Page 1

FormNo.3422-409RevB

TrackCompletionKit

TX1000NarrowTrackCompactToolCarrier

ModelNo.136-4840

InstallationInstructions

Installation

2

RemovingtheCovers

1

PreparingtheMachine

NoPartsRequired

Procedure

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury.

Usejackstandswhensupportingthe

machine.

1.Removeanyattachmentsfromthemachine.

2.Parkthemachineonalevelsurface.

3.Engagetheparkingbrake.

4.Raisetheloaderarmsandsecurethemwiththe

cylinderlocks.

5.Shutofftheengine,removethekey,andwait

forthemachinetocool.

NoPartsRequired

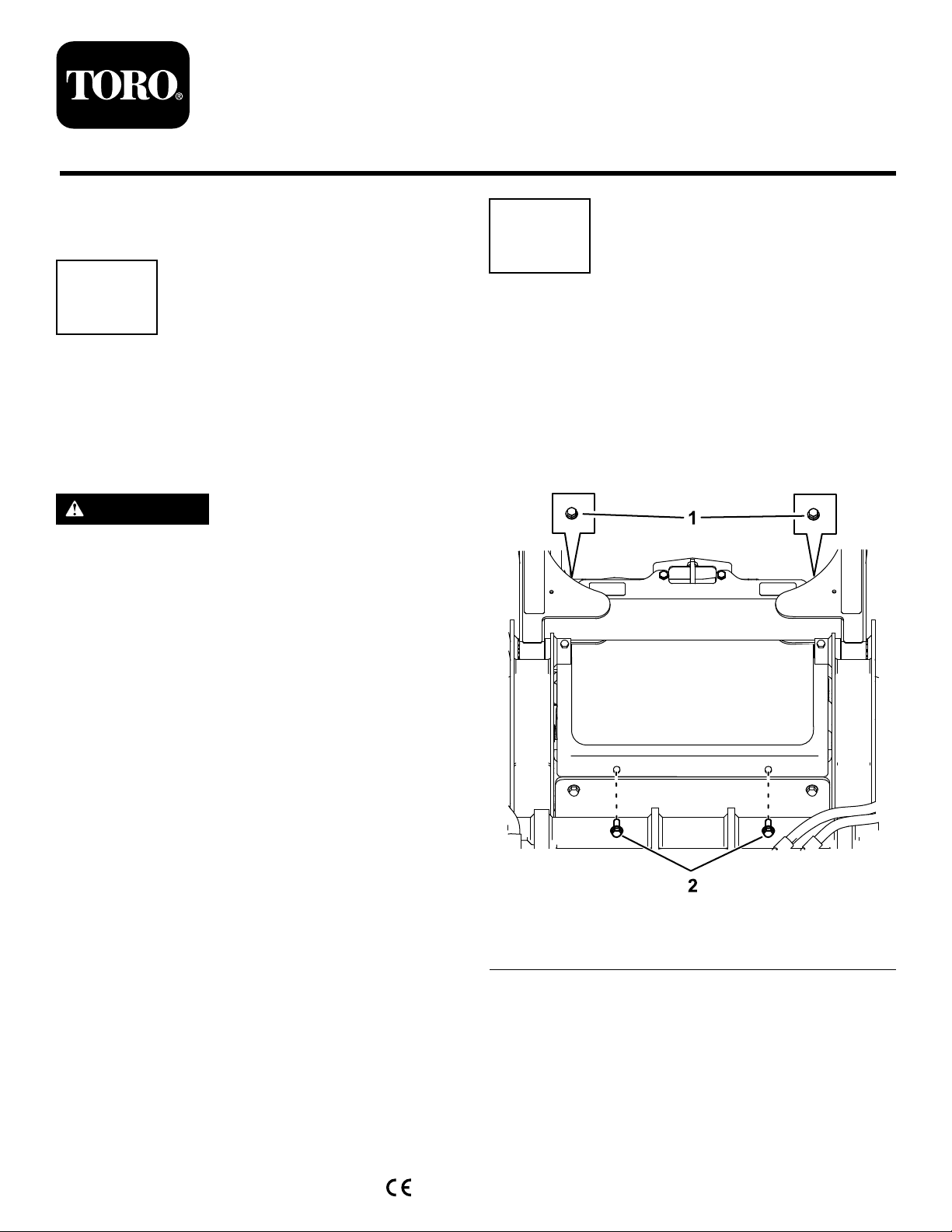

RemovingtheFrontScreen

1.Openthehoodandsecurethehoodprop.

