Page 1

INSTRUCTION MANUAL

ROTATING LASER

RL-VH4G

31339 90040 TPS

Page 2

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

FCC WARNING

Declaration of Conformity

Model Number: RL-VH4G

Tr ade Name: TOPCON CORPORATION

Responsible party: TOPCON POSITIONING SYSTEMS,Inc.

Address: 7400 National Drive,Livermore, CA 94551, U.S.A.

Te lephone number: 925-245-8300

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation of the device.

Lutilisation de ce dispositif est autorisee seulement aux conditions suivantes :

(1)il ne doit pas produire de brouillage et (2)l’utilisateur du dispositif doit être prêt

à accepter tout brouillage radioelectrique recu,même si ce brouillage est susceptible de compromettre le fonctionnement du dispositif.

This Class B digital apparatus complies with Canadian ICES-003.

Cet apparei numerique de la class B est conforme à la norme NMB-003 du Canada.

Page 3

1

Foreword

Thank you for purchasing the Topcon RL-VH4G Rotating Laser.

It is one the world’s most advanced lasers.

To quickly and effectively use the RL-VH4G, please read these brief instructions carefully, and keep them in a convenient location for future reference.

Handling Precautions

Before starting work or operation, be sure to check that the system is functioning properly.

1.Vibration and Impact Protection

When transporting the instrument, provide protection to minimize risk of severe vibration

or impact. Severe vibration or impacts may affect beam accuracy.

2. Laser Scanning Interference

Particular reflective surfaces such as mirrors and some glass surfaces, can cause beam

reflection that in very rare circumstances can interfere with the laser scanning function. If

this should happen, simply change the location of the laser or cover the reflective surface.

3. Checking battery power.

Before operating, check remaining battery life.

4. Storing the instrument for long period

When storing the instrument for long period, remove the batteries.

5. Rotating Head

When sunlight, etc. enters the laser emitting window, laser beam output may temporarily

decrease. In such a case, prevent sunlight, etc. from entering by using a parasol or other

means.

Page 4

2

Safety Information

In order to encourage the safe use of products, to prevent damage to properties, and to

prevent any danger to the operator and to others, important warnings are placed on the products and inserted in the instruction manuals.

We suggest that everyone understand the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

Injury refers to hurt, burn, electric shock, etc.

Physical damage refers to damage to equipment and structure or furnishings.

Display Meaning

WARNING

Ignoring or disregard of this display may lead to death or serious

injury.

CAUTION

Ignoring or disregard of this display may lead to personal injury or

physical damage to the instrument.

Page 5

3

Safety Cautions

WARNING

• There is a risk of fire, electric shock or physical harm if you attempt to disassemble or repair the instrument yourself.

This is to be carried out by TOPCON or an authorized dealer, only!

• Laser beam can be dangerous, and can cause eye injury if used incorrectly.

Never attempt to repair the instrument yourself.

• Cause eye injury or blindness.

Do not stare into beam. (RL-VH4G standard model)

Do not stare into beam or view directly with optical instruments. (RL-VH4G remote control compatible model)

• Risk of fire or electric shock.

Do not use a wet battery.

• May ignite explosively.

Never use an instrument near flammable gas or liquid matter, and do not use in a coal

mine.

• Battery can cause explosion or injury.

Do not dispose in fire or heat.

• The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

Page 6

4

CAUTION

Use of controls or adjustment or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Let the laser beam reach the aimed object or the target without anybody else in the laser

beam path. When operating in an open area, avoid radiating laser beam at eye level. It

is quite possible for the beam to enter into one's eyes, and it is possible to lose visual

sight temporarily, and lose one's caution and awareness of other dangers - avoid glaring

beam.

Do not allow skin or clothing to come into contact with acid from the batteries, if this does

occur then wash off with copious amounts of water and seek medical advice.

Risk of injury by dropping the instrument or case.

Do not use a carrying case with damaged belts, grips or latches.

It could be dangerous if the instrument falls over, please check that you fix the instrument

to the wallmount or tripod.

Risk of injury by dropping a tripod and an instrument.

Always check that the screws of tripod are tightened.

Please note that the tips of tripod can be hazardous, be aware of this when setting up

or carrying the tripod.

Page 7

5

User

Wear the required protectors (safety shoes, helmet, etc.) when operating.

Exceptions from Responsibility

1) The user of this product is expected to follow all operating instructions and make periodic checks of the

product’s performance.

2) The manufacturer, or its representatives, assumes no responsibility for results of a faulty or intentional

usage or misuse including any direct, indirect, consequential damage, and loss of profits.

3) The manufacturer, or its representatives, assumes no responsibility for consequential damage, and

loss of profits by any disaster, (an earthquake, a fire, an accident, storms, floods, an act of a third party

and/or a usage other than under normal conditions.)

4) The manufacturer, or its representatives, assumes no responsibility for any damage, or loss of profits

due to a change of data, loss of data, an interruption of business etc., caused by using the product or

an unusable product.

5) The manufacturer, or its representatives, assumes no responsibility for any damage, or loss of profits

caused by usage other than those usages explained in the user manual.

6) The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong

movement, or action due to connecting with other products.

