TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619

www.tippmann.com

PAINTBALL MARKER

LANCEUR DE PAINTBALL

MACADOR PAINTBALL

Owner’s Manual

Manuel d’utilisation

Manual del Usuario

®

TP04220

06/10

E

N

G

L

This is not a toy. Misuse may cause serious injury or

I

death. Eye, face, and ear protection designed for paintball

S

must be worn by the user and any person within range.

H

We recommend you be at least 18 years old to purchase.

Persons under 18 must have adult supervision when

using this product. Read the Owner’s Manual before

using this product.

WARNING

AVERTISSEMENT

F

Ceci n’est pas un jouet. Une mauvaise utilisation

R

peut causer de sérieuses blessures ou la mort. Une

A

protection pour les yeux, la tête et les oreilles et étant

N

adaptée au paintball doit être portée par l’utilisateur

Ç

ainsi que tout utilisateur situé dans le champ de tir. Nous

A

recommandons que l’acheteur ait au moins 18 ans. Les

I

personnes de moins de 18 ans doivent être supervisées

S

par un adulte durant l’utilisation de ce produit. Lisez le

Manuel avant d’utiliser ce produit.

ADVERTENCIA

Esto no es un juguete. Un uso inapropiado puede causar

serias heridas o la muerte. Ojos, cara y oidos deben ser

protegidos todo el tiempo, con la protección diseñada

E

para paintball tanto por jugadores como por cualquier

S

persona que este en el radio de alcance. Recomendamos

P

A

al menos 18 años para la compra y uso. Las personas

Ñ

menores de 18 años deben usar este producto bajo la

O

supervisión de un adulto. Lea el Manual del Usuario antes

L

de usar este producto.

2

WARNING

Safety is Your Responsibility

Read and familiarize yourself and any other user of this

marker with the

these instructions when using, working on,

transporting, or

safety instructions

in this manual. Follow

storing this marker.

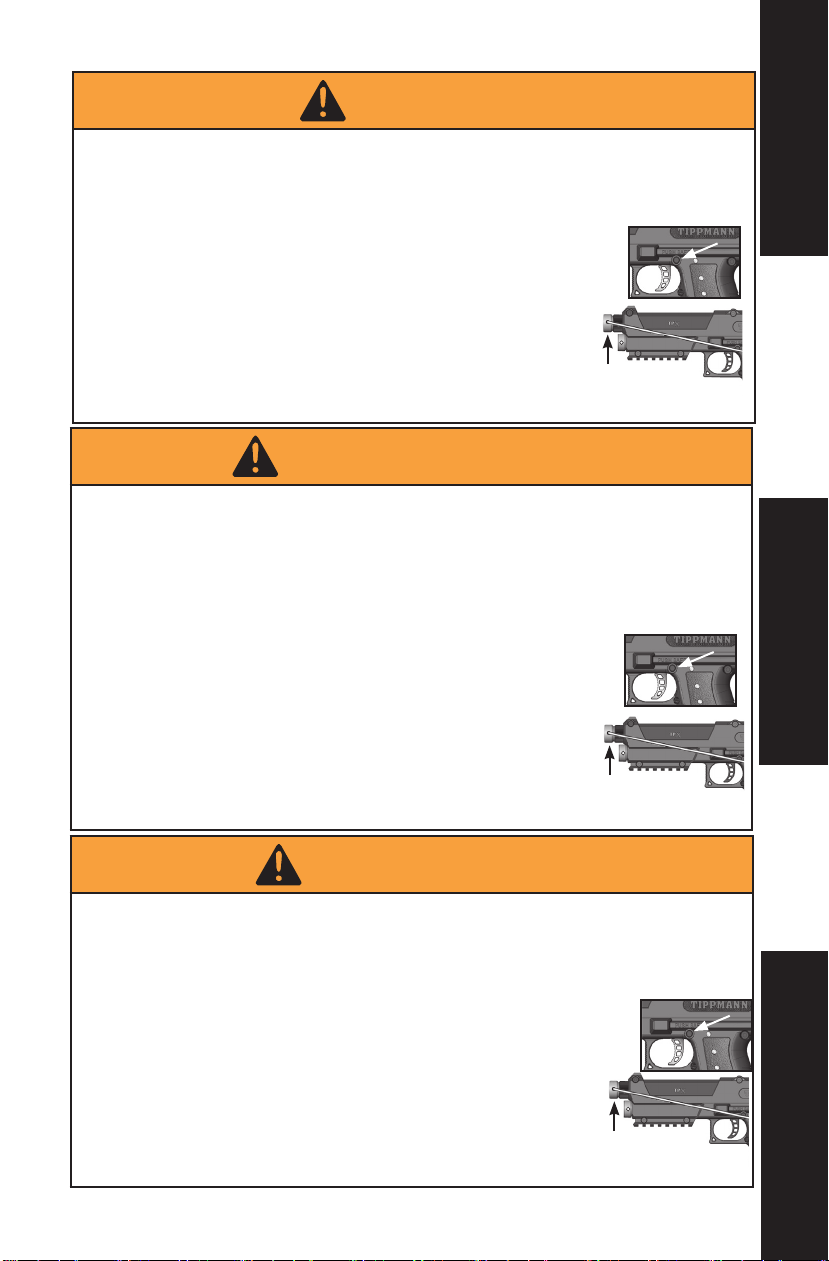

Push in for Safety

Always keep the trigger safety in Safe mode

unless ring as detailed in instructions on

page 6.

Always keep the barrel blocking device

installed when not in a shooting situation,

see instructions on page 4.

Barrel

Blocking

Device

AVERTISSEMENT

La Securite est Votre Responsabilite

Lisez et familiarisez-vous ainsi que tout autre utilisateur

de ce lanceur avec les instructions de securite contenues

dans ce manuel. Suivez ces instructions lorsque vous

utilisez, travaillez sur, transportez, ou entreposez ce

lanceur.

Si vous ne tirez pas, maintenez toujours la

securite de la detente en mode Securite comme

indique dans les instructions en page 6.

Gardez toujours le dispositif de blocage du

canon installe lorsque vous n’etes pas en

situation de tir comme indique dans les

instructions en page 4.

Securite Verrouillee

Dispositif de

Blocage du

Canon

E

N

G

L

I

S

H

F

R

A

N

Ç

A

I

S

ADVERTENCIA

La Seguridad es Su Responsabilidad

Lea y familiaricese usted y cualquier otro usuario de

este marcador con las instrucciones de seguridad de

este manual. Siga estas instrucciones cuando se utiliza,

trabajando, transporte, o almacenar este marcador.

Mantenga siempre el seguro del gatillo activado

a menos que sea necesario hacer disparos.

Como se ve en las instrucciones de la página 6.

Mantenga el mecanismo de bloqueo del barril

instalado cuando no este haciendo disparos

como se ilustra en la página 4.

3

Presione el Seguro

Mecanismo

de Bloqueo

del Barril

E

S

P

A

Ñ

O

L

E

N

G

L

This is not a toy. Misuse may cause serious injury or

I

death. Eye, face, and ear protection designed for paintball

S

must be worn by the user and any person within range.

H

WARNING

We recommend you be at least 18 years old to purchase.

Persons under 18 must have adult supervision when

using this product. Read the Owner’s Manual before

using this product.

WARNING

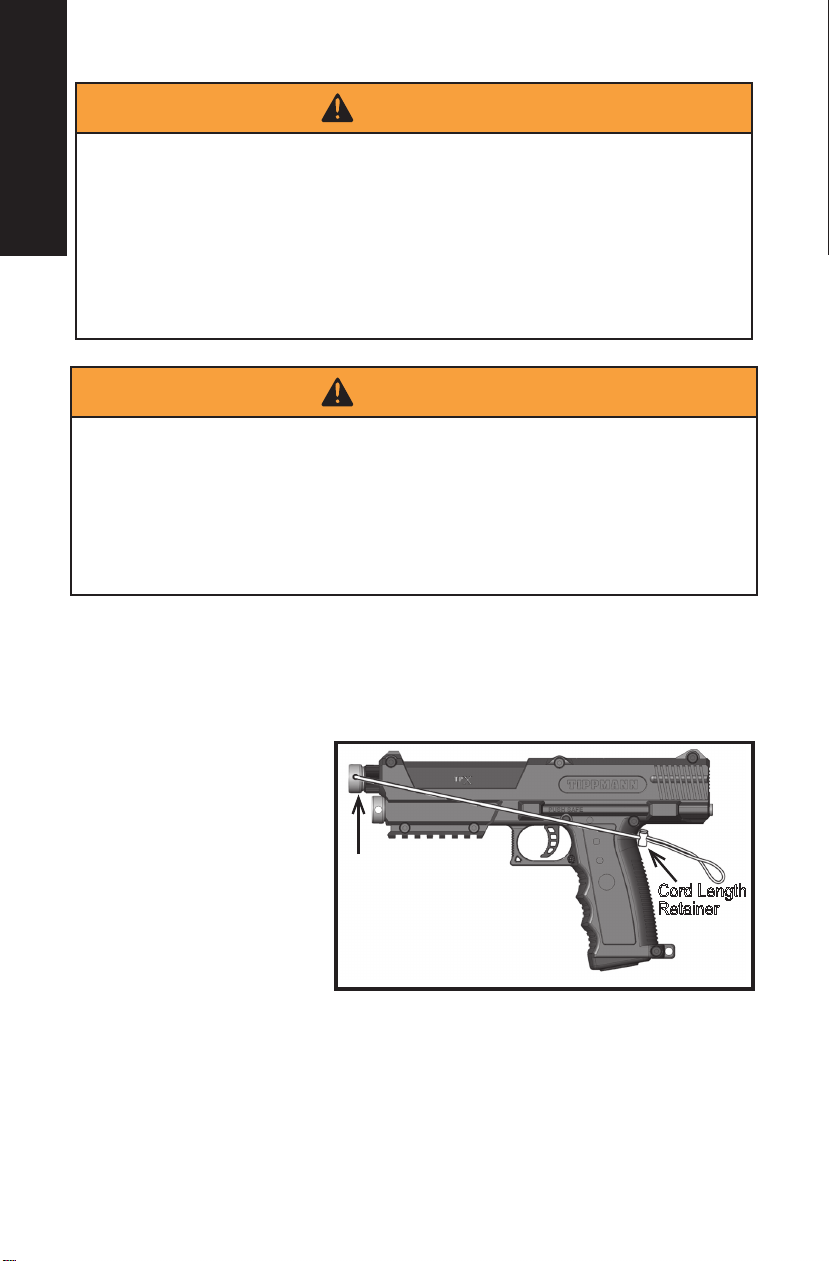

Always keep the barrel blocking device installed except

when your marker is in use. Always make sure that the

trigger safety is in the safe mode (see instructions on

page 6) and the barrel blocking device is properly installed

on your marker according to the instructions to prevent

damage to property, serious injury, or death.

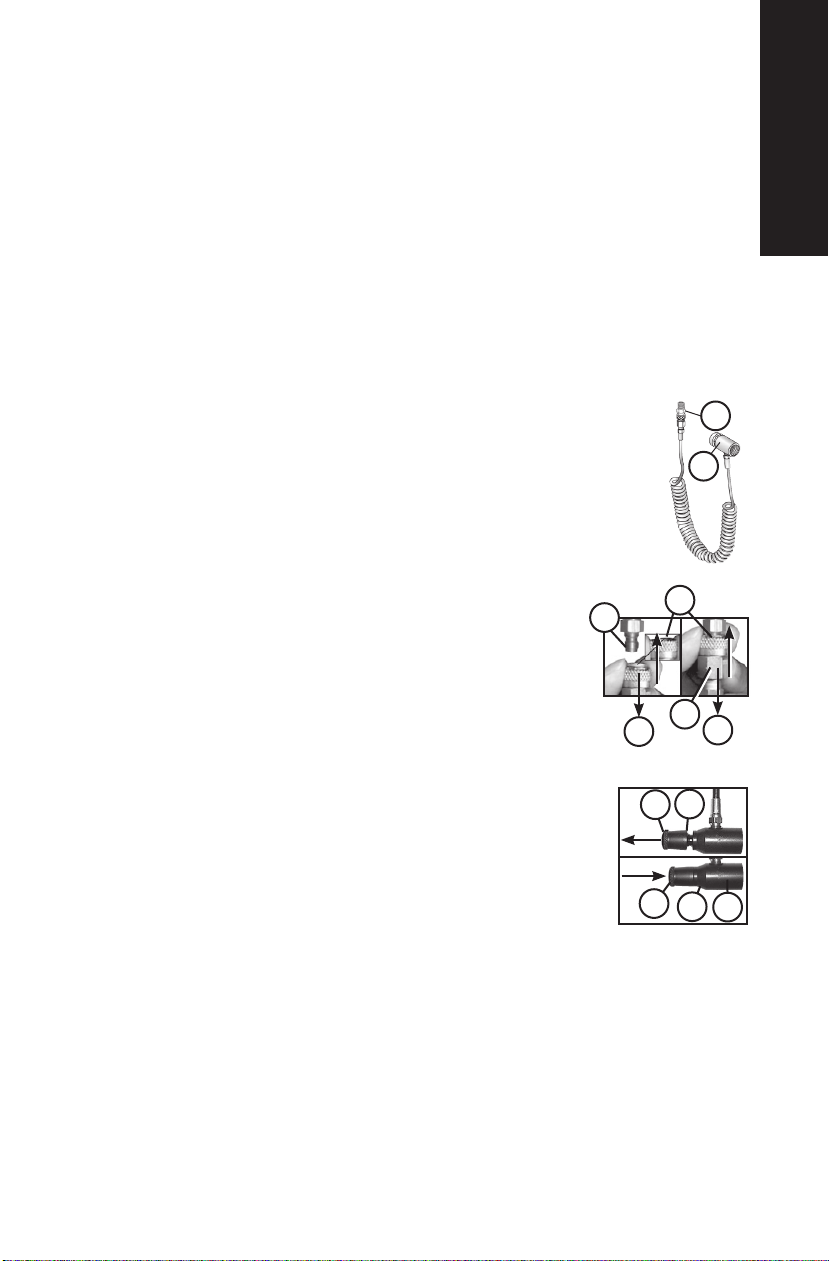

Barrel Blocking Device Installation Instructions

1. Insert the barrel blocking device into the barrel and loop the cord over the top of the

receiver and position at the back of the grip as shown.

2. Adjust the cord length

retainer up to the back of

the grip by pulling the cord

back while pushing the cord

length retainer toward the

marker. Ensure that the cord

length retainer is completely

tightened against the back of

the grip by pulling the cord

as tight as possible.

3. To remove barrel blocking

device, pull back on center

piece of cord length retainer

and slide retainer toward end of cord.

4. Before and after playing, inspect the barrel blocking device. Replace the barrel blocking

device if the cord is damaged or there is a loss of cord elasticity.

5. Clean the barrel blocking device with plain, warm water and store out of sunlight in a dry

area when not in use.

Barrel

Blocking

Device

Cord Length

Retainer

4

by TIPPMANN

®

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619 • www.tippmann.com

CONGRATULATIONS on your purchase of a Tippmann TPX paintball marker. We believe

our TPX markers to be the most accurate and durable paintball markers available. Tippmann

TPX markers will provide many years of dependable service if cared for properly.

Please take time to read this manual thoroughly and become familiar with your Tippmann

TPX marker’s parts, operation, and safety precautions before you attempt to load or re this

marker. If you have a missing or broken part, or need assistance, please contact Tippmann

Consumer Relations at 1-800-533-4831 for fast, friendly service.

TABLE OF CONTENTS

Barrel Blocking Device Installation Instructions ......................................................................4

Warning/Liability Statement ....................................................................................................6

Safety Is Your Responsibility! / Familiarize Yourself With Safety... .........................................6

Getting Started .......................................................................................................................8

1. CO2 Cartridge Installation ..........................................................................................8

2. Removing the Magazine and Loading .......................................................................................9

3. Firing the Marker ........................................................................................................9

4. Unloading the Magazine .............................................................................................9

Velocity Adjustment ..............................................................................................................10

CO2 Cartridge Removal .......................................................................................................10

Removing an Unused CO2 Cartridge (Non-Punctured) ...............................................11

Removing a Used CO2 Cartridge (Punctured) .............................................................11

Cleaning & Maintenance ......................................................................................................12

Magazine Disassembly, Reassembly, and Testing ...............................................................12

Marker Disassembly/Assembly ............................................................................................14

Firing Valve Disassembly/Assembly ............................................................................15

Puncture Valve Disassembly/Assembly ........................................................................16

Air Valve Disassembly/Assembly ..................................................................................16

Regulator Disassembly/Assembly ................................................................................17

Release Pressure From a Marker That Will Not Fire ............................................................17

Adjustable CO2 Cap .....................................................................................................18

Additional Information Regarding Performance ............................................................18

Regulator Pressure Relief Valve Adjustment ........................................................................19

Troubleshooting ....................................................................................................................19

Remote Line Adapter (optional equipment) ..........................................................................21

Connecting, Disconnecting, and Removing a Remote Air/CO2 Cylinder .....................21

Air/CO2 Cylinder Warnings...................................................................................................22

Air/CO2 Cylinder Safety Tips ........................................................................................23

Repairing Air/CO2 Cylinder Leaks ................................................................................24

Storage ................................................................................................................................24

Specications .......................................................................................................................25

TPX Parts Diagram and Parts List .................................................................................. 26-28

Warranty and Repair Information..........................................................................................29

5

E

N

G

L

I

S

H

E

Warning/Liability Statement

N

G

This marker is classied as a dangerous weapon and is surrendered by Tippmann Sports,

L

LLC with the understanding that the purchaser assumes all liability resulting from unsafe

I

handling or any action that constitutes a violation of any applicable laws or regulations.

S

Tippmann Sports, LLC shall not be liable for personal injury, loss of property or life resulting

H

from the use of this weapon under any circumstances, including intentional, reckless,

negligent or accidental discharges.

