Toshiba RAS-18UKHP-ES4, RAS-18UKP-ES4, RAS-24UKHP-ES4, RAS-24UKP-ES4 SERVICE MANUAL

SERVICE MANUAL

AIR CONDITIONER

RAS-24UKHP-ES4 / RAS-24UAH-ES4

RAS-18UKHP-ES4 / RAS-18UAH-ES4

RAS-24UKP-ES4 / RAS-24UA-ES4

RAS-18UKP-ES4 / RAS-18UA-ES4

FILE NO. SVM-05011

SPLIT WALL TYPE

18 Class

(Heat pump model)

24 Class18 Class

(Cooling only model)

May 2005

CONTENTS

1. SPECIFICATIONS

2. CONSTRUCTION VIEWS

2-1 Indoor Unit

2-2 Outdoor Unit (RAS-24UAH-ES4, RAS-24UA-ES4)

2-3 Outdoor Unit (RAS-18UAH-ES4)

2-4 Outdoor Unit (RAS-18UA-ES4)

3. WIRING DIAGRAM

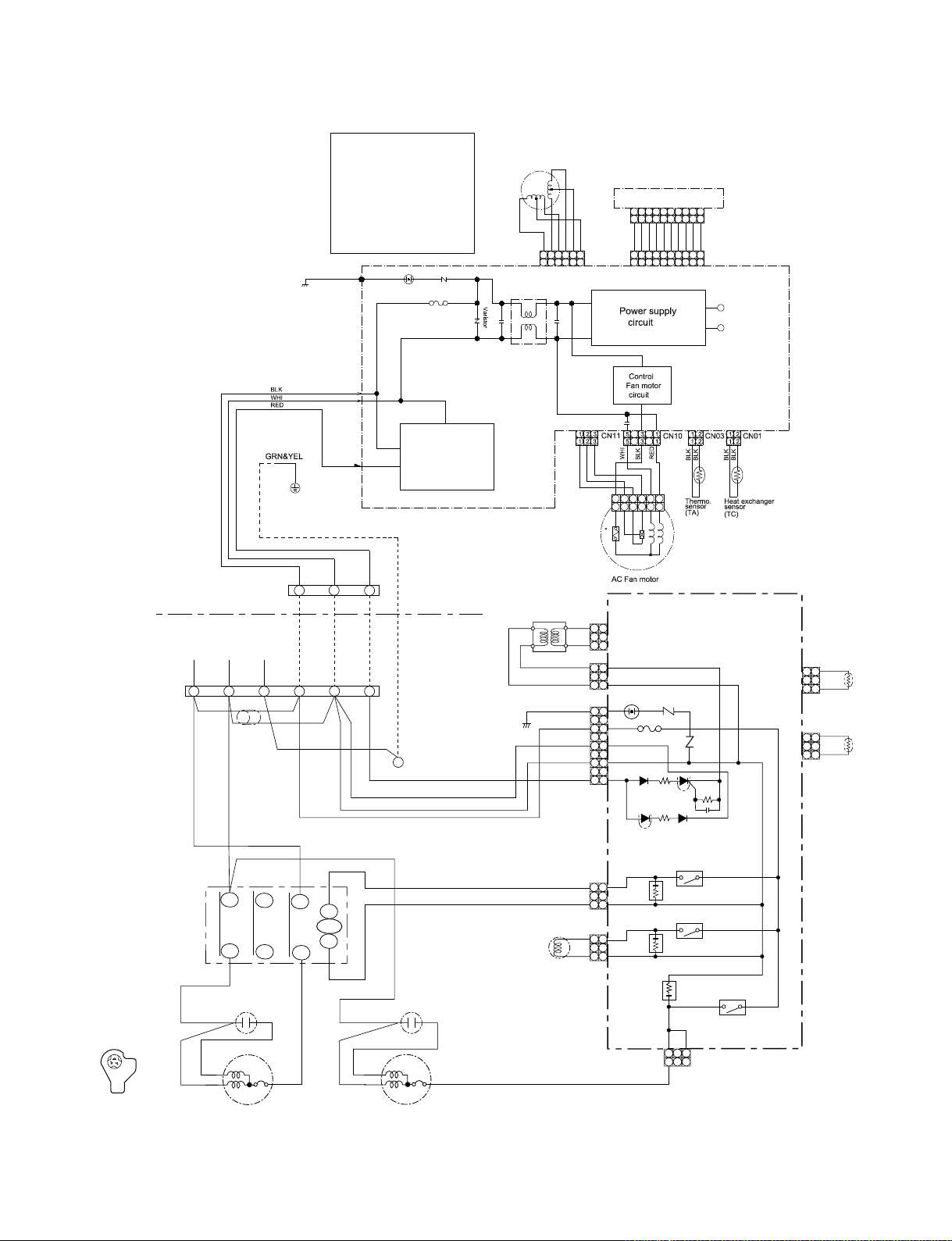

3-1 RAS-24UKHP-ES4 / RAS-24UAH-ES4

3-2 RAS-18UKHP-ES4 / RAS-18UAH-ES4

3-3 RAS-24UKP-ES4 / RAS-24UA-ES4

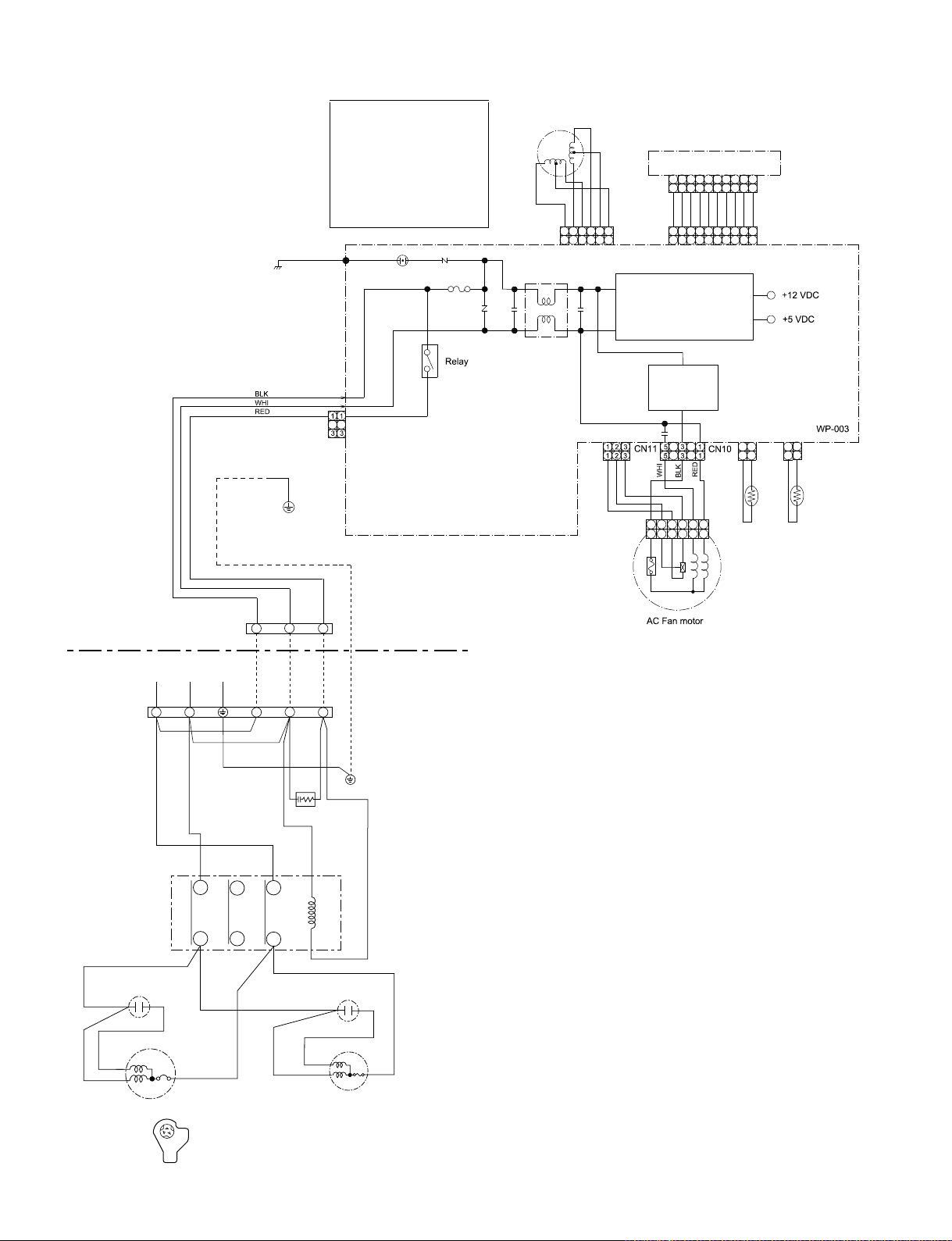

3-4 RAS-18UKP-ES4 / RAS-18UA-ES4

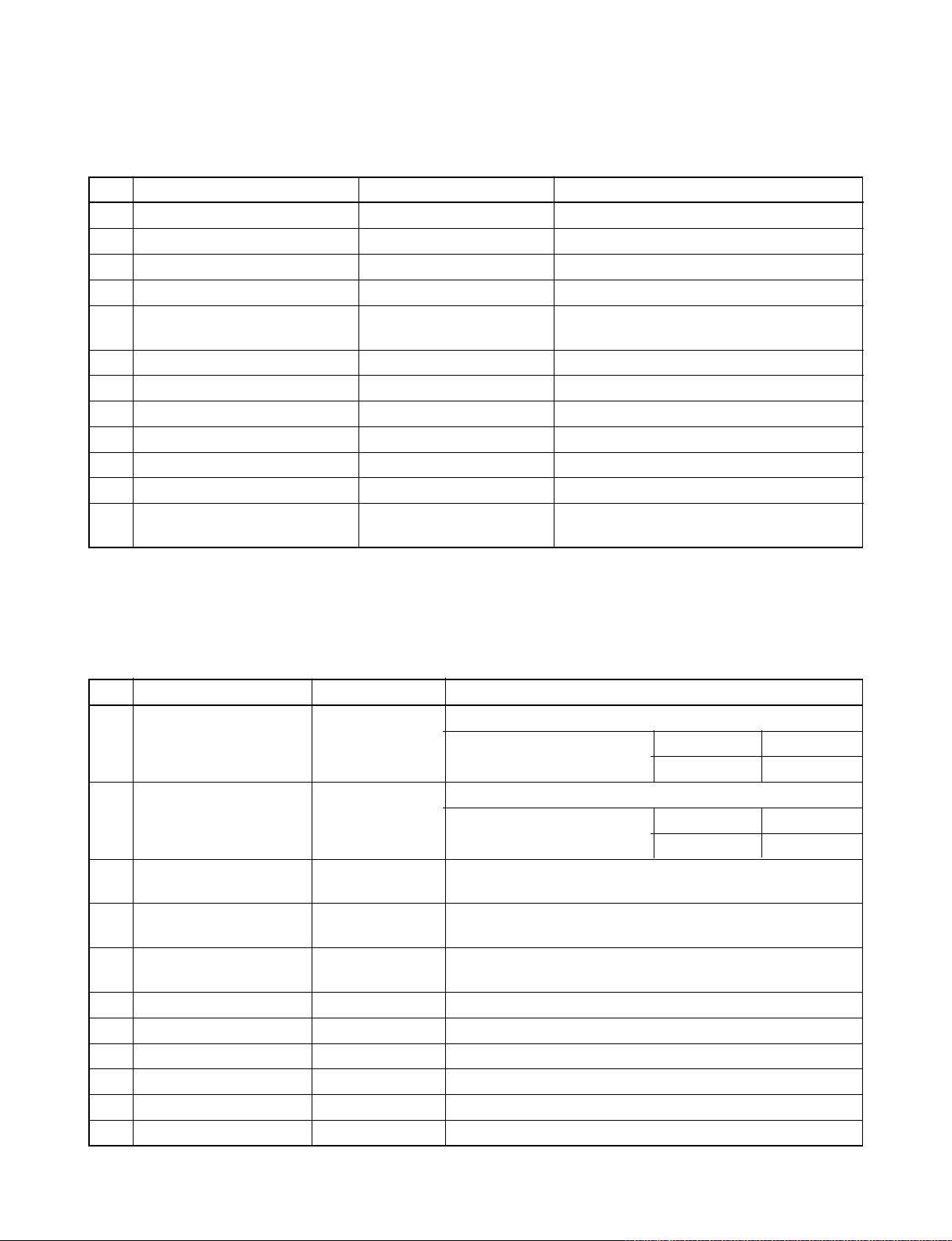

4. SPECIFICATION OF ELECTRICAL PARTS

4-1 Indoor Unit (RAS-24UKHP-ES4, RAS-18UKHP-ES4)

