Toshiba TCB-EXS21TLE INSTALLATION MANUAL

Fig.11

+01E_073002_STime_EXS21TLE.fm Page 1 Friday, January 25, 2008 4:50 PM

INSTALLATION INSTRUCTIONS Model TCB-EXS21TLE

INFORMATION FOR THE PERSON IN CHARGE OF INSTALLATION (ELECTRICAL) WORK AND SERVICING

Safety Precautions

● Read these Safety Precautions before beginning installation or electrical work, and

perform the work only in the correct manner.

● Precautions in this manual are given in the form of “Warnings” or “Cautions.” Both types

of precautions contain important information related to your safety, the safety of users,

and the correct operation, installation, or maintenance of the air conditioning system. Be

sure to carefully observe all relevant precautions.

This symbol refers to a hazard or unsafe practice which can result

in severe personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice which can result

in personal injury or product or property damage.

When installation work is completed, perform a test run and check that no trouble occurs.

Also be sure to explain the methods for using the product to the customer, based on the

contents of the Operation Manual. In addition, request that the customer keep and

conveniently store the “Information for the Person in Charge of Installation (Electrical) Work

and Servicing” together with the Operation Manual.

● Request installation and electrical work only from the dealer or a qualified air

conditioning specialist.

Attempting to carry out installation work on your own, and doing so incorrectly, may

result in electrical shock, fire, or other hazards.

● Installation procedures must be performed correctly, carefully following the instructions

in this document.

Failure to do so may result in electrical shock, fire, or other hazards.

● Electrical work must be performed by a qualified electrician. It must be performed in

accordance with technical standards related to electrical equipment, interior wiring

regulations, local codes, and the contents of these instructions. Be sure to use a

dedicated power supply circuit.

Insufficient power circuit capacity or improper electrical work may result in electrical

shock or fire.

● Use only the designated cables for wiring, and connect them securely. Fasten cables so

that no external force is applied to the terminal connections.

Insufficient connections or cable fastening may result in heat generation, fire, or other

hazards.

CAUTION

● Depending on the installation location, it may be necessary to install an earth leakage

breaker. Failure to do so may result in electrical shock or fire.

● Do not install in kitchens, workshops, or other locations where there is oil mist in the air.

● Do not install next to windows or in other locations exposed to direct sunlight or in direct

contact with outside air.

● Do not install near an elevator, automatic door, industrial sewing machine, or other

devices that can be expected to produce electrical noise.

