WARNING:

• This paintball marker/gun is not a toy nor is

it intended for unsupervised use by persons

under the age of 18 years.

• Misuse may cause serious injury or death.

• Eye Protection designed for paintball use

must be worn by the user and any person

within range.

• Read operation manual before using.

• Do not field strip or remove any parts while

marker is pressurized.

• Always keep in mind that the sport of

Paintball will be viewed and judged upon your

safe and sportsmanlike conduct.

TIPPMANN

PNEUMATICS, INC.

Get YGet Y

oo

ur Hearur Hear

t Pt P

oo

undund

ing Witing Wit

Get Y

o

ur Hear

t P

o

Get YGet Y

oo

ur Hearur Hear

t Pt P

TT

ippmann!ippmann!

T

ippmann!

TT

ippmann!ippmann!

und

oo

undund

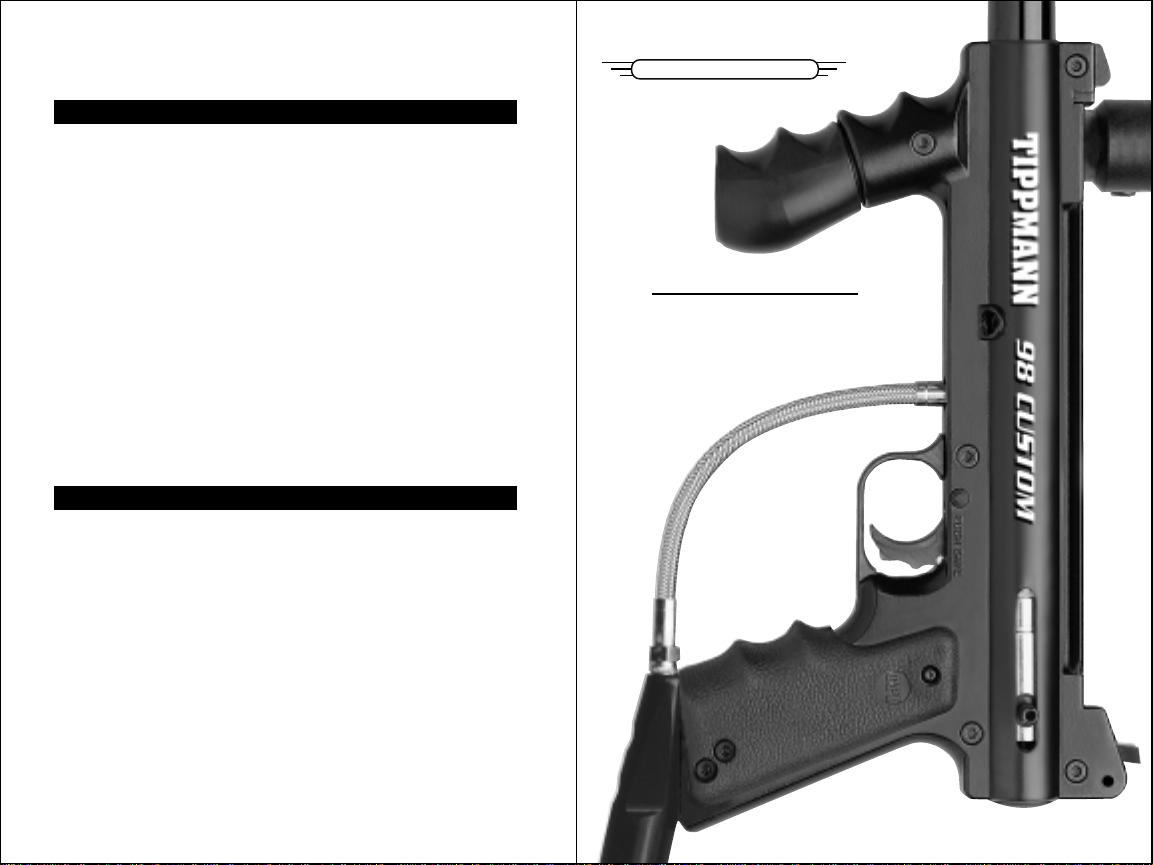

98 CUSTOM

Owner’s Manual

CO2 POWERED

PAINTBALL GUN

ing Wit

ing Witing Wit

h Ah A

h A

h Ah A

TIPPMANN

PNEUMATICS, INC.

