Page 1

TUFF-TORQ K61A TRANSAXLE SERVICE MANUAL

Table of Contents – Page 1 of 2

SAFETY INFORMATION

SPECIFICATIONS

REMOVING THE TRANSAXLE FROM THE TRACTOR

TRANSAXLE DISASSEMBLY AND INSPECTION

PINION

DIFFERENTIAL GEAR

CENTER CASE

MOTOR SHAFT

PUMP SHAFT

TRANSAXLE ASSEMBLY AND ADJUSTMENT

BYPASS RETURN

BRAKE INTERLOCK

NEUTRAL ADJUST ECCENTRIC

PUMP SHAFT

SWASH PLATE

PUMP CYLINDER BLOCK

MOTOR SHAFT

CENTER CASE

MOTOR SHAFT AND CENTER CASE INSTALLATION

DIFFERENTIAL GEAR

AXLE SHAFTS AND DIFFERENTIAL INSTALLATION

PINION

TRANSAXLE CASE

BRAKE

DAMPER

BLEEDING AIR FROM THE OIL CIRCUIT

UNIT OUT OF TRACTOR

UNIT IN TRACTOR

TRANSAXLE NEUTRAL ADJUSTMENT

BELTS AND LINKAGE

BELT REPLACEMENT

BELT ROUTING - BOTTOM VIEW

REASSEMBLY

BELT ADJUSTMENT

BRAKE LINKAGE

FOOT BRAKE

DESCRIPTION AND OPERATION

ADJUSTMENT

PARKING BRAKE

DESCRIPTION AND OPERATION

TRANSAXLE BRAKE

DESCRIPTION AND OPERATION

BRAKE BAND ADJUSTMENT

Page 2

TUFF-TORQ K61A TRANSAXLE SERVICE MANUAL

Table of Contents – Page 2 of 2

BELTS AND LINKAGE -Continued

HYDROSTATIC CONTROL LINKAGE

DESCRIPTION AND OPERATION

LUBRICATION

PEDAL ADJUSTMENT

CRUISE CONTROL

DESCRIPTION AND OPERATION

COMPONENTS

PLATE-HYDROSTATIC CONTROL ARM AND HOUSING

BRACKET MAGNET

MAGNET

BRAKE SWITCH AND MOUNTING BRACKET

RELAY

TROUBLESHOOTING

Page 3

R

Tuff-Torq

K61A Transaxle

Page 4

About This Manual

This manual was written expressly for servicing Tuff Torq K61A transaxles, as

used in 1994--1999 260-Series Toro Wheel Horse tractors. The Toro Company

has made every effort to make the information in this manual complete and

correct.

This manual was written for the service technician; basic mechanical/electrical

skills are assumed. The Contents page lists the systems and the related topics

covered in this manual.

We hope that you will find this manual a valuable addition to your service shop.

If you have any questions or comments regarding this manual, please contact

us at the following address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420--1196

Portions of this manual are reprinted courtesy of Tuff Torq Corporation and New

Holland North America.

The Toro Company reserves the right to change product specifications or this

manual without notice.

COPYRIGHT – ALL RIGHTS RESERVED

The Toro Company – 2000

Bloomington, MN 55420 – U.S.A

1

Page 5

Contents

Safety Information 3.............................

Specifications 4.................................

Removing the Transaxle from the Tractor 5........

Transaxle Disassembly and Inspection 6..........

Pinion 14..........................................

Differential Gear 14.................................

Center Case 15....................................

Motor Shaft 15.....................................

Pump Shaft 16.....................................

Transaxle Assembly and Adjustment 17............

Bypass Return 17..................................

Brake Interlock 17..................................

Neutral Adjust Eccentric 19..........................

Pump Shaft 20.....................................

Swash Plate 20....................................

Pump Cylinder Block 21.............................

Motor Shaft 22.....................................

Center Case 23....................................

Motor Shaft and Center Case Installation 23...........

Differential Gear 25.................................

Axle Shafts and Differential Installation 25.............

Pinion 26..........................................

Transaxle Case 27.................................

Brake 28..........................................

Damper 29........................................

Bleeding Air from the Oil Circuit 29...................

Unit Out of Tractor 29..........................

Unit in Tractor 29..............................

Transaxle Neutral Adjustment 30.....................

Belts and Linkage 31..............................

Belt Replacement 31...............................

Belt Routing—Bottom View 32.......................

Reassembly 32....................................

Belt Adjustment 33.................................

Brake Linkage 35..................................

Foot Brake 35.................................

Description and Operation 35...............

Adjustment 35............................

Parking Brake 35..............................

Description and Operation 35...............

Transaxle Brake 36.................................

Description and Operation 36....................

Brake Band Adjustment 37..........................

Hydrostatic Control Linkage 38.......................

Description and Operation 38....................

Lubrication 38.................................

Pedal Adjustment 38...............................

Cruise Control 39..................................

Description and Operation 39....................

Components 39...............................

Plate-Hydrostatic Control Arm and Housing 39.....

Bracket Magnet 40.............................

Magnet 40....................................

Brake Switch and Mounting Bracket 40...........

Relay 40......................................

Troubleshooting 41...............................

2 Tuff Torq Model K61A Hydrostatic TransaxleContents

Page 6

Safety Information

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION—

read the instruction because it has to do

with your safety. Failure to comply with

the instruction may result in personal

injury or even death.

This manual is intended as a service and repair manual

only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Tuff Torq

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark plug

wire(s) before c leaning, adjusting, or repair.

Avoid injury from high pressure oil...

Keep body and hands away from pin hole leaks or

nozzles that eject high pressure oil. Use cardboard or

paper to locate hydraulic leaks. Oil escaping under high

pressure can penetrate the skin and cause injury. Oil

accidentally injected into the skin must be surgically

removed within a few hours by a doctor familiar with this

form of injury or gangrene may result.

Avoid laceration and amputations...

model K61A hydrostatic transaxle. The tractor and

attachment operator’s manuals c ontain safety information

and operating tips for safe operating practices. Operator’s

manuals are available through your local Toro distributor

or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420--1196

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases can

explode. Keep cigarettes, sparks, and flames away from

the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other debris

that could be picked up and thrown by the powered

equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine.

3Tuff Torq Model K61A Hydrostatic Transaxle Safety Information

Page 7

Specifications

Axle Torque Output

Rated: 215 ft. lb. (290 NSm)........................

Peak:

Maximum Input Speed 3000 RPM.............

Input Shaft Size 0.58 in. (14.85mm)...................

.........................

654 ft. lb. (880 NSm)

Reduction Ratio

Axle Shaft Size 1.0 in. (25.4mm)....................

Maximum Static Weight on Axle 584 lb. (265kg)....

Weight — Dry

Brake

Brake Capacity 288 ft. lb. (390 NSm) at 55 lb. (245NSm) Brake Arm Force....................

Differential

Gears Heat-Treated............................

Housings Aluminum Die Castings.........................

Tow Valve

Oil

Oil Capacity

Ground Speed

.............................

...............................

Maximum Forward 5.3 MPH (8.5km/hr).............

Maximum Reverse 2.3 MPH (3.7km/hr).............

...................

.....................

........................

........................

......................

26.97:1

38 lb. (17.5kg)

Dry Band

Automotive-Type Bevel Gears

Standard (Brake Release)

10W--30 API Service Class H or Higher

3.5 qt. (3.3 liter)

4 Tuff Torq Model K61A Hydrostatic TransaxleSpecifications

Page 8

Removing the

Disconnect the brake rod, control rod, tow valve rod, and

reservoir hose from the top of the transaxle.

Transaxle from the

Tractor

Working from the bottom of the tractor, remove the

transaxle drive belt tension spring and drive belt from the

transaxle pulley.

Remove the access panel from the rear of the tractor, to

expose the fuel tank/transaxle.

Support the rear of the tractor with jack stands and

remove the rear wheels.

Remove the two bolts securing the transaxle support rods

to the tractor frame.

Remove the four nuts from the U-bolts which hold the two

axle shafts to the frame.

Remove the transaxle and place it upright on the work

bench.

Remove the fan and spacer from the input pulley (three

cap screws).

Remove the pulley from the shaft (one snap ring).

