Page 1

THURLBY THANDAR INSTRUMENTS

TGR2050

2 GHz SYNTHESISED

RF SIGNAL GENERATOR

INSTRUCTION MANUAL

Page 2

Introduction

This low cost synthesised RF signal generator features a wide amplitude range, low noise and

inherently good frequency stability. The generator also features internal and external FM, AM and

Phase Modulation. The instrument can be operated manually via the front panel or remotely

controlled via the RS232 or GPIB interfaces.

It is suitable for radio receiver sensitivity measurements, system gain measurements, oscillator

substitutions, EMC/antenna/field strength measurements and as a signal source for many other

RF circuit and system development tasks. In addition, the generator's low cost, ease of use and

remote control make it eminently suitable for most production and development applications

where a basic, stable signal source is required.

Table of Contents

Specification 3

EMC 7

Safety 8

Installation 9

Connections 10

Operation 11

Remote Operation 15

Remote Commands 23

Maintenance 27

Appendix 1. Error Messages 28

Appendix 2. Factory Defaults 29

Instructions en Francais

Sécurité 30

Installation 31

Connexions 32

Fonctionnement 34

Fonctionnement à distance 38

Commandes à distance 46

Maintenance 50

Annexe1. Messages d'erreur 51

Annexe 2. Réglages par défaut en usine 52

Bedienungsanleitung auf Deutsch

Sicherheit 53

Installation 54

Anschlüsse 55

Betrieb 56

Fernbedienung 60

Fernbedienungs-Befehle 68

Wartung 72

Anhang 1 Fehlermeldungen 73

Anhang 2 - Werkseinstellungen 74

1

Page 3

Istruzioni in Italiano

Sicurezza 75

Installazione 76

Collegamenti 77

Funzionamento 79

Operazione a distanza 83

Comandi a Distanza 91

Manutenzione 95

Appendice 1. Messaggi d’Errore 96

Appendice 2. Defaults di Fabbrica 97

Instrucciones en Español

Seguridad 98

Instalación 99

Conexiones 100

Funcionamiento 102

Funcionamiento Remoto 106

Comandos Remotos 114

Mantenimiento 118

Apéndice 1. Mensajes de Error 119

Apéndice 2. Valores Predeterminados de Fábrica 120

2

Page 4

Specification

FREQUENCY

Frequency Range: 150kHz – 2000MHz

Setting Resolution: 10Hz

Accuracy/stability: see Reference Frequency

Phase Noise: <–116dBc @ 25kHz offset, 500MHz Carrier.

Residual FM: 12Hz @ 500MHz – Equivalent peak deviation in a 300Hz to 3.4kHz

bandwidth.

REFERENCE FREQUENCY

Internal Reference Accuracy: <± 1ppm, 15ºC – 30ºC

<± 2ppm, 5ºC – 40ºC

Internal Reference Stability: <1ppm/year

Reference In/Out: Rear panel BNC; can be disabled when not required for input or

output.

External Reference IN:

Internal Reference OUT:

10MHz, 50Ω input impedance, 2 - 5Vpp

Automatic detection and selection when external reference signal is

present and Reference IN is selected on front panel.

Front panel LED indication when external is active.

10MHz, 50Ω output impedance, >2Vpp into 50Ω

Signal present when Reference OUT is selected on the front panel

OUTPUT LEVEL

Output Level range: –127dBm – +7dBm, all modes except AM

–127dBm – +1dBm, AM mode

Setting Resolution: 0.1dB, 0.01uV –1mV

Accuracy: ± 2dBm

Harmonically Related Signals: <–25dBc @ +7dBm

Sub-harmonically Related

Signals:

Non-harmonic Spurii:

Carrier Leakage:

≤1000MHz : None

>1000MHz : <–20dBc @ +7dBm

≥62.5MHz : <–60dBc

<62.5MHz : <–50dBc (150kHz – 250MHz bandwidth)

<0.5µV generated into a 50Ω load by a two turn 25mm loop 25mm

from the generator with the output set to ≤–10dBm into a sealed

50Ω load.

Output Impedance:

Output Connector: Type N

Reverse Power Protection:

Output Switch: RF OUT On/Off switch with LED showing ON status

50Ω

50V DC, up to 25W from 50Ω source. Flashing LED indication.

3

Page 5

MODULATION SOURCE

Internal: 400Hz and 1kHz sine derived from reference frequency.

External:

Connector: Front Panel BNC provides modulation input when external

Modulation I/O Impedance:

Output Level:

Maximum Input: 20V rms

Calibrated for 1Vrms sine into 600Ω

modulation is selected and outputs internal modulation when

internal is selected.

600Ω

1Vrms EMF from 600Ω source impedance.

FREQUENCY MODULATION

Max Peak Deviation: 800kHz, 1000MHz – 2000MHz

400kHz, 500MHz – 999.99999MHz

200kHz, 250MHz – 499.99999MHz

100kHz, 125MHz – 249.99999MHz

50kHz, 62.5MHz – 124.99999MHz

100kHz, 150kHz – 62.49999MHz

Setting Resolution: 0.5kHz

Deviation Accuracy:

Modulation Signal:

<±10% ± 0.5kHz for 1kHz Internal or 1kHz, 1Vrms External

Modulation.

Internal or External 100Hz – 300kHz (± 2dB relative to 1kHz)

Distortion: <2% @1kHz modulation, max. deviation (300-3.4kHz bandwidth)

PHASE MODULATION

Max Peak Deviation: 80.0rads 1000MHz – 2000MHz

40.0rads 500MHz – 999.99999MHz,

20.0rads 250MHz – 499.99999MHz,

10.0rads 125MHz – 249.99999MHz,

5.0rads 62.5MHz – 124.99999MHz,

10.0rads 150kHz – 62.49999MHz

Setting Resolution: 0.05rads <10.0rads deviation, 0.1rad >=10.0rads deviation

Deviation Accuracy:

Modulation Signal:

Distortion: <2% @ 1kHz modulation, max. deviation (300-3.4kHz bandwidth)

<±10% ± 0.05rads for 1kHz Internal or 1kHz, 1Vrms External

Modulation.

Internal or External 100Hz – 10kHz (± 2dB relative to 1kHz)

AMPLITUDE MODULATION

Max Modulation Depth: 100%, usability decreasing to 90% at 2GHz

Setting Resolution: 0.5%

Accuracy:

< ± (5% setting +1%) for 1kHz Internal or 1kHz, 1Vrms External

Modulation, <70% depth.

Modulation Signal:

Distortion - 150kHz – 1GHz:

1GHz – 2GHz:

4

Internal or External 50Hz – 200kHz (±1dB relative to 1kHz)

≤3% @ 30% depth, ≤5% @ 70% depth

≤5% @ 30% depth, ≤10% @ 70% depth

@ 1kHz modulation, 300-3.4kHz measurement bandwidth.

Page 6

INTERFACES

RS232 Variable Baud rate, 19200 Baud maximum, Addressable RS232

Chain (ARC) compatible.

IEEE Conforming to IEEE488-1, IEEE488-2

GENERAL

Power: 220 - 240VAC or 110 - 120VAC ±10%, 50/60Hz, adjustable

internally; 30VA max. Installation Category II.

Display 20 character x 4 row backlit alphanumeric LCD

Data Entry: Keyboard selection of all major parameters or stepping by user

selected increment values using up/down keys or rotary control.

Stored Settings: Up to 9 complete set-ups.

Operating Range: +5°C to +40°C, 20 - 80% RH

Storage Range: –20°C to + 60°C

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

EMC: Complies with EN61326

Safety: Complies with EN61010-1

Size: 3U high, half rack width.

Weight: 5.0 kg

Options: 19 inch rack mounting kit.

5

Page 7

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

TGR2050 2GHz Synthesised RF Signal Generator

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2007) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS WILDING

TECHNICAL DIRECTOR

6

1 May 2009

Page 8

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance A (A) and 1.4GHz to 2GHz:

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

25 cycles, 70% and 250 cycles, 0%: Performance B* (C).

* To achieve Performance B for 250 cycles, 0%, status of RF OUT at power-up must be

set to be the same as at power-down, otherwise Performance C is achieved (requires

operator to turn on RF OUT).

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (signal connections),

Performance A (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2007) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

connections <3m, therefore not tested), Performance A (A).

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) Connect the generator to other equipment using only high quality, double-screened cables.

b) After opening the case for any reason ensure that all signal and ground connections are

remade correctly and that case screws are correctly refitted and tightened.

c) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

7

Page 9

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

This instrument uses a Lithium button cell for non-volatile memory battery back-up; typical life is 5

years. In the event of replacement becoming necessary, replace only with a cell of the correct

type, i.e. 3V Li/Mn0

in accordance with local regulations; do not cut open, incinerate, expose to temperatures above

60°C or attempt to recharge.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window. The following symbols are used on the instrument and in this manual:-

20mm button cell type 2032. Exhausted cells must be disposed of carefully

2

Caution -refer to the accompanying documentation,

incorrect operation may damage the instrument.

8

l

terminal connected to chassis ground.

mains supply OFF.

mains supply ON.

alternating current.