4-2 Outdoor Unit (RAS-24UAH-ES4)

4-3 Outdoor Unit (RAS-18UAH-ES4)

4-4 Indoor Unit (RAS-24UKP-ES4, RAS-18UKP-ES4)

4-5 Outdoor Unit (RAS-24UA-ES4)

4-6 Outdoor Unit (RAS-18UA-ES4)

FILE NO. SVM-05011

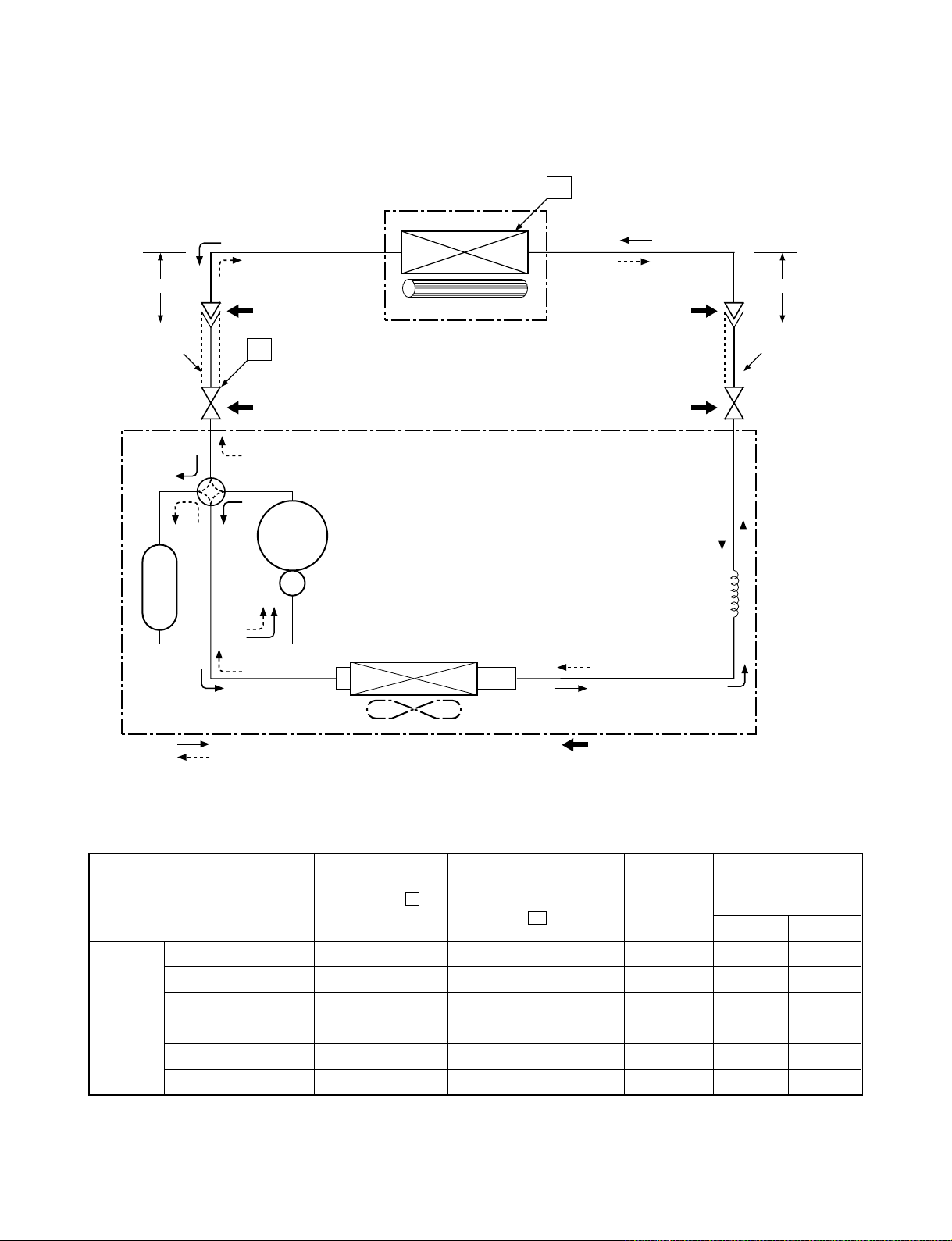

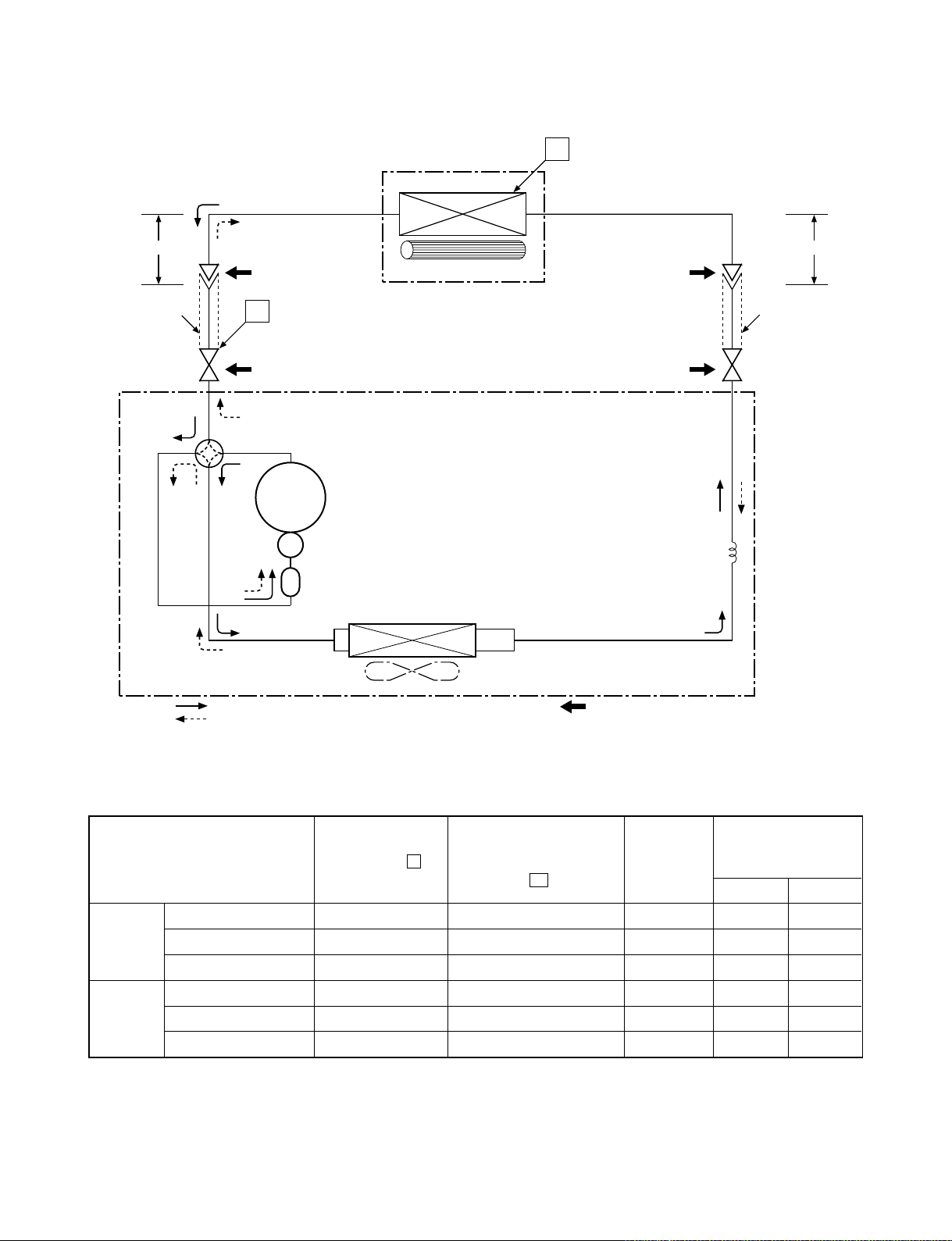

5. REFRIGERATION CYCLE DIAGRAM

5-1 RAS-24UKHP-ES4 / RAS-24UAH-ES4

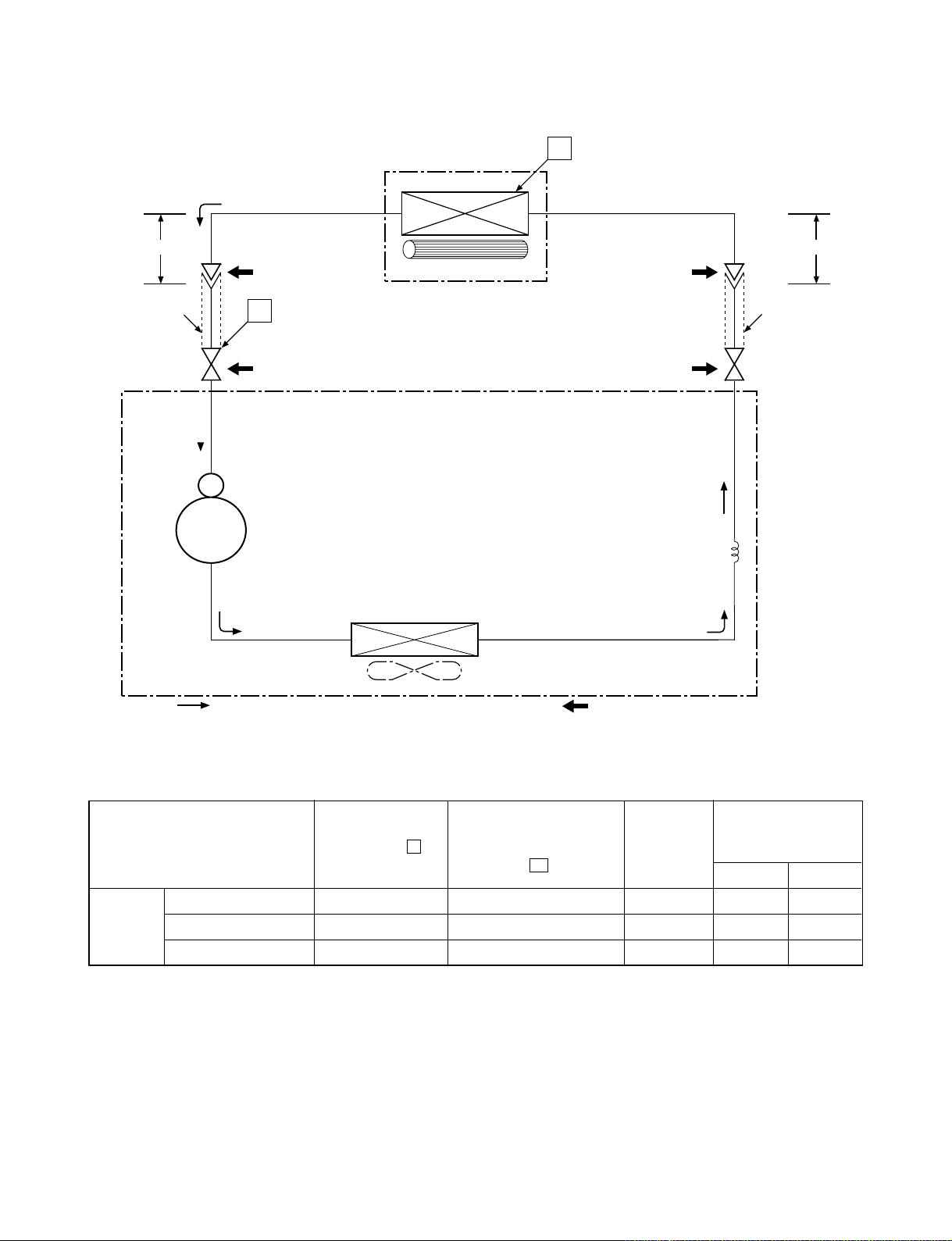

5-2 RAS-18UKHP-ES4 / RAS-18UAH-ES4

5-3 RAS-24UKP-ES4 / RAS-24UA-ES4

5-4 RAS-18UKP-ES4 / RAS-18UA-ES4

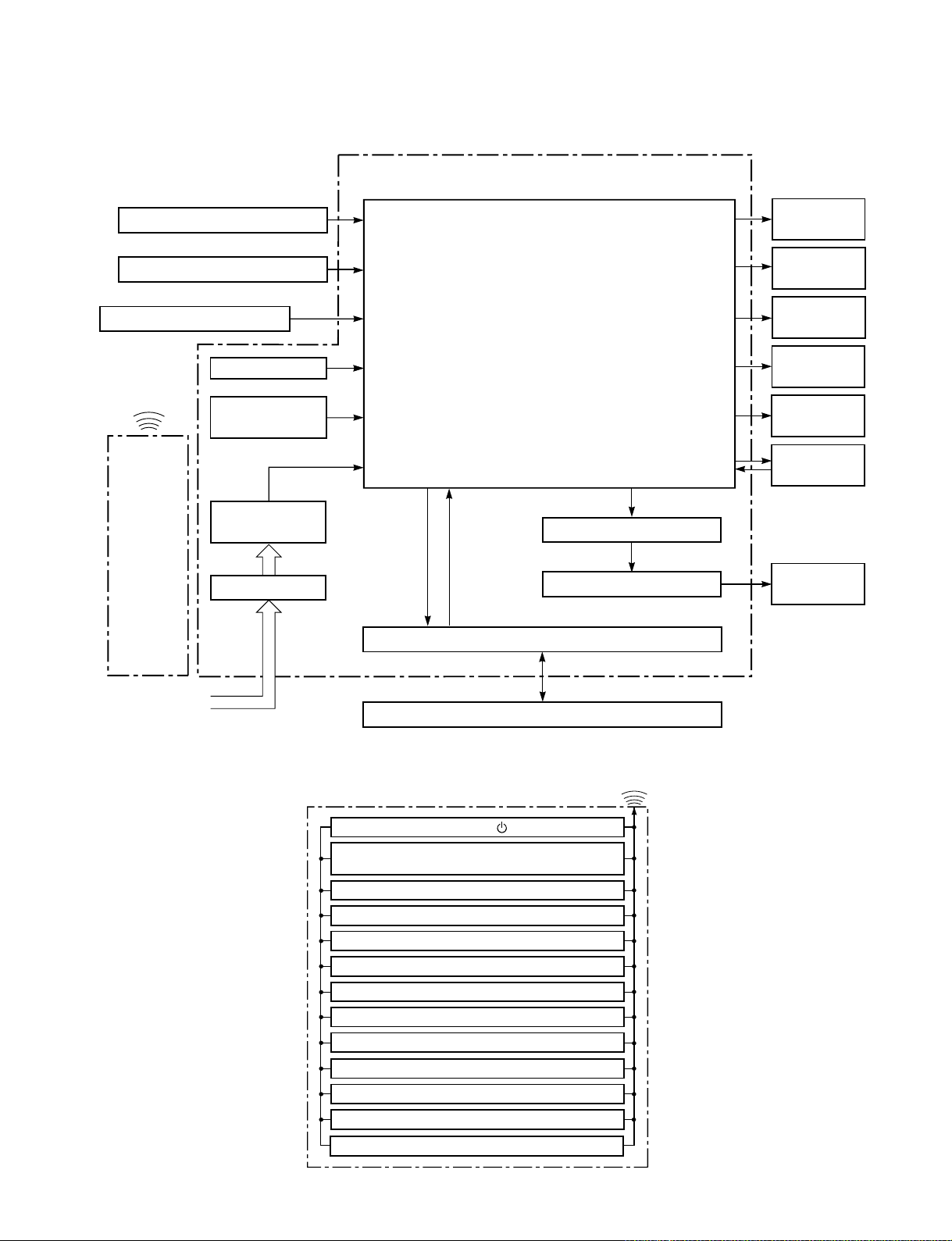

6. CONTROL BLOCK DIAGRAM

6-1 RAS-24UKHP-ES4, RAS-18UKHP-ES4

6-2 RAS-24UKP-ES4, RAS-18UKP-ES4

7. OPERATION DESCRIPTION

7-1 Outline of Air Conditioner Control

7-2 Description of Operation Circuit

7-3 Hi POWER Mode

7-4 High-Temperature Limit Control

7-5 Low-Temperature Limit Control

7-6 Defrost Operation

7-7 Auto Restart Function

7-8 Filter Check Lamp

7-9 Self-Cleaning function

7-10 QUIET Mode

7-11 COMFORT SLEEP mode

- 1 -

8. INSTALLATION PROCEDURE

8-1 Safety Cautions

8-2 Installation Diagram of Indoor and Outdoor Units

