®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619

www.tippmann.com

SL-68 II

PAINTBALL MARKER

LANCEUR DE PAINT-BALL

MACADOR PAINTBALL

Owner’s Manual

Manuel d’utilisation

Manual del Usuario

TP04115

Date: 09/09

E

N

G

L

I

S

H

WARNING

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS

INJURY OR DEATH. EYE, FACE, AND EAR PROTECTION

DESIGNED FOR PAINTBALL MUST BE WORN BY

THE USER AND ANY PERSON WITHIN RANGE. WE

RECOMMEND YOU BE AT LEAST 18 YEARS OLD TO

PURCHASE. PERSONS UNDER 18 MUST HAVE ADULT

SUPERVISION WHEN USING THIS PRODUCT. READ THE

OWNER’S MANUAL BEFORE USING THIS PRODUCT.

AVERTISSEMENT

CECI N’EST PAS UN JOUET. TOUT USAGE

INAPPROPRIE PEUT PROVOQUER DES BLESSURES

GRAVES OU MORTELLES. LE PORT DE LA

F

PROTECTION POUR LES YEUX, LE VISAGE ET LES

R

OREILLES CONCUE POUR LE PAINT-BALL EST

A

OBLIGATOIRE POUR L’UTILISATEUR AINSI QUE

N

POUR TOUTE PERSONNE A PORTEE DE TIR. POUR

Ç

L’ACHAT, NOUS RECOMMANDONS L’AGE DE 18 ANS.

A

LES PERSONNES DE MOINS DE 18 ANS DOIVENT

I

ETRE SOUS LA SURVEILLANCE D’UN ADULTE

S

LORSQU’ELLES UTILISENT CE PRODUIT. LISEZ LE

MANUEL AVANT D’UTILISER CE PRODUIT.

ADVERTENCIA

ESTO NO ES UN JUGUETE. UN USO INAPROPIADO

PUEDE CAUSAR SERIAS HERIDAS O LA MUERTE.

OJOS, CARA Y OIDOS DEBEN SER PROTEGIDOS

TODO EL TIEMPO, CON LA PROTECCIÓN DISEÑADA

PARA PAINTBALL TANTO POR JUGA-DORES COMO

E

POR CUALQUIER PERSONA QUE ESTE EN EL RADIO

S

P

DE ALCANCE. RECOMENDAMOS AL MENOS 18 AÑOS

A

PARA LA COMPRA Y USO. LAS PERSONAS MENORES

Ñ

DE 18 AÑOS DEBEN USAR ESTE PRODUCTO BAJO LA

O

SUPERVISIÓN DE UN ADULTO. LEA EL MANUAL DEL

L

USARIO ANTES DE USAR ESTE PRODUCTO.

2

WARNING

SAFETY IS YOUR RESPONSIBILITY

READ AND FAMILIARIZE YOURSELF AND ANY OTHER USER

OF THIS MARKER WITH THE

IN THIS MANUAL. FOLLOW THESE INSTRUCTIONS WHEN

USING, WORKING ON, TRANSPORTING, OR

MARKER.

ALWAYS KEEP THE TRIGGER SAFETY IN SAFE

MODE UNLESS FIRING AS DETAILED IN

INSTRUCTIONS ON PAGE 6.

ALWAYS KEEP THE BARREL SLEEVE

INSTALLED WHEN NOT IN A SHOOTING

SITUATION, SEE INSTRUCTIONS ON PAGE 4.

SAFETY INSTRUCTIONS

STORING THIS

Push Safety

AVERTISSEMENT

LA SECURITE EST VOTRE RESPONSABILITE

LISEZ ET FAMILIARISEZ-VOUS AINSI QUE TOUT AUTRE

UTILISATEUR DE CE LANCEUR AVEC LES INSTRUCTIONS

DE SECURITE CONTENUES DANS CE MANUEL. SUIVEZ CES

INSTRUCTIONS LORSQUE VOUS UTILISEZ, TRAVAILLEZ

SUR, TRANSPORTEZ OU ENTREPOSEZ CE LANCEUR.

SI VOUS NE TIREZ PAS, MAINTENEZ TOUJOURS LA

SECURITE DE LA DETENTE EN MODE SECURITE

COMME INDIQUE DANS LES INSTRUCTIONS EN

PAGE 6.

GARDEZ TOUJOURS LA DOUILLE DU CANON

INSTALLEE LORSQUE VOUS N’ETES PAS EN

SITUATION DE TIR, VOIR INSTRUCTIONS EN PAGE 4.

Push Safety

E

N

G

L

I

S

H

F

R

A

N

Ç

A

I

S

ADVERTENCIA

LA SEGURIDAD ES SU RESPONSABILIDAD

LEA Y FAMILIARICESE USTED Y CUALQUIER OTRO

USUARIO DE ESTE MARCADOR CON LAS INSTRUCCIONES

DE SEGURIDAD DE ESTE MANUAL. SIGA ESTAS

INSTRUCCIONES CUANDO LO USE,TRABAJE EN EL,

TRANSPORTE, O ALMACENE.

MANTENGA SIEMPRE EL GATILLO EN POSICION DE

SEGURO A SIN NO VA HACER UN DISPARO COMO

LO EXPLICA LAS INSTRUCCIONES EN LA PAGINA

SIEMPRE MANTENGA LA FUNDA DE

SEGURIDAD INSTALADA CUANDO NO VA

HACER DISPAROS, VER INSTRUCCIONES EN

LA PAGINA 4.

3

Push Safety

6.

E

S

P

A

Ñ

O

L

E

N

G

L

S

H

WARNING

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS INJURY OR

I

DEATH. EYE, FACE, AND EAR PROTECTION DESIGNED FOR

PAINTBALL MUST BE WORN BY THE USER AND ANY PERSON

WITHIN RANGE. WE RECOMMEND YOU BE AT LEAST 18

YEARS OLD TO PURCHASE. PERSONS UNDER 18 MUST HAVE

ADULT SUPERVISION WHEN USING THIS PRODUCT. READ THE

OWNER’S MANUAL BEFORE USING THIS PRODUCT.

WARNING

ALWAYS KEEP THE BARREL BLOCKING DEVICE INSTALLED

EXCEPT WHEN YOUR MARKER IS IN USE. ALWAYS MAKE

SURE THAT THE TRIGGER SAFETY IS IN THE SAFE MODE (SEE

INSTRUCTIONS ON PAGE 6) AND THE BARREL BLOCKING

DEVICE IS PROPERLY INSTALLED ON YOUR MARKER

ACCORDING TO THE INSTRUCTIONS TO PREVENT DAMAGE

TO PROPERTY, SERIOUS INJURY, OR DEATH.

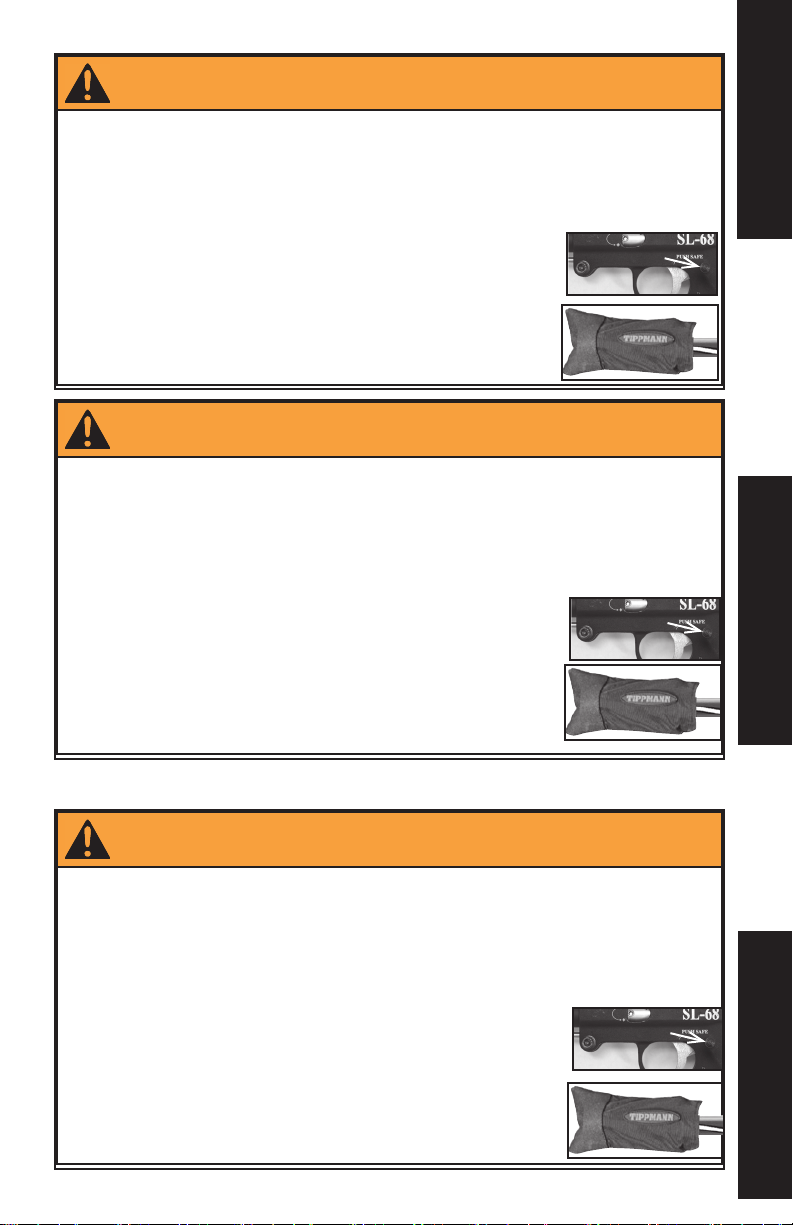

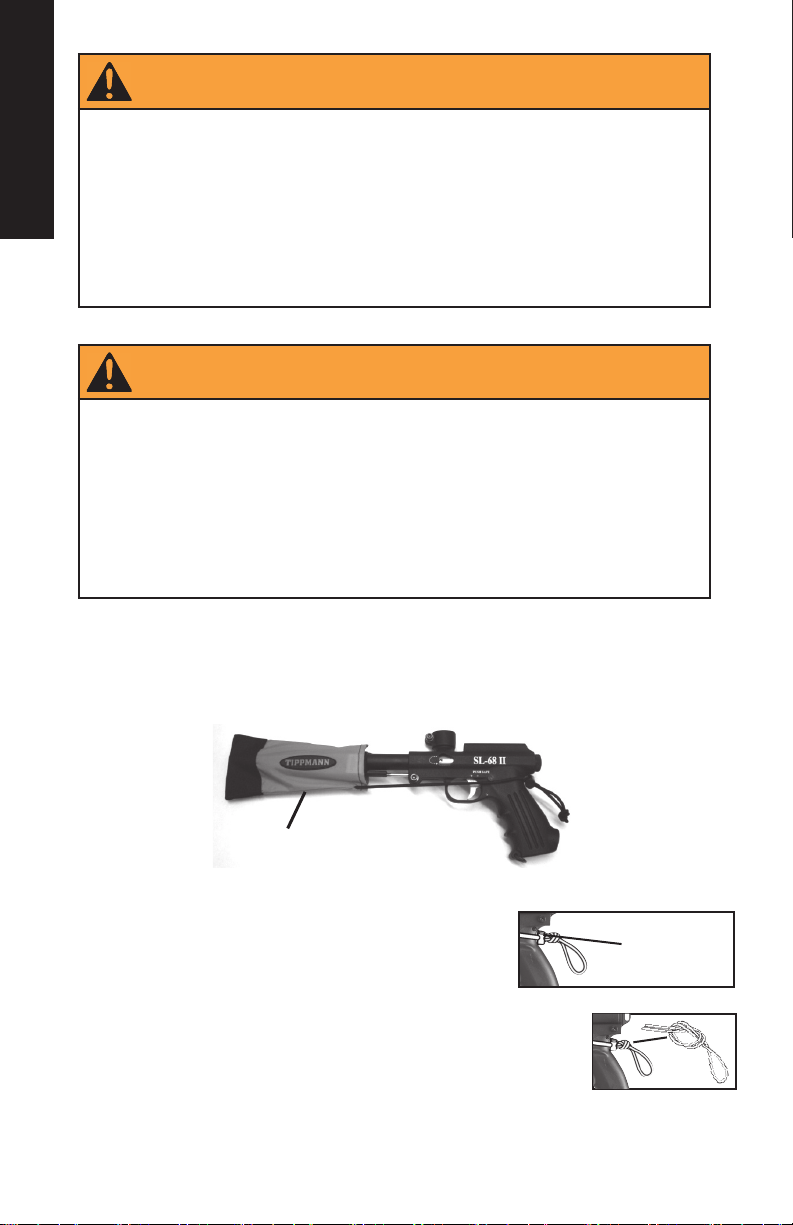

Barrel Sleeve Installation Instructions

1. Insert the barrel sleeve onto the barrel and loop the cord over the top of the receiver

and position at the back of the grip as shown.

