Page 1

INSTRUCTION MANUAL

ROTATING LASER

RL-SV2S

31365 90030

Page 2

Page 3

FOREWORD

Thank you for selecting the TOPCON instrument.

• Please read this instruction manual carefully before using this instrument.

• Verify that all equipment is included.

C “ STANDARD SYSTEM COMPONENTS” (p. iii)

• The specifications and general appearance of the instrument are subject to change without

prior notice and without obligation by Topcon Corporation and may differ from those appearing

in this manual.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

i

Page 4

HOW TO READ THIS MANUAL

XSymbols

The following conventions are used in this manual.

Indicates precautions and important items which should be read before

G

C

$

:

operations.

:

Indicates the chapter title to refer to for additional information.

:

Indicates supplementary explanation.

ii

Page 5

STANDARD SYSTEM COMPONENTS

Rechargeable battery type Dry battery type

1) RL-SV2S Instrument .......................................1pc.

2) Remote controller RC-60

(with AA Manganese battery x 2pcs.) .............1pc.

3) Level Sensor LS-80L.......................................1pc.

4) Model-6 Level Sensor Holder .........................1pc.

5) Battery holder DB-74C ....................................1pc.

6) Ni-MH battery pack BT-74Q ............................1set

7) AC/DC converter AD-15 ..................................1pc.

8) AA-size dry cell batteries*1) ............................4pcs.

9) Carrying case ..................................................1pc.

10) Instruction manual ...........................................1vol.

1) RL-SV2S Instrument....................................... 1pc.

2) Remote controller RC-60

(with AA Manganese battery x 2pcs.) ............ 1pc.

3) Level Sensor LS-80L ...................................... 1pc.

4) Model-6 Level Sensor Holder ........................ 1pc.

5) Battery holder DB-74 ...................................... 1pc.

6) D-size dry cell batteries*2).............................. 4pcs.

7) AA-size dry cell batteries*3)............................ 4pcs.

8) Carrying case ................................................. 1pc.

9) Instruction manual .......................................... 1vol.

• Please make sure that all of above items are in the box when you unpack.

*1),*2),*3) Batteries included in the package are to confirm the initial operation. Please replace

the batteries provided with new batteries (alkaline) as soon as possible.

iii

Page 6

CONTENTS

FOREWORD ................................................................................................................................. I

HOW TO READ THIS MANUAL................................................................................................... II

STANDARD SYSTEM COMPONENTS ...................................................................................... III

CONTENTS ................................................................................................................................. IV

1. PRECAUTIONS FOR SAFE OPERATION ............................................................................ 1

2. PRECAUTIONS ..................................................................................................................... 6

3. LASER SAFETY INFORMATION .......................................................................................... 8

Laser Safety................................................................................................................ 8

4. NOMENCLATURE ............................................................................................................... 11

4.1 RL-SV2S....................................................................................................................... 11

RL-SV2S Nomenclature............................................................................................ 11

RL-SV2S Display ...................................................................................................... 13

4.2 Remote controller RC-60 .............................................................................................. 14

RC-60 Nomenclature ................................................................................................ 14

RC-60 Display........................................................................................................... 14

4.3 Level Sensor LS-80L .................................................................................................... 15

LS-80L Nomenclature ............................................................................................... 15

LS-80L Display.......................................................................................................... 16

LS-80L Detective Range........................................................................................... 17

5. PREPARATION AND FUNCTIONS ..................................................................................... 18

5.1 Power Source ............................................................................................................... 18

RL-SV2S (Dry battery type) ...................................................................................... 18

iv

Page 7

CONTENTS

RL-SV2S (Rechargeable battery type)...................................................................... 20

RC-60........................................................................................................................ 23

LS-80L....................................................................................................................... 23

5.2 How to set remote controller communication channel .................................................. 24

RL-SV2S ................................................................................................................... 24

RC-60........................................................................................................................ 24

6. BASIC OPERATION............................................................................................................. 25

6.1 Setting Up Instrument ................................................................................................... 25

Horizontal Rotation.................................................................................................... 25

Example Operational................................................................................................. 27

Vertical Rotation........................................................................................................ 27

6.2 Height Alert Function .................................................................................................... 28

How to reset .............................................................................................................. 28

7. APPLIED OPERATION AND SETTING OF VARIOUS FUNCTIONS.................................. 29

7.1 Setting Grades .............................................................................................................. 29

How to enter grade values ........................................................................................ 29

How to set grades ..................................................................................................... 31

Example of how to set up.......................................................................................... 33

Matching Mode (Manual Slope) ................................................................................ 35

7.2 Line Control (manual vertical beam alignment) ............................................................ 37

7.3 Setting of Various Functions ......................................................................................... 40

Selecting MENU........................................................................................................ 40

Masking (Laser beam shutter) setting....................................................................... 41

v

Page 8

CONTENTS

How to change the rotary head speed ...................................................................... 42

Switching Auto leveling / Manual Mode .................................................................... 43

Setting channel ......................................................................................................... 44

Sleep mode ON/OFF ................................................................................................ 44

Height Alert ON/OFF................................................................................................. 46

8. CHECK AND ADJUSTING................................................................................................... 47

8.1 Check and Adjust Horizontal Rotation .......................................................................... 47

Horizontal rotation grade error .................................................................................. 47

Horizontal Rotation Cone Error ................................................................................. 51

Grade Setting Error................................................................................................... 52

8.2 Vertical Calibration........................................................................................................ 54

Checking Calibration................................................................................................. 54

Horizontal calibration and adjustment ....................................................................... 55

9. STORAGE PRECAUTIONS................................................................................................. 57

10. HOW TO STORE .................................................................................................................58

11. SPECIFICATIONS ...............................................................................................................59

12. ERROR DISPLAY ................................................................................................................62

13. REGULATIONS.................................................................................................................... 65

vi

Page 9

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well

as prevention of property damage, items which should be observed are indicated by an

exclamation point within a triangle used with WARNING and CAUTION statements in this

instruction manual.

The definitions of the indications are listed below. Be sure you understand them before reading

the manual’s main text.

Definition of Indication

Ignoring this indication and making an operation error could possibly

WARNING

CAUTION

result in death or serious injury to the operator.

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

This symbol indicates items for which caution (hazard warnings inclusive) is urged.

Specific details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or

near the symbol.

This symbol indicates items which must always be performed. Specific details are

printed in or near the symbol.

1

Page 10

1. PRECAUTIONS FOR SAFE OPERATION

General

Warning

Do not perform disassembly or rebuilding. Fire, electric shock or burns could result.

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where

there is inadequate ventilation, or near combustible materials. An explosion could

occur.

When securing the instrument in the carrying case make sure that all catches,

including the side catches, are closed. Failure to do so could result in the

instrument falling out while being carried, causing injury.

2

Caution

Do not use the carrying case as a footstool. The case is slippery and unstable so a

person could slip and fall off it.

Do not place the instrument in a case with a damaged case or belt. The case or

instrument could be dropped and cause injury.

Page 11

Power Supply

Warning

Do not short circuit. Heat or ignition could result.

Do not use voltage other than the specified power supply voltage. Fire or electrical

shock could result.

Do not use damaged power cords, plugs or loose outlets. Fire or electric shock

could result.

Do not use power cords other than those designated. Fire could result.

1. PRECAUTIONS FOR SAFE OPERATION

Do not use batteries other than those designated. An explosion could occur, or

abnormal heat generated, leading to fire.

Do not place articles such as clothing on the battery charger while charging

batteries. Sparks could be induced, leading to fire.

Use only the specified battery charger to recharge batteries. Other chargers may

be of different voltage rating or polarity, causing sparking which could lead to fire or

burns.

3

Page 12

1. PRECAUTIONS FOR SAFE OPERATION

Do not heat or throw batteries into fire. An explosion could occur, resulting in injury.

Do not use the battery or charger for any other equipment or purpose. Fire or burns

caused by ignition could result.

To prevent shorting of the battery in storage, apply insulating tape or equivalent to

the terminals. Otherwise shorting could occur, resulting in fire or burns.

Do not use batteries or the battery charger if wet. Resultant shorting could lead to

fire or burns.

Do not connect or disconnect power supply plugs with wet hands. Electric shock

could result.

4

Caution

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or

blisters.

Page 13

Tripod

1. PRECAUTIONS FOR SAFE OPERATION

Caution

When mounting the instrument to the tripod, tighten the centering screw securely.

Failure to tighten the screw properly could result in the instrument falling off the

tripod, causing injury.

Tighten securely the leg fixing screws of the tripod on which the instrument is

mounted. Failure to tighten the screws could result in the tripod collapsing, causing

injury.

Do not carry the tripod with the tripod shoes pointed at other persons. A person

could be injured if struck by the tripod shoes.

Keep hands and feet away from the tripod shoes when fixing the tripod in the

ground. A hand or foot stab wound could result.

Tighten the leg fixing screws securely before carrying the tripod. Failure to tighten

the screws could lead to the tripod legs extending, causing injury.

5

Page 14

2. PRECAUTIONS

Before starting work or operation, be sure to check that the instrument is functioning correctly

with normal performance.

Vibration and Impact Protection

When transporting the instrument, provide protection to minimize risk of severe vibration or

impact. Severe vibration or impacts may affect beam accuracy.

Protection against abrupt change in temperature

Do not leave the instrument under strong sunlight for a long time. It may cause the instrument

to malfunction.

Exceptions from Responsibility

• The user of this product is expected to follow all operating instructions and make periodic

checks of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of a faulty or

intentional usage or misuse including any direct, indirect, consequential damage, and loss of

profits.

6

Page 15

2. PRECAUTIONS

• The manufacturer, or its representatives, assumes no responsibility for consequential

damage, and loss of profits by any disaster, (an earthquake, storms, floods etc.). A fire,

accident, or an act of a third party and/or a usage any other usual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss

of profits due to a change of data, loss of data, an interruption of business etc., caused by

using the product or an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss

of profits caused by usage except for explained in the user manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by

wrong movement, or action due to connecting with other products.

7

Page 16

3. LASER SAFETY INFORMATION

The RL-SV2S is classified as a class 3R Laser Product according to IEC Standard Publication

60825-1 Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA CDRH

21CFR Part1040.10 and 1040.11 (Complies with FDA performance standards for laser products

except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

Laser Safety

This product projects a visible laser beam during operation. This product is manufactured and

sold in accordance with “Performance Standards for Light-Emitting Products” (FDA/BRH 21

CFR 1040) or “Radiation Safety of Laser Products, Equipment Classification, Requirements and

User’s Guide” (IEC Publication 60825-1) provided on the safety standards for laser beam.

As per the said standard, RL-SV2S standard model is classified as “Class 3R (IIIa) Laser

Products”. These are simple products to operate and do not require training from a laser safety

officer. In case of any failure, do not disassemble the instrument. Contact TOPCON or your

TOPCON dealer.

8

Page 17

Visible laser

3. Laser Safety Information

CLASS IIIa LASER PRODUCT

VISIBLE LASER BEAM

Laser output: 2.4mW

Warning

Use of controls or adjustments or performance of procedures other than those

Beam aperture

Explanatory Label

Each lavel is differed by the market.

specified herein may result in hazardous radiation exposure.

Do not look directly into the laser beam. Doing so could cause permanent eye

damage.

9

Page 18

3. Laser Safety Information

Do not stare at the laser beam. Doing so could cause permanent eye damage.

Never intentionally point the laser beam at another person. The laser beam is

injurious to the eyes and skin.

Caution

Perform checks at start of work and periodic checks and adjustments with the laser

beam emitted under normal conditions.

When the instrument is not being used, turn off the power.

10

When disposing of the instrument, destroy the battery connector so that the laser

beam cannot be emitted.

Operate the instrument with due caution to avoid injuries that may be caused by

the laser beam unintentionally striking a person in the eye. Avoid setting the

instrument at heights at which the path of the laser may strike pedestrians or drivers

at head height.

Page 19

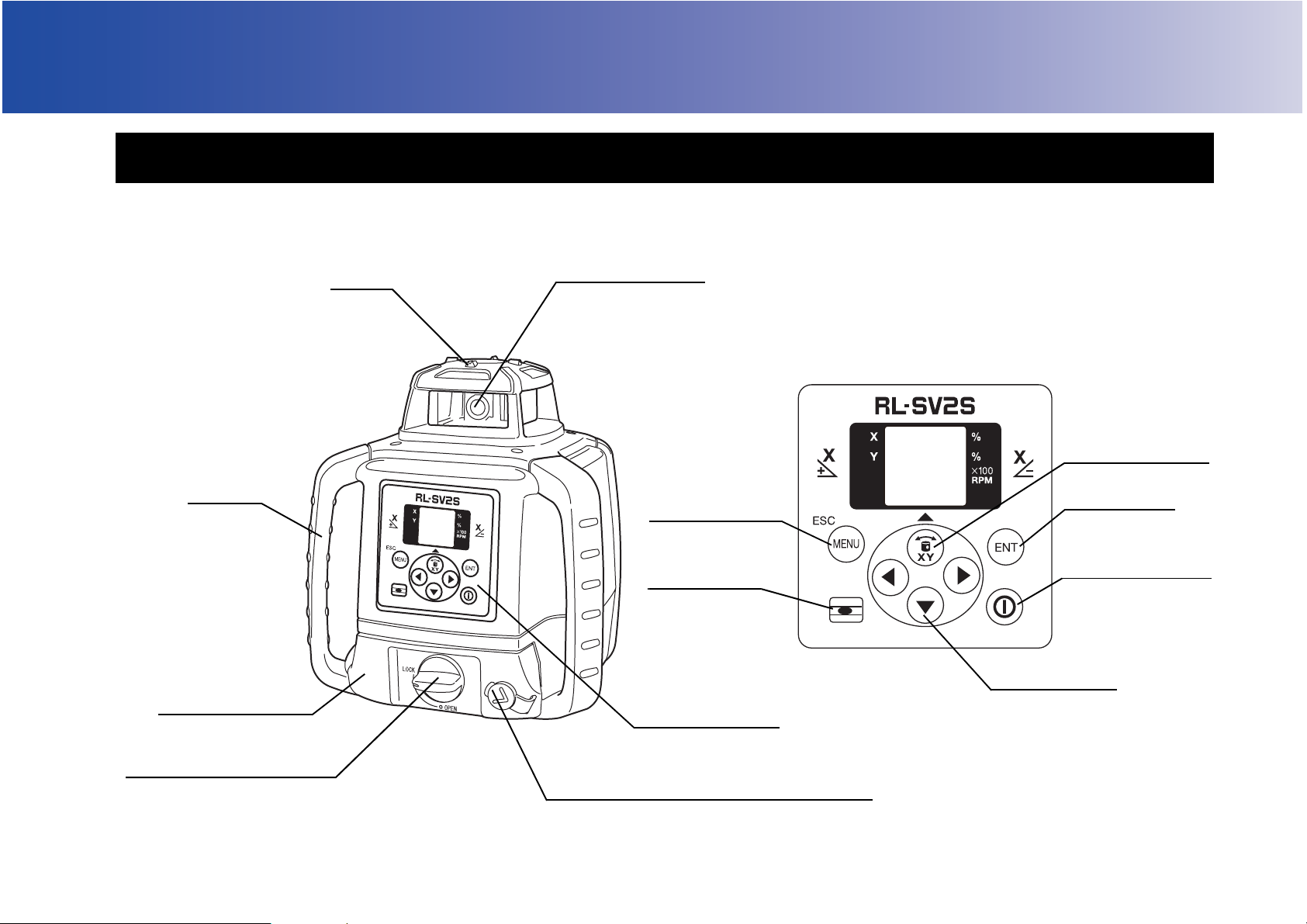

4. NOMENCLATURE

4.1 RL-SV2S

RL-SV2S Nomenclature

Handle

Battery holder

Sight

Rotary head

Beam apeature

Menu key/

Escape key

Level vial

For Vertical

Rotation

Control panel

Control panel

X/Y axis

selection key/

Alignment key/

Up key

Enter key

Power switch

Arrow keys

Battery holder knob

Carging connector (only in the

rechargeable battery type)

11

Page 20

4. Nomenclature

Key Nomenclature Function

Enter key

Menu/Escape key

X/Y axis selection key/

Alignment key

Arrow keys

End Operation of Data Input and Sends data to the

instrument.

Selects a menu item.

Cancels input or escape to previous status.

Horizontal rotation: changes to the grade setting screen for

each axis.

Vertical rotation: changes to the Alignment Mode.

The arrows indicate code selection, digit shift, and number

input during grade setting, and designates direction during

masking setting.

12

Power switch On/Off of the RL-SV2S.