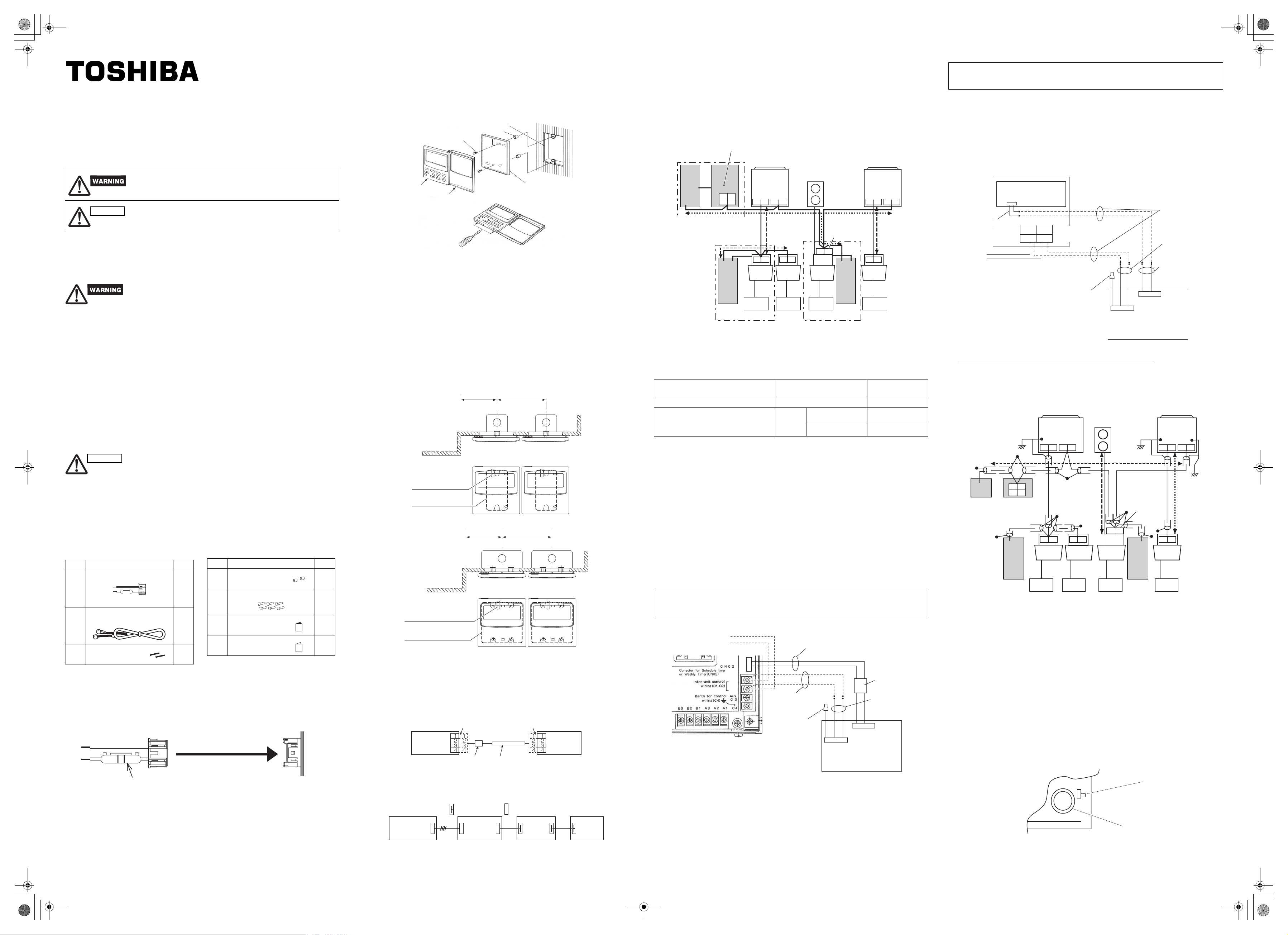

Accessories for Schedule Timer

No. Supplied parts Q'ty

CN61 (T10) power wire

1

1

(with current fuse) *1

1.2m length of connecting

2

3

wire *2

Screws

M4 × 25

1

2

*1 If the fuse blows as a result of a wiring short-circuit, miswiring, or overcurrent, replace it with a

125 V, 0.1 A fuse (Fig. 1).

*2 Use this connecting wire when using with weekly timer mode. Connect the provided

connecting wire (4 cores) to the power terminal (4P connector) of the schedule timer unit.

(Fig. 5)

Fig. 1

1. Power wire

Fuse

No. Supplied parts Q'ty

4

Spacers

2

Wire joints

5

6

7

Operation

manual

Installation

manual

6

2

1

Indoor unit control PCB CN61

(T10) connector (6P orange)

Installing the Schedule Timer

<Note 1> Avoid twisting the inter-unit control wiring or the input/output wiring together with

power or other wiring, and avoid running them in the same metal conduit. Doing

so can cause malfunction.

<Note 2> Install the schedule timer at a location away from any sources of electrical noise.

<Note 3> Install a noise filter or take other appropriate action if electrical noise affects the

power supply circuit of the unit.

Fig. 2

Switch box for 1 switch (no cover)

or switch box for 2 switches (no cover)

M4 x 25 small

Spacer

flat-head screws (2)

Schedule

timer unit

Decorative

Under-case

(back case)

cover (panel)

(1) Open the panel on the schedule timer unit. Insert a standard (flathead) screwdriver or

similar tool into the notches on the bottom of the schedule timer unit to open and

remove the back case.

(2) Use the 2 supplied M4 small screws and install the schedule timer back case onto the

switch box. Before installing, use a screwdriver or similar tool to press on and open the

screw holes that correspond to the JIS box that is used.

When fastening the case, use spacers and do not tighten the screws too much. If the

schedule timer does not fit tightly against the wall, cut the spacers as required to make

adjustments.

