Page 1

For more information contact Synergy Positioning Systems or

visit the Synergy Positioning Systems website at www.synergypositioning.co.nz

All branches: Phone 0800 867 266 Email: info@synergypositioning.co.nz

Page 2

Page 3

POSITIONING SYSTEMS

Paver System Five

Operator’s Manual

Part Number 7010-0341

Rev F

©Copyright Topcon Positioning Systems, Inc.

April, 2004

All contents in this manual are copyrighted by Topcon. All

rights reserved. The information contained herein may not be

used, accessed, copied, stored, displayed, sold, modified,

published, or distributed, or otherwise reproduced without

express written consent from Topcon.

Page 4

ECO#2223

Page 5

Table of Contents

Preface .................................................................. vii

Terms and Conditions ...................................................... vii

Manual Conventions ........................................................ x

What’s New... ........................................................ xi

Chapter 1

System Overview .................................................. 1-1

Getting Acquainted .......................................................... 1-3

Control Box ............................................................... 1-3

Sonic Tracker II ......................................................... 1-4

Slope Sensor .............................................................. 1-5

Smoothtrac Sonic Averaging System (SAS) ............. 1-6

Laser Tracker & Trackerjack ...... .............................. 1-7

Care and Preventive Maintenance ................................... 1-8

Chapter 2

Paving Principles & Control Methods ................ 2-1

Paver Components ........................................................... 2-1

How a Screed Works ....................................................... 2-2

Tow Point Force (“P”) .............................................. 2-5

Truck Exchange, Another Tow Point Force ....... 2-6

Head of Material (“M”) ............................................. 2-7

Reaction of Material Under Screed (“R”) ................. 2-9

Gradation Mix Characteristics ............................ 2-9

Mix Temperature Characteristics ....................... 2-11

Weight of Screed (“W”) ............................................ 2-12

Quality of Base Being Paved .................................... 2-13

Rolling Techniques ............................................. 2-14

i

P/N 7010-0341 www.topconpositioning.com

Page 6

Table of Contents

Controlling Mat Quality ...................................... 2-14

Control Methods .............................................................. 2-15

Sonic Control ............................................................. 2-15

Working Window and Sonic “Footprint” ........... 2-16

Sonic Tracker Operation and its Position ........... 2-18

Sonic Tracker and Temperature Changes ........... 2-22

Laser Control ............................................................. 2-24

Slope Control ............................................................. 2-26

Chapter 3

Stringline Setup ................................................... 3-1

Setting Surface Stringline ................................................ 3-2

Setting Elevated Stringline .............................................. 3-5

Making a Cut/Fill Lath .............................................. 3-7

Attaching Stringline to the Grade Stake .................... 3-9

Setting Projected Slope Stringline ................................... 3-10

Verifying Grade ............................................................... 3-12

Chapter 4

Operation & Menu Settings ................................. 4-1

Control Box ...................................................................... 4-2

LCD ........................................................................... 4-3

Light Sensor for LED Display ................................... 4-3

Power Switch ............................................................. 4-3

Grade Adjustment Knob ............................................ 4-4

Grade Adjustment Direction Arrows ........................ 4-5

Grade Adjustment LEDs ........................................... 4-5

Function Indicator LEDs ........................................... 4-6

Set/Menu Button ........................................................ 4-7

Using the Set Mode ............................................. 4-7

Using the Menu Mode ........................................ 4-8

Cross Communication Button ................................... 4-8

Slope/Elevation Button .............................................. 4-11

Slope Mode ......................................................... 4-11

ii

Elevation Mode ................................................... 4-11

Topcon Paver System Five Operator’s Manual

Page 7

Table of Contents

Survey/Indicate Button .............................................. 4-12

Using the Survey Function ................................. 4-12

Using the Indicate Function ................................ 4-12

Auto/Manual Button .................................................. 4-13

Using Automatic Mode ...................................... 4-13

Using Manual Mode ........................................... 4-13

Making Selections in the Performance Menu ..... 4-14

Jog Button ................................................................. 4-14

Other Control Box Components ................................ 4-14

Performance Menu Settings ............................................. 4-16

Gain (Elevation) ........................................................ 4-20

Gain (Slope Control) ................................................. 4-21

Valve Offset .............................................................. 4-23

Averaging .................................................................. 4-26

Deadband Elevation .................................................. 4-27

Deadband Slope ........................................................ 4-29

Beeper Alarm ............................................................ 4-31

Unit ............................................................................ 4-32

Test ............................................................................ 4-34

Chapter 5

Getting Ready to Pave ......................................... 5-1

Control Box Setup ........................................................... 5-2

Screed Setup .................................................................... 5-3

Sonic Tracker Setup ......................................................... 5-4

SAS Setup ........................................................................ 5-6

Control Box Setup for Elevation ..................................... 5-7

Control Box Setup for Cross Slope ................................. 5-11

Chapter 6

Tracker and SAS Placement ................................ 6-1

Sonic Tracker Positioning in Relation to Reference ........ 6-2

L-bar Positioning ....................................................... 6-3

Cub and Gutter Tracking .................................... 6-5

Joint Matching and Tracking Sub-grade ............ 6-5

Placement When Using a Temperature Bail ............. 6-6

P/N 7010-0341 www.topconpositioning.com

iii

Page 8

Table of Contents

Placement When Using a Mechanical Ski ................ 6-6

Placement When Using Elevated Stringline ............. 6-7

Placement When Using Surface Stringline ............... 6-8

Sonic Tracker Placement in Relation to Screed ............... 6-8

Smoothtrac SAS Placement and Setup ............................ 6-13

Positioning the SAS ......................................................... 6-16

Placement of SAS on Paver ............................................. 6-19

Chapter 7

Paving Applications ............................................. 7-1

Paving City Streets with Sonics ....................................... 7-1

Paving City Streets with Cross Slope .............................. 7-4

Paving Streets Through Intersections .............................. 7-7

Method 1 for Paving Intersections ............................ 7-7

Method 2 for Paving Intersections ............................ 7-9

Paving Intersections with Cross Slope ............................. 7-10

Chapter 8

Maintenance ......................................................... 8-1

Preventative Maintenance & Daily Care ......................... 8-1

Sonic Tracker II Transducer Cleaning ............................. 8-2

Sonic Tracker II Transducer Replacement ...................... 8-3

Chapter 9

Troubleshooting ................................................... 9-1

Control Box Symptoms .................................................... 9-1

Tracker Symptoms ........................................................... 9-11

Slope Sensor Symptoms .................................................. 9-14

SAS Symptoms .......................................... .... .................. 9-17

Appendix A

Safety Precautions ............................................... A-1

iv

Topcon Paver System Five Operator’s Manual

Page 9

Table of Contents

Appendix B

Limited Warranty .................................................. B-1

Electronic and Mechanical Components ......................... B-1

Return and Repair ............................................................ B-1

Warranty Disclaimer ........................................................ B-1

Service Information ......................................................... B-2

Glossary

Index

P/N 7010-0341 www.topconpositioning.com

v

Page 10

Table of Contents

Notes:

vi

Topcon Paver System Five Operator’s Manual

Page 11

Preface

This manual has been developed to provide the operator with

information necessary to operate and maintain TOPCON products.

Proper service and use is important to the reliable operation of the

equipment. The procedures described herein are effective methods

for performing service and operation of this system.

NOTICE

Terms and Conditions

USE – Please study this manual carefully. The benef its this product

provides can be greatly influenced by your applications knowledge.

COPYRIGHT – All information contained in this Manual is the

intellectual property of, and copyrighted material of Topcon

Positioning Systems (TPS). All rights are reserved. You may not

use, access, copy, store, display, create derivative works of, sell,

modify, publish, distribute, or allow any third party access to, any

graphics, content, information or data in this Manual without

Topcon’s express written consent and may only use such

information for the care and operation of your product. The

information and data in this Manual are a valuable asset of TPS and

are developed by the expenditure of considerable work, time and

money, and are the result of original selection, coordination and

arrangement by TPS.

NOTICE

Please read these Terms and Conditions

carefully.

vii

P/N 7010-0341 www.topconpositioning.com

Page 12

Preface

TRADEMARKS – System Five™, Topcon® and Topcon

Positioning Systems™ are trademarks or registered trademarks of

TPS. Windows® is a registered trademark of Microsoft

Corporation. Product and company names mentioned herein may be

trademarks of their respective owners.

DISCLAIMER OF WARRANTY

– EXCEPT FOR ANY

WARRANTIES IN AN APPENDIX OR A WARRANTY CARD

ACCOMPANYING THE PRODUCT , THIS MANU AL AND THE

PRODUCTS ARE PROVIDED “AS-IS.” THERE ARE NO

OTHER WARRANTIES. TPS DISCLAIMS ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR USE OR PURPOSE. TPS AND ITS

DISTRIBUTORS SHALL NOT BE LIABLE FOR TECHNICAL

OR EDITORIAL ERRORS OR OMISSIONS CONTAINED

HEREIN; NOR FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE FURNISHING,

PERFORMANCE OR USE OF THIS MATERIAL OR THE

PRODUCT. SUCH DISCLAIMED DAMAGES INCLUDE BUT

ARE NOT LIMITED TO LOSS OF TIME, LOSS OR

DESTRUCTION OF DATA, LOSS OF PROFIT, SAVINGS OR

REVENUE, OR LOSS OF THE PRODUCT’S USE. IN

ADDITION TPS IS NOT RESPONSIBLE OR LIABLE FOR

DAMAGES OR COSTS INCURRED IN CONNECTION WITH

OBTAINING SUBSTITUTE PRODUCTS OR SOFTWARE,

CLAIMS BY OTHERS, INCONVENIENCE, OR ANY OTHER

COSTS. IN ANY EVENT, TPS SHALL HAVE NO LIABILITY

FOR DAMAGES OR OTHERWISE TO YOU OR ANY OTHER

PERSON OR ENTITY IN EXCESS OF THE PURCHASE PRICE

FOR THE PRODUCT.

viii

Topcon Paver System Five Operator’s Manual

Page 13

Terms and Conditions

WEBSITE and OTHER STATEMENTS – No statement

contained at the TPS website (or any other website) or in any other

advertisements or TPS literature or made by an employee or

independent contractor of TPS modifies these Terms and

Conditions (including the Software license, warranty and limitation

of liability).

SAFETY – Improper use of the Product can lead to injury to

persons or property and/or malfunction of the product. The product

should only be repaired by authorized TPS warranty service

centers. Users should review and heed the safety warnings in

Manual.

MISCELLANEOUS – The above Terms and Conditions may be

amended, modified, superseded, or canceled, at any time by TPS.

The above Terms and Conditions will be governed by, and

construed in accordance with, the laws of the State of California,

without reference to conflict of laws.

All information, illustrations, and applications contained herein are

based on the latest available information at the time of publication.

TOPCON reserves the right to make product changes at any time

without notice.

Comments, suggestions, and questions about TOPCON products

are welcomed. Contact your local TOPCON representative or a

representative at our corporate facility.

TOPCON POSITIONING SYSTEMS, Inc.

5758 W. Las Positas Blvd.

Pleasanton, CA 94588

925 / 460 1300

925 / 460 1315 FAX

P/N 7010-0341 www.topconpositioning.com

ix

Page 14

Preface

Manual Conventions

This manual uses the following conventions:

TIP

TIP

Supplementary information that can help to

configure, maintain, or set up a system.

NOTICE

NOTICE

Supplementary information that can have an

affect on system operation, system performance,

measurements, personal safety.

CAUTION

CAUTION

Notification that an action has the potential to

adversely affect system operation, system

performance, data integrity, or personal

health.

WARNING

WARNING

Notification that an action will result in

system damage, loss of data, loss of

warranty, or personal injury.

DANGER

DANGER

x

UNDER NO CIRCUMSTANCES SHOULD THIS ACTION

BE PERFORMED.

Topcon Paver System Five Operator’s Manual

Page 15

What’s New...

This manual includes the changes for version 1.7 of the 9256

Control Box code.

In this version:

The range of the following settings has changed:

• Gain (Elevation) range is now 1–200

• Gain (Slope) range is now 1–200

See “Performance Menu Settings” on page 4-16 and Table 4-2

on page 4-16 for more information on menu settings.

P/N 7010-0341 www.topconpositioning.com

xi

Page 16

What’s New...

