Page 1

MUA-DS-4

MU A-DS-4

February 1998

Second Printing

P ackaged

Air Handling

Products

For Cooling, Ventilating and

Make-Up Air Applications

Page 2

Features

and

Benefits

The Trane packaged air handling

product line is suitable for cooling,

ventilating and make-up air

applications. Unit sizes range from

1500 to 14,000 cfm (0.7-6.6 cu. m/s)

1

/2 to 1 5 hp motor capabilities.

with

Units are ETL and CSA certified to UL-

1995 standard for heating, cooling and

ventilating equipment. Units are

available in one of eight standard

arrangements. Air handling units are

suitable for commercial, institutional

and industrial applications where

external system pressure losses are as

high as three inches WC.

Arrangements are divided into two

classifications — standard and high

cfm blower types.

The standard blower unit consists of a

blower cabinet that houses the

dampers, filters and blower in one

cabinet. An optional evaporative

cooling unit with standard 8 or optional

12-inc h media may also be included.

The high cfm blower unit uses a

separate damper/filter cabinet with a Vbank filter arrangement and a blower

cabinet. An optional coil cabinet is

offered on units with a cfm range of up

to 6,300. Both standard and high cfm

blower arrangements may also include

a downturn supply air plenum, outside

air and/or return air, intake hood and a

roof curb.

All units are completely packaged, rail

mounted and wired to help assure a

smooth installation and easy start-up.

Air control options offer a similar range

of control features from manual

dampers to modulating dampers that

may include mixed air, dry bulb,

pressure sensing, enthalpy control,

DDC interface or ASHRAE Cycle control

arrangements.

Features and Benefits

ETL and CSA UL-1995 Certified.

•

Cfm ranges from 1,500 to 14,000.

•

Motor sizes up to 15 hp.

•

ODP motors with high efficiency and

•

totally enclosed options.

Draw-thru cooling coil cabinet with

•

stainless steel drain pan.

Evaporative cooling with standard 8 or

•

optional 12-inch media (203 or 305

mm).

Insulated roof curb.

•

Standard 18-gauge cabinets.

•

Standard one-inch washable filters.

•

Standard blower door safety interlock

•

switch.

Standard 24-volt circuit breaker.

•

Standard printed circuit main

•

connection board.

Wiring harnesses with stamped wire

•

numbers.

Over 40 standard air control packages.

•

©American Standard Inc. 1998

2

Page 3

Contents

Features and Benefits 2

Unit Configurations 4

Model Number Description 5

General Data 6

Performance Adjustment Factors 7

Performance Data 8

Electrical Data 14

Controls 15

Dimensional Data 17

Weights 34

Options 35

Features Summary 35

Mechanical Specifications 36

3

Page 4

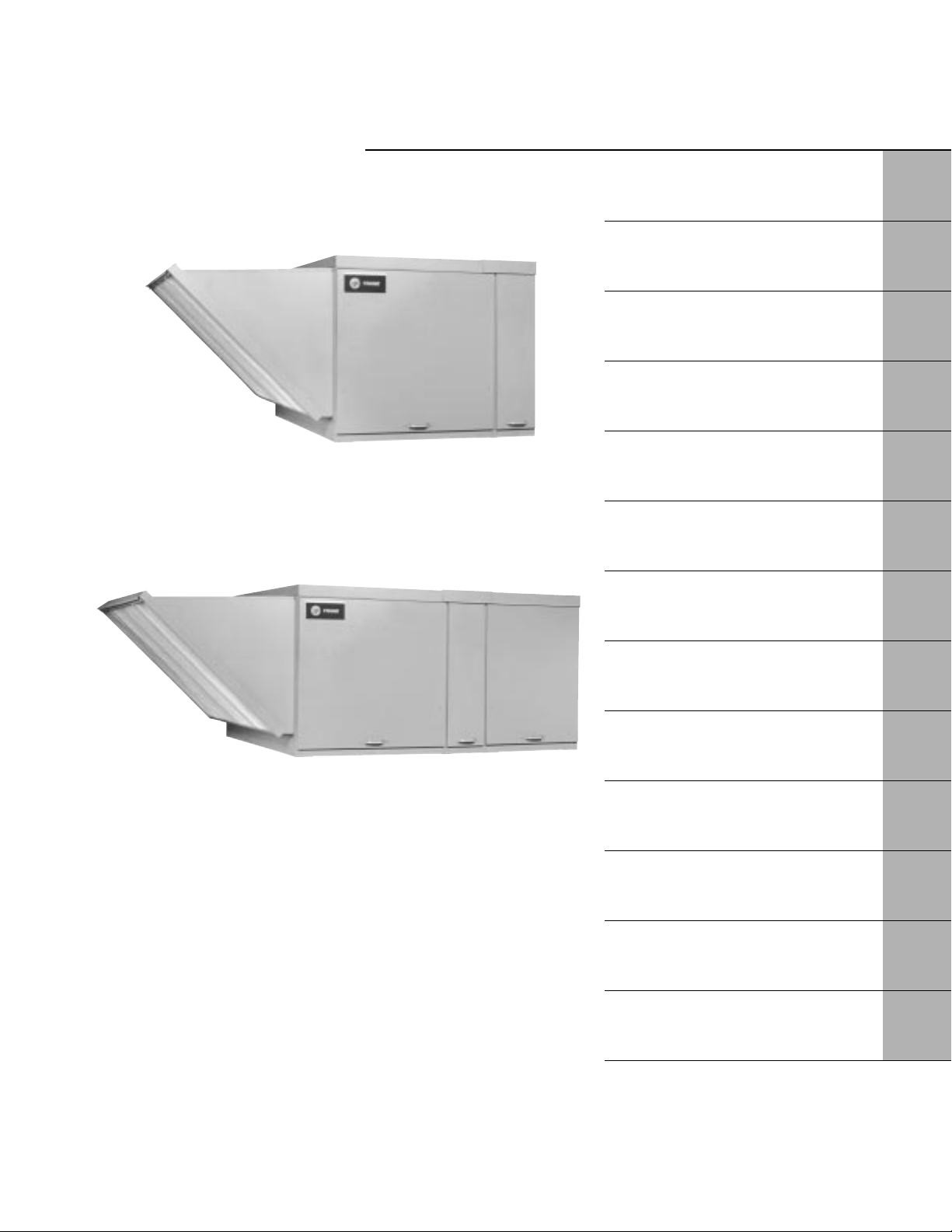

Unit Configurations

Unit T ype Standard Features

Arrangement B — — Electrical cabinet isolated from the airstream.

Air Handler with — Blower door interlock switc h with service o ver ride.

Standard Blower — Insulated Fan Section

— 1” Permanent Filters

Arrangement C — Same as Arrangement B with

Air Handler with Standard — Insulated Supply Plenum

Blower and Downflow

Supply Plenum

Arrangement D — Same as Arrangement B with

Air Handler with Standard — Evaporative Cooler

Blower and — Sealed pump motor with float valve

Evaporative Cooler — Heavy duty stainless steel water tank

— High Efficiency 8 media

— Self cleaning design

Arrangement E — Same as Arrangement D with

Air Handler with Standard — Insulated Supply Plenum

Blower, Evaporative Cooler

and Downflow

Supply Plenum

Arrangement G — — Blower door interloc k switch with service override

Air Handler with — 1” Permanent Filters

High Cfm Blower — Electrical cabinet isolated from the airstream

— Quick opening access door

— V bank filter and damper cabinet

— Fully insulated filter/damper and blower cabinet

Arrangement J — Same as Arrangement G with

Air Handler with High Cfm — Insulated Supply Plenum

Blower and Downflow

Supply Plenum

Arrangement K — Same as Arrangement G with

Air Handler with High Cfm — Coil Section

Blower and Coil Section — Mounting for 4-6 row coils

— Stainless steel drain pan with

Arrangement L — Same as Arrangement K with

Air Handler with High Cfm — Insulated Supply Plenum

Blower, Coil S ection and

Downflow Supply Plenum

Note: Motors/Air Inlet Configur ation/Air Contr ol and D amper Arrangement must be selected f or eac h unit.

Legend is as follows:

B/F/D — Standard blower/Filter/Damper

SP — Supply Plenum

EV — Evaporative Cooler

F/D — Filter/Damper

B — High cfm Blower

CC — Coil Cabinet

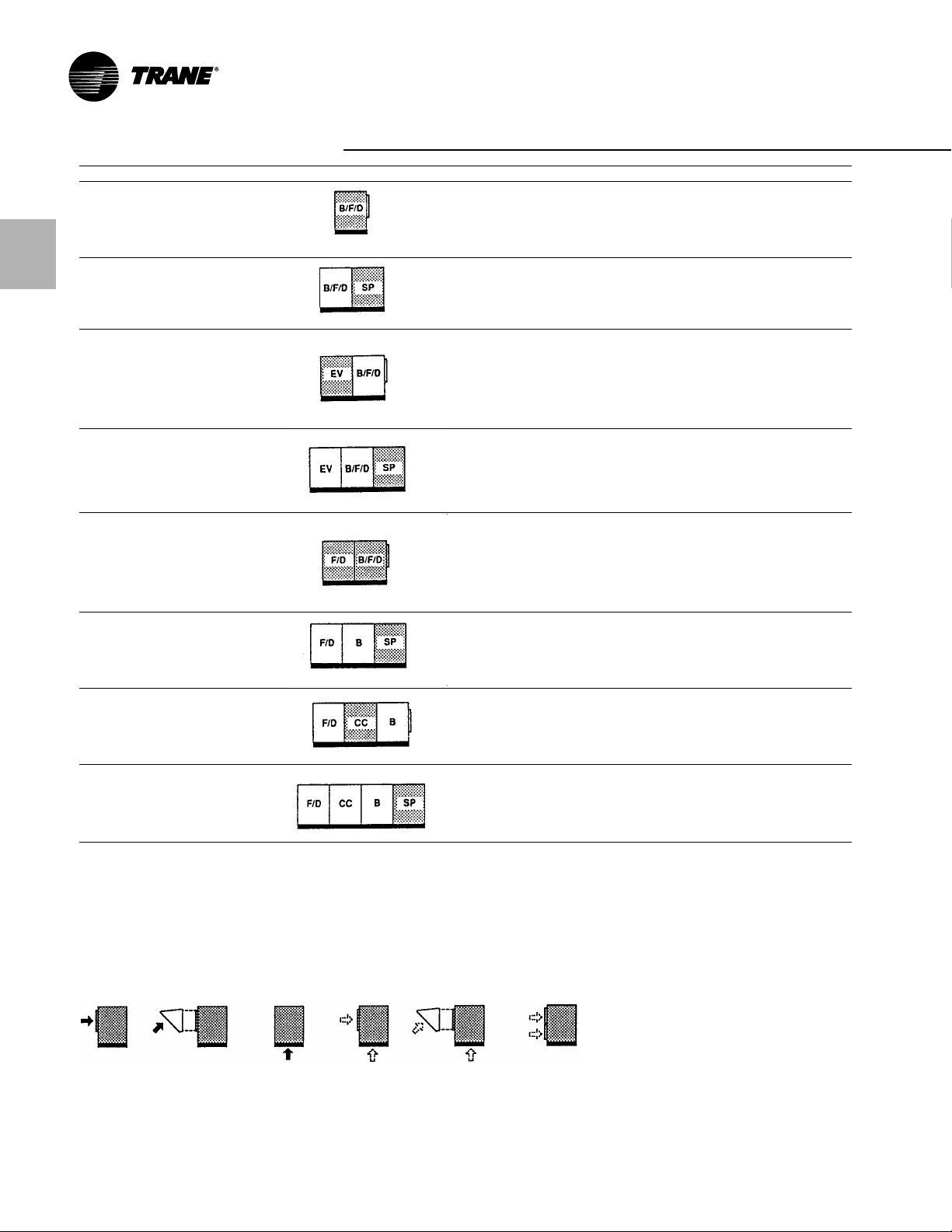

Air Inlet Configuration (Digit 18 of the Model Number)

1 2 3 4 5 See Note Below

Note: Horizontal outside air over return air . Specify air inlet configuration 4 or 5

and then select miscellaneous option “D” for horiz ontal return.

