Page 1

BACK COVER

TIPPMANN

• Owner’s Manual

• Manuel du Propriétaire

• Manual del Usuario

TM

• A-5

BASIC

TM

• A-5

WITH

E-GRIP

• A-5

RESPONSE

• A-5

BASIC

SILVER

• A-5

TM

TM

TM

TM

TM

TM

BASIC

CAMOUFLAGE

TM

TM

A-5

MARKER

®

LINE

TM

• A-5

STEALTH

TM

TP04100

Date:08-09

Page 2

WARNING

E

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS

INJURY OR DEATH. EYE, FACE AND EAR PROTECTION

N

DESIGNED FOR PAINTBALL MUST BE WORN BY THE

G

USER AND ANY PERSON WITHIN RANGE. WE

L

RECOMMEND AT LEAST 18 YEARS OLD TO PURCHASE.

PERSONS UNDER 18 MUST HAVE ADULT SUPERVISION

I

WHEN USING THIS PRODUCT. READ THE OWNER’S

S

MANUAL BEFORE USING THIS PRODUCT.

H

WARNING

READ, FAMILIARIZE

YOURSELF AND ANY

OTHER USER OF THIS

MARKER WITH THE

SAFETY INSTRUCTIONS

IN THIS MANUAL.

FOLLOW THESE

INSTRUCTIONS WHEN

USING, WORKING ON,

TRANSPORTING OR

STORING THIS MARKER.

SAFETY IS YOUR RESPONSIBILITY

ALWAYS KEEP

TRIGGER SAFETY

IN SAFE MODE

UNLESS FIRING

AS DETAILED IN

INSTRUCTIONS

ON PAGE 4.

ALWAYS KEEP

THE BARREL

BLOCKING DEVICE

INSTALLED WHEN

NOT IN SHOOTING

SITUATION, SEE

INSTRUCTIONS ON

PAGE 2.

E

N

G

L

I

S

H

AVERTISSEMENT

F

CECI N'EST PAS UN JOUET. TOUT USAGE INAPPROPRIE

PEUT PROVOQUER DES BLESSURES GRAVES OU

R

MORTELLES. LE PORT DE LA PROTECTION POUR LES

A

YEUX, LE VISAGE ET LES OREILLES CONCUE POUR LE

N

PAINTBALL EST OBLIGATOIRE POUR L'UTILISATEUR

AINSI QUE POUR TOUTE PERSONNE A PORTEE DE TIR.

Ç

POUR L'ACHAT, NOUS RECOMMENDONS UN AGE

A

MINIMUM DE 18 ANS. LES PERSONNES DE MOINS DE 18

I

ANS DOIVENT ETRE SOUS LA SURVEILLANCE D'UN

S

ADULTE LORSQU'ELLES UTILISENT CE PRODUIT. LISEZ

LE MANUEL AVANT D'UTILISER CE PRODUIT.

ADVERTENCIA

E

ESTO NO ES UN JUGUETE. UN USO INAPROPIADO

PUEDE CAUSAR SERIAS HERIDAS O LA MUERTE.

S

OJOS, CARA Y OIDOS DEBEN SER PROTEGIDOS TODO

P

EL TIEMPO, CON LA PROTECCIÓN DISEÑADA PARA

A

PAINTBALL TANTO POR JUGADORES COMO POR

CUALQUIER PERSONA QUE ESTE EN EL RADIO DE

Ñ

ALCANCE. RECOMENDAMOS AL MENOS 18 AÑOS

O

PARA LA COMPRA Y USO. LAS PERSONAS MENORES

L

DE 18 AÑOS DEBEN USAR ESTE PRODUCTO BAJO LA

SUPERVISIÓN DE UN ADULTO. ANTES DE USAR ESTE

PRODUCTO LEA EL MANUAL DEL USUARIO.

AVERTISSEMENT

LISEZ ET FAMILIARISEZVOUS AINSI QUE TOUT

AUTRE UTILISATEUR DE

CE LANCEUR AVEC LES

INSTRUCTIONS DE

SECURITE CONTENUES

DANS CE MANUEL.

SUIVEZ CES INSTRUCTIONS LORSQUE VOUS

UTILISEZ, TRAVAILLEZ

SUR, TRANSPORTEZ OU

ENTREPOSEZ CE

LANCEUR.

LA SECURITE EST VOTRE RESPONSABILITE

ADVERTENCIA

LA SEGURIDAD ES SU RESPONSABILIDAD

EL PROPIETARIO Y

TODA PERSONA QUE

VA A USAR ESTE

MARCADOR DEBE LEER

Y FAMILIARIZARCE CON

LAS INSTRUCCIONES DE

SEGURIDAD EN ESTE

MANUAL. SIGA LAS

INSTRUCCIONES DE

USO, MANTENIMIENTO,

TRANSPORTE Y

ALMACENAJE DE ESTE

MARCADOR.

SI VOUS NE TIREZ

PAS, MAINTENEZ

TOUJOURS LA

SURETE DE DETENTE

EN MODE SECURITE

COMME INDIQUE

DANS LES

INSTRUCTIONS EN

PAGE 3.

MANTENGA SIEMPRE

EL SEGURO DEL

GATILLO ACTIVADO

A MENOS QUE SEA

NECESARIO HACER

DISPAROS. COMO

SE VE EN LAS

INSTRUCCIONES

DE LA PÁGINA 3.

GARDEZ TOUJOURS

LE DISPOSITIF DE

BLOCAGE DU

CANON INSTALLE

LORSQUE VOUS

N'ETES PAS EN

SITUATION DE TIR,

VOIR INSTRUCTIONS

EN PAGE 1.

MANTENGA

EL MECANISMO

DE BLOQUEO

DEL BARRIL

INSTALADO

CUANDO NO

ESTE HACIENDO

DISPAROS COMO

SE ILUSTRA EN

LA PÁGINA 1.

F

R

A

N

Ç

A

I

S

E

S

P

A

Ñ

O

L

Page 3

WARNING

E

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS INJURY OR

DEATH. EYE, FACE AND EAR PROTECTION DESIGNED FOR

N

PAINTBALL MUST BE WORN BY THE USER AND ANY PERSON

G

WITHIN RANGE. WE RECOMMEND AT LEAST 18 YEARS OLD TO

PURCHASE. PERSONS UNDER18 MUST HAVE ADULT SUPERVISION

L

WHEN USING THIS PRODUCT. READ THE OWNER’S MANUAL

I

BEFORE USING THIS PRODUCT.

S

H

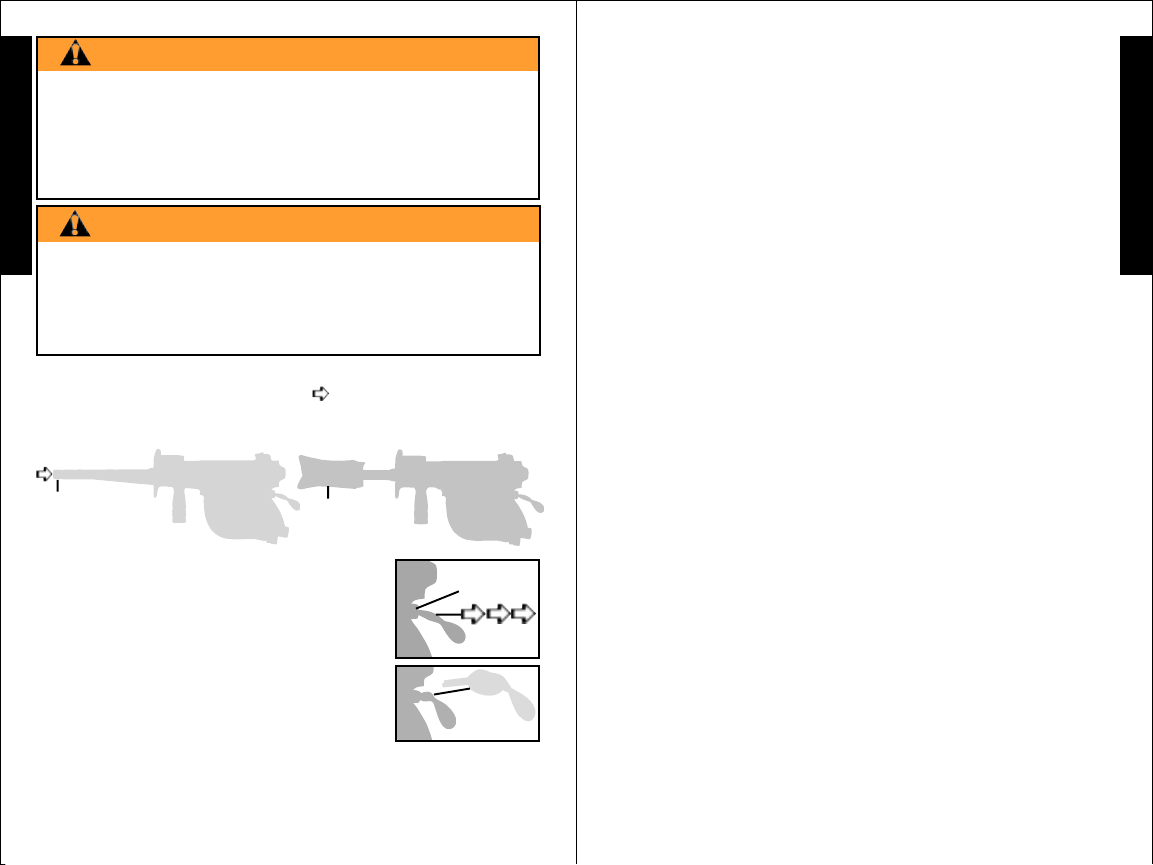

KEEP THE BARREL BLOCKING DEVICE INSTALLED EXCEPT WHEN

YOUR MARKERIS IN USE. ALWAYS MAKE SURETHAT THE TRIGGER

SAFETY IS IN THE SAFE MODE (SEE INSTRUCTIONS ON PAGE 4)

AND THE BARREL BLOCKING DEVICE IS PROPERLYINSTALLED ON

YOUR MARKER ACCORDING TO THE INSTRUCTIONS TO PREVENT

DAMAGE TO PROPERTY, SERIOUS INJURY OR DEATH.

