Trane Outdoor Gas Heating Units and Duct Furnaces Catalogue

MUA-DS-5

MUA-DS-5

January 1998

Second Printing

Outdoor Gas

Heating Units and

Duct Furnaces

Packaged Rooftop Unit for

Heating, Cooling, Ventilating

and Make-Up Air Applications

Features and Benefits

The Trane rooftop line is a packaged air

heating and cooling system, suitable

for heating, cooling, ventilating

and make- up air applications. Unit

sizes range from 800 to 14,000 cfm

(0.4-6.6 cu. m/s) with

capabilities. These rooftops are

available with inputs from 100,000

to 1,200,000 Btu/h (29.3 to 351.4 kW).

Duct furnaces are AGA and CGA

certified for safety and performance

with a range of 100,000 Btu/h input to

400,000 Btu/h (29.3 to 117.1 kW) input

per duct furnace. Packaged units are

also ETL and CSA certified for electrical

safety in compliance with UL-1995

Standard for HVAC equipment. The

rooftop units can be ordered as

individual duct furnaces only, heating

with evaporative cooling or packaged

heating and cooling systems.

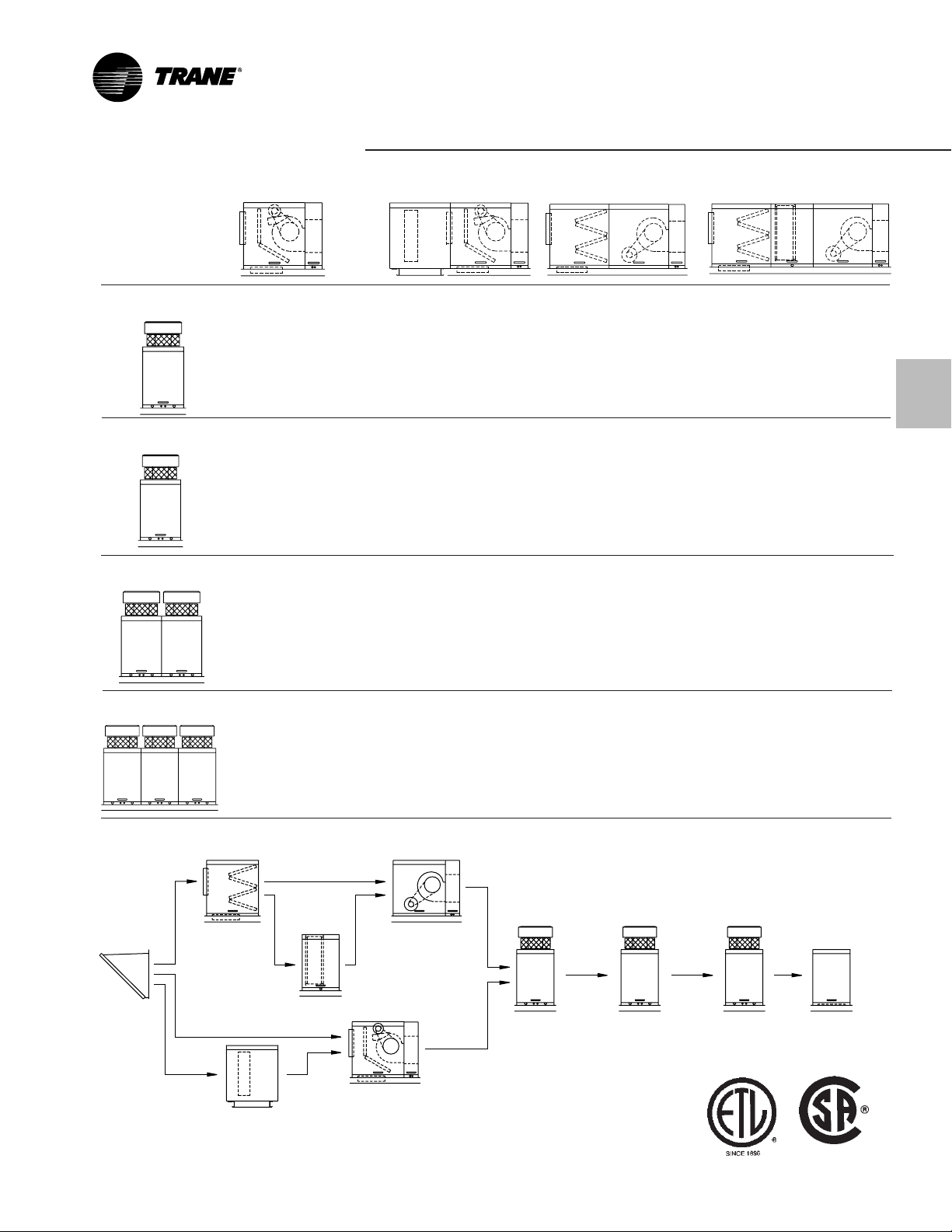

The mechanical configuration is

determined by selecting one of the nine

standard arrangements. Rooftop

arrangements are divided into two

classifications standard and high cfm

blower types.

The standard blower unit consists of a

blower cabinet that houses the

dampers, filters and blower in one

cabinet. An optional evaporative

cooling unit is available on units up to

800 MBh (234.3 kW). Trane

recommends the use of 409 stainless

steel whenever an evaporative cooling

unit is installed upstream of a duct

furnace section(s).

The high cfm blower unit utilizes a

separate damper/filter cabinet with a

V bank filter arrangement, a blower

cabinet and up to three duct furnaces

(1200 MBh) (351.4 kW). An optional

cooling coil cabinet is offered on units

up to 800 MBh. Trane recommends the

use of 409 stainless steel whenever a

cooling coil is used upstream of a

furnace section(s). Both standard and

high cfm blower arrangements may

also include a downturn supply air

plenum, outside air and/or return air,

intake hood and a roof curb.

All units are completely packaged, railmounted, wired, piped, waterproofed

and test fired to assure a smooth

installation and easy start-up.

1

/2-15 hp motor

Btu/h

Furnace types are divided into two

classifications standard temperature

rise and high temperature rise with

natural and power vented models. All

furnaces have optional left or right

hand access. Standard temperature

rise units have a lower pressure drop

across the heat exchanger allowing

higher airflow capabilities and an 80

percent efficiency rating with a

temperature rise of 20 to 60 F (11 to

33 C). High temperature rise units are

configured for higher temperature rise,

and have a higher pressure drop

across the furnace section of the unit

and a 79 percent efficiency rating with

a temperature rise of 60 to 90 F (33 to

50 C). The high temperature rise type

furnace is not available in California

and only available in a single furnace

package. The maximum discharge air

temperature for all duct furnaces is

150 F (66 C).

In addition to a versatile offering of

mechanical features, this new rooftop

unit also offers a wide variety of factory

installed control options. Control

components are located in the main

electrical cabinet. The main electrical

cabinet is located out of the air stream

as part of the blower transition,

between the blower cabinet and the

first furnace for both standard and high

cfm units. The standard electrical

control scheme consists of a solid-state

fan time delay, two pre-wired relay

sockets which are mounted on the

units main connection board, a solidstate gas ignition system and room or

duct thermostats. The units are also

equipped with a blower door safety

interlock, a 24 VAC circuit breaker, a

high temperature limit switch in each

furnace section and a reverse airflow

switch located in the blower cabinet as

standard equipment.

Gas control options range from single

stage to six stages of fire, mechanical

or electronic modulation and direct

digital control (DDC) interface. Air

control options offer a similar range of

control features from manual dampers

to modulating dampers that may

include mixed air, dry bulb, pressure

sensing, enthalpy control, DDC

interface or ASHRAE cycle control

arrangements.

The venting is an integral part of the

furnace and must not be altered in the

field. The rooftop furnaces are

equipped with a vent cap which is

designed for gravity venting. Air for

combustion enters at the base of the

vent through a protective grill, and the

design of the vent cap is such that the

products of combustion are discharged

at the upper section of the cap. This cap

is shipped in a separate carton. It

should be fastened in position and not

be altered in any way.

Gravity Venting

©American Standard Inc. 1998

Power Venting

2

Contents

The proximity of the combustion air

inlet to products of combustion

discharge is designed to provide

trouble-free operation under all types of

wind conditions.

The power vented unit has a system

with the inlet and discharge grill located

in the upper section of a split-side

panel. This balanced flue design also

performs well under virtually all wind

conditions.

Features and Benefits

AGA and CGA Certified Duct Furnaces

ETL and CSA UL-1995 Certified

Packaged Units

FM (Factory Mutual) Compliant

Heating Capacities from 100 MBh to

1200 MBh (29.3 kW to 351.4 kW)

Gravity and Power Vented Furnaces

80% Efficient Standard Temperature

Rise Furnace - 20 to 60 F (11 to 33 C) per

Furnace

79% Efficient High Temperature Rise

Furnace - 60 to 90 F (33 to 50 C) - single

furnace only

CFM ranges from 800 to 14,000 CFM

(0.4 to 6.6 Cu.m/s)

Motor sizes up to 15 horsepower

ODP motors with high efficiency, totally

enclosed and two-speed options

Left hand or right hand service access

Draw-thru coil cabinet with stainless

steel drain pan

Evaporative cooling with standard 8 or

optional 12 media (203 or 305 mm)

Uninsulated or insulated roof curb

Standard 18-gauge cabinets

Standard 20-gauge aluminized steel

heat exchanger. Optional stainless

steel.

Standard one-inch washable filters

Standard single stage combination gas

valve

Standard high temperature limit (each

furnace)

Standard blower door safety interlock

switch

Standard reverse airflow safety switch

Standard 24-volt circuit breaker

Standard printed circuit main

connection board

Wiring harnesses with stamped wire

numbers

Solid-state automatic pilot ignition

control

Solid-state fan time delay

Over 40 standard gas and air control

packages

Features and Benefits 2

Unit Configurations 4

Model Number Description 7

General Data 9

Application Considerations 11

Selection Procedure 20

Performance Adjustment Factors

26

Performance Data 26

Electrical Data 42

Controls 43

Dimensional Data 46

Weights 100

Options 102

Features Summary 105

Mechanical Specifications 106

3

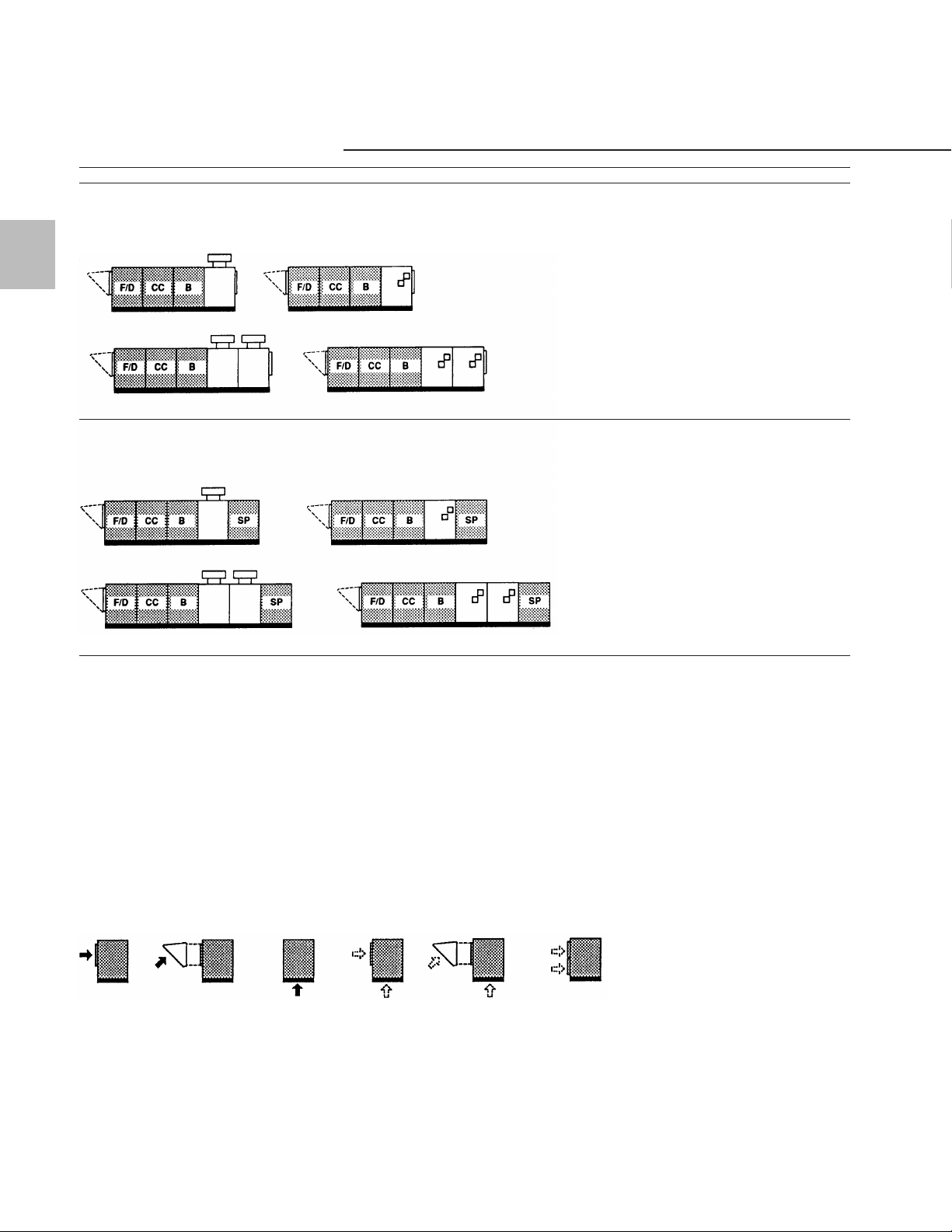

Unit

Configurations

Unit Type Standard Features

Arrangement A - Natural or LP (Propane Gas)

Rooftop Duct Furnace - Single Stage 24-Volt Gas Valve

Arrangement B Same as Arrangement A with:

Rooftop Heating Unit With Standard Blower - Insulated Blower/Filter/Damper Cabinet

- Intermittent Pilot Ignition

- Orificed for Operation Up To 2000' Above Sea Level

- Aluminized Steel Heat Exchanger

- Flue Vent Cap (Gravity Vent Only)

- 24-Volt High Temperature Safety Circuit

- Terminal Block Wiring, Single Point Connection

- Quick Opening Access Doors

- 1 Permanent Filters

- Fan Time Delay Relay

- Electrical Cabinet Isolated from the Air Stream

- 24-Volt Control Circuitry

- Low Voltage Circuit Breaker

- Blower Door Interlock Switch with Service Override

Arrangement C Same as Arrangement B with:

Rooftop Heating Unit with Standard Blower - Insulated Supply Plenum

and Downflow Supply Plenum

See page 6 for Legend.

4

Unit

Configurations

Unit Type Standard Features

Arrangement D Same as Arrangement B with:

Rooftop Heating Unit with Standard Blower - Evaporative Cooler

and Evaporative Cooler - High Efficiency 8 Media

- Self-Cleaning Design

- Sealed Pump Motor with Float Valve

- 24-Volt Control Circuitry

- Heavy-Duty Stainless Steel Water Tank

- Easy Access Intake Filter and PVC Distribution Tubes

Arrangement E

Rooftop Heating Unit with Standard Blower, Same as Arrangement D with:

Evaporative Cooler and Downflow Supply Plenum - Downflow Supply Plenum

Arrangement G - Natural or LP (Propane Gas)

Rooftop Heating Unit with High Cfm Blower - Single-Stage 24 Volt Gas Valve

- Intermittent Pilot Ignition

- Orificed for Operation up to 2000' above Sea Level

- Aluminized Steel Heat Exchanger

- Flue Vent Cap (Gravity Vent Only)

- 24-Volt High Temperature Safety Circuit

- Terminal Block Wiring, Single Point Connection

- Quick Opening Access Doors

- Permanent Filter

- Fan Time Delay Relay

- Standard V-bank Filter and Damper Cabinet

- Insulated Filter/Damper and Blower Cabinet

Arrangement J Same as Arrangement G with:

Rooftop Heating Unit with High Cfm Blower - Insulated Supply Plenum

and Downflow Supply Plenum

See page 6 for Legend.

