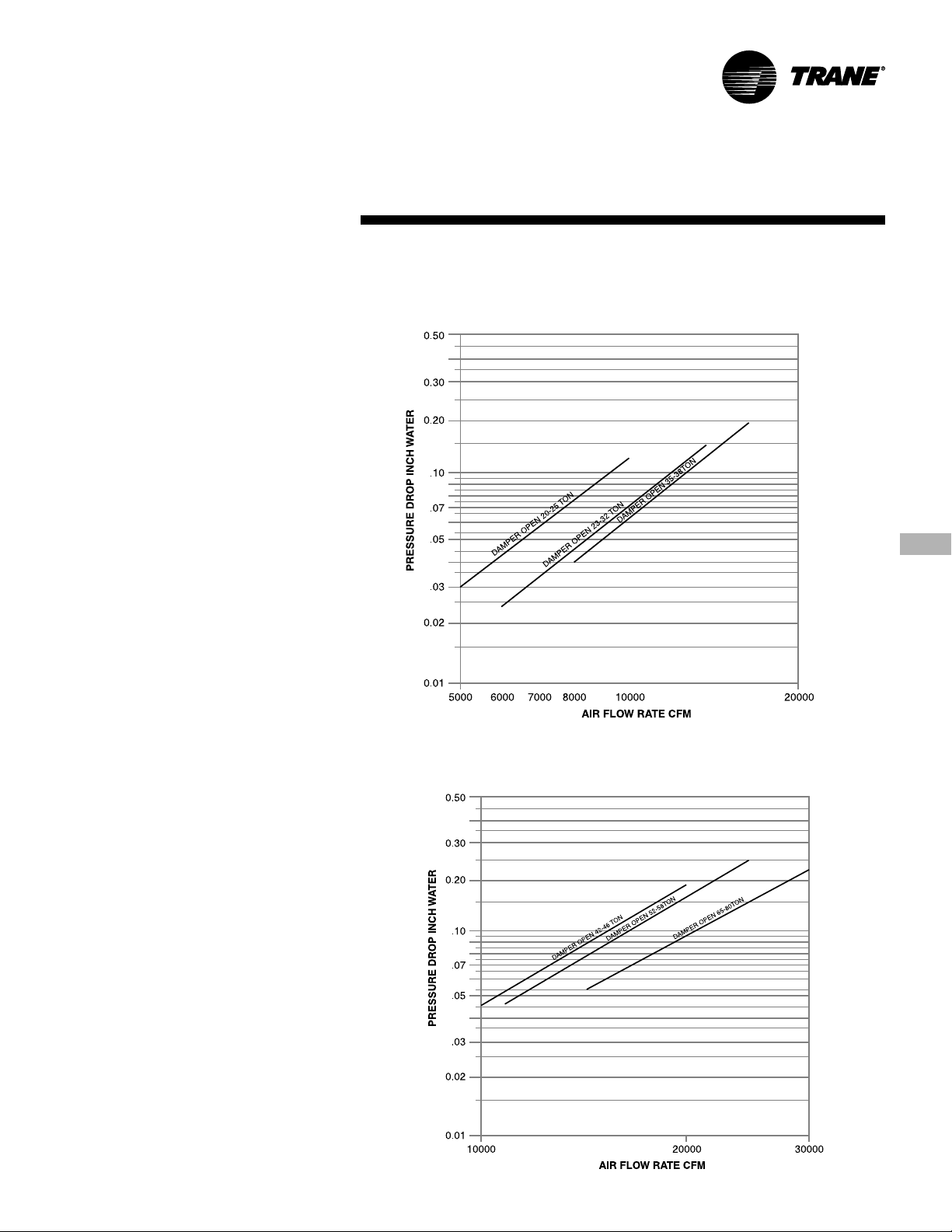

Performance Airside Pressure

Data Drops

Airside Economizer with

Standard Damper

Chart PD-16. Airside Pressure Drop

Airside Economizer with Standard Damper

20 to 38-Ton Unit

Chart PD-17. Airside Pressure Drop

Airside Economizer with Standard Damper

42 to 80-Ton Unit

PKG-PRC002-EN 27

Page 28

Performance Airside Pressure

Data Drops

Airside Economizer with

Traq™ Damper

Chart PD-18. Airside Pressure Drop

Airside Economizer with Traq™ Damper