(3) Connect the supplied power wire (2-core) and inter-unit control wire (3-core) to the

schedule timer unit.

(“Wiring for Weekly Timer mode”)

(4) Align the schedule timer unit with the tabs on the back case and press to install it.

Installation of connected schedule timers

● When installing schedule timers (remote controller switches, system controllers, etc.)

onto the wall, use the method shown in Figs. 3 and 4.

Fig. 3

Remote controller

wiring outlet

Switch box for 1

switch (no cover)

Fig. 4

Remote controller

wiring outlet

Switch box for 2 switches

(no cover)

More than

95 mm

(From wall) (For connected

More than

95 mm

(From wall)

More than 125 mm

installation)

More than

125 mm

(For connected

installation)

* For maintenance reasons, leave a gap of 25 mm or more between the remote controller switch

and schedule timer if they are arranged in parallel above/below each other.

This remote controller has two methods of usage with the weekly timer and the

schedule timer.

The wiring method and switch setting are different in each case.

Wiring for Weekly Timer mode

● Wiring Diagram (Be sure to use the provided wires for the connection wiring.)

Fig. 5

Schedule

timer

Clamp filter

● Location The schedule timer and wired remote controller can be located on

either the right and left.

● System Diagram

Fig. 6

Schedule

timer

: Terminal board

DC12V

4 wires

Wired

remote

controller

Timer terminalPower terminal

Connecting wire

(accessory)

: Connector

Indoor

unit

Wired

remote

controller

Outdoor

unit

Wiring for the Schedule Timer mode

<Basic Wiring Diagram>

Fig. 7

Wiring

specifications (1)

P1

To power terminal

To communication

terminal

Schedule timer *1

*1 In the case the schedule timer is connected to the 64 system central remote controller or

ON-OFF controller

*2 In the case the schedule timer is connected to the indoor unit for S-MMS

*3 In the case the schedule timer is connected to the TCC-LINK adapter

Wiring Max. Length Electric cable

P1: Power wire for schedule timer 100m 0.5mm

L1: Central control system wiring

L2,L3,L4: Indoor/Outdoor communication

line

P1, L1, L2, L3 and L4 have no polarity.

<Note> ● This schedule timer is device connected to TCC-LINK.

● The maximum number of schedule timer units that can be connected is 8. (A

maximum of 10 schedule timer units and other central control devices can be

connected.)

● In the case of SDI/DI, an extra TCC-LINK adapter may be required.

● Wiring

● The schedule timer wiring can be connected by the following two methods. Select one of

these connection methods according to the actual installation location. When wiring,

extend the lengths of the wires using wire joints (accessory) and extension wires (field

supply).

<Note> ● When installing multiple schedule timers, avoid the use of

communication line.

● Connection diagram (Be sure to use the provided wires as the power

wiring.)

Wiring specifications (1)

If a 64 system central remote controller (or ON-OFF controller) is installed (power is

supplied from the 64 system central remote controller):

Fig. 8

64 system central remote controller

(Back side)

● Wiring procedures Connect the provided connecting wire to the power terminal (4P

● The power wiring and communication wiring has no polarity.

64 system central remote controller or

ON-OFF controller

Refrigerant system 3

(S-MMS)

P1

To power terminal

To communication

terminal

Schedule

timer *3

Outdoor unit

(Header unit)

U2

U1

U2

U1

Indoor

unit

Remote

controller

U3

U4

U4

U3

U2

U1

L3

To power terminal

To communication

terminal

Schedule

timer *2

Refrigerant system 1

(S-MMS)

Indoor unit

(Header unit)

U1U2U3

L2 L4

U2

U1

P1

Indoor

unit

Remote

controller

U4

L1

U2

U1

Indoor

unit

Remote

controller

Refrigerant system 2

(SDI/DI)

Outdoor unit

TCC-LINK

adapter

U4

U3

Indoor

unit

Remote

controller

Wiring specifications (2)Wiring specifications (2)

specifications

2

L1+L2+

L3+L4

Inter-unit control wiring

U1

U2

Field supply

Wire joint

(Not used)

Less than 1000m MVVS 1.25mm

Less than 2000m MVVS 2.0 mm

Connecting wire (accessory)

Clamp filter

Communication

wiring

BlueBlue Pink

Communication

terminal (3P connector)

Schedule timer

(blue + pink)

Power terminal

(4P connector)

connector) of the schedule timer.