Page 21

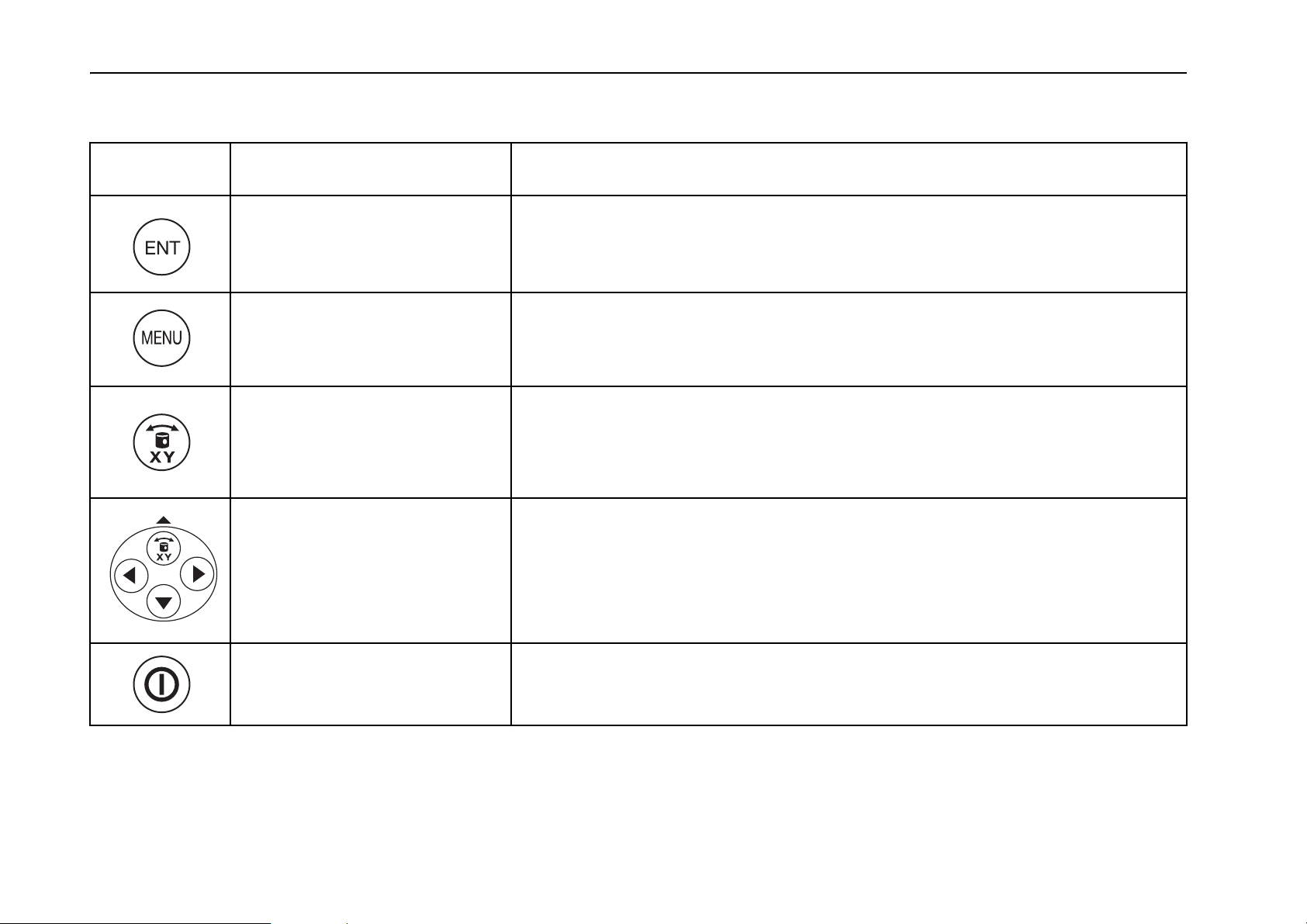

RL-SV2S Display

4. Nomenclature

X axis grade

(Flashes one digit at a time

during leveling)

Y axis grade

(Flashes one digit at a time

during leveling)

Manual Mode display

Transmission and reception display

Transmits to the receiving instrument (RC-60 or

RL-SV2S)

(Lights on until received by the receiving

instrument)

Receives from the transmitting instrument

(Lights on until the transmitting instrument

transmits next time)

When transmission from the other instrument

is not possible

(Both marks will flash slowly until the next

transmission)

Sample display

Battery remaining

Mask Mode display

Rotation speed

6:600/rpm

3:300/rpm

5:500/rpm

(Flashes when the battery is low)

Ample power for operation

Ample power for operation

Power remaining for operation

Power remaining for operation

Near power depletion. The laser speed will be

500 rpm.

Power depletion

Laser will stop

Dry cell battery type:Replace with new batteries.

Rechargeable battery type:When connecting to

AD-15 during error display, turn

OFF the power and then turn the

power back ON to restore

operation.

13

Page 22

4. Nomenclature

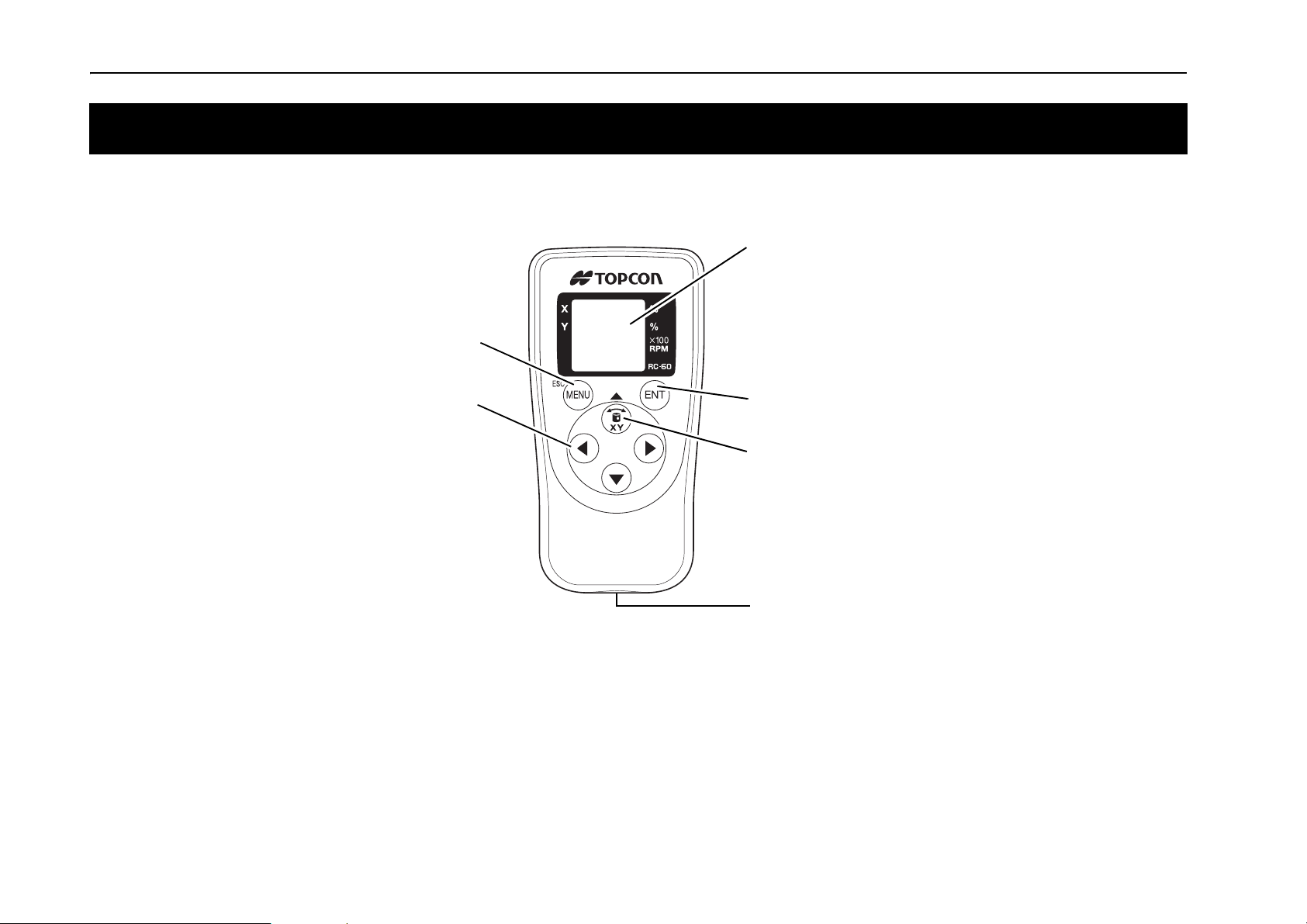

4.2 Remote controller RC-60

RC-60 Nomenclature

Menu key/Escape key

Display

Arrow keys

Enter key

X/Y axis selection key/Alignment key/

Up key

Strap hole

RC-60 Display

Display is the same as the RL-SV2S. C“RL-SV2S Display” (p. 13)

Battery power display will show the remaining battery level on the RC-60 remote controller.

14

Page 23

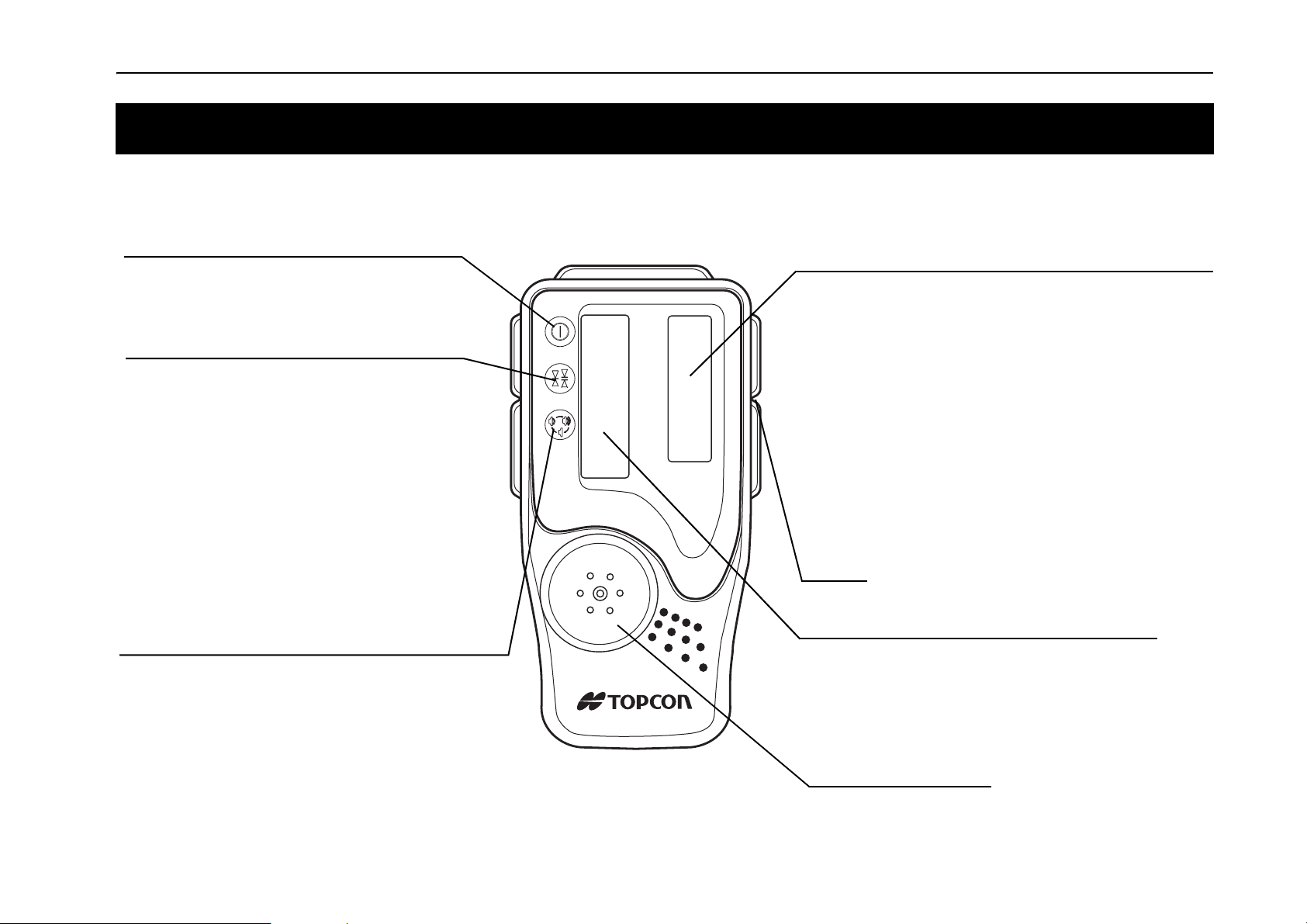

4.3 Level Sensor LS-80L

k

LS-80L Nomenclature

4. Nomenclature

Power switch

The power switch turns ON or OFF

by pressing.

On-Grade precision switch

Two on-grade precision options are

available, normal precision (±2mm)

and high precision (±1mm). By

pressing this switch, the precision

options are switched alternately.

Confirm the precision choice by the

indicator. (Normal precision is the

default setting each time the sensor

is turned on.)

Buzzer sound switch

Volume of the sensor buzzer can be

alternately switched to

LOW/LOUD/OFF by pressing the switch.

Indicator

Detect the on-grade position "---" by moving

the LS-80L up and down. Directional arrows

and audio signals assist in locating the ongrade positiion as the laser strikes the

beam receiving window. (Top of LS-80L is

40mm (1 9/16") from on-grade index for

offset marking.)

The indicators are located on front and bac

sides of the instrument.

“LS-80L Display” (p. 16)

Index

Beam receiving window

Turn the beam receiving window side

towards RL-SV2S to detect the laser

beam.

Buzzer speaker

15

Page 24

4. Nomenclature

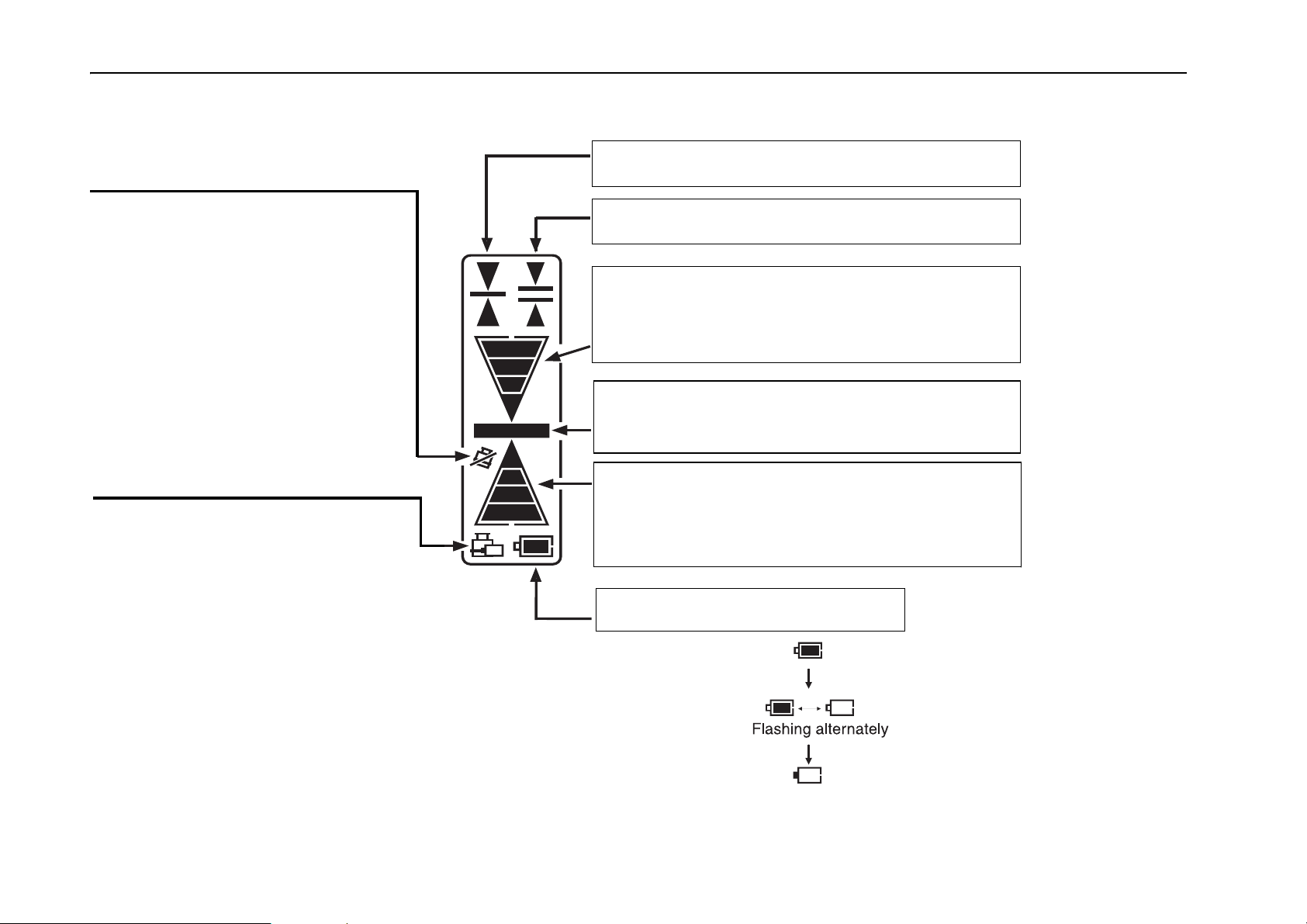

LS-80L Display

Height alert warning of rotating

laser

A flash and a buzzer sound

signifies that the height alert

function of the RL-SV2S is

*1

Rotating laser battery

warning

A flash shows that the RL-SV2S

power is low.

*2

High precision mode

Normal precision mode

Higher than datum position

(Buzzer sound:High frequent beep sound)

Move the sensor downward.

Datum position

(Buzzer sound:Continuous beep sound)

Lower than datum position

(Buzzer sound:Low frequent beep sound)

Move the sensor upward.

Battery remaining display

$

The warning displays *1 and *2 are the functions that the

LS-80L detects alarm signal from the RL-SV2S.

The LS-80L can be canceled the alarm detection from the

RL-SV2S.