Page 8

6

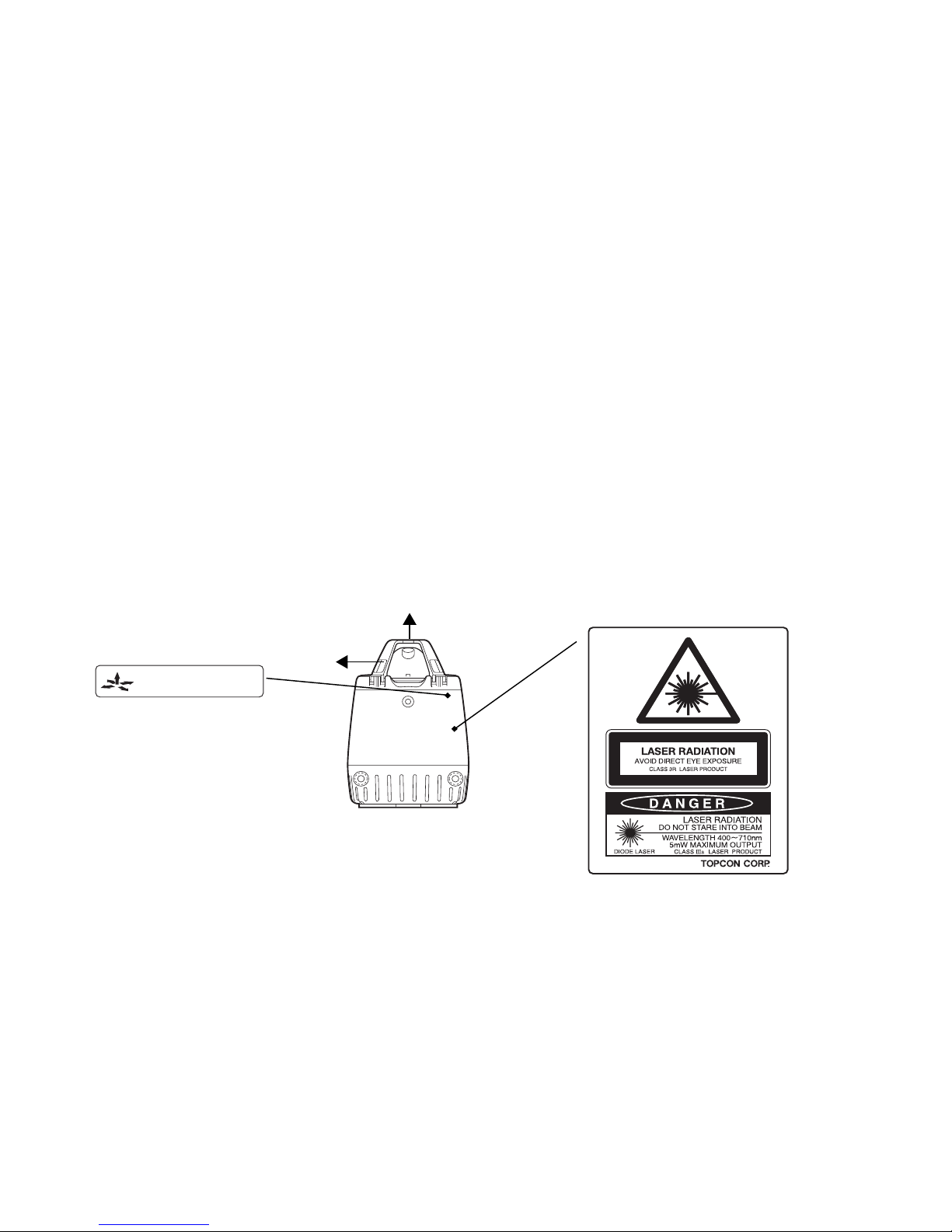

Laser Safety

This product projects a visible laser beam during operation. This product is manufactured

and sold in accordance with “Performance Standards for Light-Emitting Products” (FDA/BRH

21 CFR 1040) or “Radiation Safety of Laser Products, Equipment Classification, Requirements and User’s Guide” (IEC Publication 60825-1) provided on the safety standards for

laser beam.

As per the said standard, RL-VH4G standard model is classified as “Class 3R (IIIa) Laser

Products”. These are simple products to operate and do not require training from a laser

safety officer. In case of any failure, do not disassemble the instrument. Contact TOPCON or

your TOPCON dealer.

Labels

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

Beam aperture

Beam aperture

RL-VH4G standard model

Page 9

7

Contents

Foreword ............................................. 1

Handling Precautions ....................... 1

Safety Information ............................. 2

Safety Cautions ................................ 3

User .................................................. 5

Exceptions from Responsibility ......... 5

Laser Safety ...................................... 6

Contents ........................................... 7

Standard System Components ......... 8

Nomenclature and Functions ............ 9

Preparation for Use ............................ 11

Battery Installation ............................ 11

Instrument Set-up Procedure ........... 11

Horizontal Rotation ........................... 11

Vertical Rotation ............................... 13

Battery Warning Lamp ...................... 12

Auto-leveling Lamp ........................... 12

Tu rning Auto-leveling off ................... 12

Operation ............................................. 13

Scanning Mode ................................. 13

Continuous Scan .............................. 14

Laser Sensor Mode .......................... 15

Laser Pointing Mode (stop) ............... 15

Changing Rotation Speed ................ 15

How to Remove/Install

Head Protector ...................16

Height Alert Function ........................19

Setting Slopes ...................................20

How to Set Slopes .............................21

Cancelling Slope Settings .................21

Line Control

(manual vertical beam alignment)........22

RC-30 Remote Control ........................24

Description of RC-30 Functions .........25

How to set remote control

communication channel .................. 26

Maintaining Power Sources ...............27

Replacing Dry Batteries .................... 27

Checking and Adjusting .....................28

Horizontal Calibration ........................ 29

Horizontal Rotation Cone Error..........33

Vertical Calibration ............................34

Standard / Optional Accessories .......38

Storage Precautions ........................... 41

How to Store.........................................42

Specifications ......................................44

Error Code ...........................................46

Page 10

8

Standard System Components

1 RL-VH4G Instrument............................................................................. 1pc.

2 Remote Controller RC-30

*1) ................................................................1pc.

3 Magnetic Target .................................................................................... 2pc.

4 Battery unit

*2) ....................................................................................... 1set

5 AA-size dry batteries ...........................................................................3pcs.

6 Carrying case ....................................................................................... 1pc.

7 Calibration decals.................................................................................. 1set

8 Instruction manual.................................................................................1vol.

• Please make sure that all of the above items are in the box when you unpack.

• Additional Magnetic Scanning Targets may be included in some markets.

• Standard System Components will differ depend on the markets.

Optional Accessories(P38) may be included in some markets.

*1) Remote Controller RC-30 may not be included as attachment in some systems.

*2) The following are battery configurations. Included battery configurations vary by package.

Rechargeable battery type:

(with Built-in Run/Charge system)

Rechargeable battery (BT-63Q) ...... 1pc.

Holder (DB-49C) .............................1pc.

AC/DC converter .............................1pc.

Dry battery type:

Holder (DB-58)................................1pc.

D- cell............................................ 4pcs.