8-3 Installation

8-4 Indoor Unit

8-5 Outdoor Unit

8-6 How to Set Remote Control Selector Switch

8-7 Others

9. TROUBLESHOOTING CHART

9-1 Troubleshooting Procedure

9-2 Basic Check Items

9-3 Primary Judgement

9-4 Self-Diagnosis by Remote Control (Check Code)

9-5 How to Diagnose Faulty Part

9-6 Troubleshooting for Indoor Unit

9-7 Troubleshooting for Wiring (Interconnect cable and Serial Signal Wire)

9-8 Troubleshooting for P.C. Board

9-9 Troubleshooting for Remote Control

FILE NO. SVM-05011

10. PARTS REPLACEMENT

10-1 Indoor Unit

10-2 Outdoor Unit (RAS-24UAH-ES4, RAS-24UA-ES4)

10-3 Outdoor Unit (RAS-18UAH-ES4)

10-4 Outdoor Unit (RAS-18UA-ES4)

11. EXPLODED VIEWS AND PARTS LIST

11-1 Indoor Unit (E - Parts Assy)

11-2 Indoor Unit

11-3 Outdoor Unit (RAS-24UAH-ES4)

11-4 Outdoor Unit (RAS-18UAH-ES4)

11-5 Outdoor Unit (RAS-24UA-ES4)

11-6 Outdoor Unit (RAS-18UA-ES4)

• This air conditioner is charged with

HFC (R410A) that doesn't deplete the

Ozone layer.

• This air conditioner requires special

installation for the refrigerant R410A.