2.Loosenthe2topboltsandremovethe2front

bolts.

6.Raisethemachineoffthegroundsothatyou

canaccessunderneaththemachine.Support

themachineusingjackstands.

Note:Usejackstandsratedforyourmachine.

RefertotheOperator’sManualforyourmachine

todeterminetheweight.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Figure1

1.Topbolt2.Frontbolt

3.Removethescreen.

RemovingtheFrontCover

1.Removethe2upperbolts(3/8x1inch),2

washers,and2lowerbolts(5/16x5/8inch)from

thefrontcover.

2.Removethefrontcover(Figure2).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3422-409*B

g262277

Page 2

3

RemovingtheExisting TrackAssemblies

NoPartsRequired

Procedure

1.Placeragsoracontainerunderthetrack

motorhydraulicportstocatchanyuidasyou

completethisprocedure(Figure4).

Figure2

1.Upperbolt—3/8x1inch

(2)

2.Frontcover

3.Washer(2)

4.Lowerbolt—5/16x5/8

inch(2)

RemovingtheBottomCoverPlate

1.Removethe2bolts(3/8x1inch)thatsecurethe

bottomcoverplatetotheframeplate(Figure3).

g256988

2.Markthehosesconnectedtothemotorswith

theirportlocations(i.e.,leftfront,leftrear,right

front,rightrear).

g257080

Figure4

1.Hose(4)3.Port(4)

2.Trackmotor(2)

3.Removethehosefrom1trackmotorandinstall

protectivecoversoverthehoseopenings.

4.Removethehydraulicttingsfromthemotor.

Figure3

1.Bolts(3/8x1inch)

2.Removethebottomcoverplatefromthe

machine(Figure3).

