Page 1

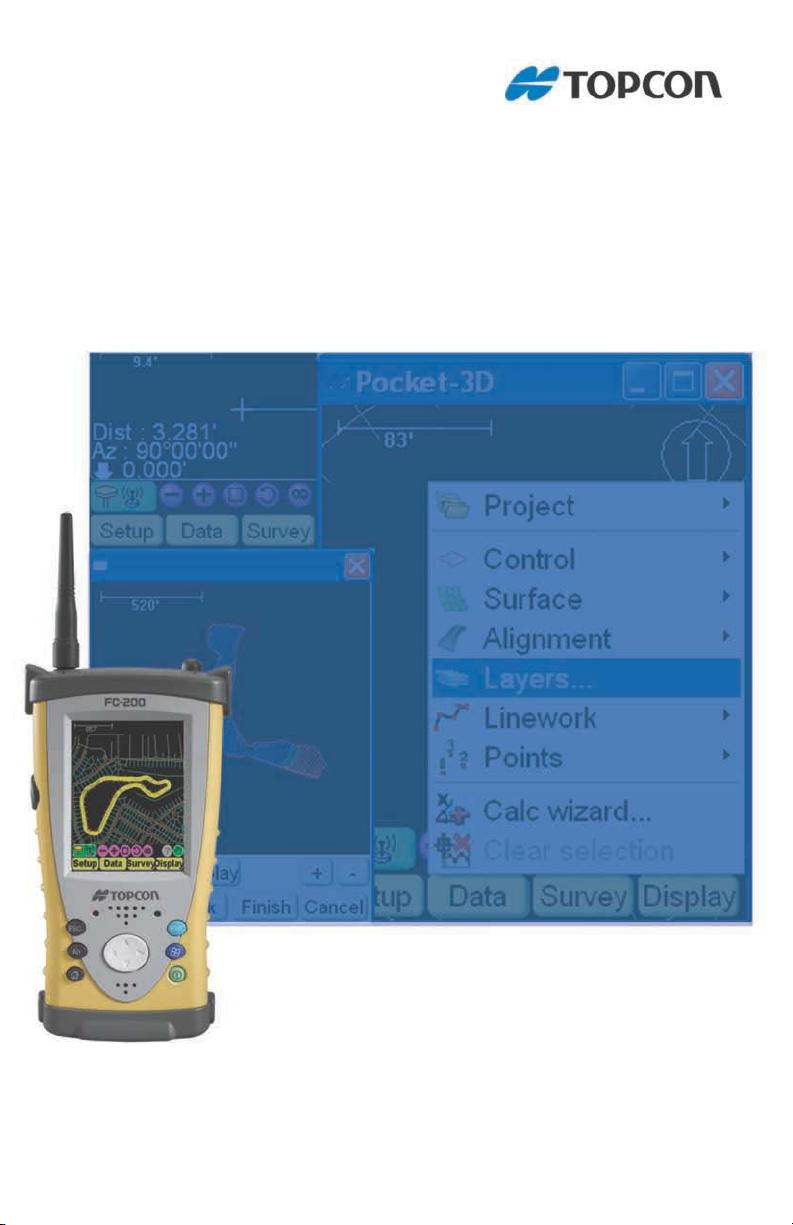

0OCKET$

2EFERENCE'UIDE

Page 2

Page 3

POSITIONING SYSTEMS

Pocket-3D

Reference Guide

Part Number 7010-0628

Rev J

©Copyright Topcon Positioning Systems, Inc.

February 2012

All contents in this manual are copyrighted by Topcon. All rights reserved.

The information contained herein may not be used, accessed, copied, stored,

displayed, sold, modified, published, or distributed, or otherwise reproduced

without express written consent from Topcon.

Page 4

ECO#000061

Page 5

TOC

Table of Contents

Preface .................................................................. iii

What’s New with Pocket-3D ................................ ix

Chapter 1

Installing Pocket-3D ............................................. 1-1

Guide to Installing Pocket-3D ......................................... 1-2

Starting Pocket-3D ........................................................... 1-5

Main Screen ..................................................................... 1-6

Context (Pop-Up) Menu Options ....................... 1-9

Toolbar ............................................................................. 1-12

Menu Bar ......................................................................... 1-13

Pocket-3D Technical Information ................................... 1-16

GPS Status Information ................................................... 1-17

GPS Status ................................................................. 1-17

Monitor GPS Status Information ........................ 1-18

View the Receiver’s Current Position ................ 1-18

Monitor Satellites and Enter the Mask ............... 1-19

View Receiver Information or Reset Receiver ... 1-19

View PDOP Values ............................................ 1-20

Apply GPS Receiver Settings ............................. 1-20

Total Station Status ................................................... 1-21

Monitor Prism Position Information ................... 1-22

Set Total Station Search Parameters ................... 1-22

Set Total Station Tracking Sensitivity and Speed 1-23

Chapter 2

Setup Menu ........................................................... 2-1

GPS Applications ............................................................. 2-1

Equipment ................................................................. 2-2

Radios ........................................................................ 2-6

Antenna ..................................................................... 2-7

P/N 7010-0628

i

Page 6

Table of Contents

Base Station ............................................................... 2-8

Units ........................................................................... 2-11

Exit ............................................................................. 2-12

Equipment Configuration Files ........................................ 2-13

Sample Configuration 1: Range-pole with

HiPer Lite Receiver ................................................ 2-13

mmGPS Applications ....................................................... 2-18

Equipment .................................................................. 2-19

mmGPS Transmitters ................................................. 2-19

TX Calibration .................................................... 2-21

Edit Channel ........................................................ 2-23

Benchmark Check ............................................... 2-24

Resection ............................................................. 2-25

mmGPS Receiver ....................................................... 2-27

Total Station Applications ................................................ 2-29

Equipment .................................................................. 2-29

Range-pole ................................................................. 2-31

Sample Configuration 4: Prism and Total Station ..... 2-32

Robotic Applications ........................................................ 2-35

Equipment ........................................................................ 2-36

Station Setup .................................................................... 2-38

SiteLink® 3D for Pocket-3D ........................................... 2-44

The Site-Link Network Connection ........................... 2-45

Connecting to SiteLink-3D .............................................. 2-46

Selecting the Current Operator .................................. 2-47

Managing Activities/Delays ...................................... 2-47

Sending, Viewing, and Deleting Messages ............... 2-48

Send Any File to the Jobsite ...................................... 2-50

Exporting a Project File Via Site-Link ...................... 2-51

Importing/Exporting Control Points Via Site-Link .......... 2-54

Importing/Exporting Surface Files Via Site-Link ............ 2-57

Importing/Exporting Alignment Files Via Site-Link ....... 2-59

Importing/Exporting Linework Files Via Site-Link ......... 2-61

Importing/Exporting Points Via Site-Link ....................... 2-63

Chapter 3

Data Menu ............................................................. 3-1

Project ............................................................................... 3-2

ii

Pocket-3D Reference Guide

Page 7

Table of Contents

Import/Export ............................................................ 3-4

Control ............................................................................. 3-13

Control Points ............................................................ 3-13

Import/Export ............................................................ 3-16

From Text File .................................................... 3-17

Conversion Formats ............................................ 3-18

Control Point Options ............................................... 3-21

Surface ............................................................................. 3-24

Current File or <none> .............................................. 3-25

TIN Surface File ................................................. 3-26

Road Surface File ............................................... 3-28

Plane Surface File ............................................... 3-39

Best-fit Plane Surface File .................................. 3-40

Compare Surface ....................................................... 3-42

Surface Options ......................................................... 3-45

Alignment ........................................................................ 3-47

Current File or <none> .............................................. 3-49

New ..................................................................... 3-49

Edit ...................................................................... 3-56

Delete .................................................................. 3-56

Import/Export ............................................................ 3-56

From RD3 File .................................................... 3-56

From LandXML File .......................................... 3-58

To RD3 File ........................................................ 3-58

Options ...................................................................... 3-59

Layers ........................................................................ 3-60

Linework .......................................................................... 3-62

Current File or <none> .............................................. 3-62

Import/Export ............................................................ 3-66

Points ............................................................................... 3-72

Listing ....................................................................... 3-72

Conversion Formats ............................................ 3-74

Export Point Files ............................................... 3-80

Conversion Formats ............................................ 3-82

Calculation Wizard .......................................................... 3-84

Inverse Between Two Points ..................................... 3-85

Inverse Between Three Points ................................... 3-86

Distance/Offset .......................................................... 3-87

P/N 7010-0628

iii

Page 8

Table of Contents

Distance From Two End Pts ...................................... 3-89

Convert Polyline to Points ......................................... 3-93

Convert Alignment to Points ..................................... 3-95

Polyline From Points ................................................. 3-98

TIN Surface from Points/Lines .................................. 3-100

Convert TIN Surface to Points .................................. 3-104

Convert Polyline to Alignment .................................. 3-105

Best-fit Plane from Points .......................................... 3-107

Compare Two Surfaces .............................................. 3-108

Move Selected Objects ..................................................... 3-111

Copy Selected Objects ..................................................... 3-113

Clear Selection ................................................................. 3-115