- 2 -

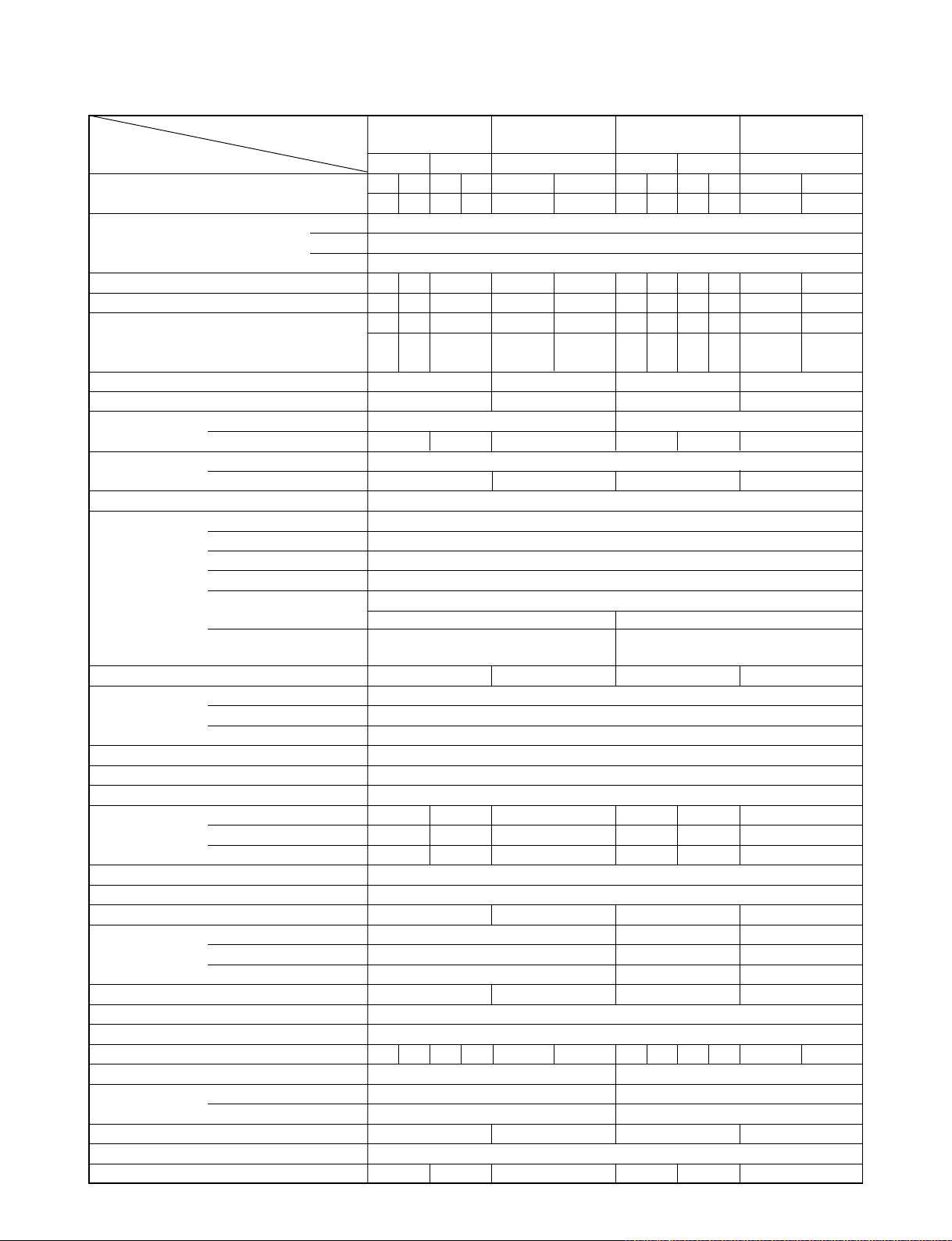

1. SPECIFICATIONS

FILE NO. SVM-05011

MODEL

ITEM

Capacity

Phase 1∅

Power source V 220 - 240

Power consumption W 2650 2760 2750 2870 2560 2690 1850 1900 1678 1748 1860 1960

Power factor % 96 91 95 90 94 89 98 97 94 92 97 96

Running current A 0.3/ 0.3/

Indoor/Outdoor 12.2 12.3 8.4 8.0 7.9 7.7

Starting current A

Moisture removal lit/h 2.5 2.7 2.0 2.0

Noise

Refrigerant

Refrigerant control Capillary tube

Interconnection Connection type Flare connection

pipe Maximum length

INDOOR UNIT RAS-24UKHP-ES4 RAS-24UKP-ES4 RAS-18UKHP-ES4 RAS-18UKP-ES4

Dimensions Width mm 998

Net weight kg 13

Evaporator type Finned tube

Indoor fan type Cross flow fan

Air volume Medium fan m3/h 750 800 750 667 708 667

Fan motor output W 30

Air filter Honeycomb woven filter with PP frame

OUTDOOR UNIT RAS-24UAH-ES4 RAS-24UA-ES4 RAS-18UAH-ES4 RAS-18UA-ES4

Dimensions Width mm 880 830 780

Net weight kg 59 63 44 39

Condenser type Finned tube

Outdoor fan type Propeller fan

Airflow volume m3/h 3380 3560 3380 3560 3380 3560 1830 2010 1830 2010 2120 2200

Fan motor output W 65 42

Compressor

Safety device IOL, Td Sensor IOL IOL, Td Sensor IOL

Louver type Automatic louver

Usable outdoor temperature range °C 15 ~ 43 -10 ~ 24 15 ~ 43 15 ~ 43 -10 ~ 24 15 ~ 43

Note *1 Chargeless pipe

*2 Maximum pipe

Indoor (H/M/L) dB

Outdoor (220-240V) dB 56-57 57-58 56-57 52-53 53-54 51-52

Name of refrigerant R410A

Rated amount

Gas side size mm ∅12.7

Connection type Flare connection

Liquid side size mm ∅6.35

(One way) 25*

Maximum height

difference

Height mm 298

Depth mm 208

High fan m3/h 900 900 900 750 800 750

Low fan m3/h 625 667 625 543 584 543

Height mm 690 538

Depth mm 310

Model

Output W 2200 1500

45/43/41/39/37

RAS-24UKHP-ES4 RAS-24UKP-ES4 RAS-18UKHP-ES4 RAS-18UKP-ES4

RAS-24UAH-ES4 RAS-24UA-ES4 RAS-18UAH-ES4 RAS-18UA-ES4

Cooling Heating Cooling Cooling Heating Cooling

220V 240V 220V 240V 220V 240V 220V 240V 220V 240V 220V 240V

kW 6.80 6.85 7.30 7.50 6.80 6.85 5.00 5.05 5.45 5.55 5.30 5.35

Hz

220V 240V 220V 240V 220V 240V 220V 240V 220V 240V 220V 240V

0.3/

0.3/

12.85

56

kg

m

m 8

1.50

5JS315DAG01

0.3/12.1 0.3/12.35

13.00

2

10

65

1.6 1.02 1.16

50

0.2/ 0.2/ 0.2/ 0.2/

35

1

15*

300

0.2/8.5 0.2/8.3

42/41/39/37/35

2

20*

5KS225DAA

32

550

270

- 3 -

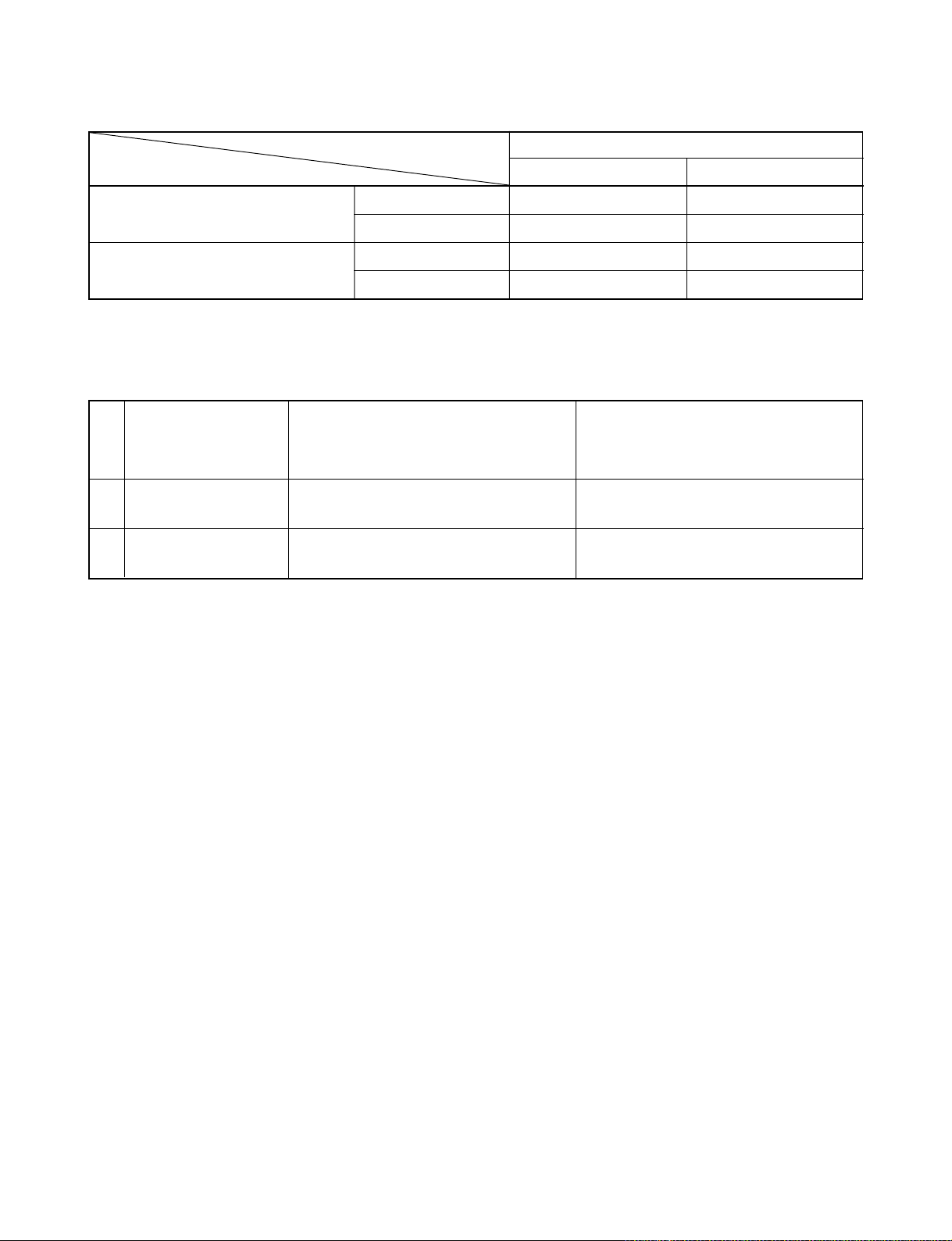

Note : 1

· Capacity is based on the following temperature conditions.

FILE NO. SVM-05011

Condition

Temperature

Indoor unit inlet air temperature

Outdoor unit inlet air temperature

Note : 2

· Charge refrigerant according to the table below.

Refrigerant

*1

No need to charge

extra refrigerant

*2 Need to charge

extra refrigerant

RAS-24UKHP-ES4 / RAS-24UAH-ES4

RAS-24UKP-ES4 / RAS-24UA-ES4 RAS-18UKP-ES4 / RAS-18UA-ES4

Over 15m up to 25m (20g/m) Over 15m up to 20m (20g/m)

