FOREWORD

This manual has been prepared to familiarize you with the new features of the 1990 model year vehicles, with the

exception of the new Celica.

MR2 and Van are not contained in this manual because 1990 models of these vehicles will not be produced.

For new features of the Celica and for detailed service specifications and repair procedures of each 1990 model year

vehicle, refer to the following manuals:

Manual Name Pub. No.

1990 Celica New Car Features

1990 model Repair Manuals

1990 model Electrical Wiring Diagram Manuals

This information is the most up–to–date at the time of publication. However, Toyota reserves the right to make changes

without prior notice.

NCF056U

Refer to the

}

respective

located

Pub. No.

1989 TOYOTA MOTOR CORPORATION

All rights reserved. This book may not be reproduced

or copied, in whole or in part, without the written

permission of Toyota Motor Corporation.

TOYOTA MOTOR CORPORATION

General 1990 Features

Page

DESCRIPTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT SEAT BELT 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAYTIME RUNNING LIGHT SYSTEM 3. . . . . . . . . . . . . . . . . . . . .

DOOR LOCK CONTROL SYSTEM 7. . . . . . . . . . . . . . . . . . . . . . . .

2

T

l

C

C

C

Toyota

Truck/

Land

GENERAL 1990 FEATURES

GENERAL 1990 FEATURES

DESCRIPTION

The following changes are made simultaneously in some models for the 1990 model year.

(1) : Door–mounted automatic belts with manual lap belts are made standard equipment for front seat belts for the U.S.

(2) : For Canada, a daytime running light system, which lights the headlights and taillights during daylight hours, is used

to improve vehicle visibility from the outside during the daytime.

(3) : In vehicles which were previously equipped with the electronically controlled door lock control system, in which

all the doors were unlocked by operating the key in the lock of the driver ’s door, the system is changed to the

2–operation type system used in the Cressida. In this system, operating the driver’s door lock one time unlocks only

the driver ’s door, while operating the driver ’s door lock twice in succession unlocks the other doors.

Models in which the above changes have been made are shown in the following table.

Model

Item

(1) — — — —

(2) —

(3) — * — —

*: Use of the 2–operation type unlock system was begun in the Cressida for the 1990 model year.

Information of Type and Application of Passive Restraint System (Only for U.S.A.)

Model Tercel Corolla Camry Cressida

’90 Model M M E*

’89 Model — — E E — — —

M: Mechanical Type (Driver and Passenger) E*1: Vehicle speed signal from August ’89

E: Electronic Type (Driver and Passenger) E*2: Vehicle speed signal from January ’90

A: SRS Airbag (Driver)

erce

orolla

amry

ressida

1

E*

2

Toyota Truck/ Land

Supra

Toyota

Supra

A — —

4Runner

Truck/

4Runner

Cruiser

Land

Cruiser

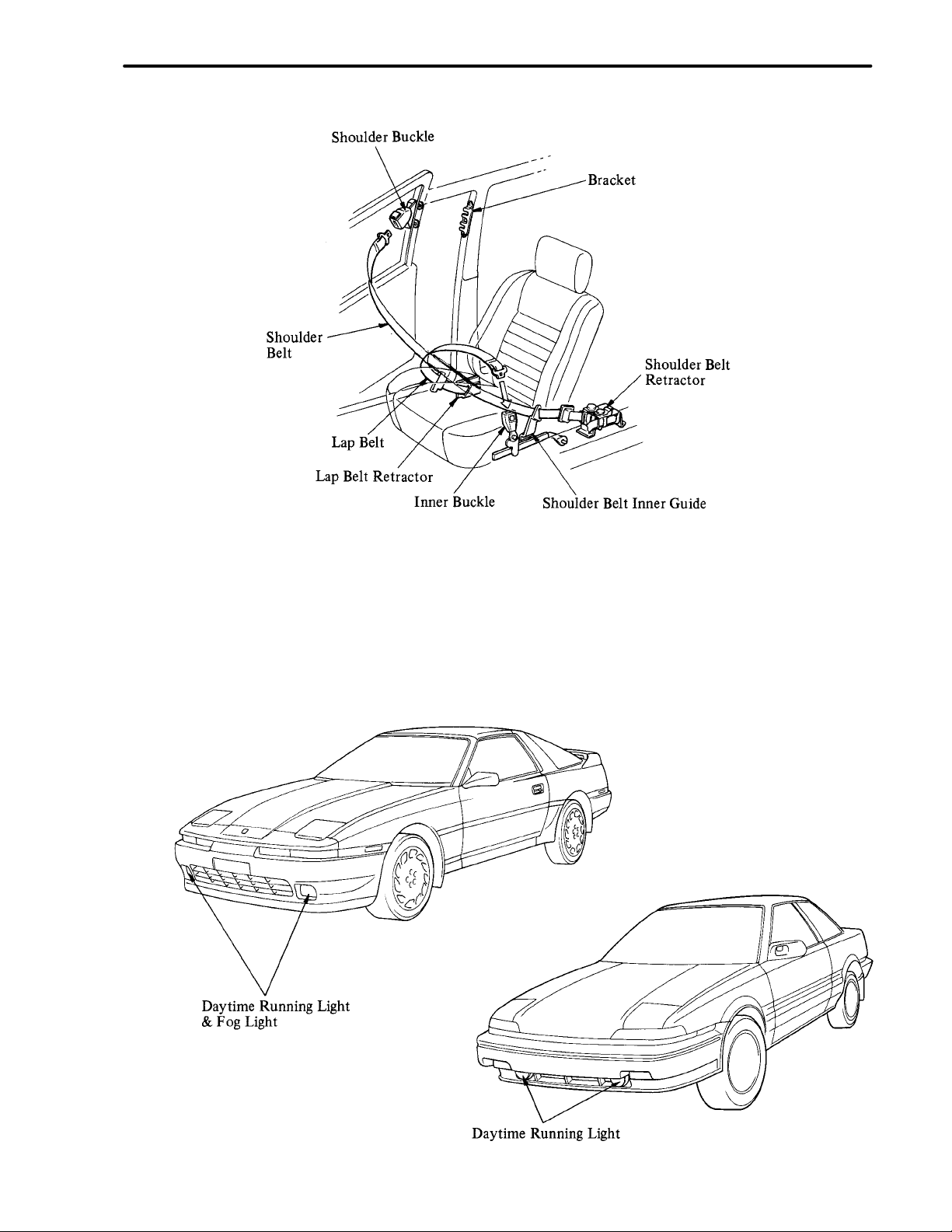

FRONT SEAT BELT

Door mounted automatic belts with manual lap belt are standard equipment in all Tercel and Corolla models for the U.S.

The shoulder belts are two–point ELR (Emergency Locking Retractor) belts. The shoulder belt retractors are mounted

in the bottom of the rear console box. The shoulder belt anchorages are mounted on the door frames and the shoulder

belts can be connected or disconnected using the buckles. A bracket is provided in each of the center pillars which assures

the rigidity of the shoulder belt anchorages.

The manual lap belts are two–point ALR (Automatic Locking Retractor) belts. The belt retractors are located at the bottom

of the center pillars in the rocker inner panel. The lap belt buckles slide fore and aft with the seats.

Construction

GENERAL 1990 FEATURES

3

DAYTIME RUNNING LIGHT SYSTEM (Only for Canada)

GENERAL

The daytime running light system, in which the headlights and taillights are turned on automatically when the engine

is started, is standard in all models for Canada. However, in the Toyota Supra, the front fog lights light up instead

of the headlights and in the Corolla 2–door coupe, exclusive daytime lights light up.