2.Bottomcover

g247034

2

Page 3

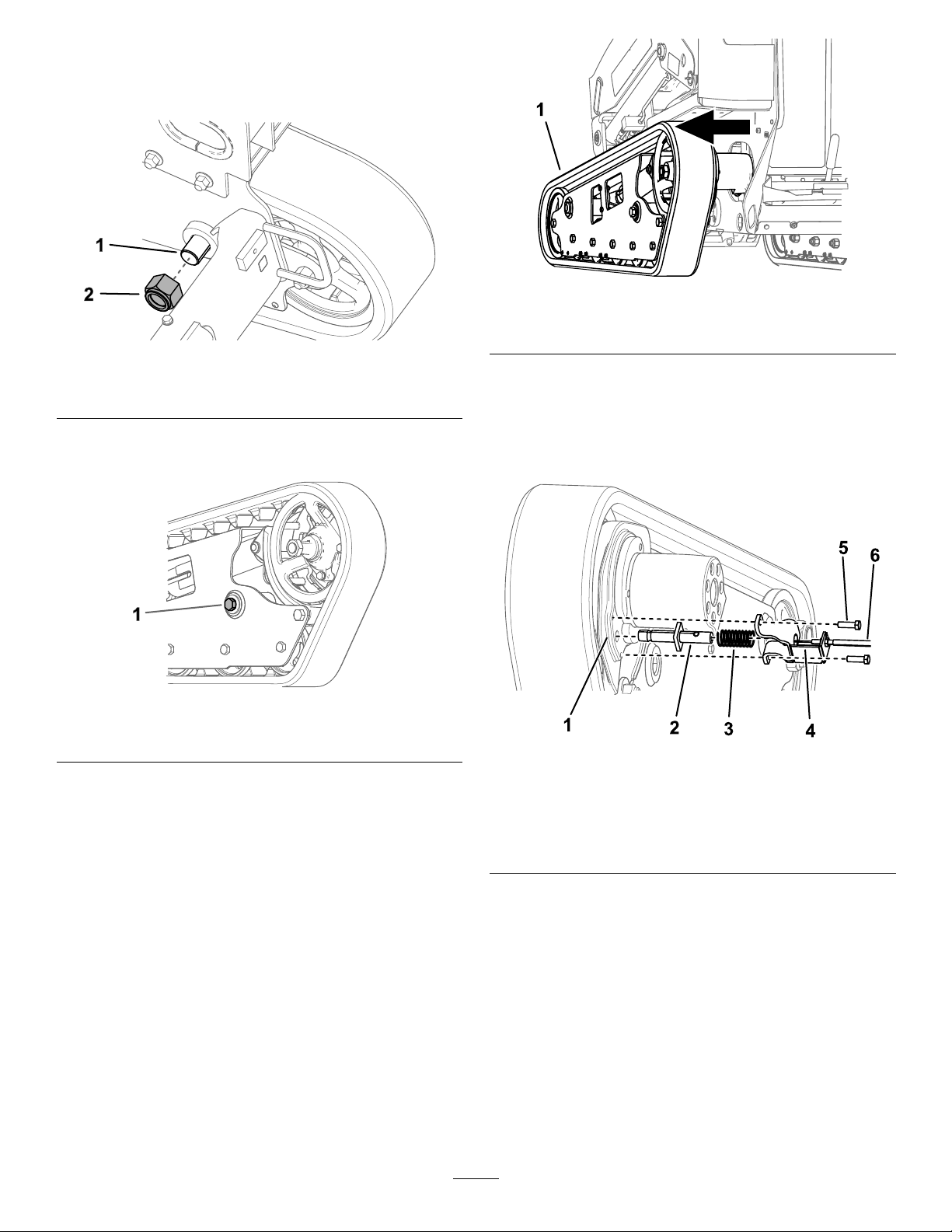

5.Removethenutfromthefronttrackpinshown

inFigure5.

Note:Donotremovethepinatthistime.

Figure5

1.Trackpin2.Nut

6.Loosentherearboltsecuringthereartrack

frametothemachine(Figure6).

g257082

Figure7

1.Trackassembly

g257083

8.Removethebrakemountassemblyfromthe

motorasfollows:

A.Removeandretainthe2boltssecuring

thebrakemounttothetrackmotorcasting

(Figure8).

Figure6

1.Rearbolt

7.Usingahoistorforkliftcapableoflifting181kg

(400lb),slidethetrackassemblyfromtheframe

about15cm(6inches)asshowninFigure7.

Important:Ensurethatthehydrauliclines

areoutoftheway.

g257081

g259801

Figure8

1.Trackmotorcasting4.Brakemount

2.Brake-shaftpin5.Bolt—3/8x1-1/4inches

3.Compressionspring

(2)

6.Brakecable

B.Loosenthenutssecuringthebrakecableto

thebrakemount(Figure8).Removethe

brakecables.

C.Removeandretainthecompressionspring

(Figure8).

9.Completelyremovethetrackassemblyfromthe

machine.

10.Repeattheprocedurefortheothertrack.

3

Page 4

4

InstallingtheNewTrack Assemblies

barrelttingofthebrakecableintotheslot

inthepin,slidethecableintothemount

notchsothatthenotchisbetweenthe2

cablenuts,andslowlyreleasethepinand

spring.

C.Adjustthenutsonthebrakecablesothat

only2threadsshowtowardthecable

(Figure9).

Partsneededforthisprocedure:

2

Trackassembly(soldseparately)

2Brakemount

2

Brake-shaftpin

1

Brakekit(soldseparately)

Procedure

1.Usingahoistorforkliftcapableoflifting181kg

(400lb),liftthetrackassemblytoapproximately

15cm(6inches)awayfromthemachine.

2.Ifyouareinstallingaseparatebrakekit,refer

totheInstallationInstructionsforthekit(see

ServiceBulletin110),thencontinuetostep3.

Important:Usethebrakemountsandpins

providedinthistrackkit.Donotusethe

brakemountsandpinsprovidedintheBrake

Kit.

Ifyouarenotinstallingaseparatebrakekit,

continueasfollows.

A.Insertthebrakecablethroughthebrake

mountandspring,andinsertthebarrel

ttingintotheslotofthebrake-shaftpin

(Figure9).

D.Tightenthenuts.

E.Securethebrakemounttothemotor

mount,withtheopensidefacingtowardthe

trackmotor,usingthe2boltsyouremoved

previously(Figure10).

Figure10

1.Brakemount

3.Installthetrackassemblyandsecureittothe

mainframeusingthebolt,washer,pin,andnut

removedfromthetrackassemblies(Figure11).