The terminal attached to the clamp filter must be connected to the

schedule timer.

Wiring specifications (2)

If a 64 system central remote controller (or ON-OFF controller) is not installed (power is

supplied from the indoor unit):

<Note>

(1) The only functions of the schedule timer are indoor unit ON/OFF and remote

controller enable/disable operations.

(2) It is required that during installation, a 64 system central remote controller or wired

remote controller be installed next to the schedule timer so that operation mode

and other information can be checked.

(3) If the 64 system central remote controller or other central control device is not

present, the schedule timer cannot be used in combination with a system that does

not utilize remote controllers including high wall (KRT series) systems.

Fig. 9

Indoor unit control PCB

CN61(T10)

Field supply

1. Supplied parts

U3

U1

Indoor/Outdoor units communication line

(for S-MMS)

Central control system wiring

(for SDI/DI)

U4

U2

(for SDI/DI)

(for S-MMS)

Wire joint

(Not used)

BlueBlue Pink

Communication

terminal (3P connector)

Schedule timer

Communication

wiring

(blue + pink)

Power wiring

(black + white)

Black White

Power terminal

(4P connector)

● The power wiring and communication wiring has no polarity.

● The length of the power wiring must be no more than 100 m.

The ground method of a shield wire (when using with the Schedule

Timer)

Fig. 10

2

2

*4

Power

terminal

Schedule

Timer *1

*1 In the case the schedule timer is connected to the 64 system central remote controller or

ON-OFF controller

*2 In the case the schedule timer is connected to the indoor unit for S-MMS

*3 In the case the schedule timer is connected to the TCC-LINK adapter

<Grounding of the shield wires>

● The shield wires of the central control wiring should be connected at closed end, and

these should be single-point ground.

● The terminal end (*4) of the shield wires should be open and insulated.

Shield wiring for

central control

system (singlepoint earth)

U3

U1

64 System central

remote controller

ON-OFF controller

*4

Communication

Schedule

Timer *2

Refrigerant system 1

(S-MMS)

U4

U2

or

terminal

Remote

controller

Outdoor unit

(Header unit)

U1U2U3

communication line

U2

U1

Indoor

unit

U4

Indoor/Outdoor

units

*4

U2

U1

Indoor

unit

Remote

controller

Refrigerant

system 2

(SDI/DI)

U3

Indoor

unit

Remote

controller

Shield wiring for

central control

system (singlepoint earth)

Outdoor

unit

Central control

system wiring

TCC-LINK

adapter

U4

Schedule

Timer *2

Refrigerant system 3

(S-MMS)

Outdoor unit

(Header unit)

U2

U1

*4

U2

U1

Indoor

unit

Power terminal

Remote

controller

U4

U3

Indoor/Outdoor units

crcommunication line

Shield wiring for central control system

(single-point earth)

Explanation to Customers

● After work is completed, present the Operation Manual and Information for the Person in

Charge of Installation (Electrical) Work to the customer.

● Explain to the customer the methods for use of the system, as described in the

Operation Manual.

Memory Backup Switch

After installation is completed, check that the backup switch on the reverse side of the

schedule timer PCB is turned to ON.

(The backup battery will retain the current time for up to 100 hours.)

OFF

ON

Backup switch

Backup battery

(E)

