Trane Performance Climate Changer CSAA Series, CSA006, CSA004, CSA010, CSA012 Installation, Operation And Maintenance Manual

...Page 1

Installation, Operation,

and Maintenance

Gas Heat — Inshot Style

Performance Climate Changer™ CSAA Air Handlers

Sizes 4 to 30 for Indoor and Outdoor Units

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

October 2018

SAFETY WARNING

CLCH-SVX014B-EN

Page 2

Introduction

Read this manual thoroughly before operating or servici ng

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

CAUTIONs

NOTICE

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified according to local rules. For

the USA, the Federal Clean Air Act (Section 608) sets forth

the requirements for handling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that is

used in these service procedures. In addition, some states

or municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

WARNI NG

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNI NG

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2018 Ingersoll Rand CLCH-SVX014B-EN

Page 3

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in

death or serious injury.

• All Ingersoll Rand personnel must follow Ingersoll

Rand Environmental, Health and Safety (EHS)

policies when performing work such as hot work,

electrical, fall protection, lockout/tagout, refrigerant

handling, etc. All policies can be found on the BOS

site. Where local regulations are more stringent than

these policies, those regulations supersede these

policies.

• Non-Ingersoll Rand personnel should always follow

local regulations.

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Introduction

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

• Updated start-up procedure.

• Updated normal sequence of operation.

• Added new chapter Troubleshooting Guide.

CLCH-SVX014B-EN 3

Page 4

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . 5

Overview of Manual . . . . . . . . . . . . . . . . . . . 5

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Information . . . . . . . . . . . . . . . . . . . . 6

Burner Specifications . . . . . . . . . . . . . . . . . 6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receiving and Handling . . . . . . . . . . . . . . . . 8

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Packaging/Shipping . . . . . . . . . . . . . . . . . . 8

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receiving Checklist . . . . . . . . . . . . . . . . . . 8

Jobsite Storage . . . . . . . . . . . . . . . . . . . . . . . 9

Outdoor Storage . . . . . . . . . . . . . . . . . . . . . 9

Dimensions and Weights . . . . . . . . . . . . . . . . 10

Service Clearances . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contractors’ Responsibilities . . . . . . . . . . . 12

Installing Contractor . . . . . . . . . . . . . . . . . 12

Electrical and/or Controls Contractor . . . 12

Lifting and Rigging . . . . . . . . . . . . . . . . . . . 13

Placement and Assembly . . . . . . . . . . . . . . 13

Flue Stack for Outdoor Air Handlers . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

High Altitude Installations . . . . . . . . . . . . 13

Installing Outdoor Flue Stacks . . . . . . . . 13

Installing Indoor Flue Stacks . . . . . . . . . . 14

Installing Rain Hood/Combustion Air Inlet 14

Installing Flue Stack for Hurricane Applica-

tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Duct Connections . . . . . . . . . . . . . . . . . . . . . 14

Combustion Air Duct . . . . . . . . . . . . . . . . 14

Duct Transitions . . . . . . . . . . . . . . . . . . . . 15

Airflow Direction . . . . . . . . . . . . . . . . . . . 15

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Wiring Checklist . . . . . . . . . . . . . . . . . . . . . . .17

High-Voltage Wiring . . . . . . . . . . . . . . . . . . .17

Wiring Entrance Locations . . . . . . . . . . . .17

Low-Voltage Wiring . . . . . . . . . . . . . . . . . . . .18

Start-Up — Indirect Gas-Fired Heating . . . . .19

Gas Heat Application Rules — Inshot . . . .19

Start-up Procedure . . . . . . . . . . . . . . . . . . . .19

Safety Controls . . . . . . . . . . . . . . . . . . . . . . . . 22

Normal Sequence of Operation . . . . . . . . .22

Normal Shutdown . . . . . . . . . . . . . . . . . . . . .23

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . .24

Routine Maintenance . . . . . . . . . . . . . . . . . . . .27

Troubleshooting Guide . . . . . . . . . . . . . . . . . .28

VB1285 Sequence of Operations . . . . . . . . .29

VB1287 Sequence of Operations . . . . . . . . .31

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Proper Gas Pressure . . . . . . . . . . . . . . . . 16

Heat Exchanger Condensate Piping . . . . . 16

4 CLCH-SVX014B-EN

Page 5

General Information

Overview of Manual

Use this manual to install, startup, operate, and maintain

the Performance Climate Changer™ air handler gas heat

section. Carefully review the procedures discussed in this

manual to minimize installation and startup difficulties.

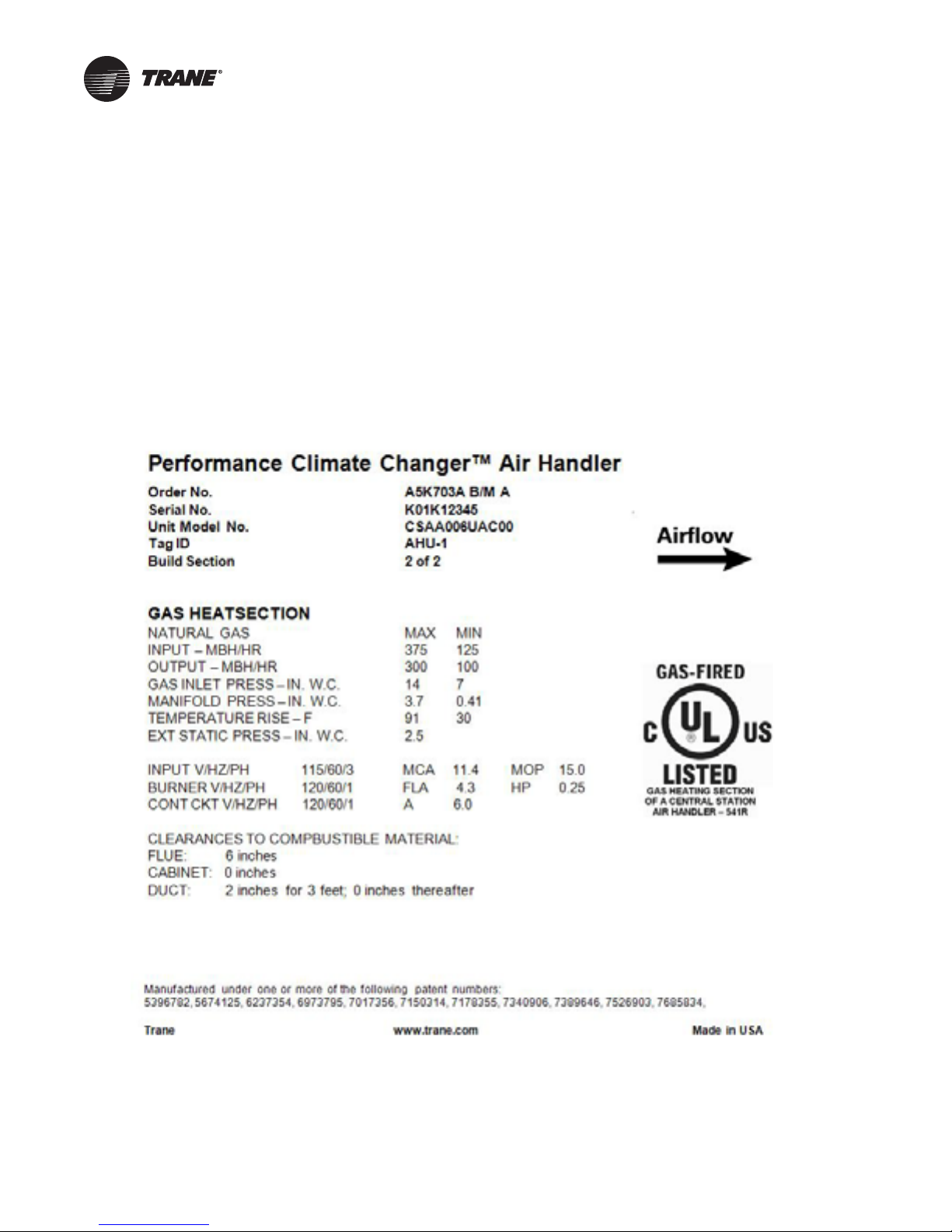

Nameplate

Each air handler section includes a nameplate/label which

identifies the type of section, customer tagging

information, the unit serial number, the unit order number,

the build-section position for installation, and the unit

model number.

