Page 1

FILE NO. A04-003

SERVICE MANUAL

R410A

System air conditioner

The indoor unit in Super Heat Recovery Multi System is common to one in Super Modular Multi System air conditioner.

Therefore refer to the service manuals for A03-009, A03-010, and A03-011 separately issued.

Heat Recovery Type

Indoor Unit

<4-way Air Discharge Cassette Type>

MMU-AP0091H, AP0121H, AP0151H,

MMU-AP0181H, AP0241H, AP0271H,

MMU-AP0301H, AP0361H, AP0481H

MMU-AP0561H

<2-way Air Discharge Cassette Type>

MMU-AP0071WH, AP0091WH, AP0121WH,

MMU-AP0151WH, AP0181WH, AP0241WH,

MMU-AP0271WH, AP0301WH, AP0481WH*

* CHINA market only

<1-way Air Discharge Cassette Type>

MMU-AP0071YH, AP0091YH, AP0121YH,

MMU-AP0151SH, AP0181SH, AP0241SH

<Concealed Duct Standard Type>

MMD-AP0071BH, AP0091BH, AP0121BH,

MMD-AP0151BH, AP0181BH, AP0241BH,

MMD-AP0271BH, AP0301BH, AP0361BH,

MMD-AP0481BH, AP0561BH

<Concealed Duct High Static Pressure Type>

MMD-AP0181H, AP0241H, AP0271H,

MMD-AP0361H, AP0481H

Outdoor Unit

<Inverter Unit>

MMY-MAP0801FT8

MMY-MAP1001FT8

MMY-MAP1201FT8

Flow Selector Unit (FS unit)

RBM-Y1121FE

RBM-Y1801FE

<Under Ceiling Type>

MMC-AP0151H, AP0181H, AP0241H,

MMC-AP0271H, AP0361H, AP0481H

<High Wall Type>

MMK-AP0071H, AP0091H, AP0121H,

MMK-AP0151H, AP0181H, AP0241H

<Floor Standing Cabinet Type>

MML-AP0071H, AP0091H, AP0121H,

MML-AP0151H, AP0181H, AP0241H

<Floor Standing Concealed Type>

MML-AP0071BH, AP0091BH, AP0121BH,

MML-AP0151BH, AP0181BH, AP0241BH

<Floor Standing Type>

MMF-AP0151H, AP0181H, AP0241H,

MMF-AP0271H, AP0361H, AP0481H,

MMF-AP0561H

PRINTED IN JAPAN, Sep, 2004 ToMo

Page 2

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its concentration will

not exceed a set limit.

The refrigerant R410A which is used in the air

conditioner is safe, without the toxicity or

combustibility of ammonia, and is not restricted by

laws to be imposed which protect the ozone layer.

However, since it contains more than air, it poses the

risk of suffocation if its concentration should rise

excessively. Suffocation from leakage of R410A is

almost non-existent. With the recent increase in the

number of high concentration buildings, however, the

installation of multi air conditioner systems is on the

increase because of the need for effective use of floor

space, individual control, energy conservation by

curtailing heat and carrying power etc.

Most importantly, the multi air conditioner system is

able to replenish a large amount of refrigerant

compared with conventional individual air conditioners.

If a single unit of the multi conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant

accidentally leaks out, its concentration does not

reach the limit (and in the event of an emergency,

measures can be made before injury can occur).

In a room where the concentration may exceed the

limit, create an opening with adjacent rooms, or install

mechanical ventilation combined with a gas leak

detection device.

The concentration is as given below.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m³)

≤ Concentration limit (kg/m³)

The concentration limit of R410A which is used in multi

air conditioners is 0.3kg/m³.

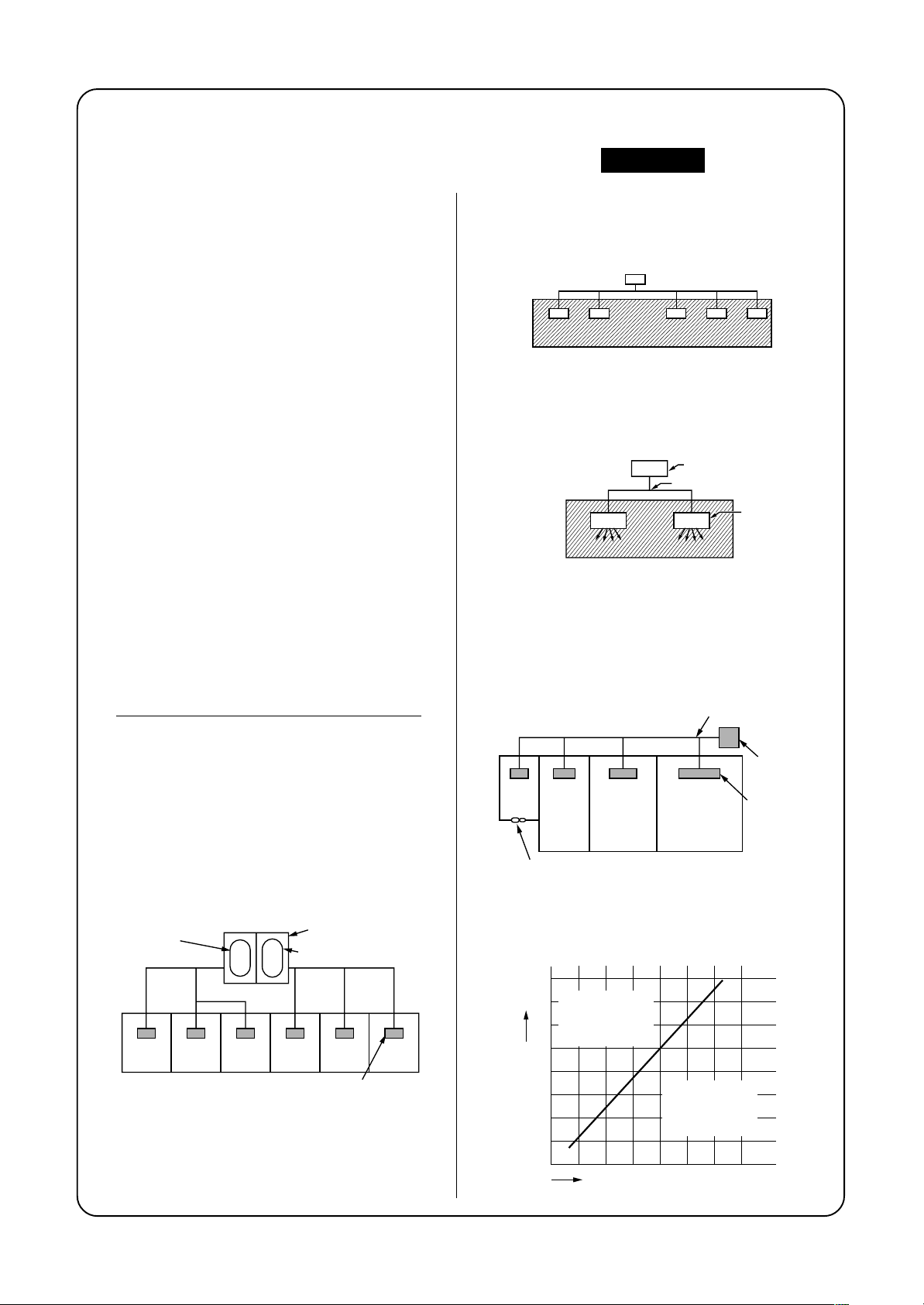

NOTE 1 :

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should

be as charged in each independent device.

e.g., charged

amount (10kg)

Room A Room B Room C Room D Room E Room F

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 10kg.

The possible amount of leaked refrigerant gas in

rooms D, E and F is 15kg.

Outdoor unit

e.g.,

charged amount (15kg)

Indoor unit

Important

NOTE : 2

The standards for minimum room volume are as

follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the

adjacent room for ventilation of leaking refrigerant

gas (opening without a door, or an opening 0.15%

or larger than the respective floor spaces at the

top or bottom of the door).

Outdoor unit

Refrigerant piping

Indoor unit

(3) If an indoor unit is installed in each partitioned

room and the refrigerant tubing is interconnected,

the smallest room of course becomes the object.

But when a mechanical ventilation is installed

interlocked with a gas leakage detector in the

smallest room where the density limit is exceeded,

the volume of the next smallest room becomes the

object.

Refrigerant piping

Outdoor unit

Very

small

room

Small

room

Mechanical ventilation device - Gas leak detector

Medium

room

Large room

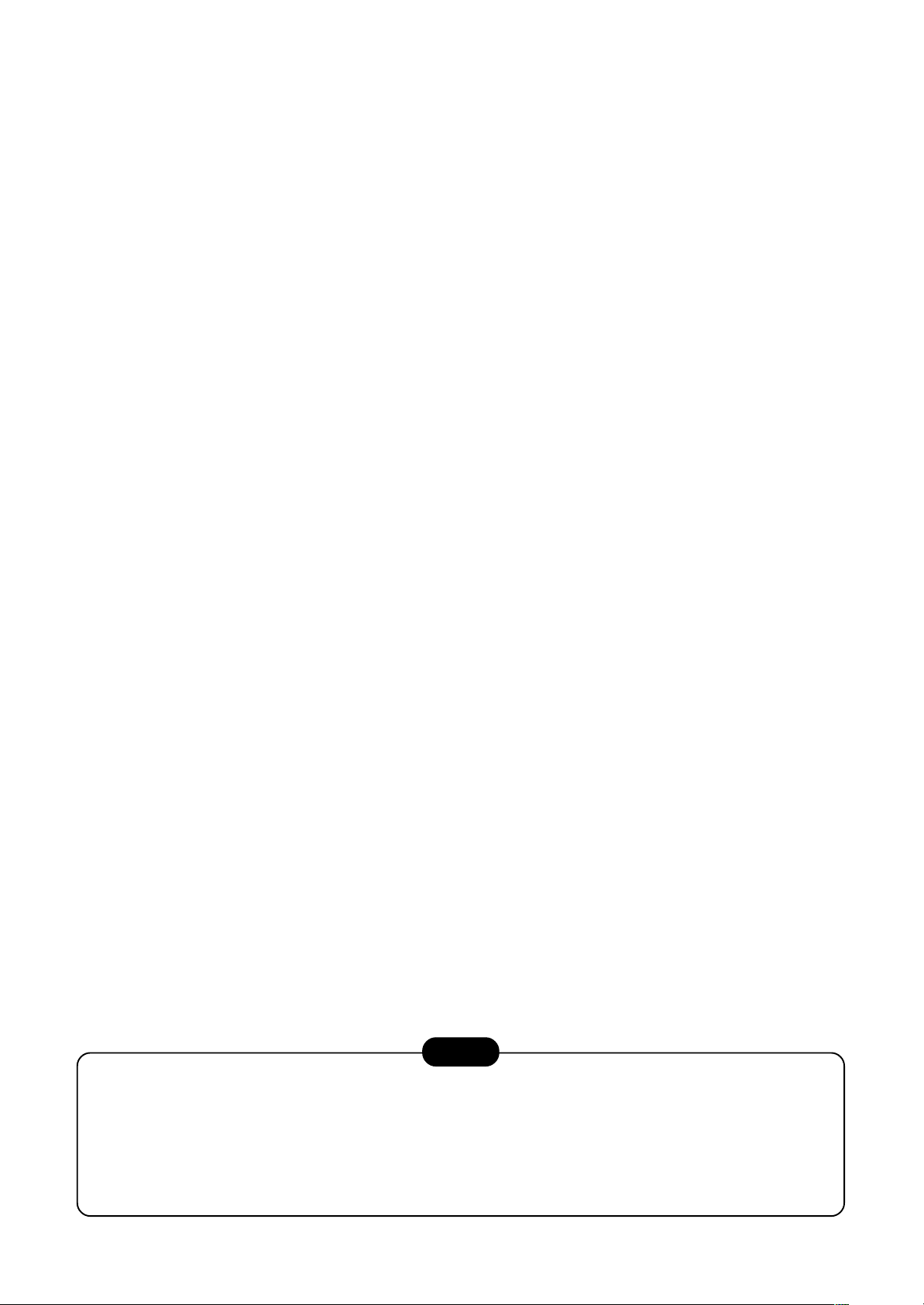

NOTE 3 :

The minimum indoor floor area compared with the

amount of refrigerant is roughly as follows:

(When the ceiling is 2.7m high)

40

Range below the

35

m²

density limit

of 0.3 kg/m³

30

(countermeasures

not needed)

25

20

15

10

5

Min. indoor floor area

0

10 20 30

Total amount of refrigerant

Range above

the density limit

of 0.3 kg/m³

(countermeasures

needed)

Indoor unit

kg

Page 3

CONTENTS

SAFETY CAUTION............................................................................................ 4

1. OUTLINE .................................................................................................... 9

2. WIRING DIAGRAM................................................................................... 13

3. PARTS RATING........................................................................................ 26

4. REFRIGERANT PIPING SYSTEMATIC DRAWING................................. 43

5. SYSTEM REFRIGERANT CYCLE DRAWING......................................... 48

6. CONTROL OUTLINE................................................................................ 55

7. APPLIED CONTROL................................................................................ 65

8. TEST OPERATION ................................................................................... 78

9. TROUBLESHOOTING............................................................................ 107

10. CONFIGURATION OF CONTROL CIRCUIT.......................................... 164

11. BACKUP OPERATIONS (EMERGENCY OPERATION) ........................ 178

12. REFRIGERANT RECOVERY

WHEN REPLACING THE COMPRESSOR ............................................ 179

13. LEAKAGE/CLOGGING OF OIL-EQUALIZATION CIRCUIT .................. 180

14. REPLACING COMPRESSOR ................................................................ 182

15. REOLACING METHOD OF PARTS ....................................................... 189

16. P.C. BOARD EXCHANGE PROCEDURES ............................................ 200

NOTE

A direct current motor is adopted for indoor fan motor in the Concealed Duct Standard Type air conditioner.

Caused from its characteristics, a current limit works on the direct current motor. When replacing the highperformance filter or when opening the service panel, be sure to stop the fan. If an above action is executed

during the fan operation, the protectiv e control works to stop the unit operation, and the check code “P12”

may be appear. However it is not a trouble. When the desired operation has finished, be sure to reset the

system to clear “P12” error code using the electric leak breaker of the indoor unit. Then push the operation

ON/OFF button of the remote controller to return to the usual operation.

Page 4

SAFETY CAUTION

The important contents concerned to the safety are described on the product itself and on this Service Man ual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

Indication

DANGER

WARNING

CAUTION

∗ Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage ( ∗) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Explanation

[Explanation of illustrated marks]

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

(Refer to the Parts disassembly diagram (Outdoor unit).)

If removing the label during parts replace, stick it as the original.

D ANGER

Turn “OFF” the breaker before removing the front panel and cabinet, otherwise an electric

shock is caused by high voltage resulted in a death or injury.

During operation, a high voltage with 400V or higher of circuit (∗) at secondary circuit of the highvoltage transformer is applied.

Turn off breaker.

Execute discharge

between terminals.

Prohibition

If touching a high voltage with the naked hands or body, an electric shock is caused even if using an

electric insulator.

∗ : For details, refer to the electric wiring diagram.

When removing the front panel or cabinet, execute short-circuit and discharge between highvoltage capacitor terminals.

If discharge is not executed, an electric shock is caused by high voltage resulted in a death or injury.

After turning off the breaker, high voltage also keeps to apply to the high-voltage capacitor.

Do not turn on the breaker under condition that the front panel and cabinet are removed.

An electric shock is caused by high voltage resulted in a death or injury.

4

Page 5

Check earth wires.

Prohibition of modification.

Use specified parts.

Do not bring a child

close to the equipment.

Insulating measures

No fire

WARNING

Before troubleshooting or repair work, check the earth wire is connected to the eart h

terminals of the main unit, otherwise an electric shock is caused when a leak occurs.

If the earth wire is not correctly connected, contact an electric engineer for rework.

Do not modify the products.

Do not also disassemble or modify the parts. It may cause a fire, electric shock or injury.

For spare parts, use those specified (

If unspecified parts are used, a fire or electric shock may be caused.

∗: For details, refer to the parts list.

Before troubleshooting or repair work, do not bring a third party (a child, etc.) except

the repair engineers close to the equipment.

It causes an injury with tools or disassembled parts.

Please inform the users so that the third party (a child, etc.) does not approach the equipment.

Connect the cut-off lead cables with crimp contact, etc, put the closed end side

upward and then apply a water-cut method, otherwise a leak or production of fire is

caused at the users’ side.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle. When using a gas stove, etc, be sure to put out fire

before work; otherwise the oil mixed with refrigerant gas may catch fire.

2) Do not use a welder in the closed room. When using it without ventilation, carbon

monoxide poisoning may be caused.

3) Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may

catch the inflammables.

∗∗

∗).

∗∗

Refrigerant

Check the used refrigerant name and use tools and materials of the parts which

match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a

position on the outdoor unit where is easy to see. To prevent miss-charging, the route of the

service por t is changed from one of the former R22.

For an air conditioner which uses R410A, never use other refrigerant than R410A.

For an air conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating cycle and an injury due to breakage may be caused.

Do not charge refrigerant additionally.

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in

the refrigerating cycle changes resulted in change of air conditioner characteristics or

refrigerant over the specified standard amount is charged and an abnormal high pressure is

applied to the inside of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute

vacuuming, and then newly recharge the specified amount of liquid refrigerant. In this time,

never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant

or air other than R410A into the specified refrigerant.

If air or others is mixed with the refrigerant, abnormal high pressure generates in the

refrigerating cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak.

If the refrigerant gas leaks in the room, poisonous gas generates when gas touches to fire

such as fan heater, stove or cocking stove though the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit.

When the equipment is moved or repaired, be sure to recover the refrigerant with recovering device. The refrigerant cannot be recovered in the outdoor unit; otherwise a serious

accident such as breakage or injury is caused.

Assembly/Cabling

After repair work, surely assemble the disassembled parts, and connect and lead the

removed cables as before. Perform the work so that the cabinet or panel does not

catch the inner cables.

If incorrect assembly or incorrect cable connection was done, a disaster such as a leak or

fire is caused at user’s side.

5

Page 6

WARNING

Insulator check

Ventilation

Be attentive to

electric shock

Compulsion

After the work has finished, be sure to use an insulation tester set (500V mugger) to

check the resistance is 2M

metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s

side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of the

refrigerant and the closed room full with gas is dangerous because a shortage of oxygen

occurs. Be sure to execute ventilation.

When checking the circuit inevitably under condition of the power-ON, use rubber

gloves and others not to touch to the charging section.

If touching to the charging section, an electric shock may be caused.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down

and tighten the service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking

stove though the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such

as a multi air conditioner in a sub-room, it is necessary that the density does not the

limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is

caused.

For the installation/moving/reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric

shock or fire is caused.

ΩΩ

Ω or more between the charge section and the non-charge

ΩΩ

Check after rerair

Check after reinstallation

Put on gloves

Cooling check

After repair work has finished, check there is no trouble.