2.Bolt—3/8x1-1/4inches

(2)

g259847

Figure9

1.Brake-shaftpin

2.Compressionspring

3.Brakemount

B.Insertthebrake-shaftpinintothespringand

thenintothebrakemount(Figure9).Push

inthepintocompressthespring,insertthe

4.Brakecable

5.Nut

6.Barreltting

g261347

Figure11

1.Nut4.Washer

2.Pin5.Trackassembly

3.Bolt

4.Torquethefrontnutto244to298N∙m(180to

220ft-lb)andtorquetherearboltto305to373

N∙m(225to275ft-lb).

4

g257331

Page 5

5.Placeragsoracontainerunderthetrackmotor

hydraulicportstocatchanyuid.Removethe

plugsfromtrackmotor.

6.InspectandreplaceanydamagedO-ringson

thehydraulicttings.

7.Installthehydraulicttingsintothenewtrack

motors(Figure12).T orquethemto136to163

N∙m(100to120ft-lb).

Figure12

1.Hose(4)3.Trackmotor(2)

2.Fittinginstalledintothe

port(4)

g260318

Figure13

g257334

1.Hoses

8.Installthehosestotheportsthatyoumarked

(Figure12).

9.Torquethehosesto50to64N∙m(37to47ft-lb).

10.Repeattheprocedurefortheothertrack.

11.Inthefrontofthemachine,removethe2hoses

onthetandempumpandinstallthemtothe

oppositeports(Figure13).T orquethettingsto

24to30N∙m(18to22ft-lb).

5

Page 6

5

ReplacingtheReliefValves

Partsneededforthisprocedure:

4

Reliefvalve

Procedure

3.Install2newreliefvalvesintheirplaceand

torquethemto34to39N∙m(25to29ft-lb).

g257483

Figure15

1.Usepressurizedairtocleanthecavitiesofeach

reliefvalvebeforeremovingthem.

2.Usea15mmsockettoremovetheexistingtop

reliefvalvesfromthetandempump(Figure14).

4.Placeragsortowelsunderthetandempumpto

catchuidfromthehosesandtting.

5.Loosenthe2hoseclampsandremovethe

hosesfromthetting(Figure16).

Figure16

1.Nut

2.Hoseclamp(2)

3.Hose(2)

g257482

1.Tandempump

6.Cleantheareaaroundthetting.

7.Usea1-1/4inchcrowfootoropen-endwrenchto

loosenthenutonthettingshowninFigure16.

g257481

Figure14

2.Topreliefvalve(2)

6

Page 7

8.Rotatethettingcounterclockwisesothatthe

atsideofthettingalignswiththereliefvalve

portopening(Figure17).

Figure17

6

InstallingtheCovers

NoPartsRequired

InstallingtheBottomCoverPlate

1.Alignthetabofthebottomcoverplatewiththe

frameplateofthemachine(Figure18).

g258053

1.Fitting

9.Removethe2lowerreliefvalves(Figure17).

10.Install2newvalvesintheirplaceandtorque

themto34to39N∙m(25to29ft-lb).

11.Rotatethettingtotheoriginalorientation

(Figure16).Torquethenutto182to222N∙m

(134to164ft-lb).

12.Installthehosesandhoseclamps(Figure16).

2.Lowerreliefvalve(2)

Figure18

1.Bottomcoverplate

2.Aligntheholesinthebottomcoverplatewiththe

frameplate(Figure18).

3.Assemblethebottomcoverplatetotheframe

plate(Figure18)withthe2capscrews(3/8x1

inch)thatyouremovedpreviously.

2.Capscrew(3/8x1inch)

g247051

7

Page 8

InstallingtheFrontCover

InstallingtheFrontScreen

Installthefrontcoverusingthe2bolts(3/8x1inch),

2washers,and2bolts(5/16x5/8inch)thatyou

removedpreviously(Figure19).

Figure19

1.Upperbolt—3/8x1inch

(2)

2.Frontcover

3.Washer(2)

4.Lowerbolt—5/16x5/8

inch(2)

1.Installthefrontscreenusingthe4bolts(3/8x1

inch)youremovedpreviously(Figure20).

g247902

g256988

1.Bolt—3/8x1inch(2)

Figure20

2.Lowerthemachinetotheground.

8

Page 9

7

InstallingtheHandle

Partsneededforthisprocedure:

1Handle

2Bolt

2Nut

Procedure

4.Installthenewhandleusing2boltsand2nuts

(Figure23).

1.Opentherear-accesscover.