5

Unit

Configurations

Unit Type Standard Features

Arrangement K Same as Arrangement G with:

Rooftop Heating Unit with High Cfm Blower - Coil Section

and Coil Cabinet - Mounting for 4 to 6 Row Coils

- Stainless Steel Drain Pan with

Arrangement L Same as Arrangement K with:

Rooftop Heating Unit with High Cfm Blower, - Insulated Supply Plenum

Coil Cabinet and Downflow Supply Plenum

3

/4 Tapped Outlets

Motors, Air Inlet Configuration/Air Control and Damper Arrangement Must Be Selected for Each Unit

Notes:

1. Gravity vent or power vent models available on all unit sizes.

2. Optional air inlet hood shown in dotted lines.

3. Legend is as follows:

B/F/D - Standard Blower/Filter/Damper

SP - Supply Plenum

EV - Evaporative Cooler

F/D - Filter/Damper

B - High cfm Blower

CC - Coil Cabinet

4. Horizontal outside air over return air. Specify air inlet configuration 4 or 5 and then select miscellaneous option D for

horizontal return.

Air Inlet Configurations (Digit 18 of the Model Number)

1 2 3 4 5 See Note 4 Above

6

Model Number Description

G R A A 40 G D C C 0 N 2 B Q 1 0 2 A 0 +

12345,6789101112131415161718192021

Digit 1 Gas Heating Equipment

G = Gas

Digit 2 Unit Type

F = Rooftop Duct Furnace

R = Rooftop Heating Unit

S = Special Unit Type

Digit 3 Furnace Type

A = Standard Temp Rise (20-60 F) LH

B = Standard Temp Rise (20-60 F) RH

C = High Temp Rise (60-90 F) LH

D = High Temp Rise (60-90 F) RH

S = Special Furnace Type

Note: LH = Left Hand

RH = Right Hand

Digit 4 Development Sequence

A = First Generation

Digit 5,6 Input Capacity

Single Furnace

10 = 100 MBh Input

15 = 150 MBh Input

20 = 200 MBh Input

25 = 250 MBh Input

30 = 300 MBh Input

35 = 350 MBh Input

40 = 400 MBh Input

Double Furnace

50 = 500 MBh Input

60 = 600 MBh Input

70 = 700 MBh Input

80 = 800 MBh Input

Triple Furnace

12 = 1200 MBh Input

SS = Special unit

Digit 7 Venting Type

G = Gravity Venting

P = Power Venting

S = Special Venting

Digit 8 Main Power Supply

A = 115/60/1

B = 208/60/1

C = 230/60/1

D = 208/60/3

E = 230/60/3

F = 460/60/3

G = 575/60/3

S = Special Main Power Supply

Digit 9 Gas Control Option (Intermittent

Pilot Ignition)

A = Single-Stage

B = Two-Stage

C = Hydraulic Modulating (60-100)

D = Hydraulic Modulating (75-200)

E = Hydraulic Modulating With Bypass and

limit (60-100)

F = Hydraulic Modulating With Bypass

(75-200)

G = Electronic Modulating With Room

T-Stat

H = Electronic Modulating With Duct T-Stat

J = Electronic Modulating With Duct T-Stat

and Override Room Thermostat

K = Electronic Modulating W/External

4-20 mA Input (Furnace 1)

L = Electronic Modulating W/External

4-20 mA Input (All furnaces)

M = Electronic Modulating W/External

0-10 VDC Input (Furnace 1)

N = Electronic Modulating W/External

0-10 VDC Input (All furnaces)

P = Two-Stage Discharge Air Control w/OA

Reset.

R = Three-Stage Discharge Air Control

w/OA Reset.

T = Four-Stage Discharge Air Control w/OA

reset.

U = S-350 2 Stage Modular Electronic

Control System

W= S-350 3 Stage Modular Electronic

Control System

X = S-350 4 Stage Modular Electronic

Control System

Y = S-350 6 Stage Modular Electronic

Control System

S = Special Gas Control

Digit 10, 11 Design Sequence

DO = Design Sequence

Digit 12 Fuel Type

N = Natural Gas

P = LP (Propane) Gas

L = Natural Gas with 100% Lockout

S = Special Fuel type

Digit 13 Heat Exchanger Material

1 = Aluminized Steel

2 = #409 Stainless Steel (First Furnace Only)

3 = #409 Stainless Steel (All Furnace

Sections)

4 = #321 Stainless Steel (First Furnace Only)

5 = #321 Stainless Steel (All Furnace

Sections)

6 = #409 Stainless Steel Package

(First Furnace Only)

7 = #409 Stainless Steel Package

(All Furnace Sections)

8 = #321 Stainless Steel Package

(First Furnace Only)

9 = #321 Stainless Steel Package

(All Furnace Sections)

S= Special Heat Exchanger Package

Digit 14 Rooftop Arrangements

A = Duct Furnace

B = Blower (Standard)

C = Blower (Standard) Plenum

D = Blower (Standard) Evaporative Cooler

E = Blower (Standard) Evaporative Cooler/

Plenum

G = Blower (High CFM) /Plenum

J = Blower (High CFM) /Plenum

K = Blower (High CFM) /Coil Cabinet

L = Blower (High CFM) /Coil Cabinet/

Plenum

S = Special Rooftop Arrangement

Digit 15 Rooftop Heating Unit Motor

Selection

0 = None (Rooftop duct furnace)

A=1/2 HP w/contactor

B=3/4 HP w/contactor

C = 1 HP w/contactor

D=1 1/2 HP w/contactor

E = 2 HP w/contactor

F = 3 HP w/contactor

G = 5 HP w/contactor

H=1/2 HP w/magnetic starter

J=3/4 HP w/magnetic starter

K = 1 HP w/magnetic starter

L=1 1/2 HP w/magnetic starter

N = 2 HP w/magnetic starter

P = 3 HP w/magnetic starter

Q = 5 HP w/magnetic starter

R=7 1/2 HP w/magnetic starter

T = 10 HP w/magnetic starter

U = 15 HP w/magnetic starter

S = Special Motor

Digit 16 Motor Speed

0 = No Selection

1 = Single Speed ODP 1800 RPM

2 = Single Speed TEFC 1800 RPM

3 = Single Speed High Efficiency ODP

1800 RPM

4 = Single Speed High Efficiency

TEFC 1800 RPM

5 = 2S1W ODP 1800/900 RPM

6 = 2S2W ODP 1800/1200 RPM

S = Special Motor Speed & Starter

Digit 17 Coil Options

0 = No cooling coil selection

A = DX coil, 4 Row, Single Circuit

B = DX coil, 4 Row, Dual Circuit

C = DX coil, 6 Row, Single Circuit

D = DX coil, 6 Row, Dual Circuit

E = Chilled Water Coil, 4 Row,

G = Chilled Water Coil, 6 Row,

S = Special coil

7

Model

Number

Description

Digit 18 Air Inlet Configuration

0 = None (Rooftop Duct Furnace)

1 = Outside Air (OA) (Horizontal Inlet)

2 = Outside Air W/Air Hood (Horizontal

Inlet

3 = Bottom Return Air (RA)

4 = Outside And Return Air (OA/RA)

5 = Outside and Return Air W/Air Hood

S= Special Air inlet configuration

Digit 19 Air Control and Damper

Arrangement

0 = None (Rooftop Duct Furnace)

A = Outside Air 2 pos. Motor/SR

B = Return Air 2 pos. Motor/SR

C = OA/RA 2 pos SR

E = OA/RA Mod Mtr W/Mixed Air Control/

Min Pot/SR

H = OA/RA Mod Mtr W/Mixed Air Control/

SR

K = OA/RA Mod Mtr W/Min Pot/SR

M = OA/RA Mod Mtr W/Dry Bulb/Mixed Air

Control/Min Pot/SR

N = OA/RA Mod Mtr W/ Enthalpy

Controlled Economizer/SR

P = OA/RA Mod Mtr W/ Space Pressure

Controller

R = OA/RA Mod Mtr W/ S-350 P

Proportional Mixed Air Control/SR

U = OA/RA Mtr. W/External 0-10 VDC and

4-20 mA Analog Input/SR (External

Input)

W= ASHRAE Cycle I (OA/RA 2 pos. w/

warm-up stat/SR

X = ASHRAE Cycle II (OA/RA Mod

W/Warm-up Stat/Mixed Air/min pot/SR

Y = ASHRAE Cycle III (OA/RA Mod.

W/Warm-up Stat/Mixed Air/SR

Z = Manual Dampers

S = Special Air Control and Damper

Arrangement

Digit 20

0 = Non-California Shipment

1 = California Shipment

Digit 21 Miscellaneous Options

A = Orifices For Elevation Above 2000 Feet

(Specify Elevation)

B = 12 Evaporative Media

C = Moisture Eliminators

D = Horizontal Return

E = Continuous Fan Relay

F = Freezestat

G = Fan Time Delay Control

(Duct Furnace Only)

H = Return Air Firestat

J = Supply Air Firestat

K = Manual Blower Switch

L = 409 Stainless Steel Furnace Drip Pan

N = Foil Face Insulation

P = Low Leak Dampers

Q = Clogged Filter Switch

R = High/Low Gas Pressure Limit Switches

T = Status Indicator Lamps (Elec Cabinet)

V = Manual Reset High LImit Switch

W= Interlock Relay 24/115V Coil

SPDT 10A

X = Interlock Relay 24/115-230V Coil

DPDT 10A

Y = Ambient Lockout

8

General Data

*The maximum CFM for

Rooftop Arrangements

K and L is 6,300

3

(3.0 m

/S). A two-speed

motor may be utilized

for non-cooling airflow

up to 14,000 CFM

3

(6.6 m

/S).

Furnace Type A,B Capacity 10-40 Capacity 10-40 Capacity 20-40 Capacity 10-40

∆T20 - 60F 10 - 1,200-3,500 CFM,

Rooftop Arrangements B,C Rooftop Arrangements D,E Rooftop Arrangements G, J Rooftop Arrangements K,L*

1

/2 - 5 HP 10 -1,200-3,500 CFM, 1/2 - 5 HP 20 -2,500-7,400 CFM, 3/4 - 10 HP 10 -1,200-3,000 CFM, 1/2 - 5 HP

15 - 2,000-4,500 CFM,

20 - 2,500-5,500 CFM,

25 - 3,000-5,500 CFM,

30 - 3,700-7,000 CFM,

35 - 4,500-8,500 CFM,

1

/2 - 5 HP 15 - 2,000-4,500 CFM, 1/2 - 5 HP 25 - 3,100-7,500 CFM, 3/4 - 10 HP 15 - 2,000-3,000 CFM, 1/2 - 5 HP

1

/2 - 5 HP 20 - 2,500-5,500 CFM, 1/2 - 5 HP 30 - 3,700-11,00 CFM, 1/2 - 15 HP 20 - 2,500-4,400 CFM, 3/4 - 10 HP

3

/4 - 5 HP 25 - 3,000-5,500 CFM, 3/4 - 5 HP 35 - 4,500-13,000 CFM, 3/4 - 15 HP 25 - 3,100-4,400 CFM, 3/4 - 10 HP

3

/4 - 5 HP 30 - 3,700-7,000 CFM, 3/4 - 5 HP 40 - 5,000-14,000 CFM, 1 - 15 HP 30 - 3,700-5,700 CFM, 1/2 - 15 HP

3

/4 - 5 HP 35 - 4,500-8,500 CFM, 3/4 - 5 HP 35 - 4,500-5,700 CFM, 3/4 - 15 HP

40 - 5,000-8,500 CFM, 1 - 5 HP 40 - 5,000-8,500 CFM, 1 - 5 HP 40 - 5,000-6,300 CFM, 1 - 15 HP

ESP .1 - 2 in. WC ESP .1 - 2 in. WC ESP .1 - 2 in. WC ESP .1 - 2 in. WC

Standard Blower Standard Blower w/Evap. High CFM Blower High CFM Blower w/Cooling

Furnace Type C,D Capacity 10-40 Capacity 10-40 NA Capacity 20-40

∆T60 - 90F 10 - 800-1,200 CFM,

15 - 12,000-1,800 CFM,

20 - 1,600-2,400 CFM,

25 - 2,000-3,000 CFM,

30 - 2,400-3,600 CFM,

35 - 2,800-4,200 CFM,

40 - 3,200-4,800 CFM,

1

/2 - 1 1/2 HP 10 - 800-1,200 CFM, 1/2 - 1 1/2 HP 20 - 1,600-2,400 CFM, 1/2 - 2 HP

1

/2 - 2 HP 15 - 12,000-1,800 CFM, 1/2 - 2 HP 25 - 2,000-3,000 CFM, 1/2 - 2 HP

1

/2 - 2 HP 20 - 1,600-2,400 CFM, 1/2 - 2 HP 30 - 2,400-3,600 CFM, 1/2 - 5 HP

1

/2 - 3 HP 25 - 2,000-3,000 CFM, 1/2 - 3 HP 35 - 3,000-4,200 CFM, 1/2 - 5 HP

1

/2 - 5 HP 30 - 2,400-3,600 CFM, 1/2 - 5 HP 40 - 3,300-5,000 CFM, 1/2 - 5 HP

1

/2 - 5 HP 35 - 2,800-4,200 CFM, 1/2 - 5 HP

1

/2 - 5 HP 40 - 3,200-4,800 CFM, 1/2 - 5 HP

ESP .1 - 2 in. WC ESP .1 - 2 in. WC ESP .1 - 2 in. WC

Furnace Type A,B Capacity 50-80 Capacity 50-80 Capacity 50-80 Capacity 50-80

∆T40 - 120F 50 - 3,000-3,500 CFM, 1 - 5 HP 50 - 3,000-3,500 CFM, 1 - 5 HP 50 - 3,100-7,500 CFM, 1 - 10 HP 50 - 3,000-4,400 CFM, 1 - 10 HP

60 - 3,700-6,500 CFM, 1 - 5 HP 60 - 3,700-6,500 CFM, 1 - 5 HP 60 - 3,700-11,000 CFM,

70 - 4,500-8,000 CFM, 1 - 5 HP 70 - 4,500-8,000 CFM, 1 - 5 HP 70 - 4,500-13,000 CFM, 1 - 15 HP 70 - 4,500-5,700 CFM, 1 - 15 HP

3

/4 - 15 HP 60 - 3,700-5,700 CFM, 3/4 - 15 HP

80 - 5,000-8,000 CFM, 1 - 5 HP 80 - 5,000-8,000 CFM, 1 - 5 HP 80 - 5,000-13,500 CFM, 1 - 15 HP 80 - 5,000-6,300 CFM, 1 - 15 HP

ESP .1 - 2 in. WC ESP .1 - 2 in. WC ESP .1 - 2 in. WC ESP .1 - 2 in. WC

Furnace Type A,B NA NA Capacity 12 NA

∆T60 - 180F 12 - 5,500-13,000 CFM, 1

1

/2 - 15 HP

ESP .1 - 2 in. WC

These minimum and maximum CFMs shown are for Arrangements K and L in the cooling mode. See Performance Data for heating mode specifications.

