Page 1

THURLBY THANDAR INSTRUMENTS

INSTRUCTION MANUAL

TG1000 & TG2000

DDS Function Generators

Page 2

Table of Contents

Introduction 2

Specifications 3

Safety 6

EMC 8

Installation 9

Connections 10

Front Panel Connections 10

Rear Panel Connections 11

General 12

Initial Operation 12

Standard Waveform Operation 15

Setting Generator Parameters 15

AUX Output 18

Warnings and Error Messages 19

Sweep Operation 20

General 20

Setting Sweep Parameters 20

Gated Mode 25

Tone Mode 26

FSK 27

Modulation 28

System Operations from the Utility Menu 29

Calibration 31

Equipment Required 31

Calibration Procedure 31

Calibration Routine 32

Remote Calibration 33

Remote Operation 34

USB Interface 38

Remote Commands 39

Maintenance 42

Appendix 1. Warning and Error Messages 43

Appendix 2. Factory System Defaults 44

1

Page 3

This manual is for both the TG2000 and TG1000 function generators. The TG1000 has a

maximum frequency of 10MHz and no remote control capability but is otherwise functionally the

same as the TG2000 20MHz generator. Wherever there are differences in the specification or

operation, the limits for the TG1000 are shown in square brackets [ ] after the TG2000 limits.

This function generator uses direct digital synthesis to provide high performance and extensive

facilities at a breakthrough price. It can generate a variety of waveforms between 1mHz and

20MHz [10MHz] with a resolution of 6 digits and an accuracy better than 10ppm.

Direct digital synthesis for accuracy & stability

Direct digital synthesis (DDS) is a technique for generating waveforms digitally using a phase

accumulator, a look-up table and a DAC. The accuracy and stability of the resulting waveforms is

related to that of the crystal master clock.

The DDS generator offers not only exceptional accuracy and stability but also high spectral purity,

low phase noise and excellent frequency agility.

A wide range of waveforms

High quality sine, square and pulse waveforms can be generated over the full frequency range of

1mHz to 20MHz [10MHz].

Introduction

Triangle waveforms can also be generated but with limitations as to the maximum usable

frequency.

Variable symmetry/duty-cycle is available for squarewave and pulse waveforms.

Sweep

All waveforms can be swept from 0.2Hz to their maximum frequency in a single sweep at a rate

variable between 50 milliseconds and 999 seconds. The sweep is fully phase continuous.

Sweep can be linear or logarithmic, single or continuous. Single sweeps can be triggered from

the front panel, the trigger input, or the digital interfaces. A sweep marker is provided.

AM

External Amplitude Modulation is available for all waveforms.

FSK and Tone modes

Frequency Shift Keying provides phase coherent switching between two selected frequencies; in

Tone mode the output is stepped asynchronously through a user-defined list of up to 16

frequencies. In both modes the switching source can be the internal trigger generator, front panel,

an external signal or a remote command.

Easy and convenient to use

All of the main generator parameters are clearly displayed together on a backlit LCD with 4 rows

of 20 characters. Sub menus are used to set the parameters for each function.

All parameters can be entered directly from the numeric keypad. Alternatively most parameters

can be incremented or decremented using the rotary encoder.

This system combines quick numeric data entry with quasi-analogue adjustment when required.

Fully programmable via USB and Addressable RS-232 (TG2000 only)

The generator has both USB and RS-232 interfaces which can be used for remote control of all of

the instrument functions.

As well as operating in conventional single instrument mode the RS-232 serial interface can also

be used in addressable mode whereby up to 32 units can be linked to a single PC serial port.

2

Page 4

Specifications apply at 18°- 28°C after one hour warm-up, at maximum output into 50Ω.

TG1000 limits, where different, are shown in square brackets [ ] after the TG2000 limits.

WAVEFORMS

Standard waveforms of sine, square, triangle, DC, positive pulse and negative pulse.

Sine

Range: 1mHz to 20MHz [10MHz]

Resolution: 1mHz or 6 digits

Accuracy: 10 ppm for 1 year; ± 1mHz below 0.2Hz

Temperature Stability: Typically <1 ppm/ºC outside 18° to 28°C

Output Level:

Harmonic Distortion: <0.3% THD to 20kHz (typically 0.1%)

Non−harmonic Spurii:

Square

Range: 1mHz to 20MHz [10MHz]

Resolution: 1mHz or 6 digits

Symmetry Control: 20% to 80% (1% resolution) 1mHz to 20MHz [10MHz]

Accuracy: 10 ppm for 1 year; ± 1mHz below 0.2Hz

Output Level:

Rise and Fall Times: <22ns

Aberrations: <5% + 2mV

Specifications

2.5mV to 10Vp−p into 50Ω

<–45dBc to 300kHz

<−35dBc to 20MHz [10MHz] (typically <−40dBc)

<–55dBc to 1MHz, <–55dBc + 6dB/octave 1MHz to 20MHz [10MHz]

2.5mV to 10Vp−p into 50Ω

Triangle

Range: 1mHz to 1 MHz

Resolution: 1mHz or 6 digits

Accuracy: 10 ppm for 1 year; ± 1mHz below 0.2Hz

Output Level:

Linearity Error: <0.5% to 100 kHz

Positive and Negative Pulses

Range: 1mHz to 20MHz [10MHz]

Resolution: 1mHz or 6 digits

Symmetry Control: 20% to 80% (1% resolution) 1mHz to 10MHz

Accuracy: 10 ppm for 1 year; ± 1mHz below 0.2Hz

Output Level:

Rise and Fall Times: <22ns

Aberrations: <5% + 2mV

OPERATING MODES

Continuous

Continuous cycles of the selected waveform are output at the programmed frequency.

2.5mV to 10Vp−p into 50Ω

1.25mV to 5Vp-p into 50Ω positive or negative only pulses, with respect

to the DC Offset baseline.

3

Page 5

Gated

Non-phase coherent gating - output carrier wave is on while Gate signal is high and off while low.

Carrier frequency: From 1mHz to 20MHz [10MHz].

Carrier waveforms: All

Trigger rep. rate: DC to 100 kHz external; to 5kHz using internal trigger generator.

Gate signal source: Manual (front panel MAN TRIG key), external signal (TRIG/GATE IN),

Sweep

Carrier Waveforms: All

Sweep Mode: Linear or logarithmic, single or continuous.

Sweep Width:

Sweep Time: 50ms to 999s (3 digit resolution).

Marker: Available from AUX output. Variable during sweep.

Sweep Trigger Source: The sweep may be free run or triggered from any of the following sources:

External Amplitude Modulation

Carrier Frequency: From 1mHz to 20MHz [10MHz].

Carrier Waveforms: All

Modulation Source: VCA IN socket

Frequency Shift Keying (FSK)

Phase coherent switching between two selected frequencies at a rate defined by the switching

signal source.

Carrier frequency: From 1Hz to 20MHz [10MHz].

Carrier waveforms: All

Switch repetition rate: DC to 5kHz (internal trigger) or DC to 1MHz (external trigger).

Switching signal source: Manual (front panel MAN TRIG key), internal trigger generator, external

Tone

The tone is output while the trigger signal is high and stopped while the trigger signal is low. The

next tone is output when the trigger signal is high again.

Carrier Waveforms: All

Frequency List:

Switching Source: Manual (front panel MAN TRIG key), internal trigger generator, external

Min Switching Time: 1ms per tone

internal gate generator or remote interface.

From 0.2Hz to 20MHz [10MHz] in one range. Phase continuous.

Independent setting of the start and stop frequency.

Manual (front panel MAN TRIG key), external from TRIG/GATE IN or from

remote interface.

signal (TRIG/GATE IN) or remote interface.

Up to 16 frequencies from 1Hz to 20MHz

signal (TRIG/GATE IN) or remote interface.

[10MHz]

OUTPUTS

Main Output

Output Impedance:

Amplitude:

Amplitude Accuracy:

Amplitude Flatness: ±0.2dB to 500kHz; ±2dB to 20MHz [±1dB to 10MHz].

4

50Ω or 600Ω

5mV to 20V pk-pk open circuit, (2.5mV to 10V pk-pk into 50Ω/600Ω).

Output can be specified as HiZ (open circuit value) or V (voltage into

characteristic impedance) in pk-pk, r.m.s. or dBm.

±3% ±1mV at 1kHz into 50Ω/600Ω.

Page 6

DC Offset Range:

DC Offset Accuracy: typically ±3% ±10mV, unattenuated.

Resolution: 3 digits for both Amplitude and DC Offset.