If check is not executed, a fire, electric shock or injury may be caused. For a check, turn off

the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test

run to check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused. Before test run, install the

front panel and cabinet.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

CAUTION

Be sure to put on gloves (

If not putting on gloves, an injury may be caused with the parts, etc.

(∗) Heavy gloves such as work gloves

When the power was turned on, start to work after the equipment has been

sufficiently cooled.

As temperature of the compressor pipes and others became high due to cooling/heating

operation, a burn may be caused.

∗∗

∗) during repair work.

∗∗

6

Page 7

• New Refrigerant (R410A)

4. Tools

(1) Required Tools for R410A

Mixing of different types of oil may cause a troub le such as generation of sludge, clogging of capillary, etc.

Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

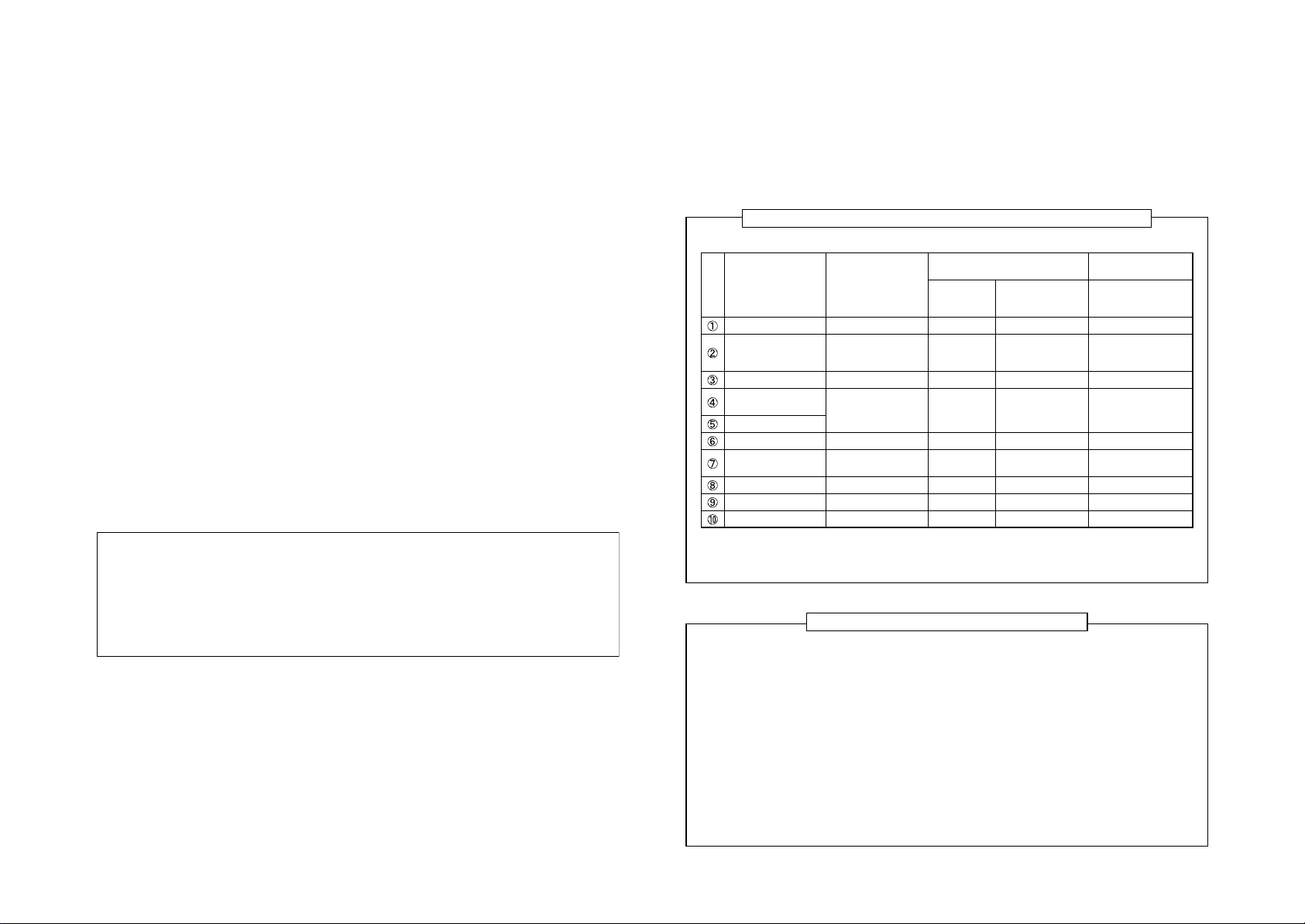

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

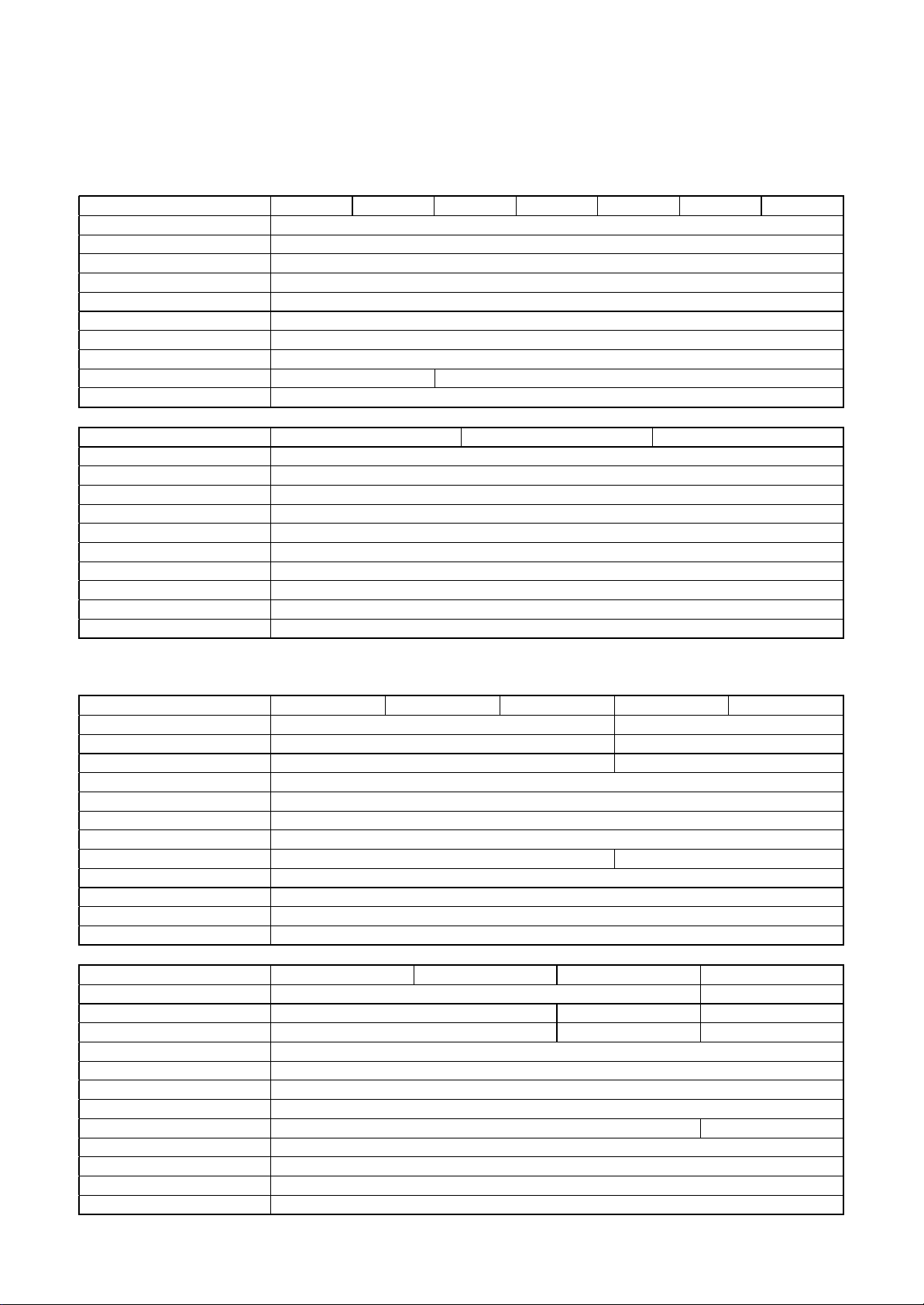

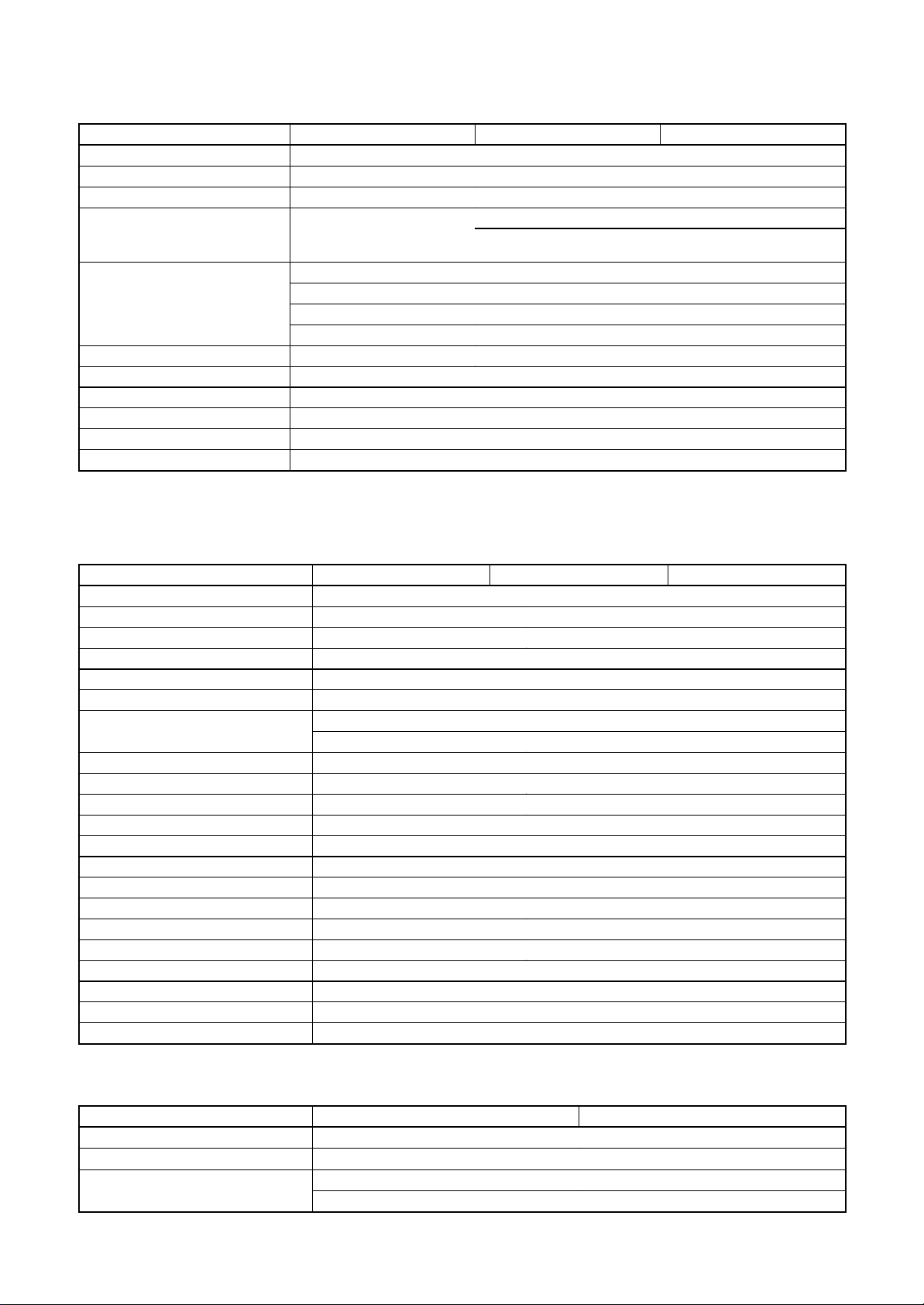

No. Used tool

Flare tool

Copper pipe gauge for

adjusting projection

margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Charging cylinder

Usage

Pipe flaring

Flaring by conventional

flare tool

Connection of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

Refrigerant charge

Conventional air

conditioner installation

Whether new equipment

can be used with

conventional refrigerant

Yes

*(Note 1)

No

No

Yes

Yes

No

Yes

No

Whether conventional equipment can

be used

*(Note 1)

*(Note 1)

No

No

No

Yes

No

No

No

(1) Vacuum pump

Use vacuum pump by

attaching vacuum pump adapter.

(2) Torque wrench

(3) Pipe cutter

(4) Reamer

(5) Pipe bender

(6) Level vial

(7) Screwdriver (+, –)

(8) Spanner or Monkey wrench

(9) Hole core drill

(10) Hexagon wrench (Opposite side 4mm)

(11) Tape measure

(12) Metal saw

Also prepare the following equipments f or other installation method and run check.

(1) Clamp meter

(2) Thermometer

(3) IInsulation resistance tester

(4) Electroscope

Existence of

new equipment

for R410A

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

(Note 2)

R410A

air conditioner installation

(Note 1) When flaring is carried out for R410A using the conventional flare tools , adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary .

(Note 2) Charging cylinder for R410A is being currently developed.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

This air conditioner adopts a new HFC type refrigerant (R410A) which does not deplete the ozone lay er.

1. Safety Caution Concerned to New Refrigerant

7

The pressure of R410A is high 1.6 times of that of the former refrigerant (R22). Accompanied with change of

refrigerant, the refrigerating oil has been also changed. Therefore, be sure that water, dust, the f ormer refrigerant or the former refrigerating oil is not mixed into the refrigerating cycle of the air conditioner with new refrigerant during installation work or service work. If an incorrect work or incorrect service is performed, there is a

possibility to cause a serious accident. Use the tools and materials exclusiv e to R410A to purpose a safe work.

2. Cautions on Installation/Service

(1) Do not mix the other refrigerant or refrigerating oil.

For the tools exclusive to R410A, shapes of all the joints including the service port differ from those of the

former refrigerant in order to prevent mixture of them.

(2) As the use pressure of the new refrigerant is high, use material thickness of the pipe and tools which are

specified for R410A.

(3) In the installation time, use clean pipe materials and work with great attention so that water and others do

not mix in because pipes are affected by impurities such as water, oxide scales, oil, etc. Use the clean

pipes.

Be sure to brazing with flowing nitrogen gas. (Never use gas other than nitrogen gas.)

(4) For the earth protection, use a vacuum pump for air purge.

(5) R410A refrigerant is azeotropic mixture type refrigerant. Therefore use liquid type to charge the refrigerant.

(If using gas for charging, composition of the refrigerant changes and then characteristics of the air condi-

tioner change.)

3. Pipe Materials

For the refrigerant pipes, copper pipe and joints are mainly used. It is necessary to select the most appropriate

pipes to conform to the standard. Use clean material in which impurities adhere inside of pipe or joint to a

minimum.

(1) Copper pipe

<Piping>

The pipe thickness, flare finishing size, flare nut and others differ according to a refrigerant type .

When using a long copper pipe for R410A, it is recommended to select “Copper or copper-base pipe without

seam” and one with bonded oil amount 40mg/10m or less. Also do not use crushed, deformed, discolored

(especially inside) pipes. (Impurities cause clogging of expansion valves and capillary tubes.)

<Flare nut>

Use the flare nuts which are attached to the air conditioner unit.

(2) Joint

The flare joint and socket joint are used for joints of the copper pipe. The joints are rarely used for installa-

tion of the air conditioner. However clear impurities when using them.

Page 8

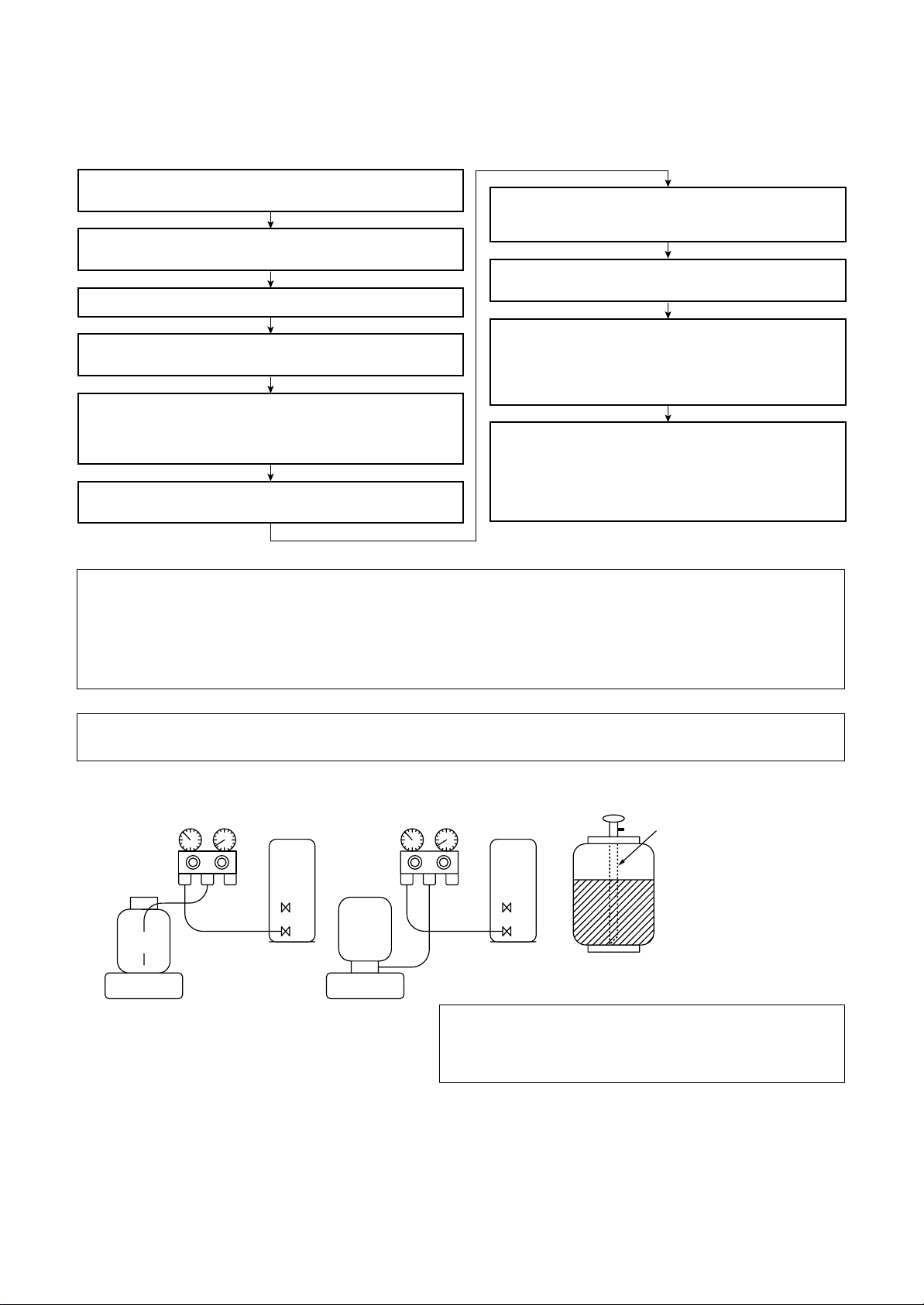

5. Recharge of Refrigerant

When recharge of the refrigerant is required, charge the new refrigerant with the specified amount in the

procedure as described below .