(DB) 27°C 20°C

(WB) 19°C 15°C

(DB) 35°C 7°C

(WB) 24°C 6°C

15m or less

B8615-1

Cooling Heating

RAS-18UKHP-ES4 / RAS-18UAH-ES4

15m or less

- 4 -

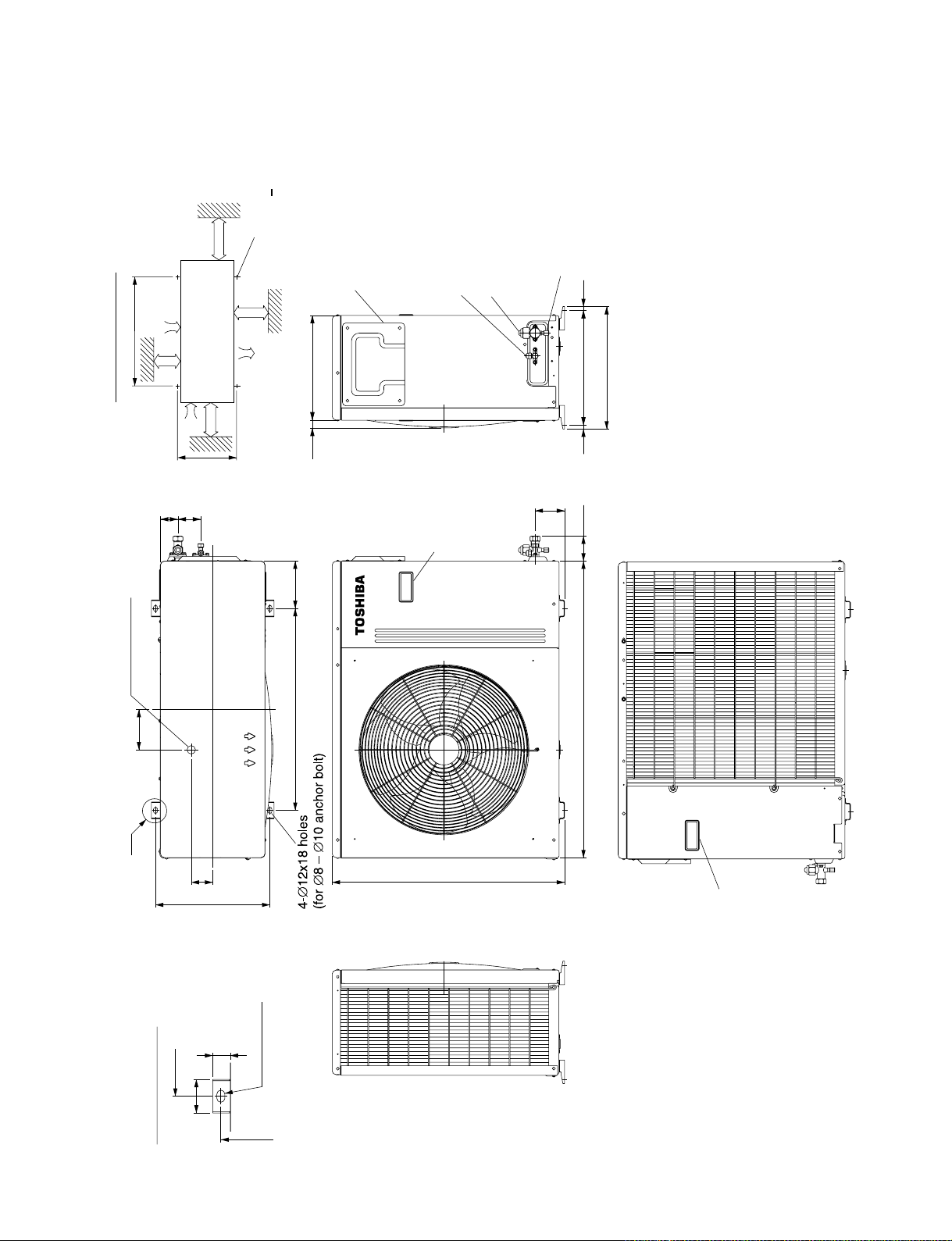

2-1. Indoor Unit

Back body

Front panel

Grille inlet

298

2. CONSTRUCTION VIEWS

998

FILE NO. SVM-05011

208

75

7

51

Knock out system

Outline of indoor unit

Connection pipe (0.39m)

(Flare

55 or more

Minimum distance

to ceiling

298

∅

12.7)

763.5

20

48

998

450

Drain hose (0.54m)

Connection pipe (0.49m) Wireless remote control

(Flare

20

10

∅

75

6.35)

56

(For stud bolt

29

50

Knock out system

57

∅

6)

41

48

55

5555

75

8

50

160

18

∅

65

∅

100

Installation

Plate outline

100

65

40

– 5 –

2-2. Outdoor Unit (RAS-24UAH-ES4, RAS-24UA-ES4)

10

∅

8

12X18

∅

600

600 or

more

-∅

for

4

600 or

more

anchor bolt

Electric

Parts cover

Liquid side

6.35)

∅

(Flare

Gas side

2.7)

∅1

(Flare

FILE NO. SVM-05011

Service Port

1212

more

52

Air inlet

340

68

Installation dimension

100 or

25 Drain outlet

∅

120

Air outlet

100 or

more

140

600

310

23

Handle

340 (pitch)

88

74

880

364

A

600

Detail Drawing

A

50

63.8

340

27

12x18 hole

∅

340

690

Handle

– 6 –

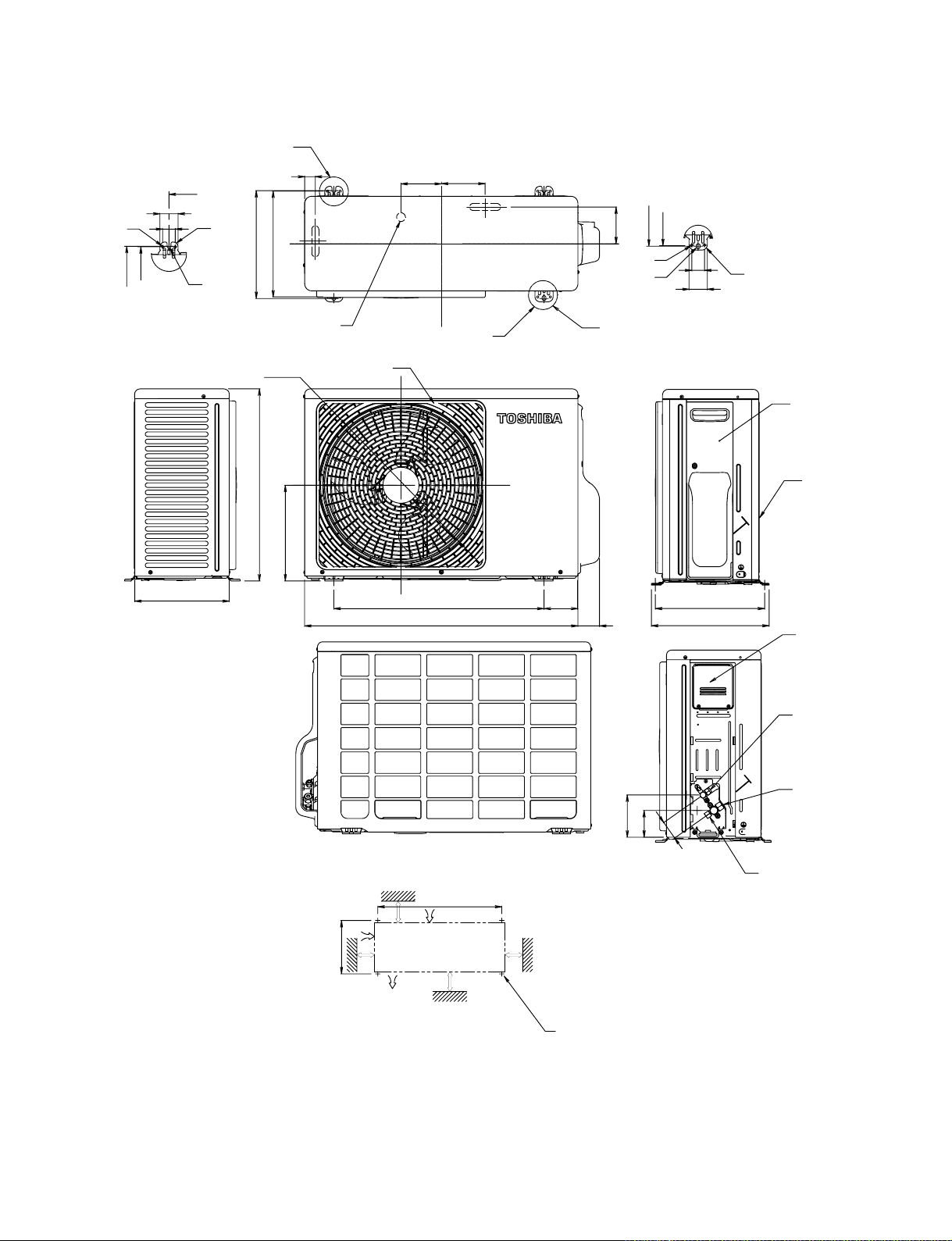

2-3. Outdoor Unit (RAS-18UAH-ES4)

10

-∅

8

11x14

∅

∅

anchor bolt

for

4x

600 or more

600

600 or

Air inlet

more

Liquid side

Electric

Parts cover

6.35)

∅

(Flare

12.7)

∅

Gas side

(Flare

FILE NO. SVM-05011

Installation dimension

120

Air inlet

325

100 or more

Air

outlet

100 or more

6 holes

-∅

8

10 anchor bolt)

— ∅

8

11x14 holes

∅

∅

(for fixing outdoor unit)

or

6-

25 Drain outlet

∅

Service Port

54

344

9

1

60

50

90

600

830

A

R10

600

50

Detail Drawing

A

35

52

325

23

6 hole

∅

11x14 hole

∅

Fan guard

Handle

420

∅

90

538

300

– 7 –

2-4. Outdoor Unit (RAS-18UA-ES4)

A

FILE NO. SVM-05011

A Detail Drawing (Back Leg)

600

52

310

36

302

270

∅

6 Hole

R15

R5.5

32.5

310

302

∅

30 Drain outlet

∅

436

530

265

FAN GUARD

115 125

2-∅11x14 Hole

(For ∅8-∅10 anchor bolt)

600 90

780 62

102

∅

∅

11x14 Hole

B

B Detail Drawing (Front Leg)

310

302

6 Hole

36

52

310

330

R15

COVER PV

Z

Electrical

part cover

Installation dimension

100 or more

325

100 or more

Z View

Air outlet

600

Air inlet

600 or more

120

75

600 or more

4x∅11 Long holes (For∅ 8-∅ 10 anchor bolt)

Liquid side

(Flare ∅6.35)

Gas side

(Flare ∅12.7)

5

4

Service port

− 8 −

3-1.

RAS-24UKHP-ES4 / RAS-24UAH-ES4

COLOR IDENTIFICATION

BRW : BROWN

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

ORN : ORANGE

GRN : GREEN

GRN&YEL : GREEN & YELLOW

P04BLK

CN30

CN31

3. WIRING DIAGRAM

Louver

motor

BLU

YEL

ORN

PNK

6

5 223311

4

6

5

4

Varistor

DSA

F01

250V6.3A

MAIN P.C. BOARD

(WP-003)

FILE NO. SVM-05011

Infrared rays receive

and Indication parts

BLU

RED

BRW

CN07

BLU

1 2 3 4 65 10

98 1071 2 3

4 65

4 6

5

BLU

BLU

BLU

BLU

5 64

321

CN25

10

9871 2 3

BLU

BLU

BLU

WHI

98

7

CN13

10

8 9

7

+12 VDC

+5 VDC

WP-003

OUTDOOR

TERMINAL

BLOCK

C

SR

COMPRESSOR TERMINAL

POWER SUPPLY

220-240 V~ 50 Hz

L

BLK

RED

BLK

RED

WHI

PNK

COMPRESSOR

INDOOR

TERMINAL

BLOCK

i

N

FERRITE CORE

RED

MAGNETIC

CONTACTOR

R

S

(1/L1)

(3/L2)

(2/T1)

(4/T2)

U

V

CAPACITOR

S

C

R

BLK

1

1

GRN&YEL

T

(5/L3)

(6/T3)

W

A1

52C

A2

CN23

2

2

RED

RE

3

3

WHI

i

CHASSIS

CAPACITOR

D

FAN MOTOR

Serial Signal

circuit

INDOOR

UNIT

OUTDOOR

UNIT

TRANSFORMER

GRN&YEL

COIL FOR

4 WAY VALVE

BLK

BLK

BLK

RED

RED

BLK

BLK

WHI

RED

GRY

BLU

YEL

BLU

BLU

YEL

GRY

BRW

1

3

1

3

1

3

5

7

9

1

313

11

33

1

2

4

3

1

2

66554

3

145 C

TEMP FUSE

MAIN P.C. BOARD (MCC-890)

1

2

CN06

3

1

CN05

3

1

3

5

CN01

7

9

SG01

F01

250VAC T6. 3A

TNR

R74

CN11

CR11

CN02

CR12

CR13

BLK

1

1

CN03

RY07

RY05

3

TNR

R73

RY06

CN07

CN08

DISCHARGE

PIPE

SENSOR (TD)

BLU

1

1

2

3

3

BLU

BLK

1

1

2

3

3

BLK

HEA

T

EXCHANGER

SENSOR (TE)