4

Ignition

l

Dimmer

Fog Light

Tailligh

F

*

1

OFF

TAIL

LOW

GENERAL 1990 FEATURES

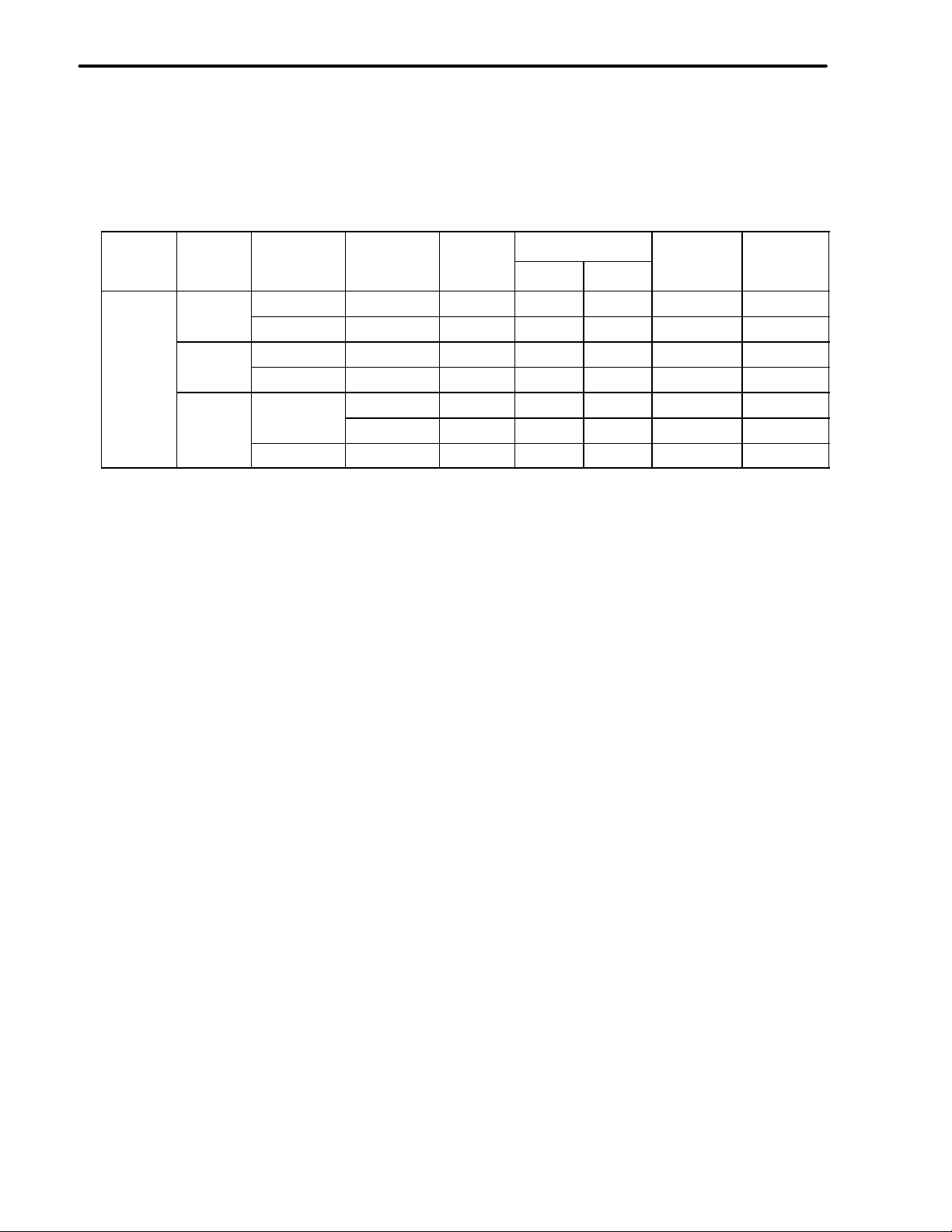

FUNCTION

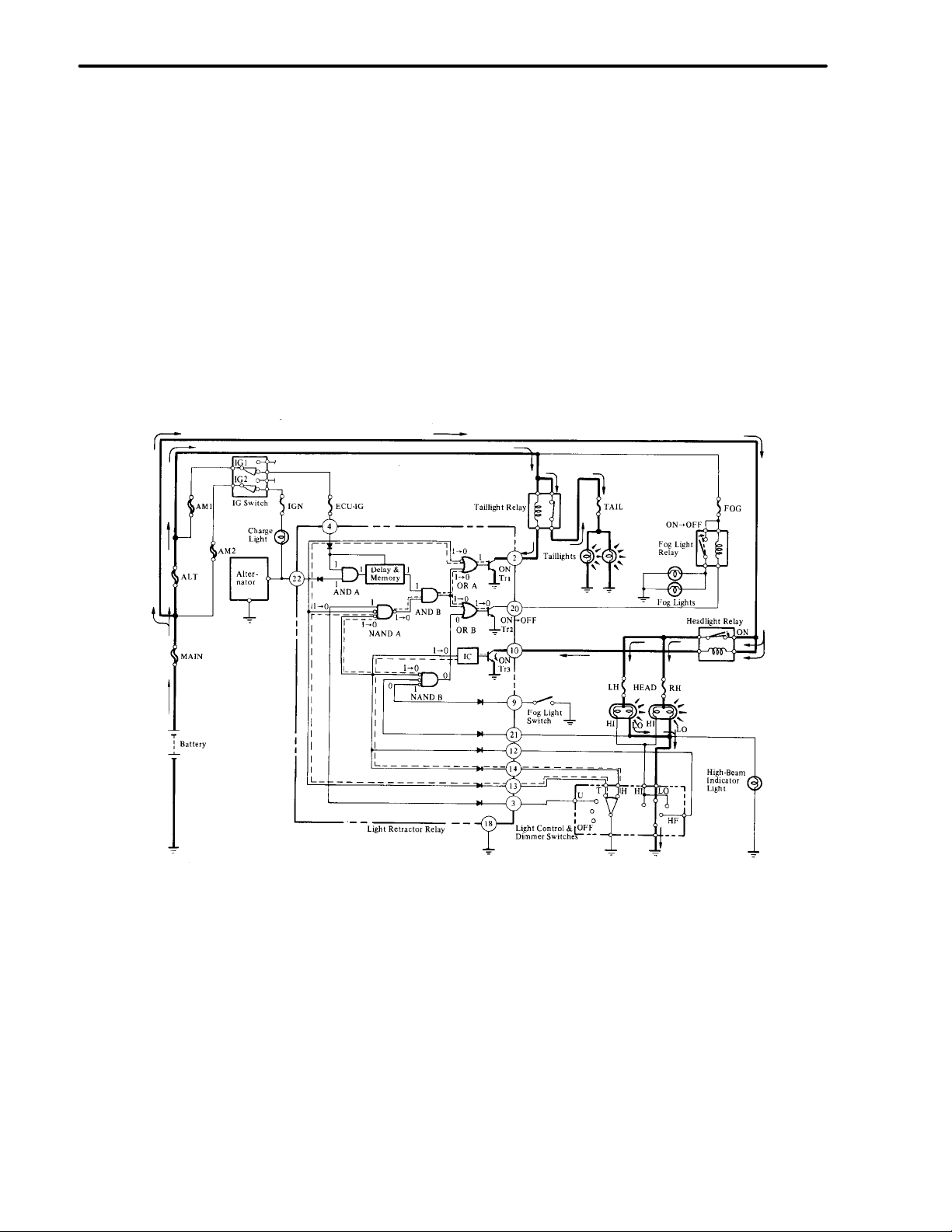

The daytime running light system operates when the ignition switch is turned to the ON position and the engine is

started, with the operation of each switch turning the lights on and off as shown in the table below. (The lights do not

go on when the ignition switch is in the ON position only. The lights also stay on in the event that the engine stalls

after the engine is started.)