Intake Hood

Damper/Filters

(High CFM)

Evaporative Cooler

(Standard)

Coil Cabinet

(High CFM)

Dampers/Filters/Blower/Main

Blower/Main Electrical

(High CFM) 0-15 HP

Electrical

(Standard) 0-5 HP

Furnace One

Furnace Two

Furnace Type A-B

Arrangement B-E

Arrangement G-L

Furnace Three

Furnace Type A-B

Arrangement G-J Only

Supply Plenum

9

General

Data

Table G-1 Filter Data

Rooftop Unit Size

Arrangement 10,15 20,25,50 30,35,60,70 40,80,12

B-E (4)16 x 20 (4)20 x 20 (4)16 x 20 (6)20 x 20

G-L (8)16 x 20 (8)20 x 20 (8)16 x 20 (12)20 x 20

Table G-2 Metric Conversion Table

Unless otherwise specified, the following conversions may be used for calculating SI unit measurements:

1 cubic foot= 0.028 m

1 foot = 0.0305 m 1 gallon = 3.785 L

1 inch = 25.4 mm 1,000 Btu/Cu. Ft. = 37.5 MJ/m3

1 psig = 6.894 kPa 1 liter/second = CFM x 0.472

1 pound = 0.453 kg 1 meter/second = FPM ÷ 196.8

1,000 Btu per hour = 0.293 kW

3

1 inch water column = 0.029 kPa

(2)20 x 20

(4)20 x 20

10

Application Considerations

General

Outdoor duct furnaces are designed for

use in ducted applications with a

separate air handling device such as a

horizontal blower assembly. By utilizing

a separate air source, greater

application flexibility in airflow delivery

can be obtained. Multiple duct furnaces

can be used with an air handling unit to

provide zone heating.

To Zone

DUCT

No. 1

FURN

Air

Handling

Unit

DUCT

FURN

DUCT

FURN

To Zone

No. 2

To Zone

No. 3

Note: When installing duct furnaces in

parallel or in series, minimum

clearance requirements must be

considered. This clearance is required

for serviceability. Duct furnaces are

approved for blow-thru applications

only. Right-hand burner drawers are

available for parallel applications.

Contact your local Trane representative

for more information.

When used in conjunction with filters,

cooling coils and an air handler, the

duct furnace can become part of a builtup heating and cooling system.

Filter

Fan

Supply

Duct

Furnace

Cooling

Coil

Outdoor heating units are designed for

make-up air or space heating

applications. These weatherproofed

units are intended for roof or slab

mounting, saving indoor space and

offering easy access for service and

maintenance. The units are typically

used in ducted applications.

Outdoor units cannot be mounted

indoors due to the flue configuration.

Gas Heating Value

The majority of gas heating units are

installed in applications where natural

gas is readily available. In areas where

natural gas is not available, Trane units

may be ordered directly from the

factory for use on LP (propane) gas.

Gas heat content varies by fuel type

and location. The standard gross

heating value for natural gas is 1,000

Btuh per cubic foot; for propane it is

2,500 Btuh per cubic foot. Significant

variations from these standard values

should be taken into account in

equipment selections. To account for

variations in the gross heating value of

the fuel, adjust the total heat input

required and select the unit on the

basis of the adjusted load using the

following formula:

Adjusted load = Calculated load x

Standard gross heat value (Btuh/cu ft)

Actual gross heat value (Btuh/cu ft)

Low Temperature Rise

Trane recommends against the set-up

of a unit which will result in a

temperature rise of less than 20 F. With

such low temperature rises, the flue

gases passing through the heat

exchanger are cooled to condensate

before reaching the flue outlet. This

condensate is corrosive and will result

in shortened heat exchanger life.

Air Density

Catalog performance data is based on

elevations up to 2,000 feet (610 m)

above sea level. Above 2,000 feet

(610 m), the units heating capacity

must be derated four percent for each

1,000 feet above sea level and special

orifice selections are required. Table

PAF-1 contains correction factors that

can be applied to the units cataloged

heating capacity, fan rpm, and fan bhp

to obtain actual values for elevations

above 2,000 feet.

Corrosive Atmospheres

Corrosion of heat exchangers and draft

diverters have two basic variables

moisture (condensation) and sulphur.

These two ingredients form to make

sulfuric acid in the combustion

process. Condensation occurs

commonly in make-up air systems,

using large amounts of fresh air, when

air temperatures entering the heat

exchanger drop to 40 F or below. This

reaction can also occur in recirculating

systems where some quantity of

outside air is introduced upstream

of the exchanger. The sulphur will

always be present as an integral

component of the gas. The resulting

concentration of the acid is governed

by the amount of sulphur in the gas.

This concentration varies from gas to

gas and geographically within the

same type of gas.

Beyond sulfuric acid corrosion, there is

the area of chlorinated or halogenated

hydrocarbon vapor corrosion. This

type of corrosion occurs when

substances are mixed with combustion

air that will cause the formation of

hydrochloric or hydrofluoric acid when

burned. These basic substances are

found in degreasers, dry cleaning

solvents, glues, cements, paint

removers and aerosol propellants.

Specific chemicals included in this

group are trichloroethylene,

perchloroethylene, carbon

tetrachloride, methylene chloride,

methyl chloroform and refrigerants 11,

12, 21, 22 and 114.

If sufficient PPM content of these

corrosives is present, none of the

common heat exchanger materials will

hold up. The dilemma becomes

whether to place the gas heating

equipment outside of the area to be

conditioned or use equipment in the

space which does not burn a fuel such

as gas (i.e., electric or hydronic).

Units should not be installed in areas

with corrosive or inflammable

atmospheres. Locations containing

solvents or chlorinated hydrocarbons

will produce corrosive acids when

coming in contact with burner flames.

This reaction will greatly reduce the life

of the heat exchanger and may void

the warranty. For added protection

against heat exchanger corrosion,

optional 409 and 321 stainless steel

construction is available.

On units using outside air, with

entering air temperature below 40 F,

condensation of flue gas in the heat

exchanger is possible. In these cases,

stainless steel heat exchangers are

recommended. An optional 409 or 321

stainless steel heat exchanger is

recommended whenever there is an

evaporative cooler or cooling coil

upstream of the furnace section(s).

11

Careful review of the job application

with respect to use, probable

contaminants within a conditioned

space and the amount of fresh air to be

brought in will help to make the proper

selection of heat exchanger material.

This review will help to eliminate

problems before they begin.

Outdoor gas heating products are used

in either make-up air or space heating

applications (constant volume or

variable air volume). These two basic

applications are discussed in detail

below.

Make-Up Air Applications

Make-up air systems provide outside

air for ventilation requirements and

replace air removed by an exhaust air

system. Typical applications include

kitchens, restaurants, manufacturing

areas, sports centers, garages and

terminals.

Local codes and ordinances frequently

specify ventilation requirements for

public places and industrial

installations. Generally accepted

industry practices are given in the

ASHRAE Handbook of Fundamentals.

Published industrial ventilation codes

are usually based on summer

ventilation conditions of a work

environment and should be reviewed

for winter operation. Exhaust

requirements should also be examined

to establish the year-round make-up

air requirement within limitations of

codes and regulations. Whenever

fresh air will be used and is present at

temperatures below 40 F, 409 stainless

steel heat exchangers are

recommended.

Application

Considerations

18

(457 mm)

Duct Furnace Duct Furnace

AIR FLOW

*Refer to Outdoor Duct Furnace Manual for specific clearances.

18

(457 mm)

Space Heating Applications

Constant Volume

Make-up air units can be used to offset

a portion of the building heat losses in

addition to supplying make-up air. This

is accomplished by heating the makeup air beyond the required space

temperature. The additional heat

supplied above room temperature can

satisfy a portion of the space heating

requirement. The additional capacity

(Btuh) available for heating can be

calculated with the following equation:

Space Heating Capacity =

1.085 x SCFM Make-up Air x

(Max ∆T - (T

room

- T

Outdoor units using 100 percent return

air or a combination of return and

outside air are more efficient in

providing space heat than make-up air

units using 100 percent outside air at a

colder temperature.

O.A.

Blower

Electrical Cabinet

F*

Space Heating Applications

Variable Air Volume

Dual duct VAV systems have one duct

to distribute cold air to those spaces

that need cooling and another to

distribute warm air to those spaces

that need heating. When separate fans

are used to handle the two duct

systems, the ductwork can be arranged

to allow simultaneous use of airside

economizers and plenum heat of

lights. The cooling unit uses return air

or cold outside air in order to save

compressor energy. The heating unit

uses only plenum heated return air.

))

This return air contains the rejected

heat from the lights in the building and

when recovered through the heating

unit, can lower gas heating costs.

In this mode, the dual duct VAV is not

unlike water source heat pumps or

three deck multizone air handlers, but

also has the added savings of variable

air volume.

Result dual duct VAV is an efficient

system capable of using economizers

and heat recovery devices. Occupant

comfort is enhanced because heating

and cooling are always available to the

perimeter zones.

Supply Plenum

18

(457 mm)

12

General System Types

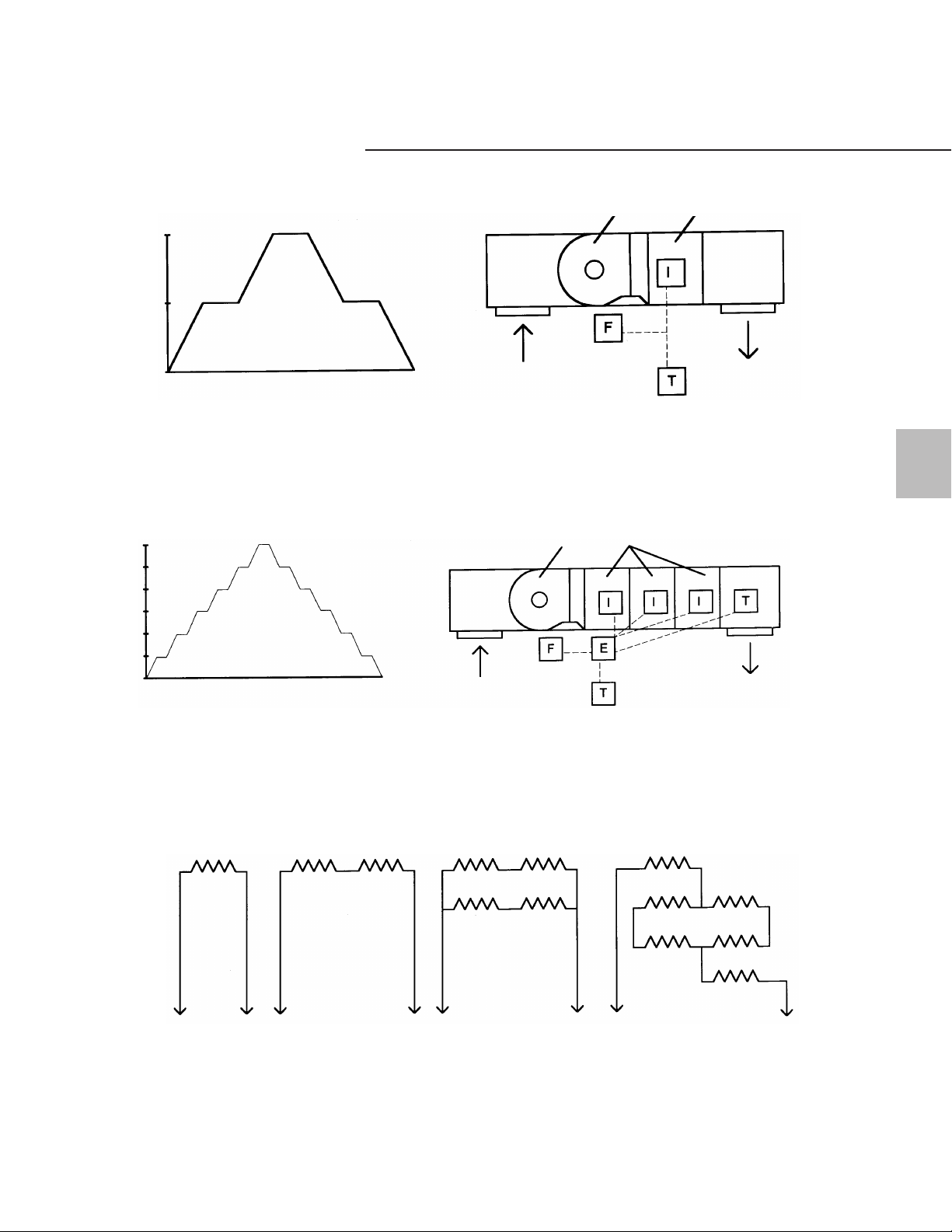

Single-Zone Staged Systems

100%

50%

Application

Considerations

Supply Fan

Gas Fired Furnace

0%

Stages of Fire

Single-zone staged systems can use

multistage thermostats or ductstats for

control of heating and cooling as well

as multi-stage electronic controls.

Systems need to be sized with respect

100%

85%

67%

50%

33%

17%

0%

Stages of Fire

Electronic controls generally provide

more stages of control with a higher

degree of precision in temperature

sensing and actuation of stages. A six-

Return Air

T = Thermostat F = Fan Switch I = Ignition System

to the heated space. Typical staged

single-zone heating is achieved with a

two-stage thermostat, delivering 50

percent of the units rated input at low

fire and 100 percent at high fire. The

thermostat is set to the desired space

Supply Fan

Return Air

T = Temperature Sensor F = Fan Switch

I = Ignition System E = Electronic Control

stage system equipped with an

electronic control system can deliver

16 percent of a units input at stage 1

(low fire), 33 percent at stage 2,

Supply Air

temperature with a differential setting

for high and low fire. A fan time delay

relay provides fan control with a post

warm-up delay period preventing

discomfort in the space.

Gas Fired Furnace

Supply Air

50 percent at stage 3, 66 percent at

stage 4, 84 percent at stage 5 and

100 percent at stage 6 (high fire).

1000 Ohms 500 Ohms 500 Ohms 1000 Ohms 1000 Ohms 333.3 Ohms

To

Controller

Direct

Controller

Large areas may incur hot and cold

spots due to thermostat location, this

can be overcome with electronic

controls by incorporating within the

1000 Ohms 1000 Ohms 333.3 Ohms 333.3 Ohms

To

Series

Controller

Series/Parallel

space a scheme of temperature

averaging, by locating a number of

series or series/paralleled temperature

sensors such as thermisters, rtds or

13

333.3 Ohms

To

To

Controller

Series/Parallel

prtd type sensors, an average

temperature within the space can be

transmitted to the control system.

Application

Considerations

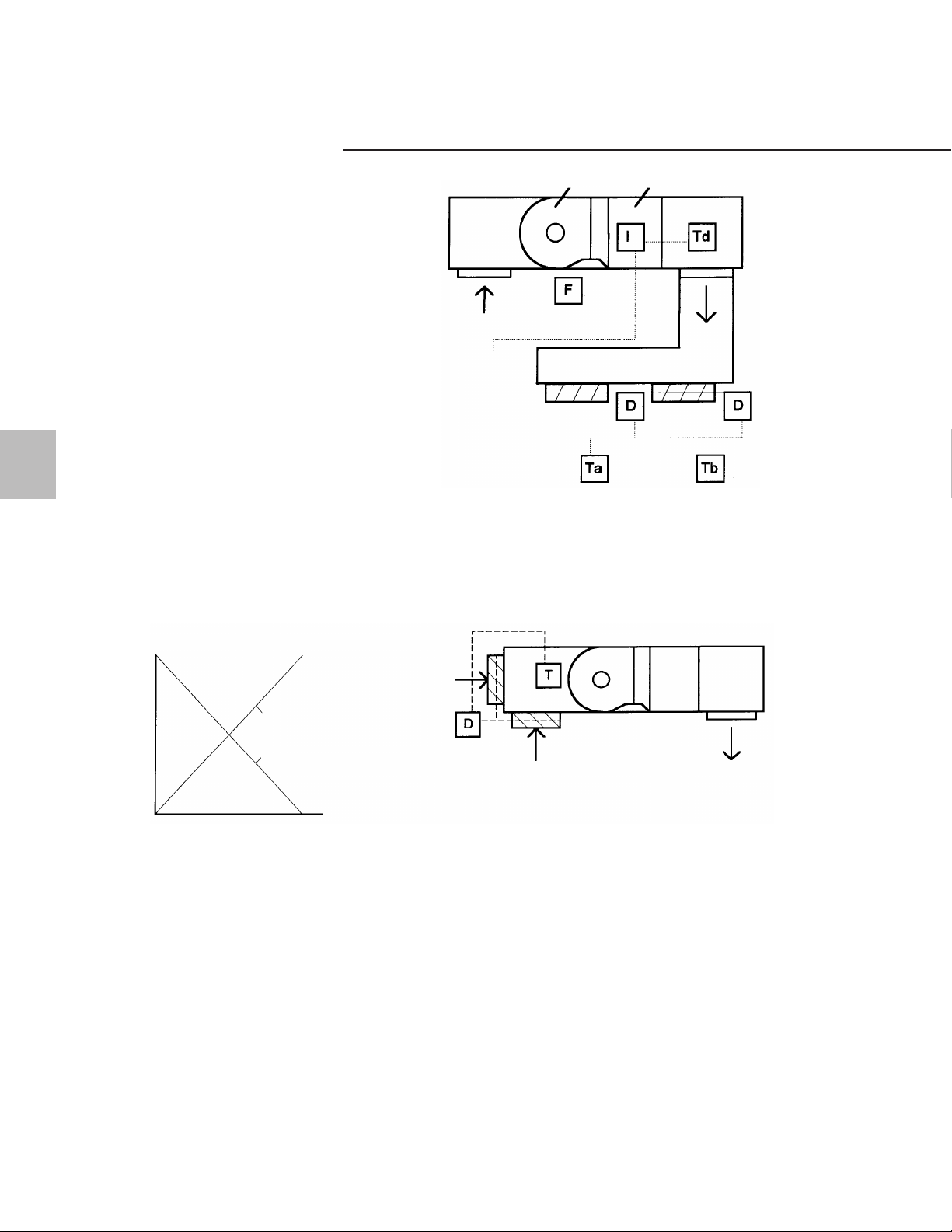

Multizone Staged Systems

Multizone staged systems act on the

same basic principals as a single-zone

staged system where as each stage is

engaged with respect to demand. With

multizone systems a thermostat or

zone sensor is used for each zone. The

system must be sized to maintain

comfort levels for all zones. Zone

dampers are used for efficient

operation of multizone systems. Upon

a call for heat from either zone the

system will fire at low fire, upon a call

from both zones the system will go to

high fire. The zone dampers shall open

and close upon a call for heat from

their respective zone sensors. Typically

a discharge air thermostat or sensor is

used to maintain supply air

temperature in multizone systems.