Pulse Aberrations: <5% + 2mV.

Aux Out

Multifunction output user definable or automatically selected to be any of the following:

Waveform Sync: A square wave at the main waveform frequency. Symmetry is 50% for

Trigger: Outputs a replica of the current trigger signal.

Sweep Sync: Outputs a trigger signal at the start of sweep to synchronize an

Output Signal Level:

INPUTS

Ext Trig /Gate

Frequency Range: DC - 1MHz for FSK; DC – 100kHz for Gate; DC – 2.5kHz for Tone and

Signal Range: Threshold nominally TTL level; maximum input ±10V.

Minimum Pulse Width: 100ns for Gate and FSK modes; 0.2ms for Sweep and Tone modes.

Input Impedance:

VCA In

Frequency Range: DC - 100kHz.

Signal Range: 2.5V for 100% level change at maximum output.

Input Impedance:

INTERFACES (TG2000 only)

RS-232: Variable Baud rate, 19200 Baud maximum. 9-pin D-connector.

USB: Standard USB hardware connection.

GENERAL

Display: 20 character x 4 row alphanumeric LCD.

Data Entry: Keyboard selection of mode, waveform etc.; value entry direct by

Stored Settings: Up to 9 complete instrument set-ups may be stored and recalled from

Size: 260(W) x 88(H) x 235(D)

Weight: 2kg. (4.5lb.)

Power: 110-120V AC or 220V-240V AC ±10%, 50/60Hz,

Operating Range: +5°C to 40°C, 20-80% RH.

Storage Range: -20°C to + 60°C.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Safety & EMC: Complies with EN61010-1 & EN61326.

±10V. DC offset plus signal peak limited to ±10V from 50Ω/600Ω.

sine and triangle waves at MAIN OUT; for square waves and pulses

symmetry is the same as that of the waveform at MAIN OUT.

oscilloscope. Can additionally output a sweep marker.

Output impedance 50Ω nominal. Logic levels of <0.8V & >3V, except

for Sweep Sync. Sweep Sync is a 3-level waveform: low at start of

sweep, high for the duration of the last frequency step at end of sweep,

with a narrow 1V pulse at the marker point.

Sweep.

10kΩ

typically 6kΩ.

As well as operating in a conventional RS-232 mode the interface can

be operated in addressable mode whereby up to 32 instruments can be

addressed from one RS-232 port.

numeric keys or by rotary control.

non-volatile memory.

adjustable internally; 35VA max. Installation Category II.

5

Page 7

Safety

This generator is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010−1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010−1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% − 80% RH (non−condensing). It may occasionally be

subjected to temperatures between +5° and −10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short−circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window.

The following symbols are used on the instrument and in this manual:−

6

l

Caution −refer to the accompanying documentation, incorrect operation may

damage the instrument.

terminal connected to chassis ground.

mains supply OFF.

mains supply ON.

alternating current.

Page 8

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

TG1000 & TG2000 DDS Function Generators

meet the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2007) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS WILDING

TECHNICAL DIRECTOR

2 March 2010

7

Page 9

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line only; signal connections <3m,

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2007) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

connections <3m, therefore not tested), Performance A (A).

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance A (A) and 1.4GHz to 2GHz:

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

25 cycles, 70%: Performance A (C); 250 cycles, 0%: Performance B (C).

therefore not tested), Performance A (B).

8

a) connect the generator to other equipment using only high quality, double−screened cables. For

the purposes of EMC testing it is assumed that signal connections from the instrument will be

<3m and therefore immunity tests for signal lines (Fast Transient and Conducted RF) have

been omitted.

b) after opening the case for any reason ensure that all signal and ground connections are

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

c) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

Page 10

Mains Operating Voltage

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Unclip the front bezel by gently pulling the centre of each long edge up and forward.

The case halves are held together by 4 plastic push-rivets. Use the blade of a small

screwdriver in the slot beside each rivet to first ease out the rivet head and then fully remove

the rivet body. Separate the case halves. Visit www.tti-test.com

3) Remove the screws securing the pcb to the case lower and lift out the pcb with front and rear

panels attached; lift one side of the pcb at a time, with the case pcb clips on that side pulled

clear of the pcb edge.

4) Change the voltage settings by changing the soldered links beside the transformer:

For 230V operation fit link LK2 only

For 115V operation fit links LK1 and LK3 only

5) Reassemble in the reverse order.

Installation

for further details.

6) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

7) Change the fuse to suit the new operating voltage, see below.

Fuse

Ensure that the correct mains fuse is fitted for the set operating voltage. The correct mains fuse

types are:

The use of makeshift fuses or the short−circuiting of the fuse holder is prohibited.

Mains Lead

Connect the instrument to the AC supply using the mains lead provided. Should a mains plug be

required for a different mains outlet socket, a suitably rated and approved mains lead set should

be used which is fitted with the required wall plug and an IEC60320 C13 connector for the

instrument end. To determine the minimum current rating of the lead-set for the intended AC

supply, refer to the power rating information on the equipment or in the Specification.

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

for 230V operation: 250 mA (T) 250V HRC

for 100V or 115V operation: 500 mA (T) 250V HRC

WARNING! THIS INSTRUMENT MUST BE EARTHED.

9

Page 11

Front Panel Connections

MAIN OUT

This is the output from the main generator; output source impedance can be set to 50Ω or 600Ω.

It will provide up to 20V peak−to−peak e.m.f. which will yield 10V peak-to-peak into a matched

load. To maintain waveform integrity only 50Ω cable should be used and the receiving end should

be terminated with a 50Ω load. It can tolerate a short circuit for 60 seconds.

Do not apply external voltages to these outputs.

AUX OUT

This is a TTL/CMOS level output which may be set to any of the following signals from the

AUX OUT screen.

Connections

waveform sync

Trigger

Sweep sync

AUX OUT logic levels are nominally 0V and 5V from typically 50Ω. AUX OUT will withstand a

short circuit.

Do not apply external voltage to this output.

TRIG/GATE IN

This is the external input for Trigger, Gate and Sweep operations.

Do not apply external voltages exceeding ±10V.

A sync signal phase coincident with the MAIN OUT waveform. For sine

and triangle waves the sync waveform rising edge is at the 0º phase

point of MAIN OUT and the falling edge is at the 180º phase point. For

square waves and pulses both phase and symmetry are coincident with

MAIN OUT.

Provides a replica version of the actual trigger signal; internal, external,

manual and remote all produce a trigger sync.

Goes low at the start of sweep and high at the last frequency step of

the sweep. In addition, a 1/4-amplitude marker pulse can be output at

a specified marker frequency.

VCA IN

10

This is the input socket for external amplitude modulation.

Do not apply external voltages exceeding ±10V.

Page 12

Rear Panel Connections (TG2000 only)

RS-232

9−pin D−connector compatible with addressable RS-232 use. The pin connections are shown

below:

Pin Name Description

USB

1

−

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4

−

5 GND Signal ground

6

−

7 RXD2 Secondary received data

8 TXD2 Secondary transmitted data

9 GND Signal ground

No internal Connection

No internal connection

No internal connection

Pin 2, 3 and 5 may be used as a conventional RS-232 interface with XON/XOFF handshaking.

Pins 7, 8 and 9 are additionally used when the instrument is used in addressable RS-232 mode.

Signal grounds are connected to instrument ground. The RS-232 address is set from the

remote menu on the UTILITY screen, see System Operations section.

The USB port accepts a standard USB cable. The Windows plug-and-play functions should

automatically recognise that the instrument has been connected.

11

Page 13

Initial Operation

This section is a general introduction to the organisation of the instrument and is intended to be

read before using the generator for the first time. Detailed operation is covered in later sections

starting with Standard Waveform Operation.

In this manual front panel keys and sockets are shown in capitals, e.g. STATUS, AUX OUT; all

soft−key labels, entry fields and messages displayed on the LCD are shown in a different

type−font, e.g

DDS Principles

In this instrument waveforms are generated by Direct Digital Synthesis (DDS). A phase

accumulator is incremented at a rate proportional to the required output frequency. The most

significant 12 bits of the accumulator are used to address a look-up table ROM that converts the

phase information into sinewave amplitude data; this data is then passed to a 10-bit Digital-toAnalogue Converter (DAC) which produces the output waveform. For triangle waves the ROM

look-up table is by-passed and the phase accumulator output is passed directly to the DAC.