: Light on as daytime running light, : Lighted up, X : Off

Ignition

Switch

ON

Light

Contro

Switch

OFF,

HOLD

Dimmer Fog Light*

Switch

LOW, HIGH ON , X*

,

HF*

4

Switch

1

ON X

LOW, HIGH ON , X*

4

HF*

ON X

t

Headlight

Low High

3

3

ON X X X

HEAD

HIGH, HF*

4

ON X X

ON X X X

*1: Toyota Supra only

*2: Corolla 2–Door Coupe only

*3: Toyota Supra and Corolla 2–Door Coupe only

*4: High Flash

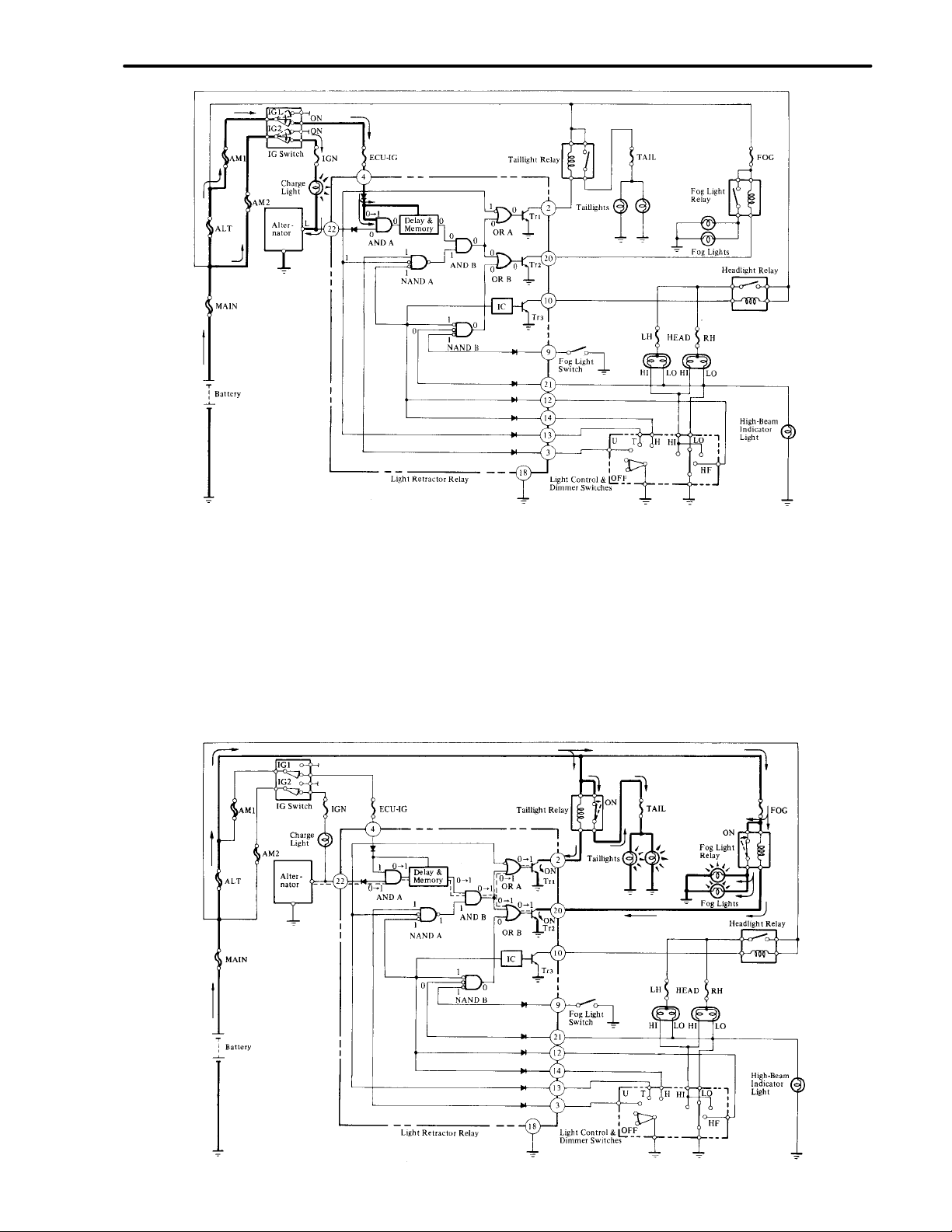

OPERATION

NOTE: Operation of the system is described using the Toyota Supra as an example.

1. Ignition Switch Turned ON (Before Starting Engine)

Daytime*

og Light

1

Running

Light

X

X

2

When the ignition switch is turned off, input and output signals at gates are in the condition shown on the next

page.

If the ignition switch is turned on in this condition, the voltage at terminal (4) goes high and the input to AND

gate A changes from “0” to “1”.

The electric current passing the charge light is grounded via the alternator and the voltage at terminal (22) is held

low. Therefore, the output from the AND gate A remains unchanged and the system remains inoperative.

If engine stalls after starting, lights stay on until ignition key is turned off.

GENERAL 1990 FEATURES

5

2. After Engine Starting

When the engine is started, the alternator begins charging and the voltage at terminal (22) goes high and the input

to AND gate A changes from “0” to “1”. Therefore, the output also changes from “0” to “1”.

When the “1” signal from AND gate A continues for 0.5 seconds or longer, the delay and memory circuit judges

that the engine has started and sends “1” to AND gate B.

Since the output from AND gate B changes from “0” to “1”, the output from OR gates A and B also changes from

“0” to “1” and causes Tr1 and Tr2 to go on respectively. Therefore, the taillight relay and fog light relay are turned

on and the daytime running lights are turned on as a result.

6

GENERAL 1990 FEATURES

3. Headlight (Low Beam) Turned ON

When the light control switch is put in the head position and the dimmer switch is put in low position while the

daytime running lights are turned on, the input to NAND gate A from light control switch terminals T and H

changes from “1” to “0”.

At the same time, the input signal to IC (Integrated Circuit) changes from “1” to “0”, so the IC then turns Tr

As a result, the headlight relay is turned on and the headlights (low beam) are turned on.

3

on.

When the input to NAND gate A changes to “0”, output changes from “1” to “0” and the output of AND gate B

also changes from “1” to “0”.

Since the output from OR gate B changes from “1” to “0” and causes Tr

and the fog lights (daytime running lights) go off automatically.

to go off, the fog light relay goes off

2

The “0” signal from AND gate B is also supplied to OR gate A. Since the “0” signal from the light control switch

(terminal T) is supplied to the other terminal, OR gate A maintains the output “1” and the taillights remain on

as a result.

NOTE: Fog lights can be turned on by turning the fog light switch on in this condition.

GENERAL 1990 FEATURES

1

2nd Ti

7

DOOR LOCK CONTROL SYSTEM

The method of unlocking all the doors when the driver’s door lock is operated by the key in models with the electronically

controlled door lock control system is changed. Previously, one operation of the driver’s door lock with the key unlocked

all the doors together with the driver’s door, but this has been changed to the method used in the current Cressida, in which

the only driver’s door is unlocked mechanically when the driver’s door lock is operated once. Operating driver’s door lock

twice in succession unlocks the other doors electronically. Operating the door lock on the passenger side once unlocks

all the doors as before. This change is made through changes in the operation of the door lock control relay.

Unlock Operation

Item

Key Cylinder

Unlock Door Driver ’s Door Only Other Doors

Control Mechanically Electrically

st Time

me

8

– MEMO –

64

CAMRY—OUTLINE OF NEW FEATURES

CAMRY

OUTLINE OF NEW FEATURES

The Toyota Camry is a compact class passenger car with a wealth of model variations which is evaluated highly by

customers. The following improvements are made for the 1990 model year to raise the Camry’s product appeal.

1. 3S–FE Engine

Plastic region tightening is used for the cylinder head bolts for good axial tension. Refer to the 1990 Camry Repair

Manual (Pub. No. RM151U) for the plastic region tightening method.

2. 2VZ–FE Engine

A knock prevention correction function, which controls the ignition timing according to engine knocking

conditions, is added to the ESA (Electronic Spark Advance) system to improve engine output and torque.

A fuel pressure control system, which raises the fuel pressure when the engine is restarted while hot, helps to

maintain restartability.