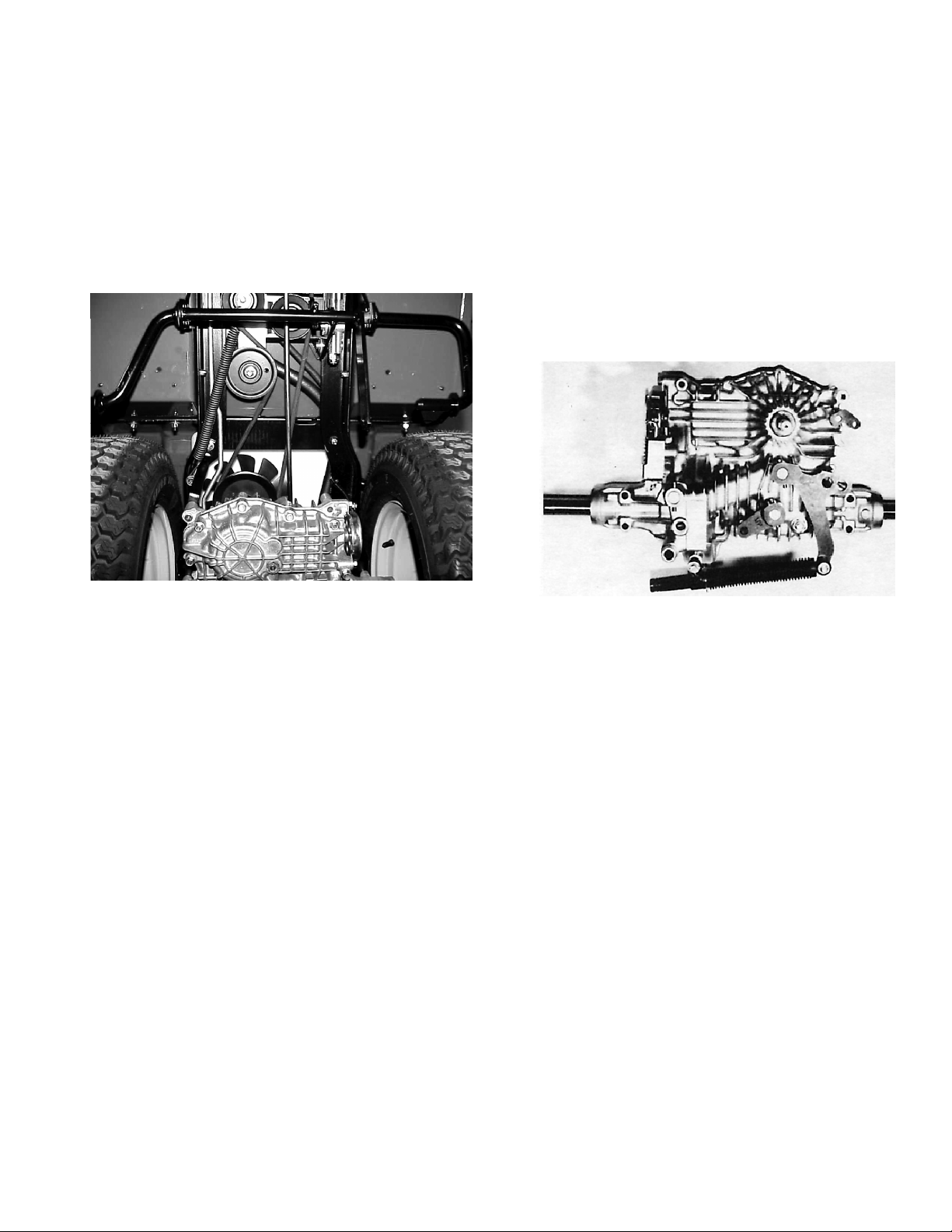

Figure 1

Figure 2

5Tuff Torq Model K61A Hydrostatic Transaxle Removing the Transaxle from the Tractor

Page 9

Transaxle

Disassembly and

Inspection

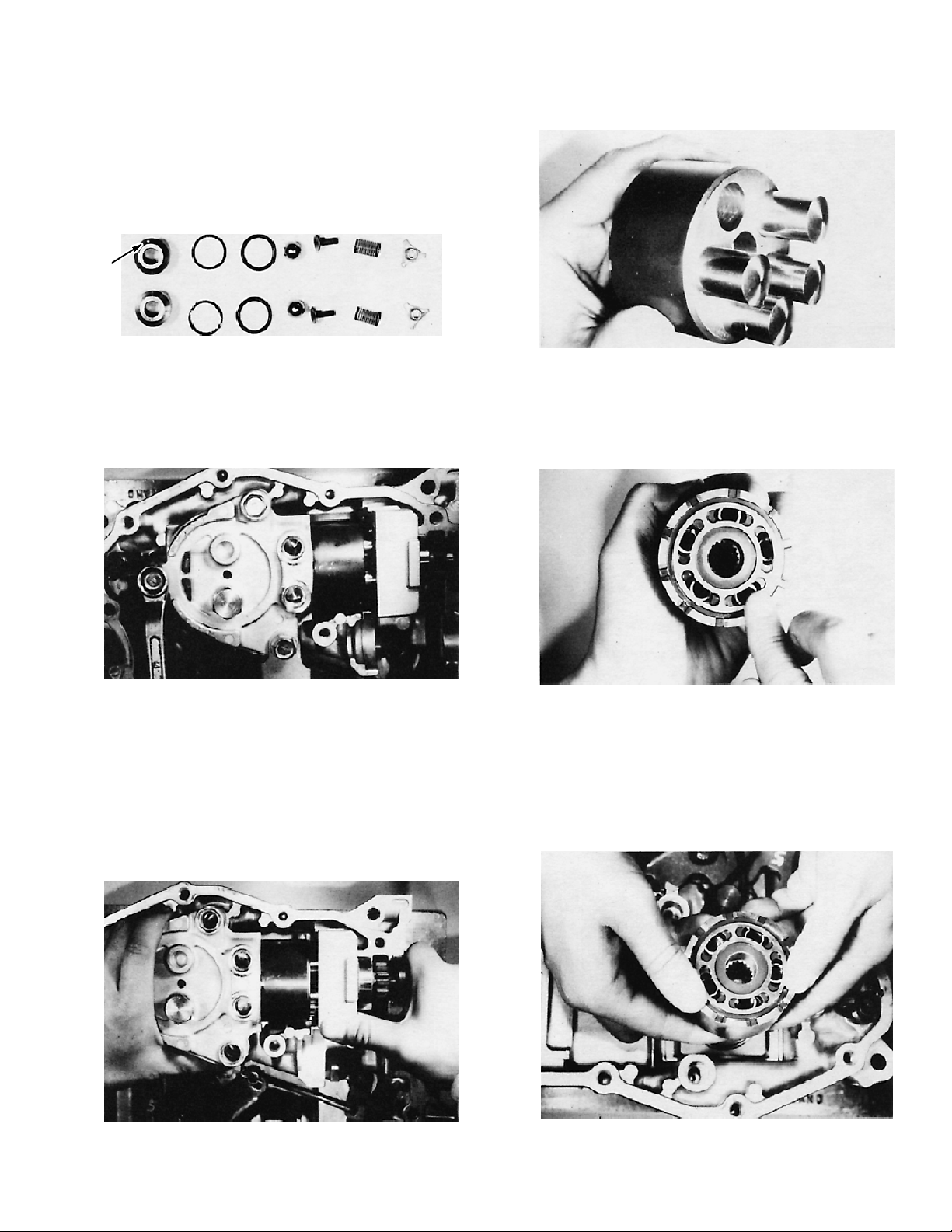

Begin disassembly and inspection of the transaxle by

thoroughly cleaning the outside surface of the

transmission.

IMPORTANT: Clean your work area thoroughly and

cover the workbench with clean paper. This is

extremely important as just one grain of sand can

cause a hydrostatic transmission to fail.

Remove the drain bolt from the bottom center and drain

the oil from the transaxle sump.

Remove the shock absorber by detaching the E clip,

washer, and cotter pin and its washer. Later models use a

spring clip retainer to secure the shock absorber.

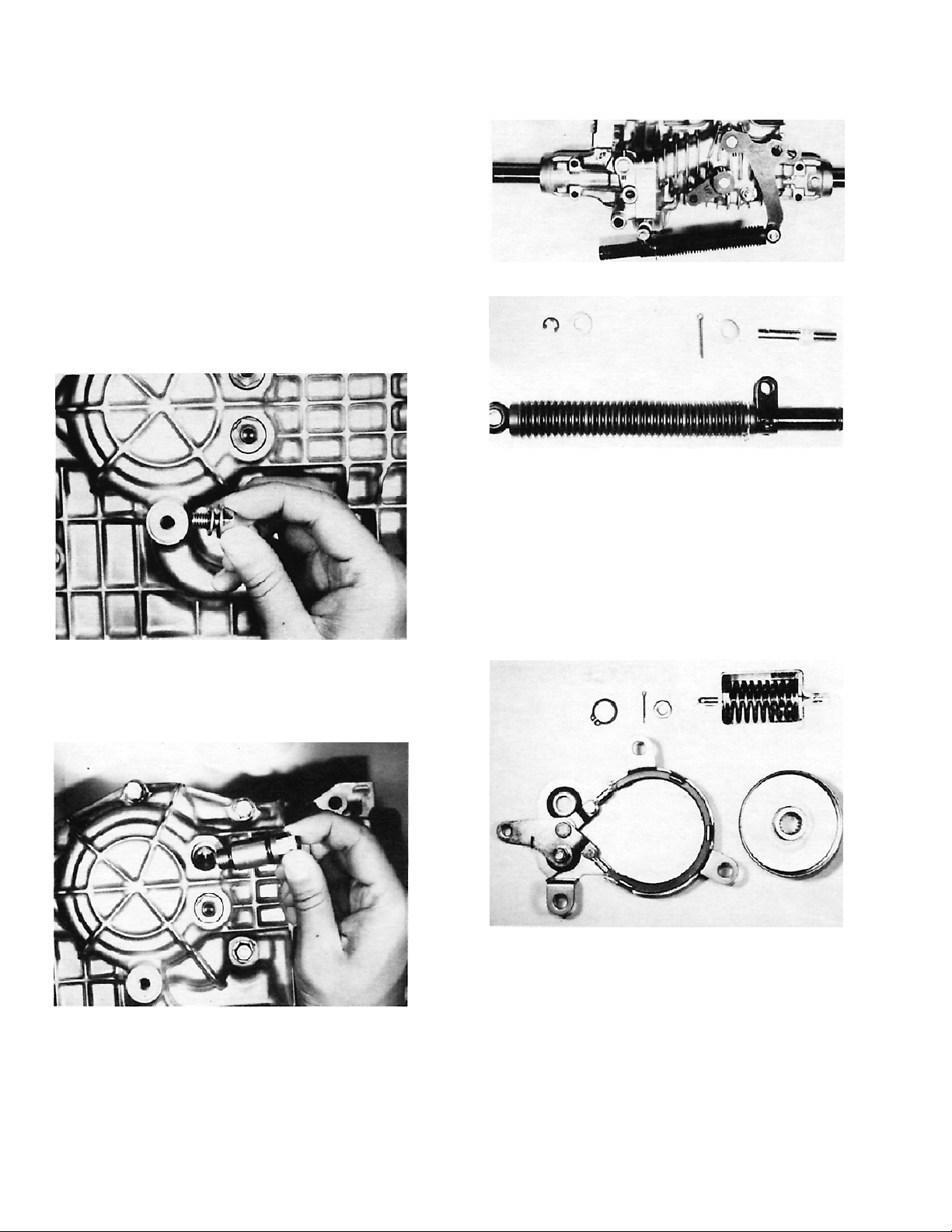

Figure 5

Figure 6

Remove the band brake assembly and brake rod

component by taking out the cotter pin, washer, and three

12mm bolts. Replace the assembly if the friction material

or actuating parts are worn or damaged.