Chapter 4

Survey Menu ........................................................ 4-1

GPS Survey Applications ................................................. 4-1

Connect to GPS/Disconnect from GPS ..................... 4-2

Measure Points ................................................................. 4-2

Topo-shot ................................................................... 4-3

Topo-shot With Offset ............................................... 4-4

Control Point .............................................................. 4-5

Reference Line ........................................................... 4-6

Start Polyline ............................................................. 4-8

Next Polyline Pt ......................................................... 4-9

End Polyline ............................................................... 4-9

Start Tape Dimension ................................................ 4-10

Tape Dimension ......................................................... 4-11

Stop Tape Dimension ................................................ 4-13

Options ....................................................................... 4-13

Auto-topo/Stop Auto-topo ................................................ 4-16

By Distance ................................................................ 4-17

By Time ..................................................................... 4-18

By Elevation .............................................................. 4-19

Polyline ...................................................................... 4-21

Stake-out ........................................................................... 4-22

Surface Check ............................................................ 4-23

Cut/Fill “Real-Time” Updates ............................. 4-24

Match Grade ........................................................ 4-27

iv

Pocket-3D Reference Guide

Page 9

Table of Contents

Point List ............................................................. 4-27

Alignment ........................................................... 4-29

Polyline ............................................................... 4-34

Coordinate .......................................................... 4-35

Control Point ....................................................... 4-37

Create/Edit Custom Point List ............................ 4-39

Side Slopes ......................................................... 4-41

Measure Stake ..................................................... 4-44

Stake-out Previous Point .................................... 4-47

Stake-out Next Point ........................................... 4-48

Measure Stake 1 .................................................. 4-49

Stake-out Previous Point ........................................... 4-52

Stake-out Next Point ................................................. 4-53

Sideslope Options ............................................... 4-53

V. Surface Offset ................................................ 4-54

Options ................................................................ 4-55

Total Station Survey Applications ................................... 4-58

Connect/Disconnect Total Station ............................. 4-59

Measure Points .......................................................... 4-59

Topo-shot With Offset ........................................ 4-59

Options ................................................................ 4-60

Stake-out ................................................................... 4-61

Options ................................................................ 4-61

Robotic Survey Applications ........................................... 4-63

Start/Stop Tracking ................................................... 4-66

Turn Face .................................................................. 4-66

Turn Instrument ......................................................... 4-67

Reflectorless Application ................................................. 4-68

Chapter 5

Display Menu ........................................................ 5-1

Zoom ................................................................................ 5-2

Cursor .............................................................................. 5-3

Show ................................................................................ 5-4

Orientation ....................................................................... 5-5

Grid Lines ........................................................................ 5-6

Show Section View .......................................................... 5-7

Cut/fill History ................................................................. 5-8

P/N 7010-0628

v

Page 10

Table of Contents

Grade Indicator ................................................................. 5-9

Color Selection ................................................................. 5-9

Language Selection .......................................................... 5-11

About Pocket-3D .............................................................. 5-12

Options ....................................................................... 5-12

Modify ....................................................................... 5-13

Index

vi

Pocket-3D Reference Guide

Page 11

Preface

NOTICE

Preface

Thank you for purchasing your Topcon receiver, survey product,

software product, or accessory (the “Product”). The materials

available in this manual (the “Manual”) have been prepared by

Topcon Positioning Systems, Inc. (“TPS”) for owners of Topcon

products. This Manual is designed to assist owners with the use of the

Product and/or software (the “Software”) used with the Product and

its use is subject to these terms and conditions (the “Terms and

Conditions”).

Please read these Terms and Conditions carefully.

Terms and Conditions

USE This product is designed to be used by a professional. The user

should have a good knowledge of the safe use of the product and

implement the types of safety procedures recommended by the local

government protection agency for both private use and commercial

job sites.

COPYRIGHT All information contained in this Manual is the

intellectual property of, and copyrighted material of TPS. All rights

are reserved. You may not use, access, copy, store, display, create

derivative works of, sell, modify, publish, distribute, or allow any

third party access to, any graphics, content, information or data in this

Manual without TPS’ express written consent and may only use such

information for the care and operation of your Product. The

information and data in this Manual are a valuable asset of TPS and

are developed by the expenditure of considerable work, time and

P/N 7010-0628

iii

Page 12

Preface

money, and are the result of original selection, coordination and

arrangement by TPS.

TRADEMARKS Pocket-3D™, 3D-Office™, FC-236™, mmGPS™,

Millimeter GPS™, HiPer®, Topcon®, and Topcon Positioning

Systems™ are trademarks of TPS. iPAQ™ is a trademark of Hewlett

Packard. Recon™ is a trademark of TDS. AutoCAD® is a registered

trademark of Autodesk, Inc. The Bluetooth® word mark and logos

are owned by Bluetooth SIG, Inc. and any use of such marks by

Topcon Positioning Systems, Inc. is used under license. Other product

and company names mentioned herein may be trademarks of their

respective owners.

DISCLAIMER OF WARRANTY EXCEPT FOR ANY

WARRANTIES IN AN APPENDIX OR A WARRANTY CARD

ACCOMPANYING THE PRODUCT, THIS MANUAL, THE

PRODUCT, AND ANY ACCOMPANYING SOFTWARE ARE

PROVIDED “AS-IS.” THERE ARE NO OTHER WARRANTIES.

TPS DISCLAIMS ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

USE OR PURPOSE. TPS AND ITS DISTRIBUTORS SHALL NOT

BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS OR

OMISSIONS CONTAINED HEREIN; NOR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE

FURNISHING, PERFORMANCE OR USE OF THIS MATERIAL,

THE SOFTWARE, OR THE PRODUCT. SUCH DISCLAIMED

DAMAGES INCLUDE, BUT ARE NOT LIMITED TO, LOSS OF

TIME, LOSS OR DESTRUCTION OF DATA, LOSS OF PROFIT,

SAVINGS OR REVENUE, OR LOSS OF THE PRODUCT’S USE.

IN ADDITION, TPS IS NOT RESPONSIBLE OR LIABLE FOR

DAMAGES OR COSTS INCURRED IN CONNECTION WITH

OBTAINING SUBSTITUTE PRODUCTS OR SOFTWARE,

CLAIMS BY OTHERS, INCONVENIENCE, OR ANY OTHER

COSTS. IN ANY EVENT, TPS SHALL HAVE NO LIABILITY

FOR DAMAGES OR OTHERWISE TO YOU OR ANY OTHER

PERSON OR ENTITY IN EXCESS OF THE PURCHASE PRICE

FOR THE PORDUCT.

iv

Pocket-3D Reference Guide

Page 13

Terms and Conditions

LICENSE AGREEMENT Use of the Software and any other computer

programs or software supplied by TPS or downloaded from a TPS

website (the “Software”) to be used with a Topcon Product constitutes

acceptance of these Terms and Conditions in this Manual and an

agreement to abide by these Terms and Conditions. The user is

granted a personal, non-exclusive, non-transferable license to use

such Software under the terms stated herein and in any case only with

a single Product or single computer. You may make one (1) backup

copy of the Software. Otherwise, the Software may not be copied or

reproduced. You may not assign or transfer the Software or this

license without the express written consent of TPS. This license is

effective until terminated. You may terminate the license at any time

by destroying the Software and Manual. TPS may terminate the

license if you fail to comply with any of the Terms or Conditions. You

agree to destroy the Software and manual upon termination of your

use of the Product. All ownership, copyright and other intellectual

property rights in and to the Software belong to TPS. If these license

terms are not acceptable, return any unused Software and the Manual.

CONFIDENTIALITY This Manual, its contents and the Software

(collectively, the “Confidential Information”) are the confidential and

proprietary information of TPS. You agree to treat TPS’ Confidential

Information with a degree of care no less stringent than the degree of

care you would use in safeguarding your own most valuable trade

secrets. Nothing in this paragraph shall restrict you from disclosing

Confidential Information to your employees as may be necessary or

appropriate to operate or care for the Product. Such employees must

also keep the Confidentiality Information confidential. In the event you

become legally compelled to disclose any of the Confidential

Information, you shall give TPS immediate notice so that it may seek a

protective order or other appropriate remedy.

WEBSITE; OTHER STATEMENTS No statement contained at the

TPS website (or any other website) or in any other advertisements or

TPS literature or made by an employee or independent contractor of

TPS modifies these Terms and Conditions (including the Software

License Agreement, Disclaimer of Warranty and limitation of

liability).

P/N 7010-0628

v

Page 14

Preface

TIP

NOTICE

CAUTION

SAFETY Improper use of a Topcon Product can lead to injury to

persons or property and/or malfunction of the Product. The Product

should only be repaired by authorized TPS warranty service centers.

Users should review and heed the safety warnings in the manual

accompanying the Product.

MISCELLANEOUS The above Terms and Conditions may be

amended, modified, superseded, or canceled, at any time by TPS. The

above Terms and Conditions will be governed by, and construed in

accordance with, the laws of the State of California, without reference

to conflict of laws.

Manual Conventions

This manual uses the following conventions:

Example Explanation

FileExit Tap/press the File menu and tap/press Exit.

Enter Tap or press the button or key labeled Enter.

Topo Indicates the name of a dialog box or screen.

Notes Indicates a field on a dialog box or screen, or a tab

within a dialog box or screen.

vi

Supplementary information that can help you

configure, maintain, or set up a system.