3. Drive Shaft

The inboard joint tulip of the drive shafts and the differential side gear shaft are integrated in models equipped with

the S51 manual transaxle in order to reduce the number of parts and weight.

4. Brake

The front disc brake rotor diameter in models equipped with the 2VZ–FE engine with A.B.S. (Anti–Lock Brake

System) is changed from 10.04 in. (255 mm) to 10.91 in. (277 mm) to improve the braking performance of the front

brakes.

5. Others (see GENERAL 1990 FEATURES for details)

For Canada, a daytime running light system, which lights up the headlights and taillights during daylight hours,

is used to improve a vehicle’s visibility from the outside during the daytime.

In models with power windows, the door unlock control system is changed from a system where a single key

operation of the driver’s door lock opened all the doors to the system used in the Cressida where the driver’s door

is unlocked with one operation of the driver’s door lock, and all the doors are unlocked if the driver’s door lock

is operated two times in succession.

CAMRY—OUTLINE OF NEW FEATURES

65

66

(2)

(4)

(8)

CAMRY—MODEL CODE

MODEL CODE

VZV21 L G – U W P N K A

(1)(2)(3)(4)(5)(6)(7)(8)(9)

BASIC MODEL CODE

SV21 : FWD with 3S–FE Engine

(1)

SV25 : All–Trac/4WD with 3S–FE Engine

VZV21 : FWD with 2VZ–FE Engine

STEERING WHEEL POSITION

L : Left–Hand Drive

BODY TYPE

(3)

Blank : Sedan

G : Wagon

MODEL NAME

U : Camry

BODY TYPE

(5)

E : Sedan

W : Wagon

GEARSHIFT TYPE

(6)

M : 5–Speed Manual

P : 4–Speed Automatic

GRADE

B : STD

(7)

D : DLX

N : LE

ENGINE SPECIFICATION

K : EFI and DOHC

DESTINATION

(9)

A : U.S.A.

K : Canada

MODEL LINE–UP

CAMRY—MODEL LINE–UP

67

68

CAMRY—NEW FEATURES

NEW FEATURES

2VZ–FE ENGINE

1. Description

The 2.5 liter, V–6, 24–valve, DOHC 2VZ–FE engine is liked by customers because of its quietness and good

performance.

The following improvements are made in the engine for the 1990 model year.

Modification Purpose Contents

Improve Performance

Maintain Restartability

A knock prevention correction function is added to the ESA to control the

ignition timing according to engine knocking conditions.

A fuel pressure control system is used to raise the fuel pressure when the

engine is restarted while hot.

CAMRY—NEW FEATURES

NewP

2. Engine Specifications and Performance Curve

69

Engine

Item

No. of Cyls. & Arrangement 6–Cylinder, V Type ←

Valve Mechanism

Combustion Chamber Pentroof Type ←

Manifold Cross–flow ←

Displacement cu. in. (cc) 153.0 (2508) ←

Bore x Stroke in. (mm) 3.44 x 2.74 (87.5 x 69.5) ←

Compression Ratio 9.0 : 1 ←

Max. Output (SAE–NET) 156 HP @ 5600 rpm 153 HP @ 5600 rpm

Max. Torque (SAE–NET) 160 ft.lbs @ 4400 rpm 155 ft.lbs @ 4400 rpm

Fuel Octane Number (RON) 96 91

4 Valves, DOHC, Belt

& Gear Drive

revious

←

70

NewP

CAMRY—NEW FEATURES

3. TCCS (TOYOTA Computer–Controlled System)

The following table is a comparison of the TCCS engine control systems between the new 2VZ–FE engine and

previous 2VZ–FE engine.

Engine

System

EFI

(Electronic Fuel

Injection)

Cold Start

Injector Control

ESA

(Electronic Spark

Advance)

ISC

(Idle Speed Control)

Oxygen Sensor

Heater Control

Air Conditioner

Control

Fuel Pressure

Control

An L–type EFI system is used, which

directly detects the intake air volume

with a vane type air flow meter.

The fuel injection system is a 3–group

type.

When the coolant temperature is between

71.6°F and 95°F (22°C and 35°C), the

injection duration of the cold start injector

is controlled by the ECU. At 71.6°F

(22°C) or lower, it is controlled by the

start injector time switch and the ECU.

Ignition timing is determined by the ECU

based on signals from various sensors.

In vehicles equipped with automatic

transaxle, the torque control

compensation during gear shifting is

used to provide smooth engagement of

brakes and clutches.

Corrects ignition timing in response to

engine knocking.

( Page 72)

A step motor type ISC is used, which

controls the fast idle and idle speeds.

Maintains the temperature of the oxygen

sensor at an appropriate level to increase

accuracy of detection of the oxygen

concentration in the exhaust gas.

By controlling the air conditioner

compressor in accordance with the

throttle valve opening angle and the

vehicle speed, drivability is maintained.

Maintains restartability by controlling the

fuel pressure.

( Page 72)

revious

←

←

←

←

←

N.A.

←

←

←

N.A.

Diagnosis

Fail–Safe

When a malfunction occurs, the ECU

diagnoses and stores code in memory.

17 diagnostic items (19 for California)

are monitored by the ECU.

( Page 73)

When a malfunction occurs, the ECU

stops or controls the engine according to

the data stored in memory.

15 diagnostic items (17 for California)

are monitored by the ECU.

←

CAMRY—NEW FEATURES

System Construction

The TCCS is the same as in the previous model with the exception of the items indicated.

71

*1: Applicable only to California specification vehicles.

*2: Applicable only to automatic transaxle models.

72

ESA (Electronic Spark Advance)

A knock sensor is mounted between the right and

left banks of the cylinder block in the new 2VZ–FE

engine.

This sensor detects if the engine is knocking or not

and also detects the strength of the knocking from

the vibrations of the cylinder block.

This ESA includes a knock prevention correction

function which corrects the ignition timing

according to the engine knocking conditions. This

correction prevents excessive knocking while at the

same time improving engine performance and

providing good fuel economy.

The construction and operation of the knock sensor

as well as the contents of knock prevention

correction control are the same as for the 3S–GTE

engine. However, fuel judgment is not included. For

details, see the Celica All–Trac/4WD New Car

Features (Pub. No. NCF033U).

CAMRY—NEW FEATURES

Fuel Pressure Control

1) General

This system is the same as that used in the 4A–GE engine for the Corolla. It includes a VSV in the vacuum line

from the intake manifold to the pressure regulator to control the fuel pressure in accordance with whether or not

intake manifold vacuum or atmospheric pressure is acting on the diaphragm chamber of the pressure regulator.

When the coolant temperature and intake air temperature are higher than predetermined levels during starting,

the ECU turns on the VSV and increases the fuel pressure to prevent the fuel percolation, which maintains engine

restartability and idling stability.

2) General

od of time or adaptive control value is not renewed for a certain period

When the coolant temperature is 203°F (95°C)

or higher and the intake air temperature is

140°F (60°C) or higher and the engine is

cranked, the ECU turns on the VSV. When the

VSV goes on, atmospheric air is introduced

into the diaphragm chamber of the pressure

regulator and the fuel pressure becomes higher

by the amount of the intake manifold vacuum

than the fuel pressure under normal engine

operating conditions.

The VSV is turned off when the air–fuel ratio becomes too thin and when the vehicle speed reaches 12.4 mph

(20 km/h) or more.

Self–Diagnosis

Due to the use of the knock sensor, diagnostic codes No. 52 and No. 53 have been added. Code No. 11 is also deleted.

Diagnostic codes in the new 2VZ–FE engine are as shown in the table below.

Code

No.

12 RPM Signal

13 RPM Signal No “Ne” signal to ECU when the engine speed is above 1000 rpm.

14 Ignition Signal No “IGf” signal to ECU 6–8 times in succession.

16

21

22

24

25*

26*

Item Diagnosis Trouble Area

No “Ne” or “G” signal to ECU within 2 seconds after the engine has been

cranked.