All information contained in this manual is subject to change without notice. Tippmann Sports,

LLC reserves the right to make changes and improvements to products without incurring any

obligation to incorporate such improvements into products previously sold.

If you as a user do not accept liability, Tippmann Sports, LLC requests you do not use a

Tippmann Sports, LLC marker. By using this paintball marker you release Tippmann Sports,

LLC of any and all liability associated with its use.

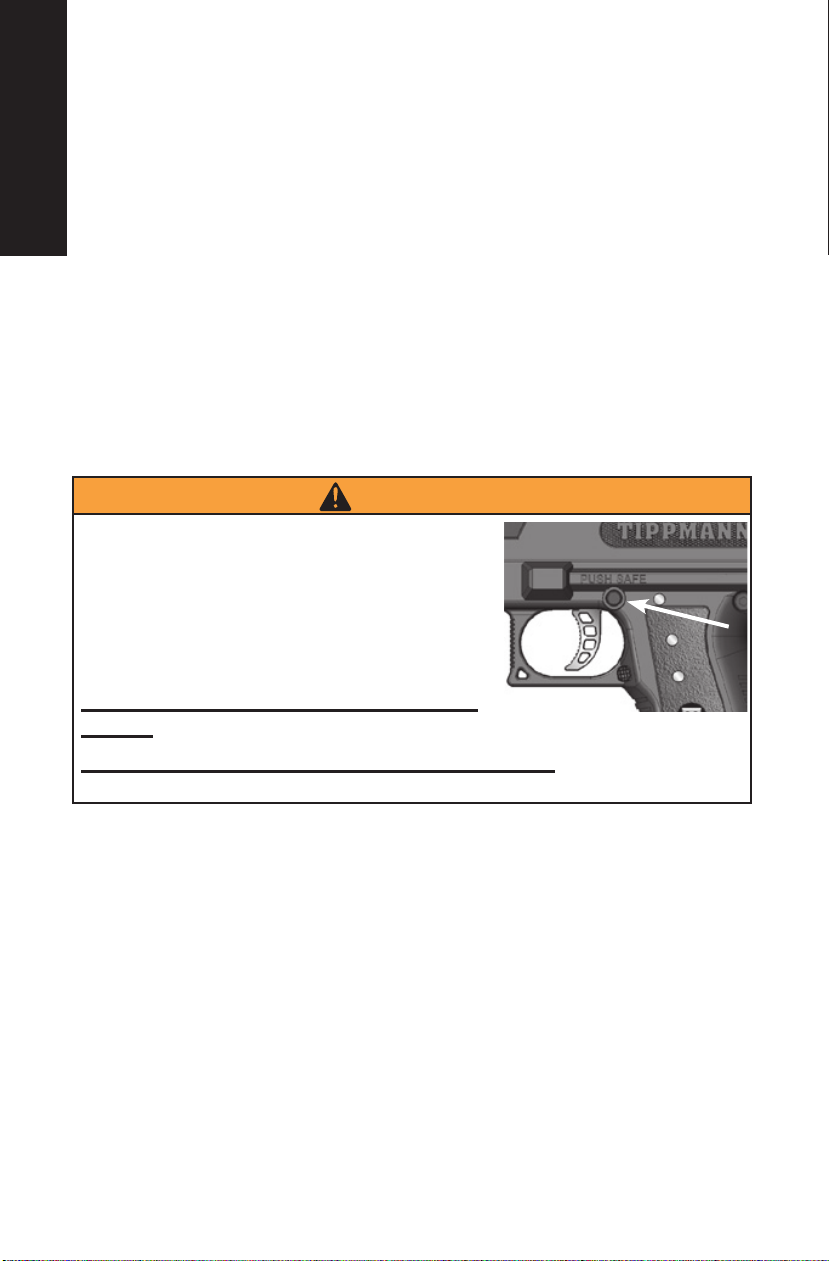

SAFETY IS YOUR RESPONSIBILITY!

WARNING

Except when your marker is in use,

always make sure that the trigger

safety is in Safe mode, and that the

barrel blocking device is properly

installed (see page 4).

To turn ON the trigger safety (Safe

mode), push in the safety (arrow) as shown above.

To turn OFF the trigger safety (Fire mode), push in the

safety from the opposite side of the receiver.

Familiarize Yourself With Safety...

The ownership of this marker places upon you the total responsibility of its safe and lawful

use. You must observe the same safety precautions as you would any rearm to assure

the safety of not only yourself but everyone around you. Outlined here are some general

precautions to be aware of. The user should at all times use caution and common sense when

using this marker and always remember that the game of paintball can only survive and grow

if it remains SAFE!

• Do not load or re this marker until you have completely read this manual and are

familiar with its safety features, mechanical operation and handling characteristics.

• Handle this and any marker as if it were loaded at all times.

• Keep your nger off the trigger until you are ready to shoot.

• Do not look down the barrel of a paintball marker. Accidental discharge into the eyes

may cause permanent injury or death.

6

• Keep the marker in Safe mode until ready to shoot (page 6).

• Keep the barrel blocking device installed on marker when not shooting (page 4).

• Never point the marker at anything you do not intend to shoot.

• Never re your marker at anything you do not intend to shoot because there may be

paintballs or foreign debris lodged in the chamber, barrel, and/or the marker valve.

• Do not shoot at fragile objects such as windows.

• Never re your marker at personal property of others. The paintball impact can

cause damage and the paint can stain the nish of automobiles, houses, etc.

• Always keep the muzzle pointed down or in a safe direction, even if you stumble or

fall.

• Eye, face, and ear protection designed specically to stop paintballs in the form of

goggles and full face mask meeting ASTM Specication F 1776 must be worn by the

user and any person within range.

• Never shoot at a person who is not protected by eye, face, and ear protection

designed for paintball.

• Pressurize and load the marker only when the marker will be immediately used.

• Store the marker unloaded and degassed in a secure place.

NOTE: Before storing or disassembling, be sure to remove paintballs and air/CO2

supply (see unloading and air/CO2 removal instructions on pages 9 -11) and install

the barrel blocking device (see page 4).

• Do not eld strip or otherwise disassemble this marker while it is pressurized with

air/CO2 supply.

• Dress appropriately when playing the game of paintball. Avoid exposing any skin

when playing the game of paintball. Even a light layer will absorb some of the

impact and protect you from the paintballs.

• Keep exposed skin away from escaping gas when installing or removing air/CO2

cylinder or if the marker or air/CO2 supply is leaking. Compressed air, CO2, and

nitrogen gasses are very cold and can cause frostbite under certain conditions.

• Use only .68 caliber paintballs. Never load or re any foreign objects.

• Avoid alcoholic beverages before and during the use of this marker. Handling

markers while under the inuence of drugs or alcohol is a criminal disregard for

public safety.

• Avoid shooting an opponent at point blank, 6 feet or less.

• Familiarize yourself with instructions listed on air/CO2 cylinder or adapter. Contact

the air/CO2 cylinder or adapter manufacturer with any questions.

• Read the Air/CO2 Cylinder Warnings and Safety Tips on pages 22–24 before

beginning the cylinder installation or removal.

• Always measure your marker’s velocity before playing paintball and never shoot at

velocities in excess of 300 feet per second (see instructions on page 10).

E

N

G

L

I

S

H

7

E

Getting Started

• Eyeprotectiondesignedforpaintballusemustbewornbytheuserandanyperson

withinrange.

• Donotdisassemblethismarkerwhileitispressurized.

• Donotpressurizeapartiallyassembledmarker.

• Readeachstepcompletelybeforeperformingtheinstruction.

NOTE:Carefullyhandstartallthreadedpartswhenassembling,anddonotovertighten,as

thismaypotentiallystripthethreadedparts.Inthismanual,itemnumbersofpartsarein

parentheses.YoucanalsondtheseitemnumbersinthePartsDiagramonpages26-27.

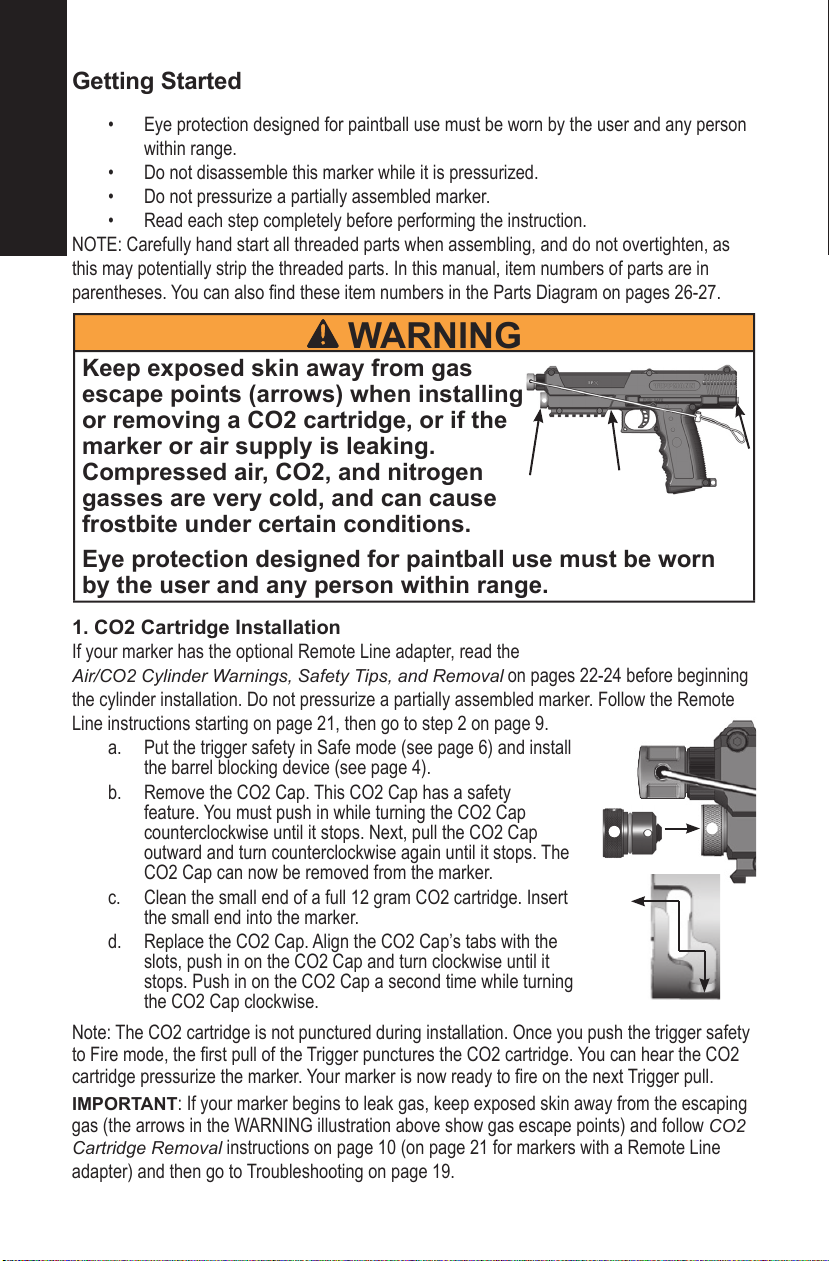

1. CO2 Cartridge Installation

IfyourmarkerhastheoptionalRemoteLineadapter,readthe

Air/CO2 Cylinder Warnings, Safety Tips, and Removal onpages22-24beforebeginning

thecylinderinstallation.Donotpressurizeapartiallyassembledmarker.FollowtheRemote

Lineinstructionsstartingonpage21,thengotostep2onpage9.

a. PutthetriggersafetyinSafemode(seepage6)andinstall

thebarrelblockingdevice(seepage4).

b. RemovetheCO2Cap.ThisCO2Caphasasafety

feature.YoumustpushinwhileturningtheCO2Cap

counterclockwiseuntilitstops.Next,pulltheCO2Cap

outwardandturncounterclockwiseagainuntilitstops.The

CO2Capcannowberemovedfromthemarker.

c. Cleanthesmallendofafull12gramCO2cartridge.Insert

thesmallendintothemarker.

d. ReplacetheCO2Cap.AligntheCO2Cap’stabswiththe

slots,pushinontheCO2Capandturnclockwiseuntilit

stops.PushinontheCO2Capasecondtimewhileturning

theCO2Capclockwise.

Note:TheCO2cartridgeisnotpuncturedduringinstallation.Onceyoupushthetriggersafety

toFiremode,therstpulloftheTriggerpuncturestheCO2cartridge.YoucanheartheCO2

cartridgepressurizethemarker.YourmarkerisnowreadytoreonthenextTriggerpull.

IMPORTANT:Ifyourmarkerbeginstoleakgas,keepexposedskinawayfromtheescaping

gas(thearrowsintheWARNINGillustrationaboveshowgasescapepoints)andfollowCO2

Cartridge Removal

instructionsonpage10(onpage21formarkerswithaRemoteLine

adapter)andthengotoTroubleshootingonpage19.