Return Air

Td = Discharge Air Temperature

Ta/b = Temperature Sensor Zone A/B

F = Fan Switch

I = Ignition System

D = Damper Actuator

Supply Fan

Zone A

Two Zone System

Gas Fired Furnace

Supply Air

Zone B

100%

Damper

Percent

Open

50%

0%

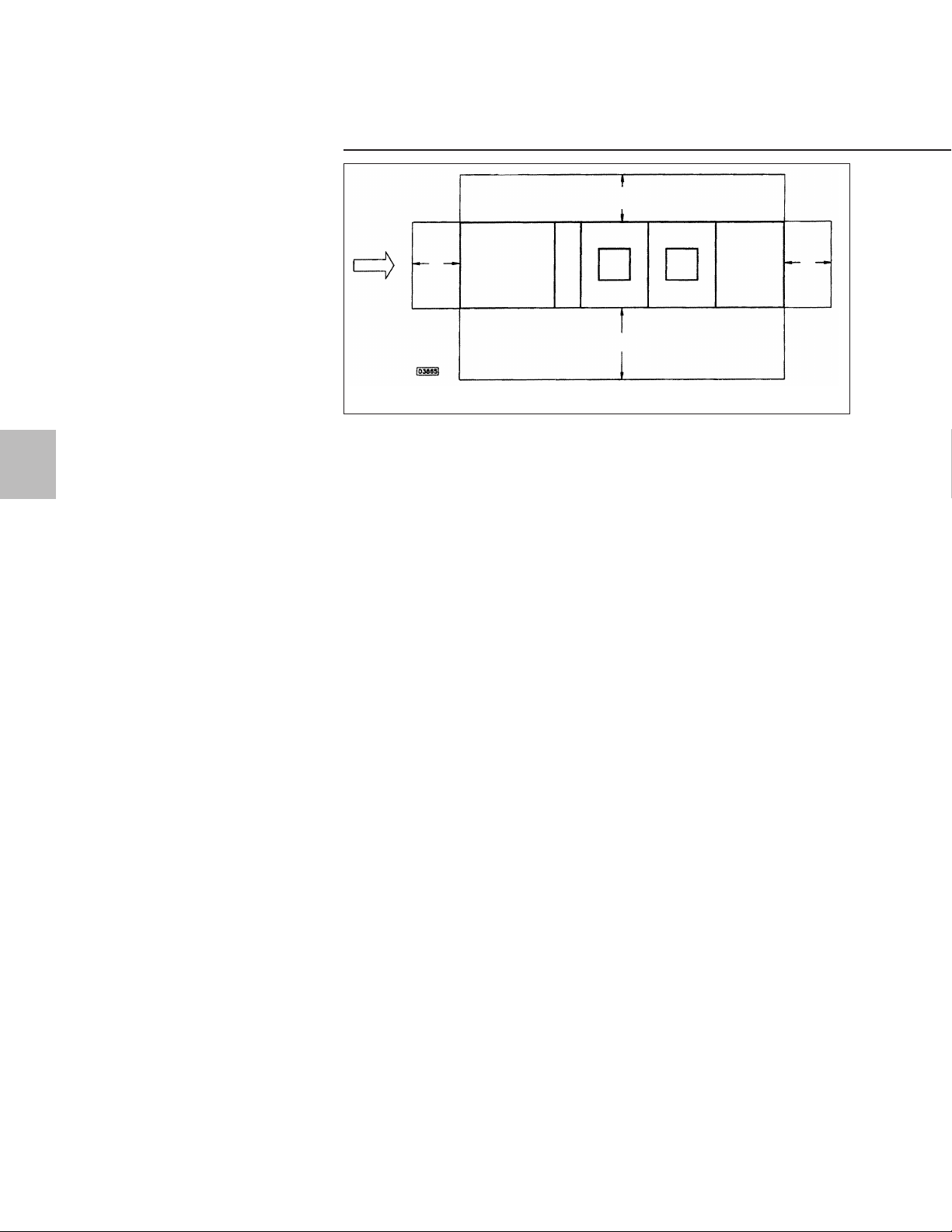

Interlocked Outside and Return Air Dampers

Outside Air Damper

Return Air Damper

Outside and Return Air Damper

Control

Outside and return air damper control

may be included in a staged single or

multizone system. Interlocked outside

and return air dampers with

proportional actuator control, either

electronic or electromechanical can

maintain a minimum outside air setting

and a mixed air setting. Damper

control may also include enthalpy or

pressure control.

Outside Air

T = Temperature Sensor

D = Damper Actuator

Outside and Return Air Damper Arrangement

Return Air

Supply Air

14

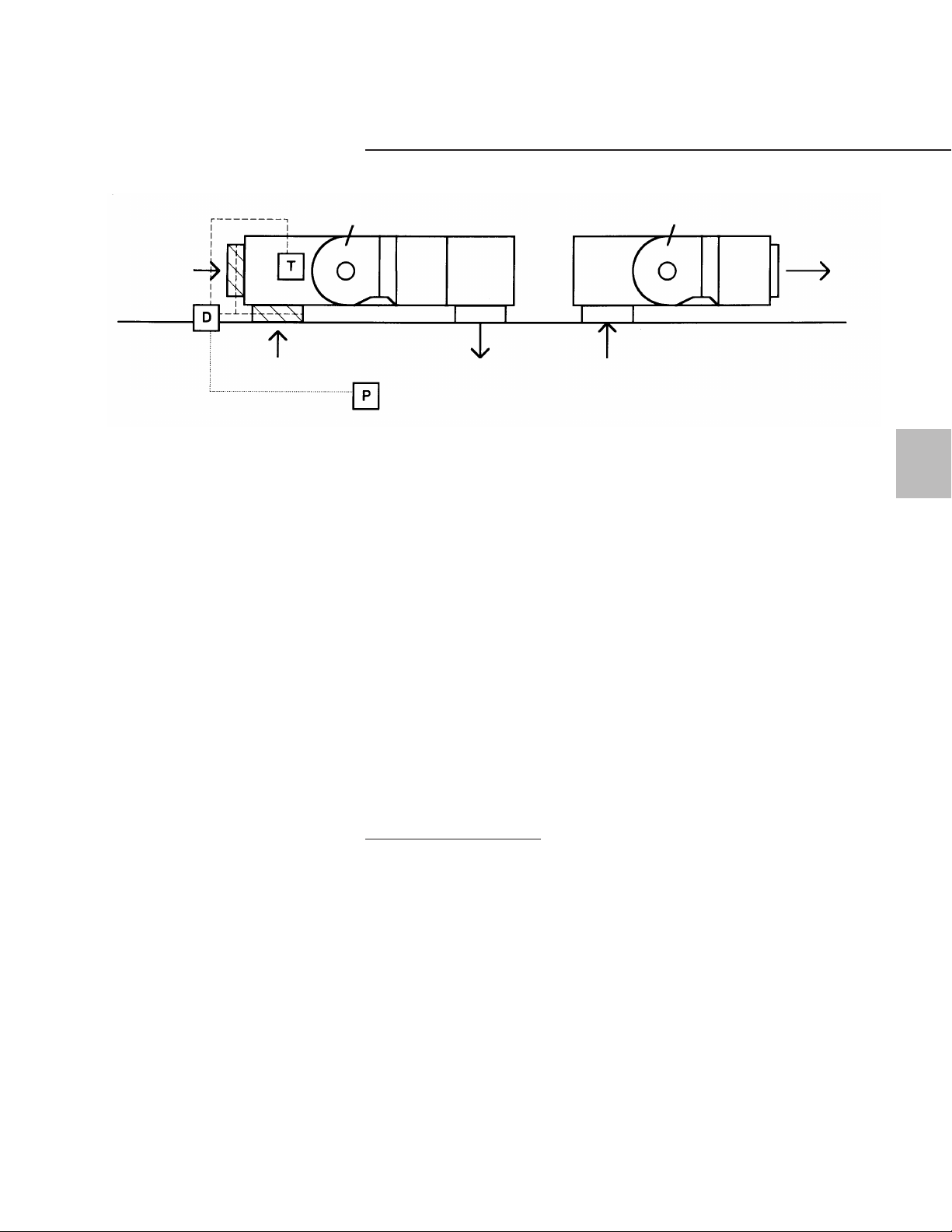

Make-Up Air Systems

Application

Considerations

Outside Air

T = Temperature Sensor

D = Damper Actuator

P = Pressure Sensor

Return Air

Supply Fan

Supply Air

Rooftop Make-Up Air Unit with a

Rooftop Exhaust Unit

Outside air is introduced in order to

replace or make up for exhausted air

due to commercial or industrial

processes that require exhausted air

within a space. The make up air is

heated to a comfortable level relieving

any additional load on the space

heating system. Make-up air systems

may also be configured to supplement

space heating by increasing the

discharge air temperature beyond the

required temperature for the space.

This additional heat above space

temperature can offset a portion of the

buildings heat losses. The additional

heating capacity (Btuh) can be

calculated as:

Space Heating Capacity =

1.085 x SCFM Make-Up Air x

(Max ∆T - (T

ROOM

- T

O.A.

)).

Exhaust Fan

Exhaust Air

Inside Air

Typical applications for make up air

may include restaurants, kitchens,

public arenas, airport and bus

terminals, parking and maintenance

garages, manufacturing and process

areas. Make-up air and exhaust units

may be matched in size and electrically

interlocked with 100 percent outside air

introduced when the exhaust fan is

engaged. The make-up air system may

also incorporate outside and return air

and modulate the mixture based upon

building pressure typically maintaining

a slightly positive pressure within the

space in order to reduce infiltration.

The mixed air arrangement is

generally the more efficient method

due to the tempering of the outside air,

however some applications may

require 100 percent outside air due to

poor return air quality. The use of 409

or 321 stainless steel heat exchangers

is recommended whenever outside air

is used.

15

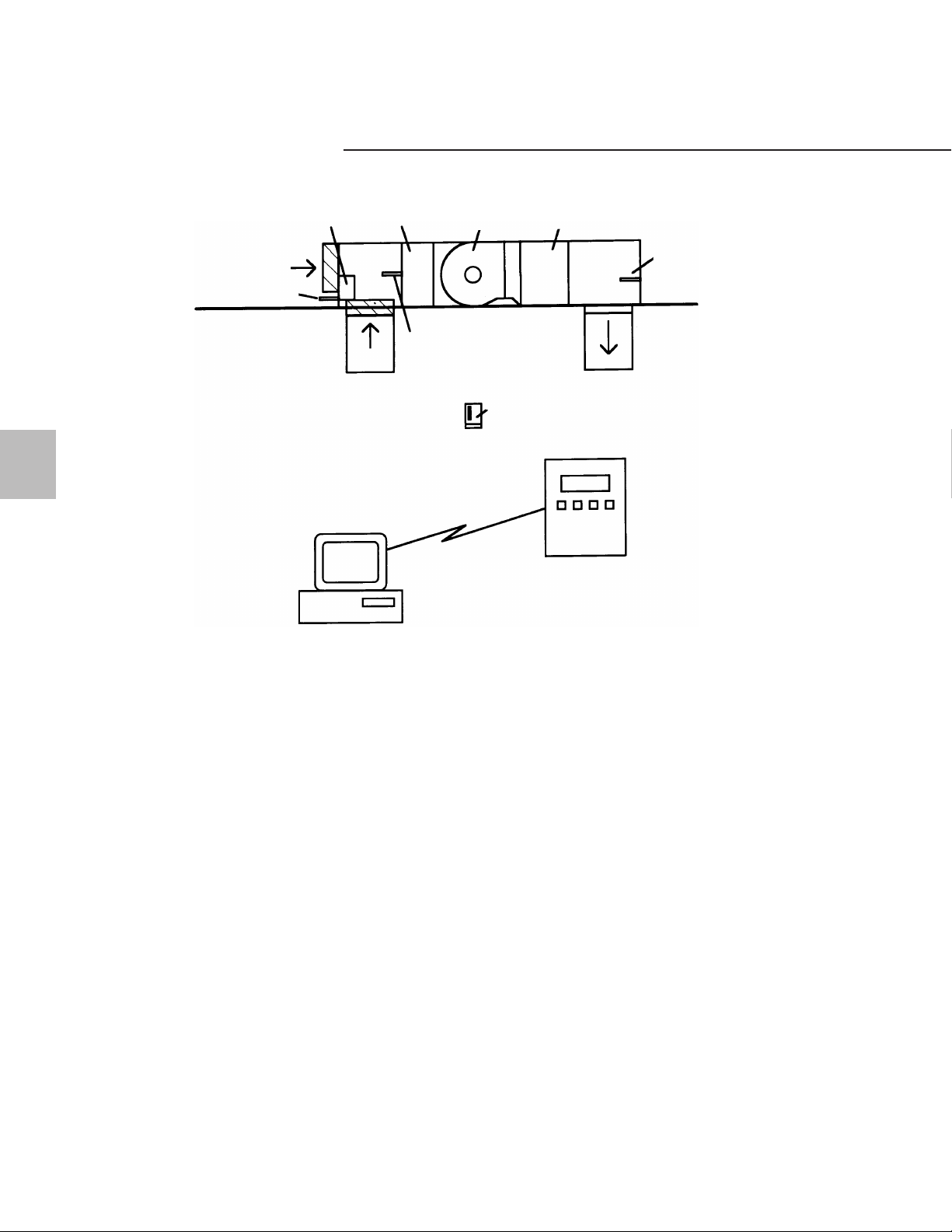

Direct Digital Control (DDC) Systems

Application

Considerations

Outside Air

Sensor

Damper

Actuator

Personal Computer

Cooling

Supply Fan

Mixed Air

Sensor

Communication

Via Modem

Heating

Discharge

Air Sensor

Room Sensor

Digital Control Panel

Basic DDC Control System with Heating/Cooling Rooftop Unit

The basic direct digital control (DDC)

system uses a microprocessor based

controller and software to perform

system and building control functions.

The controller receives input from

sensors mounted within the system.

Based upon input data, the controller

outputs a programmed response to the

systems actuators (gas valves, fan

motors and damper motors). Inputs

may consist of temperature, pressure

or flow and can be analog or digital

signals. Output can also be analog or

digital; analog output signals are

generally 4-20 mA or 0-10 VDC and

digital outputs a relay actuation.

