Toshiba TCS-NET, TCB-IFCG1TLE Service Manual

SERVICE MANUAL

Model name:

TCS-NET General Purpose Interface

TCB-IFCG1TLE

FILE NO. A08-014

TCS-NET General Purpose Interface

Service Manual

SAFETY CAUTION

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

Indication Explanation

DANGER

WARNING

CAUTION

Indicates contents assumed that an imminent danger causing a death or serious injury of the

repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the repair

engineers, the third parties, and the users due to troubles of the product after work when an

incorrect work has been executed.

Indicates contents assumed that an injury or property damage (*) may be caused on the repair

engineers, the third parties, and the users due to troubles of the product after work when an

incorrect work has been executed.

* Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

[Explanation of illustrated marks]

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

WARNING

Do not modify the products.

Do not also disassemble or modify the parts. It may cause a fire, electric shock or injury.

Prohibition of modification.

For spare parts, use those specified (*).

If unspecified parts are used, a fire or electric shock may be caused.

*: For details, refer to the parts list.

Use specified parts.

Before troubleshooting or repair work, do not bring a third party (a child, etc.) except the repair

engineers close to the equipment.

It causes an injury with tools or disassembled parts.

Do not bring a child

close to the equipment.

Insulating measures

Assembly/Cabling

Please inform the users so that the third party (a child, etc.) does not approach the equipment.

Connect the cut-off lead cables with crimp contact, etc, put the closed end side upward and

then apply a water-cut method, otherwise a leak or production of fire is caused at the users’

side.

After repair work, surely assemble the disassembled parts, and connect and lead the removed

cables as before. Perform the work so that the cabinet or panel does not catch the inner

cables.

If incorrect assembly or incorrect cable connection was done, a disaster such as a leak or fire is

caused at user’s side.

2

TCS-NET General Purpose Interface

After the work has finished, be sure to use an insulation tester set (500V mugger) to check the

resistance is 2MΩ or more between the charge section and the non-charge metal section

(Earth position).

Insulator check

Be attentive to

electric shock

Check after rerair

Check after reinstallation

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s side.

When checking the circuit inevitably under condition of the power-ON, use rubber gloves and

others not to touch to the charging section.

If touching to the charging section, an electric shock may be caused.

After repair work has finished, check there is no trouble.

If check is not executed, a fire, electric shock or injury may be caused. For a check, turn off

the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test run to

check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused. Before test run, install the front panel

and cabinet.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

Service Manual

WARNING

Put on gloves

Cooling check

CAUTION

Be sure to put on gloves (*) during repair work.

If not putting on gloves, an injury may be caused with the parts, etc.

(*) Heavy gloves such as work gloves

When the power was turned on, start to work after the equipment has been sufficiently cooled.

As temperature of the compressor pipes and others became high due to cooling/heating operation, a

burn may be caused.

3

TCS-NET General Purpose Interface

Service Manual

Contents

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Required Devices and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Checking the Board inside the TCB-IFCG1TLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4

TCS-NET General Purpose Interface

Service Manual

1. Outline

This document describes how to troubleshoot individual problems in interfacing with general-purpose devices

using the TCB-IFCG1TLE. For information on Applications/Functions/Specifications, Installation, Connection of

Power cable and Signal wires, Setting, Trial Operation Check, Connection to External Devices, and so on, see the

Installation Manual of the TCB-IFCG1TLE.

2. Required Devices and Tools

• Screw driver (for +M4 screw)

• TESTER

• DYNA KIT (for TEST 4-3)

• The setting tool software for the advanced conjunction function for the general purpose interface must be

installed on the PC (with Windows 2000, XP or later) for TEST 4-3.

3. Checking the Board inside the TCB-

IFCG1TLE

In troubleshooting procedures described in Section 4 or later, you need to check the settings, connections, and

LEDs of the board inside the case.

Disconnect the DC plug of the AC adapter, remove the screws located in the four corners of the case lid, and open

the lid of the case. Connect the DC plug again, and turn on the unit.