Page 11

9

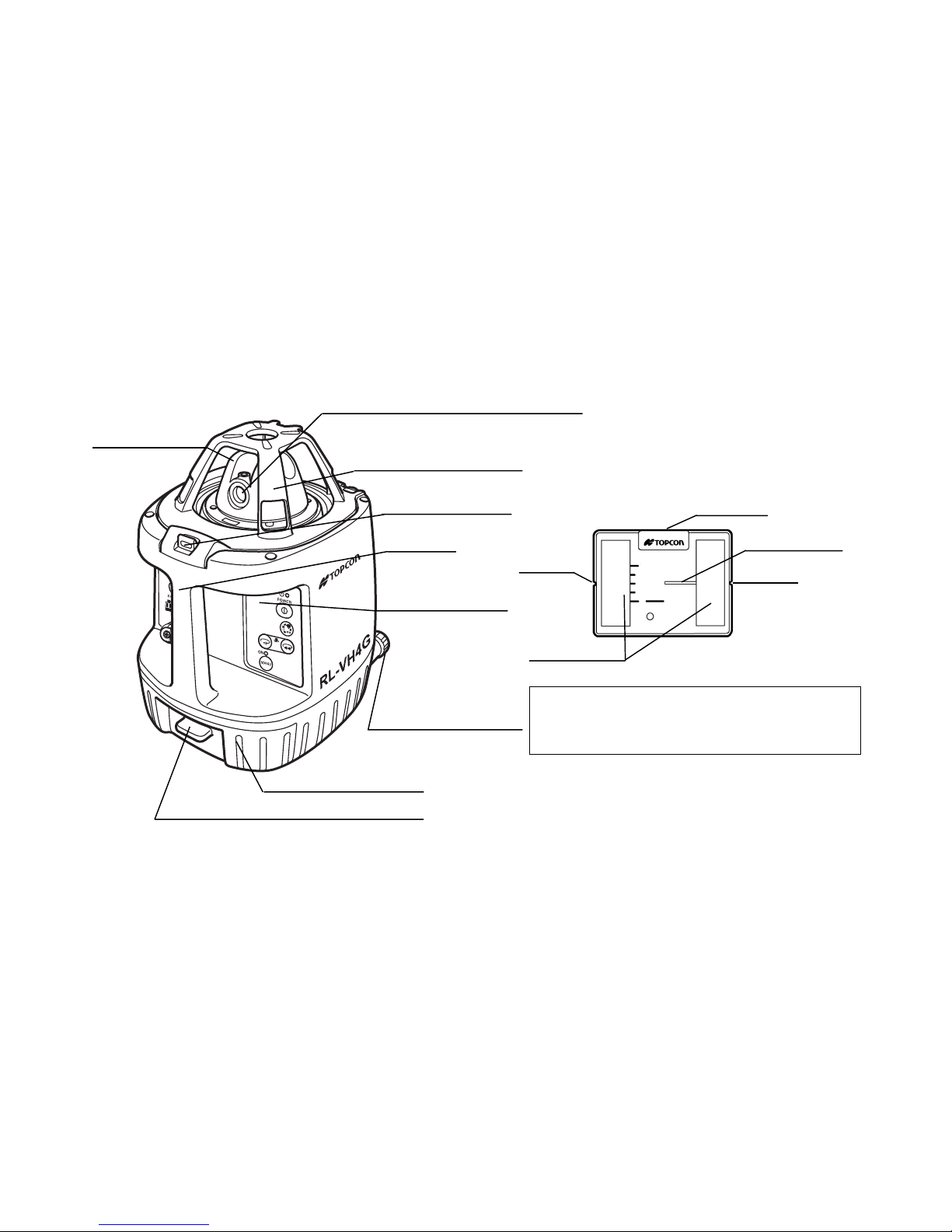

Nomenclature and Functions

Handle

Rotary head

Battery compartment lock

Battery holder

Laser emitting window

Beam aperture

Leveling screw

Control panel

RL-VH4G

Magnetic Scanning Target

Magnet

Datum line

Index

Index

Reflectors

Lines may appear on the reflector strips.

They are part of normal manufacturing

process and do not effect performance.

Head protector

Lock button

Page 12

10

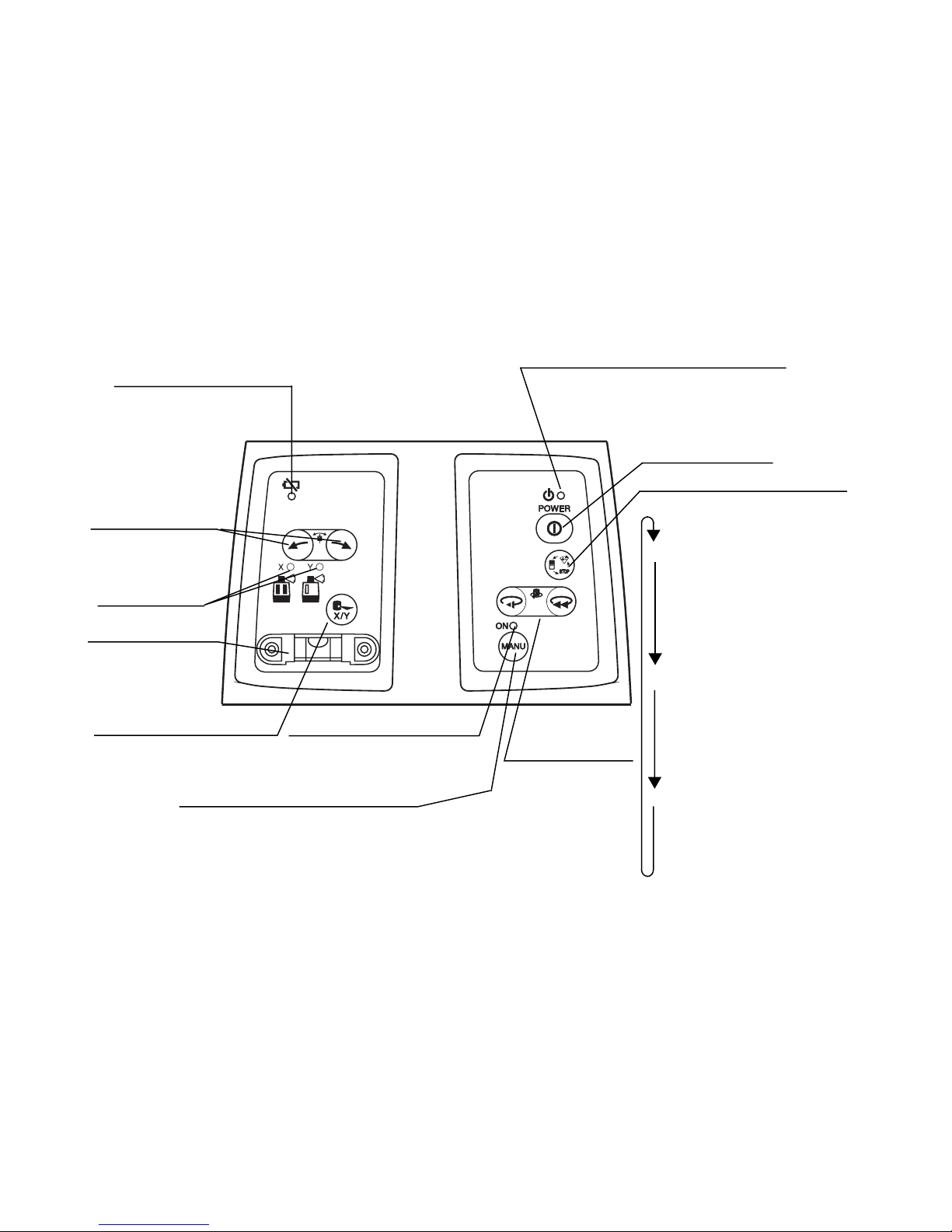

Control Panel

Auto/manual leveling control

Leveling lamp

Power switch

Manual mode lamp

Mode switch control

Scan mode

Laser sensor mode

Laser pointing mode

X/Y axis selection key

X/Y axis lamp

Head rotates slowly,

searching for Magnetic

Scanning Target. When

target is placed in beam

path, laser rapidly scans

back and forth on target.

Laser sensor mode

Head rotates at 300 rpm.

Use this setting when using

an optional electronic laser

sensor such as the Topcon

LS-70.

Head stops rotating and the

beam can be positioned by

manually turning the head.

Select X or Y axis for

manual beam sloping.

ON: Manual leveling mode

OFF: Auto-leveling mode

ON/OFF of Auto-leveling. To turn

off the auto-leveling, press this

key twice. To turn on the auto-leveling again, press this key once.