The control may be located in the unit

or in the building. A personal computer

(PC) and software may be provided for

remote communication. Temperature

setpoints, night setback, time limited

cycling, safety interlock input and

system override functions may be

setup at the controller or by PC

interface via modem or direct

connection. The controller may store in

memory a number of previous cycles

of operation with date, time, sensed

temperatures, rate of fire and durationof-cycle information available for down

loading to a PC for report generation

and printout. With digital control,

energy use can be easily optimized for

economical operation while

maintaining comfort levels with a

higher degree of accuracy.

Unit Placement

Refer to the applicable Trane

Installation, Operation and

Maintenance literature for specific

installation instructions. Installations

must conform with local building

codes or, in the absence of local codes,

with the National Fuel Gas Code ANSI

Z223.1.

Outdoor units are designed and

certified for outdoor use only. They

may be located on the roof or at any

convenient location outside the

building to be heated. When locating

units on the roof, make certain that it is

capable of carrying the additional load

of this equipment.

Units are mounted on skids and are

suitable for curb or slab mounting. It is

recommended that the units skids be

mounted either on solid planking or

steel channels, but not on a soft tar roof

where the skids could sink and reduce

the clearance between the bottom of

the unit and the roof.

16

Application

Considerations

Venting

The venting is an integral part of the

furnace and must not be altered in the

field. The rooftop furnaces are

equipped with a vent cap which is

designed for gravity venting. Air for

combustion enters at the base of the

vent through a protective grill, and the

design of the vent cap is such that the

products of combustion are

discharged at the upper section of the

cap. This cap is shipped in a separate

carton. It should be fastened in

position and not be altered in any way.

The proximity of the combustion air

inlet to products of combustion

discharge is designed to provide

trouble-free operation under all types

of wind conditions.

The power vented unit has a system

with the inlet and discharge grill

located in the upper section of a splitside panel. This balanced flue design

also performs well under virtually all

wind conditions.

FM and IRI Requirements

IRI, which stands for Industrial Risk

Insurers, and FM, which stands for

Factory Mutual, are both basically

insurance companies which insure

commercial/industrial firms against a

variety of losses. Both publish

requirements which must be met by

certain equipment operating in the

facilities they are preparing to insure.

Listed below is our interpretation of

the requirements of both insurers

pertaining to heating units only to the

extent of features/controls required by

IRI and/or FM. There are a number of

additional requirements which pertain

to electrical service, details of

installation, etc., and we urge you to

obtain copies of the publications

pertaining to these details if you are

involved in a job where IRI or FM

adherence has been indicated. The

requirements detailed herein are our

interpretations of the latest

publications in our possession and we

must disclaim any responsibility for

errors due to our interpretation and/or

lack of any updated revision of these

standards. Our intent is to provide you

with an understanding of the

application of these standards and

how we believe our indirect-fired gas

heating equipment applies.

IRI Requirements

1

All input sizes require 100 percent

shutoff. This requires that any natural

gas unit, equipped with intermittent

pilot ignition, must employ a lockout type ignition system which will

shut off pilot gas if the pilot fails to

light at any time. This system is

required by AGA on LP gas units as

standard equipment. However, for

natural gas units, you will need to

specify fuel type L Natural Gas with

100 percent lockout.

2

All units require AGA certification or

UL listed controls. Our units are

AGA certified and meet this

requirement.

3

Models with inputs of 150,000 to

400,000 Btuh (43.9-117.1 kW) require

mechanical exhaust and a safety

interlock. For our units this means a

power vented unit.

FM Requirements

1

All units must be AGA certified or UL

listed. Our units are AGA certified.

2

The high limit control must be in a

circuit, the voltage of which does not

exceed 120 VAC. All of our high limits

would meet this requirement.

The specific requirement for an IRI or

FM gas train, while it applies to direct

and indirect-fired gas heating

equipment as well as oil-fired, comes

into play only with units having an

input in excess of 400,000 Btuh (117.1

kW). This may be one of the reasons

why the majority of gas heating

equipment manufacturers (indirectfired) limit their largest individual

furnace to 400,000 Btuh (117.1 kW).

Minimum/Maximum Gas

Inlet Pressures

Gas valves are suitable to a maximum

inlet pressure of 0.5 psi (14 inches

water column) on natural gas. If the

main gas supply pressure is greater

than 14 inches WC (3.5 kPa), a step

down pressure regulator must be field

installed ahead of the gas valve.

Minimum inlet pressure for natural gas

units is 6

For LP (propane) gas, the minimum

inlet pressure is 11

(2.9 kPa) and the maximum inlet

pressure is 14.0 inches WC (3.5 kPa).

1

/2 inches W.C (1.6 kPa).

1

/2 inches WC

17

Application

Considerations

High Pressure Regulators

Natural Gas Only

The Trane gas heating products

contained in this catalog are designed

to operate at a pressure of 3.5-inch WC

(0.9 kPa) (water column) when firing

on natural gas. This is the manifold

pressure or that which is present at the

burner orifices. All five and six-function

valves provide a built-in pressure

regulator which is capable of reducing

supply pressures from a maximum

of 14-inch WC (3.5 kPa) (

3.5-inch WC (0.9 kPa) on the leaving

side of the valve. The valve typically

drops about 1

minimum supply pressure is 5-inch

WC.

Whenever supply pressures exceed

14-inch WC (3.5 kPa), a high pressure

regulator should be selected. We

supply an Equimeter regulator which

is fitted with pressure springs and

capacity orificing to meet the

requirements of each specific job. In

order to select the proper spring/orifice

combination, we need to know what

the supply pressure is on that

particular job and the input size of the

unit being ordered. More than one unit

can be run from one regulator;

however, we recommend that each

unit have its own regulator.

1

/2 psi) down to

1

/2-inch so the

We require that the job supply

pressure be included on all jobs

requiring high pressure regulators

along with the unit size. The table that

follows displays the regulators range

as it pertains to inlet pressure and

MBh. NA requires the customer to

contact a local utility or an industrial

supply house.

These devices are not available from

Trane for LP gas. LP accessories must

be secured from the gas supplier or

industrial supply house.

18

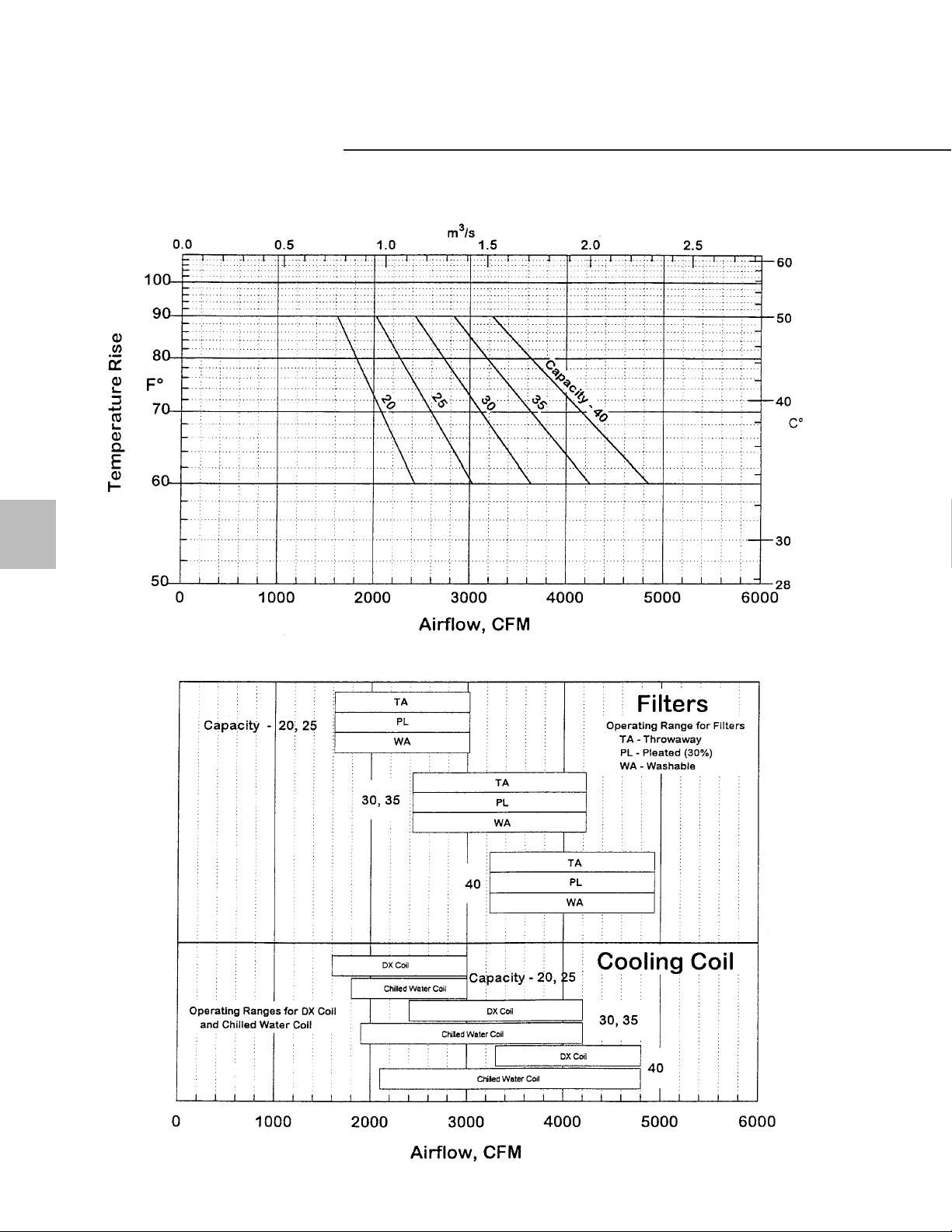

Selection Procedure

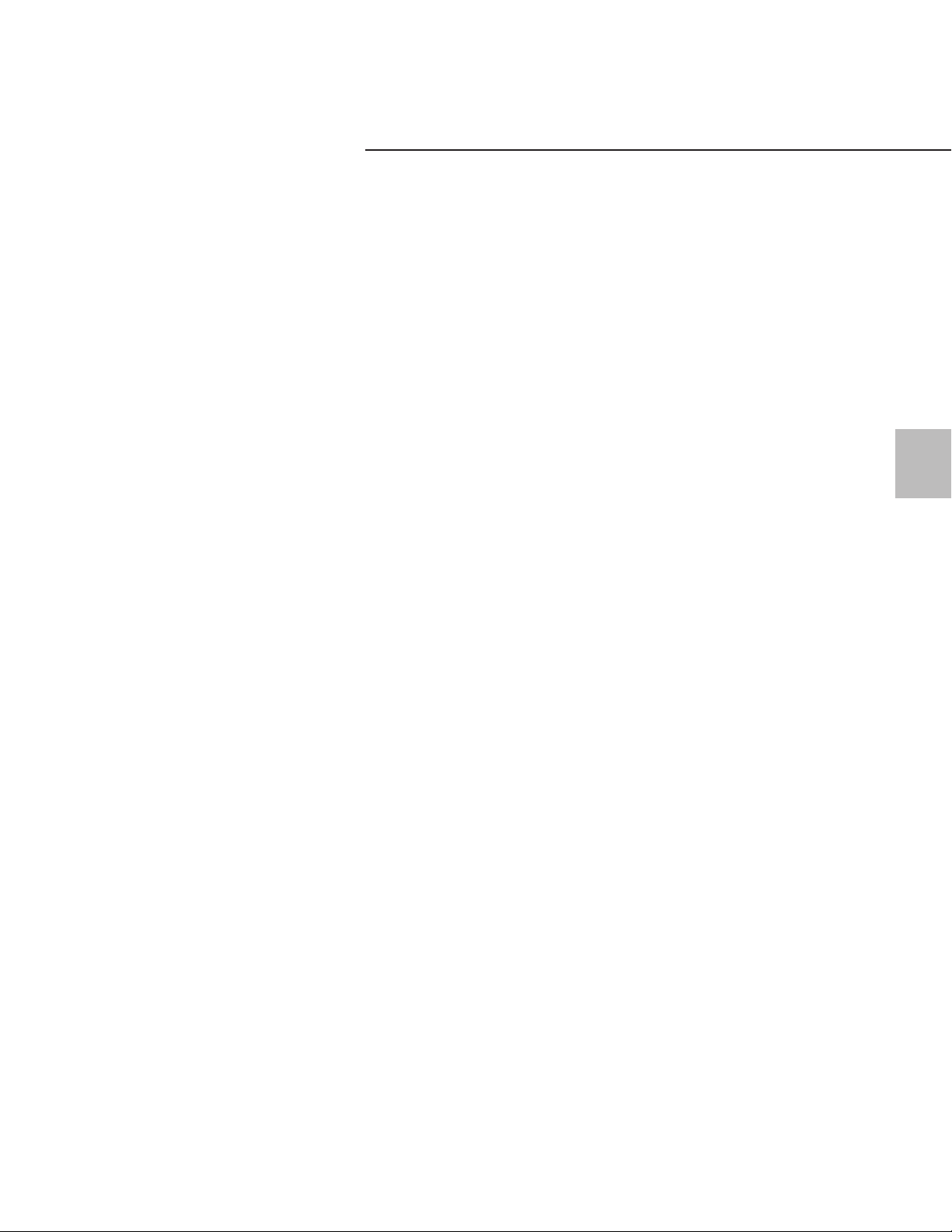

Quick Sizer Chart 1

Furnace Type (A, B) Standard Temperature Rise

Rooftop Arrangement (B, C, D, E)

19

Selection

Procedure

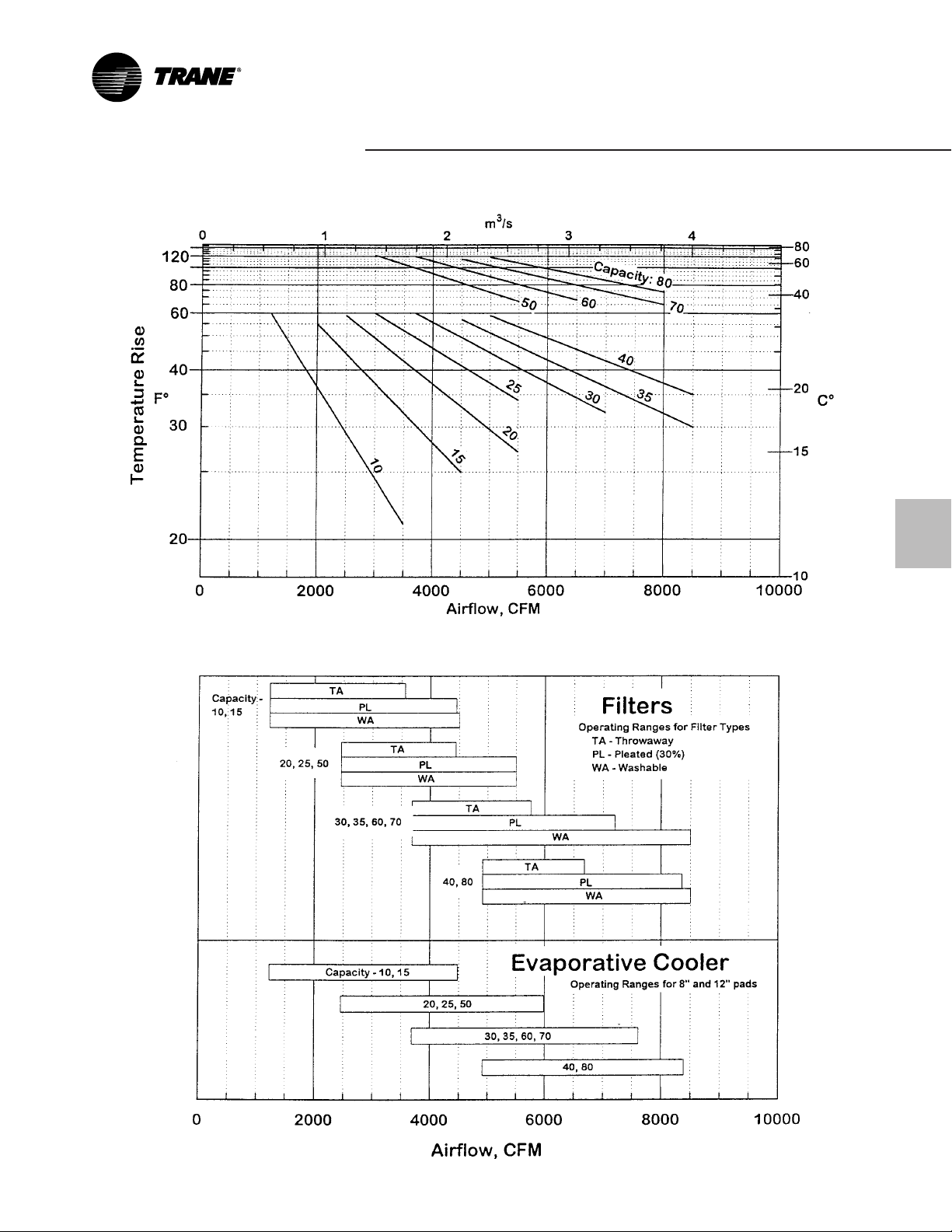

Quick Sizer Chart 2

Furnace Type (C, D) High Temperature Rise

Rooftop Arrangement (B, C, D, E)