Recover the refrigerant and check there is no refrigerant in the

equipment.

Connect the charge hose to the packed valve service ports at gas

side, liquid side, and balance side of the outdoor unit.

Connect the charge hose to vacuum pump adaptor.

Open the packed valves of the balance pipe fully at liquid and gas

sides, and then return the valve at gas side a little to the closed side.

Open fully PMV of the outdoor unit.

• Turn on power of the outdoor unit.

• Short CN30 on I/F P.C. board of the outdoor unit.

Turn off power of the outdoor unit within 2 minutes after short-circuiting.

•

Open fully the handle Low of the gauge manifold, and then turn on

the power of vacuum pump for vacuuming.

When the pressure has lowered until indication of the

compound gauge pointed -0.1MPa (-76cmHg), open fully the

handle Low and turn off the power of vacuum pump.

Leave it as it is for 1 to 2 minutes and check the indicator of

the compound gauge does not return.

Set the refrigerant cylinder on the electron balance, connect

the charging hose to connecting ports of the cylinder and the

electron gauge, and then charge the liquid refrigerant from the

service port at liquid side. (Shield with the gauge manifold so

that refrigerant does not flow to gas side.)

When the specified amount of refrigerant cannot be charged,

charge the liquid refrigerant into the service port at suction

gas side while carrying out the all cooling operation.

In this time, reduce slightly amount of refrigerant with valve of

the cylinder for charging. The liquid refrigerant may be rapidly

charged, so charge the refrigerant carefully and slowly.

Never charge the refrigerant ov er the specified amount.

Q

Do not charge the additional refrigerant.

R

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in the refrigerating cycle

changes resulted in change of air conditioner characteristics or refrigerant over the specified standard amount is

charged and an abnormal high pressure is applied to the inside of the refrigerating cycle resulted in cause of breakage

or injury.

Set the equipment so that liquid refrigerant can be charged.

Q

When using a cylinder with siphon pipe, liquid can be charged without inversing the cylinder.

R

[ Cylinder with siphon ] [ Cylinder without siphon ]

Refrigerant

cylinder

Electronic

balance

Gauge manifold

OUTDOOR unit

Electronic

balance

Gauge manifold

cylinder

Refrigerant

OUTDOOR unit

Siphon

R410A refrigerant is consisted with HFC mixed refrigerant.

Therefore if the refrigerant gas is charged, the composition

of the charged refrigerant changes and characteristics of

the equipment changes.

6. Environment

Use “Vacuum pump method” for an air purge (Discharge of air in the connecting pipe) in installation time.

• Do not discharge flon gas into the air to protect the earth environment.

• Using the vacuum pump method, clear the remained air (Nitrogen, etc.) in the unit. If the air remains , the

pressure in the refrigerating cycle becomes abnormally high and an injury and others are caused due to burst.

8

Page 9

1. OUTLINE

“Super Heat Recovery Multi System” is a multi air conditioning system which enables each

indoor unit in a refrigerant line to independently select cooling or heating operation.

As it is available to operate simultaneously in cooling and heating modes, more amount of

heat recovery becomes possible. This system is the most appropriate one for a building or

etc. where cool and heat air are mixed such as a building of which temperature difference

between each room is large due to influence of daylight or a building which has a server room

requiring for cool air all day.

Heating and cooling operation are automatically selected in individual unit;

You can save time for operation.

For example, when heating is required for early morning and cooling for daytime, a Flow Selector Unit provides

automatically a smooth selection of heating or cooling operation. Therefore you can obtain a comfortable

room environment without feeling somewhat out of place and moreover you can save time to select heat/

cool operation.

INFORMATION

The Super Heat Recovery Multi system is different from the conventional Multi air conditioner in several points

such as that heating and cooling operations are mixed or only a part of the air conditioner works cooling function. For this reason, the fo llowing table explains the operation modes of this air conditioner.

The following table explains representation of the operation modes in this Manual.

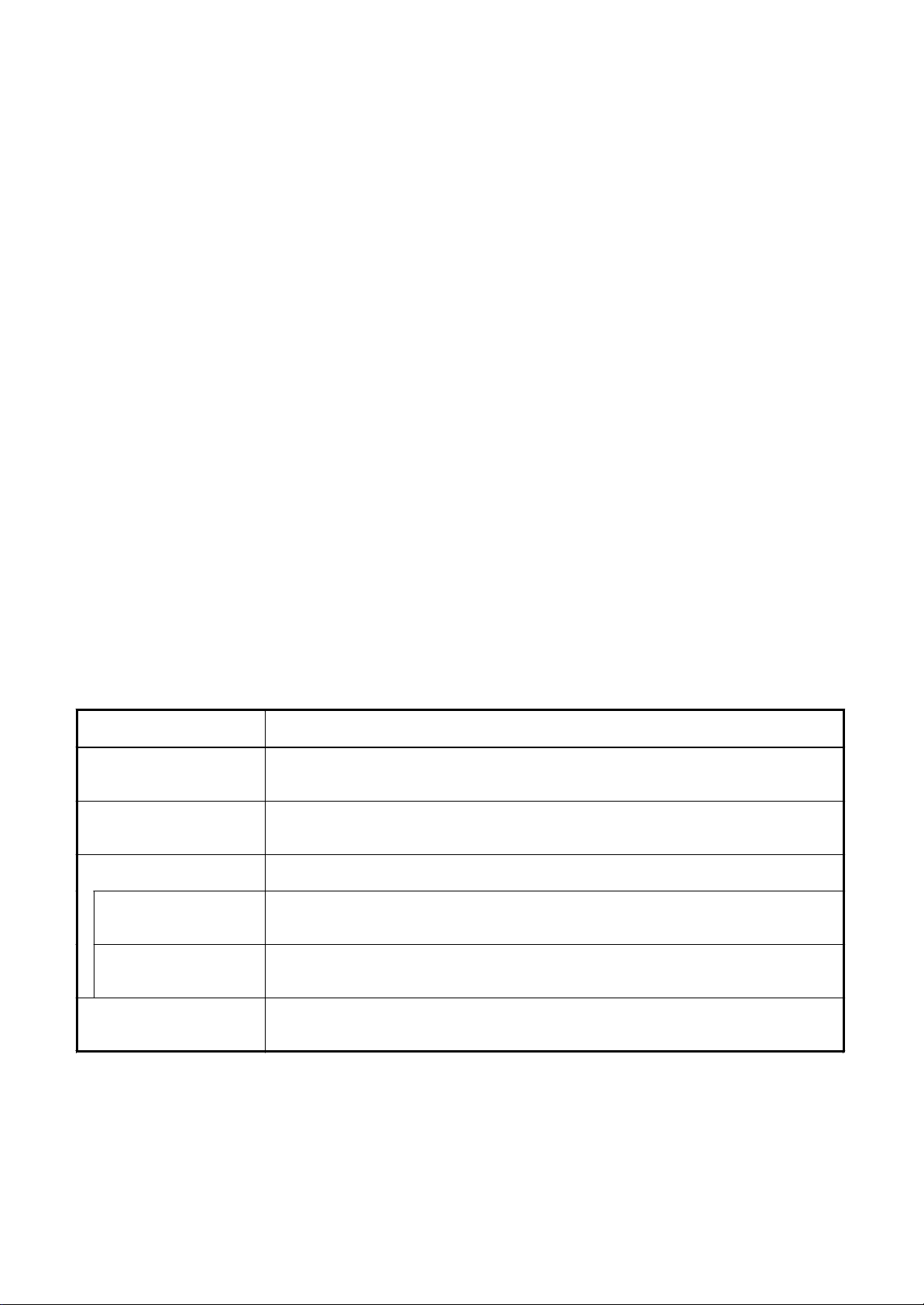

<Operation mode>

Operation mode Outline

1. All Cooling All indoor units are under cooling operation only without heating operation.

Outdoor heat exchanger (Main heat exchanger) is used as condenser .

2. All Heating All indoor units are under heating operation only without cooling operation.

Outdoor heat exchanger (Main heat exchanger) is used as ev apor ator.

3. Simultaneous operation MIU for simultaneous operation

3-1. Mainly cooling, partly

heating operation

3-2. Mainly heating, partly

cooling operation

Indoor units are under heating/cooling simultaneous operation with subjective cooling operation

Outdoor heat exchanger (Sub heat exchanger) is used as condenser.

Indoor units are under heating/cooling simultaneous operation with subjective heating operation

Outdoor heat exchanger (Main heat exchanger) is used as ev apor ator.

4. Defrost Using reversing operation of 4-way valve , ice of the outdoor heat exchanger is dissolv ed w ith

single cooling cycle.

9

Page 10

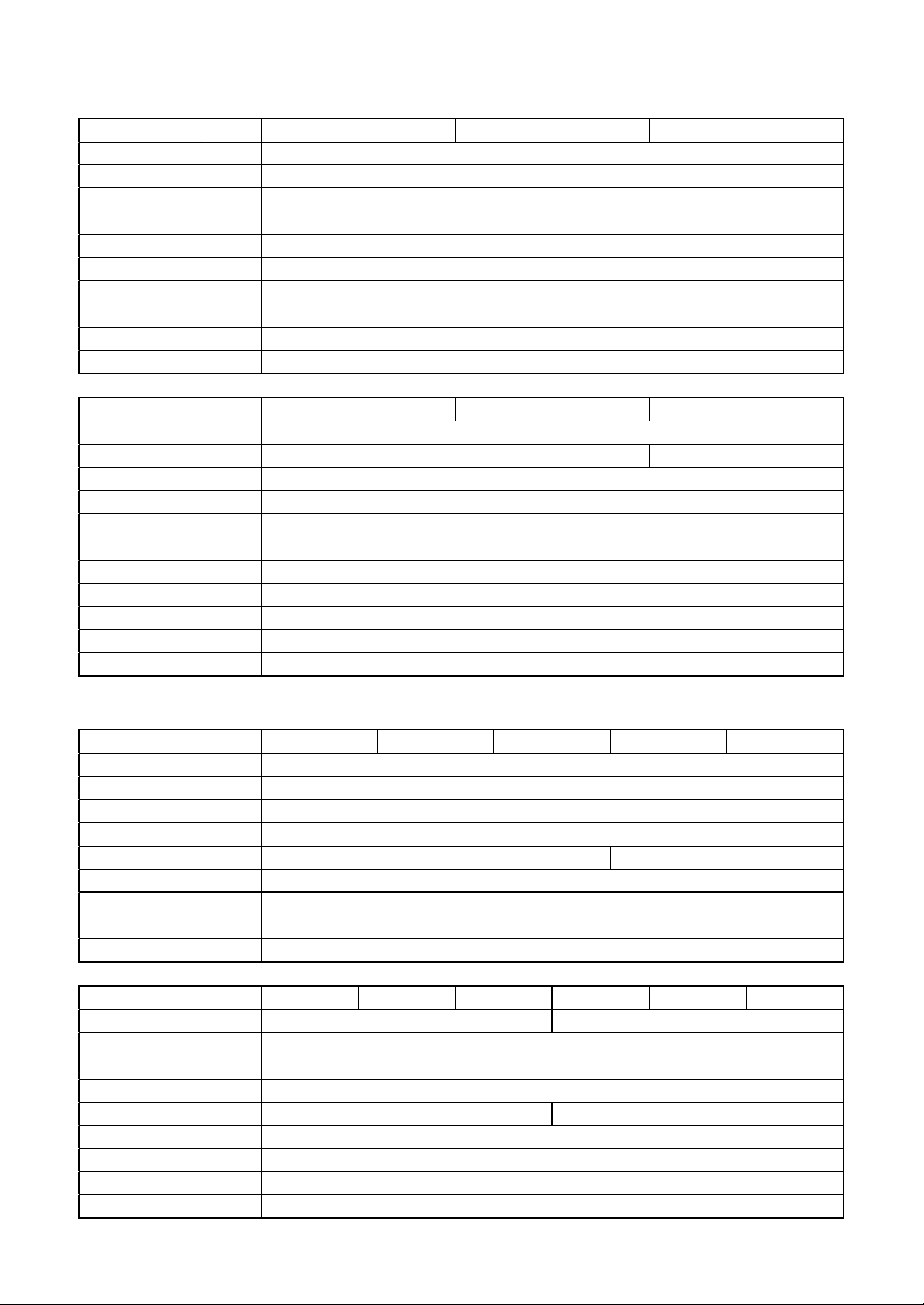

1-1. Components Lineup in Super Heat Recovery Multi Using

High-efficiency Refrigerant R410A

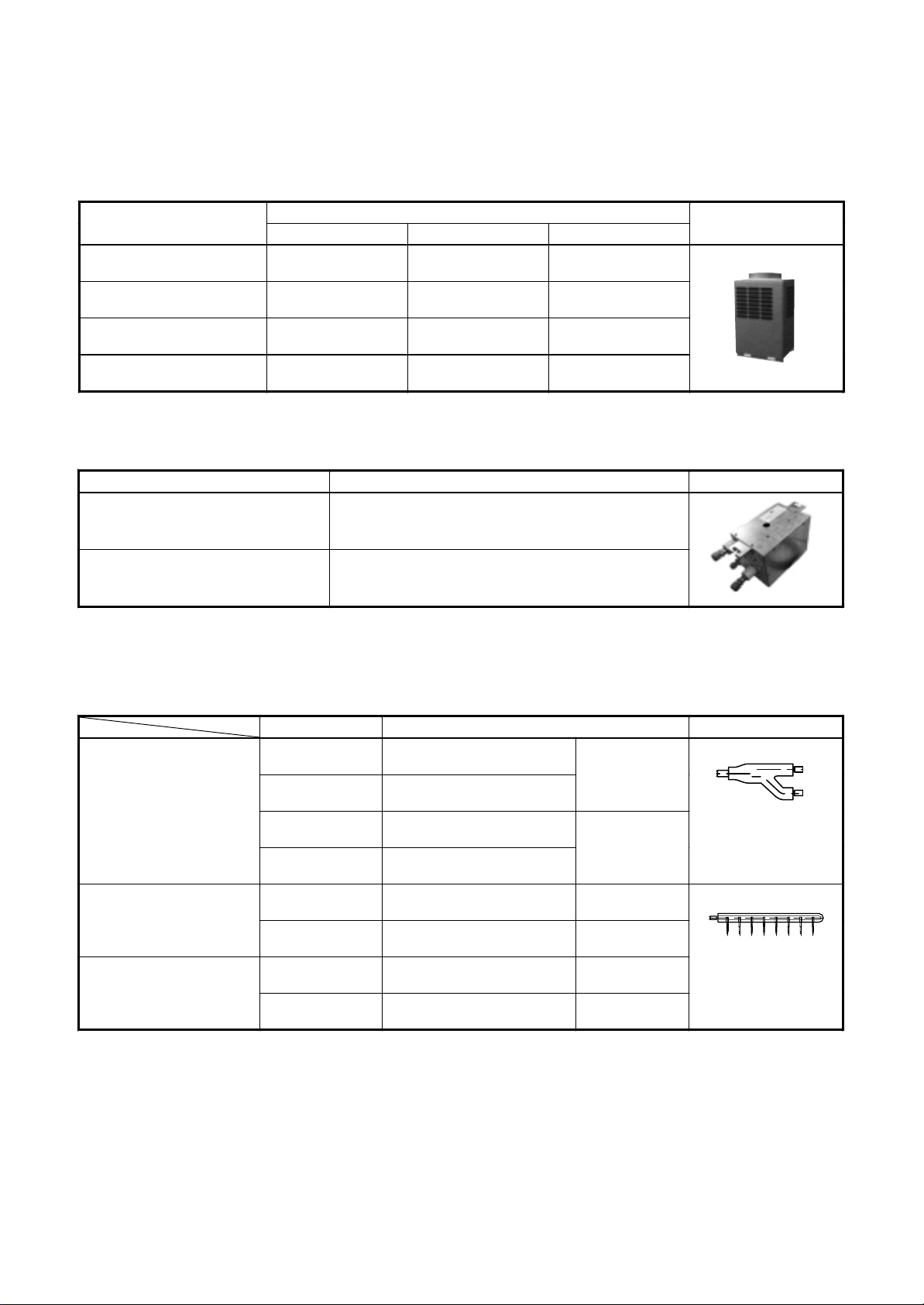

1. Outdoor units

Corresponding HP

Model name

Cooling capacity (kW) 22.4 28.0 33.5

Heating capacity (kW) 25.0 31.5 35.5

Number of connectable

indoor units

MMY- MAP0801FT8 MAP1001FT8 MAP1201FT8

8HP 10HP 12HP

13.0 16.0 16.0

Inverter unit

2. Flow selector units (FS unit)

Model name Usage Appearance

RBM-Y1121FE Capacity rank for indoor unit : Type 007 to 030

RBM-Y1801FE Capacity rank for indoor unit : Type 036 to 056

* Accessory part (Sold separately): Connection cable kit (RBC-CBK15FE), up to 15m.

Appearance

3. Branching joints and headers

Model name Usage Appearance

RBM-BY53FE

RBM-BY103FE

Y-shape branching joint (∗3)

RBM-BY53E

RBM-BY103E

RBM-HY1043FE

4-branching header (∗4)

RBM-HY1043E

RBM-HY1083FE

8-branching header (∗4)

RBM-HY1083E

∗1 “Capacity code” can be obtained from page 11. (Capacity code is not actual capacity)

∗2 If total capacity code value of indoor unit exceeds that of outdoor unit, apply capacity code of outdoor unit.

∗3 When using Y-shape branching joint for 1st branching, select according to capacity code of outdoor unit.

∗4 Max. 6.0 capacity code in total can be connected.

∗5 This is used for branching to “cooling only” indoor unit.

∗6 Model names for outdoor described in this guide are shortened because of the space constraint.