Flashing: Laser is leveling

On: Auto-leveling is completed

(RL-VH4G remote control model has

standby mode)

Laser mode is switched

alternately as follows.

Speed control

With 'Laser Pointing Mode'

selected, the rotation speed of the

head can be

changed.

Alignment

control

Low battery alert

Level

For vertical

operation

Page 13

11

Preparation for Use

Battery Installation

For battery placement or replacement instructions, see Maintaining Power Sources section,

page 20.

Instrument Set-up Procedure

Horizontal Rotation

1

Set the instrument on any smooth surface that is

within ±5° of true level. The RL-VH4G auto-level

system will not function if the unit is placed more

that 5° out of level. For best operation, it is recommended that it be mounted to a tripod or the

Topcon Wall Mount Model 1C .

Slope can be set in both axes, X and Y. See "Setting Slope" section, page 20.

Horizontal

Leveling range

Page 14

12

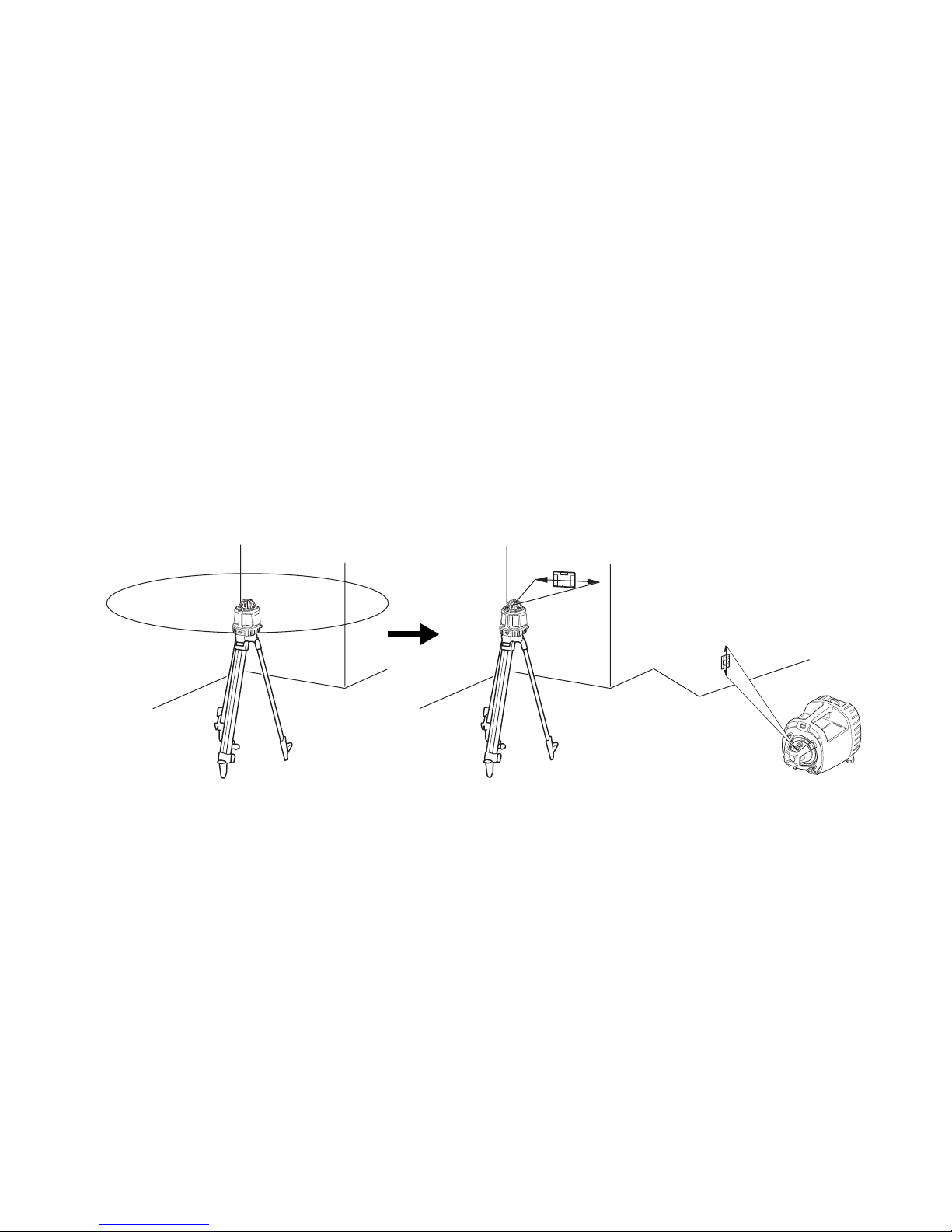

Ver tical Rotation

1

Place the instrument on its back as shown in the illustration.

2

Tu rn the leveling screw (s) underneath the instrument until the

bubble in the level vial on the operational panel is centered.

Battery Warning Lamp

Flashing : The power is low

ON Solid: Dead batteries

Replace the batteries with new ones.

Auto-leveling Lamp

Flashing : Auto-leveling is in process. When automatic leveling is almost complete, the

flashing rate will be slow. The head will not rotate and the laser beam will not

emit during the auto-leveling process.

ON Solid: Auto-leveling is complete.

The rotary head is active and emits the laser beam.

Turn ing Auto-leveling Off

To turn OFF the auto-leveling function (manual mode), press the Auto/Manual control pad

twice in quick succession. The manual mode indicator light will illuminate. The instrument

can be positioned in any direction, the laser beam remains on and the head will rotate.

IMPORTANT:

In manual mode, the laser beam will not shut off if disturbed! To return to Auto-leveling mode,

press Auto/Manual control pad once.

Page 15

13

Operation

Scanning Mode

In scan mode, the laser rotates slowly, "searching" for the Magnetic Scanning Target. When

the target is properly placed in the beam path, the laser beam will scan rapidly back and forth

on the target and "track" the target as it is moved in its path.

1

To change to scanning mode when operating, press the Mode Control Pad (see page 10).

2

To initiate target scanning, place the Magnetic Scanning Target in the beam path with the

reflective strips facing toward the laser.

3

To end target scanning and resume searching beam, remove target from beam path.

Vertical rotation

Horizontal rotation

Set scanning mode

Face the target toward the instrument to start scanning.

Page 16

14

Continuous scan

(Scan line length can be "Drawn" and held for "Hands-free" operation)

Place target in beam path and hold for a moment. The scanning beam will hesitate, then

start again.

When the target is now removed the beam will continue to scan automatically.

To change the length of the scanning line, move the target left or right after the initial scan

hesitation and the scanning line length will increase until the target is removed.

To cancel the "Drawn" scan simply:

Place the target into the scanning laser beam path again for more than two seconds.

Scanning hesitates

and starts again.

Move the target left or right while

scanning, the scanning line will

lengthen. The "drawn" line will

continue to scan without target

for hands-free scan operation.

Page 17

15

Laser Sensor Mode

For long range or outdoor applications, the instrument can be used with an optional electronic laser sensor. The Topcon LS-70G model is recommended. Press the Mode Control

Pad to select Laser sensor mode. The beam rotates at 300 rpm in this setting.