3

/4” tapped outlets

4

Page 5

Model Number Description

A H 0 A 20 0 A 0 D0 0 0 C F 1 0 5 H 0 P

123 45,678910,1112131415161718192021

Digit 1,2 — Unit Type

AH = Air Handling Unit

Digit 3 — Furnace T ype

0 = None

Digit 4 — Development Sequence

A = First Generation

Digit 5,6 — Unit Size

20 = 1500 - 8000 Cfm

40 = 4000 - 14000 Cfm

Digit 7 — Venting T ype

0 = None

Digit 8 — Main Pow er Supply

A = 115/60/1

B = 208/60/1

C = 230/60/1

D = 208/60/3

E = 230/60/3

F = 460/60/3

G = 575/60/3

S = Special Main Power Supply

Digit 9 — Gas Control Option

0 = No gas control option

Digit 10, 11 — Design Sequence

DO = Design Sequence

Digit 12 — Fuel Type

0 = No selection

Digit 13 — Heat Exchanger Mater ial

0 = No selection

Digit 14 — Air Handler Arrangements

B = Blower (Standard)

C = Blower (Standard) Plenum

D = Blower (Standard) Evaporative Cooler

E = Blower (Standard) Evaporative Cooler/

Plenum

G = Blower (High CFM)

J = Blower (High CFM)/Plenum

K = Blower (High CFM)/Coil Cabinet

L = Blower (High CFM)/Coil Cabinet/

Plenum

S = Special Air Handler Arrangement

Digit 15 — Motor Selection

A=1/2 HP w/contactor

B=3/4 HP w/contactor

C = 1 HP w/contactor

D=1 1/2 HP w/contactor

E = 2 HP w/contactor

F = 3 HP w/contactor

G = 5 HP w/contactor

H=1/2 HP w/magnetic starter

J=3/4 HP w/magnetic starter

K = 1 HP w/magnetic starter

L=1 1/2 HP w/magnetic star ter

N = 2 HP w/magnetic starter

P = 3 HP w/magnetic starter

Q = 5 HP w/magnetic starter

R=7 1/2 HP w/magnetic star ter

T = 10 HP w/magnetic starter

U = 15 HP w/magnetic starter

S = Special Motor

Digit 16 — Motor Speed and Starter

0 = No Selection

1 = Single Speed ODP 1800 RPM

2 = Single Speed TEFC 1800 RPM

3 = Single Speed High Efficiency ODP

1800 RPM

4 = Single Speed High Efficiency TEFC

1800 RPM

5 = 2S1W ODP 1800/900 RPM

6 = 2S2W ODP 1800/1200 RPM

S= Special Motor Speed and Starter

Digit 17 — Coil Options

0 =No cooling coil selection

A =DX coil, 4 Row, Single Circuit

B =DX coil, 4 Row, Dual Circuit

C =DX coil, 6 Row, Single Circuit

D =DX coil, 6 Row, Dual Circuit

E = Chilled Water Coil, 4 Row, Single

Circuit

G = Chilled W ater Coil, 6 R ow, Dual Circuit

S =Special coil

Digit 18 — Air Inlet Configuration

1 = Outside Air (OA) Horizontal Inlet

2 = Outside Air W/Air Hood, Horiz ontal Inlet

3 = Bottom Return Air (RA)

4 = Outside and Return Air (OA/RA)

5 = Outside and Return Air W/Air Hood

S= Special Air inlet configuration

Digit 19 — Air Contr ol and Damper

Arrangements

0 =No Selection

A =Outside Air 2 pos. Motor/ SR

B =Return Air 2 pos. Motor/ SR

C =O A/RA 2 pos SR

E = OA/RA Mod Mtr W/Mixed Air Control/

Min Pot/SR

H =OA/RA Mod Mtr W/Mixed Air Control/

SR

K =O A/RA Mod Mtr W/Min Pot/SR

M =O A/RA Mod Mtr w/Dry Bulb/Mixed Air

Control/Min Pot/SR

N = OA/RA Mod Mtr w/Enthalpy Controlled

Economizer/SR

P = OA/RA Mod Mtr W/ Space Pressure

Controller

R =O A/RA Mod Mtr W/ S-350 P

Proportional Mixed Air Control/SR

U = OA/RA MTR. W/External 0-10 VDC and

4-20 mA Analog Input/SR

(External Input)

W= ASHRAE Cycle I (OA/RA 2 pos.

w/warm-up stat/SR

X =ASHRAE Cycle II (OA/RA Mod

W/Warm-up Stat/Mixed Air/min pot/SR

Y =ASHRAE Cycle III (O A/RA Mod.

W/Warm-up Stat/Mixed Air/SR

Z = Manual Dampers

S =Special air control and damper

arrangement

Digit 20 — California Shipment

0 = Non-California Shipment

1 = California Shipment

Digit 21 — Miscellaneous Options

B =12” Evaporative Media (Celdek)

C =Moisture Eliminators

D =Horizontal Return

E = Continuous Fan Relay

F =Freezestat

H =Return Air Firestat

J =Supply Air Firestat

K =Manual Blower Switc h

N = Double Wall Construction

P = Low Leak Dampers

Q = Clogged Filter Switch

W= Interlock Relay — 24/115V Coil

SPDT10A

X =Interlock Relay — 24/115/230V Coil

DPDT 10A

Z = 8” Evaporative Media (Glasdek)

1 = 12” Evaporative Media (Glasdek)

2 = Hinged Service Access Doors

5

Page 6

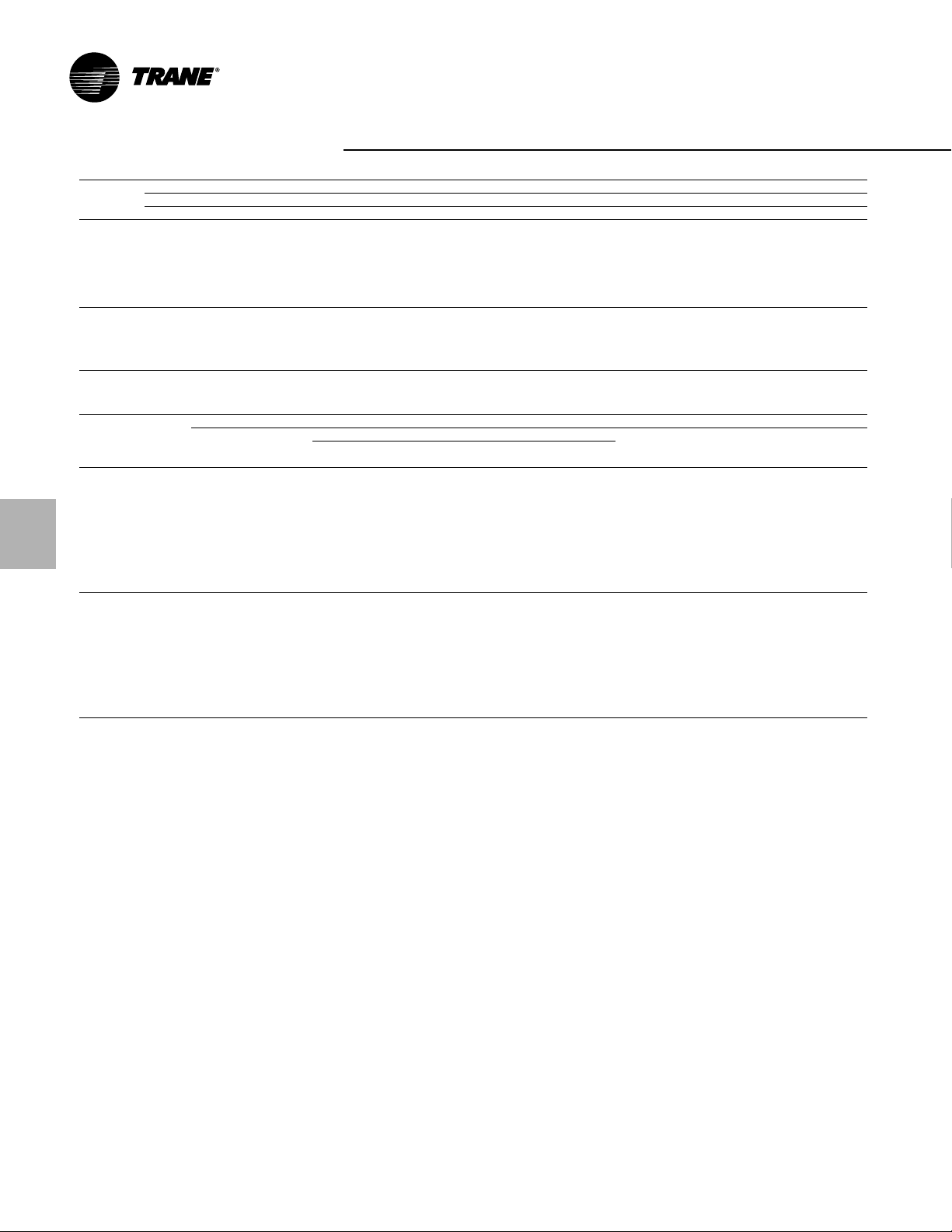

General Data

Pack aged Air Handler Arrangement Reference

Standard Blower Standard Blower W/EC-Mate High CFM Blower High CFM Blower W/Cooling

Arrang ements B, C Arrangements D , E Arrangements G, J Arrang ements K, L

Capacity 20, 40 Capacity 20, 40 Capacity 20, 40 Capacity 20, 40

20 - 1,500-6,000 CFM, 1/2-5 HP 20 - 1,500-6,000 CFM, 1/2-5 HP 20 - 3,000-8,000 CFM, 3/4-1 0 HP 20 - 3,000-4,300 CFM, 3/4-5 HP

40 - 4,000-8,000 CFM,

ESP .1-3” in WC ESP .1-3” in WC ESP .1-3” in WC ESP .1-3” in WC

Filter Data

Unit Size

Arrangement 20 40

B-E (4) 20 x 20 (6) 20 x 20

G-L (8) 20 x 20 (12) 20 x 20

1

/2-5 HP 40 - 4,000-8,000 CFM, 1/2-5 HP 40 - 5,000-14,000 CFM, 3/4-15 HP 40 - 5,000-6,300 CFM, 3/4-7 1/2 HP

Intake Hood

Damper/Filters

(High CFM)

Evaporative Cooler

(Standard)

Coil Cabinet

(High CFM)

Blower/Main Electrical

(High CFM) 0-15 HP

Dampers/Filters/Blower/Main Electrical

(Standard) 0-5 HP

Supply Plenum

6

Page 7

P erformance Adjustment Factors

Table PAF -1 — Cor r ection Factors f or Altitude

0’ 500’ 1000’ 1500’ 2000’ 2500’ 3000’ 3500’ 4000’ 4500’ 5000’ 5500’ 6000’

Temp. Barometric Pressure (In. Hg)