Indoor unit capacity code (∗1)

Total below 6.4

Indoor unit capacity code (∗1)

Total below 14.2

Indoor unit capacity code (∗1)

Total below 6.4

Indoor unit capacity code (∗1)

Total below 14.2

Indoor unit capacity code (

Total below 14.2

Indoor unit capacity code (∗1)

Total below 14.2

Indoor unit capacity code (∗1)

Total below 14.2

Indoor unit capacity code (

Total below 14.2

∗

∗

For 3 piping

For 2 piping (

1)

For 3 piping

For 2 piping (

For 3 piping

1)

For 2 piping (∗5)

5)

∗

5)

∗

10

Page 11

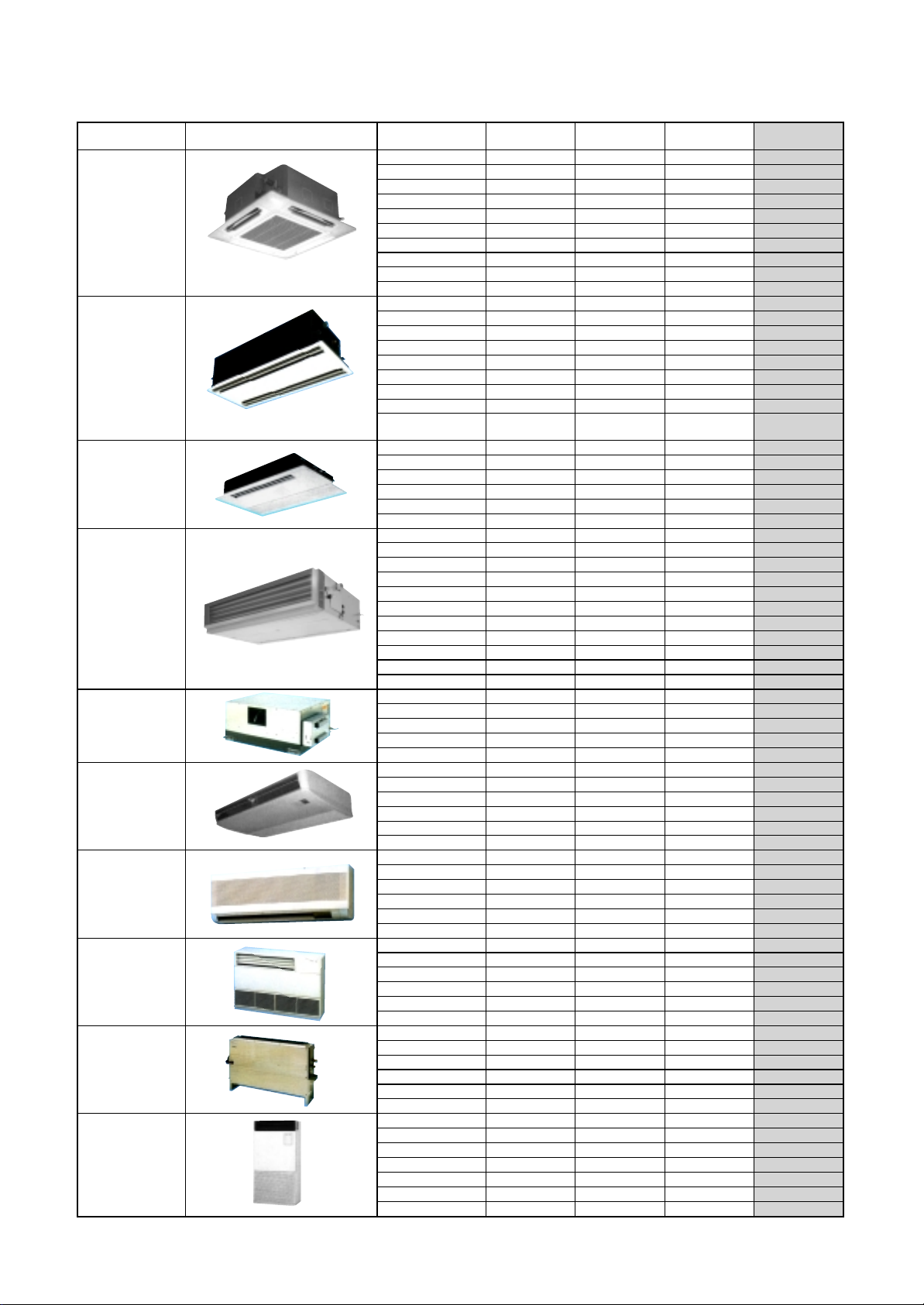

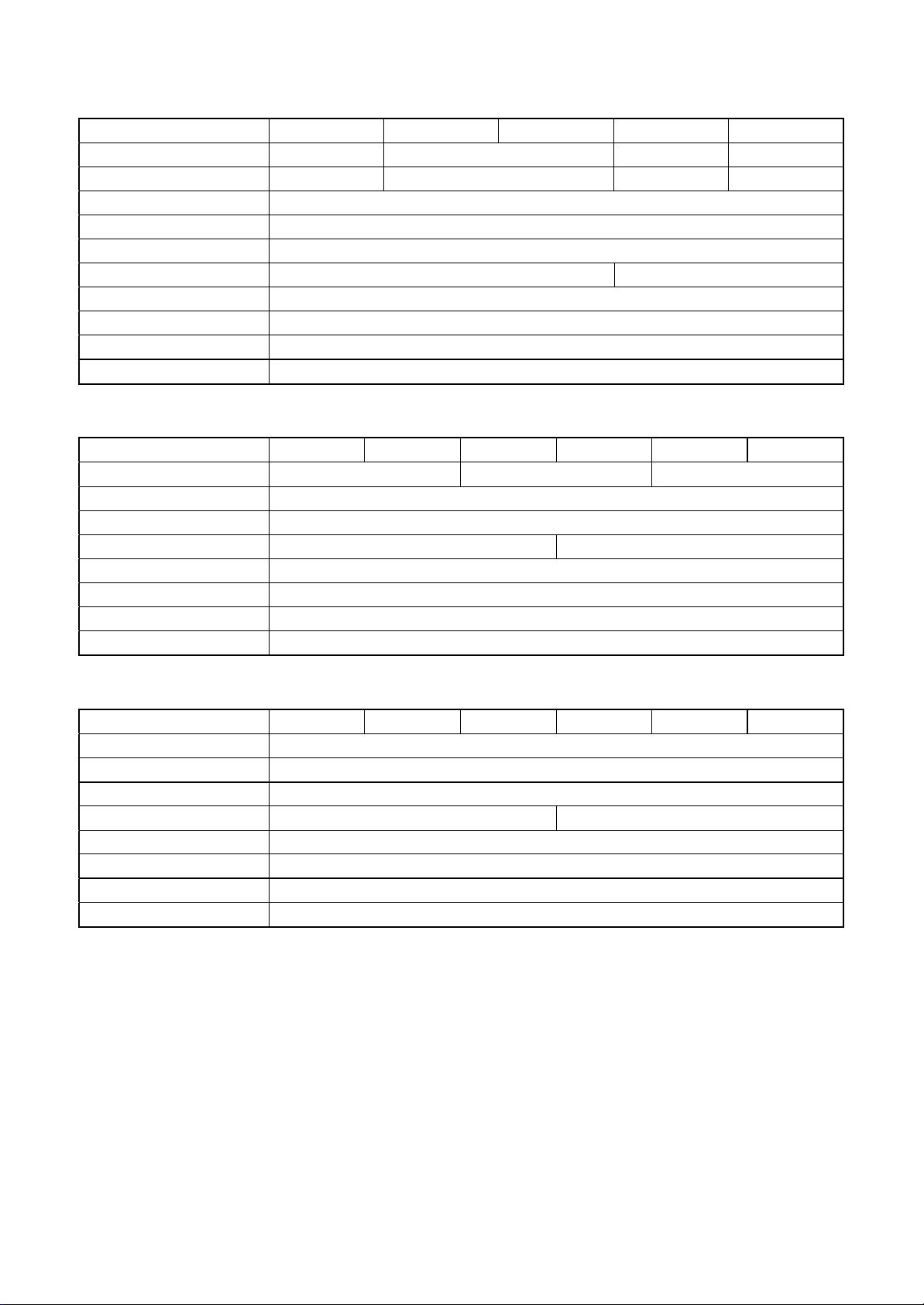

4. Indoor units

Type Appearance Model name Capacity rank Capacity code

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

048 type 5 14.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

4-way Air Discharge

Cassette Type

2-way Air Discharge

Cassette Type

1-way Air Discharge

Cassette Type

Concealed Duct

Standard Type

Concealed Duct

High Static

Pressure Type

Under Ceiling Type

High Wall Type

Floor Standing

Cabinet Type

Floor Standing

Concealed Type

Floor Standing Ty pe

MMU-AP0091H

MMU-AP0121H

MMU-AP0151H,

MMU-AP0181H

MMU-AP0241H

MMU-AP0271H

MMU-AP0301H

MMU-AP0361H

MMU-AP0481H

MMU-AP0561H

MMU-AP0071WH

MMU-AP0091WH

MMU-AP0121WH

MMU-AP0151WH

MMU-AP0181WH

MMU-AP0241WH

MMU-AP0271WH

MMU-AP0301WH

MMU-AP0481WH

(CHINA only)

MMU-AP0071YH

MMU-AP0091YH

MMU-AP0121YH

MMU-AP0151SH

MMU-AP0181SH

MMU-AP0241SH

MMD-AP0071BH

MMD-AP0091BH

MMD-AP0121BH

MMD-AP0151BH

MMD-AP0181BH

MMD-AP0241BH

MMD-AP0271BH

MMD-AP0301BH

MMD-AP0361BH

MMD-AP0481BH

MMD-AP0561BH

MMD-AP0181H

MMD-AP0241H

MMD-AP0271H

MMD-AP0361H

MMD-AP0481H

MMC-AP0151H

MMC-AP0181H

MMC-AP0241H

MMC-AP0271H

MMC-AP0361H

MMC-AP0481H

MMK-AP0071H

MMK-AP0091H

MMK-AP0121H

MMK-AP0151H

MMK-AP0181H

MMK-AP0241H

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MML-AP0071BH

MML-AP0091BH

MML-AP0121BH

MML-AP0151BH

MML-AP0181BH

MML-AP0241BH

MMF-AP0151H

MMF-AP0181H

MMF-AP0241H

MMF-AP0271H

MMF-AP0361H

MMF-AP0481H

MMF-AP0561H

Cooling

capacity (kW)

Heating

capacity (kW)

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

16.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

6.3

8.0

9.0

12.5

16.0

5.0

6.3

8.0

9.0

12.5

16.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

9.0

12.5

16.0

18.0

11

Page 12

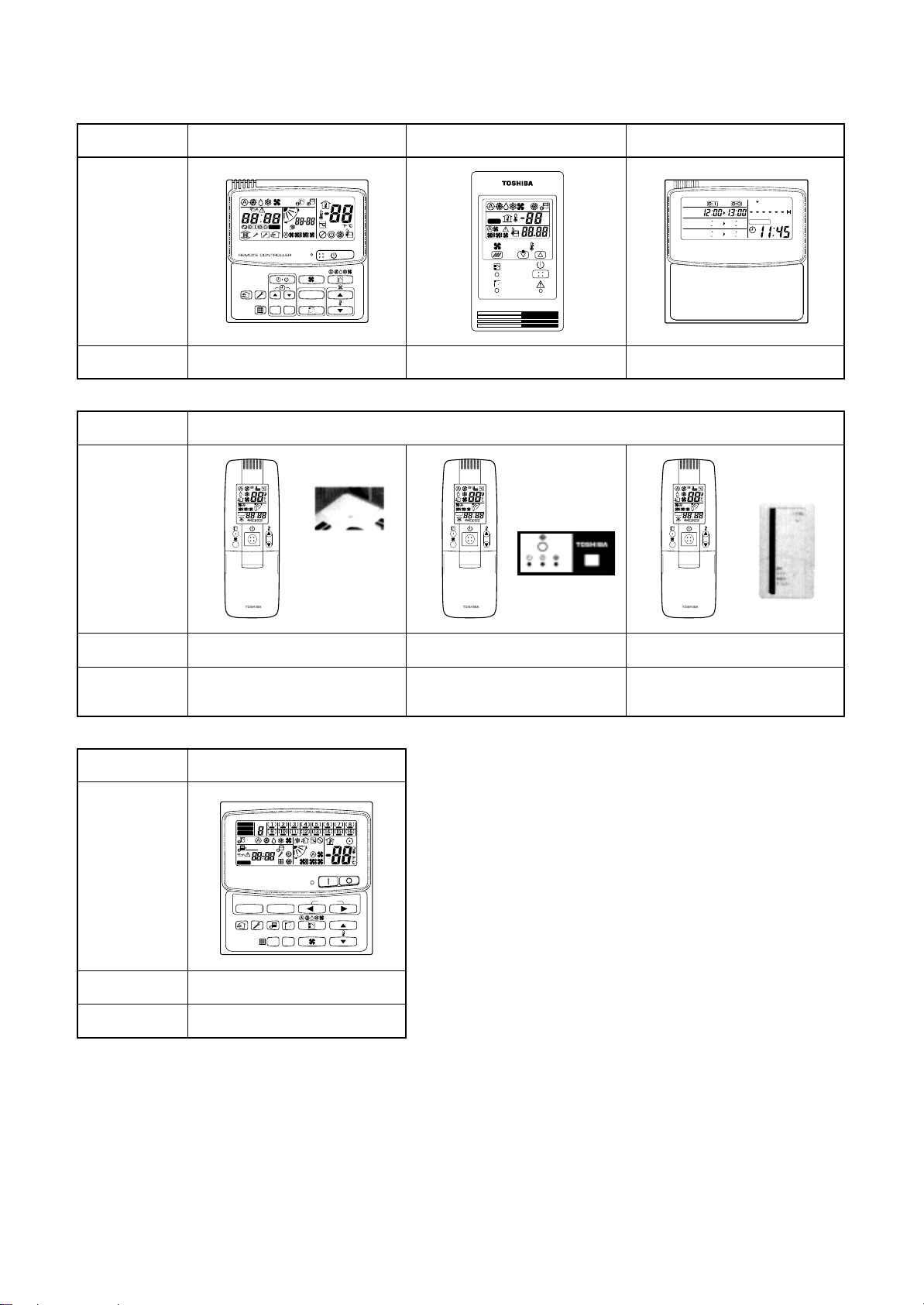

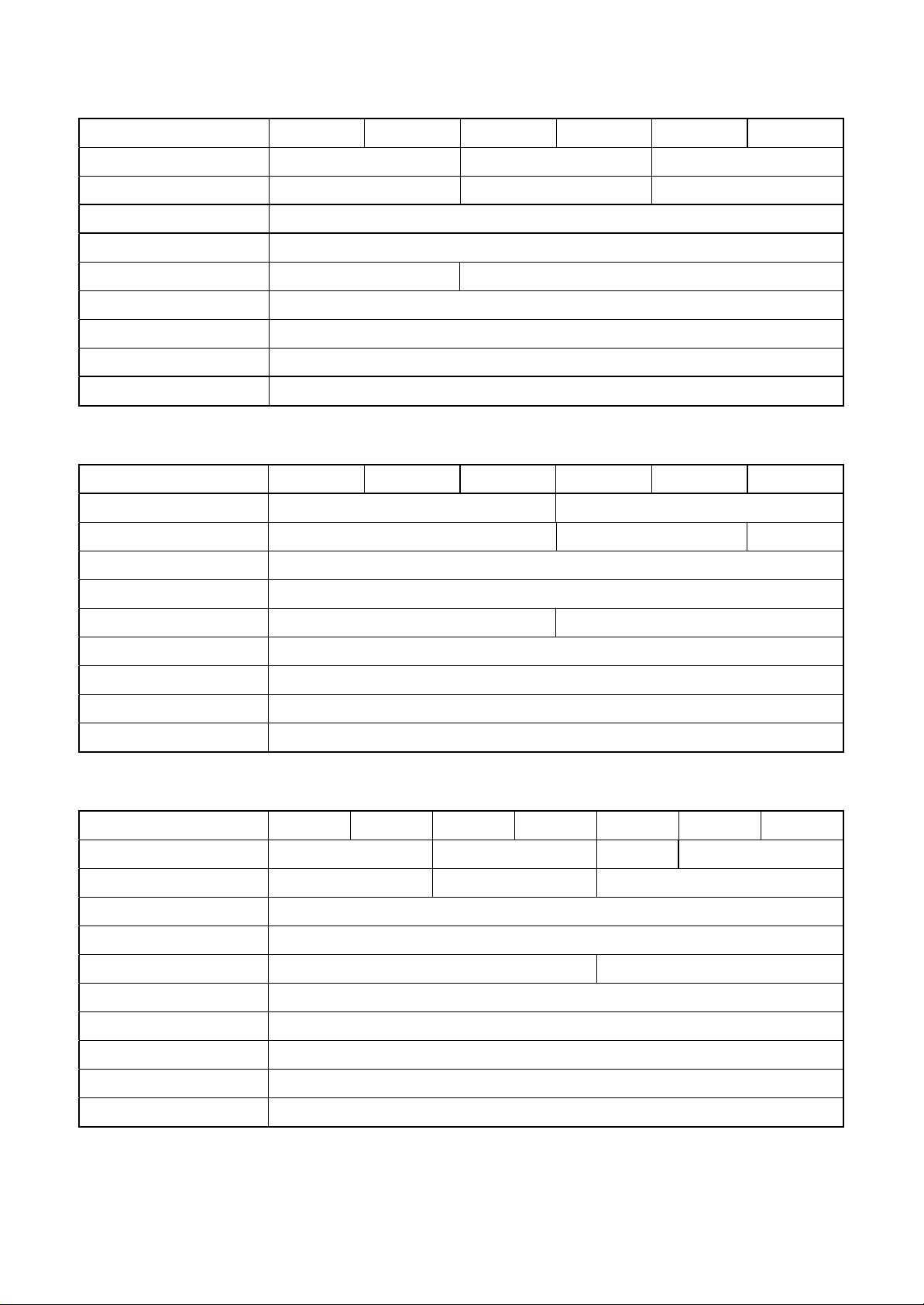

n Remote controller switch

˚C

˚F

TEST

SETTING

Name

Appearance

Model name

Appearance

Wired remote controller

UNIT No.

R.C. No.

CODE No.

UNIT

SET DATA

SETTING

TEST

CL

SET

RBC-AMT21E

Simple wired remote controller

RBC-AS21E

Wireless remote controller kitName

Receiver section

ADR ADR ADR

Receiver section

Weekly timer

PROGRAM1

PROGRAM2

PROGRAM3

WEEKLY TIMER

SuMoTuWeThFr Sa

ERROR

RBC-EXW21E

Receiver section

laid separately

Model name

Type

Name

Appearance

Model name

Type

RBC-AX2U (W)-E

4-way Air Discharge

Cassette type

Central remote controller

ZONE

ALL

ZONE

GROUP

1234

UNIT No.

SET DATA

SETTING

No.

R.C.

SELECT ZONE

CL

TEST

SET

GROUP

CODE

No.