Laser Pointing Mode (stop)

This mode stops rotation and allows the laser beam to be pointed

by manually rotating the head. Press the mode control pad to select

Laser pointing mode. Beam rotation stops in this mode.

Changing rotation speed

(only available in Laser pointing mode)

After selecting Laser pointing mode, press either Speed Control

pad to change rotation speed. The right pad increases the rotation

speed. The left pad reduces the rotation speed.

• This mode can also be set with the Remote Controller RC-30.

• Level sensors other than the LS-70G cannot be used.

• The laser beam cannot be moved with the Remote Controller RC-30.

• This mode can be used with the Remote Controller RC-30.

Laser pointing

Page 18

16

How to Remove/Install Head Protector

When the head protector post blocks the laser beam and interferes with operation, remove the head protector from the instrument.

How to Remove

1

Press the lock button to release the lock.

2

Set the angle of the head protector to approximately 45°.

Post

Lock button

Page 19

17

3

Pull the head protector in the direction of the arrow.

Note

• When the head protector is installed, do not hold by upper section of the head

protector when transporting. Doing so may cause head protector to come off,

with instrument falling off and may be damaged.

Page 20

18

How to Install

1

Insert the head protector pin into the groove of the instrument until you feel it click.

2

Bring down the head protector until you hear a clicking sound.

3

Check that the head protector is securely locked.

Pin, Groove

Page 21

19

Height Alert function

When auto-leveling and height alert function are active, this function prevents the instrument from operating if it is disturbed (after the laser beam emits for one minute). This

helps insures accurate control. If the height or inclination of the instrument changes, the

height of instrument should be verified and re-established if necessary.

1

To activate the Height Alert function, depress and

hold the left Alignment control pad (see page 10) on

the control panel while turning on the instrument by

pressing the Power control pad. The three LEDs

(Leveling, Manual, Battery) will flash at the same time

for three seconds.

2

When this function is active and the unit is disturbed,

three visible LEDs will rapidly flash.

3

To re-activate auto-leveling and check the beam height, turn the unit off, then on again by

pressing the Power control pad twice. After auto-leveling is complete, check the beam

height to confirm it has not changed.

4

The Height Alert function is now inactive. To re-activate, turn unit off and repeat step 1.

Battery LED

Leveling LED

Manual LED

Page 22

20

Setting Slopes

The laser beam can be manually sloped in either the X or Y axis (single slope) or both axes

(compound slope).

With the inclination of the instrument as the standard, laser beam can be sloped within

the range of ±5° up or down.

• The standard for the inclination is the inclination of the instrument, not that of the

rotating head immediately after the auto-leveling.

• This mode can be used with the Remote Controller RC-30.

X axis

Y axis

Single Axis

Dual Axes

Compound slope

Horizontal

Inclination of the

instrument

Page 23

21

How to set slopes

1

Tu rn the instrument on by pressing the Power control pad. Auto-leveling will start.

2

Press the X/Y Axis Selection control pad once (see page 10). The X axis lamp will flash.

To change to Y axis, press the X/Y pad once again. Pressing the X/Y pad toggles between

X and Y axis selection.

3

Select the axis for which you would like to set the slope.

4

Select Laser pointing mode to stop beam rotation and manually align the beam over the direction of the selected axis

(see illustration on previous page.)

5

To move the laser beam up or down, press and hold the right

or left Alignment Control pad. The Manual mode lamp will

illuminate. The flashing lamp for the selected axis will

change to solid after several seconds indicating that the

slope has been entered in the direction of the selected axis.

6

After setting the slope for one axis, press the X/Y axis selection key to select the second axis. Repeat procedures 4 and

5 to set the slope for the second axis.

Cancelling slope settings

Press the Manual Mode pad. The instrument returns to autoleveling mode.

Sample; Laser pointing mode

Move the beam up or down by

pressing the right or left alignment keys

Page 24

22

Line Control (manual vertical beam alignment)

1

Position the instrument for vertical operation as

instructed on page 12.

2

Press the Power Control pad to turn unit on.

When auto-leveling is complete, the laser beam

will be emitted.

3

Select the Laser Pointing operating mode and

manually rotate the rotating head to align the tri-

angular mark t with the center of the mountain

mark on the rotating head.

4

Move the instrument to align Point A with the

center of the laser.

5

Rotate the head so the beam is pointing toward

point B. Press either one of the Alignment Con-

trol pads to move the beam right or left until it is

precisely aligned to point B.

Page 25

23

6

Select the operating mode using the Mode Control pad best suited for your application.

• This mode can be used with the Remote Controller RC-30.

• While an alignment control pad is pressed the auto-leveling beam shut-off will not

operate.

Page 26

24

RC-30 Remote Control

Battery warning lamp

for RC-30

Transmission lamp

Laser Power Switch (Standby mode)

Pressing this switch for more than three seconds

puts laser in standby mode,

allowing the user to conserve battery power.

If laser remains in standby mode for 2 hours,

laser will turn off automatically.

Mode switch control

Slope mode /

X/Y axis selection

Press this key for more than three seconds to

set slope mode or select X or Y axis.

X/Y axis lamp

Alignment control

Speed control

Stop beam control

(Not operable)

Manual focus control

(Not operable)

RC-30 Remote Control (for remote compatible units only, see page 8)

Page 27

25

Description of RC-30 functions

Laser power switch

(Standby mode)

Pressing for more than three seconds turns laser standby mode on or off.

Laser turns off if standby mode continues for two hours.

(This mode cannot be used when the main power of the rotating laser is OFF.)

Transmission lamp This lamp will indicates a signal is being transmitted by the RC-30.

It should illuminate any time a control pad is pressed.

Battery warning

lamp for RC-30

Battery warning for RC-30.

Replace the batteries with new ones.

Speed control The rotation speed of the rotary head can be changed.

Alignment control Moves beam up or down (horizontal rotation).

Moves beam right or left (vertical rotation).

(Valid when axis is selected with the X/Y axis selection key.)

X/Y axis lamp Indicates axis selected during beam sloping operation.

Mode switch

control

Laser mode is switched alternately as follows.

Scan mode / Laser sensor mode / Laser pointing mode.

X/Y axis selection Sets slope mode by pressing for more than three seconds.

Lightly pressing this key for short time will switchover the X and Y axis.

Select X or Y axis for manual grading.

To cancel the slope mode press this key for more than three seconds.

(Press the alignment key when in the slope mode, only then will the rotating laser

switch to the slope mode.)

Stop beam control (Not operable)

Manual focus

control

(Not operable)

Page 28

26

How to set remote control communication channel

The same channel must be set on the RL-VH4G and the RC-30 remote controller.

RL-VH4G

1

Remove the battery cover by turning the

battery compartment lock to “OPEN”.

2

Tu rn the channel switch to set a channel

by using a small straight screwdriver

(see illustration for switch location).

3

Replace the battery cover and turn the

knob to “Lock”.

RC-30

1

Remove the rubber cover from the channel switch on the back of the RC-30.