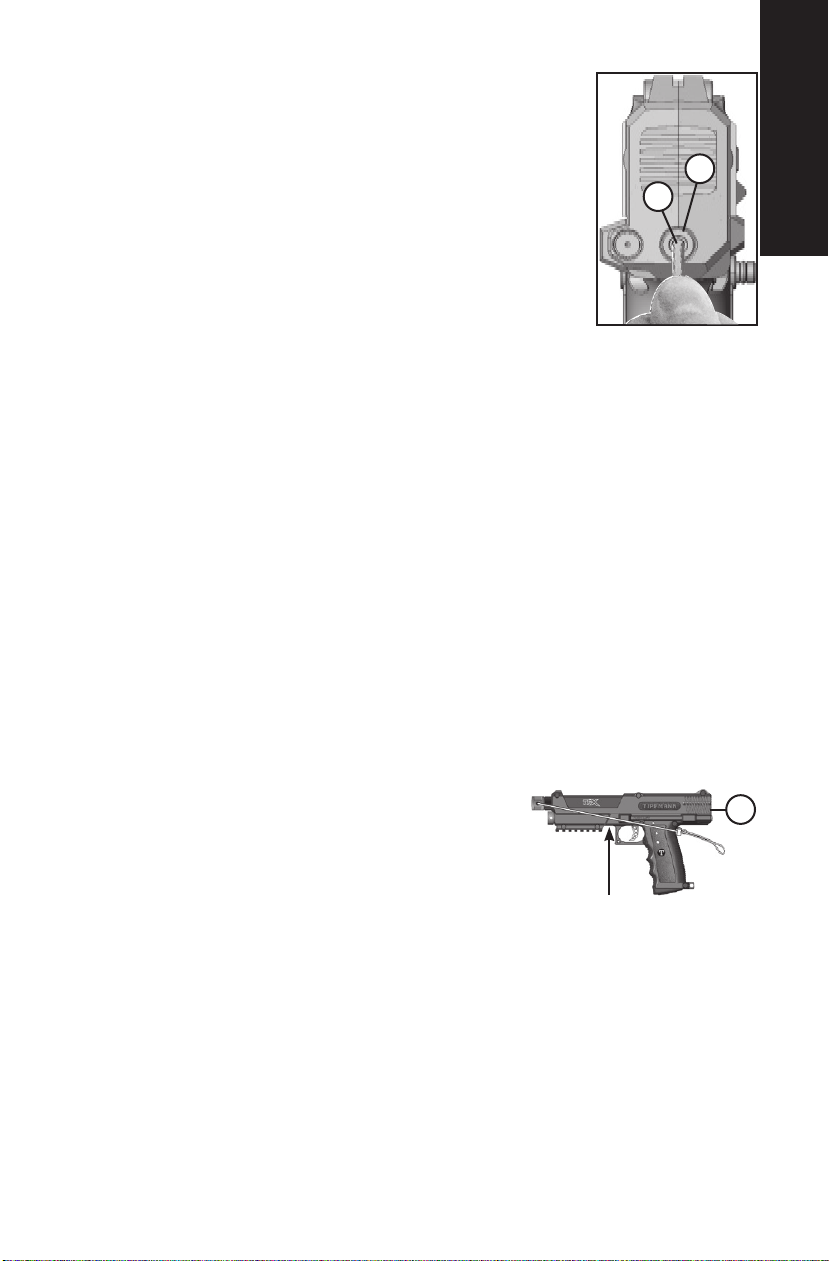

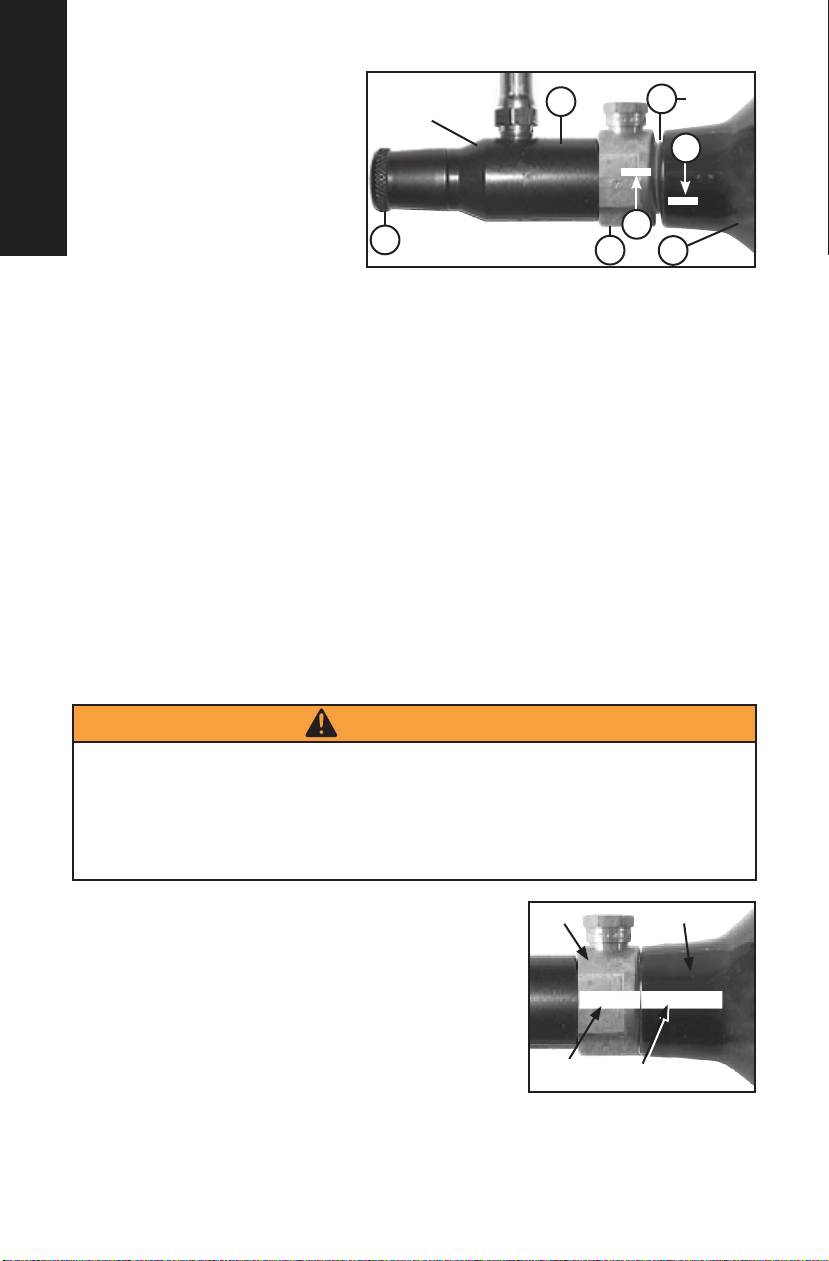

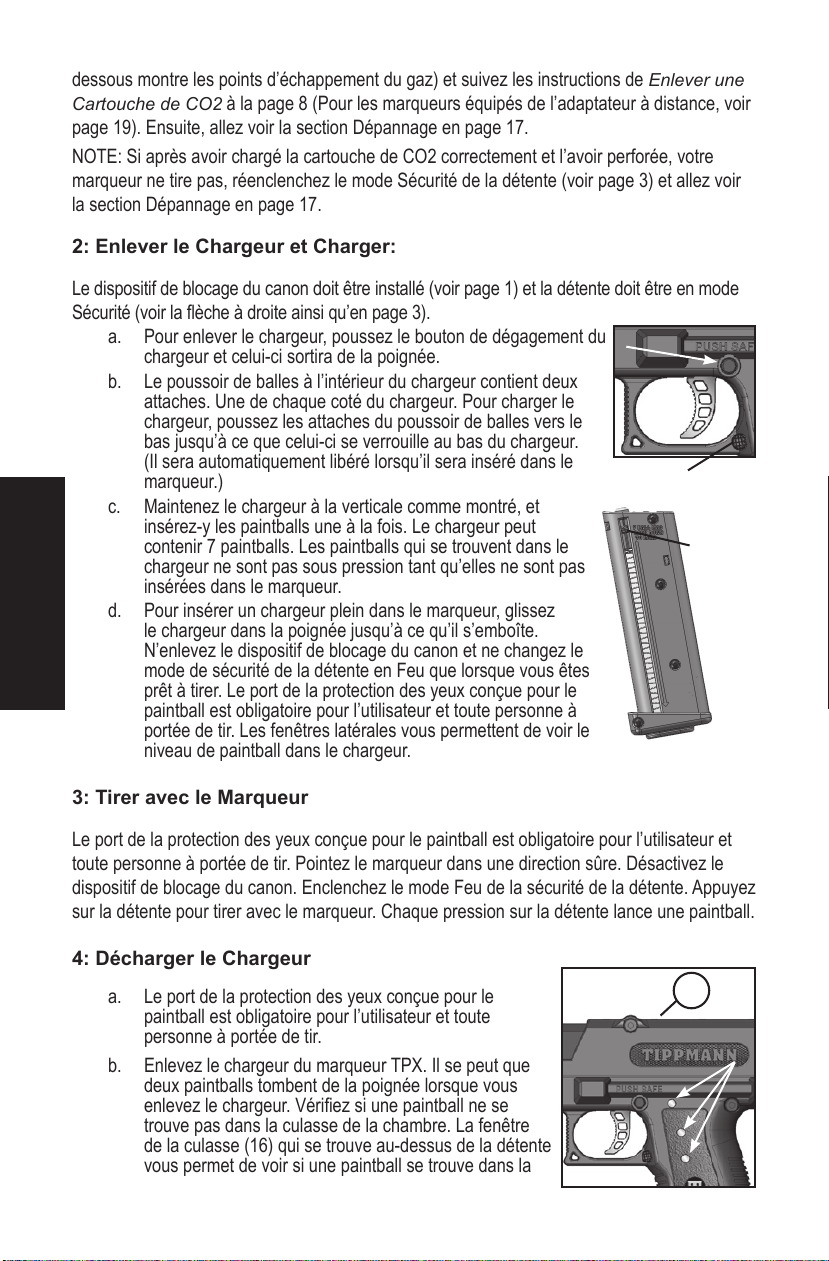

WARNING

Keep exposed skin away from gas

escape points (arrows) when installing

or removing a CO2 cartridge, or if the

marker or air supply is leaking.

Compressed air, CO2, and nitrogen

gasses are very cold, and can cause

frostbite under certain conditions.

Eye protection designed for paintball use must be worn

by the user and any person within range.

N

G

L

I

S

H

8

NOTE: If your marker does not re after you have successfully loaded and punctured your

CO2 cartridge, put the trigger safety back into Safe mode (see page 4)

and go to Troubleshooting on page 19.

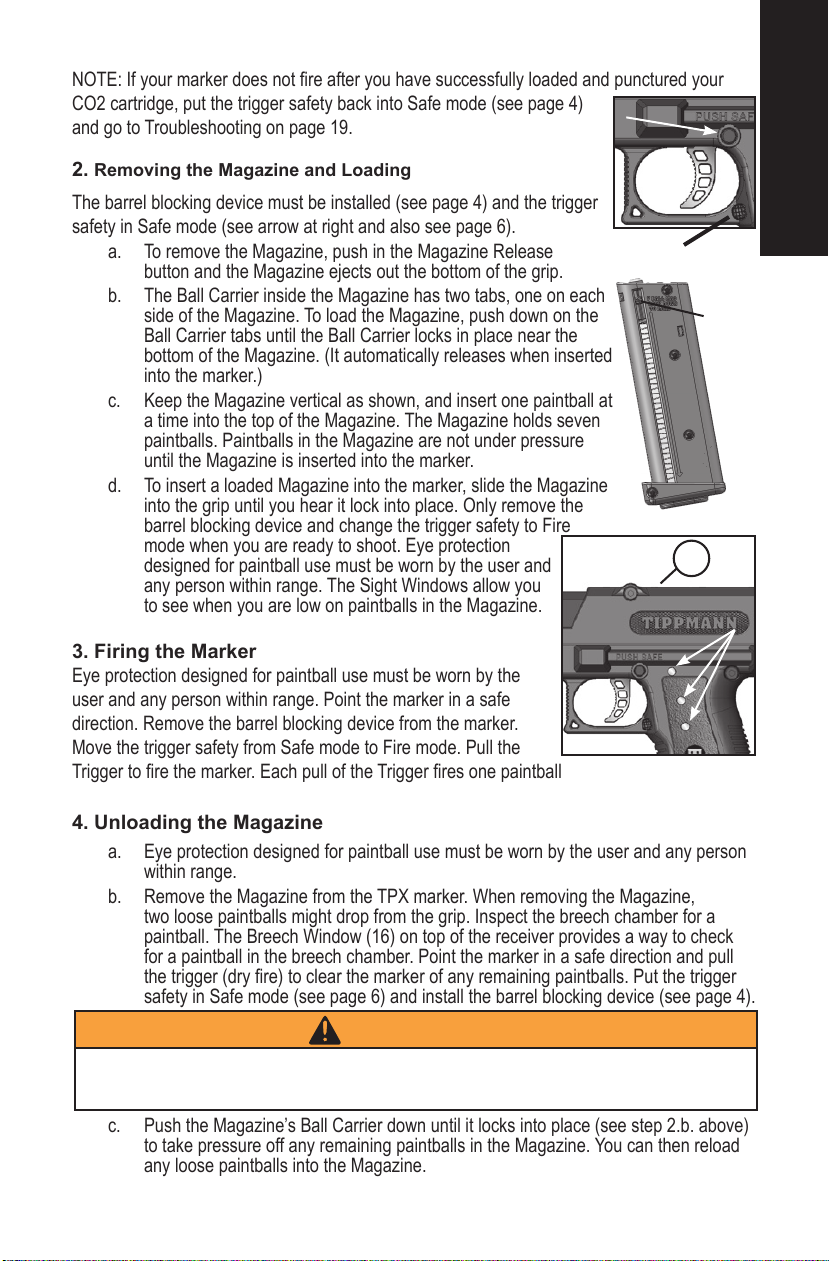

2. Removing the Magazine and Loading

The barrel blocking device must be installed (see page 4) and the trigger

safety in Safe mode (see arrow at right and also see page 6).

a. To remove the Magazine, push in the Magazine Release

button and the Magazine ejects out the bottom of the grip.

b. The Ball Carrier inside the Magazine has two tabs, one on each

side of the Magazine. To load the Magazine, push down on the

Ball Carrier tabs until the Ball Carrier locks in place near the

bottom of the Magazine. (It automatically releases when inserted

into the marker.)

c. Keep the Magazine vertical as shown, and insert one paintball at

a time into the top of the Magazine. The Magazine holds seven

paintballs. Paintballs in the Magazine are not under pressure

until the Magazine is inserted into the marker.

d. To insert a loaded Magazine into the marker, slide the Magazine

into the grip until you hear it lock into place. Only remove the

barrel blocking device and change the trigger safety to Fire

mode when you are ready to shoot. Eye protection

designed for paintball use must be worn by the user and

any person within range. The Sight Windows allow you

to see when you are low on paintballs in the Magazine.

3. Firing the Marker

Eye protection designed for paintball use must be worn by the

user and any person within range. Point the marker in a safe

direction. Remove the barrel blocking device from the marker.

Move the trigger safety from Safe mode to Fire mode. Pull the

Trigger to re the marker. Each pull of the Trigger res one paintball

4. Unloading the Magazine

a. Eye protection designed for paintball use must be worn by the user and any person

within range.

b. Remove the Magazine from the TPX marker. When removing the Magazine,

two loose paintballs might drop from the grip. Inspect the breech chamber for a

paintball. The Breech Window (16) on top of the receiver provides a way to check

for a paintball in the breech chamber. Point the marker in a safe direction and pull

the trigger (dry re) to clear the marker of any remaining paintballs. Put the trigger

safety in Safe mode (see page 6) and install the barrel blocking device (see page 4).

c. Push the Magazine’s Ball Carrier down until it locks into place (see step 2.b. above)

to take pressure off any remaining paintballs in the Magazine. You can then reload

any loose paintballs into the Magazine.

Magazine Release

Sight Windows

E

N

G

L

I

S

H

Ball

Carrier

Tab

16

Not seeing a paintball in the Breech Window does not

WARNING

indicate that the marker is unloaded or safe.

9

E

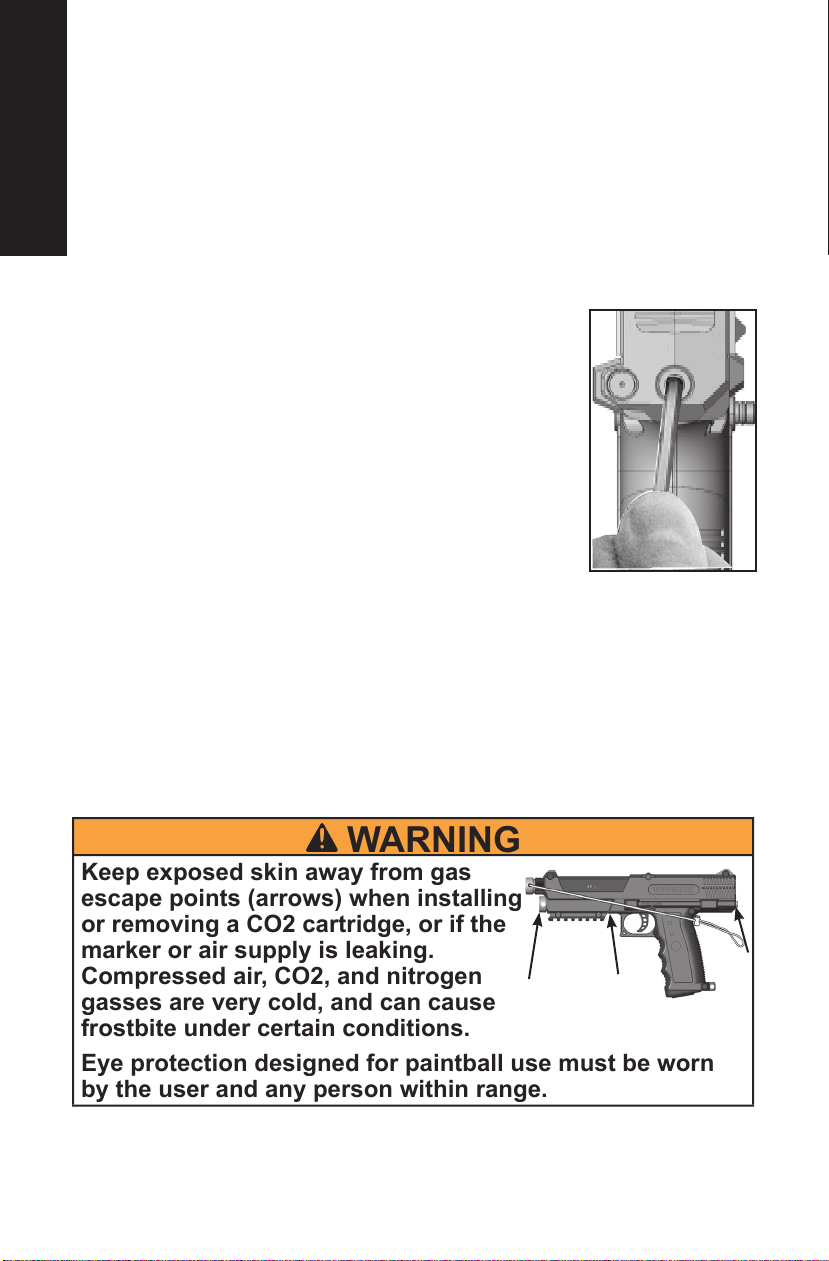

WARNING

Keep exposed skin away from gas

escape points (arrows) when installing

or removing a CO2 cartridge, or if the

marker or air supply is leaking.

Compressed air, CO2, and nitrogen

gasses are very cold, and can cause

frostbite under certain conditions.

Eye protection designed for paintball use must be worn

by the user and any person within range.

N

G

L

I

S

H

d. To remove all paintballs from the Magazine, press down on the top of the Carrier

Release Armature with a at object, and any remaining paintballs are pushed out

the top of the Magazine (Magazine parts are shown on page 13).

TIP: For best results and to keep your TPX marker running at peak performance, it is

recommended you use a paintball that is not too old or fragile, and is free of dimples or

defects. To determine if the paintball is proper for use with the TPX marker, press the tip of

your ngernail against the paintball to see if it is easily dimpled. Tippmann discourages leaving

paintballs sitting in Magazines for an extended period of time, as this can lead to the paintball

becoming out of round. Only load Magazines with paintballs on the day of play.

Velocity Adjustment

Each time you play paintball, check the velocity of your paintball

marker with a chronograph (an instrument for measuring velocity)

prior to playing paintball. Verify that the marker’s velocity is set below

300 feet per second (or less if required by the playing eld).

To adjust the velocity, use the 3/16” Allen wrench included with your

marker. The Velocity Adjustment Screw is located at the back of the

receiver, as shown at right. (Do not use a smaller Allen wrench and

mistakenly adjust the Regulator Pressure Relief Valve Set Screw

which is accessed through the Velocity Adjustment Set Screw - see

note below.) To reduce the velocity, turn the screw counterclockwise. To increase the velocity,

turn the screw clockwise.

NOTE: This marker has a Regulator Pressure Relief Valve that prevents excessive air/CO2

pressure that could damage your marker, and is factory set at 350 psi. If a cartridge with

excessive air/CO2 pressure is loaded, or if extreme temperature conditions cause excessive

cartridge pressure buildup, it will vent excessive gas out the access point. Adjust only as

outlined in the Regulator Pressure Relief Valve Adjustment instructions on page 19.

CO2 Cartridge Removal

Do not store or disassemble a marker with the CO2 cartridge (punctured or unpunctured)

installed. If your marker has an optional remote line adapter kit installed, do not remove the

CO2 cartridge until you rst follow the air/CO2 cylinder removal instructions in the Remote

10

Line Adapter instructions on page 21. Read each step completely before performing the

instruction.

Removing an Unused CO2 Cartridge (Non-Punctured)

1. Put the trigger safety in the Safe mode (see page 6) and install the barrel blocking

device (see page 4).

2. Press the Magazine Release button (4) and the Magazine (78) ejects out of the grip.

NOTE: When removing a loaded Magazine from the marker, two loose paintballs might

drop from the grip. Pull the Magazine’s Ball Carrier down until it locks to take pressure

off the paintballs, and reload any loose paintballs into the Magazine.

3. Keep the marker pointed in a safe direction, and remove the CO2 Cap (15).

a. Push in and turn the CO2 Cap counterclockwise until it stops. Then pull out until it

stops to partially unscrew the cap. NOTE: The cap should be easy to turn; if you

are unable to turn it, or if it is difcult to turn, the cartridge has been punctured

and you must follow the instructions below, Removing a Used CO2 Cartridge

(Punctured)

b. Turn the CO2 Cap a second turn counterclockwise until it stops and pull it out. The

empty CO2 cartridge will then slide out.