Notes:

xii

Topcon Paver System Five Operator’s Manual

Page 17

Chapter 1

S

ystem

F

ive

System Overview

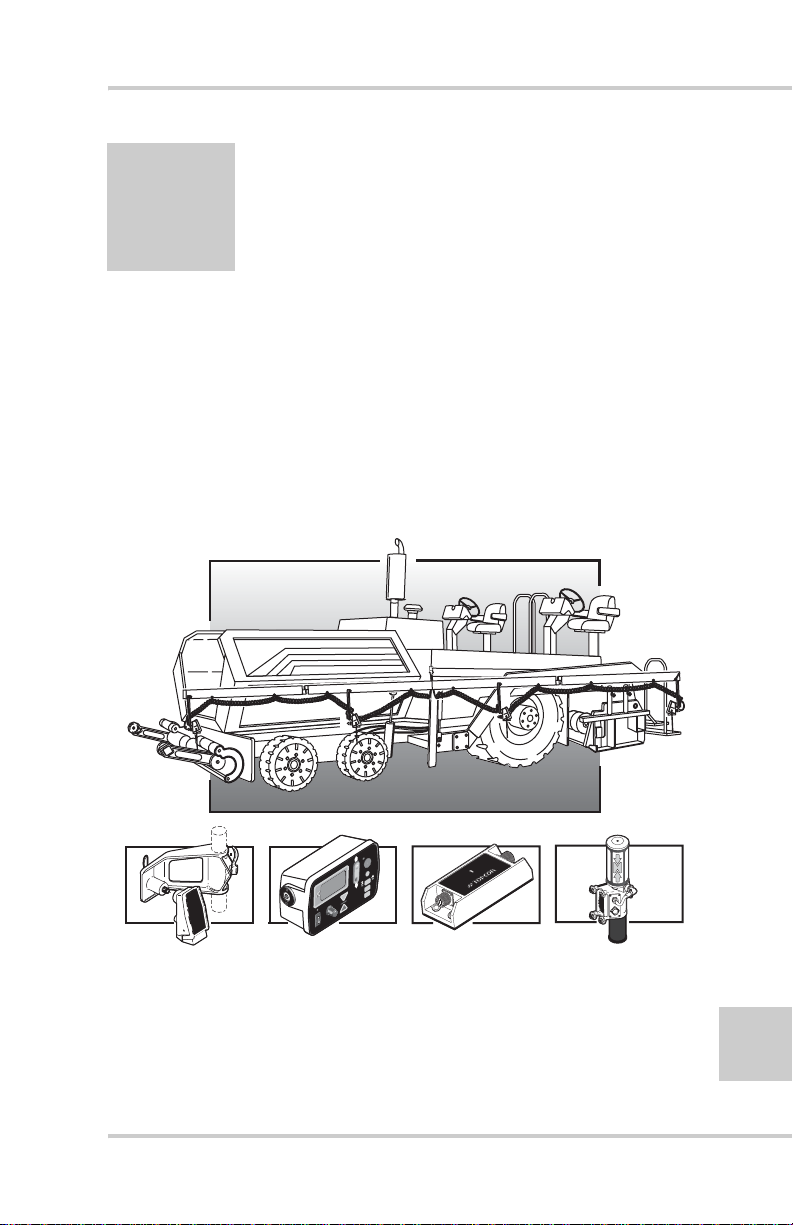

System Five™ is a complete, non-contacting control system which

combines both elevation control and slope control into a simple,

easy to use package (Figure 1-1).

The primary function of System Five is to provide screed control so

that the paving material is placed into position at the correct

elevation and slope.

TO

AU

VEY

UR

S

y

g

o

l

o

n

h

c

e

T

e

d

a

r

G

d

e

c

AGTEK

n

a

v

d

A

II

racker

T

onic

S

)

SET

NU

E

(M

ive

F

ystem

S

D

R

A

W

R

O

F

Figure 1-1. Paver System Five Components

P/N 7010-0341 www.topconpositioning.com

1-1

Page 18

System Overview

S

yst

em

F

ive

S

ys

t

e

m

F

i

ve

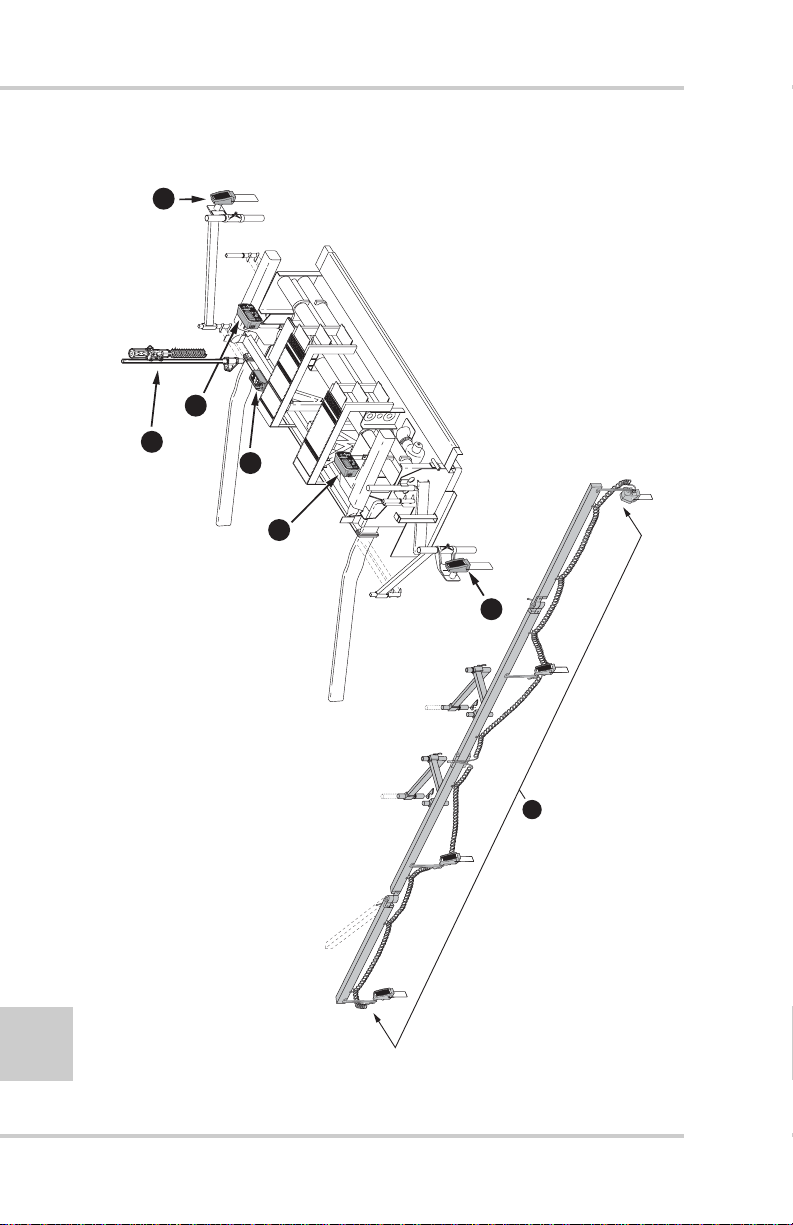

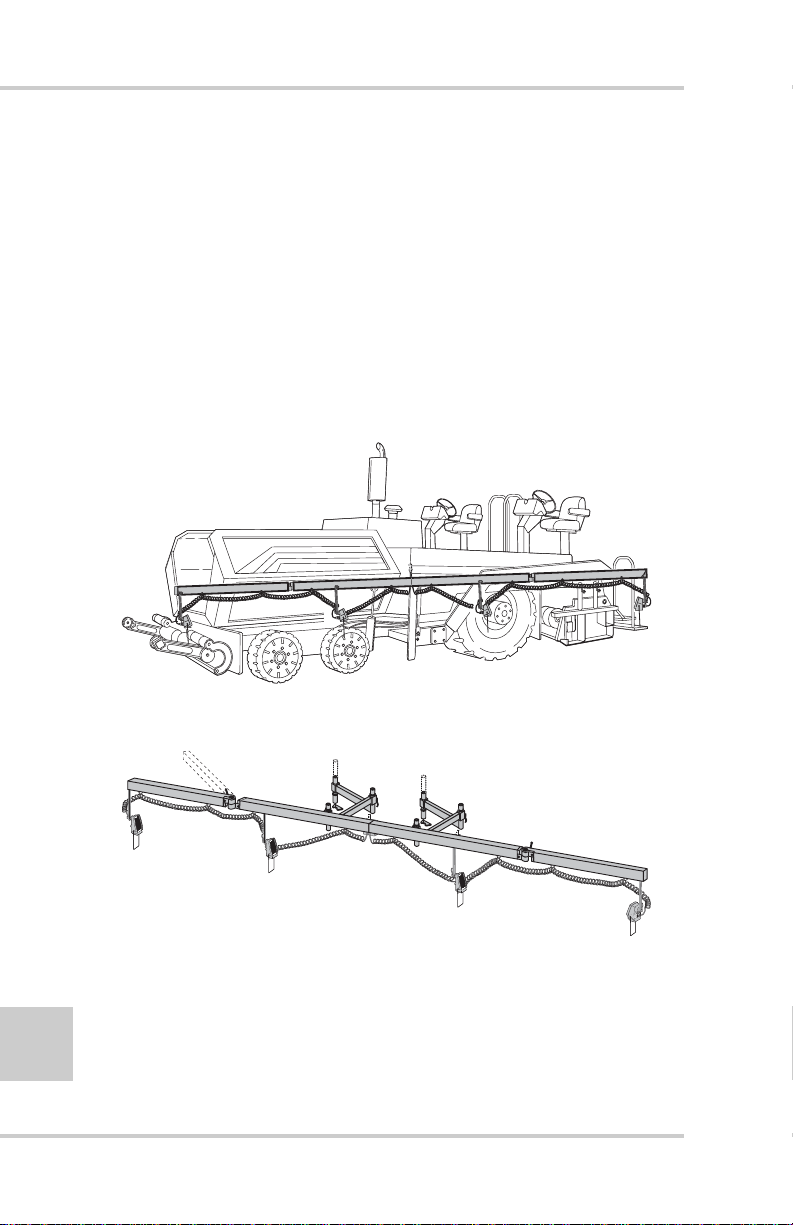

Figure 1-2 displays the setup of components on a screed.

TM

x

o

B

ol

r

t

on

C

ve

i

F

m

e

t

ys

. S

1

)

S

A

S

(

m

e

t

ys

S

TM

ging

a

r

ve

A

c

oni

. S

2

II

r

r

o

s

n

acke

e

r

T

S

c

e

oni

lop

. S

. S

3

4

ack

j

r

acke

r

T

&

r

acke

r

T

r

ase

. L

5

3

EY

V

UR

O

S

T

)

U

U

N

ET

E

S

A

M

(

e

v

i

F

m

e

t

s

y

S

FORWARD

1

5

4

VEY

UR

S

TO

)

T

U

NU

E

E

S

A

M

(

e

v

i

F

m

e

t

s

y

S

1

3

1-2

2

Figure 1-2. Paver System Five Top View

Topcon Paver System Five Operator’s Manual

Page 19

Getting Acquainted

S

ystem

F

ive

Getting Acquainted

A standard System Five Paver system includes two Control Boxes,

two Sonic Trackers and a single Slope Sensor. When setup and

connected, the Control Boxes control either the left or right side of

the machine for either elevation or slope.