To be canceled the detection; Press the power switch

while pressing the buzzer sound switch when powering on.

16

Battery is sufficient.

The power is low, but laser

is still usable.

Dead battery.

Replace the dry battery with

new one.

Page 25

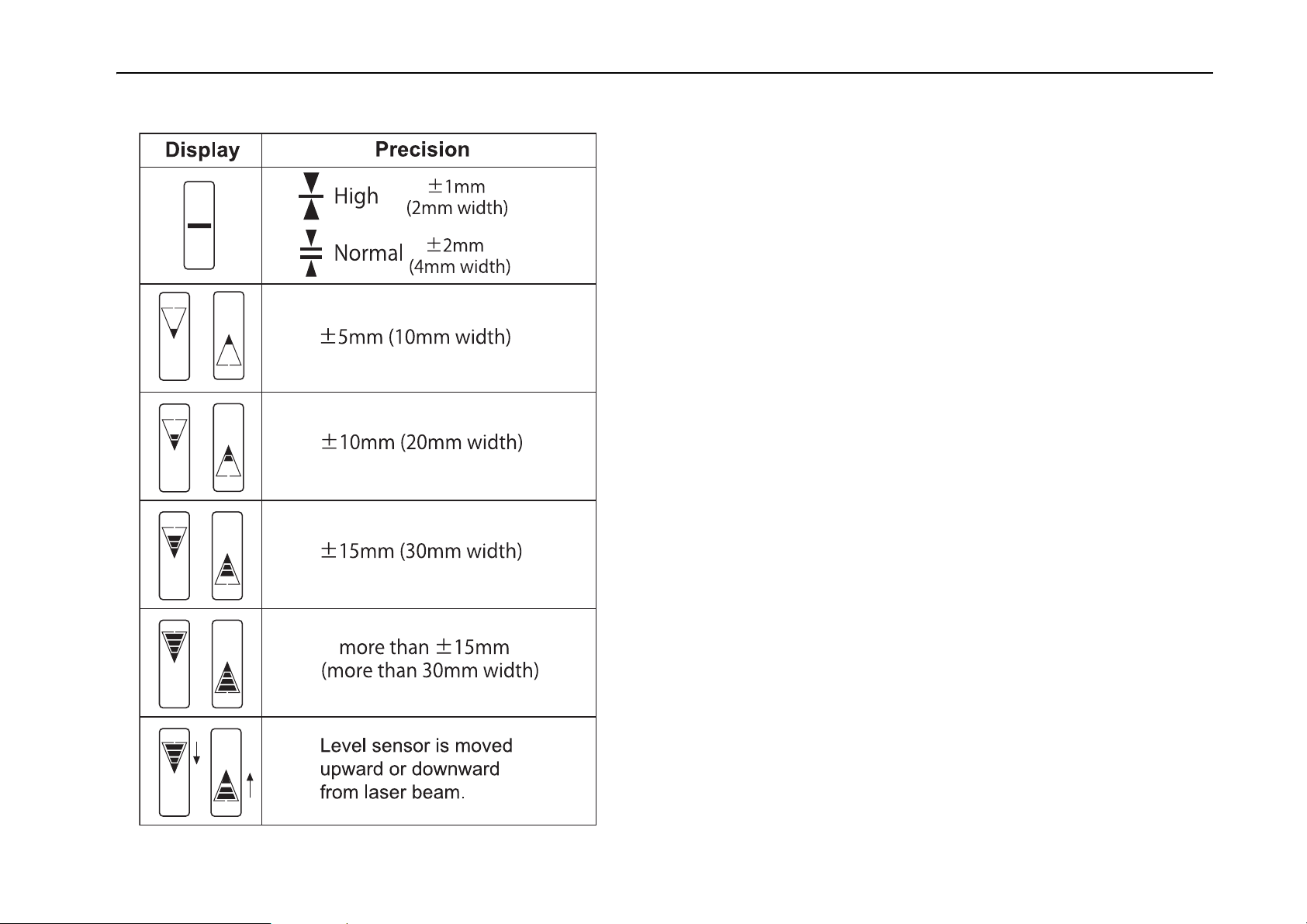

LS-80L Detective Range

4. Nomenclature

17

Page 26

5. PREPARATION AND FUNCTIONS

5.1 Power Source

Connect the battery according to the battery type purchased.

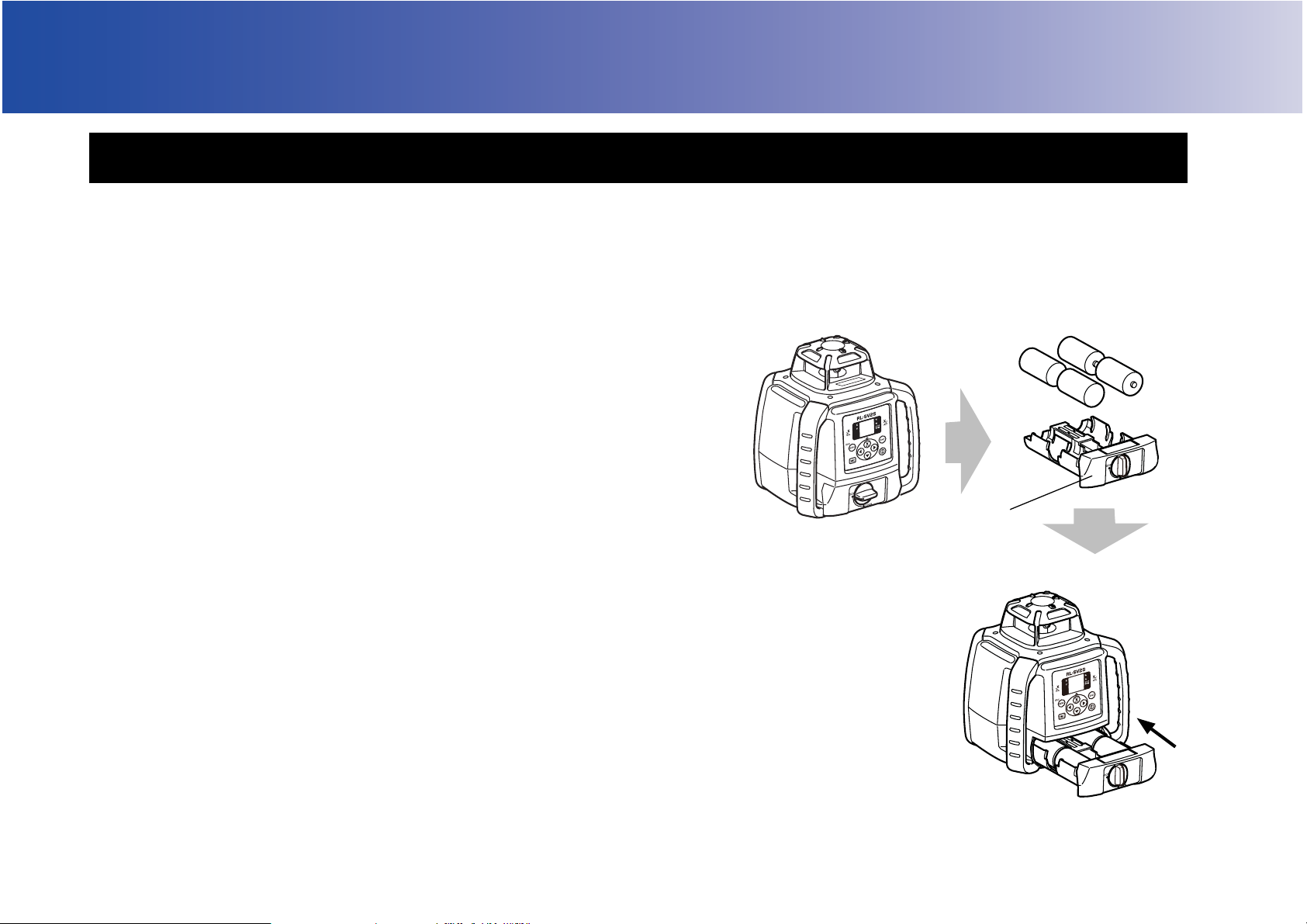

RL-SV2S (Dry battery type)

• How to install dry cell batteries

1 Remove the DB-74 battery holder by turning

battery holder knob to "OPEN" side.

2 Install the new 4xD size dry cell batteries (alkaline)

referring to the illustration on the DB-74 battery

holder.*1), 2), 3)

3 Install the battery holder. Tighten the battery cover

knob to "LOCK" side.

18

Ä·´

Page 27

5. Preparation and Functions

• How to remove dry cell batteries

1 Remove the DB-74 battery holder by turning battery holder

knob to "OPEN" side.

2 Remove the dry cell batteries from the DB-74 battery holder.

G

*1 Replace all 4 batteries with new ones at the same time. Do not mix used and new batteries,

and do not mix different types of batteries together.

*2 Use alkaline dry cells. (Dry cells for movement confirmation are packed in shipment.)

Nickel hydrogen dry cells and nickel cadmium dry cells can be used too, but the operating

time is different from the time of alkaline dry cells.

*3 Generally, performances of dry cell deteriorate temporarily in low temperature, but recover

in normal temperature.

• It is possible to remove the dry cell batteries from the DB-74 battery holder and use the battery

pack BT-74Q.

• The DB-74 dry cell battery holder cannot be used to charge the BT-74Q Ni-MH battery pack.

Use the DB-74C charging battery holder instead.

19

Page 28

5. Preparation and Functions

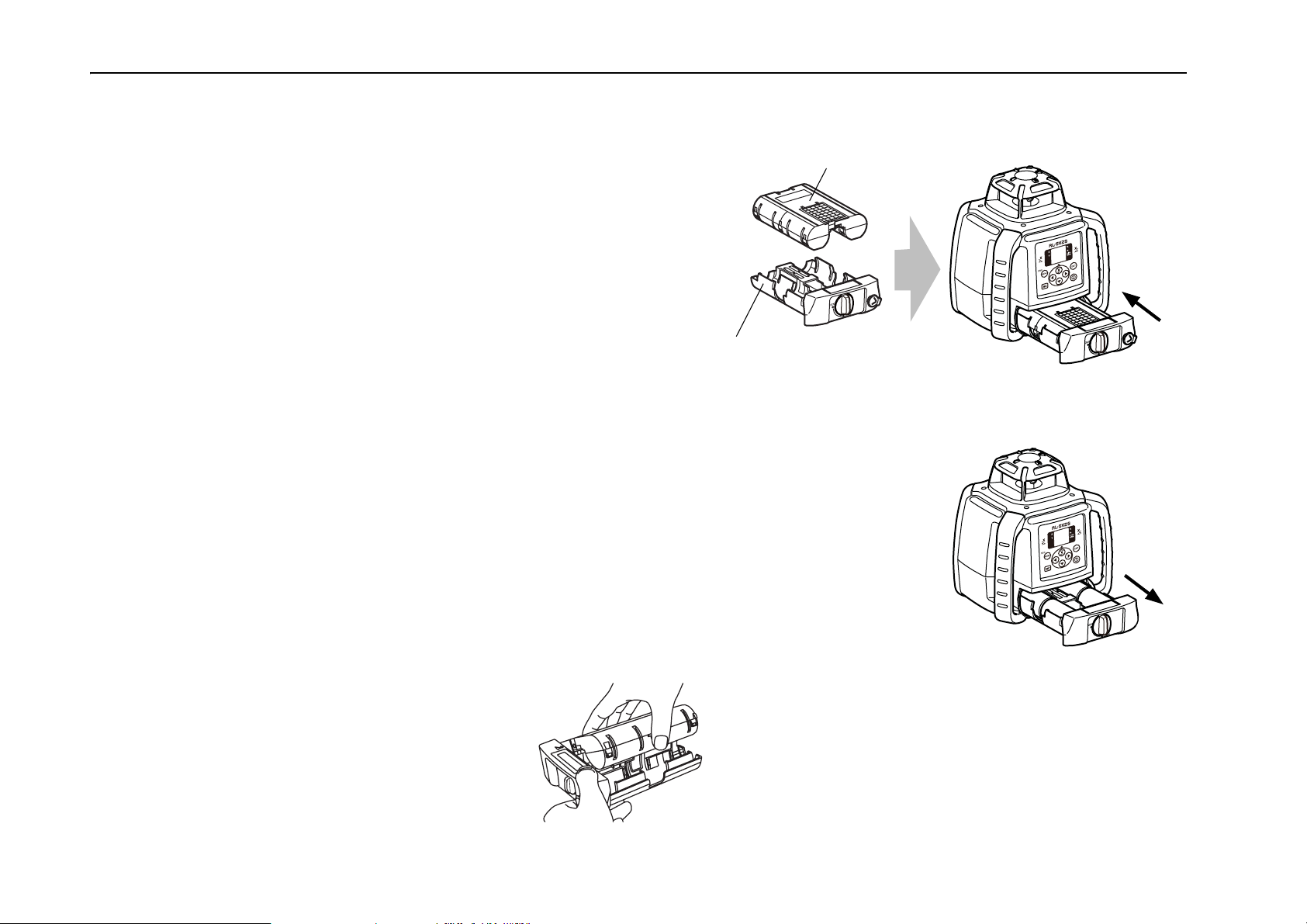

RL-SV2S (Rechargeable battery type)

• How to install the battery pack

1 Insert the battery pack BT-74Q into the DB-74C

battery holder in the direction shown in the

diagram on the right.

2 Install the battery holder. Tighten the battery

Ä·´Ã

cover knob to "LOCK" side.

• How to remove the battery pack

1 Remove the DB-74C battery holder by turning battery holder

knob to "OPEN" side.

• It is possible to remove the battery pack BT-74Q from the DB74C battery holder and use the dry cell batteries.

ÂÔ·´Ñ

20

Grasp the specified place on the battery holder, which is shown below,

and remove the battery pack.

Page 29

5. Preparation and Functions

• For Charging

1 Plug the AC/DC converter (AD-15) into the

DB-74C battery holder or plug the AD-15

into the battery pack BT-74Q.

2 Insert the AD-15 power cord in an outlet.

3 Complete charging by unplugging the plug

from the DB-74C battery holder or battery

pack BT-74Q after approximately 13

hours.

4 Unplug the AD-15 power cord from the

outlet.

Plug

AD-15

• RUN charge

As illustrated at the right, while charging is

in process with the power supply unit

installed to the instrument, you can use the

instrument.

21

Page 30

5. Preparation and Functions

G

• Recharging should take place in a room with an ambient temperature range of 10°C to 40°C

(50°F to 104°F).

• Do not perform charging with others except the AC/DC converter AD-15.

• For longer battery life, conform to the suggested charging time to the extent possible.

• The battery source will discharge when stored and should be checked before using with

instrument.

• Be sure to charge stored battery source every 3 or 6 months and store in a place at 30 °C or

below. If you allow the battery to become completely discharged, it will have an effect on future

charging.

22

Page 31

5. Preparation and Functions

RC-60

• How to install dry cell batteries

1 Open the battery cover.

2 Remove the old batteries and replace with new 2xAA size dry cell batteries (alkaline)

making sure each is placed in the proper direction as indicated.

3 Shut the battery cover until click sound can be heard.

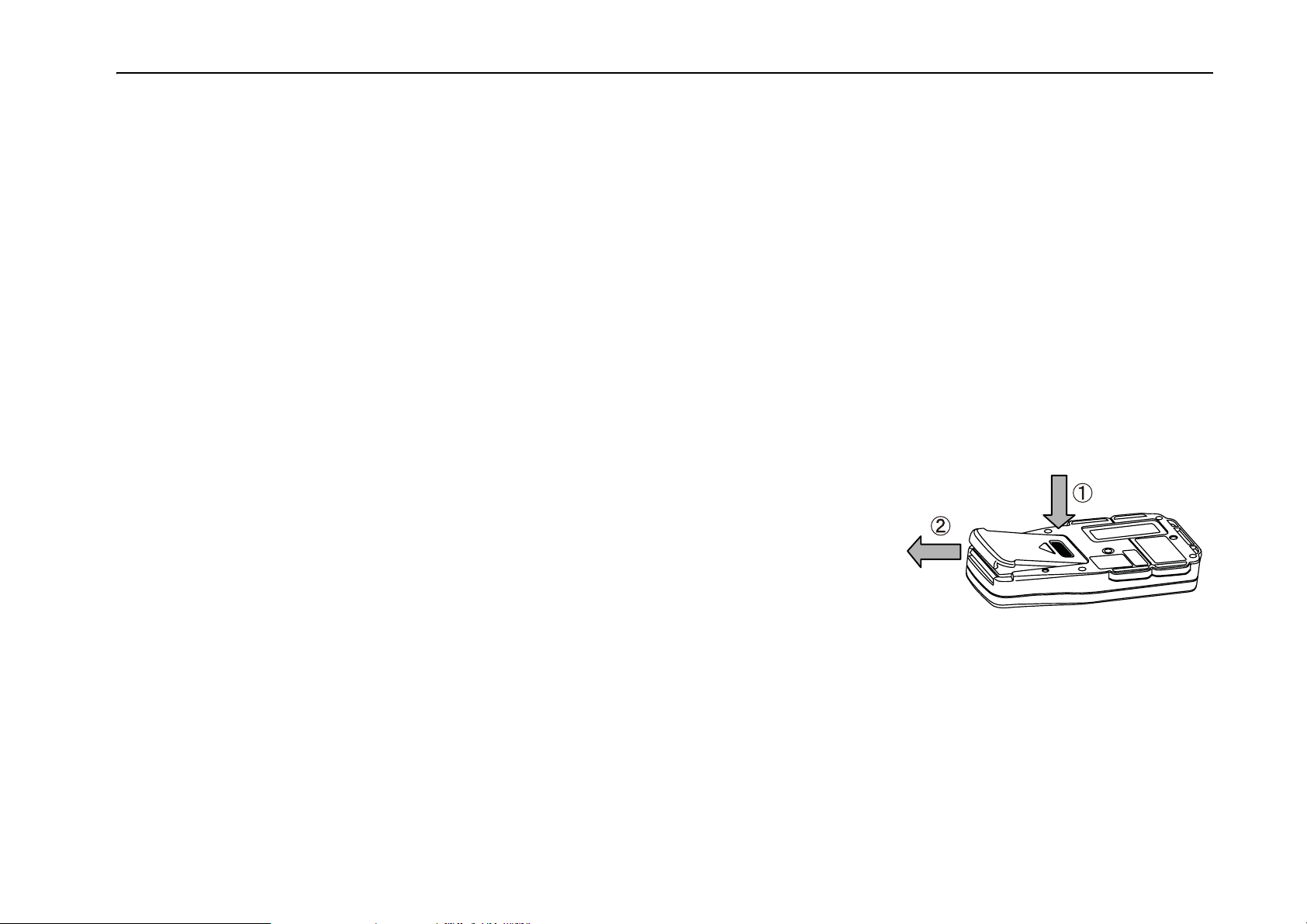

LS-80L

• How to install dry cell batteries

1 Keep pushing the battery cover in 1 direction, and then try to

slide the cover in 2 direction.The cover does not move but it

will be open.