4. Replace the CO2 Cap. Align the cap pins with the pin guides of the Cap Receiver

Insert (14). Push the cap in and turn clockwise. Push the cap in a second time and turn

clockwise.

Removing a Used CO2 Cartridge (Punctured)

NOTE: A punctured CO2 cartridge must be emptied before it is removed.

1. Put the trigger safety in Safe mode (see page 6) and install the barrel blocking device

(see page 4).

2. Press the Magazine release button (4) and the Magazine (78) ejects out of the grip.

NOTE: When removing a loaded Magazine from the marker, two loose paintballs might

drop from the grip. Push the Magazine’s Ball Carrier down until it locks to take pressure

off the paintballs, and reload any loose paintballs into the Magazine.

3. Go to a designated ring area and remove the barrel blocking device.

4. Point the marker in a safe direction, move the trigger safety to Fire mode, and re

until there is no CO2 left in the cartridge. NOTE: If you have a punctured cartridge in

your marker and the marker will not re, follow the instructions on page 17, Release

Pressure From a Marker That Will Not Fire

5. Put the trigger safety in Safe mode (see page 6) and install the barrel blocking device

(see page 4).

6. Visually inspect the chamber for paintballs through the Magazine opening at the bottom

of the grip.

7. Keep the marker pointed in a safe direction during CO2 Cap removal.

a. Keep exposed skin away from escaping CO2 - the arrows in the WARNING

illustration on page 10 show CO2 escape points. Push in and turn the CO2 Cap

slowly counterclockwise until it stops, and pull until it stops to partially unscrew the

cap, then wait as any remaining CO2 in the cartridge escapes before performing

step (b) (keep exposed skin away from escaping CO2).

b. Turn the CO2 Cap a second turn counterclockwise until it stops and pull it out. The

empty cartridge then slides out.

8. Replace the CO2 Cap by aligning the CO2 Cap pins with the pin guides of the Cap

Receiver Insert (14) and pushing the Cap in while turning clockwise. Push the Cap in a

second time, turn clockwise, and release.

.

.

E

N

G

L

I

S

H

11

E

Cleaning & Maintenance

N

G

Always wear eye protection (safety glasses) when cleaning or performing maintenance on

L

your TPX marker. To reduce the chance of an accidental discharge, follow CO2 Cartridge

I

Removal

S

Never disassemble a marker that is under pressure. Clean and lubricate your marker with

H

Tippmann grease after approximately 5000 shots.

instructions on page 10 (on page 21 for markers with a Remote Line Adaptor).

• Familiarize yourself with instructions and follow warnings on CO2 cartridge and/or

air/CO2 cylinder packaging for use, handling, storage and disposal. Contact the air/

CO2 cylinder manufacturer with any questions.

• Read and follow Air/CO2 Cylinder Warnings and Safety Tips on pages 22-24.

• Petroleum based products and aerosol products can damage marker O-rings. Do

not use any petroleum based cleaning solvents. Do not use any cleaning solvents

that come in aerosol cans.

• Clean your marker using a damp towel to wipe off paint, grease, and debris.

• To clean inside the barrel, turn the barrel counterclockwise and remove. Push the

cable of the squeegee through the barrel, then pull the squeegee through to remove

debris.

• To clean the breech and barrel with the Magazine removed, push the cable of the

squeegee up into the grip and out the barrel, then pull the squeegee through to

remove debris.

• Clean the Magazine with a damp towel to wipe off paint, grease, and debris. Dry

springs immediately to help prevent rusting.

• To maintain your marker in good working condition, inspect, clean, and replace

any damaged parts. Lubricate as instructed in the following Marker Disassembly/

Assembly section. The best valve O-rings are made of urethane. Urethane

O-rings are not affected by high air/CO2 pressures. These may be purchased from

Tippmann or your local paintball dealer. Use Tippmann grease to lightly lubricate the

O-rings and springs, to maintain your marker in good working condition.

Magazine Disassembly, Reassembly, and Testing

Read these instructions completely before attempting Magazine disassembly or reassembly.

Magazine Disassembly

Refer to the diagram on the next page for these instructions.

1. Set the Magazine on a workbench with the Left Shell side facing up.

2. Remove four #4 x 5/8 Screws.

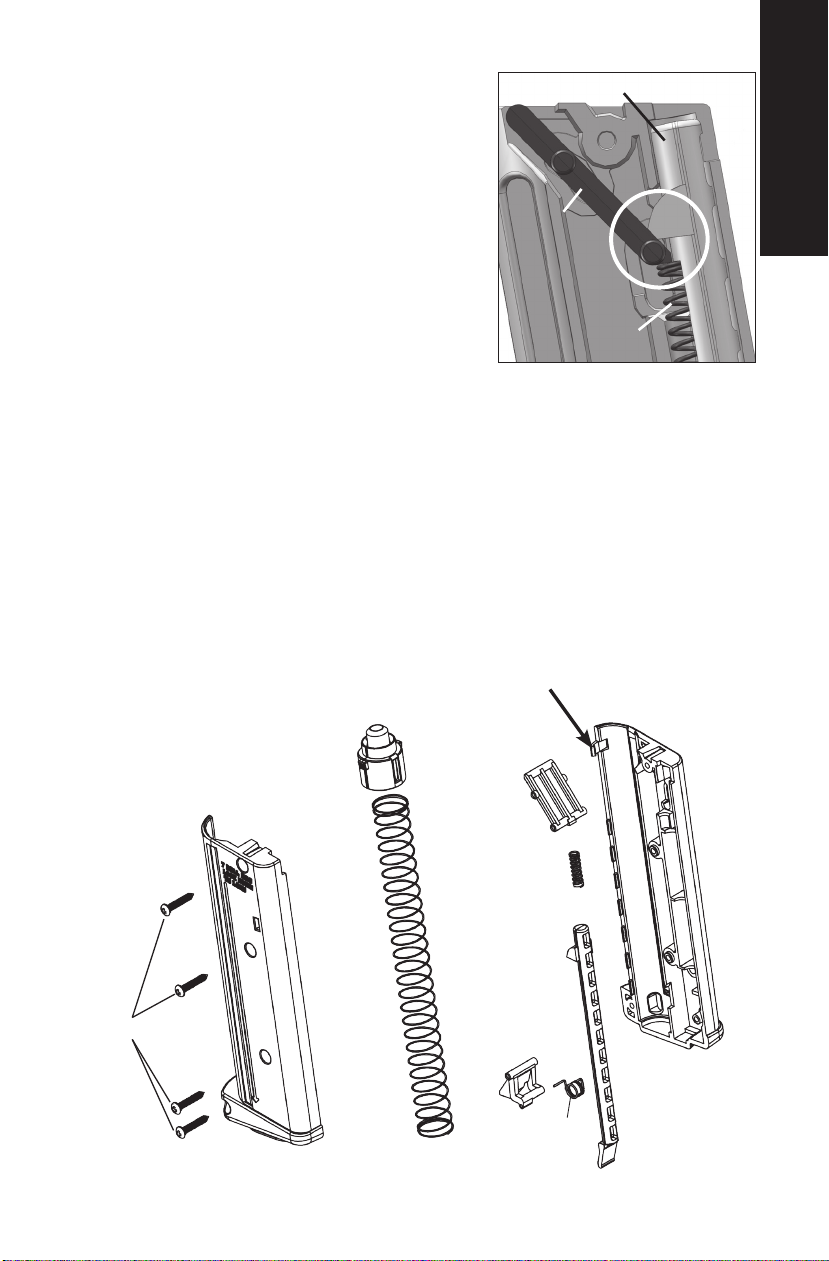

3. Gently disengage the top hook (arrow in bottom illustration on the next page), then

separate both halves of the Magazine.

4. Remove and clean the internal parts as necessary.

NOTE: If you clean the Ball Carrier Spring with water, prevent rusting by thoroughly drying it

before reassembly.

12

Magazine Reassembly

Carrier Release Armature

1. Place the Carrier Release Lever Spring into the

Right Shell.

2. Properly orient the Carrier Release Lever onto the

Carrier Release Lever Spring in the Right Shell.

3. Place the Magazine Ball Latch and Carrier

Release Armature into the Right Shell.

4. Set the Latch Spring between the Magazine Ball

Latch and the Carrier Release Armature. The

Magazine

Ball

Latch

Latch Spring sets in a pocket formed by the two

parts inside the Right Shell.

5. Conrm that the Magazine Ball Latch and Carrier

Release Armature are oriented as shown in

Latch

Spring

the circled area at right. The at surfaces of the

Magazine Ball Latch and the Carrier Release Armature t together, and must align

correctly for the Magazine to operate properly.

6. Place the Ball Carrier Spring into the Right Shell.

7. Install the Left Shell onto the Right Shell, but do not fully press the two pieces together.

Be sure the internal parts stay in their locations while putting the two shell halves

together. The top hook (see arrow) of the Right Shell does not engage at this time.

8. Install the bottom #4 x 5/8 Screw. Tighten it until snug.

9. Place the Ball Carrier onto the Ball Carrier Spring (aligning the two tabs on the Ball

Carrier with the slots in the Left Shell and Right Shell) and slide down into the top of the

assembled shell halves. Push down on the Ball Carrier until it snaps into place inside

the Magazine.

10. Push the top of the Magazine together so the top hook engages (arrow below).

11. Install the three remaining #4 x 5/8 Screws. Tighten them until they are snug.

E

N

G

L

I

S

H

#4 x 5/8 Screws

Ball Carrier

Left Shell

Ball

Carrier

Spring

13

Magazine

Ball Latch

Latch

Spring

Carrier

Release

Armature

Carrier

Release

Lever

Carrier Release

Lever Spring

Right Shell

E

Magazine Testing

N

G

1. Pull down on the Ball Carrier tabs until the Ball Carrier is about midway down the

L

I

S

H

Magazine.

2. While holding onto the Ball Carrier tabs, push down on the Carrier Release Armature

and ensure that the Magazine Ball Latch moves freely.

3. Release the Ball Carrier. The Ball Carrier should move freely when properly

reassembled.

4. Push the Ball Carrier all the way to the bottom of the Magazine until it locks into place.

5. Press down on the Carrier Release Armature to release the Ball Carrier.

Magazine testing is complete.

Marker Disassembly/Assembly

Set up a table with plenty of space to work to make sure no small parts become lost.

Eye protection must be worn during disassembly and reassembly. Do not disassemble a

pressurized paintball marker. Do not pressurize a partially assembled paintball marker. Follow

CO2 Cartridge Removal instructions on page 10 (page 21 if a Remote Line Adapter is

installed), leave the CO2 cap (15) off.

1. For Remote Line equipped

markers, rst remove the

27

10

26

Remote Line Adapter by

turning it counterclockwise

on the ats with a 1/2”

15

wrench, and pull it out.

(For reassembly, insert the

Remote Line Adapter into

the hole in the back of the

marker as shown. Carefully

hand start and screw it into

the air tting until nger

tight.)

2. Remove the Barrel (27) by

NOTE:

Failure to reassemble

correctly can cause damage

to parts, air leaks, and other

problems. As you reassemble your marker, double check

to be sure parts are clean, not damaged, lubricated, and

installed correctly.

8.

turning it counterclockwise, and pull it out.

3. Remove the left-side receiver (2) by unscrewing the 7 receiver bolts (items 8, 9, and

10). Carefully lift the Left Receiver half to access the internal parts.

4. Lift out the CO2 Cap Receiver Insert (14), Barrel Shroud (26), and Barrel Adapter (25).

Lift out (as one piece) the Long Gas Line (19), Puncture Valve (7), Regulator (21), Air

Valve (23) (with Firing Valve

(items 45-51), and Short Gas

Line (20) assembly.

To separate this sub-

NOTE: Carefully hand start all threaded parts and

do not overtighten and strip threaded parts when

reassembling.

assembly, pull the Long Gas

Line (19) out of the two Air

Fittings (12). (At reassembly,

lubricate the Long Gas Line

O-rings.) Pull the Regulator

14

26

25

(21) from the Air Valve

(23) and pull out the Short

Gas Line (20) (lubricate

O-rings at reassembly).

Remove the Firing Valve

14

9.

10

4.

12

23

7. 19 21

2.

Remote Line

12

10

10

Adapter

10

20

46

(46) from Air Valve (23) (see Firing Valve

Disassembly

5. Lift out the Magazine Release (4) Spring

(13), Safety (22) (at reassembly, the black

O-ring end goes into right receiver half);

below).

Red

Black O-

ring

Trigger (5), Trigger Pin (long) (33), Ball

Latch (24), Breech Window (16), Release

Actuator (3), and the Actuator Link (6).

33

22

5.

24

16 4. 13 6.

6. Clean and inspect parts. Replace any

damaged parts. Use Tippmann grease to

lightly lubricate the Safety O-rings, Spring

(13), Trigger hinge (arrow above), and

Trigger Pin (33) to maintain your marker in

good working condition.

7. To reassemble, follow these instructions in

reverse and be sure the Actuator Pin (arrow, below right) is pushed in ush to the Firing

Valve Body as shown.

NOTE: Carefully hand start all threaded parts. Do not overtighten

and strip threaded parts when reassembling.

NOTE: Failure to reassemble correctly can cause damage to parts, air/CO2 leaks, and

other problems. As you reassemble your marker, double check to be sure parts are

clean, not damaged, lubricated, and installed correctly.

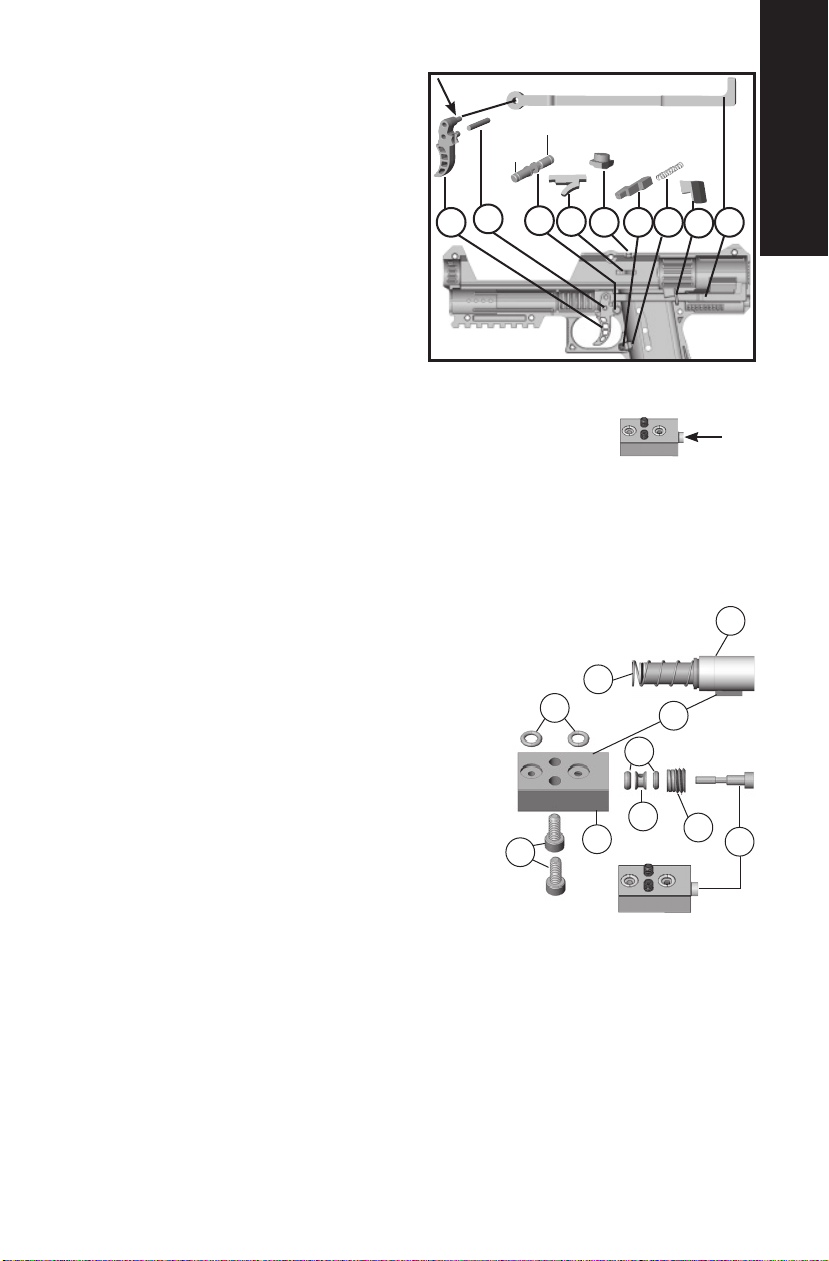

Firing Valve Disassembly/Assembly

E

N

G

L

I

S

3.

H

1. Follow Marker Disassembly/Assembly on page 14.

2. Remove the Firing Valve (46) from the Air Valve (23),

23

by removing the 2 Screws (47) with a 3/32” Allen

wrench.

3. The 2 O-rings (45) are not attached.

NOTE: Be sure the 2 O-rings are in place when

reassembling the Firing Valve to the Air Valve.

4. Pull the Actuator Pin (51) out. NOTE: When

45

52

46

48

reassembling be sure this Pin is pushed in ush to

the Firing Valve body as shown.

5. Remove the Firing Valve Pin Guide (50) using a 3/32”

wrench.

47

46

49

50

6. Tap on the Firing Valve Body (46). Two O-rings (48)

and the Valve Bushing (49) should fall out (if you

need to pull the parts out, use a plastic tool so you do

not damage the parts).

7. Clean and inspect parts. Replace any damaged parts. Use Tippmann grease to lightly

lubricate the Spring (52) and O-rings (45 and 48) to maintain your marker in good

working condition.

8. To reassemble and reattach the Firing Valve to the Air Valve, follow these instructions

in reverse. NOTE: Carefully hand start all threaded parts and do not overtighten and

strip threaded parts when reassembling. NOTE: Failure to reassemble correctly can

cause damage to parts, air/CO2 leaks, and other problems. As you reassemble your

marker, double check to be sure parts are clean, not damaged, lubricated, and installed

correctly.