Supplementary information that can have an affect

on system operation, system performance,

measurements, or personal safety.

Notification that an action has the potential to

adversely affect system operation, system

performance, data integrity, or personal health.

Pocket-3D Reference Guide

Page 15

Manual Conventions

WARNING

DANGER

Notification that an action will result in system

damage, loss of data, loss of warranty, or personal

injury.

Under no circumstances should this action be

performed.

P/N 7010-0628

vii

Page 16

Preface

Notes:

viii

Pocket-3D Reference Guide

Page 17

What’s New

What’s New with Pocket-3D

The following list briefly describes new features and functions for the

latest version (v.10.0) of Pocket-3D.

Stake-out Options

• You can now display customized information for the

following, including content and size and color of text.

– surface check

– point staking

– road staking

Internal GPS – on the FC-25 and FC-236 hand-helds

(controllers) you can use the device’s internal GPS for rough GPS

guidance and measurement (low accuracy less than 5m).

DGPS Support features

• There is now a DGPS (low accuracy <1m) option receiver

type for dozers and compactors. (Designed to be used in

conjunction with DGPS network corrections).

MAC/VRS option for Network RTK – you can now

choose between VRS and (Leica) MAC network types.

The password protection mechanism has been changed to allow a

larger number of options and to provide a better security. Because

the new codes are much longer, you now have the ability to

import them directly from an option file on a USB dongle, etc.

Existing installs of Pocket-3D will automatically be upgraded to

the new protection mechanism

See “Starting Pocket-3D” on page 1-5 for more information

P/N 7010-0628

ix

Page 18

What’s New with Pocket-3D

Base station manufacturer – On the Advanced tab of

the “GPS info” screen, you can now select which GPS reference

station manufacturer to use. This helps with correct RTK

operation where GLONASS is used at the Base and Rover when

the base is not a Topcon base. See

Settings” on page 1-20 for more information.

“Apply GPS Receiver

NTRIP virtual ports – It is no longer necessary to manually

specify a “virtual port” for NTRIP corrections because it is

handled automatically handled by the software.

The following list briefly describes the features and functions for

version 9.2 of Pocket-3D, which was an incremental release version

of the Pocket-3D 9.x series for Windows Mobile, Windows CE, and

Windows XP/Vista/7 platforms.

Platforms – In addition to the FC-120, FC-200, and the GRS-

1 controller platforms and Windows platforms, Pocket-3D now

runs on the FC-25 and FC-2500 controllers.

Site-Link 3D – Pocket-3D now supports Site-Link

connectivity, allowing users to transfer files, project data, and

messages to other 3DMC, 3D-Office, and Pocket-3D users on the

jobsite.

• NOTE: This is an Optional feature controlled by OAF. You

must be connected to a Site-Link service (provided directly

by Topcon or by a Site-Link server hosted on the job).

DGPS – You can now select a “GPS (Augmented)” sensor type

for the equipment configuration, which allows you to run without

RTK corrections (or without RTK options in the receiver). See

“Sample Configuration 4: Prism and Total Station” on page 2-32

for details.

RC-4 – Pocket-3D 9.2 supports the new RC-4 modem for

communicating with robotic total stations. See

Configuration 4: Prism and Total Station” on page 2-32 for

details.

x

“Sample

Pocket-3D Reference Guide

Page 19

What’s New with Pocket-3D

Other – Pocket-3D 9.2 now handles significantly larger project

files (up to 10 times larger than before). Also, on-screen panning/

zooming selection with large data files is greatly improved.

The following list briefly describes the features and functions for

version 9.1 of Pocket-3D:

TP3 Project Files:

• All project/design data is now contained within a single

Topcon TP3 file, via 3D-Office, which is the standard project

configuration for all 9.1 series releases.

• Existing TIN/Road/Linework/Point/Control files can be

imported/exported for TP3 files.

• A brief summary of the TP3 project file contents can be

viewed from the Project file(s) listing (“Info”).

MX3 Machine Files – all machine configurations are now

stored with MX3 file extensions and are in human-readable XML

format. Older (*.MB3) machine configurations are not supported.

Authorization Codes – the password protection

mechanism has been changed to allow a larger number of options

and to provide a better security. Because the new codes are much

longer, you now have the ability to import them directly from an

option file on a USB dongle, etc. Existing installs of Pocket-3D

will automatically be upgraded to the new protection mechanism

See “Starting Pocket-3D” on page 1-5 for more information.

Grade Indicator – A grade-indicator bar, similar to

3DMC, can be displayed when doing a surface check. In

Surface Check mode the user can now select to see a tri-color

grade-indicator similar to the one seen in the 3DMC software

that gives real-time cut/fill updates to the design surface. The

grade-indicator option is located in the display menu and

only shows up when there is an active surface or alignment.

To adjust the grade indicator settings, press and hold on the

grade-indicator strip to access a sub-menu containing options

for tolerances and range.

P/N 7010-0628

xi

Page 20

See “Cut/Fill “Real-Time” Updates” on page 4-24 for more

information on how to access and use the grade indicator.

Cosmetic Changes:

• Buttons now have 3D edges.

• Menu items, surface, and equipment lists now have

descriptive bitmaps.

Miscellaneous Changes:

• File and point lists are now sorted alphabetically. Point lists

can also be sorted by clicking the column header.

• Point description fields are now drop-down lists where

previously set descriptions can be retrieved.

• Multiple selections have been added for Points, Lines,

Layers, and Surfaces.

• New layers can now be created inside the layer selection

drop-down list.

• Updated projections list, now also includes support for table

projection and multiple datums.

• Polyline segments can be viewed and edited within a list.

• The direction of a polyline can now be reversed by using the

pop-up menu. Click Linework>Reverse from the context

pop-up menu, which is activated by holding the stylus down

for one second or alternatively pressing the ALT button.

See “Main Screen” on page 1-6 for more information.

• Also, in the context menu, the length of the selected polyline

and single or multiple polyline segments can be shown. Click

Calcs ><Station>.

• Polylines can now be joined together.

• Added support for NAD83_NO_Trans. This is an added

datum option to support the use of a non-Topcon base station.

There is a difference between NAD83 and WGS84

parameters. When using a non-Topcon base station, a shift

would appear. A third-party base receiver use to be the only

option.

See “Support for non-Topcon Base Station” on page 3-22 for

Page 21

What’s New with Pocket-3D

more information.

NOTE: When using an RS1 radio on the FC_250, you must select

COM3 for the radio port in the configuration. The port is not labeled

‘radio’ but it is the only port available for RS1 communication.

NOTE: Due to an increase in program size, we recommend users do

NOT use any data files over 2MB in Pocket-3D. This DOES NOT

mean that you cannot use data files over 2MB, but you should be

aware that issues could arise if you go over this limit.

The following list briefly describes the features and functions for

version 9.0 of Pocket-3D.

Auto-topo improvements – Improvements have been

made to the management of very large topo survey data sets and

to auto-topo logging at high speed (up to 5 points per second).

User Interface – Screen colors and fonts have been

enhanced to improve visibility in sunlight and to achieve a more

modern look and feel.

• Buttons now have 3D edges.

Menu items, surface, and equipment lists now have descriptive

bitmaps.

P/N 7010-0628

xiii

Page 22

What’s New with Pocket-3D

Notes:

xiv

Pocket-3D Reference Guide

Page 23

Chapter 1

Installing Pocket-3D

Welcome to Pocket-3D™, the software contractors use to build job

files, check cuts and fills, layout points, and survey all or part of a

jobsite. This software comes on a CD and is ready to install on a

hand-held controller—such as, the Topcon FC-236™, GRS-1, or the

FC-250—and is only available as part of the 3DMC Bundle from

Topcon™ dealers.

Figure 1-1. Pocket-3D on Controller (Topcon’s FC-236)

NOTE: Pocket-3D now runs on FC25 and FC2500 controllers.

P/N 7010-0628

1-1

Page 24

Installing Pocket-3D

Guide to Installing Pocket-3D

Pocket-3D installs on any hand-held controller that runs the Windows

Pocket PC operating system, including Topcon’s FC236. Pocket-3D

initially loads onto your computer, then uses Microsoft®

ActiveSync® to synchronize with the controller and install Pocket-3D

onto the controller. ActiveSync is available for free from the

Microsoft website (www.microsoft.com) and must be installed on the

computer before installing Pocket-3D.

The Pocket-3D program for your hand-held controller is located on

the 3DMC CD. It will first be loaded onto your computer, then

ActiveSync will install it onto your controller.

1. Connect your computer and hand-held controller.

Because ActiveSync will automatically install Pocket-3D once it

has been loaded onto the computer, this step is can be performed

at any time.

2. Insert the 3DMC software CD into the computer CD drive of the

computer. Navigate to the CD’s files using Explorer and open the

Pocket-3D folder.

3. Click the Pocket-3D setup icon to run the install program and

click Next on the Welcome screen (

Figure 1-2).

