Toshiba MMY-MAP0802FT8, MMY-MAP1002FT8 DATA BOOK

FILE NO. A05-004-1

Revised: Jan./2006

SERVICE MANUAL

R410A

System air conditioner

The indoor units in the Super Heat Recovery Multi System are common to those used in the Super Modular Multi

System air conditioner. Therefore refer to the service manuals A03-009, A03-010, and A03-011 separately issued.

Heat Recovery Type

Indoor Unit

4-way Air Discharge Cassette Type

MMU-AP0091H, AP0121H, AP0151H,

MMU-AP0181H, AP0241H, AP0271H,

MMU-AP0301H, AP0361H, AP0481H

MMU-AP0561H

2-way Air Discharge Cassette Type

MMU-AP0071WH, AP0091WH, AP0121WH,

MMU-AP0151WH, AP0181WH, AP0241WH,

MMU-AP0271WH, AP0301WH, AP0481WH*

* CHINA market only

1-way Air Discharge Cassette Type

MMU-AP0071YH, AP0091YH, AP0121YH,

MMU-AP0151SH, AP0181SH, AP0241SH,

MMU-AP0152SH, AP0182SH, AP0242SH

Concealed Duct Standard Type

MMD-AP0071BH, AP0091BH, AP0121BH, AP0151BH,

MMD-AP0181BH, AP0241BH, AP0271BH, AP0301BH,

MMD-AP0361BH, AP0481BH, AP0561BH

Concealed Duct High Static Pressure Type

MMD-AP0181H, AP0241H, AP0271H,

MMD-AP0361H, AP0481H

Slim Duct Type

MMD-AP0071SPH, AP0091SPH, AP0121SPH,

MMD-AP0151SPH, AP0181SPH

Under Ceiling Type

MMC-AP0151H, AP0181H, AP0241H,

MMC-AP0271H, AP0361H, AP0481H

High Wall Type

MMK-AP0071H, AP0091H, AP0121H,

MMK-AP0151H, AP0181H, AP0241H,

MMK-AP0072H, AP0092H, AP0122H

Floor Standing Cabinet Type

MML-AP0071H, AP0091H, AP0121H,

MML-AP0151H, AP0181H, AP0241H

Floor Standing Concealed Type

MML-AP0071BH, AP0091BH, AP0121BH,

MML-AP0151BH, AP0181BH, AP0241BH

Floor Standing Type

MMF-AP0151H, AP0181H, AP0241H,AP0271H,

MMF-AP0361H, AP0481H, AP0561H

Outdoor Unit

Flow Selector Unit (FS unit)

Inverter Unit

MMY-MAP0802FT8

MMY-MAP1002FT8

MMY-MAP1202FT8

RBM-Y1122FE

RBM-Y1802FE

RBM-Y2802FE

PRINTED IN JAPAN, Jan., 2006 ToMo

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its concentration will

not exceed a set limit.

The refrigerant R410A which is used in the air

conditioner is safe, without the toxicity or

combustibility of ammonia, and is not restricted by

laws to be imposed which protect the ozone layer.

However, since it contains more than air, it poses the

risk of suffocation if its concentration should rise

excessively. Suffocation from leakage of R410A is

almost non-existent. With the recent increase in the

number of high concentration buildings, however, the

installation of multi air conditioner systems is on the

increase because of the need for effective use of floor

space, individual control, energy conservation by

curtailing heat and carrying power etc.

Most importantly, the multi air conditioner system is

able to replenish a large amount of refrigerant

compared with conventional individual air conditioners.

If a single unit of the multi conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant

accidentally leaks out, its concentration does not

reach the limit (and in the event of an emergency,

measures can be made before injury can occur).

In a room where the concentration may exceed the

limit, create an opening with adjacent rooms, or install

mechanical ventilation combined with a gas leak

detection device.

The concentration is as given below.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m³)

≤ Concentration limit (kg/m³)

The concentration limit of R410A which is used in multi

air conditioners is 0.3kg/m³.

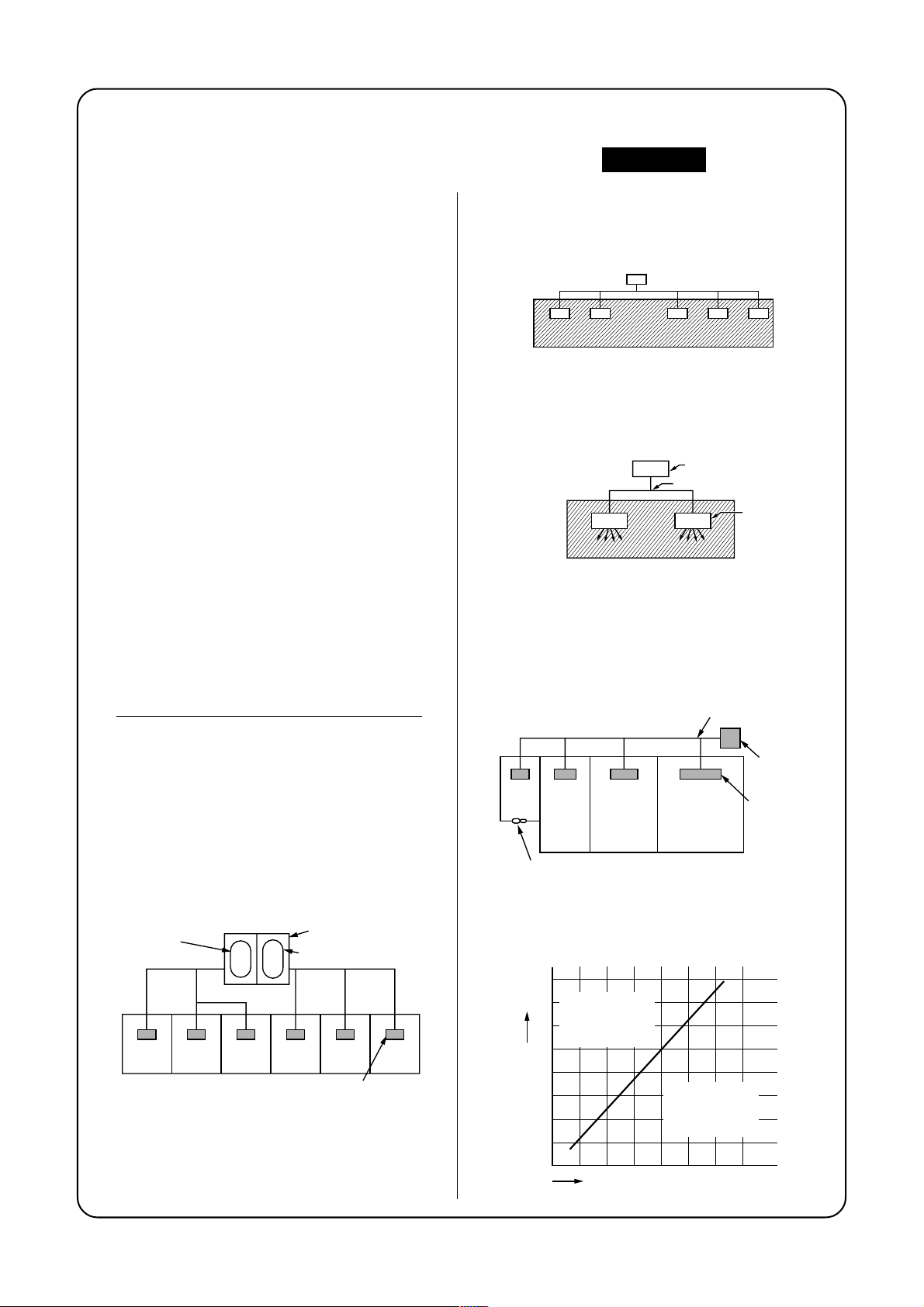

NOTE 1 :

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should

be as charged in each independent device.

e.g., charged

amount (10kg)

Room A Room B Room C Room D Room E Room F

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 10kg.

The possible amount of leaked refrigerant gas in

rooms D, E and F is 15kg.

Outdoor unit

e.g.,

charged amount (15kg)

Indoor unit

Important

NOTE 2 :

The standards for minimum room volume are as

follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the

adjacent room for ventilation of leaking refrigerant

gas (opening without a door, or an opening 0.15%

or larger than the respective floor spaces at the

top or bottom of the door).

Outdoor unit

Refrigerant piping

Indoor unit

(3) If an indoor unit is installed in each partitioned

room and the refrigerant tubing is interconnected,

the smallest room of course becomes the object.

But when a mechanical ventilation is installed

interlocked with a gas leakage detector in the

smallest room where the density limit is exceeded,

the volume of the next smallest room becomes the

object.

Refrigerant piping

Outdoor unit

Very

small

room

Small

room

Mechanical ventilation device - Gas leak detector

Medium

room

Large room

NOTE 3 :

The minimum indoor floor area compared with the

amount of refrigerant is roughly as follows:

(When the ceiling is 2.7m high)

40

Range below the

35

m²

density limit

of 0.3 kg/m³

30

(countermeasures

not needed)

25

20

15

10

5

Min. indoor floor area

0

10 20 30

Total amount of refrigerant

Range above

the density limit

of 0.3 kg/m³

(countermeasures

needed)

Indoor unit

kg

CONTENTS

SAFETY CAUTION ............................................................................................ 4

1. OUTLINE................................................................................................... 9

2. WIRING DIAGRAM ................................................................................. 14

3. PARTS RATING ...................................................................................... 30

4. REFRIGERANT PIPING SYSTEMATIC DRAWING ............................... 48

5. SYSTEM REFRIGERANT CYCLE DRAWING ....................................... 53

6. CONTROL OUTLINE .............................................................................. 60

7. APPLIED CONTROL .............................................................................. 71

8. TEST OPERATION ................................................................................. 86

9. TROUBLESHOOTING .......................................................................... 116

10. CONFIGURATION OF CONTROL CIRCUIT ........................................ 174

11. BACKUP OPERATIONS (EMERGENCY OPERATION)....................... 188

12. OIL LEVEL JUDGMENT DISPLAY....................................................... 190

13. REFRIGERANT RECOVERY

WHEN REPLACING THE COMPRESSOR ........................................... 191

14. LEAKAGE/CLOGGING OF OIL-EQUALIZATION CIRCUIT................. 197

15. REPLACING COMPRESSOR............................................................... 199

16. REPLACING PROCEDURE OF PARTS............................................... 206

17. P.C. BOARD .......................................................................................... 217

NOTE

Ensure power is isolated from the unit when replacing the high perf ormance filter or when opening the

service panel.

SAFETY CAUTION

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

Indication

DANGER

WARNING

CAUTION

∗ Property damage : Enlarged damage concerned to property , furniture, and domestic animal/pet

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage ( ∗) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Explanation

[Explanation of illustrated marks]

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

(Refer to the Parts disassembly diagram (Outdoor unit).)

If removing the label during parts replace, stick it as the original.

DANGER

Turn “OFF” the breaker before removing the front panel and cabinet, otherwise an electric

shock is caused by high voltage resulted in a death or injury.

During operation, a high voltage with 400V or higher of circuit (∗) at secondary circuit of the highvoltage transformer is applied.

Turn off breaker.

Execute discharge

between terminals.

Prohibition

If touching a high voltage with the naked hands or body, an electric shock is caused even if using an

electric insulator.

∗ : For details, refer to the electric wiring diagram.

When removing the front panel or cabinet, execute short-circuit and discharge between highvoltage capacitor terminals.

If discharge is not executed, an electric shock is caused by high voltage resulted in a death or injury.

After turning off the breaker, high voltage also keeps to apply to the high-voltage capacitor.

Do not turn on the breaker under condition that the front panel and cabinet are removed.

An electric shock is caused by high voltage resulted in a death or injury.

4

Check earth wires.

Prohibition of modification.

Use specified parts.

Do not bring a child

close to the equipment.

Insulating measures

No fire

WARNING

Before troubleshooting or repair work, check the earth wire is connected to the earth

terminals of the main unit, otherwise an electric shock is caused when a leak occurs.

If the earth wire is not correctly connected, contact an electric engineer for rework.

Do not modify the products.

Do not also disassemble or modify the parts. It may cause a fire, electric shock or injury.

For spare parts, use those specified (

If unspecified parts are used, a fire or electric shock may be caused.

∗: For details, refer to the parts list.

Before troubleshooting or repair work, do not bring a third party (a child, etc.) except

the repair engineers close to the equipment.

It causes an injury with tools or disassembled parts.

Please inform the users so that the third party (a child, etc.) does not approach the equipment.

Connect the cut-off lead cables with crimp contact, etc, put the closed end side

upward and then apply a water-cut method, otherwise a leak or production of fire is

caused at the users’ side.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle. When using a gas stove, etc, be sure to put out fire

before work; otherwise the oil mixed with refrigerant gas may catch fire.

2) Do not use a welder in the closed room. When using it without ventilation, carbon

monoxide poisoning may be caused.

3) Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may

catch the inflammables.

∗∗

∗).

∗∗

Refrigerant

Check the used refrigerant name and use tools and materials of the parts which

match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a

position on the outdoor unit where is easy to see. To prevent miss-charging, the route of the

service port is changed from one of the former R22.

For an air conditioner which uses R410A, never use other refrigerant than R410A.

For an air conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating cycle and an injury due to breakage may be caused.

Do not charge refrigerant additionally.

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in

the refrigerating cycle changes resulted in change of air conditioner characteristics or

refrigerant over the specified standard amount is charged and an abnormal high pressure is

applied to the inside of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute

vacuuming, and then newly recharge the specified amount of liquid refrigerant. In this time,

never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant

or air other than R410A into the specified refrigerant.

If air or others is mixed with the refrigerant, abnormal high pressure generates in the

refrigerating cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak.

If the refrigerant gas leaks in the room, poisonous gas generates when gas touches to fire

such as fan heater, stove or cocking stove though the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit.

When the equipment is moved or repaired, be sure to recover the refrigerant with recovering device. The refrigerant cannot be recovered in the outdoor unit; otherwise a serious

accident such as breakage or injury is caused.

Assembly/Cabling

After repair work, surely assemble the disassembled parts, and connect and lead the

removed cables as before. Perform the work so that the cabinet or panel does not

catch the inner cables.

If incorrect assembly or incorrect cable connection was done, a disaster such as a leak or

fire is caused at user’s side.

5

WARNING

Insulator check

Ventilation

Be attentive to

electric shock

Compulsion

After the work has finished, be sure to use an insulation tester set (500V mugger) to

check the resistance is 2M

metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s

side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of the

refrigerant and the closed room full with gas is dangerous because a shortage of oxygen

occurs. Be sure to execute ventilation.

When checking the circuit inevitably under condition of the power-ON, use rubber

gloves and others not to touch to the charging section.

If touching to the charging section, an electric shock may be caused.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down

and tighten the service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking

stove though the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such

as a multi air conditioner in a sub-room, it is necessary that the density does not the

limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is

caused.

For the installation/moving/reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric

shock or fire is caused.

ΩΩ

Ω or more between the charge section and the non-charge

ΩΩ

Check after rerair

Check after reinstallation

Put on gloves

Cooling check

After repair work has finished, check there is no trouble.

If check is not executed, a fire, electric shock or injury may be caused. For a check, turn off

the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test

run to check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused. Before test run, install the

front panel and cabinet.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

CAUTION

Be sure to put on gloves (

If not putting on gloves, an injury may be caused with the parts, etc.

(∗) Heavy gloves such as work gloves

When the power was turned on, start to work after the equipment has been

sufficiently cooled.

As temperature of the compressor pipes and others became high due to cooling/heating

operation, a burn may be caused.

∗∗

∗) during repair work.

∗∗

6

• New Refrigerant (R410A)

This air conditioner adopts a new HFC type refrigerant (R410A) which does not deplete the ozone lay er.