Figure 1. Example - performance air handler section nameplate

Note: The unit serial number and order number is

required when ordering parts or requesting service

for a Trane air handler.

CLCH-SVX014B-EN 5

Page 6

General Information

Product Information

Model and serial numbers for the gas heat section are

designated on the nameplate located on the piping-side

access door inside the section. Record the information

below for a permanent record of the equipment installed

on your job site. The nameplate also contains the range of

Model Number____________________________________________________________________________

Serial Number_____________________________________________________________________________

Air Handler Sales Order Number____________________________________________________________

Air Handler Serial Number_________________________________________________________________

Startup Date_______________________________________________________________________________

Altitude Above Sea Level___________________________________________________________________

Calorific Value_____________________________________________________________________________

settings for which the gas heat unit is capable. Record and

retain these settings in case the unit should ever need

adjustment after service repairs.

Note: This information is required when ordering repair

parts.

Burner Specifications

Maximum Firing MBh______________________________________________________________________

Minimum Firing MBh______________________________________________________________________

Type of Gas________________________________________________________________________________

Maximum Inlet Gas Pressure_______________________________________________________________

Minimum Inlet Gas Pressure________________________________________________________________

Temperature Rise (ºF)_______________________________________________________________________

Manifold Pressure at Maximum MBh________________________________________________________

6 CLCH-SVX014B-EN

Page 7

Table 1. Motor and electrical specifications

Specifications Gas Heater Input Power Inducer Motor

Volts 115 115

Hertz 60 60 60

Phase 11

HP n/a n/a

FLA/Amps n/a 6

(a) Powered by a “line to 115 volt” transformer for all gas heaters except 115/60/1 rated units.

Description

The gas heat section consists of an inshot tubular heat

exchanger gas train components, and a control panel for

electrical connections. It is an integral part of the entire airhandling system.

An access door is provided for service and maintenance of

the burner and gas train components.

The gas heat section must be in a blow-thru position

downstream from the supply fan. Downstream sections

must be separated by a blank access section and discharge

temperatures must be controlled so as not to exceed the

temperature limits of components in the downstream

sections.

(a)

General Information

Control Power(a)

CLCH-SVX014B-EN 7

Page 8

Pre-Installation

Receiving and Handling

Inspection

Upon delivery, thoroughly inspect all components for any

shipping damage that may have occurred, and confirm

that the shipment is complete. See “Receiving Checklist”

for detailed instructions.

Note: Delivery cannot be refused. All units are shipped

F.O.B. factory. Trane is not responsible for shipping

damage.

Packaging/Shipping

Gas heat sections arrive at the jobsite with an integral base

frame for the purpose of mounting units to a

housekeeping pad or roof curb. The base frame variables

in height from the standard 2.5 inches to 8 inches.

Outdoor gas heat sections ship with wooden blocks

fastened under the base channel. The blocks elevate the

section for shipping protection and ease of handling.

Leave the wooden blocks attached until the section is

placed in its final position to avoid bending the base

channel during rigging and handling.

Protective Covering

The large openings of the gas heat section are covered

with shipping protection parts. The parts are held in place

by sheet metal screws. Leave the covering attached to the

section until it is ready to install to prevent debris from

entering the section.

Flue Stack

A stainless-steel flue stack is provided with outdoor air

handlers. It ships inside the gas heat section or in one of

the other sections of the air handler, and must be mounted

on the flue opening on the side of the unit.

NOTICE

Equipment Damage!

Failure to follow this instruction could result in

equipment damage. Do not use type B flue stacks with

this product as they are not suitable for the flue gas

temperatures.

Hardware Kits

Hardware kids ship inside the air handler fan section in a

plastic bag or cardboard box. This kit contains gasketing

and screws. For outdoor units, roof joint connection strips

and wall panel seam caps are included. These are used

when fastening the gas heat section to the air handler.

Keep the hardware with the gas heat section until it is

ready to install.

Rain Hood

A rain hood is provided for outdoor units and is shipped

attached. Rain hoods for units with hurricane certifications

are shipped on a separate wood skid. A kit containing

mounting hardware ships inside the gas heat section and

must be removed before assembly to the air handler.

Instruction Manuals

Individual instruction manuals for all of the gas train

components (such as flame-control relay valves, pressure

switches, and actuators) ship inside the piping vestibule.

Retain these manual for future repair or troubleshooting.

Handling

The gas heat section is designed with the necessary

number of lift points for safe installation. The lift points are

designed to accept standard rigging devices and are

removable after installation.

Indoor sections size 4 to 30 will be shipped with a shipping

skid designed for forklift transport. If shipped on a skid, do

not remove the gas heat section from the skid at this time.

Receiving Checklist

Complete the following checklist immediately after

receiving shipment to detect possible shipping damage.

Check to ensure that the shipment is complete. Small

components may ship inside the unit or ship

separately. Check the parts list to ensure all materials

are present. If any component is missing, contact your

local Trane sales office.

Check all units, components, connections, and piping.

Check all doors, latches and hinges. Inspect interior of

each unit or section. Check for rattles, bent corners, or

other visible indications of shipping damage.

If a unit is damaged, make specific notations

concerning the damage on the freight bill. Do not

refuse delivery.

Notify the carrier’s terminal of the damage

immediately by phone and mail. Request an

immediate joint inspection of the damage by the

carrier and consignee.

Notify your Trane sales representative of the damage

and arrange for repair. Do not attempt to repair the unit

without consulting the Trane representative.

Inspect the unit for concealed damage as soon as

possible after delivery. Report concealed damage to

the freight line. It is the receiver’s responsibility to

provide reasonable evidence that concealed damage

did not occur after delivery. Take photos of damaged

material if possible.

Note: Concealed damage must be reported within 15

days of receipt.

8 CLCH-SVX014B-EN

Page 9

Pre-Installation

Jobsite Storage

Indoor air handlers and field-installed accessories must be

protected from the elements. A controlled indoor

environment is recommended for proper storage.

Note: All factory shipping protection should be removed,

This wrapping is for transit protection only.

The unit controller and all other electrical/electronic

components should be stored in conditions of -20°F to

120°F and 5 to 95 percent relative humidity, noncondensing. Electrical components are not moisturetolerant.

Gas heat sections for outdoor units require no special

protection for storage prior to installation.

Outdoor Storage

NOTICE

Corrosion!

Plastic tarps can cause condensation to form in and on

the equipment, which could result in corrosion damage

or wet storage stains. Use only canvas tarps to cover air

handlers and components.

Outdoor storage is not recommended for units that will be

installed indoors. However, when outdoor storage is

necessary, several things must be done to prevent

damage:

Note: Keep the equipment on the original wooden blocks/

skid for protection and ease of handling.

• Select a well-drained area, preferably a concrete pad or

blacktop surface.

• Place the unit on a dry surface or raised off the ground

to assure adequate air circulation beneath the unit and

to assure no portion of the unit will contact standing

water at any time.

• Cover the unit securely with a canvas tarp.

• Do not stack units.

• Do not pile other material on the unit.

Trane warranty does not cover equipment damage due to

negligence during storage.