3518 Adams Center Road, Fort Wayne, IN 46806

P) 260-749-6022 • F) 260-749-6619

CONGRATULATIONS on your purchase of a “Tippmann

98 CUSTOM”

accurate and durable paintball gun available. The

CUSTOM

for properly.

Please take time to read through this manual thoroughly and

become familiar with the “Tippmann

operation, and safety precautions before you attempt to load

or fire this gun.

Table of Contents

Warning/Liability Statement...............................................5

Safety is your Responsibility..............................................5

Specifications.....................................................................7

Getting Started...................................................................8

1. Tank Installation..................................................8

2. Ammo Box ..........................................................8

3. Velocity Adjustment ............................................9

Schematic ...................................................................10-11

Unloading Your Gun.........................................................12

1. Tank Removal...................................................1 2

Cleaning & Maintenance .................................................13

Field Stripping..................................................................1 3

1. Receiver Disassembly ......................................14

Repairing Tank Leaks ......................................................16

Storage ............................................................................16

Warranty and Repair Policy.............................................17

1. Warranty or Repair Procedure..........................18

paintball gun. We believe it to be the most

will give many years of dependable service if cared

www.tippmann.com

INDEX

4

98 CUSTOM”

98

parts,

Warning/Liability Statement

This gun is classified as a dangerous weapon and is

surrendered by Tippmann Pneumatics, Inc. with the

understanding that the purchaser assumes all liability

resulting from unsafe handling or any action that

constitutes a violation of any applicable laws or

regulations. Tippmann Pneumatics, Inc. shall not be

liable for personal injury , loss of property or life resulting

from the use of this weapon under any circumstances,

including the intentional, reckless, negligent or accidental

discharges.

All information contained in this manual is subject to

change without notice. Tippmann Pneumatics, Inc.

reserves the right to make changes and improvements

to products without incurring any obligation to incorporate

such improvements in products previously sold.

Safety is Your Responsibility!

The ownership of this weapon places upon you the total

responsibility of its safe and lawful use. Y ou must observe

the same safety precautions as you would any firearm to

assure the safety of not only yourself but everyone around

you. The user should at all times use caution when using

this gun. Always remember that the game of Paintball can

only survive and grow if it remains SAFE!

• Do not load or fire this gun until you have completely

read this manual and are familiar with its mechanical

operation and handling characteristics.

• Handle this and any other gun as if it were loaded at all

times.

5

• Never point the gun at anything you do not intend to

shoot.

• Always keep the muzzle pointed down or in a safe

direction, even if you stumble or fall.

• All persons within a 200 yard radius should always wear

eye protection in the form of approved goggles or full

face mask and never shoot at a person who is not similarly

protected.

• Avoid alcoholic beverages before and during the use

of this gun. Handling guns while under the influence

of drugs or alcohol is a criminal disregard for public

safety.

• A void shooting an opponent at point blank (6 feet or less).

• If you purchased a 12 gram cartridge or any other form of

adapter with this gun be sure to read and follow the instructions that came with the adapter.

• Pressurize and load the gun only when the gun will be

immediately used. Unload and remove the CO

2 cylinder

immediately after use for safe storage.

• Dress appropriately when playing the game of paintball.

Avoid exposing any skin when playing the game of

paintball. Even a light layer will absorb some of the impact

and protect you from the paintballs.

• Keep exposed skin away from escaping CO2 gas when

installing or removing cylinder. CO2 gas is very cold and

can cause frostbite under certain conditions.

• Use only .68 caliber paintballs. Never load or fire any

foreign objects.

• Do not field strip or otherwise disassemble this gun

while it is pressurized with gas.

• Do not look directly into the barrel. Accidental discharge

into the eyes may cause permanent injury or death.

6

• Never fire your gun at personal property of others, the

paintball can stain the paint of automobiles and houses.