Barrel Sleeve

2. Adjust the cord length retainer up to the back of the grip by pulling the cord through it

until the retainer is snug against the back of the grip.

Keeping the cord as tight as possible, leave just enough

cord elasticity to pull the cord/retainer up over the top of

the marker to remove the barrel sleeve for ring.

3. After the cord length is properly adjusted, lock the cord length by

tying a knot in the cord against the back of the retainer as shown.

4. Before and after playing, inspect the barrel sleeve and replace if

the sleeve or cord is damaged, or there is a loss of cord elasticity.

5. Clean the barrel sleeve with plain, warm water and store out of sunlight in a dry area

when not in use.

4

Cord Length

Retainer

®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619

www.tippmann.com

CONGRATULATIONS on your purchase of your Tippmann® paintball marker. We believe our

SL-68 II™ marker to be the most accurate and durable paintball marker available, and it is

proudly manufactured in the USA. All Tippmann® SL-68 II markers will provide many years of

dependable service if cared for properly.

Please take time to read this manual thoroughly and become familiar with your Tippmann®

SL-68 II™ marker’s parts, operation, and safety precautions before you attempt to load or

re this marker. If you have a missing or broken part, or need assistance, please contact

Tippmann Consumer Relations at 1-800-533-4831 for fast, friendly service.

Table of Contents

Barrel Sleeve Installation Instructions ....................................................................................4

Warning / Liability Statement ..................................................................................................6

Safety Is Your Responsibility! ................................................................................................6

Familiarize Yourself with Safety... ...................................................................................6

Getting Started .......................................................................................................................8

Velocity Adjustment ................................................................................................................8

Unloading Your Marker ..........................................................................................................9

Air Supply Cylinder Warnings .................................................................................................9

Air Supply Cylinder Safety Tips ....................................................................................10

Air Supply Cylinder Removal ........................................................................................11

Repairing Air Supply Cylinder Leaks ...........................................................................11

Cleaning and Maintenance ...................................................................................................12

Storage .........................................................................................................................12

Field Barrel Cleaning ....................................................................................................12

Field Disassembly .......................................................................................................13

Re-assembly .................................................................................................................13

General Troubleshooting .............................................................................................16

Valve Troubleshooting .................................................................................................16

Warranty and Repair Information .........................................................................................18

Specications ......................................................................................................................19

SL-68 II Diagram and Parts List ...........................................................................................20

E

N

G

L

I

S

H

5

E

Warning / Liability Statement

N

G

This marker is classied as a dangerous weapon and is surrendered by Tippmann Sports,

L

LLC with the understanding that the purchaser assumes all liability resulting from unsafe

handling or any action that constitutes a violation of any applicable laws or regulations.

I

Tippmann Sports, LLC shall not be liable for personal injury, loss of property or life resulting

S

from the use of this weapon under any circumstances, including intentional, reckless,

H

negligent or accidental discharges.

All information contained in this manual is subject to change without notice. Tippmann

Sports, LLC reserves the right to make changes and improvements to products without

incurring any obligation to incorporate such improvements into products previously sold.

If you as a user do not accept liability, Tippmann Sports, LLC requests you do not use a

Tippmann Sports, LLC marker. By using this paintball marker you release Tippmann Sports,

LLC of any and all liability associated with its use.

Safety Is Your Responsibility!

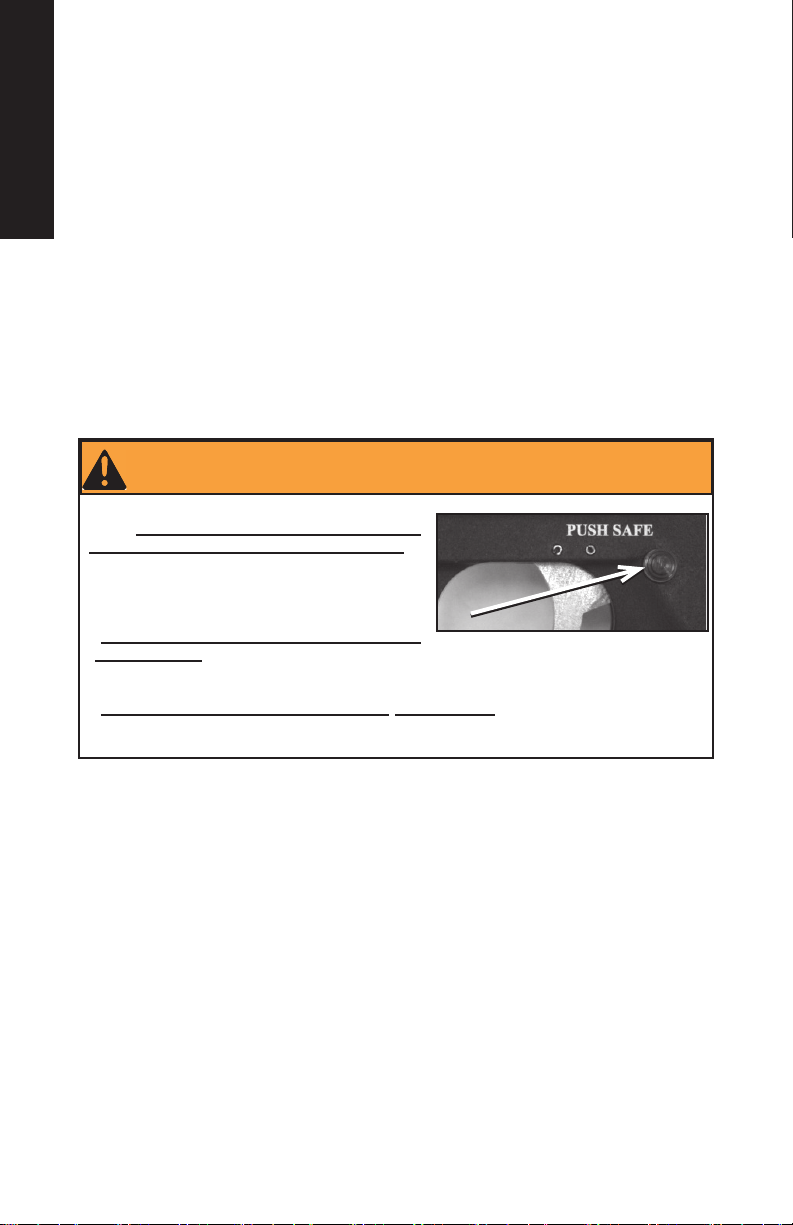

WARNING

• EXCEPT WHEN YOUR MARKER IS IN

USE, ALWAYS MAKE SURE THAT THE

TRIGGER SAFETY IS IN SAFE MODE,

WHICH DISABLES THE TRIGGER, AND

THE BARREL SLEEVE IS INSTALLED

(SEE PAGE 4).

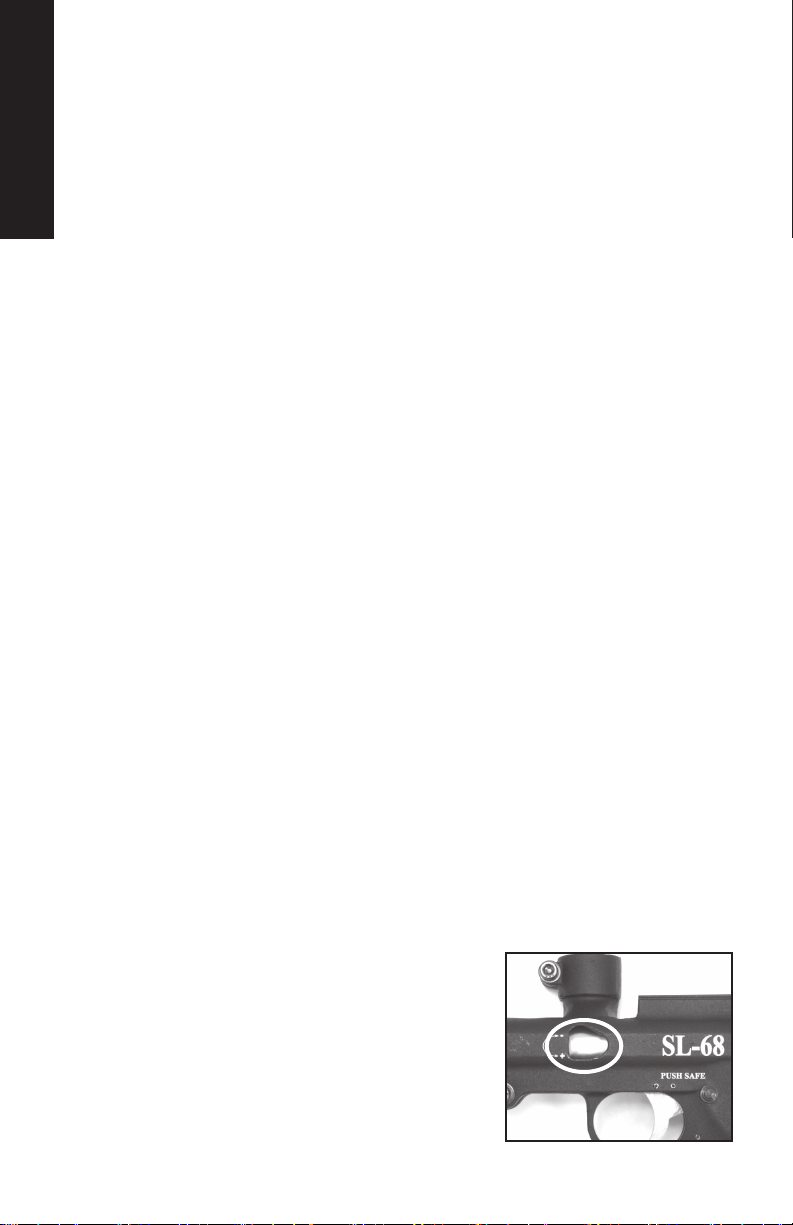

• TO TURN ON THE TRIGGER SAFETY

(SAFE MODE): PUSH THE SAFETY IN

AS SHOWN IN FIGURE 1.

• TO TURN TRIGGER SAFETY OFF (FIRE MODE): PUSH SAME BUTTON

ON THE OPPOSITE SIDE OF RECEIVER.

Familiarize Yourself with Safety...

The ownership of this marker places upon you the total responsibility of its safe and lawful

use. You must observe the same safety precautions as you would any rearm to assure

the safety of not only yourself but everyone around you. Outlined here are some general

precautions to be aware of. The user should at all times use caution and common sense

when using this marker and always remember that the game of Paintball can only survive

and grow if it remains SAFE!

• Do not load or re this marker until you have completely read this manual and are

familiar with its safety features, mechanical operation and handling characteristics.

• Handle this and any marker as if it were loaded at all times.

• Keep your nger off the trigger until ready to shoot.

• Do not look down the barrel of a paintball marker. Accidental discharge into the

eyes may cause permanent injury or death.

• Keep the trigger safety in safe mode until ready to shoot (see Warning above).

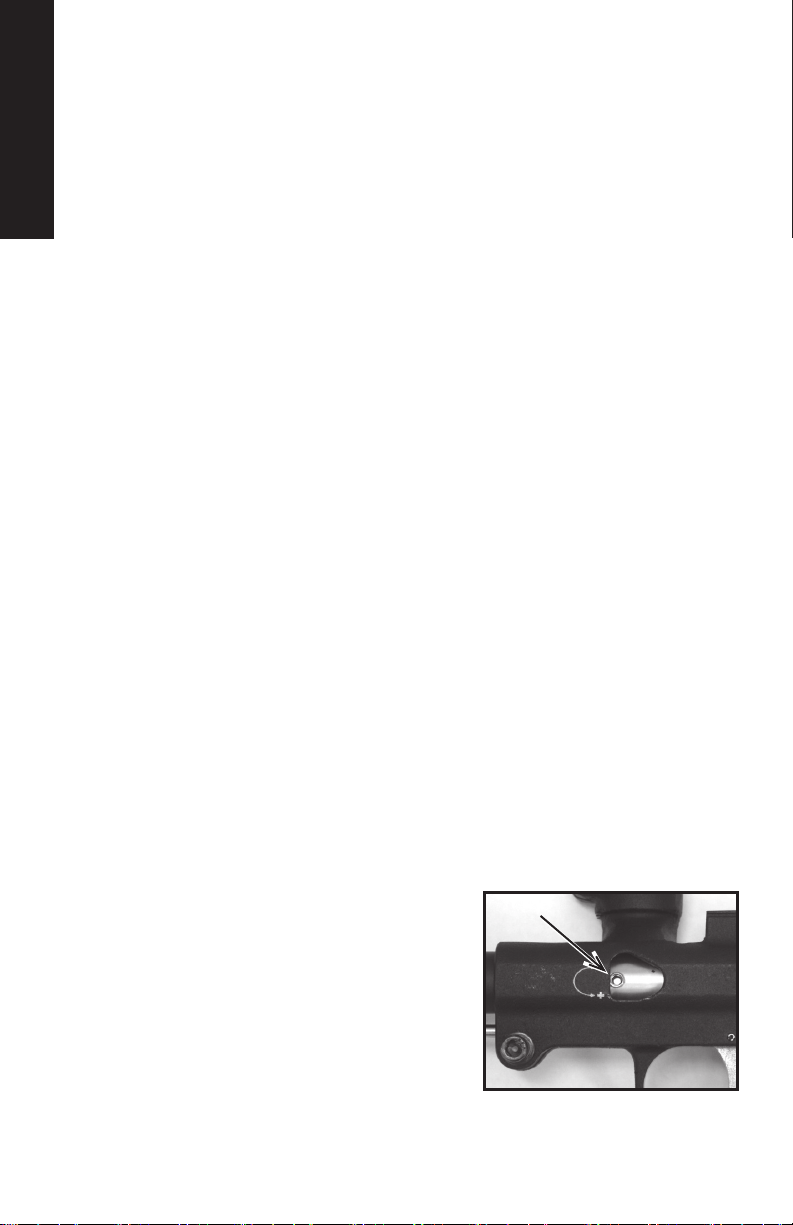

Figure 1: Trigger Safety Location

6

• Keep a barrel blocking device installed on marker when not shooting (see page 4).