2

Tu rn the channel switch to the same

channel position set on the RL-VH4G.

3

Replace the rubber cover.

0

9

8

7

6

5

4

3

2

1

X

Y

9

8

7

6

5

4

3

2

1

0

RC-30

RL-VH4G

Channel

switch

Channel

switch

Page 29

27

Maintaining Power Sources

Replacing dry batteries

1

Remove the battery cover by turning the battery compartment lock to “OPEN”.

2

Remove the old batteries and replace with four (4)

new “D” cell alkaline batteries making sure each is

placed in the proper direction as indicated.

3

Replace the battery cover and turn the knob to “Lock”.

Note

• Replace all 4 batteries with new ones.

• Do not mix old batteries and new ones.

Page 30

28

Checking and Adjusting

There are three areas of performance the user should check periodically.

Horizontal Calibration

Horizontal Rotation Cone

Vertical Calibration

The Horizontal Calibration and Vertical Calibration can be easily checked and, in most cases,

adjustments can be made by the user. Horizontal Rotation Cone can be checked by the user,

but if an error is found, adjustments must be made by a Topcon service facility.

Attaching the calibration decals

Before calibration, attach the calibration decals to the instrument as shown below. The calibration decal shows the calibration function of certain control pads on the control panel.

CALIBRATION

START-While pressing ,press

X

CAL

-ON,Y

CAL

-

press ON

V

CAL

-ON

LASER BEAM CORRECTION

- or

ENTER-press

START

1

1

XV

Y

2

3

ENTER

ERROR

4

2

3

4

X/Y

X/Y

X

Y

V

Calibration Decals

Page 31

29

Horizontal Calibration

(1)Checking Calibration

1

Set up a tripod 30m(98ft) from a wall. Mount the instrument on the tripod, facing the X1 side toward the wall.

2

Tu rn the unit on and allow auto-leveling to complete.

3

Place a piece of paper on the wall. Detect the laser position on the wall with target and mark it. Turn the instru-

ment off.

4

Loosen the tripod screw, rotate the instrument 180

degrees.

Note

• When rotating the instrument, make sure the heights of the instruments are aligned.

•When the laser beam is difficult to see, it can be checked in the Laser sensor

mode or the Laser pointing mode.

30m (98feet)

Target

Wall

Instrument as seen from above

Panel side

Page 32

30

5

Tu rn the unit on again and allow auto-leveling to

complete.

6

Make a new mark (Mb) where the laser beam

strikes the paper.

7

Measure the distance between the first mark (Ma)

and the second mark (Mb). No calibration is neces-

sary if distance is within 6mm (1/4 of an inch).

8

Repeat procedure for the Y axis.

30m (98feet)

X1 laser beam

X2 laser beam

If less than 6mm(.23 inches)

No calibration Necessary

Page 33

31

(2) Adjusting Calibration

If the distance between either set of marks is more than 6mm (1/4 of an inch) but less than

25mm (1 inch), turn the unit off by pressing the [START] pad once and use the following

procedure to calibrate the laser. Confirm that unit has shut off before beginning the procedure.

(In steps 2 and 3, use of optional RC-30 remote control can be helpful. See page 33.)

1

While pressing the [ENTER] key, press the [START] key. This activates the X axis calibration mode. Confirm that the [X] LED is lit.

2

By pressing the right or left Alignment Control pad, move the X2 (Mb) laser beam up or

down until its centered between marks Ma and Mb.

Note

• This operation can be performed with the Remote Controller RC-30.

•When using the RC-30, select the X axis with the X/Y axis selection key and

move the laser beam up or down with the alignment key.

START

1

XV

Y

2

3

ENTER

ERROR

4

X/Y

Laser beam

up or down

Center

position

Page 34

32

3

When the beam is precisely centered, press the [ENTER] key.

The [X] LED will flash.

When the flashing stops, the X axis calibration adjustment is made and power is turned off.

4

For Y axis calibration, turn the unit as instructed in step 1 then press the X/Y Axis Selection

pad.

Confirm that the [Y] LED is lit, then repeat steps 2 to 4 for the Y axis.

Repeat the checking procedure to confirm proper calibration has been made.

• This operation can be performed with the Remote Controller RC-30.

When using the RC-30, press the [ENTER] key on the RC-30 unit.

(The [ENTER] key for the RC-30: The same mark as the [ENTER] key for the instrument.)

• This operation can be performed with the Remote Controller RC-30.

When using the RC-30, select the Y axis using the X/Y axis selection key and

move the laser beam up and down with the Alignment control key.

Note

• If the calibration is greater than the adjustment allows, the error LED will start

flashing. (See “Error Code” on

If this occurs, contact your Topcon dealer.

•When the laser beam is difficult to see, it can be adjusted in the Laser sensor

mode or the Laser pointing mode.

Page 35

33

Horizontal Rotation Cone Error

Perform the following check after completing "Horizontal Calibration" on the previous page.

1

Set up the laser centered between two walls approximately 30m (98 ft) apart. Orient the

instrument so one axis, either X or Y, is facing the walls.

2

Locate and mark the position of the rotating laser beam on both walls using the target.

3

Tu rn off the instrument and move the instrument closer to wall A (1m to 2m /3 ft to 6 ft).

Do not change the axis orientation of the instrument. Turn the instrument on.

4

Again locate and mark the position of the rotating laser beam on both walls.

5

Measure the distance between the first and second marks on each wall.

6

If the difference between each set of marks is less than 3mm (1/8 of an inch), no error

exists.

Note

• If the error is grater than 3mm (1/8 of an inch), contact your Topcon dealer.

Cone error

Datum position

Wall

Wall

B

A

Wall

A

Wall

B

Minimum about 30m/98ft

Page 36

34

Vertical Calibration

Perform the following check after completing "Horizontal Calibration" on the previous page.

(1)Checking

1

Set up the instrument half way between

two walls a minimum of 30m (98 ft) apart.

(The instrument can be facing either

direction X or Y. No tripod is used.)

2

Tu r n the power switch on.

3

Place a piece of paper on each wall (A

and B).

Mark the horizontal laser positions (Ma and Mb) on each wall using target.

4

Tu r n the power switch off. Position the

instrument for vertical operation (see

instruction on page 12) with the rotary

head directly facing wall A (see illustration). Make sure the unit is level by checking the level vial. Use the leveling screw

to adjust if necessary.

5

Tu rn the power switch on. (Laser beam

should be in scanning mode.)

6

Mark where the split beam emitted from

the top of the rotary head strikes wall A

(Ha). Measure the distance (dHa)

between marks Ma and Ha.

about 15 m

(49ft)

about 15 m

(49ft)

Wall

A

Wall

B

about 30 m (98ft)

Wall

A

Wall

B

about 1m

Foot

Page 37

35

7

Without moving the position of the front foot, pivot the instrument so the rotary head is

now facing wall B.

8

Mark where the split beam emitted from

the top of the rotary head strikes wall B

(Hb). Measure the distance (dHb)

between marks Mb and Hb.