1. Safety Caution Concerned to New Refrigerant

The pressure of R410A is high 1.6 times of that of the former refrigerant (R22). Accompanied with change of

refrigerant, the refrigerating oil has been also changed. Therefore, be sure that water, dust, the former refrigerant or the former refrigerating oil is not mixed into the refrigerating cycle of the air conditioner with new refrigerant during installation work or service work. If an incorrect work or incorrect service is performed, there is a

possibility to cause a serious accident. Use the tools and materials exclusiv e to R410A to purpose a safe work.

2. Cautions on Installation/Service

(1) Do not mix the other refrigerant or refrigerating oil.

For the tools exclusive to R410A, shapes of all the joints including the service port differ from those of the

former refrigerant in order to prevent mixture of them.

(2) As the use pressure of the new refrigerant is high, use material thickness of the pipe and tools which are

specified for R410A.

(3) In the installation time, use clean pipe materials and work with great attention so that water and others do

not mix in because pipes are affected by impurities such as water, oxide scales, oil, etc. Use the clean

pipes.

Be sure to brazing with flowing nitrogen gas. (Never use gas other than nitrogen gas.)

(4) For the earth protection, use a vacuum pump for air purge.

(5) R410A refrigerant is azeotropic mixture type refrigerant. Therefore use liquid type to charge the refrigerant.

(If using gas for charging, composition of the refrigerant changes and then characteristics of the air condi-

tioner change.)

7

3. Pipe Materials

For the refrigerant pipes, copper pipe and joints are mainly used. It is necessary to select the most appropriate

pipes to conform to the standard. Use clean material in which impurities adhere inside of pipe or joint to a

minimum.

(1) Copper pipe

<Piping>

The pipe thickness, flare finishing size, flare nut and others differ according to a refrigerant type .

When using a long copper pipe for R410A, it is recommended to select “Copper or copper-base pipe without

4. Tools

(1) Required T ools for R410A

Mixing of different types of oil may cause generation of sludge, clogging of capillary, etc.

Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive for R410A (Those which cannot be used for conv entional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

R410A

No. Used tool

Flare tool

Copper pipe gauge for

adjusting projection

margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Charging cylinder

Usage

Pipe flaring

Flaring by conventional

flare tool

Connection of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

Refrigerant charge

air conditioner installation

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Whether conventional equipment can

be used

Existence of

new equipment

for R410A

(Note 2)

*(Note 1)

*(Note 1)

No

No

No

Yes

No

No

No

(Note 1) When flaring is carried out for R410A using the conventional flare tools , adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary .

(Note 2) Charging cylinder for R410A is being currently developed.

Conventional air

conditioner installation

Whether new equipment

can be used with

conventional refrigerant

Yes

*(Note 1)

No

No

Yes

Yes

No

Yes

No

seam” and one with bonded oil amount 40mg/10m or less. Also do not use crushed, deformed, discolored

(especially inside) pipes. (Impurities cause clogging of expansion valves and capillary tubes.)

<Flare nut>

Use the flare nuts which are attached to the air conditioner unit.

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

General tools (Conventional tools can be used.)

as the general tools.

(2) Joint

The flare joint and socket joint are used for joints of the copper pipe. The joints are rarely used for installa-

tion of the air conditioner. However clear impurities when using them.

(1) Vacuum pump

Use vacuum pump by

attaching vacuum pump adapter.

(2) T orque wrench

(3) Pipe cutter

(4) Reamer

(5) Pipe bender

(7) Screwdriver (+, –)

(8) Spanner or Monkey wrench

(9) Hole core drill

(10) Hexagon wrench (Opposite side 4mm)

(11) Tape measure

(12) Metal saw

(6) Level vial

Also prepare the following equipments f or other installation method and run check.

(1) Clamp meter

(2) Thermometer

(3) Insulation resistance tester (Megger)

(4) Electroscope (Volt meter)

5. Recharge of Refrigerant

When recharge of the refrigerant is required, charge the new refrigerant with the specified amount in the

procedure as described below .

Recover the refrigerant and check there is no refrigerant in the

equipment.

Connect the charge hose to the packed valve service ports at gas

side, liquid side, and balance side of the outdoor unit.

Connect the charge hose to vacuum pump adaptor.

Open the packed valves of the balance pipe fully at liquid and gas

sides, and then return the valve at gas side a little to the closed side.

Leave it as it is for 1 to 2 minutes and check the indicator

of the compound gauge does not return.

Set the refrigerant cylinder on the electronic balance,

connect the charge hose to connecting ports of the

cylinder and the electronic gauge, and then charge the

liquid refrigerant from the service port at liquid side.

(Shield with the gauge manifold so that refrigerant does

not flow to gas side.)

(Charge the refrigerant as below.)

Open fully PMV of the outdoor unit.

• Turn on power of the outdoor unit.

• Short CN30 on I/F P.C. board of the outdoor unit.

•

Turn off power of the outdoor unit within 2 minutes after

Open fully the handle on the Low side of the gauge manifold, and

then turn on the power of vacuum pump for vacuuming.

When the pressure has lowered until indication of the compound

gauge pointed –0.1MPa (–76cmHg), open fully the handle Low and

turn off the power of vacuum pump.

Never charge the refrigerant over the specified amount.

Q

Do not charge the additional refrigerant.

R

shorting CN30

If charging refrigerant additionally when refrigerant gas

leaks, the refrigerant composition in the refrigerating cycle

changes resulted in change of air conditioner characteristics or refrigerant over the specified standard amount is

.

Connected to

indoor unit

Main

pipe

Brazed

Fully

tightened

Fully

tightened

Connected to other

terminal units

Valve fully closed

(gas side)

Valve fully closed

(liquid side)

Valve fully closed

(balance)

charged and an abnormal high pressure is applied to the

inside of the refrigerating cycle resulted in cause of

breakage or injury.

Set the equipment so that liquid refrigerant can be charged.

Q

When using a cylinder with siphon pipe, liquid can be charged without inverting the cylinder.

R

4mm-hexagonal wrench is required.

pressure gauge

Center unit

Service

port

Copper pipe

Service port

Low-

Ø6.4

High-

pressure gauge

VLV

Gauge

H

manifold

Reducing

valve

Ø6.4

Copper pipe

Nitrogen

gas

[ Cylinder with siphon ] [ Cylinder without siphon ]

Refrigerant

cylinder

Electronic

balance

Gauge manifold

OUTDOOR unit

Electronic

balance

Gauge manifold

cylinder

Refrigerant

OUTDOOR unit

Siphon

R410A refrigerant is consisted with HFC mixed refrigerant.

Therefore if the refrigerant gas is charged, the composition

of the charged refrigerant changes and characteristics of

the equipment changes.

6. Environmental concern

Use “Vacuum pump method” for an air purge (Discharge of air in the connecting pipe) in installation time.

• Do not discharge flon gas into the air to protect the earth environment.

• Using the vacuum pump method, clear the remaining air (Nitrogen, etc.) in the unit. If the air remains, the

pressure in the refrigerating cycle becomes abnormally high and an injury could occur through failure of

the product.

8

1. OUTLINE

“Super Heat Recovery Multi System” is a multi air conditioning system which enables each

indoor unit in a refrigerant line to independently select cooling or heating operation.

As it is able to operate simultaneously in cooling and heating modes, further heat recovery

becomes possible. This system is most suitable for a building etc. where cool and hot air are

mixed, such as a building where there are large temperature differences between rooms,

caused by the influence of daylight or where used in a server room and permanent cooling is

required.

Heating and cooling operation are automatically selected in individual unit;

You can save time for operation.

For e xample, when heating is required for early morning and cooling for daytime, a Flow Selector Unit provides

automatically a smooth selection of heating or cooling operation.

Therefore you can obtain a comf ortable room environment without feeling somewhat out of place and moreover

you can save time to select heat/cool operation.

INFORMATION

The Super Heat Recovery Multi system is different from that of the conventional Multi air conditioner in several

ways such as the heating and cooling oper ations are mixed and only a part of the air conditioning system

operates in cooling function.

For this reason, the f ollowing table explains the operation modes of this air conditioner.

The following table explains the representation of the operation modes within this Manual.

Operation mode

Operation mode Outline

1. All Cooling All indoor units are under cooling operation only.

Outdoor heat exchanger (Main heat exchanger) is used as condenser .

2. All Heating All indoor units are under heating operation only.

Outdoor heat exchanger (Main heat exchanger) is used as ev apor ator.

3. Simultaneous operation MIU for simultaneous operation

3-1. Mainly cooling, partly

heating operation

3-2. Mainly heating, partly

cooling operation

4. Defrost Using the reversing operation of the 4-wa y v alv e, ice on the outdoor heat e xchanger is dissolved

Indoor units are under heating/cooling simultaneous operation with subjective cooling operation

Outdoor heat exchanger (Sub heat exchanger) is used as condenser.

Indoor units are under heating/cooling simultaneous operation with subjective heating operation

Outdoor heat exchanger (Main heat exchanger) is used as ev apor ator.

within single cooling cycle.

9

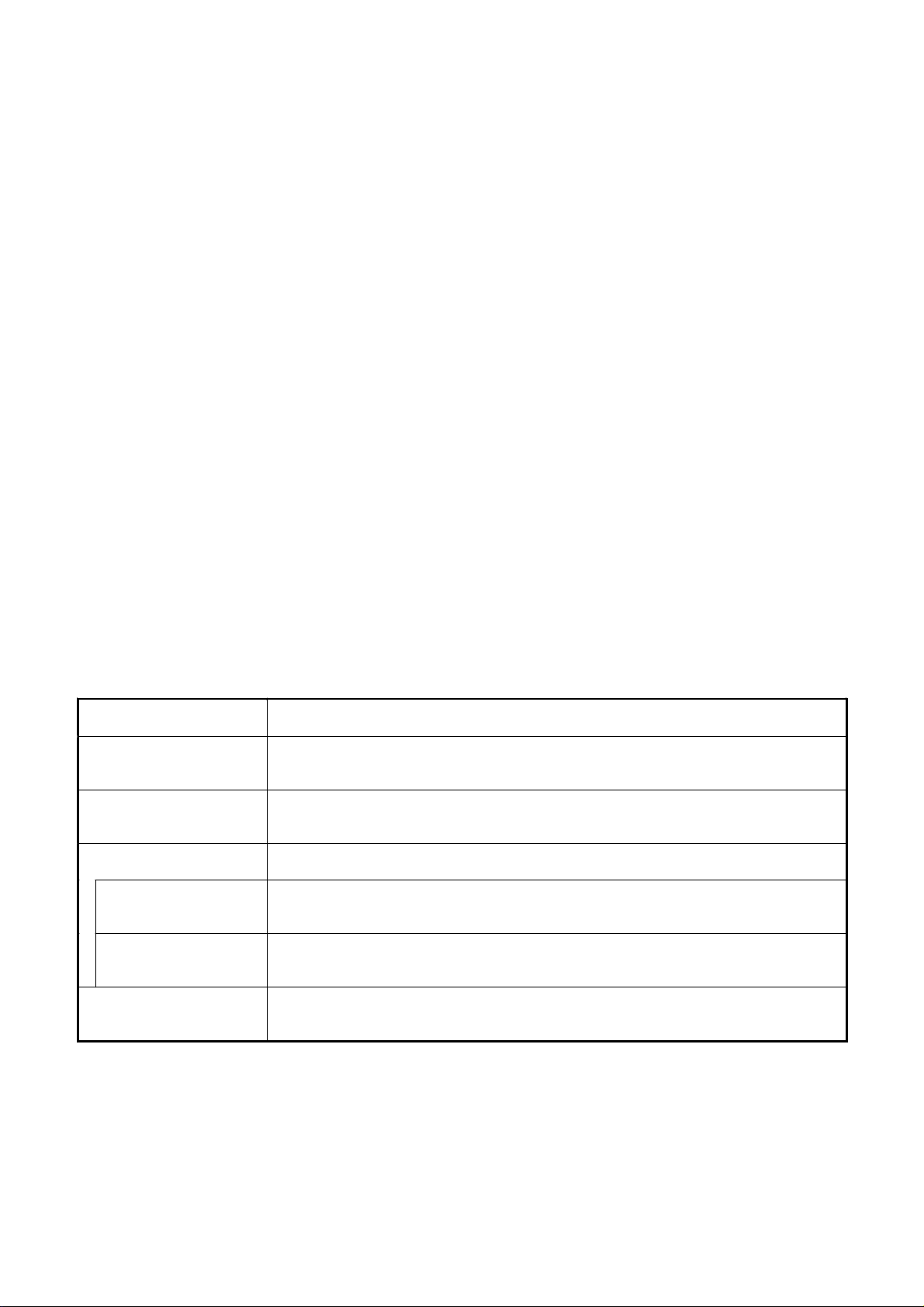

1-1. Component Multi Using High-efficiency Refrigerant R410A

1. Outdoor units

Corresponding HP

Model name Heat pum p

Cooling capacity (kW) 22.4 28.0 33.5

Heating capacity (kW) 25.0 31.5 37.5

No. of connectable indoor units 13 16 20

MMY- MAP0802FT8 MAP1002FT8 MAP1202FT8

8 HP 10 HP 12 HP

Inverter unit

Appearance

2. Combination of outdoor units

Corresponding HP 16 HP 18 HP 20 HP 24 HP 26 HP 28 HP 30 HP

Combined Model

Coo li n g capa c i t y (kW) 45.0 50.4 56.0 68.0 73.0 78.5 84.0

Hea t in g capa c i ty ( kW) 50.0 56.5 63.0 76.5 81.5 88.0 95.0

Combined outdoor units

No. of connectable indoor units 27 30 33 40 43 47 48

MMY- AP1602FT8 AP1802FT8 AP2002FT8 AP2402FT8 AP2602FT8 AP2802FT8 AP3002FT8

8 HP 10 HP 10 HP 8 HP 10 HP 10 HP 10 HP

8 HP 8 HP 10 HP 8 HP 8 HP 10 HP 10 HP

———8 HP 8 HP 8 HP 10 HP

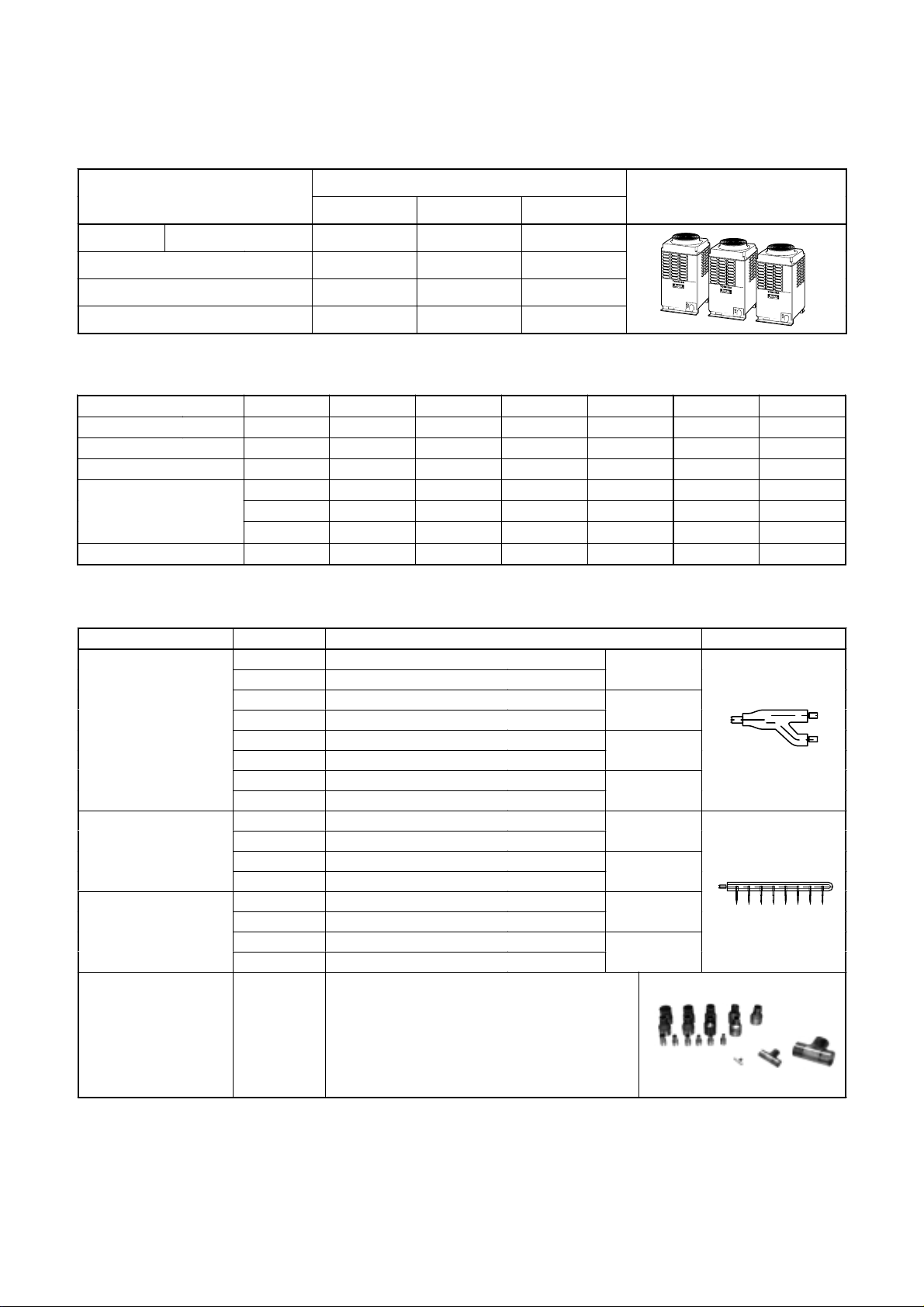

3. Branching joints and headers

Model name Usage Appearance

RBM-BY53FE Indoor unit capacity code (∗1) Total below 6.4

RBM-BY103FE Indoor unit capacity code (∗1) Total below 14. 2

RBM-BY53E Indoor unit capacity code (∗1) Total below 6.4

Y-shape branching joint (∗3)