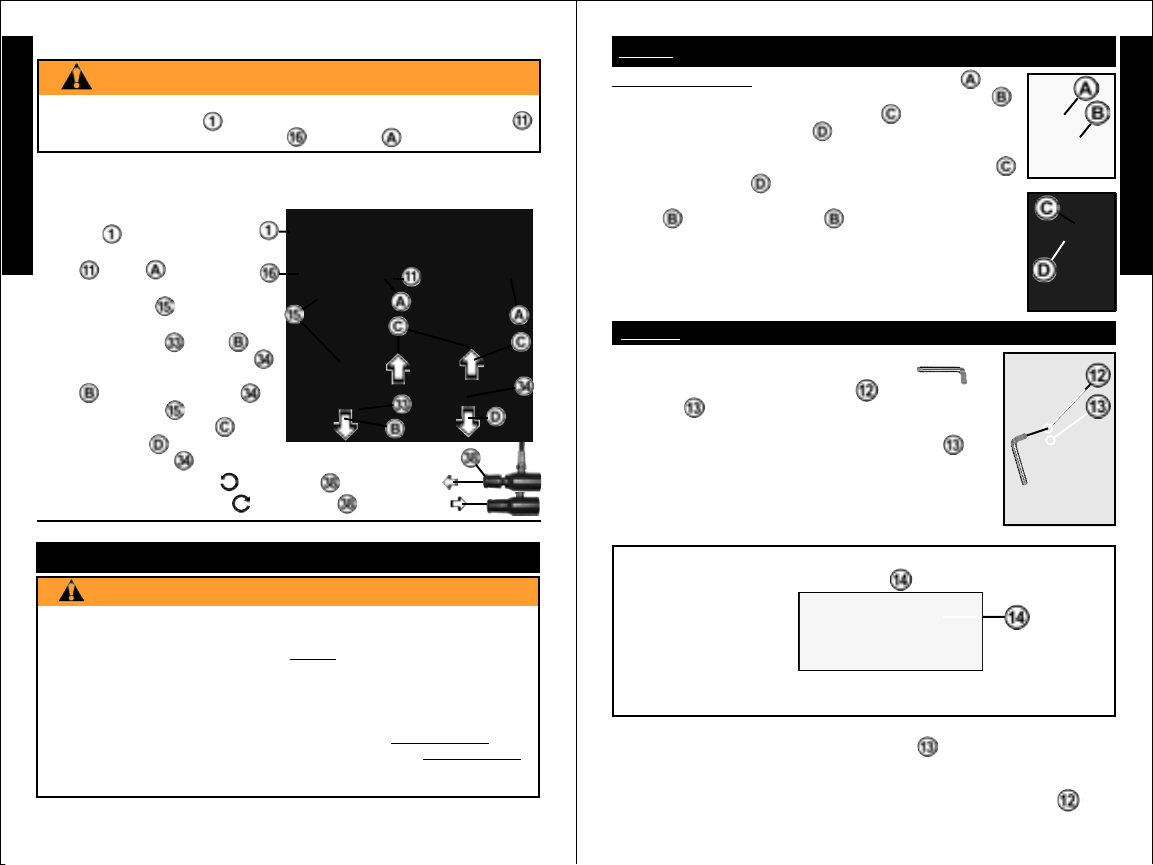

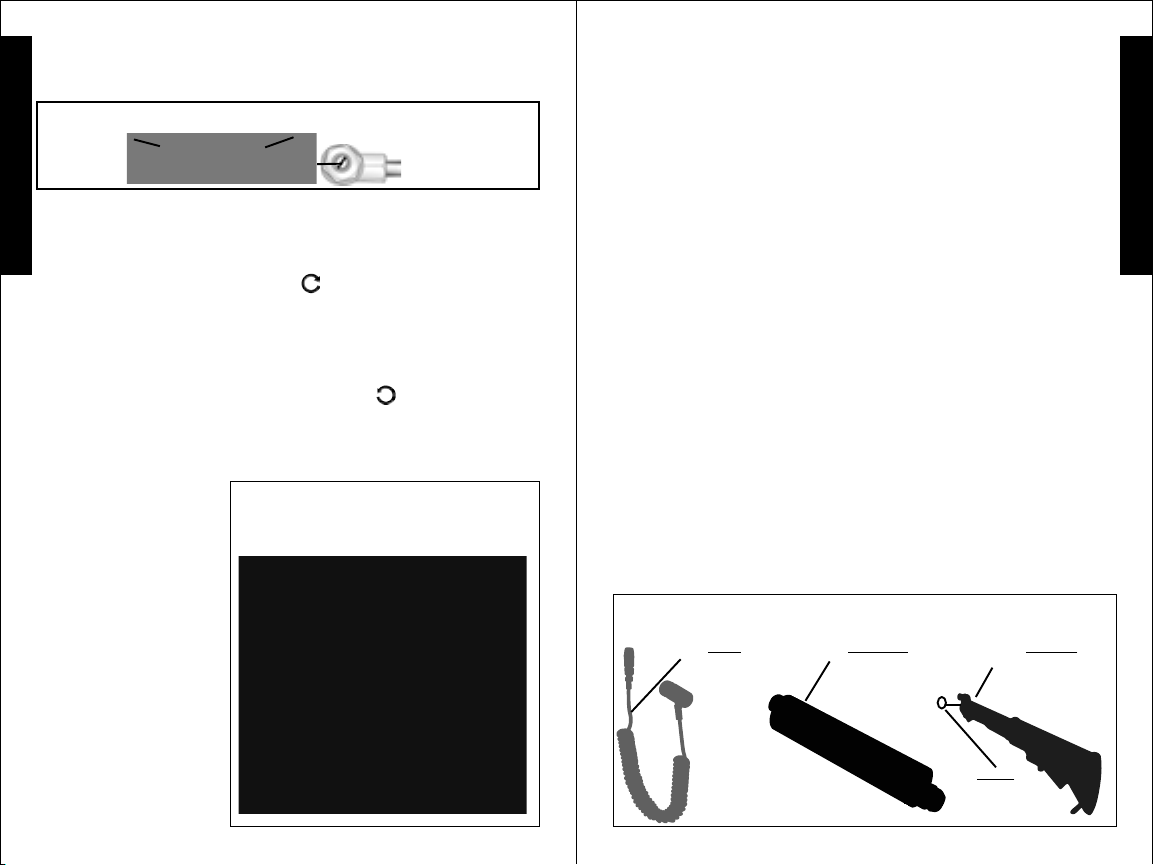

BARREL BLOCKING DEVICE INSTALLATION INSTRUCTIONS

1) Insert the barrel blocking device into the barrel (or over the

barrel, depending on the style of barrel blocking device) and loop

the cord over the top of the receiver and position at the back of the

grip as shown .

Barrel

Blocking

Device

2) Adjust the cord length retainer up to the back

of the grip by pulling the cord through it until

the retainer is snug against the back of the grip.

Keeping the cord as tight as possible, leave

just enough cord elasticity to pull the cord/

retainer up over the top of the marker to remove

the barrel blocking device for firing.

3) After the cord length is properly adjusted,

lock the cord length by tying a knot in the cord

against the back of the retainer as shown.

4) Before and after playing, inspect the barrel blocking device and

replace if bag, plug, or cord damage, or loss of cord elasticity is found.

5) Clean the barrel blocking device with plain, warm water and store

out of sunlight in a dry area when not in use.

WARNING

Barrel

Blocking

Device

2

Cord Length

Retainer

®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619

www.tippmann.com

CONGRATULATIONS on your purchase of your Tippmann®paintball

marker. We believe ourA-5TMline of markers to be the most accurate

and durable paintball markers available, and proudly manufactured

in the USA. All Tippmann®A-5TMmodels will provide many years of

dependable service if cared for properly.

Please take time to read this manual thoroughly and become

familiar with your Tippmann®A-5TMmarkers’ parts, operation,

and safety precautions before you attempt to load or fire this

marker. If you have a missing or broken part or need

assistance, please contact Tippmann Consumer Relations at

1-800-533-4831 for fast, friendly service.

TABLE OF CONTENTS

Warning/Caution............................................................................... 2

Warning/Caution Barrel Blocking Device Installation ................... 2

Warning/Liability Statement ............................................................ 4

Safety is your Responsibility ........................................................... 4

Safe Mode = Turning The Safety On (PUSH SAFE) .................... 4

Fire Mode = Turning The Safety Off (PUSH FIRE)....................... 4

Getting Started ................................................................................. 6

1. Prepare Marker for Air Supply Cylinder Installation ............. 6

2. Air Supply Cylinder Installation .............................................. 6

3. Hopper and CycloneTMFeeder ................................................ 6

4. Rate of Fire Adjustments and Troubleshooting .................... 7

5. Velocity Adjustment ................................................................. 7

6. Rear Sight................................................................................. 7

Marker Model Specifications ......................................................... 15

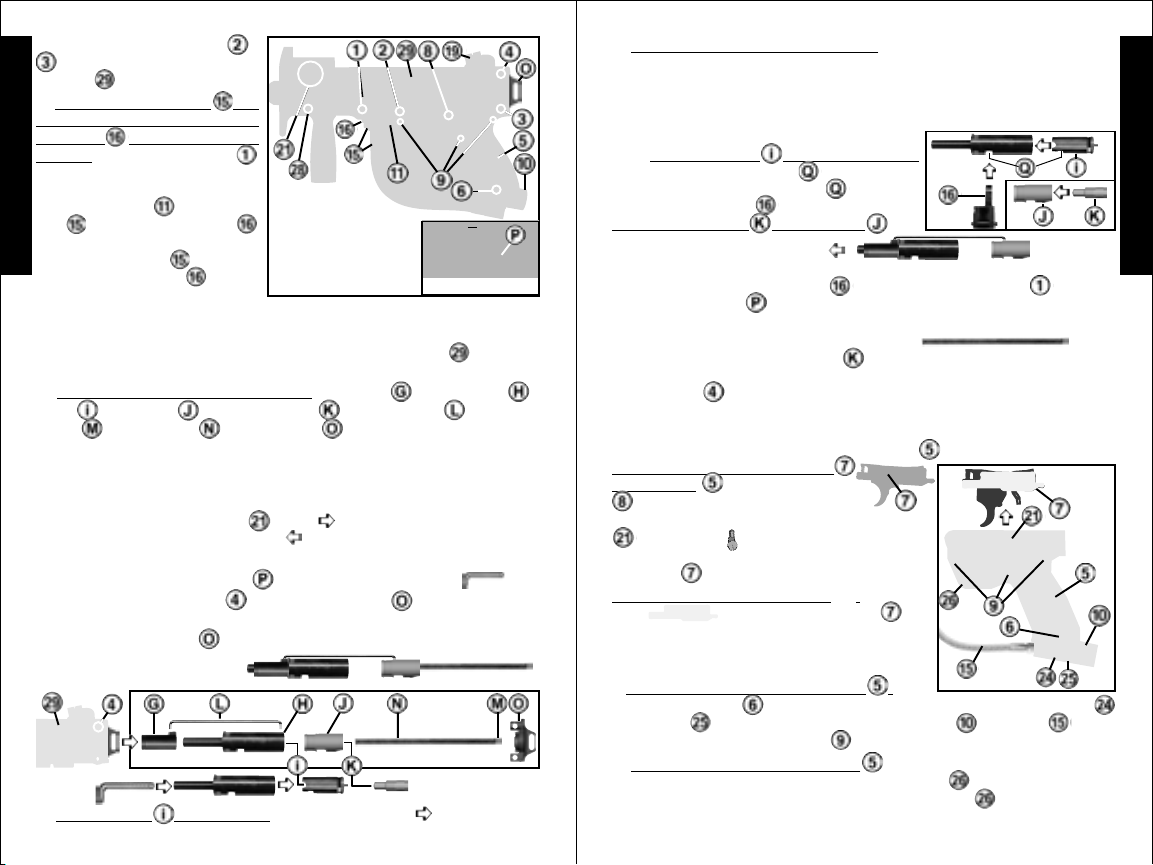

Schematic: A-5TMBasic Parts List ................................................. 16

Unloading Your Marker .................................................................. 18

Air Supply Cylinder Removal / Air or CO2 Cylinder Safety Tips ..... 18

Repairing Air Supply Leaks ........................................................... 20

Cleaning & Maintenance ............................................................... 20

Storage ............................................................................................ 21

Marker / Receiver Disassembly and Assembly........................... 21

Warranty Information, Registration and Repairs ........................ 28

3

E

N

G

L

I

S

H

Page 4

Warning / Liability Statement

This marker is classified as a dangerous weapon and is surrendered

E

by Tippmann Sports, LLC with the understanding that the purchaser

assumes all liability resulting from unsafe handling or any action that

N

constitutes a violation of any applicable laws or regulations. Tippmann

G

Sports, LLC shall not be liable for personal injury, loss of property or

life resulting from the use of this weapon under any circumstances,

L

including intentional, reckless, negligent or accidental discharges.

I

All information contained in this manual is subject to change without

notice. Tippmann Sports, LLC reserves the right to make changes and

S

improvements to products without incurring any obligation to incorporate

H

such improvements into products previously sold.

If you as a user do not accept liability, Tippmann Sports, LLC requests you

do not use a TippmannSports, LLC marker. By using this paintball marker you

release Tippmann Sports, LLC of any and all liability associated with its use.

SAFETY IS YOUR RESPONSIBILITY!

WARNING

• EXCEPT WHEN YOUR MARKER IS IN USE, ALWAYS MAKE SURE THAT

THE TRIGGER SAFETY IS IN SAFE MODE, WHICH DISABLES THE

TRIGGER, AND THE BARREL BLOCKING DEVICE IS

INSTALLED (SEE PAGE 2).

• TO TURN ON THE SAFETY (SAFE MODE):

❏

PUSH THE SAFETY IN AS SHOWN (PUSH SAFE).

• TO TURN OFF THE SAFETY (FIRE MODE):

❏

PUSH THE SAME BUTTON ON THE OPPOSITE

SIDE OF THE RECEIVER (PUSH FIRE).

E-GRIP MODELS:

• TO TURN ON THE SAFETY (SAFE MODE):

❏

PUSH THE SAFETY SELECTOR UP AS

SHOWN. (SAFE MODE = ).

• TO TURN OFF THE SAFETY (FIRE MODE):

❏

PUSH THE SAFETY SELECTOR DOWN.

(FIRE MODE = RED OR RED ).

FAMILIARIZE YOURSELF WITH SAFETY...

The ownership of this weapon places upon you the total responsibility for its

safe and lawful use. You must observe the same safety precautions as

you would any firearm to assure the safety of not only yourself but everyone

around you. The user should atall times use cautionwhen using this marker.

The sport of Paintball will be viewed and judged upon your safe and

sportsmanlike conduct. Always remember that the game of Paintball can

TRIGGER SAFETY ACTIVATION

4

Safety Is Your Responsibility

SAFETY

PUSH SAFE

SAFETY

SELECTOR

(continued on page 5)

Safety Is Your Responsibility (continued from page 4)

only survive and grow if it remains SAFE!

• Do not load or fire this marker until you have completely read this

manual and are familiar with its safety features, mechanical operation

and handling characteristics.

• Handle this and any marker as if it were loaded at all times.

• Keep your finger off the trigger until ready to shoot.

• Do not look down the barrel of a paintball marker. Accidental discharge

into the eyes may cause permanent injury or death.

• Keep the the trigger safety in safe mode until ready to shoot (see page 4).

• Keep the barrel blocking device installed on marker when not shooting

(see page 2).

• Never point the marker at anything you do not intend to shoot.

• Never fire your marker at anything you do not intend to shoot because

there may be balls or foreign debris lodged in the chamber, barrel and / or

the marker valve.

• Do not shoot at fragile objects such as windows.

• Never fire your marker at personal property of others. The paintball impact can

cause damage and the paint can stain the finish of automobiles, houses etc.

• Always keep the muzzle pointed down or in a safe direction, even

if you stumble or fall.

• Eye, face and ear protection designed specifically to stop paintballs in the

form of goggles and full face mask meetingASTM Specification F 1776

must be worn by the user and any person within range.

• Never shoot at a person who is not protected by eye, face and ear

protection designed for paintball.

• Pressurize and load a marker only when marker will be immediately used.

• NOTE: Before storing or disassembling be sure to remove paintballs and

air supply(see unloading and air supply removal onpage 18), put the safety

in the safe mode (see page 4) andinstall barrel blocking device (see page 2).

• Store the marker unloaded and degassed in a secure place.