Figure 3

Remove the pressure fill plug and drain the oil from the

rotating groups.

Figure 4

Remove the ring and brake drum.

IMPORTANT: The brake drum and brake band must

be free from oil or dust.

Figure 7

6 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Disassembly and Inspection

Page 10

Open the transaxle case by taking out the 13 perimeter

12mm bolts and the single center bolt. Pry the bottom

half of the case free from the top half, using care not to

damage the seating surface.

Remove the differential gear assembly.

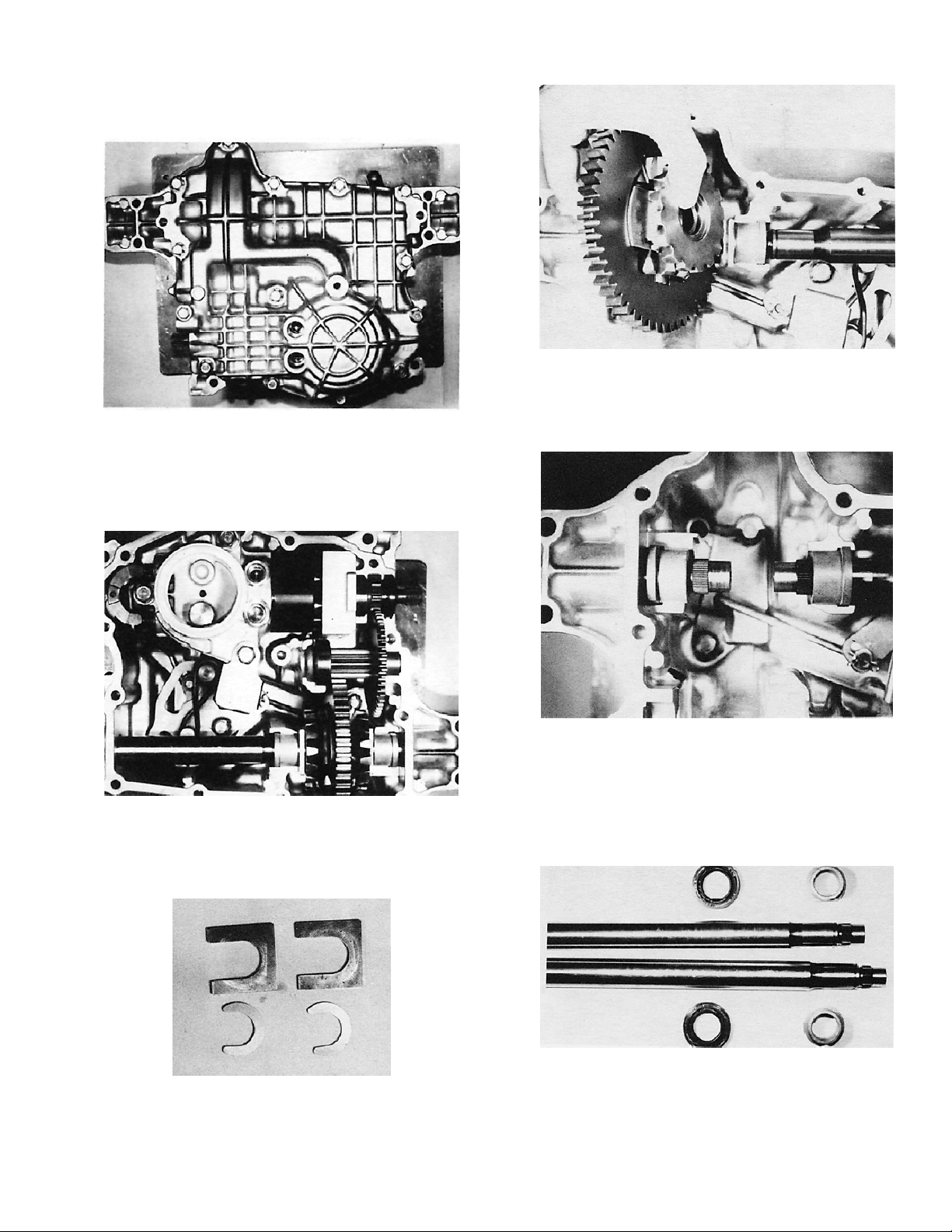

Figure 11

Figure 8

Lift the pinion shaft assembly from the upper case. There

is a ball bearing on one end of the shaft and a bushing on

the other end.

Figure 9

Remove the collar and ring from the left and right axle

shaft.

Remove the left and right axle shaft and two bushings

from the upper case.

Figure 12

Remove the two seals from the upper case. Remove the

axle bearings if replacing.

Inspect all parts for wear or damage and replace if

necessary.

Figure 10

Figure 13

7Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Disassembly and Inspection

Page 11

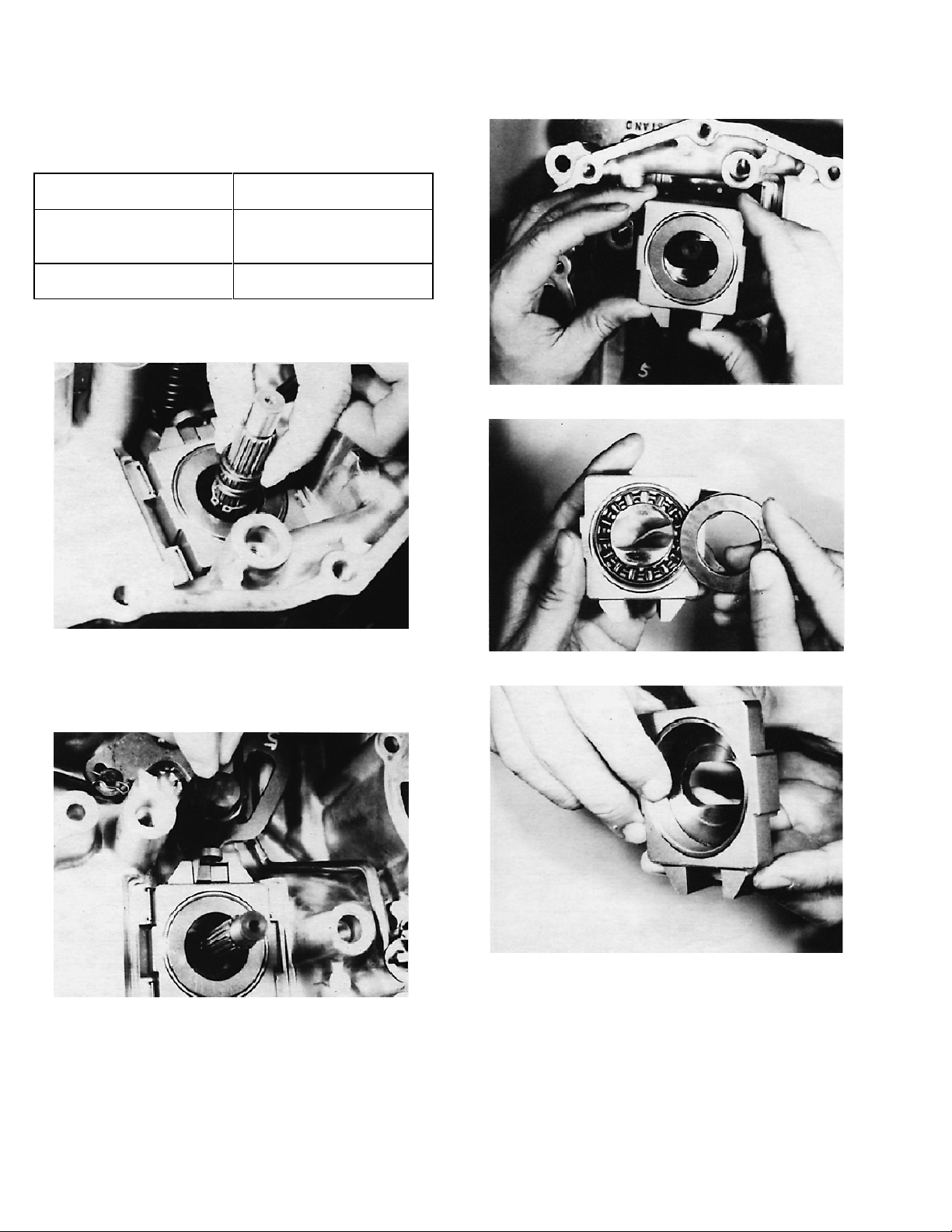

Measure the inside diameter of the bushings and the

outside diameter of the left and right axle shaft.