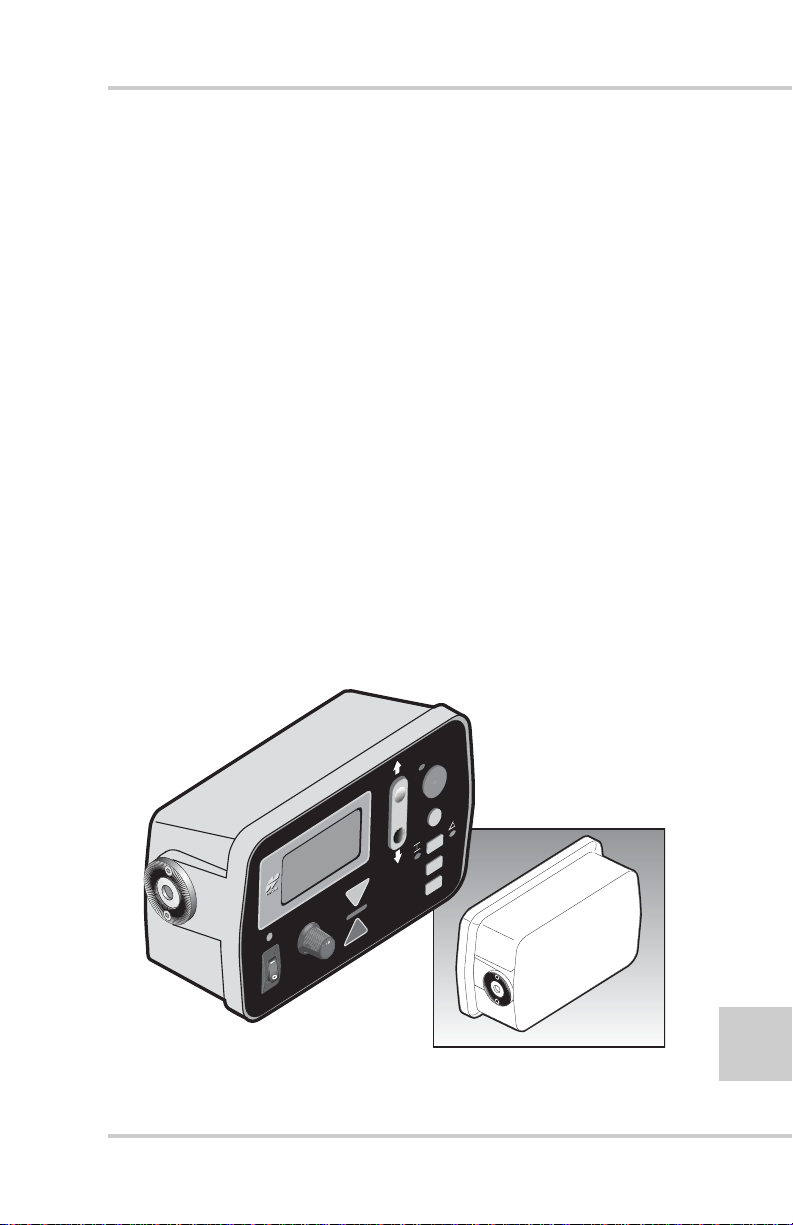

Control Box

The Control Box (Figure 1-3) is the operator’s interface to

System Five. The Control Box recei ves signals from the sensors

(Sonic Tracker II™, Laser Tracker, and/or Slope Sensor), and

uses these signals to determine if grade or slope corrections are

necessary. If a change in grade or slope is required, the Control

Box sends a signal to the valve controlling the tow point

cylinder on the appropriate side of the machine to raise or

lower, thus maintaining correct mat thickness.

The Control Box connects to the Sonic Tracker II™, the Slope

Sensor, and to the paver through electrical cables. The Control

Box easily attaches to its mounting bracket with one clamp, and

at the end of the day should be removed for storage.

TO

AU

VEY

UR

S

)

SET

NU

E

M

(

ive

F

ystem

S

Figure 1-3. Control Box

P/N 7010-0341 www.topconpositioning.com

1-3

Page 20

System Overview

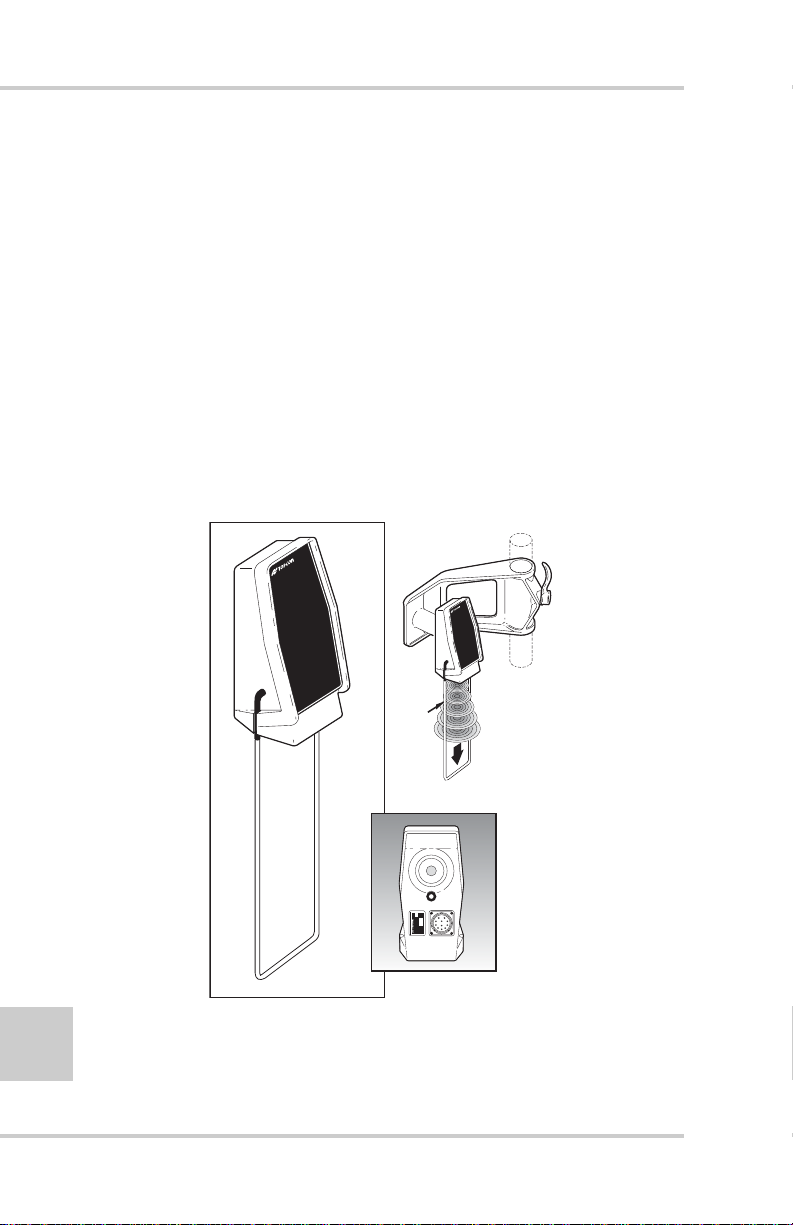

Sonic Tracker II

The Sonic Tracker II™ (Figure 1-4) measures and controls the

elevations of the screed. A transducer, located in the bottom of

the Sonic Tracker II™, generates sound pulses like a speaker

and listens for returned echoes like a microphone. The Tracker

measures the distance, and controls grade from a physical grade

reference, such as a curb, stringline, or existing road surface. A

bail is used to compensate for rapid air temperature changes. In

paving applications a bail should always be used.

The Sonic Tracker II attaches to the system through one quick

connect cable and attaches to the machine with a single bolt. At

the end of the day, Sonic Tracker II should be removed for

proper storage in the carrying case.

1-4

II

racker

T

onic

S

II

racker

T

onic

S

UND

SO

LSES

U

P

Figure 1-4. Sonic Tracker II

Topcon Paver System Five Operator’s Manual

Page 21

Getting Acquainted

Slope Sensor

The slope sensor (Figure 1-5) is a precision electronic sensor

which functions much like a precision carpenter's level. The

slope sensor reads the inclination (tilt) of the screed and sends

the signal to the Control Box. The slope sensor measures slopes

from +20% to -20%.

The slope sensor connects to each Control Box through an

electrical cable and requires no adjustments, and is the only

component of System Five that can be used to control either

side of the paver. The slope sensor is a sealed component, and

once attached to the Paver, should not be removed.

F

O

R

W

AR

D

-2.0

SLOPE

0.0 %

SLOPE

+2.0

%

SLOPE

%

+

+

+

CONTR

OL BOX L

ISPLAY

D

%

IND

%

IND

%

IND

CD

Figure 1-5. Slope Sensor

P/N 7010-0341 www.topconpositioning.com

1-5

Page 22

System Overview

Smoothtrac Sonic Averaging System (SAS)

The Smoothtrac® SAS (Figure 1-6) is an elevation control

system that combines multiple sonic trackers to calculate an

average of the physical reference. Each tracker sends its

distance measurement to the Control Box which then averages

those measurements and sends a correction signal to the tow

point cylinder . The Smoothtrac replaces the mechanical ski that

drags on the ground.

The Smoothtrac connects to the Control Box through the

tracker cable.

1-6

Figure 1-6. Smoothtrac Sonic Averaging System (SAS)

Topcon Paver System Five Operator’s Manual

Page 23

Getting Acquainted

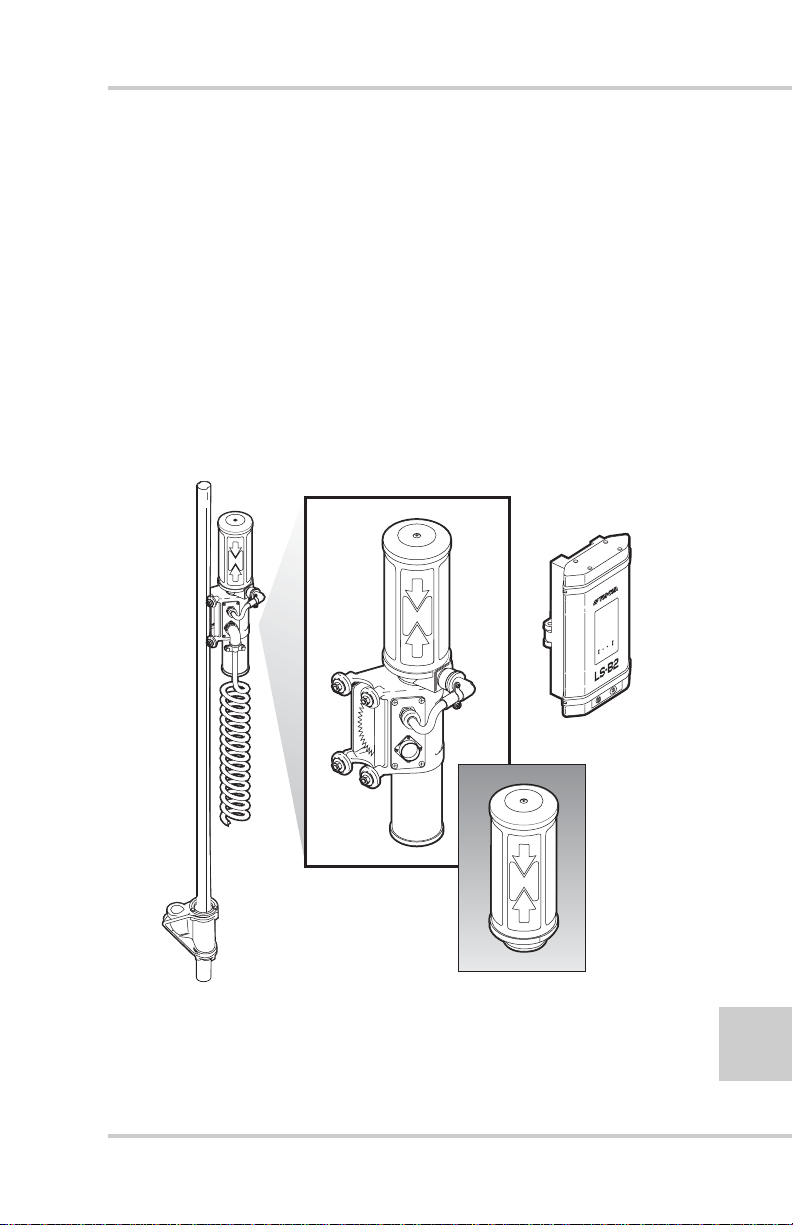

Laser Tracker & Trackerjack

The laser tracker (Figure 1-7) is an elevation control sensor that

measures and controls the elevation of the screed. After

receiving a signal from a rotating laser, the laser tracker sends a

signal to the Control Box, which then sends a raise or lower

signal to the tow point cylinder.

The Trackerjack attaches to the laser receiver and then mounts

to a vibration pole (Figure 1-7). Use the same cable from the

Sonic Tracker II to power the laser tracker/Trackerjack system.

The laser trackerjack should be removed at the end of each day

and stored in its carrying case.

OPTIONAL

LS

-

B

2

4

1 2 3

Figure 1-7. Laser Tracker & Trackerjack

P/N 7010-0341 www.topconpositioning.com

1-7

Page 24

System Overview

Care and Preventive Maintenance

In general, follow these guidelines when using System Five:

• Always clean and thoroughly dry the removable components

before storing them in carrying cases. Use a clean, soft cloth

moistened with a neutral detergent or water.

• Keep carrying cases clean and dry. Do not leave them open and

exposed to the elements.

• Some moisture on the Control Box and its components is

acceptable during working conditions. Do not spray water or

use high pressure steam cleaner hoses directly on cables and

components.

• Use protective connector caps on cables when not using the

System Five for a period of time. Water accumulating on the

connectors can cause electrical shorts.