F 39.92 29.38 28.86 28.33 27.82 27 .31 26.82 26.32 25.84 25.36 24.9 24.43 29.98

-40 0.79 0.81 0.82 0.84 0.85 0.87 0.88 0.90 0.92 0.93 0.95 0.97 0.99

0 0.87 0.88 0.90 0.92 0.93 0.95 0.97 0.99 1.00 1.02 1.04 1.06 1.08

40 0.94 0.96 0.98 1.00 1.01 1.03 1.05 1.07 1.09 1.11 1 .13 1 .16 1.18

70 1.00 1.02 1.04 1.06 1.08 1.1 0 1.12 1.1 4 1.16 1.18 1.20 1.22 1.25

80 1.02 1.04 1.06 1.08 1.1 0 1 .12 1.1 4 1.16 1.18 1.20 1.22 1.25 1.27

100 1.06 1.08 1.1 0 1.12 1.1 4 1.16 1.18 1.20 1.22 1.25 1.27 1.29 1.32

120 1.90 1.11 1 .13 1.16 1.18 1.20 1.22 1.24 1.27 1.29 1.31 1.34 1.37

1 . Actual ESP = Duct ESP x F actor ÷ Accs. SP

2. Actual BHP = Cat. BHP ÷ Factor

3. Correct BTUH Input = Catalog BTUH Input ÷ Factor

4. Corrected BTUH Output = Corrected BTUH Input x Ef ficiency

Altitude (Feet)

Metric Conv ersion T able

Unless otherwise specified, the following conversions may be used for calculating SI unit

measurements:

1 cubic foot= 0.028 m

1 foot = 0.0305 m 1 gallon = 3.785 L

1 inch = 25.4 mm 1,000 Btu/Cu. Ft. = 37.5 MJ/m

1 psig = 6.894 kPa 1 liter/second = CFM x 0.472

1 pound = 0.453 kg 1 meter/second = FPM ¸ 196.8

1,000 Btu per hour = 0.293 kW

3

1 inch water column = 0.029 kP a

3

7

Page 8

P erformance Data

Table PD-1 — Air Handling Perf or mance Data — Arrangements B-E

Capacity CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

1,500 395 0.12 530 0.19 645 0.27 750 0.35 845 0.44 930 0.54 1010 0.65 1085 0.76

2,000 435 0.22 550 0.3 655 0.4 750 0.49 835 0.59 915 0.7 995 0.81 1065 0.93 11 35 1.06

3,000 555 0.61 630 0.71 710 0.83 790 0.96 865 1.09 935 1.23 1000 1.37 1065 1.51 1125 1.66 1180 1.81 1240 1.96 1295 2.12 1350 2.28 1405 2.45 1455 2.62

20 4,000 700 1.33 750 1.47 805 1 .61 865 1.75 930 1 . 9 990 2.07 1045 2.25 11 05 2.43 1160 2.61 1210 2.8 1260 2.98 1310 3.17 1360 3.35 1405 3.54 1455 3.74

5,000 855 2.51 890 2.68 930 2.85 975 3.02 1020 3.19 1070 3.37 11 20 3.55 11 70 3.75 1220 3.96 1265 4.18 1310 4.4 1360 4.63 1400 4.86

5,500 935 3.3 965 3.49 1000 3.67 1040 3.86 1080 4.05 1120 4.24 1 165 4.43 1210 4.63 1255 4.84

6,000 10 15 4.25 1040 4.45 1075 4.65 11 05 4.85

4,000 450 0.46 565 0.64 670 0.82 760 1.0 1 845 1.22 930 1.43 1005 1.66 1075 1.9 11 40 2.15 1205 2.42

5,000 51 0 0.79 605 0.99 700 1.21 785 1.44 860 1.67 935 1 .91 1005 2.16 1070 2.42 11 35 2.69 1200 2.97

40 6,000 575 1.28 655 1.49 7 40 1.73 815 2. 885 2.28 955 2.56 1020 2.84 1085 3.12 1140 3.41 1200 3.71 1255 4.02 1315 4.34 1365 4.67 1420 5.

7,000 650 1.95 715 2.19 785 2.44 855 2.73 920 3.04 985 3.36 1045 3.68 1105 4. 11 60 4.33 1215 4.66 1270 4.99

8,000 725 2.83 780 3.1 840 3.38 905 3.67 965 3.99 1025 4.34 1080 4.71

Note: Refer to Table for Accessory Pressure Losses (Rooftop Arrangement B-E)

0.2 0.4 0.6 0.8 1 1 .2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3

Total External Static Pressure (Inches of Water)

Table PD-2 — Air Handling Accessory Pressure Loss Data — Arrangements B-E

Rainhood Filters Supply Evaporative Return or Outside

Capacity CFM Screen Mstr. Elim. 2” 1” 2” 1” 2” Plenum 8” 12” Damper

20 2,400 .03 .05 .09 .02 .02 .11 .06 .05 .04 .06 .05

40 4,800 .06 .09 .13 .03 .04 .18 .10 .05 .09 .13 .10

1,600 .02 .02 .05 <.01 .01 .06 .03 .02 .02 .03 .03

1,800 .02 .03 .06 <.01 .01 .07 .04 .03 .02 .03 .03

2,000 .02 .03 .07 .01 .02 .08 .04 .03 .03 .04 .04

2,200 .03 .04 .08 .01 .02 .09 .05 .04 .03 .05 .05

2,500 .04 .05 .09 .02 .03 .12 .07 .05 .04 .07 .06

3,000 .05 .07 .12 .03 .04 .16 .09 .07 .06 .10 .08

4,000 .09 .13 .17 .05 .07 .26 .16 .13 .11 .17 .15

5,000 .15 .20 .07 .1 1 .38 .23 .21 .18 .27 .23

5,500 .18 .25 .09 .1 3 .44 .28 .25 .22 .32 .28

3,200 .03 .04 .07 .01 .02 .09 .05 .02 .04 .06 .04

3,600 .04 .05 .09 .02 .02 .11 .06 .03 .05 .07 .05

4,000 .04 .06 .10 .02 .03 .13 .07 .04 .06 .09 .07

4,400 .05 .07 .11 .03 .04 .15 .09 .05 .07 .11 .08

5,000 .07 .10 .13 .03 .05 .19 .11 .06 .09 .14 .10

6,000 .10 .14 .17 .05 .07 .26 .16 .08 .14 .20 .15

7,000 .13 .19 .07 .09 .33 .21 .1 1 .18 .27 .20

8,000 .17 .24 .09 .12 .42 .26 .15 .24 .36 .26

8,500 .20 .28 .10 .14 .17 .27 .41 .30

With Throwaway Washable Pleated Air Media Air

Pressure Loss (Inches of Water)

8

Page 9

P erformance

Data

Table PD-3 — Air Handling P erfor mance Data — Arrangements G-J

Capacity CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3,000 455 0.52 495 0.6 550 0.7 610 0.82 670 0.93 730 1.06 785 1 .21 840 1.37 890 1.53 940 1.69 985 1.86 1030 2.02 1075 2.19

4,000 575 1.13 610 1 .24 645 1.35 680 1.47 720 1.61 760 1.7 6 810 1.92 855 2.07 900 2.23 940 2.4 985 2.58 1025 2.78 1070 2.99 1110 3.2 1 1 50 3.41

5,000 695 2.11 730 2.27 7 60 2.41 790 2.55 815 2.68 840 2.83 870 2.99 905 3.17 940 3.36 975 3.56 1015 3.76 1050 3.95 1085 4.15 1 1 20 4.35 1155 4.55

20 6,000 820 3.54 850 3.75 880 3.94 905 4.12 930 4.28 950 4.44 975 4.6 995 4.77 1020 4.96 1045 5.15 1070 5.36 1100 5.59 1 130 5.82 1 1 60 6.06 1190 6.3

7,000 945 5.51 975 5.78 1000 6.02 1025 6.24 1050 6.45 1070 6.64 1090 6.83 1105 7 .021125 7 .21 11 45 7.4 1 1 65 7.6 1185 7.81 1205 8.04 1225 8.28 1250 8.52

7,500 1005 6.74 1035 7 .03 1060 7.3 1085 7.54 1110 7.77 1130 7.99 1 1 50 8.19 1 1 65 8.4 11 85 8.59 1200 8.8 1215 9. 1235 9.21 1255 9.43 1270 9.66 1290 9.91

8,000 1070 8.13 1095 8.45 1125 8.74 1 145 9.01 11 70 9.27 1 1 90 9.5 1210 9.731225 9.95

5,000 405 0.67 465 0.84 540 1.03 610 1.25 675 1.5 740 1.77 800 2.04 855 2.31 905 2.59 955 2.88

6,000 470 1.08 510 1.26 570 1 .48 630 1.71 690 1.95 745 2.22 800 2.53 855 2.85 905 3.17 955 3.5

40 8,000 595 2.4 630 2.62 665 2.84 700 3.1 745 3.39 790 3.71 835 4.02 880 4.33 925 4.66 965 5.01

10,000 730 4.52 760 4.81 785 5.07 810 5.34 840 5.64 870 5.96 900 6.31 935 6.7 975 7.1 10 10 7.49 1045 7.88 1085 8.27 11 20 8.66 1 1 55 9.07 1190 9.5

12,000 860 7.64 890 8.01 915 8.35 935 8.67 960 8.99 980 9.32 1000 9.661025 10.04105010.44 108010.88 1 110 1 1.33 11 40 11.8 117012.28 120012.76 123013.23

14,000 995 1 1.97 1020 12.41 104512.83 1065 13.22 1085 13.6 1105 13.97 112014.34 114014.73

Note: Refer to T able for Accessory P ressure Losses (R oof top Arrangement G-L)

0.2 0.4 0.6 0.8 1 1 .2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3

T otal External Static P ressure (Inc hes of Water)

Table PD-4 — Air Handling P erfor mance Data — Arrangements K-L

Capacity CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3,000 455 0.52 495 0.6 550 0.7 610 0.82 670 0.93 730 1.06 785 1.21 840 1.37 890 1.53 940 1.69 985 1.86 1030 2.02 1075 2.19

20 4,000 575 1.13 610 1.24 645 1.35 680 1 .47 720 1 .61 760 1.7 6 810 1.92 855 2.07 900 2.23 940 2.4 985 2.58 1025 2.78 1070 2.99 1110 3.2 1 1 50 3.41

5,000 405 0.67 465 0.84 540 1.03 610 1.25 675 1. 5 740 1.77 800 2.04 855 2.31 905 2.59 955 2.88

40 6,000 470 1.08 510 1.26 570 1 .48 630 1.71 690 1 .95 745 2.22 800 2.53 855 2.85 905 3.17 955 3.5

Note: Refer to T able for Accessory Pressure Losses (Rooftop Ar rangement G-L) and Tables for Cooling Coil Data. (Roof top A r rangement K-L) Do not exceed 6,300

Cfm for units with cooling coils.