2

3

6

+01E_073002_STime_EXS21TLE.fm Page 2 Friday, January 25, 2008 4:50 PM

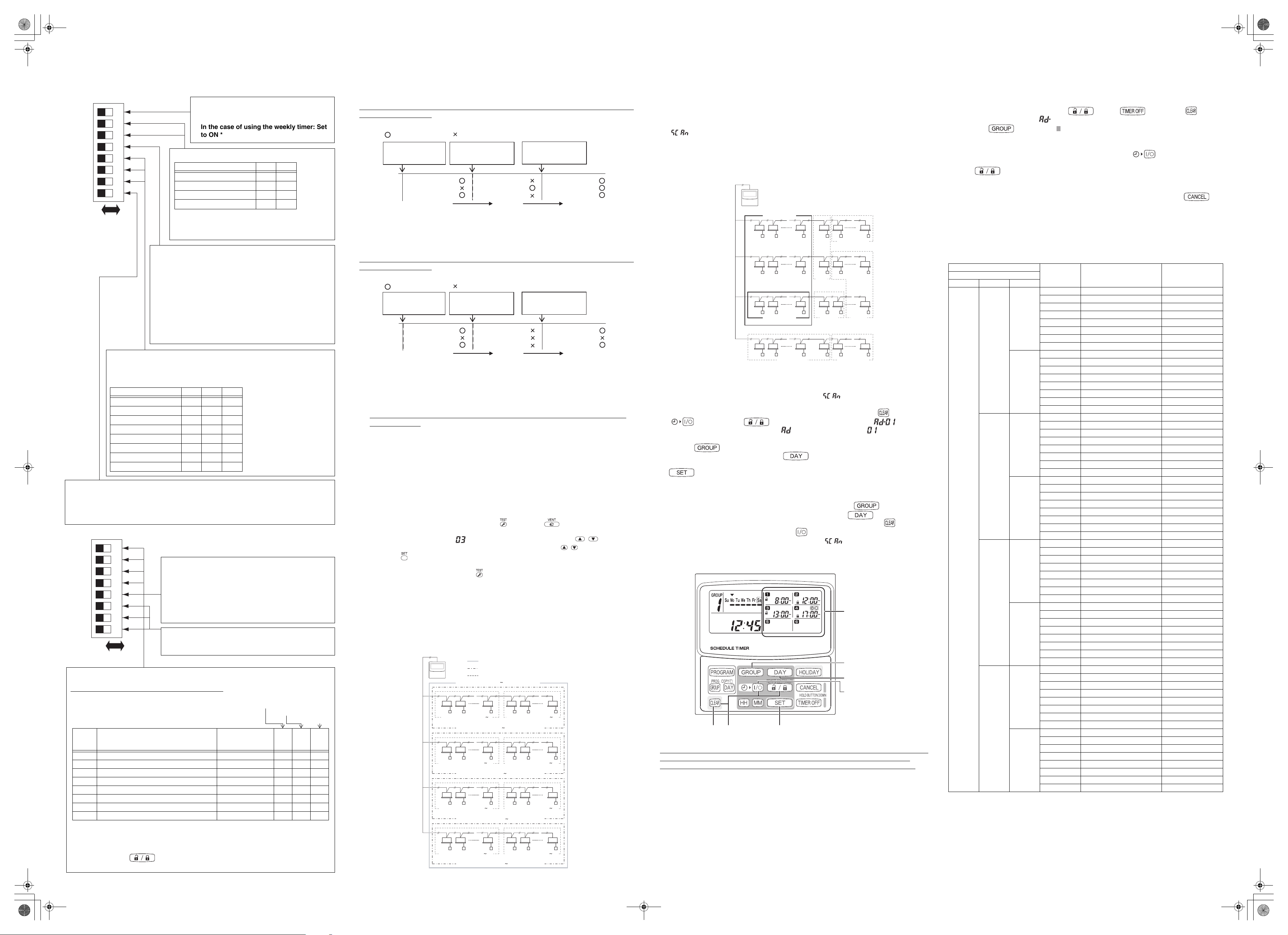

When using with the Weekly Timer, all switch settings should be OFF except S41-1.

About the Setting Switches

● Complete the switch settings before turning ON the schedule timer power.

S41

1

2

3

4

5

6

7

8

OFF ON

*

These switches are all

OFF at the time of

delivery.

Central Control Main/Sub

Switching (4)

Function selector switch (1) settings

• In the case of using the schedule timer:

Set to OFF

• In the case of using the weekly timer: Set

to ON *

Timer Group Settings (2, 3)

Function 2 3

1 timer group – fixed OFF OFF

4 timer group – fixed OFF ON

8 timer group – fixed ON OFF

Manual group setting ON ON

For details of the timer groups, refer to the Creating

Timer Groups when using the Schedule Timer as

described in below.