• Do not field strip or otherwise disassemble this marker while

it is pressurized with air supply.

• Dress appropriately when playing the game of paintball. Avoid

exposing any skin when playing the game of paintball. Even a light

layer will absorb some of the impact and protect you from the paintballs.

• Keep exposed skin away from escaping gas when installing or removing

air supply cylinder or if the marker or air supply is leaking. Compressed

air, CO

2, and nitrogen gasses are very cold and can cause frostbite

under certain conditions.

• Use only .68 caliber paintballs, never load or fire any foreign objects.

• Avoid alcoholic beverages before and during the use of this marker.

Handling markerswhile under the influenceof drugs or alcoholis a criminal

disregard for public safety.

• Avoid shooting an opponent at point blank, 6 feet or less.

• Familiarize yourself with instructions listed on air supply cylinder or adaptor.

Contact the air supply cylinder or adaptor manufacturer with any questions.

5

Safety Is Your Responsibility

(continued on page 6)

E

N

G

L

I

S

H

Page 5

Safety Is Your Responsibility (continued from page 5)

• Read theAir Supply Cylinder Removal and SAFETYTIPS on pages

18-20 before beginning the cylinder installation or removal.

• Always measure your marker’s velocity before playing paintball and never

E

shoot atvelocities in excess of300feet per second (see instructions on page 7).

N

GETTING STARTED:

G

❏

Eye protection designed for paintball use must be worn by the user and

L

any person within range. Do not disassemble this marker while it is

I

pressurized with air. Do not pressurize a partially assembled marker.

Read each step completely before performing the step:

S

NOTE: Carefully hand start all threaded parts and do not overtighten and

H

strip threaded parts when assembling.

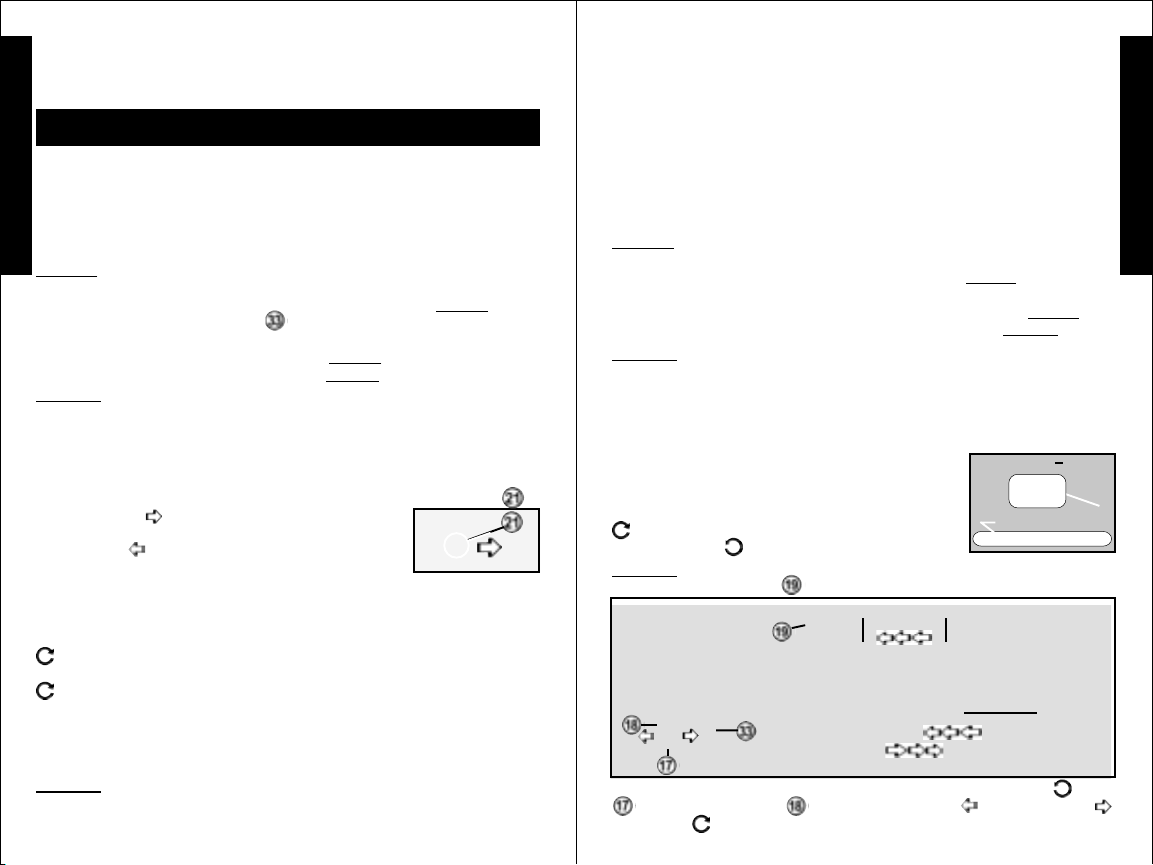

STEP 1: Prepare Marker for Air Supply Cylinder Installation

• For markers with E-GripTM-❏You must first read and follow E-Grip

Operating Instructions on pages 8-13) before performing STEP 2.

• For markers with Remote Coil

(A-5TMStealthTM)-❏You must first

check that the remote coil is properly connected - read & follow the

Instructions on page 8 before performing

• For markers without E-GRIP

TM

-❏Go to STEP 2.

STEP 2.

STEP 2: Air Supply Cylinder Installation

❏

You must first read the Air Supply Cylinder Removal and SAFETY TIPS

on pages 18-20 before beginning the cylinder installation.

❏

Do not pressurize a partially assembled paintball marker.

❏

First put trigger safety in Safe Mode (see page 4 instructions)

and

❏

install barrel blocking device (see instructions on page 2).

❏

Next you need to cock the marker by sliding the bolt cocking handle

all the way back

until you hear / feel it click into place.

Then release the cocking handle. Cocking handle will

slide forward

. Marker is now cocked. Always keep

the marker in the cocked position when air supply

is attached to the marker. This will help prevent an accidental discharge.

❏

To install the air supply cylinder, lubricate the cylinder valve o-ring with a

little marker oil then insert the cylinder valve end into the air supply adapter

at theback end of the marker grip (orremote coil). Twist thecylinder clockwise

into theadapter until it stops. Your marker is ready to fire once youswitch

to Fire Mode from Safe Mode (and on remote coil - turn the air flow valve on

-see page 8). If the tank is full and you do not hear the air supply engage,

the pin valve could be too short or the pin valve seal is damaged. (Follow

theAir Supply Cylinder Removal instructions on pages 18-20 and take your

air or CO2 cylinder to a “C5” Certified Airsmith for inspection or contact the

cylinder manufacturer).

STEP 3: Hopper and CycloneTMFeeder

Barrel blocking device must be installed (see page 2) and trigger safety in

Safe Mode (see page 4) before filling the hopper.

6

❏

Make sure that the

Getting Started

(continued on page 7)

Getting Started (continued from page 6)

CycloneTMfeeder housing is clean, free of debris, and the CycloneTMfeeders

turn freely when the manual advance lever knob is pushed.

❏

Make sure that the hopper is clean, free of sharp edges or debris. This

will keep the paintballs from breaking and feed the marker smoothly.

❏

Install the hopper neck into the CycloneTMfeeder housing aligning the

hopper neck tab to fit into the cutout in the Cyclone

TM

feeder housing. With

the barrel blocking device installed and trigger safety in Safe Mode, you are

now ready to load your hopper with paintballs. After filling the hopper with

paintballs thechamber will still be empty. You needto push the feeder manual

advance lever to chamber a paintball. Only remove the barrel blocking

device and turn off the trigger safety when ready to shoot.

STEP 4: Rate of Fire Adjustments and Troubleshooting

• Marker: A-5TMwith E-GripTM-❏ Go to pages 8-13 and follow E-Grip

TM

Tuning and OperatingInstructions before performing STEP 5.

• Marker: A-5

Response

• Markers: A-5

TM

ResponseTM-❏ Go to page 14 and follow Tuning The

TM

Trigger Rate of Fire instructions before performing STEP 5.

TM

Basic and A-5TMSTEALTHTM-❏ Go to STEP 5.

E

N

G

L

I

S

H

TM

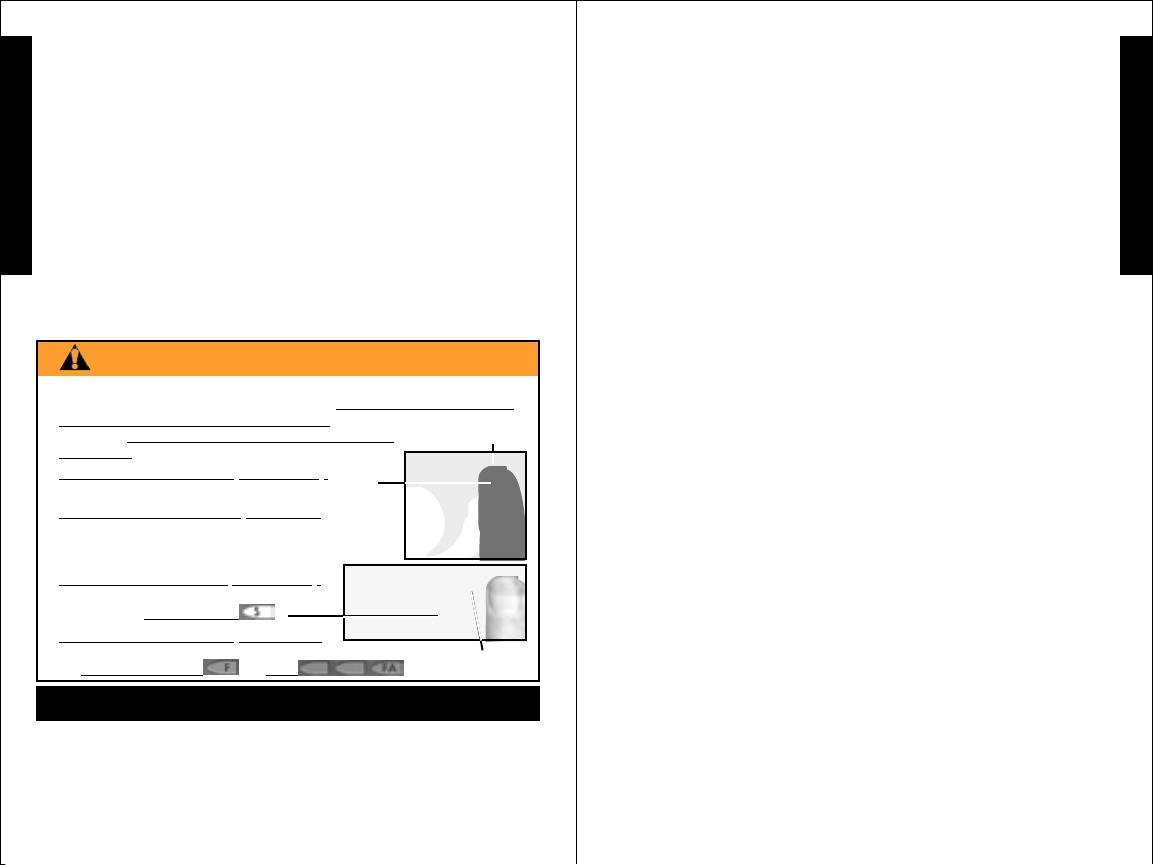

STEP 5: Velocity Adjustment

❏

Each time you play paintball, the velocity of your paintball marker should

be checked with a chronograph, an instrument for measuring velocity, prior

to playing paintball to verify that the marker’s velocity is set below 300 feet

per secondor less if required by playing field. NOTE:For markers with Flatline

TM

barrel system,260-275 feet persecond is recommended forbest performance.

❏

To adjust the velocity use the 3/16” allen wrench

included with your marker. The velocity adjustment

screw is located on the right side of the receiver. To

reduce thevelocity, turn the screw inwardor clockwise

. To increase the velocity, turn the screw

counterclockwise

. Donot remove the velocity screw.

3/16”Allen Wrench

Velocity

Adjustment

Screw

Feeder Manual AdvanceLever

STEP 6: Rear Sight Adjustment:

❏

Rotate the rear sight to preferred width to allow easy sighting.

❏

Collapsible Stock Length Adjustment:

Front Grip adjustment:❏ Use the 3/16” allen wrench to loosen screw

inside the Front Grip to slide the front grip forward or back ,

and tighten

to lock in place.

Shorten

Squeeze the

adjustment lever

and slide to shorten

or lengthen stock.

7

Page 6

Remote Coil: Connecting and Disconnecting

E

NEVER INSTALL PRESSURIZED AIR TO THE MARKER WITHOUT THE

N

TOMBSTONE PUSH PIN INSTALLED AND THE TOMBSTONE LATCH

G

IS SET - HOLDING THE TOMBSTONE IN PLACE .

L

1)

❏

Remove the air supply from the marker Remote Coil as outlined in

the Air Supply Cylinder Removal instructions on pages 18-20. Never

I

disassemble a marker or remove a remote coil that is under pressure.

S

2)❏Check that the Tombstone

Push Pin

H

3)

❏

Latch

4)

❏

and nipple fitting

5)

❏

fitting Locking Ring

or remove the Remote Coil fitting

6)❏With the Locking Ring held

down

up onto the nipple and release

the locking ring up to lock

7)❏Pull down on the

Remote Coil fitting

❏

To turn off air supply: turn flow control completely out

❏

To turn on air supply: turn flow control completely in

is installed.