2 Remove the old batteries and replace with new 2xAA size dry

cell batteries (alkaline) making sure each is placed in the proper direction as indicated.

3 Press the lid down and click to close.

G

• Replace all 2 batteries with new ones.

• Do not mix old batteries and new ones.

23

Page 32

5. Preparation and Functions

5.2 How to set remote controller communication channel

The same channel (1 to 9) must be set on the RL-SV2S and the RC-60 remote controller.

RL-SV2S

C“Setting channel” (p. 44)

RC-60

The setting method is the same as for the RL-SV2S. Use the RC-60 control panel for setting.

C“Setting channel” (p. 44)

24

Page 33

6. BASIC OPERATION

6.1 Setting Up Instrument

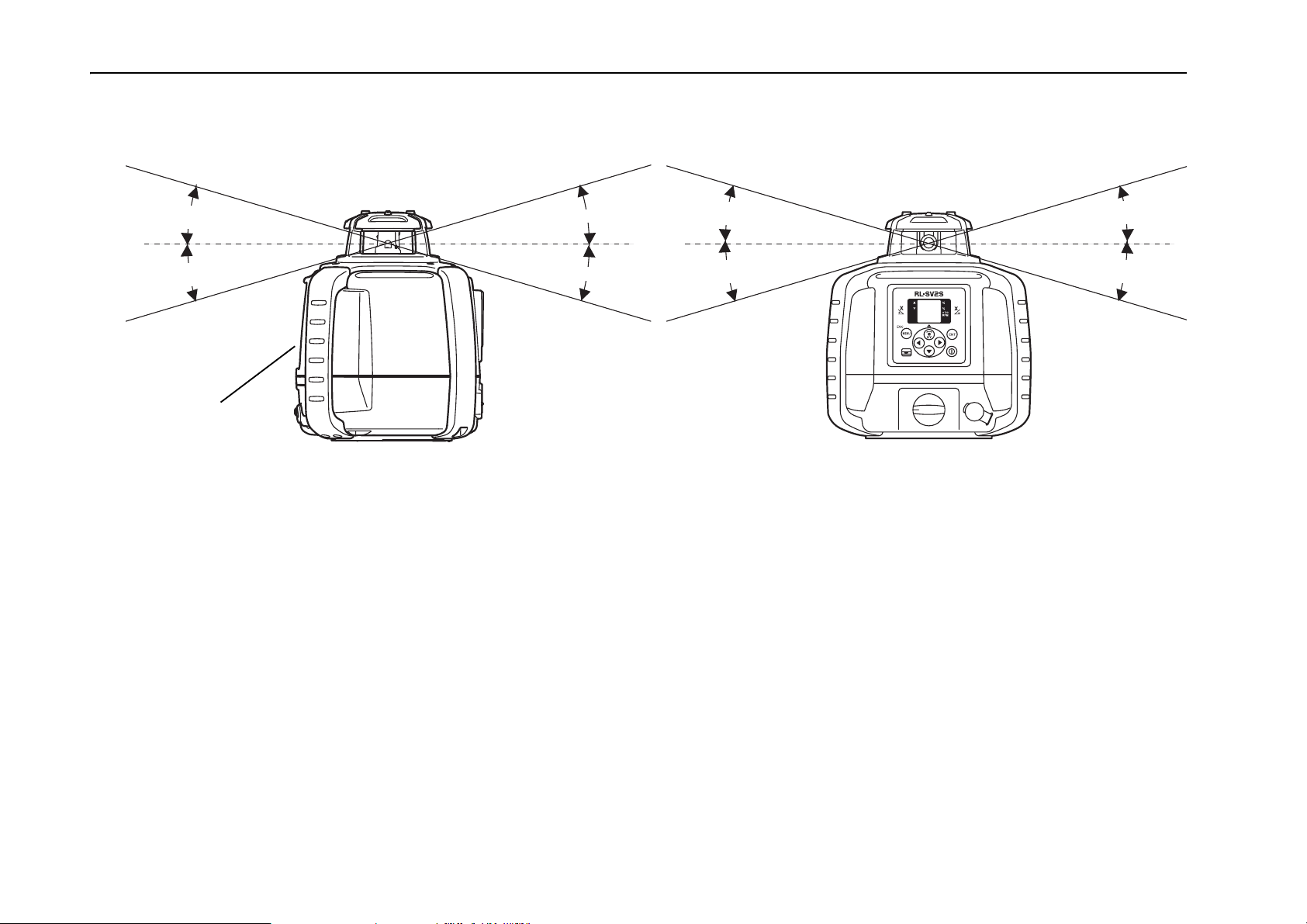

Horizontal Rotation

1

Set the instrument to the tripod or smooth surface.

2 Press power switch (ON). After auto leveling, the laser

beam will emit horizontally.

The RL-SV2S automatically levels within the range of ±5° as

shown below.

It is also possible to set grades for the RL-SV2S in the

direction of 2 axes. C7.1 Setting Grades(p. 29) on how to

set grades.

±5°

25

Page 34

6. Basic Operation

3 Press power switch on the LS-80L (ON).

4 Select the precision mode by pressing the On-Grade

precision switch.

C4.3 Level Sensor LS-80L(p. 15)

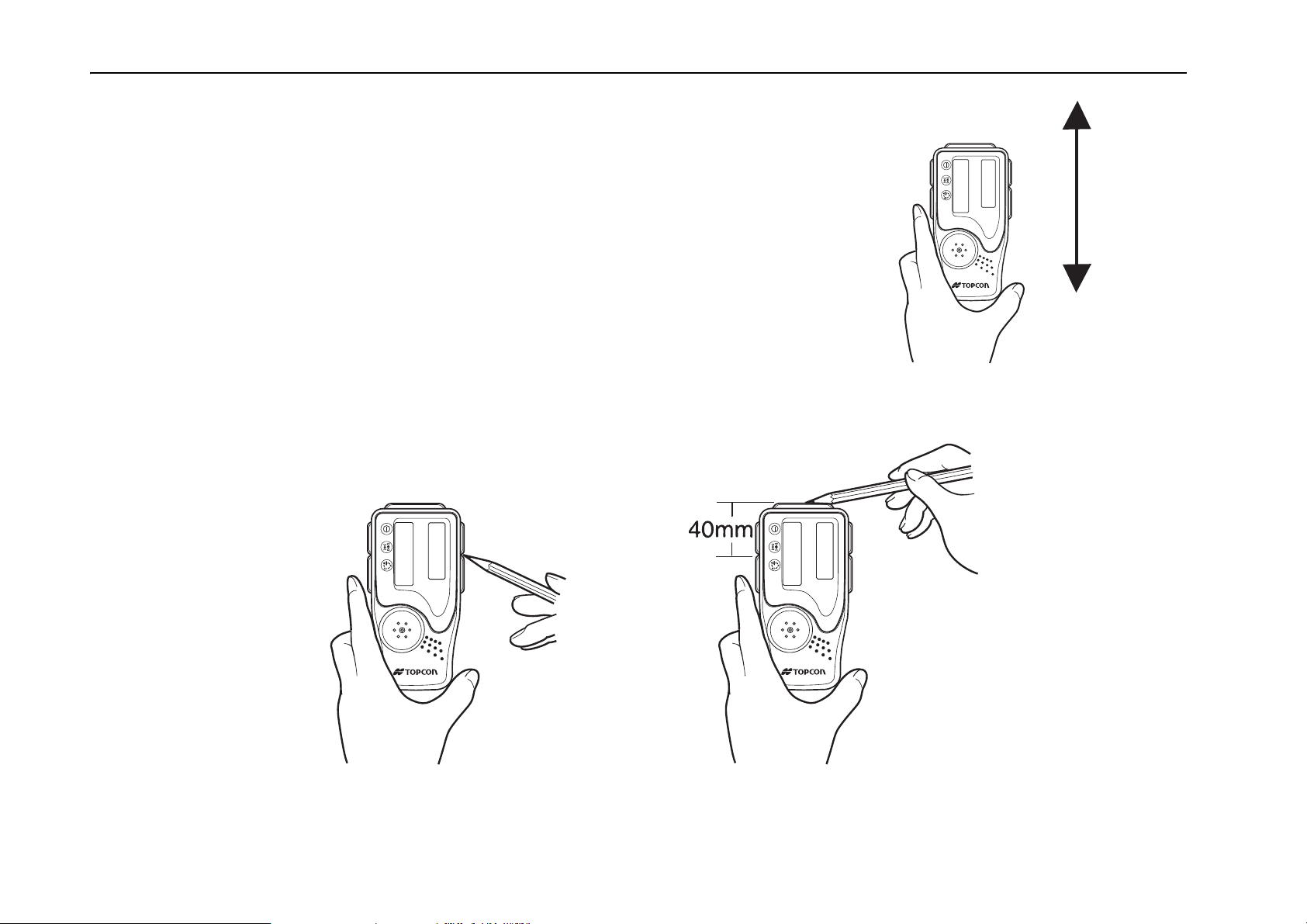

5 Locate the on-grade position “---” by moving the LS-80L

up and down.

6 Mark the position of On-Grade index.

(Top of the LS-80L is 40mm [1 9/16”] from index for

offset marking.)

26

Page 35

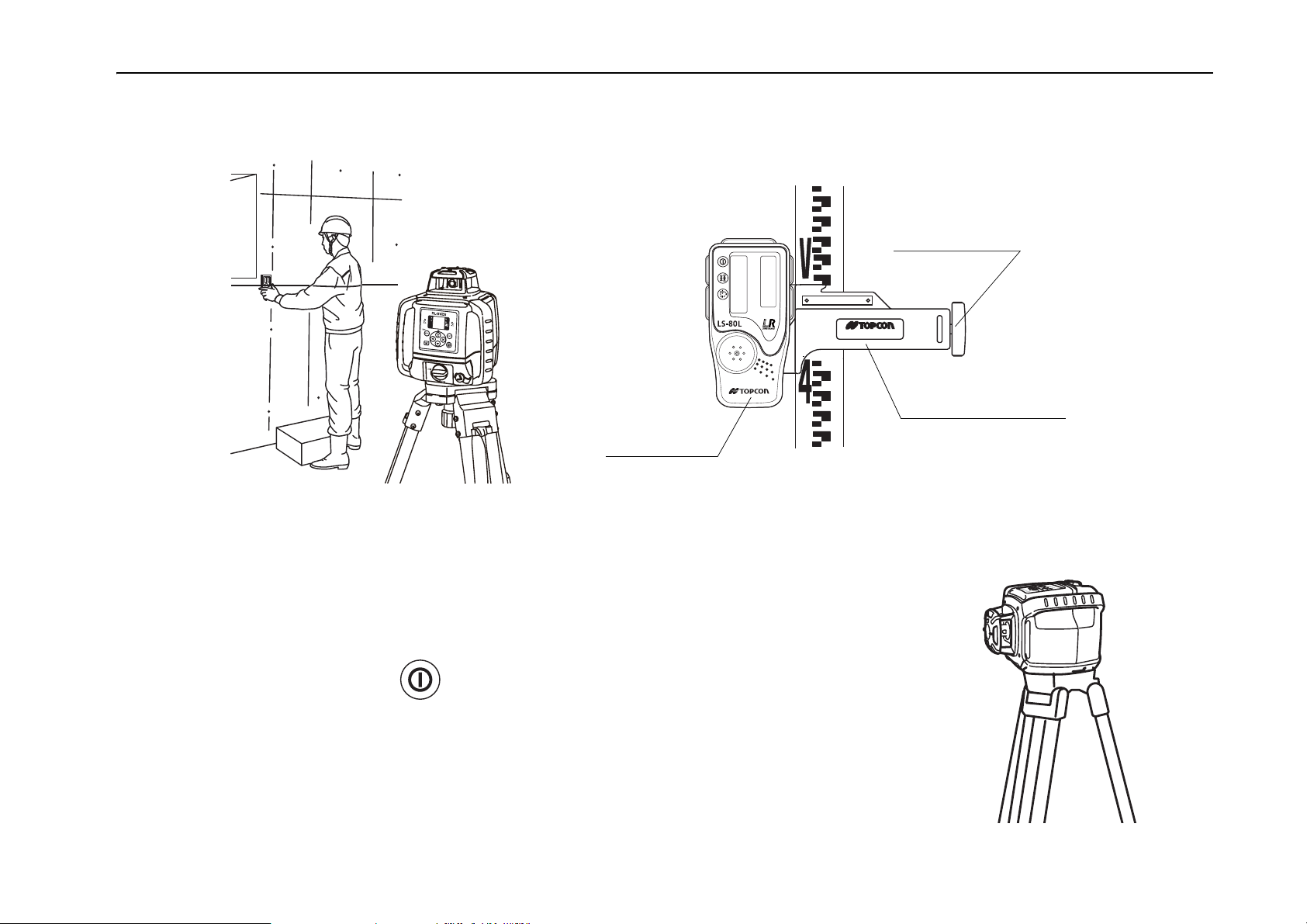

Example Operational

6. Basic Operation

Install the LS-80L on a staff in the manner shown

below.

LS-80L

Vertical Rotation

1

Install the RL-SV2S on to the tripod and set so that the bubble is

154

153

152

151

150

149

148

147

146

131

139

138

137

136

135

134

133

132

131

Clamp knob

HOLDER-6

Level sensor

holder model 6

at the center of the vertical rotation circular level vial.

2 Press power switch .

When auto leveling is complete, the laser beam will emit vertically.

About manual line control C7.2 Line Control (manual vertical

beam alignment)(p. 37)

27

Page 36

6. Basic Operation

6.2 Height Alert Function

When the instrument system detects a shock, this

function informs the operator of it.

• When the instrument’s installation status (height)

is sharply changed by the contact of the operator

or the like, this function stops auto leveling to

keep the operation accuracy and informs the

operator of the situation. The three lamps blink at

the same time as shown at the right.

• After 1 minute has passed since the auto leveling

function was activated and the laser beam was emitted, this function works.

• The height alert function does not work in the “Manual” mode.

Shock is given to the instrument.

How to reset

1

Turn off the power switch.

Height Alert Display

(Flashing)

2 Check whether the instrument is installed correctly.

3 Turn on the power switch. Auto leveling starts again. After auto leveling is finished, the

laser beam is emitted.

4 Make sure that the laser beam is set at the correct height. Then, restart the operation.

CHeight Alert ON/OFF(Refer to “Height Alert ON/OFF” (p. 46)

28

Page 37

7. APPLIED OPERATION AND SETTING OF VARIOUS FUNCTIONS

It is possible to set grades for the laser beam and various functions from the menu screen.

7.1 Setting Grades

There are two methods to set grades on the laser beam: 1) direct entry of the grade values for

the X and Y axes, and 2) matching to set grades on laser beam according to the slope of the

ground on site.

How to enter grade values

Grade can be set in both axes, X and Y, as shown below.

Grades can be set in the range indicated below.

Single axis Dual axes

Grade range:

X: –15% to +15%

or

Y: –15% to +15%

X axis

Grade range:

X: –15% to +15%

Y: –15% to +15%

Y axis

29

Page 38

7. Applied Operation and Setting of Various Functions

Grade axes and axis symbols are as shown in the diagram below.

+15%

-15%

Y axis X axis

Minus

Plus

Panel side

Plus

Minus

-15%

Plus

Minus

Minus

Plus

+15%

On the tripod set on level ground, grades will automatically level to approximately ±8%. When

setting larger grades, tilt the RL-SV2S towards the direction of the slope to maintain within the

auto leveling range. When exceeding the auto leveling range, the error message "Exceeding

leveling range" will be displayed.

