Page 1

WearBlockKit

TX1000WideTrackCompactToolCarrier

ModelNo.136-5821

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

FormNo.3414-689RevA

InstallationInstructions

Safety

SafetyandInstructional

Decals

1.ReadtheOperator's

Manual.

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

136-5750

2.Tensionblockguide

Installation

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Removeanyattachmentsfromthemachine.

3.Engagetheparkingbrake.

4.Lowertheloaderarmssothattheyare

approximately20to25cm(8to10inches)

abovetheframe.

5.Shutofftheengineandremovethekey.

6.Raisethemachineoffthegrounduntilyou

canaccesstheinsideofthetrackbeneath

decal136-5750

themachine.Supportthemachineusingjack

stands.

Note:Usejackstandsratedforyourmachine.

RefertotheOperator’sManualforyourmachine

todeterminetheweight.

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3414-689*A

Page 2

2

3

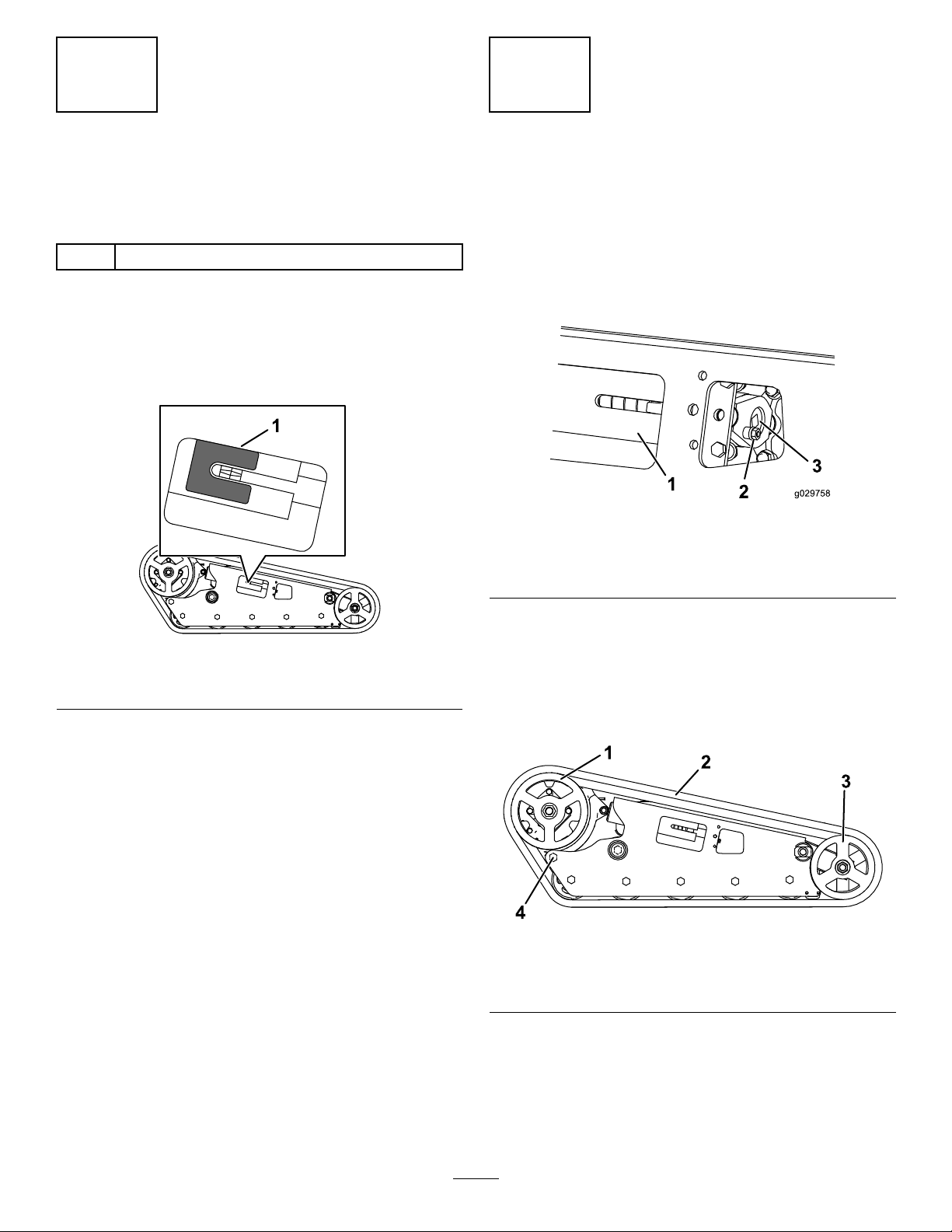

InstallingtheTensioning

Decal

Partsneededforthisprocedure:

2Decal

Procedure

Installthetensioningdecalonaclean,drysurfaceon

thetensiontubeasshowninFigure1onbothsides

ofthemachine.

RemovingtheTracks

NoPartsRequired

Procedure

Note:Completetheprocedureforbothtracks.