At the end of the day, performing general maintenance and storing

mobile parts will help to keep the System Five in top condition.

• Remove the Control Box and the Laser T racke r and dust with a

dry or damp non-abrasive, soft cloth.

1-8

• Insert cables into appropriate storage connectors after removing

the Control Box.

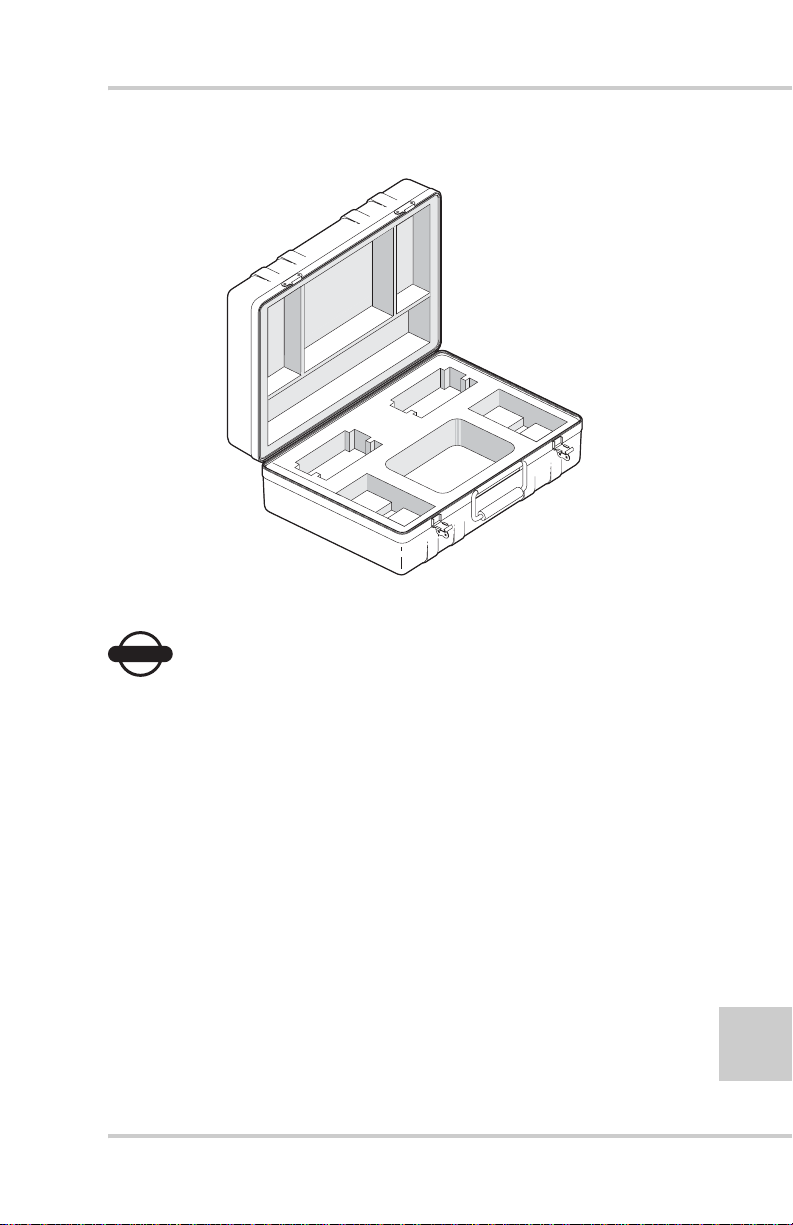

A Carrying Case is provided with each System Five. The Carrying

Case is lined and includes pre-cut sections for each Sonic Tracker II

and the Control Boxes. A cut-out section is also provided for

storing coil cords (Figure 1-8 on page 1-9).

Topcon Paver System Five Operator’s Manual

Page 25

Care and Preventive Maintenance

Figure 1-8. Carrying Case

NOTICE

NOTICE

Keep the carrying case dry and store in a dry

location. Never let the interior of the carrying

case become wet. If the case does become wet,

remove the components and let it dry.

P/N 7010-0341 www.topconpositioning.com

1-9

Page 26

System Overview

Notes:

1-10

Topcon Paver System Five Operator’s Manual

Page 27

Chapter 2

Tractor

Screed

Screed Pivot PointTow Point

Paving Principles &

Control Methods

This chapter describes the components of pavers and the basics in

paving principles, as well as control methods used for paving.

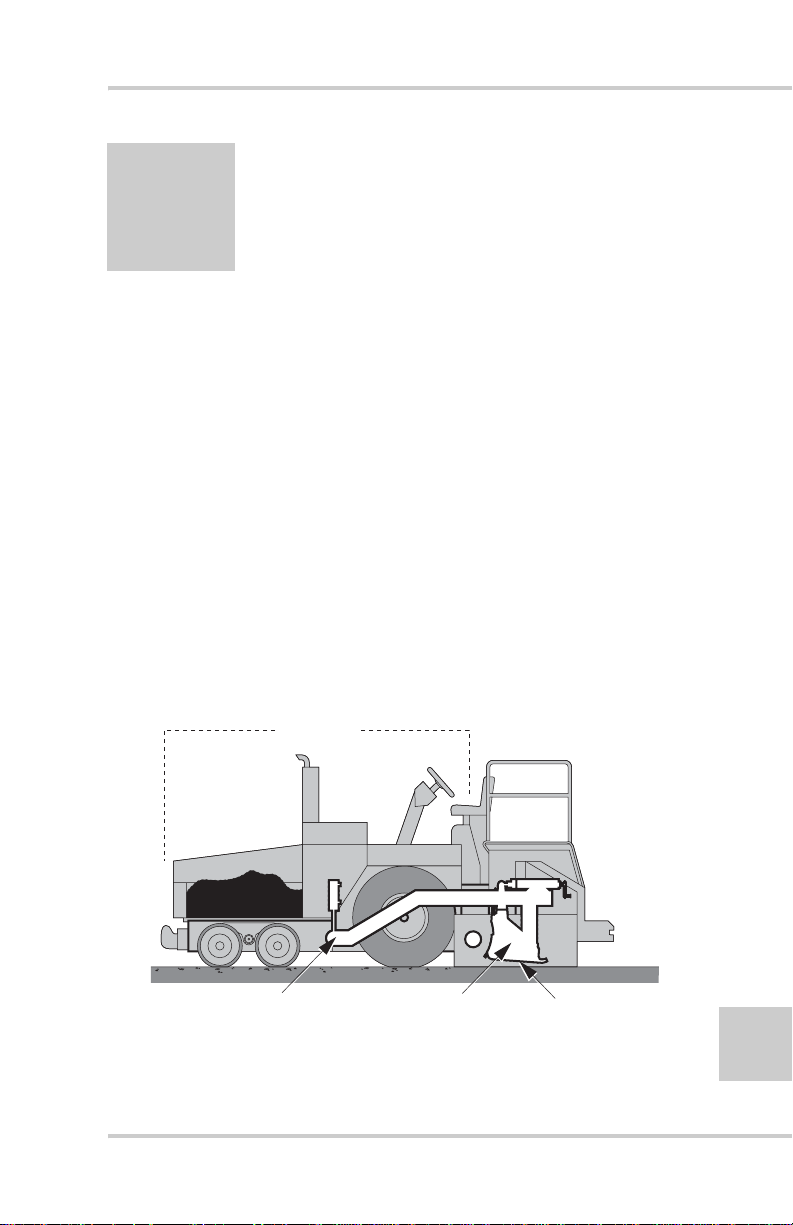

Paver Components

Modern pavers (Figure 2-1) consist of two major units: the Tractor

and the Screed.

The primary function of the tractor is to propel the truck or paver

feeding device, to convey and distribute the paving material and to

tow the screed. The function of the screed is to strike off the

material in preparation for further compaction. The screed is

mounted to the tow arms at the screed piv ot points and is attached to

the paver at the tow points.

Figure 2-1. Paver Components

P/N 7010-0341 www.topconpositioning.com

2-1

Page 28

Paving Principles & Control Methods

How a Screed Works

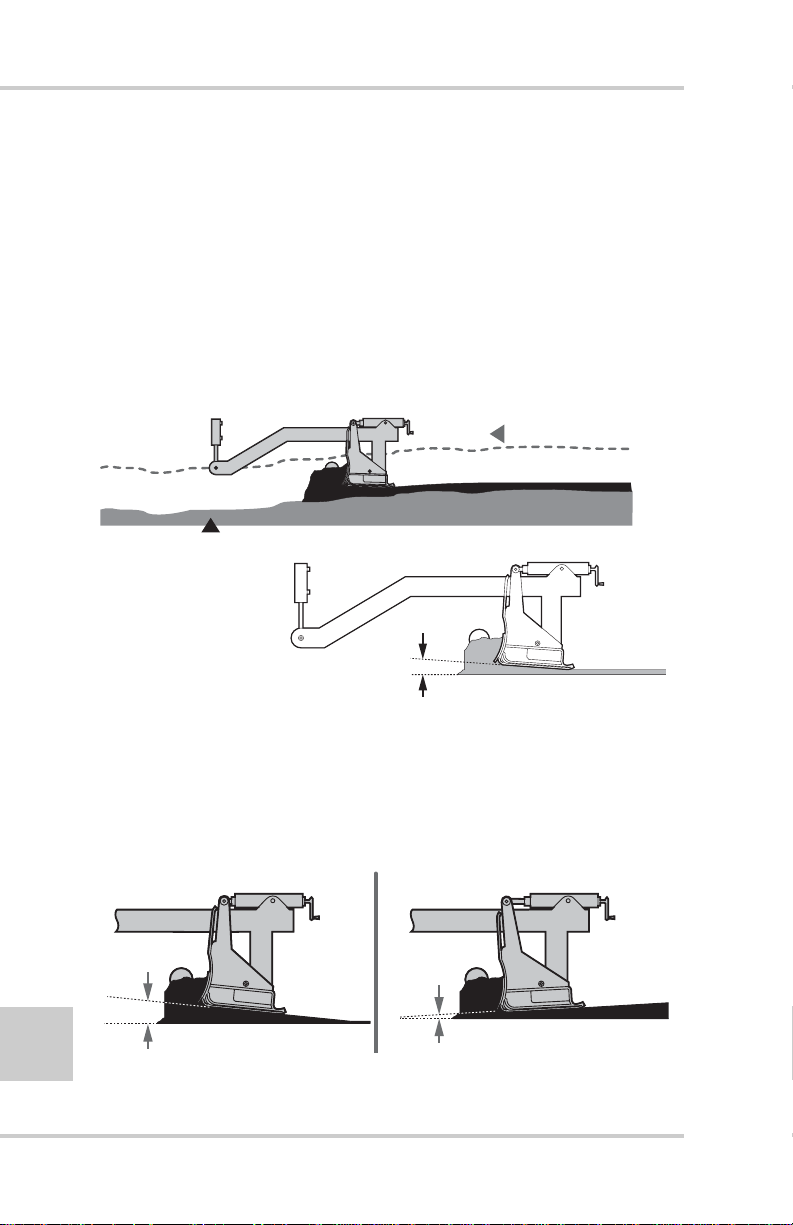

The screed on all modern pavers is of the “floating, self leveling”

type. As the paver tows the screed unit forward, paving material

flows under the screed. This causes the screed to float on the mat of

material, thus establishing mat thickness. Since the screed is

mounted to the paver only at the tow points, the screed is

completely free to float up or down (Figure 2-2). The screed will

always seek it's own “Planing An gle”, or angle of attack, dependen t

on the combination of forces acting upon the screed (Figure 2-2).

Tow P

oin

t Path

E

xisting

S

urf

ace

2-2

S

cree

d

A

ngl

e o

f

A

tt

ack

Figure 2-2. Tow Point Path and Planning Angle

• If the screed angle of attack is increased the screed rises,

increasing the mat thickness (Figure 2-3).

• If the angle of attack is decreased, the screed will settle,

providing a thinner mat surface (Figure 2-3).