At low frequencies all 4096 points in the output wave are stepped through, but as the frequency

increases points are progressively missed out. Sinewaves and triangles are subsequently filtered

to smooth the steps in the DAC output; this technique ensures good sinewave purity up to the

maximum frequency of the generator but the practical limit to which excellent triangle linearity is

maintained is only about 100kHz. Squarewaves and pulses are derived from the sinewave using

a variable threshold comparator; this permits symmetry control of these waveforms across the

whole instrument frequency range.

. WAVEFORM, sine.

General

The major advantages of DDS over conventional analogue generation are:

• Frequency accuracy and stability is that of the crystal oscillator.

• Frequencies can be set with high resolution from mHz to MHz.

• Low phase noise and distortion.

• Very wide frequency sweeps are possible.

• Fast phase continuous frequency switching.

• In addition, being a digital technique, it is easier to make every parameter programmable from

the keyboard, or remotely via the USB or RS-232 interfaces.

Switching On

Switch on the generator using the ON/OFF switch on the rear panel. To fully disconnect from the

AC supply unplug the mains cord from the back of the instrument or switch off at the AC supply

outlet; make sure that the means of disconnection is readily accessible. Disconnect from the AC

supply when not in use.

At power up the generator displays the installed software revision and conducts a self-test.

Power-on self-test takes a few seconds, after which the status screen is displayed, showing the

generator parameters set to their default values, with the MAIN OUT output set off. Refer to the

System Operations section for how to change the power up settings to either those at power

down or to any one of the stored settings. Recall the status screen at any time with the STATUS

key; a second press returns the display to the previous screen.

12

Change the basic generator parameters as described in the Standard Waveform Operation

section and switch the output on with the ON key; the lamp above the key will light to show that

output is on.

Page 14

Display Contrast

All parameter settings are displayed on the 20 character x 4 row backlit liquid crystal display

(LCD). The contrast may vary a little with changes of ambient temperature or viewing angle but

can be optimised for a particular environment by using the front panel contrast control. Insert a

small screwdriver or trimmer tool through the adjustment aperture marked LCD and rotate the

control for optimum contrast.

Keyboard

Pressing the MENU key calls the top-level menu from which all functions can be accessed.

Selections are made from this menu using the display soft-keys and numeric values are then

changed using the numeric keys or rotary control, see the Principles of Editing section.

The keys are as follows:

• MENU calls the top-level menu screen from which the main functions can be directly

selected. These are WAVEFORM, FREQUENCY, AMPLITUDE, DC OFFSET, SYMMETRY,

MODE, UTILITY and AUX OUT. Pressing the associated soft-key of any of these functions

calls a further screen which permits the parameters of that function to be edited either from

the numeric keypad or by using the rotary control/cursor keys.

• Numeric/Unit keys permit direct entry of a value for the parameter currently selected. Thus,

having selected the FREQUENCY screen (by pressing the FREQUENCY soft-key on the

MENU screen), a new frequency of 100kHz, for example, is set by pressing 1, 0, 0, kHz.

CE (Clear Entry) undoes a numeric entry digit by digit. ESCAPE returns a setting being

edited to its last value.

• Eight soft-keys around the display are used to directly set or select parameters from the

currently displayed menu; their operation is described in more detail in the next section.

• The STATUS key always returns the display to the default start-up screen which gives an

overview of the generator’s status. Pressing STATUS again returns the display to the

previous screen.

Further explanations will be found in the detailed descriptions of the generator’s operation in the

sections that follow.

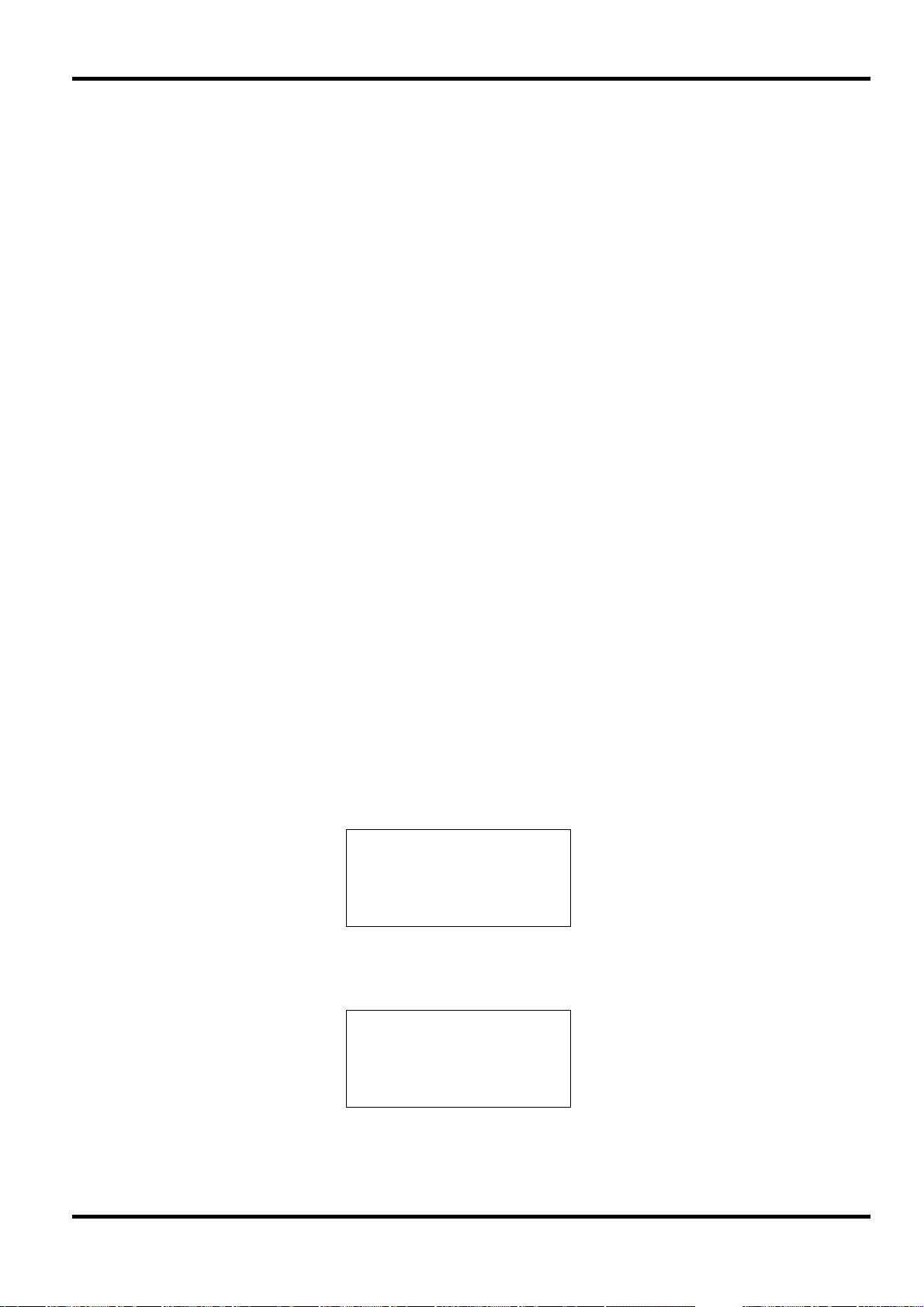

Status Display

After the messages at switch-on, or at any time the STATUS key is pressed, the Status display is

shown. With the generator set to the factory defaults (Appendix 2), the display will be:

This display gives an overview of the status of the main generator parameters. If a waveform is

selected for which symmetry can be set (see Specification) the additional field of

shown to the right of the waveform type, see example below:

WAVE:sine

FREQ:10·0000kHz CONT

AMPL:+4·00Vpp

DC:+0·00Vdc (+0·00V)

SYMmetry is

WAVE:square SYM:35%

FREQ:10·0000kHz CONT

AMPL:+4·00V

DC:+0·00Vdc (+0·00V)

For convenience, the WAVEFORM, FREQUENCY, AMPLITUDE, DC OFFSET, SYMMETRY and

MODE screens can be directly selected from the Status display, (i.e. without having to first return

to the main MENU) by pressing the appropriate soft-key beside WAVE, FREQ, AMPL, etc.