5

TCS-NET General Purpose Interface

Service Manual

4. Troubleshooting

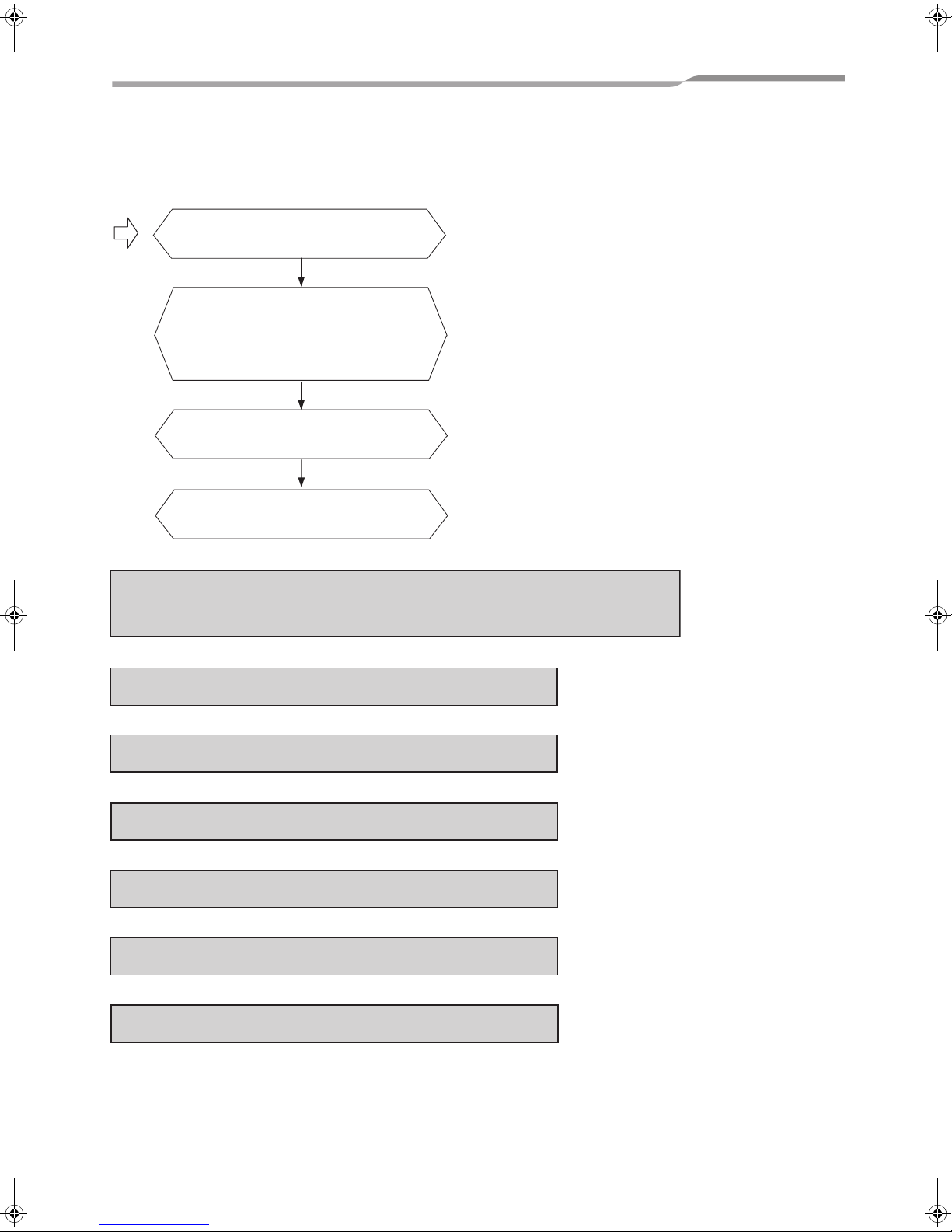

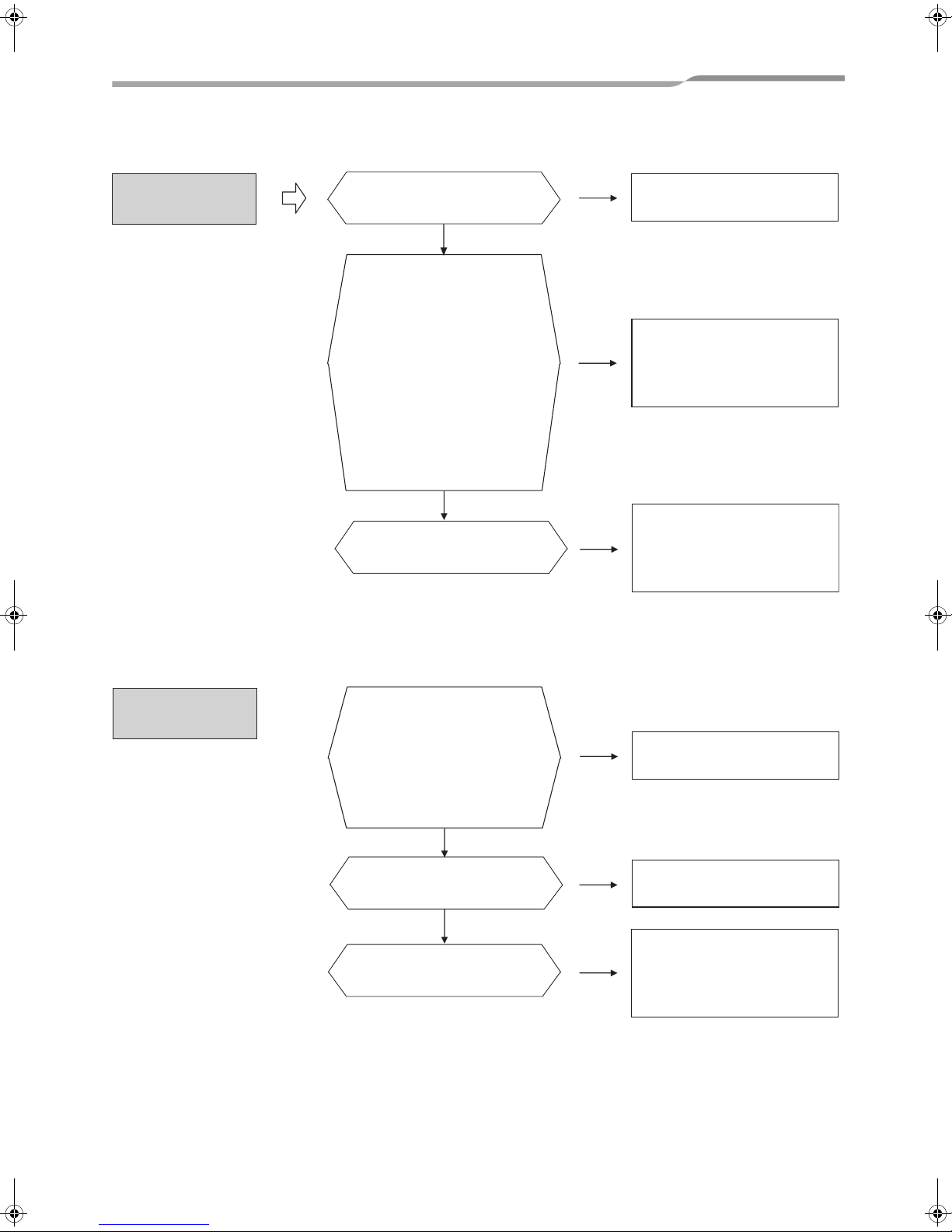

Follow the flowchart show in 4-1to perform common checks that apply to every kind of troubleshooting.

Is an appropriate AC adapter used?

Are the voltage and polarity set correctly?

YES

Is the TCC-LINK connection (U1 and U2)

made correctly?

Is the address set correctly (SW1 and

SW2)?

YES

Is the board operating normally in test

mode?

YES

Are wires for functions to be used

connected to the terminal block securely?

Troubleshoot following problems by using the applicable procedure shown in 4-2 and its following.

An air conditioning operation connected to the RO1 relay contact is not available from the

central remote controller. Refer to 4-2.

Air conditioning conjunction function is not available. Refer to 4-3.

Temperature can not be measured. Refer to 4-4.

RO1, RO2, RO3, and RO4 cannot be controlled. Refer to 4-5.

DI input is unreadable. Refer to 4-6.

AO output is not produced. Refer to 4-6.

AI input is unreadable. Refer to 4-6.

Details are described in the following sections using flowcharts.

