Page 1

TECHNICAL TRAINING

PROGRAM

- PRE-STUDY MANUAL -

e-STUDIO900/1050

Toshiba America Business Solutions

Page 2

A

f

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that's in the best interest of Toshiba

Corporation and its member companies.

ll product names, domain names or product illustrations, including desktop images, used in this

document are trademarks, registered trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion only and for the benefit o

such companies. No such use, or the use of any trade name, or web site is intended to convey

endorsement or other affiliation with Toshiba products.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF TOSHIBA CORPORATION.

2003 TABS Corporation. All rights reserved.

Page 3

s

y

y

y

p

WARNING

The Pre-Training Manual contains information

regarding service techniques, procedures, processe

and spare parts of office equipment distributed b

Toshiba Corporation. Users of this manual should be

either service trained or certified by successfull

completing a Toshiba Technical Training Program.

Untrained and uncertified users utilizing information

contained in this pre-training manual to repair or modif

Toshiba equipment risk personal injury, damage to

roperty or loss of warranty protection.

Toshiba Corporation

Page 4

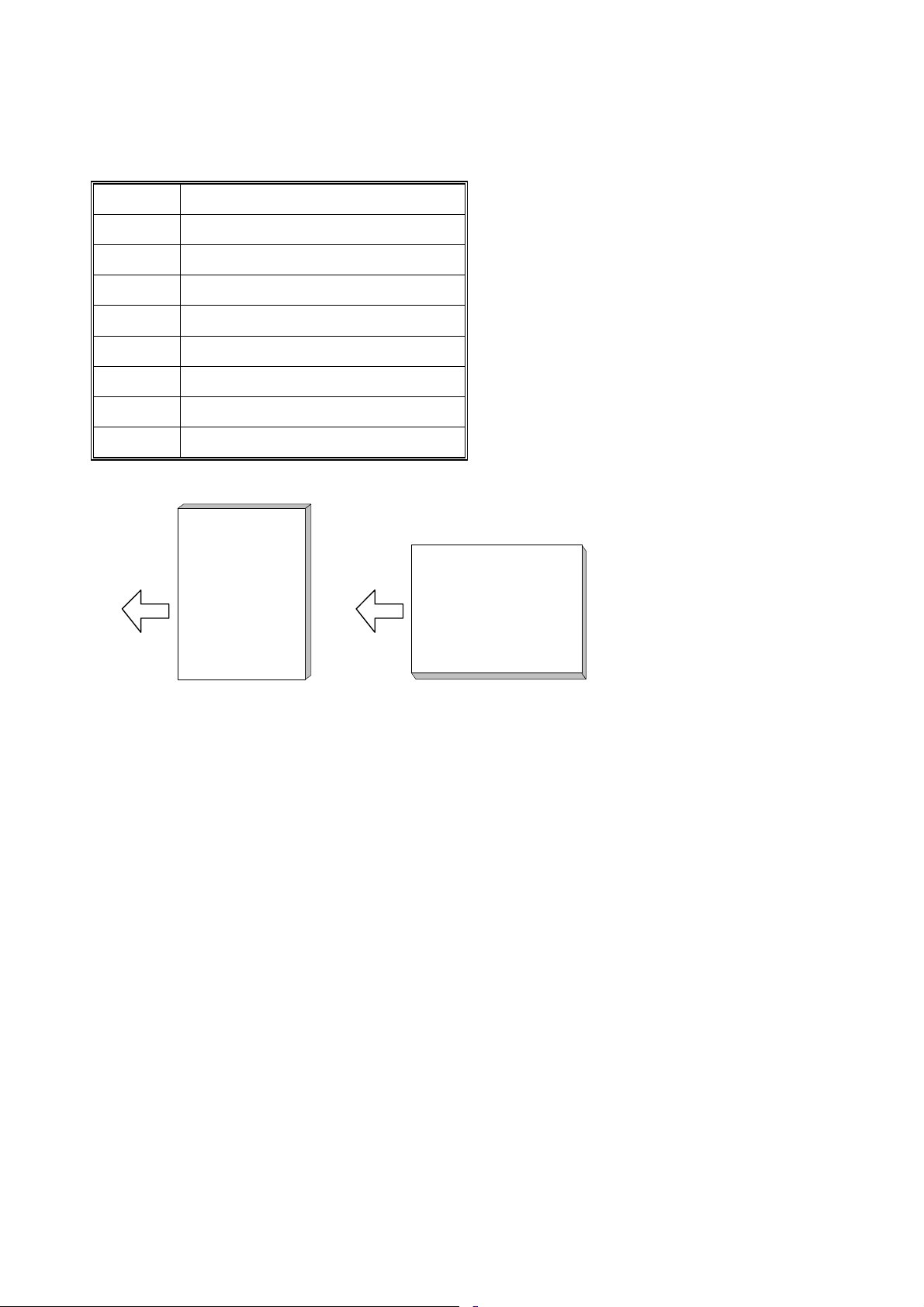

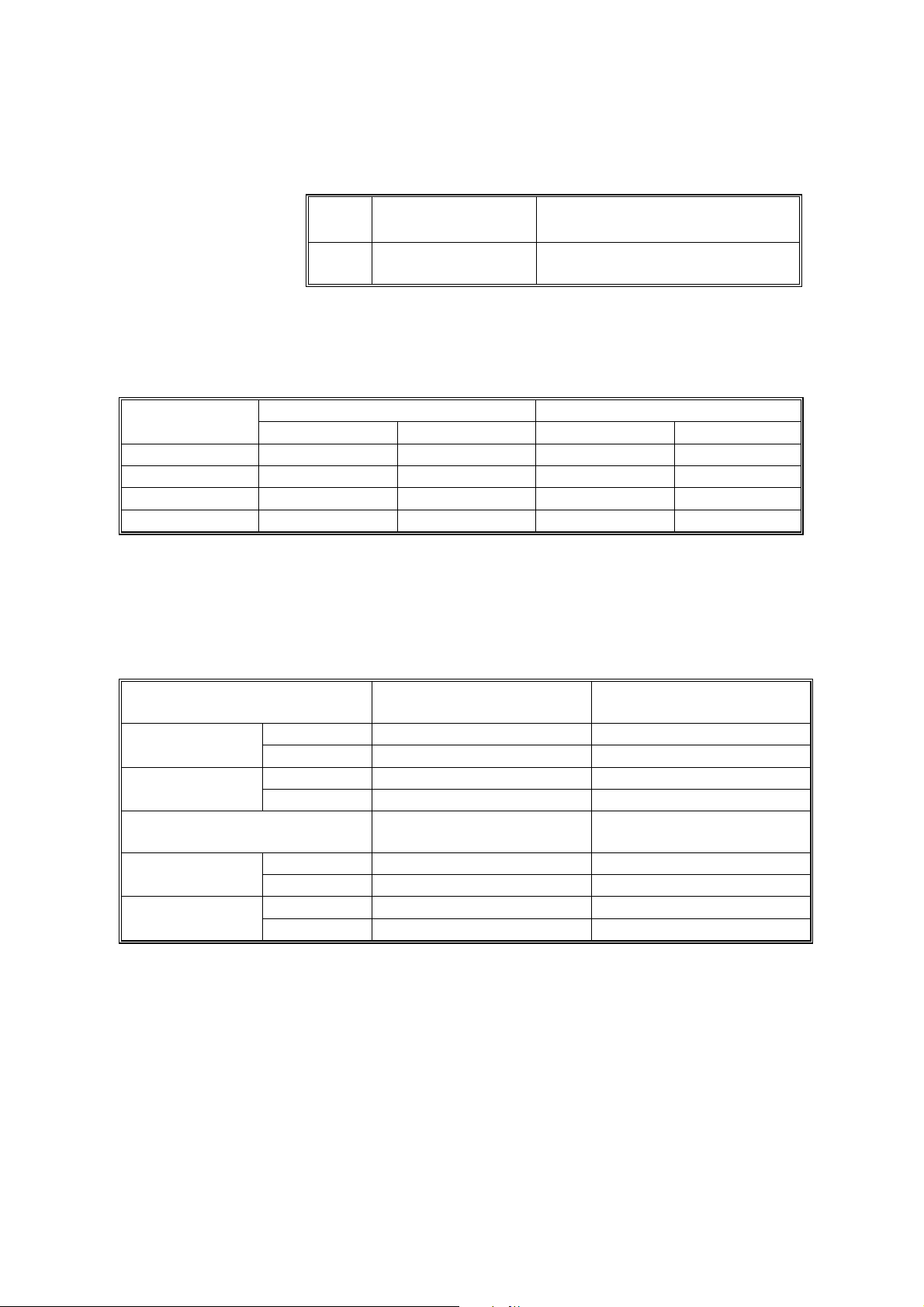

LEGEND

PRODUCT CODE COMPANY

Toshiba

B070

B071

900

1050

LCT B511

Finisher B478

Cover Int. B470

Bypass Tray B512

MJ-1026(SR840 3,000-SHEET FINISHER)

MJ-7002(Cover Interposer Tray Type 1075)

MP-4501L(RT46 Large Capacity Tray)

MY-1024(Multi Bypass Tray Type 2105)

Page 5

INTRODUCTION

The Pre-Training Manual for the 900/1050 has been designed to give the Service

Technician an overview of these products prior to attending the training program. This

manual starts with the basic fundamentals utilized in the machine and reviews the entire

copy process and accessories.

It is the aim of the Service Education and Development Division to give the Service

Technician as much hands-on experience as possible while attending training. In order to

accomplish this, a relatively small amount of time will be spent on the basic fundamentals

in class. For these reasons a thorough understanding of this document is necessary.

At the end of this Pre-Training Manual it is necessary to complete a Pre-Training Test

found on the Toshiba FYI Website.

This test is provided to ensure that the Service Technician has an understanding

of the electronics, the copy process and the machine operations. When this pre training

been completed and passed the technician is approved for the 5-day classroom course.

Should you have any questions, please contact the Service Training

Division.

.

Page 6

Page 7

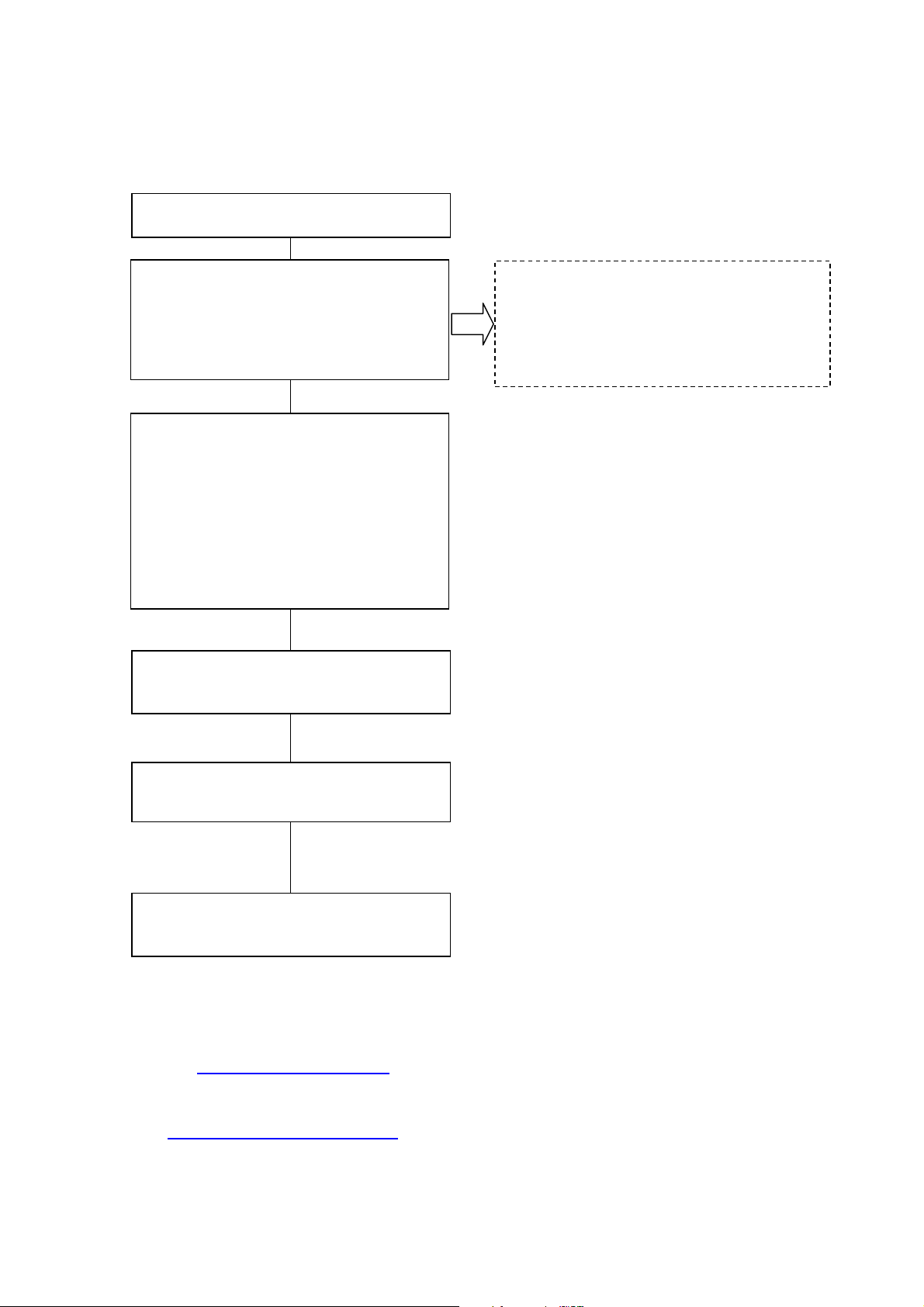

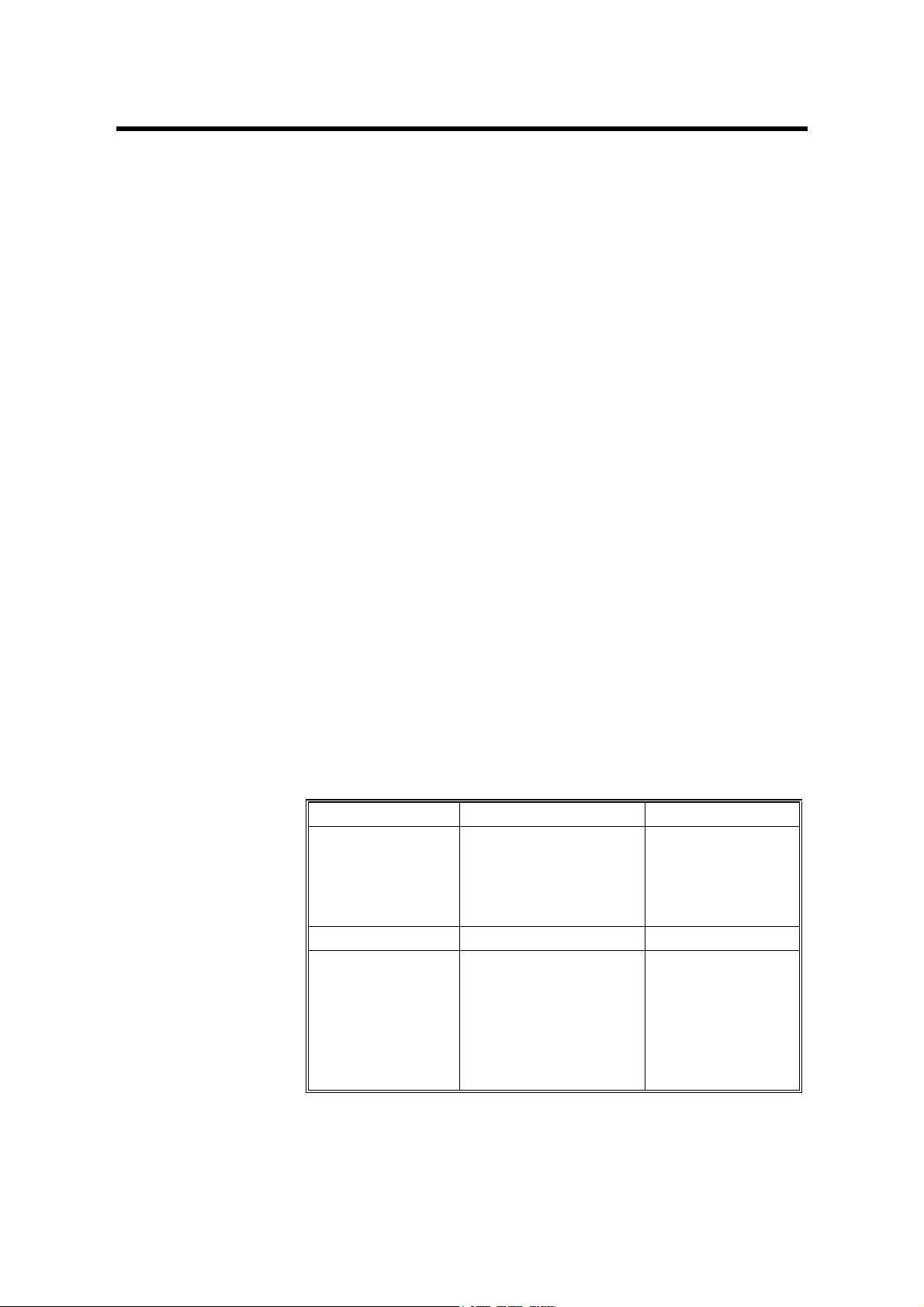

FLOWCHART FOR PRE-TRAINING MANUAL

Technician is scheduled for school.