20

Selection

Procedure

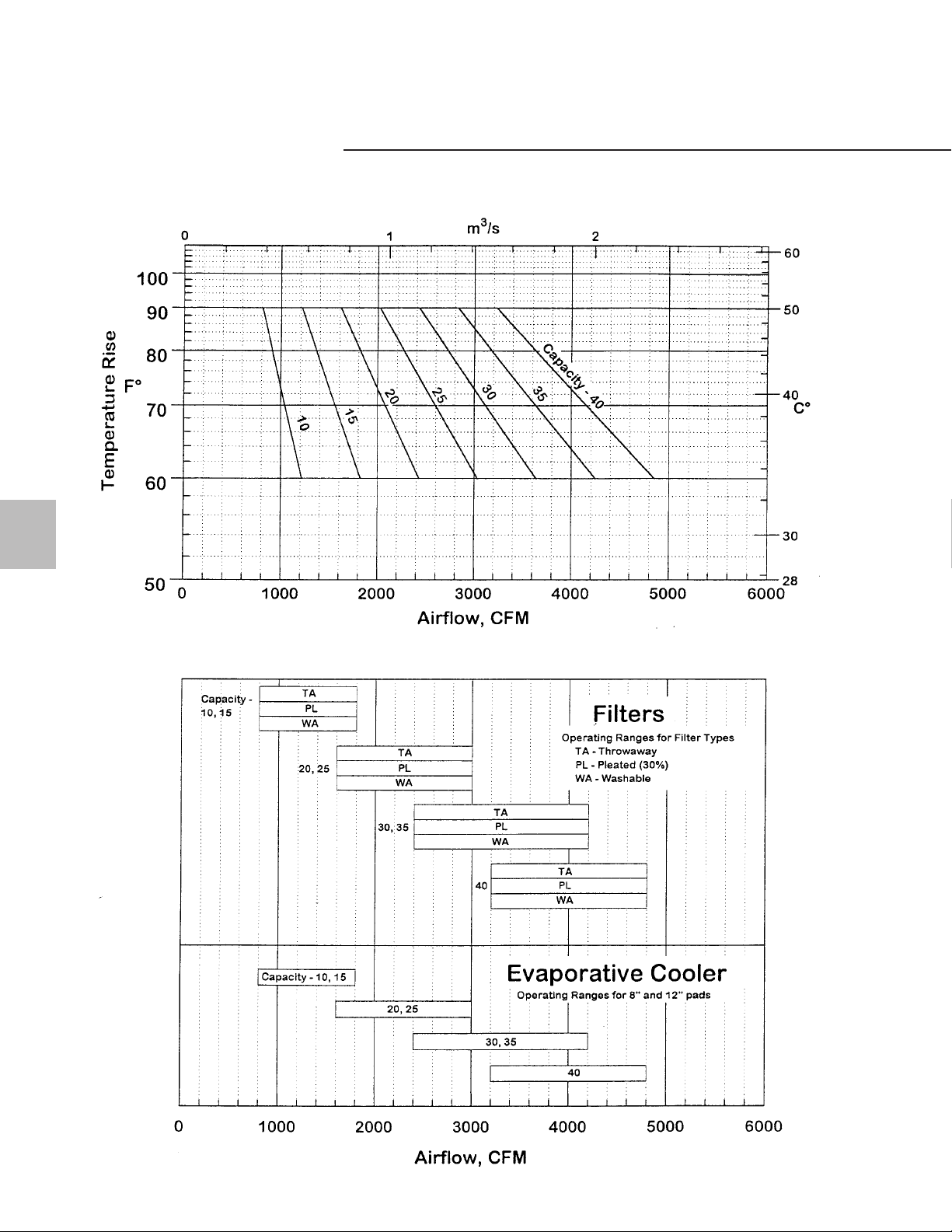

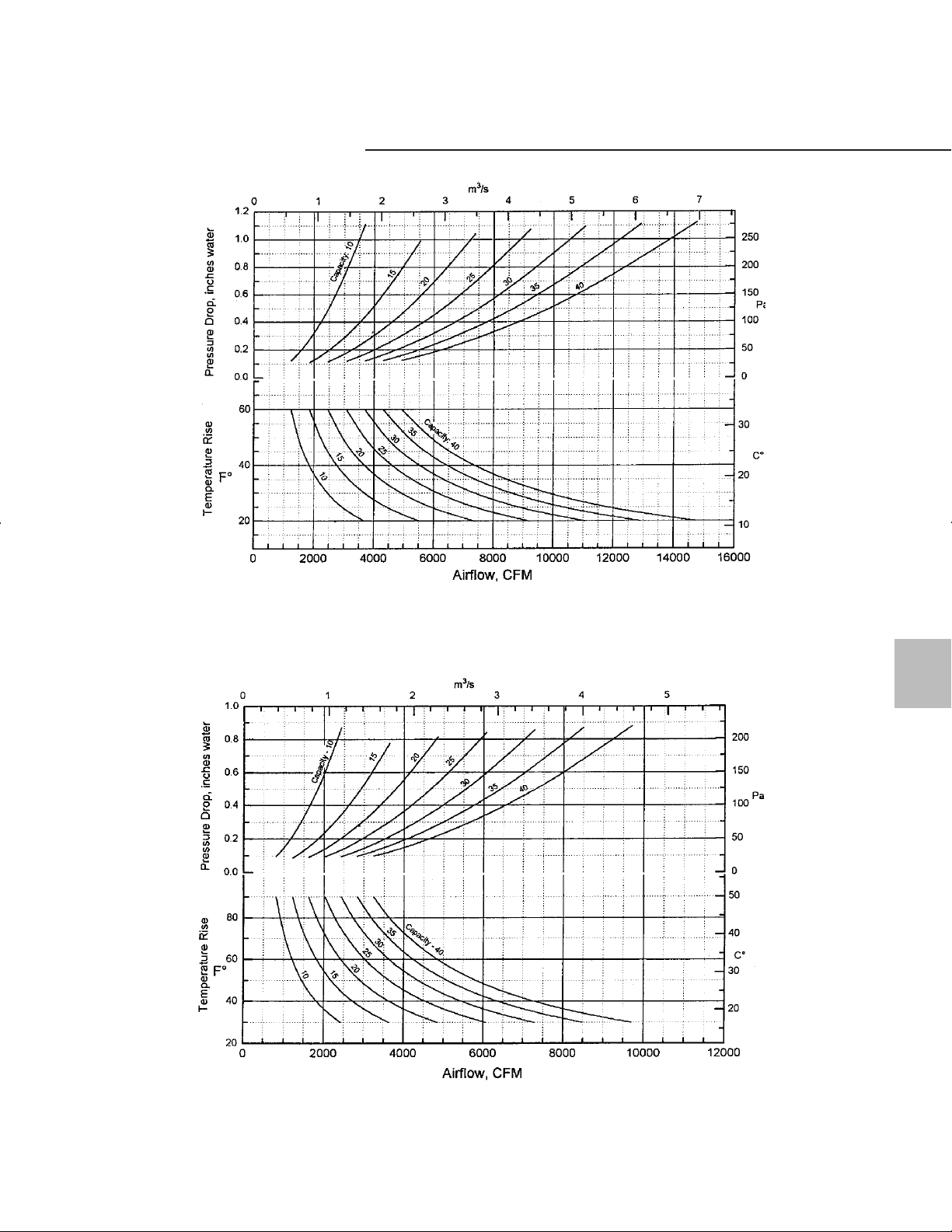

Quick Sizer Chart 3

Furnace Type (A, B) Low Temperature Rise

Rooftop Arrangement (G, J, K, L)

21

Selection

Procedure

Quick Sizer Chart 4

Furnace Type (C, D) High Temperature Rise

Rooftop Arrangement (G, J, K, L)

22

Step 1

To properly select a unit, two of the

three following items must be known:

temperature rise (TR) required, cubic

feet per minute of air delivery (cfm)

required and output (Btu/h out)

required. From any two of these items

the third item can be determined, as

well as the input (Btu/h In) required by

using the following:

TR = BTU/H Out ÷ (1.085 x CFM)

CFM = BTU/H ÷ (1.085 x TR)

BTU/H Out = (CFM x 1.085) x TR

BTU/H In = BTU/H Out ÷ Efficiency

.80 or .79

(The value 1.085 represents a constant.)

With any two of the three required

values, match these requirements to a

unit with the nearest input (Btu/h),

temperature rise (TR) and airflow (cfm)

capabilities keeping in mind that:

BTU/H Out = BTU/H In x Efficiency

Refer to the Packaged Rooftop

Arrangement Reference, page 9, to

match a capacity range (Btu/h), air

delivery (cfm) and temperature rise

(TR) with a rooftop arrangement.

The top portion of Quick Sizer Charts 1,

2, 3 and 4 allows the use of

temperature rise and cfm to determine

capacity, or temperature rise and

capacity to determine cfm, or capacity

and cfm to determine temperature rise.

Follow the top chart down to the

corresponding filter and cooling range

for the selection.

Step 2

Once capacity, temperature rise and

cfm have been determined, go to the

accessory pressure losses table for the

arrangement and calculate pressure

losses for unit accessories. Add the

losses for filters, plenums, dampers,

rainhood with screen or moisture

eliminators, evaporative cooler or

cooling coil and losses due to ductwork

to determine the total esp.

Step 3A 2000 ft. Altitude and Below

Refer to the performance table for the

selection and determine rpm and bhp

for the total external static pressure

(esp). Go to the table row that most

closely matches unit capacity,

temperature rise and cfm, follow the

row out to the column that equals the

total esp for rpm and bhp values.

Selection

Procedure

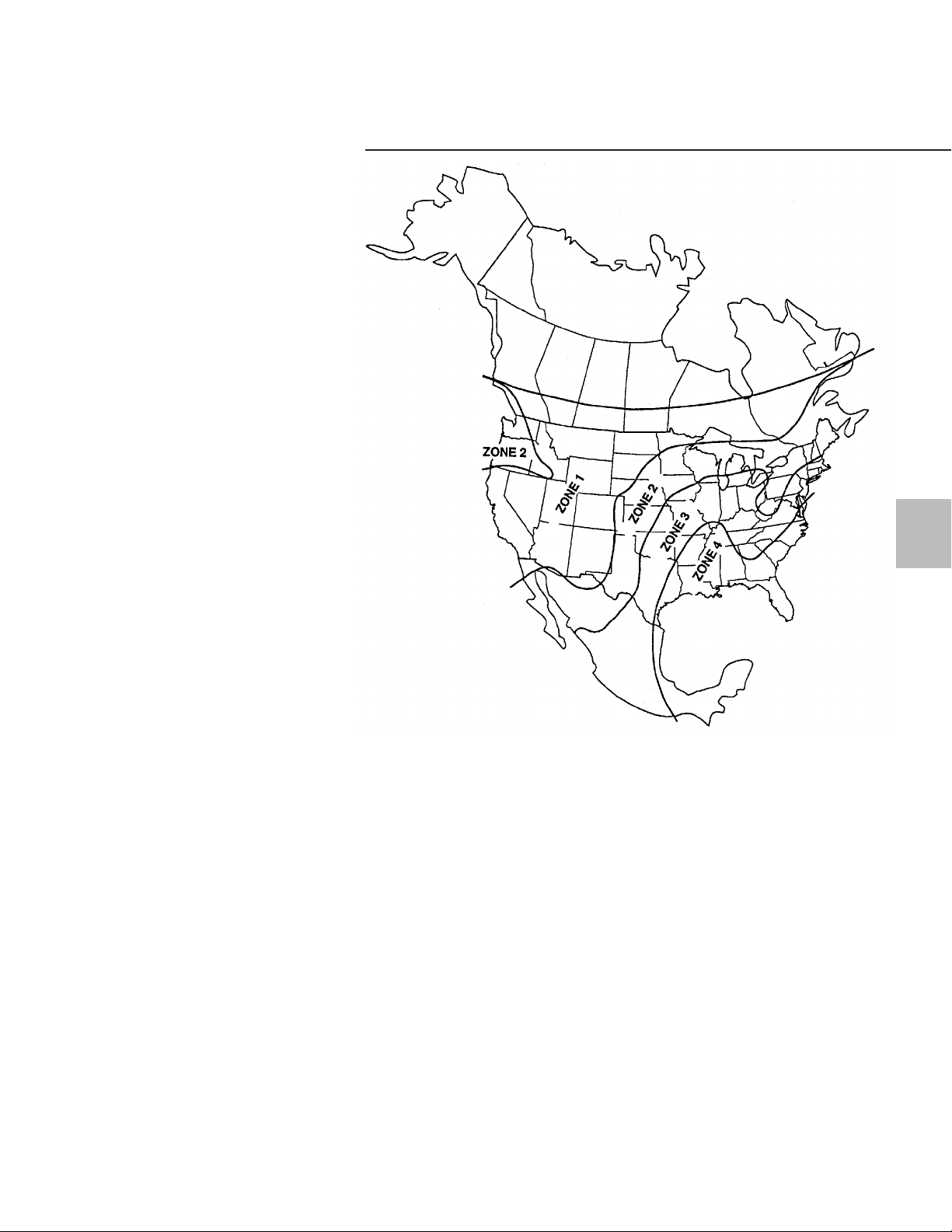

Figure SP-1 Zone Chart

Step 3B Above 2000 ft. Altitude

To correct for altitude, go to Table

PAF-1, Correction Factors for Altitude.

From this table, determine the

correction factor from temperature and

altitude for the system.

Correct the esp from ductwork to actual

esp for altitude, then add sp from

accessories as shown below. Refer to

the performance table for the selected

unit. Go to the row that most closely

matches unit capacity, temperature rise

and cfm, and follow the row out to the

column that equals the corrected actual

esp for rpm and bhp values. The bhp

value can now be corrected to actual

bhp for altitude as shown below.

Actual ESP = Duct ESP x Factor +

Access. SP

Actual BHP = Cat. BHP ÷ Factor

Corrected BTUH Input =

Catalog BTUH Input ÷ Factor

Corrected BTUH Output =

Corrected BTUH Input x Efficiency

Performance

Evaporative cooling is most commonly

used in areas where the relative

humidity is low and the dry bulb

temperatures are high. However,

cooling through evaporation can be

used in most areas.

Evaporative cooling is best utilized

whenever the wet bulb depression

(difference between dry and wet bulb

temperature) is a minimum of 15 F.

The efficiency of the evaporative cooler

is determined by a variety of factors:

geographical location, application, air

change requirements, sufficient water

supply, airflow and maintenance. In

most instances, efficiency is expected

to be between 77 percent and 88

percent. Heat gains in the distribution

system will affect the final output

temperature.

Note: For SI metric conversion, see

Table G-2 on page 10.