• Never point the marker at anything you do not intend to shoot.

• Never re your marker at anything you do not intend to shoot because there may

be paintballs or foreign debris lodged in the chamber, barrel, or the marker valve.

• Do not shoot at fragile objects such as windows.

• Never re your marker at personal property of others. The paintball impact can

cause damage and the paint can stain the nish of automobiles, houses, etc.

• Always keep the barrel pointed down or in a safe direction, even if you stumble or

fall.

• Eye, face, and ear protection designed specically to stop paintballs in the form of

goggles and full face mask meeting ASTM Specication F 1776 must be worn by

the user and any person within range.

• Never shoot at a person who is not protected by eye, face, and ear protection

designed for paintball.

• Pressurize and load a marker only when the marker will be immediately used.

• Store the marker unloaded and degassed in a secure place.

NOTE: Before storing or disassembling, be sure to remove paintballs and air

supply (see Unloading Your Marker on page 9, and Air Supply Cylinder

Removal

the barrel blocking device (see page 4).

• Do not eld strip or otherwise disassemble this marker while it is pressurized with

air supply.

• Dress appropriately when playing the game of paintball. Avoid exposing any skin

when playing the game of paintball. Even a light layer of clothing will help absorb

some of the impact and protect you from the paintballs.

• Keep exposed skin away from escaping gas when installing or removing the air

supply cylinder, or if the marker or air supply is leaking. Compressed air and CO2

gasses are very cold and can cause frostbite under certain conditions.

• Use only .68 caliber paintballs. Never load or re any foreign objects.

• Avoid alcoholic beverages before and during the use of this marker. Handling

markers while under the inuence of drugs or alcohol is a criminal disregard for

public safety.

• Avoid shooting an opponent at point blank range, 6 feet or less.

• Familiarize yourself with instructions listed on the air supply cylinder. Contact the

air supply cylinder manufacturer with any questions.

• Always measure your marker’s velocity before playing paintball and never shoot at

velocities in excess of 300 feet per second (see instructions on page 8).

• Always keep in mind that the sport of Paintball is viewed and judged by your safe

and sportsmanlike conduct.

on page 11), put the trigger safety in Safe mode (see page 6) and install

E

N

G

L

I

S

H

7

E

Getting Started

N

G

L

I

S

H

• Eye protection designed for paintball use must be worn by the user and any person

within range.

• Do not disassemble this marker while it is pressurized with air.

• Do not pressurize a partially assembled marker.

• Read each step completely before performing the steps.

NOTE: Carefully hand start all threaded parts when assembling, and do not

overtighten, as this may potentially strip the threaded parts.

1. Air Supply Cylinder Installation.

Review Air Supply Cylinder Safety Tips (see page 10).

Push the trigger safety to the Safe mode (see page 6).

Install the barrel sleeve (see page 4).

Lubricate the cylinder valve o-ring with a little marker oil, then insert the cylinder valve

end into the air supply adapter at the back end of the marker grip. Twist the cylinder

clockwise into the air supply adapter until it stops. Use caution as the marker is now

ready to re.

2. Loading the Hopper

Insert the hopper into the feed neck of the receiver. Tighten the clamp bolt to secure

the hopper, but be careful not to over tighten, as this might collapse the hopper feed

tube.

Fill the hopper with .68 caliber paintballs. Do not force excessive numbers of paintballs

into the hopper.

3. Firing

Remove the barrel sleeve from the marker. Take the marker off Safe mode by pushing

the trigger safety to the Fire position. Grip the forearm grip with one hand and the

receiver in your other hand, pull the forearm grip rearward until it runs out of travel,

then push it forward until it again runs out of travel. Point the marker in a safe direction

and pull the trigger to shoot a paintball.

Breech lock: After one pump cycle, the marker cannot be pumped again until the

trigger is pulled. This is a feature to prevent double loading paintballs.

Auto Trigger: If you hold the trigger back while cycling the forearm grip, the marker will

re each time the forearm grip is pumped.

Note: If you attempt to pump the marker with the trigger safety in Safe mode, the

forearm grip will not travel forward to complete the pump cycle.

Velocity Adjustment

Velocity

Screw

Each time you play paintball, check the velocity of your

paintball marker with a chronograph (an instrument for

measuring velocity) prior to playing paintball. Verify that

the marker’s velocity is set below 300 feet per second or

less if required by the playing eld.

To adjust the marker’s velocity, use the included 3mm

allen wrench. The velocity adjustment screw is located

on the left side of the receiver, as shown in Figure 2. To

reduce the velocity, turn the screw clockwise. To increase

the velocity, turn the screw counterclockwise. Do not remove the velocity screw.

8

Figure 2: Velocity Adjustment

Unloading Your Marker

1. Eye protection designed for paintball use must be worn by the user and any person

within range.

2. Empty and remove the hopper.

3. Go to a designated ring area, remove the barrel sleeve and turn off trigger safety.

4. Point your marker in a safe direction and re several times to be sure there are no

paintballs lodged in the chamber or barrel. Visually inspect the chamber for paintballs.

5. Return the trigger safety to the Safe mode (see page 6). Reinstall the barrel sleeve (see

page 4).

Air Supply Cylinder Warnings

WARNING

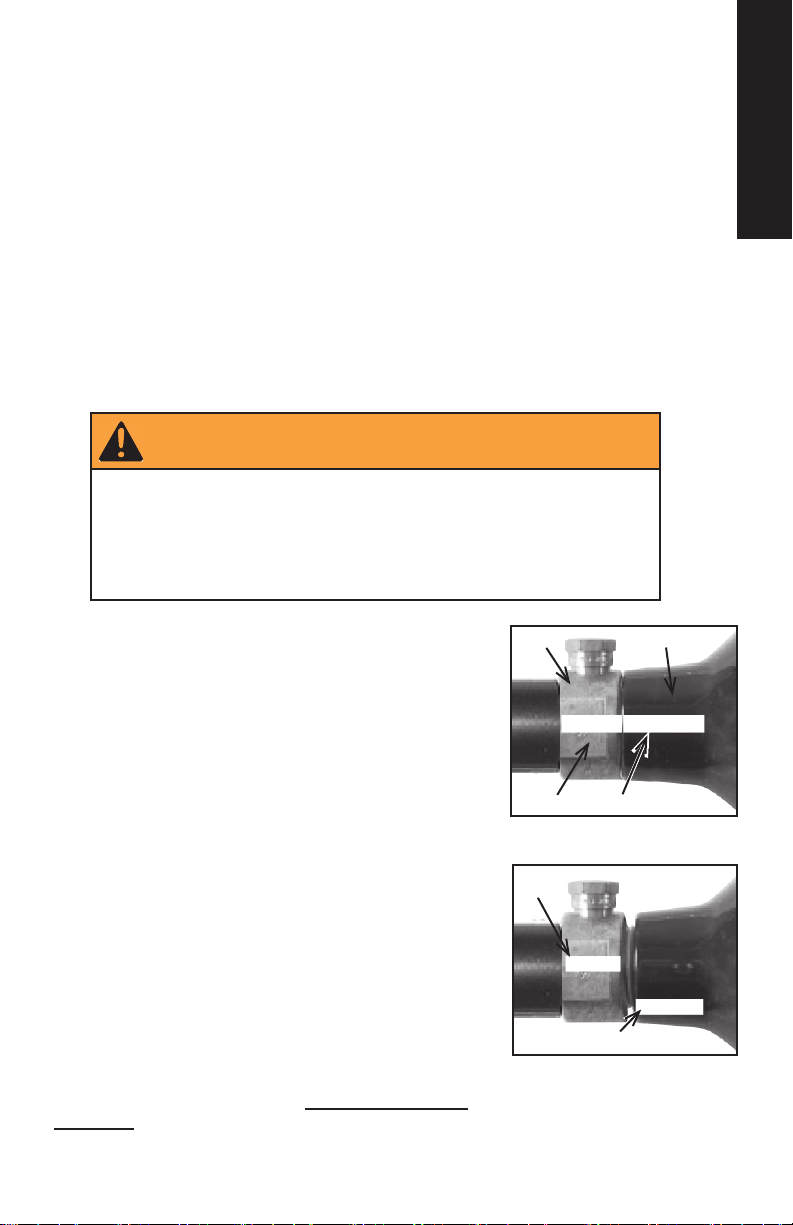

The brass or nickel plated cylinder valve (Figure 3, #1)

is intended to be permanently attached to the air or CO2

cylinder (2).

An air or CO2 cylinder can y off with enough force to cause

serious injury or death if the cylinder (2) unscrews from a

cylinder valve (1).

E

N

G

L

I

S

H

Refer to Figure 3. There have been reported incidents caused

by players unknowingly unscrewing the cylinder (2) from the

cylinder valve (1). This occurs when the player thinks the

entire valve-cylinder assembly is being unscrewed from the

air supply adaptor of the paintball marker, when in fact they

are unscrewing the cylinder from the cylinder valve.

To avoid this danger, it is recommended (if your cylinder is

not already marked) that you use paint or nail polish to place

a mark (3) on the cylinder valve, and place another mark (4)

on the cylinder, in line with the #3 mark as shown.

Whenever you turn the cylinder during removal, watch the

marks on the cylinder and the cylinder valve to be sure

that they rotate together. If at any time these marks start

to separate as shown in Figure 4, the cylinder is starting to

unscrew from the cylinder valve and you must STOP and

take the entire unit to a “C5” certied airsmith for safe removal

and/or repair.

NOTE: The cylinder valve should unscrew from the paintball

marker in about 3 or 4 full turns. If you nish the 4th full turn

and the cylinder valve is not unscrewed from the paintball

marker, STOP! Take the entire unit to a “C5” certied

airsmith for safe removal and/or repair.

Locate a “C5” Certied Airsmith at www.paintball-pti.com/

search.asp.

9

1

3

Figure 3: Marked Cylinder and

Valve

3

Figure 4: Misaligned Cylinder

and Valve

2

4

4

E

Whether you have a new or used rellable air or CO2 cylinder, you are at risk if any of the

N

following has occurred:

G

L

I

S

H

• The valve unit was replaced or altered after purchase.

• An anti-siphon device was installed.

• The valve unit was removed from the cylinder for any reason.

• Any modication was done to the rellable air or CO2 cylinder.

If any of these conditions has occurred, take your air or CO2 cylinder to a “C5” Certied

Airsmith for inspection or contact the cylinder manufacturer.

Air Supply Cylinder Safety Tips

SAFETY TIPS to ensure that your air or CO2 cylinder is safe for play:

• Improper use, lling, storage, or disposal of air or CO2 cylinder may result in

property damage, serious personal injury or death.

• Make sure that any maintenance or modication to any air or CO2 cylinder is done

by a qualied professional, such as a “C5” certied airsmith.

• The use of anti-siphon devices is not recommended. However, if one is already

installed on your air or CO2 cylinder or is desired, it is critical that your cylinder be

checked by, or the device installed by, a qualied professional.

• All air or CO2 cylinders must be lled only by properly trained personnel.

• Cylinder valves must be installed only by properly trained personnel.

• Do not overll!! Never exceed the air or CO2 cylinder’s capacity.

• Do not expose pressurized air or CO2 cylinder to temperatures exceeding 130

degrees Fahrenheit (55 degrees Celsius).

• Do not use caustic cleaners or strippers on the air or CO2 cylinder or cylinder valve

and do not expose to corrosive materials.