Page 10

Installation

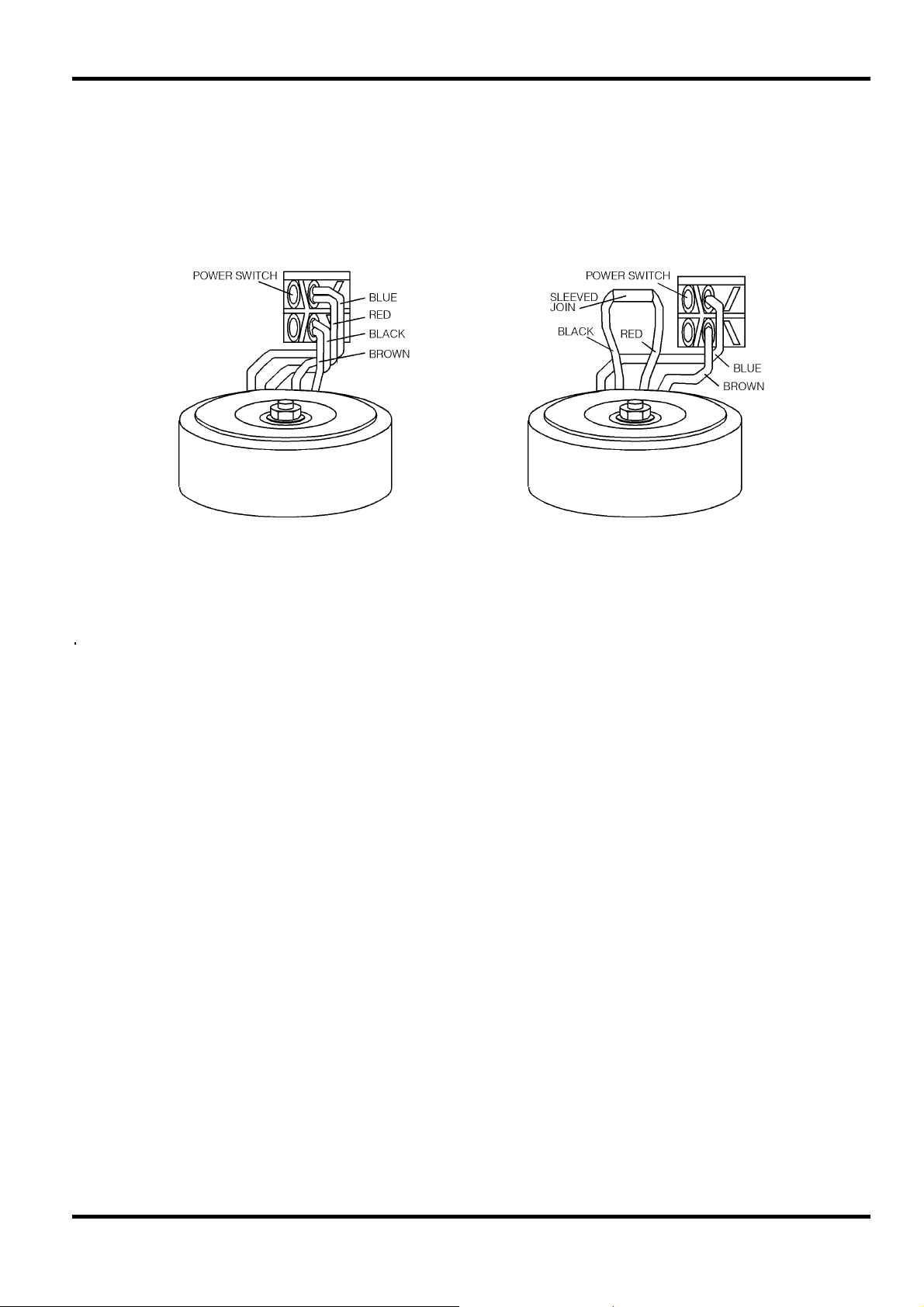

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Remove the screws which retain the top cover and lift off the cover.

3) Change the transformer connections following the appropriate diagram below:

115V OPERATION 230V OPERATION

4) Refit the cover and secure with the same screws.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

6) Change the fuse to one of the correct rating, see below.

Fuse

Ensure that the correct mains fuse is fitted for the set operating voltage. The correct mains fuse

types are:

for 230V or 115V operation: 1A (T) 250 V HRC

To replace the fuse, disconnect the mains lead from the inlet socket and release the fuse drawer

below the socket pins by depressing both clips together, with miniature screwdrivers, so that the

drawer can be eased open. Change the fuse and replace the drawer.

The use of makeshift fuses or the short-circuiting of the fuse holder is prohibited.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:-

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting one or two of these Half-width 3U high units in a 19” rack is available from

the Manufacturers or their overseas agents.

9

Page 11

Front Panel Connections

RF OUT

This is the 50Ω generator output. The maximum output is 500mVrms (+7dBm) into 50Ω. It can

tolerate a short circuit indefinitely.

The Type N connector is a precision component that should be protected from excessive wear to

ensure that its RF characteristics (impedance and VSWR) are accurately maintained. If the

instrument is used in a manner that demands many connections/disconnections to and from the

RF OUT it is good practice to fit a male–to–female adaptor to the socket which can be replaced

periodically.

Do not apply an external voltage to this output. Protected against accidental connection of up to

50VDC and reverse power of up to 25 Watts from 50Ω.

MODULATION IN/OUT

This is the external modulation input and internal modulation output. Input frequency range is

50Hz to 300kHz (depending on modulation type) and impedance is nominally 600Ω as input or

output.

Do not apply external voltages exceeding ± 10V peak to this input/output.

Connections

Rear Panel Connections

EXTERNAL REFERENCE IN/OUT

Can be set to be the External Reference In (10MHz, 2V to 5Vpp, 50Ω), Internal Reference Out

(10MHz, 4Vpp from 50Ω) or Off.

Do not apply external voltages exceeding ± 10Vpp to this input/output.

RS232

9-pin D-connector compatible with addressable RS232 use. The pin connections are shown

below:

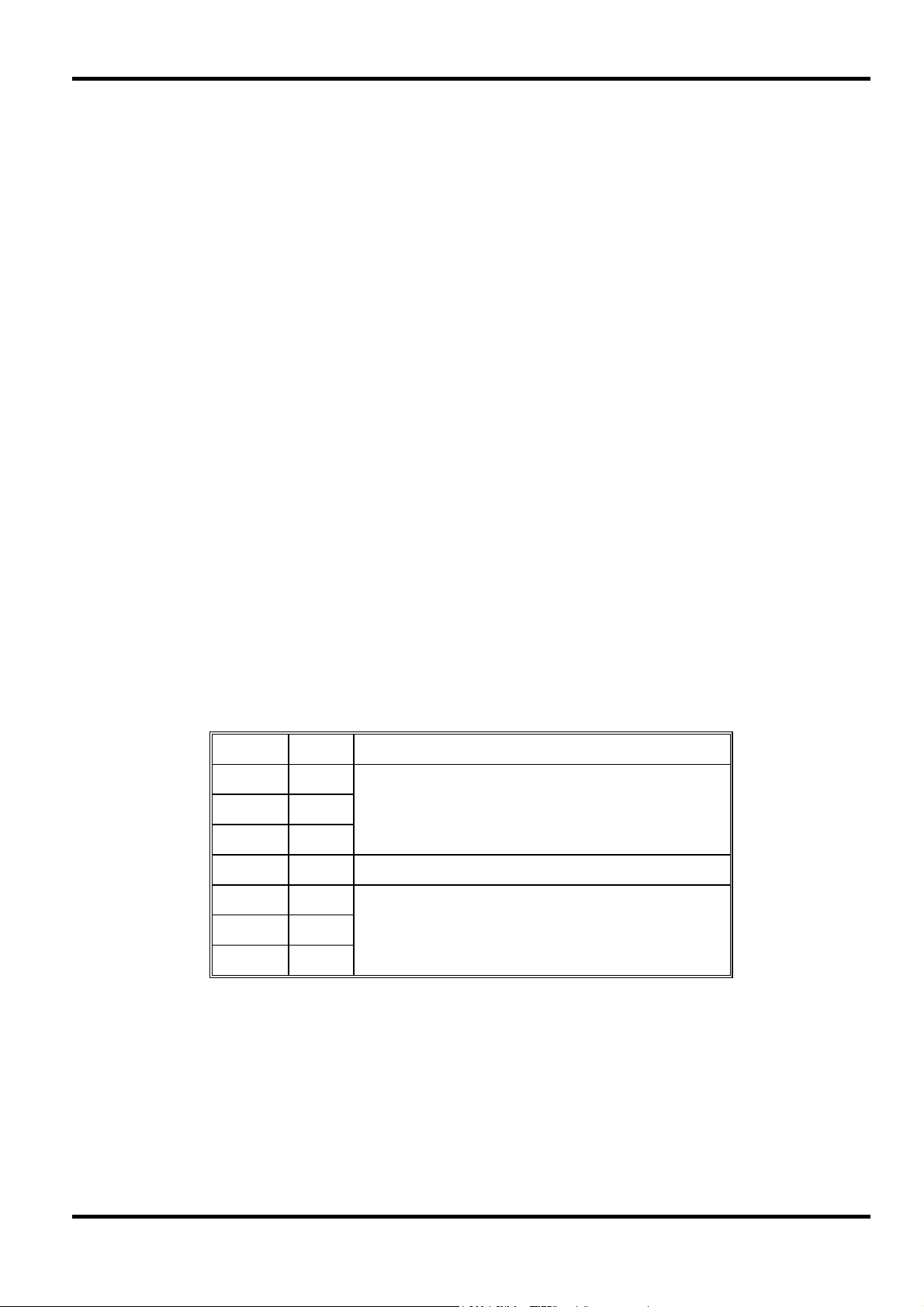

Pin Name Description

1 - No internal Connection

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data (addressable RS232 only)

8 TXD2 Secondary transmitted data (addressable RS232 only)

9 GND Signal ground (addressable RS232 only)

Pins 2, 3 and 5 may be used as a conventional RS232 interface with XON/XOFF handshaking.

Pins 7,8 and 9 are additionally used when the instrument is used in addressable RS232 mode.

Signal grounds are connected to instrument ground. The RS232 address is set from the front

panel using the COMMS menu.

GPIB (IEEE-488)

The GPIB interface is not isolated; the GPIB signal grounds are connected to the instrument

ground. The implemented subsets are:

The GPIB address is set from the front panel using the C0MMS menu.

10

SH1 AH1 T6 TE0 L4 LE0 SR1 RL1 PP1 DC1 DT0 C0 E2

Page 12

General

This section is a general introduction to the operation of the generator, intended to be read before

using the instrument for the first time.

Switching On

The power switch is located at the bottom left of the front panel.

At power up the generator displays the installed software revision for 2 seconds before reverting

to the main menu. The factory default is for the RF OUT output to be always off at switch on but

this can be changed, see the RF OUT Setting at Switch On section; all the other settings will be

the same as when the instrument was last powered down. Should an error with the batterybacked RAM be encountered at power up a message will be displayed, see the Error Messages

section.