Service Manager gives Technician

Pre-Training Manual. (download)

Technician completes pre-training.

Once completing the training, the

student completes the on-line exam.

After the exam is passed the student

receives immediate results.

Service manager receives results.

The Service Manager enrolls technican

for the class and pre-requisite exam.

This is done on-line at the FYI website.

The technician reviews the pre training

material.

Student reviews the material and

does further preparation.

Student attends instructor led 5-day

training program.

Page 8

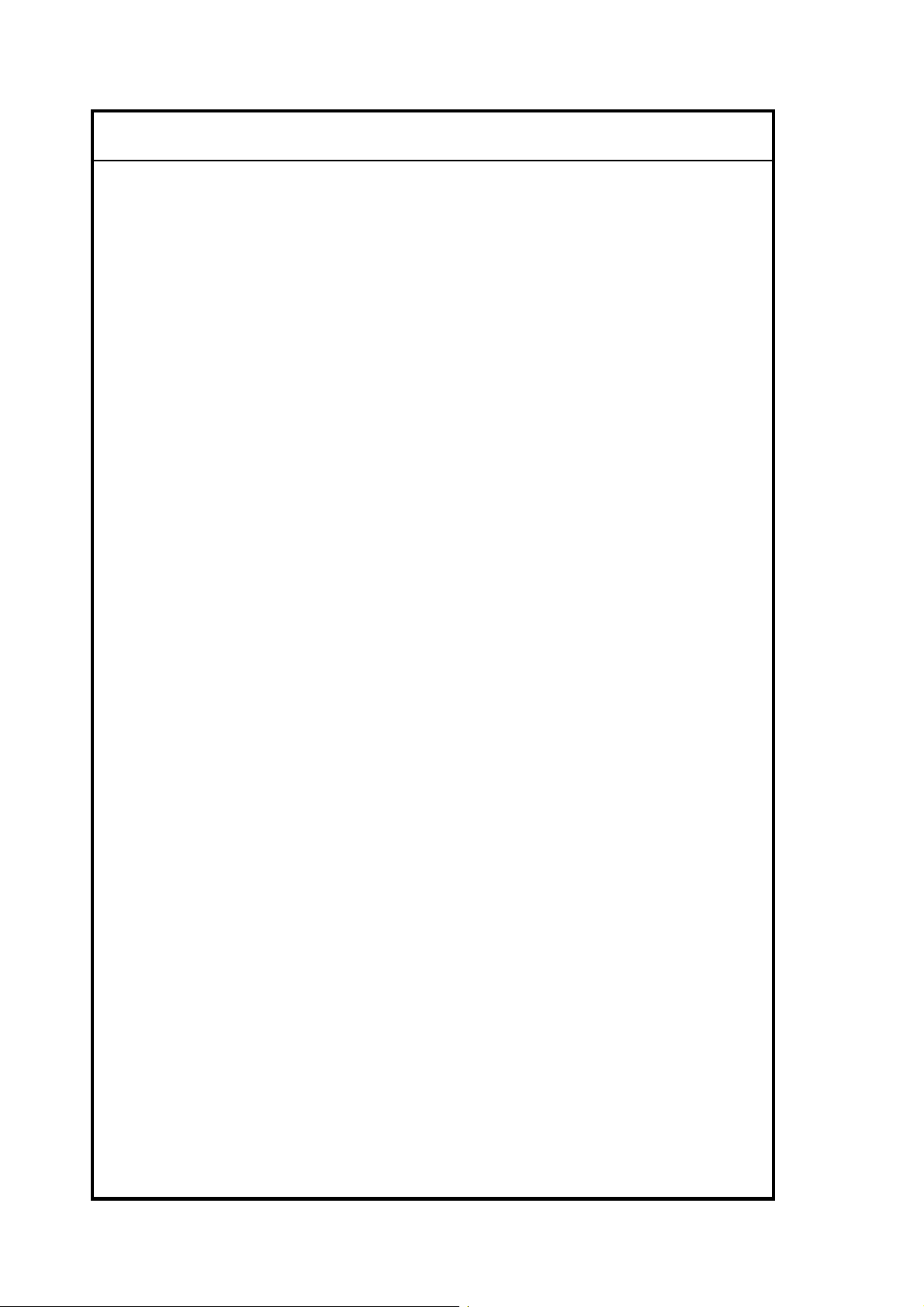

CONTENTS

SECTION 1

OVERALL INFORMATION

SECTION 2

DETAILED DESCRIPTIONS

SECTION 3

SERVICE TABLES

SECTION 4

INSTALLATION

SECTION 5

LARGE CAPACITY TRAY

SECTION 6

SR860 BOOKLET FINISHER

with PUNCH UNIT

SECTION 7

SR840 3,000-SHEET FINISHER

with PUNCH UNIT

SECTION 8

COVER INTERPOSER TRAY TYPE 1075

SECTION 9

MULTI BYPASS TRAY TYPE 2105

Page 9

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with cold water as first aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the controller board has a lithium battery which can explode

if replaced incorrectly. Replace the NVRAM only with an identical type.

However, the manufacturer recommends replacing the entire NVRAM, not

just the battery. Never recharge or incinerate a used NVRAM battery.

Dispose of a used NVRAM or NVRAM battery in accordance with local

regulations.

3. The danger of explosion exists if the battery on the controller board is

incorrectly replaced. Replace the battery only with the equivalent type

recommended by the manufacturer. Discard the used controller board

battery in accordance with the manufacturer’s instructions and local

regulations.

Page 10

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laserbased optical units in the field. The optical housing unit can only be repaired in a factory or

at a location with the requisite equipment. The laser subsystem is replaceable in the field

by a qualified Customer Engineer. The laser chassis is not repairable in the field.

Customer engineers are therefore directed to return all chassis and laser subsystems to

the factory or service depot when replacement of the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 11

CONVENTIONS IN THIS MANUAL

This manual uses several symbols.

Symbol What it means

Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

Clip ring

NA North America

EUR/A Europe/Asia

LEF (Long Edge Feed) SEF (Short Edge Feed)

LEFSEF.WMF

Page 12

SECTION 1

OVERALL INFORMATION

Page 13

Page 14

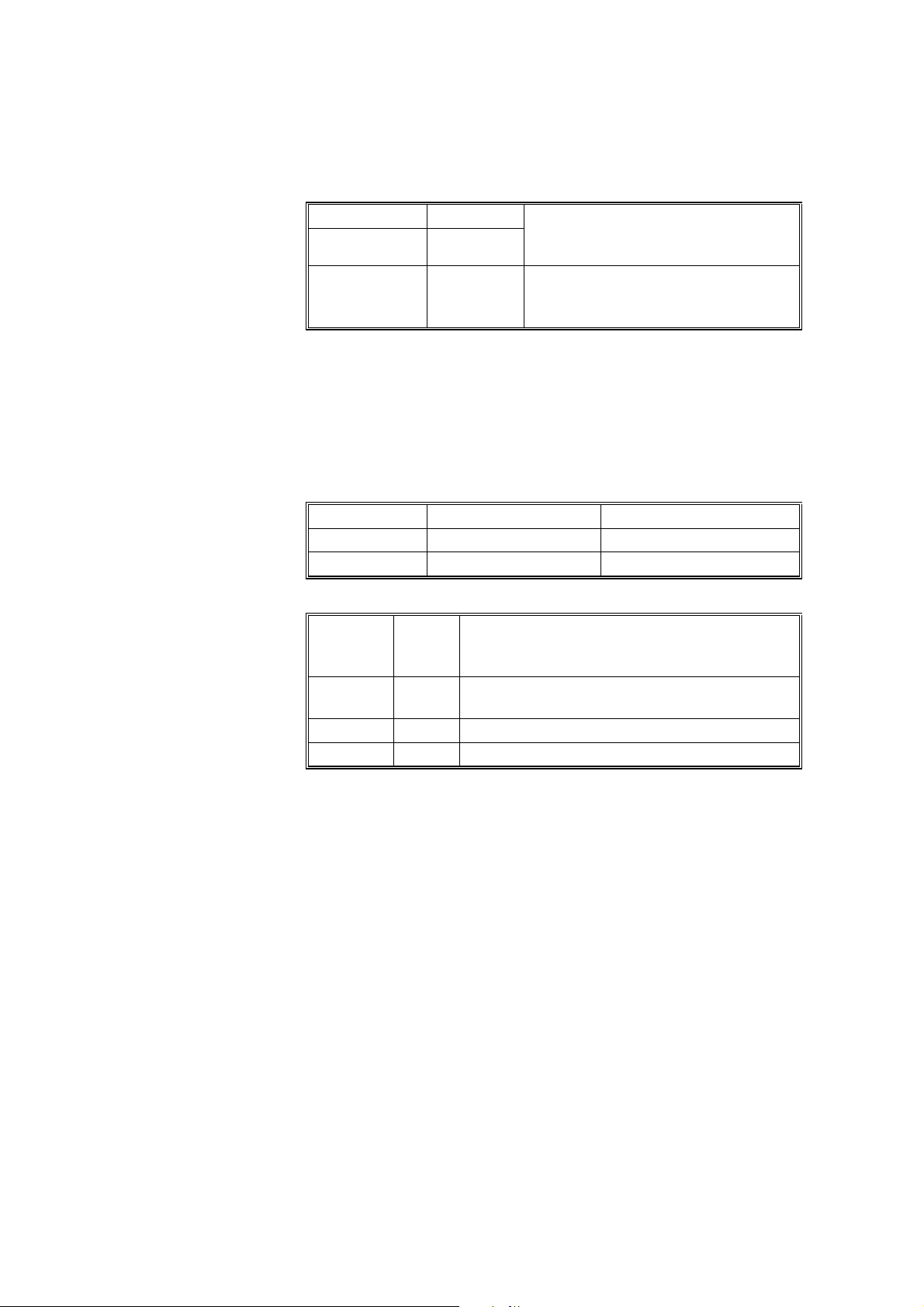

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 COPIER ENGINE

Configuration: Console

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book/Object

Max.: A3/11" x 17" Original Size:

Min.: A5, 51/2" x 81/2" (with ADF)

Original Alignment: Rear left corner (for platen mode, ADF mode)

Paper Weight: Tray 1~3:

Tray 6 (LCT):

Tray 4~5 (LCT):

Tray 7 (Bypass):

Duplex Tray

(Possible

Weight):

Paper Size: Tray 1 (Tandem): 81/2" x 11" LEF, A4 LEF

Tray 2, Tray 3:

Duplex Tray

(Possible Sizes):

Reproduction Ratios: 7 reduction and 5 enlargement

Enlargement 400%

Full Size

Reduction

52 to 163 g/m2

Bond: 16 to 40 lb.

Cover: 50 to 60 lb.

Index: 90 lb.

52 to 216 g/m2

Bond: 16 to 40 lb.

Cover: 50 to 60 lb.

Index: 90 to 110 lb.

64 to 163 g/m2

Bond: 20 to 40 lb.

Cover: 50 to 60 lb.

Index: 90 lb.

51/2" x 81/2" to 11" x 17", 12" x 18"

A5 to A3

A5 to A3, 51/2" x 81/2" to 11" x 17",

12" x 18"

Metric Version Inch Version

400%

200%

141%

122%

115%

100% 100%

93%

82%

75%

71%

65%

50%

25%

200%

155%

129%

121%

93%

85%

78%

73%

65%

50%

25%

PTM 1-1 B070/B071

Page 15

Zoom:

25 ~ 400% (allows manual adjustment in 1% steps

vertically, horizontally)

Copy Speed:

900/1050 75 ppm

900 90 ppm

1050 105 ppm

Copying with image stored in

memory with A4/LT LEF feeding

from the same tray.

When using ADF 1-to-1 with

A4/LT LEF magnification feeding

from the same tray.

Resolution Scanning 600 dpi

Printing 1200 dpi

Gradation: 256 levels Scanning (8 bits/pixel)

Printing (1 bit/pixel, 9

values):

Warm-up Time:

Less than 360 s from Off mode at 23°C (73.4°F)

First Copy Time Copy Tray 1, A4/81/2" x 11" LEF

Face-up Less than 3.5 s Less than 3.2 s

Face-down Less than 5.0 s Less than 4.2 s

900 (90 cpm) 1050 (105 cpm)

Copy Number Input: 1 to 9999

Copy Paper Capacity

(Sheets):

Copier 3,000

LCT 4,550

Bypass 500

Total 8,050

Tray 1: (Tandem) 1000 x 2

Tray 2: 500

Tray 3: 500

Tray 4: 1,000 , Tray 5: 1,000, Tray 6:

2,550

Tray 7, 500 (Optional Bypass Tray B512)

Memory Capacity: RAM; 256 MB (128 x 2) Standard

256 MB (Optional, Required for Scanner/Printer

Option)

HDD; 80 GB (40 GB x2), approximately 1,735 copies

Toner Replenishment: Cartridge exchange (1,450 g/cartridge)

Toner Yield:

55 K copies, (A4 LEF, 6% chart, B070 (90 cpm) 1 to 25

Repeat Copying), (B071 (105 cpm), 1 to 50 Repeat

Copying)

Power Source: North America; 208 to 240 V, 60 Hz, 20 A

Europe/Asia; 220 to 240 V, 50/60 Hz, 16 A

Dimensions

(W x D x H)

Full System;

Copier;

870 x 858.5 x 1476 mm

32.3" x 33.8" x 58.1"

2218 x 8585 x 1476 mm

87.3" x 33.8" x 58.1"

Weight: Less than 275 kg (605 lb.) including ADF, and no options

B070/B071 1-2 PTM

Page 16

Space Requirements:

Copier (w x d) 1202 x 858.5 mm (47.3" x 33.8")

Full System

(w x d)

Full System: Mainframe + ADF + Finisher B478 + LCT B511 + Cover Interposer Tray B470

*1

Max.

Min.

+ Bypass Tray B512

2528 x 858.5 mm

"

99

x 33.7"

2804 x 858.5 mm

"

110.4

x 33.7"

Finisher + Bypass with bypass

tray extended for A3 SEF

Finisher + Bypass with bypass

tray extended for A4 LEF.

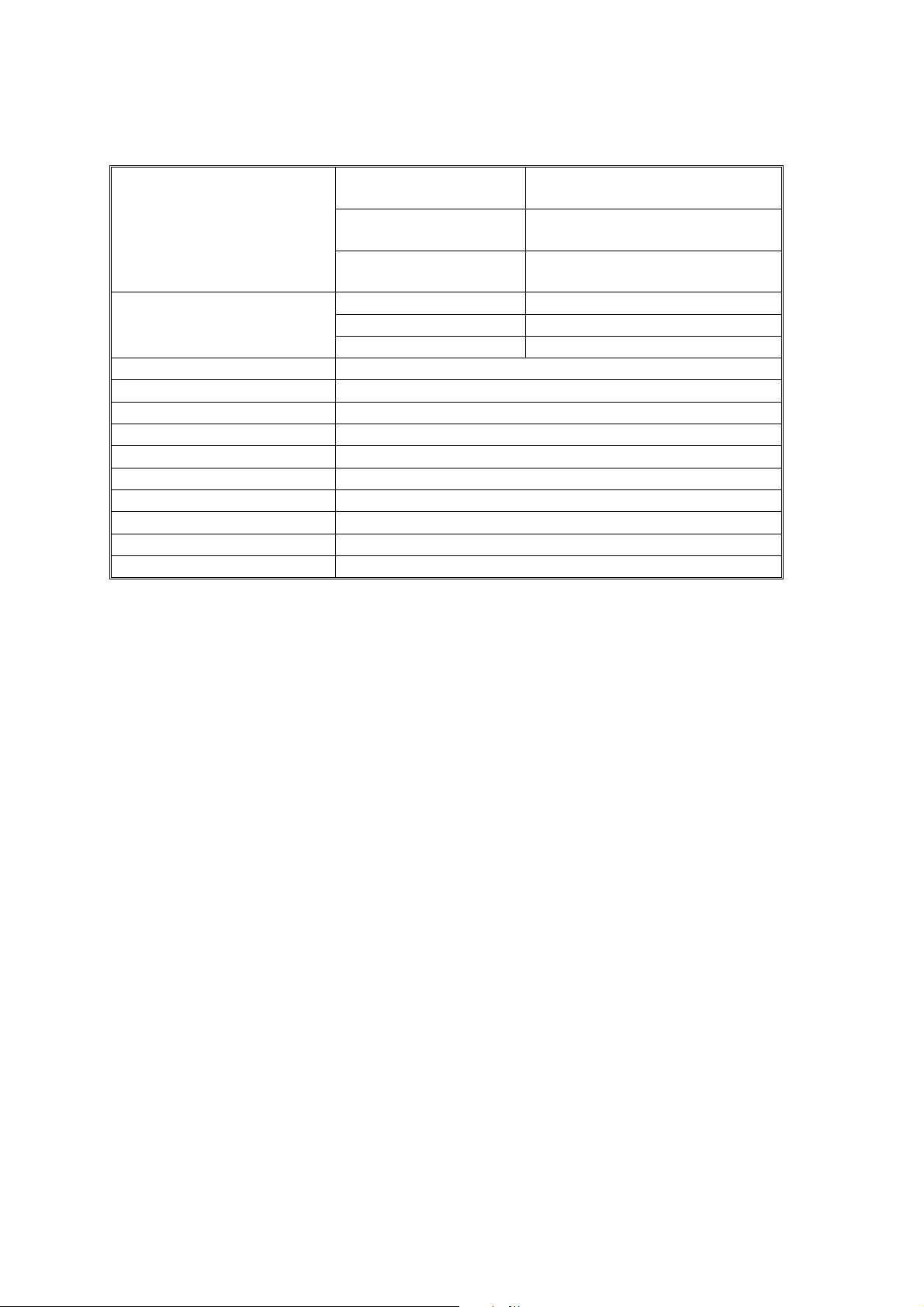

Power Consumption: North America Version

Mainframe Only Full System*

(Unit: W)