CLCH-SVX014B-EN 9

Page 10

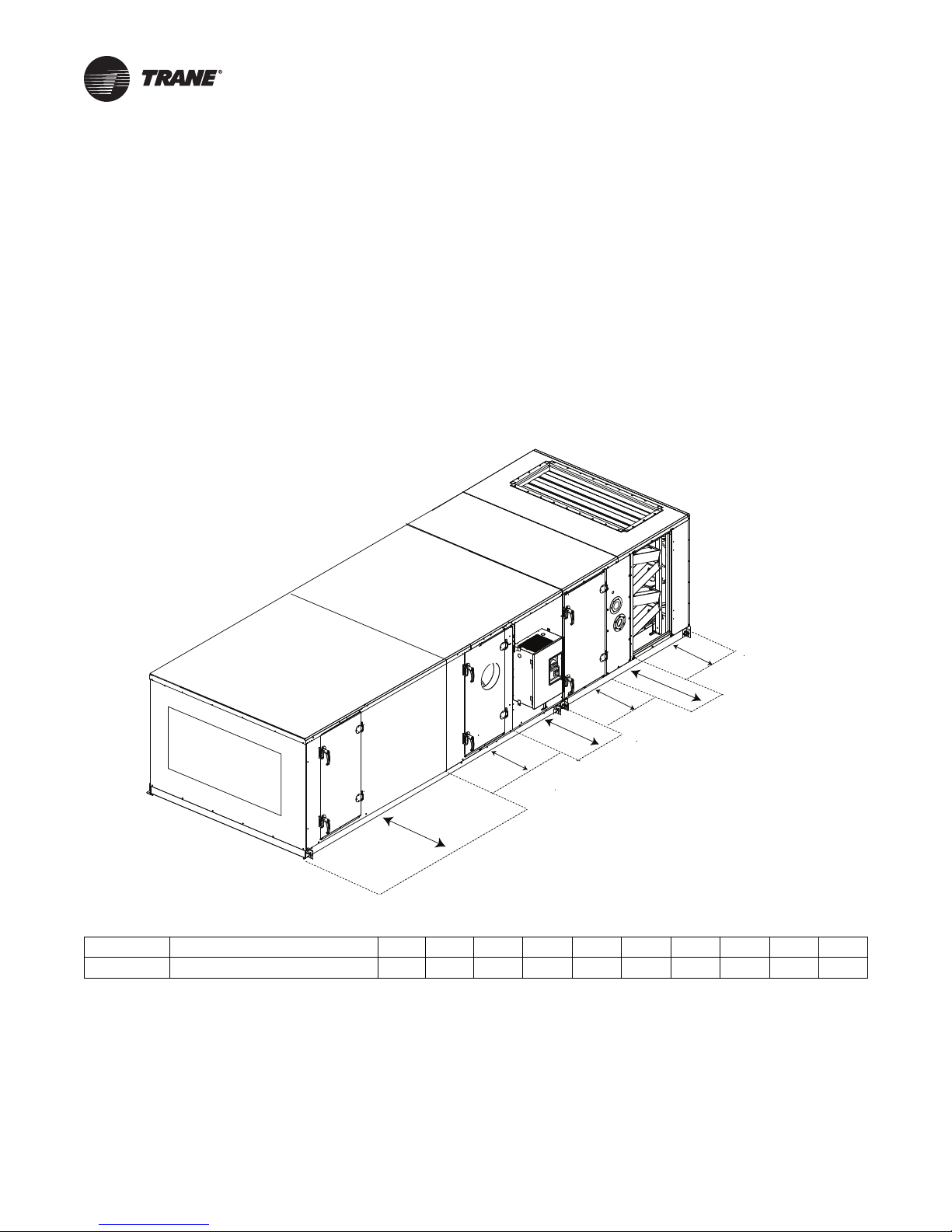

Dimensions and Weights

Filter mixing box

Coil

Fan

Gas heat

Access

door

UV

lights

VFD

F

E

D

C

B

A

Service Clearances

A minimum clearance of the section width plus 12 inches

on the access door side of the gas heat section is

recommended for routine maintenance. This clearance

provides enough room to replace the heat exchanger in

the event of failure. The section side panels must be

removed to access the heat exchanger. Refer to the

following figure for service clearance recommendations

for the air handler.

Note: At a minimum, the clearance dimensions listed in

table below are recommended on one side of the

unit for regular service and maintenance. Refer to

Figure 2. Service clearance for indoor units

as-built submittal for locations of items such as

filter access doors, coil, piping connections, motor

locations, hoods, pipe cabinets, etc. Sufficient

clearance must be provided on all sides of unit for

removal of access panels, plug panels, or sectionto-section attachment brackets. Clearance for

starters, VFDs, or other high-voltage devices must

be provided per NEC requirements. For specific

dimensional and weight information, refer to the

unit submittals. The dimensions and weights in this

manual are approximate. Trane has a policy of

continuous product and product data

improvement and reserves the right to change

design and specifications without notice.

Table 2. Service clearance dimensions (in)

Component Description 4 6 8 10121417212530

F Gas Heat n/a5663747984849292106

10 CLCH-SVX014B-EN

Page 11

Table 3. Dimensions and weights

Unit Size Output Capacity (MBh) Length (in) Weight (lb)

004

006

008

010

012

014

017

021

025

030

95 41.136 432

205 56.636 625

95 41.136 441

205 56.636 636

325 74.136 856

205 56.636 691

325 74.136 919

405 84.136 1027

205 56.636 733

325 74.136 970

405 84.136 1068

240 44.386 639

325 57.386 854

485 67.136 997

240 44.386 657

325 57.386 875

485 67.136 1021

240 44.386 686

325 57.386 910

485 67.136 1060

650 66.006 1348

970 81.006 1646

650 66.006 1391

970 81.006 1695

650 66.006 1453

970 81.006 1767

Dimensions and Weights

CLCH-SVX014B-EN 11

Page 12

Installation

WARNING

Improper Unit Lift!

Failure to properly lift unit could result in unit dropping

and possibly crushing operator/technician which could

result in death or serious injury and possible equipment

or property-only damage. Do not lift unit from top! Lift

unit from lifting lugs only located at bottom of unit.

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level.

WARNING

Heavy Objects!

Failure to follow instructions above or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury. Ensure that all the lifting equipment

used is properly rated for the weight of the unit being

lifted. Each of the cables (chains or slings), hooks, and

shackles used to lift the unit must be capable of

supporting the entire weight of the unit. Lifting cables

(chains or slings) may not be of the same length.

Adjust as necessary for even unit lift. Other lifting

arrangements could cause equipment or property

damage.

WARNING

Hazardous Gases and Flammable Vapors!

Failure to follow all instructions could result in death or

serious injury. Exposure to hazardous gases from fuel

substances have been shown to cause cancer, birth

defects or other reproductive harm. Improper

installation, adjustment, alteration, service or use of

this product could cause flammable mixtures or lead to

excessive carbon monoxide. To avoid hazardous gases

and flammable vapors follow proper installation and

set up of this product and all warnings as provided in

this manual.

WARNING

Combustible Materials!

Failure to maintain proper clearances could result in

death or serious injury or property damage. Maintain

proper clearance between the unit heat exchanger, vent

surfaces and combustible materials. Refer to unit

nameplate and installation instructions for proper

clearances. Improper clearances could result in

combustible materials catching on fire.

Contractors’ Responsibilities

Installing Contractor

• Unpack the gas heat section and remove the skid.

• Remove protective coverings.

• Rig and/or move the section to the air handler location.

The contractor must provide slings, spreader bars,

clevis hooks, pins, etc. for rigging.

• For outdoor gas heat sections, a level roof curb or

structural steel support system is required.

• For outdoor sections, install the flue stack. The flue

must be removed from the airstream before assembly.

Install the flue stack on the gas heat section before

assembling the gas heat section to the air handler.

• Clear debris from combustion air inlets located on the

side or bottom of the gas heat section. Remove any

debris obstructing combustion air inlets.

• In areas where snow drifts are higher than the bottom

of the vestibule, a hood or louver may have to be

installed for combustion air.

• Assemble the gas heat section to the air-handling

system. Refer to CLCH-SVX07*-EN Performance

Climate Changer™ Air Handler Installation, Operation,

and Maintenance manual for specific assembly

instructions. This manual ships inside the supply fan

section of the air handler.

• Penetrate the unit casing and connect the supply gas

line to the gas train.