13

Page 15

Principles of Editing

Each screen called up by pressing a soft-key on the top level MENU display shows parameter

value(s) and/or a list of choices. Choices are made using the soft−key associated with the screen

item to be selected. Parameter values can be edited by using the ROTARY CONTROL in

combination with the left and right arrowed CURSOR keys, or by direct numeric keyboard entry;

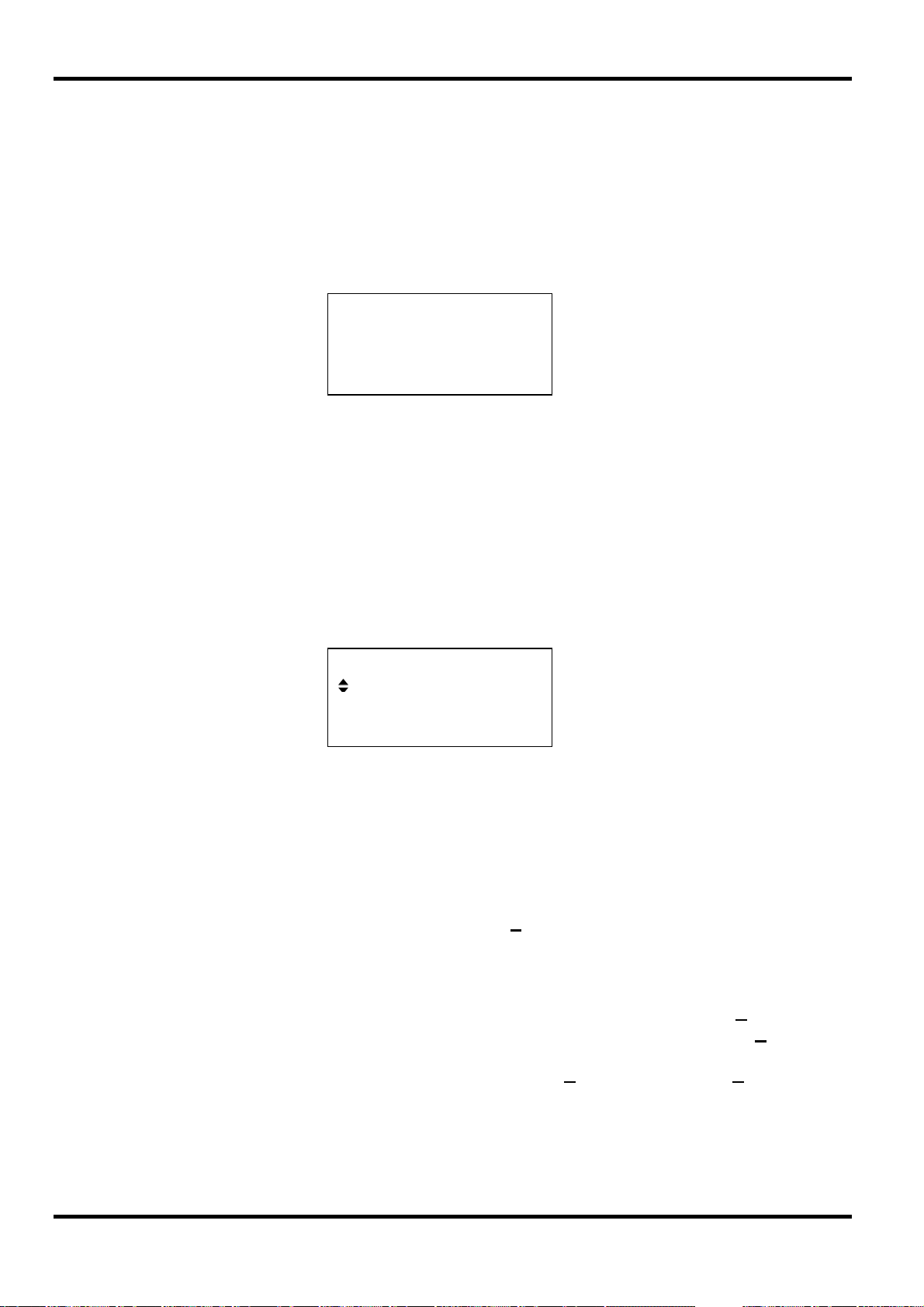

The examples which follow assume factory default settings.

A diamond beside a screen item indicates that it is selectable; hollow diamonds identify

deselected items and filled diamonds denote selected items. For example, press the

soft-key on the main menu to get the screen shown below:

The filled diamond indicates that the selected mode is continuous. Gated or sweep

modes are selected by pressing the associated soft−key which will make the diamond beside that

item filled and the diamond beside

ellipsis (three dots following the screen text) indicates that a further screen follows when that item

is selected. In the case of the MODE screen illustrated, pressing the

bottom line brings up the

the

continuous mode selection.

MODE

MODE more…◊

♦continuous

◊ gated setup…◊

◊ sweep setup…◊

continuous hollow. This screen also illustrates how an

setup... soft−key on the

SWEEP SETUP menu; note that selecting this item does not change

Some screen items are marked with a double−headed arrow (a split diamond) when selected to

indicate that the item’s setting can be changed by further presses of the soft−key, by pressing

either cursor key or by using the rotary control. For example, pressing the AUX OUT soft-key on

the main menu brings up the screen shown below.

AUX OUT

output: on

◊ mode: auto

◊ srce: waveform sync

Repeated presses of the output soft-key will toggle the output between on and off.

Similarly when srce (source) is selected, repeated presses of the srce soft-key will step

through all possible selections of the AUX OUT source (

sweep sync

). The rotary control can also be used to step through the selections.

waveform sync, trigger, and

In screens where a parameter with a numeric value is displayed the cursor keys move the edit

cursor (a flashing underline) through the numeric field and the rotary control will increment or

decrement the value; the step size is determined by the position of the edit cursor within the

numeric field. Thus for

FREQUENCY set to 1.00000 MHz rotating the control will change

the frequency in 1kHz steps. Turning the control quickly will step numeric values in multiple

increments.

The display will auto-range up or down as the frequency is changed but the increment size and

displayed units are maintained. In the example above (

the lowest frequency that can be set by rotating the control is 1kHz, shown as

FREQUENCY set to 1.00000 MHz) ,

0.00100 MHz.

The displayed units can be changed at any time by pressing the appropriate key, e.g. pressing

kHz or Hz will change the display for the above example to

1.00000 kHz or 1000.00 Hz

respectively. To reduce the frequency further using the rotary control it is necessary to move the

cursor to set a smaller increment size.

14

Page 16

Standard Waveform Operation

When first switched on, and at all subsequent power-ups, unless specified otherwise on the

UTILITY menu, the generator will be set to the factory defaults (Appendix 2), with the MAIN OUT

off. The basic parameters can be changed as described below.

Setting Generator Parameters

Main Menu

The starting point for changing any parameter is the Main Menu, accessed by pressing the MENU

key.

◊ WAVEFORM SYMMETRY ◊

◊ FREQUENCY MODE ◊

◊ AMPLITUDE UTILITY ◊

◊ DC OFFSET AUX OUT ◊

The set-up screen for each of the principal parameters is displayed by pressing the appropriate

soft-key on this Main Menu; the parameters can then be changed as described below.

Waveform Selection

WAVEFORM

♦sine +pulse ◊

◊ square - pulse ◊

◊ triangle dc only ◊

Pressing the WAVE soft-key on the main menu gives the WAVEFORM screen which lists all the

waveforms available. The currently selected waveform (sine with the factory defaults setting) is

indicated by the filled diamond; the selection is changed by pressing the soft−key beside the

required waveform.

Sine square and triangle are bipolar waveforms centred about the baseline level set from the DC

Offset screen; +pulse and –pulse are uni-polar waveforms that are respectively positive and

negative with respect to the baseline. When

baseline DC voltage only, set from the DC Offset screen.

Frequency

Pressing the FREQ key gives the FREQUENCY screen. With freq selected as shown above,

the frequency can be entered directly from the keyboard in any convenient units, e.g. 12.34kHz

can be entered directly in kHz but can also be entered as 12340Hz or 0.01234MHz.

With

period can be entered directly in any convenient units, e.g. 0.1ms can also be entered as 0.0001s

or 100us. The hardware is actually programmed in terms of frequency and when a period entry is

made the synthesised frequency is the nearest equivalent value that the frequency resolution and

conversion calculation gives. Since the instrument’s frequency resolution is 1mHz there will

generally be no noticeable loss of precision for frequencies above 1kHz (periods <1ms) but the

conversion errors will increase progressively for entries of longer periods; to maintain precision,

low frequencies (<1kHz) should be entered in terms of frequency.

Turning the rotary control will increment or decrement the numeric value in steps determined by

the position of the edit cursor (flashing underline); the cursor is moved with the left and right

arrowed cursor keys.

Note that the upper frequency limits vary for the different waveform types; refer to the

Specifications section for details.

dc only is selected the output ‘waveform’ is the

FREQUENCY

10·0000 kHz

♦freq period ◊

period selected instead of freq the frequency can be set in terms of a period; the

15

Page 17

Amplitude

Pressing the AMPLITUDE soft-key on the main menu gives the AMPLITUDE screen.