C12. Error Display(p. 62)

30

Page 39

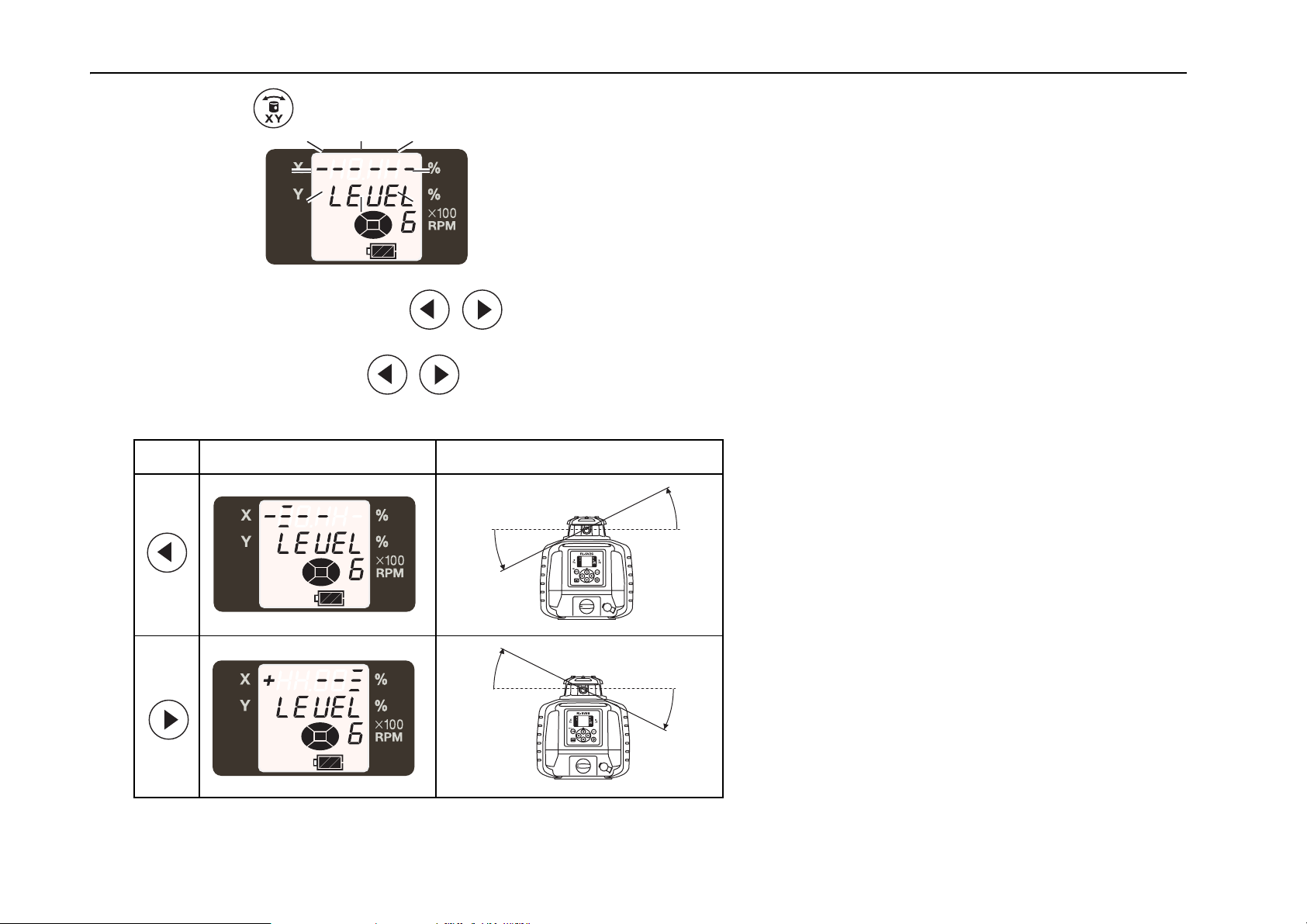

7. Applied Operation and Setting of Various Functions

How to set grades

1

Press the key and the X axis display will start flashing. It is possible to enter the grade.

(Pressing the key will toggle between the X axis and Y axis.)

2 Press the key.

3 Press the keys and select the + or - mark.

4 Press the keys to change the digit position.

31

Page 40

7. Applied Operation and Setting of Various Functions

5 Press the keys to increase or decrease the value of the digit.

6 Press the key to confirm the value.

7 When setting the grade for the Y axis, press the key. The Y axis display will start

flashing.

Set up the grade in the same manner as the X axis.

$

• To reset the grade value while setting, press the and keys simultaneously before

proceeding to step 5.

• To set with the RC-60, check the transmission and reception display.

32

Page 41

7. Applied Operation and Setting of Various Functions

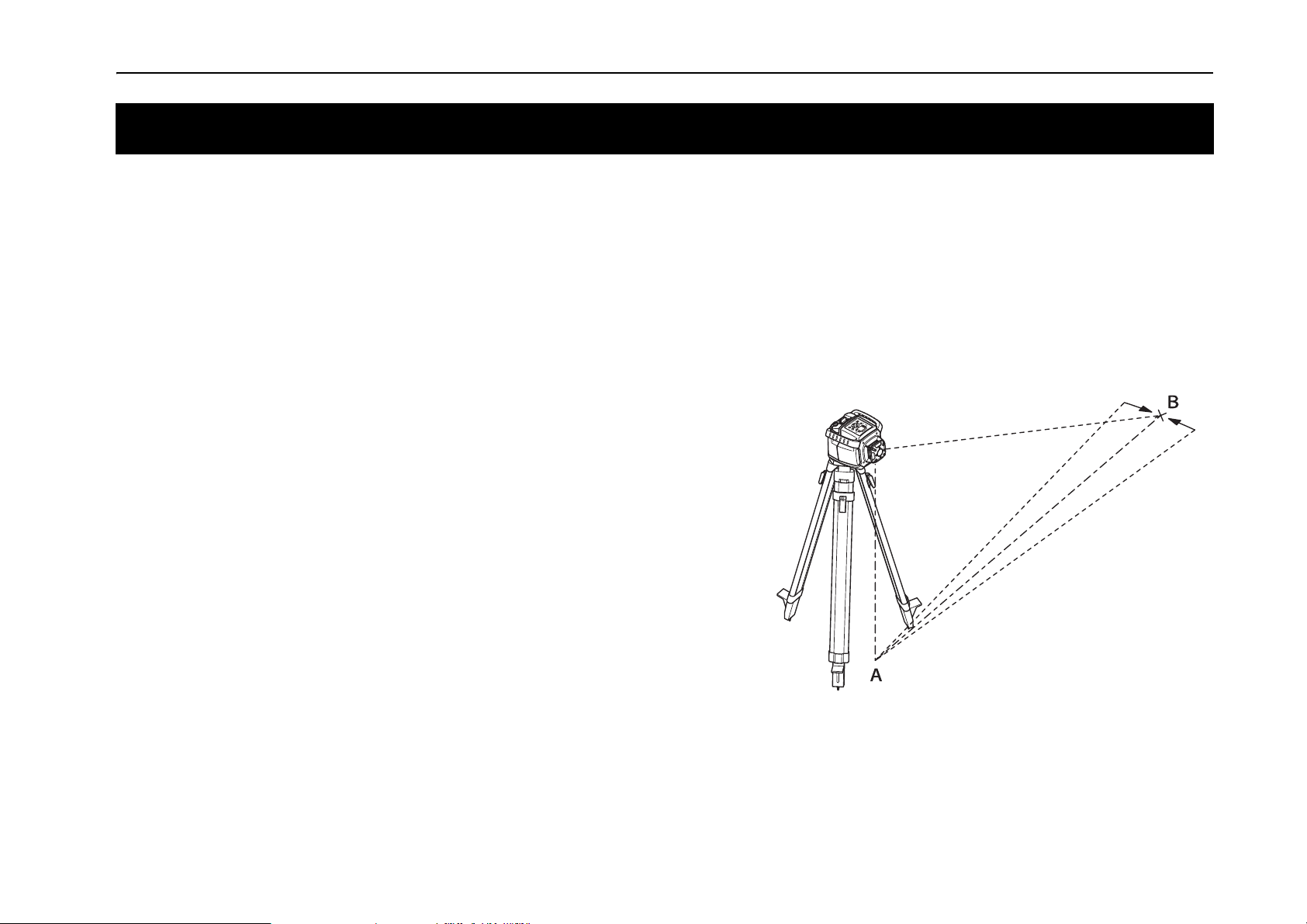

Example of how to set up

When using the RL-SV2S after grade setting, it is necessary to accurately set the RL-SV2S

to the direction of grade setting.

Below is an example of how to set grades to the accurate grade setting direction. (To work

at Y-3% grade surface to the on-grade line)

ÌÓ¸°Ì

On-grade line

Grade to work

33

Page 42

7. Applied Operation and Setting of Various Functions

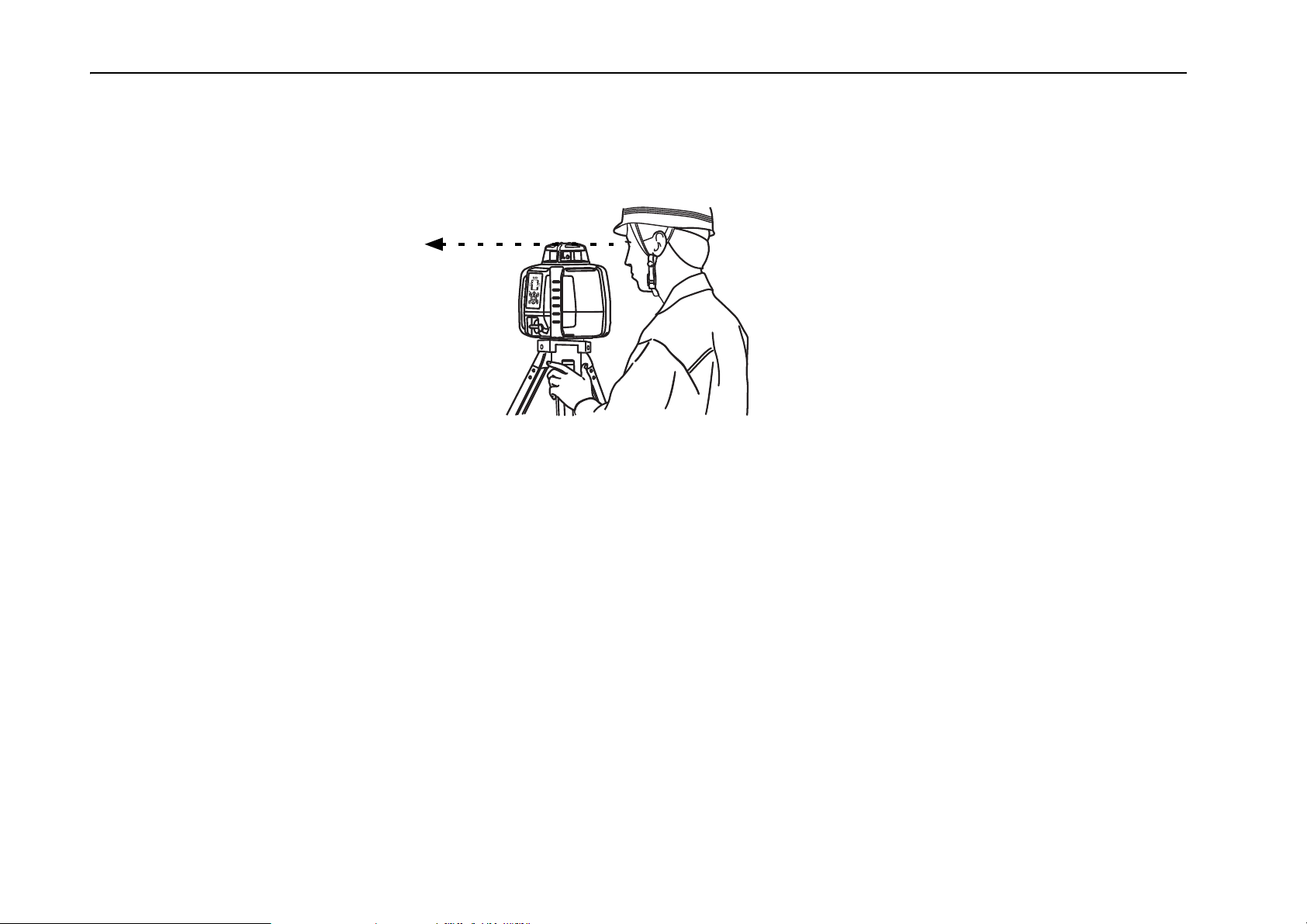

1 Set up the RL-SV2S on Point A of the on-grade line using the weight on the tripod.

2 Using the sight at the upper section of the RL-SV2S, adjust the direction on top of the tripod

and roughly align the X+ direction to Point B on the standard axis.

3 Horizontally rotate the laser beam of the RL-SV2S. (X+0%,Y+0%)

4 At Point B adjust the height of the LS-80L installed on a pole, align the standard position of

the LS-80L with the laser beam and fix.

5 Set the RL-SV2S at X+0% and Y-3% grades.

6 Align the RL-SV2S direction on top of the tripod so as to have the laser beam in the on-

grade position of the LS-80L in step

4.

G

Do not change the height of the LS-80L installed on the pole.

If the height of the RL-SV2S is changed, return to step

4 and redo the adjustment.

34

Page 43

7. Applied Operation and Setting of Various Functions

Matching Mode (Manual Slope)

This mode is used to align the grades of the laser calibration to the worked grade.

1 Horizontally rotate the laser beam of the RL-SV2S

set up at the standard height.

2 Adjust the height of the LS-80L installed on the pole

and align the standard position of the LS-80L with

the laser beam and fix.

3 Set up the LS-80L in step 2 on the grade surface.

4 Using the sight, roughly align the position of the RL-

SV2S on top of the tripod to the direction of the LS80L. Using the Matching Mode, move the laser up

and down according to the steps described below

to match the on-grade position of the LS-80L.

5 Press the key.

LS-80L

6 Screen has switched to Matching Mode (SLOPE). Press the key.

35

Page 44

7. Applied Operation and Setting of Various Functions

Ø«

Ø«

7 Press the keys described on the right

Key Display

to move the direction of laser beam to

Grade direction

match the grade.

$

• When the , , , or key is

pressed, the laser beam will emit even

if automatic alignment starts.

• This mode can be used with the RC-60.

• When the RC-60 is used in an

environment in which similar radio

signals (wireless LAN, etc.) are

transmitted, and when the , ,

, or key is long-pushed in step

7, the laser beam grading may stop. If

this interferes with the operation,

Ø

Ø

Ù

Ù

change the communication channel for

the RL-SV2S and RC-60 and try again.

C5.2 How to set remote controller

communication channel(p. 24)

36

Ù«

Ù«

Page 45

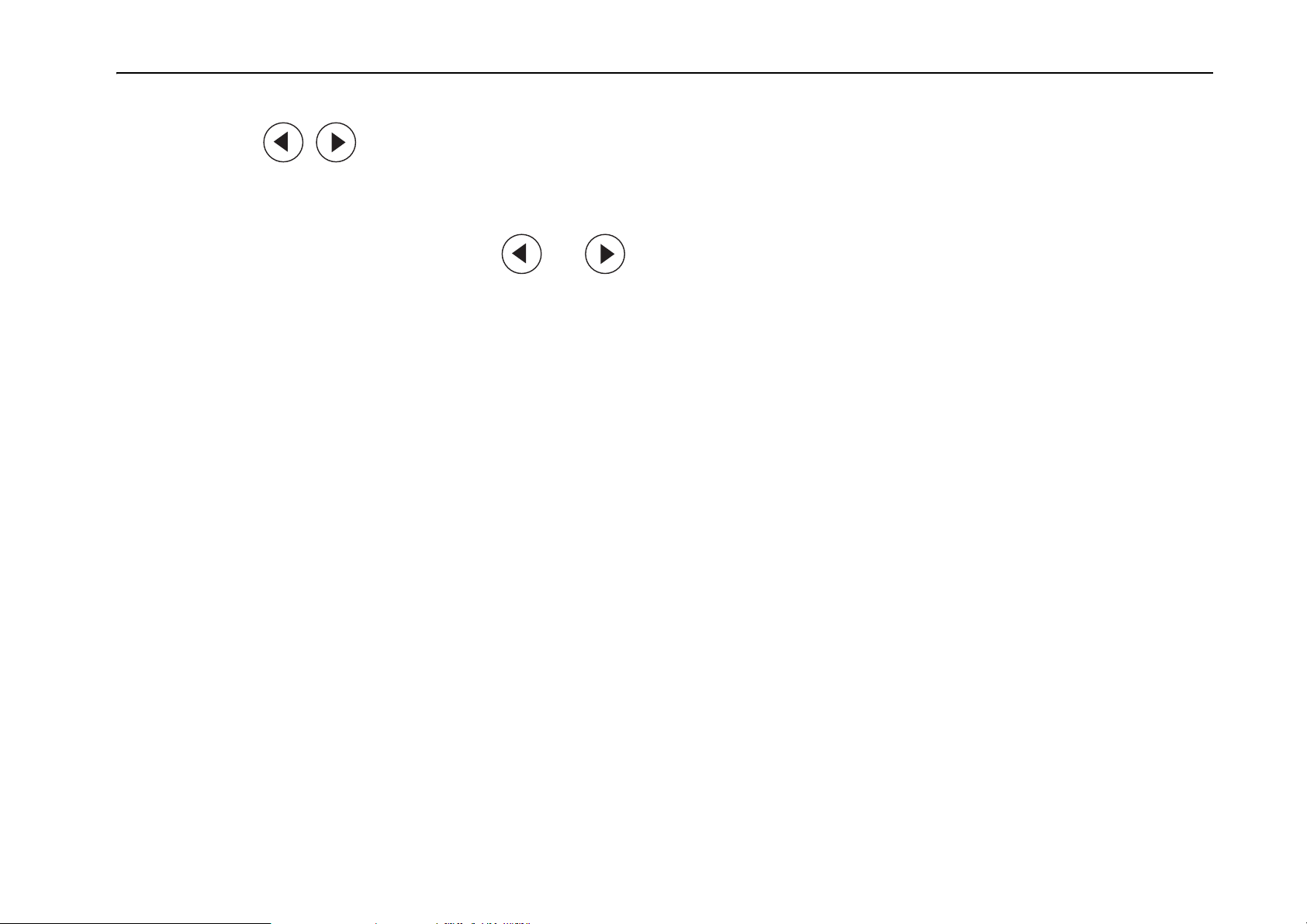

7. Applied Operation and Setting of Various Functions

7.2 Line Control (manual vertical beam alignment)

The laser beam can be moved to the direction of the key during vertical rotation.