900 1050 900 1050

Warm-up 2.20 K 2.20 K 2.30 K 2.30 K

Stand-by 0.65 K 0.65 K 0.70 K 0.70 K

Copying 2.70 K 2.80 K 2.80 K 2.90 K

Maximum 2.80 K 2.90 K 2.90 K 3.00 K

*Full System: Mainframe + ADF + LCT + Bypass Tray + Cover Interposer + Finisher1

1

Finisher: B478 + Punch Unit with B071 (105 cpm), B468 + Punch Unit with B070

(90 cpm)

Noise Emission

900 (90 cpm)

Mainframe

Full System

1050 (105 cpm)

Mainframe

Full System

Sound Power

Level db (A)

Stand-by 60 45

Copying 74 60

Stand-by 59 46

Copying 78 68

Sound Power

Level dB (A)

Stand-by 60 45

Copying 76 61

Stand-by 59 46

Copying 79 68

Sound Pressure

Level dB (A)

Sound Pressure

Level dB (A)

PTM 1-3 B070/B071

Page 17

1.1.2 ADF

Original Size:

Original Weight:

Normal Original Mode: A3 to B5, 11" x 17" to 51/2" x

Thin Original Mode A3 to B5, 11" x 17" to 51/2" x

Duplex Original Mode: A3 to B5, 11

"

8

1/2

"

8

1/2

"

8

1/2

"

Normal Original Mode: 52~128 g/m2 (Note 1)

Thin Original Mode 40~128 g/m2 (Note 1)

Duplex Original Mode: 52~105 g/m

2

Table Capacity: 100 sheets (80 g/m2, 20 lb)

Original Feeding Speed: 75 cpm (A4/81/2" x 11" LEF, 1 to 1)

Original Standard Position: Rear left corner (Face-up)

Separation: FRR

Original Transport: One flat belt

Original Feed Order: From the top original

Power Source: DC 24 V and DC 38 V from the copier

Power Consumption: Less than 130 W

Dimensions (W x D x H): 680 x 560 x 150 mm (26.8" x 22" x 5.9")

Weight Less than 17.5 kg (38.5 lb.)

Note 1:156 g/m

Note 2:128 g/m

2

possible, but not guaranteed.

2

possible, but not guaranteed.

x 17" to 51/2" x

(Note 2)

B070/B071 1-4 PTM

Page 18

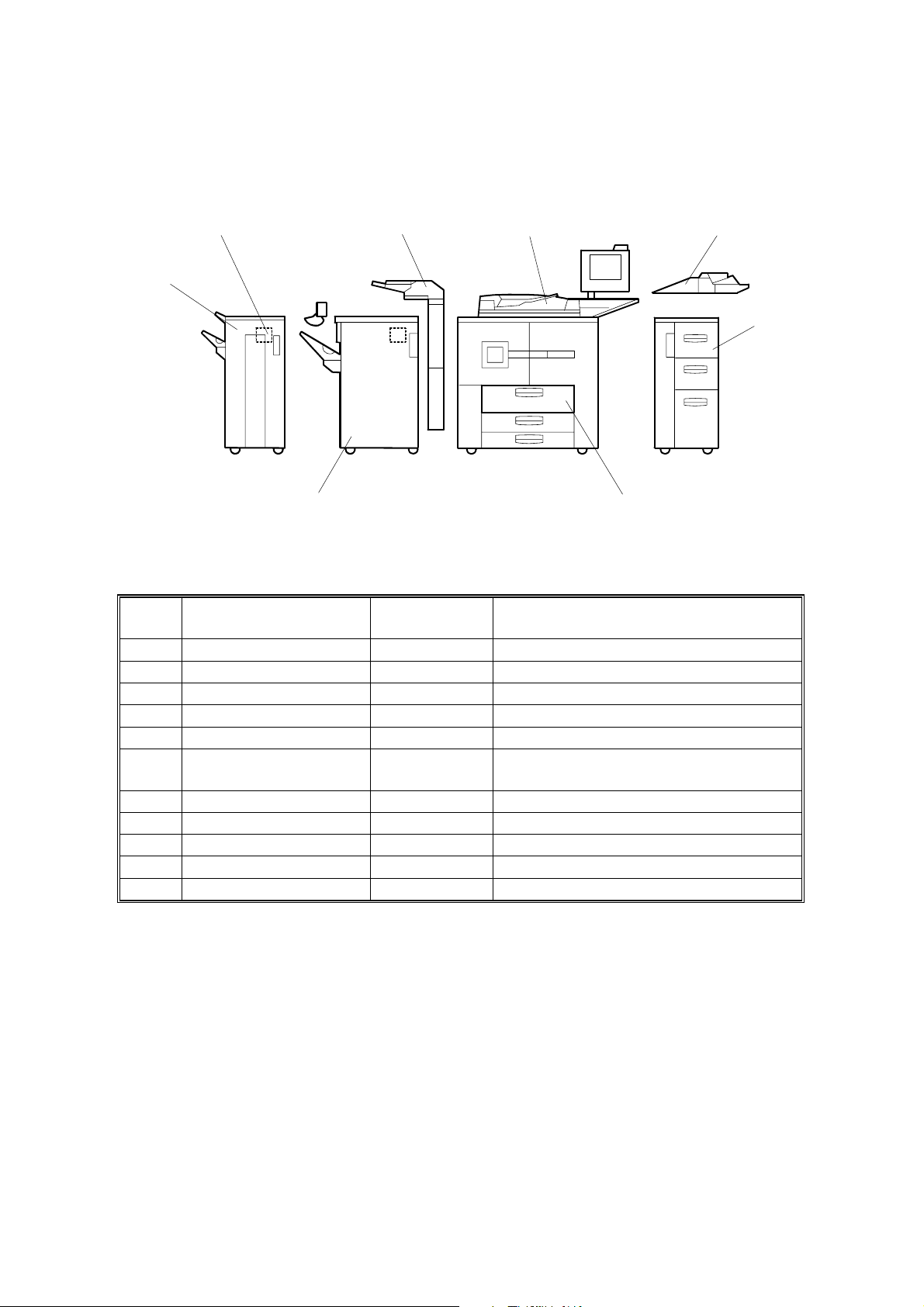

1.2 MACHINE CONFIGURATION

7

6

10

1

2

3

5

4

B070I413.WMF

No. Item

1 Mainframe eStudio900/1050 900 (90 cpm), 1050 (105 cpm).

2 Bypass Tray MY1024

3 LCT MP4501

4 A3/DLT Tray Kit*1 KF9000 Replace Tray 1 (tandem tray) inside.

5 3000 Sheet Finisher MJ1026

3000 Sheet Booklet

6

Finisher

7 Punch Unit N/A

8 Output Jogger Unit KK9000 Attached to Finisher

9 Cover Interposer Tray MJ7002 Attached to Finisher.

10 Punch Unit MJ6006 Inside Finisher

Copier Connection Kit GE1130 Not shown.

*1

: Replaces Tandem Tray in main unit.

Machine

Code

N/A

Comments

PTM 1-5 B070/B071

Page 19

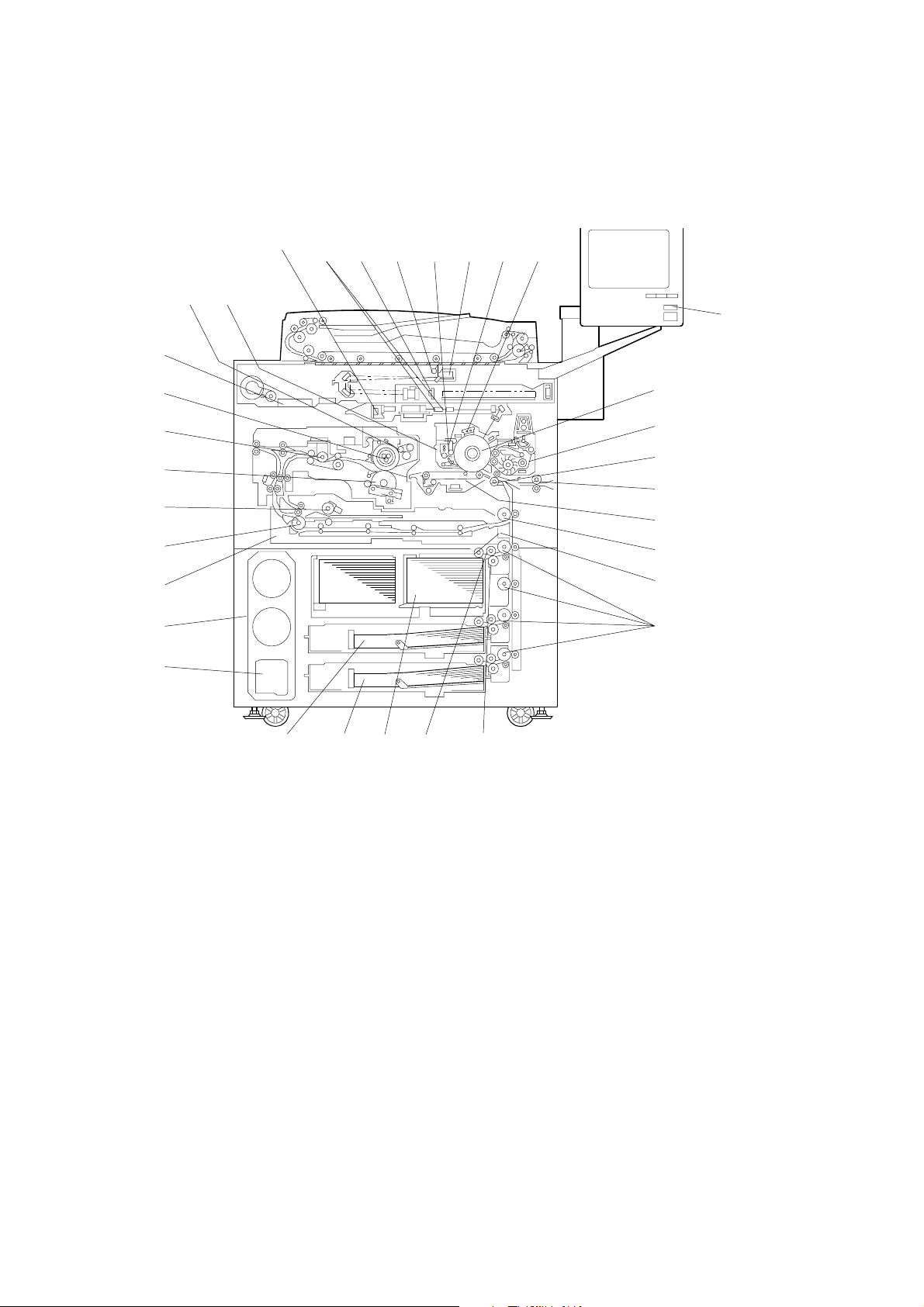

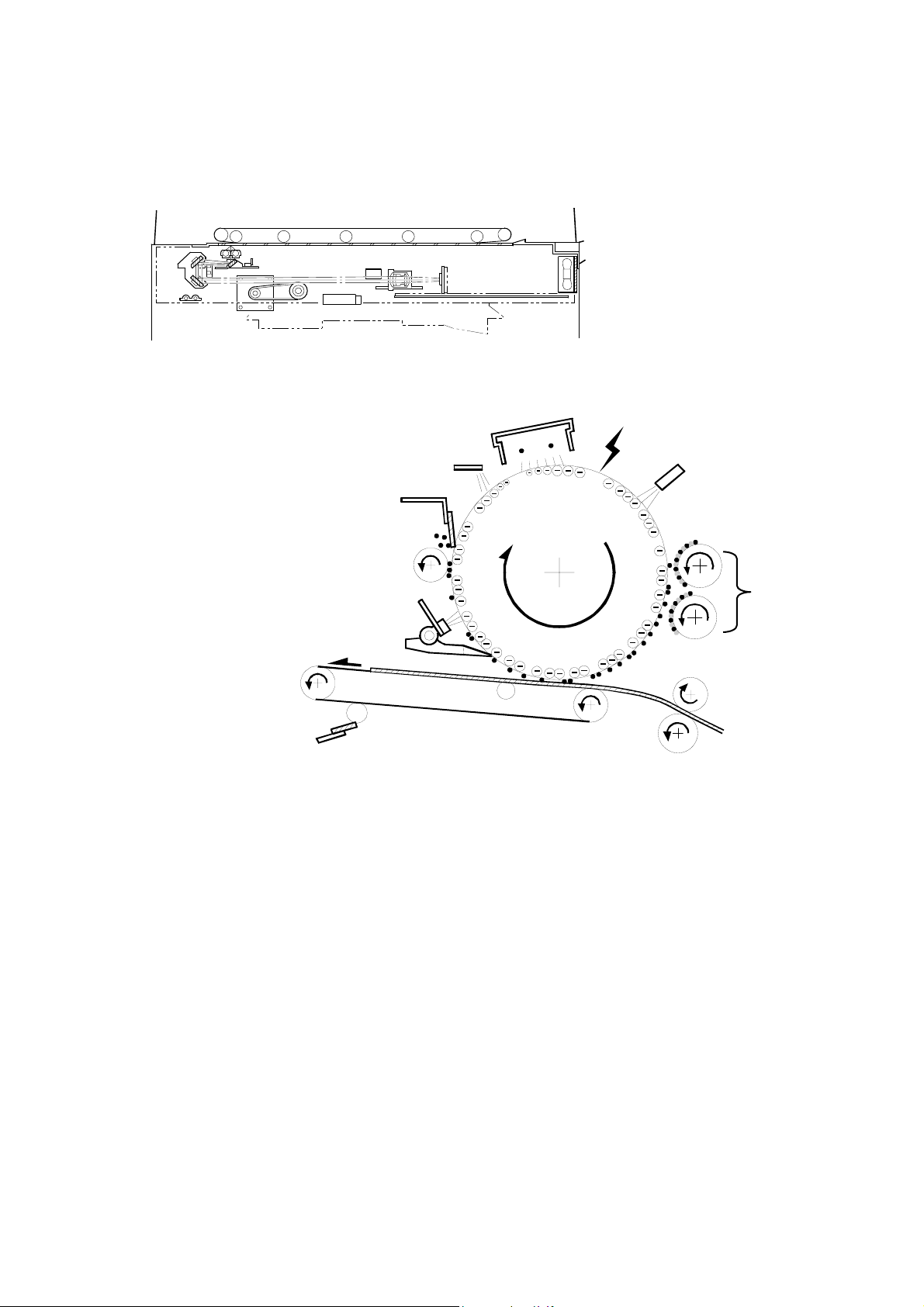

1.3 COMPONENT LAYOUT

1.3.1 COPIER ENGINE

31

30

29

28

27

26

25

24

23

6 753 41 2

8

33 32

9

10

11

12

13

14

15

16

17

22 21 20 19 18

1. Laser Diode Board

2. fθ Lenses

3. Sensor Board Unit

4. Exposure Lamp

5. Cleaning Brush

6. Lamp Regulator

7. Cleaning Blade

8. Charge Corona Unit

9. Color LCD

10. Drum

11. Development Unit

12. Registration Roller

13. LCT Relay Roller

14. Transfer Belt Unit

15. Relay Roller

16. Pick-up Roller

17. Vertical Transport Rollers

B070D870.WMF

18. Separation Roller

19. Feed Roller

20. 1st Tray (Tandem, 1,000 sheets each)

21. 3rd Tray (500 sheets)

22. 2nd Tray (500 sheets)