6

TCS-NET General Purpose Interface

Service Manual

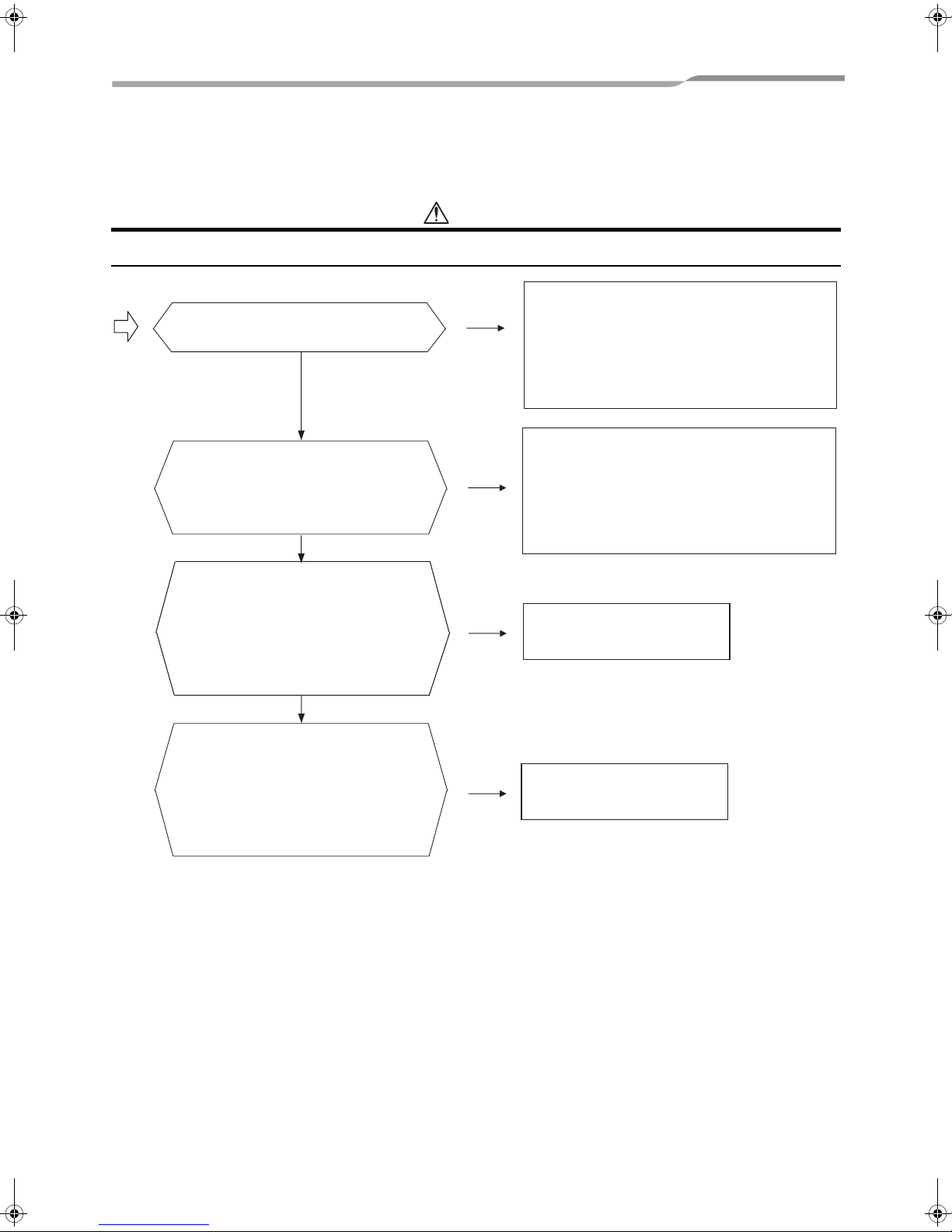

4-1. Common Checks

Be sure to always perform the checks shown in the flowchart below when a problem occurs.

CAUTION

The changes to DIP SW settings take effect after the SW7 RESET button is pressed or the unit is turned on again.

Is an appropriate AC adapter used?

Are the voltage and polarity set correctly?

YES

Is the TCC-LINK connection (U1 and U2)

made correctly?

Is the address set correctly (SW1 and

SW2)?

YES

Is the board operating normally in test

mode?

To enable test mode, set SW2 as follows:

1 and 4 to ON; 2 and 3 to OFF.

The D23, D24, D25, and D26 LEDs must

be turned ON/OFF according to whether

each bit of SW1 is ON or OFF.

YES

Are wires for functions to be used

connected to the terminal block securely?

Visually check the terminal block to see if

the stripped part of each wire is correctly

placed between the contacts. Check

continuity between each contact of the

terminal block and the end of the

corresponding wire with a tester.

NO

NO

NO

NO

Use an appropriate power supply. Check that

the POWER LED (LED D10) is lit in red.