The basic generator parameters can all be set from this main menu as described in the following

sections. The output is switched on with the RF OUT key; the ON lamp will light to show that the

output is on.

Keyboard Principles

Operation

The keys can be considered in the following groups:

• The numeric/unit keys permit direct entry of a value for the parameter currently selected

(indicated by the ► cursor beside the parameter). Thus, with frequency selected,

123.45689 MHz is set by keying 1, 2, 3, • , 4, 5, 6, 8, 9 MHz. The parameter actually changes

only when the units key (dB, MHz, etc.) is pressed.

FREQUENCY can be entered in kHz, MHz, or GHz but will always be displayed in MHz.

LEVEL can be entered in dBm, mV or µV; mV values below 1.00mV will be displayed in µV

and µV values above 1000µV will be displayed in mV. With the ► cursor set to LEVEL the

value displayed can be switched from dBm to µV/mV and vice-versa by pressing the

appropriate key.

To enter negative numbers (for dB) the ± key can be used at any time during the number

entry.

ESCAPE aborts the entry and leaves the parameter at its previous setting.

• To the left of the numeric keys are the 5 parameter keys which select the parameter to be

changed; the ► cursor moves to the selected parameter and that parameter can then be

changed as described above.

Next to the MODULATION TYPE key is the MODULATION ON/OFF key which turns

modulation on and off with alternate presses; the MODULATION lamp lights when modulation

is on.

• The FIELD keys provide an alternative means of moving the ► cursor between parameters

on a menu. The rotary control and the ▲▼keys below it provide alternative means of

incrementing/decrementing the value of the currently selected parameter (for FREQUENCY

and LEVEL) or stepping through the parameter settings (for ADDRESS, etc.). When

incrementing/decrementing frequency and level the parameter value changes in steps set up

on the STEP SIZE menu, see Step Size section. During numeric entries the ▼ key also acts

as a backspace/delete.

• The COMMS key selects the communications menu and allows the communication interface

parameters to be set up. When the instrument is in remote control the COMMS key doubles

as the LOCAL key, which returns the instrument to local (keyboard) control.

11

Page 13

• The UTILITIES key selects the Utilities menu which gives access to the stored set-up,

reference socket control and buzzer control.

• The EXECUTE key is used to confirm operations other than numeric parameter entries,

e.g. during store and recall of set-ups.

Step Size

When changing the FREQUENCY or LEVEL using the rotary control or ▲▼keys the size of each

step change will be that previously set on the Step Size menu. The default FREQUENCY step is

0.1MHz. The defaults for the two separate LEVEL step sizes are 10dB and 10mV; the active

LEVEL step size is the one currently displayed in the Step Size menu. Note that either LEVEL

step setting can be used with either LEVEL display mode; i.e. mV steps can be used in a dB

display and vice-versa. However, it will generally be most useful to use dB steps in a dB level

display and µV/mV steps in a µV/mV display.

To change the step size, select the STEP SIZE menu and move the ► selection cursor to the

required parameter with the FIELD keys. Alternatively, because the cursor automatically points to

the step size of the most recently selected main menu parameter, pressing FREQUENCY

followed by STEP SIZE will set the ► cursor to frequency step size and pressing LEVEL followed

by STEP SIZE will set the cursor to level step size.

FREQUENCY steps can be entered directly from the keyboard in kHz, MHz or GHz but will

always be displayed in MHz. The smallest step that can be set is 10Hz and this is the amount by

which the step is changed if the rotary control or ▲▼keys are used; large changes in step size

are therefore made most quickly by direct keyboard entry.

LEVEL steps can be entered directly from the keyboard in dB or µV/mV; separate step sizes are

stored for dB and µV/mV and the choice of units will determine which of the two LEVEL steps is

changed. The active LEVEL step size is the one currently displayed; pressing dB or µV/mV will

switch between the two without changing either. Note that mV values below 1.00mV will be

displayed in µV and µV values above 1000µV will be displayed in mV. The smallest step size that

can be set is 0.1dB or 0.01µV; when using the rotary control or ▲▼keys to set step size the

amount by which the step is changed is 0 .1dB for dB steps or 1 least significant digit for µV/mV

steps.

Having set the step size, return to the main menu by pressing FREQUENCY or LEVEL, etc.

Setting Frequency

Set the ► cursor to FREQUENCY on the main menu by pressing the FREQUENCY key. The

generator frequency can then be set directly from the keyboard, in kHz, MHz or GHz, or changed

using the rotary control or ▲▼keys. Refer to Keyboard Principles for further information on

keyboard entries and to Step Size for setting the rotary control and ▲▼key increment size.

Note that when an increment would have taken the frequency above the instrument's maximum,

the setting becomes 2000 MHz. The next decrement returns the frequency to the last in-range

setting and further decrements decrease the frequency by the specified step size. Similarly when

a decrement would have taken the frequency below the instrument's minimum the setting

becomes 150kHz and the next increment returns the frequency to the last in-range setting, etc.

Setting Level

12

Set the ► cursor to LEVEL on the main menu by pressing the LEVEL key. The output level can

then be set directly from the keyboard, in dBm or µV/mV, or changed using the rotary control or

▲▼ keys. Refer to Keyboard Principles for further information on keyboard entries and to Step

Size for setting the rotary control and ▲▼key increment size.

Page 14

Note that when an increment would have taken the level above the instrument's maximum output

the setting becomes +7dBm (or 500mV). The next decrement returns the level to the last in-range

setting and further decrements reduce the level by the specified step size. Similarly when a

decrement would have taken the level below the instrument's minimum the setting becomes

–127dBm (or 0.1µV) and the next increment returns the setting to the last in-range setting, etc.

Modulation

The generator can be set for internal or external AM, FM or Phase Modulation (PM). With the ►

selection cursor in the MODulation field of the main menu, successive presses of the TYPE key

will step the generator through all available combinations of internal and external AM, FM and

PM; alternatively the selection can be made by using the rotary control or ▲▼ keys.

Amplitude Modulation (AM)

The choices are INTernal at 400Hz, INTernal at 1kHz or EXTernal; with EXTernal selected the

specified modulation frequency range can be applied to the MODULATION IN/OUT socket.

With AM selected the DEPTH/DEVIATION field automatically displays DEPTH. With the ►

selection cursor in the depth field the modulation depth can be set directly from the keyboard in

%, or changed using the rotary control or ▲▼ keys; modulation depth can be set from 0.5% to

100% in 0.5% increments.

With EXTernal modulation selected, the specified modulation depth is achieved with a 1Vrms

sinewave modulation signal.

With AM selected the maximum RF output level is +1.0dBm. If a higher output level has been set

(with AM and/or RF OUT off) then a warning message “+1dBm MAX WITH AM ON” will show

temporarily and the RF OUT level will be reduced to +1dBm. The output level setting will remain

at +1dBm when AM and/or RF OUT are turned off.

Frequency Modulation (FM)

The choices are INTernal at 400Hz, INTernal at 1kHz or EXTernal; with EXTernal selected the

specified modulation frequency range can be applied to the MODULATION IN/OUT socket.

With FM selected the DEPTH/DEVIATION field automatically displays Peak DEViation. With the

► selection cursor in the PK. DEV field the peak deviation can be set directly from the keyboard,

in kHz, MHz or GHz, or changed using the rotary control or ▲▼ keys; peak deviation can be set

to a resolution of 0.5kHz.

With EXTernal modulation selected, the specified peak deviation is achieved with a 1Vrms

sinewave modulation signal.

The maximum peak deviation achievable depends on the carrier frequency, see Specification

section. If a peak deviation is entered (with MOD ON) which is greater than the maximum for the

set carrier frequency then a warning message “PK. DEV LIMITED BY CARRIER FREQUENCY”

will show temporarily and the peak deviation will be changed to the maximum permitted for the

set carrier frequency. The peak deviation frequency in the display is marked with a ∗ to show that

it differs from that entered; the entered value will be restored when FM and/or MOD ON/OFF are

turned off.

The default FM settings are internal 1kHz modulation, 50kHz peak deviation, modulation off; FM

is also the instrument’s default modulation setting.

Phase Modulation (PM)

The choices are INTernal at 400Hz, INTernal at 1kHz or EXTernal; with EXTernal selected the

specified modulation frequency range can be applied to the MODULATION IN/OUT socket.

With PM selected the DEPTH/DEVIATION field automatically displays Peak DEViation. With the

► selection cursor in the PK. DEV field the peak deviation can be set directly from the keyboard,

in rads, or changed using the rotary control or ▲▼ keys; peak deviation can be set to a

resolution of 0.05 rads up to 10.0 rads and to a resolution of 0.1 rads above 10.0 rads.

13

Page 15

With EXTernal modulation selected, the specified peak deviation is achieved with a 1Vrms

sinewave modulation signal.

The maximum peak deviation achievable depends on the carrier frequency, see Specification

section. If a peak deviation is entered (with MOD ON) which is greater than the maximum for the

set carrier frequency then a warning message “PK. DEV LIMITED BY CARRIER FREQUENCY”

will show temporarily and the peak deviation will be changed to the maximum permitted for the

set carrier frequency. The peak deviation frequency in the display is marked with a ∗ to show that

it differs from that entered; the entered value will be restored when PM and/or MOD ON/OFF are

turned off.

The default PM settings are internal 1kHz modulation, 5.00 rads peak deviation, modulation off.

RF OUT Setting at Switch On

The factory default is for the RF OUT output to always be off at switch on, but this can be

changed as follows.

Hold down the ▼ edit key at instrument switch on; after a few seconds a special screen is

displayed. Scroll through the choices using the ▲ key until the required mode is displayed

(always off, always on, or same state as at last power-down). Press EXECUTE to confirm the

selection and exit the menu.

Storing and Recalling Set-ups

Complete instrument set-ups can be stored or recalled from non-volatile RAM using the STORE

and RECALL facilities on the Utilities menu, accessed by pressing the UTILITIES key.

With the ► selection cursor in the STORE field of the Utilities menu the store to be used can be

selected with the rotary control or ▲▼ keys. Nine stores, numbered 1 to 9 inclusive are available.