0.2 0.4 0.6 0.8 1 1 .2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3

T otal External Static P ressure (Inc hes of Water)

Table PD-5 — Air Handling Accessory Pressure Loss Data — Arrangements G-L

Rainhood Filters Supply Return or Outside

Capacity CFM Screen Mstr. Elim. 2” 1” 2” 1” 2” Plenum Damper

Note: Refer to T able for Cooling Coil and Table for Chilled Water Coil Pressure Losses. (Air Handler A rrangements K,L)

1,600 .02 .02 .03 <.01 <.01 .03 .01 .02 .03

1,800 .02 .03 .03 <.01 <.01 .03 .02 .03 .03

2,000 .02 .03 .04 <.01 <.0 1 .04 .02 .03 .04

2,200 .03 .04 .04 <.01 <.01 .04 .02 .04 .05

2,400 .03 .05 .05 <.01 <.01 .05 .03 .05 .05

2,500 .04 .05 .05 <.01 .0 1 .05 .03 .05 .06

20 3,000 .05 .07 .06 .01 .02 .07 .04 .07 .08

4,000 .09 .13 .09 .02 .03 .12 .07 .13 .15

5,000 .15 .20 .12 .03 .04 .17 .10 .21 .23

6,000 .21 .29 .16 .04 .06 .23 .14 .30 .33

6,500 .25 .34 .17 .05 .07 .26 .16 .35 .39

7,000 .29 .40 .19 .06 .08 .30 .18 .40 .45

7,400 .32 .45 .06 .09 .33 .20 .45 .50

3,300 .03 .04 .03 <.01 <.01 .03 .02 .03 .05

3,500 .03 .05 .03 <.01 <.01 .03 .02 .03 .05

4,000 .04 .06 .04 <.01 <.0 1 .04 .02 .04 .07

4,500 .05 .08 .05 <.01 <.01 .05 .03 .05 .08

40 5,000 .07 .10 .05 <.01 .01 .06 .03 .06 .10

6,000 .10 .14 .07 .01 .02 .08 .04 .08 .15

8,000 .17 .24 .10 .02 .03 .13 .07 .15 .26

10,000 .27 .38 .13 .03 .05 .19 .11 .23 .41

12,000 .39 .55 .17 .05 .07 .26 .16 .34 .59

14,000 .53 .75 .07 .09 .33 .21 .46 .80

With Throwaway Washable Pleated Air Air

Pressure Loss (Inches of Water)

9

Page 10

P erformance

Data

Table PD-6 — DX Cooling Coil Performance D ata (Ref . R-22) — Rooft op Arrangements K, L

Capacity based on 95 F EDB, 74 F EWB, 45 F Sat. Suction, 100 F Liquid

Unit Flow Velocity Spacing Capacity L.A.T. A.P.D. WT. Capacity L.A.T. A.P.D. WT.

Capacity (SCFM) (FPM) (FPF) (MBH) (DB/WB) In. W.C. (LBS) (MBH) (DB/WB) In. W .C. (LBS)

20 1600 217 *96 91 .1 59 / 58 0.11 84 115

40 3300 304 96 173.1 61 / 59 0.21 115 207.5 56 / 55 0.31 158

Air Face Fin 4 6

*120 99.5 56 / 56 0.12 89 1 22

2000 271 96 105.3 61 / 59 0.17 84 129.3 55 / 55 0.25 115

3000 407 96 136.1 64 / 61 0.33 84 171.4 58 / 57 0.50 115

4000 542 96 160.0 66 / 63 0.51 84 204.4 61 / 60 0.77 11 5

4400 596 96 168.6 67 / 64 0.58 84 215.7 62 / 60 0.87 11 5

4000 369 96 194.3 63 / 60 0.29 1 1 5 238.6 57 / 57 0.43 158

5000 461 96 219.9 65 / 62 0.40 1 1 5 277.9 59 / 58 0.60 158

6000 553 96 241.3 66 / 63 0.53 115 312.4 60 / 59 0.79 158

6300 581 96 247.1 67 / 63 0.56 115 321.9 61 / 60 0.84 158

144 106.4 54 / 54 0.13 95 120.8 51 / 51 0.20 130

120 117.2 58 / 57 0.18 89 138.7 53 / 53 0.27 122

144 126.6 56 / 55 0.20 95 145.3 52 / 52 0.29 130

120 154.4 61 / 59 0.36 89 186.6 56 / 56 0.54 122

144 169.8 58 / 58 0.38 95 198.1 54 / 54 0.57 130

120 184.1 63 / 61 0.55 89 224.8 58 / 58 0.82 122

144 205.2 61 / 59 0.59 95 243.3 56 / 56 0.87 130

120 194.5 64 / 62 0.63 89 238.1 59 / 59 0.94 122

144 217.7 61 / 60 0.67 95 261.2 57 / 57 1.00 130

120 191.6 58 / 57 0.22 122 224.7 54 / 54 0.33 170

144 205.9 56 / 56 0.24 130 237.6 52 / 52 0.36 182

120 216.5 60 / 58 0.31 122 260.6 55 / 55 0.46 170

144 234.1 58 / 57 0.33 130 277.7 53 / 53 0.49 182

120 246.8 62 / 60 0.43 122 306.9 56 / 56 0.65 170

144 271.9 59 / 58 0.46 130 330.3 54 / 54 0.69 182

120 273.5 63 / 61 0.56 122 348.2 58 / 57 0.85 170

144 307.7 61 / 59 0.60 130 377.9 56 / 55 0.91 182

120 281.7 64 / 62 0.60 122 359.7 58 / 57 0.91 170

144 317.7 61 / 60 0.64 130 391.3 56 / 56 0.97 182

Number of Rows

Conversions:

2119 SCFM = 1 m/s

196.8 FPM = 1 m/s

3.412 MBH = 1 kW

(F-32) 5/9 = C

1 In. W.C. = 248.8 Pa

1 LB. = 0.453 kg

Notes:

1 .) Data cer tified in accordance with ARI Standard 410.

2.) Capacity based on 95 F EDB, 74 F EWB, 45 F Sat. Suction, 100 F Liquid.

3.) Weight listed is the total weight of the dry coil.

4.) Coils denoted by an asterisk ( * ) require special pricing; consult product marketing for special coil requirements and pricing.

10

Page 11

P erformance

Data

Table PD-7 — DX Cooling Coil Performance D ata (Ref . R-22) — Rooft op Arrangements K, L

Capacity based on 80 F EDB, 67 F EWB, 45 F Sat. Suction, 100 F Liquid

Unit Flow Velocity Spacing Capacity L.A.T. A.P.D. WT. Capacity L.A.T. A.P.D. WT.

Capacity (SCFM) (FPM) (FPF) (MBH) (DB/WB) In. W.C. (LBS) (MBH) (DB/WB) In. W.C. (LBS)

20 1600 217 *96 84 1 15

40 3300 304 *96 113.2 57 / 56 0.21 1 1 5 1 58

Air Face Fin 4 6

*120 89 122

2000 271 *96 84 115

3000 407 96 88.2 59 / 58 0.33 84 112.0 56 / 55 0.50 1 15

4000 542 96 101.3 61 / 59 0.51 84 134.3 57 / 56 0.77 1 15

4400 596 96 105.6 62 / 60 0.58 84 142.1 58 / 57 0.87 1 15

4000 369 96 127.4 58 / 57 0.29 115 156.7 55 / 54 0.43 158

5000 461 96 144.9 60 / 58 0.40 115 179.0 56 / 56 0.60 158

6000 553 96 159.7 61 / 59 0.53 115 199.4 57 / 56 0.79 158

6300 581 96 163.8 61 / 59 0.56 115 205.6 58 / 57 0.84 158

*144 95 79.8 50 / 50 0.19 130

*120 89 122

144 82.2 54 / 54 0.20 95 97.7 51 / 51 0.29 130

120 97.7 58 / 57 0.36 89 123.1 54 / 54 0.53 122

144 107.5 56 / 56 0.38 95 131.8 53 / 53 0.57 130

120 116.3 59 / 58 0.54 89 149.4 55 / 55 0.82 122

144 130.5 57 / 57 0.58 95 161.7 54 / 54 0.87 130

120 123.1 60 / 58 0.62 89 158.7 56 / 55 0.94 122

144 138.6 58 / 57 0.66 95 172.3 55 / 54 1.00 130

*120 126.2 55 / 55 0.22 122 170

144 136.5 54 / 54 0.24 130 155.2 51 / 51 0.36 182

120 143.1 56 / 56 0.31 122 168.7 53 / 53 0.46 170

144 155.9 55 / 54 0.33 130 179.8 52 / 52 0.48 182

120 164.1 58 / 57 0.43 122 197.6 55 / 54 0.64 170

144 180.2 56 / 55 0.46 130 213.9 53 / 53 0.68 182

120 182.0 59 / 58 0.57 122 224.5 55 / 55 0.84 170

144 20 1.1 57 / 56 0.61 130 245.1 54 / 54 0.90 182

120 186.9 59 / 58 0.61 122 232.1 56 / 55 0.90 170

144 206.9 57 / 57 0.65 130 253.9 54 / 54 0.96 182

Number of Rows

Conversions:

2119 SCFM = 1 m/s

196.8 FPM = 1 m/s

3.412 MBH = 1 kW

(F-32) 5/9 = C

1 In. W.C. = 248.8 Pa

1 LB. = 0.453 kg

Notes:

1 .) Data cer tified in accordance with ARI Standard 410.

2.) Capacity based on 80 F EDB, 67 F EWB, 45 F Sat. Suction, 100 F Liquid.

3.) Weight listed is the total weight of the dry coil.

4.) Coils denoted by an asterisk ( * ) require special pricing; consult product marketing for special coil requirements and pricing.

Table PD-8 — Standard Conditions and Specifications — Refrigerant DX Coil

CONDITIONS

Elevation 0 Ft.

Entering Air Temperature DB: 80 F 95 F

Entering Air Temperature WB: 67 F 74 F

Suction Temperature: 45 F 45 F

Liquid Temperature: 100 F 100 F

Fouling Factor: 0 HR x FT2 x F/BTU

SPECIFICATIONS

Coil Type: DE optional DH

T ube Size:

Row Sizes: 4,6

Fin Type: Delta-Flo

Fin Size: 0.0055” Aluminum

Fin Spacing: Standard — 96, (120), 144 Fins/Ft.

Circuiting: Standard —Single

Turbulators: No

DIMENSIONAL DATA LISTING

Unit Size Finned Width Fixed Finned Length

20 30.00 34.00

40 30.00 50.00

Note:

1 . Above specification is for standard coil with standard fin spacing.

Specify fin spacing and dual circuiting.

2. Special coils — contact Product Marketing.

3. Every order requires a coil selection.

1

/2” O.D. x 0.016” TWT Copper

Optional — 72 thru 180 Fins/Ft.

Optional — Dual:

a) Intertwined

b) Face-Split

11

Page 12

Perf ormance

Data

Table PD-9 — Chilled Water Coil Performance D ata — Roof top Arrangements K, L

Capacity based on 95 F EDB, 74 F EWB, 45 EWT, 70 GPM

Unit Flow Velocity Spacing Capacity L.A.T. A.P.D. WT . Capacity L.A.T . A.P.D. WT.