Air Flow Rate CFM

PKG-PRC002-EN28

Page 29

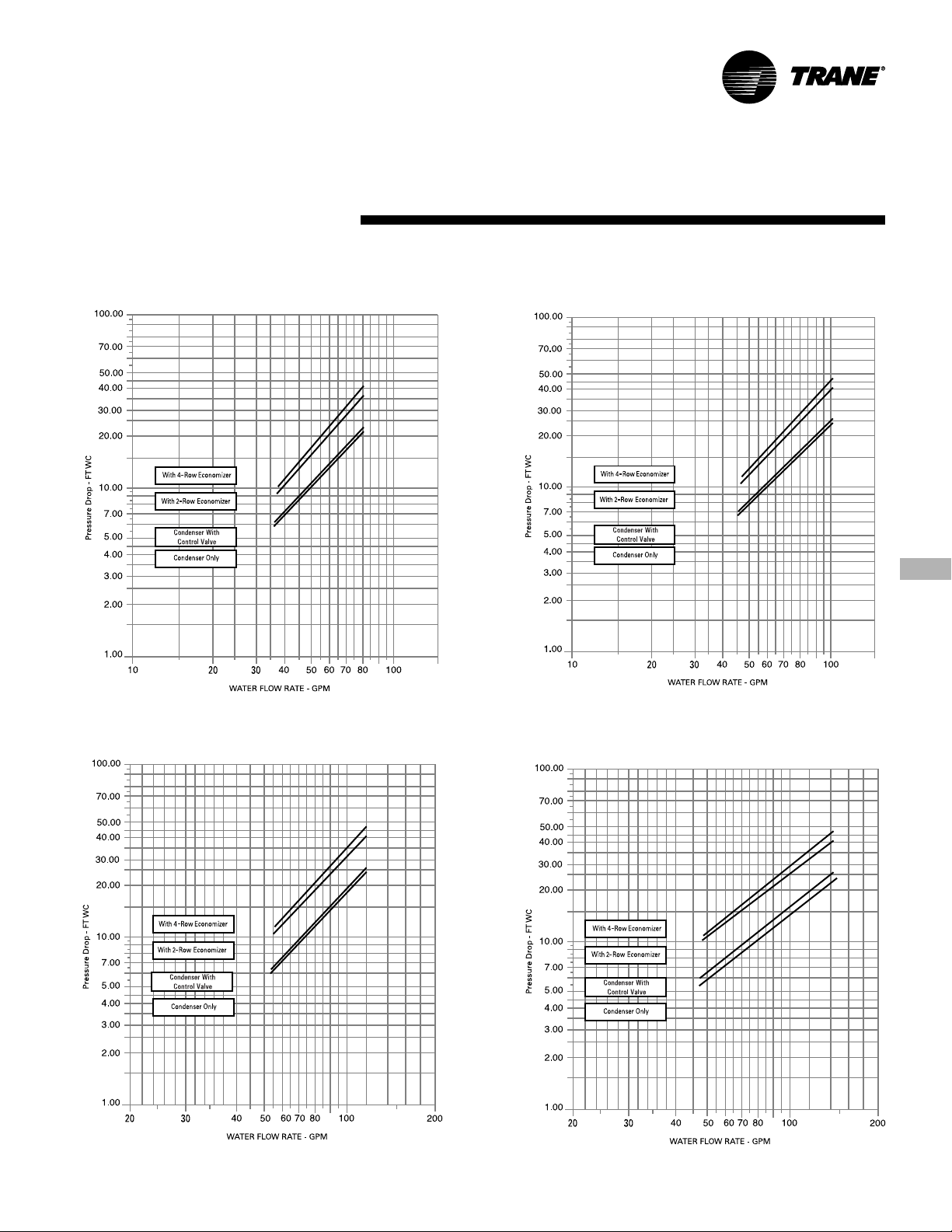

Performance Waterside

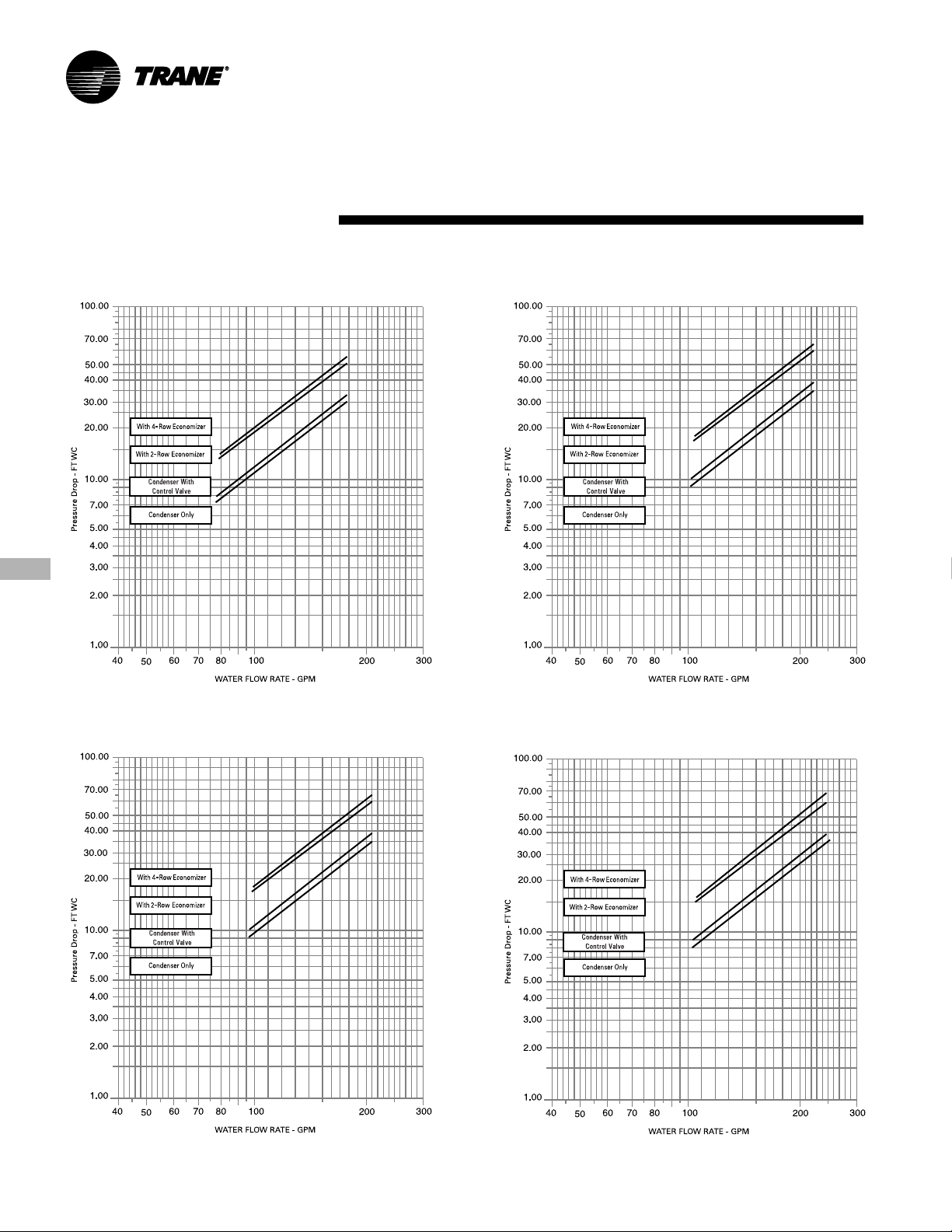

Data Pressure Drop

Chart PD-19. Waterside Pressure Drop

SCWF/SIWF 20, 22, 25

Chart PD-21. Waterside Pressure Drop

SCWF/SIWF 35, 38

Chart PD-20. Waterside Pressure Drop

SCWF/SIWF 29, 32

Chart PD-22. Waterside Pressure Drop

SCWF/SIWF 42, 46

Note: Each curve provides total water pressure drop through the entire unit including all accessories and internal valves and piping. Do not add curves together.

PKG-PRC002-EN 29

Page 30

Performance Waterside

Data Pressure Drop

Chart PD-23. Waterside Pressure Drop

SCWF/SIWF 52, 58

Chart PD-25. Waterside Pressure Drop

SCWF/SIWF 72

Chart PD-24. Waterside Pressure Drop

SCWF/SIWF 65

Chart PD-26. Waterside Pressure Drop

SCWF/SIWF 80

Note: Each curve provides total water pressure drop through the entire unit including all accessories and internal valves and piping. Do not add curves together.