1-2

Figure 1-2. Begin Pocket-3D Installation

Pocket-3D Reference Guide

Page 25

Guide to Installing Pocket-3D

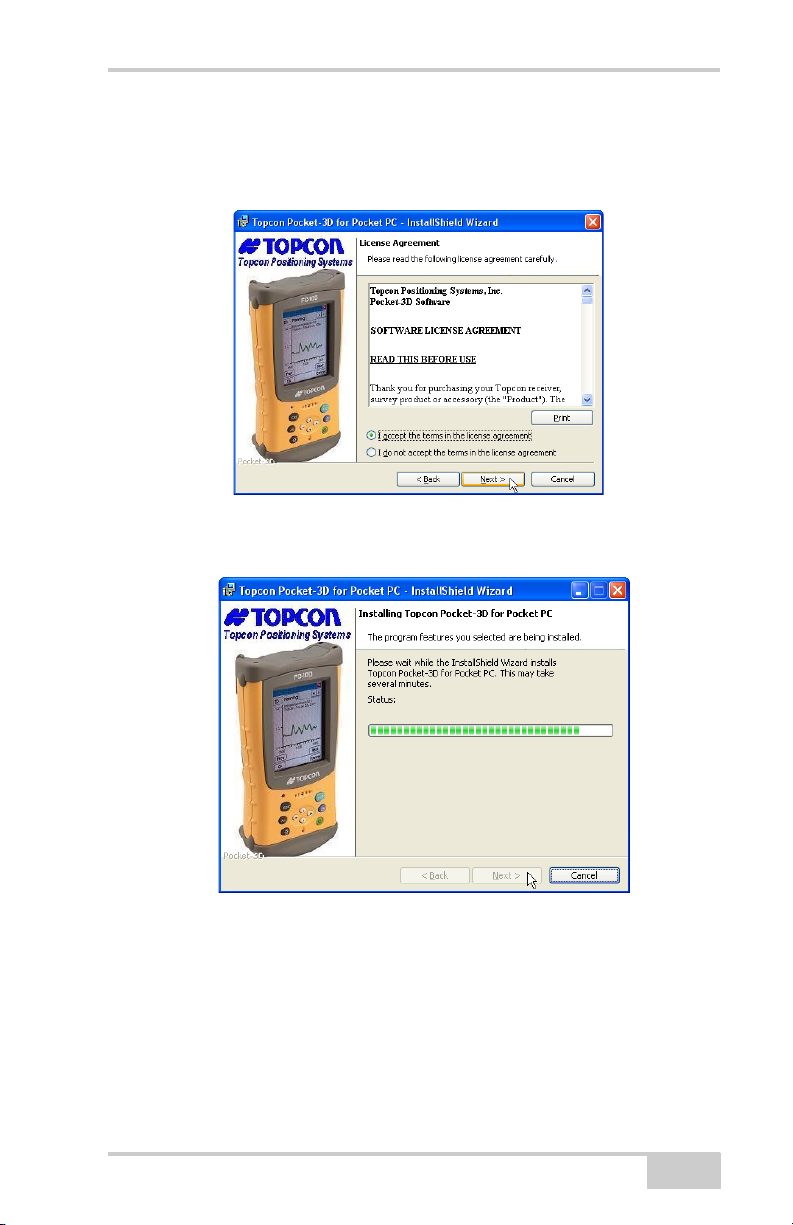

4. Review the License Agreement. If you accept the terms, click the

“I accept...” radio button, then click Next (

Figure 1-3).

Click “I do not accept...” to terminate the installation.

Figure 1-3. Review and Accept License Agreement

5. Click Install to load Pocket-3D on the computer (Figure 1-4).

Figure 1-4. Install Pocket-3D on Computer

6. With the computer and controller connected, ActiveSync will

start up and retrieve the controller’s programs.

If Pocket-3D is already installed, ActiveSync ask to uninstall it

from the controller. When ActiveSync completes the uninstall

process, double-click the Pocket-3D setup icon to have

ActiveSync install the software on the controller.

P/N 7010-0628

1-3

Page 26

Installing Pocket-3D

7. ActiveSync will begin the Pocket-3D install process for the handheld controller (

Figure 1-5).

Figure 1-5. Install Pocket-3D on Controller

8. Click Yes to install Pocket-3D to the default directory on the

controller (

Figure 1-6).

Figure 1-6. Installing into Default Directory

When the controller install completes, ActiveSync displays a

notice to check the controller for any further installation

procedures. However, Pocket-3D has no further installation steps.

Click OK to continue.

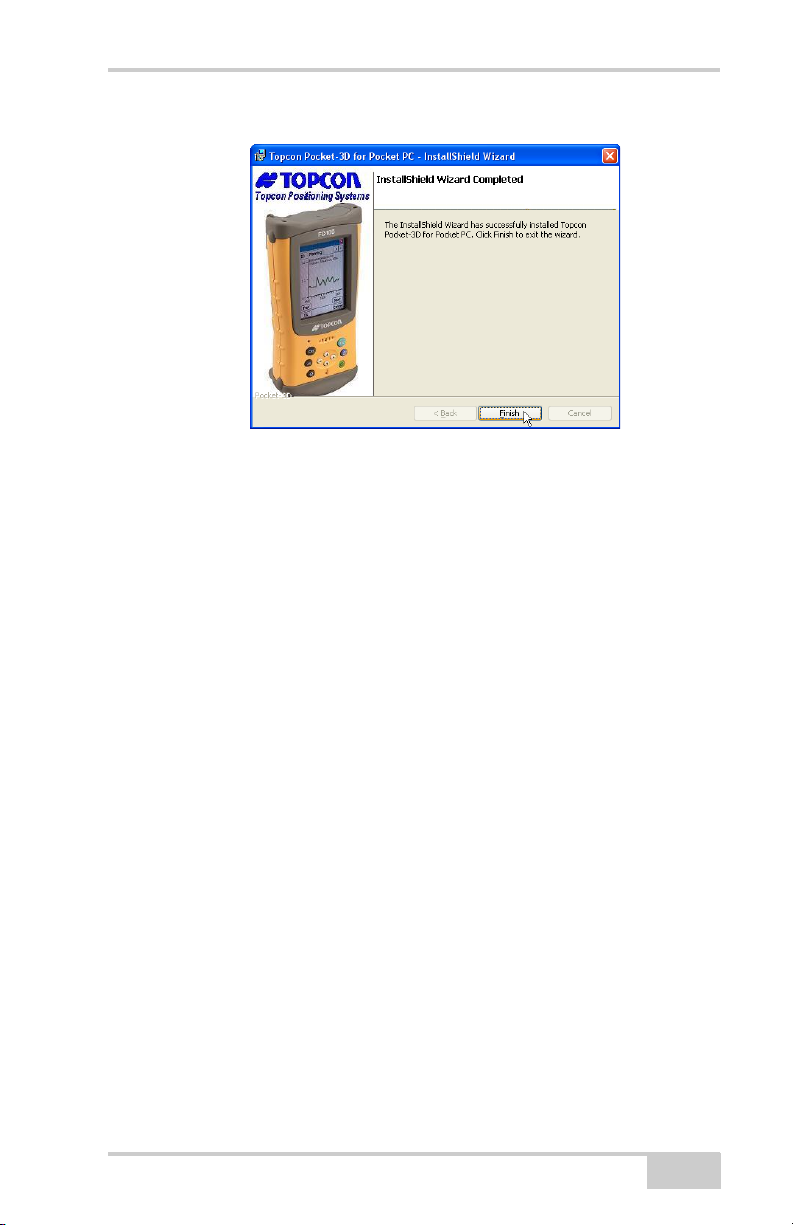

9. Click Finish to exit the install program (Figure 1-7 on page 1-5).

1-4

Pocket-3D Reference Guide

Page 27

Starting Pocket-3D

Figure 1-7. Finish Install and Exit

Starting Pocket-3D

To start Pocket-3D, press theWindows icon and press Pocket3D in

the program list.