ECT Control

Signal in ECU

Oxygen Sensor

Signal

Oxygen Sensor

Heater Signal

Water Temp.

Sensor Signal

Intake Air

Temp. Sensor

Signal

Air–Fuel

1

Ratio Lean

Malfunction

Air–Fuel

2

Ratio Rich

Malfunction

ECT control in ECU faulty.

Deterioration of the main oxygen sensor.

Open or short circuit in main oxygen sensor heater signal (HT).

Open or short circuit in water temp. sensor signal (THW).

Open or short circuit in intake air temp. sensor signal (THA).

(1) When feedback frequency of air–fuel ratio feedback correction or

adaptive control is abnormally high during feedback condition.

(2) When air–fuel ratio feedback correction value or adaptive control val-

ue continues at the upper (lean) or lower (rich) limit for a certain period of time or adaptive control value is not renewed for a certain period

of time.

(3) Open or short circuit in oxygen sensor signal.

CAMRY—NEW FEATURES

Distributor circuit

Distributor

Starter signal circuit

ECU

Distributor circuit

Distributor

ECU

Igniter and ignition coil circuit

Igniter and ignition coil

ECU

ECU

Main oxygen sensor circuit

Main oxygen sensor

Main oxygen sensor heater circuit

Main oxygen sensor heater

ECU

Water temp. sensor circuit

Water temp. sensor

ECU

Intake air temp. sensor circuit

Intake air temp. sensor

ECU

Injector circuit

Injector

Fuel line pressure

Ignition system

Oxygen sensor circuit

Oxygen sensor

Air flow meter

Water temp. sensor

ECU

Injector circuit

Injector

Fuel line pressure

Cold start injector

Air flow meter

Water temp. sensor

ECU

ON

73

“CHECK ENGINE”

Lamp

ON

ON

ON

OFF

ON

ON

ON

(Calif. Only)

ON

(Calif. Only)

ON

(Calif. Only)

74

CAMRY—NEW FEATURES

Code

No.

2

27*

31

32

41

42

43 Starter Signal

Item Diagnosis Trouble Area

Sub–oxygen

Sensor Signal

Air Flow

Meter Signal

Air Flow

Meter Signal

Throttle Position

Sensor Signal

Vehicle Speed

Sensor Signal

Open or short circuit in sub–oxygen

sensor signal (Ox2).

Open circuit in Vc signal or short

circuit between Vs and E2when idle

contacts are closed.

Open circuit in E2 or short circuit

between Vc and Vs.

Open or short circuit in throttle

position sensor signal (VTA).

No “SP1” signal to ECU for 8

seconds when engine speed is

between 2550 rpm and 4500 rpm

and coolant temp. is above 158

°C) except when racing the

(70

engine.

No “ST A” signal to ECU until

engine speed reaches 800 rpm with

vehicle not moving.

°F

Sub–oxygen sensor circuit

Sub–oxygen sensor

ECU

Air flow meter circuit

Air flow meter

ECU

Air flow meter circuit

Air flow meter

ECU

Throttle position sensor circuit

Throttle position sensor

ECU

No. 1 vehicle speed sensor circuit

No. 1 vehicle speed sensor

ECU

Ignition switch circuit

Ignition switch

ECU

“CHECK

ENGINE” Lamp

ON

ON

ON

ON

(Calif. Only)

OFF

OFF

Knock sensor circuit

Knock sensor

ECU

ECU

EGR system

EGR gas temp. sensor circuit

EGR gas temp. sensor

ECU

ON

OFF

ON

52

53

71*

2

Knock Sensor

Signal

Knock Control

Signal in ECU

EGR System

Malfunction

Open or short circuit in knock

sensor signal (KNK).

Knock control in ECU faulty.

EGR gas temp. below

predetermined level during EGR

operation.

Open circuit in EGR gas temp.

sensor signal (THG).

A/C amplifier

A/C switch circuit

Neutral start switch circuit

Switch Condition

51

Signal

No “IDL” signal or No “NSW” or

“A/C” signal to ECU, with the

check terminals E1 and T shorted.

Neutral start switch

Throttle position sensor circuit

OFF

Throttle position sensor

Accelerator pedal and cable

ECU

*1: No. (1) and (2) in the diagnostic contents of codes No. 25 and 26 apply to California specification vehicles only,

while (3) applies to all models.

*2: Applicable only to California specification vehicles.

Fail–Safe

The following two items are added to the previous items.

1) ECT Control System Malfunction

If trouble develops in the ECT control system in the ECU, the transmission will not operate properly. At this

time, the ECU prevents engine torque control correction by the ESA.

2) Knock Sensor or Knock Control System Malfunction

If the knock sensor circuit becomes open or shorted, or if trouble develops in the knock control system in the

ECU, the ECU corrects ignition timing to the maximum retard condition of the knock prevention correction to

prevent knocking.

CAMRY—NEW FEATURES

O

DRIVE SHAFT

The inboard joint in models equipped with the S51 manual transaxle is changed from the flange type, with separate

joint tulip and differential side gear shaft to the flangeless type, in which these parts are integrated. This design helps

to simplify the parts and reduce weight. Furthermore, the combination of the slidable tripod type inboard joint and

rzeppa type outboard joint is not changed.

75

BRAKE

The front brake disc rotor in models equipped with

the 2VZ–FE engine with A.B.S. (Anti–Lock Brake

System) is made larger.

The sizes of the disc brake caliper and disc pad are

unchanged from the previous model.

Disc Rotor Specifications

Item

Model

New 10.91 in. (277 mm)

Previous 10.01 in. (255 mm)

uter Diameter

142

Turn ng D ameter

Overall

Curb Weight

Gross V ehicle Weight

APPENDIX—CAMRY

CAMRY

Item Area U.S.A.

Engine Type 3S–FE ← ← ←

Valve Mechanism 4 Valves, DOHC ← ← ←

Bore x Stroke in. (mm) 3.39 x 3.39 (86 x 86) ← ← ←

Displacement cu.in (cc) 121.9 (1,998) ← ← ←

Compression Ratio 9.3 ← ← ←

Engine

Carburetor Type EFI ← ← ←

Research Octane No. RON 91 ← ← ←

Max. Output (SAE–NET) HP @ rpm (kW / rpm) 115 @ 5,200 (86/5,200) ← ← ←

Max. Torque (SAE–NET) ft–lbs @ rpm (N.m / rpm) 124 @ 4,400 (168/4,400) ← ← ←

Battery Capacity (5HR) Voltage & Amp. hr. 12–40, 12–48

Alternator Output Watts 840 ← ← ←

Starter Output kW 1.0, 1.4

Engine

Electrical

Max. Speed mph (km/h) 112 (180) ← 112 (180) ←

Max. Cruising Speed mph (km/h) 96 (155) 90 (145) 96 (155) 90 (145)

Acceleration

Max. Permissible Speed

Performance

Turning Diameter

(Outside Front)

Fuel Tank Capacity U.S. gal (L, Imp.gal.)

Clutch Type DST — DST ←

Transmission Type S51 A140L S51 A140E

Transmission Gear Ratio

Counter Gear Ratio — 0.945 — 0.945

Defferential Gear Ratio (FWD) 3.736 ← ← ←

Center Differential Gear Ratio (4WD) — — — —

Transfer and REar Drifferential Gear Ratio (4WD) — — — —

Rear Differential Gear Size (4WD) in. — — — —

Chassis

Suspension Type

Stabilizer Bar

Brake Type

Parking Brake Type L.T. Drum ← ← ←

Brake Booster Type and Size in. Tandem, 8” + 9” ← ← ←

Steering Gear Type Rack & Pinion ← ← ←

Steering Gear Ratio (Overall) 17.4 ← ← ←

Power Steering Type Integral Valve ← ← ←

Overall

Wheel Base in. (mm)

Tread

Effective Head Room

Effective Leg Room

Shoulder Room

Overhang

Min. Running Ground Clearance in. (mm) 5.3 (135) ← ← ←

Angle of Approach degree 21°00’ ← ← ←

Angle of Departure degree 14°3 0’ ← ← ←

Major Dimenstions & Vehicle Weights

Curb Weight

Gross Vehicle Weight

Luggage Compartment Capacity cu. ft. (m3) — — — —

*1: Set Option with Cold Area Spec., *2: Set Option without Cold Area Spec., *3: With Moon Roof (Option)

Body Type

Vehicle Grade STD DLX

Model Code SV21L–UEMBKA SV21L–UEPBKA SV21L–UEMDKA SV21L–UEPDKA

*1

*1

0 to 100 km/h

sec.