Select the required store and press the EXECUTE key; the display requests that you press

EXECUTE again to confirm the operation (or any other key to cancel). A set-up already in that

store will be overwritten. The status of the RF OUT is ignored; when a store is recalled the RF

OUT will remain as previously set.

With the ► cursor in the RECALL field of the Utilities menu a previously stored set-up, or the

factory defaults, can be recalled. Select the required store, or DEFAULTS for factory defaults, and

press the EXECUTE key; the display requests that you press EXECUTE again to confirm (or any

other key to cancel). If there is no valid data in the specified store the message 'NO VALID DATA

IN STORE' will be displayed and the set-up will remain unchanged.

14

Page 16

The instrument can be remotely controlled via its RS232 or GPIB interfaces. When using RS232

it can either be the only instrument connected to the controller or it can be part of an Addressable

RS232 Chain (ARC) which permits up to 32 instruments to be addressed from one RS232 port.

Some of the following sections are general and apply to all 3 modes (single instrument RS232,

ARC and GPIB); others are clearly only relevant to a particular interface or mode. It is only

necessary to read the general sections plus those specific to the intended remote control mode.

Remote command format and the remote commands themselves are detailed in the Remote

Commands chapter.

Address and Baud Rate Selection

For successful operation, each instrument connected to the GPIB or Addressable RS232 Chain

(ARC) must be assigned a unique address and, in the case of addressable RS232, all must be

set to the same Baud rate.

The instrument’s remote address for operation on both the GPIB and RS232 interfaces is set on

the COMMS menu, accessed by pressing the COMMS key. With the ► selection cursor in the

ADDRESS field the address can be changed using the rotary control or ▲▼keys. On this

instrument addresses 0 to 30 inclusive are allowed; the factory default is address 1. The address

setting is ignored in single instrument RS232 operation.

With the ► selection cursor in the REMOTE field, the rotary control or ▲▼keys can be used to

select GPIB or RS232 with Baud rates of between 300 and 19200; the factory default selection is

RS232 at 9600 Baud.

Remote Operation

Remote/Local Operation

At power-on the instrument will be in the local state with the REMOTE lamp off. In this state all

keyboard operations are possible. When the instrument is addressed to listen and a command is

received the remote state will be entered and the REMOTE lamp will be turned on. In this state

the keyboard is locked out and remote commands only will be processed. The instrument may be

returned to the local state by pressing the LOCAL key; however, the effect of this action will only

remain until the instrument is addressed again or receives another character from the interface,

when the remote state will once again be entered.

RS232 Interface

RS232 Interface Connector

The 9-way D-type serial interface connector is located on the instrument rear panel. The pin

connections are as shown below:

Pin Name Description

1 - No internal connection

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data (addressable RS232 only)

8 TXD2 Secondary transmitted data (addressable RS232 only)

9 GND Signal ground (addressable RS232 only)

15

Page 17

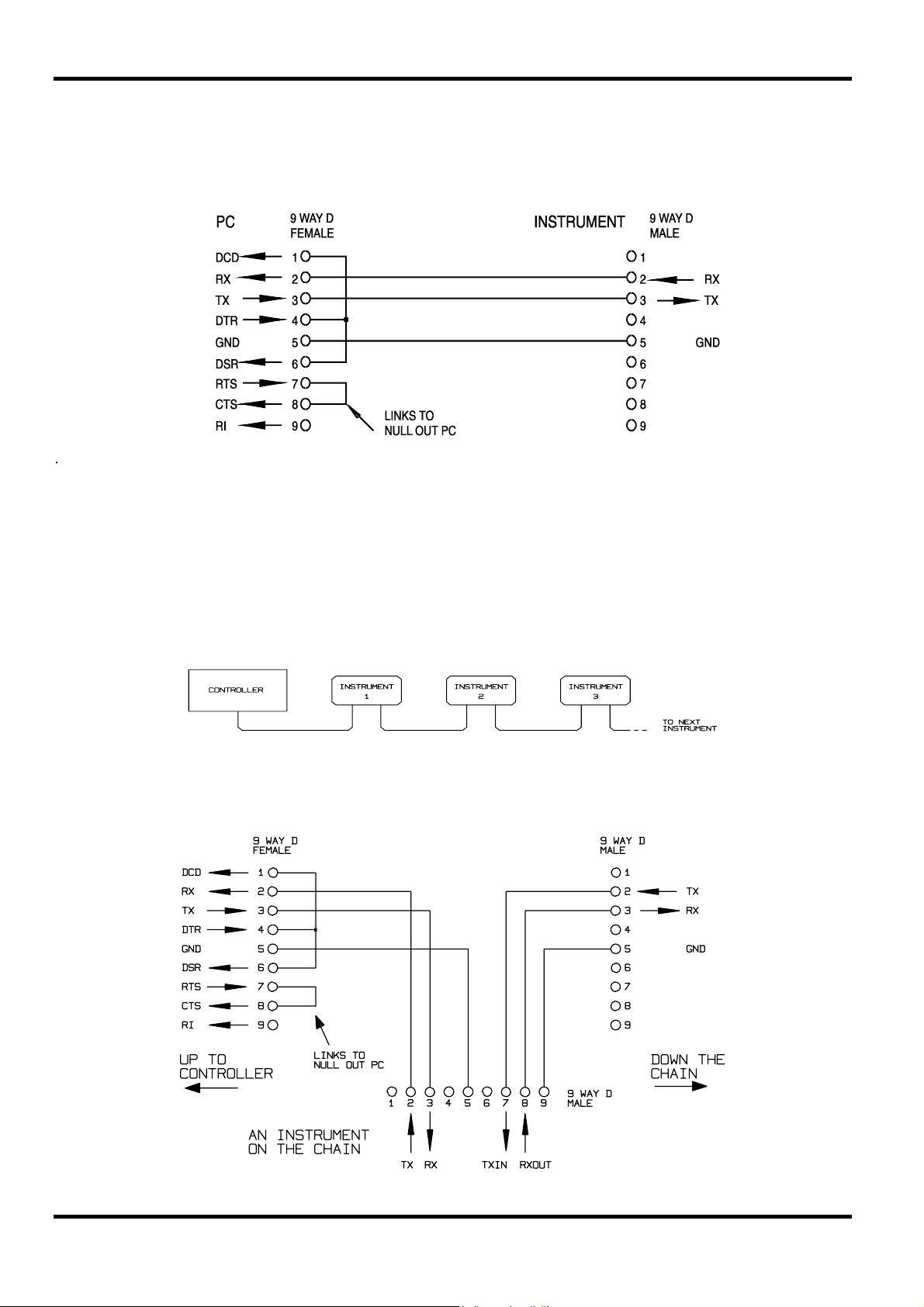

Single Instrument RS232 Connections

For single instrument remote control only pins 2, 3 and 5 are connected to the PC. However, for

correct operation links must be made in the connector at the PC end between pins 1, 4 and 6 and

between pins 7 and 8, see diagram. Pins 7 and 8 of the instrument must not be connected to the

PC, i.e. do not use a fully wired 9–way cable.

Baud Rate is set as described above in Address and Baud Rate Selection; the other parameters

are fixed as follows:

Start Bits: 1 Parity: None

Data Bits: 8 Stop Bits: 1

Addressable RS232 Connections

For addressable RS232 operation pins 7, 8 and 9 of the instrument connector are also used.

Using a simple cable assembly, a ‘daisy chain’ connection system between any number of

instruments, up to the maximum of 32 can be made, as shown below:

The daisy chain consists of the transmit data (TXD), receive date (RXD) and signal ground lines

only. There are no control/handshake lines. This makes XON/XOFF protocol essential and allows

the inter-connection between instruments to contain just 3 wires. The wiring of the adaptor cable

is shown below:

16

Page 18

All instruments on the interface must be set to the same baud rate and all must be powered on,

otherwise instruments further down the daisy chain will not receive any data or commands.

The other parameters are fixed as follows:

Start Bits: 1 Parity: None

Data Bits: 8 Stop Bits: 1

RS232 Character Set

Because of the need for XON/XOFF handshake it is possible to send ASCII coded data only;

binary blocks are not allowed. Bit 7 of ASCII codes is ignored, i.e. assumed to be low. No

distinction is made between upper and lower case characters in command mnemonics and they

may be freely mixed. The ASCII codes below 20H (space) are reserved for addressable RS232

interface control. In this manual 20H, etc. means 20 in hexadecimal

Addressable RS232 (ARC) Interface Control Codes

All instruments intended for use on the ARC bus use the following set of interface control codes.

Codes between 00H and 1FH which are not listed here as having a particular meaning are

reserved for future use and will be ignored. Mixing interface control codes inside instrument

commands is not allowed except as stated below for CR and LF codes and XON and XOFF

codes.

When an instrument is first powered on it will automatically enter the Non- Addressable mode. In

this mode the instrument is not addressable and will not respond to any address commands. This

allows the instrument to function as a normal RS232 controllable device. This mode may be

locked by sending the Lock Non-Addressable mode control code, 04H. The controller and

instrument can now freely use all 8 bit codes and binary blocks but all interface control codes are

ignored. To return to addressable mode the instrument must be powered off.

To enable addressable mode after an instrument has been powered on the Set Addressable

Mode control code, 02H, must be sent. This will then enable all instruments connected to the

ARC bus to respond to all interface control codes. To return to Non-Addressable mode the Lock

Non-Addressable mode control code must be sent which will disable addressable mode until the

instruments are powered off.

Before an instrument is sent a command it must be addressed to listen by sending the Listen

Address control code, 12H, followed by a single character which has the lower 5 bits

corresponding to the unique address of the required instrument, e.g. the codes A-Z or a-z give

the addresses 1-26 inclusive while @ is address 0 and so on. Once addressed to listen the

instrument will read and act upon any commands sent until the listen mode is cancelled.

Because of the asynchronous nature of the interface it is necessary for the controller to be

informed that an instrument has accepted the listen address sequence and is ready to receive

commands. The controller will therefore wait for Acknowledge code, 06H, before sending any

commands, The addressed instrument will provide this Acknowledge. The controller should timeout and try again if no Acknowledge is received within 5 seconds.