Check that the Tombstone

is set .

Check that Gas Line Adapter

Pull and hold the Remote Coil

, push the coil fitting

WARNING

are secure.

down to install

.

.

to be sure it has locked properly.

E-GRIP OPERATING INSTRUCTIONS

WARNING

READ AND FOLLOW THE E-GRIPTMOPERATING INSTRUCTIONS (PAGES 8-

13) COMPLETELY BEFORE INSTALLING THE AIR SUPPLY CYLINDER AS

OUTLINED IN – GETTING STARTED - STEP 2: ON PAGE 6.

• INSTALL THE AIR SUPPLY AND LOAD THE HOPPER WITH PAINTBALLS

ONLY AFTER YOU:

❏ ❏

❏

HAVE THE BARREL BLOCKING DEVICE INSTALLED (SEE PAGE 2);

❏ ❏

❏ ❏

❏

HAVE THE TRIGGER SAFETY IN SAFE MODE (SEE PAGE 4);

❏ ❏

❏ ❏

❏

HAVE SUCCESSFULLY INSTALLED THE BATTERY ( STEP 1: PAGE 9) AND

❏ ❏

❏ ❏

❏

ARE FAMILIAR WITH THE E-GRIP NORMAL OPERATION (STEP 2: PAGE 9).

❏ ❏

• EYE PROTECTION DESIGNED FOR PAINTBALL USE MUST BE WORN

BY THE USER AND ANY PERSON WITHIN RANGE.

• READ EACH STEP COMPLETELY BEFORE PERFORMING THE STEP:

8

E-GRIPTMOperating Instructions

(continued on page 9)

E-GRIPTMOperating Instructions (continued from page 8)

STEP 1: E-GRIPTMBattery Installation or Replacement:

To Install the battery:❏ Remove the battery door from

the back of the E-Grip

NOTE: When removing the battery clip

Do Not pull it off by the wires

❏

Plug a 9 volt battery into the battery clip.

❏

Insert the battery into the E-GripTMwith the battery clip

TM

by pullingup and back on the tab .

from the battery,

.

at the top and wires as shown.

❏

Reinstall the battery door - Replace the battery door with

the tab

it locks back into the E-Grip

NOTE: The E-Grip

down, press the tab and listen for the snap as

TM

TM

.

Low BatteryIndicator feature: the “Ready

To Fire” Flashing Green LED will turn to blinking red when

the battery is low and needs replaced (see -

Condition

on page 10).

Low Battery

STEP 2: Power On - Basic Operation

TM

1) To turn the E-Grip

❏

Use a small object like an allen wrench ( )to

press and hold the power button

The LED

will light orange then green when the

power on:

for 2 seconds.

electronics have been activated.

❏

Release the power button and the green LED will

begin flashing green to show the power is on and the

❏

battery is good. (NOTE:

If the LED begins flashing

red, see - Low Battery Condition on page 10).

❏

If pressing the power button failed to turn on

the LED light, see Troubleshooting section on page 13.

2) Safety/Selector operation -

The 3-position safety/selector switch

has three settings:

S = Safe (as shown);

F = Semi-Auto

(One pull/release

of the trigger

fires 1 time).

FA= Special Firing Mode. The Special Firing Mode can be set to any 1

of 5 firing options as detailed in the Special Firing Mode section.

3) To fire the marker -

selector switch and pull the trigger. The LED

❏ ❏

❏

select either the F or FA position using the safety/

❏ ❏

will light orange with each

pull of the trigger.

4) ChangingSpecial Firing Modes-

while the E-Grip

TM

is powered on, press and hold the power button for a

1/2 second. The LED will flash orangeto represent the numberof the Special

❏ ❏

❏

To change the Special Firing Mode

❏ ❏

9

E-GRIPTMOperating Instructions

(continued on page 10)

E

N

G

L

I

S

H

Page 7

E-GRIPTMOperating Instructions (continued from page 9)

Firing Mode. The corresponding numbers are listed in the

Modes section

Special Firing Mode to the default mode. The default Special Firing Mode

E

can be changed by following the instructions in the

N

Programming section

5) Turn power off -

G

2 seconds. The LED will change from green to red when the power-off

L

condition hasbeen achieved. The E-Grip

button is released. (NOTE: The trigger electronics are set to shut-off

I

automatically after a prolonged period of inactivity (120 minutes).

S

6) Low battery condition -

When the battery has begun to lose power, the LED will stop flashing green

H

and beginflashing red. While performance will vary while theLED is flashing

red, the E-Grip

of these instructions. Powering off the E-GripTMwill reset the

.

❏ ❏

❏

To turn the power off, hold the power button for

❏ ❏

TM

will powerdown when the power

❏ ❏

❏

The E-GripTMLow Battery Indicator Feature:

❏ ❏

TM

will still function under this condition until the battery has

Special Firing

Advanced User

lost power to the point that it will not cycle the marker.

❏

TOURNAMENT LOCK: Because the E-GripTMrequires a tool to turn it

on and off, no tournament lock is necessary for competition paintball.

Special Firing Modes of the E-Grip

TM

The Special Firing Mode of the E-GripTMmay be programmed to one of five

firing options which are:

1. Safe Three-round Burst - Pulling the trigger three times in less than

one second will result in a 3-shot burst at a rate of 13 balls per second (bps)

on thethird trigger pull. Each pull of the trigger in less thanone second after

this will result in another 3-shot burst (up to 3 bursts per second).

2. Safe Full-Auto (factory default) - Pulling the trigger three times in less

than one second will result in full-automatic firing. Holding the trigger down

on the third pull will sustain this full-auto mode. The default rate of fire for

this mode is 13 bps.

3. Auto-Response - The marker will fire on the pull and the release of the

trigger. This mode effectively doubles your manual firing rate.

4. Turbo Mode - Pulling the trigger three times in less than one second will

result in full-automatic firing at a rate of 15 bps. To sustain this rate of fire,

the trigger must be pulled at least once per second.

5. Semi-Auto - A semi-automatic Special Firing Mode is available for fields

or tournaments which restrict the use of automatic firing modes. This mode

is the same as selecting the F firing mode with the safety/selector switch

(One pull/release of the trigger fires 1 time).

Advanced User Programming Section

There are several programming options which affect the operation of the

Tippmann

to allow users the maximum amount of customization possible for their EGrip

Dwell, Debounce

®

E-GripTM. TheAdvanced User Programming has been designed

TM

. There are four menu items in the Advanced User Programming:

TM

, Rate-of-fire, and Special Firing Mode. Read and

10 11

Advanced User Programming Section

(continued on page 11)

Advanced User Programming Section (continued from page 10)

familiarize yourself with each of these items as they are explained in the

following sections.

Menu Items– Dwell, DebounceTM, Rate-of-fire,and Special Firing Mode

Explained:

This section will discuss the four menu items in detail so that a

user will understand fully the purpose and use of each menu item.

Dwell - (Factory Default Value = 8 milli-seconds) The Dwell menu item is

used to change the amount of time that power is supplied to the solenoid.

The solenoidis the part of the electronics which actually contacts the searof

the marker, allowing it to fire. This setting will directly affect the battery life

of the E-Grip

E-Grip

TM

. If this is changed to a value less than 8 milli-seconds, your

TM

battery will last longer, but this may not allow the solenoid enough

time to trip the sear properly. If this value is set greater than 8 milli-seconds,

the solenoid will have power supplied to it for a longer time, but will reduce

the life of the battery. Changing this value can cure or create performance

issues for the user. This menu item can only be updated with the values of

2-20 milli-seconds.

Debounce

TM

- (Factory Default Value = 52 milli-seconds) The Debounce

TM

menu item is used to change the amount of time between accepted trigger

pulls. Quite simply, this adjusts the amount of time from one trigger pull

being accepted by the electronics to the next trigger pull which can be

accepted. If a Debounce

TM

setting is too low, a user may shoot more times

than they had expected. This can be explained by what is called "Trigger

Bounce." When a paintball marker is fired, the marker will move and vibrate

in a user's hand. This vibration can allow the trigger to reset itself and trip

without the user realizing that their finger has actually moved. NOTE: This

menu item can only be updated with the values of 25-65 milli-seconds.

Rate-of-Fire - (Factory Default Value = 13 bps) The Rate-of-Fire menu

item may be used to update the Safe Full-auto Firing mode. This is the only

Special Firing Mode which is affected by this menu item. All other Special

Firing modes cannot have their rate of fire adjusted. This menu item can

only be updated with the values of 8-15 bps.

Special FiringMode - (Factory DefaultValue = 2 Safe Full-auto)The Special

Firing Mode menu item is used to change the default Special Firing Mode.

The value and corresponding Special Firing Mode are listed below.

1. Safe Three-shot Burst

2. Safe Full-auto (factory default)

3. Auto-Response

4. Turbo Mode

5. Semi-automatic

This menu item can only be updated with the values of 1- 5.

Step 1) Accessing the Advanced User Programming

❏ ❏

❏

1) Before attempting to Access the Advanced User Programming:

❏ ❏

prepare themarker for safety before any programming:

❏

Remove TheAir Supply (as outlined on pages 18-20). Do Not attempt to

and

❏

Unload Your Marker

Advanced User Programming Section

(continued on page 12)

E

N

G

L

I

S

H

Page 8

Advanced User Programming Section (continued from page 11)

perform Advanced User Programming on a marker that is under pressure.

❏❏

❏

Put the marker in the uncocked position before

❏❏

beginning todisassemble it. To uncock the marker,

E

pull and hold the bolt cocking handle

N

then pull the trigger and slowly release the handle

forward

G

❏❏

❏

❏❏

L

Programming, make sure the power is off. If the

power is on, press and hold the power button for 2 seconds. The LED will

I

change to a solid red color. The E-Grip

S

button is released.

❏❏

❏

❏❏

H

❏❏

❏

❏❏

❏❏

❏

❏❏

The E-Grip

which will uncock the marker.

2) Power off - To begin the Advanced User

3) Place Safety Selector in the fire position ( ).

4) Pull the trigger - Pull and hold the trigger down.

5) Power on - Press and hold the power button down for 2 seconds.

TM

will appear to power on normally. Release the power button

back -

TM

will power down when the power

once the LED turns green.

❏❏

❏

6) Continue holding the trigger - Continue to hold the trigger down for

❏❏

5 seconds. After 5 seconds, the LED will change to a solid red color.

❏❏

❏

7) Release the trigger - Once the LED changes to the solid red color,

❏❏

release the trigger. The E-Grip

TM

is now in the main menu of the Advanced

User Programming.

Step 2) Choosing a menu item

The four menu items contained in the Advanced User Programming menu

are Dwell,Debounce

TM

, Rate-of-fire,and Special Firing Mode. Each of these

menu items has a corresponding color code as follows.

1. Solid Red - Dwell

2. Solid Green - Debounce

TM

3. Flashing Green - Rate of fire

4. Alternating Red/Green - Special Firing Mode

❏❏

❏

1) Cycling through the menu - To cycle through the menu, pull and

❏❏

release the trigger. Each time the trigger is pulled and released, a different

color will be displayed on the LED in accordance with the list above.

❏❏

❏

2) Enter a menu option - Once the LED displays the color of the menu

❏❏

item that is needed, pull and hold the trigger for two seconds.

❏❏

❏

3) Current Value - Upon entering a menu item, the LED will begin to

❏❏

flash red. The flashes represent the current menuvalue. The current value

will be flashed twice with a short pause between the number flashes. If a

new value is not entered before the end of the second value display, the

electronics will automatically return to the main menu.

❏❏

❏

4) Enter a new value - At any time while the menu is flashing the LED in

❏❏

accordance with its current value, a new value can be entered by pulling

and releasing the trigger. Each pull and release of the trigger willcount as a

1 when entering the new value. Example: To enter a number 5, pull and

release the trigger five times. Once the user is done entering the value,

release the trigger.

12 13

Step 2: Choosing a menu item

(continued on page 13)

Advanced User Programming Section (continued from page 12)

❏❏

❏

5) Successfully updated menu confirmation - Once the user has

❏❏

entered a new value for a menu item, the LED will flash red/orange/green

twice to signify an acceptable value has been entered. The electronics will

then return to the main menu. If an unacceptable value has been entered,

the LED will quickly flash red and return to the main menu. The value of the

menu item will not be updated if this happens.

❏❏

❏

6) Poweroff - Once amenu item has been changed,the user must power-

❏❏

E

N

G

off the electronics before the change will take effect. Hold the power button

for 2 seconds. The LED will change to solid red. Release the power button

and the electronics will power off.

❏❏

❏

7) Optional: Factory settings reset - A factory settings reset can be

❏❏

accomplished by pressing and holding the power button for 10 seconds.

S

H

The board will appear to power on normally, but after 10 seconds, the LED

will flash red/orange/green twice, then the board will power-off. All factory

settings will be reset at this point.

Troubleshooting

PROBLEM: The LED light does not light when you push the power

button to turn ON the E-Grip

TM

.

1) Battery must be installed.

❏

Check that the battery is installed.

2) Battery may be disconnected.

❏

Check the battery clip connection.

3) Battery may be bad.

❏

Check the battery, replace if bad.

4) Wire may be disconnected from the

❏

battery clip connections to the batteryclip

Inspect the wire

/ .