0 to 400 m sec. 17.5 18.0 17.5 18.0

1st Gear mph (km/h) 39 (49) 40 (65) 30 (49) 40 (65)

2nd Gear mph (km/h) 55 (89) 74 (119) 55 (89) 74 (119)

3rd Gear mph (km/h) 86 (139) — 86 (139) —

4th Gear mph (km/h) — — — —

Wall to Wall ft. (m)

Curb to Curb ft. (m)

In First 3.538 2.810 3.538 2.810

In Second 1.960 1.549 1.960 1.549

In Third 1.250 1.000 1.250 1.000

In Fourth 0.945 0.706 0.945 0.706

In Fifth 0.731 — 0.731 —

In Reverse 3.153 2.296 3.153 2.296

Front Mac Pherson Strut ← ← ←

Rear Mac Pherson Strut ← ← ←

Front STD ← ← ←

Rear — — STD ←

Front Ventilated Disc ← ← ←

Rear L.T. Drum ← ← ←

Length in. (mm) 182.1 (4,625) ← ← ←

Width in. (mm) 66.5 (1,690) ← 67.3 (1,710) ←

Height in. (mm) 54.1 (1,375) ← ← ←

Front in. (mm) 58.1 (1,475) ← ← ←

Rear in. (mm) 56.9 (1,445) ← ← ←

Front in. (mm) 38.2 (970), 36.9 (937)

Rear in. (mm) 37.0 (939), 35.9 (911)

Front in. (mm) 42.9 (1,090) ← ← ←

Rear in. (mm) 34.1 (866.1) ← ← ←

Front in. (mm) 54.3 (1,378) ← ← ←

Rear in. (mm) 53.7 (1,363) ← ← ←

Front in. (mm) 36.4 (925) ← ← ←

Rear in. (mm) 43.3 (1,100) ← ← ←

Front lb (kg) 1,642 (745) 1,698 (770) 1,665 (755) 1,720 (780)

Rear lb (kg) 1,047 (475) — 1,069 (485) ←

Total lb (kg) 2,689 (1,220) 2,745 (1,245) 2,734 (1,240) 2,789 (1,265)

Front lb (kg) — — — —

Rear lb (kg) — — — —

Total lb (kg) 3,880 (1,760) ← ← ←

11.0 13.0 11.0 13.0

— — — —

34.8 (10.6) ← ← ←

15.9 (60, 13.2) ← ← ←

102.4 (2,600) ← ← ←

*3

*3

← 12–48, 12–40

← 1.4, 1.0

← ← ←

← ← ←

Sedan

*2

*2

←

←

APPENDIX—CAMRY

U.S.A.

VZV21L–UEMDKA VAV21L–UEPDKA SV25L–UEMDKA SV25L–UEPDKA SV21L–UEPNKA VAV21L–UEPNKA

DLX LE

2VZ–FE ← 3S–FE ← ← 2VZ–FE

← ← ← ← ← ←

3.44 x 2.74 (87.5 x 69.5) ← 3.39 x 3.39 (86 x 86) ← ← 3.44 x 2.74 (87.5 x 69.5)

153.0 (2,508) ← 121.9 (1,998) ← ← 153.0 (2,508)

9.0 ← 9.3 ← ← 9.0

← ← ← ← ← ←

96 ← 91 ← ← 96

156 @ 5,600 (116/5,600) ← 115 @ 5,200 (86/5,200) ← ← 156 @ 5,600 (116/5,600)

160 @ 4,400 (217/4,400) ← 124 @ 4,400 (168/4,400) ← ← 160 @ 4,400 (217/4,400)

12–48 ← 12–48, 12–40

← ← ← ← ← ←

← ← ← ← ← ←

127 (205) 121 (195) 112 (180) 109 (175) 112 (180) 121 (195)

109 (175) 103 (165) 96 (155) 90 (145) ←

9.2 10.2 12.6 13.9 13.0 10.2

17.0 17.5 18.1 19.9 18.0 17.5

33 (52) 40 (64) 28 (45) 32 (52) 40 (65) 40 (64)

52 (83) 72 (116) 48 (78) 60 (96) 74 (119) 72 (116)

79 (127) 111 (179) 75 (120) 93 (149) — 111 (179)

109 (175) ← — — — —

— ← — — — —

35.4 (10.8) ← 34.8 (10.6) ← 35.4 (10.8)

← ← ← ← ← ←

DST — DST — — —

E52 A540E E56F5 A540H A140E A540E

3.230 2.810 3.538 2.810 ← ←

2.045 1.549 2.045 1.549 ← ←

1.333 1.000 1.333 1.000 ← ←

0.972 0.734 1.028 0.734 0.706 0.734

0.820 — 0.820 — — —

3.583 2.296 3.583 2.296 ← ←

— 1.027 — 1.027 0.945 1.027

3.933 3.625 — — 3.736 3.625

— — 4.235 4.285 — —

— ← 2.928 ← — —

— ← 6.7 ← ← —

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

Solid Disc ← ← ← L.T. Drum Solid Disc

Duo Servo ← ← ← L.T. Drum Duo Servo

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

57.9 (1,470) ← 58.1 (1,475) ← ← 57.9 (1,470)

56.7 (1,440) ← ← ← 56.9 (1,445) 56.7 (1,440)

← ← ← ← ← ←

← ← ← ← — ←

← ← ← ← ← ←

← ← ← ← — —

← ← ← ← ← ←

← ← ← ← — —

← ← ← ← ← ←

← ← ← ← ← ←

← ← 5.4 (136) ← 5.3 (135) ←

← ← ← ← ← ←

← ← ← ← ← ←

1,863 (845) 1,896 (860) 1,775 (805) 1,841 (835) 1,720 (780) 1.951 (885)

1,102 (500) 1,124 (510) 1,312 (595) ← 1,091 (495) 1,136 (515)

2,965 (1,345) 3,020 (1,370) 3,087 (1.400) 3,153 (1,430) 2.811 (1,275) 3,087 (1,400)

— — — — — —

— — — — — —

4,123 (1,870) ← 4,266 (1,935) ← 3,880 (1,760) 4,123 (1,870)

— — — — — —

Sedan

*2

← ← 12–48

←

143

103 (165)

144

T

O

ll

Curb Weight

Gross V ehicle Weight

APPENDIX—CAMRY

Item Area U.S.A.

