Page 1

BrakeKit

TX1000CompactToolCarrier

ModelNo.136-4799

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3422-159RevA

InstallationInstructions

ProcedureDescription

1

2

3

4

5

6

7

8

Nopartsrequired

Nopartsrequired

Brakebracketassembly1

Bolt(5/16x1inch)

Nut(5/16inch)

Spring

Brakemount2

Bolt(3/8x1-1/4inches)

Cabletie

Nopartsrequired

Cabletie

Nopartsrequired

Qty.

Use

–

–

2

2

1

4

1

–

1

–

Removetheaccesspanels.

Removetheexistingbrakeassembly.

Assemblethecablestothebrake-mount

plate.

Installthebrakebracketassembly.

Installthebrakemounts.

Adjustthebrakecables.

Completetheinstallation.

Installthecoverplates.

©2018—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3422-159*A

Page 2

1

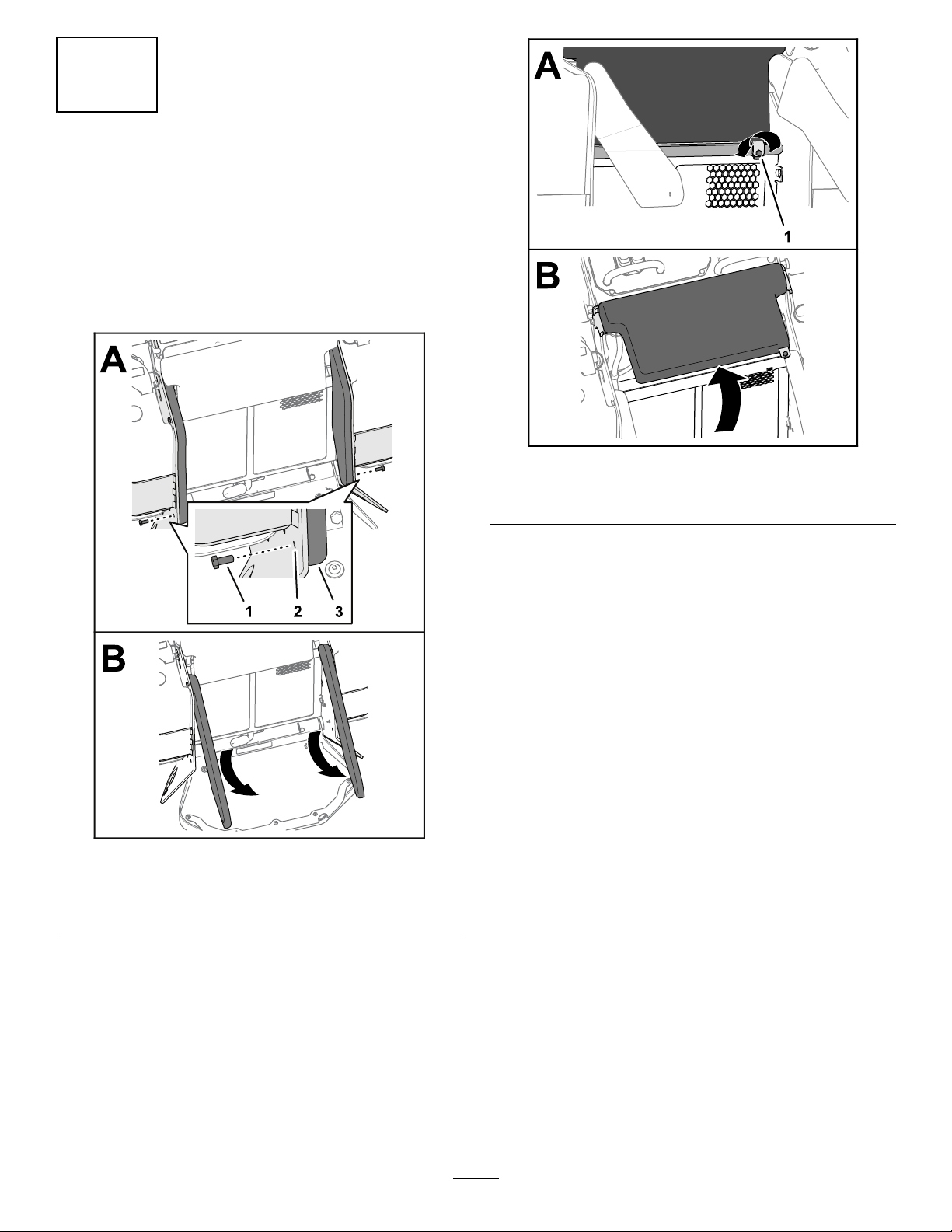

RemovingtheCoverPlates

NoPartsRequired

RotatingtheSideandFrontPads

1.Removethebottom2bolts(5/16x3/4inch)that

securetheleftandrightsidepadstotheframe

plates(Figure1).

g247038

Figure2

1.Captivebolt

4.Rotatethepadup(Figure2).

Figure1

1.Bolts(5/16x3/4inch)3.Sidepad

2.Frameplate

2.Rotatethepadsup(Figure1).

3.Loosenthecaptiveboltthatsecuresthefront

padtothescreenframe(Figure2)