4-branching header (∗4)

8-branching header (∗4)

T-branch joint BT13-FE

RBM-BY103E Indoor unit capacity code (∗1) Total below 14. 2

RBM-BY203FE Indoor unit capacity code (∗1) Total below 25. 2

RBM-BY303FE Indoor unit capacity code (∗1) Total below 25. 2

RBM-BY203E Indoor unit capacity code (∗1) Total below 25. 2

RBM-BY303E Indoor unit capacity code (∗1) Total below 25. 2

RBM-1043FE Indoor unit capacity code (∗1) Total below 14. 2

RBM-2043FE Indoor unit capacity code (∗1) Total below 25. 2

RBM-1043E Indoor unit capacity code (∗1) Total below 14. 2

RBM-2043E Indoor unit capacity code (∗1) Total below 25. 2

RBM-1083FE Indoor unit capacity code (∗1) Total below 14. 2

RBM-2083FE Indoor unit capacity code (∗1) Total below 25. 2

RBM-1083E Indoor unit capacity code (∗1) Total below 14. 2

RBM-2083E Indoor unit capacity code (∗1) Total below 25. 2

For 3 piping

For 2 piping (∗5)

For 3 piping

For 2 piping (∗5)

For 3 piping

For 2 piping (∗5)

For 3 piping

For 2 piping (∗5)

The following 3 types of T joint pipes are supplied as 1 set.

• Balance pipe (Ø9.5) × 1

• Liquid side

(Corresponded dia. Ø12.7 to Ø19.1) × 1

• Suction gas side

(Corresponded dia. Ø22.2 to Ø34.9) × 1

• Discharge gas side

(Corresponded dia. Ø19.1 to Ø22.2) × 1

∗1 “Capacity code” can be obtained from page 11, 12. (Capacity code is not actual capacity)

∗2 If the total capacity code value of indoor unit exceeds that of the outdoor unit, apply capacity code of the outdoor unit.

∗3 When using a Y-shape branching joint for 1st branching, select according to the capacity code of the outdoor unit.

∗4 Max. 6.0 capacity code in total can be connected.

∗5 This is used for branching to “cooling only” indoor unit.

∗6 Model names for outdoor described in this guide are shortened because of the space constraint.

10

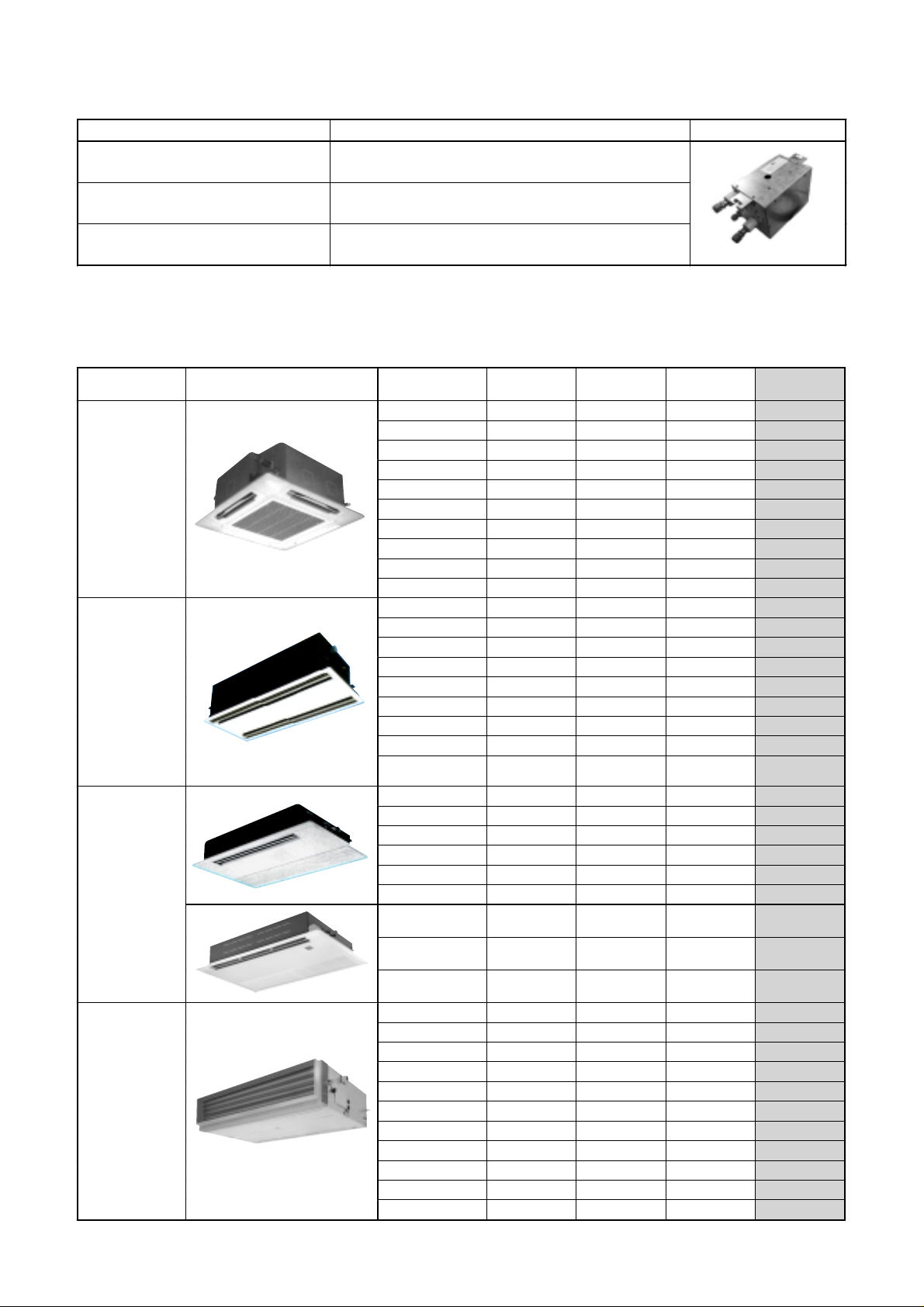

4. Flow selector units (FS unit)

Model name Usage Appearance

RBM-Y1121FE Capacity rank for indoor unit : Type 007 to 030

RBM-Y1801FE Capacity rank for indoor unit : Type 036 to 056

RBM-Y2802FE Capacity rank for indoor unit : Type 018 to 096

* Accessory part (Sold separately): Connection cable kit (RBC-CBK15FE), up to 15m.

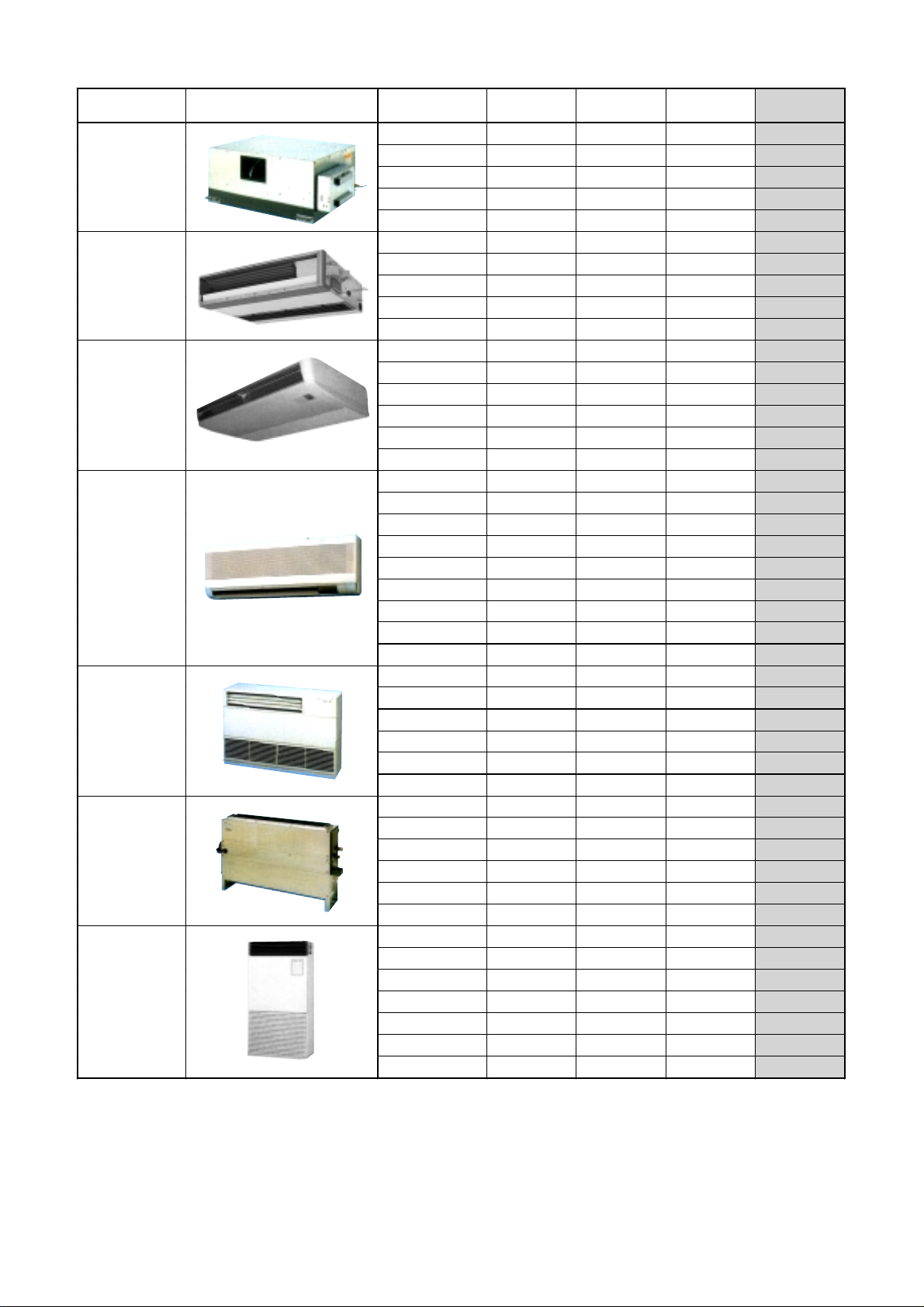

5. Indoor units

Type Appearance Model name Capacity rank Capac ity code

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

048 type 5 14.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

015 type 1.7 4.5

4-way Air Discharge

Cassette Type

2-way Air Discharge

Cassette Type

1-way Air Discharge

Cassette Type

MMU-AP0091H

MMU-AP0121H

MMU-AP0151H,

MMU-AP0181H

MMU-AP0241H

MMU-AP0271H

MMU-AP0301H

MMU-AP0361H

MMU-AP0481H

MMU-AP0561H

MMU-AP0071WH

MMU-AP0091WH

MMU-AP0121WH

MMU-AP0151WH

MMU-AP0181WH

MMU-AP0241WH

MMU-AP0271WH

MMU-AP0301WH

MMU-AP0481WH

(CHINA only)

MMU-AP0071YH

MMU-AP0091YH

MMU-AP0121YH

MMU-AP0151SH

MMU-AP0181SH

MMU-AP0241SH

MMU-AP0152SH

Cooling

capacity (kW)

Heating

capacity (kW)

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

16.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

Concealed Duct

Standard Type

MMU-AP0182SH

MMU-AP0242SH

MMD-AP0071BH

MMD-AP0091BH

MMD-AP0121BH

MMD-AP0151BH

MMD-AP0181BH

MMD-AP0241BH

MMD-AP0271BH

MMD-AP0301BH

MMD-AP0361BH

MMD-AP0481BH

MMD-AP0561BH

11

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

Type Appearance Model name Capacity rank Capac ity code

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

Concealed Duct

High Static

Pressure Type

Slim Duct Type

Under Ceiling Type

High Wall Type

Floor Standing

Cabinet Type

Floor Standing

Concealed Type

Floor Standing Ty pe

MMD-AP0181H

MMD-AP0241H

MMD-AP0271H

MMD-AP0361H

MMD-AP0481H

MMD-AP0071SPH

MMD-AP0091SPH

MMD-AP0121SPH

MMD-AP0151SPH

MMD-AP0181SPH

MMC-AP0151H

MMC-AP0181H

MMC-AP0241H

MMC-AP0271H

MMC-AP0361H

MMC-AP0481H

MMK-AP0071H

MMK-AP0091H

MMK-AP0121H

MMK-AP0151H

MMK-AP0181H

MMK-AP0241H

MMK-AP0072H

MMK-AP0092H

MMK-AP0122H

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MML-AP0071BH

MML-AP0091BH

MML-AP0121BH

MML-AP0151BH

MML-AP0181BH

MML-AP0241BH

MMF-AP0151H

MMF-AP0181H

MMF-AP0241H

MMF-AP0271H

MMF-AP0361H

MMF-AP0481H

MMF-AP0561H

Cooling

capacity (kW)

Heating

capacity (kW)