Figure 2-3. Screed Determines Mat Thickness

Topcon Paver System Five Operator’s Manual

Page 29

How a Screed Works

Lengths Travel

Lengths Travel

Lengths Travel

Lengths Travel

Elevation

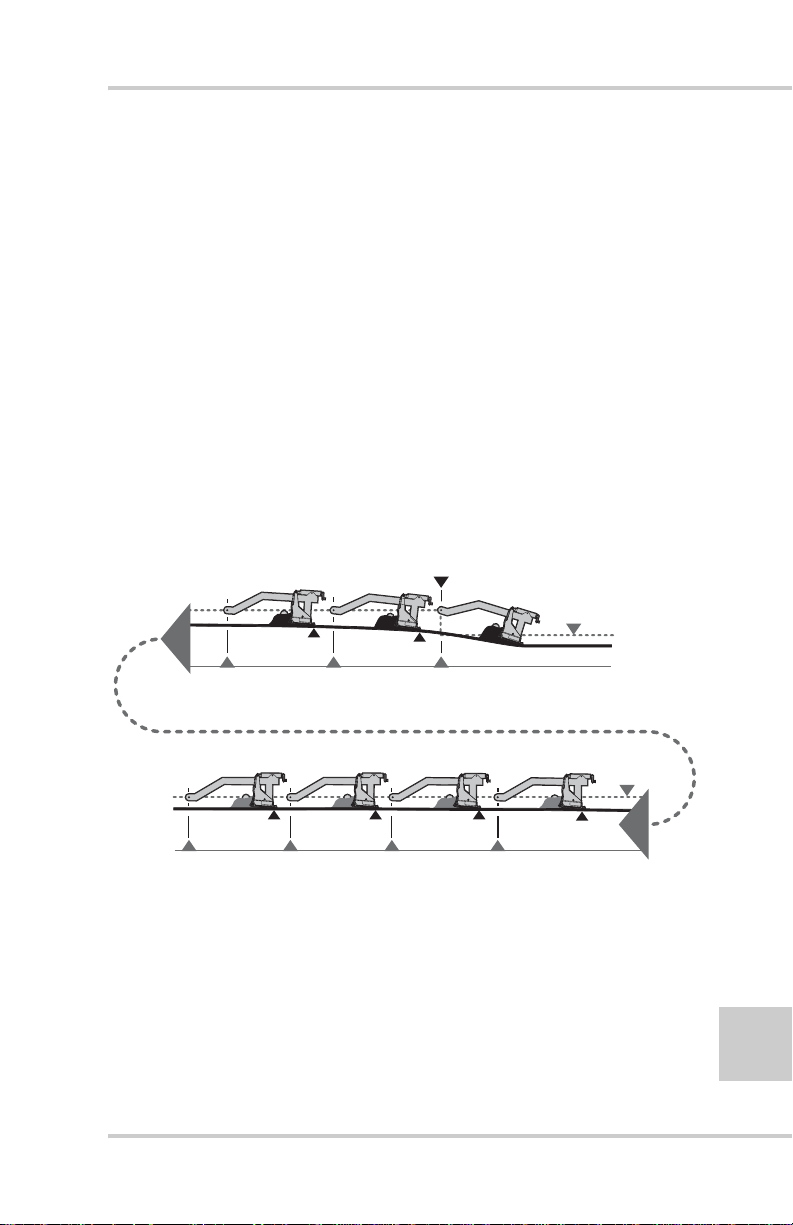

Because the screed floats, it will not immediately react to a change

in the tow point. It needs a certain amount of time or distance to

make a correction in the mat thickness (Figure 2-4).

• If the tow point is changed by a unit of one, the paver must

move one tow arm length before the screed will correct 63% of

the elev ation.

• After 2 tow arm lengths 83% of the correction is made and 3

tow arm lengths would account for 95%.

• It takes 6 tow arm lengths to achieve 100% of the elevation

change.

Considering that 95% of the change takes place after 3 tow arm

lengths, this can be used in practical applications to qualify for full

correction.

Change to

Tow Point Path

Tow Point Path

2 Tow Arm

Lengths Travel

87%

1 Tow Arm

Length Travel

63%

Tow Point Path

98%99%100%

6 Tow Arm

P/N 7010-0341 www.topconpositioning.com

5 Tow Arm

Figure 2-4. Tow Arm Travel

4 Tow Arm

95%

3 Tow Arm

2-3

Page 30

Paving Principles & Control Methods

The same is true when making elevation changes with the manual

thickness cranks (Figure 2-5).

Change in Screed

Angle of Attack

from Crank

Tow Point Path

2 Tow Arm Lengths Travel

87%

100%

1 Tow Arm Length Travel

63%

Tow Point Path

99%

4 Tow Arm Lengths Travel5 Tow Arm Lengths Travel6 Tow Arm Lengths Travel

98%

3 Tow Arm Lengths Travel

95%

Figure 2-5. Manually Changing Mat Thickness

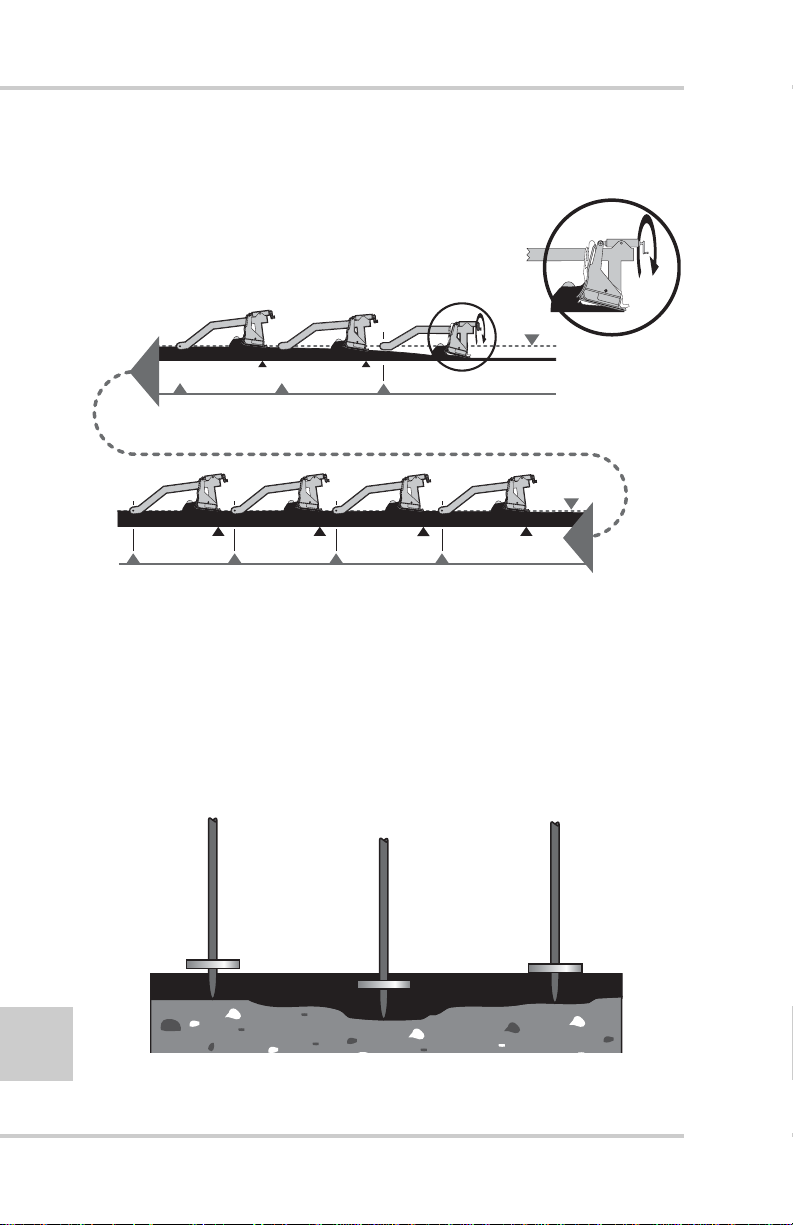

Always check mat depth in several locations before making any

elevation corrections. The surface being paved may have wheel

ruts, dips and ridges that will give an untrue indication of overall

mat depth. Check sev eral sp ots t o get an average (Figure 2-6). If an

elevation change is made, wait 3 to w arm lengths for full correction.

T oo much cranking and stabbing will cause raise and lo wer changes

that will produce an uneven mat surface.

2-4

Figure 2-6. Checking Mat Thickness

Topcon Paver System Five Operator’s Manual

Page 31

How a Screed Works

(

Weight of Screed

(Force "P")

The screed has four main forces acting on it at all times, whether

paving in manual or with automatics (Figure 2-7). A change in any

one of the forces will cause the screed to rise or fall, changing the

mat depth. The key to smoother paving is to keep these forces as

constant as possible. The following sections revie w these forces and

the factors that will have an effect on the paving.

(Force "W")

P

Tow Point

Force "P")

Head of

Material

(Force "M")

Figure 2-7. Forces Affecting the Screed

M

W

R

Reaction of Material

Under Screed

(Force "R")

Tow Point Force (“P”)

The tow point force (P) is the resistance to forward travel

(Figure 2-8).

P

Tow Point

Figure 2-8. Tow Point Force (“P”)

The P force will remain constant if the paver is kept mo ving at a

consistent speed at all times. If the paver is allowed to stop, the

screed will settle in the fresh mat and leave a mark. The mark

cannot be fully smoothed out by the roller and a bump will end

2-5

P/N 7010-0341 www.topconpositioning.com

Page 32

Paving Principles & Control Methods

up in the mat that will show up in the profilograph readings.

Changing the speed of the paver will also cause the screed to

rise and fall, affecting the mat thickness.

The optimum paving speed is determined by the depth and

width being paved and the rate at which material can be

delivered to the job . Calculate the tons/hour into feet per minute

(Figure 2-9). Do not start and stop the paver.

Figure 2-9. Travel Speed to Reduce Tow Point Force (“P”)

Truck Exchange, Another Tow Point Force

It is very important that truck exchanges be carried out as

smoothly as possible to avoid disturbing the smooth,

uninterrupted forward motion of the paver. The following

lists some steps to take to avoid disturbance of the paving

operation by trucks.

2-6

1. Stop the mix delivery truck close, but not too short of

the paver. Always allow the paver to pickup trucks on

the run.

2. Never allow the truck to bump the paver. Allowing

trucks to bump the paver when backing up, can drive

the screed into the mat and produces bumps and ridges

which may not roll out.

3. Trucks applying and holding their brakes excessively

while dumping their load may cause the paver to slow,

which in turn will cause the screed to rise. The truck

driver should apply only light pressure on the brakes,

sufficient to maintain contact with the paver.

Topcon Paver System Five Operator’s Manual

Page 33

How a Screed Works

4. Dumping of material in front of the paver as the truck

pulls away after emptying its load into the hopper, can

cause the paver to ride over the pile of material with

subsequent adverse effects on mat quality. Avoid

trucks pulling away prior to completely dumping all

material. Use a dump person to monitor and regulate

truck movements in front of the pav e r.

Head of Material (“M”)

One of the primary functions of the paver tractor is to convey

and distribute paving material onto the ground in front of the

entire width of the screed. This material, once deposited in

front of the screed is the head of material over which the screed

will pass.

One of the keys to smooth paving is to maintain this head of

material as constant as is possible. The resistance to forward

motion exerted by the head of material (M) is one of the major

component of resistance to forward motion (Figure 2-10).

Control of this force is a basic and necessary function of any

paving operation.

Head of

Material

M

(Force "M")

Figure 2-10. Head of Material Force (“M”)

The volume and consistency of the head of material determines

how much paving material flows under the screed and

influences mat thickness and surface texture.

The most common factor affecting force “M”, the head of

material, is incorrectly adjusting the Automatic Feeder

Controls.

P/N 7010-0341 www.topconpositioning.com

2-7

Page 34

Paving Principles & Control Methods

s

th

es

These systems, whether of the “hanging paddle” type or the

sonic sensor type, should be adjusted to operate the auger/

conveyor assemblies 95% to 100% of the time. On/off

operation of the auger system will cause fluctuation in the head

of material.

The highest quality mat will generally result when a constant

head of material is maintained across the entire width of the

screed and the material almost covers the auger shaft. If the

volume of paving material is too high, there is resistance to the

travel of the screed. This causes the screed to rise and can result

in ripples, auger shadows and long waves. It also results in

increased auger wear (Figure 2-11).

C

Indicates Centerline

of Auger

Correct Dep

of Mat

Correct

Head of

Material

C

Maintained

2-8

Screed Rise

Due To

Head of

Material

Too High

C

Increased

Resistance

Screed Settl

Due To

Head of

Material

C

Decreased

Resistance

Too Low

Figure 2-11. Head of Material Affects Mat

Topcon Paver System Five Operator’s Manual

Page 35

How a Screed Works

Reaction of Material Under Screed (“R”)

Ideally, every truck load of material delivered to the paver

would be exactly like every other load, with no variation.