• For indoor gas heat sections, install a field-engineered

flue stack according to local codes.

Electrical and/or Controls Contractor

• Provide power to the gas heat section. See Wiring

chapter for power requirements.

• Provide a binary start–stop signal.

• Provide an analog 0 to 10 Vdc modulating signal. A 0 to

10 Vdc interface module is installed as standard

equipment. A 4 to 20 mA interface module is available

and may have been installed on the unit for the control

signal in lieu of the 0 to 10 Vdc signal.

• Provide an interlock in the start-stop signal circuit with

the air handler supply fan. This interlock must insure

the start-stop signal is interrupted to the gas heat

system if the supply fan is shut off. The gas heat system

must not operate without the supply fan providing

airflow.

• All wiring must comply with applicable local and

National Electric Code (NEC) specifications.

• For VAV units, provide temperature sensors for

entering and leaving air in gas heat section.

12 CLCH-SVX014B-EN

Page 13

Installation

Note: All power and control wiring for the gas heat

section must be field-provided. All power and

control wiring for any section downstream of the

gas heat must be field-provided.

Lifting and Rigging

Refer to CLCH-SVX07*-EN Performance Climate

Changer™ Air Handler Installation, Operation, and

Maintenance manual for instructions on equipment

rigging and lifting. This manual ships inside the unit fan

section.

Placement and Assembly

Refer to the design engineer’s plans and submittals for the

location of the gas heat section in the air handler. The gas

heat section will arrive at the job site as an individual

section. It is not shipped with the air handler.

Hardware for fastening the gas heat section to the air

handler can be found in the unit fan section.

Final assembly of the air handler should be done at the unit

installation site. Refer to CLCH-SVX07*-EN Performance

Climate Changer™ Air Handler Installation, Operation,

and Maintenance manual for instructions on equipment

assembly.

Flue Stack for Outdoor Air Handlers

The flue stack for outdoor air handlers must be mounted

on the flue opening on the side of the unit. The flue stack

must be installed on the gas heat section before

assembling the gas heat section to the air handler. It is very

difficult to remove the flue from inside the unit once the

unit is assembled.

It is recommended that the services of an experienced,

qualified gas heat technician be employed to adjust air-fuel

ratios for proper combustion.

Installing Outdoor Flue Stacks

The flue stack for outdoor gas heat sections ships inside

the gas heat section or in one of the other sections of the

air handler.

Figure 3. Outdoor air handler flue stack

Outdoor air handler flue stack

Attach the flue stack to the flue collar and secure it with

screws as indicated in the following figure.

A field-provided rain hood or screen is recommended on

the flue to prevent possible blockage from bird nests and

beehives.

Figure 4. Outdoor air handler flue stack installation

Installation

High Altitude Installations

WARNI NG

Hazard of Explosion!

Failure to follow these instructions could result in

death or serious injury or equipment or property-only

damage. Installations at altitudes of 3,000 feet above

sea level or higher may require adjustment of the airfuel linkage for proper combustion. Air-fuel adjustment

should only be done by an experienced, qualified gas

heat technician.

Air-fuel adjustment is not normally required. However, for

high altitude installations, adjustment to the air-fuel may

be necessary for proper combustion. Heater outputs must

be derated four percent for every 1000 feet over 2000 feet

above sea level. When specifying gas heaters, the

engineer should provide the MBh and airflow required at

altitude. All Trane literature is based on nominal outputs at

sea level.

CLCH-SVX014B-EN 13

Page 14

Installation

Hood

Butyl tape

Attach the gas

heat flue duct

to the L angles

on both sides

Gas heat

flue

See note

L bracket

Right side view

#10 x 3/4-in.

self-drilling

sheet metal

screws

Installing Indoor Flue Stacks

Gas heat sections for indoor air handlers require a fieldengineered and field-installed flue stack. Local codes and

practices vary throughout the country. The engineer

should size the flue based on MBh output, horizontal and

vertical run lengths, type of flue material, NFPA 54 Fuel Gas

Code, and local codes. The flue should be designed for 800

degrees F (430 degrees C). If horizontal runs over 20 feet or

other static-increasing transitions are necessary, a flue

booster fan will be required.

Install according to local codes.

Installing Rain Hood/Combustion Air Inlet

Rain hoods are only required on an outdoor unit with an

internal vestibule. The combustion air opening will be in

the side panel.

Rain hoods for the combustion air opening ship attached

to the side panel or ship loose and must be installed at the

job site. The assembly consists of the hood, butyl tape and

number 10 screws.

• Install butyl tape between the hood and the side panel

or door panel. See the following figure.

Figure 5. Installation of rain hood for combustion air

opening

Figure 6. Center inlet air opening

Access door

Hinge

side

Rain hood

Airflow

2 3/8 in.

Combustion

air opening

Center hood left-to-right

over opening

Installing Flue Stack for Hurricane

Applications

Figure 7. Flue stack installation for hurricane

applications

• Locate the bottom edge of the hood 2 3/8 inches below

the bottom edge of the inlet air opening and center the

hood left-to-right over the inlet air opening. See the

following figure.

• Install the hood to the unit with number 10 screws.

14 CLCH-SVX014B-EN

Note: When installing flue, leave enough clearance to

avoid roof’s edge and anything above the roof.

Duct Connections

All duct connections to the gas heat section should be

installed in accordance with the standards of the National

Fire Protection Association (NFPA) and the Sheet Metal

and Air Conditioning Contractors National Association,

Inc. (SMACNA).

Combustion Air Duct

• Outdoor units have a rain hood that either ships

attached to the side panel or ships loose and requires

field mounting.

• All indoor units ship with a screened opening on the

combustion air inlet.

Page 15

If combustion air is ducted to the vestibule, it is strongly

recommended that an experienced gas heat technician

check the system and emission levels in the exhaust flue at

start up. Carbon dioxide should be between 8.2 and 9.4

percent. This corresponds to the allowable range of excess

air needed for combustion. The additional static pressure

of the inlet air duct may change the fuel-air ratio slightly

necessitating system adjustment.

Combustion air cannot be ducted directly to the

combustion air fan. The airflow through the vestibule is

needed to keep the temperatures in the vestibule down.

Duct Transitions

When the gas heat section is the last section of the air

handler, and duct transitions should be smooth and

uniform from all sides. Follow recommendations for duct

transitions from SMACNA.

Fasten the ductwork directly to the ductwork opening.

When using lined ductwork, the insulation should not

obstruct the discharge opening.

Airflow Direction

The airflow direction through the gas heater is important

because it prevents localized “hot spots” on the heat

exchanger. Airflow direction labels denoting correct

airflow direction through the gas heat section are provided

on the burner side of the heating section. See Figure 8.

Installation

Figure 8. Airflow direction label

CLCH-SVX014B-EN 15

Page 16

Piping

WARNING

Hazard of Explosion and Deadly Gases!

Failure to follow all proper safe refrigerant handling

practices could result in death or serious injury. Never

solder, braze or weld on refrigerant lines or any unit

components that are above atmospheric pressure or

where refrigerant may be present. Always remove

refrigerant by following the guidelines established by

the EPA Federal Clean Air Act or other state or local

codes as appropriate. After refrigerant removal, use dry

nitrogen to bring system back to atmospheric pressure

before opening system for repairs. Mixtures of

refrigerants and air under pressure may become

combustible in the presence of an ignition source

leading to an explosion. Excessive heat from soldering,

brazing or welding with refrigerant vapors present can

form highly toxic gases and extremely corrosive acids.

Gas Piping

Note: Installation must conform with the American

National Standard Z223.1 (NFPA 54), the National

Fuel Gas Code, latest edition, in the absence of local

codes.

• Gas piping should always be done in accordance with

local codes.

• Tighten all joints securely.

• Pipe unions should be a “ground joint” type to prevent

leakage.

• Provide adequate support for field-installed piping to

avoid placing stress on the gas train and controls.