PKG-PRC002-EN30

Page 31

Performance Water-Cooled

Data

Table PD-1. CFM Capacity Correction Table

Cfm Compared Cooling Sensible

To Rated Capacity Capacity

Quanitity Multiplier Multiplier

-20% 0.970 0.910

DX Cooling Std 1.000 1.000

Waterside Std 1.000 1.000

Economizer +3% 1.005 1.014

-10% 0.985 0.955

+3% 1.005 1.014

+6% 1.009 1.027

-20% 0.970 0.910

-10% 0.985 0.955

+6% 1.009 1.027

PKG-PRC002-EN 31

Page 32

Performance Water-Cooled

Data

20 Ton

Table PD-2. SCWF/SIWF 20 - Economizer Full Capacity - 8,000 cfm

Entering Air 45 F 55 F

EDB EWB Flow Total Sensible LWT Total Sensible LWT

F F gpm MBh MBh F MBh MBh F

50 210.3 189.3 53.4 132.5 132.5 60.3

62 60 220.8 193.7 52.4 136.2 136.2 59.5

70 228.8 197.1 51.5 138.9 138.9 59.0

50 265.7 160.4 55.6 155.2 119.1 61.2

75 67 60 284.6 167.9 54.5 164.4 122.4 60.5

70 299.0 173.7 53.5 171.8 125.0 59.9

50 339.2 133.9 58.6 221.4 92.8 63.9

72 60 364.8 143.3 57.2 238.3 98.5 62.9

70 383.9 150.5 56.0 251.4 103.0 62.2

50 230.9 226.2 54.2 165.6 165.6 61.6

62 60 239.2 234.5 53.0 170.2 170.2 60.7

70 245.2 240.6 52.0 173.5 173.5 60.0

50 271.3 204.6 55.9 171.1 166.8 61.8

80 67 60 288.1 211.3 54.6 178.2 169.4 60.9

70 300.9 216.5 53.6 183.7 171.4 60.2

50 338.5 176.3 58.5 222.0 135.4 63.9

72 60 363.9 185.8 57.1 238.0 140.8 62.9

70 383.0 193.1 55.9 250.6 145.1 62.2

50 262.5 262.5 55.5 198.6 198.6 62.9

62 60 270.4 270.4 54.0 204.1 204.1 61.8

70 275.9 275.9 52.9 208.0 208.0 60.9

50 283.5 251.3 56.3 199.2 199.2 63.0

85 67 60 298.0 257.1 54.9 204.8 204.8 61.8

70 309.0 261.6 53.8 208.8 208.8 61.0

50 340.7 219.3 58.6 230.6 180.5 64.2

72 60 364.4 228.2 57.1 244.2 185.1 63.1

70 382.6 235.1 55.9 255.1 188.8 62.3

Entering Water Temp

Table PD-3. SCWF/SIWF 20 - Economizer Low Capacity - 8,000 cfm

Entering Air 45 F 55 F

EDB EWB Flow Total Sensible LWT Total Sensible LWT

F F gpm MBh MBh F MBh MBh F

50 140.0 135.3 50.6 92.8 92.8 58.7

62 60 147.0 144.0 49.9 96.1 96.1 58.2

70 152.4 146.2 49.4 98.4 98.4 57.8

50 175.6 114.8 52.0 102.0 88.3 59.1

75 67 60 188.4 119.7 51.3 107.8 90.3 58.6

70 198.0 123.3 50.7 112.6 92.0 58.2

50 224.3 90.6 54.0 146.7 64.5 60.9

72 60 241.1 96.5 53.0 157.3 68.0 60.2

70 253.7 101.0 52.2 165.5 70.7 59.7

50 160.2 160.2 51.4 116.1 116.1 59.6

62 60 166.4 166.4 50.5 120.1 120.1 59.0

70 170.7 170.7 49.9 123.0 123.0 58.5

50 177.8 149.8 52.1 116.4 111.3 59.7

80 67 60 189.3 154.2 51.3 120.8 115.7 59.0

70 198.1 157.5 50.7 124.2 119.1 58.5

50 223.8 124.8 54.0 146.2 98.8 60.8

72 60 240.5 130.7 53.0 156.8 102.2 60.2

70 253.1 135.2 52.2 165.0 104.8 59.7

50 183.2 183.2 52.3 139.3 139.3 60.6

62 60 190.2 190.2 51.3 144.1 144.1 59.8

70 195.1 195.1 50.6 147.6 147.6 59.2

50 188.1 187.8 52.5 139.6 139.6 60.6

85 67 60 197.7 191.4 51.6 144.4 144.4 59.8

70 205.0 194.3 50.9 147.9 147.9 59.2

50 223.6 158.9 53.9 151.1 134.6 61.0

72 60 240.0 164.7 53.0 159.8 137.4 60.3

70 252.6 169.2 52.2 166.7 139.7 59.8

Entering Water Temp

PKG-PRC002-EN32

Page 33

Performance Water-Cooled

Data

Table PD-4. SCWF/SIWF 20 Gross Cooling Capacity - 8,000 cfm, 60 gpm

Entering Air 75 F 85 F 95 F

EDB EWB Total Sensible Total Sensible Total Sensible

F F MBh MBh LWT MBh MBh LWT MBh MBh L WT

62 244 185 84.7 235 181 94.7 225 176 104.6

75 67 266 150 85.5 256 146 95.4 246 141 105.3

72 289 114 86.3 278 110 96.2 267 106 106.0

62 244 218 84.7 235 214 94.7 226 209 104.6

80 67 266 183 85.5 256 179 95.4 245 174 105.3

72 289 147 86.3 278 143 96.1 267 139 106.0

62 247 246 84.8 239 239 94.8 231 231 104.8

85 67 265 216 85.5 256 211 95.4 245 207 105.3

72 288 180 86.3 278 176 96.1 267 171 106.0

Chart PD-27. SCWF/SIWF 20 Fan Performance for CV or with VFD

Entering Water Temp

20 Ton

Chart PD-28. SCWF/SIWF 20 Fan Performance with Inlet Guide Vanes

Note:

1. Fan curves include refrigerant coil and internal

cabinet static losses. To determine static pressure to

be used with these curves, add filter, economizer,

flexible horizontal discharge and heat pressure

drops to external duct static pressure.