$

• Only the X axis can be moved.

• Allowable alignment range: ±5½ (when the instrument is set up on the 0½ surface)

1 Set the instrument.

2 Press the Power control key to turn unit on. When

auto leveling is complete, the laser beam will be

vertically emitted.

3 Move the RL-SV2S to align Point A and the laser

beam, and make sure that the bubble is at the

center of the vertical rotation circular level vial on

the control panel.

37

Page 46

7. Applied Operation and Setting of Various Functions

4 Press the key.

5 Press either one of the key to move the beam right or left until it is precisely

aligned to point B. The speed of laser beam movement will change according to the

duration of time the key is being pressed. (The speed will change from low to high

speed.)

38

Key Display

Alignment direction

Ø

Ø

Ø«

Ø«

Page 47

7. Applied Operation and Setting of Various Functions

$

• While the key is pressed the auto-leveling beam shut-off will not operate.

• This mode can be used with the Remote Controller RC-60.

• When the RC-60 is used in an environment in which similar radio signals (wireless LAN, etc.)

are transmitted, and when the or key is long-pushed in step 7, the laser beam

grading may stop.

If this interferes with the operation, change the transmission channels for the RL-SV2S and

the RC-60 and try again.(C5.2 How to set remote controller communication channel(p. 24))

39

Page 48

7. Applied Operation and Setting of Various Functions

7.3 Setting of Various Functions

Selecting MENU

After pressing the key, pressing the or key will change the menu items and setting

can be performed for the functions listed below.

Safety lock ON/OFF

setting

Remote channel settingSleep Mode ON/

OFF setting

• For Matching Mode, see the “Matching Mode (Manual Slope)” (p. 35).

Matching Mode

Manual Mode ON/

OFF setting

Masking setting

40

Speed setting

Page 49

7. Applied Operation and Setting of Various Functions

Masking (Laser beam shutter) setting

Depending on the status of the location where the instruments are used, laser beam emission

to unnecessary direction can be shut off.

1 Press key to display the menu screen.

2 Use the key to position on the Mask display and press the key.

3 Select the direction you desire to mask using the arrow keys.

Each press repeats mask activating/releasing.

Arrow keys and masking

setting directions

RL-SV2S upper

surface diagram and

masking directions

The state when masking is not

activated. (Laser beams are emitted

to all directions.)

Displays the masking direction

The status in which the Y+ direction

is masked.

(Laser beam is shut off in the Y+

direction.)

41

Page 50

7. Applied Operation and Setting of Various Functions

4 When desired masking is displayed, press the key to finish.

How to change the rotary head speed

The rotary head speed can be set to 600 or 300 R.P.M.

1 Press the key to display the menu screen.

2 Use the key to select the rotary head speed (SPEEd) and press the key.

3 When the rotary head speed selected using the keys, press the key to finish.

42

Page 51

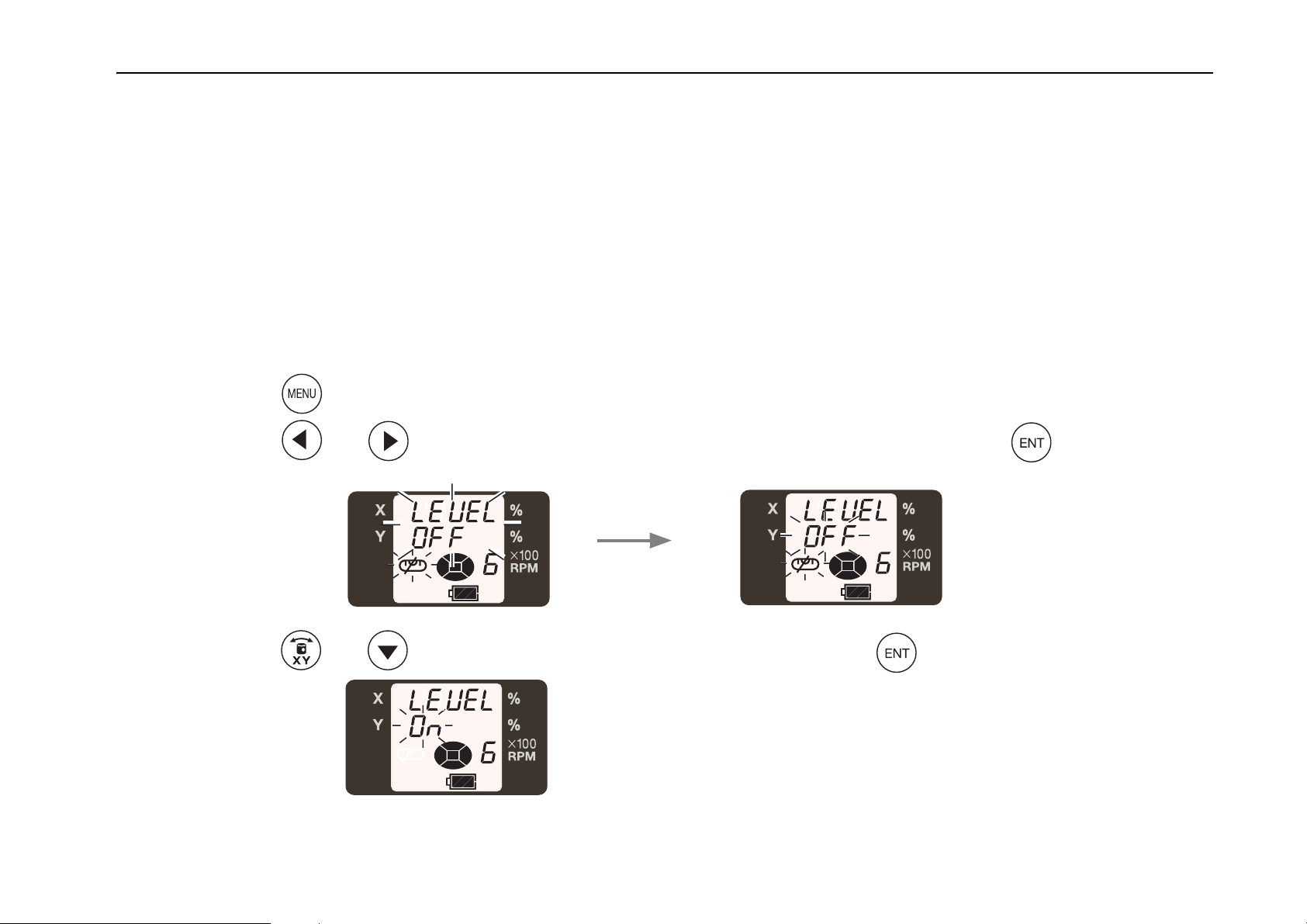

7. Applied Operation and Setting of Various Functions

Switching Auto leveling / Manual Mode

Auto leveling function can be canceled and switched to Manual Mode.

Auto leveling OFF (LEVEL OFF): After auto leveling is complete, the auto leveling function

will stop. (Manual Mode)

Auto leveling ON (LEVEL ON): Auto leveling function will be effective at all times.

1 Press the key.

2 Press the or key to select auto leveling (LEVEL), and press the key.

3 Press the or key to select ON or OFF and press the key. Setting is complete.

43

Page 52

7. Applied Operation and Setting of Various Functions

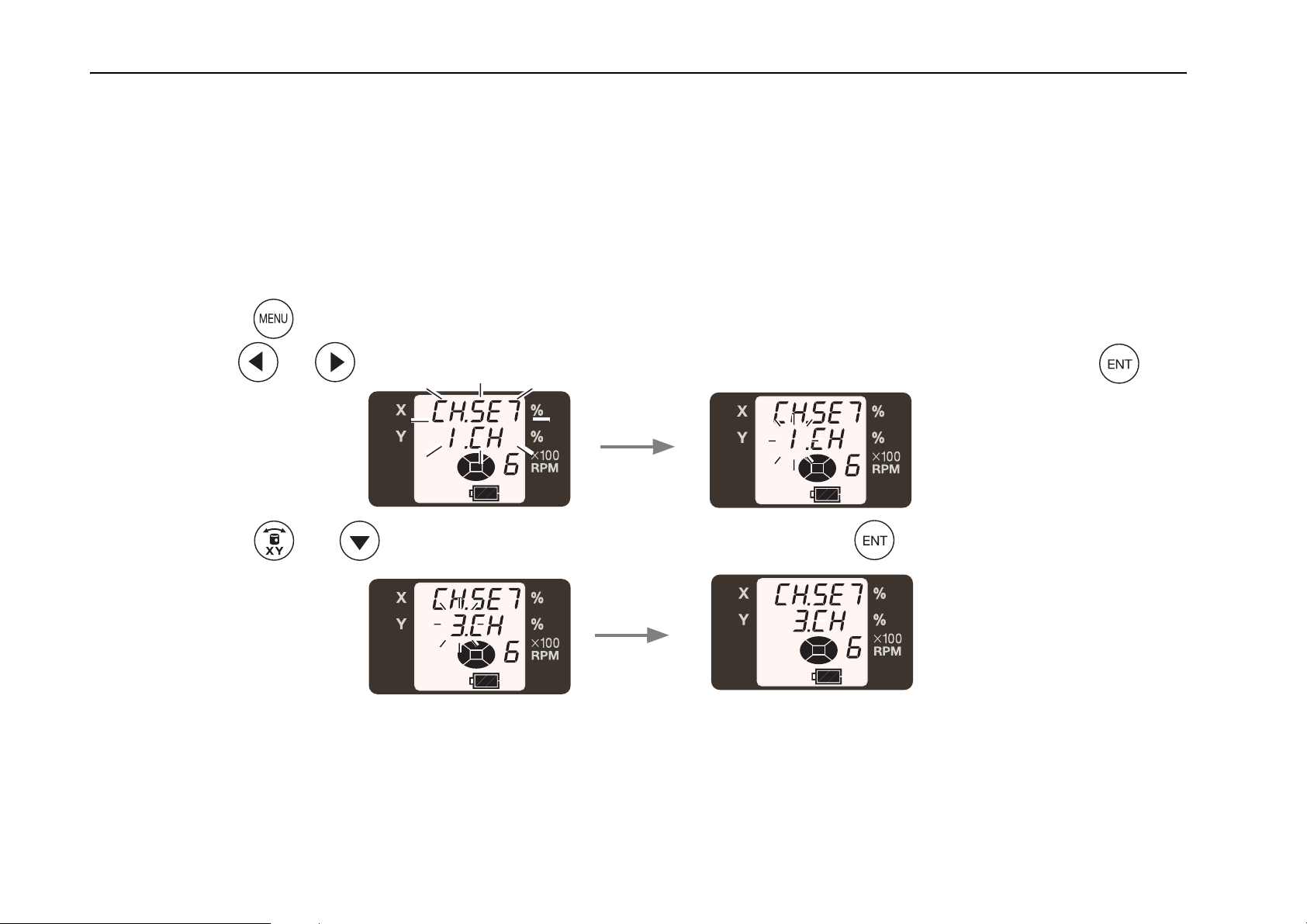

Setting channel

When more than one RL-SV2Ss is used at the same location, change the communication

channel to prevent interference.

$

You may set the channel from 1 to 9.

1 Press the key to display the menu screen.

2

Press the or key to select the communication channel (CH.SET) setting, and press the key.

3 Press the or key to select the channel and press the key. Setting is complete.

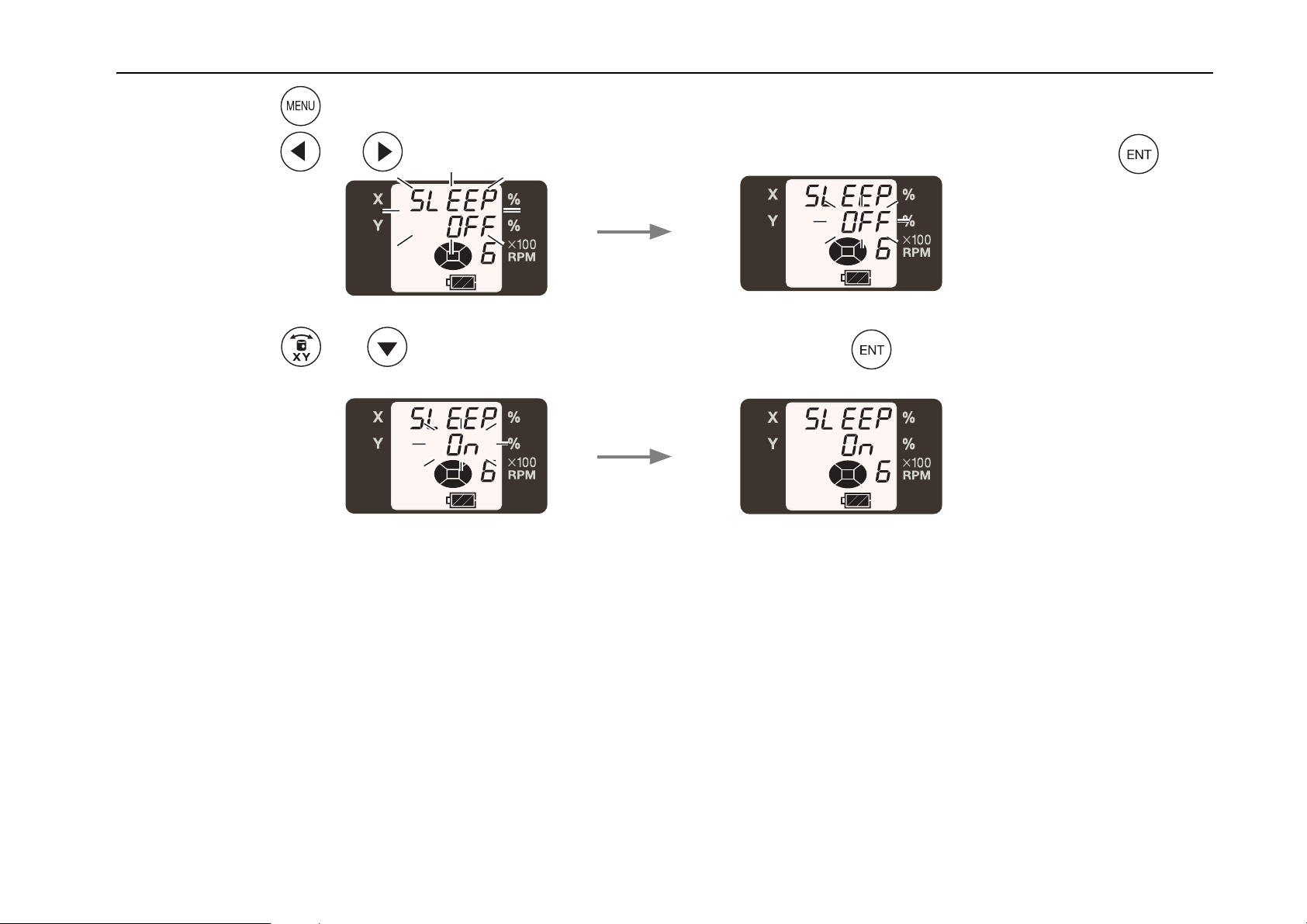

Sleep mode ON/OFF

When the Sleep Mode is turned ON with the RC-60, the RL-SV2S will change to the Standby

Mode (Laser OFF, head rotation OFF and auto leveling OFF).

44

Page 53

7. Applied Operation and Setting of Various Functions

1 Press the key.

2 Press the or key and select Sleep Mode ON/OFF (SLEEP), and press the key.

3 Press the or key to select ON/OFF, and press the key. Setting is complete.

$

There are two ways to revert from the Sleep Mode.

• Press one of the keys on RC-60.

• Turn OFF the power using the power key for the RL-SV2S, and turn the power back on.

After reverting from the Sleep Mode, all previous settings are maintained.

45

Page 54

7. Applied Operation and Setting of Various Functions

Height Alert ON/OFF

C6.2 Height Alert Function(p. 28)

1 Press the key.

2 Press the or key and select Safety Lock ON/OFF (Hl.ALr), and press the key.

3 Press the or key and select ON or OFF, and press the key. Setting is

complete.

46

Page 55

8. CHECK AND ADJUSTING

Please perform check and adjusting regularly. First check, and then make adjustments accordingly.

8.1 Check and Adjust Horizontal Rotation

Horizontal rotation grade error

• How to check

1 Set up tripod approximately 50 meters

away from a wall, and set the instrument on

level with the X1 facing the wall.

2 While pressing the grade key, turn ON the

power. (Only the main unit is operable).

[CaLIb] will flash on the X axis screen. *1)

Handle

Control Pannel

X+

LS-80L

X- laser beam

X- laser position

Y+

X-

Y-

3 Press the key. (Hereafter, the RL-SV2S

and RC-60 become operable.)