PROBLEM: Paint breakage occurs in Safe Full-Auto Mode.

❏

Current Rate-of-Fire may exceed maximum CycloneTMFeed Rate and

you need to reduce the Rate-of-Fire -

see details in Rate-of-Fire section.

PROBLEM: You can hear E-GripTMoperating but marker does not fire.

❏

Check to be sure sufficient air supply is hooked up to the marker.

❏

Check to be sure the battery is good.

❏

Dwell setting may be too low and you need to increase the Dwell time -

see details in Dwell section.

❏

PROBLEM: Marker fires more times than expected.

❏

DebounceTMsetting maybe to low causing“Trigger Bounce” and you need

to increase the Debounce time - see details in Debounce

❏

Check therear bolt and sear fordamage (see pages 21-25 - Marker / Receiver

Disassembly andAssembly).

❏

If a double trigger has been installed check

TM

section.

to be sure the slider has been removed from the trigger (see page 24).

NOTE: If a problem still exists, call the Tippmann Service Department at

1-800-533-4831.

L

I

Page 9

Tuning The ResponseTMTrigger Rate of Fire

❏

Eye protection designed for paintball use must be worn by the user and

E

any person within range.

N

With a screwdriver, turn the Flow Control Adjustor to the desired speed.

G

❏

Clockwise

to slow the

L

rate of fire.

I

Tuning - Troubleshooting A:

S

If tuning the ResponseTMtrigger, above, produces little or no response

H

in the rate of fire, reset the Flow Control as follows:

1) With marker properly unloaded (see page 18), begin adjusting rate

of fire by turning flow control clockwise

or damage will occur. In a safe direction fire 2 to 4 shots. Trigger

should become very hard to pull or even unable to be pulled. If this

occurs, the response trigger system is functioning properly. Go to step

2). If it does not occur, go to Troubleshooting B.

2) Now while firing in a safe direction with marker still unloaded, slowly

turn the flow control adjustor counterclockwise

fire is achieved.

Tuning - Troubleshooting B:

If the trigger remains easy to pull after adjusting the flow control, there

may be a leak in the system.

Double check installation

making sure all fittings are

tight and o-rings are

properly seated. If you

need to disassemble to

check that all fittings are

tight and o-rings are

properly seated, follow the

Marker / Receiver

Disassembly instructions

beginning on page 21.

Do NOT disassemble the

marker whileit is pressurized

with air.

If a problem still exists,

call the Tippmann

Service Department at

1-800-533-4831.

❏

Counterclockwise to increase

rate of fire to the

desired speed.

completely. Do not over tighten

until desired rate of

Model Specific Parts: Not Shown on

A-5TMRESPONSE

TM

A-5

Basic Parts List pages 16-17.

14 15

TM

MODEL SPECIFICATIONS

Model Basic ........................................................ TIPPMANN®A-5

TM

Caliber ............................................................................................ .68

Action ................................. Semi-Automatic (open bolt blow-back)

Power/Air Supply........... compressed air, nitrogen or CO2 cylinder

Hopper Capacity......................................................... 200 Paintballs

Ball Feed ........................................ TIPPMANN®CycloneTMSystem

Standard Barrel Length ............................................. 8.5” /21.59 cm

Length (with standard barrel & no tank) .................... 20” / 50.8 cm

Effective Range ...................................... 150+ feet / 45.72+ meters

Cycle Rate ..................................................... 8 Rounds Per Second

Weight (without tank) .......................................... 3.12 lbs / 1.415 kg

Velocity................. Always measure your marker’s velocity before

playing paintball and never shoot at velocities in excess of 300

feet / 91.44 meters per second (see instructions on page 7).

Model Specific ...................... TIPPMANN®A-5TMWITH E-GRIP

TM

Cycle Rate .......................... adjustable8-15Rounds Per Second

Battery ........................................................................................ 9 Volt

Weight (without tank) ............................................ 3.27 lbs / 1.48 kg

Model Specific ......................... TIPPMANN®A-5TMRESPONSE

TM

Cycle Rate ................................................... 15 Rounds Per Second

Weight (without tank) ............................................ 3.16 lbs / 1.43 kg

Model Specific ............................. TIPPMANN®A-5TMSTEALTH

TM

Flatline Barrel Length ..............................................8.75” / 22.23cm

Length (no tank) ................. 27.25” - 30.75” / 69.21 cm - 78.1 cm

Weight (without tank) ................................................. 5 lbs / 2.27 kg

Cycle Rate ...................................................... 8 Rounds per second

Effective Range ...............................................250+ ft / 76.2 meters

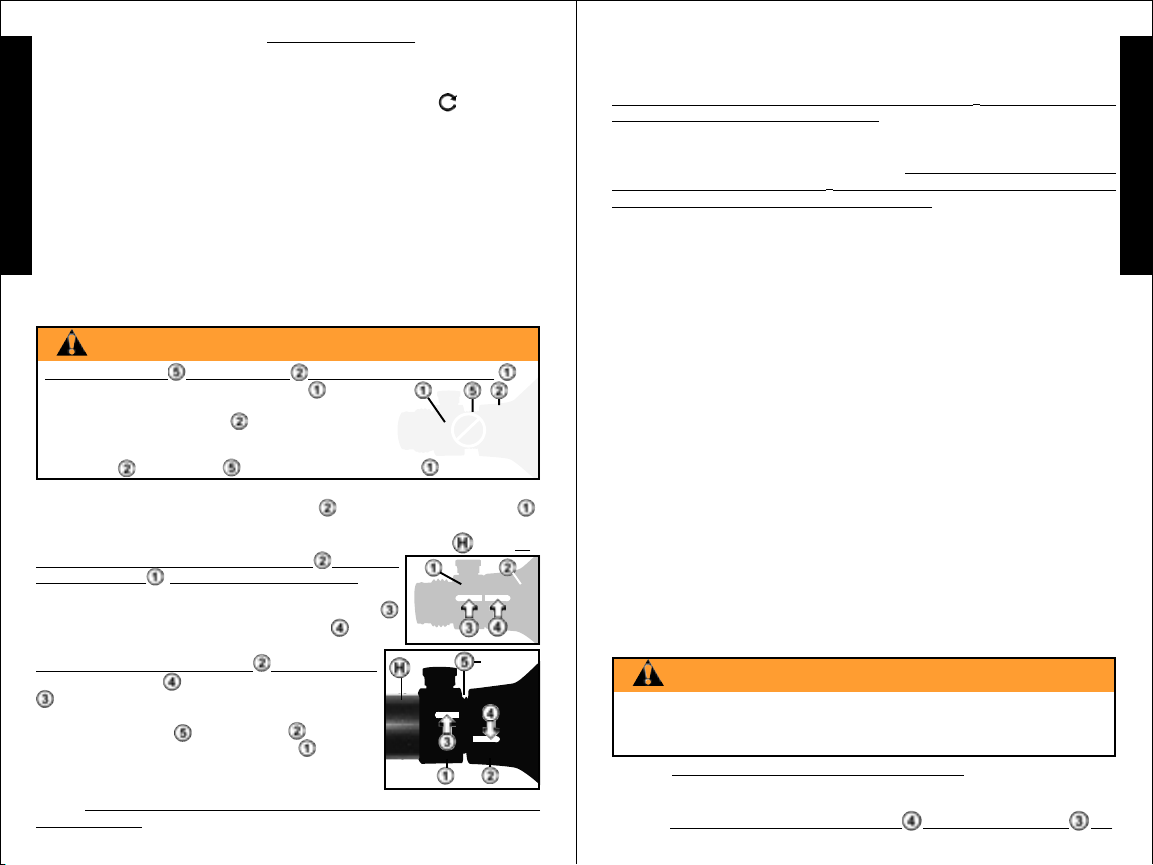

Model SpecificParts: A-5TMSTEALTH

TM

Not Shown on A-5TMBasic Parts List pages 16-17.

H-01

Remote Coil

(replaces

standard

Gas Line

and Tank

Adaptor)

T201012

FLATLINE

(replaces standard

Barrel & Barrel

TM

Adaptor)

02-TAC

Collapsible Stock

(replaces

standard End

Cap assembly)

98-40

O-ring

E

N

G

L

I

S

H

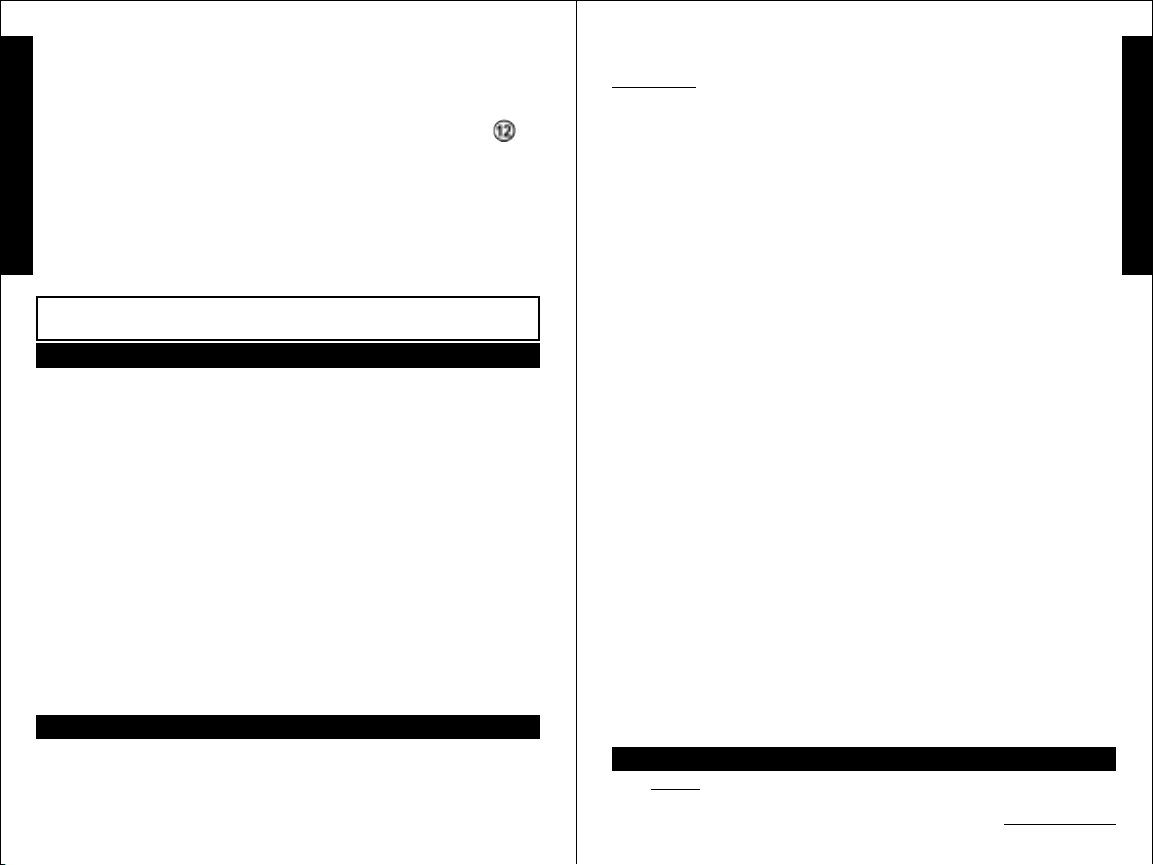

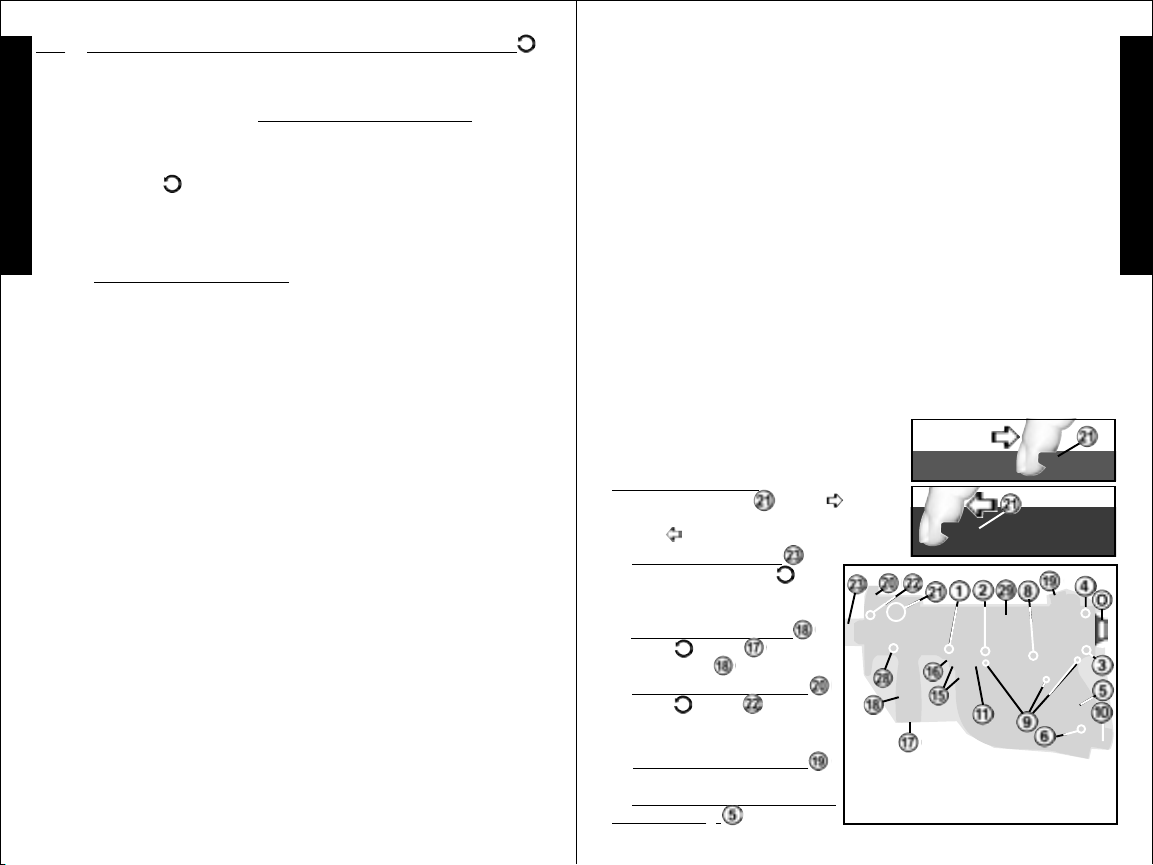

Page 10

TIPPMANN

E

N

G

L

I

S

H

®

BASIC PARTS LIST

DO NOT DISASSEMBLE THIS MARKER WHILE IT IS PRESSURIZED

WITH AIR. DO NOT PRESSURIZE A PARTIALLY ASSEMBLED MARKER.