TCB-SC642TLE

64 system center controller

RBC-AX22CE

Under Ceiling type

TCB-AX21E

Separate sensor type

12

Page 13

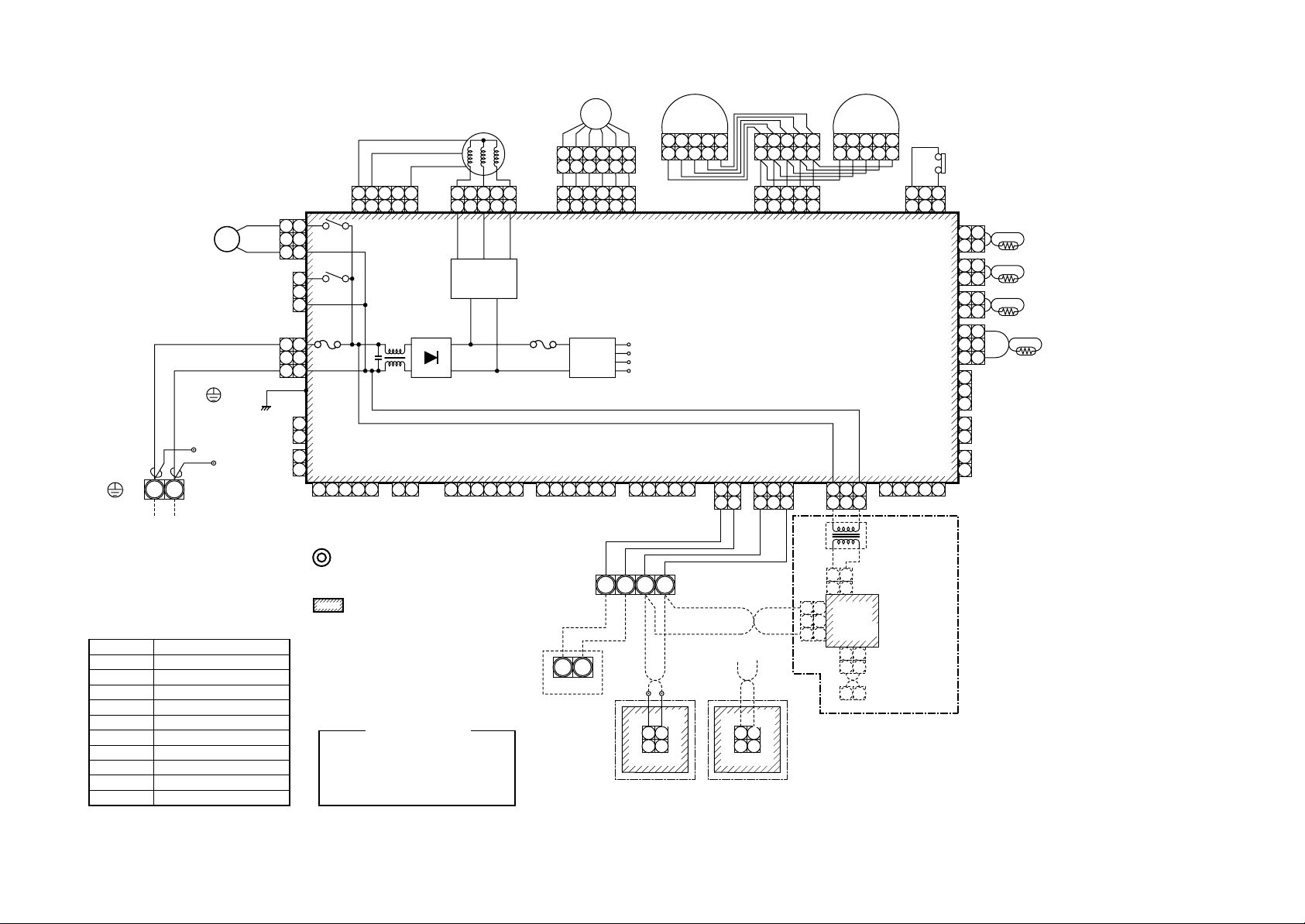

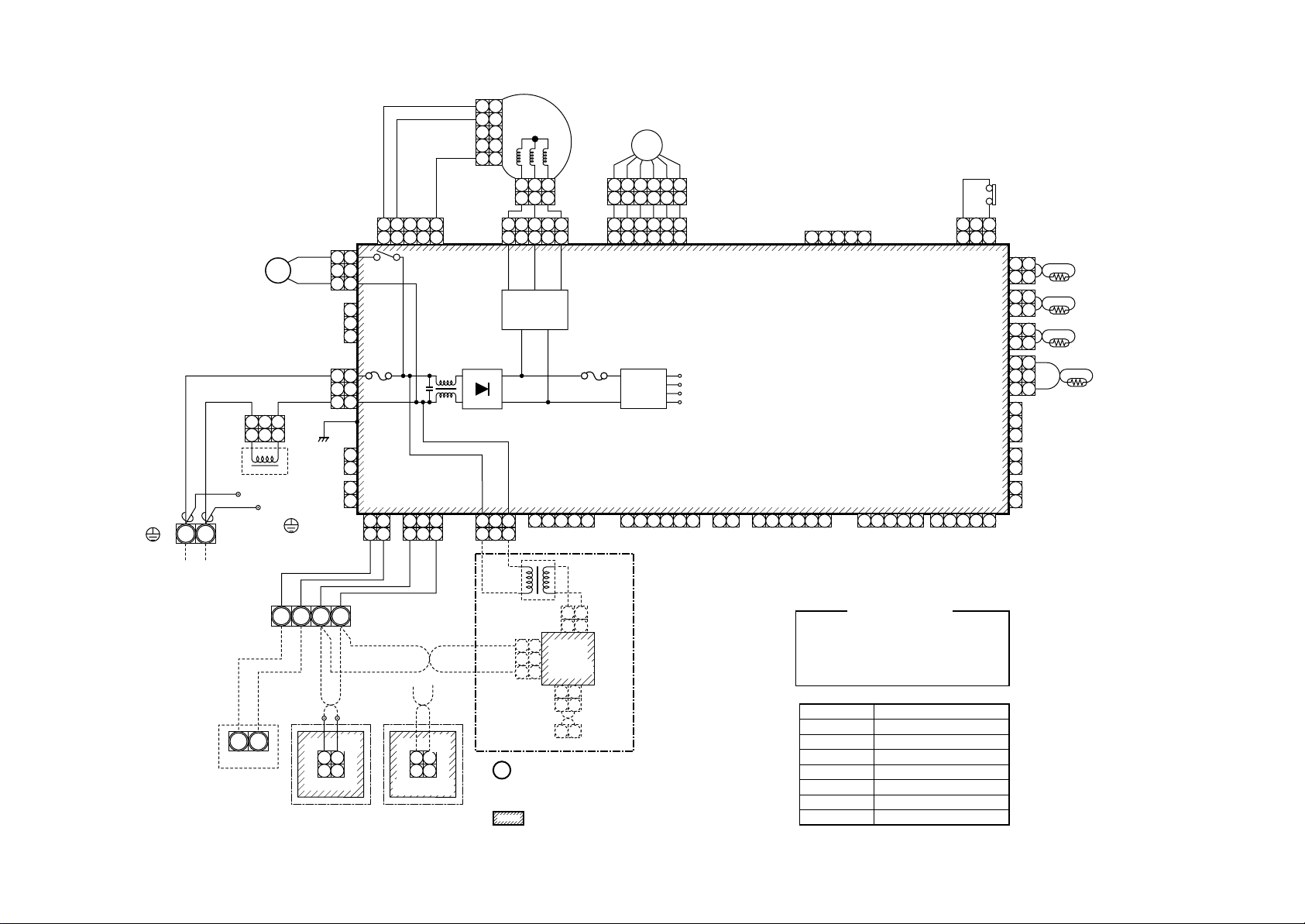

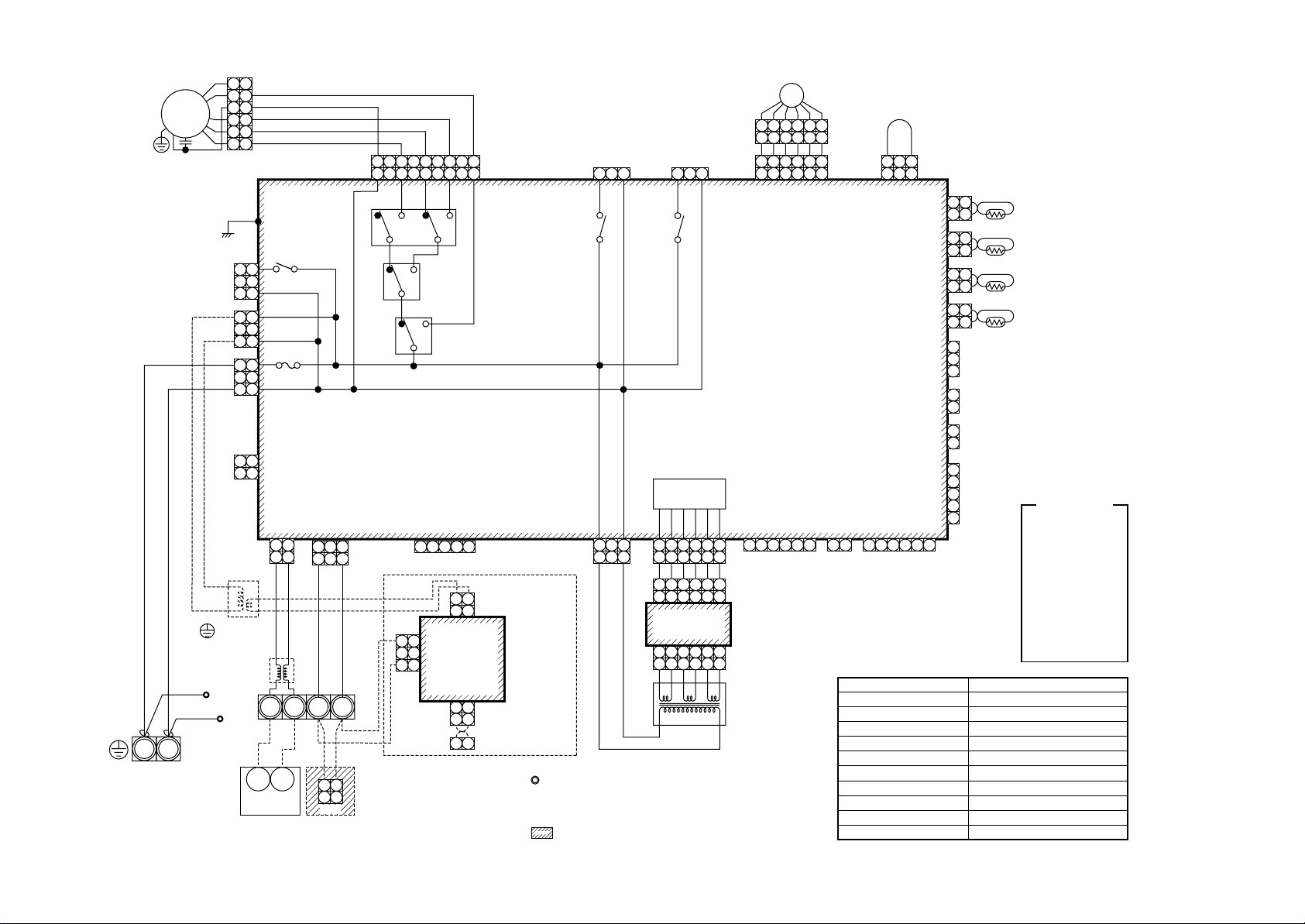

2. WIRING DIA GRAM

2-1. Indoor Unit

2-1-1. 4-way Air Discharge Cassette Type

Model: MMU-AP0091H, AP0121H, AP0151H, AP0181H, AP0241H,

13

Indoor unit

Earth screw

Symbol

FM

TA

TC1

TCJ

TC2

LM1, LM2

DM

FS

RY302

PMV

Flow selector

S(N)R(L)

Power supply

Single phase

220-240V 50Hz

220V 60Hz

Fan motor

Indoor temp sensor

Temp sensor

Temp sensor

Temp sensor

Lover motor

Drain pump motor

Float switch

Drain control relay

Pulse Motor Valve

DM

unit earth

screw

RED

WHI

Closed end

connector

Parts name

~

~

CN32

(WHI)

1 2

(Fandrive)

CN334

(BLU)

T10

RY302

RY303

Fuse

T6.3A

250V~

P301

5 4 3 2 1

5 4 3 2 1

CN50

(WHI)

CN304

(GRY)

RED

CN67

(BLK)

WHI

CN66

(WHI)

CN44

(BLN)

CN68

(BLU)

1

2

3

1

2

3

BLK

1

2

3

1

2

3

1

2

3

1

2

1

2

4 5 6

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

Color identification

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BRN : BROWN

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

PMV

FM

6 4 3 1 2 5

6 4 3 1 2 5

CN333

1 2 3 4 5

1 2 3 4 5 6

Motor drive

circuit

+

–

CN61

(YEL)

1 2 3 4 51 2 3

(WHI)

Fuse

T3.15A

250V~

1 2 3 4 5 6

1 2 3 4 5

CN60

(WHI)

1 2

3 4 5 6

(Option)

Power

supply

circuit

U2U1

Outdoor unit

U2

U1

LM2

1 2 3 4 5

1 2 3 4 5

CN82

(BLU)

Indoor control P.C. board

MCC-1402

DC20V

DC15V

DC12V

DC7V

CN81

(BLK)

1 2 3 4 5

CN40

(BLU)

1 2

1 2

BLU

BA

WHI

BLK WHI BLK

CN1

(WHI)

1 2

1 2

Wired remote

controller

Adaptor for wireless

remote controller

BLU

1 2

1 2

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

CN41

(BLU)

1 2 3

1 2 3

BLK

BLK

BLK

WHI

CN001

(WHI)

CN309

(YEL)

CN01

(WHI)

3 3

2 2

1 1

CN02

(BLU)

LM1

1 2 3 4 5

1 2 3 4 5

CN33

(WHI)

1 2 3

1 2 3

1 2

Network adaptor

(Option)

1 2

Network

adaptor

P.C. board

1 2

1 2

X Y

CN20

(BLU)

1 2 3 4 5

TR

MCC-1401

CN03

(RED)

3 1

321

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRN)

CN80

(GRN)

CN73

(RED)

CN70

(WHI)

FS

CN34

(RED)

121

2

121

2

121

2

121

2

33

1

PNL

2

3

1

EXCT

2

1

Filter input

2

MMU-AP0271H, AP0301H, AP0361H, AP0481H, AP0561H

TA

TCJ

TC2

TC1

Page 14

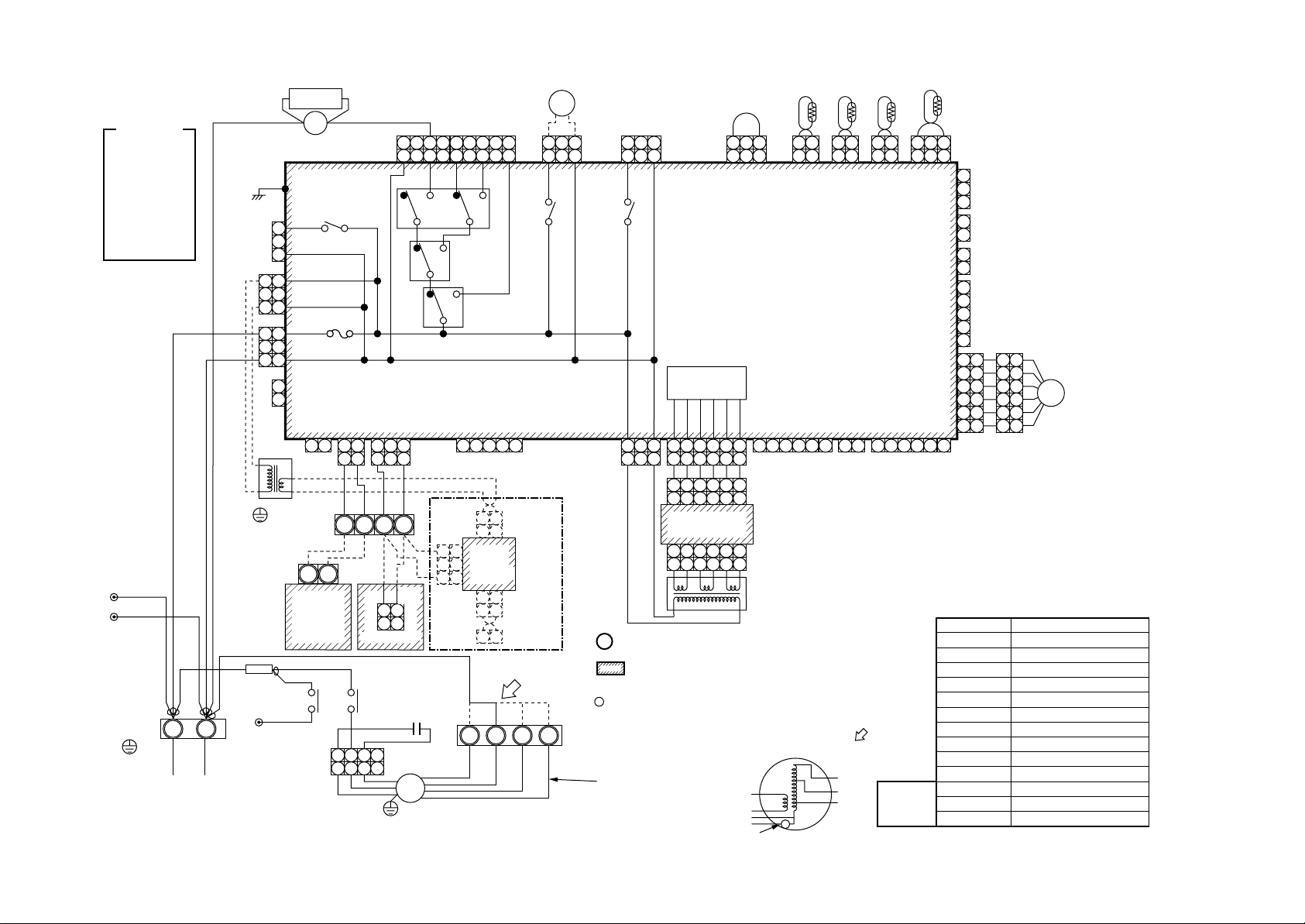

14

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Indoor unit

Earth screw

220-240V 50Hz

220V 60Hz

Flow selector

S(N)R(L)

Power supply

Single phase

FM

unit earth

screw

Closed end

connector

CN039

(YEL)

WHI

121

2

RED

343

4

565

6

77

9

(BLK)

CN304

(GRY)

1

2

3

1

2

3

CN066

(WHI)

CN044

(BRW)

TR

Line Filter

1

Outdoor unit

1

2

3

1

2

3

1

2

3

1

2

1

2

U2U

P301

CN067

(BLK)

CN040

(BLU)

1 2

1 2

BLU

BLU

U

1

U

RY004

Fuse

T5.0A

250V~

CN041

(BLU)

1 2 3

1 2 3

BLK

BLK

BA

2

CN1

(WHI)

1 2

1 2

Remote controller

FAN

CN083

YX

(WHI)

RED

RY007

3 3

1 1

CN02

(BLU)

RC

BLK

9 8 7 6

9 8 7 6

ORN

5 4 3 2 1

5 4 3 2 1

HML UL

RY006

RY005

CN050

(WHI)

1 2 3 4 5

Network

1 2

1 2

adaptor

(Option)