PKG-PRC002-EN 33

Page 34

Performance Water-Cooled

Data

22 Ton

Table PD-5. SCWF/SIWF 22 - Economizer Full Capacity - 8,800 cfm

Entering Water Temp

Entering Air 45 F 55 F

EDB EWB Flow Total Sensible LWT Total Sensible LWT

F F gpm MBh MBh F MBh MBh F

62 66 237.6 210.2 52.2 147.3 147.3 59.5

75 67 66 305.8 181.4 54.3 176.4 132.6 60.3

72 66 391.8 154.1 56.9 255.6 106.1 62.7

62 66 258.1 253.0 52.8 184.0 184.0 60.6

80 67 66 309.6 228.8 54.4 191.8 184.1 60.8

72 66 390.8 200.5 56.8 255.2 152.2 62.7

62 66 292.5 292.5 53.9 220.7 220.7 61.7

85 67 66 320.5 279.0 54.7 221.4 221.4 61.7

72 66 391.3 246.8 56.9 262.1 200.7 62.9

55 226.8 205.7 53.2 143.3 143.3 60.2

77 245.9 213.8 51.4 150.2 150.2 58.9

55 286.3 173.7 55.4 167.0 129.3 61.1

77 320.8 187.5 53.3 184.2 135.4 59.8

55 365.5 144.5 58.3 238.0 100.2 63.7

77 411.9 161.6 55.7 269.5 110.8 62.0

55 249.7 244.6 54.1 179.1 179.1 61.5

77 264.5 259.4 51.9 187.6 187.6 59.9

55 292.3 222.0 55.6 184.5 181.5 61.7

77 322.9 234.2 53.4 197.6 186.2 60.1

55 364.6 190.8 58.3 238.6 146.7 63.7

77 410.9 208.1 55.7 268.6 156.8 62.0

55 284.2 284.2 55.3 214.8 214.8 62.8

77 298.4 298.4 52.7 225.0 225.0 60.8

55 305.7 273.1 56.1 215.5 215.5 62.8

77 332.0 283.6 53.6 225.8 225.8 60.9

55 366.9 237.7 58.3 247.9 195.9 64.0

77 410.3 254.0 55.7 273.5 204.6 62.1

Table PD-6. SCWF/SIWF 22 - Economizer Low Capacity - 8,800 cfm

Entering Air 45 F 55 F

EDB EWB Flow Total Sensible LWT Total Sensible LWT

F F gpm MBh MBh F MBh MBh F

55 150.1 145.0 50.5 99.6 99.6 58.6

62 66 157.1 155.1 49.8 102.9 102.9 58.1

77 162.5 157.3 49.2 105.4 105.4 57.7

55 188.1 123.5 51.8 108.9 95.1 59.0

75 67 66 200.9 128.4 51.1 114.8 97.1 58.5

77 210.7 132.1 50.5 119.7 98.9 58.1

55 240.1 97.1 53.7 156.6 69.2 60.7

72 66 256.9 103.0 52.8 167.3 72.6 60.1

77 269.8 107.6 52.0 175.9 75.4 59.6

55 172.2 172.2 51.3 124.5 124.5 59.5

62 66 178.4 178.4 50.4 128.6 128.6 58.9

77 182.9 182.9 49.7 131.7 131.7 58.4

55 190.4 161.4 51.9 124.8 119.3 59.5

80 67 66 201.9 165.8 51.1 129.2 123.7 58.9

77 210.8 169.2 50.5 132.7 127.1 58.4

55 239.6 134.1 53.7 156.1 106.2 60.7

72 66 256.4 140.0 52.8 166.8 109.7 60.1

77 269.2 144.6 52.0 175.3 112.4 59.6

55 196.8 196.8 52.2 149.5 149.5 60.4

62 66 203.9 203.9 51.2 154.4 154.4 59.7

77 209.0 209.0 50.4 158.1 158.1 59.1

55 201.6 195.7 52.3 149.7 149.7 60.4