• Do not modify the air or CO2 cylinder in any way. Never try to disassemble the

cylinder valve from the air or CO2 cylinder.

• Any air or CO2 cylinder that has been exposed to re or heated to a temperature

of 250 degrees Fahrenheit (121 degrees Celsius) or more must be destroyed by

properly trained personnel.

• Use appropriate gas for your cylinder. Only use CO2 in a CO2 cylinder and only use

compressed air in a compressed air cylinder.

• Keep all cylinders out of the reach of children.

• The Air or CO2 cylinder should be inspected and hydrostatically retested at least

every 5 years by a DOT licensed agency.

• Keep exposed skin away from escaping gas when installing or removing air supply,

or if the marker or air supply is leaking. Compressed air and CO2 gasses are very

cold, and can cause frostbite under certain conditions.

NOTE: Locate a “C5” certied airsmith at www.paintball-pti.com/search.asp

10

Air Supply Cylinder Removal

1. Read Air Supply Cylinder Warnings and Air Supply Cylinder Safety Tips before

beginning the cylinder removal process.

2. Eye protection designed for paintball use must be worn by the user and any person

within range.

3. Follow the Unloading Your Marker instructions on page 9.

4. Watch the marks on the cylinder and cylinder valve (as shown in Figure 3 on page 9)

as you turn the cylinder approximately 3/4 of a turn counterclockwise. This allows the

air supply pin valve to close so that no air will enter the marker.

5. Remove the barrel sleeve and push the trigger safey to the Fire mode. Point the

marker in a safe direction, and discharge the remaining gas in the marker by ring until

the marker stops ring (this may take 4-5 shots). If your marker continues to re, the

cylinder pin valve has not closed yet (the cylinder pin valve could be too long. Because

of the variances in cylinder pin valve parts, each cylinder varies slightly on exactly how

far it should be turned). Turn the cylinder counterclockwise a little further and repeat

this step until the marker does not re, then remove the cylinder.

NOTE: If during this step, you turned the cylinder and it began to leak before you

pulled the trigger, the cylinder o-ring should be checked for damage before reassembly

(see Repairing Air Supply Cylinder Leaks below).

6. After the air supply cylinder is removed, again point and re the marker in a safe

direction to verify the marker is completely discharged.

E

N

G

L

I

S

H

7. Put the trigger safety in Safe mode (see page 6) and install the barrel sleeve (see

page 4).

Repairing Air Supply Cylinder Leaks

The most common leak occurs from a bad air supply valve O-ring. To replace a valve O-ring

you must rst remove the bad O-ring and then install a new one. This O-ring is located on the

tip of your air supply valve. The best valve o-rings are made of urethane. Urethane O-rings

are not affected by high air supply pressures. These may be purchased from Tippmann® or

your local paintball dealer.

NOTE: If a new air supply valve O-ring does not resolve an air supply leak, do not attempt

to repair the air supply cylinder. Contact Tippmann Sports, LLC, your local paintball dealer, or

a “C5” Certied Airsmith.

11

E

Cleaning and Maintenance

N

G

L

I

S

H

• Eye protection designed for paintball use must be worn by the user and any person

within range.

• To reduce the chance of an accidental discharge, follow the Unloading Your

Marker

(see page 9) and Air Supply Cylinder Removal (see page 11).

• Do not disassemble a marker while it is pressurized with air.

• Do not pressurize a partially assembled marker.

• Follow warnings listed on the air supply cylinder for handling and storage.

• Familiarize yourself with instructions listed on air supply cylinder.

• Contact the air supply cylinder manufacturer with any questions.

• Do not use any petroleum based cleaning solvents.

• Do not use any cleaning solvents that come in aerosol cans.

NOTE: Petroleum based products and aerosol products can damage your

marker’s O-rings.

• To clean your paintball marker use a damp towel to wipe off paint, oil, and debris.

• Use Tippmann® marker oil or other premium marker oil to maintain your marker

in good working condition. Oil with a few drops to the front bolt O-ring. Oil the air

supply valve O-ring.

Storage

Before storage, unload marker (see page 9) and remove air supply (see page 11). Then put

the trigger safety in Safe Mode (see page 6) and install the barrel sleeve (see page 4). Store

your marker in a dry area.

When removing your marker from storage, make sure the trigger safety is in Safe mode (see

page 6) and the barrel sleeve is installed (see page 4).

Field Barrel Cleaning

The cleaning port in the left side of the receiver (see circled area in Figure 5) has been

designed to clean the barrel in the eld from the breech end quickly and efciently with the

included barrel squeegee.

If this marker is kept clean and good quality paintballs are used, there is little chance of a ball

breaking. If a paintball should break in the barrel, follow these simple instructions to get back

into the game.

1. Eye protection designed for paintball use must be worn by the user and any person

within range.

2. Turn marker right side down to prevent a ball from

dropping into the chamber and pump action all the

way rearward until the marker locks open.

3. Point the barrel down, and insert small end of

squeegee into the port (see Figure 5), and feed it into

the barrel until it extends out of the end of the barrel.

Figure 5: Cleaning Port Location

12

4. Grasp small end of squeegee and pull it through the barrel; it will pull the paint and

shell fragments out of the barrel.

5. You can now tilt the receiver back up to let a ball fall into the chamber and pump it

closed.

Field Disassembly

• Do not disassemble this marker while it is pressurized.

• Do not pressurize a partially assembled marker.

1. Perform the marker unloading instructions on page 9.

2. Perform the air supply removal instructions on page 11.

3. Using the supplied 3/16 allen wrench, loosen the barrel bolt at the front of the receiver

(item 16 on page 20).

4. The barrel, forearm grip, and front bolt will remove as an assembly by pulling straight

out on the forearm grip.

5. Tip the receiver forward to remove the bolt/hammer spring (item 18 on page 20), and

the hammer assembly (items 19, 20, 21, and 22 on page 20). You will have to pull

the trigger and tap the front of the receiver to get these parts out. The valve assembly

remains in the receiver.

E

N

G

L

I

S

H

This is the only disassembly required to perform periodic cleaning.

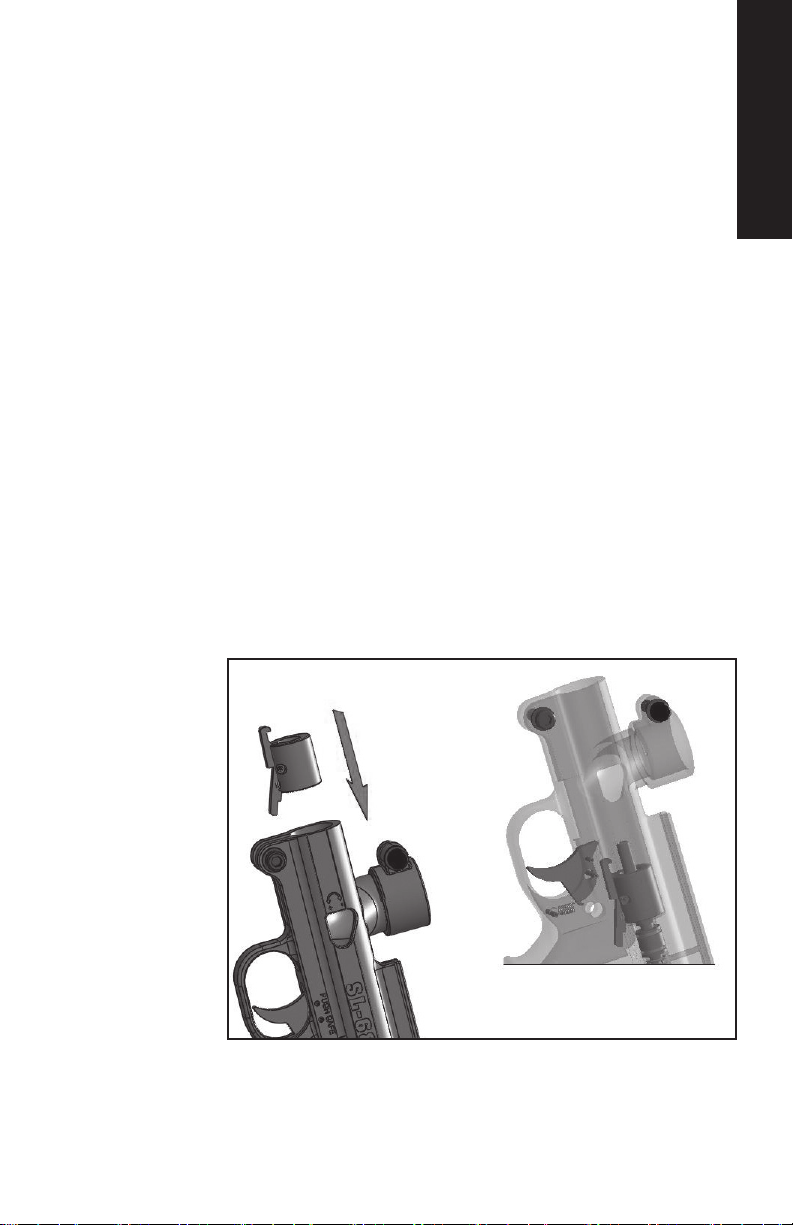

Re-assembly

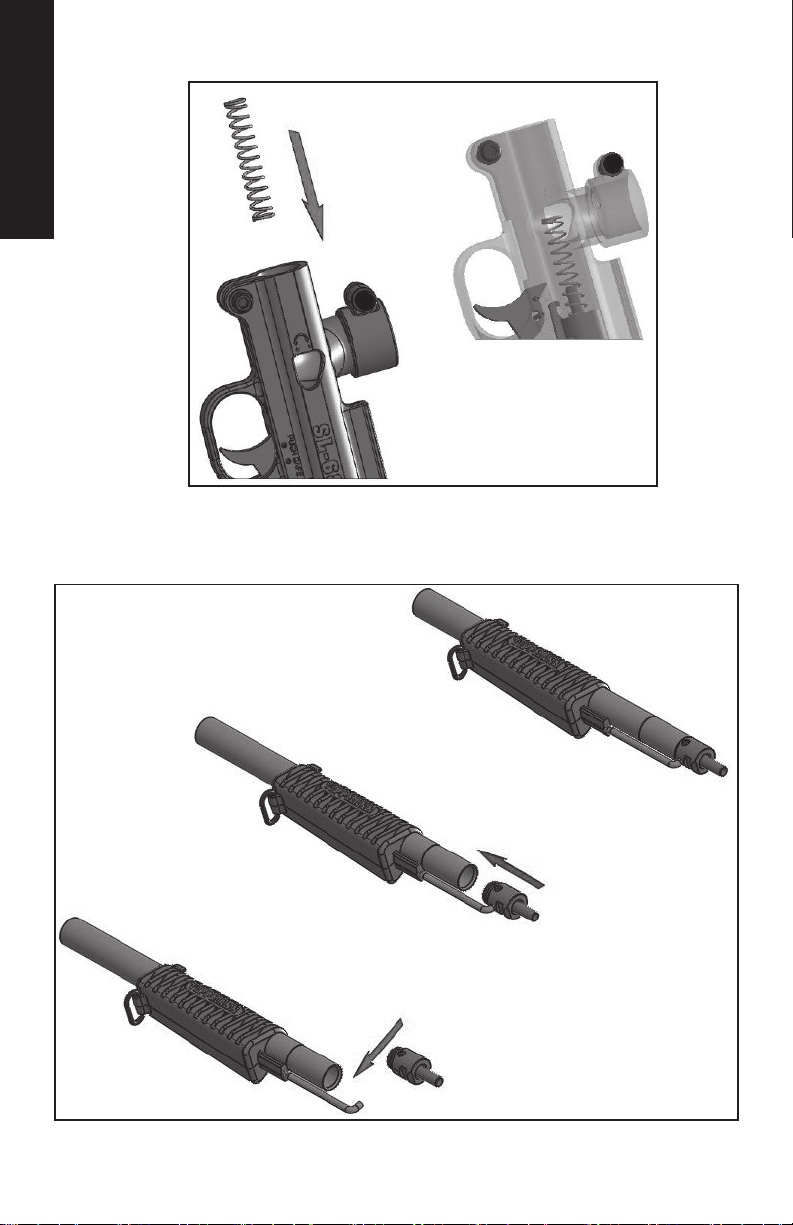

Re-assembly is in the

reverse order of eld

stripping. Be sure to

insert the hammer

assembly facing with

the “hook” of the sear

towards the front of

the receiver as shown

in Figure 6.