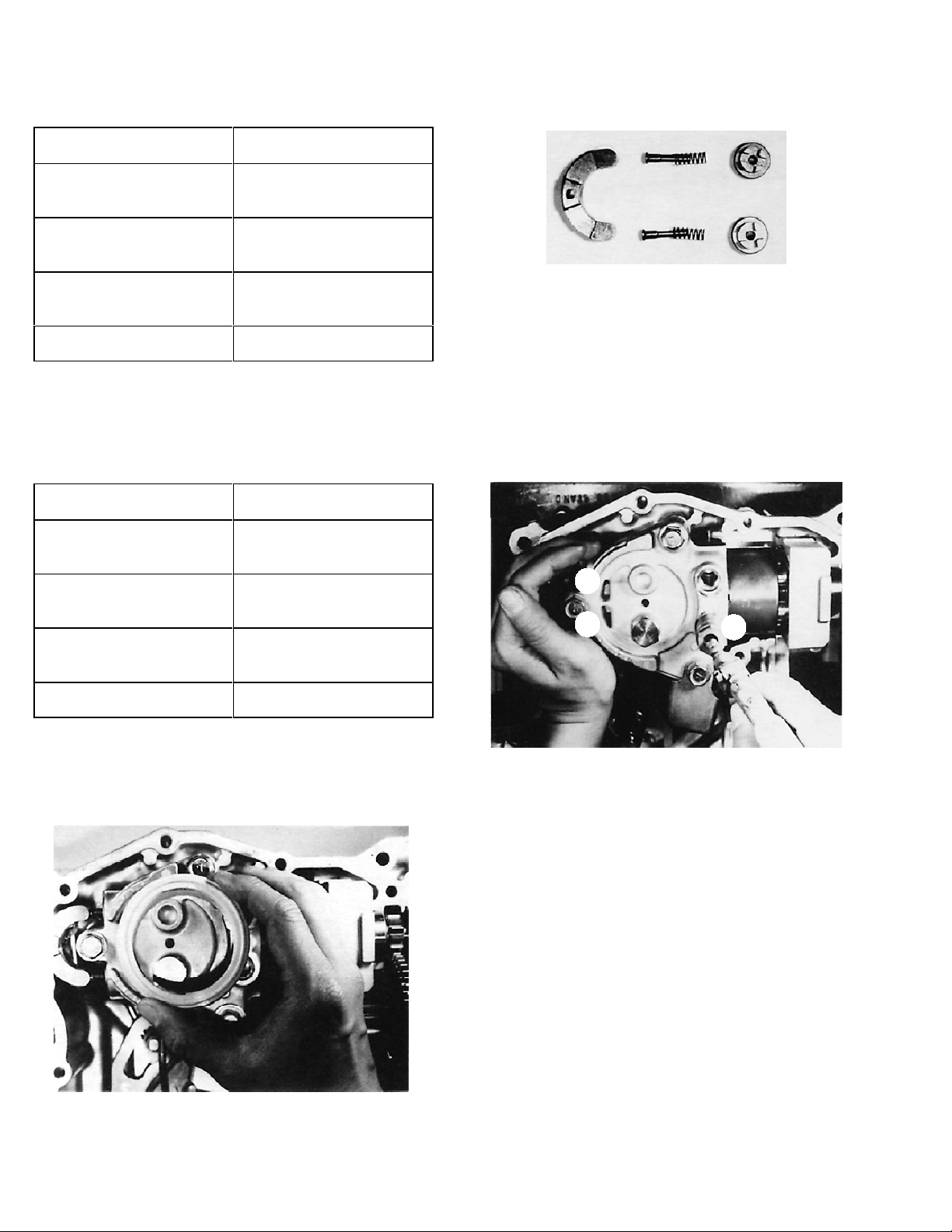

Tab le 1

Measurement Should be:

Disconnect the C arm from the push valve bypass shaft.

Remove the two push pins, springs, and valves from the

center case.

Bushings -

Inside Diameter

Axle Shaft

Outside Diameter

22.06-22.15mm

(.868-.872″)

21.98-22mm

(.865-.866″)

Clearance 0.08-0.17mm

(.003-.006″)

Maximum Wear Limit 0.5mm (.019″)

Measure the inside diameter of the axle bores in the

housing and the outside diameter of the left and right axle

shaft.

Tab le 2

Measurement

Housing Axle Bore --

Inside Diameter

Axle Shaft

Outside Diameter

Should be:

25.44-25.53mm

(1.001-1.005″)

25.32-25.38mm

(.996-.999″)

Clearance 0.06-0.21mm

(.002-.008″)

Figure 15

Remove sleeve A1, sleeve A2, the two backup rings,

packings, balls, ball holders, springs, and bypass holders,

using air pressure if necessary.

Note: Remove the two check valve assemblies only if

necessary (leaking, sticking, or if extra-thorough cleaning

is necessary). Air pressurization will remove one valve;

the other can be pushed out from behind, after the center

section is removed.

1

2

3

Maximum Wear Limit 0.5mm (.019″)

Take the filter out of the center case.

Replace the filter whenever transaxle is

Note:

disassembled for service.

Figure 14

1. Valve A1

2. Valve A2

Figure 16

3. Pressurize with air to

remove valves, if needed

(pressure fill plug shown

installed, with allen head

plug removed).

8 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Disassembly and Inspection

Page 12

Carefully inspect the packings (o-rings) to ensure they

are not deformed, cut, or scratched. Use new packings

on reassembly.

IMPORTANT: When removing the sleeves, note that

their valves are different, and therefore not

interchangeable. The A1 valve, located farthest from

the axle, has a small hole in it, in addition to the

large hole in the center. For reassembly purposes,

mark the port from which this valve is removed.

1

Remove the cylinder block from the pump shaft.

IMPORTANT: Be sure the pistons do not fall out of

the block during removal.

Figure 17

1. Note hole

Loosen the three bolts and remove the magnet from the

center case. Clean the magnet thoroughly; use air

pressure if necessary.

Figure 18

Make a mark on the top of the motor thrust bearing

housing, for easy identification during reassembly.

Remove the motor shaft assembly, along with the center

case assembly, from the upper case.

IMPORTANT: Pay close attention to t he contact

surfaces of the center case and cylinder blocks to

prevent damage.

Figure 20

Inspect the five cylinder bores for burrs or scoring. The

cylinder block and center section must be replaced if any

scratch is deep enough to catch on a fingernail.

Figure 21

Inspect the five pistons and all parts of the cylinder block

assembly for wear or damage.

Replace the center case and both cylinder block

assemblies if any cylinder block assembly parts are

damaged.

Figure 19

Figure 22

9Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Disassembly and Inspection

Page 13

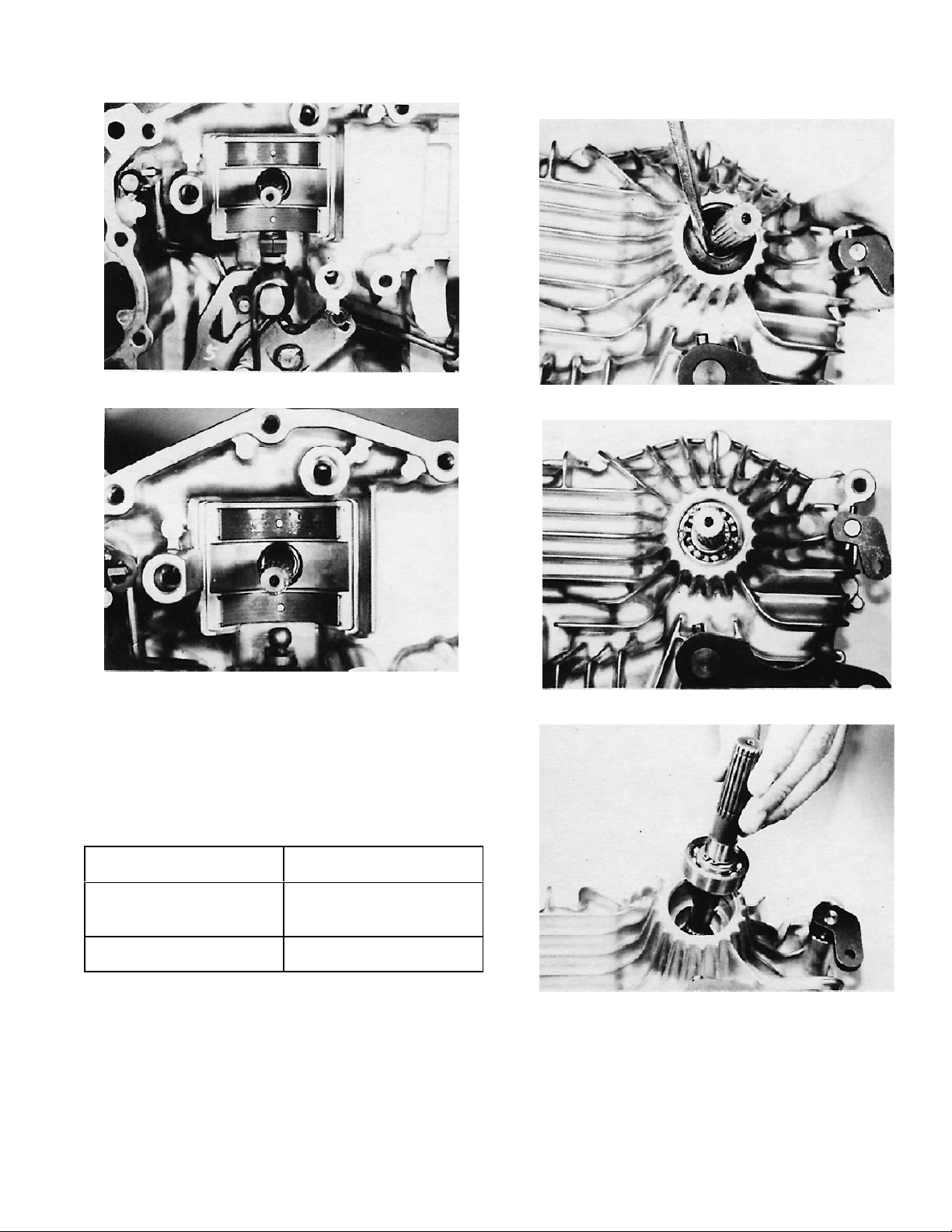

Measure the clearance between the swash plate and shift

blocks.