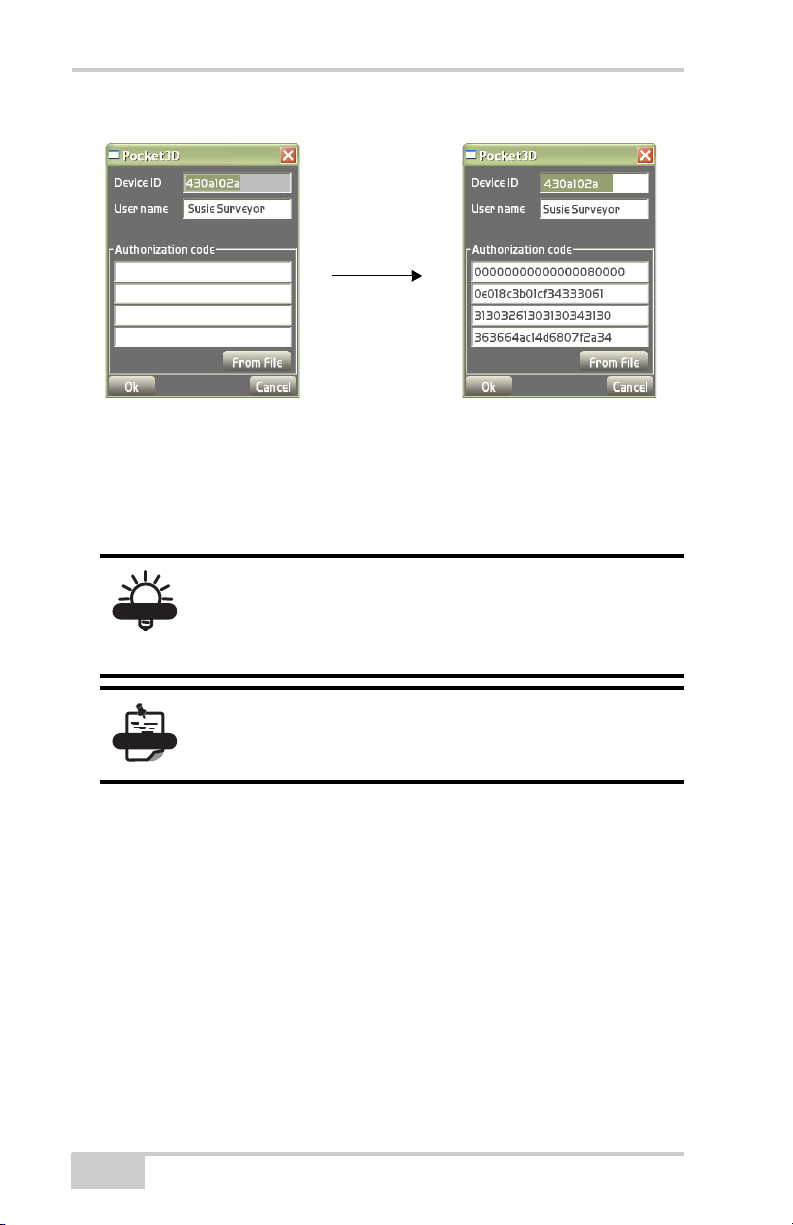

Upon initial startup, Pocket-3D requires authorization codes to

properly run (

mechanism has been changed to allow a larger number of options and

to provide better security. Because the codes are much longer now,

you can import directly from an option file on a USB dongle, etc.

Existing installs of Pocket-3D will automatically be upgraded to the

new protection mechanism. New users will require codes generated

via the new “Keygen2” application.

Figure 1-8 on page 1-6). The password protection

• Device identification

• Company name

•Contact name

• Contact phone number

• Contact email address

• Software Type (Pocket-3D)

• Company address

When you receive the authorization codes, enter them into the

appropriate fields on the Device Identification screen and press Ok

(

Figure 1-8 on page 1-6).

P/N 7010-0628

1-5

Page 28

Installing Pocket-3D

TIP

NOTE

Figure 1-8. Enter Authorization Codes

Once entered, the authorization codes can then be located on the

about Pocket-3D screen for easy access. In v10.0, the authorization

codes no longer change due to new installations. To view updated

installed options, see

“Main Screen” below.

Authorization Codes: More options are now

available to provide better security. Because new

codes are much longer, you can now import them

directly from an option file onto a USB dongle, etc.

Existing installs of Pocket-3D will automatically be

upgraded to the new password protection

mechanism.

Main Screen

The Pocket-3D main screen (Figure 1-9 on page 1-7) has the

following components:

• Main Window – displays a graphical representation of the design

surface and machine. The display varies according to the selected

file and display options.

• Toolbar – provides icons for frequently used functions. See

“Toolbar” on page 1-12 for more information.

Pocket-3D Reference Guide

1-6

Page 29

Main Screen

• Menu bar – contains pop-up menus for the various functions

available in Pocket-3D. The following chapters describe each

menu in detail.

Figure 1-9. Pocket-3D Main Screen

The pop-up menus on the main screen (Figure 1-12 on page 1-9)

contain frequently accessed functions, and information about selected

data. To display the pop-up menu, rest the controller’s stylus on the

point, station, or polyline for at least one (1) second or alternatively

press the ALT button.

The pop-up (context) menu options depend on the type of file open

and the information selected.

• Clear selection – deselects the selected entities (functions the

same as the Data

Clear selection menu option).

• Hide layer(s) – hides selected layers on the main screen.

• Surface (Figure 1-12 on page 1-9) – sends a message, via SiteLink to the machine operator in the field.

• Alignment (Figure 1-13 on page 1-10):

– Stakeout: stakes out the selected point

– Use as reference line: uses the selected alignment as a

reference line to create/measure new points at a specific

station and offset – same for polyline.

– Send Via Site-Link: sends a message to the operator in the

field.

P/N 7010-0628

1-7

Page 30

Installing Pocket-3D

•Segment (Figure 1-15 on page 1-10) – Add, insert, edit, delete,

create or select entire polyline(s).

•Linework (Figure 1-10):

– Delete: deletes the selected linework/polyline or the last

segment.

– Join Selected Polyline(s): joins highlighted polylines on the

main screen.

– Merge Selected Polyline(s): merges highlighted polylines on

the main screen.

– Unclose polyline(s): opens previously closed polylines.

– Send via Site-Link: sends a message to the operator in the

field.

– Length: total length of selected polyline

Figure 1-10. Lengths Context Menu Option

• Points – adds, edits, deletes, or stakes-out point(s) (Figure 1-16

on page 1-11)

– Add a point: adds the selected point(s).

– Delete a point: deletes the selected point(s).

– Send via Site-Link: sends a message to the machine operator

in the field.

– Stake-out point: stakes out the selected point(s).

– Use as reference line: uses the selected polyline as a reference

line during a stake-out.

• Calcs – performs common polyline calculations (Figure 1-17 on

page 1-11)

– Create new polyline: creates a new polyline.

1-8

Pocket-3D Reference Guide

Page 31

Main Screen

– Create closed polyline: creates a closed polyline.

– Create tin surface: creates a TIN surface.

– Move object(s): moves the current cursor position to where

the stylus clicked on the main screen (only available in

simulation mode).

– Copy object(s): copies the selected entity with the mouse.

Figure 1-11. Calcs Context Menu Option

Context (Pop-Up) Menu Options

Figure 1-13 through Figure 1-18 shows the context menu options for

Surface, Alignment, Linework, Segment, Point, Calcs, and GoTo

parameters.

P/N 7010-0628

Figure 1-12. Context Menu – Surface Options

1-9

Page 32

Installing Pocket-3D

Figure 1-13. Context Menu – Alignment Options

Figure 1-14. Context Menu – Linework Options

1-10

Figure 1-15. Context Menu – Segment Options

Pocket-3D Reference Guide

Page 33

Figure 1-16. Context Menu – Points Options

Main Screen

P/N 7010-0628

Figure 1-17. Context Menu – Calcs Options

Figure 1-18. Context Menu – GoTo Options

1-11

Page 34

Installing Pocket-3D

Toolbar

The toolbar (Figure 1-19) contains icons for frequently used

functions.

Figure 1-19. Pocket-3D Toolbar – GPS Example

Table 1-1 lists and describes the available icons.

Table 1-1. Pocket-3D Toolbar Icons

Icon Description

GPS, LPS, mmGPS, total station status – displays symbols for the

GPS Status

mmGPS Status

Total Station

Status

Robotic Status

type of control application used on the jobsite, as well as the

connection status (red for unconnected, green for connected, and

orange for low precisions in GPS applications).

• In GPS control applications, press this icon to display GPS

information. See “GPS Status Information” on page 1-17 for

details.

• In mmGPS control applications, press this icon to display GPS

information. See

details.

• In total station applications, press this icon to display total

station information. See

details.

• In robotic applications, press this icon to display robotic

information. See “Robotic Survey Applications” on page 4-63

for details.

Zoom out – decreases the magnification of the design view each

time you tap this button. The zooming pivot is the center of the

screen.

Zoom in – increases the magnification of the design view each

time you tap this button. The zooming pivot is the center of the

screen.

Zoom window – increases the magnification of a design area

when drawing a box around the selected area.

“GPS Status Information” on page 1-17 for

“Total Station Status” on page 1-21 for

1-12

Zoom previous – displays the previous design view.

Pocket-3D Reference Guide

Page 35

Table 1-1. Pocket-3D Toolbar Icons (Continued)

Icon Description

Zoom extents – displays the extent of the design view/area.

Info – displays information for selected points/polylines and a

dialog box to save the information as a text file.

New Message – press to send a new message to the machine

operator in the field.

Site-Link Connection – connects you to Site-Link

Menu Bar

Auto-pan

Selection

window

Selection

polygon

Pan

Click to rotate through the four button options:

• Auto-pan – tracks the user’s current position in the field and

displays the position as a cross symbol in the middle of the

screen. Available only in GPS connection.

• Selection window – selects points/polylines on the screen when

drawing a box around them.

• Selection polygon – selects point/polylines on the screen when

drawing a polygon around them.

• Pan – moves the design view around when pressing down on

the screen and dragging.

Menu Bar

The menu bar provides access to the Pocket-3D configuration, setup,

display, and other jobsite functions (

menus, see the following:

• “Setup Menu” on page 2-1

• “Data Menu” on page 3-1

• “Survey Menu” on page 4-1

Figure 1-20). For details on the

• “Display Menu” on page 5-1

P/N 7010-0628

1-13

Page 36

Installing Pocket-3D

GPS

mmGPS

Total

Station

Figure 1-20. Pocket-3D Menu Bar

Table 1-2 describes the functions available in each menu.