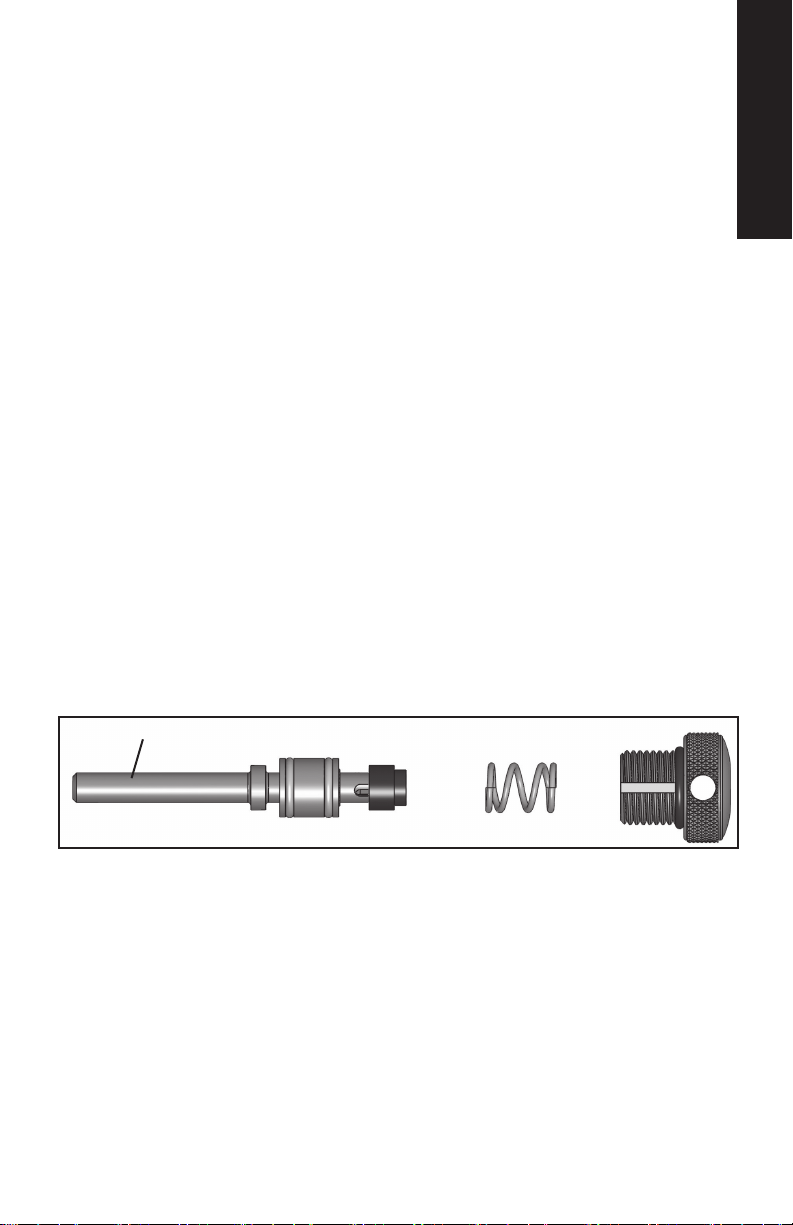

Figures 7 through

9 show progressive

steps of the reassembly procedure.

Figure 6: Insert the Hammer and Sear Assembly

You will have to pull the trigger and depress the sear to get the

assembly all the way in.

13

E

N

G

L

S

H

I

Figure 7: Insert Bolt/Hammer Spring

3

2

1

Figure 8: Assemble Bolt to Pump Rod and then into Barrel

14

Barrel Bolt

E

N

G

L

I

S

H

Figure 9: Insert Barrel Assembly into Marker Body; Tighten Barrel Bolt.

Recommended torque: 50 in-lbs.

NOTE: Over-tightening could prevent the marker from cocking properly.

An under-tightened barrel bolt will allow the barrel to slowly creep out during play.

15

E

General Troubleshooting

N

G

L

I

S

H

• Issue — Blast of gas out the barrel when pumping.

Cause — Pump rod is screwed too far out of forearm grip (pump handle).

Solution —Turn rod into forearm grip two turns, reassemble and test. Repeat if

necessary.

• Issue — Marker will not cock.

Cause — Pump rod screwed too far into forearm grip.

Solution —Turn rod out of forearm grip two turns, reassemble, and test. Repeat if

necessary.

Cause — Velocity adjuster is too far out.

Solution — Turn velocity adjuster in (clockwise) until it is ush with bolt and marker

will cock.

• Issue — Gas leak around cylinder to receiver connection.

Cause — Worn out or damaged air supply cylinder O-ring.

Solution — Replace air supply cylinder O-ring, see page 11 for correct instructions.

• Issue — Minor gas leak.

Cause — Worn or damaged valve seat O-rings.

Solution— Replace valve seat O-ring or return valve it is defective.

• Issue — Marker will not re.

Cause — Trigger safety engaged.

Solution— Disengage trigger safety.

Cause — Empty or near-empty air cylinder.

Solution— Rell or replace air cylinder.

Cause — Barrel is sliding out of receiver.

Solution— Loosen, push barrel back into receiver, then tighten to specied torque

(see page 15).

Valve Troubleshooting

The valve is virtually maintenance free, and we do not recommend its removal unless it

develops a leak. Unlike the cylinder O-ring, the valve’s two O-rings are stationary and not

stressed due to wear.

In case of leaking O-rings, simply replace the two valve O-rings to correct the problem. If the

valve cup seal is leaking, return the entire valve assembly to Tippmann Sports, LLC.

16

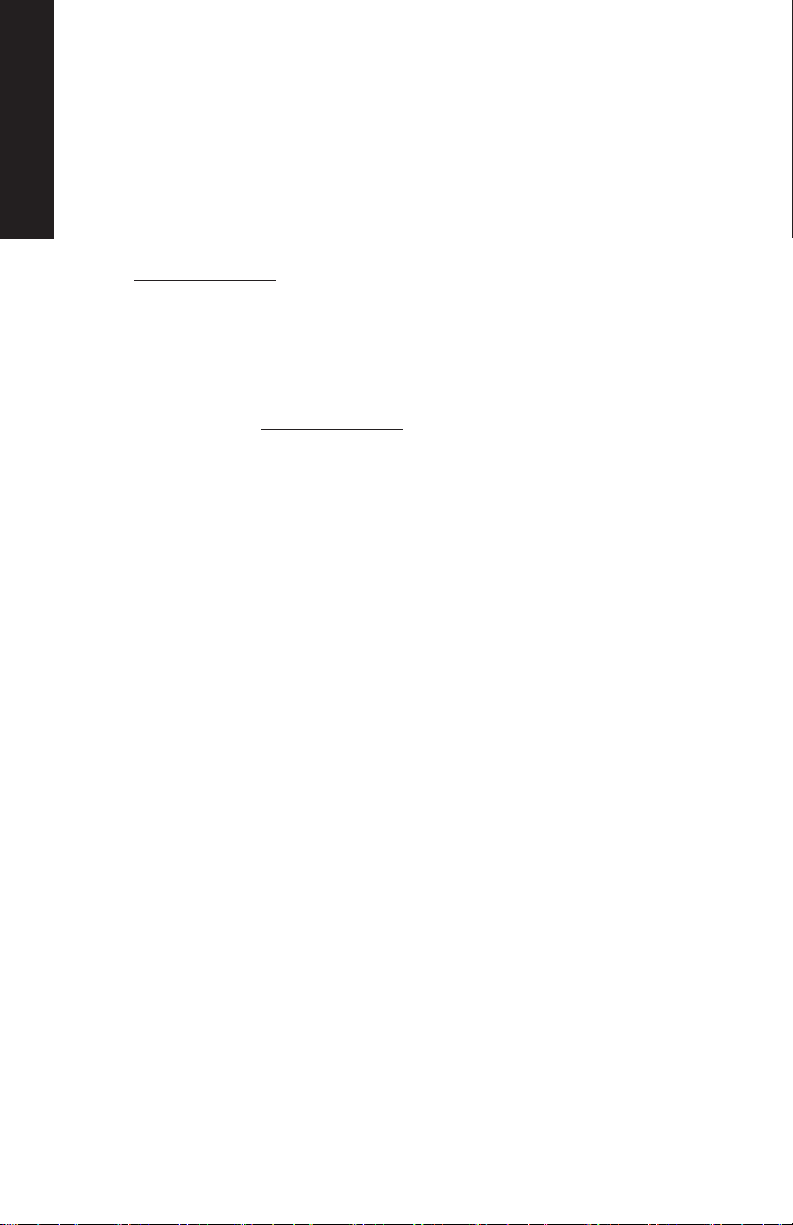

Valve Removal

• Do not disassemble this marker while it is pressurized.

• Do not pressurize a partially assembled marker.

1. Unscrew the rear end cap by inserting an allen wrench through the hole in the end cap

and turning counter clockwise.

2. Remove the end cap and then pull the spring out.

3. Field strip the marker (see Field Disassembly on page 13) which allows you access

from the front of the receiver to push the valve out through the rear end cap opening.

Valve Installation

1. Inspect the O-rings.

2. Lubricate them with a light coat of oil or Molykote® 33 before re-assembly to avoid

O-ring damage.

3. Insert the valve into the rear of the receiver (valve tube rst).

4. Lightly coat the end cap O-ring with a light oil or Molykote® 33 to eliminate pinching the

O-ring.

5. Insert the valve spring and then turn the end cap into place by hand.

E

N

G

L

I

S

H

6. Using an allen wrench, tighten the end cap.

Valve Tube end of the Valve Assembly Valve Spring End Cap

Figure 10: Valve Assembly, Spring, and End Cap

17

E

Warranty and Repair Information

N

G

TIPPMANN SPORTS, LLC (“Tippmann”) is dedicated to quality paintball products and

L

outstanding service. In the unlikely event of a problem with this Tippmann paintball marker

(“Marker”) and/or Tippmann accessories (“Accessories”), Tippmann’s customer service

I

personnel are available to assist you. For customer service and/or other information, please

S

contact:

H

Tippmann Sports, LLC

2955 Adams Center Road

Fort Wayne, IN 46803

www.tippmann.com

1-800-533-4831

Warranty Registration

To activate the Marker’s Limited Warranty, you must register the Marker within thirty (30)

days of the date of original retail sale by:

1. Registering online at www.tippmann.com; or

2. Completing the attached warranty registration card and returning it to Tippmann at the

address above.

The Limited Warranty for Tippmann Accessories does not require activation or registration;

by registering the Marker, you activate the warranty for the Accessories.

Limited Warranty

Tippmann warrants to the original purchaser that it will make any repairs or replacements

necessary to correct defects in material or workmanship, at no charge to you, for the Marker

for a period of two (2) years from the date of original retail sale. Further, Tippmann warrants

to the original purchaser that it will make any repairs or replacements necessary to correct

defects in material or workmanship, at no charge to you, for Tippmann Accessories for a

period of ninety (90) days from the date of original retail sale. All Tippmann asks is that you

properly maintain and care for the Marker and Accessories (collectively, the “Product”) and

that you have warranty repairs performed by Tippmann or a Tippmann Certied Tech Center.

This Limited Warranty is non-transferable, and it does not cover damage or defects to the

Product caused by (a) improper maintenance; (b) alteration or modication; (c) unauthorized

repair; (d) accident; (e) abuse or misuse; (f) neglect or negligence; and/or (g) normal wear

and tear.

Tippmann does not authorize any person or representative to assume or grant any other

warranty obligation with the sale of this Product.

THIS IS THE ONLY EXPRESS WARRANTY GIVEN WITH THE PURCHASE OF THIS

PRODUCT; ANY AND ALL OTHER EXPRESS WARRANTIES ARE DISCLAIMED. THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED TO THE APPLICABLE LIMITED WARRANTY PERIOD SET

FORTH HEREIN, AND NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, SHALL

APPLY AFTER EXPIRATION OF SUCH PERIOD.

Some states and nations do not allow limitations on the duration of implied warranties, so the

above limitation may not apply to you.

The sole and exclusive liability of Tippmann and/or its authorized dealers under this Limited

Warranty shall be for the repair or replacement of any part or assembly determined to be

defective in material or workmanship. TIPPMANN SHALL NOT BE LIABLE FOR, AND YOU

18

EXPRESSLY DISCLAIM, ANY DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL

DAMAGES (COLLECTIVELY, “DAMAGES”) ARISING OUT OF THE SALE OR USE OF, OR

YOUR INABILITY TO USE, THE PRODUCT. NO PAYMENT OR OTHER COMPENSATION

WILL BE MADE FOR DAMAGES, INCLUDING INJURY TO PERSON OR PROPERTY OR

LOSS OF REVENUE WHICH MIGHT BE PAID, INCURRED OR SUSTAINED BY REASON

OF THE FAILURE OF ANY PART OR ASSEMBLY OF THE PRODUCT.

Some states and nations do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you. This

warranty gives you specic legal rights, and you may also have other rights that may vary

from state to state or nation to nation.

Warranty and Non-Warranty Repairs

When shipping the Product to Tippmann for warranty or non-warranty repair:

1. If you have aftermarket parts on your Marker, please test the Marker with original stock

parts before returning the Marker for service or repair.