Replace both shift blocks and the swash plate with new

parts if they are beyond the maximum wear limit.

Tab le 3

Inspect the swash plate, thrust bearing, thrust plates, and

bushing for w ear or damage. Replace with new parts if

necessary.

Measurement

Should be:

Clearance 0.01-0.11mm

(.0003-.004″)

Maximum Wear Limit 0.15mm (.005″)

Remove the spring and ring from the pump s haft.

Figure 25

Figure 23

Remove the swash plate subassembly from the pump

shaft.

Figure 24

Figure 26

Figure 27

10 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Disassembly and Inspection

Page 14

Remove the shift blocks from the control shaft and

inspect them for wear or damage. Replace if necessary.

Remove the input shaft, seal, and bearing from the upper

case. Remove oil seal and large snap ring from the upper

case. Remove the input shaft and bearing from the case.

Figure 28

Figure 29

Remove the two metal thrust pads from the upper case

and inspect them for wear or damage.

Replace both thrust pads with new parts if the maximum

wear limit is exceeded.

Tab le 4

Figure 30

Figure 31

Measurement

Should be:

Thickness 1.45-1.55mm

(.057-0.61″)

Maximum Wear Limit 1.30mm (.051″)

Figure 32

11Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Disassembly and Inspection

Page 15

Note: If servicing a transaxle with low to moderate use, it

is not necessary to disassemble or remove any of the

levers or linkages from the upper case, unless a part is

damaged or there is an oil leak. If doing a complete

rebuild, all shafts should be removed, inspected, and

packings (o-rings) replaced. If leaving the shafts in place,

avoid excessive use of cleaning solvent on the upper

case half, and do not use solvent that will damage the

packings.

Detach the torsion spring from the control shaft.

Figure 33

Inspect the control shaft, fulcrum, and torsion spring for

wear or damage and replace if necessary.

Figure 36

Inspect the packings (o-rings) to ensure that they are not

cut, scratched, or deformed.

Remove the roll pin and lever from the control shaft

subassembly and the lock nut from the neutral adjusting

fulcrum.

Figure 34

Figure 37

Drive the roll pin from the brake arm secured to the

internal brake shaft.

Remove the brake arm from the brake shaft.

Figure 35

Figure 38

12 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Disassembly and Inspection

Page 16

Drive the roll pin from the brake arm for the external band

brake.

Remove the brake rod and brake arm from the upper

case.

Inspect the packing for cuts, scratches, or deformation.

Figure 39

Remove the snap pin and washer from the brake rod.

Figure 40

Remove the brake shaft from the upper case.

Inspect the packing (o-ring) for cuts, scratches, or

deformation.

Figure 42

Remove the roll pin from the push valve bypass release

arm.

Disconnect the push valve bypass release arm from the

bypass shaft.

Figure 43

Remove the bypass shaft subassembly, spring, and

bypass rod.

Inspect the packing (o-ring) for cuts, scratches, or

deformation.

Figure 41

Figure 44

13Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Disassembly and Inspection

Page 17

Pinion

Differential Gear

Remove the bearing, bushing, washer, and shaft gear

from the pinion shaft.

Inspect all parts for wear or damage. Replace if

necessary.

Figure 45

Measure the inside diameter of the bushing and the

outside diameter of the pinion shaft.

Tab le 5

Measurement

Bushings --

Inside Diameter

Pinion Shaft --

Outside Diameter

Clearance 0.06-0.16mm

Maximum Wear Limit 0.5mm (.019″)

Should be:

15.05-15.13mm

(.592-.595″)

14.97-14.99mm

(.589-.590″)

(.002-.006″)

Remove the differential side gears, thrust washers,

differential pinion gears, and differential pinion shaft from

the final gear.

Inspect all parts for wear or damage. Replace if

necessary.

Figure 46

Measure the inside diameter of the differential pinion

gears and the outside diameter of the differential pinion

shaft.

Tab le 6

Measurement

Differential Pinion Gears --

Inside Diameter

Differential Pinion Shaft --

Outside Diameter

Clearance 0.05-0.10mm

Maximum Wear Limit 0.5mm (.019″)

Should be:

15.05-15.06mm

(.592-.593″)

14.96-14.98mm

(.589-.590″)

(.019-.003″)

14 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Disassembly and Inspection

Page 18

Center Case

Motor Shaft

Take out the two knock pins, plug, and packing (o-ring)

(early models), if required. If the shaft bushings require

replacement, remove them.

Figure 47

Inspect the center case by running your fingernail over its

surface. Replace the center case and cylinder blocks if

fingernail catches on scratches.

Remove the cylinder block assembly from the motor

shaft.

Inspect the five cylinder bores for burrs or scoring.

Figure 50

Inspect the five pistons and all parts of the cylinder block

assembly for wear or damage.

Replace the center case and both cylinder block

assemblies if any cylinder block assembly parts are

damaged.

Figure 48

Figure 49

Figure 51

Remove the spring and snap ring from the motor shaft.

Remove the thrust bearing and housing from the motor

shaft and inspect them for wear or damage. Replace if

necessary.

Figure 52

15Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Disassembly and Inspection

Page 19

Remove the snap rings, washer, bearing, and seal from

the motor shaft (brake shaft).

Do not remove the bearing unless it needs to be

Note:

replaced. It is a press fit and will likely be damaged in the

process of removing it.

Figure 53

Pump Shaft

Remove the two snap rings, washer, and bearing from

the pump shaft.

Do not remove the bearing unless it needs to be

Note:

replaced. It is a press fit and will likely be damaged in the

process of removing it.

Inspect the motor shaft and bearing for wear or damage

and replace if necessary.

Figure 54

Figure 55

Inspect the bearing and pump shaft for wear or damage

and replace if necessary.

Figure 56

16 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Disassembly and Inspection