The actual source impedance of the generator can be set to either 50Ω (factory default) or 600Ω

with alternate presses of the

600Ω or hiZ (open-circuit) can be selected with successive presses of the

When an amplitude setting is made the selected source impedance and expected load

termination are taken into account such that the actual output amplitude is that shown in the

display.

The waveform amplitude can be set in terms of peak-to-peak Volts (Vpp), r.m.s. Volts (Vrms) or

dBm (referenced to a 50Ω or 600Ω terminating load). The most appropriate units can be selected

with successive presses of the units soft-key, which steps through the three options of

Vrms

automatically changed to

load:50Ω soft-keys will now only toggle between load:50Ω and load:600Ω

settings.

AMPLITUDE

+4·00 Vpp Vpp ◊

◊ srce:50Ω load:hiZ ◊

srce (source) soft-key. In addition, an assumed load of 50Ω,

load soft-key.

Vpp,

and dBm in turn. Note that when dBm is selected a load:hiZ setting is

load:50Ω because a termination is always assumed; pressing the

With the appropriate form of amplitude selected, numeric entries can be made directly from the

keyboard in either mV or Volts, e.g. 250mV can be entered as 250mV or 0.25V. Turning the rotary

control will increment or decrement the numeric value in steps determined by the position of the

edit cursor (flashing underline); the cursor is moved with the left and right arrowed cursor keys.

Alternate presses of the ± key will invert the MAIN OUT output; if DC OFFSET is non−zero, the

signal is inverted about the same offset. The exception to this is if the amplitude is specified in

dBm; since low level signals are specified in −dBm (0dBm = 1mW into 50Ω = 224mVrms) the

− sign is interpreted as part of a new amplitude entry and not as a command to invert the signal.

DC Offset

Pressing the OFFSET key gives the DC OFFSET screen. The offset can be entered directly

from the keyboard in mV or Volts, e.g. 100mV can be entered as 100mV or 0.1V. During a new

offset entry the ± key can be used at any time to set the offset negative; alternate presses toggle

the sign between + and −.

Turning the rotary control will increment or decrement the numeric value in steps determined by

the position of the edit cursor (flashing underline); the cursor is moved by the left and right

arrowed cursor keys. Because DC offset can have negative values, the rotary control can take the

value below zero; although the display may autorange to a higher resolution if a step takes the

value close to zero, the increment size is maintained correctly as the offset is stepped negative.

For example, if the display shows

DC OFFSET

program +0·00 Vdc

(actual +0·00 Vdc)

◊ srce:50Ω load:hiZ ◊

16

program = +205 mVdc

Page 18

with the cursor in the most significant digit, the rotary control will decrement the offset in 100mV

steps as follows:

program = +1

program = +0

program = +205 mVdc

05 mVdc

05 mVdc

program = −0

program = −1

The actual DC offset at the MAIN OUT socket is attenuated by the fixed−step output attenuator

when this is in use. Since it is not obvious when the signal is being attenuated the actual offset is

shown in brackets as a non−editable field below the programmed value.

For example, if the amplitude is set to 2·5Vpp the output is not attenuated by the fixed attenuator

and the actual DC offset (in brackets) is the same as that set. The

DC OFFSET

program +1.50 Vdc

(actual +1.50 Vdc)

◊ srce:50Ω load:hiZ ◊

If the amplitude is now reduced to 250mVpp which introduces the attenuator, the actual DC offset

changes by the appropriate factor:

DC OFFSET

program +1.50 Vdc

(actual +151 mVdc)

◊ srce:50Ω load:hiZ ◊

The above display shows that the set DC offset is +1.50V but the actual offset is +151mV.

Note that the actual offset value also takes into account the true attenuation provided by the fixed

attenuator, using the values determined during the calibration procedure. In the example

displayed the output signal is 250mVpp exactly and takes account of the small error in the

fixed attenuator; the offset is 151.mV exactly, taking account of the effect of the known

attenuation (slightly less than the nominal) on the set offset of 1.50V.

95 mVdc

95 mVdc

DC OFFSET display shows:

Whenever the set DC offset is modified by a change in output level in this way a warning

message that this has happened will be displayed. Similarly, because waveform clipping occurs if

the DC offset plus signal peak exceeds ± 10V, a warning message will be displayed if this

condition is set. This is explained more fully in the Warnings and Error Messages section.

When

DC voltage only, set from this screen. Since there is no switching waveform, the DC level can be

set over the full ± 10V range; the attenuator is automatically used to give a setting resolution

down to 1mV below 1Vdc and the

The source impedance and assumed load can also be set from this screen.

Symmetry

Pressing SYMMETRY on the Main menu gives the SYMMETRY screen.

dc only is selected on the WAVEFORM screen the output ‘waveform’ is the baseline

actual value will always match the program value.

SYMMETRY 50%♦

◊ 20% 60% ◊

◊ 30% 50 % 70% ◊

◊ 40% 80% ◊

17

Page 19

Symmetry can only be varied for squarewave and pulse waveforms; selecting SYMMETRY for

any other waveform will cause the error message

wave

to be displayed before the SYMMETRY screen is shown.

For squarewave and pulse waveforms the symmetry can be set between 20% and 80%

(mark:space). 20%, 30%, etc. can be set directly with the appropriate soft-key or any in-range

value can be set with a 1% resolution by direct numeric entry or by using the rotary control.

AUX Output

AUX OUT is a multifunction CMOS/TTL level output that can be automatically or manually set to

be any of the following:

•

waveform sync : A sync signal phase coincident with the MAIN OUT waveform. For sine

•

trigger : Outputs a replica of the current trigger signal, i.e. the trigger source

•

sweep sync : Outputs the sweep trigger and marker signals.

Symmetry has no effect on this

and triangle waves the sync waveform rising edge is at the 0º phase

point of MAIN OUT and the falling edge is at the 180º phase point. For

square waves and pulses both phase and symmetry are coincident with

MAIN OUT.

selected on the TRIG/GATE SETUP screen.

The setting up of the signals themselves is discussed in the relevant sections later in this manual.

Pressing the AUX OUT key calls the AUX OUT setup screen.

AUX OUT

output: on

◊ mode: auto

◊ srce: waveform sync

AUX OUT is turned on and off by alternate presses of the output soft−key.

The selection of the signal to be output from the AUX OUT socket is made using the

(source) soft−key; repeated presses of srce cycle the selection through the choices

(

waveform sync, etc.) listed above. Alternatively, with the srce selected (double−headed

arrow) the rotary control or cursor keys can be used to step backwards and forwards through the

choices.

The source selection of the AUX OUT waveform can be made automatic (

(

manual) with alternate presses of the mode soft−key. In automatic mode the AUX OUT

waveform most appropriate for the current main waveform is selected.

For example,

waveform sync is automatically selected for continuous waveforms but

auto) or user−defined

srce

trigger is selected in gated waveform mode.

The automatic selection can still be changed manually by the

mode has been selected but the selection will revert to the automatic choice if the mode is

changed.

automatic choice to remain set. The

signal, e.g.

Manual must be selected by the mode soft−key for a source other than the

auto selection will generally set the most frequently used

waveform sync for all continuous main waveforms.

srce soft−key even when auto

18

Page 20

Warnings and Error Messages

Two classes of message are displayed on the screen when an illegal combination of parameters

is attempted.

WARNING messages are shown when the entered setting causes some change which the user

might not necessarily expect. Examples are:

1. Changing the amplitude from, for example, 2·5 Volts pk−pk to 25mV pk−pk brings in the

step attenuator; if a non−zero offset has been set then this will now be attenuated too. The

message DC OFFSET CHANGED BY AMPLITUDE

screen but the setting will be accepted; in this case the actual, attenuated, offset will be

shown in brackets below the set value.

2. With the output level set to 10V pk−pk, increasing the DC offset beyond ± 5V will cause

the message DC OFFSET + LEVEL MAY CAUSE CLIPPING

be accepted (producing a clipped waveform) and the user may then choose to change the

output level or the offset to produce a signal which is not clipped.

(clip?) will show in the display beside AMPLITUDE or DC OFFSET

condition exists.

ERROR messages are shown when an illegal setting is attempted, most generally a number

outside the range of values permitted. In this case the entry is rejected and the parameter setting

is left unchanged. Examples are:

will be shown temporarily on the

. The offset change will

while the clipped

1. Entering a frequency of 2MHz for a triangle waveform. The error message:

Frequency too high for the triangle wave is shown.