Sub: OFF

Main: ON

(Central Control Devices center/ Terminal switching)

(1) Set to “sub” (OFF) when using together with the 64 system

central remote controller. (Factory setting: Sub)

(2) Set to “main” (ON) when using together with an ON-OFF

controller, wired remote controller or wireless remote

controller.

* When using with multiple schedule timer units, set only

1 unit to “main” (ON) and set the remainder to “sub”

(OFF).

Schedule Timer Address Settings (5, 6, 7)

A maximum of 8 schedule timer units can be connected to the inter-unit

control wiring (central control wiring). If multiple units are connected, use the

setting switches and allocate the addresses, taking care to avoid duplication.

Address 5 6 7

Address 1 OFF OFF OFF

Address 2 OFF OFF ON

Address 3 OFF ON OFF

Address 4 OFF ON ON

Address 5 ON OFF OFF

Address 6 ON OFF ON

Address 7 ON ON OFF

Address 8 ON ON ON

Holiday and Operation Disable Settings for Each Group (8).

When this switch is set to OFF, units are all controlled together. When this switch is ON, the

units are controlled by the settings for each timer group.

(For details of the timer groups, refer to the Creating Timer Groups when using the Schedule

Timer as described in below.)

S42

1

2

3

4

5

6

7

8

OFF ON

*

These switches are all OFF

at the time of delivery.

● The following switch setting is required when selecting remote controller enable/disable

button to enable with the schedule timer.

Remote controller disabled item Switch (2, 3, 4)

When remote controller enable/disable is used with the schedule timer, set the remote controller item switches 2,

3 and 4 to the specific item according to the following items.

OFF: No setting

ON: Setting

Remote controller disabled items

Mode 0 Remote controller enable/disable not used No indication OFF OFF OFF

Mode 1 Start/stop Central 1 OFF OFF ON

Mode 2 Operation mode Central 4 OFF ON OFF

Mode 3 Operation mode + Start/stop Central OFF ON ON

Mode 4 Temperature setting Central ON OFF OFF

Mode 5 Temperature setting + Start/stop Central ON OFF ON

Mode 6 Temperature setting + Start/stop Central 3 ON ON OFF

Mode 7

Temperature setting + Operation mode + Start/stop

• All switch settings should be set to OFF when enable/disable is not used.

•

Central 1 – 4 are the designations for the remote-controller disable modes for the 64 system central remote

controller.

• After the above setting is completed, perform the enable/disable setting using the

remote controller button with schedule timer. For more information, refer to

[Setting Up Programmed Operations] in the Operation Manual of the Schedule Timer.

Simultaneous time

communications (5)

Disabled: OFF

Enabled: ON

When multiple schedule timers are installed, set this

switch to ON to perform time settings for multiple units

simultaneously. One minute after the time is set, the time

at the other schedule timers will change to match the set

time. (Ordinarily this switch is set to OFF.)

Spare (6, 7, 8)

Be sure that these switches are OFF when the system is

used.

2: Temperature setting

3: Operation mode

64 system central

remote controller

indication

Central ON ON ON

234

4: Start/stop

::: Continue from the previous section :::

Remote Controller Enable Items Switch (1) (Substitute/Addition Selector)

OFF: (Substitute mode)

All setting contents will be substituted to setting contents using the remote controller disabled item

switches 2, 3 and 4 as opposed to the remote controller enable/disable items in setting presently.

Example: In the case of setting to [Mode 5] during remote controller disabled item (Temperature

setting+ Start/stop mode)

Use to remote controller

: Setting changeable : Setting cannot be changed

Set to central 4 with the

64 system central

controller

Temperature setting

Operation mode

Start/Stop

Change to all of the setting items

with switches

Set to remote controller

disabled item via the

timer

Temperature setting

Operation mode

Start/Stop

Set to remote controller

enabled item via the

timer

Temperature setting

Operation mode

Start/Stop

Enable all items independently of

determined by setting switches

ON: (Addition mode)

Items set to ON using the remote controller disabled item switches 2, 3 and 4 will be added to the

remote controller enable/disable items in the current setting.