23

Selection

Procedure

Figure SP-2 Psychrometrics Chart

Use the psychrometric chart (shown in

Figure SP-2) or actual humidity

temperature readings to estimate the

leaving dry bulb temperature at the

outlet of the evaporative cooler.

Example:

Entering Dry Bulb: 95 F

Entering Wet Bulb: 75 F

Wet Bulb Depression (95 F - 75 F)

= 20 F

Effective Wet Bulb Depression

(20 F x .85) = 17 F

Leaving Dry Bulb Temperature

(95 F - 17 F) = 78 F

Leaving Wet Bulb = Entering Wet Bulb

= 75 F

Selection Method

The easiest method for selecting an

evaporative cooler is to first determine

the required number of air changes per

minute.

1

Using Figure SP-1, choose the

geographical zone in which the unit is

to be installed.

2

Determine the internal load within the

structure:

Normal Load: structures with normal

people loads, and without high internal

heat gains.

High Load: Structures with high

equipment loads (i.e. factories,

laundromats, beauty salons, restaurant

kitchens, etc.), and structures with high

occupancy (night clubs, arenas, etc.).

3

Determine whether the structure has

normal or high heat gains.

Normal Gain: Structures that have

insulated roofs or are in shaded areas.

Structures that have two or more

stories or facing directions with no sun.

High Gain: Structures that have

uninsulated roofs, unshaded areas, or

rooms that are exposed to sun.

4

Using Table SP-1, determine the

required air changes per minute based

on zone selection and the type of heat

load.

5

Finally, determine the air quantity for

the space chosen, by calculating the

volume (L x W x H). Multiply this

volume by the air changes per minute.

Example:

Structure Dimensions:

25 L x 24 W x 10 H = 6000 Ft

3

Exterior Load Type: Normal

Interior Load Type: Normal

Location: Dallas, Texas Zone 3

Air Changes Per Minute:

3

/4

Evaporative Cooler Requirements:

6000 Ft3 x 3/4 Air Change/Minute =

4500 CFM Required

See the evaporative cooler

performance chart for unit size that

would best apply.

Table SP-1 Air Changes Per Minute

Type Heat Load 1 2 3 4

High Load/High Gain 3/4 11 1/3 2

High Load/Normal Gain 1/2 3/4 11 1/3

Normal Load/High Gain 1/2 3/4 11 1/3

Normal Load/Normal Gain 1/2 1/2 3/4 1

Zone

Cooling Coils

Cooling coils are used in air handling

systems to cool and dehumidify an air

stream for comfort purposes. To reduce

the cooling load in buildings, most

applications recirculate a large

percentage of the air. Usually

recirculated air is 75 to 80 percent of

the airflow with the remainder being

outside fresh air. Some codes require

100 percent outside air, particularly for

hospitals and schools. Also many

engineers specify higher percentages

of outside air to meet the requirements

of ASHRAE Standard 62-1989

Ventilation for Acceptable Indoor Air

Quality.

1

In order to select the least expensive

coil to meet the specific performance

criteria, the following information is

required:

- Unit size

- Airflow in SCFM or ACFM and altitude

(see Fan Selection at Altitude)

- Entering air dry bulb and wet bulb

temperatures based on ratio of

outside to return air.

- Cooling load MBh (1000s Btu/h) or

leaving air wet bulb.

2

For chilled water coils, the following

additional information is required.

- Fluid type: water, ethylene glycol,

propylene glycol and percent of

mixture.

- Entering fluid temperature F

- Leaving fluid temperature F or rate

of flow GPM.

Chilled water catalog tables are based

on:

45 F entering water temperature

Entering air temperature of 80 F DB/67

F WB. Data is certified in accordance

with ARI Standard 410. For other than

these conditions, please consult the

.

factory

24

Selection

Procedure

3

For DX (refrigerant) coils the following

additional information is required:

- Refrigerant type

- Suction temperature F

- Liquid temperature F

- Type of circuiting desired

- Hot gas bypass required?

DX catalog tables are based on:

45 F suction temperature

Entering air temperature of 80 F DB/

67 F WB

R-22 refrigerant

100 F liquid temperature

Data is certified in accordance with

ARI Standard 410. For other than

these conditions, please consult the

factory.

4

When specifying a coil, one of the most

important pieces of information is the

airflow in SCFM. As stated in the Fan

Selection at Altitude section, SCFM

means Standard CFM or air at a

density of 0.075 lb./cu. ft. A fan must be

selected using ACFM or ACTUAL CFM.

A cooling coil or heating coil must be

selected using SCFM. Up to an altitude

of approximately 1,500 feet above sea

level, very little error would be

introduced in the selection of a cooling

coil. For altitudes above 1,500 feet

above sea level, the coil must be

selected using SCFM. The relationship

between ACFM and SCFM is shown by

the following equation:

SCFM = ACFM x (Actual Density

÷ 0.075)

The term 0.075 ÷ Actual Density is

referred to as the density correction

factor, herein called the Factor. This

factor can be found in Table PAF-1. The

previous equation can then be

rewritten as:

SCFM = (ACFM ÷ Factor)

Example: A cooling coil must be

selected at 5,000 ft. altitude. The unit

delivers 10,000 ACFM. What is the

SCFM? At 5,000 ft. altitude, the factor

from Table PAF-1 is 1.20, therefore:

SCFM = 10,000 ACFM ÷ 1.20 =

8.333 SCFM

5

The entering air temperatures, both

wet bulb and dry bulb, must also be

considered when selecting a coil. A

majority of units usually use

recirculated air with a percentage of

outside air. The cooling coil must be

selected using the mixed air

temperature entering the coil.

The following example shows how to

calculate the mixed air temperature:

25 percent outside air at 95 F DB/

75 F WB

75 percent recirculated air at 78 F DB/

67 F WB

The mixed dry bulb is simply the

proportional value between the outside

and recirculated dry bulb

temperatures.

.25 x 95 + .75 x 78 = 82.3 F

The mixed wet bulb temperatures

must be calculated using either the

humidity ratio from a psychrometric

chart or from Table SP-2, The enthalpy

of saturated air at various wet bulb

temperatures.

Using Table SP-2, the enthalpy of the

outside air at 75 F WB is 38.62 Btu/lb.

and the recirculated air at 67 F WB is

31.63 Btu/lb., the mixed enthalpy is:

.25 x 38.62 + .75 x 31.63 = 33.38 Btu/lb.

Using this value in Table SP-2, the

interpolated wet bulb temperature is

69.1 F.

So the final mixed temperatures are:

82.3 F DB/69.1 F WB

Table SP-2 Enthalpy of Saturated Air at

Wet BTU Wet BTU

Bulb per Bulb Per

Temp. Pound Temp. Pound

50 20.38 65 30.05

50.5 20.64 65.5 30.44

51 20.90 66 30.83

51.5 21.17 66.5 31.23

52 21.45 67 31.63

52.5 21.73 67.5 32.03

53 22.01 68 32.44

53.5 22.29 68.5 32.86

54 22.59 69 33.27

54.5 22.88 69.5 33.70

55 23.18 70 34.12

55.5 23.48 70.5 34.55

56 23.79 71 34.99

56.5 24.10 71.5 35.42

57 24.42 72 35.87

57.5 24.74 72.5 36.31

58 25.06 73 36.77

58.5 25.39 73.5 37.22

59 25.73 74 37.68

59.5 26.06 74.5 38.15

60 26.40 75 38.61

60.5 26.75 75.5 39.09

61 27.10 76 39.56

61.5 27.45 76.5 40.04

62 27.81 77 40.53

62.5 28.17 77.5 41.02

63 28.54 78 41.51

63.5 28.91 78.5 42.01

64 29.29 79 42.51

64.5 29.67 79.5 43.02

Various Wet Bulb

Temperatures

25

Performance Adjustment Factors

Table PAF-1 Correction Factors for Altitude

Temp. Barometric Pressure (In. Hg)

70 1.00 1.02 1.04 1.06 1.08 1.10 1.12 1.14 1.16 1.18 1.20 1.22 1.25

80 1.02 1.04 1.06 1.08 1.10 1.12 1.14 1.16 1.18 1.20 1.22 1.25 1.27

1. Actual ESP = Duct ESP x Factor ÷ Accs. SP

2. Actual BHP = Cat. BHP ÷ Factor

3. Correct BTUH Input = Catalog BTUH Input ÷ Factor

4. Corrected BTUH Output = Corrected BTUH Input x Efficiency

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

F 39.92 29.38 28.86 28.33 27.82 27.31 26.82 26.32 25.84 25.36 24.9 24.43 29.98

-40 0.79 0.81 0.82 0.84 0.85 0.87 0.88 0.90 0.92 0.93 0.95 0.97 0.99

0 0.87 0.88 0.90 0.92 0.93 0.95 0.97 0.99 1.00 1.02 1.04 1.06 1.08

40 0.94 0.96 0.98 1.00 1.01 1.03 1.05 1.07 1.09 1.11 1.13 1.16 1.18

100 1.06 1.08 1.10 1.12 1.14 1.16 1.18 1.20 1.22 1.25 1.27 1.29 1.32

120 1.90 1.11 1.13 1.16 1.18 1.20 1.22 1.24 1.27 1.29 1.31 1.34 1.37

Altitude (Feet)

Performance

Data

Table PD-1 Rooftop Gas Duct Furnace Performance Data Arrangement A

Capacity 10-12 Rating Rating Deg. F CFM in. of Water Nat. Gas L.P. Gas

Furnace Type A,B/C,D BTU/Hr BTU/Hr Eff. (Deg. C) (cu. m/s) (cu. m/s) (kPa) (kPa) Inlet Inlet

Rooftop Arrangement A (kW) (kW) % Min. Max. Min. Max. Min. Max. in. in.

Ratings shown are for elevations up to 2000 feet (610 m) above sea level. Above 2000 feet (610 m), input must be derated four percent for each 1000 feet (305 m)

above sea level.

10 A/B 100,000 80,000 80 20 60 1,235 3,704 0.15 1.10 1/2 1/2

15 A/B 150,000 120,000 80 20 60 1,852 5,556 0.15 1.00

20 A/B 200,000 160,000 80 20 60 2,469 7,407 0.15 1.05

25 A/B 250,000 200,000 80 20 60 3,086 9,259 0.15 1.08

30 A/B 300,000 240,000 80 20 60 3,704 11,111 0.15 1.10

35 A/B 350,000 280,000 80 20 60 4,321 12,963 0.15 1.11

40 A/B 400,000 320,000 80 20 60 4,938 14,815 0.15 1.12

50 A/B 500,000 400,000 80 40 120 3,086 9,269 0.30 2.16 3/4 1/2 OR 3/4

60 A/B 600,000 480,000 80 40 120 3,704 11,111 0.30 2.20

70 A/B 700,000 560,000 80 40 120 4,321 12,963 0.30 2.22

80 A/B 800,000 640,000 80 40 120 4,938 14,815 0.30 2.24

12 A/B 1,200,000 960,000 80 60 180 4,938 14,815 0.45 3.36

10 C/D 100,000 79,000 79 30 90 823 2,469 0.10 0.88 1/2 1/2

15 C/D 150,000 118,500 79 30 90 1,219 3,657 0.10 0.78

20 C/D 200,000 158,000 79 30 90 1,626 4,876 0.10 0.81

25 C/D 250,000 197,500 79 30 90 2,032 6,096 0.10 0.85

30 C/D 300,000 237,000 79 30 90 2,438 7,315 0.10 0.86

35 C/D 350,000 276,500 79 30 90 2,845 8,534 0.10 0.87

40 C/D 400,000 316,000 79 30 90 3,251 9,753 0.10 0.88

Input Output Temp. Rise Pressure Drop

(29.3) (23.4) (11) (33) (0.583) (1.748) (0.04) (0.27)

(43.9) (35.1) (11) (33) (0.874) (2.622) (0.04) (0.25)

(58.6) (46.9) (11) (33) (1.165) (3.496) (0.04) (0.26)

(73.2) (58.6) (11) (33) (1.457) (4.370) (0.04) (0.27)

(87.8) (70.3) (11) (33) (1.748) (5.244) (0.04) (0.27)

(102.5) (82.0) (11) (33) (2.040) (6.119) (0.04) (0.28)

(117.1) (93.7) (11) (33) (2.331) (6.993) (0.04) (0.28)

(146.4) (117.1) (22) (67) (1.457) (4.375) (0.07) (0.54)

(175.7) (140.6) (22) (67) (1.748) (5.244) (0.07) (0.55)

(205.0) (164.0) (22) (67) (2.040) (6.119) (0.07) (0.55)

(234.3) (187.4) (22) (67) (2.331) (6.993) (0.07) (0.56)

(351.4) (281.1) (33) (100) (2.331) (6.993) (0.11) (0.84)

(29.3) (23.1) (17) (50) (0.388) (1.165) (0.02) (0.22)

(43.9) (34.7) (17) (50) (0.575) (1.726) (0.02) (0.19)

(58.6) (46.3) (17) (50) (0.767) (2.301) (0.02) (0.20)

(73.2) (57.8) (17) (50) (0.959) (2.877) (0.02) (0.21)

(87.8) (69.4) (17) (50) (1.151) (3.453) (0.02) (0.21)

(102.5) (81.0) (17) (50) (1.343) (4.028) (0.02) (0.22)

(117.1) (92.5) (17) (50) (1.534) (4.603) (0.02) (0.22)

1

/2 1/2

1

/2 1/2

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

1

/2 1/2

1

/2 1/2

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

3

/4 1/2 OR 3/4

26

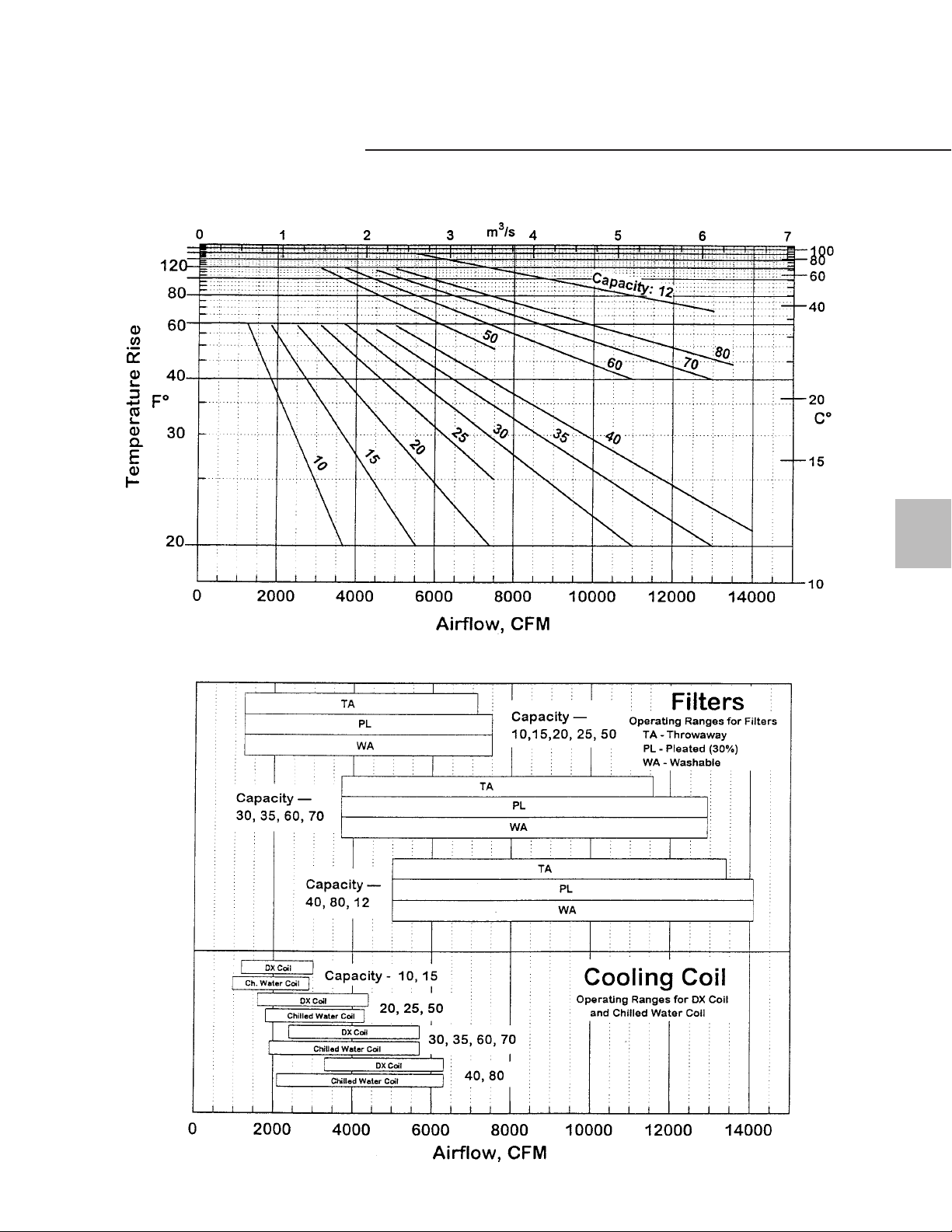

Chart PD-1 Duct Furnace Performance

Furnace Type (A, B)