2. Entering an amplitude of 25Vpp. The error message:

Number too high – value unchanged is shown.

The messages are shown on the display for approximately two seconds. The last two messages

can be viewed again by pressing the last error... soft−key on the UTILITY screen, see

System Operations section.

Each message has a number and the full list appears in Appendix 1.

The default set−up is for all warning and error messages to be displayed and for a beep to sound

with each message. This set−up can be changed on the

The

error menu is shown below:

error beep: ON

◊

◊ error message: ON

◊ warn beep: ON

◊ warn message: ON

Each feature can be turned ON and OFF with alternate presses of the associated soft−key; the

factory default is for all features to be ON. If the setting is changed and is required for future use it

should be saved by changing the

the UTILITY screen to

restore last setup.

POWER-ON SETTING on the power on... menu of

error... menu on the UTILITY screen.

19

Page 21

General

Principles of Sweep Operation

All waveforms can be swept phase-continuously from 0.2Hz up to the maximum frequency for the

selected waveform. Although the frequency is stepped, not truly swept as in an analogue

generator, the short step interval (100us) gives a close approximation to an analogue instrument

except for the widest sweeps in the shortest time; see the Frequency Stepping Resolution section

for further discussion.

The frequency steps are calculated in real-time using a 2-stage process. Major steps are

calculated every 5ms with full precision; the values calculated follow a linear or log sweep law

depending on the choice made on the

steps are calculated every 100us by linear interpolation for both linear and log sweeps. Linear

interpolation gives a small loss of precision for the minor points of log sweeps but the error is still

less than ±1 digit of the displayed frequency except for the widest sweeps in the shortest time.

The advantage that linear interpolation of the minor points gives is that it is fast enough for all

points (major and minor) to be calculated in real time. This is turn permits Start, Stop and Marker

frequencies to be changed with Sweep still running, making performance much closer to that of

an analogue instrument.

Sweep Operation

SWEEP SPACING menu. Within each major step minor

Sweep mode is turned on and off either by the

(accessed from the Main menu), by the

accessed by pressing

any of the

returns the operating mode to continuous.

SWEEP SETUP sub-menus. Turning sweep off from any of the latter menus always

setup... on the MODE screen, or by the on and off soft-keys on

on and off soft-key on the SWEEP SETUP screen,

sweep soft−key on the MODE screen

Connections for Sweep Operation. Aux Out and Trig In

Sweeps are generally used with an oscilloscope or hard−copy device to investigate the frequency

response of a circuit. The MAIN OUT is connected to the circuit input and the circuit output is

connected to an oscilloscope or, for slow sweeps, a recorder.

An oscilloscope can be triggered by connecting its trigger input to the generator’s AUX OUT; AUX

OUT defaults to

of sweep and high at the last frequency step of the sweep; depending on the sweep time set this

should be long enough for an oscilloscope to retrace, for example.

AUX OUT will additionally output a marker pulse if the marker frequency is set within the sweep

frequency range. See Sweep Marker section for setting marker frequency.

For triggered sweeps, a trigger signal must be provided at the front panel TRIG/GATE IN socket

or by pressing the MAN TRIG key or by a remote command.

The generator does not provide a ramp output for use with X−Y displays or recorders.

sweep sync when sweep is turned on. sweep sync goes low at the start

Setting Sweep Parameters

20

Pressing the sweep setup... soft−key on the MODE screen displays the SWEEP SETUP

screen.

SWEEP SETUP off

◊ range… type… ◊

◊ time… spacing… ◊

◊ manual… marker… ◊

◊

Page 22

Menus for setting up the range, time (sweep rate), type (continuous, triggered, etc.) spacing

(lin/log) and marker position are all accessed from this screen using the appropriate soft−key. In

addition the control screen for manual sweep (i.e. sweeping using the rotary control) is selected

from this screen and Sweep Mode itself is turned on and off with alternate presses of the

and off soft−key; sweep can also be turned on by the sweep soft−key on the MODE

screen.

On all the following menus, pressing the

SETUP

presses of the

always returns the mode to continuous.

Sweep Range

Pressing the range... soft−key calls the SWEEP RANGE screen.

on

done soft−key returns the display to this SWEEP

screen. On all the following menus sweep can be turned on and off with alternate

on and off soft-key. Turning sweep off from this or the following menus

The maximum sweep range for all waveforms is 0.2Hz to 20MHz[10MHz], except triangle

(1MHz). Sweep range can be defined by start and stop frequencies or in terms of a centre

frequency and span. Start

set directly from the keyboard or by using the rotary control; frequencies can be entered with a

resolution of 0.1Hz (or 5 digits) but in sweep mode the instrument operates with an increment

resolution of 0.2Hz and the actual frequency of any particular step will be rounded up to the

nearest 0.2Hz increment. The start frequency must be lower than the stop frequency (but see

Sweep Type for selecting sweep direction).

Pressing the centre/span

frequency and sweep span about that frequency; pressing the start/stop soft−key on that

screen returns the display to the start and stop frequency form of entry.

Note that when the sweep is displayed in terms of centre frequency and span, the span will be

shown to the nearest 0.2Hz increment but the centre frequency can be shown to 0.1Hz

resolution.

Sweep Time

Pressing the time... soft−key calls the SWEEP TIME screen.

SWEEP RANGE off

◊

♦start: 100·00 kHz

◊ stop: 20·000 MHz

◊ centre/span done ◊

and Stop soft−keys permit the two end points of the sweep to be

soft−key changes the screen to permit entry in terms of centre

SWEEP TIME off

◊

0·05 s

done ◊

The sweep time can be set from 0·05s to 999s with 3−digit resolution by direct keyboard entry or

by using the rotary control. The shortest sweep times will have the fewest steps (a 100ms sweep

will have only 1000 steps whereas a 10s sweep will have 100,000 steps) and will consequently

have a coarse stepping resolution with very wide sweeps, see Frequency Stepping Resolution

section for more discussion.

Sweep Type

Pressing the type soft−key calls the SWEEP TYPE screen.

SWEEP TYPE off ◊

mode:continuous

◊ direction: up

◊ sync: on done ◊

21

Page 23

This screen is used to set the sweep mode (continuous; triggered; hold and reset; manual) and

sweep direction.

Successive presses of the direction soft−key select one of the following sweep directions:

up

down

up/down

down/up

The total sweep time is always that set on the

start frequency to stop frequency.

stop frequency to start frequency.

start frequency to stop frequency and back to start frequency.

stop frequency to start frequency and back to stop frequency.

SWEEP TIME screen, i.e. for up/down and

down/up operation the sweep time in each direction is half the total. Similarly the total number

of steps is the same for all choices, i.e. there will be half the number of steps in each direction for

up/down and down/up operation. In the sweep mode descriptions which follow the direction

is assumed to be

continuous mode the generator sweeps continuously between the start and stop

In

frequencies, triggered repetitively by an internal trigger generator whose frequency is determined

by the sweep time setting. At the stop frequency the generator resets to the start frequency after

a delay long enough for an oscilloscope to retrace, for example, and begins a new sweep.

If

sync is set to on (the default) the generator actually steps from the stop frequency to zero

frequency and then starts the next sweep from the first point of the waveform, synchronised to the

(internally generated) trigger signal. This is useful because the sweep always starts from the

same point in the waveform but the waveform discontinuity can be undesirable in some

circumstances, e.g. filter evaluation.

up but all modes can be used with all sweep directions.

With

sync set to off, the frequency steps directly and phase continuously from the stop

frequency to the start frequency but is not synchronised to the software−generated trigger signal.

In

triggered mode the generator holds the output at the start frequency until it recognises a

trigger. When triggered, the frequency sweeps to the stop frequency, resets, and awaits the next

trigger. If

starts a new sweep at the first point of the waveform when the next trigger is recognised. If

sync is set to on the frequency resets to zero frequency (i.e. no waveform) and

sync is set to off the waveform resets to the start frequency and runs at that frequency until

the next trigger initiates a new sweep.

In

hold & reset mode the generator holds the output at the start frequency until it

recognises a trigger; when triggered, the frequency sweeps to the stop frequency and holds. At

the next trigger the output is reset to the start frequency where it is held until the next sweep is

initiated by a further trigger. If

above; if

new sweep at the first point of the waveform.

For

generator, an external signal applied to TRIG IN, pressing the MAN TRIG key on the front panel,

or a remote command. The trigger source is selected on the TRIG/GATE SETUP screen, called

by pressing the

paragraph in the Gated Mode section for further details.