– 9 −

3-2. RAS-18UKHP-ES4 / RAS-18UAH-ES4

COLOR IDENTIFICATION

BRW : BROWN

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

ORN : ORANGE

GRN : GREEN

GRN&YEL : GREEN & YELLOW

CN30

CN31

P04BLK

DSA

Varistor

F01

250V6.3A

MAIN P.C. BOARD

(WP-003)

Louver

motor

BLU

PNK

6

5 223311

5

6

FILE NO. SVM-05011

Infrared rays receive

and Indication parts

BLU

CN07

BLU

1 2 3 4 65 10

RED

YEL

ORN

BRW

4

4

98 1071 2 3

4 65

4 6

5

BLU

BLU

BLU

BLU

5 64

321

CN25

10

9871 2 3

WHI

BLU

BLU

BLU

98

7

CN13

10

8 9

7

+12 VDC

+5 VDC

WP-003

OUTDOOR

TERMINAL

BLOCK

C

SR

COMPRESSOR TERMINAL

POWER SUPPLY

220-240 V~ 50 Hz

L

BLK

RED

BLK

RED

WHI

PNK

COMPRESSOR

CN23

INDOOR

TERMINAL

BLOCK

i

N

FERRITE CORE

RED

MAGNETIC

CONTACTOR

R

S

1

1

GRN&YEL

T

A1

2

3

2

3

i

CHASSIS

INDOOR

UNIT

OUTDOOR

UNIT

GRN&YEL

52C

BLK

A2

W

RED

WHI

D

RE

FAN MOTOR

U

V

CAPACITOR CAPACITOR

S

C

R

Serial Signal

circuit

TRANSFORMER

YEL

BLK

BLK

RED

RED

BLK

BLK

WHI

RED

GRY

BLU

YEL

BLU

BLU

COIL FOR

4 WAY VALVE

BLK

GRY

BRW

1

3

1

3

1

3

5

7

9

1

313

11

33

1

2

4

3

1

2

66554

3

145 C

TEMP FUSE

MAIN P.C. BOARD (MCC-890)

1

2

CN06

3

1

CN05

3

1

3

5

CN01

7

9

SG01

F01

250VAC T6. 3A

TNR

R74

CN11

CR11

CN02

CR12

CR13

CN03

1

1

BLK

RY07

RY05

3

TNR

R73

RY06

CN07

CN08

DISCHARGE

PIPE

SENSOR (TD)

BLU

1

1

2

3

3

BLU

BLK

1

1

2

3

3

BLK

HEA

T

EXCHANGER

SENSOR (TE)

– 10 −

3-3. RAS-24UKP-ES4 / RAS-24UA-ES4

COLOR IDENTIFICATION

BRW : BROWN

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

ORN : ORANGE

GRN : GREEN

GRN&YEL : GREEN & YELLOW

P04

BLK

CN30

CN31

CN27

DSA

Varistor

6.3A

F01

250V

Varistor

Louver

motor

BLU

PNK

6

5 223311

6

5

FILE NO. SVM-05011

Infrared rays receive

and Indication parts

1 2 3 4 6 10

BLU

BLU

BLU

YEL

RED

BRW

ORN

4

CN07

4

BLU

1 2 3 4 65 10

321

Power supply

circuit

Control

Fan motor

circuit

7

5 98

7

BLU

BLU

7

5 64

7

105 64321

8 9

CN25

BLU

BLU

BLU

WHI

98

CN13

10

8 9

OUTDOOR

TERMINAL

BLOCK

INDOOR

TERMINAL

BLOCK

POWER SUPPLY

220 − 240 V ~ 50 Hz

L

N

BLK

RED

BLK

RED

RED

1

1

BLK BLK

SPARK KILLER

A2 A1

52C

1/L1 2/T1

3/L2 4/T2

6/T35/L3

GRN&YEL

2

2

GRN&YEL

RED

CAPACITOR

3

3

GRY

CHASSIS

RED

WHI

PNK

COMPRESSOR

MAIN P.C. BOARD

(WP-003)

INDOOR

UNIT

OUTDOOR

UNIT

CAPACITOR

S

C

R

WHI

RED

FAN MOTOR

BLK

COMPRESSOR TERMINAL

2

1

21

1

GRY

BRW

YEL

1

2

4

3

1

2

66554

3

145 C

TEMP FUSE

BLK2BLK

Thermo.

sensor

(TA)

CN03

Heat exchanger

sensor

(TC)

CN01

2

1

BLK

BLK

BLK

C

SR

MAGNETIC CONTACTOR

− 11 −

RAS-18UKP-ES4 / RAS-18UA-ES4

3-4.

P04

BLK

CN30

CN31

CN27

GRN&YEL

COLOR IDENTIFICATION

BRW : BROWN

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

ORN : ORANGE

GRN : GREEN

GRN&YEL : GREEN & YELLOW

Varistor

DSA

6.3A

MAIN P.C. BOARD

(WP-003)

F01

250V

Varistor

Louver

motor

BLU

YEL

PNK

6

5 223311

4

6

5

4

FILE NO. SVM-05011

Infrared rays receive

and Indication parts

1 2 3 4 6 10

BLU

BLU

BLU

RED

BRW

ORN

CN07

BLU

1 2 3 4 65 10

321

Power supply

circuit

Control

Fan motor

circuit

GRY

BRW

YEL

5 98

BLU

BLU

5 64

105 64321

8 9

7

7

BLU

7

7

8 9

CN25

BLU

BLU

WHI

98

CN13

10

2

1

21

1

BLK2BLK

CN03

CN01

2

1

BLK

BLK

OUTDOOR

TERMINAL

BLOCK

POWER SUPPLY

220 − 240 V ~ 50 Hz

L

BLK

MAGNETIC

CONTACTOR

BLK

RED

INDOOR

TERMINAL

BLOCK

N

RED

R

U

1

1

GRN&YEL

S

V

2

2

RED

SPARK KILLER

T

W

BLK

1

2

4

3

1

2

3

145 C

TEMP FUSE

3

3

BLK

CHASSIS

(or A)

A1

(or B)

A2

INDOOR

UNIT

OUTDOOR

UNIT

GRN&YEL

GRY

Thermo.

sensor

66554

(TA)

Heat exchanger

sensor

(TC)

CAPACITOR

RED

S

WHI

PNK

R

COMPRESSOR

COMPRESSOR TERMINAL

CAPACITOR

RED

C

BLK

WHI

RED

BLK

FAN MOTOR

C

R

S

− 12 −

FILE NO. SVM-05011

4. SPECIFICATION OF ELECTRICAL PARTS

4-1. Indoor Unit (RAS-24UKHP-ES4, RAS-18UKHP-ES4)

No. Parts name Type Specifications

1 Fan motor (for indoor) AFS-220-31A AC 200 − 240V, 31W

2 Thermo sensor (TA-sensor) ——— 10 kΩ at 25°C

3 Micro Power Module (M01) µRM1260V DC 390 V, Secondary DC 12 V

4 Microcontroller TMP87CM40AN

5 Heat exchanger sensor

(TC-sensor)

6 Line filter (L01) LC*SS11V-06270 27mH, 600mA

7 Diode (DB01) D3SBA60 4 A, 600 V

8 Capacitor (C63) KMH400VSSN47M22S 4.7µF, 400 V

9 Fuse (F01) BET6.3A T6.3 A, 250 V

10 Varistor (R21, R22) 15G561K 560 V

11 Resistor (R319) RF-2TK5R6 5.6Ω , 2 W

12 Louver motor MP35EA12 Output (Rated) 2 W, 10 poles, 1 phase,

——— 10 kΩ at 25°C

DC 12 V

4-2. Outdoor Unit (RAS-24UAH-ES4)

No. Parts name Type Specifications

Output (Rated) 2200W, 2poles, 1 phase, 220 − 240V, 50Hz

1 Compressor 5JS315DAG01 Winding resistance (Ω) Red-Black White-Black

(at 20°C) 0.830 2.257

Output (Rated) 65W, 6poles, 1 phase, 220 – 240V, 50Hz

2 Fan motor (for outdoor) KFG6-71SB5P-T1 Winding resistance (Ω) Red-Black White-Black

(at 20°C) 64.4 127.4

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

Solenoid coil

5

(for 4-way valve)

6 Thermo sensor TE / TD 10kΩ at 25°C / 50kΩ at 25°C

7 Magnetic contactor A35 220 ~ 240V, 50Hz

8 Transformer TT-05 220 ~ 240V

9 Microcontroller TMP47C840N

10 Varistor (R73, R74) 15G471K 470V

11 Fuse (F01) TSCR T6.3A, 250V

451355L AC 450V, 3.5µF

BUM44X4505B AC 440V, 45µF

VHV (STF) AC 220 ~ 240V

– 13 –

FILE NO. SVM-05011

4-3. Outdoor Unit (RAS-18UAH-ES4)

No. Parts name Type Specifications

Output (Rated) 1500W, 2poles, 1 phase, 220 − 240V, 50Hz

1 Compressor 5KS225DAA Winding resistance (Ω) Red-Black White-Black

(at 20°C) 1.632 2.457

Output (Rated) 65W, 6poles, 1 phase, 220 – 240V, 50Hz

2 Fan motor (for outdoor) WLF-240-42A-2 Winding resistance (Ω) Red-Black White-Black

(at 20°C) 188 289

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

Solenoid coil

5

(for 4-way valve)

6 Thermo sensor TE / TD 10kΩ at 25°C / 50kΩ at 25°C

7 Magnetic contactor CLK-26J 220 − 240V, 50Hz

8 Transformer TT-05 220 − 240V

9 Microcomputer TMP47C840N

10 Varistor (R73, R74) 15G471K 470V

11 Fuse (F01) TSCR T6.3A, 250V

451155L AC 450V, 1.5 µF

BUM44X4505B AC 440V, 45µF

VHV (STF) AC 220 − 240V

4-4. Indoor Unit (RAS-24UKP-ES4, RAS-18UKP-ES4)

No. Parts name Type Specifications

1 Fan motor (for indoor) AFS-220-31A AC 200 − 240V, 31W

2 Thermo sensor (TA-sensor) ——— 10 kΩ at 25°C

3 Micro Power Module (M01) µRM1260V DC 390 V, Secondary DC 12 V

4 Microcontroller TMP87CM40AN

5 Heat exchanger sensor

(TC-sensor)

6 Line filter (L01) LC*SS11V-06270 27mH, 600mA

7 Diode (DB01) D3SBA60 4 A, 600 V

8 Capacitor (C63) KMH400VSSN47M22S 4.7µF, 400 V

9 Fuse (F01) BET6.3A T6.3 A, 250 V

10 Varistor (R21, R22) 15G561K 560 V

11 Resistor (R319) RF-2TK5R6 5.6Ω, 2 W

12 Louver motor MP35EA12 Output (Rated) 2 W, 10 poles, 1 phase,

13 Relay : (RY04) G5NB-1A Coil DC 12V, 16.7mA, Contact AC 250V, 1A

——— 10 kΩ at 25°C

DC 12 V

– 14 –

FILE NO. SVM-05011

4-5. Outdoor Unit (RAS-24UA-ES4)

No. Parts name Type Specifications

Output (Rated) 2200W, 2poles, 1 phase, 220 − 240V, 50Hz

1 Compressor 5JS315DAG01 Winding resistance (Ω ) Red-Black White-Black

(at 20°C) 0.830 2.257

Output (Rated) 65W, 6poles, 1 phase, 220 − 240V, 50Hz

2 Fan motor (for outdoor) KFG6-71SB5P-T Winding resistance (Ω) Red-Black White-Black

(at 20° C) 64.4 127.4

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

5

Magnetic contactor

451355L AC 450V, 3.5µ F

BUM44X4505B

A35

AC 440V, 45µ F

220 − 240V, 50Hz

4-6. Outdoor Unit (RAS-18UA-ES4)

No. Parts name Type Specifications

Output (Rated) 1500W, 2poles, 1 phase, 220 − 240V, 50Hz

1 Compressor 5KS225DAA Winding resistance (Ω) Red-Black White-Black

(at 20°C ) 1. 632 2.457

Output (Rated) 42W, 6poles, 1 phase, 220 − 240V, 50Hz

2 Fan motor (for outdoor) WLF-240-42A-1 Winding resistance (Ω) Red-Black White-Black

(at 20°C) 188 289

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

5

Magnetic contactor

451155L AC 450V, 1.5µF

BUM44X4505B AC 440V, 45µF

CLK-26J

220 − 240V, 50Hz

– 15 –

5. REFRIGERATION CYCLE DIAGRAM

5-1. RAS-24UKHP-ES4 / RAS-24UAH-ES4

FILE NO. SVM-05011

0.39m

(Connecting pipe)

12.7

∅

O.D.:12.7mm

Cooling

Heating

Tank

Indoor unit

Cooling

Heating

P

Packed valve

(∅

12.7)

Gas container connection (Reinstall etc.)