WARNING

MODEL SPECIFIC PARTS

• A-5TME-GRIPTMMarker Parts (see page 24).

TM

RESPONSETMMarker Parts (see page 14).

• A-5

TM

• A-5

STEALTHTMMarker Parts (see page 15).

E

N

:

G

L

I

S

H

16

17

Page 11

Unloading Your Marker To unload your marker:

❏

Eye protection

designed forpaintball use must be worn bythe userandanyperson within range.

1)

❏

E

N

G

L

S

H

Put thetrigger safety in Safe Mode (see instructions on page 4) and

install the barrel blocking device (see page 2).

2)

❏

Empty and remove the hopper (turn hopper clockwise and lift out).

3)

❏

Go to a designated firing area, remove the barrel blocking device (see

page 2) and turn off the trigger safety (see page 4).

4)

❏

Point your marker in a safe direction and fire several times to be sure

there are no balls lodged in the chamber or barrel. IMPORTANT: Do not

I

uncock your marker as uncocking your marker may push a ball into the

chamber or down into the barrel in which case the ball will be hidden from view.

5)

❏

Put the trigger safety in Safe Mode (see page 4) and❏ install the

barrel blocking device (see page 2).

6)

❏

Visually inspect the CycloneTMFeeder and chamber for paintballs.

Air Supply Cylinder Removal Step1)

❏

You must first read the

following Air Supply Cylinder WARNINGS and SAFETY TIPS ( before

beginning the cylinder removal in Step 2 on page 19).

WARNING

NEVER UNSCREW THE CYLINDER FROM THE CYLINDER VALVE .

THEBRASSORNICKELPLATEDVALVE IS

INTENDED TO BE PERMANENTLY ATTACHED TO

THE AIR OR CO2 CYLINDER . AN AIR OR CO2

CYLINDER CAN FLY OFF WITH ENOUGH FORCE

TO CAUSE SERIOUS INJURY OR DEATH IF THE

CYLINDER UNSCREWS FROM A CYLINDER VALVE .

There have been reported incidents that were caused by players

unknowingly unscrewing the cylinder

This occurs when the player thinks the entire valve-cylinder assembly is

being unscrewed from the air adaptor of the paintball marker

fact they are unscrewing the cylinder from the

cylinder valve . To Avoid This Danger: It is

recommended, if your cylinder is not already marked,

that you use paint or nail polish to

❏

on the cylinder valve and❏place a mark on the

cylinder as shown.

Whenever you turn the cylinder during removal,

❏

watch the mark on the cylinder and the mark

on the cylinder valve to be sure that they rotate

together. If at any time these marks start to

separate asshown

, thecylinder is starting

to unscrew from the cylinder valve

should STOP and take the entire unit to a “C5”

certified airsmith for safe removal and/or repair.

NOTE: The cylinder valve should unscrew from the paintball markerin about

3 or 4 full turns. If you finish the 4th full turn and the cylinder valve is not

18

from the cylinder valve .

place a mark

and you

Air Supply Cylinder Removal

when in

STOP!

(continued on page 19)

Air Supply Cylinder Removal (continued from page 18)

unscrewed from the paintball marker, STOP! Take the entire unit to a “C5”

❏

certified airsmith for safe removal and/or repair.

Airsmith at www.paintball-pti.com/search.asp

Whether you have a new or used refillable Air or CO2 cylinder, you are at

risk if any of the following has occurred:❏The valve unit was replaced or

altered afterpurchase.

❏

An anti-siphondevice was installed.❏ The valve

unit was removed from the cylinder for any reason.

done to the refillable Air or CO

2 cylinder. If any of these conditions has

occurred take your air or CO2 cylinder to a “C5” Certified Airsmith for

inspection or contact the cylinder manufacturer.

SAFETY TIPS to ensure that your Air or CO2 cylinder is safe for play:

• Improper use, filling, storage or disposal of Air or CO

❏

Locate a “C5” Certified

❏

Any modificationwas

2 cylinder may result

E

N

G

L

I

S

H

in property damage, serious personal injury or death.

• Make sure that any maintenance or modification to any Air or CO

2 cylinder

is done by a qualified professional, such as a “C5” certified airsmith.

• The use of anti-siphon devices is not recommended. However, if one is

already installed on yourAir or CO

2 cylinder or is desired, it is critical that your

cylinder be checked by, or the device installed by, a qualified professional.

• AllAir or CO

2 cylinders must be filled only by properly trained personnel.

• Cylinder valves must be installed only by properly trained personnel.

• Do not overfill!! Never exceed the Air or CO

• Do not expose pressurized Air or CO

2 cylinder’s capacity.

2 cylinder to temperatures exceeding

130 degrees Fahrenheit ( 55 degrees Celsius ).

• Do not use caustic cleaners or strippers on theAir or CO

2 cylinder or tank

valve and do not expose to corrosive materials.

• Do not modify the Air or CO

the tank valve from the Air or CO

• AnyAir or CO

2 cylinder that has been exposed to fire or heated to a

2 cylinder in any way. Never try to disassemble

2 cylinder.

temperature of 250 degrees Fahrenheit ( 121 degrees Celsius ) or more

must be destroyed by properly trained personnel.

• Use appropriate gas for your cylinder. Only use CO

2 inaCO2 cylinder and

only use compressed air in a compressed air cylinder.

• Keep all cylinders out of the reach of children.

• TheAir or CO

2 cylinder should be inspected andhydrostatically retested at

least every 5 years by a DOT licensed agency.

❏

Locate a “C5” Certified Airsmith at www.paintball-pti.com/search.asp

WARNING

KEEP EXPOSED SKIN AWAY FROM ESCAPING GAS WHEN INSTALLING

OR REMOVING AIR SUPPLY OR IF THE MARKER OR AIR SUPPLY IS

LEAKING. COMPRESSED AIR, CO2, AND NITROGEN GASSES ARE VERY

COLD AND CAN CAUSE FROSTBITE UNDER CERTAIN CONDITIONS.

Step 2: To remove a charged air supply cylinder:

designed for paintball use must be worn by the user and any person

within range.

Step 3:

❏

Unload Your Marker (follow the instructions on page 18).

Watch the marks on the cylinder and cylinder valve as

19

❏

Eye protection

Air Supply Cylinder Removal

(continued on page 20)

Page 12

Air Supply Cylinder Removal (continued from page 19)

you

❏

turn the cylinder approximately 3/4 of a turn counterclockwise .

This allows the air supply pin valve to close so that no air will enter the

marker.

E

remaining gas in the marker by pulling the trigger until the marker stops

N

firing (this may take 4-5 shots).

pin valve has not closed yet (the tank pin valve could be too long, because

G

of the variances in tank pin valve parts, each tank varies slightly on exactly

L

how far it should be turned) and

counterclockwise

I

does not fire,

S

turned the tank and it began to leak before you pulled the trigger, the

tank o-ring should be checked for damage before reassembly (see

H

Repairing Air Supply Cylinder Leaks - page 20 below).

Step 4:

direction until stored air is completely discharged. NOTE: Before storing or

disassembling be sure to follow

Cylinder Removal instructions (see pages 18-20).

in safe mode (see page 4) and Install the barrel blocking device (see page 2).

❏

Point the marker in a safe direction and discharge the

If your marker continues to fire, the tank

❏

a little further and repeat this step until the marker

❏

then remove the tank. NOTE: If during this step, you

After air cylinder is removed,❏ point & fire the marker in a safe

❏

you will have to turn the tank

Unloading Your Marker and❏Air Supply

❏

Put the trigger safety

Repairing Air Supply Cylinder Leaks

The most common leak occurs from a bad air supply valve o-ring. To

replace a valve o-ring you must first remove the bad o-ring and then

install a new one. This o-ring is located on the tip of your air supply

valve. The best valve o-rings are made of urethane. Urethane o-rings

are not affected by high air supply pressures. These may be purchased

from Tippmann

ring does not resolve air supply leak, do not attempt to repair air supply

cylinder. Contact Tippmann Sports, LLC, your local paintball dealer or a

“C5” CertifiedAirsmith.

®

or your local paintball dealer.❏ NOTE: If new valve o-

Cleaning & Maintenance

❏

Eye protection designed for paintball use must be worn by the user

and any person within range.

discharge: First follow

Cylinder Removal instructions (see pages 18-20).

marker while it is pressurized with air. Do not pressurize a partially

assembled marker.

• Follow warnings listed on the air supply cylinder for handling and storage.

• Familiarize yourself with instructionslisted on air supply cylinder or adaptor.

Contact theair supply cylinder or theadaptor manufacturer with any questions.

• Do not use any petroleum based cleaning solvents.

• Do notuse any cleaning solvents that come in aerosolcans. NOTE: Petroleum

based productsand aerosol products can damage your markers’ o-rings.

• To clean the barrel: remove the barrel and insert the tab of the cable

squeegee into the barrel, then pull the squeegee through the barrel to

remove debris. (To remove the Flatline

❏

❏

To reduce the chance of accidental

Unloading Your Marker and❏Air Supply

Do not disassemble a

TM

barrel - see page 27).

20

Cleaning and Maintenance

(continued on page 21)

Cleaning and Maintenance (continued from page 20)

• To clean your paintball marker use a damp towel with water to wipe off

paint, oil, and debris.

marker oil to maintain your marker in good working condition.

❏

Use Tippmann®marker oil or other premium

❏

Re-oil

with a few drops to the front bolt o-ring and rear bolt o-ring (see - Drive

Assembly Removal and Installation instructions pages 22-23.

❏

Oil the barrel o-ring and air supply valve o-ring.

Storage: Before storage unload and remove air supply (seepages 18-20).

Then put the trigger safety in Safe Mode (see page 4) and install the barrel

blocking device (see page 2). You should store your marker in a dry area.

Before storing your marker make sure that the marker is cleaned and oiled

(see cleaning and maintenance on page 20) so that it does not rust. Store

your markerwith the bolt in the forward position, uncocked(see page 21 below).

❏

When removing your marker out of storage make sure the trigger safety

is in Safe Mode (see page 4) and the barrel blocking device is installed (see

page 2). Re-oil the rear bolt o-ring and the front bolt o-ring before use.

Marker / Receiver Disassembly and Assembly

❏

Eye protection designed for paintball use must be worn by the user and

any person within range. First follow

Supply Cylinder Removal instructions on pages 18-20.

supply before any disassembly. Do not disassemble a pressurized

paintball marker. Do not pressurize a

partially assembled paintball marker.

❏

Put the marker in the uncocked position:

To uncock the marker:

bolt cocking handle

❏

pull and hold the

back - then

pull thetrigger and slowly release the handle

forward

❏

Twist counterclockwise

remove (for Flatline

to uncock the marker.

To remove the Barrel :

TM

Barrel

to

removal see page 27).

❏

To remove the Front Grip :

Remove

the Front Grip

❏

To remove the Front Sight :

Remove

screw inside

.

screw just below

the FrontSight and slide thesight

upward.

❏

To remove the Rear Sight :

Pull it up and out.

❏

To remove the lower receiver

(grip or E-GripTM) : Remove the

❏

Unloading Your Marker and❏ Air

NOTE: Carefully hand start all threaded

parts and do not overtighten and strip

threaded parts when assembling.

21

Receiver Disassembly / Assembly

❏

Remove air

(continued on page 22)

E

N

G

L

I

S

H

Page 13

Receiver Disassembly Assembly (continued from page 21)

2 lower receiver push pins /

and pull grip from upper

receiver

E

❏

To remove the gas line (or

N

a remotecoil) and the Tombstone

G

adapter from the upper

receiver: Remove push pin

L

in frontof the Tombstone fromthe

I

upper receiver, release the

Tombstone Latch

S

line

H

will pull out. NOTE: If you remove

the gas line plug

Tombstone adapter

reinstalling, clean, inspect and

.

and the gas

/ Tombstone adapter

from the

; when

NOTE: Carefully hand

start all threaded parts

and do not overtighten

and stripthreaded parts

when assembling.