• Run takeoff lines from the side or top of the main gas

line to prevent moisture from being drawn into the gas

train of the unit.

• Provide a drip leg in the field-installed piping, installing

it near the unit.

• Select an appropriately sized gas pressure regulator to

assure the required gas supply pressure is maintained

at the unit.

• For unit to operate unit properly, the inlet gas pressure

must be maintained at 7 inches wc. Required gas

pressure to the gas train is 5 to 13 inches wc

• Gas pressure and volume must be maintained and

stable at high fire.

• If the gas pressure regulator serves more than one

heating unit, it must be sized appropriately to ensure

that the inlet gas pressure at each unit is 5 to 13 inches

wc while all burners are firing.

• Check the gas supply pressure before making the final

connection to the unit. If the gas pressure is too high,

damage to the gas valve could occur.

Heat Exchanger Condensate

Piping

Condensate usually does not form in the heat exchanger

during normal heating operation. However, if the unit

operates for extended periods of time at very low fire, or

if the air handler serves as a cooling unit also, condensate

can form in the heat exchanger and should be removed.

All units are equipped with a condensate drain. The

condensate drain is on the same side as the gas train.

If a p-trap and drain is to be connected to the condensate

drain line, consult local plumbing codes for disposal of the

condensate may be a slightly acidic solution.

Proper Gas Pressure

NOTICE

Excessive Gas Pressure!

Failure to maintain proper gas pressure could result in

damage to the gas train components. The gas pressure

at the inlet to the gas train must not exceed 13 in. wc.

A properly sized gas regulator that provides a

maximum of 13 in wc. of gas pressure, must be

supplied in the gas inlet line to unit.

• To assure sufficient gas pressure at the unit, use

appropriately sized gas pipe for unit capacity. Refer to

the National Fuel Gas Code for pipe sizing information.

16 CLCH-SVX014B-EN

Page 17

Wiring

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury. Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/tagout procedures to ensure the

power can not be inadvertently energized.

NOTICE

Use Copper Conductors Only!

Failure to use copper conductors could result in

equipment damage.Unit terminals are not designed to

accept other types of conductors.

Wiring Checklist

• All field wiring must be in accordance with the National

Electric Code and state and local requirements.

• All wiring (including low-voltage wiring) must be

copper conductors only with the insulation rated for

600 volts.

• Refer to the nameplate located on the gas heater

section for the proper Input Voltage, Minimum Circuit

Ampacity (MCA) and Maximum Overcurrent

Protection (MOP) requirements for proper electrical

installation.

• Input voltage must be within +/- 10 percent of specified

value.

• Ground the supply power in the junction box to the

ground lead provided.

• Do not route any wires through the heat exchanger

section unless the insulation is rated for 600?F or

higher. Radiant heat from the heat exchanger will

damage wire insulation that is unsuitable for high

temperatures.

• See table in the next section for electrical

specifications.

Note: Factory wiring routed through the heated part of

the cabinet has insulation rated for 600°F.

High-Voltage Wiring

Wiring Entrance Locations

Indoor air handlers can accept conduit penetrations on

any side of the piping vestibule. For outdoor air handlers,

the recommended conduit entrance into the gas heat

section is through the floor of the piping vestibule.

Terminate conduits on the power junction box or gas

heater control panel as appropriate.

Table 4. Motor and electrical specifications

Specifications Gas Heater Input Power Inducer Motor

Volts 115 115

Hertz 60 60 60

Phase 1 1

HP n/a n/a

FLA/Amps n/a 6

(a) Powered by a “line to 115 volt” transformer for all gas heaters except 115/60/1 rated units.

Single-phase 120, 208, 230, 460 or 575 volt power is

required to operate the heater controls or power the

transformer (TRANS1), if provided.

Single-phase power for 208, 230, 460, and 575 voltage is

provided for the gas heat off two legs of the three-phase

supply to the air-handling unit. A transformer in the piping

vestibule is provided to step down the voltage required for

gas heat.

CLCH-SVX014B-EN 17

(a)

Control Power(a)

Page 18

Wiring

Low-Voltage Wiring

NOTICE

Equipment Damage!

Do not operate the gas heat system without a supply

fan providing airflow. Operating the gas heat system

without a supply fan could result in damage to

equipment or property.

The gas heat control system requires a binary signal for

on/off control. A field provided interlock is recommended

in the start-stop signal circuit with the air handler supply

fan. This interlock must insure the start-stop signal is

interrupted to the gas heat system if the supply fan is shut

off. The gas heat system must not operate without the

supply fan providing airflow.

The control system also requires a 0 to 10 Vdc analog

signal for modulation where 10 Vdc is a signal for full heat.

18 CLCH-SVX014B-EN

Page 19

Start-Up — Indirect Gas-Fired Heating

Gas Heat Application Rules — Inshot

WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

• Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical

hazards, MUST follow precautions in this manual and

on the tags, stickers, and labels, as well as the

following instructions: Unless specified otherwise,

disconnect all electrical power including remote

disconnect and discharge all energy storing devices

such as capacitors before servicing. Follow proper

lockout/tagout procedures to ensure the power can

not be inadvertently energized. When necessary to

work with live electrical components, have a

qualified licensed electrician or other individual who

has been trained in handling live electrical

components perform these tasks.

• Do not attempt the following procedures until all

electrical and gas connections to the unit have been

completed and the outdoor air damper and

evaporator fan operation have been verified and are

operating correctly.

Notes:

1. This furnace module does not have a pilot. It is

equipped with a direct spark ignition device that

automatically lights the gas burner. DO NOT try to light

burners by hand.

WARNING

Hazard of Explosion!

Failure to follow proper safe leak test procedures could

result in death or serious injury or equipment or

property-only-damage. NEVER use an open flame to

detect gas leaks. You MUST use a leak test solution for

leak testing.

2. BEFORE OPERATING, leak test all gas piping up to

heater gas valve. Smell around the unit area for gas. If

gas is smelled, do NOT attempt to place heater in

operation until source of gas leak is identified and

corrected.

3. Use only hand force to operate the gas control lever to

the “ON” position. NEVER use tools. If lever does not

operate by hand, replace gas valve prior to staring the

unit. Forcing or attempting to repair the gas valve may

result in fire or explosion.

4. Do not attempt to operate unit, if there is indication that

any part or control has been under water. Any control

or component that has been under water must be

replaced prior to trying to start the unit.

• The maximum allowable temperature rise is as listed

in table for minimum cfm.

• Nominal airflow is based on 500 fpm through a

nominal coil (i.e. 500 x unit size 8 = 4000 cfm).

• The minimum allowable airflow at full fire is 75 percent

of the nominal airflow (i.e. 0.75 x 500 x unit size 8 =

3000 cfm).

• The minimum allowable airflow at reduced fire is 50

percent of the nominal airflow (i.e. 0.50 x 500 x unit size

8 = 2000 cfm).

• Calculate temperature rise at airflows other than

nominal with this equation: Temp Rise = (1000 x MBh)

/ (1.1 x CFM)

• On high altitude applications, derate the heating

capacity (MBh) by 4 percent for every 1,000 feet of

altitude over 2,000 feet above sea level.

• Temperature rise is listed for nominal cfm/minimum

cfm.

Start-up Procedure

1. Check Inlet Gas Pressure:

Ensure the gas pressure supplied to the unit is within

the pressure requirement listed on the nameplate. DO

NOT expose gas controls to pressures above 13 in. wc).

If required by local code, a field provided gas supply

line should be installed with a field provided external

manual shutoff and pressure tap.

2. Verify Fan Failure Switch Operation:

The supply fan air proving switch is located in the

heater electrical control compartment near the top of

the heater panel. The switch will fail if not proven

within 30 seconds of call for indoor fan—ON. All unit

air filters must be clean before proceeding to properly

complete this verification.

Important: If the unit air filters are not clean, unit

performance could be affected. Remove

and clean or replace air filters as required

prior to proceeding with the burner

pressure testing.

Hazardous Voltage and Gas!