85 67 66 211.1 206.2 51.4 154.7 154.7 59.7

77 218.5 209.0 50.7 158.4 158.4 59.1

55 239.3 171.1 53.7 161.4 145.1 60.9

72 66 255.8 177.0 52.8 170.1 147.9 60.2

77 268.6 181.5 52.0 177.3 150.2 59.6

Entering Water Temp

PKG-PRC002-EN34

Page 35

Performance Water-Cooled

Data

Table PD-7 — SCWF/SIWF 22 Gross Cooling Capacity - 8,800 cfm, 66 gpm

Entering Air 75 F 85 F 95 F

EDB EWB Total Sensible Total Sensible Total Sensible

F F MBh MBh LWT MBh MBh LW T MBh MBh L WT

62 257 197 84.3 248 193 94.3 238 188 104.2

75 67 280 159 85.0 270 155 94.9 259 150 104.9

72 305 120 85.8 294 116 95.7 282 112 105.6

62 257 233 84.3 248 228 94.3 238 223 104.2

80 67 280 194 85.0 270 190 94.9 259 186 104.9

72 304 156 85.8 294 152 95.7 282 147 105.6

62 262 261 84.4 254 254 94.4 246 246 104.4

85 67 280 230 85.0 270 226 94.9 259 221 104.8

72 304 191 85.8 293 187 95.7 282 183 105.6

Chart PD-29 — SCWF/SIWF 22 Fan Performance for CV or with VFD

22 Ton

Entering Water Temp

Chart PD-30 — SCWF/SIWF 22 Fan Performance with Inlet Guide Vanes

Note:

1. Fan curves include refrigerant coil and internal cabinet

static losses. To determine static pressure to be used

with these curves, add filter, economizer, flexible

horizontal discharge and heat pressure drops to

external duct static pressure.

PKG-PRC002-EN 35

Page 36

Performance Water-Cooled

Data

25 Ton

Table PD-8. SCWF/SIWF 25 - Economizer Full Capacity -10,000 cfm

Entering Air 45 F 55 F

EDB EWB Flow Total Sensible LWT Total Sensible LWT

F F gpm MBh MBh F MBh MBh F

63 250.7 229.6 53.0 159.0 159.0 60.0

62 75 261.4 234.1 52.0 163.2 163.2 59.4

80 265.2 235.7 51.6 164.6 164.6 59.1

63 316.1 193.1 55.0 183.8 144.0 60.8

75 67 75 335.6 200.8 53.9 193.5 147.5 60.2

80 342.5 203.6 53.6 197.0 148.7 59.9

63 404.1 160.2 57.8 262.3 110.9 63.3

72 75 429.9 169.5 56.5 280.2 116.9 62.5

80 439.1 172.9 56.0 286.5 119.0 62.2

63 276.9 271.1 53.8 198.7 198.7 61.3

62 75 285.3 279.5 52.6 203.9 203.9 60.4

80 288.2 282.4 52.2 205.6 205.6 60.1

63 322.6 247.4 55.2 203.9 202.9 61.5

80 67 75 339.8 254.2 54.1 211.3 205.6 60.6

80 345.9 256.6 53.6 213.9 206.5 60.3

63 403.2 212.1 57.8 262.8 163.2 63.3

72 75 428.9 221.6 56.4 279.7 168.8 62.5

80 438.1 225.0 56.0 285.8 170.9 62.1

63 315.6 315.6 55.0 238.3 238.3 62.6

62 75 324.1 324.1 53.6 244.6 244.6 61.5

80 326.9 326.9 53.2 246.6 246.6 61.2