6.3

8.0

9.0

12.5

16.0

2.5

3.2

1.0

5.0

6.3

5.0

6.3

8.0

9.0

12.5

16.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

9.0

12.5

16.0

18.0

12

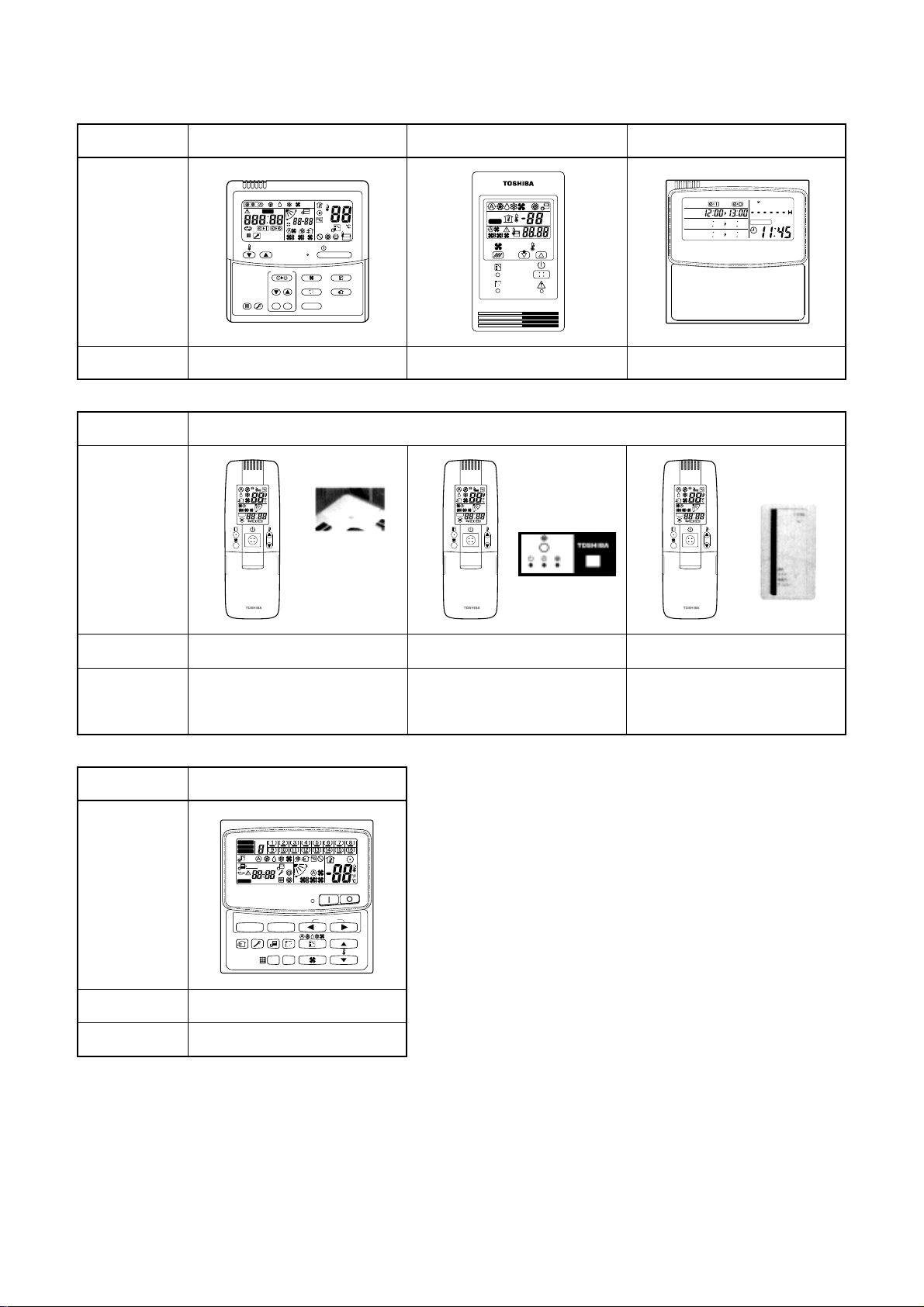

n Remote controllers

Name

Appearance

Model name

Name

Appearance

Wired remote controller

UNIT No.

R.C. No.

CODE No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

FILTER

RESET

DATA

SET

TEST

SETTING

H

TEMP.

TIMER SET

TEST

RBC-AMT31E

Receiver section

ADR

Simple wired remote controller

TEST

SETTING

˚C

˚F

RBC-AS21E

Wireless remote controller kit

ADR

Receiver section

Weekly timer

PROGRAM1

PROGRAM2

PROGRAM3

WEEKLY TIMER

RBC-EXW21E

Receiver section

mounted separately

ADR

SuMoTuWeThFr Sa

ERROR

Model name

Type

Name

Appearance

Model name

Type

RBC-AX2U (W)-E

4-way Air Discharge

Cassette type

Central remote controller

ZONE

ALL

ZONE

GROUP

1234

UNIT No.

SET DATA

SETTING

R.C.

No.

SELECT ZONE

CL

TEST

SET

GROUP

CODE

No.

TCB-SC642TLE

64 system center controller

RBC-AX22CE

Under Ceiling type

1-way Air Discharge Cassette

type (MMU-AP✽✽✽2SH Series)