Table 1-2. Pocket-3D Menu Options

Menu Functions

Setup Menus The options available in the Setup menu

depend on the equipment file selected.

• configures equipment and machine setups

• configures radios, antennas, and base

stations in GPS applications

• configures transmitters and receivers in

mmGPS applications

• configures GRT-2000 setup and LS-2000

receivers in LPS applications

• configures total stations and prisms in total

station applications

• sets the units for the job

• Connect to Site-Link

Data Menu The options available in the Data menu

depend on the equipment file and design

surface file selected.

• creates, configures, and sets control point

files

• creates, configures, and sets surface files

• creates, configures and sets linework files

• creates, configures and provides access to

importing or exporting control, files, point

files, and Site-Link files.

• performs various calculations

1-14

Pocket-3D Reference Guide

Page 37

Menu Bar

GPS

mmGPS

Total

Station

Table 1-2. Pocket-3D Menu Options (Continued)

Menu Functions

Survey Menu The options available in the Survey menu

depend on the equipment file selected.

• connects and disconnects the GPS receiver

or total station

• starts and stops tracking the total station in

total station applications

• sets the type of connection for the total

station

• enables and disables the use of a

reflectorless total station in total station

applications

• measures points and polylines in the field

• performs auto-topo operations for

topographic surveys (not available for

some total station instruments/applications)

• performs stake-outs

P/N 7010-0628

1-15

Page 38

Installing Pocket-3D

Table 1-2. Pocket-3D Menu Options (Continued)

Menu Functions

Display Menu The options available in the Display menu

depend on the equipment file selected and the

types of data active.

• zooms in, out, or pans around the main

screen

• selects points and/or polylines individually

or in bunches

• shows the scale bar, the direction of travel,

and/or the point of reference

• orients the screen to a desired direction

• displays, orients, aligns grid lines as

desired

• shows a section view of the design surface

(only available for certain surfaces)

• shows the cut/fill history (available for

mmGPS applications)

• shows the grade indicator when an active

surface displays.

• changes the background color

• selects the language for Pocket-3D on the

next start up of program

• displays the about Pocket-3D dialog box

For pop-up context menu options, see “Main Screen” on page 1-6.

Pocket-3D Technical Information

To view Pocket-3D information, press DisplayAbout Pocket-3D.

The about Pocket-3D dialog box displays the version levels for the

application program, copyright information, registration, and ID

number (

See “Main Screen” on page 1-6 for viewing options.

1-16

Figure 1-21 on page 1-17).

Pocket-3D Reference Guide

Page 39

GPS Status Information

Figure 1-21. About Pocket-3D

GPS Status Information

Once connected to a GPS/mmGPS system, the status button on the

toolbar turns green (GPS) or blue (mmGPS). Press the status button to

view or edit the different application-specific parameters (

on page 1-18).

Figure 1-22

GPS Status

While in GPS control, to view GPS information, change the mask

angle or reset the receiver, press the GPS status button on the toolbar.

The GPS status dialog box displays (

The color of the button and state of the hardware symbol indicates the

status of the system.

• Background color – green means the entire system communicates

with Pocket-3D; red means all or some part of the system is not

communicating with Pocket-3D; orange means low precisions.

• Hardware symbol state – if the symbol is crossed out, the

corresponding sensor/receiver is not available. If the radio link is

between 3 and 10 seconds old, the radio icon will flash (bad or

weak signal); after 10 seconds, it will be crossed out (unavailable

signal).

P/N 7010-0628

Figure 1-22 on page 1-18).

1-17

Page 40

Installing Pocket-3D

GPS Status Icon

mmGPS GPS

Figure 1-22. GPS/mmGPS Status Button and Dialog Box

Monitor GPS Status Information

To monitor the fix status of the GPS+ receiver, press the GPS status

button. The Fix tab displays the following information (

• The initialization status of the GPS+ and mmGPS system

• Total sats tracked – the total (GPS and GLONASS) number of

satellites being tracked

Figure 1-22):

• GPS sats used and GLONASS sats used – the number of GPS and

GLONASS satellites being used

• Horz. RMS and Vert. RMS – an estimation of the positioning

quality computed from a valid satellite status (RMS = Root Mean

Square)

View the Receiver’s Current Position

To view the current position of the GPS+ receiver, press the GPS

status button, then tap the Position tab on the GPS status dialog box.

The Position tab displays the following information (Figure 1-23 on

page 1-19):

• latitude, longitude, and ellipsoid height of the GPS+ antenna

• northing, easting, and elevation of the GPS+ antenna

• the distance from the receiver to the base station

1-18

Pocket-3D Reference Guide

Page 41

GPS Status Information

Monitor Satellites and Enter the Mask

To monitor the current distribution of satellites or enter the mask

angle for satellites, press the GPS status button, then tap the

Satellites tab on the GPS status dialog box.

The Satellites tab displays the following information (Figure 1-23).

• Satellite plot – displays used and unused satellites, and the

current mask angle.

– Blue dots: GPS satellites

– Red-with-cross dots: GLONASS satellites

– Black dots: unused satellites

– Red mask circle: satellites inside will be used for positioning

• Mask – enters and sets the mask angle for the job.

Figure 1-23. Position and Satellites Tabs

View Receiver Information or Reset Receiver

To view the receiver’s ID number and firmware version, press the

GPS status button, then tap the Info tab on the GPS status dialog

box. Use the left/right arrows to navigate to the Info tab.

The Info tab displays the following (Figure 1-24 on page 1-20):

• Identification information, firmware revision, and radio link

information (type, latency, and quality) for the receiver.

• Reset receiver – press to clear all data and reset all settings stored

for the GPS+ receiver.

P/N 7010-0628

1-19

Page 42

Installing Pocket-3D

• Reset RTK – press to reset RTK ambiguities.

View PDOP Values

To view PDOP values for planning purposes, press the GPS status

button, then tap the Planning tab on the GPS status dialog box. Use

the left/right arrows to navigate to the Planning tab.

The Planning tab displays PDOP information at an hourly scale and

covers a 24-hour period (

• Press Next to display PDOP values for the next day.

• Press Previous to display PDOP values for past days.

Figure 1-24).

Figure 1-24. Info and Planning Tabs

Apply GPS Receiver Settings

To apply advanced GPS receiver settings, press the GPS status

button, then tap the Advanced tab (

GPS status dialog box. Use the left/right arrows to navigate to the

Advanced tab.

The Advanced tab contains the following GPS receiver settings.

• Use multipath reduction – leave enabled to reduce multiple

reflections from nearby objects.

• Use GLONASS satellites – leave enabled to include in position

calculations and to display on the satellite plot.

• Base Manufacturer – from the drop-down box, select which GPS

station manufacturer to use, i.e., Sokkia, Ashtech, Javad, Leica,

1-20

Figure 1-25 on page 1-21) on the

Pocket-3D Reference Guide

Page 43

GPS Status Information

NOTE

Select a Base

manufacturer from the

drop-down list

Magellan, Trimble, etc. This helps with correct RTK operation

where GLONASS is used at the base and rover where the base is

not a Topcon base.

Figure 1-25. Advanced Tab

Total Station Status

While in total station control, to view total station information,

change search area or change track sensitivity and speed, press the

Total Station status button on the toolbar (

page 1-22).

Figure 1-26 on

The color of the button and state of the hardware symbol indicates the

status of the system.

• Background color – green means the entire system communicates

with Pocket-3D; red means all or some part of the system is not

communicating with Pocket-3D.

• Hardware symbol state – if the symbol is crossed out, the

corresponding sensor/receiver is not available.

For non-robotic total stations, the prism symbol will

remain crossed out.

The instrument selected during equipment setup determines the tabs

that display.

P/N 7010-0628

1-21

Page 44

Installing Pocket-3D

Total Station

Status Icon

Figure 1-26. Total Station Status Button and Dialog Box

Monitor Prism Position Information

To monitor the position status of the prism, press the Total Station

status button. The Position tab displays the following information

(Figure 1-26):

• whether or not the prism is connected and tracks the total station

• horizontal/vertical angles and slope distance to the prism

• northing, easting, and elevation of the prism

Set Total Station Search Parameters

To set total station search parameters, press the Total Station status

button, then tap the Search tab on the total station status dialog box

(

Figure 1-27 on page 1-23).

Depending on the total station used and the sensor type, enter or

select the following information (

Ok:

• Search wait (secs) – sets the wait time in seconds until the total

station starts to search for the prism (robotic total stations only).

• Pattern – selects the pattern for tracking the prism.

• Search area left and right of prism – when enabled, sets the search

area at the total station for tracking the prism.

1-22

Figure 1-27 on page 1-23) and press

Pocket-3D Reference Guide

Page 45

GPS Status Information

• Above and below prism – enter the angle above and below the

prism in which to search.

Set Total Station Tracking Sensitivity and Speed

To set total station tracking parameters (Figure 1-27), press the Total

Station status button, then tap the Track tab on the total station

status dialog box.

Figure 1-27. Search/Track Tabs for Total Station

P/N 7010-0628

1-23

Page 46

Installing Pocket-3D

Notes:

1-24

Pocket-3D Reference Guide

Page 47

Chapter 2

Setup Menu

Depending on the application (GPS, mmGPS, or total station), the

Setup menu contains different options for configuring system

components.