2. Always unload and remove the air supply from the Marker. Do not ship the air supply

cylinder if it is not completely empty.

3. Ship the Product to the Tippmann address identied above.

4. You must pre-pay postage and delivery charges.

5. Provide the date of purchase for the Product.

6. Briey describe the repair requested.

7. Include your name, return address and a telephone number where you can be reached

during normal business hours, if possible.

E

N

G

L

I

S

H

Tippmann makes every effort to complete its repair work within twenty-four (24) hours of

receipt. Tippmann will return the Product to you via regular ground UPS. If you wish to have

it returned using a faster service, you can request NEXT DAY AIR UPS OR SECOND DAY

AIR UPS, but you will be charged for this service and must include your credit card number

with the expiration date. Your credit card will be charged the difference in additional cost over

regular ground shipping service.

Specications

Model ..................................................... Tippmann SL-68 II

Caliber ......................................................................... 0.68

Action ......................................................................... Pump

Propellant .................................... CO2 or High Pressure Air

Feed ......................................................................... Gravity

Barrel Length ................................................................. 11”

Length ............................................................. 17.1” Overall

Width ................................................................. 2.6” Overall

Height ............................................................... 6.9” Overall

Weight ...................................................35.75 oz. / 2.24 lbs.

Finish ............................................................. Black Anodize

19

E

N

G

L

S

H

I

SL-68 II Diagram and Parts List

20. Sear (SL2-13)

21. Sear Pin (SL2-11)

22. Sear Spring (SL2-14)

23. Pump Rod (SL2-20)

24. Retaining Clip (SL2-7)

25. Flat Washer (2) (98-45)

1. Barrel (TA11002)

2. Forearm Grip (TA11004)

3. Hopper Feed Neck Bolt (02-41)

4. Receiver (TA11001)

5. Valve Tube (SL2-22)

6. Valve Seat Assembly (TA11007)

7. Valve Spring (SL2-23)

8. End Cap Assembly (TA11006)

9. Valve Cup Seal (SL2-24)

10. Safety Assembly (TA11005)

11. Sling Swivel (2) (4-PA)

12. Trigger Spring Pin (SL2-15)

13. Trigger Pins (2) (SL2-9)

14. Trigger (SL2-8)

15. Trigger/Sear Spring (SL2-10)

16. Barrel Bolt (SL2-29)

17. Front Bolt Assembly (TA11003)

18. Hammer Spring (SL2-18)

Parts List

20

19. Hammer (SL2-27)

AVERTISSEMENT

CECI N’EST PAS UN JOUET. TOUT USAGE INAPPROPRIE PEUT

PROVOQUER DES BLESSURES GRAVES OU MORTELLES.

LE PORT DE LA PROTECTION POUR LES YEUX, LE VISAGE

ET LES OREILLES CONCUE POUR LE PAINT-BALL EST

OBLIGATOIRE POUR L’UTILISATEUR AINSI QUE POUR

TOUTE PERSONNE A PORTEE DE TIR. POUR L’ACHAT, NOUS

RECOMMANDONS L’AGE DE 18 ANS. LES PERSONNES DE

MOINS DE 18 ANS DOIVENT ETRE SOUS LA SURVEILLANCE

D’UN ADULTE LORSQU’ELLES UTILISENT CE PRODUIT. LISEZ

LE MANUEL AVANT D’UTILISER CE PRODUIT

AVERTISSEMENT

GARDEZ TOUJOURS LE DISPOSITIF DE BLOCAGE DU CANON

INSTALLE LORSQUE VOUS N’UTILISEZ PAS LE LANCEUR. ASSUREZ-VOUS TOUJOURS QUE LA SECURITE DE LA DETENTE

EST EN MODE SECURITE (VOIR INSTRUCTIONS EN PAGE 3) ET

QUE LE DISPOSITIF DE BLOCAGE DU CANON EST CORRECTEMENT INSTALLE SUR VOTRE LANCEUR CONFORMEMENT AUX

INSTRUCTIONS POUR EVITER TOUT DOMMAGE MATERIEL,

DES BLESSURES GRAVES OU MORTELLES

Instructions de montage de la douille du canon

F

R

A

N

Ç

A

I

S

1. Insérez la douille du canon dans le canon et enroulez le cordon sur le dessus de la

asque et la position à l’arrière du

grip comme indiqué.

2. Ajustez le dispositif d’arrêt de

longueur de cordon jusqu’à l’arrière

du grip en tirant le cordon à travers

lui jusqu’à ce que l’arrêt repose juste

contre l’arrière du grip. Gardez le

cordon aussi serré que possible,

laissez juste assez d’élasticité pour tirer le cordon/arrêt

sur le dessus du lanceur an de retirer la douille du

canon pour tirer.

3. Une fois la longueur du cordon correctement réglée, bloquez-la en

faisant un nœud contre l’arrière de l’arrêt comme indiqué.

4. Avant et après avoir joué, inspectez la douille du canon et

remplacez-la en cas d’endommagement de la douille ou du cordon

ou encore si vous constatez que le cordon a perdu de son élasticité.

5. Nettoyez la douille du canon à l’eau chaude claire et conservez-le à l’abri de la lumière

dans un endroit sec lorsque vous ne l’utilisez pas.

Douille du canon

Dispositif

d’arrêt de

longueur de

cordon

1

®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619

www.tippmann.com

FELICITATIONS pour l’achat de votre lanceur de paint-ball Tippmann®. Nous sommes

persuadés que notre lanceur SL-68 II™ est le plus précis et le plus durable du marché. Il est

èrement fabriqué aux Etats-Unis. Tous les lanceurs Tippmann® SL-68 II™ vous offriront des

années de dèle service s’ils sont entretenus avec soin.

Veuillez prendre le temps de lire attentivement ce manuel et familiarisez-vous avec les

pièces de votre lanceur Tippmann® SL-68 II™, son fonctionnement et les consignes de

sécurité avant d’essayer de charger ou de tirer avec ce lanceur. Si une pièce manque ou est

cassée ou si vous avez besoin d’aide, veuillez contacter Tippmann Consumer Relations au

1-800-533-4831 pour un service rapide et convivial.

Sommaire

Instructions de montage de la douille du canon .....................................................................1

Sommaire ...............................................................................................................................2

Avertissement/Déclaration de responsabilité .........................................................................3

F

La sécurité est votre responsabilité ! .....................................................................................3

R

A

N

Ç

A

I

S

Familiarisez-vous avec la sécurité... ...............................................................................3

Pour commencer ....................................................................................................................5

Réglage de la vitesse .............................................................................................................6

Décharger votre lanceur .........................................................................................................6

Avertissements relatifs au cylindre d’alimentation d’air ..........................................................6

Conseils de sécurité relatifs au cylindre d’alimentation d’air ..........................................7

Retrait du cylindre d’alimentation d’air ............................................................................8

Réparation de fuites de cylindre d’alimentation d’air ......................................................9

Nettoyage et entretien ............................................................................................................9

Rangement ...................................................................................................................10

Nettoyage du canon sur le terrain ................................................................................10

Démontage sommaire .................................................................................................10

Remontage ..................................................................................................................11

Dépistage général des pannes .....................................................................................13

Dépistage de panne de valve .......................................................................................14

Informations sur la garantie et la réparation .........................................................................15

Enregistrement de garantie ..........................................................................................15

Garantie limitée ....................................................................................................................15

Réparations sous garantie et hors garantie ..................................................................16

Spécications ......................................................................................................................16

Diagramme et Liste des Pièces de SL68-II ..........................................................................17

2

Avertissement/Déclaration de responsabilité

Ce lanceur est considéré comme une arme dangereuse et est fourni par Tippmann

Sports, LLC en sous-entendant que l’acheteur assume toute responsabilité résultant

d’une manipulation dangereuse ou de toute action constituant une violation à toute loi

ou tout règlement en vigueur. Tippmann Sports, LLC décline toute responsabilité pour

les dommages corporels, matériels ou le décès résultant de l’utilisation de cette arme en

toutes circonstances, y compris les décharges intentionnelles, imprudentes, négligentes ou

accidentelles.

Toutes les informations contenues dans ce manuel sont susceptibles de changements

sans préavis. Tippmann Sports, LLC se réserve le droit d’apporter des changements et des

améliorations aux produits sans être tenu d’intégrer ces améliorations dans des produits

vendus au préalable.

Si, en tant qu’utilisateur, vous n’acceptez pas la responsabilité, Tippmann Sports, LLC

vous prie de ne pas utiliser un lanceur LLC de Tippmann Sports. Par l’usage de ce lanceur

de paint-ball, vous dégagez Tippmann Sports, LLC d’une quelconque et de toutes les

responsabilités liées à son utilisation.

AVERTISSEMENT

• EXCEPTÉ LORSQUE VOUS UTILISEZ

VOTRE LANCEUR, ASSUREZ VOUS

TOUJOURS QUE LA SURETÉ DU

LANCEUR EST ACTIVÉE, CE QUI

DÉSACTIVE LA DÉTENTE, ET VÉRIFIEZ

QUE LA CAPOTE DE CANON EST

INSTALLÉE (VOIR EN PAGE 1).

• POUR ACTIVER LA SURETÉ DE

DÉTENTE (MODE SÉCURITÉ) :

POUSSEZ LE BOUTON DE SÉCURITÉ

COMME MONTRÉ DANS FIGURE 1.

• POUR DÉSACTIVER LA SURETÉ DE DÉTENTE (MODE DE TIR) :

POUSSEZ LE MÊME BOUTON DE L’AUTRE COTÉ DE LA FLASQUE.

La sécurité est votre responsabilité !

Familiarisez-vous avec la sécurité...

Par la propriété de ce lanceur, vous assumez la responsabilité totale de son utilisation en

toute sécurité et légalité. Vous devez respecter les mêmes précautions de sécurité que pour

toute autre arme à feu pour assurer la sécurité non seulement de votre personne mais aussi

de tous ceux qui vous entourent. Nous soulignons ici certaines précautions générales dont

vous devez être conscient. L’utilisateur doit à tout moment faire preuve de prudence et de

sens commun lorsqu’il utilise ce lanceur et ne jamais oublier que le jeu de Paint-ball ne peut

survivre et se développer que s’il reste SÛR !

• Ne chargez ou ne tirez avec ce lanceur qu’après avoir terminé la lecture de ce

manuel et être familiarisé avec ses dispositifs de sécurité, son fonctionnement

mécanique et ses caractéristiques de manipulation.

• Manipulez ce lanceur et tous les autres comme s’il était toujours chargé.

• Gardez votre doigt éloigné de la détente jusqu’à ce que vous soyez prêt à tirer.

• Ne regardez pas dans le canon d’un lanceur de paint-ball. Une décharge

Figure 1 : Emplacement de la sûreté

de la détente

3

F

R

A

N

Ç

A

I

S

F

R

A

N

Ç

A

S

accidentelle dans vos yeux peut provoquer des blessures permanentes ou

mortelles.

• Gardez la sécurité de la détente en mode sécurité jusqu’à ce que vous soyez prêt à

tirer (voir avertissement ci-dessus).

• Gardez le dispositif de blocage du canon installé sur le lanceur lorsque vous ne tirez

pas (voir page 1).

• Ne pointez jamais le lanceur vers une cible que vous n’avez pas l’intention de

toucher.

• Ne tirez jamais avec votre lanceur sur un objet que vous n’avez pas l’intention de

toucher car des billes ou des débris étrangers pourraient se loger dans la chambre,

le canon et/ou la valve du lanceur.

• Ne tirez pas sur des objets fragiles comme des fenêtres.

• Ne tirez jamais avec votre lanceur sur les biens personnels d’autrui. L’impact de

la bille de paint-ball peut provoquer des dommages et la peinture peut abîmer la

nition de voitures, maisons, etc.

• Gardez toujours le canon pointé vers le bas ou dans une direction sûre, même si

vous trébuchez ou tombez.

• Le port de la protection pour les yeux, le visage et les oreilles conçue

spéciquement pour arrêter les billes de paint-ball sous la forme de lunettes et de

masques complets conformes aux spécications ASTM F 1776 par l’utilisateur ou

toute personne à portée de tir est obligatoire.

• Ne tirez jamais vers une personne qui ne porte pas de protection des yeux, du

visage et des oreilles conçue pour le paint-ball.

• Ne chargez et ne mettez le lanceur sous pression que lorsqu’il va être utilisé dans

I

l’immédiat.

• Entreposez le lanceur déchargé et dégazé dans un endroit sûr.

NOTE: Avant l’entreposage ou le démontage, assurez-vous que vous avez

retiré toutes les billes de paint-ball et l’alimentation d’air (voir instructions

de Déchargement de votre lanceur en page 6 et de Retrait de cylindre

d’alimentation d’air

(voir page 3) et installez le dispositif de blocage du canon (voir page 1).