23. Used Toner Bottle

24. Toner Bank Unit

25. Duplex Tray

26. Inverter Unit Paper Exit Roller

27. Inverter Feed Roller

28. Pressure Roller

29. Paper Cooling Pipe

30. Hot Roller

31. Motor Control Unit

32. Oil Supply & Cleaning Web

33. Drum Unit

B070/B071 1-6 PTM

Page 20

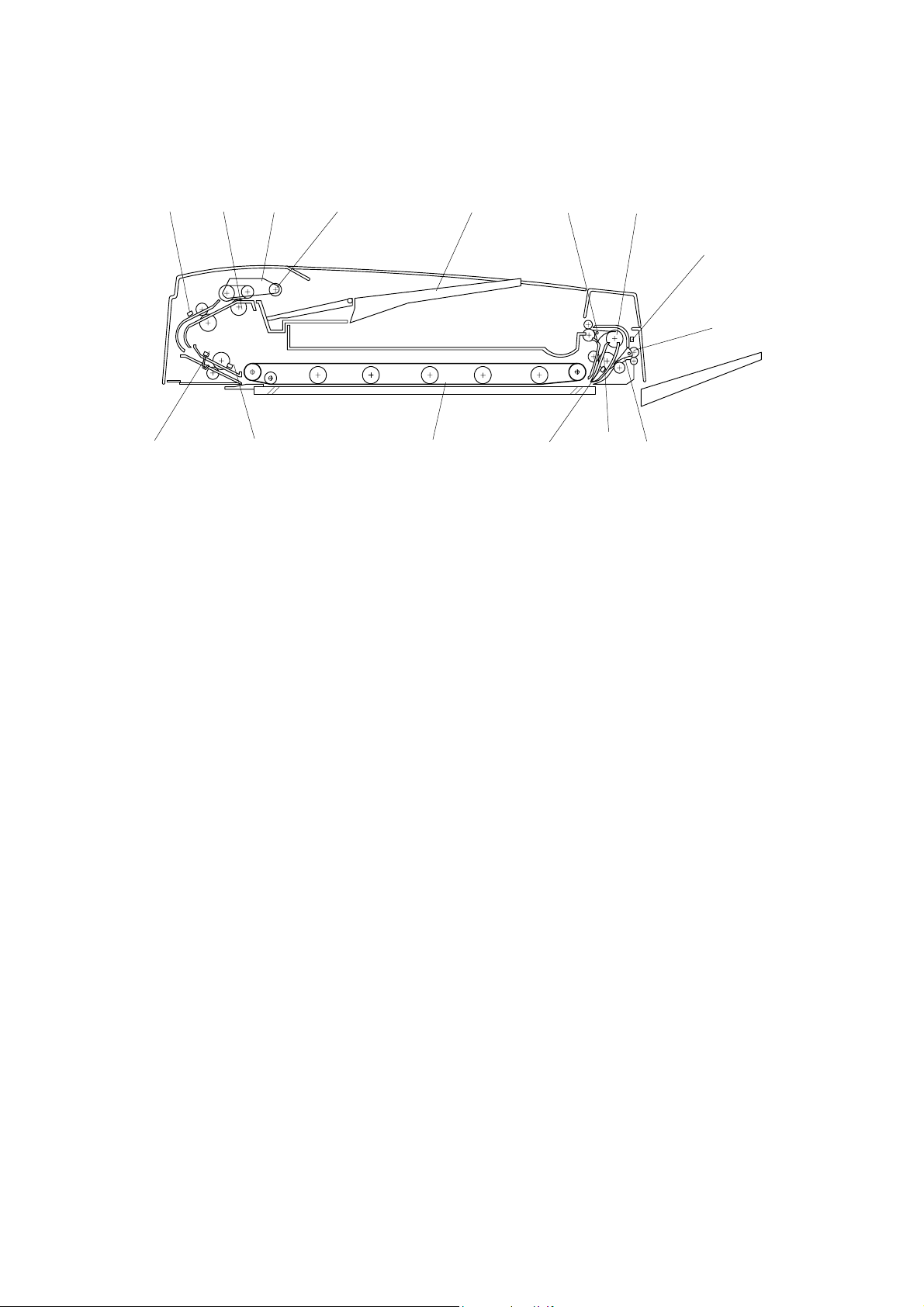

1.3.2 ADF

Overview

1 2

3

4

5

6

15

14

13

12

11

1. Entrance Sensor 9. Feed-out Roller

2. Separation Roller 10. Exit Junction Gate

3. Feed Belt 11. Inverter Roller

4. Pick-up Roller 12. Exit Sensor

5. Original Tray 13. Transport Belt

7

8

9

B070D869.WMF

10

6. Inverter Junction Gate 14. Registration Sensor

7. Inverter Guide Roller 15. Width Sensors (x3)

8. Inverter Sensor

PTM 1-7 B070/B071

Page 21

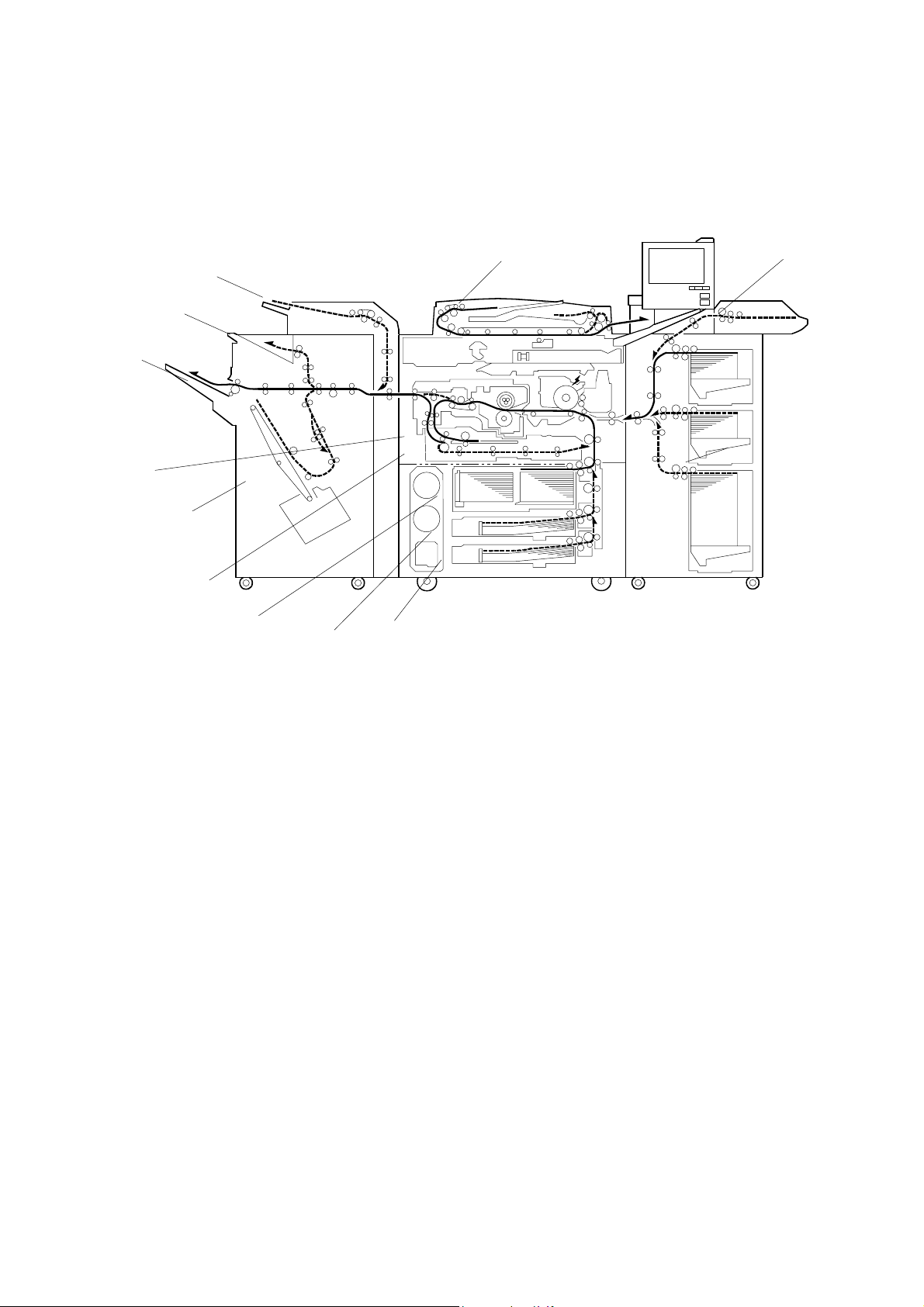

1.4 PAPER PATH

10

9

11

8

12

7

6

5

1

2

3

4

B070D871.WMF

1. ADF

2. Bypass Tray

3. Optional LCT

4. Tray 3

5. Tray 2

6. Tray 1

7. Duplex Unit

8. Optional Finisher

9. Inverter Unit

10. Shift Tray

11. Upper Tray

12. Cover Interposer

B070/B071 1-8 PTM

Page 22

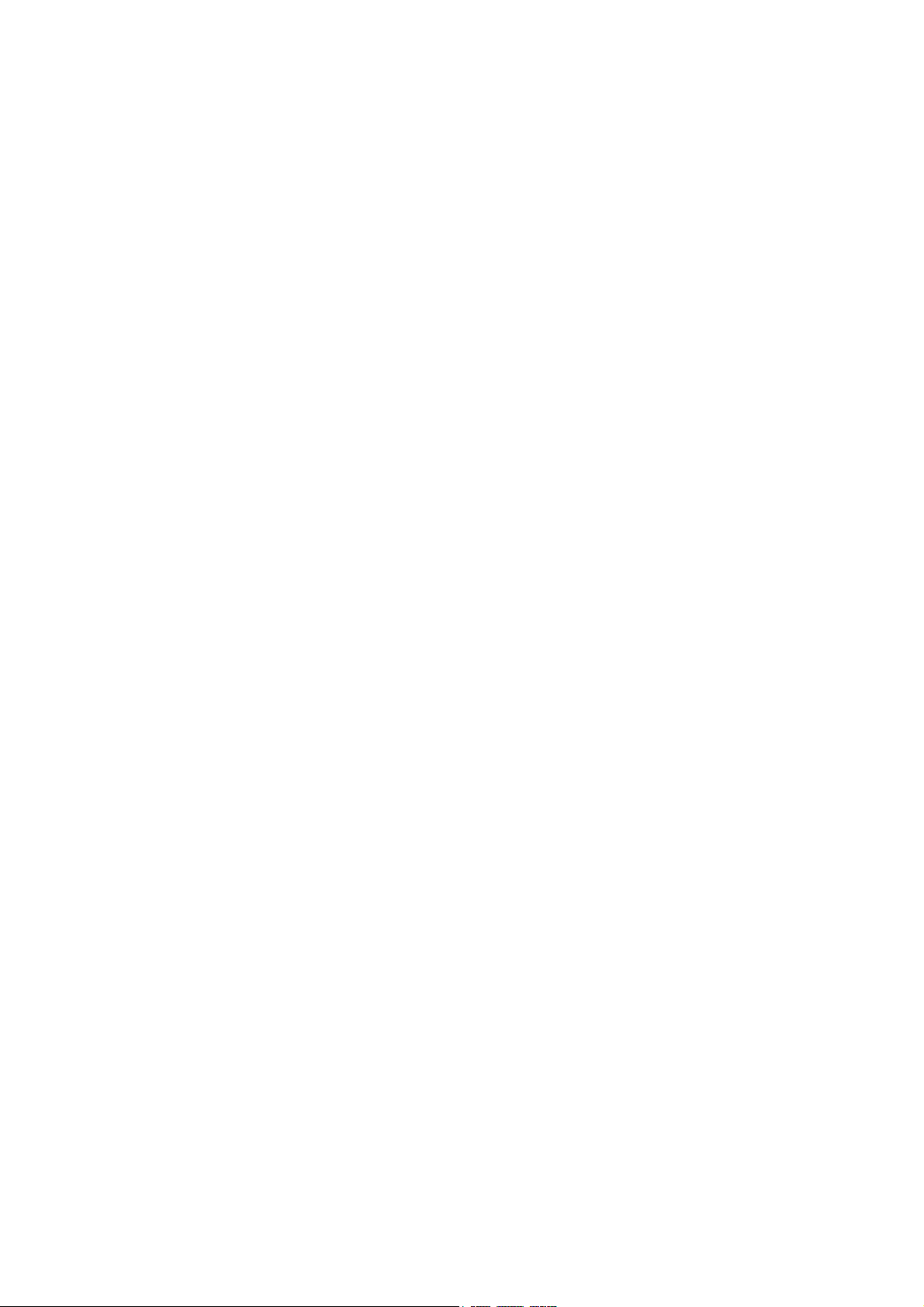

1.5 COPY PROCESS

1

B070D872.WMF

2

10

3

4

9

8

7

6

B070D873.WMF

1. EXPOSURE

A xenon lamp exposes the original. Light reflected from the original passes to

the CCD, where it is converted into an analog data signal. This data is

converted to a digital signal, processed, and stored in the memory. At the time

of printing, the data is retrieved and sent to the laser diode. For multi-copy runs,

the original is scanned once only and stored to the hard disk.

5

2. DRUM CHARGE

An OPC (organic photoconductor) drum is used in this machine. In the dark,

the charge corona unit gives a negative charge to the drum. The grid plate

ensures that corona charge is applied uniformly. The charge remains on the

surface of the drum because the OPC layer has a high electrical resistance in

the dark.

PTM 1-9 B070/B071

Page 23

3. LASER EXPOSURE

The processed data from the scanned original is retrieved from the hard disk

and transferred to the drum by four laser beams, which form an electrostatic

latent image on the drum surface. The amount of charge remaining as a latent

image on the drum depends on the laser beam intensity, which is controlled by

the laser diode board (LDB).

4. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric potential on the drum to correct

various process control elements.

5. DEVELOPMENT

The magnetic developer brush on the development rollers comes in contact

with the latent image on the drum surface. Toner particles are electrostatically

attracted to the areas of the drum surface where the laser reduced the negative

charge on the drum.

6. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer belt at the

proper time to align the copy paper and the developed image on the drum.

Then, the transfer bias roller and brush apply a high positive charge to the

reverse side of the paper through the transfer belt. This positive charge pulls

the toner particles from the drum to the paper. At the same time, the paper is

electrically attracted to the transfer belt.

7. PAPER SEPARATION

Paper separates from the drum as a result of the electrical attraction between

the paper and the transfer belt. The pick-off pawls also help separate the paper

from the drum.

8. ID SENSOR

The laser forms a sensor pattern on the drum surface. The ID sensor measures

the reflectivity of the pattern. The output signal is one of the factors used for

toner supply control.

9. CLEANING

The cleaning brush removes toner remaining on the drum after image transfer

and the cleaning blade scrapes off all remaining toner.

10. QUENCHING

The light from the quenching lamp electrically neutralizes the charge on the

drum surface.

B070/B071 1-10 PTM

Page 24

SECTION 2

DETAILED DESCRIPTIONS

Page 25

Page 26

2. DETAILED SECTION DESCRIPTIONS

2.1 DOCUMENT FEEDER

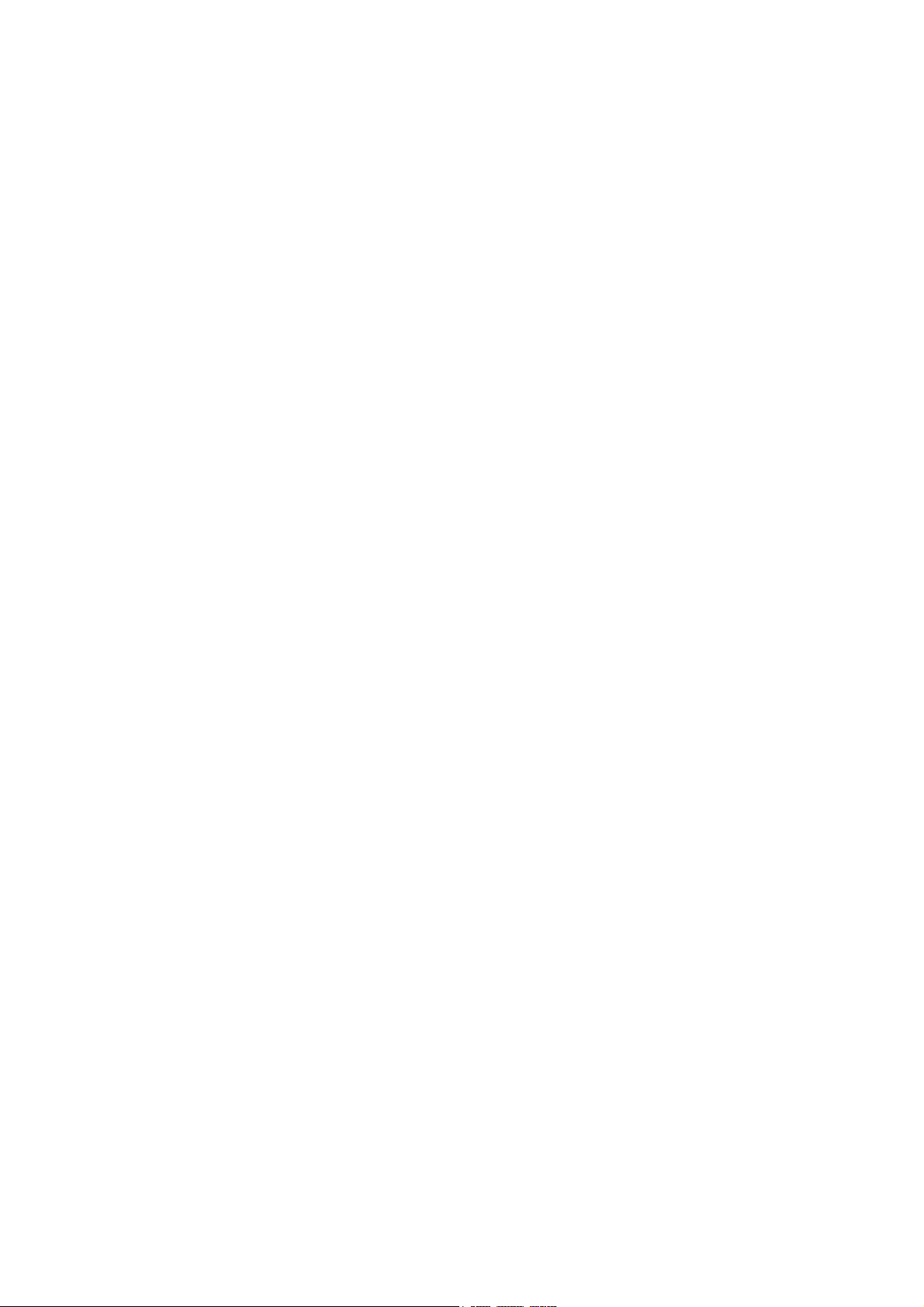

2.1.1 PICK-UP ROLLER RELEASE

[B]

[C]

[D]

[F]

[E]

[A]

B070D916.WMF

When the original set sensor is off (no original on the original tray), the pick-up roller

stays in the up position.