2.Removeandretainthe4boltsandnutssecuring

thecontrolpanelcovertothemachine(Figure

21).

Figure21

1.Boltandnut(4)

3.Liftupthecontrolpanelcoverandremovethe

fronthandle(Figure22).

g257389

Figure23

1.Bolt(2)3.Nut(2)

2.Handle

5.Securethecontrolpanelcoverusingthe4bolts

and4nutsyouremovedpreviously.

6.Closetherear-accesscover.

g257391

Figure22

1.Handle2.Bolt

g257390

9

Page 10

Maintenance

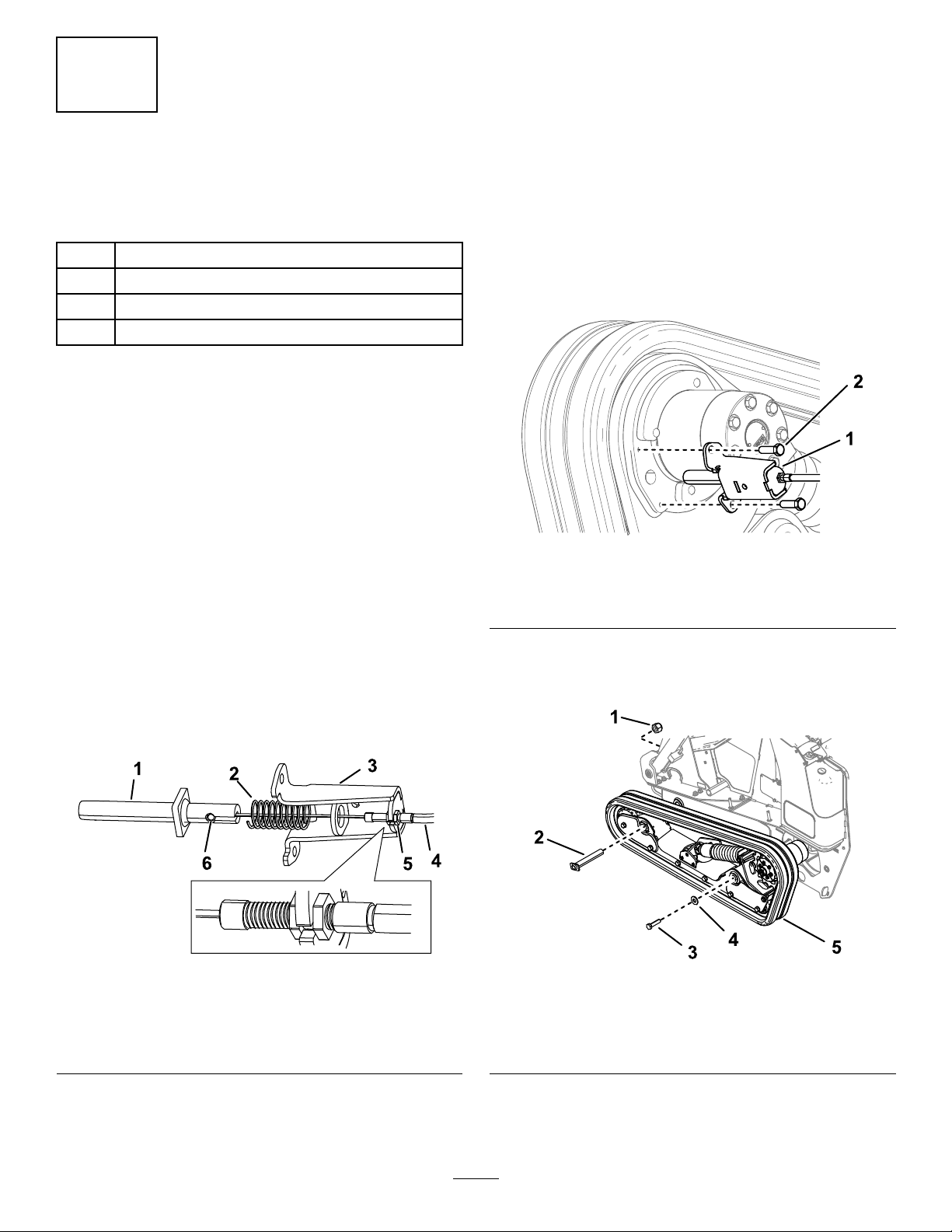

5.Usinga1/2inchdriveratchet,turnthetensioning

screwuntilthetrackgapis13mm(1/2inch)as

showninFigure24.