Heating

4-way valve

Cooling

Compressor

5JS315DAG01

Heat exchanger

Cross flow fan

T1

Packed valve

(∅

6.35)

Capillary tube

2.0x800

∅

s

0.

49m

(Connecting pipe)

6.35

∅

O.D.:6.35mm

Condenser

Refrigerant

R410A 1.5 kg

)means check points of Gas Leak.

Cooling

Heating

Propeller fan

Outdoor unit

Mark(

Ambient temp.

50Hz

Standard

pressure

(MPaG)

P

Surface temp. of heat

exchanger interchanging

pipe

T1

(°C)

Fan speed

(indoor)

conditions DB/WB

(°C)

Indoor Outdoor

Standard 3.1 50.9 High 20/– 7/6

Heating Overload*1 3.8 ~ 4.0 57.0 ~ 59.0 Low 27/– 24/18

Low temperature 2.6 35.0 High 20/– –10/–10

Standard 0.8 7.2 High 27/19 35/24

Cooling Overload 1.3 12.0 High 32/23 43/26

Low temperature 0.6 1.0 Low 21/15 21/15

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

*1 • During heating overload operation, a value for the high temperature limit control operation is included.

– 16 –

5-2. RAS-18UKHP-ES4 / RAS-18UAH-ES4

FILE NO. SVM-05011

0.39m

(Connecting pipe)

∅

12.7

O.D.:12.7mm

Cooling

Heating

Indoor unit

Cooling

Heating

P

Packed valve

(

∅

Heating

4-way valve

Cooling

Compressor

12.7)

5KS225DAA

Accumulator

Evaporator

Cross flow fan

T1

Packed valve

∅

6.35)

(

Capillary tube

∅

2.0x1200

s

0.49m

(Connecting pipe)

∅

6.35

O.D.:6.35mm

Condenser

Cooling

Heating

Propeller fan

Outdoor unit

Mark(

Refrigerant

R410A 1.

)means check points of Gas Leak.

02 kg

Ambient temp.

50Hz

Standard

pressure

(MPaG)

P

Surface temp. of heat

exchanger interchanging

pipe

T1

(°C)

Fan speed

(indoor)

conditions DB/WB

(°C)

Indoor Outdoor

Standard 2.6 44.7 High 20/– 7/6

Heating Overload*1 3.0 ~ 3.6 49.0 ~ 56.0 Low 27/– 24/18

Low temperature 2.0 32.0 High 20/––10/–10

Standard 0.9 9.5 High 27/19 35/24

Cooling Overload 1.1 12.6 High 32/23 43/26

Low temperature 0.7 2.4 Low 21/15 21/15

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

*1 • During heating overload operation, a value for the high temperature limit control operation is included.

– 17 –

5-3. RAS-24UKP-ES4 / RAS-24UA-ES4

FILE NO. SVM-05011

0.39m

(Connecting pipe)

12.7

∅

O.D.:12.7mm

Cooling

Compressor

Indoor unit

Cooling

P

Packed valve

(∅

12.7)

Gas container connection (Reinstall etc.)

Accumulator

5JS315DAG01

Heat exchanger

Cross flow fan

T1

Packed valve

∅

6.35)

(

Capillary tube

2.0x700

∅

s

0.49m

(Connecting pipe)

∅

6.35

O.D.:6.35mm

Condenser

Refrigerant

R410A 1.6kg

)means check points of Gas Leak.

Cooling

Propeller fan

Outdoor unit

Mark(

Ambient temp.

50Hz

Standard

pressure

(MPaG)

P

Surface temp. of heat

exchanger interchanging

pipe

T1

(° C)

Fan speed

(indoor)

conditions DB/WB

(° C)

Indoor Outdoor

Standard 0.6 6.0 High 27/19 35/24

Cooling Overload 1.10 10.0 High 32/23 43/26

Low temperature 0.5 2.0 Low 21/15 21/15

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

– 18 –

5-4. RAS-18UKP-ES4 / RAS-18UA-ES4

FILE NO. SVM-05011

0.39m

(Connecting pipe)

∅

12.7

O.D.:12.7mm

Cooling

Compressor

Indoor unit

Cooling

P

Packed valve

(

∅

12.7)

5KS225DAA

Evaporator

Cross flow fan

T1

Packed valve

∅

6.35)

(

Capillary tube

1.7x600

∅

s

0.49m

(Connecting pipe)

∅

6.35

O.D.:6.35mm

Condenser

Cooling

Propeller fan

Outdoor unit

Mark(

Refrigerant

R410A 1.

)means check points of Gas Leak.

16 kg

Ambient temp.

50Hz

Standard

pressure

(MPaG)

P

Surface temp. of heat

exchanger interchanging

pipe

T1

(°C)

Fan speed

(indoor)

conditions DB/WB

(°C)

Indoor Outdoor

Standard 1.1 10.0 High 27/19 35/24

Cooling Overload 1.2 13.0 High 32/23 43/26

Low temperature 0.6 2.0 Low 21/15 21/15

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

– 19 –

6. CONTROL BLOCK DIAGRAM

6-1. RAS-24UKHP-ES4, RAS-18UKHP-ES4

Indoor Unit Control Panel

Heat Exchanger Sensor

Functions

• Louver Control

FILE NO. SVM-05011

M.C.U.

Operation

Display

Temperature Sensor

Infrared Rays Signal Receiver

Infrared

Rays

Remote

Control

From Outdoor Unit

220 ~ 240 V AC 50 Hz

Initiallizing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Noise Filter

• 3-minute Delay at Restart for Compressor

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

• Serial Signal Communication

Louver ON/OFF Signal

Louver Driver

Serial Signal Transmitter/Receiver

Serial Signal Communication

Timer

Display

Filter Sign

Display

PRE DEF.

Sign Display

Hi Power

Sign Display

Indoor

Fan Motor

Louver Motor

REMOTE CONTROL

Infrared Rays

Remote Control

Operation ( )Operation ( )

Operation Mode Selection

AUTO, COOL, DRY, HEAT, FAN ONLY

Temperature Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver Auto Swing

Louver Direction Setting

ECO

Hi power

TIMER 1.3.5.9H

COMFORT SLEEP

QUIET

– 20 –

6-2. RAS-24UKP-ES4, RAS-18UKP-ES4

Indoor Unit Control Panel

Heat Exchanger Sensor

Functions

Louver Control

FILE NO. SVM-05011

M.C.U.

Operation

Display

Temperature Sensor

Infrared Rays Signal Receiver

Infrared

Rays

Remote

Control

From Outdoor Unit

220 ~ 240V AC 50Hz

Initiallizing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Noise Filter

3-minute Delay at Restart for Compressor

Motor Revolution Control

Processing

(Temperature Processing)

Timer

Outdoor unit

ON/OFF Signal

Relay Driver

Relay RY04

Outdoor Unit

Louver ON/OFF Signal

Louver Driver

Timer

Display

Filter Sign

Display

Fan Only

Sign Display

Hi Power

Sign Display

Indoor

Fan Motor

Louver Motor

REMOTE CONTROL

Infrared Rays

Remote Control

Operation ( )Operation ( )