Engine Type 3S–FE ← 2VZ–FE ←

Valve Mechanism 4 Valves, DOHC ← ← ←

Bore x Stroke in. (mm) 3.39 x 3.39 (86 x 86) ← 3.44 x 2.74 (87.5 x 69.5) ←

Displacement cu.in. (cc) 121.9 (1,998) ← 153.0 (2508) ←

Compression Ratio 9.3 ← 9.0 ←

Engine

Carburetor Type EFI ← ← ←

Research Octane No. RON 91 ← 96 ←

Max. Output (SAE–NET) HP @ rpm (kW / rpm) 115 @ 5,200 (86/5,200) ← 156 @ 5,600 (116/5,600) ←

Max. Torque (SAE–NET) ft–lbs @ rpm (N.m / rpm) 124 @ 4,400 (168/4,400) ← 160 @ 4,400 (217/4,400) ←

Battery Capacity (5HR) Voltage & Amp. hr. 12–48, 12–40

Alternator Output Watts 840 ← ← ←

Engine

Electrical

Starter Output kW 1.4, 1.0

Max. Speed mph (km/h) 109 (175) 112 (180) 124 (200) 118 (190)

Max. Cruising Speed mph (km/h) 90 (145) 87 (140) 106 (170) 99 (160)

Acceleration

Max. Permissible Speed

Performance

Turning Diameter

urning Diameter

(Outside Front)

Fuel Tank Capacity U.S. gal (L, Imp.gal) 15.9 (60, 13.2) ← ← ←

Clutch Type — — — —

Transmission Type A540H A140E A540E ←

Transmission Gear Ratio

Counter Gear Ratio 1.027 0.945 1.027 ←

Differential Gear Ratio (FWD) — 3.736 3.625 ←

Center Differential Gear Ratio (4WD) 4.285 — — —

Transfer and Rear Differential Gear Ratio (4WD) 2.928 — — —

Rear Differential Gear Size (4WD) in. 6.7 — — —

Chassis

Suspension Type

Stabilizer Bar

Brake Type

Parking Brake Type Duo Servo L.T. Drum Duo Servo ←

Brake Booster Type and Size in. Tandem, 8” + 9” ← ← ←

Steering Gear Type Rack & Pinion ← ← ←

Steering Gear Ratio (Overall) 17.4 ← ← ←

Power Steering Type Integral Valve ← ← ←

Overall

vera

Wheel Base in. (mm) 102.4 (2,600) ← ← ←

Tread

Effective Head Room

Effective Leg Room

Shoulder Room

Overhang

Min. Running Ground Clearance in. (mm) 5.4 (136) 5.3 (135) ← ←

Angle of Approach degree 21°00’ ← ← ←

Angle of Departure degree 14°30’ 12°30’ ← ←

Major Dimenstions & Vehicle Weights

Curb Weight

Gross Vehicle Weight

Luggage Compartment Capacity cu. ft. (m3) — — — —

Body Type

Vehicle Grade LE DLX LE

Model Code SV25L–UEPNKA SV21LG–UWPDKA VZV21LG–UWPDKA VAV2LG–UWPNKA

0 to 100 km/h sec. 13.9 13.5 9.5 10.5

0 to 400 m sec. 19.9 18.7 17.2 17.7

1st Gear mph (km/h) 32 (52) 40 (65) 40 (64) ←

2nd Gear mph (km/h) 60 (96) 74 (119) 72 (116) ←

3rd Gear mph (km/h) 93 (149) — 111 (179) ←

4th Gear mph (km/h) — — — —

Wall to Wall ft. (m) — — — —

Curb to Curb ft. (m) 34.8 (10.6) ← 35.4 (10.8) ←

In First 2.810 ← ← ←

In Second 1.549 ← ← ←

In Third 1.000 ← ← ←

In Fourth 0.734 0.706 0.734 ←

In Fifth — — — —

In Reverse 2.296 2.296 ← ←

Front Mac Pherson Strut ← ← ←

Rear Mac Pherson Strut ← ← ←

Front STD ← ← ←

Rear STD ← ← ←

Front Ventilated Disc ← ← ←

Rear Solid Disc L.T. Drum Solid Disc ←

Length in. (mm) 182.1 (4,625) 183.1 (4,650) ← ←

Width in. (mm) 67.3 (1,710) ← ← ←

Height in. (mm) 54.1 (1,375) 54.5 (1,385) ← ←

Front in. (mm) 58.1 (1,475) ← 57.9 (1,470) ←

Rear in. (mm) 56.7 (1,440) 56.9 (1,445) 56.7 (1,440) ←

Front in. (mm) 38.2 (970), 36.9 (937)

Rear in. (mm) 37.0 (939), 35.9 (911)

Front in. (mm) 42.9 (1,090) ← ← ←

Rear in. (mm) 34.1 (866.1) 34.4 (873) ← ←

Front in. (mm) 54.3 (1,378) ← ← ←

Rear in. (mm) 53.7 (1,363) ← ← ←

Front in. (mm) 36.4 (925) ← ← ←

Rear in. (mm) 43.3 (1,100) 44.3 (1,125) ← ←

Front lb (kg) 1,841 (835) 1,686 (765) 1,874 (850) 1,929 (875)

Rear lb (kg) 1,334 (605) 1,224 (555) 1,257 (570) 1,268 (575)

Total lb (kg) 3,175 (1,440) 2,910 (1,835) 3,131 (1,420) 3,197 (1,450)

Front lb (kg) — — — —

Rear lb (kg) — — — —

Total lb (kg) 4,266 (1,935) 4,045 (1,835) 4,288 (1.945) ←

Sedan Wagon

*1

*1

*2

*2

← ← ←

← ← ←

38.3 (972), 37.1 (943)

37.7 (958), 36.1 (917)

*2

*2

← ←

← ←

*1 Set Option without Cold Area Spec.,*2 With Moon Roof.

APPENDIX—CAMRY

Canada

SV21L–UEMDKK SV21L–UEPDKK SV25L–UEMDKK SV25L–UEPDKK SV21–UEMNKK SV21L–UEPNKK

3S–FE ← ← ← ← ←

← ← ← ← ← ←

3.39 x 3.39 (86 x 86) ← ← ← ← ←

121.9 (1,998) ← ← ← ← ←

9.3 ← ← ← ← ←

← ← ← ← ← ←

91 ← ← ← ← ←

115 @ 5,200 (86/5,200) ← ← ← ← ←

124 @ 4,400 (168/4,400) ← ← ← ← ←

12–48 ← ← ← ← ←

← ← ← ← ← ←

1.4 ← ← ← ← ←

112 (180) ← ← 109 (175) 112 (180) ←

109 (155) ← ← 90 (145) 96 (155) 90 (145)

11.0 13.0 12.6 13.9 11.0 13.0

17.5 18.0 18.1 19.9 17.5 18.0

30.5 (49) 40.4 (65) 28 (45) 32 (52) 30 (49) 40 (65)

55.1 (89) 74.0 (119) 48 (78) 60 (96) 55 (89) 74 (119)

86.4 (139) ← 75 (120) 93 (149) 86 (139) —

— — — — — —

— — — — — —

34.8 (10.6) ← ← ← ← ←

← ← ← ← ← ←

DST — DST — DST —

S51 A140E E56F5 A540H S51 A140E

3.538 2.810 3.538 2.810 3.538 2.810

1.960 1.549 2.045 1.549 1.960 1.549

1.250 1.000 1.333 1.000 1.250 1.000

0.945 0.706 1.028 0.734 0.945 0.706

0.731 — 0.820 — 0.731 —

3.153 2.296 3.583 2.296 3.153 2.296

— 0.945 — 1.027 — 0.945

3.736 ← — — 3.736 ←

— — 4.235 4.285 — —

— — 2.928 ← — —

— — 6.7 ← — —

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← Venitlated Disc ← ← ←

L.T. Drum ← Solid Disk ← L.T. Drum ←

L.T. Drum ← Duo Servo ← L.T. Drum ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

182.1 (4,625) ← ← ← ← ←

← ← ← ← ← ←

54.1 (1,375) ← ← ← ← ←

← ← ← ← ← ←

58.1 (1,475) ← ← ← ← ←

56.9 (1,445) ← 56.7 (1,440) ← 56.9 (1,445) ←

3.82 (970), 36.9 (937)

37.0 (939), 35.9 (911)

34.1 (866.1) ← ← ← ← ←

43.4 (1,100) ← ← ← ← ←

14°30’ ← ← ← ← ←

1,642 (745) 1,698 (770) 1,753 (795) 1,819 (825) 1,642 (745) 1,698 (770)