AdjustingtheTrackTension

Lift/support1sideofthemachineandusingtheweight

ofthetrack,verifythatthegapbetweenthebottom

ofthelipoftheroadwheelandthetrackis13mm

(1/2inch)asshowninFigure24.Ifitisnot,adjustthe

tracktensionusingthefollowingprocedure.

Figure24

1.Roadwheel

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

Note:Turningthescrewcounter-clockwise

tightensthetrack;turningthescrewclockwise

loosensthetrack.

6.Aligntheclosestnotchinthetensionscrewto

thelocking-boltholeandsecurethescrewwith

thelockingboltandnut(Figure25).

7.Repeattheprocedurefortheothertrack.

8.Drivethemachine,thenparkthemachineona

levelsurface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

9.Verifythatthetrackdeectionis13mm(1/2

inch)asshowninFigure24.Adjustifnecessary.

ReplacingtheTracks

Replacethetrackswhentheyarebadlyworn.

g257979

RemovingtheTracks

1.Removeanyattachments.

2.Parkthemachineonalevelsurface,ensuring

thatonly1sprockethalfisengagedwiththe

track(Figure26).

2.Shutofftheengineandremovethekey.

3.Raisethesideofthemachinethatyouare

adjustingsothatthetrackisofftheground.

4.Removethelockingbolt,spacer,andnut(Figure

25).

Figure25

1.Lockingbolt

2.Tensioningscrew4.Nut

3.Spacer

g259714

Figure26

1.Sprockethalf

3.Engagetheparkingbrake.

4.Lowertheloaderarmssothattheyare

g257903

approximately20to25cm(8to10inches)

abovetheframe.

5.Shutofftheengineandremovethekey.

6.Liftthesideofthemachinewiththetrackyou

arereplacing.Supportthemachineusingjack

stands.

Note:Usejackstandsratedforyourmachine.

10

Page 11

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

7.Removethelockingbolt,spacer,andnut(Figure

25).

8.Usinga1/2-inchdriveratchet,releasethe

drivetensionbyturningthetensioningscrew

clockwise(Figure25andFigure27).

11.Movethetractioncontrolforwarduntiltheother

halfofthedrivesprocketisnotengagedwith

thetrack(Figure29).

g259736

Figure29

12.Engagetheparkingbrake,shutofftheengine,

andremovethekey.

13.Removethetrackfromthetrackframe,drive

hub,thenfrontwheel.

Figure27

1.Sprocket4.Ratchet(1/2inch)

2.Track

3.Frontwheel

5.Roadwheel(5)

9.Removethe3boltssecuringthesprockethalf

thatisnotengagedwiththetrack(Figure28).

InstallingtheTracks

1.Wrapthenewtrackaroundthefrontwheel,then

wrapthetrackaroundthedrivehubontheside

withoutthesprocket(Figure27).

g258146

2.Pushthetrackunderandbetweentheroad

wheelsandwrapitaroundthelowerframe

(Figure27).

Note:Ensurethattheroadwheelsarecentered

onthetrack.

3.Starttheengineanddisengagetheparking

brake.

4.Movethetractioncontrolforwarduntilthedrive

sprockethalfengageswiththetrack(Figure30).

Figure28

1.Bolt(3)2.Sprockethalf

10.Startthemachineanddisengagetheparking

brake.

g259737

g257925

Figure30

5.Engagetheparkingbrake,shutofftheengine,

andremovethekey.

6.Applythread-lockingcompoundtotheboltsof

thedrivesprockethalfthatyouremovedand

11

Page 12

installthesprockethalf(Figure28).Torquethe

boltsto95to115N∙m(70to85ft-lb).

7.Usinga1/2inchdriveratchet,turnthetensioning

screwcounter-clockwiseuntilthetrackdeection

is13mm(1/2inch)asshowninFigure24.

8.Aligntheclosestnotchinthetensionscrewto

thelockingboltholeandsecurethescrewwith

thelockingbolt,spacer,andnut.

9.Lowerthemachinetotheground.

10.Repeattheproceduretoreplacetheothertrack.

11.Drivethemachine,thenparkthemachineona

levelsurface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

12.Verifythatthetrackdeectionis13mm(1/2

inch)asshowninFigure24.

12

Loading...

Loading...