Staff or Wall

50m (164feet)

47

Page 56

8. Check and Adjusting

The screen will be in the X-axis check and adjusting mode.

Auto leveling on the RL-SV2S is complete and the laser will emit.

4 Turn the LS-80L to the high precision mode.

5 Detect the center of the laser beam on the wall with the LS-80L and mark it. (X1)

6 Press the key.

7 Loosen the centering screw and rotate the RL-SV2S 180°, and tighten the screw to secure.

The RL-SV2S X+ surface will face the wall. When rotating the RL-SV2S, ensure that the

instrument height is not misaligned.

The RL-SV2S auto leveling is complete and the laser will emit.

48

Page 57

8 Detect the center of the LS-80L laser

8. Check and Adjusting

beam on the wall and mark (X2).

9 If the difference in height of the two laser

beam marks (X1 and X2) is less than 5

mm, no adjustment is required. Turn OFF

X2 laser beam

the power. If the difference is more than 5

mm, follow adjusting steps for horizontal

rotation.

50m

C e How to adjust¨ð® µ°©

10 Perform check on the Y axis after the adjustment for the X axis is complete.

When checking and adjusting

the Y axis direction, press the

key.

Press the key.

The screen will switch to the Y

axis check and adjusting mode.

X1

X2

X2 laser position

G

A difference between X1 and X2 is more than 40 mm (±90"), it is outside of the adjustment

range. Contact your dealer or Topcon.

49

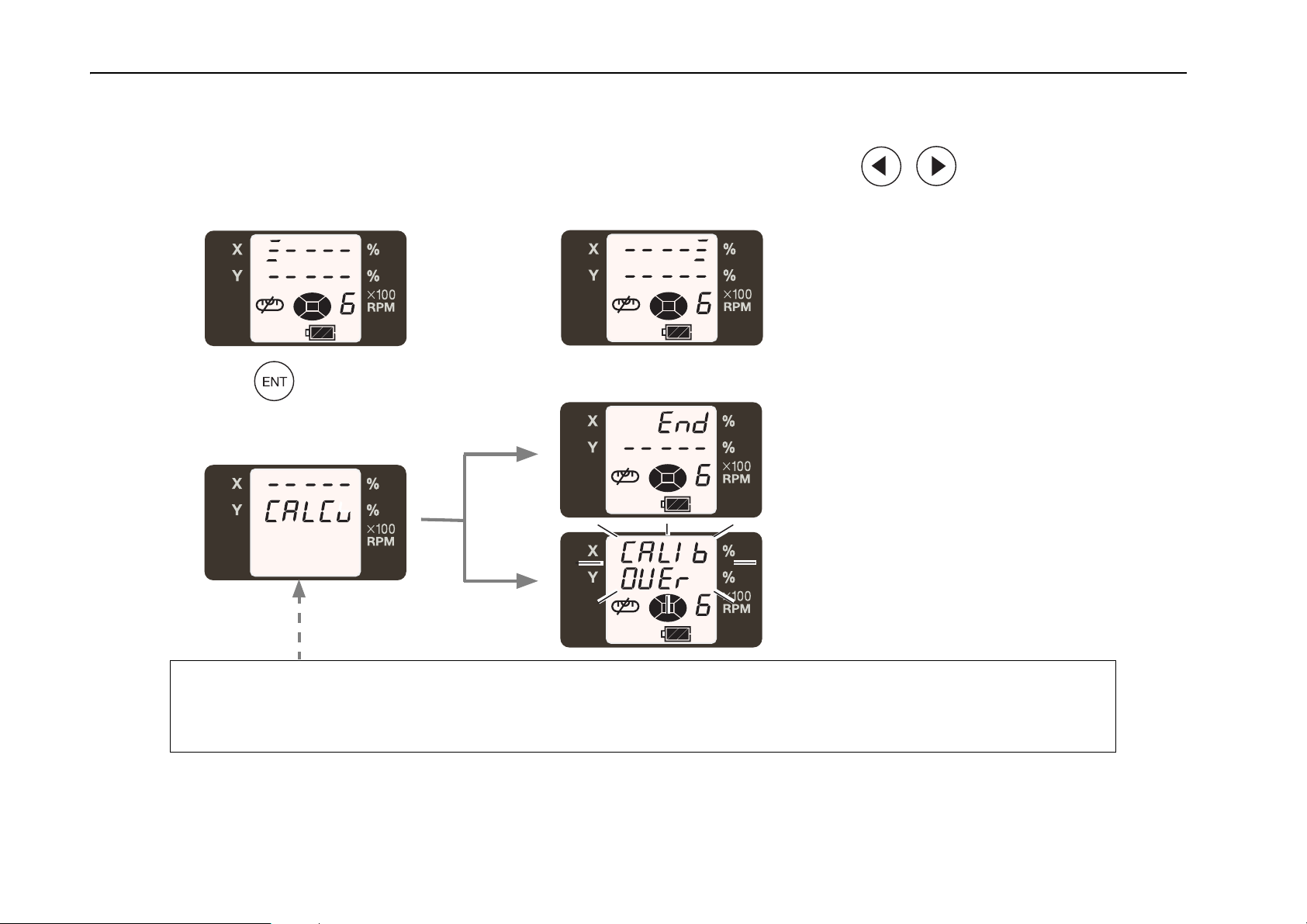

Page 58

8. Check and Adjusting

• How to adjust

1 According to step 9 of the horizontal rotation check, press the keys to move the

laser beam between X1 and X2.

OR

2 Press the key.

Adjustment for X axis is complete.

50

Exceeding the range of adjustment.

C12. Error Display(p. 62)

The RL-SV2S is calculating the correction value. Do not touch the RL-SV2S until

[End] is displayed. (If you touch it, you will need to readjust.)

Page 59

8. Check and Adjusting

Horizontal Rotation Cone Error

Perform the following check after completing “Horizontal Calibration” on the previous page.

Approx.µ°í

Wall B

Wall A

Cone Error

Standard

location

Wall B

Wall A

1 Set up the laser centered between two walls approximately 50 m (164 ft) apart. Orient the

instrument so one axis, either X or Y, is facing the walls. Grade should be set to 0.00% in

both axes.

2 Locate and mark the position of the RL-SV2S beam on both walls using the LS-80L.

3 Turn off the RL-SV2S and move the RL-SV2S closer to wall A (1 m to 2 m /3 ft to 6 ft).

Do not change the axis orientation of the RL-SV2S. Turn the RL-SV2S on.

4 Again locate and mark the position of the RL-SV2S beam on both walls using the LS-80L.

5 Measure the distance between the first and second marks on each wall.

51

Page 60

8. Check and Adjusting

6 If the difference between each set of marks is less than ±5 mm (±7/32 of an inch), no error

exists.

G

If the difference between [wall A]-side and [wall B]-side exceeds ±5 mm (±7/32 of an inch),

contact your dealer or Topcon.

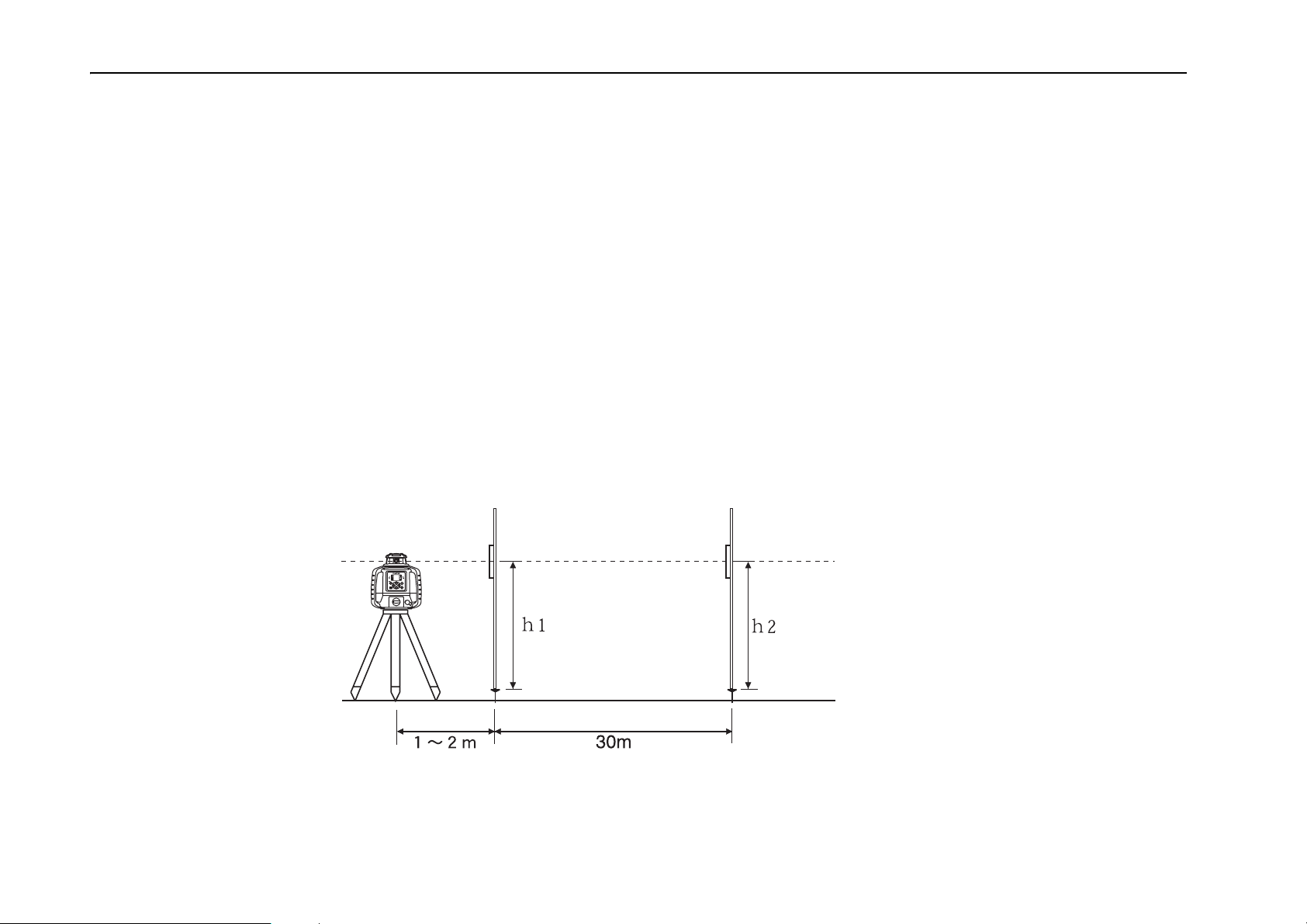

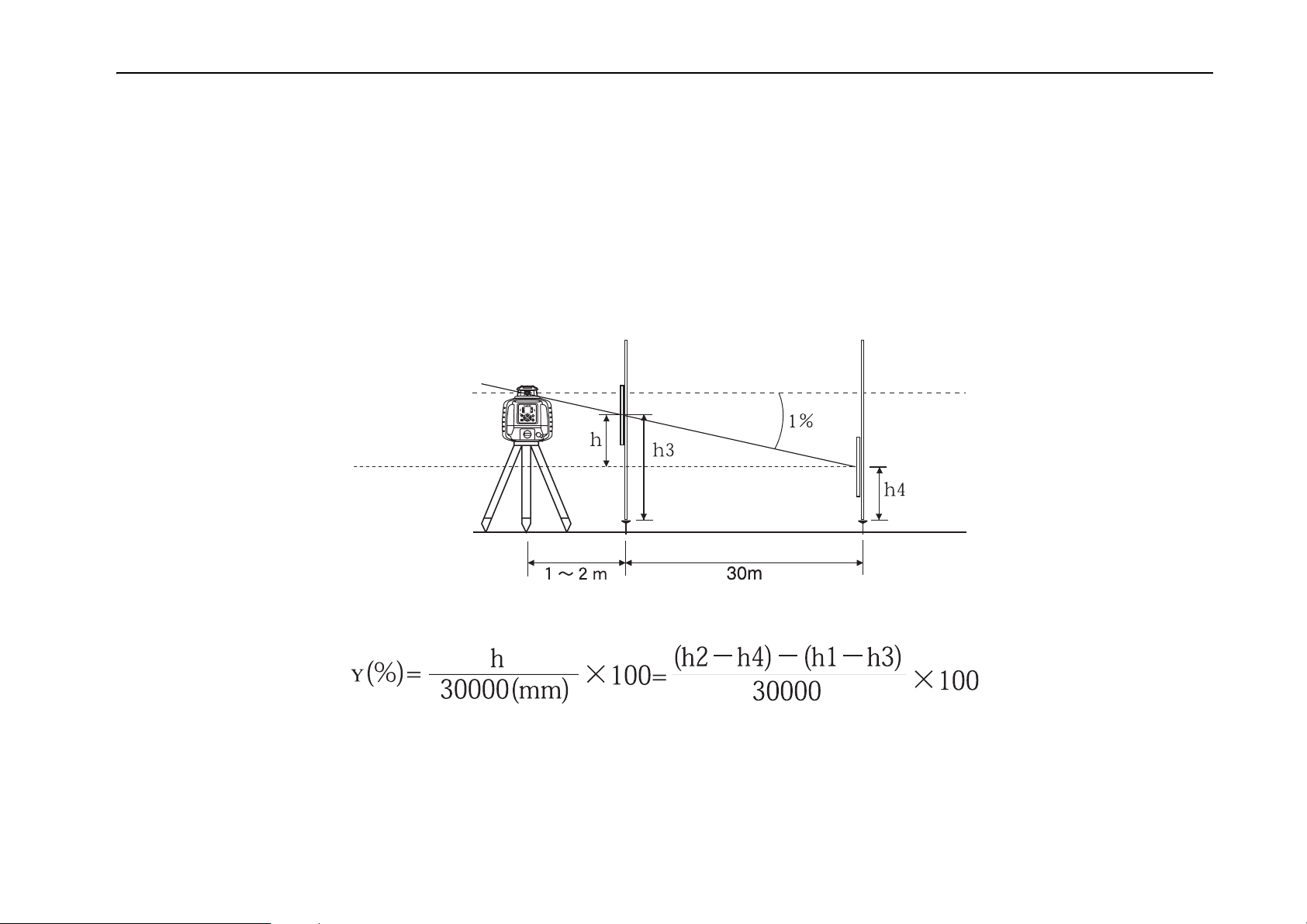

Grade Setting Error

Perform the following check only after completing “Horizontal Calibration” and “Horizontal

Rotation Cone Error”.

• Checking

1 Setup the X- side facing the staff as shown in the figure.

Staff

ÌÓ¸°Ì

Nail 1

Securely position Nail 1 and Nail 2 exactly 30m apart.

52

Nail 2

Page 61

8. Check and Adjusting

2 Turn on power for the RL-SV2S and verify the staff height of Nail 1 and Nail 2 at grade

setting of 0% with LS-80L and record.

At this time the staff height for Nail 1 and Nail 2 should recorded as h1 and h2 (mm). Check

the LS-80L is set at high precision.

3 Set Y axis grade to 1.00%.

Align read the elevation of the laser beam in millimeters at Nail 1 and Nail 2.

Designate these elevations as “h3” at Nail 1, and “h4” at Nail 2.

4 Using the elevation readings for h1, h2, h3 and h4, complete the equation below.

If the calculated result is the range of 0.990% - 1.010%, the instrument is normal.

If the calculated result for either axis is out of the range, contact your dealer or Topcon.

Repeat the procedure aligning the “X” axis on the line created by Nail 1 and Nail 2.