Failure to turn off gas or disconnect power before

servicing could result in an explosion or electrocution

which could result in death or serious injury. Turn off

the gas supply and disconnect all electric power,

including remote disconnects, before servicing the unit.

Follow proper lockout/tagout procedures to ensure the

power can not be inadvertently energized.

WARNI NG

CLCH-SVX014B-EN 19

Page 20

Start-Up — Indirect Gas-Fired Heating

3. Confirm Gas Flow at Unit:

Open door to unit vestibule housing the gas heater.

Move gas control lever to “OFF” position. Remove

1/8-in. pressure taps from both modulating and on-off

sections of the split heater manifold. Install a barbed

fitting in both 1/8-in. tapped holes for connection to

individual gas manometers.

Note: There is a third 1/8-in. gas pressure tap located

in the pipe connecting the main valve/regulator

and modulating valve. Maximum pressure into

modulating valve is 5-in. The On-Off gas valve

includes a regulator adjustment device that is

located on the top of the valve. Use this device

to regulate valve output to modulating valve as

required.

4. Wait 5 minutes for any gas to clear. If you smell gas,

Step 2 and correct leak. If you don’t smell gas or have

corrected any leaks, go to the next step.

5. Main Gas Supply:

Turn manual gas cock “ON”.

6. Pre-purge and Ignition:

a. Open all manual gas valves.

b. Turn power on at the gas heat switch inside the gas

heat vestibule.

c. A call for heat is initiated by the AHU unit control

through a 0-10V analog signal.

d. The heater controller will then go through a system

check to ensure that the high temperature limit and

rollout switches are closed, the air pressure switch

is open, and the modulating valve is positioned

correctly.

e. The control will then enter the pre-purge cycle,

where the inducer will run at the programmed

purge pressure. During this cycle, the control will

look for the air pressure switch to close and open at

the correct settings.

f. Once the system check and pre-purge cycles are

complete, the control will enter the ignition cycle.

The modulating valve and inducer will go to their

“light off” settings.

The DSI ignition module will be energized and the

spark ignitor will activate.

The redundant safety valve will open, allowing gas

flow.

The burners will ignite and the control will receive

a signal from the flame sensor.

The spark ignitor will remain active for the duration

of the ignition cycle, regardless of flame status.

g. If flame is not established during the ignition cycle,

the control will repeat the pre-purge and ignitions

cycles up to three times. After three failed ignition

attempts, the board will enter a 1 hour lockout.

h. Once flame has been established, the control will

enter a warm-up period to ensure flame

stabilization and reduce condensation in the heat

exchanger.

i. After the warm-up period, the control will enter the

run cycle. During the run cycle, the burner firing rate

and draft inducer pressure are determined based on

the heat demand received by the control via a 0-10V

analog signal.

Note: If the control is paired with a split manifold, Step c

through Step h pertain to the primary burners.

Once the control exits the warm-up period and the

firing rate is dictated by the rooftop control, the

control will ignite the secondary burners and

modulate the primary burners based on the

demand for heat.

j. The run cycle will continue until any of the following

conditions are met.

• The call for heat is terminated.

• Any of the safety devices (high limit, air

pressure, rollout, etc.) are triggered.

The control reaches it’s maximum run time of 6

•

hours. If this condition is reached, the control

will terminate the run cycle, continue through

the proper sequence of operations, and then

immediately enter the system check and prepurge cycles to prepare for re-ignition,

assuming conditions A and B haven't been met.

k. Once the run cycle has terminated, the redundant

safety valve will close, the modulating valve will

return to its set position, and the draft inducer will

ramp up to its “light-off” setting for a 45 second

post-purge cycle.

l. After the conclusion of the post-purge, the control

will enter the “OFF” state. All system outputs are

de-energized but all safety devices are still

monitored.

m. When the building management system

temperature is satisfied and the demand for heat

ends, the gas valve is de-energized immediately

and the combustion blower is energized on high

speed for 30-second post-purge period.

n. If the unit fails to ignite see Troubleshooting

chapte r.

20 CLCH-SVX014B-EN

Page 21

Start-Up — Indirect Gas-Fired Heating

Burner flame at startup: 1.2 in. wc manifold pressure

draft inducer—high speed

Burner flame at high fire: 3.5 in. wc manifold pressure

draft inducer—high speed

Figure 9. Flame characteristics of properly-adjusted

natural gas systems

Figure 10. Flame characteristics of properly-adjusted

natural gas systems

Main Burner Flame

• The burner flame should be predominately blue in

color and well defined and centered at the tube

entry as shown in the previous figure above.

Distorted flame or yellow tipping of natural gas

flame, or a long yellow flame on propane, may be

caused by lint and dirt accumulation inside burner

or at burner ports, at air inlet between burner and

manifold pipe, or debris in the main burner orifice.

Soft brush or vacuum clean affected areas.

• Poorly defined, substantially yellow flames, or

flames that appear lazy, indicate poor air supply to

burners or excessive burner input. Verify gas

supply type and manifold pressure with rating

plate.

• Poor air supply can be caused by obstructions or

blockage in heat exchanger tubes or vent discharge

pipe. Inspect and clean as necessary to eliminate

blockage. Vacuum any dirt or loose debris. Clean

heat exchanger tubes with stiff brush. Poor flame

characteristics can also be caused by flue gas

recirculation into combustion air supply. If

surrounding buildings or prevailing winds cause

recirculation, a flue extension may be required to

prevent recirculation. Contact manufacturer prior

to making any flue adjustments.

• Reduced air delivery can also be the result of

inducer fan blade slippage, dirt accumulation in the

fan blade or low voltage to draft inducer motor.

Inspect draft fan assembly and be sure fan blade is

secure to motor shaft. Check line voltage to heater.

NOTICE

Meter Damage!

Measuring voltage with meter connect to a circuit

could result in meter damage. Do NOT measure voltage

with meter connected to a circuit.

1. Flame Sensor Current Check:

Flame current is the current which passes through the

flame from the sensor to ground. A flame signal of 0.5

to 1.0 microamp (A) is marginal. For dependable

operation, a flame signal of greater than 1.0 A is

required. To measure flame current, connect a meter

capable of reading micro-amp current so the flame

signal will be read thru the meter’s COM and A

connections. The meter should read greater than

1.0 A.

Note: If the meter reads below “0” on scale, meter

leads are reversed; disconnect power and

reconnect meter leads for proper polarity.

2. Manifold Pressure Adjustment:

• The manifold pressure for high fire second stage

should be at 3.5-in. wc, if it needs adjustment,

adjust the HI Regulator on the two stage gas valve.

• The manifold pressure for Low Fire First Stage

should be set at 1.2-in. wc, if it needs adjustment,

adjust the LO Regulator on the two stage gas valve.

CLCH-SVX014B-EN 21

Page 22

Start-Up — Indirect Gas-Fired Heating

Modulating

Gas Valve

Inducer Blower

Inducer Motor

Condensate Drain

(Typ 2)

Rollout Switch

Maximum Inlet

Pressure = 14 in w.c.

On/Off Gas Valve

Manifolder Gas

Pressure Tap

Component locations are approximate.

Flame

Sensor

Minimum/Maximum

Inlet Pressure =

7 in w.c./14 in w.c.

On/Off Gas Valve

Modulating Valve Inlet

Pressure Tap

Manifolder Gas

Pressure Tap

High Limit

Switch

Rollout

Switch

Ignition

Controllers

Air Proving

Switch

Safety Controls

Figure 11. Component locations

• Inducer Air Proving Switch:

A n a ir p re ss u re sw i tch is pr ov id ed as pa rt of th e c on tr ol

system to verify airflow through draft inducer by

monitoring the difference in pressure between the

draft inducer and the atmosphere. If sufficient negative

pressure is not present, indicating lack of proper air

movement through heat exchanger, the switch opens

shutting off gas supply though the ignition control

module. On units with two speed draft inducer

operation, a dual air pressure switch is used,

monitoring high and low speed pressures. The air

pressure switches have fixed settings and are not

adjustable.