Listen mode will be cancelled by any of the following interface control codes being received:

12H Listen Address followed by an address not belonging to this instrument.

14H Talk Address for any instrument.

03H Universal Unaddress control code.

04H Lock Non-Addressable mode control code.

18H Universal Device Clear.

Before a response can be read from an instrument it must be addressed to talk by sending the

Talk Address control code,14H, followed by a single character which has the lower 5 bits

corresponding to the unique address of the required instrument, as for the listen address control

code above. Once addressed to talk the instrument will send the response message it has

available, if any, and then exit the talk addressed state. Only one response message will be sent

each time the instrument is addressed to talk.

17

Page 19

Talk mode will be cancelled by any of the following interface control codes being received:

12H Listen Address for any instrument.

14H Talk Address followed by an address not belonging to this instrument.

03H Universal Unaddress control code.

04H Lock Non-Addressable mode control code.

18H Universal Device Clear.

Talk mode will also be cancelled when the instrument has completed sending a response

message or has nothing to say.

The interface code 0AH (LF) is the universal command and response terminator; it must be the

last code sent in all commands and will be the last code sent in all responses.

The interface code 0DH (CR) may be used as required to aid the formatting of commands; it will

be ignored by all instruments. Most instruments will terminate responses with CR followed by LF.

The interface code 13H (XOFF) may be sent at any time by a listener (instrument or controller) to

suspend the output of a talker. The listener must send 11H (XON) before the talker will resume

sending. This is the only form of handshake control supported by ARC.

Full List of Addressable RS232 (ARC) Interface Control Codes

02H Set Addressable Mode.

03H Universal Unaddress control code.

04H Lock Non-Addressable mode control code.

06H Acknowledge that listen address received.

0AH Line Feed (LF); used as the universal command and response terminator.

0DH Carriage Return (CR); formatting code, otherwise ignored.

11H Restart transmission (XON).

12H Listen Address – must be followed by an address belonging to the required instrument.

13H Stop transmission (XOFF).

14H Talk Address – must be followed by an address belonging to the required instrument.

18H Universal Device Clear.

GPIB Interface

The GPIB interface 24-way connector is located on the instrument rear panel. The pin

connections are as specified in IEEE Std. 488.1-1987 and the instrument complies with IEEE Std.

488.1-1987 and IEEE Std. 488.2-1987.

GPIB Subsets

This instrument contains the following IEEE 488.1 subsets:

Source Handshake SH1

Acceptor Handshake AH1

Talker T6

Listener L4

Service Request SR1

Remote Local RL1

Parallel Poll PP1

Device Clear DC1

Device Trigger DT0

Controller C0

Electrical Interface E2

18

Page 20

GPIB IEEE Std. 488.2 Error Handling

The IEEE 488.2 UNTERMINATED error (addressed to talk with nothing to say) is handled as follows.

If the instrument is addressed to talk and the response formatter is inactive and the input queue is

empty then the UNTERMINATED error is generated. This will cause the Query Error bit to be set in

the Standard Event Status Register, a value of 3 to be placed in the Query Error Register and the

parser to be reset. See the Status Reporting section for further information.

The IEEE 488.2

send a response message and a

or the input queue contains more than one END message then the instrument has been

INTERRUPTED and an error is generated. This will cause the Query Error bit to be set in the

Standard Event Status Register, a value of 1 to be placed in the Query Error Register and the

response formatter to be reset thus clearing the output queue. The parser will then start parsing

the next

<PROGRAM MESSAGE UNIT> from the input queue. See the Status Reporting section for

further information.

The IEEE 488.2

a response message and the input queue becomes full then the instrument enters the

state and an error is generated. This will cause the Query Error bit to be set in the Standard Event

Status Register, a value of 2 to be placed in the Query Error Register and the response formatter

to be reset thus clearing the output queue. The parser will then start parsing the next

MESSAGE UNIT>

GPIB Parallel Poll

Complete parallel poll capabilities are offered on this generator. The Parallel Poll Enable Register

is set to specify which bits in the Status Byte Register are to be used to form the

The Parallel Poll Enable Register is set by the ∗PRE <nrf> command and read by the ∗PRE?

command. The value in the Parallel Poll Enable Register is ANDed with the Status Byte Register;

if the result is zero then the value of

The instrument must also be configured so that the value of

during a parallel poll operation. The instrument is configured by the controller sending a Parallel

Poll Configure command (PPC) followed by a Parallel Poll Enable command (PPE). The bits in

the PPE command are shown below:

INTERRUPTED error is handled as follows. If the response formatter is waiting to

<PROGRAM MESSAGE TERMINATOR> has been read by the parser

DEADLOCK error is handled as follows. If the response formatter is waiting to send

DEADLOCK

<PROGRAM

from the input queue. See the Status Reporting section for further information.

ist local message

ist is 0 otherwise the value of ist is 1.

ist can be returned to the controller

bit 7 = X don’t care

bit 6 = 1

bit 5 = 1 Parallel poll enable

bit 4 = 0

bit 3 = Sense sense of the response bit; 0 = low, 1 = high

bit 2 = ?

bit 1 = ? bit position of the response

bit 0 = ?

Example. To return the RQS bit (bit 6 of the Status Byte Register) as a 1 when true and a 0 when

false in bit position 1 in response to a parallel poll operation send the following commands

∗PRE 64

<pmt>, then PPC followed by 69H (PPE)

The parallel poll response from the generator will then be 00H if RQS is 0 and 01H if RQS

is 1.

During parallel poll response the DIO interface lines are resistively terminated (passive

termination). This allows multiple devices to share the same response bit position in either wiredAND or wired-OR configuration, see IEEE 488.1 for more information.

19

Page 21

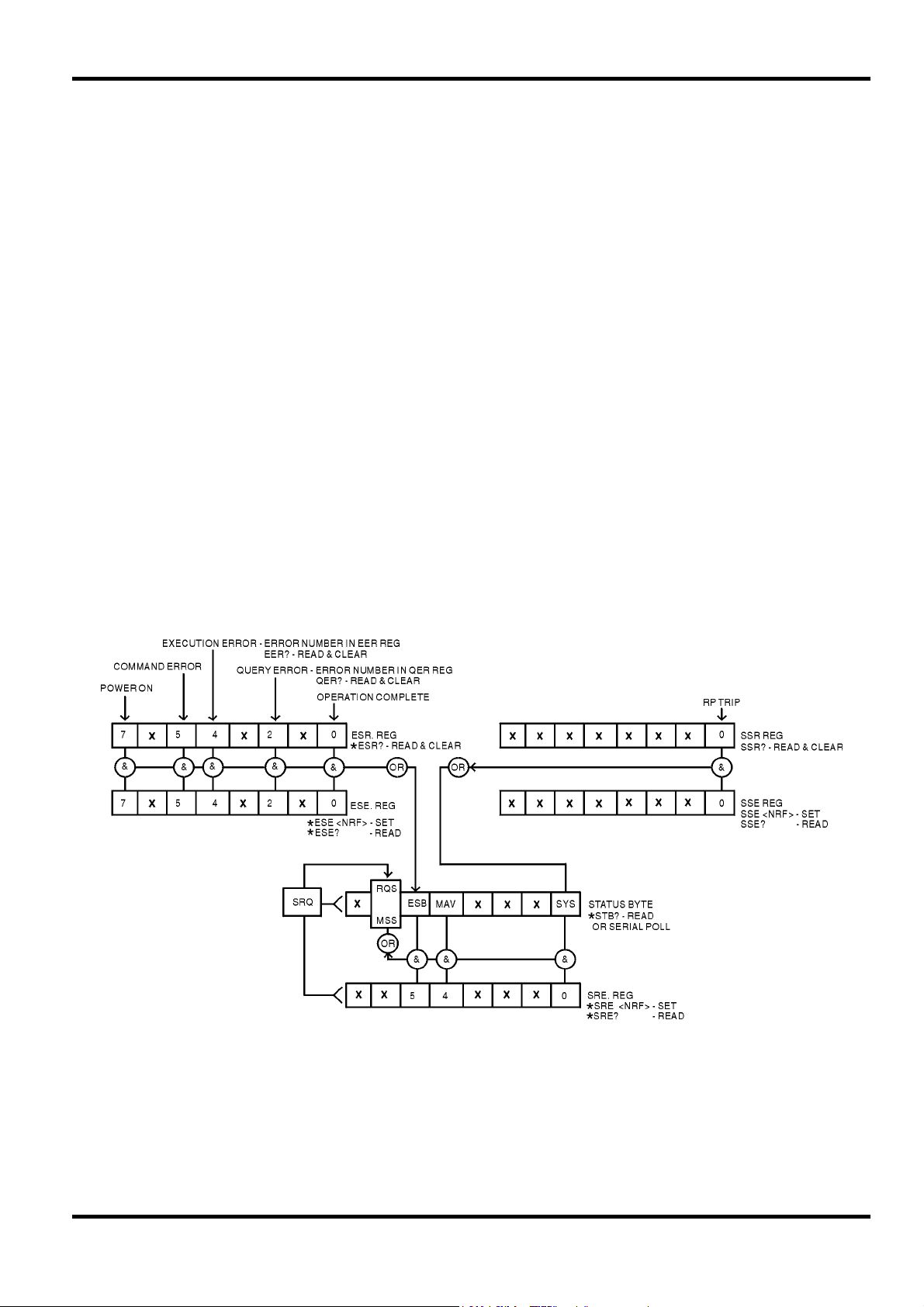

Status Reporting

This section describes the complete status model of the instrument. Note that some registers are

specific to the GPIB section of the instrument and are of limited use in an RS232 environment.

Standard Event Status and Standard Event Status Enable Registers

These two registers are implemented as required by the IEEE std. 488.2.

Any bits set in the Standard Event Status Register which correspond to bits set in the Standard

Event Status Enable Register will cause the ESB bit to be set in the Status Byte Register.

The Standard Event Status Register is read and cleared by the ∗ESR? command. The Standard

Event Status Enable register is set by the ∗ESE <nrf> command and read by the ∗ESE?

command.