However, as a practical matter, changes in mix characteristics

such as mix temperature, density, gradation, A.C. Content,

segregation, etc., will affect the internal stresses developed

within the mix, which in turn affects the resistance of the mix to

flow under the screed (reaction of material under screed, “R”).

The key element to bear in mind is that the screed passing over

the paving material will compact the material to a certain

degree. Variables in the resistance of the material to compactive

forces will cause changes in the screed's angle of attack, which

in turn will affect mat thickness and therefore mat smoothness

(Figure 2-12).

R

Reaction of Material

Under Screed

(Force "R")

Figure 2-12. Reaction of Material Under Screed

Gradation Mix Characteristics

This aspect of the paving material will vary according to

the intended use of the material as abase course, binder

course or the final wearing surface. Normally, maximum

aggregate size, ratio of aggregates, fines content and most

importantly, asphaltic binder content, is specified by the

contracting agency.

P/N 7010-0341 www.topconpositioning.com

2-9

Page 36

Paving Principles & Control Methods

Adherence to mix design specifications is usually the

responsibility of the material supplier.

Segregation is a material deficienc y caused by a separation

of the larger aggregate sizes from the bulk of the paving

material.

This condition is encountered especially in mixes with

relatively large maximum size aggregate (example: 1" and

larger, the so called “large-particle” mixes). When paving

material is deposited in piles, as in an asphalt plant silo, a

haul truck, a paver hopper, on the ground in front of the

paver in a windrow, or on the ground in the auger chamber,

segregation can and does frequently occur.

2-10

NOTICE

NOTICE

The areas listed above where segregation can

occur are all areas that the material may

encounter before being laid down as a mat.

Therefore, these areas of segregation must be

addressed prior to any paving. The screed

cannot rectify segregation during the paving

process.

Segregation can also be the result of improper hopper

dumping.

During normal operation, the vibration of the pavers hopper

will cause segregation. Therefore, dumping the hopper after

each truck should be avoided because material that has

rolled to the outside of the hopper (the large aggregate) will

fill the conveyors and auger chamber and result in a

segregated area behind the paver with a noticeable

difference in surface texture.

If It Doesn't Look Right, It Isn't Right:

irregularities indicate that the homogeneous characteristics

Surface and texture

Topcon Paver System Five Operator’s Manual

Page 37

How a Screed Works

of the material in the mat have been interrupted, which

usually results in bumpiness and premature failu re of the

pavement in those areas.

Segregation can also be the result of excessively worn

augers: “Center Streak” segregation can be caused by worn

“Kicker Paddles” at the center chain cause or near the

outside auger bearings. In fact center streak segregation is

frequently caused by incorrect arrangement of the auger

segments adjacent to the auger chain case. (Consult the

Manufacturers Manual).

“Center Streak” segregation is also caused by feeder gates

being set to tow. Adjust as necessary to provide sufficient

uniform material at the center of the paver.

NOTICE

NOTICE

“Center Streak” segregation can be limited and

even eliminated by slowing paving speed.

Mix Temperature Characteristics

A common paving problem is inconsistent temperatures in

the asphalt mix. As the material cools it loses its viscosity

making it more difficult to compact. If the resistance to

compaction increases, the screed will naturally increase its

angle of attack and begin to float up. This will change the

mat depth, resulting in bumps in the surface. If the mix and

or screed temperature are too low , the screed may no longer

slide smoothly over the material and a tearing of the mat

will occur.

Simple steps to take to control temperature variations:

1. Ensure that haul trucks take the shortest, most practical

route to the paver. Make certain that all trucks take the

same route to the paver.

2-11

P/N 7010-0341 www.topconpositioning.com

Page 38

Paving Principles & Control Methods

Weight of Screed

2. Make sure that the trucks arrive at the same order in

which they were loaded at the asphalt plant.

3. Ensure that no bunching of trucks occurs at the paver,

with several trucks waiting to dump their loads.

4. Match lay-down rate to material delivery rate.

NOTICE

NOTICE

Temperature problems may occur will before the

time the material is loaded into the trucks, or

during the trip to the paver. They can be the

result of temperature variations at the plant. If

this is not addressed prior to delivery of material

to the paver, waviness in the he mat will be the

result.

Weight of Screed (“W”)

For the weight of screed force “W” to remain constant, the

weight of the screed or the downward pressure exerted by the

screed on the paving material should not change (Figure 2-13).

The weight of the screed is measured in pounds per square inch.

(Force "W")

2-12

W

Figure 2-13. Weight of Screed

Members of the paving crew climbing on and off the screed

will also have some affect on the weight of screed force.

Topcon Paver System Five Operator’s Manual

Page 39

How a Screed Works

The primary factor affecting this force is changi ng the wid th of

the screed (Figure 2-14). Extendible screeds weigh the same

whether they are fully retracted or fully extended. The

difference is the wider the extension of the screed the greater

the surface area of paving material to support. An extended

screed has fewer psi, which means less compaction, causing the

screed to raise.

Figure 2-14. Width of Screed Affects Weight of Screed

Quality of Base Being Paved

There are factors other than the four main forces that can have

an effect on the quality of the mat. An important one is the

quality of the base to be paved. It makes more sense to build

smoothness from the base up, than to try to smooth a road in the

last lift of paving. However, on overlay paving jobs we have to

work with what we have.

Remember that a mat which appears smooth immediately

behind the paver, may actually contain areas of considerably

varying thickness of material as a result of undulations in the

base being paved. Due to the principle of “Differential

Compaction” high spots will not compact as much as the low,

therefore allowing some of the irregularities to be rolled back

onto the mat (Figure 2-15 on page 2-14). To minimize this

problem, lay a leveling course in the lo w spots or pa v e multiple

lifts to average out the irregularities.

P/N 7010-0341 www.topconpositioning.com

2-13

Page 40

Paving Principles & Control Methods

Mat Before Rolling

Mat Before Rolling

Figure 2-15. Differential Compaction

Rolling Techniques

A well laid mat can end up with a poor ride quality if

proper rolling methods are not followed. Consult your

compaction equipment manufacture's manuals and

handbooks on compaction techniques.

Mat After Rolling

2-14

Controlling Mat Quality

The primary purpose of the asphalt paver is to place a

smooth mat of material. The primary function of System

Five is to control the vertical position of the screed in

relation to the surface being paved. Automatic grade and

slope control systems can help tremendously in controlling

mat smoothness but mat quality is also dependent on the

following factors:

• Non-stop, continuous operation of paver

• Constant speed of paver

• Truck exchange

• Head of material

Topcon Paver System Five Operator’s Manual

Page 41

• Mix characteristics

– Gradation

– Segregation

– Mix Temperature

• Screed Compaction

• Quality of Base Being Paved

• Rolling Techniques

Control Methods

NOTICE

NOTICE

Changes in any of these factors will cause a

change in mat thickness, density, surface

appearance and mat quality. If changes must be

made, make them as gradually as possible.

Abrupt changes in any of the above factors will

produce rapid changes in mat thickness,

adversely affecting mat quality.

Control Methods

The following sections describe the three types of control possible

with the Pave System Five: sonic, laser, and slope.

Sonic Control

The Sonic Tracker II™ measures and controls the elevation of

the screed, controlling grade from a physical grade reference,

such as a curb, stringline, or existing road surface.

A transducer, located in the bottom of the T racker, generates 39

sound pulses per second and listens for returned echoes like a

microphone. As soon as the Tracker sends out a sound wave, it

starts a stop watch. The sound waves go down, bounce off of a

physical reference, and reflect back to the Tracker. The Tracker

measures the time it takes for the sound wave to return to the

2-15

P/N 7010-0341 www.topconpositioning.com

Page 42

Paving Principles & Control Methods

STOPWATCH

Tracker. Knowing the speed of sound, the Tracker accurately

calculates the exact distance to the grade reference

(Figure 2-16).

E

c

ho

B

oun

T

ransducer Generates

S

ound Pul

se

P

hysical Grad

ces Off

e

R

eference

T

r

acke

C

alculate

r

U

ses Ec

D

istan

ho's

R

ce To Grad

eturn Time To

e

R

eference

2-16

II

racker

T

onic

S

Figure 2-16. Timed Sound Pulses Determine Distance

II

racker

T

onic

S

Working Window and Sonic “Footprint”

Built into the Tracker is an operational zone, or Working

Window, 2.4 inches above and below the grade reference

(Figure 2-17 on page 2-17). The grade lights on the Sonic

Tracker and Control Box continuously display this grade

information to the operator.

Topcon Paver System Five Operator’s Manual

Page 43

E

NO CORRECTION

W

MADE

(OUT OF

ORKING WINDOW)

COARSE

CORRECTION

(AUTOMATIC)

FINE

CORRECTION

(AUTOMATIC)

2.4''

2.4''

S

onic Tracker

II

SLOW BLINKING UP ARROW

SOLID UP ARROW

BLINKING UP ARROW

BLINKING UP ARROW/ON GRADE

ON GRADE

BLINKING DOWN ARROW/ON GRAD

BLINKING DOWN ARROW

SOLID DOWN ARROW

SLOW BLINKING DOWN ARROW

Control Methods

Figure 2-17. Sonic Tracker Working Window

When setting up the Tracker o ver a grade reference, the size

of the Sonic Cone or the “footprint” needs to be considered

(Figure 2-18 on page 2-18). As an example, at about 2 feet

from the tracker, you will have a footprint or cone of about

6 inches.

As the Tracker is positioned closer to the grade reference

the working footprint decreases in size. As the Tracker is

moving farther away from the grade reference the sonic

footprint or cone will increase in size.

2-17

P/N 7010-0341 www.topconpositioning.com

Page 44

Paving Principles & Control Methods

SONIC "FOOTPRINT"

24"

S

onic Tracker

II

6.0"

2-18

Figure 2-18. Sonic Tracker “Footprint”

Sonic Tracker Operation and its Position

On the paver, the Sonic Tracker II will be positioned above

the grade reference to maintain an exact distance from the

tracker to the reference (Figure 2-19 on page 2 - 19). If the

Tracker is on-grade, the mat being laid will be at the

desired depth.

Topcon Paver System Five Operator’s Manual

Page 45

Control Methods

STOPWATCH

STOPWATCH

On

S

onic Tracker

II

II

racker

T

nic

o

S

Grade

Figure 2-19. Sonic Tracker On-Grade

If the screed and the Sonic Tracker II start to raise, the

watch stops at a longer time (Figure 2-20). The Tracker and

Control Box will indicate a down correction arrow, and

lower hydraulic valve corrections are applied to bring the

Tracker back to on-grade.

S

onic Tracker

II

II

r

ke

rac

T

onic

S

Grade

On

Figure 2-20. Sonic Tracker above Grade

P/N 7010-0341 www.topconpositioning.com

2-19

Page 46

Paving Principles & Control Methods

If the screed and Sonic Tracker II are lowered, the watch

stops at a shorter time (Figure 2-21). The Tracker and

Control Box indicate a raise correction arrow, and raise

hydraulic valve corrections are applied to bring the Tracker

back to on-grade.

S

onic Tracker

II

II

ker

rac

T

onic

S

Figure 2-21. Sonic Tracker Below Grade

Grade

STOPWATCH

On

2-20

If the Sonic Tracker II is side shifted off a stringline, the sound

waves reflect off the ground and the Tracker's stopwatch

indicate a longer time (Figure 2-22 on page 2-21). The Tracker

is out of the Working Window, and no on-grade corrections are

applied.

Topcon Paver System Five Operator’s Manual

Page 47

Control Methods

STOPWATCH

S

onic Tracker

II

II

racker

T

ic

on

S

Grade

On

Figure 2-22. Sonic Tracker Scanning Outside of Stringline

If the Tracker sees an obstruction closer than the reference

signal, such as a grade pin, the watch stops at an even

shorter time (Figure 2-23). The Tracker is out of the

Working Window, and no on-grade correction signals are

applied.

STOPWATCH

S

onic Tracker

II

II

racker

T

ic

on

S

Grade

On

Figure 2-23. Obstructions within the Sonic Tracker’s Working Window

P/N 7010-0341 www.topconpositioning.com

2-21

Page 48

Paving Principles & Control Methods

STOPWATCH

T

STOPWATCH

Sonic Tracker and Temperature Changes

Since temperature affects the speed of sound, the tracker

has a built in temperature sensor for applications with

gradual temperature changes such as on graders or dozers.

In paving applications you can get a more dramatic and

rapid change in air temperature. To compensate for these

variations a temperature bail is positioned below the

tracker.