51

15

E

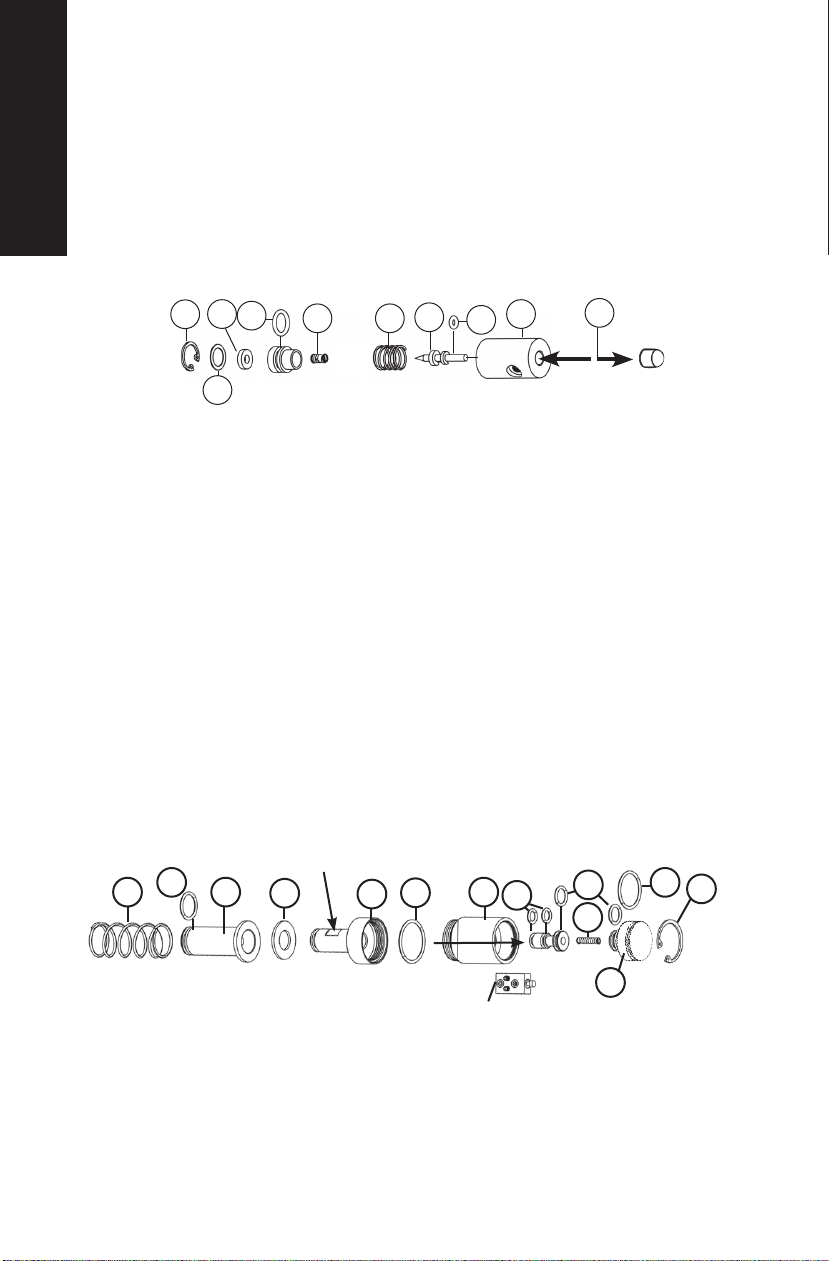

Puncture Valve Disassembly/Assembly

N

G

1. Follow Marker Disassembly/Assembly on page 14. Unscrew the Air Fitting from the

L

I

S

H

open hole in part 43 below. Do not overtighten and strip threads when reassembling.

2. To access the Puncture Valve internals, remove the Snap Ring (34) with a snap ring

tool. NOTE: The snap ring tool tips should t snugly into the snap ring - using a snap

ring tool with tips too small may cause the snap ring to y off the tool and cause injury

and/or damage parts.

To remove the internals from the Puncture Valve Body (43), remove the Puncture Pin

Cap (44) and carefully push Puncture Pin (41) and internal parts out as shown at the

arrow below.

34

35

36

37

39 40

41

42

43

44

3. Clean and inspect parts. Replace any damaged parts. NOTE: O-rings are shown

removed: It is not necessary to remove O-rings as shown to inspect, clean, and

lubricate. Use Tippmann grease to lightly lubricate the O-rings (37 and 42) and Springs

(39 and 40) to maintain your marker in good working condition.

4. To reassemble, follow these instructions in reverse. NOTE: Carefully hand start all

threaded parts and do not overtighten and strip threaded parts when reassembling.

NOTE: Failure to reassemble correctly can cause damage to parts, air/CO2 leaks, and

other problems. As you reassemble your marker, double check to be sure parts are

clean, not damaged, lubricated, and installed correctly.

Air Valve Disassembly/Assembly

1. Follow Marker Disassembly/Assembly on page 14.

2. Refer to the diagram below. Slide the Front Bolt Spring (52), Front Bolt (54), and

Damper (55) off the Power Tube (56).

3. Remove Power Tube from the Air Valve Body (58) by unscrewing the Power Tube with a

1/2” wrench on the “wrench ats” (see arrow below).

4. To access the Air Valve Body internal parts, remove the Snap Ring (65) with a snap ring

tool. NOTE: The snap ring tool tips should t snugly into the snap ring. Using a snap

ring tool with tips too small may cause the snap ring to y off the tool and cause injury

and/or damaged parts. To remove the internals from the Air Valve body (58), carefully

push them out with a plastic tool in the direction shown.

53

52 54

55

57

56

NOTE: The Firing Valve Assembly attaches to the Air

Valve (58) (see Firing Valve Disassembly/Assembly).

58

60

61

63

64

62

65

5. Clean and inspect parts. Replace any damaged parts. NOTE: O-rings are shown

removed. It is not necessary to remove O-rings as shown to inspect, clean, and

lubricate. Use Tippmann grease to lightly lubricate the O-rings (53, 57, 60, 61, and 62)

and springs (52 and 63) to maintain your marker in good working condition.

6. To reassemble, follow these instructions in reverse. NOTE: Carefully hand start all

threaded parts and do not overtighten and strip threaded parts when reassembling.

16

WARNING

Keep exposed skin away from escaping gas when

installing or removing a CO2 cartridge, or if the marker or

air supply is leaking. Compressed air, CO2, and nitrogen

gasses are very cold, and can cause frostbite under

certain conditions.

NOTE: Failure to reassemble correctly can cause damage to parts, air/CO2 leaks, and

other problems. As you reassemble your marker, double check to be sure parts are

clean, not damaged, lubricated, and installed correctly.

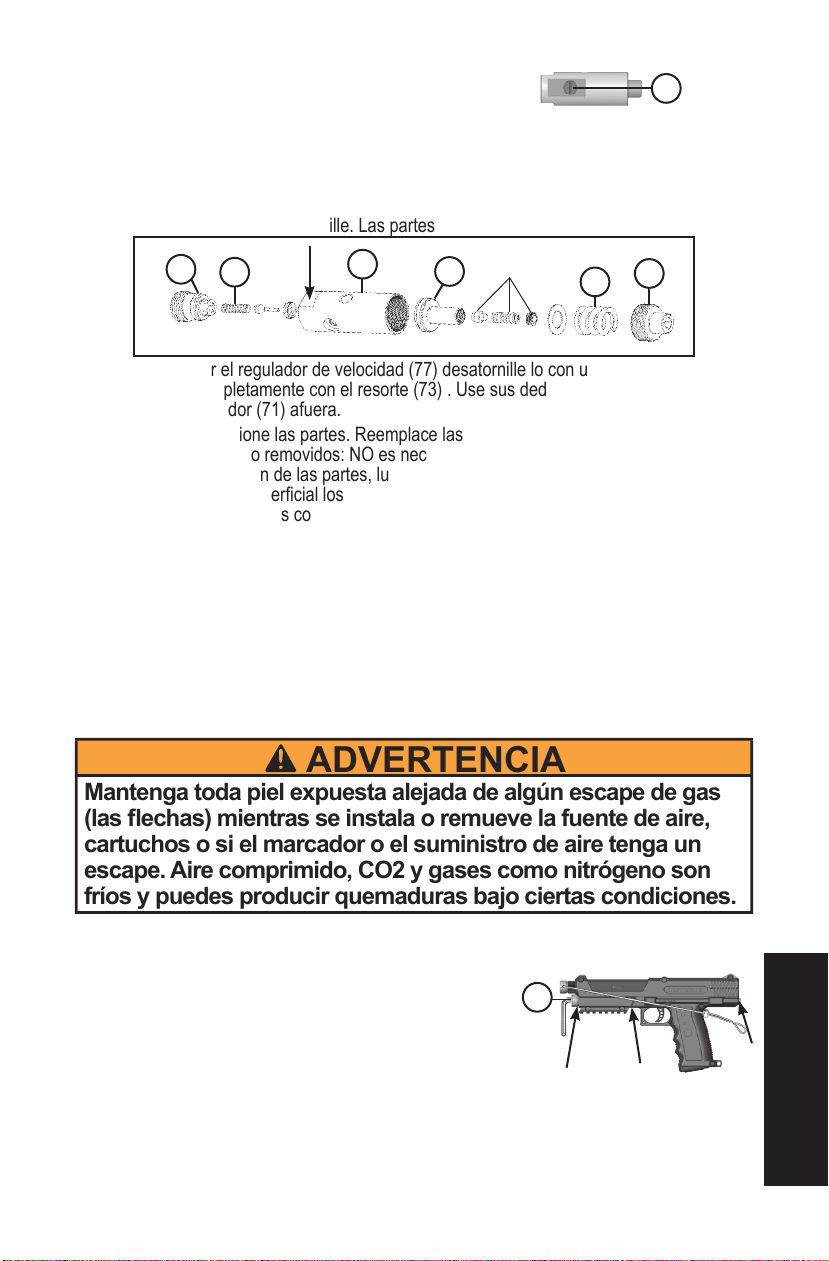

Regulator Disassembly/Assembly

1. Follow Marker Disassembly/Assembly on page 14.

Remove the Air Fitting (12).

2. Remove the Regulator End Cap (66) from the

Regulator Body (70) by holding the Regulator Body on the “wrench ats” (arrow) with a

5/8” wrench, and remove the End Cap by turning to the left with a 3/16” Allen wrench.

Internal parts slide out.

66

67

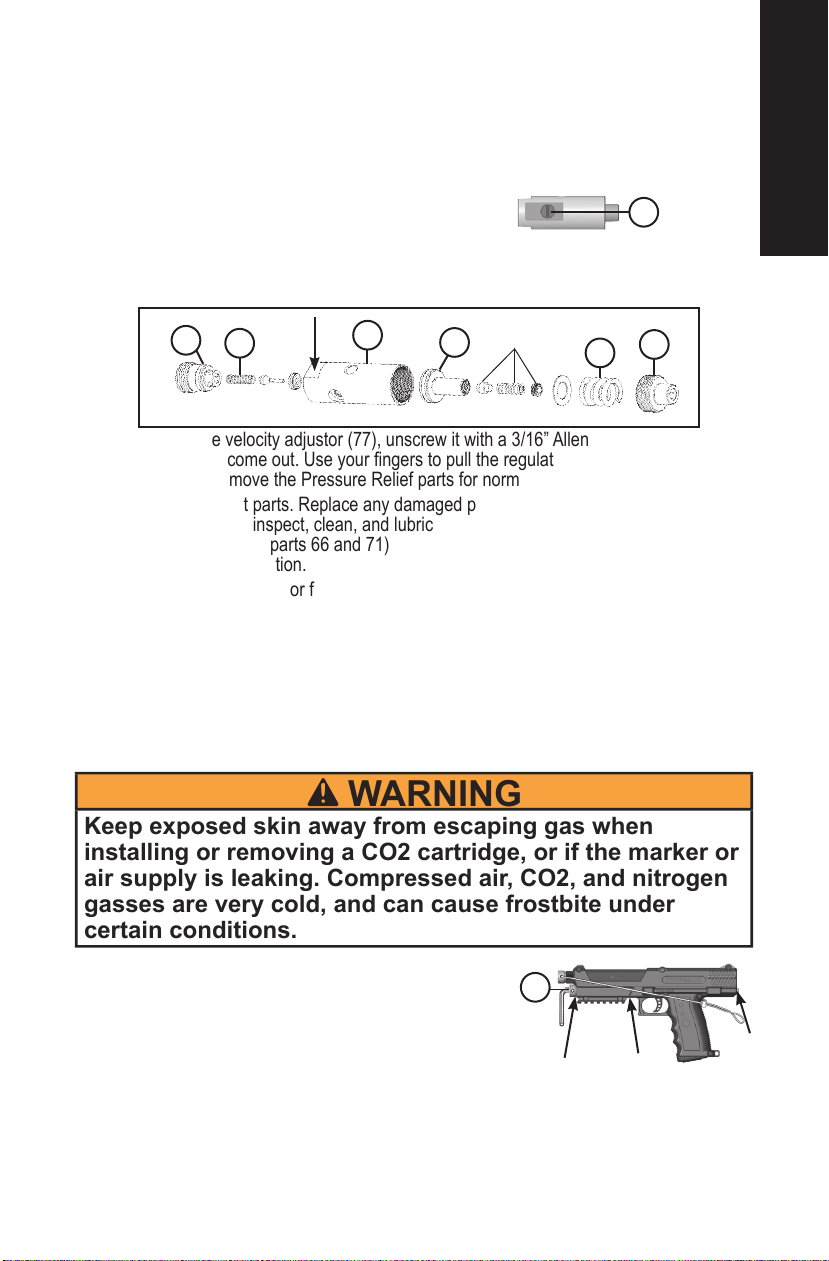

3. To remove the velocity adjustor (77), unscrew it with a 3/16” Allen wrench until it and

the spring (73) come out. Use your ngers to pull the regulator piston (71) out. It is not

necessary to remove the Pressure Relief parts for normal maintenance.

4. Clean and inspect parts. Replace any damaged parts. NOTE: It is not necessary to

remove O-rings to inspect, clean, and lubricate them. Use Tippmann grease to lightly

lubricate O-rings (on parts 66 and 71) and springs (67 and 73) to maintain your marker

in good working condition.

5. Reassemble the regulator following these instructions in reverse. NOTE: Failure to

reassemble correctly can cause damage to parts, air/CO2 leaks, and other problems.

As you reassemble your marker, double check to be sure parts are clean, not damaged,

lubricated, and installed correctly.

6. Upon marker reassembly, you will need to adjust the Regulator Pressure Relief Valve if

you removed the Pressure Relief parts from item #71 (see Regulator Pressure Relief

Valve Adjustment

on page 19).

70

71

Pressure Relief

parts

73

12

77

E

N

G

L

I

S

H

Release Pressure From a Marker That Will Not Fire

Only use this procedure if marker will not re and the CO2

cartridge has been punctured. Put the trigger safety in Safe

mode (see page 6) and install the barrel blocking device

(see page 4). Remove the Magazine as outlined in CO2

Cartridge Removal

Keep marker pointed in a safe direction during CO2 cap (15) removal. Keep exposed skin

away from escaping gas as it rushes out at the air

Remove exterior locking set screw, and then slowly loosen adjusting set screw to empty CO2

from the cartridge. Remove and dispose of the CO2 cartridge.

(see page 10).

/CO2 release points (arrows).

17

15

E

Adjustable CO2 Cap

N

G

CO2 cartridges vary from brand to brand. Your Tippmann TPX can be tuned to easily puncture

L

a variety of cartridge brands. The internal parts for the CO2 cap cannot be purchased

separately. You must order the adjustable CO2 cap as an assembly (see parts list).

I

1. Push the trigger safety to Safe mode (see page 6). Install the barrel blocking device

S

H

(see page 4). Remove the CO2 Cap (see page 10) and ensure the CO2

compartment is empty. Remove the Magazine (see page 9). Inspect the breech to

conrm the marker is unloaded.