When the original set sensor turns on (or when the trailing edge of a page passes the

entrance sensor while pages remain on the original tray), the pick-up motor [A] turns

on. The cam [B] rotates away from the pick-up roller release lever [C]. The lever then

rises and the pick-up roller [D] drops onto the original.

When the original reaches the entrance sensor, the pick-up motor turns on again. The

cam pushes the lever down, and the pick-up roller rises until the pick-up roller HP

sensor [E] detects the actuator [F].

PTM 2-1 B070/B071

Page 27

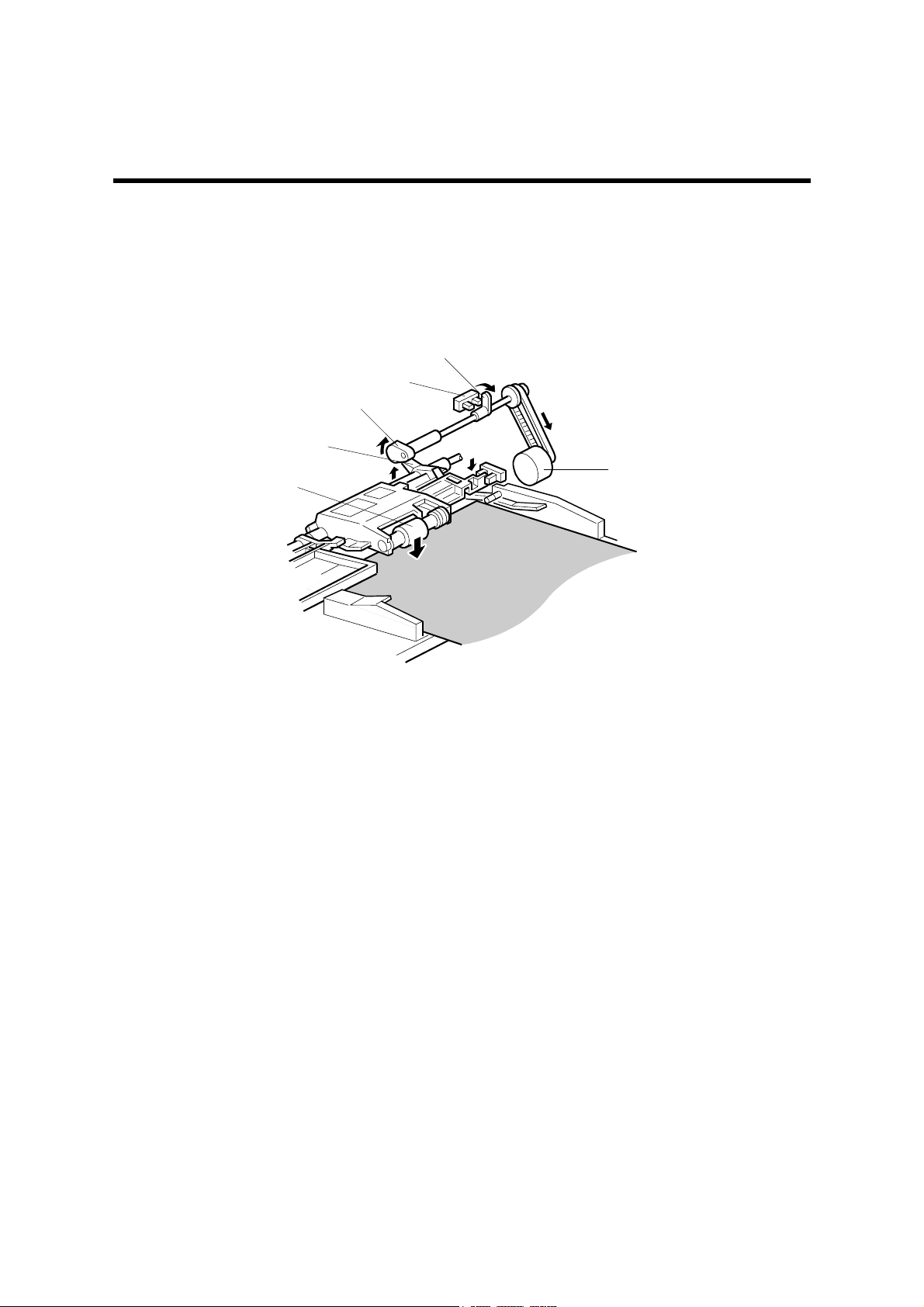

2.1.2 BOTTOM PLATE LIFT

[F]

[E]

[B]

[A]

[C]

[D]

[B]

[F]

B070D917.WMF

When an original is placed on the original tray, the original set sensor [A] turns on, the

pick-up roller [B] drops on to the original, and the bottom plate position sensor [C]

turns off. Then the bottom plate motor [D] turns on and lifts the bottom plate [E] by

raising the lift lever [F] until the bottom plate position sensor turns on.

The level of the pick-up roller drops as the stack of originals becomes smaller, and

eventually, the bottom plate position sensor [C] turns off. Then, the bottom plate motor

turns on and lifts the bottom plate until the bottom plate position sensor turns on. This

keeps the original at the correct height for feeding.

PTM 2-2 B070/B071

Page 28

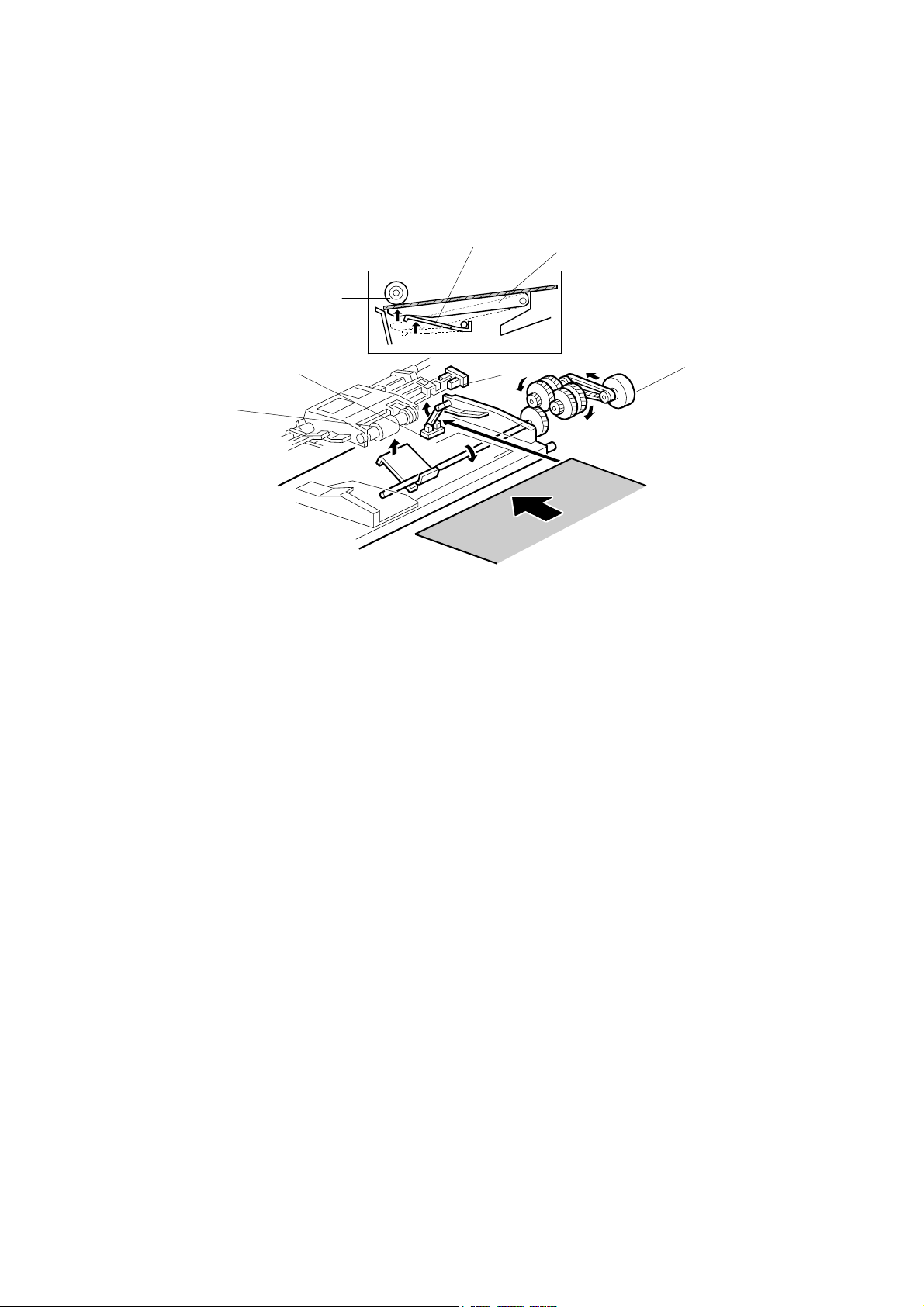

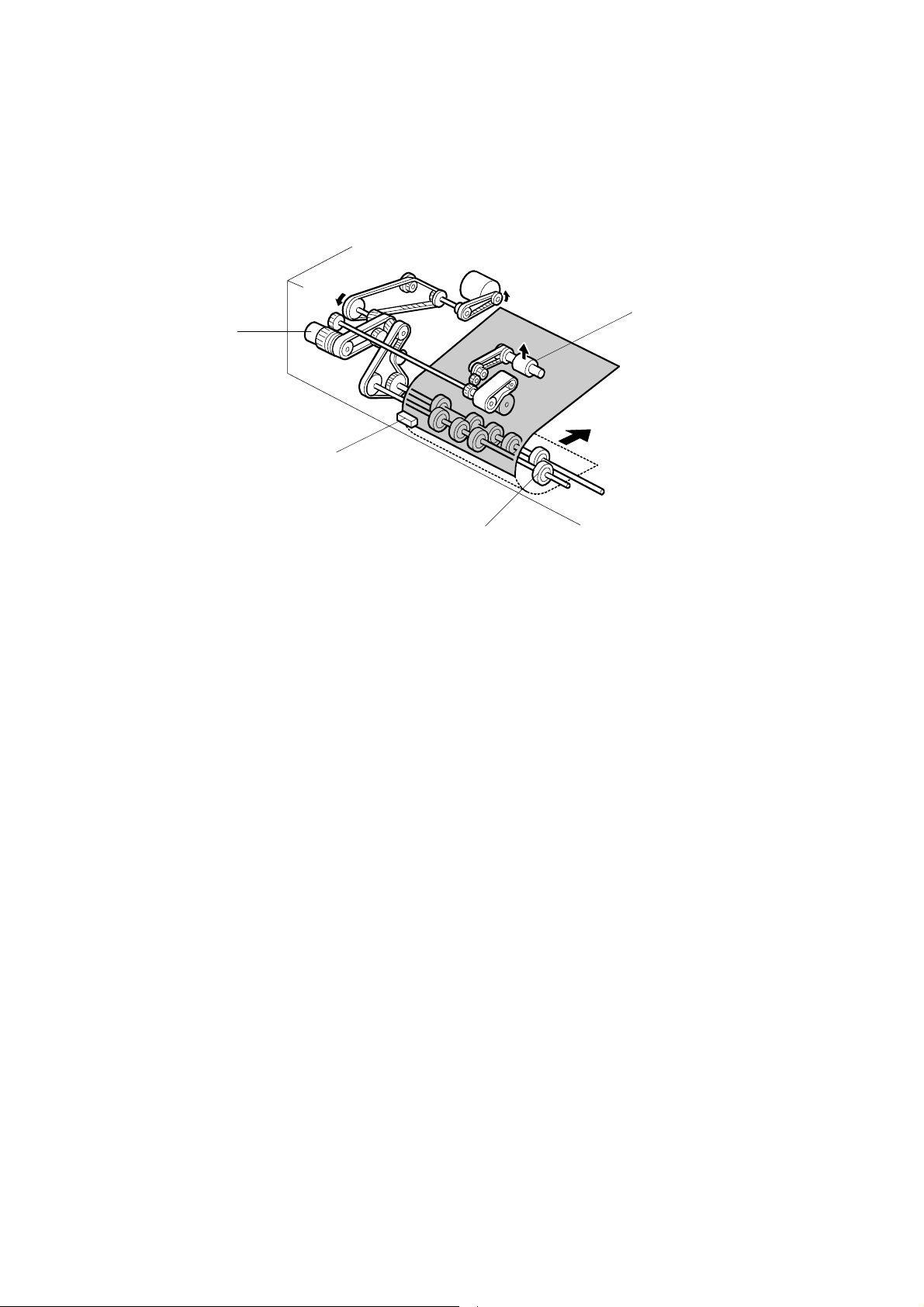

2.1.3 PICK-UP AND SEPARATION

[D]

[A]

[E]

[B]

[C]

[A]

B070D918.WMF

[B]

[C]

B070D919.WMF

The original separation system is a Feed and Reverse Roller (FRR) system. The pickup roller [A], feed belt [B], and separation roller [C] are driven by the feed-in motor [D].

To drive this mechanism, the feed-in motor [D] and feed-in clutch [E] turn on.

(

Handling Paper> Handling Originals> Document Feed> FRR with Feed Belt)