Specifications

Model ...................................... Tippmann 98 CUSTOM

Caliber .......................................................................68

Action ..............Semi-Automatic (Open bolt blow-back)

Power ...........compressed air, nitrogen or CO2 cylinder

Magazine Capacity..................................150 Rd Hopper

Cycle Rate...........................................................11 RPS

Standard Barrel Length..............................................8.5”

Overall Length (with standard barrel & no tank)..... 19.63”

Weight (without tank)........................................... 2.9 lbs.

Effective Range ...................................................150+ ft.

7

Getting Started

3) Velocity Adjustment

Note:

Safety goggles must be worn at all times when

handling this gun.

1) Tank Installation

First make sure that the gun is on SAFE mode. Next you

need to cock the gun by sliding the bolt handle all the way

back until it locks into place.

To install the tank, insert the tank valve end into the tank

adapter at the back end of the pistol grip. Twist the tank

clockwise into the gun, until it stops. Adjust the butt plate

if necessary. Your gun is ready to fire once you switch to

firing mode from safe mode.

If the tank is full and you do not hear the CO2 engage, the

pin valve could be too short or the pin valve seal is

damaged.

2) Ammo Box

Make sure that the neck is clean and to keep the paintballs

from breaking and to feed the gun smoothly. You do not

want any sharp edges or debris in your hopper.

Install the neck into the feed elbow of your gun and tighten

the hopper down with the large allen wrench. Now you

are ready to load your hopper with paintballs.

T o adjust the velocity use the 5/32” allen wrench included

with your gun. The velocity adjustment screw is located

on left side receiver at a 45° angle. T o adjust the velocity

down, turn the screw inward or clockwise. To turn the

velocity up, turn the screw out or counterclockwise (

not remove velocity screw

).

Do

Note: You must turn the velocity screw all the way in

before doing any disassembly .

4) Rear Sight Adjustment

If your paintball is hitting low, slide the rear sight back

towards rear of gun. Do the opposite if paintball is hitting

high.

Note:

Do not overtighten or the elbow will break.

8

91011

Unloading Your Gun

Cleaning & Maintenance

T o unload your gun remove the ammo box or completely

empty the ammo box. Then, point your gun in a safe

direction and fire several times to be sure there are no

balls lodged in the chamber.

1) Tank Removal

To remove a charged CO2 cylinder, turn the cylinder

approximately 3/4 of a turn counterclockwise or out. This

allows the tank pin valve to close so that no CO2 will

enter the gun. Point the gun in a safe direction and fire

the remaining CO2 in the gun by pulling the trigger until

the gun stops firing. (This may take 4-5 shots)

If your gun keeps firing after you have turned the tank 3/

4 of a turn, the tank pin valve has not closed yet and

you may have to turn the tank counterclockwise a little

further.

If you turn the tank 3/4 of a turn and it begins to leak

before you pull the trigger you have turned it too far and

may have damaged the tank o-ring.

Because of the variances in tank valve parts, each tank

varies slightly on exactly how far it should be turned. If

this process does not work the tank pin valve could be

too long.

T o clean your paintball gun use a damp towel with water

to wipe off paint, oil, and debris. We recommend using

a premium gun oil to maintain your gun in good working

condition. (Hoppes #9 gun oil) Re-oil with a few drops

to the front bolt, rear bolt, linkage arm, and tank o-ring.

We also recommend using white lithium grease on the

barrel o-ring and CO2 tank o-ring.

Note: Before doing any cleaning, remove the CO2

cylinder from your gun and do not use any

cleaning solvents.

Field Stripping

Y ou must first unload your gun before trying to field strip

it and have the gun in the uncocked position. If your

gun is cocked, hold the bolt handle while pulling the

trigger which will un-cock the gun.

Note: The barrel and tank adapter must be removed

first. Next, turn the velocity screw in until it stops.

12

13

1) Receiver Disassembly

Power tube and valve removal.

Note:

Do not remove the gas line fitting unless it is

leaking or you need to replace the valve. If

you should do so you will need some teflon

tape or paste to reinstall it.

T o remove the left-side receiver , unscrew all (6) receiver

connection bolts. Then carefully lift the left-side receiver

to access the internals.

Note: The Safety will stay on the left-side receiver and

should be reassembled the same way.