Bit 7 - Power On. Set when power is first applied to the instrument.

Bit 6 - Not used.

Bit 5 - Command Error. Set when a syntax type error is detected in a command from

the bus. The parser is reset and parsing continues at the next byte in the input

stream.

Bit 4 - Execution Error. Set when an error is encountered while attempting to execute a

completely parsed command. The appropriate error number will be reported in

the Execution Error Register.

Bit 3 - Not used.

Bit 2 - Query Error. Set when a query error occurs. The appropriate error number will

be reported in the Query Error Register as listed below.

1. Interrupted error

2. Deadlock error

3. Unterminated error

Bit 1 - Not used.

Bit 0 -

Operation Complete. Set in response to the ∗OPC command.

System Event Status Register and System Event Status Enable Register

These two registers are implemented as device specific, event and event enable registers

according to the IEEE Std. 488.2. Their purpose is to inform the controller when the reverse

power protection system is operating or has operated since the last read of the System Event

Status Register.

If the reverse power protection system operates the specified bit will be set in the System Event

Status Register. If the corresponding bit is also set in the System Event Status Enable Register

then the SYS bit will become set in the Status Byte Register.

The System Event Status Register is read and cleared by the SSR? command and the System

Event Status Enable Register is set by the SSE <nrf> command.

20

The bits are defined as:-

Bit 7 – Bit 1 - Not used

Bit 0 -

Set when the reverse power protection system operates

Page 22

Status Byte Register and Service Request Enable Register

These two registers are implemented as required by the IEEE std. 488.2.

Any bits set in the Status Byte Register which correspond to bits set in the Service Request

Enable Register will cause the RQS/MSS bit to be set in the Status Byte Register, thus generating

a Service Request on the bus.

The Status Byte Register is read either by the ∗STB? command, which will return MSS in bit 6, or

by a Serial Poll which will return RQS in bit 6. The Service Request Enable register is set by the

∗SRE <nrf> command and read by the ∗SRE? command.

Bit 7 - Not used.

Bit 6 - RQS/MSS. This bit, as defined by IEEE Std. 488.2, contains both the Requesting

Service message and the Master Status Summary message. RQS is returned in

response to a Serial Poll and MSS is returned in response to the ∗STB? command.

Bit 5 - ESB. The Event Status Bit. This bit is set if any bits set in the Standard Event Status

Register correspond to bits set in the Standard Event Status Enable Register.

Bit 4 - MAV. The Message Available Bit. This will be set when the instrument has a

response message formatted and ready to send to the controller. The bit will be

cleared after the Response Message Terminator has been sent.

Bit 3 - Not used.

Bit 2 - Not used.

Bit 1 - Not used.

Bit 0 - SYS. This bit will be set if any bits in the System Event Status Register are set and

corresponding bits are set in the System Event Status Enable Register.

Status Model

21

Page 23

Power on Settings

The following instrument status values are set at power on:

Status Byte Register †

Service Request Enable Register † (SRE)

Standard Event Status Register (ESR) = 128 (pon bit set)

Standard Event Status Enable Register (ESE) = 0

Execution Error Register (EER) = 0

Query Error Register (QER) = 0

Parallel Poll Enable Register †

System Event Status Register (SSR) = 0

System Event Status Enable Register (SSE) = 0

† Registers marked thus are specific to the GPIB section of the instrument and are not

implemented in an RS232 environment.

The instrument will be in local state with the keyboard active.

The instrument parameters at power on are the same as at last switch off with the exception of

RF OUT which is always off.

If for any reason an error is detected at power up in the non-volatile ram a warning will be issued

and all settings will be returned to their default states as for a ∗RST command.

= 0

= 0

= 0

22

Page 24

RS232 Remote Command Formats

Serial input to the instrument is buffered in a 256 byte input queue which is filled, under interrupt,

in a manner transparent to all other instrument operations. The instrument will send XOFF when

approximately 200 characters are in the queue. XON will be sent when approximately 100 free

spaces become available in the queue after XOFF was sent. This queue contains raw (unparsed) data which is taken, by the parser, as required. Commands (and queries) are executed in

order and the parser will not start a new command until any previous command or query is

complete. In non–addressable RS232 mode responses to commands or queries are sent

immediately; there is no output queue. In addressable mode the response formatter will wait

indefinitely if necessary, until the instrument is addressed to talk and the complete response

message has been sent, before the parser is allowed to start the next command in the input

queue.

Commands must be sent as specified in the commands list and must be terminated with the

command terminator code 0AH (Line Feed, LF). Commands may be sent in groups with

individual commands separated from each other by the code 3BH (;). The group must be

terminated with command terminator 0AH (Line Feed, LF).

Responses from the instrument to the controller are sent as specified in the commands list. Each

response is terminated by 0DH (Carriage Return, CR) followed by 0AH (Line Feed, LF).

Remote Commands

<WHITE SPACE> is defined as character codes 00H to 20H inclusive with the exception of those

which are specified as Addressable RS232 (ARC) control codes.

<WHITE SPACE> is ignored except in command identifiers. e.g. ‘∗C LS’ is not equivalent to ‘∗CLS’.

The high bit of all characters is ignored.

The commands are case insensitive.

GPIB Remote Command Formats

GPIB input to the instrument is buffered in a 256 byte input queue which is filled, under interrupt,

in a manner transparent to all other instrument operations. The queue contains raw (un-parsed)

data which is taken, by the parser, as required. Commands (and queries) are executed in order

and the parser will not start a new command until any previous command or query is complete.

There is no output queue which means that the response formatter will wait, indefinitely if

necessary, until the instrument is addressed to talk and the complete response message has

been sent, before the parser is allowed to start the next command in the input queue.

Commands are sent as

or more

<PROGRAM MESSAGE UNIT> elements separated by <PROGRAM MESSAGE UNIT SEPARATOR>

elements.

A <PROGRAM MESSAGE UNIT> is any of the commands in the remote commands list.

<PROGRAM MESSAGE UNIT SEPARATOR> is the semi-colon character ‘;’ (3BH).

A

<PROGRAM MESSAGES> are separated by <PROGRAM MESSAGE TERMINATOR> elements which may

be any of the following:

NL The new line character (0AH)

NL^END The new line character with the END message

^END The END message with the last character of the message

Responses from the instrument to the controller are sent as

<RESPONSE MESSAGE> consists of one <RESPONSE MESSAGE UNIT> followed by a <RESPONSE

MESSAGE TERMINATOR>.

<RESPONSE MESSAGE TERMINATOR> is the new line character with the END message NL^END.

A

<PROGRAM MESSAGES> by the controller, each message consisting of zero

<RESPONSE MESSAGES>. A

Each query produces a specific

<RESPONSE MESSAGE> which is listed along with the command in

the remote commands list.

23

Page 25

<WHITE SPACE> is ignored except in command identifiers. e.g. ‘∗C LS’ is not equivalent to ‘∗CLS’.

<WHITE SPACE> is defined as character codes 00H to 20H inclusive with the exception of the NL

character (0AH).

The high bit of all characters is ignored.

The commands are case insensitive.

Command List

This section lists all commands and queries implemented in this instrument. The commands are

listed in alphabetical order within the function groups.

Note that there are no dependent parameters, coupled parameters, overlapping commands,

expression program data elements or compound command program headers; each command is

completely executed before the next command is started. All commands are sequential and the

operation complete message is generated immediately after execution in all cases.

The following nomenclature is used:

<rmt>

<RESPONSE MESSAGE TERMINATOR>

<nrf> A number in any format. e.g. 12, 12.00, 1.2 e1 and 120 e-1 are all accepted as

the number 12. Any number, when received, is converted to the required

precision consistent with the use then rounded up to obtain the value of the

command.

<nr1> A number with no fractional part, i.e. an integer.

The commands which begin with a ∗ are those specified by IEEE Std. 488.2 as Common

commands. All will function when used on the RS232 interface but some are of little use.

Output Parameters

FREQ <nrf> Set the output frequency to <nrf> kHz

DBMLEV <nrf> Set the output level to <nrf> in dBm

MVLEV <nrf> Set the output level to <nrf> in mV

UVLEV <nrf> Set the output level to <nrf> in uV

MODON Set modulation to ON

MODOFF Set modulation to OFF

FM <nrf> Set the FM peak deviation to <nrf> kHz

PM <nrf> Set the PM peak deviation to <nrf> rads

AM <nrf> Set the AM depth to <nrf> %

RFON Switch on RF output

RFOFF Switch off RF output

MOD_TYPE <nrf> Select the modulation type according to <nrf> defined as:

1 = FM INT 400Hz

2 = FM INT 1000Hz

3 = FM EXT

4 = PM INT 400Hz

5 = PM INT 1000Hz

6 = PM EXT

7 = AM INT 400Hz

8 = AM INT 1000Hz

9 = AM EXT

24

Page 26

REF_OUT Set the reference socket to output

REF_IN Set the reference socket to input

REF_DIS Disable the reference socket

BUZZON Enable the internal buzzer

BUZZOFF Disable the internal buzzer

Editing and Cursor Movement Commands

FSTEP <nrf> Set the frequency step size to <nrf> kHz

DBSTEP <nrf> Set the dB step size to <nrf> dB

MVSTEP <nrf> Set the linear step size to <nrf> mV

UVSTEP <nrf> Set the linear step size to <nrf> uV

STEP_UP Performs the same function as pressing the ▲ key

STEP_DOWN Performs the same function as pressing the ▼ key

FIELD_UP Performs the same function as pressing the FIELD ▲ key

FIELD_DOWN Performs the same function as pressing the FIELD ▼ key

FREQ_PTR Moves the edit cursor to FREQUENCY and displays the appropriate menu to

make FREQUENCY viewable.

LEV_PTR Moves the edit cursor to output LEVEL and displays the appropriate menu to

make output LEVEL viewable.

MOD_TYPE_PTR Moves the edit cursor to the MODULATION TYPE and displays the appropriate

menu to make MODULATION TYPE viewable.

MOD_VAL_PTR Moves the edit cursor to the MODULATION VALUE and displays the

appropriate menu to make the MODULATION VALUE viewable.