TCB-AX21E

Separate sensor type

13

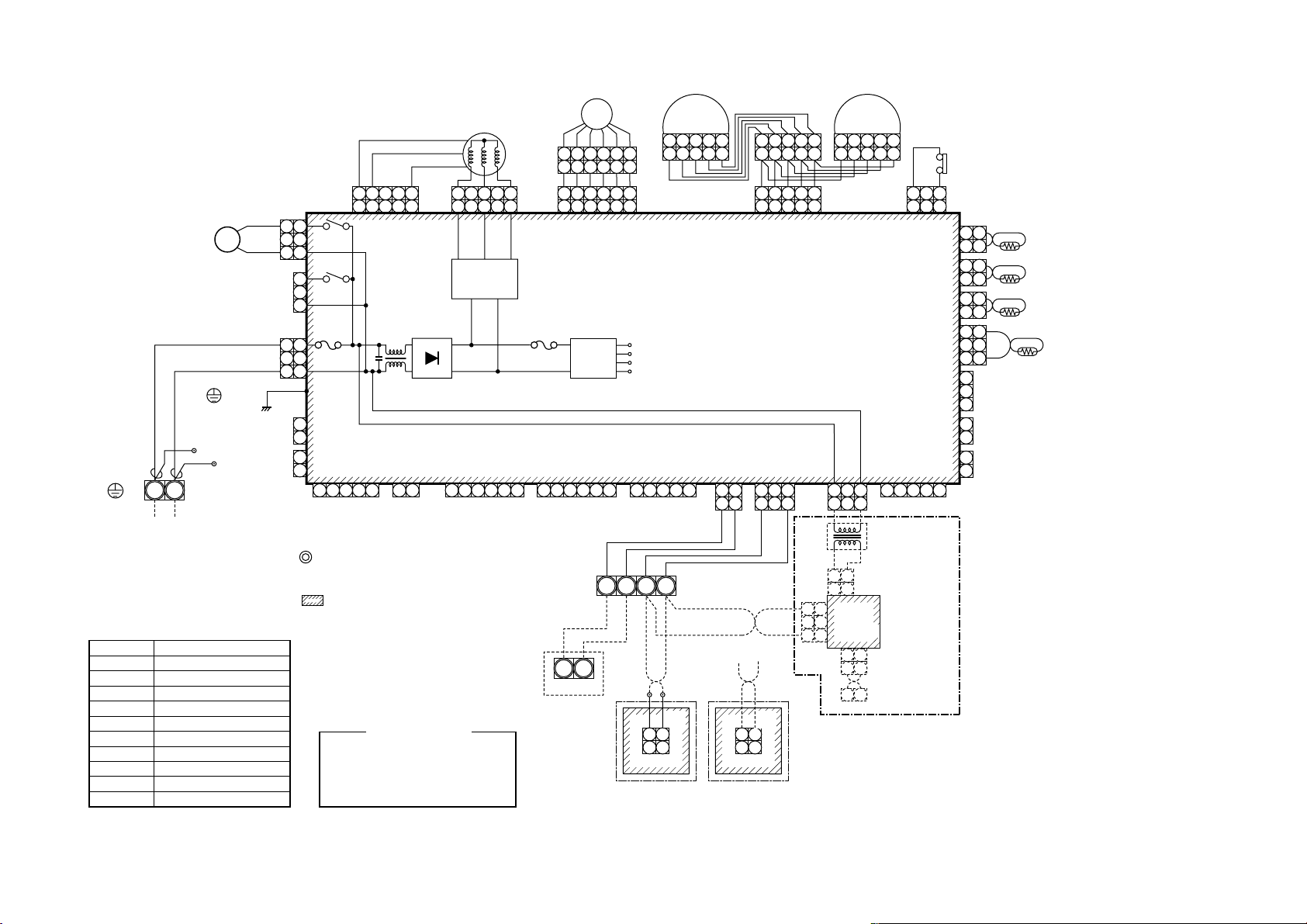

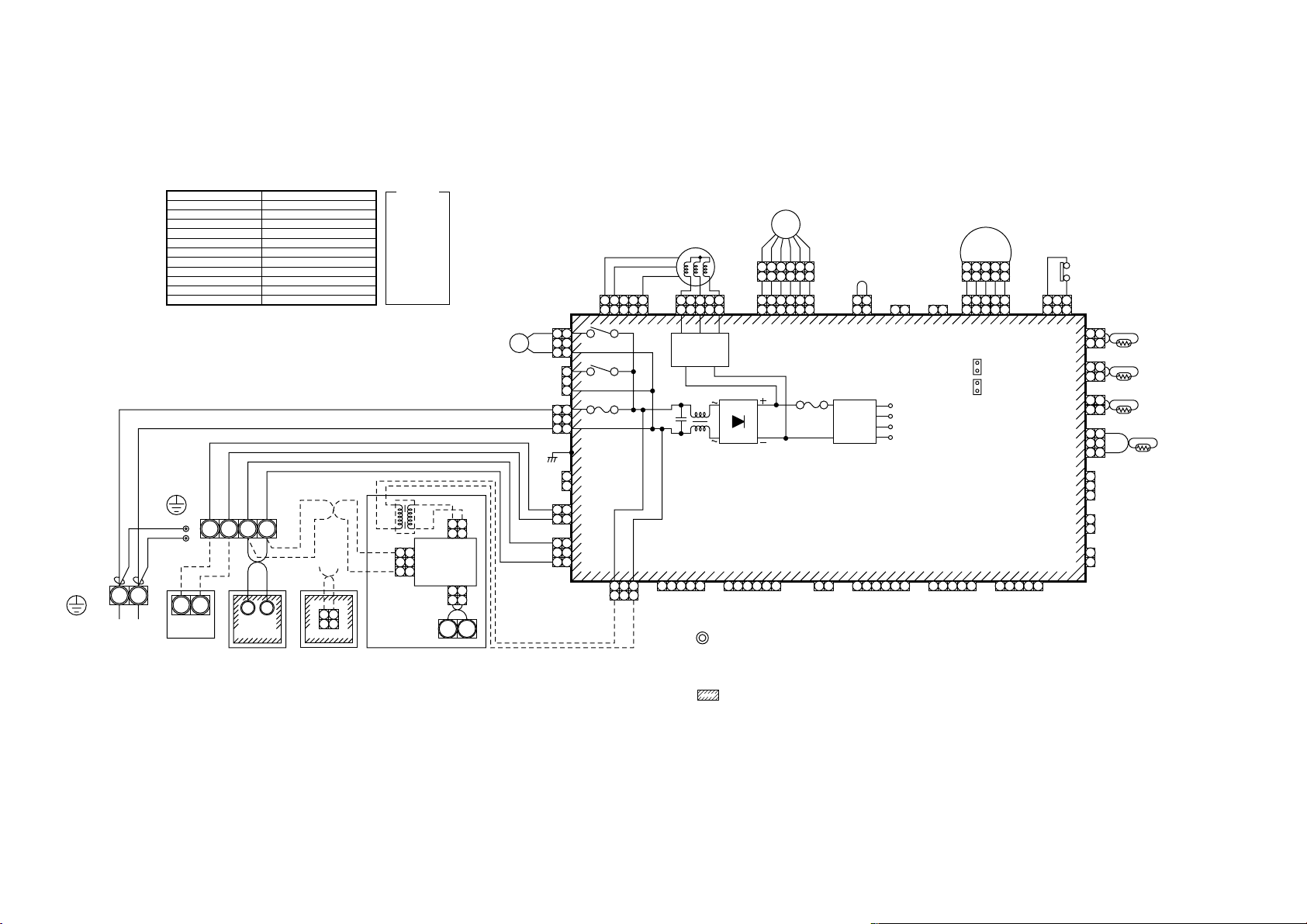

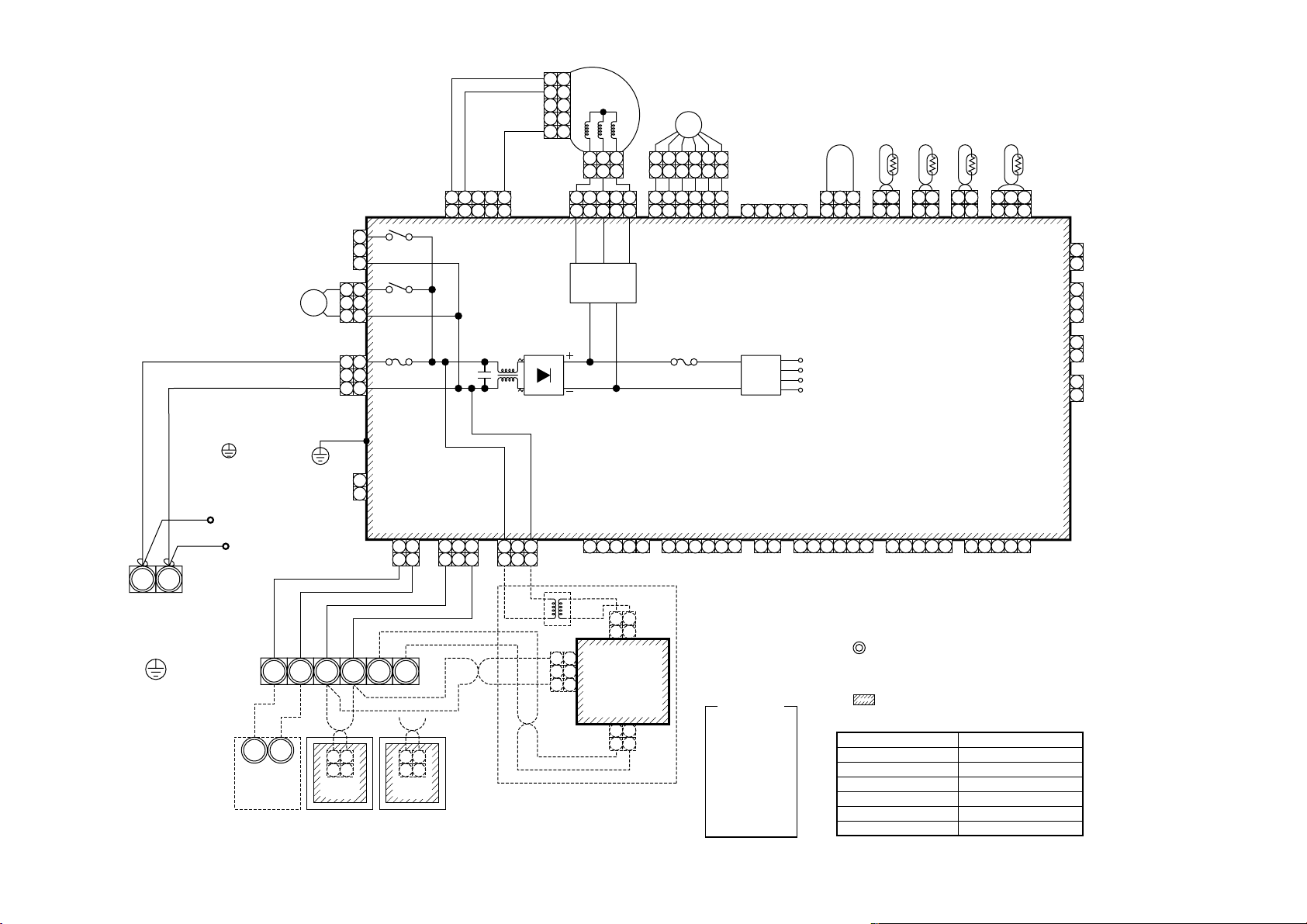

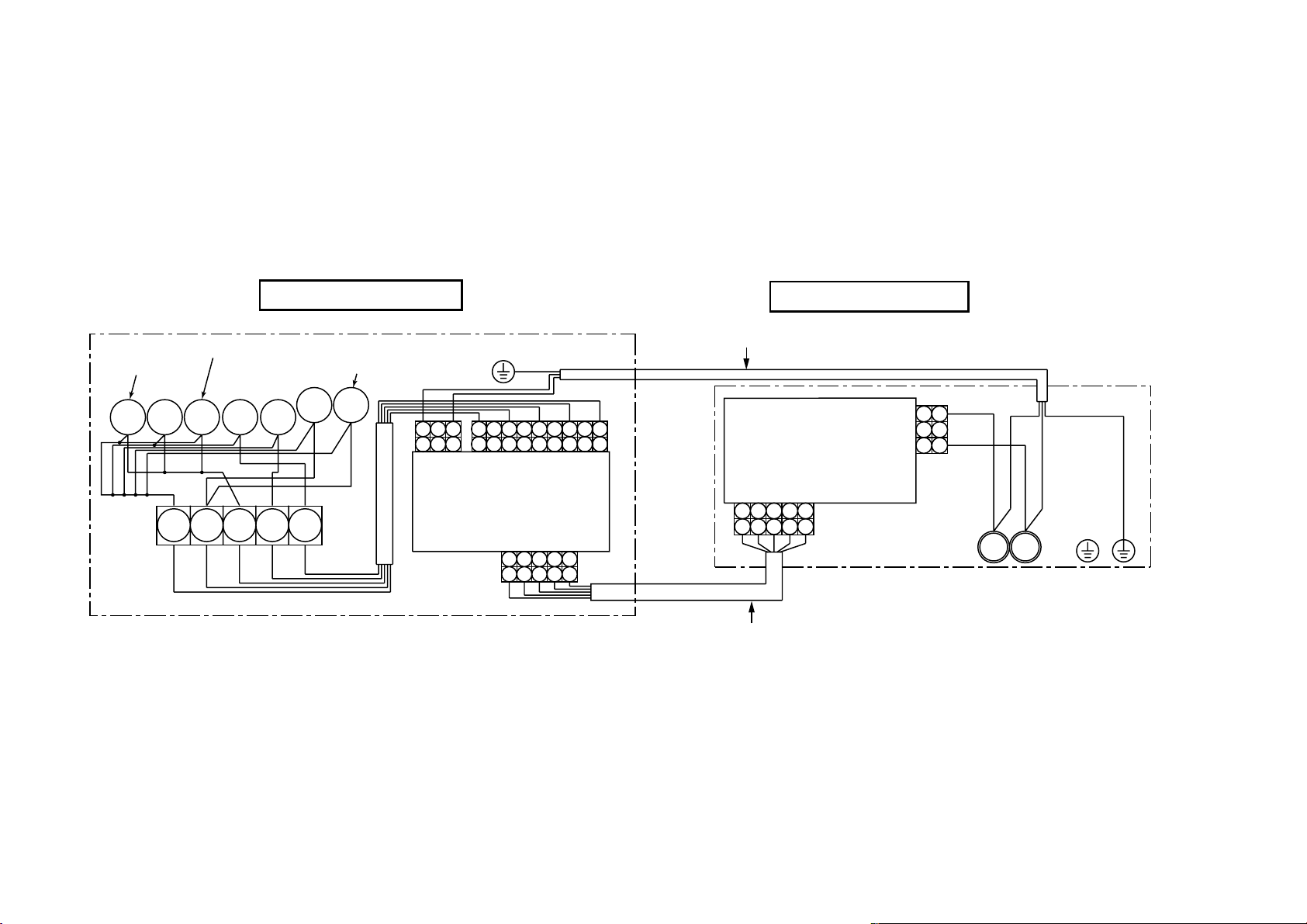

2. WIRING DIAGRAM

2-1. Indoor Unit

2-1-1. 4-way Air Discharge Cassette Type

Model: MMU-AP0091H, AP0121H, AP0151H, AP0181H, AP0241H,

14

Indoor unit

Earth screw

Symbol

FM

TA

TC1

TCJ

TC2

LM1, LM2

DM

FS

RY302

PMV

Flow selector

S(N)R(L)

Power supply

Single phase

220-240V 50Hz

220V 60Hz

Fan motor

Indoor temp sensor

Temp sensor

Temp sensor

Temp sensor

Louver motor

Drain pump motor

Float switch

Drain control relay

Pulse Motor Valve

DM

unit earth

screw

RED

WHI

Closed end

connector

Parts name

FM

CN334

5 4 3 2 1

5 4 3 2 1

RY302

RY303

Fuse

T6.3A

250V~

~

~

P301

CN50

(WHI)

CN32

(WHI)

1 2

4 5 6

(Fandrive)

CN304

(GRY)

RED

CN67

(BLK)

WHI

CN66

(WHI)

CN44

(BLN)

CN68

(BLU)

1

2

3

1

2

3

BLK

1

2

3

1

2

3

1

2

3

1

2

1

2

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

Color identification

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BRN : BROWN

1 2 3 4 5

(BLU)

1 2 3 4 5 6

Motor drive

circuit

+

CN61

(YEL)

T10

1 2 3 4 51 2 3

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

CN333

(WHI)

Fuse

T3.15A

250V~

6 4 3 1 2 5

6 4 3 1 2 5

1 2 3 4 5 6

1 2 3 4 5

CN60

(WHI)

1 2

3 4 5 6

(Option)

U2U

1

Outdoor unit

PMV

Power

supply

circuit

U

1

LM2

1 2 3 4 5

1 2 3 4 5

CN82

(BLU)

Indoor control P.C. board

MCC-1402

DC20V

DC15V

DC12V

DC7V

CN81

(BLK)

1 2 3 4 5

BAU

2

WHI

BLK WHI BLK

CN1

(WHI)

1 2

1 2

Wired remote

controller

CN40

(BLU)

1 2

1 2

BLU

Adaptor for wireless

remote controller

BLU

1 2

1 2

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

CN41

(BLU)

1 2 3

1 2 3

BLK

BLK

BLK

WHI

CN001

(WHI)

CN309

(YEL)

CN01

(WHI)

3 3

2 2

1 1

CN02

(BLU)

LM1

1 2 3 4 5

1 2 3 4 5

CN33

(WHI)

1 2 3

1 2 3

1 2

Network adaptor

(Option)

1 2

Network

adaptor

P.C. board

1 2

1 2

X Y

CN20

(BLU)

1 2 3 4 5

TR

MCC-1401

CN03

(RED)

3 1

321

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRN)

CN80

(GRN)

CN73

(RED)

CN70

(WHI)

FS

CN34

(RED)

121

2

121

2

121

2

121

2

33

1

PNL

2

3

1

EXCT

2

1

Filter input

2

MMU-AP0271H, AP0301H, AP0361H, AP0481H, AP0561H

TA

TCJ

TC2

TC1

15

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Indoor unit

Earth screw

220-240V 50Hz

220V 60Hz

Flow selector

S(N)R(L)

Power supply

Single phase

FM

unit earth

screw

Closed end

connector

CN039

(YEL)

WHI

121

2

RED

343

4

565

6

77

9

(BLK)

CN304

(GRY)

1

2

3

1

2

3

CN066

(WHI)

CN044

(BRW)

TR

Line Filter

1

Outdoor unit

1

2

3

1

2

3

1

2

3

1

2

1

2

U2U

P301

CN067

(BLK)

CN040

(BLU)

1 2

1 2

BLU

BLU

U

1

U

RY004

Fuse

T5.0A

250V~

CN041

(BLU)

1 2 3

1 2 3

BLK

BLK

BA

2

CN1

(WHI)

1 2

1 2

Remote controller

FAN

CN083

YX

(WHI)

RED

RY007

3 3

1 1

CN02

(BLU)

RC

BLK

9 8 7 6

9 8 7 6

ORN

5 4 3 2 1

5 4 3 2 1

HML UL

RY006

RY005

CN050

(WHI)

1 2 3 4 5

Network

1 2

1 2

adaptor

(Option)

CN01

(WHI)

2

MCC-1401

1. indicates the terminal block, letter at inside

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

DM

YEL

BLU

1 2 3

1 2 3

RY002

CN074

(WHI)

DP

(BLU)

CN068

RY001

Power supply

1 2 3

1 2 3

1 2 3

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

1 2 3 4 5 6

1 2 3 4 5 6

1 1

2 2

CN03

(RED)

indicates the terminal number.

LM

1 2

1 2

1 2 3

1 2 3

circuit

4 5 6

MCC-1520

FS

LM

(GRN)

CN033

1 2 3

1 2 3

FS

(RED)

CN030

Indoor control P.C. board

CN075

(WHI)

CN02

(YEL)

CN01

(WHI)

TR

CN061

(YEL)

1 2 3 4 5 61 2 3 4 5 6

CN032

(WHI)

1 2

Fan drive

Symbol

FM

RC

TR

LM

TA

TC1,TC2,TCJ

RY001

RY002

RY004

RY005~007

FS

DM

PMV

PMV

6 4 3

1 2 5

6 4 3

1 2 5

1 2 3

4 5 6

1 2 3

4 5 6

CN060

(WHI)

1 2 3 4 5 6

Option

Fan motor

Running capacitor

Transformer

Louver motor

Indoor temp sensor

Temp sensor

Louver control relay

Drain control relay

Heater control relay

Fan motor control relay

Float switch

Drain pump motor

Pulse Motor Valve

PMV

(BLU)