1,069 (485) ← 1,301 (590) ← 1,080 (490) ←

2,712 (1,230) 2,767 (1,255) 3,035 (1,385) 3,120 (1,415) 2,722 (1,235) 2,778 (1,260)

3,880 (1,760) ← 4,266 (1,935) ← 3,880 (1760) ←

*3

*3

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← ← ← ← ←

← ← 5.4 (136) ← 5.3 (135) ←

← ← ← ← ← ←

— — — — — —

— — — — — —

— — — — — —

DLX LE

← ← ← ← ←

← ← ← ← ←

Sedan

145

146

Turn ng D ameter

Overall

Curb Weight

Gross V ehicle Weight

APPENDIX—CAMRY

Item Area Canada

Engine Type 2VZ–FE ← 3S–FE ←

Valve Mechanism 4 Valves, DOHC ← ← ←

Bore x Stroke in. (mm) 3.44 x 2.74 (87.5 x 69.5) ← 3.39 x 3.39 (86 x 86) ←

Displacement cu.in (cc) 153.0 (2,508) ← 121.9 (1,993) ←

Compression Ratio 9.0 ← 9.3 ←

EngineChassisMajor Dimenstions & Vehicle Weights

Carburetor Type EFI ← ← ←

Research Octane No. RON 96 ← 91 ←

Max. Output (SAE–NET) HP @ rpm (kW / rpm) 156 @ 5,600 (116/5,600) ← 115 @ 5,200 (86 x 86) ←

Max. Torque (SAE–NET) ft–lbs @ rpm (N.m / rpm) 160 @ 4,400 (217/4,400) ← 124 @ 4,400 (168/4,400) ←

Battery Capacity (5HR) Voltage & Amp. hr. 12–48 ← ← ←

Alternator Output Watts 840 ← ← ←

Engine

Electrical

Starter Output kW 1.4 ← ← ←

Max. Speed mph (km/h) 127 (205) 121 (195) 109 (175) 112 (180)

Max. Cruising Speed mph (km/h) 109 (175) 103 (165) 90 (145) 93 (150)

Acceleration

Max. Permissible Speed

Performance

Turning Diameter

(Outside Front)

Fuel Tank Capacity U.S. gal (L, Imp.gal.)

Clutch Type DST — — ←

Transmission Type E52 A540E A540H S51

Transmission Gear Ratio

Counter Gear Ratio — 1.027 ← —

Defferential Gear Ratio (FWD) 3.933 3.625 — 3.736

Center Differential Gear Ratio (4WD) — — 4.285 —

Transfer and REar Drifferential Gear Ratio (4WD) — — 2.928 —

Rear Differential Gear Size (4WD) in. — — 6.7 —

Suspension Type

Stabilizer Bar

Brake Type

Parking Brake Type Duo Servo ← ← ←

Brake Booster Type and Size in. Tandem, 8” + 9” ← ← ←

Steering Gear Type Rack & Pinion ← ← ←

Steering Gear Ratio (Overall) 17.4 ← ← ←

Power Steering Type Integral Valve ← ← ←

Overall

Wheel Base in. (mm)

Tread

Effective Head Room

Effective Leg Room

Shoulder Room

Overhang

Min. Running Ground Clearance in. (mm) 5.3 (135) ← 5.4 (136) 5.3 (135)

Angle of Approach degree 21°00’ ← ← ←

Angle of Departure degree 14°3 0’ ← ← 12°30’

Curb Weight

Gross Vehicle Weight

Luggage Compartment Capacity cu. ft. (m3) — — — —

Body Type

Vehicle Grade LE DLX

Model Code VZV21L–UEMNKK VZV21L–UEPNKK XV25L–UEPNKK SV21LG–UWMDKK

0 to 100 km/h

sec.

0 to 400 m sec. 17.0 17.5 19.9 17.7

1st Gear mph (km/h) 32 (52) 40 (64) 32 (52) 30 (49)

2nd Gear mph (km/h) 52 (83) 72 (116) 60 (96) 55 (89)

3rd Gear mph (km/h) 79 (127) 111 (179) 93 (149) 86 (139)

4th Gear mph (km/h) 109 (175) — — —

Wall to Wall ft. (m)

Curb to Curb ft. (m)

In First 3.230 2.810 ← 3.538

In Second 2.045 1.549 ← 1.960

In Third 1.333 1.000 ← 1.250

In Fourth 0.972 0.734 ← 0.945

In Fifth 0.820 — — 0.731

In Reverse 3.583 2.296 ← 3.153

Front Mac Pherson Strut ← ← ←

Rear Mac Pherson Strut ← ← ←

Front STD ← ← ←

Rear STD ← ← L.T. Drum

Front Ventilated Disc ← ← L.T. Drum

Rear Solid Disc ← ← ←

Length in. (mm) 182.1 (4,625) ← ← 183.1 (4,650)

Width in. (mm) 67.3 (1,710) ← ← ←

Height in. (mm) 54.1 (1,375) ← ← 54.5 (1,385)

Front in. (mm) 57.9 (1,470) ← 58.1 (1,475) ←

Rear in. (mm) 56.7 (1,440) ← ← 56.7 (1,445)

Front in. (mm) 38.2 (970), 36.9 (937)

Rear in. (mm) 37.0 (939), 35.9 (911)

Front in. (mm) 42.9 (1,090) ← ← ←

Rear in. (mm) 34.1 (866.1) ← ← 34.4 (873)

Front in. (mm) 54.3 (1,378) ← ← ←

Rear in. (mm) 53.7 (1,378) ← ← ←

Front in. (mm) 36.4 (925) ← ← ←

Rear in. (mm) 43.3 (1,100) ← ← 44.3 (1,125)

Front lb (kg) 1,896 (860) 1,929 (875) 1,819 (825) 1,609 (730)

Rear lb (kg) 1,102 (500) 1,124 (510) 1,323 (600) 1,213 (550)

Total lb (kg) 2,998 (1,360) 3,053 (1,385) 3,142 (1,425) 2,822 (1,280)

Front lb (kg) — — — —

Rear lb (kg) — — — —

Total lb (kg) 4,090 (1,855) ← 4,266 (1,935) 4,045 (1,835)

9.2 10.2 13.9 11.5

— — — —

35.4 (10.8) ← 34.8 (10.6) ←

15.9 (60, 13.2) ← ← ←

102.4 (2,600) ← ← ←

*1

*1

Sedan Wagon

← ← 38.3 (972), 37.1 (943)

← ← 37.7 (958), 36.1 (917)

*1: With Moon Roof

*1

*1

APPENDIX—CAMRY

Canada

DLX LE

SV21LG–UWPDKK SV21LG–UWPNKK VZV21LG–UWPNKK

← ← 2VZ–FE

← ← ←

← ← 3.44 X 2.74 (87.5 X 69.5)

← ← 153.0 (2,508)

← ← 9.0

← ← ←

← ← 96

←

←

← ← ←

← ← ←

← ← ←

← ← 118 (190)

87 (140) ← 99 (160)

13.5 ← 10.5

18.7 ← 17.7

40 (65) ← 40 (64)

74 (119) ← 72 (116)

— — 111 (179)

— — —

— — —

← ← 35.4 (10.8)

← ← ←

— — —

A140E ← A540E

2.810 ← 2.810

1.549 ← ←

1.000 ← ←

0.706 ← 0.734

— — —

2.296 ← ←

0.945 ← 1.027

← ← 3.625

— — —

— — —

— — —

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← Solid Disc

← ← Duo Servo

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← 57.9 (1,470)

← ← 56.7 (1,440)

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← ←

← ← 5.3 (135)

← ← ←

← ← ←

1,664 (755) 1,675 (760) 1,907 (865)

← ← 1,259 (570)

2,877 (1,305) 2,888 (1,310) 3,164 (1,435)

— — —

— — —

← ← 4,266 (1,935)

— — —

Wagon

← 156 @ 5,600 (116/5,600)

← 160 @ 4,400 (217/4,400)

147

Loading...

Loading...