When the Sonic Tracker’s transducer emits a sound wave,

the tracker records the time to the bail and continues to

listen for the grade reference. If a temperature variation

occurs, such as heat off a freshly paved mat, a difference in

time to the temperature bail is recorded. The correction for

the speed of sound is then applied to the grade reference

signal, preventing a change in mat depth. The tracker

corrects for temperature variations with every sound wave,

39 times per second. Figure 2-24 illustrates this concept.

2-22

On Grade

arget Reference

Temperature Bail

Target Reference

S

onic Tracker

II S

Heat Induced

Target Error

On Grade

Wind Blown Heat

Freshly Paved mat

Off of

Temperature Bail

Heat Induced

Target Error

onic Tracker

II

Figure 2-24. Working with Sonic Trackers and Temperature Changes

Topcon Paver System Five Operator’s Manual

Page 49

Control Methods

In the upper right hand corner of the Sonic Tracker II

faceplate is a small symbol used to represent the use of the

temperature bail. The LED symbol automatically

illuminate when the bail is connected to the tracker. The

tracker is cast with holes on each side for the bail to snap

and lock into place (Figure 2-25).

II

racker

T

onic

S

T

T

S

onic Tracker

II

Figure 2-25. Sonic Tracker and Components

P/N 7010-0341 www.topconpositioning.com

2-23

Page 50

Paving Principles & Control Methods

Laser Control

For Laser Control a laser transmitter is used to produce a plane

of light which becomes the grade control reference for the job

site. The laser receiver will control the screed to lay a mat

parallel to the laser beam reference.

When the laser beam is in the center of the receiver, it indicates

an on-grade signal (Figure 2-26).

+

2-24

Figure 2-26. Laser Control – On-Grade

As the screed is raised, the beam of light hits the laser receiver

below the center and a lower signal is indicated (Figure 2-27 on

page 2-25).

Topcon Paver System Five Operator’s Manual

Page 51

Control Methods

+

Figure 2-27. Laser Control – Above Grade

As screed is lowered the beam of light hits the Laser Receiver

above the center a raise signal is indicated (Figure 2-28).

+

Figure 2-28. Laser Control – Below Grade

P/N 7010-0341 www.topconpositioning.com

2-25

Page 52

Paving Principles & Control Methods

Slope Control

System Five uses a slope sensor mounted to the transducer

beam on the paver to measure and control the slope of the mat

being laid (Figure 2-29). The sensor contains an electronic level

vial, that acts as a “precision carpenter's le vel”. Slope control

with this electric level vial is very accurate and repeatable.

2-26

2% Slope

Figure 2-29. Position of Slope Control on Paving System

Topcon Paver System Five Operator’s Manual

Page 53

Control Methods

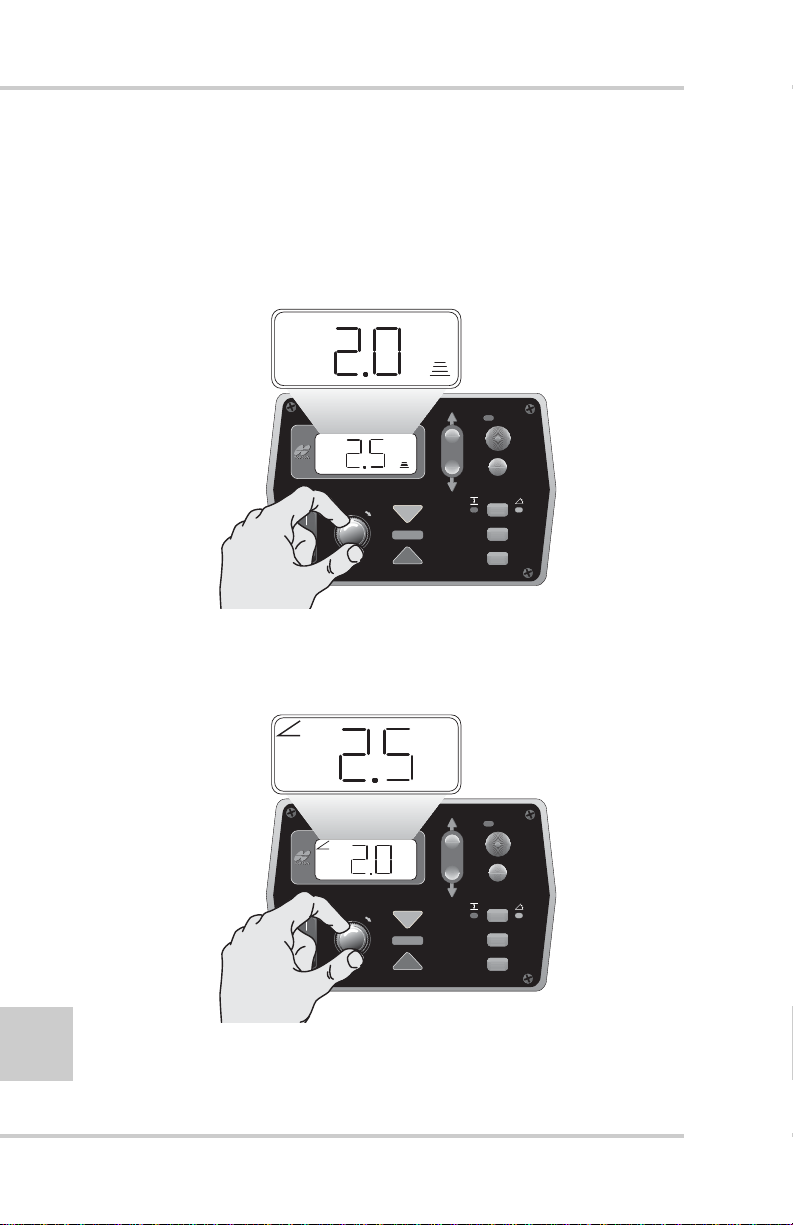

If the required slope changes, the screed operator dials the new

slope into the System Five Control Box (Figure 2-30). The tow

point cylinder on the slope side will raise or lower until the

slope sensor measures the new slope.

2.5% Slope

AU

TO

+

%

SURVEY

FiveSystem

SET

(MENU

)

Figure 2-30. System Five Box directing the Slope Sensor position

P/N 7010-0341 www.topconpositioning.com

2-27

Page 54

Paving Principles & Control Methods

Notes:

2-28

Topcon Paver System Five Operator’s Manual

Page 55

Chapter 3

Stringline Setup

Sonic Stringline provides an inexpensive, easy to set up, continuous

reference that takes the best advantage of the non-contacting feature

of the Sonic Tracker II™. Stringline takes a few minutes to setup,

and becomes a constant grade reference. The stringline also

becomes a visual reference for the job, allowing any mistakes in a

hub elevation to be quickly spotted by sighting down the string.

Sonic stringline is both a reference and an averaging solution.

• As a reference, surface and elevated stringline provides

consistent results for level and sloped surfaces.

• As an averaging solution, surface stringline takes the place of

averaging skis.

The sonic stringline setup consists of readily available materials and

up to 500 feet of nylon stringline. Topcon’s Sonic Tracker II works

with many sizes and types of stringline, for best results use an 1/8

inch diameter nylon stringline.

NOTICE

For a review of how the Sonic Tracker II works, see “Sonic

Control” on page 2-1. If the Sonic T racker tracks the ground but not

a 1/8 inch diameter stringline, clean or replace the transducer. See

Chapter 7 for this procedure.

P/N 7010-0341 www.topconpositioning.com

NOTICE

Using steel wire or a plastic coated stringline

with a smooth surface can provide erroneous

results.

3-1

Page 56

Stringline Setup

Setting Surface Stringline

Surface stringline provides a low-impact reference and averaging

solution for steering and grade control. Because it rests close to the

surface, trucks and other traffic can dri ve ov er the stringline without

causing control problems and reference damage.

As a grade reference, Pavers use the Sonic Tracker II to track the

stringline, producing a consistent and constant cut. When si ghting

down the stringline, problem areas can be spotted, and marked or

fixed, before paving begins.

Surface stringline replaces a contacting averaging ski when a

reference is unavailable or impractical. Averaging skis average out

the irregularities of the surface being cut, but can be impractical,

bulky, complex, and fragile. Surface stringline is simple, more

practical, and easier to maintain than an averaging ski. When

stretched over the ground, surface stringline levels the high places

and bridges the low (Figure 3-1), creating a natural average over a

distance as long as 500 feet.

3-2

Surface String

Low Spot High Spot

Figure 3-1. Surface String Averaging

Surface stringline is a verifiable reference for any job, replacing

cumbersome av eraging skis. In coordination with the Sonic T rack er

II, stringline acts as 5 to 500 foot long, virtual, and more accurate,

averaging ski.

Sometimes, the surface to be milled contains pot holes or surfaces

too broken to use as a joint match reference Setting elevated

stringline would be too time consuming, especially for small,

divided projects. In these applications, surface stringline pro vides a

simple, easy alternative.

Topcon Paver System Five Operator’s Manual

Page 57

Setting Surface Stringline

Position the tracker 14 to 18 inches above the stringline

(Figure 3-2).

T

S

onic Tracker

II

14"

to

18"

Figure 3-2. Position of Tracker in Correlation to Stringline

NOTICE

NOTICE

It is important to use a stringline with a diameter

at least 1/8” thick. The sonic tracker can detect a

smaller diameter stringline, but when stretched

on the surface to be paved the surface below the

stringline will be within the working window so

you want to make sure you have a strong return

signal.

P/N 7010-0341 www.topconpositioning.com

3-3

Page 58

Stringline Setup

To setup surface string in two simple steps:

1. Drive a concrete nail into the existing surface to be cut

(Figure 3-3) and tie the stringline to the concrete nail.

Figure 3-3. Setup Concrete Nails

3-4

2. Roll out the stringline to the desired length. Pull tight and

secure to another nail at the opposite end. The tightened

stringline rests on top of the existing surface (Figure 3-4).

Figure 3-4. Stringline Reference

• When the sonic tracker sends out a sound wave, the first

thing the tracker sees will be the reference stringline.

Topcon Paver System Five Operator’s Manual

Page 59

Setting Elevated Stringline

• Since the stringline is pulled tight, any small irregularities

in the existing surface will be spanned (Figure 3-5).

Figure 3-5. Stringline Spans Surface Irregularities

As a verifiable grade reference, potential problems can be pointed

out to the inspector before paving.

Setting Elevated Stringline

On some projects the asphalt must be laid to a specified elevation.

For this application an elevated stringline must be set. Elevated

stringline is positioned 1–2 feet above the finished grade using

referencing hubs or lath placed by the surveyor (Figure 3-6).

Figure 3-6. Elevated Stringline

Once positioned, the Sonic Tracker II tracks the stringline,

providing a verifiable slope and cut reference.

NOTICE

NOTICE

Do Not disturb the hubs.

P/N 7010-0341 www.topconpositioning.com

3-5

Page 60

Stringline Setup

B

S

C

Your local Topcon dealer carries the following supplies for setting

elevated stringline:

• Sonic Stringline, 1000’ roll (p/n 7020-0101)

• Sonic Grade Clips, box of 100 (p/n 7020-0121)

• Cut/fill Offset Tap, feet/tenths (p/n 7000-1026)

• Cut/fill Offset Tap, metric (p/n 7000-1027)

Although Topcon’s Sonic Tracker will work with many sizes and

types of stringline, for best results use an 1/8 inch diameter nylon

stringline. Using steel wire or a plastic coated stringline with a

smooth surface can cause erroneous results.

1. Place the Sonic Grade Clips on stakes and drive the stakes

approximately 6 to 8 inches away from, but in line with, the

hubs—Do Not disturb the hubs (Figure 3-7).

LIP

STAKE

6.0" to 8.0"

ALIGN STAKES

3-6

2. Using an anchor pin at each end, roll out the Sonic Stringline

WITH HUB

Figure 3-7. Place Clips and Position Stakes

GRADE

STAKE

HU

the length of the working area and pull the stringline tight.

Topcon Paver System Five Operator’s Manual

Page 61

Setting Elevated Stringline

M

3. After the stringline has been pulled tight, place it into the

“fingers” of each Sonic Grade Clip (Figure 3-8).

Figure 3-8. Place Stringline in Clip

4. Decide what the Sonic Stringline hike-up (the distance from

Finished Grade to the Sonic Stringline) should be; in this

example, two feet.

Making a Cut/Fill Lath

Once you have the stringline setup, fine-tune the height of the

stringline above the grade. To do this, make a cut/fill lath using

a lath and a Topcon Cut/Fill Decal.