g247039

2

Page 3

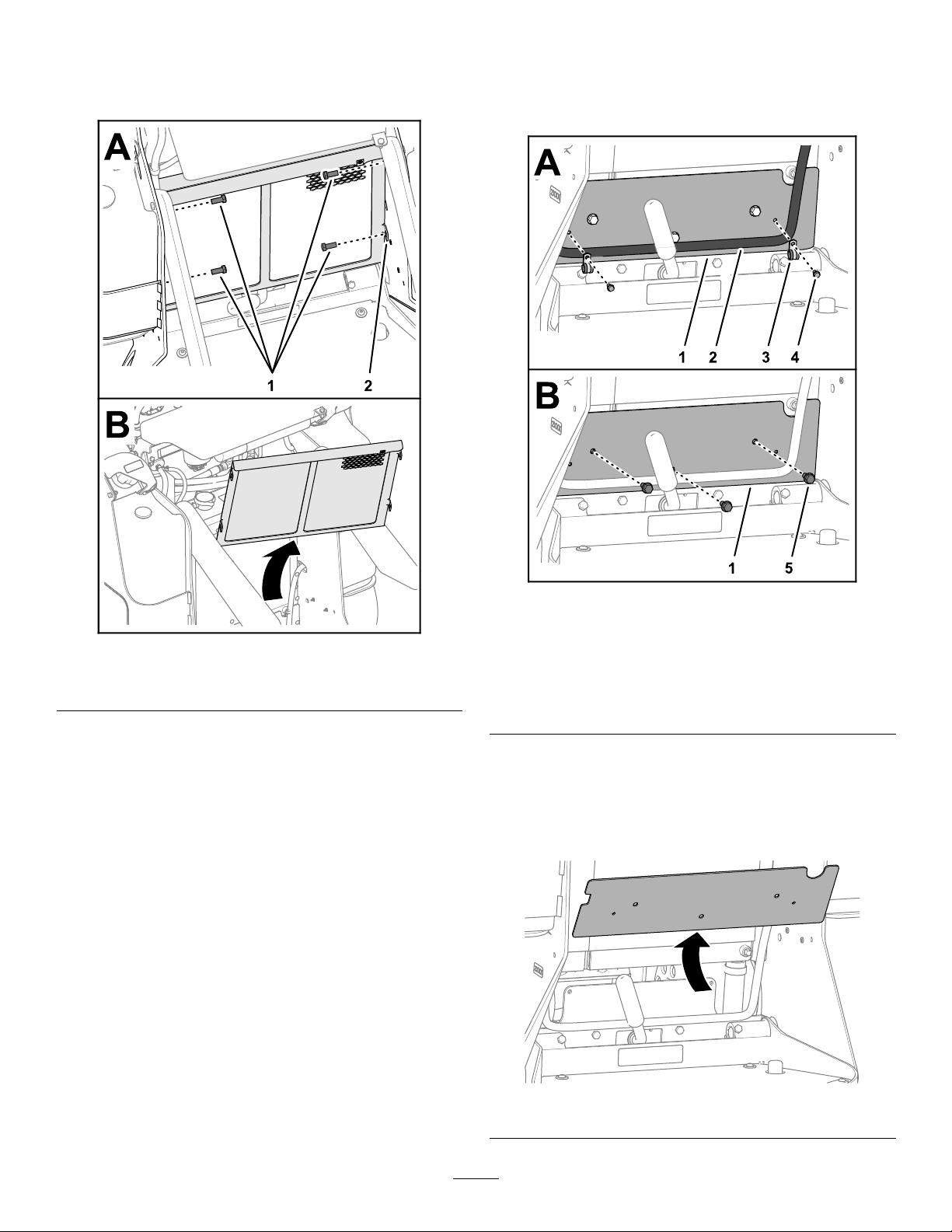

RemovingtheScreen

RemovingtheRear-CoverPlate

1.Removethe4bolts(3/8x7/8inch)thatsecure

thescreenframetotheframeplates(Figure3)

1.Removethe2ange-headbolts(1/4x1/2inch)

and2clampsthatsecurethefuelhosetothe

rear-coverplate(Figure4).

Figure3

1.Bolts(3/8x7/8inch)2.Screenframe

2.Removethescreenframefromthemachine

(Figure3).

g247035

Figure4

g247037

1.Rear-coverplate

2.Fuelhose

3.Clamp

4.Flange-headbolt(1/4x

1/2inch)

5.Flange-headbolt(5/16x

5/8inch)

2.Removethe3ange-headbolts(5/16x5/8

inch)thatsecuretherear-coverplatetothe

rear-frameplate(Figure4).

3.Removetherear-coverplatefromthemachine

(Figure5).