CN01

(WHI)

2

MCC-1401

LM

BLU

YEL

RY002

DM

1 2 3

1 2 3

CN068

DP

(BLU)

RY001

1 2

1 2

1 2 3

1 2 3

LM

(GRN)

CN033

Indoor control P.C. board

Power supply

circuit

4 5 6

CN075

(WHI)

CN02

(YEL)

CN01

(WHI)

TR

CN074

(WHI)

1 2 3

1 2 3

1 2 3

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

1 1

2 2

CN03

(RED)

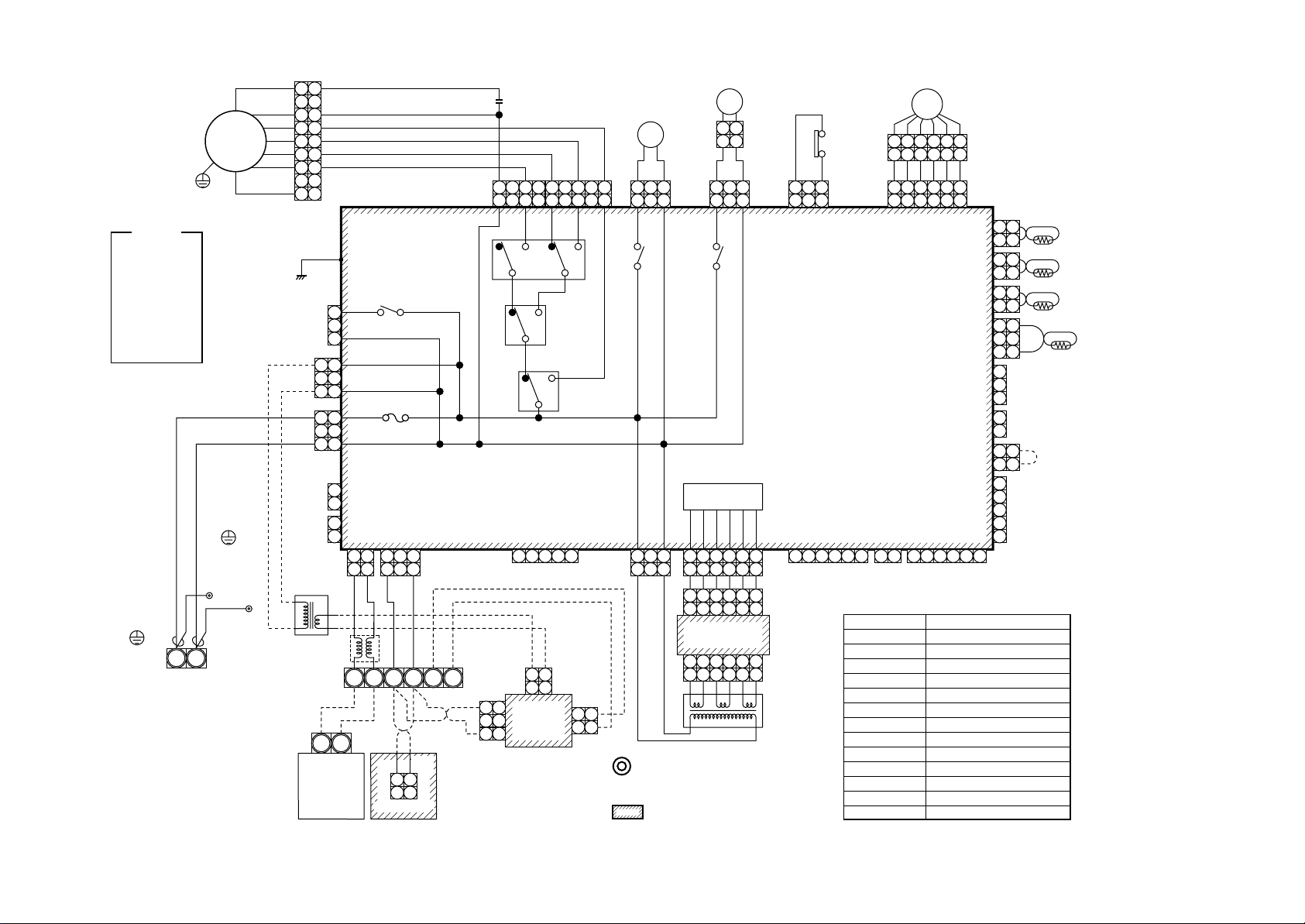

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

1 2 3

1 2 3

1 2 3 4 5 61 2 3 4 5 6

FS

CN061

(YEL)

FS

(RED)

CN030

6 4 3

6 4 3

1 2 3

1 2 3

CN032

(WHI)

1 2

Fan drive

Symbol

FM

RC

TR

LM

TA

TC1,TC2,TCJ

RY001

RY002

RY004

RY005~007

FS

DM

PMV

PMV

1 2 5

1 2 5

PMV

4 5 6

(BLU)

4 5 6

CN082

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

CN060

(WHI)

1 2 3 4 5 6

Option

Parts name

Fan motor

Running capacitor

Transformer

Louver motor

Indoor temp sensor

Temp sensor

Louver control relay

Drain control relay

Heater control relay

Fan motor control relay

Float switch

Drain pump motor

Pulse Motor Valve

2

2

2

2

1

2

3

1

2

1

2

1

2

3

4

5

121

121

121

121

33

PNL

EXCT

1

2

TA

TCJ

TC2

Filter

TC1

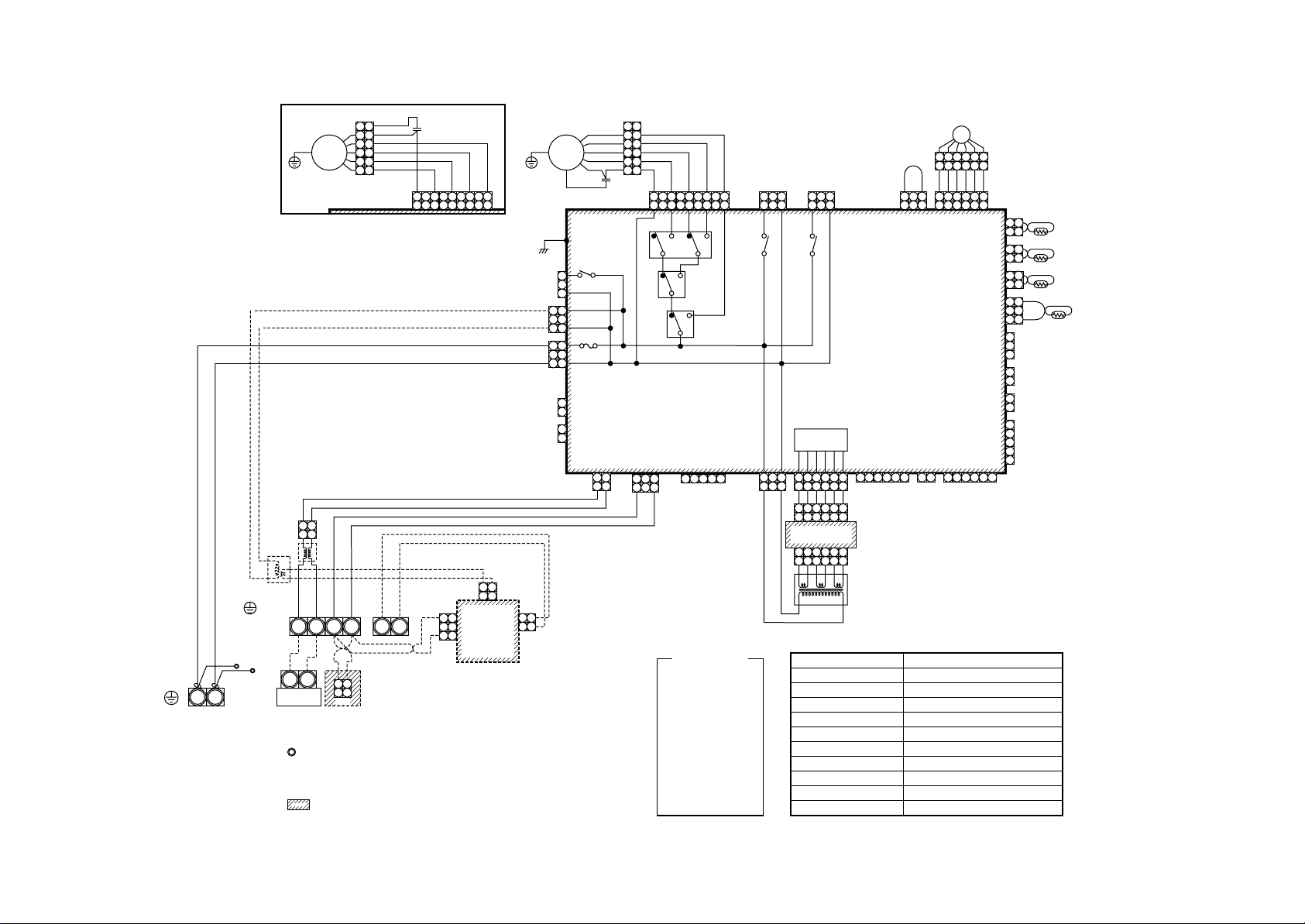

2-1-2. 2-way Air Discharge Cassette Type

Model: MMU-AP0071WH, AP0091WH, AP0121WH, AP0151WH, AP0181WH,

MMU-AP0241WH, AP0271WH, AP0301WH, AP0481WH

Page 15

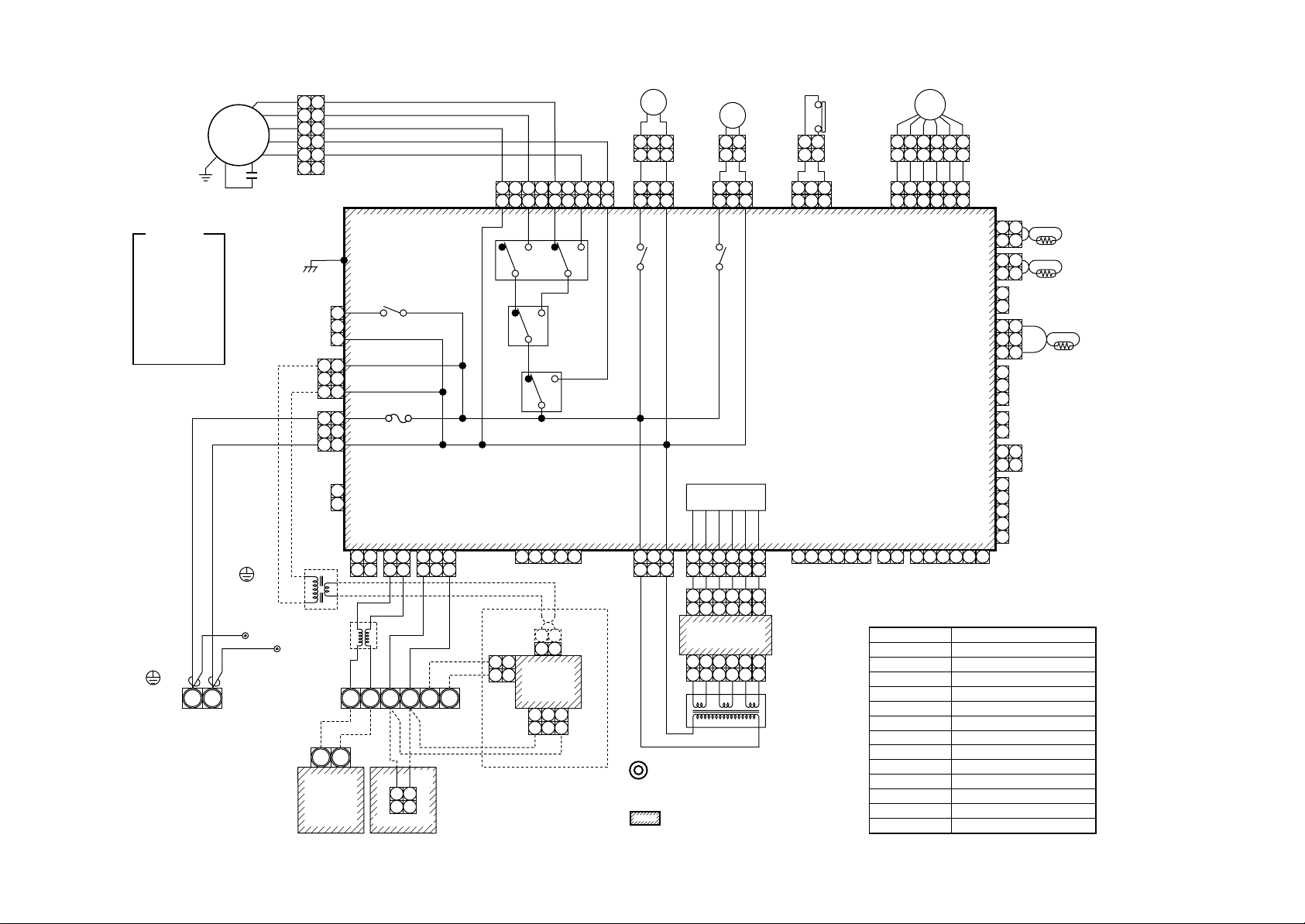

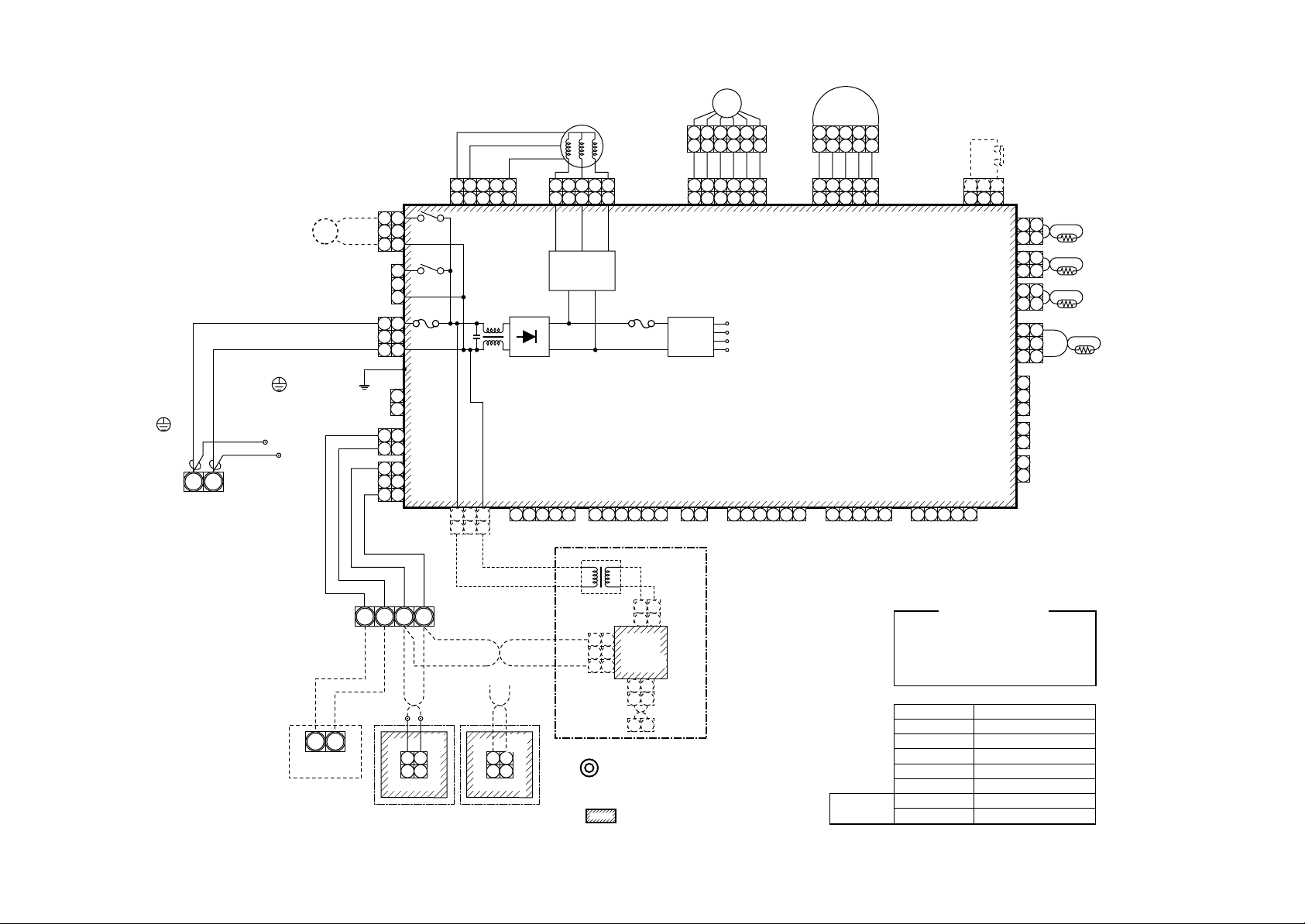

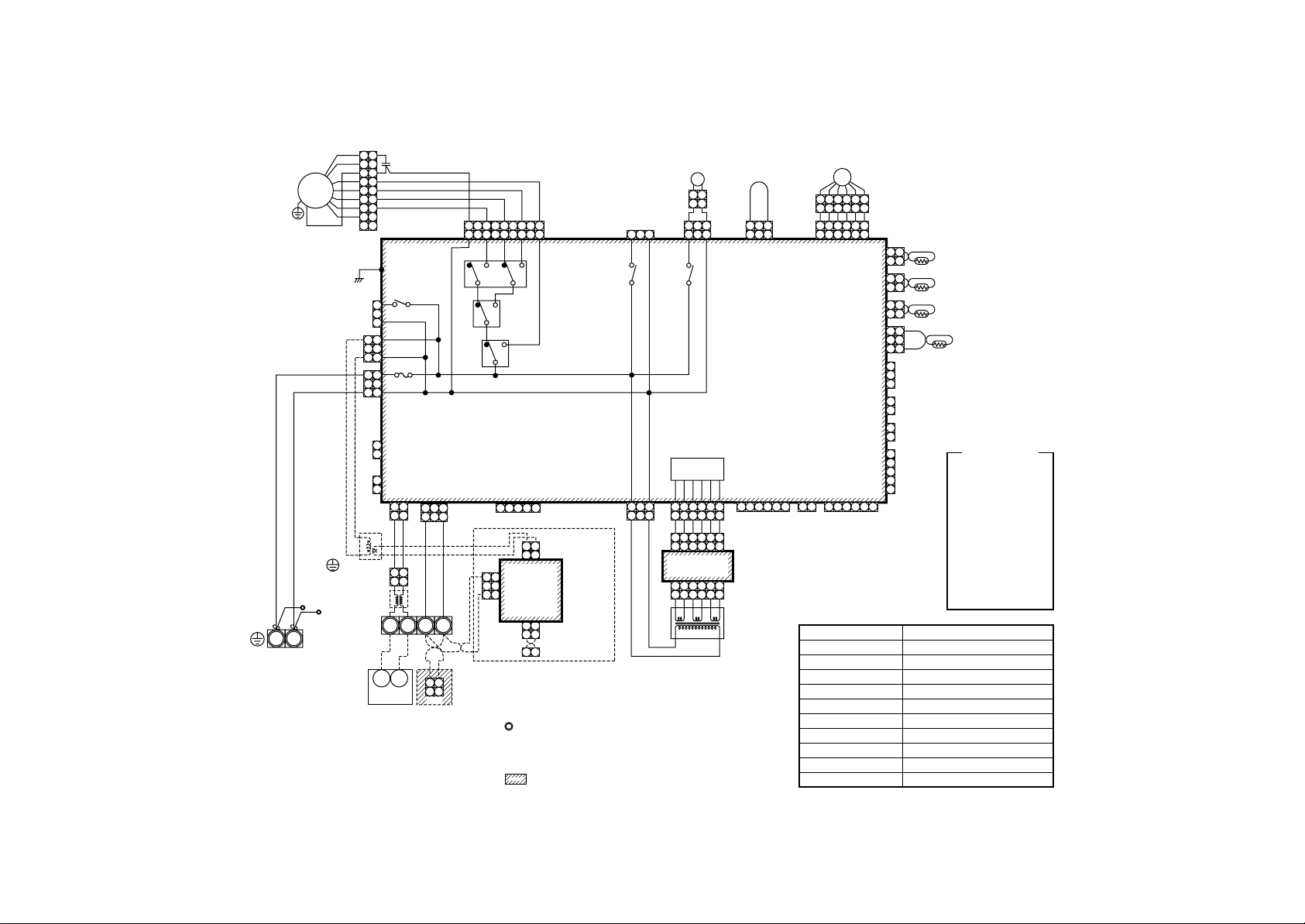

2-1-3. 1-way Air Discharge Cassette Type (Compact type)