Capacity (SCFM) (FPM) (FPF) (MBH) (DB/WB) In. W.C. (LBS) (MBH) (DB/WB) In. W.C. (LBS)

20 1800 254 96 109.8 58 / 56 0.12 84 131.2 52 / 52 0.18 115

40 2100 202 96 136.2 56 / 55 0.08 115 159.5 51 / 51 0.12 158

Conversions:

21 19 SCFM = 1 m/s

196.8 FPM = 1 m/s

3.412 MBH = 1 kW

(F-32) 5/9 = C

1 In. W.C. = 248.8 Pa

1 LB. = 0.453 kg

Air Face Fin 4 6

120 119.0 55 / 54 0.14 89 138.6 50 / 50 0.21 122

3000 424 96 148.1 63 / 60 0.27 84 185.5 57 / 56 0.40 115

4300 607 96 175.1 67 / 63 0.47 84 226.1 61 / 59 0.70 1 15

3500 336 96 188.4 61 / 59 0.19 115 230.8 55 / 54 0.28 158

4900 470 96 223.8 64 / 61 0.32 115 281.9 59 / 57 0.47 158

6300 605 96 250.4 67 / 63 0.46 115 321.3 61 / 60 0.68 158

144 126.3 53 / 53 0.16 95 143.9 49 / 49 0.24 130

120 163.0 60 / 58 0.31 89 199.9 55 / 54 0.46 122

144 174.9 58 / 57 0.35 95 210.8 53 / 53 0.52 130

120 195.3 64 / 61 0.52 89 247.5 58 / 57 0.78 122

144 210.8 62 / 60 0.60 95 263.2 56 / 56 0.90 130

120 146.9 54 / 53 0.09 122 167.5 49 / 49 0.14 170

144 155.0 52 / 51 0.1 1 130 172.9 48 / 48 0.16 182

120 205.7 58 / 57 0.22 122 246.5 53 / 53 0.33 170

144 219.6 56 / 55 0.25 130 258.6 51 / 51 0.37 182

120 247.4 62 / 60 0.36 122 305.8 56 / 56 0.54 170

144 265.9 60 / 58 0.41 130 323.6 55 / 54 0.61 182

120 278.8 64 / 62 0.51 122 351.4 59 / 58 0.77 170

144 300.7 62 / 61 0.59 130 373.6 57 / 57 0.89 182

Notes:

1 .) Data cer tified in accordance with ARI Standard 410.

2.) Capacity based on 95 F EDB, 74 F EWB, 45 F Sat. Suction, 100 F Liquid.

3.) Weight listed is the total weight of the dry coil.

4.) Contact product marketing for special coil requirements.

Number of Rows

Table PD-10 — Chilled Water Coil Performance D ata — Roof t op Arrangements K, L

Capacity based on 80 F EDB, 67 F EWB, 45 EWT, 70 GPM

Unit Flow Velocity Spacing Capacity L.A.T. A.P.D. WT. Capacity L.A.T. A.P.D. WT .

Capacity (SCFM) (FPM) (FPF) (MBH) (DB/WB) In. W .C. (LBS) (MBH) (DB/WB) In. W.C. (LBS)

20 1800 254 96 77.4 54 / 53 0.12 84 92.3 50 / 50 0.18 115

40 2100 202 96 95.9 53 / 52 0.08 115 112.1 49 / 49 0.12 158

Conversions:

2119 SCFM = 1 m/s

196.8 FPM = 1 m/s

3.412 MBH = 1 kW

(F-32) 5/9 = C

1 In. W.C. = 248.8 Pa

1 LB. = 0.453 kg

Air Face Fin 4 6

120 83.9 52 / 52 0.14 89 97.5 49 / 49 0.21 122

3000 424 96 104.9 58 / 56 0.27 84 131.0 53 / 53 0.40 115

4300 607 96 124.5 60 / 58 0.47 84 160.1 56 / 55 0.70 1 15

3500 336 96 133.3 56 / 55 0.19 115 162.9 52 / 52 0.28 158

4900 470 96 158.9 59 / 57 0.32 115 199.6 55 / 54 0.47 158

6300 605 96 177.7 61 / 58 0.47 1 1 5 227.4 56 / 55 0.69 158

144 89.0 51 / 50 0.16 95 1 01.2 48 / 48 0.24 130

120 115.5 56 / 55 0.31 89 141.2 52 / 51 0.47 122

144 123.7 54 / 54 0.35 95 148.6 51 / 50 0.53 130

120 138.4 58 / 57 0.53 89 174.9 54 / 54 0.79 122

144 149.2 57 / 56 0.60 95 185.9 53 / 53 0.90 130

120 103.4 51 / 51 0.09 122 11 7.7 48 / 48 0.14 170

144 109.0 50 / 49 0.11 130 121.5 47 / 47 0.16 182

120 145.5 54 / 53 0.22 122 174.0 51 / 50 0.33 170

144 155.2 53 / 52 0.25 130 182.2 49 / 49 0.37 182

120 175.2 57 / 56 0.36 122 216.1 53 / 53 0.54 170

144 188.1 55 / 55 0.41 130 228.4 52 / 52 0.61 182

120 197.5 59 / 57 0.52 122 248.5 55 / 54 0.78 170

144 212.8 57 / 56 0.59 130 263.9 54 / 53 0.89 182

Notes:

1 .) Data cer tified in accordance with ARI Standard 410.

2.) Capacity based on 80 F EDB, 67 F EWB, 45 F Sat. Suction, 100 F Liquid.

3.) Weight listed is the total weight of the dry coil.

4.) Contact product marketing for special coil requirements.

Number of Rows

12

Page 13

P erformance

Data

Table PD-11 — Standar d Conditions and Specifications — Chilled Water Coil

CONDITIONS

Elevation 0 Ft.

Entering Air Temperature DB: 80 F 95 F

Entering Air T emperature WB: 67 F 74 F

Entering Water Temperature: 45 F 45 F

Water Flow Rate: 70 GPM 70 GPM

T ube Velocity: 4 Ft./Sec.

Fouling Factor: 0 HR x FT2 x F/BTU

SPECIFICATIONS

Coil Type: W — Full Row Serpentine

T ube Size: 5/8” O.D. x 0.024” TWT Copper

Row Sizes: 4,6

Fin Type: Prima-Flo

Fin Size: 0.0075” Aluminum

Fin Spacing: Standard — 96, (120), 144 Fins/Ft.

Circuiting: Single Circuit

Drainable: Yes

T urbulators: No

DIMENSIONAL DATA LISTING

Unit Size Finned Width Fixed Finned Length

20 30.00 34.00

40 30.00 50.00

Note:

1 . Above specification is for standard coil with standard fin spacing.

2. Special coils — contact Product Marketing.

3. Every order requires a coil selection.

Optional — 80 thru 168 Fins/Ft.

Table PD-12 — Evaporative Cooling P erfor mance D ata and Pr essur e Drop — Roof t op Arrangements D,E

CFM Efficiency Efficiency 8” or 12” Deep Media in. of Water “A ” Unit Shipping Operating

Unit Size Min. Max. Min. Max. Min. Max. Ft.2 (m2) In. (mm) Min. Max. In. (mm) lb. (kg) lb. (kg)

20 1,600 5,500 77 88 88 92 9.38 31 x 43 9/16 0.03 0.20 43 3/4 166 386

40 3,200 8,500 77 86 87 92 12.92 31 x 60 0.07 0.28 60 1/4 206 509

Note:

1. These weights are for evaporative cooler only.

(cu. m/s) (cu. m/s) Range Range Face Area Size (KPa) (KPa) Width Wt. Wt.

(0.755) (2.596) (0.87) (787) (1106) (0.01) (0.05) (1 111) (75) (175)

(1.510) (4.012) (1.20) (787) (1524) (0.02) (0.07) (1530) (93) (231)

8” Saturation 12” Saturation Pressure Drop (1) (1)

Chart PD-1 — Evaporative Cooler Efficiency/A.P.D. Chart

CELdek® Evaporative Media

The Trane Evaporative Cooler uses high

efficiency CELdek

®

media. CELdek® is

made from a special cellulose paper,

impregnated with insoluble anti-rot

salts and rigidifying saturants. The cross

fluted design of the pads induces highturbulent mixing of air and water for

optimum heat and moisture transfer.

The Trane evaporative coolers are

standard with eight-inch deep media

which produce high efficiency and high

face velocities, along with a two-inch

distribution pad to disperses the water

evenly over the pads. We offer an

optional 12-inch deep media (see c har t

at right for efficiencies).

13

Page 14

Electrical Data

Air Handling Units Motor Electrical Data

Voltage 1/2 HP 3/4 HP 1 HP 1 1/2 HP 2 HP 3 HP 5 HP 7 1/2 HP 10 HP 15 HP

115/60/1 ODP 7.2 10.9 13.4 18.0 26.0 33.0 NA NA NA NA

208/60/1 ODP 4.3 6.0 6.7 9.3 11.5 16.5 NA NA NA NA

230/60/1 ODP 4.3 5.5 6.7 9.0 13.0 16.5 NA NA NA NA

208/60/3 ODP 2.8 2.6 3.2 4.8 6.2 8.4 12.2 24.0 28.0 44.9

230/60/3 ODP 2.8 2.6 3.2 4.8 6.2 8.4 12.2 21.6 26.6 40.6

460/60/3 ODP 1 .4 1.3 1.6 2.4 3.1 4.2 6.1 1 0.8 13.3 20.3

575/60/3 ODP 1 .1 1.4 1.5 1.9 2.5 3.6 5.3 8.6 10.6 15.6

1 15/60/1 TE 9.0 1 1.4 13.6 17 .6 24.6 34.0 NA NA NA NA

208/60/1 TE 3.9 4.5 6.8 8.0 12.3 17 .0 NA NA NA NA

230/60/1 TE 4.5 5.7 6.8 8.8 12.3 17 .0 NA NA NA NA

208/60/3 TE 2.1 2.8 3.4 4.8 6.4 9.4 14.0 21.8 28.7 42.6

230/60/3 TE 2.2 2.8 3.6 4.9 6.4 9.2 13.0 20.4 26.4 28.4

460/60/3 TE 1.1 1.4 1.8 2.4 3.2 4.6 6.5 10.2 13.2 19.2

575/60/3 TE 0.9 1.3 1.7 1.9 2.6 3.6 5.1 7 .6 9.6 14.4

115/60/1 HEODP 5.2 6.4 9.2 12.5 16.4 NA NA NA NA NA

208/60/1 HEODP 2.8 4.2 NA NA NA NA NA NA NA NA

230/60/1 HEODP 2.6 5.2 4.6 6.3 8.2 NA NA NA NA NA

208/60/3 HEODP 1.8 2.5 3.6 5.0 6.7 9.2 14.7 22.1 29.0 40.0

230/60/3 HEODP 1.6 2.3 2.8 3.8 5.4 8.0 12.8 19.2 25.2 36.0

460/60/3 HEODP 0.8 1 .2 1.4 1.9 2.7 4.0 6.4 9.6 25.2 18.0

575/60/3 HEODP NA NA 1.1 1.8 2.3 3.2 5.2 7.7 10.1 14.5

115/60/1 HETE 5.5 7.6 9.2 14.0 19.2 NA NA NA NA NA

208/60/1 HETE NA NA NA NA NA NA NA NA NA NA

230/60/1 HETE 2.8 3.8 4.6 7 .0 9.6 NA NA NA NA NA

208/60/3 HETE NA NA 3.2 4.6 6.2 8.8 14.7 21.4 29.0 41.2

230/60/3 HETE 4.6 6.3 3.0 4.2 5.8 8.0 12.0 18.8 25.2 37 .0

460/60/3 HETE 2.3 3.2 1.5 2..1 2.9 4.0 6.0 9.4 12.6 18.5

575/60/3 HETE NA NA 1.1 1.8 2.4 3.2 4.8 7.5 10.2 14.9

208/60/3 2S1W NA NA 3.0/1.0 4.4/1.8 6.2/3.0 9.0/3.4 15.0/6.0 21.0/7.5 29.0/9.6 NA

230/60/3 2S1W NA NA 3.0/1.0 4.4/1.8 5.9/2.9 8.0/3.3 14.0/6.2 19.5/7.5 25.0/9.3 NA

460/60/3 2S1W NA NA 1.5/0.5 2.2/1.9 3.1/1.3 3.8/1 .6 6.8/2.8 10.0/4.0 12.0/4.3 18.0/6.0

575/60/3 2S1W NA NA NA NA NA NA NA NA NA NA

115/60/1 2S2W 9.2/6.0 9.2/4.6 1 1.9/6.9 NA NA NA NA NA NA NA

208/60/1 2S2W NA 5.0/2.5 6.3/3.0 NA NA NA NA NA NA NA

230/60/1 2S2W 4.6/3.0 4.6/2.3 6.0/3.6 NA NA NA NA NA NA NA

208/60/3 2S2W 2.4/1 .6 3.0/1 .9 3.4/2.0 5.0/2.6 6.5/3.5 9.3/4.9 NA 20.0/1 1.0 27.0/14.0 NA

230/60/3 2S2W 2.1/1 .4 2.7/1.7 3.2/2.0 4.8/2.9 6.3/3.5 8.5/4.6 NA 19.0/10.0 25.0/12.5 NA

460/60/3 2S2W 1 .1/0.7 1.3/0.9 1.5/1.0 2.3/1.3 3.0/1.7 4.6/2.7 NA 9.7/5.5 12.2/7.0 NA

575/60/3 2S2W NA NA NA NA NA NA NA NA NA NA

Notes:

1. ODP = Open Drip Proof

2. TE = Totally enclosed

3. HEODP = High Efficiency Open Drip Proof

4. HETE = High Efficiency T otally Enclosed

5. 2S1W = Two Speed One Winding

6. 2S2W = Two Speed Two Winding

7. NA = Not A vailable

FLA based on NEC Ratings

14

Page 15

Controls

Air Inlet Configuration

The air inlet configuration defines the

entering air opening for the air

handling units. This selection does not

include dampers and must match the

required opening for the air control

and damper arrangement. A horiz ontal

return air feature is offered on air inlet

configurations 3 and 4.

Air Inlet Configuration

1

4

Note: Horizontal outside air over return

air. Specify air inlet configuration 4 or 5

and then select miscellaneous option

“D” for horizontal return.

Damper Options

Dampers shall be of the opposed blade

type, constructed of galvanized steel

with neoprene nylon bushings, blades

to be mechanically interloc ked.

Optional low leak outside air dampers

shall be of the opposed blade type,

construction of galvanized steel with

neoprene nylon bushings and vinyl

blade edge seals, blades to be

mechanically interloc ked.

Outside Air or Retur n Air/Two- Position

Motor/Spring Retur n

Units with outside air or return air only

shall be provided with damper, twoposition spring return damper motor

and controls. The motor shall power

the damper full open when the unit is

on and full closed when the unit is off.

2

5

3

See Note

Below

Outside Air/Return Air T w o-Position

Spring Retur n

T wo-position spring return motor with

interlocked outside and return air

dampers shall be provided. The motor

shall power either the outside air

damper full open and the return air

damper full closed or the outside air

damper full closed and the return air

damper full open in response to an

outside air temperature sensor.

(Includes an outside air thermostat that

makes on a rise in temperature and

drives the damper open.) When the unit

is off, the motor will drive the outside

air damper full closed and the return air

damper full open.

Outside Air/Return Air Modulating

Motor with Mixed Air Contr ol/

Minimum Position P otentiomet er/

Spring Retur n

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller located in the mixed air

stream. Units shall also be provided

with a minimum position

potentiometer for minimum outside air

damper position.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is off.

Outside Air/Return Air Modulating

Motor with Mixed Air Temperature

Control/Spring Retur n

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller located in the mixed air

stream.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is off.

Outside Air/Return Air Modulating

Motor with Minimum Position

Potentiomet er/Spr ing Retur n

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall position the

outside and return air dampers in

response to a manually set

potentiometer.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is off.

Outside Air/Return Air Modulating

Motor with Dry Bulb/Mixed Air

Temperature Contr ol and Minimum

Position P otentiomet er/Spr ing Retur n

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller and dry bulb thermostat

located in the mixed air stream. Units

shall also be provided with a minimum

position potentiometer for minimum

outside air damper position.

The spring return feature drives the

outside air damper full open and the

return air damper full closed when the

unit is off.

Outside Air/Return Air Modulating

Motor with Enthalpy Controlled

Economizer/Spring Return

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to an enthalpy controlled

economizer . When the unit is off the

motor will drive the outside air damper

full closed and the return air damper

full open.

Outside Air/Return Air Modulating

Motor with Space Pressure Contr oller

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to a pressure sensor located

in the building.

15

Page 16

Controls

Outside Air/Return Air Modulating

Motor with S-350P Proportional Mix ed

Air Control/Spring Ret ur n

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to a solid-state mixed air

sensor and S-350 proportional

controller. When the unit is off the

motor will drive the outside air damper

full closed and the return air damper

full open.

Outside Air/Return Air Modulating

Motor with External 4-20 mA or

0-10 VDC Analog Input/Spring Retur n

Modulating motor interlocked with

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a 4-10 mA or

0-10 VDC signal supplied by an external

DDC controller.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is shut down.

ASHRAE Cycle I (Outside/Retur n Air

Two-Position with Warm-Up Stat/

Spring Retur n)

T wo-position spring return motor with

interlocked outside and return air

dampers shall be provided. The motor

shall power the outside air damper full

open after a warm-up period

determined by a minimum supply air

temperature sensor when the unit is

on, and full closed when the unit is off.

ASHRAE Cycle II (Outside Air/Return

Air Modulating Motor with Warm-Up

Stat/Mixed Air T emperatur e Controller/

Minimum Position P ot entiometer/

Spring Retur n)

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller located in the mixed air

stream after a warm-up period

determined by a minimum supply air

temperature sensor. Units shall also be

provided with a minimum position

potentiometer for minimum outside air

damper position.

When the unit is off, the motor will

drive the outside air damper full closed

and the return air damper full open.

ASHRAE Cycle III (Outside Air/Return

Air Modulating Motor with Warm-Up

Thermostat/Mixed Air T emper ature

Controller/Spr ing Retur n)

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to a thermostatic controller

located in the mixed airstream after a

warm-up period determined by a

minimum supply air temperature

sensor. Units shall also be provided

with a minimum position

potentiometer for minimum outside air

damper position. When the unit is of f ,

the motor will drive the outside air

damper full closed and the return air

damper full open.

Manual Dampers

Units with outside air and return air

shall be provided with manually set

outside and return air dampers.

16

Page 17

Dimensional Data

Air Intake Hood

Arrang ements B, C, D, E, G J , K, L

Unit Sizes 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS IN

P AREN THESES ARE IN MILLIMETERS.

Model E Dimension

20 40 3/8”

40 56 7/8”

(1025)

(1445)

17

Page 18

Dimensional

Data

Over/Under Air Intak e with Hood

Arrang ements B, C, D , E, G J , K, L

Unit Sizes 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS IN

PAREN THESES ARE IN MILLIMETERS.

Model E Dimension

20 40 3/8”

(1025)

40 56 7/8”

(1445)

18

Page 19

Dimensional

Data

Over/Under Air Intak e without Hood

Arrang ements B, C, D , E, G J , K, L

Unit Sizes 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS IN

P AREN THESES ARE IN MILLIMETERS.

19

Page 20

Dimensional

Data

Supply Plenum Module

Arrang ement C, E, J , L

Unit Sizes 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS IN

P AREN THESES ARE IN MILLIMETERS.

Note: The dimensions shown do not include base skid rail.

Model A J

20 43 7/8” 35”

40 60 3/8” 51”

(111 4) (889)

(1534) (1295)

20

Page 21

Model A

20 43 7/8”

40 60 3/8”

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(111 4)

(1534)

Dimensional

Data

Cooling Coil Module

Arrang ements K, L

Unit Sizes 20, 40

Maximum Coil Dimensions

Unit Size Cabinet Opening

20 42 1/4” (1 073)

40 58 3/4” (1492)

The coil section drain pan connection is 3/4 inc h NPT pipe thread. It is a female fit ting that just protrudes outside of the unit base

•

rail. It is located on the service side of the unit.

The drain pan is constructed of stainless steel, including the fitting. It is sloped towards the center of the pan and level across

•

the width of the unit.

P-trap required external to the unit provided by others.

•

“L” Inside Max.

Side Opening of Cooling Module

21

Page 22

Dimensional

Data

Evaporativ e Cooler Module

Arrangements D , E

Unit Sizes 20, 40

Model A

20 43 7/8”

40 60 3/8”

DIMENSIONS ARE IN INCHES, DIMENSIONS IN

P AREN THESES ARE IN MILLIMETERS.

(111 4)

(1534)

22

Page 23

Dimensional

Data

Air Handler with Standard Blower

Arrang ement B

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PARENTHESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C G J

20 43-7/8 23-13/16 21-15/16 42-1/16 35

40 60-3/8 45-13/16 30-3/16 58-9/16 51-1/2

(1 114) (605) (557) (1068) (889)

(1534) (1 164) (767) (1487) (1308)

23

Page 24

Dimensional

Data

Air Handler with Standard Blower and Do wnflow Supply Plenum

Arrang ement C

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C G J

20 43-7/8 23-13/16 21-15/16 42-1/16 35

40 60-3/8 45-13/16 30-3/16 58-9/16 51-1/2

(1 114) (605) (557) (1068) (889)

(1534) (1 164) (767) (1487) (1308)

24

Page 25

Dimensional

Data

Air Handler with Standard Blower and Ev apor ativ e Cooler

Arrang ement D

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C J

20 43-7/8 23-13/16 21-15/16 35

40 60-3/8 45-13/16 30-3/16 51-1/2

(1 114) (605) (557) (889)

(1534) (1 164) (767) (1308)

25

Page 26

Dimensional

Data

Air Handler with Standard Blower, Evaporative Cooler and

Downflow Supply Plenum

Arrang ement E

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C J

20 43-7/8 23-13/16 21-15/16 35

40 60-3/8 45-13/16 30-3/16 51-1/2

(111 4) (605) (557) (889)

(1534) (11 64) (767) (1308)

26

Page 27

Dimensional

Data

Air Handler with High Cfm Blower

Arrang ement G

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PARENTHESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C G J

20 43-7/8 23-13/16 21-15/16 42-1/16 35

40 60-3/8 45-13/16 30-3/16 58-9/16 51-1/2

(1 114) (605) (557) (1068) (889)

(1534) (1 164) (767) (1487) (1308)

27

Page 28

Dimensional

Data

Air Handler with High Cfm Blower and Downflo w Supply Plenum

Arrang ement J

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C G J

20 43-7/8 23-13/16 21-15/16 42-1/16 35

40 60-3/8 45-13/16 30-3/16 58-9/16 51-1/2

(111 4) (605) (557) (1068) (889)

(1534) (1 164) (767) (1487) (1308)

28

Page 29

Dimensional

Data

Air Handler with High Cfm Blower and Cooling Coil Section

Arrang ement K

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C G J

20 43-7/8 23-13/16 21-15/16 42-1/16 35

40 60-3/8 45-13/16 30-3/16 58-9/16 51-1/2

(1 114) (605) (557) (1068) (889)

(1534) (1 164) (767) (1487) (1308)

29

Page 30

Dimensional

Data

Air Handler with High Cfm Blower, Cooling Coil Section and

Downflow Supply Plenum

Arrang ement L

AH0A 20, 40

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

(Left Hand Service Access Shown)

Unit Dimensional Data

Capacity A B C G J

20 43-7/8 23-13/16 21-15/16 42-1/16 35

40 60-3/8 45-13/16 30-3/16 58-9/16 51-1/2

(111 4) (605) (557) (1068) (889)

(1534) (1 164) (767) (1487) (1308)

30

Page 31

Dimensional

Data

Roof Curb— Air Handler

Arrangements B-L

20, 40

Capacity Rooftop

(CA) Arr. (RA) F G H J Q R

20 or 40 G 38-1/8 N/A 81-7/16 77-11/16 79-5/16 86-11/16

B,D N/A N/A 45-1/4 41-1/2 43-1/8 50-1/2

C,E 29-5/8 8-1/8 71-1/8 67-3/8 69 76-3/8

(752) (206) (1,806) (1,711) (1,753) (1,940)

(968) (2,069) (1,973) (2,015) (2,202)

J,K 37-3/16 29-3/16 107-5/16 103-9/16 105-3/16 112-9/16

(944) (7 41) (2,726) (2,630) (2,672) (2,859)

L37-1/8 55-1/4 133-1/4 129-1/2 131-1/8 138-1/2

(943) (1,403) (3,385) (3,289) (3,331) (3,518)

(1,149) (1,054) (1,095) (1,283)

Capacity

Arr. (CA) W B C

All (951) (1,046) (1,179)

20 37-7/16 41-3/16 46-7/16

40 53-15/16 57-11/16 62-15/16

(1,370) (1,465) (1,599)

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PARENTHESES ARE IN MILLIMETERS.