PTM 2-3 B070/B071

Page 29

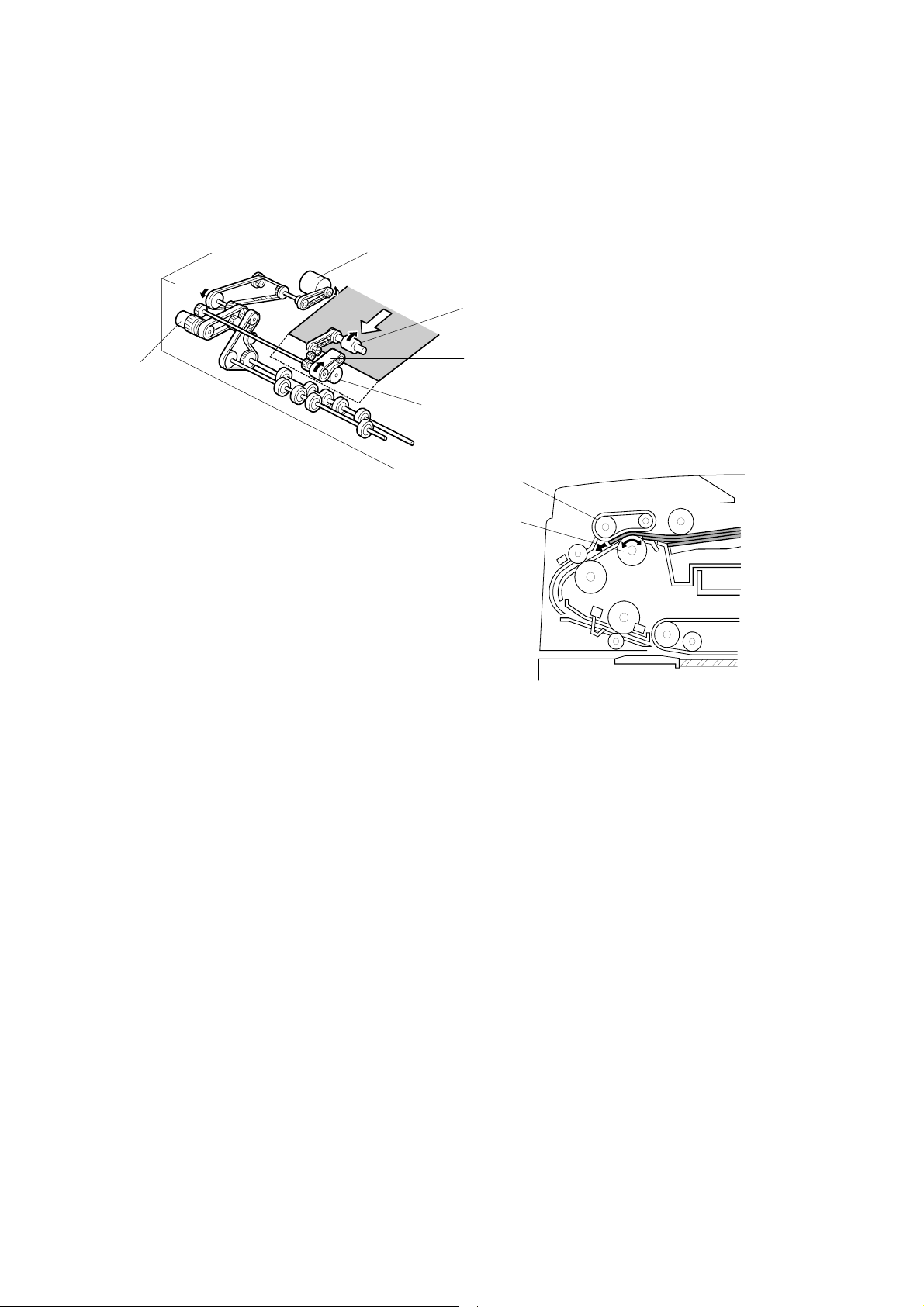

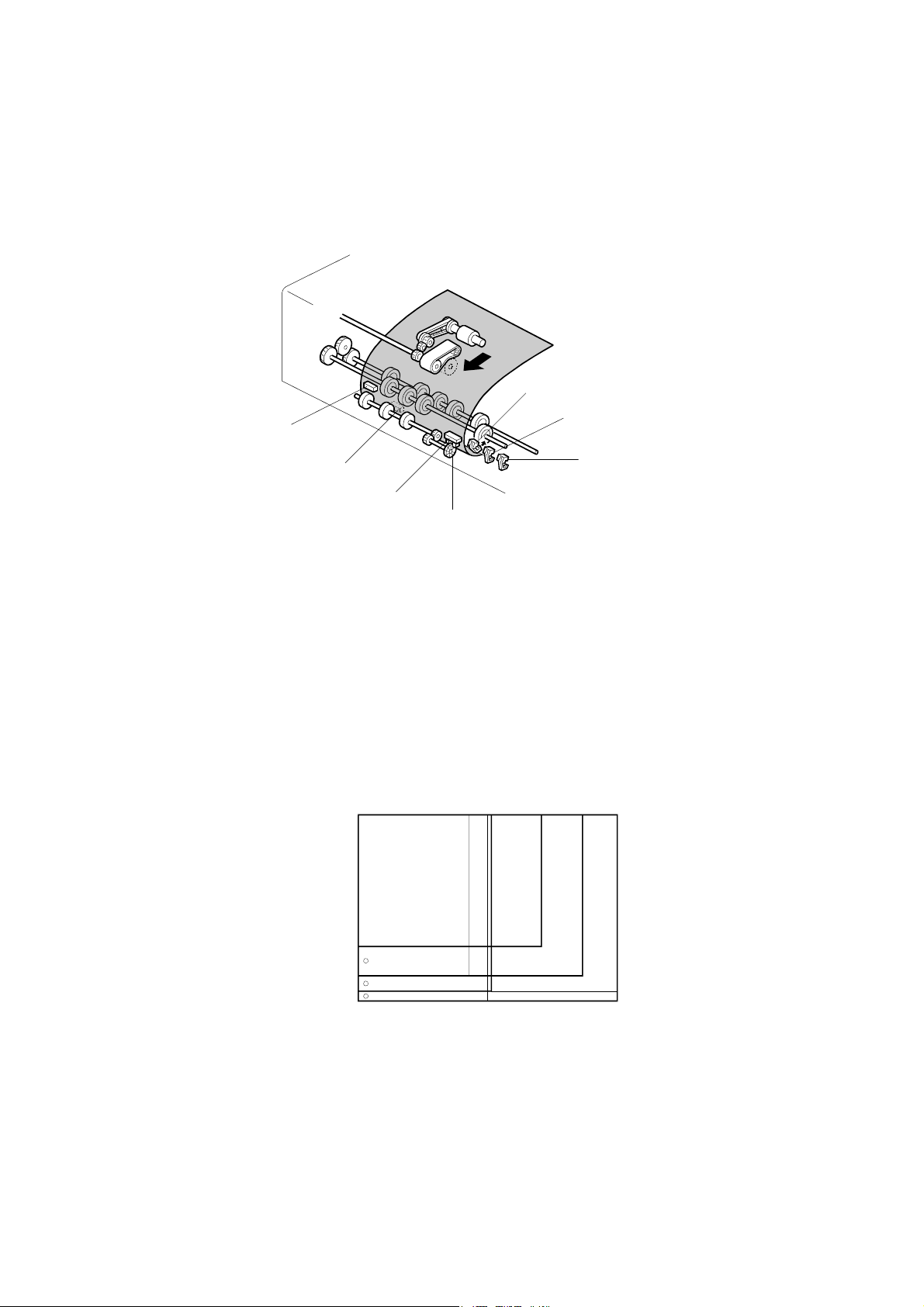

2.1.4 ORIGINAL FEED

[D]

[B]

[A]

[C]

B070D920.WMF

When the leading edge of the original turns the entrance sensor [A] on, the feed-in

clutch [B] turns off and the drive for the feed belt is released. The original is fed by the

transport rollers [C].

At the same time, the pick-up motor starts again and the pick-up roller [D] is lifted up.

When the pick-up roller HP sensor turns on, the pick-up motor stops (see Pick-up

Roller Release).

PTM 2-4 B070/B071

Page 30

2.1.5 ORIGINAL SIZE DETECTION

[B]

[G]

[C]

[F]

[D]

[A]

B070D921.WMF

[E]

The ADF detects the original size by combining the readings of original length sensor

[A], and original width sensors-1 [B], -2 [C], and -3 [D].

Original Length

The original length sensor and the disk [E] (connected to the transport roller) generate

a pulse signal. The CPU counts pulses, starting when the leading edge of the original

turns on the registration sensor [F], until the trailing edge of the original turns off the

entrance sensor [G].

Original Width

The CPU detects original width using three original width sensors -1, -2, -3 as shown

above. Three small circles on the diagram indicate the positions of the sensors.

Original Width Sensor Location

A4 SEF

B 4/B5 L EF

DLT/LT LEF

A 3/A4 L EF

B070D922.WMF

Detectable Paper Sizes

Please refer to the “1.2 ADF” table in “Specifications”.

PTM 2-5 B070/B071

Page 31

2.1.6 ORIGINAL TRANSPORT

[B]

[A]

[C]

B070D923.WMF

[E]

[D]

3.5 mm

B070D924.WMF

The transport belt [A] is driven by the transport belt motor [B]. The transport belt motor

starts when the copier sends an original feed-in signal.

The pressure rollers inside the transport belt maintain the correct pressure between

belt and original. The pressure roller [C] closest to the left original scale is made of

rubber for the stronger pressure needed for thick originals. The other rollers are

sponge rollers.

Normally, originals are manually placed at the left rear corner, so an original [D] fed

from the ADF must also be at this position. But if the original touches the rear scale [E]

as it feeds, original skew, jam, or wrinkling may occur.

To prevent such problems, the original transfer position is set to 3.5 mm away from

the rear scale as shown. The 3.5 mm gap is compensated for by changing the starting

position of the main scan for when the image is exposed on the drum.

PTM 2-6 B070/B071

Page 32

2.1.7 ORIGINAL SKEW CORRECTION

[A]

7 mm

B070D925.WMF

The transport belt motor remains energized to carry the original to the right about 7

mm past the left scale [A]. Then the motor stops and reverses to feed the original 12

mm to the left against the left scale to correct skew. This forces the original to hit the

left scale, which aligns the trailing edge to minimize original skew on the exposure

glass.

If thin original mode is selected, the original is not forced back against the left scale.

This is to prevent damage to the original.

After a two-sided original has been inverted to copy the 2nd side, it is fed in from the

inverter against the left scale [B] without skew correction.

NOTE: The bottom drawing applies to duplex scanning; the top two drawings do not

The amount of reverse feed against the left scale can be adjusted as follows:

[B]

apply in this mode.

• One-sided originals, and side 1 of two-sided originals: SP6006-3 (DF Registration

Adjustment – Leading Edge Duplex 1st)

• Side 2 of two-sided originals: SP6006-4 (DF Registration Adjustment – Leading

Edge Duplex 2nd).

PTM 2-7 B070/B071

Page 33

2.1.8 ORIGINAL INVERSION AND FEED-OUT

General Operation

[A]

B070D926.WMF

When the scanner reaches the return position, the copier CPU sends the feed-out

signal to the ADF. When the ADF receives the feed-out signal, the transport belt motor

and feed-out motor [A] turn on. The original is then fed out to the exit tray or fed back

to the exposure glass after reversing in the inverter section.

This ADF has two exit trays. For single-sided original mode, the original is fed out

straight out to the right exit tray, but for double-sided original mode, the original is fed

out to the upper exit tray.

This causes the originals to be fed out in the correct order on the exit trays and allows

the maximum one-to-one copy speed for each mode.

PTM 2-8 B070/B071

Page 34

Original Inversion

[F]

[B]

[E]

[G]

[D]

[A]

[C]

B070D927.WMF

When the ADF receives the original invert signal from the copier, the transport belt

motor, feed-out motor, exit gate solenoid [A], and inverter gate solenoid [B] turn on

and the original is fed back to the exposure glass through the inverter roller [C], exit

gate [D], inverter guide roller [E], inverter gate [F], and inverter roller.

The transport belt motor reverses shortly after the leading edge of the original turns on

the inverter sensor [G], and feeds the original to the left scale.

PTM 2-9 B070/B071

Page 35

Original Exit (Single-Sided Original Mode)

[B]

[A]

[C]

B070D928.WMF

The exit gate solenoid [A] remains off, the exit gate [B] remains closed, and the

original is fed out to the right exit tray.

The speed of the motor is reduced about 30 mm from the trailing edge of the original

to ensure the originals stack neatly on the exit tray. This timing is determined by the

length of the original, and the time since the exit sensor [C] detected the leading edge.

The transport belt motor turns off after the exit sensor [C] turns off.

PTM 2-10 B070/B071

Page 36

Original Exit (Double-Sided Original Mode)

[C]

[E]

[A]

[B]

[D]

B070D929.WMF

The exit gate solenoid [A] turns on and the exit gate [B] opens.

The inverter gate solenoid [C] remains off, and the original is fed out to the upper tray.

The transport belt motor turns off when the trailing edge of the original passes the exit

sensor [D].

To stack the originals neatly on the upper tray, the feed-out motor speed is reduced

shortly after the trailing edge of the original turns off the inverter sensor [E].

PTM 2-11 B070/B071

Page 37

2.2 SCANNING

2.2.1 OVERVIEW

1

2

3

4

5

13

12

6

8

7

9

B070D001.WMF

11

1. Scanner Motor 10. LCDC (LCD Control Board)

2. White Plate (on exposure glass) 11. CCD (Charge Coupled Device)

3. 2nd Mirror 12. Original Length Sensor (APS)

4. Exposure Lamp (Xenon) 13. Scanner Lens

5. Exposure Glass 14. 3rd Mirror

6. 1st Mirror 15. Original Width Sensors 1, 2, 3 (APS)

10

7. Lamp Regulator 16. Scanner HP Sensor

8. SBU Cooling Fan 17. Optics Anti-condensation Heater (option)

9. Optics Cooling Fan

One xenon lamp (23W) as the exposure lamp [4] illuminates the original. The image is

reflected onto the CCD [11] (600 dpi resolution) via the 1st, 2nd, and 3rd mirrors, and

through the lens [13].

The lens, CCD, and SBU are in a single unit, the lens block. The optical axis, focus,

and MTF are pre-adjusted, so this lens block requires no adjustment in the field. The

1st scanner consists of the exposure lamp [4], the lamp regulator [7] and the 1st

mirror.

Two fans, the optics cooling fan [9] and the SBU cooling fan [8], draw cool air into the

scanning unit. The optics cooling fan turns on when the scanner motor starts and turns

off 10 seconds after the scanner motor turns off. The SBU cooling fan operates while

the operation switch is on. The optional optics anti-condensation heater [17] (if

installed as an option) turns on while the main switch is off, to prevent moisture from

forming on the optics.

PTM 2-12 B070/B071

Page 38

2.2.2 SCANNER DRIVE

[C]

[D]

[E]

[B]

[A]

[F]

[G]

B070D003.WMF

The scanner motor is a dc servo motor. The 1st and 2nd scanners [A, B] are driven by

the scanner motor [C] through the timing belt [D], scanner drive pulley [E], scanner

drive shaft [F], and two scanner wires [G].

The MCU (Motor Control Unit) board controls the scanner motor. The exposure lamp

scans a sheet with 100% magnification at 515 mm/s and returns to the scan position

for the next scan at 2500 mm/s.

Magnification and Reduction

Magnification and reduction in the main scan direction are done in the IPU board.

Magnification and reduction in the sub scan direction, however, are done by

controlling the speed of the scanner motor in sync with the main scan processing done

in the IPU.

• Magnification above 101% is done in the IPU. For example, at 200% magnification,

the IPU doubles magnification while the scanner motor speed remains at 100%.

• Reduction in the range 51% to 100% is done by the scanner motor.

•

Reduction in the range 25% to 50% is done by the scanner motor, assisted by IPU

processing. For example, at 40% reduction, the scanner motor speed is 80% and

the IPU reduces the image by 1/2.

• Reduction below 25% is done by the scanner motor, assisted by IPU processing.

For example, at 24% reduction the scanner motor speed is 96% and the IPU

reduces the image by 1/4.

NOTE: Magnification in the sub scan direction can be adjusted by changing the

scanner motor speed with SP4008 (Scanner Sub Scan Magnification).

PTM 2-13 B070/B071

Page 39

2.2.3 ORIGINAL SIZE DETECTION

[F]

[G]

[A]

B070D052.WMF

[B]

[C]

[D]

[E]

B070D535.WMF

There are three reflective sensors at three locations in the optics cavity for original

size detection.

The original width sensor [A] detects the original width, and the original length sensor

1 [B] and original length sensor 2 [C] detect the original length. These are the APS

(Auto Paper Select) sensors.

Inside each APS sensor, there is an LED [D] and either three photoelectric devices [E]

(for the width sensor) or one photoelectric device (for each length sensor). In the width

sensor, the light generated by the LED is separated into three beams and each beam

scans a different point of the exposure glass (in each length sensor, there is only one

beam). If the original or ADF cover is present over the scanning point, the beam is

reflected and each reflected beam exposes a photoelectric device and activates it.

While the main switch is on, these sensors are active and the original size data is

always sent to the main CPU. However, the main CPU checks the data only when the

ADF is being closed.

The ADF functions as the platen. The DF position sensor [F] (attached to the ADF)

detects whether the ADF is open or closed.

The APS start sensor [G] triggers auto paper size detection.

PTM 2-14 B070/B071

Page 40

NOTE: The Europe/Asia model has one length sensor (L1), but the North American

A4/A3 Version LT/DLT Version 2 1 1 2 3

:High (Paper Present) L: Low

H

model has two length sensors (L1, L2)

Original Size

A3 11" x 17"

B4 10" x 14"

F4 81/2" x 14" (8" x 13")

A4 SEF 8

B5 SEF —

A5 SEF 51/2" x 81/2"

A4 LEF 11" x 81/2"

B5 LEF —

A5 LEF 81/2" x 51/2"

1/2

" x 11"

Length

Sensor

H

H H H

Width Sensor

H

H H H H L

H H H L L

L

H H L L

L H L L L

L L L L L

L L H H

H

L L H H L

L L H

L

L

SP4301

Display

00011111

00011110

00011100

00001100

00001000

00000000

00000111

00000110

00000100

The original size data is taken by the main CPU when the DF position sensor is

activated. This is when the ADF is positioned about 12 cm above the exposure glass.

At this time, only the sensor(s) underneath the original receive the reflected light and

switch on. The other sensor(s) are off. The main CPU recognizes the original size

from the on/off signals from the five sensors.

If the copy is made with the ADF open, the main CPU decides the original size from

the sensor outputs when the Start key is pressed.

The above table shows the outputs of the sensors for each original size. This original

size detection method eliminates the necessity for a pre-scan and increases the

machine productivity.

0,0

Width Sensor 1

Width Sensor 2

Width Sensor 3

PTM 2-15 B070/B071

A5 SEF

B5 SEF

Length Sensor 1

A5 LEF

A4 LEF

A4 SEF

Length Sensor 2

B4

A3

B070D931.WMF

Page 41

2.3 IMAGE PROCESSING

2.3.1 IMAGE PROCESSING STEPS AND RELATED SP MODES

The following tables describe the image processing path and the related SP modes

used for each image processing mode.

The user can adjust many of the image processing parameters with a UP mode

(Copy/Document Server Features> General Features> Original Mode Quality Level),

using fixed settings such as Sharp, Normal, and Soft. Each of these fixed settings

have different parameters, but user changes do not affect the relevant SP mode

settings.

If the user is not satisfied with any of the available settings for this UP mode, the

technician can adjust the SP modes. However, the SP mode settings are not used

unless the user selects ‘Service Mode’ with the UP Mode.

Text

Text/Photo

Photo

Pale

Generation

Soft

Photo Priority

Screened Printed

Soft

Soft

Normal

Normal

Normal

Normal

Normal

Sharp

Text Priority

Glossy Phot

Sharp

Sharp

Service Mode

Service Mode

Service Mode

Service Mode

Service Mode

B070D011.WMF

PTM 2-16 B070/B071

Page 42

2.3.2 IMAGE PROCESSING OVERVIEW

CCD

Polygon Motor

OPC

SBU

IPUBCU

LDB

PCI BUS

Controller

HDD

Key

Data flow

Signal flow

B070D934.WMF

SBU: Photoelectric conversion, Odd/even allocation, Amplification, A/D

Conversion (analog to digital), Light intensity detection (scanning)

BCU: Engine control, Scanner control, SBU settings, IPU settings, LDB

settings

IPU: Shading correction, Image Processing, Main/Sub scan

magnification, Video path switching, Image Compression/

Decompression. The GAVD on this board performs density

conversion processing, FCI processing, and edge processing, and

also generates the test patterns.