Performance Data

Chart PD-2 Duct Furnace Performance

Furnace Type (C, D)

Standard Temperature Rise Duct Furnace Performance

Furnace Type (A, B)

20-60 F Rise/Furnace

80% Efficiency

High Temperature Rise Duct Furnace Performance

Furnace Type (C, D)

60-90 F Rise/Furnace

79% Efficiency

27

Performance

Data

Table PD-2 Rooftop Gas Heating Units Performance Data Furnace Type (A,B) Standard Temperature Rise

Rooftop Arrangement B,C,D,E

Capacity TOTAL EXTERNAL STATIC PRESSURE (INCHES OF WATER)

Furnace TR Input Output 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Type (F) CFM BTU/H BTU/H RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

61 1,200 100,000 80,000 575 0.16 705 0.23 825 0.31 940 0.4 1040 0.5 1135 0.6 1220 0.7 1300 0.8 1375 0.91 1440 1.02

10-A,B 37 2,000 795 0.55 890 0.65 975 0.77 1055 0.88 1130 1 1205 1.12 1280 1.25 1355 1.39 1425 1.54 1490 1.68

15-A,B 37 3,000 935 1.28 1005 1.44 1075 1.6 1140 1.75 1205 1.88 1270 2.02 1335 2.18 1390 2.35 1450 2.53 1500 2.7

20-A,B 37 4,000 790 1.58 855 1.72 915 1.86 975 2.03 1035 2.21 1090 2.39 1145 2.57 1200 2.76 1250 2.94 1300 3.13

25-A,B 46 4,000 770 1.53 830 1.66 895 1.81 955 1.97 1015 2.14 1070 2.32 1125 2.51 1180 2.69 1235 2.87 1285 3.06

30-A,B 44 5,000 815 1.59 895 1.85 975 2.1 1055 2.32 1125 2.58 1195 2.88 1260 3.17 1325 3.46 1385 3.75 1445 4.05

35-A,B 43 6,000 650 1.48 735 1.72 810 1.99 880 2.26 950 2.54 1015 2.82 1080 3.1 1140 3.39 1195 3.69 1255 4

40-A,B 42 7,000 715 2.19 785 2.44 855 2.73 920 3.04 985 3.36 1045 3.68 1105 4 1160 4.33 1215 4.66 1270 4.99

50-A,B 92 4,000 815 1.63 875 1.77 940 1.92 1000 2.09 1055 2.27 1110 2.46 1165 2.64 1220 2.82 1270 3.01 1320 3.19

60-A,B 88 5,000 880 1.79 960 2.05 1035 2.27 1110 2.53 1180 2.82 1250 3.11 1310 3.4 1370 3.69 1430 3.99 1490 4.29

70-A,B 86 6,000 720 1.68 800 1.95 870 2.22 940 2.5 1005 2.78 1070 3.06 1130 3.35 1190 3.65 1245 3.96 1300 4.27

80-A,B 98 6,000 690 1.59 770 1.84 845 2.12 915 2.39 980 2.67 1045 2.95 1105 3.24 1165 3.53 1225 3.84 1280 4.15

Notes:

1. Refer to Accessory Pressure Loss table.

2. Values are based on the Basic Packaged Unit which includes pressure drop of the duct furnace(s) and system effect of the blower module.

3. Brake horsepower (BHP) includes drive losses.

4. Unit leaving air temperature is limited to 150 F (66 C) and is equal to: Entering Air Temperature + Duct Furnace(s) Temperature Rise.

5. Total External Pressure is the sum of the units Internal accessory pressure loss(es) plus the external static pressure.

6. Ratings shown are for elevations between 0 and 2000 ft. (610 m). For unit installation in the U.S.A. above 2000 ft. (610 m), the unit input must be derated 4%

for each 1000 ft. (305 m) above sea level; refer to local codes, or in absence of local codes, refer to the National Fuel Gas Code, ANSI Standard Z223.1-1992

(N.F.P.A. No. 54), or the latest edition.

For installation in Canada, any references to deration at altitudes in excess of 2000 ft. (610 m) are to be ignored. At altitudes of 2000 to 4500 ft. (610 to 1372 m),

the unit must be derated to 90% of the normal rating, and be so marked in accordance with the C.G.A. certification.

49 1,500 655 0.26 765 0.35 870 0.44 965 0.54 1060 0.64 1150 0.75 1235 0.87 1315 0.99 1390 1.12 1460 1.24

29 2,500 950 1.01 1030 1.12 1105 1.25 1175 1.39 1240 1.54 1305 1.68 1365 1.83 1425 1.98 1485 2.13 1545 2.29

25 3,000 1110 1.68 1175 1.82 1240 1.95 1305 2.1 1365 2.27 1420 2.44 1475 2.62 1530 2.79 1580 2.97 1635 3.14

21 3,500 1270 2.59 1330 2.77 1385 2.93 1440 3.08 1495 3.25 1550 3.43 1600 3.63 1650 3.83 1695 4.04 1745 4.25

55 2,000 150,000 120,000 685 0.44 785 0.54 880 0.63 965 0.75 1045 0.87 1120 0.98 1195 1.11 1270 1.24 1345 1.37 1415 1.52

44 2,500 805 0.78 890 0.91 970 1.04 1045 1.15 1120 1.28 1190 1.43 1255 1.57 1320 1.72 1380 1.86 1440 2.01

32 3,500 1065 1.97 1130 2.15 1190 2.33 1250 2.52 1305 2.7 1360 2.87 1420 3.02 1475 3.17 1525 3.35 1580 3.55

28 4,000 1200 2.88 1255 3.08 1310 3.28 1365 3.49 1415 3.7 1465 3.91 1515 4.12 1565 4.3 1615 4.48 1660 4.65

25 4,500 1340 4.04 1390 4.26 1435 4.49 1485 4.72 1530 4.95

59 2,500 200,000 160,000 555 0.44 650 0.55 740 0.66 820 0.78 895 0.89 965 1.02 1035 1.14 1105 1.28 1170 1.41 1230 1.56

49 3,000 630 0.71 710 0.83 790 0.96 865 1.1 935 1.23 1000 1.37 1065 1.52 1125 1.66 1180 1.81 1240 1.96

29 5,000 965 2.98 1010 3.15 1060 3.32 1110 3.5 1160 3.7 1205 3.9 1255 4.12 1300 4.35 1345 4.57 1390 4.8

27 5,500 1050 3.92 1095 4.11 1135 4.3 1180 4.49 1225 4.7 1270 4.91

61 3,000 250,000 200,000 615 0.69 695 0.8 775 0.93 850 1.07 920 1.21 985 1.34 1050 1.49 1110 1.63 1170 1.78 1225 1.93

53 3,500 690 1.05 760 1.17 830 1.31 900 1.46 965 1.62 1025 1.78 1085 1.94 1140 2.11 1195 2.27 1250 2.44

41 4,500 855 2.13 905 2.29 960 2.44 1015 2.61 1070 2.79 1125 2.98 1175 3.19 1225 3.39 1275 3.6 1320 3.8

37 5,000 940 2.88 985 3.05 1030 3.23 1080 3.4 1130 3.59 1180 3.79 1230 4 1275 4.22 1320 4.45 1365 4.68

34 5,500 1025 3.8 1065 3.98 1110 4.17 1150 4.36 1195 4.56 1240 4.77 1285 4.98

60 3,700 300,000 240,000 655 0.73 760 0.91 860 1.11 945 1.32 1030 1.54 1110 1.76 1190 2.01 1270 2.26 1345 2.53 1415 2.81

55 4,000 690 0.89 790 1.09 885 1.28 970 1.51 1050 1.74 1125 1.98 1200 2.22 1275 2.48 1345 2.76 1415 3.05

37 6,000 945 2.6 1015 2.91 1080 3.23 1150 3.53 1215 3.79 1280 4.07 1340 4.39 1400 4.74

34 6,500 1010 3.25 1075 3.58 1140 3.92 1200 4.26 1260 4.58 1320 4.86

32 7,000 1075 4 1140 4.35 1200 4.71

57 4,500 350,000 280,000 535 0.7 640 0.9 730 1.11 815 1.32 890 1.55 970 1.78 1040 2.02 1110 2.28 1175 2.55 1235 2.82

52 5,000 575 0.91 670 1.13 755 1.36 835 1.59 910 1.83 980 2.08 1050 2.33 1115 2.6 1180 2.88 1240 3.16

37 7,000 735 2.25 805 2.51 875 2.81 940 3.12 1000 3.44 1060 3.76 1120 4.09 1175 4.41 1230 4.74

32 8,000 820 3.27 880 3.56 940 3.87 1000 4.21 1060 4.57 1115 4.94

30 8,500 860 3.88 920 4.18 980 4.51 1035 4.86

59 5,000 400,000 320,000 560 0.89 655 1.1 745 1.33 825 1.56 900 1.8 970 2.04 1040 2.3 1105 2.56 1170 2.84 1230 3.12

45 6,500 675 1.78 750 2.03 825 2.3 895 2.6 960 2.9 1025 3.2 1085 3.5 1145 3.8 1200 4.12 1255 4.44

37 8,000 800 3.18 860 3.46 920 3.76 980 4.09 1040 4.45 1095 4.81

35 8,500 840 3.77 895 4.07 955 4.38 1015 4.72

123 3,000 500,000 400,000 645 0.73 730 0.85 805 0.99 880 1.12 950 1.26 1015 1.4 1075 1.55 1135 1.69 1195 1.84 1250 1.99

105 3,500 730 1.12 800 1.25 870 1.39 935 1.55 1000 1.71 1060 1.87 1115 2.03 1175 2.2 1225 2.36 1280 2.53

82 4,500 900 2.27 955 2.43 1010 2.59 1065 2.77 1120 2.97 1170 3.17 1220 3.37 1270 3.58 1320 3.78 1365 3.99

74 5,000 990 3.07 1040 3.25 1085 3.42 1135 3.61 1185 3.81 1235 4.03 1280 4.25 1325 4.47 1370 4.7 1415 4.93

67 5,500 1080 4.05 1120 4.23 1165 4.43 1210 4.63 1255 4.84

120 3,700 600,000 480,000 700 0.82 805 0.99 900 1.2 985 1.42 1065 1.64 1145 1.87 1225 2.12 1305 2.38 1375 2.65 1450 2.94

111 4,000 740 1 840 1.18 930 1.4 1010 1.63 1090 1.86 1165 2.1 1240 2.36 1310 2.63 1385 2.91 1455 3.2

74 6,000 1025 2.95 1090 3.27 1155 3.57 1220 3.83 1285 4.11 1345 4.43 1405 4.78

68 6,500 1095 3.69 1160 4.03 1220 4.37 1280 4.67 1340 4.95

115 4,500 700,000 560,000 590 0.8 685 1.01 770 1.22 855 1.43 930 1.66 1005 1.9 1075 2.15 1140 2.41 1205 2.68 1265 2.96

103 5,000 630 1.04 720 1.27 805 1.5 880 1.74 950 1.98 1020 2.23 1090 2.49 1155 2.76 1215 3.05 1275 3.34

74 7,000 815 2.55 885 2.85 950 3.17 1010 3.49 1070 3.81 1130 4.13 1185 4.46 1240 4.79

65 8,000 910 3.7 970 4.03 1030 4.38 1085 4.75

118 5,000 800,000 640,000 605 0.98 695 1.21 780 1.44 860 1.67 935 1.91 1005 2.16 1070 2.42 1135 2.69 1200 2.97 1260 3.26

84 7,000 780 2.41 850 2.7 915 3.01 980 3.33 1040 3.65 1100 3.97 1155 4.29 1210 4.62 1265 4.96

74 8,000 870 3.51 930 3.81 990 4.15 1050 4.51 1105 4.87

28

Performance

Data

Table PD-3 Rooftop Gas Heating Units Performance Data Furnace Type C,D High Temperature Rise

Rooftop Arrangement B,C,D,E

Capacity TOTAL EXTERNAL STATIC PRESSURE (INCHES OF WATER)

Furnace TR Input Output 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Type (F) CFM BTU/H BTU/H RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

91 800 100,000 79,000 550 .09 710 .15 840 .22 950 .29 1045 .37 1135 .45 1210 .53 1285 .61 1355 .69 1420 .78

10-C,D 73 1,000 605 .14 745 .21 870 .29 980 .37 1080 .46 1165 .55 1245 .64 1320 .74 1390 .83 1455 .93

15-C,D 78 1,400 630 .23 745 .31 855 .39 960 .49 1055 .59 1150 .70 1235 .81 1315 .93 1385 1.05 1460 1.17

20-C,D 73 2,000 560 .31 665 .41 755 .50 845 .60 925 .71 1000 .83 1075 .95 1140 1.07 1205 1.20 1265 1.34

25-C,D 73 2,500 625 .51 715 .63 795 .74 875 .86 945 .98 1015 1.10 1085 1.23 1150 1.37 1210 1.51 1270 1.66

30-C,D 73 3,000 665 .54 775 .72 875 .90 975 1.09 1070 1.30 1160 1.53 1245 1.76 1325 2.00 1395 2.25 1470 2.50

35-C,D 75 3,400 535 .46 645 .62 745 .79 840 .98 920 1.19 1000 1.40 1070 1.63 1140 1.88 1210 2.14 1275 2.41

40-C,D 73 4,000 570 .64 670 .82 760 1.01 845 1.22 930 1.43 1005 1.66 1075 1.90 1145 2.15 1205 2.42 1265 2.69

Notes:

1. Refer to Accessory Pressure Loss table.

2. Values are based on the Basic Packaged Unit which includes pressure drop of the duct furnace(s) and system effect of the blower module.

3. Brake horsepower (BHP) includes drive losses.

4. Unit leaving air temperature is limited to 150 F (66 C) and is equal to: Entering Air Temperature + Duct Furnace(s) Temperature Rise.

5. Total External Pressure is the sum of the units Internal accessory pressure loss(es) plus the external static pressure.

6. Ratings shown are for elevations between 0 and 2000 ft. (610 m). For unit installation in the U.S.A. above 2000 ft. (610 m), the unit input must be derated 4%

for each 1000 ft. (305 m) above sea level; refer to local codes, or in absence of local codes, refer to the National Fuel Gas Code, ANSI Standard Z223.1-1992

(N.F.P.A. No. 54), or the latest edition.

For installation in Canada, any references to deration at altitudes in excess of 2000 ft. (610 m) are to be ignored. At altitudes of 2000 to 4500 ft. (610 to 1372 m),

the unit must be derated to 90% of the normal rating, and be so marked in accordance with the C.G.A. certification.

81 900 575 .11 730 .18 855 .25 965 .33 1065 .41 1150 .50 1230 .58 1305 .67 1375 .76 1440 .86

66 1,100 635 .17 770 .25 890 .33 995 .42 1095 .51 1180 .61 1260 .71 1335 .81 1410 .91 1475 1.01