1 . R oof curbs ship knoc ked

down for full assembly.

2. Arrangement D and E

require a separate platform

for the evaporative cooler.

See separate drawing for

dimensional information

on the platform.

Model D E

20 35 37

(889) (940)

40 51-1/2 53-1/2

(1,308) (1,359)

SECTION Y -Y

SECTION X-X

31

Page 32

Dimensional

Data

Roof Openings —Air Handler

Arrangements B-L

20,40

➀ Roof Mounting Angle

➁ Curb End Rail Channel

➂ Screw - #10 x 5/8 Lg. Pan Hd. Type “AB”8 Req’d .

➃ Fasteners by Others

Blower/Filter/Damper or Filt er/D amper Area

Capacity (CA) B

20 4

40 5

➀ Curb Cross Brace Channel

➁ Curb Side Rail Channel

➂ Curb End Rail Channel

➃ Screw - #10 x 5/8 Lg. Pan Hd. Type “AB” 8 Req’d.

Curb Specifications

*Roof Openings

Supply Plenum Ar ea

Arrg, Cap. A

C,E 20,40 18-7/8

J 20,40 19-1/8

L 20,40 19-1/8

Capacity Dimension “B”

20 37.00 (940)

*All dimensions shown have been calculated to include a

one (1) inch clearance around return and supply ducts.

** Blower

Arrg. CA Std HI Coil Supply A

C,E 20

J 20

L 20

**Arrangements B, D, G, K, are without a supply plenum;

RA - Rooftop arrangement.

40 53.50 (1,359)

Ö

or 40 (631)

or 40 (1551)

or 40 (2211)

use the same return air dimensions for these unit roftop

openings. Refer to unit submittals for more detail.

Capacity (CA) D B

20 35 14

40 51-1/2 16

Unit Type AH

Ö

ÖÖ

24.859

Ö

61 .047

Ö

87.035

Ö

32

DIMENSIONS ARE IN INCHES, DIMENSIONS

IN PAREN THESES ARE IN MILLIMETERS.

Page 33

Dimensional

Data

Evaporative Cooler

Curb/Platform 20, 40

Curb Cap End Adaptor Supplied with the Unit

(one each end)

Unit/Curb End Rail Assembly

Unit/Base Rail Assembly

See View A

View A

T yp. (8) PLC’s.

➀ Evaporative Cooler Assembly

➁ Curb

➂1/4-20 “KEPS” Nut (8) R equired

➃1/4-20 x 5/8 Lg. Hex Hd. Bolt (8) Required

Evaporative Cooler Curb/Platf orm Mounting Assembly

33

Page 34

Weights

Table W -1 — Shipping Weights

Unit Size

Arrangement Net Ship Net Ship

B 406 408 529 621

C 509 616 649 767

D 612 725 785 909

E 715 852 905 920

G 567 680 7 64 888

J 649 786 913 928

K 652 789 865 880

L 734 896 1014 1 191

Metric Conversion — 1 lb = 0.453 kg.

Table W -4 — Mot or Weights

Voltage

115/60/1 ODP 20 25 25 40 42 80 NA NA NA NA

208/60/1 ODP 21 27 25 40 66 80 NA NA NA NA

230/60/1 ODP 21 25 25 40 42 80 NA NA NA NA

208/60/3 ODP 20 24 31 29 35 47 49 99 1 1 8 152

230/60/3 ODP 20 24 31 29 35 47 49 99 1 1 8 150

460/60/3 ODP 20 24 31 29 35 47 49 99 1 1 8 150

575/60/3 ODP 20 20 27 31 37 56 73 105 1 16 150

1 15/60/1 TE 26 30 34 41 65 74 NA NA NA NA

208/60/1 TE 27 36 39 48 65 74 NA NA NA NA

230/60/1 TE 26 30 34 41 65 74 NA NA NA NA

208/60/3 TE 18 23 28 32 36 55 65 90 123 295

230/60/3 TE 18 23 28 32 36 55 65 90 123 295

460/60/3 TE 18 23 28 32 36 55 65 90 123 295

575/60/3 TE 21 21 26 36 40 90 92 161 199 284

115/60/1 HEODP 32 33 38 58 72 NA NA NA NA NA

208/60/1 HEODP 32 30 NA NA NA NA NA NA NA NA

230/60/1 HEODP 32 33 38 58 72 NA NA NA NA NA

208/60/3 HEODP 22 25 40 44 44 83 89 139 141 213

230/60/3 HEODP 24 26 40 43 44 80 91 137 138 238

460/60/3 HEODP 24 26 40 43 44 80 91 137 138 238

575/60/3 HEODP NA NA 41 44 45 90 100 170 141 215

115/60/1 HETE 28 37 38 41 53 NA NA NA NA NA

208/60/1 HETE NA NA NA NA NA NA NA NA NA NA

230/60/1 HETE 28 37 38 41 53 NA NA NA NA NA

208/60/3 HETE NA NA 39 34 48 71 78 107 124 225

230/60/3 HETE 32 52 39 34 48 94 11 0 158 166 294

460/60/3 HETE 32 52 39 34 48 94 11 0 158 166 294

575/60/3 HETE NA NA 44 69 88 76 80 132 140 260

208/60/3 2S1W NA NA 34 38 48 66 81 125 143 NA

230/60/3 2S1W NA NA 34 38 48 66 81 125 143 NA

460/60/3 2S1W NA NA 34 38 41 58 94 125 136 218

575/60/3 2S1W NA NA NA NA NA NA NA NA NA NA

115/60/1 2S2W 23 30 37 NA NA NA NA NA NA NA

208/60/1 2S2W NA 29 36 NA NA NA NA NA NA NA

230/60/1 2S2W 23 29 36 NA NA NA NA NA NA NA

208/60/3 2S2W 27 32 44 47 67 84 NA 221 192 NA

230/60/3 2S2W 26 32 44 47 67 84 NA 221 192 NA

460/60/3 2S2W 26 33 40 44 55 67 NA 214 230 NA

575/60/3 2S2W NA NA NA NA NA NA NA NA NA NA

Notes:

1. ODP = Open Drip P roof

2. TE = Totally enclosed

3. HEODP = High Efficiency Open Drip Proof

4. HETE = High Efficiency T otally Enclosed

5. 2S1W = Two Speed One Winding

6. 2S2W = Two Speed Two Winding

7. NA = Not A vailable

8. Metric Conversion — 1 lb = 0.453 kg.

FLA based on NEC Ratings

20 40

1

/2 HP

3

/4 HP 1 HP 1 1/2 HP 2 HP 3 HP 5 HP 7 1/2 HP 10 HP 15 HP

Table W-2 — Roof Curb W eights

Unit Size

Arrangement 20 40

B 85 1 1 2

C133161

D 85 112

E133161

G140168

J 179 207

K 177 204

L 210 238

Outside Air Hood 51 63

Metric Conversion — 1 lb = 0.453 kg.

Table W-3 — Evaporative Cooler Weights

Unit Size lb. (Kg) lb. (Kg)

20 166 386

40 206 509

Metric Conversion — 1 lb = 0.453 kg.

Shipping Wt. Operating Wt.

34

Page 35

Options

Remote Control Station

(Order No. 134-0201 -01)

Wall mounted

•

Six LED status lamps

•

System on/off, fan auto/on, heat auto/

•

off, cool auto/of f , auxiliary on/off

switching and modulating damper

potentiometer mounting.

Plug-in terminal block wiring and wall

•

mounting bracket.

6 1/4” W x 3 3/4” H x 1 1/2” D

•

Seven-Day Timeclock

(Order No. 134-0201 -02)

Single pole double throw (SPDT) relay

•

output at setpoint time

Maximum of six setpoints per day

•

7 3/4” H x 5” W x 3 7/16” D

•

24-Hour Timeclock

(Order No. 134-0201 -03)

Single pole double throw (SPDT) relay

•

output at setpoint time.

Maximum 12 setpoints per day .

•

7 3/4” H x 5” W x 3 7/16” D

•

Roof Curbs

Roof curbs are available for all Trane

packaged air handlers offered in this

catalog. All curbs are shipped knoc ked

down for field assembly. Curbs are

normally available on a short lead time

basis so that they may be on the

jobsite well in advance of the units.

Curbs are 12 inches high, factoring in

the four -inc h unit base rail, o verall

height to the bottom of the rooftop

unit is actually 16 inches. R oof curbs

can be supplied with one-inch

fiberglass insulation.

Features Summary

T rane roof top pac kaged air handlers

have the following design features:

ETL and CSA UL-1995 certified.

•

Units are completely wired, tested and

•

rail-mounted with blower drives preset.

Draw-thru cooling coil cabinet

•

arrangements with stainless steel drain

pan.

Evaporative cooling arrangement with

•

standard 8 or optional 12-inch media

(203 or 305 mm).

35

Page 36

Mec hanical Specifications

Arr angements B-L

General

Units shall be completely factory

assembled, wired and test fired. Units

shall be mounted on metal rails with

lifting and anchor holes and shall be

suitable for slab or curb mounting. All

units shall be ETL or UL certified for

electrical safety in compliance with UL

1995 safety standard for heating,

ventilating and cooling equipment.

Electrical

Standard control relays shall be socket

mounted with terminal block

connections. All control wiring shall

terminate at terminal strips (single

point connection) and include an

identifying marker corresponding to

the wiring diagram. Motor and control

wiring shall be harnessed with terminal

block connections.

Casing

Casings shall be die-formed, 18-gauge

galvanized steel and finished in air-dry

enamel. Service and access panels

shall be provided through easily

removable side access panels with

captive fasteners. Fan sections and

supply plenums (when provided) shall

be insulated with fire resistant,

odorless, matte-faced one-inch glass

fiber material. Outside air hoods, when

provided, ship with a wire mesh inlet

screen.

Evaporativ e Cooler (Standard on

Arrang ement D and E only)

An evaporative cooler with 8-inch

media shall be provided. The

evaporative cooler shall be of a selfcleaning design with a stainless steel

water tank, regulated water flow and

overflow protection. The cooler shall

have a cabinet assembly of heavygauge aluminized steel with

weatherproof finish, a UL recognized

thermally protected sealed

recirculating pump motor, two-inc h

distribution pad, and corrosion

resistant PVC water distribution tubes.