Allen Wrench

RIGHT SIDE VIEW

oil the o-ring and be careful not to overtighten and strip threaded parts.

Drive Assembly Removal and Installation:

NOTE: It is not necessary to disassemble the upper receiver to access

and service the drive assembly internal parts .

❏

To remove the drive assembly parts: front bolt ; power tube /

valve

guide

1)

; rear bolt / rear bolt plug ; linkage arm ; drive pin

; drive spring ; and end cap (or collapsible stock).

❏

Remove air supply before any disassembly: First follow

Unloading Your Marker and❏ Air Supply Cylinder Removal

instructions on pages 18-20 and put the marker in the uncocked position

before beginning to disassemble it. To uncock the marker, pull and

hold the bolt cocking handle

slowly release the handle forward

back - then pull the trigger and

which will uncock the marker.

2)❏ Remove lower receiver (grip) and gas line as instructed - see page 21).

3)

❏

Screw the velocity screw in past the receiver (3/16” ).

4)

❏

Remove last push pin holding the end cap (or the collapsible

stock) in place.

5)

❏

Pull the end cap (or collapsible stock) out and tilt marker up,

the drive assembly parts

should slide out the back.

❏

To remove valve from power tube: carefully push valve out with allen wrench.

Drive Assembly Removal and Installation:

22

(continued on page 23)

Drive Assembly Removal and Installation: (continued from page 22)

❏

To reinstall the drive assembly parts:

❏

Clean inside the upper receiver and the removed parts.

1)

2)

❏

Inspect and replace any damaged parts.❏ Lubricate the front bolt oring, the valve o-ring, the rear bolt o-ring, the linkage arm and the drive

spring/guide pin with a few drops of Tippmann

®

paintball marker oil (or other

premium paintball marker oil) before reinstalling.

❏

Insert the valve into the power tube

3)

with the Tombstone cutout

to match the power tube cutout

Tombstone adapter

aligned down

.❏ Insert

to check the fit.

❏

Insert rear bolt plug into rear bolt .

4)❏ Insert reassembled parts: (front bolt,

E

N

G

L

I

S

H

power tube/valve, rear bolt/rear bolt plug, with linkage arm facing up, until

the Tombstone adapter/gas line

and velocity screw

can be accessed. You may need to jiggle marker

can be inserted, push pin replaced

while sliding parts in.

5)❏ Insert the guide pin into the drive spring and

❏

drive spring into the rear bolt plug .❏ Insert the end cap (or collapsible

stock), while keeping the guide pin centered in it.

cap push pin

.

❏

Install the upper end

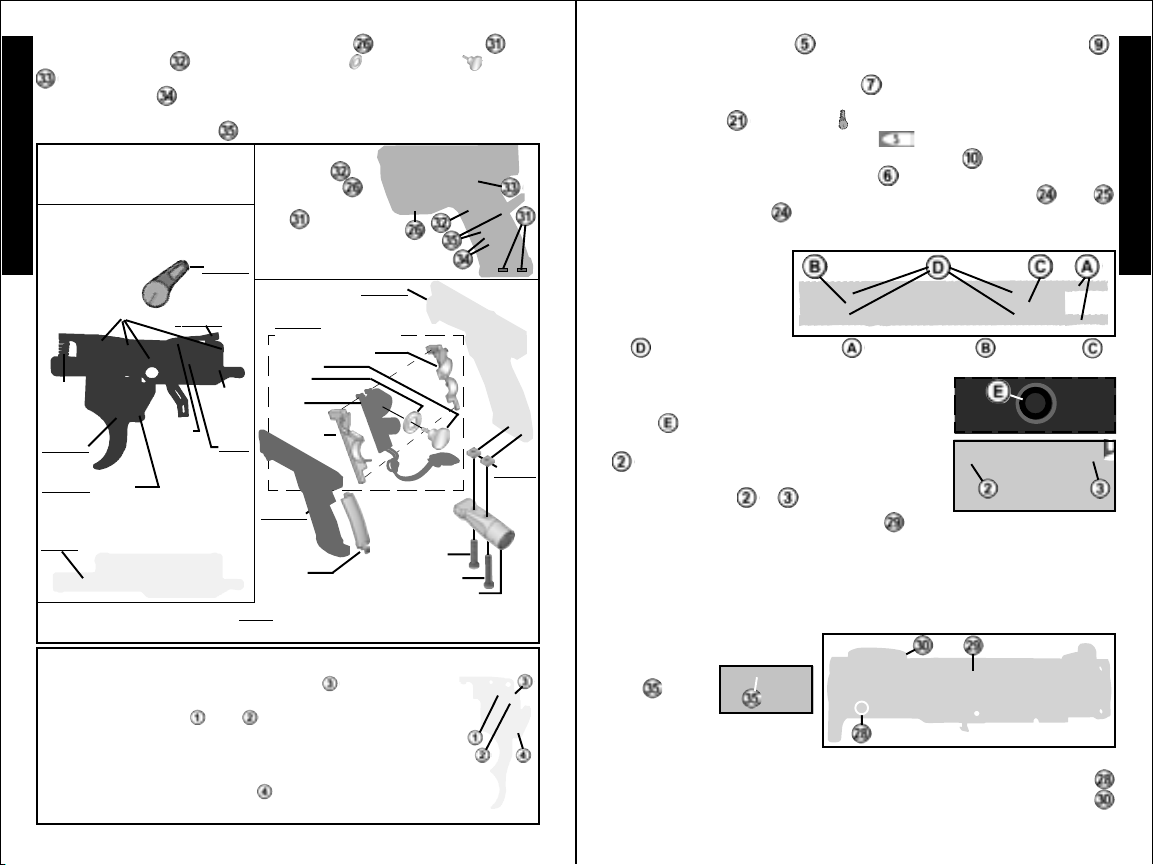

LOWER RECEIVER (grip or E-GripTM) Disassembly/Assembly:

❏

Follow the Marker / Receiver Disassembly instructions on pages 21-22

❏

until you have

To remove the trigger assembly

from the grip :❏ Push the Safety

❏

detached the lower receiver .

E-Grip

TM

out of the left side of the grip

(on E-GripTM: rotate the Safety Selector Switch

straight up and❏pull it out of the left

side of lower receiver).

assembly

keeping it intact.

❏

Pull up on the trigger

To access trigger assembly parts:❏ Pull theleft

plate

not remove 5 dowel pins from right plate, see

trigger assemblyon page 17 (for E-Grip

off the trigger assembly .Do

TM

Trigger

Assembly see page 24).

❏

To disassemble the lower receiver :

❏

Remove bolt ( and on E-GripTMremove 2 tank adapter bolts (

1)

short) and ( long) and remove the tank adapter / gas line .

2)

❏

Remove the 3 grip screws holding the two lower halves together.

❏

To reassemble the lower receiver (E-GripTMShown - page 24):

❏

On A-5TMBasic Make sure the trigger guard is in place.

1)

❏

On A-5TMResponseTM: make sure trigger guard and Response

parts are in place and o-rings lubricated (see page 14).

23

To reassemble the lower receiver

(continued on page 24)

Page 14

❏

On A-5TME-GripTM: make sure trigger guard , 2 adapter nuts , and

TM

E-Grip

E

around the posts

N

the left grip half is replaced. Visually inspect wires for damage or

disconnected wire ends at

G

L

I

S

H

assembly (with armature spacer and armature in place

); are positioned in the right grip half as shown below. Position wires

as shown so wires are not pinched or sheared when

.

A-5TME-GripTMModel Specific

Parts: Not Shown on A-5

Basic Parts List on pages 16-17.

E-GripTMparts shown in position in

the Right Trigger Plate with basic

parts (Note: E-Grip

Specific parts

in bold).

02-33 Pins (4)

02-20S

Trigger

Spring

(Red-short)

TA10021

Trigger

TA10072Magnet

(the red dot on the magnet must be

visible on this side of the trigger to

operate properly).

02-67L Left Trigger Plate

NOTE: A-5TME-GripTMSear Spring 02-88 has tensions specifically designed for the E-

GripTMand it will not operate properly if you replace this spring with any other spring.

TM

TA10073 Sear

02-33A

Sear Pin

(black)

(silver - long)

E-GripTMElectronics

TM

Assembled ;

trigger guard

and 2 adapter

nuts - shown

positioned in the right

grip half for reassembly

TA01022

of the E-GripTM- see above.

Safety

Selector

02-67R

Right

Trigger

Plate

02-88

Sear

Spring

Lower Receiver Right

TA99500

Electronics Assembly

Frame Half - Right

Armature

Spacer

Electronics

board

Frame

Half - Left

TA01018

Lower

Receiver

Left

TA10066

Battery Door

TA01019

TA07074

AdapterBolt

(short)

98-01B

Adapter Bolt (long)

TA02061 Tank Adapter

Double Trigger Kit (Optional, not included with A-5TME-GripTMMarker):

Installation: The trigger slider & spring will need to be

removed from the double trigger before installation into the E-

TM

. Remove pins and from the double trigger and

Grip

remove the trigger slider & spring.

NOTE: If the double trigger kit does not include a magnet take the magnet from the single trigger that came with your

marker andinsert the magnet at

(the reddot on the magnet

must be visible (see above) to operate properly.

Lower Receiver Disassembly/Assembly:

24

(continued on page 25)

CA-08B

Adapter

Nut (2)

Lower Receiver Disassembly/Assembly: (continued from page 24)To reassemble the lower receiver: (continued from page 23)

2)❏ Replace left grip half .❏Secure grip halves with 3 grip screws .

❏

Reinstall the battery door onA-5TME-GripTM(see instructions - page 9).

3)

❏

Reinstall the trigger assembly into the grip and insert the safety

into the left side of the grip (on E-Grip

Selector Switch

straight up and❏insert it into the left side of the

grip and then rotate it to the “SAFE” =

4)

❏

Attach the Tank Adapter: Slide tank adapter into lower receiver

and align holes;

❏

Insert receiver bolt and tighten ( onA-5TME-Grip

TM

marker:❏Rotate the Safety

position).

TM

position the tank adapter and insert the 2 tank adapter bolts and

(the short adapter bolt goes in front - see page 23).

❏ ❏

❏

To attach the lower receiver (grip) to the upper receiver:

❏ ❏

❏

Check to becertain the

trigger plates have not

separated and the trigger

assembly is intact as

shown. If there are gaps

at

between the trigger plates and the trigger or the sear –

squeeze the plates together to look as shown.

(On the A-5TMResponseTMmarker,❏first put a

couple dropsof marker oil onto the cylinderfitting

o-ring

❏

in the lower receiver.)

Line upthe lower receiver front push pin holes

with theupper receiver holes thengently rock

rear of grip until you can insert the two lower

receiver push pins

❏❏

❏

To disassemble the upper receiver : NOTE: It is only necessary to

❏❏

& to attach.

disassemble upperreceiver halvesto access the ball latch, front grip nut, cocking

handle, cockinghandle spring, receiver o-ring, Tombstone latch andTombstone

latch spring (plus the flow connector fitting on A-5

❏

1) Followthe Marker/Receiver Disassembly/Assembly instructions beginning

on page 21 until you have removed the drive assembly parts on page 22.

❏

2) Remove the Cyclone

Feed System:

❏

Remove the

TM

TM

ResponseTMMarker).

banjo fitting

bolt

from

upper receiver

(and on Response

TM

marker remove the flow control

adjustor fitting and banjo fitting bolt from the upper receiver - see

Response

TM

parts on page 14).❏ Remove the CycloneTMhousing bolt

from the left front side of upper receiver and remove the feed system

(NOTE: To install the CycloneTMFeed System reverse the process).

25

Upper Receiver Disassembly:

(continued on page 26)

E

N

G

L

I

S

H

Page 15

Upper Receiver Disassembly: (continued from page 25)

3)❏ Remove the 5 receiver bolts (4

on Response

receiver halves together.

E

❏

To reassemble upper receiver follow the

N

Upper ReceiverAssembly instructions below.

G

Upper Receiver Assembly

L

For ResponseTMMarker only: Install two parts & to the right receiver

half before assembling receiver halves.

I

❏❏

❏

1) Oil o-ring of the exterior flow control adapter .

❏❏

S

❏❏

❏

2) Align threaded opening of interior flow connector

❏❏

fitting

H

❏❏

❏

3) Carefully thread adapter through the right

❏❏

receiver half into

or damage o-ring

1) Make sure all parts are clean before reassembling. Place right upper

receiver half flat with Tombstone Latch & Spring, Front Grip Nut, Receiver

O-ring and Ball Latch in position as shown below.

2) With left hand, grip left upper

receiver half as shown to hold

Cocking Handle and spring in place

by applying side pressure with

index finger pushing in direction of

arrows

Right

Hand

Left

Half

Receiver O-ring

TM

Marker) holding the upper

to inside of right receiver half.

(do not overtighten and strip threaded parts

against Cocking Handle.

Tombstone

Latch & Spring

properly inserted

and tighten with a 3/8” wrench

).

Cocking Handle Spring

will be

bowed.

Spring

3) With left hand holding as shown below,

use righthand to seat cocking handlewith

spring into receiver cutout then position

edge of spring in end of spring cutout

bowed as shown below. Then grip left

receiver with right hand as shown.

Cocking Handle

Latch

Front Grip Nut

with flat side facing

bottom of marker.