Check that the DC plug input is 15±0.5v.

Check the voltages of 3.3V, 12V, and 5V

with a tester as necessary. See the PCB

layout diagram below that shows the

locations of the checkpoints.

Make the connection correctly, and use an

appropriate address.

For details, see Chapters 5 and 6 of the

Installation Manual.

Check the termination resistance setting of

SW6 also.

Replace the product.

Connect the wires to the

terminal block securely.

7

TCS-NET General Purpose Interface

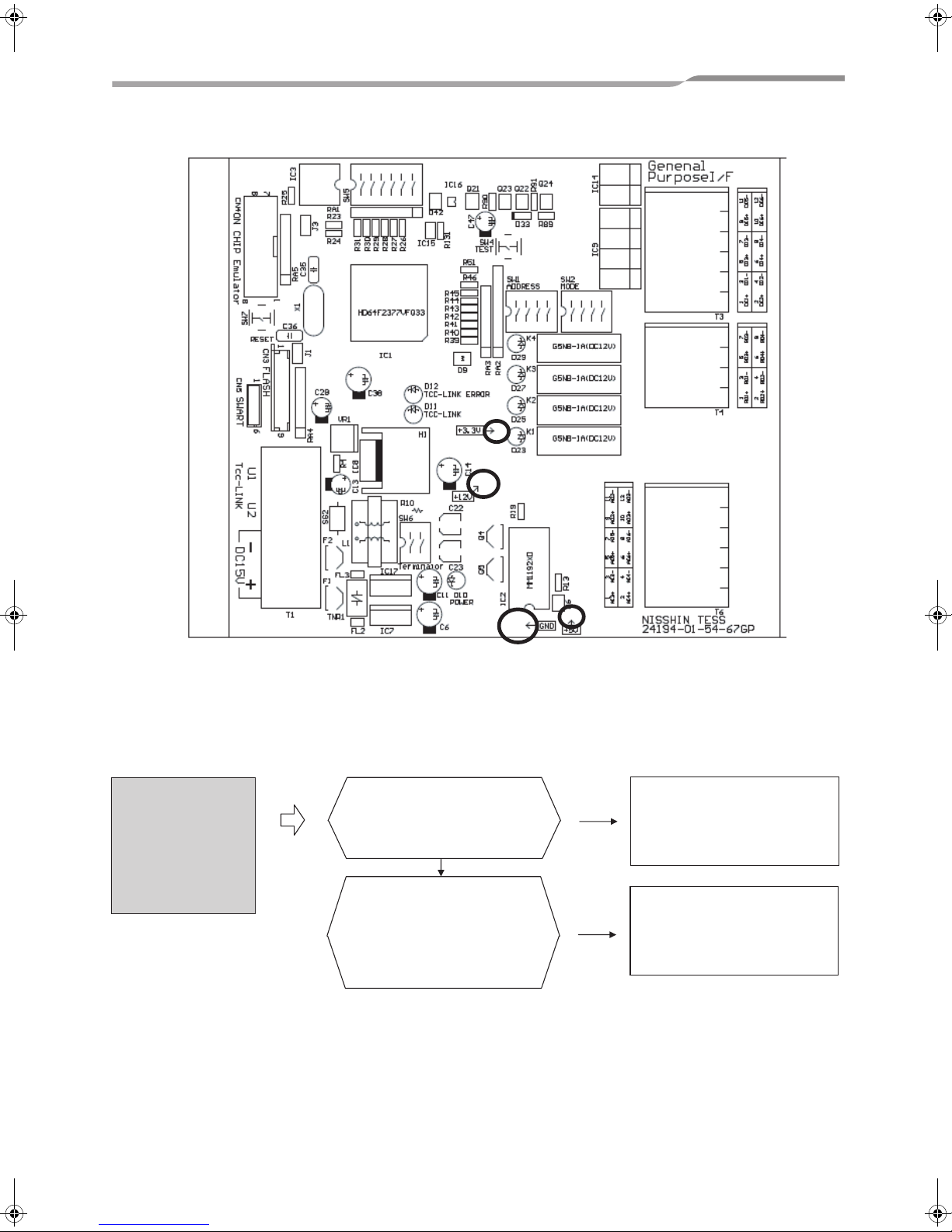

The PCB layout is shown below. Checkpoints are circled.