9

Compare the two measurements dHa and

dHb. If the difference between the two

measurements is less than 3mm (1/8 of

an inch), no adjustment is necessary. Otherwise, adjust as follows.

about 1m

about 30 m (98ft)

Page 38

36

(2)Adjusting Calibration

Tu rn the unit off by pressing the [START] pad once. Confirm that unit has shut off before

beginning the following procedure.(In step 2 and 3, optional RC-30 remote control is helpful.)

1

Without moving the unit, press the [ENTER] and [START] keys simultaneously.

2

Press either the right or left key on the Alignment Control pad to move the laser beam up

or down on wall B until the measurement for the distance dHb is the same as the mea-

surement dHa on wall A.

• This operation can be performed with the Remote Controller RC-30.

When using the RC-30, select the Y axis using the X/Y axis selection key and

move the laser beam up and down with the Alignment control key.

START

1

XV

Y

2

3

ENTER

ERROR

4

X/Y

Laser beam

up or down

Page 39

37

3

When the beam is positioned so the two measurements are the same, press the [ENTER]

key. The [V] LED will flash.

When the flashing stops, the vertical calibration adjustment is made and power is turned

off.

Repeat the checking procedure to confirm proper calibration has been made.

• This operation can be performed with the remote controller RC-30.

When using the RC-30, press the [ENTER] key on the RC-30 unit.

(The [ENTER] key for the RC-30: The same mark as the [ENTER] key for the

instrument.)

Note

• If the calibration is greater than the adjustment allows, the error LED will

start flashing. If this occurs, contact your Topcon dealer.

Page 40

38

Standard / Optional Accessories

Auto-cut off function(LS-70G)

The power will be turned off automatically if no laser beam is detected within

approximately 30 minutes. (To turn the sensor on again, press the power switch.)

Tw o on-grade precision options are available,

normal precision and high precision. By pressing this switch, the precision options are

switched alternately. Active precision setting

is shown on the display.

(Normal precision is the default setting when

power is turned on.)

On-grade precision switch

Audio indicator switch

(Quite/Loud/OFF)

Audio speaker

Beam receiving window

Power switch

LS-70G Laser Sensor

On-grade Index

Display

On-grade Index

The indicators are located on front and back

sides of the instrument.

The rotating laser safety lock system display and rotating laser battery level display

are not available with the LS-70G.

Level sensors other than the LS-70G cannot be used.

Page 41

39

154

152

150

153

151

138

136

134

132

139

137

135

133

131

131

149

147

148

146

HOLDER-6

Laser sensor holder model 6

Laser sensor

holder model 6

Clamp knob

Laser sensor

Wall Mount 1C

Clamp lever

Laser Mounting

screw

Elevation

clamp knob

Page 42

40

Battery holder DB-49C

Rechargeable battery pack BT-63Q

AC/DC converter

For Charging

1

Plug the AC/DC converter into the DB-49C battery holder.

2

Insert the converter power cord in an outlet.

3

Complete charging by unplugging the converter connector from the DB-49C battery

holder after approximately 9 hours.

4

Unplug the converter power cord from the outlet.

The LED of DB-49C will indicate charging status;

Red ON : Charging.

Green ON : Charging completed.

Green flashing : DB-49C is not connected to BT-63Q.

Red flashing : BT-63Q protection feature is working automatically.

RL-VH4G can be used in this state.

Automatic protection feature; In case of overcharge or high or low temperature state exceeding

charging range, charging will be stopped or changed to protect battery.

• DB-49C can be used with dry batteries instead of BT-49Q.

DB-49C

AC/DC converter

BT-63Q

DB-49C

Page 43

41

Storage Precautions

Always clean the instrument after use.

Use a clean cloth, moistened with a neutral detergent or water. Never use an abrasive

cleaner, ether, thinner benzene, or other solvents.

Always make sure instrument is completely dry before storing. Dry any moisture with a soft,

clean cloth.

Page 44

42

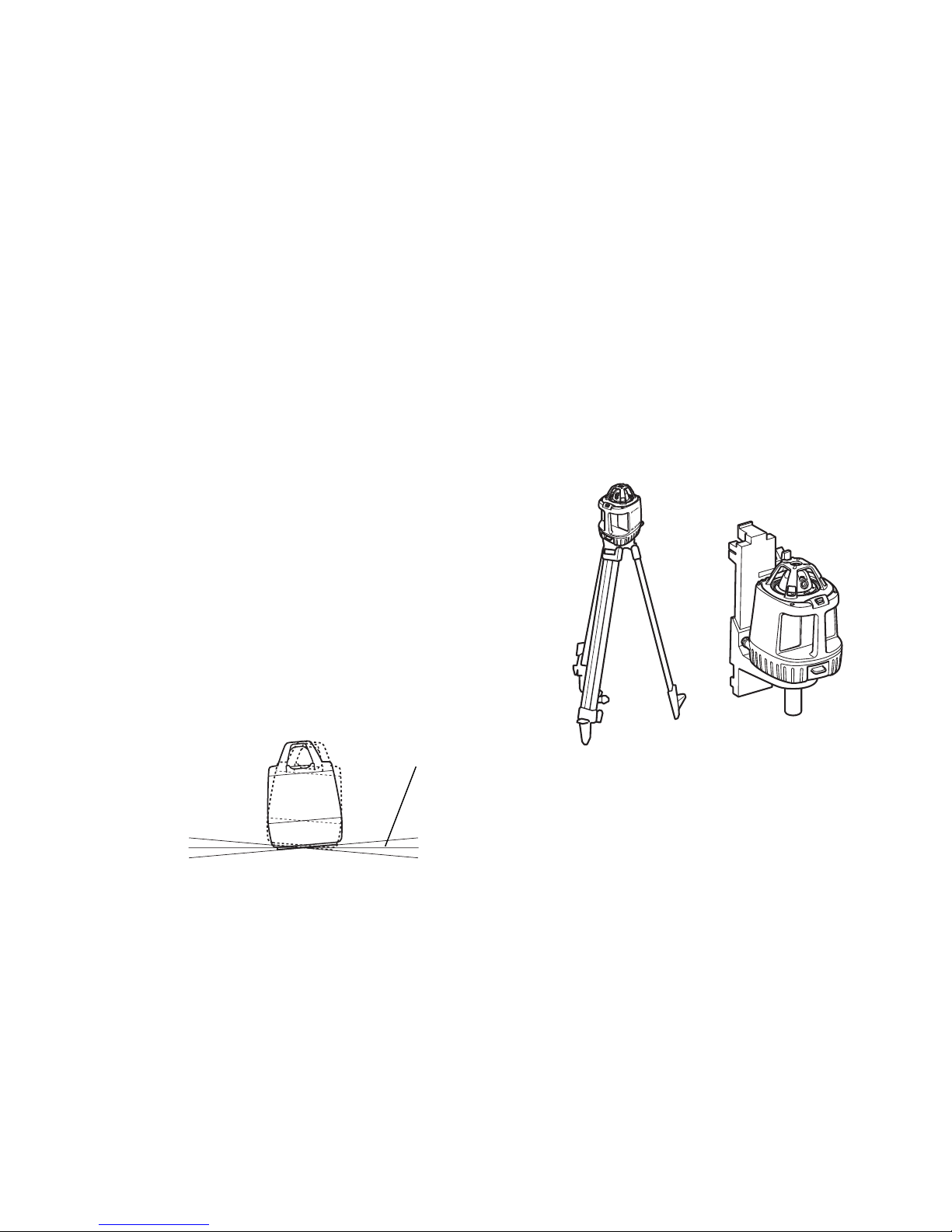

How to Store

How to Store (1)