CN082

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

Parts name

2

2

2

2

1

2

3

1

2

1

2

1

2

3

4

5

121

121

121

121

33

PNL

EXCT

1

2

TA

TCJ

TC2

Filter

TC1

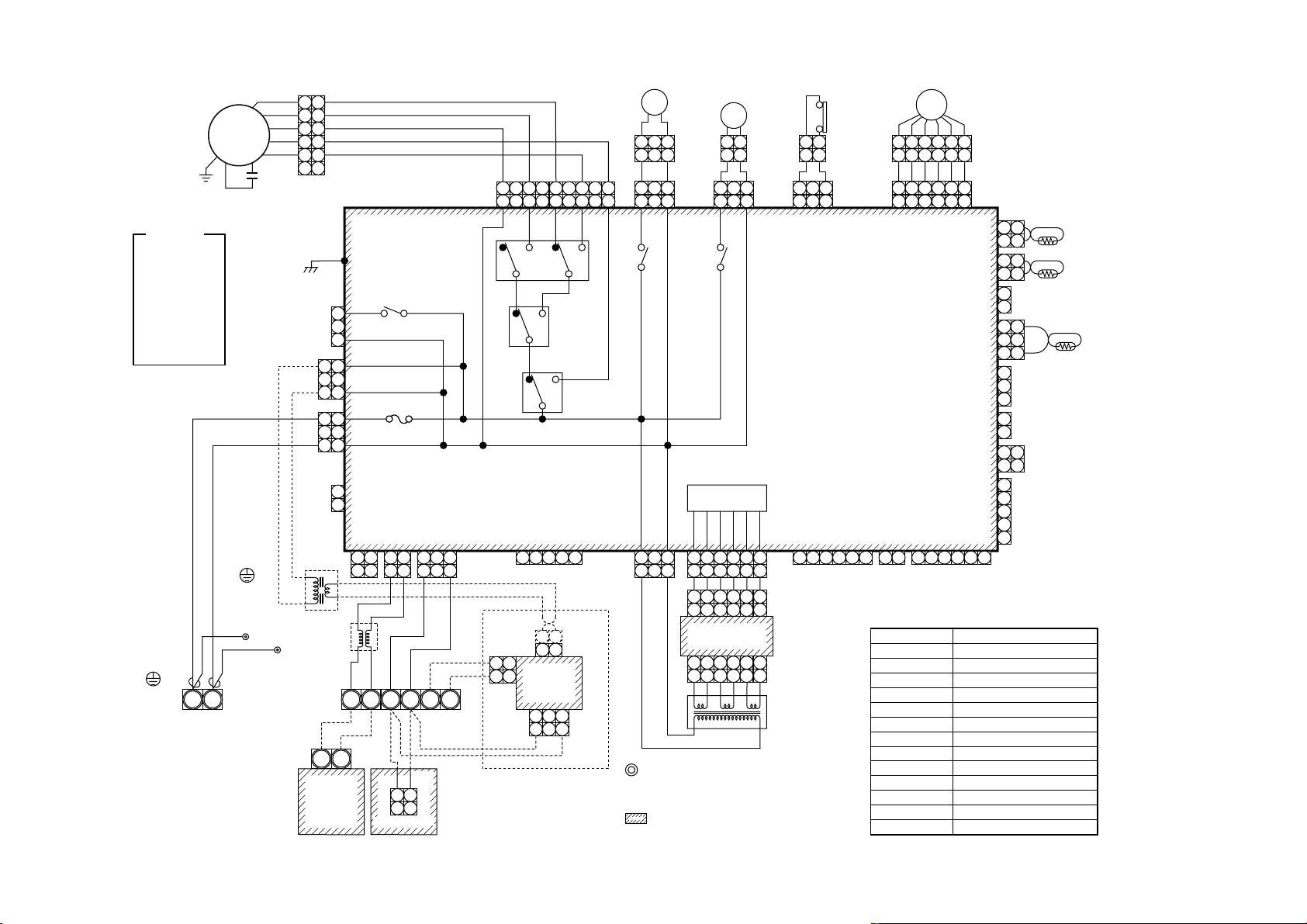

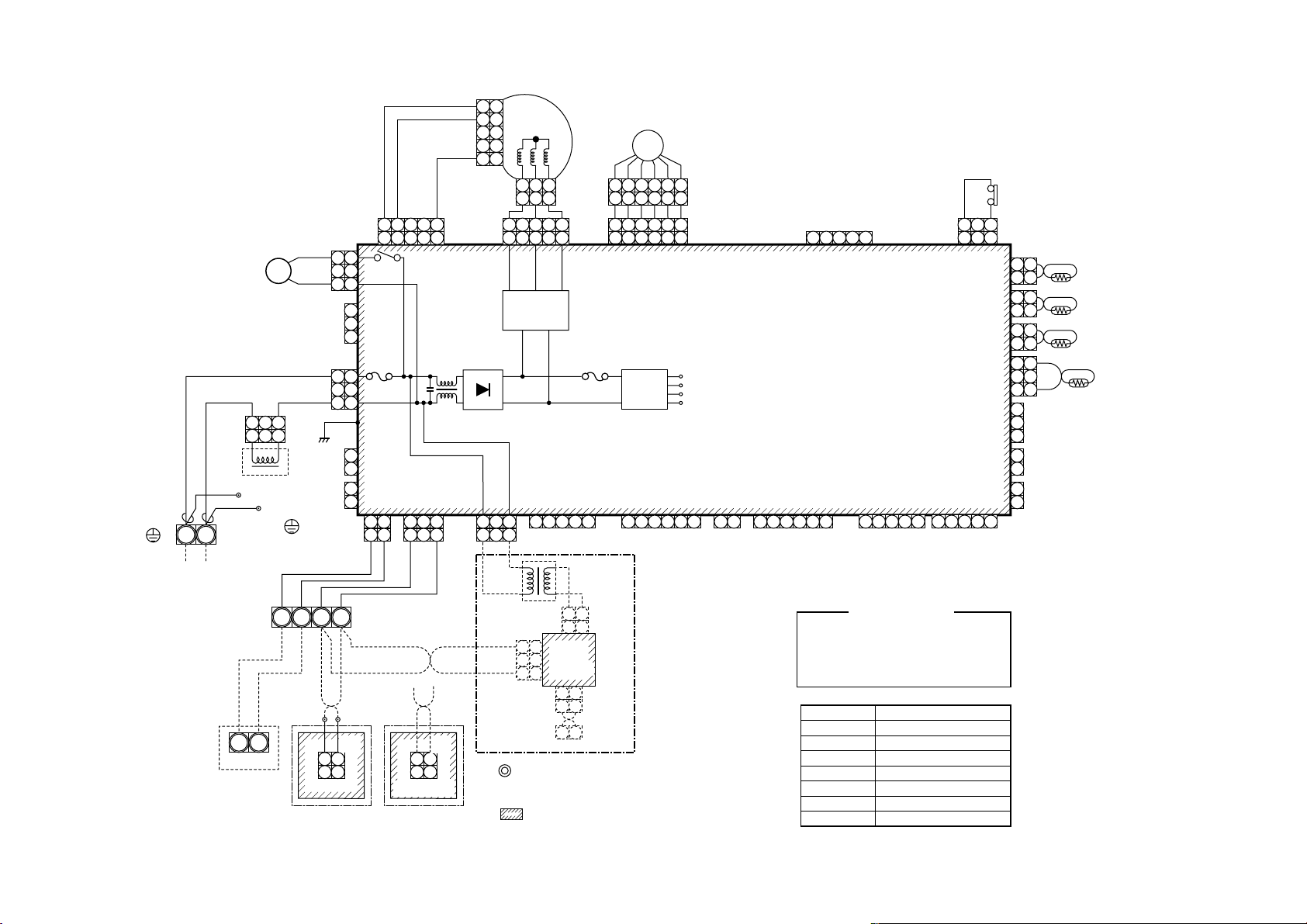

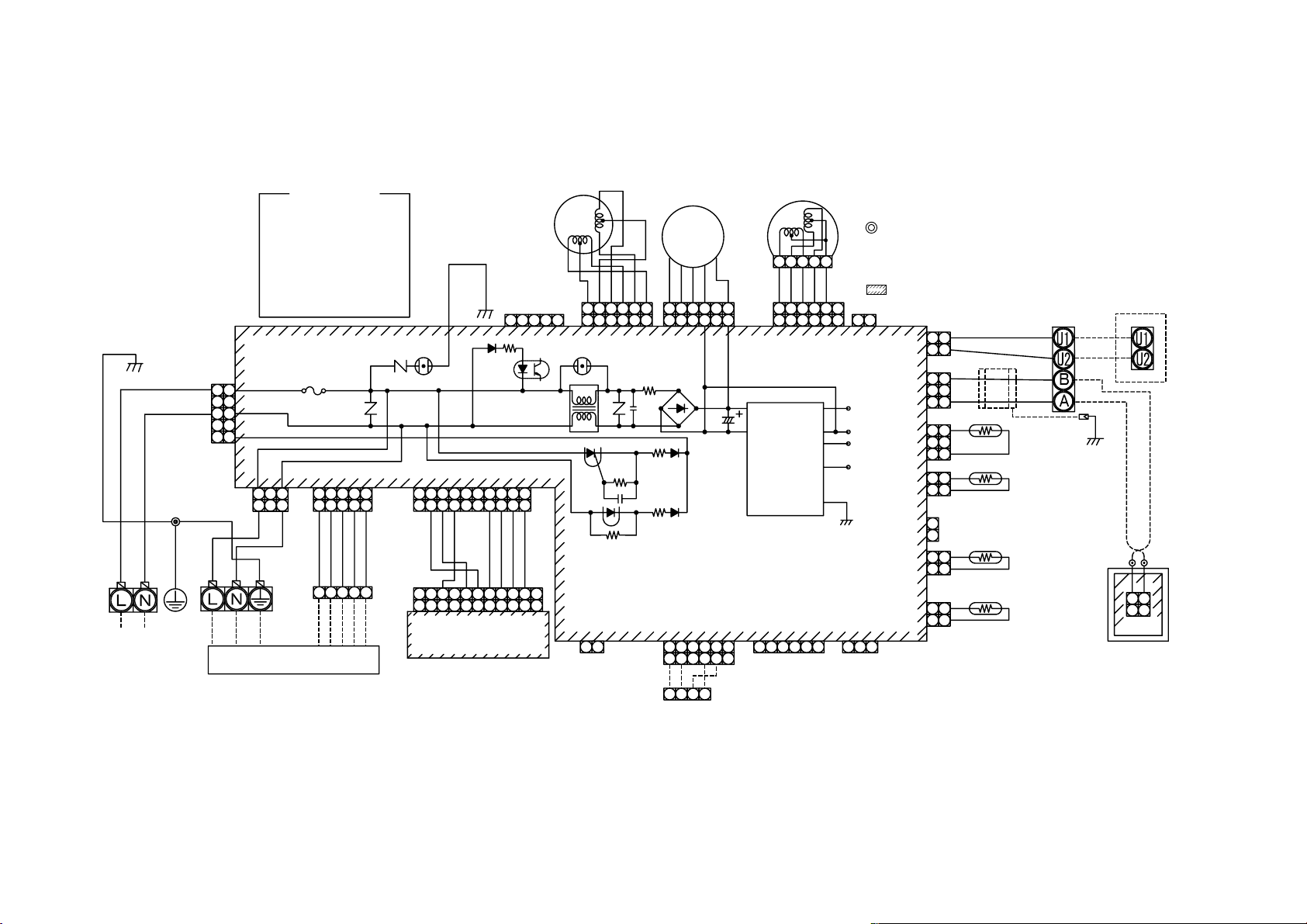

2-1-2. 2-way Air Discharge Cassette Type

Model: MMU-AP0071WH, AP0091WH, AP0121WH, AP0151WH, AP0181WH,

MMU-AP0241WH, AP0271WH, AP0301WH, AP0481WH

2-1-3. 1-way Air Discharge Cassette Type (Compact type)

Model: MMU-AP0071YH, AP0091YH, AP0121YH

16

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Indoor unit

Earth screw

Flow selector

WHI

RED

RED

S(N)R(L)

Power supply

Single phase

220-240V 50Hz

220V 60Hz

FM

unit earth

screw

Closed end

connector

WHI

RC

CN304

(GRY)

CN309

(YEL)

AC IN

CN066

BLU

2

4

6

CN301

(BLK)

Heater

(WHI)

Line Filter

Outdoor

121

343

565

TR

1

2

3

1

2

3

1

unit

1

2

3

1

2

3

1

2

3

1

2

U2U

CN067

(BLK)

CN044

(BRW)

1 2

1 2

BLU

U

1

BLU

U

RY004

Fuse

T5.0A

CN040

(BLU)

1 2

1 2

BLU

BLK

BLK

BLU

BA

2

1 2

1 2

Remote controller

CN041

(BLU)

1 2 3

1 3

AI-NET

central control

terminal

CN1

(WHI)

FAN

CN083

YX

(WHI)

BLK

RED

9 8 7 6

9 8 7 6

HML UL

RY007

CN050

(WHI)

1 2 3 4 5

MCC-1401

CN01

(WHI)

1 1

Network

2 2

adaptor

CN03

P.C. board

(RED)

ORN

5 4 3 2 1

5 4 3 2 1

RY006

RY005

Network

1 2

adaptor

(Option)

1 2

2 1

233 1

DM

1 2 3

1 2 3

YEL

BLU

RY002

1 2 3

1 2 3

(BLU)

CN068

DP

RY001

LM

2 1

2 1

1 2 3

1 2 3

LM

(GRN)

CN033

Indoor control P.C. board

Power supply

circuit

4 5 6

CN075

(WHI)

CN02

(YEL)

CN01

(WHI)

TR

CN074

(WHI)

1 2 3

1 2 3

1 2 3

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

CN02

(BLU)

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

2 1

2 1

1 2 3

1 2 3

1 2 3 4 5 61 2 3 4 5 6

FS

CN030

CN061

(YEL)

FS

(RED)

6 4 3

6 4 3

1 2 3

1 2 3

CN032

(WHI)

1 2

Fan drive

Symbol

FM

RC

TR

LM

TA

TC1,TCJ

RY001

RY002

RY004

RY005~007

FS

DM

PMV

PMV

1 2 5

1 2 5

4 5 6

4 5 6

CN082

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

CN060

(WHI)

1 2 3 4 5 6

Option

Fan motor

Running capacitor

Power transformer

Louver motor

Indoor temp sensor

Temp sensor

Louver motor control relay

Drain pump control relay

Heater control relay

Fan motor control relay

Float switch

Drain pump motor

Pulse Motor Valve

PMV

(BLU)

Parts name

2

2

1

2

2

1

2

3

1

2

1

2

1

2

3

4

5

121

121

121

33

PNL

EXCT

1

2

TA

TCJ

TC1

Filter

17

Indoor unit

earth screw

220-240V 50Hz

FM

RC

Flow selector

R(L) S(N)

Power supply

single phase

220V 60Hz

1

2

313

4

4

5

5

6

6

P301

BLK

RY004

1

(GRY)

3

CN304

1

(YEL)

313

AC IN

CN066

(WHI)

CN044

(BRW)

unit earth

screw

Line Filter

Closed-end

connector

CN309

1

FUSE

T5.0A 250V~

313

(BLK)

CN067

1

2

1

CN040

2

EMG

TR

U1

U1 U2

Outdoor unit Remote controller

CN041

(BLU)

(BLU)

2

1 233 1 2 3 4 5

112

1

BLU

BLU

BLK

2

112

U2 A B

2

112

CN1

RED BLK ORN BLU YEL

FAN

CN083

(WHI)

9 5 3 1

RY007

RC

BLK

3

1 1

5 3 1779

M LUL

H

RY006

RY005

CN050

(WHI)

CN01(WHI)

3

CN02

2

(BLU)

CN03(RED)

LM

2

112

113

RY001

Power supply

circuit

1 2 3 4 5 6 1 2 1 23 4 5 6 1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

Network adapter

2

112

2

112

MCC-1401

X Y

(Option)

CN068

(BLU)

RY002

CN074

(WHI)

DM

133

1

113

DM

3

1. indicates the terminal bolock, letter.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate

the wiring at side.

3. indicates the control P.C. board.

LM

3

CN033

(GRN)

Control P.C. board

for Indoor unit

CN075

(WHI)

CN02

(YEL)

CN01

(WHI)

TR

FS

FS

3

CN030

(RED)

113

MCC-1403

CN061

(YEL)

1 2 3 4 5 6

1 2 3 4 5 6

CN032

(WHI)

Fan

drive

Symbol

FM

RC

TR

LM

TA

TC1,TC2,TCJ

RY001

RY002

RY005~007

FS

DM

PMV

PMV

CN060

(WHI)

Option

Model: MMU-AP0151SH, AP0181SH, AP0241SH

1 234 56

1 234 56

PMV

CN082

(BLU)

TA

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

1

212

TCJ

1

212

TC2

1

1

2

2

1

2

313

1

2

3

1

2

1

2

1

2

3

4

5

PNL

EXCT

Filter

TC1

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Parts name

Fan motor

Running capacitor

Transformer

Louver motor

Indoor temp sensor

Temp sensor

Louver control relay

Drain control relay

Fan motor control relay

Float switch

Drain pump motor

Pulse motor valve

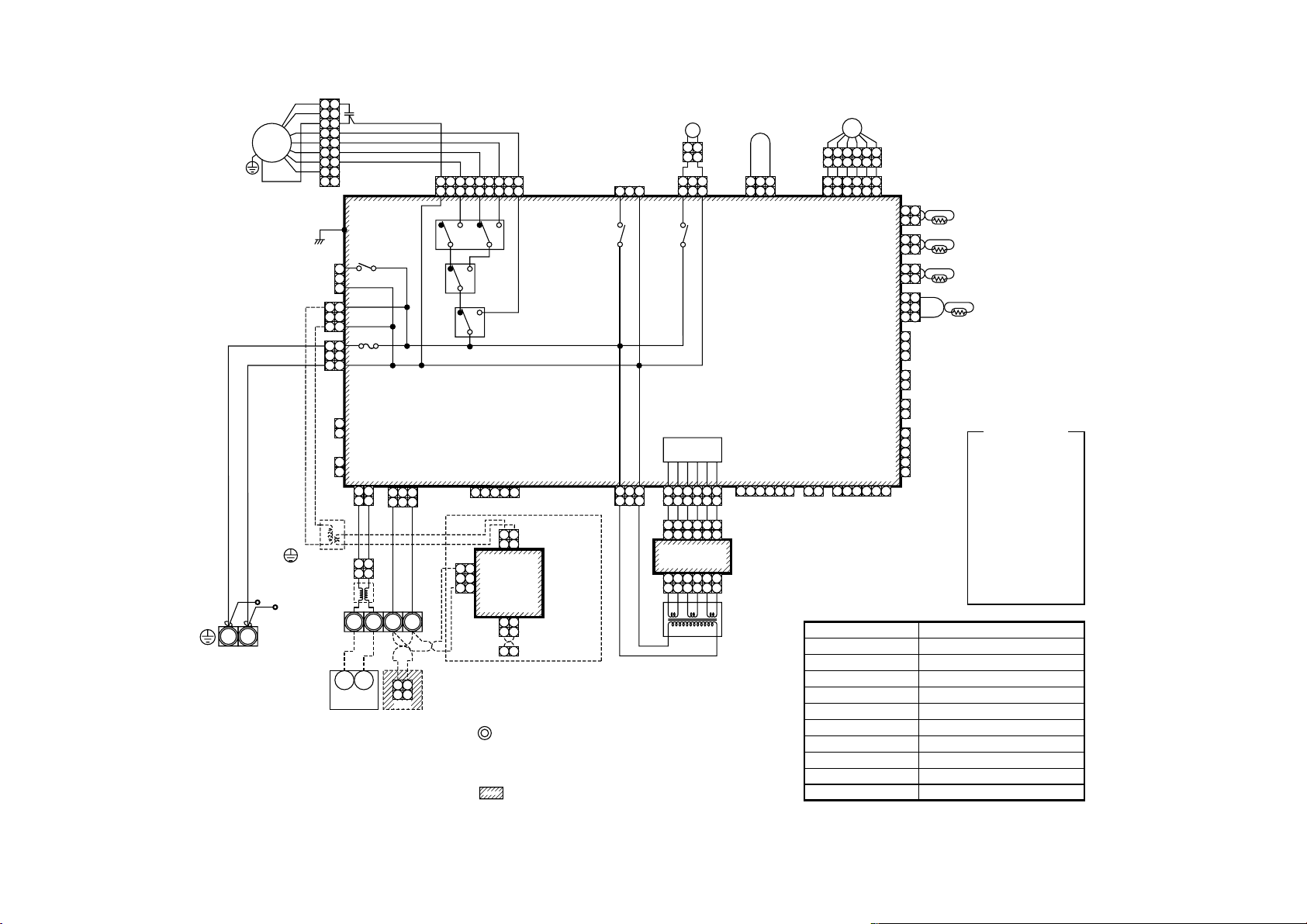

2-1-4. 1-way Air Discharge Cassette Type

Model: MMU-AP0152SH, AP0182SH, AP0242SH

18

Indoor unit

earth screw

S(N)R(L)

Power supply

single phase

220-240V 50Hz

220V 60Hz

FM

TA

TC1

TCJ

TC2

LM

DP

FS

RY302

PMV

TR

Flow selector unit

earth screw

RED

WHI

Closed-end

connector

U

U

1

Outdoor

unit

Symbol

1

2

U2U

Fan motor

Indoor temp sensor

Temp sensor

Temp sensor

Temp sensor

Louver motor

Drain pump motor

Float switsh

Drain control relay

Pulse motor valve

Transformer

BA

A B

Wired

remote

controller

Parts name

WHI

WHI

2

112

CN001(WHI)

Adapter for

wireless remote

controller

BLK

BLK

Color

indication

RED: RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY: GRAY

PNK: PINK

ORN: ORANGE

BRN: BRWN

GRN: GREEN

TR

131

2

3

MCC-1401

AI-NET

Network adapter

CN02

(BLU)

(Option)

RED

WHI

112

CN01

(WHI)

CN03

(RED)

112

X Y

PMV

FM

5

5

CN82

(BLU)

6

CN112

Power

supply

circuit

Control P.C. board

CN32

(WHI)

Fan

drive

High ceiling setup

1 2

1 2 1 2 1 2

CN111

(WHI)

DC20V

DC15V

DC12V

DC7V

CN110

(WHI)

for indoor unit

MCC-1402

CN60

(WHI)

1 2 3 4 5 6

Option

(WHI)

1 2 3 4 5

1

2

3

4

6

1

2

3

4

6

CN334

5 4 1

(WHI)

313

1

3

1

3

1

2

2

2

131

2

3

5

RY302

RY303

Fuse

T6.3A 250V~

P301

CN66

(WHI)

CN40

(BLU)

CN41

(BLU)

1

1

CN68

(BLU)

1

DP

CN304

(GRY)

1

CN67

(BLK)

3

BLK

BLU

1

1

2

2

BLU

BLK

BLK

CN309

(YEL)

3

3

1

1

Motor drive

CN50

(WHI)

1 2 3 4 5

CN333

1 2 3 4 5 6

5

3

(WHI)

1

2

3

4

54 3

32 1

5

circuit

Fuse

T3.15A

250V~

CN061

(YEL)

1 2 1 23 4 5 6 1 2 3 4 5

T10 GRL

1. indicates the terminal bolock letter.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate the

wiring at side

LM

1 2 3 4 5

1 2

3

1 2 3 4 5

1 2 3 4 5

CN71 (CHK)

CN72 (DISP)

CN81

(BLK)

4 5

CN33

(WHI)

CN20

(BLU)

1 3

1 2 3

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN80

(GRN)

CN73

(RED)

CN70

(WHI)

FS

CN34

(RED)

212

212

1

2

131

1

2

3

1

2

1

2

1

1

1

2

3

PNL

EXCT

Filter

TA

TCJ

TC2

TC1

3. indicates a control P.C. board.