Page 20

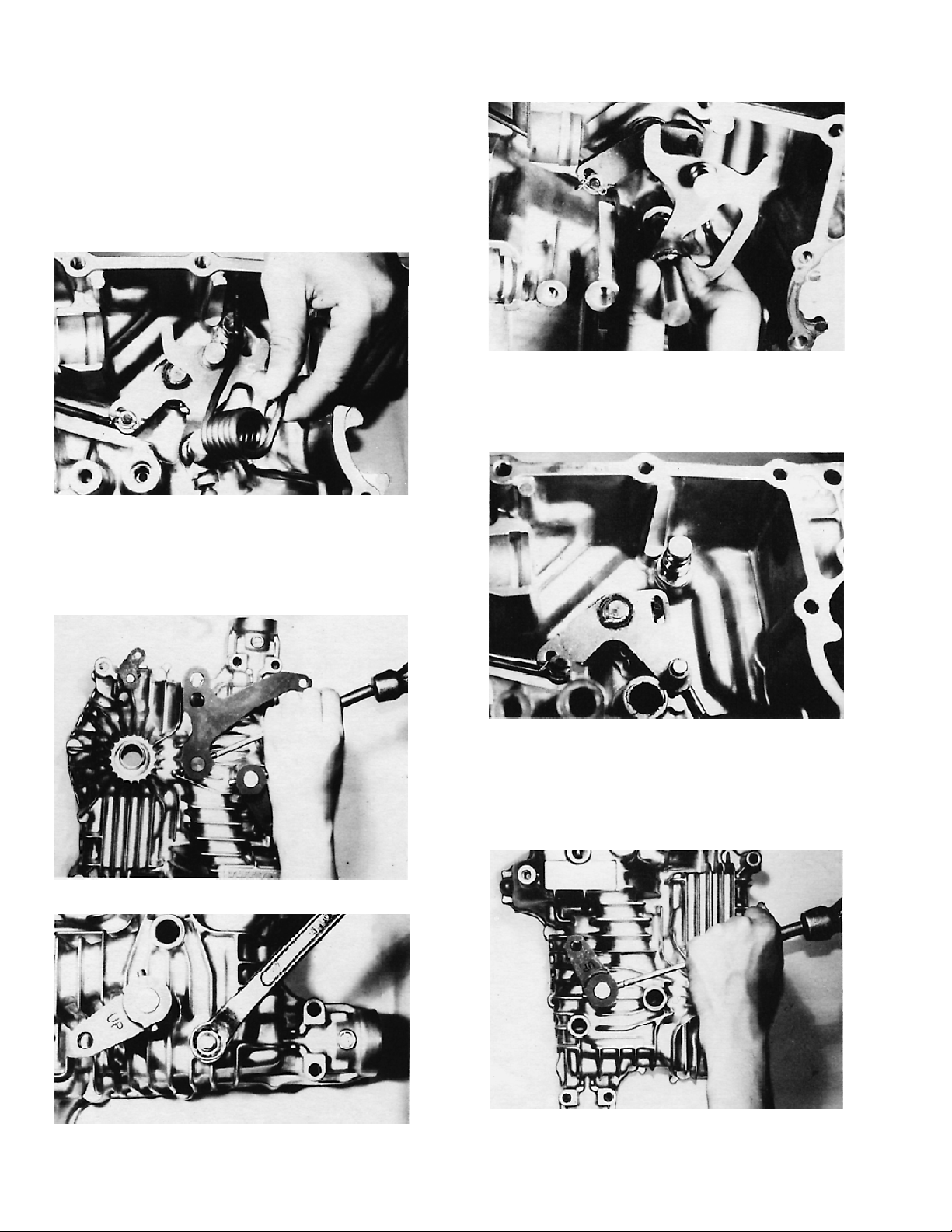

Transaxle Assembly

and Adjustment

IMPORTANT: A clean working environment is

essential during assembly of the transaxle.

Otherwise, your rebuild efforts may not be

successful.

Clean all parts thoroughly prior to assembly. Do not reuse

o-rings or seals; replace with new parts.

Bypass Return

Place the new packing (o-ring) and spring on the bypass

shaft.

Apply grease to packing before installation.

Note:

Brake Interlock

Place the new packing (o-ring) and brake rod on brake

arm.

Apply grease to packing before installation.

Note:

Apply a light film of grease into the hole of the upper

case, then insert the brake arm into the upper case.

Install the bushing, E-ring, and new packing (o-ring) on

the brake shaft.

Figure 57

Attach the bypass s haft to the upper case.

Figure 58

Place the push valve release arm on the bypass shaft.

Drive the roll pin through the arm and shaft.

Install the bypass rod on the bypass shaft.

Figure 60

Place the spring on the brake shaft.

Figure 61

Apply a light film of grease into the hole in the upper

case, then insert the brake shaft in the upper case, hook

the spring to the housing, and connect the bypass valve

rod to the brake shaft.

Figure 59

Figure 62

17Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 21

Connect the brake rod to the brake shaft. Place the

washer on the brake rod and then attach the snap pin to

the brake rod.

Figure 63

Install the brake arm on the brake shaft. Make sure the

word “UP” on the brake arm is visible.

Figure 66

Drive the roll pin through the brake arm and brake shaft.

Figure 64

Figure 65

Figure 67

18 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 22

Neutral Adjust Eccentric

Place new packing (o-ring) on the neutral adjust

eccentric.

Apply grease to packing before installation.

Note:

Figure 68

Apply a light film of grease into the hole on the upper

case and insert the neutral adjust eccentric into the upper

case.

Install the control shaft in the upper case and position the

torsion spring as shown.

Figure 71

Drive the roll pin through the hydrostatic control arm and

control shaft.

Figure 69

Place new packing (o-ring) and torsion spring on the

control shaft.

Note: Apply grease to packing before installation.

Figure 70

Figure 72

Install the washer and nut on the neutral adjust eccentric.

Figure 73

19Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 23

Pump Shaft

Install the bearing on the pump shaft.

Install two washers and two snap rings on the pump

shaft.

Make sure the snap rings are seated correctly in

Note:

the pump shaft grooves.

Figure 74

Insert the pump shaft into the upper case.

Install the snap ring and the new seal onto the pump

shaft.

Apply grease to the lip of the seal and place tape

Note:

on the spline of the pump shaft to keep the seal lip from

becoming damaged during installation.

Figure 77

Swash Plate

Insert the two metal thrust pads into the upper case.

Apply oil to the pads.

Figure 75

Figure 76

Figure 78

Apply grease to the inside of the shift blocks to hold them

in place and install the shift blocks on the control shaft.

Figure 79

20 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 24

Assemble thin thrust plate, thrust bearing, and thick

thrust plate to the swash plate.

Apply new oil to all parts prior to installation.

Note:

Be sure to place the thinner thrust plate at the

Note:

bottom of the swash plate.

Pump Cylinder Block

Place the snap ring and spring on the pump shaft.

Figure 80

Place the swash plate on the pump shaft. The shift

blocks should be facing toward the slit found on the

swash plate.

Figure 81

Tab le 7

Figure 82

Insert a backup washer and spring into each piston, and

install the pistons in the cylinder block holes.

Note: All parts should be cleaned, and new oil applied to

them, before assembly.

Figure 83

Measurement

Clearance Between Swash

Plate and Shift Blocks

Should be:

0.01--0.11mm

(.0003-.004″)

Figure 84

21Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 25

Install the cylinder block subassembly on the pump shaft.

Figure 85

Motor Shaft

Install the bearing, washer, and two snap rings on the

motor shaft.

Note: Be sure to place the bearing retainer, which has

the larger inner diameter, at the bottom of the housing.

Figure 89

Assemble the housing to the motor shaft. Install snap ring

and spring on the motor shaft.

Figure 86

Attach the new seal to the motor shaft.

Note: Apply grease to the lip of the seal and place tape

on the spline of the motor shaft to keep the seal lip from

becoming damaged during installation.

Figure 87

Apply new oil to the thrust bearing and install the thrust

bearing on the housing.

Figure 90

Insert a backup washer and spring into each piston, and

install the pistons in the cylinder block.

Note: Clean all parts and apply new oil to them before

assembly.

Assemble the cylinder block to the motor shaft.

Figure 91

Figure 88

22 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 26

Center Case

Motor Shaft and Center Case

Install the two knock pins and shaft bushings in the

center case, if removed.

When installing the bushings, make sure they are

Note:

seated correctly in the center case.

Figure 92

Install the two retainers, springs, ball holders, balls, new

packings (o-rings), backup rings, as well as sleeve A1

and sleeve A2 into the center case.

Installation

Oil contact surfaces of center case and cylinder blocks.

Figure 95

Note: Be careful that no damage occurs to the center

case surface during reassembly.

Figure 93

IMPORTANT: Remember, sleeve A1 and sleeve A2

have different valves. The A1 valve has a small hole

in it, in addition to the large hole in the center, and

must be installed in the port located farthest from the

axle.

Note: Apply grease to the packings prior to installation.

To reassemble, place each part in the bore one at a time,

using tweezers or similar tool. Carefully press or tap each

sleeve into its final position.

Check ball movement after assembly.

A1A2

Figure 96

Figure 94

23Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 27

Install the motor s haft subassembly and center case

subassembly in the case at the same time.

The motor housing is installed so the pistons are

Note:

“in” at the top and “out” at the bottom. Make sure the

pump cylinder block splines are aligned with the pump

shaft. Compress the motor pistons into the cylinder block

while aligning the center case with the mounting holes.

Slowly work the parts into final position, making sure the

pump shaft engages with the cylinder block, the motor

housing and shaft bearing/seal go straight down into their

notches in the upper case, and the motor thrust bearing

stays in the correct position.

Attach the two bypass actuating valves, springs, and

push pins to the center case. Check push pin movement

after assembly.

Figure 99

Note: Assemble and handle components with care so

that no damage occurs to center case surfaces.

Figure 97

Secure the three bolts and magnet to the upper case.

Tighten using a torque of 32 ft. lbs. - 46 ft. lbs. (4.5N

.

m).

6.5N

.

m-

Attach the C arm to the bypass shaft.

Figure 100

Place a new filter on the center case groove.

Figure 98

Figure 101

24 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 28

Differential Gear

Axle Shafts and Differential

Attach the two differential pinions to the differential pinion

shaft.

Connect the differential pinion shaft to the final gear.

Place the two thrust washers on the final gear.

Figure 102

Attach the two differential side gears to the final gear.

Installation

Install new seal on the left and right axle shaft.

Figure 104

Apply grease to the lip of each seal before

Note:

installing and use tape on axle to protect seal from

damage during installation.

Figure 103

Figure 105

Install the left and right axle shaft and two bushings in the

upper case.

Figure 106

25Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 29

Connect the differential gear assembly to the left and

right axle shaft.

Figure 107

Pinion

Secure the bearing to the pinion shaft.

Attach the shaft gear, washer, and bushing to pinion

shaft.

Install a retaining ring on the left and right axle shaft.

Figure 108

Install a collar on the left and right axle shaft.

Figure 110

Install the pinion shaft in the upper case.

Note: Place the bushing on the end of the pinion shaft so

that the flat surface of the bushing collar rests parallel to

the top case surface.

Figure 111

Figure 109

26 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 30

Transaxle Case

You can significantly speed up the filling and bleeding

process by adding oil to the upper case half before

installing the lower half. To do this, plug the oil vent hose

fitting. Secure the case so it does not move, and then fill

it to half full with oil.

Thoroughly clean the mating surface of each case half.

Apply a thin, even bead of Loctite 587 or Permatex Ultra

Blue RTV sealant to the upper case mating surface.

IMPORTANT: Do not turn the transaxle over until the

sealant has had time to set up.