Once inside, pull the end cap out to remove the drive

spring guide pin and drive spring. These parts must be

removed before the bolt handle will release. Disconnect

the linkage arm from the rear and front bolts. Slide the

front bolt off the power tube and check the o-ring. Clean

and oil the o-ring or if damaged, replace with a new one.

Do the same with the rear bolt o-ring.

14

1

1

To release the power tube and valve, unscrew the two

valve bolts on the outer right-side receiver.

2

2

When Reinstalling: Do not over tighten bolts when

reinstalling.

V alve removal from power tube: If it is necessary to

remove the valve, use a wrench to slowly unscrew the

gas line fitting. Once the fitting is out, the valve will slide

out the back of the power tube.

Note:

Check the external valve o-ring at this time.

If the o-ring is damaged your gun will not

function correctly.

To reinstall valve: insert valve into power tube, align

holes and with teflon tape or paste on gas line fitting

threads, slowly screw into valve and snug with wrench.

15

Repairing Tank Leaks

Warranty and Repair Policy

The most common leak occurs from a bad tank o-ring.

To replace a tank o-ring you must first remove the bad

o-ring and then install a new one. This o-ring is located

on the tip of your tank valve.

The best tank o-rings are made of urethane. The

urethane o-rings are not affected by high CO2 pressures.

These may be purchased from Tippmann Pneumatics

or your local paintball dealer.

Storage

You should store you gun in a dry area. The only parts

that can rust are the rear bolt and linkage arm. Before

storing your gun make sure that the rear bolt and linkage

arm are cleaned and oiled so that they do not rust. Store

your gun with the bolt in the forward position. Empty

and remove the CO2 tank from the gun.

When removing your gun out of storage you should reoil the rear bolt, linkage arm and the front bolt before

use.

Tippmann Pneumatics, Inc. is dedicated to providing you

with the ultimate paintball gun and the quality support

necessary for the utmost satisfaction in its use.

Tippmann Pneumatics, Inc. warrants that this product is

found free from defects in materials and workmanship

for a period of 1 year from the original date of purchase

by the initial owner/purchaser. On claims submitted as

outlined, Tippmann Pneumatics, Inc. will repair or

replace, without charge, any of its guns that have failed

through defect in material or workmanship.

In the event warranty or other non-warranty related

repairs are required, send the product(s) to Tippmann

Pneumatics, Inc. We strive to complete the necessary

repair work within 24 hours and return it to you via regular

ground UPS. For assistance with warranty and repair

call 1-800-533-4831.

Note: If you should encounter any problems with your

gun and you have aftermarket parts on your gun, please

test it with the original stock parts before sending it in.

16

17

Warranty or Repair Procedure

For warranty and non-warranty repair, ship or deliver

your product(s) to Tippmann Pneumatics, Inc., with

postage or delivery charges prepaid. Include a brief

statement regarding the requested repair, your name,

return address and telephone number where you can

be reached during normal business hours, if possible.

If you wish to have it returned quicker than regular ground

shipping, you can request for Next day air or Second

day air and include your credit card number with the

expiration date. Y our card will be charged the dif ference

in additional cost of Next day air or Second day air over

regular ground shipping cost.

Warranty Card Note:

The 98 Custom number is just

the name of the gun and the serial number is

on the side of the gun. (It is not the Pat. #)

Ship to: Tippmann Pneumatics, Inc.

3518 Adams Center Road

Fort Wayne, IN 46806

18

PNEUMATICS, INC.

(Not Pat. #)

TIPPMANN

WARRANTY REGISTRATION CARD

98 CUSTOM

PERFORATION AND MAIL.

CAREFULLY TEAR OFF AT

COMPLETE WARRANTY CARD,

MODEL ______________________ SERIAL # ________________________________

PURCHASED FROM ____________________________________________________

P) 260-749-6022 F) 260-749-6619 www.tippmann.com

TIPPMANN PNEUMATICS, INC. 3518 ADAMS CENTER ROAD FT. WAYNE, IN 46806

_____________________________________________________________________

DATE_______ CITY ___________________________ STATE _______ ZIP _______

YOUR NAME (Please print) _______________________________________________

STREET ______________________________________________________________

CITY ________________________________________ STATE _______ ZIP _______

PHONE # _____________________________________________________________

Loading...

Loading...