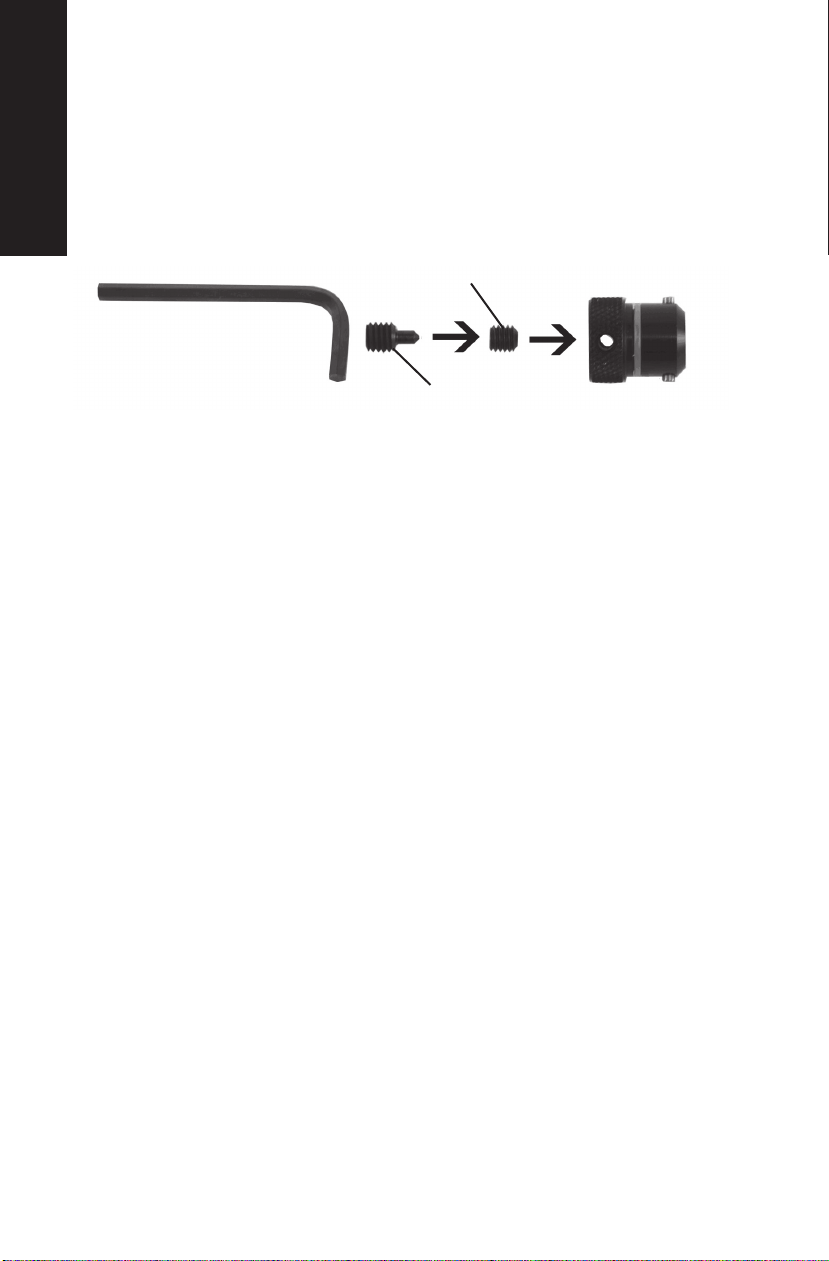

Adjusting Set Screw

3/16” Allen Wrench

cartridge

Locking Set Screw

2. Replace the CO2 Cap. With CO2 Cap in the marker and the trigger safety in Safe

mode, remove the exterior Locking Set Screw from the CO2 Cap using the 3/16” Allen

wrench supplied with your marker. Remove the CO2 Cap from the marker. Unscrew the

Adjusting Set Screw until it does not protrude from the end of the CO2 Cap.

3. Insert a full CO2 cartridge and reinstall the CO2 Cap.

4. With the trigger safety in Fire mode, tighten the Adjusting Set Screw while lightly pulling

the trigger until you feel the Puncture Pin make contact with the CO2 cartridge. Loosen

the Adjusting Set Screw 1/4 turn. Push the trigger safety to Safe mode.

5. Remove the CO2 Cap and the CO2 cartridge from the marker.

6. Without a CO2 cartridge in the marker, reinstall the CO2 Cap into the marker, then

install exterior Locking Set Screw and tighten.

7. Reinstall the CO2 cartridge. If the cartridge punctures without pulling the trigger, the

Adjusting Set Screw is set too deep. If you fully pull the trigger and the cartridge does

not puncture, the Adjusting Set Screw is set too shallow.

8. Remove and dispose of the CO2 cartridge (see

Because manufacturer’s tolerances vary for CO2 cartridge length, steps 1 through 6

may need to be repeated in order to nd the optimal setting for your particular brand of

CO2 cartridge.

Additional Information Regarding Performance

1. For best results, and to keep your TPX pistol running at peak performance, it is

recommended that you use a paintball that is not too old or fragile and free of dimples

or defects. Tippmann also discourages leaving paint in Magazines for an extended

period of time as this can lead to the paintball deforming. Only load Magazines the day

of play.

2. To determine if the paintballs are appropriate for use with the TPX pistol, press the tip

of your ngernail against a paintball to determine if it is easily dimpled. If the paintball

dimples, this paintball should not be used in the TPX pistol.

3. Please thoroughly read this TPX manual, and in particular, review the Magazine

Removal, Loading, and Unloading

Magazine. Proper loading will ensure proper feeding of the paintballs into your TPX

pistol.

instructions (see page 9) before loading your

CO2 Cartridge Removal on page 10).

CO2 Cap

18

Regulator Pressure Relief Valve Adjustment

The regulator pressure relief valve is factory set to 350 psi. Do not reset

it higher than 350 psi because that could cause damage to marker parts

or cause personal injury. If you disassemble the Regulator (page 17)

and remove the indicated parts from item #71, you will need to reset the

Regulator Pressure Relief Valve before using your marker.

1. Adjust the velocity as outlined in Velocity Adjustment on page

10 until your marker chronographs at 300 fps.

2. Put the trigger safety in Safe mode (see page 6) and install the

barrel blocking device (see page 4). Remove the Magazine as

outlined in Magazine Removal, Loading, and Unloading (see

page 9).

3. Insert a 1/8” wrench through the Velocity Adjuster Set Screw (S) and into the Regulator

Relief Set Screw (V) and turn it slowly counterclockwise only until air/CO2 begins to

escape through the Relief Valve. Then turn the set screw slowly back clockwise only

until air/CO2 stops escaping, setting the relief pressure. NOTE: Do not turn any further

clockwise which would set it higher than 350 psi. This could cause damage to marker

parts or cause personal injury.

4. Follow the Velocity Adjustment Instructions on page 10 to adjust the velocity until the

marker chronographs to 300 fps or less.

s

v

Troubleshooting

PROBLEM: You have successfully loaded and punctured a new cartridge, put the trigger

safety in Fire mode. Your marker will not re and you can’t get the CO2 cartridge out of the

marker.

SOLUTION: Put the trigger safety in Safe mode (see page 6) and install the barrel blocking

device (see page 4). Remove the Magazine as outlined in Magazine Removal (see page 9).

Follow the instructions Release Pressure From a Marker That Will Not Fire on page 17.

PROBLEM: Air/CO2 is leaking out of the gas vent hole (see arrow).

SOLUTION: The most common air/CO2 leak is caused by a

dirty or damaged puncture seal. Check the Puncture Seal (36)

for dirt or damage (see Puncture Valve Disassembly on

page 16).

PROBLEM: Magazine will not feed paintballs correctly.

SOLUTION: Try using fresh paintballs

SOLUTION: Clean the Magazine with a damp towel to wipe off paint, grease, and debris. Dry

springs immediately, if necessary, to help prevent rusting.

PROBLEM: You pull the trigger, and the marker does not pressurize.

SOLUTION: Adjust the CO2 Cap assembly (see instructions on page 18).

PROBLEM: Air/CO2 is leaking from the air/CO2 cylinder connection to the remote coil tank

adapter.

SOLUTION: The most common leak occurs from a bad air/CO2 cylinder valve O-ring (see

Repairing Air/CO2 Cylinder Leaks on page 24).

19

77

E

N

G

L

I

S

H

E

Problems After Disassembly/Assembly Of Your Marker

N

Failure to reassemble parts correctly can cause damage to parts, air/CO2 leaks, and other

G

problems. Always double check to be sure parts are clean, not damaged, lubricated, and

L

installed correctly when you disassemble/reassemble your marker.

I

PROBLEM: You pull the trigger and the marker does not pressurize.

S

H

SOLUTION: Check that the puncture pin cap (44) is installed (see Puncture Valve

Disassembly

SOLUTION: Adjust the CO2 cap (see page 18).

PROBLEM: You install a cartridge and you hear air/CO2 leaking.

SOLUTION: Check to be sure the O-rings of the long gas line and the short gas line are not

damaged (see Marker Disassembly on page 14).

PROBLEM: The Regulator (#77 in illustration on previous page) vents air/CO2 continuously.

SOLUTION: Adjust the Pressure Relief Valve (see page 19).

SOLUTION: Check the Regulator Pin (68) for dirt, damage, or if it is not inserted into the

Regulator Piston (71) properly. Clean, inspect, and replace if damaged.

NOTE: When assembling, be sure the Regulator Pin seats into the Regulator Piston (see

Regulator Disassembly on page 17).

PROBLEM: You pull the trigger back and it binds and will not release.

SOLUTION: Check the Firing Pin (51) for misalignment. Disassemble the Firing Valve and

make sure the Firing Pin is pushed in ush with the Firing Valve Body during assembly (see

Firing Valve Disassembly on page 15).

PROBLEM: There is air/CO2 leaking out of the barrel.

SOLUTION: Check the Front Valve Spool O-ring (60) for dirt or damage (see Air Valve

Disassembly

PROBLEM: When the trigger is pulled slowly, a short leaking sound is normal. The leak

continues without the gun ring.

SOLUTION: Check the Valve Spool rear O-ring (61) and the Air Valve End Cap O-ring (61) for

dirt or damage (see Air Valve Disassembly diagram on page 16).

PROBLEM: The trigger will not move at all when trying to re.

SOLUTION: Check the trigger safety (22) to be sure it is not installed backwards. The red

O-ring (32) should be on the left side of the marker (PUSH SAFE is embossed on this side),

and the black O-ring (31) on the right side of the marker (PUSH FIRE is embossed on this

side) (see Marker Disassembly on page 14).

PROBLEM: You re the marker but no paintballs are red.

SOLUTION: If the Front Bolt (54) sticks in the forward position, paintballs will not load. Check

the Ball Latch (24) to be sure it is not installed backwards (see Marker Disassembly on

page 14).

SOLUTION: If the Front Bolt (54) is installed correctly and does not return completely, the

paintballs will not load. Check the Barrel Adapter (25) and the Air Valve Assembly (23) for dirt

or damage (see Marker Disassembly on page 14).

NOTE: If a problem still exists, contact Tippmann Service Department at 1-800-533-4831 or

see your local paintball dealer.

on page 16).

on page 16).

20

Remote Line Adapter (optional equipment)

NOTE: The following includes instructions for installation, turning on, and turning off the air/

CO2 cylinder of the Tippmann H-01 Remote Line. If your remote line is not this Tippmann

model, follow the instructions provided with your remote line for installation, turning on, and

turning off the remote air/CO2 cylinder.

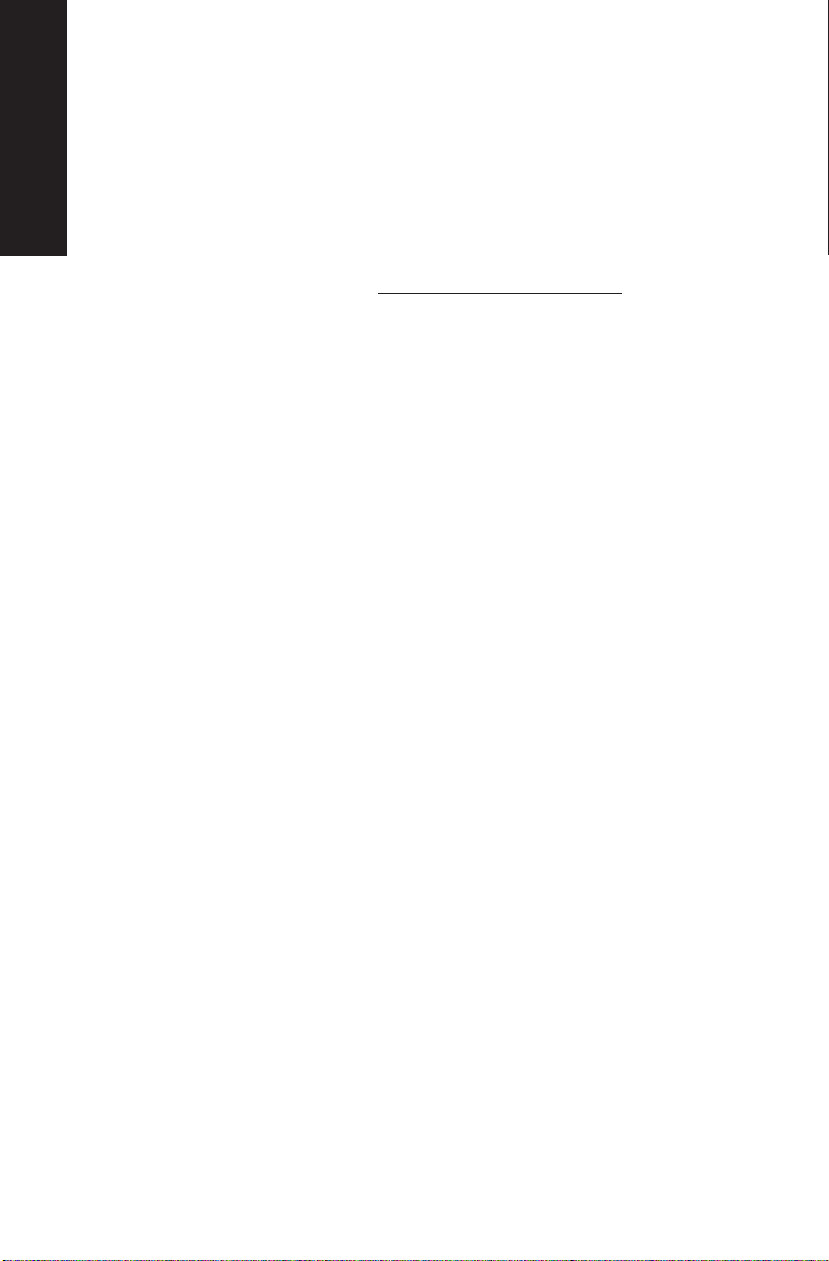

Connecting, Disconnecting, and Removing a Remote Air/CO2 Cylinder

1. Eye protection designed for paintball use must be worn by the user and any person

within range. Put trigger safety in Safe mode (see page 6). Install the barrel blocking

device (see page 4). Remove and unload the Magazine (go to page 9 and follow

Magazine Removal, Loading, and Unloading instructions).

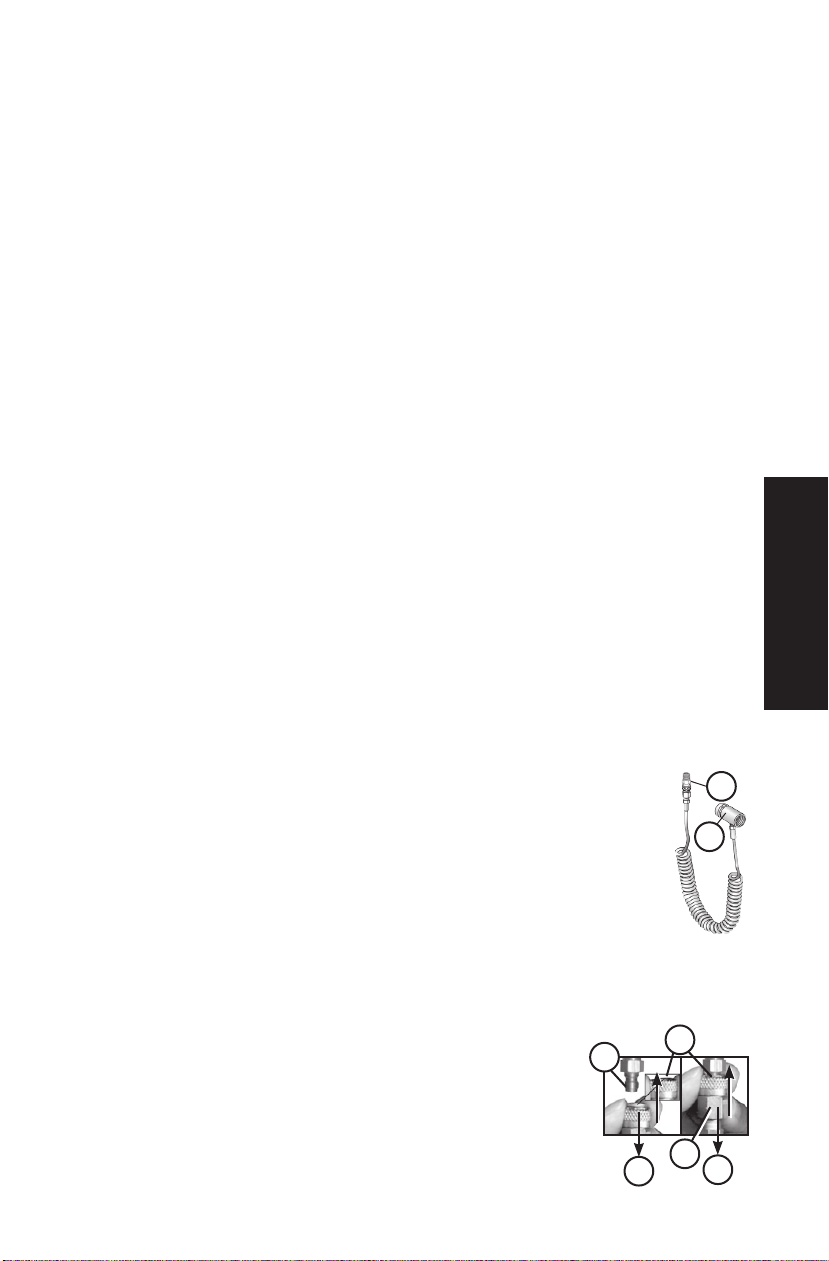

2. Pull and hold the Remote Coil tting Locking Ring (A) down to connect or remove the

Remote Coil tting (B).

3. To connect to the marker, with the Locking Ring (A) held down, push the

coil tting (B) up onto the nipple (C) and release the locking ring up to

lock (D). Pull down on the Remote Coil tting (E) to be sure it is locked

properly.

4. Before attaching the air/CO2 cylinder to the Remote Line, markers with

a Remote Line Adaptor must rst have an empty 12 gram CO2 cartridge

installed to operate properly. Turn off the Remote Line air/CO2 ow control

valve (F) by turning the ow control (G) counterclockwise outward until it

stops (see illustration at right). Install a 12 gram CO2 cartridge

by following the CO2 Cartridge Installation instructions on

page 8. Empty the cartridge of all CO2 by following steps 1-6 in

Removing a Used CO2 Cartridge (Punctured) on page 11,

leaving the empty cartridge installed in the marker.