Join the lower case to the upper case.

Torque Sequence

1 280 in. lbs. (31.6N·m)

2 280 in. lbs. (31.6N·m)

3 280 in. lbs. (31.6N·m)

4 280 in. lbs. (31.6N·m)

5 280 in. lbs. (31.6N·m)

6 280 in. lbs. (31.6N·m)

7 280 in. lbs. (31.6N·m)

8 280 in. lbs. (31.6N·m)

9 280 in. lbs. (31.6N·m)

10 280 in. lbs. (31.6N·m)

11 280 in. lbs. (31.6N·m)

12 300 in. lbs. (33.9N·m)

13 300 in. lbs. (33.9N·m)

Torque Value

Figure 112

Note: Apply sealant to the inside surface around the bolt

holes, and to the surface of the inner boss for the single

center bolt.

Figure 113

Figure 114

Figure 115

27Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 31

Install new packings (o-rings) on the pressure fill

connector.

Attach the connector to the center case through the lower

case. (Install finger tight if planning to bleed air from

transaxle before installing in tractor.)

Note: For quick air bleeding, apply new oil into the

connector hole of the center case while rotating the pump

and motor shaft by hand. See

Circuit

completely filling transaxle with oil.

. Be sure sealant has had time to set up before

Bleeding Air from the Oil

Brake

Secure the brake drum to the motor shaft with retaining

ring.

IMPORTANT: The brake drum must be free from oil or

dust.

Figure 118

Figure 116

Secure the drain bolt to the lower case using a new seal

washer. Tighten using a torque of 9 ft. lbs. - 12 ft. lbs.

.

m - 1.7N.m).

(1.3N

Figure 117

Attach the band brake using the three bolts. Secure the

bolts while pushing the band brake assembly toward the

lower case side. Tighten using a torque of 16 ft. lbs. - 21

ft. lbs. (2.3N·m - 3.0N·m).

Figure 119

28 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 32

Attach the brake rod to brake arm. When inserting the

rod (adjuster) into the hole on the brake cam lever, adjust

the length of the rod to fit the brake arm hole.

Put the brake rod component onto the band brake and

install the washer and cotter pin on the brake rod.

Figure 120

Note: Alternate oil—a synthetic oil (5W--50 or similar

viscosity range) may be used in place of SAE 10W--30.

This oil will permit an increase in the maximum operating

temperature of approximately 18_F(10_C).

Install the transaxle in the tractor.

Top off the reservoir with oil through the reservoir/fill cap,

filling it to the cold fill mark.

Test operate the transaxle as described in the following

section, and make sure transaxle is filled to the correct oil

level.

Damper

Attach stud to the upper transaxle case.

Install the shock absorber, washer, and cotter pin on the

stud. (Later production is secured with spring clips.)

Install the washer and ring.

Figure 121

Bleeding Air from the Oil Circuit

Unit Out of Tractor

You can bleed the transaxle oil circuit free of air before

installing it in the tractor.

Plug the reservoir/fill hose port on top of the transaxle.

Position the transaxle with the bottom side facing up.

Rotate the input shaft by hand while adding

approximately 2 quarts (1.9 liters) of SAE 10W-30 API

Service Classification SH or higher oil through the

transaxle pressure fill port.

Figure 122

Unit in Tractor

Bleed the oil circuit so that it is free of air whenever you

install a new or rebuilt transaxle in the tractor.

Add SAE 10W-30 API Service C lassification SH or higher

oil to the transaxle through the reservoir fill cap. Fill to the

reservoir’s cold fill mark. Attempt to get as much air as

possible out of the hose before starting the bleeding

process.

Alternate oil—a synthetic oil (5W--50 or similar

Note:

viscosity range) may be used in place of SAE 10W--30.

This oil will permit an increase in the maximum operating

temperature of approximately 18_F(10_C).

Raise the two rear tires from the ground and support the

tractor securely with jack stands.

Disconnect the seat switch and attach a jumper wire

across the terminals so that the tractor will run without an

operator in the seat.

Start the engine and maintain low idle speed.

Depress the forward and reverse hydrostatic control

pedals alternately until the wheels begin to rotate. Shut

engine off.

Lower the tractor to the ground.

29Tuff Torq Model K61A Hydrostatic Transaxle Transaxle Assembly and Adjustment

Page 33

Use extreme caution while completing the

following bleeding process.

Restart the engine and set at low idle speed.

Depress the forward hydrostatic control pedal and push

the tractor rearward. Then depress the reverse

hydrostatic control pedal and push the tractor forward

until the tractor is able to move under its own power.

Loosen the locknut, B, and turn the eccentric, A,

counterclockwise until the wheels start to rotate

forward, C.

Turn the eccentric clockwise until the wheels begin to

rotate in reverse, D.

Move the eccentric to the center of the neutral band, E,

and tighten the locknut.

Increase engine speed to full RPM.

Operate the tractor, making quick starts and panic stops,

until the transaxle is operating properly. Top forward

speed is 5 MPH--5.5 MPH (8km/hr--8.8km/hr).

Top off the reservoir with oil through the reservoir/fill cap,

filling it to the cold fill mark.

Note: Transaxle oil capacity is 3.5 qts. (3.3 liters).

Transaxle Neutral Adjustment

You must perform a neutral adjustment whenever a

tractor creeps in neutral, or whenever a new or rebuilt

transaxle is installed in the tractor.

Remove the access panel at the rear of the tractor to

gain access to the neutral adjusting eccentric, which is

located on the top right-hand side next to the gas damper

arm. (Fig. 123 shows wrench applied to eccentric—seat,

fender, and fuel tank are removed in photo for clarity.)

Raise the rear wheels off the ground and support the

tractor securely on jack stands.

Disconnect the seat switch and attach a jumper wire

across the terminals. This enables the tractor to run

without an operator in the seat.

Check the neutral adjustment by depressing the motion

control pedal in forward and reverse. At full throttle, there

should be no wheel movement after the pedal returns to

neutral. Readjust as needed until neutral is obtained.

Figure 124

Set engine speed at full throttle.

Figure 123

30 Tuff Torq Model K61A Hydrostatic TransaxleTransaxle Assembly and Adjustment

Page 34

Belts and Linkage

Belt Replacement

Note: Perform V-belt installation, routing, and inspection

procedures from beneath the tractor.

Take out the four screws holding the tunnel cover in

place. Remove the cover.

Detach the belt tension spring, A.

Disconnect the electric clutch wire.

Remove the two steering link rods from the sector gear.

Disconnect the brake rod from the transaxle.

Detach the hydrostatic control rod from the hydrostatic

pedal lever, B.

Disconnect the brake pedal safety start switch wires and

remove the bracket to which the switch(es) is/are

mounted.

Loosen the rear bolt and remove the front bolt retaining

the right-hand footrest to the frame (provides brake shaft

clearance).

Remove the hydrostatic cross shaft support brackets

from both footrests, C.

Remove the far right pin only

(the pin closest to the

hydrostatic pedal), D, from the hydrostatic cross shaft.

(Later models do not have pins.)

Note: There are three pins in the hydrostatic cross shaft.

Do not remove the other two pins.

Slide the hydrostatic cross shaft, E, to the left and

remove the hydrostatic pedal assembly, F.

Remove the roll pin from the left end of the brake cross

shaft, G.

Move the brake cross shaft to the right and route the

V-belt out of the tractor.

Figure 125 -- Bottom View

A. Belt tension spring

B. Hydrostatic control rod

C. Hydrostatic cross shaft

support bracket

D. Hydrostatic cross shaft

pin

E. Hydrostatic cross shaft

F. Hydrostatic pedal

assembly

G. Brake cross shaft

31Tuff Torq Model K61A Hydrostatic Transaxle Belts and Linkage

Page 35

Belt Routing—Bottom View

The drive belt contacts a single V-idler pulley on the left

side as it is routed from the engine pulley to the transaxle

pulley.

As it travels back from the transaxle pulley to the engine

pulley, it passes between a pair of idler pulleys (a flat idler

pulley and a V-idler pulley).

All three idler pulleys are mounted to the idler arm. Two

pulleys are spring loaded; one is held in place with an

eccentric.

Figure 126

Reassembly

After routing the V-belt, reconnect the following parts:

• Belt tension spring

• Electric clutch wire

• Two steering link rods at the sector gear

• Brake rod at the transaxle

• Hydrostatic control rod at the hydrostatic pedal lever

• Brake pedal

safety start switch

• Hydrostatic cross shaft support bracket at each

footrest

• Far right pin in the hydrostatic cross shaft (N/A, newer

models)

• Hydrostatic pedal assembly

• Roll pin in left end of the brake cross shaft

Finally, secure the tunnel cover in place.

32 Tuff Torq Model K61A Hydrostatic TransaxleBelts and Linkage

Page 36

Belt Adjustment

Remove the tunnel cover to check or adjust belt tension.

Loosen the back side idler pulley, A, and move it in the

slotted mounting hole on the idler arm, B.

For additional adjustment, turn the eccentric, C, on the

eccentric mounted idler pulley, D.