Model: MMU-AP0071YH, AP0091YH, AP0121YH

15

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Indoor unit

Earth screw

Flow selector

WHI

RED

RED

S(N)R(L)

Power supply

Single phase

220-240V 50Hz

220V 60Hz

FM

unit earth

screw

Closed end

connector

WHI

RC

2

4

6

CN304

(GRY)

CN309

(YEL)

AC IN

CN066

(WHI)

BLU

121

343

565

CN301

(BLK)

Heater

1

2

3

1

2

3

TR

Line Filter

1

Outdoor

unit

1

2

3

1

2

3

1

2

3

1

2

U

U2U

CN067

(BLK)

CN044

(BRW)

1 2

1 2

BLU

BLU

U

1

BLU

RY004

Fuse

T5.0A

CN040

(BLU)

1 2

1 2

BLU

BLK

BLK

BA

2

CN1

(WHI)

1 2

1 2

Remote controller

FAN

CN083

CN041

(BLU)

1 2 3

1 3

YX

AI-NET

central control

terminal

(WHI)

BLK

RED

9 8 7 6

9 8 7 6

HML UL

RY007

CN050

(WHI)

1 2 3 4 5

MCC-1401

1 2

CN01

(WHI)

1 2

1 1

Network

2 2

adaptor

CN03

P.C. board

(RED)

BLU

ORN

5 4 3 2 1

5 4 3 2 1

RY006

RY005

Network

adaptor

(Option)

2 1

CN02

(BLU)

233 1

YEL

RY002

DM

1 2 3

1 2 3

1 2 3

1 2 3

(BLU)

CN068

DP

RY001

LM

2 1

2 1

1 2 3

1 2 3

LM

(GRN)

CN033

2 1

2 1

1 2 3

1 2 3

Indoor control P.C. board

Power supply

circuit

CN074

(WHI)

CN075

(WHI)

1 2 3

1 2 3

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

1 2 3

4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

CN02

(YEL)

CN01

(WHI)

TR

CN061

(YEL)

1 2 3 4 5 61 2 3 4 5 6

FS

(RED)

CN030

FS

6 4 3

6 4 3

1 2 3

1 2 3

CN032

(WHI)

1 2

Fan drive

Symbol

FM

RC

TR

LM

TA

TC1,TCJ

RY001

RY002

RY004

RY005~007

FS

DM

PMV

PMV

1 2 5

1 2 5

4 5 6

4 5 6

CN082

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

CN060

(WHI)

1 2 3 4 5 6

Option

Fan motor

Running capacitor

Power transformer

Louver motor

Indoor temp sensor

Temp sensor

Flap motor control relay

Drain pump control relay

Heater control relay

Fan motor control relay

Float switch

Drain pump motor

Pulse Motor Valve

PMV

(BLU)

Parts name

2

2

1

2

2

1

2

3

1

2

1

2

1

2

3

4

5

121

121

121

33

PNL

EXCT

1

2

TA

TCJ

TC1

Filter

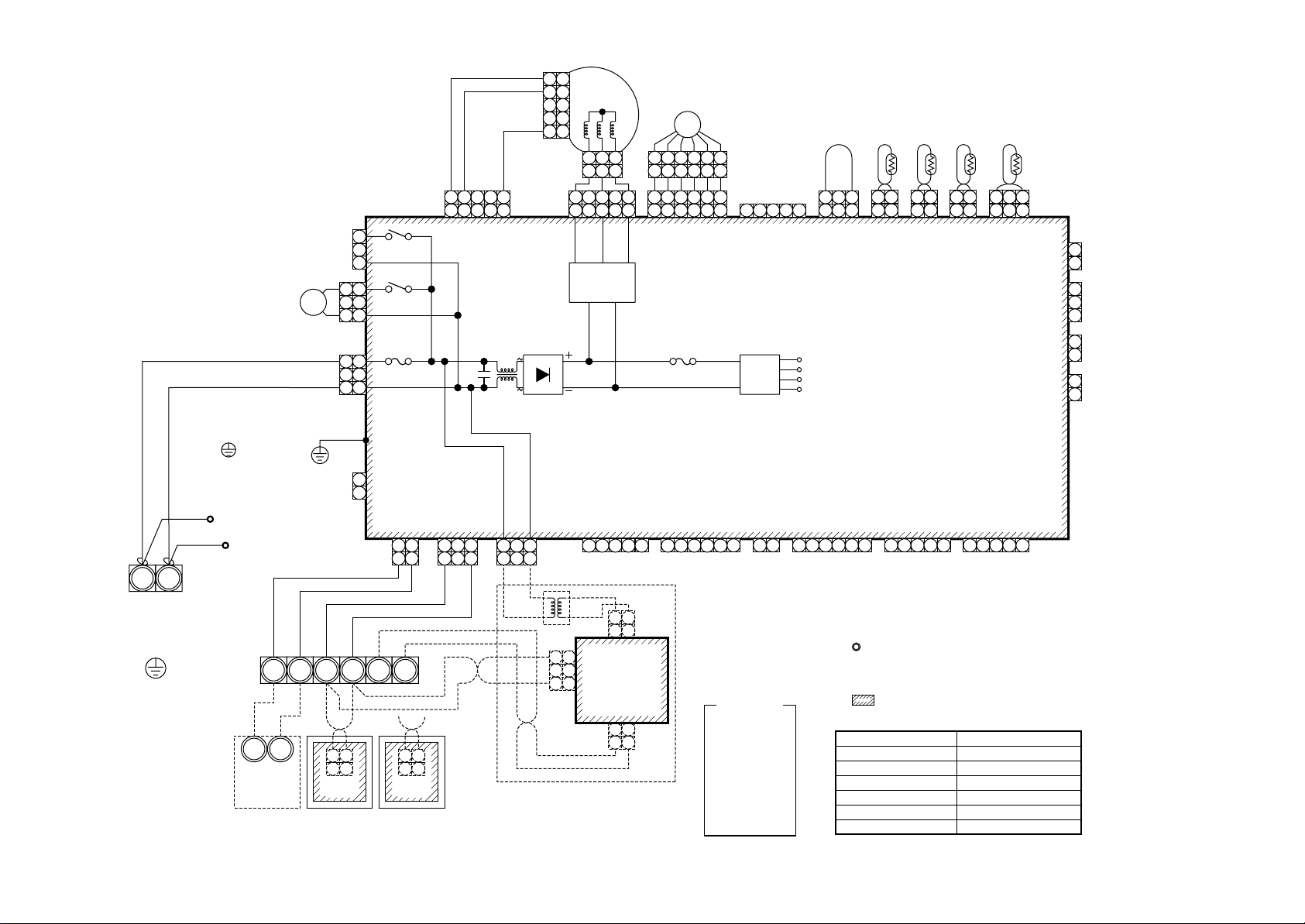

Page 16

16

Indoor unit

earth screw

220-240V 50Hz

FM

RC

Flow selector

R(L) S(N)

Power supply

single phase

220V 60Hz

1

2

313

4

4

5

5

6

6

P301

BLK

RY004

1

(GRY)

3

CN304

1

(YEL)

313

AC IN

CN066

(WHI)

CN044

(BRW)

unit earth

screw

Line Filter

Closed-end

connector

CN309

1

FUSE

T5.0A 250V~

313

(BLK)

CN067

1

2

1

CN040

2

EMG

TR

U1

U1 U2

Outdoor unit Remote Controller

CN041

(BLU)

(BLU)

2

1 233 1 2 3 4 5

112

1

BLU

BLU

BLK

2

112

U2 A B

2

112

CN1

RED BLK ORN BLU YEL

FAN

CN083

(WHI)

9 5 3 1

RY007

RC

BLK

3

1 1

5 3 1779

M LUL

H

RY006

RY005

CN050

(WHI)

CN01(WHI)

3

CN02

2

(BLU)

CN03(RED)

LM

2

112

113

RY001

Power supply

circuit

1 2 3 4 5 6 1 2 1 23 4 5 6 1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

Network Adapter

2

112

112

X Y

(Option)

2

MCC-1401

CN068

(BLU)

RY002

CN074

(WHI)

DM

133

1

113

DM

3

1. Indicates the terminal bolock, letter.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate

the wiring at side.

3. indicate the control p.c. board.

LM

3

CN033

(GRN)

Control P.C. board

for Indoor unit

CN075

(WHI)

CN02

(YEL)

CN01

(WHI)

TR

FS

FS

3

CN030

(RED)

113

MCC-1403

CN061

(YEL)

1 2 3 4 5 6

1 2 3 4 5 6

CN032

(WHI)

FAN

DRIVE

Symbol

FM

RC

TR

LM

TA

TC1,TC2,TCJ

RY001

RY002

RY005~007

FS

DM

PMV

PMV

1 234 56

1 234 56

CN060

(WHI)

OPTION

PMV

CN082

(BLU)

212

212

1

2

1

2

313

1

2

3

1

2

1

2

1

2

3

4

5

1

1

1

2

PNL

EXCT

FILTER

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

Parts name

Fan motor

Running capacitor

Transformer

Lover motor

Indoor temp sensor

Temp sensor

Louver control relay

Drain control relay

Fan motor control relay

Float switch

Drain pump motor

Pulse motor valve

TA

TCJ

TC2

TC1

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Model: MMU-AP0151SH, AP0181SH, AP0241SH

Page 17

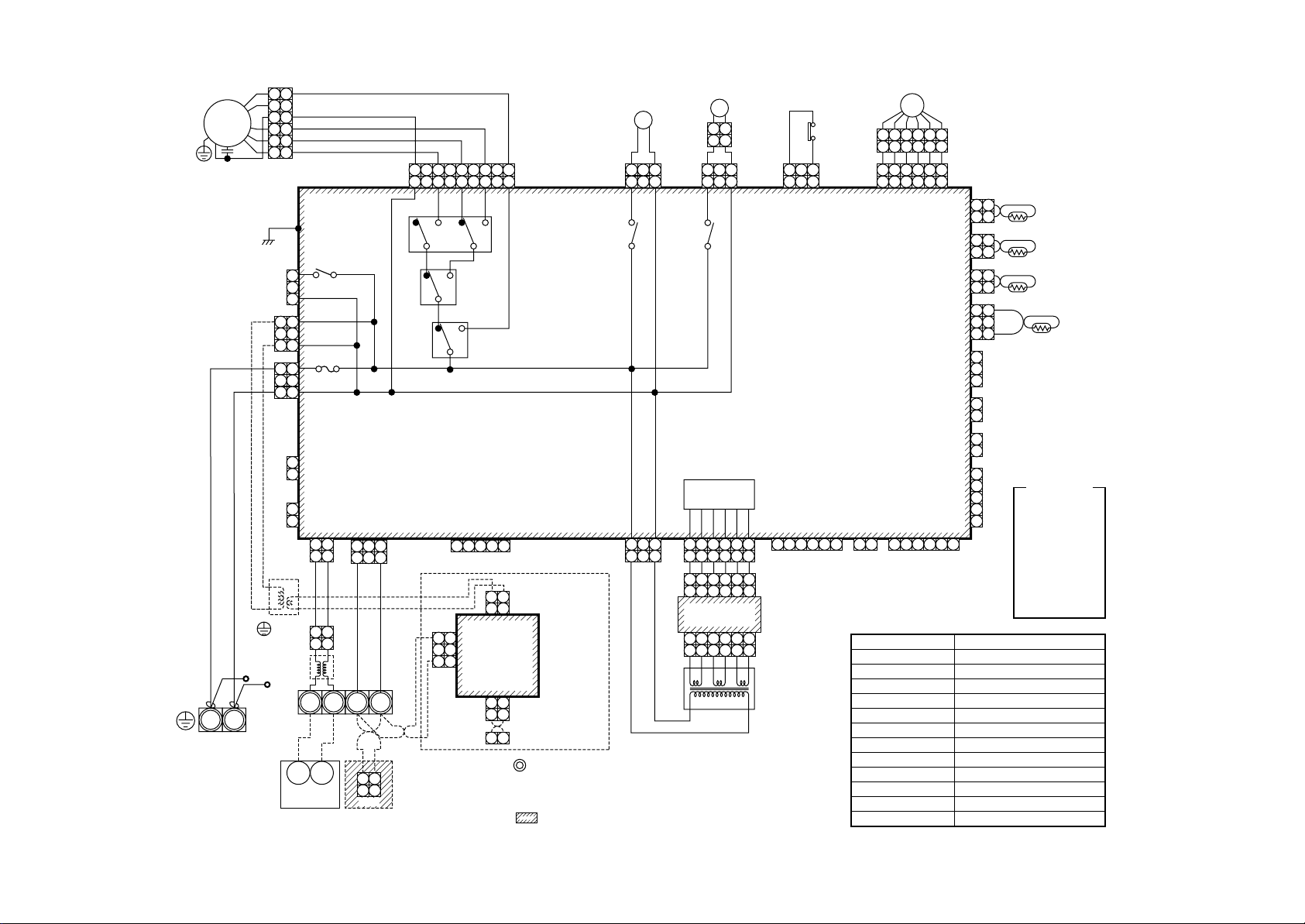

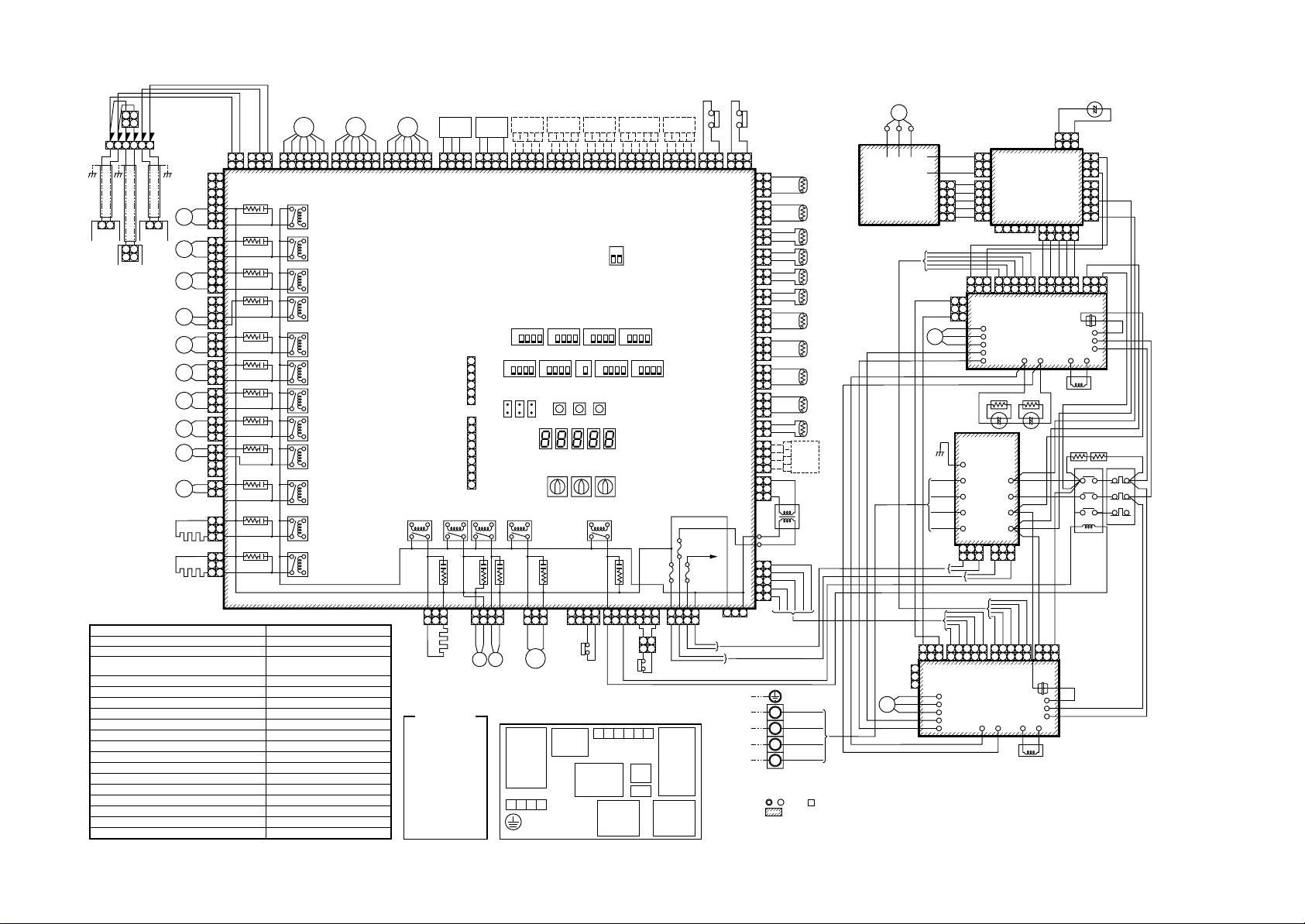

2-1-4. Concealed Duct Standard Type

Model: MMD-AP0071BH, AP0091BH, AP0121BH, AP0151BH, AP0181BH, AP0241BH

17

Indoor unit

S(N)R(L)

Earth screw

Indoor unit power supply

Single phase

220-240V 50Hz

220V 60Hz

RED

WHI

Closed end

connector

Outdoor unit

1 3

1 2 2

Reactor

WHI

Flow selector

U2U

1

DM

unit earth

screw

U

U

1

WHI

Wired remote

CN68

(BLU)