g247036

Figure5

3

Page 4

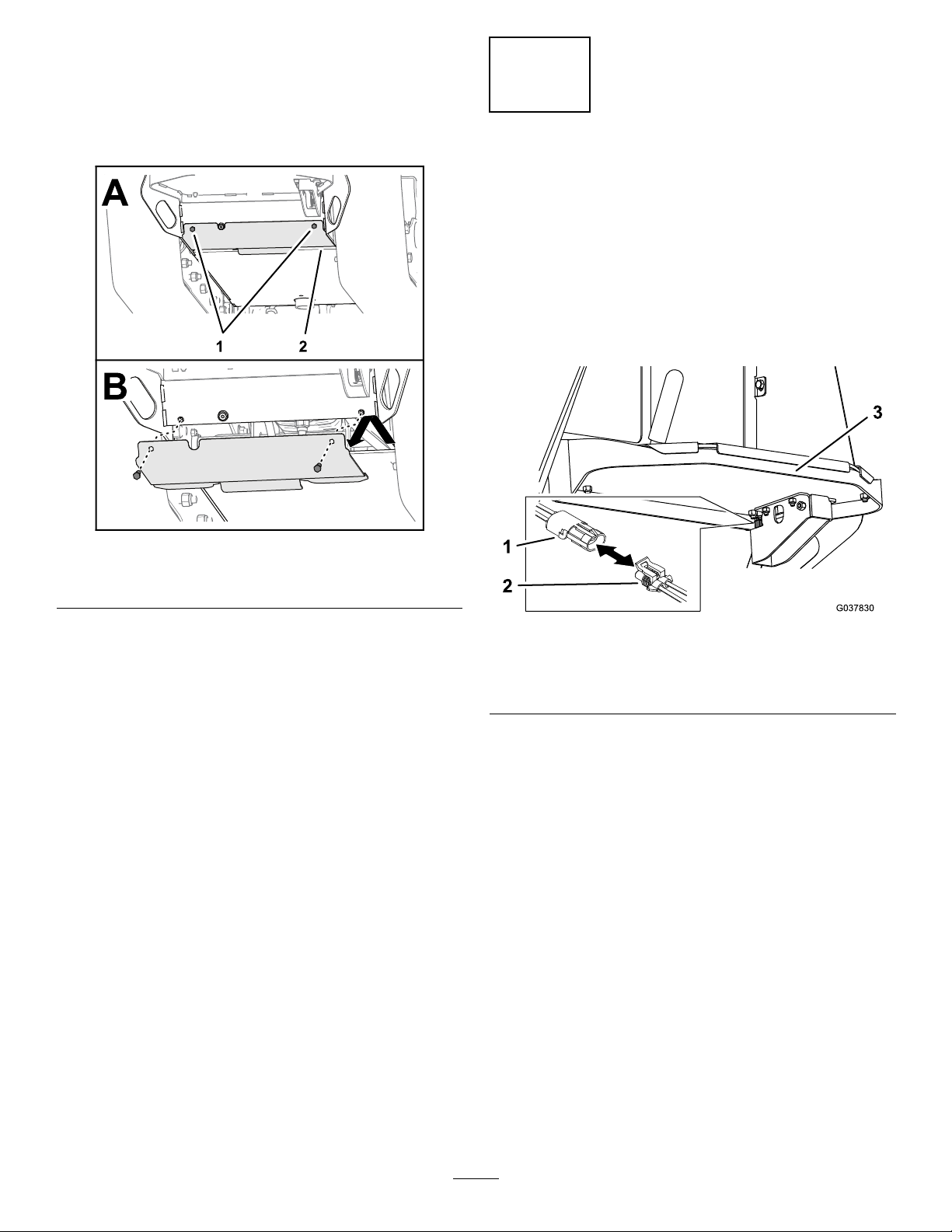

RemovingtheBottom-Access

Plate

1.Removethe2capscrews(3/8x1inch)that

securethebottomcoverplatetotheframeplate

(Figure6).

2

RemovingtheExisting

BrakeAssembly

NoPartsRequired

Procedure

1.Beneaththeoperator’splatform,unplugthe

auxiliary-switchwireharnessfromthemainwire

harnessofthemachine(Figure7).

Figure6

1.Capscrew(3/8x1inch)

2.Removethebottomcoverplatefromthe

machine(Figure6).

2.Bottomcoverplate

g247034

g037830

Figure7

1.Mainwireharness

2.Auxiliary-switchharness

2.Disconnectthewireharnessfromthebrake

switch.

3.Removethe2bolts,2nuts,andbrakelever

assembly(Figure8).

3.Operator’splatform

4

Page 5

Figure10

g240461

Figure8

1.Nut(2)3.Bolt(2)

2.Brakeleverassembly

4.Removeandretainthebrakeswitchand

fastenersfromtheassembly(Figure9).

1.Trackmotorcasting

2.Brake-shaftpin

3.Compressionspring

g242415

B.Removeandretainthecompressionspring

andbrake-shaftpin(Figure10).

C.Loosenthenutssecuringthebrakecableto

thebrakemount(Figure10).Removethe

brakecables.

4.Bolt(2)

5.Brakemount

6.Brakecable

3

AssemblingtheCablesto

theBrake-MountPlate

Partsneededforthisprocedure:

1Brakebracketassembly

Figure9

1.Screw(2)3.Jamnut(2)

2.Brakeswitch

5.Removethebrakemountassemblyfromboth

sidesofthemachineasfollows:

A.Removethe2boltssecuringthebrake

mounttothetrackmotorcasting(Figure

10).