The high limit switch will automatically reset when the

air temperature drops to approximately 50°F below the

limit setpoint. Determine the cause of the reduced air

flow and correct.

• Supply Fan Air Proving Switch:

A supply fan air proving switch is provided as a part of

the gas heat control system to verify air handling unit

supply fan air flow across the heat exchanger by

monitoring the difference in pressure between the gas

heat plenum section and the atmosphere. If sufficient

positive pressure is present, the switch will be closed.

The air proving switch has fixed settings and is not

adjustable.

• Rollout Switch (Manual Reset):

The furnace module is equipped with manual reset

Normal Sequence of Operation

rollout switch(es) in the event of burner flame rollout.

The switch will open on temperature rise and shut-off

gas supply through the ignition control module. Flame

rollout can be caused by insufficient airflow for the

burner firing rate (high gas pressure), blockage of the

vent system or in the heat exchanger. The furnace

module should not be placed back in operation until

the cause of rollout condition is identified and

corrected. The rollout switch can be reset by pressing

the button on top of the switch.

• High Limit Switch:

The furnace module is equipped with one or two fixed

temperature high limit switches mounted on the

vestibule panel that shuts off gas to the heater through

the ignition control module in the event of reduced

airflow over the heat exchanger tubes. Reduced airflow

can be caused by indoor fan failure, dirty or blocked

filters, or restriction of the air inlet or outlet to the unit.

22 CLCH-SVX014B-EN

The gas heat module/section goes through the following

routine every time it is started. The air handler fan must be

running.

1. A call for heat is initiated by the AHU unit control

through a 0-10V analog signal.

2. The 1285 control will then go through a system check

to ensure that the high temperature limit and rollout

switches are closed, the air pressure switch is open,

and the modulating valve is positioned correctly.

3. The control will then enter the pre-purge cycle, where

the inducer will run at the programmed purge

pressure. During this cycle, the control will look for the

air pressure switch to close and open at the correct

settings.

Page 23

Start-Up — Indirect Gas-Fired Heating

4. Once the system check and pre-purge cycles are

complete, the control will enter the ignition cycle.

The modulating valve and inducer will go to their “light

off” settings.

The DSI ignition module will be energized and the

spark ignitor will activate.

The redundant safety valve will open, allowing gas

flow.

The burners will ignite and the control will receive a

signal from the flame sensor.

The spark ignitor will remain active for the duration of

the ignition cycle, regardless of flame status.

5. If flame is not established during the ignition cycle, the

control will repeat the pre-purge and ignitions cycles

up to three times. After three failed ignition attempts,

the board will enter a 1 hour lockout.

6. Once flame has been established, the control will enter

a warm-up period to ensure flame stabilization and

reduce condensation in the heat exchanger.

7. After the warm-up period, the control will enter the run

cycle. During the run cycle, the burner firing rate and

draft inducer pressure are determined based on the

heat demand received by the control via a 0-10V analog

signal.

Note: If the control is paired with a split manifold, steps 1

through 6 pertain to the primary burners. Once the

control exits the warm-up period and the firing rate

is dictated by the rooftop control, the control will

ignite the secondary burners and modulate the

primary burners based on the demand for heat.

8. The run cycle will continue until any of the following

conditions are met.

a. The call for heat is terminated.

b. Any of the safety devices (high limit, air pressure,

rollout, etc.) are triggered.

c. The control reaches it’s maximum run time of 6

hours. If this condition is reached, the control will

terminate the run cycle, continue through the

proper sequence of operations, and then

immediately enter the system check and pre-purge

cycles to prepare for re-ignition, assuming

conditions A and B haven't been met.

9. Once the run cycle has terminated, the redundant

safety valve will close, the modulating valve will return

to its set position, and the draft inducer will ramp up to

its “light-off” setting for a 45 second post-purge cycle.

10. After the conclusion of the post-purge, the control will

enter the “OFF” state. All system outputs are

de-energized but all safety devices are still monitored.

11. Operation will continue in high-fire mode until the

signal from the building management controller drops

to below 4.7 VDC. At this point the gas heat control

module de-energizes the second stage gas valve and

the combustion blower switches to low speed.

12. When the building thermostat is satisfied and the

demand for heat ends, the gas valve is de-energized

immediately the combustion blower is energized on

high speed for 30-second post-purge period.

Normal Shutdown

The air-handling unit fan should run for a minimum of

three to ten minutes after heater shutdown to cool the heat

exchanger.

CLCH-SVX014B-EN 23

Page 24

Wiring Diagrams

Figure 12. Typical wiring diagram for 5:1 turndown heater

24 CLCH-SVX014B-EN

Page 25

Figure 13. Typical wiring diagram for 10:1 turndown heater

Wiring Diagrams

CLCH-SVX014B-EN 25

Page 26

Wiring Diagrams

Figure 14. Typical wiring diagram for 20:1 turndown heater

26 CLCH-SVX014B-EN

Page 27

Routine Maintenance

WARNING

Hazardous Gases and Flammable Vapors!

Failure to follow all instructions could result in death or

serious injury.Exposure to hazardous gases from fuel

substances have been shown to cause cancer, birth

defects or other reproductive harm. Improper

installation, adjustment, alteration, service or use of

this product could cause flammable mixtures or lead to

excessive carbon monoxide. To avoid hazardous gases

and flammable vapors follow proper installation and set

up of this product and all warnings as provided in this

manual. Failure to follow all instructions could result in

death or serious injury.

Table 5. Routine maintenance for trained service personnel

Task Frequency Remarks

Clean drain from heat exchanger Annually Required only if the unit runs for extended hours at low fire.

Clean air inlet louver/screen Monthly Use brush and vacuum cleaner.

Clean inducer blower and motor Annually Use brush and vacuum cleaner.

Clean exhaust flue Annually Use brush and vacuum cleaner.

Check combustion air inlets for

obstruction. Remove debris

Check gas piping for leaks Annually Use soap bubble solution or equivalent leak tester.

Annually Use brush and vacuum cleaner.

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury. Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/tagout procedures to ensure the

power can not be inadvertently energized.

Hazard of Explosion!

Failure to follow proper safe leak test procedures could

result in death or serious injury or equipment or

property-only-damage. NEVER use an open flame to

detect gas leaks. You MUST use a leak test solution for

leak testing.

WARNI NG

WARNI NG

CLCH-SVX014B-EN 27

Page 28

Troubleshooting Guide

WARN ING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical hazards,

MUST follow precautions in this manual and on the

tags, stickers, and labels, as well as the following

instructions: Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks.

WARN ING

Hazardous Gases and Flammable Vapors!

Failure to observe following instructions could result in

death or serious injury. Exposure to hazardous gases

from fuel substances have been shown to cause cancer,

birth defects or other reproductive harm. Improper

installation, adjustment, alteration, service or use of

this product could cause flammable mixtures or lead to

excessive carbon monoxide. To avoid hazardous gases

and flammable vapors follow proper installation and

set up of this product and all warnings as provided in

this manual.

28 CLCH-SVX014B-EN

Page 29

Table 6. Troubleshooting guide for VB1285 modulating control

Failure Code Description of Symptom Actions

1. Ensure there is no voltage to gas valve—repair/replace wiring if

E08 3 or 4 Flame is detected without call for heat

E04 28

E05 29

E01 11 F ailed ignition, retries have been exhausted

E02 7 Primary limit or limit switch failure

E18 Unexpected flame (split manifold burners)

Air pressure sensor reading low and/or

pressure switch failed to open

Air pressure sensor readin g high and/or

pressure switch failed to close

voltage is present.

2. If voltage is not present , check for gas flow. If gas is flowi ng, verify

line and manifold pressures before replacing valve.

1. Failed combustion blower.

2. Check pressure hoses for leaks or blockage.

3. Check for blockage in the inducer barb fitting.

4. Check for condensate accumulation in the pressure switch and

hose.