Example: In the case of setting to [Mode 5] during remote controller disabled item (Temperature

setting+ Start/stop mode)

Use to remote controller

: Setting changeable : Setting cannot be changed

Set to central 4 with the

64 system central

controller

Temperature setting

Operation mode

Start/Stop

Disabled addition with switch

setting items only (Temperature

setting + Start/stop)

Set to remote controller

disabled item via the

timer

Temperature setting

Operation mode

Start/Stop

Set to remote controller

enabled item via the

timer

Temperature setting

Operation mode

Start/Stop

Enabled addition with switch

setting items only (Temperature

setting + Start/stop)

Setting Central Control Addresses when using with the Schedule

Timer

● When using the schedule timer, central control addresses setting of the indoor

unit is required.

(If central control address of the indoor unit has not been set, the schedule timer cannot be

used to start and stop these units normally. Therefore, be sure to set the central control

addresses of the indoor unit before turning on the power of the schedule timer.)

(1) Turn on the power of all the indoor units.

(2) Confirm the setting for the system addresses, indoor addresses and group addresses

of all indoor units. If a wrong setting is found, reset the system addresses, indoor

addresses and group addresses correctly.

(3) Perform the address settings that turn off the power of the indoor units.

• Central control address setting using the wired remote controller

<Perform the following procedures, 1 to 5, to all the indoor units>

1. Press and hold the wired remote controller button and button for at least 4

seconds.

2.

Assign the item code (DN) to

using the temperature setting button

/.

3. Set the desired control address (1 to 64) using the timer button / .

4. Press the button.

(Confirm the remote controller indication changes from flashing to fully lit.)

5.

After setting is completed, press the

button and then return the unit to general off status.

(In this case, it will take about 1 minute for normal remote controller operation to resume.)

<Central control address setting using the 64 system central remote controller>

Refer to the [Address switch setting] in the [Installation manual of 64 system central remote

controller] that is supplied to the 64 system central remote controller.

Creating Timer Groups when using the Schedule Timer

● The schedule timer can be used to create up to 8 timer groups (8 zones).

<Setting fixed timer groups (zones)>

Fig. 12

Schedule

timer

Central control address 1 64 (Group (Zone) 1)

1

Central control address 1 8

(Group (Zone) 1)

18

17

Central control address 17 24

(Group (Zone) 3)

33 34

Central control address 33 40

(Group (Zone) 5)

49 50

Central control address 49 56

(Group (Zone) 7)

1 fixed timer group (1 setting zone) (64 units together)

4 fixed timer group (4 setting zone) (16 units together)

8 fixed timer group (8 setting zone) (8 units together)

2

Central control address 1 16 (Group (Zone) 1)

Central control address 17 32 (Group (Zone) 2)

Central control address 33 48 (Group (Zone) 3)

Central control address 49 64 (Group (Zone) 4)

8

24

40

56

9

Central control address 9 16

25

Central control address 25 32

41

Central control address 41 48

57

Central control address 57 64

10

(Group (Zone) 2)

26

(Group (Zone) 4)

42

(Group (Zone) 6)

58

(Group (Zone) 8)

16

32

48

64

● Procedure for making fixed timer group settings (zone)

(1) First, use a 64 system central remote controller or the wired remote controllers to set

the central control addresses, as assigned in the figure above, to the indoor units that

will be subject to group timer control.

(2)

Next, use S41 switches 2 and 3 to set the number of timer groups (zones) you wish to

create.

(For setting of switches 2 and 3, refer to the [About the Setting Switches] item above.

(3) Finally, turn on the schedule timer power. Initial communications are performed.

( flashes in the display.) The normal display appears after several minutes, and

the timer group settings are confirmed.

<Procedure for making manual timer group settings (zone)>

Manual timer group settings allow central control addresses to be assigned freely within the timer

groups such as the setting example below.

Fig. 13

Setting example

● Procedure for making manual timer group settings (zone)

(1) Turn on (manual settings) S41 setting switches 2 and 3, then turn on the power.

Restart and initial communications are performed. ( flashes in the display.) The

normal display appears after several minutes.

(2) When the normal display appears, press and hold the schedule timer button, the

button, and the button

flashing, in the present time display. ( indicates “address” and is the central

address number.)