Procedure

g241737

1.Slidethecablewiperoffthethreadedconduit

ttingandthreadtheendjamnutoffthetting

(Figure1 1).

5

Page 6

Figure11

1.Cablewiper4.Cable

2.Jamnut5.Brake-mountplate

3.Threadedconduittting

2.Alignthecablethroughslotinthebrake-mount

plateandslidethethreadedconduittting

throughthebracket(Figure11).

3.Threadtheendjamnutontothettingthreaded

conduittting(Figure12).

g247371

g247370

1.Cablewiper

2.Jamnut

4.Adjustthepositionofthejamnutstocenter

thethreaded-conduitttingtothebrake-mount

plate,andtightenthejamnuts(Figure12).

5.Slidethecablewiperovertheendofthe

threaded-conduittting(Figure12).

6.Repeatsteps1through5fortheotherbrake

cable(Figure11andFigure12).

Figure12

3.Brake-mountplate

4

InstallingtheBrakeBracket

Assembly

Partsneededforthisprocedure:

2

Bolt(5/16x1inch)

2

Nut(5/16inch)

1

Spring

Procedure

1.Installthebrakeswitchtothenewbrakebracket

assembly(Figure9).

Note:Ensurethattheplungerhousingisush

withorslightlyinsidetheedgeofthebrake

bracket.

6

Page 7

2.Frominsidethemachine,insertthebrake

handlethroughtheholeintherearplatesothat

thehandlepointsupward.

3.Securethebrakebracketassemblyusing2

bolts(5/16x1inch)and2nuts(5/16inch)as

showninFigure13.

g242891

Figure14

Figure13

1.Nut—5/16inch(2)2.Bolt—5/16x1inch(2)

5

1.Brake-shaftpin

2.Compressionspring

3.Brakemount

4.Brakecable

5.Nut

6.Barreltting

2.Insertthebrake-shaftpinintothespringand

thenintothebrakemount(Figure14).Pushin

thepintocompressthespring,insertthebarrel

ttingofthebrakecableintotheslotinthepin,

slidethecableintothenotchinthebrakemount,

andslowlyreleasethepinandspring.

3.Tightenthenutsonthebrakecable.

4.Securethebrakemounttothemotormount,

withtheopensidefacingtowardtheoperator’s

g242428

platform,using2bolts(3/8x1-1/4inches)as

showninFigure15andFigure16.

Note:Ensuretoroutethecablestotheinside

oftheoilcoolerandradiatorhoses(Figure16).

InstallingtheBrakeMounts

Partsneededforthisprocedure:

2Brakemount

4

Bolt(3/8x1-1/4inches)

1

Cabletie

Procedure

1.Loosenthenutsontheendofthebrakecable

withthebarreltting.Insertthecablethrough

thebrakemountandspring,andinsertthe

barrelttingintotheslotofthebrake-shaftpin

(Figure14).

Figure15

1.Brakemount

1.Hose2.Brakecable

2.Bolt—3/8x1-1/4inches

(2)

Figure16

5.Repeattheprocedurefortheotherbrakemount

ontheothersideofthemachine.

g234347

g242491

7

Page 8

6.Routethemachinewireharnessandthebrake

switchharnessasshowninFigure17.Connect

thebrakeswitchtothemachinewireharness.

g240527

Figure18

Figure17

1.Brakeswitchconnector

2.Machinewireharness

(ConnectorP42)

7.Securethemachinewireharnesstotheupper

brakecableusingacabletie(Figure17).

3.Cabletie

6

AdjustingtheBrakeCables

NoPartsRequired

Procedure

1.Movetheparking-brakelevertotheONposition.

g242890

1.Trackmotorcasting2.Pin

5.Cycletheparkingbrakestoensurethey

consistentlyengageanddisengage.

7

ConnectingtheWire

Harness

Partsneededforthisprocedure:

1

Cabletie

Procedure

1.Plugtheauxiliary-switchwireharnesstothe

mainwireharnessofthemachine(Figure19).