PKDEV_PTR Moves the edit cursor to PK DEVIATION and displays the appropriate menu to

make PK DEVIATION viewable.

UTILS_PTR Moves the edit cursor to the last selected parameter on the Utilities menu and

displays the Utilities menu.

STEP_PTR Moves the edit cursor to the last selected parameter on the Step Size menu

and displays the Step Size menu.

System Commands

∗RST

∗CL <nrf>

Resets the instrument to default settings with the exception of all remote

interface settings.

Recalls the instrument set–up contained in store number <nrf>. Valid store

numbers are 1–10. Recalling store 10 sets all parameters to default settings

with the exception of remote interface settings. An attempt to recall from a

store which has not been previously loaded with a set–up will create an

execution error.

RPP_RST Reset the reverse power protection trip latch. If the reverse power is still

present the trip condition will be re-asserted immediately.

∗SAV <nrf>

25

Saves the complete instrument set–up in store number <nrf>. Valid store

numbers are 1 – 9.

Page 27

Status Commands

∗LRN?

LRN <character data>

EER? Query and clear Execution Error Register. The response format is

QER? Query and clear Query Error Register. The response format is <nr1><rmt>.

∗CLS

∗ESE <nrf>

∗ESE?

∗ESR?

Returns the complete set up of the instrument as a hexadecimal character

data block approximately 108 bytes long. The syntax of the response is

LRN <data><rmt>.

To re–install the set–up return the block exactly as received, including the

LRN header at the beginning of the block, see below. The settings in the

instrument are not affected by execution of the ∗LRN? command.

Install data from a previous ∗LRN? command. Note that the LRN header is

provided by the ∗LRN? response block.

<nr1><rmt>.

Clear Status. Clears the Standard Event Status Register, Query Error Register

and Execution Error Register. This indirectly clears the Status Byte Register.

Set the Standard Event Status Enable Register to the value of <nrf>.

Returns the value in the Standard Event Status Enable Register in <nr1>

numeric format. The syntax of the response is <nr1><rmt>.

Returns the value in the Standard Event Status Register in <nr1> numeric

format. The register is then cleared. The syntax of the response is

<nr1><rmt>.

∗IST?

∗OPC

∗OPC?

∗PRE <nrf>

∗PRE?

∗SRE <nrf>

∗SRE?

SSR? Query and clear System Event Status Register. The response format is

SSE <nrf> Set the System Event Status Enable Register to <nrf>.

SSE? Returns the value of the System Event Status Enable Register in <nr1>

Returns ist local message as defined by IEEE Std. 488.2. The syntax of the

response is 0<rmt>, if the local message is false or 1<rmt>, if the local

message is true.

Sets the Operation Complete bit (bit 0) in the Standard Event Status Register.

This will happen immediately the command is executed because of the

sequential nature of all operations.

Query Operation Complete status. The syntax of the response is 1<rmt>.

The response will be available immediately the command is executed

because of the sequential nature of all operations.

Set the Parallel Poll Enable Register to the value <nrf>.

Returns the value in the Parallel Poll Enable Register in <nr1> numeric

format. The syntax of the response is <nr1><rmt>.

Set the Service Request Enable Register to <nrf>.

Returns the value of the Service Request Enable Register in <nr1> numeric

format. The syntax of the response is <nr1><rmt>.

<nr1><rmt>.

numeric format. The syntax of the response is <nr1><rmt>.

∗STB?

∗WAI

26

Returns the value of the Status Byte Register in <nr1> numeric format. The

syntax of the response is <nr1><rmt>.

Wait for Operation Complete true. As all commands are completely executed

before the next is started this command takes no additional action.

Page 28

Miscellaneous Commands

∗IDN?

∗TST?

∗TRG

Returns the instrument identification. The exact response is determined by the

instrument configuration and is of the form <NAME>,<model>, 0, <version><rmt>

where <NAME> is the manufacturer’s name, <model> defines the type of

instrument and <version> is the revision level of the software installed.

The generator has no self test capability and the response is always 0 <rmt>

The generator has no trigger capability.

Calibration Specific Commands

See Service Manual for details of calibration specific commands.

The Manufacturers or their agents overseas will provide a repair service for any unit developing a

fault. Where owners wish to undertake their own maintenance work, this should only be done by

skilled personnel in conjunction with the service manual which may be purchased directly from

the Manufacturers or their agents overseas.

Cleaning

If the instrument requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent.

Maintenance

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE INSTRUMENT, NEVER

ALLOW WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE NEVER

CLEAN WITH SOLVENTS.

27

Page 29

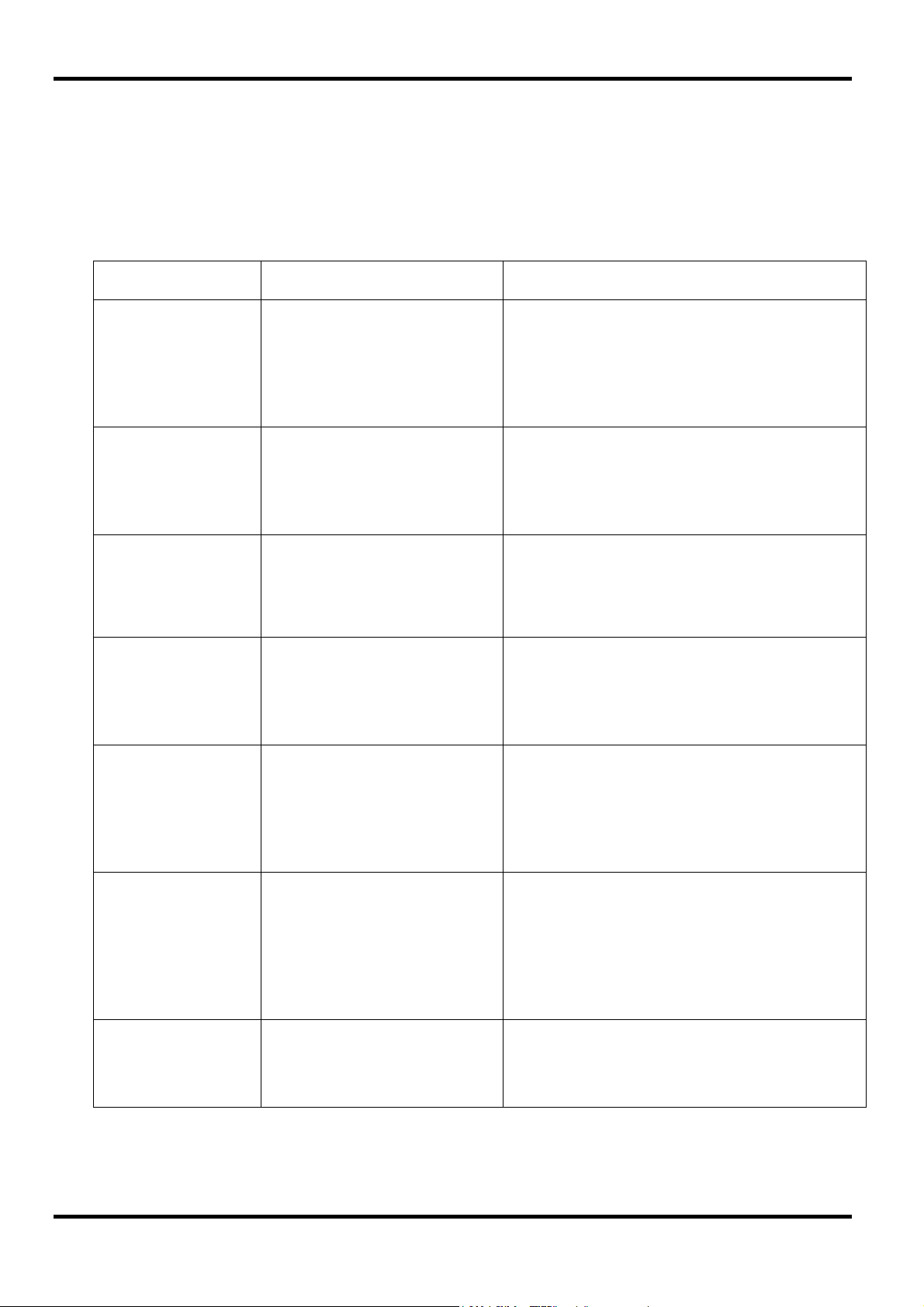

Appendix 1. Error Messages

Error messages are given when a system fault is found or an illegal setting is attempted; the

previous setting is retained if an OUT OF RANGE value is sent via a remote interface.

Each error message has a number; only this number is reported via the remote control interfaces.

The following is a complete list of messages as they appear on the display.

Error Message No. Message Explanation

50 EEPROM READ ERROR

To set

default calibration

press any key

51

EEPROM WRITE ERROR

Press any key to continue

52 RAM READ ERROR

RECALLING

DEFAULT SETUP

Calib. not affected

120 ERROR

OUT OF RANGE

121 NO VALID DATA IN STORE

<STORE NUMBER>

Press any key

Displayed at power up if a checksum error is

encountered when reading calibration

constants from EEPROM. A key press is

necessary to continue operation but the

instrument will almost certainly be outside

specification.

Displayed if default calibration constants

could not be successfully written into the

EEPROM following an EEPROM read error. A

key press is necessary to continue operation

but operation is unpredictable.

Displayed at power up if a checksum error is

encountered when reading set up information

from non–volatile RAM. Operation continues

automatically after three seconds delay.

Displayed if a REMOTE command attempts

to set any parameter to a value which is

beyond its acceptable range of values.

Operation continues automatically after three

seconds.

Displayed if an attempt is made to retrieve an

instrument set up from a store which has not

yet been programmed. In LOCAL mode a key

press is necessary to continue operation. In

REMOTE mode operation continues

automatically after three seconds delay.

28

122 PK. DEV LIMITED

BY CARRIER FREQUENCY

123 +1dBm MAX WITH

AM ON

Error message numbers are not displayed but are placed in the Execution Error Register where

they can be read via the remote interfaces.