GPS Applications

In GPS applications, the Setup menu (Figure 2-1) has the following

menu items. Some menu items depend on the type of equipment

configured (machine or rover).

•Equipment

•Radios

• Antenna

• Base Station

• mmGPS transmitters (mmGPS application)

• mmGPS receiver (mmGPS application)

•Units

Figure 2-1. Setup Menu for GPS Applications

P/N 7010-0628

2-1

Page 48

Setup Menu

NOTICE

Equipment

The Equipment menu creates and edits equipment configuration files.

Equipment configuration files contain information specific to the

equipment; such as, machine type, receiver type and location,

dimensions of the cutting edge, offset lengths depending on the

position of the receiver, and radio configuration.

Equipment setup is used for Rover setups, not Base

station setups.

To access available equipment configuration files, tap Setup

Equipment (Figure 2-2).

Figure 2-2. SetupEquipment

From the Equipment configurations dialog box (Figure 2-3 on

page 2-3), equipment configuration files can be created within

Pocket-3D and transferred to the machine Control Box to be used for

machine configuration. (A machine configuration file must be created

before grading.) Refer to the System Five-3D Reference Manual for

more information on the Control Box.

2-2

Pocket-3D Reference Guide

Page 49

GPS Applications

Figure 2-3. Equipment Configurations Dialog Box

Once equipment configuration files are created and stored in the

internal memory, they can be selected and adjusted at the beginning of

the job, depending on the receiver’s setup.

On the Equipment configurations dialog box, press New to display

the Configuration name/type dialog box (

Figure 2-4 on page 2-4)

and create an Equipment Configuration file. Enter the following

information and press Next. Some selections depend on purchased

options for Pocket-3D.

• Configuration name – enter a name for the Equipment

Configuration.

• Machine type – select Range pole, Bulldozer, or Motor grader.

The screens display different settings depending on the machine

type selection.

• Sensor – select the type of sensor used on the machine; either

GPS antenna, GPS Augmented, mmGPS Receiver, Prism, or LS2000 for 3-track curb & gutter.

• Location – select the sensor’s location, either Top of pole for

Range pole, Middle for Bulldozer, or Left/Right for Motor grader.

• Units – select the unit of measure.

Note: These units do not relate to job units.

P/N 7010-0628

2-3

Page 50

Setup Menu

Figure 2-4. Configuration Name/Type

On the antenna information dialog box, enter the following

information using the same units of measure entered in the previous

step and press Next. These settings have a corresponding Image tab to

illustrate the setup.

For range poles, enter the following antenna information

(Figure 2-5):

• Antenna type – select the type of antenna.

• Antenna height – enter the antenna height of the GPS+ antenna

from antenna measurement point to pole tip.

• Measured to – enter where on the GPS+ antenna the antenna

height was measured.

• Connection (Pocket-3D) – select the communication port used

between controller and instrument.

2-4

Figure 2-5. Range Pole Antenna Setup Information

Pocket-3D Reference Guide

Page 51

GPS Applications

On the radio setup dialog box (Figure 2-6), set the following

parameters and press Next:

• Radio type – the type of radio.

• Connected – the port used for radio connection.

• Baud rate – the speed of communication rate between the radio

unit and the GPS+ receiver.

• Format – current GPS+ systems are capable of either CMR or

RTCM corrections.

Figure 2-6. Radio Setup

On the Machine configuration complete dialog box (Figure 2-7),

press Finish to save the configuration file.

Figure 2-7. Machine Configuration Complete Dialog Box

P/N 7010-0628

2-5

Page 52

Setup Menu

Radios

To configure radio settings, tap SetupRadios (Figure 2-8).

Figure 2-8. SetupRadio

On the radio setup dialog box, set the following parameters and press

Ok (

Figure 2-9 on page 2-7):

• Radio type – the type of radio.

• Port – the port used for radio connection.

• Baud rate – the speed of communication rate between the radio

unit and the GPS+ receiver.

• Format – current GPS+ systems are capable of either CMR or

RTCM corrections.

• Configure – changes the radio channel; press to display the

channel configuration dialog box (

Select the desired channel and the corresponding Frequency

displays. Press Set to apply the radio channel parameters.

Figure 2-9 on page 2-7).

2-6

Pocket-3D Reference Guide

Page 53

GPS Applications

Figure 2-9. Radio Setup and Channel Configuration Dialog Boxes

Antenna

To edit/view antenna measurements, tap SetupAntenna

(Figure 2-10).

Figure 2-10. SetupAntenna

On the antenna setup dialog box, set the following parameters and

press Ok (

Figure 2-11 on page 2-8):

• Antenna type – select the type of antenna.

• Antenna height – enter the antenna height of the GPS+ antenna.

• Measured to – enter where on the GPS+ antenna the antenna

height was measured.

• Units – select the unit of measure.

P/N 7010-0628

2-7

Page 54

Setup Menu

NOTE

Figure 2-11. Antenna Setup

Base Station

To set Base Station information, tap SetupBase Station

(Figure 2-12).

If the Base station menu item is unavailable,

disconnect from the GPS receiver (Survey

Disconnect from GPS).

Figure 2-12. SetupBase Station

On the base station configuration dialog box (Figure 2-13 on

page 2-9), set the following parameters and press Next:

• Control point – select the appropriate control point for the base

position from the control point drop-down list.

2-8

Pocket-3D Reference Guide

Page 55

GPS Applications

• Connection (Pocket-3D) – select the connection to the receiver.

Figure 2-13. Base Station Configuration

On the antenna setup dialog box (Figure 2-14), set the following

parameters and press Ok:

• Antenna type – select the type of antenna.

• Antenna height – enter the antenna height of the GPS+ antenna.

• Measured to – enter where on the GPS+ antenna the antenna

height was measured.

• Units – select either meters, feet, inches, or centimeters.

Figure 2-14. Antenna Setup – Base Station

P/N 7010-0628

2-9

Page 56

Setup Menu

On the radio setup dialog box, set the following parameters

Figure 2-15):

(

• Radio type – the type of radio.

• Port – the port used for radio connection.

• Baud rate – the speed of communication rate between the radio

unit and the GPS+ receiver.

• Format – current GPS+ systems are capable of either CMR or

RTCM corrections.

• Configure – changes the radio channel; press to display the

channel configuration dialog box (

Figure 2-15). Select the

desired channel and the corresponding Frequency displays.

• Set – press to apply the radio channel parameters.

• Next – press to display the GPS receiver settings dialog box

(

Figure 2-16 on page 2-11).

Figure 2-15. Radio Setup and Channel Configuration Dialog Boxes

On the GPS receiver settings dialog box (Figure 2-16 on page 2-11)

do the following and press Finish to connect to the GPS receiver.

• Use co-op tracking – if enabled, allows higher efficiency of

multipath reduction. This option is only valid for a base station

receiver (non-moving).

• Use multipath reduction – if enabled, reduces multiple reflections

from nearby objects.

2-10

Pocket-3D Reference Guide

Page 57

GPS Applications

• Use GLONASS satellites – if enabled, these satellites will not be

included in the position calculations and will not display on the

satellite plot if disabled.

Figure 2-16. Select GPS Receiver Settings

Units

To set project units, tap SetupUnits (Figure 2-17).

Figure 2-17. SetupUnits

On the units dialog box (Figure 2-18 on page 2-12), select the desired

units for each item from the drop-down lists. Press Ok to continue;

Pocket-3D saves the entered units.

The units can be changed at any time; Pocket-3D automatically saves

the changes.

• Distances – select either Meters, US Survey feet, International

feet, or Feet + Inches.

P/N 7010-0628

2-11

Page 58

Setup Menu

If using Feet+Inches, all values will show as 1'11''1/2 where 12

inches equal 1 foot and any value smaller than an inch will show

as a fraction of an inch.

• Decimal Places – select either 0, 1, 2, 3, or 4 decimal places.

• Angles – select either DD°MM’SS”, NDD°MM’SS”E, Gons, or

DD.DDDD°.

• Areas – select either Square meters, Square feet, Acres, or

Hectares.

• Volumes – select either Cubic meters or Cubic yards.

• Coords – select either North-East-Elev, East-North-Elev,

X-Y-Z, or X-Y-Z South Azimuth.

• Stations – select either 100.000, 1+00.000, 10+0.000, or

1+000.000.

• Grades – select either Percent (%), Run : Rise, or Rise : Run.

Figure 2-18. Units Parameters

Exit

To exit Pocket-3D, tap the icon in the upper-right corner of the

screen.

2-12

Pocket-3D Reference Guide

Page 59

Equipment Configuration Files

NOTICE

Equipment Configuration Files

Equipment configuration files contain information on the specific

machine, GPS+ receiver, prism, radio, etc., for the job application and

setup. Pocket-3D uses this information to accurately portray jobsite

information on the main screen.

The following sections provide example equipment configurations:

one for a range-pole with a HiPer® Lite receiver, one for a motor

grader machine rover with mmGPS, one for a motor grader with an

LS-2000 receiver, and another one for a prism/total station setup.

An equipment configuration file can be created in one of two ways:

• Import the file created at the System Five-3D Control Box

through the compact flash card using the Copy button. See

“Project” on page 3-2 for details.