2.Loosenthe2nutsonthepinsideofeachbrake

cableandadjustthecablesothatitistautand

thepinisushagainstthetrackmotorcasting

(Figure10).

Note:Adjustthenutstowardthepintomove

thepinfurtherinward;adjustthenutsawayfrom

thepintomovethepinfurtheroutward.

3.Movetheparking-brakelevertotheOFFposition.

4.Adjustthespringsideofeachbrakecableso

thatthecableistaut,butthepinisushwiththe

outsideofthetrackmotorcasting(Figure18).

1.Mainwireharness

2.Auxiliary-switchharness

8

g037848

Figure19

3.Operator’splatform

Page 9

2.Useacabletietosecuretheauxiliary-switch

wireharnesstotherightbrakecablesothat

theharnessdoesnotrubagainstorbecome

pinchedbetweenparts.

8

InstallingtheCoverPlates

NoPartsRequired

InstallingtheBottom-AccessPlate

InstallingtheRear-CoverPlate

1.Aligntheholesintherear-coverplatetothe

holesintherear-frameplate(Figure21).

1.Alignthetabofthebottomcoverplatewiththe

frameplateofthemachine(Figure20).

Figure20

1.Bottomcoverplate

2.Capscrew(3/8x1inch)

g247052

Figure21

1.Rear-coverplate

2.Assembletherear-coverplatetotherear-frame

plate(Figure22)withthe3ange-headbolts

(5/16x5/8inch)thatyouremovedinRemoving

theRear-CoverPlate(page3).

g247051

2.Rear-frameplate

2.Aligntheholesinthebottomcoverplatewiththe

frameplate(Figure20).

3.Assemblethebottomcoverplatetotheframe

plate(Figure20)withthe2capscrews(3/8

x1inch)thatyouremovedinRemovingthe

Bottom-AccessPlate(page4).

4.Torquethecapscrewsto37to45N∙m(27to33

ft-lb).

1.Rear-coverplate

2.Flange-headbolt(5/16x

5/8inch)

3.Fuelhose

9

g247054

Figure22

4.Clamp

5.Flange-headbolt(1/4x

1/2inch)

Page 10

3.Torquethe3ange-headboltto1978to2542

N∙cm(175to225in-lb).

4.Securethefuelhosetotherear-coverplatewith

the2clampsand2ange-headbolt(1/4x1/2

inch),andtightentheboltsbyhand(Figure22).

InstallingtheScreen

1.Aligntheholesinthemountingtabsofthe

screenframewiththeholesontheframeplates

(Figure23).

AssemblingthePads

1.Rotatethefrontpaddown(Figure24).

Figure23

1.Screenframe3.Mountingtab(screen

frame)

2.Bolts(3/8x7/8inch)

2.Assemblethescreenframetotheframeplates

(Figure23)withthe4bolts(3/8x7/8inch)that

youremovedinRemovingtheScreen(page3).

3.Torquetheboltsto7to45N∙m(27to33ft-lb).

g247057

Figure24

1.Frontpad

2.Captivebolt

2.Assemblethefrontpadtothescreenframewith

thecaptivebolt,andtightentheboltbyhand

(Figure24).

3.Rotatetheleftandrightsidepadsdown,and

alignthelowerholesinthepadswiththeholes

intheframeplates(Figure25).

4.Assemblethesidepadstotheframeplates

g247055

(Figure25)atthebottomholeswiththe2bolts

(5/16x3/4inch)thatyouremovedinRotating

theSideandFrontPads(page2).

10

Page 11

Figure25

g247058

1.Frameplate

2.Sidepads

3.Bolts(5/16x3/4inch)

4.Topbolts

5.Torquethe2boltsthatsecurethesidepadsto

theframeplatesto1978to2542N∙cm(175to

225in-lb).

11

Page 12

Loading...

Loading...