In

manual mode the whole sweep process is controlled from the MANUAL SWEEP screen.

sync is set to on the frequency actually goes to zero at the start and begins each

triggered and hold & reset modes the trigger source can be the internal trigger

gated setup... soft-key on the MODE screen; refer to the Gate Source

sync is set to off the output operates exactly as described

Manual Sweep

Pressing the manual soft−key on the SWEEP SETUP screen calls the MANUAL SWEEP

screen.

22

MANUAL SWEEP off

1·6308 MHz

◊ wrap:on

◊ res: medium done ◊

◊

Page 24

Before manual control can be used, manual must be selected on the SWEEP TYPE screen,

see above; if

selected

manual has not been set, the message manual sweep mode not

will be displayed before the menu is shown.

In manual mode the frequency can be stepped through the sweep range, defined on the

RANGE

anticlockwise sweeps the frequency down; the direction setting on the SWEEP TYPE

screen is ignored in Manual Sweep mode. The resolution of the frequency steps is set by the

screen, using the rotary control. Clockwise rotation sweeps the frequency up and

resolution soft-key. With res: coarse the sweep range is divided into 100 increments for

the purposes of manual stepping;

10,000 steps. Each complete turn of the rotary knob corresponds to 36 steps; turning the rotary

control rapidly will cause the frequency to jump by more than one step.

The frequency stepping resolution can be changed during a manual sweep such that

resolution can be used to quickly find a frequency of interest and

to step the frequency in smaller increments.

If

wrap is set on the sweep wraps−round from start frequency to stop frequency and

vice−versa; if

depending on the direction of the rotary control.

Sweep Spacing

Pressing the spacing... soft−key on the SWEEP SETUP screen calls the SWEEP

SPACING

SWEEP

medium splits it into 1000 steps and fine splits it into

coarse

fine resolution then selected

wrap is set off the sweep finishes at either the start or stop frequency

screen.

SWEEP SPACING off

♦logarithmic

◊ linear

done ◊

◊

With linear selected the sweep changes the frequency at a linear rate; with logarithmic

selected the sweep spends an equal time in each frequency decade.

Sweep Marker

Pressing the marker... soft−key on the SWEEP SETUP screen calls the MARKER FREQ

screen.

When set to

frequency is set within the sweep frequency range. The marker pulse is approximately 25% of the

amplitude of the sweep sync pulse.

A new marker frequency can be programmed directly from the keyboard or by using the rotary

control and cursor keys. The marker can be programmed to be any frequency within the sweep

range but the actual frequency will be that of the nearest ‘minor’ step, see Principles of Operation

section for an explanation of major and minor frequency steps. The minimum marker duration is

100us (1 minor step) but for longer sweeps the marker duration is increased (in 100us

increments) such that is never less than 1/250th of the complete sweep in order to keep the

marker visible if the whole sweep is displayed on an oscilloscope. Thus for a sweep time of

100ms the marker duration would be 400us. The first 100us increment represents the closest

frequency step to the programmed marker value.

MARKER FREQ off

program:10·0000 MHz

done ◊

◊

sweep sync AUX OUT will additionally output a marker pulse if the marker

The marker will not show if it is programmed to a frequency outside of the sweep range.

23

Page 25

Frequency Stepping Resolution

The generator frequency is stepped, not truly linearly swept, between the Start and Stop

frequencies. The number of discrete frequency steps in a sweep is determined by the sweep

time set on the

resolution, is determined by the number of steps and the sweep range (set on the

RANGE

At the shortest sweep times ( i.e. the fewest steps) with the widest frequency spans the frequency

changes will be quite large at each step; if the output is applied to a filter, for example, the

response will be a succession of step-change levels with (at higher frequencies) many cycles of

the same frequency at each step. This is a limitation of a DDS generator in sweep mode but in

part, of course, this effect can only be created because of the very wide sweeps that can be

achieved with DDS techniques; analogue generators usually have more restricted capabilities.

screen).

SWEEP TIME screen; the size of each step, i.e. the frequency stepping

SWEEP

24

Page 26

General

In Gated mode the generator outputs the waveform whenever the gating signal is high. The

generator is not synchronised with the gate source and the start and stop phase of the generator

waveform is therefore unpredictable. Except for the ability to turn the output signal on and off,

Gated mode is identical to Continuous mode. The same frequency setting is used in the two

modes. This permits the signal to be set up and applied before enabling the Gate.

Gated Mode

Gated mode is turned on by pressing the

MODE soft-key on the main menu.

The selection of the gate source signal is made by pressing the setup... soft-key opposite

gated on the MODE screen:

Gate Source

Successive presses of the source: soft-key on the TRIG/GATE SETUP screen step the

source through the three possible options of

With

front panel MAN TRIG key or by the

gated soft-key on the MODE screen, called by the

MODE more…◊

◊ continuous

♦gated setup…◊

◊ sweep setup…◊

TRIG/GATE SETUP

source: manual

◊ int period: 90.8ms

manual, external and internal.

manual selected the generator output is turned on and off by successive presses of the

∗TRG command from a remote interface.

With

external selected the generator output runs when the signal at the TRIG/GATE IN

socket is high; this input has a TTL level (1.5V) threshold. The minimum pulse width that can be

used in this mode is 100ns and the maximum repetition rate is 100kHz. The maximum signal

level that can be applied without damage is ±10V.

With

internal selected the generator is gated by an internal gate source whose period is set

by selecting

The period can be set from 0.2ms to 999s by direct keyboard entries in ms or seconds. Turning

the rotary control will increment or decrement the numeric value in steps determined by the

position of the edit cursor (flashing underline); the cursor is moved with the left and right arrowed

cursor keys. The internal source is a square wave; the duration of the gate is therefore 0.1ms to

499.5s in step with the source period of 0.2ms to 999s.

int period on the same TRIG/GATE SETUP screen.

AUX OUT in Gate Mode

When Gated mode is selected the AUX OUT source automatically defaults to trigger ;

trigger is a replica of the actual gate signal , i.e. the signal at the TRIG/GATE IN socket, the

internal gate source or the high/low condition ‘toggled’ by alternate presses of the MAN TRIG key

or the

∗TRG remote command.

TRIG/GATE SETUP

◊ source:internal

♦int period: 12.2ms

25

Page 27

General

In Tone mode the output is stepped through a user−defined list of up to 16 frequencies under the

control of the selected trigger source. The frequency list is defined using the

screen and the trigger source is selected on the TRIG/GATE SETUP screen. Tone mode is

turned on using the

Tone Frequency

Press the tone setup... soft−key on the MODE screen, called by pressing the MODE soft-key

on the main menu to get the TONE SETUP screen:

Each frequency in the list can be changed by pressing the appropriate soft−key and entering the

new value from the keyboard. The selected frequency can be deleted from the list by pressing the

del (delete) soft−key. Additional frequencies can be added to the end of the list by selecting

end of list with the appropriate soft−key and entering the new frequency from the keyboard.

Tone Mode

TONE SETUP

tone soft-key on the MODE screen.

TONE SETUP

source as gate setup

◊ 1·00000 kHz #1

♦2·00000 kHz del◊

The whole list can be scrolled back and forward through the display using the rotary control.

Tone Gate Source

The tone frequency steps (changes) when the specified trigger signal goes high and continues

until the level changes again, at which point the output immediately returns to the DC Offset level

specified; the output is then gated off until the next occurrence of the trigger signal at which time

the next frequency in the list is gated on. Note that, just as with Gated mode, the tone frequency

is not synchronised with the tone stepping gate source and the start and stop phase of each tone

is therefore entirely unpredictable.

The trigger signal used for stepping the tone is exactly the same source as that used for Gated

mode and is set up on the TRIG/GATE SETUP screen, called by pressing the

setup

(front panel MAN TRIG key, or remote command), an external signal applied to the

TRIG/GATE IN socket, or

Source paragraph in the Gated Mode section for selection of the trigger source.

When

frequency that is recommended (applied to the TRIG/GATE IN socket) is 1kHz.

... soft-key on the MODE screen. The tone switching trigger source can be manual

external is the selected tone stepping trigger source the maximum switching

gated

internal from the internal trigger generator. Refer to the Gate

26

Page 28

General

FSK (Frequency Shift Keying) mode permits fast phase-continuous switching between two

frequencies within the range of 1Hz to 20MHz [10MHz]. All other parameters of the waveform

(amplitude, offset, symmetry) remain the same as the frequency is switched.

FSK

FSK mode is turned on by pressing the

the

MODE soft-key on the main menu.