Controller: System control, software application control, image storage control,

file compression/decompression

LDB: 8-beam laser exposure, binary-to-grayscale conversion,

synchronization detection

PTM 2-17 B070/B071

Page 43

2.3.3 IMAGE PROCESSING FLOW

Image processing is done by the IPU (Image Processing Unit), following the steps

shown below.

Overall image processing for this machine is designed to:

• Target edges with filters to improve the angles of text characters and reduce the

occurrence of moiré filled areas.

•

Improve the evenness of granular areas in images

Shading Correction

Ð

Gamma Correction Background erase

Ð

Pre-Filter Reduces the occurrence of moiré.

Ð

Main Scan Magnification

Ð

Auto Select

Ð

Filtering

Ð

Independent Dot Erase Removes isolated pixels.

Ð

Line Width Correction

Ð

Density Control

Ð

Grayscale Processing

Ð

Video Path

Ð

LD Unit

Corrects the dispersion of the scanning

lens and CCD.

Determines if an image is text or raster

image data and processes the data

accordingly.

Selects the best methods for Filtering,

Density Control, and Grayscale

Processing.

MTF and smoothing (MTF filter of

previous machines)

Either of two filters is selected by Auto

Select above.

Employs one of two gamma tables,

selected by Auto Select above

Error diffusion, dithering, or binary picture

processing

Black-and-white digitization or dithering is

selected by “Auto Select above.

ÍÎ

Application (printer)

PTM 2-18 B070/B071

Page 44

PTM 2-19 B070/B071

Page 45

2.3.4 IMAGE PROCESSING MODES

The user can select one of the following five modes with the User Tools screen: Text,

Text/Photo, Photo, Pale, Generation.

Each mode has four different settings (described below). Each mode has a Custom

Setting that can be customized with SP modes to meet special requirements that

cannot be covered by the standard settings.

NOTE:

Tex/Photo

Generation

To see these settings in the User Tools mode, press the User Tools key, press

“Copier/Document Server Functions”, then press “Copy Quality”.

Mode Setting Function

Soft Rough texture background drops out.

Used for black-and-white printed material and

Text

Photo

Pale

Copy

Normal

Sharp

Custom

Setting

Photo Priority

Normal

Text Priority

Custom

Setting

Print Photo

Normal

Glossy Photo

Custom

Settings

Soft

Normal

Sharp

Custom

Setting

Soft Used to achieve an image smoother than Normal.

Normal

Sharp

documents that contain mainly text. Easily reads lines

as well as text.

Use for newspapers, time schedules, or any type of

printed material with fine print. Emphasizes black over

white.

Stores SP command settings.

Used for documents that contain text and color or blackand-white photos, such as catalogs, magazines, maps,

etc. Provides more faithful reproduction than the Text

mode.

Stores SP command settings.

Used for magazines, graphics, for smooth reproduction.

Employs dithering.

Used for copying photographs, graphics, for sharp

reproduction. Employs error diffusion.

Used for best results in copying glossy photographs for

sharp reproduction. Employs error diffusion.

Stores SP command settings. Employs either error

diffusion or dithering, depending on an SP setting.

Used for low density documents with text handwritten in

black or color pencil (or carbon copies) such as

receipts, invoices, etc.

Stores SP command settings.

Used to achieved best reproduction of “copies of

copies” by smoothing the image.

Used to emphasize lines and text stronger than Normal

for better image quality.

PTM 2-20 B070/B071

Page 46

Custom

Background

Dropout

Setting

Strong

Medium

Weak

Stores SP command settings.

Drops out the blue background color of tab sheets or

other paper.

Drops out the green background color of tab sheets or

other paper.

Drops out the orange background color of tab sheets or

other paper.

PTM 2-21 B070/B071

Page 47

2.3.5 IMAGE QUALITY SP ADJUSTMENTS

Adjustments are easier with this machine, because the parameters have been

grouped and no longer have to be adjusted one by one.

In this section, we will cover the custom settings for each of the 5 original modes:

These custom settings are:

•

Image Quality

•

Line Width Correction

Settings adjustable for each original mode will also be covered (these do not just

affect the custom settings; they also affect all sub original modes, such as sharp text).

•

Independent Dot Erase

• Background Erase

Custom Settings for Each Mode: Image Quality

Custom Setting: Text Mode Image Quality

Item Range Default SP No.

25~55% SP4903 001

55.5~75% SP4903 002

Text

75.5~160% SP4903 003

160.5~400

%

If the value is increased, the outlines of lines become sharper but this could cause

moiré to appear in dot patterns. If the value is decreased, image patterns become

smoother, the occurrence of moiré decreases, but the corners of characters and

intersections of lines at acute angles may not be as sharp.

There are two sets of custom settings for photo mode. One is for dithering, and one is

for error diffusion. The set of custom settings that will be used depends on the setting

of SP4904 002. The possible settings are:

0~10 5 Normal

SP4903 004

0 Dither (106 line)

1 Dither (141 line)

2 Dither (212 line)

3 Error Diffusion

PTM 2-22 B070/B071

Page 48

Custom Setting: Photo Mode (Dithering) Image Quality

Item Range Default SP No.

25~55% SP4903 005

55.5~75% SP4903 006

Photo

75.5~160% SP4903 007

160.5~400

%

0~6 3 Print Photo

SP4903 008

Used for coarse, dithered tone photographs such as newsprint.

If the value is increased, the photo becomes sharper, but blurring could occur in the

sub scan direction. If the value is decreased, blurring in the sub scan direction is less

obvious but outlines become fuzzy.

Custom Setting: Photo Mode (Error Diffusion) Image Quality

Item Range Default SP No.

25~55% SP4903 009

55.5~75% SP4903 010

0~6 1 Normal

SP4903 012

Photo

75.5~160% SP4903 011

160.5~400

%

Used for printed materials (magazines, etc.) with photographs to sharp patterns in

copies.

If the photos have dithered tones, the image becomes sharper if the value is

increased, but blurring could occur in the sub scan direction. If the value is decreased,

blurring in the sub scan direction is less obvious but outlines become fuzzy.

Custom Setting: Text/Photo Mode Image Quality

Item Range Default SP No.

25~55% SP4903 013

Text/Phot

o

55.5~75% SP4903 014

75.5~160% SP4903 015

160.5~400

%

0~10 5 Normal

SP4903 016

See the remarks for ‘Custom Setting: Text Mode Image Quality’ above.

PTM 2-23 B070/B071

Page 49

Custom Setting: Pale Mode Image Quality

Item Range Default SP No.

25~55% SP4903 017

55.5~75% SP4903 018

Pale

75.5~160% SP4903 019

160.5~400

0~10 5 Normal

SP4903 020

%

If the value is increased, low density areas become sharper, but the background could

become dirtier. If the value is decreased, the background disappears but the density of

low density areas becomes low.

Custom Setting: Generation Mode Image Quality

Item Range Default SP No.

25~55% SP4903 021

Generatio

n

55.5~75% SP4903 022

75.5~160% SP4903 023

160.5~400

0~10 5 Normal

SP4903 024

%

See the remarks for ‘Custom Setting: Pale Mode Image Quality’ above.

PTM 2-24 B070/B071

Page 50

Custom Settings for Each Mode: Line Width Correction

Custom Setting: Text Mode Line Width Correction

Selection Range Default Content SP No.

Item

Line Width

Correction

Main Scan 0~1 1 0:OFF 1:ON SP4903 081

Sub Scan 0~1 1 0:OFF 1:ON SP4903 082

0~8 2

0 (Thin) - 4 (Off) - 8

(Thick)

SP4903 080

If the value is made smaller, the line width correction becomes thinner, and if the value

is made larger, the line width correction becomes thicker. To switch this feature off,

select “4”.

If the above settings do not make the lines thin enough, use SP4904 020 (Image

Quality Exposure: Thin Line - Text Mode). Normally, SP4904 020 is set to 0 (OFF). As

the setting is increased (1~3), the line width correction effect becomes stronger, and

lines become thinner. All settings of SP4903 080 will be affected by the same amount.

Custom Setting: Photo Mode Line Width Correction

Selection Range Default Content SP No.

Item

Line Width

Correction

Main Scan 0~1 1 0:OFF 1:ON SP4903 084

Sub Scan 0~1 1 0:OFF 1:ON SP4903 085

0~8 4

0 (Thin) - 4 (Off) - 8

(Thick)

SP4903 083

See the remarks for ‘Custom Setting: Text Mode Line Width Correction’ above.

If the above settings do not make the lines thin enough, use SP4904 021 (Image

Quality Exposure: Thin Line – Photo Mode). Normally, SP4904 021 is set to 0 (OFF).

As the setting is increased (1~3) the line width correction effect becomes stronger,

and lines become thinner. All settings of SP4903 083 will be affected by the same

amount.

Custom Setting: Text/Photo Mode Line Width Correction

Selection Range Default Content SP No.

Item

Line Width

Correction

Main Scan 0~1 1 0:OFF 1:ON SP4903 087

Sub Scan 0~1 1 0:OFF 1:ON SP4903 088

0~8 4

0 (Thin) - 4 (Off) - 8

(Thick)

SP4903 086

See the remarks for ‘Custom Setting: Text Mode Line Width Correction’ above.

If the above settings do not make the lines thin enough, use SP4904 022 (Image

Quality Exposure: Thin Line – Text/Photo Mode). Normally, SP4904 022 is set to 0

(OFF). As the setting is increased (1~3) the line width correction effect becomes

stronger, and lines become thinner. All settings of SP4903 086 will be affected by the

same amount.

PTM 2-25 B070/B071

Page 51

Custom Setting: Pale Mode Line Correction

Selection Range Default Content SP No.

Item

Line Width

Correction

Main Scan 0~1 1 0:OFF 1:ON SP4903 090

Sub Scan 0~1 1 0:OFF 1:ON SP4903 091

0~8 4

0 (Thin) - 4 (Off) - 8

(Thick)

SP4903 089

See the remarks for ‘Custom Setting: Text Mode Line Width Correction’ above.

If the above settings do not make the lines thin enough, use SP4904 023 (Image

Quality Exposure: Thin Line – Pale Mode). Normally, SP4904 023 is set to 0 (OFF).

As the setting is increased (1~3) the line width correction effect becomes stronger,

and lines become thinner. All settings of SP4903 089 will be affected by the same

amount.

Custom Setting: Generation Copy Line Width Correction

Selection Range Default Content SP No.

Item

Line Width

Correction

Main Scan 0~1 1 0:OFF 1:ON SP4903 093

Sub Scan 0~1 1 0:OFF 1:ON SP4903 094

0~8 1

0 (Thin) - 4 (Off) - 8

(Thick)

SP4903 092

See the remarks for ‘Custom Setting: Text Mode Line Width Correction’ above.

If the above settings do not make the lines thin enough, use SP4904 024 (Image

Quality Exposure: Thin Line – Generation Mode). Normally, SP4904 024 is set to 0

(OFF). As the setting is increased (1~3) the line width correction effect becomes

stronger, and lines become thinner. All settings of SP4903 092 will be affected by the

same amount.

PTM 2-26 B070/B071

Page 52

Settings Adjustable for Each Original Mode

Independent Dot Erase

Item Range Default SP No.

Text 8 SP4903 060

Photo 0 SP4903 061

Text/Photo 0 SP4903 062

Pale 0 SP4903 063

Generation

0~14

8 SP4903 064

Copy

Independent dot erase removes isolated black pixels. As this setting is increased, the

greater the number of eliminated isolated pixels. Setting to zero switches this function

off.

Background Erase

Item Range Default SP No.

Text SP4903 070

Photo SP4903 071

Text/Photo SP4903 072

Pale SP4903 073

Generation

0~255 0 (Off)

SP4903 074

Copy

Background erase attempts to eliminate the heavy background texture from copies of

newspaper print or documents printed on coarse paper. Pixels of density below the

selected threshold level are eliminated. Setting this feature to zero switches it off.

Increasing this setting increases the effect of background erase.

PTM 2-27 B070/B071

Page 53

2.3.6 RELATION BETWEEN THE SP AND UP SETTINGS

The tables below illustrate the relationship between the UP and SP settings for each

of the 5 original modes. The scale across the top of the table is the range of settings

for the SP modes.

The settings in the gray areas indicate the UP settings overlaid on the SP scale of the

table. Words that are not shaded within the tables, such as ‘softer’, indicate how the

image changes if you change the SP setting is a certain direction. The related UP

mode is User Tools> Copier Features> General Features> Copy Quality.

Text Mode

Setting 0 1 2 3 4 5 6 7 8 9 10 SP No.

25% ~55% SP4903 001

55.5 ~ 75% SP4903 002

75.5 ~ 160% SP4903 003

160.5 ~ 400%

Soft

Normal

Sharp

SP4903 004

Photo Mode (Dithering)

Setting 0 1 2 3 4 5 6 SP No.

25% ~55% SP4903 005

55.5 ~ 75% SP4903 006

75.5 ~ 160% SP4903 007

Softer

160.5 ~ 400%

Sharper

Print Photo

SP4903 008

Photo Mode (Error Diffusion)

Setting 0 1 2 3 4 5 6 SP No.

25% ~55% SP4903 009

55.5 ~ 75% SP4903 010

75.5 ~ 160% SP4903 011

Softer

Normal

160.5 ~ 400%

Sharper

Glossy Photo

SP4903 012

PTM 2-28 B070/B071

Page 54

Text/Photo Mode

Setting 0 1 2 3 4 5 6 7 8 9 10 SP No.

25% ~55% SP4903 013

55.5 ~ 75% SP4903 014

75.5 ~ 160% SP4903 015

160.5 ~ 400%

Photo Priority

Normal

Text Priority

SP4903 016

Pale Mode

Setting 0 1 2 3 4 5 6 7 8 9 10 SP No.

25% ~55% SP4903 017

55.5 ~ 75% SP4903 018

75.5 ~ 160% SP4903 019

160.5 ~ 400%

Soft

Normal

Sharp

SP4903 020

Generation Copy

Setting 0 1 2 3 4 5 6 7 8 9 SP No.

25% ~55% SP4903 021

55.5 ~ 75% SP4903 022

75.5 ~ 160% SP4903 023

Soft

Normal

10

Sharp

160.5 ~ 400%

SP4903 024

Background Color Dropout

SP NO. MODE NAME

4901 020 Background Dropout – Weak Orange 165 ~ 255 (Default: 180)

4901 021

Background Dropout –

Medium

4901 022 Background Dropout - Strong Blue 15 ~ 144 (Default: 105)

TARGETTED

COLOR

VALUES

Green 115 ~164 (Default: 155)

PTM 2-29 B070/B071

Page 55

2.4 LASER EXPOSURE

2.4.1 OVERVIEW

1

2

3

12

11

10

9

1. LD Unit 7. 2nd Mirror

2. Polygon Mirror Motor Control Board 8. Drum

4

5

6

7

8

B070D101.WMF

3. Polygon Mirror Motor 9. Toner Shield Glass

4. F-Theta Lens 1 10. 1st Mirror

5. F-Theta Lens 2 11. Laser Synchronization Detector

6. BTL Lens 12. Cylindrical Lens

PTM 2-30 B070/B071

Page 56

2.4.2 LASER EXPOSURE MECHANISM

[D]

[A]

[B]

[C]

B070D102.WMF

The LD unit consists of two 4-channel LDA’s (Laser Diode Arrays) and two collimating

lenses.

Each LDA produces 4 beams [A]. Each collimating lens [B] is a fixed lens, seated in a

V-groove and held in place by a spring and a screw.

Four beams from each LDA [C] pass through the collimating lenses, though the

apertures [D], then strike the polygonal mirror. Due to this multi-beam writing, the

polygonal mirror motor speed can be reduced, thus the noise generated by the

polygon mirror motor and the wear on the motor can be reduced.

Auto Power Control (APC)

A built-in photo diode detects the light emitted from the LD unit. When the photo diode

detects this light, it generates a signal and the feedback of this signal to the LD control

board is used to adjust the strength and amount of light in the laser beams.

NOTE: The laser diode array is assembled and adjusted in the factory, and does

not require physical position adjustment in the field.

LD drivers control the power output from the laser diodes.

(

Digital Processes > Printing > Laser Printing > Laser Diode Power Control)

NOTE: The reference levels are adjusted on the production line. Never touch the

variable resistors on the LD unit.

PTM 2-31 B070/B071

Page 57

2.4.3 LD SAFETY SWITCHES

Inte r L o c k S W

DATA0

DATA0

XAPC0

DATA1

DATA1

XAPC1

DATA2

DATA2

DATA3

DATA3

DATA4

DATA4

XAPC4

DATA5

DATA5

XAPC5

DATA6

DATA6

DATA7

DATA7

LDO FF

+5V

+24V

DATA0

1k

DATA1

DATA2

DATA3

DATA4

1k

DATA5

1k

DATA6

DATA7

LD5V

XAPC0

1k

XAPC 1

XAPC 4

XAPC 5

6.8k

LDO FF

10k

PSU

IP U

BGAVD2

LD D

LD0

LD1

LD4

LD5

LD B

+LD 5V

FAN

POLYGON

510

5k

510

5k

B070D998.WMF

To ensure technician and user safety and to prevent the laser beam from inadvertently

switching on during servicing, there are four safety switches inside the front cover

(these are the 4th front left and 4th front right door safety switches).

When one of the front covers is open, the 5 V line connecting to the LD drivers (LDD)

is disconnected.