5. Install the air/CO2 cylinder. First mark the cylinder and cylinder

valve if necessary (see Air/CO2 Cylinder Warnings and

Safety Tips on pages 22-24). Lubricate the cylinder valve

O-ring with a little marker grease, then insert the cylinder valve

end into the Air Supply Adapter (ASA) of the Remote Line. Twist

the cylinder clockwise into the ASA (H) until it stops. Your marker is

ready to re once you:

• turn on the ow control (G) clockwise all the way in (J),

• remove the barrel blocking device, and

• switch the trigger safety from Safe mode to Fire mode.

To turn off the air/CO2 supply, turn the ow control (G) completely

clockwise out (F). To turn on air supply, turn ow control

counterclockwise completely in (J).

NOTE: If the air/CO2 cylinder is full, and you do not hear the marker pressurize, the Pin

Valve could be too short or the Pin Valve Seal is damaged. You will need to remove the

remote air/CO2 cylinder and take it to a “C5” Certied Airsmith for repair.

6. Air/CO2 Cylinder Removal — You must rst read the Air/CO2 Cylinder Warnings and

Safety Tips on pages 22–24 before beginning the cylinder removal process in

step 7.

C.

A.

G.

G.

B.

H.

D.

B.

E.

F.

H.

J.

E

N

G

L

I

S

H

21

E

7. Refer to the illustration at

N

G

L

I

S

H

right. Whenever you turn the

air/CO2 cylinder (2) during

removal, watch the mark (4)

on the cylinder and the mark

(3) on the cylinder valve to be

sure that they rotate together.

If you see the marks begin

to separate (5), STOP! and

take your marker to a qualied

professional, such as a “C5” certied airsmith.

8. Turn the cylinder approximately 3/4 turn counterclockwise. This allows the air supply pin

valve to close so that no air will enter the marker. Point the marker in a safe direction

and discharge the remaining gas in the marker by pulling the trigger until the marker

stops ring. If your marker continues to re, the cylinder pin valve has not closed yet

(the cylinder pin valve could be too long, because of the variances in cylinder pin valve

parts, each cylinder varies slightly on exactly how far it should be turned) and you will

have to turn the cylinder counterclockwise a little further and repeat this step until the

marker does not re, then remove the cylinder. NOTE: If during this step, you turned the

cylinder and it began to leak before you pulled the trigger, the cylinder O-ring should be

checked for damage before reassembly (see Repairing Air/CO2 Cylinder Leaks on

page 24).

9. After the air/CO2 cylinder is removed, point and re the marker in a safe direction until

stored air is completely discharged.

NOTE: Before storing or disassembling be sure to follow Magazine Removal,

Loading, and Unloading

instructions on page 10. Put the trigger safety in Safe mode (see page 6) and install the

barrel blocking device (see page 4).

instructions on page 9 and CO2 Cartridge Removal

Remote Coil Air

Supply Adapter

G.

H.

3.

1.

5.

STOP

4.

2.

Air/CO2 Cylinder Warnings

WARNING

The brass or nickel plated cylinder valve (#1) is intended

to be permanently attached to the air or CO2 cylinder (2).

An air or CO2 cylinder can y off with enough force to

cause serious injury or death if the cylinder (2) unscrews

from a cylinder valve (1).

Refer to the gure at right. There have been reported incidents

caused by players unknowingly unscrewing the cylinder (2)

from the cylinder valve (1). This occurs when the player thinks

the entire valve-cylinder assembly is being unscrewed from

the air/CO2 adaptor of the paintball marker, when in fact he or

she is unscrewing the cylinder from the cylinder valve.

To avoid this danger, it is recommended (if your cylinder is not

already marked) that you use paint or nail polish to place a

mark (3) on the cylinder valve, and place another mark (4) on the cylinder, in line with the #3

mark as shown.

22

1

3

2

4

Whenever you turn the cylinder during removal, watch the

marks on the cylinder and the cylinder valve to be sure

that they rotate together. If at any time these marks start to

separate as shown in the gure at right, the cylinder is starting

to unscrew from the cylinder valve and you must STOP and

take the entire unit to a “C5” certied airsmith for safe removal

and/or repair.

NOTE: The cylinder valve should unscrew from the paintball

marker in about 3 or 4 full turns. If you nish the 4th full turn

and the cylinder valve is not unscrewed from the paintball marker, STOP! Take the entire unit

to a “C5” certied airsmith for safe removal and/or repair.

Locate a “C5” Certied Airsmith at www.paintball-pti.com/search.asp.

Whether you have a new or used rellable air/CO2 cylinder, you are at risk if any of the

following has occurred:

• The valve unit was replaced or altered after purchase.

• An anti-siphon device was installed.

• The valve unit was removed from the cylinder for any reason.

• Any modication was done to the rellable air/CO2 cylinder.

If any of these conditions has occurred, take your air/CO2 cylinder to a “C5” Certied Airsmith

for inspection or contact the cylinder manufacturer.

Air/CO2 Cylinder Safety Tips

3

4

E

N

G

L

I

S

H

SAFETY TIPS to ensure that your air/CO2 cylinder is safe for play:

• Improper use, lling, storage, or disposal of air/CO2 cylinder may result in property

damage, serious personal injury or death.

• Make sure that any maintenance or modication to any air/CO2 cylinder is done by

a qualied professional, such as a “C5” certied airsmith.

• The use of anti-siphon devices is not recommended. However, if one is already

installed on your air/CO2 cylinder or is desired, it is critical that your cylinder be

checked by, or the device installed by, a qualied professional.

• All air/CO2 cylinders must be lled only by properly trained personnel.

• Cylinder valves must be installed only by properly trained personnel.

• Do not overll a cylinder! Never exceed the air/CO2 cylinder’s capacity.

• Do not expose pressurized air/CO2 cylinder to temperatures exceeding 130 degrees

Fahrenheit (55 degrees Celsius).

• Do not use caustic cleaners or strippers on the air/CO2 cylinder or cylinder valve

and do not expose to corrosive materials.

• Do not modify the air/CO2 cylinder in any way. Never try to disassemble the cylinder

valve from the air/CO2 cylinder.

• Any air/CO2 cylinder that has been exposed to re or heated to a temperature

of 250 degrees Fahrenheit (121 degrees Celsius) or more must be destroyed by

properly trained personnel.

23

E

N

G

L

I

S

H

• Use appropriate gas for your cylinder. Only use CO2 in a CO2 cylinder and only use

compressed air in a compressed air cylinder.

• Keep all cylinders out of the reach of children.

• The Air or CO2 cylinder should be inspected and hydrostatically retested at least

every 5 years by a DOT licensed agency.

• Keep exposed skin away from escaping gas when installing or removing air/CO2, or

if the marker or air/CO2 is leaking. Compressed air and CO2 gasses are very cold,

and can cause frostbite under certain conditions.

NOTE: Locate a “C5” certied airsmith at www.paintball-pti.com/search.asp

Repairing Air/CO2 Cylinder Leaks

The most common leak occurs from a bad air/CO2 valve O-ring. To replace a valve O-ring

you must rst remove the bad O-ring and then install a new one. This O-ring is located on

the tip of your air/CO2 valve. The best valve O-rings are made of urethane. Urethane O-rings

are not affected by high air/CO2 pressures. These may be purchased from Tippmann or your

local paintball dealer.

NOTE: If a new air/CO2 valve O-ring does not resolve an air/CO2 leak, do not attempt to

repair the air/CO2 cylinder. Contact Tippmann Sports, LLC, your local paintball dealer, or a

“C5” Certied Airsmith.

Storage

Before storage, follow the Magazine Removal, Loading, and Unloading instructions on

page 9 and CO2 Cartridge Removal instructions on page 10 (on page 21 for markers with a

Remote Line Adapter installed). Do not store a marker with any of the following installed:

• 12 gram air/CO2 supply cartridge (punctured or unpunctured)

• an air/CO2 cylinder

• Magazine

Store the Magazine empty, with the Ball Carrier in its topmost position.

Put the trigger safety in Safe mode (see page 6) and install the barrel blocking device (see

page 4). You should store your marker in a dry area. Before storing your marker, make sure

that the marker is cleaned and lubricated (see Cleaning & Maintenance on page 12) so that

it does not rust.

When removing your marker out of storage, make sure that the trigger safety is in Safe mode

(see page 6) and the barrel blocking device is installed (see page 4).

24

Specications

Model ...........................................................................................................TIPPMANN® TPX

Caliber ............................................................................................................................... .68

Action ................................................................... Semi-Automatic (Open Bolt Blow Forward)

Power/Propellant ................................................................compressed air, nitrogen, or CO2

Cartridge ............................................................................................................12 gram CO2

Shots per 12 gram CO2 cartridge .................................................................approximately 19

Paintball Feed ............................................................................ TPX Magazine (spring feed)

Magazine Capacity ................................................................................................7 Paintballs

Cycle Rate ..................................................................... 1 trigger pull = 1 shot (6 per second)

Standard Barrel Length ..............................................................................6.25” / 15.875 cm

Overall Length (with standard barrel) ............................................................10.8” / 27.43 cm

Weight (without 12 gram CO2 cartridge or paintballs) .................................1.81 lbs. / .821 kg

Effective Range ..............................................................................................150+ ft. / 46+ m

Velocity ................................................................................................................... Adjustable

Always measure your marker’s velocity before playing paintball and never shoot at velocities

in excess of 300 feet/91.44 meters per second (see Velocity Adjustment instructions on

page 10).