Service Manual

4-2. An air conditioner indoor unit connected to the RO1

and DI3 relay contacts using the HA connector cannot

be operated from the central remote controller

An air

conditioning

operation

connected to the

RO1 relay contact

is not available

from the central

remote controller

Is the relay mode set correctly

(SW5)?

SW5-2 and SW5-4 = OFF;

SW5-3 = ON

YES

Are DI3/RO1 and the air

conditioner HA connector

connected correctly?

See the chapter titled "WIRING"

of the Installation Manual.

NO

NO

See the Installation Manual,

and make the settings

correctly.

See the Installation Manual,

and make the connection

correctly.

8

TCS-NET General Purpose Interface

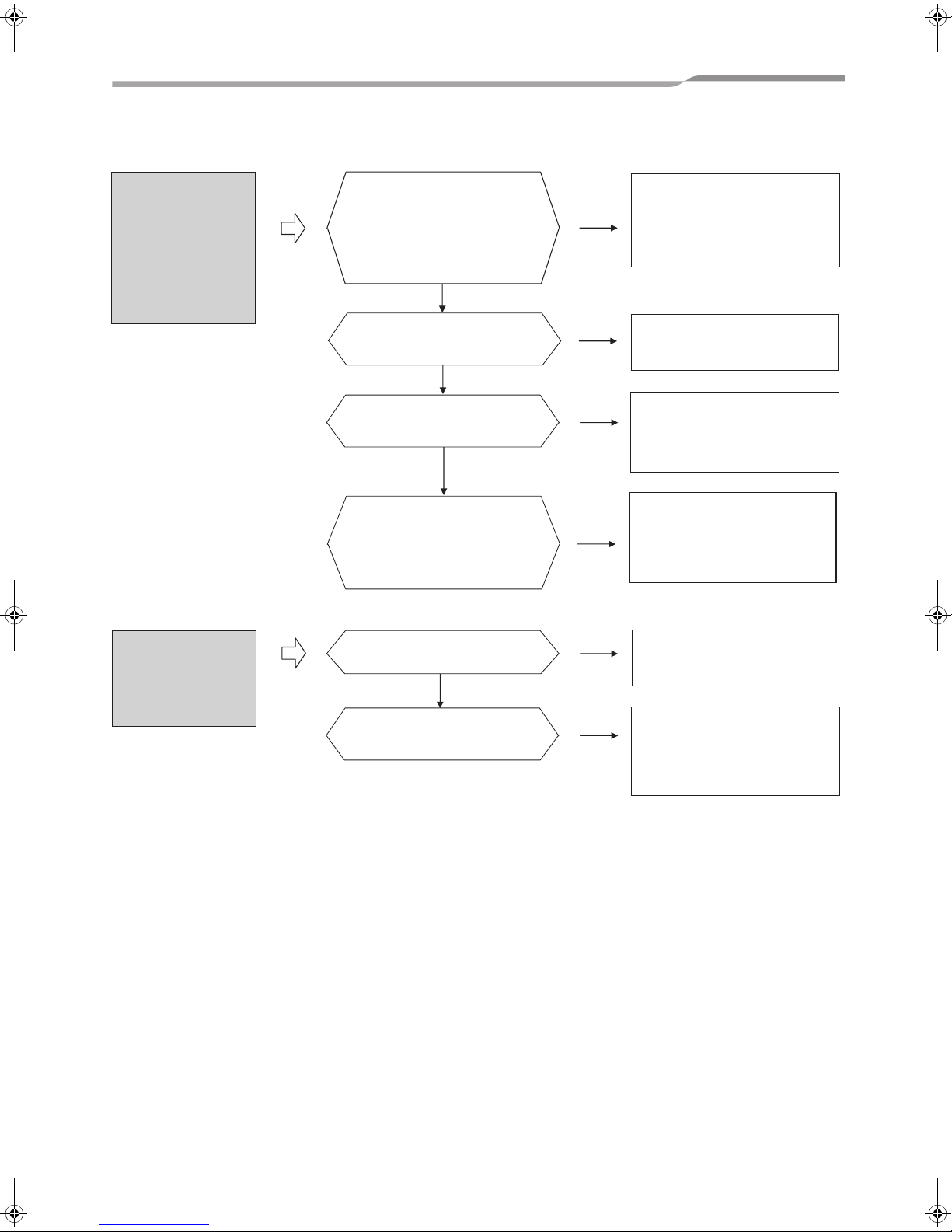

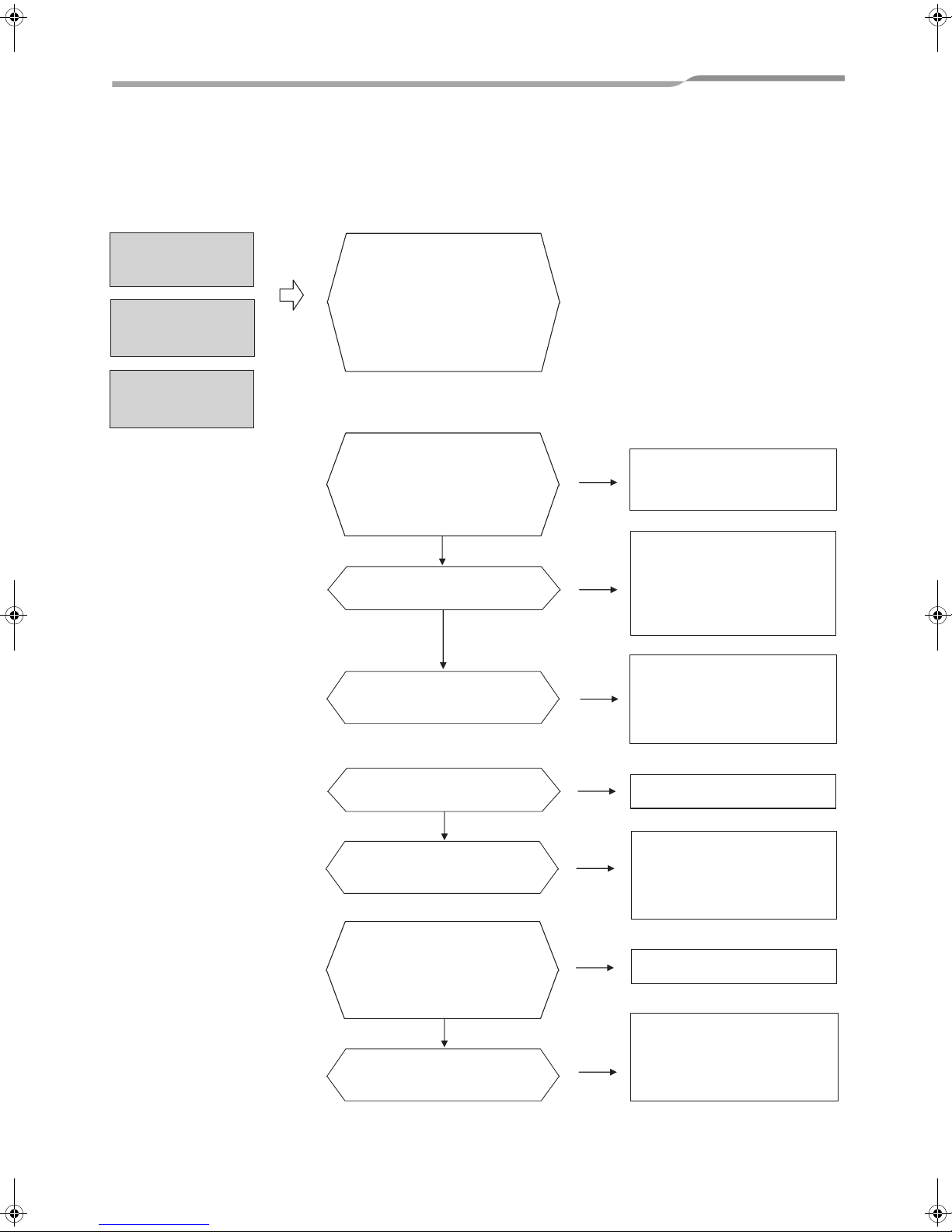

4-3. Conjunction function is not available

Service Manual

Conjunction function

cannot be set, or air

conditioning

operation is not

available.

(Using the setting

tool software for the

advanced

conjunction function)

Conjunction

function is not

available.

DI4/DI1 fixed trigger

mode

Is the setting tool software for

advanced conjunction function

installed on the configuration PC?

Is the connection to the TCBIFCG1TLE made correctly? Are

values written correctly?

YES

Is the setting value of SW5

correct?

YES

Are the input polarity and level

specified for the trigger port

provided correctly?

YES

Is the address for central control

of the specified air conditioner

correctly registered using the

setting tool software for

advanced conjunction function?