5. Check the pressure switch wiring.

6. Replace the pressure switch.

1. Check wiring to the pressure switch and draft inducer.

2. Replace the pressure switch.

1. Verify gas supply available and manifold pressure is correct.

2. Verify the gas valve is in the ON position.

3. Verify that a spark in present; if not check igniter for debris

between the electrodes, for cracked ceramic and check ignition

wire for cracks.

4. Check to see if the sensor ceramic is cracked or if the electrode

wire is coated with dirt or oils.

5. Check to see if the flame sensor wire is connected properly and not

grounded due to wire abrasions.

6. Check for air leaks.

7. Check for re-circulation of flue product.

1. Determine which switches are open using an OHM meter.

2. If limit switch is open, check temperature rise and airflow over the

heat exchanger.

3. If high limit does not reset with proper airflow, change limit.

4. If rollout switch is open check for flue vent blockage or air leaks

in the cabinet.

5. Reset the rollout switch and observe the flame for signs of rolling

out.

1. Unplug flame sensor, replace sensor if error corrects.

2. Is there voltage to the gas valve with no call for heat? Remove

voltage source, rewire.

3. Check for excessive gas line pressur e. Install regulator if high gas

pressure.

4. Replace gas valve.

5. If rollout switch is open, check for flue vent blockage or air leaks

in the cabinet.

6. Reset the rollout switch and observe the flame for signs of rolling

out.

Troubleshooting Guide

VB1285 Sequence of Operations

1. A call for heat is initiated by the rooftop unit control

through a digital Modbus signal or the analog

thermostat.

2. The VB1285 control will then go through a system

check to ensure that the high temperature limit and

rollout switches are closed, the air pressure switch is

open, and the modulating valve is positioned correctly.

3. The control will then enter the pre-purge cycle, where

the inducer will run at the programmed purge

pressure. During this cycle, the control will look for the

air pressure switch to close and open at the correct

settings.

CLCH-SVX014B-EN 29

4. Once the system check and pre-purge cycles are

complete, the control will enter the ignition cycle.

a. The modulating valve and inducer will go to their

“light off” settings.

b. The DSI ignition module will be energized and the

spark ignitor will activate.

c. The redundant safety valve will open, allowing gas

flow.

d. The burners will ignite and the control will receive

a signal from the flame sensor.

e. The spark ignitor will remain active for the duration

of the ignition cycle, regardless of flame status.

5. If flame is not established during the ignition cycle, the

control will repeat the pre-purge and ignitions cycles

Page 30

Troubleshooting Guide

up to three times. After three failed ignition attempts,

the board will enter a 1 hour lockout.

6. Once flame has been established, the control will enter

a warm-up period to ensure flame stabilization and

reduce condensation in the heat exchanger.

7. After the warm-up period, the control will enter the run

cycle. During the run cycle, the burner firing rate and

draft inducer pressure are determined based on the

heat demand received by the control via a Modbus

signal or the analog thermostat.

Note: If the control is paired with a split manifold, steps 1

through 6 pertain to the primary burners. Once the

control exits the warm-up period and the firing rate

is dictated by the rooftop control, the control will

ignite the secondary burners and modulate the

primary burners based on the demand for heat.

8. The run cycle will continue until any of the following

conditions are met.

Table 7. Troubleshooting guide for VB1287

Failure Code Description of Symptom Actions

eFLAME_SPLIT 21 Flame is detected without call for heat

eAIR_FLOW_LOW

eAIR_FLOW_HIGH

eAIR_ZERO_LO

eAIR_ZERO_HIGH

eNO_IGNITION_PRIME

eNO_IGNITION_SPLIT1222

eFLAME_DROP_OUT_PR

IMARY

eFLAME_DROP_OUT_SP

LIT

4344Low pressure switch is open

High pressure switch is open

41 Low pressure switch closed at start

High pressure switch closed at start

Primary burner exceeds a number of trials

for ignition

Split burner exceeds nu mber of tri als for

ignition, primary burner remains

operational

Primary burner flame loss count exceeds

33

a threshold

Split burner flame loss count exceeds a

23

threshold

a. The call for heat is terminated.

b. Any of the safety devices (high limit, air pressure,

rollout, etc.) are triggered.

c. The control reaches it’s maximum run time of 6

hours. If this condition is reached, the control will

terminate the run cycle, continue through the

proper sequence of operations, and then

immediately enter the system check and pre-purge

cycles to prepare for re-ignition, assuming

conditions A and B haven't been met.

9. Once the run cycle has terminated, the redundant

safety valve will close, the modulating valve will return

to its set position, and the draft inducer will ramp up to

its “light-off” setting for a 45 second post-purge cycle.

10. After the conclusion of the post-purge, the control will

enter the “OFF” state. All system outputs are deenergized but all safety devices are still monitored.

1. Ensure there is no voltage to gas valve—repair/replace wiring if

voltage is present.

2. If voltage is not present, check for gas flow. If gas is flowing, verify

line and manifold pressures before replacing valve.

1. Failed combustion blower.

2. Check pressure hoses for leaks or blockage.

3. Check for blockage in the inducer barb fitting.

4. Check for condensate accumulation in the pressure switch and

hose.

5. Check the pressure switch wiring.

6. Replace the pressure switch.

1. Check wiring to the pressure switch and draft inducer.

2. Check pressure switch for closed contact using an OHM meter.

3. Replace the pressure switch.

1. Verify gas supply available and manifold pressure is correct.

2. Verify the gas valve is in the ON position.

3. Verify that a spark in present; if not check igniter for debris

between the electrodes, for cracked ceramic and check ignitio n

wire for cracks.

4. Check to see if the sensor ceramic is cracked or if the electrode

wire is coated with dirt or oils.

5. Check to see if the flame sensor wire is connected properly and n ot

grounded due to wire abrasions.

6. Check for air leaks.

7. Check for re-circulation of flue product.

1. Check to see if the sensor ceramic is cracked or if the electrode

wire is coated with dirt or oils. Clean or replace.

2. Check to see if the senor wire is connected properly and not

grounded due to wire abrasions.

3. Check for re-circulation of flue product.

4. Check to see if the flame is unstable or floating away from the

senor.

5. Check that all burner components are assembled correctly and all

seals are tight.

30 CLCH-SVX014B-EN

Page 31

Table 7. Troubleshooting guide for VB1287 (continued)

Failure Code Description of Symptom Actions

ePRIMARY_LIMIT 51

eGAS_VALVE_HI_PRIME

eGAS_VALVE_HI_SPLIT

eGAS_VALVE_HI_PRIME

_SPLIT

Primary limit and/or rollout switches are

open

Prime burner staging failure. Gas valve is

15

in the incorrect state.

25

Split burner staging failure. Gas valve is in

the incorrect state.

35

Both the split and primary gas valves are

in the incorrect state.

Troubleshooting Guide

1. Determine which switches are open using an OHM meter.

2. If limit switch is open, check temperature rise and airflow over the

heat exchanger.

3. If high limit does not reset with proper airflow, change limit.

4. If rollout switch is open, check for flue vent blockage or air leaks

in the cabinet.

5. Reset the rollout switch and observe the flame for signs of rolling

out.

1. Check gas valve wiring.

2. Check for shorts in 24V circuit.

3. Replace control.

VB1287 Sequence of Operations

1. A call for heat is initiated by the rooftop unit control

through a digital Modbus signal or the analog

thermostat.

2. The VB1287 control will then go through a system

check to ensure that the high temperature limit and

rollout switches are closed, the air pressure switch is

open, and the modulating valve is positioned correctly.

3. The control will then enter the pre-purge cycle, where

the inducer will run at the programmed purge

pressure. During this cycle, the control will look for the

air pressure switch to close and open at the correct

settings.

4. Once the system check and pre-purge cycles are

complete, the control will enter the ignition cycle.

a. The inducer will go to its “light off” setting (usually

high speed).

b. The DSI ignition module will be energized and the

spark ignitor will activate.