1.Removethelockingboltandnut(Figure2).

g029758

Figure2

1.Tensiontube3.Tensioningscrew

2.Lockingbolt

2.Loosentherearboltnearthedrivewheelonthe

g203951

Figure1

1.Decal

track(Figure3).

Note:Thisenablesthedrivewheeltopivot

forwardandreleasethetensionofthetrack.If

itdoesnotpivot,turnontheengineandbriey

movethetractioncontrolforward.

g215026

Figure3

1.Drivewheel3.Frontwheel

2.Track4.Rearbolt

3.Usinga1/2-inchdriveratchet,releasethe

drivetensionbyturningthetensioningscrew

clockwise(Figure2).

2

Page 3

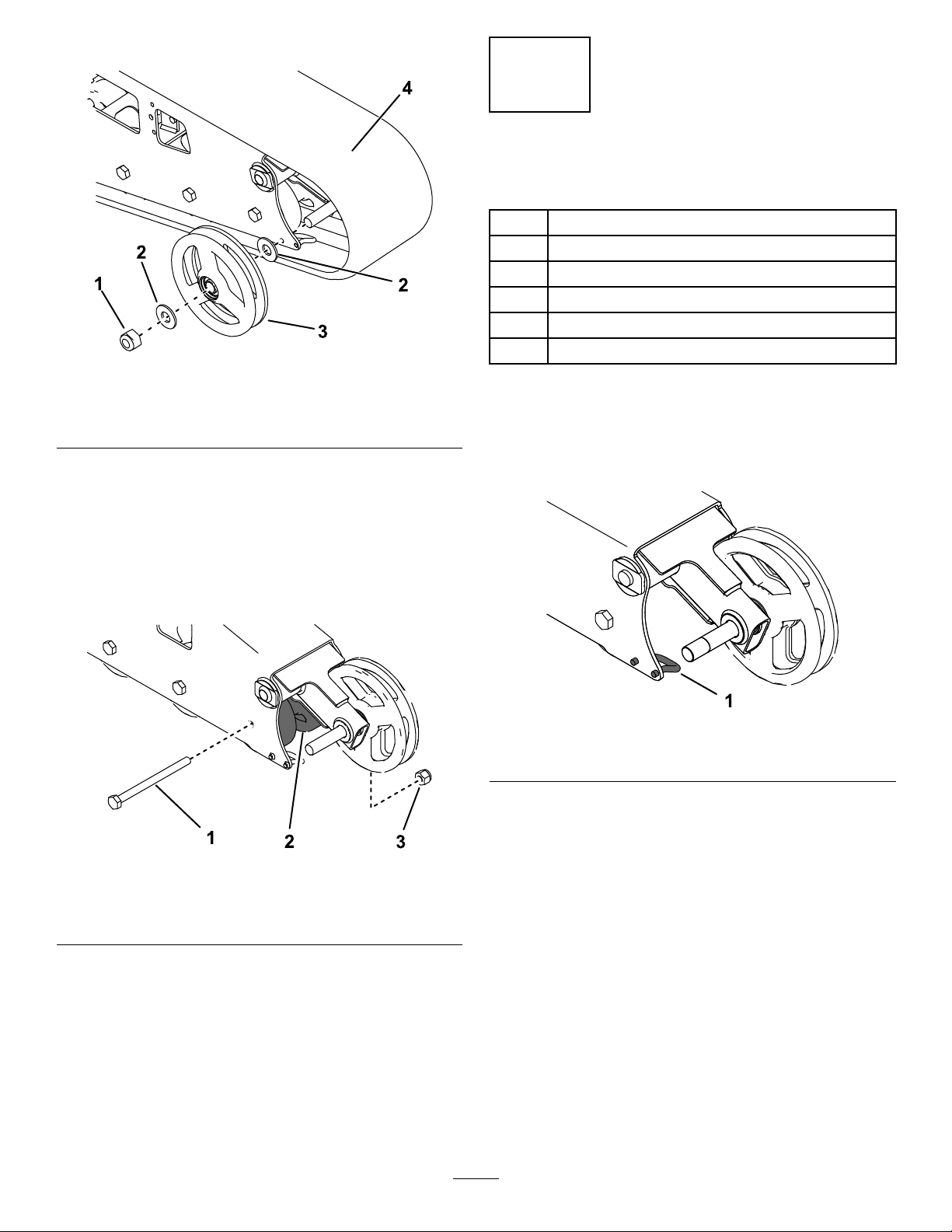

4.Removetheouterfrontwheel(Figure4).

Figure4

4

InstallingtheTrackGuides

Partsneededforthisprocedure:

2Template

4

TrackGuide

12Button-headbolt

2Hex-socket-headbolt

2Nut

g217640

2Thread-lockingcompound

1.Nut

2.Washer(2)

5.Removethetrackatthetopoftheinnerfront

wheel,peelingitoffthewheelwhilerotatingthe

trackforward.(Figure4).

6.Whenthetrackisofftheinnerfrontwheel,

removeitfromthedrivewheelandroadwheels

(Figure3).

7.Removethefrontroadwheel(Figure5).