PTM 2-32 B070/B071

Page 58

2.4.4 MULTI-BEAM LINE EXPOSURE

[A]

B070D212.WMF

The LD unit contains two laser diode arrays (LDA) [A], each with one 4-channel array,

allowing the LD unit to produce a total of eight beams. This multi-beam exposure

mechanism has the following advantages:

•

Reduces the number of rotations required of the polygon mirror motor.

• Reduces the amount of noise generated by the polygon mirror motor because it is

rotating at lower speed.

• Reduces the need for LD unit replacement.

• Allows production of a more precision beam on a stable platform.

The laser synchronization detector detects only Channel 0 and Channel 1, the

uppermost beams of each parallel array.

The main scan pitch of Channels 2 to 7 is determined by setting SP2115 001~006

(Main Scan Beam Pitch Adjustment) at the factory. For this reason, when the LD unit

is replaced, these SP codes must be input for the new unit. The correct SP settings

are printed on a label attached to the LD unit.

An SC code is issued for a laser synchronization detector error if the LD unit

malfunctions and does not emit the laser beams.

PTM 2-33 B070/B071

Page 59

2.4.5 POLYGON MIRROR MOTOR

The polygon mirror reflects the laser beam onto the OPC drum to expose the image

line by line in the main scan direction. The polygon mirror motor rotates at a constant

speed, even while the copier is in standby mode, but shuts off when the copier enters

the energy conservation mode.

The polygon mirror motor has no brake mechanism, so it requires about 3 minutes to

stop rotating. Before moving the machine or before servicing the motor or the area

around the polygon mirror motor, you should switch off the copier main power switch,

disconnect the machine, and wait at least three minutes for the motor to stop rotating.

NOTE: The polygon mirror motor requires about 10 seconds to reach full speed after

the machine awakes from the energy conservation mode, or after the machine

is switched from the normal mode to low speed mode for printing on thick

paper. The machine cannot print during this 10 second interval until it reaches

full rotation speed.

PTM 2-34 B070/B071

Page 60

)

2.4.6 1200-DPI RESOLUTION

Sub Scan

0 LDA 1-0 4 LDA 1-2

7

42.3 µm

(600 dpi)

1 3 5

22.3 mm

Main Scan

0

1 LDA 2-0 5 LDA 2-2

2 LDA 1-1 6 LDA 1-3

2

21.2 µm (1200 dpi

4

B070D210.WMF

6

3 LDA 2-1 7 LDA 2-3

The original is scanned at 600 dpi, then the 600 dpi output is boosted to 1200 dpi 1-bit

data during image processing in the IPU.

This machine can produce an image at 1200 dpi by writing each dot twice, possibly

with two different values, depending on the results of image processing. This is

achieved with the LD unit, which has two laser diode arrays, each with 4 channels

which together produce 8 beams. As shown in the illustration above, the beams from

each laser diode are emitted in two parallel lines.

For copying, 1200 dpi is used. For printing, the default is 600 dpi, but 1200 dpi can be

selected.

The diagram shows how the two sets of four beams are interlaced to produce a sub

scan resolution of 1200 dpi.

There are two parallel rows of four beams, separated by 22.3 mm in the main scan

direction. In each of these rows, the beams are spaced at 42.3 micrometer intervals

(this is the same as 600 dpi).

The rows are also offset in the sub scan direction by 21.2 micrometers.

The net result is that we have dots at 21.2 micrometer intervals, which is the same as

1200 dpi

PTM 2-35 B070/B071

Page 61

2.4.7 OPTICAL PATH

[C]

[D]

[B]

[A]

[E]

[F]

[G]

[H]

[I]

[J]

[K]

B070D101.WMF

The output path from the laser diode to the drum is shown above.

The LD unit [A] outputs eight laser beams to the polygonal mirror [B] (six mirror

surfaces) through the cylindrical lens [C] and the 1st mirror [D].

Each surface of the polygon mirror reflects eight full main scan lines. The laser beams

go to the F-theta lens 1 [E], F-theta lens 2 [F], BTL (barrel toroidal lens) [G], and mirror

[H]. Then these laser beams go to the drum through the toner shield glass [I].

The laser synchronizing detector [J] determines the main scan starting position. This

sensor sends a synchronization signal when the laser synchronization detector mirror

[K] reflects the laser beam to the detector as the laser beam starts its sweep across

the drum.

The laser synchronization detector detects only the beams emitted from Channels 1

and 0, the uppermost beams of each parallel array.

PTM 2-36 B070/B071

Page 62

2.5 DRUM UNIT

2.5.1 PROCESS CONTROL

Drum potential gradually changes for the following reasons:

• Dirty optics, exposure glass

•

Dirty charge corona casing, grid plate

• Deterioration of drum sensitivity

What Happens at Power On

Here is a description of what happens while the fusing temperature is below 100°C

immediately after the main power switch is switched on (process control must also be

enabled with SP3901 001, or this will not happen).

At any time, this process can also be executed manually by using SP2962. However,

process control must be enabled with SP3901 001 and the fusing temperature must

be below 100°C, or this will not work.

1. Drum potential sensor is calibrated.

2. Drum starts first rotation after fusing temperature reaches 100°C.

3. ID sensor is calibrated (Vsg).

4. Readout from the drum potential sensor is used to adjust:

• Grid voltage (Vg)

• Laser diode (LD) power.

NOTE: This step occurs only if process control is enabled with SP3901 001 (Auto

Process Control On/Off Setting). If this SP is disabled, then:

• Development bias is set to the value stored in SP2201 1

• Grid voltage is set to the value stored in SP2001 1

•

Laser power is set to the values stored in SP2103

5. TD sensor is calibrated (Vref).

Any SC codes that are generated during auto process control are logged in the

memory and do not appear. The machine will continue to operate.

PTM 2-37 B070/B071

Page 63

2.5.2 DRUM UNIT COMPONENTS

8

7

6

5

4

3

The drum unit consists of the components shown in the above illustration. An organic

photoconductor drum (diameter: 100 mm) is used for this model.

9

1

2

B070D865.WMF

1. OPC Drum

2. Drum Potential Sensor

3. Pick-off Pawl

4. Image Density Sensor

6. Cleaning Brush

7. Cleaning Blade

8. Quenching Lamp

9. Charge Corona Unit

5. Toner Collection Coil

PTM 2-38 B070/B071

Page 64

2.5.3 DRUM DRIVE

[C]

[A]

[B]

[D]

B070D202.WMF

The drive from the drum motor [A] is transmitted to the drum and the cleaning unit

through timing belts, gears, the drum drive shaft [B], and the cleaning unit coupling

[C].

The drum motor has a drive controller, which outputs a motor lock signal when the

rotation speed is out of the specified range. The drum speed for the B070 (90 cpm) is

450 mm/s and for the B071 (105 cpm) 500 mm/s.

The flywheel [D] on the end of the drum drive shaft stabilizes the rotation speed.

PTM 2-39 B070/B071

Page 65

2.5.4 DRUM CHARGE

Overview

[A]

B070D203.WMF

This copier uses a double corona wire Scorotron system to charge the drum. Because

of the high speed of this copier, two corona wires are needed to give a sufficient,

uniform negative charge to the drum surface. The stainless steel grid plate makes the

corona charge uniform and controls the amount of negative charge on the drum

surface by applying a negative voltage to the grid.

The CBG (Charge, Bias, Grid) power pack [A] supplies a constant corona current to

the corona wires, –1600 µA for Photo mode and –1400 µA for all other modes (Text,

Text/Photo, Pale, Generation Copy).

The voltage to the grid plate is automatically controlled to maintain the correct image

density in response to changes in drum potential caused by dirt on the grid plate and

charge corona casing. This is described in Process Control section in more detail.

PTM 2-40 B070/B071

Page 66

Charge Corona Wire Cleaning

[D]

[A]

[A]

[B]

[C]

B070D558.WMF

Air flowing around the charge corona wire may deposit toner particles on the corona

wires. These particles may interfere with charging and cause low density bands on

copies.

The wire cleaner pads [A] automatically clean the wires to prevent such a problem.

The wire cleaner is driven by a dc motor [B]. Normally the wire cleaner [C] is at the

front end (the home position). Just after the main switch is turned on, the wire cleaner

motor turns on to bring the wire cleaner to the rear and then back to the home

position. When the wire cleaner [D] moves from the rear to the home position, the wire

cleaner pads swivel, bringing the pads into contact with the wires, and clean the wires

as it moves forward.

Cleaning is executed when:

• The machine is switched on and the fusing temperature is less than 100°C while

auto process control executes.

• Every 24 hours.

• After every 5,000 copies. This can be adjusted with SP2804 002 (Charge Corona

Cleaner Setting – Corona Wire Cleaning Interval).

PTM 2-41 B070/B071

Page 67

2.5.5 DRUM CLEANING

Overview

[C]

[A]

[B]

[A]

[A]

[D]

B070D866.WMF

[B]

B070D867.WMF

[B]

[E]

This copier uses a counter blade system to clean the drum. In a counter blade system,

the drum cleaning blade [A] is angled against drum rotation. The counter blade system

has the following advantages:

• Less wearing of the cleaning blade edge

• High cleaning efficiency

Due to the high efficiency of this cleaning system, the pre-cleaning corona and

cleaning bias are not used for this copier.

The cleaning brush [B] helps the cleaning blade. The brush removes toner from the

drum surface and any remaining toner is scraped off by the cleaning blade. Toner on

the cleaning brush is scraped off by the mylar [C] and falls onto the toner collection

coil [D]. The coil transports the toner to back to the toner entrance tank in the toner

bank unit for recycling.

To remove any accumulated toner at the edge of the cleaning blade, the drum turns in

reverse for about 40 ms [E] at the end of every copy job. This is also during long copy

jobs every 30 min. For details, refer to SP2506 002 (Cleaning Interval – Multiple Copy

- Inteval) in Section “5. Service Tables”.

The accumulated toner is deposited on the drum and is removed by the cleaning

brush.

PTM 2-42 B070/B071

Page 68

2.5.6 CLEANING UNIT DRIVE

[B]

[A]

[D]

[C]

B070D206.WMF

Drive from the drum motor is transmitted to the cleaning unit drive gear via the timing

belt [A] and the cleaning unit coupling [B]. This coupling drives the cleaning brush [C]

directly. The cleaning brush then transmits the drive to the gear at the front, which

drives the toner collection coil gear [D].

PTM 2-43 B070/B071

Page 69

Cleaning Blade Pressure and Side-to-Side Movement

[C]

[D]

[B]

[A]

B070D868.WMF

The spring [A] always pushes the cleaning blade against the drum. The cleaning blade

pressure can be manually released by pushing up the release lever [B]. To prevent

cleaning blade deformation during transportation, the release lever must be locked in

the pressure release (upper) position.

The guide roller [C] at the rear end of the cleaning blade holder touches the cam gear

[D], which moves the blade from side to side. This movement helps to disperse

accumulated toner to prevent early blade edge wear.

PTM 2-44 B070/B071

Page 70

2.5.7 OTHERS

Air Flow Around the Drum

[E]

[G

[B]

[A]

[C]

B070D208.WMF

[F]

[D]

The drum cooling fan [A] draws cool air through the filter [B] and sends it to the center

of the drum [C], then over the charge corona unit [D].

Holes in the flanges on both ends of the drum allow air to pass through the drum to

cool it. After the air has passed through the center of the drum, the exhaust fan [E]

draws the air out of the interior of the machine, through the toner filter [F] to remove

free floating toner, through the ozone filter [G] to remove ozone, then finally out of the

machine.

To keep the temperature inside the machine constant, the drum cooling fan turns

slowly during standby, but turns faster during copying.

NOTE: This ozone filter does not require replacement.

PTM 2-45 B070/B071

Page 71

Drum Pick-off Pawls

[A]

[B]

[C]

B070D559.WMF

[D]

If the paper does not separate from the drum after image transfer, the drum pick-off

pawls strip the paper from the drum.

Pressure from small springs [A] press the pick-off pawls [B] against the surface of the

drum.

The shaft [C] and the cam [D] move the pick-off pawls from side to side to ensure that

they never remain at the same location (this prevents wear on the drum).

PTM 2-46 B070/B071

Page 72

Drum Quenching

[A]

B070D209.WMF

In preparation for the next copy cycle, light from the quenching lamp [A] neutralizes

any charge remaining on the drum.

The quenching lamp consists of an array of 16 red LEDs extending across the full

width of the drum.

PTM 2-47 B070/B071

Page 73

2.6 DEVELOPMENT

2.6.1 OVERVIEW

7

6

8

1

2

3

9

4

10

13

B070D301.WMF

1. Hopper Filter

2. Hopper Center Filter

3. Toner Hopper Sensor

4. Agitator

5. Toner Supply Roller

6. Upper Development Roller

7. Doctor Blade

12

11

8. Separator

9. Toner Transport Coil

10. Development Agitator

11. TD Sensor

12. Paddle Roller

13. Lower Development Roller

5

B070D302.WMF

This copier uses a double roller development system and a dual component

development process with toner particles 6.8 µm and developer particles 50 µm. To

improve image quality, the width of the magnetic area on the lower development roller

has been reduced.

This system differs from single roller development systems in that:

• It develops the image in a narrower area

• It develops the image twice

•

The relative speed of each development roller against the drum is reduced.

This machine contains a toner recycling system. Toner recycled from the drum

cleaning unit is transferred to the toner hopper with fresh toner, where they are mixed

by the toner agitator. The mechanism is explained in the Toner Supply and Recycling

section.

PTM 2-48 B070/B071

Page 74

2.6.2 DEVELOPMENT MECHANISM

[E]

[C]

[F]

[G]

[H]

[A]

[D]

B070D303.WMF

Toner and developer are mixed in the toner agitator by the cross-mixing roller [A]. The

[B]

paddle roller [B] picks up the developer and sends it to the upper development roller

[C]. Internal permanent magnets in the development rollers attract the developer to the

development roller sleeve. Developer from the upper development roller sleeve is also

attracted to the lower development roller [D].

The upper development roller carries the developer past the doctor blade [E] which

trims the developer to the desired thickness. Backspill (excess toner) spills over the

separator [F] to the toner transport coil [G] which sends the developer from back to

front to the cross-mixing roller.

In this machine, black areas of the latent image are at a low negative charge (about –

150 V) and white areas are at a high negative charge (about –800 V).

The development roller is given a negative bias to attract negatively charged toner to

the black areas of the latent image on the drum.

The development rollers continue to turn, carrying the developer to the drum [H].

When the developer brush contacts the drum surface, the low-negatively charged

areas of the drum surface attract and hold the negatively charged toner. In this way,

the latent image is developed.

PTM 2-49 B070/B071

Page 75

2.6.3 DRIVE

[C]

[D]

[F]

[B]

[E]

[A]

B070D304.WMF

The gears in the development unit are driven by the development drive gear [A] when

the development motor [B] (a dc servomotor) turns.

The gears in the toner hopper are driven by the toner supply roller drive gear [C] when

the toner supply roller clutch [D] activates.

A one-way clutch on the paddle roller knob [F] prevents counter-clockwise rotation of

the paddle roller.

PTM 2-50 B070/B071

Page 76

2.6.4 CROSSMIXING

[B]

[C]

[E]

[F]

[A]

[D]

[C]

B070D303.WMF

[E]

[B]

[F]

[A]

[D]

B070D571.WMF

This copier uses a standard cross-mixing mechanism to keep the toner and developer

evenly mixed. It also helps agitate the developer to prevent developer clumps from

forming and helps create the triboelectric charge.

The developer on the turning development rollers [A] is split into two parts by the

doctor blade [B]. The part that stays on the development rollers forms the magnetic

brush and develops the latent image on the drum. The part that is trimmed off by the

doctor blade goes to the backspill plate [C].

As the developer slides down the backspill plate to the agitator [D], the mixing vanes

[E] move it slightly toward the rear of the unit. Part of the developer falls into the auger

inlet and is transported to the front of the unit by the auger [F].

PTM 2-51 B070/B071

Page 77

2.6.5 DEVELOPMENT BIAS

[A] [B] [C]

[D]

B070D305.WMF

The CBG (Charge Bias Grid) power pack [A] applies the negative development bias (550V) to both the lower sleeve roller and upper sleeve roller through the receptacles

[B] and the sleeve roller shafts [C].

The development bias prevents toner from being attracted to the non-image areas on

the drum where there is residual voltage. In addition, the development bias changes

with the image density setting chosen for the copy job by the user.

The development rollers [D] employ fixed shafts that do not rotate. This eliminates

friction on the shafts so they never require lubrication.

PTM 2-52 B070/B071

Page 78

2.7 TONER SUPPLY AND RECYCLING

2.7.1 OVERVIEW

[G]

[C]

[F]

[B]

[E]

[A]

B070D902.WMF

[D]

Toner is supplied from a toner bank [A] on the left side of the machine and separated

from the development unit. The toner bank holds two bottles, but only one bottle

operates at a time.

A toner bottle motor turns the bottle [B], causing toner to leave the bottle and drop into

the toner entrance tank [C].

The toner transport coil in the toner transport tube [D] transports toner to the toner

supply cylinder [E]. Due to the length of the toner supply path, a toner supply pump [F]

is needed to draw the toner into the toner hopper [G].

Here are some important points to remember about the toner bank:

•

The toner bank holds two toner bottles. This doubles the toner supply capacity for

the machine and allows replacement of an empty toner bottle while the machine is