2-1-5. Concealed Duct Standard Type

Model: MMD-AP0071BH, AP0091BH, AP0121BH, AP0151BH, AP0181BH, AP0241BH

19

Indoor unit

S(N)R(L)

Earth screw

Indoor unit power supply

Single phase

220-240V 50Hz

220V 60Hz

RED

WHI

Closed end

connector

Outdoor unit

1 3

1 2 2

Reactor

WHI

Flow selector

U2U

1

DM

unit earth

screw

U

U

1

WHI

Wired remote

CN68

(BLU)

1

1

2

2

3

3

1

CN304

2

(GRY)

3

RED

1

1

CN67

2

2

(BLK)

3

3

WHI

BLK

1

CN66

(WHI)

2

1

CN44

(BRW)

2

BA

2

BLK WHI BLK

CN1

(WHI)

1 2

1 2

controller

5

CN334

RY302

(WHI)

Fuse

T6.3A

250V~

P301

CN41

CN40

(BLU)

(BLU)

1 2 3

1 2

1 2

1 2 3

BLK

BLU

BLU

1 2

1 2

Adaputor for wired

remote controller

11223445

BLK

BLK

WHI

CN001

(WHI)

545

FM

4

11

PMV

6 4 3 1 2 5

6 4 3 1 2 5

1 2 3 4 5 6

1 2 3 4 5 6

Fuse

T3.15A

250V~

4 5 6

T10

Power

supply

circuit

CN61

(YEL)

~

~

CN309

(YEL)

CN333

(WHI)

1 2 3

1 2 3

1 3

1 3 5

Motor drive

circuit

+

5

CN50

(WHI)

1 2 3

TR

CN02

(BLU)

3 3

2 2

1 1

CN01

(WHI)

1 2

1 2

Network

adaptor

P.C. board

1 2

1 2

Network

adaptor

(Option)

CN03

(RED)

X Y

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

CN82

(BLU)

Indoor control P.C. board

DC20V

DC15V

DC12V

DC7V

CN32

(WHI)

CN60

(WHI)

1 21 2 3 4 5 61 2 3 4 51 2 31 2 3

(Signal output)(Fan drive)

1 2 3 4 5

Color identification

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BRW : BROWN

Symbol

FM

TA

TC1,TC2,TCJ

DM

FS

RY302

PMV

CN33

(WHI)

CN81

(BLK)

1 2 3 4 5

1 2 3 4 5

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

Parts name

Fan motor

Indoor temp sensor

Indoor temp sensor

Drain pump motor

Float switch

Drain pump control relay

Pulse Motor Valve

CN20

(BLU)

3 1

321

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRN)

CN80

(GRN)

CN73

(RED)

CN70

(WHI)

FS

CN34

(RED)

2

2

2

2

1

2

3

1

2

1

2

121

121

121

121

33

PNL

EXCT

MMD-AP0271BH, AP0301BH, AP0361BH, AP0481BH, AP0561BH

TA

TCJ

TC2

TC1

20

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

RED

WHI

Closed

end

connector

Indoor unit

Earth screw

S(N)R(L)

Power supply

Single phase

220-240V 50Hz

220V 60Hz

(BLK)

CN304

(GRY)

1

2

3

1

2

3

TR

Flow selector

unit earth

screw

T10A,250V~

Closed end

connector

Spark

killer

87

43F1

FAN

CN083

P301

1

RY004

2

3

1

CN309

2

(YEL)

3

CN067

(BLK)

1

2

3

1

2

YEL

CN066

(WHI)

CN044

(BRW)

EMG

U2U

1

Outdoor unit

REDRED F

RED

6

43F1

4

Fuse

T5.0A

CN040

(BLU)

1 21 2

1 2

OC

U

1

WHI

1 2 3 4

RC

U

2

Remote controller

5

43F1

3

RED

GRY

1 2 3 4

WHI

RED

(WHI)

CN041

1 2 3

1 3

1 2

1 2

REDWHI

9 8 7 6

9 8 7 6

HML UL

RY007

(BLU)

BA

CN1

CN02

(WHI)

(BLU)

RC

GRY

FM

4 2

5 4 3 2 1

RY006

RY005

CN050

(WHI)

1 2 3 4 5

1 2

CN01

(WHI)

1 2

3 3

2

1 1

1 2

1 2

X Y

WHI

F1F2F3F

BLU

(Option)

RY002

Network adaptor

(Option)

MCC-1401

CN03

(RED)

A

ORN

BLK

DP

1 2 3

1 2 3

DP

(BLU)

CN068

RY001

1 2 3

1 2 3

LM

(GRN)

CN033

1 2 3

1 2 3

FS

CN030

(RED)

1 2

1 2

CN104

(YEL)

CN102

(RED)

Indoor control P.C. board

Power

supply

circuit

TA

CN074

(WHI)

1 2 3

1 2 3

1 2 3

4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

1. indicates the terminal block, letter at inside indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

4. When attaching a drain pump, exchange CN030 connector with the connector

of the float switch.

5. A part is connected to the terminal block.

When exchanging to the outside static pressure necessary at the local site,

check the terminal No. and lead color of the fan motor in the below diagram,

4

BRN

and then exchange the lead wire indicated by the arrow mark ( ).

Wired for MMD-AP0481 only

(BRN Wire)

Motor over heating protection switch

CN075

BLK

WHI

GRY

RED

(WHI)

1 2 3 4 5 61 2 3 4 5 6

T10

CN02

(YEL)

CN01

(WHI)

TR

CN061

(YEL)

49F

TCJ

1 2

1 2

CN032

(WHI)

1 2

Fan drive

BLU

ORN

BRN

CN060

(WHI)

TC1

1 2 3

1 2 3

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

CN082

(BLU)

TC2

1 2

1 2

CN101

(BLK)

1 2 3 4 5 6

Option

Sold

separately

CN100

(BRN)