• Create the file manually.

Sample Configuration 1: Range-pole with HiPer Lite Receiver

Before initializing or localizing a GPS+ system, there must be an

equipment configuration file defined in Pocket-3D. The following

procedure is an example of a HiPer Lite receiver configuration.

Incorrect measurements or typographical errors will

have a direct affect on grading accuracy.

1. Press SetupEquipment. The Machine files dialog box

displays.

2. On the Machine files dialog box, press New to create (or Edit to

change a selected file) an equipment configuration (

on page 2-14).

3. On the Configuration name dialog box, set the following

equipment parameters, and press Next (

page 2-14):

P/N 7010-0628

Figure 2-19 on

Figure 2-19

2-13

Page 60

Setup Menu

• Configuration name – enter a name for the Equipment

Configuration file on the alphanumeric pop-up keyboard.

• Machine type – select Range pole from the drop-down list.

• Sensor – select GPS Antenna from the drop-down list.

• Mounting location – select Top of pole from the drop-down

list.

• Units – select the type of unit measurement from the

drop-down list.

Figure 2-19. Equipment Configuration Dialog Box

4. Enter the following information on the Dimensions tab using the

same units of measurement entered in the previous step, then

press Next to continue (

Figure 2-20). These settings have a

corresponding Image tab to illustrate the setup.

• Antenna type – select Topcon HiPer Lite.

• Antenna height – enter the antenna’s measured height.

• Measured to – select either Base or Rim.

• Connection (Pocket-3D) – select the appropriate connection.

2-14

Pocket-3D Reference Guide

Page 61

Equipment Configuration Files

Figure 2-20. Antenna Information – Dimensions/Image Tab

5. On the advanced dialog box (Figure 2-21), set the following

radio parameters, and press Next to continue:

• Radio type – for a HiPer Lite, the default is selected;

otherwise, select the radio type for the receiver.

• Connected to – select serial port (usually Port C) from the

drop-down list.

• Baud rate – select 38400 from the drop-down list.

• Format – select CMR from the drop-down list.

6. On the confirmation screen, press Finish to save the

configuration file (

Figure 2-21).

Pressing Cancel will cause the configuration’s information to be

lost.

P/N 7010-0628

Figure 2-21. Radio Setup Dialog Box

2-15

Page 62

Setup Menu

7. On the Equipment configuration dialog box, highlight the new

or edited configuration file, and press Ok to return to the Main

Screen (

GPS Augmented Sensor Type Now you can select a GPS

Figure 2-22).

Figure 2-22. Select Equipment Configuration

(Augmented) sensor type, which allows you to run without RTK

corrections (or without RTK options in your receiver) and to perform

rough grade-checking and stakeout using GPS positions computed

with the help of the WAAS (North America) or EGNOS (Europe)

GPS augmentation system. The expected position accuracies can

range from anywhere between 0.5’ and 4.0’ (0.2m and 1.5m)

depending on satellite availability.

Sample Configuration: GPS Augmented Sensor Type The

following procedure is an example of selecting GPS (Augmented) as

the sensor type for GPS.

1. Follow steps 1 & 2 above, then on the Configuration name

dialog box, select GPS (Augmented) as the sensor type, and press

Next.

2. On the Dimensions tab (Figure 2-23 on page 2-17), select the

antenna type, enter antenna height, measure to either the Base or

the Rim, and select the appropriate connection for Pocket-3D.

The corresponding Image tab illustrates the setup.

2-16

Pocket-3D Reference Guide

Page 63

Equipment Configuration Files

Figure 2-23. Example – GPS (Augmented) Equipment Configuration

3. Press Next to display the confirmation screen dialog box

Figure 2-25).

(

4. Press Finish to return to the Machine files dialog box

(Figure 2-24).

Figure 2-24. Machine Configuration Complete

5. On the Machine files dialog box (Figure 2-25), select the new or

edited configuration file and press Ok.

P/N 7010-0628

2-17

Page 64

Setup Menu

mmGPS Icon

6. On the Machine files dialog box (Figure 2-25), press Ok to apply

the configuration file as the current equipment.

Figure 2-25. Select Equipment Configuration

mmGPS Applications

In mmGPS applications, the Setup menu (Figure 2-26) has the

following additional menu items. Except for mmGPS setup options,

the Setup menu for mmGPS applications is the same as for GPS

applications. Other differences are noted below.

• mmGPS transmitters

• mmGPS receiver

Figure 2-26. Setup Menu for mmGPS Applications

2-18

Pocket-3D Reference Guide

Page 65

mmGPS Applications

Equipment

For further details on the Equipment menu option and setup screens,

“Equipment” on page 2-2. During rover equipment setup for

see

mmGPS applications, an additional screen configures GPS

connections; machine setups for mmGPS remains the same.

mmGPS Transmitters

Transmitter calibration data must first be downloaded into Pocket-3D

using the Transmitters tab (

contains a list of transmitters, up to four transmitters can be set up on

unique channels using the channel tabs (see below). The channel

button on the transmitter determines the channel that the transmitter

broadcasts on.

To set up transmitter information, tap SetupmmGPS transmitters

Figure 2-27).

(

Figure 2-28 on page 2-20). Once this tab

Figure 2-27. SetupmmGPS Transmitters

The Transmitters tab performs the following (Figure 2-28 on

page 2-20):

• To select a Serial Cable – select the communication port used

between the controller and transmitter; either COM or

Bluetooth® comport.

• To add a transmitter – tap Add and enter a transmitter serial

number or other description.

• To delete a transmitter – select a transmitter and tap Delete.

P/N 7010-0628

2-19

Page 66

Setup Menu

• To calibrate the transmitter – see “TX Calibration” on

page 2-21.

• To load transmitter data for the first time – tap Download to

retrieve calibration data from the connected transmitter.

The download is complete when the firmware version displays in

the Firmware column.

Figure 2-28. View Transmitters Loaded into Pocket-3D

The Channel tab displays the following transmitter information

(

Figure 2-29 on page 2-21):

• Channel – the channel the transmitter is using.

• Transmitter – the ID of the transmitter.

• ControlPt. – the control point over which the transmitter is set up.

• Height – the height of the transmitter.

• Edit Channel – see “Edit Channel” on page 2-23.

2-20

Pocket-3D Reference Guide

Page 67

mmGPS Applications

NOTICE

Figure 2-29. Enter Transmitter Channel Information

TX Calibration

The transmitter calibration (adjustment) function fixes errors in

incline in the self-leveling mechanism of the transmitter, applying an

offset to the transmitter. The transmitter must be in calibration mode

for this function and the Rover setup approximately 30 meters (100

feet) away. The height of the sensor must be at an angle less than 1° in

relation to the transmitter.

If the sensor experiences excessive movement

during any stage of the adjustment, an error

message will display. Press Cancel and stabilize the

Rover pole. Then press TX calibration again.

To begin a resection, tap TX Calibration on the Transmitters tab of

the transmitter setup dialog box. If needed, check the setup listed

on-screen (Figure 2-30 on page 2-22) and tap OK.

P/N 7010-0628

2-21

Page 68

Setup Menu

Figure 2-30. Begin TX Calibration Adjustment

On the transmitter adjustment process dialog boxes (Figure 2-31),

follow the instructions on each screen. Press Next to continue.

Figure 2-31. Transmitter Adjustment Process

When the adjustment completes, the Adjustment dialog box displays

the offsets (

Figure 2-32 on page 2-23).

• If both Axis measurements are less than 10'', no adjustment is

needed at the transmitter.

2-22

Pocket-3D Reference Guide

Page 69

mmGPS Applications

TIP

NOTE

• If either or both Axis measurements are more than 10'', disconnect

from the sensor and connect to the transmitter.

• Press Finish to upload the adjustments to the transmitter. When

finished uploading, the transmitter will apply the adjustments and

turn off.

After loading the new self-leveling offset data into

the transmitter, re-calibrate to check the system.

The transmitter may need to be calibrated a couple

of times depending on site conditions.

Figure 2-32. Adjustment Results

This process only applies an offset to the selfleveling mechanism to ensure correct grade. The

control point file is not affected.

Edit Channel

To edit information for the selected transmitter, tap the Edit Channel

button on the Channel tab (

On the edit channel dialog box, edit and select the following

parameters and press Ok to save (

1. Transmitter – select the desired transmitter from the drop-down

list.

2. Control point – select the control point for the transmitter’s

position from the drop-down list.

P/N 7010-0628

Figure 2-33 on page 2-24).

Figure 2-33 on page 2-24).

2-23

Page 70

Setup Menu

3. TX height – enter the height of the transmitter.

4. Measured to – select where on the transmitter (Base or Mark/

Slant) the height was measured.

5. Benchmark check – see “Benchmark Check” below.

6. Resection – see “Resection” on page 2-25.

Figure 2-33. Edit Channel

Benchmark Check

This function determines the height of the mmGPS transmitter over a

known control point (benchmark) or a point of known elevation.

To take a height measurement of the transmitter, tap Benchmark

check on the channel setup dialog box after entering transmitter

information (

2-24

Figure 2-34).

Figure 2-34. Begin Height Check

Pocket-3D Reference Guide

Page 71

mmGPS Applications