E

N

G

L

I

S

H

25

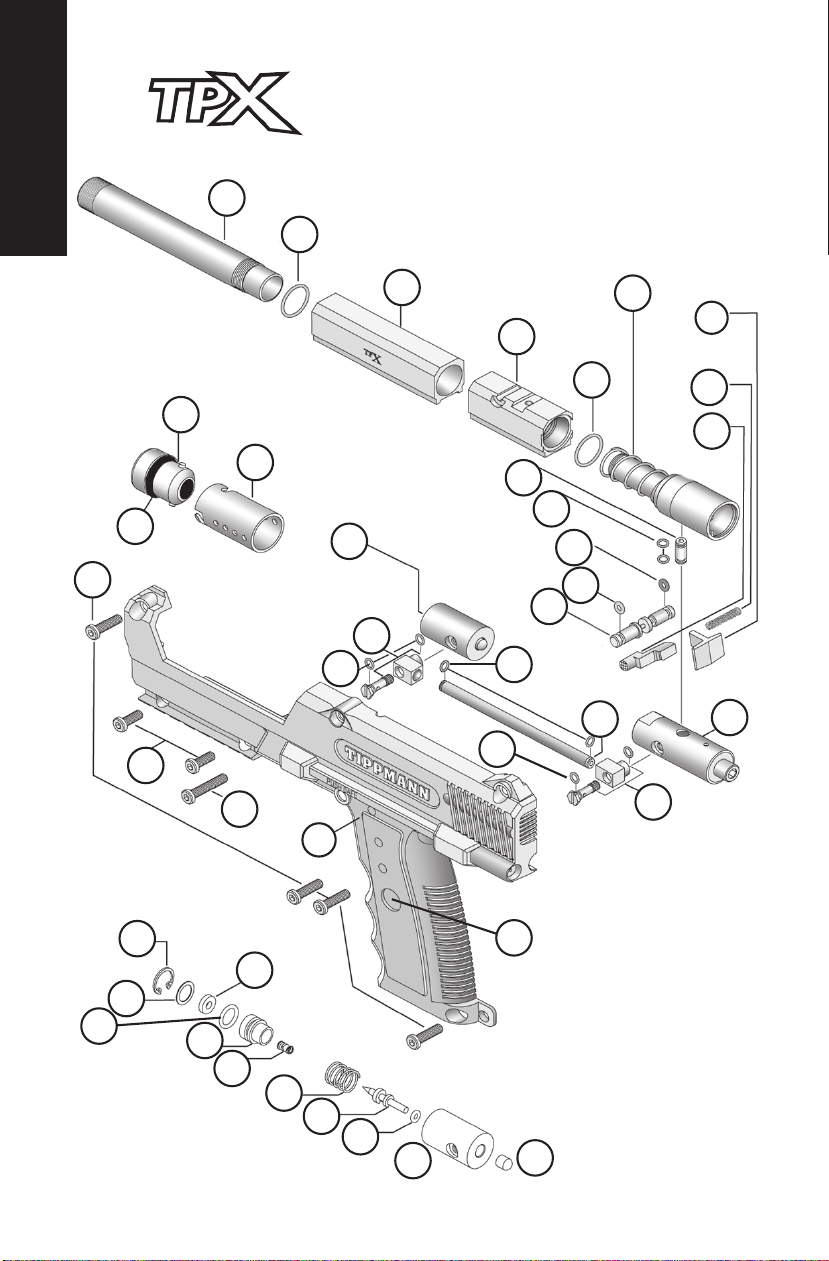

E

N

G

L

S

H

by TIPPMANN

I

27

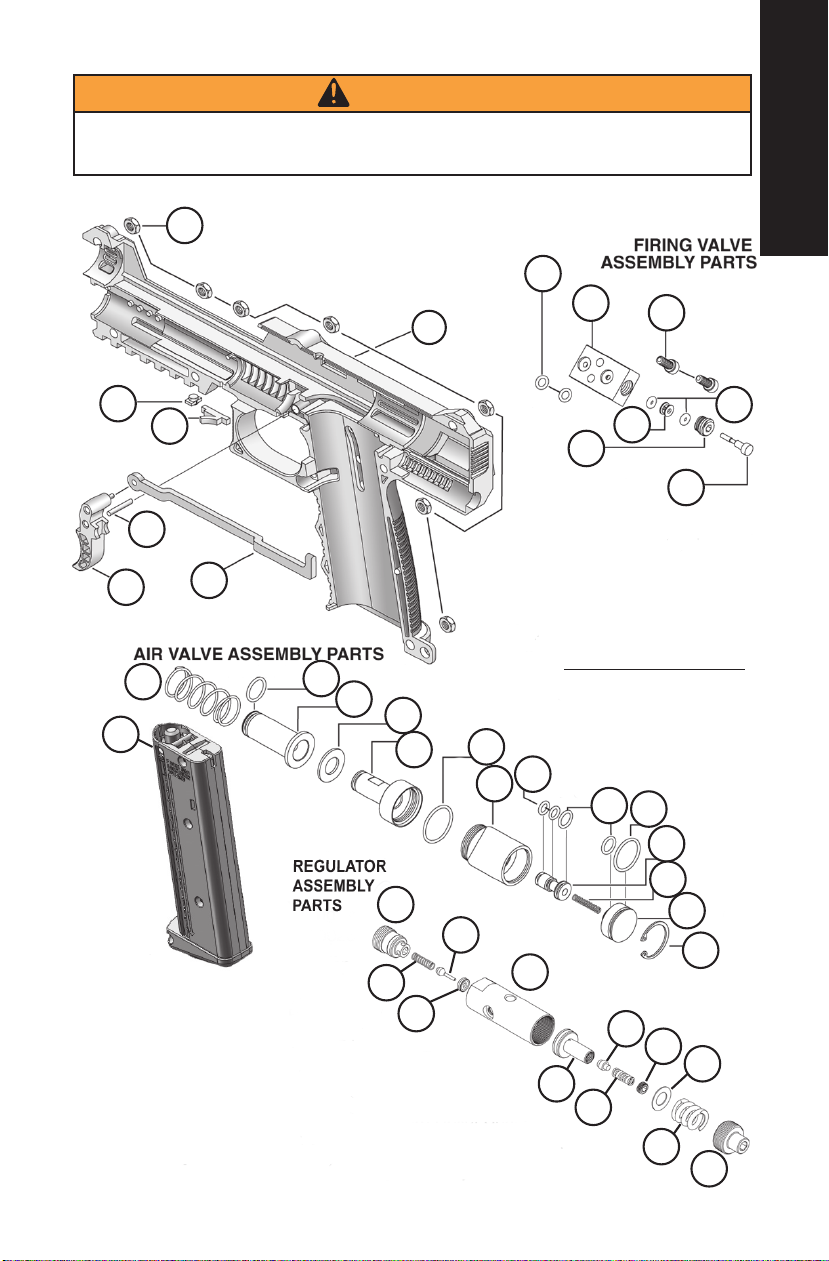

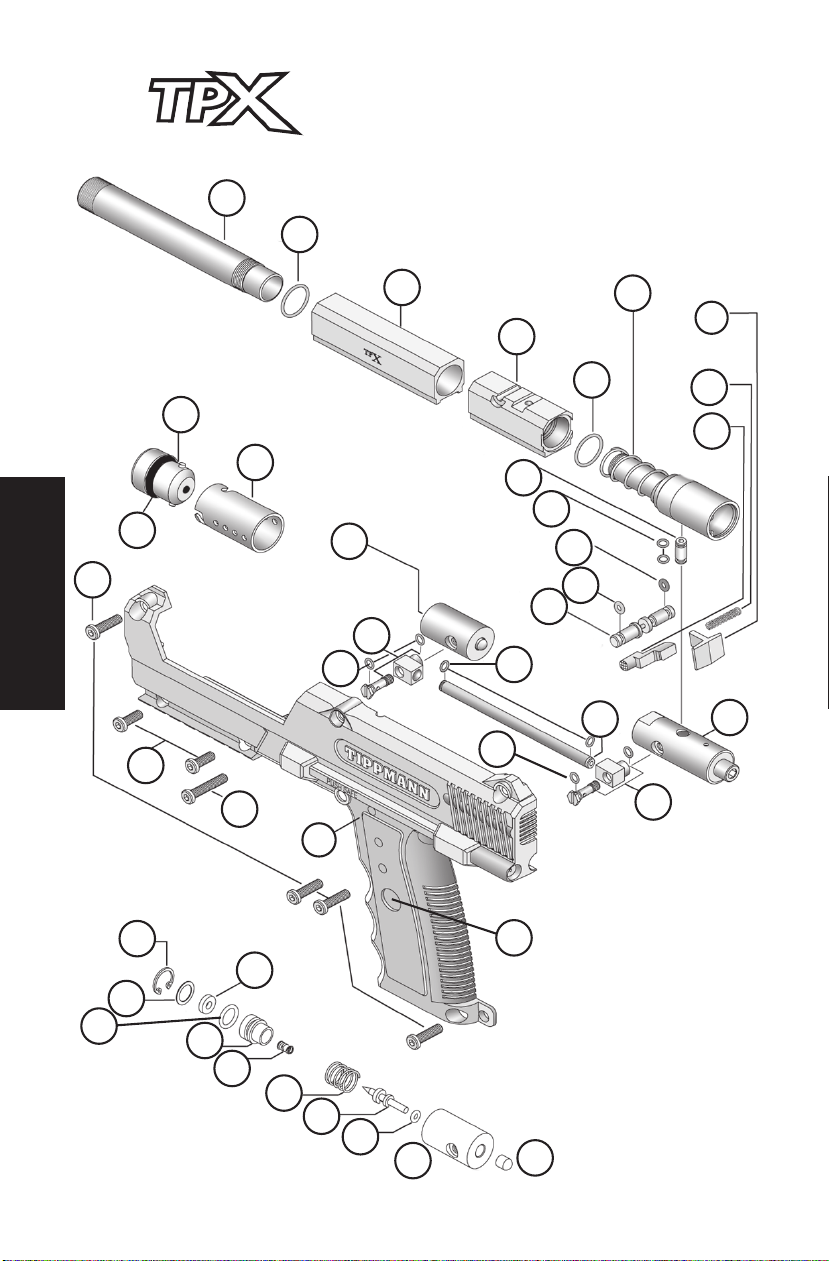

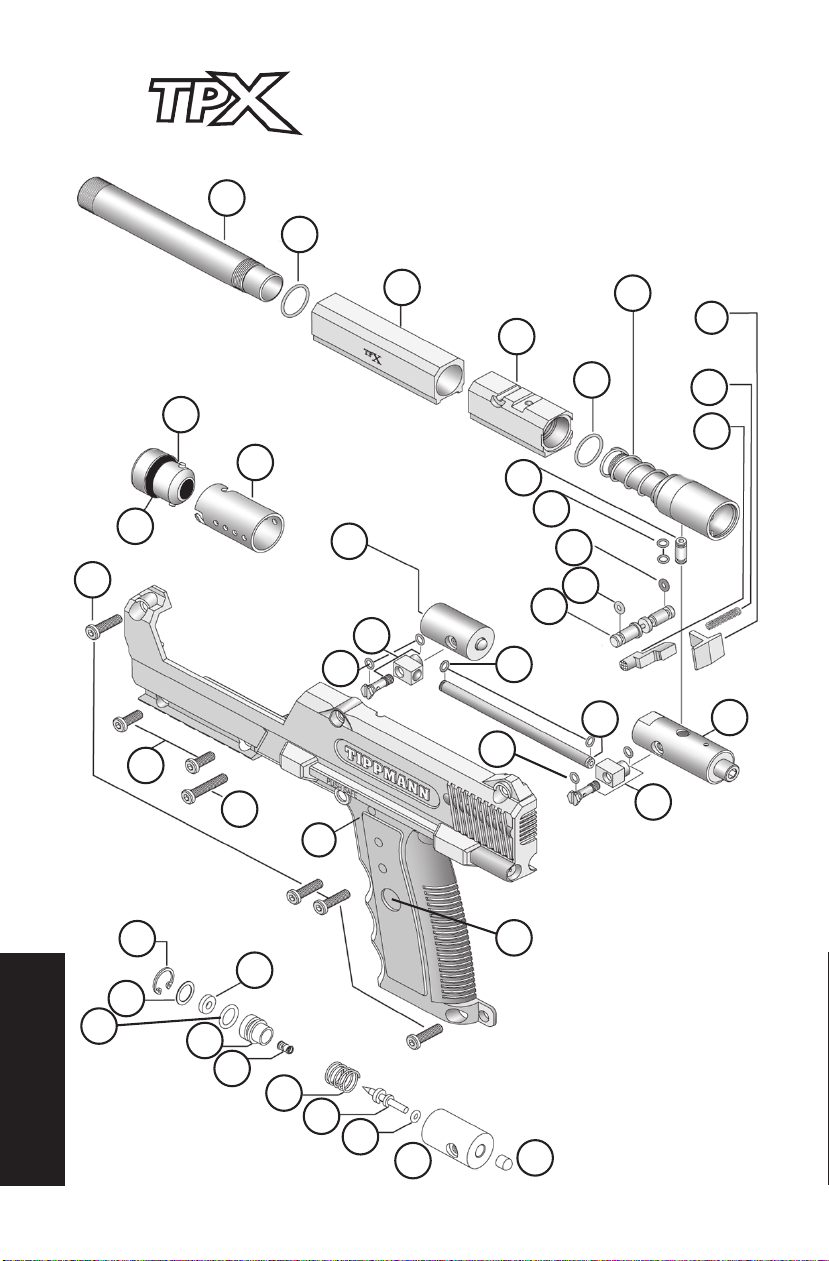

Parts Diagram

29

®

10

18

26

23

3

25

28

15

13

4

14

7

12

30

30

30

20

30

22

31

32

19

21

8

9

12

2

PUNCTURE VALVE

ASSEMBLY PARTS

34

35

37

38

39

36

40

41

42

43

26

17

44

WARNING

Do not disassemble this marker while it is pressurized.

Do not pressurize a partially assembled marker.

11

45

46

1

47

E

N

G

L

I

S

H

16

78

48

24

33

5

6

49

50

51

Tippmann® Service Department

1-800-533-4831

www.tippmann.com

60

61

62

70

74

71

75

59

63

64

65

76

72

52

53

54

67

66

55

56

69

57

58

68

Rev. 06/09/10

73

77

27

E

N

G

L

I

S

H

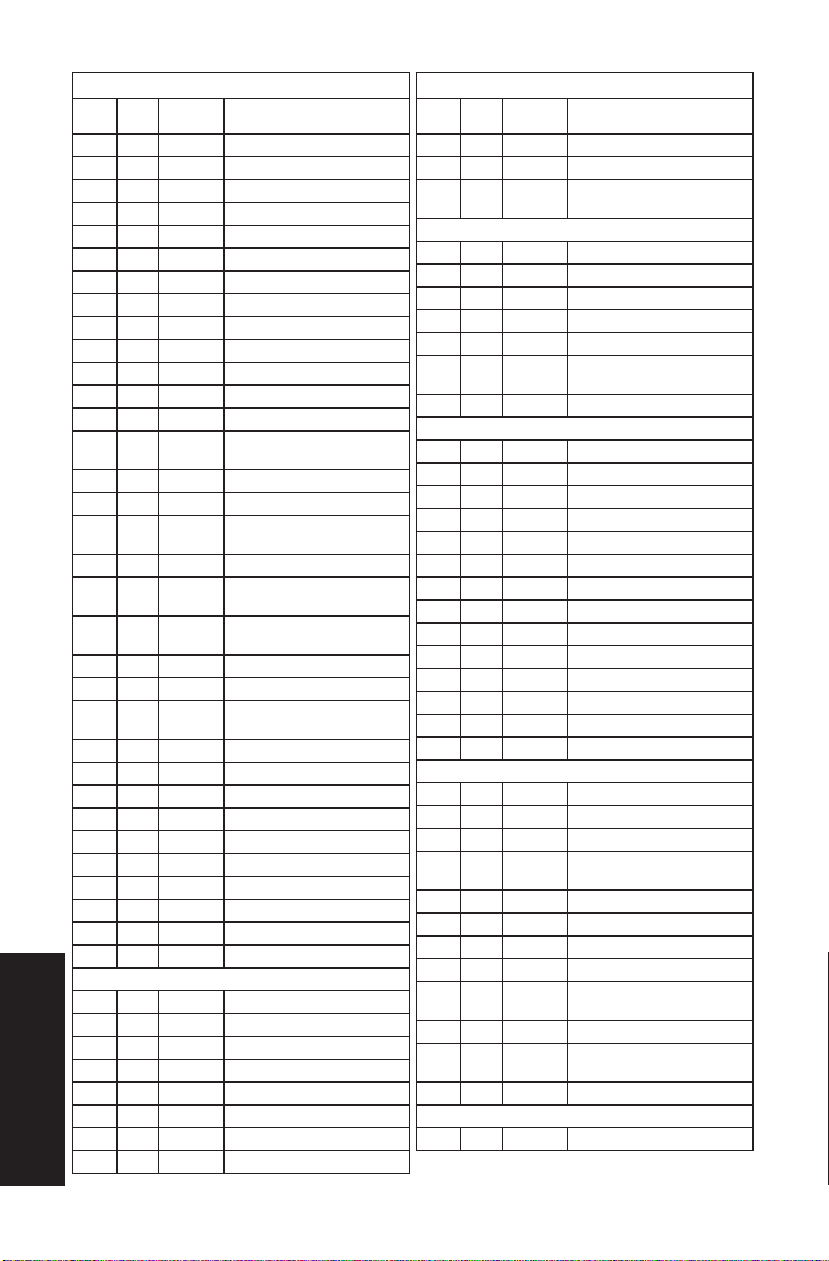

TPX Marker Parts List

ITEM

NO. QTY. PT. NO. DESCRIPTION

1 1 TA20002 Receiver, Right Half

2 1 TA20001 Receiver, Left Half

3 1 TA20042 Magazine Release

4 1 TA20040 Magazine Release

5 1 TA20029 Trigger

6 1 TA20037 Actuator Link

7 1 TA20103 Puncture Valve Complete

8 2 TA20036 LHSH Cap Screw

9 1 TA07074 Bolt

10 4 98-01A LHSH Cap Screw

11 7 TA02060 Hex Nut

12 2 TA20108 Air Fitting

13 1 TA20051 Spring

14 1 TA20053 CO2 Cap Receiver Insert

15 1 TA20062 CO2 Cap

16 1 TA20043 Breech Window

17 1 TP01018 Tippmann “T” Jewel (not

18 1 18-PA CO2 Cap O-ring

19 1 TA20112 Gas Line, Long

20 1 TA20113 Gas Line, Short

21 1 TA20102 Regulator Complete

22 1 TA20110 Safety

23 1 TA20105 Air Valve Complete (with

24 1 FA-18 Ball Latch

25 1 TA20027 Barrel Adapter

26 1 TA20012 Barrel Shroud

27 1 TA20006 TPX Barrel

28 1 TA20046 O-ring

29 1 02-40 O-ring

30 8 TA20050 O-ring

31 1 FA-07 Safety O-ring (black)

32 1 98-55 Safety O-ring (red)

33 1 TA20063 Trigger Pin, Long

Puncture Valve Assembly parts

34 1 TA07089 Snap Ring

35 1 TA20069 Washer

36 1 TA20034 Puncture Seal

37 1 SL2-25 O-ring

38 1 TA20115 Puncture Piston

39 1 TA20015 Spring

40 1 TA20048 Spring

41 1 TA20031 Puncture Pin

42 1 TA20049 O-ring

Actuator

shown)

Firing Valve)

TPX Marker Parts List

ITEM

NO. QTY. PT. NO. DESCRIPTION

43 1 TA20033 Puncture Valve Body

44 1 TA20039 Puncture Pin Cap

Firing Valve Assembly parts

45 2 TA20047 O-ring

46 1 TA20004 Firing Valve Body

47 2 TA20052 Screws

48 2 TA20008 O-ring

49 1 TA20014 Valve Bushing

50 1 TA20030 Firing Valve Pin Guide

51 1 TA20005 Actuator Pin

Air Valve Assembly parts

52 1 TA20085 Front Bolt Spring

53 1 SL2-4 Front Bolt O-ring

54 1 TA20109 Front Bolt

55 1 TA20077 Damper

56 1 TA20016 Power Tube

57 1 TA20010 O-ring

58 1 TA20009 Air Valve Body

59 1 TA20114 Valve Spool

60 2 TA20003 O-ring

61 2 SL2-25 O-ring

62 1 98-12A O-ring

63 1 02-88 Spring

64 1 TA20011 Air Valve End Cap

65 1 TA20035 Retaining Ring

Regulator Assembly parts

66 1 TA20119 Regulator End Cap

67 1 02-88 Spring

68 1 TA20080 Regulator Pin

69 1 TA20075 Regulator Pin Seat

70 1 TA20079 Regulator Body

71 1 TA20120 Regulator Piston

72 1 TA20081 Wear Disk

73 1 TA20038 Spring

74 1 TA20118 Pressure Relief Seal

75 1 TA20067 Spring

76 1 TA20068 Hollow Lock Set Screw

77 1 TA20023 Regulator Adjustment

Magazine Assembly

78 1 TA20122 7 Ball Straight Feed

Guide

Cap

Magazine

28

Warranty and Repair Information

TIPPMANN SPORTS, LLC (“Tippmann”) is dedicated to quality paintball products and

outstanding service. In the unlikely event of a problem with this Tippmann paintball marker

(“Marker”) and/or Tippmann accessories (“Accessories”), Tippmann’s customer service

personnel are available to assist you. For customer service and/or other information, please

contact:

Tippmann Sports, LLC

2955 Adams Center Road

Fort Wayne, IN 46803

www.tippmann.com

1-800-533-4831

Warranty Registration

To activate the Marker’s Limited Warranty, you must register the Marker within thirty (30) days

of the date of original retail sale by:

1. Registering online at www.tippmann.com or

2. Completing the attached warranty registration card and returning it to Tippmann at the

address above.

The Limited Warranty for Tippmann Accessories does not require activation or registration; by

registering the Marker, you activate the warranty for the Accessories.

E

N

G

L

I

S

H

Limited Warranty

Tippmann warrants to the original purchaser that it will make any repairs or replacements

necessary to correct defects in material or workmanship, at no charge to you, for the Marker

for a period of two (2) years from the date of original retail sale. Further, Tippmann warrants

to the original purchaser that it will make any repairs or replacements necessary to correct

defects in material or workmanship, at no charge to you, for Tippmann Accessories for a

period of ninety (90) days from the date of original retail sale. All Tippmann asks is that you

properly maintain and care for the Marker and Accessories (collectively, the “Product”) and

that you have warranty repairs performed by Tippmann or a Tippmann Certied Tech Center.

This Limited Warranty is non-transferable, and it does not cover damage or defects to the

Product caused by (a) improper maintenance; (b) alteration or modication; (c) unauthorized

repair; (d) accident; (e) abuse or misuse; (f) neglect or negligence; and/or (g) normal wear

and tear.

Tippmann does not authorize any person or representative to assume or grant any other

warranty obligation with the sale of this Product.

THIS IS THE ONLY EXPRESS WARRANTY GIVEN WITH THE PURCHASE OF THIS

PRODUCT; ANY AND ALL OTHER EXPRESS WARRANTIES ARE DISCLAIMED. THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED TO THE APPLICABLE LIMITED WARRANTY PERIOD SET

FORTH HEREIN, AND NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, SHALL

APPLY AFTER EXPIRATION OF SUCH PERIOD.

29

E

Some states and nations do not allow limitations on the duration of implied warranties, so the

N

above limitation may not apply to you.

G

The sole and exclusive liability of Tippmann and/or its authorized dealers under this Limited

L

Warranty shall be for the repair or replacement of any part or assembly determined to be

I

defective in material or workmanship. TIPPMANN SHALL NOT BE LIABLE FOR, AND YOU

S

EXPRESSLY DISCLAIM, ANY DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL

H

DAMAGES (COLLECTIVELY, “DAMAGES”) ARISING OUT OF THE SALE OR USE OF, OR

YOUR INABILITY TO USE, THE PRODUCT. NO PAYMENT OR OTHER COMPENSATION

WILL BE MADE FOR DAMAGES, INCLUDING INJURY TO PERSON OR PROPERTY OR

LOSS OF REVENUE WHICH MIGHT BE PAID, INCURRED OR SUSTAINED BY REASON

OF THE FAILURE OF ANY PART OR ASSEMBLY OF THE PRODUCT.

Some states and nations do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This warranty gives you

specic legal rights, and you may also have other rights that may vary from state to state or

nation to nation.

Warranty and Non-Warranty Repairs

When shipping the Product to Tippmann for warranty or non-warranty repair:

1. If you have aftermarket parts on your Marker, please test the Marker with original stock

parts before returning the Marker for service or repair.

2. Always unload and remove the air/CO2 supply from the marker. Do not ship the air/CO2

supply cylinder if it is not completely empty.

3. Ship the Product to the Tippmann address identied.

4. You must pre-pay postage and delivery charges.

5. Provide the date of purchase for the Product.

6. Briey describe the repair requested.

7. Include your name, return address and a telephone number where you can be reached

during normal business hours, if possible.

Tippmann makes every effort to complete its repair work within twenty-four (24) hours of

receipt. Tippmann will return the Product to you via regular ground UPS. If you wish to have

it returned using a faster service, you can request NEXT DAY AIR UPS OR SECOND DAY

AIR UPS, but you will be charged for this service and must include your credit card number

with the expiration date. Your credit card will be charged the difference in additional cost over

regular ground shipping service.

30

Avertissement

Ceci n’est pas un jouet. Une mauvaise utilisation peut causer de

sérieuses blessures ou la mort. Une protection pour les yeux, la

tête et les oreilles et étant adaptée au paintball doit être portée

par l’utilisateur ainsi que tout utilisateur situé dans le champ de

tir. Nous recommandons que l’acheteur ait au moins 18 ans. Les

personnes de moins de 18 ans doivent être supervisées par un

adulte durant l’utilisation de ce produit. Lisez le manuel avant

d’utiliser ce produit.

AVERTISSEMENT

Gardez toujours le dispositif de blocage du canon activé sauf

lorsque vous utilisez votre marqueur. Assurez-vous toujours

que la détente est en mode Sécurité (voir instructions à la page

3) et que le dispositif de blocage du canon est installé correctement sur votre marqueur an d'éviter des dégâts matériels, des

blessures graves ou la mort.

Instructions d’installation du dispositif de blocage du canon

F

R

A

N

Ç

A

I

S

1. Insérez le dispositif de blocage du canon dans le canon et attachez la corde derrière la

poignée comme sur la photo

ci-contre.