Frequency Setting

The two frequencies f0 and f1 , between which the waveform is switched, are set on the

FSK FREQUENCIES screen, called by pressing the

screen.

With each frequency selected in turn (filled diamond) the frequency can be set using direct

numeric keyboard entries or by using the cursor keys and rotary control.

Trigger Source

The trigger source is the same source as that used for Gated and Tone modes and is accessed

and set up in the same way from the

gated setup... soft-key on the MODE screen.

For an external trigger,

is the frequency output with the TRIG/GATE IN signal high.

FSK soft-key on the MODE screen, called by pressing

FSK set-up... soft-key on the MODE

FSK FREQUENCIES

source as gate setup

♦f0: 1·000 kHz

◊ f1: 10·0000 kHz

TRIG/GATE SETUP screen, called by pressing the

f0 is the frequency output with the TRIG/GATE IN signal low and f1

27

Page 29

Modulation

Amplitude Modulation of the carrier is possible by applying a suitable signal (which can be AC

coupled if required) to the front panel VCA IN socket. A positive voltage increases the output

amplitude and a negative voltage decreases the amplitude. The modulating signal is applied at

the appropriate level to obtain the modulation depth required at the set output amplitude. If the

output amplitude is changed the amplitude of the modulating signal will have to be changed if the

same modulation depth is to be maintained. Note that clipping will occur if the combination of

amplitude setting and VCA IN signal attempts to drive the output above 20Vpp open-circuit

voltage (10Vpp into 50Ω).

The VCA IN signal is applied to the amplifier chain prior to the output attenuators. The amplifier

itself is controlled over a limited range (~10dB) and the full amplitude range is achieved by

switching in up to five –10dB attenuation stages. Peak modulation cannot exceed the maximum

of the ‘range’ within which the output has been set by choice of amplitude setting. It is up to the

user to observe the waveforms when using external VCA and to make adjustments if the

waveform is clipping.

Within each ‘range’ the maximum output setting at which clipping is avoided is reduced from

range maximum to half this value as modulation is increased from 0% to 100%; 100% modulation

will be achieved at this mid-range setting with a VCA IN signal of approximately 2.5Vpp.

Any waveform can be modulated, including DC. Modulation frequency range is DC to 100kHz.

Modulating the generator with a squarewave gives step changes in the output amplitude which

are suitable for testing signal compressors and automatic gain control circuits.

Suppressed Carrier Modulation can be achieved by first DC biasing the VCA IN sufficient to

suppress the carrier and then applying the modulating signal.

28

Page 30

System Operations from the Utility Menu

Pressing the UTILITY soft-key on the main menu calls a list of further menus which give access

to various system operations including storing/recalling set−ups from non−volatile memory, error

messages, power-on settings and calibration.

Storing and Recalling Set-ups

Complete waveform set−ups can be stored to or recalled from non−volatile RAM using the menus

called by the store... and recall... soft−keys on the UTILITIES screen.

Pressing store... calls the store screen:

Save to store No: 1

◊ execute

Nine stores, numbered 1 to 9 inclusive, are available. Select the store using the rotary control or

direct keyboard entry and press execute to implement the store function.

Pressing recall... calls the recall screen:

Recall store No: 1

◊ set defaults

◊ execute

In addition to the user−defined stores, the factory defaults can be reloaded by pressing the

set defaults soft−key. Note that loading the defaults does not change the set−ups stored in

memories 1 to 9, or the RS-232/USB interface settings.

Warnings and Error messages

The default setup is for all warning and error messages to be displayed and for a beep to sound

with each message. This setup can be changed on the error... menu:

error beep: ON

◊

◊ error message: ON

◊ warn beep: ON

◊ warn message: ON

Each feature can be turned ON or OFF with alternate presses of the appropriate soft−key.

The last two error messages can be viewed by pressing the last error... soft−key on the

UTILITIES screen. Each message has a number and the full list appears in Appendix 1. See

also Warnings and Error Messages in the Standard Waveform Operation section.

Remote Interface Setup

Pressing remote... calls the REMOTE SETUP screen which permits RS-232/USB choice and

selection of address and Baud rate. Full details are given in the Remote Operation section.

Power On Setting

Pressing the power on... soft−key calls the POWER ON SETTING screen:

POWER ON SETTING

◊ default values

◊ restore last setup

recall store no. 1

29

Page 31

The setting loaded can be selected with the appropriate soft−key to be default values (the

default setting), restore last setup (i.e. the settings at power down are restored at power

up) or any of the settings stored in non−volatile memories 1 to 9. Default values restores

the factory default settings, see Appendix 2.

Calibration

Pressing calibrate... calls the calibration routine, see Calibration section.

30

Page 32

All parameters can be calibrated without opening the case, i.e. the generator offers ‘closed−box’

calibration. All adjustments are made digitally with calibration constants stored in Flash. The

calibration routine requires only a DVM, an oscilloscope and a frequency counter and takes no

more than a few minutes.

The crystal in the timebase is pre−aged but a further ageing of up to ±5ppm can occur in the first

year. Since the ageing rate decreases exponentially with time it is an advantage to recalibrate

after the first 6 month’s use. Apart from this it is unlikely that any other parameters will need

adjustment.

Calibration should be carried out only after the generator has been operating for at least 30

minutes in normal ambient conditions.

Equipment Required

• 3½ digit DVM with 0·25% DC accuracy and 0·5% AC accuracy at 1kHz.

• Frequency counter capable of measuring 20·00000MHz.

• An oscilloscope for the Symmetry adjustment (CAL 13 & CAL14).

The DVM is connected to the MAIN OUT and the counter to the AUX OUT.

Frequency meter accuracy will determine the accuracy of the generator’s clock setting and

should ideally be ±1ppm.

Calibration

Calibration Procedure

The calibration procedure is accessed by pressing the calibrate... soft−key on the

UTILITIES screen.

The software provides for a 4−digit password in the range 0000 to 9999 to be used to access the

calibration procedure. If the password is left at the factory default of 0000 no messages are

shown and calibration can proceed as described in the Calibration Routine section; only if a

non−zero password has been set will the user be prompted to enter the password.

Setting the Password

On opening the Calibration screen press the password... soft−key to show the password

screen:

CALIBRATION SELECTED

Are you sure ?

◊ password… tests…◊

◊ exit continue ◊

ENTER NEW PASSWORD

----

Enter a 4−digit password from the keyboard; the display will show CONFIRM NEW PASSWORD.

Re-enter the password; the display will show the message NEW PASSWORD STORED! for two

seconds and then revert to the UTILITIES menu. If any keys other than 0−9 are pressed while

entering the password, or if the password is re-entered incorrectly, the message ILLEGAL

PASSWORD! will be shown.

31

Page 33

Using the Password to Access Calibration or Change the Password

With the password set, pressing calibration... on the UTILITIES screen will now

show:

ENTER PASSWORD

----

When the correct password has been entered from the keyboard the display changes to the

opening screen of the calibration routine and calibration can proceed as described in the

Calibration Routine section. If an incorrect password is entered the message

PASSWORD! is shown for two seconds before the display reverts to the UTILITIES menu.

With the opening screen of the calibration routine displayed after correctly entering the password,

the password can be changed by pressing

password... soft−key and following the procedure

described in Setting the Password. If the password is set to 0000 again, password protection is

removed.

The password is held in Flash. In the event of the password being forgotten, contact the

manufacturer for help in resetting the instrument.

Calibration Routine

INCORRECT

The calibration procedure proper is entered by pressing continue on the opening Calibration

screen; pressing

exit returns the display to the UTILITIES menu. At each step the display

changes to prompt the user to adjust the rotary control or cursor keys, until the reading on the

specified instrument is at the value given. The cursor keys provide coarse adjustment, and the

rotary control fine adjustment. Pressing

pressing

previous decrements back to the previous step. Alternatively, pressing exit

returns the display to the last CAL screen at which the user can choose to either

values,

recall old values or calibrate again.

next increments the procedure to the next step;

save new

The first two displays specify the connections and adjustment method. The subsequent displays,

CAL 01 to CAL 15, permit all adjustable parameters to be calibrated.

The full procedure is listed below; the name of the control signal being adjusted at each step and

the default DAC value are shown in brackets. The display itself shows a summary of the step

adjustment procedure and the actual DAC value.

CAL 01

Output DC offset zero; adjust for 0V ± 5mV (DCOFFSET, 0007).

CAL 02 Output DC offset +ve full scale; adjust for 10V ± 20mV (DCOFFSET, -1973).