LS-70G

Laser sensor

holder model 6

Wall Mount 1C

Page 45

43

AC/DC convertor

How to Store (2)

BT-63Q

Page 46

44

Specifications

RL-VH4G

Accuracy

Horizontal : ±20"

Ver tical : ±20"

Auto-leveling range : ±5°

Measuring range (Diameter) : 60m(197ft)

Using with LS-70G : 2m(6.5ft)~300m(984ft)

Rotation speeds : Changeable (0 ~ 300rpm)

Scanning width Maximum 180°

Light source : Solid-state laser (Visible laser)

Power supply : 4D-CELL Alkaline dry batteries

Continuous operating time : Approx. 27 hours

at +20°C (+68°F) Approx. 247 hours (When using the rechargeable internal

power source BT-63Q)

Tripod screw : Flat and dome head type, W 5”/8 × 11threads

Operating temperature : -20°C to +50°C (-4°F to +122°F)

Protection against

water and dust

: IP54 (Category 2)

Dimensions : 182(L) × 167(W) × 240(H) mm [7.2(L) × 6.6(W) × 9.4(H) in]

Weight : 2.6 kg [5.7 lbs] (without dry batteries)

Page 47

45

Remote controller RC-30

Operating range (Radius)

Power supply

Operating time

Protection against

Dimensions

Weight

:

:

:

:

:

:

Approx. 80m (262ft)

(Operating range will vary depending on environmental

conditions.)

Three "AA" alkaline batteries, DC4.5V

Approx. 3 months (depends on the nature of use)

×

×

×

×

g[0.35 lbs]

Page 48

46

Error Code

Use the table below to determine operation errors indicated by blinking lamps on

the control panel.

If corrective action listed does not correct

error, please contact your local Topcon

dealer.

Lamp Indication Error Code Corrective Action

Lamp A, B and C blink in turn Auto-leveling range error Correct tilt of the instrument until it less than 5 de-

grees.

Lamp C lights Battery power out error Replace all 4 batteries with new ones at the same

time.

Lamp A, B and C blink simultaneously

Height alert error Turn power off, rough level the instrument, then turn

power on again. Check height of laser beam as it

may have changed.

Lamp B blinks Calibration error Repeat calibration procedure. If error repeats con-

tact your local Topcon dealer.

Lamp D and E blink simultaneously

Internal error Turn power off, then on again. If error repeats con-

tact your local Topcon dealer.

C E

D

A

B

Page 49

2006 TOPCON CORPORATION

ALL RIGHTS RESERVED

Page 50

TOPCON CORPORATION

75-1 Hasunuma-cho, Itabashi-ku, Tokyo 174-8580, Japan

Phone: 3-3558-2520 Fax: 3-3960-4214 www.topcon.co.jp

TOPCON POSITIONING SYSTEMS, INC.

7400 National Drive, Livermore, CA 94551, U.S.A.

Phone: 925-245-8300 Fax: 925-245-8599 www.topcon.com

TOPCON CALIFORNIA

3380 Industrial Blvd, Suite 105, West Sacramento, CA 95691, U.S.A.

Phone: 916-374-8575 Fax: 916-374-8329

TOPCON EUROPE POSITIONING B.V.

Essebaan 11, 2908 LJ Capelle a/d IJssel, The Netherlands.

Phone: 010-458-5077 Fax: 010-284-4941 www.topconeurope.com

TOPCON DEUTSCHLAND G.m.b.H.

Giesserallee 31, 47877 Willich, GERMANY

Phone: 02154-885-100 Fax: 02154-885-111 info@topcon.de

www.topcon.de

TOPCON S.A.R.L.

89, Rue de Paris, 92585 Clichy, Cedex, France.

Phone: 33-1-41069490 Fax: 33-1-47390251 topcon@topcon.fr

TOPCON SCANDINAVIA A. B.

Neongatan 2 S-43151 Mölndal, SWEDEN

Phone: 031-7109200 Fax: 031-7109249

TOPCON (GREAT BRITAIN)LTD.

Topcon House Kennet Side, Bone Lane, Newbury, Berkshire RG14 5PX U.K.

Phone: 44-1635-551120 Fax: 44-1635-551170

survey.sales@topcon.co.uk laser.sales@topcon.co.uk

TOPCON SOUTH ASIA PTE. LTD.

Blk 192 Pandan Loop, #07-01 Pantech Industrial Complex, Singapore 128381

Phone: 62780222 Fax: 62733540 www.topcon.com.sg

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn Tower, 37th Fl.,

Krungdhonburi Rd., Klongtonsai, Klongsarn, Bangkok 10600 Thailand.

Phone: 02-440-1152~7 Fax: 02-440-1158

TOPCON INSTRUMENTS (MALAYSIA) SDN. BHD.

Excella Business Park Block C, Ground & 1st Floor, Jalan Ampang Putra,

Taman Ampang Hilir, 55100 Kuala Lumpur, MALAYSIA

Phone: 03-42701068 Fax: 03-42704508

TOPCON KOREA CORPORATION

2F Yooseoung Bldg., 1595-3, Seocho-Dong, Seocho-gu, Seoul, 137-876, Korea.

Phone: 82-2-2055-0321 Fax: 82-2-2055-0319 www.topcon.co.kr

TOPCON OPTICAL (H.K.) LIMITED

2-4/F Meeco Industrial Bldg., No. 53-55 Au Pui Wan Street, Fo Tan Road,

Shatin, N.T., Hong Kong

Phone: 2690-1328 Fax: 2690-2221 www.topcon.com.hk

TOPCON CORPORATION BEIJING OFFICE

Building A No.9, Kangding Street

Beijing Economic Technological Development Area, Beijing, China 100176

Phone: 10-6780-2799 Fax: 10-6780-2790

TOPCON CORPORATION BEIRUT OFFICE

P. O. BOX 70-1002 Antelias, BEIRUT-LEBANON.

Phone: 961-4-523525/961-4-523526 Fax: 961-4-521119

TOPCON CORPORATION DUBAI OFFICE

C/O Atlas Medical FZCO., P. O. Box 54304, C-25, Dubai Airport Free Zone,UAE

Phone: 971-4-2995900 Fax: 971-4-2995901

IRELAND OFFICE

Unit 69 Western Parkway Business Center

Phone: 01460-0021 Fax: 01460-0129

Lower Ballymount Road, Dublin 12, Lreland

3C

Loading...

Loading...