• N’effectuez pas un démontage sommaire ou tout autre type de démontage de ce

lanceur lorsqu’il est mis sous pression par l’alimentation d’air.

• Portez des vêtements appropriés lorsque vous jouez au paint-ball. Evitez d’exposer

toute partie de peau lorsque vous jouez au paint-ball. Même une ne épaisseur de

vêtement aidera à absorber l’impact et vous protègera des billes de paint-ball.

• Protégez les parties de peau exposées de l’échappement de gaz lorsque vous

installez ou retirez le cylindre d’alimentation d’air ou s’il y a une fuite au niveau du

lanceur ou de l’alimentation d’air. L’air comprimé, le CO2 et l’azote sont très froids et

peuvent provoquer des gelures dans certaines conditions.

• Utilisez uniquement des billes de paint-ball de calibre .68. Ne chargez ou ne tirez

jamais des objets étrangers.

• Evitez les boissons alcoolisées avant et pendant l’utilisation de ce lanceur. La

manipulation de lanceurs sous l’inuence de drogue ou d’alcool est une atteinte

criminelle à la sécurité publique.

• Evitez de tirer sur un adversaire à bout portant, à 6 pieds (1,83 m) ou moins.

en page 8), mettez la sûreté de la détente en mode sécurité

4

• Familiarisez-vous avec les instructions gurant sur le cylindre d’alimentation d’air.

Contactez le fabricant du cylindre d’alimentation d’air pour toute question.

• Mesurez toujours la vitesse de votre lanceur avant de jouer au paint-ball et ne

tirez jamais à des vitesses supérieures à 300 pieds par seconde (91,44 m/s) (voir

instructions en page 6).

• N’oubliez pas que le sport du Paint-ball est considéré et évalué selon votre

conduite sûre et sportive.

Pour commencer

• Le port de la protection des yeux conçue pour le paint-ball est obligatoire pour

l’utilisateur et toute personne à portée de tir.

• Ne démontez pas le lanceur lorsqu’il est sous pression de l’air.

• Ne mettez pas sous pression un lanceur partiellement assemblé.

• Lisez entièrement chaque étape avant de la réaliser.

NOTE: Serrez d’abord prudemment à la main toutes les pièces letées lors

de l’assemblage sans serrer trop fort pour éviter de les griffer.

1. Installation du cylindre d’alimentation d’air

Révision des Conseils de sécurité relatifs au cylindre d’alimentation d’air (voir

page 7).

Poussez la sûreté de la détente en Mode de sécurité (voir page 3).

Installez la douille du canon (voir page 1).

Lubriez le joint de la valve du cylindre avec un peu d’huile pour lanceur puis insérez

l’extrémité de la valve du cylindre dans l’adaptateur d’alimentation d’air à l’extrémité

du grip du lanceur. Tournez le cylindre dans le sens horaire dans l’adaptateur

d’alimentation d’air jusqu’à ce qu’il se bloque. Soyez prudent car le lanceur est

maintenant prêt à tirer.

2. Charger le réservoir

Insérez le réservoir dans le collet d’alimentation de la asque. Serrez le boulon pour

verrouiller le réservoir en faisant attention de ne pas serrer trop fort pour ne pas casser

le tube d’alimentation du réservoir.

Remplissez le réservoir de billes de calibre .68. Ne forcez pas un nombre excessif de

billes dans le réservoir.

F

R

A

N

Ç

A

I

S

3. Tirer

Retirez la douille du canon du lanceur. Désactivez le Mode de sécurité du lanceur en

poussant la sûreté de la détente en position de Tir. Saisissez le grip d’avant-bras d’une

main et la asque de l’autre main, tirez le grip d’avant-bras vers l’arrière à fond puis

ramenez-le vers l’avant jusqu’à bout de course. Pointez le lanceur dans une direction

sûre et tirez la détente pour lancer une bille de paint-ball.

Verrouillage de chambre : Après un cycle de pompe, le lanceur ne peut plus être

pompé jusqu’à ce que la détente soit tirée. C’est un dispositif qui empêche le double

chargement de billes de paint-ball.

Détente automatique : Si vous maintenez la détente vers l’arrière tout en enclenchant

le grip d’avant-bras, le lanceur tirera à chaque pompage du grip d’avant-bras.

Note: Si vous tentez de pomper le lanceur alors que la sûreté est en mode de sécurité,

le grip d’avant-bras n’ira pas vers l’avant pour réaliser un cycle de pompage.

5

Réglage de la vitesse

À chaque fois que vous jouez au paint-ball, véries la vitesse de votre lanceur à l’aide d’un

chronographe (un instrument de mesure de la vitesse) avant de jouer. Vériez si la vitesse du

lanceur est inférieure à 300 pieds par seconde (91,44

m/s) ou moins comme requis par l’aire de jeu.

Pour régler la vitesse du lanceur, utilisez la clé Allen de

3 mm fournie. La vis de réglage de la vitesse se situe à

gauche de la asque, comme illustré à la gure 2. Pour

réduire la vitesse, tournez la vis dans le sens horaire.

Pour augmenter la vitesse, tournez la vis dans le sens

antihoraire. Ne retirez pas la vis de réglage de la vitesse.

Vis de

vélocité

Décharger votre lanceur

1. Le port de la protection des yeux conçue pour le paint-ball est obligatoire pour

l’utilisateur et toute personne à portée de tir.

2. Videz et retirez le réservoir.

3. Rendez-vous dans une zone de tir indiquée, retirez la douille de canon et désactivez la

F

R

A

N

Ç

A

I

détente en sécurité.

4. Pointez votre lanceur dans une direction sûre et tirez quelques fois pour vous assurer

qu’il n’y a pas de billes dans la chambre ou dans le canon. Inspectez visuellement la

chambre à la recherche de billes.

5. Remettez la sûreté de la détente en Mode de sécurité (voir page 3). Réinstallez la

douille du canon (voir page 1).

Figure 2 : Réglage de la vélocité

S

Avertissements relatifs au cylindre d’alimentation d’air

AVERTISSEMENT

La valve plaquée au laiton ou au nickel (Figure 3, #1) doit

être branchée en permanence au cylindre d’air ou de CO2

(2).

Un cylindre d’air ou de CO2 peut être projeté avec

sufsamment de force pour entraîner des blessures graves

ou mortelles si le cylindre (2) se dévisse d’une valve de

cylindre (1).

Voir Figure 3. Des accidents ont été rapportés provoqués par des joueurs dévissant sans

savoir le cylindre (2) de la valve du cylindre (1). Ceci se produit lorsque le joueur pense

dévisser tout l’ensemble valve-cylindre de l’adaptateur d’air du lanceur de paint-ball alors

qu’en réalité, il dévisse le cylindrer de la valve de cylindre.

Pour éviter ce risque, il est recommandé (si votre cylindre n’est pas encore marqué) de faire

sur la valve du cylindre une marque (3) à la peinture ou au vernis à ongles et une autre (4) sur

le cylindre, alignée à la marque #3 illustrée.

Lorsque vous tournez le cylindre pendant la dépose, faites attention aux marques sur le

6

cylindre et la valve du cylindre pour s’assurer qu’ils tournent

ensemble. Si, à n’importe quel moment, les marques

commencent à se séparer comme illustré à la Figure 4, le

cylindre commence à se dévisser de la valve du cylindre.

Vous devez ARRETER et emmener l’unité complète chez

un armurier fournissant des armes à air comprimé agréé C5

pour retrait et/ou réparation.

NOTE : La valve du cylindre devrait se dévisser du lanceur

de paint-ball en 3 ou 4 tours complets. Si vous achevez le

4e tour et que la valve du cylindre n’est pas dévissée du

lanceur, ARRETEZ ! Emportez toute l’unité chez un armurier

fournissant des armes à air comprimé agréé C5 pour un

retrait en toute sécurité et/ou une réparation.

Localisez un armurier fournissant des armes à air comprimé

agréé “C5” sur le site www.paintball-pti.com/search.asp

Que vous ayez un cylindre d’air rechargeable ou de CO2

nouveau ou usagé, vous êtes en danger dans les cas

suivants :

• L’unité de valve a été remplacée ou altérée après

l’achat.

• Un dispositif antisiphon a été installé.

• L’unité de valve a été retirée du cylindre pour une

quelconque raison.

• Une quelconque modication a été apportée au cylindre d’air rechargeable ou de

CO2.

En présence de l’une de ces conditions, apportez votre cylindre d’air ou de CO2 chez un

armurier fournissant des armes à air comprimé agréé « c5 » pour inspection ou contactez le

fabricant du cylindre.

1

3

Figure 3 : Bouteille et valve

marquées

3

Figure 4 : Bouteille et valve mal

alignées

2

4

4

F

R

A

N

Ç

A

I

S

Conseils de sécurité relatifs au cylindre d’alimentation d’air

CONSEILS DE SECURITE pour vous assurer que votre cylindre d’air ou de CO2 ne présente

aucun danger :

• L’usage, le remplissage, l’entreposage ou l’évacuation inappropriés du cylindre

d’air ou de CO2 peut entraîner des dommages matériels, des blessures graves ou

mortelles.

• Assurez-vous que tout entretien ou modication à un cylindre d’air ou de CO2 est

effectué par du personnel qualié comme un armurier agréé C5.

• L’utilisation de dispositifs antisiphon est déconseillée. Cependant, s’il y en a déjà

un installé sur votre cylindre d’air ou de CO2 ou s’il est souhaité, il est important de

faire vérier votre cylindre ou le dispositif installé par un professionnel qualié.

• Le remplissage de tous les cylindres d’air ou de CO2 doit être exclusivement

réservé à du personnel dûment qualié.

• Les valves de cylindre doivent uniquement être installées par du personnel dûment

qualié.

• Ne remplissez pas à l’excès !!! Ne dépassez jamais la capacité du cylindre d’air ou

de CO2.

7

• N’exposez pas le cylindre d’air comprimé ou de CO2 à des températures

dépassant les 55 degrés Celsius.

• N’utilisez pas des nettoyants ou décapants agressifs sur le cylindre d’air ou de

CO2 ou sur la valve du réservoir et évitez l’exposition à des matériaux corrosifs.

• Ne modiez en aucune façon le cylindre d’air ou de CO2. N’essayez jamais de

démonter la valve du réservoir du cylindre d’air ou de CO2.

• Tout cylindre d’air ou de CO2 qui a été exposé au feu ou à une température

supérieure à 121 degrés Celsius ou plus doivent être détruits par du personnel

dûment qualié.

• Utilisez le gaz qui convient à votre cylindre. Utilisez du CO2 uniquement dans un

cylindre CO2 et de l’air comprimé dans un cylindre à air comprimé.

• Gardez tous les cylindres hors de portée des enfants.

• Le cylindre d’air ou de CO2 doit être inspecté et testé au niveau de l’hydrostatique

au moins tous les 5 ans par une agence certiée DOT.

• Protégez les parties de peau exposées de l’échappement de gaz lorsque vous

F

R

A

N

Ç

A

I

Retrait du cylindre d’alimentation d’air

S

installez ou retirez le cylindre d’alimentation d’air ou s’il y a une fuite au niveau

du lanceur ou de l’alimentation d’air. L’air comprimé et le CO2 sont très froids et

peuvent provoquer des gelures dans certaines conditions.

NOTE: Localisez un armurier fournissant des armes à air comprimé agréé “C5”

sur le site www.paintball-pti.com/search.asp

1. Lisez Avertissements relatifs au cylindre d’alimentation d’air et Conseils de

sécurité relatifs au cylindre d’alimentation d’air

de démontage.

avant de commencer le processus

2. Le port de la protection des yeux conçue pour le paint-ball est obligatoire pour

l’utilisateur et toute personne à portée de tir.

3. Suivez les instructions Décharger votre lanceur en page 6.

4. Regardez les marques sur le cylindre et la valve du cylindre (comme illustré à la

Figure 3 de la page 7) lorsque vous tournez le cylindre d’environ ¾ de tour dans le

sens antihoraire. Ceci permet à la valve d’axe de l’alimentation d’air de se fermer et à

l’air d’entrer dans le lanceur.

5. Retirez la douille du canon et poussez délicatement la détente en mode de tir. Pointez

le lanceur dans une direction sûre et déchargez le gaz qui reste dans le lanceur en

tirant jusqu’à ce que le lanceur s’arrête de tirer (ceci peut nécessiter 4-5 tirs). Si votre

lanceur continue à tirer, la valve d’axe du réservoir ne s’est pas encore fermée (la

valve d’axe du réservoir pourrait être trop longue. En raison des divergences dans les

pièces de valve d’axe de réservoir, la longueur exacte de rotation du réservoir peut

varier légèrement). Tournez encore un peu le réservoir dans le sens antihoraire et

répétez cette étape jusqu’à ce que le lanceur ne tire plus puis retirez le réservoir.