Displayed if both MOD and FM (or PM) are

turned on with a peak deviation already set to

greater than that permitted for the current

carrier frequency. The entered deviation is

remembered and is restored when the carrier

frequency is changed or MOD ON/OFF

and/or FM (or PM) are turned off.

Displayed if both RF OUT and AM are turned

on with the output level already set to

>+1dBm. The level is permanently changed

to +1dBm.

Page 30

Appendix 2. Factory Defaults

The instrument will be set to the following condition if RECALL DEFAULTS is executed on the

Utilities menu or if the remote commands ∗RST or ∗RCL 10 are issued.

FREQUENCY = 100.000 MHz

LEVEL = 0.0 dBm – RF output OFF

MODULATION = FM @ 1kHz internal OFF – modulation is turned off

PK. DEVIATION = 50.0 kHz

FREQUENCY STEP = 0.10000 MHz

LINEAR LEVEL STEP = 10.0mV

dB LEVEL STEP = 10.0dB

29

Page 31

Sécurité

Cet instrument est de Classe de sécurité 1 suivant la classification IEC et il a été construit pour

satisfaire aux impératifs EN61010-1 (Impératifs de sécurité pour le matériel électrique en vue de

mesure, commande et utilisation en laboratoire). Il s'agit d'un instrument d'installation Catégorie II

devant être exploité depuis une alimentation monophasée habituelle.

Cet instrument a été soumis à des essais conformément à EN61010-1 et il a été fourni en tout

état de sécurité. Ce manuel d'instructions contient des informations et avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement en toute sécurité et de conserver

l'instrument dans un état de bonne sécurité.

Cet instrument a été conçu pour être utilisé en interne dans un environnement de pollution

Degré 2, plage de températures 5°C à 40°C, 20% - 80% HR (sans condensation). Il peut être

soumis de temps à autre à des températures comprises entre +5°C et –10°C sans dégradation

de sa sécurité. Ne pas l'utiliser lorsqu'il y a de la condensation.

Toute utilisation de cet instrument de manière non spécifiée par ces instructions risque d'affecter

la protection de sécurité conférée. Ne pas utiliser l'instrument à l'extérieur des tensions

d'alimentation nominales ou de la gamme des conditions ambiantes spécifiées.

AVERTISSEMENT! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Il est absolument interdit d'effectuer une interruption à dessein. Ne

pas utiliser de cordon de prolongation sans conducteur de protection, car ceci annulerait sa

capacité de protection.

Lorsque l'instrument est relié à son alimentation, il est possible que les bornes soient sous

tension et par suite, l'ouverture des couvercles ou la dépose de pièces (à l'exception de celles

auxquelles on peut accéder manuellement) risque de mettre à découvert des pièces sous

tension. Il faut débrancher toute source de tension éventuelle de l'appareil avant de l'ouvrir pour

effectuer des réglages, remplacements, travaux d'entretien ou de réparation.

Eviter dans la mesure du possible d'effectuer des réglages, travaux de réparation ou d'entretien

lorsque l'instrument ouvert est branché à une source d'alimentation, mais si c'est absolument

nécessaire, seul un technicien compétent au courant des risques encourus doit effectuer ce

genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité sera amoindrie et il

faut retirer l'appareil, afin qu'il ne soit pas utilisé, et le renvoyer en vue de vérifications et de

réparations.

Uniquement remplacer les fusibles par des fusibles d'intensité nominale requise et de type

spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter des porte-fusibles.

L’instrument utilise une pile bouton au lithium pour la mémoire non-volatile ; sa durée de vie est

environ 5 ans. Pour son remplacement, utilisé une pile du même type : 3V Li/ Mn0

Les piles usées doivent être jetées en accord avec les lois locales ; ne pas les couper, les brûler,

les exposer à des températures au delà de 60°C ou essayer de la recharger.

Ne pas mouiller l’instrument lors de son nettoyage; en particulier, n’utiliser qu’un chiffon doux et

sec pour nettoyer la vitre de l’afficheur.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce manuel.

type 2032.

2

30

l

ATTENTION - se référer à la documentation ci-jointe; toute utilisation

incorrecte risque d'endommager l'appareil.

Borne reliée à la terre du châssis

Alimentation secteur ON (allumée)

Alimentation secteur OFF (éteinte)

Courant alternatif (c.a.)

Page 32

Vérifier que la tension de fonctionnement de l'instrument indiquée sur le panneau arrière est

appropriée pour l'alimentation locale. Procéder de la manière décrite ci-dessous s'il s'avère

nécessaire de modifier la tension de fonctionnement:

1) Débrancher l'instrument de toutes les sources de tension.

2) Enlever les vis qui retiennent le couvercle supérieur et retirer le couvercle.

3) Changer les connexions du transformateur en suivant le schéma approprié ci-dessous:

4) Remettre le couvercle et l'immobiliser en utilisant les mêmes vis.

5) Changer la tension de fonctionnement indiquée sur le panneau arrière pour bien indiquer le

6) Remplacer le fusible par un fusible de régime correct, comme indiqué ci-dessous.

Fusible

S'assurer que le fusible secteur correct est monté pour la tension de fonctionnement réglée. Les

types de fusibles secteur corrects sont les suivants:

Installation

nouveau réglage de tension afin de satisfaire aux impératifs des normes de sécurité.

Pour remplacer le fusible, débrancher le fil secteur de la prise d'entrée et relâcher le tiroir de

fusible situé sous les broches de la prise en appuyant en même temps sur les deux attaches au

moyen de tournevis miniaturisés, de manière à ouvrir le tiroir. Remplacer le fusible et remettre le

tiroir. Il est interdit d'utiliser des fusibles bricolés ou de court-circuiter le porte-fusible.

Fil secteur

Lorsqu'un fil secteur à trois conducteurs avec extrémités dénudées est fourni, il faut le relier de la

manière suivante:

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Toute interruption à dessein est interdite. Il ne faut pas annuler

l'action de protection en utilisant un cordon de rallonge ne disposant pas de conducteur de

protection.

Montage

Cet instrument est approprié pour être utilisé sur banc ou sur châssis. Il est fourni avec des pieds

en vue de montage sur banc. Les pieds avant comprennent une béquille pour permettre

d'obtenir un angle du panneau avant optimum.

On peut se procurer un kit pour le montage en rack d'un ou de deux de ces appareils de hauteur

3U de demi-largeur dans un châssis de 19" auprès du constructeur ou de ses agents à l'étranger.

pour fonctionnement 230 V ou 115V: 1A (T) 250 V capacité de rupture élevée

Marron – Phase secteur

Bleu – Neutre secteur

Vert / Jaune – Terre secteur

AVERTISSEMENT! IL FAUT METTRE CET INSTRUMENT A LA TERRE

31

Page 33

Connexions du panneau avant

RF OUT

Connexions

Il s'agit de la sortie du générateur de 50 Ω. La sortie maximale est de 500 mV

50 Ω. Elle peut accepter un court-circuit indéfiniment.

Le connecteur Type N est un composant de précision qu'il faut protéger contre toute usure

excessive afin de garantir que de ses caractéristiques RF (impédance et VSWR) (taux d'ondes

stationnaires) seront maintenues avec précision). Si on utilise l'instrument de manière nécessitant

de nombreuses connexions/ déconnexions vers RF OUT ou depuis RF OUT, il est recommandé

de monter un adaptateur mâle-femelle dans la prise que l'on peut alors remplacer régulièrement.

Ne pas appliquer de tension externe sur cette sortie. Protégé contre les connexions

accidentelles allant jusqu'à 50Vcc et les retours de puissance allant jusqu'à 25 Watts à partir de

50Ω.

MODULATION IN/OUT

Il s'agit de l'entrée de modulation externe et de la sortie de modulation interne. La plaque de

fréquences d'entrée va de 50Hz à 300kHz (selon le type de modulation) et l'impédance nominale

est de 600Ω que ce soit en entrée ou en sortie.

Ne pas appliquer cette entrée/sortie des tensions externes dépassant ±10 V crête.

Connexions du panneau arrière

EXTERNAL REFERENCE IN/OUT

(+7 dBm) dans

eff

RS232

Réglable en entrée de référence externe (10MHz, 2V à 5Vpp, 50Ω), sortie de référence interne

(10MHz, 4Vpp à partir de 50Ω) ou arrêt.

Ne pas appliquer cette entrée/sortie des tensions externes dépassant ±10 V crête.

Un connecteur D à 9 broches compatible avec l'utilisation du RS232 adressable.

Les connexions des broches sont indiquées ci-dessous:

Broche

1 – Pas de connexion interne

2 TXD Données transmises de l'instrument

3 RXD Données reçues à l'instrument

4 – Pas de connexion interne

5 GND Terre signal

6 – Pas de connexion interne

7 RXD2 Données secondaires reçues (RS232 adressable uniquement)

8 TXD2 Données secondaires transmises (RS232 adressable uniquement)

Nom Description

32

9 GND Terre signal (RS232 adressable uniquement)

Page 34

Il est possible d'utiliser les broches 2, 3 et 5 comme une interface RS232 classique avec

protocole d'établissement de liaison XON/XOFF (marche/arrêt). Les broches 7, 8 et 9 sont en

outre utilisées lorsque l'instrument est utilisé en mode RS232 adressable. Les terres de signal

sont reliées à la terre de l'instrument. L'adresse RS232 est réglée depuis le panneau avant au

moyen du menu COMMS.

GPIB (IEEE-488)

L'interface GBIB n'est pas isolée; les terres de signal GPIB sont reliées à la terre de l'instrument.

Les sous-ensembles mis en oeuvre sont les suivants:

L'adresse GPIB est réglée depuis le panneau avant au moyen du menu utilitaires.

SH1 1H1 T6 TE0 L4 LE0 SR1 RL1 PP1 DC1 C0 E2

33

Page 35

Généralités

Cette section est une présentation générale du fonctionnement du générateur et elle doit être lue

avant que l'instrument soit utilisé pour la première fois.

Mise en marche

L'interrupteur d'alimentation se trouve dans le coin inférieur gauche du panneau avant.

A la mise sous tension, le générateur affiche pendant 2 secondes la version du logiciel installée