Cooling Coil Section (Standard on

Arrang ement K and L only)

A cooling coil section, constructed of

galvanized steel, shall be provided with

the unit. This section shall be insulated

with fire resistant, odorless, mattefaced one-inch glass fiber material.

Fans

Centrifugal fan shall be belt-driven,

forward curved with double inlet,

statically and dynamically balanced.

The blower wheel shall be fixed on a

keyed shaft, supported with rubber

grommet on bearing only and ball

bearing secured. 7

1

/2 through 15 hp

motors are equipped with a pillow

block bearing assembly on the drive

side. An access interloc k switc h shall be

installed in the blower compartment

and will disengage the blower upon

removing the service panel. An

override shall be incorporated into the

interlock switc h for serviceability.

Filters

Filter rack shall be constructed of

galvanized steel with access through

the side service panel. Standard filters

are one-inch permanent washable type

(Arrangement B-E).

OR

Filter rack shall be of v-bank design for

minimal pressure drop and be

constructed of galvanized steel with

access through the side service panel.

Standard filters are one-inch

permanent washable type

(Arrangement G-L).

Electrical Cabinet

Electrical cabinet shall be isolated from

the airstream with a non-removable

access panel interior to the outer

service panel. There is provision in this

cabinet for component mounting, wire

routing and high voltage isolation.

Motor and control wiring shall be

harnessed with terminal block

connections.

Controls

All rooftop units shall be provided with

a low voltage circuit breaker rated for

150 percent of the units normal 24-volt

operating load.

Factory Installed Options

Motors — General

All motors shall be ball bearing type

with resilient base mount and NEMA

frame sizes from 48 to 256T. Windings

are Class “B”, 1800 rpm with service

factors of

1

/2 - 3/4 hp = 1.25 and 1 - 15 hp

= 1 .15.

Single-Speed Open Drip-proof

60 HZ/1800 RPM

Single-Phase (with contactor) —

Optional 115V , 208V and 230V motors

available in

1

/2 - 2 hp models.

Three-Phase (with contactor) —

Optional 208V , 230V and 460V motors

available in

1

/2 - 5 hp models.

Single-Phase (with magnetic starter) —

Optional 115V , 208V and 230V motors

available in

1

/2 - 3 hp models.

Three-Phase (with magnetic starter) —

Optional 208V , 230V, 460V and 575V

motors available in

1

/2 - 1 5 hp models.

Single-Speed TEFC

60HZ/1800 RPM

Single-Phase (with contactor) —

Optional 115V , 208V and 230V motors

available in

1

/2 - 1 1/2 hp models.

Single-Phase (with magnetic starter) —

Optional 115V , 208V and 230V motors

available in

1

/2 - 3 hp models.

Three-Phase (with magnetic starter) —

Optional 208V , 230V, 460V and 575V

motors available in

1

/2 - 1 5 hp models.

Single-Speed High Efficiency ODP

60 HZ/1800 RPM

Single-Phase (with contactor) —

Optional 115V and 230V motors

available in

208V motors available in

1

/2 - 1 hp models. Optional

1

/2 - 3/4 hp

models.

Single-Phase (with magnetic starter) —

Optional 115V and 230V motors

available in

208V motors available in

1

/2 - 2 hp models. Optional

1

/2 - 3/4 hp

models.

Three-Phase (with magnetic starter) —

Optional 208V , 230V and 460V motors

available in

1

/2 -1 5 hp models. Optional

575V motors available in 1 - 15 hp

models.

36

Page 37

Mec hanical

Specifications

Single-Speed High Efficiency TEFC

60 HZ/1800RPM

Single-Phase (with contactor) —

Optional 115V and 230V motors

available in

Single-Phase (with magnetic starter) —

Optional 115V and 230V motors

available in

Three-Phase (with magnetic starter) —

Optional 230V and 460V motors

available in

208V and 575V available in 1 - 15 hp

models.

T wo-Speed/One Winding Motors

(Three-Phase Only)

60 HZ/1800/900 RPM

Three-Phase (with magnetic starter) —

Optional 208V , 230V and 460V motors

available in 1 - 15 hp models.

T wo-Speed/Two Winding Motors

60 HZ/1800/1200 RPM

Single-Phase (with magnetic starter) —

Optional 115V and 230V motors

available in

208V motors available in 3/4 - 1 hp

models.

Three-Phase (with magnetic starter) —

Optional 208V and 230V motors

available in

460V motors available in 1/2 - 3 hp and

1

/2 - 10 hp models. Optional 575V

7

motors available in 7

Manual Blower Switch

Manual blower switch shall be factory

installed in the electrical cabinet.

DX or Chilled Water Cooling Coils

Available on arrangement K and L only.

A direct expansion (DX) or chilled

water coil certified by ARI shall be

provided with the unit.

Damper Options

Dampers shall be of the opposed blade

type, constructed of galvanized steel

with neoprene nylon bushings, blades

to be mechanically interloc ked.

Optional low leak outside air dampers

shall be of the opposed blade type,

construction of galvanized steel with

neoprene nylon bushings and vinyl

blade edge seals, blades to be

mechanically interloc ked.

1

/2 - 1 1/2 hp models.

1

/2 - 2 hp models.

1

/2 - 1 5 hp models. Optional

1

/2 - 1 hp models. Optional

1

/2 - 1 5 hp models. Optional

1

/2 - 10 hp models.

Outside Air or Return Air/ T wo- P osition

Motor/ Spring Return

Units with outside air or return air only

shall be provided with damper, twoposition spring return damper motor

and controls. The motor shall power the

damper full open when the unit is on

and full closed when the unit is off.

OA/RA T wo-P osition Spring R eturn

T wo-position spring return motor with

interlocked outside and return air

dampers shall be provided. The motor

shall power either the outside air

damper full open and the return air

damper full closed or the outside air

damper full closed and the return air

damper full open in response to an

outside air temperature sensor.

(Includes an outside air thermostat that

makes on a rise in temperature and

drives the damper open.) When the

unit is off, the motor will drive the

outside air damper full closed and the

return air damper full open.

OA/RA Mod Motor with Mixed Air

Control/Min. Pot/Spring Return

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller located in the mixed air

stream. Units shall also be provided

with a minimum position

potentiometer for minimum outside air

damper position.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is off.

OA/RA Mod Motor with Mixed Air

Control/Spring Return

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller located in the mixed air

stream.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is off.

OA/RA Mod Motor with Min P ot/

Spring Return

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall position the

outside and return air dampers in

response to a manually set

potentiometer.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is off.

OA/RA Mod Motor with Dry Bulb/

Mixed Air Control/Min Pot/

Spring Return

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller and dry bulb thermostat

located in the mixed airstream. Units

shall also be provided with a minimum

position potentiometer for minimum

outside air damper position.

The spring return feature drives the

outside air damper full open and the

return air damper full closed when the

unit is off.

OA/RA Mod Motor with Enthalpy

Controlled Economizer/Spring Return

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to an enthalpy controlled

economizer . When the unit is off, the

motor will drive the outside air damper

full closed and the return air damper

full open.

OA/RA Mod Motor with Space

Pressure Controller

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to a pressure sensor located

in the building.

37

Page 38

Mec hanical

Specifications

OA/RA Mod Mtr with S-350P

Proportional Mixed Air Control/

Spring Return

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to a solid-state mixed air

sensor and S-350 Proportional

controller. When the unit is off, the

motor will drive the outside air damper

full closed and the return air damper

full open.

OA/RA Mtr . with External 4-20 mA or 010 VDC Analog Input/Spring Return

Modulating motor interlocked with

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a 4-10 mA or 010 VDC signal supplied by an external

DDC controller.

The spring return feature drives the

outside air damper full closed and the

return air damper full open when the

unit is shut down.

ASHRAE Cycle I (OA/RA Two- Position

with Warm-up Stat/SR)

T wo-position spring return motor with

interlocked outside and return air

dampers shall be provided. The motor

shall power the outside air damper full

open after a warm-up period

determined by a minimum supply air

temperature sensor when the unit is

on, and full closed when the unit is off.

ASHRAE Cycle II OA/RA Mod with

Warm-up Stat/Mixed Air/Min P ot/

Spring Return

Modulating motor with interlocked

outside and return air dampers shall be

provided. The motor shall modulate the

position of the outside and return air

dampers in response to a thermostatic

controller located in the mixed air

stream after a warm-up period

determined by a minimum supply air

temperature sensor. Units shall also be

provided with a minimum position

potentiometer for minimum outside air

damper position. When the unit is of f ,

the motor will drive the outside air

damper full closed and the return air

damper full open.

ASHRAE Cycle III O A/RA Mod. with

Warm-up Stat/Mixed Air/SR

Modulating motor with spring return

and interlocked outside and return air

dampers shall be provided. The motor

shall modulate the position of the

outside and return air dampers in

response to a thermostatic controller

located in the mixed airstream after a

warm-up period determined by a

minimum supply air temperature

sensor. When the unit is off, the motor

will drive the outside air damper full

closed and the return air damper full

open.

Manual Dampers

Units with outside air and return air

shall be provided with manually set

outside and return air dampers.

Additional Factory Installed Options

Firestat

If temperature reaches the setpoint, the

dampers will return to their normal

position and shut down the blower.

Manual reset.

Return Air Mounted (setpoint typically

130 F)

Supply Air Mounted (setpoint typically

150 F)

Freezestat

Unit shall be provided with a freezestat

(0-100 F) with the sensing bulb located

in the discharge airstream. Wired as an

interlock to prevent cold air disc harge.

12-inc h Evaporative Media

12-inc h media shall be provided for the

evaporative cooler.

Double Wall Construction

The construction will consist of a 24gauge inner liner wall with 1 -inc h 1½

lb. density insulation. Access doors on

the specified side will be hinged and of

the same double wall design. Double

wall is not available on the applicable

evaporative cooler and furnace

sections. Double wall construction will

be provided by the manufacturer on

applicable filter/damper, blower , coil

and plenum cabinets.

Clogged Filter Switch

A clogged filter pressure switch with

adjustable operating range and

normally open switch shall be installed

to sense increased suction pressure by

the blower due to filter obstruction.

Provision for remote indication shall be

provided by terminal block connection

points. Includes a status lamp mounted

in the electrical cabinet.

Moisture Eliminators

Provided in place of an inlet screen on

the outside air hood. Includes a

pressure switch.

Horizontal Return

Unit shall be supplied with the return

air opening at or under the outside air

opening location depending on the air

inlet configuration.

Continuous Fan Relay — 24V Coil

DPDT 10A

Relay provided with 24-volt coil and

double pole double-throw 10-amp

contacts. Plugs into the main

connection PC board in the electrical

cabinet. Included as standard on

Arrangement D and E. May also be

utilized as an exhaust fan interlock.

Interlock Relay — 24/115V Coil SPDT

10A

Relay has a selectable coil voltage of 24

or 115 volts and single-pole double

throw 10-amp contacts with LED on

indicator lamp. Relay is utilized as an

auxiliary relay.

Interlock Relay — 24/115-230V Coil

DPDT 10A

Relay has a selectable coil voltage of

24, 115 or 230-volts and double pole

double throw 10-amp contacts. Utilized

as an auxiliary relay for general

purpose duty.

Ambient Lockout

Airflow proving switch

Hinged Service Access Doors

Optional hinged doors are mounted to

the access side of the standard blower/

filter/damper cabinet and high CFM

filter/damper and blower cabinets in

leau of the standard removable access

doors. The hinged doors include dual