WARNING

DO NOT REASSEMBLE WITHOUT MAKING SURE

TOMBSTONE LATCH & SPRING ARE PROPERLY

INSERTED IN PLACE AS SHOWN.

4) Use your finger tips to guide the left half straight down on to the right half

26

Upper Receiver Assembly

(continued on page 27)

Left

Hand

Right

Half

Ball

Latch

Upper Receiver Assembly (continued from page 26)

until receiver halves fit flush. If it does not fit flush the first time, check to

make surethe spring and other parts have stayed in place and repeat until

halves fit flush.

5) Insert 5 (4 on Response

bolt yet) & tighten them just enough to hold halves flush yet loose enough

to allow you to now insert and twist Barrel / Adapter unit (or FLATLINE

clockwise

to reinstall.

TM

Marker) Receiver Bolts (not front sight

TM

6) Insert Front Sight with its slot facing back of marker, into the top front

of the receiver and insert the front sight bolt to hold in place.

7) Make sure all receiver bolts are tight (do not overtighten & strip threads).

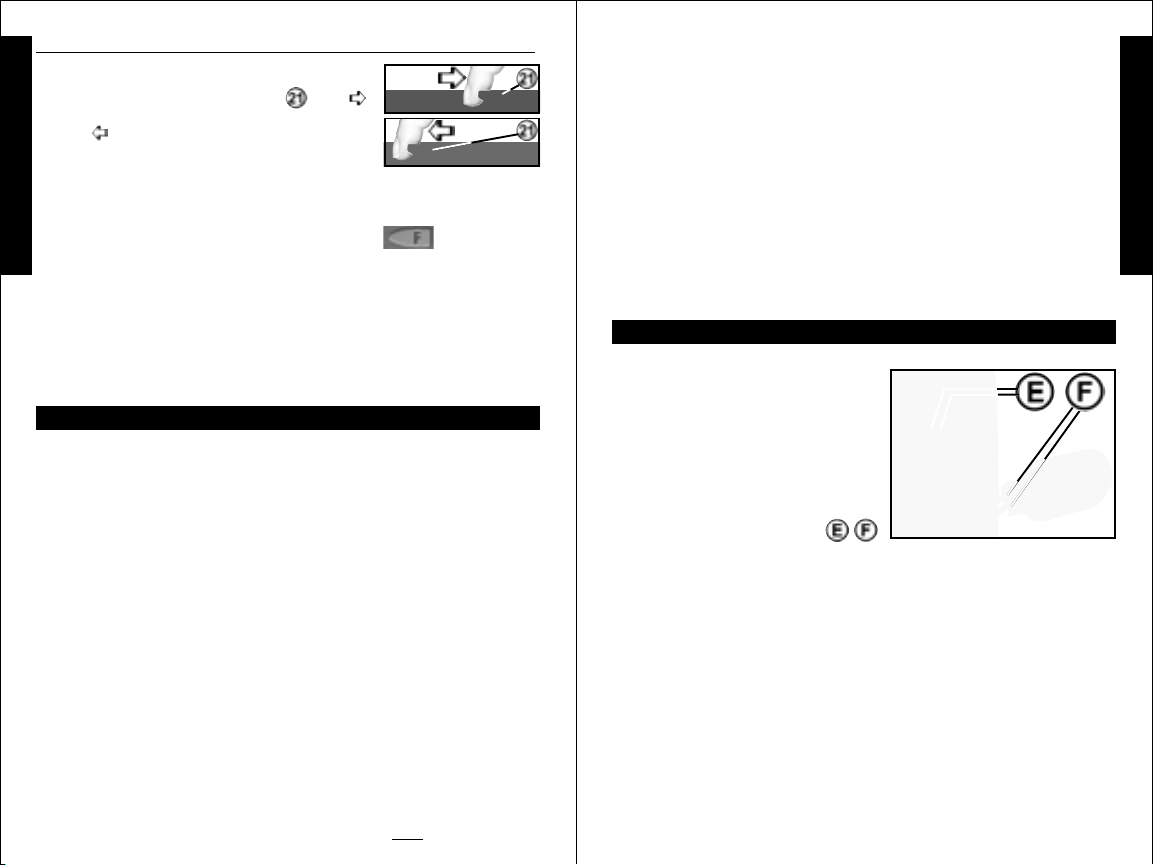

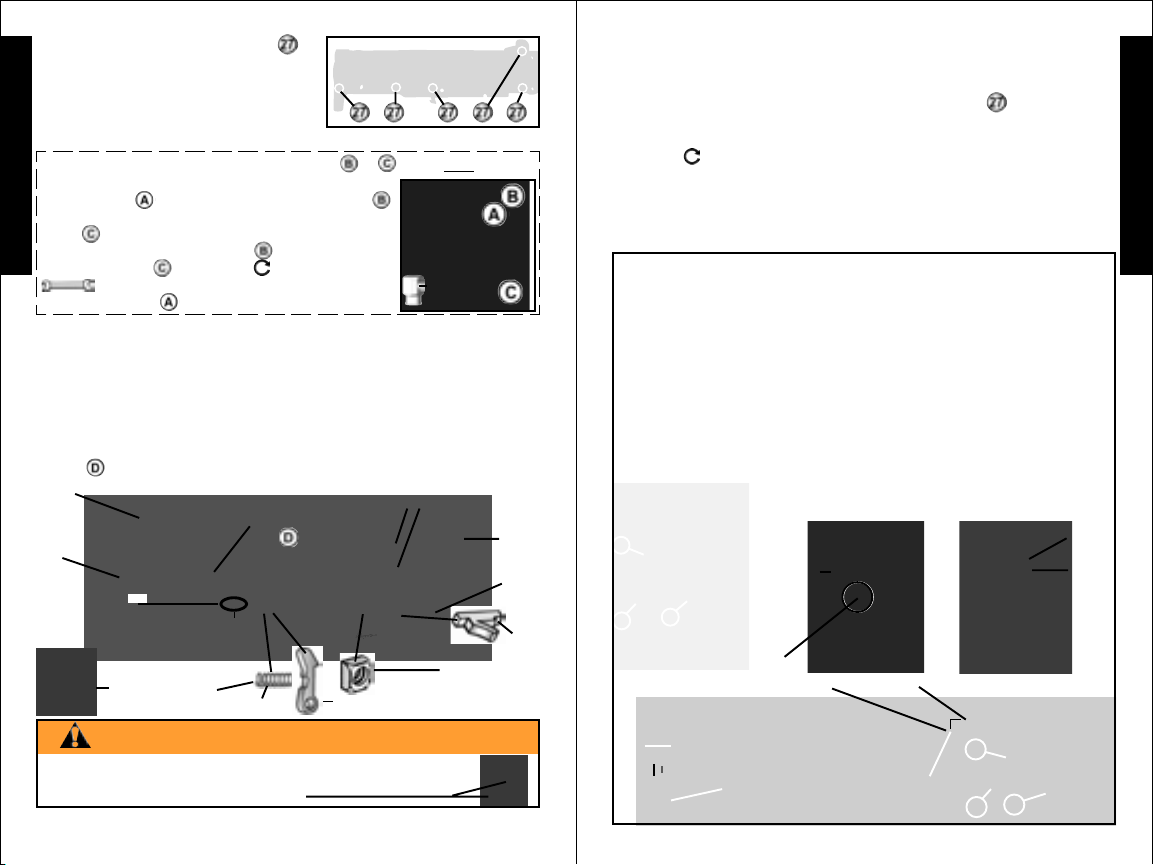

FLATLINETMBarrel Removal & Installation

❏

First follow❏ Unloading Your Marker and❏ Air Supply Cylinder

Removal instructions on pages 18-20. Never disassemble a marker

that is under pressure or pressurize a partially assembled marker.

FlatlineTMBarrel Removal:

❏

Loosen 3 receiver bolts (A,B&C-seebelow) then turn barrel /

adapter to left and remove as one piece from upper receiver.

FlatlineTMBarrel Installation:

❏

Position the Barrel

1)❏Loosen 3

receiver bolts

(A, B, & C).

2)

Adapter cap screw

facing to the left toward

the feeder housing and

insert into receiver.

A

Feeder

Housing

C

B

Cap

screw

to the

left

4)

❏

While keeping cap screw and front sight aligned, tighten the

3 receiver screws A,B&C

to complete the installation.

Barrel at top

Proper

screw

Proper screw position

position

Properly installed barrel will look like this.

27

3)

❏

Turn the Barrel

Assembly 1/4turn tothe

right until the adapter

cap screw aligns with

the front sight.

Front

Sight

Cap

Screw

A

B

C

E

N

G

)

L

I

S

H

Page 16

WARRANTY AND REPAIR INFORMATION

E

TIPPMANN SPORTS, LLC ("Tippmann") is dedicated to quality paintball

products and outstanding service. In the unlikely event of a problem with

N

this Tippmann paintball marker ("Marker") and/or Tippmann accessories

G

("Accessories"), Tippmann's customer service personnel are available to

assist you. For customer service and/or other information, please contact:

L

I

S

H

Tippmann Sports, LLC

2955 Adams Center Road

Fort Wayne, IN 46803

www.tippmann.com

1-800-533-4831

WARRANTY REGISTRATION

To activate the Marker's Limited Warranty, you must register the Marker within

thirty (30) days of the date of original retail sale by:

1. Registering online at

2. Completing the attached warranty registration card and returning it to

Tippmann at the address above.

The LimitedWarranty for Tippmann Accessories does not require activation

or registration; by registering the Marker, you activate the warranty for the

Accessories.

www.tippmann.com; or

LIMITED WARRANTY

Tippmann warrants to the original purchaser that it will make any repairs or

replacements necessary to correct defects in material or workmanship, at

no chargeto you, for the Marker for a period of two (2)years from the date of

original retail sale. Further, Tippmann warrants to the original purchaser

that it will make any repairs or replacements necessary to correct defects in

material or workmanship, at no charge to you, for TippmannAccessories for

a periodof ninety (90) days from the date of original retail sale.All Tippmann

asks is that you properly maintain and care for the Marker and Accessories

(collectively, the "Product") and that you have warranty repairs performed by

Tippmann or a Tippmann Certified Tech Center.

This Limited Warranty is non-transferable, and it does not cover damage or

defects tothe Product caused by (a) improper maintenance; (b) alteration or

modification; (c) unauthorized repair; (d) accident; (e) abuse or misuse; (f)

neglect or negligence; and/or (g) normal wear and tear.

Tippmann does not authorize any person or representative to assume or

grant any other warranty obligation with the sale of this Product.

THIS ISTHE ONLY EXPRESS WARRANTY GIVENWITH THE PURCHASE

OF THIS PRODUCT; ANYAND ALL OTHER EXPRESS WARRANTIESARE

WARRANTY AND REPAIR INFORMATION:

28

(continued on page 29)

WARRANTY AND REPAIR INFORMATION: (continued from page 28)

DISCLAIMED. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE

APPLICABLE LIMITED WARRANTY PERIOD SET FORTH HEREIN,AND

NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, SHALL APPLY

AFTER EXPIRATION OF SUCH PERIOD.

Some states and nations do not allow limitations on the duration of implied

warranties, so the above limitation may not apply to you.

The sole and exclusive liability of Tippmann and/or its authorized dealers

under this Limited Warranty shall be for the repair or replacement of any

part or assembly determined to be defective in material or workmanship.

TIPPMANN SHALL NOT BE LIABLE FOR, AND YOU EXPRESSLY

DISCLAIM, ANY DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL

DAMAGES (COLLECTIVELY, "DAMAGES") ARISING OUT OF THE SALE

OR USEOF, OR YOUR INABILITY TOUSE, THE PRODUCT. NO PAYMENT

OR OTHER COMPENSATION WILL BE MADE FOR DAMAGES,

INCLUDING INJURY TO PERSON OR PROPERTY OR LOSS OF

REVENUE WHICH MIGHT BE PAID, INCURRED OR SUSTAINED BY

REASON OF THE FAILURE OF ANY PART OR ASSEMBLY OF THE

PRODUCT.

Some statesand nations do not allow the exclusionor limitation of incidental

or consequential damages, so the above limitation or exclusion may not

apply toyou. This warranty gives you specific legal rights,and you may also

have other rights that may vary from state to state or nation to nation.

WARRANTY AND NON-WARRANTY REPAIRS

When shippingthe Product to Tippmann for warranty ornon-warranty repair:

(1) If you have aftermarket parts on your Marker, please test the Marker with

original stock parts before returning the Marker for service or repair.

(2) Always unload and remove the air supply from the Marker. Do not ship

the air supply tank if it is not completely empty.

(3) Ship the Product to the Tippmann address identified above.

(4) You must pre-pay postage and delivery charges.

(5) Provide the date of purchase for the Product.

(6) Briefly describe the repair requested.

(7) Include your name, return address and a telephone number where you

can be reached during normal business hours, if possible.

Tippmann makes every effort to complete its repair work within twenty-four

(24) hours of receipt. Tippmann will return the Product to you via regular

ground UPS. If you wish to have it returned using a faster service, you can

request NEXT DAY AIR UPS OR SECOND DAY AIR UPS, but you will be

charged for this service and must include your credit card number with the

expiration date. Your credit card will be charged the difference in additional

cost over regular ground shipping service.

29

E

N

G

L

I

S

H

Page 17

AVERTISSEMENT

CECI N'EST PAS UN JOUET. TOUT USAGE INAPPROPRIE PEUT PROVOQUER DES