Figure 127

A. Back side idler pulley

B. Idler arm

C. Eccentric

D. Eccentric mounted idler

pulley

33Tuff Torq Model K61A Hydrostatic Transaxle Belts and Linkage

Page 37

A. Fan

B. Fan spacer

C. Snap ring

Figure 128

D. Pulley

E. Setscrew 1/4″--2 0 x 1 / 4

″

34 Tuff Torq Model K61A Hydrostatic TransaxleBelts and Linkage

Page 38

Brake Linkage

Foot Brake

Description and Operation

The foot and parking brake linkage consists of the

following main components:

• Brake pedal

• Brake lever

• Brake rod

• Return spring

• Trunnion

• Parking brake lever

When the brake pedal, A, is depressed, the brake lever,

B, (located on the other end of the brake pedal shaft)

rotates. This activates the brake rod, C, and return

spring, D, which are both connected to the brake lever.

The other end of the return spring is fastened to a

bracket located below the eccentric-mounted idler pulley.

The action is then transferred to the trunnion, F, which

connects the threaded brake rod to the control lever, E,

on the transaxle, stopping the tractor.

Adjustment

Move the control lever, E, to its most rearward position

and hold it there.

Adjust the trunnion, F, on the brake rod, C, until it slips

into the control lever, E.

Parking Brake

Description and Operation

When the brake pedal, A, is depressed and the parking

brake lever, G, is lifted, the end of the parking brake lever

lowers into position behind the brake lever, B. This

prevents the return spring, D, from disengaging the brake

when the brake pedal is released.

A. Brake pedal

B. Brake lever

C. Brake rod

D. Return spring

Figure 129

E. Control lever

F. Trunnion

G. Parking brake lever

35Tuff Torq Model K61A Hydrostatic Transaxle Belts and Linkage

Page 39

Transaxle Brake

Description and Operation

Fig. 130 illustrates the main components of the transaxle

brake.

When the brake pedal is depressed, internal linkage pulls

the brake control arm, A, forward and rotates the brake

lever, B. This movement is then transferred to the brake

rod, C, which rotates the brake shaft, D. The brake shaft

projects through the top of the case and is attached to

the brake arm, E.

When the brake arm rotates, it activates the brake spring

assembly, F. The brake link assembly then allows only so

much force to be applied to the brake band, G, for

braking action. Because the brake band encircles the

B

J

K

A

C

brake drum, H, and the brake drum is splined to the

hydrostatic motor output shaft, the tractor comes to a

stop.

At the same time, the lobe, I, located on the brake lever

acts upon the cam slot, J, profile of the swash plate

control cam, K. This locks the hydrostatic control linkage

in place (neutral position).

When the hydrostatic push valve is activated via a

hand-operated rod at the rear of the tractor, the rod, L,

connected to the brake lever is pulled to the end of the

slot in the brake lever, B. When the brake is next applied,

this rod rotates the push valve shaft, M, and actuator, N,

and deactivates the push valve plungers, O.

E

D

A. Brake control arm

B. Brake lever

C. Brake rod

D. Brake shaft

G

H

E. Brake arm

F. Brake spring assembly

G. Brake band

H. Brake drum

F

I

M

Figure 130

I. Brake lever lobe

J. Swash plate control cam slot

K. Swash plate control cam

L. Push valve rod

L

N

A

B

O

M. Push valve shaft

N. Actuator

O. Push valve plunger

36 Tuff Torq Model K61A Hydrostatic TransaxleBelts and Linkage

Page 40

Brake Band Adjustment

Loosen the rod, A, from the brake band assembly, B.

Move the brake lever, C, to its most rearward position

and hold it there.

Adjust the rod, A, until it slips easily into the hole in the

brake band assembly actuator arm, D.

Figure 131

A. Rod

B. Brake band assembly

C. Brake lever

D. Brake band assembly

actuator arm

37Tuff Torq Model K61A Hydrostatic Transaxle Belts and Linkage

Page 41

Hydrostatic Control Linkage

Pedal Adjustment

Description and Operation

The hydrostatic control pedal assembly has a forward

and reverse pad and is fitted to the cross shaft, C, for

rotation. One end of the control rod, D, is attached to the

pedal assembly; the other end is attached to the

transaxle control arm, E. The ends of the control rod are

threaded.

When the pedal is depressed, the control rod moves the

transaxle control arm. When the pedal is released, the

transaxle control arm’s internal spring deactivates the

control rod, returning the transaxle to the neutral position.

Lubrication

Grease the hydrostatic control pedal after every 50 hours

of operation.

Remove the rear fender and seat assembly.

Take out the two fuel tank mounting bolts. Remove the

tank and set it to the left side of the tractor.

Loosen the jam nut and remove the bolt from the rear rod

end of the control rod, F (where it fastens to the transaxle

control arm, E).

Adjust the rear rod end, F, of the control rod, D, so that

the rear edge of the control pedal reverse pad, B, is 1.25″

(32mm) from the footrest.

A. Forward

pedal pad

B. Reverse

pedal pad

Figure 132

C. Cross shaft

D. Control rod

E. Control arm

F. Rod ends

38 Tuff Torq Model K61A Hydrostatic TransaxleBelts and Linkage

Page 42

Cruise Control

Description and Operation

The hydrostatic transaxle can be held at a desired speed

with cruise control, standard equipment on some models.

Its effect on the transmission system is described below.

For electrical troubleshooting, refer to the Toro Riding

Products Demystification Guide, form 492--4509.

The cruise control is activated by a three-position rocker

switch located on the right-hand side of the dash panel.

Cruise can b e set with the ignition switch in the LIGHTS

or RUN position. A green light on the rocker switch

illuminates to indicate that the cruise control is ON.

After starting the tractor and reaching the desired

operating speed, engage the cruise control by placing the

control switch in the SET position. This activates the

electromagnet which holds the hydrostatic pedal in place.

The cruise can be disengaged by depressing the brake

pedal or by placing the rocker switch in the OFF position.

Electrical current to the magnet is interrupted, and the

hydrostatic pedal returns to neutral.

Components

1. Rocker switch and

housing

2. Plate-hydrostatic control

arm and bracket

3. Bracket magnet

Figure 133

4. Magnet

5. Brake switch and

mounting bracket

6. Replay

7. Wire harness

Cruise control will function with the hydrostatic pedal in

either the forward or reverse position.

The tractor cannot be started w ith the cruise control

engaged. To start the tractor, the brake pedal must be

depressed, and this disengages the cruise feature.

Figure 132

Plate-Hydrostatic Control Arm and Housing

The plate is mounted to the hydrostatic control arm by a

bracket. Because of the plate’s thickness, a longer bolt is

needed to fasten the hydrostatic linkage to the control

arm.

The magnet’s electrical leads are routed along and tied to

the hydrostatic reservoir hose. These leads must not

come in contact with any moving parts, i.e., the fan, belts,

pulleys, linkage, etc.

Figure 134

39Tuff Torq Model K61A Hydrostatic Transaxle Belts and Linkage

Page 43

Bracket Magnet

Relay

The bracket which holds the magnet is secured to the

frame by two bolts and locknuts.

Magnet

The magnet is located on the spring post of the bracket.

It is correctly seated when the tab is inserted through the

bracket slot.

Figure 135

A fourth relay is added to the relay panel when cruise

control is installed. The relay receptacle on the cruise

wire harness attaches to the existing receptacle on the

relay panel.

Figure 137

Brake Switch and Mounting Bracket

A second brake switch is used with cruise control. It is

mounted back to back with the brake safety start switch.

The bracket has a slotted hole, allowing for adjustment of

the switches. The cruise brake switch should be adjusted

to disengage when the brake pedal is slightly depressed.

Figure 136 -- Bottom View

40 Tuff Torq Model K61A Hydrostatic TransaxleBelts and Linkage

Page 44

Troubleshooting

Problem Possible Cause

No drive Incorrect oil/oil level in unit

Drive belt has failed, is worn, or tension is out of adjustment

Push valve in push position

Parking brake engaged

Control pedal linkage

Engine pulley or transmission pulley

Hydrostatic filter plugged

Push valve plunger, springs, or valve body

Directional valves stuck or spring broken

Damage to rotating groups or valve body

Damaged pinion shaft or differential assembly

No drive—one direction Control pedal bent or broken

Control pedal rod bent or binding

Control arm roll pin sheared

Directional valves sticking, broken springs, or need to be cleaned of debris

Low power—both directions Incorrect oil/oil level in unit

Drive belt has failed, is worn, is out of position, at incorrect tension, or engine

RPM

Push valve partially activated

Parking brake engaged or binding

Control pedal or linkage binding

Engine or transaxle drive pulleys loose, damaged, worn

Hydrostatic filter plugged

Directional valves sticking, need to be cleaned of debris, broken springs

Damage to rotating groups or valve body

Swash plate worn, damaged, not operating properly

Damaged output pinion or differential assembly

Low power—one direction Incorrect oil/oil level in unit

Control pedal or shaft bent, binding, or travel

Control rod bent or binding

Control arm is not secure on shaft

Clogged oil filter

Swash plate worn, damaged, or not operating properly

Check directional valve plungers for binding, broken spring, debris, or leakage

Differential assembly binding or damaged

41Tuff Torq Model K61A Hydrostatic Transaxle Troubleshooting

Page 45

Problem Possible Cause

Creeps in neutral Neutral adjustment eccentric out of position

Control pedal bent or binding

Control rod bent or binding

Swash plate control lever pin damaged, bent, binding, or worn

Swash plate cradle bearings failed, worn, or damaged

Swash plate control arm ball and socket damaged or worn

Neutral return spring failed, fatigued, or out of position

42 Tuff Torq Model K61A Hydrostatic TransaxleTroubleshooting

Page 46

Page 47

Loading...

Loading...