Is the setting value of SW5

correct?

YES

Are inputs to DI4 and DI1

provided correctly?

NO

NO

NO

NO

NO

NO

See the setting tool manual for

advanced conjunction

function, and install the

software and make the

connection correctly.

Make the following

settings: 6 POSITION =

ON; 5 POSITION = OFF.

See the Installation Manual,

and set the polarity, voltage

level, and current level of the

specified trigger port.

See the setting tool manual for

advanced conjunction

function, and set the address

of the applicable air

conditioner correctly.

Make the following

settings: 5 POSITION =

ON; 6 POSITION = OFF.

See the Installation Manual,

and check that the connection

is made securely and an

appropriate input current level

and polarity are provided.

9

TCS-NET General Purpose Interface

Service Manual

4-4. Temperature measurement can not be measured

Temperature

measurement can

not be measured

Is the specified thermistor

connected to AI3 or AI4

correctly?

YES

Connect the DYNA KIT to CN5.

Set SW2 as follows: 1 and 4 to

ON; 2 and 3 to OFF. Press

RESET SW7. Test mode is

enabled. Start the

communication software on the

PC, and display the

communication log in ASCII

format. The calculated

resistance value of the

thermistor connected to AI3/4 is

displayed at intervals of 1

second. Check that the value is

correct by comparing it to the

specified value.

YES

Are the TCB-IFMB640TLE and

Modbus Master operating

normally?

NO

NO

NO

Connect it correctly.

Replace the wire with a

shielded one, or avoid

induction from other wires.

Check the operation of the

TCB-IFMB640TLE and

Modbus Master.

For details, see the manual of

each device.

4-5. A relay contact cannot be controlled from the center

controller

RO1, RO2, RO3,

and RO4 cannot be

controlled

Is the board operating normally

in test mode?

To enable test mode, set SW2

as follows: 1 and 4 to ON; 2

and 3 to OFF.

The D23, D24, D25, and D26

LEDs must be turned ON/OFF

according to whether each bit

of SW1 is ON or OFF.

YES

Can the output pattern of RO1

and RO2 be set with SW5-1, 2,

and 3?

YES

Are the TCB-IFMB640TLE and

Modbus Master operating

normally?

NO

NO

NO

Replace the product.

Replace the product.

Check the operation of the

TCB-IFMB640TLE and

Modbus Master.

For details, see the manual of

each device.

10

TCS-NET General Purpose Interface

Service Manual

4-6. The port I/O value is unreadable or the port output

value is not produced when the center controller is

used

DI input is

unreadable

AO output is not

produced

AI input is

unreadable

For DI:

Connect the DYNA KIT to CN5.

Set SW2 as follows: 1 and 4 to

ON; 2 and 3 to OFF. Press

RESET SW7. Test mode is

enabled. Start the

communication software on the

PC, and display the

communication log in ASCII

format.

In test mode, are the DI1, DI2,

DI3, DI4, DI5 and DI6 levels

displayed as H or L correctly

according to the actual input in

the communication software on

the PC?

YES

Are the applied current value

and polarity provided correctly?

YES

Are the TCB-IFMB640TLE and

Modbus Master operating

normally?

NO

NO

NO

Check the input from the

external circuit and the

connection.

Check the input from the

external circuit and the

connection. For the applied

current value, refer to the

regulation value in the

installation manual.

Check the operation of the

TCB-IFMB640TLE and

Modbus Master.

For details, see the manual of

each device.

For AO:

For AI:

In test mode, is 5 V output to

AO2 and AO3?

YES

Are the TCB-IFMB640TLE and

Modbus Master operating

normally?

In test mode, measure the AI5

and AI6 input values with a

tester. Are they displayed at

1024 level in the communication

software on the PC?

YES

Are the TCB-IFMB640TLE and

Modbus Master operating

normally?

11

NO

NO

NO

NO

Replace the product.

Check the operation of the

TCB-IFMB640TLE and

Modbus Master.

For details, see the manual of

each device.

Replace the product.

Check the operation of the

TCB-IFMB640TLE and

Modbus Master.

For details, see the manual of

each device.

DE89308801

Copyright © 2009 TOSHIBA CARRIER CORPORATION, ALL Rights Reserved.

23-17, TAKANAWA 3-CHOME, MINATO-KU, TOKYO, 108-0074, JAPAN

Loading...

Loading...