Operation Mode Selection

AUTO, COOL, DRY, HEAT, FAN ONLY

Temperature Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver Auto Swing

Louver Direction Setting

ECO

Hi power

TIMER 1.3.5.9H

COMFORT SLEEP

QUIET

− 21 −

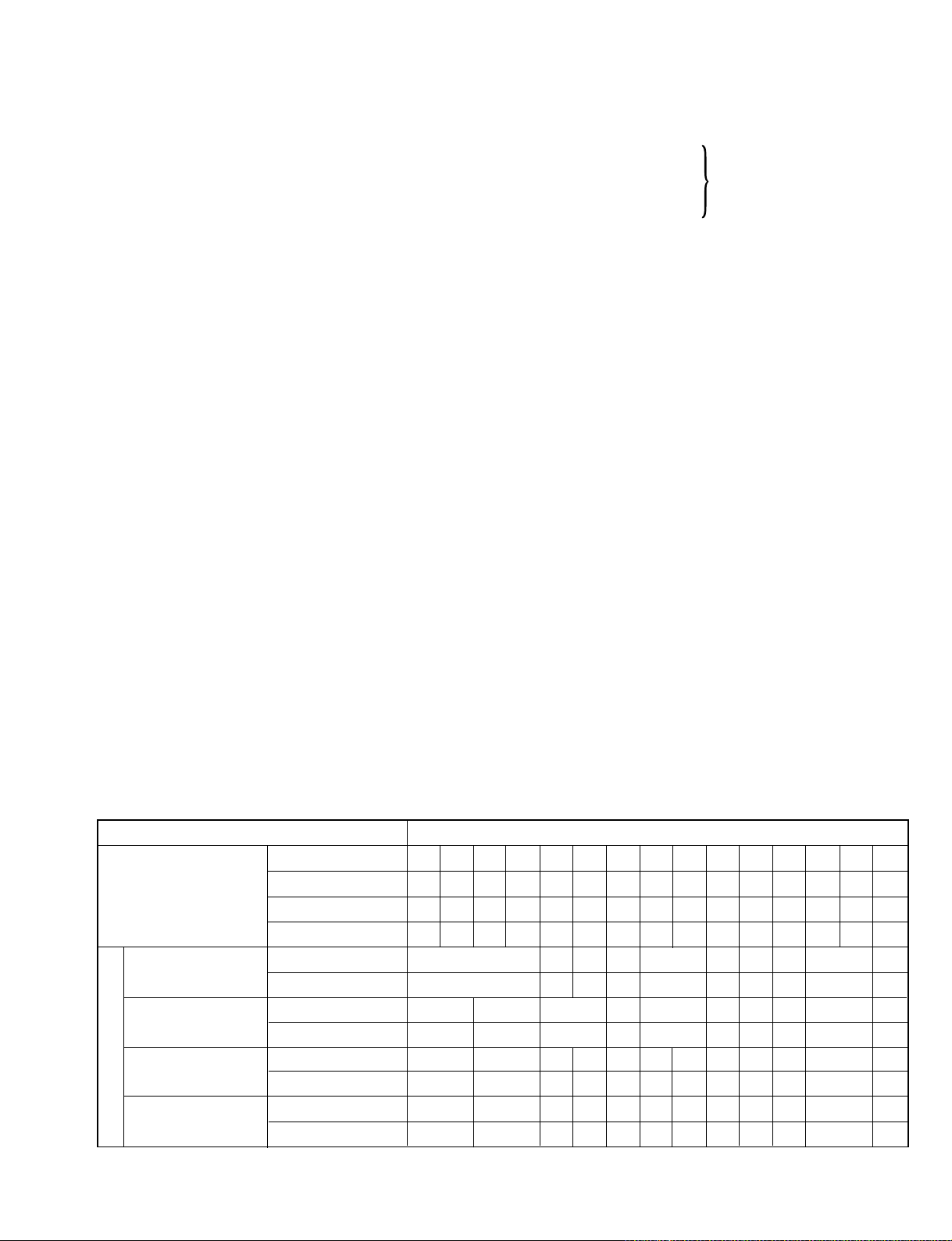

7. OPERATION DESCRIPTION

FILE NO. SVM-05011

7-1. Outline of Air Conditioner Control

This is a fixed capacity type air conditioner, which uses

a AC motor for an indoor fan. The AC motor drive

circuit is mounted in the indoor unit. And electrical

parts which operate the compressor and the outdoor

fan motor, are mounted in the outdoor unit.

The air conditioner is mainly controlled by the indoor

unit controller. The controller operates the indoor fan

motor based upon commands transmitted by the

remote control and transfers the operation commands

to the outdoor unit controller.

The outdoor unit controller receives operation

commands from the indoor unit, and operates the

outdoor fan motor and the compressor.

(1) Role of indoor unit controller

The indoor unit controller receives the operation

commands from the remote control and executes

them.

· Temperature measurement at the air inlet of the

indoor heat exchanger by the indoor

temperature sensor

· Temperature setting of the indoor heat

exchanger by the heat exchanger sensor

· Louver motor control

· Indoor fan motor operation control

· LED display control

· T ransferring of operation commands to the

outdoor unit

· Receiving of information of the operation status

and judging of the information or indication of

error

Table 7-1-1

OPERATION

MODE

RAS-24UKHP Series

RAS-18UKH Series

Model

RAS-24UKP Series

RAS-18UKP Series

Cooling

Heat

Fan Only

Dry

rpm

Air Flow volume(m /h)

rpm

Air Flow volume(m /h)

rpm

Air Flow volume(m /h)

rpm

Air Flow volume(m /h)

3

3

3

3

1300

790

−

−

−

−

(2) Role of outdoor unit controller

The outdoor unit controller receives the operation

commands from the indoor controller and

executes them.

· Compressor operation

control

· Operation control of

outdoor fan motorf

Turning off the compressor and outdoor fan

·

when the outdoor unit receives the shutdown

command

· Defrost control in heating operation

(Temperature measurement by the outdoor heat

exchanger and control for the four-way valve

and the outdoor fan motor) *Heat pump Model

only

7-1-1. Louver contr

ol

(1) Vertical air flow louver

Position of veritcal air flow louver is automatically

controlled according to the operation mode.

Besides, position of vertical air flow louver can be

arbitrarily set by pressing [FIX] button.

The louver position which is set by [FIX] button is

stored in the microcomputer, and the louver is

automatically set at the stored position for the next

operation.

(2) Swing

If [SWING] button is pressed when the indoor unit

is in operation, the vertical air flow louver starts

swinging. When [FIX] button is pressed, it stops

swinging.

7-1-2. Indoor fan control (AC Fan motor)

(1) The indoor fan is operated by the stepless speed

change AC motor

(2) For air flow level, speed of the indoor fan motor is

controlled in five steps (LOW, LOW

and HIGH). If AUTO mode is selected, the fan

motor speed is automatically controlled by the

difference between the preset temperature and

the room temperature.

FAN TAP

UH H

900

M+

H M+ M

M+ M

1250 1200

830

11501200

750

1300

900

1150

750

1100

1250

830

1100

708

708

M L+

MUH H

1150 1050 1000 900 800 700

790

−

−

−

750

1050

667

1150

750

1050

−

667

667

950

584

−

−

−

−

.

1050

667

950

584

Operations according

to the commands

from the indoor unit

L L- UL SUL/SL-

L L-

L L-

625

900

543

1000

625

900

543

UL

543

800

461

900

543

800

461

461

700

380

800

461

700

380

L-LL+

L+

L+

+

, MED, MED

UL SUL

380

600

300

700

380

600

300

+

SUL/SL-

600

300

500

220

−

−

−

−

Note : Under some function of setting. The fan motor is controlled automatically.

Then LOW+ = LOW + MED and MED

2

+

= MED + HIGH

2

– 22 –

FILE NO. SVM-05011

7-2. Description of Operation Circuit

(1) When turning on the breaker, the operation lamp

blinks. This means that the power is on (or the

power supply is cut off.)

(2) When pressing [ ] button on the

remote control, receiving beep sounds from the

indoor unit, and the next operation is performed

together with opening the vertical air flow louver.

(3) Once the operation mode is set, it is memorized in

the microcomputer so that the previous operation

can be effected thereafter simply by pressing

[ ] button.

7-2-1. Fan only operation

([MODE] button on the remote control is set

to the fan only operation.)

(1) When [FAN] button is set to AUTO, the indoor fan

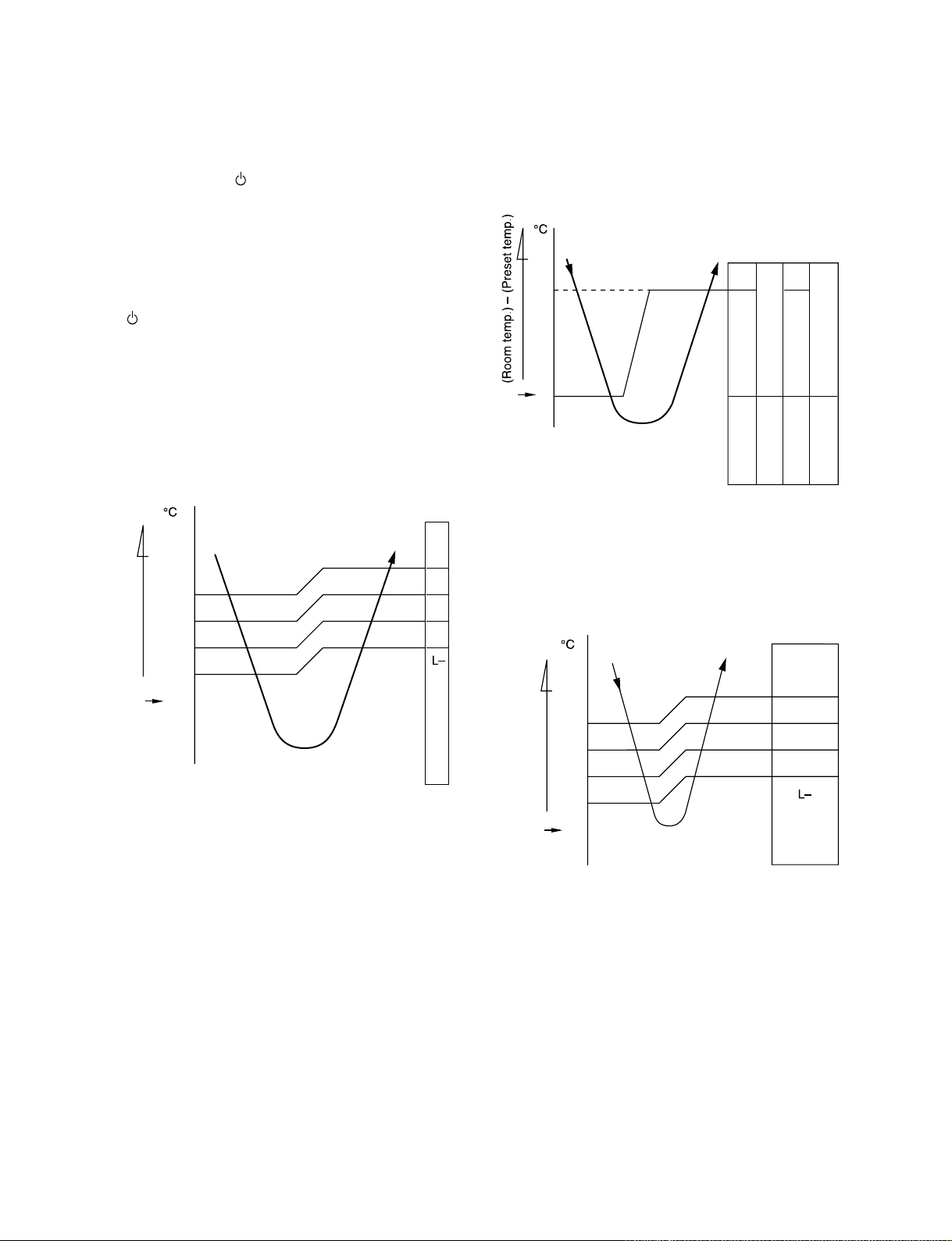

motor operates as shown in Fig. 7-2-1. When

[FAN] button is set to LOW, LOW

HIGH, the motor operates with a constant air flow.

+

, MED, MED+ or

7-2-2. Cooling operation

([MODE] button on the remote control is set

to the cooling operation.)

(1) The compressor, 4-way valve, outdoor fan and

operation display lamp are controlled as shown in

Fig. 7-2-2.

ON

4-way valve

Compressor

Outdoor fan

(Heat pump model)

Preset

temp.

0.5

ON

OFF OFF OFF ON

0

Fig. 7-2-2

display lamp

OPERATION

+3

+2.5

(Preset temp.)

-

+2

+1.5

+1

+0.5

(Room temp.)

Preset

temp.

0

(Preset temp.: 24°C)

NOTE :

*1: The values marked with *1 are calculated and

controlled by the difference in motor speed

between M+ and L-.

(2)

The Hi Power, ECO and COMFORT SLEEP

operation cannot be set.

Fig. 7-2-1 Setting of air flow [FAN:AUTO]

M+

*1

*1

*1

(2) When [FAN] button is set to AUTO, the indoor fan

motor operates as shown in Fig. 7-2-3. When

[FAN] button is set to LOW, LOW

+

, MED, MED+ or

HIGH, the motor operates with a constant air flow.

(Preset temp.)

-

(Room temp.)

Preset

temp.

+3

+2.5

+2

+1.5

+1

+0.5

0

-0.5

M+

*1

*1

*1

NOTE :

*1: The values marked with *1 are calculated and

controlled by the difference in motor speed

between M+ and L-.

Fig. 7-2-3 Setting of air flow [FAN:AUTO]

- 23 -

Loading...

Loading...