(3) Use the button

programmed operation. Then use the button

select the central control address to assign and register for that timer group. Press the

button

control address appears on the [Timer program] display area of the schedule timer.)

(4) To continue registering addresses, repeat step (3). Central control address numbers

will be added to the right side on the [Timer program] display area of the schedule

timer. To cancel a registered central control address, use the button

Setting buttons area to select the timer group, then use the button

Setting buttons area to select the central control address and press the button

(5) When registration is completed, press the button

automatically and performs initial communications. ( flashes in the display.) The

normal display appears after several minutes, and the manually assigned timer group

settings are confirmed.

4 to register the selected central control address. (Registered central

Schedule timer

(Group (Zone) 1)

1

18

17

33 34

(Group (Zone) 4)

49 50

2

8

24

40

56

25

(Group

(Zone))

41

(Zone) 5)

57

9

(Group

10

(Group (Zone) 3)

26

42

(Group

(Zone) 6)

58

(Group (Zone) 8)(Group (Zone) 7)

16

32

48

64

1 for 4 seconds or longer. “ ” appears,

2 in the Setting buttons area to select the timer group for

3 in the Setting buttons area to

2 in the

3 in the

6. The schedule timer restarts

5.

Fig. 14

Timer program display

area

154

• During manual timer group settings, the schedule timer can be used to create up to 8 groups (8

zones), and the central control addresses can be registered up to 64 units in 1 group (1

zone).In addition, one of the central control addresses can be set in multiple timer groups.

(Indoor units of the central control address 33-40 are performed to start/stop and enable/

disable operation according to the programmed operation for both timer group (zone) 1 and 4

to illustrate with reference to the thick frame marking as shown in above setting example of

Fig. 13)

Checking the Central Control Addresses and Operating the Units

that are Controlled by the Schedule Timer

● The schedule timer communicates with the indoor units to check which central control

addresses can be controlled with the current timer control.

The schedule timer can then be used to start and stop these units.

(1) Press and hold the schedule timer button, button, and button

for 4 seconds or longer. “ (central control address)” appears in sequence, blinking.

(2) Use the button in the area to display the blinking central control addresses

in sequential order. In this way, it is possible to check which central control addresses

in the displayed timer group can be operated by the timer.

(3) With the selected timer group displayed, press the timer button. Each time the

button is pressed the indoor units in the displayed timer group start or stop. Pressing

the button in this mode permits all items (operation start/stop, operation

mode, temperature setting items) at the indoor units in the displayed timer group where

remote controller prohibit is in effect.

(4) After checking the addresses and operating the units, press and hold the

button for 2 seconds or longer. The schedule timer display returns to the normal

display and all controllable indoor units stop.

Installation Work Plan

● Use the wired remote controller to check the unit No. of the indoor units.

(Start the A/C unit with the wired remote controller, then press the remote controller

UNIT SELECT button once to display the unit No. of the master unit.)

Schedule timer Central

148

1

1

2

3

2

4

1 At the

time of

shipment

5

3

6

7

4

8

control

addresses

1–,–

2–,–

3–,–

4–,–

5–,–

6–,–

7–,–

8–,–

9–,–

10 – , –

11 – , –

12 – , –

13 – , –

14 – , –

15 – , –

16 – , –

17 – , –

18 – , –

19 – , –

20 – , –

21 – , –

22 – , –

23 – , –

24 – , –

25 – , –

26 – , –

27 – , –

28 – , –

29 – , –

30 – , –

31 – , –

32 – , –

33 – , –

34 – , –

35 – , –

36 – , –

37 – , –

38 – , –

39 – , –

40 – , –

41 – , –

42 – , –

43 – , –

44 – , –

45 – , –

46 – , –

47 – , –

48 – , –

49 – , –

50 – , –

51 – , –

52 – , –

53 – , –

54 – , –

55 – , –

56 – , –

57 – , –

58 – , –

59 – , –

60 – , –

61 – , –

62 – , –

63 – , –

64 – , –

Indoor unit Unit No.

System - Indoor

Room nameFixed timer group

85464369073002 (E)

Loading...

Loading...