1.Bolt(5/8x8-1/2inches)3.Nut(5/8inch)

2.Frontroadwheel

3.Outerfrontwheel

4.Track

Figure5

Procedure

Note:Completetheprocedureforbothtrackframes.

1.Completelycutofftheouterguiderod(Figure6).

g215023

Figure6

1.Guiderod

2.Removeanyweldsontheinsideoroutsideof

thetrackframe.

g217543

3.Stackthe2templatesontopofeachother,and

alignthemwiththefrontholeandthebottom

edgeofthetrackframe(Figure7).Usea

hex-socket-headboltandnutinthefrontholeto

securethetemplatestotheframe.

3

Page 4

Figure7

1.Nut3.Hex-socket-headboltin

fronthole

2.Templates4.Marktheseholes.

g217544

g215024

1.Innerguiderod

Figure9

4.Markthelocationsoftheother2holesusinga

1/4-inchcenterdrillbit(Figure7).

Note:Youmayusea1/4-inchdrillbitifyoudo

nothaveacenteringdrill.

5.Drillholes(3/8-inchdiameter)atthemarked

locations,slottingtherearholewiththehole

fromtheguiderod.

6.Removethetemplates.

7.Paintanybaremetalontheframebefore

installingthetrackguide.

8.Installatrackguideusing3button-headbolts

(Figure8).

5

InstallingtheTrack

Partsneededforthisprocedure:

2

Track(optional,soldseparately)

Procedure

Note:Completetheprocedureforbothtracks.

1.Installthefrontroadwheel(Figure5).Torque

thenutto183to223N∙m(135to165ft-lb).

2.Beginningatthedrivewheel,coilanewor

existingtrackaroundthewheel,ensuringthat

thelugsonthetracktbetweenthespacerson

thewheel(Figure3).

Note:Ensurethatthelugsinthetrackt

betweenthespacersinthemiddleofthedrive

wheel.

Figure8

1.Button-headbolt(3)

9.Applythread-lockingcompoundtotheboltsand

torquethemto27to34N∙m(20to25ft-lb).

10.Repeatthisprocedureforinnertrackframe

(Figure9).

2.Trackguide

Note:Youcanaccesstheinnerguiderodfrom

beneaththemachine.

3.Pushthetrackunderandbetweentheroad

wheels(Figure3).

g215025

4.Startingatthebottomofthefrontwheels,install

thetrackaroundthewheelsbyrotatingthetrack

rearwardwhilepushingthelugsintothewheels.

5.Intheouterfrontwheels,cleantheoldgrease

anddirtoutoftheareabetweenwherethe

washerswereinstalledandthebearingsinside

thewheels,thenllthisareaoneachsideof

eachwheelwithgrease(Figure4).

6.Installtheouterfrontwheeland2washerson

theaxleasshowninFigure4.Securethemwith

thenutremovedpreviously.

7.Torquethenutsto340to475N∙m(250to350

ft-lb).

4

Page 5

9.Aligntheclosestnotchinthetensionscrewto

thelocking-boltholeandsecurethescrewwith

thelockingboltandnut(Figure2).

6

AdjustingtheTrackTension

NoPartsRequired

ForNewTracks

1.Forbothtracks,turnthetensioningscrew

counterclockwiseuntilthetensionblockaligns

withthewhitelineclosesttothecurveoftheslot

onthedecal(Figure10).

Figure10

ForExistingTracks

1.Removethelockingboltandnut(Figure2).

2.Usinga1/2inchdriveratchet,turnthetensioning

screwcounterclockwiseuntilthetensionnut

alignswiththegreensectionofthedecal(Figure

10).

3.Aligntheclosestnotchinthetensionscrewto

thelocking-boltholeandsecurethescrewwith

thelockingboltandnut(Figure2).

4.Drivethemachine,thenparkthemachineona

levelsurface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

5.Verifythatthetensionblockalignswiththe

greenguideofthedecaloris1.3cm(1/2inch)

awayfromtherearofthetensiontubeforboth

tracks(Figure10).Adjustifnecessary.

g203962

1.Decal

2.Tensionblock

2.Aligntheclosestnotchinthetensionscrewto

thelocking-boltholeandsecurethescrewwith

thelockingboltandnut.

3.Torquetherearboltto108to122N∙m(80to

90ft-lb).

4.Lowerthemachinetotheground.

5.Drivethemachine,thenparkthemachineona

levelsurface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

6.Verifythatthetensionblockiswithinthegreen

guideofthedecaloris1.3cm(1/2inch)away

fromtherearofthetensiontubeforbothtracks

(Figure10).

Note:Thetracktensionloosensaftersome

use.

7.Removethelockingboltandnut(Figure2).

8.Usinga1/2-inchdriveratchet,turnthetensioning

screwcounterclockwiseuntilthetensionblock

alignswiththegreenguideonthedecaloris1.3

cm(1/2inch)awayfromtherearofthetension

tubeslotforbothtracks(Figure10).

5

Page 6

Notes:

Page 7

Notes:

Page 8

Loading...

Loading...