1. Assemble the required number of laths for the job.

2. Measure from the bottom of the lath to the desired height

above grade, and make a mark at that point. Place the Cut/

Fill Decal on the lath with “0” at the marked point

(Figure 3-9).

LATH

2.0'

BOTTOM

Figure 3-9. Measure Height Above Grade and Place Cut/Fill Decal

P/N 7010-0341 www.topconpositioning.com

LATH

011

SET "0" ON DECAL

AT 2.0' MARK FRO

BOTTOM OF LATH

3-7

Page 62

Stringline Setup

3. Set the cut/fill lath on the hub and read the cut or fill from

the grade stake next to the hub. Adjust the clip up or down

until the stringline crosses the cut/fill lath at that point

(Figure 3-10).

E

A

cut o

f

.25

feet

2

CU

L

.

1

.

0

1

.

2

.

3

.

T/FILL

H

T

A

L

B

FILL

R

CU

E

U

=

D

E

=

T

G

ST

RAD

AK

CU

.

E

T

25

3-8

Figure 3-10. Adjust Clip and Stringline to Desired Cut/Fill

The stringline is now set to 2 feet above finished grade.

4. Repeat step 3 on page 3-8 at each station before starting to

cut (Figure 3-11).

2.0'

2.0%

2.0' OFFSET

Figure 3-11. Stringline Set at Desired Elevation

Topcon Paver System Five Operator’s Manual

Page 63

Setting Elevated Stringline

Hub

Attaching Stringline to the Grade Stake

Some jobs may require the stringline to be secured directly to

the grade stake rather than attached to the clip.

1. Mark the lath with the desired “hike-up” above grade

(Figure 3-12).

2

V

2. Secure an anchor pin at each end of the stringline and pull

the stringline tight.

3. At each station, staple or Ty-Wrap the stringline directly to

the witness lath at the desired “hike-up” (Figure 3-13).

2

V

2

V

Figure 3-12. Mark Lath with Hike-up Height

2

V

2

V

Hub

Hub

2

V

Figure 3-13. Stringline Attached to Lath

4. Due to the height of some stakes, raise the Tracker or cut

off the tops of the stakes.

P/N 7010-0341 www.topconpositioning.com

3-9

Page 64

Stringline Setup

2.0% SLOPE X 2.00' OFFSET = .04'

R

Setting Projected Slope Stringline

Jobs with slope transitions or super-elevations will have the

stringline set to the “projected slope. ” As the profiler cuts, the Sonic

Tracker and mill follow the slope of the job, preventing elevation

errors at the edge of the road as the slope changes.

To set the stringline to the projected slope,

1. Set up the string at the desired elevation as shown in “Setting

Elevated Stringline” on page 3-5.

2. Raise or lower the stringline to compensate for the percentage

of slope and the distance from the edge of the road to the

stringline:

Rise Run SlopePercentage×=

• If the road rises away from the stringline, the stringline will

need to be lowered (Figure 3-14).

3-10

PROJECTED SLOPE

2.0'

2.0%

2.0' OFFSET

Figure 3-14. Lower Stringline: 2% Cross Slope with 2 Foot Offset

Topcon Paver System Five Operator’s Manual

LOWE

.04'

Page 65

Setting Projected Slope Stringline

3.0% SLOPE X 2.00' OFFSET = .06'

E

• If the road slopes down from the stringline, the stringline

will need to be raised (Figure 3-15).

RAIS

PROJECTED SLOPE

2.0'

2%

.06'

3.0% SLO PE

Figure 3-15. Raise Stringline: 3% Cross Slope with 2 Foot Offset

2.0' OFFSET

3. Repeat step 2 for each station.

3-11

P/N 7010-0341 www.topconpositioning.com

Page 66

Stringline Setup

Verifying Grade

Verifying grade requires measuring the distance from the cut

ground to the Sonic Stringline. To check grade, use a Grade

Checking Lath to check the levelness and depth of cut with the

Sonic Stringline.

The following figures show an example of a hub offset of 1.5 feet

from the edge of the road, and a hike-up of 2.0 feet.

1. Construct a Grade Checking Lath using a lath, a level bubble,

nails, and standard hand tools as shown in Figure 3-16.

TY-WRAP OR TAPE

LEVEL BUBBLE TO LATH

1.5'

NAILS

1.5'

3-12

2.0'

Figure 3-16. Grade Checking Lath

Topcon Paver System Five Operator’s Manual

Page 67

Verifying Grade

2. Set the Grade Checking Lath on the edge of the newly cut

ground so the level bubble extends over the Sonic Stringline

(Figure 3-17).

'

5

.

1

STRINGLINE

STRINGLINE

FI

NISHED GRAD

APPR

OX. .05' TOO HIG

E

H

Figure 3-17. Check Finished Grade

NISHED GRADE (CORRECT

FI

)

3. Tilt the Grade Checking Lath to center the level bubble.

Finished grade is correct if the level just touches the Sonic

Stringline (Figure 3-17).

P/N 7010-0341 www.topconpositioning.com

3-13

Page 68

Stringline Setup

Notes:

3-14

Topcon Paver System Five Operator’s Manual

Page 69

Chapter 4

Operation & Menu

Settings

System Five™ uses a Control Box and Sonic Trackers to produce

exceptional paving solutions. This chapter describes using the

various components, including:

• The buttons, knobs, and switches on the Control Box.

• How to change settings, access information, and take readings

using the various buttons, knobs, and switches.

• The menus available in the Performance Menu.

• How to access, change settings, and apply features using the

Performance Menu.

• How the Sonic Tracker II™ works.

NOTICE

P/N 7010-0341 www.topconpositioning.com

NOTICE

When operating in rainy weather or in wet

conditions, the Control Box, Sonic Tracker II, and

cables must be thoroughly dried BEFORE

placing them in the Carrying Case at the end of

the day.

Any moisture in the Carrying Case will cause

condensation on the inside of the components

which may severely affect accurate operation during

the next paving application.

4-1

Page 70

Operation & Menu Settings

Control Box

The Control Box is the operator’s interface to System Five™

(Figure 4-1), receiving signals from the sensors, and using these

signals to determine if grade or slope corrections are necessary. If

the paving requires a change in grade or slope, the Control Box

sends a signal to the valve controlling the tow point cylinder on the

appropriate side of the paver to raise or lower, thus maintaining

correct mat thickness. The operator can control and monitor the

slope and thickness of the mat using the buttons and displays

located on the front panel of the Control Box.

4-2

Figure 4-1. 9256 Control Box

1. LCD

2. Light Sensor for LED Display

3. Power Switch

4. Grade Adjustment Knob

5. Grade Adjustment LED

6. Set (Menu) Button

Topcon Paver System Five Operator’s Manual

7. Cross Communication Button

8. Slope/Elevation Button

9. Survey Button

10. Auto/Manual Button

11. Jog Button

Page 71

Control Box

LCD

The LCD (Liquid Crystal Display) allows the operator to view

text and graphic symbols that represent elevation or slope

settings that System Five

TM

currently maintains for the paver

(Figure 4-2).

Figure 4-2. LCD Display

Light Sensor for LED Display

The light sensor monitors ambient light to adjust the brightness

of the LED display for better visibility.

The light sensor is located above the power switch.

Power Switch

The power switch (Figure 4-3) for the System Five Control Box

turns it on and off.

O

N

OFF

Figure 4-3. Power Switch

P/N 7010-0341 www.topconpositioning.com

4-3

Page 72

Operation & Menu Settings

Grade Adjustment Knob

The grade adjustment knob makes measured adjustments to

elevation and slope settings, or cycles through menu options.

• Knob adjusts the grade height while in elevation control

(Figure 4-4).

AU

TO

SURVEY

4-4

FiveSystem

SET

(MENU

)

Figure 4-4. Adjusting Grade Height

• Knob adjusts the percentage of slope while in cross slope

control (Figure 4-5).

+

%

AU

TO

+

FiveSystem

Figure 4-5. Adjusting Cross Slope Control

%

SURVEY

SET

(MENU

)

Topcon Paver System Five Operator’s Manual

Page 73

Control Box

Grade Adjustment Direction Arrows

The grade adjustment arrows are located at the upper left and

upper right of the grade adjustment knob.

These two arrows (Figure 4-6) light up in red to indicate the

direction to turn the knob to reach on-grade.

R

otate

K

R

eac

nob

h Grad

e

C

ounterclockwise

To

Figure 4-6. Grade Adjustment Direction Arrows

R

otate

C

lockwi

R

eac

K

nob

se To

h Grad

e

Grade Adjustment LEDs

The grade adjustment LEDs (Figure 4-7) indicate raise, ongrade, and lower information and corrections.

Figure 4-7. Grade Adjustment LEDs

Table 4-1 describes grade adjustment LED indications.

Table 4-1. LED Indications for Elevation/Slope Control

LED Display

Slowly blinking,

yellow down

arrow

Solid yellow

down arrow

Blinking yellow

down arrow

LED

Elevation

Description

Out of range;

beyond .2’ above

grade

Above grade;

between .05' and .2'

Above grade;

between .02

' and

.05'

P/N 7010-0341 www.topconpositioning.com

Slope Description

Beyond 2% above

grade

Above grade,

between 1% and 2%

Above grade,

between .5% and

1%

4-5

Page 74

Operation & Menu Settings

Table 4-1. LED Indications for Elevation/Slope Control (Continued)

LED Display

Blinking yellow

down arrow w/

green bar

Blinking green

bar

Blinking red up

arrow w/ green

bar

Blinking red up

arrow

Solid red up

arrow

Slowly blinking

red up arrow

LED

Elevation

Description

Within .02

On grade On grade

Within .02

Below grade;

between .02

.05

Below grade;

between .05

Out of range;

beyond .2

grade

' of grade

' of grade

' and

'

' and .2'

' below

Slope Description

Within .5% of grade

Within .5% of grade

Below grade,

between .5% and

1%

Below grade,

between 1% and 2%

Beyond 2% below

grade

Function Indicator LEDs

The function indicator LEDs (Figure 4-8 on page 4-7) are

located below the jog button and next to the slope/elevation,

cross communication, and set/menu buttons:

4-6

• CON – indicates the box is in Control Mode.

• SUR – indicates the box is in Survey Mode.

• ELEV – indicates the LCD displays the current elevation.

• AVG – indicates the LCD displays the calculated average

elevation.

Topcon Paver System Five Operator’s Manual

Page 75

Control Box

S

F

unct

I

ndicator

LE

D

s

ion

UR

C

O

ELEV

A

VG

N

SET

(MENU)

Figure 4-8. Function Indicator LEDs

Set/Menu Button

The Set/Menu button (Figure 4-9) has two functions:

• Set Mode – used to change the reference number vie wed on

the display to a desired value.

• Menu Mode – used to access the performance menu.

AU

TO

SURVEY

SET

(MENU)

FiveSystem

SET

NU

)

(ME

Figure 4-9. Set/Menu Button

Using the Set Mode

The Set mode is used to change the reference number

viewed on the display to a desired value. The reference

number is used to set the elev ati on or slope display number.

1. Press and hold the Set/Menu button.

2. Dial in the desired value using the Grade Adjustment

Knob. Both the grade correction indicator lights and the

double arrows light up.

P/N 7010-0341 www.topconpositioning.com

4-7

Page 76

Operation & Menu Settings

3. Release the Set/Menu button and the value will be

saved.

NOTICE

NOTICE

Using Set only changes the reference number

viewed on the display, leaving the existing

cutting depth unchanged.

Using the Menu Mode

The Menu mode assigns menu mode functions, allowing

you to set valve offsets, units of measurements, an alarm,

deadband, and other useful functions.

See “Performance Menu Settings” on page 4-16 for

information on using the menu settings.

Cross Communication Button

If enabled, the Cross Communication button (Figure 4-10)

allows you to remotely control a second Control Box.

AU

TO

SURVEY

4-8

FiveSystem

Figure 4-10. Cross Communication Button

SET

NU

)

(ME

During cross communication, the Control Box that initiates the

communication (primary) displays and controls the settings of

the second Control Box.

Topcon Paver System Five Operator’s Manual

Page 77

1. Press and hold the Cross Communication button

(Figure 4-11).

AU

TO

SURVEY

Control Box

FiveSystem

(MENU

SET

)

Figure 4-11. Initiate Cross Communication

• The left arrow illuminates, indicating cross

communication has started (Figure 4-12).

AU

TO

SURVEY

FiveSystem

(MENU

SET

)

Figure 4-12. Cross Communication Started

• The right arrow illuminates once cross communication

with the second Control Box has been established. The

display now shows the settings of the second box

(Figure 4-13 on page 4-10). The cross communication