53

Page 62

8. Check and Adjusting

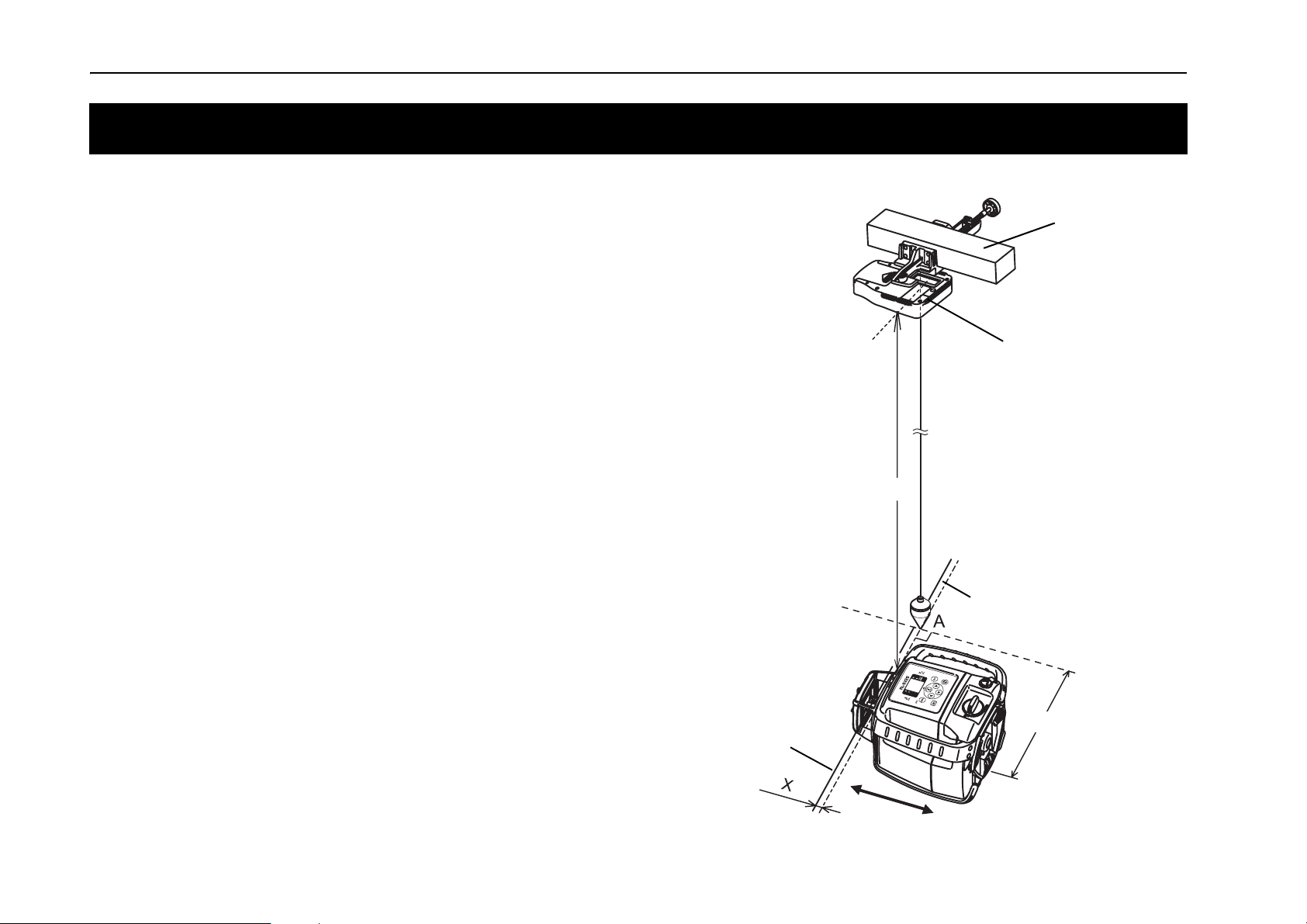

8.2 Vertical Calibration

Checking Calibration

1

Turn ON the power for the LS-80L and move

into high precision mode.

Beam

2 Install the LS-80L on a beam 10 meters or

higher above the floor, as shown in the diagram.

3 Hang the weight from the LS-80L indicator to the

floor (Point A).

4

Mark the standard line on the floor perpendicular to

the direction of the beam where Point A crosses.

5

Set up the RL-SV2S for vertical rotation at the

position shown in the diagram and turn ON the power.

6 Maintain the level of the standard line on the

floor and laser beam, and move the RL-SV2S to

the direction of the arrow.

Ensure that the laser beam is at the LS-80L

indicator position (check with the buzzer sound

Label sensor

Approx.10m

Standard line

Approx.10cm

Laser beam

from the LS-80L).

54

Page 63

8. Check and Adjusting

7 Measure the difference X between the standard line and laser beam.

8 If X is within 1 mm, no adjustment is required. If the difference exceeds 1 mm, move on to

the next adjustment.

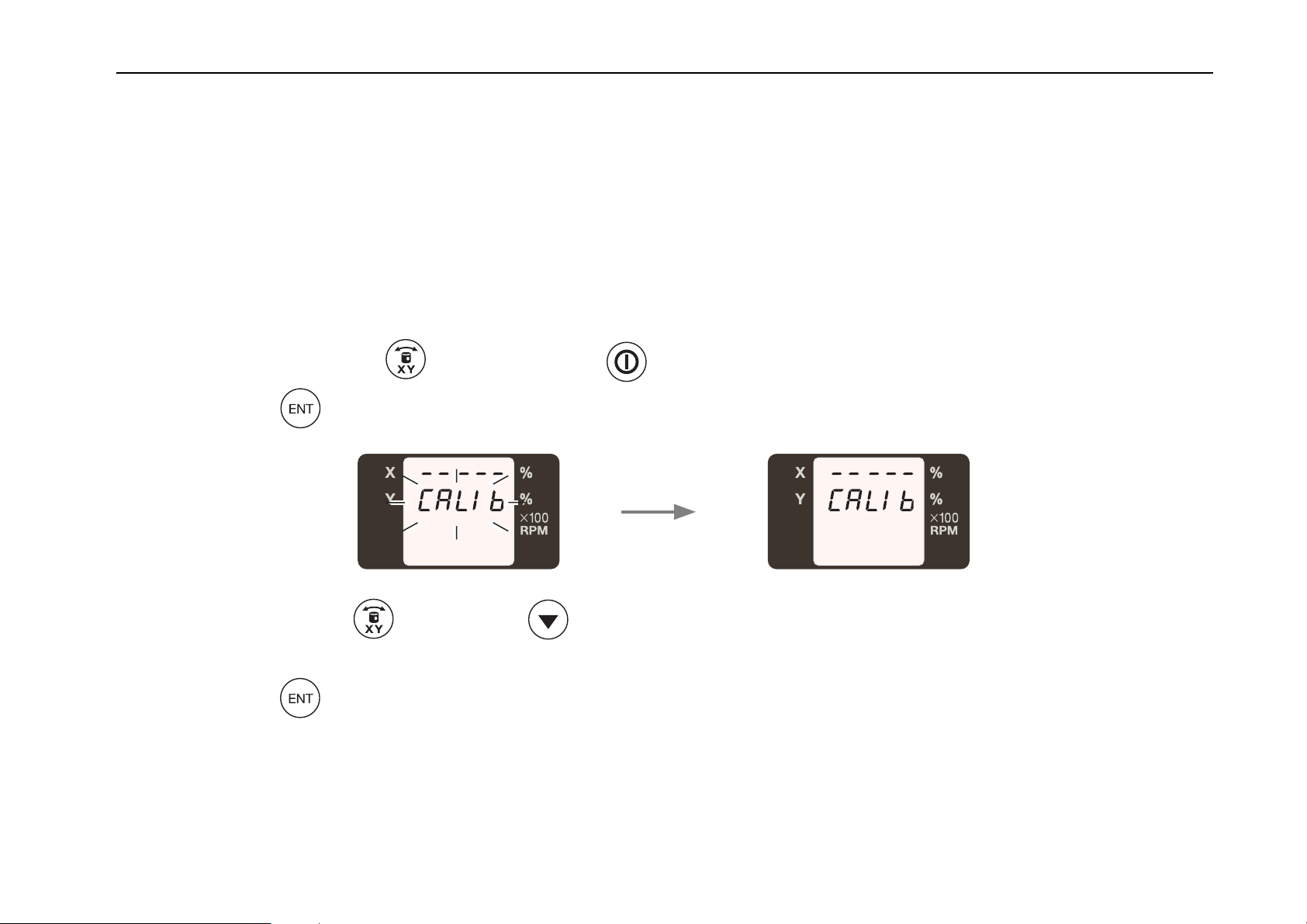

Horizontal calibration and adjustment

1

Move the RL-SV2S in the direction of the arrow to align the standard line and laser beam.

2 While pressing the key, press the key.

Press the key.

3 Press either the key or the key to align the laser beam with the LS-80L indicator

position. (check with the buzzer sound from the LS-80L)

4 Press the key.

55

Page 64

8. Check and Adjusting

If the screen below is displayed, the adjustment is complete.

$

If [CALIb OVEr] is displayed C12. Error Display(p. 62)

56

Page 65

9. STORAGE PRECAUTIONS

Always clean the instrument after use.

• If the instrument got wet with rain, wipe it well before storing in the storage case.

• Wipe away stain or dirt with soft cloth after dusting.

• Clean storage case using cloth moistened with neutral detergent or water. Do not use ether,

benzene, thinner or other solvents.

• Clean the lens by first removing dust with a cleaning brush and then lightly wiping with the

cleaning cloth included in the package or with a clean non-sticky or non-oily cloth (washed

cotton cloth is the best) moistened with alcohol (or ether-mixed liquid).

57

Page 66

10. HOW TO STORE

After using the instrument, store it as shown below.

LS-80L

(LS-80A/80B/90)

Level sensor

holder model 6

(LS-B10)

D size dry cell

battery

• The LS-80A/80B/90 and LS-B10 can be stored in this carrying case (The LS-70 cannot be

stored in this carrying case).

• Holders other than the holder model 6 cannot be stored.

RL-SV2S

AD-15

BT-74Q

AA size dry cell

battery

58

Page 67

11. SPECIFICATIONS

RL-SV2S

Light source : Laser diode (Visible, 635nm)

Laser output : 2.4mW

Safety standard for laser beam : CDRH (FDA) Class IIIa, IEC Class 3R

Automatic correction range : Horizontal ±5°

Vertical ±5°

Grade setting range : X:±15% Y:±15%

Accuracy : Horizontal ±10"

Vertical ±10"

Manual slope settable range : ±5° (When the instrument is installed on the 0°surface)

The slope range is increased or decreased according to the tilt of

thesurface on which the instrument is installed.

Line control during vertical rotation: ±5° (When the instrument is installed on the 0°surface)

Rotation speeds : 300/600rpm (Changeable)

Operating range :

Power supply/Operating time : 4 x D size dry cell batteries (alkaline)

Diameter Approx. 2m to 800m (rotation speed 600 r.p.m/Using with LS-80L)

or

Ni-MH battery pack BT-74Q (7000mAh)

Charging time : Approx. 13 hours (Using with AD-15)

Operating time : Approx. 90 hours(Using with alkaline manganese

drybattery / at +20° C (+68° F))

Approx. 55 hours (Using with Ni-MH battery pack

BT-74Q/ at +20° C (+68° F))

59

Page 68

11. Specifications

Protection against water and dust : IP66 (Based on the standard IEC60529)

Operating temperature : –20 °C to +50 °C (–4 °F to +122 °F)

Storable temperature range : –30 °C to +60 °C (–22 °F to +140 °F)

МУчбтойоздйурмбщ : RL-SV2S height alert warning

(Warning is displayed on the indicator of LS-80L.)

RL-SV2S battery warning

(Warning is displayed on the indicator of LS-80L.)

Dimensions : 177 (L) × 196 (W) × 217 (H) mm [7.0 (L) × 7.7 (W) × 8.5 (H) in]

Laser beam height : 187mm

(Height from the instrument’s bottom surface to the center point of

laser beam)

Weight : 2.5kg (lbs) (Dry battery type: Including dry batteries)

2.7kg (lbs) (Ni-MH battery type: Including BT-74Q)

Tripod screw : 5"/8X11 threads for surveying instrument

RC-60

Operating range (Radius) : 100m or more

Power source : 2×AA size dry cell batteries

Continuous operating time(+20°C): Approx. 3.5 months (depends on the nature of use)

Protection against water and dust : IP66 (Based on the standard IEC60529)

Operating temperature : –20 °C to +50 °C (–4 °F to +122 °F)

Storable temperature range : –30 °C to +60 °C (–22 °F to +140 °F)

Dimensions : 116 (L) × 59 (W) × 31.4 (H) mm [4.6 (L) × 2.3 (W) × 1.2 (H) in]

Weight : 0.2kg (0.4lbs) (Including dry cell batteries)

60

Page 69

11. Specifications

LS-80L (Back side display area)

Beam detection window : 50 mm (2.0 in)

Beam detection precision

High precision : ±1 mm (±0.04 in)

Normal precision : ±2 mm (±0.08 in)

Beam detection indication : Liquid crystal (both sides) and buzzer

Power source : 2×AA size dry cell batteries

Operating time : Approx. 120 hours (Using alkaline manganese dry cell batteries)

Auto shut-off delay : Approx. 30 minutes without beamdetection

Protection against water and dust : IP66 (Based on the standard IEC60529)

Operating temperature : -20°C to +50°C (-4°F to +122°F)

Storage temperature : -30°C to +60°C (-22°F to +140°F)

Dimensions : 146(L) x 76(W) x 26(H)mm (5.7 x 2.9 x 1.0 in)

Weight : 0.19 kg [0.41 lbs] (including dry cell batteries)

61

Page 70

12. ERROR DISPLAY

If an error is displayed, follow the procedures shown below.

Error Display Description/Countermeasure

If an error is displayed, follow the procedures shown below.

C6.2 Height Alert Function(p. 28)

RL-SV2S setting exceeds the leveling range.

Reset tilting to the direction to raise the X+ side.

62

Alternate

flashing

OR

Reset tilting to the direction to raise the X- side.

Reset tilting to the direction to raise the Y+ side.

Reset tilting to the direction to raise the Y- side.

Page 71

Error Display Description/Countermeasure

Transmission error with remote control.

Change both the RL-SV2S and RC-60 to other channel.

If the error persists, check the transmission

environment and reduce wireless LAN and

other similar wireless transmissions as

much as possible.

More than 2 RL-SV2S devices are within the transmission range of the

RC-60, making transmission impossible. Change the channel for both

the RL-SV2S (1) and RC-60 used for the operation to another channel.

12. Error Display

Exceeding the adjustment range.

Turn the power of the RL-SV2S OFF, turn ON the power back again

and readjust.

E-05 Turn the power for the instrument off, and then turn it back on.

63

Page 72

12. Error Display

Error Display Description/Countermeasure

Internal error

E-??

E-51,55

E-65

E-70’s

E-80’s

E-99

Transmission not possible with the RL-SV2S.

Remove and replace the dry cell batteries from the RC-60.

Wireless function error for the RL-SV2S.

Unable to transmit with the RC-60.

Turn the power for the instrument off, and then turn it back on.

Internal transmission error for the RL-SV2S.

Turn the power for the instrument off, and then turn it back on.

Slope function error.

Turn the power for the instrument off, and then turn it back on.

Leveling incomplete.

Turn the power for the instrument off, and then turn it back on.

Internal memory error for the RL-SV2S.

Turn the power for the instrument off, and then turn it back on.

• If errors still persist after attempting to clear them, contact Topcon or your dealer.

64

Page 73

13. REGULATIONS

Region/

Country

Directives/

Regulations

U.S.A. FCC

Labels/Declarations

FCC Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Contains FCC ID: XXXXXXXX(RL-SV2S)/XXXXXXX(RC-60)

NOTE:

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

This equipment should be installed and operated with at least 20cm and more

between the radiator and person’s body (excluding extremeties: hands, wrists,

feet and ankles).

65

Page 74

13. Regulations

WARNING:

Change or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

Specified cables must be used for connection to computer and/or peripherals in

order to meet FCC emission limits.

CAUTION:

This device and its antenna(s) must not be co-located or operating in conjunction

with any other antenna or transmitter. End user cannot modify this transmitter

device. Any unauthorized modification made on the device could avoid the user's

authority to operate this device.

Declaration of Conformity

Model Number:RL-SV2S/RC-60

Trade Name:TOPCON CORPORATION

66

Manufacture

Name: TOPCON CORPORATION

Address: 75-1, Hasunuma-cho, Itabashi-ku, Tokyo, 174-8580 JAPAN

Country: JAPAN

U.S.A. Representative

Responsible party:TOPCON POSITIONING SYSTEMS,INC.

Address: 7400 National Drive Livermore, CA94551, U.S.A

Telephone number:925-245-8300

Page 75

13. Regulations

Region/

Country

California,

U.S.A.

Directives/

Labels/Declarations

Regulations

Proposition65

67

Page 76

13. Regulations

California,

and NY,

U.S.A.

68

Recycling

Batteries

Page 77

13. Regulations

Region/

Country

Directives/

Regulations

Canada ICES

Labels/Declarations

Contains IC: XXXXX-XXXXX(RL-SV2S)/XXXXX-XXXXX(RC-60)

The term “IC:” before the radio certification number only signifies that

Industry Canada technical specifications were met.

“Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may

cause undesired operation of the device.”

“The installer of this radio equipment must ensure that the antenna is located

or pointed such that it does not emit RF field in excess of Health Canada

limits for the general population; consult Safety Code 6, obtainable from

Health Canada’s website www.hc-sc.gc.ca/rpb”

“This device has been designed to operate with the antennas listed below,

and having a maximum gain of 0.61 dB. Antennas not included in this list or

having a gain greater than 0.61 dB are strictly prohibited for use with this

device. The required antenna impedance is 50 ohms.”

“To reduce potential radio interference to other users, the antenna type and

its gain should be so chosen that the equivalent isotropically radiated power

(e.i.r.p.) is not more than that permitted for successful communication.”

69

Page 78

13. Regulations

Region/

Country

Directives/

Regulations

Australia C-Tick

R&TTE

EU

CE

Labels/Declarations

The compliance label indicates that the product complies with the applicable

standard and establishes a traceable link between the equipment and the

manufacturer, importer or their agent responsible for compliance and for placing it

on the Australian market.

R&TTE Directive

EU R&TTE

70

ROTATING LASER RL-SV2S, REMOTE CONTROLLER RC-60

Hereby, TOPCON CORP., declares that the above-mentioned equipment is in

compliance with the essential requirements and other relevant provisions of

Directive 1999/5/EC.

Please inquire below if you wish to receive a copy of Topcon's Declaration of

Conformity.

Topcon Europe Positioning B.V.

Essebaan 11, 2908 LJ Capelle a/d IJssel, The Netherlands

Tel:+31-10-4585077 Fax:+31-10-2844949

http://www.topcon-positioning.eu/index.asp

Page 79

13. Regulations

Region/

Country

EU

Directives/

Labels/Declarations

Regulations

WEEE

Directive

EU

EU Battery

Directive

71

Page 80

Page 81

Page 82

http://www.topcon.co.jp

Please see the attached address list or the following website for contact addresses.

GLOBAL GATEWAY http://global.topcon.com/

Loading...

Loading...