8

NOTE: Si, pendant cette étape, vous avez tourné le réservoir et qu’il a commencé

à se vider avant que vous ayez appuyé sur la détente, il faut vérier si le joint du

réservoir n’est pas endommagé avant de le remonter (voir Réparation de fuites de

cylindre d’alimentation d’air

6. Après avoir déposé le cylindre d’alimentation d’air, pointez à nouveau et tirez avec le

lanceur dans une direction sûre pour vérier s’il est totalement déchargé.

7. Mettez la sûreté de la détente en Mode de sécurité (voir page 3) et installez la douille

du canon (voir page 1).

Réparation de fuites de cylindre d’alimentation d’air

La cause la plus courante d’une fuite est un mauvais joint de valve d’alimentation d’air. Pour

remplacer un joint de valve, vous devez d’abord enlever le mauvais joint et en installer un

nouveau. Ce joint - se situe à l’extrémité de votre valve d’alimentation d’air. Les meilleurs

joints de valve sont fabriqués en uréthane. Les joints en uréthane ne sont pas affectés par

les hautes pressions de l’alimentation d’air. Ceux-ci peuvent être achetés chez Tippmann®

ou votre revendeur de paint-ball local.

ci-dessous).

NOTE : Si un nouveau joint de valve d’alimentation d’air ne résout pas la fuite d’air,

n’essayez pas de réparer le cylindre d’alimentation d’air. Contactez Tippmann Sports LLC,

votre revendeur de paint-ball local ou un armurier agréé « C5 ».

Nettoyage et entretien

• Le port de la protection des yeux conçue pour le paint-ball est obligatoire pour

l’utilisateur et toute personne à portée de tir.

• Pour réduire le risque de décharge accidentelle, suivez les instructions de

Déchargement de votre lanceur (voir page 6) et Retrait du cylindre

d’alimentation d’air

• Ne démontez pas un lanceur lorsqu’il est sous pression de l’air.

• Ne mettez pas sous pression un lanceur partiellement assemblé.

• Respectez les avertissements mentionnés sur le cylindre d’alimentation d’air pour

la manipulation et le stockage.

• Familiarisez-vous avec les instructions gurant sur le cylindre d’alimentation d’air.

• Contactez le fabricant du cylindre d’alimentation d’air pour toute question.

• N’utilisez pas de solvants de nettoyage à base de pétrole.

• N’utilisez pas de solvants de nettoyage provenant d’aérosols.

NOTE : Les produits à base de pétrole et les aérosols peuvent endommager les

joints de votre lanceur.

• Pour nettoyer votre lanceur de paint-ball, utilisez un chiffon humide pour essuyer la

peinture, l’huile et les débris.

• Utilisez de l’huile pour lanceur Tippmann

maintenir votre lanceur en bon état. Huilez avec quelques gouttes sur le joint du

boulon avant. Huilez le joint de valve d’alimentation d’air.

(voir page 8).

®

ou une huile de bonne qualité pour

9

F

R

A

N

Ç

A

I

S

Rangement

Avant le rangement, déchargez le lanceur (voir page 6) et retirez l’alimentation d’air (voir

page 6). Mettez la sûreté de la détente en Mode de sécurité (voir page 3) et installez la

douille du canon (voir page 1). Rangez votre lanceur dans un endroit sec.

Lorsque vous retirez votre lanceur de son entreposage, assurez-vous que la sûreté de la

détente est en Mode de sécurité (voir page 3) et que la douille du canon est installée (voir

page 1).

Nettoyage du canon sur le terrain

Le port de nettoyage à gauche de la asque (voir zone

entourée sur la Figure 5) a été conçu pour nettoyer

rapidement et efcacement le canon sur le terrain

au départ du regard avec notre raclette de canon

spécialement conçue.

Si le lanceur est gardé propre et que des billes de paint-ball

de bonne qualité sont utilisées, il y a peu de chance que

la bille se brise. Si une bille se brise dans le canon, suivez

ces instructions simples pour revenir dans le jeu.

F

1. Le port de la protection des yeux conçue pour le paint-ball est obligatoire pour

R

l’utilisateur et toute personne à portée de tir.

Figure 5 : Ouverture de

nettoyage

A

2. Tournez le côté droit du lanceur vers le bas pour éviter qu’une bille ne tombe dans la

N

Ç

chambre et le mouvement de la pompe à fond vers l’arrière jusqu’à ce que le lanceur

s’ouvre.

A

3. Pointez le lanceur vers le bas et insérez la petite extrémité de la raclette dans le port

I

S

(voir Figure 5) et poussez-la dans le canon jusqu’à ce qu’il dépasse.

4. Saisissez la petite extrémité de la raclette et tirez-la dans le canon. Ceci retirera la

peinture et les fragments de coquille du canon.

5. Vous pouvez alors soulever à nouveau la asque pour laisser une bille tomber dans la

chambre. Pompez pour fermer.

Démontage sommaire

• Ne démontez pas le lanceur lorsqu’il est sous pression.

• Ne mettez pas sous pression un lanceur partiellement assemblé.

1. Suivez les instructions de déchargement du lanceur en page 6.

2. Suivez les instructions de retrait de l’alimentation d’air en page 8.

3. À l’aide de la clé Allen 3/16 fournie, desserrez le boulon du canon à l’avant de la

asque (article 16 de page 17).

4. Le canon, le grip d’avant-bras et le boulon avant se détacheront ensemble en tirant

directement du grip d’avant-bras.

10

5. Basculez la asque vers l’avant pour retirer le boulon/ressort du chien (article 18 de

page 17) et l’ensemble du chien (articles 19, 20, 21 et 22 de page 17). Vous devrez

tirer la détente et taper sur l’avant de la asque pour retirer ces pièces. L’ensemble de

valve reste dans la asque.

C’est le seul démontage nécessaire pour effectuer le nettoyage périodique.

Remontage

Le remontage est effectué dans l’ordre inverse du démontage sommaire. Assurez-vous

d’insérer l’ensemble de chien face du « crochet » de la gâchette vers l’avant de la asque

comme indiqué à la Figure 6.

Les Figures de 7 à 9 montrent les étapes successives de la procédure de remontage.

F

R

A

N

Ç

A

I

S

Figure 6 : Insérez le marteau et l’assemblage du sear

Vous aurez à appuyer sur la détente et presser le sear pour pouvoir

rentrer l’assemblage jusqu’à son emplacement..

11

F

R

A

N

Ç

A

S

Figure 7 : Insérez le ressort de marteau/culasse

I

3

2

1

Figure 8 : Assemblez la culasse à la tige de pompe, puis dans le canon

12

NOTE: Serrer excessivement peut

empêcher le lanceur de s’armer

correctement. Une vis mal serrée

peut laisser le canon se dégager

légèrement pendant la partie.

Boulon de canon

Figure 9 : Insérez l’assemblage dans le corps du lanceur. Serrez la vis de

canon. Serrage recommandé 50in-Lbs.

Dépistage général des pannes

• Problème — Jet de gaz du canon lors du pompage.

Cause — Tige de pompe vissée trop loin de grip d’avant-bras (poignée de pompe).

Solution — Tournez la tige dans le grip de deux tours, remontez et testez. Répétez

si nécessaire.

• Problème — Le lanceur ne charge pas.

Cause — Tige de pompe vissée trop loin dans grip d’avant-bras.

Solution — Dévissez la tige du grip de deux tours, remontez et testez. Répétez si

nécessaire.

Cause — Régulateur de vitesse trop loin.

Solution — Revissez le réglage de vitesse (dans le sens horaire) jusqu’à ce qu’il

soit à eur du boulon et le lanceur chargera.

• Problème — Fuite de gaz autour du cylindre à la connexion de la

asque.

Cause — Joint de cylindre d’alimentation d’air usé ou endommagé.

Solution — Remplacez le joint de cylindre d’alimentation d’air, voir page 8 pour des

instructions correctes.

• Problème — Fuite de gaz mineure.

Cause — Joint de valve usé ou endommagé.

Solution— Remplacez le joint de siège de valve ou valve de retour si défectueux.

F

R

A

N

Ç

A

I

S

13

• Problème — Le lanceur ne tire pas.

Cause — Sûreté de détente engagée.

Solution— Désactivez la sûreté de la détente.

Cause — Cylindre d’air vide ou pratiquement vide.

Solution— Remplissez ou remplacez le cylindre d’air.

Cause — Le canon glisse de la asque.

Solution— Desserrez, repoussez le canon dans la asque puis serrez au couple

spécié (voir page 13).

Dépistage de panne de valve

La valve ne nécessite pratiquement aucun entretien et nous ne recommandons son retrait

qu’en cas de fuite. Contrairement au joint de réservoir, les deux joints de la valve sont

stationnaires et non soumis à l’usure.

En cas de fuite des joints, remplacez simplement les deux joints de valve pour résoudre le

problème. Si le joint de coupelle de valve fuit, renvoyez l’ensemble de valve à Tippmann

Sports, LLC.

F

Retrait de la valve

R

A

N

• Ne démontez pas le lanceur lorsqu’il est sous pression.

• Ne mettez pas sous pression un lanceur partiellement assemblé.

Ç

1. Dévissez le bouchon arrière en insérant une clé Allen dans l’orice du bouchon et en

A

I

S

tournant dans le sens antihoraire.

2. Retirez le bouchon puis tirez le ressort.

3. Démontez sommairement le lanceur (voir Démontage sommaire en page 10) ce

qui permet d’accéder par l’avant de la asque pour repousser la valve par l’orice du

bouchon arrière.

Montage de la valve

1. Inspectez les joints.

2. Lubriez-les avec une légère couche d’huile ou du Molykote® 33 avant le remontage

pour éviter d’endommager les joints.

3. Insérez la valve à l’arrière de la asque (en commençant par le tube de valve).

4. Recouvrez le joint du bouchon d’une légère couche d’huile ou de Molykote® 33 pour

éviter de pincer le joint.

5. Insérez le ressort de valve puis tournez le bouchon en place à la main.

6. À l’aide d’une clé Allen, serrez le bouchon.

Tube de valve à l’extrémité de la valve

Ressort de valve

Figure 10 : Assemblage de la valve, ressort et bouchon de corps

14

Bouchon de corps

Informations sur la garantie et la réparation

TIPPMANN SPORTS, LLC (« Tippmann ») s’engage à fournir des produits de paint-ball de

qualité et un service parfait. Dans le cas peu probable où vous rencontreriez un problème

avec ce lanceur de paint-ball Tippmann (« Lanceur ») et/ou des accessoires Tippmann («

Accessoires »), le personnel du service à la clientèle de Tippmann est disponible pour vous

aider. Pour le service à la clientèle et/ou d’autres informations, veuillez contacter :

Tippmann Sports, LLC

2955 Adams Center Road

Fort Wayne, IN 46803

www.tippmann.com

1-800-533-4831

Enregistrement de garantie

Pour activer la Garantie limitée du lanceur, vous devez inscrire le lanceur dans les trente

(30) jours qui suivent la date de la vente originale :

1. Par enregistrement en ligne sur le site www.tippmann.com; ou

2. En complétant la carte d’enregistrement de garantie ci-jointe et en la retournant à

Tippmann à l’adresse ci-dessus.

La Garantie limitée pour les accessoires Tippmann ne nécessite aucune activation ni

enregistrement. Par l’enregistrement du lanceur, vous activez celle pour les accessoires.

Garantie limitée

Tippmann garantit à l’acheteur original la réalisation gratuite de toutes les réparations ou

remplacements nécessaires pour corriger les défauts de matériaux ou vices de fabrication

sur le lanceur pour une période de deux (2) ans à compter de la date d’achat d’origine. En

outre, Tippmann garantit à l’acheteur original la réalisation gratuite de toutes les réparations

ou remplacements nécessaires pour corriger les défauts de matériaux ou vices de

fabrication sur les accessoires Tippmann pour une période de quatre-vingt-dix (90) jours à

compter de la date d’achat d’origine. Tippmann demande uniquement que vous entreteniez

et soigniez correctement le lanceur et les accessoires (collectivement le « Produit ») et que

les réparations sous garantie soient réalisées par Tippmann ou par un centre technique

Tippmann agréé.

Cette Garantie limitée n’est pas transférable et ne couvre pas les dommages et

défectuosités du produit provoqués par (a) un entretien inapproprié; (b) une altération ou

modication; (c) une réparation non autorisée; (d) un accident; (e) un abus ou un mauvais

usage; (f) un manque de soin ou une négligence; et/ou (g) l’usure normale.

Tippmann n’autorise personne ni aucun représentant à assumer ou à accorder toute autre

obligation de garantie lors de la vente de ce produit.

CECI EST LA SEULE GARANTIE EXPRESSE ACCORDEE LORS DE L’ACHAT DE CE

PRODUIT ; TOUTE AUTRE OU TOUTES LES AUTRES GARANTIES EXPRESSES SONT