1

2

PNL

3

1

EXCT

2

1

Filter

2

1

2

3

4

5

6

6

5

5

4

4

3

3

2

2

1

1

Symbol

FM

RC

TR

TA

TC1,TC2,TCJ

RY005~007

RY001

RY002

PMV

F

43F1

DM

FS

5

5

2

2

1

1

PMV

3

3

4

4

6

6

Parts name

Fan motor

Running capacitor

Transformer

Indoor temp sensor

Temp sensor

Fan motor control relay

Louver motor control relay

Drain control relay

Pulse Motor Valve

Fuse

Fan motor control relay

Drain pump motor

Float switch

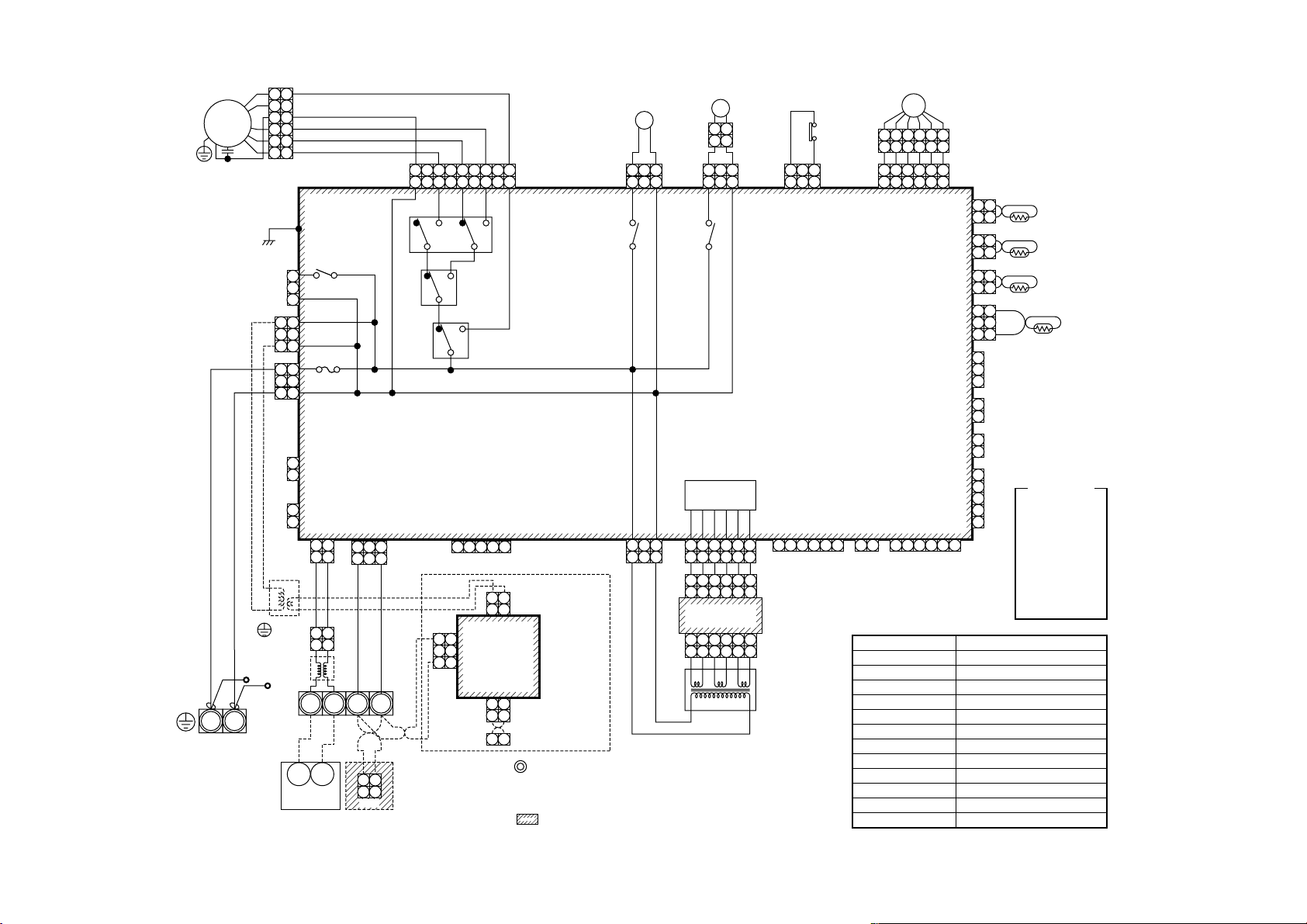

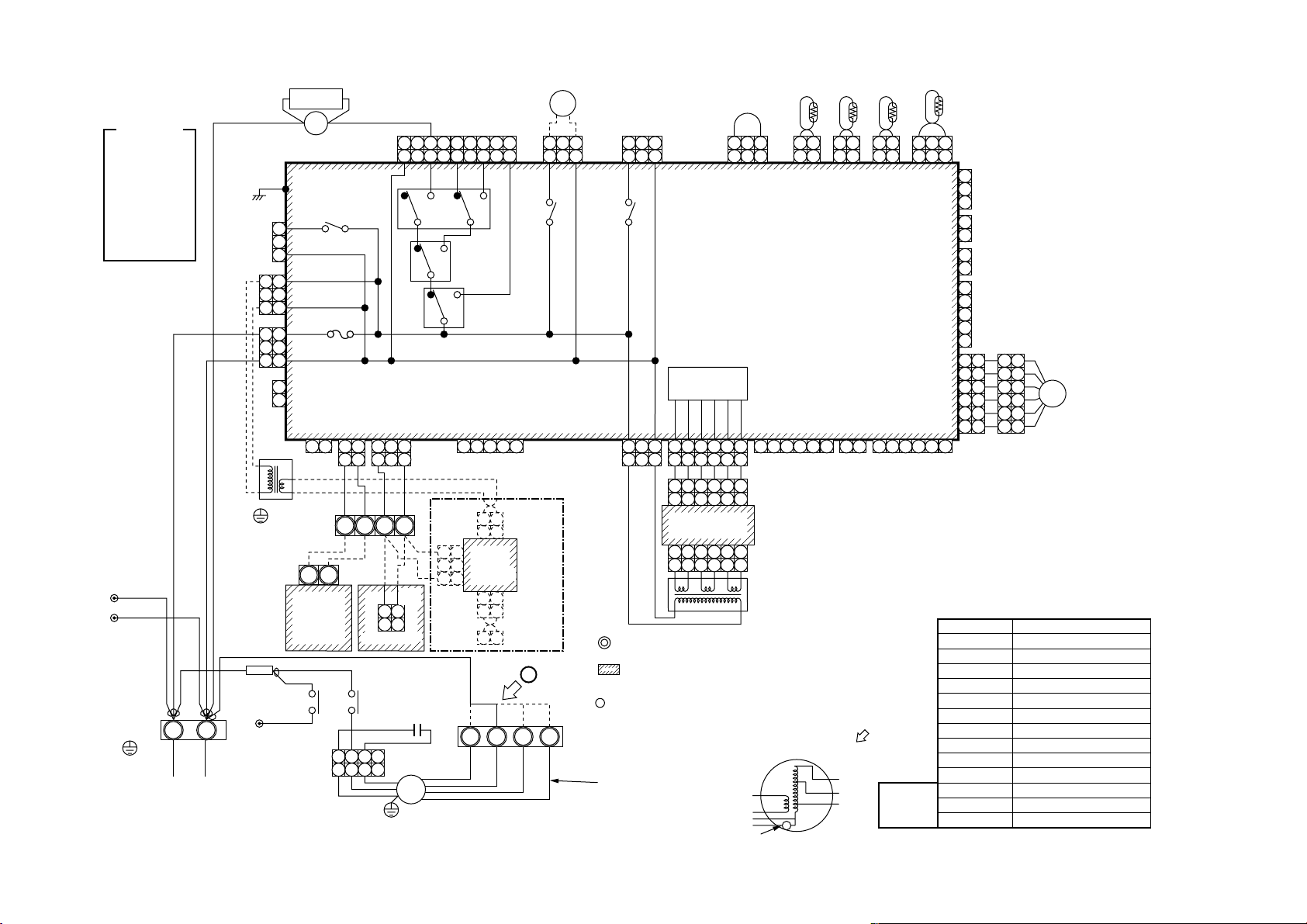

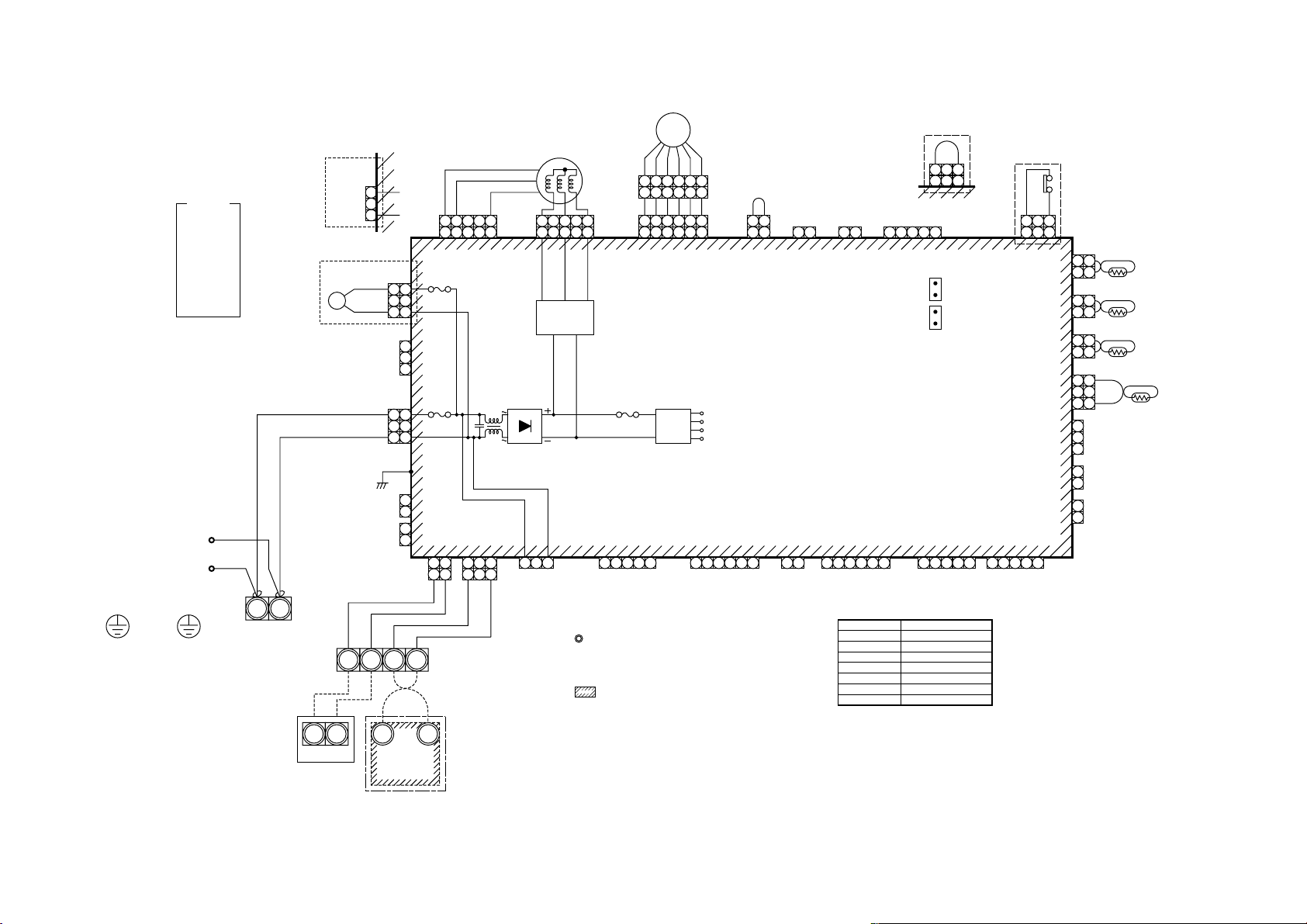

2-1-6. Concealed Duct High Static Pressure Type

Model: MMD-AP0181H, AP0241H, AP0271H, AP0361H, AP0481H

FM

2-1-7. Under Ceiling Type

Model: MMC-AP0151H, AP0181H, AP0241H, AP0271H, AP0361H, AP0481H

PMV

1

2

3

4

6

4

6

5

1

2

3

5

LM

1 2 3 4 5

1 2 3 4 5

FS

21

Indoor unit

Earth screw

Power supply

single phase

200-240V 50Hz

200V 60Hz

RED

WHI

S(N)R(L)

RED

WHI

Flow selector

unit earth

screw

Closed end

terminal

DM

U2U

1

Outdoor unit

CN68

(BLU)

1

1

2

2

3

3

CN304

1

(GRY)

2

3

1

1

CN67

2

2

(BLK)

3

3

BLK

1

2

BLU

121

BLU

2

BLK

121

BLK

33

U2U

1

WHI BLK BLKWHI

1 2

1 2

Wired remote

controller

RY302

RY303

Fuse

T6.3A

250V~

P301

CN66

(WHI)

CN40

(BLU)

CN41

(BLU)

BA

CN1

(WHI)

5 4 1

5 4 3 2 1

CN334

(WHI)

~

~

CN309

(YEL)

1 2 3

BLK

WHI

CN001

(WHI)

1 2

1 2

Adaptor for wireless

remote controller

1 2 3 4 5

1 2 3 4 5

Motor drive

circuit

+

CN50

(WHI)

4 5 6

TR

3 3

2 2

1 1

CN02

(BLU)

CN333

(WHI)

CN61

(YEL)

CN01

(WHI)

T10

Fuse

T3.15A

1 2

1 2

Network

adaptor

P.C. board

1 2

1 2

Network

adaptor

(Option)

CN03

(RED)

1 2 3 4 5

1

2

6

3

4

5

6

Indoor control P.C. board

Power

supply

circuit

CN32

(WHI)

DC20V

DC15V

DC12V

DC7V

CN60

(WHI)

1 21 2 3 4 5 6

Option GRLFandrive

X Y

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

CN82

(BLU)

1 2 3 4 5

1 2 3 4 5

CN81

(BLK)

1 2 3 4 51 2 3 4 51 2 31 2 3

Sold

separately

CN33

(WHI)

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BRW : BROWN

TC,TC2,TCJ

CN20

(BLU)

1 2 3 4 5

Color identification

Symbol

FM

TA

LM

RY302

DM

FS

CN34

1 3

(RED)

123

CN104

(YEL)

2

CN102

(RED)

2

CN101

(BLK)

2

CN100

2

(BRW)

1

CN80

2

(GRN)

3

1

CN73

(RED)

2

1

CN70

(WHI)

2

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

Parts name

Fan motor

Indoor temp sensor

Temp sensor

Louver motor

Drain control relay

Drain pump motor

Float switch

121

121

121

121

33

PNL

EXCT

FILTER

TA

TCJ

TC2

TC1

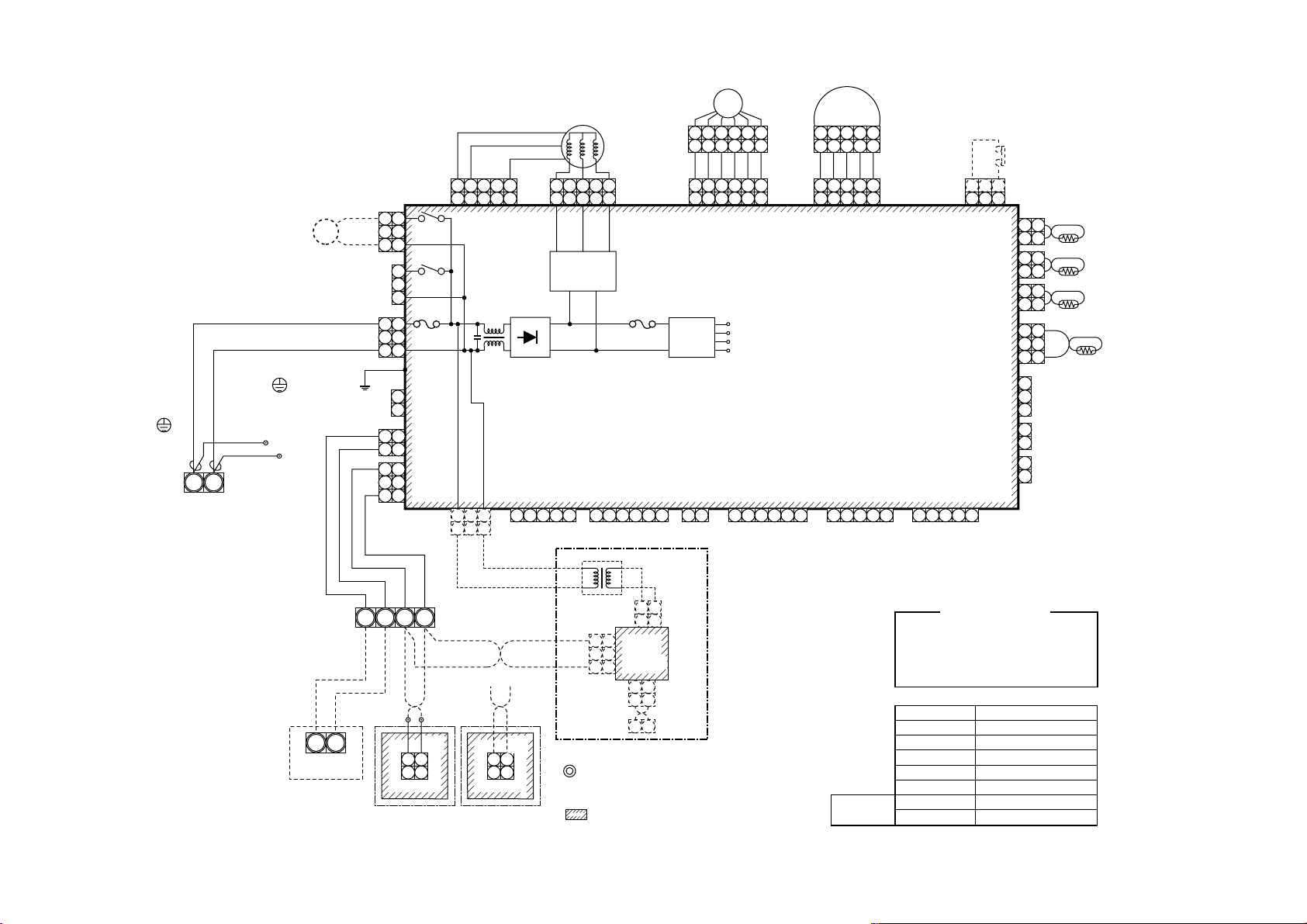

2-1-8. High Wall T ype

545

4

FM

Model: MMK-AP0071H, AP0091H, AP0121H, AP0151H, AP0181H, AP0241H

22

RED

WHI

R(L) S(N)

Power supply

single phase

220-240V 50Hz

220V 60Hz

Indoor unit

Earth screw

Flow selector

unit earth

screw

Closed-end

connector

RED

WHI

U1 U2

Outdoor

unit

U1 U2

1

CN68

(BLU)

3

1

LM

CN304

(GRY)

1

3

CN67

(BLK)

P301

BLK

CN66

(WHI)

313

1

3

1

2

A B X Y

WHI BLK

2

112

CN1

(WHI)

Wired remote

controller

CN334

(WHI)

RY302

RY303

FUSE

T6.3A 250V~

CN40

(BLU)

1 231 3

BLU

BLU

BLK

GRY

GRY

WHI BLK

2

112

CN001

(WHI)

Adaptor for

wireless remote

controller

BLK

5

CN41

(BLU)

1 21 2

11

1 2 3

1 2 3

CN333

1 2 3 4 5 6

1

223445

1 3

BLK

WHI

(WHI)

CN309

(YEL)

TR

3

1 1

1 3

1 3 5

Motor drive

circuit

CN50

(WHI)

1 2 31 3

CN01(WHI)

3

CN02

2

(BLU)

CN03(RED)

5

4 5

2

112

2

112

1

1 2 3 4 5 6

T3.15A 250V~

Network adaptor

(Option)

MCC-1401

PMV

1 234 56

1 234 56

CN82

(BLU)

FUSE

CN61

(YEL)

1 2 3 4 5

CN33

(WHI)

Power

supply

circuit

CN32

(WHI)

6

1 2

Fandrive

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

TC2

TCJ

113

CN34

(RED)

TA

3

21212121212

CN104

CN102

(YEL)

(RED)

CN101

(BLK)

TC1

1

112 31 2 3 4 5

CN100

(BRW)

Control P.C. board

for Indoor unit

DC20V

DC15V

DC12V

DC7V

CN60

(WHI)

1 2 3 4 5 6

Option

MCC-1402

CN81

(BLK)

1 2 3 4 5

CN20

(BLU)

1 2 3 4 5

1. indicates the terminal bolock.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate

the wiring at side.

3. indicates the control P.C. board.

Symbol

FM

TA

TC1,TC2,TCJ

PMV

LM

RY303

Parts name

Fan motor

Indoor temp sensor

Temp sensor

Pulse motor valve

Louver motor

Louver control relay

3

CN103

(GRN)

CN080

(GRN)

CN73

(RED)

CN70

(WHI)

1

2

1

2

3

1

2

1

2

EXCT

23

Heat exchanger

GRN & YEL

Power Supply

Single phase

220-240V 50Hz

220V 60Hz

RED

WHI

GRN & YEL

GRN & YEL

1

3

CN67

(BLK)

CN309

(YEL)

1

3

5

Color identification

BRW

RED

WHI

YEL

BLU

BLK

GRY

PNK

ORN

GRN & YEL

GRN

F301 Fuse

T3. 15A 250V~

CN81 (BLK)

1 3

1 3

WHI

WHI

RED

Flow selector unit

(Sold separately)

:

BROWN

:

RED

:

WHITE

:

YELLOW

:

BLUE

:

BLACK

:

GRAY

:

PINK

:

ORANGE

:

GREEN &

YELLOW

:

GREEN

54321

54321

BRW

YEL

GRY

54321

PNK

Pulse motor

valve

BLK

F

S

CN22

CN213 (WHI)

WHI

BRW

YEL

GRY

1011

7899

Infrared rays receive

and indication parts

(MCC-861)

987654321

9874321

ORN

Louver

motor

Fan

motor

RED

BRW

HBS

54321 21

CN50

(WHI)

10

10

RED

BLU

BLU

6

CN82

(BLU)

ORN

YEL

WHI

12345

123456

BLU

YEL

CN210

(WHI)

WHI

BLK

RED

13456

13456

(MCC-1510)

Control P.C.board for indoor unit

234567

123456

CN32

(WHI)

Fan drive

CN61

(YEL)

65432121 654321 321

654321

4321

HA

YEL

Power

supply

circuit

CN60

(WHI)

Option

YEL

YEL

CN33

(WHI)

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the

12345

wiring at site.

3. indicates the control P.C. board.

YEL

WHI

23456

123456

CN44

(BRW)

DC 15V

DC 0V

DC 12V

DC 7V

CN80

(GRN)

PNL/EMG

CN40

(BLU)

CN41

(BLU)

CN100

(BRW)

CN101

(BLU)

CN103

(GRN)

CN102

(YEL)

CN104

(WHI)

BLU

121

BLU

2

BLK

313

2

WHI

1

BLK

131

2

BLK

3

BLK

121

BLK

2

1

TF

2

BLK

121

BLK

2

BLK

121

BLK

2

Heat

exchanger

sensor

(TC1)

Heat

exchanger

sensor

(TC2)

Heat

exchanger

sensor

(TCJ)

Thermo

sensor

(TA)

Outdoor unit

WHI BLK

221

1

CN1(WHI)

Wierd remote

controller

(Sold separately)