1

1

2

2

3

3

1

CN304

2

(GRY)

3

RED

1

1

CN67

2

2

(BLK)

3

3

WHI

BLK

1

CN66

(WHI)

2

1

CN44

(BRW)

2

BA

2

BLK WHI BLK

CN1

(WHI)

1 2

1 2

controller

5

CN334

RY302

(WHI)

Fuse

T6.3A

250V~

P301

CN41

CN40

(BLU)

(BLU)

1 2 3

1 2

1 2

1 2 3

BLK

BLU

BLU

1 2

1 2

Adaputor for wired

remote controller

11223445

BLK

BLK

WHI

CN001

(WHI)

545

FM

4

11

PMV

6 4 3 1 2 5

6 4 3 1 2 5

1 2 3 4 5 6

1 2 3 4 5 6

Fuse

T3.15A

250V~

4 5 6

T10

Power

supply

circuit

~

~

CN309

(YEL)

CN333

(WHI)

1 2 3

1 2 3

1 3

1 3 5

Motor drive

circuit

+

–

5

CN50

(WHI)

1 2 3

TR

CN02

(BLU)

3 3

2 2

1 1

CN01

(WHI)

1 2

1 2

Network

adaptor

P.C. board

1 2

1 2

Network

adaptor

(Option)

CN03

(RED)

X Y

1. indicates the terminal block, letter at inside

indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

CN61

(YEL)

CN82

(BLU)

Indoor control P.C. board

DC20V

DC15V

DC12V

DC7V

CN32

(WHI)

CN60

(WHI)

1 21 2 3 4 5 61 2 3 4 51 2 31 2 3

(Signal output)(Fan drive)

1 2 3 4 5

Color identification

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BRW : BROWN

Symbol

FM

TA

TC1,TC2,TCJ

DM

FS

RY302

PMV

CN33

(WHI)

CN81

(BLK)

1 2 3 4 5

1 2 3 4 5

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

Parts name

Fan motor

Indoor temp sensor

Indoor temp sensor

Drain pump motor

Float switch

Drain pump control relay

Pulse Motor Valve

CN20

(BLU)

3 1

321

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRN)

CN80

(GRN)

CN73

(RED)

CN70

(WHI)

FS

CN34

(RED)

2

2

2

2

1

2

3

1

2

1

2

121

121

121

121

33

PNL

EXCT

MMD-AP0271BH, AP0301BH, AP0361BH, AP0481BH, AP0561BH

TA

TCJ

TC2

TC1

Page 18

18

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

RED

WHI

Closed

end

connector

Indoor unit

Earth screw

S(N)R(L)

Power supply

Single phase

220-240V 50Hz

220V 60Hz

(BLK)

CN304

(GRY)

1

2

3

1

2

3

TR

Flow selector

unit earth

screw

T10A,250V~

Closed end

connector

Spark

killer

87

43F1

FAN

CN083

P301

1

RY004

2

3

1

CN309

2

(YEL)

3

CN067

(BLK)

1

2

3

1

2

YEL

CN066

(WHI)

CN044

(BRW)

EMG

1

Outdoor unit

REDRED F

RED

6

4

Fuse

T5.0A

OC

U

U2U

43F1

WHI

1 2 3 4

CN040

(BLU)

1 21 2

1 2

RC

U

2

1

Remote controller

5

43F1

3

RED

GRY

1 2 3 4

WHI

RED

(WHI)

CN041

1 2 3

1 3

1 2

1 2

REDWHI

9 8 7 6

9 8 7 6

HML UL

RY007

(BLU)

BA

CN1

CN02

(WHI)

(BLU)

RC

GRY

FM

4 2

5 4 3 2 1

RY006

RY005

CN050

(WHI)

1 2 3 4 5

1 2

CN01

(WHI)

1 2

3 3

2

1 1

1 2

1 2

X Y

WHI

F1F2F3F

BLU

RY002

Network adaptor

(Option)

MCC-1401

CN03

(RED)

ORN

BLK

(Option)

DP

1 2 3

1 2 3

DP

(BLU)

CN068

RY001

1 2 3

1 2 3

LM

(GRN)

CN033

1 2 3

1 2 3

FS

CN030

(RED)

TA

1 2

1 2

CN104

(YEL)

Indoor control P.C. board

Power

supply

circuit

CN074

(WHI)

1 2 3

1 2 3

1 2 3

4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

1. indicates the terminal block, letter at inside indicates the terminal number.

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

4. When attaching a drain pump, exchange CN030 connector with a connector

of the float switch.

5. A part is connected to the terminal block.

When exchanging to the outside static pressure necessary at the local site,

check the terminal No. and lead color of the fan motor in the below diagram,

4

BRN

and then exchange the lead wire indicated by the arrow mark ( ),

6. Pay attention to change static pressure because the outside static pressure of

H tap in 50 or 60Hz.

Wired for MMD-AP0481 only

(BRN Wire)

Motor over heating protection switch

CN075

(WHI)

BLK

WHI

GRY

RED

1 2 3 4 5 61 2 3 4 5 6

T10

CN02

(YEL)

CN01

(WHI)

TR

CN061

(YEL)

49F

TCJ

1 2

1 2

CN102

(RED)

CN032

(WHI)

1 2

Fan drive

BLU

ORN

BRN

1 2

1 2

CN060

(WHI)

TC1

1 2 3

1 2 3

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

CN082

(BLU)

TC2

CN101

(BLK)

1 2 3 4 5 6

Option

Sold

separately

CN100

(BRN)

1

2

PNL

3

1

EXCT

2

1

Filter

2

1

2

3

4

5

6

6

5

5

4

4

3

3

2

2

1

1

Symbol

FM

RC

TR

TA

TC1,TC2,TCJ

RY005~007

RY001

RY002

PMV

F

43F1

DM

FS

5

5

2

2

1

1

PMV

3

3

4

4

6

6

Parts name

Fan motor

Running capacitor

Transformer

Indoor temp sensor

Temp sensor

Fan motor control relay

Flap motor control relay

Drain control relay

Pulse Motor Valve

Fuse

Fan motor control relay

Drain pump motor

Float switch

2-1-5. Concealed Duct High Static Pressure Type

Model: MMD-AP0181H, AP0241H, AP0271H, AP0361H, AP0481H

Page 19

FM

2-1-6. Under Ceiling Type

Model: MMC-AP0151H, AP0181H, AP0241H, AP0271H, AP0361H, AP0481H

PMV

1

2

3

4

6

4

6

5

1

2

3

5

LM

1 2 3 4 5

1 2 3 4 5

FS

19

Indoor unit

Earth screw

Power supply

single phase

200-240V 50Hz

200V 60Hz

RED

S(N)R(L)

WHI

RED

WHI

Flow selector

unit earth

screw

Closed end

terminal

DM

U2U

1

Outdoor unit

CN68

(BLU)

1

1

2

2

3

3

CN304

1

(GRY)

2

3

1

1

CN67

2

2

(BLK)

3

3

P301

BLK

1

2

BLU

121

BLU

2

BLK

121

BLK

33

U2U

1

WHI BLK BLKWHI

1 2

1 2

Wired remote

controller

RY302

RY303

Fuse

T6.3A

250V~

CN66

(WHI)

CN40

(BLU)

CN41

(BLU)

BA

CN1

(WHI)

5 4 1

5 4 3 2 1

~

~

CN309

(YEL)

1 2 3

BLK

WHI

CN001

(WHI)

1 2

1 2

Adpter for wireless

remote controller

CN334

1 2 3 4 5

(WHI)

1 2 3 4 5

Motor drive

circuit

+

–

CN50

(WHI)

4 5 6

1. indicates the terminal block, letter at inside

2. A dotted line and broken line indicate the wiring at site.

3. indicates the control P.C. board.

CN333

(WHI)

Fuse

TR

3 3

2 2

1 1

CN02

(BLU)

CN61

(YEL)

T10

CN01

(WHI)

T3.15A

Network

adaptor

P.C. board

1 2

1 2

1 2

1 2

Network

adaptor

(Option)

CN03

(RED)

Power

supply

circuit

CN32

(WHI)

X Y

indicates the terminal number.

1 2 3 4 5

1

2

3

CN82

6

(BLU)

4

5

6

Indoor control P.C. board

DC20V

DC15V

DC12V

DC7V

CN60

(WHI)

1 21 2 3 4 5 6

Option GRLFandrive

1 2 3 4 5

1 2 3 4 5

CN81

(BLK)

1 2 3 4 51 2 3 4 51 2 31 2 3

Sold

separately

CN33

(WHI)

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BRW : BROWN

TC,TC2,TCJ

1 3

123

CN20

(BLU)

1 2 3 4 5

Color identification

Symbol

FM

TA

LM

RY302

DM

FS

CN34

(RED)

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRW)

CN80

(GRN)

CN73

(RED)

CN70

(WHI)

Fan motor

Indoor temp sensor

Temp sensor

Louver motor

Drain control relay

Drain pump motor

Float switch

121

2

121

2

121

2

121

2

33

1

PNL

2

3

1

EXCT

2

1

FILTER

2

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

Parts name

TA

TCJ

TC2

TC1

Page 20

2-1-7. High Wall T ype

545

4

FM

Model: MMK-AP0071H, AP0091H, AP0121H, AP0151H, AP0181H, AP0241H

20

RED

WHI

R(L) S(N)

Power supply

single phase

220-240V 50Hz

220V 60Hz

Indoor unit

Earth screw

Flow selector

unit earth

screw

Closed-end

connector

RED

WHI

U1 U2

Outdoor

unit

U1 U2

1

CN68

(BLU)

3

1

LM

CN304

(GRY)

1

3

CN67

(BLK)

P301

BLK

CN66

(WHI)

313

1

3

1

2

A B X Y

WHI BLK

2

112

CN1

(WHI)

Wired remote

controller

CN334

(WHI)

RY302

RY303

FUSE

T6.3A 250V~

CN40

(BLU)

1 231 3

BLU

BLU

BLK

GRY

GRY

WHI BLK

2

112

CN001

(WHI)

Adapter for

wireless remote

controller

BLK

5

CN41

(BLU)

1 21 2

11

1 2 3

1 2 3

CN333

1 2 3 4 5 6

1

223445

1 3

BLK

WHI

(WHI)

CN309

(YEL)

TR

3

1 1

1 3

1 3 5

Motor drive

circuit

CN50

(WHI)

1 2 31 3

CN01(WHI)

3

CN02

2

(BLU)

CN03(RED)

5

4 5

2

112

2

112

1

1 2 3 4 5 6

T3.15A 250V~

Network Adapter

(Option)

MCC-1401

PMV

1 234 56

1 234 56

CN82

(BLU)

FUSE

CN61

(YEL)

1 2 3 4 5

CN33

(WHI)

Power

supply

circuit

CN32

(WHI)

6

1 2

Fandrive

Color

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

TC2

TCJ

113

CN34

(RED)

TA

3

21212121212

CN104

CN102

(YEL)

(RED)

CN101

(BLK)

TC1

1

112 31 2 3 4 5

CN100

(BRW)

Control P.C. board

for Indoor unit

DC20V

DC15V

DC12V

DC7V

CN60

(WHI)

1 2 3 4 5 6

Option

MCC-1402

CN81

(BLK)

1 2 3 4 5

CN20

(BLU)

1 2 3 4 5

1. Indicates the terminal bolock.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate

the wiring at side.

3. indicate the control p.c. board.

Symbol

FM

TA

TC1,TC2,TCJ

PMV

LM

RY303

Parts name

Fan motor

Indoor temp sensor

Temp sensor

Pulse motor valve

Lover motor

Louver control relay

3

CN103

(GRN)

CN080

(GRN)

CN73

(RED)

CN70

(WHI)

1

2

1

2

3

1

2

1

2

EXCT

Page 21

21

Indoor unit

earth screw

220-240V 50Hz

AC IN RED

R(L) S(N)

Power supply

single phase

220V 60Hz

FM

RC

WHI

Flow selector

unit earth

screw

RED

Closed-end

connector

WHI

2

323

4

4

5

5

6

6

P301

(BLK)

313

313

T5.0A 250V~

313

212

CN040

(BLU)

U1

RY004

(GRY)

CN304

(YEL)

CN309

FUSE

CN041

(BLU)

2

1 233 1 2 3 4 5

112

1

BLU

BLU

BLK

U2 A B

1

1

1

CN067

(BLK)

CN066

(WHI)

1

TR

Line Filter

U1 U2

Outdoor unit Remote Controller

112

CN1

RED BLK ORN BLU YEL

FAN

CN083

(WHI)

9 5 3 1

RY007

RC

BLK

2

5 3 1779

M LUL

H

RY006

RY005

CN050

(WHI)

3

3

CN02

2

(BLU)

1 1

2

112

CN01(WHI)

CN03(RED)

2

112

X Y

1

113

DP

3

3

1 3

RY001

Power supply

circuit

1 2 3 4 5 6 1 2 1 23 4 5 6 1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P .C. board

MCC-1520

1 2 3 4 5 6

1 2 3 4 5 6

Network Adapter

(Option)

CN068

(BLU)

RY002

CN074

(WHI)

LM

MCC-1401

1. Indicates the terminal bolock.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate

the wiring at side.

3. indicate the control p.c. board.

(GRN)

1 2 3 4 5 6

1 2 3 4 5 6

CN033

Control P.C. board

for Indoor unit

MCC-1403

CN061

CN075

(YEL)

(WHI)

T10

CN02

(YEL)

CN01

(WHI)

TR

PMV

2-1-8. Floor Standing Cabinet Type

Model: MML-AP0071H, AP0091H, AP0121H, AP0151H, AP0181H, AP0241H

1 234 56

1 234 56

PMV

CN082

(BLU)

CN032

(WHI)

112 3

CN060

(WHI)

FS

3

CN030

(RED)

CN104

(YEL)

CN102

(RED)

CN101

(BLK)

CN100

(BRN)

CN080

(GRN)

CN073

(RED)

CN070

(WHI)

CN081

(BLK)

212

212

1

2

212

1

2

3

1

2

1

2

1

2

3

4

5

1

1

1

2

1

PNL

EXCT

FILTER

TA

TCJ

TC2

TC1

Color

indication

RED : RED

WHI : WHITE

FAN

DRIVE

OPTION

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

Symbol

FM

RC

TR

TA

TC1,TC2,TCJ

RY001

RY002

RY004

RY005~007

PMV

Parts name

Fan motor

Running capacitor

Transformer

Indoor temp sensor

Temp sensor

Louver control relay

Drain control relay

Heater control relay

Fan motor control relay

Pulse motor valve

Page 22

22

Indoor unit

earth screw

RED

WHI

RED

R(L) S(N)

Power supply

single phase

220-240V 50Hz

220V 60Hz

Flow selector

unit earth

screw

Closed-end

connector

WHI

WHI

1

GRN

1

3

3

2

2

4

4

FM

5

5

6

6

RED

RED BLK ORN BLU YEL

FAN

CN083

(WHI)

9 5 3 1

RC

5 3 1779

For AP0071BH,AP0091BH,AP0121BH

2

112

Network

adapter

3

CN02

2

(BLU)

2

112

CN01(WHI)

CN03(RED)

MCC-1401

(Option)

1 1

2 2

CN03

(RED)

TR

U1 U2

U1 U2

Outdoor unit

A B X Y

2

112

CN1

Remote Controller

3

1 1

1. Indicates the terminal bolock.

Letter at inside indicates the terminal number.

2. A dotted line and broken line indicate

the wiring at side.

3. indicate the control p.c. board.

GRN

R301

(BLK)

AC IN

1

1

EMG

FM

RED

WHI

1

3

313

T5.0A 250V~

313

1

CN066

(WHI)

2

1

CN044

(BRW)

2

(GRY)

CN304

(YEL)

CN309

FUSE

(BLK)

CN067

RC

RY004

CN040

(BLU)

112

2

2

424

5

5

6

6

3

3

RED BLK ORN BLU YEL

FAN

CN083

(WHI)

CN041

(BLU)

1 233 1 2 3 4 5

1

5 3 1779

9 5 3 1

M LUL

H

RY007

RY006

indication

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

GRN : GREEN

RY005

CN050

(WHI)

Color

CN068

(BLU)

RY002

CN074

(WHI)

133

1

113

3

3

CN033

(GRN)

113

RY001

Control P.C. board

for undoor unit

Power supply

circuit

CN075

MCC-1520

(WHI)

CN02

(YEL)

CN01

(WHI)

TR

1 2 3 4 5 6 1 2 1 23 4 5 6 1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Sub P.C. boar d

1 2 3 4 5 6

1 2 3 4 5 6

MCC-1403

CN061

(YEL)

112 3

CN030

(RED)

Symbol

FM

RC

TR

TA

TC1,TC2,TCJ

RY001

RY002

RY004

RY005~007

PMV

Fan motor

Running capacitor

Transformer

Indoor temp sensor

Temp sensor

Louver control relay

Drain control relay

Heater control reley

Fan motor control relay

Pulse motor valve

3

CN032

(WHI)

FAN

DRIVE

PMV

1 234 56

1 234 56

1 2 3 4 5 6

1 2 3 4 5 6

CN082

CN104

(BLU)

CN102

(RED)

CN101

CN100

(BRW)

CN080

(GRN)

CN073

(RED)

CN070

CN081

CN060

(WHI)

OPTION

Parts name

(YEL)

(BLK)

(WHI)

(BLK)

PMV

212

212

1

2

131

2

1

2

3

1

2

1

2

1

2

3

4

5

1

1

1

2

3

PNL

EXCT

FILTER

TCJ

TC2

2-1-9. Floor Standing Concealed Type

Model: MML-AP0071BH, AP0091BH, AP0121BH, AP0151BH, AP0181BH, AP0241BH

TA

TC1

Page 23

23

Indoor unit

earth screw

RED

WHI

R(L) S(N)

Power supply

single phase

220-240V 50Hz

220V 60Hz

FM

Flow selector

unit earth

screw

Closed-end

connector

1

RC

313

4

4

5

5

6

6

787

BRW

P301

(BLK)

1

(GRY)

3

CN304

1

(YEL)

313

CN309

AC IN

1

T5.0A 250V~

313

(BLK)

CN067

CN066

(WHI)

1

2

CN044

(BRW)

1

CN040

2

(BLU)

EMG

112

BLU

TR

112

Line Filter

U1

U1 U2

Outdoor unit Remote Controller

CN083

RY004

FUSE

CN041

(BLU)

2

1 233 1 2 3 4 5

1

BLU

BLK

2

U2 A B

2

112

CN1

RED BLK ORN BLU YEL

FAN

(WHI)

9 5 3 1

RY007

RC

BLK

3

1 1

LM

1

221

5 3 1779

M LUL

H

RY006

RY005

CN050

(WHI)

CN01(WHI)

3

CN02

2

(BLU)

CN03(RED)

Network Adapter

2

112

2

112

MCC-1401

X Y

(Option)

CN068

(BLU)

RY002

CN074

(WHI)